SERVICE

INFORMATION

Corp. 9622−L12

Revised 04−2002

HS26 SERIES UNITS

The HS26 is a high efficiency residential split−system con

densing unit which features a scroll compressor. Early

model HS26 units (−261,−311,−411, and −461) are available

in sizes ranging from 2 through 3−1/2 tons. Late model

HS26 units (−018, −024, −030, −036, −042, −048 and −060)

are available in sizes ranging from 1−1/2 through 5 tons.

The series is designed for use with an expansion valve in

the indoor unit.This manual is divided into sections which

discuss the major components, refrigerant system, charg

ing procedure, maintenance and operation sequence. In

formation in this manual covers both early and late model

HS26 units.

All specifications in this manual are subject to change.

UNIT

HS26

EARLY/LATE

MODEL SERIES

Litho U.S.A.

Late Model

HS26 shown

SPECIFICATIONS (Early Model)

Model No. HS26−261 HS26−311 HS26−411 HS26−461

Face area (sq.ft.)

Outdoor

Coil

Condenser

Fan

HCFC−22 (charge furnished)

Liquid line connection

Suction line connection

*Refrigerant charge sufficient for 25 ft. (7.6 m) length of refrigerant lines.

outer / inner

Tube diameter (in.)

No. of Rows

Fins per inch

Diameter (in.)

No. of Blades

Motor hp

Cfm

RPM

Watts

11.8/5.4 15.9/5.5 15.9/15.3 21.6/20.8

3/8 3/8 3/8 3/8

1.36 1.36 2.0 2.0

20 20 20 20

24 24 24 24

3333

1/6 1/6 1/6 1/6

3150 3150 3000 3230

820 820 820 820

210 210 230 205

7lbs. 11oz. 8lbs. 1oz. 9lbs. 0oz. 11lbs. 3oz.

3/8 3/8 3/8 3/8

3/4 3/4 3/4 11/8

ELECTRICAL DATA (Early Model)

Model No.

Line voltage data − 60hz./1 phase

Rated load amps

Compressor

Condenser

Fan Motor

Max fuse or c.b. size (amps)

*Minimum circuit ampacity

*Refer to National Electrical Code Manual to determine wire, fuse and disconnect size requirements.

NOTE − Extremes of operating range are plus 10% and minus 5% of line voltage

Power factor

Locked rotor amps

Full load amps

Locked rotor amps

HS26−261 HS26−311 HS26−411 HS26−461

208/230V 208/230V 208/230V 208/230V

11.6 13.5 18.0 20

.96 .96 .96 .97

62.5 76.0 90.5 107

1.1 1.1 1.1 1.1

2.0 2.0 2.0 2.0

25 30 40 45

15.6 18.0 23.6 26.1

Page 1

1996 Lennox Industries Inc.

Net face area

Condenser

Coil

Cond

Condenser Coil

Condenser Coil

Coil

SPECIFICATIONS (Late Model)

Model No. HS26018 HS26024 HS26030 HS26036 HS26042 HS26048 HS26060

Net face area

sq. ft. (m2)

Tube diameter in. (mm) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9)

No. of rows 1.48 1.48 1.36 1.86 1.86 1.75 2

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866)

Outer coil 11.9 (1.11) 11.9 (1.11) 16.0 (1.59) 16.0 (1.59) 16.0 (1.59) 18.2 (1.69) 21.6 (2.01)

Inner coil 5.5 (0.51) 5.5 (0.51) 5.6 (0.52) 13.3 (1.24) 13.3 (1.24) 13.3 (1.24) 20.8 (1.93)

Dia. − in. (mm) no. of blades 20 (508) − 4 20 (508) − 4 24 (610) − 3 24 (610) − 3 24 (610) − 3

Motor hp (W) 1/10 (75) 1/6 (124) 1/6 (124) 1/6 (124) 1/6 (124) 1/4 (187) 1/4 (187)

enser

Fan Cfm (L/s) 2500 (1180) 2450 (1155) 3150 (1485) 3150 (1485) 3000 (1415) 3900 (1840) 4200 (1980)

