Page 1

i200 Series Scanners

A-61167

Part No. 9E3968

CAT No. 850 7543

User’s

Guide

KODAK iNnovation Series Scanners

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Scanner features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Paper transport features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Speed/capacity (throughput) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Image quality features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparing documents for scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Recommended documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

User precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety and regulatory agency approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Environmental information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Acoustic emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

EMC statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Taiwan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

People’s Republic of China . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

European Union (EU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Site specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Minimum system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unpacking the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Registering your scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Scanner components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Making connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the IEEE-1394 (FireWire) card in the host computer . . . . . . . . 13

Installing the Kodak Driver Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the IEEE-1394 (FireWire) cable . . . . . . . . . . . . . . . . . . . . . . . . 13

Power setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

A-61167 April 2005 i

Page 3

Input and output trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Attaching the input tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Attaching the output tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Tray extenders and side guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjusting the output tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Closing the input and output trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting and stopping scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Automatic feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Continuous feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Manual feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Damaged documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Additional features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Long Paper mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Special Document mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Perfect Page with iThresholding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Toggle Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the separator module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning the feed module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning the drive rollers and transport area . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning the imaging guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning the paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Calibrating the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Indicator lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Clearing document jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adjusting the separator module tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System is not responding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Color image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transporting the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ii A-61167 April 2005

Page 4

Appendix A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C Kodak i200 Series Imprinter . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Contents of the imprinter kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Installing the imprinter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Removing the circuit board cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Attaching the imprinter board and cable . . . . . . . . . . . . . . . . . . . . . . . . C-3

Completing the imprinter installation . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Installing the ink blotter strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Installing an ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Setting the imprinter position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Imprinter maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

Imprinting problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

Expected life of imprinter components . . . . . . . . . . . . . . . . . . . . . . . . . C-13

When the imprinter is not in use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

Replacing an ink cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

Replacing the ink blotter strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Replacing the ink cartridge carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-15

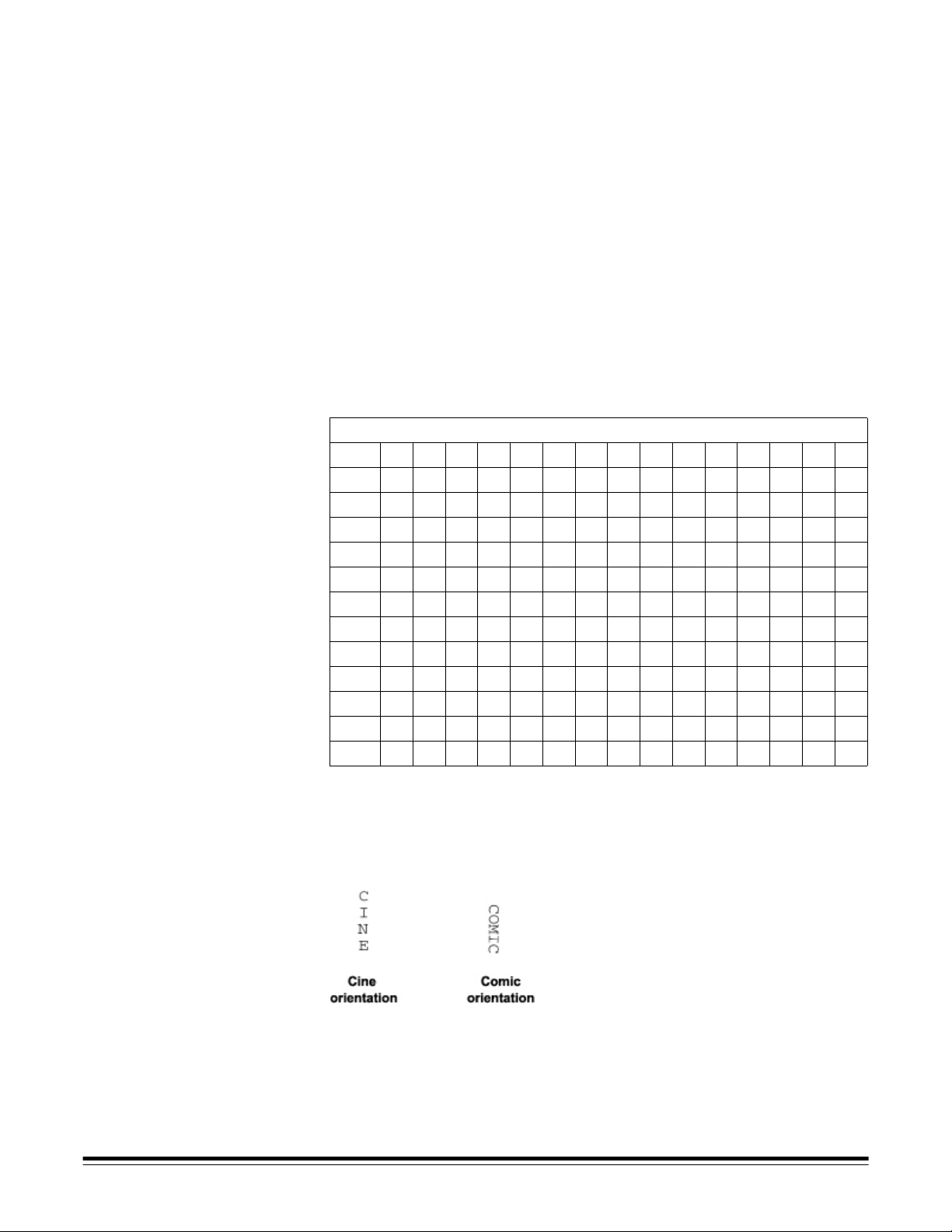

Imprinting overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Print characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Imprinter specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-17

Appendix D Kodak i200 Series Dockable Flatbed . . . . . . . . . . . . . . . . . . D-1

Contents of the dockable flatbed kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

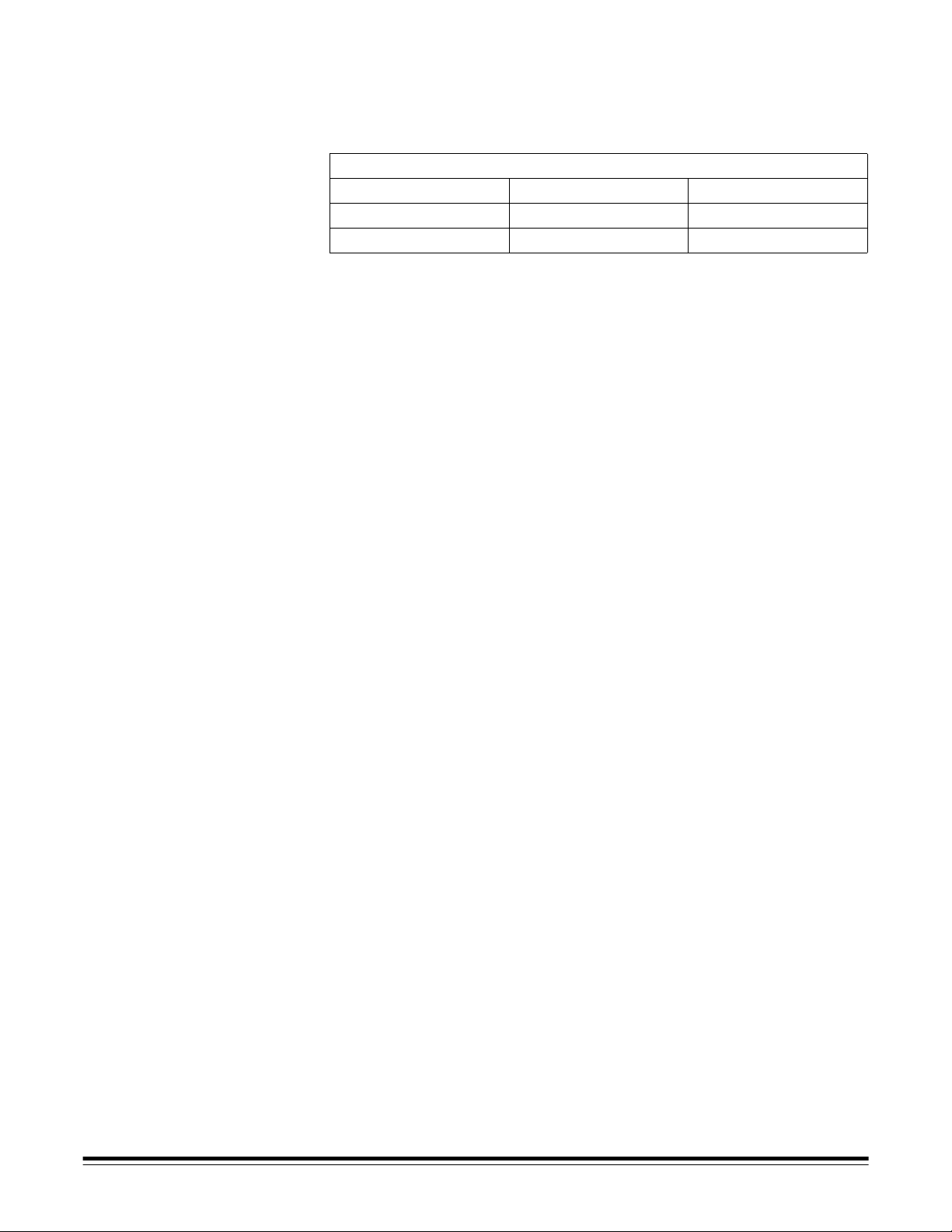

Flatbed specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

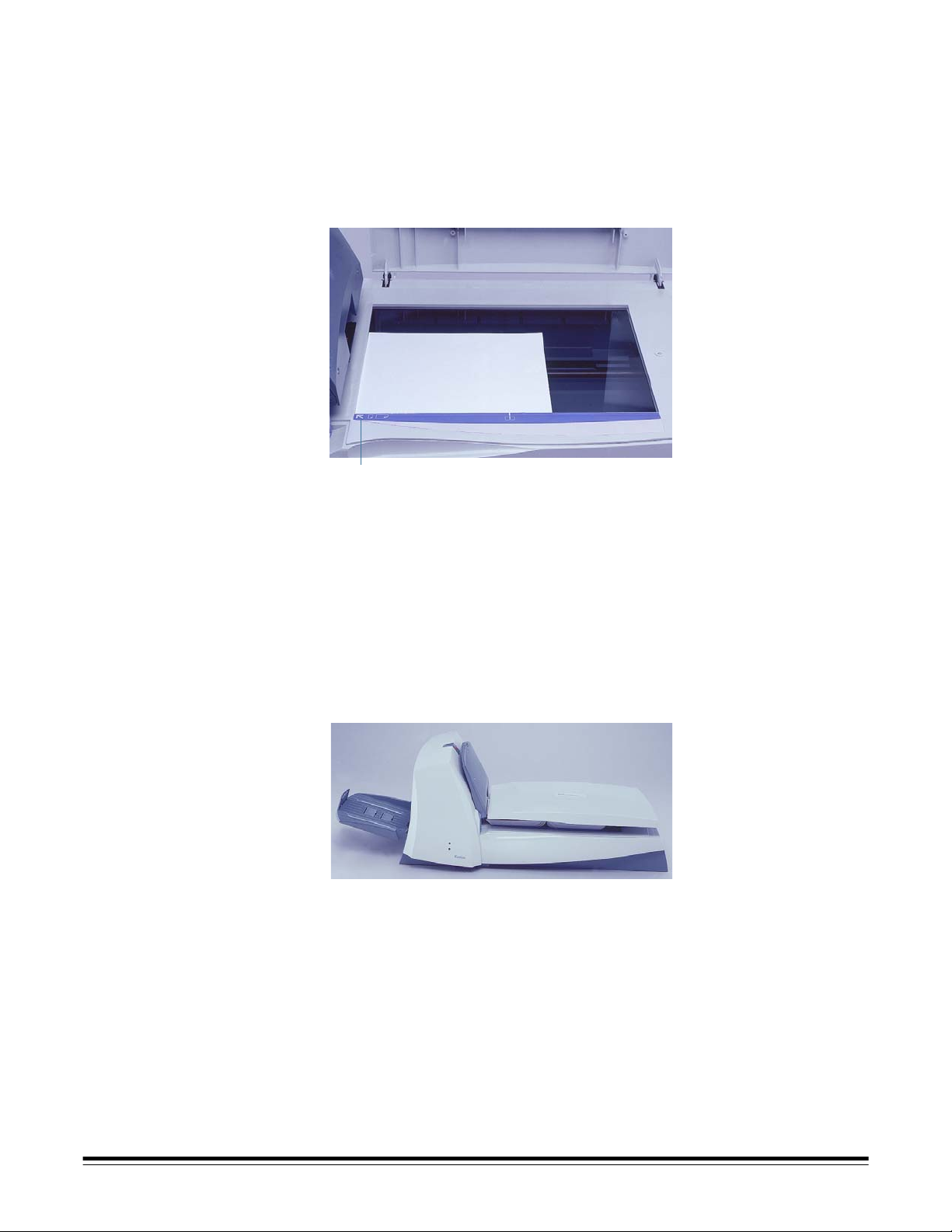

Installing the dockable flatbed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Using the flatbed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Book scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Calibrating the flatbed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Cleaning the flatbed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

After a power failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Removing the dockable flatbed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Appendix E Installing Optional Memory . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Installing memory in the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

A-61167 April 2005 iii

Page 5

Introduction

Before you install and operate your Kodak i200 Series Scanner, take a few

minutes to read through this guide. It contains important information about

installing, using, and maintaining your scanner.

