SERVICE

UNIT

INFORMATION

Corp. 9428–L10

Replaces Corp. 9330-L4

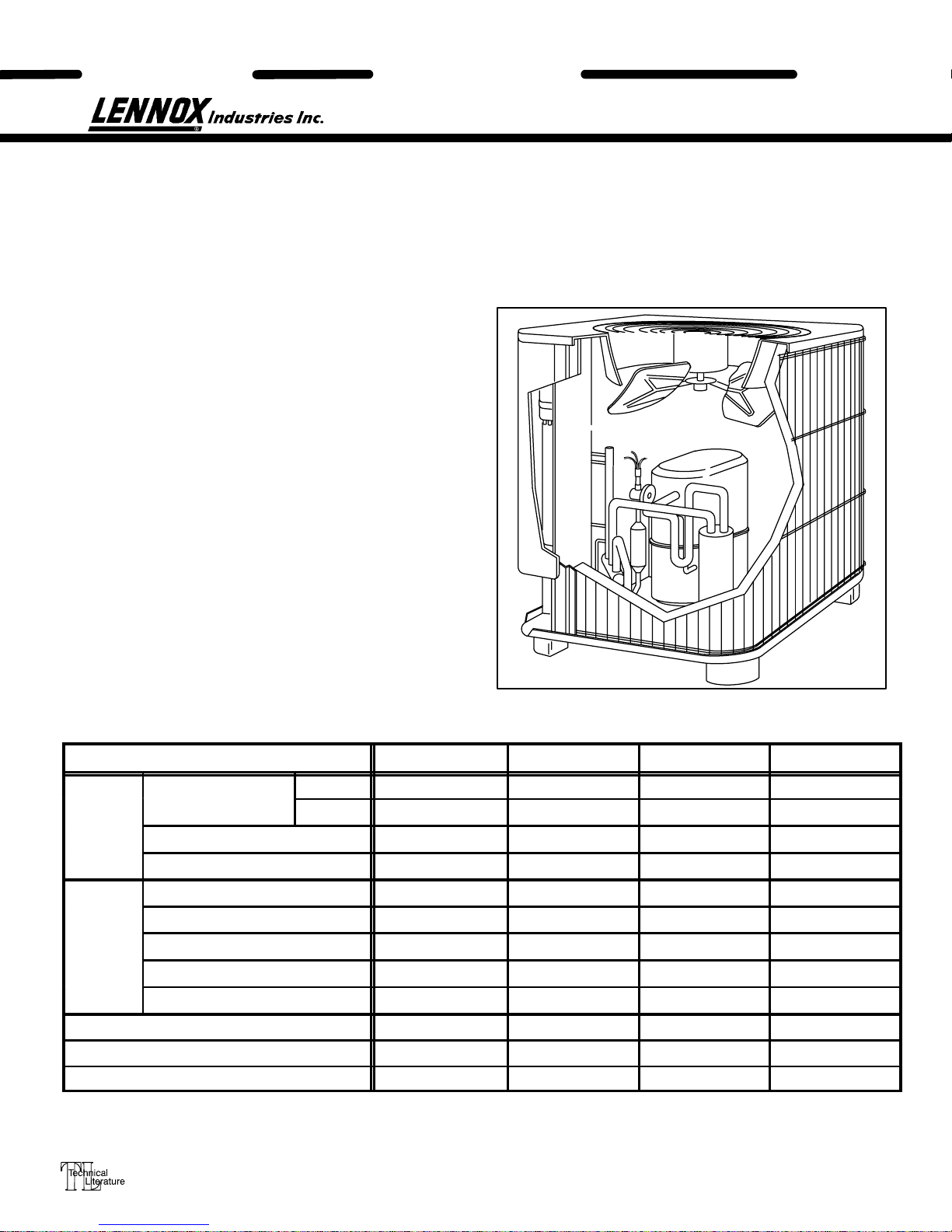

HP23 SERIES UNITS

HP23

Litho U.S.A.

The HP23 is a high-efficiency residential

split-system heat pump. Extra large outdoor coil,

coil circuiting and high outdoor coil air volume

result in a high SEER rating (minimum of 10.0).

HP23-141 through HP23-510 units are designed for

use with an expansion valve or RFCIII system in the

indoor unit. HP23-651/653 units are designed for use

with an expansion valve only in the indoor unit.

All compressors are hermetically sealed for

trouble-free operation and long service life.

Compressor components are spring mounted within

the sealed housing. The compressor is installed in the

unit on resilient rubber mounts to assure quiet,

vibration-free operation. A built-in limit protects the

compressor from excessive current and temperatures.

A high pressure safety limit is furnished as standard.

HP23–211 through HP23–650 models are furnished with

crankcase heaters as standard equipment. The heater

prevents liquid from accumulating in the compressor.

The heater is temperature-actuated and operates only

when required. A crankcase heater for HP23-141 units is

optional, but suction accumulator is factory installed.

Several models are available in sizes ranging from 1

through 5 tons.

This manual is divided into sections which discuss major

components refrigerant system, charging procedures,

maintenance, and operation sequence.

Canadian specifications are marked (CAN).

All specifications in this manual are subject to change.

SPECIFICATIONS

Model No. HP23-141 HP23-211 HP23-261 HP23-311

Outer coil 12.60 12.60 12.60 14.70

Net face area (sq. ft.)

