Lennox HSXA15, HSXA15-030, HSXA15-024, HSXA15-042, HSXA15-036 Installation Instructions Manual

...

INSTALLATION

2001 Lennox Industries Inc.

Dallas, Texas

HSXA15 Outdoor Unit

HSXA15 outdoor units use R410A which is an ozone friendly HFC refrigerant. This unit must be installed with a matching indoor coil and line set as outlined in the Lennox Engineering Handbook. HSXA15 outdoor units are designed for

use in expansion valve systems only. They are not designed

to be used with other refrigerant flow control devices. An expansion valve and filter drier approved for use with R410A

have been shipped with the unit. These components must

be installed prior to unit operation. Failure to install the

provided filter drier will void the warranty.

INSTRUCTIONS

HSXA15 SERIES UNITS

CONDENSING UNITS

504,668M

02/04

Supersedes 12/02

Table of Contents

HSXA15 Outdoor Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting The Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Piping 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Existing Line Set & Indoor Coil 6. . . . . . . . . . .

Manifold Gauge Set 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Valves 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Testing 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evacuation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 13. . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up & Performance Check List 13. . . . . . . . . . . . . .

Retain These Instructions

For Future Reference

Litho U.S.A.

Shipping & Packing List

1 − Assembled HSXA15 outdoor unit

1 − Filter/Drier (approved for use with R410A systems)

1 − Expansion valve (approved for use with R410A)

2 − Grommets (for liquid and suction lines)

1 − Bushing (for low voltage wiring)

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox’ Engineering Handbook. Coils

previously charged with HCFC−22 must be flushed.

02/04

*2P0204*

General Information

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

WARNING

This product and/or the indoor unit it is matched with

may contain fiberglass wool.

Disturbing the insulation during installation, maintenance, or repair will expose you to fiberglass wool

dust. Breathing this may cause lung cancer. (Fiberglass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

504,668M

Page 1

*P504668M*

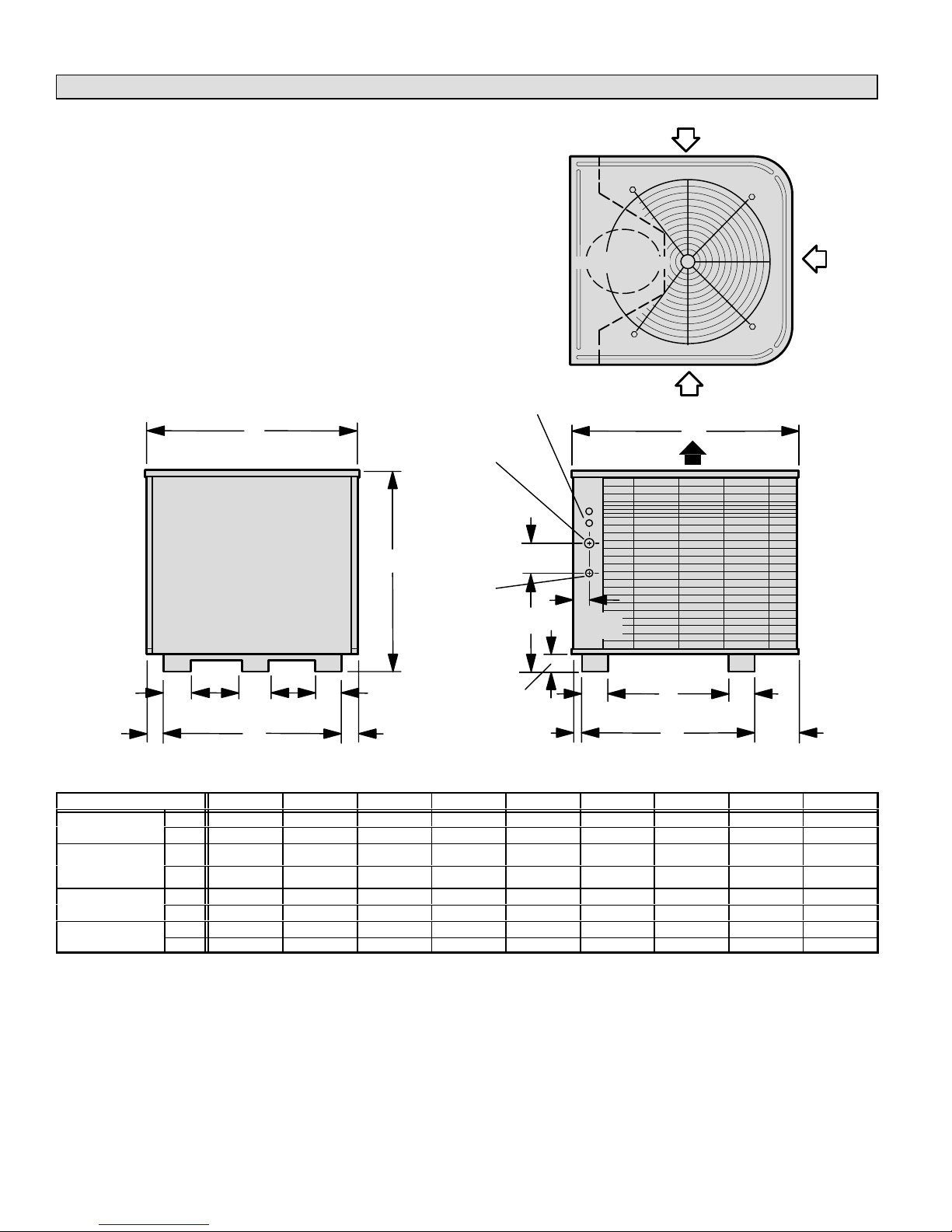

Unit Dimensions – Inches (mm)

HSXA15

Outdoor Unit

AIRINLET

INLET

COMPRESSOR

AIR

AIRINLET

C

4

(102)

E

2

(51)

B

JJ

H

4-7/8 (22)

G

ELECTRICAL

INLETS

VAPOR LINE

INLET

A

LIQUID

LINE INLET

H

2

(51)

4-1/2 (114)

2-3/4 (70)

D

1-3/8

(35)

2-9/16

(65)

4

(102)

TOP VIEW

DISCHARGE AIR

F

SIDE VIEWACCESS VIEW

Model No. A B C D E F G H J

HSXA15-024

HSXA15-030,

HSXA15-036,

HSXA15-042

HSXA15-048

HSXA15-060

in. 27-7/8 25-7/8 29-7/8 12-1/4 22-7/16 14-7/16 22-1/8 2-7/8 5-1/2

mm 708 657 759 311 570 367 562 73 140

in. 30-7/8 32-1/8 34-1/16 12-3/4 26-5/8 18-5/8 28-1/8 3-7/8 7-1/2

mm 784 816 865 324 676 473 718 98 191

in. 34−7/8 32-1/8 34-1/16 13-3/4 26-5/8 18-5/8 28-1/8 3-7/8 7-1/2

mm 886 816 865 349 676 473 718 98 191

in. 40-7/8 32-1/8 34-1/16 19-3/4 26-5/8 18-5/8 28-1/8 3-7/8 7-1/2

mm 1038 816 865 502 676 473 718 98 191

6-1/16

(154)

