Lennox G61MP-60C-090, G61MP-36B-070, G61MP-60C-091, G61MP-48C-110, G61MP-60C-110 Installation Instructions Manual

...Page 1

INSTALLATION

E 2009 Lennox Industries Inc.

Dallas, Texas, USA

THIS MANUAL MUST BE LEFT WITH THE

HOMEOWNER FOR FUTURE REFERENCE

INSTRUCTIONS

G61MP SERIES UNITS

GAS UNITS

506406−01

08/2009

Supersedes 505,124M

Table of Contents

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G61MP Parts Identification 3. . . . . . . . . . . . . . . . . . . . . .

Shipping and Packing List 4. . . . . . . . . . . . . . . . . . . . . .

Safety Information 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Use of Furnace as Construction Heater 5. . . . . . . . . . .

General 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combustion, Dilution & Ventilation Air 6. . . . . . . . . . . .

Installation − Setting Equipment 8. . . . . . . . . . . . . . . . . .

Filters 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duct System 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pipe & Fittings Specifications 16. . . . . . . . . . . . . . . . . . . .

Vent Piping Guidelines 18. . . . . . . . . . . . . . . . . . . . . . . . .

Joint Cementing Procedure 20. . . . . . . . . . . . . . . . . . . . .

Venting Practices 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Piping 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Control Board 42. . . . . . . . . . . . . . . . . . . . . . .

Unit Start−Up 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Pressure Adjustment 44. . . . . . . . . . . . . . . . . . . . . .

High Altitude Information 45. . . . . . . . . . . . . . . . . . . . . . .

Other Unit Adjustments 46. . . . . . . . . . . . . . . . . . . . . . . . .

Service 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control Board Diagnostic Codes 56. . . . . . . . . .

Troubleshooting 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Parts List 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vent Pipe Sizing Worksheet 63. . . . . . . . . . . . . . . . . . . . .

Start−Up & Performance Check List 63. . . . . . . . . . . . . .

Litho U.S.A.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

08/09

*2P0809*

WARNING

FIRE OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could result in serious injury, death,

or property damage.

WHAT TO DO IF YOU SMELL GAS:

D Do not try to light any appliance.

D Do not touch any electrical switch; do not

use any phone in your building.

D Leave the building immediately.

D Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

D If you cannot reach your gas supplier, call

the fire department.

Page 1

*P506406-01*

506406−01

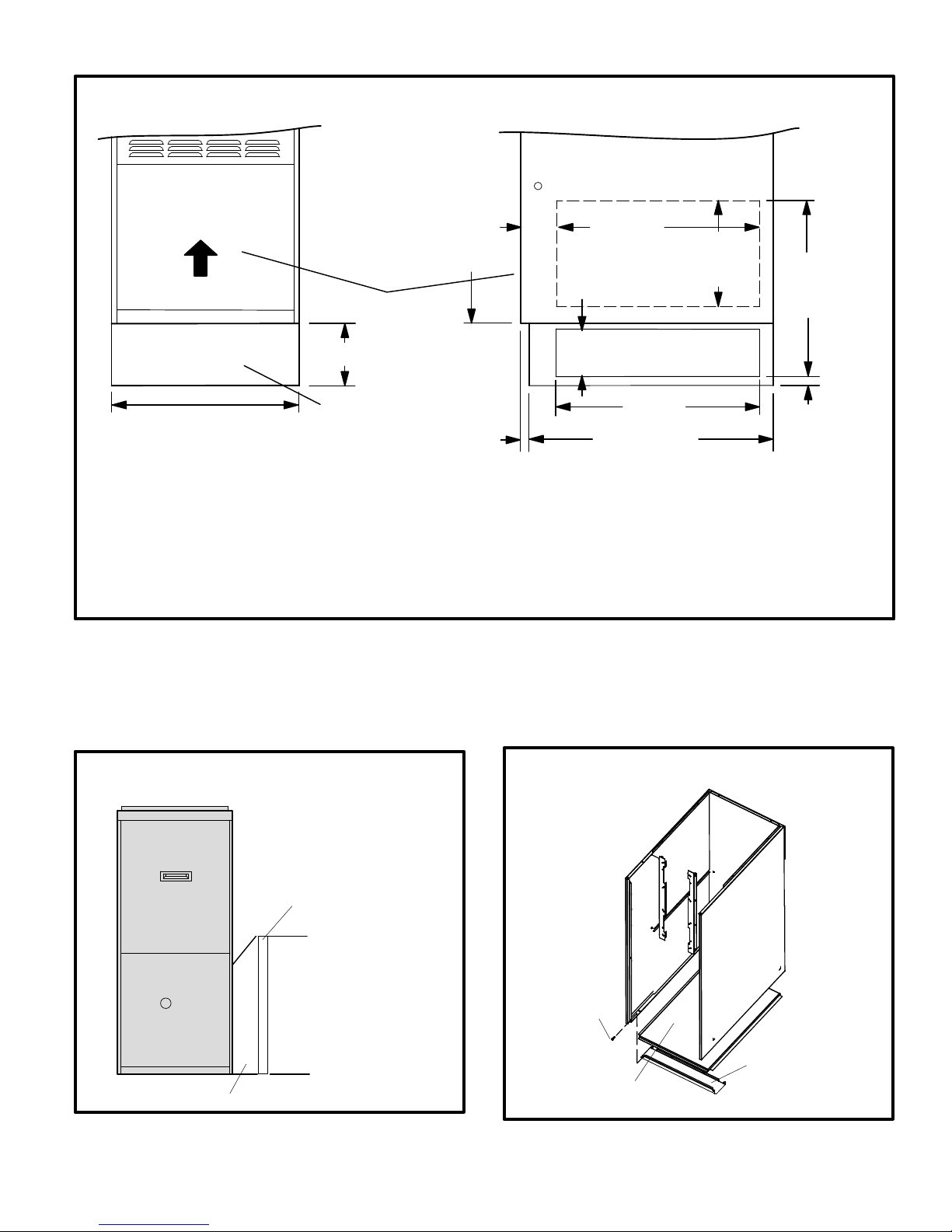

Page 2

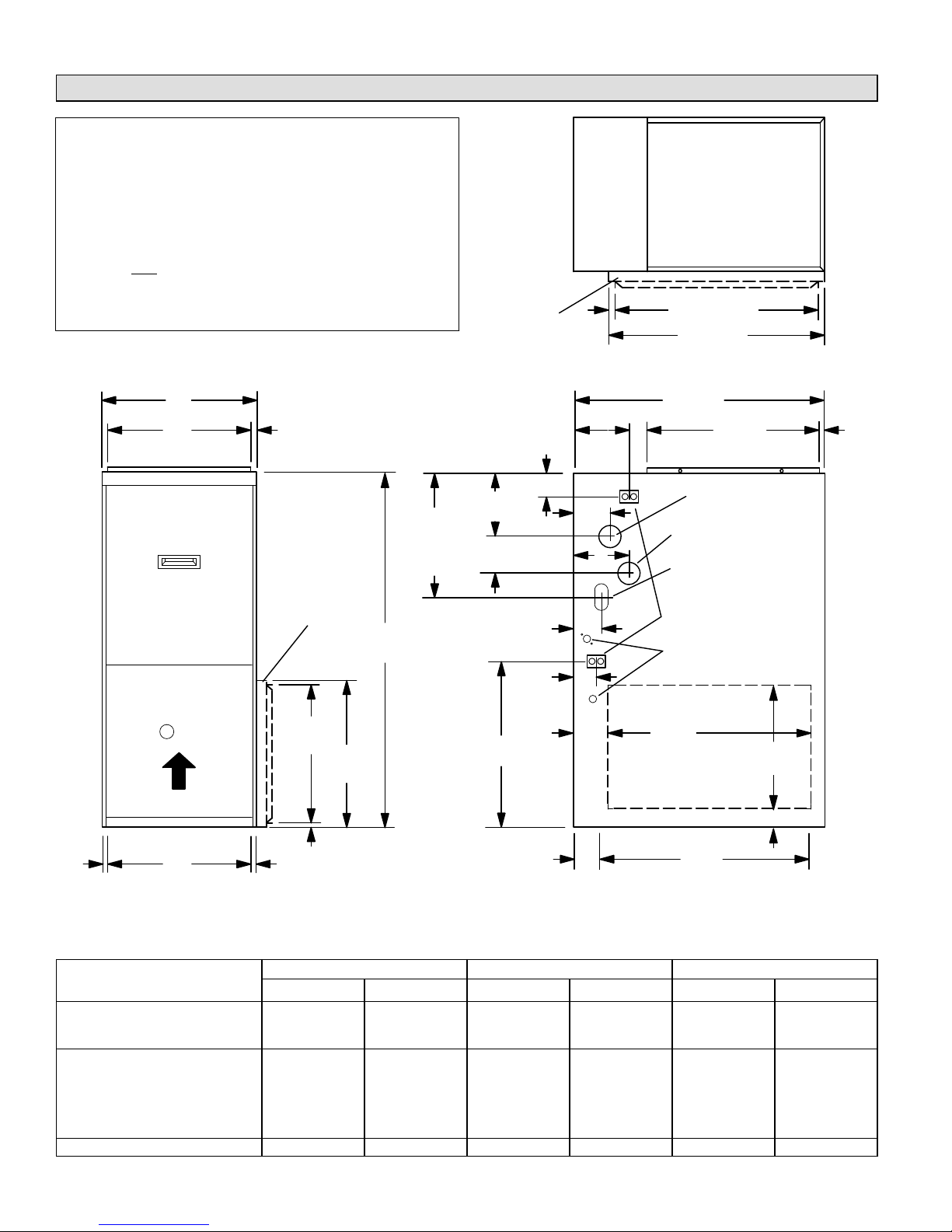

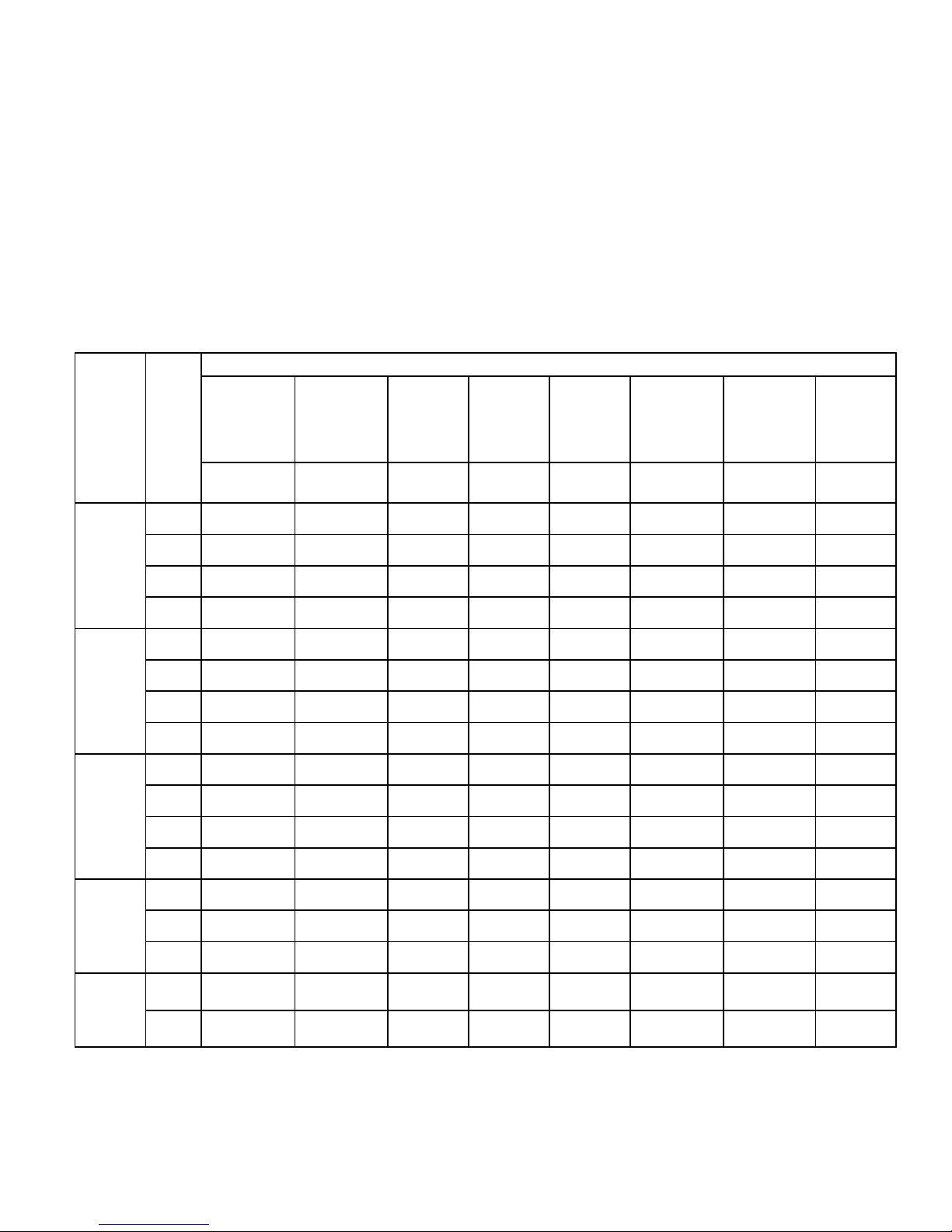

G61MP Unit Dimensions − inches (mm)

*NOTE − 60C and 60D size units installed in upflow applications that require air volumes over 1800 cfm (850 L/s)

must have one of the following:

1. Single side return air with transition, to accommodate

20 x 25 x 1 in. (508 x 635 x 25 mm) air filter.

Required to maintain proper air velocity.

2. Single side return air with optional RAB Return Air Base

3. Bottom return air.

4. Return air from both sides.

5. Bottom and

Refer to Engineering Handbook for additional information.

**Consider sizing requirements for optional IAQ equipment before cutting side return opening.

1

Optional External Side Return Air Filter Kit is not for use

with the optional RAB Return Air Base.

3/4 (19)

one side return air.

A

B 9/16 (14)

11−5/8 (295)

Right

1

OPTIONAL

EXTERNAL

SIDE RETURN

AIR FILTER KIT

(Either Side)

9−3/4 (248)

Left

40

(1016)

14−3/4

(375)

16

(406)

AIR FLOW

5/8 (16)

C

*Bottom Return

Air Opening

3/4 (19)

FRONT VIEW SIDE VIEW

1

OPTIONAL

EXTERNAL

SIDE RETURN

AIR FILTER KIT

(Either Side)

5−1/2

(140)

6−1/2

(165)

4−1/8

(103)

6−3/4

(171)

4−7/8 (124) Right

2−1/4 (57) Left

2−1/2

(64)

18-3/4 (476)

6−1/2

(165)

3−1/8

(79)

4

(102)

4−1/4

(108)

SUPPLY AIR

OPENING

23-3/4 (603)

25 (635)

TOP VIEW

28−1/2

(724)

19−7/16

(378)

COMBUSTION AIR INTAKE

(Either Side)

EXHAUST AIR OUTLET

(Either Side)

GAS PIPING INLET

(Either Side)

CONDENSATE

TRAP CONNECTION

(Either Side)

ELECTRICAL INLET

(Either Side)

23

(584)

*OPTIONAL

RETURN CUTOUT

(Either Side)

1−15/16 (49)

23−1/2

(597)

*Bottom Return

Air Opening

9/16

(14)

14**

(356)

Model No.