Condenser

Coil

Condenser

Fan

*Refrigerant — 22 charge furnished 5 lbs. 3 oz. 5 lbs. 6 oz. 6 lbs. 2 oz. 7 lbs. 3 oz.

Liquid line (o.d. in.) connection (sweat) **3/8 ***3/8 ***3/8 3/8

Suction line (o.d. in.) connection (sweat) 1/2 5/8 5/8 3/4

*Refrigerant charge sufficient for 20 ft. length of refrigerant lines.

**3/8” x 1/4” reducer furnished to adapt to 1/4 field fabricated line set.

***3 /8” x 5/16” reducer furnished to adapt unit to 5/16” line set.

Tube diameter (in.) & no. of rows 3/8 — 1 3/8 — 1 3/8 — 1 3/8 — 1

Fins per inch 20 20 20 20

Diameter (in.) & no. of blades 20 — 3 20 — 3 20 — 3 20 — 3

Motor hp 1/6 1/6 1/6 1/6

Cfm 2630 2630 2630 2665

Rpm 840 840 840 850

Watts 210 210 210 210

Inner coil - - - - - - - - - - - - - - - -

Page 1

1993 Lennox Industries Inc.

SPECIFICATIONS (contd.)

Net f

)

Cond

Fan

Model No. HP23-411/HP23-413 HP23-461/HP23-463 HP23-511/HP23-513 HP23-651/HP23-653

Condenser

Coil

enser

*Refrigerant — 22 charge furnished 7lbs. 14oz. / 7lbs. 5oz. 8 lbs. 3 oz. 9 lbs. 6 oz. 12 lbs. 13 oz.

Liquid line (o.d. in.) connection (sweat) 3/8 3/8 3/8 3/8

Suction line (o.d. in.) connection (sweat) 3/4 7/8 7/8 1-1/8

*Refrigerant charge sufficient for 20 ft. length of refrigerant lines.

ace area (sq. ft.

Tube diameter (in.) & no. of rows 3/8 — 1.3 3/8 — 1.0 3/8 — 1.3 3/8 — 2.0

Fins per inch 20 20 20 20

Diameter (in.) & no. of blades 20 — 3 20 — 4 24 — 4 24 — 4

Motor hp 1/6 1/4 1/4 1/4

Cfm 2600 3980 3980 3950

Rpm 845 840 830 825

Watts 200 350 340 370

Outer coil 14.70 20 20.00 20.00

Inner coil 3.9 - - - - 6.3 19

ELECTRICAL DATA

Model No. HP23-141 HP23-211 HP23-261 HP23-311-1 HP23-311-2 HP23-411 HP23-411–2

Line voltage data 208/230v 60hz-1ph

Rated load amps 5.0 8.1 10.9 12.2 13.7 16.3 16.2

Compressor Power factor .97 .99 .95 .97 0.99 .99 .91

Locked rotor amps 26.3 49.0 61.0 71.0 75.0 86.7 96.0

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size

(amps)

*Minimum circuit ampacity 7.4 11.3 14.8 16.4 18.2 21.5 21.3

*Refer to National Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE — Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 1.1 1.1 1.1 1.1 1.1 1.1 1.1

Locked rotor amps 1.7 1.7 1.7 1.7 1.7 1.7 1.7

15 15 25 25 30 35 35

ELECTRICAL DATA

Model No. HP23-413 HP23-461-1 HP23-463-1

Line voltage data — 60hz.

Rated load amps 11.6 5.1 18.6 12.7 5.8

Compressor Power factor .88 .88 .94 .82 .82

Locked rotor amps 65.1 32.8 102.0 91.0 42.0

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 25 15 40 30 15

*Minimum circuit ampacity 15.6 7.0 25.0 17.6 8.4

*Refer to National Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE — Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 1.1 0.6 1.7 1.7 1.1

Locked rotor amps 1.7 0.9 3.1 3.1 2.2

208/230

3ph

460v

3ph

208/230v 1ph

208/230v

3ph

460v

3ph

ELECTRICAL DATA

Model No. HP23-511 HP23-513 HP23-651 HP23-653

Line voltage data — 60 hz 208/230v 1ph 208/230v 3ph 460v 3ph 208/230v 1ph 208/230v 3ph 460v 3ph

Rated load amps 24.4 16.1 8.4 30.8 17.4 9.7

Compressor Power factor .98 .78 .78 .98 .78 .78

Locked rotor amps 135.0 137.0 68.0 147.0 150.0 73.0

Condenser Coil

Fan Motor

Rec. max. fuse or circuit breaker size (amps) 50 35 15 60 40 20

*Minimum circuit ampacity 32.2 21.9 10 40.2 23.5 13.3

*Refer to National Electrical Code manual to determine wire, fuse and disconnect size requirements.

NOTE — Extremes of operating range are plus 10% and minus 5% of line voltage.

Full load amps 1.7 1.7 1.1 1.7 1.7 1.1

Locked rotor amps 3.1 3.1 2.2 3.1 3.1 2.2

Page 2

I – UNIT INFORMATION

HP23 units are available in 1, 1 -1/2, 2, 2 -1/2, 3, 3 -1/2, 4

and 5 ton capacities.

All major components (indoor blower/coil) must be

matched according to Lennox recommendations for

the compressor to be covered under warranty. Refer to

the Engineering Handbook for approved system

matchups. A misapplied system will cause erratic

operation and can result in early compressor failure.