Page 2

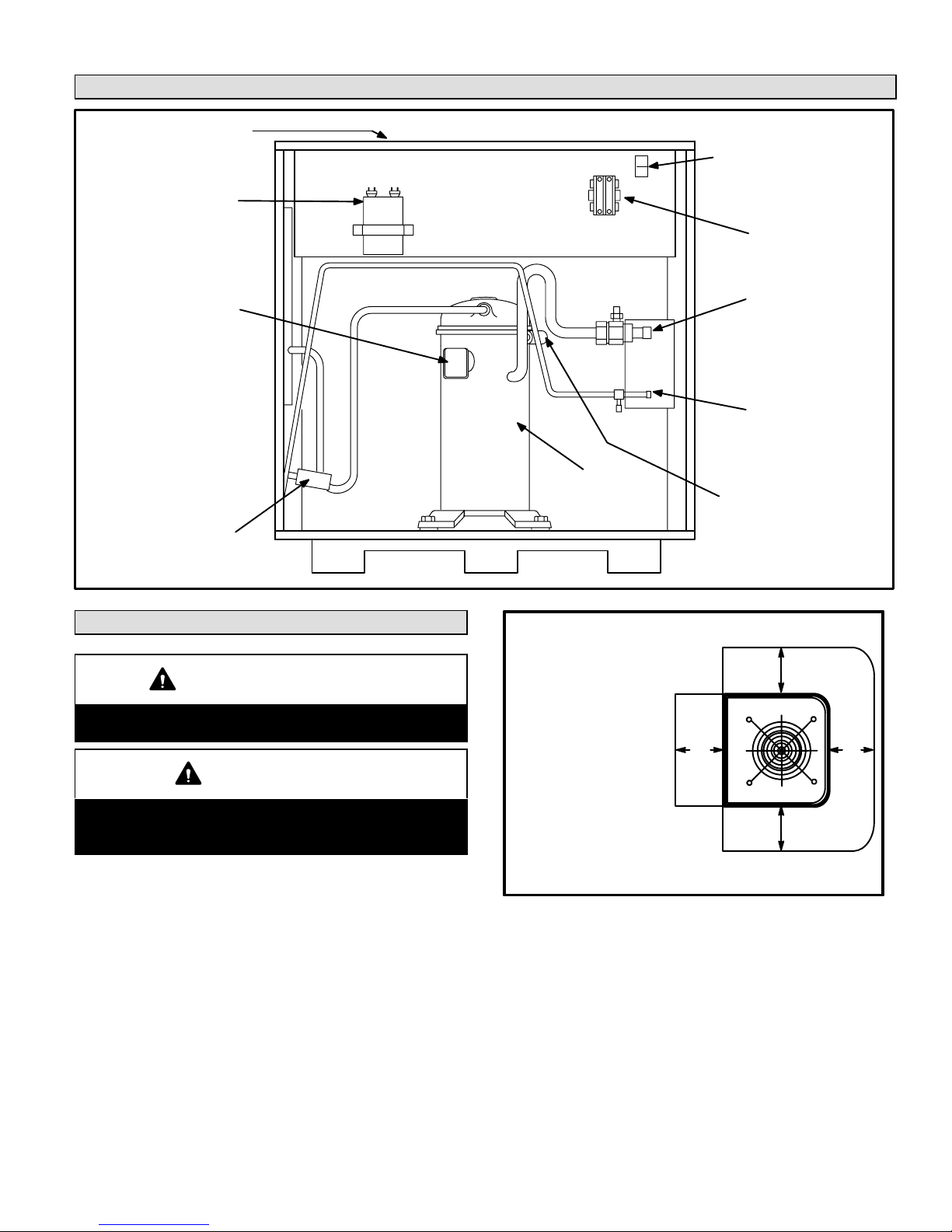

Parts Arrangement

CONDENSER FAN

(NOT SHOWN)

TOP OF CABINET

RUN CAPACITOR

GROUND LUG

CONTACTOR

COMPRESSOR POWER

TERMINALS

HIGH PRESSURE

SWITCH

Figure 1

Setting the Unit

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

CAUTION

Sharp sheet metal edges can cause injury. When

installing the unit, avoid accidental contact with

sharp edges.

Refer to unit dimensions for sizing mounting slab, platforms or supports. Refer to figure 2 for installation clearances.

VAPOR VALVE

AND GAUGE PORT

LIQUID LINE

SERVICE VALVE

AND GAUGE

COMPRESSOR

LOW PRESSURE

SWITCH

Installation Clearances

NOTE − A service access

clearance of 30" (762 mm)

must be maintained in front

of the service access panel.

Clearance to one side must

be 36" (914 mm). Clearance

to one of the remaining two

sides may be 12" (304 mm)

and the final side may be 6"

(152 mm).

NOTE − A clearance of 24" (610 mm)

must be maintained between two units.

NOTE − 48" (1219 mm) clearance required on top

of unit. Maximum soffit overhang is 36" (914 mm).

36"

(914 mm)

Figure 2

PORT

*36"

(914 mm)

*36"

(914 mm)

36"

(914 mm)

