Lennox HP25 Series, HP25-211, HP25-261, HP25-311, HP25-461-463 Installation Instructions Manual

...

INSTALLATION

PRODUCT LITERATURE

1995 Lennox Industries Inc.

Dallas, Texas

HP25 HEAT PUMP UNIT

HP25 heat pump units are designed for expansion valve

systems only. They are not designed for RFC systems.

Refer to Lennox engineering handbook for expansion

valve kits which must be ordered separately.

INSTRUCTIONS

HP25 SERIES UNITS

HEAT PUMP UNITS

503,302M

6/95

Supersedes 503,247M

TABLE OF CONTENTS

HP25 HEAT PUMP UNIT 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING AND PACKING LIST 1. . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . .

HP25 UNIT DIMENSIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . .

HP25 PARTS ARRANGEMENT 3. . . . . . . . . . . . . . . . . . . . . .

SETTING THE UNIT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLUMBING 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEAK TESTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVACUATION 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START-UP 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHARGING 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM OPERATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEFROST SYSTEM 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP25 CHECK POINTS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Litho U.S.A.

SHIPPING AND PACKING LIST

1- Assembled HP25 heat pump unit

Check unit for shipping damage. Consult last carrier

immediately if damage is found.

GENERAL INFORMATION

These instructions are intended as a general guide and

do not supersede national or local codes in any way.

Authorities having jurisdiction should be consulted be

fore installation.

IMPORTANT

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC's and HCFC's) as of July

1, 1992. Approved methods of recovery, recycling

or reclaiming must be followed. Fines and/or in

carceration may be levied for non-compliance.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose

you to fiberglass wool. Breathing this may cause

lung cancer. (Fiberglass wool is known to the

State of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

Page 1

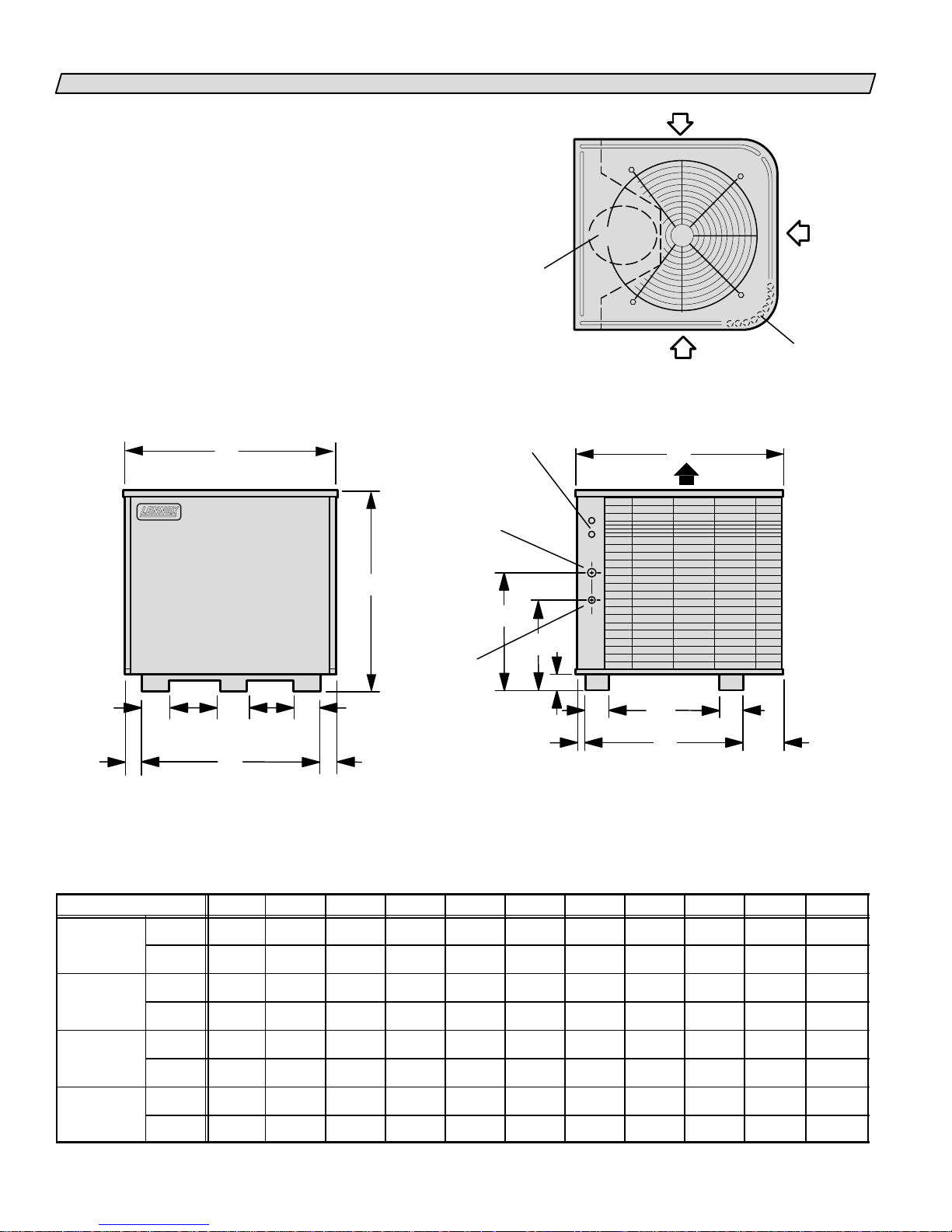

HP25 UNIT DIMENSIONS-INCHES (MM)

HP25211

HP25 311

HP25 511 513

HP25

HEAT PUMP UNIT

B

COMPRESSOR

ELECTRICAL

INLETS

VAPOR

LINE INLET

(HP25211460)

LIQUID

LINE INLET

(HP25510650)

INLET

INLET AIR

AIR

TOP VIEW

C

DISCHARGE AIR

INLET

AIR

COIL DRAIN

OUTLETS

(Around perimeter

of base)

A

LIQUID

LINE INLET

(HP25211460)

VAPOR

LINE INLET

(HP25510650)

KK

LL

47/8 (22)

GHH

FRONT VIEW

Model No. A B C D E F G H J K L

HP25211

HP25261

HP25311

HP25411413

in. 277/8 257/8 297/8 121/4 227/16 147/16 221/8 17/8 163/4 51/2 27/8

mm 708 657 759 311 570 367 562 48 425 140 73

in. 307/8 321/8 341/16 123/4 265/8 185/8 281/8 2 171/4 71/2 37/8

mm 784 816 865 324 676 473 714 51 438 191 98

J

23/4

(70)

D

13/8

(35)

4

(102)

F

E

SIDE VIEW

4

(102)

61/16

(154)