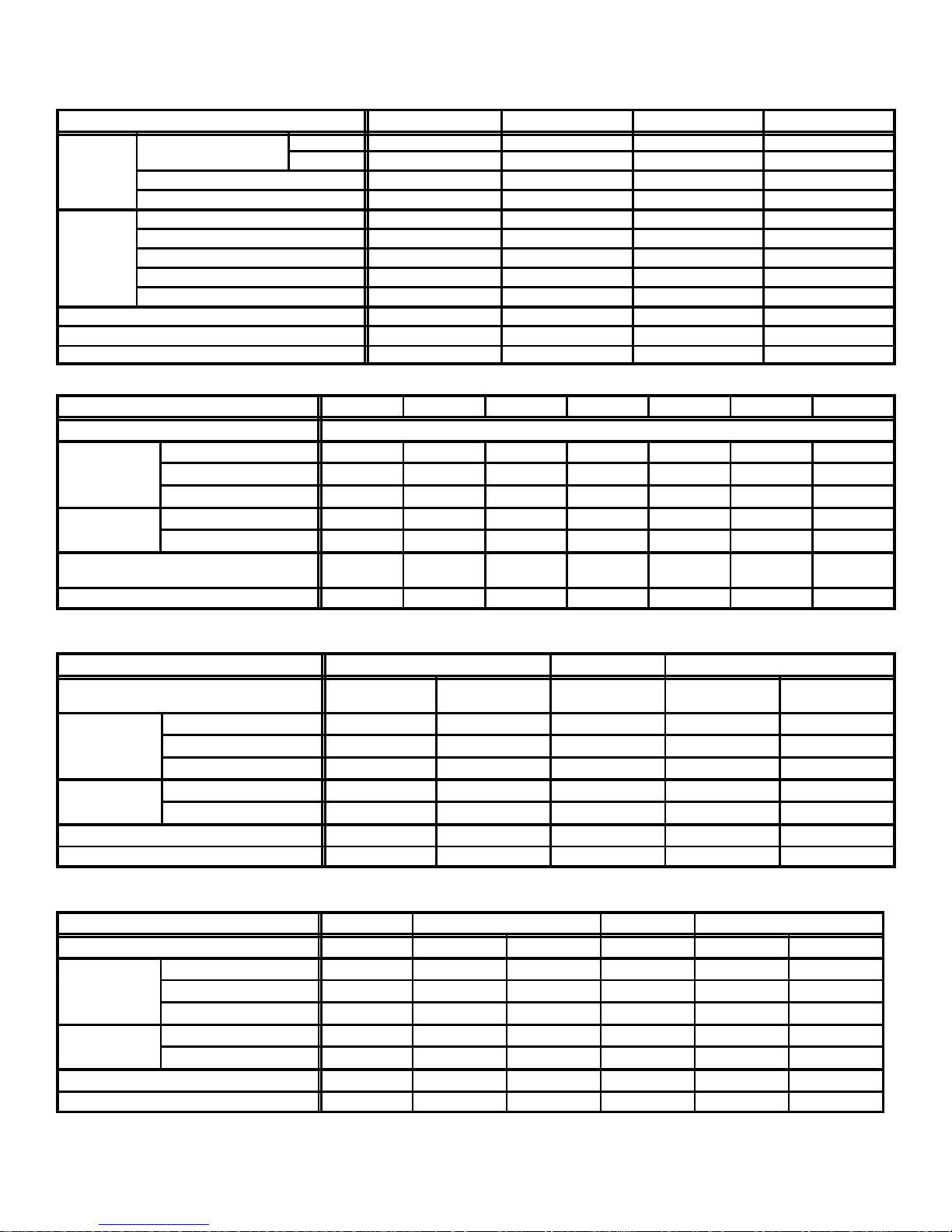

II – UNIT COMPONENTS

Unit components are illustrated in figures 1 and 2.

