Page 1

Service Literature

HS29 SERIES UNITS

The HS29 is a residential split-system condensing unit.

Condensing coil size, circuiting and air volume result in a

minimum SEER rating of 10.0. The series is designed for

use with an expansion valve or RFCIV system in the indoor unit. However, the HS29−651 and −060 use only the

TXV system.

The HS29−141 and −012 utilizes a rotary compressor. Other

HS29 units (−018, −024−2 and −211 through −653) utilize a reciprocating compressor. All compressors are hermetically sealed

for trouble-free operation and long service life. Compressor

components are spring-mounted within the sealed housing.

The compressor is installed in the unit on resilient rubber

mounts to assure quiet, vibration-free operation. A built-in

protection device assures protection from excessive

current and temperatures.

HS29−460 through HS29−650 models are furnished with

crankcase heaters to assure proper compressor lubrication at all times. The heater is temperature-actuated and

operates only when required. HS29−024−3 and HS29−030

through −060 units utilize a scroll compressor. The scroll operates like a standard compressor but it is unique in the way it

compresses refrigerant.

Several models are available in sizes ranging from 1 through 5

tons.

HS29

Corp. 9802−L3

Revised 04−2004

This manual is divided into sections which discuss the

major components, refrigerant system, charging procedure, maintenance and operation sequence.

All specifications in this manual are subject to change.

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

TABLE OF CONTENTS

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Data 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Unit Information 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II Unit Components 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Refrigerant System 8. . . . . . . . . . . . . . . . . . . . . . . . . .

IV Charging 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VI Wiring Diagrams and Operation Sequence 15. . . . . .

Page 1

©1998 Lennox Industries Inc.

Page 2

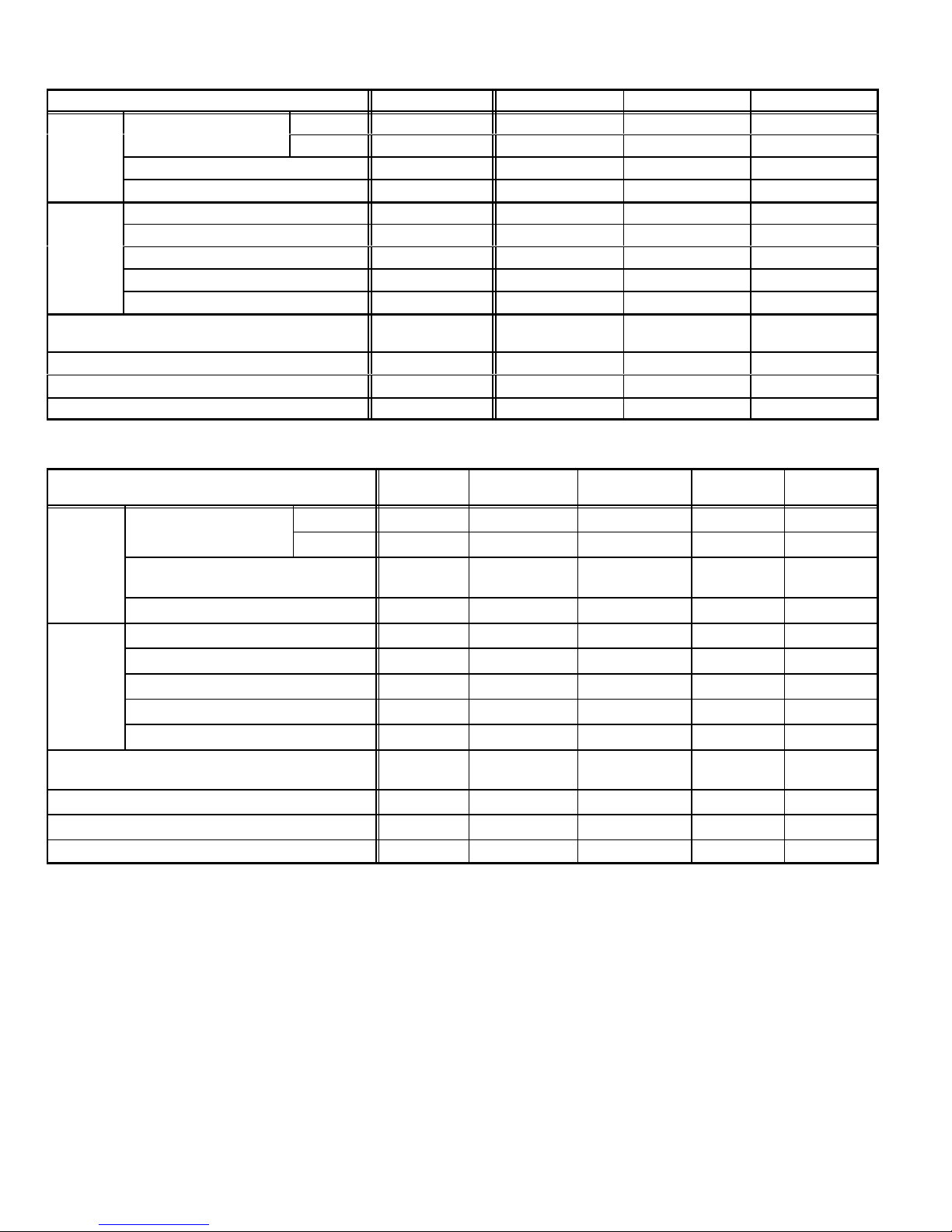

SPECIFICATIONS

Condenser

Fan

Fan

Model No. HS29-141 HS29-211 HS29-261 HS29-311

Condenser

Net face area - sq. ft. (m2)

Coil

Tube diameter in. (mm) & no. of rows 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866)

Diameter in. (mm) & no. of blades 18 (457) 3 18 (457) 3 18 (457) 3 18 (457) 3

Motor hp (W) 1/6 (124) 1/6 (124) 1/6 (124) 1/6 (124)

Condenser

Cfm (L/s) 2400 (1135) 2400 (1135) 2400 (1135) 2460 (1160)

Rpm 1105 1105 1105 1125

Watts 180 180 180 170

*Refrigerant charge furnished (HCFC-22)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9) 3/4 (19.1)

Shipping weight lbs. (kg) 1 package 146 (66) 146 (66) 148 (67) 157 (71)

*Refrigerant charge sufficient for 20 ft. (6.1 m) length of refrigerant lines.

3/8x5/16 in. (9.5x7.9mm) adaptor furnished for liquid line connection.

Model No.

Net face area - sq. ft. (m2)

Condenser

Coil

Tube diameter in. (mm) & no. of rows

Outer coil 7.56 (0.70) 11.33 (1.05) 11.33 (1.05) 13.22 (1.23)

Inner coil - - - - - - - - - - - - - - - -

2 lbs. 12 oz.

(1.25 kg)

3 lbs. 10 oz.

(1.64 kg))

3 lbs. 13 oz.

(1.73 kg))

4 lbs. 5 oz. (1.96 kg)

