Page 1

G A S F U R N A C E S

G43UF

MERIT® SERIES

Up−Flow

E N G I N E E R I N G D A T A Bulletin No. 210394

Supersedes December 2004

August 2005

MODEL NUMBER IDENTIFICATION

G 43 24−B− 045

Unit Type

G = Gas Furnace

Series

43 = 90% Minimum AFUE

Configuration

UF = Up−Flow

Nominal Add−On Cooling Capacity

24 = 2 tons (7.0 kW)

36 = 3 tons (10.5 kW)

48 = 4 tons (14.10 kW)

60 = 5 tons (17.5 kW)

UF

AFUE − up to 92.1%

Input − 44,000 to 132,000 Btuh

Nominal Add−on Cooling − 2 to 5 Tons

Nominal Gas Heat Input

045 = 44,000 Btuh (12.9 kW)

070 = 66,000 Btuh (19.3 kW)

090 = 88,000 Btuh (25.8 kW)

110 = 110,000 Btuh (32.2 kW)

135 = 132,000 Btuh (38.7 kW)

1

Cabinet Width

B = 17−1/2 in. (445 mm)

C = 21 in. (533 mm)

D = 24−1/2 in. (622 mm)

1

Indoor coils with the same letter designation

will physically match the furnace.

Page 2

FEATURES

CONTENTS

Blower Data Pages 13−15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions Pages 9−12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Pipe Venting Information Page 7. . . . . . . . . . . . . . . . . . .

Features and Options Pages 2−4. . . . . . . . . . . . . . . . . . . . . . . . . .

Filter Air Resistance Page 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Altitude Information Page 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Clearances Page 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model Number Identification Page 1. . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories Selection table Page 6. . . . . . . . . . . . . . . .

Specifications Page 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY

Duralok Plus® Aluminized Steel Heat Exchanger − Twenty

years limited warranty.

All other covered components − Five years limited warranty.

Refer to Lennox Equipment Limited Warranty certificate

included with equipment for details.

APPROVALS

Units certified by CSA International and ratings are certified by

GAMA.

Units tested and rated according to US DOE test procedures and

FTC labeling regulations.

Blower data from unit tests conducted in Lennox Laboratory air

test chamber.

Approved by the California Energy Commission and meets

California Seasonal Efficiency requirements and California

Nitrogen Oxides (NOx) Standards.

NERGY STAR

E

help save money on utility bills, and help protect the

environment.

ISO 9001 Registered Manufacturing Quality System.

APPLICATIONS

Input capacities of 44,000, 66,000, 88,000, 110,000, and

132,000 Btuh (12.9, 19.3, 25.8, 32.2, and 38.7 kW).

Energy efficiency (AFUE) up to 92.1%.

Compact cabinet with either side or bottom return air entry.

Lennox add-on indoor coils, high−efficiency air cleaners and

humidifiers can easily be added to furnace.

Shipped factory assembled with all controls installed and wired.

Each unit factory test operated to ensure proper operation.

DIRECT VENT / NON−DIRECT VENT

Furnace can be installed in either Direct Vent or Non−Direct

applications. In Direct Vent applications, combustion air is

supplied from outdoors and flue gases are discharged outdoors.

In Non−Direct Vent applications, combustion air is supplied from

indoors and flue gases are discharged outdoors.

OPTIONS

Termination Kits

Facilitates installation of combustion air intake pipe and flue

exhaust pipe.

Refer to venting table in this bulletin to determine pipe size

needed and proper termination kit required.

See Specifications table and dimension drawings.

Termination Kit − Concentric − Direct Vent Applications

Only

1−1/2, 2, or 3 inch (38, 51, or 76 mm) kit contains concentric

termination assembly, reducer bushing and 45 degree elbow.

Kit requires single hole penetration of roof or wall for installation.

Roof Termination Flashing Kit is available for use with 1−1/2 and

2 inch Kits.

CSA certified.

®

certified units are designed to use less energy,

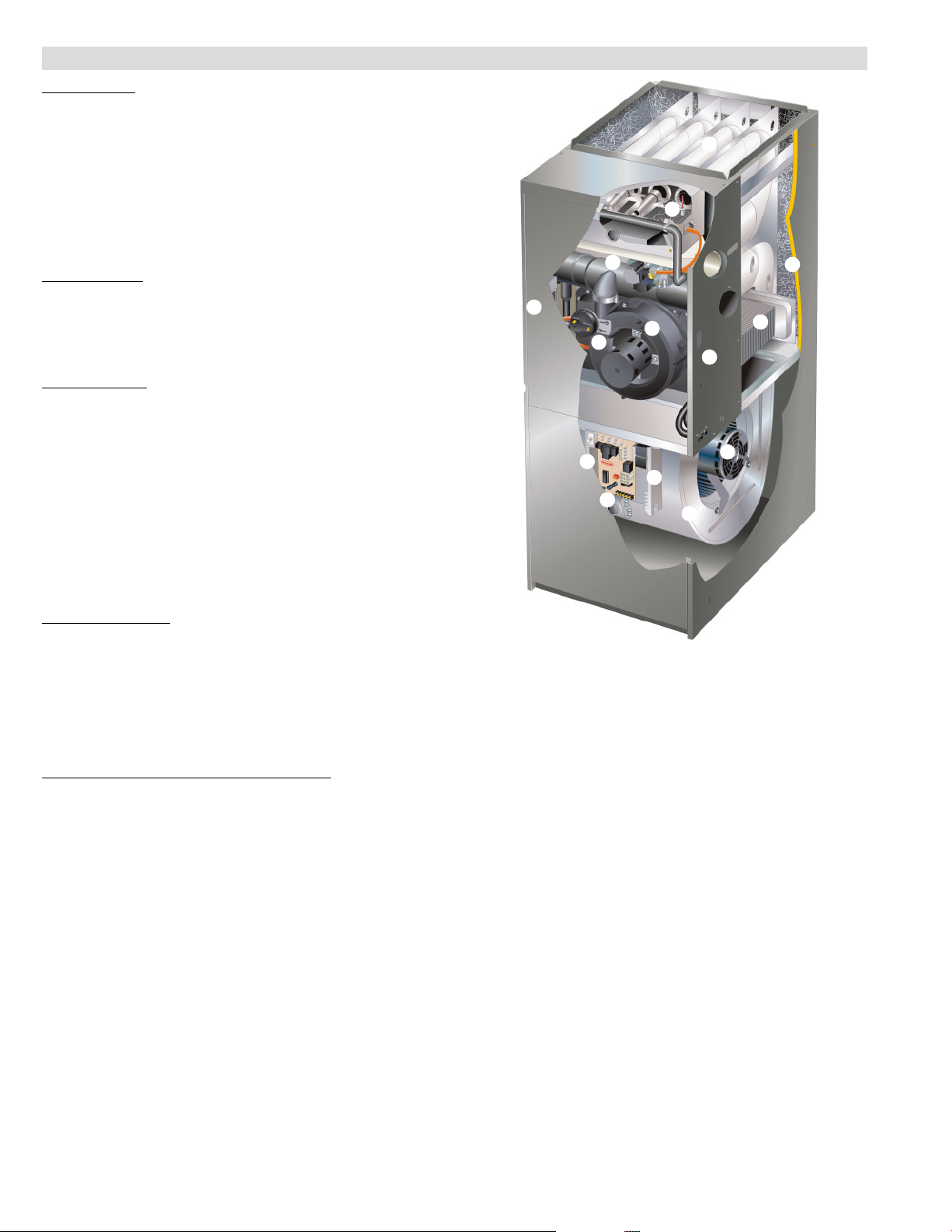

B

D

E

N

K

F

C

G

P

O

H

L

J

I

M

Termination Kits − Wall Assembly

Close Couple − Direct Vent Applications Only

2 or 3 inch (51 or 76 mm) kit consists of close-couple,

side-by-side PVC piping with galvanized steel wall cover plate

for sealing and isolating piping penetration of the wall.

