Page 1

06/04

*2P0604*

504,538M

*P504538M*

Page 1

2000 Lennox Industries Inc.

Dallas, Texas, USA

®

HP40 Heat Pump Unit

HP40 heat pumps use R407C which is an ozone friendly

HFC refrigerant. This unit must be installed with a matching indoor coil and line set as outlined in the Lennox Engineering Handbook. HP40 heat pumps are designed for

use in expansion valve systems only. They are not designed to be used in RFC systems. An expansion valve

and filter drier approved for use with R407C have been

shipped with the unit. These components must be

installed prior to unit operation.

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox’ Engineering Handbook.

Coils previously charged with R22 must be

flushed.

WARNING

This equipment must only be installed and serviced

by properly qualified personnel. Equipment contains dangerous voltages and moving parts. Always switch off power supply before opening any

access panel. Electrical control panel doors and fan

access door must be locked to prevent unauthorized access at beginning of instruction.

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

INSTALLATION

INSTRUCTIONS

HP40 Heat Pump Units

HEAT PUMP UNITS

1−1/2 through 5 ton

504,538M

06/04

Supersedes 11/02

Table of Contents

HP40 Heat Pump Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plumbing 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Metering Device 5. . . . . . . . . . . . . . . . . . . . .

Manifold Gauge Set 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Liquid & Vapor Line Service Valves 7. . . . . . . . . . . . . . .

Leak Testing 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Evacuation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging Considerations 10. . . . . . . . . . . . . . . . . . . . . . .

System Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defrost System 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Shipping & Packing List

1 − Assembled HP40 heat pump unit

1 − Bag assembly:

1 − Sight glass

1 − Coupling reducer, 5/16 x 3/8 inch (024)

Check unit for shipping damage. If any damage is found,

contact the last carrier immediately.

General Information

These instructions are intended as a general guide and

do not supersede national or local codes in any way. Consult authorities having jurisdiction before installation.

The HP40 unit is CE marked" in accordance with the requirements of the latest European Directives for Electrical

and Machinery Safety and Electromagnetic Compatibility.

In addition, HP40 units have type Approval Certification

with the Gas Appliance Directive.

IMPORTANT

International Legislation bans the intentional venting of refrigerant (CFCs and HCFCs). Approved

methods of recovery, recycling or reclaiming must

be followed. Fines and/or incarceration may be levied for noncompliance.

Litho U.S.A.

Page 2

Page 2

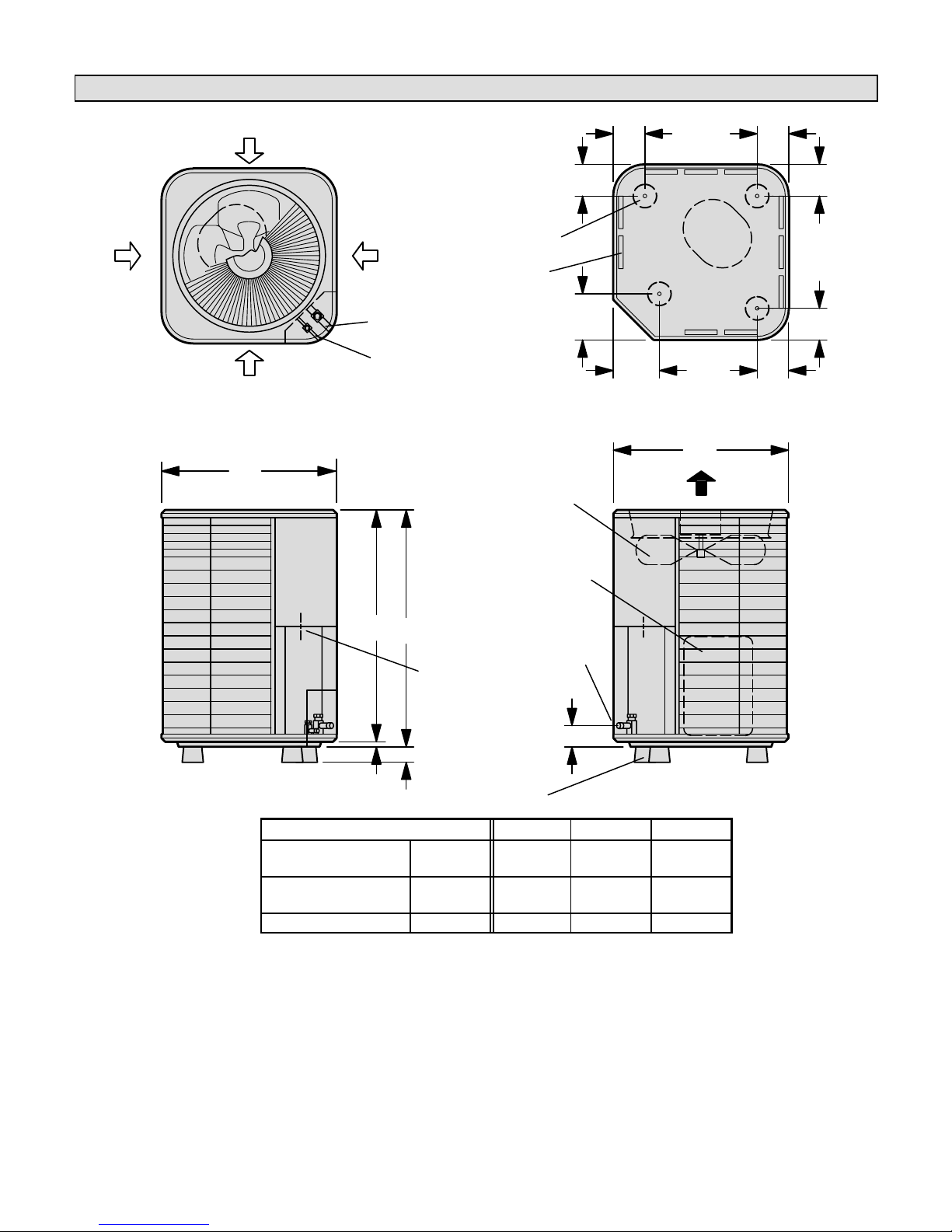

Unit Dimensions − mm

SIDE VIEW

VAPOR &

LIQUID LINE

CONNECTION

INLET

AIR

INLET

AIR

DISCHARGE AIR

SIDE VIEW

TOP VIEW

A

OUTDOOR

COIL FAN

COMPRESSOR

INLET AIR

INLET AIR

B

70

HP40

ELECTRICAL

INLETS

111

162

162

TOP VIEW BASE SECTION

51

19

111

111

111111

111

COMPRESSOR

COIL DRAIN OUTLETS

(Around perimeter of base)

