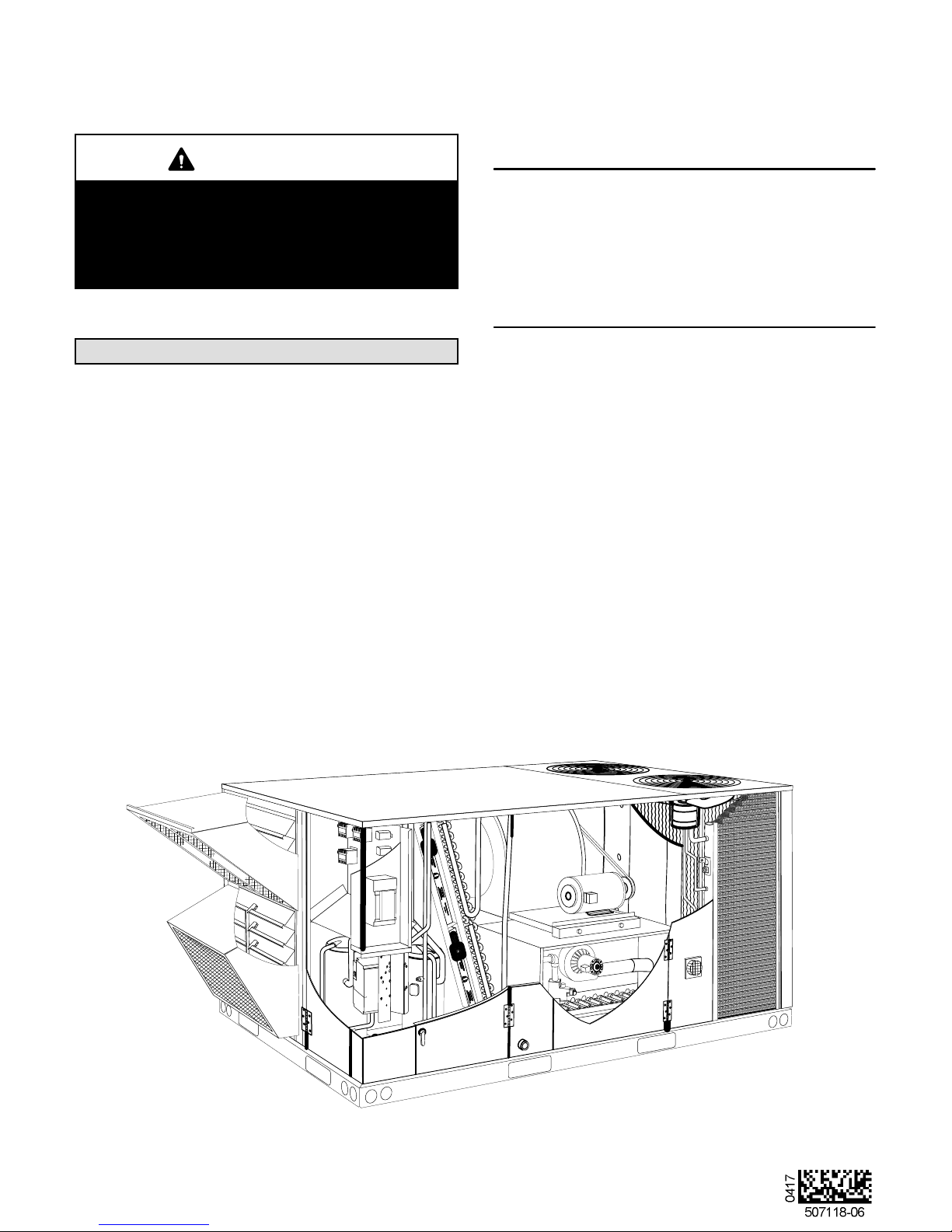

Lennox KGA092KGA102KGA120KGA150, KCA092, KCA150, KCA120, KCA102 Installation Instructions Manual

Page 1

©2017

WARNING

Improper installation, adjustment, alteration, ser

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and ser

vice must be performed by a licensed professional

HVAC installer or equivalent, service agency, or the

gas supplier

INSTALLATION

INSTRUCTIONS

KGA/KCA092

KGA/KCA102

KGA/KCA120

(7.5 Ton)

(8.5 Ton)

(10 Ton)

Table Of Contents

Dimensions Page 2.................................

Parts Arrangements Page 3.........................

Shipping and Packing List Page 4....................

General Page 4....................................

Safety Page 4.....................................

Unit Support Page 5................................

Duct Connection Page 5............................

Rigging Unit For Lifting Page 5.......................

Condensate Drains Page 6..........................

Connect Gas Piping Page 7.........................

Pressure Test Gas Piping Page 8.....................

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

KGA/KCA150

GAS AND COOLING PACKAGED UNITS

507118-06

4/2017

Supersedes 10/2016

High Altitude Derate Page 9.........................

Electrical Connections Page 9.......................

Unit Power-Up Page 10..............................

Blower Operation and Adjustments Page 10............

Cooling Start-Up Page 18............................

Gas Heat Start-Up Page 26...........................

Heating Operation and Adjustments Page 27............

Electric Heat Start-Up Page 27........................

Supply Air Inverter Start-Up Page 28...................

Service Page 30....................................

(12-1/2 Ton)

KGA SHOWN

Page 2

KGA/KCA092, 102, 120, & 150 DIMENSIONS - Gas heat section shown

4-1/8

(105)

19-3/4

(502)

27-3/4

(705)

58-1/8

(1476)

BOTTOM

POWER ENTRY

5-1/2 (140) Dia.

46-7/8

(1191)

43-3/8

(1102)

6-1/8

(156)

60-1/8 (1527)

BASE

7 (178)

(25)

6-1/8

(156)

(686)

OPTIONAL DISCONNECT

(FACTORY INSTALLED)

1

24

(610)

27

BOTTOM RETURN

AIR OPENING

6-5/8

(168)

7 (178)

34-7/8

(886)

CONDENSATE

DRAIN (FRONT)

5-3/8

(137)

10-3/4

(273)

BOTTOM

CONDENSATE

TOP VIEW

18-1/2

5-5/8

BOTTOM SUPPLY

(143)

28

(711)

20

(508)

101-1/4

(2572)

99-1/4

(2521)

GAS SUPPLY

INLET

(470)

AIR OPENING

BASE

FLUE

OUTLET

46-7/8

(1191)

6

(152)

60-1/8

(1527)

END VIEW

OPTIONAL RETURN AIR OPENING

WITH ECONOMIZER AND HORIZONTAL

DISCHARGE KIT (required)

(Field Installed)

3-1/2

(89)

ELECTRIC

INLETS

15-1/2

(394)

6-1/8

(156)

34-7/8

(886)

31-1/2

(800)

FORKLIFT SLOTS

39-7/8

(1013)

(BOTH SIDES)

101-1/4

(2572)

SIDE VIEW

HORIZONTAL

SUPPLY AIR

OPENING

CONDENSATE

DRAIN (BACK)

30

66-3/8

(1686)

(762)

SIDE VIEW

(Horizontal Openings)

LIFTING HOLES

(FOR RIGGING)

15-1/2

(394)

5-3/8

HORIZONTAL

(137)

RETURN AIR

OPENING

WITHOUT ECONOMIZER

1-5/8

(41)

30

(762)

12-1/8

(308)

Page 2

Page 3

KGA092, 102, 120, & 150 PARTS ARRANGEMENT

DISCONNECT /

ECONOMIZER

(OPTIONAL)

INVERTER

(OPTIONAL)

COMPRESSORS

CIRCUIT BREAKER

(FACTORY OR FIELD

INSTALLED OPTION)

FILTERS

(FOUR - 20 X 25 X 2”)

EVAPORATOR

COIL

CONDENSATE

DRAIN

BLOWER

MOTOR

BLOWER

GAS VALVE

CONDENSER

FANS

CONDENSER

COIL

COMBUSTION

AIR INDUCER

BURNERS

KCA092, 102, 120, & 150 PARTS ARRANGEMENT

ECONOMIZER

(OPTIONAL)

INVERTER

(OPTIONAL)

COMPRESSORS

DISCONNECT /

CIRCUIT BREAKER

(FACTORY OR FIELD

INSTALLED OPTION)

(FOUR - 20 X 25 X 2”)

EVAPORATOR

COIL

FILTERS

BLOWER

MOTOR

BLOWER

CONDENSATE

DRAIN

CONDENSER

FANS

CONDENSER

COIL

ELECTRIC

HEAT

Page 3

Page 4

CAUTION

As with any mechanical equipment, contact with

sharp sheet metal edges can result in personal in

jury. Take care while handling this equipment and

wear gloves and protective clothing.

Shipping and Packing List

Package 1 of 1 contains:

1- Assembled unit

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is found.

General

These instructions are intended as a general guide

and do not supersede local codes in any way.

Authorities having jurisdiction should be consulted

before installation.

The KGA units are available in three heating inputs.

The KCA cooling packaged rooftop unit is the same

basic design as the KGA unit except for the heating

section. Optional electric heat is available for KCA

units. KGA and KCA units have identical refrigerant

circuits with respective 7-1/2, 8‐1/2, 10, and 12-1/2 ton

cooling capacities.