Page 3

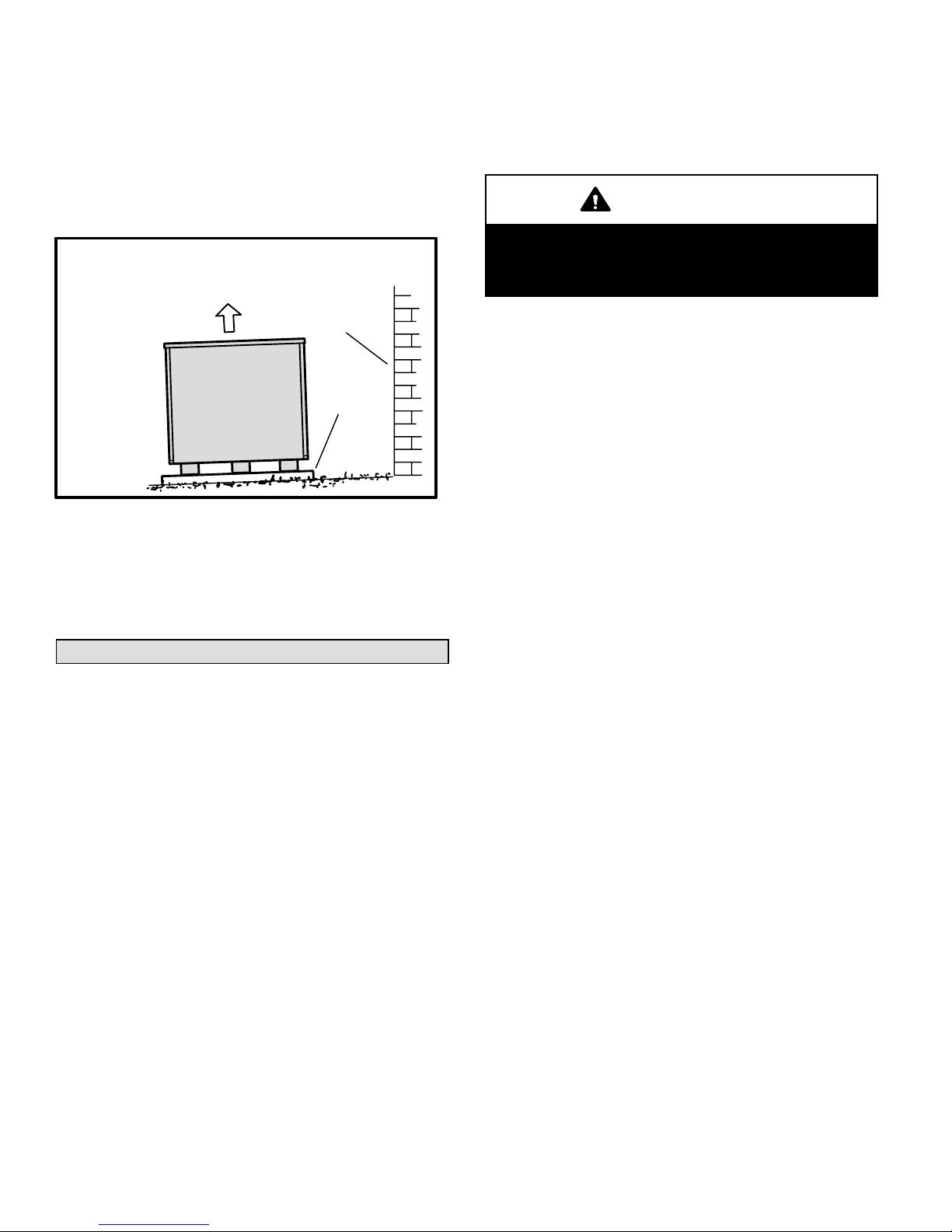

A − Slab Mounting

When you install the unit at grade level, the top of the slab

should be high enough above the grade so that water from

higher ground will not collect around the unit. See figure 3.

Slab should have a slope tolerance away from the building

of 2 degrees or 2 inches per 5 feet (51 mm per 1.5 m). Refer

to the next section (roof mounting) for barrier construction if

the unit must face prevailing winter winds.

2 degrees or

2 in. per 5 foot

(51 mm per 1.5 m)

slope tolerance away

from building structure

ground level

Slab Mounting

discharge air

building

structure

mounting

slab

Figure 3

B − Roof Mounting

Install unit at a minimum of 4 inches above surface of the roof.

Care must be taken to ensure weight of unit is properly distributed over roof joists and rafters. Either redwood or steel supports are recommended.

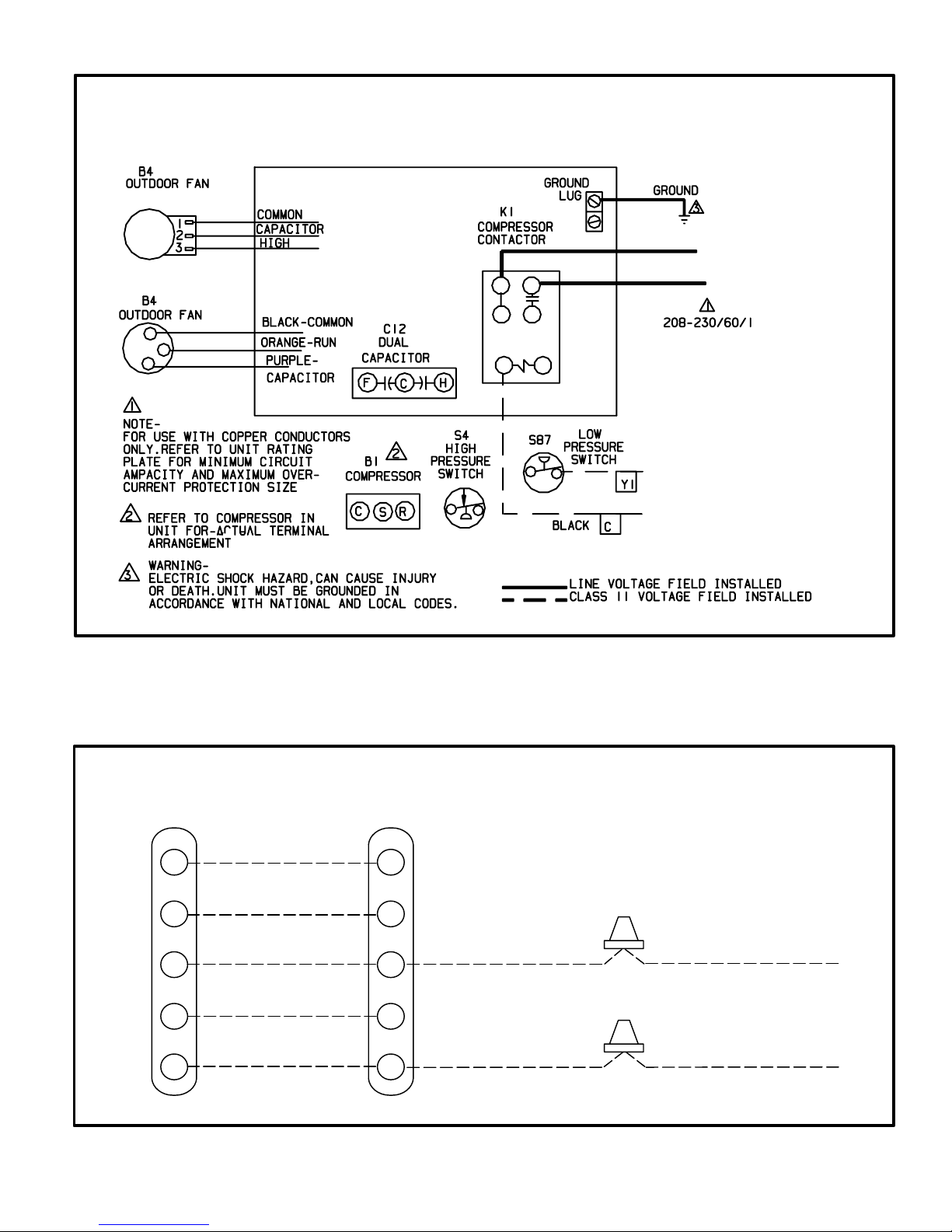

Electrical

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to the furnace or blower coil installation instructions

for additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

WARNING

Unit must be grounded in accordance with national

and local codes.

