Page 1

INSTALLATION INSTRUCTIONS

®

G1N80BU, GIN80BR, GIN80BT, CG80UB, CG80RB, & CG80TB

80% Gas-Fired Furnace

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. Refer to this manual. For assistance or additional information,

consult a qualified installer, service agency, or the gas supplier.

W ARNING

Do not store combustible materials, including

gasoline and other flammable vapors and

liquids, near the furnace, vent pipe, or warm

air ducts. The homeowner should be cautioned that the furnace area must not be

used as a broom closet or for any other

storage purposes. Such uses may result in

actions that could cause property damage,

personal injury, or death.

SAFETY ................................................. 2

INSTALLATION ...................................... 2

START-UP ............................................ 14

OPERATION ........................................ 15

MAINTENANCE................................... 16

T ABLE OF CONTENTS

CONTROL SYSTEM DIAGNOSTICS .. 18

W ARNING

REPAIR PARTS ................................... 18

This furnace is not approved for installation in

a mobile home. Do not install this furnace in a

WIRING DIAGRAMS ............................ 19

mobile home. Installation in a mobile home

could result in actions that could cause property damage, personal injury, or death.

A Lennox International Company

Manufactured By

A.A.C.

421 Monroe Street

Bellevue, OH 44811

®

IMPORT ANT

The installation of the furnace, wiring, warm air ducts, venting, etc. must conform to the requirements of the

National Fire Protection Association; the National Fuel Gas Code, ANSI Z223.1/NFPA No. 54 (latest edition)

and the National Electrical Code, ANSI/NFPA No. 70 (latest edition) in the United States; CSA B149.1

(latest edition) Natural Gas and Propane Installation Codes and the Canadian Electrical Code Part 1, CSA

22.1 (latest edition) in Canada; and any state or provincial laws, local ordinances (including plumbing or

wastewater codes), or local gas utility requirements. Local authorities having jurisdiction should be consulted before installation is made. Such applicable regulations or requirements take precedence over the

general instructions in this manual.

# 45464K003 Page 1

Page 2

IMPORT ANT SAFETY INFORMATION

The following is a list of safety rules and precautions

that must be followed when installing this furnace.

1. Use only with the type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specified in the Location section on page 3 of

these instructions.

3. Provide adequate combustion and ventilation air to

the furnace space as specified in the Combustion

and Ventilation Air section beginning on page 4 of

these instructions.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system

only, as specified in Venting beginning on page 6 of

these instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for the detection of leaks to check all connections, as specified in Gas Supply and Piping

beginning on page 12 of these instructions.

6. Always install furnace to operate within the furnace’s

intended temperature rise range with a duct system

which has an external static pressure within the

allowable range, as specified in Temperature Rise

on page 16 of these instructions. See furnace rating

plate.

7. When a furnace is installed so that the supply ducts

carry air circulated by the furnace to areas outside

the space containing the furnace, the return air shall

also be handled by duct(s) sealed to the furnace

casing and terminating outside the space containing

the furnace. See Circulating Air Supply on page 8

of these instructions.

8. A gas-fired furnace for installation in a residential

garage must be installed as specified in the Loca-

tion section on page 3 of these instructions.

9. The furnace is not to be used for temporary heating of

buildings or structures under construction as specified

on page 4 of these instructions.

In the State of Massachusetts:

This product must be installed by a licensed Plumber

or Gas Fitter. When flexible connectors are used, the

maximum length shall not exceed 36". When levertype gas shutoffs are used, they shall be T-handle

type.

INSTALLATION

These instructions must be placed on or near the

furnace in a conspicuous place.

This furnace is design certified by CSA International as a

Category I furnace using air from inside the structure for

combustion. The combustion system is fan-assisted, which

means it is equipped with an integral mechanical means to

draw products of combustion through the heat exchanger.

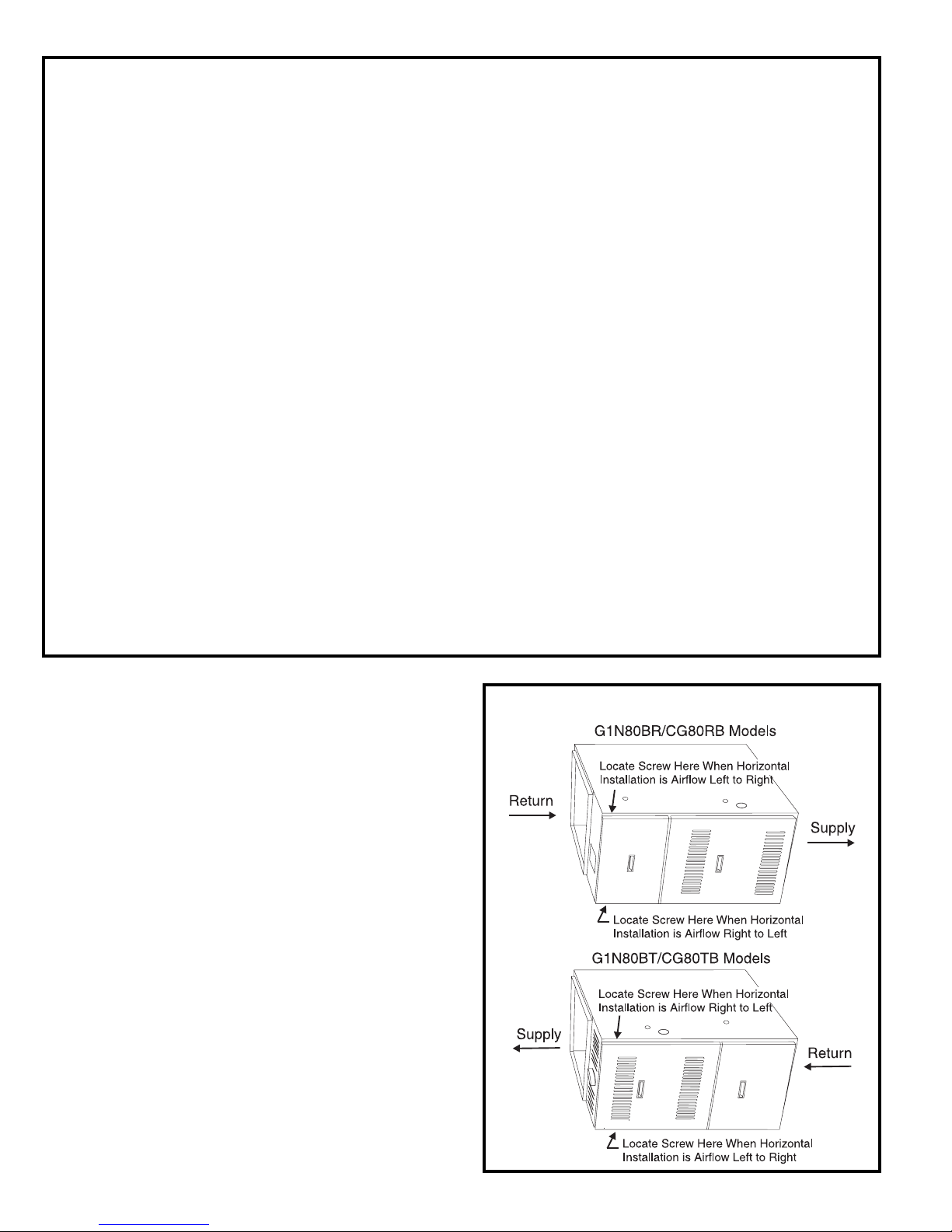

G1N80BT and CG80TB models may be installed as upflow

or horizontal furnaces. G1N80BR and CG80RB models

may be installed as counterflow (downflow) or horizontal

furnaces. When installed horizontally, the installer must

install a sheet metal screw to retain the upper door as

shown in Figure 1.

G1N80BU and CG80UB models must be installed only as

upflow furnaces.

Never install any furnace on its back.

Horizontal Installations

Figure 1

# 45464K003Page 2

Page 3

Inspection of Shipment

tenibaC

htdiW

sediS tnorF kcaB tneV

wolfriA

LotR RotL

poT mottoB poT mottoB

5.4108106

232

013

2

5.71 0 81 0 622

2

0 1 2

2

0.1208106210 10

5.42 0 81 0 621 0 1 0

tenibaC

htdiW

sediS tnorF kcaB tneV

wolfriA

LotR RotL

poT mottoB poT mottoB

5.411810621313

1

0

5.71 1 81 0 621 2

2

2

2

0

0.1218106210 10

This furnace is shipped in one package, completely

assembled and wired. The thermostat is shipped in a

separate carton when ordered.