G61MP−36B−045

G61MP−36B−070

G61MP−36B−071

G61MP−48C−090

G61MP−60C−090

G61MP−60C−091

G61MP−48C−110

G61MP−60C−110

G61MP−60C−111

G61MP−60D−135 24−1/2 622 23−3/8 546 23 584

in. mm in. mm in. mm

17−1/2 446 16−3/8 416 16 406

21 533 19−7/8 505 19−1/2 495

A B C

Page 2

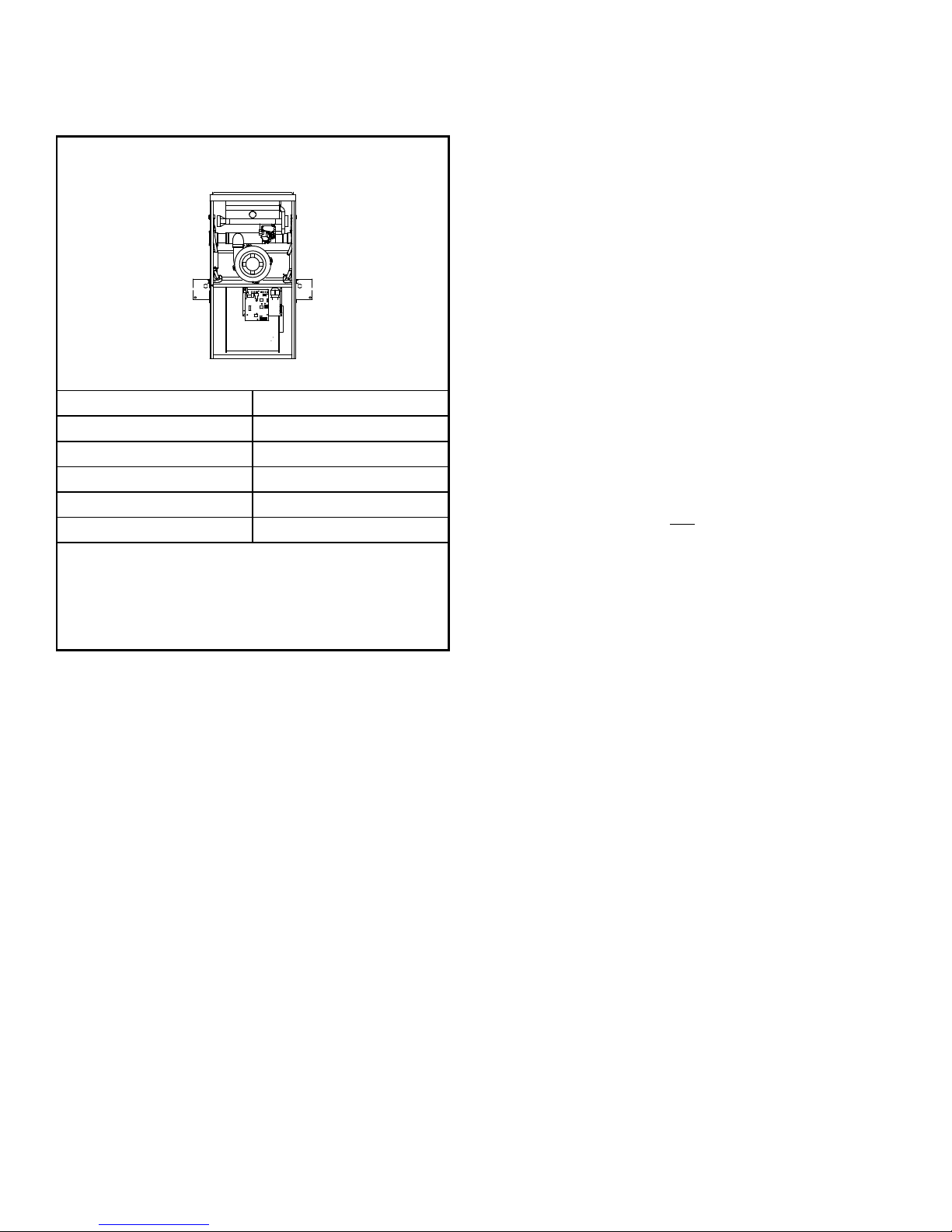

Page 3

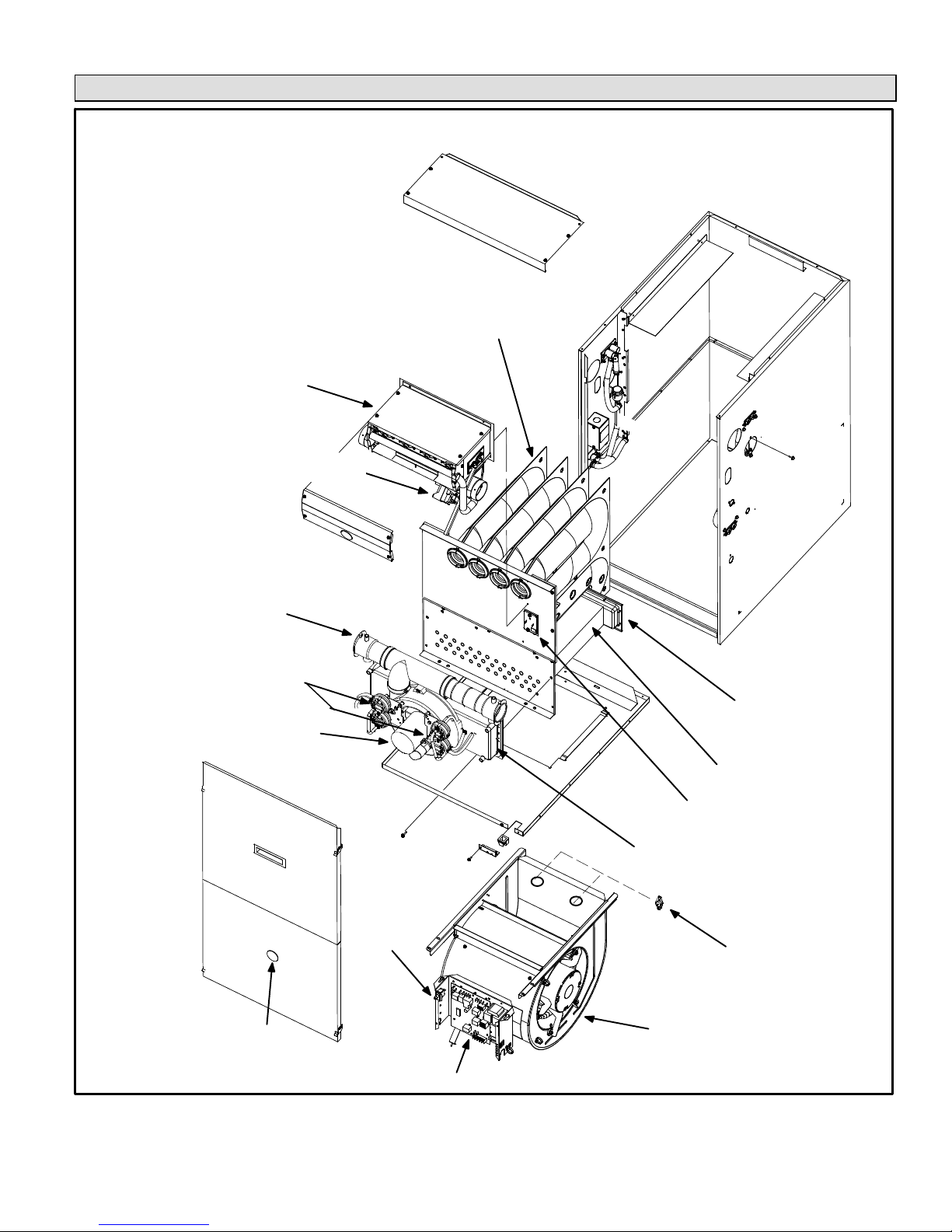

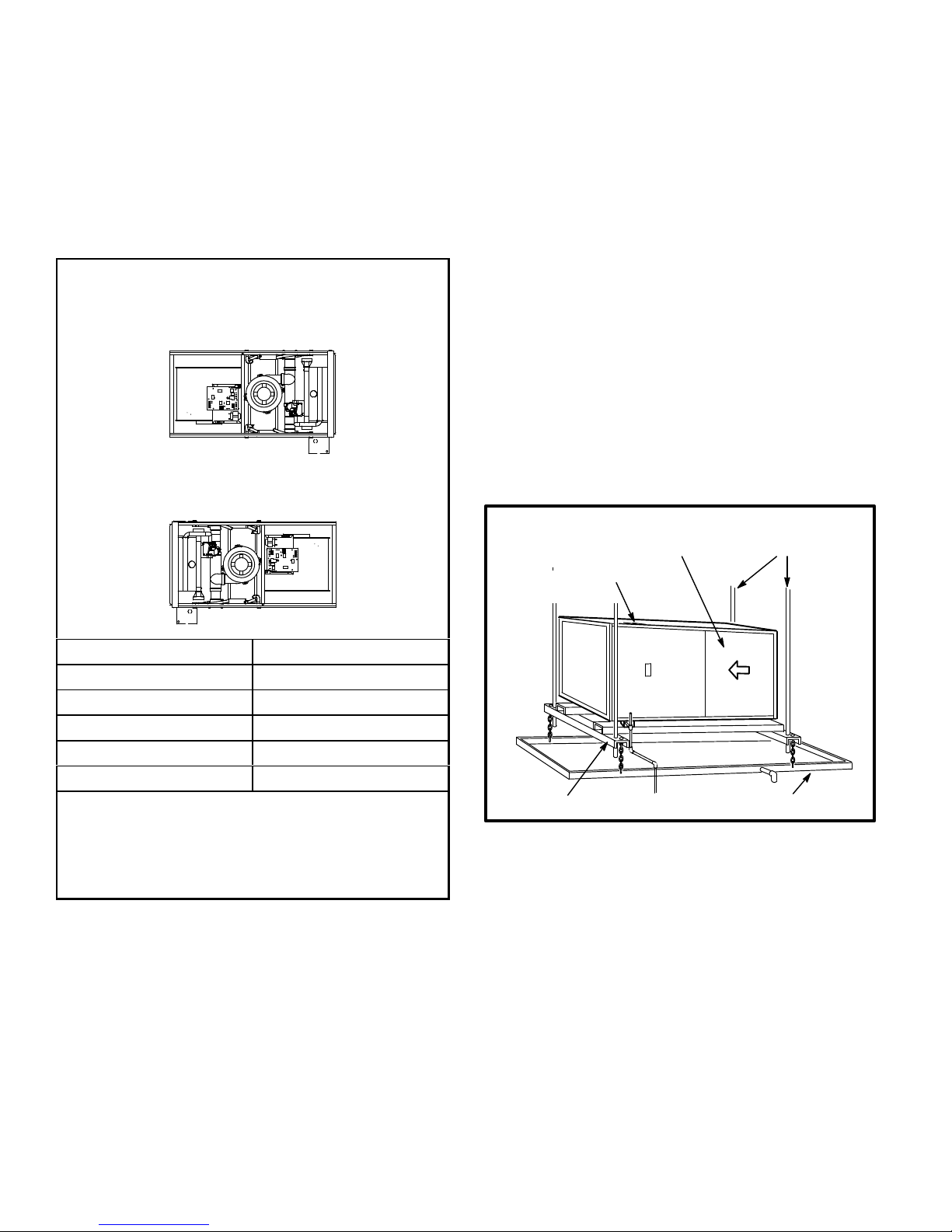

G61MP Parts Arrangement

G61MP PARTS IDENTIFICATION

TOP CAP

BURNER BOX

ASSEMBLY

GAS VALVE

AND MANIFOLD

FLUE

COLLAR

COMBUSTION

AIR PRESSURE

PROVE SWITCHES*

COMBUSTION AIR

INDUCER

DuralokPlus

HEAT EXCHANGER

ASSEMBLY

TM

CABINET

WARM HEADER

(COLLECTOR)

BOX

CONDENSER COIL

BURNER

ACCESS

PANEL

BLOWER

ACCESS

DOOR

*G61MP−090 shown.

G61MP−045 and −070

are equipped with

two switches.

SIGHT

GLASS

DOOR

INTERLOCK

SWITCH

PRIMARY LIMIT

COLD HEADER

(COLLECTOR)

BOX

SECONDARY

LIMITS (2)

BLOWER

ASSEMBLY

CONTROL BOX

FIGURE 1

Page 3

Page 4

G61MP Gas Furnace

The G61MP category IV gas furnace is shipped ready for

installation in the upflow, downflow, horizontal left air discharge or horizontal right air discharge position. The furnace is shipped with the bottom panel in place. The bottom panel must be removed if the unit is to be installed in

upflow applications with bottom return air. The bottom

panel must also be removed and discarded in all downflow

or horizontal applications.

The furnace is equipped for installation in natural gas applications. A conversion kit (ordered separately) is required for use in propane/LP gas applications.

