SERVICE

INFORMATION

Corp. 9622−L12

Revised 04−2002

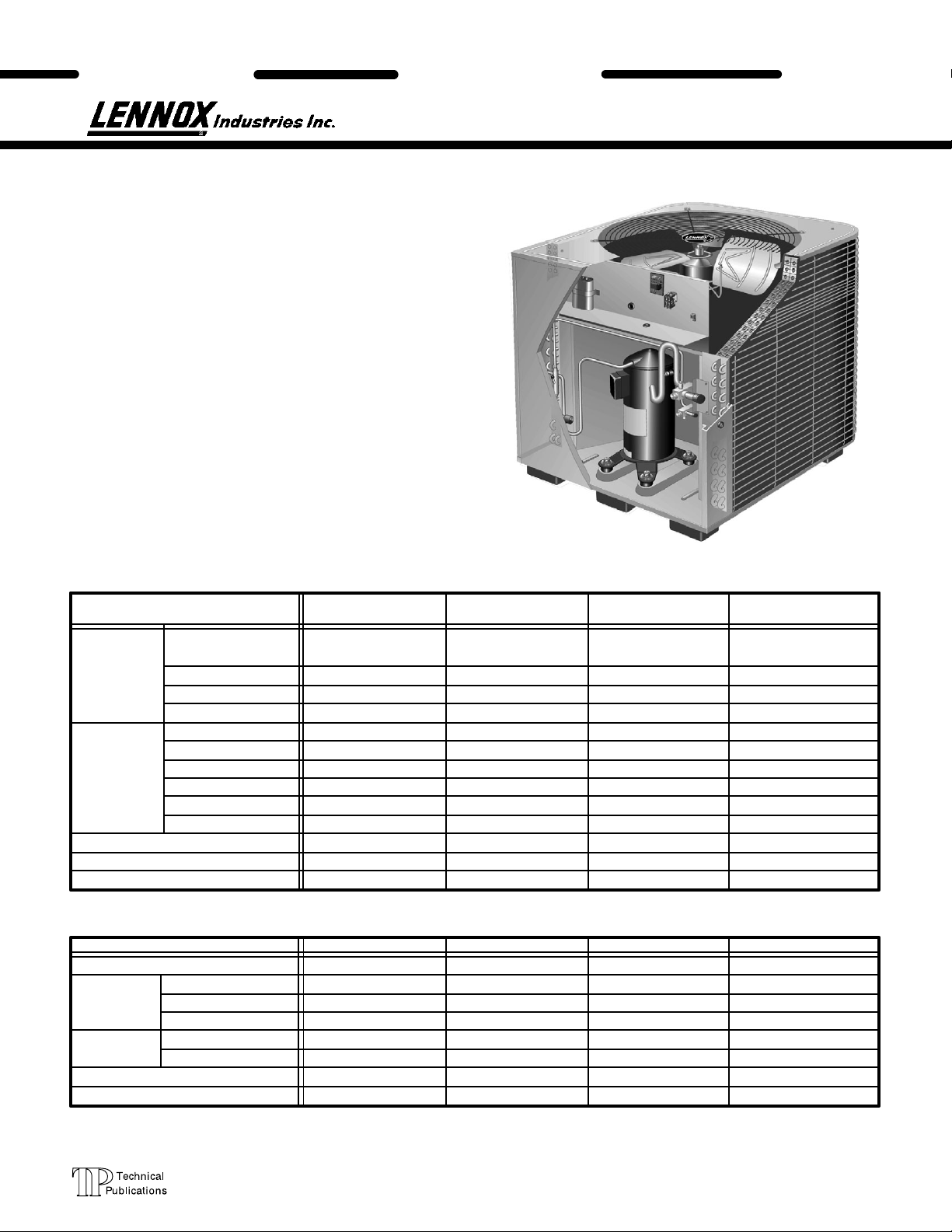

HS26 SERIES UNITS

The HS26 is a high efficiency residential split−system con

densing unit which features a scroll compressor. Early

model HS26 units (−261,−311,−411, and −461) are available

in sizes ranging from 2 through 3−1/2 tons. Late model

HS26 units (−018, −024, −030, −036, −042, −048 and −060)

are available in sizes ranging from 1−1/2 through 5 tons.

The series is designed for use with an expansion valve in

the indoor unit.This manual is divided into sections which

discuss the major components, refrigerant system, charg

ing procedure, maintenance and operation sequence. In

formation in this manual covers both early and late model

HS26 units.

All specifications in this manual are subject to change.

UNIT

HS26

EARLY/LATE

MODEL SERIES

Litho U.S.A.

Late Model

HS26 shown

SPECIFICATIONS (Early Model)

Model No. HS26−261 HS26−311 HS26−411 HS26−461

Face area (sq.ft.)

Outdoor

Coil

Condenser

Fan

HCFC−22 (charge furnished)

Liquid line connection

Suction line connection

*Refrigerant charge sufficient for 25 ft. (7.6 m) length of refrigerant lines.

outer / inner

Tube diameter (in.)

No. of Rows

Fins per inch

Diameter (in.)

No. of Blades

Motor hp

Cfm

RPM

Watts

11.8/5.4 15.9/5.5 15.9/15.3 21.6/20.8

3/8 3/8 3/8 3/8

1.36 1.36 2.0 2.0

20 20 20 20

24 24 24 24

3333

1/6 1/6 1/6 1/6

3150 3150 3000 3230

820 820 820 820

210 210 230 205

7lbs. 11oz. 8lbs. 1oz. 9lbs. 0oz. 11lbs. 3oz.

3/8 3/8 3/8 3/8

3/4 3/4 3/4 11/8

ELECTRICAL DATA (Early Model)

Model No.

Line voltage data − 60hz./1 phase

Rated load amps

Compressor

Condenser

Fan Motor

Max fuse or c.b. size (amps)

*Minimum circuit ampacity

*Refer to National Electrical Code Manual to determine wire, fuse and disconnect size requirements.

NOTE − Extremes of operating range are plus 10% and minus 5% of line voltage

Power factor

Locked rotor amps

Full load amps

Locked rotor amps

HS26−261 HS26−311 HS26−411 HS26−461

208/230V 208/230V 208/230V 208/230V

11.6 13.5 18.0 20

.96 .96 .96 .97

62.5 76.0 90.5 107

1.1 1.1 1.1 1.1

2.0 2.0 2.0 2.0

25 30 40 45

15.6 18.0 23.6 26.1

Page 1

1996 Lennox Industries Inc.

Net face area

Condenser

Coil

Cond

Condenser Coil

Condenser Coil

Coil

SPECIFICATIONS (Late Model)

Model No. HS26018 HS26024 HS26030 HS26036 HS26042 HS26048 HS26060

Net face area

sq. ft. (m2)

Tube diameter in. (mm) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9)

No. of rows 1.48 1.48 1.36 1.86 1.86 1.75 2

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866) 22 (866)

Outer coil 11.9 (1.11) 11.9 (1.11) 16.0 (1.59) 16.0 (1.59) 16.0 (1.59) 18.2 (1.69) 21.6 (2.01)

Inner coil 5.5 (0.51) 5.5 (0.51) 5.6 (0.52) 13.3 (1.24) 13.3 (1.24) 13.3 (1.24) 20.8 (1.93)

Dia. − in. (mm) no. of blades 20 (508) − 4 20 (508) − 4 24 (610) − 3 24 (610) − 3 24 (610) − 3

Motor hp (W) 1/10 (75) 1/6 (124) 1/6 (124) 1/6 (124) 1/6 (124) 1/4 (187) 1/4 (187)

enser

Fan Cfm (L/s) 2500 (1180) 2450 (1155) 3150 (1485) 3150 (1485) 3000 (1415) 3900 (1840) 4200 (1980)

Rpm 825 825 825 825 825 820 820

Watts 160 210 225 225 230 310 350

*Refrigerant HCFC22 charge furnished

Liquid line (o.d.) in. (mm) sweat 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Suction line (o.d.) in. (mm) sweat 5/8 (16) 3/4 (19) 3/4 (19) 3/4 (19) 7/8 (22.2) 7/8 (22.2) 11/8 (28.6)

Shipping weight lbs. (kg) 1 package 177 (80) 185 (84) 192 (87) 221 (100) 231 (105) 274 (124) 308 (140)

*Refrigerant charge sufficient for 25 ft. (7.6 m) length of refrigerant lines.