HP25461463

HP25511513

HP25651653

in. 347/8 321/8 341/16 133/4 265/8 185/8 281/8 2 181/4 71/2 37/8

mm 886 816 865 349 676 473 714 51 464 191 98

in. 447/8 321/8 341/16 291/4 265/8 185/8 281/8 2 203/4 71/2 37/8

mm 1140 816 865 743 676 473 714 51 527 191 98

Page 2

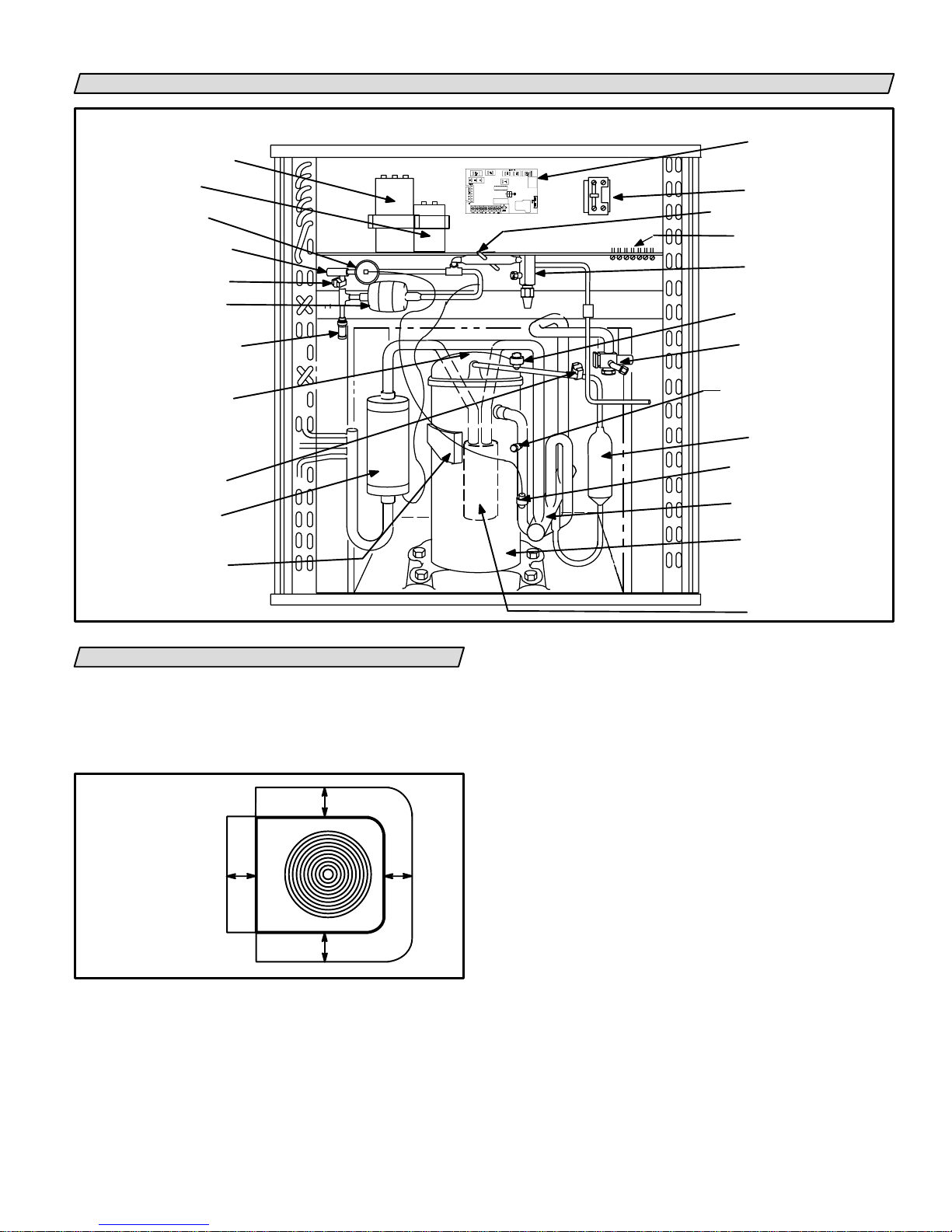

HP25 PARTS ARRANGEMENT

HP25 UNIT COMPONENTS

DUAL CAPACITOR

(Single-Phase Units)

FAN CAPACITOR

(Three-Phase Units)

EXPANSION

VAL VE

DISTRIBUTOR

DEFROST

THERMOSTAT

FILTER/DRIER

WITH

INTERNAL CHECK VALVE

FACTORY

CHARGE

PROCESS PORT

COMPRESSOR

TEMPERATURE

SENSOR

HP25211 THRU 460 ONLY

SERVICE LIGHT

THERMOSTAT

CHARGE

COMPENSATOR

COMPRESSOR

TERMINAL BOX

FIGURE 1

SETTING THE UNIT

HP25 heat pump units are approved and warranted

only for installation with specially matched indoor

coils, L10 or L15 line sets, and refrigerant control de

vices as designated by Lennox. Refer to the Lennox En

gineering Handbook for approved systems.

INSTALLATION

CLEARANCES

NOTE-48"

(1219mm)

clearance required

on top of unit.

*One side dimension

may be 12" (305mm).

36"

(914mm)

*36"

(914mm)

FIGURE 2

Heat pump units operate under a wide range of weath

er conditions; therefore, several factors must be con

sidered when positioning the outdoor unit.