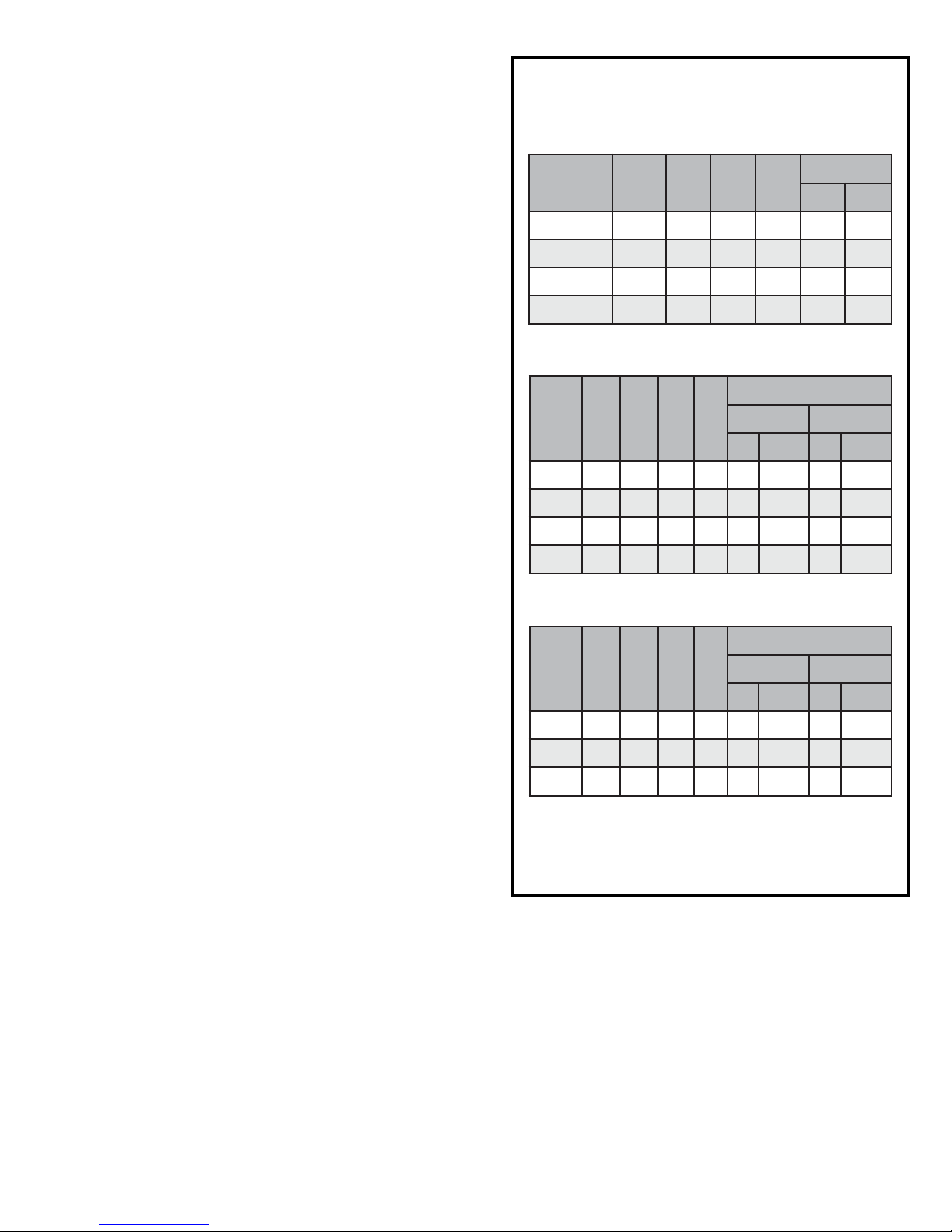

Minimum Clearances to Combustibles

(all measurements in inches)

Upflow and Counterflow Installations

Upon receipt of equipment, carefully inspect it for possible

shipping damage. If damage is found, it should be noted on

the carrier’s freight bill. Damage claims should be filed with

the carrier immediately. Claims of shortages should be

filed with the seller within 5 days.

Check the rating plate for correct model number, type of

gas, and input.

Clearances

All servicing and cleaning of the furnace can be performed

from the front. If installed in a closet or utility room, provide

18" clearance in front for service if the door to the room is

not in line with the front of the furnace.

All models are suitable for installation at reduced clearances to combustibles as noted in the tables in Figure 2.

Where servicing clearances are greater than clearances to

combustibles, servicing clearances take precedence.

G1N80BU, G1N80BT, CG80UB, and CG80TB models, and

horizontally installed G1N80BR and CG80RB models may

be installed on wood flooring, but shall not be installed

directly on carpeting, tile, or other combustible material

other than wood flooring.

tenibaC

htdiW

5.414

5.71 4

0.124

5.42 4

tnorF kcaB poT tneV

1

01623

1

0 1 6

1

016210

1

0 1 6

Horizontal Installations

(G1N80BR and CG80RB models)

Horizontal Installations

(G1N80BT and CG80TB models)

2

2

tfeL thgiR

3

3

2

0 0

sediS

0

0

G1N80BR and CG80RB models installed as counterflow

(downflow) units may be installed on combustible flooring

provided a special combustible floor base is used. Refer to

the Counterflow (Downflow) Installations section begin-

ning on page 10 for more information on using the special

base assembly.

Location

All models are suitable for closet or utility room installation.

The furnace must be installed so that electrical components are protected from water.

The furnace is suitable for installation in buildings constructed on-site. The furnace should be centralized in

respect to the heat distribution system as much as

practicable. When installed in a utility room, the door

should be wide enough to allow the largest part of the

furnace to enter, or permit the replacement of another

appliance, such as a water heater.

A gas-fired furnace for installation in a residential garage

must be installed so the burner(s) and the ignition source

are located not less than 18" above the floor. The furnace

is to be located or protected to avoid physical damage by

vehicles.

# 45464K003 Page 3

1

May be 2" when Type B-1 vent pipe is used.

2

May be 1" when Type B-1 vent pipe is used.

3

Where values greater than 0 are shown, may be 0"

when Type B-1 vent pipe is used.

Figure 2

G1N80BR, G1N80BT, CG80RB, and CG80TB models

installed in the horizontal position are approved for attic

installations. If the furnace is to be installed in an attic

or other insulated space, it must be kept free and

clear of insulating materials. When a furnace is

installed in conjunction with an evaporator coil in an

attic or above a finished ceiling where condensate

overflow could result in property damage, a drain

pan should be provided under the units as specified

by most local building codes.

Page 4

G1N80BR, G1N80BT, CG80RB, and CG80TB models may

be installed as suspended units in the horizontal position.

These furnaces are not designed for direct attachment of

suspension rods to the furnace casing.

However, in a building of unusually tight construction,

additional outdoor air should be provided.

Confined Space

The suspending means must be field fabricated, and

should consist of two “cradles” made by attaching two rods

to a length of angle iron or suitable gage steel. Locate the

cradles so that they are as close as possible to the ends

of the furnace (this will provide access for removal of

major components such as the blower assembly). Provide

enough clearance between the suspension rods and the

furnace to allow removal of access panels.

CAUTION

Do not use the furnace as a heater in a

building under construction. The furnace can

be severely damaged due to the abnormal

environment caused by construction. Chlorides from sources such as paint, stain, or

varnish; tile and counter cements; adhesives;

and foam insulation are abundant in a structure under construction and can be highly

corrosive. Low return air temperature can

cause condensation in the furnace and other

damage that can shorten the life of the unit.

