Lennox HPXA12 Series, HPXA12-018, HPXA12-024, HPXA12-030, HPXA12-036 Unit Information

...

Corp. 0208−L3

Service Literature

Revised 09−2004

HPXA12 SERIES UNITS

The HPXA12 is a high efficiency residential split−system

heat pump unit, which features a scroll compressor and

R410A refrigerant. HPXA12 units are available in sizes

ranging from 1 1/2 through 5 tons. The series is designed

for use with an expansion valve only (approved for use with

R410A) in the indoor unit.This manual is divided into sections which discuss the major components, refrigerant system, charging procedure, maintenance and operation sequence.

Information contained in this manual is intended for use by

qualified service technicians only. All specifications are

subject to change.

IMPORTANT

Operating pressures of this R410A unit are higher

than pressures in R22 units. Always use service

equipment rated for R410A.

HPXA12

WARNING

Warranty will be voided if covered equipment is removed from original installation site. Warranty will

not cover damage or defect resulting from:

Flood, wind, lightning, or installation and operation in a corrosive atmosphere (chlorine, fluorine,

salt, recycled waste water, urine, fertilizers, or other damaging chemicals).

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect switch(es). Unit may have multiple

power supplies.

TABLE OF CONTENTS

General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications / Electrical 2. . . . . . . . . . . . . . . . . . . . . . . .

I Unit Information 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II Unit Components 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Refrigerant System 13. . . . . . . . . . . . . . . . . . . . . . . . . .

IV Charging 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V Service and Recovery 19. . . . . . . . . . . . . . . . . . . . . . . .

VI Maintenance 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII Wiring Diagram and Operating Sequence 20. . . . . .

Page 1

©2002 Lennox Industries Inc.

SPECIFICATIONS single phase

Fan

Net face area

Kit

M

General

Data

Connections

(sweat)

Refrigerant (R410A) furnished 7 lbs. 5 oz. (3.31 kg) 6 lbs. 12 oz. (3.06

Outdoor

Coil

Fan

Outdoor

Coil

Shipping Data lbs. (kg) 1 package 160 (73) 160 (73) 176 (80) 181 (82)

Diameter − in. (mm) & no. of blades

Net face area

sq. ft. (m2)

Tube diameter − in. (mm) & no. of rows

Nominal Tonnage (kW) 1.5 (5.3) 2 (7.0) 2.5 (8.8) 3 (10.6)

Liquid line o.d. − in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Vapor line o.d. − in. (mm) 3/4 (19.1) 3/4 (19.1) 3/4 (19.1) 7/8 (22.2)

Model No. HPXA12−018 HPXA12−024 HPXA12−030 HPXA12−036

Motor hp (W)

Cfm (L/s)

Rpm

Watts

Outer coil

Inner coil

Fins per inch (m)

18 (457) − 3

1/6 (124)

2500 (1180)

1100

200

15.21 (1.41)

5.44 (0.51)

5/16 (8) − 1.37

18 (709)

kg)

18 (457) − 3 18 (457) − 4 18 (457) − 4

1/6 (124) 1/6 (124) 1/6 (124)

2500 (1180) 2450 (1155) 2450 (1155)

1100 1100 1100

200 200 200

15.21 (1.41) 15.21 (1.41) 15.21 (1.41)

5.44 (0.51) 14.50 (1.35) 14.50 (1.35)

5/16 (8) − 1.37 5/16 (8) − 2 5/16 (8) − 2

18 (709) 18 (709) 18 (709)

7 lbs. 12 oz. (3.51

kg)

8 lbs. 15 oz. (4.1 kg)

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

Compressor Monitor (Canada Only) 45F08 45F08 45F08 45F08

Hail Guards 17L73 17L73 17L73 17L73

Mild Ambient Kit (LB-101122) 32M08 32M08 32M08 32M08

Monitor Kit (Canada Only) 76F53 76F53 76F53 76F53

Outdoor

Thermostat

Kit

Plastic

ounting

Base

Refrigerant

Line Set

Unit Stand-Off Kit 94J45 94J45 94J45 94J45

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Refrigerant charge is sufficient for 15 ft. (4.5 m) length line set.

NOTE − Extremes of operating range are plus 10% and minus 5% of line voltage

Part No. − Catalog Number MB2-S (69J06) MB2-S (69J06) MB2-S (69J06) MB2-S (69J06)

Suction/Vapor Line o.d. − in. (mm) 3/4 (19) 3/4 (19) 3/4 (19) 7/8 (22.2)

Liquid Line o.d. − in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Thermostat 56A87 56A87 56A87 56A87

Mounting Box − US 31461 31461 31461 31461

Canada 33A29 33A29 33A29 33A29

Net Weight 6 lbs. (3 kg) 6 lbs. (3 kg) 6 lbs. (3 kg) 6 lbs. (3 kg)

30 ft. (9 m) length L15−41−30 L15−41−30 L15−41−30 L15−65−30

40 ft. (12 m) length L15−41−40 L15−41−40 L15−41−40 L15−65−40

50 ft. (15 m) length L15−41−50 L15−41−50 L15−41−50 L15−65−50

Page 2

SPECIFICATIONS single phase Cont.

