Lennox HS27-024, HS27-042, HS27 Series, HS27-030, HS27-036 Installation Instructions Manual

INSTALLATION

2000 Lennox Industries Inc.

Dallas, Texas, USA

HS27 Outdoor Unit

HS27 outdoor units are designed for expansion valve systems only. They are not designed for RFC systems. Refer to

Lennox engineering handbook for expansion valve kits

which must be ordered separately.

Shipping & Packing List

1 − Assembled HS27 outdoor unit

2 − Grommets (for liquid and vapor lines)

1 − Bushing (for low voltage wiring)

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of refrigerant (CFC’s and HCFC’s) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incarceration may be levied for noncompliance.

INSTRUCTIONS

HS27 SERIES UNITS

CONDENSING UNITS

504,669M

02/04

Supersedes 12/02

Table of Contents

HS27 Outdoor Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Piping 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Metering Device 9. . . . . . . . . . . . . . . . . . . . .

Manifold Gauge Set 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Valves 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Testing 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evacuation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Operation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 14. . . . . . . . . . . . . . . . . . . . . . . . . .

Start−up & Performance Check List 15. . . . . . . . . . . . . . .

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

General Information

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

WARNING

This product and/or the indoor unit it is matched with

may contain fiberglass wool.

Disturbing the insulation during installation, maintenance, or repair will expose you to fiberglass wool

dust. Breathing this may cause lung cancer. (Fiberglass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

Litho U.S.A.