4 lbs. 1 oz.

(1.84 kg)

4 lbs. 1 oz.

(1.84 kg)

5 lbs. 1 oz.

(2.30 kg)

5 lbs. 13 oz.

(2.64 kg)

6 lbs. 11 oz.

(3.03 kg)

24 (610) 424 (610)

7 lbs. 5 oz.

(3.32 kg)

4

10 lbs. 8 oz.

(4.76 kg)

ELECTRICAL DATA (Late Model)

Model No. HS26018 HS26024 HS26030 HS26036 HS26042

Line voltage data 60hz

Rated load amps 8.4 10.3 13.5 16.0 10.3 18.0 12.5

Compressor Power factor 0.97 0.96 0.96 0.96 0.82 0.94 0.82

Locked rotor amps 47 56 72.5 88 77 104 88

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 15 20 30 35 20 40 25

*Minimum circuit ampacity 13 14 18 21.3 14 23.6 16.4

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 0.8 1.1 1.1 1.1 1.1 1.1 1.1

Locked rotor amps 1.6 2.0 2.0 2.0 2.0 2.0 2.0

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

1ph

208/230v

3ph

208/230v

1ph

208/230v

3ph

ELECTRICAL DATA (Late Model)

Model No. HS26048 HS26060

Line voltage data 60hz

Rated load amps 23.7 13.5 7.4 28.8 17.4 9.0

Compressor Power factor .97 .87 .87 .97 .85 .85

Locked rotor amps 129 99 49.5 169 123 62

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 50 30 15 60 40 20

*Minimum circuit ampacity 31.4 18.6 10.4 37.7 23.5 12.4

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 1.7 1.7 1.1 1.7 1.7 1.1

Locked rotor amps 3.1 3.1 2.2 3.1 3.1 2.2

208/230v

1ph

208/230v

3ph

460v

3ph

208/230v

1ph

208/230v

3ph

460v

3ph

Page 2

DISCHARGE

SUCTION

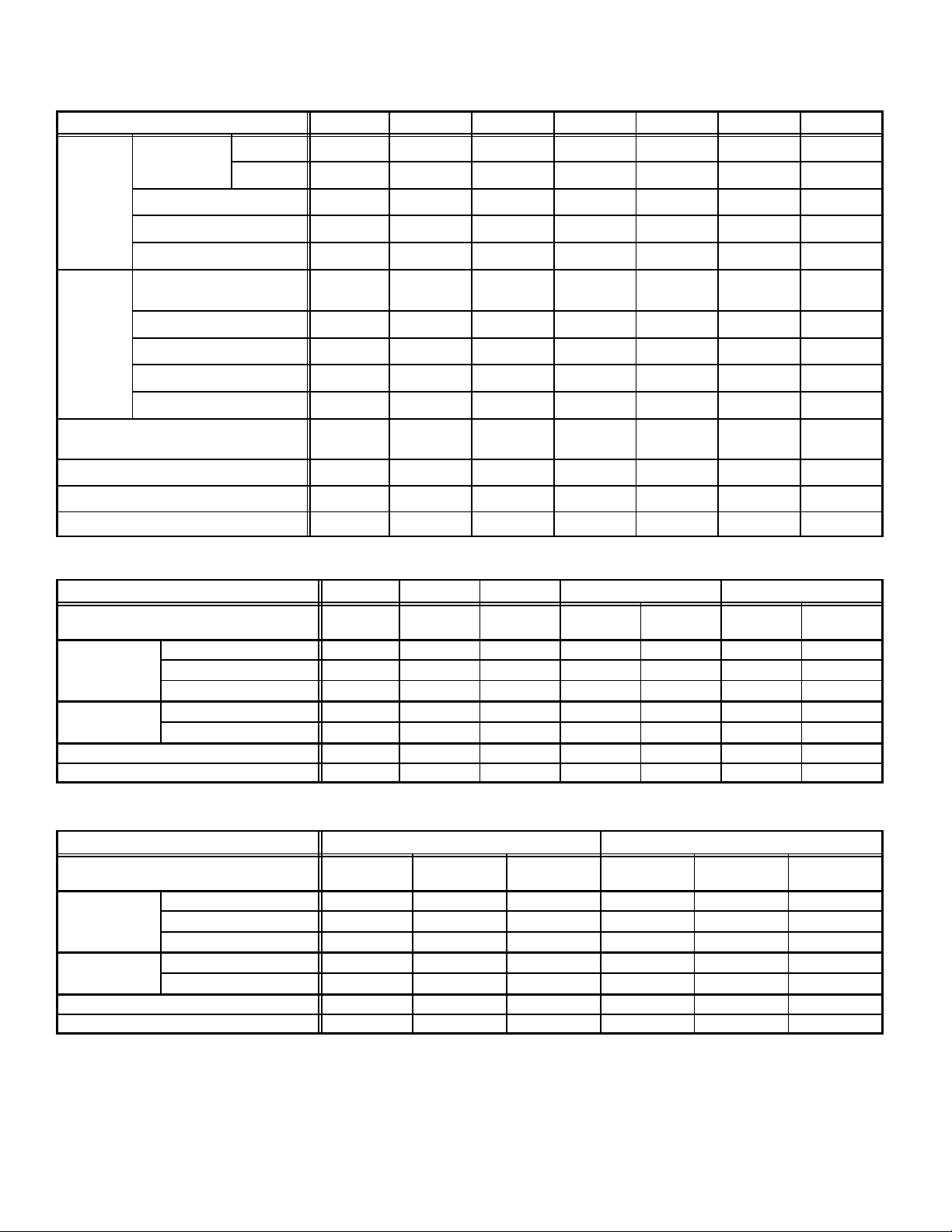

SCROLL COMPRESSOR

SCROLL FORM

CROSS−SECTION OF SCROLLS

DISCHARGE

DISCHARGE

PRESSURE

FIGURE 2

STATIONARY SCROLL

SUCTION

Early Model HS26

Compressor shown

FIGURE 1

I−APPLICATION

All major components (indoor blower and coil) must be

matched according to Lennox recommendations for the

compressor to be covered under warranty. Refer to the

Engineering Handbook for approved system matchups. A

misapplied system will cause erratic operation and can re

sult in early compressor failure.

II−SCROLL COMPRESSOR

The scroll compressor design is simple, efficient and re

quires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 1.The scrolls are located in

the top of the compressor can and the motor is located just

below. The oil level is immediately below the motor.

The scroll is a simple compression concept centered

around the unique spiral shape of the scroll and its inherent

properties. Figure 2 shows the basic scroll form. Two iden

tical scrolls are mated together forming concentric spiral

shapes (figure 3 ). One scroll remains stationary, while the

other is allowed to orbit" (figure 4). Note that the orbiting

scroll does not rotate or turn but merely orbits" the station

ary scroll.

