HP27

Netfacearea

Coil

Fan

p

Outdoor Coil

Corp. 9621−L10

Service Literature

HP27 SERIES UNITS

The HP27 is a high efficiency residential split−system heat

pump which features a scroll compressor. It operates

much like a standard heat pump, but the scroll compressor

is unique in the way that it compresses refrigerant. Several

models are available in sizes ranging from 2 through 3-1/2

tons. The series uses expansion valves in the outdoor unit

and in the indoor unit.

This manual is divided into sections which discuss the major components, refrigerant system and charging procedures, maintenance and operation sequences. All specifications in this manual are subject to change.

Model No. HP27−024 HP27−030 HP27−036 HP27−042

Netfacearea

sq. ft. (m2)

Condenser

Condenser

Fan

Refrigerant furnished (HCFC-22) 12 lbs. 5 oz. (5.6 kg) 11 lbs. 5 oz. (5.1 kg) 11 lbs. 13 oz. (5.3 kg) 12 lbs. 12 oz. (5.8 kg)

Liquid line conn. o.d. in. (mm) (sweat) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Vapor line conn. o.d. in. (mm) (sweat) 3/4 (19) 3/4 (19) 7/8 (22.2) 7/8 (22.2)

Shipping wt. lbs. (kg) 1 package 268 (122) 271 (123) 328 (149) 328 (149)

Refrigerant charge sufficient for 15 ft. (4.5 m) length of refrigerant lines.

Line voltage data 208/230v 60hz−1ph

Compressor

Outdoor Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 20 25 30 40

Minimum circuit ampacity 13.8 16.2 17.8 23.4

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE Extremes of operating range are plus 10% and minus 5% of line voltage.

Tubediameter in. (mm) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9) 5/16 (7.9)

No. of rows 2 2 2 2

Fins per inch (m) 22 (866) 22 (866) 22 (866) 22 (866)

Diameter in. (mm) No. of blades 24( 610) − 3 24( 610) − 3 24( 610) − 3 24( 610) − 3

Motor hp (W) 1/10 (75) 1/10 (75) 1/10 (75) 1/10 (75)

Cfm (L/s) 2800 (1320) 2800 (1320) 2800 (1320) 2800 (1320)

Rpm 825 825 825 825

Watts 165 165 170 170

Model No. HP27−024 HP27−030 HP27−036 HP27−042

Rated load amps 10.26 12.18 13.46 18.0

Power factor 0.96 0.96 0.96 0.97

Locked rotor amps 56 61 73 104

Full load amps 0.9 0.9 0.9 0.9

Locked rotor amps 1.6 1.6 1.6 1.6

Outer Coil 21.77 (2.02) 21.77 (2.02) 24.06 (2.24) 24.06 (2.24)

Inner Coil 21.11 (1.96) 21.11 (1.96) 23.33 (2.17) 23.33 (2.17)

Revised 08−2004

SPECIFICATIONS

ELECTRICAL DATA

Page 1

© 1997 Lennox Industries Inc.

Litho U.S.A.

DISCHARGE

SUCTION

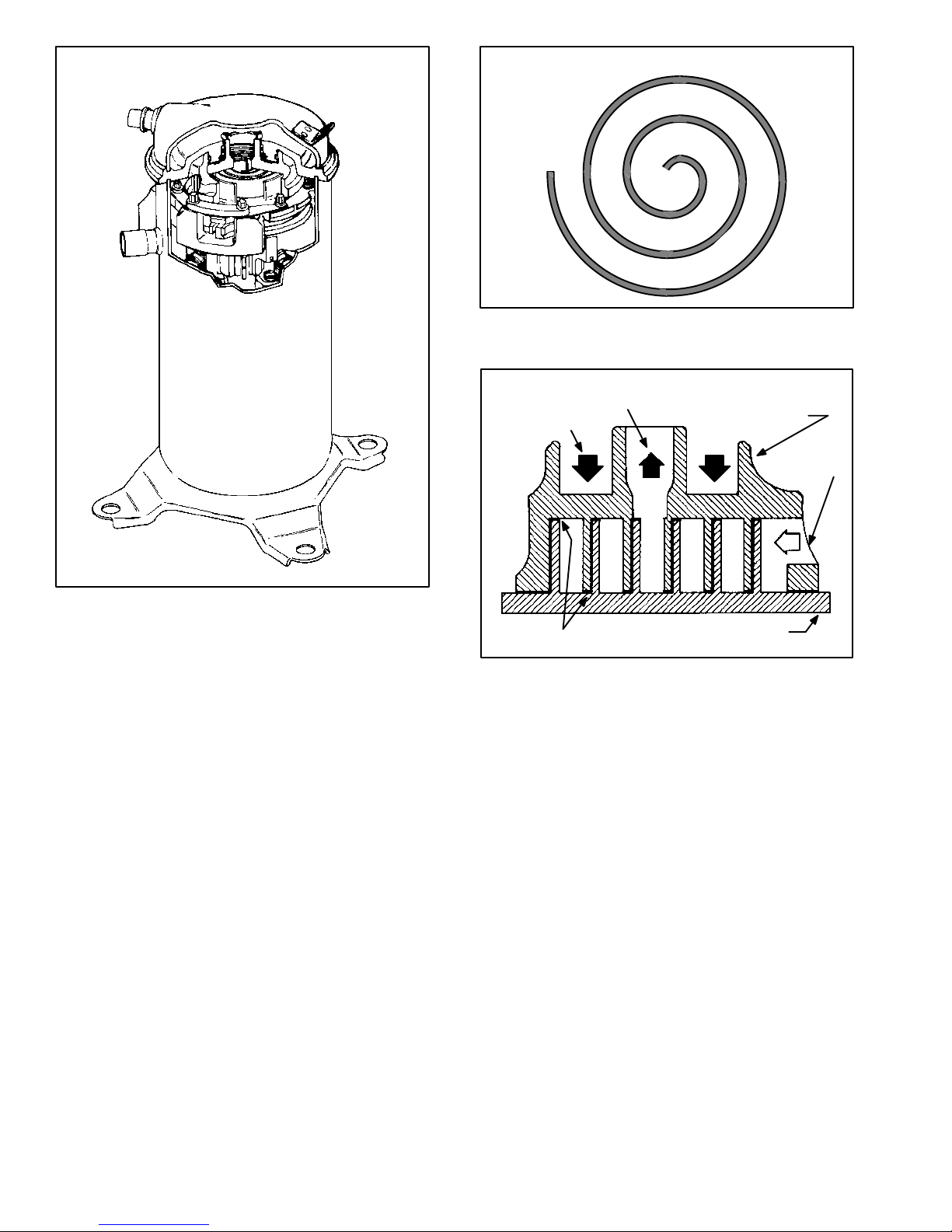

SCROLL COMPRESSOR

CROSS−SECTION OF SCROLLS

DISCHARGE

DISCHARGE

PRESSURE

SCROLL FORM

FIGURE 2

STATIONARY SCROLL

SUCTION

FIGURE 1

I−APPLICATION

All major components (indoor blower/coils) must be

matched according to Lennox recommendations for the

compressor to be covered under warranty. Refer to the

Engineering Handbook for approved system matchups. A

misapplied system will cause erratic operation and can result in early compressor failure.

II−SCROLL COMPRESSOR

The scroll compressor design is simple, efficient and requires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 1. The scrolls are located in

the top of the compressor can and the motor is located in

the bottom of the compressor can. The oil level is immediately below the motor.

The scroll is a simple compression concept centered

around the unique spiral shape of the scroll and its inherent properties. Figure 2 shows the basic scroll form. Two

identical scrolls are mated together forming concentric

spiral shapes (figure 3). One scroll remains stationary,

while the other is allowed to "orbit" (figure 4). Note that the

orbiting scroll does not rotate or turn but merely orbits the

stationary scroll.

NOTE − The head of a scroll compressor may be hot since

it is in constant contact with discharge gas.

