Lennox G60DFV-36A-070X, G60DFV-36A-070, G60DFV-36B-090, G60DFV-60C-090, G60DFV-60C-090X Unit Information

...Page 1

Page 1

© 2002 Lennox Industries Inc.

Corp. 0211−L3

G60DFV(X)

Service Literature

Revised 08−2007

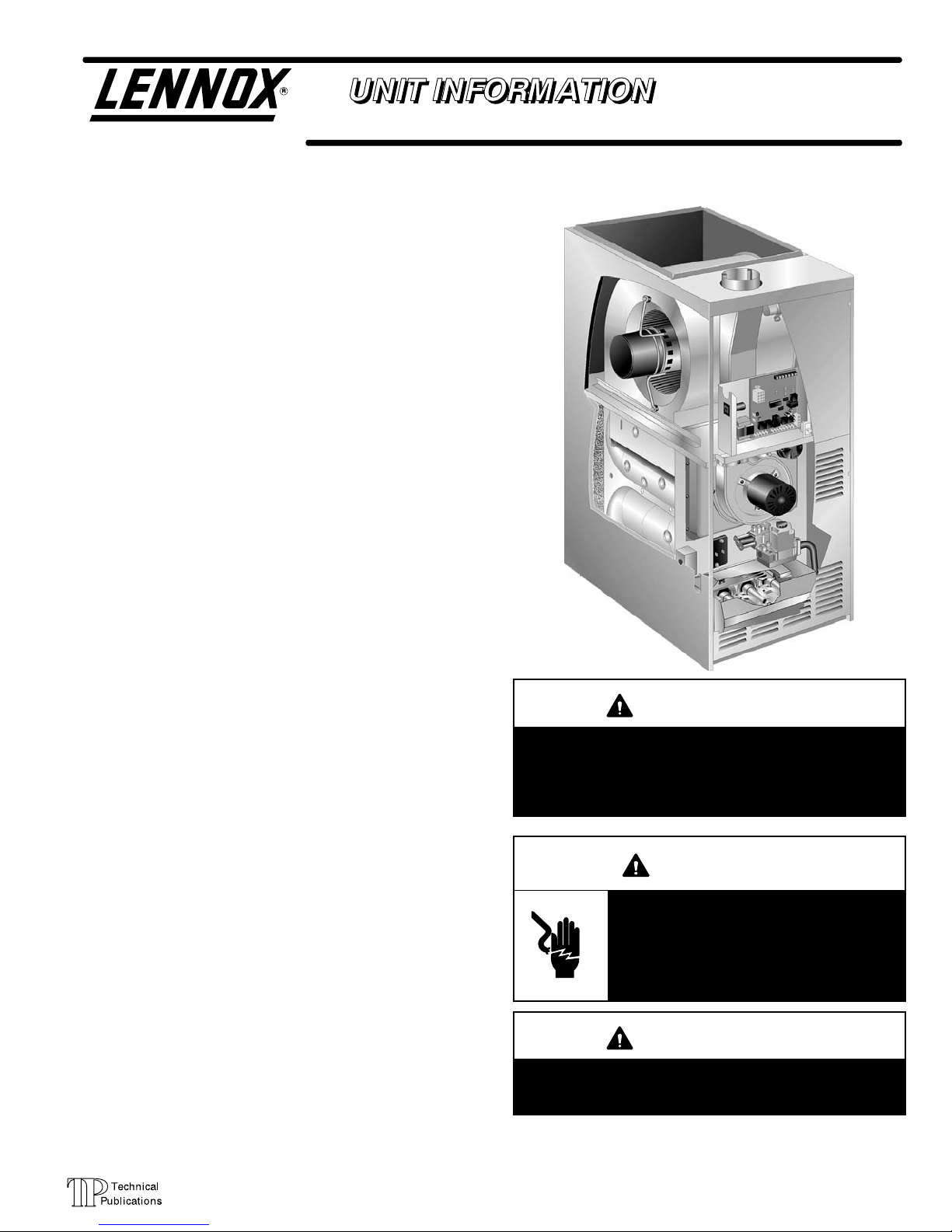

G60DFV(X) SERIES UNITS

G60DFV series units are mid−efficiency gas furnaces used

for downflow applications only, manufactured with Lennox

Duralok Plus heat exchangers formed of aluminized steel.

Units are available in heating capacities of 66,000 to

132,000 Btuh and cooling applications up to 5 tons. Refer

to Engineering Handbook for proper sizing.

Units are factory equipped for use with natural gas. Kits are

available for conversion to LPG operation. G60DFV model

units are equipped with the two−stage variable speed inte-

grated SureLight control. G60DFV model units meet the

California Nitrogen Oxides (NO

x

) Standards and California

Seasonal Efficiency requirements. All units use a redundant

gas valve to assure safety shut−off as required by C.S.A.

All specifications in this manual are subject to change. Pro-

cedures outlined in this manual are presented as a recom-

mendation only and do not supersede or replace local or

state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except

where noted) are recommendations only and do not consti-

tute code.

TABLE OF CONTENTS

Specifications Page 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Data Page 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Altitude Page 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Identification Page 7. . . . . . . . . . . . . . . . . . . . . . . . .

I Unit Components Page 8. . . . . . . . . . . . . . . . . . . . . . . .

II Installation Page 30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Start Up Page 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV Heating System Service Checks Page 31. . . . . . . . .

V Typical Operating Characteristics Page 33. . . . . . . . .

VI Maintenance Page 33. . . . . . . . . . . . . . . . . . . . . . . . . .

VII Wiring and Sequence of Operation Page 37. . . . . .

VIII Field Wiring and Jumper Settings Page 52. . . . . . .

IX Integrated Control Board Troubleshooting Page 57.

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer, service agency

or the gas supplier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect switch(es). Unit may have multiple

power supplies.

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges

which may result in personal injury.

Page 2

Page 2

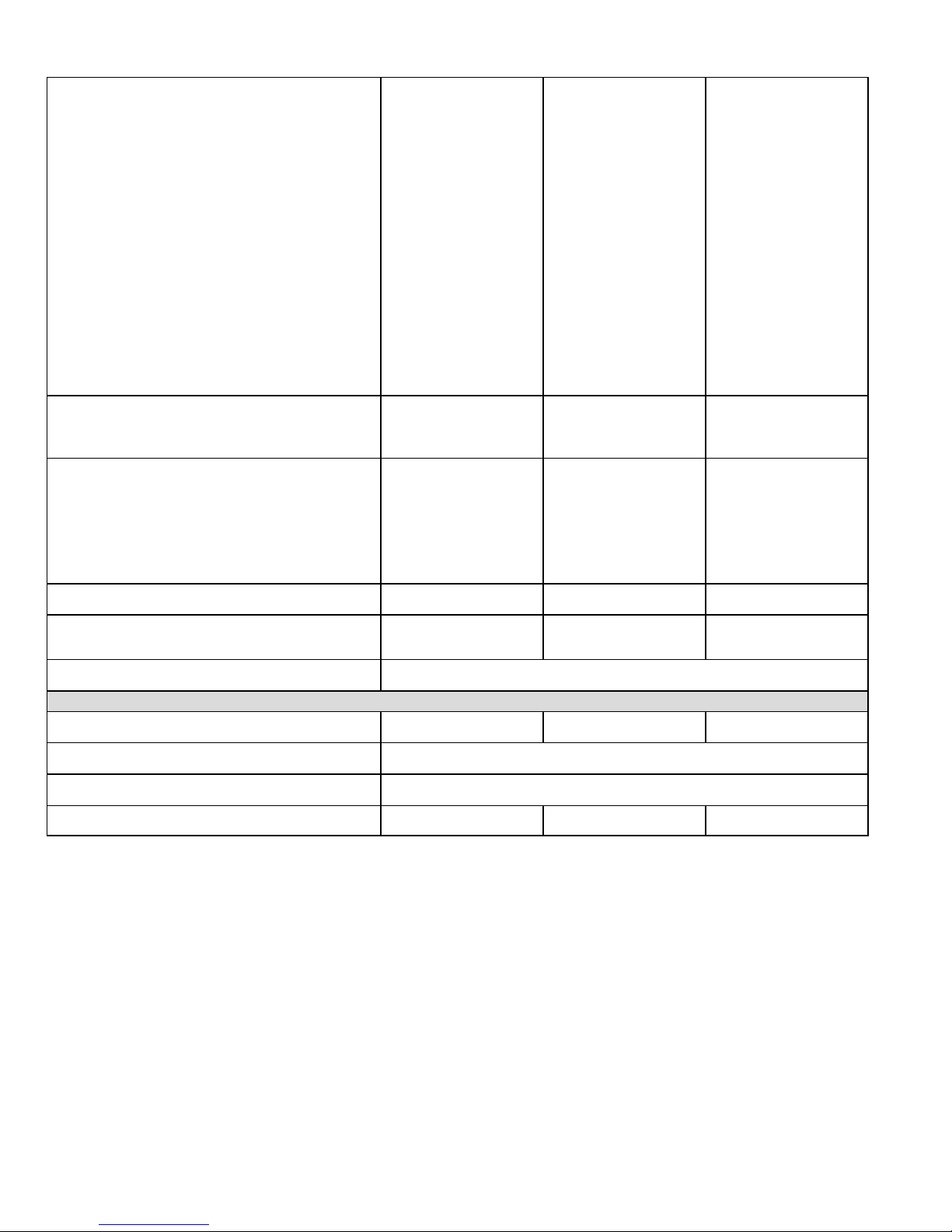

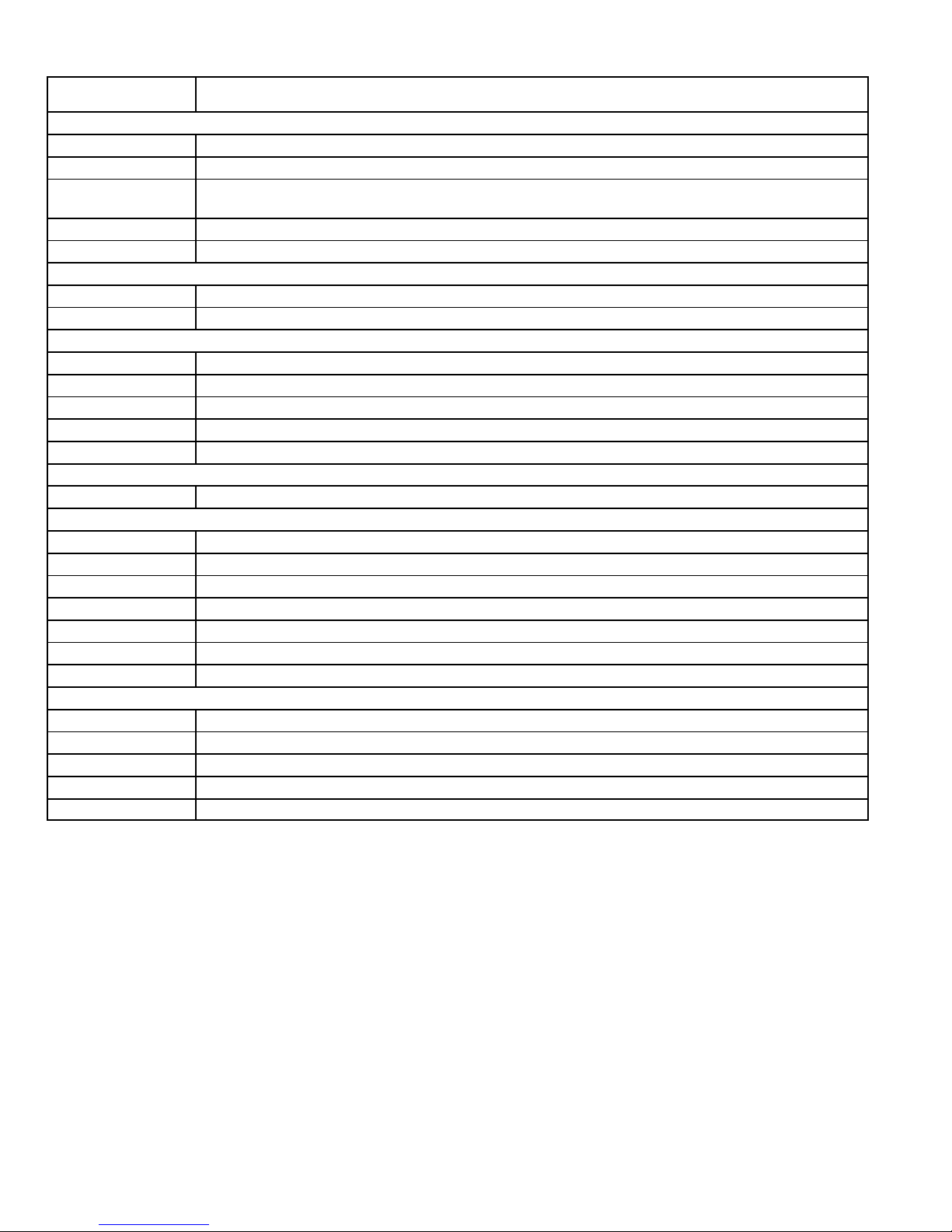

SPECIFICATIONS

Gas

ModelNo. G60DFV−36A−070 G60DFV−36B−090 G60DFV−60C−090

Heating

Low NO

x

Model No. G60DFV−36A−070X − − − G60DFV−60C−090X

Perf

ormance

Input− Btuh (kW) low fire 45,000 (13.2) 60,000 (17.6) 60,000 (17.6)

Output− Btuh (kW) low fire 36,000 (10.5) 48,000 (14.1) 48,000 (14.1)

Input− Btuh (kW) high fire 66,000 (19.3) 88,000 (25.8) 88,000 (25.8)

Output− Btuh (kW) high fire 54,000 (15.8) 72,000 (21.1) 72,000 (21.1)

lAFUE 80.0% 80.0% 80.0%

California Seasonal Efficiency 77.0% 77.1% 77.0%

Highstatic− in.w.g. (Pa) .80 (200) .80 (200) .80 (200)

Temperature rise range − _F (_C) low fire 20 − 50 (11 − 28) 25 − 55 (14 − 31) 20 − 50 (11 − 28)

Temperature rise range − _F (_C) high fire 35 − 65 (19 − 36) 45 − 75 (25 − 42) 30 − 60 (17 − 33)

Connections GaspipesizeIPS− in. (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Flue connection − in. (mm) round 4 (102) 4 (102) 4 (102)

Indoor

Blower

Wheelnominaldiameter xwidth −in. 10 x 8 10 x 8 11−1/2 x 10

Blower

mm 254 x 203 254 x 203 292 x 254

Motoroutput − hp (W) 1/2 (373) 1/2 (373) 1 (746)

Tons(kW) ofadd-oncooling 2 − 3 (7.0 − 10.6) 2 − 3.5 (7.0 − 12.3) 3.5 − 5 (12.3 − 17.6)

Shippingweight − 1 package 132 lbs. (60 kg) 154 lbs. (70 kg) 172 lbs. (78 kg)

Matching Coils CR26−18N−F, CR26−30N−F,

CR26−36N−F

CR26−36W−F,

CR26−48N−F

CR26−48N−F,

CR26−60N−F

Electricalcharacteristics 120 volts − 60 hertz − 1 phase (less than 12 amps)

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

Down−Flow Additive Base − Shipping Weight − lbs. (kg) 11M59 − 9 (4) 11M 60 − 10 (5) 11M 61 − 11 (5)

High Altitude See Page 6

LPG/Propane Kit See Page 6

Propane/Natural Gas Kit 0 to 7500 ft. (0 to 2286 m) 59M87 59M87 59M87

lAnnual Fuel Utilization Efficiency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces.

NOTE − Filters and provisions for mounting are not furnished and must be field provided.