OPTIONAL

STAND-OFF KIT

(Field−installed

4 required)

LIQUID LINE

CONNECTION

VAPOR LINE

CONNECTION

C

C

OPTIONAL

STAND-OFF KIT

(Field−installed

4 required)

Model Number A B C

HP40-018

HP40-024

mm 635 616 616

HP40-036

HP40-048

mm 838 819 616

HP40-060 mm 946 927 718

Page 3

Page 3

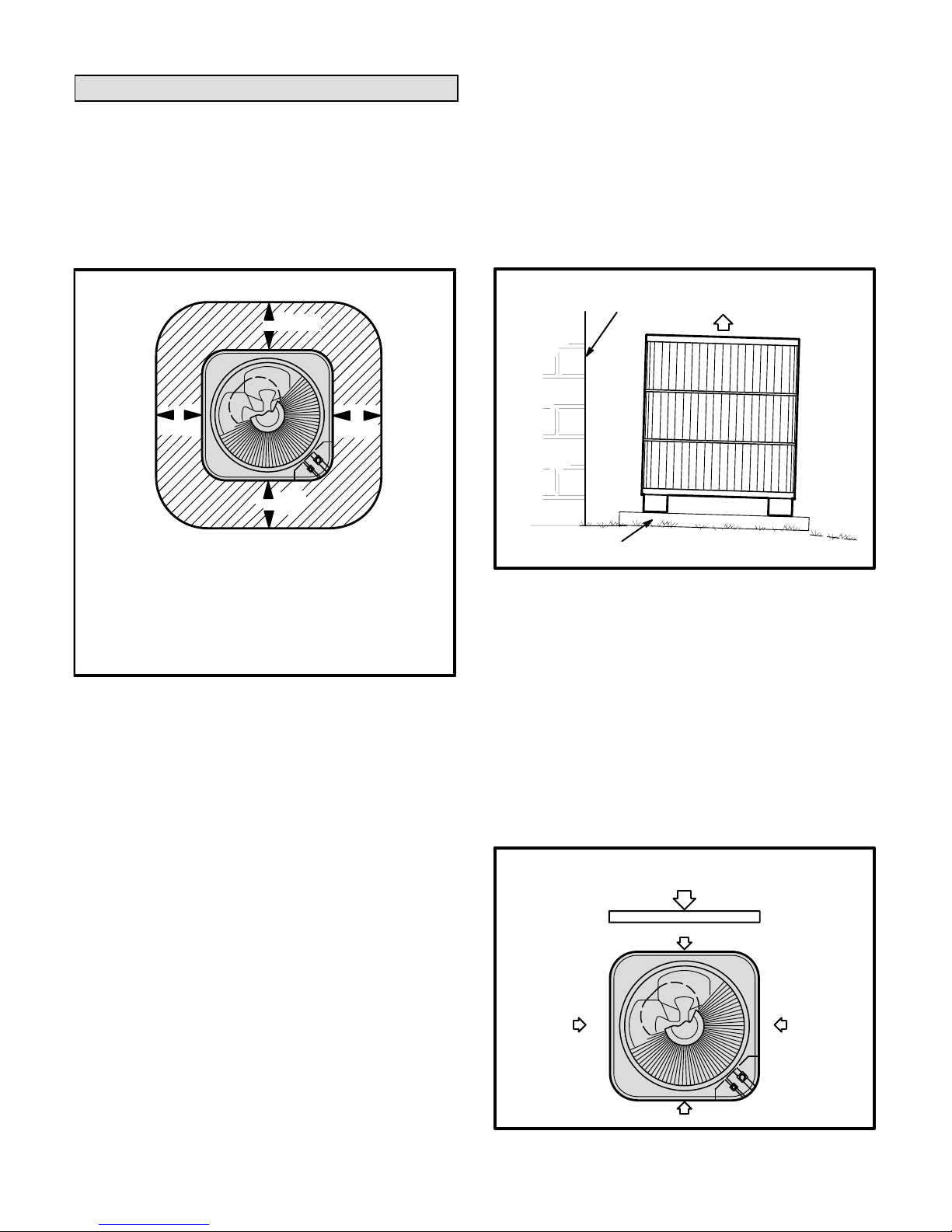

Setting the Unit

Heat pump units operate under a wide range of weather

conditions; therefore, several factors must be considered when positioning the outdoor unit. The unit must be

positioned to give adequate clearances for sufficient airflow and servicing. Maintain a minimum clearance of 610

mm between multiple units. Refer to figure 1 for installation clearances.

36

(914 mm)

Installation Clearances

36*

(914 mm)

*NOTE − A service clearance of 30" (762 mm) must be maintained on one of the sides adjacent to the control box. Clearance to one of the other three sides must be 36" (914 mm).

Clearance to one of the remaining two sides may be 12" (304

mm) and the final side may be 6" (152 mm).

36*

(914 mm)

NOTE − A clearance of 24" (610 mm) must be maintained

between two units.

NOTE − 48" (1219 mm) clearance required on top

of unit. Maximum soffit overhang is 36" (914 mm).

36

(914 mm)

FIGURE 1

1 − Place a sound-absorbing material, such as Isomode,

under the unit if it will be installed in a location or position that will transmit sound or vibration to the living

area or adjacent buildings.

2 − Install the unit high enough above the ground or roof

to allow adequate drainage of defrost water and prevent ice buildup.

3 − In areas that receive heavy snow, do not locate the

unit where drifting will occur. Ensure that the unit base

is elevated above the depth of average snows.

NOTE − Elevate the unit by constructing a frame using

suitable materials. If a support frame is constructed, it

must not block drain holes in the base of the unit.

4 − When you install the unit in areas where low ambient

temperatures exist, locate the unit so winter prevailing winds do not blow directly into outdoor coil.