Piping spacing and length is sized for proper wall installations.

CSA certified.

Close Couple WTK − Direct Vent Applications Only

2 or 3 inch (51 or 76 mm) kit contains one insulated faceplate,

one insulated exhaust pipe, elbow and fittings.

Wall Ring − Direct or Non−Direct Vent

2 inch (51 mm) kit contains 2 stainless steel outside seal caps, 2

galvanized steel inside seal caps, 4 seal rings for the caps and

18 inch (457 mm) insulation sleeve for sealing and isolating

intake and exhaust piping penetration of wall.

Maintain a maximum of 6 inches (152 mm) between the inlet

and outlet openings in the installation of the pipes.

Roof Termination Flashing Kit − Direct or Non−Direct Vent

2 or 3 inch (51 or 76 mm) kit contains two neoprene rubber roof

flashings for vertical venting through a roof.

Vent pipe and insulation not furnished. Each kit contains

enough parts for two non−direct vent installations.

Also available for use with 1−1/2 inch (use 2 inch flashing) and 2

inch (use 3 inch flashing) Concentric Vent Termination Kits used

in vertical venting rooftop applications.

G43UF / Page 2

Page 3

FEATURES

HEATING SYSTEM

B

Lennox Duralok Plus

Lennox developed heat exchanger assembly consists of primary

heat exchanger and secondary condenser coil assembly.

Main 3-pass clamshell type heat exchanger constructed of

heavy−gauge, aluminized steel.

Designed for normal expansion and contraction.

Crimped seam design and construction provides maximum

efficiency and minimum resistance to airflow.

Secondary heat exchanger condenser coil constructed of

C

aluminum fins fitted to stainless steel tubes.

Coil is factory tested for leaks.

Condensate drain header box assembly located on front of coil.

Compact size of complete heat exchanger assembly permits low

overall design of furnace cabinet.

All components mounted in a heavy−gauge steel frame.

Heat exchanger assembly has been laboratory life cycle tested.

Lennox Designed Header Box

Header box on end of condenser coil collects flue condensate for

disposal through condensate collars.

Hose connects the header box drains to the condensate collars.

The condensate collars are located on each side of the cabinet

for easy field installation of condensate drain trap. Only one

collar is used, the other is plugged.

Condensate drain trap is included with the unit for field installation.

Lennox Designed Flue Condensate Trap Assembly

Condensate trap assembly is mounted outside the conditioned

air stream.

Assembly can be mounted on either side of cabinet. See

Installation Instructions.

Connection can be made with field provided 1/2 in. PVC pipe, 3/4 in.

PVC coupling, or 1−1/4 in. OD x 1 in. ID vinyl tubing with hose clamp.

Easy to clean and winterize.

Inshot Burners

D

Aluminized steel inshot burners provide efficient, trouble−free

operation.

Burner venturi mixes air and gas in correct proportion for proper

combustion.

Burner assembly is removable from the unit as a single

component for ease of service.

Hot Surface Mini−Nitride Ignitor

Unique, non−porous, high strength proprietary ceramic material

provides long life and trouble−free maintenance.

Low mass element provides fast heat−up and consistent igniter

temperature with low power usage.

Cemented to alumina block for positive mounting and protection

against current leakage.

High temperature Teflon

dependable operation.

Gas Control Valve

E

24 volt redundant combination gas control valve combines

manual shut off valve (On−Off), automatic electric valve (dual)

and gas pressure regulation into a compact combination control.

Combustion Air Inducer

F

Shaded pole heavy−duty blower prepurges heat exchanger and

safely vents flue products.

Pressure switch proves blower operation before allowing gas

G

valve to open.

Operates only during heating cycle.

Limit Control

Automatic reset, primary limit is accurately located.

Factory installed on vestibule panel on all units.

Flame Rollout Switch

Manual reset switches are factory installed on burner box.

Switch provides protection from abnormal operating conditions.

®

Heat Exchanger Assembly

®

insulated ignition lead wires for

OPTIONS

High Altitude Orifice Kit − Natural Gas Only

Required for all natural gas models for proper unit operation at

altitudes of 7501 to 10,000 feet (2286 to 3048 m).

Proper orifice for LPG/Propane models is included with

LPG/Propane Conversion Kit.

High Altitude Pressure Switch Kit

Required on certain units for proper unit operation on

installations above 4,500 ft. (1372 m).

LPG/Propane Conversion Kit

Required for field changeover from natural gas to LPG/Propane.

CONTROLS

Integrated Furnace Control Board

H

Solid−state board contains all necessary controls and relays to

operate furnace.

Combustion air inducer is controlled by board. Prior to ignition, a

pre−purge cycle for 15 seconds is initiated. After the main

burners are turned off, a post−purge cycle for 5 seconds is run.

Ignition control board continuously monitors line voltage and

maintains the igniter power at a constant level to provide

consistent lighting and maximum igniter life.

Electronic flame sensor control assures safe and reliable operation.

Should loss of flame occur, flame sensor controls will initiate 4

attempts at re−ignition before locking out unit operation for 60

minutes.

Watchguard type circuit automatically resets ignition controls

after one hour of continuous thermostat demand after unit

lockout, eliminating nuisance calls for service.

Fan control consists of adjustable blower timed−off delay (60, 90,

120, 180 seconds − factory setting 90 seconds) and fixed blower

timed−on delay (45 seconds).

For air−conditioning applications, blower is automatically

energized on thermostat demand for cooling.

Two accessory terminals furnished for additional power supply

I

requirements for 120 volt (less than 1 amp) power humidifiers and

powered air cleaners.

Ignition control has two LED’s to indicate status and as an aid in

troubleshooting.

24 Volt Transformer

J

Furnished and factory installed in control box.

40VA transformer has fuse wired in series.

Field Wiring Make-up Box

K

Furnished for line voltage wiring.

Factory installed internally on left side of furnace.

Box may be installed internally or externally on either side of

furnace.

OPTIONS

Thermostat

See Thermostat bulletins in Controls section and Lennox Price

Book for a complete list of thermostats.

Twinning Kit

Required to operate two furnaces simultaneously.

Kit consists of twinning control and two fan sensors.

BLOWER

Multi-speed, direct drive blower.

L

Statically and dynamically balanced.

Resiliently mounted.

Blower assembly slides out of unit for servicing.

M

Blower speeds are easily changed on the integrated furnace

control board. See blower performance tables.

G43UF / Page 3

Page 4

FEATURES

FILTER (NOT FURNISHED)

Filter and provisions for external mounting must be field

provided.

OPTIONS

Air Filter and Rack Kit for Side Return Air Applications

(Not for use with RAB Return Air Base)

Washable or vacuum cleanable polyurethane frame type filter

and external side return air rack available for field installation.

Available in single and ten pack kits.

Rack has filter door for easy filter servicing.

Flanges on rack allow easy duct connection.

Field installs on either side of unit cabinet.

See dimension drawing.

EZ Filter Base for Bottom Return Air Applications

Hinged door with thumbscrew for easy filter access.

Uses standard size filters (field provided).

CABINET

Low−profile, narrow width cabinet allows easy installation.

Heavy−gauge, cold rolled steel construction.

Pre−painted cabinet finish.

Flanges provided on supply air opening for ease of plenum

connection or alignment with indoor coil.

Cabinet is insulated with foil faced insulation on sides and back

N

of heating compartment.

Complete service access.

O

Safety interlock switch automatically shuts off power to unit

when blower compartment access door is removed.

Gas piping and electrical inlets are provided in both sides of cabinet.

P

Return Air Entry:

For bottom return−air entry, remove furnished bottom seal panel

from cabinet.

For side return−air entry, corners are marked on either side of

cabinet for return air cut−outs. On furnaces with side return air

and condensate trap on the same side of the cabinet, a field

fabricated transition or RAB is required to use an IAQ product

higher than 14−3/16 in. (360 mm) when installed next to the unit

and serviced from the front. IAQ products higher than 20 in. (508

mm) require a field fabricated transition. See dimension

drawings.