HP23-141, -210, -260, -310 and -410

EXPANSION

VALVE

UNIT COMPONENTS

OUTDOOR

FAN/MOTOR

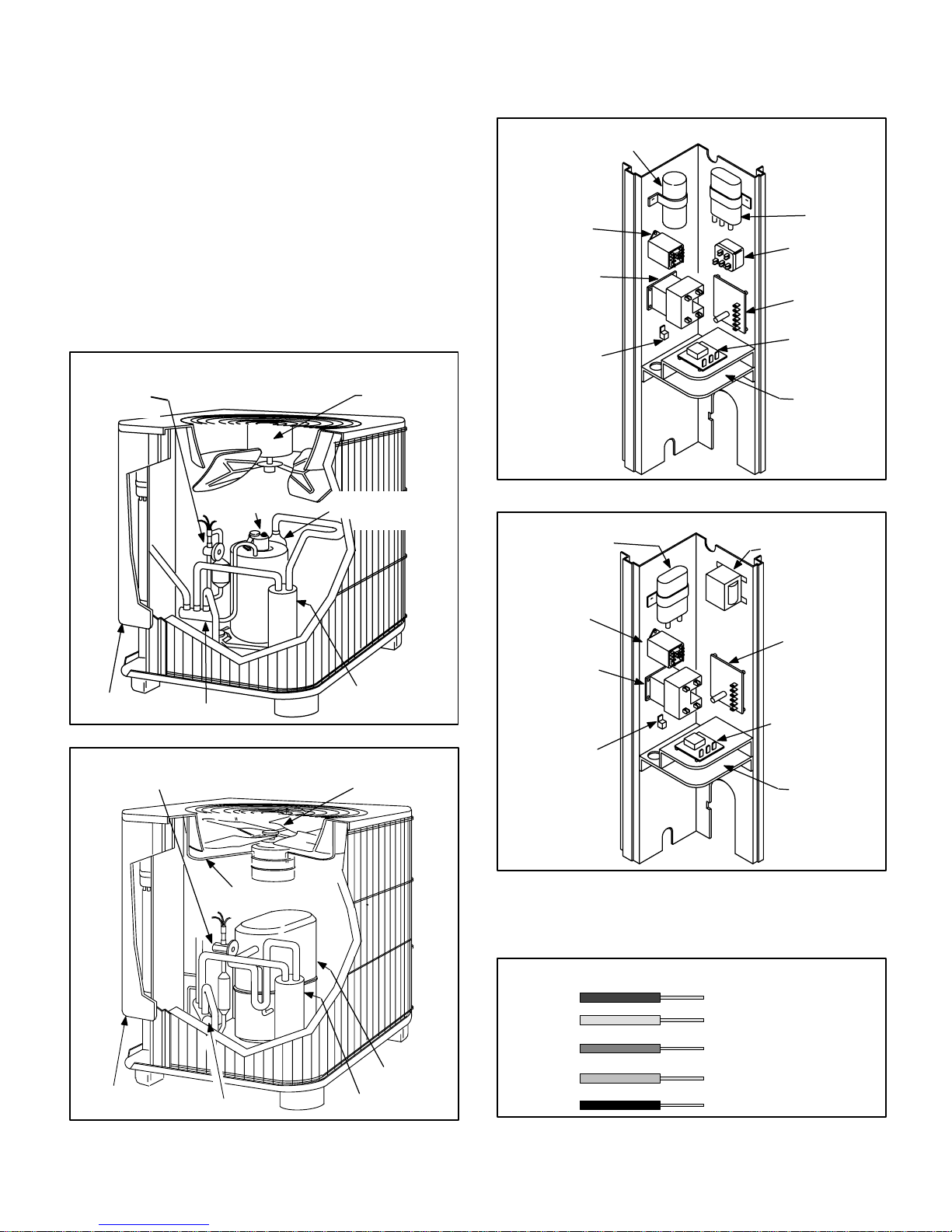

A – Control Box (Figures 3 and 4)

HP23 UNIT CONTROL BOX SINGLE PHASE UNITS

START CAPACITOR

(C7)

DUAL CAPACITOR

DEFROST

RELAY (K4)

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

(C12)

POTENTIAL

RELAY (K31)

DEFROST

CONTROL

CMC1

TIMED OFF

CONTROL (A4)

HP24-651 ONLY

LOW VOLTAGE

MAKEUP

AREA

CONTROL

BOX

COMPRESSOR

HP23-141 SHOWN

REVERSING VALVE

SUCTION

MUFFLER HP23-141

ONLY

ACCUMULATOR

HP23-141 ONLY

FIGURE 1

HP23-460, -510 and -650 UNIT COMPONENTS

EXPANSION

VALVE

FAN

SPIDER

OUTDOOR

FAN/MOTOR

FIGURE 3

HP23 UNIT CONTROL BOX THREE PHASE UNITS

FAN CAPACITOR

(C1)

DEFROST

RELAY (K4)

COMPRESSOR

CONTACTOR

(K1)

GROUNDING

LUG

TRANSFORMER(T5)

“J” VOLTAGE

UNITS ONLY

DEFROST

CONTROL

CMC1

TIMED OFF

CONTROL (A4)