ELECTRIC SHOCK HAZARD.

Can cause injury or death.

1 − Install line voltage power supply to unit from a properly

sized disconnect switch.

2 − Ground unit at unit disconnect switch or to an earth

ground.

NOTE − To facilitate conduit, a hole is in the bottom of

the control box. Connect conduit to the control box us

ing a proper conduit fitting.

NOTE − Units are approved for use only with copper

conductors.

24V, Class II circuit connections are made in the low

voltage junction box. Refer to figure 4 for field wiring

diagram.

NOTE − A complete unit wiring diagram is located in

side the unit control box cover.

3 − Install room thermostat (ordered separately) on an in-

side wall approximately in the center of the conditioned

area and 5 feet (1.5 m) from the floor. It should not be

installed on an outside wall or where it can be effected

by sunlight, drafts or vibrations.

4 − Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit. See figure 5.

Page 4

(LEADLESS)

Outdoor Unit

Field Wiring Diagram

YELLOW

Thermostat Designations

Thermostat Indoor Unit

R

W1

Y

G

C

power

heat

cooling

indoor blower

common

R

W

Y

G

C

Figure 4

NOTE − see unit wiring diagram for

power supply connections.

Outdoor Unit

Y1 Outdoor Unit

C Outdoor Unit

NOTE − If the indoor unit is not equipped with blower relay. It must be field−provided and installed (P−8−3251 or equivalent).

Figure 5

Page 5

Refrigerant Piping

Model

If the HSXA15 unit is being installed with a new indoor coil

and line set, the connections should be made as outlined in

this section. If an existing line set and/or indoor coil (used

with mineral oil) is going to be used to complete the

HSXA15 system, refer to the following section which includes flushing procedures.

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections). Use Lennox L15 (sweat, nonflare) series line sets as shown in table 1 or use field-fabricated refrigerant lines. Refer to Refrigerant Piping Guide

(Corp. 9351−L9) for proper size, type, and application of

field−fabricated lines. Valve sizes are also listed in table 1.

Table 1

Refrigerant Line Sets

Model

No.

−024

−030

−036

−042

−048

−060

Valve Field Size

Connections

Liquid

Line

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

Vapor

Line

3/4 in.

(19 mm)

7/8 in.

(22 mm)

1−1/8 in.

(29 mm)

Recommended Line Set

Liquid

Line

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

Vapor

Line

3/4 in.

(19 mm)

7/8 in.

(22 mm)

1−1/8 in.

(29 mm)

(4.6 m − 15 m)

(4.6 m − 15 m)

L15

Line Sets

L15−41

15 ft. − 50 ft.

L15−65

15 ft. − 50 ft.

Field

Fabricated

NOTE − Units are designed for line sets of up to fifty feet (15 m).

For applications longer than fifty feet, consult the Lennox Refrigerant Piping Guide (Corp. 9351−L9). Select line set diameters

from table 1 to ensure that oil returns to the compressor.

Installing Refrigerant Line

During the installation of any heat pump or a/c system, it is

important to properly isolate the refrigerant lines to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling or floor) causes some objectionable noise

when vibration is translated into sound. As a result, more

energy or vibration can be expected. Closer attention to

line set isolation must be observed.

Following are some points to consider when placing and

installing a high−efficiency outdoor unit:

1- Placement − Be aware some localities are adopting

sound ordinances based on how noisy the unit is from

the adjacent property not at the original installation.

Install the unit as far as possible from the property line.

When possible, do not install the unit directly outside a

window. Glass has a very high level of sound transmission.

2- Line Set Isolation − The following illustrations demon-

strate procedures which ensure proper refrigerant line

set isolation. Figure 6 shows how to install line sets on

vertical runs. Figure 7 shows how to install line sets on

horizontal runs. Figure 8 shows how to make a transition

from horizontal to vertical. Finally, figure 9 shows how to

place the outdoor unit and line set.

Page 6

Refrigerant Line Sets

How To Install Vertical Runs

(new construction shown)

NOTE - Similar installation practices should be used if

line set is to be installed on exterior of outside wall.

Outside Wall

Wood Block

Between Studs

Liquid Line

Vapor Line

(wrapped with Armaflex)

Outside Wall

IMPORTANT - Refrigerant

lines must not contact wall.

Liquid LineVapor Line

Wire Tie

Inside Wall

Strap

Sleeve

Wire Tie

Wood Block

Wire Tie

Caulk

PVC Pipe

Fiberglass

Insulation

IMPORTANT - Refrigerant

lines must not contact

structure.

Strap

Sleeve

Figure 6

Page 7

Installing Horizontal Runs

To hang line set from joist or rafter,

use either metal strapping material

or anchored heavy nylon wire ties.

Floor Joist or

Roof Rafter

Refrigerant Line Sets:

Wire Tie

(around vapor line only)

8 feet

Tape or Wire Tie

8 feet

Strapping Material (around vapor line only)

Tape or Wire Tie

Metal Sleeve

Floor Joist or Roof Rafter

Strap the vapor line to the joist or rafter at 8 ft.

intervals then strap the liquid line to the vapor line.

Figure 7

Page 8

Refrigerant Line Sets:

Transition From Vertical To Horizontal

Anchored Heavy

Nylon Wire Tie

Wall

Stud

Metal

Sleeve

Vapor Line

Wrapped in

Armaflex

Strap Liquid Line

To Vapor Line

Liquid Line

Figure 8

Automotive

Muffler-Type

Hanger

Wall

Stud

Metal

Sleeve

Strap Liquid Line

To Vapor Line

Liquid Line

Vapor Line

Wrapped in

Armaflex

Outside Unit Placement and Installation

Install unit away from windows.

Two 90° elbows

installed in line set

will reduce line set

vibration.

Figure 9

Page 9

Refrigerant Connections

HSXA15 Matched with New Indoor Coil and Line Set

If an existing indoor coil that was equipped with an

RFCI metering device is being replaced, the liquid line

must also be replaced prior to the installation of the

HSXA15 unit.