5 − Locate unit away from overhanging roof lines which

would allow water or ice to drop on, or in front of, coil

or into unit.

Slab Mounting (See figure 2)

When the unit is installed at grade level, the top of the slab

should be high enough above the grade so that water

from higher ground will not collect around unit. Slab

should have a slope tolerance away from the building of 2

degrees or 51 mm per 1.5 m. This will prevent ice from

building up under the unit during a defrost cycle. Refer to

roof mounting section for barrier construction if unit must

face prevailing winter winds.

SLAB MOUNTING AT GROUND LEVEL

DISCHARGE AIR

MOUNTING SLAB MUST SLOPE

AWAY FROM BUILDING.

GROUND LEVEL

STRUCTURE

FIGURE 2

Roof Mounting (See figure 3)

If you are unable to mount the unit coil away from prevailing winter winds, construct a wind barrier. Size the barrier

at least the same height and width as the outdoor unit.

Mount the barrier 610 mm from the sides of the unit in the

direction of prevailing winds.

Install the unit at a minimum of 152 mm above the roof

surface to keep ice from building up around the unit. Locate the unit above a load bearing wall or area of the roof

that can adequately support the unit. Consult local codes

for rooftop applications.

WIND BARRIER

INLET AIR

INLET AIR

INLET AIR

INLET AIR

PREVAILING WINTER WINDS

ROOFTOP APPLICATION

WIND BARRIER CONSTRUCTION

FIGURE 3

Page 4

Page 4

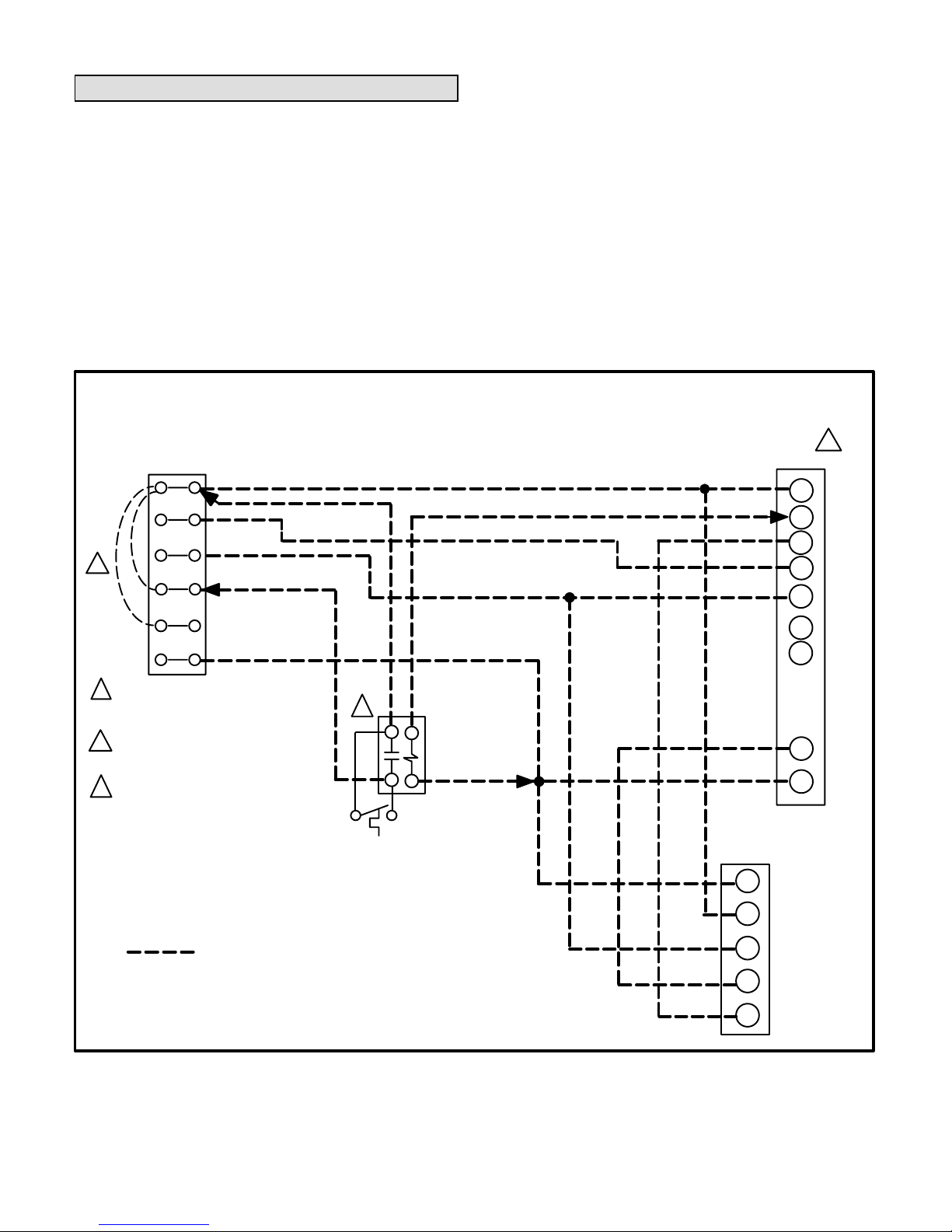

Electrical

Wiring must conform with current local codes. An application diagram is included in this instruction and in the indoor

unit instructions.

Refer to the unit rating plate, located on the control box cover, for minimum circuit ampacity and maximum fuse size.

1 − Provide line voltage power supply to the unit from a

properly sized disconnect switch. The disconnect

switch should be located so that it is easily accessible

and within sight of the unit.

2 − Route the power and ground wires from the discon-

nect switch to the unit. The electrical openings are

provided under the control box cover. See the unit di-

mensions illustration on page 2.

3 − Remove the control box cover and connect the power

wiring to the contactor. Connect ground wire to ground

lug.

4 − Install the room thermostat (ordered separately) in

the conditioned area. Place the thermostat where it

will not be affected by sunlight, drafts, or vibration. Do

not install the thermostat on an outside wall. The most

desirable position for the thermostat is near the center of the conditioned area and approximately 1.5 m

from the floor.

5 − Route 24VAC control wires from the thermostat to the

indoor unit and from the indoor unit to the defrost control terminals in the outdoor unit as shown in figure 4.