TIPS SEALED BY

DISCHARGE PRESSURE

ORBITING SCROLL

FIGURE 3

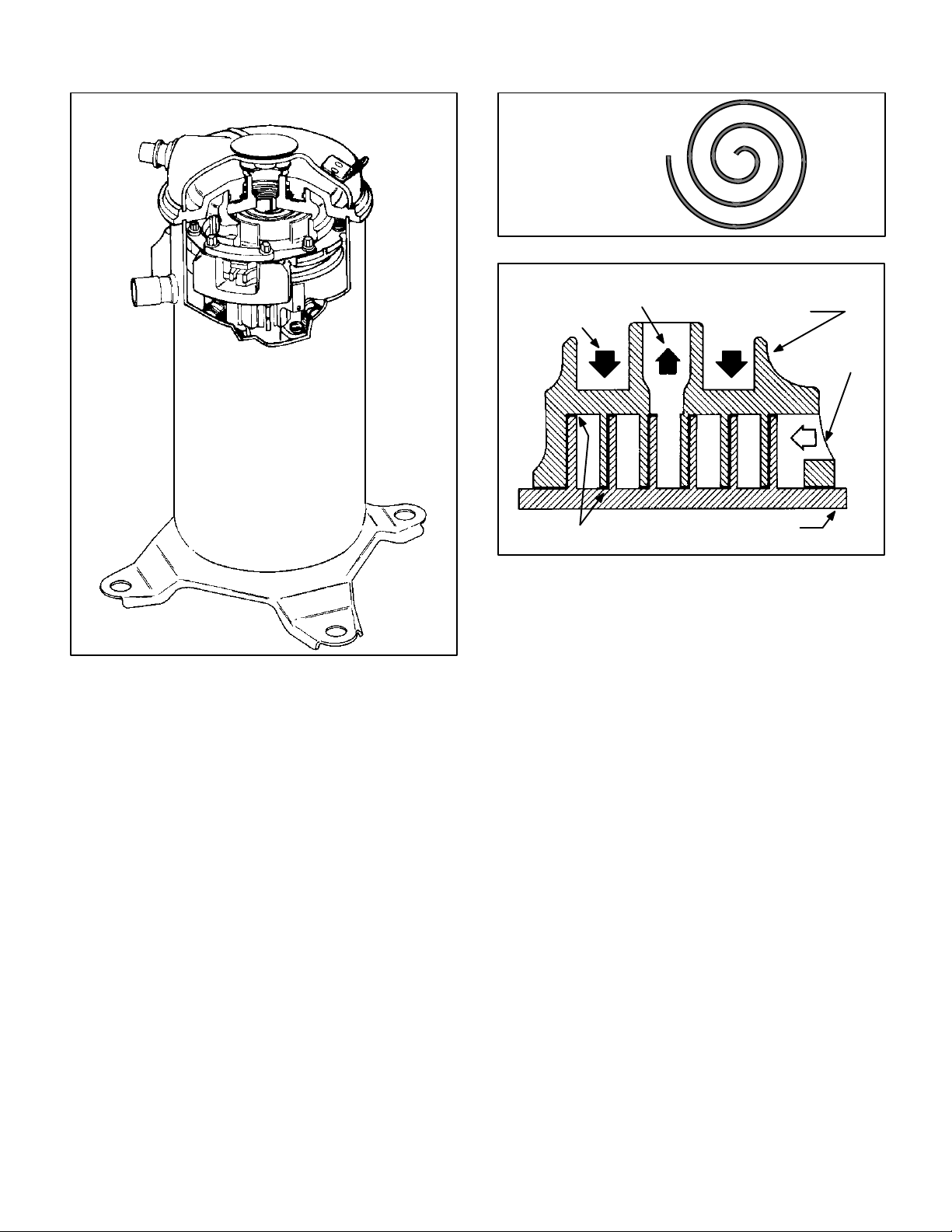

The counterclockwise orbiting scroll draws gas into the out

er crescent shaped gas pocket created by the two scrolls

(figure 4 − 1). The centrifugal action of the orbiting scroll

seals off the flanks of the scrolls (figure 4 − 2). As the orbiting

motion continues, the gas is forced toward the center of the

scroll and the gas pocket becomes compressed (figure 4

−3). When the compressed gas reaches the center, it is dis

charged vertically into a chamber and discharge port in the

top of the compressor (figure1). The discharge pressure

forcing down on the top scroll helps seal off the upper and

lower edges (tips) of the scrolls (figure 3 ). During a single

orbit, several pockets of gas are compressed simultaneous

ly providing smooth continuous compression.

The scroll compressor is tolerant to the effects of liquid re

turn. If liquid enters the scrolls, the orbiting scroll is allowed

to separate from the stationary scroll. The liquid is worked

toward the center of the scroll and is discharged. If the

compressor is replaced, conventional Lennox cleanup

practices must be used.

Due to its efficiency, the scroll compressor is capable of

drawing a much deeper vacuum than reciprocating com

pressors. Deep vacuum operation can cause internal fu

site arcing resulting in damaged internal parts and will re

sult in compressor failure. Never use a scroll compressor

for evacuating or pumping−down" the system. This type of

damage can be detected and will result in denial of warran

ty claims.

NOTE − During operation, the head of a scroll compressor

may be hot since it is in constant contact with discharge

gas.

Page 3

SUCTION

POCKET

HOW A SCROLL WORKS

MOVEMENT OF ORBIT

SUCTION

ORBITING

SCROLL

SUCTION

INTERMEDIATE

PRESSURE

GAS

CRESCENT

SHAPED GAS

POCKET

12

FLANKS

STATIONARY SCROLL

SUCTION

SEALED BY

CENTRIFUGAL

FORCE

SUCTION

34

HIGH

PRESSURE

GAS

FIGURE4

III−UNIT COMPONENTS

A−Transformer

The contactor coil, time delay and temperature sensor

are all energized by 24VAC supplied by the indoor unit.

All other controls in the outdoor unit are powered by line

voltage. Refer to unit wiring diagram. The HS26 is not

equipped with an internal line voltage to 24V transform

er.

B−Contactor

The compressor is energized by a contactor located in the

control box. Early model units use single−pole contactors.Late

model single−phase units use single pole and two−pole con

tactors. See wiring diagrams for specific unit. Late model

three−phase units use three−pole contactors. The contactor is

energized by indoor thermostat terminal Y when thermostat

demand is present.

DISCHARGE

POCKET

CAUTION

Some HS26 units use single−pole contactors. One

leg of the compressor, capacitor and condenser

fan are connected to line voltage at all times. Po

tential exists for electrical shock resulting in inju

ry or death. Remove all power at disconnect be

fore servicing

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit instal

lation and service to protect the unit’s electronic

controls. Precautions will help to avoid control

exposure to electrostatic discharge by putting

the unit, the control and the technician at the

same electrostatic potential. Neutralize electro

static charge by touching hand and all tools on an

unpainted unit surface before performing any

service procedure.

Page 4

C−TD1−1 Time Delay (Early Models)

Some early model HS26 units are equipped with a Lennox−

built TD1−1 time delay located in the control box (figure 5).

The time delay is electrically connected between thermostat

terminal Y and the compressor contactor. On initial thermo

stat demand, the compressor contactor is delayed for 8.5

seconds. At the end of the delay, the compressor is allowed

to energize. When thermostat demand is satisfied, the time

delay opens the circuit to the compressor contactor coil and

the compressor is de−energized.

The time delay performs no other functions. Without the

delay it would be possible to short cycle the compressor. A

scroll compressor, when short cycled, can run backward if

head pressure is still high. It does not harm a scroll com

pressor to run backward, but it could cause a nuisance trip

of safety limits (internal overload). For this reason, if a

TD1−1 delay should fail, it must be replaced. Do not bypass

the control.

D−TOC Timed Off Control

(Early and Late Models)

Some early and all late model HS26 units are equipped with

a TOC, timed off control.The TOC is located in the control

box (figure 6). The time delay is electrically connected be

tween thermostat terminal Y and the compressor contactor.

Between cycles, the compressor contactor is delayed for 5

minutes + 2 minutes. At the end of the delay, the compres

sor is allowed to energize. When thermostat demand is sat

isfied, the time delay opens the circuit to the compressor

contactor coil and the compressor is de−energized. Without

the time delay it would be possible to short cycle the com

pressor. A scroll compressor, when short cycled, can run

backward if head pressure is still high. It does not harm a

scroll compressor to run backward, but it could cause a nui

sance tripout of safety limits. For this reason, if a TOC fails it

must be replaced.

DANGER

DO NOT ATTEMPT TO REPAIR THE TD1−1 OR THE

TOC CONTROL. UNSAFE OPERATION WILL RE

SULT. IF THE CONTROL IS FOUND TO BE INOP

ERATIVE, SIMPLY REPLACE IT.