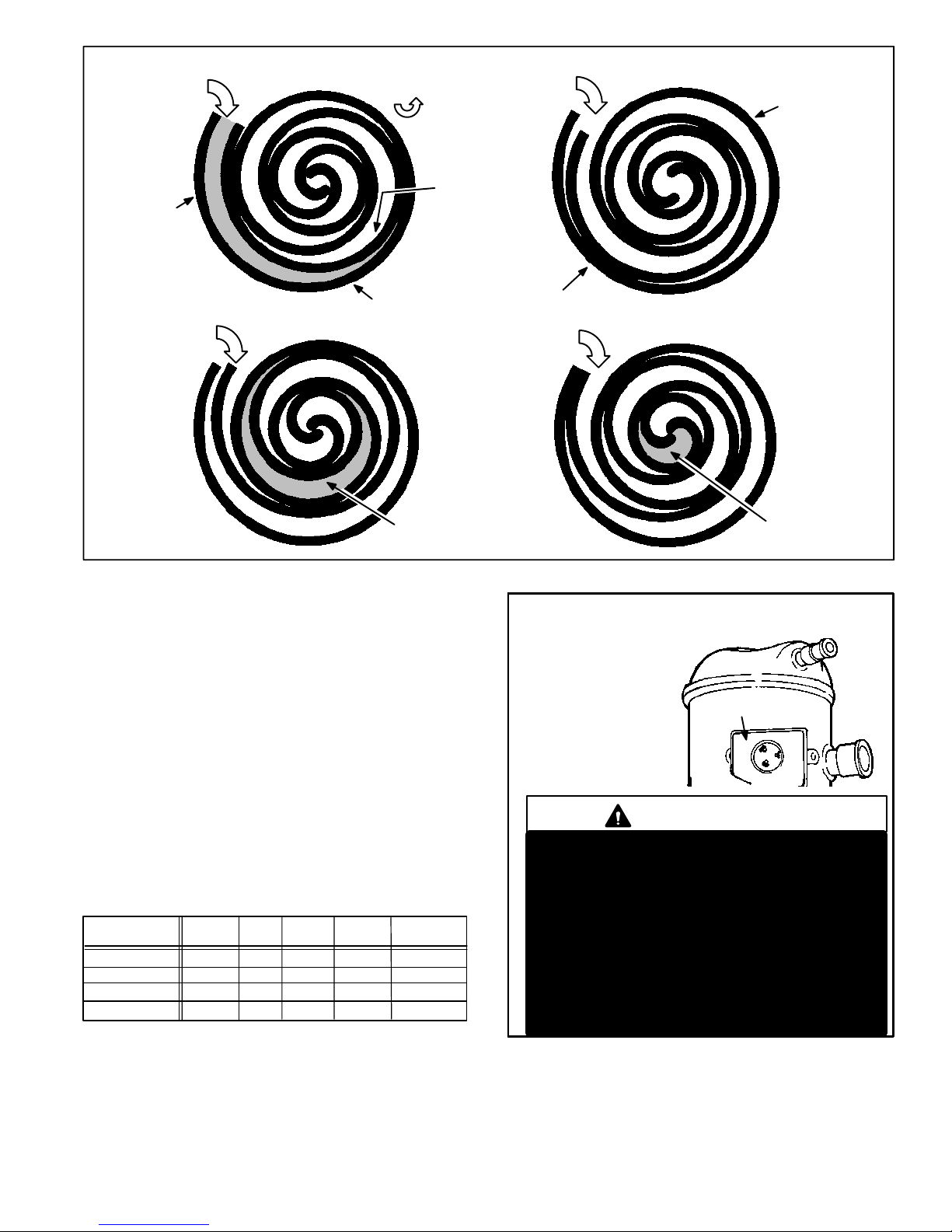

TIPS SEALED BY

DISCHARGE PRESSURE

ORBITING SCROLL

FIGURE 3

The counterclockwise orbiting scroll draws gas into the outer crescent shaped gas pocket created by the two scrolls

(figure 4 − 1). The centrifugal action of the orbiting scroll

seals off the flanks of the scrolls (figure 4 − 2). As the orbiting motion continues, the gas is forced toward the center of

the scroll and the gas pocket becomes compressed (figure

4 − 3). When the compressed gas reaches the center, it is

discharged vertically into a chamber and discharge port in

the top of the compressor (figure 1). The discharge pressure forcing down on the top scroll helps seal off the upper

and lower edges (tips) of the scrolls (figure 3). During a

single orbit, several pockets of gas are compressed simultaneously providing smooth continuous compression.

The scroll compressor is tolerant to the effects of liquid return. If liquid enters the scrolls, the orbiting scroll is allowed to separate from the stationary scroll. Continued

slugging of liquid will cause damage to the scroll and replacement will be necessary. The liquid is worked toward

the center of the scroll and is discharged. If the compressor is replaced, conventional Lennox cleanup practices

must be used.

Page 2

SUCTION

POCKET

HOW A SCROLL WORKS

SUCTION

MOVEMENT OF ORBIT

ORBITING

SCROLL

SUCTION

INTERMEDIATE

PRESSURE

GAS

CRESCENT

SHAPED GAS

POCKET

12

FLANKS

STATIONARY SCROLL

SUCTION

SEALED BY

CENTRIFUGAL

FORCE

SUCTION

34

HIGH

PRESSURE

GAS

FIGURE 4

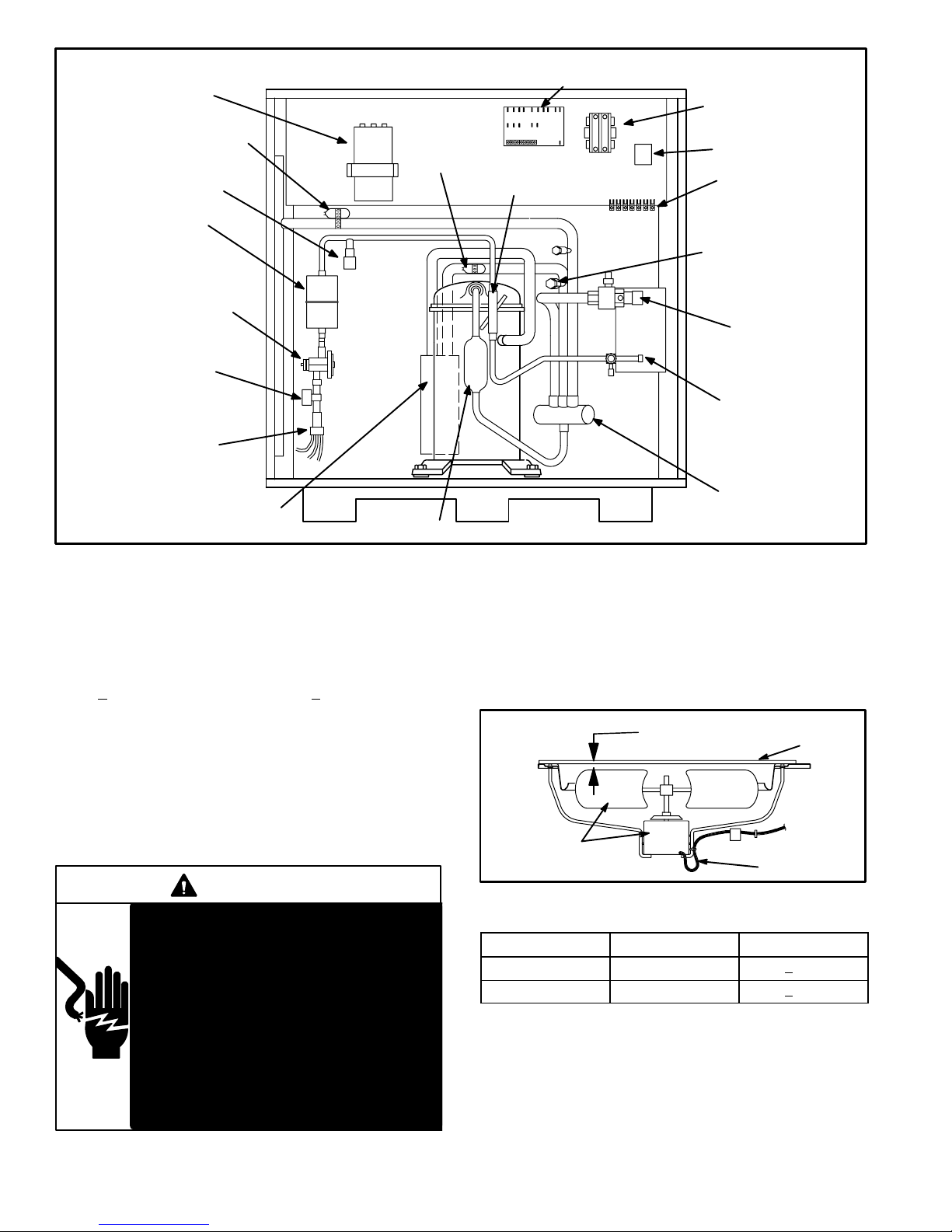

III−UNIT COMPONENTS

A−Transformer

The contactor, reversing valve, time delay, and defrost timer are all powered by 24VAC supplied by the indoor unit.

All other controls in the outdoor unit are powered by line

voltage. Refer to unit wiring diagram. The HP27 is not

equipped with an internal line voltage to 24V transformer.

B−Terminal Strip

All HP27s are equipped with a low voltage terminal strip

located in the unit control box for making thermostat wiring

connections (refer to figure 6).

C−Compressor

Table 1 shows the specifications of compressors (B1)

used in HP27 series units.