FIELD WIRING DIAGRAM FOR HP40 UNIT

W2

C

W1

G

O

Y1

S1 THERMOSTAT

1

LOW VOLTAGE

FIELD INSTALLED

1

EMERGENCY HEAT RELAY (USED ONLY

IF OUTDOOR THERMOSTAT IS USED)

FIELD PROVIDED AND INSTALLED NEAR

INDOOR UNIT 24VAC 5VA MAX NEC

CLASS 2.

2

NOTE−ALL REMAINING WIRES FACTORY INSTALLED

3

HP40

LOW VOLTAGE

TERMINAL

CONNECTIONS

THERMOSTAT HEAT ANTICIPATION SETTING .4 AMP ELECTRIC HEAT FOR THERMOSTATS WITH ADJUSTABLE ANTICIPATORS.

IF OUTDOOR THERMOSTAT IS USED, REMOVE JUMPER BETWEEN TERMINALS R"

AND W2."

R

Y2

E

COMMON

BEIGE (ELECTRIC HEAT)

ORANGE

YELLOW (COMPRESSOR)

RED (POWER)

TB1 TERMINAL STRIP

(INDOOR UNIT CONTROL BOX)

C

G

W1

W2

W3

R

S23

EM HEAT RELAY K26

OUTDOOR

THERMOSTAT

(IF USED)

2

3

R

C

O

W1

Y1

REVERSINNG VALVE

FIGURE 4

Page 5

Page 5

Plumbing

Field refrigerant piping consists of liquid and vapor lines

from the heat pump (sweat connections) to the indoor

evaporator coil. Use Lennox L15 (sweat connection) series line sets as shown in table 1 or use field-fabricated refrigerant lines. Refer to Refrigerant Piping Guide (Corp.

9351−L9) for proper size, type, and application of field−

fabricated lines.

If refrigerant tubes are routed through a wall, seal and isolate the opening so vibration is not transmitted to the

building.

NOTE − Line length should be no greater than 15.2 m. Select line set diameters from table 1 to ensure that the oil

returns to the compressor.

TABLE 1

REFRIGERANT LINE SET KITS

HP40 UNIT

LIQUID

LINE

SUCTION

LINE

L15 LINE

SETS

HP40−024 8 mm* 16 mm

L15 − 21

4.6 m − 15 m

HP40−036 10 mm 19 mm

L15 − 41

4.6 m − 15 m

HP40−048 10 mm 22 mm

L15 − 65

4.6 m − 15 m

HP40−060 10 mm 29 mm

FIELD

FABRICATED

*Use the coupling reducer that is supplied in the bag assembly.

Sweat Connection Procedure

1 − The ends of refrigerant lines must be cut square, free

from nicks or dents and deburred. The pipe must remain round. Do not pinch the end of the line.

2 − Wrap a wet cloth around the liquid line valve body and

copper tube stub to protect them from heat damage

during brazing. Wrap another wet cloth underneath

the liquid valve to protect the base paint.

3 − Quench the joints with a wet cloth to prevent possible

heat damage to the valve core and opening port.

Refrigerant Metering Device

HP40 units are applicable to thermal expansion valve

systems only. An expansion valve appropriate for use

with R407C refrigerant is shipped with the outdoor unit.

IMPORTANT

Failure to remove an existing refrigerant flow control orifice when installing an expansion valve on

the indoor coil will result in improper operation and

damage to the system.

Flushing Existing Line Set and Indoor Coil

IMPORTANT

If this unit is being matched with an approved line

set or indoor coil which was previously charged

with R22 refrigerant, or if it is being matched with

a coil which was manufactured before January of

1999, the coil and line set must be flushed prior to

installation. Take care to empty all existing traps.

Polyol ester (POE) oils are used in Lennox units

charged with R407C refrigerant. Polyol ester oils

are not compatible with mineral oils. Residual

mineral oil can act as an insulator, preventing

proper heat transfer. It can also clog the thermal

expansion valve, reducing system performance

and capacity.

Failure to properly flush the system per the instructions below will void the warranty.

CAUTION

This procedure should not be performed on systems which contain contaminants (Example:

compressor burn out).

Required Equipment

You will need the following equipment in order to flush the

existing line set and indoor coil: two clean R22 recovery

bottles, an oilless recovery machine with a pump down

feature, and two sets of gauges (one or use with R22 and

one for use with the R407C).

Flushing Procedure

1 − Remove existing R22 refrigerant using the appropri-

ate procedure below.

If the existing outdoor unit is not equipped with shut−

off valves, or if the unit is not operational AND you

plan to use the existing R22 refrigerant to flush the

system −− Disconnect all power to the existing out-

door unit. Connect the existing unit, a clean recovery

cylinder and the recovery machine according to the

instructions provided with the recovery machine. Remove all R22 refrigerant from the existing system.

Refer to gauges after shutdown to confirm that the

entire system is completely void of refrigerant. Disconnect the liquid and vapor lines from the existing

outdoor unit.

If the existing outdoor unit is equipped with manual

shut−off valves AND you plan to use NEW R22 refrigerant to flush the system −− Start the existing R22 sys-

tem in the cooling mode and close the liquid line

valve. Pump all of the existing R22 refrigerant back

into the outdoor unit. (It may be necessary to bypass

Page 6

Page 6

the low pressure switches to ensure complete refrigerant evacuation.) When low side system pressures

reach 0 psig, close the suction line valve. Disconnect

all power to the existing outdoor unit. Refer to gauges

after shutdown to confirm that the valves are not allowing refrigerant to flow back into the low side of the

system. Disconnect the liquid and vapor lines from

the existing outdoor unit.

2 − Remove the existing outdoor unit. Set the new

R407C unit and follow the brazing connection procedure to make line set connections. DO NOT install

provided R407C check/expansion valve at this

time.

Make low voltage and line voltage connections to the

new outdoor unit. DO NOT turn on power to the

unit or open the outdoor unit service valves at

this time.

3 − Remove the existing refrigerant flow control orifice or

thermal expansion/check valve before continuing

with flushing procedures. The existing devices are

not approved for use with R407C refrigerant and may

prevent proper flushing. Use a field−provided fitting to

reconnect the lines.

