Page 1

See unit nameplate for manufacturer

and address.

504,502M

8/2002

Supersedes 10/2001

AWARNING 150, 180,

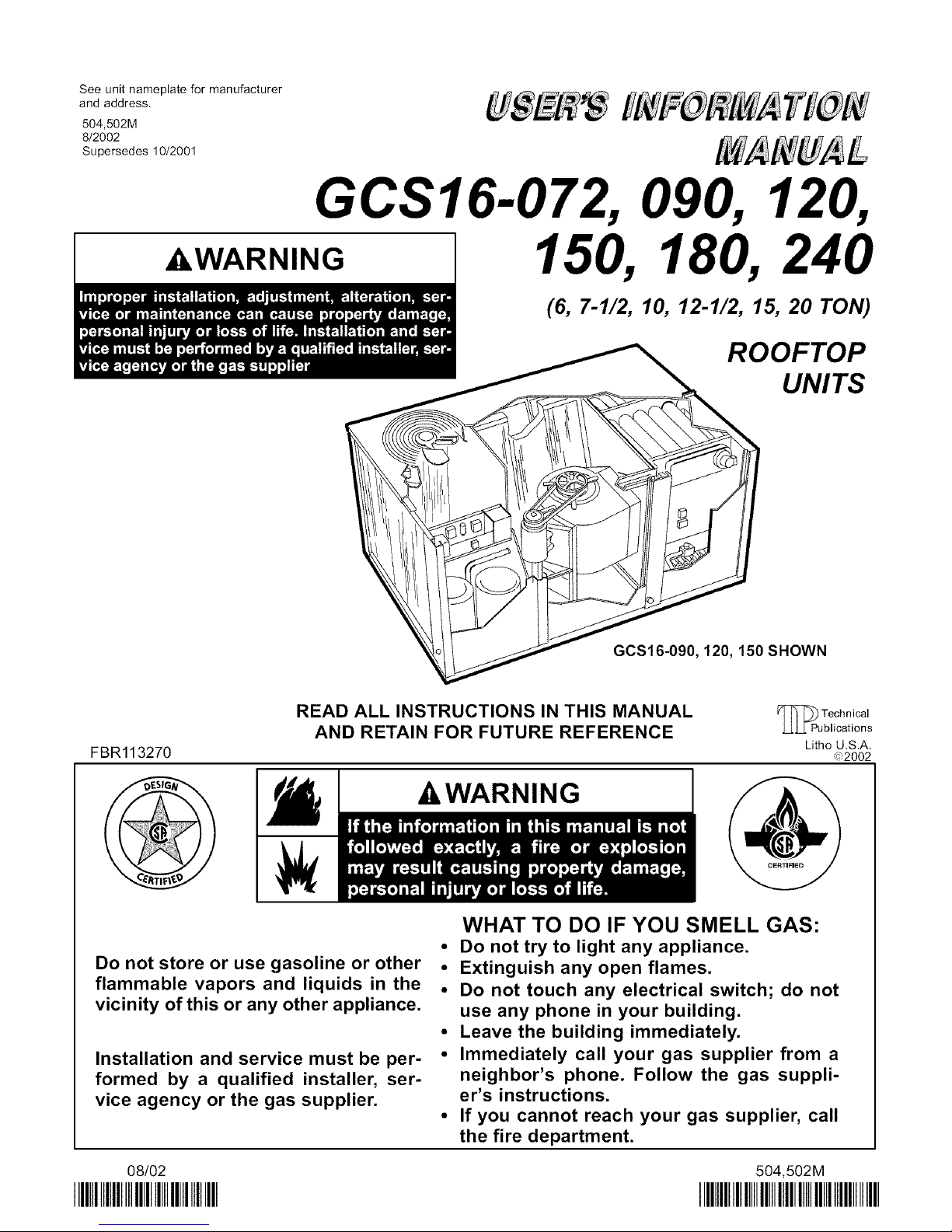

GCS16-072, 090,

(6, 7-1/2, 10, 12-1/2, 15, 20 TON)

ROOFTOP

UNITS

READ ALL INSTRUCTIONS IN THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE

FBR113270

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be per-

formed by a qualified installer, ser-

vice agency or the gas supplier.

GCS16-090, 120, 150 SHOWN

-&WARNING

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Extinguish any open flames.

• Do not touch any electrical switch; do not

use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas suppli-

er's instructions.

• If you cannot reach your gas supplier, call

the fire department.