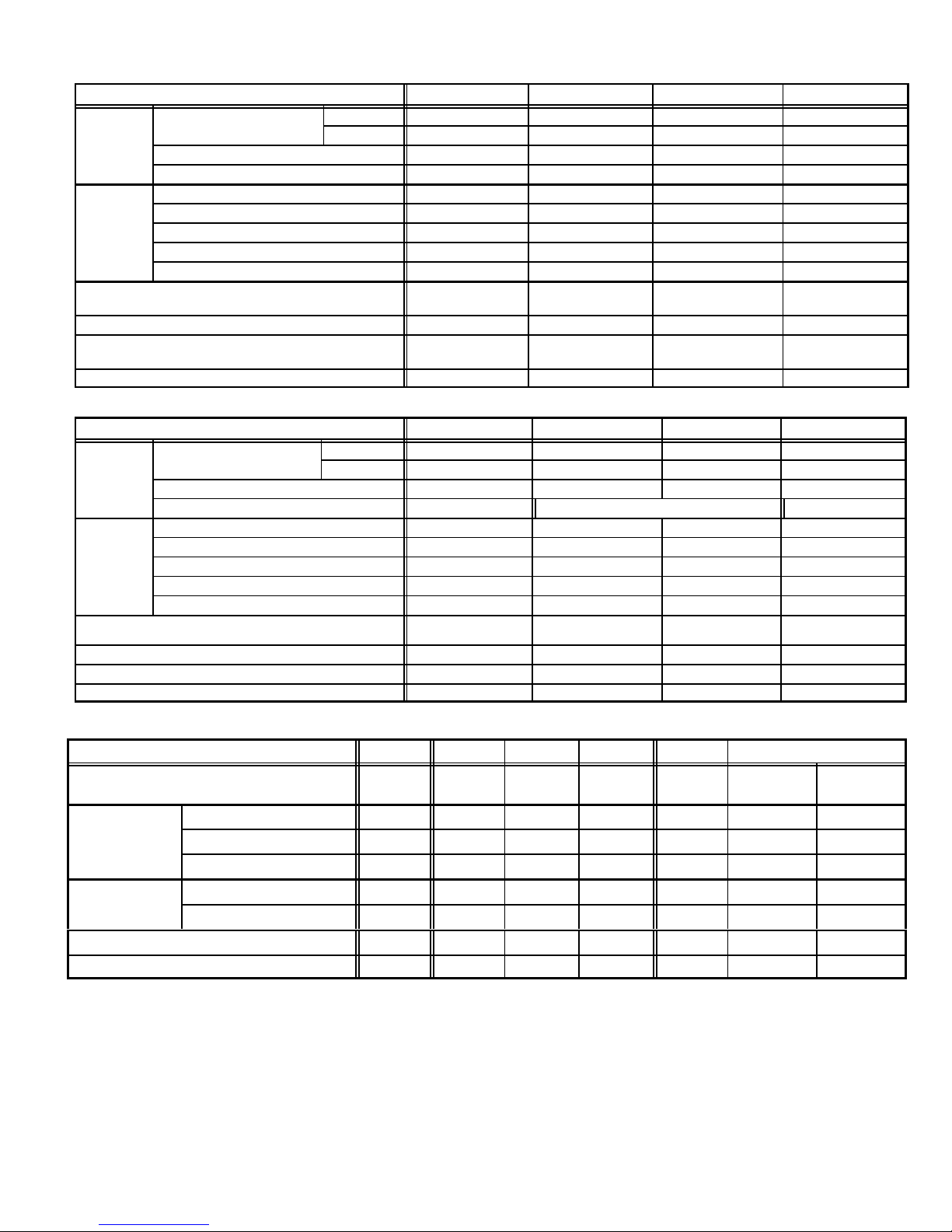

SPECIFICATIONS (contd.)

HS29-411

HS29-413

Outer coil 15.11 (1.40) 15.11 (1.40) 15.11 (1.40) 15.21 (1.41) 21.11 (1.96)

Inner coil - - - - 5.40 (0.50) 5.44 (0.50) 14.0 (13.4) 20.3 (1.89)

5/16 (7.9)

1

HS29-461

HS29-463

HS29-511

HS29-513

HS29-651

HS29-653

HS29-681

HS29-683

5/16 (7.9) 1.37 5/16 (7.9) 1.37 5/16 (7.9) 2 5/16 (7.9) 2

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866)

Diameter in. (mm) & no. of blades 18 (457) 4 18 (457) 4 18 (457) 4 18 (457) 4 18 (457) 4

Motor hp (W) 1/6 (124) 1/6 (124) 1/3 (249) 1/3 (249) 1/3 (249)

Condenser

Fan

Cfm (L/s) 2520 (1190) 2500 (1180) 2950 (1390) 2930 (1385) 2930 (1385)

Rpm 1100 1100 1100 1100 1100

Watts 200 200 310 310 310

*Refrigerant charge furnished (HCFC-22)

5 lbs. 0 oz.

(2.26 kg)

5 lbs. 9 oz. (2.52

kg)

6 lbs. 3 oz.

(2.81 kg)

7 lbs. 10 oz.

(3.46 kg)

12 lbs. 0 oz.

(5.44 kg)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 3/4 (19.1) 7/8 (22.2) 7/8 (22.2) 1-1/8 (28.6) 1-1/8 (28.6)

Shipping weight lbs. (kg) 1 package 165 (75) 191 (87) 196 (89) 212 (96) 254 (115)

*Refrigerant charge sufficient for 20 ft. (6.0 m) length of refrigerant lines.

Page 2

Page 3

SPECIFICATIONS (contd.)

Condenser

Fan

Condenser

Fan

Condenser Coil

Model No. HS29-012 HS29-018 HS29-024 HS29-030

Outer coil 7.56 (0.70) 11.33 (1.05) 11.33 (1.05) 13.22 (1.23)

Inner coil - - - - - - - - - - - - - - - -

Condenser

Coil

Net face area - sq. ft. (m2)

Tube diameter in. (mm) & no. of rows 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1

Fins per inch (m) 22 (866) 22 (866) 22 (866) 18 (748)

Diameter in. (mm) & no. of blades 18 (457) 3 18 (457) 3 18 (457) 3 18 (457) 3

Motor hp (W) 1/6 (124) 1/6 (124) 1/6 (124) 1/6 (124)

Condenser

Cfm (L/s) 2400 (1135) 2400 (1135) 2400 (1135) 2545 (1201)

Rpm 1105 1105 1105 1110

Watts 180 180 180 195

*Refrigerant charge furnished (HCFC-22)

3 lbs. 1 oz.

(1.38 kg)

3 lbs. 7 oz.

(1.55 kg)

3 lbs. 10 oz.

(1.64 kg)

4 lbs. 1 oz.

(1.83 kg)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 5/8 (15.9) 5/8 (15.9)

5/8 (15.9) −1, −2 units

3/4 (19) −3 units

3/4 (19.1)

Shipping weight lbs. (kg) 1 package 146 (66) 146 (66) 148 (67) 140 (64)

*Refrigerant charge sufficient for 15 ft. (4.5 m) length of refrigerant lines. 3/8 x 5/16 in. (9.5 x 7.9 mm) adaptor furnished for liquid line connection.

SPECIFICATIONS (contd.)

Model No. HS29-036 HS29-042 HS29-048 HS29-060

Outer coil 15.11 (1.40) 15.11 (1.40) 15.11 (1.40) 15.11 (1.40)

Inner coil - - - - 5.40 (0.50) 5.40 (0.50) 14.40 (1.34)

Condenser

Coil

Net face area - sq. ft. (m2)

Tube diameter in. (mm) & no. of rows 5/16 (7.9) 1 5/16 (7.9) 1.37 5/16 (7.9) 1.37 5/16 (7.9) 2

Fins per inch (m) 22 (866) 18 (748) 18 (748)

Diameter in. (mm) & no. of blades 18 (457) 4 18 (457) 4 18 (457) 4 18 (457) 4

Motor hp (W) 1/6 (124) 1/6 (124) 1/3 (249) 1/3 (249)

Condenser

Cfm (L/s) 2520 (1190) 2610 (1232) 3115 (1470) 3010 (1420)

Rpm 1100 1105 1125 1125

Watts 200 200 325 315

*Refrigerant charge furnished (HCFC-22)

1 ph−4 lbs. 6 oz. (1.98 kg)

3 ph−4 lbs 13 oz. (2.17 kg)

1 ph−5 lbs. 7 oz. (2.45 kg)

3 ph−5 lbs 6 oz. (2.43

1ph 5 lbs. 8 oz. (2.48 kg)

3ph 6 lbs 0 oz. (2.72)

1 ph 8 lbs. 0 oz. (3.62 kg)

3 ph 7 lbs 7 oz. (3.36)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 3/4 (19.1) 7/8 (22.2) 7/8 (22.2) 1-1/8 (28.6)

Shipping weight lbs. (kg) 1 package 145 (66) 158 (72) 191 (87) 207 (94)

*Refrigerant charge sufficient for 15 ft. (4.5 m) length of refrigerant lines.