Fan

Net face area

Kit

M

g

p

General

Data

Connections

(sweat)

Refrigerant (R410A) furnished 9 lb. 2 oz. (4.13 kg) 11 lbs. 5 oz. (5.12 kg) 11 lbs. 3 oz. (5.06 kg)

Outdoor

Coil

Outdoor

Coil

Shipping Data lbs. (kg) 1 package 190 (86) 244 (111) 244 (111)

Diameter − in. (mm) & no. of blades 18 (457) − 4 22 (559) − 4 22 (559) − 4

Net face area

sq. ft. (m2)

Tube diameter − in. (mm) & no. of rows 5/16 (8) − 2 5/16 (8) − 2 5/16 (8) − 2

Nominal Tonnage (kW) 3.5 (12.3) 4 (14.1) 5 (17.6)

Liquid line o.d. − in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Vapor line o.d. − in. (mm) 7/8 (22.2) 7/8 (22.2) 1−1/8 (28.6)

Model No. HPXA12−042 HPXA12−048 HPXA12−060

Motor hp (W) 1/3 (249) 1/3 (249) 1/3 (249)

Cfm (L/s) 2930 (1385) 3890 (1835) 3890 (1835)

Rpm 1100 1085 1085

Watts 310 375 375

Outer coil 15.21 (1.41) 21.11 (1.96) 21.11 (1.96)

Inner coil 14.50 (1.35) 20.31 (1.89) 20.31 (1.89)

Fins per inch (m) 22 (860) 22 (860) 22 (860)

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

Compressor Monitor (Canada Only) 45F08 45F08 45F08

Hail Guards 17L73 17L74 17L74

Mild Ambient Kit (LB-101122) 32M08 32M08 32M08

Monitor Kit (Canada Only) 76F53 76F53 76F53

Outdoor

Thermostat

Plastic

ounting

Base

Refrigerant

Line Set

Unit Stand-Off Kit 94J45 94J45 94J45

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Refrigerant charge is sufficient for 20 ft. (6.1 m) length line set.

NOTE − Extremes of operating range are plus 10% and minus 5% of line voltage

Part No. − Catalog Number MB2-S (69J06) MB2-L (69J07) MB2-L (69J07)

Suction/Vapor Line o.d. − in. (mm) 7/8 (22.2) 7/8 (22.2) 1−1/8 (28.5)

Liquid Line o.d. − in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Thermostat 56A87 56A87 56A87

Mounting Box − US 31461 31461 31461

Canada 33A29 33A29 33A29

Net Weight 6 lbs. (3 kg) 15 lbs. (7 kg) 15 lbs. (7 kg)

30 ft. (9 m) length L15−65−30 L15−65−30 Field Fabricate

40 ft. (12 m) length L15−65−40 L15−65−40 Field Fabricate

50 ft. (15 m) length L15−65−50 L15−65−50 Field Fabricate

ELECTRICAL DATA

Model No. HPXA12−018 HPXA12−024 HPXA12−030 HPXA12−036 HPXA12−042 HPXA12−048 HPXA12−060

Line voltage data − 60 hz − 1 phase 208/230v 208/230v 208/230v 208/230v 208/230v 208/230v 208/230v

Recommended maximum fuse or

circuit breaker size (amps)

{Minimum circuit ampacity 14.0 18.0 20.0 20.4 25.9 30.8 36.4

Compressor

Outdoor Coil

Fan Motor

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

Rated load amps 10.3 13.5 15.1 15.4 19.2 23.1 27.6

Power factor .98 .98 .98 .98 .99 .99 .99

Locked rotor amps 51 61 72.5 83 104 134 158

Full load amps 1.1 1.1 1.1 1.1 1.9 1.9 1.9

Locked rotor amps 1.9 1.9 1.9 1.9 4.1 4.1 4.1

20 30 35 35 45 50 60

Page 3

SPECIFICATIONS three phase

Fan

Net face area

p

Kit

g

g

General

Data

Connections

(sweat)

1

Refrigerant (R410A) furnished 8 lbs. 15 oz. (4.1 kg) 11 lbs. 5 oz. (5.1 kg) 11 lbs. 3 oz. (5.1 kg)