If refrigerant lines are routed through a wall, seal and isolate

the opening so vibration is not transmitted to the building.

WARNING

Polyol ester (POE) oils used with R410A refrigerant

absorb moisture very quickly. It is very important

that the refrigerant system be kept closed as much

as possible. DO NOT remove line set caps or ser-

vice valve stub caps until you are ready to make

connections.

Flushing Existing Line Set & Indoor Coil

IMPORTANT

If this unit is being matched with an approved line

set or indoor coil which was previously charged

with mineral oil, or if it is being matched with a coil

which was manufactured before January of 1999,

the coil and line set must be flushed prior to installation. Take care to empty all existing traps. Polyol

ester (POE) oils are used in Lennox units charged

with R410A refrigerant. Residual mineral oil can act

as an insulator, preventing proper heat transfer. It

can also clog the thermal expansion valve, reducing system performance and capacity.

Failure to properly flush the system per the instructions below will void the warranty.

Brazing Connection Procedure

1 − Cut ends of the refrigerant lines square (free from nicks

or dents). Debur the ends. The pipe must remain

round, do not pinch end of the line.

2 − Before making line set connections, use dry nitrogen to

purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the system.

3 − Use silver alloy brazing rods (5 or 6 percent silver alloy

for copper−to−copper brazing or 45 percent silver alloy

for copper−to−brass or copper−to−steel brazing) which

are rated for use with R410A refrigerant. Wrap a wet

cloth around the valve body and the copper tube stub.

Remove light maroon washers from service valves and

shield light maroon stickers in order to protect them

during brazing. Braze the line set to the service valve.

4 − Wrap a wet cloth around the valve body and copper

tube stub to protect it from heat damage during brazing. Wrap another wet cloth underneath the valve body

to protect the base paint.

NOTE − The tube end must stay bottomed in the fitting

during final assembly to ensure proper seating, sealing

and rigidity.

5 − Install the provided thermal expansion valve (ap-

proved for use with R410A refrigerant) in the liquid line

at the indoor coil.

6 − Install the provided filter drier (approved for use with

R410A refrigerant) in the liquid line as close as possible to the expansion device. Do not leave the filter

drier uncapped for more than 10 to 15 minutes

prior to brazing, evacuation and leak testing.

Polyol ester oils used in this system absorb moisture quickly. Failure to install the filter drier will

void the warranty.

CAUTION

This procedure should not be performed on systems which contain contaminants (Example: compressor burn out).

Required Equipment

You will need the following equipment in order to flush the

existing line set and indoor coil: two clean HCFC−22 recovery bottles, an oilless recovery machine with a pump down

feature, and two sets of gauges (one for use with HCFC−22

and one for use with the R410A).

Flushing Procedure

1 − Remove existing HCFC−22 refrigerant using the ap-

propriate procedure below.

If the existing outdoor unit is not equipped with

shut−off valves, or if the unit is not operational

AND you plan to use the existing HCFC−22 refrigerant to flush the system – Disconnect all power to

the existing outdoor unit. Connect to the existing unit,

a clean recovery cylinder and the recovery machine

according to the instructions provided with the recovery machine. Remove all HCFC−22 refrigerant from

the existing system. Refer to gauges after shutdown to

confirm that the entire system is completely void of refrigerant. Disconnect the liquid and vapor lines from

the existing outdoor unit.

If the existing outdoor unit is equipped with manual shut−off valves AND you plan to use NEW

HCFC−22 refrigerant to flush the system – Start the

existing HCFC−22 system in the cooling mode and

close the liquid line valve. Pump all of the existing

HCFC−22 refrigerant back into the outdoor unit. (It may

be necessary to bypass the low pressure switches to

ensure complete refrigerant evacuation.) When the

low side system pressures reach 0 psig, close the va-

Page 10

por line valve. Disconnect all power to the existing outdoor unit. Refer to gauges after shutdown to confirm

that the valves are not allowing refrigerant to flow back

into the low side of the system. Disconnect the liquid

and vapor lines from the existing outdoor unit.

2 − Remove the existing outdoor unit. Set the new R410A

unit and follow the brazing connection procedure

which begins on the previous page to make line set

connections. DO NOT install provided R410A

check/expansion valve at this time.

Make low voltage and line voltage connections to the

new outdoor unit. DO NOT turn on power to the unit

or open the outdoor unit service valves at this time.

Flushing Connections

Inverted HCFC−22 Cylinder

(Contains clean HCFC−22 to be

used for flushing)

3 − Remove the existing refrigerant flow control orifice or

thermal expansion valve before continuing with flushing procedures. The existing devices are not approved for use with R410A refrigerant and may prevent proper flushing. Use a field−provided fitting to reconnect the lines.

IMPORTANT

The line set and indoor coil must be flushed with at

least the same amount of clean refrigerant that previously charged the system. Check the charge in

the flushing cylinder before proceeding.

Existing

Indoor Coil

RECOVERY

CYLINDER

EXISTING VAPOR LINE

EXISTING LIQUID LINE

VAPOR LINE

SERVICE VALVE

LIQUID LINE

SERVICE VALVE

TANK RETURN

INLET

DISCHARGE

RECOVERY MACHINE

Figure 10

HSXA15 UNIT

NOTE − The inverted HCFC−22

cylinder must contain at least

the same amount of refrigerant

as was recovered from the existing system.

LOW

PRESSURE

GAUGE MANIFOLD

PRESSURE

HIGH

CLOSEDOPENED

Page 11

4 − Remove the pressure tap valve cores from the

HSXA15 unit’s service valves. Connect an HCFC−22

cylinder with clean refrigerant to the vapor service

valve. Connect the HCFC−22 gauge set to the liquid

line valve and connect a recovery machine with an

empty recovery tank to the gauge set.

5 − Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the existing system line set and indoor coil.

If you install a expansion valve with an indoor coil that

includes a fixed orifice, remove the orifice before the

expansion valve is installed.

Metering Device Installation

distributor

o−ring

expansion

valve

6 − Invert the cylinder of clean HCFC−22 and open its

valve to allow liquid refrigerant to flow into the system

through the vapor line valve. Allow the refrigerant to

pass from the cylinder and through the line set and the

indoor coil before it enters the recovery machine.

7 − After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the HCFC−22 vapor is recovered. Allow the recovery machine to pull a vacuum on the system.

NOTE − A single system flush should remove all of the

mineral oil from the existing refrigerant lines and indoor coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush. Each time the system

is flushed, you must allow the recovery machine

to pull a vacuum on the system at the end of the

procedure.

8 − Close the valve on the inverted HCFC−22 drum and

the gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off.