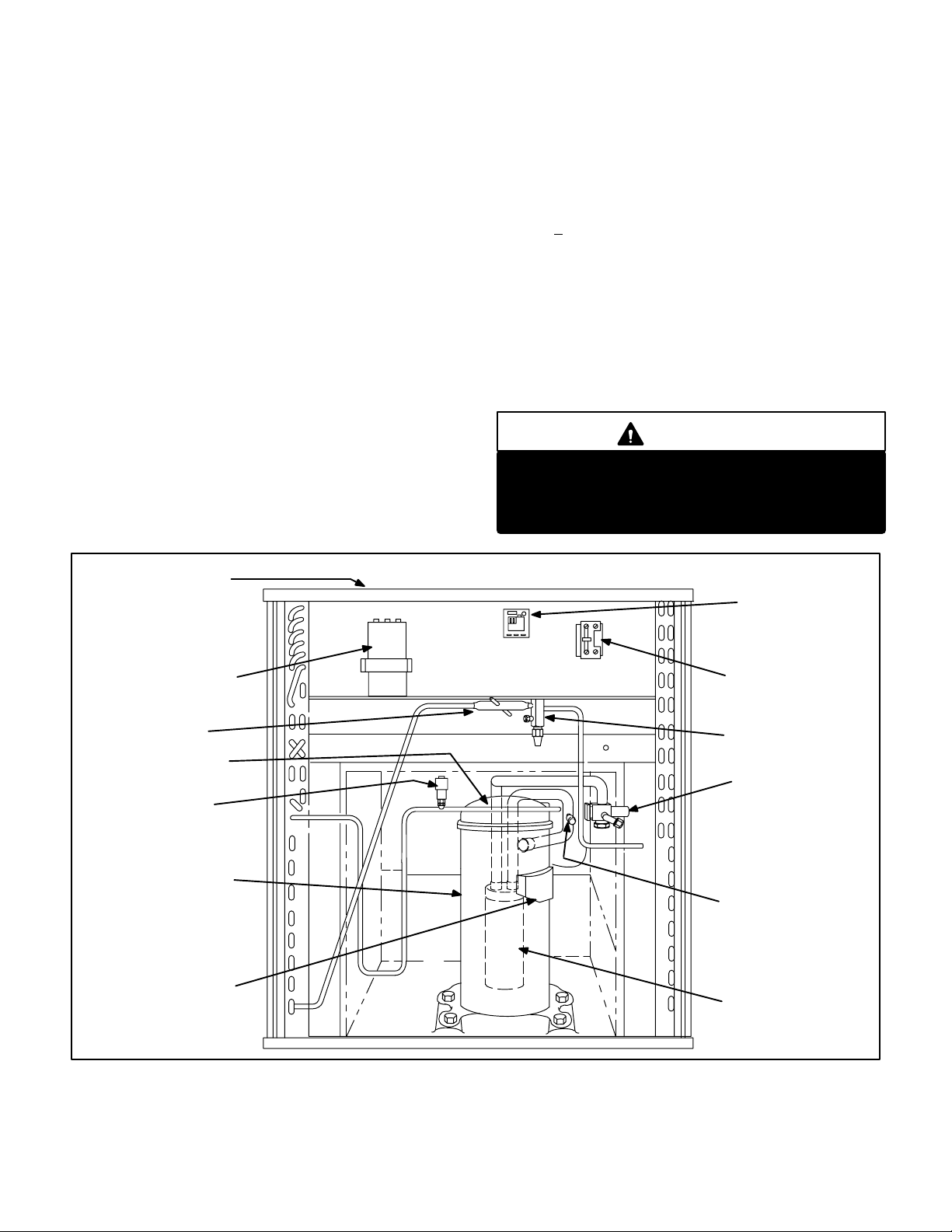

CONDENSER FAN

(NOT SHOWN)

TOP OF CABINET

DUAL CAPACITOR

THERMOMETER

WELL

COMPRESSOR

TEMPERATURE

SENSOR

HIGH

PRESSURE

SWITCH

COMPRESSOR

COMPRESSOR

TERMINAL BOX

HS26 UNIT COMPONENTS (EARLY MODEL)

TD−1 TIME DELAY

OR T.O.C. TIMED OFF

CONTROL

CONTACTOR

LIQUID LINE

SERVICE VALVE

AND GAUGE PORT

SUCTION

VALV E

AND GAUGE PORT

LOW PRES

SURE SWITCH

ACCUMULATOR

(411, 461 only

all others equipped

with suction muffler)

FIGURE 5

Page 5

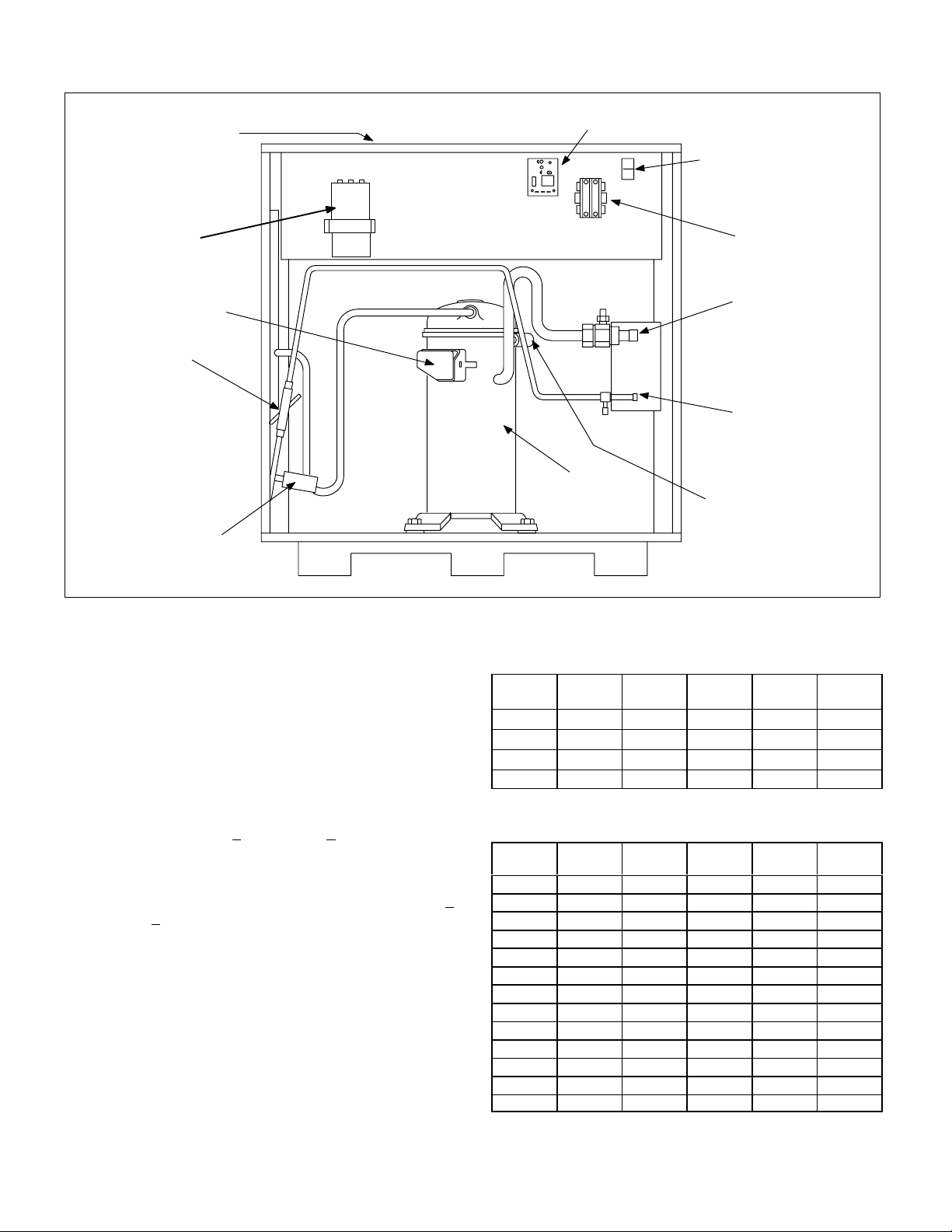

CONDENSER FAN

(NOT SHOWN)

TOP OF CABINET

PARTS ARRANGEMENT FOR HS26 (LATE MODEL)

TIMED OFF CONTROL (TOC)

GROUND LUG

DUAL CAPACITOR

TERMINAL BOX

THERMOME

TER

WELL

HIGH PRESSURE

SWITCH

FIGURE 6

E−Compressor

Tables1 and 2 show the specifications for compressors

used in HS26 series units.