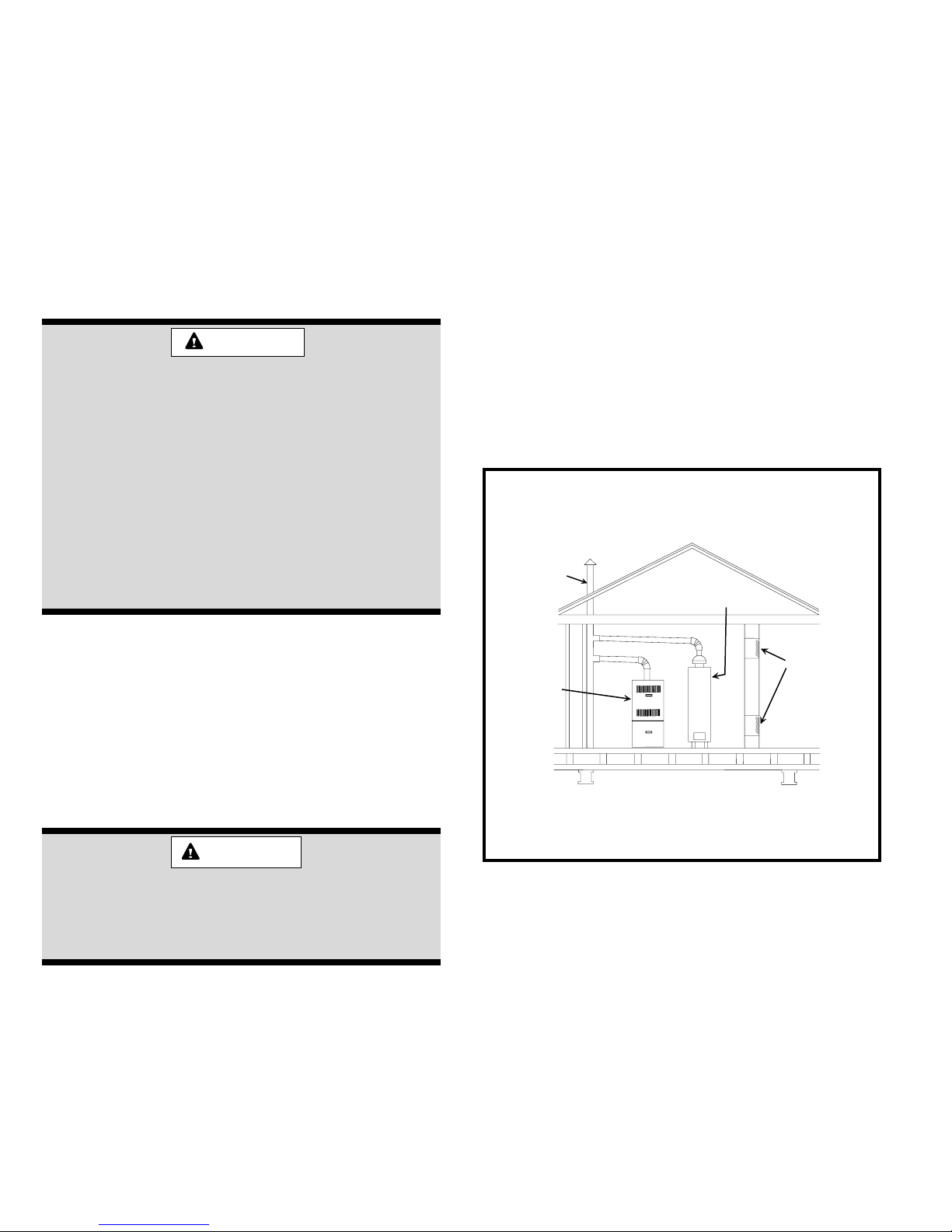

A confined space is defined as “a space whose volume is

less than 50 cubic feet per 1000 BTU per hour of the

combined input rating of all appliances installed in that

space.”

Confined Space Installation/Air from Inside Structure

If the furnace is installed in a confined space within the

building and combustion air is taken from a heated space,

the combustion air and ventilating air must enter and leave

the space through two permanent openings of equal area.

One opening shall be located within 12" of the ceiling and

the other within 12" of the floor, each having a free area of

1 square inch per 1000 BTU/HR of total input rating of all

appliances within the space and not less than 100 square

inches each (see Figure 3).

Equipment in Confined Space

All Air From Inside

Chimney or

Gas Vent

Water

Heater

Combustion and Ventilation Air

Adequate provisions for combustion air and ventilation of

furnace must be made. Refer to Section 5.3, “Air for

Combustion and Ventilation,” of the National Fuel Gas

Code, ANSI Z223.1/NFPA54 (latest edition), Sections 7.2,

7.3, or 7.4 of CSA B149.1 Natural Gas and Propane

Installation Codes (latest editions), or applicable provisions of the local building codes.

WARNING

Air openings in the front of the furnace must

be kept free of obstructions. Any obstruction

may cause improper operation that can result

in a fire hazard or carbon monoxide injury.

Unconfined Space

An unconfined space is defined as “a space whose volume

is more than 50 cubic feet per 1000 BTU per hour of the

combined input rating of all appliances installed in that

space.” When a furnace is installed in an unconfined space

in a building, it can be assumed that the infiltration will be

sufficient to supply the required air. If the furnace is

installed in a ventilated attic or crawl space, it is assumed

that the infiltration is sufficient to supply the required air.

Openings

Furnace

Note: Each opening shall have a free area of at least one square

inch per 1000 BTU per hour of the total input rating of all

equipment in the enclosure, but not less than 100 square

inches.

Figure 3

Confined Space Installation/Air from Outside Structure

If air from outside is brought in for combustion, the confined

space shall be provided with two permanent openings. One

opening shall be within 12" of the ceiling and one opening

within 12" of the floor. Several methods can be used to bring

the outside air in through these openings. The openings

shall open directly or by ducts with the outdoors, through

spaces (crawl space or attic) that freely open to the outdoors, or indirectly through vertical ducts (see Figures 4 and

5). If any of these methods are used, each opening shall

have a free area of 1 square inch per 4000 BTU/HR of the

total input rating of all appliances within the enclosure.

# 45464K003Page 4

Page 5

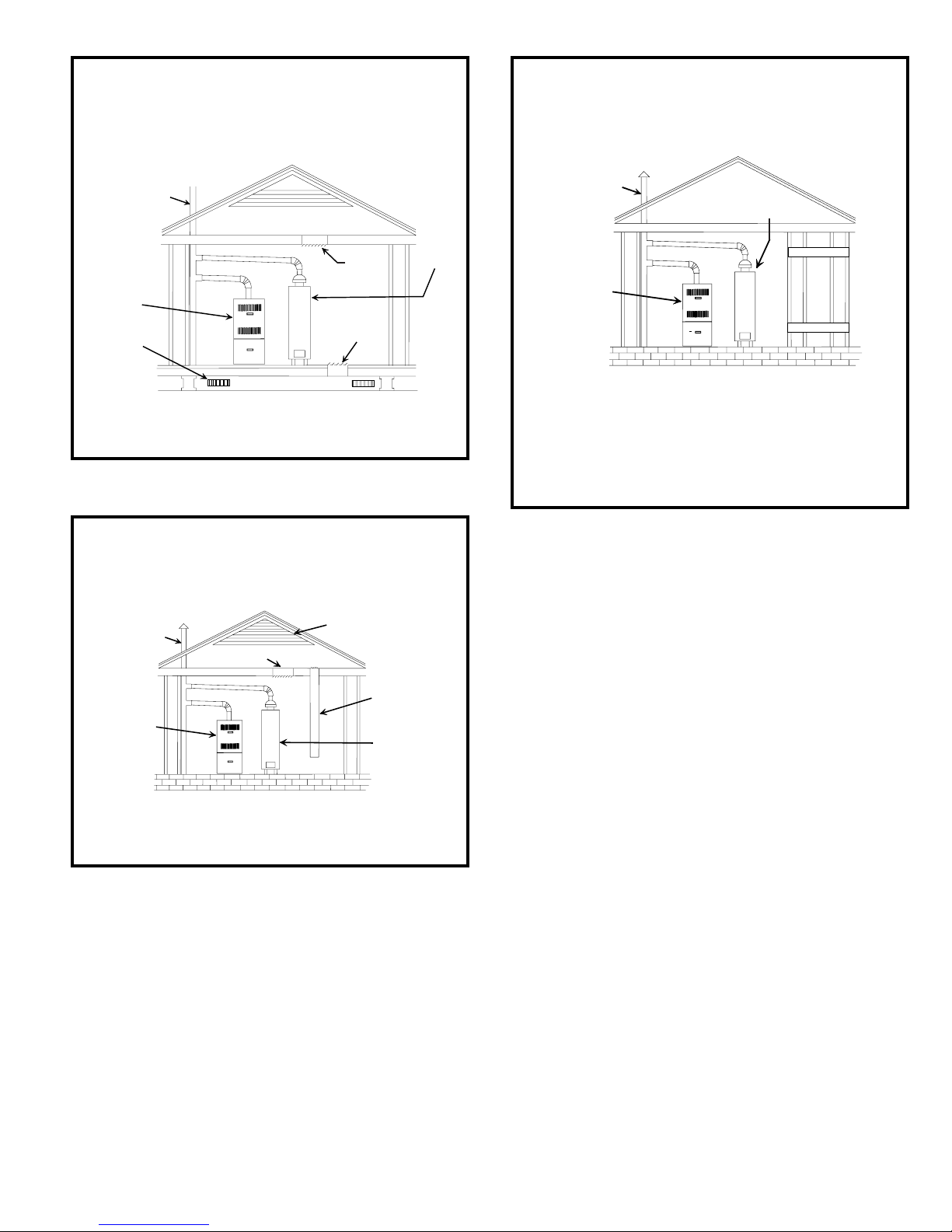

Equipment in Confined Space

All Air from Out side

(Inlet Air from Crawl Sp ace and

Outlet Air to V entilated Attic)

Equipment in Confined Space

All Air from Out side

(All Air Through Horizontal Ducts)

Chimney or

Gas Vent

Furnace

Ventilation

Louvers

(For unheated

crawl space)

Note: The inlet and outlet air opening shall each have a free area of

at least one square inch per 4000 BTU per hour of the total

input rating of all equipment in the enclosure.