02/04

*2P0204*

Page 1

504,669M

*P504669M*

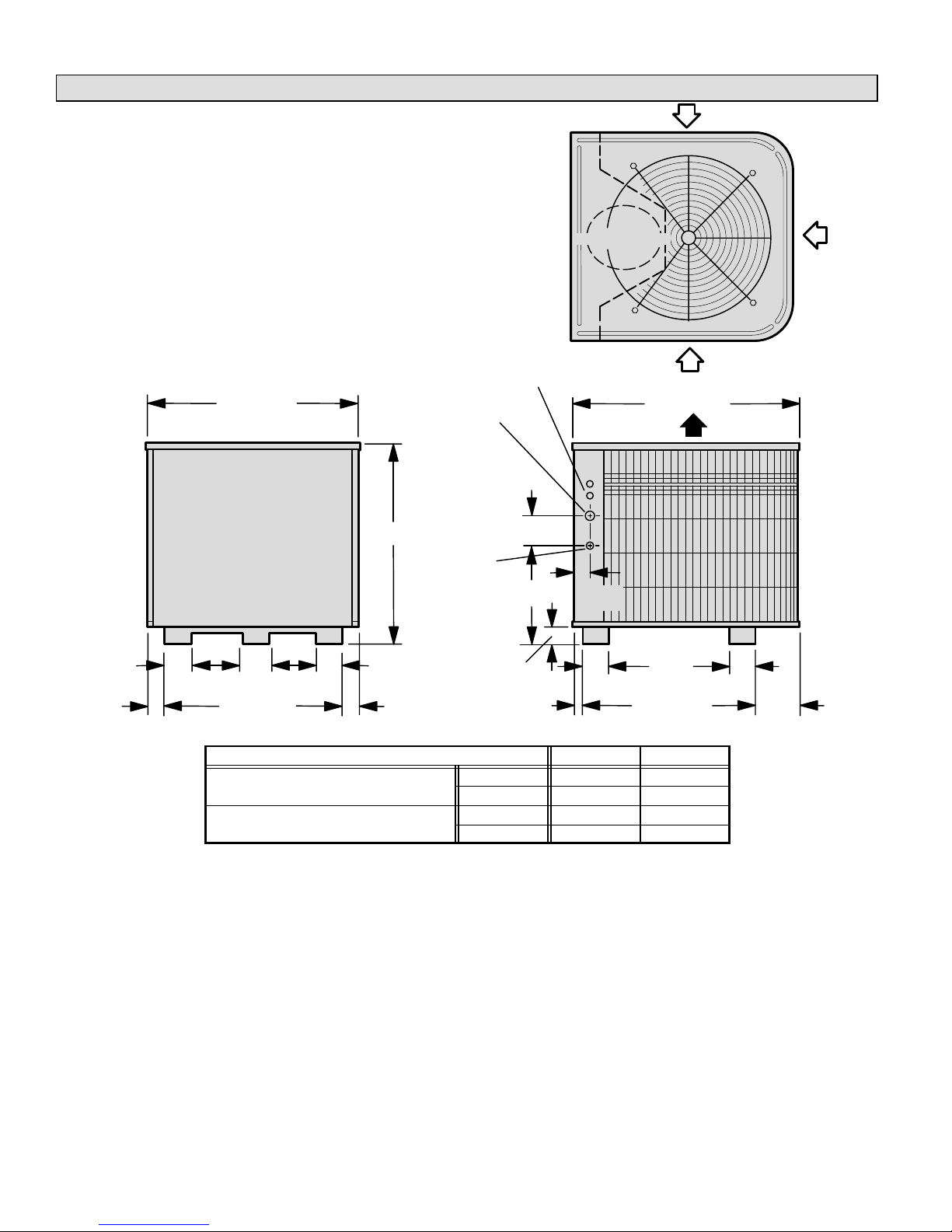

Unit Dimensions − inches (mm)

HS27-024

HS27-036

airinlet

inlet

COMPRESSOR

air

2

(51)

3-7/8

(98)

32-1/8 (816)

7-1/2

(191)

4-7/8 (22)

28-1/8 (714)

HS27-024

HS27-030

HS27-036

HS27-042

7-1/2

(191)

electrical

3-7/8

(98)

(51)

inlets

vapor line

inlet

A

liquid

line inlet

4-1/2 (114)

B

2-3/4 (70)

2

1-3/8

(35)

DISCHARGE AIR

2-9/16

(65)

4

(102)

Top View

34-1/16 (865)

18-5/8

(473)

26-5/8 (676)

Side ViewAccess View

Model No. A B

in. 30-7/8 12-3/4

mm 784 324

in. 40-7/8 19-3/4

mm 1038 502

airinlet

4

(102)

6-1/16

(154)