Outdoor

Diameter − in. (mm) & no. of blades 18 (457) − 4 22 (559) − 4 22 (559) − 4

Nominal Tonnage (kW) 3 (10.6) 4 (14.1) 5 (17.6)

Liquid line o.d. − in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Vapor line o.d. − in. (mm) 7/8 (22.2) 7/8 (22.2) 1−1/8 (28.6)

Coil

Outdoor

Coil

Net face area

sq. ft. (m2)

Tube diameter − in. (mm) & no. of rows 5/16 (8) − 2 5/16 (8) − 2 5/16 (8) − 2

Shipping Data 1 package − lbs. (kg) 181 (82) 244 (111) 244 (111)

ELECTRICAL DATA

Line voltage data − 60 hz − 3 phase 208/230V 460V 208/230V 460V 208/230V 460V

2

Maximum overcurrent protection (amps) 25 10 35 15 40 20

3

Minimum circuit ampacity 15.4 6.9 21.9 9.8 24.5 12.2

Compressor

Locked Rotor amps 77 35 91 46 137 62

Outdoor Coil

Fan Motor

Locked Rotor Amps 2.3 1 4.1 2.1 4.1 2.1

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

Compressor Low Ambient Cut−Off 45F08 45F08 45F08

Compressor Sound Cover 69J03 69J03 69J03

Compressor Crankcase Heater 67K90 67K89 Factory Installed Factory Installed

Freezestat

Hail Guards 17L73 17L74 17L74

Low Ambient Kit 54M89 54M89 54M89

Mild Weather Kit 33M07 33M07 33M07

Monitor Kit − Service Light 76F53 76F53 76F53

Outdoor

Thermostat

Kit

Mounting

Base

Refrigerant

Line Set

Unit Stand-Off Kit 94J45 94J45 94J45

NOTE − Extremes of operating range are plus 10% and minus 5% of line voltage.

1

Refrigerant charge is sufficient for 15 ft. (4.6 m) length line set.

2

HACR tyoe circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

Mounting Box − US 31461 31461 31461

15 ft. (4.6 m) length L15−65−15 L15−65−15 Field Fabricate

40 ft. (12 m) length L15−65−40 L15−65−40 Field Fabricate

50 ft. (15 m) length L15−65−50 L15−65−50 Field Fabricate

Model No. HPXA12−036 HPXA12−048 HPXA12−060

Motor hp (W) 1/6 (124) 1/3 (249) 1/3 (249)

Cfm (L/s) 2450 (1155) 3890 (1835) 3890 (1835)

Rpm 1100 1085 1085

Watts 200 375 375

Outer coil 15.21 (1.41) 21.11 (1.96) 21.11 (1.96)

Inner coil 14.50 (1.35) 20.31 (1.89) 20.31 (1.89)

Fins per inch (m) 18 (709) 22 (860) 22 (860)

Model No. HPXA12−036

Rated load amps

−233

11.5 5.1 16 7.1 18.1 9

HPXA12−036

−463

HPXA12−048

−233

HPXA12−048

−463

HPXA12−060

−233

HPXA12−060

Power Factor .98 .98 .99 .99 .99 .99

Full load amps

1 .55 1.9 .9 1.9 .9

3/8 in. tubing 93G35 93G35 93G35

1/2 in. tubing 39H29 39H29 39H29

5/8 in. tubing 50A93 50A93 50A93

Thermostat 56A87 56A87 56A87

Canada 33A09 33A09 33A09

Model (Catalog) No. MB2-S (69J06) MB2-L (69J07) MB2-L (69J07)

Net Weight 6 lbs. (3 kg) 15 lbs. (7 kg) 15 lbs. (7 kg)

30 ft. (9 m) length L15−65−30 L15−65−30 Field Fabricate

−463

Page 4

I − UNIT INFORMATION

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit installation and service to protect the unit’s electronic

controls. Precautions will help to avoid control

exposure to electrostatic discharge by putting

the unit, the control and the technician at the

same electrostatic potential. Neutralize electrostatic charge by touching hand and all tools on an

unpainted unit surface before performing any

service procedure.

All major components (indoor blower and coil) must be

matched according to Lennox recommendations for the

compressor to be covered under warranty. Refer to the Engineering Handbook for approved system matchups. A

missapplied system will cause erratic operation and can result in early compressor failure.