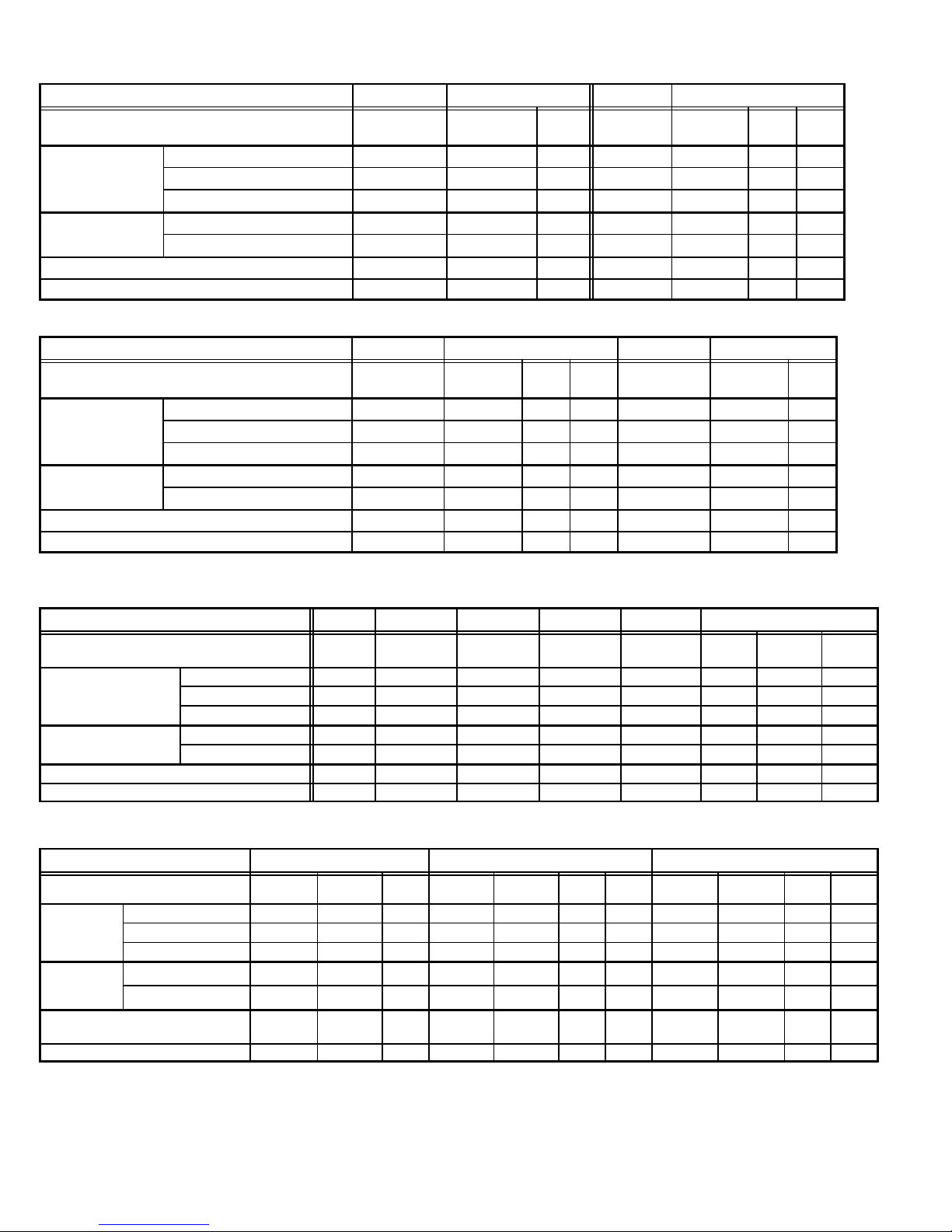

ELECTRICAL DATA

Model No. HS29-141 HS29-211 HS29-261 HS29-311 HS29-411 HS29-413

Line voltage data 60 hz

208/230v

1ph

208/230v

1ph

Rated load amps 4.9 8.6 10.1 11.8 17.5 10.3 4.3

Compressor Power factor .97 .97 .96 .92 .90 .83 .83

Locked rotor amps 26.3 48.3 60.0 69.4 96.0 75.0 40.0

Condenser Coil

Fan Motor

Full load amps 1.1 1.1 1.1 1.1 1.1 1.1 0.55

Locked rotor amps 1.9 1.9 1.9 1.9 1.9 1.9 1.0

Rec. maximum fuse or circuit breaker size (amps) 15 15 20 25 40 20 10

*Minimum circuit ampacity 7.3 11.0 13.8 15.9 23.8 14.0 6.5

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

3ph

460v

3ph

Page 3

Page 4

ELECTRICAL DATA

Condenser Coil

Condenser Coil

Condenser Coil

Model No. HS29-461 HS29-463 HS29-511 HS29-513

Line voltage data 60 hz

208/230v

1ph

208/230v

3ph

460v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

Rated load amps 17.5 12.8 6.4 23.4 14.0 7.1 5.8

Compressor Power factor .98 .93 .93 .98 .88 .88 .88

Locked rotor amps 92.0 87.0 44.0 110.0 91.0 46.0 37.0

Condenser Coil

Fan Motor

Full load amps 1.1 1.1 0.55 1.9 1.9 0.90 0.90

Locked rotor amps 1.9 1.9 1.0 4.1 4.1 2.1 2.1

Rec. maximum fuse or circuit breaker size (amps) 40 25 15 50 30 15 10

*Minimum circuit ampacity 23.0 17.1 8.6 31.2 19.4 9.8 8.2

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

ELECTRICAL DATA

Model No. HS29-651 HS29-653 HS29-681 HS29-683

Line voltage data 60 hz

208/230v

1ph

Rated load amps 26.9 17.3 9.0 7.1 27.1 18.6 7.9

Compressor Power factor .98 .86 .86 .86 .97 .86 .86

Locked rotor amps 123.0 128.0 64.0 51.0 175.0 128.0 63.0

Condenser Coil

Fan Motor

Full load amps 1.9 1.9 0.90 0.90 1.9 1.9 0.90

Locked rotor amps 4.1 4.1 2.1 2.1 4.1 2.1 2.1

Rec. maximum fuse or circuit breaker size (amps) 60 40 20 15 60 40 15

*Minimum circuit ampacity 35.5 23.5 12.2 9.8 35.8 24.2 10.8

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

208/230v

3ph

460v

3ph

575v

3ph

208/230v

1ph

208/230v

3ph

460v

575v

3ph

3ph

ELECTRICAL DATA

Model No. HS29-012 HS29-018 HS29-024−2 HS29-024−3 HS29-030 HS29-036

Line voltage data 60 hz 208/230v

1ph

Rated load amps 4.9 8.6 7.9 12.2 14.7 16.0 10.3 5.1

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230

v

1ph

208/230v

3ph

460v

Compressor Power factor .97 .97 .97 .96 .90 .91 .83 .83

Locked rotor amps 26.3 48.3 48.3 61.0 84.0 100.0 77.0 39.0

Condenser Coil

Fan Motor

Full load amps 1.1 1.1 1.1 1.1 1.1 1.1 1.1 0.55

Locked rotor amps 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.0

Rec. maximum fuse or circuit breaker size (amps) 15 20 15 25 30 35 20 10

*Minimum circuit ampacity 7.3 11.9 11.0 16.4 19.5 21.1 14.0 6.9

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

ELECTRICAL DATA

Model No. HS29−042 HS29-048 HS29-060

Line voltage data 60 hz

208/230v

1ph

Rated load amps 20.3 12.4 6.4 23.7 12.8 6.4 5.1 28.8 15.4 7.6 5.9

Compressor Power factor .84 .93 .93 .98 .88 .88 .88 .95 0.86 0.86 0.86

Locked rotor amps 127.0 88.0 44.0 129.0 91.0 46.0 37.0 169.0 124.0 59.6 49.4

Condenser

Coil

Fan Motor

Rec. maximum fuse or circuit breaker

size (amps)

Full load amps 1.1 1.1 .55 1.9 1.9 0.9 0.9 1.9 1.9 0.90 0.90

Locked rotor amps 1.9 1.9 1.0 4.1 4.1 2.1 2.1 4.1 4.1 2.1 2.1

40 25 15 50 30 15 10 60 35 15 10

*Minimum circuit ampacity 26.4 16.6 8.6 31.5 17.9 8.9 7.3 37.9 21.2 10.4 8.3

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

208/230v

3ph

460v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

575v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

3ph

575v

3ph

Page 4

Page 5

I − UNIT INFORMATION

HS29 condensing units are available in 1, 1 -1/2, 2, 2 -1/2, 3, 3

-1/2, 4 and 5 ton capacities.

All major components (indoor blower/coil) must be matched according to Lennox recommendations for the compressor to be

covered under warranty. Refer to the Engineering Handbook

for approved system matchups. A misapplied system will

cause erratic operation and can result in early compressor failure.

II − UNIT COMPONENTS

Unit components are illustrated in figure 3.

DANGER

Electric Shock Hazard.

May cause injury or death.

Disconnect all remote electrical power

supplies berore opening unit panel. Unit

may have multiple power supplies.

Some units are equipped with single−

pole contactors. When unit is equipped

with a single−pole contactor, line voltage

is present at all components (even when

unit is not in operation).

3 − Transformer T5

Transformer T5 is used on all J" voltage units. T5 is used as a

step-down transformer for the outdoor fan motor. The transformer is located inside the unit control box (see figure 1). The

transformer is rated at 3.4 VA with a 575 volt primary and a 460

volt secondary.

4 − Start Capacitor C7

All HS29−461, 511, 651, 012, 018 and 024−2 units use a

start capacitor (C7) wired in parallel with the compressor

side of the dual capacitor. The capacitor is located inside

the unit control box (see figure 1). C7 is switched off by

potential relay (K31) when the compressor nears full

speed. See side of capacitor for MFD ratings.

5 − Fan Capacitor C1

The fans in three-phase HS29−413, −463, −513, −653,

−683, −036, −042, −048 and −060 units use permanent split

capacitor motors. A single capacitor C1 is used for the

fan motor. The capacitor is located inside the unit control

box (see figure 1). See side of capacitor for MFD ratings.

