Page 1

507739-01

10/2017

Supersedes 9/2017

iComfort® M30 Smart Thermostat

Installation and Setup Guide

Disponible en español en www.LennoxPros.com.

Page 2

2

Tables of Contents

Shipping and Packing List ........................... 3

Thermostat .................................................... 3

Wall Plate Dimensions (H x W) ............................... 3

Compressor Short-Cycle Protection

(Compressor Protect) .............................................. 3

Installation Considerations ......................... 4

Outdoor Temperature Sensor Installation

(Optional) ....................................................... 5

Thermostat Installation ............................... 5

New Installation ....................................................... 5

Replacement Installation ......................................... 6

Common Installation Practices ................................ 6

Thermostat Terminal Information ............................ 8

System Wiring Diagrams ......................................... 9

Connecting Thermostat Wiring ................................ 9

Supported Congurations ....................................... 9

Install Thermostat to Backplate ............................. 12

Commissioning and Advanced Settings .. 12

Commissioning ...................................................... 12

Advanced Settings ................................................ 15

Advanced Settings Parameter Descriptions .......... 18

Stage Control .............................................. 22

Wi-Fi Connection ........................................ 27

Connecting to Visible Home Wi-Fi Access Point ... 28

Connecting to Hidden Home Wi-Fi Access Point .. 28

Wireless Terminology ............................................ 29

Wireless Connectivity Troubleshooting Tips ... 29

Determining Wireless Connection Signal

Strength ................................................................. 29

Alert Codes ................................................. 30

System Test Modes .................................... 33

Save Energy Default ................................... 33

Dehumidication Control ........................... 34

Normal and Max .................................................... 34

Humiditrol ............................................................. 35

Auxiliary Dehumidier ........................................... 36

Humidication Control ............................... 36

Normal and Max .................................................... 37

Normal and Max Dew Point Control ...................... 37

Installer Checklist ....................................... 39

Index ............................................................ 40

Page 3

3

WARNING

This product contains a chemical known to the

State of California to cause cancer, birth defects,

or other reproductive harm.

Shipping and Packing List

Item Quantity

M30 Thermostat with backplate attached 1

Wall plate 1

Mounting screws (M3.5x25mm self-tapping screws) 2

Wall anchors 2

Warranty sheet 1

Installation & setup guide 1

User guide 1

System Wiring Diagrams Fold-Out Sheet 1

Thermostat

Unit Dimensions (H x W x D)

Dimensions: 3-5/16 x 4-5/16 x 7/8 in. (84 x 110 x

22mm)

Wall Plate Dimensions (H x W)

Dimensions: 4-1/2” x 5-3/4” (114 x 146mm)

ComPressor sHort-CyCle ProteCtion

(ComPressor ProteCt)

This thermostat is equipped with automatic

compressor protection to prevent potential damage

due to short cycling or extended power outages.

The non-adjustable short-cycle protection provides

a 5-minute delay between heating or cooling cycles

to prevent the compressor from being damaged.

NOTE: There is an option in advanced settings that

will allow this safety feature to be disabled.

By default it is set to ON. Short Cycle

protection is disabled during testing of the

outdoor unit. It is automatically reset once

the test is completed.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury or loss of life.

Installation and service must be performed

by a li censed professional HVAC installer (or

equivalent) or a service agency.

Page 4

4

IMPORTANT

In all applications, the M30 thermostat can only

be used with all residential units and approved

commercial split-system matches, and those

which meet the following installation criteria:

Installation uses 18 gauge thermostat wire or

larger and wire run length DOES NOT EXCEED

300 feet (91 meters).

Load from any thermostat connection is 1 AMP

or less.

WARNING

Always turn off power at the main power source by

switching the circuit breaker to the OFF position

before installing or removing this thermostat.

All wiring must conform to local and national

building and electrical codes and ordinances.

CAUTION

This is a 24VAC low-voltage thermostat. Do not

install on voltages higher than 30VAC.

Do not short (jumper) across terminals on the gas

valve or at the system control to test installation.

This will damage the thermostat and void the

warranty.

Installation Considerations

Before beginning installation, note the type of

equipment, number of stages, and any accessories

being installed. This thermostat is a 24VAC lowvoltage thermostat and requires a common wire to

the thermostat to operate.

• Shut off all power to system components before

installing thermostat.

• Make sure that all wiring conforms to local

and national building and electrical codes and

ordinances.

• Never short (jumper) across terminals on the gas

valve or at the system control to test installation.

This will damage the thermostat and void the

warranty.

• Never install thermostat on outside walls or in

direct sunlight.

Page 5

5

Outdoor Temperature Sensor

Installation (Optional)

Install the optional (purchase separately) outdoor

sensor (X2658) on a northern wall of the home,

away from direct sunlight or other heat sources that

may affect its sensitivity.

The sensor is required for:

• Outdoor temperature displays on the home

screen if enabled

• Balance point adjustment and control. The sensor

enables optimal heating equipment operation via

programmable balance points.

• Dew point humidity control

• Humiditrol EDA operation (required)

• Requires 22AWG thermostat wire or larger and

not to exceed 300 feet (91 meters) maximum run.

• Connects to To and Tc terminals on thermostat

Connect outdoor sensor to terminals Tc and To on

thermostat.

NOTE: If alert code 108 appears on the screen,

check your wiring connections to terminals

To and Tc on the thermostat. Check

resistances using the resistance table

provided in the outdoor sensor instruction.

Thermostat Installation

neW installation

The following procedure is for new installation or

installing the M30 to a new location in an existing

home.

1. Unpacked the thermostat and open the case

with a thin-blade screwdriver. Place between

wall base and unit and twist to separate unit

from base.

2. Select a location for the thermostat about 5

feet (1.5 meters) above the oor in an area with

good air circulation at average temperature.

3. Do not install the thermostat where it can be

affected by:

• Drafts or dead spots behind doors and in

corners.

• Building entrances or automatic doors

• Heat generating equipment such as kitchen

equipment

• Enclose environment unless a remote indoor

sensor is used.

• Hot or cold air from ducts.

• Radiant heat from sun or appliances.

• Concealed pipes and chimneys.

• Non-heated (non-cooled) areas such as an

outside wall behind the thermostat.

Page 6

6

4. Run thermostat wiring from indoor unit to

location where thermostat will be installed.

5. Drill or make opening through wall for thermostat

wiring 3/4” x 3/4” (19mm x 19mm).

6. Pull about 3 inches (76mm) of thermostat

wire through the opening and removed outer

thermostat wire jacket. This will help in routing

the thermostat wiring to the proper thermostat

terminals.

NOTE: Thermostat wires and outdoor sensor wire

can be run in the same bundle of wires if

needed.

7. Seal the hole in the wall with a suitable material

to prevent drafts from entering the thermostat

case. Not doing so could affect the thermostat’s

internal temperature sensor.

8. Trim 1/4 inch (6 mm) insulation from end of

each thermostat wire lead.

1/4”

rePlaCement installation

Use the following two steps to replace an existing

thermostat.