4 − Remove the pressure tap valve cores from the HP32

unit’s service valves. Connect an R22 cylinder with

clean refrigerant to the suction service valve. Connect the R22 gauge set to the liquid line valve and

connect a recovery machine with an empty recovery

tank to the gauge set.

IMPORTANT

The line set and indoor coil must be flushed with

at least the same amount of clean refrigerant that

previously charged the system. Check the charge

in the flushing cylinder before proceeding.

5 − Set the recovery machine for liquid recovery and

start the recovery machine. Open the gauge set

valves to allow the recovery machine to pull a vacuum on the existing system line set and indoor coil.

6 − Invert the cylinder of clean R22 and open its valve to

allow liquid refrigerant to flow into the system through

the suction line valve. Allow the refrigerant to pass

from the cylinder, through the line set and the indoor

coil before entering the recovery machine.

7 − After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so

that all of the R22 vapor is recovered. All the recovery

machine to pull a vacuum on the system.

NOTE − A single system flush should remove all of

the mineral oil from the existing refrigerant lines and

indoor coil. A second flushing may be done (using

clean refrigerant) if insufficient amounts of mineral oil

were removed during the first flush. Each time the

system is flushed, you must allow the recovery

machine to pull a vacuum on the system at the

end of the procedure.

FLUSHING CONNECTIONS

LOW

PRESSURE

HIGH

PRESSURE

SUCTION LINE

SERVICE VALVE

INDOOR COIL

HP40 UNIT

GAUGE MANIFOLD

RECOVERY MACHINE

INVERTED R22

CYLINDER

LIQUID LINE

SERVICE VALVE

INLET

DISCHARGE

TANK RETURN

CLOSEDOPENED

EXISTING

EXISTING SUCTION LINE

EXISTING LIQUID LINE

RECOVERY

CYLINDER

FIGURE 5

Page 7

Page 7

HP40 COOLING CYCLE (SHOWING MANIFOLD GAUGE CONNECTIONS)

OUTDOOR

COIL

DEFROST THERMOSTAT

EXPANSION/CHECK

VALV E

BIFLOW

FILTER / DRIER

TO

R407C

DRUM

LOW

PRESSURE

HIGH

PRESSURE

COMPRESSOR

REVERSING VALVE

VAPOR

LINE

VALV E

MUFFLER

NOTE − ARROWS INDICATE DIRECTION OF REFRIGERANT FLOW

SERVICE

PORT

SUCTION

EXPANSION/CHECK

VALV E

INDOOR UNIT

OUTDOOR UNIT

LIQUID LINE

SERVICE

PORT

GAUGE MANIFOLD

INTERNAL

COMPRESSOR

LIMIT

DISTRIBUTOR

INDOOR

COIL

FIGURE 6

8 − Close the valve on the inverted R22 drum and the

gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off.

9 − Use nitrogen to break the vacuum on the refrigerant

lines and indoor coil before removing the recovery

machine, gauges and R22 refrigerant drum. Reinstall pressure tap valve cores into HP32 service

valves.

10 −Install the provided check/expansion valve (ap-

proved for use with R407C refrigerant) in the liquid

line at the indoor coil.

Manifold Gauge Set

Manifold gauge sets used with systems charged with

R407C refrigerant must be able to accommodate higher

system operating pressures. The gauges should be rated

for pressures of 0−800 psi on the high side and a low side

of 30" vacuum to 250 psi with dampened speed of 500 psi.

Gauge hoses must be rated for use at up to 800 psi of

pressure with a 4000 psi burst rating.

Liquid & Vapor Line Service Valves

Access the liquid line and vapor line service valves (figures 7 and 8) and the gauge ports from inside the unit, behind access panel. The service ports are used for leak

testing, evacuating, charging, and checking the charge.

The valve is equipped with a service port, and a Schrader

valve is factory installed. A service port cap is supplied to

protect the Schrader valve from contamination and to serve

as the primary leak seal.

LIQUID AND VAPOR LINE SERVICE VALVES

VALVE OPEN)

SCHRADER

VALV E

SERVICE

PORT

SERVICE

PORT

CAP

INSERT HEX

WRENCH HERE

TO INDOOR

COIL

TO OUTDOOR

COIL

STEM CAP

SCHRADER VALVE OPEN

TO LINE SET WHEN VALVE IS

CLOSED (FRONT SEATED)

SERVICE

PORT

SERVICE

PORT CAP

STEM CAP

TO OUTDOOR

COIL

INSERT HEX

WRENCH HERE

(VALVE CLOSED)

(VALVE FRONT

SEATED)

TO INDOOR COIL

FIGURE 7

Page 8

Page 8

IMPORTANT

Service valves are closed to the heat pump unit and

open to line set connections. Do not open until refrigerant lines have been leak tested and evacuated. All precautions should be exercised in keeping

the system free from dirt, moisture and air.

Accessing the Schrader Port:

1 − Remove service port cap with an adjustable wrench.

2 − Connect gauge to the service port.

3 − When testing is completed, replace the service port

cap. Tighten finger tight, then tighten an additional 1/6

turn.

To Open Liquid or Vapor Line Service Valve:

1 − Remove the stem cap with an adjustable wrench.

2 − Use a service wrench with a hex−head extension to

back the stem out counterclockwise as far as possible.

WARNING

Do not attempt to backseat this valve. Attempts to

backseat this valve will cause the snap ring to explode from the valve body under pressure of the refrigerant. Personal injury and unit damage will result.

3 − Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

To Close Liquid or Vapor Line Service Valve:

1 − Remove the stem cap with an adjustable wrench.

2 − Use a service wrench with a hex−head extension to

turn the stem clockwise to seat the valve. Tighten

firmly.

3 − Replace the stem cap. Tighten finger tight, then tight-

en an additional 1/6 turn.

VAPOR LINE (BALL−TYPE) SERVICE VALVE

(VALVE OPEN)

SCHRADER

VALV E

SERVICE PORT

SERVICE

PORT

CAP

STEM CAP

TO OUTDOOR

COIL

STEM

USE ADJUSTABLE WRENCH.

ROTATE STEM CLOCKWISE 90 TO CLOSE.

ROTATE STEM COUNTERCLOCKWISE 90 TO OPEN.