TABLE 1

Unit Phase LRA RLA

*Shipped with conventional white oil (Sontex 200LT). 3GS oil may be

used if additional oil is required.

Vac

208/230HP27−024 56 10.3 38

208/230

208/230

208/230

1

1HP27−030

61 42

1HP27−036

73

1HP27−042

12.2

13.5

18.0104

Oil

fl.oz.

42

42

DISCHARGE

POCKET

COMPRESSOR TERMINAL BOX

COMPRESSOR

TERMINALS

C

S

R

WARNING

COMPRESSOR MUST BE GROUNDED. DO

NOT OPERATE WITHOUT PROTECTIVE COVER

OVER TERMINALS. DISCONNECT ALL POWER

BEFORE REMOVING PROTECTIVE COVER.

DISCHARGE CAPACITORS BEFORE SERVICING UNIT. COMPRESSOR WIRING DIAGRAM IS FURNISHED INSIDE COMPRESSOR

TERMINAL BOX COVER. FAILURE TO FOLLOW

THESE PRECAUTIONS COULD CAUSE ELECTRICAL SHOCK RESULTING IN INJURY OR

DEATH.

FIGURE 5

Page 3

DUAL CAPACITOR

TXV

SENSING BULB −036,

−042 ONLY

HIGH PRESSURE

SWITCH

BIFLOW FILTER/DRIER

EXPANSION VALVE

WITH

INTERNAL CHECK

VALV E

DEFROST

THERMOSTAT

DISTRIBUTOR

ACCUMULATOR

HP27 UNIT COMPONENTS

DEFROST CONTROL/TIMED−OFF CONTROL

TXV

SENSING BULB

−024, −030 ONLY

THERMOMETER WELL

MUFFLER

CONTACTOR

GROUND LUG

TERMINAL STRIP

SUCTION

GAUGE

PORT

VAPOR LINE

SERVICE VALVE

AND GAUGE

PORT

LIQUID LINE

SERVICE VALVE

AND GAUGE

PORT

REVERSING

VALV E

AND SOLENOID

D−High Pressure Switch

An automatic reset high pressure switch (S4) located in the

liquid line of the compressor shuts off the compressor when

liquid line pressure rises above the factory setting. The switch

is normally closed and is permanently adjusted to trip (open)

at 410 + 10 psi. The switch closes at 210 + 10 psi. See figure 6

for switch location.

E−Contactor

The compressor is energized by a contactor (K1) located

in the control box. Units will use single−pole or double−pole

contactors. See wiring diagrams for specific unit. The contactor is energized by indoor thermostat terminal Y when

thermostat demand is present.

DANGER

Electric Shock Hazard.

May cause injury or death.

Disconnect all remote electrical power

supplies berore opening unit panel. Unit

may have multiple power supplies.

FIGURE 6

F−Condenser Fan Motor

See page 1 for specifications for all condenser fan motors

(B4) used. See figure 7 if condenser fan motor replacement is necessary. In all units, the condenser fan motor is

controlled by the compressor contactor and is de−energized when the defrost relay is energized.

"A" SEE TABLE 2

Condenser fan

and motor

FAN GUARD

Wiring

Drip loop

FIGURE 7

TABLE 2

UNIT "A" DIM. TOLERANCE

HP27−024, −030 1 1/16" + 1/8"

HP27−036, −042 1 3/16" + 1/8"

Some units are equipped with single−

pole contactors. When unit is equipped

with a single−pole contactor, line voltage

is present at all components (even when

unit is not in operation).

G−Accumulator

The accumulator is located on the liquid line (see figure 6.)

The accumulator retains liquid and releases mostly vapor

to the compressor. This ensures that the liquid refrigerant

will not enter and damage the compressor.

Page 4

H−Service Light Thermostat HP27

HP27−1 through −7 units are equipped with a service light

thermostat (S54) located on the compressor discharge

line. The switch is electrically connected to the service

light in the indoor thermostat. The service light, when lit,

indicates the compressor is not running. The service light

is powered from W1 (2nd stage heat) terminal of the indoor

thermostat. The service light thermostat will close when

the discharge line falls below 110 + 5F, indicating a problem in the system. The service light thermostat opens and

the service light goes off when discharge line reaches 130

+ 5F indicating the compressor is running.

I−Ambient Compensating Thermistor

HP27−1 through −7 units have an ambient compensating

thermistor (RT3) mounted on the outdoor fan wiring harness. The thermistor is an NTC thermistor (negative temperature coefficient − increase in temperature equals decrease in resistance) (see figure 8). The device is connected in series with the heat anticipation resistor inside the

indoor thermostat. This feature helps to prevent abnormal

droop caused by the anticipation resistors. As outdoor temperature increases, the resistance across the thermistor

drops. As the resistance across the thermistor drops, the

current through the heat anticipation resistor increases.

Therefore, heat anticipation increases as outdoor temperature decreases. Resistance at 77F = 260 ohms + 5%; at

100F = 150 ohms; at 32F = 861 ohms.

TABLE 3

HP27 DUAL CAPACITOR RATING

UNITS FAN MFD HERM MFD VAC

HP27−024 4 40 370

HP27−030 4 40 370

HP27−036 4 45 370

HP27−042 4 55 370

K−Reversing Valve and Solenoid

A refrigerant reversing valve (L1) with electromechanical

solenoid is used to reverse refrigerant flow during unit operation. The reversing valve is energized during cooling

demand and during defrost.

L−Defrost System HP27−1, −2, −3 and −5 units

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit

installation and service to protect the unit’s

electronic controls. Precautions will help to

avoid control exposure to electrostatic discharge by putting the unit, the control and the

technician at the same electrostatic potential.

Neutralize electrostatic charge by touching

hand and all tools on an unpainted unit surface

before performing any service procedure.

OUTDOOR FAN, BRACKET AND

AMBIENT COMPENSATING

THERMISTOR

OUTDOOR FAN

FAN MOTOR

BRACKET

FIGURE 8

J−Dual Capacitor

The compressor and fan in the HP27 series units use permanent split capacitor motors. A single dual capacitor

(C12) is used for both the fan motor and the compressor

(see unit wiring diagram). The fan side of the capacitor

and the compressor side of the capacitor have different

mfd ratings. The capacitor is located inside the unit control

box (see figure 6). Table 3 shows the ratings of the dual capacitor.

The defrost system includes two components: a defrost

thermostat (S6) and a defrost control.

Defrost Thermostat

The defrost thermostat is mounted on the liquid line between the check/expansion valve and the distributor. When

defrost thermostat senses 35F (2C) or cooler, its contacts close and send a signal to the defrost control board to

start the defrost timing. It also terminates defrost when the

liquid line warms up to 70F (21C).

Defrost Control

The defrost control board has the combined functions

of a time/temperature defrost control, defrost relay,

time delay, diagnostic LEDs and field connection terminal strip. See figure 9.

The control provides automatic switching from normal

heating operation to defrost mode and back. During compressor cycle (room thermostat demand cycle), if the O"

input is not on and the defrost thermostat is closed, the

control accumulates compressor run times at 30, 60 or 90

minute field adjustable intervals. If the defrost thermostat

remains closed when the accumulated compressor run

time ends, the defrost relay is energized and defrost begins.

Page 5

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated compressor run period during one thermostat run

cycle. This time period must occur before a defrost cycle

is initiated. The defrost interval can be adjusted to 30, 60

or 90 minutes. See figure 9. The defrost period is a maximum of 14 minutes and cannot be adjusted. If no timing

is selected, the control defaults to 90 minutes.

DEFROST CONTROL BOARD

NOTE − COMPONENT LOCATIONS WILL VARY

WITH BOARD MANUFACTURER

PRESSURE SWITCH

SAFETY CIRCUIT

CONNECTIONS

DIAGNOSTIC

LEDs

AMBIENT

THERMISTOR

CONNECTION

SERVICE LIGHT

CONNECTION

NOTE− There is an internal jumper between

inside PS1 and PS2 terminals.

FIGURE 9

A TEST option is provided for troubleshooting. When the

jumper is placed across the TEST pins, the timing of all

functions is reduced by a factor of 128. For example, a 30

minute interval during TEST is 14 seconds and the 14 minute defrost is reduced to 6.5 seconds.

The TEST mode may be started at anytime. If the jumper is

in the TEST position at power−up or for longer than five minutes, the control will ignore the TEST selection and will default to a 90 minute interval. In order to test defrost cycle,

defrost thermostat must be closed or jumpered. Once defrost is initiated, remove jumper immediately. Failure to remove jumper will reduce defrost cycle to seconds.

DEFROST

INTERVAL

TIMING PINS

24V TERMINAL

STRIP

CONNECTIONS

Time-Delay

A 5-minute timed-off delay protects the compressor from

short-cycling when there is an interruption in power to the

unit or when a pressure switch resets.

