Lennox HS29-261, HS29-411, HS29-141, HS29-311, HS29-413 Unit Information

...

Service Literature

HS29 SERIES UNITS

The HS29 is a residential split-system condensing unit.

Condensing coil size, circuiting and air volume result in a

minimum SEER rating of 10.0. The series is designed for

use with an expansion valve or RFCIV system in the indoor unit. However, the HS29−651 and −060 use only the

TXV system.

The HS29−141 and −012 utilizes a rotary compressor. Other

HS29 units (−018, −024−2 and −211 through −653) utilize a reciprocating compressor. All compressors are hermetically sealed

for trouble-free operation and long service life. Compressor

components are spring-mounted within the sealed housing.

The compressor is installed in the unit on resilient rubber

mounts to assure quiet, vibration-free operation. A built-in

protection device assures protection from excessive

current and temperatures.

HS29−460 through HS29−650 models are furnished with

crankcase heaters to assure proper compressor lubrication at all times. The heater is temperature-actuated and

operates only when required. HS29−024−3 and HS29−030

through −060 units utilize a scroll compressor. The scroll operates like a standard compressor but it is unique in the way it

compresses refrigerant.

Several models are available in sizes ranging from 1 through 5

tons.

HS29

Corp. 9802−L3

Revised 04−2004

This manual is divided into sections which discuss the

major components, refrigerant system, charging procedure, maintenance and operation sequence.

All specifications in this manual are subject to change.

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

TABLE OF CONTENTS

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Data 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Unit Information 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II Unit Components 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Refrigerant System 8. . . . . . . . . . . . . . . . . . . . . . . . . .

IV Charging 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VI Wiring Diagrams and Operation Sequence 15. . . . . .

Page 1

©1998 Lennox Industries Inc.