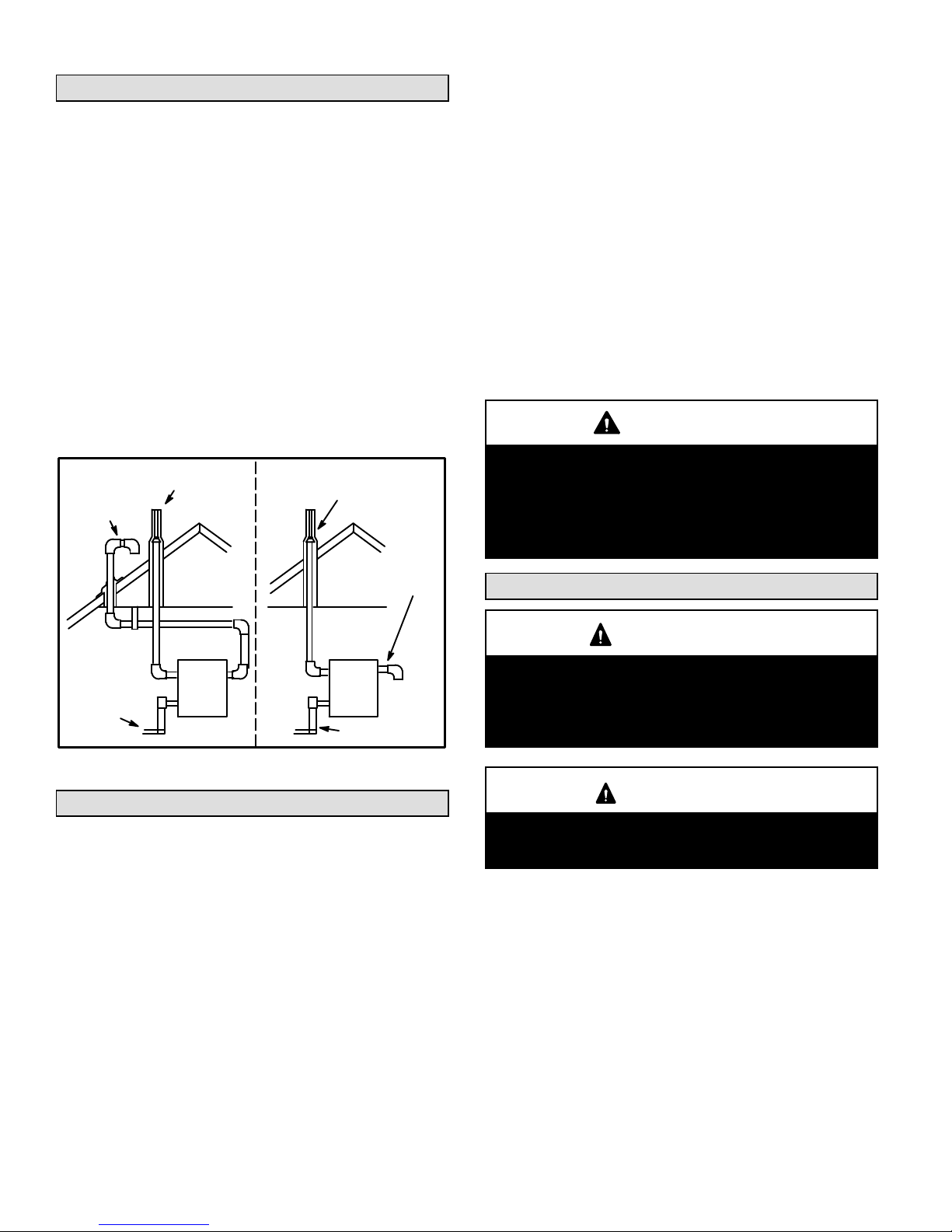

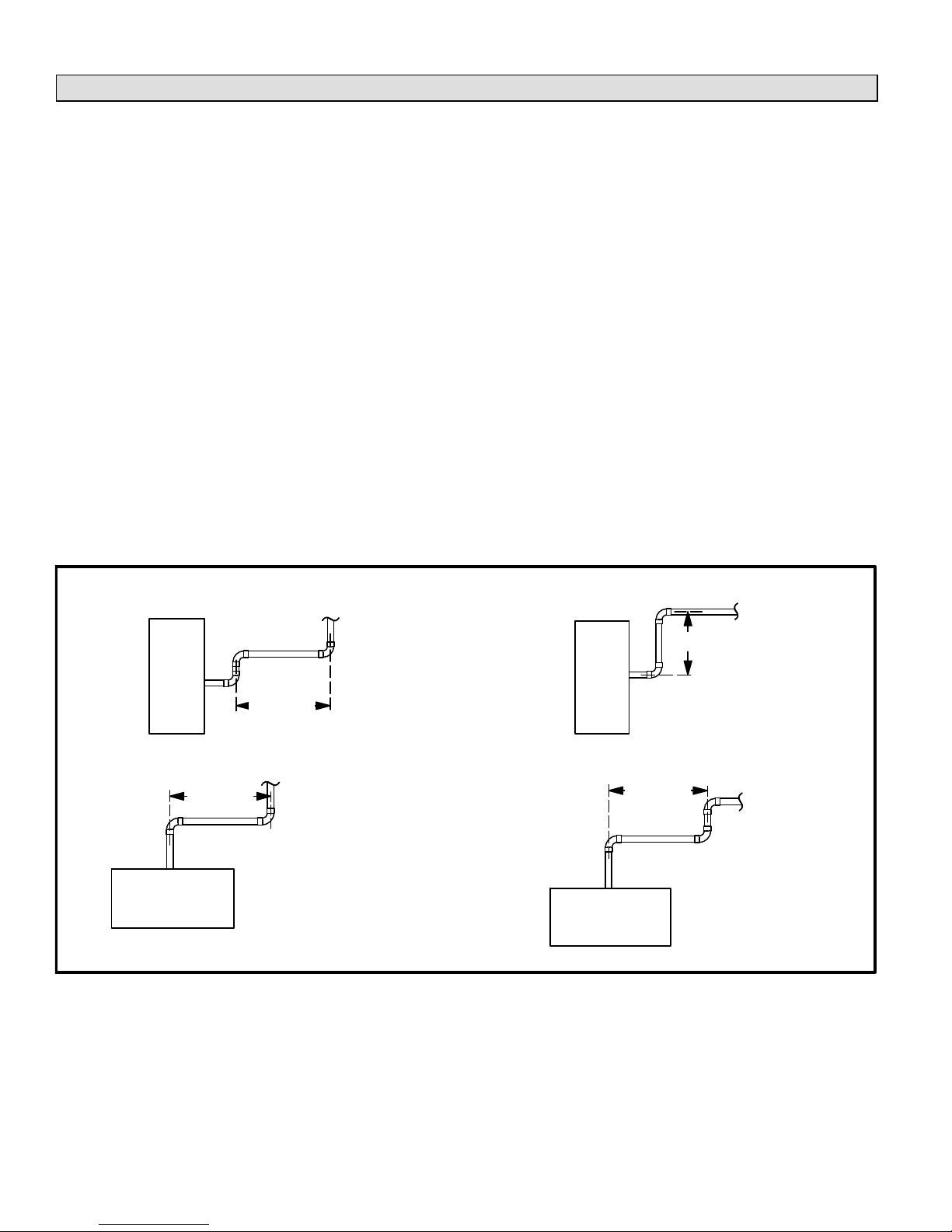

The G61MP can be installed as either a Direct Vent or a

Non−Direct Vent gas central furnace.

NOTE − In Direct Vent installations, combustion air is taken

from outdoors and flue gases are discharged outdoors. In

Non−Direct Vent installations, combustion air is taken from

indoors and flue gases are discharged outdoors. See figure

2 for applications involving roof termination.

DIRECT VENT INSTALLATION NON−DIRECT VENT

COMBUSTION

AIR INTAKE

OUTSIDE OF

HOUSE

EXHAUST

OUTLET

INSTALLATION

EXHAUST

OUTLET

COMBUSTION

AIR INTAKE INSIDE

OF HOUSE

NOTE − G61MP−48C−110, G61MP−60C−110 and

G61MP−60C−111 units also include a 2" diameter PVC

street elbow, which is shipped on the blower deck in the

heating compartment. G61MP−60D−135 units are shipped

with a 3" to 2" PVC reducing elbow.

Canadian Installations Only − Replace the provided 2"

street elbow shipped with the G61MP−48C−110,

G61MP−60C−110 and G61MP−60C−111 units with 2" street

elbow Y0162. Replace the provided 3" X 2" reducing elbow

shipped with the G61MP−60D−135 units with 3" X 2" reducing elbow 40W22. Y0162 and 40W22 meet B149 vent requirements.

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

The following items may also be ordered separately:

1 − Thermostat

1 − Propane/LP changeover kit

DANGER

Danger of explosion.

There are circumstances in which odorant used with

LP/propane gas can lose its scent. In case of a leak,

LP/propane gas will settle close to the floor and may

be difficult to smell. An LP/propane leak detector

should be installed in all LP applications.

Safety Information

G61MP

CONDENSATE

CONDENSATE

DRAIN

G61MP

FIGURE 2

Shipping and Packing List

Package 1 of 1 contains

1 − Assembled G61MP unit

1 − Bag assembly containing the following:

3 − Screws

3 − Wire nuts

1 − Snap bushing

1 − Snap plug

1 − Wire tie

1 − Condensate trap

1 − Condensate trap cap

2 − 2" diameter vent / intake plugs

1 − 3" diameter cabinet plug (intake)

1 − 2" diameter debris screen

1 − Logo sticker (for use in downflow applications)

DRAIN

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a licensed professional installer (or

equivalent), service agency or the gas supplier.

CAUTION

As with any mechanical equipment, personal injury

can result from contact with sharp sheet metal

edges. Be careful when you handle this equipment.

Use only the type of gas approved for use with this furnace.

Refer to unit nameplate.

G61MP units are CSA International certified to ANSI

Z21.47 and CSA 2.3 standards.

In the USA, installation of gas furnaces must conform with local building codes. In the absence of local codes, units must

be installed according to the current National Fuel Gas Code

(ANSI-Z223.1/NFPA 54). The National Fuel Gas Code is

available from the following address:

American National Standards Institute, Inc.

11 West 42nd Street

New York, NY 10036

Page 4

Page 5

In Canada, installation must conform with current National

Standard of Canada CSA-B149 Natural Gas and Propane

Installation Codes, local plumbing or waste water codes

and other applicable local codes.

In order to ensure proper unit operation in non−direct vent

applications, combustion and ventilation air supply must be

provided according to the current National Fuel Gas Code

or CSA-B149 standard.

This furnace is CSA International certified for installation

clearances to combustible material as listed on the unit

nameplate and in the tables in figures 8, 13 and 17. Accessibility and service clearances must take precedence over fire

protection clearances.

NOTE − For installation on combustible floors, the furnace

shall not be installed directly on carpeting, tile, or other

combustible material other than wood flooring.

For installation in a residential garage, the furnace must

be installed so that the burner(s) and the ignition source

are located no less than 18 inches (457 mm) above the

floor. The furnace must be located or protected to avoid

physical damage by vehicles. When a furnace is installed

in a public garage, hangar, or other building that has a hazardous atmosphere, the furnace must be installed according to recommended good practice requirements and current National Fuel Gas Code or CSA B149 standard.

NOTE − Furnace must be adjusted to obtain a temperature

rise within the range specified on the unit nameplate. Failure

to do so may cause erratic limit operation.

This G61MP furnace may be used as a high−static unit

heater. The G61MP may also be installed in an aircraft hangar in accordance with the Standard for Aircraft Hangars

(ANSI/NFPA No. 408−1990).

Installation in parking structures must be in accordance

with the Standard for Parking Structures (ANSI/NFPA No.

88A−1991). Installation in repair garages must be in accordance with the Standard for Repair Garages (ANSI/NFPA

No. 88B−1991).

This G61MP furnace must be installed so that its electrical

components are protected from water.

When this furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of, cooling

units to avoid condensation in the heating compartment.

With a parallel flow arrangement, a damper (or other means

to control the flow of air) must adequately prevent chilled air

from entering the furnace. If the damper is manually operated, it must be equipped to prevent operation of either the

heating or the cooling unit, unless it is in the full HEAT or

COOL setting.

When installed, this furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National Electric

Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following address:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

In Canada, all electrical wiring and grounding for the unit

must be installed according to the current regulations of the

Canadian Electrical Code Part I (CSA Standard C22.1)

and/or local codes.

NOTE − This furnace is designed for a minimum continuous return air temperature of 60°F (16°C) or an intermittent operation down to 55°F (13°C) dry bulb for cases

where a night setback thermostat is used. Return air temperature must not exceed 85°F (29°C) dry bulb.

The G61MP furnace may be installed in alcoves, closets,

attics, basements, garages, and utility rooms.

This furnace design has not been CSA certified for installation in mobile homes, recreational vehicles, or outdoors.

Never use an open flame to test for gas leaks. Check all

connections using a commercially available soap solution

made specifically for leak detection.

Use of Furnace as Construction Heater

Lennox does not recommend the use of G61MP units as a

construction heater during any phase of construction. Very

low return air temperatures, harmful vapors and operation

of the unit with clogged or misplaced filters will damage the

unit.

G61MP units may be used for heating of buildings or structures under construction, if the following conditions are

met:

D The vent system must be permanently installed per

these installation instructions.

D A room thermostat must control the furnace. The use of

fixed jumpers that will provide continuous heating is not

allowed.

D The return air duct must be provided and sealed to the

furnace.

D Return air temperature range between 60°F (16°C) and

80°F (27°C) must be maintained.

D Air filters must be installed in the system and must be

maintained during construction.

D Air filters must be replaced upon construction comple-

tion.

D The input rate and temperature rise must be set per the

furnace rating plate.

Page 5

Page 6

D One hundred percent (100%) outdoor air must be pro-

vided for combustion air requirements during construction. Temporary ducting may supply outdoor air to the

furnace. Do not connect duct directly to the furnace.

Size the temporary duct following these instructions in

section for Combustion, Dilution and Ventilation Air in a

confined space with air from outside.

D The furnace heat exchanger, components, duct system,

air filters and evaporator coils must be thoroughly

cleaned following final construction clean−up.

D All furnace operating conditions (including ignition, in-

put rate, temperature rise and venting) must be verified

according to these installation instructions.

CAUTION

G61MP unit should not be installed in areas normally

subject to freezing temperatures.

Combustion, Dilution & Ventilation Air

If the G61MP is installed as a Non−Direct Vent Furnace, follow the guidelines in this section.

NOTE − In Non−Direct Vent installations, combustion air

is taken from indoors and flue gases are discharged out−

doors.

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

In addition to the requirements outlined previously, the following general recommendations must be considered

when installing a G61MP furnace:

• Place the furnace as close to the center of the air distribution system as possible. The furnace should also be

located close to the chimney or vent termination point.

• When the furnace is installed in non−direct vent applications, do not install the furnace where drafts might blow

directly into it. This could cause improper combustion

and unsafe operation.

• When the furnace is installed in non−direct vent applications, do not block the furnace combustion air opening

with clothing, boxes, doors, etc. Air is needed for proper

combustion and safe unit operation.

• When the furnace is installed in an attic or other insulated space, keep insulation away from the furnace.

• When the furnace is installed in an unconditioned

space, consider provisions required to prevent freezing

of condensate drain system.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool. Breathing this may cause lung

cancer. (Fiberglass wool is known to the State of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

WARNING

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rusting and premature heat exchanger failure. Excessive

exposure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substances in the combustion air supply:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine base swimming pool chemicals

Water softening chemicals

De−icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

In the past, there was no problem in bringing in sufficient

outdoor air for combustion. Infiltration provided all the air

that was needed. In today’s homes, tight construction

practices make it necessary to bring in air from outside

for combustion. Take into account that exhaust fans, appliance vents, chimneys, and fireplaces force additional

air that could be used for combustion out of the house.

Unless outside air is brought into the house for combustion, negative pressure (outside pressure is greater than

inside pressure) will build to the point that a downdraft

can occur in the furnace vent pipe or chimney. As a result,

combustion gases enter the living space creating a potentially dangerous situation.

In the absence of local codes concerning air for combus−

tion and ventilation, use the guidelines and procedures in

this section to install G61MP furnaces to ensure efficient

and safe operation. You must consider combustion air

needs and requirements for exhaust vents and gas piping. A portion of this information has been reprinted with

permission from the National Fuel Gas Code (ANSI−

Page 6

Page 7

Z223.1/NFPA 54). This reprinted material is not the complete and official position of the ANSI on the referenced

subject, which is represented only by the standard in its

entirety.

In Canada, refer to the standard CSA B149 installation

codes.

CAUTION

Do not install the furnace in a corrosive or contaminated atmosphere. Meet all combustion and ventilation air requirements, as well as all local codes.

All gas-fired appliances require air for the combustion process. If sufficient combustion air is not available, the furnace or other appliance will operate inefficiently and unsafely. Enough air must be provided to meet the needs of all

fuel−burning appliances and appliances such as exhaust

fans which force air out of the house. When fireplaces, exhaust fans, or clothes dryers are used at the same time as

the furnace, much more air is required to ensure proper

combustion and to prevent a downdraft. Insufficient air

causes incomplete combustion which can result in carbon

monoxide.