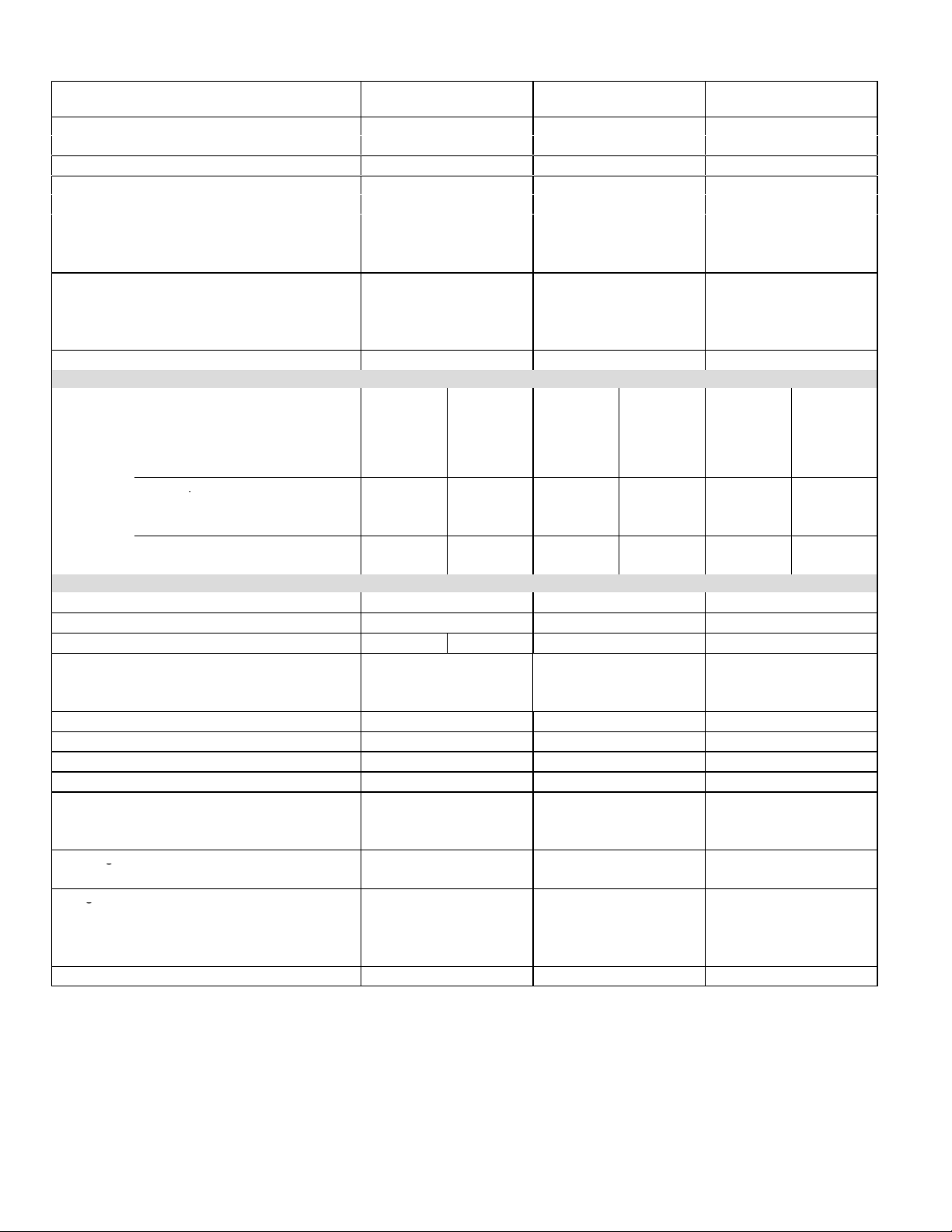

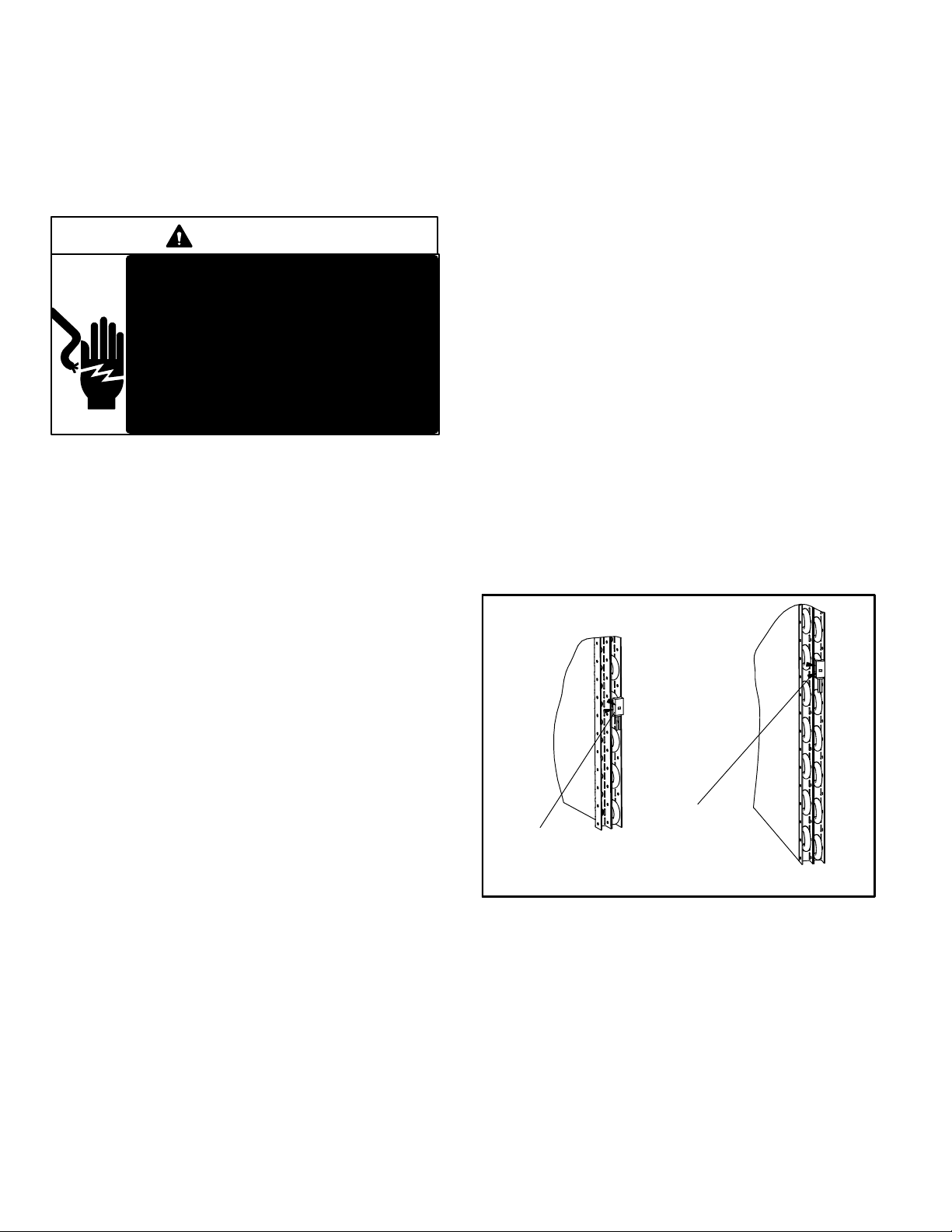

A − Control Box (Figures 2 and 3)

HPXA12 units are not equipped with a 24V transformer. All

24 VAC controls are powered by the indoor unit. Refer to

wiring diagram.

SINGLE PHASE UNIT CONTROL BOX

DUAL CAPACITOR

(C12)

COMPRESSOR

CONTACTOR

(K1)

DEFROST

GROUNDING

LUG

FIGURE 2

CONTROL

(A108)

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox’ Engineering Handbook.