Pressure Switch Safety Circuits

The defrost control incorporates a safety circuit that allows

the application of an additional pressure switch. The unit’s

high pressure switch (S4) is factory-wired into this circuit.

See figure 9. PS1 and PS2 terminals are wired in series

with a jumper internal to the control board. This feature is

available on all units.

During one demand cycle, the defrost control will lock out

the unit on the third instance that the unit goes off on any

auto−reset pressure switch wired to this circuit. In addition,

the diagnostic LEDs will indicate a locked out pressure

switch after the third occurrence of an open pressure

switch. See table 4. The unit will remain locked out until 24

volt power is broken to terminal R" on the defrost board

and then remade.

The PS2 safety circuit terminals are connected to the compressor thermostat. An optional loss of charge switch may

be field-installed by connecting it in series with the other

switches. See unit wiring diagram.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the condition.

TABLE 4

DEFROST CONTROL BOARD DIAGNOSTIC LED

MODE LED 1 LED 2

Normal Operation/

Power to board

Time Delay

To Protect Compressor

Pressure Switch Open Off On

Pressure Switch Lockout On Off

Board Malfunction On On

Flash together with

LED 2

Alternating Flashes

with LED 2

Flash together with

LED 1

Alternating Flashes

with LED 1

Ambient Thermistor & Service Light Connection

The defrost control board provides terminal connections

for the ambient thermistor and a service light. The thermistor compensates for changes in ambient temperature

which might cause thermostat droop. The service light

thermostat provides a signal which activates the room

thermostat service light during periods of inefficient operation.

Page 6

M−Defrost System HP27−4 and −6 ONLY

HP27−4 and −6 units are equipped with a demand defrost

system. The self−calibrating defrost control board includes

defrost relays, sensors (two) which monitor coil and out-

door ambient temperatures, a timed−off control, protection

circuits (two), a 3−strike lockout feature, a test mode jump-

er and a terminal strip. The demand defrost control board

initiates a defrost cycle based on temperature differential

and compressor run time. This type of system allows

greater frost accumulation on the outdoor coil and initiates

fewer defrost cycles than the time/temperature defrost

system. The defrost board is shown in figure 10.

Temperature Sensors

The demand defrost control board includes two perma-

nently attached sensors which monitor coil and outdoor

ambient temperatures. The coil temperature sensor is

equipped with a spring clip to allow proper positioning on

the outdoor coil. These sensors must not be detached

from the control board and must be replaced as part of the

control board. Do not attempt to cut or splice the tempera-

ture sensor wires. See figure 11 for ambient and coil tem-

perature sensor location.

Timed−Off Control

The control board includes a 5−minute timed−off delay

which protects the compressor from short cycling. The

5−minute delay is initiated at the end of a compressor

cycle, any time a system protection switch is reset, or if the

Y1 circuit is interrupted for more than two continuous line

cycles.

If a system protection switch opens while the Y1 OUT" circuit is energized, the timed−off control will initiate a 5−minute delay when the pressure switch closes.

The timed−off control run times can be bypassed by

shorting the TEST" pins.

Protection Circuits

The control board includes two protection circuits.

The unit high pressure switch is factory−wired to the HI −

PS terminals. The circuit through Y1" (input and Y1

OUT") is completed through the high pressure switch.

When the high pressure switch opens, the control board

de−energizes the compressor and the 3−strike lockout

counter registers one strike. If, for any reason, the high

pressure switch is removed, a jumper must be applied

across the HI − PS terminals to complete the circuit.

The second protection circuit is not used in this application

A jumper must be applied across the LO − PS terminals

to ensure proper control board operation.

Inputs (24V Terminal Strip Connections)

Y1 Thermostat input, controls unit operation

O Thermostat input, reversing valve

R 24VAC power

C 24VAC common

W1 24VAC input/output from indoor thermostat to indoor unit

L Service light thermostat

Ambient sensor (connection for Room Thermostat with

T

ambient compensation)

(1/4" Quick Connect Terminal Factory Connections)

HI−PS Pressure switch / system fault sensor

LO−PS Pressure switch / system fault sensor

Y1 Out Compressor contactor

O Out Reversing valve

FAN Condenser fan

W/L/C Service light thermostat

T/T Ambient sensor

Defrost Control Board

FAN

CC

Y1−OUT

Y

HI−PS

LO−PS

RV

O−OUT

C

LED1 LED2

100

AMB

90

80

70

PRESS

TEST

COIL

PS2

AUX

PS1

CUR

FAN

W1

C

L

T

DIS

IND

CLT

R

W1

O

Y1

FIGURE 10

Page 7

3−Strike Lockout

The demand defrost system control board includes a

3−strike lockout feature. This internal feature registers

protection circuit interruptions while Y1" (input) is energized. If any protection circuit switch opens three times

during a single Y1" (input) cycle, the control initiates lockout. If the circuit is interrupted once or twice during a single

Y1" (input) cycle, the control resets the strike register to

zero at the end of the cycle.

The 3−strike register can be reset by interrupting 24V

power to the control board or by shorting the TEST"

pins.

TEST Mode

The control board includes a test mode to facilitate service. During the test mode, the 14−minute defrost period is

shortened. Initiate the test mode by placing the defrost

temperature selection jumper across the TEST" pins.

Normal test mode operation is described below and in figure 12:

24V power must be applied to the demand defrost con-

trol board BEFORE the jumper is installed on the

TEST" pins.

If test pins are shorted before 24V power is applied to

the board, the test mode will be ignored until the short

is removed and reapplied. Each test pin short will result

in one test event. For each test, the shunt (jumper)

must be removed for at least 1 second then reapplied.

If the Y signal is interrupted, the unit will exit the test

mode.

LO − PS input is ignored during test mode operation.

Test mode operation is limited to 5 minutes. The control

will revert to normal operation and ignore the test mode

after this period of time.

Defrost Temperature Selection Jumper

The control board can be set to terminate defrost at one of

four temperature settings: 70°F, 80°F, 90°F, or 100°F. If the

jumper is removed, the control board will terminate defrost

at the default setting of 100°F.

Communication Port

The demand defrost system control board is equipped

with a communication port. This port has been included for

future use and is not functional at this time.

Normal Operation

During normal operation, the control board continuously

monitors the system operation mode (heating / cooling),

the outdoor ambient temperature, the outdoor coil temperature and compressor run time to determine the need for a

defrost cycle.

Calibration Mode

The demand defrost control board is considered uncalibrated when one of the following conditions applies: immediately after power has been applied to the control

board, immediately after operation in the cooling mode, or

any time the outdoor coil temperature exceeds the termination temperature during the heating mode. During the

calibration mode, the demand defrost control board measures the outdoor coil and outdoor ambient temperatures

to establish an average (calibrated) temperature differential between the two.

Defrost Mode

The following operation sequence applies when the demand defrost control initiates a defrost cycle:

1 − The control board energizes the reversing valve and

de−energizes the condenser fan motor.

2 − The control energizes the W1" (auxiliary heat) circuit.

The unit will operate in this mode until the outdoor coil

temperature rises above the selected termination

temperature, the 14−minute defrost interval has been

completed, or the room temperature rises to satisfy

the heating demand.

NOTE − If the termination temperature selection jumper has been left off, the defrost termination temperature is set at the 100°F default.

3 − If the defrost cycle is terminated by the room thermo-

stat because the heating demand has been satisfied,

the call for a defrost cycle will be carried over to the

next heating demand cycle. If the outdoor coil temperature is still below the selected termination temperature when the heating demand is re−initiated, the defrost cycle will be continued until it is terminated by

one of the three methods outlined in step 2.

4 − If the defrost cycle is terminated by the 14−minute de-

frost interval and the outdoor coil has not remained

above 35°F (2°C) for 4 minutes, the control will initiate

a 34−minute time/temperature defrost mode.

IMPORTANT

Do not connect an electronic device to the communication port. Incompatibility between the control

board and the device could result in damage to both.

Defrost Operation (Table 5)

The demand defrost control board has three modes of operation: normal, calibration and defrost.

Ambient Thermistor & Service Light Connection

The defrost control board provides terminal connections

for the ambient thermistor and a service light. The thermistor compensates for changes in ambient temperature

which might cause thermostat droop. The service light

thermostat provides a signal which activates the room

thermostat service light during periods of inefficient operation.

Page 8

Diagnostic LEDs (Table 5)

Improper refrigerant charge.

Check approach, superheat & subcooling

Replace metering device

The defrost board includes two LEDs used for diagnostics. The LED flashes indicate a specific diagnostic code as detailed

in the table below.