Page 2

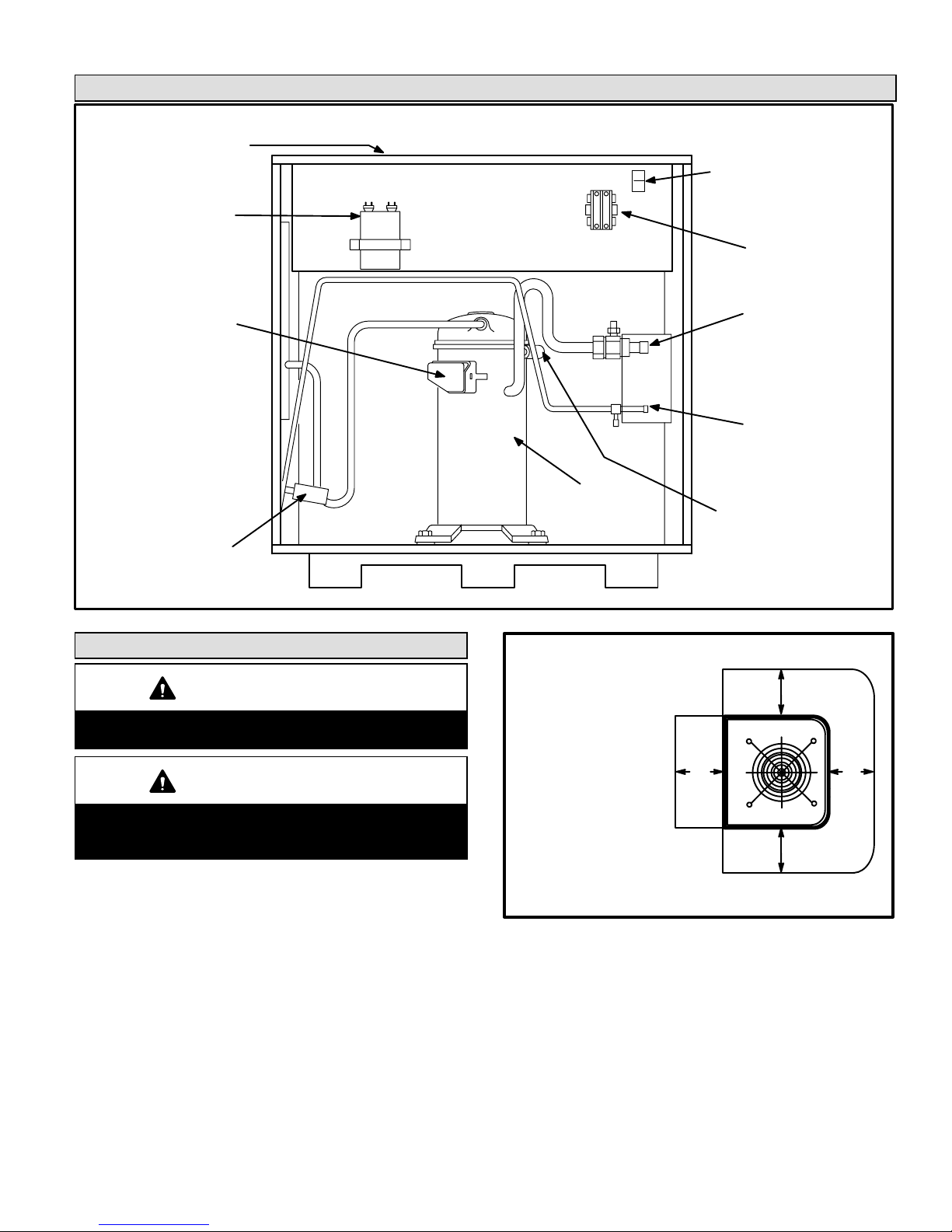

Parts Arrangement

outdoor fan

(not shown)

top of cabinet

run capacitor

ground lug

contactor

terminal box

high pressure

switch

Figure 1

Setting the Unit

CAUTION

In order to avoid injury, take proper precaution when

lifting heavy objects.

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care when servicing unit to avoid accidental

contact with sharp edges.

Refer to unit dimensions for sizing mounting slab, platforms, or supports. Refer to figure 2 for installation clearances.

vapor valve

and gauge port

liquid line

service valve

and gauge port

compressor

low pressure

switch

Installation Clearances

NOTE − A service access

clearance of 30" (762 mm)

must be maintained in front

of the service access panel.

Clearance to one side must

be 36" (914 mm). Clearance

to one of the remaining two

sides may be 12" (304 mm)

and the final side may be 6"

(152 mm).

NOTE − A clearance of 24" (610 mm)

must be maintained between two units.

NOTE − 48" (1219 mm) clearance required on top

of unit. Maximum soffit overhang is 36" (914 mm).

36"

(914 mm)

*36"

(914 mm)

*36"

(914 mm)

36"

(914 mm)