II − UNIT COMPONENTS

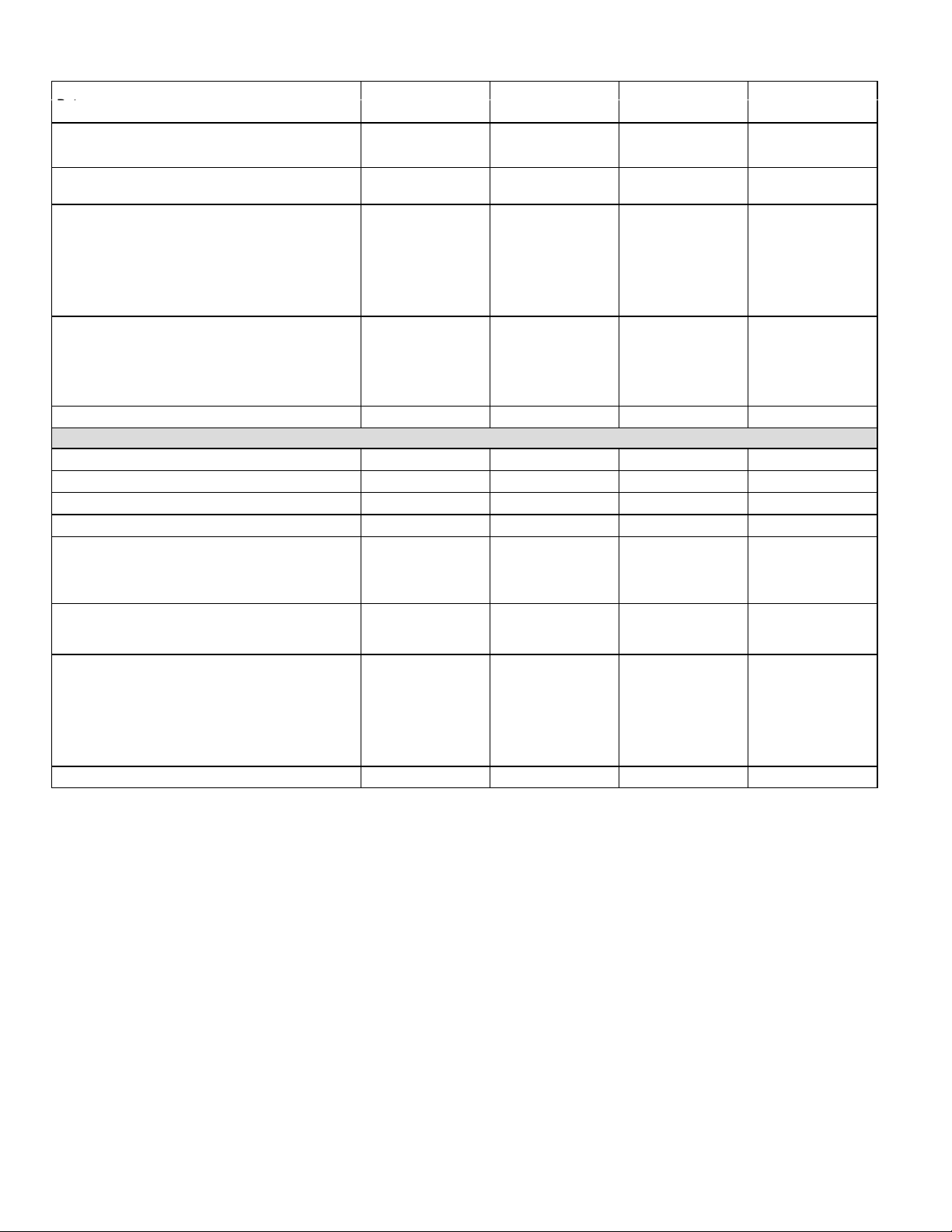

Unit components are illustrated in figure 1.

OUTDOOR

FAN/MOTOR

HPXA12 UNIT COMPONENTS

CONTROL

BOX

SUCTION

MUFFLER

REVERSING

VALV E

THREE PHASE UNIT CONTROL BOX

RUN CAPACITOR

(C1)

OUTDOOR FAN

RELAY (K10)

460 VOLTAGE

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

ONLY

DEFROST

CONTROL

(A108)