Ventilation Louvers

(Each end of attic)

Outlet

Air

Inlet

Air

Water

Heater

Figure 4

Equipment in Confined Space

All Air from Out side

(All Air Through V entilated Attic)

Chimney or

Gas Vent

Outlet Air

Furnace

Ventilation Louvers

(Each end of attic)

Inlet Air

(Ends 12”

above bottom)

Water

Heater

Chimney or

Gas Vent

Water Heater

Outlet Air

Furnace

Inlet Air

Note: Each air duct opening shall have a free area of at least one

square inch per 2000 BTU per hour of the total input rating of

all equipment in the enclosure. If the equipment room is

located against an outside wall and the air openings communicate directly with the outdoors, each opening shall have a free

area of at least one square inch per 4000 BTU per hour of the

total input rating of all other equipment in the enclosure.

Figure 6

come from the outdoors by way of an attic, crawl

space, air duct, or direct opening.

2. If indoor combustion air is used, there must be no

exposure to the substances listed in item 5.

3. All provisions for indoor combustion air must meet the

requirements for combustion air indicated in the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition), and/or any applicable local codes. In Canada,

see CSA B149.1, Natural Gas and Propane Installation Codes (latest edition).

Note: The inlet and outlet air opening shall each have a free area of

at least one square inch per 4000 BTU per hour of the total

input rating of all equipment in the enclosure.

Figure 5

Another option is to use horizontal combustion ducts (see

Figure 6). If horizontal combustion ducts are run, 1 square

inch per 2000 BTU/HR is required.

Contaminated Combustion Air

Excessive exposure to contaminated combustion air will

result in safety and performance related problems. The

recommended source of combustion air is outdoor air.

However, the use of indoor air in most applications is

acceptable if the following guidelines are followed:

1. If the furnace is installed in a confined space, it is

recommended that the necessary combustion air

# 45464K003 Page 5

4. The following types of installation may require outdoor air for combustion, due to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces installed in hobby or craft rooms

• Furnaces installed near chemical storage areas

5. Exposure to the following substances in the combustion

air supply may also require outdoor air for combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool chemicals

• Water softening chemicals

• Deicing salts or chemicals

• Carbon tetrachloride

• Halogen-type refrigerants

• Cleaning solvents (such as perchloroethylene)

Page 6

• Printing inks, paint removers, varnishes, etc.

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

• Chlorinated laundry products

• Hydrochloric acid

Venting

This furnace has a fan-assisted combustion system

designed for vertical venting into a suitable chimney or

listed gas vent, and is classified as a Category I furnace

as shipped from the factory.

If this furnace is used to replace an existing furnace,

it is possible that the existing venting system is not

suitable for venting this furnace. Furthermore, the

existing venting system may have to be modified to

properly vent any other gas appliance, such as a water

heater, that remains connected to it. Carefully read the

Vertical Venting, Sidewall Venting, and Existing Vent

Systems sections that follow to determine proper venting

practices for the installation.

vent connector is permissible only in conditioned

space. Use Doublewall Type B vent pipe through

unconditioned space such as attics and crawl

spaces. The vent material used should be in accor-

dance with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54 (latest edition) or the CSA B149.1, Natural

Gas and Propane Installation Codes and local codes.

Fan-assisted combustion system Category I furnaces

shall not be vented into single wall metal vents.

4. The vent connector must have an upward slope toward

the chimney on all horizontal runs of at least 1/4" per

foot of horizontal run and should be supported by a

sheet metal strap. The vent pipe connection must be

secured to the induced draft blower outlet. A single

screw is sufficient. On G1N80BR and CG80RB models,

a hole in the door hook will allow access to the blower

outlet without removing the door hook.

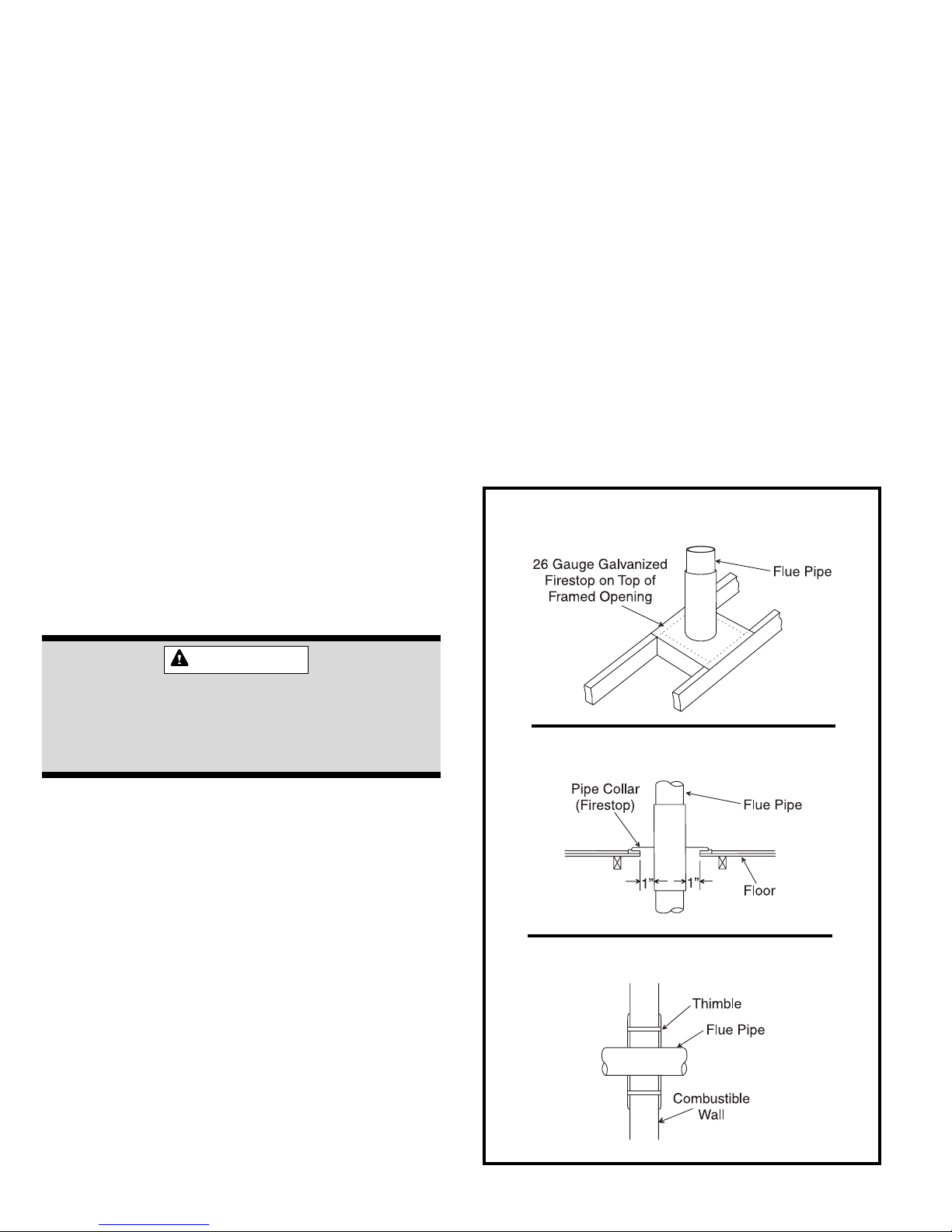

5. All vents passing through floors, ceilings, and walls

must be firestopped according to the requirements of

the National Fuel Gas Code (see Figure 7).

Installation shall be in accordance with Parts 7 and 11 of

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition) and/or Section 7 and Appendix B of the CSA

B149.1, Natural Gas and Propane Installation Codes

(latest edition); local building codes; vent manufacturer

instructions; and these instructions.

IMPORT ANT

For 100K, 125K, and 150K BTUH input models,

the minimum vent connector diameter is 5". The

transition from 4" diameter flue outlet to 5"

diameter pipe must be made at the flue outlet.

Vertical Venting

Category I furnaces must be vented vertically or nearly

vertically. Common venting and multistory venting are

permitted when done in accordance with applicable codes,

such as local and national codes.

The venting system should be designed in accordance with

the “FAN” columns in the venting tables in the latest editions

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the

CSA B149.1, Natural Gas and Propane Installation Codes.

Vent Through Ceiling

Vent Through Floor

V ent Through W all

1. Consult local building codes for installation requirements.

2. The vent connector should be as short as possible with

the least number of elbows and angles to do the job.