*36"

(914mm)

*36"

(914mm)

DEFROST CONTROL

CONTACTOR

THERMOMETER WELL

TERMINAL STRIP

LIQUID LINE

SERVICE VALVE

AND GAUGE PORT

HIGH PRESSURE SWITCH

VAPOR LINE

SERVICE VALVE

AND GAUGE PORT

SUCTION GAUGE PORT

MUFFLER

EXPANSION VALVE

SENSING BULB

REVERSING VALVE

AND SOLENOID

COMPRESSOR

ACCUMULATOR

HP25510 AND

-650 ONLY

1- Place a sound-absorbing material, such as Iso

mode, under the unit if it will be installed in a loca

tion or position that will transmit sound or vibra

tion to the living area or adjacent buildings.

2- Mount unit high enough above ground or roof to al

low adequate drainage of defrost water and prevent

ice build-up.

3- In heavy snow areas, do not locate unit where drift

ing will occur. The unit base should be elevated

above the depth of average snows.

NOTE-Elevation of the unit may be accomplished

by constructing a frame using suitable materials. If

a support frame is constructed, it must not block

drain holes in unit base.

4- When installed in areas where low ambient tem

peratures exist, locate unit so winter prevailing

winds do not blow directly into outdoor coil.

5- Locate unit away from overhanging roof lines

which would allow water or ice to drop on, or in

front of, coil or into unit.

Page 3

Slab Mounting (See figure 3)

When installing unit at grade level, top of slab should

be high enough above the grade so that water from

higher ground will not collect around unit. Slab should

have a slope tolerance away from the building of 2 de

grees or 2 inches per 5 feet (51mm per 1.5m). This will

prevent ice build-up under unit during a defrost cycle.

Refer to roof mounting section for barrier construction

if unit must face prevailing winter winds.

SLAB MOUNTING

BUILDING

STRUCTURE

MOUNTING SLAB

DISCHARGE

AIR

2 DEGREES or 2 IN. PER 5 FT.

(51mm per 1.5m)

TOLERANCE AWAY FROM

BUILDING STRUCTURE

SLOPE

GROUND LEVEL

FIGURE 3

Roof Mounting (See figure 4)

If unit coil cannot be mounted away from prevailing

winter winds, a wind barrier should be constructed.

Size barrier at least the same height and width as out

door unit. Mount barrier 24 inches (610mm) from the

sides of the unit in the direction of prevailing winds.

ROOFTOP APPLICATION

WIND BARRIER CONSTRUCTION

PREVAILING WINTER WINDS

WIND BARRIER

INLET AIR

24"

(610mm)