Rpm 825 825 825 825 825 820 820

Watts 160 210 225 225 230 310 350

*Refrigerant HCFC22 charge furnished

Liquid line (o.d.) in. (mm) sweat 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line (o.d.) in. (mm) sweat 5/8 (16) 3/4 (19) 3/4 (19) 3/4 (19) 7/8 (22.2) 7/8 (22.2) 11/8 (28.6)

Shipping weight lbs. (kg) 1 package 177 (80) 185 (84) 192 (87) 221 (100) 231 (105) 274 (124) 308 (140)

*Refrigerant charge sufficient for 25 ft. (7.6 m) length of refrigerant lines.

4 lbs. 1 oz.

(1.84 kg)

4 lbs. 1 oz.

(1.84 kg)

5 lbs. 1 oz.

(2.30 kg)

5 lbs. 13 oz.

(2.64 kg)

6 lbs. 11 oz.

(3.03 kg)

24 (610) 424 (610)

7 lbs. 5 oz.

(3.32 kg)

4

10 lbs. 8 oz.

(4.76 kg)

ELECTRICAL DATA (Late Model)

Model No. HS26018 HS26024 HS26030 HS26036 HS26042

Line voltage data 60hz

Rated load amps 8.4 10.3 13.5 16.0 10.3 18.0 12.5

Compressor Power factor 0.97 0.96 0.96 0.96 0.82 0.94 0.82

Locked rotor amps 47 56 72.5 88 77 104 88

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 15 20 30 35 20 40 25

*Minimum circuit ampacity 13 14 18 21.3 14 23.6 16.4

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 0.8 1.1 1.1 1.1 1.1 1.1 1.1

Locked rotor amps 1.6 2.0 2.0 2.0 2.0 2.0 2.0

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

3ph

208/230v

1ph

208/230v

3ph

ELECTRICAL DATA (Late Model)