TABLE 5

LED 1 LED 2 Condition Possible Cause(s) Solution

OFF OFF Power problem

ON ON Coil sensor problem

OFF ON Ambient sensor problem

FLASH FLASH Normal operation

3−Strike pressure lockout

ON OFF

ON FLASH

FLASH ON

ALTERNATING

FLASH

ALTERNATING

FLASH

(Short test pins or reset 24V

power to board to override

lockout)

Low pressure switch circuit

open during Y1 demand

High pressure switch circuit

open during Y1 demand

5−minute delay

(Jumper test pins to override

delay)

The demand defrost control board initiates a defrost cycle based on either frost detection or time.

Frost Detection − If the compressor runs longer than 34 minutes and the actual difference between the clear coil and frosted coil temperatures exceeds the maximum differ-

ence allowed by the control, a defrost cycle will be initiated.

IMPORTANT − The demand defrost control board will allow a greater accumulation of frost and will initiate fewer defrost cycles than a time/temperature defrost system.

Time − If 6 hours of heating mode compressor run time has elapsed since the last defrost cycle while the coil temperature remains below 35°F (2°C), the demand defrost

control will initiate a defrost cycle.

Actuation − When the reversing valve is de−energized, the Y1 circuit is energized, and the coil temperature is below 35°F (2°C), the board logs the compressor run time. If

the board is not calibrated, a defrost cycle will be initiated after 34 minutes of heating mode compressor run time. The control will attempt to self−calibrate after this (and all

other) defrost cycle(s). Calibration success depends on stable system temperatures during the 20−minute calibration period. If the board fails to calibrate, another defrost

cycle will be initiated after 90 minutes of heating mode compressor run time. Once the defrost board is calibrated, it will use demand defrost logic to initiate a defrost cycle.

A demand defrost system initiates defrost when the difference between the clear coil and frosted coil temperatures exceeds the maximum difference allowed by the control

OR after 6 hours of heating mode compressor run time has been logged since the last defrost cycle.

Termination − The defrost cycle ends when the coil temperature exceeds the termination temperature or after 14 minutes of defrost operation. If the defrost is terminated

by the 14−minute timer, another defrost cycle will be initiated after 34 minutes of run time.

Test Mode − When Y1 is energized and 24V power is being applied to the board, a test cycle can be initiated by placing the termination temperature jumper across the Test"

pins for 2 to 5 seconds. If the jumper remains across the Test" pins longer than 5 seconds, the control will ignore the test pins and revert to normal operation. The jumper

will initiate one cycle per test.

1

No power (24V) to board terminals R &

C.

2

Board failure.

1

Coil temperature outside of sensor

range.

2

Faulty sensor wiring connections at

board or poor sensor contact on coil.

3

Sensor failure.

1

Ambient temperature outside of sensor

range.

2

Faulty sensor wiring connections at

board or sensor.

3

Sensor failure.

Unit operating normally or in standby

mode.

1

Restricted air flow over indoor or outdoor

coil.

2

Improper refrigerant charge.

3

Improper metering device operation.

4

Poor contact between coil sensor and

coil.

Thermostat demand for cooling or heat

pump operation. Unit operating in 5−minute

anti−short−cycle mode.

OPERATION

1

Check control transformer power (24V).

2

If power is available and LED(s) are unlit,

replace board and all sensors.

1

Sensor function will resume when coil

temperature is between −20°F and 110°F.

2

Check sensor wiring connections at

board and sensor contact on coil.

3

Replace board and all sensors.

1

Sensor function will resume when coil

temperature is between −20°F and 110°F.

2

Check sensor wiring connections at

board and sensor.

3

Replace board and all sensors.

None required.

1

Remove any blockages or restrictions.

Check outdoor fan motor for proper operation.

2

Check approach, superheat & subcooling

temperatures.

3

Check system pressures. Repair leaks.

Replace metering device.

4

Make sure that sensor is properly positioned on coil and that firm contact is established. Refer to service manual for

proper placement.

.

None required.

HP27−036/042 PLUMBING SHOWN

See detail A" and B"

ambient sensor

inside PVCpipe

FIGURE 11

Page 9

Detail A"

−024, −030, 042

Coil Temperature

Sensor

Detail B"

−036

Test Mode Operation

To Engage Test Mode − Place the temperature select shunt (jumper) across the test pins.

Y1 Active

Apply jumper to test pins for longer than

0.5 seconds, but less than 2 seconds.

Short cycle lockout and/or 3−strike pressure

fault lockout function are cleared, if applicable.

Unit continues operating in existing mode.

COOLING MODE

Remove and reapply test jumper

to return to test mode, if desired.

Controller will check ambient and coil temperature sensors to see if sensors are open or shorted. If one of the

sensor circuits is open, the unit will remain in Heating

Mode. Remove and reapply test jumper to return to test

mode, if desired. If sensor circuits are closed, the unit

Short cycle lockout or 3−strike pressure fault

lockout function are cleared, if applicable.

HEATING MODE

will go into Defrost Mode.

Apply jumper to test pins for more than

2 seconds.

DEFROST MODE

Defrost mode ends. Unit enters Heating

Mode with defrost timer set for 34 minute

test. Remove and reapply test jumper to

return to test mode, if desired.

Test jumper is applied longer than 5 seconds.

Unit returns to Heating mode with defrost

timer set for 34 minute calibration defrost.

Remove and reapply test jumper to return

to test mode, if desired.

Test jumper is removed before 5 seconds.

Unit remains in Defrost Mode until defrost

is terminated by time or temperature.

FIGURE 12

Page 10

N−Defrost System HP27−7 and later

The defrost system includes two components:

a defrost thermostat

a defrost control

Defrost Thermostat

The defrost thermostat is located on the liquid line between the check/expansion valve and the distributor.

When the defrost thermostat senses 42°F (5.5°C) or

cooler, its contacts close and send a signal to the defrost

control board to start the defrost timing. It also terminates

defrost when the liquid line warms up to 70°F (21°C).

Defrost Control

The defrost control board includes the combined functions of a time/temperature defrost control, defrost

relay, time delay, diagnostic LEDs, and a terminal strip

for field wiring connections. See figure 9.

The control provides automatic switching from normal

heating operation to defrost mode and back. During compressor cycle (call for defrost), the control accumulates

compressor run times at 30, 60, or 90 minute field adjustable intervals. If the defrost thermostat is closed when the

selected compressor run time interval ends, the defrost

relay is energized and defrost begins.

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated compressor run time period during one thermostat

run cycle. This time period must occur before a defrost

cycle is initiated. The defrost interval can be adjusted to

30 (T1), 60 (T2), or 90 (T3) minutes. See figure 9. The defrost timing jumper is factory−installed to provide a

60−minute defrost interval. If the timing selector jumper

is not in place, the control defaults to a 90−minute defrost

interval.The maximum defrost period is 14 minutes and

cannot be adjusted.

A TEST option is provided for troubleshooting. The TEST

mode may be started any time the unit is in the heating

mode and the defrost thermostat is closed or jumpered. If the jumper is in the TEST position at power-up, the

control will ignore the test pins. When the jumper is placed

across the TEST pins for two seconds, the control will enter the defrost mode. If the jumper is removed before an

additional 5−second period has elapsed (7 seconds total),

the unit will remain in defrost mode until the defrost thermostat opens or 14 minutes have passed. If the jumper is

not removed until after the additional 5−second period has

elapsed, the defrost will terminate and the test option will

not function again until the jumper is removed and re−applied.

Time Delay

The timed−off delay is five minutes long. The delay helps

protect the compressor from short−cycling in case the power to the unit is interrupted or a pressure switch opens. The

delay is bypassed by placing the timer select jumper

across the TEST pins for 0.5 seconds.

Pressure Switch Circuits

The defrost control includes two pressure switch circuits.

The high pressure switch (S4) is factory−connected to the

board’s HI PS terminals. The board also includes LO PS

terminals to accommodate the addition of a field−provided

low pressure or loss of charge pressure switch. See figure

9. This feature is available on all units.

During a single demand cycle, the defrost control will lock

out the unit after the third time that the circuit is interrupted

by any pressure switch that is wired to the control board. In

addition, the diagnostic LEDs will indicate a locked out

pressure switch after the third occurrence of an open pressure switch. See table 4. The unit will remain locked out

until power is broken then remade to the control or until the

jumper is applied to the TEST pins for 0.5 seconds.

NOTE − The defrost control board ignores input from the

low pressure switch terminals during the TEST mode, during the defrost cycle, during the 90−second start−up period,

and for the first 90 seconds each time the reversing valve

switches heat/cool modes. If the TEST pins are jump-

ered and the 5−minute delay is being bypassed, the LO

PS terminal signal is not ignored during the 90−second start−up period.