Figure 2

Page 3

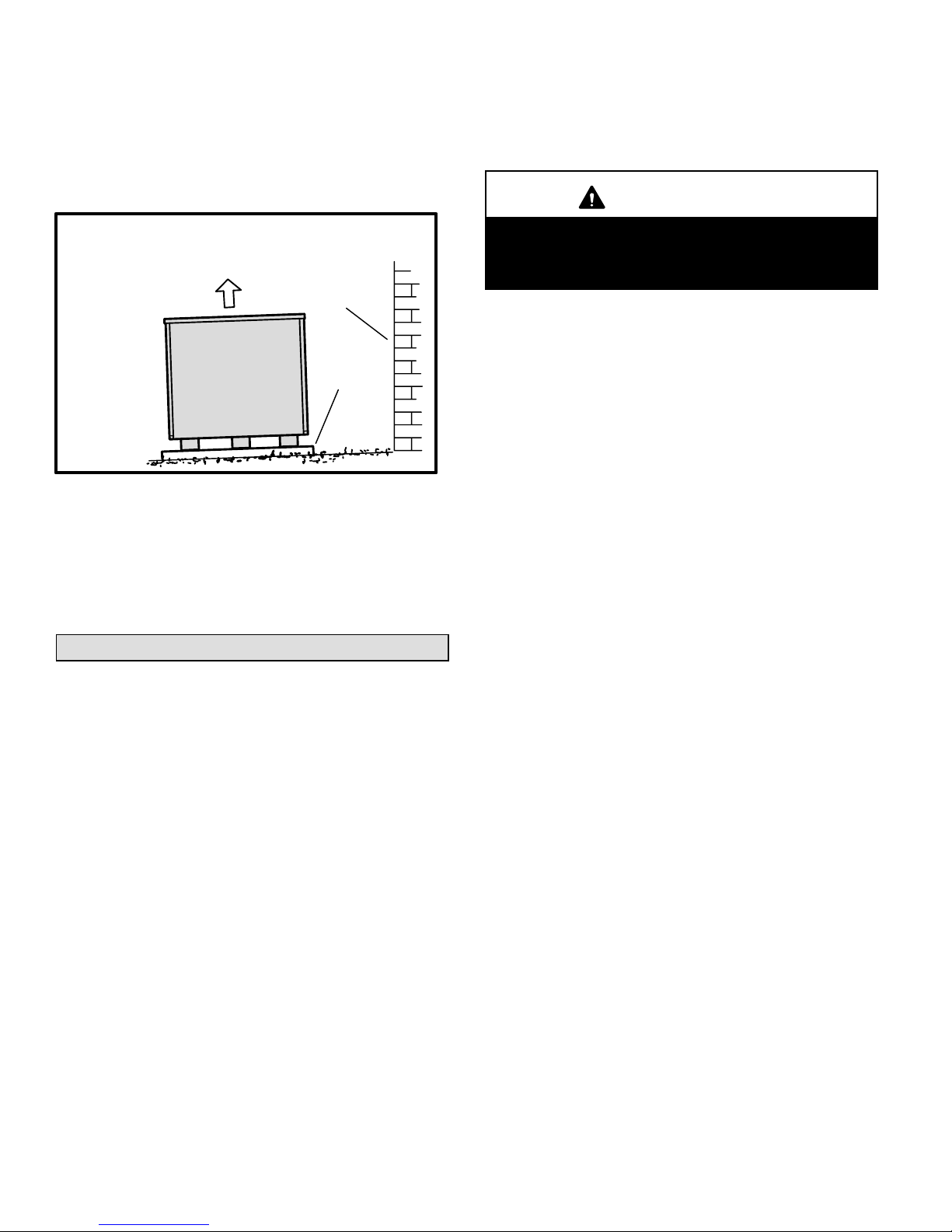

A − Slab Mounting

When you install the unit at grade level, the top of the slab

should be high enough above the grade so that water from

higher ground will not collect around the unit. See figure 3.

Slab should have a slope tolerance away from the building

of 2 degrees or 2 inches per 5 feet (51 mm per 1.5 m).