Model No. HS26048 HS26060

Line voltage data 60hz

Rated load amps 23.7 13.5 7.4 28.8 17.4 9.0

Compressor Power factor .97 .87 .87 .97 .85 .85

Locked rotor amps 129 99 49.5 169 123 62

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 50 30 15 60 40 20

*Minimum circuit ampacity 31.4 18.6 10.4 37.7 23.5 12.4

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 1.7 1.7 1.1 1.7 1.7 1.1

Locked rotor amps 3.1 3.1 2.2 3.1 3.1 2.2

208/230v

1ph

208/230v

3ph

460v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

Page 2

DISCHARGE

SUCTION

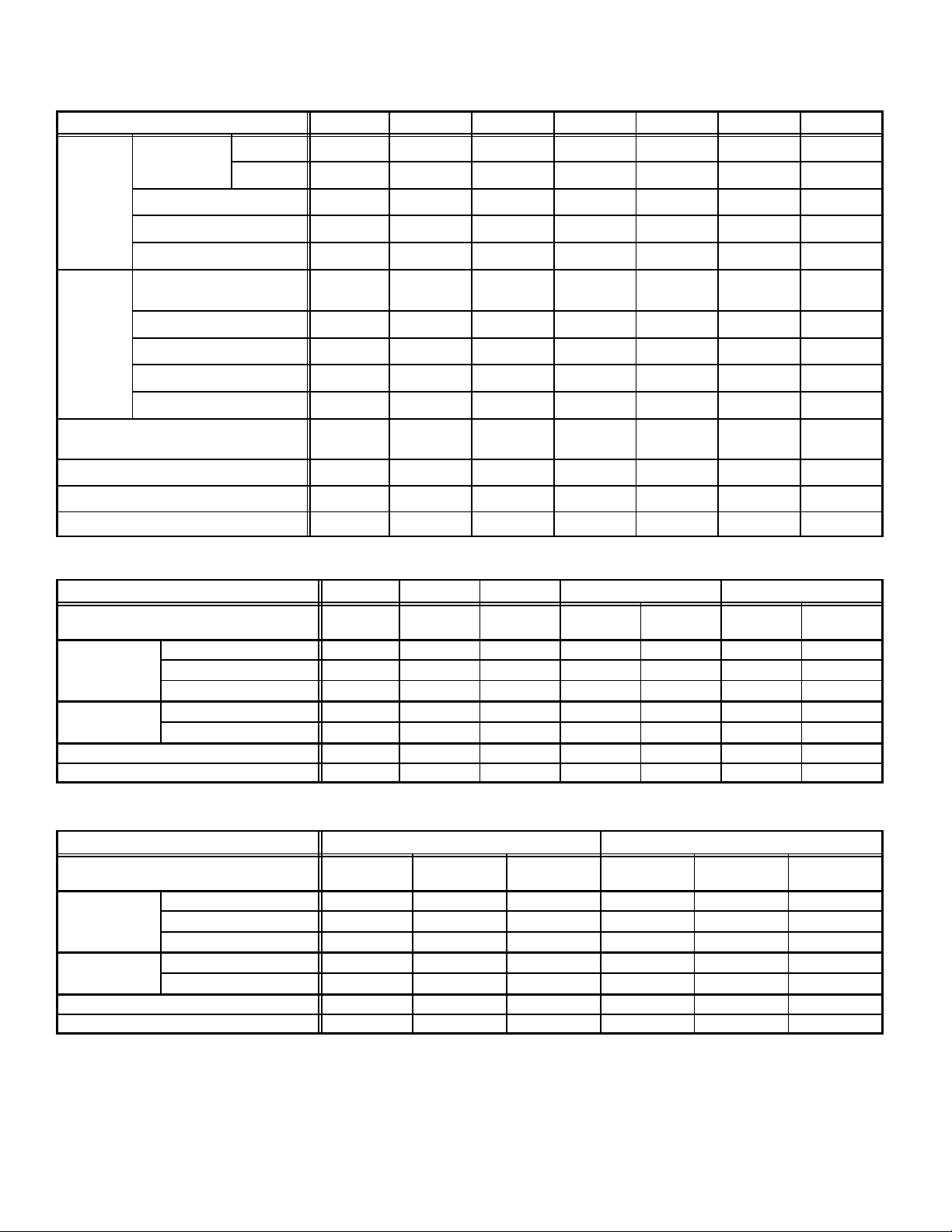

SCROLL COMPRESSOR

SCROLL FORM

CROSS−SECTION OF SCROLLS

DISCHARGE

DISCHARGE

PRESSURE

FIGURE 2

STATIONARY SCROLL

SUCTION

Early Model HS26

Compressor shown

FIGURE 1

I−APPLICATION

All major components (indoor blower and coil) must be

matched according to Lennox recommendations for the

compressor to be covered under warranty. Refer to the

Engineering Handbook for approved system matchups. A

misapplied system will cause erratic operation and can re

sult in early compressor failure.

II−SCROLL COMPRESSOR

The scroll compressor design is simple, efficient and re

quires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 1.The scrolls are located in

the top of the compressor can and the motor is located just

below. The oil level is immediately below the motor.

The scroll is a simple compression concept centered

around the unique spiral shape of the scroll and its inherent

properties. Figure 2 shows the basic scroll form. Two iden

tical scrolls are mated together forming concentric spiral

shapes (figure 3 ). One scroll remains stationary, while the

other is allowed to orbit" (figure 4). Note that the orbiting

scroll does not rotate or turn but merely orbits" the station

ary scroll.