• Kodak i250 Scanner is a desktop simplex color scanner with an automatic

document feeder.

• Kodak i260 Scanner is a desktop duplex color scanner with an automatic

document feeder.

• Kodak i280 Scanner is a desktop duplex color scanner with an automatic

document feeder.

Scanner features • Excellent paper handling, image quality, and reliability

• Color at the same speed as bi-tonal and grayscale

• Simultaneous color and bi-tonal output

• Long Paper and Special Document scanning modes (i280 Scanner only)

• Perfect Page with iThresholding for better image and text legibility, smoother

lines, minimal to no artifacts, and fewer shaded areas

• Toggle patch to enable color on-the-fly processing (i280 Scanner only)

• Aggressive cropping capability to eliminate residual black border on any

image edges

• Easy to use and maintain

• Handles a broad range of paper weights and sizes

• Small footprint; fits easily on a desktop or table

• Low noise level

• Easy installation

• ISIS and TWAIN device drivers are included on a CD that is packed with

each scanner

• International language support

• Automatic overlap/multifeed detection

• All scanner models support multiple electrical power requirements for

use worldwide

• May be user-calibrated at any time

• Electronic red, green, and blue color dropout

A-61167 April 2005 1

Page 6

Paper transport features

• Automatic and manual feeding

• Multifeed detection by document length and/or document thickness

• Automatic document feeder (ADF) with operator-assisted “infinite” and

single-sheet feeding

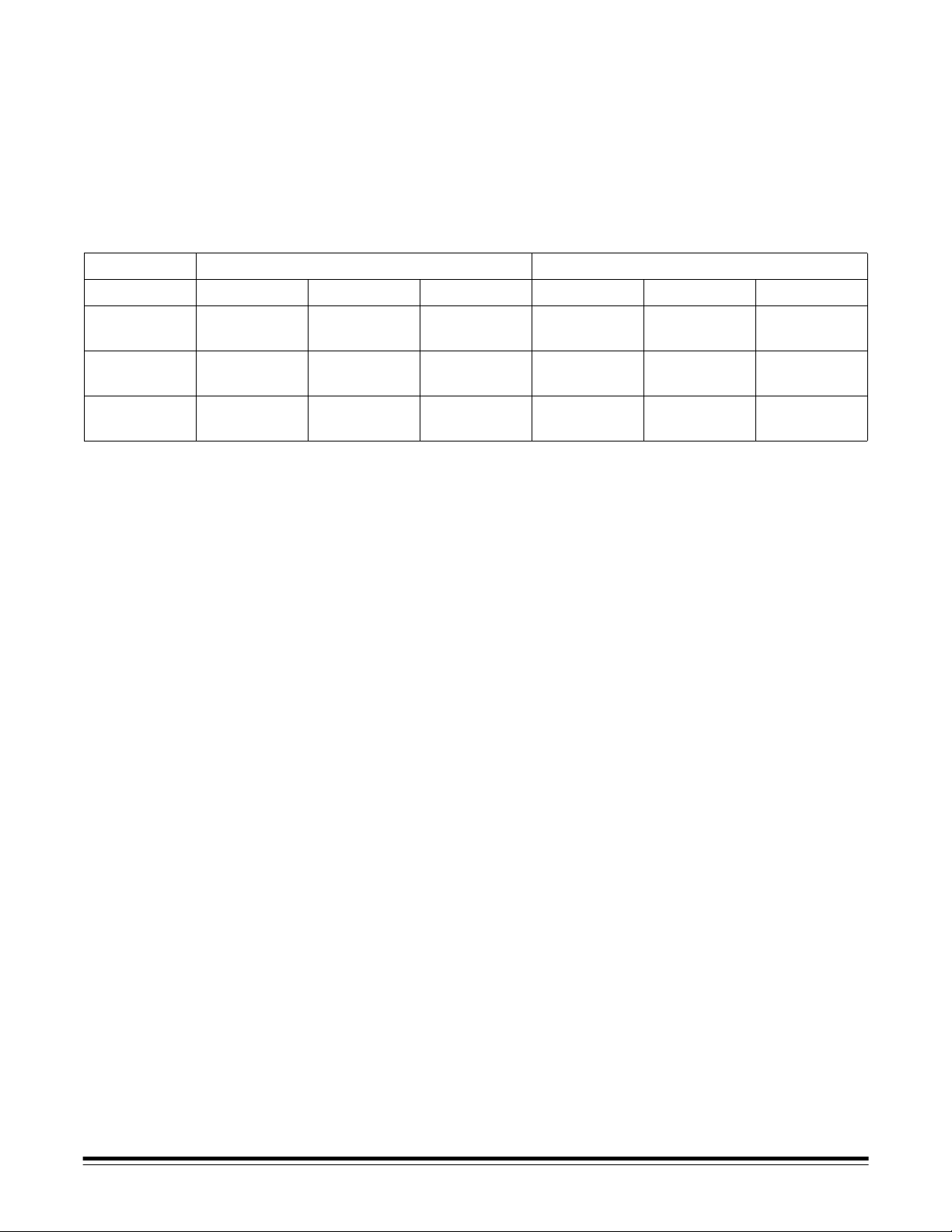

Speed/Capacity (throughput)

Resolution Landscape (A4) Portrait (Letter)

i250 Scanner i260 Scanner i280 Scanner i250 Scanner i260 Scanner i280 Scanner

150 dpi 67 ppm 67 ppm

200 dpi 50 ppm 50 ppm

300 dpi 33 ppm 33 ppm

The following speeds in pages per minute (ppm) are for color, grayscale, and

bi-tonal output.

(134 ipm)

(100 ipm)

(66 ipm)

82 ppm

(164 ipm)

60 ppm

(120 ipm)

40 ppm

(80 ipm)

53 ppm 53 ppm

(106 ipm)

40 ppm 40 ppm

(80 ipm)

26 ppm 26 ppm

(53 ipm)

67 ppm

(134 ipm)

50 ppm

(100 ipm)

33 ppm

(66 ipm)

Image quality features • Adaptive Threshold Processing (ATP), image compression, despeckle, and

dithering for bi-tonal scanning

• Built-in iThresholding for bi-tonal scanning uses a single setting to produce

the highest quality images for mixed document sets of varying quality (i.e.,

faint text, shaded backgrounds, color backgrounds).

• Image capture optical resolution: 300 dpi

• Image output resolution: 75/100/150/200/240/300/400/600 dpi for bi-tonal,

grayscale, and color scanning

NOTE: Throughput speed at 400 dpi and 600 dpi is dependent upon your

PC configuration.

• Auto-color balancing (auto-white balancing) to ensure good color balance

after calibration

• Pixel and color correction for the best color image quality

• Five levels of JPEG compression allow images to be viewed in many

image viewers

Maintenance • Easily replaceable feed module and separator module

• Easy one-step paper jam clearance

• LED indicators for power, ready, error, and operating conditions

2 A-61167 April 2005

Page 7

Optional accessories • Kodak i200 Series Imprinter—prints a date, time, fixed string, and/or

sequential number on document backs. For information about this

accessory, refer to Appendix C, Kodak i200 Series Imprinter.

• Kodak i200 Series Dockable Flatbed—the A3 flatbed adds scanning

capability for exception documents. For information about this accessory,

refer to Appendix D, Kodak i200 Series Dockable Flatbed.

NOTE: For information about ordering the above accessories, refer to

Appendix B, Supplies and Accessories.

• Additional memory (SODIMM)—purchase a memory card at a computer

supply retailer near you. For information about installing a memory card,

refer to Appendix E, Installing Optional Memory.

Preparing documents for scanning

• A batch of documents to be fed into the scanner must be arranged so that

the leading edges of all documents are aligned and centered under the

automatic document feeder. This allows the feeder to introduce documents

into the scanner one at a time. Documents must be positioned face down

for scanning.

• Staples and paper clips in documents may damage the scanner. Remove all

staples and paper clips before scanning.

• Torn, damaged, or crushed pages can be transported successfully through

the scanner. However, no scanner can transport every possible type of

damaged paper. If in doubt about whether a specific damaged document

can be transported through the scanner, place the document in a clear

protective sleeve. Sleeves should be manually fed, one at a time, folded

edge first, while lifting the gap release lever.

NOTES: You also can use the optional Kodak i200 Series Dockable Flatbed to

scan damaged documents.

In addition, the automatic document feeder on the i280 Scanner

can scan irregularly shaped documents (e.g., pages with coupons

removed or documents with large holes or cutouts in them) when

you use Special Document mode. For more information, refer to the

section “Additional Features.”

• When scanning documents in a clear protective sleeve, the input tray guides

must be adjusted to accommodate the width of the sleeve.

NOTE: Kodak scanners have been tested with a range of documents that

represent the broad spectrum of document types found in the most

common business applications. Optimal scanner performance is

achieved when scanning documents within the recommended

document specifications. Scanning documents that are outside of

these specifications may lead to undesirable results in terms of

scanner reliability, image quality, and/or consumable life.

A-61167 April 2005 3

Page 8

Recommended documents The following chart lists the recommended document attributes.

Materials • Virgin and recycled papers

• Photographic papers

Paper Types •Bond

• Laser

• Clear protective sleeves meeting the size and

thickness requirements in this section

•Inkjet

• Offset

Paper Weights The document feeder handles a broad range of paper weights from 50 to 200 g

(13 to 110 lb.)

Minimum Document Size

8.9 x 6.4 cm (3.5 x 2.5 in.)

(Width x Length)

Maximum Document Size

(Width x Length)

i250 Scanner/i260 Scanner

With standard memory: 29.7 x 43.2 cm (11.7 x 17 in.)

With extended memory: 29.7 x 66.0 cm (11.7 x 26.0 in.)

Dockable Flatbed: 29.7 x 43.2 cm (11.7 x 17 in.)

i280 Scanner

With standard memory: 29.7 x 86.4 cm (11.7 x 34 in.)

Dockable Flatbed: 29.7 x 43.2 cm (11.7 x 17 in.)

NOTE: The i280 Scanner has a feature (Long Paper mode) that allows you to scan

long roll-type documents up to 609 cm (20 feet) in length.

Paper Inks NOTE: All inks on the paper must be dry before scanning is started.

• Standard offset printing

• Inkjet printer

• Thermal transfer

• Handwriting inks

Correction Fluids NOTE: All correction fluids on the paper must be dry before scanning is started.

Document Batch Height

for Automatic Feeding

• Liquid Paper

•Tipp-Ex

®

®

• Wite-out

• Other, similar correction fluids

When feeding batched documents, the maximum height of the batched documents

is 10.2 mm (0.4 in.) or approximately 150 sheets of 60 g (16 lb.) paper.

®

4 A-61167 April 2005

Page 9

Safety information • When placing the scanner, make sure that the electrical power outlet is

located within 1.52 metres (5 feet) of the scanner and is easily accessible.

CAUTION: The scanner and power supply must only be used indoors in a

dry location.

• Material Safety Data Sheets (MSDS) for information about chemicals

used in Kodak products are available on the Kodak web site at

www.kodak.com/go/MSDS. Refer to Appendix B, “Supplies,” for

catalog number information.

Warning labels

CAUTION: High voltage. Avoid contact.

CAUTION: Hot surface. Avoid contact.

CAUTION: Moving parts. Avoid contact.

WARNING: The scanner front panel must be in place and closed during

scanner operation.

The imprinter access door must be in place and closed

during scanner operation, except when changing the

printhead location or replacing the ink cartridge.

When the imprinter access door is removed, DO NOT allow

loose clothing, jewelry, hair, or other objects to enter the

imprinter area.

User precautions Users and their employer need to observe the common sense precautions

applicable to the operation of any machinery. These include, but are not limited

to, the following:

• Do not wear loose clothing, unbuttoned sleeves, etc.

• Do not wear loose jewelry, bracelets, bulky rings, long necklaces, etc.

• Hair should be kept short, using a hair net if needed or by tying long hair up

in a bun.

• Remove all loose objects from the area that could be drawn into

the machine.

• Take sufficient breaks to maintain mental alertness.

Supervisors should review their practices and make the compliance with

these precautions a part of the job description for the operator of the

Kodak i200 Series Scanners and any other mechanical devices.

A-61167 April 2005 5

Page 10

Safety and regulatory agency approvals

Kodak i200 Series Scanners Regulatory Agency Approvals

Country or Region Safety Approval Safety Mark Electromagnetic Compatibility EMC Mark

Australia

Canada CAN/CSA-C22.2

No. 60950-00

3rd Edition Standard

The Kodak i200 Series Scanners conform to all applicable national and

international product safety and electronic emission regulatory requirements.

This includes, but is not limited to, the following:

AS/NZS 3548 Class A C-Tick

C - UL Canada ICES - 003 Issue 3

Class A

China GB4943-1995 CCC “S&E” GB 9254:98 Class A

GB 17625.1:2003 Harmonics

European Union

Germany EN 60950 : 2000 TUV GS

International IEC 60950

rd

Edition

3

Japan VCCI Class A

Taiwan CNS 13438 Class A BSMI

United States UL 60950

3rd Edition

CE EN 55022:95

ITE Emissions Class B

ITE Emissions Class A when

scanning with the i200 Series

Dockable Flatbed

EN 61000-3-2

Powerline harmonics

EN 61000-3-3 Flicker

EN 55024:95 ITE Immunity

CISPR 22 Class B

CISPR 22 Class A when

scanning with the i200 Series

Dockable Flatbed

UL CFR 47 Part 15 Subpart B

FCC Class A

CCC “S&E”

CE

6 A-61167 April 2005

Page 11

Environmental information

•The Kodak i200 Series Scanners are designed to meet worldwide

environmental requirements.