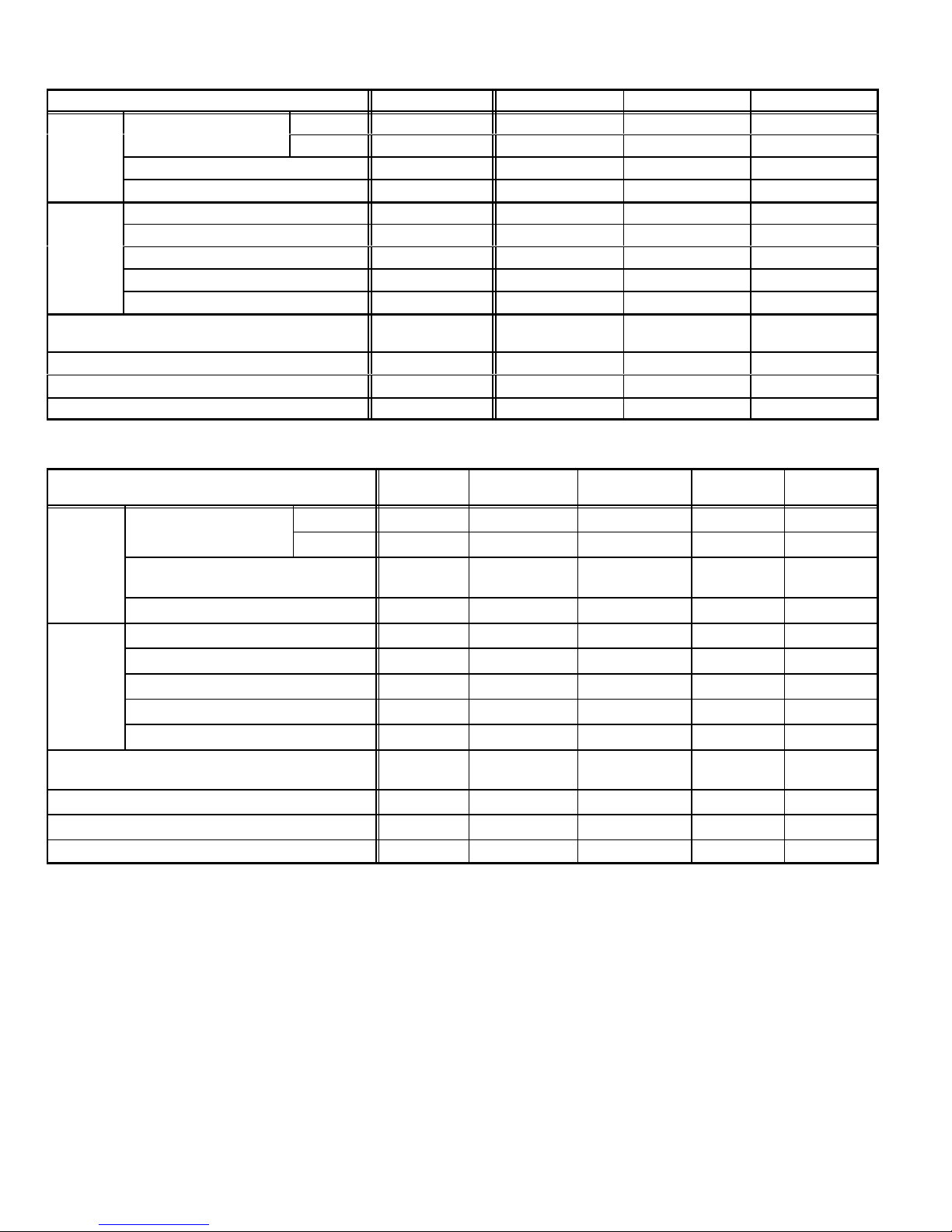

SPECIFICATIONS

Condenser

Fan

Fan

Model No. HS29-141 HS29-211 HS29-261 HS29-311

Condenser

Net face area - sq. ft. (m2)

Coil

Tube diameter in. (mm) & no. of rows 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866)

Diameter in. (mm) & no. of blades 18 (457) 3 18 (457) 3 18 (457) 3 18 (457) 3

Motor hp (W) 1/6 (124) 1/6 (124) 1/6 (124) 1/6 (124)

Condenser

Cfm (L/s) 2400 (1135) 2400 (1135) 2400 (1135) 2460 (1160)

Rpm 1105 1105 1105 1125

Watts 180 180 180 170

*Refrigerant charge furnished (HCFC-22)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9) 3/4 (19.1)

Shipping weight lbs. (kg) 1 package 146 (66) 146 (66) 148 (67) 157 (71)

*Refrigerant charge sufficient for 20 ft. (6.1 m) length of refrigerant lines.

3/8x5/16 in. (9.5x7.9mm) adaptor furnished for liquid line connection.

Model No.

Net face area - sq. ft. (m2)

Condenser

Coil

Tube diameter in. (mm) & no. of rows

Outer coil 7.56 (0.70) 11.33 (1.05) 11.33 (1.05) 13.22 (1.23)

Inner coil - - - - - - - - - - - - - - - -

2 lbs. 12 oz.

(1.25 kg)

3 lbs. 10 oz.

(1.64 kg))

3 lbs. 13 oz.

(1.73 kg))

4 lbs. 5 oz. (1.96 kg)

SPECIFICATIONS (contd.)

HS29-411

HS29-413

Outer coil 15.11 (1.40) 15.11 (1.40) 15.11 (1.40) 15.21 (1.41) 21.11 (1.96)

Inner coil - - - - 5.40 (0.50) 5.44 (0.50) 14.0 (13.4) 20.3 (1.89)

5/16 (7.9)

1

HS29-461

HS29-463

HS29-511

HS29-513

HS29-651

HS29-653

HS29-681

HS29-683

5/16 (7.9) 1.37 5/16 (7.9) 1.37 5/16 (7.9) 2 5/16 (7.9) 2

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866)

Diameter in. (mm) & no. of blades 18 (457) 4 18 (457) 4 18 (457) 4 18 (457) 4 18 (457) 4

Motor hp (W) 1/6 (124) 1/6 (124) 1/3 (249) 1/3 (249) 1/3 (249)

Condenser

Fan

Cfm (L/s) 2520 (1190) 2500 (1180) 2950 (1390) 2930 (1385) 2930 (1385)

Rpm 1100 1100 1100 1100 1100

Watts 200 200 310 310 310

*Refrigerant charge furnished (HCFC-22)

5 lbs. 0 oz.

(2.26 kg)

5 lbs. 9 oz. (2.52

kg)

6 lbs. 3 oz.

(2.81 kg)

7 lbs. 10 oz.