NOTE − 60C and 60D size units that require air volumes over

1800 cfm (850 L/s) must have one of the following:

1. Single side return air with transition, to accommodate 20 x

25 x 1 in. (508 x 635 x 25 mm) cleanable air filter, required to

maintain proper air velocity.

2. Single side return air with optional RAB Return Air Base.

3. Bottom return air.

4. Return air from both sides.

5. Bottom and

See Blower Performance Tables for additional information.

Coil Match−up

All furnaces exactly match C33 and CX34 cased up−flow indoor

coils with same letter designation in model number. No adaptor

required. Engaging holes furnished on cabinet for alignment.

C33 uncased coils match furnaces without any overhang but

require an optional adaptor base or field fabricated transition to

match furnace opening. See C33 coil bulletin for additional

information.

one side return air.

OPTIONS

Condensate Drain Heat Cable Kits

Self-limiting wattage heat cable prevents condensate drain from

freezing in unconditioned areas.

Available in 6, 24 or 50 ft. (1.8, 7.3, or 15.2 m) lengths.

Heat Cable Tape:

66 ft. (20 m) length, 1/2 in. (13 mm) wide fiberglass.

60 ft. (18 m) length, 2 in. (51 mm) wide aluminum foil.

Condensate Trap Alternate Location Kit

Allows condensate drain to be installed on the opposite side of

the furnace from the exhaust venting (up−flow applications only).

RAB Return Air Base

On furnaces with side return air and condensate trap on the

same side of the cabinet, a field fabricated transition or RAB is

required when installing an IAQ product higher than 14−3/16 in.

(360 mm) when installed next to the unit and serviced from the

front. IAQ products higher than 20 in. (508 mm) require a field

fabricated transition.

Must be used for 60C and 60D models with air volumes over

1800 cfm (850 L/s) in up−flow applications when only one side

return is required.

Cabinet is pre−painted steel to match the furnace.

See Dimension Drawing.

G43UF / Page 4

Page 5

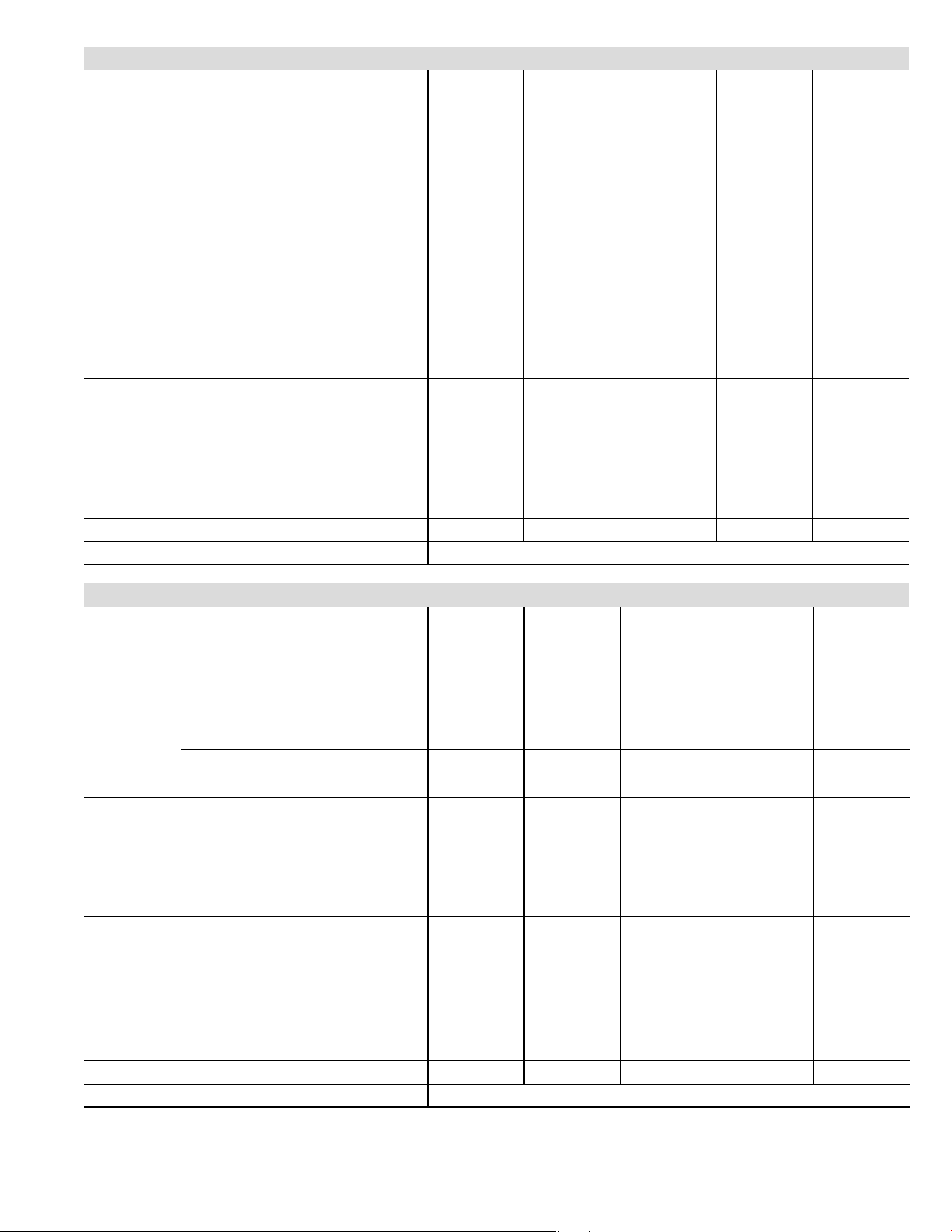

SPECIFICATIONS

Gas

Heating

ModelNo. G43UF

−24B−045

Performance

Input− Btuh (kW) 44,000 (12.9) 66,000 (19.3) 66,000 (19.3) 88,000 (25.8) 88,000 (25.8)

Output− Btuh (kW) 40,300 (11.8) 61,000 (17.9) 62,000 (18.2) 82,000 (24.0) 81,000 (23.7)

Temperature rise range − F (C) 30 − 60

(18 − 36)

1

AFUE 92.1% 90.0% 92.1% 92.1% 90.0%

Highstatic(CSA)− in.w.g. (Pa) .50 (124) .50 (124) .50 (124) .50 (124) .50 (124)

Connections

in.

Condensate Drain Trap (PVC pipe) − i.d. 1/2 1/2 1/2 1/2 1/2

Intake / Exhaust Pipe (PVC) 2 / 2 2 / 2 2 / 2 2 / 2 2 / 2

with field supplied (PVC coupling) − o.d. 3/4 3/4 3/4 3/4 3/4

hose with hose clamp − i.d. x o.d. 1−1/4 x 1 1−1/4 x 1 1−1/4 x 1 1−1/4 x 1 1−1/4 x 1

GaspipesizeIPS 1/2 1/2 1/2 1/2 1/2

Indoor

Blower

Wheel nominal diameter x width −in.