• The i200 Series Scanners’ power supply cord jacket and the solder on the

circuit boards contain lead. Disposal of lead may be regulated due to

environmental considerations. For disposal or recycling information, contact

your local authorities, or in the U.S.A., visit the Electronics Industry Alliance

web site at www.eiae.org.

• Based on a review of the available information, disposal of the ink cartridge

would not be regulated under U.S. EPA’s (RCRA), U.S. Clean Water Act

(CWA), or both. However, disposal may be subject to state or local landfill,

incineration, or recycling requirements.

• Guidelines are available for the disposal of consumable items that are

replaced during maintenance or service; follow local regulations or contact

Kodak locally for more information.

• The product packaging is recyclable.

• Parts are designed for reuse or recycling.

• The i200 Series Scanners are Energy Star compliant.

Acoustic emission Maschinenlärminformationverordnung — 3, GSGV

Der arbeitsplatzbezognene Emissionswert beträgt <70 dB(A).

[Machine Noise Information Ordinance — 3, GSGV

The operator-position noise emission value is <70 dB(A).]

Power system This equipment was designed for connection to IT Power Systems.

A-61167 April 2005 7

Page 12

EMC statements

United States This equipment has been tested and found to comply with the limits for a

Class A digital device pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Japan This is a Class A product based on the standard of the Voluntary Control

Council for interference by information Technology Equipment (VCCI). If this

equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective action.

Taiwan WARNING: This is a class A product. In a domestic environment this product

may cause radio interference in which case the user may be required to take

adequate measures.

People’s Republic of China WARNING: This is a Class A product. In a domestic environment this product

may cause radio interference in which case the user may be required to take

adequate measures.

声明,该产

此为 A 级产品,在生活环境中品可能会造成无线电干扰。在这种情况下,可能需

要用户对其干扰采取切实可行的措施

European Union (EU) WARNING: This is a Class A product. In a domestic environment this product

may cause radio interference in which case the user may be required to take

adequate measures.

8 A-61167 April 2005

Page 13

Installing the Scanner

Site specifications Place the scanner:

• in a clean area with temperature and relative humidity typical of an

office environment

CAUTION: The scanner and power supply must only be used indoors in a

dry location.

• on a stable, level work surface capable of supporting the following weights:

- i250 Scanner: 12.5 kg (27.5 lb.)

- i260 Scanner: 13.9 kg (30.5 lb.)

- i280 Scanner: 13.9 kg (30.5 lb.)

- i250 Scanner with optional flatbed accessory: 19.8 kg (43.5 lb.)

- i260 Scanner with optional flatbed accessory: 21.2 kg (46.5 lb.)

- i280 Scanner with optional flatbed accessory: 21.2 kg (46.5 lb.)

• within 1.52 metres (5 feet) of an electrical power outlet

NOTE: For more information about the scanner specifications, refer to

Appendix A, Specifications.

A-61167 April 2005 9

Page 14

System requirements

Minimum system configuration

To operate the scanner, the following minimum configuration is required.

NOTES: The actual performance of the system depends upon the scanning

application, choice of scanning parameters, and the host computer

configuration. If the scanner is not performing at the optimal speed,

a faster computer and/or more RAM may be necessary to obtain the

rated throughput.

• IBM PC (or compatible) with a Pentium III 1 GHz processor

- i260 Scanner: for scanning at 300 dpi with deskew, you will need at least

a 1.8 GHz processor for bi-tonal scanning or a 2.5 GHz processor for

color scanning.

- i280 Scanner: for scanning at 300 dpi with deskew, you will need at least

a 2.5 GHz processor for bi-tonal scanning or a 3.2 GHz processor for

color scanning.

• Microsoft Windows 98SE, Windows Millennium Edition (Me),

Windows 2000, or Windows XP

• 100 MB of available hard disk space (200 MB is recommended)

• 128 MB of RAM

• Monitor (VGA)

•Mouse

Recommended system configuration

To operate the scanner at its optimum speed, the following configuration (or

better) is recommended.

NOTE: The actual performance of the system depends on the scanning

application, choice of scanning parameters, and the host

computer configuration.

• IBM PC (or compatible) with a Pentium IV 3.2 GHz processor

• Microsoft Windows 98SE, Windows Millennium Edition (Me),

Windows 2000, or Windows XP

• 200 MB of available hard disk space

• 512 MB of RAM

• Additional memory (SODIMM) installed in the scanner

- i250 Scanner: up to 256 MB of memory is allowed

- i260 Scanner: up to 256 MB of memory is allowed

- i280 Scanner: up to 512 MB of memory is allowed

• Monitor (VGA)

•Mouse

10 A-61167 April 2005

Page 15

Unpacking the scanner The scanner box contains the following items:

• Kodak i200 Series Scanner

• Input tray

• Output tray

• Power supply

• Power cord(s)

• Installation CD

• Kodak Capture Software Lite CD

• Read Me Now sheet

• User’s Guide (printed English version; User’s Guide .pdf files in nine other

languages are included on the Installation CD)

• Registration sheet

• Cleaning materials

• Calibration target pack

NOTE: Save all packing materials for possible future use.

Registering your scanner

Scanner components

Front

1 Scanner door

2 Gap release lever

3 Scanner door release

4 Paper guides

5 Input tray

6 Input tray extender

7 Front panel

8 Front panel latch

It is very important that you register your scanner so Kodak can provide you

with the best possible service and support. Registering your scanner will help

us provide you with firmware and hardware updates as they become available.

NOTE: The scanner must be registered before any service support can

be provided.

You can register your scanner’s new equipment warranty online at

www.kodak.com/go/DIwarrantyregistration.

For more information about Kodak’s service and support options, contact

your reseller of Kodak Document Imaging products or visit us on the web at

www.kodak.com/go/DIserviceandsupport.

1

2

3

4

7 85 6

A-61167 April 2005 11

Page 16

Rear

1 Imprinter access door

(for optional imprinter)

2 Imprinter access door handle

3 IEEE-1394 (FireWire) port

4 Power input

5Output tray

6 Output tray extender

Side

1 Output tray extender

2Output tray

3 Indicator lights (red, green)

4 Input tray

5 Input tray extenders

1

2

5 63 4

Internal

1 Separator module

2 Drive rollers

3 Channels for ink blotter strips

(for optional imprinter)

4 Rear roller cover

5 Front roller cover

6 Feed module

3

1 2 4 5

1

2

3

4

5

6

12 A-61167 April 2005

Page 17

Making connections Follow the instructions for installing the IEEE-1394 (FireWire) card and the

Kodak Driver Software before you plug the scanner into the host computer.

IMPORTANT: You must install the software on the host computer before you

install the scanner.

Installing the IEEE-1394 (FireWire) card in the host computer

Installing the Kodak Driver software

Installing the IEEE-1394 (FireWire) cable

An IEEE-1394 six-pin connector is provided on the rear panel of the scanner

for IEEE-1394 (FireWire) connectivity.

1. Install the IEEE-1394 (FireWire) card in the host computer as described by

the instructions included with the card.

IMPORTANT: Use proper precautions to avoid static when you install the

IEEE-1394 (FireWire) card in your computer.

2. Power up the host computer after the IEEE-1394 (FireWire) card

installation is complete.

1. Insert the Kodak i200 Series Installation CD in the CD-ROM drive.

The installation program starts automatically.

2. Follow the onscreen instructions to install the TWAIN and ISIS drivers and

the Kodak Scan Validation Tool.

1. Attach the beaded end of the IEEE-1394 (FireWire) cable to the IEEE-1394

port on the back of the scanner.

WARNING: Make sure that the position of the IEEE-1394 (FireWire) cable

connector end correlates to the IEEE-1394 port configuration

before you plug the cable in. Damage to the scanner will

occur if the cable is attached in the wrong position.

IMPORTANT: Only use the IEEE-1394 cable that is supplied with the

i200 Series Scanner.

A-61167 April 2005 13

Page 18

2. Attach the other end of the IEEE-1394 (FireWire) cable to the

host computer.

WARNING: Make sure that the position of the IEEE-1394 (FireWire) cable

connector end correlates to the IEEE-1394 port configuration

before you plug the cable in. Damage to the scanner will

occur if the cable is attached in the wrong position.

IMPORTANT: The i200 Series Scanner should be the only item plugged in to

the IEEE-1394 (FireWire) card on the host computer.

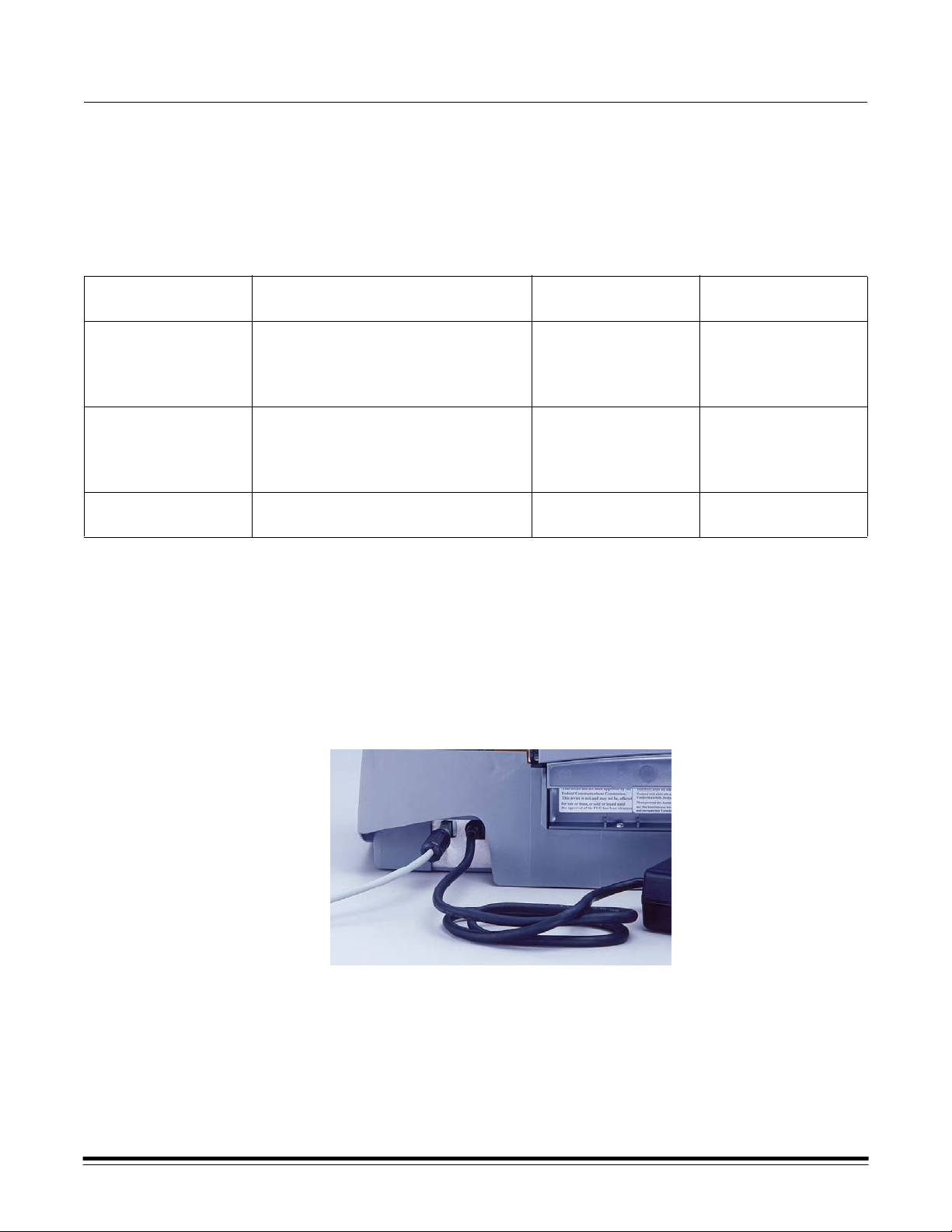

Power setup One or more power cords may be supplied with the scanner. Use only the cord

required for your power type. Dispose of any unneeded power cords properly.

Use only the power supply that was provided with the scanner.

CAUTION: The scanner and power supply must only be used indoors in a

dry location.

IMPORTANT: Do not substitute another power supply model or another

manufacturer’s power supply.

1. Press the side labeled “O” on the power switch to make sure that the

power is off.

On/Off (I/O) power switch

NOTE: The power switch is on the power supply.

2. Attach the power cord for your power type to the power supply.

3. Attach the power supply to the power input on the back of the scanner.

14 A-61167 April 2005

Page 19

4. Plug the power cord into a power outlet.

NOTE: Make sure that the power outlet is located within 1.52 metres (5 feet) of

the scanner and is easily accessible.

5. Press the side labeled “I” on the power switch to power up the scanner.

After you power up the scanner, the red and green indicator lights will

illuminate. After approximately one minute, both lights go out. When the

green indicator light comes back on, the scanner is installed and ready to

begin scanning. However, the host computer may require a few more

seconds to detect the scanner.

For best calibration and scanning results, allow the scanner lamps to warm

up for at least three minutes.