In addition to providing combustion air, fresh outdoor air dilutes contaminants in the indoor air. These contaminants

may include bleaches, adhesives, detergents, solvents

and other contaminants which can corrode furnace components.

The requirements for providing air for combustion and ventilation depend largely on whether the furnace is installed in

an unconfined or a confined space.

Unconfined Space

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 50 cubic

feet (1.42 m3) per 1,000 Btu (.29 kW) per hour of the combined input rating of all appliances installed in that space.

This space also includes adjacent rooms which are not

separated by a door. Though an area may appear to be unconfined, it might be necessary to bring in outdoor air for

combustion if the structure does not provide enough air by

infiltration. If the furnace is located in a building of tight

construction with weather stripping and caulking around

the windows and doors, follow the procedures in the air

from outside section.

Confined Space

A confined space is an area with a volume less than 50 cubic

feet (1.42 m3) per 1,000 Btu (.29 kW) per hour of the com−

bined input rating of all appliances installed in that space. This

definition includes furnace closets or small equipment rooms.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the furnace, the return air must be handled by ducts

which are sealed to the furnace casing and which terminate

outside the space containing the furnace. This is especially

important when the furnace is mounted on a platform in a

confined space such as a closet or small equipment room.

Even a small leak around the base of the unit at the platform

or at the return air duct connection can cause a potentially

dangerous negative pressure condition. Air for combustion

and ventilation can be brought into the confined space either from inside the building or from outside.

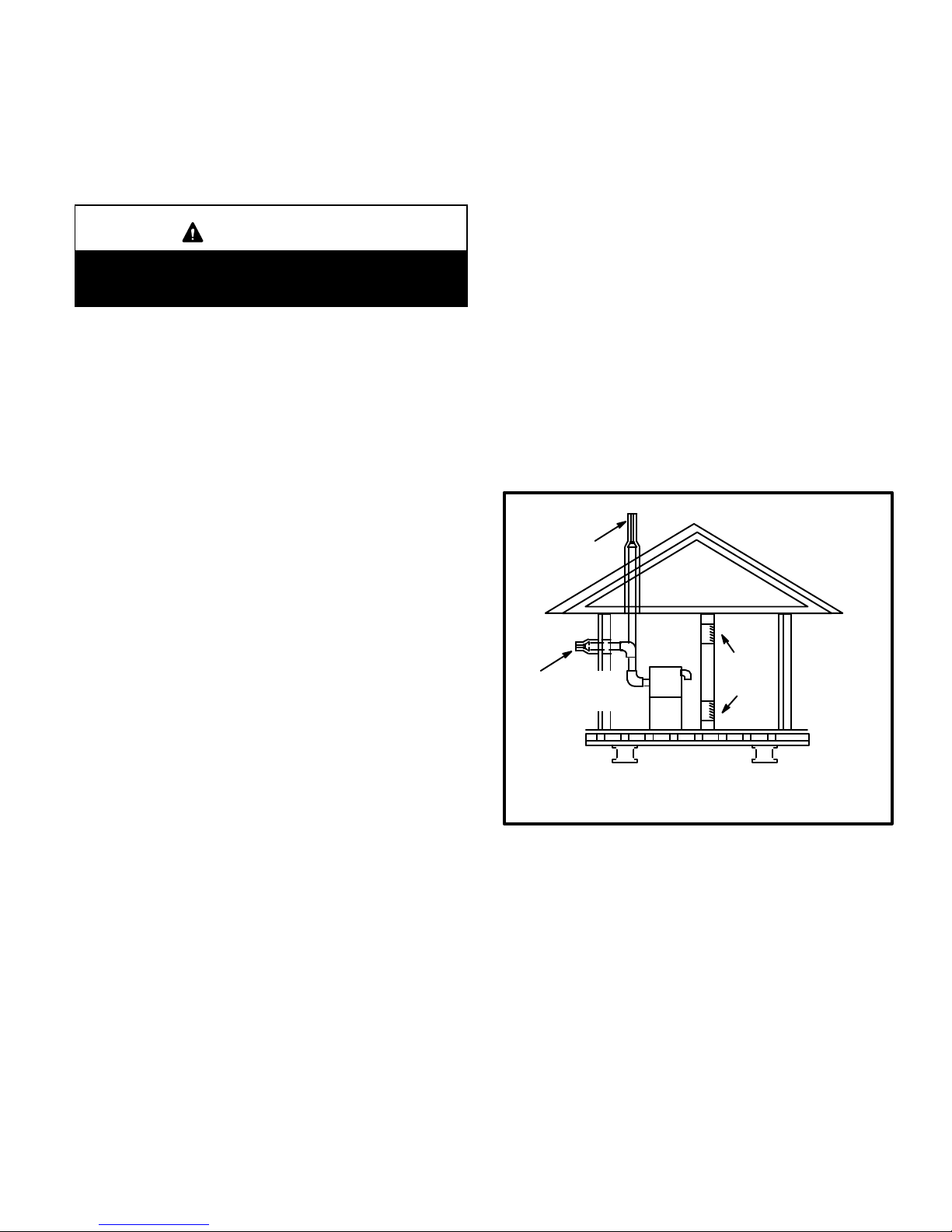

Air from Inside

If the confined space that houses the furnace adjoins a

space categorized as unconfined, air can be brought in by

providing two permanent openings between the two

spaces. Each opening must have a minimum free area of 1

square inch (645 mm2) per 1,000 Btu (.29 kW) per hour of

total input rating of all gas−fired equipment in the confined

space. Each opening must be at least 100 square inches

(64516 mm2). One opening shall be within 12 inches (305

mm) of the top of the enclosure and one opening within 12

inches (305 mm) of the bottom. See figure 3.

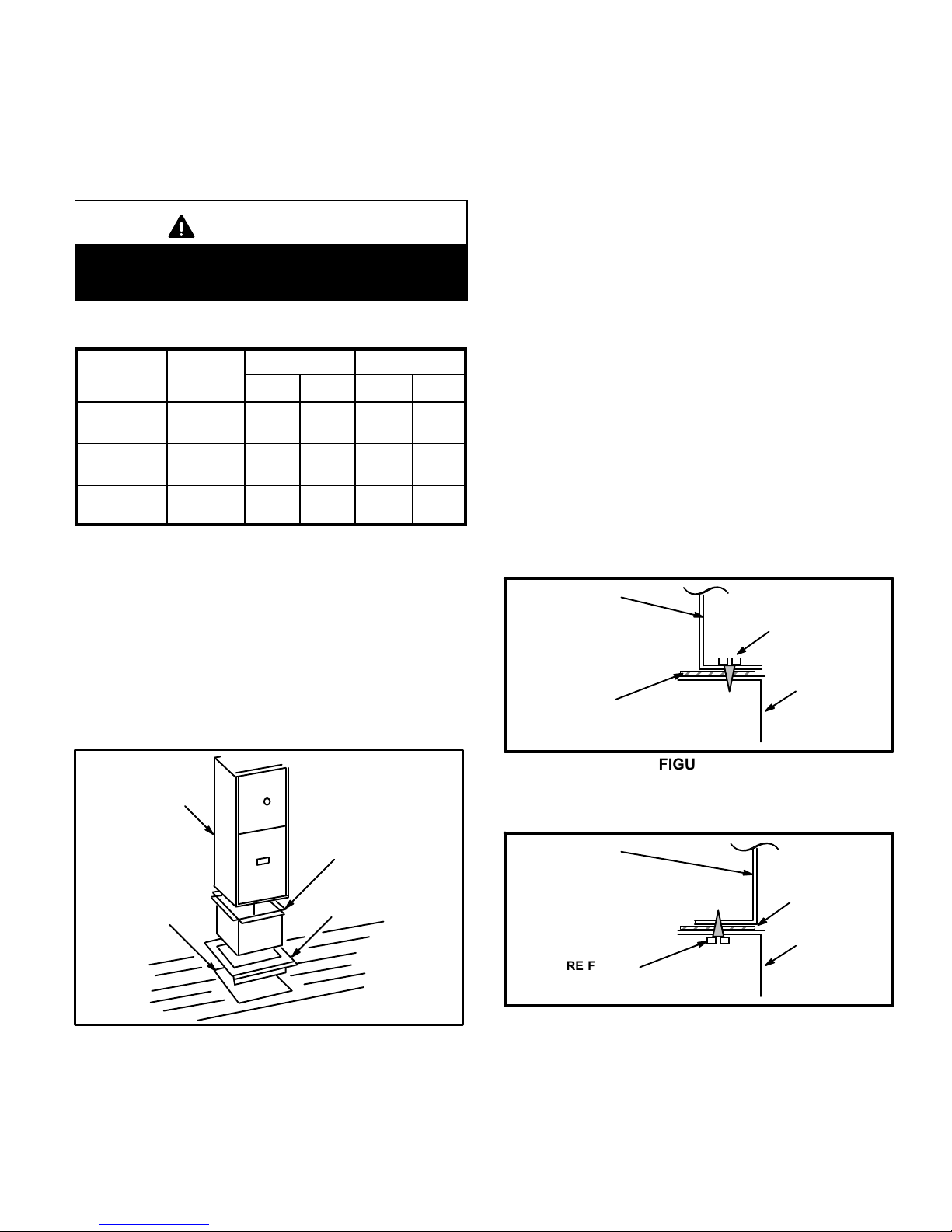

EQUIPMENT IN CONFINED SPACE − ALL AIR FROM INSIDE

ROOF TERMINATED

EXHAUST PIPE

OPENINGS

SIDE WALL

TERMINATED EX-

HAUST PIPE (ALTER-

NATE LOCATION)

NOTE − Each opening shall have a free area of at least one square

inch per 1,000 Btu (645mm

rating of all equipment in the enclosure, but not less than 100 square

inches (64516mm.

G61MP

2

2).

(To Adjacent

Unconfined

Space)

per .29kW) per hour of the total input

FIGURE 3

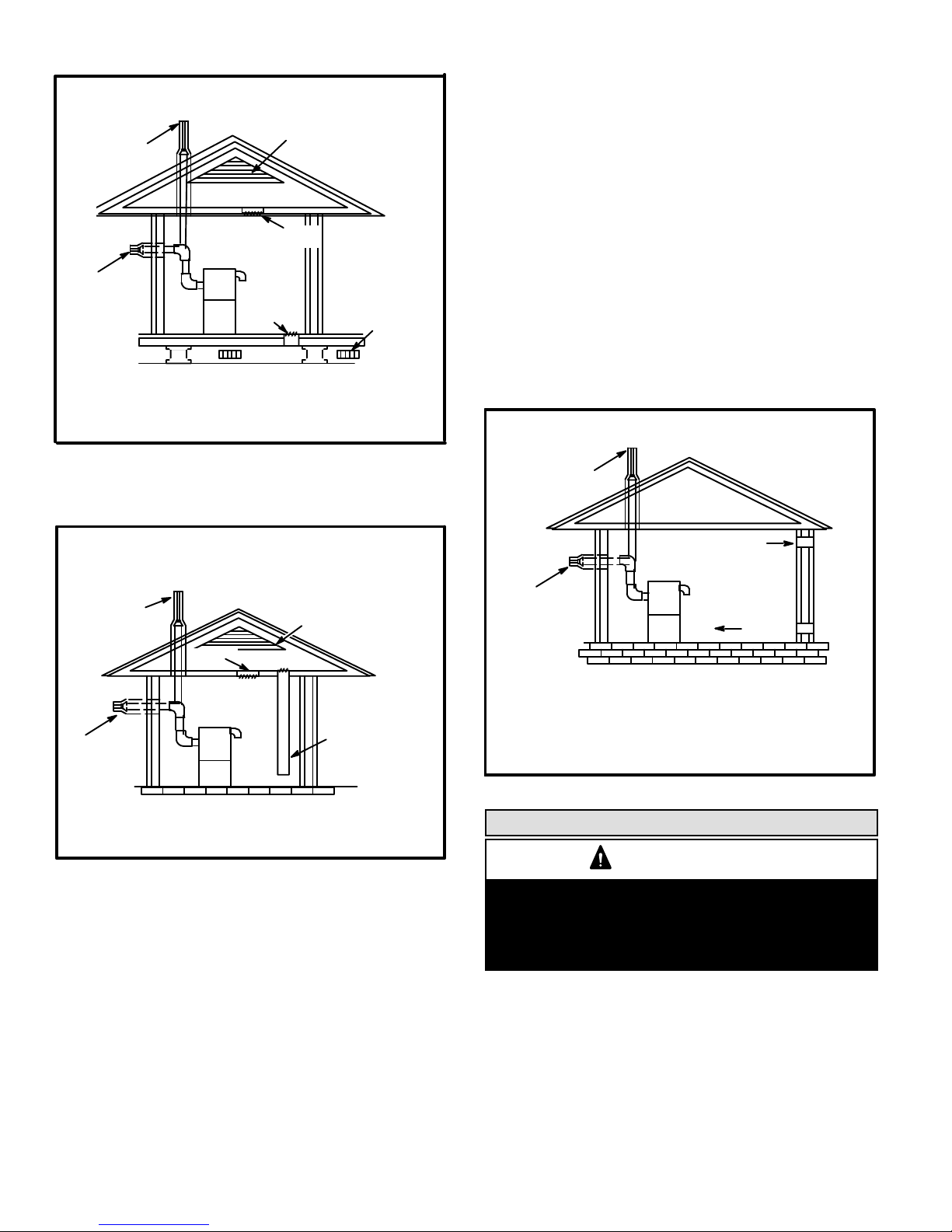

Air from Outside

If air from outside is brought in for combustion and ventilation, the confined space shall be provided with two permanent openings. One opening shall be within 12" (305mm)

of the top of the enclosure and one within 12" (305mm) of

the bottom. These openings must communicate directly

or by ducts with the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors or indirectly

through vertical ducts. Each opening shall have a minimum free area of 1 square inch per 4,000 Btu (645mm

per 1.17kW) per hour of total input rating of all equipment

in the enclosure. When communicating with the outdoors

through horizontal ducts, each opening shall have a minimum free area of 1 square inch per 2,000 Btu (645mm

per .59kW) per total input rating of all equipment in the enclosure (See figure 4).

2

2

Page 7

Page 8

EQUIPMENT IN CONFINED SPACE − ALL AIR FROM OUTSIDE

(Inlet Air from Crawl Space and Outlet Air to Ventilated Attic)

VENTILATION LOUVERS

OUTLET

AIR

(Each end of attic)

VENTILATION

LOUVERS

(For unheated

crawl space)

2

per 1.17kW) per

ROOF TERMINATED

EXHAUST PIPE

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

NOTE−The inlet and outlet air openings shall each have a free area

of at least one square inch per 4,000 Btu (645mm

hour of the total input rating of all equipment in the enclosure.

G61MP

INLET

AIR

FIGURE 4

in the enclosure. See figures 4 and 5. When communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 square inch (645

mm2) per 2,000 Btu (.56 kW) per total input rating of all

equipment in the enclosure. See figure 6.