HP24-653 ONLY

LOW VOLTAGE

MAKEUP

AREA

FIGURE 4

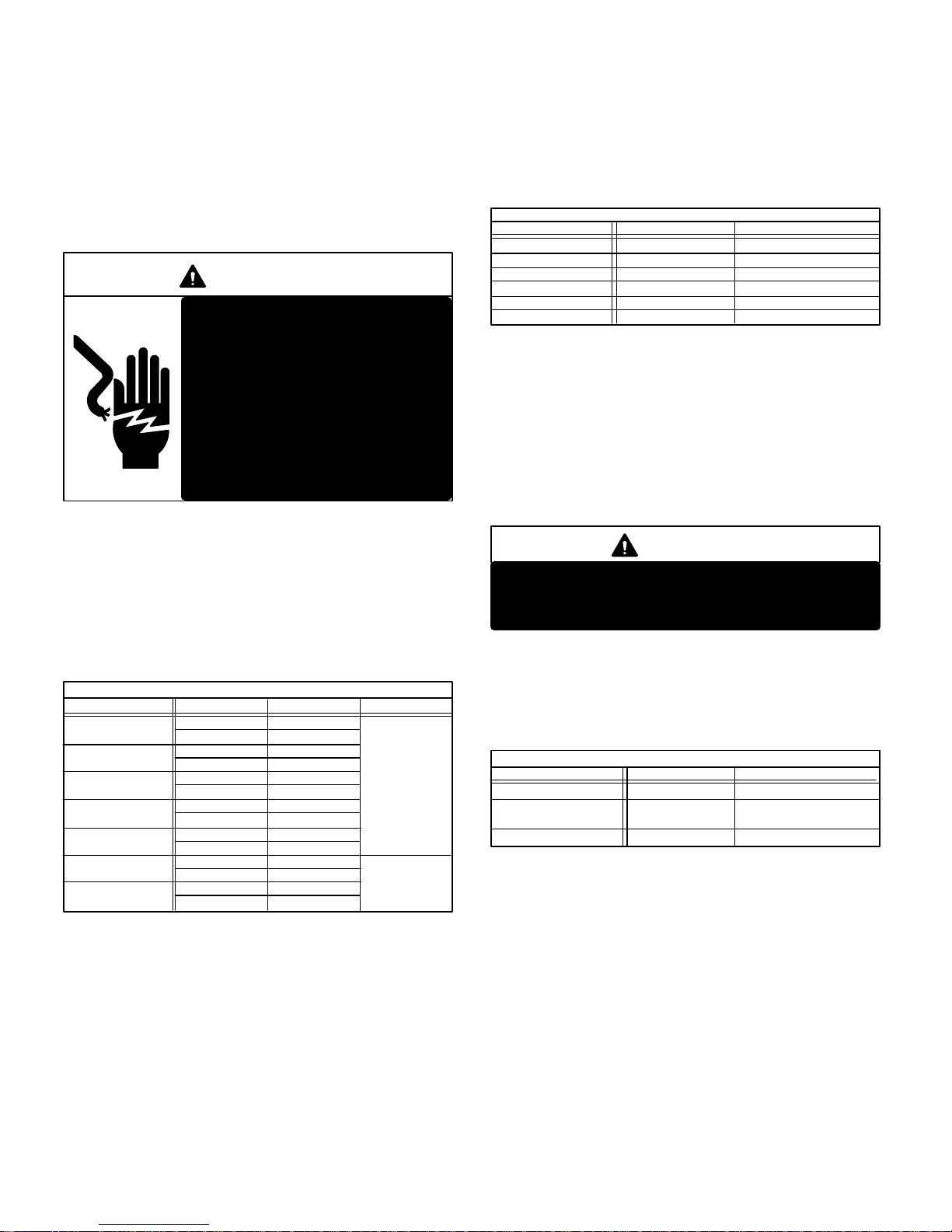

A low voltage make up area is provided for thermostat

field wiring. Field thermostat wiring is made to color

coded pigtail connections as illustrated in figure 5.

CONTROL BOX

REVERSING VALVE

FIGURE 2

COMPRESSOR

ACCUMULATOR

Page 3

THERMOSTAT WIRING IDENTIFICATION

RED

YELLOW

ORANGE

BEIGE

FROM OUTDOOR UNIT

BLACK

24V (POWER) INPUT

TO OUTDOOR UNIT

(COMPRESSOR)

(REVERSING VALVE)

INPUT

(ELECTRIC HEAT)

DEFROST OUTPUT

(COMMON)

FIGURE5

INPUT

THERMOSTAT

TO INDOOR UNIT/

1 – Compressor Contactor K1

The compressor is energized by a contactor located in

the control box. See figures 3 and 4. Contactors are

SPST in single phase units and 3PST in three phase

units. K1 is energized by the indoor thermostat

terminal Y (24V). HP23 units are not equipped with a line

voltage to 24V transformer. All 24 VAC controls are

powered by the indoor unit. Refer to unit wiring diagram.

DANGER

Shock Hazard

All single phase HP23 units use

single-pole contactors. One leg of

compressor, capacitor and outdoor

fan are connected to line voltage at

all times. Potential exists for

electrical shock resulting in injury

or death. Remove all power at

disconnect before servicing.

Can cause personal injury or death.

2 – Dual Capacitor C12

The compressor and fan in single phase units use

permanent split capacitor motors. The capacitor is

located inside the unit control box (see figure 3). A single

“dual” capacitor (C12) is used for both the fan motor and

the compressor (see unit wiring diagram). The fan side

and the compressor side of the capacitor have different

MFD ratings. See table 1 for dual capacitor ratings.

HP23 (C12) DUAL CAPACITOR RATING

Unit MFD VAC

HP23–141

HP23–211/261

HP23–311-1/411

HP23–311-2

HP23–411-2

HP23–461

HP23–511/651

3 – Potential Relay K31 (Start)

All single phase units use a potential relay which

controls the operation of the starting circuit. The

potential relay is located inside the unit control box (see

figure 3). The relay is normally closed when contactor

K2 is de-energized. When K1 energizes, the compressor

immediately begins start-up. K31 remains closed

during compressor start-up and start capacitor C7

remains in the circuit. As the compressor gains speed,

K31 is energized. When K31 energizes, the contacts

open and start capacitor C7 is taken out of the circuit.

TABLE 1

Terminal

FAN

HERM

FAN

HERM

FAN

HERM

FAN

HERM

FAN

HERM

FAN

HERM

FAN

HERM

25

35

45

35

40

10

40

10

60

5

5

5

5

5

370

440

4 – Start Capacitor C7

All single phase units use a start capacitor (C7). C7 is

located inside the unit control box (see figure 3). C7 is

wired in parallel with the compressor side of the dual

capacitor. See table 2 for start capacitor ratings.

TABLE 2

HP23 START CAPACITOR RATING (C7)

Unit MFD VAC

HP23–141/211/261

HP23–311-1/411 88–108 330

HP23–311-2 145–175 330

HP23–411 (CAN)

HP23–411–2/461/511

HP23–651 270-324 330

88–108 250

25088–108

189-227 330

5 – Timed Off Control A4 (–651 / –653 only)

A time delay (A4) located in the control box is used on

the HP23-650-2 series. See figures 3 and 4. The time

delay is electrically connected between thermostat

terminal Y and the compressor contactor. After cooling

demand has stopped, A4 begins counting for five

minutes. During the timing period, A4 disables the

compressor contactor. Thermostat demand will have

no effect on the unit.The unit cannot operate. After the

delay, the compressor contactor can be energized.