(3.46 kg)

12 lbs. 0 oz.

(5.44 kg)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 3/4 (19.1) 7/8 (22.2) 7/8 (22.2) 1-1/8 (28.6) 1-1/8 (28.6)

Shipping weight lbs. (kg) 1 package 165 (75) 191 (87) 196 (89) 212 (96) 254 (115)

*Refrigerant charge sufficient for 20 ft. (6.0 m) length of refrigerant lines.

Page 2

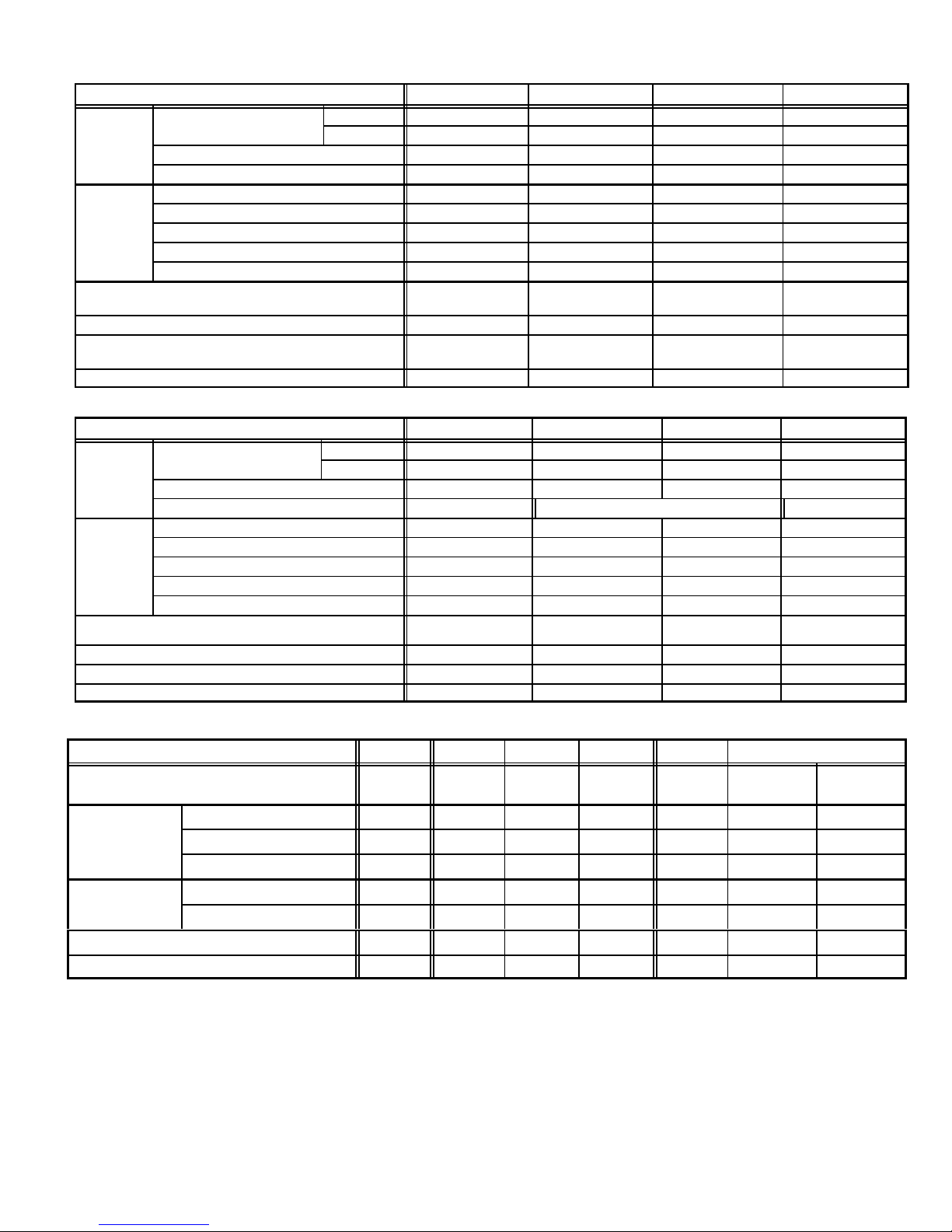

SPECIFICATIONS (contd.)