1. Remove existing thermostat.

2. Note the wire colors and what terminals they are

connected for future reference.

Common installation PraCtiCes

1. Use the provided wall plate as a template on

where to drill the mounting holes.

NOTE: Installation of wall plate is optional. Use

a eld-provided level to allow for proper

alignment.

(Use a level) Align Wall Plate

Use unit wall plate as template to mark desired

mounting nhole locations on wall.

Page 7

7

2. Drill 3/16” (5 mm) holes in wall for provided

wall anchors. Insert provided wall anchors into

drilled holes.

3. Remove back plate from main thermostat

assembly using a at-head screw driver.

4. Route thermostat and outdoor temperature

sensor (optional) wiring from wall through

center openings on wall plate (use is optional)

and back plate.

Wall Plate (optional)

Thermostat

Back Plate

Run thermostat wire

through openings

5. Secure back plate and wall plate (optional) to

wall with the two provided mounting screws.

Wall Plate (optional)

Thermostat

Back Plate

Screw

Page 8

8

tHermostat terminal information

Table 1. Terminal Designations

Terminal Purpose

Tc and To

Used for connection to an optional outdoor temperature sensor.

ACC1 and

ACC2

Default factory software setting for ACC (Accessory)

is off.

Terminal function setting can be changed by going to

settings > advanced settings > terminal settings.

Available settings are off, humidify and dehumidify.

Connect accessory to terminal ACC2 and change

software setting to the applicable type of accessory.

Power is supplied by R2 to ACC1 factory jumper.

NOTE: Do not remove the factory installed

jumper between ACC1 and R2 terminals

unless a secondary 24VAC power

source is connected to ACC1.

R2

This is the secondary 24VAC power source for ACC

(Accessory). The R2 terminal is connected to the

ACC1 terminal by factory provided jumper.

D/H

This terminal is for an optional dehumidier or humidier.

Factory default software setting is for dehumidify.

Terminal settings can be changed by going to set-

tings > advanced settings > terminal settings.

Available settings are off, humidify and dehumidify.

NOTE: The user interface refers to the terminal

as H/D.

W2

Second-stage heating (non-heat pump) or 4th stage

(heat pump).

Y2 Second-stage heating or cooling.

Table 1. Terminal Designations

Terminal Purpose

O/B

Heat pump reversing valve operations. When O (default) is selected under settings > advanced set-

tings > terminal settings, the relay is ON during

cooling and OFF during heating.

When B is selected, the relay is ON during heating

and OFF during cooling.

C Common 24VAC

G Fan relay

W1

First-stage heating (non-heat pump or emergency

heat) or third-stage heating (heat pump)

Y1 First-stage heating or cooling

R 24VAC power

Table 2. O/B Terminal Relationship States

State O/B Terminal Control

Power ON

O terminal : ON (If O terminal selected)

B terminal : OFF (If B terminal selected

Heat only or

emergency

heat mode

O terminal : always OFF

B terminal : always ON

Cool mode

only

O terminal : always ON

B terminal : always OFF

Page 9

9

Table 2. O/B Terminal Relationship States

State O/B Terminal Control

Heat/Cool

mode

During heating

O terminal : OFF

B terminal : ON

During cooling

O terminal : ON

B terminal : OFF

No Demand

The terminal continues the previous ON / OFF

state

Off mode

The terminal state continues the state before entering off mode

system Wiring Diagrams

For system diagrams, see the included fold-out

iComfort® M30 Smart Thermostat System

Diagrams sheet.

ConneCting tHermostat Wiring

Use “Table 1. Terminal Designations” on page 8

for connecting the thermostat wiring to the back

plate terminals.

If this is a replacement thermostat, connect

to terminals as noted when removing the old

thermostat. If terminals were different on old

thermostat, use “Table 1. Terminal Designations” on

page 8 and wiring diagrams provided in the kit.

NOTE: Remember to seal the hole in the wall with

a suitable material to prevent drafts from

entering the thermostat case. Not doing

so could affect the thermostat’s internal

temperature sensor.

sUPPorteD ConfigUrations

See “Table 3. Supported Congurations” on page

10.