Page 3

Page 3

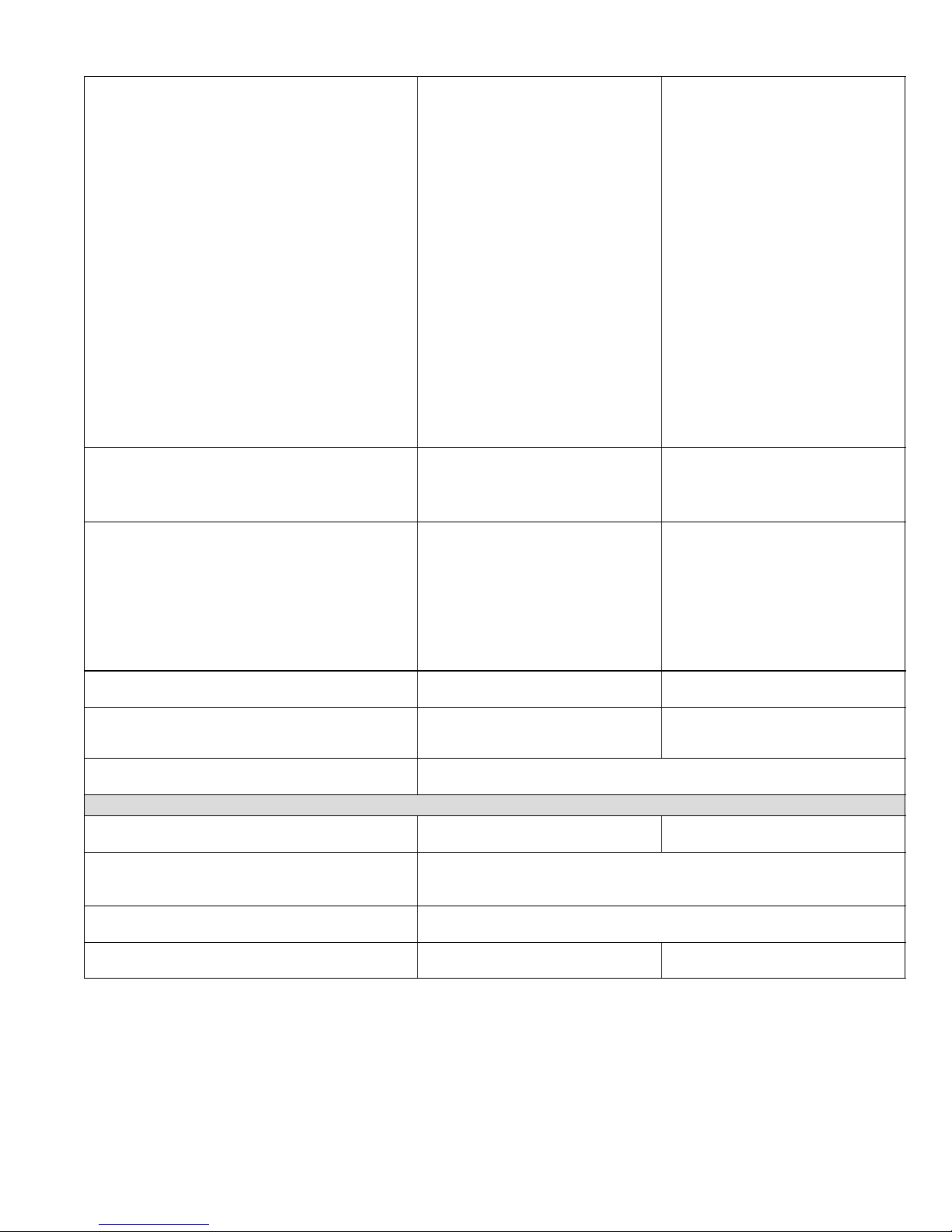

SPECIFICATIONS Cont.

Gas

ModelNo. G60DFV−60C−110 G60DFV−60D−135

Heating

Low NOx Model No. G60DFV−60C−110X − − − −

Perf

ormance

Input− Btuh (kW) low fire 75,000 (22.0) 90,000 (26.4)

Output− Btuh (kW) low fire 61,000 (17.9) 73,000 (21.4)

Input− Btuh (kW) high fire 110,000 (32.2) 132,000 (38.7)

Output− Btuh (kW) high fire 91,000 (26.7) 109,000 (31.9)

lAFUE 80.0% 80.0%

California Seasonal Efficiency 75.8% 76.5%

Highstatic− in.w.g. (Pa) .80 (200) .80 (200)

Temperature rise range − _F (_C) low fire 20 − 50 (11 − 28) 25 − 55 (14 − 31)

Temperature rise range − _F (_C) high fire 30 − 60 (17 − 33) 40 − 70 (22 − 39)

Connections

GaspipesizeIPS− in. (mm) 1/2 (12.7) 1/2 (12.7)

Flue connection − in. (mm) round 4 (102) 4 (102)

Indoor

Blower

Wheelnominaldiameter xwidth −in. 11−1/2 x 10 11−1/2 x 10

Blower

mm 292 x 254 292 x 254

Motoroutput − hp (W) 1 (746) 1 (746)

Tons(kW) ofadd-oncooling 3.5 − 5 (12.3 − 17.6) 4 − 5 (14.1 − 17.6)

Shippingweight − 1 package 184 lbs. (83 kg) 198 lbs. (76 kg)

Matching Coils CR26−48N−F,

CR26−60N−F

CR26−48W−F,

CR26−60W−F

Electricalcharacteristics 120 volts − 60 hertz − 1 phase (less than 12 amps)

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

Down−Flow Additive Base − Shipping Weight − lbs. (kg) 11M 61 − 11 (5) 11M 62 − 13 (6)

High Altitude Page 6

LPG/Propane Kit Page 6

Propane/Natural Gas Kit 0 to 7500 ft. (0 to 2286 m) 59M87 59M87

lAnnual Fuel Utilization Efficiency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces.

NOTE − Filters and provisions for mounting are not furnished and must be field provided.

Page 4

Page 4

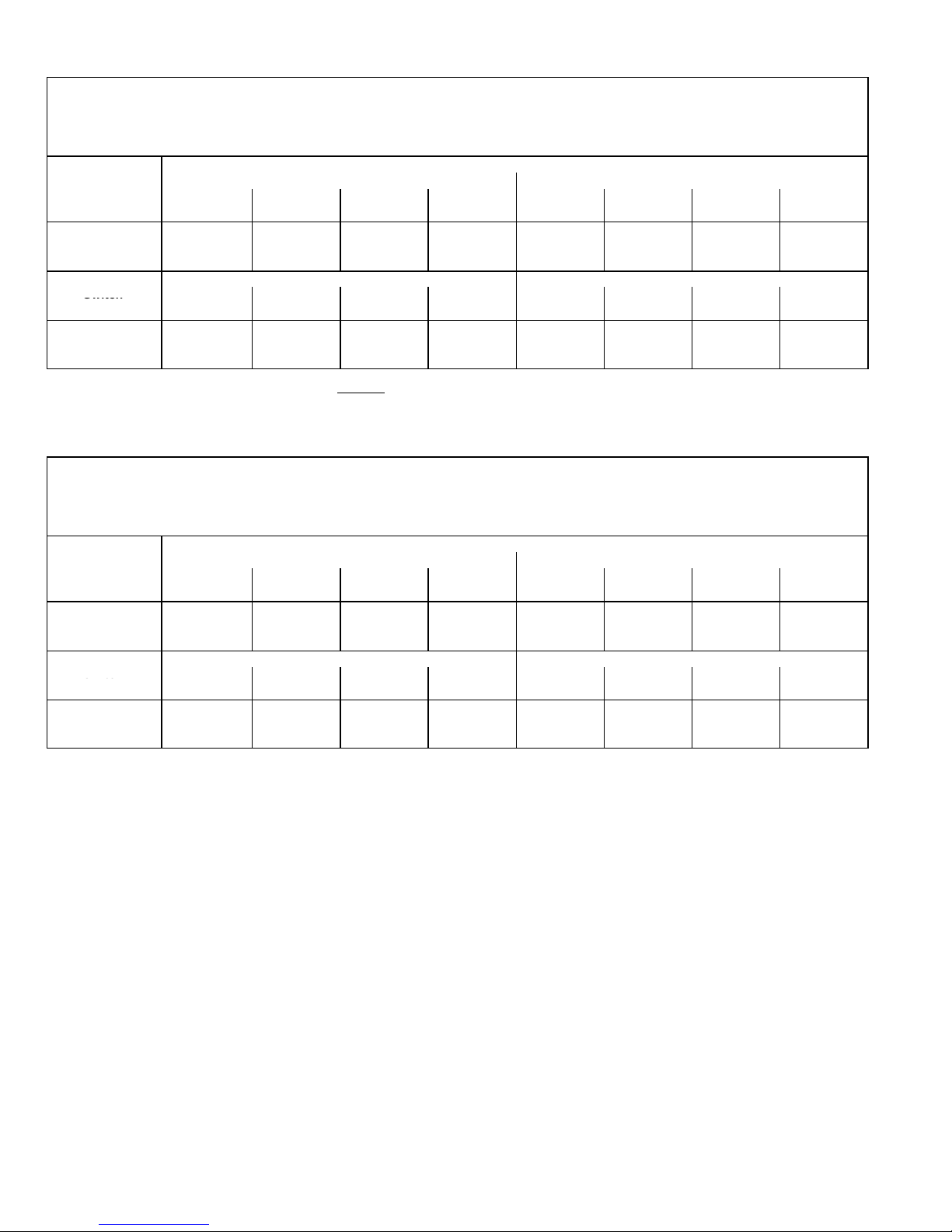

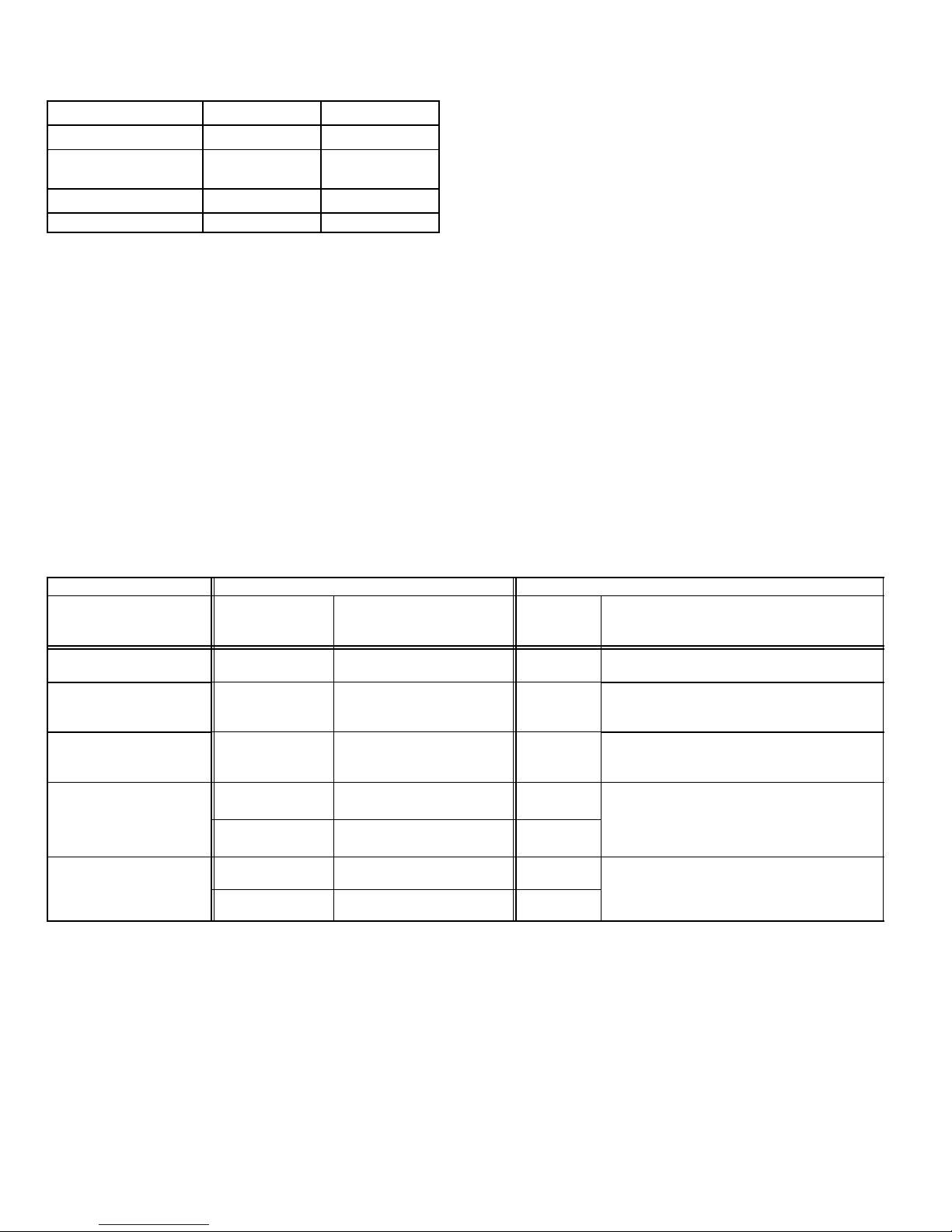

BLOWER DATA

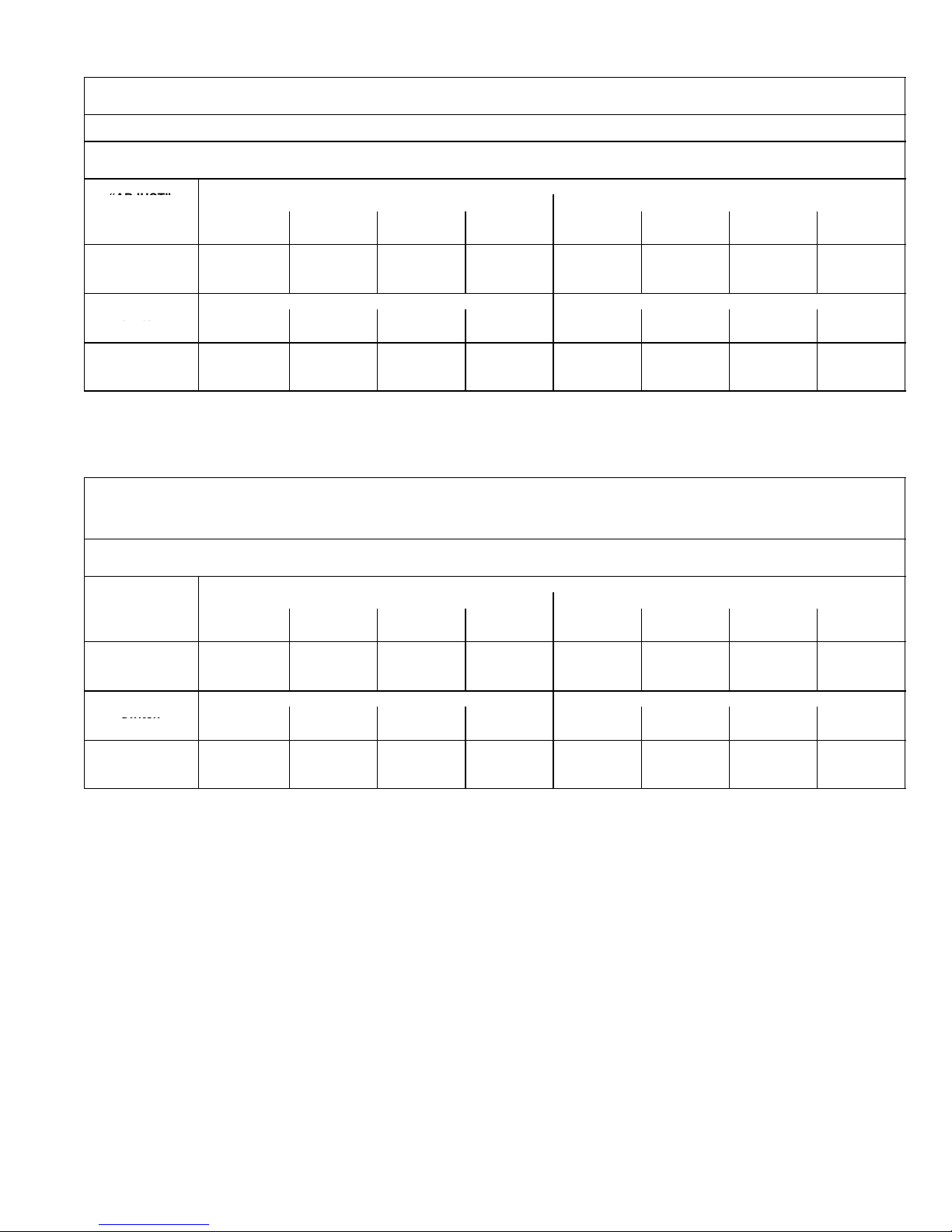

G60DFV−36A−070 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

Blower Control Factory Settings ADJUST − NORM

HEAT − 2

COOL − 4

Speed Switch Positions

ADJUST"

2nd Stage HEAT" Speed 2nd Stage COOL" Speed

Switch

Position

s

1 2 3 4 1 2 3 4

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 880 415 1025 485 1135 535 1320 625 1045 495 1210 570 1300 615 1400 660

NORM (Normal) 800 380 930 440 1035 490 1200 565 950 450 1100 520 1180 555 1275 600

" (Minus) 720 340 835 395 930 440 1080 510 855 405 990 465 1060 500 1145 540

ADJUST"

1st Stage HEAT" Speed 1st Stage COOL" Speed

ADJUST

Switch

1 2 3 4 1 2 3 4

Switch

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 815 385 945 445 1055 500 1210 570 700 330 785 370 840 395 900 425

NORM (Normal) 740 350 860 405 960 455 1100 520 640 300 715 335 765 360 820 385

" (Minus) 665 315 775 365 865 410 990 465 575 270 645 305 690 325 735 350

NOTES − The effect of static pressure and filter resistance is included in air volumes shown.

1st stage HEAT is approximately 91% of the same 2nd stage

HEAT speed position.

1st stage COOL (two speed air conditioning units only) is approximately 70% (65% for units built prior to 09−2002) of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position − minimum 500 cfm (235 L/s).

Lennox Harmony IIt zone control applications − Minimum blower heating speed is approximately 75% of the 1st stage HEAT speed position.

Lennox Harmony IIt zone control applications − Minimum blower cooling speed is approximately 45% of the 2nd stage COOL speed position.