TeChnical

blications

Lithe U.S.A.

G_)2002

08/02

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIll

504,502M

IIIllllllllllllllllllllllllllHIIIIIIIIlllll

Page 2

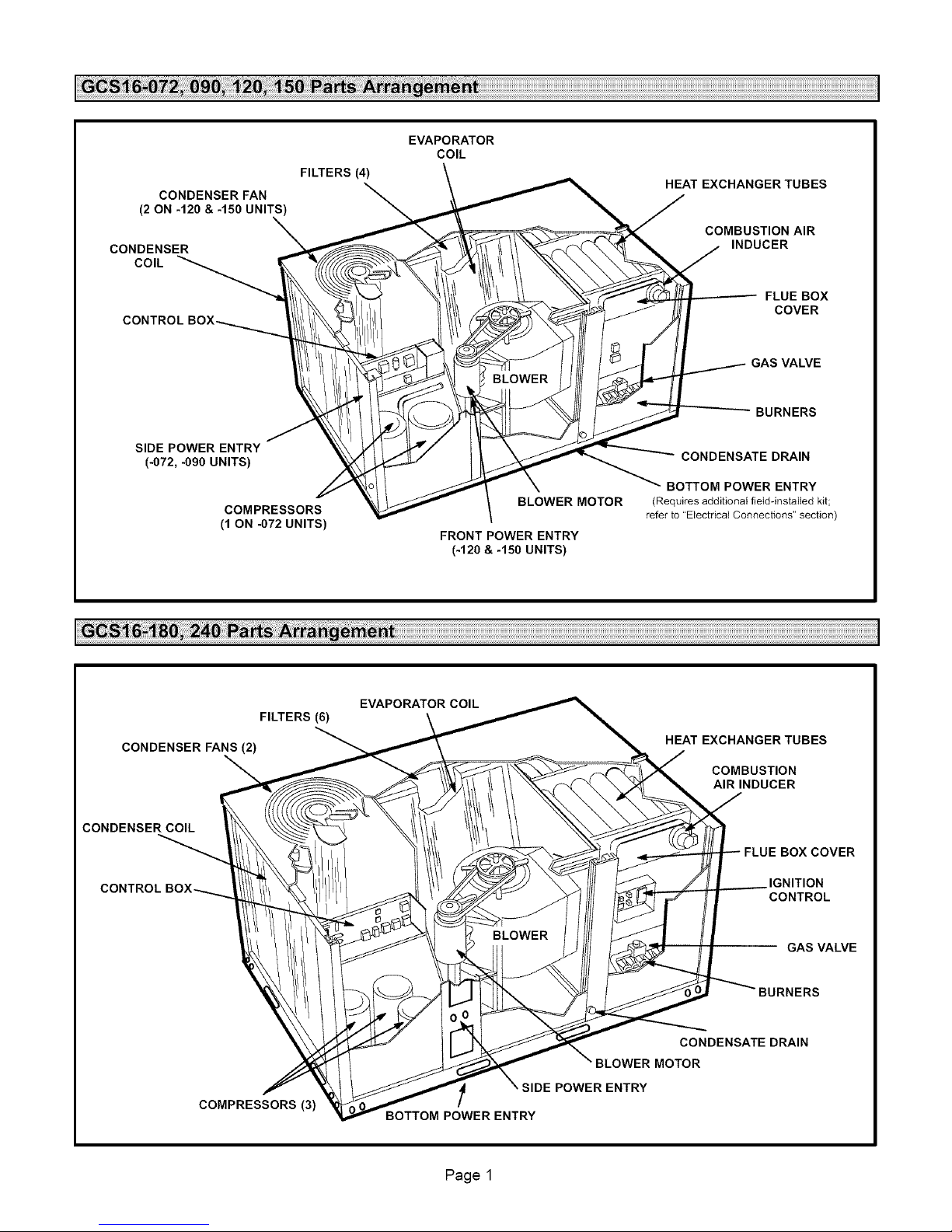

CONDENSER FAN

(2 ON -120 & -150 UNITS)

CONDENSER

FILTERS (4)

EVAPORATOR

COIL

HEAT EXCHANGERTUBES

COMBUSTION AIR

INDUCER

COIL

CONTROLBOX_

SIDE POWER ENTRY

(-072, -090 UNITS)

COMPRESSORS

(10N-072UNITS)

CONDENSER FANS (2)

FILTERS (6)