Condenser

Fan

Condenser

Fan

Condenser Coil

Model No. HS29-012 HS29-018 HS29-024 HS29-030

Outer coil 7.56 (0.70) 11.33 (1.05) 11.33 (1.05) 13.22 (1.23)

Inner coil - - - - - - - - - - - - - - - -

Condenser

Coil

Net face area - sq. ft. (m2)

Tube diameter in. (mm) & no. of rows 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1 5/16 (7.9) 1

Fins per inch (m) 22 (866) 22 (866) 22 (866) 18 (748)

Diameter in. (mm) & no. of blades 18 (457) 3 18 (457) 3 18 (457) 3 18 (457) 3

Motor hp (W) 1/6 (124) 1/6 (124) 1/6 (124) 1/6 (124)

Condenser

Cfm (L/s) 2400 (1135) 2400 (1135) 2400 (1135) 2545 (1201)

Rpm 1105 1105 1105 1110

Watts 180 180 180 195

*Refrigerant charge furnished (HCFC-22)

3 lbs. 1 oz.

(1.38 kg)

3 lbs. 7 oz.

(1.55 kg)

3 lbs. 10 oz.

(1.64 kg)

4 lbs. 1 oz.

(1.83 kg)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 5/8 (15.9) 5/8 (15.9)

5/8 (15.9) −1, −2 units

3/4 (19) −3 units

3/4 (19.1)

Shipping weight lbs. (kg) 1 package 146 (66) 146 (66) 148 (67) 140 (64)

*Refrigerant charge sufficient for 15 ft. (4.5 m) length of refrigerant lines. 3/8 x 5/16 in. (9.5 x 7.9 mm) adaptor furnished for liquid line connection.

SPECIFICATIONS (contd.)

Model No. HS29-036 HS29-042 HS29-048 HS29-060

Outer coil 15.11 (1.40) 15.11 (1.40) 15.11 (1.40) 15.11 (1.40)

Inner coil - - - - 5.40 (0.50) 5.40 (0.50) 14.40 (1.34)

Condenser

Coil

Net face area - sq. ft. (m2)

Tube diameter in. (mm) & no. of rows 5/16 (7.9) 1 5/16 (7.9) 1.37 5/16 (7.9) 1.37 5/16 (7.9) 2

Fins per inch (m) 22 (866) 18 (748) 18 (748)

Diameter in. (mm) & no. of blades 18 (457) 4 18 (457) 4 18 (457) 4 18 (457) 4

Motor hp (W) 1/6 (124) 1/6 (124) 1/3 (249) 1/3 (249)

Condenser

Cfm (L/s) 2520 (1190) 2610 (1232) 3115 (1470) 3010 (1420)

Rpm 1100 1105 1125 1125

Watts 200 200 325 315

*Refrigerant charge furnished (HCFC-22)

1 ph−4 lbs. 6 oz. (1.98 kg)

3 ph−4 lbs 13 oz. (2.17 kg)

1 ph−5 lbs. 7 oz. (2.45 kg)

3 ph−5 lbs 6 oz. (2.43

1ph 5 lbs. 8 oz. (2.48 kg)

3ph 6 lbs 0 oz. (2.72)

1 ph 8 lbs. 0 oz. (3.62 kg)

3 ph 7 lbs 7 oz. (3.36)

Liquid line in. (mm) o.d. connection (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line in. (mm) o.d. connection (sweat) 3/4 (19.1) 7/8 (22.2) 7/8 (22.2) 1-1/8 (28.6)

Shipping weight lbs. (kg) 1 package 145 (66) 158 (72) 191 (87) 207 (94)

*Refrigerant charge sufficient for 15 ft. (4.5 m) length of refrigerant lines.