Page 10

10

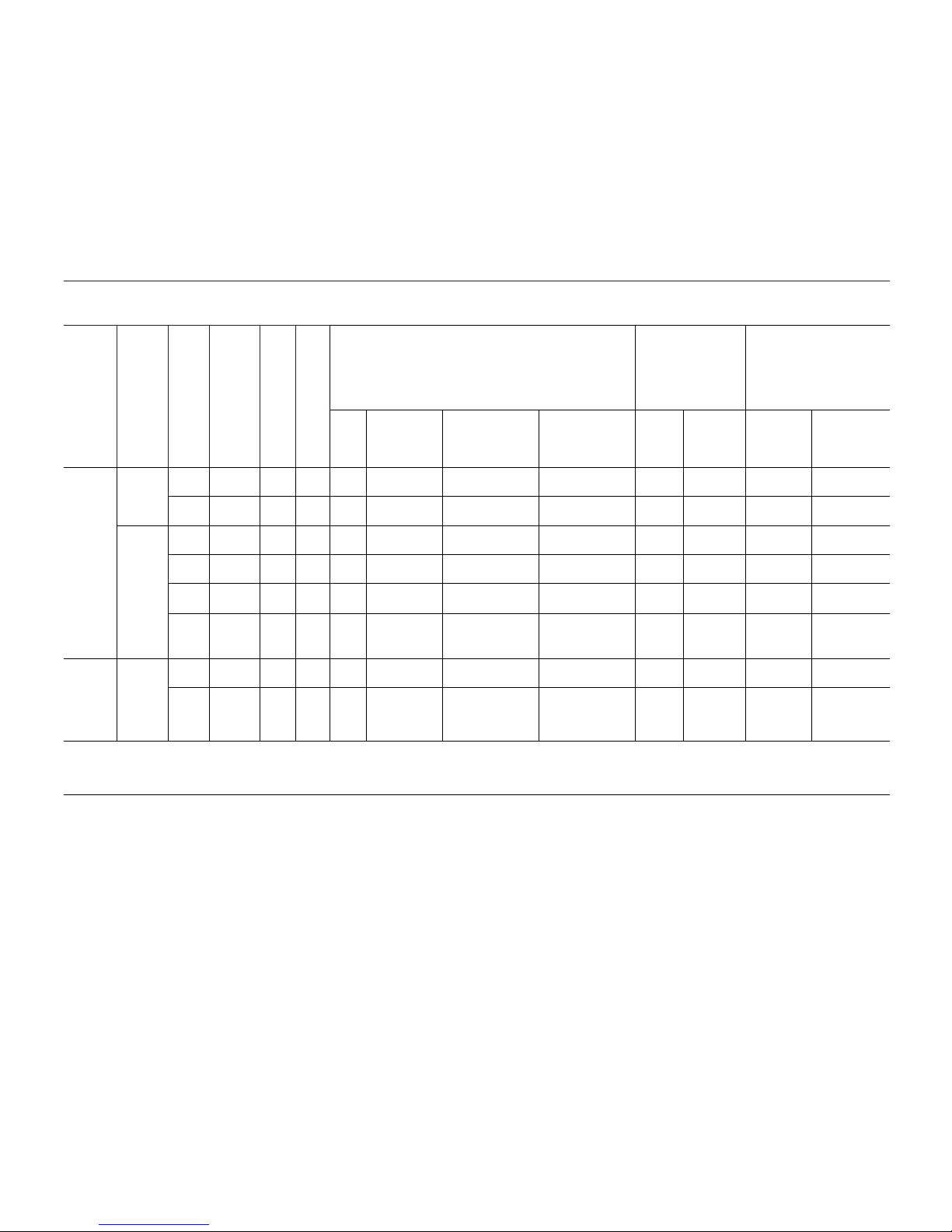

Table 3. Supported Congurations

Outdoor unit

setting

Indoor unit

setting

Comp. Stages

Indoor Heat

Stages

Heat Stages

Cool Stages

Heat Stage

EM Heat

Stage

Cool Stage

1st

2nd

3rd

4th

1st

2nd

1st

2nd

HP

No Heat

1 0 1 1 Y1 - - - - - Y1 -

2 0 2 2 Y1 Y1+Y2 - - - - Y1 Y1+Y2

Gas / Oil

1 1 2 1 Y1 W1 - - W1 - Y1 -

1 2 3 1 Y1 W1 W1+W2 - W1 W1+W2 Y1 -

2 1 3 2 Y1 Y1+Y2 W1 - W1 - Y1 Y1+Y2

2 2 4 2 Y1 Y1+Y2 W1 W1+ W2 W1 W1+W2 Y1 Y1+Y2

Elec

1 1 2 1 Y1 Y1+W1 - - W1 - Y1 -

1 2 3 1 Y1 Y1+W1 Y1+W1+W2 - W1 W1+W2 Y1 -

2 1 3 2 Y1 Y1+Y2 Y1+Y2+W1 - W1 - Y1 Y1+Y2

2 2 4 2 Y1 Y1+Y2 Y1+Y2+W1 Y1+Y2+W1 +W2 W1 W1+W2 Y1 Y1+Y2

Page 11

11

Table 3. Supported Congurations

Outdoor unit

setting

Indoor unit

setting

Comp. Stages

Indoor Heat

Stages

Heat Stages

Cool Stages

Heat Stage

EM Heat

Stage

Cool Stage

1st

2nd

3rd

4th

1st

2nd

1st

2nd

A/C

No Heat

1 0 - 1 - - - - - - Y1 -

2 0 - 2 - - - - - - Y1 Y1+Y2

Gas /

Oil or

Elect

1 1 1 1 W1 - - - - - Y1 -

1 2 2 1 W1 W1+W2 - - - - Y1 -

2 1 1 2 W1 - - - - - Y1 Y1+Y2

2 2 2 2 W1 W1+W2 - - - - Y1 Y1+Y2

No OU

Gas /

Oil or

Elect

0 1 1 0 W1 - - - - - - -

0 2 2 0 W1 W1+W2 - - - - - -

OU = Outdoor Unit

Elect = Electrical Heat

Page 12

12

install tHermostat to BaCkPlate

The thermostat assembly simply snaps onto the

back plate. Once secure to the back plate apply

power to the system. Thermostat should boot up

and go into the commissioning process.

Figure 1. Installing Thermostat

If power is applied and the thermostat screen

remains off, inspect and verify all wire connections.

Commissioning and Advanced Settings

After power is applied to the thermostat for the rst

time it displays the Lennox® “splash screen”.

The Installer is then presented with the several

Setup Screens to congure the system prior to

operation.

Commissioning

“Table 4. Commissioning Screens” on page 13

list all of the screens and parameters that can be

congured during the commissioning phase.

Page 13

13

Table 4. Commissioning Screens

MENU SETTING (default is bold) Notes:

DEALER INFO

Dealer ID Number Enter id

Installer can add the dealer number

and phone number using the keyboard tool.

Dealer Phone Number Enter phone

Name, email, website, dealer address (address1, address2, city, state and zip/postal code

GENERAL

Language

English

Français

Español

Country/Region

United States

Canada

Australia

GENERAL Date and Time

Time

Adjust the date and time using the

set date and set time tools.

Date

Time Zone\

Atlantic

Eastern

Central

Mountain

Pacic

Alaska

Hawaii

Samoa

Chamorro (Guam)

Page 14

14

Table 4. Commissioning Screens

MENU SETTING (default is bold) Notes:

GENERAL Date and Time

Daylight Savings On or Off

Temperature Units °F or °C

TERMINAL SETTINGS (See Terminal Settings on page 17)

SYSTEM SETUP (See System Setup on page 15)

OUTDOOR SENSOR (See Outdoor Sensor on page 16)

HUMIDITY Humidity Control

Off

Dehumidify

NOTIFICATIONS

(Reminders)

Replace Filter 1 Disabled

Adjustable 3, 6, 12, 24 months or

custom date, can be set to calendar

time or run-time.

Touch custom to access the Set

date Tool screen to input custom

date settings.

Replace Filter 2 Disabled

Replace UV Bulb Disabled

Replace Humidier Pad Disabled

PureAir Maintenance Disabled

Maintenance Reminder Disabled

Page 15

15

aDvanCeD settings

“Table 5. Advanced Settings” on page 15 list the menu options and parameters that can be set under the

Advance Settings menu option.

Table 5. Advanced Settings

MENU SETTING (default is bold) Notes:

SYSTEM

SETUP

Outdoor Unit

Type

Not Installed

1 Stage A/C Unit

2 Stage A/C Unit

1 Stage HP Unit

2 Stage HP Unit

Outdoor Unit Capacity - 36 kBtu Adjustable 18 to 60 kBu

Outdoor Unit 1st Stage Capac (capacity)

Adjustable 30 to 100%

(This setting is only available if outdoor unit is

2-stage.)

Indoor Unit

Type

Not Installed

1 Stage Electric

2 Stage Electric

1 Stage Oil

2 Stage Oil

1 Stage Gas

2 Stage Gas

Page 16

16

Table 5. Advanced Settings

MENU SETTING (default is bold) Notes:

SYSTEM SETUP

Humidier

Not Installed

These options only appear under System

Setup if the H/D and ACC terminals have been

enabled for the specic type of accessory.

Go to Terminal Settings to enabled attached

accessory for the specic terminal being used.

Humidication

Dehumidier

Not Installed

Humiditrol - Min

Humiditrol - Mid

Humiditrol - Max

Auxiliary Dehumidier

OUTDOOR SENSOR Yes or No

Required for high and low balance points

option.