G60DFV−36B−090 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

Blower Control Factory Settings ADJUST − NORM

HEAT − 2

COOL − 4

Speed Switch Positions

ADJUST"

2nd Stage HEAT" Speed 2nd Stage COOL" Speed

Switch

Positions

1 2 3 4 1 2 3 4

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) N/A N/A 111 0 525 1295 610 1350 635 1075 505 1240 585 1345 635 1475 695

NORM (Normal) N/A N/A 1005 475 1180 555 1225 580 975 460 1130 530 1220 575 1345 635

" (Minus) N/A N/A 905 430 1060 500 1105 520 880 415 1015 480 1100 520 1210 570

ADJUST"

1st Stage HEAT" Speed 1st Stage COOL" Speed

ADJUST

Switch

1 2 3 4 1 2 3 4

Switch

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) N/A N/A 956 450 1175 555 1210 570 800 377 870 410 930 438 1000 471

NORM (Normal) N/A N/A 870 410 1070 505 1110 525 725 3423 800 377 845 398 910 429

" (Minus) N/A N/A 780 370 960 455 995 470 650 306 720 339 770 363 825 389

NOTES − The effect of static pressure and filter resistance is included in air volumes shown.

1st stage HEAT is approximately 91% of the same 2nd stage HEAT speed position.

1st stage COOL (two speed air conditioning units only) is approximately 70% (65% for units built prior to 09−2002) of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position − minimum 500 cfm (235 L/s).

Lennox Harmony IIt zone control applications − Minimum blower heating speed is approximately 75% of the 1st stage HEAT speed position.

Lennox Harmony IIt zone control applications − Minimum blower cooling speed is approximately 45% of the 2nd stage COOL speed position.

N/A − 1st stage and 2nd stage HEAT, speed position 1, cannot be used with this model.

Page 5

Page 5

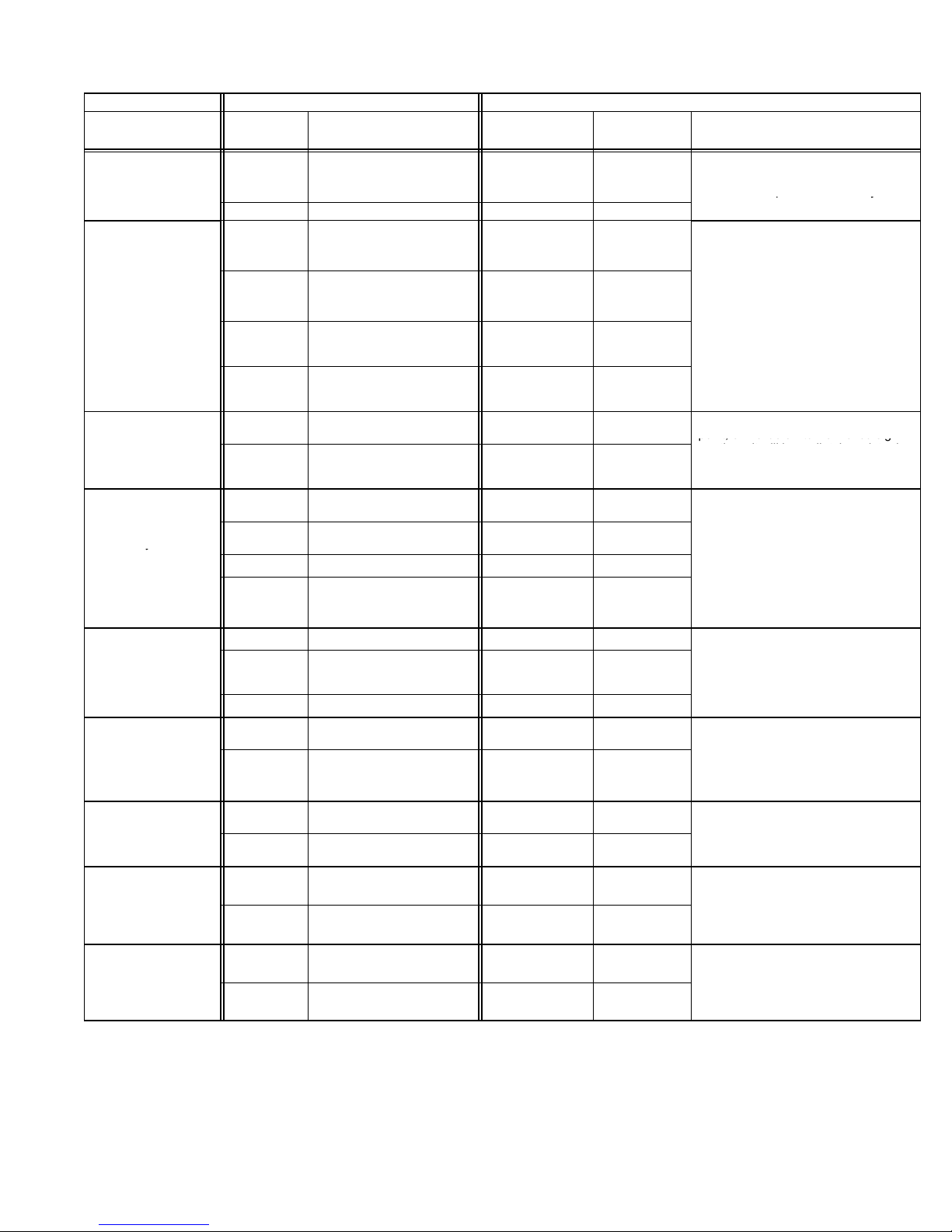

BLOWER DATA

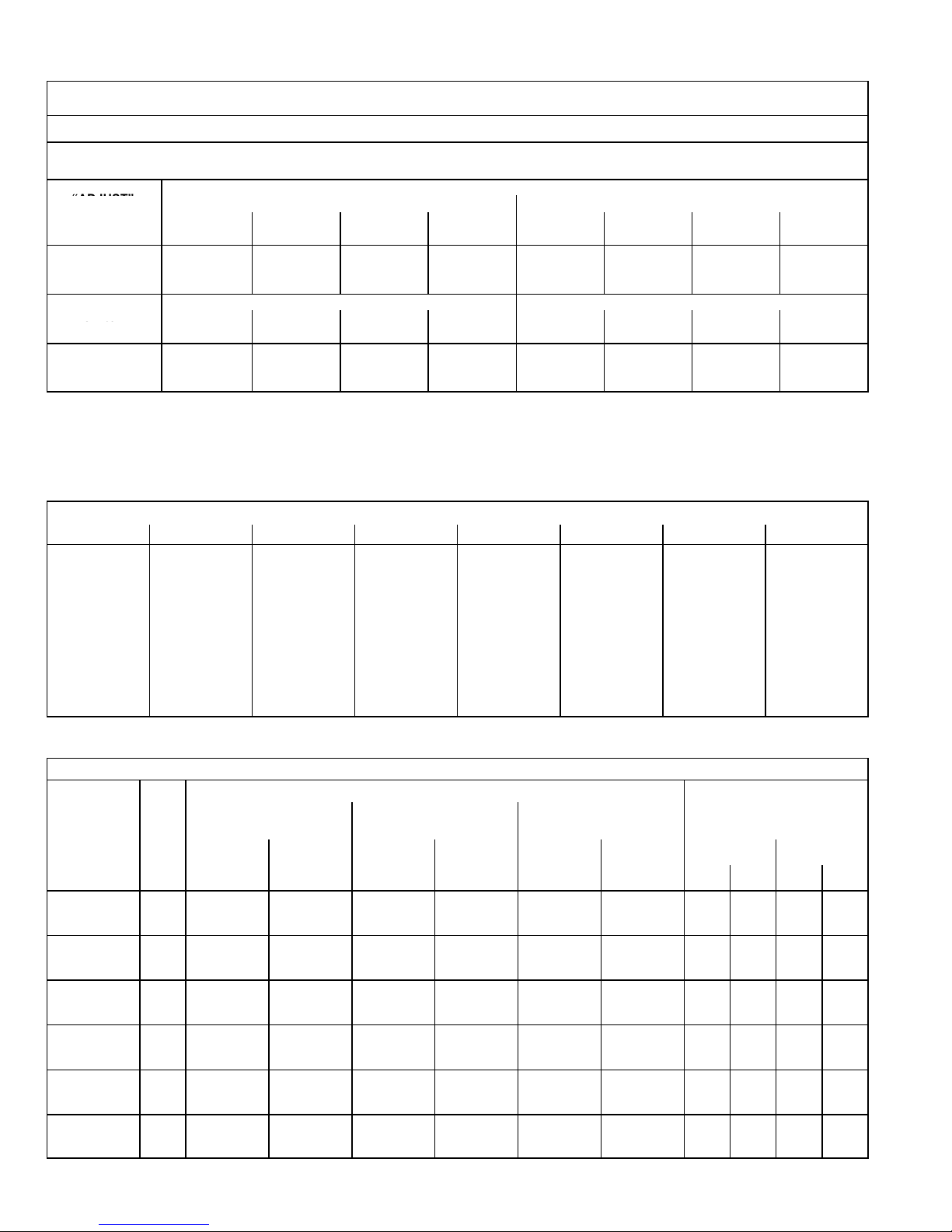

G60DFV−60C−090 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or

Return Air from Bottom and One Side.

Blower Control Factory Settings ADJUST − NORM

HEAT − 2

COOL − 4

Speed Switch Positions

ADJUST"

2nd Stage HEAT" Speed 2nd Stage COOL" Speed

Switch

Positions

1 2 3 4 1 2 3 4

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 1525 720 1730 815 1850 870 2130 1005 1670 790 1805 850 2035 960 2275 1075

NORM (Normal) 1385 655 1575 745 1770 835 1935 915 1520 715 1640 775 1850 870 2070 975

" (Minus) 1245 590 1415 670 1595 750 1745 825 1365 645 1475 695 1665 785 1860 880

ADJUST"

1st Stage HEAT" Speed 1st Stage COOL" Speed

ADJUST

Switch

1 2 3 4 1 2 3 4

Switch

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 1380 650 1580 745 1800 850 1980 935 1070 504 1270 599 1385 653 1545 729

NORM (Normal) 1255 590 1440 680 1635 775 1800 850 955 450 1075 507 1240 585 1370 646

" (Minus) 1130 535 1295 610 1475 695 1620 765 865 408 910 429 1110 523 1220 575

NOTES − The effect of static pressure and filter resistance is included in air volumes shown.

1st stage HEAT is approximately 91% of the same 2nd stage HEAT speed position.

1st stage COOL (two speed air conditioning units only) is approximately 70% (60% for units built prior to 09−2002) of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony IIt zone control applications − Minimum blower heating speed is approximately 75% of the 1st stage HEAT speed position.

Lennox Harmony IIt zone control applications − Minimum blower cooling speed is approximately 42% of the 2nd stage COOL speed position.

G60DFV−60C−110 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or

Return Air from Bottom and One Side.

Blower Control Factory Settings ADJUST − NORM

HEAT − 2

COOL − 4

Speed Switch Positions

ADJUST"

2nd Stage HEAT" Speed 2nd Stage COOL" Speed

Switch

P

ositions

1 2 3 4 1 2 3 4

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 1530 720 1720 810 1955 925 2145 1010 1665 785 1810 855 2030 960 2300 1085

NORM (Normal) 1390 655 1565 740 1780 840 1950 920 1510 715 1645 775 1845 870 2090 985

" (Minus) 1250 590 1405 665 1600 755 1755 830 1360 640 1480 700 1660 785 1885 890

ADJUST"

1st Stage HEAT" Speed 1st Stage COOL" Speed

ADJUST

Switch

1 2 3 4 1 2 3 4

Switch

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 1375 650 1555 735 1795 850 1960 925 1035 488 1035 488 1300 613 1445 681

NORM (Normal) 1250 590 1410 665 1635 770 1785 840 950 448 1030 486 1180 556 1315 620

" (Minus) 1125 530 1270 600 1470 695 1605 755 855 403 925 436 1065 502 1195 563

NOTES − The effect of static pressure and filter resistance is included in air volumes shown.

1st stage HEAT is approximately 91% of the same 2nd stage HEAT speed position.

1st stage COOL (two speed air conditioning units only) is approximately 70% (60% for units built prior to 09−2002) of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony IIt zone control applications − Minimum blower heating speed is approximately 75% of the 1st stage HEAT speed position.

Lennox Harmony IIt zone control applications − Minimum blower cooling speed is approximately 42% of the 2nd stage COOL speed position.

Page 6

Page 6

BLOWER DATA

G60DFV−60D−135 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or

Return Air from Bottom and One Side.

Blower Control Factory Settings ADJUST − NORM

HEAT − 2

COOL − 4

Speed Switch Positions

ADJUST"

2nd Stage HEAT" Speed 2nd Stage COOL" Speed

Switch

Position

s

1 2 3 4 1 2 3 4

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 1545 730 1775 840 1985 935 2175 1025 1710 805 1850 875 2080 980 2300 1085

NORM (Normal) 1405 665 1615 760 1805 850 1980 935 1555 735 1680 795 1890 890 2095 990

" (Minus) N/A N/A 1455 685 1625 765 1780 840 1400 660 1515 715 1700 805 1885 890

ADJUST"

1st Stage HEAT" Speed 1st Stage COOL" Speed

ADJUST

Switch

1 2 3 4 1 2 3 4

Switch

Positions

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+" (Plus) 1400 660 1620 765 1825 860 2020 955 1090 514 1175 554 1350 637 1500 707

NORM (Normal) 1275 600 1475 695 1660 785 1835 865 1000 471 1090 514 1230 580 1375 648

" (Minus) N/A N/A 1325 625 1495 705 1650 780 885 417 975 460 1100 519 1230 580

NOTES − The effect of static pressure and filter resistance is included in air volumes shown.

1st stage HEAT is approximately 91% of the same 2nd stage HEAT speed position.

1st stage COOL (two speed air conditioning units only) is approximately 70% (60% for units built prior to 09−2002) of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony IIt zone control applications − Minimum blower heating speed is approximately 75% of the 1st stage HEAT speed position.

Lennox Harmony IIt zone control applications − Minimum blower cooling speed is approximately 45% of the 2nd stage COOL speed position.

N/A − 1st stage and 2nd stage HEAT, speed position 1 with " (Minus) adjust, cannot be used with this model.

FILTER AIR RESISTANCE

cfm L/s in. w.g. Pa cfm L/s in. w.g. Pa

0 0 0.00 0 1400 660 0.15 35

200 95 0.01 0 1600 755 0.19 45

400 190 0.03 5 1800 850 0.23 55

600 285 0.04 10 2000 945 0.27 65

800 380 0.06 15 2200 1040 0.33 80

1000 470 0.09 20 2400 1130 0.38 95

1200 565 0.12 30 2600 1225 0.44 110

Data is for 1 inch (25 mm) cleanable filter (field provided).

HIGH ALTITUDE / MANIFOLD PRESSURE INFORMATION

Altitude

Manifold Pressure

Model

In

p

ut

Gas

0 − 4500 ft.

(0 − 1372 m)

4,501 − 7500 ft.

(1373 − 2286 m)

7501−10,000 ft.

(2286 − 3048 m)

at all altitudes

Input

Size

Gas

Required

Pressure

Required

Pressure

Required

Pressure

Low Fire High Fire

C

onversion

Kit

Pressure

Switch

C

onversion

Kit

Pressure

Switch

C

onversion

Kit

Pressure

Switch

in. w.g. kPa in. w.g. kPa

Nat. No Change No Change No Change No Change 59M16 18M64 1.7 0.42 3.5 0.87

045/070−1

to −

6

LPG 59M13 No Change 59M13 No Change 59M14 18M64 4.9 1.22 10.0 2.5

Nat. No Change No Change No Change 18M61 59M16 18M64 1.7 0.42 3.5 0.87

090−1

to −

6

LPG 59M13 No Change 59M13 18M61 59M14 18M64 4.9 1.22 10.0 2.5

Nat. No Change No Change No Change 18M63 59M16 18M61 1.7 0.42 3.5 0.87

110/−135−1

to−−

6

LPG 59M13 No Change 59M13 18M63 59M14 18M61 4.9 1.22 10.0 2.5

045/070−7 and

Nat. No Change No Change No Change No Change 59M17 18M64 1.7 0.42 3.5 0.87

045/070 7 and

later

LPG 59M13 No Change 59M13 No Change 59M14 18M64 4.9 1.22 10.0 2.5

Nat. No Change No Change No Change 18M61 59M17 18M64 1.7 0.42 3.5 0.87

090−7

and later

LPG 59M13 No Change 59M13 18M61 59M14 18M64 4.9 1.22 10.0 2.5

110/135−7 and

Nat. No Change No Change No Change 18M63 59M17 18M61 1.7 0.42 3.5 0.87

110/135 7 and

later

LPG 59M13 No Change 59M13 18M63 59M14 18M61 4.9 1.22 10.0 2.5

Pressure switch is factory set. No adjustment necessary. All models use the factory installed pressure switch from 0−4500 feet (0−1372 m).