ELECTRICAL DATA

Model No. HS29-141 HS29-211 HS29-261 HS29-311 HS29-411 HS29-413

Line voltage data 60 hz

208/230v

1ph

208/230v

1ph

Rated load amps 4.9 8.6 10.1 11.8 17.5 10.3 4.3

Compressor Power factor .97 .97 .96 .92 .90 .83 .83

Locked rotor amps 26.3 48.3 60.0 69.4 96.0 75.0 40.0

Condenser Coil

Fan Motor

Full load amps 1.1 1.1 1.1 1.1 1.1 1.1 0.55

Locked rotor amps 1.9 1.9 1.9 1.9 1.9 1.9 1.0

Rec. maximum fuse or circuit breaker size (amps) 15 15 20 25 40 20 10

*Minimum circuit ampacity 7.3 11.0 13.8 15.9 23.8 14.0 6.5

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

3ph

460v

3ph

Page 3

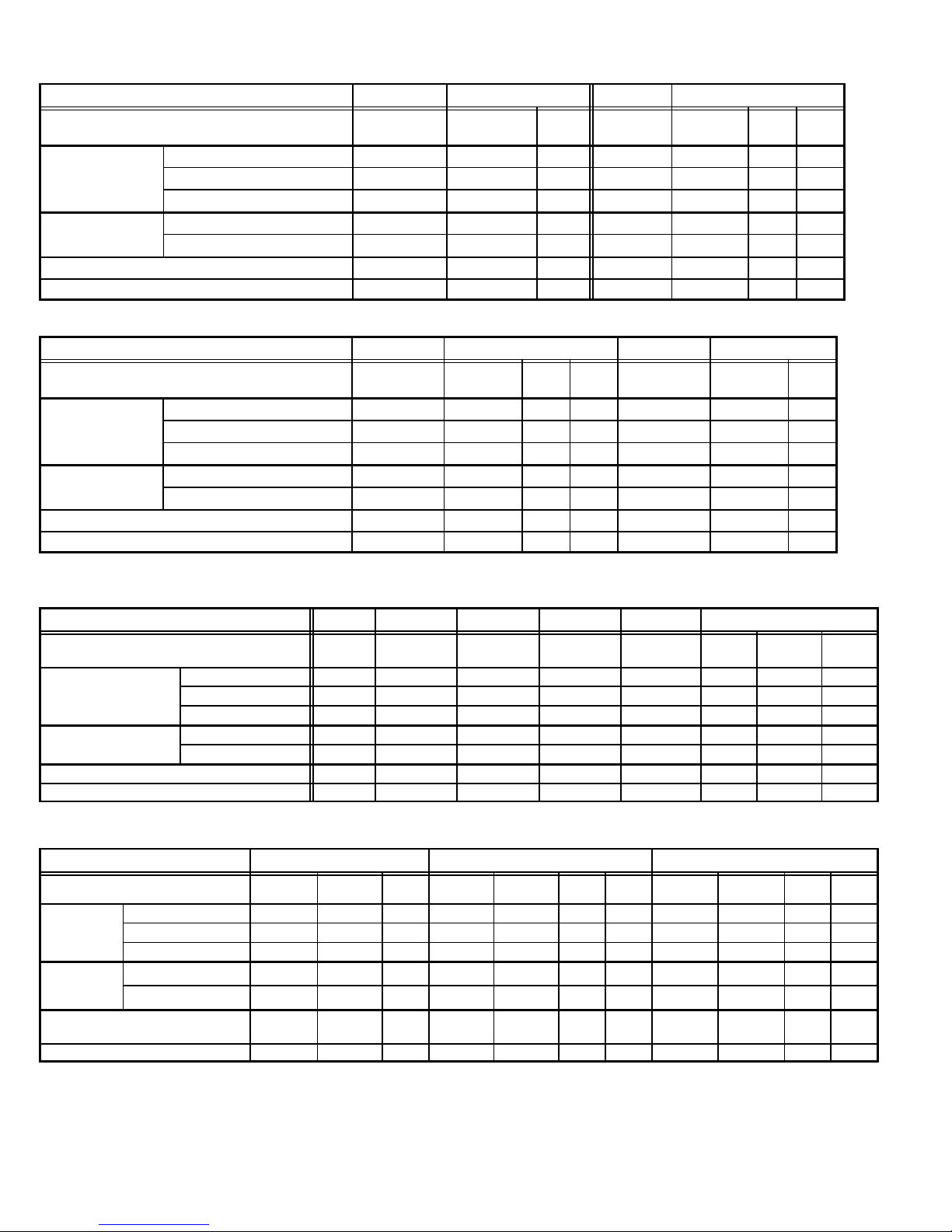

ELECTRICAL DATA

Condenser Coil

Condenser Coil

Condenser Coil

Model No. HS29-461 HS29-463 HS29-511 HS29-513

Line voltage data 60 hz

208/230v

1ph

208/230v

3ph

460v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

Rated load amps 17.5 12.8 6.4 23.4 14.0 7.1 5.8

Compressor Power factor .98 .93 .93 .98 .88 .88 .88

Locked rotor amps 92.0 87.0 44.0 110.0 91.0 46.0 37.0

Condenser Coil

Fan Motor

Full load amps 1.1 1.1 0.55 1.9 1.9 0.90 0.90

Locked rotor amps 1.9 1.9 1.0 4.1 4.1 2.1 2.1

Rec. maximum fuse or circuit breaker size (amps) 40 25 15 50 30 15 10

*Minimum circuit ampacity 23.0 17.1 8.6 31.2 19.4 9.8 8.2

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

ELECTRICAL DATA

Model No. HS29-651 HS29-653 HS29-681 HS29-683

Line voltage data 60 hz

208/230v

1ph

Rated load amps 26.9 17.3 9.0 7.1 27.1 18.6 7.9

Compressor Power factor .98 .86 .86 .86 .97 .86 .86

Locked rotor amps 123.0 128.0 64.0 51.0 175.0 128.0 63.0

Condenser Coil

Fan Motor

Full load amps 1.9 1.9 0.90 0.90 1.9 1.9 0.90

Locked rotor amps 4.1 4.1 2.1 2.1 4.1 2.1 2.1

Rec. maximum fuse or circuit breaker size (amps) 60 40 20 15 60 40 15