NOTICE

Roof Damage!

This system contains both refrigerant and oil.

Some rubber roofing material may absorb oil,

causing the rubber to swell. Bubbles in the rubber

roofing material can cause leaks. Protect the roof

surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow

this notice could result in damage to roof surface.

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent

ing of refrigerant (CFC's and HCFC's) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incar

ceration may be levied for non-compliance.

UNIT CLEARANCES

Optional

Outdoor

Air Hood

D

C

B

Units are available with an optional supply air inverter.

The blower will operate at lower speeds when demand is

low and increase to higher speeds when demand is high.

Refer to Inverter Start-Up section.

Availability of units and options varies by brand.

Safety

See figure 1 for unit clearances.

Use of this unit as a construction heater or air conditioner

is not recommended during any phase of construction.

Very low return air temperatures, harmful vapors and

operation of the unit with clogged or misplaced filters will

damage the unit.

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

gas and electrical power to unit before

performing any maintenance or

servicing operations on the unit. Follow

lighting instructions attached to unit

when putting unit back into operation

and after service or maintenance.

A

FIGURE 1

1

Unit

Clearance

Service

Clearance

Clearance to

Combustibles36(914)1(25)1(25)1(25)

Minimum Opera

tion Clearance36(914)36(914)36(914)36(914)

Note - Entire perimeter of unit base requires support when elevated above

mounting surface.

1

Service Clearance - Required for removal of serviceable parts.

Clearance to Combustibles - Required clearance to combustible material

(gas units).

Minimum Operation Clearance - Required clearance for proper unit operation.

A

in.(mm)Bin.(mm)Cin.(mm)Din.(mm)

60

(1524)36(914)36(914)60(914)

If this unit has been used for heating or cooling of

buildings or structures under construction, the following

conditions must be met or the warranty will be void:

A room thermostat must control the unit. The use of

fixed jumpers that will provide continuous heating or

cooling is not allowed.

A pre-filter must be installed at the entry to the return

air duct.

Page 4

To p

Clearance

Unob

structed

Unob

structed

Unob

structed

Page 5

The return air duct must be provided and sealed to

the unit.

Return air temperature range between 55°F (13°C)

and 80°F (27°C) must be maintained.

Air filters must be replaced and pre-filters must be

removed upon construction completion.

The input rate and temperature rise must be set per

the unit rating plate.

The heat exchanger, components, duct system, air

filters and evaporator coil must be thoroughly

cleaned following final construction clean-up.

The unit operating conditions (including airflow,

cooling operation, ignition, input rate, temperature

rise and venting) must be verified according to these

installation instructions.

Unit Support

In downflow discharge installations, install the unit on a

non-combustible surface only. Unit may be installed on

combustible surfaces when used in horizontal discharge

applications or in downflow discharge applications when

installed on an C1CURB roof mounting frame.

NOTE - Securely fasten roof frame to roof per local codes.

CAUTION

To reduce the likelihood of supply / return air by

pass and promote a proper seal with the RTU, duct

work / duct drops / diffuser assemblies must be

supported independently to the building structure.

A-Downflow Discharge Application

Roof Mounting with C1CURB

Make sure the cap over the unit bottom drain hole is

secure.

1- The C1CURB roof mounting frame must be installed,

flashed and sealed in accordance with the

instructions provided with the frame.

2- The frames or supports must be constructed with

non-combustible materials and should be square and

level to 1/16” per linear foot (5mm per linear meter)

in any direction.

3- Frame or supports must be high enough to prevent

any form of moisture from entering unit.

Recommended minimum frame height is 14”

(356mm).

4- Duct must be attached to the roof mounting frame

and not to the unit. Supply and return plenums must

be installed before setting the unit.

5- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

NOTE-When installing a unit on a combustible surface for

downflow discharge applications, an C1CURB roof

mounting frame is required.

B-Horizontal Discharge Applications

1- Units installed in horizontal airflow applications must

use a horizontal conversion kit (K1HECK00).

2- Specified installation clearances must be maintained

when installing units. Refer to figure 1.

3- Top of support slab should be approximately 4”

(102mm) above the finished grade and located so no

run-off water from higher ground can collect around

the unit.

4- Units require support along all four sides of unit base.

Supports must be constructed of steel or suitably

treated wood materials.

Duct Connection

All exterior ducts, joints and openings in roof or building

walls must be insulated and weather-proofed with

flashing and sealing compounds in accordance with

applicable codes. Any duct passing through an

unconditioned space must be insulated.

2- The C1CURB roof mounting frame should be square

and level to 1/16” per linear foot (5mm per linear

meter) in any direction.

3- Duct must be attached to the roof mounting frame

and not to the unit; supply and return plenums must

be installed before setting the unit.

Installer's Roof Mounting Frame

Many types of roof frames can be used to install the unit

depending upon different roof structures. Items to keep

in mind when using the building frame or supports are:

1- The base is fully enclosed and insulated, so an

enclosed frame is not required.

CAUTION

In downflow applications, do not drill or punch

holes in base of unit. Leaking in roof may occur if

unit base is punctured.

Rigging Unit For Lifting

Rig unit for lifting by attaching four cables to holes in unit

base rail. See figure 2.

1- Detach wooden base protection before rigging.

2- Connect rigging to the unit base using both holes in

each corner.

3- All panels must be in place for rigging.

Page 5

Page 6

4- Place field‐provided H‐style pick in place just above

top edge of unit. Frame must be of adequate

strength and length. (H-style pick prevents damage

to unit.)

CONDENSATE SIDE DRAIN CONNECTION

CAULK AROUND CONDENSATE COUPLING

RIGGING

UNIT

KGA

KCA

*Maximum weight with all available ins

talled accessories.

*WEIGHT

LBS. KG.

1401

1366

636

620

LIFTING POINT SHOULD

BE DIRECTLY ABOVE

CENTER OF GRAVITY

CAUTION - Do not

walk on unit.

IMPORTANT - ALL

PANELS MUST BE IN

PLACE FOR RIGGING.

NOTE - Allow clearance to

open doors when installing

condensate piping.

Minimum Pitch

1” (25 mm) per

10' (3 m) of line

OPEN VENT

UNIT

MOUNTING

FRAME

FIGURE 3

CONDENSATE BOTTOM DRAIN CONNECTION

UNIT

DRAIN PAN

CAULK AROUND

CONDENSATE COUPLING

OPEN VENT

FIGURE 2

Condensate Drains

Make drain connection to the 1” N.P.T. drain coupling

provided on unit.

Note - The drain pan is made with a glass reinforced

engineered plastic capable of withstanding typical joint

torque but can be damaged with excessive force. Tighten

pipe nipple hand tight and turn an additional quarter turn.

A trap must be installed between drain connection and an

open vent for proper condensate removal. See figure 3 or

4. It is sometimes acceptable to drain condensate onto

the roof or grade; however, a tee should be fitted to the

trap to direct condensate downward. The condensate line

must be vented. Check local codes concerning

condensate disposal. Refer to pages 2 and 3 for

condensate drain location.

Units are shipped with the drain coupling facing the front

of the unit. Condensate can be drained from the back or

bottom of the unit with the following modifications. The

unit can be installed in either downflow or horizontal air

discharge regardless of condensate drain location.

Rear Drain Connection

1- Remove heat access door. See figure 5.

2- Remove filter access door.

MOUNTING

FRAME

Minimum Pitch

1” (25 mm) per 10'

(3 m) of line

FIGURE 4

FILTER

ACCESS DOOR

HEAT

ACCESS DOOR

CONDENSATE

DRAIN MULLION

FIGURE 5

3- Remove eight screws holding condensate drain

mullion and remove mullion.

Page 6

Page 7

4- Lift front edge of the drain pan (to clear bottom drain

plug) and slide drain pan out of unit. See figure 6.

DRAIN PAN

FIGURE 6

5- Make sure the cap over the unit bottom drain hole is

secure.

6- Rotate the drain pan until the downward slope is

toward the back of the unit. Slide the drain pan back

into the unit. Be careful not to dislodge the cap over

the bottom drain hole.

7- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

8- Replace the condensate drain mullion and reinstall

eight screws.

9- Reinstall access doors.

11- Use a field-provided 1” plug to seal side drain

connection.

12- Replace the condensate drain mullion and reinstall

eight screws.

13- Reinstall access doors.

BOTTOM CONDENSATE DRAIN

CAUTION: Be careful not to

damage the coupling threads

when drilling the hole.

After drilling the pilot

hole, drill a 7/8” hole from

the inside of the pan.

DRILL A PILOT

HOLE IN CENTER

OF COUPLING

FIGURE 7

Connect Gas Piping (Gas Units)

Bottom Drain Connection

1- Remove heat access door. See figure 5.

2- Remove filter access door.

3- Remove eight screws holding condensate drain

mullion and remove mullion.

4- Lift front edge of the drain pan (to clear bottom drain

plug) and slide drain pan out of unit. See figure 6.

5- Turn the drain pan upside down and drill a pilot hole

through the bottom of the drain pan in the center of

the coupling. See figure 7.