FIGURE 3

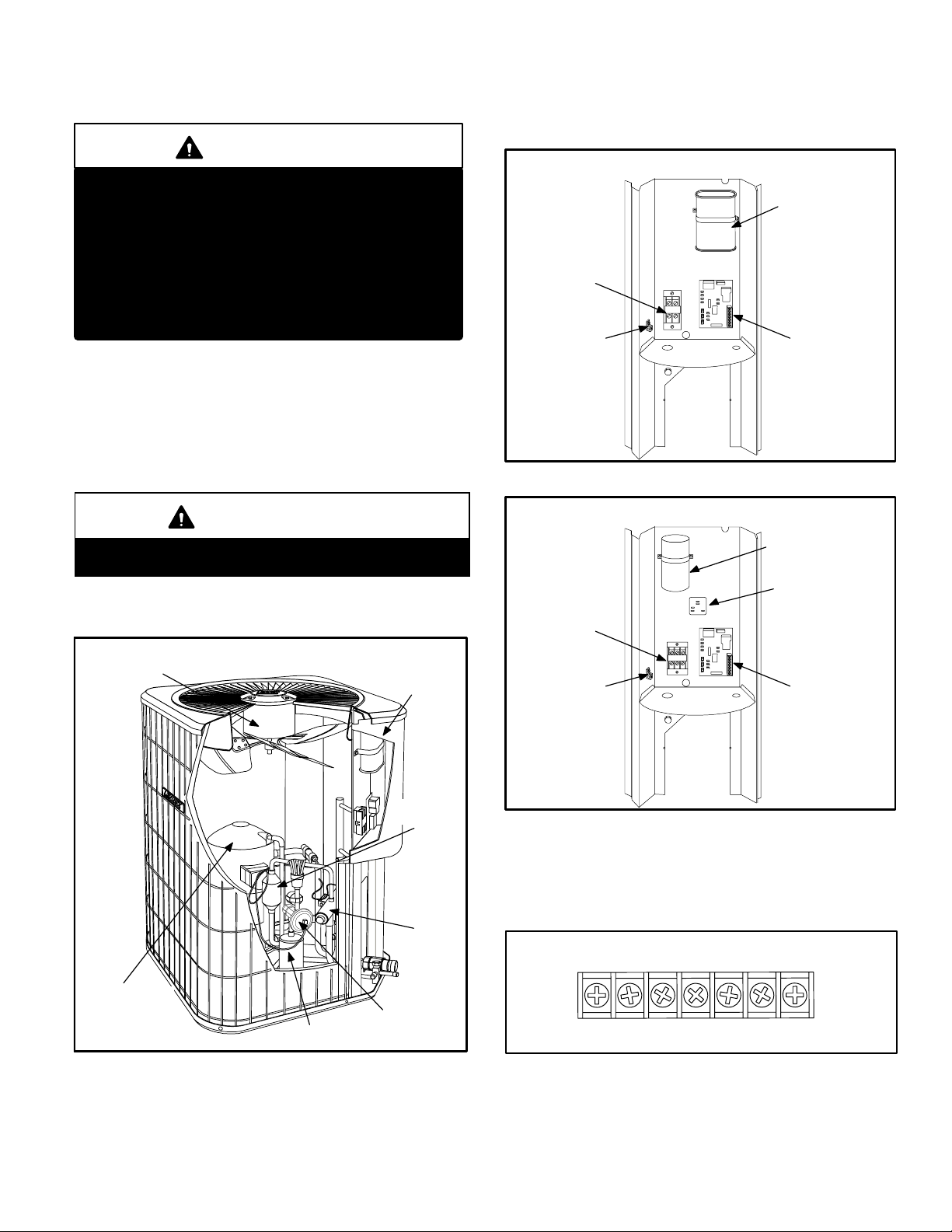

Electrical openings are provided under the control box cover. Field thermostat wiring is made to a 24V terminal strip

located on the defrost control board located in the control

box. See figure 4.

24V THERMOSTAT TERMINAL STRIP

COMPRESSOR

BI-FLOW

FILTER DRIER

FIGURE 1

CHECK/EXPANSION

VALV E

Page 5

Y2

CRW1OY1L

FIGURE 4

1 − Compressor Contactor K1

The compressor is energized by a contactor located in the

control box. See figure 2. Single−pole contactors are used

in single−phase HPXA12 series units and three pole contactors are used in HPXA12 three−phase units. K1 is energized through the control board by the indoor thermostat

terminal Y1 (24V) when thermostat demand is present.

DANGER

Electric Shock Hazard.

May cause injury or death.

Line voltage is present at all components when unit is not in operation on

units with single pole contactors.

Disconnect all remote electrical power

supplies before opening unit panel.

Unit may have multiple power supplies.

2 − Outdoor Fan Relay K10 (460V units only)

Outdoor fan relay K10, used in 460V units only, is a SPST

normally open relay. K10 is energized by contactor K1

which in turn energizes outdoor fan B4 in response to thermostat demand.

3 − Run Capacitor C1 (three phase only)

The fan in all three−phase units uses a single−phase permanent split capacitor motor. A single capacitor C1 is used for

the fan motor. C1 is located inside the control box. See figure 3. Fan motor nameplate will have capacitor ratings.

The demand defrost board uses basic differential temperature means to detect degradation of system performance

due to ice build−up on the outdoor coil. Further, the controller uses self−calibrating" principles to calibrate itself when

the system starts and after each time the system defrosts.

The control board has defrost relays, anti−short cycle

timed−off control, pressure switch/safety control, 3−strike

lockout circuit, field test pins, ambient and coil temperature sensors, field selectable termination temperature and

a field low voltage connection terminal strip.

The control monitors ambient temperature, outdoor coil

temperature and total run time to determine when a defrost cycle is required. Two temperature probes are permanently attached to the control. The coil temperature

probe is designed with a spring clip to allow mounting to

the outside coil tubing. The location of the coil sensor is important for proper defrost operation. On HPXA12−018 &

−024 the sensor should located on the 4th hairpin bend

from the bottom. HPXA12−030 through −060 units the sensor should located on the 6th hairpin bend from the bottom. See figure 5.

NOTE − The logic of the Demand Defrost Board provides

accurate performance measurements of the system as

FROST accumulates on the outdoor coil. This will translate

into longer running time in the heating mode with FROST

accumulations on the outdoor coil before the board initiates

any defrost cycles.

COIL SENSOR LOCATION

4 − Dual Capacitor C12

The compressor and fan in single phase HPXA12 series units

use permanent split capacitor motors. The capacitor is located

inside the unit control box (see figure 2). A single dual" capacitor (C12) is used for both the fan motor and the compressor

(see unit wiring diagram). The fan side and the compressor

side of the capacitor have different MFD ratings. See side of

capacitor for ratings.