RESIDUAL COOL 0, 30, 60, 90, 120 seconds, -300 (5 min delayed)

BALANCE POINT Disabled or Enabled

When enabled:

Low Balance Point: 25°F (-20 to 72°F)

High Balance Point: 50°F

(-17 to 75°F)

TEMPERATURE CONTROL MODE Normal and Comfort

WALL INSULATION Poor, Average and Good

DEADBAND 3°F Adjustable (3 to 8°F)

SMOOTH SETBACK RECOVERY Enabled or Disabled

OFFSET

Temperature Offset - 0°F Adjustable (-5 to 5°F)

Humidity Offset - 0% Adjustable (-10 to 10%)

Page 17

17

Table 5. Advanced Settings

MENU SETTING (default is bold) Notes:

STAGE DIFFERENTIAL

Stage 1 - 1.0°F Adjustable (0.5 to 8.0°F)

Stage 2 - 1.0°F Adjustable (0.5 to 8.0°F)

Stage 3 - 0.5°F Adjustable (0.5 to 8.0°F)

Stage 4 - 0.5°F Adjustable (0.5 to 8.0°F)

STAGE DELAY

On or Off

Stage 2 through 4 - 20 min. Adjustable (5 to 120 minutes)

H/C STAGES LOCKED IN Enable or Disable Turns heating stages off separately

STAGE 2 HP LOCK TEMP Off, 40°F, 45°F, 50°F, 55°F

Heat Pump - for dual-fuel applications (locks

out 2nd stage compressor)

COMPRESSOR PROTECT On or Off

DISPLAY PERFORMANCE REPORT On or Off

TERMINAL SETTINGS

H/D

Off

Humidify

Dehumidify

ACC

Off

Humidify

Dehumidify

Ventilation (future use) Not selectable at this time.

O/B

O (energized during cooling)

B (energized during heating)

SYSTEM TEST MODE Conrm Button

Installer run tests to check all output relays.

Tests conrm signals between thermostat/unit

are being sent/received. Stops system to run

system tests

Page 18

18

Table 5. Advanced Settings

MENU SETTING (default is bold) Notes:

RESET SETTING Conrm Button Resets all parameters to factory settings

RESTART Conrm Button Reboot the thermostat.

aDvanCeD settings Parameter DesCriPtions

Table 6. Parameter Descriptions

Parameter Name Denition

Smooth Setback

Recovery (SSR)

SSR is an algorithm designed to smoothly” reach a occupied program schedule setpoint. The algorithm looks 2

hours ahead for the occupied program schedule period’s setpoint. If the occupied setpoint requires the system

to turn on (present temperature below the heat setpoint or above the cool setpoint), then SSR will calculate a

new setpoint. Once initiated, SSR monitors the change in room temperature and calculates a new setpoint every 30 seconds. Then SSR provides this new setpoint for the heating and cooling algorithms; the new setpoint

will be displayed on the User Interface.

SSR Rules:

• SSR is enabled when both Smooth Setback Recovery” is set to enabled

(default) and the program schedule is turned on.

• SSR does NOT turn off stage delay timers.

• SSR will NOT change the dead band between heating and cooling modes.

• SSR will not overshoot the target set point.

• SSR will reset if the user updates the program schedule during the active

SSR period. Smooth Setback Recovery - default is enabled .

NOTE: SSR aims to bring the sensor temperature (room temperature) to the value of the next active set

point at the exact time the next active set point is associated with. This means that conditioning to

reach the next active set point starts before the currently active set point period expires.

Offset

This is a feature that lets you adjust the room temperature reading +/- 5°F. This helps if your thermostat is in a

slightly warm or cold spot, or if the room temperature does not match your old thermostat.

The other option setting in our thermostat is humidity offset which is basically the same as temperature, but

works on a humidity percentage instead.

Page 19

19

Table 6. Parameter Descriptions

Parameter Name Denition

Stage Differential

There are four options for stage differential:

• 1st Stage Differential: The default is 1.0°F. The rst stage differential is the difference between

the equipment activation and deactivation temperatures. The rst stage differential is used

in all models. It can be programmed between 0.5 and 8.0°F in 0.5°F steps.

• 2nd Stage Differential: The default is determined by the system setup. The second stage differential is

used in the multi-stage model only. The second stage differential is the difference in temperature between

the second stage activation and the rst stage activation. It can be programmed between 0.5 and 8.0°F

in 0.5°F steps. If system has only 1st stage equipment, this item is hidden from installer screen.

• 3rd Stage Differential: This setting is used with the multi-stage model, in heat pump

applications only. The default is determined by the system setup. The third stage differential

is the difference in temperature between the third stage activation and the second stage

activation. It can be programmed between 0.5 and 8.0°F in 0.5°F steps. If system has no

more than three stages equipment, this item is hidden from installer screen.

• 4th Stage Differential: This setting is used with the multi-stage model, in heat pump

applications only. The default is determined by the system setup. The fourth stage differential

is the difference in temperature between the fourth stage activation and the third stage

activation. It can be programmed between 0.5 and 8.0°F in 0.5°F steps. If system does

not have fourth stage equipment, this item is hidden from installer screen.

Page 20

20

Table 6. Parameter Descriptions

Parameter Name Denition

Stage Delays

There are four settings for this option:

• Stage Delay Timer: The user shall be able to select ON (default) or OFF for stage delay timers.

When OFF is selected all STG DELAYS timers (STG 2 DELAY, STG 3 DELAY, STG 4 DELAY) are

disabled. This means that the stages are changed based on the temperature and not the timer

delays. When ON is selected all STG DELAYS timers are enabled and set to their default values

(20min). If system has only rst stage equipment, this item is hidden from installer screen.

• 2nd Stage Delays: The Stage Delay option is enabled when ON is selected from STG Delay

Timers. The second stage delay is used in the multi-stage model only. The default is 20

minutes. If the rst stage fails to advance the ambient temperature toward the setpoint by

1.0°F during each consecutive programmed time delay, then the second stage is activated

until demand is satised. It can be programmed from 5 to 120 minutes in 5-minute steps. If

system has only rst stage equipment, this item is hidden from installer screen.

• 3rd Stage Delays: The Stage Delay option is enabled when ON is selected from STG Delay

Timers. This setting is used with the multi-stage model, in heat pump applications only. The default

is 20 minutes. If the second stage fails to advance the ambient temperature toward the setpoint

by 1.0°F during each consecutive programmed time delay, then the third stage is activated

until demand is satised. It can be programmed from 5 to 120 minutes in 5-minute steps. If the

system has no more than three stages, this item is hidden from the installer screen.

• 4th Stage Delays: The Stage Delay option is enabled when ON is selected from STG Delay Timers.

This setting is used with the multistage model, in heat pump applications only. The default is 20 minutes.

If the third stage fails to advance the ambient temperature toward the set point by 1.0°F during each

consecutive programmed time delay, then the fourth stage is activated until demand is satised. It can

be programmed from 5 to 120 minutes in 5-minute increments. If the system does not have a fourth

stage, this item is hidden from installer screen. If temperature is stuck at a value lower than the set

point and multiple stages have been turned on because of the delay timers expired (not because of the

temperature), all these stages shall stay on until the required temperature (set point + 0.5) is reached.