®

6- From the inside of the pan, use a Vari-Bit

bit to

enlarge the hole to 7/8”. Do not damage coupling

threads.

7- Remove the cap over the unit bottom drain hole.

8- Slide the drain pan back into the unit.

9- From the back side of the unit, pull the drain pan

coupling through the rear condensate opening.

10- From the front side of the unit, move the drain pan

until the bottom coupling settles into the unit bottom

drain opening. Once in place, check to make sure the

coupling is still positioned through the rear

condensate drain hole.

Before connecting field-provided piping, check with gas

company or authorities having jurisdiction for local code

requirements. When installing gas supply piping, length

of run from gas meter must be considered in determining

pipe size for 0.5” w.c. (.12kPa) maximum pressure drop.

Do not use supply pipe smaller than unit gas connection.

For natural gas units, operating pressure at the unit gas

connection must be a minimum of 4.7” w.c. (1.19kPa)

and a maximum of 10.5” (2.60kPa) w.c. For LP/propane

gas units, operating pressure at the unit gas connection

must be a minimum of 11” w.c. (2.74kPa) and a maximum

of 13.0” w.c. (3.23kPa).

When making piping connections a drip leg should be

installed on vertical pipe runs to serve as a trap for

sediment or condensate. A 1/8” N.P.T. plugged tap is

located on gas valve for test gauge connection. Refer to

Heating Start-Up section for tap location. Install a ground

joint union between the gas control manifold and the main

manual shut-off valve. See figure 8 for gas supply piping

entering outside the unit. Figure 9 shows bottom gas entry

piping through the curb. Figure 10 shows bottom gas

entry piping through the unit.

Compounds used on threaded joints of gas piping shall be

resistant to the action of liquified petroleum gases.

Page 7

Page 8

OUTSIDE OF UNIT GAS PIPE CONNECTION

TO GAS

VALV E

GROUND

JOINT UNION

ALL ELBOWS ARE 3/4”

10” NIPPLE

GROMMET

7-1/2” NIPPLE

BOTTOM GAS ENTRY

THROUGH THE UNIT

MULLION BETWEEN

HEAT AND COMPRES

SOR SECTIONS

GROMMET

5” NIPPLE

4” NIPPLE

4” NIPPLE

TO GAS

SUPPLY

GAS PIPING

SUPPORT

MANUAL MAIN

SHUT-OFF VALVE

BOTTOM ENTRY GAS PIPING

THROUGH THE CURB

MULLION BETWEEN

HEAT AND COMPRES

SOR SECTIONS

4” NIPPLE

FIGURE 8

DRIP LEG

TO GAS

VALV E

(REFER TO

LOCAL CODES)

4” NIPPLE

TO GAS

VALV E

7”

NIPPLE

ALTERNATE

KNOCKOUTS

ROOF MOUNTING

FRAME

TO GAS

SUPPLY

DRIP LEG

GROUND

JOINT UNION

4” NIPPLE

MANUAL MAIN

SHUT-OFF VALVE

3-1/2” NIPPLE

3” NIPPLE

FIGURE 10

Pressure Test Gas Piping (Gas Units)

When pressure testing gas lines, the gas valve must

be disconnected and isolated. Gas valves can be

damaged if subjected to more than 0.5 psig (3.48kPa).

See figure 11.

GROMMET

ALL ELBOWS ARE 3/4”

MANUAL MAIN

SHUT-OFF VALVE

TO GAS

SUPPLY

10” NIPPLE

ROOF

MOUNTING

FRAME

FIGURE 9

5” NIPPLE

7-1/2” NIPPLE

GROUND

JOINT UNION

4” NIPPLE

3-1/2” NIPPLE

3” NIPPLE

DRIP LEG

NOTE-Codes may require that manual main shut-off

valve and union (furnished by installer) be installed in

gas line external to unit. Union must be of the ground

joint type.

After all connections have been made, check all piping

connections for gas leaks. Also check existing unit gas

connections up to the gas valve; loosening may occur

during installation. Use a leak detection solution or other

preferred means. Do not use matches candles or other

sources of ignition to check for gas leaks.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or othe sources of ignition

to check for gas leaks.

Page 8

Page 9

WARNING

Danger of explosion. Can cause injury

or product or property damage. Do not

use matches, candles, flame or other

sources of ignition to check for leaks.

NOTE-In case emergency shut down is required, turn off

the main manual shut-off valve and disconnect main

power to unit. These devices should be properly labeled

by the installer.

PRESSURE TEST GAS LINE

MANUAL MAIN

SHUT-OFF VALVE

GAS VALVE

FIGURE 11

CAP

Refer to unit nameplate for minimum circuit ampacity

and maximum fuse size.

1- 230/460/575 volt units are factory wired. For 208V

supply, disconnect the pink wire (230V) at all control

power transformer(s). Reconnect the pink wire

(208V). Tape the exposed end of the 230V pink wire.

2- Route power through the bottom power entry area

and connect to L1, L2, and L3 on the bottom of TB2

in control box for gas units or units equipped with

electric heat. Route power to F4 on cooling only

units (no electric heat). Route power to S48

disconnect switch when the option is

factory-installed. See unit wiring diagram.

3- Connect separate 120v wiring to optional GFCI outlet

pigtails.

CONTROL WIRING

A-Thermostat Location

Room thermostat mounts vertically on a standard 2” X 4”

handy box or on any non-conductive flat surface.

Locate thermostat approximately 5 feet (1524mm)

above the floor in an area with good air circulation at

average temperature. Avoid locating the room

thermostat where it might be affected by:

-drafts or dead spots behind doors and in corners

-hot or cold air from ducts

-radiant heat from sun or appliances

-concealed pipes and chimneys

High Altitude Derate

Locate the high altitude conversion sticker in the unit

literature bag. Fill out the conversion sticker and affix next

to the unit nameplate.

Refer to table 1 for high altitude adjustments.

TABLE 1

HIGH ALTITUDE DERATE

Altitude Ft.* Gas Manifold Pressure

2000-4500 See Unit Nameplate

4500 And Above Derate 2% / 1000 Ft. Above Sea Level

*Units installed at 0-2000 feet do not need to be modified.

NOTE ‐ This is the only permissible derate for these units.

Electrical Connections

POWER SUPPLY

Do not apply power or close disconnect switch until

installation is complete. Refer to start-up directions.

Refer closely to unit wiring diagram.

B-Control Wiring

1- Route thermostat cable or wires from subbase to

control box (refer to unit dimensions to locate bottom

and side power entry).

IMPORTANT - Unless field thermostat wires are rated

for maximum unit voltage, they must be routed away

from line voltage wiring. Use wire ties located near the

lower left corner of the controls hat section to secure

thermostat cable.

Use18 AWG wire for all applications using remotely

installed electro-mechanical and electronic

thermostats.

2- Install thermostat assembly in accordance with

instructions provided with thermostat.

3- Connect thermostat wiring to TB1 terminal board on

the lower side of the controls hat section. Wire as

shown in figure 12 for electro-mechanical and

electronic thermostats. If using other temperature

control devices or energy management systems see

instructions and wiring diagram provided by

manufacturer.

Page 9

Page 10

24 VOLT FIELD WIRING WITH ELECTRONIC AND

ELECTRO-MECHANICAL THERMOSTATS

TB1

NOT ALL TERMINALS

ARE FOUND ON ALL

THERMOSTATS

Jumper terminals R and

OC when thermostat has

no night setback terminals

A2 THERMOSTAT

Note - On electro-mechanical thermo

stats set anticipator at 0.1 amps.

on units equipped with an

economizer.

FIGURE 12

IMPORTANT-Terminal connections at the wall plate or

subbase must be made securely. Loose control wire

connections may allow unit to operate but not with proper

response to room demand.

1- Observe suction and discharge pressures and

blower rotation on unit start-up.

If pressure differential is not observed or blower rotation is

not correct:

2- Suction pressure must drop, discharge pressure

must rise, and blower rotation must match rotation

marking.

3- Disconnect all remote electrical power supplies.

4- Reverse any two field-installed wires connected to

the line side of K3, TB2 or F4. Do not reverse wires

at blower contactor or compressors.

5- Make sure the connections are tight.

Discharge and suction pressures should operate at

their normal start‐up ranges.

Supply Air Inverter Units - Units are equipped with a

phase monitor located in the control compartment. The

phase monitor will detect the phasing of incoming

power. If the incoming power is out of phase or if any of

the three phases are lost, the indicating LED on the

phase monitor will turn red and the unit will not start. In

normal operation with correct incoming power phasing,

the LED will be green.

Unit Power-Up

A-General

1- Make sure that unit is installed in accordance with the

installation instructions and applicable codes.

2- Inspect all electrical wiring, both field‐ and

factory‐installed, for loose connections. Tighten as

required.

3- Check to ensure that refrigerant lines do not rub

against the cabinet or against other refrigerant lines.

4- Check voltage at main unit power connection.

Voltage must be within range listed on nameplate. If

not, consult power company and have voltage

condition corrected before starting unit.

5- Make sure filters are in place before start‐up.

6- Make sure there is no heating, cooling, or blower

demand from thermostat. Apply power to unit.