BALL

(SHOWN OPEN)

TO INDOOR COIL

FIGURE 8

Vapor Line (Ball−Type) Service Valve −− 5−Ton Units

A ball-type full−service valve is used on five-ton units. These

vapor line service valves function the same way, the differences are in construction. Valves are not rebuildable. If a

valve has failed, it must be replaced. A ball valve is illustrated in figure 8.

The ball valve is equipped with a service port and a factory−installed Schrader valve. A service port cap is

supplied to protect the Schrader valve from contamination and to assure a leak−free seal.

Leak Testing

After the line set has been connected to the indoor and

outdoor units, check all connections for leaks.

IMPORTANT

The leak detector must be capable of sensing HFC

refrigerant.

WARNING

Never use oxygen to pressurize refrigeration or air

conditioning system. Oxygen will explode on contact with oil and could cause personal injury. When

using high pressure gas such as nitrogen for this

purpose, be sure to use a regulator that can control

the pressure down to a range of 6.9 to 13.8 kPa.

Using an Electronic Leak Detector

1 − Connect a cylinder of nitrogen with a pressure regulat-

ing valve to center port of manifold gauge set.

2 − Connect the high pressure hose of the manifold

gauge set to the service port of the vapor valve. (Normally, the high pressure hose is connected to the liquid line port, however, connecting it to the vapor port

better protects the manifold gauge set from high pressure damage.)

3 − With both manifold valves closed, open the valve on

the R407C cylinder (liquid only).

4 − Open the high pressure side of the manifold to allow

R407C into the line set and indoor unit. Weigh in a

trace amount of R407C. (A trace amount is a maximum of 59 ml or 21 kPa pressure.) Close the valve on

the R407C cylinder and the valve on the high pressure side of the manifold gauge set. Disconnect

R407C cylinder and attach a nitrogen cylinder.

5 − Adjust nitrogen pressure to 1034 kPa. Open the valve

on the high side of the manifold gauge set which will

pressurize line set and indoor unit.

6 − After a short period of time, open a refrigerant port to

make sure the refrigerant added is adequate to be detected. (Amounts of refrigerant will vary with line

lengths.) Check all joints for leaks. Purge nitrogen

and R407C mixture. Correct any leaks and recheck.

Page 9

Page 9

System Evacuation

WARNING

Unit contains a NITROGEN holding charge. The

holding charge must be purged and the system

must be evacuated prior to charging with R407C.

Evacuating the system of non−condensables is critical for

the unit to operate properly. Non−condensables are defined as any gas that will not condense under temperatures

and pressures present during operation of an air conditioning system. Non−condensables and water vapor combine

with refrigerant to produce substances that corrode copper

piping and compressor parts.

1− Connect manifold gauge set to the service valve ports

as follows:

low pressure gauge to suction line service valve

high pressure gauge to liquid line service valve

IMPORTANT − Compliant scroll compressors (as with

any refrigerant compressor) should never be used to

evacuate a refrigeration or air conditioning system.

NOTE − Use a temperature vacuum gauge, mercury

vacuum, or thermocouple gauge. The usual Bourdon

tube gauges are inaccurate in the vacuum range.

2 −The nitrogen holding charge in the unit must be re-

leased. Open both manifold valves to release the nitrogen from the unit. See the liquid and suction line

service valves section for how to operate the service

valves.

3 −Connect the vacuum pump (with vacuum gauge) to

the center port of the manifold gauge set.

4 −Open both manifold valves and start the vacuum

pump.

5 −Evacuate the line set, condensing unit, and indoor

unit to an absolute pressure of 23 mm (23,000 mi-

crons) of mercury. During the early stages of evacuation, it is desirable to close the manifold gauge valve

at least once to determine if there is a rapid rise in ab-

solute pressure. A rapid rise in pressure indicates a

relatively large leak. If this occurs, the leak testing

procedure must be repeated.

NOTE − The term absolute pressure means the total

actual pressure within a given volume or system,

above the absolute zero of pressure. Absolute pressure in a vacuum is equal to atmospheric pressure

minus vacuum pressure.

6 − When the absolute pressure reaches 23 mm (23,000

microns) of mercury, close the manifold gauge

valves, turn off the vacuum pump, and disconnect the

manifold gauge center port hose from the vacuum

pump. Attach the manifold center port hose to a nitro-

gen cylinder with the pressure regulator set to 150

psig (1034 kPa) and purge the hose. Open the manifold gauge valves to break the vacuum in the system.

Close the manifold gauge valves.

WARNING

Danger of Equipment Damage.

Avoid deep vacuum operation. Do not use compressors to evacuate a system.

Extremely low vacuums can cause internal arcing

and compressor failure.

Damage caused by deep vacuum operation will

void warranty.

7 −Shut off the nitrogen cylinder and remove the man-

ifold gauge hose from the cylinder. Open the manifold

gauge valves to release the nitrogen from the system.

8 −Reconnect the manifold gauge to the vacuum pump,

turn the pump on and continue to evacuate the system

until the absolute pressure does not rise above .5 mm

(500 microns) of mercury within a 20−minute period after shutting off the vacuum pump and closing the manifold gauge valves.

9 − When the absolute pressure requirement from step 9

has been met, disconnect the manifold gauge hose

from the vacuum pump. Then, weigh in a LIQUID

charge of R407C through the liquid and suction service valves.

Refer to the unit nameplate for the correct liquid

charge. If you can not measure in the total amount, refer to the start−up section and set the final system

charge according to the charging instructions. The

R407C refrigerant cylinder should be chocolate

brown.

Start−Up

Cooling Start-Up

1 − Check the unit disconnect switch to make sure power

is off.

2 − Rotate the fan to check for frozen bearings or binding.

3 − Inspect all factory and field-installed wiring for loose

connections.

4 − Replace the stem caps. Tighten finger tight, then

tighten an additional 1/6 turn.

5 − Check the voltage supply at the disconnect switch.

The voltage must be within the range listed on the unit

nameplate. If not, do not start the equipment until the

you have consulted the power company, and the voltage condition has been corrected.

6 − Set the thermostat for cooling demand, turn on the

power to the indoor blower coil, and close the heat

pump unit disconnect switch to start the unit.

Page 10

Page 10

7 − Recheck the unit voltage while the unit is running.