H/C STGS Locked In

The user shall be able to select disable or enable for H/C STGS LOCKED IN mode. In disable, mode different

stages of heat or cool are turned off separately. In enable mode, different stages of heat or cool are turned

off together.

Stage 2 HP Lock Temp

The User shall be able to select the STG 2 HP lock temp from 40F, 45F, 50F, 55F or OFF. The value is used

in dual fuel algorithm to lock the second stage of compressor .The default is OFF which means it is disabled

and is not used in dual fuel algorithm. If system has only 1st stage equipment, this item is hidden from installer

screen. For more information see “Stage 2 HP Lock Temp” on page 28.

Page 21

21

Table 6. Parameter Descriptions

Parameter Name Denition

Feels Like

This feature will display the home temperature based on a combination of inputs. Feels Like uses outdoor

temperature, indoor temperature, and indoor humidity to determine the “feels like” condition of the home.

Wider Set Point Range

By default your thermostat operates within a range of 60-90°F. Enabling this options changes the range to

44-99°F.

Heating Mode: Normal

or Comfort

Options are Normal and Comfort. Default is Normal. When changing to Comfort Mode, several parameters

are automatically modied for optimal system operations. The changed parameters are listed on the screen

when set to Comfort.

• Normal - This setting cools the home to the desired temperature setting. Once second-stage is activated

by timer or differential, it will not stage down to rst-stage until the next heating cycle demand.

• Comfort - This is when the system could automatically stage up

or down based on the current load demand.

Smart Away

This setting when enabled controls the temperature in the home when no one is home. For this to function, the

Lennox Mobile app needs to be installed on a mobile device.

Low Balance Point

(Multistage Heat Pump Model only) -The default is 25°F. This option will only be available if an outdoor sensor

is installed. If the outside temperature is below the programmed Low Balance Point, then the compressor

stage operation is disallowed. This protects the compressor from operation and damage in cold outdoor temperatures. Also, if the heat pump is not effective at a low outdoor temperature, then it is more comfortable and

efcient to go directly to the second stage. Low Balance Point can be disable in this screen. When this is

enable, the options are from –40°F to (the High Balance Point temperature -2) in 1.0°F steps.

High Balance Point

The default is 50°F. This option is only available if an outdoor sensor is installed. If the outside temperature is

above the High Balance point, then the auxiliary heat stage is disallowed. This prevents the more expensive

auxiliary heat stage from operating, and forces the more efcient heat pump to satisfy the demand. High

Balance Point can be disable in this screen. When this is enable, the high balance point range is from (the low

balance point + 2) up to 75°F.

Deadband

The deadband setting is the minimum difference between the cooling and heating setpoints. This setting is

used in auto-changeover to ensure smooth equipment operation. It also allows for exibility of Humiditrol operation. The default deadband is 3 and the deadband is adjustable from 3 to 9°F degrees.

Page 22

22

Table 6. Parameter Descriptions

Parameter Name Denition

Offset

There are two options for offset which are:

• Temperature offset can be used to offset the displayed space temperature by up to +/- 5 degrees.

The default temperature offset is zero. This offset also applies to the control temperature.

• Humidity offset can be used to offset the displayed room humidity

by up to +/- 10%, the default offset is 0.

Stage Control

• The following gures list typical congurations.

H/C

Stages

Locked =

YES

H/C

Stages

Locked =

NO

POINTS:

2nd stage

ON

2nd stage

OFF

1st stage

ON

1st stage

OFF

2nd stage

ON

2nd stage

OFF

1st stage

ON

1st stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

SP +1.5SP +1.0 0.2+ PS5.0+ PS

Stg1 Differential

Stg2 Differential

Stg2 Differential

Stg1 Differential

Figure 2. Cooling - 1 or 2 stages

Page 23

23

H/C

Stages

Locked =

YES

H/C

Stages

Locked =

NO

1st stage

ON

2nd stage

ON

1st stage

ON

2nd stage

ON

2nd stage

OFF

1st stage

OFF

1st stage

OFF

2nd stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

Stg2 Differential

SP -2.5SP -3.0

Stg1 Differential

Stg2 Differential

POINTS:

Figure 3. Heating - Non-Heat Pump or Heat Pump w/o backup heat - 1 or 2 stages

H/C

Stages

Locked =

NO

H/C

Stages

Locked =

YES

POINTS:

3rd stage

ON

1st stage

ON

2nd stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

2nd stage

OFF

3rd stage

OFF

1st stage

OFF

1st stage

OFF

2nd stage

OFF

3rd stage

OFF

SP -1.5SP -1.0 SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Figure 4. Heating - Heat Pump w/electric - 3 stage (2 compressor / 1 backup OR 1 compressor / 2 backup)

Page 24

24

H/C

Stages

Locked =

YES

H/C

Stages

Locked =

NO

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

2nd stage

OFF

3rd stage

OFF

4th stage

OFF

1st stage

OFF

Stg4 Differential

1st stage

OFF

2nd stage

OFF

3rd stage

OFF

4th stage

OFF

POINTS:

SP -1.5 SP -1.0 SP -0.5 SP SP +0.5SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Stg4 Differential

Figure 5. Heating - Heat Pump w/electric - 4 stage (2 compressor / 2 backup)

H/C

Stages

Locked =

NO or

YES

2nd stage

ON

1st stage

ON

2nd stage

OFF

1st stage

OFF

SP -1.5 SP -1.0SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

SP -2.5SP -3.0

Stg2 Differential

POINTS:

Figure 6. Heating - dual fuel - 2 stage (1 compressor / 1 backup)

Page 25

25

H/C

Stages

Locked =

NO

H/C

Stages

Locked =

YES

POINTS:

3rd stage

ON

1st stage

ON

2nd stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

2nd stage

OFF

3rd stage

OFF

1st stage

OFF

1st stage

OFF

2nd stage

OFF

3rd stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Diff.

Stg2 Differential

Figure 7. Heating - dual fuel - 3 stage (1 compressor / 2 backup)

H/C

Stages

Locked =

NO

H/C

Stages

Locked =

YES

POINTS:

3rd stage

ON

1st stage

ON

2nd stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

2nd stage

OFF

3rd stage

OFF

1st stage

OFF

1st stage

OFF

2nd stage

OFF

3rd stage

OFF

SP -1.5 SP -1.0 SP -0.5

SP

SP +0.5SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Figure 8. Heating - dual fuel - 3 stage (2 compressor / 1 backup)

Page 26

26

Stg4 Diff.

H/C

Stages

Locked =

YES

H/C

Stages

Locked =

NO

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

3rd stage

ON

1st stage

ON

2nd stage

ON

4th stage

ON

2nd stage

OFF

3rd stage

OFF

4th stage

OFF

1st stage

OFF

Stg4 Differential

1st stage

OFF

2nd stage

OFF

3rd stage

OFF

4th stage

OFF

POINTS:

SP -1.5SP -1.0SP -0.5 SP SP +0.5SP -2.0

Stg1 Differential

Stg3 Differential

Stg2 Differential

SP -2.5SP -3.0SP -3.5

Stg1 Differential

Stg3 Differential

Stg2 Differential

Figure 9. Heating - dual fuel - 4 stage (2 compressor / 2 backup)

Page 27

27

Wi-Fi Connection

Wireless networks supported by this system are:

• 802.11b is 2.4Ghz band (max 11 Mbit/s)

• 802.11g is 2.4Ghz band (max 54 Mbit/s)

• 802.11n is 2.4Ghz band (max 130 Mbit/s)

This is for connecting the thermostat to a secure

home wireless network.