TIPS SEALED BY

DISCHARGE PRESSURE

ORBITING SCROLL

FIGURE 3

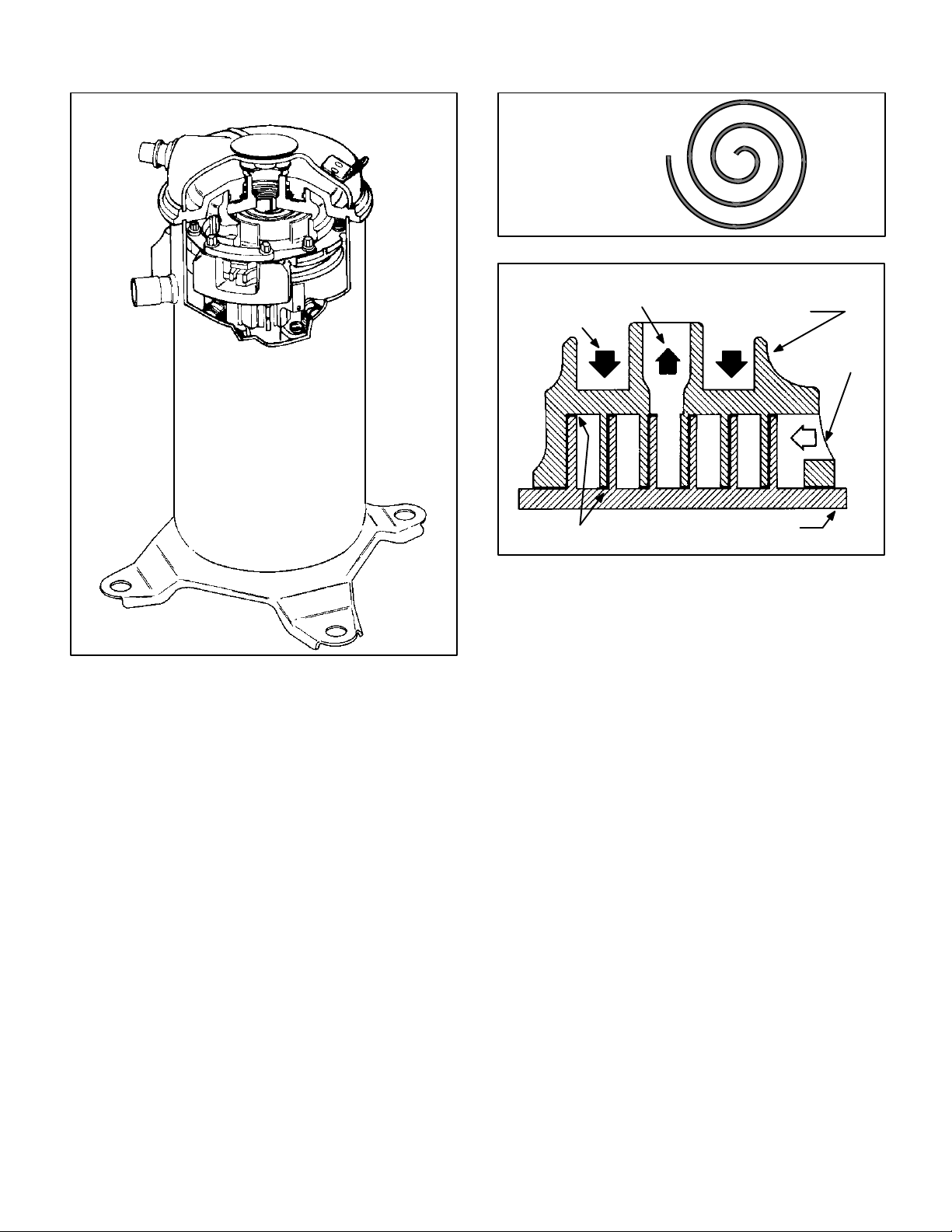

The counterclockwise orbiting scroll draws gas into the out

er crescent shaped gas pocket created by the two scrolls

(figure 4 − 1). The centrifugal action of the orbiting scroll

seals off the flanks of the scrolls (figure 4 − 2). As the orbiting

motion continues, the gas is forced toward the center of the

scroll and the gas pocket becomes compressed (figure 4

−3). When the compressed gas reaches the center, it is dis

charged vertically into a chamber and discharge port in the

top of the compressor (figure1). The discharge pressure

forcing down on the top scroll helps seal off the upper and

lower edges (tips) of the scrolls (figure 3 ). During a single

orbit, several pockets of gas are compressed simultaneous

ly providing smooth continuous compression.