9 − Use nitrogen to break the vacuum on the refrigerant

lines and indoor coil before removing the recovery machine, gauges and HCFC−22 refrigerant drum. Reinstall pressure tap valve cores into HSXA15 service

valves.

10 −Install the provided expansion valve (approved for use

with R410A refrigerant) in the liquid line at the indoor

coil.

Refrigerant Metering Devices

Use HSXA15 units in TXV systems systems. See the Len-

nox Engineering Handbook for approved TXV match-ups

and application information.

o−ring

strainer

liquid line

stub

Figure 11

Manifold Gauge Set

Manifold gauge sets used with systems charged with

R410A refrigerant must be capable of handling the higher

system operating pressures. The gauges should be rated

for use with pressures of 0 − 800 on the high side and a low

side of 30" vacuum to 250 psi with dampened speed to 500

psi. Gauge hoses must be rated for use at up to 800 psi of

pressure with a 4000 psi burst rating.

Service Valves

The liquid line and vapor line service valves (figure 12) and

gauge ports are used for leak testing, evacuating, charging

and checking charge. See table 2 for torque requirements

Each valve is equipped with a service port which has a factory−installed Schrader valve. A service port cap protects

the Schrader valve from contamination and serves as the

primary leak seal.

Table 2

Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.− lb. 11 N M

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 N M

Expansion Valve Systems

Expansion valves equipped with either Chatleff or flare

type fittings are available from Lennox. Refer to the Engineering Handbook for expansion valves for use with specific match−ups. See figure 11 for installation of the expansion

valve.

To Access Schrader Port:

1 − Remove access panel.

2 − Remove service port cap with an adjustable wrench.

3 − Connect gauge to the service port.

4 − When testing is complete, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

Page 12

To Open Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Use a service wrench with a hex−head extension to

back the stem out counterclockwise as far as possible.

NOTE − Use a 3/16" hex head extension for liquid line

sizes or a 5/16" extension for vapor line sizes.

3 − Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

Service Valve

(Valve Closed)

service

port

to outdoor coil

service

port cap

Schrader valve open

to line set when valve is

closed (front seated)

wrench here

(valve front seated)

stem cap

insert hex

to indoor coil

Service Valve

insert hex

wrench here

to outdoor coil

service port

cap

(Valve Open)

service

port

Schrader

valve

stem cap

to indoor coil

Figure 12

To Close Service Valve:

1 − Remove the stem cap with an adjustable wrench.

2 − Use a service wrench with a hex−head extension to

turn the stem clockwise to seat the valve. Tighten it

firmly.

NOTE − Use a 3/16" hex head extension for liquid line

sizes or a 5/16" extension for vapor line sizes.

3 − Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

Leak Testing

After the line set has been connected to the indoor and

outdoor units, check the line set connections and indoor

unit for leaks.

Danger of explosion: Can cause

equipment damage, injury or death.

Never use oxygen to pressurize a refrigeration or air conditioning system.

Oxygen will explode on contact with

oil and could cause personal injury.

WARNING

Danger of explosion: Can cause equipment damage,

injury or death. When using a high pressure gas

such as dry nitrogen to pressurize a refrigeration or

air conditioning system, use a regulator that can

control the pressure down to 1 or 2 psig (6.9 to 13.8

kPa).

Using an Electronic Leak Detector

1 − Connect the high pressure hose of the manifold gauge

set to the vapor valve service port. (Normally, the high

pressure hose is connected to the liquid line port, however, connecting it to the vapor port helps to protect the

manifold gauge set from damage caused by high pressure.)

2 − With both manifold valves closed, connect the cylinder

of R410A refrigerant to the center port of the manifold

gauge set. Open the valve on the R410A cylinder (vapor only).

3 − Open the high pressure side of the manifold to allow

R410A into the line set and indoor unit. Weigh in a trace

amount of R410A. [A trace amount is a maximum of 2

ounces (57 g) refrigerant or 3 pounds (31 kPa) pressure.] Close the valve on the R410A cylinder and the

valve on the high pressure side of the manifold gauge

set. Disconnect R410A cylinder.

4 − Connect a cylinder of nitrogen with a pressure regulat-

ing valve to the center port of the manifold gauge set.

5 − Adjust nitrogen pressure to 150 psig (1034 kPa). Open

the valve on the high side of the manifold gauge set in

order to pressurize the line set and the indoor coil.

6 − After a few minutes, open a refrigerant port to check

that an adequate amount of refrigerant has been added for detection (refrigerant requirements will vary

with line lengths). Check all joints for leaks. Purge nitrogen and R410A mixture. Correct any leaks and recheck.

Page 13

IMPORTANT

Leak detector must be capable of sensing HFC re-

frigerant.

Evacuation

Evacuating the system of noncondensables is critical for

proper operation of the unit. Noncondensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Noncondensables and water vapor combine with

refrigerant to produce substances that corrode copper piping and compressor parts.

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

that reads from 50 microns to at least 10,000 microns.

1 − Connect manifold gauge set to the service valve ports :

low pressure gauge to vapor line service valve

high pressure gauge to liquid line service valve

2 − Connect micron gauge.

3 − Connect the vacuum pump (with vacuum gauge) to the

center port of the manifold gauge set.

4 − Open both manifold valves and start the vacuum

pump.

5 − Evacuate the line set and indoor unit to an absolute

pressure of 23,000 microns (29.01 inches of mercury). During the early stages of evacuation, it is desirable to close the manifold gauge valve at least once to

determine if there is a rapid rise in absolute pressure.

A rapid rise in pressure indicates a relatively large leak.

If this occurs, repeat the leak testing procedure.

NOTE − The term absolute pressure means the total

actual pressure within a given volume or system,

above the absolute zero of pressure. Absolute pressure in a vacuum is equal to atmospheric pressure minus vacuum pressure.

6 − When the absolute pressure reaches 23,000 microns

(29.01 inches of mercury), close the manifold gauge

valves, turn off the vacuum pump and disconnect the

manifold gauge center port hose from vacuum pump.

Attach the manifold center port hose to a nitrogen cylinder with pressure regulator set to 150 psig (1034 kPa)

and purge the hose. Open the manifold gauge valves

to break the vacuum in the line set and indoor unit.

Close the manifold gauge valves.

WARNING

Danger of Equipment Damage.

Avoid deep vacuum operation. Do not use compressors to evacuate a system.

Extremely low vacuums can cause internal arcing

and compressor failure.

Damage caused by deep vacuum operation will

void warranty.

7 − Shut off the nitrogen cylinder and remove the manifold

gauge hose from the cylinder. Open the manifold

gauge valves to release the nitrogen from the line set

and indoor unit.