Page 7

Page 7

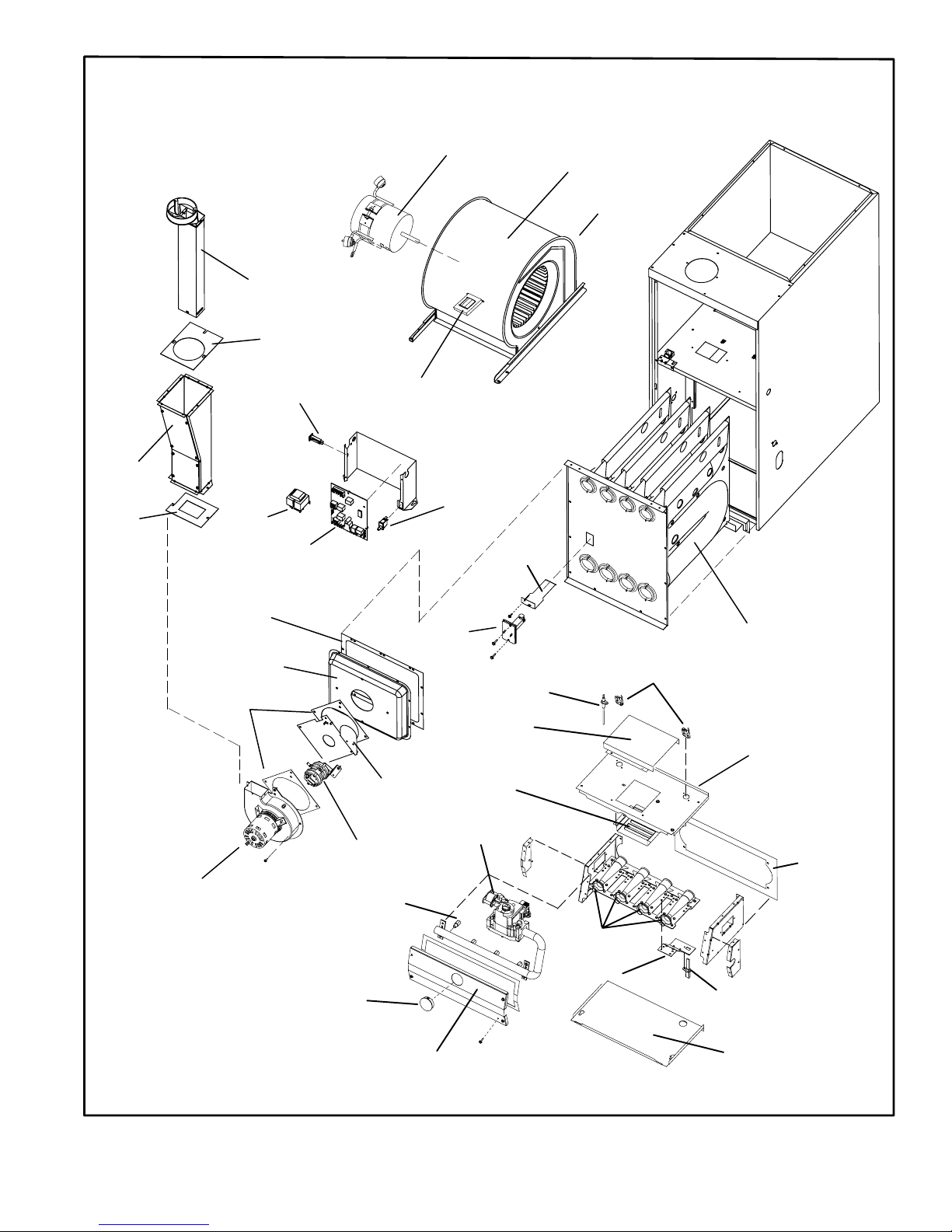

FIGURE 1

G60DFV(X) PARTS ARRANGEMENT

Combustion Air Pres-

sure Switch Assembly

(Two switches)

Blower Assembly

Variable Speed

Blower Motor

Internal Flue Pipe

Assembly

Flue Box Gasket

Flue Collector Box

Gasket

Combustion Air Inducer

Gasket

Primary

Limit

Heat Exchanger

Combustion

Air Orifice

Transformer

SureLightt Two−Stage

Variable Spee Integrated

Control Board

Flue

Chase

Gasket

Door

Interlock Switch

Flame Sensor

Gas

Valve

Burners

Ignitor

Gas

Orifices

Ignitor

Bracket

Burner Box Bottom

Flame Rollout Switches

Air Intake

Cover

Air Baffle

Gasket

Limit

Shield

Burner Box Cover

Power Choke

(1HP Only)

Circuit

Breaker

Sight Glass

Burner Box Top

Secondary Limit

(not shown)

Page 8

Page 8

I−UNIT COMPONENTS

Unit components are shown in figure 1. The gas valve,

combustion air inducer and burners can be accessed by removing the burner access panel. Electrical components

are in the control box (figure 2) found in the blower section.

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace’s

electronic controls. Precautions will help to avoid

control exposure to electrostatic discharge by

putting the furnace, the control and the technician at the same electrostatic potential. Neutralize electrostatic charge by touching hand and all

tools on an unpainted unit surface, such as the

gas valve or blower deck, before performing any

service procedure.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. Transformers on all

models are rated 40VA with a 120V primary and a 24V secondary.

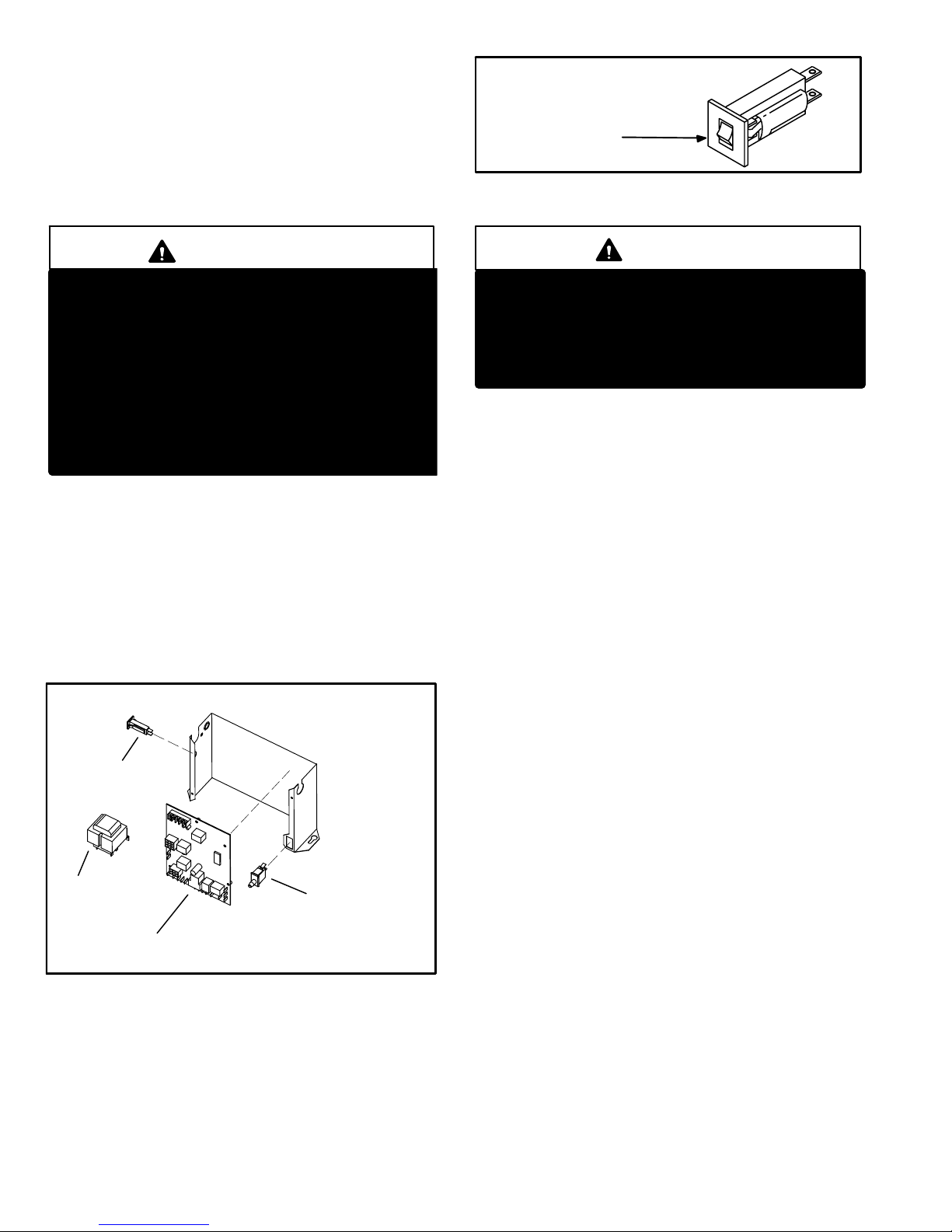

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VAC is wired in series with line voltage. When the blower door is removed the

unit will shut down.

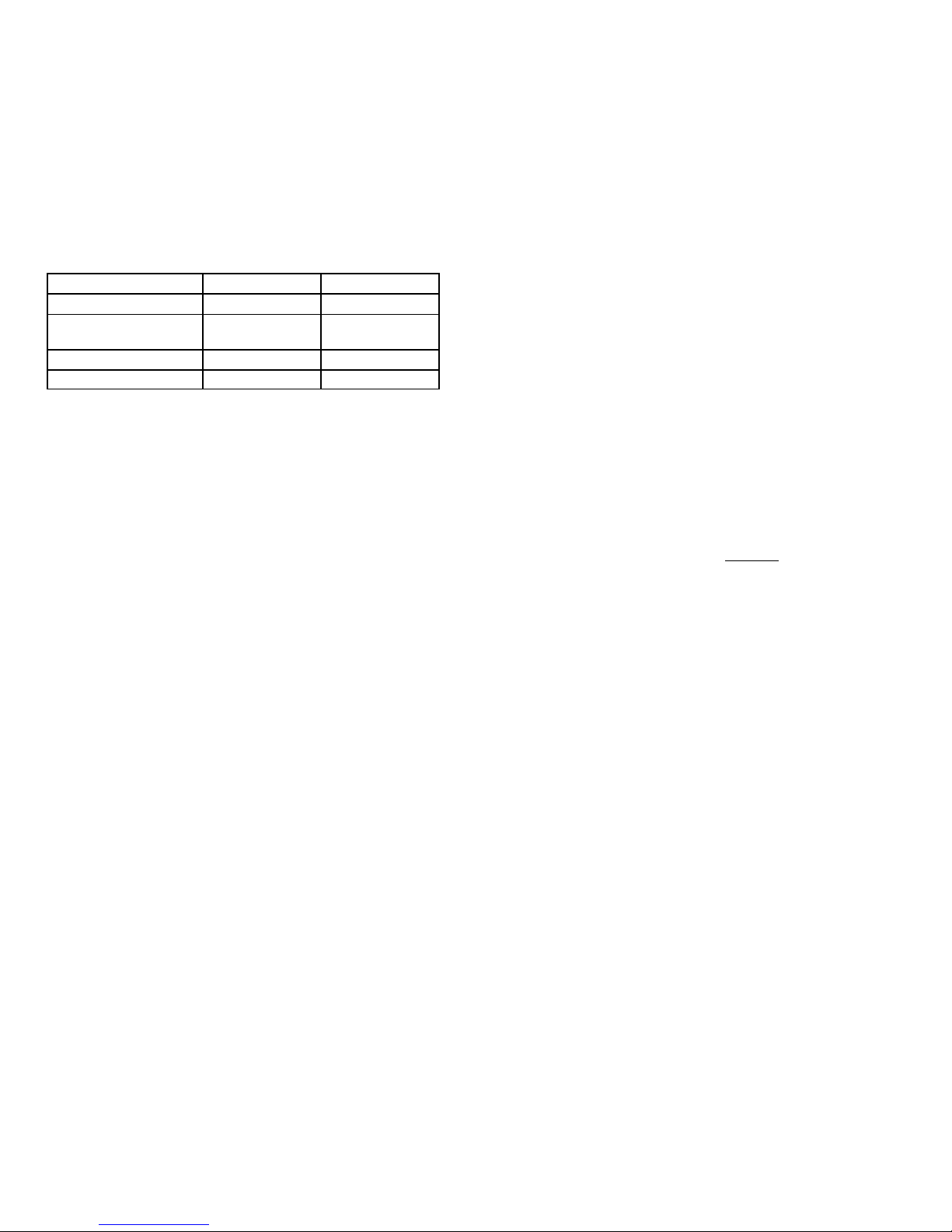

FIGURE 2

CONTROL BOX G60DFV

Transformer

SureLightt Two−Stage

Integrated Control Board

Door

Interlock Switch

Circuit

Breaker

3. Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box.

The switch provides overcurrent protection to the transformer (T1). The breaker is rated 3A at 32V. If the current

exceeds this limit the breaker will trip and all unit operation will shutdown. The breaker can be manually reset

by pressing the button on the face. See figure 3.

FIGURE 3

CIRCUIT BREAKER CB8

PRESS TO RESET

WARNING

Shock hazard.

Disconnect power before servicing. Integrated

Control Board is not field repairable. If control is

inoperable, simply replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

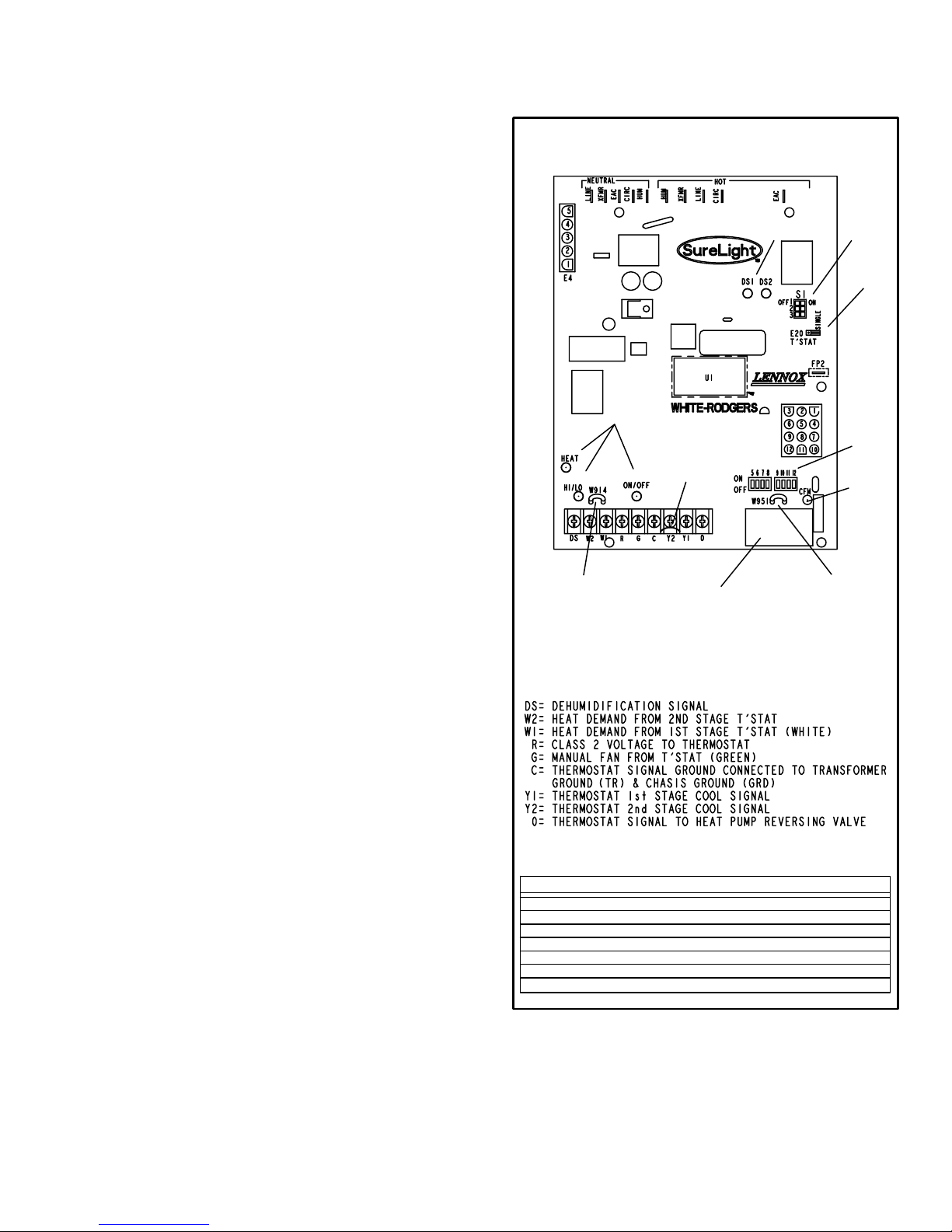

4. Integrated Control Board (A92)

Board 18M99

G60DFV units are equipped with the Lennox two−stage,

variable speed integrated SureLight control board. The

system consists of a ignition / blower control board (figure

4 with control terminal designations in tables 1 through 4)

and ignitor (figure 12). The board and ignitor work in combination to ensure furnace ignition and ignitor durability.

The SureLight integrated board controls all major furnace

operations. The board features two LED lights, DS1 and

DS2 for troubleshooting and four LED lights (DS3, DS6,

DS7 and DS8) to show furnace status. The board also has

two accessory terminals rated at (1) one amp each. See

table 5 for status code and table 6 for troubleshooting

diagnostic codes.

Electronic Ignition

At the beginning of each heating cycle, the SureLight control monitors the first stage and second stage combustion

air inducer prove switch. The control will not begin the heating cycle if the first stage prove switch is closed (by−

passed). Likewise the control will not begin the second

stage heating cycle if the second stage prove switch is

closed, and will allow first stage heat only. However if the

second stage prove switch closes during the first stage pre−

purge, the control WILL respond to second stage heat call.