The scroll compressor is tolerant to the effects of liquid re

turn. If liquid enters the scrolls, the orbiting scroll is allowed

to separate from the stationary scroll. The liquid is worked

toward the center of the scroll and is discharged. If the

compressor is replaced, conventional Lennox cleanup

practices must be used.

Due to its efficiency, the scroll compressor is capable of

drawing a much deeper vacuum than reciprocating com

pressors. Deep vacuum operation can cause internal fu

site arcing resulting in damaged internal parts and will re

sult in compressor failure. Never use a scroll compressor

for evacuating or pumping−down" the system. This type of

damage can be detected and will result in denial of warran

ty claims.

NOTE − During operation, the head of a scroll compressor

may be hot since it is in constant contact with discharge

gas.

Page 3

SUCTION

POCKET

HOW A SCROLL WORKS

MOVEMENT OF ORBIT

SUCTION

ORBITING

SCROLL

SUCTION

INTERMEDIATE

PRESSURE

GAS

CRESCENT

SHAPED GAS

POCKET

12

FLANKS

STATIONARY SCROLL

SUCTION

SEALED BY

CENTRIFUGAL

FORCE

SUCTION

34

HIGH

PRESSURE

GAS

FIGURE4

III−UNIT COMPONENTS

A−Transformer

The contactor coil, time delay and temperature sensor

are all energized by 24VAC supplied by the indoor unit.

All other controls in the outdoor unit are powered by line

voltage. Refer to unit wiring diagram. The HS26 is not

equipped with an internal line voltage to 24V transform

er.

B−Contactor

The compressor is energized by a contactor located in the

control box. Early model units use single−pole contactors.Late

model single−phase units use single pole and two−pole con

tactors. See wiring diagrams for specific unit. Late model

three−phase units use three−pole contactors. The contactor is

energized by indoor thermostat terminal Y when thermostat

demand is present.

DISCHARGE

POCKET

CAUTION

Some HS26 units use single−pole contactors. One

leg of the compressor, capacitor and condenser

fan are connected to line voltage at all times. Po

tential exists for electrical shock resulting in inju

ry or death. Remove all power at disconnect be

fore servicing

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit instal

lation and service to protect the unit’s electronic

controls. Precautions will help to avoid control

exposure to electrostatic discharge by putting

the unit, the control and the technician at the

same electrostatic potential. Neutralize electro

static charge by touching hand and all tools on an

unpainted unit surface before performing any

service procedure.

Page 4

C−TD1−1 Time Delay (Early Models)

Some early model HS26 units are equipped with a Lennox−

built TD1−1 time delay located in the control box (figure 5).

The time delay is electrically connected between thermostat

terminal Y and the compressor contactor. On initial thermo

stat demand, the compressor contactor is delayed for 8.5

seconds. At the end of the delay, the compressor is allowed

to energize. When thermostat demand is satisfied, the time

delay opens the circuit to the compressor contactor coil and

the compressor is de−energized.

The time delay performs no other functions. Without the

delay it would be possible to short cycle the compressor. A

scroll compressor, when short cycled, can run backward if

head pressure is still high. It does not harm a scroll com

pressor to run backward, but it could cause a nuisance trip

of safety limits (internal overload). For this reason, if a

TD1−1 delay should fail, it must be replaced. Do not bypass

the control.

D−TOC Timed Off Control

(Early and Late Models)

Some early and all late model HS26 units are equipped with

a TOC, timed off control.The TOC is located in the control

box (figure 6). The time delay is electrically connected be

tween thermostat terminal Y and the compressor contactor.