Blower Operation and Adjustments

A-Three Scroll Compressor Voltage Phasing

Three phase scroll compressors must be phased

sequentially to ensure correct compressor and blower

rotation and operation. Compressor and blower are

wired in phase at the factory. Power wires are

color-coded as follows: line 1-red, line 2-yellow, line

3-blue.

B-Blower Operation

Initiate blower demand at thermostat according to

instructions provided with thermostat. Unit will cycle on

thermostat demand. The following steps apply to

applications using a typical electro-mechanical

thermostat.

1- Blower operation is manually set at the thermostat

subbase fan switch. With fan switch in ON position,

blowers will operate continuously.

2- With fan switch in AUTO position, the blowers will

cycle with demand. Blowers and entire unit will be off

when system switch is in OFF position.

C-Blower Access

The blower assembly is secured to a sliding frame which

allows the blower motor to be pulled out of the unit. See

figure 13.

1- Loosen the reusable wire tie which secures the

blower wiring to the blower motor mounting plate.

2- Remove and retain screws on either side of sliding

frame. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws on either side of the sliding

frame.

Page 10

Page 11

TO INCREASE BELT TENSION

1- Loosen four bolts securing motor mounting base

to frame.

2- Turn adjusting bolt to the right, or clockwise, to

move the motor away from the blower housing.

IMPORTANT - Gap between end of frame and motor

mounting base should be equal at both ends, i.e. par

allel along gap.

3- Tighten four bolts securing motor mounting base

to frame.

4- Relieve tension on two adjusting bolts.

MOTOR MOUNTING

BASE

BELT ADJUSTING BOLTS

- TURN CLOCKWISE

TO TIGHTEN BELT

GAP BETWEEN

EDGES SHOULD BE

PARALLEL ON BOTH

ENDS BEFORE

TIGHTENING MOTOR

MOUNTING BASE IN

PLACE

STANDARD BLOWER ASSEMBLY

BLOWER

HOUSING

MOTOR

SIDE VIEW

MOTOR

BLOWER

FRAME

ALLEN

SCREW

PULLEY

REMOVE TWO SCREWS

TO COMPLETELY SLIDE

BLOWER OUT OF UNIT

REMOVE TWO SCREWS ON EACH

SIDE TO SLIDE FRAME PARTIALLY

OUT OF UNIT FOR SERVICE ACCESS

FIGURE 13

D-Determining Unit CFM

IMPORTANT - Units equipped with an inverter are

factory-set to run the blower at full speed when there is a

blower (G) demand without a heating or cooling demand.

Use the following procedure to adjust motor pulley to

deliver the full load cooling or heating CFM. See Inverter

Start-Up section to set blower CFM for all modes once the

motor pulley is set.

1- The following measurements must be made with a

dry indoor coil. Run blower without a cooling demand.

Measure the indoor blower shaft RPM. Air filters must

be in place when measurements are taken.

2- With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

readings taken in locations shown in figure 14.

Note - Static pressure readings can vary if not taken

where shown.

3- Referring to page 13, 14, or 15, use static pressure

and RPM readings to determine unit CFM. Use pages

16 and 17 when installing units with any of the

optional accessories listed.

Page 11

LOOSEN BEFORE

ADJUSTING BELT TENSION

(TWO EACH SIDE)

4- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley

clockwise to increase CFM. Turn counterclockwise to

decrease CFM. See figure 13. Do not exceed

minimum and maximum number of pulley turns as

shown in table 2.

TABLE 2

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt

Minimum

Turns Open

A Section 0 5

B Section 1* 6

*No minimum number of turns open when B belt is used on

pulleys 6” O.D. or larger.

Maximum

Turns Open

E-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only

if proper pulley alignment and belt tension are

maintained. Tension new belts after a 24-48 hour

period of operation. This will allow belt to stretch and

seat in the pulley grooves. Make sure blower and motor

pulleys are aligned as shown in figure 15.

1- Loosen four bolts securing motor base to mounting

frame. See figure 13.

Page 12

LOCATION OF STATIC PRESSURE READINGS

INSTALLATIONS WITH DUCTWORK

INSTALLATIONS WITH CEILING DIFFUSERS

ROOFTOP UNIT

RETURN AIR

READING LOCATION

SUPPLY

MAIN

DUCT RUN

RE

TURN

FIRST BRANCH

OFF OF MAIN RUN

SUPPLY AIR

READING

LOCATION

2- To increase belt tension -

Turn both adjusting bolts to the right, or clockwise, to

move the motor outward and tighten the belt. This

increases the distance between the blower motor and

the blower housing.

To loosen belt tension -

Turn the adjusting bolts to the left, or

counterclockwise to loosen belt tension.

SUPPLY AIR

LOCATION

FIGURE 14

F-Check Belt Tension

Overtensioning belts shortens belt and bearing life.

Check belt tension as follows:

ROOFTOP UNIT

RETURN AIR

RE

TURN

READING

SUPPLY

DIFFUSER

1- Measure span length X. See figure 16.

MEASURE BELT TENSION

READING

LOCATION

IMPORTANT - Align top edges of blower motor base and

mounting frame base parallel before tightening two bolts

on the other side of base. Motor shaft and blower shaft

must be parallel.

3- Tighten two bolts on each side of the motor mounting

base. This secures the mounting base to the frame.

PULLEY ALIGNMENT

ALIGNED

MOTOR

PULLEY

BELT

NOT ALIGNED

BLOWER

PULLEY

FIGURE 15

FORCE

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FIGURE 16

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch

of span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span

would be 6mm.

3- Measure belt deflection force. For a new 2 and 3hp

belt, the deflection force should be 5.0-7.0 lbs.

(35-48kPa). For a new 5hp belt, the deflection force

should be 7-10lbs. (48-69kPa).

A force below these values indicates an

undertensioned belt. A force above these values

indicates an overtensioned belt.

G-Field-Furnished Blower Drives

For field-furnished blower drives, use pages 13 through

17 to determine BHP and RPM required. Reference table

3 for drive component manufacturer's numbers.

Page 12

Page 13

BLOWER DATA

092S AND 102S STANDARD EFFICIENCY BELT DRIVE BLOWER − BASE UNIT

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE. FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

Then determine from blower table blower motor output required.

See page 17 for blower motors and drives.

See page 17 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

MINIMUM AIR VOLUME REQUIRED FOR USE WITH OPTIONAL ELECTRIC HEAT (Maximum Static Pressure - 2.0 in. w.g.)

7.5 kW, 15 kW, 22.5 kW, 30 kW and 45 kW - 2800 cfm

Total

Air

Volume

cfm

1750 608 0.05 651 0.03 696 0.06 744 0.22 794 0.60 845 0.95 894 1.24 934 1.38 978 1.47 1047 1.66 1120 1.89 1179 2.15 1230 2.40

2000 615 0.07 657 0.05 702 0.10 748 0.36 797 0.72 846 1.05 892 1.30 933 1.45 977 1.55 1049 1.75 1124 2.00 1181 2.23 1234 2.47

2250 624 0.09 664 0.07 707 0.14 753 0.50 800 0.84 847 1.15 892 1.38 934 1.53 979 1.65 1051 1.86 1126 2.12 1183 2.36 1238 2.62

2500 632 0.11 672 0.09 714 0.29 758 0.64 803 0.97 849 1.26 893 1.48 936 1.63 983 1.75 1052 1.96 1124 2.22 1184 2.49 1241 2.77

2750 641 0.13 680 0.11 721 0.45 763 0.78 807 1.09 852 1.37 896 1.58 940 1.74 989 1.88 1053 2.08 1121 2.34 1185 2.63 1244 2.93

3000 651 0.15 689 0.29 728 0.61 770 0.93 812 1.23 856 1.49 901 1.70 947 1.87 996 2.02 1055 2.21 1120 2.47 1186 2.78 1248 3.10

3250 661 0.17 698 0.46 737 0.78 777 1.09 819 1.38 862 1.63 908 1.84 955 2.01 1004 2.17 1059 2.36 1122 2.62 1189 2.94 1252 3.28

3500 672 0.36 708 0.65 746 0.95 786 1.25 827 1.53 870 1.78 916 1.99 965 2.17 1013 2.33 1065 2.52 1126 2.79 1193 3.12 1257 3.47

3750 684 0.56 719 0.85 756 1.14 795 1.43 836 1.70 880 1.95 927 2.16 976 2.34 1023 2.51 1073 2.71 1133 2.98 1198 3.32 1263 3.67

4000 697 0.78 731 1.05 768 1.34 807 1.62 848 1.89 892 2.13 940 2.34 988 2.53 1034 2.71 1083 2.91 1141 3.19 1205 3.53 1270 3.89

4250 710 1.00 745 1.27 781 1.55 819 1.83 861 2.09 906 2.33 954 2.55 1001 2.74 1046 2.93 1094 3.14 1151 3.42 1214 3.76 1278 4.12

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Total Static Pressure − in. w.g.

Page 13

Page 14

BLOWER DATA

092H AND 102H HIGH EFFICIENCY BELT DRIVE BLOWER − BASE UNIT

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE. FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

Then determine from blower table blower motor output required.

See page 17 for blower motors and drives.