NOTE: A router with Bonjour capabilities is required

for this function. Check the router functions

if the thermostat does not connect. Apple

Bonjour® is an implementation of zero-

conguration networking (Zeroconf), a

group of technologies that includes service

discovery, address assignment, and host

name resolution.

NOTE: Never use a home guest account and

never use an open router connection (nonsecure).

NOTE: Always use a secure connection physically

located in the home where the thermostat

is located.

NOTE: If thermostat will not connect to the home

router, then try using a hot spot to check

thermostat Wi-Fi connectivity. A Wi-Fi

extender may be required or move the

router closer to thermostat for connection.

1. Touch the Menu icon in the upper right-hand

corner of the display.

2. Touch the settings option on the menu.

Page 28

28

3. If Wi-Fi is set to disabled, touch the > icon to

enabled. The Wi-Fi screen will appear where

you can toggle it to ON.

ConneCting to visiBle Home Wi-fi aCCess Point

1. Touch Wi-Fi network. This will display a list

of visible Wi-Fi networks within range of the

thermostat.

2. Select the homeowner network and type in the

password. Touch join to continue.

NOTE: The thermostat can connect to a home

wireless router that uses up to 32 characters

in the access point name (visible or hidden).

NOTE: If you wish to see the characters you

are typing, check show password. The

thermostat will support up to a 63 character

password. The password cannot contain the

% or # symbols.

3. If joining the network was successful, the access

point name will appear next to Wi-Fi networks.

ConneCting to HiDDen Home Wi-fi aCCess Point

1. Touch Wi-Fi network. Scroll down to others.

2. Enter new network information. You will need

the name of the access point and the type of

security being used. Select Security. Options

are: none, WEP, WPA and WPA2. If your home

Wi-Fi connection is unsecured, then Wi-FI

security must be enabled using WEP, WPA or

WPA2 via the router before proceeding. Consult

your router documentation on how to enable WiFi security.

3. Enter the password.

4. Touch join to complete.

5. If joining the hidden network was successful,

the access point name will appear next to wi-

networks.

Whether connecting to a visible or hidden network,

if successful, a check mark will appear above both

the router and Internet icons.

HOME WI-FI

ROUTER

INTERNET

ACCESS

SERVER

CONNECTION

M30

THERMOSTAT

Page 29

29

Wireless terminology

The following terminology is used:

• Received Signal Strength Indication (RSSI). This

indicates the signal strength of the Wi-Fi router

being received by the scanning device (i.e.,

smart phone). So the higher the RSSI number (or

less negative in some devices), the stronger the

signal.

• Internet Protocol Address (IP address). This is

an address assigned by your home router for

each network device (e.g., computer, printer,

thermostat).

Wireless ConneCtivity troUBlesHooting tiPs

Locate the thermostat and router away from other

devices that could possibility interfere with wireless

communications. Some examples of other devices

that could interfere are:

• Microwave ovens

• Wireless cameras

• Portable phones and bases

• Baby monitors

• Wireless speakers

• Bluetooth devices

• Garage door openers

• Neighbor’s wireless devices

To eliminate a possible source of interference,

temporally disable any nearby 2.4Ghz band devices

in the home and see if Wi-Fi performance has

improved.

Determining Wireless ConneCtion signal strengtH

The ideal signal strength range for the thermostat

is -1 to -69 Received Signal Strength Indication

(RSSI). The signal strength can be viewed from the

thermostat interface.

1. Press NETWORK SETTINGS; This screen

shows a graphical view of buttons representing

OPEN and SECURE wireless networks, along

with button for adding a network.

2. Select the access point that has already been

established and connected.

3. When selecting the info icon, a screen will

appear which will display an option to forget

the network and IP address assigned to the

thermostat by your router, sub-net mask, router,

DNS and RSSI.

4. If the RSSI signal strength is anywhere between

-9 to -69, then the signal strength is sufcient.

If outside this range, then either relocate the

router closer to the thermostat, add a repeater,

or move the thermostat. Adjusting antenna on

router may resolve the issue.

Home Network ........................

IP address 192.168.1.4

subnet mask 255.255.255.0

router

DNS

MAC address

i

forget this network

192.168.1.1

192.168.1.1

00:23:a7:b7:a1:70

Page 30

30

Alert Codes

Table 7. Alert Codes and Reminders

Alert

Code

Priority

Condition

Display Message Condition System Action Clear/Recovery

18 Minor

Low Ambient HP

Heat Lockout

The outside temperature is

below the level where the

heat pump is programmed

to heat the home.

When the thermostat is in heat

mode and a heat demand

exists, if the temperature

measured by outdoor sensor

is below the low balance point,

the heat pump is turned off and

only the electric heat or gas/oil

heat is used.

NOTE: This alert message

is not displayed.

If the temperature

measured by outdoor

sensor is rises above low

the balance point, then any

available heat source (heat

pump, electric heat or gas/

oil heat) can be used.

19 Minor

High Ambient

Auxiliary Heat

Lockout

The outside temperature is

higher than the level where

the furnace or electric heat

is programmed to work.

When the thermostat is in heat

mode and a heat demand

exists, if the temperature

measured by outdoor sensor is

above the high balance point,

the electric heat or gas/oil heat

is turned off and only the heat

pump is used.

NOTE: This alert message

is not displayed.

If the temperature

measured by outdoor

sensor drops below the

high balance point, then

any available heat source

(heat pump, electric heat

or gas/oil heat) can be

used.

29 Critical

Over Temperature

Protection

Indoor temperature that is

higher than 99ºF.

• All stages of heat and cool

are turned off by safety relay.

• Heating and cooling

operation is not allowed.

• This error is displayed in

notication screen.

If room temperature goes

less then 99°F, it will start

working again.

30 Moderate

Low Temperature

Protection

Indoor temperature that is

lower than 40ºF.

If room temperature goes

more then 40°F, it will start

working again.

Page 31

31

Table 7. Alert Codes and Reminders

Alert

Code

Priority

Condition

Display Message Condition System Action Clear/Recovery

180 Critical

Outdoor Temperature

Sensor Problem

Outdoor sensor reads out

of range (-50ºF to 180ºF)

• Operation will be performed.

(Weather information

is not used)

• Thermostat will stop the

operation that requires

outdoor temperature

information (i.e. balance

point control and 2nd

stage lock-in).

• Thermostat will switch the

control to the operation that

does not require outdoor

temperature information.

• This error is displayed in

notication screen.

If the outdoor sensor reads

a value not within its normal

range then replace sensor.