Between cycles, the compressor contactor is delayed for 5

minutes + 2 minutes. At the end of the delay, the compres

sor is allowed to energize. When thermostat demand is sat

isfied, the time delay opens the circuit to the compressor

contactor coil and the compressor is de−energized. Without

the time delay it would be possible to short cycle the com

pressor. A scroll compressor, when short cycled, can run

backward if head pressure is still high. It does not harm a

scroll compressor to run backward, but it could cause a nui

sance tripout of safety limits. For this reason, if a TOC fails it

must be replaced.

DANGER

DO NOT ATTEMPT TO REPAIR THE TD1−1 OR THE

TOC CONTROL. UNSAFE OPERATION WILL RE

SULT. IF THE CONTROL IS FOUND TO BE INOP

ERATIVE, SIMPLY REPLACE IT.

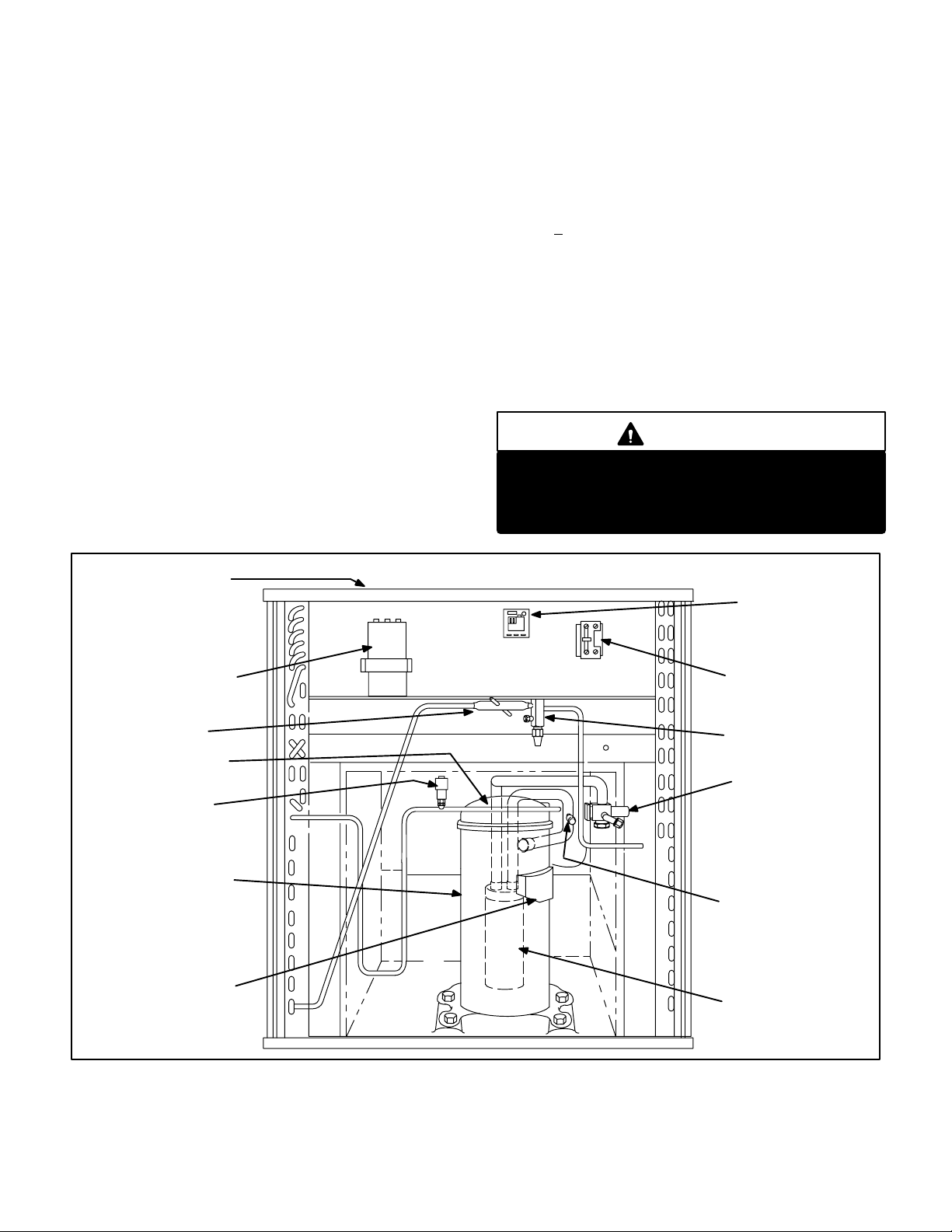

CONDENSER FAN

(NOT SHOWN)