8 − Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set

and indoor unit until the absolute pressure does not

rise above 500 microns (29.9 inches of mercury) within

a 20−minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

9 − When the absolute pressure requirement above has

been met, disconnect the manifold hose from the vacuum pump and connect it to an upright cylinder of R410A

refrigerant. Open the manifold gauge valves to break

the vacuum from 1 to 2 psig positive pressure in the line

set and indoor unit. Close manifold gauge valves and

shut off the R410A cylinder and remove the manifold

gauge set.

Start−Up

1 − Rotate fan to check for frozen bearings or binding.

2 − Inspect all factory− and field−installed wiring for loose

connections.

3 − After evacuation is complete, open the liquid line and

vapor line service valves to release the refrigerant

charge (contained in outdoor unit) into the system.

4 − Replace the stem caps and secure finger tight, then

tighten an additional one-sixth (1/6) of a turn.

5 − Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit’s

nameplate. If not, do not start the equipment until you

have consulted the power company and the voltage

condition has been corrected.

6 − Set the thermostat for a cooling demand. Turn on pow-

er to the indoor blower and close the outdoor unit disconnect switch to start the unit.

7 − Recheck voltage while the unit is running. Power must

be within range shown on the nameplate.

Page 14

Charging

This system is charged with R410A refrigerant which operates at much higher pressures than HCFC−22. The expansion valve and liquid line filter drier provided with the unit

are approved for use with R410A. Do not replace them with

components designed for use with HCFC−22. This unit is

NOT approved for use with coils which include metering

orifices or capillary tubes.

Processing Procedure

Units are factory charged with the amount of R410A refrigerant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with 15

feet (4.6 m) line set. For varying lengths of line set, refer to

table 3 for refrigerant charge adjustment.

Table 3

Liquid Line Set

Diameter

5/16 in

(8 mm)

3/8 in.

(10 mm)

*If line length is greater than 15 ft. (4.6 m), add this amount.

If line length is less than 15 ft. (4.6 m), subtract this amount.

Oz. per 5 ft. (grams per 1.5m) adjust

from 15 ft. (4.6 m) line set*

2 ounces per 5 feet

(57 g per 1.5 m)

3 ounces per 5 feet

(85 g per 1.5 m)

IMPORTANT

Mineral oils are not compatible with R410A. If oil

must be added, it must be a polyol ester oil.

The compressor is charged with sufficient polyol ester

oil for line set lengths up to 50 feet (15.2 m). If oil must

be added in the field, Copeland has approved Mobil

EALt Arctic 22CC and ICI EMKARATEt RL32CF for

use with these compressors.

If the system is void of refrigerant, clean the system using the procedure described below.

1 − Use nitrogen to pressurize the system and check for

leaks. Repair leaks, if possible.

2 − Evacuate the system to remove as much of the mois-

ture as possible.

3 − Use nitrogen to break the vacuum and install the pro-

vided filter drier in the system.

4 − Evacuate the system again. Then, weigh the appropri-

ate amount of R410A refrigerant (listed on unit nameplate) into the system.

5 − Monitor the system to determine the amount of mois-

ture remaining in the oil. Use test kit 10N46 to verify

that the moisture content is within the kit’s dry color

range. It may be necessary to replace the filter drier

several times to achieve the required dryness level. If

system dryness is not verified, the compressor will

fail in the future.

The outdoor unit should be charged during warm weather.

However, applications arise in which charging must occur

in the colder months. The method of charging is deter-

mined by the unit’s refrigerant metering device and the

outdoor ambient temperature.

Measure the liquid line temperature and the outdoor ambient temperature as outlined below:

1 − Connect the manifold gauge set to the service valves:

low pressure gauge to vapor valve service port

high pressure gauge to liquid valve service port

Connect the center manifold hose to an upright cylinder of HCFC-22. Close manifold gauge set valves.

2 − Set the room thermostat to call for heat. This will create

the necessary load for properly charging the system in

the cooling cycle.

3 − Use a digital thermometer to record the outdoor ambi-

ent temperature.

4 − When the heating demand has been satisfied, switch

the thermostat to cooling mode with a set point of 68F

(20C). When pressures have stabilized, use a digital

thermometer to record the liquid line temperature.

5 − The outdoor temperature will determine which charg-

ing method to use. Proceed with the appropriate charging procedure.

Weighing in the Charge Fixed Orifice or

TXV Systems – Outdoor Temp < 65F (18C)

If the system is void of refrigerant, or if the outdoor ambient

temperature is cool, the refrigerant charge should be

weighed into the unit. Do this after any leaks have been repaired.

1 − Recover the refrigerant from the unit.

2 − Conduct a leak check, then evacuate as previously

outlined.

3 − Weigh in the unit nameplate charge.

If weighing facilities are not available or if you are charging

the unit during warm weather, follow one of the other procedures outlined below.

Charging Using Normal Operating Pressures

and the Approach Method

TXV Systems – Outdoor Temp. >

The following procedure is intended as a general guide and

is for use on expansion valve systems only. For best results,

indoor temperature should be 70°F (21°C) to 80°F (26°C).

Monitor system pressures while charging.

1 − Record outdoor ambient temperature using a digital

thermometer.

2 − Attach high pressure gauge set and operate unit for

several minutes to allow system pressures to stabilize.

3 − Compare stabilized pressures with those provided in

table 5, Normal Operating Pressures." Minor variations in these pressures may be expected due to differences in installations. Significant differences could

mean that the system is not properly charged or that a

problem exists with some component in the system.

Pressures higher than those listed indicate that the

system is overcharged. Pressures lower than those

65F (18C)

Page 15

listed indicate that the system is undercharged. Verify

Mod

Entering Air

pressures with the R410A refrigerant pressure chart in

table 6. Verify adjusted charge using the approach

method.

Approach Method

4 − Use the same digital thermometer you used to check

the outdoor ambient temperature to check the liquid

line temperature.

5 − The difference between the ambient and liquid temper-

atures should match values given in table 4. If the values don’t agree with the those in table 4, add refrigerant to lower the approach temperature, or recover refrigerant from the system to increase the approach

temperature.