DANGER

Do not attempt to repair this control. Unsafe

operation will result. If the control has failed,

replace the control.

6 – Fan Capacitor C1

The fan in three-phase units uses a single phase

permanent split capacitor motor. A single capacitor C1 is

used for the fan motor. C1 is located inside the unit

control box (see figure 4). Table 3 shows the ratings of C1.

HP23 FAN CAPACITOR RATING (C1)

Unit MFD VAC

HP23–413Y,G

HP23–463/513/653G

HP23-513,653J

HP23-463/513/653Y 10 370

7 – Transformer T5

Transformer T5 is used on all “J” voltage units. T5 is

used as a step-down transformer for fan B4. T5 is rated at

3.4 VA with a 575 volt primary and a 460 volt secondary.

8 – Defrost Relay K4

The defrost relay controls defrost. The relay is a 3PDT

relay powered 24 VAC from the thermostat. K4 is

enabled during both cooling and heating modes

(except emergency heat). It is only powered when the

defrost control is calling for defrost. When energized,

the reversing valve and indoor auxiliary heat are

energized. Simultaneously, the outdoor fan is

de-energized. K4 latches in for the duration of the

defrost period. Refer to unit wiring diagram and

operation sequence in the back of this manual.

TABLE 3

5 370

7.5 370

Page 4

9 – Defrost Control CMC1

The CMC1 defrost control (figure 6) is a solid state control

manufactured by Hamilton Standard. The control

provides automatic switching from normal heating

operation to defrost mode and back. The control

provides 14 minute defrost periods at 30, 60 or 90 minute

field changeable intervals. The control monitors

thermostat demand and “holds” the timer in place

between thermostat demand. A set of diagnostic pins are

also provided for troubleshooting the unit.

The control contains a solid state timer which switches

an external defrost relay through 1/4” male spades

mounted on the control’s circuit board. When the

defrost thermostat closes (call for defrost), the defrost

timer initiates a 30, 60 or 90 minute (depending on how

the control is preset) timing sequence. If the defrost

thermostat remains closed when the timing sequence

ends, the defrost relay is energized and defrost begins.

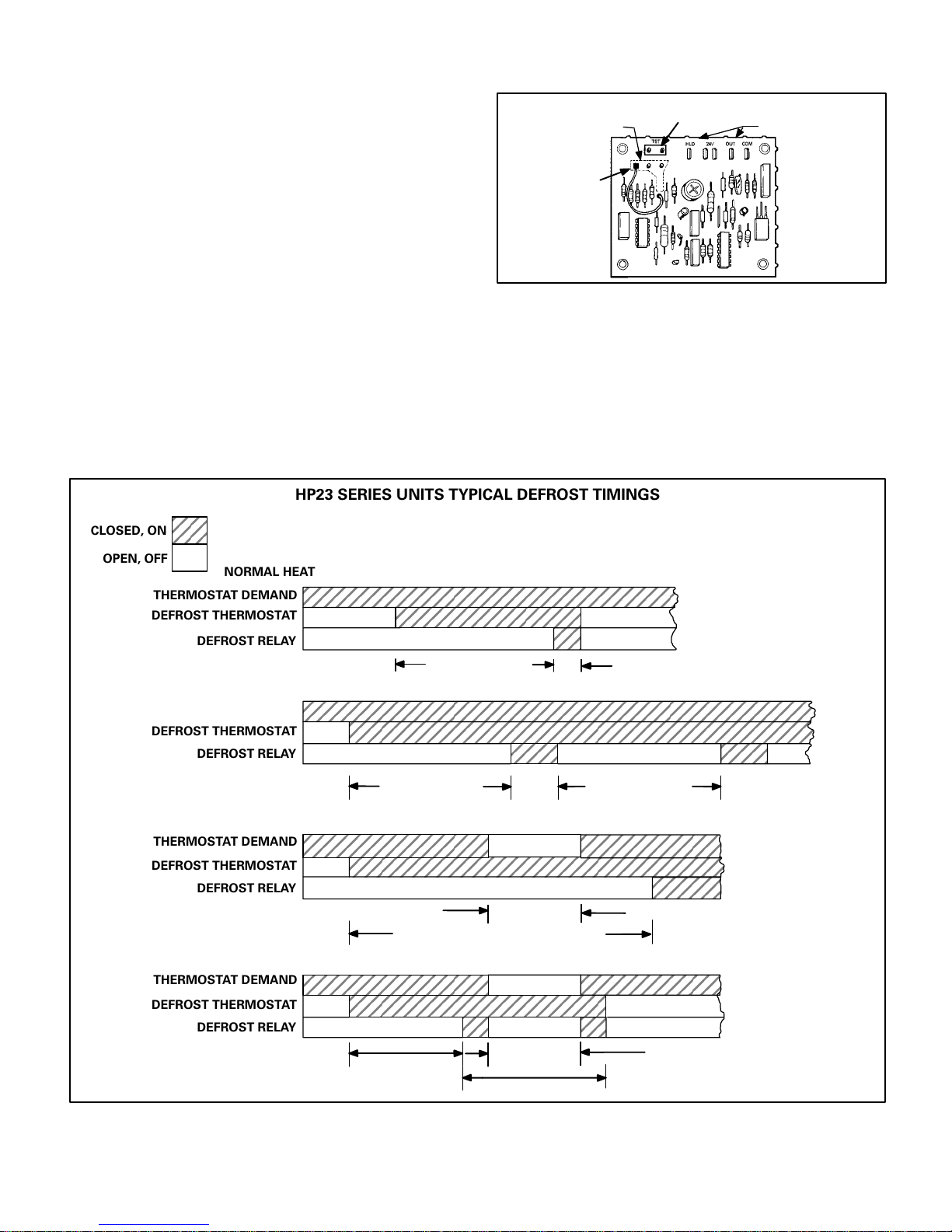

HP23 SERIES UNITS TYPICAL DEFROST TIMINGS

Note – Control begins timing at 0 when defrost thermostat closes. Defrost is terminated when defrost