(mm)

10 x 7

(254 x 178)

Motoroutput − hp (W) 1/5 (149) 1/5 (149) 1/3 (249) 1/3 (249) 1/3 (249)

Tons(kW) ofadd−oncooling 1.5 − 2

(5.3 − 7.0)

Air Volume Range − cfm (L/s) 465 − 1125

(220 − 530)

ShippingData − lbs. (kg) − 1 package 132 (60) 141 (64) 146 (66) 162 (74) 162 (74)

Electricalcharacteristics 120 volts − 60 hertz − 1 phase (less than 12 amps)

G43UF

−24B−070

50 − 80

(28 − 44)

10 x 7

(254 x 178)

1.5 − 2

(5.3 − 7.0)

425 − 1020

(200 − 480)

G43UF

−36B−070

40 − 70

(22 − 39)

10 x 8

(254 x 203)

2 − 3

(8.8 − 10.5)

710 − 1640

(335 − 775)

G43UF

−36C−090

40 − 70

(22 − 39)

10 x 8

(254 x 203)

2 − 3

(7.0 − 10.5)

730 − 1630

(345 − 770)

G43UF

−36C−090H

Canada Only

50 − 80

(28 − 44)

10 x 8

(254 x 203)

2 − 3

(7.0 − 10.5)

730 − 1630

(345 − 770)

SPECIFICATIONS

Gas

Heating

ModelNo.

G43UF

−48C−090

Performance

Input− Btuh (kW) 88,000 (25.8) 110,000 (32.2) 110,000 (32.2) 110,000 (32.2) 132,000 (38.7)

Output− Btuh (kW) 82,000 (24.0) 103,000 (30.2) 101,000 (29.6) 103,000 (30.2) 123,000 (36.0)

Temperature rise range − F (C) 40 − 70

(22 − 39)

1

AFUE 92.1% 92.1% 90.0% 92.1% 92.1%

Highstatic(CSA)− in.w.g. (Pa) .50 (124) .50 (124) .50 (124) .50 (124) .50 (124)

Connections

in.

Condensate Drain Trap (PVC pipe) − i.d.

Intake / Exhaust Pipe (PVC) 2 / 2 2 / 2 2 / 2 2 / 2 3 / 3

1/2 1/2 1/2 1/2 1/2

with field supplied (PVC coupling) − o.d. 3/4 3/4 3/4 3/4 3/4

hose with hose clamp − i.d. x o.d. 1−1/4 x 1 1−1/4 x 1 1−1/4 x 1 1−1/4 x 1 1−1/4 x 1

GaspipesizeIPS 1/2 1/2 1/2 1/2 1/2

Indoor

Blower

Wheelnominaldiameter xwidth −in.

(mm)

10 x 10

(254 x 254)

Motoroutput − hp (W) 1/2 (373) 1/2 (373) 1/2 (373) 1 (746) 1 (746)

Tons(kW) ofadd−oncooling 3 − 4

(10.5 − 14.0)

Air Volume Range − cfm (L/s) 950 − 2180

(450 − 1030)

ShippingData − lbs. (kg) − 1 package 168 (76) 178 (81) 178 (81) 186 (84) 203 (92)

Electricalcharacteristics 120 volts − 60 hertz − 1 phase (less than 12 amps)

NOTE − Filters and provisions for mounting are not furnished and must be field provided.

1

Annual Fuel Utilization Efficiency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non−weatherized furnaces

G43UF

−48C−110

45 − 75

(27 − 45)

10 x 10

(254 x 254)

3 − 4

(10.5 − 14.0)

885 − 2160

(420 − 1020)

G43UF

−48C−110H

Canada Only

50 − 80

(28 − 44)

10 x 10

(254 x 254)

3 − 4

(10.5 − 14.0)

885 − 2160

(420 − 1020)

G43UF

−60C−110

40 − 70

(22 − 39)

11−1/2 x 10

(292 x 229)

4 − 5

(14.0 − 17.5)

1470 − 2720

(695 − 1285)

G43UF

−60D−135

45 − 75

(27 − 45)

11−1/2 x 10

(292 x 229)

4 − 5

(14.0 − 17.5)

1440 − 2730

(680 − 1290)

G43UF / Page 5

Page 6

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

p

Di

t

Applications

B" Width Models C" Width Models D" Width Models

FILTER KITS

1

Air Filter and

Rack Kit

EZ Filter Base

CABINET ACCESSORIES

Down−Flow Additive Base 11M60 11M61 11M62

Horizontal Support Frame Kit 56J18 56J18 56J18

Return Air Base 76M88 74M74 74M75

CONDENSATE DRAIN KITS

Condensate Drain Heat Cable

Heat Cable Tape

Condensate Trap Alternate Location Kit − Up−Flow Only 76M20 76M20 76M20

CONTROLS

Twinning Kit 15L38 15L38 15L38

TERMINATION KITS − See Installation Instructions for specific venting information.

4

Termination

Kits

rect Ven

Applications

Only

2, 4

Termination

Kits − Direct or

Non−Direct Vent

4

Roof Termination Flashing Kit − Direct or Non−Direct

Vent − Contains two flashings.

1

Cleanable polyurethane frame type filter.

2

Kits contain enough parts for two, non−direct vent installations.

3

Non−direct vent only.

Horizontal (end) Size of filter − in.

(mm)

Side Return

Single 44J22 44J22 44J22

87L96 − 18 x 25 x 1

(457 x 635 x 25)

87L97 − 20 x 25 x 1

(508 x 635 x 25)

87L98 − 25 x 25 x 1

(635 x 635 x 25)

Ten Pack 66K63 66K63 66K63

Size of filter − in. (mm) 16 x 25 x 1

(406 x 635 x 25)

16 x 25 x 1

(406 x 635 x 25)

(406 x 635 x 25)

Catalog No. − Ship. Wt. − lbs. (kg) 73P56 − 7 (3) 73P57 − 8 (4) 73P58 − 10 (5)

Size of field provided filter − in.

(mm)

16 x 25 x 1

(406 x 635 x 25)

20 x 25 x 1

(508 x 635 x 25)

(610 x 610 x 25)

6 ft. (1.8 m) 26K68 26K68 26K68

24 ft. (7.3 m) 26K69 26K69 26K69

50 ft. (15.2 m) 26K70 26K70 26K70

Fiberglass − 1/2 in. x 66 ft. 39G04 39G04 39G04

Aluminum foil − 2 in. x 60 ft. 39G03 39G03 39G03

Concentric

1−1/2 in. (38 mm) 71M80 − − − − − −

2 in. (51 mm) − − − 69M29 − − −

3 in. (76 mm) − − − 60L46 60L46

Wall − Close

Couple

2 in. (51 mm) 22G44 − − − − − −

3 in. (76 mm) 44J40 44J40 44J40

Close Couple WTK − 2 in. (51 mm) 30G28 − − − − − −

3 in. (76 mm) 81J20 81J20 81J20

Roof 2 in. (51 mm) 15F75 15F75

Wall − Wall Ring

2 in (51 mm) 15F74 15F74

Kit

44J41 44J41 44J41

16 x 25 x 1

24 x 24 x 1

− − −

3

15F74

GAS HEAT ACCESSORIES

1

High Altitude

Orifice Kit

Input

−045

Natural Gas Only

59M16 − − − 95M22 83M74 83M75

−070 59M16 56M05 56M06 83M74 83M75

−090 59M16 75M20 56M07 83M74 83M75

−110 59M16 75M20 56M07 83M74 83M75

−135 59M16 56M04 60M35 83M74 83M75

1

Required for proper operation at altitudes from 7501 to 10,000 ft. (2286 to 3048 m).

G43UF / Page 6

High Altitude Pressure

Switch Kit

4501−7500 ft.

(1372−2286 m)

7501−10,000 ft.

(2286−3048 m)

LPG/Propane Kit

0−7500 ft.

(0−2286 m)

7501−10,000 ft.

(2286−3048 m)

Page 7

EXHAUST PIPE VENTING TABLE

()

,

Heat

Altitude

0 − 2000 ft.

(0 − 609 m)

2001 − 4500 ft.

(610 − 1371 m)

4501 − 7500 ft.

(1372 − 2286 m)

7501 − 10,000 ft.

(2287 − 3048 m)

NOTE − Minimum Equivalent Vent Pipe length is 15 feet (4.6 m).

1

Maximum Equivalent Vent Length" permitted is defined as Total Length (linear feet) of vent pipe, plus equivalent length (ft.) of fittings, plus equivalent length (ft.) of termination".