FRONT POWER ENTRY

(-120 & -150 UNITS)

EVAPORATOR COIL

FLUE BOX

COVER

GAS VALVE

BURNERS

CONDENSATE DRAIN

BOTTOM POWER ENTRY

BLOWER MOTOR (Requires additionalfield-installed kit;

refer to "Electrical Connections" section)

HEAT EXCHANGERTUBES

COMBUSTION

AIRINDUCER

CONDENSER COIL

CONTROL

COMPRESSORS(3)

COVER

IGNITION

CONTROL

GAS VALVE

CONDENSATE DRAIN

BLOWER MOTOR

POWER ENTRY

BOTTOM POWER ENTRY

Page 1

Page 3

, ,WARNING

-

Keep gas heat section clear and free of combustible

materials, gasoline and other flammable vapors and

liquids,

.

Inspect return air duct to ensure duct is sealed to the

curb external to the unit,

-

Inspect physical support of unit to guarantee that it is

sound without sagging, cracks, or gaps around base,

On downflow units, seal between base and support

must also be checked to make sure it is tight,

-

Do notobstruct air flow around unit, Unit must receive an

unobstructed flow of combustion and ventilating air.

,&,WARNING

,&IMPORTANT

A,WARNING

,&,CAUTION

,&WARNING

,&WARNING

,&WARNING

FOR YOUR SAFETY READ BEFORE LIGHTING

BEFORE LIGHTING smell all around the furnace area for

gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor,

Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

,&,WARNING

Page 2

Page 4

,WARNING

This unit is equipped with an automatic spark ignition

system. There is no pilot. In case of a safety shutdown,

move thermostat switch to OFF and return the thermostat

switch to HEAT to reset ignition control. See figure 1. For

units which have electronic temperature control devices,

shut off the main disconnect and return it to the on position

to reset the ignition control.

HEAT I!! lil COOL

/_ THERMOSTAT .

50 60 70 80

10 15 20 2530

\\\\'_\\\"III1"////'1111

I II I

7- Turn the knob on the gas valve counterclockwise41_

to "ON". Do not force.

8- Close or replace the heat section access panel.

9- Turn on all electrical power to furnace.

10- Set thermostat to desired setting.

11- The combustion air inducer will start. The burners will

light within 40 seconds.

12- If the furnace does not light the first time (gas line not

fully purged), it will attempt up to two more ignitions

before locking out.

WHITE RODGERS 36C76 GAS VALVE

STAGE2 MANIFOLD

INLET

PRESSURE

PRESSURE ADJUSTMENT

SCREW UNDER CAP

MANIFOLD

PRESSURE

TAP_SIDE)

FAN ON HEAT OFF COOL

I

FIGURE 1

A-Placing Unit In Operation

,WARNING

Gas Valve Operation for White Rodgers 36C (figure 2)

and Honeywell VR8305Q (figure 3)

1- Set thermostat to lowest setting.

2- Turn off all electrical power to furnace.

3- This furnace is equipped with an ignition device which

automatically lights the burner. Do not try to light the

burner by hand.

4- Open or remove the heat section access panel.

5- Turn the knob on the gas valve clockwise 4_ to

"OFF". Depress 36C knob slightly. Do not force.

6- Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your

gas supplier from a neighbor's phone. Follow the gas

supplier's instructions. If you do not smell gas, go to

the next step.

Page 3

FIGURE 2

HONEYWELL VR8305Q SERIES GAS VALVE

HIGH FIRE ADJUSTMENT

ADJUSTMENT

LOW FIRE

MANIFOLD

PRESSURE

TAP

,

PRESSURE I(( _ _ 4'''_t_" ,

TAP L._._=Vi oF_/

Gas valve knob is shown in OFF position,

FIGURE 3

13- If lockout occurs, repeat steps 1 through 10.

14- If the furnace will not operate, follow the instructions

"Turning Off Gas to Furnace" and call your service

technician or gas supplier.

Page 5

Turning Off Gas to Furnace

-

If using an electromechanical thermostat, set to the

lowest setting.

2-

Before performing any service, turn off all electrical

power to the furnace.

&CAUTION

3- Open or remove the heat section access panel.

4- Turn the knob on the gas valve clockwise _1_ to

"OFF". Depress 36C knob slightly. Do not force.

5- Replace heat section access panel.

The combustion air pressure switch checks the

combustion air inducer operation before allowing power

to the ignition controller. Ignition controller will not

operate if blower is obstructed.