*Minimum circuit ampacity 35.5 23.5 12.2 9.8 35.8 24.2 10.8

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

208/230v

3ph

460v

3ph

575v

3ph

208/230v

1ph

208/230v

3ph

460v

575v

3ph

3ph

ELECTRICAL DATA

Model No. HS29-012 HS29-018 HS29-024−2 HS29-024−3 HS29-030 HS29-036

Line voltage data 60 hz 208/230v

1ph

Rated load amps 4.9 8.6 7.9 12.2 14.7 16.0 10.3 5.1

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230

v

1ph

208/230v

3ph

460v

Compressor Power factor .97 .97 .97 .96 .90 .91 .83 .83

Locked rotor amps 26.3 48.3 48.3 61.0 84.0 100.0 77.0 39.0

Condenser Coil

Fan Motor

Full load amps 1.1 1.1 1.1 1.1 1.1 1.1 1.1 0.55

Locked rotor amps 1.9 1.9 1.9 1.9 1.9 1.9 1.9 1.0

Rec. maximum fuse or circuit breaker size (amps) 15 20 15 25 30 35 20 10

*Minimum circuit ampacity 7.3 11.9 11.0 16.4 19.5 21.1 14.0 6.9

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

ELECTRICAL DATA

Model No. HS29−042 HS29-048 HS29-060

Line voltage data 60 hz

208/230v

1ph

Rated load amps 20.3 12.4 6.4 23.7 12.8 6.4 5.1 28.8 15.4 7.6 5.9

Compressor Power factor .84 .93 .93 .98 .88 .88 .88 .95 0.86 0.86 0.86

Locked rotor amps 127.0 88.0 44.0 129.0 91.0 46.0 37.0 169.0 124.0 59.6 49.4

Condenser

Coil

Fan Motor

Rec. maximum fuse or circuit breaker

size (amps)

Full load amps 1.1 1.1 .55 1.9 1.9 0.9 0.9 1.9 1.9 0.90 0.90

Locked rotor amps 1.9 1.9 1.0 4.1 4.1 2.1 2.1 4.1 4.1 2.1 2.1

40 25 15 50 30 15 10 60 35 15 10

*Minimum circuit ampacity 26.4 16.6 8.6 31.5 17.9 8.9 7.3 37.9 21.2 10.4 8.3

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

208/230v

3ph

460v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

575v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

3ph

575v

3ph

Page 4

I − UNIT INFORMATION

HS29 condensing units are available in 1, 1 -1/2, 2, 2 -1/2, 3, 3

-1/2, 4 and 5 ton capacities.