6 − Potential (Start) Relay K31

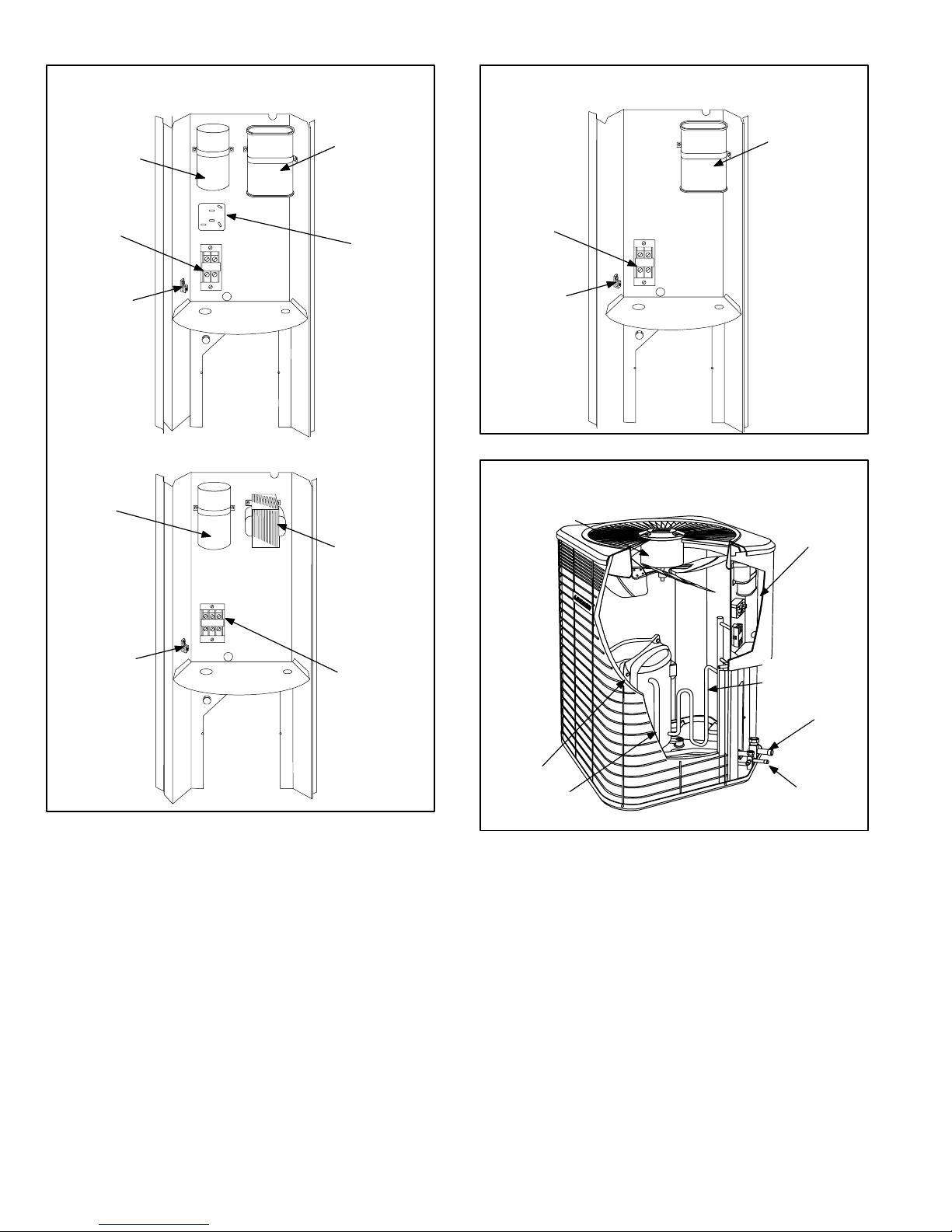

A − Control Box (Figure 1 and Figure 2)

Electrical openings are provided under the control box cover. Field thermostat wiring is made to color-coded pigtail

connections.

1 − Compressor Contactor K1

The compressor is energized by a contactor located in the

control box. See figure 1 and figure 2. Single−pole and twopole contactors are used in single-phase units. See wiring

diagrms for specific unit. Three-pole contactors are used in

three-phase units. K1 is energized by the indoor thermostat terminal Y1 (24V) when thermostat demand is present.

HS29 units are not equipped with a 24V transformer. All

24 VAC controls are powered by the indoor unit. Refer to

wiring diagram.

2 − Dual Capacitor C12

The compressor (scroll, rotary or reciprocating) and fan

in single-phase units use permanent split capacitor motors. The capacitor is located inside the unit control box

(see figure 1 and figure 2). A single dual" capacitor

(C12) is used for both the fan motor and the compressor

(see unit wiring diagram). The fan side and the compressor side of the capacitor have different MFD ratings and

must be exact when replacing. See side of capacitor for

ratings.

All HS29−461, 511, 651, 012, 018 and 024−2 units use a

potential relay which controls the operation of the starting circuit. The potential relay is located inside the unit control box

(see figure 1). The relay is normally closed when contactor

K1 is de-energized. When K1 energizes, the compressor im-

mediately begins start-up. K31 remains closed during compressor start-up and the start capacitor C7 remains in the cir-

cuit. When the compressor reaches 75% of its speed, K31 is

energized. When K31 energizes, the contacts open and

the start capacitor C7 is taken out of the circuit.

B − Compressor

(Rotary, Reciprocating and Scroll)

HS29−141 and −012 units utilize a rotary compressor.

HS29−018,−024−2, and −211 through −653 units utilize a

conventional reciprocating compressor. See ELEC-

TRICAL DATA tables or compressor nameplate for compressor specifications.

HS29−024−3 and HS29−030 through −060 units utilize a scroll

compressor. The scroll compressor design is simple, efficient

and requires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 4. The scrolls are located in the

top of the compressor can and the motor is located just below.

The oil level is immediately below the motor.

Page 5

Page 6

HS29 SINGLE-PHASE UNIT CONTROL BOX

WITH NON−SCROLL COMPRESSOR

HS29 SINGLE−PHASE UNIT CONTROL BOX

WITH SCROLL COMPRESSOR

START

CAPACITOR

(C7)

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

DUAL CAPACITOR

RELAY (K31)

HS29 THREE-PHASE UNIT CONTROL BOX

FAN

CAPACITOR (C1)

TRANSFORMER

(T5) J" VOLT-

AGE UNITS ON LY

(C12)

POTENTIAL

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

HS29 UNIT COMPONENTS

OUTDOOR

FAN/MOTOR

DUAL CAPACITOR

(C12)

FIGURE 2

CONTROL

BOX

GROUNDING

LUG

FIGURE 1

COMPRESSOR

CONTACTOR

(K1)

COMPRESSOR

SUCTION

LINE

FIGURE 3

DISCHARGE

LINE

SUCTION LINE

SERVICE VALVE

LIQUID LINE

SERVICE VALVE

Page 6

Page 7

DISCHARGE

SUCTION

SCROLL COMPRESSOR

FIGURE 4

1 − Crankcase Heater

A crankcase heater is used on all HS29−460 through

HS29−650 models and an option on all others. Some

heaters will be insertion−type and self−regulating while

others will be the band type. The heater is temperatureactuated and operates only when required.

2 − Compressor Cover (Figure 5)

A compressor cover constructed of vinyl−faced fiberglass is

an option on all HS29 units. The cover provides an acoustic

barrier. The cover slides over the compressor and is held

secure with snap buttons. Slits are provided for installation

around the discharge and suction lines.

COMPRESSOR COVER

COVER

SLIT FOR

SUCTION

LINE

The scroll is a simple compression concept centered around

the unique spiral shape of the scroll and its inherent properties.

Two identical scrolls are mated together forming concentric spiral shapes. One scroll remains stationary, while the other is allowed to "orbit." The orbiting scroll does not rotate or turn but

merely orbits the stationary scroll. Due to its efficiency, the

scroll compressor is capable of drawing a much deeper vacuum than reciprocating compressors . Deep vacuum operation can cause internal fusite arcing resulting in damaged internal parts and will result in compressor failure.

Never use a scroll compressor for evacuating or for deep

vacuum operation (operating compressor at 0 psig or

lower) on the system.

Three-Phase Compressor Rotation

Three-phase scroll compressors must be phased sequentially to ensure correct compressor rotation and operation.

At compressor start-up, a rise in discharge and drop in suction pressures indicates proper compressor phasing and

operation. If discharge and suction pressures do not perform normally, follow the steps below to correctly phase the

unit.

1 − Disconnect power to the unit.

2 − Reverse any two field power leads to the unit.

(Prefer L1 and L3).

3 − Reapply power to the unit.

Discharge and suction pressures should operate within

their normal start-up ranges.

NOTE − Compressor noise level may be significantly higher

when phasing is incorrect and the unit will not provide cooling when compressor is operating backwards. Continued

backward operation will cause the compressor to cycle on

internal protector.

SNAP

BUTTONS

COMPRESSOR

SLIT FOR DISCHARGE LINE

FIGURE 5

C − Condenser Fan Motor

DANGER

Make sure all power is disconnected before

beginning electrical service procedures.

All units use single−phase PSC fan motors which require

a run capacitor. In all units, the condenser fan is controlled by the compressor contactor.