F−Compressor High Temperature Limit

(Early Models)

Each scroll compressor in the HS26−261, −311, −411, −461

is equipped with a compressor high temperature limit lo

cated on the outside top of the compressor. The sensor is a

SPST thermostat which opens when the discharge tem

perature exceeds 280_F + 8_F (138_C + 4.5_C) on a tem

perature rise. When the switch opens, the circuit to the

compressor contactor and the time delay is de−energized

and the unit shuts off. The switch automatically resets

when the compressor temperature drops below 130_F +

14_F. (54_C + 8_C)

The sensor can be accessed by prying off the snap plug on

top of the compressor (see figure 7). Make sure to securely

seal the limit after replacement. The limit pigtails are lo

cated inside the unit control box. Figure 8 shows the ar

rangement of compressor line voltage terminals and dis

charge sensor pigtails.

CONTACTOR

SUCTION VALVE

AND GAUGE PORT

LIQUID LINE

SERVICE VALVE

AND GAUGE

PORT

COMPRESSOR

LOW PRESSURE

SWITCH

Table 1 (Early Models)

HS 26

Unit

−261 208/230 1 62.5 11.6 28*

−311 208/230 1 76.0 13.5 28*

−411 208/230 1 90.5 18.0 34*

−461 208/230 1 107 20.0 38*

*Shipped with conventional white oil (Sontex 200LT). 3GS oil may be

used if additional oil is required.

Vac Phase LRA RLA Oil fl.oz.

Table 2 (Late Models)

HS26

Unit

−018 208/230 1 47.0 8.4 38*

−024 208/230 1 56.0 10.3 30*

−030 208/230 1 72.5 13.5 30*

−036 208/230 1 88.0 16.0 42*

−042 208/230 1 104.0 18.0 42*

−048 208/230 1 129.0 23.7 53*

−060 208/230 1 169.0 28.8 50*

−036 208/230 3 88.8 10.3 42*

−042 208/230 3 77.0 12.5 42*

−048 208/230 3 99.0 13.5 53*

−048 460 3 49.5 7.4 53*

−060 208/230 3 123.0 17.4 53*

−060 460 3 62.0 9.0 53*

*Shipped with conventional white oil (Sontex 200LT). 3GS oil may be

used if additional oil is required.

Vac Phase LRA RLA Oil fl. oz.

Page 6

COMPRESSOR HIGH TEMPERATURE LIMIT CHANGEOUT (EARLY MODELS ONLY)

PLASTIC CAP

SEALANT

(BLUE)

PRONG

THERMAL

GREASE

(WHITE)

COMPRESSOR

GROMMET

LIMIT

(THERMOSTAT)

FIGURE 7

G−High/Low Pressure Switch

A manualreset singlepole singlethrow high pressure switch

located in the liquid line, shuts off the compressor when liquid

line pressure rises above the factory setting. The switch is nor

mally closed and is permanently adjusted to trip (open) at 410

+ 10 psi. See figure 5 or 6 for switch location

COMPRESSOR TERMINAL BOX

DISCHARGE TEMPERATURE

SENSOR WIRES

TO CONTROL BOX

(TO COMP. TERM. BOX IN

461 UNITS)

EARLY MODELS ONLY

COMPRESSOR

TERMINALS

C

S

R

WARNING

COMPRESSOR MUST BE GROUNDED. DO

NOT OPERATE WITHOUT PROTECTIVE COV

ER OVER TERMINALS. DISCONNECT ALL

POWER BEFORE REMOVING PROTECTIVE

COVER. DISCHARGE CAPACITORS BEFORE

SERVICING UNIT. COMPRESSOR WIRING DIA

GRAM IS FURNISHED INSIDE COMPRESSOR

TERMINAL BOX COVER. FAILURE TO FOL

LOW THESE PRECAUTIONS COULD CAUSE

ELECTRICAL SHOCK RESULTING IN INJURY

OR DEATH.

FIGURE 8

Instructions

1 With power off, disconnect wiring to limit.

2 Dislodge limit/cap assembly from compressor. Plastic cap and silicone seal

will break away. Discard all pieces.

3 Remove thermostat and grommet from compressor. Thoroughly clean all

blue adhesive and white silicone thermal grease from compressor and the

inside of the thermostat tube. Thermostat tube should be clean and free of

debris.

4 Using Lennox kit 93G8601, dip end of thermostat into plastic bottle labeled

Silicone Thermal Grease G.E. #G641" and coat end of thermostat. Care

fully insert thermostat/grommet assembly into thermostat tube of compres

sor. Avoid contact with top of compressor.

5 Clean excess thermal grease from under cap lip and top lip of compressor

opening.

6 Install protector assembly as shown, feeding wire leads through channel

provided in cap.

7 Apply a bead of sealant around lip of cap at area shown in illustration and

into the thermostat tube area.

8 Install assembly as shown. Align wires to channel in compressor shell. Suf

ficient force is required to snap plastic cap into tube to engage all three

prongs.

9 Reconnect wiring.

10After completing thermostat replacement, discard remaining parts.

An autoreset singlepole singlethrow low pressure switch

located in the suction line shuts off the compressor when

suction pressure drops below the factory setting. The

switch is normally closed and is permanently adjusted to

trip (open) at 25 + 5 psi. The switch automatically resets

when suction line pressure rises above 55 + 5 psi. See fig

ure 5 or 6 for switch location.

H−Dual Capacitor

The compressor and fan in HS26 single−phase units use

permanent split capacitor motors. A single dual" capacitor

is used for both the fan motor and the compressor (see unit

wiring diagram). The fan side of the capacitor and the com

pressor side of the capacitor have different mfd ratings. The

capacitor is located inside the unit control box (see figure 5

or 6). Tables 3 and 4 show the ratings of the dual capacitor.

TABLE 3 (Early Models)

HS26 DUAL CAPACITOR RATING

UNITS

HS26−261 5 30 370

HS26−311 5 35 370

HS26−411,−461 5 35 440

TABLE 4 (Late Models)

HS26 DUAL CAPACITOR RATING

UNITS FAN MFD HERM MFD VAC

HS26−018 4 30 370

HS26−024,−030 5 40 370

HS26−036 5 50 370

HS26−042 5 55 370

HS26−048 7.5 60 370

HS26−060 10 80 370

FAN

MFD

HERM MFD VA C

Page 7

I−Condenser Fan Motor

018

024

261

7/8"

030, 311, 036,

1−1/16"

048

060

1−3/16"

All units use single−phase PSC fan motors which require a

run capacitor. The FAN" side of the dual capacitor is used

for this purpose. The specifications tables on page 1 and 2

of this manual show the specifications of outdoor fans used

in HS26s. In all units, the outdoor fan is controlled by the

compressor contactor. See figure 9 if condenser fan motor

replacement is necessary.

"A" SEE TABLE 5

Condenser fan

and motor

FAN

GUARD

Wiring

Drip loop

FIGURE 9

TABLE 5

HS26 UNIT "A" DIM. + 1/8" Fan Blade Ven

−

, −

, −

−030, −311, −036,

−411, −042, −461

,

"

"

1−3/4" Lau

−

−

1−1/2" Revcor

"

dor

Lau

Revcor

Lau

Revcor

Lau

Revcor

IV−REFRIGERANT SYSTEM

A−Plumbing

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections). Use Lennox

L10 or L15 series line sets as shown in table 6 or 7 for field−

fabricated refrigerant lines. Refer to the piping section of

the Lennox Service Unit Information Manual (SUI−803−L9)

for proper size, type and application of field−fabricated

lines.