All major components (indoor blower/coil) must be matched according to Lennox recommendations for the compressor to be

covered under warranty. Refer to the Engineering Handbook

for approved system matchups. A misapplied system will

cause erratic operation and can result in early compressor failure.

II − UNIT COMPONENTS

Unit components are illustrated in figure 3.

DANGER

Electric Shock Hazard.

May cause injury or death.

Disconnect all remote electrical power

supplies berore opening unit panel. Unit

may have multiple power supplies.

Some units are equipped with single−

pole contactors. When unit is equipped

with a single−pole contactor, line voltage

is present at all components (even when

unit is not in operation).

3 − Transformer T5

Transformer T5 is used on all J" voltage units. T5 is used as a

step-down transformer for the outdoor fan motor. The transformer is located inside the unit control box (see figure 1). The

transformer is rated at 3.4 VA with a 575 volt primary and a 460

volt secondary.

4 − Start Capacitor C7

All HS29−461, 511, 651, 012, 018 and 024−2 units use a

start capacitor (C7) wired in parallel with the compressor

side of the dual capacitor. The capacitor is located inside

the unit control box (see figure 1). C7 is switched off by

potential relay (K31) when the compressor nears full

speed. See side of capacitor for MFD ratings.

5 − Fan Capacitor C1

The fans in three-phase HS29−413, −463, −513, −653,

−683, −036, −042, −048 and −060 units use permanent split

capacitor motors. A single capacitor C1 is used for the

fan motor. The capacitor is located inside the unit control

box (see figure 1). See side of capacitor for MFD ratings.