Once the first stage prove switch is determined to be open,

the combustion air inducer is energized on low (first stage)

heat speed. When the differential in the prove switch is

great enough, the prove switch closes and a 15−second

pre−purge begins. If the switch is not proven within 2−1/2

minutes, the control goes into Watchguard−Pressure

Switch mode for a 5−minute re−set period.

Page 9

Page 9

After the 15−second pre−purge period, the SureLight ignitor

warms up for 20 seconds after which the gas valve opens

for a 4−second trial for ignition. The ignitor energizes during

the trial until flame is sensed. If ignition is not proved during

the 4−second period, the control will try four more times with

an inter purge and warm−up time between trials of 35 seconds. After a total of five trials for ignition (including the initial trial), the control goes into Watchguard−Flame Failure

mode. After a 60−minute reset period, the control will begin

the ignition sequence again.

The SureLight control board has an added feature that prolongs the life of the ignitor. After a successful ignition, the

SureLight control utilizes less power to energize the ignitor

on successive calls for heat. The control continues to ramp

down the voltage to the ignitor until it finds the lowest

amount of power that will provide a successful ignition. This

amount of power is used for 255 cycles. On the 256th call

for heat, the control will again ramp down until the lowest

power is determined and the cycle begins again.

Two Stage Operation / Thermostat Selection Jumper

The control can be utilized in two modes: SINGLE−STAGE

thermostat or TWO−STAGE thermostat. The thermostat

selection jumper E20, located just below dip switches 1

through 3 (figure 4), must be positioned for the particular

application. The jumper is factory set on TWO" for use

with a two−stage thermostat with two stage heat. Re−position jumper to SINGLE" for use with a single stage thermostat with two stage heat.

While in the single−stage thermostat mode (single jumper

setting), the burners will always fire on first−stage heat. The

combustion air inducer will operate on low speed and indoor blower will operate on low heat speed. After a field selectable 10 or 15 minute delay (dip switch 3), the unit will

switch to second stage heat. While in the two−stage thermostat mode (two jumper setting) the burners will fire on

first−stage heat. The combustion air inducer will operate on

low speed and indoor blower will operate on low heat

speed. The unit will switch to second−stage heat on call

from the indoor thermostat. If there is a simultaneous call

for W1 and W2 (first and second stage heat) the unit will fire

on first stage heat and switch to second stage heat after 30

seconds of operation. See Sequence of Operation flow

charts in the back of this manual for more detail.

TW0−STAGE, VARIABLE SPEED INTEGRATED

CONTROL BOARD

FIGURE 4

DIP

SWITCHES

1 − 3

DIP

SWITCHES

5 − 12

DIAGNOSTIC

LEDs

ON−BOARD

JUMPER W951

(cut when heat pump

is used with FM21)

ON−BOARD

JUMPER W914

(cut when CCB1,

Harmony II or

SignatureStat are used)

LEDs

LED

FACTORY−

INSTALLED

JUMPER

THERMOSTAT CONNECTIONS (TB1)

DIP SWITCH FUNCTIONS

DIP SWITCH(ES) FUNCTION

1 and 2 Blower Off Delay

3 Second Stage ON Delay (Single−stage t’stat)

4 Not used

5 and 6 Cooling Mode Blower Speed

7 and 8 Blower Speed Adjustment

9 and 10 Cooling Mode Blower Ramping Profile

11 and 12 Heating Mode Blower Speed

E20

JUMPER

16 PIN BLOWER

CONTROL TERMINALS

DS8

DS7

DS3

DS6

Page 10

Page 10

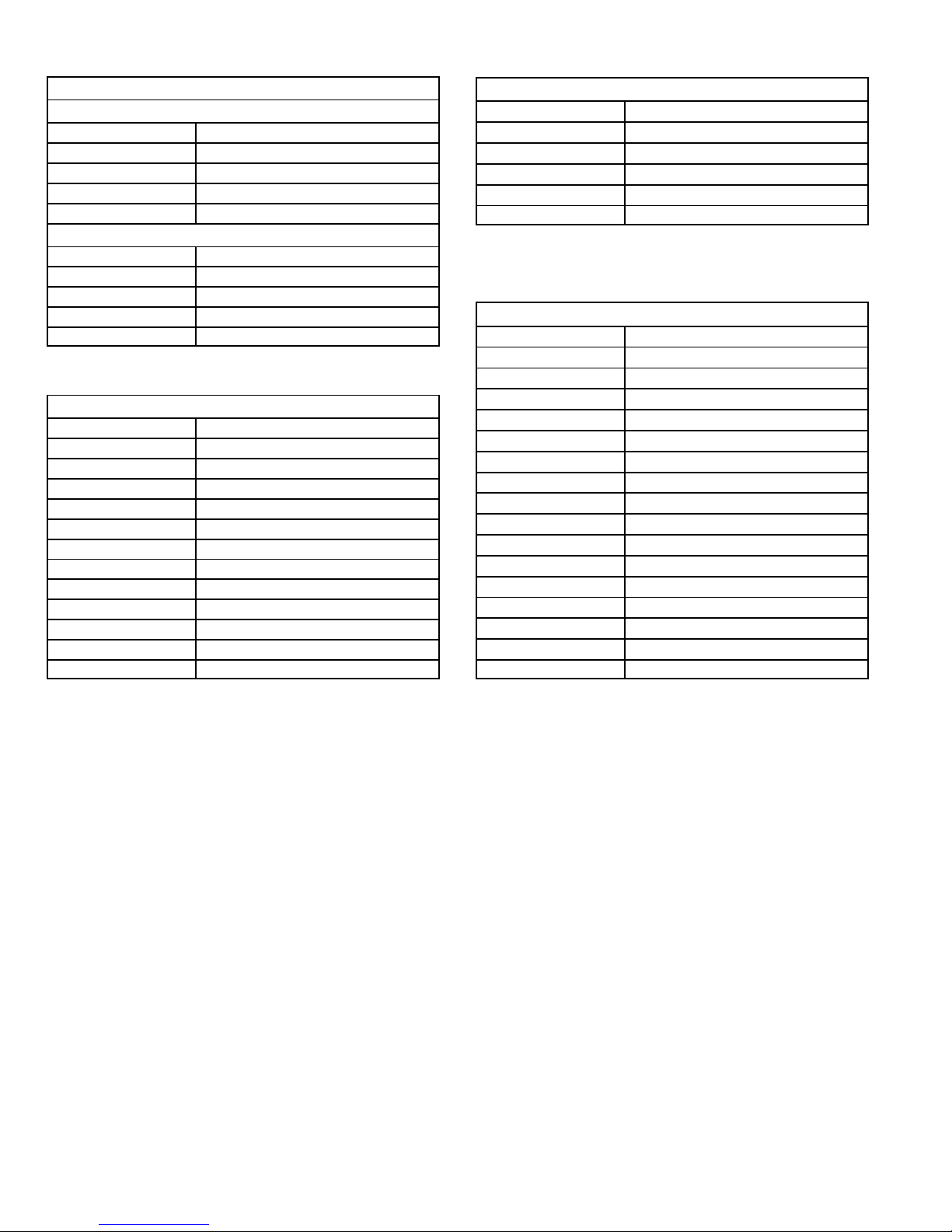

TABLE 1

Two Stage Ignition / Blower Control Terminals

120VAC Neutral

LINE Line 120VAC Neutral

XFMR Transformer 120VAC Neutral

EAC Electronic Air Cleaner 120VAC Neutral

CIRC Indoor Blower 120VAC Neutral

HUM Humidifier 120VAC Neutral

120VAC Line

HUM Humidifier 120VAC Hot

XMFR Transformer 120VAC Hot

LINE Line 120VAC Hot

CIRC Indoor Blower 120VAC Hot

EAC Electronic Air Cleaner 120VAC Hot

TABLE 2

SureLight Board 12Pin Terminal Designation

PIN # Function

1 Gas Valve 2nd. Stage (High Fire)

2 Second Stage Pressure Switch

3 Not Used

4 Ground

5 24V Hot

6 Primary Limit In

7 Gas Valve 1st. Stage (Low Fire)

8 Gas Valve Common

9 24V Neutral

10 Ground

11 Primary Limit Out

12 1st Stage Pressure Switch

TABLE 3

SureLight Board 5 Pin Terminal Designation

PIN # Function

1 Ignitor

2 Combustion Air Inducer High Speed

3 Combustion Air Inducer Low Speed

4 Combustion Air Inducer Neutral

5 Ignitor Neutral

TABLE 4

SureLight Board 16 Pin Blower Control Terminals

PIN # Function

1 Ground

2 Low Heat Speed

3 Ground

4 DELAY" Dip Switch Selection

5 COOL" Dip Switch Selection

6 Y1" Signal

7 ADJUST" Dip Switch Selection

8 Ground

9 o" From Thermostat

10 DS" Output Signal

11 HEAT" Dip Switch Selection

12 24 VAC

13 HIGH HEAT Speed

14 Y2" Signal

15 G"

16 CFM LED

Page 11

Page 11

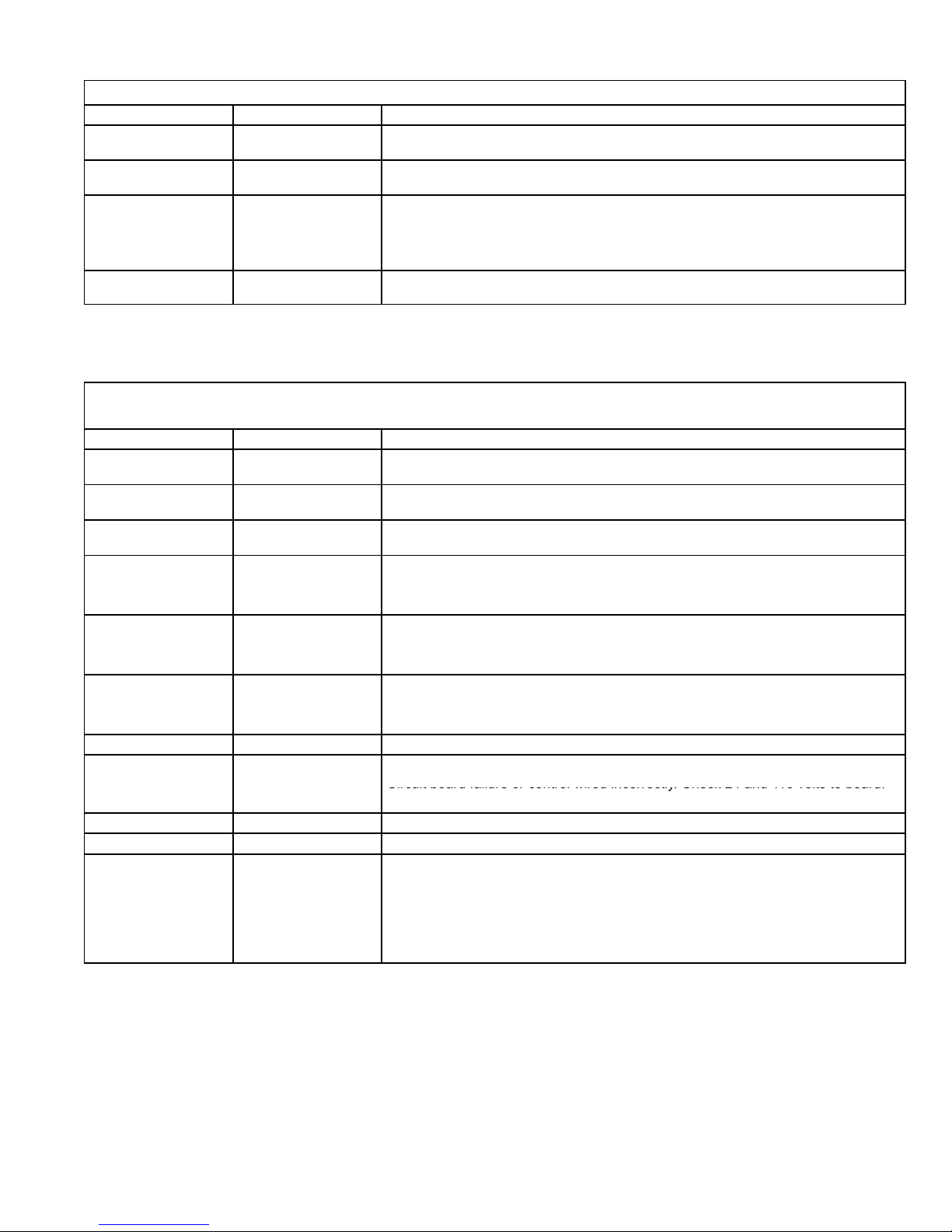

TABLE 5

STATUS CODES

STATUS LED COLOR FUNCTION

DS3

ON / OFF ’

GREEN

DS3−ON indicates that the motor has a demand to operate. (This LED must be on in all

modes).

DS6

CFM"

GREEN

DS6−blinking indicates the airflow (CFM) demand in the motor. The air flow is determined by

counting blinks between two (2) second pauses. One blink equals roughly 100 CFM.

DS7

HI / LO"

YELLOW

DS7−ON indicaties the DS to R" jumper has not been cut. When the jumper is cut the system

will be operating with LENNOX HARMONY IIt (See Harmony Installation Instructions) or

with the CCB1 Efficiency Plus control.

CCB1: When ON, a 24 VAC is being applied and when OFF, it has been removed. This on/off

operation varies the indoor blower’s performance so dehumidification can be enhanced.

DS8

HEAT"

YELLOW DS8−ON indicates the system is in HEAT mode.

TABLE 6

DIAGNOSTIC CODES

Diagnostic LEDs are labeled DS1 and DS2. See figure 4 for location of diagnostic LEDs.

DS1 DS2 DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS

SLOW FLASH

Power on − Normal operation.

Also signaled during cooling and continuous fan.

SIMULTANEOUS

FAST FLASH

SIMULTANEOUS

FAST FLASH

Normal operation − signaled when heating demand initiated at thermostat.

SLOW FLASH ON

Primary, secondary or rollout limit switch open. Limits must close within 3 minutes

or unit goes into 1 hour Watchguard.

OFF SLOW FLASH

Low prove switch open;

OR: Blocked inlet/exhaust vent;

OR: Low prove switch closed prior to activation of combustion air inducer.

OFF FAST FLASH

High prove switch open;

OR: Blocked inlet/exhaust vent;

OR: High pressure switch closed prior to activation of combustion air inducer.

ALTERNATING

SLOW FLASH

ALTERNATING

SLOW FLASH

Watchguard −− burners failed to ignite; OR limit open more than 3 minutes;

OR lost flame sense 5 times in one heating cycle;

OR pressure switch opened 5 times in one heating cycle.

SLOW FLASH OFF Flame sensed without gas valve energized.

ON ON

ONONON

OFF

Circuit board failure or control wired incorrectly. Check 24 and 115 volts to board.

OFF ON

Circuit board failure or control wired incorrectly. Check 24 and 115 volts to board.

FAST FLASH SLOW FLASH Main power polarity reversed. Switch line and neutral.

SLOW FLASH FAST FLASH Low flame signal. Measures below 0.23 microAmps. Replace flame sense rod.

ALTERNATING

FAST FLASH

ALTERNATING

FAST FLASH

The following conditions are sensed during the ignitor warm−up period only:

1) Improper main ground;

2) Broken ignitor; OR: Open ignitor circuit;

3) Line voltage below 75 volts.

(If voltage lower than 75 volts prior to ignitor warm-up, control will signal waiting on

call from thermostat, and will not respond.

NOTE − Slow flash rate equals 1 Hz (one flash per second). Fast flash rate equals 3 Hz (three flashes per second).

Low flame sense current = 0.17−0.22 microAmps.

Page 12

Page 12

Dip Switch Settings

Switches 1 and 2 − Blower Off Delay The blower−on delay

of 45 seconds is not adjustable. The blower−off delay (time

that the blower operates after the heating demand has

been satisfied) can be adjusted by moving switches 1 and 2

on the integrated control board. The unit is shipped from

the factory with a blower−off delay of 90 seconds. The

blower off delay affects comfort and is adjustable to satisfy

individual applications. Adjust the blower off delay to

achieve a supply air temperature between 90° and 110°F at

the exact moment that the blower is de−energized. Longer

off delay settings provide lower supply air temperatures;

shorter settings provide higher supply air temperatures.The table below provides the blower off timings that will

result from different switch settings.