Normal Operating Pressure

(Liquid ±10 and Vapor ±5 psig)

TXV

Outdoor Coil

e

Temp. °F (°C)

Entering Air

65

(18.3)

75

(23.9)

85

(29.4)

95

(35.0)

105

(40.6)

HSXA15−024 HSXA15−030 HSXA15−036 HSXA15−042 HSXA15−048 HSXA15−060

Liquid Vapor Liquid Vapor Liquid Vapor Liquid Vapor Liquid Vapor Liquid Vapor

239 129 232 130 235 128 241 131 226 130 240 130

278 131 271 132 276 130 282 133 266 132 279 132

321 133 314 135 320 132 326 135 310 135 321 135

368 135 360 137 367 134 373 137 356 137 368 137

420 138 412 140 421 137 424 139 407 139 418 140

Table 4

Model Number

HSXA15−024 8 ± 1 (4.5 ± .5)

HSXA15−030 8 ± 1 (4.5 ± .5)

HSXA15−036 6 ± 1 (3.3 ± .5)

HSXA15−042 9 ± 1 (5 ± .5)

HSXA15−048 8 ± 1 (4.5 ± .5)

HSXA15−060 12 ± 1 (6.7 ± .5)

Liquid Line Temp. − Outdoor Ambient °F (°C)

NOTE − For best results, the same electronic thermometer

should be used to check both outdoor ambient and liquid line

temperatures.

Approach Temperature

Table 5

s

Page 16

Table 6

R410A Temperature/Pressure Chart

Temperature°FPressure

Psig

32 100.8 63 178.5 94 290.8 125 445.9

33 102.9 64 181.6 95 295.1 126 451.8

34 105.0 65 184.3 96 299.4 127 457.6

35 107.1 66 187.7 97 303.8 128 463.5

36 109.2 67 190.9 98 308.2 129 469.5

37 111.4 68 194.1 99 312.7 130 475.6

38 113.6 69 197.3 100 317.2 131 481.6

39 115.8 70 200.6 101 321.8 132 487.8

40 118.0 71 203.9 102 326.4 133 494.0

41 120.3 72 207.2 103 331.0 134 500.2

42 122.6 73 210.6 104 335.7 135 506.5

43 125.0 74 214.0 105 340.5 136 512.9

44 127.3 75 217.4 106 345.3 137 519.3

45 129.7 76 220.9 107 350.1 138 525.8

46 132.2 77 224.4 108 355.0 139 532.4

47 134.6 78 228.0 109 360.0 140 539.0

48 137.1 79 231.6 11 0 365.0 141 545.6

49 139.6 80 235.3 111 370.0 142 552.3

50 142.2 81 239.0 11 2 375.1 143 559.1

51 144.8 82 242.7 11 3 380.2 144 565.9

52 147.4 83 246.5 11 4 385.4 145 572.8

53 150.1 84 250.3 11 5 390.7 146 579.8

54 152.8 85 254.1 11 6 396.0 147 586.8

55 155.5 86 258.0 11 7 401.3 148 593.8

56 158.2 87 262.0 11 8 406.7 149 601.0

57 161.0 88 266.0 11 9 412.2 150 608.1

58 163.9 89 270.0 120 417.7 151 615.4

59 166.7 90 274.1 121 423.2 152 622.7

60 169.6 91 278.2 122 428.8 153 630.1

61 172.6 92 282.3 123 434.5 154 637.5

62 195.5 93 286.5 124 440.2 155 645.0

Temperature°FPressure

Psig

Temperature°FPressure

Psig

Temperature°FPressure

Psig

System Operation

The outdoor unit and indoor blower cycle on demand from

the room thermostat. When the thermostat blower switch is

in the ON position, the indoor blower operates continuously.

High Pressure Switch

HSXA15 units are equipped with a high pressure switch

that is located in the liquid line of the compressor. The

switch (SPST, manual reset, normally closed) removes

power from the compressor when discharge pressure rises

above factory setting at 640 + 10 psi.

Low Pressure Switch

HSXA15 units are also equipped with a low pressure switch

that is located in the vapor line of the compressor. The

switch (SPST, auto−reset, normally closed) removes power

from the compressor when vapor line pressure drops below factory setting at 40 + 5 psi.

Page 17

Filter Drier

A filter drier is shipped with each HSXA15 unit. The filter drier must be field installed in the liquid line between the liquid

line service valve and the expansion valve. This filter drier

must be installed to ensure a clean, moisture−free system. A replacement filter drier is available as Lennox part

no. 37L5201.

Maintenance

WARNING

Electric shock hazard. Can cause injury or death. Before attempting to perform any service or maintenance, turn

the electrical power to unit OFF at disconnect switch(es). Unit may have

multiple power supplies.

Maintenance and service must be performed by a qualified

installer or service agency. At the beginning of each cooling

season, the system should be checked as follows:

1 − Clean and inspect the outdoor coil. The coil may be

flushed with a water hose. Ensure the power is turned

off before you clean the coil.

2 − Condenser fan motor is prelubricated and sealed. No

further lubrication is needed.

3 − Visually inspect connecting lines and coils for evidence

of oil leaks.

4 − Check wiring for loose connections.

5 − Check for correct voltage at unit (unit operating).

6 − Check amp−draw condenser fan motor.

Unit nameplate _________ Actual ____________ .

NOTE − If owner complains of insufficient cooling, the

unit should be gauged and refrigerant charge

checked. Refer to section on refrigerant charging in

this instruction.

Indoor Coil

1 − Clean coil, if necessary.

2 − Check connecting lines and coils for evidence of oil

leaks.

3 − Check condensate line and clean, if necessary.

Indoor Unit

1 − Clean or change filters.

2 − Adjust blower speed for cooling. Measure the pressure

drop over the coil to determine the correct blower CFM.

Refer to the unit information service manual for pressure

drop tables and procedure.

3 − Belt Drive Blowers − Check belt for wear and proper

tension.

4 − Check all wiring for loose connections

5 − Check for correct voltage at unit (blower operating).

6 − Check amp−draw on blower motor

Unit nameplate_________ Actual ____________.

Optional Accessories

Refer to the Engineering Handbook for optional accessories that may apply to this unit. The following may or may

not apply:

Loss of Charge Kit

High Pressure Switch Kit

Compressor Monitor

Compressor Crankcase Heater

Hail Guards

Mounting Bases

Timed Off Control

Stand−off Kit

Sound Cover

Low Ambient Kit

Start−Up & Performance Check List

Job Name

Job Location

Installer

Unit Model No.

Nameplate Voltage

Rated Load Ampacity

Maximum Fuse or Circuit Breaker

Electrical Connections Tight?

Indoor Blower RPM

Discharge Pressure

Refrigerant Lines:

Service Valves Fully Opened?

Voltage With Compressor Operating

Leak Checked?

S.P. Drop Over Indoor (Dry)

Vapor Pressure

Start−up and Performance Check List

Job No.

City

City

Serial No.

Compressor

Indoor Filter Clean?

Properly Insulated?

Service Valve Caps Tight?

Calibrated? Properly Set?

Page 18

Outdoor Fan

Outdoor Coil Entering Air Temp.

Refrigerant Charge Checked?

Date

State

State

Service Technician

Supply Voltage (Unit Off)

Outdoor Fan Checked?

Thermostat

Level?

Loading...

Loading...