610 Critical

Low Room

Temperature

Detected

The the freeze protection

temperature range is 30ºF

to 50ºF and with default

of 40ºF.

• This alert message is

displayed when safety

protection is enabled.

• If the room temperature

drops below the setting

range, an alert will

be displayed.

(System will raise alert only)

The system automatically

clears the alert message

when the temperature rises

above the freeze protection

temperature.

611 Critical

High Room

Temperature

Detected

The heat protection

temperature range is 80ºF

to 100ºF with a default

of 90ºF.

• This alert message is

displayed when safety

protection is enabled.

• If the room temperature rises

above the setting range, an

alert will be displayed.

(System will raise alert only)

The system clears the

alert message when

the temperature goes

below the heat protection

temperature.

Page 32

32

Table 7. Alert Codes and Reminders

Alert

Code

Priority

Condition

Display Message Condition System Action Clear/Recovery

700 Critical

Internal Temperature

Sensor Problem

Local temperature sensor

reads out of range -4ºF

to 158ºF.

There is a difference

between main thermistor

and sub-thermistor of

more than 5ºF.

• Indoor temp is displayed as

“–“ on the home screen. This

will STOP all temperature

related operation.

• All stages of heat and

cool are turned off by

safety relay.

• This error is displayed in

notication screen.

Thermostat will have to

be replace or if sensor

returns to with in the normal

operating range (0ºF to

113ºF), the error message

will be automatically

cleared. System will return

to normal operations.

703 Critical

Comfort Sensor

Humid Sensor

Problem

Sensor reads out of range

0% to 100%

• This message indicates

humidity sensor is not

functioning correctly.

• The humidity display

on the home screen will

indicated “–“.

• This error is displayed in

notication screen.

Thermostat will have to

be replace or if sensor

returns to with in the

normal operating range,

the error message will

be automatically cleared.

System will return to normal

operations.

3000 Reminder Replace lter 1

Not Applicable Displayed in notication screen

Press the “back” button,

“clear” button or “remind

later” button.

3001 Reminder Replace lter 2

3002 Reminder

Replace humidier

pad

3003 Reminder Replace UV bulb

3004 Reminder

Maintenance

reminder

3005 Reminder

Pure Air

maintenance

Page 33

33

System Test Modes

After the thermostat has been installed and setup, the installer may run a system test function

(accessed through the installer settings menu), to

test all cooling, heating, emergency heating stages

and FAN outputs.

Select system test mode. A pop-up will be

displayed indicating all equipment will be stopped.

Touch conrm to continue.

Pressing the OFF button next to the desired option

will change the status to ON and will enable the

relay for that terminal. Pressing again will turn OFF

the relay. Touch the left arrow (<) to exit the system

test mode.

Save Energy Default

Energy saving recommended set points for heating

and cooling can help save energy. The time and

temperatures reference in the following table are

pre-programmed into the thermostat to achieve

energy savings.

Scroll to ENERGY SAVING DEFAULT; touch to

select. Read the message on the screen and to

continue, touch CONFIRM.

Table 8. Energy Saving Set Points

Time Heating Cooling

Wake 70°F (21°C) 78°F (25°C)

Leave 62°F (17°C) 85°F (29°C)

Return 70°F (21°C) 78°F (25°C)

Sleep 62°F (17°C) 82°F (28°C)

NOTE: Humidication and dehumidication are not part of the

energy savings program. A higher utility bill may occur

when not using the setpoints in this table.

Page 34

34

Dehumidication Control

normal anD max

Dehumidication options are listed at menu > settings > humidity. Under Humidity Control, select

dehumidify to enable dehumidication. By default it is disabled.

There are four setting options which are Normal, Max, Humiditrol* and Aux Dehumidier*.

* Requires hardware accessory

Slide bar adjust with a range of 40% to 60% RH.

Table 9. Dehumidication Modes

Option Description

Normal

• Activate: If RH measured is >= (RH set point + 2%), and, Cool is ON, then D is inactive

(open circuit), and G is ON (if not already ON), and Y2 (if available) is ON.

• Deactivate: If RH measured is <= (RH set point - 2%) or Cool is OFF, then D is active (24VAC

present). G returns to the state determined by the thermostat control, either ON, Auto, or CIRC. (OR)

If there is no more cool demand, then D is active (24VAC present). G returns to the state determined

by the thermostat control, either ON, Auto, or CIRC, and Y2 (if available) is OFF.

NOTE: Note that H is inactive (open circuit) during dehumidication.

Max

• Activate: IF RH measured is >= (RH set point + 2%), and if T measured >= T set point – 0°F to 4°F )AND

unit is in Cool mode (O = ON), then D is inactive (open circuit), and G, Y1, and Y2 (if available) are ON.

• Deactivate: IF RH measured is <= (RH set point - 2%), or if T measured < T set point 0°F to 4°F) or unit isn’t in Cool mode(B = ON), then D is active. Y1, Y2, are OFF and G returns

to the state determined by the thermostat control, either ON, Auto, or CIRC.

NOTE: H is inactive (open circuit) during dehumidication.

Page 35

35

HUmiDitrol

This option is available if the Humiditrol accessory

is present and enabled in the Advanced Settings

> System Setup. Under Advanced Settings >

Terminal Settings, verify that the H/D or ACC

terminals are congured correctly for dehumidify

control. In this mode, the H/D terminal (if selected

for dehumidify) is always ON (24VAC) when

the outdoor temperature is greater than 95°F.

This prevents the system blower from running at

reduced speed if the outdoor temperature is greater

than 95°F.

NOTE: The outdoor temperature sensor MUST

be attached to the unit in order to use this

mode.

Equipment Operation with Humiditrol Enabled

IS THERE A COOLING

DEMAND?

START

NO

RUN EQUIPMENT IN

NORMAL COOLING

MODE

YES

IS THERE A HEATING

DEMAND?

RUN EQUIPMENT IN

NORMAL HEATING

MODE

YES

NO

IS THERE A

DEHUMIDIFICATION

DEMAND?

DEACTIVATE ALL

EQUIPMENT

NO

YES

IS HCA = MAX, AND

INDOOR TEMPERATURE > 2

o

F

ABOVE HEATING SETPOINT?

NO

DEACTIVATE ALL

EQUIPMENT

YES

RUN HUMIDITROL

Notes:

The Humiditrol Comfort Adjust (HCA) variable is user-selectable and can be set to MIN, MAX,or

MID

Humiditrol prohibited if outdoor temperature > 95

o

F OR if indoor temperature < 65oF

IS HCA = MIN, AND

INDOOR TEMPERATURE >

2

o

F BELOW COOLIING

SETPOINT?

IS HCA = MID, AND

INDOOR TEMPERATURE >

(HEATING

SETPOINT+COOLIING

SETPOINT)/2?

NO

NO

YES

YES

Figure 10. Equipment Operation with Humiditrol

Enabled

Page 36

36

aUxiliary DeHUmiDifier

This option is available if the Auxiliary Dehumidier

accessory is present and enabled in the Advanced

Settings > System Setup. Under Advanced

Settings > Terminal Settings, verify that the

H/D or ACC terminals are congured correctly for

dehumidify control.