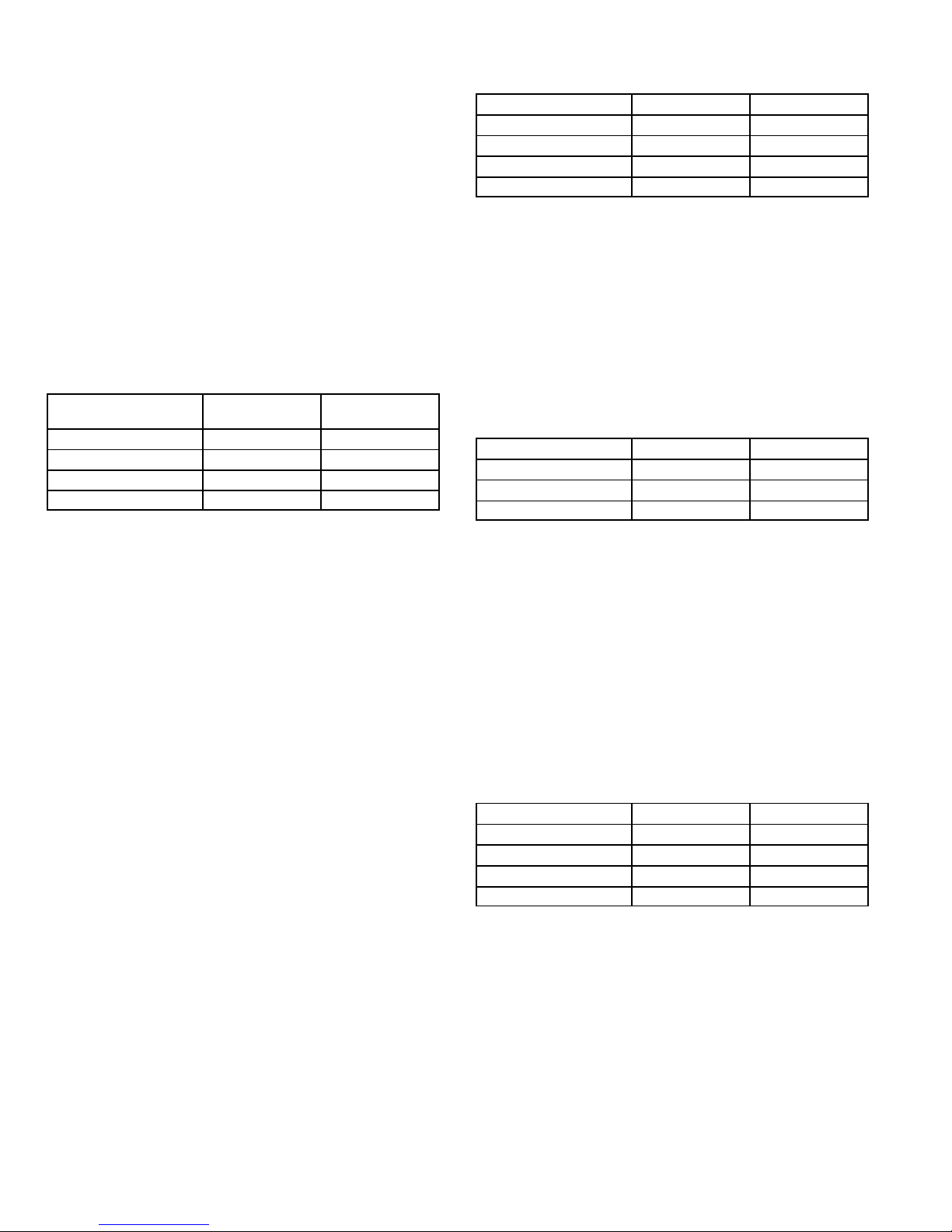

TABLE 7

Blower Off Delay Switch Settings

Blower Off Delay

(Seconds)

Switch 1 Switch 2

60 Off Off

90 Off On

120 On Off

180 On On

Switch 3 − Second Stage Delay (Used with Single−Stage

Thermostat Only) This switch is used to determine the

second stage on delay when a single−stage thermostat is

being used. The switch is factory−set in the ON position,

which provides a 10−minute delay before second−stage

heat is initiated. If the switch is toggled to the OFF position,

it will provide a 15−minute delay before second−stage heat

is initiated. This switch is only activated when the thermostat selector jumper is positioned for SINGLE−stage thermostat use.

Switch 4 − Not used

Switches 5 and 6 − Cooling Mode Blower Speed

Switches 5 and 6 are used to select cooling blower motor

speed. The unit is shipped from the factory with the dip

switches positioned for high speed (4) indoor blower motor

operation during the cooling mode. The table below provides the cooling mode blower speeds that will result from

different switch settings. Refer to blower data tables at the

front of this manual for corresponding cfm values.

TABLE 8

Cooling Mode Blower Speeds

Speed

Switch 5 Switch 6

1 − Low On On

2 − Medium Low Off On

3 − Medium High On Off

4 − High (Factory) Off Off

Switches 7 and 8 − Blower Speed Adjustment Switches

7 and 8 are used to select blower speed adjustment settings. The unit is shipped from the factory with the dip

switches positioned for NORMAL (no) adjustment. The dip

switches may be positioned to adjust the blower speed by

+10% or −10% to better suit the application. The table below provides blower speed adjustments that will result from

different switch settings. Refer to blower data tables at the

front of this manual for corresponding cfm values.

TABLE 9

Blower Speed Adjustment

Adjustment

Switch 7 Switch 8

+10% (approx.) On Off

NORMAL (Factory) Off Off

−10% (approx.) Off On

Switches 9 and 10 − Cooling Mode Blower Speed

Ramping −− Switches 9 and 10 are used to select cooling

mode blower speed ramping options. Blower speed ramping may be used to enhance dehumidification performance. The switches are factory set at option A which has

the greatest effect on blower motor performance. The table

below provides the cooling mode blower speed ramping

options that will result from different switch settings. The

cooling mode blower speed ramping options are detailed

on the next page. See unit nameplate for manufacturing

date.

TABLE 10

Cooling Mode Blower Speed Ramping

Ramping Option

Switch 9 Switch 10

A (Factory) Off Off

B On Off

C Off On

D On On

Page 13

Page 13

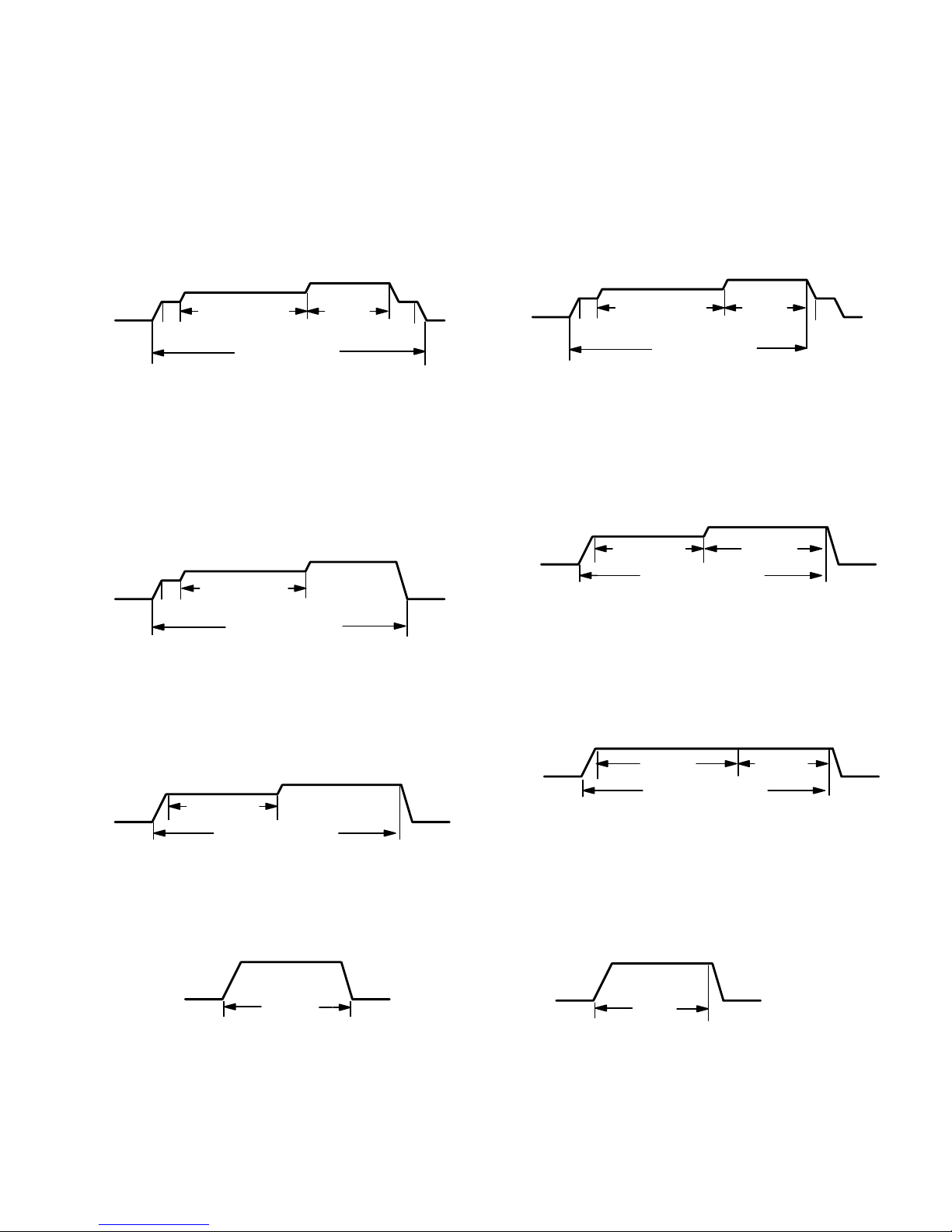

G60DFV units manufactured before April 2003

Ramping Option A (Factory Selection)

D Motor runs at 50% for 1/2 minute.

D Motor then runs at 82% for approximately 7−1/2 min-

utes.

D If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D Once demand is met, motor runs at 50% for 1/2 min-

ute.

D Motor ramps down to off.

OFF

OFF

1/2 MIN

50% CFM

COOLING DEMAND

7−1/2 MIN

82% CFM

100%

CFM

1/2 MIN

50% CFM

Ramping Option B

D Motor runs at 50% for 1/2 minute.

D Motor then runs at 82% for approximately 7−1/2 min-

utes.

D If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D Once demand is met, motor ramps down to off.

OFF

OFF

1/2 MIN

50% CFM

7−1/2 MIN

82% CFM

100% CFM

COOLING DEMAND

Ramping Option C

D Motor runs at 82% for approximately 7−1/2 minutes.

D If demand has not been satisfied after 7−1/2 minutes,

the motor runs at 100% until demand is satisfied.

D Once demand is met, motor ramps down to off.

OFF

OFF

82%CFM

100% CFM

COOLING DEMAND

7−1/2 MIN

Ramping Option D

D Motor runs at 100% until demand is satisfied.

D Once demand is met, motor ramps down to off.

OFFOFF

100% CFM

COOLING

DEMAND

G60DFV units manufactured April 2003 and later

Ramping Option A (Factory Selection)

S Motor runs at 50% for 30 seconds.

S Motor then runs at 82% for approximately 7−1/2 min-

utes. If demand has not been satisfied after 7−1/2 minutes.

S Motor runs at 100% until demand is satisfied.

S Once demand is met, motor runs at 50% for 30 sec-

onds then −

S ramps down to stop.

OFF

OFF

1/2 MIN

50% CFM

COOLING DEMAND

7 1/2 MIN

82% CFM

100%

CFM

1/2 MIN

50% CFM

Ramping Option B

S Motor runs at 82% for approximately 7−1/2 minutes. If

demand has not been satisfied after 7−1/2 minutes −

S motor runs at 100% until demand is satisfied.

S Once demand is met, motor ramps down to stop.

OFF

OFF

82%CFM

100% CFM

COOLING DEMAND

7 1/2 MIN

Ramping Option C

S Motor runs at 100% until demand is satisfied.

S Once demand is met, motor runs at 100% for *45 sec-

onds. Then,

S ramps down to stop.

OFF

OFF

100% CFM

100% CFM

COOLING DEMAND

G60DFV units date coded prior to 2−2006 will delay 60 seconds

Ramping Option D

S− Motor runs at 100% until demand is satisfied.

S− Once demand is met, motor ramps down to stop.

OFFOFF

100% CFM

COOLING

DEMAND

Page 14

Page 14

Switches 11 and 12 − Heating Mode Blower Speed

Switches 11 and 12 are used to select heating mode blower

motor speed. The unit is shipped from the factory with the

dip switches positioned for medium low (2) speed indoor

blower motor operation during the heating mode. The table

below provides the heating mode blower speeds that will

result from different switch settings. Refer to blower data

tables at the front of this manual for corresponding cfm values.

TABLE 11

Heating Mode Blower Speeds

Speed

Switch 11 Switch 12

1 − Low On On

2 − Medium Low

(Factory)

Off On

3 − Medium High On Off

4 − High Off Off

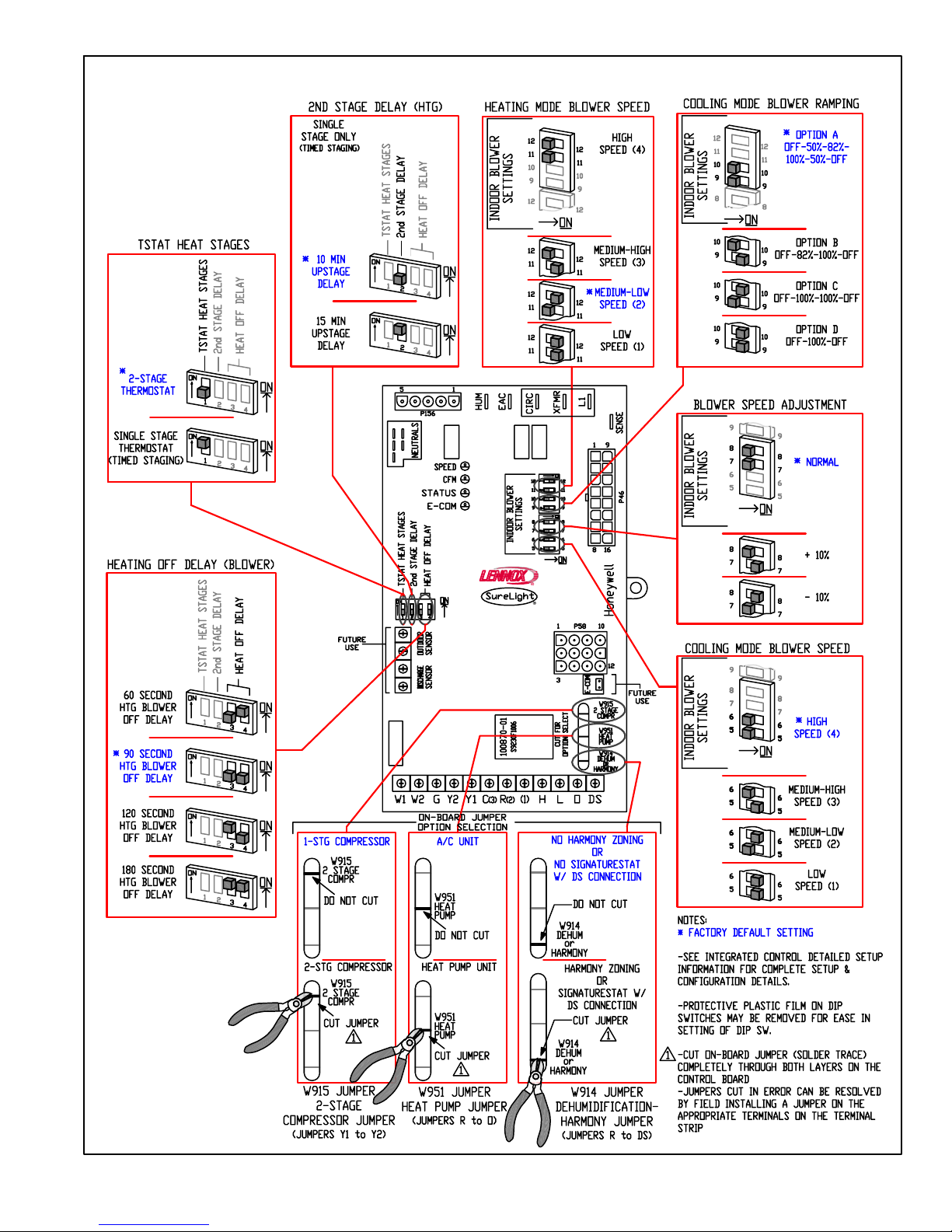

On−Board Jumper W914

On−board jumper W914, which connects terminals DS and

R on the integrated control board, must be cut when the furnace is installed with the Harmony II zone control board,

the CCB1 EfficiencyPlus humidity control or Lennox SignatureStatt. Refer to table 21 for operation sequence in applications including a G60DF, CCB1 and single−speed outdoor unit. Table 22 gives the operation sequence in applications with a two−speed outdoor unit. Refer to table 23

for operation sequence in applications including a G60DF,

SignatureStat and single−speed outdoor unit. Table 24

gives the operation sequence in applications with a two−

speed outdoor unit.

On−Board Jumper W951

On−board jumper W951, which connects terminals R and O

on the integrated control board, must be cut when the furnace is installed in applications which include a heat pump

unit and the FM21 FuelMaster control board.

Factory−Installed Jumper Y1 to Y2

A factory−installed jumper from Y1 to Y2 terminals on the

integrated control board terminal strip must be removed if

two−stage cooling will be used.

Diagnostic LEDs (DS1 and DS2)

Two diagnostic LEDs are located on the two−stage, variable speed integrated control just to the left of the first bank

of dip switches. These lights’ flashes correspond with diagnostic codes detailed on in table 6.

Status LEDs (HEAT, HI/LO, ON/OFF and CFM)

The integrated control includes four LEDs which indicate

operating status. The green ON/OFF LED is lit any time the

blower is operating. The green CFM LED indicates the

blower motor speed. Count the number of blinks between

the two−second pauses to determine the CFM. Each blink

represents approximately 100 CFM. The yellow HI/LO LED

is lit when the W914 (DS to R) jumper has not

been clipped

for CCB1, SignatureStat or Harmony operation. The yellow

HEAT LED is lit when the indoor blower is operating at the

HEATING speed.