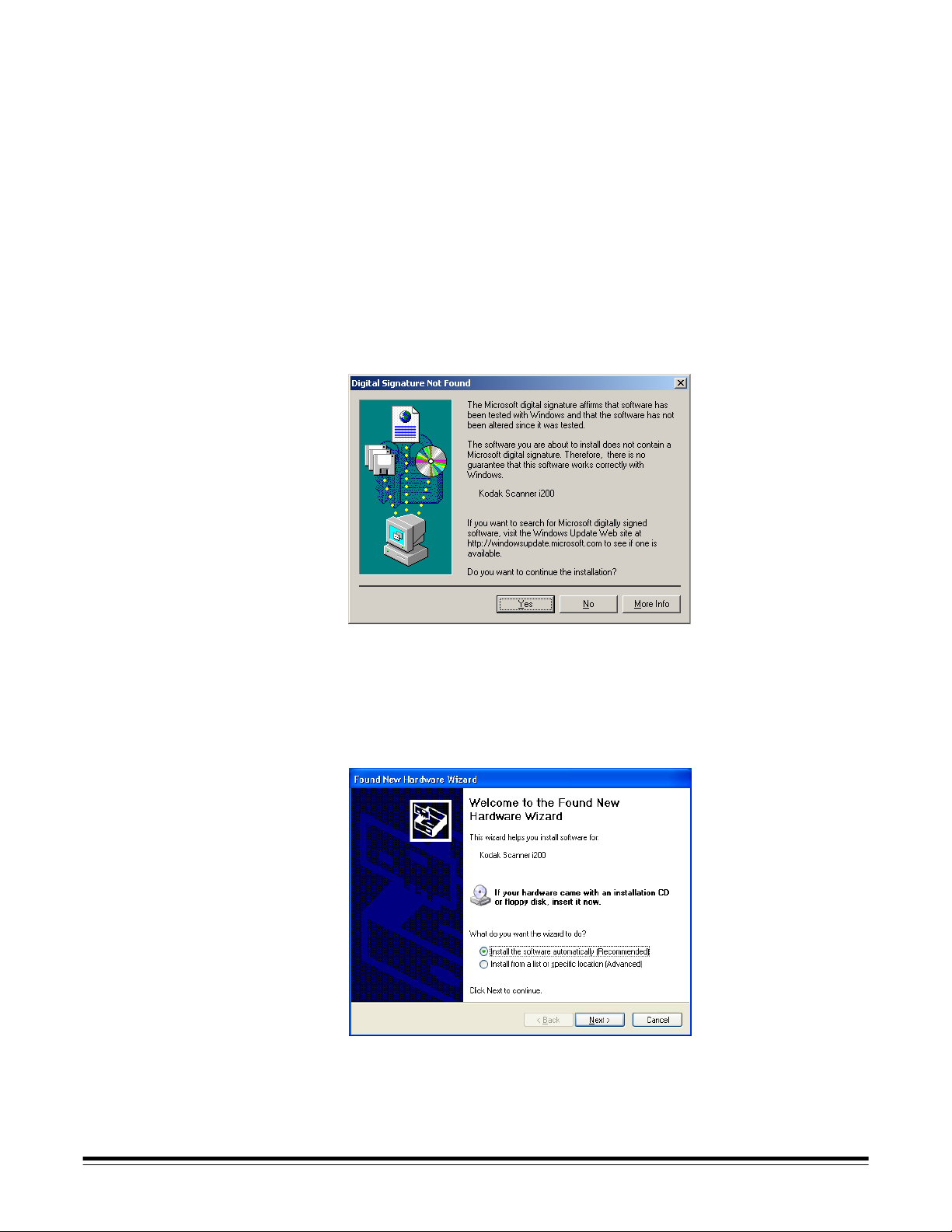

• If you are installing the scanner on a computer that is running

Windows 2000, the following screen may appear.

Select Yes. Kodak has successfully tested the i200 Series Scanners with

Windows 2000.

Your scanner is now installed.

• If you are installing the scanner on a computer that is running Windows XP,

the following screen may appear.

A-61167 April 2005 15

Page 20

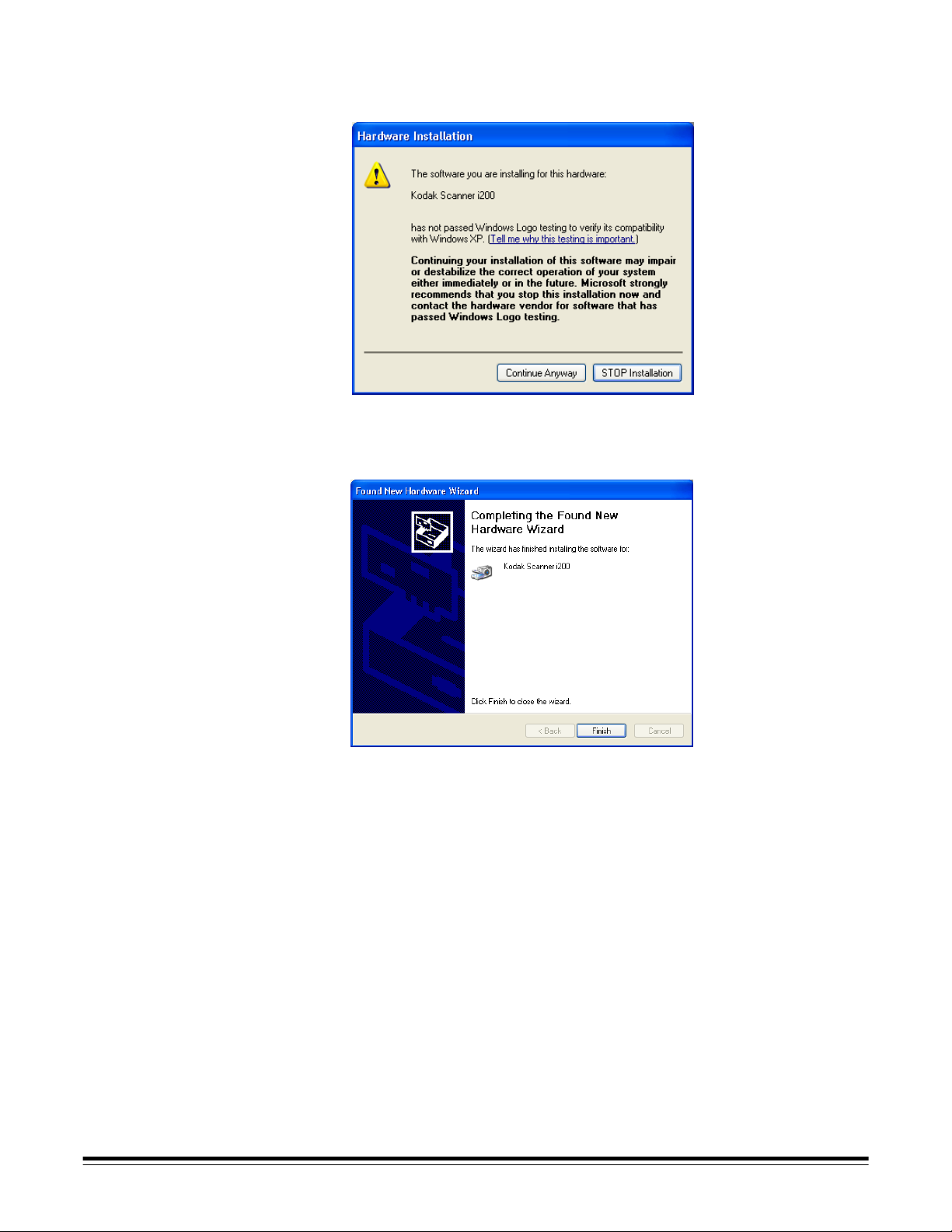

Select Next.

The following screen appears.

Select Continue Anyway. Kodak has successfully tested the i200 Series

Scanners with Windows XP.

The following screen appears.

Select Finish.

Your scanner is now installed.

16 A-61167 April 2005

Page 21

Input and output trays The input and output trays snap into place. They also may be adjusted to fit

different document sizes. The input and output trays also may be folded flat up

against the scanner to save space when the scanner is not in use.

Input trayOutput tray Document stops

Attaching the input tray 1. Locate the input tray slots (large holes) on the scanner.

2. Align the input tray pins with the slots.

3. Press the input tray until it snaps into place.

Attaching the output tray 1. Locate the output tray slots on the scanner.

2. Align the output tray pins with the slots.

3. Press the output tray until it snaps into place.

Tray extenders and side guides

• Both the input and output trays have extenders to accommodate long

documents. Grasp the tray extender and pull it out to the desired position.

• The input tray has side guides that allow you to adjust the feeder to fit

different document sizes. Grasp the side guides and slide them to the

desired position.

Input tray extenderOutput tray extender

A-61167 April 2005 17

Page 22

Adjusting the output tray The adjustable output tray has three possible positions.

Closing the input and output trays

Lowest position for

long documents

• Set the output tray to the lowest position when you are scanning

long documents.

• Set the output tray to the middle position when you are scanning letter-

or A4-size documents.

• Set the output tray to the highest position with the first document stop

raised when you are scanning checks.

Use the highest position with the second document stop raised when you

are scanning documents that are 14 cm (5.5 in.) long.

1. Grasp the tray on each side.

2. Lift up the tray and move it up or down to the desired position.

You can move the scanner trays out of the way when the scanner is not in use.

1. Grasp the input tray.

2. Lift up the input tray until it rests against the scanner front.

3. Grasp the output tray.

4. Lift up the output tray until it rests against the scanner back.

Middle position for

letter or A4 documents

Highest position

for checks

Installing optional

accessories

18 A-61167 April 2005

If you have purchased a Kodak i200 Series Imprinter, Kodak i200 Series

Dockable Flatbed, and/or additional memory (SODIMM), refer to the

appropriate appendix in this guide for installation instructions.

Page 23

Using the Scanner

Starting and stopping scanning

Scanning is controlled by software developed for your application. To start and

stop scanning, refer to the documentation provided with your software.

Automatic feeding To scan a batch of documents, follow the guidelines for size, type, quantity,

etc., in the Introduction section. For faster throughput, feed documents into the

automatic document feeder (ADF) in landscape orientation (longer side as the

leading edge).

IMPORTANT: Staples and paper clips in documents may damage the scanner.

Remove all staples and paper clips before scanning.

1. Align the leading edges of the stacked documents.

2. Position the leading edge of the documents face down and centered

in the ADF.

3. Adjust the document feeder guides.

4. Adjust the output tray position, if necessary.

5. Pull out the output tray extender, if necessary.

6. Start scanning.

Continuous feeding Continuous feeding allows you to place additional batches of documents in the

feeder for “infinite” feeding (with operator assistance).

• When only a few documents from one batch remain in the feeder, place the

next batch face down on top of those documents.

A-61167 April 2005 19

Page 24

Manual feeding Follow the guidelines for document size, type, weight, quantity, etc., in the

Introduction section. Position the leading edge of the document face down

and centered in the ADF, then start scanning.

Damaged documents You can scan torn or fragile documents through the automatic document

feeder if they are placed in a protective plastic sleeve.

NOTE: The i280 Scanner has a feature (Special Document mode) that allows

irregularly shaped documents or documents with holes to be scanned

through the ADF. Refer to the following section, “Additional Features”

for more information.

1. Place the damaged document into a protective sleeve.

2. Position the sleeve face down, folded edge first, and centered in the ADF.

Gap release lever

3. Lift the gap release lever, if necessary (this provides more clearance to

ease document feeding).

4. Start scanning.

20 A-61167 April 2005

Page 25

Additional features

Following are additional scanning capabilities that allow you to scan more

document types faster and with better results. With the exception of Perfect

Page with iThresholding, these features are for the i280 Scanner only:

• Long Paper mode

• Special Document mode

• Perfect Page with iThresholding - for all i200 Series Scanners

• Toggle patch

Long Paper mode Long Paper mode allows you to scan documents that exceed the 34-inch

maximum length that the scanner normally handles. You can scan documents

that are up to 609 cm (20 feet) long at resolutions of up to 300 dpi with Long

Paper mode. These document types include document rolls (e.g., EKG charts,

chart recorder rolls, and other roll-type documents).

The scanned document is delivered in multiple images. You can specify the

length and width of the images in the fixed cropping option in your scanning

application. The recommended segment size is 10 to 12 inches.

Special Document mode Special Document mode allows you to scan irregularly shaped documents

(e.g., pages with coupons removed or documents with large holes or cutouts

in them) that would normally produce unexpected results such as truncated

images or jams.

Using Special Document mode will reduce scanner throughput (e.g., for A4 or

letter-sized documents scanned in portrait orientation at 200 dpi, throughput

may reduced by as much as 25%).

NOTES: Documents with a cutout on the side and bottom

(e.g., as shown at right) may stop in the scanner

during scanning even when you are using

Special Document mode because the scanner

will sense the end of the document at the short

cutout edge.

You can scan this type of document by placing it

under a tire on the feed module or in a plastic

sleeve.

For a document that is especially ragged or

tattered, place it in a plastic sleeve for scanning.

A-61167 April 2005 21

Page 26

Perfect Page with iThresholding

Perfect Page with iThresholding is essential when you are scanning

mixed batches of documents of varied contrast in background and/or text.

Brightness is automatically adjusted for each individual document for

highlighting, low contrast, and lightweight paper — situations that previously

required manual adjustments.

Using the iThresholding feature, the scanner dynamically evaluates each

document in the batch to determine the optimal threshold value to produce the

highest quality image.

The iThresholding feature delivers high-quality images from a large range of

both poor- and high-contrast documents and reduces the need to pre-sort,

rescan, and perform post-image processing. You get better image and text

legibility, smoother lines, minimal to no artifacts, and fewer shaded areas with

minimal or no user intervention.