2

110 models must have the supplied 90° street ell installed directly into the unit flue collar. The street ell must be included in the elbow count.

3

135 models must have 3 in. to 2 in. reducing elbow (supplied) installed directly into the flue collar. Reducing ell must be included in elbow count.

4

90 elbows must be limited to 3 in. sweep type elbows.

VENTING NOTES One 90elbow is equivalent to 5 feet (1.5 m) of straight vent pipe.

Wall and roof termination (non−concentric) exhaust pipe must terminate with reducer to improve exhaust velocity away from intake piping.

TERMINATION KITS − EQUIVALENT VENT LENGTHS

Heat

Size

−045

−070

−090

−110

−135

1

Requires field provided 1−1/2 in. (38 mm) outdoor exhaust accelerator.

2

Requires field provided 2 in. (51 mm) outdoor exhaust accelerator.

3

For use only in non−direct vent applications, when snow riser is not required. Requires field provided 2 in. (51 mm) outdoor exhaust accelerator.

1

Maximum Equivalent Vent Length − One or Two Pipe Applications

Vent Size

(diameter)

G43UF−24B−045

G43UF−24B−070

G43UF−36B−070

G43UF−36C−090

G43UF−48C−090

ft. mft.mft.mft.mft.m

2 in. 11 0 34 70 21 50 15 30 9 n/a n/a

2−1/2 in.

3 in.

4 in.

135 41 135 41 100 31 70 21 n/a n/a

160 49 160 49 125 38 125 38

250 76 250 76 225 69 200 61 180 55

2 in. 11 0 34 70 21 50 15 20 6 n/a n/a

2−1/2 in.

3 in.

4 in.

135 41 135 41 100 31 70 21 n/a n/a

160 49 160 49 125 38 125 38

250 76 250 76 225 69 200 61 180 55

2 in. 11 0 34 70 21 30 9 n/a n/a n/a n/a

2−1/2 in.

3 in.

4 in.

135 41 135 41 100 31 70 21 n/a n/a

160 49 160 49 125 38 125 38

250 76 250 76 225 69 200 61 180 55

2 in. 11 0 34 70 21 n/a n/a n/a n/a n/a n/a

2−1/2 in.

3 in.

135 41 135 41 100 31 70 21 n/a n/a

160 49 160 49 125 38 125 38

4 in. 250 76 250 76 225 69 200 61 180 55

Two 45 elbows are equal to one 90 elbow.

One 45 elbow is equivalent to 2.5 feet (.75 m) of straight vent pipe.

045 and 070 − 2, 2−1/2, 3 or 4 in. − terminate with 1−1/2 in. pipe

090 − 2, 2−1/2, 3 or 4 in. − terminate with 2 in. pipe

110 − 2, 2−1/2, 3 or 4 in. − terminate with 2 in. pipe

135 − 3 or 4 in. − terminate with 2 in. pipe

Vent Pipe Equivalent Length − ft. (m)

Vent Pipe

Diameter

1−1/2 in.

(38 mm)

Concentric

Kits

2 in.

(51 mm)

3 in.

(76 mm)

in. mm 71M80 69M29 60L46

2 51 12 (3.6) not allowed not allowed 4 (1.2)

2−1/2 64 15 (4.6) not allowed not allowed 5 (1.5)

3

76 21 (6.4) not allowed not allowed 7 (2.1)

4 102 42 (12.8) not allowed not allowed 14 (4.3)

2 51 12 (3.6) not allowed not allowed 4 (1.2)

2−1/2 64 15 (4.6) not allowed not allowed 5 (1.5)

3

76 24 (7.3) not allowed not allowed 8 (2.4)

4 102 42 (12.8) not allowed not allowed 14 (4.3)

Close Couple

2 in.

(51 mm)

22G44

30G28 (WTK)

Kits

3 in.

(76 mm)

44J40

81J20 (WTK)

1

4 (1.2) 4 (1.2) 4 (1.2) not allowed

1

5 (1.5) 5 (1.5) 5 (1.5) not allowed

1

7 (2.1) 7 (2.1) 7 (2.1) not allowed

1

14 (4.3) 14 (4.3) 14 (4.3) not allowed

1

4 (1.2) 4 (1.2) 4 (1.2) not allowed

1

5 (1.5) 5 (1.5) 5 (1.5) not allowed

1

8 (2.4) 8 (2.4) 8 (2.4) not allowed

1

14 (4.3) 14 (4.3) 14 (4.3) not allowed

2 51 not allowed 3 (1) 3 (1) not allowed 1 (0.3)

2−1/2 64 not allowed 6 (1.8) 6 (1.8) not allowed 2 (0.6)

3

76 not allowed 6 (1.8) 6 (1.8) not allowed 2 (0.6)

4 102 not allowed 12 (3.7) 12 (3.7) not allowed 4 (1.2)

2 51 not allowed 3 (1) 3 (1) not allowed 1 (0.3)

2−1/2 64 not allowed 6 (1.8) 6 (1.8) not allowed 2 (0.6)

3

76 not allowed 6 (1.8) 6 (1.8) not allowed 2 (0.6)

4 102 not allowed 12 (3.7) 12 (3.7) not allowed 4 (1.2)

3 76 not allowed not allowed 15 (4.6) not allowed 6 (1.8)

4 102 not allowed not allowed 25 (7.6) not allowed 10 (3.0)

2

G43UF−48C−110

2

G43UF−60C−110

Wall Ring

Kit

2 in.

(51 mm)

1−1/2 x 12 in.

(38 x 305 mm)

3

G43UF−60D−135

4

125

4

90

4

90

4

90

Outdoor Exhaust

Accelerator

(Diameter X Length)

2 x 12 in.

(51 x 305 mm)

15F74 − − − − − −

2

1 (0.3) not allowed 1 (0.3)

2

2 (0.6) not allowed 2 (0.6)

2

2 (0.6) not allowed 2 (0.6)

2

4 (1.2) not allowed 4 (1.2)

2

1 (0.3) not allowed 1 (0.3)

3

2 (0.6) not allowed 2 (0.6)

3

2 (0.6) not allowed 2 (0.6)

3

4 (1.2) not allowed 4 (1.2)

3

6 (1.8) not allowed 6 (1.8)

3

10 (3.0) not allowed 10 (3.0)