When ducts are used, they shall be of the same cross−sectional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3 inches (75 mm). In calculating free

area, the blocking effect of louvers, grilles, or screens

must be considered. If the design and free area of protective covering is not known for calculating the size opening

required, it may be assumed that wood louvers will have

20 to 25 percent free area and metal louvers and grilles

will have 60 to 75 percent free area. Louvers and grilles

must be fixed in the open position or interlocked with the

equipment so that they are opened automatically during

equipment operation.

EQUIPMENT IN CONFINED SPACE −

ALL AIR FROM OUTSIDE

ROOF TERMINATED

EXHAUST PIPE

EQUIPMENT IN CONFINED SPACE − ALL AIR FROM OUTSIDE

ROOF TERMINATED

EXHAUST PIPE

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

NOTE−The inlet and outlet air openings shall each have a free area of

at least one square inch per 4,000 Btu (645mm

of the total input rating of all equipment in the enclosure.

(All Air Through Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

OUTLET

AIR

G61MP

2

per 1.17kW) per hour

INLET AIR

(Ends 12" above

bottom)

FIGURE 5

If air from outside is brought in for combustion and ventilation, the confined space must have two permanent openings. One opening shall be within 12 inches (305 mm) of

the top of the enclosure and one opening within 12 inches

(305 mm) of the bottom. These openings must communicate directly or by ducts with the outdoors or spaces (crawl

or attic) that freely communicate with the outdoors or indirectly through vertical ducts. Each opening shall have a

minimum free area of 1 square inch (645 mm2) per 4,000

Btu (1.17 kW) per hour of total input rating of all equipment

OUTLET AIR

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

NOTE−Each air duct opening shall have a free area of at least one

square inch per 2,000 Btu (645mm

input rating of all equipment in the enclosure. If the equipment room

is located against an outside wall and the air openings communicate directly with the outdoors, each opening shall have a free area

of at least 1 square inch per 4,000 Btu (645mm

hour of the total input rating of all other equipment in the enclosure.

G61MP

2

per .59kW) per hour of the total

INLET AIR

2

per 1.17kW) per

FIGURE 6

Installation − Setting Equipment

WARNING

Do not install the furnace on its front or its back. Do

not connect the return air ducts to the back of the furnace. Doing so will adversely affect the operation of

the safety control devices, which could result in personal injury or death.

Select a location that allows for the required clearances

that are listed on the unit nameplate. Also consider gas

supply connections, electrical supply, vent connection,

condensate trap and drain connections, and installation

and service clearances [24 inches (610 mm) at unit

front].

Page 8

Page 9

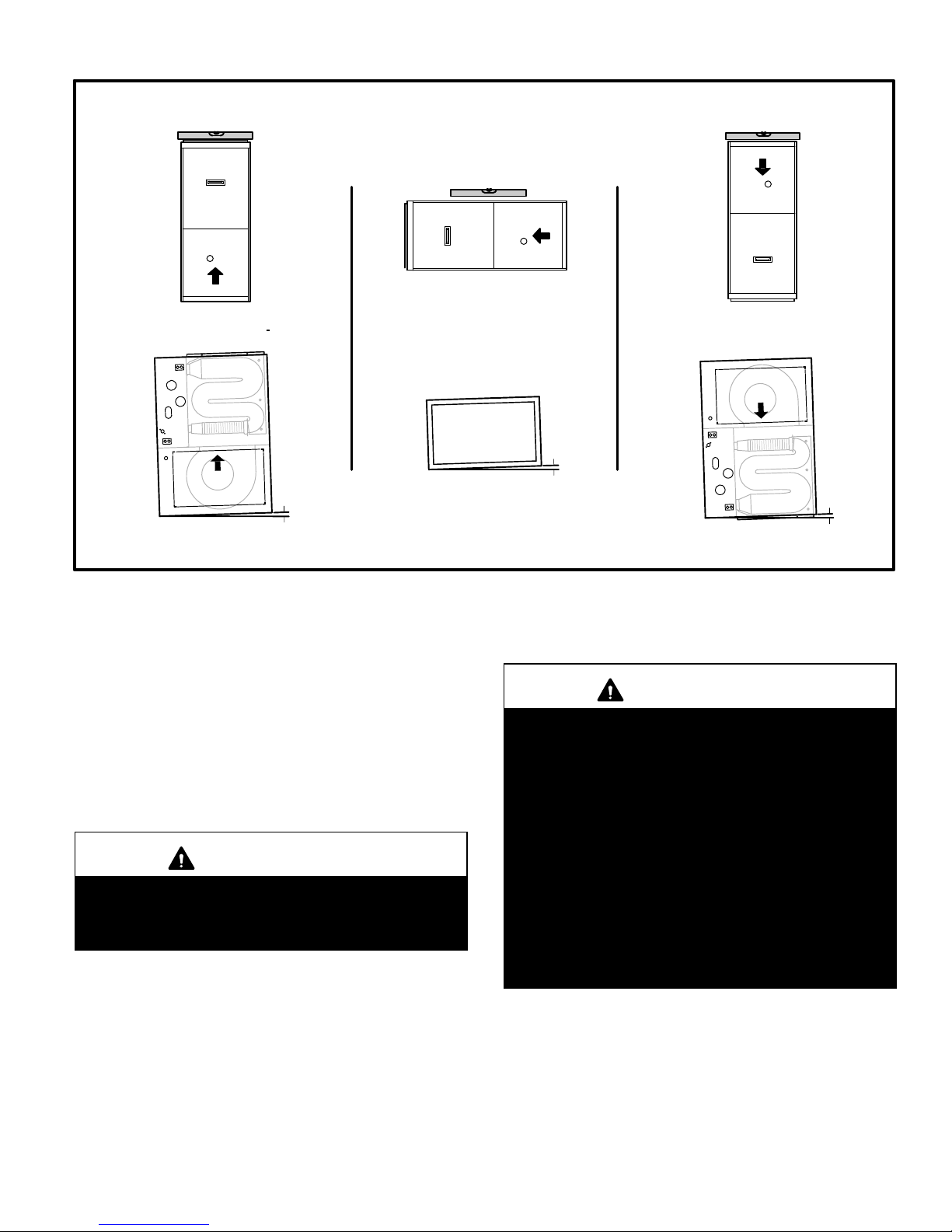

SETTING EQUIPMENT

UPFLOW APPLICATION DOWNFLOW APPLICATION

AIR FLOW

UNIT MUST BE LEVEL SIDE−TO−SIDE IN ALL APPLICATIONS.

AIR FLOW

HORIZONTAL APPLICATION

AIR FLOW

UNIT

FRONT

FRONT VIEW

AIR FLOW

SIDE VIEW

UNIT

FRONT

1/2"

max.

UNIT SHOULD BE LEVEL FROM LEFT TO RIGHT BUT MAY BE

TILTED SLIGHTLY (MAX. 1/2") FROM BACK TO FRONT

TO AID IN THE DRAINING OF THE HEAT EXCHANGER.

FRONT VIEW

The unit must be level from side to side. The unit may be

tilted slightly (maximum 1/2 in.) from back to front to aid

in the draining of the heat exchanger. See figure 7.

NOTE − Units with 1/2 hp blower motors are equipped with

three flexible legs and one rigid leg. The rigid leg is

equipped with a shipping bolt and a flat white plastic washer (rather than the rubber mounting grommet used with a

flexible mounting leg). The bolt and washer must be re-

moved before the furnace is placed into operation. After the bolt and washer have been removed, the rigid leg

will not touch the blower housing.

WARNING

Blower access panel must be securely in place when

blower and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into

living space resulting in personal injury or death.

END VIEW

FIGURE 7

Allow for clearances to combustible materials as indicated

on the unit nameplate. Minimum clearances for closet or alcove installations are shown in figures 8, 13 and 17.

Improper installation of the furnace can result in personal injury or death. Combustion and flue products

must never be allowed to enter the return air system

or air in the living space. Use sheet metal screws and

joint tape to seal return air system to furnace.

In platform installations with furnace return, the furnace should be sealed airtight to the return air plenum. A door must never be used as a portion of the

return air duct system. The base must provide a

stable support and an airtight seal to the furnace. Allow absolutely no sagging, cracks, gaps, etc.

For no reason should return and supply air duct systems ever be connected to or from other heating devices such as a fireplace or stove, etc. Fire, explosion, carbon monoxide poisoning, personal injury

and/or property damage could result.

1/2"

max.

FRONT VIEW

AIR FLOW

UNIT

FRONT

SIDE VIEW

WARNING

1/2"

max.

Page 9

Page 10

Upflow Applications

The G61MP gas furnace can be installed as shipped in

the upflow position. Refer to figure 8 for clearances.

Installation Clearances

Top

Left Side

Bottom (Floor)

Top/Plenum 1 in. (25 mm)

*Front 0

Back 0

Sides 0†

Vent 0

Floor 0‡

*Front clearance in alcove installation must be 24 in. (610 mm).

Maintain a minimum of 24 in. (610 mm) for front service access.

†Allow proper clearances to accommodate condensate trap and

vent pipe installation.

‡For installations on a combustible floor, do not install the furnace

directly on carpeting, tile or other combustible materials other

than wood flooring.

FIGURE 8

Right Side

Return Air −− Upflow Units

Return air can be brought in through the bottom or either

side of the furnace installed in an upflow application. If the

furnace is installed on a platform with bottom return, make

an airtight seal between the bottom of the furnace and the

platform to ensure that the furnace operates properly and

safely. The furnace is equipped with a removable bottom

panel to facilitate installation.

Markings are provided on both sides of the furnace cabinet

for installations that require side return air. Cut the furnace

cabinet at the maximum dimensions shown on page 2.

NOTE − When air volumes over 1800 cfm (850 L/s) are

required with 60C or 60D models in an upflow application, the following return air options are available:

1 − Return air from single side with transition which will

accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) air filter.

(Required to maintain proper air velocity.) See figure 10.

2 − Return air from single side with optional RAB Return

Air Base. See figure 9.

3 − Return air from bottom.

4 − Return air from both sides.

5 − Return air from bottom and

one side.

Refer to Engineering Handbook for additional information.

Page 10

Page 11

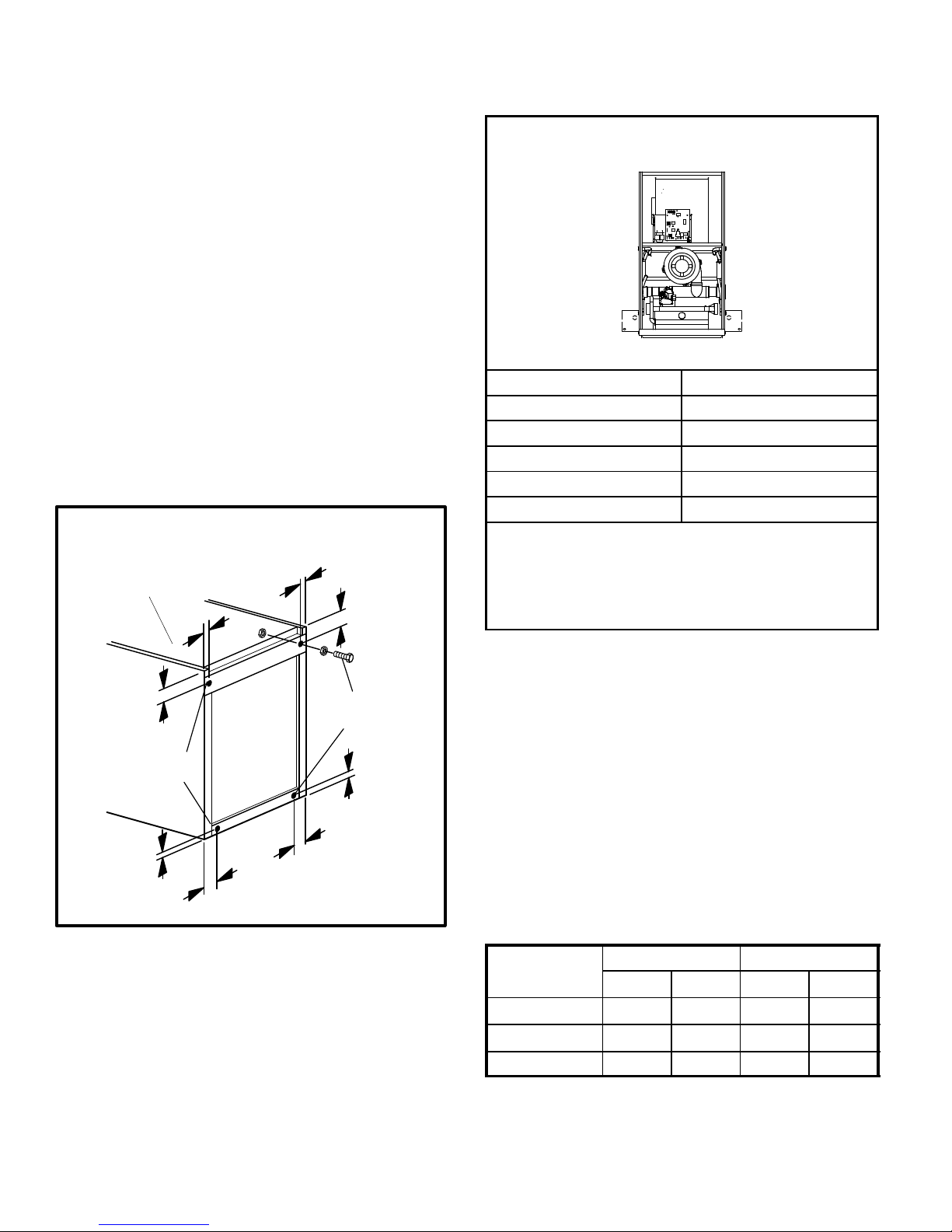

(Upflow Applications Only −− For use with B, C and D cabinets only)

AIR FLOW

FURNACE

7−1/4 (184)

Optional Return Air Base

4

(102)

14

(356)

FRONT

1

23 (584)

Overall

(Maximum)

1

Unit side return air

Opening

5−5/8

(143)

SIDE RETURN

AIR OPENINGS

(Either Side)

1

Minimum

11 (279)

2

Maximum

14 (356)

1

22−7−16

(570)

Overall

(Maximum)

17−1/2 (446) RAB−B (98M60)

21 (533) RAB−C (98M58)

24−1/2 (622) RAB−D (98M59)

OPTIONAL RAB

RETURN AIR BASE

7/8

(22)

23 (584)

27−5/8 (702)

SIDE VIEW

FRONT VIEW

NOTE− Optional Side Return Air Filter Kits are not for use with RAB Return Air Base.

1

Both the unit return air opening and the base return air opening must be covered by a single plenum or IAQ cabinet.

Minimum unit side return air opening dimensions for units requiring 1800 cfm or more of air (W x H): 23 x 11 in.

(584 x 279 mm).

The opening can be cut as needed to accommodate plenum or IAQ cabinet while maintaining dimensions shown.

Side return air openings must be cut in the field. There are cutting guides stenciled on the cabinet for the side return

air opening. The size of the opening must not extend beyond the markings on the furnace cabinet.

2

To minimize pressure drop, the largest opening height possible (up to 14 inches) is preferred.