Toggle patch The Toggle patch triggers the scanner to switch from the current scanning

mode to the alternative mode (i.e., bi-tonal to color or color to bi-tonal).

When you scan using a Toggle patch (shown at right),

color on-the-fly processing is enabled. With color on-thefly, scanning automatically switches between scanning

modes whenever a Toggle patch is read by the scanner.

NOTES: The Toggle patch document is available as a

.pdf file on the Installation CD. Print the Toggle

patch document on a good-quality printer.

Do not scan a duplex Toggle patch document

(where the Toggle patch printed on both sides)

in duplex mode.

22 A-61167 April 2005

Page 27

Maintenance

Cleaning the scanner The scanner will collect dust and other debris during routine scanning.

For optimal scanner performance, follow the detailed cleaning instructions

in this section and clean the feed module tires, separator module tires, imaging

guides, transport area, and paper path at least once per week. Clean the

scanner and paper path daily if you are scanning carbonless paper or

newsprint, or if you are using the imprinter.

Use only these cleaning materials:

Item CAT No.

Kodak Digital Science Roller Cleaning Pads (24) 853 5981

Staticide Wipes for Kodak Scanners (144) 896 5519

Kodak Digital Science Transport Cleaning Sheets (50) 169 0783

IMPORTANT: Staticide Wipes contain isopropanol which can cause eye

irritation and dry skin. Wash your hands with soap and

water after performing maintenance procedures. Refer to

the Material Data Safety Sheet (MSDS) for more information.

The MSDS is available on the Kodak web site at

www.kodak.com/go/MSDS.

Allow all tires to dry completely before using the scanner.

NOTES: The use of any other cleaning materials could damage your scanner.

Use fresh cleaning material unless otherwise indicated.

In addition to the recommended cleaning supplies, you may use a

vacuum cleaner to remove debris from the scanner.

Some debris from the rubber tires on the feed module and separator

module is normal. Tire debris does not always mean that the tires

are worn or damaged. After cleaning, inspect the tires for wear and

replace the separator module or feed module if necessary.

To order cleaning supplies, refer to Appendix B, Supplies

and Accessories.

A-61167 April 2005 23

Page 28

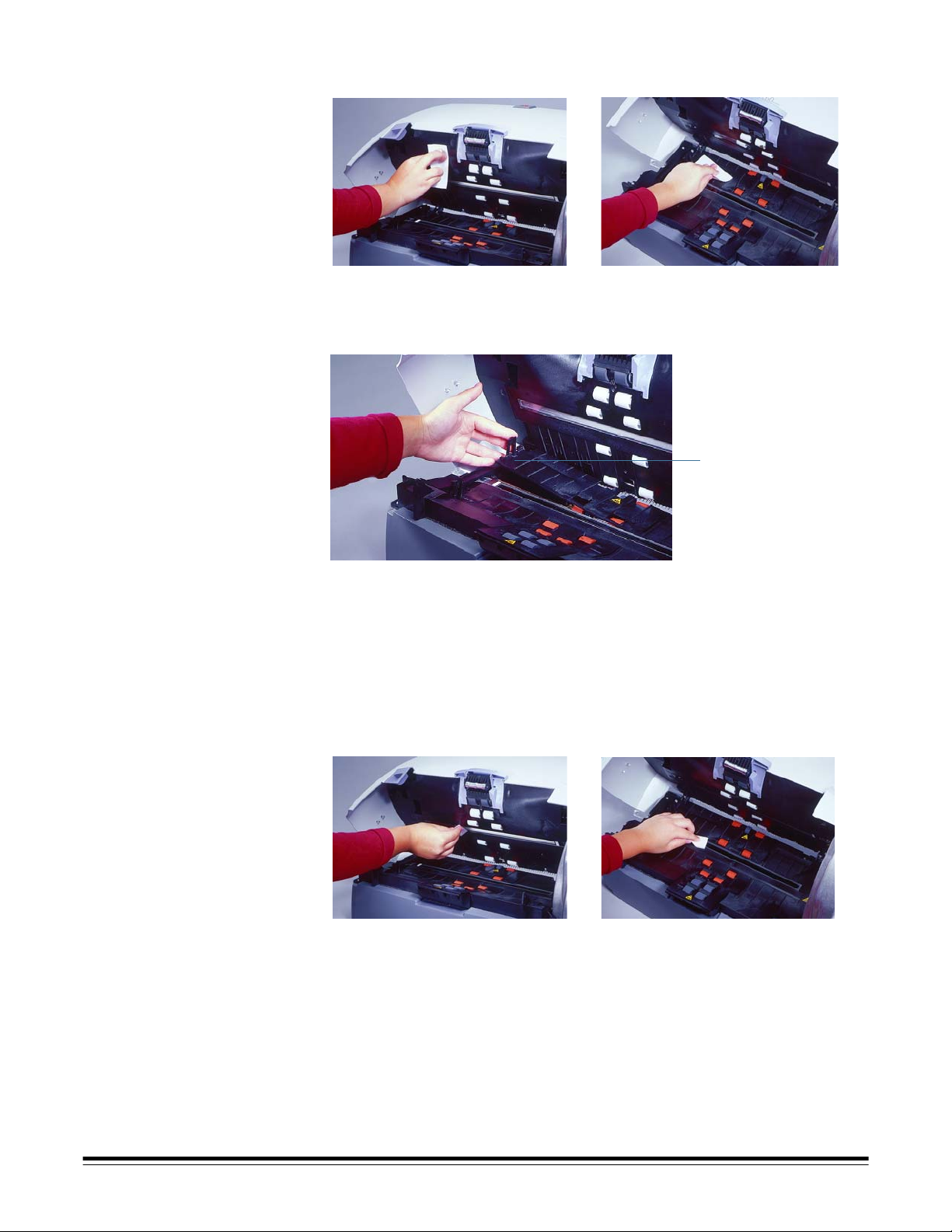

Cleaning the separator module

1. Power down the scanner.

2. Remove any documents from the feeder area.

3. Lift up the scanner door release to unlatch the scanner door.

4. Pull up to open the scanner door.

5. Remove the separator module by pulling it down and lifting it off.

Separator module

6. Manually rotate and wipe the separator module tires with a roller

cleaning pad.

24 A-61167 April 2005

Page 29

7. Inspect the tires.

If the separator module tires show signs of wear or damage, replace the

tires or the separator module.

8. Insert the separator module and align the shaft ends.

9. Press until the separator module clicks into place.

10. Go to the next section to clean the feed module.

Cleaning the feed module 1. Push against the raised edge on the left side of the front roller cover to

the side and pull the cover up and out to remove it.

Front roller cover

NOTE: You may need to lift the input tray slightly to remove the front

roller cover.

2. Remove the feed module by pushing it to the right and lifting it out.

Feed module

A-61167 April 2005 25

Page 30

3. Manually rotate and wipe the feed module s with a roller cleaning pad.

4. Inspect the feed module.

If the feed module tires show signs of wear or damage, replace the tires or

the feed module.

5. Remove any dust or debris from the tray area under the feed module and

the front roller cover.

6. Insert the feed module by aligning the pins and pushing it toward the right

to fit it into position.

Cleaning the drive rollers and transport area

7. Re-install the front roller cover.

8. Go to the next section to clean the drive rollers and transport area.

1. Manually rotate and wipe the drive rollers with a roller cleaning pad.

2. Clean any dust or debris in the slots around the drive rollers.

26 A-61167 April 2005

Page 31

3. Wipe the upper and lower transport areas with a roller cleaning pad.

4. Dry the transport area with a dry Staticide Wipe.

5. Push against the raised edge on the left side of the rear roller cover and

pull the cover up and out to remove it.

Rear roller cover

Cleaning the imaging guides

6. Remove any dust or debris under the rear roller cover.

7. Re-install the rear roller cover.

8. Go to the next section to clean the imaging guides.

Clean the exposed (top side) surfaces of the imaging guides. You do not need

to remove the imaging guides for cleaning.

1. Wipe the upper and lower imaging guides with a Staticide Wipe.

2. Dry the imaging guides with a dry Staticide Wipe.

3. Lower the scanner door and press it down firmly until it latches into place.

4. Go to the next section to clean the paper path.

A-61167 April 2005 27

Page 32

Cleaning the paper path 1. Remove the wrapping from the Transport Cleaning Sheet.

2. Adjust the paper feeder guides to fit the cleaning sheet.

3. Feed the cleaning sheet (adhesive side up) through the scanner in portrait

orientation until all residue is removed from the drive rollers.

4. Adjust the feeder guides to fit, then feed the cleaning sheet (adhesive side

up) through the scanner in landscape orientation until all residue is

removed from the drive rollers.

5. Using the same cleaning sheet, repeat Steps 3 and 4, but feed the

cleaning sheet through the scanner with the adhesive side down until all

residue is removed from the drive rollers.

NOTE: When a cleaning sheet gets very dirty, discard it and use a new one.

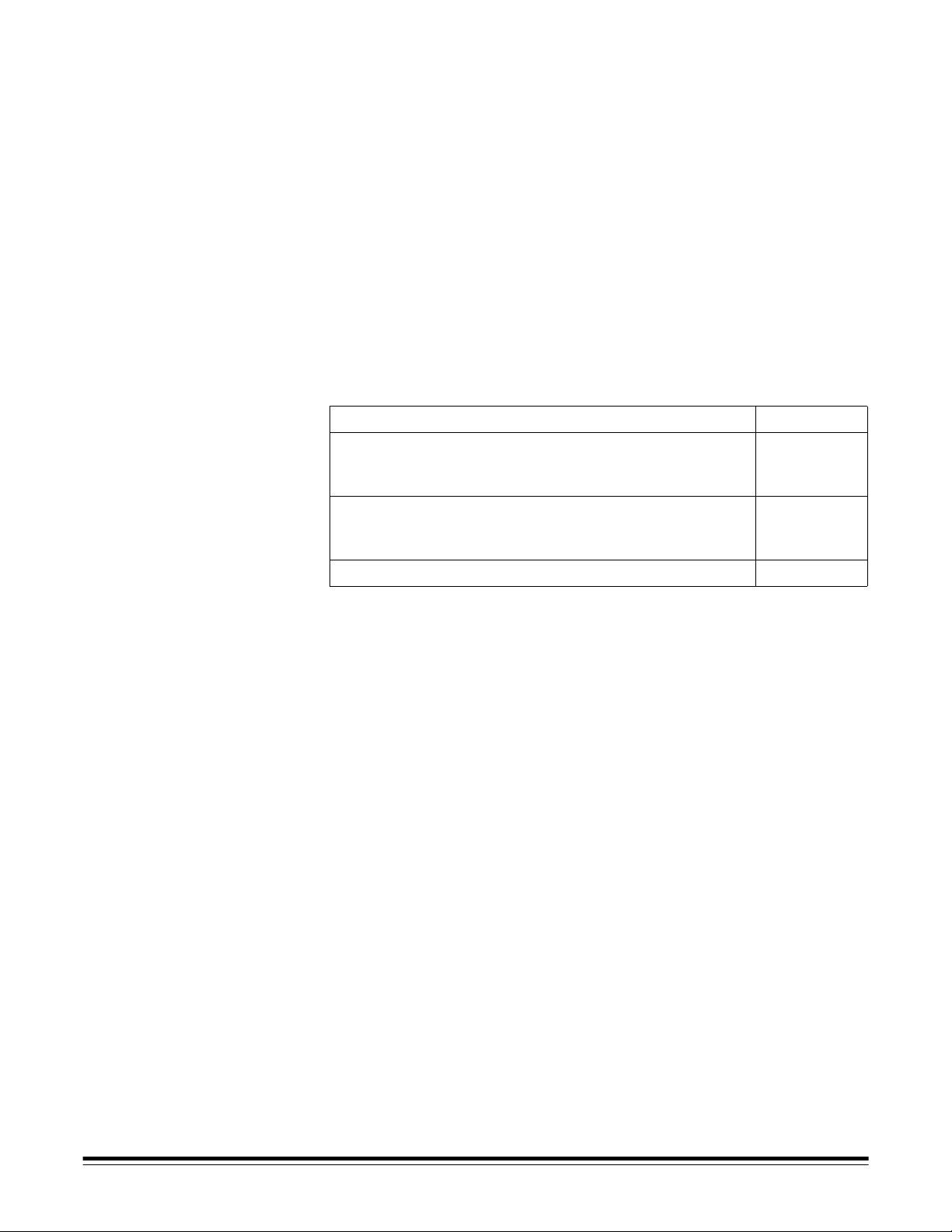

Replacing parts Customer-replacement parts (feed module, separator module, pre-separation

pad, roller tires, and installation instructions) are available in the following kits:

Item CAT No.

Kodak Feeder Consumables Kit for i200 Series Scanners (1

complete feed module, 1 complete separator module, 2 preseparation pads, 24 tires)

Kodak Extra-Large Feeder Consumables Kit for i200 Series

Scanners (5 complete feed modules, 5 complete separator

modules, 10 pre-separation pads, 120 tires)

Kodak Imaging Guide Set (1 upper, 1 lower) 120 0278

Use only these replacement parts in your scanner.

The expected life of customer-replaceable parts is shown below.

• Kodak Separator Module for i200 Series Scanners:

200,000 document pages

• Kodak Feed Module for i200 Series Scanners:

500,000 document pages

NOTES: The composition of the tire materials was engineered to provide the

ultimate in feeding reliability across the broadest range of document

types, sizes, and thicknesses. Expected life figures are offered as

guidelines for operations that follow the recommended scanner

cleaning procedures in this section and that scan document types

within the recommended paper types (refer to “Preparing documents

for scanning” in the Introduction section).