CLOSED, ON

OPEN, OFF

THERMOSTAT DEMAND

DEFROST THERMOSTAT

THERMOSTAT DEMAND

DEFROST THERMOSTAT

relay is de–energized. Anytime defrost thermostat opens, defrost relay is immediately de–energized,

NORMAL HEATING OPERATION: DEFROST TERMINATED BY DEFROST THERMOSTAT

DEFROST RELAY

NORMAL HEATING OPERATION: DEFROST TERMINATED BY TIME

DEFROST RELAY

defrost timer resets and “HOLD” function stops.

30/60/90 MINUTES

SOLID STATE DEFROST CONTROL CMC1

Timing Pins

Timing

Jumper

Troubleshooting Pins

30 60 90

Control Terminals

FIGURE 6

A defrost period can last up to 14 minutes and can be

terminated two ways. If the defrost thermostat does

not open within 14 minutes after defrost begins, the

timer will de–energize the defrost relay and the unit

will resume normal operation. If the defrost

thermostat opens during the 14 minute defrost period,

the defrost relay is de–energized and the unit resumes

normal operation. Refer to figure 7.

DEFROST THERMOSTATOPEN WITHIN 14 MINUTES

NORMAL HEATING OPERATION INTERRUPTED BY THERMOSTAT DEMAND: “HOLD” FUNCTION

THERMOSTAT DEMAND

DEFROST THERMOSTAT

DEFROST RELAY

DEFROST PERIOD INTERRUPTED BY THERMOSTAT DEMAND: “HOLD” FUNCTION

THERMOSTAT DEMAND

DEFROST THERMOSTAT

DEFROST RELAY

30/60/90 MINUTES 14 MIN. 30/60/90 MINUTES

DEFROST THERMOSTAT

MUST REMAIN CLOSED

FOR TIMER TO REMAIN

IN “HOLD”

“HOLD” TIME

30/60/90 MINUTES PLUS “HOLD” TIME

DEFROST THERMOSTAT

MUST REMAIN CLOSED

FOR TIMER TO REMAIN

IN “HOLD”