6 − Potential (Start) Relay K31

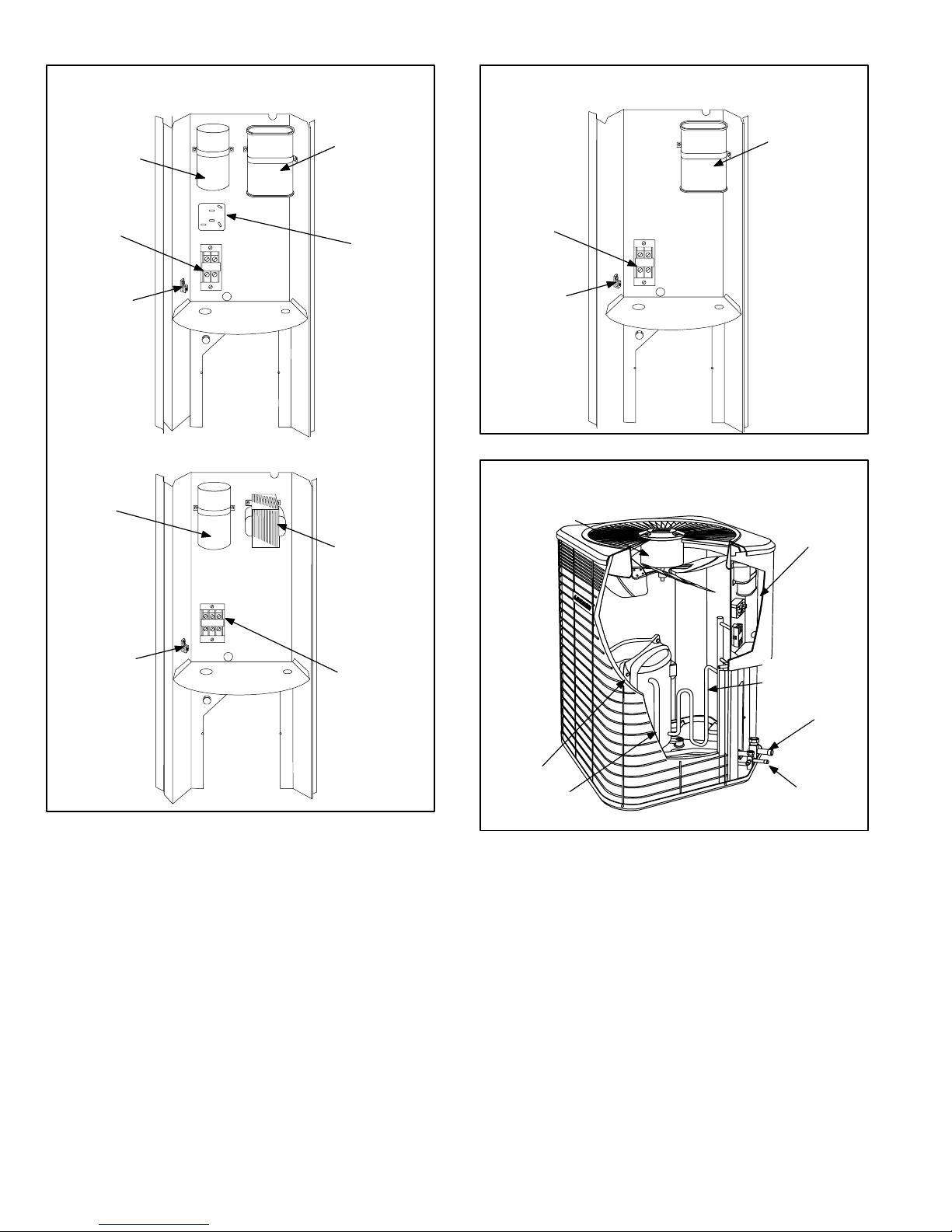

A − Control Box (Figure 1 and Figure 2)

Electrical openings are provided under the control box cover. Field thermostat wiring is made to color-coded pigtail

connections.

1 − Compressor Contactor K1

The compressor is energized by a contactor located in the

control box. See figure 1 and figure 2. Single−pole and twopole contactors are used in single-phase units. See wiring

diagrms for specific unit. Three-pole contactors are used in

three-phase units. K1 is energized by the indoor thermostat terminal Y1 (24V) when thermostat demand is present.

HS29 units are not equipped with a 24V transformer. All

24 VAC controls are powered by the indoor unit. Refer to

wiring diagram.

2 − Dual Capacitor C12

The compressor (scroll, rotary or reciprocating) and fan

in single-phase units use permanent split capacitor motors. The capacitor is located inside the unit control box

(see figure 1 and figure 2). A single dual" capacitor

(C12) is used for both the fan motor and the compressor

(see unit wiring diagram). The fan side and the compressor side of the capacitor have different MFD ratings and

must be exact when replacing. See side of capacitor for

ratings.

All HS29−461, 511, 651, 012, 018 and 024−2 units use a

potential relay which controls the operation of the starting circuit. The potential relay is located inside the unit control box

(see figure 1). The relay is normally closed when contactor

K1 is de-energized. When K1 energizes, the compressor im-

mediately begins start-up. K31 remains closed during compressor start-up and the start capacitor C7 remains in the cir-

cuit. When the compressor reaches 75% of its speed, K31 is

energized. When K31 energizes, the contacts open and

the start capacitor C7 is taken out of the circuit.

B − Compressor

(Rotary, Reciprocating and Scroll)

HS29−141 and −012 units utilize a rotary compressor.

HS29−018,−024−2, and −211 through −653 units utilize a

conventional reciprocating compressor. See ELEC-

TRICAL DATA tables or compressor nameplate for compressor specifications.

HS29−024−3 and HS29−030 through −060 units utilize a scroll

compressor. The scroll compressor design is simple, efficient

and requires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 4. The scrolls are located in the

top of the compressor can and the motor is located just below.

The oil level is immediately below the motor.

Page 5

HS29 SINGLE-PHASE UNIT CONTROL BOX

WITH NON−SCROLL COMPRESSOR

HS29 SINGLE−PHASE UNIT CONTROL BOX

WITH SCROLL COMPRESSOR

START

CAPACITOR

(C7)

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

DUAL CAPACITOR

RELAY (K31)

HS29 THREE-PHASE UNIT CONTROL BOX

FAN

CAPACITOR (C1)

TRANSFORMER

(T5) J" VOLT-

AGE UNITS ON LY

(C12)

POTENTIAL

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

HS29 UNIT COMPONENTS

OUTDOOR

FAN/MOTOR

DUAL CAPACITOR

(C12)

FIGURE 2

CONTROL

BOX

GROUNDING

LUG

FIGURE 1

COMPRESSOR

CONTACTOR

(K1)

COMPRESSOR

SUCTION

LINE

FIGURE 3

DISCHARGE

LINE

SUCTION LINE

SERVICE VALVE

LIQUID LINE

SERVICE VALVE

Page 6

Loading...

Loading...