Ambient Thermistor & Service Light Connection

The defrost control board provides terminal connections

for the ambient thermistor and a service light. The thermistor compensates for changes in ambient temperature

which might cause thermostat droop. The service light

thermostat provides a signal which activates the room

thermostat service light during periods of inefficient operation.

Diagnostic LEDs

The defrost board uses two LEDs for diagnostics. The

LEDs flash a specific sequence according to the diagnosis.

TABLE 6

DEFROST CONTROL BOARD DIAGNOSTIC LED

MODE LED 1 LED 2

Normal operation /

power to board

Board failure or no power Off Off

Board failure On On

High pressure switch open Flash On

Low pressure switch open On Flash

Pressure switch lockout On Off

Anti−short−cycle /

5−minute delay

Synchronized

Flash with LED 2

Alternating Flash

with LED 2

Synchronized

Flash with LED 1

Alternating Flash

with LED 1

Page 11

DEFROST CONTROL BOARD

PRESSURE SWITCH

WIRING CONNECTIONS

High

Pressure

Switch

(Factory−wired)

Optional

Pressure

Switch

(Field−provided

and installed −−

jumper removed)

S4

S5

HIGH PRESSURE

SWITCH

TERMINALS

OPTIONAL

PRESSURE

SWITCH

TERMINALS

(Remove factory−

installed jumper

to install

pressure switch.)

CC

Y

TIMING PINS

DEFROST

INTERVAL

DIAGNOSTIC

LEDs

SERVICE

LIGHT

TERMINALS

AMBIENT

THERMISTER

TERMINALS

24V

TERMINAL

STRIP

FIGURE 13

IV−REFRIGERANT SYSTEM

A−Plumbing

An expansion/check valve is used in parallel in the liquid

line. The check valve is closed when the unit is in heating

mode to force refrigerant through the expansion valve.

The check valve is open when the unit is in cooling mode.

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections). Use Lennox

L10 (flare) or L15 (sweat) series line sets as shown in table

7 or field fabricated refrigerant lines. Refer to the piping

section of the Lennox Unit Information Service Manual for

proper size, type and application of field-fabricated lines.

If refrigerant tubes are routed through a wall, seal and isolate the opening so vibration is not transmitted to the building.

NOTE − Line length should be no greater than 50 feet (15.2

m). Select line set diameters from table 1 to ensure oil return to compressor.

TABLE 7

REFRIGERANT LINE SET KITS

HP27

UNIT

−024

−030

−036

−042

LIQUID VAPOR

LINE LINE LINE SETS

3/8 in. 3/4 in.

(9.5 mm) (19.1 mm)

3/8 in.

(9.5 mm)

7/8 in.

(22.2 mm)

L10

L10−41

20 ft. − 50 ft.

(6.1 m−15.2 m)

L10−65

30 ft. − 50 ft.

(9.1 m − 15.2 m)

L15

LINE SETS

L15−41

15 ft. − 50 ft.

(4.5 m−15.2 m)

L15−65

15 ft. − 50 ft.

(4.5 m−15.2 m)

Separate discharge and suction service ports are provided at the compressor for connection of gauge manifold

during charging procedure. Figure 14 and 15 show HP27

gauge manifold connections.

Page 12

HP27 COOLING CYCLE (WITH GAUGE MANIFOLD CONNECTIONS)

DEFROST

THERMOSTAT

OUTDOOR UNIT

OUTDOOR COIL

NOTE − ARROWS INDICATE

DIRECTION OF REFRIGERANT FLOW

EXPANSION/CHECK

VALV E

BIFLOW

LOW

PRESSURE

GAUGE

MANIFOLD

NOTE−Use gauge ports on vapor line valve and liquid valve for evacuating refrigerant lines

and indoor coil. Use suction gauge port to measure suction pressure during charging.

TO

HCFC-2

2

DRUM

HIGH

PRESSURE

FILTER/DRIER

HIGH PRESSURE

LIMIT

THERMOME-

TER

WELL

LIQUID LINE

SERVICE

PORT

MUFFLER

DISTRIBUTOR

COMPRESSOR

SUCTION

SERVICE

PORT

ACCUMULATOR

FIGURE 14

HP27 HEATING CYCLE (WITH GAUGE MANIFOLD CONNECTIONS)

OUTDOOR UNIT

DISTRIBUTOR

COMPRESSOR

OUTDOOR COIL

SUCTION

SERVICE

PORT

ACCUMULATOR

PRESSURE

GAUGE

MANIFOLD

LOW

TO

HCFC-2

2

DRUM

PRESSURE

DEFROST

THERMOSTAT

EXPANSION/CHECK

VALV E

HIGH

FILTER/DRIER

HIGH PRESSURE

THERMOME-

BIFLOW

LIMIT

TER

WELL

MUFFLER

REVERSING

VALV E

VAPOR

LINE

VALV E

EXPANSION/CHECK

VALV E

NOTE − ARROWS INDICATE

DIRECTION OF REFRIGERANT FLOW

REVERSING

VALV E

VAPOR

LINE

VALV E

INDOOR UNIT

INDOOR

INDOOR UNIT

COIL

LIQUID LINE

SERVICE

PORT

NOTE−Use gauge ports on vapor line valve and liquid valve for evacuating refrigerant lines

and indoor coil. Use suction gauge port to measure suction pressure during charging.

FIGURE 15

Page 13

EXPANSION/CHECK

VALV E

INDOOR

COIL

B−Liquid and Vapor Line Service Valves

The liquid line and vapor line service valves and gauge

ports are accessible from outside of the unit. Full service

liquid and vapor line valves are used. The service ports are

used for leak testing, evacuating, charging and checking

charge.

A full-service liquid and vapor line valve made by one of

several manufacturers may be used. All liquid and vapor

line service valves function the same way, differences are

in construction. Valves manufactured by Parker are forged

assemblies. Valves manufactured by Primore are brazed

together. Valves are not rebuildable. If a valve has failed it

must be replaced. The liquid line service valve is illustrated

in figure16. The vapor line service valve is illustrated in figure17.

The valves are equipped with a service port. A schrader

valve is factory installed. A service port cap is supplied to

protect the schrader valve from contamination and serve

as the primary leak seal. Service port cap must be in place

and turned 1/8 to 1/4 turn to assure proper seal.

NOTE− Always keep valve stem clean.

LIQUID LINE SERVICE VALVE (VALVE OPEN)

INSERT HEX

WRENCH HERE

SERVICE

PORT

UNIT SIDE

STEM CAP

To Access Schrader Port:

1 − Remove access panel.

2 − Remove service port cap with an adjustable wrench.

3 − Connect gauge to the service port.

4 − When testing is completed, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Liquid or Vapor Line Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − For liquid line valve use service wrench and 3/16 hex

head extension. Back the stem out counterclockwise

until the valve stem just touches the retaining ring. For

vapor line valve use adjustable wrench and back the

stem out counterclockwise 1/4 turn.

3 − Replace stem cap tighten firmly. Tighten finger tight,

then tighten an additional 1/6 turn.

DANGER

Do not attempt to backseat this valve. Attempts to

backseat this valve will cause snap ring to explode

from valve body under pressure of refrigerant.

Personal injury and unit damage will result.

To Close Liquid or Vapor Line Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − For liquid line valve use service wrench and 3/16 hex

head extension. Turn stem clockwise to seat valve.

Tighten firmly. For vapor line valve use adjustable

wrench and turn stem clockwise 1/4 turn to seat valve.

Tighten firmly.

3 − Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

SERVICE

PORT

CAP

SCHRADER

VALV E

FIELD SIDE

LIQUID LINE SERVICE VALVE (VALVE CLOSED)

RETAINING RING

SERVICE

PORT

UNIT SIDE

SERVICE

PORT CAP

SCHRADER VALVE OPEN

TO LINE SET WHEN VALVE IS

CLOSED (FRONT SEATED)

(VALVE FRONT SEATED)

STEM CAP

INSERT HEX

WRENCH HERE

FIELD SIDE

FIGURE 16

VAPOR LINE (BALL TYPE) SERVICE VALVE

(VALVE OPEN)

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90 TO CLOSE

ROTATE STEM COUNTER-CLOCKWISE 90 TO OPEN

OUTLET

(TO COMPRESSOR)

SERVICE PORT

CAP

SERVICE PORT

SCHRADER VALVE

STEM CAP

STEM

(SHOWN OPEN)

(FROM INDOOR COIL)

FIGURE 17

BALL

INLET

Page 14

V−CHARGING

Unit charge is based on a matching indoor coil and outdoor

coil with a 15 foot (4.5m) line set. For varying lengths of line

set, refer to table 8.

1− Attach gauge manifold. Connect vacuum pump (with

vacuum gauge) to center port of gauge manifold. With

both manifold service valves open, start pump and evacuate indoor coil and refrigerant lines.