ELECTRICAL DATA tables in this manual show specifications for condenser fans used in HS29s.

Access to the condenser fan motor on all units is gained

by removing the seven screws securing the fan assembly. See figure 6. The condenser fan motor is removed

from the fan guard by removing the four nuts found on the

top panel. See figure 7 if condenser fan motor replacment is necessary.

Page 7

Page 8

CONDENSER FAN MOTOR

Unit

Model No

HS29−261

HS29-510

Unit

Model No

HS29-030

HS29-048

AND COMPRESSOR ACCESS

Remove (7) screws

Remove (4) nuts

FAN

MOTOR

RACEWAY

REMOVE (7) SCREWS

SECURING FAN GUARD.

REMOVE FAN GUARD/FAN

ASSEMBLY.

FAN GUARD

WIRING

FIGURE 6

ALIGN FAN HUB FLUSH WITH END OF SHAFT

FIGURE 7

III − REFRIGERANT SYSTEM

A − Plumbing

Field refrigerant piping consists of liquid and suction lines

from the condensing unit (sweat connections) to the indoor

evaporator coil (flare or sweat connections). Use Lennox

L10 (flare) or L15 (sweat, non−flare) series line sets as

shown in table 1 or table 2 or use field−fabricated refrigerant

lines.

Separate discharge and suction service ports are provided outside the unit for connection of gauge manifold

during charging procedure.

TABLE 1

Condensing

Unit

Model No.

HS29−141

HS29−211

HS29−261

HS29-311

HS29-410

HS29-460

-

HS29-651

HS29−681

*Field fabricate.

Line Set

Model No.

(L10 or L15)

L10/15-21-20 20 6

L10/15-21-25 25 8

L10/15-21-35 35 11

L10/15-21-50 50 15

L15-31-20 20 6

L15-31-30 30 9

L15-31-40 40 12

L15-31-50 50 15

L10/15-41-20 20 6

L10/15-41-30 30 9

L10/15-41-40 40 12

L10/15-41-50 50 15

L10/15-65-30 30 9

L10/15-65-40 40 12

L10/15-65-50 50 15

*Field fabricate 3/8 9.5 1-1/8 28.5

Length of

Lines

.

ft. m in. mm in. mm

Liquid Line

Outside Dia.

5/16 7.9 5/8 15.9

5/16 7.9 3/4 19

3/8 9.5 3/4 19

3/8 9.5 7/8 22.2

Suction Line

Outside Dia.

TABLE 2

Condensing

Unit

Model No.

HS29−012

HS29−018

HS29−024−2

HS29-030

HS29−024−3

HS29-036

HS29-042

HS29-048

HS29-060 *Field fabricate 3/8 9.5 1-1/8 28.5

*Field fabricate.

Line Set

Model No.

(L10 or L15)

L15-21-20 20 6

L15-21-25 25 8

L15-21-35 35 11

L15-21-50 50 15

L15-31-20 20 6

L15-31-30 30 9

L15-31-40 40 12

L15-31-50 50 15

L15-41-20 20 6

L15-41-30 30 9

L15-41-40 40 12

L15-41-50 50 15

L15-65-30 30 9

L15-65-40 40 12

L15-65-50 50 15

Length of

Lines

.

ft. m in. mm in. mm

Liquid Line

Outside Dia.

5/16 7.9 5/8 15.9

5/16 7.9 3/4 19

3/8 9.5 3/4 19

3/8 9.5 7/8 22.2

Suction Line

Outside Dia.

Page 8

Page 9

B − Service Valves

The liquid and suction line service valves (figures 8 and 9) and

gauge ports are accessible from outside the unit.

The valve is equipped with a service port. The service ports are

used for leak testing, evacuating, charging and checking

charge. A schrader valve is factory installed. A service port cap

is supplied to protect the schrader valve from contamination

and serve as the primary leak seal.

NOTE-Always keep valve stem caps clean.

To Access Schrader Port:

1 − Remove service port cap with an adjustable wrench.

2 − Connect gauge to the service port.

3 − When testing is completed, replace service port cap. Tight-

en finger tight, then an additional 1/6 turn.

To Open Liquid or Suction Line Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Using service wrench and hex head extension (3/16" for

liquid line and 5/16" for suction line) back the stem out

counterclockwise until the valve stem just touches the re-

taining ring. For 5 ton unit with ball type suction line valve,

use adjustable wrench and back stem out counterclock-

wise 1/4 turn.

3 − Replace stem cap tighten firmly. Tighten finger tight, then

tighten an additional 1/6 turn.

To Close Liquid or Suction Line Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Using service wrench and hex head extension (3/16" for liq-

uid line and 5/16" for suction line), turn stem clockwise to

seat the valve. Tighten firmly. For 5 ton unit with ball type

suction line valve, use adjustable wrench and turn stem

clockwise 1/4 turn.

3 − Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

Suction Line (Ball Type) Service Valve

(5 Ton Only)

A ball-type full service valve is used on HS29 5 ton units.

These suction line service valves function the same way,

differ ence s are in co nstr uction. Val v es are not rebuildable.

If a valve has failed it must be replaced. A ball valve is illustrated

in figure 10.

The ball valve is equipped with a service port. A schrader

valve is factory installed. A service port cap is supplied to

protect the schrader valve from contamination and assure a leak free seal.

DANGER

Do not attempt to backseat the service valves

past the retaining ring. Attempts to backseat

the service valves past the retaining ring will

cause snap ring to explode from valve body

under pressure of refrigerant. Personal injury

and unit damage will result.

Page 9

Page 10

LIQUID LINE SERVICE VALVE (VALVE OPEN)

INSERT HEX

WRENCH HERE

SERVICE

PORT

STEM CAP

SUCTION LINE SERVICE VALVE (VALVE OPEN)

INSERT HEX

WRENCH HERE

INLET FROM

INDOOR COIL

STEM CAP

INLET FROM

COMPRESSOR

SERVICE

PORT

CAP

SCHRADER

VALV E

OUTLET TO

INDOOR COIL

LIQUID LINE SERVICE VALVE (VALVE CLOSED)

RETAINING RING

SERVICE

PORT

INLET FROM

COMPRESSOR

SERVICE

PORT CAP

SCHRADER VALVE OPEN

TO LINE SET WHEN VALVE

IS CLOSED (FRONT

SEATED)

(VALVE FRONT

SEATED)

STEM CAP

INSERT HEX

WRENCH HERE

OUTLET TO

INDOOR COIL

FIGURE 8

SUCTION LINE (BALL TYPE) SERVICE VALVE

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90 TO CLOSE

ROTATE STEM COUNTER-CLOCKWISE 90 TO CLOSE

SUCTION LINE SERVICE VALVE (VALVE CLOSED)

INLET FROM

INDOOR COIL

TO LINE SET WHEN VALVE IS

(VALVE OPEN)

SCHRADER

VALV E

SERVICE PORT

CAP

SERVICE PORT

RETAINING RING

SERVICE

PORT

SERVICE

PORT

CAP

SCHRADER VALVE OPEN

CLOSED (FRONT SEATED)

FIGURE 9

OUTLET TO

COMPRESSOR

STEM CAP

INSERT HEX

WRENCH HERE

(VALVE FRONT

SEATED)

OUTLET (TO

COMPRESSOR)

(TO COMPRESSOR)

SERVICE PORT

OUTLET

SERVICE

PORT

CAP

SCHRADER

VALV E

FIGURE 10

Page 10

STEM CAP

STEM

BALL

(SHOWN OPEN)

INLET

(FROM INDOOR COIL)

Page 11

IV − CHARGING

The unit is factory−charged with the amount of HCFC−22 refrigerant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with a 15

foot (4.5 m) line set. For varying lengths of line set, refer to

table 3 for refrigerant charge adjustment. A blank space is

provided on the unit rating plate to list actual field charge.

TABLE 3

LIQUID LINE SET

DIAMETER

1/4 in. (6mm) 1 ounce per 5 ft. (30 ml per 1524 mm)

5/16 in. (8mm) 2 ounce per 5ft. (60 ml per 1524 mm)

3/8 in. (10 mm) 3 ounce per 5 ft. (90 ml per 1524 mm)

*If line set is greater than 15 ft. (4.5 m) add this amount. If line set

is less than 15 ft. (4.5 m) subtract this amount.

Units are designed for line sets up to 50 ft (15.2 m). Consult Lennox Refrigerant Piping Manual for line sets over

50 ft (15.2 m).

Ounce per 5 ft. (ml per mm) adjust line set*

IMPORTANT

If line length is greater than 20 feet (6.1 m) add

this amount. If line length is less than 20 feet (6.1

m), subtract this amount.

CAUTION

When using dry nitrogen, a pressure reducing

regulator must be used to prevent excessive

pressure in gauge manifold, connecting hoses,

and within the system. Regulator setting must

not exceed 150 psig (1034 kpa). Failure to use a

regulator can cause equipment failure resulting

in injury.