See page 17 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

MINIMUM AIR VOLUME REQUIRED FOR USE WITH OPTIONAL ELECTRIC HEAT (Maximum Static Pressure - 2.0 in. w.g.)

7.5 kW, 15 kW, 22.5 kW, 30 kW and 45 kW - 2800 cfm

Total

Air

Volume

cfm

1750 481 0.21 549 0.4 618 0.57 688 0.7 758 0.82 824 0.93 885 1.08 941 1.23 991 1.39 1038 1.54 1082 1.68 1124 1.82 1166 1.95

2000 493 0.29 561 0.47 629 0.64 700 0.77 768 0.9 832 1.02 892 1.17 946 1.33 995 1.49 1041 1.66 1085 1.81 1126 1.97 1167 2.12

2250 507 0.37 574 0.56 643 0.72 712 0.86 779 0.99 842 1.13 900 1.28 953 1.44 1001 1.61 1045 1.78 1088 1.95 1128 2.12 1168 2.3

2500 521 0.46 588 0.64 657 0.81 727 0.95 792 1.09 853 1.24 909 1.4 960 1.57 1007 1.74 1050 1.93 1091 2.11 1130 2.29 1170 2.48

2750 537 0.56 604 0.74 674 0.91 743 1.06 806 1.21 865 1.36 920 1.53 969 1.71 1014 1.89 1055 2.08 1095 2.27 1133 2.47 1172 2.66

3000 554 0.67 622 0.86 692 1.02 760 1.18 822 1.34 878 1.5 931 1.68 979 1.86 1021 2.06 1061 2.26 1099 2.46 1136 2.65 1174 2.85

3250 572 0.78 641 0.98 712 1.15 778 1.32 838 1.49 892 1.66 943 1.84 989 2.03 1030 2.24 1068 2.45 1105 2.65 1141 2.85 1178 3.06

3500 592 0.9 663 1.12 733 1.3 798 1.47 855 1.65 907 1.83 956 2.02 1000 2.22 1039 2.44 1076 2.65 1111 2.86 1146 3.07 1183 3.27

3750 614 1.04 687 1.28 756 1.47 818 1.65 872 1.83 923 2.02 970 2.22 1011 2.43 1049 2.65 1084 2.87 1118 3.09 1152 3.29 1189 3.51

4000 639 1.22 713 1.48 780 1.66 838 1.83 890 2.02 939 2.22 984 2.44 1023 2.66 1059 2.89 1093 3.11 1126 3.33 1160 3.54 1197 3.77

4250 667 1.43 741 1.69 805 1.86 859 2.02 909 2.22 956 2.45 998 2.68 1036 2.92 1070 3.15 1103 3.37 1135 3.59 1169 3.81 1207 4.05

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Total Static Pressure − in. w.g.

Page 14

Page 15

BLOWER DATA

120S STANDARD EFFICIENCY BELT DRIVE BLOWER − BASE UNIT

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE. FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

Then determine from blower table blower motor output required.

See page 17 for blower motors and drives.

See page 17 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

MINIMUM AIR VOLUME REQUIRED FOR USE WITH OPTIONAL ELECTRIC HEAT (Maximum Static Pressure - 2.0 in. w.g.)

15 kW, 22.5 kW, 30 kW and 45 kW - 2800 cfm

60 kW - 4000 cfm

Total

Air

Volume

cfm

2000 593 0.11 636 0.07 682 0.10 731 0.22 784 0.60 840 0.96 898 1.26 948 1.38 996 1.47 1045 1.57 1092 1.71 1140 1.92 1188 2.32

2250 604 0.15 645 0.11 690 0.15 739 0.39 790 0.74 846 1.08 901 1.34 953 1.48 1002 1.57 1052 1.70 1100 1.86 1149 2.09 1197 2.42

2500 615 0.19 655 0.15 699 0.20 747 0.55 797 0.89 851 1.20 906 1.44 959 1.58 1009 1.68 1059 1.83 1108 2.01 1158 2.26 1206 2.52

2750 626 0.23 666 0.19 709 0.37 755 0.71 805 1.03 858 1.32 912 1.55 966 1.70 1017 1.81 1067 1.97 111 7 2.17 1166 2.44 1215 2.71

3000 637 0.27 677 0.24 719 0.55 764 0.87 813 1.18 866 1.45 920 1.67 975 1.82 1026 1.96 1076 2.13 1126 2.35 1176 2.63 1225 2.92

3250 650 0.31 688 0.43 730 0.73 775 1.04 823 1.34 875 1.60 930 1.81 985 1.97 1036 2.12 1086 2.31 1136 2.54 1186 2.83 1235 3.13

3500 663 0.35 700 0.63 741 0.92 786 1.22 834 1.50 886 1.76 942 1.96 997 2.14 1048 2.31 1097 2.51 1147 2.75 1196 3.04 1245 3.35

3750 676 0.57 714 0.84 754 1.12 798 1.41 846 1.68 899 1.93 956 2.14 1010 2.32 1060 2.51 1109 2.72 1158 2.98 1207 3.27 1255 3.58

4000 691 0.79 728 1.05 768 1.33 812 1.61 860 1.88 914 2.12 971 2.34 1023 2.53 1072 2.73 1121 2.95 1169 3.22 1218 3.51 1266 3.83

4250 706 1.03 743 1.28 783 1.55 827 1.82 876 2.09 931 2.33 987 2.55 1037 2.76 1085 2.97 1133 3.20 1181 3.47 1229 3.76 1277 4.08

4500 722 1.27 759 1.52 799 1.78 844 2.05 894 2.31 949 2.56 1003 2.79 1052 3.00 1098 3.22 1145 3.46 1193 3.73 1241 4.03 1289 4.34

4750 739 1.53 776 1.77 817 2.03 862 2.30 913 2.56 968 2.81 1020 3.04 1066 3.27 111 2 3.49 1158 3.74 1205 4.01 1253 4.30 1301 4.61

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Total Static Pressure − in. w.g.

5000 757 1.79 794 2.04 835 2.30 882 2.56 934 2.83 988 3.08 1036 3.32 1081 3.55 1

125 3.78 1171 4.02 1218 4.29 1265 4.59 1312 4.89

Page 15

Page 16

BLOWER DATA

120H HIGH EFFICIENCY AND 150S STANDARD EFFICIENCY BELT DRIVE BLOWER − BASE UNIT

BLOWER TABLE INCLUDES RESISTANCE FOR BASE UNIT ONLY (NO HEAT SECTION) WITH DRY INDOOR COIL AND AIR

FILTERS IN PLACE. FOR ALL UNITS ADD:

1 − Wet indoor coil air resistance of selected unit.

2 − Any factory installed options air resistance (heat section, economizer, etc.)

3 − Any eld installed accessories air resistance (duct resistance, diffuser, etc.)

Then determine from blower table blower motor output required.

See page 17 for blower motors and drives.

See page 17 for wet coil and option/accessory air resistance data.

MAXIMUM STATIC PRESSURE WITH GAS HEAT - 2.0 in. w.g.

MINIMUM AIR VOLUME REQUIRED FOR USE WITH OPTIONAL ELECTRIC HEAT (Maximum Static Pressure - 2.0 in. w.g.)

15 kW, 22.5 kW, 30 kW and 45 kW - 2800 cfm

60 kW - 4000 cfm

Total

Air

Volume

cfm

2000 497 0.25 558 0.44 624 0.6 694 0.74 764 0.85 830 0.99 889 1.16 943 1.34 994 1.52 1045 1.71 1096 1.89 1146 2.08 1197 2.27

2250 511 0.34 573 0.52 638 0.68 708 0.82 776 0.94 839 1.09 896 1.26 948 1.45 998 1.64 1048 1.83 1098 2.01 1149 2.2 1200 2.4

2500 527 0.44 589 0.62 654 0.78 723 0.91 789 1.05 850 1.21 904 1.39 955 1.58 1003 1.77 1052 1.96 1101 2.14 1152 2.33 1203 2.53

2750 545 0.55 606 0.72 672 0.88 740 1.03 804 1.17 861 1.34 914 1.53 962 1.72 1010 1.92 1057 2.10 1105 2.29 1154 2.47 1206 2.68

3000 564 0.66 626 0.84 692 1.01 759 1.16 819 1.32 874 1.49 924 1.68 971 1.88 1017 2.08 1063 2.26 1110 2.44 1158 2.63 1208 2.83

3250 585 0.79 648 0.98 714 1.14 778 1.31 836 1.48 887 1.66 935 1.86 981 2.06 1026 2.26 1071 2.45 1117 2.63 1163 2.80 1213 3.00

3500 607 0.93 672 1.13 737 1.31 798 1.48 852 1.66 901 1.85 948 2.05 993 2.26 1037 2.46 1081 2.65 1125 2.83 1171 3.01 1221 3.21

3750 632 1.10 698 1.31 762 1.50 819 1.67 869 1.86 915 2.05 961 2.25 1005 2.47 1049 2.68 1092 2.88 1136 3.05 1181 3.24 1231 3.45

4000 660 1.30 726 1.52 787 1.70 838 1.87 885 2.06 930 2.26 974 2.48 1018 2.71 1062 2.93 1105 3.12 1149 3.30 1194 3.49 1245 3.72

4250 691 1.53 755 1.75 810 1.91 857 2.07 901 2.27 945 2.50 990 2.74 1034 2.98 1077 3.20 1120 3.39 1163 3.58 1210 3.79 1262 4.03

4500 724 1.78 783 1.98 831 2.12 874 2.28 917 2.50 962 2.75 1006 3.02 1051 3.27 1094 3.49 1137 3.70 1181 3.89 1228 4.11 1281 4.38

4750 757 2.05 809 2.20 851 2.33 891 2.51 935 2.76 980 3.05 1025 3.33 1070 3.59 111 3 3.82 1156 4.03 1201 4.24 1249 4.47 1303 4.75

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

Total Static Pressure − in. w.g.