G43UF / Page 7

4

4

4

4

38

27

27

27

Page 8

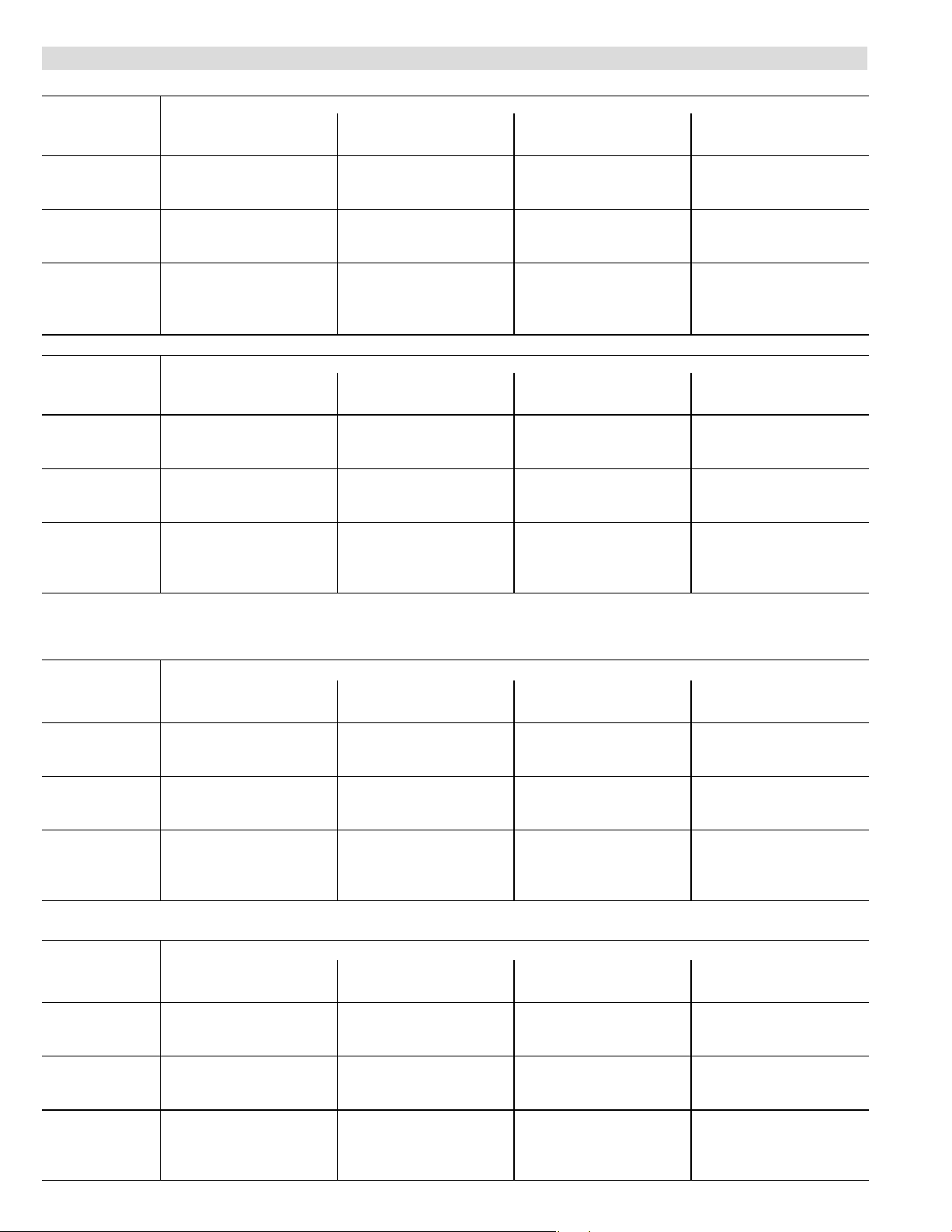

FILTER AIR RESISTANCE

For 1 Inch (25 mm) Cleanable Filter (Field Provided)

cfm L/s in. w.g.

0

200 95 0.01 0

400 190 0.03

600

800 380 0.06 15

1000 470 0.09

1200

1400 660 0.15 35

1600 755 0.19

1800

2000 945 0.27 65

2200 1040 0.33

2400

2600 1225 0.44 110

0 0.00 0

285 0.04 10

565 0.12 30

850 0.23 55

1130 0.38 95

Pa

5

20

45

80

HIGH ALTITUDE INFORMATION

Pressure regulator adjustment may be required depending on

altitude. See below for proper pressure regulator setting.

Manifold Pressure

(Outlet)

Fuel Altitude − ft. (m)

Natural

0−4500 (0−1372) 3.5 (0.87)

4501−7500 (1373−2286)

7501−10000 (2287−3048)

3

LPG

Propane

0−4500 (0−1372) 10.0 (2.49)

4501−7500 (1373−2286)

7501−10,000 (0−3048)

1

High Altitude Orifice Kit required, see Gas Heat Accessories table for order number.

2

High Altitude Pressure Switch Kits as required, see Gas Heat Accessories table for

order number.

3

LPG/Propane conversion kit required, see Gas Heat Accessories table for order

number.

in. w.g. (kPa)

2

3.5 (0.87)

1,2

3.5 (0.87)

2

10.0 (2.49)

2

10.0 (2.49)

INSTALLATION CLEARANCES

Sides

Rear 0 inches (0 mm)

Top/Plenum 1 inch (25 mm)

Front 0 inches (0 mm)

Front (service/alcove) 24 inches (610 mm)

Floor

NOTE − Air for combustion and supply air ventilation must conform to the methods

outlined in American National Standard (ANSI-Z223.1) National Fuel Gas Code or

National Standard of Canada CAN/CGA-149.1, & CAN/CGA-149.2 Installation Code

for Gas Burning Appliances".

NOTE−In the U.S. flue sizing must conform to the methods outlined in current

GAMA/A.G.A. venting tables, American National Standard (ANSI-Z223.1) National

Fuel Gas Code or applicable provisions of local building codes. In Canada flue sizing

must conform to the methods outlined in National Standard of Canada

CAN/CGA-149.1 and .2.

1

Allow proper clearances to accommodate condensate trap and vent pipe installation.

2

Do not install the furnace directly on carpeting, tile, or other combustible materials other

than wood flooring.

1

0 inches (0 mm)

2

Combustible

INSTALLATION CONFIGURATIONS

VENT

PIPING

CONDENSATE

DRAIN

AIR FLOW

HEAT

EXCHANGER

BLOWER

NOTE − The vent

piping and condensate drain can be

moved to the other

side of the unit. Vent

piping and drain

must be installed on

the same side of the

unit with each other

unless optional Condensate Trap Alternate Location Kit is

used.

G43UF / Page 8

Page 9

DIMENSIONS − INCHES (MM)

Model N

1

NOTE − 60C and 60D size units that require air volumes over

1800 cfm (850 L/s) must have one of the following:

a. Single side return air with transition, to accommodate

20 x 25 x 1 in. (508 x 635 x 25 mm) air filter. Required to

maintain proper air velocity.

b. Single side return air with optional RAB Return Air Base

c. Bottom return air.

d. Return air from both sides.

e. Bottom and

See Blower Performance Tables for additional information.

2

Optional External Side Return Air Filter Kit is not for use with the

optional RAB Return Air Base.

3/4 (19)

one side return air.

A

B 9/16 (14)

11−5/8 (295)

Right

2

OPTIONAL

EXTERNAL

SIDE RETURN

AIR FILTER KIT

(Either Side)

9−3/4 (248)

Left

4−7/8 (124) Right

40

(1016)

14−3/4

(375)

16

(406)

AIR FLOW

5/8 (16)

C

1

Bottom Return

Air Opening

3/4 (19)

FRONT VIEW SIDE VIEW

2

OPTIONAL

EXTERNAL

SIDE RETURN

AIR FILTER KIT

(Either Side)

6−1/2

(165)

4−1/8

(103)

2−1/4 (57) Left

2−1/2

(64)

18-3/4 (476)

6−3/4

(171)

3−1/8

(79)

4

(102)

4−1/4

(108)

SUPPLY AIR

OPENING

23-3/4 (603)

25 (635)

TOP VIEW

28−1/2

(724)

19−7/16

(494)

COMBUSTION AIR INTAKE

(Either Side)

EXHAUST AIR OUTLET

(Either Side)

GAS PIPING INLET

(Either Side)

CONDENSATE

TRAP CONNECTION

(Either Side)

ELECTRICAL INLET

(Either Side)

23

(584)

1

OPTIONAL

RETURN CUTOUT

(Either Side)

1−15/16 (49)

23−1/2

(597)

1

Bottom Return

Air Opening

9/16

(14)

14

(356)

o.

in. mm in. mm in. mm

A B C

G43UF−24B−045

G43UF−24B−070

17−1/2 446 16−3/8 416 16 406

G43UF−36B−070

G43UF−36C−090

G43UF−48C−090

G43UF−48C−110

21 533 19−7/8 454 19−1/2 495

G43UF−60C−110

G43UF−60D−135 24−1/2 622 23−3/8 546 23 584

G43UF / Page 9

Page 10

OPTIONAL ACCESSORY DIMENSIONS − INCHES (MM)

Model No

RAB RETURN AIR BASE (Up−Flow Applications Only)

For use with B, C, and D size furnaces only

4

(102)

AIR FLOW

17−1/2 (446) RAB−B−6 (76M88)

21 (533) RAB−C−6 (74M74)

24−1/2 (622) RAB−D−6 (74M75)

CONDENSATE

TRAP

14

(356)

FURNACE

FRONT

6 (152)

OPTIONAL RAB

RETURN AIR BASE

14

(356)

7/8

(22)

4

(102)

1

23 (584)

Overall

(Maximum)

1

Unit side return

air Opening

SIDE RETURN

5

(102)

AIR OPENINGS

(Either Side)

20−1/2 (521)

27−5/8 (702)

SIDE VIEW

1

Minimum

11 (279)

2

Maximum

14 (356)

1

18−1/2

(470)

Overall

(Maximum)

3/4

(19)

FRONT VIEW

1

Both the unit return air opening and the base return air opening must be covered by a single plenum or IAQ cabinet.