C − Evacuating the System

1− Attach gauge manifold. Connect vacuum pump (with vac-

uum gauge) to center port of gauge manifold. With both

manifold service valves open, start pump and evacuate in-

door coil and refrigerant lines.

IMPORTANT

A temperature vacuum gauge, mercury vacuum

(U−tube), or thermocouple gauge should be

used. The usual Bourdon tube gauges are not

accurate enough in the vacuum range.

A − Pumping Down System

CAUTION

Vacuum operation (operating compressor at 0

psig or lower) can cause internal fusite arcing

resulting in a damaged or failed compressor.

This type of damage will result in denial of

warranty claim.

The system may be pumped down when leak checking the

line set and indoor coil or making repairs to the line set or

indoor coil.

1− Attach gauge manifold.

2− Front seat (close) liquid line valve.

3− Start outdoor unit.

4− Monitor suction gauge. Stop unit when 0 psig is reached.

5− Front seat (close) suction line valve.

B − Leak Testing (To Be Done

Before Evacuating)

1− Attach gauge manifold and connect a drum of dry nitro-

gen to center port of gauge manifold.

2− Open high pressure valve on gauge manifold and

pressurize line set and indoor coil to 150 psig (1034

kPa).

3− Check lines and connections for leaks.

NOTE-If electronic leak or Halide detector is used, add a

small amount of HCFC−22 (3 to 5 psig (20kPa to 34kPa)) then

pressurize with nitrogen to 150 psig.

4− Release nitrogen pressure from the system, correct any

leaks and recheck.

IMPORTANT

The compressor should never be used to evacuate a refrigeration or air conditioning system.

2− Evacuate the system to 29 inches (737mm) vacuum.

During the early stages of evacuation, it is desirable to

stop the vacuum pump at least once to determine if there

is a rapid loss of vacuum. A rapid loss of vacuum would

indicate a leak in the system and a repeat of the leak testing section would be necessary.

3− After system has been evacuated to 29 inches

(737mm), close gauge manifold valves to center port,

stop vacuum pump and disconnect from gauge manifold. Attach an upright nitrogen drum to center port of

gauge manifold and open drum valve slightly to purge

line at manifold. Break vacuum in system with nitrogen

pressure by opening manifold high pressure valve.

Close manifold high pressure valve to center port.

4− Close nitrogen drum valve and disconnect from

gauge manifold center port. Release nitrogen pressure from system.

5− Connect vacuum pump to gauge manifold center

port. Evacuate system through manifold service

valves until vacuum in system does not rise above

.5mm of mercury absolute pressure or 500 microns

within a 20−minute period after stopping vacuum

pump.

6− After evacuation is complete, close manifold center port,

and connect refrigerant drum. Pressurize system slightly

with refrigerant to break vacuum.

Page 11

Page 12

D − Charging

If the system is completely void of refrigerant, the recommended and most accurate method of charging is to weigh the

refrigerant into the unit according to the total amount shown on

the unit nameplate. Also refer to the SPECIFICATIONS tables

on pages 1 and 2.

If weighing facilities are not available or if unit is just low on

charge, the following procedure applies.

1 − Expansion Valve Systems

The following procedures are intended as a general guide for

use with expansion valve systems only. For best results, indoor

temperature should be between 70°F and 80°F (21.1°C and

26.7°C). Outdoor temperature should be 60°F (15.6°C) or

above. Slight variations in charging temperature and pressure

should be expected. Large variations may indicate need for further servicing.

TABLE 4

HS29 MODEL NO.

−141, −012 7 (3 .6)

−211, −018 4 (2. 2)

−261, −024−2 5 (2 .8)

−024−3, −030 11 (6. 1)

−311 10 (5.6)

−410, −460, −048 12 (6.7)

−036 14 (7.8)

−510, −650 13 (7.2)

−042 17 (9.5)

−060 12 (6.7)

Liquid Line − Outdoor Ambient F (C)

Approach Temperature

IMPORTANT

IMPORTANT

The following procedure requires accurate

readings of ambient (outdoor) temperature, liquid temperature and liquid pressure for proper

charging. Use a thermometer with accuracy of

+2 °F (+ 1.1°C) and a pressure gauge with accuracy of +5 PSIG ( +34.5 kPa).

APPROACH METHOD (TXV SYSTEMS)

(Ambient Temperature of 60F [16C] or Above)

1 − Connect gauge manifold. Connect an upright

HCFC−22 drum to center port of gauge manifold.

2 − Record outdoor air (ambient) temperature.

3 − Operate indoor and outdoor units in cooling mode. Al-

low outdoor unit to run until system pressures stabi-

lize.

4 − Make sure thermometer well is filled with mineral oil

before checking liquid line temperature.

5 − Place thermometer in well and read liquid line tem-

perature. Liquid line temperature should be warmer

than the outdoor air temperature. Table 4 shows how

many degrees warmer the liquid line temperature

should be.

Add refrigerant to lower the liquid line tempera-

ture.

Recover refrigerant to raise the liquid line tem-

perature.

Add refrigerant slowly as the unit approaches the

correct temperature. This will allow refrigerant

to stabilize allowing the correct temperature to

be read.

6 − When unit is properly charged, liquid line pressures

should approximate those in table 6.

Use tables 6 and 7 as a general guide for performing maintenance checks. Tables 6 and 7 are

not a procedure for charging the system. Minor

variations in these pressures may be expected

due to differences in installations. Significant

deviations could mean that the system is not

properly charged or that a problem exists with

some component in the system. Used prudently, tables 6 and 7 could serve as a useful service

guide.

2 − RFCIV Systems

The following procedures are intended as a general guide for

use with RFCIV systems only. For best results, indoor temperature should be between 70°F and 80°F (21.1°C and 26.7°C).

Outdoor temperature should be 60°F (15.6°C) or above. Slight

variations in charging temperature and pressure should be expected. Large variations may indicate a need for further servicing.

1 − Connect gauge manifold. Connect an upright

HCFC−22 drum to center port of gauge manifold.

2 − Operate indoor and outdoor units. Allow outdoor unit to

run until system pressures stabilize.

3 − Make sure thermometer well is filled with mineral oil

before checking liquid line temperature.

4 − Read liquid line pressure and convert to condensing

temperature using temperature/ pressure conversion chart.

Condensing temperature (read from gauges) should

be warmer than liquid line temperature.

5 − Place thermometer in well and read liquid line temper-

ature. Table 5 and table 8 show how much warmer

the condensing temperature should be.

6 − Subtract liquid line temperature from condensing tem-

perature to determine subcooling. Compare with

table 6.

Add refrigerant to lower liquid line temperature.

Recover refrigerant to raise liquid line temp.

7 − When unit is properly charged liquid line pres-

sures should approximate table 6 .

E − Oil Charge

See compressor nameplate.

Page 12

Page 13

V − MAINTENANCE

OUTDOOR

At the beginning of each heating or cooling season, the system should be cleaned as follows:

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect switch(es). Unit may have multiple

power supplies.

A − Outdoor Unit

1 − Clean and inspect condenser coil. (Coil may be

flushed with a water hose).

2 − Visually inspect all connecting lines, joints and coils

for evidence of oil leaks.

B − Indoor Coil

1 − Clean coil if necessary.

2 − Check connecting lines and coil for evidence of oil

leaks.

3 − Check condensate line and clean if necessary.

C − Indoor Unit

1 − Clean or change filters.

2 − Bearings are pre-lubricated and need no further oil-

ing.

3 − Check all wiring for loose connections.

4 − Check for correct voltage at unit.

5 − Check amp−draw on blower motor.

Unit nameplate_________Actual_________.

TABLE 5

SUBCOOLING FOR RFC SYSTEMS

OUTDOOR

TEMP.