NOTE− Optional Side Return Air Filter Kits are not for use with RAB Return Air Base.

FIGURE 9

G61MP applications which include side return air and

a condensate trap installed on the same side of the

cabinet require either a return air base or field−fabricated transition to accommodate an optional IAQ accessory taller than 14.2".

Side Return Air

Remove the two screws that secure the bottom cap to the

furnace. Pivot the bottom cap down to release the bottom

panel. Once the bottom panel has been removed, reinstall

the bottom cap. See figure 11.

Removing the Bottom Panel

Removing the Bottom Panel

(with transition and filter)

3/4

(19)

20" X 25" X 1"

(508mm X635mm X 25mm)

Return

Air

Plenum

Transition

FIGURE 10

Air Filter

Screw

Bottom Cap

Bottom Panel

FIGURE 11

Page 11

Page 12

Setting an Upflow Unit

When the side return air inlets are used in an upflow application, it may be necessary to install leveling bolts on the

bottom of the furnace. Use field−supplied corrosion−resistant 5/16 inch machine bolts (4) and nuts (8). See figure 12.

NOTE − The maximum length of the bolt is 1−1/2 inches.

1 − Lie the furnace on its back and drill a 5/16 inch diame-

ter hole in each corner of the furnace’s bottom. See figure 12 for the correct location of the holes. Drill through

the bottom panel and the bottom flange of the cabinet.

2 − Install one bolt and two nuts into each hole. Screw the

first nut onto a bolt and then insert the bolt into a hole. A

flat washer may be added between the nut and the bottom of the unit.

3 − Screw another nut onto the bolt on the inside of the fur-

nace base. A flat washer may be added between the

nut and the bottom of the unit.

4 − Adjust the outside nut to the appropriate height and

tighten the inside nut to secure the arrangement.

NOTE − The unit may be tilted back−to−front a maximum of

1". This will ensure proper draining of the heat exchanger.

Leveling Bolt Installation

Inches (mm)

3/8

(10)

Furnace Front

3/8

(10)

1−3/4

(44)

Furnace

1−3/4

(44)

Leveling Bolt

Locations

Bottom

Leveling Bolt

Locations

3/8

(10)

1−3/4

(44)

1−3/4 (44)

3/8

(10)

FIGURE 12

Downflow Applications

The unit may be installed three ways in downflow applications: on non−combustible flooring, on combustible flooring

using an additive base, or on a reverse−flow cooling cabinet. Do not drag the unit across the floor in the down-

flow position. Flange damage will result.

After unit has been properly set in place, position provided

logo over existing logo and affix sticker on front panel.

Refer to figure 13 for clearances in downflow applications.

Downflow Application Installation Clearances

Top

Left Side

Bottom

Top 0

*Front 0

Back 0

Sides 0†

Vent 0

Floor NC‡

*Front clearance in alcove installation must be 24 in. (610 mm).

Maintain a minimum of 24 in. (610 mm) for front service access.

†Allow proper clearances to accommodate condensate trap and

vent pipe installation.

‡The furnace may be installed on a combustible wood floor if an optional additive base is installed between the furnace and the combustible floor.

Right Side

FIGURE 13

Installation on Non−Combustible Flooring

1 − Cut floor opening keeping in mind clearances listed on

unit rating plate. Also keep in mind gas supply connections, electrical supply, flue and air intake connections

and sufficient installation and servicing clearances.

See table 1 for correct floor opening size.

2 − Flange warm air plenum and lower the plenum into the

opening.

3 − Set the unit over the plenum and seal the plenum to

the unit.

4 − Ensure that the seal is adequate.

TABLE 1

NON−COMBUSTIBLE FLOOR OPENING SIZE

Model No.

B Cabinet (17.5") 19 − 3/4 502 16 − 5/8 422

C Cabinet (21") 19 − 3/4 502 20−1/8 511

D Cabinet (24.5") 19 − 3/4 502 23 − 5/8 600

NOTE − Floor opening dimensions listed are 1/4 inch (6 mm) larger than

the unit opening. See dimension drawing on page 2.

Front to Rear Side to Side

in. mm in. mm

Page 12

Page 13

Installation on Combustible Flooring

(Using an Additive Base)

1 − When unit is installed on a combustible floor, an addi-

tive base must be installed between the furnace and

the floor. The base must be ordered separately. See

table 2 for opening size to cut in floor.

CAUTION

The furnace and additive base shall not be installed

directly on carpeting, tile, or other combustible material other than wood flooring.

TABLE 2

ADDITIVE BASE FLOOR OPENING SIZE

Cabinet

Width

B Cabinet

(17.5")

C Cabinet

(21")

D Cabinet

(24.5")

Catalog

Number

11M60

11M61

11M62

2 − After opening is cut, set additive base into opening.

3 − Check fiberglass strips on additive base to make sure

they are properly glued and positioned.

4 − Lower supply air plenum into additive base until ple-

num flanges seal against fiberglass strips.

NOTE − Be careful not to damage fiberglass strips.

Check for a tight seal.

5 − Set the furnace over the plenum.

6 − Ensure that the seal between the furnace and plenum

is adequate.

Front to Rear Side to Side

in. mm in. mm

22 559 18 − 3/4 476

22 559 22 − 3/4 578

22 559 25 − 3/4 654

Installation on Cooling Coil Cabinet

1 − Refer to reverse−flow coil installation instructions for

correctly sized opening in floor and installation of cabinet.

2 − When cooling cabinet is in place, set and secure the

furnace according to the instructions that are provided

with the cooling coil. Secure the furnace to the cabinet.

3 − Seal the cabinet and check for air leaks.

Return Air Opening −− Downflow Units

Return air may be brought in only through the top opening

of a furnace installed in the downflow position.The following steps should be taken when installing plenum:

1 − Bottom edge of plenum should be flanged with a

hemmed edge (See figure 15 or 16).

2 − Sealing strips should be used to ensure an airtight seal

between the cabinet and the plenum.

3 − In all cases, plenum should be secured to top of fur-

nace using sheet metal screws.

4 − Make certain that an adequate seal is made.

PLENUM

(Field Provided)

SEALING STRIP

(Field Provided)

SECURE FROM

OUTSIDE CABINET

CABINET

SIDE PANEL

Side View

G61MP UNIT

PROPERLY

SIZED FLOOR

OPENING

FIGURE 14

SUPPLY AIR PLENUM

ADDITIVE BASE

Page 13

PLENUM

(Field Provided)

SECURE FROM

INSIDE CABINET

FIGURE 15

SEALING STRIP

(Field Provided)

CABINET

SIDE PANEL

Side View

FIGURE 16

Page 14

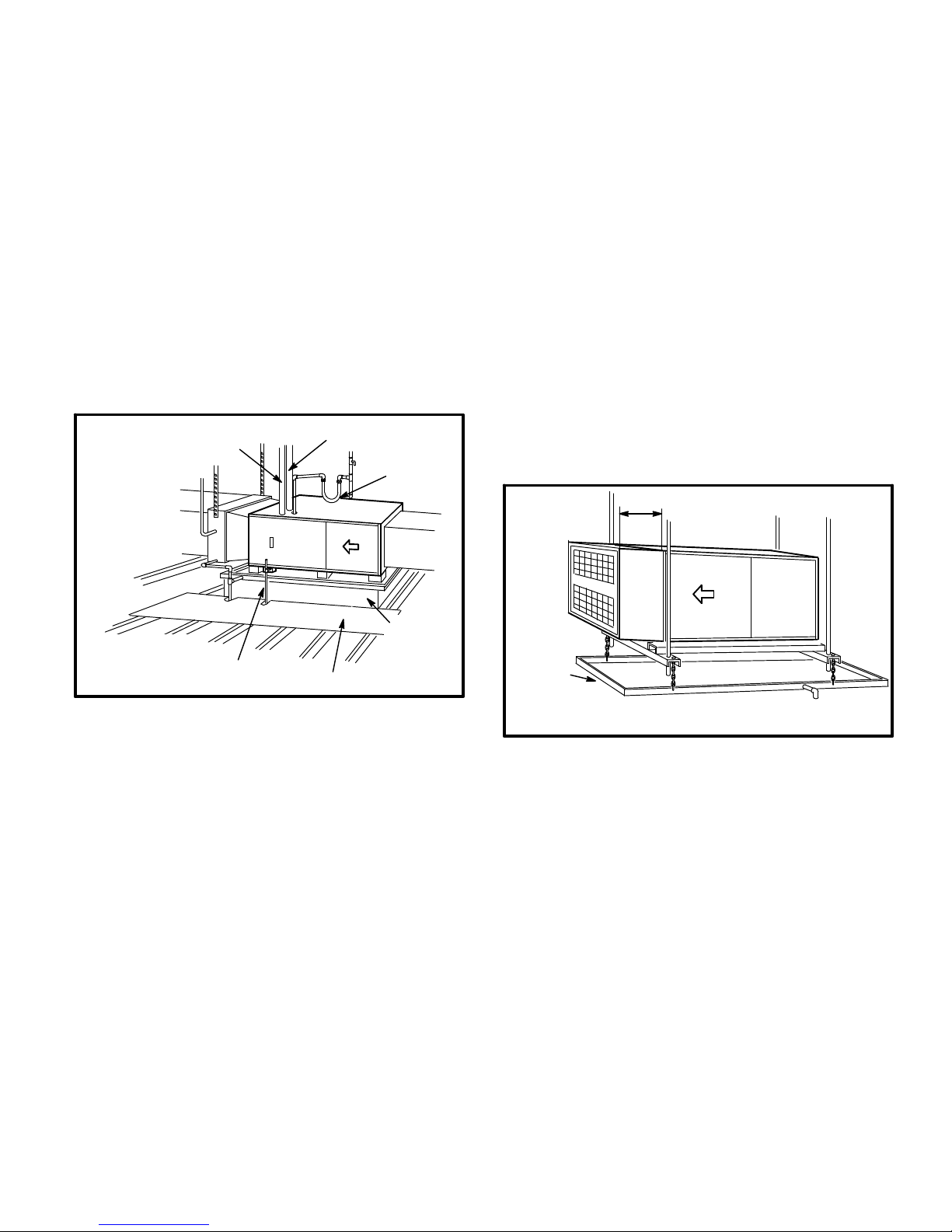

Horizontal Applications

The G61MP furnace can be installed in horizontal applications with either right− or left−hand air discharge.

The G61MP may also be installed as a unit heater. Either

suspend the furnace as shown in figure 18, or install the

furnace on a field−fabricated raised platform. The unit

must be supported at both ends and beneath the blower

deck to prevent sagging.

Refer to figure 17 for clearances in horizontal applications.

Horizontal Application

Installation Clearances

Right−Hand Discharge

Top

Left End Right End

Bottom (Floor)**

Left−Hand Discharge

Top

3 − If unit is installed above finished space, fabricate a

drain pan fitted with a 1/2 inch or 3/4 inch N.P.T. fitting.

4 − Using 3/8 inch rods and support frame kit or field−fabri-

cated supports, fabricate suspension hangers, keeping in mind front service access clearances.

5 − Mount unit on support frame as shown in figure 18.

6 − Continue with exhaust, condensate and intake line

piping instructions.

7 − If unit is suspended above finished space, hang the

field−provided drain pan below the support frame as

shown in figure 18. Leave 5−1/2 inches for service

clearance below unit for condensate trap.

8 − Route auxiliary drain line so that water draining from

this outlet will be easily noticed by the homeowner. If

necessary, run the condensate line into a condensate

pump to meet drain line slope requirements. The

pump must be rated for use with condensing furnaces.

Protect the condensate discharge line from the pump

to the outside to avoid freezing.

TYPICAL HORIZONTAL CEILING APPLICATION

Left End Right End

Bottom (Floor)**

Top 0

Front* 0

Back 0

Ends 0

Vent 0

Floor 0‡

*Front clearance in alcove installation must be 24 in. (610 mm).

Maintain a minimum of 24 in. (610 mm) for front service access.

**A 5−1/2 service clearance must be maintained below the unit to

provide for servicing of the condensate trap.

‡For installations on a combustible floor, do not install the furnace

directly on carpeting, tile or other combustible materials other

than wood flooring.

FIGURE 17

Suspended Installation of Horizontal Unit

NOTE − If unit is suspended in attic or crawl space, horizontal support kit (Cat No. 56J18 ordered separately) must be

used to ensure proper unit support and coil drainage.

1 − Select location for unit keeping in mind service and

other necessary clearances. See figure 17.

2 − Provide service platform in front of unit.

BLOWER ACCESS PANEL 3/8 in. RODS

INTAKE/EXHAUST

CONNECTION

SUPPORT FRAME

DRAIN PAN

(to protect finished space)

FIGURE 18

Platform Installation of Horizontal Unit

1 − Select location for unit keeping in mind service and

other necessary clearances. See figure 17.

2 − Construct a raised wooden frame and cover frame

with a plywood sheet. Provide a service platform in

front of unit. If unit is installed above finished space,

fabricate a drain pan to be installed under unit.

When installing the unit in a crawl space, a proper support platform may be created using cement blocks and

the horizontal support frame kit (ordered separately,

Page 14

Page 15

Lennox part number 56J18). Position the support

frame on top of the blocks and install the unit on the

frame. Leave 5−1/2 inches for service clearance for

condensate trap.

3 − Route auxiliary drain line so that water draining from

this outlet will be easily noticed by the homeowner. If

necessary, run the condensate line into a condensate

pump to meet drain line slope requirements. The

pump must be rated for use with condensing furnaces.

Protect the condensate discharge line from the pump

to the outside to avoid freezing.

4 − Set unit in drain pan as shown in figure 19. Leave 5−1/2

inches for service clearance below unit for condensate

trap.

5 − Continue with exhaust, condensate and intake piping

installation according to instructions.

EXHAUST PIPE

INTAKE PIPE

*GAS

CONNECTOR

Unit Heater Discharge Duct Guidelines

A field−fabricated and installed discharge air duct and grille

cabinet is suitable for use with the G61MP heater. Keep the

following items in mind when constructing the cabinet.

1 − Outer dimensions of cabinet should match those of the

unit heater, so the duct/grille cabinet installs flush with

the unit heater cabinet. See figure 20.

2 − Flange both ends of duct/grille cabinet so that screws

can be used to secure cabinet to discharge end of unit

heater.

3 − To ensure proper operation, the duct/grille cabinet

must be at least 18 inches long.

4 − Use #10−16 x 1/2 inch sheet metal screws to secure

duct/grille cabinet to unit, taking care not to damage internal components of unit heater when drilling holes or

installing screws. See figure 20.

5 − Use adjustable, double−deflection grille(s) to distribute

discharge air. Adjust static pressure to be in the 0.06

inch to 0.10 inch w.c. range.

*Gas connector may be

used for Canadian

installation if acceptable by local authority

having jurisdiction.

RAISED

PLATFORM

CONDENSATE LINE

SERVICE PLATFORM

FIGURE 19

G61MP Installed in Unit Heater Applications

The G61MP may also be installed as a unit heater. Either

suspend the furnace from roof rafters or floor joists, as

shown in figure 18, or install the furnace on a field−fabricated raised platform, as shown in figure 19. The unit must

be supported at both ends and beneath the blower deck to

prevent sagging. The condensate trap must be installed

where it can be serviced at a later date.