The power must be within the range shown on the

unit nameplate. Check the amperage draw of the

unit. Refer to the unit nameplate for approximate

running amps.

Charging

Liquid charge the unit with the amount of R407C refrigerant that is indicated on the nameplate.

IMPORTANT

If existing refrigerant lines which were previously

charged with R22 are going to be used, they must

first be flushed of existing mineral oil. Take care

to empty all existing traps. Polyol ester (POE) oils

are used in Lennox units charged with R407C refrigerant. Mineral oils are not compatible with

polyol ester oils.

This charge is based on a matching indoor coil and outdoor coil with a 4.6 m line set. For varying lengths of line

set, refer to table 2 for refrigerant charge adjustment.

TABLE 2

Liquid Line

Set Diameter

g per 1524 mm adjust

from 4.6 m line set*

8 mm 57 g per 1524 mm

10 mm 85 g per 1524 mm

*If line length is greater than 4.6 m, add this amount.

If line length is less than 4.6 m, subtract this amount.

Charging Using the Subcooling Method

If the outdoor ambient temperature is below 13C, airflow

over the outdoor coil will need to be reduced to drive up

the liquid line pressure to a range of 1379 to 1724 kPa. To

do this, block off the outdoor coil with cardboard or a plastic sheet.

BLOCKING OUTDOOR COIL

CARDBOARD OR

PLASTIC SHEET

OUTDOOR COIL SHOULD

BE BLOCKED ONE SIDE

AT A TIME WITH CARD−

BOARD OR PLASTIC

SHEET UNTIL PROPER

TESTING PRESSURES

ARE REACHED.

FIGURE 9

1 − Remove the cap from the liquid line service valve

stem and turn the stem clockwise 1/4 to 1/2 turn. This

will open the service port.

2 − With the manifold gauge hose still on the liquid ser-

vice port and the unit operating, read the liquid line

pressure.

3 − If the pressure is too low, block the airflow through

the outdoor coil until the liquid line pressure stabilizes in a range from 1379 to 1724 kPa. At that time,

record the liquid line temperature and the liquid line

pressure reading.

4 − Use a temperature/pressure chart for R407C to de-

termine the saturation temperature for the liquid line

pressure reading.

5 − Subtract the liquid line temperature from the satura-

tion temperature (according to the chart) to determine

subcooling. (Saturation temperature − Liquid line

temperature = Subcooling.) Subcooling should

be between 4.4−5.5°C. If subcooling is greater than

4.4 − 5.5°C, recover some refrigerant. If subcooling is

less than 4.4 − 5.5°C, add some refrigerant.

Page 11

Page 11

TABLE 3

R407C Saturated Liquid Temperature and Pressure Chart

Use this chart for subcooling only, not superheat.

Liquid Line Pressure

Liquid Line Pressure

S

aturated Liqu

id

Temperature °C

R407C

Psig (kPa)

R22

Psig (kPa)

S

aturated Liqu

id

Temperature °C

R407C

Psig (kPa)

R22

Psig (kPa)

15 116 (799) 102 (703) 33 197 (1358) 174 (1199)

16 118 (813) 104 (717) 33 200 (1378) 176 (1213)

16 120 (827) 105 (723) 34 203 (1399) 179 (1234)

17 123 (848) 107 (737) 35 206 (1420) 182 (1254)

17 125 (861) 109 (751) 35 210 (1447) 184 (1268)

18 127 (875) 111 (765) 36 213 (1468) 187 (1289)

18 129 (889) 113 (779) 36 216 (1489) 190 (1310)

19 131 (903) 115 (792) 37 219 (1509) 193 (1330)

20 134 (923) 117 (806) 37 222 (1530) 196 (1351)

20 136 (937) 119 (820) 38 226 (1558) 199 (1372)

21 138 (951) 121 (834) 38 229 (1578) 202 (1392)

21 141 (972) 123 (848) 39 232 (1599) 205 (1413)

22 143 (985) 126 (868) 40 236 (1627) 208 (1431)

22 146 (1006) 128 (882) 40 239 (1647) 211 (1454)

23 148 (1020) 130 (896) 41 242 (1668) 214 (1475)

23 151 (1041) 132 (910) 41 246 (1696) 217 (1496)

24 153 (1054) 134 (923) 42 249 (1716) 220 (1516)

25 156 (1075) 137 (944) 42 253 (1744) 223 (1537)

25 158 (1089) 139 (958) 43 257 (1771) 226 (1558)

26 161 (1110) 141 (972) 43 260 (1792) 229 (1578)

26 163 (1123) 144 (992) 44 264 (1820) 233 (1606)

27 166 (1144) 146 (1006) 45 268 (1847) 236 (1627)

27 169 (1165) 148 (1020) 45 271 (1868) 239 (1647)

28 171 (1179) 151 (1041) 46 275 (1896) 243 (1675)

28 174 (1199) 153 (1054) 47 279 (1923) 246 (1696)

29 177 (1220) 156 (1075) 47 283 (1951) 250 (1723)

30 180 (1241) 158 (1089) 47 287 (1978) 253 (1744)

30 183 (1261) 161 (1110) 48 290 (1999) 256 (1765)

31 186 (1282) 163 (1123) 48 294 (2027) 260 (1792)

31 188 (1296) 166 (1144) 51 315 (2171) 278 (1916)

32 191 (1316) 168 (1158) 54 336 (2316) 297 (2047)

32 194 (1337) 171 (1179) 57 358 (2468) 317 (2185)

Page 12

Page 12

System Operation

Filter Drier

The unit is equipped with a biflow filter drier. See figure 6.

If the filter needs to be replaced, order another of the

same design.

Thermostat Operation

Some heat pump thermostats incorporate isolating contacts and an emergency heat function (which includes an

amber indicating light). The thermostat is not included

with the unit and must be purchased separately.

Emergency Heat Function

Some thermostats have an emergency heat function.

This feature is applicable only to those systems that have

auxiliary electric heat staged by outdoor thermostats.

When the thermostat is placed in the emergency heat

position, the outdoor unit control circuit is isolated from

the power source, and field−provided relays bypass the

outdoor thermostats. An amber indicating light simultaneously comes on to remind the homeowner that the unit

is operating in the emergency heat mode.