F (C)

60

(16)

65

(18)

70

(21)

75

(24)

80

(27)

85

(29)

90

(32)

95

(35)

100

(38)

105

(41)

110

(43)

115

(45)

LIQUID SUBCOOLING [+ 1F (.6C)]

−141 −211 −261 −311 −411 −461 −511

14

(7.8)17(9.5)18(10)18(10)14(7.8)16(8.9)15(8.3)

13

(7.2)16(8.9)16(8.9)17(9.5)13(7.2)15(8.3)14(7.8)

12

(6.7)15(8.3)14(7.8)16(809)12(6.7)14(7.8)13(7.2)

10

(5.6)14(7.8)12(6.7)15(8.3)10(5.6)13(7.2)11(6.1)

9

(5)13(7.2)11(6.1)14(7.8)9(5)12(6.7)10(5.6)

8

(4.5)12(6.7)10(5.6)13(7.2)8(4.5)11(6.1)8(4.5)

7

(3.9)11(6.1)9(5)12(6.7)7(3.9)10(5.6)7(3.9)

6

(3.3)9(5)8(4.5)11(6.1)6(3.3)9(5)7(3.9)

4

(2.2)8(4.5)7(3.9)10(5.6)5(2.8)8(4.5)6(3.3)

2

(1.1)7(3.9)6(3.3)9(5)4(2.2)6(3.3)4(2.2)

2

(1.1)6(3.3)6(3.3)7(3.9)3(1.7)5(2.8)3(1.7)

1

(0.6)5(2.8)5(2.8)5(2.8)2(1.1)3(1.7)2(1.1)

HS29−141 HS29−211 HS29−261 HS29−311 HS29−411 HS29−461 HS29−511 HS29−651

ENTERING AIR

TEMPERATURE

F (C)

65 (18.3) (RFCIV) − − 155 65 160 65 168 63 176 62 174 64 181 65 − −

75 (24) (RFCIV) − − 181 70 188 70 197 68 203 66 205 69 208 70 − −

85 (29.4) (RFCIV) − − 208 75 216 74 227 73 233 70 236 73 239 75 − −

95 (35) (RFCIV) − − 238 80 247 78 258 77 266 74 271 77 271 79 − −

105 (40.6)

(RFCIV)

65 (18.3) (TXV) 150 70 159 73 164 71 173 71 179 68 180 71 187 73 150 70

75 (24) (TXV) 179 71 183 75 189 73 199 73 205 70 208 73 212 75 179 71

85 (29.4) (TXV) 211 73 209 77 217 75 228 75 235 72 238 75 241 77 211 73

95 (31.2) (TXV) 269 76 238 80 247 78 258 77 266 74 271 77 271 79 269 76

105 (40.6) (TXV) 286 75 269 82 279 80 292 79 299 77 305 79 305 80 286 75

* These are typical pressures only. Indoor evaporator match up, indoor air quantity and evaporator load will cause the pressures to vary.

LIQ.

SUC.

+1 0

PSIG

LIQ.

+1 0

PSIG

+1 0

PSIG

− − 270 84 280 82 292 80 299 77 305 80 306 82 − −

SUC.

+1 0

PSIG

TABLE 6

NORMAL OPERATING PRESSURES*

LIQ.

SUC.

LIQ.

SUC.

+1 0

PSIG

+1 0

PSIG

+1 0

PSIG

+1 0

PSIG

LIQ.

+1 0

PSIG

Page 13

SUC.

+1 0

PSIG

LIQ.

+1 0

PSIG

SUC.

+1 0

PSIG

LIQ.

+1 0

PSIG

SUC.

+1 0

PSIG

LIQ.

+1 0

PSIG

SUC.

+1 0

PSIG

Page 14

OUTDOOR

DOOR

ENTERING AIR

TEMPERATURE

F (C)

65 (18.3)

(RFCIV))

75 (24)

(RFCIV)

85 (29.4)

(RFCIV)

95 (35)

(RFCIV)

105 (40.6)

(RFCIV)

HS29−012 HS29−018

LIQ.

1 0

+

PSIG

SUC.

+1 0

PSIG

LIQ.

1 0

+

PSIG

SUC.

PSIG

145 71 155 65

167 77 181 70

192 81 208 75

221 84 238 80

253 87 270 84

+1 0

TABLE 7

NORMAL OPERATING PRESSURES*

HS29−024−3

(HS29−024−2)

LIQ.

+1 0

PSIG

147

(160)58(65)

174

(188)63(70)

204

(216)68(74)

234

(247)75(78)

272

(280)77(82)

1

HS29−030 HS29−036 HS29−042 HS29−048 HS29−060 HS29−060−3

SUC.

+1 0

PSIG

LIQ.

1 0

+

PSIG

SUC.

+1 0

PSIG

LIQ.

1 0

+

PSIG

SUC.

+1 0

PSIG

160 64 165 62 166 67 160 66 159 64 158 67

185 67 192 66 194 70 187 69 188 68 185 71

216 71 223 69 223 72 208 71 219 72 216 74

248 73 257 71 257 75 249 75 253 75 247 77

284 76 292 73 291 76 284 77 287 76 283 79

LIQ.

1 0

+

PSIG

SUC.

1 0

+

PSIG

LIQ.

1 0

+

PSIG

SUC.

+1 0

PSIG

LIQ.

1 0

+

PSIG

SUC.

+1 0

PSIG

LIQ.

+1 0

PSIG

SUC.

+

PSIG

5

65 (18.3) (TXV) 140 79 159 73

75 (24) (TXV) 161 80 183 75

85 (29.4) (TXV) 189 81 209 77

95 (31.2) (TXV) 220 83 238 80

105 (40.6) (TXV) 254 84 269 82

143

(164)71(71)

170

(189)73(73)

202

(217)75(73)

236

(247)78(75)

271

(279)76(80)

154 68 162 66 156 70 158 71 151 69 154 75

174 70 190 67 184 71 188 73 179 71 181 77

204 70 224 68 214 72 210 73 211 73 213 79

246 72 257 71 261 74 253 75 249 74 249 80

276 74 296 72 291 75 291 76 286 75 285 82

* These are typical pressures only. Indoor evaporator match up, indoor air quantity and evaporator load will cause the pressures to vary.

1

HS29−024−03 units use scroll compressors. HS29−024−2 units use reciprocating compressors.

TABLE 8

SUBCOOLING FOR RFC SYSTEMS

OUTDOOR

TEMP.

_F (_C)

−012 −018 024−3 −024−2 −030 −036 −042 −048 −060 −060−3

60 (16) 14 (7.8) 17 (9.5) 14 (7.8) 18 (10) 14 (7.8) 13 (7.2) 12 (6.7) 11 (6.1) 13 (7.2) 15 (8.3)

65 (18) 13 (7.2) 16 (8.9) 13 (7.2) 16 (8.9) 14 (7.8) 13 (7.2) 11 (6.1) 10 (5.6) 12 (6.7) 15 (8.3)

70 (21) 12 (6.7) 15 (8.3) 13 (7.2) 14 (7.8) 13 (7.2) 12 (6.7) 11 (6.1) 10 (5.6) 12 (6.7) 14 (7.8)

75 (24) 10 (5.6) 14 (7.8) 12 (6.7) 12 (6.7) 13 (7.2) 12 (6.7) 10 (5.6) 10 (5.6) 12 (6.7) 14 (7.8)

80 (27) 9 (5) 13 (7.2) 11 (6.1) 11 (6.1) 13 (7.2) 12 (6.7) 10 (5.6) 10 (5.6) 12 (6.7) 13 (7.2)

85 (29) 8 (4.5) 12 (6.7) 10 (5.6) 10 (5.6) 13 (7.2) 11 (6.1) 10 (5.6) 9 (5) 11 (6.1) 13 (7.2)

90 (32) 7 (3.9) 11 (6.1) 9 (5) 9 (5) 13 (7.2) 11 (6.1) 9 (5) 9 (5) 11 (6.1) 12 (6.7)

95 (35) 6 (3.3) 9 (5) 8 (4.5) 8 (4.5) 12 (6.7) 11 (6.1) 9 (5) 9 (5) 11 (6.1) 11 (6.1)

100 (38) 4 (2.2) 8 (4.5) 7 (3.9) 7 (3.9) 12 (6.7) 10 (5.6) 8 (4.5) 8 (4.5) 10 (5.6) 10 (5.6)

105 (41) 2 (1.1) 7 (3.9) 6 (3.3) 6 (3.3) 11 (6.1) 10 (5.6) 7 (3.9) 8 (4.5) 10 (5.6) 10 (5.6)

110 (43) 2 (1.1) 6 (3.3) 6 (3.3) 6 (3.3) 11 (6.1) 9 (5) 6 (3.3) 7 (3.9) 9 (5) 9 (5)

115 (45) 1 (0.6) 5 (2.8) 4 (2.2) 5 (2.8) 10 (5.6) 9 (5) 5 (2.8) 6 (3.3) 8 (4.5) 9 (5)

LIQUID SUBCOOLING [+ 1_F (.6_C)]