Your experience may vary. Certain paper types (such as carbonless

paper or newsprint), failure to clean regularly, and/or use of nonrecommended cleaning solvents can shorten tire life.

124 1066

821 5808

Tire life may be reduced due to a long transport timeout setting.

To order replacement parts, refer to Appendix B, Supplies

and Accessories.

28 A-61167 April 2005

Page 33

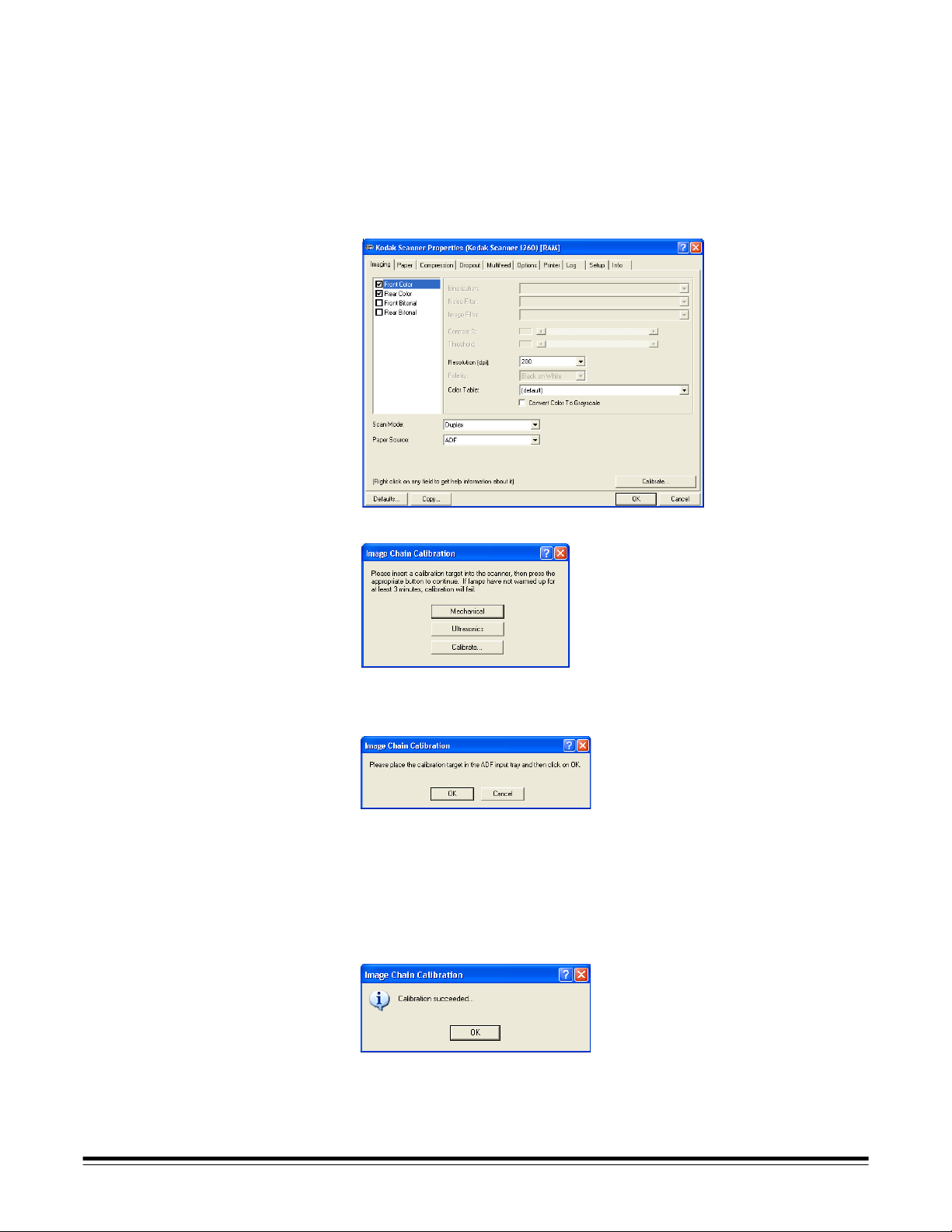

Calibrating the scanner Calibration optimizes the optical system in your scanner in order to achieve

the best overall quality of scanned images. Frequent calibration is not needed

or recommended.

NOTE: The screens shown in this section are for the TWAIN driver. Your

screens may be different.

1. Allow the lamps to warm up for three minutes.

2. Click on Calibrate in the Imaging tab.

The Image Chain Calibration dialog box appears.

3. Click Calibrate.

A message appears.

4. Place the calibration target in the scanner ADF.

Use the 29.7 cm (11.7 in.) square calibration target (CAT No. 131 7304)

that is included with your scanner.

5. Click OK.

Calibration begins. A confirmation box appears when the ADF calibration

has finished.

6. Click OK.

A-61167 April 2005 29

Page 34

Troubleshooting

Indicator lights There are two indicator lights — one red, one green — on the scanner that

give some information about what the scanner is doing.

Red indicator light

Green indicator light

Green on — scanner is ready to scan

Green flashing — scanner is busy

Red on — an error condition exists (refer to “Problem Solving” in this section

for help with some common error conditions)

Red and green on — scanner is powering up

After you power up the scanner, the red and green indicator lights will

illuminate. After approximately one minute, both lights go out. When the

green indicator light comes back on, the scanner is ready to begin scanning.

However, the host computer may require a few more seconds to detect

the scanner.

Lamps The scanner has a lamp saver feature to prolong lamp life. The lamps shut off

after five minutes of scanner idle time.

Clearing document jams

1. Remove any documents from the feeder area.

2. Lift up the scanner door release to unlatch the scanner door.

3. Pull up to open the scanner door.

4. Locate the jammed document and remove it.

5. Lower the scanner door and press it down firmly until it latches into place.

30 A-61167 April 2005

Page 35

Adjusting the separator module tension

Most documents will feed perfectly fine with the default separator module

tension. However, there may be times when you are scanning documents

that are lighter or heavier than normal. Two additional positions for the

separator module spring allow you to adjust the tension to improve the

scanning these types of documents. The spring can be placed in one of the

two channels or it can be released and left on the flat surface.

Heavy documents Normal documents

(default position)

1. Power down the scanner.

2. Remove any documents from the feeder area.

3. Lift up the scanner door release to unlatch the scanner door.

4. Pull up to open the scanner door.

5. Remove the separator module by pulling it down and lifting it off.

6. Pull the spring gently into the position you want.

Light documents

7. Insert the separator module and align the shaft ends.

8. Press until the separator module clicks into place.

9. Lower the scanner door and press it down firmly until it latches into place.

A-61167 April 2005 31

Page 36

System is not responding

If the scanner and/or host computer are not responding, perform the

following steps.

1. Power down the computer.

2. Power down the scanner.

3. Disconnect the IEEE-1394 (FireWire) cable from the IEEE-1394 port on

the back of the scanner.

4. Power up the computer.

5. Power up the scanner.

After you power up the scanner, the red and green indicator lights will

illuminate. After approximately one minute, both lights go out. When

the green indicator light comes back on, the scanner is ready to begin

scanning. However, the host computer may require a few more seconds

to detect the scanner.

6. Wait until the scanner light is green and no longer in the power-up mode.

7. Attach the IEEE-1394 (FireWire) cable to the IEEE-1394 port on the back

of the scanner.

8. Wait a few moments for the host computer’s operating system to recognize

the scanner.

The scanner is now ready to use.

Color image quality Color image quality is highly subjective. Here are some things to consider

when scanning in color:

• The difference in the color outputs of scanners, printers, and monitors can

affect the perception of the scanned document.

• Computer displays and printer output can vary from model to model, and

from manufacturer to manufacturer. An image may be acceptable on one

display and unacceptable on another.

• Area lighting (fluorescent, natural, incandescent) can affect

color perception.

• The appearance of a colored area within an image can be perceived

differently, based on what surrounds it.

• The characteristics and condition of a document can have an impact on

color consistency.

• Color requirements may differ between environments (e.g., in a business

document environment, images are generally viewed on a monitor, whereas

in a “print on demand” environment, scanned images are printed).

To ensure that your scanner is delivering the best image:

• Clean the scanner. Contamination within the scanner degrades image

quality. (Refer to the Maintenance section for cleaning information.)

• Calibrate the scanner occasionally and make sure that the calibration target

is clean and unwrinkled.

32 A-61167 April 2005

Page 37

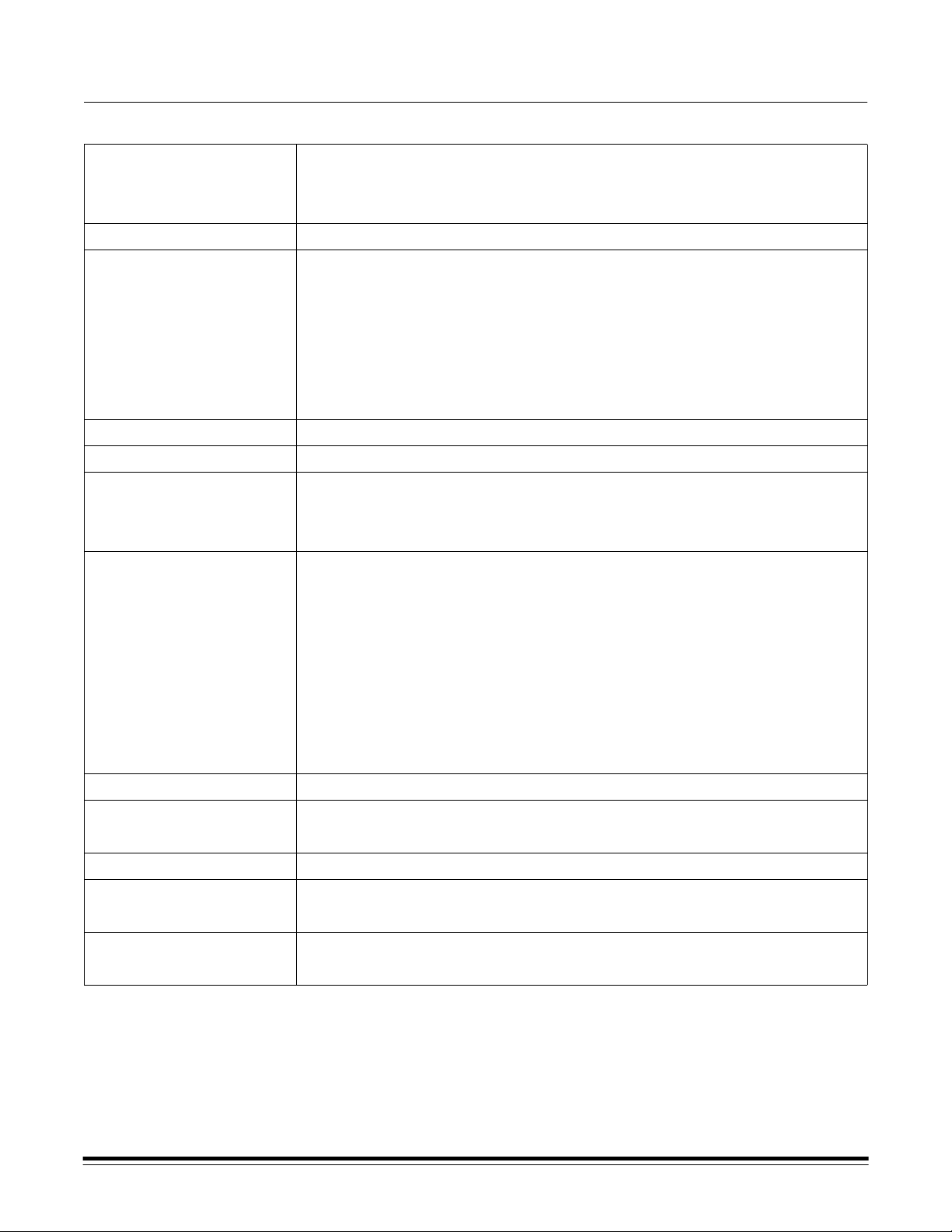

Problem solving Occasionally, you may experience a problem with your scanner. In many

cases, you can easily fix the problem yourself. To perform suggested

maintenance, refer to the Maintenance section. You may also need to

check your scanning application.

Problem Possible Solution

The scanner will not scan/

feed documents

Calibration has failed Make sure that:

Documents are jamming Make sure that:

“False” paper jams

are occurring

35.6 cm (14 in.) or longer

documents are not feeding or

are jamming

Jam error appears

when scanning with

Long Paper mode

Make sure that:

• the power cord is plugged in and the power is on.

• the scanner and printer access doors are completely closed.

• the proper power-up sequence was followed, the scanner’s green light is on,

and the software has enabled scanning.

• documents are making contact with the feed module.

• the height of batched documents is less than 10.2 mm (0.4 in.) or

approximately 150 sheets of 60 g (16 lb.) paper.

• documents meet specifications for size, weight, and type, etc.

• for thicker documents, you lift the gap release button during feeding.

• you check the feed module and separator module for signs of wear, and

replace these parts if necessary.

• the imaging guides are securely in place and pushed all the way in.

You can also power the scanner down and power up again or follow the

instructions in “System is not responding” in this section.

• the lamps have been on at least three minutes.

• you are using a proper calibration target. Use the 29.7 cm (11.7 in.) square

calibration target (CAT No. 131 7304) that is included with your scanner.

• the transport area is clear of obstructions.

• the output tray and guides are adjusted for the length of documents

being scanned.

• all jammed documents have been removed from the paper transport area.