IMPORTANT

If line length is greater than 15 feet (4.5m), add

the amount of refrigerant listed in table 8 . If line

length is less than 15 feet (4.5), subtract this

amount.

Liquid Line

Set Diameter

3/8 in. (9.5 mm)

*If line set is greater than 15 ft. (4.5m) add this amount. If line set is less than

15 ft. (4.5m) subtract this amount

Ounce per 5 foot (ml per mm) adjust from

TABLE 8

15 ft. (4.5m)*

3 ounce per 5 feet (88.05g per 1.5m)

A−Leak Testing

1 − Attach gauge manifold and connect a drum of dry ni-

trogen to center port of gauge manifold.

2 − Add a small amount of refrigerant to the lines and coil.

Open high pressure gauge valve and pressurize line

set and indoor coil to 150 psig (1034 kPa).

WARNING

Danger of Explosion.

Can cause injury, death and equipment

damage.

When using dry nitrogen, use a pressure−reducing regulator, set at 150 pig

(1034 kPa) or less to prevent excessive

pressure.

3 − Check lines and connections for leaks.

NOTE-If electronic leak detector is used, add a trace of refrigerant to nitrogen for detection by leak detector.

4 − Release nitrogen pressure from the system, correct

any leaks and recheck.

B−Evacuating the System

Evacuating the system of non−condensables is critical for

proper operation of the unit. Non−condensables are defined

as any gas that will not condense under temperatures and

pressures present during operation of an air conditioning

system. Non−condensables such as water vapor, combine

with refrigerant to produce substances that corrode copper

piping and compressor parts.

CAUTION

Danger of Equipment Damage. Avoid deep vacuum operation. Do not use compressors to evacuate a system. Extremely low vacuums can cause

internal arcing and compressor failure. Damage

caused by deep vacuum operation will void warranty.

IMPORTANT

A temperature vacuum gauge, mercury vacuum

(U−tube), or thermocouple gauge should be used.

The usual Bourdon tube gauges are not accurate

enough in the vacuum range.

2− Evacuate the system to 29 inches (737mm) vacuum.

During the early stages of evacuation, it is desirable to

stop the vacuum pump at least once to determine if there

is a rapid loss of vacuum. A rapid loss of vacuum would

indicate a leak in the system and a repeat of the leak testing section would be necessary.

3− After evacuating system to 29 inches (737mm), close

gauge manifold valves to center port, stop vacuum pump

and disconnect from gauge manifold. Attach an upright

nitrogen drum to center port of gauge manifold and open

drum valve slightly to purge line at manifold. Break vacuum in system with nitrogen pressure by opening manifold

high pressure valve. Close manifold high pressure valve

to center port.

4− Close nitrogen drum valve and disconnect from

gauge manifold center port. Release nitrogen pressure from system.

5− Connect vacuum pump to gauge manifold center

port. Evacuate system through manifold service

valves until vacuum in system does not rise above

.5mm of mercury absolute pressure or 500 microns

within a 20−minute period after stopping vacuum

pump.

6− After evacuation is complete, close manifold center port,

and connect refrigerant drum. Pressurize system slightly with refrigerant to break vacuum.

C−Charging

Charging must be done in the cooling mode.If system is

completely void of refrigerant, the recommended and most

accurate method of charging is to weigh the refrigerant into

the unit according to the total amount shown on the unit

nameplate. Length of refrigerant lines should be considered. See table 8 for varying line lengths.

If weighing facilities are not available or if unit is just low on

charge, the following procedure applies.

Separate discharge and vapor line service ports are provided outside the unit for connection of gauge manifold

during charging procedure as well as a suction line service

port.

Page 15

1 − Expansion Valve Systems

The following procedures are intended as a general guide for

use with expansion valve systems only. For best results, indoor temperature should be between 70°F and 80°F (21C

and 26.5C). If outdoor temperature is 60F (16 °C) or above

the approach method of charging is used. If outdoor temperature is less than 60 °F (16 °C) the subcooling method of

charging is used. Slight variations in charging temperature

and pressure should be expected. Large variations may indicate a need for further servicing.

IMPORTANT

The following procedures require accurate

readings of ambient (outdoor) temperature, liquid

temperature and liquid pressure for proper

charging. Use a thermometer with accuracy of +2

°F and a pressure gauge with accuracy of +5 PSIG.

APPROACH METHOD (TXV SYSTEMS)

(Ambient Temperature Above 60F [16C] )

1 − Connect gauge manifold. Connect an upright HCFC-22

drum to center port of gauge manifold.

2 − Record outdoor air (ambient) temperature.

3 − Operate indoor and outdoor units in cooling mode. Al-

low outdoor unit to run until system pressure stabilize.

4 − Make sure thermometer well is filled with mineral oil

before checking liquid line temperature.

5 − Place thermometer in well and read liquid line temper-

ature. Liquid line temperature should be a few de-

grees warmer than the outdoor air temperature. Table

9 shows how many degrees warmer the liquid line

should be.

Add refrigerant to make the liquid line cooler.

Remove refrigerant to make the liquid line warmer.

TABLE 9

Model

HP27−024

HP27−030

HP27−036

HP27−042

SUBCOOLING METHOD (TXV SYSTEMS)

(Ambient Temperature Below 60F [16C] )

NOTE- It may be necessary to restrict air flow in order to

reach liquid pressures in the 200-250 psig range which

are required for checking charge. Block equal sections of

air intake panels as shown in figure 18, moving obstructions sideways until liquid pressures in the 200-250 psig

range are reached.

Liquid Temp. Minus

Ambient Temp. F (C)

8 + 1 (4.4 + .5)

5 + 1 (2.8 + .5)

5 + 1 (2.8 + .5)

8 + 1 (4.4 + .5)

BLOCKING OUTDOOR COIL

Block outdoor coil one side at a time

with cardboard or plastic sheets until

proper testing pressures are reached.

CARDBOARD OR PLASTIC SHEET

FIGURE 18

1 − Connect gauge manifold. Connect an upright HCFC-22

drum to center port of gauge manifold.

2 − Operate indoor and outdoor units in cooling mode. Allow

units to run until system pressures stabilize.

3 − Make sure thermometer well is filled with mineral oil be-

fore checking liquid line temperature.

4 − Read liquid line pressure and convert to condensing tem-

perature using temperature/ pressure conversion chart.

Condensing temperature (from gauges) should be a few

degrees warmer than the liquid line.

5 − Place thermometer in well and read liquid line tempera-

ture. Table 10 shows how much warmer the condensing

temperature should be.

TABLE 10

Model Subcooling F (C)

HP27−024

HP27−030

HP27−036

8 + 2 (4.4 + 1)

7 + 2 (3.9 + 1)

8 + 2 (4.4 + 1)

7 + 2 (3.9 + 1)HP27−042

Add refrigerant to make the liquid line cooler.

Recover refrigerant to make the liquid line warmer.

6 − When unit is properly charged liquid line pressures

should approximate those given in table 11.

IMPORTANT

Use table 11 as a general guide for performing

maintenance checks. Table 11 is not a procedure for

charging the system. Minor variations in pressures

may be expected due to differences in installations.

Significant deviations may mean the system is not

properly charged or that a problem exists with some

component in the system. Used prudently, table 11

could serve as a useful service guide.

D−Oil Charge

Refer to table 1 on page 3.

Page 16

MODE/

TYPE OF

OUTDOOR COIL

Cooli

TXV

y

EXPANSION

ng

TXV

Only

Heating

TABLE 11

NORMAL OPERATING PRESSURES

OUTDOOR COIL

AIR ENTERING

TEMPERATURE

F

65 134 82 136 80 137 80 134 75

75 159 83 161 81 163 81 167 76

85 186 84 188 82 190 82 199 77

95 216 83 217 83 221 83 232 78

105 248 86 251 85 257 85 257 80

20 179 36 173 36 177 33 184 29

30 188 49 192 49 195 40 194 39

40 203 58 205 58 208 46 205 48

50 228 65 218 65 217 58 216 58

HP27-024 HP27-030 HP27−036 HP27-042

LIQ.

+10

PSIG

SUC.

+5

PSIG

LIQ.

+10

PSIG

SUC.

+5

PSIG

LIQ.

+10

PSIG

SUC.

+5

PSIG

LIQ.

+10

PSIG

SUC.

+5

PSIG

VI−MAINTENANCE

At the beginning of each heating or cooling season, the

system should be cleaned as follows:

A−Outdoor Unit

1 − Clean and inspect outdoor coil. (Coil may be flushed

with a water hose).

2 − Visually inspect all connecting lines, joints and coils

for evidence of oil leaks.

IMPORTANT

If insufficient heating or cooling occurs, the unit

should be gauged and refrigerant charge

checked.

B−Indoor Coil

1 − Clean coil if necessary.