3. It is recommended a minimum of 26 gauge galvanized

flue pipe be used. Use of single-wall vent pipe for the

Figure 7

# 45464K003Page 6

Page 7

6. The furnace shall be connected to a factory-built

chimney or vent complying with a recognized standard, or a masonry or concrete chimney lined with a

lining material acceptable to the authority with jurisdic-

tion. Venting into an unlined chimney or a single

wall metal vent is prohibited in all cases. A lined

chimney may be used if a draft hood equipped

appliance, such as a water heater, is connected to

the same flue (see Figures 8 and 9).

7. Extend the vent connector into the chimney so that it

is flush with the inside of the flue liner. Seal the joint

between the pipe and the liner.

8. Masonry chimneys serving fireplaces cannot be used

for venting purposes unless the fireplace opening is

permanently sealed.

9. A vent connector serving this appliance must not be

connected into any portion of mechanical draft systems operating under positive pressure.

10. The vent pipe must not be connected to a chimney

flue serving a solid fuel appliance.

11. A manual damper, barometric draft regulator, or flue

restrictor must not be installed between the furnace

and the chimney.

12. Where local experience indicates that condensate may

be a problem, the vent shall be constructed to prevent

condensation from entering the combustion blower.

Provision shall be made to drain off the condensate

(see Figures 8 and 9).

14. All vent pipe run through unconditioned areas or

outside shall be constructed of factory-built chimney

sections (see Figure 8).

15. Multistory venting is allowed as permitted by the

National Fuel Gas Code or local codes.

16. Install all vents in accordance with the vent

manufacturer’s instructions. For unlisted material,

install in accordance with the National Fuel Gas Code.

17. Vent terminals must be installed in accordance with

the vent terminals listing or in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest

edition) or the CSA B149.1, Natural Gas and Propane

Installation Codes, and local codes.

Sidewall Venting

This furnace can be sidewall (horizontally) vented with a

listed sidewall venter, such as Field Controls Model SWG4HD with CK-43 Control Kit, or Tjernlund Model GPAK-JT.

Category I venting classification is maintained when vented

in this manner. The furnace, power venter, and control kit

(where applicable) must be installed in accordance with their

installation instructions and all applicable codes.

The following limitations also apply to the two previously

mentioned venters.

Vent pipe diameter: 4"

Minimum vent pipe length: 4'

Maximum vent pipe length: 25'*

Maximum number of 90° elbows: 4

13. All unused chimney openings should be closed.

Factory-Built Chimney V enting

Factory-Built

Chimney

Cleanout

* When fewer than four elbows are used, maximum vent

pipe length can be increased by 5' per unused elbow.

Masonry Chimney Venting

Liner

Masonry

Chimney

Cleanout

Figure 8

# 45464K003 Page 7

Figure 9

Page 8

For Canadian installations, only the Field Controls

venter and control kit mentioned above are authorized by CSA for use with this furnace.

See Figure 11 for information on where the sidewall vent

terminal can and cannot terminate.

Existing Venting Systems

When an existing Category I furnace is removed or replaced,

the original venting system may no longer be sized to

properly vent the attached appliances. An improperly sized

venting system can result in spillage of flue products into the

living space, the formation of condensate, leakage, etc. See

the WARNING box below for proper test procedure.

Circulating Air Supply

When the furnace is installed so that the supply ducts

carry air circulated by the furnace to areas outside the

space containing the furnace, the return air shall be

handled by a duct or ducts sealed to the furnace casing

and terminated outside the space containing the furnace.

A return air duct system is recommended. If the unit is

installed in a confined space or closet, a return connection

must be run, full size, to a location outside the closet. The

air duct in the closet must be tight to prevent any entrance

of air from the closet into the circulating air.

If there is no complete return air duct system, the return air

connection must be sealed to the furnace casing and run

full size to a location outside the utility room or space

housing the furnace to prevent a negative pressure on the

venting system.

CAUTION

When an air conditioning unit is used in

conjunction with the furnace, the evaporator

coil must be installed in the discharge (supply) air. Do not install an evaporator coil in the

return air; excessive condensation will occur

within the furnace.

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system being placed into operation could result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance connected to the venting system being placed into operation,

while all other appliances connected to the common venting system are not in operation:

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch, as required in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 (latest edition) or the CSA B149.1 Natural Gas and Propane Installation Codes and these

instructions. Determine that there is no blockage or restriction, leakage, corrosion, or other deficiencies which could

cause an unsafe condition.

3. As far as practical, close all building doors and windows between the space in which the appliance(s) connected to the

venting system are located and other spaces in the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the unit being inspected in operation. Adjust the thermostat so appliance is

operating continuously.

7. Test for spillage from draft hood equipped appliances at the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above tests, the venting system must be corrected in accordance with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 (latest edition) and/or the CSA B149.1 Natural Gas and Propane

Installation Codes.

9. After it has been determined that each appliance remaining connected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans, fireplace dampers, and any other gas-fired burning appliance to

their previous conditions of use.

# 45464K003Page 8

Page 9

Sidewall V ent Terminal Clearances

V

Vent Terminal

Air Supply Inlet

X

Area Where Terminal

Is Not Permitted

1

snoitallatsnInaidanaC

A

ynoclabro,kced,hcrop,adnarev,edargevobaecnaraelC )mc03(sehcni21)mc03(sehcni21

2

snoitallatsnISU

<secnailpparof)mc51(sehcni6

03(sehcni21,)Wk3(hutB000,01

B

denepoebyamtahtroodrowodniwotecnaraelC

3(hutB000,01>secnailpparof)mc

,)Wk03(hutB000,001<dna,)Wk

>secnailpparof)mc19(sehcni63

gninepo

foedisotrowoleb)m2.1(teef4

evoba)m003(toof1;gninepo

)Wk03(hutB000,001

C

wodniwdesolcyltnenamrepotecnaraelC **

ehtevobadetacoltiffosdetalitnevotecnaraelclacitreV

D

ehtmorf)mc16(teef2foecnatsidlatnozirohanihtiwlanimret

**

lanimretehtfoenilretnec

E

evnuotecnaraelC **

F

G

H

I

tiffosdetalitn

renrocedistuootecnaraelC **

renrocedisniotecnaraelC **

ylbmessarotaluger/retem

evobadednetxeenilretnecfoedishcaeotecnaraelC

51thgiehanihtiw)mc19(teef3

ehtevoba)m5.4(teef

*

ylbmessarotaluger/retem

teltuotnevrotalugerecivresotecnaraelC )mc19(teef3*

<secnailpparof)mc51(sehcni6

J

ecnailpparehtoynaottelnirianoitsubmoc

ehtrognidliubottelniylppusrialacinahcemnonotecnaraelC

3(hutB000,01>secnailpparof)mc

,)Wk03(hutB000,001<dna,)Wk

>secnailpparof)mc19(sehcni63

gninepo

03(sehcni21,)Wk3(hutB000,01

foedisotrowoleb)m2.1(teef4

evoba)m003(toof1;gninepo

)Wk03(hutB000,001

K

L

ytreporpcilbupno

M

1

In accordance with the current CSA B149.1, Natural Gas and

Propane Installation Code

2

In accordance with the current ANSI Z2223.1/NFPA 54, National

Fuel Gas Code

†

A vent shall not terminate directly above a sidewalk or paved

driveway that is located between two single family dwellings and

serves both dwellings.

# 45464K003 Page 9

telniylppusrialacinahcemaotecnaraelC )m38.1(teef6

detacolyawevirddevaproklawedisdevapevobaecnaraelC

ynoclabro,kced,hcrop,adnarevrednuecnaraelC )mc03(sehcni21*

‡

Permitted only if veranda, porch, deck, or balcony is fully open on a

†

)m31.2(teef7)m31.2(teef7

‡

01nihtiwfievoba)mc19(teef3

yllatnoziroh)m3(teef

minimum of two sides beneath the floor.

* For clearances not specified in ANSI Z2223.1/NFPA 54 or CSA

B149.1, the following statement shall be included:

“Clearance in accordance with local installation codes and the

requirements of the gas supplier and the manufacturer’s installation

instructions.”

Figure 10

Page 10

When installing a CAM coil in a horizontal position with a

horizontal gas furnace, always keep the open end of the

A-coil facing the supply air outlet of the furnace (blow into

the open end of the A-coil). The A-coil should point away

from the supply air outlet of the furnace (see Figure 11).

Correct Positioning of CAM Coil in the

Horizontal Position with a Gas Furnace

Correct

Return

Supply

Incorrect

Return

Supply

WARNING

When side return is desired on a furnace with

an open bottom, the bottom must be sealed

with a piece of sheet metal large enough to

cover the entire opening. Failure to connect a

return air duct to the bottom, or to enclose

the bottom when side return is desired, may

result in combustion products being drawn

into the circulating air stream which could

result in asphyxiation.