5 − Demand Defrost System

Boards 60L3901, 46M8201, 56M8501

The HPXA12 will be equipped with one of three model defrost boards. Differences are minimal:

Three strike lock out feature (60L3901)

Five strike out feature (46M8201, 56M8501)

Terminal T" for ambient sensor (60L3901)

Terminal Y2" for 2nd stage thermostat input (46M8201,

56M8501).

DELAY" pins (56M8501)

On HPXA12−030 /

On HPXA12−018,

−024 units,clip the coil

sensor clip on the 4th

bend from the bottom

The temperature probes cannot be detached from the control. The control and the attached probes MUST be replaced as a unit. Do not attempt to cut or splice probe wires.

−060 units,clip the coil

sensor clip on the 6th

bend from the bottom

FIGURE 5

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the condition.

See table 1.

Page 6

HI−PS/LO−PS Terminals

High pressure switch (S4) is factory wired into the defrost

board HI−PS terminals. When (S4) trips, the defrost board

will cycle off the compressor and the strike counter in the

board will count one strike.

Low pressure switch (S87) is factory wired into the defrost

board LO−PS terminals. When (S87) trips, the defrost

board will cycle off the compressor and the strike counter

in the board will count one strike.

(S87) is ignored during certain conditions:

During the defrost cycle and 90 seconds after the

termination of defrost

When the average ambient sensor temperature is

below 15 F (−9)

For 90 seconds following the start up of the

compressor

During "Test" mode

3−Strike Lockout Feature

(Board 60L3901)

The internal control logic of the board counts the pres-

sure switch trips only while the Y1 (Input) line is active. If

a pressure switch opens and closes twice during a Y1

(Input), the control logic will reset the pressure switch

trip counter to zero at the end of the Y1 (Input). If the

pressure switch opens for a third time during the current

Y1 (Input), the control will enter a lockout condition.

The 3−strike pressure switch lockout condition can be re-

set by cycling OFF the 24−volt power supply to the control board or by shorting the TEST pins. All timer functions (run times) will also be reset.

If a pressure switch becomes open while the Y1 Out line

is engaged, a 5 minute short cycle will occur after the

switch closes.

5−Strike Lockout Feature

(Boards 46M8201, 56M8501)

The internal control logic of the board counts the pres-

sure switch trips only while the Y1 (Input) line is active. If

a pressure switch opens and closes 4 times during a Y1

(Input), the control logic will reset the pressure switch

trip counter to zero at the end of the Y1 (Input). If the

pressure switch opens for a fifth time during the current

Y1 (Input), the control will enter a lockout condition.

The 5−strike pressure switch lockout condition can be re-

set by cycling OFF the 24−volt power supply to the control board or by shorting the TEST pins. All timer functions (run times) will also be reset.

If a pressure switch becomes open while the Y1 Out line

is engaged, a 5 minute short cycle will occur after the

switch closes.

Operational Description

The demand defrost board has three basic operational

modes: Normal, Defrost, and Calibration.

Normal Mode

The demand defrost board monitors the O" line, to determine the system operating mode (heat/cool), outdoor ambient temperature, coil temperature (outdoor coil) and compressor run time to determine when a defrost cycle is required.

Defrost Mode

When a defrost cycle is initiated, the control energizes the

reversing valve solenoid and turns off the condenser fan.

The control will also put 24VAC on the W1" (auxiliary heat)

line. The unit will stay in this mode until either the coil sensor

temperature is above the selected termination temperature, the defrost time of 14 minutes has been completed, or

the room thermostat demand cycle has been satisfied. (If

the temperature select shunt is not installed, the default termination temperature will be 100°F.) If the room thermostat

demand cycle terminates the cycle, the defrost cycle will be

held until the next room thermostat demand cycle. If the coil

sensor temperature is still below the selected termination

temperature, the control will continue the defrost cycle until

the cycle is terminated in one of the methods mentioned

above. If a defrost is terminated by time and the coil temperature did not remain above 35°F (2°C) for 4 minutes, the

control will go to the 34−minute Time/Temperature mode.

DELAY" PINS

The 56M8501 defrost board has a field selectable function

to reduce occasional noise that may occur while the unit is

cycling in and out of defrost mode. When a jumper is

installed on the DELAY" pins, the compressor will cycle off

for 30 seconds going in and out of defrost mode. Units are

shipped with jumper installed on DELAY" pins.

NOTE − 30 second off cycle is not functional when

jumpering TEST" pins.

Calibration Mode

The board is considered uncalibrated when power is applied to the board, after cool mode operation, or if the coil

temperature exceeds the termination temperature when it

is in heat mode. Calibration of the board occurs after a defrost cycle to ensure that there is no ice on the coil. During

calibration, the temperature of both the coil and the ambient

sensor are measured to establish a temperature differential

required to allow a defrost cycle.

Page 7

Loading...

Loading...