Emergency heat is usually used during a heat pump shutdown. However, emergency heat should also be used following a power outage if the power has been off for over

an hour, and the outdoor temperature is below 10C. The

system should be left in the emergency heat mode for at

least six hours to allow the crankcase heater sufficient

time to prevent compressor from slugging.

Defrost System

The HP40 defrost system includes two components: a defrost thermostat and a defrost control.

Defrost Thermostat

The defrost thermostat is located on the liquid line between the check/expansion valve and the distributor.

When defrost thermostat senses 5.5°C or cooler, the thermostat contacts close and send a signal to the defrost

control board to start the defrost timing. It also terminates

defrost when the liquid line warms up to 21°C.

Defrost Control

The defrost control board includes the combined functions of a time/temperature defrost control, defrost relay,

diagnostic LEDs and terminal strip for field wiring connections. See figure 10.

The control provides automatic switching from normal

heating operation to defrost mode and back. During compressor cycle (call for defrost), the control accumulates

compressor run times at 30, 60, or 90 minute field−adjustable intervals. If the defrost thermostat is closed when the

selected compressor run time interval ends, the defrost

relay is energized and defrost begins.

HP40 DEFROST CONTROL BOARD

24V

TERMINAL

STRIP

HIGH PRESSURE SWITCH

SAFETY CIRCUIT

CONNECTIONS

NOTE − Remove factory−

installed jumper to add

pressure switch.

S4

CONNECTION FOR

OPTIONAL

HIGH PRESSURE

SWITCH

DEFROST

INTERVAL

TIMING PINS

High

Pressure

Switch

DIAGNOSTIC

LEDs

FIGURE 10

Page 13

Page 13

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated compressor run time period during one thermostat run cycle. This time period must occur before a defrost cycle is initiated. The defrost interval can be adjusted to 30 (T1), 60 (T2), or 90 (T3) minutes. See figure

10. The defrost timing jumper is factory−installed to provide a 60−minute defrost interval. If the timing selector

jumper is not in place, the control defaults to a 90−minute defrost interval. The maximum defrost period is 14

minutes and cannot be adjusted.

A TEST option is provided for troubleshooting. The TEST

mode may be started any time the unit is in the heating mode and the defrost thermostat is closed or

jumpered. If the jumper is in the TEST position at power-

up, the control will ignore the test pins. When the jumper is

placed across the TEST pins for two seconds, the control

will enter the defrost mode. If the jumper is removed before an additional 5−second period has elapsed (7 seconds total), the unit will remain in defrost mode until the

defrost thermostat opens or 14 minutes have passed. If

the jumper is not removed until after the additional 5−second period has elapsed, the defrost will terminate and the

test option will not function again until the jumper is removed and re−applied.

Pressure Switch Circuit

The defrost control incorporates a pressure switch circuit

that allows the application of an optional high pressure

switch. See figure 10. During a demand cycle, the defrost

control will lock out the unit if the optional high pressure

switch opens. The diagnostic LEDs will display a pattern

for an open high pressure switch. See table 3. The unit will

remain locked out until the switch resets or is reset.

Remove the factory-installed jumper before connecting

the optional high pressure switch to the control board.

NOTE − If not using a pressure switch, the factoryinstalled jumper wire must be connected.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the condition.

TABLE 3

DEFROST CONTROL BOARD DIAGNOSTIC LED

MODE LED 1 LED 2

Normal operation /

power to board

Synchronized

Flash with LED 2

Synchronized

Flash with LED 1

Board failure or no power Off Off

Board failure On On

High pressure switch open Flash On

Maintenance

WARNING

Electric shock hazard. Can cause injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF

at disconnect switch(es). Unit may

have multiple power supplies.

At the beginning of each heating or cooling season, check

the system as follows:

Heat Pump Unit

1 − Clean and inspect the outdoor coil. You may flush the

coil with a water hose. Make sure the power is off before you clean the coil.

2 − The outdoor unit fan motor is pre-lubricated and

sealed. The fan motor requires no more lubrication.

3 − Inspect all connecting lines, joints, and coils for evi-

dence of oil leaks.

4 − Check all wiring for loose connections.

5 − Check for correct voltage at the unit while the unit is

operating.

6 − Check amp draw on the heat pump fan motor.

Unit nameplate__________Actual__________.

7 − Inspect the drain holes in the coil compartment base

and clean them if necessary.

NOTE − If insufficient heating or cooling occurs, gauge the

unit and check the refrigerant charge.

Indoor Coil

1 − If necessary, clean the coil.

2 − Inspect the connecting lines, joints, and coil for evi-

dence of oil leaks.

4 − Check all wiring for loose connections.

5 − Check for correct voltage at the unit.

6 − Check the amp draw on the blower motor.

Motor nameplate__________Actual__________.

3 − Check the condensate line and clean it if necessary.

Indoor Unit

1 − Clean or change the filters.

2 − Lennox blower motors are pre-lubricated and perma-

nently sealed. The blower motor requires no more lubrication.

3 − Adjust the blower speed for cooling. Measure the

pressure drop over the coil to determine the correct

blower m

3

/s.

Page 14

Page 14

Start−Up and Performance Check List

Job Name

Job Location

Installer

Unit Model No.

Nameplate Voltage

Minimum Circuit Ampacity

Maximum Overcurrent Protection Size

Refrigerant Lines:

Outdoor Fan Checked?

Job No.

City

City

Serial No.

Date

State

State

Service Technician

Amps:

Supply Outdoor Fan

Compressor

Indoor Filter Clean?

Indoor Blower RPM

Electrical Connections Tight?

Supply Voltage (Unit Off)

Outdoor Coil Entering Air Temperature

Discharge Pressure Suction Pressure

COOLING SECTION

THERMOSTAT

Refrigerant Charge Checked?

Calibrated? Properly Set?

Level?

Properly Insulated?

Voltage With Compressor Operating

Leak Checked?

Service Valve Caps Tight?

S.P. Drop Over Evaporator (Dry)

Service Valves Fully Opened?

Page 15

Page 15

Page 16

Page 16

Lennox Industries

P.O. Box 174, Westgate Interchange,

Northampton NN5 5AG

Telephone: 01604 591159

Facsimile: 01604 587536

Loading...

Loading...