TOP OF CABINET

DUAL CAPACITOR

THERMOMETER

WELL

COMPRESSOR

TEMPERATURE

SENSOR

HIGH

PRESSURE

SWITCH

COMPRESSOR

COMPRESSOR

TERMINAL BOX

HS26 UNIT COMPONENTS (EARLY MODEL)

TD−1 TIME DELAY

OR T.O.C. TIMED OFF

CONTROL

CONTACTOR

LIQUID LINE

SERVICE VALVE

AND GAUGE PORT

SUCTION

VALV E

AND GAUGE PORT

LOW PRES

SURE SWITCH

ACCUMULATOR

(411, 461 only

all others equipped

with suction muffler)

FIGURE 5

Page 5

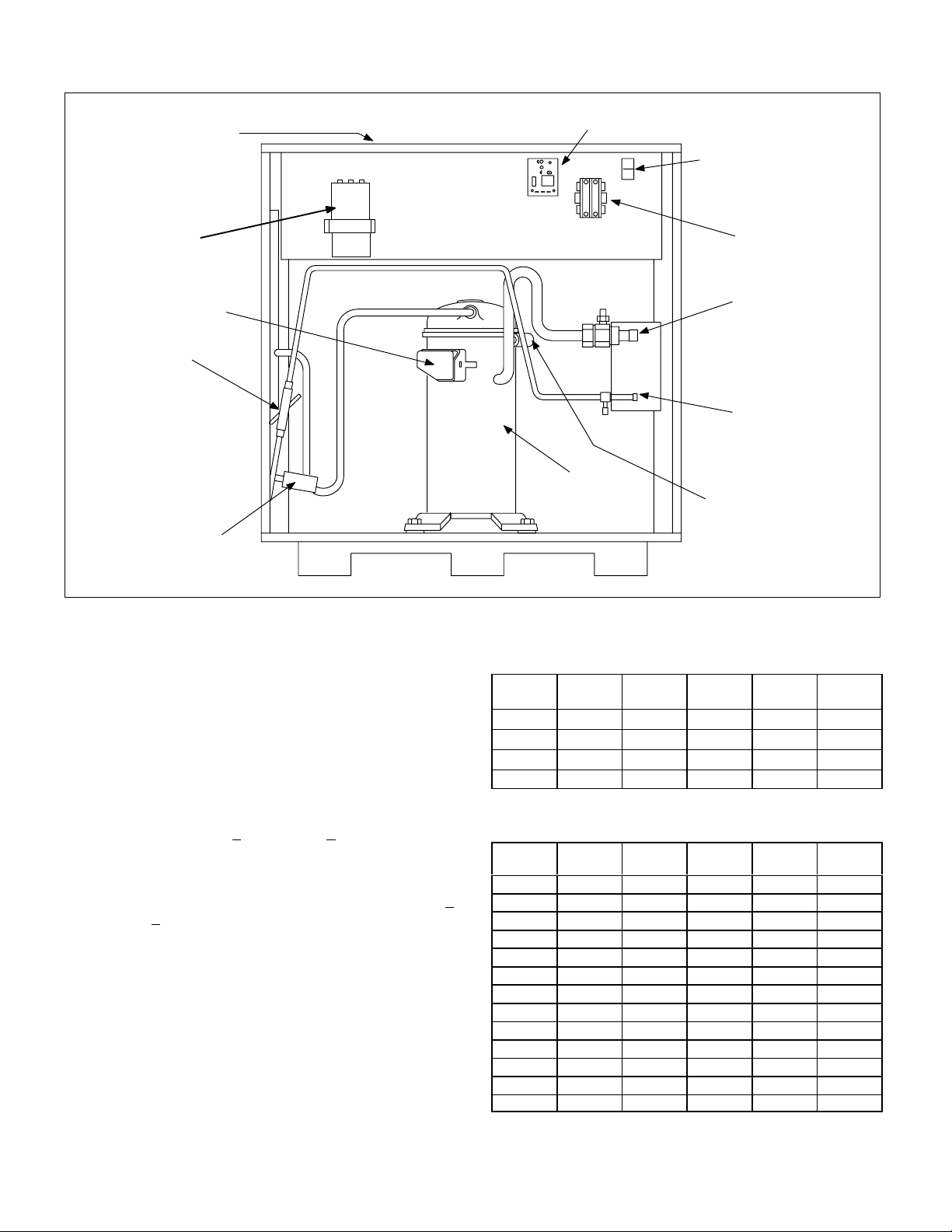

CONDENSER FAN

(NOT SHOWN)

TOP OF CABINET

PARTS ARRANGEMENT FOR HS26 (LATE MODEL)

TIMED OFF CONTROL (TOC)

GROUND LUG

DUAL CAPACITOR

TERMINAL BOX

THERMOME

TER

WELL

HIGH PRESSURE

SWITCH

FIGURE 6

E−Compressor

Tables1 and 2 show the specifications for compressors

used in HS26 series units.

F−Compressor High Temperature Limit

(Early Models)

Each scroll compressor in the HS26−261, −311, −411, −461

is equipped with a compressor high temperature limit lo

cated on the outside top of the compressor. The sensor is a

SPST thermostat which opens when the discharge tem

perature exceeds 280_F + 8_F (138_C + 4.5_C) on a tem

perature rise. When the switch opens, the circuit to the

compressor contactor and the time delay is de−energized

and the unit shuts off. The switch automatically resets

when the compressor temperature drops below 130_F +