Cooling demand only: Y1 and Y2 come on

initiating the conventional cooling only demand.

Dehumidication demand only: D is deenergized (G should also be energized) but with

out Y1 or Y2. D remains off until the demand is

satised or if a true cooling demand comes on (unit

must be in cooling mode).

Both cooling and dehumidication demands:

Y1 and Y2 are ON (G must be ON and D is also

0 volts) When cooling is satised , D is still 0 volts

and G must stay ON until dehumidication demand

is satised.

Table 10. Auxiliary Dehumidier Option

Option Description

Normal

• Activate: If RH measured is >= (RH set

point + Activate: IF RH measured is >=

(RH set point + 2%), and AND unit is in

Cool mode (O = ON),, THEN D is inactive

(open circuit), AND G is ON.

• Deactivate: IF RH measured is <= (RH set

point - 2%), or unit isn’t in Cool mode(B

= ON), THEN D is active. G returns to

the state determined by the thermostat

control, either ON, Auto, or CIRC.

Humidication Control

This option is available if the humidier accessory

is present and enabled in the Advanced Settings

> System Setup.

Under Advanced Settings > Terminal Settings,

verify that the H/D or ACC terminals are congured

correctly for humidify control.

Humidication is provided only when both a

humidication accessory is installed and the

thermostat is in heat mode.

• Setpoint Range: 15 – 45% RH

• Relative Humidity Controlled to 2% of Setpoint

(1% resolution)

• “H/D” Terminal to Humidier (deactivated during

cooling)

• This behavior changes based on H/D terminal or

ACC terminal

Page 37

37

normal anD max

The following table describes the function of normal

and max humidication settings.

Table 11. Humidication Modes

Option Description

Normal

(Humidication only with Heat Demand)

• Activate: If RH measured is <= (RH

setpoint - 2%), and, heat is ON, then H is

ON, and G is ON (if not already ON).

NOTE: In Normal humidication mode, thermostat

should not activate G when used with

Gas/Oil systems

• Deactivate: If RH measured is >= (RH set point

+ 2%) or Heat is OFF then H is Off. G returns to

the state determined by the thermostat control,

either ON, Auto, or CIRC. (OR) If there is no

more heat demand, then H is Off. G returns

to the state determined by the thermostat

control, either ON, Auto, or CIRC.

NOTE: The D terminal is active during

humidication.

Table 11. Humidication Modes

Option Description

Max

(Humidication with or without Heat Demand)

• Activate: IF RH measured is <= (RH set

point - 2%), and unit is in heat mode (regardless

of whether a heating demand exists), then H

is ON, and G is ON (if not already ON).

• Deactivate: IF RH measured is >= (RH set point

+ 2%) or unit is not in Heat mode (O = ON), then

H is Off. G returns to the state determined by the

thermostat control, either ON , Auto, or CIRC.

NOTE: The D terminal is active during

humidication. Following is the table that

shows status of FAN for different humidity

modes and system outputs.

normal anD max DeW Point Control

To set the system to Normal Dew Point Control,

select normal and dew point options under settings

humidity option.

To set the system for Max Dew Point Control, select

Max and Dew Point Control.

NOTE: Outdoor air temperature sensor is required

for this feature.

Page 38

38

Table 12. Dew Point Control Modes

Option Description

Normal

Normal Dew Point Control mode is useful in colder

climates where moisture can collect on interior

window surfaces. Normal dew point control helps

to minimize this condensation. In this mode the

activation and deactivation of H/D terminal is

controlled as follows.

RH set point= .5*Outdoor Temp + 25 + RH user dew

point adjustment

where:

RH user dew point adjustment is user-selectable and

cannot exceed +/-15%, default RH user dew point

adjustment = 0

The RH set point cannot exceed 45%

The minimum RH set point is 15%

Max

Max Dew Point Control mode is also useful in colder

climates where moisture can collect on interior

window surfaces. Max Dew point control helps

to minimize this condensation. In this mode the

activation and deactivation of H terminal is controlled

as it is done in the Max.

RH set point= .5*Outdoor Temp + 25 + RH user dew

point adjustment

where:

RH user dew point adjustment is user-selectable and

cannot exceed +/-15%, default RH user dew point

adjustment = 0

The RH set point cannot exceed 45%

Page 39

39

Installer Checklist

Table 13. Installation Checklist

Item Description Yes No

1 Is the thermostat properly mounted to either a wall stud or wall? (Do not mount on exterior wall or near any

ventilation outputs, doorways or location that could be directly exposed to sunlight)

2 Are all terminals wiring properly connected and tight?

3 When required, is the outdoor air temperature sensor (OATS) properly connected and isolated when used?

Is the input enabled using the user interface? Go to advanced settings > outdoor sensor and set

to YES if not done so already. Then go to settings > display and make sure the outdoor temperature

display setting is congured for sensor. If OATS is not used, leave the setting on Internet.

4 Have all the Thermostat Features been explained to the Home Owner?

5 Has User manual been given to Home Owner?

6 Has additional Alexa information not in user manual been given to Home Owner and shown where to nd

answers to additional questions?

Go to www.myicomfort.com Support page & FAQ.

7 Is the Wi-Fi connected?

8 Can the homeowner access the consumer portal (www.myicomfort.com) from either a PC or tablet?

9 Has the homeowner downloaded the Lennox Thermostat application from either Google Play or IOS App

Store to their mobile devices?

10 Is the Lennox Dealer account number or your main shop phone number been added to the dealer information

screen? This will tie the homeowners system to your LennoxPROS account.

11 If applicable, has the air handler’s electric heat strips been commissioned? If not, commissioning of heat

strips must be performed.

12 Has a complete system test been run? If not, from the HD Display home screen go to settings >

advanced settings > view dealer control center > and select tests.

Page 40

40

Index

A

Advanced Settings 15

Alert Codes 30

Auxiliary Dehumidier 36

C

Commissioning 12

Common Practices 6

Compressor Short Cycle 3

D

Deadband 21

Dehumidication Control 34

Dimensions 3

E

Energy Saving Defaults 33

F

Feels Like 21

H

H/C Stage Locked In 20

Heating Mode 21

High Balance Point 21

Humidication Control 36

Humiditrol 35

I

Installer Checklist 39

L

Low Balance Point 21

N

New Installation 5

O

Offset 18, 22

Outdoor Temperature Sensor 5

P

Parameter Descriptions 18

R

Received Signal Strength Indica-

tion (RSSI) 29

Replacement Installation 6

S

Smart Away 21

Smooth Setback Recovery 18

Stage 2HP Lock Temp 20

Stage Control 22

Stage Delays 20

Stage Differential 19

System Congurations 9

System Test Mode 33

T

Terminal Descriptions 8

W

Wider Set Point Range 21

Wi-Fi Connection 27

Wi-Fi Signal Strength 29

Wi-Fi Troubleshooting 29

Wiring Diagrams 9

Loading...

Loading...