Page 15

Page 15

WARNING

Shock hazard.

Disconnect power before servicing. Integrated

Control Board is not field repairable. If control is

inoperable, simply replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

5. Integrated Control Board(A92)

Board 100870

Beggining with the G60DFV−7, units are equipped with the

Lennox two−stage, variable speed integrated SureLight

control board. The system consists of a ignition / blower

control board (figures 5 and 6) with control pin designations in tables 12, 13 and 14 and ignitor (figure 13). The

board and ignitor work in combination to ensure furnace

ignition and ignitor durability. The SureLight integrated

board controls all major furnace operations. The board

features a red LED light, for furnace status and troubleshooting. The LED flashes in X" + Y" codes. For example

using table 15 under PRESSURE SWITCH CODES", if

the red LED flashes 2 times, then off for 2 seconds then

flashes 3 times, the low pressure switch is failed open.

Two green LEDs show indoor blower status and CFM. See

Page 20 for more detail. The board also has two 120 volt

accessory terminals rated at (1) one amp each. In addition

there is a 24 volt accessory terminal located on TB1.

Electronic Ignition

At the beginning of the heat cycle the SureLight control

monitors the first stage and second stage combustion air

inducer prove switch. The control will not begin the heating

cycle if the first stage prove switch is closed (by−passed).

Likewise the control will not begin the second stage heating

cycle if the second stage prove switch is closed, and will remain in first stage heat. However, if the second stage prove

switch closes during the first stage heat pre−purge, the control will allow second stage heat. Once the first stage prove

switch is determined to be open, the combustion air inducer is energized on low (first stage) heat speed. When the

differential in the prove switch is great enough, the prove

switch closes and a 15−second pre−purge begins. If the

switch is not proven within 2−1/2 minutes, the control goes

into Watchguard−Pressure Switch mode for a 5−minute re−

set period.

After the 15−second pre−purge period, the SureLight ignitor

warms up for 20 seconds after which the gas valve opens

for a 4−second trial for ignition. The ignitor energizes during

the trial until flame is sensed. If ignition is not proved during

the 4−second period, the control will try four more times with

an inter purge and warm−up time between trials of 35 seconds. After a total of five trials for ignition (including the initial trial), the control goes into Watchguard−Flame Failure

mode. After a 60−minute reset period, the control will begin

the ignition sequence again.

NOTE − Board 100870 provides 95 volts regulated to

the ignitor.

Two Stage Operation / Thermostat Selection Jumper

The control can be utilized in two modes: SINGLE−STAGE

thermostat or TWO−STAGE thermostat. The thermostat

selection is made using a dip switch (figure 4) and must be

positioned for the particular application. The dip switch is

factory set on TWO" for use with a two−stage thermostat

with two stage heat. Re−position dip switch to SINGLE" for

use with a single stage thermostat with two stage heat.

While in the single−stage thermostat mode (single dip

switch setting), the burners will always fire on first−stage

heat. The combustion air inducer will operate on low speed

and indoor blower will operate on low heat speed. After a

factory default 10 minute recognition period, the unit will

switch to second stage heat. While in the two−stage thermostat mode (two dip switch setting) the burners will fire on

first−stage heat. The combustion air inducer will operate on

low speed and indoor blower will operate on low heat

speed. The unit will switch to second−stage heat on call

from the indoor thermostat. If there is a simultaneous call

for first and second stage heat, the unit will fire an first stage

heat and switch to second stage heat after 30 seconds of

operation. See Sequence of Operation flow charts in the

back of this manual for more detail.

Page 16

Page 16

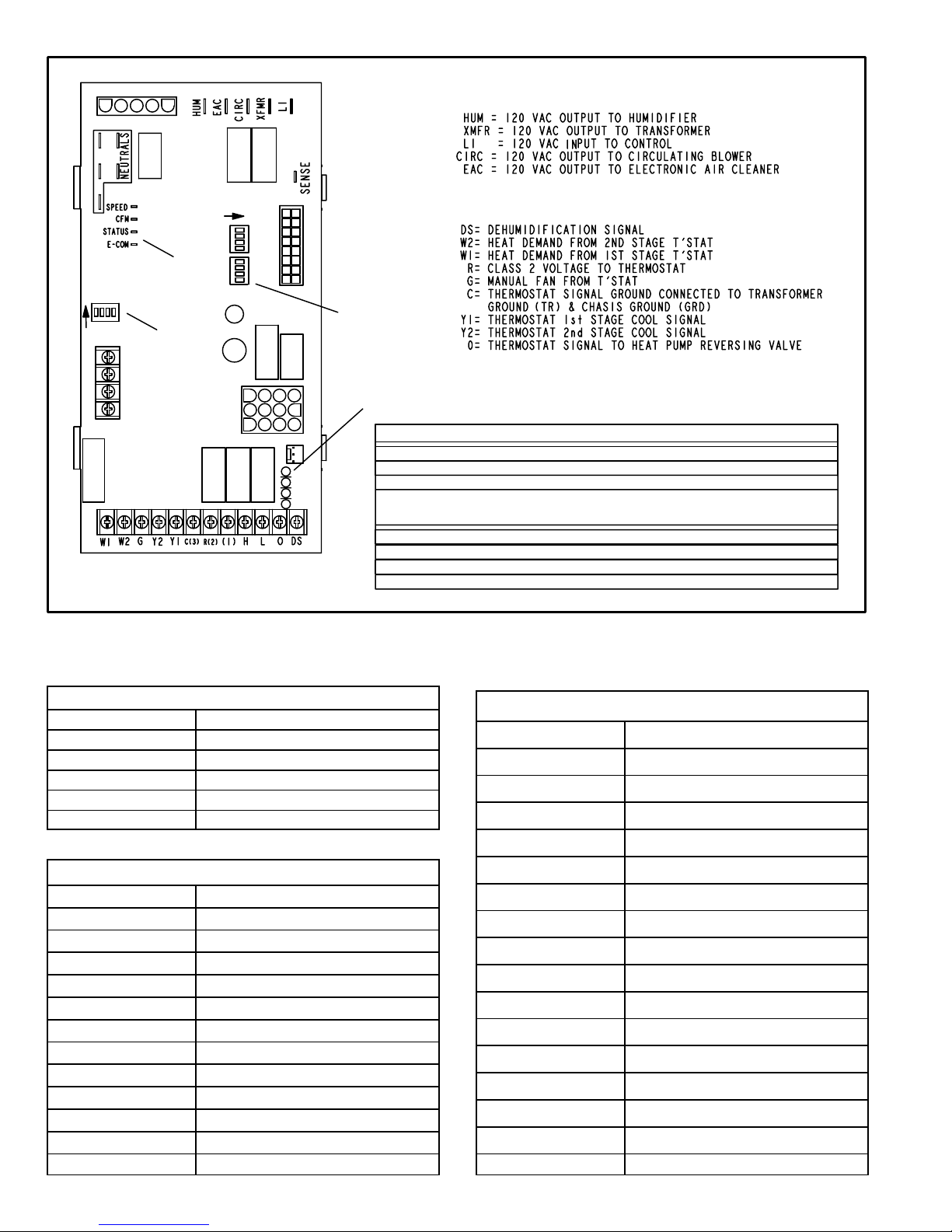

TWO−STAGE, VARIABLE SPEED INTEGRATED CONTROL BOARD

FIGURE 5

THERMOSTAT CONNECTIONS (TB1)

1/4" QUICK CONNECT TERMINALS

DIP SWITCH FUNCTIONS

INDOOR

BLOWER DIP

SWITCHES

HEATING

DIP

SWITCHES

DIAGNOSTIC

LEDs

ON−BOARD

JUMPERS

H= 24V HUMIDIFIER OUTPUT

L= LENNOX SYSTEM OPERATION MONITOR

1= FUTURE USE

NEUTRALS= 120 VAC NEUTRAL

W914

W951

W915

HTG DIP SWITCH(ES) FUNCTION

5 and 6 Cooling Mode Blower Speed

7 and 8 Blower Speed Adjustment

9 and 10 Cooling Mode Blower Ramping Profile

11 and 12 Heating Mode Blower Speed

1 T’stat Heat Stages (single or two−stage)

2 Second Stage ON Delay (single−stage t’stat)

3 and 4 Heating Fan OFF Delay

INDOOR BLOWER

DIP SWITCH(ES)

FUNCTION

1

16

5

12

1

4

ON

ON

9

8

TABLE 12

SureLight Board 5 Pin Terminal Designation

PIN # Function

1 Ignitor

2 Combustion Air Inducer High Speed

3 Combustion Air Inducer Low Speed

4 Combustion Air Inducer Neutral

5 Ignitor Neutral

TABLE 13

SureLight Board 12Pin Terminal Designation

PIN # Function

1 Gas Valve High Fire

2 Second Stage Prove Switch

3 Rollout In

4 Ground

5 24V Hot

6 Primary Limit In

7 Gas Valve Low Stage

8 Gas Valve Common

9 24V Neutral

10 Ground

11 Rollout Switch Out

12 1st Stage Prove Switch

TABLE 14

SureLight Board 16 Pin Blower Control Terminals

PIN # Function

1 Ground

2 Low Heat Speed

3 Ground

4 DELAY" Dip Switch Selection

5 COOL" Dip Switch Selection

6 Y1" Signal

7 ADJUST" Dip Switch Selection

8 Ground

9 0" From Thermostat

10 DS" Output Signal

11 HEAT" Dip Switch Selection

12 24 VAC

13 HIGH HEAT Speed

14 Y2" Signal

15 G"

16 CFM LED

Page 17

Page 17

FIGURE 6

TWO−STAGE, VARIABLE SPEED INTEGRATED CONTROL BOARD

Page 18

Page 18

TABLE 15

FLASH CODE

(X + Y)

STATUS / ERROR DESCRIPTION

FLASH CODE DESCRIPTIONS

Pulse A 1/4 second flash followed by four seconds of off time.

Heartbeat Constant 1/2 second bright and 1/2 second dim cycles.

X + Y

LED flashes X times at 2Hz, remains off for two seconds, flashes Y times at 2Hz, remains off for four

seconds, then repeats.

Pulse Power on − Standby.

Heartbeat Normal operation − signaled when heating demand initiated at thermostat.

FLAME CODES

1 + 2 Low flame current −− run mode.

1 + 3 Flame sensed out of sequence −− flame still present.

PRESSURE SWITCH CODES

2 + 3 Low pressure switch failed open.

2 + 4 Low pressure switch failed closed.

2 + 5 High pressure switch failed open.

2 + 6 High pressure switch failed closed.

2 + 7 Low pressure switch opened during ignition trial or heating demand.

LIMIT CODE

3 + 1 Limit switch open.

WATCHGUARD CODES

4 + 1 Watchguard −− Exceeded maximum number of retries.

4 + 2 Watchguard −− Exceeded maximum number of retries or last retry was due to pressure switch opening.

4 + 3 Watchguard −− Exceeded maximum number of retries or last retry was due to flame failure.

4 + 5 Watchguard −− Limit remained open longer than three minutes.

4 + 6

Watchguard −− Flame sensed out of sequence; flame signal gone.

4 + 7 Ignitor circuit fault −− Failed ignitor or triggering circuitry.

4 + 8 Low line voltage.

HARD LOCKOUT CODES

5 + 1 Hard lockout −− Rollout circuit open or previously opened.

5 + 2 Control failed self check, internal error (control will restart if error recovers).

5 + 3 No Earth ground (control will restart if error recovers).

5 + 4 Reversed line voltage polarity (control will restart if the error recovers).

5 + 6 Low secondary (24VAC) voltage.

Page 19

Page 19

Dip Switch Settings

Heating Operation DIP Switch Settings

Switch 1 −− Thermostat Selection −− This unit may be used

with either a single−stage or two−stage thermostat. The

thermostat selection is made using a DIP switch which

must be properly positioned for the particular application.

TheDIP switch is factory−positioned for use with a two−

stage thermostat. If a single−stage thermostat is to be used,

the DIP switch must be repositioned.

a − Select OFF" for two−stage heating operation con-

trolled by a two−stage heating thermostat (factory setting);

b − Select ON" for two−stage heating operation con-

trolled by a single−stage heating thermostat. This setting provides a timed delay before second−stage heat

is initiated.

Switch 2 −− Second Stage Delay (Used with Single−

Stage Thermostat Only) −− This switch is used to deter-

mine the second stage on delay when a single−stage thermostat is being used. The switch is factory−set in the OFF

position, which provides a 10−minute delay before second−

stage heat is initiated. If the switch is toggled to the ON

position, it will provide a 15−minute delay before second−

stage heat is initiated. This switch is only activated when

the thermostat selector jumper is positioned for SINGLE−

stage thermostat use.

Switches 3 and 4 −− Blower−Off Delay −− The blower−on

delay of 45 seconds is not adjustable. The blower−off delay

(time that the blower operates after the heating demand

has been satisfied) can be adjusted by moving switches 3

and 4 on the integrated control board. The unit is shipped

from the factory with a blower−off delay of 90 seconds. The

blower off delay affects comfort and is adjustable to satisfy

individual applications. Adjust the blower off delay to

achieve a supply air temperature between 90° and 110°F at

the exact moment that the blower is de−energized. Longer

off delay settings provide lower supply air temperatures;

shorter settings provide higher supply air temperatures.Table 16 provides the blower off timings that will result

from different switch settings.

TABLE 16

Blower Off Delay Switch Settings

Blower Off Delay

(Seconds)

Switch 3 Switch 4

60 Off On

90 Off Off

120 On Off

180 On On

Indoor Blower Operation DIP Switch Settings

Switches 5 and 6 −− Cooling Mode Blower Speed −−

Switches 5 and 6 are used to select cooling blower motor

speed. The unit is shipped from the factory with the DIP

switches positioned for high speed (4) indoor blower motor

operation during the cooling mode. The table below provides the cooling mode blower speeds that will result from

different switch settings. Refer to blower tables at the front

of this manual for corresponding cfm values.

TABLE 17

Cooling Mode Blower Speeds

Speed

Switch 5 Switch 6

1 − Low On On

2 − Medium Low Off On

3 − Medium High On Off

4 − High (Factory) Off Off

Switches 7 and 8 −− Blower Speed Adjustment −−

Switches 7 and 8 are used to select blower speed adjustment settings. The unit is shipped from the factory with the

DIP switches positioned for NORMAL (no) adjustment.

The DIP switches may be positioned to adjust the blower

speed by +10% or −10% to better suit the application. The

table below provides blower speed adjustments that will result from different switch settings. Refer to blower tables at

the front of this manual for corresponding cfm values.

TABLE 18

Blower Speed Adjustment

Adjustment

Switch 7 Switch 8

+10% (approx.) On Off

NORMAL (Factory) Off Off

−10% (approx.) Off On

Switches 9 and 10 −− Cooling Mode Blower Speed

Ramping −− Switches 9 and 10 are used to select cooling

mode blower speed ramping options. Blower speed ramping may be used to enhance dehumidification performance. The switches are factory set at option A which has

the greatest effect on blower motor performance. Table 19

provides the cooling mode blower speed ramping options

that will result from different switch settings. The cooling

mode blower speed ramping options are detailed on

Page 13 under units manufactured April 2003 and later".

NOTE − The off portion of the selected ramp profile also applies during heat pump operation in dual fuel applications.

TABLE 19

Cooling Mode Blower Speed Ramping

Ramping Option

Switch 9 Switch 10

A (Factory) Off Off

B On Off

C Off On

D On On

Switches 11 and 12 −− Heating Mode Blower Speed −−

Switches 11 and 12 are used to select heating mode blower

motor speed. The unit is shipped from the factory with the

dip switches positioned for medium low (2) speed indoor

blower motor operation during the heating mode. The table

below provides the heating mode blower speeds that will

result from different switch settings. Refer to blower tables

at the front of this manual for corresponding cfm values.

Page 20

Page 20

TABLE 20

Heating Mode Blower Speeds

Speed

Switch 11 Switch 12

1 − Low On On

2 − Medium Low

(Factory)

Off On

3 − Medium High On Off

4 − High Off Off

On−Board Jumper W914

On−board jumper W914, which connects terminals DS and

R on the integrated control board, must be cut when the furnace is installed with either the Harmony III zone control

board or a thermostat which features humidity control. If

the jumper is left intact the PWM signal from the HARMONY III control will be blocked and also lead to control damage. Refer to table 21 (CCB1) and table 23 (SignatureStat)

for operation sequence in applications including G60DFV,

a thermostat which features humidity control and a single−

speed outdoor unit. Table 22 (CCB1) and table 24 (SignatureStatt) gives the operation sequence in applications with

a two−speed outdoor unit.

On−Board Jumper W951

On−board jumper W951, which connects terminals R and O

on the integrated control board, must be cut when the furnace is installed in applications which include a heat pump

unit and a thermostat which features dual fuel use. If the

jumper is left intact, terminal O" will remain energized eliminating the HEAT MODE in the heat pump.

On−Board Jumper W915

On−board jumper W915, which connects terminals Y1 and

Y2 on the integrated control board, must be cut if two−stage

cooling will be used. If the jumper is not cut the outdoor unit

will operate in second−stage cooling only.