Horizontal Installations

G1N80BR, G1N80BT, CG80RB, and CG80TB series

furnaces can be horizontally installed for airflow right to left

or left to right. These furnaces are to be installed so that

the burner and blower access panels are in a vertical

plane; they are NOT to be installed such that these panels

are in a horizontal plane (see Figure 1 on page 2). Never

install any furnace on its back.

Figure 11

If a cooling coil is not installed with the furnace, then a

removable access panel should be provided in the supply

plenum for purposes of inspecting the heat exchanger.

This opening shall be accessible when the furnace is

installed, and shall be of such size that the heat exchanger

can be viewed for possible openings using light assistance

or a probe can be inserted for sampling the air stream. The

cover for the opening shall be leaktight.

Upflow Installations

G1N80BU, G1N80BT, CG80UB, and CG80TB series

furnaces can be installed as upflow units with either a side

or bottom air return. For units that do not include a side

return filter rack, kit AFILT524 can be used. Bottom filter

kit AFILT529 can be used with all G1N80BU, G1N80BT,

CG80UB, and CG80TB series furnaces.

For side return installation, a full-size return air opening

must be cut in the side panel. A starter hole and corner

embossments are provided in each side (see Figure 13 in

the Filters section).

Counterflow (Downflow) Installations

G1N80BR and CG80RB furnaces may be installed directly

on the supply plenum or coil cabinet if the furnace is

installed on a non-combustible floor.

For installations on combustible flooring, a special base

must be ordered and used. (See the Accessories section on

page 18 for more information.) To install the special base:

1. Cut a hole in the floor, sized to provide 1" clearance

between all four sides of the duct and the edge of the

flooring (see Figure 12). The four angles on the base

assembly should recess into the floor joists and the

base should rest on all four outside flanges.

2. Construct duct connections with 1" to 1-3/4" right

angle flanges, and long enough to extend below the

floor joists.

3. Drop the duct connections through the top of the base

assembly with the right angle flanges in good contact

with the glass tape on top of the base assembly.

4. Carefully position furnace over right angle duct flanges.

Filters

To provide sufficient filter area for installations requiring

more than 1600 CFM nominal air delivery, return air will

have to be brought through both sides of the furnace,

through one side and the bottom, or optional filter rack

AFILTHA7 may be used.

Filters are not supplied with CG80UB, CG80TB, or

CG80RB series furnaces.

G1N80BU Models

A filter rack and washable 16" x 25" x 1/2" filter are

supplied with each G1N80BU furnace. (Models designed

# 45464K003Page 10

Page 11

Combustible Floor Installation

(Counterflow Models Only)

Filter Rack Installation

Filter Rack Mounting Hole

Screw

Woven

Glass Tape

Combustible

Figure 12

Base

Assembly

Flooring

Furnace

1"

Duct

Front of Cabinet

Corner Embossments

Filter Rack

Figure 13

installer’s responsibility to install properly sized filters in

accordance with Table 1 on page 12.

If filters are needed at the furnace only, use the following kits:

• AFILT524 for side return on upflow installations.

• AFILT529 for bottom return on upflow installations or

horizontal installations of G1N80BT or CG80TB furnaces.

• AFILT525 for counterflow installations of G1N80BR or

CG80RB furnaces.

Other filter accessories are also available from the manufacturer including a full line of indoor air quality products. For

information on these products, contact the local distributor.

for more than 1600 CFM nominal air delivery include two of

each.) The filter rack is to be installed between the return

air duct and the side of furnace. Refer to Figure 13 and the

following instructions to install the filter rack:

1. Using the corner embossments as a guide, mark and

cut a full-size opening in the side panel(s).

2. Using the filter rack as a template, mark and drill four

7/64" diameter screw holes in the side panel(s).

3. With the filter access opening toward the front of the

furnace, use sheet metal screws to fasten the rack(s)

to the side panel(s).

4. Install the filter(s) in the rack(s), mesh side of filter

towards furnace.

Model AFIL THA7 external filter frame accessory is available for single side return air connection in installations

requiring more than 1600 CFM nominal air delivery .

G1N80BT , CG80TB, G1N80BR, and CG80RB Models

Filters are not supplied with G1N80BT, CG80TB, G1N80BR,

or CG80RB series furnaces since filters are commonly

located behind a return grille for ease of servicing. It is the

Upflow Model Filter Location

Side

Base

Filter

BOTTOM RETURN

R/A Duct

Filter Rack

Filter - Slides in from Front of Unit

SIDE RETURN

Figure 14

# 45464K003 Page 11

Page 12

Minimum Filter Requirements

(see Figure 15). The screws must be re-installed in the

vest panel after the insert s are removed.

wolfriA

rotpircseD

90084

01 084

21675

41 276

61867

22,02 069

1. The Airflow Descriptor is the two digits following the “D” in

the model number.

2. Areas and dimensions shown for permanent filters are

based on filters rated at 600 feet per minute face velocity.

3. Typical filter sizes are shown; however, any combination

of filters whose area equals or exceeds the minimum

area shown is satisfactory.

aerA.niM

).ni.qs(

eziS

).ni(

52x02

52x02

02x61

02x02

02x02

52x02

sretliFelbasopsiD sretliFtnenamreP

.ytQ

1042

1 042

2882

2 633

2483

2 084

eziS

aerA.niM

).ni.qs(

).ni(

02x61

1

02x61

1

02x61

1

02x02

1

02x02

1

52x02

1

Table 1

Gas Supply and Piping

Refer to the furnace rating plate to make sure the furnace

is equipped to burn the gas supplied (natural or propane).

.ytQ

NOx Insert

Location

Figure 15

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly

could result in serious injury, death, or property damage.

WARNING

Any conversion of a natural gas unit to propane gas must be done by qualified personnel using a conversion kit available from the

manufacturer, following the instructions in the

conversion kit. If done improperly, overfiring of

the burners and improper burner operation

can result. This can create carbon monoxide

which could cause asphyxiation.

WARNING

When converting a low NOx furnace (desig-

nated by an “L” in the model number, such as

G1N80BU100D20CL-1A) to propane, the

NOx inserts must be removed. Failure to

remove the inserts can create a situation

where carbon monoxide is produced which

may lead to asphyxiation.

Never test for gas leaks with an open flame.

Use a commercially available soap solution

made specifically for the detection of leaks to

check all connections. A fire or explosion may

result causing property damage, personal

injury, or loss of life.

Gas supply piping should be installed in accordance with

local codes and the regulations of the utility. Piping must be

of adequate size to prevent undue pressure drop. Consult

the local utility or gas supplier for complete details on special

requirements for sizing gas piping.

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use

a connector which has previously serviced another gas

appliance.

Pipe connections must be tight, and a non-hardening pipe

compound resistant to liquefied petroleum gases should

be used.

To remove the NOx inserts, first take out the burners. After

removing the burners, remove the screw holding each

insert and pull the insert from the combustion chamber

Connect gas pipe to furnace controls providing a ground joint

union as close to the controls as is possible to facilitate

removal of controls and manifold. Provide a drip leg on the

outside of furnace. A manual shutoff valve shall be installed

# 45464K003Page 12

Page 13

in the gas line, outside the unit, 5' above the floor, or in

accordance with any local codes. A test gauge connection

must be installed with a 1/8" NPT plugged tapping immediately upstream of the shutoff valve (see Figure 16).

Gas Connection

Manual

Gas Valve

Union

1/8" NPT

Plugged

Tapping

After gas piping is complete, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means. Some soaps

used for leak detection are corrosive to certain

metals. Carefully rinse piping thoroughly after leak

detection has been completed.

Electrical Wiring

WARNING

Te e

Drip Leg

Cap

Upflow/

Counterflow

Installation

Manual

Gas Valve

Union

Te e

Drip Leg

Cap

1/8" NPT

Plugged

Tapping

Horizontal

Installation

Figure 16

The furnace must be isolated from the gas supply piping

system by closing the individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 1/2 psig

(3.5 kPa) or 14" W.C. If the piping system is to be tested at

pressures in excess of 1/2 psig (3.5 kPa), the furnace and

its appliance main gas valve must be disconnected from

the gas supply piping system.

Risk of electrical shock. Disconnect electrical

power at the circuit breaker or service panel

before making electrical connections. Failure

to disconnect power supplies can result in

property damage, personal injury, or death.

The furnace must be grounded and wired in accordance

with local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

and/or CSA C22.1 Electrical Code (latest edition) if an

external electrical source is utilized.

In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall

conform with the temperature limitation for Type T wire –

63°F (35°C) rise.

Connect a sufficiently sized wire with ground to the furnace’s

line voltage connections and ground lug. Refer to the

furnace rating plate for electrical characteristics to be used

in sizing field supply wiring and over-current protection.

The line voltage supply should be routed through a

readily accessible disconnect located within sight of the

furnace. A junction box on the furnace side panel is

provided for line voltage connections. Refer to the furnace

wiring diagram for specific connection information.