5000 787 2.31 831 2.43 870 2.57 910 2.78 954 3.06 1000 3.38 1046 3.68 1091 3.95 1

5250 814 2.55 852 2.66 889 2.83 930 3.09 975 3.41 1023 3.76 1070 4.08 111 5 4.35 1159 4.59 1203 4.81 1248 5.03 1297 5.27 1350 5.53

5500 835 2.78 871 2.91 909 3.13 952 3.44 999 3.81 1049 4.18 1096 4.51 1142 4.79 1186 5.03 1229 5.24 1275 5.46 1324 5.69

5750 854 3.01 890 3.19 930 3.48 977 3.86 1027 4.27 1078 4.66 1126 4.99 1171 5.26 1214 5.49 1258 5.70

6000 871 3.26 910 3.53 955 3.90 1006 4.34 1060 4.80 1111 5.19 1158 5.51

6250 890 3.57 934 3.94 985 4.41 1041 4.91 1096 5.38

135 4.19 1178 4.40 1224 4.62 1272 4.86 1325 5.13

- - - - - -

- - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Page 16

Page 17

BLOWER DATA

FACTORY INSTALLED BELT DRIVE KIT SPECIFICATIONS

Nominal

hp

2 2.3 1 590 - 890

2 2.3 2 800 - 1105

2 2.3 3 795 - 1195

3 3.45 4 730 - 970

3 3.45 5 940 - 1200

3 3.45 6 1015 - 1300

5 5.75 10 900 - 1135

5 5.75 11 1040 - 1315

5 5.75 12 1125 - 1425

NOTE - Using total air volume and system static pressure requirements determine from blower performance tables rpm and motor output required. Maximum usable

output of motors furnished are shown. In Canada, nominal motor output is also maximum usable motor output. If motors of comparable output are used, be sure to keep

within the service factor limitations outlined on the motor nameplate.

NOTE – Units equipped with supply air inverter option are limited to a motor service factor of 1.0.

POWER EXHAUST FAN PERFORMANCE

Return Air System Static Pressure Air Volume Exhausted

Maximum

Drive Kit Number RPM Range

hp

in. w.g. cfm

0 3175

0.05 2955

0.10 2685

0.15 2410

0.20 2165

0.25 1920

0.30 1420

0.35 1200

FACTORY INSTALLED OPTIONS/FIELD INSTALLED ACCESSORY AIR RESISTANCE - in. w.g.

Air

Volume

cfm

Wet Indoor Coil

092, 102 120, 150

Gas Heat Exchanger

Standard

Heat

Medium

Heat

High

Heat

Electric

Heat

Econo-

mizer

1750 0.04 0.04 0.06 0.02 0.02 0.03 0.05 0.01 0.03

2000 0.05 0.05 0.07 0.05 0.06 0.03 0.06 0.01 0.03

2250 0.06 0.06 0.07 0.07 0.08 0.04 0.08 0.01 0.04

2500 0.07 0.07 0.09 0.10 0.11 0.04 0.11 0.01 0.05

2750 0.08 0.08 0.09 0.11 0.12 0.05 0.12 0.02 0.05

3000 0.10 0.09 0.11 0.12 0.13 0.06 0.13 0.02 0.06

3250 0.11 0.10 0.12 0.15 0.16 0.06 0.15 0.02 0.06

3500 0.12 0.11 0.12 0.16 0.17 0.09 0.15 0.03 0.07

3750 0.14 0.13 0.14 0.19 0.20 0.09 0.15 0.03 0.08

4000 0.15 0.14 0.14 0.21 0.22 0.09 0.19 0.04 0.08

4250 0.17 0.15 0.14 0.24 0.28 0.13 0.19 0.04 0.09

4500 0.19 0.17 0.15 0.26 0.32 0.14 0.22 0.04 0.09

4750 0.20 0.18 0.16 0.29 0.37 0.17 0.25 0.05 0.10

5000 0.22 0.20 0.16 0.34 0.43 0.20 0.29 0.06 0.10

5250 0.24 0.22 0.16 0.37 0.47 0.22 0.32 0.06 0.11

5500 0.25 0.23 0.18 0.44 0.54 0.25 0.34 0.07 0.12

5750 0.27 0.25 0.19 0.49 0.59 0.31 0.45 0.07 0.12

6000 0.29 0.27 0.20 0.54 0.64 0.33 0.52 0.08 0.13

Filters

MERV 8 MERV 13

Page 17

Page 18

MANUFACTURER'S NUMBERS

TABLE 3

DRIVE

NO.

1 1VP34x7/8 31K6901 AK61x1 100244-20 AX54 100245-25

2 1VP40x7/8 79J0301 AK59x1 31K6801 AX55 100245-26

3 1VP34x7/8 31K6901 AK46x1 100244-17 AX52 100245-33

4 1VP44x7/8 53J9601 AK74x1 100244-21 AX58 100245-34

5 1VP50x7/8 98J0001 AK69x1 37L4701 AX58 100245-34

6 1VP50x7/8 98J0001 AK64x1 12L2501 AX57 100245-28

10 1VP50x1-1/8 P-8-1977 BK77x1 49K4001 BX59 59A5001

11 1VP50x1-1/8 P-8-1977 BK67x1 100244-24 BX57 78L5301

12 1VP50x1-1/8 P-8-1977 BK62x1 100244-23 BX56 100245-11

ADJUSTABLE SHEAVE FIXED SHEAVE BELT

BROWNING NO. OEM PART NO. BROWNING NO. OEM PART NO. BROWNING NO. OEM PART NO.

Cooling Start-Up

DRIVE COMPONENTS

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant,

reclaim the charge,

evacuate the system, and add

required nameplate charge.

IMPORTANT

If unit is equipped with a crankcase heater. Make

sure heater is energized 24 hours before unit startup to prevent compressor damage as a result of

slugging.

A-Operation

Supply Air Inverter Units - Refer to the Inverter

Start-Up section.

1- Initiate first and second stage cooling demands

according to instructions provided with thermostat.

2- No Economizer Installed in Unit -

A first-stage cooling demand (Y1) will energize

NOTE - System charging is not recommended below

60F (15C). In temperatures below 60F (15C), the

charge must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1- Make sure outdoor coil is clean. Attach gauge

manifolds and operate unit at full CFM in cooling mode

with economizer disabled until system stabilizes

(approximately five minutes). Make sure all outdoor air

dampers are closed.

REFRIGERANT STAGES

compressor 1 and both condenser fans. An

increased cooling demand (Y2) will energize

compressor 2.

CONDENSER COIL

KG/KC 092 - Stage 1

KG/KC 102, 120, 150 - Stage 2

Units Equipped With Economizer -

When outdoor air is acceptable, a first-stage

cooling demand (Y1) will energize the economizer.

An increased cooling demand (Y2) will energize

compressor 1 and both condenser fans. When

outdoor air is not acceptable unit will operate as

though no economizer is installed.

3- Units contain two refrigerant circuits or stages. See

figure 17.

4- Each refrigerant circuit is separately charged with

R-410A refrigerant. See unit rating plate for correct

amount of charge.

5- Refer to Cooling Operation and Adjustment section for

proper method to check refrigerant charge.

B-Refrigerant Charge and Check - All-Aluminum Coil

WARNING-Do not exceed nameplate charge under

any condition.

Page 18

CONDENSER COIL

KG/KC 092 - Stage 2

KG/KC 102, 120, 150 - Stage 1

EVAPORATOR

COIL STAGE 2

2

1

FIGURE 17

(BOTH FANS ARE ENERGIZED

WITH A Y1 DEMAND)

EVAPORATOR

COIL STAGE 1

Page 19

2- Check each system separately with all stages

operating. Compare the normal operating pressures

(see tables 4 - 10) to the pressures obtained from the

gauges. Check unit components if there are

significant differences.

3- Measure the outdoor ambient temperature and the

suction pressure. Refer to the appropriate circuit

charging curve to determine a target liquid

temperature.

Note - Pressures are listed for sea level applications.

4- Use the same thermometer to accurately measure the

liquid temperature (in the outdoor section).

If measured liquid temperature is higher than

the target liquid temperature, add refrigerant to

the system.