18 in.

MIN.

DRAIN PAN

(to protect

finished

space)

NOTE − When installing duct/grille cabinet, take care not to damage internal unit

heater components when drilling holes or installing screws.

FIGURE 20

Return Air −− Horizontal Applications

Return air may be brought in only through the end of a furnace installed in the horizontal position. The furnace is

equipped with a removable bottom panel to facilitate

installation. See figure 11.

Page 15

Page 16

Filters

This unit is not equipped with a filter or rack. A field−provided filter is required for the unit to operate properly. Table

3 lists recommended filter sizes.

A filter must be in place whenever the unit is operating.

TABLE 3

Furnace

Cabinet Width

17−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

21" 16 X 25 X 1 (1) 20 X 25 X 1 (1)

24−1/2" 16 X 25 X 1 (2) 24 X 25 X 1 (1)

Side Return Bottom Return

Filter Size

Duct System

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution.

NOTE − Operation of this furnace in heating mode (indoor

blower operating at selected heating speed) with an external static pressure which exceeds 0.5 inches w.c. may result in erratic limit operation.

Supply Air Plenum

If the furnace is installed without a cooling coil, a removable

access panel should be installed in the supply air duct. The

access panel should be large enough to permit inspection

(by reflected light) of the heat exchanger for leaks after the

furnace is installed. If present, this access panel must always be in place when the furnace is operating and it must

not allow leaks into the supply air duct system.

Return Air Plenum

NOTE − Return air must not be drawn from a room

where this furnace, or any other gas−fueled appliance (i.e., water heater), or carbon monoxide−

producing device (i.e., wood fireplace) is installed.

When return air is drawn from a room, a negative pressure is created in the room. If a gas appliance is operating

in a room with negative pressure, the flue products can

be pulled back down the vent pipe and into the room. This

reverse flow of the flue gas may result in incomplete combustion and the formation of carbon monoxide gas. This

toxic gas might then be distributed throughout the house

by the furnace duct system.

Return air can be brought in through the bottom or either

side of the furnace. If a furnace with bottom return air is

installed on a platform, make an airtight seal between the

bottom of the furnace and the platform to ensure that the

unit operates properly and safely. Use fiberglass sealing

strips, caulking, or equivalent sealing method between the

plenum and the furnace cabinet to ensure a tight seal. If a

filter is installed, size the return air duct to fit the filter frame.

Pipe & Fittings Specifications

All pipe, fittings, primer and solvent cement must conform

with American National Standard Institute and the American Society for Testing and Materials (ANSI/ASTM) standards. The solvent shall be free flowing and contain no

lumps, undissolved particles or any foreign matter that adversely affects the joint strength or chemical resistance of

the cement. The cement shall show no gelation, stratification, or separation that cannot be removed by stirring. Refer to the table 4 for approved piping and fitting materials.

CAUTION

Solvent cements for plastic pipe are flammable liquids and should be kept away from all sources of

ignition. Do not use excessive amounts of solvent

cement when making joints. Good ventilation should

be maintained to reduce fire hazard and to minimize

breathing of solvent vapors. Avoid contact of cement

with skin and eyes.

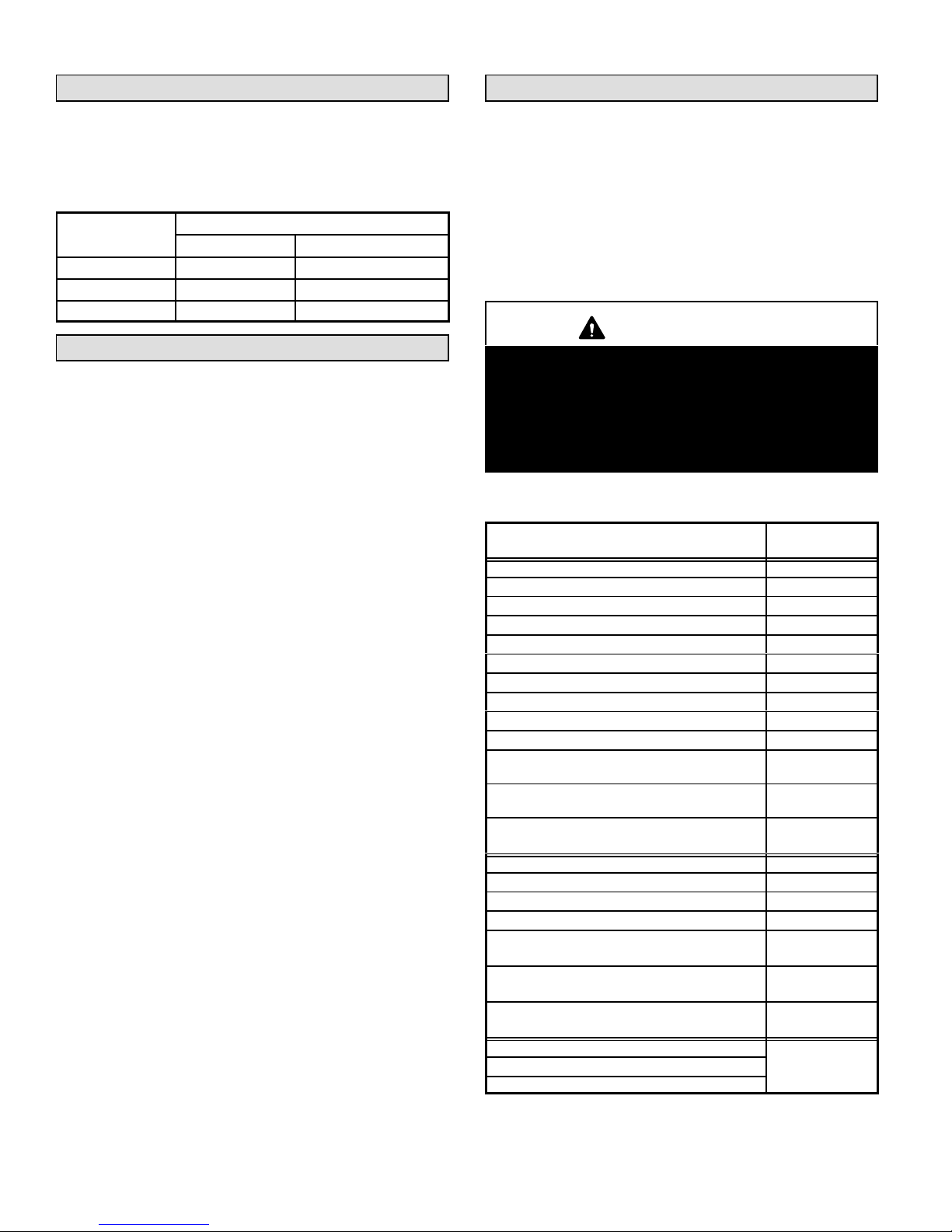

PIPING AND FITTINGS SPECIFICATIONS

PIPE & FITTING MATERIAL

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

Schedule 40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR−21 PVC or SDR−26 PVC (Pipe) D2241

SDR−21 CPVC or SDR−26 CPVC (Pipe) F442

Schedule 40 ABS Cellular Core DWV (Pipe) F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS−DWV (Drain Waste & Vent)

(Pipe & Fittings)

PVC−DWV (Drain Waste & Vent)

Pipe & Fittings)

PRIMER & SOLVENT CEMENT

PVC & CPVC Primer F656

PVC Solvent Cement D2564

CPVC Solvent Cement F493

ABS Solvent Cement D2235

PVC/CPVC/ABS All Purpose Cement For Fittings & Pipe of the same material

ABS to PVC or CPVC Transition Solvent

Cement

CANADA PIPE & FITTING & SOLVENT

CEMENT

PVC & CPVC Pipe and Fittings

PVC & CPVC Solvent Cement

ABS to PVC or CPVC Transition Cement

TABLE 4

ASTM

SPECIFICATION

D2661

D2665

ASTM

SPECIFICATION

D2564, D2235,

F493

D3138

MARKING

ULCS636

Page 16

Page 17

Use PVC primer and solvent cement or ABS solvent cement

meeting ASTM specifications, refer to Table 4. As an alternate, use all purpose cement, to bond ABS, PVC, or CPVC

pipe when using fittings and pipe made of the same materials. Use transition solvent cement when bonding ABS to either PVC or CPVC.

Low temperature solvent cement is recommended. Metal or

plastic strapping may be used for vent pipe hangers. Uniformly apply a liberal coat of PVC primer for PVC or use a

clean dry cloth for ABS to clean inside socket surface of fitting and male end of pipe to depth of fitting socket.

TABLE 5

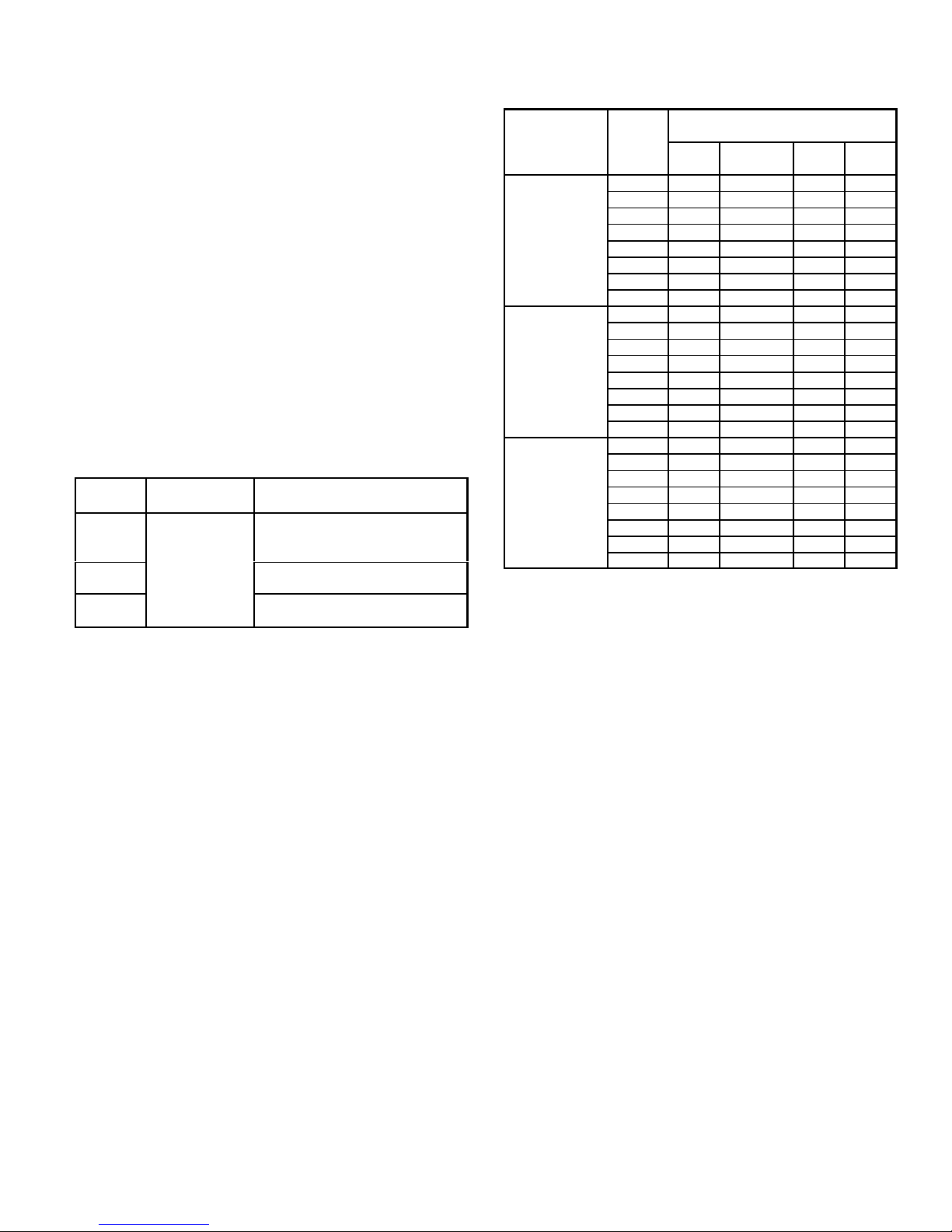

OUTDOOR TERMINATION KITS AND CORRESPONDING EQUIVALENCIES

Vent Pipe Length Equivalency (feet)

Outdoor Exhaust Accel-

erator

(Dia. X

Length)

UNIT

MODEL

VENT

PIPE

DIA.

(in.)

1−1/2" X 12"

2 4

2−1/2 5

36B−045

36B−070

36B−071

48C−090

60C−090

60C−091

48C−110

60C−110

60C−111

60D−135

3 7

4 14

2 4

2−1/2 5

3 8

4 14

2

2−1/2

3

4

2−1/2

3

4

3

4

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

*Requires field−provided and installed 1−1/2" exhaust accelerator.

**Requires field−provided and installed 2" exhaust accelerator.

Outdoor Ex-

haust Accel-

erator

(Dia. X

Length)

2" X 12"

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

1

2

2

4

2

2

4

6

10

1−1/2"

Concentric

Kit

71M80

or 44W92

12

15

21

42

12

15

24

42

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Canadian Applications Only − Pipe, fittings, primer

and solvent cement used to vent (exhaust) this appliance must be certified to ULC S636 and supplied by a

single manufacturer as part of an approved vent (exhaust) system. When bonding the vent system to the furnace, use ULC S636 approved One−Step Transition Cement to bond the pipe to the flue collar, or to bond the 90°

elbow or reducing 90° elbow to the flue collar. In addition, the first three feet of vent pipe from the furnace flue

collar must be accessible for inspection.

Table 5 lists the available exhaust termination kits, as well

as vent pipe equivalencies which must be used when sizing vent pipe. All Lennox vent terminations are PVC.

2" Con-

centric Kit

69M29

or 44W92

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

3 3

6 6

6 6

12 12

6 6

6 6

12 12

Not

Allowed

Not

Allowed

Termination kits 44W92 (includes 1−1/2" reducer), 44W93,

30G28 and 81J20 approved for use in Canadian installations.

3" Con-

centric Kit

60L46

or 44W93

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

15

25

2" Wall Plate

Kit

22G44

or 30G28

4 4* 4

5 5* 5

7 7* 7

14 14* 14

4 4* 4

5 5* 5

8 8* 8

14 14* 14

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

Not

Allowed

3" Wall Plate

Kit

44J40

or 81J20

1 1**

2 2**

2 2**

4 4**

2 2

2 2

4 4

6

10

2" Wall

Ring Kit

15F74

Not

Allowed

Not

Allowed

Page 17

Page 18

Vent Piping Guidelines

The G61MP can be installed as either a Non−Direct Vent

or a Direct Vent gas central furnace.

NOTE − In Non-Direct Vent installations, combustion air is

taken from indoors and flue gases are discharged outdoors.

In Direct Vent installations, combustion air is taken from outdoors and flue gases are discharged outdoors.