Page 14

Page 15

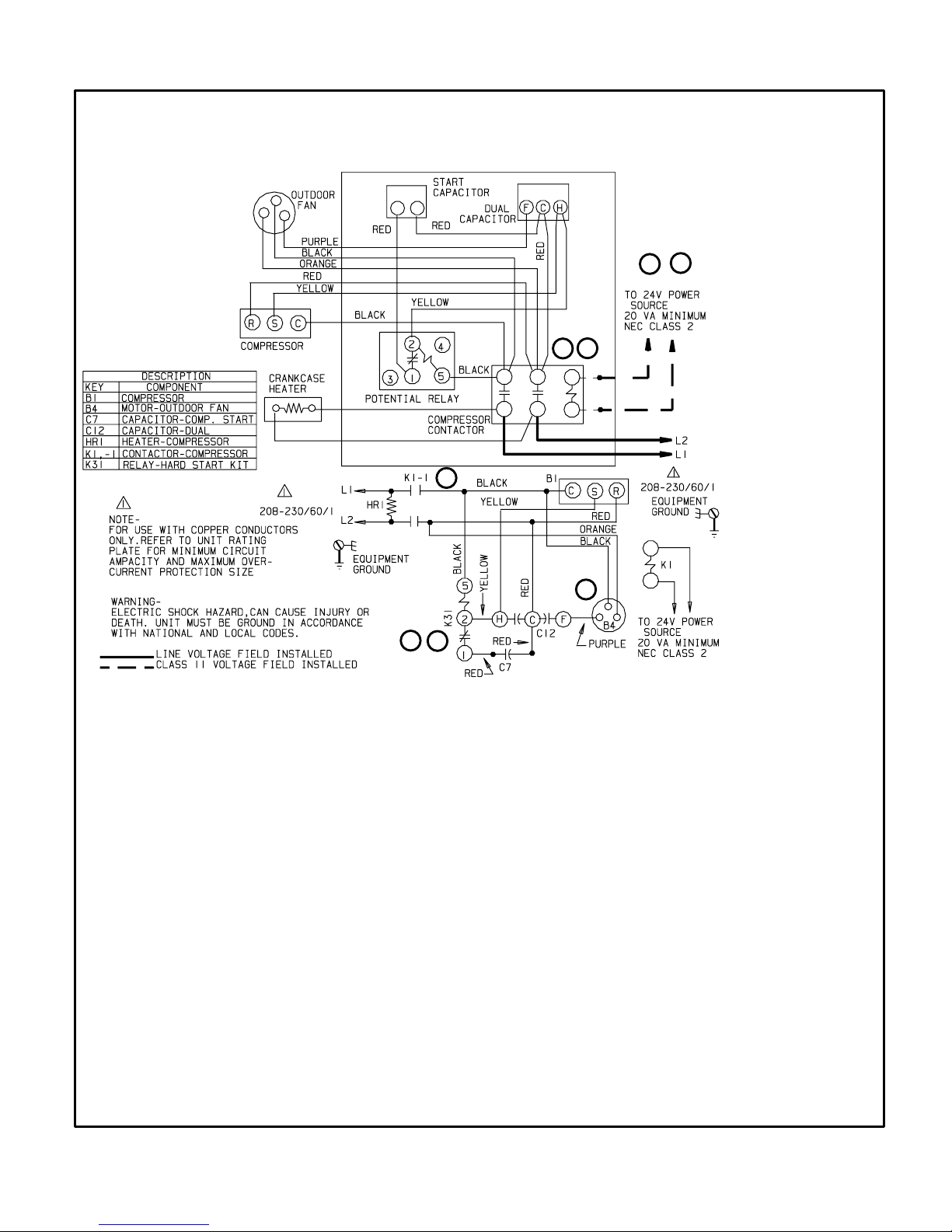

VI − WIRING DIAGRAMS AND SEQUENCE OF OPERATION

HS29−1 SINGLE-PHASE OPERATING SEQUENCE

RECIPROCATING OR ROTARY COMPRESSOR)

(

2

3

1

6

7

4

5

8

a−HS29 P" Voltage Operation Sequence

This is the sequence of operation for HS29−461/511/651 and HS29−012/018/024 P" voltage units. The

HS29−141/211/261/311/411/681 P" voltage units are similar; however, these units are not equipped with the hard

start kit. The sequence is outlined by numbered steps which correspond to circled numbers on the adjacent diagram.

NOTE− The thermostat used may be electromechanical or electronic.

NOTE− Transformer in indoor unit supplies power (24 VAC) to the thermostat and outdoor unit controls.

COOLING:

2Cooling demand initiates at Y1 in the thermostat.

324VAC from indoor unit energizes compressor contactor K1.

4K1-1 N.O. closes, energizing terminal C" of compressor (B1) and outdoor fan motor (B4).

5Outdoor fan motor (B4) begins immediate operation.

6Compressor (B1) begins start-up. Hard start contactor K31 remains closed during start-up and start capacitor C7 remains in

the circuit. As the compressor gains speed, K31 is energized. When K31 is energized, the contacts open and start capacitor C7 is taken out of the circuit.

END OF COOLING DEMAND:

7Cooling demand is satisfied. Terminal Y1 is de-energized.

8Compressor contactor K1 is de-energized.

9K1-1 opens and compressor (B1) and outdoor fan motor (B4) are de-energized and stop immediately.

Page 15

Page 16

HS29−2 & −3 SINGLE-PHASE OPERATING SEQUENCE

RECIPROCATING OR ROTARY COMPRESSOR)

(

1

6

7

2

3

4

5

8

NOTE− The thermostat used may be electromechanical or electronic.

NOTE− Transformer in indoor unit supplies power (24 VAC) to the thermostat and outdoor unit controls.

COOLING:

2Cooling demand initiates at Y1 in the thermostat.

324VAC from indoor unit energizes compressor contactor K1.

4K1-1 N.O. closes, energizing terminal C" of compressor (B1) and outdoor fan motor (B4).

5Outdoor fan motor (B4) begins immediate operation.

6Compressor (B1) begins start-up. Hard start contactor K31 remains closed during start-up and start capacitor C7 remains in

the circuit. As the compressor gains speed, K31 is energized. When K31 is energized, the contacts open and start capacitor C7 is taken out of the circuit.

END OF COOLING DEMAND:

7Cooling demand is satisfied. Terminal Y1 is de-energized.

8Compressor contactor K1 is de-energized.

9K1-1 opens and compressor (B1) and outdoor fan motor (B4) are de-energized and stop immediately.

Page 16

Page 17

HS29 THREE-PHASE OPERATING SEQUENCE

(ALL COMPRESSORS)

1

5

6

2

3

4

7

a−HS29 Y", G", and J" Voltage Operation Sequence

This is the sequence of operation for HS29 Y" voltage units. The HS29 G"voltage sequence is the same; however the

J" voltage units have an outdoor fan transformer. The sequence is outlined by numbered steps which correspond to

circled numbers on the adjacent diagram.

NOTE− The thermostat used may be electromechanical or electronic.

NOTE− Transformer in indoor unit supplies power (24 VAC) to the thermostat and outdoor unit controls.

COOLING:

2Cooling demand initiates at Y1 in the thermostat.

324VAC energizes compressor contactor K1.

4K1-1 N.O. closes energizing compressor (B1) and outdoor fan motor (B4).

5Compressor (B1) and outdoor fan motor (B4) begin immediate operation.

END OF COOLING DEMAND:

6Cooling demand is satisfied. Terminal Y1 is de-energized.

7Compressor contactor K1 is de-energized.

8K1-1 opens and compressor (B1) and outdoor fan motor (B4) are de-energized and stop immediately.

Page 17

Page 18

HS29−1 SINGLE−PHASE OPERATING SEQUENCE

(SCROLL COMPRESSORS)

1

6

7

2

3

8

4

a−HS29 P" Voltage Operation Sequence

This is the sequence of operation for HS29−030/036/042/048/060 P" voltage units. The sequence is outlined by

numbered steps which correspond to circled numbers on the adjacent diagram.

NOTE− The thermostat used may be electromechanical or electronic.

NOTE− Transformer in indoor unit supplies power (24 VAC) to the thermostat and outdoor unit controls.

COOLING:

2Cooling demand initiates at Y1 in the thermostat.

324VAC from indoor unit energizes compressor contactor K1.

4K1-1 N.O. closes, energizing terminal C" of compressor (B1) and outdoor fan motor (B4).

5Outdoor fan motor (B4) begins immediate operation.

6Compressor (B1) begins operation.

END OF COOLING DEMAND:

7Cooling demand is satisfied. Terminal Y1 is de-energized.

8Compressor contactor K1 is de-energized.

9K1-1 opens and compressor (B1) and outdoor fan motor (B4) are de-energized and stop immediately.

5

Page 18

Page 19

HS29−2 & −3 SINGLE−PHASE OPERATING SEQUENCE

(SCROLL COMPRESSORS)

1

6

2

7

8

3

5

4

NOTE− The thermostat used may be electromechanical or electronic.

NOTE− Transformer in indoor unit supplies power (24 VAC) to the thermostat and outdoor unit controls.

COOLING:

2Cooling demand initiates at Y1 in the thermostat.

324VAC from indoor unit energizes compressor contactor K1.

4K1-1 N.O. closes, energizing terminal C" of compressor (B1) and outdoor fan motor (B4).

5Outdoor fan motor (B4) begins immediate operation.

6Compressor (B1) begins operation.

END OF COOLING DEMAND:

7Cooling demand is satisfied. Terminal Y1 is de-energized.

8Compressor contactor K1 is de-energized.

9K1-1 opens and compressor (B1) and outdoor fan motor (B4) are de-energized and stop immediately.

Page 19

Page 20

SERVICE NOTES

Page 20

Loading...

Loading...