Under normal operating conditions, the combustion air

blower wheel should be inspected prior to heating

season. With power supply disconnected, the condition

of the blower wheel can be determined by removing the

vent cap assembly and looking through the exhaust

vent. Remove any deposits of debris from vent cap

assembly before reinstalling it on unit. If cleaning

combustion air inducer is necessary, contact a qualified

service technician. See figure 4 and 5.

To maintain efficiency and longevity, your equipment

must be serviced yearly by a qualified service technician.

Failure to provide proof of service can void warranty.

GAS HEAT SECTION - 072,090

._OMBUSTION _--

_,IRINDUCER

COMBUSTION

AIR LOUVERS

MANUALKNOB

GAS VALVE --_

VENT

CAP

O

BURNERS /

FIGURE 4

GAS HEAT SECTION - 120, 150, 180, 240

I

&WARNING

&WARNING

The primary air is permanently set for normal operation.

The flame will be basically blue with some clear yellow

streaking in the end of the flame. Inspect burner flame

periodically during heating season using inspection port

provided on the burner access panel.

Page 4

;OMBUSTION .

_IRINDUCER

COMBUSTION

AIR LOUVERS

MANUALKNOB

GAS VALVE --_

VENT

CAP

O

BURNERS _

FIGURE 5

A-Servicing Filter

GCS16 units are equipped with pleated 2"

throwaway-type filters, Filters should be checked

monthly and replaced when necessary with filters of like

kind and size. Take note of air flow direction marking on

filter frame when reinstalling filters. See figure 6,

NOTE--Filters must be U.L,C, approved or equivalent

for use in Canada,

Page 6

Unit Qty.

TABLE 1

FILTER SIZE

Filter Size - inches (mm)

To keep your heating and cooling system in peak

operating condition year after year, contact a qualified

service technician about a regular maintenance program.

072, 090 4

120

150

180, 240 6

B-Blower Motor

16 X 20 X 2 (406 X 508 X 51)

2

16 X 20 X 2 (406 X 508 X 51)

2

16 X 25 X 2 (406 X 635 X 51)

2

20 X 20 X 2 (508 X 508 X 51)

2

20 X 25 X 2 (508 X 635 X 51)

18 X 24 X 2 (457 X 610 X 51)

Blower motor is prelubricated. No further lubrication is

required.

Contact a qualified service technician if the unit is

inoperative. Before calling, always check the following

to be sure service is required:

1- Be sure electrical disconnect switches are ON.

2- Check room thermostat for proper setting.

3- Replace any blown fuses or reset circuit breakers.

4- Gas valve(s) should be ON for heating cycle.

5- Air filters should not be plugged, limiting air flow.

6- Make sure all access panels are in place.

FILTER REMOVAL

(Four Filters On -072, 090, 120 & 150 Units)

FIGURE 6

The following repair parts are available. When ordering parts, include the complete model number listed on either the

CSA International rating plate (e.g. GCS16-240-375-1Y) or the U.L.C.S.A. rating plate (e.g. CHA16-240-1 G)

Heat Section Parts

Heat Exchanger

Combustion Air Inducer

Burner Assembly

Ignition Lead

Ignition Control (A3)

Sensor Lead

Combination Gas Valve

Flue Baffle

Limit Control (S10)

CAB Proving Switch (s18)

Auxiliary Limit Control (S21)

Burner Manifold Assembly

Main Burner Orifices

Ignition Electrode Assembly

Hi Heat Delay (DL3)

Rollout Switch (S47)

Cooling Parts

Compressor

High Pressure Switch (S4, S7)

Condenser Fan Motor

Condenser Fan Blade

Cond, Fan Run Capacitors (C1, C2)

Freezestat (S49, S50)

Cond, Fan Mount, Bracket

Fan Grille

Blower Wheel

Expansion Valve Distributor

Expansion Valve

Indoor Blower Motor

Electrical Control Parts

Compressor Contactor (K1, K2)

Transformer (Control) T1

Blower Contactor (K3)

Limit, Blower Relay (K20)

Capacitor CAB (C3)

Transformer (T3) (575/460V only)

Combustion Air Inducer Relay (K13)

Firestat Switches (S74, S75)

Blower Delay (K25)

Low Amb. Pressure Sw. (S11, S84)

Condenser Fan Contactor (K10)

Reversing Valve

Crankcase Heater Relay (K191)

Page 5

Loading...

Loading...