Intake and exhaust pipe sizing in Direct Vent applications

and exhaust pipe sizing in Non-Direct Vent applications −−

Size pipe according to tables 6 and 7. Table 6 lists the minimum equivalent vent pipe lengths permitted. Table 7 lists

the maximum equivalent pipe lengths permitted.

Maximum vent length is defined as:

Total length (linear feet) of pipe,

Plus Equivalent length (feet) of fittings,

Plus Equivalent length (feet) of termination.

NOTE − Include ALL pipe and ALL fittings, both in

doors and outdoors.

Regardless of the diameter of pipe used, the standard roof

and wall terminations described in section Exhaust Piping

Terminations should be used. Exhaust vent termination

pipe is sized to optimize the velocity of the exhaust gas as

it exits the termination. Refer to table 8.

*NOTE − The exhaust pipe should be offset a minimum of

12 inches to avoid the possibility of water droplets being re-

leased from the exhaust termination. The minimum exhaust vent length is 15 ft. Shorter exhaust vent lengths may

result in the discharge of water droplets from the exhaust

termination, in spite of the 12−inch vertical offset. See figure 21.

Each 90° elbow (including those provided with the furnace)

of any diameter is equivalent to 5 feet (1.52m) of vent pipe

of the same diameter. Two 45° elbows are equivalent to

one 90° elbow of the same diameter. One 45° elbow is

equal to 2.5 feet (.76m) of vent pipe of the same diameter.

In some applications which permit the use of several different sizes of vent pipe, a combination vent pipe may be

used. Contact the Application Department for assistance in

sizing vent pipe in these applications.

NOTE − The flue collar on all models is sized to accommodate 2" Schedule 40 flue pipe. When vent pipe which is

larger than 2" must be used in an upflow application, a 2"

elbow must be applied at the flue collar in order to properly transition to the larger diameter flue pipe. This elbow

must be added to the elbow count used to determine acceptable vent lengths. Assign an equivalent feet value to

this elbow according to the larger size pipe being used.

Contact Lennox’ Application Department for more information concerning sizing of vent systems which include

multiple pipe sizes.

*12" Min.

Upflow and Downflow Application

Rooftop Termination

*12" Min.

Horizontal Application

Rooftop Termination

*A minimum of 1/4" (6mm) drop for each 12" (305mm) of horizontal run is mandatory for drainage

Exhaust Pipe Offset

12" Min.

Upflow and Downflow Application

Side Wall Termination

*12" Min.

Horizontal Application

Side Wall Termination

FIGURE 21

Page 18

Page 19

Use the following steps to correctly size vent pipe diameter.

Refer to Vent Pipe Size Determination Worksheet on

page 53.

1 − Determine the vent termination and its corresponding

equivalent feet value according to table 5.

2 − Determine the number of 90° elbows required for both

indoor and outdoor (e.g. snow riser) use. Calculate the

corresponding equivalent feet of vent pipe.

3 − Determine the number of 45° elbows required for both

indoor and outdoor use. Calculate the corresponding

equivalent feet of vent pipe.

4 − Determine the length of straight pipe required.

5 − Add the total equivalent feet calculated in steps 1

through 4 and compare that length to the maximum

values given in table 6 for the proposed vent pipe diameter. If the total equivalent length required exceeds

the maximum equivalent length listed in the appropriate table, evaluate the next larger size pipe.

TABLE 6

MINIMUM VENT PIPE LENGTHS

G61MP

MODEL

045, 070,

071, 090,

091

110, 111**

135***

*Any approved termination may be added to the minimum equivalent length

listed.

**G61MP−48C−110, G61MP−60C−110 and G61MP−60C−111 must have 90°

street ell (supplied or field replacment Canadian kit) installed directly into unit

flue collar.

***G61MP−60D−135 must have 3" to 2" reducing ell (supplied or field replacment Canadian ki) installed directly into unit flue collar.

MIN. EQUIV.

VENT LENGTH

15 ft.*

EXAMPLE

5 ft. plus 2 elbows of 2", 2−1/2", 3"

or 4" diameter pipe

5 ft. plus 2 elbows of 2−1/2" 3" or 4"

diameter pipe

5 ft. plus 2 elbows of 3" or 4"

diameter pipe

MAXIMUM VENT PIPE LENGTHS

TABLE 7

MAXIMUM EQUIVALENT VENT

ALTITUDE

0 − 4500

(0 − 1371 m)

4501−7500

(1372−2286 m)

7501 − 10000

(2287 − 3048 m)

n/a −− Not allowed.

*G61MP−48C−110, G61MP−60C−110 and G61MP−60C−111must have 90°

street ell (supplied or field replacment Canadian ki) installed directly into unit

flue collar.

**G61MP−60D−135 must have 3" to 2" reducing ell (supplied or field replacment

Canadian ki) installed directly into unit flue collar.

***90° elbows used in configuration of G61MP−60D−135 vent, must be limited to 3" sweep elbows.

†On G61MP−071, −091 and −111 units, sweep elbows must be used for

all 90° elbows in the venting system when 2", 2−1/2" or 3" vent pipe is

used. Sweep elbows are recommended for use in vent systems of

other G61MP units.

G61MP

MODEL

045 59 65 77 234

070 59 65 78 214

071† 59 65 78 214

090 26 42 72 204

091† 26 42 72 204

110* n/a 32 72 179

111*† n/a 32 72 179

135**‡ n/a n/a 61 160

045 59 65 77 234

070 59 65 78 214

071† 59 65 78 214

090 26 42 72 204

091† 26 42 72 204

110* n/a 32 72 179

111*† n/a 32 72 179

135**‡ n/a n/a 46 160

045 59 65 77 234

070 59 65 78 214

071† 59 65 78 214

090 26 42 72 204

091† 26 42 72 204

110* n/a 32 72 179

111*† n/a 32 72 179

135**‡ n/a n/a 46 160

2"

PIPE

LENGTH FEET

2−1/2"

PIPE

PIPE4"PIPE

3"

Page 19

Page 20

Joint Cementing Procedure

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

WARNING

DANGER OF EXPLOSION!

Fumes from PVC glue may ignite during system

check. Allow fumes to dissipate for at least 5 minutes

before placing unit into operation.

1 − Measure and cut vent pipe to desired length.

2 − Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

3 − Clean and dry surfaces to be joined.

4 − Test fit joint and mark depth of fitting on outside of pipe.

5 − Uniformly apply a liberal coat of PVC primer for PVC or

use a clean dry cloth for ABS to clean inside socket

surface of fitting and male end of pipe to depth of fitting

socket.

NOTE − Furnace flue collar and air inlet fitting are both

made of ABS material. Use transition solvent cement

when bonding ABS to either PVC or CPVC, refer to the

procedure specified in ASTM D3138..

6 − Promptly apply solvent cement to end of pipe and in-

side socket surface of fitting. Cement should be applied lightly but uniformly to inside of socket. Take

care to keep excess cement out of socket. Apply second coat to end of pipe.

NOTE − Time is critical at this stage. Do not allow primer to dry before applying cement.

7 − Immediately after applying last coat of cement to pipe,

and while both inside socket surface and end of pipe

are wet with cement, forcefully insert end of pipe into

socket until it bottoms out. Turn PVC pipe 1/4 turn during assembly (but not after pipe is fully inserted) to distribute cement evenly. DO NOT turn ABS or cellular

core pipe.

NOTE − Assembly should be completed within 20 seconds after last application of cement. Hammer blows

should not be used when inserting pipe.

8 − After assembly, wipe excess cement from pipe at end

of fitting socket. A properly made joint will show a

bead around its entire perimeter. Any gaps may indicate a defective assembly due to insufficient solvent.

9 − Handle joints carefully until completely set.

Page 20

Page 21

Venting Practices

The thickness of construction through which vent pipes

may be installed is 24" (610mm) maximum and 3" (76mm)

minimum. If a G61MP furnace replaces a furnace which

was commonly vented with another gas appliance, the size

of the existing vent pipe for that gas appliance must be

checked. Without the heat of the original furnace flue products, the existing vent pipe is probably oversized for the

single water heater or other appliance. The vent should be

checked for proper draw with the remaining appliance.

1 − Use recommended piping materials for exhaust pip-

ing.

2 − Secure all joints so that they are gas-tight using ap-

proved cement.

Suspend piping using hangers at a minimum of every 5

feet (1.52m) for schedule

40 PVC and every 3 feet

(.91m) for ABS−DWV, PVC−

DWV, SPR−21 PVC, and

SDR−26 PVC piping. A suitable hanger can be fabricated by using metal or

plastic strapping or a large

wire tie.

3 − In areas where piping penetrates joists or interior

walls, hole must be large enough to allow clearance on

all sides of pipe through center of hole using a hanger.

STRAPPING

(metal, plastic

or large wire

ties)

FIGURE 22

4 − Isolate piping at the point where it exits the outside wall

or roof in order to prevent transmission of vibration to

the structure.

5 − When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a

vacation home, make provisions for draining condensate collection trap and lines.

Exhaust Piping

NOTE − A 2" diameter PVC street ell is located on the

blower deck of 48C−110, 60C−110 and 60C−111 units. In

upflow or downflow applications the street ell must be

glued using transition solvent cement directly into the

unit flue collar. See figure 23. A 3" to 2" PVC reducing ell is

located on the blower deck of the 60D−135 units. In up-

flow or downflow applications, the reducing ell must

be glued using transition solvent cement directly into the

unit flue collar.

1 − Choose the appropriate side for venting in upflow or

downflow positions. Exhaust piping exits from the top

of the unit in horizontal air discharge applications.

Glue the field−provided exhaust vent pipe (or provided

street ell or reducing ell in upflow or downflow applications) to the flue collar. All PVC cement joints should

be made according to the specifications outlined in

ASTM D 2855. Refer to pipe and fittings specifications

and gluing procedures.

TYPICAL EXHAUST PIPE CONNECTIONS AND CONDENSATE TRAP INSTALLATION

IN UPFLOW OR DOWNFLOW DIRECT OR NON−DIRECT VENT APPLICATIONS

(Right−Hand Exit in Upflow Application Shown)

PLUG

VENT PLUG

(Must be

glued in

place)

PLUG

*2" diameter street elbow provided.

**Street elbow may be used on −045, −070, 071, −090 and −091.

PLUG

2"

CONDENSATE

TRAP

(Must be installed

on same side as

exhaust piping)

2"

2"

2−1/2",

3", OR

or

**2"

2"

2−1/2",

3", OR

4"

TRANSITION

*2"

G61MP−110, −111 with

2−1/2", 3", OR 4" vent

pipe

FIGURE 23

4"

2"

2" max

length

TRANSITION

G61MP−045,

−070, −071 or

−090, −091 with

2−1/2", 3", or 4"

vent pipe

TRANSITION

(use only if 4"

pipe is

required)

G61MP−135, −110, −111

with

3" OR 4" vent pipe

45°

MAX

SIDE VIEW

4"

2" max

length

3" to 2" REDUCING ELBOW

45°

MAX

(provided)

Page 21

Page 22

TYPICAL EXHAUST PIPE CONNECTIONS

HORIZONTAL DIRECT OR NON−DIRECT VENT

APPLICATIONS

(Horizontal Right−Hand Air

Discharge Application Shown)

* 2" maximum length

for −110, −111 −135 only

DO NOT transition

from smaller to larger

pipe size in horizontal

runs of exhaust pipe.

2−1/2",

3", OR

4"

TRANSITION

*2"

2"

36B−045

36B−070

36B−071

48C−090

60C−090

60C−091

48C−110

60C−110*

60C−111*

60D−135*

2"

2"

36B−045

36B−070

36B−071

36C−090

60C−090

60C−091

FIGURE 24

IMPORTANT

Exhaust piping and condensate trap must be

installed on the same side of the unit in upflow and

dowflow applications or use alternate drain kit

76M20.

2 − All horizontal runs of exhaust pipe must slope back to-

ward unit. A minimum of 1/4" (6mm) drop for each 12"

(305mm) of horizontal run is mandatory for drainage.

Horizontal runs of exhaust piping must be supported every 5 feet (1.52m) using hangers.

NOTE − Exhaust piping should be checked carefully to

make sure there are no sags or low spots.

3 − On the opposite side of the cabinet, glue the provided

2" ABS vent plug into the unused ABS flue collar with

ABS or all purpose solvent cement.

4 − Route piping to outside of structure. Continue with

installation following instructions given in piping termination section.

CAUTION

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If vertical discharge through an existing unused stack is required, insert PVC pipe inside the stack until the end

is even with the top or outlet end of the metal stack.

CAUTION

The exhaust vent pipe operates under positive pressure and must be completely sealed to prevent leakage of combustion products into the living space.

Intake Piping

The G61MP furnace may be installed in either direct vent

or non−direct vent applications. In non−direct vent applica-

tions, when intake air will be drawn into the furnace from the

surrounding space, the indoor air quality must be considered and guidelines listed in Combustion, Dilution and Ventilation Air section must be followed.

The G61MP unit is designed for either left−side or right−side

air intake connections in either upflow or downflow applications. In horizontal applications, air intake must be brought

in through the top. Intake air piping is independent of exhaust piping.

Follow the next four steps when installing the unit in direct

vent applications, where combustion air is taken from outdoors and flue gases are discharged outdoors. The pro-

vided air intake screen must not be used in direct vent applications.

1 − Use transition solvent cement to connect PVC pipe to

the ABS slip connector located on the side of the burner box.

2 − Use a #7 sheet metal screw to secure the intake pipe to

the connector, if desired. A pilot indentation is provided in

the slip connector to assist in locating and starting the fastener.

3 − Glue the provided 2" ABS plug into the unused ABS air

intake connector on the opposite side of the cabinet with

ABS all pupose cement.

4 − Route piping to outside of structure. Continue with instal-

lation following instructions given in general guide lines for

piping terminations and in intake and exhaust piping terminations for direct vent sections. Refer to figure 25 for

pipe sizes.

Page 22

Page 23

TYPICAL AIR INTAKE PIPE CONNECTIONS

UPFLOW OR DOWNFLOW DIRECT VENT APPLICATIONS

(Right−Hand Exit in Upflow Application Shown)

2

PLUG

(Must be

glued in

place)

2

−36B−045−

−36B−070

−36B−071

−48C−090

−60C−090

−60C−091

2

TYPICAL AIR INTAKE PIPE CONNECTIONS

HORIZONTAL DIRECT VENT APPLICATIONS

(Horizontal Right−Hand Air Discharge Application Shown)

2−1/2",

3" OR

4

TRANSITION

2

2

2

−36B−045

−36B−070

−36B−071

−48C−090

−60C−090

−60C−091

−48C−110

−60C−110

−60C−111

*Limit pipe length to 4" in G61MP−110,

−111, −135 applications.

FIGURE 25

Follow the next three steps when installing the unit in NonDirect Vent applications where combustion air is taken

from indoors and flue gases are discharged outdoors.

TRANSITION

*2"

2−1/2",

3" OR

4

−36B−045

−36B−070

−36B−071

−48C−090

−60C−090

−60C−091

−48C−110

−60C−110*

−60C−111*

−60D−135*

*Limit pipe

length to 4" in −110, −111,

−135 applications.

−36B−045

−36B−070

−36B−071

−48C−090

−60C−090

−60C−091

−48C−110

−60C−110

−60C−111

−36B−045