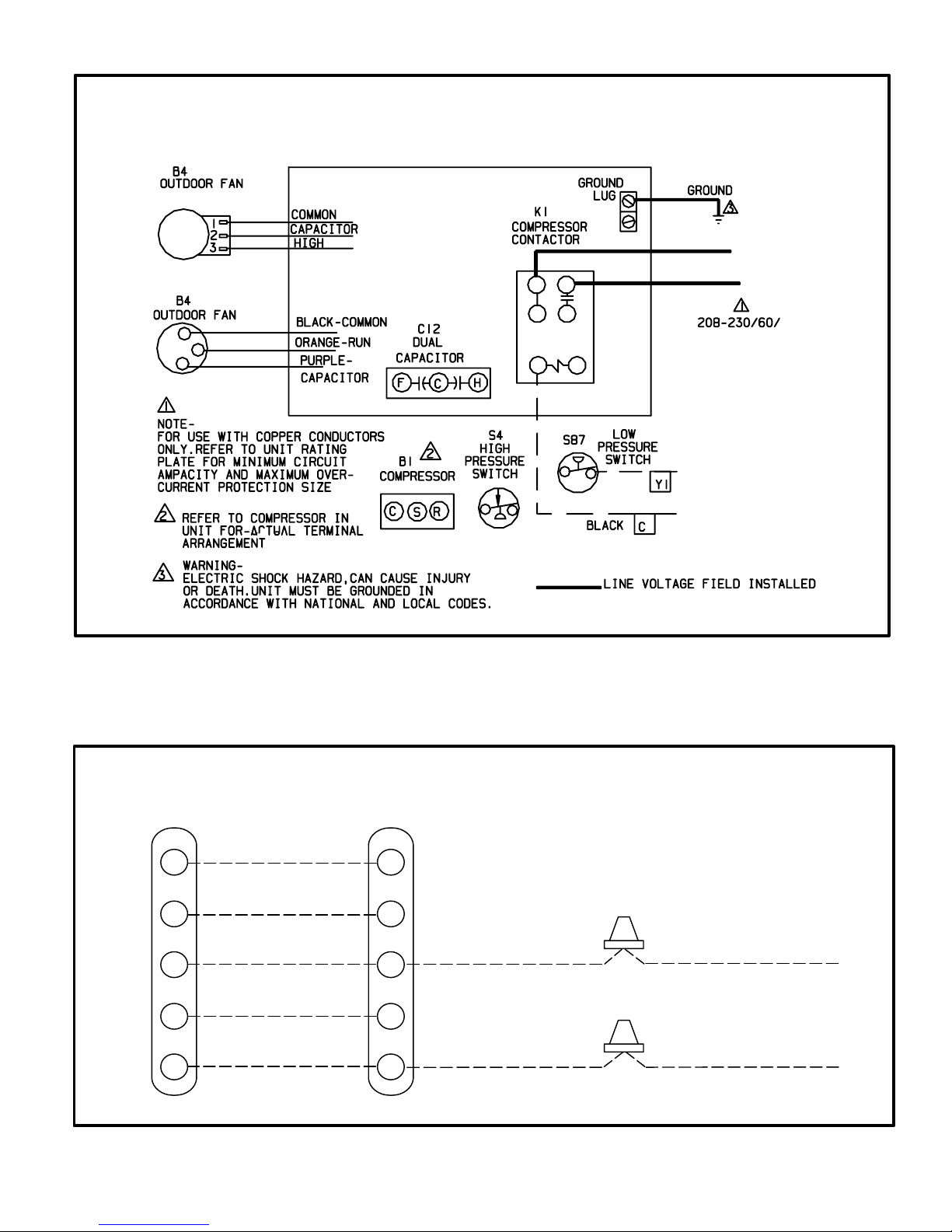

Refer to the furnace or blower coil installation instructions

for additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

WARNING

2 degrees or

2 in. per 5 foot

(51 mm per 1.5 m)

slope tolerance away

from building structure

ground level

Slab Mounting

discharge air

building

structure

mounting

slab

Figure 3

B − Roof Mounting

Install unit at a minimum of 4 inches above surface of the roof.

Care must be taken to ensure weight of unit is properly distributed over roof joists and rafters. Either redwood or steel supports are recommended.

Electrical

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Unit must be grounded in accordance with

national and local codes.

Electric Shock Hazard.

Can cause injury or death.

1. Install line voltage power supply to unit from a properly

sized disconnect switch.

2. Ground unit at unit disconnect switch or to an earth

ground.

NOTE − To facilitate conduit, a hole is in the bottom of

the control box. Connect conduit to the control box us

ing a proper conduit fitting.

NOTE − Units are approved for use only with copper

conductors.

24V, Class II circuit connections are made in the low

voltage junction box. Refer to figure 4 for field wiring

diagram.

NOTE − A complete unit wiring diagram is located in

side the unit control box cover.

3. Install room thermostat (ordered separately) on an inside wall approximately in the center of the conditioned

area and 5 feet (1.5 m) from the floor. It should not be

installed on an outside wall or where it can be effected

by sunlight, drafts or vibrations.

4. Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit. See figure 5.

Page 4

(LEADLESS)

Outdoor Unit

Field Wiring Diagram

YELLOW

Thermostat Designations

Thermostat Furnace

R

W1

Y

G

C

power

heat

cooling

indoor blower

common

R

W

Y

G

C

Figure 4

NOTE − see unit wiring diagram for

power supply connections.

Outdoor Unit

Y1 Outdoor Unit

C Outdoor Unit

NOTE − If the indoor unit is not equipped with blower relay, it must be field−provided and installed (P−8−3251 or equivalent).

Figure 5

Page 5

Loading...

Loading...