092S Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Circuit 1

Circuit 2

Suct

(psig)

103 243 107 282 11 0 325 11 3 371 116 423 119 473

110 249 113 286 11 7 327 120 369 123 422 126 472

122 259 127 297 131 339 135 386 139 436 142 493

135 272 140 310 145 351 150 396 155 447 159 501

106 243 111 282 113 323 117 368 119 417 123 466

113 249 117 285 120 325 123 365 126 415 130 468

127 268 131 304 135 342 139 385 143 434 147 493

141 287 146 324 150 363 154 405 159 451 163 502

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

092S Charging Curves

130

Circuit 1

Circuit 2

120

TABLE 4

Disc

(psig)

If measured liquid temperature is lower than

the target liquid temperature, recover some

refrigerant from the system.

5- Add or remove charge in increments. Allow the

system to stabilize each time refrigerant is added or

removed.

6- Continue the process until measured liquid

temperature agrees with the target liquid

temperature. Do not go below the target liquid

temperature when adjusting charge. Note that

suction pressure can change as charge is adjusted.

7- Example KG/KC 092S Circuit 1: At 95°F outdoor

ambient and a measured suction pressure of

130psig, the target liquid temperature is 103°F. For a

measured liquid temperature of 112°F, add charge in

increments until measured liquid temperature agrees

with the target liquid temperature.

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Outdoor Temperature (°F)

115°

110

100

90

Liquid Temperature ( ° F)

80

70

60

100 110 120 130 140 150 160

105°

95°

85°

75°

65°

Suction Pressure (psig)

Page 19

Page 20

Circuit 1

Circuit 2

TABLE 5

102S Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

111 252 11 4 289 117 332 11 9 378 122 428 125 483

118 256 122 295 125 337 128 383 131 434 133 489

132 269 136 307 141 350 145 396 149 447 151 502

148 285 152 322 157 367 161 413 166 465 170 518

111 249 11 4 288 117 331 11 9 377 121 428 124 482

118 254 122 295 125 336 128 383 129 433 130 483

132 271 136 308 141 350 145 397 148 447 147 500

149 291 152 325 157 371 162 417 166 468 168 520

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Liquid Temperature (° F)

130

120

110

100

90

80

70

Circuit 1

Circuit 2

Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

65°

60

110 120 130 140 150 160 170

Suction Pressure (psig)

Page 20

Page 21

Circuit

1

Circuit

2

TABLE 6

120S Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

108 263 110 303 109 345 11 8 399 121 452 124 509

115 269 119 308 123 352 125 398 128 454 132 516

130 290 135 328 139 369 143 420 147 474 150 537

148 319 151 354 155 398 160 440 166 508 170 567

108 258 109 298 107 340 11 7 394 120 447 123 506

116 265 119 305 122 350 124 394 127 450 130 512

132 289 135 326 139 366 143 417 146 473 149 539

149 319 152 354 156 397 160 437 165 505 170 566

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

130

120

110

100

Liquid Temperature ( ° F)

90

80

70

Circuit 1

Circuit 2

120S Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

65°

60

100 110 120 130 140 150 160 170

Suction Pressure (psig)

Page 21

Page 22

Circuit 1

Circuit 2

TABLE 7

150S Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

110 257 113 296 115 338 117 383 119 432 122 486

116 263 120 302 123 344 125 391 128 441 131 495

131 276 135 315 139 358 142 405 145 457 148 514

148 293 152 332 156 375 160 424 164 476 168 533

109 249 112 287 115 328 118 375 120 425 123 481

115 255 119 294 122 336 126 383 128 434 131 490

130 269 134 308 138 350 142 400 145 450 148 508

145 288 150 325 154 368 159 416 163 467 168 525

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

(psig)

Disc

Liquid Temperature ( ° F)

130

120

110

100

90

80

70

Circuit 1

Circuit 2

150S Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

65°

60

100 110 120 130 140 150 160 170

Suction Pressure (psig)

Page 22

Page 23

Circuit 1

Circuit 2

TABLE 8

092H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

110 234 112 273 11 5 317 116 367 119 428 121 503

118 236 120 275 123 319 125 369 127 426 130 497

136 240 139 278 142 320 145 369 147 422 150 483

157 248 159 284 163 325 166 373 168 424 171 482

112 232 115 269 11 7 313 118 371 120 441 122 523

119 237 122 273 125 316 128 367 129 431 132 508

134 243 139 279 143 320 146 370 149 424 151 488

155 253 156 287 161 328 165 376 169 427 172 487

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Liquid Temperature ( ° F)

120

110

100

90

80

70

Circuit 1

Circuit 2

092H Charging Curves

−

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

65°

60

100 110 120 130 140 150 160 170 180

Suction Pressure (psig)

Page 23

Page 24

Circuit 1

Circuit 2

TABLE 9

102H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

111 234 113 273 115 316 117 365 119 419 121 480

120 236 121 275 124 317 126 365 128 417 130 476

139 241 142 279 144 321 147 367 148 420 151 476

156 251 160 287 164 328 168 374 171 424 175 480

113 233 116 273 118 317 120 371 122 439 125 530

122 233 124 273 126 317 128 369 131 428 134 502

137 242 142 278 145 320 148 369 150 426 153 489

155 251 159 288 164 328 168 375 171 429 174 488

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

(psig)

Disc

Liquid Temperature ( ° F)

120

110

100

90

80

70

Circuit 1

Circuit 2

102H Charging Curves

Outdoor Temperature (°F)

115°

105°

95°

85°

75°

65°

60

110 120 130 140 150 160 170 180

Suction Pressure (psig)

Page 24

Page 25

Circuit 1

Circuit 2

130

120

TABLE 10

120H Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

113 251 11 3 290 112 331 116 383 117 439 120 520

120 254 123 293 124 338 126 388 127 441 129 510

139 264 142 303 144 345 147 393 146 445 148 510

155 278 160 314 164 357 167 403 169 456 173 512

110 251 111 287 111 329 114 388 11 7 454 120 538

119 249 120 291 122 336 124 389 126 447 128 520

139 259 142 297 143 337 145 390 144 444 149 514

155 274 160 307 164 349 166 393 169 448 170 510

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

(psig)

120H Charging Curves

Circuit 1

Circuit 2

Outdoor Temperature (°F)

115°

Disc

110

100

90

Liquid Temperature (° F)

80

70

60

100 110 120 130 140 150 160 170 180

Suction Pressure (psig)

C-Compressor Controls

See unit wiring diagram to determine which controls are

used on each unit. Optional controls are identified on

wiring diagrams by arrows at junction points.

1- High Pressure Switches (S4, S7)

Compressor circuits are protected by a high pressure

switch which cuts out at 640 psig +

+

70 kPa).

10 psig (4413 kPa

105°

95°

85°

75°

65°

evaporator freeze-up. Switches reset when

evaporator coil temperature reaches 58°F (15°C).

3- Crankcase Heater (HR1, HR2)

Compressors have belly band compressor oil heaters

which must be on 24 hours before running

compressors. Energize by setting thermostat so that

there is no cooling demand, to prevent compressor

from cycling, and apply power to unit.

2- Freezestats (S49, S50)

Switches de-energize compressors when evaporator

coil temperature falls below 29°F (-2°C) to prevent

Page 25

Page 26

Gas Heat Start-Up (Gas Units)

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

Electric shock hazard. Can cause injury

or death. Do not use this unit if any part

has been under water. Immediately call

a qualified service technician to inspect

the unit and to replace any part of the

control system and any gas control

which has been under water.

This unit is equipped with an automatic spark ignition

system. There is no pilot. In case of a safety shutdown,

move thermostat switch to OFF and return the thermostat

switch to HEAT to reset ignition control.

A-Placing Unit In Operation

WARNING

Danger of explosion and fire. Can cause

injury or product or property damage.

You must follow these instructions

exactly.

WARNING

Danger of explosion. Can cause injury

or product or property damage. If over

heating occurs or if gas supply fails to

shut off, shut off the manual gas valve

to the appliance before shutting off

electrical supply.

WARNING

Electric shock hazard. Can cause

injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF at

disconnect switch(es). Unit may have

multiple power supplies.

WARNING

SMOKE POTENTIAL

The heat exchanger in this unit could be a source of

smoke on initial firing. Take precautions with re

spect to building occupants and property. Vent ini

tial supply air outside when possible.

Gas Valve Operation for Honeywell

VR8205Q/VR8305Q and White Rodgers 36H54 (figure

18 and 19)

1- Set thermostat to lowest setting.

2- Turn off all electrical power to appliance.

3- This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

4- Open or remove the heat section access panel.

WHITE RODGERS 36H54 GAS VALVE

INLET

PRESSURE

TAP

GAS VALVE SWITCH SHOWN IN ON POSITION.

Two- Stag e

MANIFOLD

PRESSURE

TAP

HIGH FIRE

ADJUSTMENT

LOW FIRE

ADJUSTMENT

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

WARNING

Danger of explosion. Can cause injury or

death. Do not attempt to light manually.

Unit has a direct spark ignition system.

Page 26

FIGURE 18

HONEYWELL VR8205Q/VR8305Q SERIES GAS VALVE

HIGH FIRE

ADJUSTMENT

INLET

PRESSURE

TAP

GAS VALVE KNOB IS SHOWN IN OFF POSITION.