Separate discharge and suction service ports are provided

at the compressor for connection of gauge manifold during

charging procedure.

TABLE 6 (Early Models)

HS26

UNIT

−261, −311,

−411

−461

−511

−651

LIQUID

LINE

3/8 in.

(10 MM)

3/8 in.

(10 MM)

3/8 in.

(10 MM)

3/8 in.

(10 MM)

SUCTION

LINE

3/4 in.

(19 mm)

1−1/8 in.

(29 m)

7/8 in.

(22 m)

1−1/8 in.

(29 m)

L10 LINE

SET

L10−41

20ft. − 50 ft.

(6m − 15 m)

Field

Fabricated

L10−65

30 ft. − 50 ft.

(9 m − 15m)

Field

Fabricated

L15 LINE

SET

L15 − 41

20 ft. − 50 ft.

(6 m − 15 m)

Field

Fabricated

L15−65

30 ft. − 50 ft.

(9 m − 15m)

Field

Fabricated

TABLE 7 (Late Models)

HS26

UNIT

−018

−024 −030

−036

−042 −048

−060

NO SCHRADER

SERVICE PORT OPEN TO

LINE SET WHEN FRONT

SEATED AND CLOSED

LIQUID

LINE

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

LIQUID LINE SERVICE VALVE

TO

CONDENSER

COIL

SERVICE

PORT

CAP

(OFF) WHEN BACK

SEATED

SUCTION

LINE

5/8 in.

(16 mm)

3/4 in.

(19 mm)

7/8 in.

(22 m)

1−1/8 in.

(29 m)

L10 LINE

SET

L10−26

20ft. − 50 ft.

(6m − 15 m)

L10−41

20 ft. − 50 ft.

(6m − 15 m)

L10−65

30 ft. − 50 ft.

(9 m − 15m)

Field

Fabricated

TO LINE

SET

KNIFE EDGE SEAL

VALVE STEM

USE SERVICE

WRENCH

(PART #18P66,

54B64 or 12P95)

STEM CAP

L15 LINE

SET

L15 − 26

20 ft. − 50 ft.

(6 m − 15 m)

L15−41

20 ft. − 50 ft.

(6m − 15m)

L15−65

30 ft. − 50 ft.

(9 m − 15m)

Field

Fabricated

IMPORTANT

A schrader valve is not provided on the liquid line

service port. Valve must be backseated to turn off

pressure to service port.

FIGURE 10

B−Service Valves (Early Models)

The liquid line and suction line service valves and gauge

ports are accessible by removing the compressor access

cover. Full service liquid and suction line valves are

used.The service ports are used for leak testing, evacuat

ing, charging and checking charge.

1 − Liquid Line Service Valve

A fullservice liquid line valve made by one of several

manufacturers may be used. All liquid line service valves

function the same way, differences are in construction.

Valves are not rebuildable. If a valve has failed it must be

replaced. The liquid line service valve is illustrated in figure

10.

Page 8

The valve is equipped with a service port. There is no

schrader valve installed in the liquid line service port. A ser

vice port cap is supplied to seal off the port.

The liquid line service valve is a front and back seating

valve. When the valve is backseated, the service port is not

open.The service port cap can be removed and gauge

connections can be made.

To Access Service Port:

1− Remove the stem cap. Use a service wrench

(part #18P66, 54B64 or 12P95) to make sure the ser

vice valve is backseated.

CAUTION

The service port cap is used to seal the liquid

line service valve. Access to service port

requires backseating the service valve to

isolate the service port from the system. Failure

to do so will cause refrigerant leakage.

2 − Suction Line (Seating Type) Service Valve

A full service nonbackseating suction line service valve is

used on all early HS26 series units (except 461). Different

manufacturers of valves may be used. All suction line service

valves function the same way, differences are in construction.

Valves are not rebuildable. If a valve has failed it must be

replaced. The suction line service valve is illustrated in

figure 11.

The valve is equipped with a service port. A schrader

valve is factory installed. A service port cap is supplied

to protect the schrader valve from contamination and

assure a leak free seal.

SUCTION LINE SERVICE VALVE (VALVE

INSERT HEX WRENCH

HERE (PART #49A71

(FROM INDOOR COIL)

AND

SERVICE WRENCH)

INLET

OPEN)

SNAP RING

KNIFE

EDGE

SEAL

IMPORTANT

A schrader valve is not provided on the liquid line

service port. Valve must be backseated to turn off

pressure to service port.

2− Remove service port cap and connect high pressure

gauge to service port.

3− Using service wrench, open valve stem (one turn

clockwise) from backseated position.

4− When finished using port, backseat stem with service

wrench. Tighten firmly.

5− Replace service port and stem cap. Tighten finger

tight, then tighten an additional 1/6 turn.

To Close Off Service Port:

1− Using service wrench, backseat valve.

a − Turn stem counterclockwise.

b − Tighten firmly, but do not overtighten.

To Open Liquid Line Service Valve:

1− Remove the stem cap with an adjustable wrench.

2− Using service wrench, backseat valve.

a − Turn stem counterclockwise until backseated.

b − Tighten firmly, but do not overtighten.

3− Replace stem cap, finger tighten then tighten an addi

tional 1/6 turn.

To Close Liquid Line Service Valve:

1− Remove the stem cap with an adjustable wrench.

2− Turn the stem in clockwise with a service wrench to

front seat the valve. Tighten firmly.

3− Replace stem cap, finger tighten then tighten an addi

tional 1/6 turn.

SCHRADER VALVE

SERVICE

PORT

CAP

SERVICE PORT

STEM CAP

OUTLET

(TO

COMPRESSOR)

SUCTION LINE SERVICE VALVE (VALVE

SNAP RING

KNIFE EDGE SEAL

(FROM INDOOR COIL)

SCHRADER VALVE

OPEN TO LINE SET

WHEN VALVE IS CLOSED

INLET

SERVICE PORT

SERVICE

PORT

CAP

(FRONT SEATED)

CLOSED)

FIGURE 11

STEM

CAP

INSERT

HEX WRENCH HERE

(PART #49A71 AND

SERVICE

WRENCH)

(VALVE

FRONT SEATED)

OUTLET

(TO

COMPRESSOR)

To Access Schrader Port:

1− Remove service port cap with an adjustable wrench.

2− Connect gauge to the service port.

3− When testing is completed, replace service port

cap. Tighten finger tight, then tighten an additional

1/6 turn.

To Open Suction Line Service Valve:

1− Remove stem cap with an adjustable wrench.

2− Using service wrench and 5/16" hex head extension

(part #49A71) back the stem out counterclockwise until

the valve stem just touches the retaining ring.

Page 9

DANGER

Do not attempt to backseat this valve. Attempts to

backseat this valve will cause snap ring to explode

from valve body under pressure of refrigerant.

Personal injury and unit damage will result.

3− Replace stem cap and tighten firmly. Tighten finger

tight, then tighten an additional 1/6 turn.

To Close Suction Line Service Valve:

1− Remove stem cap with an adjustable wrench.

2− Using service wrench and 5/16" hex head extension

(part #49A71) turn stem in clockwise to seat the valve.

Tighten firmly, but do not overtighten.

3− Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

3 − Suction Line (Ball Type) Service Valve

A balltype full service valve is used on the early model

HS26461 units. This valve is manufactured by Aeroquip. All

suction line service valves function the same way, differences

are in construction. Valves are not rebuildable. If a valve

has failed it must be replaced. A ball valve is illustrated

in figure 12.

The ball valve is equipped with a service port. A schrad

er valve is factory installed. A service port cap is sup

plied to protect the schrader valve from contamination

and assure a leak free seal.