ELECTRICAL

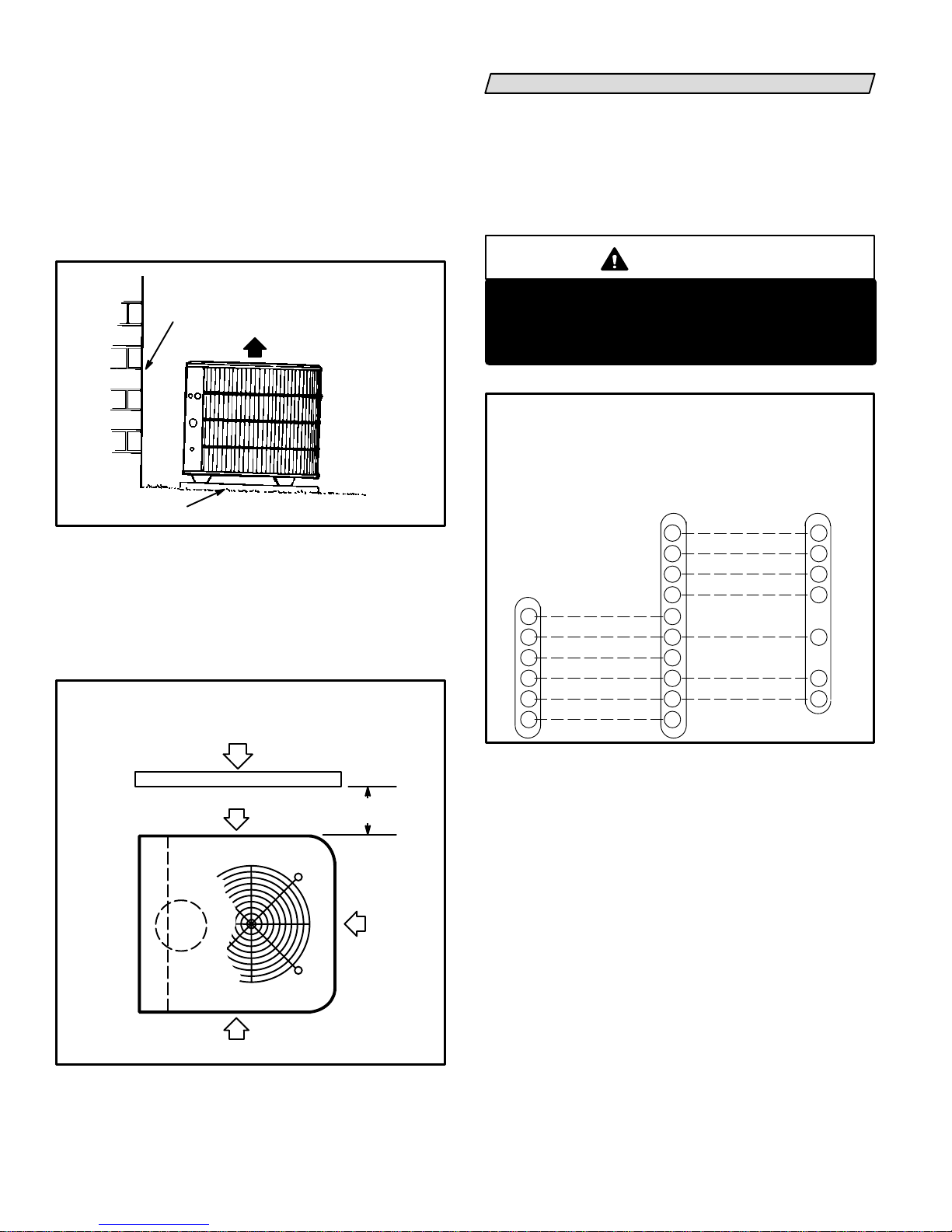

Wiring must conform to the National Electric Code

(NEC) and local codes. Application diagram is included

in this instruction (see figure 6) and in indoor unit

instructions. Refer to figure 5 for thermostat designa

tions. Refer to unit rating plate for minimum circuit am

pacity and maximum fuse size.

WARNING

Unit must be grounded in accordance with

national and local codes.

Electric Shock Hazard.

Can cause injury or death.

HP25 and BLOWER UNIT

THERMOSTAT DESIGNATIONS

(WITH OR WITHOUT AUXILIARY HEAT)

(Some connections may not apply.

Refer to specific thermostat and indoor unit.)

HP25ThermostatIndoor

Blower

Unit

EMERGENCY HEAT

E

C

W2

R

W1

G

COMMON

2ND STAGE AUX. HEAT

POWER

1ST STAGE AUX. HEAT

INDOOR BLOWER

FIGURE 5

1- Provide line voltage power supply to unit from a

properly sized disconnect switch. See figure 6.

AMBIENT SENSOR

T

SERVICE LIGHT

L

REVERSING VALVE

O

COMPRESSOR

Y1

E

C

W2

R

W1

G

COMMON

POWER

DEFROST SENSING/

1ST STAGE AUX. HEAT

T

L

O

Y1

C

R

W1

INLET AIR

FIGURE 4

INLET

AIR

2- Install room thermostat (ordered separately) in

the conditioned area. Locate where it will not be

affected by sunlight, drafts or vibration. Do not

install on an outside wall. A position approxi

mately 5 feet (1.5m) from the floor and near the

center of the conditioned area is most desirable.

3- Provide low voltage wiring from outdoor to indoor

unit and from thermostat to indoor unit as indi

cated on the field wiring diagram in this instruc

tion. See figure 6.

4- Ground unit either through supply wiring or with

an earth ground.

Page 4

Loading...

Loading...