LOW FIRE

ADJUSTMENT

FIGURE 19

MANIFOLD

PRESSURE

TAP

Page 27

5- Turn gas valve switch to OFF. See figure 18. On

Honeywell VR8305Q gas valves, turn the knob on the

gas valve clockwise to “OFF”. Do not force. See

figure 19.

6- Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your

gas supplier from a neighbor's phone. Follow the gas

supplier's instructions. If you do not smell gas, go to

the next step.

7- Turn gas valve switch to ON. See figure 18. On

Honeywell VR8305Q gas valves, turn the knob on the

gas valve counterclockwise

force. See figure 19.

8- Close or replace the heat section access panel.

9- Turn on all electrical power to appliance.

10- Set thermostat to desired setting.

11- The ignition sequence will start.

12- If the appliance does not light the first time (gas line

not fully purged), it will attempt up to two more

ignitions before locking out.

13- If lockout occurs, repeat steps 1 through 10.

14- If the appliance will not operate, follow the

instructions “Turning Off Gas to Appliance” and call

your service technician or gas supplier.

Turning Off Gas to Unit

1- If using an electromechanical thermostat, set to the

lowest setting.

2- Before performing any service, turn off all electrical

power to the appliance.

3- Open or remove the heat section access panel.

4- Turn gas valve switch to OFF. On Honeywell

VR8305Q gas valves, turn the knob on the gas valve

clockwise

5- Close or replace the heat section access panel.

to “OFF”. Do not force.

to “ON”. Do not

WARNING

3- Spark ignitor energizes and gas valve solenoid opens.

4- Spark ignites gas, ignition sensor proves the flame

and combustion continues.

5- If flame is not detected after first ignition trial, ignition

control will repeat steps 3 and 4 two more times

before locking out the gas valve.

6- For troubleshooting purposes, an ignition attempt

after lock out may be re-established manually. Move

thermostat to “OFF” and return thermostat switch to

“HEAT” position.

B-Ignition Control Diagnostic LED's

IGNITION CONTROL HEARTBEAT LED STATUS

LED

Flashes

Slow Normal operation. No call for heat.

Fast Normal operation. Call for heat.

Steady Off

Steady On Control internal failure.

2 Lockout. Failed to detect or sustain flame.

3

4

5

C-Limit Controls

Limit controls are factory-set and are not adjustable. The

primary limit is located on the blower deck to the right of

blower assembly.

D-Heating Adjustment

Internal control fault OR no power to

control OR Gas Valve Relay Fault.

Prove switch open or closed or rollout

switch open.

Limit switch is open and/or limit has

opened three times.

Flame sensed but gas valve solenoid

not energized.

TABLE 11

Indicates

Danger of explosion. Can cause injury or

death. Do not attempt to light manually.

Unit has a direct spark ignition system.

Heating Operation and Adjustments

(Gas Units)

A-Heating Sequence of Operation

1- On a heating demand the combustion air inducer

starts immediately.

2- Combustion air pressure switch proves inducer

operation. After a 30-second pre-purge, power is

allowed to ignition control. Switch is factory set and

requires no adjustment.

Page 27

Main burners are factory-set and do not require

adjustment.

The following manifold pressures are listed on the gas valve.

Natural Gas Units - Low Fire - 1.6” w.c.

Natural Gas Units - High Fire - 3.7” w.c.

LP Gas Units - Low Fire - 5.5” w.c.

LP Gas Units - High Fire - 10.5” w.c.

(not adjustable)

(not adjustable)

Electric Heat Start-Up (KCA Units)

Optional electric heat will stage on and cycle with

thermostat demand. Number of stages of electric heat will

vary depending on electric heat assembly. See electric

heat wiring diagram on unit for sequence of operation.

Page 28

Inverter Start-Up

A-General

Units equipped with a supply air inverter are available

which provide two blower speeds. The blower will operate

at lower speeds when cooling demand is low and higher

speeds when cooling demand is high. This results in

lower energy consumption.

Inverter-driven blowers will operate at high speed during

ventilation (blower “G” only signal) but can be adjusted to

operate at low speed.

Low speed is approximately 2/3 of the full speed RPM.

B-Set Maximum Blower CFM

1- Initiate a blower (G) only signal from the room

thermostat or control system.

2- Adjust the blower pulley to deliver the full (high

speed) CFM in the typical manner. See Determining

Unit CFM in the Blower Operation and Adjustment

section.

C-Set Blower Speed During Ventilation

To save energy during ventilation, the blower speed can

be set to low. This is accomplished by changing the

ventilation speed switch on the VFD control board to “LO”.

See figure 20.

Note - On units equipped with an economizer, set damper

minimum position as shown in the next section. After

adjusting the low speed minimum position, the ventilation

speed switch will be in the “LO” position.

D-Set Damper Minimum Position (Units W/ Economizer)

Note - Intake air CFM can also be determined using the

outdoor air temperature, return air temperature and

mixed air temperature. Refer to the economizer or

outdoor air damper installation instructions.

Set Low Speed Minimum Position

1- Initiate a blower (G) only AND occupied demand from

the room thermostat or control system.

2- Set the ventilation speed switch on the VFD control

board to “LO”.

3- Rotate the low speed potentiometer on the VFD

control board to set the low speed minimum damper

position.

4- Measure the intake air CFM. If the CFM is lower than

the design specified CFM for ventilation air, use the

potentiometer to increase the damper percent open.

If the CFM is higher than specified, decrease the

damper percent open.

Note - Intake air CFM can also be determined using the

outdoor air temperature, return air temperature and

mixed air temperature. Refer to the economizer or

outdoor air damper installation instructions.

LVC2 (A183) VFD CONTROL BOARD

VENTILATION

SPEED SWITCH

POWER

LED

To maintain required minimum ventilation air volumes

when the unit is in the occupied mode, two minimum

damper positions must be set. A high and a low speed

potentiometer are provided on the VFD control board to

adjust minimum damper position. See figure 20.

Set High Speed Minimum Position

1- Initiate a blower (G) only AND occupied demand from

the room thermostat or control system.

2- Set the ventilation speed switch on the VFD control

board to “HI”.

3- Rotate the high speed potentiometer on the VFD

control board to set the high speed minimum damper

position.

4- Measure the intake air CFM. If the CFM is lower than

the design specified CFM for ventilation air, use the

potentiometer to increase the damper percent open.

If the CFM is higher than specified, decrease the

damper percent open.

Page 28

LOW SPEED

MINIMUM POSITION

POTENTIOMETER

HIGH SPEED

MINIMUM POSITION

POTENTIOMETER

FIGURE 20

Troubleshoot LVC2 Board (A183)

Refer to wiring diagram sections B (unit), C (control) and

D (economizer) located on inside of unit panels.

1- Inspect the LVC2 for damaged components. Replace

the LVC2 if damaged components are found.

2- Check all wire connections to LVC2; secure if loose.

3- Check for 24VAC signal at the thermostat blower

input (G to GND terminal). See figure 21.

Page 29

LVC2 BOARD TERMINAL DESIGNATIONS

24VDC

VFD INPUTS;

H2 HEADER

THERMOSTAT INPUTS;

24VAC

H1 HEADER

FIGURE 21

4- If there is no thermostat signal, troubleshoot back

toward the thermostat.

5- Check the power LED on the board. See figure 20.

6- If the power LED is not on, check voltage between

LVC2 terminals PC (H2-1) and SD (H2-5). Voltage

should read 24VDC.

7- If voltage does not read 24VDC, disconnect the H2

header from the LVC2 VFD inputs terminal block (to

make sure the LVC2 is not shorting 24VDC supply

from the inverter). Measure the voltage between the

end terminals on the H2 header. If 24VDC is present,

replace the LVC2 board. If no voltage is read,

troubleshoot the VFD.

8- When LVC2 24VAC thermostat blower (G) input and

24VDC power are present, check the LVC2 low and

high speed outputs. The LVC2 uses inverse logic to

enable the blower; 1VDC will be read at the enabled

blower speed terminal. See table 12.

9- If all inputs are correct and the unit still does not

operate as intended, replace LVC2 board.

TABLE 12

LVC2 BOARD BLOWER OUTPUTS

Output

Terminals

RL-SD 1VDC

RH-SD 24VDC

RL-SD 24VDC

RH-SD 1VDC

RL-SD 1VDC

RH-SD 1VDC

RL-SD 24VDC

RH-SD 24VDC

Voltage Blower Operation

Low Speed

High Speed

Illegal State

(replace board)

Blower Off

(replace board)

Page 29

Page 30

Service

The unit should be inspected once a year by a qualified

service technician.

C-Burners (Gas Units)

Periodically examine burner flames for proper

appearance during the heating season. Before each

heating season examine the burners for any deposits or

blockage which may have occurred.

CAUTION

Label all wires prior to disconnection when servic

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

WARNING

This product contains a chemical known to the

State of California to cause cancer, birth defects, or

other reproductive harm.

A-Filters

Units are equipped with four 20 X 25 X 2” filters. Filters

should be checked monthly and replaced when

necessary with filters of like kind and size. Take note of

air flow direction marking on filter frame when

reinstalling filters. See figure 22.

NOTE-Filters must be U.L.C. certified or equivalent for