Proper polarity of the supply connections (“HOT”

and “NEUTRAL”) must be observed to ensure that

safety controls provide the protection intended.

A connection to the ground lug and actual earth ground

(typically a ground stake or buried steel pipe) must be

maintained for proper operation.

WARNING

The gas valve supplied with this furnace is

rated at 1/2 psig maximum. Any higher pressure may rupture the pressure regulator diaphragm and may cause overfiring of the burners

and improper burner operation. The overfiring

may result in the creation of carbon monoxide

which could cause asphyxiation.

# 45464K003 Page 13

Thermostat

Install a room thermostat according to the instructions

furnished with it. Select a location on an inside wall that is

not subject to drafts, direct sunshine, or other heat

sources. The initial heat anticipator setting should be equal

to the total current draw of the control circuit.

Low voltage thermostat connections are to be made to the

blower control board as indicated on the wiring diagram.

Page 14

Continuous Blower Operation

What to do if you smell gas:

If continuous blower operation on low speed is desired,

connect the lowest speed motor tap to the “CONT” terminal

on the blower control board (refer to the furnace wiring

diagram.) The blower will operate on low speed whenever

main power is connected to the furnace, except when it

operates on heating or cooling speed during thermostat

call for heat or cooling. This constant air terminal is

intended for low speed only . If a motor is wired for a

higher speed, the increased amp draw could cause the

board control to fail and void the warranty.

Humidifier

Terminals are provided on the blower control board for

connection to a 120-volt humidifier. The “HUM” terminal is

energized whenever the thermostat calls for heat. Refer to

furnace wiring diagram for specific connection information.

Electronic Air Cleaner

Terminals are provided on the blower control board for

connection of a 120-volt electronic air cleaner. The “EAC”

terminal is energized whenever the thermostat calls for

heat, cooling, or continuous blower. Refer to the furnace

wiring diagram for specific connection information.

Twinning

• Do not try to light any appliances.

• Extinguish any open flame.

• Do not touch any electric switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Do not use this furnace if any part has been under water.

Immediately call a qualified service technician to inspect

the furnace and to replace any part of the control system

and gas control which has been under water.

IMPORTANT: Refer to the Lighting Instruction label on

the furnace for instructions on operating the specific

controls used on your unit.

To Start Furnace:

CAUTION

Be sure the manual gas control has been in

the “OFF” position for at least 5 minutes

before starting the unit. Do not attempt to

manually light the burners.

The blower control board is designed to permit “twinning” of

furnaces (two furnaces connected to a common supply

and return air system, and controlled by one thermostat).

An accessory kit must be ordered from the manufacturer.

Specific wiring and operating instructions are included

with the kit.

Each furnace must have its own dedicated vent system.

START -UP

Lighting Instructions

For Your Safety, Read Before Operating

WARNING

If you do not follow these instructions exactly,

a fire or explosion may result causing property damage, personal injury, or loss of life.

These furnaces are equipped with an ignition device which

automatically lights the burner. Do not try to light the

burner by hand.

1. Set the room thermostat to lowest setting.

2. Remove burner access door.

3. Move the gas control knob to the “ON” position. Use

only your hand to turn the gas control knob; never use

tools. If the knob will not turn by hand, don’t try

to repair it; call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

4. Replace the burner access door.

5. Turn on the electrical power to the furnace.

6. Set the room thermostat to a point above room temperature to light the main burners. After the burners have

ignited, set the room thermostat to desired temperature.

To Shut Down Furnace:

1. Set the room thermostat to the lowest setting.

2. Turn off all electric power to the furnace.

3. Remove burner access door.

Before operating, smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

4. Shut off the gas by moving the gas control knob to the

“OFF” position.

5. Replace the burner access door.

# 45464K003Page 14

Page 15

WARNING

Should overheating occur or the gas supply

fail to shut off, shut off the manual gas valve

to the appliance before shutting off the electrical supply.

OPERATION

The call for cooling has priority over continuous fan

operation while a call for heating has priority over both a

call for cooling or continuous fan. Ignition lockouts for any

reason do not affect cooling operation.

As cooling demand is met, the thermostat de-energizes

the R-Y circuit of the control board. After a 60-second

cooling “off” delay, the control de-energizes the cooling

speed fan. At the end of the cooling “off” delay period, the

control returns to the standby mode.

Sequence of Operation

Heating

During a call for heat the thermostat closes the R-W circuit

of the control board. The control board verifies limit

switches are closed and pressure switch is open. The

induced draft blower relay closes causing the blower to

run. As vent pressure is developed by the induced draft

blower, the pressure switch closes. After a 15-second prepurge, the control energizes the hot surface ignitor. After

the 7-second warmup time, the control energizes the main

gas valve causing the main burners to ignite. The hot

surface ignitor is de-energized 3 seconds after the main

valve opens. If flame is sensed during this time the main

valve remains energized and the control starts the

30-second heat blower “on” delay.

As heating demand is met, the thermostat de-energizes the

R-W circuit. The control de-energizes the main valve causing

the burners to shut off. The induced draft blower shuts off

after a 15-second post-purge delay. The circulating air blower

will continue to operate until the user-selectable heat blower

“off” delay expires. The control return to standby mode once

the heat blower “off” delay expires.

Controls

Following is a description of the operation of some of the

controls used in this furnace. All models use one of each

control, except as noted.

Pressure Switch

The pressure switch is a normally open switch that

monitors combustion air flow. Inadequate air flow resulting

from excessive venting system restriction or a failed

combustion blower will cause the switch to remain open.

Rollout Switch

The rollout switch is a normally closed switch that opens

when abnormal temperatures exist in the burner area. This

can be caused by a restricted heat exchanger causing

main burner flame to “roll out” into the vestibule area or

burner box.

This switch must be manually reset by pushing the button

on top to restore furnace operation. G1N80BR, G1N80BT,

CG80RB, and CG80TB series units incorporate two rollout

switches.

Fan “On”

During a fan “on” call, the thermostat energizes the R-G

circuit of the control board, immediately causing the fan to

energize the COOL speed. The fan remains energized as

long as the thermostat calls for fan “on” operation.

If a call for cooling is energized during a fan “on” call, the fan

continues to operate at the COOL speed. If a call for heat is

energized during a fan “on” call, the control de-energizes the

fan immediately and begins the heat call/ignition sequence.

At the end of the fan “on” call the thermostat de-energizes

the R-G circuit of the control, causing the fan to be deenergized immediately.

Cooling

During a call for cooling, the thermostat energizes the R-Y

circuit of the control board. After a 1-second cooling “on”

delay, the control energizes the cooling fan speed. If the fan

is already energized, it remains running and does not de-

energize for the 1-second cooling fan “on” delay.

# 45464K003 Page 15

Primary Limit Control

This is a normally closed control that opens if abnormally

high circulating air temperatures occur. It is an automatic

reset control.

Auxiliary Limit Control

This is a normally closed control, located on the circulating

air blower housing, that opens under abnormal

“reverse air flow” conditions that could occur in a

counterflow or horizontal installation if the circulating air

blower fails. It is an automatic reset control.

G1N80BU and CG80UB models do not include an auxiliary

limit control.

Interlock (Blower Door) Switch

When the blower door is removed, the interlock switch

breaks the power supply to the burner controls and blower

motor. The switch operation must be checked to confirm it

is operating correctly.

Page 16

Blower Control Board

The blower control board operates the circulating air

blower, the combustion blower, and any accessories

connected to it. These models feature user-selectable

blower “off” delay times (60, 90, 120, and 180 seconds)

that are factory set to provide a 120-second blower “off”

delay on heating (see wiring diagram on page 19).

For Natural Gas: Check the furnace rate by observing the

gas meter, when available, making sure all other gas

appliances are turned off. The test hand on the meter

should be timed for at least one revolution. Note the

number of seconds for one revolution.

Cubic Feet Per RevolutionBTU/HR

INPUT # Seconds Per Revolution

=

x 3600 x

Heating

Value

Refer to the furnace wiring diagram while using the

following procedure to change motor speed:

1. Turn off electrical power to the unit.

2. Connect the desired speed tap for cooling on the

blower control board.

3. For heating speed, check the temperature rise and, if

necessary, adjust blower speed tap to maintain temperature rise within the range shown on furnace rating plate.

To use the same speed tap for both heating and

cooling, install a piggyback terminal on the speed tap

using a short jumper. Wire 1/4" quick connect termi-

nals on both ends to jumper the “HEAT” and “COOL”

speed on the blower control board.

4. The remaining speed taps must be connected to dummy

terminals marked “PARK” on the blower control board.