“HOLD” TIME

30/60/90 MINUTES

14 MIN. PLUS “HOLD” TIME

FIGURE 7

Page 5

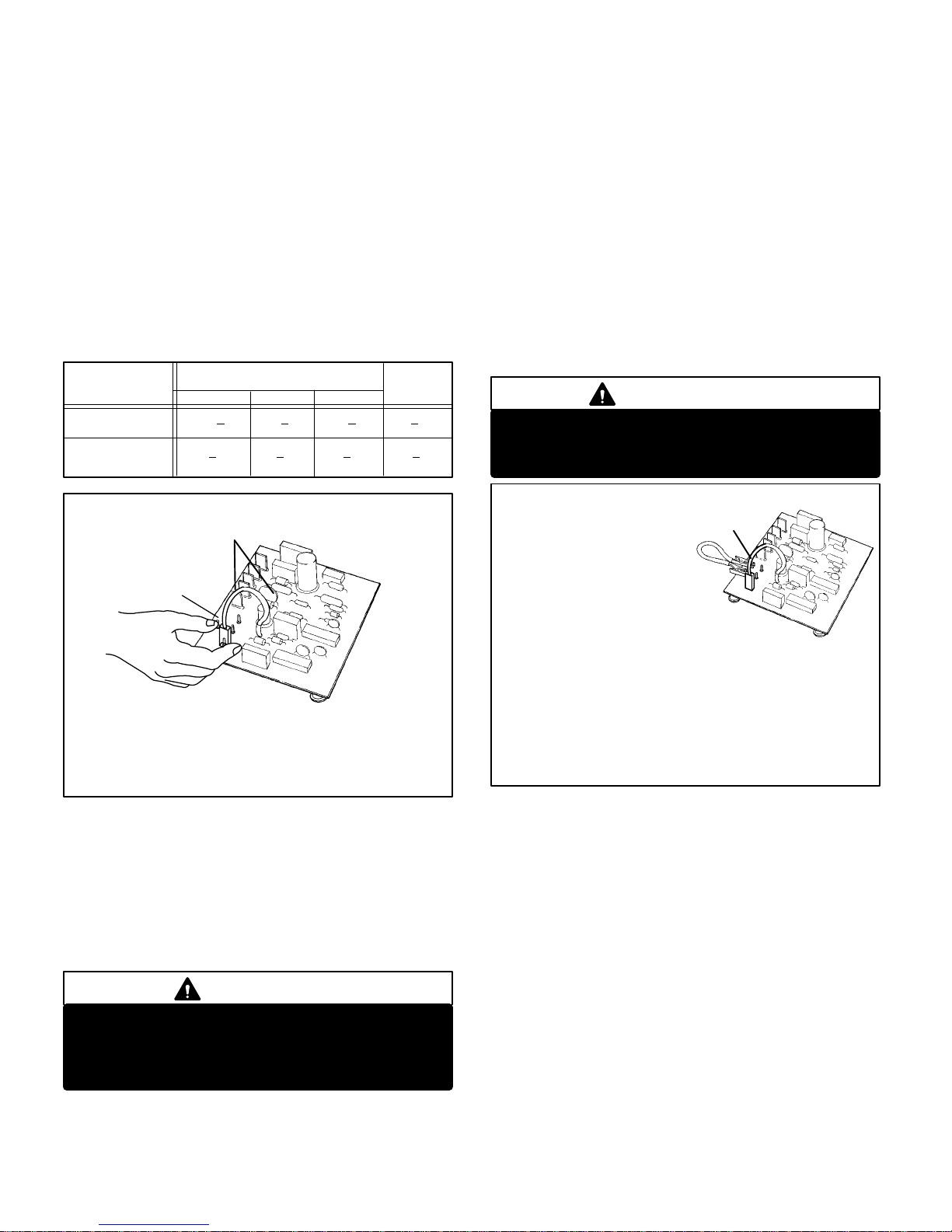

Defrost Control Components

1– Timing Pins 30, 60, 90

Each of these pins provides a different timed

interval between defrosts. A jumper connects the

pins to circuit board pin W1. Table 4 shows the

timings of each pin. The defrost interval can be field

changed to 30, 60 or 90 minutes. The defrost period

(14 minutes) cannot be changed. To change the

interval between defrosts, simply remove the

jumper from the pin it is connected to and

reconnect the jumper to one of the other available

pins (see figure 8).

TABLE 4

CMC1 DEFROST

CONTROL

TIMINGS

NORMAL

OPERATION

“TST” PINS

JUMPER

TOGETHER

INTERVAL BETWEEN DEFROSTS

WITH JUMPER CONNECTED TO:

30 60 90

30 + 3 60 + 6 90 + 9 14 + 1.4

MIN. MIN. MIN. MIN.

7 + 0.7 14 + 1.4 21 + 2.1 3.3 + 0.3

SEC. SEC. SEC. SEC.

DEFROST

TIME

4– “HLD” Terminal

Terminal “HLD” holds the internal timer in place

between thermostat demands and allows the unit

to continue timing upon resumption of thermostat

demand. Terminal “HLD” is connected directly to

thermostat demand.

NOTE – Hold function operates between thermostat

demands only when defrost thermostat is closed. This

is the only time that the timer is operating.

5– “TST” Pins

Each board is equipped with a set of test pins for

use in troubleshooting the unit. When jumpered

together, these pins reduce the control timing to

about 1/256 original time (see table 4 and figure 9).

IMPORTANT

Control will begin test mode only if normal load is

applied to control terminals. Do not attempt to

operate or test control out of unit.

DEFROST CONTROL TIMING CHANGES

WARNING – AVOID CONTACT WITH OTHER CONTROL TERMINALS OR CONTROL COMPONENTS.

WARNING – DO NOT

CONNECT TIMING

JUMPER TO EITHER

“TST” PIN.

TO CHANGE CONTROL TIMINGS:

1– Turn off all power to the unit to avoid circuit board damage.

2– Grasp wire connector firmly with fingers.

3–

Gently

4– Select new timing pin. DO NOT SELECT A “TST” PIN.

5– Gently push connector onto desired pin (see Table 4 for timings).

6– Turn on power to unit.

pull connector from pin.

FIGURE 8

2– Timing Jumper

The timing jumper is a factory installed jumper

on the circuit board used to connect pin W1 to

one of the three timing pins. The jumper may be

connected to any one of the timing pins but must

never be connected to either of the “TST” pins.

See Caution below.

CAUTION

3– “COM” Terminal

Terminal “COM” provides 24VAC Common.

DEFROST CONTROL TEST MODE

WARNING – AVOID CONTACT WITH

OTHER CONTROL TERMINALS OR

CONTROL COMPONENTS.

TO PLACE CONTROL

1– Turn off all power to avoid

2– Make sure all control terminals are

3– Connect jumper to “TST” pins as shown.

4– Turn indoor thermostat to heat mode and adjust to highest

5– Turn on power to unit.

6– See Table 4 for control timings in “TST” mode.

7– Be sure to turn off power and remove jumper when test is com-

IN TEST MODE:

damaging the circuit board.

connected as shown on unit wiring

diagram before attempting to place control in

test mode. See NOTE below.

NOTE – Control will not go into test mode when disconnected

from unit. Unit load must be applied to control terminals before

the control will go into test mode.

temperature setting.

plete. Turn on power and re–adjust thermostat.

FIGURE 9

6– “24V” Terminal

Terminal “24V” receives 24VAC from the control

transformer through the defrost thermostat. This

terminal powers the control’s internal timer and

relays. Terminal “24V” is powered only when there is

a call for defrost (defrost thermostat closed). The

timer begins timing at 0 only after terminal “24V”

receives power.

7– “OUT” Terminal

Terminal “OUT” controls defrost when connected

to one side of the defrost relay coil. An internal

relay connected to terminal “OUT” closes to allow

external defrost relay to energize and initiate

defrost. At the end of the defrost period, the

internal relay connected to terminal “OUT” opens

to de-energize the external defrost relay.

Page 6

Loading...

Loading...