2 − Check lines and coil for evidence of oil leaks.

3 − Check condensate line and clean if necessary.

C−Indoor Unit

1 − Clean or change filters.

2 − Adjust blower cooling speed. Static pressure drop

over coil should be checked to determine correct

blower CFM. Refer to Lennox Engineering Hand-

book.

3 − Belt Drive Blowers-Check condition and tension.

4 − Check all wiring for loose connections.

5 − Check for correct voltage at unit.

6 − Check amp−draw on blower motor.

Unit nameplate_________Actual_________.

Page 17

VII−WIRING DIAGRAM/OPERATING SEQUENCE

A−Field Wiring, Thermostat Connections

HP27 and TYPICAL BLOWER UNIT THERMOSTAT

TERMINAL DESIGNATIONS

Thermostat

Indoor

Blower Unit

HP27

T

L

O

Y1

E

C

W2

R

W1

G

AMBIENT SENSOR

SERVICE LIGHT

REVERSING VALVE

COMPRESSOR

EMERGENCY HEAT

COMMON

2ND STAGE AUX. HEAT

POWER

1ST STAGE AUX. HEAT

INDOOR BLOWER

B−Field Wiring, Thermostat Connections

FIELD WIRING DIAGRAM HP27 WITH INDOOR UNIT

DEFROST CONTROL

E

C

W2

R

W1

G

COMMON

POWER

DEFROST SENSING

T

L

O

Y1

C

R

W1

L O Y1 E C V/R R W1 G

T

C12

DENOTES OPTIONAL COMPONENT

1

THERMOSTAT HEAT ANTICIPATION SETTING .4 AMP ELECTRIC HEAT.

2

WHEN TWO−STAGE THERMOSTAT IS USED,

CONNECT SECOND−STAGE HEAT BULB TO TERMINAL W2" AND REMOVE JUMPER BETWEEN

TERMINALS R" AND W2."

K1

TLCRW1Y1O

WHEN OUTDOOR THERMOSTAT IS USED,

3

CONNECT LEADS TO TERMINALS R" AND

W2’’ AND REMOVE JUMPER BETWEEN

TERMINALS R" AND W2."

Page 18

4

3

S23

EMERGENCY HEAT RELAY (USED ONLY

4

IF OUTDOOR THERMOSTAT IS USED)

FIELD PROVIDED AND INSTALLED NEAR

INDOOR UNIT. 24 VAC, 5VA MAX. NEC

CLASS 2.

K22

CLASS II 24V FIELD INSTALLED

LINE VOLTAGE FIELD INSTALLED

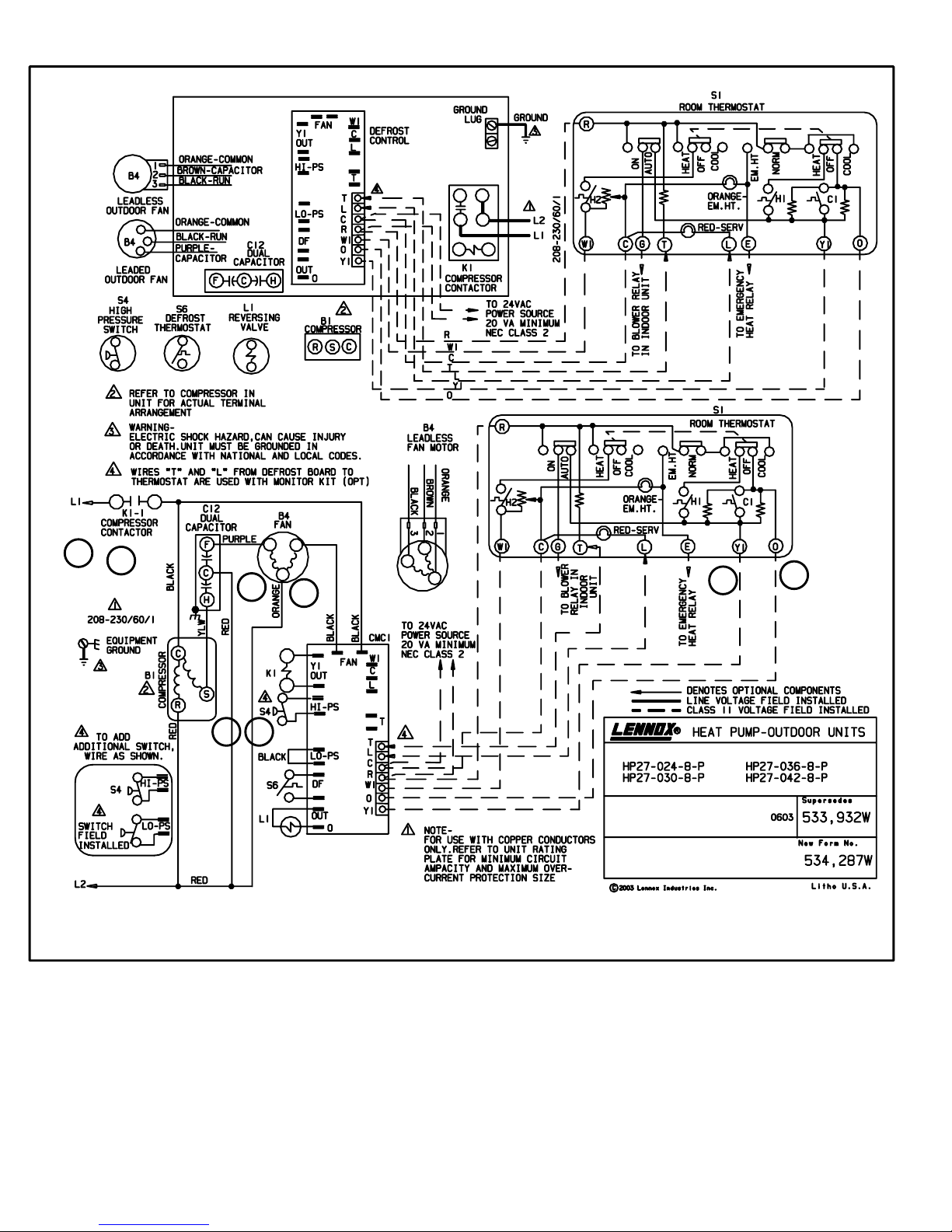

C−Diagram HP27−1−208/230 Volt

3

7

2

6

8

4

1

5

Page 19

D−Diagram HP27−6−208/230 Volt

8

4

3

7

1

5

2

6

Page 20

E−Diagram HP27−7−208/230 Volt

8

4

3

7

5

2

6

1

Page 21

F−Diagram HP27−7−208/230 Volt

3

7

8

6

4

2

5

1

Page 22

Operating Sequence HP27

NOTE− Transformer in indoor unit supplies power

(24VAC) to the thermostat and outdoor unit controls.

COOLING

1 − Internal wiring energizes terminal O by cooling mode

selection, energizing the reversing valve. Cooling demand initiates at Y1 in the thermostat.

2 − 24VAC energizes N.C. high pressure limit S4 which

energizes compressor contactor K1.

3 − K1−1 N.O. contacts close energizing compressor B1

and outdoor fan motor B4.

4 − Compressor B1 and outdoor fan motor B4 begin im-

mediate operation.

HEATING

5 − Internal thermostat wiring de−energizes terminal O by

heating mode selection, de−energizing the reversing

valve. Heating demand initiates at Y1.

6 − 24VAC energizes N.C. high pressure limit S4 and

compressor contactor K1.

7 − K1−1 N.O. contacts close energizing compressor and

outdoor fan motor.

8 − Compressor B1 and outdoor fan motor B4 begin im-

mediate operation.

DEFROST MODE

9− During heating operation when outdoor coil tempera-

ture drops below 35F (2C) or 42(5.5C) see de-

frost system description for specific unit dash number

defrost switch (thermostat) S6 closes.

10− Defrost control CMC1 begins timing. If defrost

ther−mostat (S6) remains closed at the end of the

30,60 or 90 minute period, defrost relay energizes

and defrost begins.

11 − During defrost CMC1 energizes the reversing valve

and W1 on the terminal strip (operating indoor unit on

the first stage heat mode), while de-energizing outdoor

fan motor B4.

12 − Defrost continues 14 + 1 minutes or until thermostat

switch (S6) opens. When defrost thermostat opens,

defrost control timer loses power and resets.

13 − When CMC1 resets, the reversing valve and W1 on

the terminal strip are de-energized, while the outdoor

fan motor B4 is energized.

14− After each thermostat demand, time delaylocks out

the circuit to compressor contactor coil and defrost

control for 5 minutes + 2 minutes. At the end of the

timed period, the time delay allows the compressor

contactor and defrost control to be energized upon demand as in step 1.

Page 23

Loading...

Loading...