Minimum unit side return air opening dimensions for units requiring 1800 cfm or more of air (W x H): 23 x 11 in. (584 x 279 mm).

The opening can be cut as needed to accommodate plenum or IAQ cabinet while maintaining dimensions shown.

Side return air openings must be cut in the field. There are cutting guides stenciled on the cabinet for the side return air

opening. The size of the opening must not extend beyond the markings on the furnace cabinet.

2

14 inches (356 mm) is the maximum size the height of the unit opening can be cut. This may interfere with the condensate drain

(if located on the same side of the unit as the opening).

To minimize pressure drop, the largest opening height possible (up to 14 inches) is preferred.

NOTE− Optional Side Return Air Filter Kits are not for use with RAB Return Air Base.

DIMENSIONS − INCHES (MM) − FURNACE/COIL COMBINED DIMENSIONS

Cased Uncased (CX34 − cased only)

UP−FLOW POSITION

A

40

(1016)

Model No

A

in. mm in. mm in. mm in. mm

CX34−18/24B−6F

CX34−18/24C−6F

C33−24B

C33−24C

16−1/2 419 56−1/2 1435 13−7/8 352 53−7/8 1368

CX34−25B−6F C33−25B 19−1/2 495 59−1/2 1511 15−7/8 403 55−7/8 1419

CX34−30B−6F

CX34−30C−6F

C33−30B

C33−30C

20−1/2 521 60−1/2 1537 17−3/4 451 59−3/4 1467

CX34−31B−6F C33−31B 23−1/2 597 63−1/2 1613 20−1/4 514 60−1/4 1530

CX34−36B−6F C33−36B 24−1/2 622 64−1/2 1638 21−7/8 556 61−7/8 1572

CX34−36C−6F C33−36C 24−1/2 622 64−1/2 1638 21−1/4 540 61−1/4 1556

B

CX34−38B−6F C33−38B 24−1/2 622 64−1/2 1638 22 559 62 1575

CX34−42B−6F C33−42B 24−1/2 622 64−1/2 1638 21−7/8 556 61−7/8 1572

CX34−43B−6F C33−43B 28−1/2 724 68−1/2 1740 26−1/4 667 66−1/4 1683

CX34−43C−6F C33−43C 28−1/2 724 68−1/2 1740 25−3/4 654 65−3/4 1670

C33−44C 24−1/2 622 64−1/2 1638 21−1/2 546 61−1/2 1562

CX34−44/48B−6F C33−48B 24−1/2 622 64−1/2 1638 22−1/8 562 62−1/8 1578

CX34−44/48C−6F C33−48C 24−1/2 622 64−1/2 1638 21−1/2 546 61−1/2 1562

CX34−49C−6F C33−49C 30−1/2 775 70−1/2 1791 28−1/2 724 68−1/2 1740

CX34−50/60C−6F C33−50/60C 27−1/2 699 67−1/2 1715 24−3/4 629 64−3/4 1645

CX34−60D−6F C33−60D 25−1/2 648 65−1/2 1664 24−3/4 629 64−3/4 1645

CX34−62C−6F C33−62C 32−1/2 826 72−1/2 1842 30−5/8 778 70−5/8 1793

CX34−62D−6F C33−62D 29−1/2 749 69−1/2 1765 28−3/4 730 68−3/4 1746

B A B

G43UF / Page 10

Page 11

OPTIONAL ACCESSORY DIMENSIONS − INCHES (MM)

CONCENTRIC WALL

TERMINATION APPLICATIONS

10-1/2

(267)

INTAKE

AIR

INTAKE

AIR

GRADE

12 (305)

Minimum

EXHAUST

AIR

INTAKE

AIR

OUTSIDE

WALL

CLAMP

(Not Furnished)

71M80 1−1/2 inch (38 mm)

69M29 2 inch (51 mm)

See Installation Instructions for specific usage.

2 x 1-1/2 in. (51 x 38 mm) 60G77

3 x 2 in. (76 x 51 mm) 33K97

REDUCER BUSHING (Furnished)

37

(940)

INTAKE AIR

EXHAUST

AIR

Above

Grade

CONCENTRIC ROOF

TERMINATION APPLICATIONS

FLASHING

(Not Furnished)

12 (305)

Minimum

Above Average

Snow

Accumulation

SHEET METAL STRAP

(Clamp and sheet metal strap

must be field installed to support

CLAMP

the weight of the termination kit.)

60L46 3 inch (76 mm)

See Installation Instructions for specific usage.

46−3/4

(1187)

6−1/2

(165)

3 (76)

ELBOW

(Furnished)

CLAMP

(Furnished)

INTAKE AIR

TERMINATION

ASSEMBLY

(Furnished)

EXHAUST

AIR

WALL ASSEMBLY TERMINATION KIT − RING KIT

15F74 − 2 inch (51 mm)

See Installation Instructions for specific usage.

DIRECT VENT APPLICATION

8 in. (203 mm)

minimum

NOTE − 12 in. (305 mm) minimum height above

average snow accumulation.

12 in. (305 mm) maximum

without support

6 in. (152 mm)

maximum

4−1/2 (114)

INTAKE AIR

ELBOW

(Field Supplied)

TERMINATION

ASSEMBLY

(Furnished)

NON−DIRECT VENT APPLICATION

NOTE EXHAUST PIPE SHOWN

Kit Contains Enough Parts For Two Installations

NOTE 12 in. (305 mm) minimum height above

average snow accumulation.

12 in. (305 mm) maximum

without support

EXHAUST

AIR

G43UF / Page 11

Page 12

OPTIONAL ACCESSORY DIMENSIONS − INCHES (MM)

DIRECT VENT APPLICATIONS

WALL TERMINATION KITS (CLOSE-COUPLE) − 22G44 − 2 inch (51 mm) or 44J40 − 3 inch (76 mm)

See Installation Instructions for specific usage.

12

(305)

If Intake and Exhaust Pipe is less than

12 in. (305 mm) above snow accumulation or other obstructions, field fabricated piping must be installed.

EXHAUST

AIR

INTAKE

AIR

5 (127)

5-1/2

(140)

EXHAUST

AIR

GRADE

INSULATION

(Not Furnished)

12

(305)

2

(51)

INTAKE

AIR

12

(305)

ABOVE GRADE

GRADE

12 (305)

Minimum

WTK WALL ASSEMBLY TERMINATION KIT WITH FIELD FABRICATED ABOVE GRADE EXTENDED CLEARANCE

30G28 − 2 inch (51 mm) or 81J20 − 3 inch (76 mm)

See Installation Instructions for specific usage.

12

(305)

INTAKE

AIR

5

(127)

5-1/2

(140)

EXHAUST

AIR

GRADE

INSULATION

(Not Furnished)

If Intake and Exhaust Pipe is less than

12 in. (305 mm) above snow accumulation or other obstructions, field fabricated piping must be installed.