SUCTION LINE (BALL TYPE) SERVICE VALVE

(VALVE OPEN)

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90_ TO CLOSE

ROTATE STEM COUNTERCLOCKWISE 90_ TO OPEN

OUTLET

(TO

COMPRESSOR)

STEM CAP

C−Service Valves (Late Models)

The liquid line and suction line service valves and gauge

ports are accessible by removing the compressor access

cover. Full service liquid and suction line valves are used.

See figures13 and 14. The service ports are used for leak

testing, evacuating, charging and checking charge. Ser

vice valves have a factory installed schrader valve. A ser

vice port cap is supplied to protect the schrader valve from

contamination and assure a leak free seal. Valves are not

rebuildable. If a valve has failed it must be replaced.

LIQUID LINE SERVICE VALVE ALL UNITS

VAPOR LINE SERVICE VALVE

−018, −024, −030, −036, −042, −048

(VALVE OPEN)

INSERT HEX

WRENCH HERE

OUTLET (TO

COMPRESSOR)

SERVICE

PORT

CAP

LIQUID/VAPOR LINE SERVICE

OUTLET (TO

COMPRESSOR)

SER

VICE

PORT

SCHRADE

R

VALV E

VALV E

RETAINING RING

(VALVE CLOSED)

SERVICE

PORT

STEM CAP

INLET (TO

INDOOR COIL)

STEM CAP

INSERT HEX

WRENCH HERE

SERVICE

PORT

CAP

SCHRADE

R VALVE

FIGURE 12

STEM

SERVICE PORT

(FROM INDOOR COIL)

BALL

(SHOWN OPEN)

INLET

SERVICE

PORT CAP

SCHRADER VALVE OPEN

TO LINE SET WHEN VALVE

IS CLOSED (FRONT

SEATED)

FIGURE 13

(TO INDOOR COIL)

(VALVE FRONT

SEATED)

To Access Schrader Port:

1− Remove service port cap with an adjustable wrench.

2− Connect gauge to the service port.

3− When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

Page 10

INLET

To Open Liquid or Suction Line Service Valve:

1− Remove stem cap with an adjustable wrench.

2− Using service wrench and 5/16" hex head extension

back the stem out counterclockwise until the valve stem

just touches the retaining ring.

3− Replace stem cap and tighten finger tight, then tighten

an additional 1/6 turn.

DANGER

Do not attempt to backseat this valve. Attempts to

backseat this valve will cause snap ring to explode

from valve body under pressure of refrigerant.

Personal injury and unit damage will result.

To Close Liquid or Suction Line Service Valve:

1− Remove stem cap with an adjustable wrench.

2−Using service wrench and 5/16" hex head extension, turn

stem clockwise to seat the valve. Tighten firmly, but do not

overtighten.

3− Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

SUCTION LINE (BALL TYPE) SERVICE VALVE

HS26−060 MODEL ONLY

(VALVE OPEN)

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90_ TO CLOSE

ROTATE STEM COUNTERCLOCKWISE 90_ TO OPEN

V−CHARGING

The unit is factory−charged with the amount of R22 refrig

erant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with a 25

foot (7.6m) line set. For varying lengths of line set, refer to

table 8 for refrigerant charge adjustment for both, early and

late model HS26 units. A blank space is provided on the

unit rating plate to list actual field charge.

TABLE 8

LIQUID LINE

SET DIAMETER

5/16 in. (8mm) 2 ounce per 5 ft. (60 ml per 1524 mm)

3/8 in. (10 mm) 3 ounce per 5 ft. (90 ml per 1524 mm)

If line set is greater than 25 ft. (7.6m) add this amount. If line set is less

than 25 ft. (7.6m) subtract this amount.

Ounce per 5 ft. (ml per mm) adjust

from 25 ft. (7.6m) line set*

Units are designed for line sets up to 50 ft. (15m).Consult Len

nox Refrigerant Piping Manual for line sets over 50 ft. (15m).

IMPORTANT

If line length is greater than 25 feet (7.6m), add this

amount. If line length is less than 25feet ( 7.6m),

subtract this amount.

A−Leak Testing

1− Attach gauge manifold and connect a drum of dry nitro

gen to center port of gauge manifold.

2− Add a small amount of refrigerant to the lines and

coil. Open high pressure valve on gauge manifold

and pressurize line set and indoor coil to 150 psig

(1034 kPa).

WARNING

OUTLET

(TO

COMPRESSOR)

SERVICE

PORT

CAP

SCHRADE

R VALVE

SERVICE PORT

FIGURE 14

STEM CAP

STEM

BALL

(SHOWN OPEN)

INLET

(FROM INDOOR COIL)

Danger of Explosion.

Can cause injury, death and equipment

damage.

When using dry nitrogen, use a pres

sure−reducing regulator, set at 150 psig

(1034 kPa) or less to prevent excessive

pressure.

3− Check lines and connections for leaks.

NOTEIf electronic leak detector is used, add a trace of re

frigerant to nitrogen for detection by leak detector.

4− Release nitrogen pressure from the system, correct

any leaks and recheck.

B−Evacuating the System

Evacuating the system of non−condensables is critical for

proper operation of the unit. Non−condensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Non−condensables such as water vapor, combine

with refrigerant to produce substances that corrode copper

piping and compressor parts.

Page 11

1− Attach gauge manifold and connect vacuum pump

(with vacuum gauge) to center port of gauge man

ifold. With both gauge manifold service valves open,

start pump and evacuate evaporator and refrigerant

lines.

IMPORTANT

A temperature vacuum gauge, mercury vacuum

(U−tube), or thermocouple gauge should be used.

The usual Bourdon tube gauges are not accurate

enough in the vacuum range.

IMPORTANT

The compressor should never be used to evacu

ate a refrigeration or air conditioning system.

CAUTION

Danger of Equipment Damage. Avoid deep vacuum

operation. Do not use compressors to evacuate a

system. Extremely low vacuums can cause internal

arcing and compressor failure. Damage caused by

deep vacuum operation will void warranty.

2− Evacuate the system to an absolute pressure of

.92 inches of mercury, 23 mm of mercury, or 23,000

microns.

3− After system has been evacuated to an absolute

pressure of .92 inches of mercury, 23 mm of mercury,

or 23,000 microns, close manifold valve to center

port.

4− Stop vacuum pump and disconnect from gauge man

ifold. Attach a drum of dry nitrogen to center port of

gauge manifold, open drum valve slightly to purge line,

then break vacuum in system to 3 psig (20.7 kPa) pres

sure by opening manifold high pressure valve to center

port.

5− Close nitrogen drum valve, disconnect drum from

manifold center port and release nitrogen pressure

from system.

6− Reconnect vacuum pump to manifold center port

hose. Evacuate the system to an absolute pressure

less than .197 inches of mercury, 5 mm of mercury, or

5000 microns, then turn off vacuum pump. If the abso

lute pressure rises above .197 inches of mercury, 5

mm of mercury, or 5000 microns within a 20−minute

period after stopping vacuum pump, repeat step 6. If

not, evacuation is complete.

This evacuation procedure is adequate for a new

installation with clean and dry lines. If excessive mois

ture is present, the evacuation process may be re

quired more than once.

7− After evacuation has been completed, close gauge

manifold service valves. Disconnect vacuum pump

from manifold center port and connect refrigerant

drum. Pressurize system slightly with refrigerant to

break vacuum.

IMPORTANT

Use tables 9 and 10 as a general guide for perform

ing maintenance checks. Table 9 is not a procedure

for charging the system. Minor variations in these

pressures may be expected due to differences in

installations. Significant deviations could mean that

the system is not properly charged or that a problem

exists with some component in the system. Used

prudently, tables 9 and 10 could serve as a useful

service guide.

OUTDOOR

TEMP. (_F)

65

75

85

95

105

C−Charging

TABLE 9 (Early Models)

HS26−261 HS26−311 HS26−411

LIQ.

+ 10

PSIG PSIG

141

163

191

220

255

SUC.

+ 10

77

79

80

82

83

NORMAL OPERATING PRESSURES

LIQ.