• documents meet specifications for size, weight, and type, etc.

• all staples and paper clips have been removed from the documents.

• the separator module and feed module are clean and properly installed.

• the drive rollers are clean.

• the imaging guides are clean.

• Make sure that the paper transport area is clean.

• If you are scanning documents that contain holes (e.g., 3-hole punch paper),

rotate the documents and rescan.

NOTE: If you are using an i280 Scanner, use Special Document mode to scan

documents containing holes.

Make sure that the input and output tray extenders are pulled out to provide

support for long documents.

Change the scanning resolution to 300 dpi or less and scan the document again.

A-61167 April 2005 33

Page 38

Problem Possible Solution

Image quality is poor or

has decreased

The lamps shut off too soon The lamps in the i200 Series Scanners will turn off after 5 minutes of no scanner

Documents are skewed

during scanning

Scanner pauses excessively

during scanning

Documents are multifeeding Make sure that:

Roller marks or streaks appear

on documents after scanning

Vertical lines appear on

the image

Make sure that:

• the scanner is clean. Refer to the Maintenance section.

• the scanner is calibrated. Refer to the Maintenance section.

activity. If the lamps are off, but the scanner has not yet gone into the Energy Star

mode (default 15 minutes), there will be a delay of about 5 seconds for the lamps

to warm up again.

The default setting for the Energy Star is 15 minutes, and if not changed to

another value between 16 and 60 minutes, the lamps will turn off after

5 minutes of no scanner activity, followed 10 minutes later by the fan turning

off (15 minutes total).

If you set the Energy Star timeout to a new value greater than 15 minutes, you

must scan at least one document for that setting to be enabled. After this setting

has been enabled, it will be enforced until a new setting is selected or the

scanner is powered off and back on.

Make sure that:

• the document side guides are adjusted to fit the documents being fed.

• documents are being fed perpendicular to the feed module.

• documents are being fed in the center of the ADF.

• all staples and paper clips have been removed from the documents.

• the feed module, separator module, and drive rollers are clean.

Make sure that:

• the host computer meets minimum requirements for scanning.

• there is enough free space on the hard disk drive.

• all other applications are closed.

• the scanner has the correct amount of memory installed for the documents

being scanned.

You can also try changing the scanning options (compression, etc.) in your

scanning software.

• the leading edges of all batched documents are centered in the ADF so that

each document will come in contact with the feed rollers.

• the feed module and separator module are clean and not worn.

• documents with an unusual texture or surface are fed manually.

Clean the feed module and separator module tires and the drive rollers. Refer to

the Maintenance section.

• Clean the imaging guides. Refer to the Maintenance section.

• Calibrate the scanner. Refer to the Maintenance section.

34 A-61167 April 2005

Page 39

Transporting the scanner

If it becomes necessary to transport the scanner after installation, you must

repack the scanner using the original packaging materials. If you do not have

the original packaging materials, contact your supplier.

1. Power down the computer.

2. Power down the scanner.

3. Disconnect the power cord from the back of the scanner.

4. Disconnect the IEEE-1394 (FireWire) cable from the IEEE-1394 port on

the back of the scanner.

5. Place the foam end caps on each end of the scanner.

6. Place the scanner in the box.

7. Place the power cord and power supply in the box.

8. Tape down the input and output trays to secure them.

9. Close the box.

The scanner is now ready for moving.

A-61167 April 2005 35

Page 40

Appendix A Specifications

Scanner Type i250 Scanner: simplex color scanner with automatic document feeder

i260 Scanner: duplex color scanner with automatic document feeder

i280 Scanner: duplex color scanner with automatic document feeder

Image Capture Resolution 75 dpi to 300 dpi color and bitonal

ADF Scanning Speed i250 Scanner/i260 Scanner:

50 ppm: 200 dpi landscape A4

42 ppm: 200 dpi portrait letter

i280 Scanner:

60 ppm: 200 dpi landscape A4

50 ppm: 200 dpi portrait letter

Scanning Output Bitonal, 256-level, 8-bit grayscale, 24-bit color

Output Resolution 75 to 600 dpi

File Format Output Color: compressed JPEG, uncompressed TIFF

Grayscale: compressed JPEG, uncompressed TIFF

Bitonal: G4 TIFF, uncompressed TIFF

Scan Area i250 Scanner/i260 Scanner:

Width: 6.4 to 29.7 cm (2.5 to 11.7 in.)

Length: 8.9 to 43.2 cm (3.5 to 17 in.) with standard memory

8.9 to 66.0 cm (3.5 to 26.0 in.) with extended memory

i280 Scanner:

Width: 6.4 to 29.7 cm (2.5 to 11.7 in.)

Length: 8.9 to 86.4 cm (3.5 to 34 in.) with standard memory

up to 609 cm (20 feet) when using Long Paper mode

Input Tray Capacity 150 sheets of 60 g (16 lb.) bond paper (up to A3)

Recommended

Daily Volume

Light Source Xenon lamp

Electrical Requirements 100-127V, AC 50/60 Hz, 4.0 amps

Scanner Power Scanner with ADF: 24 Vdc/4.2 A max, operating

i250/i260 Scanner: up to 5,000 pages/day

i280 Scanner: up to 7,000 pages/day

200-240V, AC 50/60 Hz, 2.0 amps

Scanner with flatbed: 24 Vdc/3.7 A max, operating

A-61167 April 2005 A-1

Page 41

Power Source Phihong PSM 1564-240

IMPORTANT: Do not substitute another power supply model or another

manufacturer’s power supply.

Scanner Dimensions Height:

35.4 cm (14.0 in.) without trays

36.4 cm (14.4 in.) with trays folded up

Width:

62.5 cm (24.6 in.)

Depth:

28.7 cm (11.3 in.) without trays

30.0 cm (11.8 in.) with trays folded up

68.1 cm (26.8 in.) with trays extended

Scanner Weight i250 Scanner: 12.5 kg (27.5 lb.)

i260 Scanner: 13.9 kg (30.5 lb.)

i280 Scanner: 13.9 kg (30.5 lb.)

Dockable Flatbed

Dimensions

Dockable Flatbed Weight 7.3 kg (16.0 lb.)

Host Connection IEEE-1394 (FireWire) interface, 6-pin connector

Height: 16.3 cm (6.4 in.)

Width: 48.6 cm (19.1 in.)

Length: 64.3 cm (25.3 in.)

Operating Temperature 15 to 35°C (59-95°F)

Humidity 15 to 76% (dry bulb)

Environmental Feature Energy Star compliant

Power Consumption i250/i260 Running: <156W

i250/i260 Energy Star: <12W

Heat Load 600 BTU

Altitude Up to 2440 m (8000 ft)

Acoustic Noise Data was measured in accordance with DIN 45 635, ANSI S12.10-1985, and

ISO 7779 in a semi-anechoic chamber. Data reported was measured at Sound

Pressure level.

• Operating: 39.7 dB

• Standby: 57 dB

Specification values apply to all of the i200 Series Scanners except where

noted. Specifications are subject to change without notice.

A-2 A-61167 April 2005

Page 42

Appendix B Supplies and Accessories

Contact your scanner supplier to order supplies.

Item CAT No.

Kodak i200 Series Dockable Flatbed 130 5390

Kodak i200 Series Imprinter 892 7964

Kodak Feeder Consumables Kit for i200 Series Scanners

(1 complete feed module, 1 complete separator module, 2 pre-separation pads, 24 tires)

Kodak Extra-Large Feeder Consumables Kit for i200 Series Scanners

(5 complete feed modules, 5 complete separator modules, 10 pre-separation pads, 120 tires)

Kodak Printer Ink Blotters for i200 Series Scanners (60) 840 5425

Kodak Printer Ink Cartridge Carrier for i200/i800/3000/4000/7000/9000 Series Scanners 826 7486

Kodak Printer Ink Cartridges for i200/i800/3000/4000/7000/9000 Series Scanners (10) 135 5155

Kodak Imaging Guide Set 120 0278

Kodak Digital Science Transport Cleaning Sheets (50) 169 0783

Kodak Digital Science Roller Cleaning Pads (24) 853 5981

Staticide Wipes for Kodak Scanners (144) 896 5519

Kodak Calibration Kit for i200 Series Scanners 131 7304

124 1066

821 5808

A-61167 April 2005 B-1

Page 43

Appendix C Kodak i200 Series Imprinter

The Kodak i200 Series Imprinter adds imprinting capability to your Kodak i200

Series Scanner. The imprinter prints a date, time, fixed string, and/or

sequential number on document backs. Purchase the imprinter separately

(CAT No. 892 7964).

The imprinter operates at full scanner speed, and prints on the document after

scanning on the rear side of the document (top side as placed in the input

tray). Imprinting is controlled through software.

IMPORTANT: Clean the scanner's internal components daily when you use

the imprinter.

WARNING: The imprinter access door must be in place and closed

during scanner operation, except when changing the

printhead location or replacing the ink cartridge.

When the imprinter access door is removed, DO NOT allow

loose clothing, jewelry, hair, or other objects to enter the

imprinter area.

Contents of the imprinter kit

The Kodak i200 Series Imprinter kit contains the following items:

• Imprinter board

• Mounting bracket

• Thumbscrews (4)

• Imprinter cable

• Ink cartridge carrier

• Ink cartridge

• Ink blotters (2)

• Installation instructions

A-61167 April 2005 C-1

Page 44

Installing the imprinter

Removing the circuit board cover

1. Make sure that the scanner is powered down and there are no documents

in the feeder area.

2. Disconnect the power cord from the back of the scanner.

3. Disconnect the IEEE-1394 (FireWire) cable from the IEEE-1394 port on

the back of the scanner.

4. Lift up the scanner door release to unlatch the scanner door.

5. Pull up to open the scanner door.

6. Remove the output tray.

7. Lift up the scanner door release again and open the scanner door past the

circuit board cover.

Circuit board cover

8. Use a Phillips-head screwdriver to remove the two screws (one front, one

back) that hold the circuit board cover in place.

C-2 A-61167 April 2005

Page 45

9. Lift up the circuit board cover and remove it.

10. Go to the next section to attach the imprinter board and cable.

Attaching the imprinter board and cable

The imprinter board is first attached to a mounting bracket which is connected

to the main control board, then the imprinter cable is plugged in.

IMPORTANT: Use proper precautions to avoid static when you install the

imprinter card.

1. Place the imprinter board on the circuit board mounting bracket.

A-61167 April 2005 C-3

Page 46

2. Align the three thumbscrews on the imprinter board with the corresponding

holes on the circuit board mounting bracket.

3. Loosely attach the imprinter board to the circuit board mounting bracket

with the three thumbscrews.

Thumbscrews

Hook

4. Slide the hook near the bottom of the circuit board mounting bracket into

the support slot on the main control board.

Support slot

5. Press the imprinter board firmly into the main control board.

C-4 A-61167 April 2005

Page 47

6. Attach and tighten the fourth thumbscrew on top of the circuit board

mounting bracket.

7. Make sure that the imprinter board is seated and secure.

8. Tighten the three thumbscrews that connect the imprinter board and the

circuit board mounting bracket.

9. Replace the circuit board cover.

10. Secure the circuit board cover with its two screws.

11. Locate the imprinter connector on the circuit board cover.

The imprinter connector should be protruding from the opening on top of

the circuit board cover.

Imprinter connector

A-61167 April 2005 C-5

Page 48

12. Attach the end of the imprinter cable that has the metal block (ferrite block

end) to the connector in the opening on the circuit board cover.

13. Peel off the backing from the first self-stick hook-and-loop pad that is

attached to the imprinter cable.

14. Align the imprinter cable along the channel in the circuit board cover and

press the first self-stick hook-and-loop pad firmly to attach it to the circuit

board cover.

15. Continue to align the imprinter cable along the channel in the circuit board

cover until it is behind the circuit board cover.

C-6 A-61167 April 2005

Page 49

16. Peel off the backing from the second self-stick hook-and-loop pad that is

attached to the imprinter cable.

17. Press the second self-stick hook-and-loop pad firmly to attach it to the

circuit board cover.

18. Thread the imprinter cable through the opening and into the imprinter area.

19. Lower the scanner door and press it down firmly until it latches into place.

20. Go to the next section to complete the imprinter installation.

A-61167 April 2005 C-7

Page 50

Completing the imprinter installation

After installing the imprinter board and cable, you must seat the cable in its

supports and install the ink cartridge and carrier.

IMPORTANT: An ink cartridge must be in the ink cartridge carrier in order for

the imprinter to be recognized.

1. Locate the imprinter access door on the back of the scanner.

2. Slide your fingers under the imprinter access door handle and pull the door

toward you.