14_F. (54_C + 8_C)

The sensor can be accessed by prying off the snap plug on

top of the compressor (see figure 7). Make sure to securely

seal the limit after replacement. The limit pigtails are lo

cated inside the unit control box. Figure 8 shows the ar

rangement of compressor line voltage terminals and dis

charge sensor pigtails.

CONTACTOR

SUCTION VALVE

AND GAUGE PORT

LIQUID LINE

SERVICE VALVE

AND GAUGE

PORT

COMPRESSOR

LOW PRESSURE

SWITCH

Table 1 (Early Models)

HS 26

Unit

−261 208/230 1 62.5 11.6 28*

−311 208/230 1 76.0 13.5 28*

−411 208/230 1 90.5 18.0 34*

−461 208/230 1 107 20.0 38*

*Shipped with conventional white oil (Sontex 200LT). 3GS oil may be

used if additional oil is required.

Vac Phase LRA RLA Oil fl.oz.

Table 2 (Late Models)

HS26

Unit

−018 208/230 1 47.0 8.4 38*

−024 208/230 1 56.0 10.3 30*

−030 208/230 1 72.5 13.5 30*

−036 208/230 1 88.0 16.0 42*

−042 208/230 1 104.0 18.0 42*

−048 208/230 1 129.0 23.7 53*

−060 208/230 1 169.0 28.8 50*

−036 208/230 3 88.8 10.3 42*

−042 208/230 3 77.0 12.5 42*

−048 208/230 3 99.0 13.5 53*

−048 460 3 49.5 7.4 53*

−060 208/230 3 123.0 17.4 53*

−060 460 3 62.0 9.0 53*

*Shipped with conventional white oil (Sontex 200LT). 3GS oil may be

used if additional oil is required.

Vac Phase LRA RLA Oil fl. oz.

Page 6

Loading...

Loading...