+ 10

PSIG PSIG

140

160

186

216

254

SUC.

+ 10

69

74

78

80

81

LIQ.

+ 10

PSIG PSIG

Page 12

141

167

195

225

260

SUC.

+ 10

75

77

79

80

81

HS26−461

LIQ.

+ 10

PSIG PSIG

140

170

170

223

261

SUC.

+ 10

62

77

77

80

81

OUTDOOR

TEMP. (_F)

65

75

85

95

105

TABLE 10 (Late Models)

NORMAL OPERATING PRESSURES

HS26−018 HS26−024 HS26−030 HS26−036 HS26−042 HS26−048 HS26−060

Liq.+

10 psig

142

167

194

223

256

Suct.+

5 psig

75

76

77

78

79

Liq.+

10 psig

143

168

196

226

260

Suct.+

5 psig

Liq.+

10 psig

76

77

78

79

80

Suct.+

5 psig

139

163

191

223

255

Liq.+

10 psig

72

73

74

76

77

Suct.+

5 psig

138

164

192

223

256

Liq.+

10 psig

70

71

72

73

75

Suct.+

5 psig

141

166

186

227

261

Liq.+

10 psig

74

75

76

78

79

Suct.+

5 psig

130

156

175

216

251

Liq.+

10 psig

71

72

73

75

77

171

196

225

232

251

Suct.+

5 psig

73

74

75

76

77

If the system is completely void of refrigerant, the recom

mended and most accurate method of charging is to weigh

the refrigerant into the unit according to the total amount

shown on the unit nameplate. Also refer to the SPECIFI

CATIONS tables on page 1 for early model HS26 units and

page 2 for late model HS26 units.

If weighing facilities are not available or if unit is just low on

charge, the following procedure applies.

The following procedures are intended as a general guide

for use with expansion valve systems only. For best re

sults, indoor temperature should be between

70 °F and 80 °F. Outdoor temperature should be 60 °F or

above. Slight variations in charging temperature and pres

sure should be expected. Large variations may indicate a

need for further servicing.

APPROACH METHOD (TXV SYSTEMS)

(Ambient Temperature of 60_F [16_C] or Above)

1− Connect gauge manifold. Connect an upright HCFC22

drum to center port of gauge manifold.

IMPORTANT

The following procedure requires accurate read

ings of ambient (outdoor) temperature, liquid tem

perature and liquid pressure for proper charging.

Use a thermometer with accuracy of +2 °F and a

pressure gauge with accuracy of +5 PSIG.

2− Record outdoor air (ambient) temperature.

3− Operate indoor and outdoor units in cooling mode. Allow

units to run until system pressures stabilize.

4− Make sure thermometer well is filled with mineral oil be

fore checking liquid line temperature.

5− Place thermometer in well and read liquid line tempera

ture. Liquid line temperature should be a few degrees

warmer than the outdoor air temperature. Tables 11 and

12 show how many degrees warmer the liquid line tem

perature should be.

Add refrigerant to make the liquid line cooler.

Recover refrigerant to make the liquid line warmer.

TABLE 11

APPROACH METHOD − EXPANSION VALVES SYSTEM

MODEL

H2−26−261,311 3 + 1 (1.6 + .5)

HS26−411 4 + 1 (2.2 + .5)

HS26−461 6 + 1 (3.3 + .5)

Liquid Line _F (_C) Warmer Than

Outside Ambient Temperature

TABLE 12

APPROACH METHOD − EXPANSION VALVES SYSTEMS

MODEL

HS26−036, 048 5 + 1 (2.8 + .5)

HS26−018, 030, 042, 060 8 + 1 (4.44 + .5)

HS26−024 9 + 1 (5+ .5)

Liquid Line _F (_C) Warmer Than

Outside Ambient Temperature

6− When unit is properly charged liquid line pressures

should approximate those in table 9 or table 10.

D−Oil Charge

Refer to Table 1 and 2 on page 6.

Page 13

VI−MAINTENANCE

B−Indoor Coil

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at discon

nect switch(es). Unit may have multiple

power supplies.

At the beginning of each heating or cooling season, the

system should be cleaned as follows:

A−Outdoor Unit

1− Clean and inspect condenser coil. (Coil may be

flushed with a water hose).

2− Visually inspect all connecting lines, joints and coils for

evidence of oil leaks.

IMPORTANT

If insufficient heating or cooling occurs, the unit

should be gauged and refrigerant charge

checked.

1− Clean coil if necessary.

2− Check connecting lines and coil for oil leaks.

3−Check condensate line and clean if necessary.

C−Indoor Unit

1− Clean or change filters.

2− Adjust blower cooling speed. Check static pressure drop

over coil to determine correct blower CFM. Refer to Len

nox Engineering Handbook.

3− Belt Drive BlowersCheck condition/tension.

4− Check all wiring for loose connections.

5− Check for correct voltage at unit.

6− Check amp−draw on blower motor.

Unit nameplate_________Actual_________.

Page 14

VII−DIAGRAMS / OPERATING SEQUENCE

A−Unit Diagram HS26−261/461−1P (Early Models)

UNIT DIAGRAM

2

3

1

4

Operation Sequence

1− WARNING−Early HS26 units use single−

pole contactors. Capacitor terminal

COM," orange condenser fan wire and

red R" compressor wire are all con

nected to L2 at all times. Remove all

power at disconnect before servicing.

2− Cooling demand energizes thermostat ter

minal Y. Voltage from terminal Y passes

through discharge temperature sensor

(compressor thermostat) and low pressure

switch to energize time delay terminal 2.

3− Time delay action is at the beginning of a

thermostat demand. When energized, time

delay TD1−1 delays 8.5 seconds before en

ergizing TD1−1 terminal 3. When TD1−1 ter

minal 3 is energized, the contactor coil is en

ergized.

4− When compressor contactor is energized,

N.O. contactor contacts close to energize

compressor terminal C" (black wire) and

black condenser fan motor wire. Condens

er fan and compressor immediately begin

operating.

Page 15

B−Unit Diagram HS26−018/060−2P (Late Models)

Operation Sequence

1− Cooling demand energizes thermostat terminal Y. Voltage from terminal Y passes through low pressure

switch and the timed off control (TOC), which energizes K1 compressor contactor coil (provided 5 minute

delay is satisfied).

2− K1−1 and K1−2 contacts close energizing B1 compressor and B4 outdoor fan.

3− When cooling demand is satisfied, K1−1 and K1−2 contacts open de−energizing compressor and outdoor fan.

Timed off control begins 5 minute off time.

Page 16

C−Unit Diagram HS26−018/060−3 & 4−P (Late Models)

Operation Sequence

1− Cooling demand energizes thermostat terminal Y. Voltage from terminal Y passes through low pressure

switch and the timed off control (TOC), which energizes K1 compressor contactor coil (provided 5 minute

delay is satisfied).

2− K1−1 and K1−2 contacts close energizing B1 compressor and B4 outdoor fan.

3− When cooling demand is satisfied, K1−1 and K1−2 contacts open de−energizing compressor and outdoor fan.

Timed off control begins 5 minute off time.

Page 17

C−Unit Diagram HS26−036/060−1Y, −048/−060−1G Three−phase (Late Models)

Operation Sequence

1− Cooling demand energizes thermostat terminal Y. Voltage from terminal Y passes through low pressure

switch and timed off control (T.O.C.), which energizes K1 compressor contactor coil (provided 5 minute delay

is satisfied.)

2− K1−1, K1−2 and K1−3 contacts close energizing B1 compressor and B4 outdoor fan.

3− When cooling demand is satisfied, K1−1, K1−2 and K1−3 contacts open de−energizing compressor and out

door fan. Timed off control begins 5 minute off time.

NOTE−Three−phase compressors must be phased correctly. Compressor noise will be significantly higher if phasing is

incorrect. Compressor will operate backwards so unit will not provide cooling. Continued backward operation will cause

compressor to cycle on internal protector.

Page 18

Loading...

Loading...