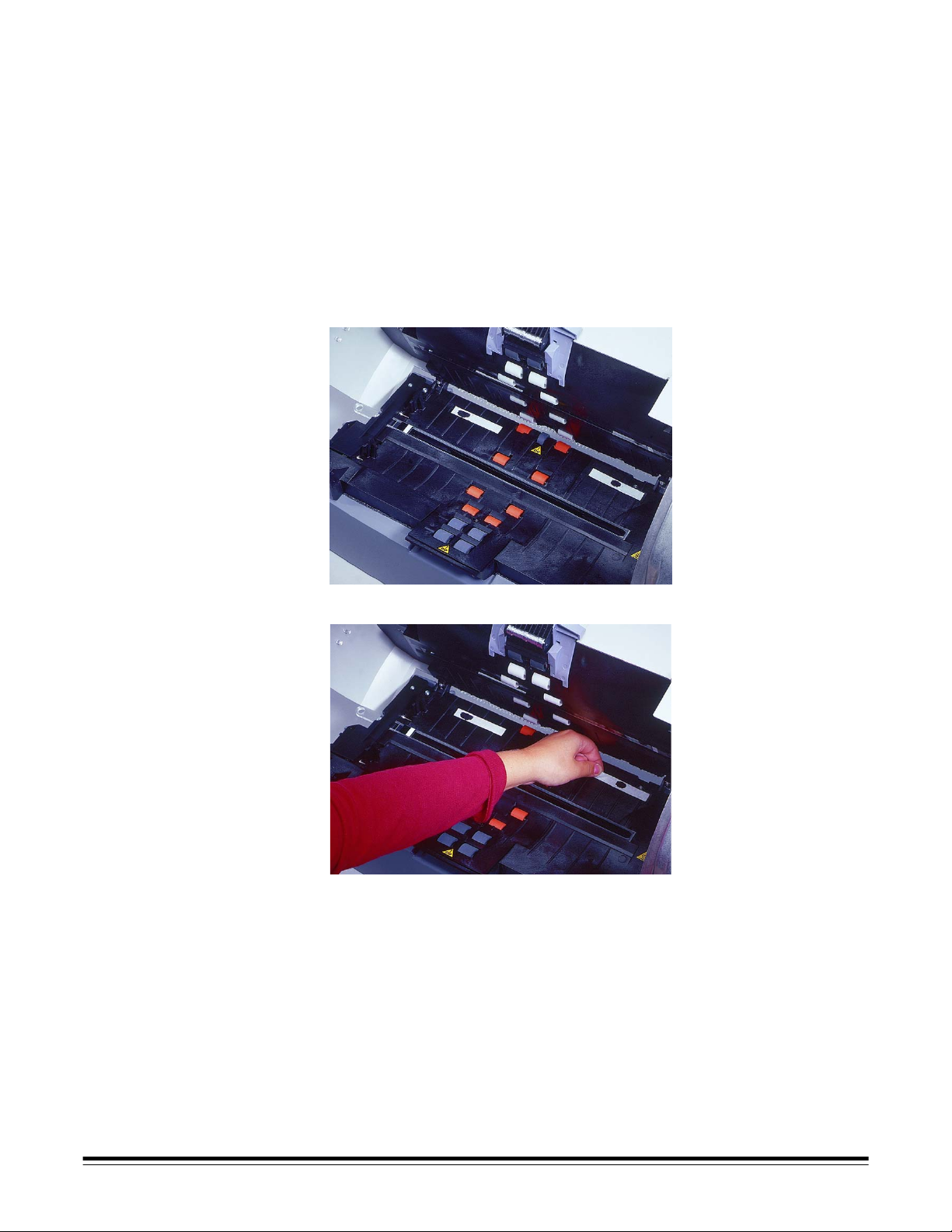

3. Lift the imprinter access door off the scanner.

4. Pull the imprinter cable from the circuit board cover area carefully through

and to the right across the imprinter area.

5. Thread the cable through the left and center imprinter cable supports,

lining up the black lines on the imprinter cable with the supports.

This ensures that the imprinter cable will not be pulled too tightly when the

scanner door is opened.

C-8 A-61167 April 2005

Page 51

6. Remove the ink cartridge from its packaging.

NOTE: Detailed information about installing ink cartridges may be found later

in this chapter.

7. Place the ink cartridge in the ink cartridge carrier.

8. Lower the locking bar around the ink cartridge.

9. Push the connector on the imprinter cable firmly into the ink

cartridge carrier.

10. Slide the ink cartridge carrier into the desired position.

NOTE: Detailed information about setting the imprinter position may be found

later in this chapter.

11. Replace the imprinter access door.

12. Re-attach the output tray.

13. Go to the next section to install the ink blotter strips in the scanner.

A-61167 April 2005 C-9

Page 52

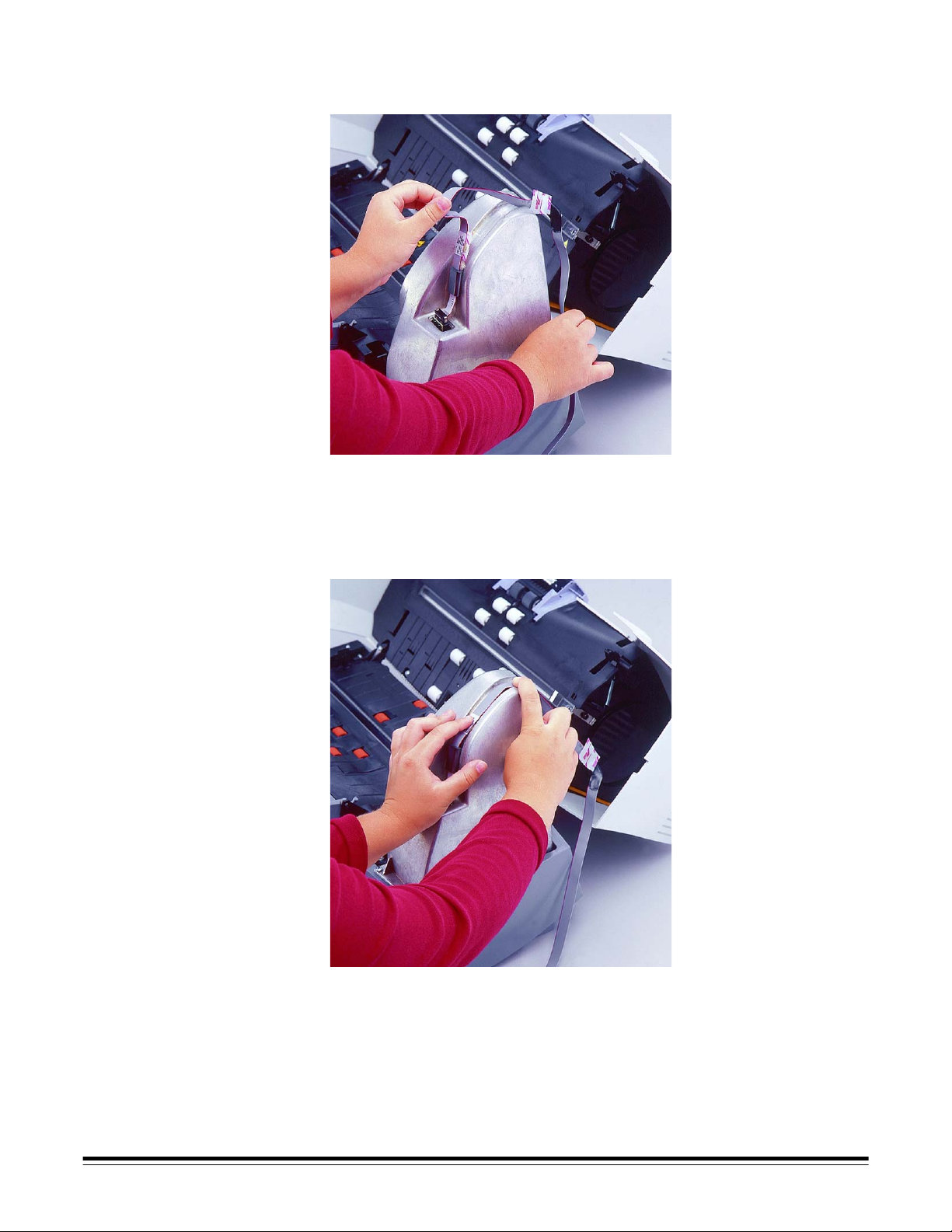

Installing the ink blotter strips

Two ink blotter strips in the scanner transport area collect ink overflow.

NOTE: Improperly aligned blotter strips may cause paper jams.

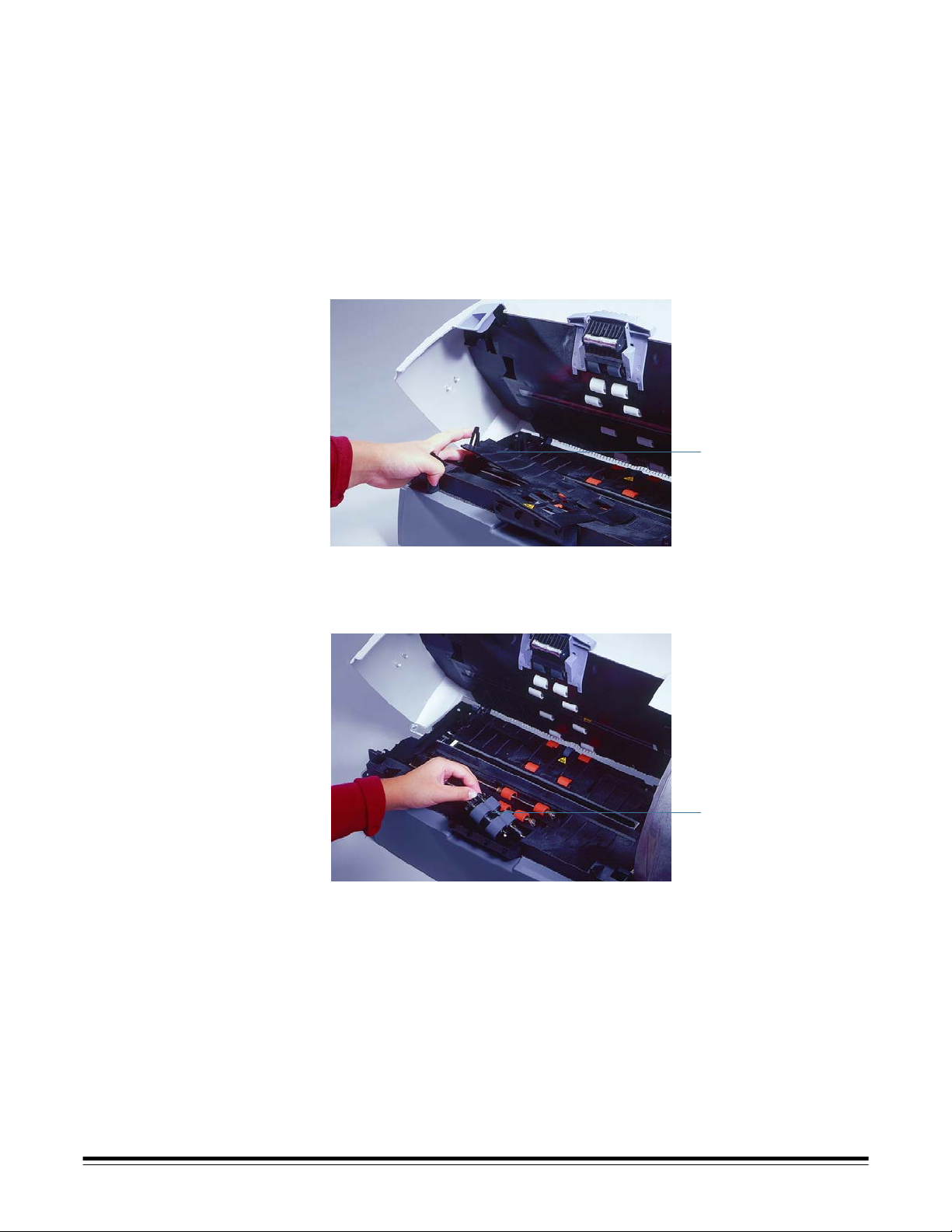

1. Lift up the scanner door release to unlatch the scanner door.

2. Pull up to open the scanner door.

3. Locate the two channels in the rear of the transport area.

These channels are where the blotter strips will be installed.

Channels

4. Remove the backing from a new blotter strip.

5. Align the blotter strip in one of the channels.

NOTE: Improperly aligned blotter strips may cause paper jams.

6. Press the adhesive side of the blotter strip down firmly into the channel.

7. Repeat Steps 4-6 for the other strip.

8. Lower the scanner door and press it firmly until it snaps into place.

C-10 A-61167 April 2005

Page 53

Installing an ink cartridge

To install the ink cartridge:

1. Locate the imprinter access door on the back of the scanner.

2. Slide your fingers under the imprinter access door handle and pull the door

toward you.

3. Lift the imprinter access door off the scanner.

4. Slide the ink cartridge carrier out of its position.

5. Raise the locking bar.

6. Remove the empty ink cartridge, if one is present.

NOTE: Dispose of empty ink cartridges properly. Do not incinerate

ink cartridges.

7. Insert a new ink cartridge.

8. Lower the locking bar around the ink cartridge.

9. Slide the ink cartridge carrier into its position.

NOTE: You may change the ink cartridge carrier positions. Refer to the

following section, “Setting the imprinter position.”

10. Replace the imprinter access door.

A-61167 April 2005 C-11

Page 54

Setting the imprinter position

There are 14 possible positions for the imprinter. Make sure that the imprinter

is in the correct position for your documents.

1. Locate the imprinter access door on the back of the scanner.

2. Slide your fingers under the imprinter access door handle and pull the door

toward you.

3. Lift the imprinter access door off the scanner.

4. Locate the imprinter positioning slots.

5. Determine which position is suitable for your imprinting needs.

6. Lift the ink cartridge carrier out of its position.

7. Slide the ink cartridge carrier into the desired position.

8. Replace the imprinter access door.

C-12 A-61167 April 2005

Page 55

Imprinter maintenance The ink cartridges, ink blotter strips, and ink cartridge carrier used in the

imprinter will need replacing occasionally.

Imprinting problems If you are having problems imprinting on scanned documents:

• Verify that the ink cartridge is not empty. The ink bladder inside the cartridge

is flat when it is empty.

• Make sure that the ink cartridge is properly installed in the imprinter.