Checking and Adjusting Gas Input

The minimum permissible gas supply pressure for the

purpose of input adjustment is 5" W.C. for natural gas and

11" W.C. for propane gas. This furnace requires conversion

for use with propane (see Accessories section on page 18

for correct kit). The maximum inlet gas supply pressure is

10.5" W.C. for natural gas and 13" W.C. for propane.

The heating value of the gas can be obtained from the

local utility company.

For Propane Gas: The only check for the furnace rate is to

properly adjust the manifold pressure using a manometer

and the information provided in Tables 2 and 3. Typical

manifold set point for installations at altitudes from 0 to

4500 feet above sea level is 10.0" W.C.

Temperature Rise

Check the temperature rise and, if necessary, adjust

blower speed to maintain temperature rise within the

range shown on the unit rating plate.

High Altitude

In both the United States and Canada, this furnace is

approved for operation at altitudes from 0 to 4500 feet

above sea level without any required modifications. From

4500 to 7500 feet, the gas manifold pressure needs to be

adjusted according to the information shown in Tables 2

and 3. To adjust the manifold pressure, refer to previous

section Checking and Adjusting Gas Input. For installations above 7500 feet, call Technical Service at 1-800-4485872 ext. 2610 for assistance.

MAINTENANCE

Gas input must never exceed the value shown on the

furnace rating plate. This furnace is equipped for rated

input at manifold pressures of 3.5" W.C. for natural gas and

10.0" W.C. for propane gas.

The manifold pressure can be measured by removing the

pipe plug in the downstream side of the gas valve and

connecting a water manometer or gauge.

To adjust the regulator, turn the adjusting screw on the

regulator clockwise to increase pressure and input; counterclockwise to decrease pressure and input.

CAUTION

The furnace rate must be within +/– 2% of the

appliance rating input.

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly

could result in dangerous operation, serious

injury, death, or property damage.

Improper servicing could result in dangerous

operation, serious injury, death, or property

damage.

• Before servicing, disconnect all electrical

power to furnace.

• When servicing controls, label all wires prior

to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.

# 45464K003Page 16

Page 17

Manifold Pressure vs. Altitude

saGlarutaN )PL(enaporP

edutitlA

).tf(

000284905.3872200.016669.0

0003 419 05.3 6912 00.01 9949.0

000418805.3611200.012339.0

0054 568 05.3 7702 00.01 9429.0

000594892.3930214.90098.0

0055 338 72.3 0002 53.9 0978.0

000681852.3469192.90868.0

0056 208 32.3 7291 42.9 0758.0

000778712.3198181.90648.0

0057 177 91.3 3581 21.9 0538.0

* Consult local utility for actual heating value.

Furnace Input = Input Factor x Nameplate Input

Above 7500 feet, call Technical Services at 1-800-4485872 ext. 2610.

gnitaeH

*eulaV

3

)

tf/UTB(

dlofinaM

erusserP

).C.W.ni(

gnitaeH

*eulaV

3

)

tf/UTB(

dlofinaM

erusserP

).C.W.ni(

Manifold Pressure vs. Altitude

(G1N80BU150 and CG80UB150 only)

)

saGlarutaN )PL(enaporP

dlofinaM

erusserP

).C.W.ni(

gnitaeH

*eulaV

3

tf/UTB(

)

dlofinaM

erusserP

tupnI

rotcaF

).C.W.ni(

tupnI

rotcaF

* Consult local utility for actual heating value.

Furnace Input = Input Factor x 148,000

Above 7500 feet, call Technical Services at 1-800-4485872 ext. 2610.

edutitlA

).tf(

000284914.3872200.016669.0

0003 419 14.3 6912 00.01 9949.0

000418814.3611200.012339.0

0054 568 14.3 7702 00.01 9429.0

000594802.3930214.90098.0

0055 338 81.3 0002 53.9 0978.0

000681861.3469192.90868.0

0056 208 41.3 7291 42.9 0758.0

000778721.3198181.90648.0

0057 177 11.3 3581 21.9 0538.0

gnitaeH

*eulaV

3

tf/UTB(

Table 2

It is recommended that this furnace be inspected by a

qualified service technician at the beginning of each heating

season.

Filters

Filters should be checked at least every 6 weeks. Disposable filters should be replaced when dirty, and permanent

filters should be cleaned regularly. It is important to keep the

air filters clean, as dirty filters can restrict airflow and the

blower and induced draft motors depend upon sufficient air

flowing across and through them to keep from overheating.

Main Burners

Light the burners and allow to operate for a few minutes to

establish normal burning conditions. Observe the main

burner flames. Compare this observation to Figure 17 to

determine if proper flame adjustment is present. Flame

should be predominantly blue in color and strong in appearance. Check that all burners are lit, and that the flame does

not impinge on the sides of the heat exchanger.

Distorted flame or yellow tipping of the natural gas main

burner flame, or long yellow tips on propane, may be

caused by lint accumulation or dirt inside the burner or

burner ports, at the air inlet between the burner and

manifold pipe, or obstructions over the main burner orifice.

Use a soft brush or vacuum to clean the affected areas.

# 45464K003 Page 17

Table 3

T ypical Flame Appearance

(Main Burners)

Heat

Exchanger

Burner

Gas

Manifold

Burner

Flame

(Blue Only)

Figure 17

Lubrication

The blower motor and induced draft motor are pre-lubricated by the manufacturer and do not require further

lubricating attention. However, the motors should be

cleaned periodically to prevent the possibility of overheating due to an accumulation of dust and dirt on the windings

or on the motor exterior.

Page 18

CONTROL SYSTEM DIAGNOSTICS

Fault Code History Button

Troubleshooting

The following visual checks should be made before

troubleshooting:

1. Check to see that the power to the furnace and the

blower control board is on.

2. The manual shutoff valves in the gas line to the

furnace must be open.

3. Make sure all wiring connections are secure.

4. Review the Sequence of Operation (see page 15).

Start the system by setting the thermostat above the room

temperature. Observe the system’s response. Then use the

information provided in this section to check the system’s

operation.

The furnace has a built-in, self-diagnostic capability. If a

system problem occurs, a fault code is shown by an LED

on the control board. The control continuously monitors its

own operation and the operation of the system. If a failure

occurs, the LED will indicate the failure code. The flash

codes are presented in Table 4.

Failure Codes

The control stores the last five fault codes in memory. A

pushbutton switch is located on the control (see Figure 18).

When the pushbutton switch is pressed and released, the

control flashes the stored fault codes. The most recent fault

code is flashed first; the oldest fault code is flashed last.

To clear the fault code history, press and hold the pushbutton

switch in for more than 5 seconds before releasing.

REPAIR PARTS

The following repair parts are available from the local

distributor. When ordering parts, include the complete

furnace model number and serial number which are

printed on the rating plate located on the furnace.

Control Group

Transformer

High limit control

Auxiliary limit (if used)

Gas valve

Ignition/blower control board

Flame sensor

Heat Exchanger Group

Heat exchanger

Flue box cover

Blower Group

Pressure switch

Blower door interlock switch

Combustion blower assembly

Flame rollout protector switch

Hot surface igniter

Combustion blower transition

DEL

sutatS

nODEL noitarepolamroN

hsalF1ffoevlavsaghtiwtneserpemalF

ffODEL

sehsalF2 fforecudnihtiwdesolchctiwserusserP

sehsalF3norecudnihtiwnepohctiwserusserP

sehsalF4 nepohctiwstimilhgiH

sehsalF5nepohctiwstuolloR

sehsalF6 tuokcolelcychctiwserusserP

sehsalF7noitingionoteudtuokcoL

sehsalF8 stuopordemalfynamoototeudtuokcoL

sehsalF9gnisahpegatloveniltcerrocnI

Table 4

noitpircseDtluaF

Blower housing assembly

Blower wheel

lortnocrolortnocotrewopoN

detcetedtluaferawdrah

Blower mount

Burner Group

Gas manifold

Blower motor mount

Blower motor capacitor

Main burners

Main burner orifices

Accessories

ALPKT572 Natural Gas to Propane Conversion Kit

ANGKT557 Propane to Natural Gas Conversion Kit

AFILTHA7 Single Side Filter Frame Kit

AFILT524 Side Return Filter Kit (Upflow Models)

AFILT525 Return Filter Kit (Counterflow Models)

AFILT529 Bottom Return Filter Kit

ATWIN579 Twinning Kit

ABASE511 Combustible Floor Base (14.5" cabinets)

ABASE512 Combustible Floor Base (17.5" cabinets)

ABASE568 Combustible Floor Base (21.0" cabinets)

ABASE569 Combustible Floor Base (24.5" cabinets)

# 45464K003Page 18

Page 19

# 45464K003 Page 19

Connection Diagram

P/N 45198-005

Figure 18

Page 20

Schematic Diagram

P/N 45198-005

Figure 19

# 45464K003Page 20

Loading...

Loading...