Status LEDs (SPEED, CFM, E−COM)

The green SPEED LED indicates circulating blower speed

in response to the DS signal. The LED is lit during normal

blower operation and is off during a dehumidification demand. In Harmony III applications, the brightness of the

LED indicates the requested blower speed.

The green CFM LED indicates the blower air flow. Count

the number of blinks between the two−second pauses to

determine the CFM. Each blink represents approximately

100 CFM.

The green E−COM LED indicates that the control is receiving and processing of commands and inputs. The LED may

flash rapidly or may display a single flash, depending upon

the activity.

TABLE 21

G60DFV, CCB1 and Single−Speed Outdoor Unit

OPERATING MODE

SYSTEM DEMAND SYSTEM RESPONSE

System Condition

Thermostat

Demand

*Relative Humidity

(EfficiencyPlus Lights)

Blower

CFM

(COOL)

Comments

Normal operation Y1

No demand. Humidity

level is acceptable

COOL

Compressor demand and indoor blower speed

controlled by thermostat demand.

*Call for humidity

removal during

cooling demand

Y1

Humidity level rises above

setpoint. Demand initiated.

60%/65%

of COOL

Call for dehumidification initiated by CCB1 control.

Indoor blower speed reduced by CCB1 control.

Dehumidification

demand satisfied

during cooling demand.

Y1

Humidity level falls below set-

point. No demand

COOL

When humidity demand is satisfied, blower speed

immediately increases to the COOL CFM to hasten the end of the cycle.

Call for cooling after call for

None

Humidity level above setpoint.

Demand initiated.

Off

Dehumidification mode begins when relative hu-

humidity

removal.

Y1

Humidity level above setpoint.

Demand initiated.

60%/65%

of COOL

Dehumidification mode begins when relative hu

midity is greater than setpoint.

Humidity demand

satisfied between

None Over setpoint (1 or more) Off

While unit is not operating (no thermostat de-

thermostat demands (unit

off cycle).

Y1 Change to acceptable COOL

mand), slide switch is moved down and back up

.

Blower operates at COOL CFM.

NOTE − When changing unit mode of operation from cooling to heating, indicating lights that are on will stay on until the first thermostat heating

demand.

* Reduced blower speed is 65% of COOL for the −36A and −36B units; 60% of COOL for −60C and −60D series units.

Page 21

Page 21

TABLE 22

G60DFV, CCB1 and Two−Speed Outdoor Unit

OPERATING MODE SYSTEM DEMAND SYSTEM RESPONSE

System

Condition

Thermostat

Demand

*Relative Humidity

(EfficiencyPlus Lights)

****Compressor

Speed

Blower CFM

(COOL)

Comments

Normal operation

Y1 No demand. Acceptable Low

**42%/46%/49

% of HIGH

COOL

Compressor demand and indoor

blower speed controlled by

Y2 No demand. Acceptable High HIGH COOL

py

thermostat demand

Y1 No demand. Acceptable Low

**42%/46%/49

% of HIGH

COOL

Call for humidity

removal during

Y1

Humidity level rises slightly

(1) above setpoint. Demand

initiated.

Low

**42%/46%/49

% of HIGH

COOL

Dehumidification mode does not begin

until after initial thermostat demand is

1st−stage cooling

demand

Demand

satisfied

Humidity level remains

slightly (1) above setpoint.

Demand continues.

Off

Off

satisfied and new cooling demand is

initiated.

Y1

Humidity level remains

slightly (1) above setpoint.

Demand continues.

High

***65%/60% of

HIGH COOL

Significant increase in

Y1

No demand. Acceptable

Low

**42%/46%/49

% of HIGH

COOL

If humidity rises significantly above setpoint, or if slide switch is moved signifi-

humidity duri

ng

thermostat cooling

demand.

Y1

Humidity level rises signifi-

cantly (2 or more) above

setpoint. Demand initiated.

High

***65%/60% of

HIGH COOL

point, or if slide switch is moved signifi

cantly, unit will immediately go into de-

humidification mode (in presence of

thermostat demand).

Y1

Humidity level

above setpoint.

High

***65%/60% of

HIGH COOL

Humidity demand

Y1

Humidity level falls below

setpoint. No demand.

High

HIGH COOL

When humidity demand is satisfied,

blower immediately shifts to the COOL

CFM in order to hasten the end of the

y

satisfied during

thermostat demand.

None

No demand. Acceptable

Off

Off

CFM in order to hasten the end of the

cycle. Unit can only shift out of high

thermostat demand

.

Y1

No demand. Acceptable

Low

**42%/46%/49

% of HIGH

COOL

speed compressor operation at begin-

ning of next cycle.

Y2

No demand. Acceptable

High

HIGH COOL

Call for humidity

removal during 2nd

stage thermostat

Y2

Humidity level rises slightly

(1) above setpoint. Demand

initiated.

High

***65%/60% of

HIGH COOL

Blower immediately changes speed in

response to thermostat demand.

d

eman

d

Y2

No demand. Acceptable

High

HIGH COOL

*Call for 1st stage

None

Humidity level is slightly (1)

above setpoint.

Off

Off

Dehumidification mode (high speed

Call for 1st stage

cooling after call for

humidity removal.

Y1

Humidity level is slightly (1)

above setpoint.

Low

**42%/46%/49

% of HIGH

COOL

compressor) begins with next thermo-

stat demand after initial demand is sat-

isfied.

Call for 2nd stage

None

Humidity level is slightly (1)

above setpoint.

Off

Off

Reduced blower speed (dehumidifica-

cooling after call for

humidity removal

Y2

Humidity level is slightly (1)

above setpoint.

High

***65%/60% of

HIGH COOL

tion speed) begins immediately with

thermostat demand

Call for cooling after

None

Humidity level is significantly

above setpoint (2 or more).

Off

Off

If humidity increases significantly over

setpoint, or if slide switch is moved,

significant increase in

humidity

Y1 or Y2

Humidity level is significantly

above setpoint (2 or more).

High

***65%/60% of

HIGH COOL

unit immediately goes into dehumidifi-

cation mode (in presence of thermostat

demand).

Humidity demand

satisfied between

None

Humidity level is slightly (1)

above setpoint.

Off

Off

While unit is not operating (no thermo-

stat demand), slide switch is moved

satisfied between

thermostat demands

(unit off cycle).

Y1 or Y2

Humidity level falls below

setpoint. No demand.

High

HIGH COOL

down and back up. Blower and com-

pressor operate at high speed until

next thermostat demand.

NOTE − When changing unit mode of operation from cooling to heating, indicating lights that are on will stay on until the first thermostat heating demand.

*IMPORTANT - If power to unit is turned on with CCB1 calling for humidity removal, outdoor unit may be locked into high speed indefinitely. To

reset, move humidity slide switch all the way down then back up to desired setpoint (with unit running)

** Reduced blower speed is 49% for ALL model units manufactured September 2002 and later. (Earlier date code − 42% of HIGH COOL for −36A

and −36B units; 46% of HIGH COOL for −60C and −60D series units).

*** Reduced blower speed is 65% of HIGH COOL for −36A and −36B units; 60% of HIGH COOL for −60C and −60D series units.

****If the two−speed control on a two−speed outdoor unit is set for LATCH 2 (15 minutes) or LATCH 3 (30 minutes), the compressor will latch into

high speed after a Y1 demand has occurred for that period of time.

Page 22

Page 22

TABLE 23

G60FDV, SignatureStatt and SINGLE STAGE OUTDOOR UNIT

OPERATING

SEQUENCE

SYSTEM DEMAND SYSTEM RESPONSE

Thermostat Demand Relative Humidity

Blower

Syst

em

Condition

Step

Y1 O G

W

1

Status D

C

ompres-

sor

Blower

CFM

(COOL)

Comments

NO CALL FOR DEHUMIDIFICATION

Normal Operation 1 On On On Acceptable

24

VAC

High 100%

Compressor and indoor

blower follow thermostat

demand

BASIC MODE (only active on a Y1 thermostat demand)

Normal Operation 1 On On On Acceptable

24

VAC

High 100%

SignatureStat energizes

Dehumidification

Call

2 On On On On Demand

0

VAC

High

60%, 65%,

70%*

Y1

and de−energizes D on

a call for de−humidification

PRECISION MODE (operates independent of a Y1 thermostat demand)

Normal Operation 1 On On On Acceptable

24

VAC

High 100%

Dehumidification mode

Dehumidification

call

2 On On On Demand

0

VAC

High

60%, 65%,

70%*

begi

ns when hum

idity i

s

greater than set point

Dehumidification

call ONLY

1 On On On Demand

0

VAC

High

60%, 65%,

70%*

SignatureStat will try to

maintain room humidity

set

p

oint by allowing the

Jumpers at indoor unit with a single stage outdoor unit

setpoint by allowing the

room space to maintain a

Jumpers at indoor unit with a single stage outdoor unit

With Condensing unit − Cut W914 (R to DS) on SureLight board

room space to maintain a

cooler room thermostat

With Condensing unit Cut W914 (R to DS) on SureLight board

With Heat Pump − Cut W914 (R to DS) & W951 (R to O) on SureLight board

setpoint**

Dave Lennox SignatureStat to use for this application − 51M26 1 heat / 1 cool or 51M28 − 2 heat / 2 cool for heat pumps

*Dehumidification blower speed is 65% of COOL speed for 36A & 36B units and 60% COOL speed for 60C & 60D units

manufactured before 09−2002. Dehumidification blower speed is 70% of COOL speed for all units manufactured 09−2002

and later.

**In Precision mode, SignatureStats built before 10−2003 will maintain room temperature up to 3°F(1.8°C) cooler than room

setting. Signature Stats built 10−2003 and later will maintain room temperature up to 2 °F (1.2°C) cooler than room setting.

Page 23

Page 23

TABLE 24

G60DFV, SignatureStatt and TWO STAGE OUTDOOR UNIT

OPERATING

SEQUENCE

SYSTEM DEMAND SYSTEM RESPONSE

Thermostat Demand Relative Humidity

Blower

Syst

em

Condition

Step

Y1 Y2 O G

W1W

2

Status D

Compressor

Blower

CFM

(COOL)

Comments

NO CALL FOR DEHUMIDIFICATION

Normal Operation −

Y1

1 On On On Acceptable

24

VAC

Low

60%, 65%

70%*

Compressor and indoor

Normal Operation −

Y2

2 On On On On Acceptable

24

VAC

High 100%

bl

ower follow thermosta

t

demand

ROOM THERMOSTAT CALLS FOR FIRST STAGE COOLING

BASIC MODE (only active on a Y1 thermostat demand)

Normal Operation 1 On On On Acceptable

24

VAC

Low

60%, 65%

70%*

SignatureStat energizes

Dehumidification

Call

2 On On On On Demand

0

VAC

High

60%, 65%

70%**

Y2

and de−energizes D on

a call for de−humidification

PRECISION MODE (operates independent of a Y1 thermostat demand)

Normal Operation 1 On On On Acceptable

24

VAC

Low

60% 65%

70%*

Dehumidification mode be-

Dehumidification

call

2 On On On On Demand

0

VAC

High

60% 65%

70%**

gins when hum

idity i

s

greater than set point

Dehumidification

call ONLY

1 On On On On Demand

0

VAC

High

60% 65%

70%**

SignatureStat will try to

maintain room humidity

setpoint by allowing the

room space to maintain a

cooler room thermostat

setpoint***

ROOM THERMOSTAT CALLS FOR FIRST AND SECOND STAGE COOLING

BASIC MODE (only active on a Y1 thermostat demand)

Normal Operation 1 On On On On Acceptable

24

VAC

High 100%

SignatureStat energizes

Dehumidification

Call

2 On On On On Demand

0

VAC

High

60% 65%

70%**

Y2

and de−energizes D on

a call for de−humidification

PRECISION MODE (operates independent of a Y1 thermostat demand)

Normal Operation 1 On On On Acceptable

24

VAC

Low

60% 65%

70%*

Dehumidification mode be-

Dehumidification

call

2 On On On On Demand

0

VAC

High

60% 65%

70%**

gins when hum

idity i

s

greater than set point

Dehumidification

call ONLY

1 On On On On Demand

0

VAC

High

60% 65%

70%**

SignatureStat will try to

maintain room humidity

Jumpers at indoor unit with a two stage outdoor unit

setpoint by allowing the

room s

p

ace to maintain a

pg

Cut factory jumper from Y1 to Y2 or cut W915 (Y1 to Y2)

With Condensin

g

unit − Cut W914 (R to DS) on SureLight board

room space to maintain a

cooler room thermostat

With Condensing unit

−

Cut W914 (R to DS) on SureLight board

With Heat Pump − Cut W914 (R to DS) & W951 (R to O) on SureLight board

setpoint***

Dave Lennox SignatureStat to use for this application − 51M27 2 heat / 2 cool or 51M28 − 2 heat / 2 cool for heat pumps

*Normal operation first stage cooling blower speed is as follows for units built before 09−2002: 65% of COOL for 36A, 36B,

60% COOL for 60C, 60D units. ALL units built 09−2002 and later first stage blower speed is 70% COOL speed.

**Dehumidification blower speed is as follows for units built before 09−2002: 65% of COOL for 36A, 36B 60% of COOL for

60C, 60D. ALL units built 09−2002 and later, reduced blower speed is 70% of COOL.

***In Precision mode, Signature Stats built before 10−2003 will maintain room temperature up to 3°F(1.8°C) cooler than room

setting. Signature Stats built 10−2003 and later will maintain room temperature up to 2 °F (1.2°C) cooler than room setting.

Page 24

Page 24

6. Blower Motor

FIGURE 7

SUPPLY AIR BLOWER

BLOWER

MOTOR (B6)

POWER

CHOKE

(L13)

BLOWER

WHEEL

To Remove Blower From Unit:

1. Disconnect Power, 2. Remove internal flue pipe and

chase (Section VI− Heat exchanger and Burners). 3. Re-

move Control Box, 4. Remove Bolts. 5. Unplug Motor

Wires From Control Board. Then Slide Out Front of Unit.

Blower Motor (B3)

G60DFV units use a three-phase, electronically controlled

D.C. brushless motor (controller converts single phase a.c. to

three phase D.C.), with a permanent-magnet-type rotor (figure 8). Because this motor has a permanent magnet rotor it

does not need brushes like conventional D.C. motors. Internal components are shown in figure 9. The stator windings

are split into three poles which are electrically connected to the

controller. This arrangement allows m o t o r windings t o turn

on and off in sequence by the controller.

FIGURE 8

G60DFV BLOWER MOTOR B3

MOTOR

CONTROLLER

SHAFT

J49

J48

G60DFV BLOWER MOTOR COMPONENTS

FIGURE 9

STATOR

(WINDINGS)

OUTPUT

SHAFT

BEARING

ROTOR

A solid-state controller is permanently attached to the

motor. The controller is primarily an A.C. to D.C. converter. Converted D.C. power is used to drive the motor.

The controller contains a microprocessor which monitors varying conditions inside the motor (such as motor

workload).

The controller uses sensing devices to sense what position

the rotor is in at any given time. By sensing the position of the

rotor and then switching the motor windings on and off in sequence, the rotor shaft turns the blower.

All G60DFV blower motors use single phase power. An

external run capacitor is not used. The motor uses permanently lubricated ball-type bearings.

Internal Operation

Each time the controller switches a stator winding (figure 9) on

and off, it is called a pulse." The length of time each pulse

stays on is called the pulse width." By varying the pulse width

(figure 11), the controller varies motor speed (called pulsewidth modulation"). This allows for precise control of motor

speed and allows the motor to compensate for varying load

conditions as sensed by the controller. In this case, the controller monitors the static workload on the motor and varies motor

rpm in order to maintain constant airflow (cfm).

The motor is equipped with 11 incremental taps which are driven by the integral controller. The controller is capable of controlling three of the 11 taps.

The motor controller is driven by the Two−stage Variable

Speed Integrated control board. The board receives its

demand (PWM signal or fixed 24 VAC or VDC signal) from

optional controls such as the Harmony zone control system,

Efficiency Plus Humidity Control (CCB1) or a conventional

thermostat.

Motor rpm is continually adjusted internally to maintain

constant static pressure against the blower wheel. The controller monitors the static work load on the motor and motor ampdraw to determine the amount of rpm adjustment. Blower rpm

may be adjusted any amount in order to maintain a constant

cfm as shown in Blower Ratings Tables. The amount of adjustment is determined by the incremental taps which are used

and the amount of motor loading sensed internally. The cfm

remains relatively stable over a broad range of static pressure.

Since the blower constantly adjusts rpm to maintain a specified

cfm, motor rpm is not rated. Hence, the terms cool speed" ,

heat speed " or speed tap" in this manual, on the unit wiring

diagram and on blower B3, refer to blower cfm regardless of

motor rpm.

When Harmony is used, speed taps are overridden and a

PWM signal generated by the Harmony controller continuously varies motor speed based upon zone demands.

Page 25

Page 25

Initial Power Up

When line voltage is applied to B3, there will be a large inrush

of power lasting less than 1/4 second. This inrush charges a

bank of DC filter capacitors inside the controller. If the disconnect switch is bounced when the disconnect is closed, the disconnect contacts may become welded. Try not to bounce the

disconnect switch when applying power to the unit.

Motor Start-Up

When B3 begins start-up, the motor gently vibrates back and