EXHAUST

AIR

INTAKE

AIR

8 (203)

Minimum

12 (305)

Maximum

ABOVE GRADE

GRADE

12 (305)

Minimum

G43UF / Page 12

Page 13

BLOWER/WATTS DATA

External Static

External Static

External Static

External Static

G43UF−24B−045 PERFORMANCE (Less Filter)

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 1125 530 425 900 425 360 745 350 295 690 325 265

0.10 25 1115 525 410 905 425 350 760 360 285 695 330 260

0.20 50 1090

0.30

75 1060 500 380 880 415 325 740 350 270 675 320 250

515 395 895 420 335 755 355 280 685 325 255

0.40 100 1020 480 365 860 405 315 720 340 260 665 315 240

0.50 125 970

0.60

150 920 435 335 795 375 290 665 315 240 600 285 220

460 345 835 395 300 700 330 255 640 300 230

0.70 175 860 405 315 730 345 270 620 295 230 565 265 215

0.80 200 760

0.90

225 675 320 275 585 275 230 495 235 200 465 190 175

360 295 665 315 250 560 265 215 510 240 200

G43UF−24B−070 PERFORMANCE (Less Filter)

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 1115 525 435 875 415 360 720 340 290 665 315 255

0.10 25 1115 525 425 865 410 350 725 340 285 670 315 255

0.20 50 1100

0.30

75 1080 510 400 870 410 330 725 340 270 655 310 240

520 415 870 410 335 730 345 280 665 315 250

0.40 100 1050 495 385 855 405 320 715 335 265 645 305 240

0.50 125 1010

0.60

150 980 460 355 810 380 295 675 320 250 600 285 225

475 365 835 395 310 695 330 255 625 295 230

0.70 175 930 440 340 770 365 285 640 300 235 565 265 215

0.80 200 855

0.90

225 770 365 295 650 305 250 525 245 205 465 220 190

405 320 720 340 270 585 275 220 520 245 200

G43UF−36B−070 PERFORMANCE (Less Filter)

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 1640 775 660 1415 665 575 1160 545 485 1005 475 410

0.10 25 1600 755 635 1395 660 550 1160 545 460 1000 470 385

0.20 50 1540

0.30

75 1495 705 580 1345 635 505 1145 540 425 990 465 365

725 605 1370 650 525 1160 545 445 995 470 375

0.40 100 1420 670 545 1275 605 480 1125 530 395 965 455 345

0.50 125 1360

0.60

150 1275 600 490 1165 550 410 1025 485 350 900 425 305

640 525 1245 590 450 1080 510 375 945 445 325

0.70 175 1170 555 465 1085 515 385 965 430 335 860 405 295

0.80 200 1080

0.90

225 945 445 400 840 395 320 765 360 275 710 335 245

510 440 1010 475 360 865 410 310 775 365 270

G43UF−36C−090(H) PERFORMANCE (Less Filter)

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 1630 770 745 1360 640 635 1125 530 540 975 460 440

0.10 25 1620 765 715 1365 645 610 1160 545 515 1000 470 430

0.20 50 1590

0.30

75 1550 730 655 1355 640 565 1170 550 475 985 465 395

750 680 1365 645 580 1160 545 495 990 465 405

0.40 100 1520 715 630 1330 630 545 1160 545 460 980 460 380

0.50 125 1465

0.60

150 1415 670 570 1250 590 490 1095 515 420 940 445 350

690 605 1300 615 515 1140 540 440 960 455 360

0.70 175 1350 635 545 1215 575 470 1065 500 400 905 425 335

0.80 200 1260

0.90

NOTES − All air data is measured external to unit without filter (not furnished − field provided).

Air volume based on bottom air return air. Actual air volume may vary on side return air applications.

225 1165 550 475 1035 485 395 900 425 335 730 345 285

595 510 1140 540 440 1005 475 375 850 400 310

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

G43UF / Page 13

Page 14

BLOWER/WATTS DATA

External Static

External Static

G43UF−48C−090 PERFORMANCE (Less Filter)

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 2180 1030 930 1835 865 790 1520 715 630 1280 605 510

0.10 25 2135 1005 885 1825 860 750 1510 710 610 1275 600 495

0.20 50 2085

0.30

75 2030 955 800 1775 835 685 1500 705 565 1265 595 460

985 840 1810 855 720 1505 710 580 1270 600 475

0.40 100 1940 915 760 1735 820 650 1480 700 535 1250 590 440

0.50 125 1865

0.60

150 1740 820 670 1590 750 575 1380 650 475 1175 555 410

880 725 1660 785 600 1430 675 505 1215 575 425

0.70 175 1645 775 640 1475 695 520 1290 610 450 1105 520 375

0.80 200 1540

0.90 225 1335

725 600 1340 630 465 1175 555 405 1020 480 355

630 540 1170 555 440 1070 505 375 950 450 330

G43UF−48C−110(H) PERFORMANCE (Less Filter)

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 2160 1020 880 1880 890 755 1490 705 602 1235 580 485

0.10 25 2100 990 850 1855 875 730 1480 700 585 1230 580 475

0.20 50 2035

0.30

75 1965 925 750 1755 830 650 1475 695 545 1220 575 445

960 805 1815 860 690 1475 695 560 1225 580 460

0.40 100 1885 890 725 1715 810 625 1465 690 510 1215 575 430

0.50 125 1780

0.60

150 1690 800 660 1550 735 550 1360 640 460 1110 525 380

840 680 1630 770 580 1420 670 490 1150 540 400

0.70 175 1575 745 620 1410 665 505 1210 570 405 1035 490 350

0.80 200 1375

0.90

NOTES − All air data is measured external to unit without filter (not furnished − field provided).

Air volume based on bottom air return air. Actual air volume may vary on side return air applications.

225 1225 580 520 1120 530 415 1050 495 365 885 420 310

650 550 1230 580 450 1125 530 380 970 460 325

G43UF−60C−110 PERFORMANCE (Less Filter) − Single Side Return Air − Air volumes in bold require field fabricated transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) air filter in order to maintain proper air velocity.

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 2625 1240 1350 2310 1090 1080 1885 890 885 1515 715 700

0.10 25 2570 1215 1330 2325 1095 1060 1910 900 865 1575 745 700

0.20 50 2410

0.30

75 2425 1145 1265 2230 1055 990 1925 905 825 1635 770 675

1135 1305 2285 1080 1035 1930 910 845 1620 765 690

0.40 100 2335 1100 1220 2175 1025 950 1910 900 810 1640 775 660

0.50 125 2270

0.60

150 2170 1025 1155 2045 965 885 1860 875 765 1630 770 630

1070 1195 2120 1000 935 1895 895 785 1640 775 640

0.70 175 2110 995 1130 1950 920 855 1795 845 730 1590 750 610

0.80 200 2035

0.90

225 1900 895 1055 1760 830 780 1665 785 680 1470 695 565

960 1090 1885 890 820 1745 825 705 1540 725 580

G43UF−60C−110 PERFORMANCE (Less Filter) − Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or Return Air from Bottom and One Side.

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 2720 1285 1385 2410 1135 1090 2055 970 935 1620 765 710

0.10 25 2665 1255 1355 2385 1125 1075 2025 955 885 1730 815 735

0.20 50 2585

0.30

75 2505 1180 1275 2290 1080 990 2025 955 840 1695 800 675

1220 1315 2350 1110 1015 2030 955 865 1680 795 690

0.40 100 2435 1150 1250 2235 1055 940 2030 960 830 1695 800 660

0.50 125 2350

0.60

150 2255 1065 1185 2100 990 895 1915 905 765 1720 810 650

1110 1205 2170 1025 930 1975 930 790 1735 820 665

0.70 175 2160 1020 1150 2005 945 840 1865 880 730 1680 795 635

0.80 200 2020

0.90

NOTES − All air data is measured external to unit without filter (not furnished − field provided).

G43UF / Page 14

225 1910 900 1050 1820 860 795 1705 805 675 1540 725 590

955 1090 1905 900 825 1810 855 710 1625 765 610

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Page 15

BLOWER/WATTS DATA

G43UF−60D−135 PERFORMANCE (Less Filter) − Single Side Return Air − Air volumes in bold require field fabricated transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) air filter in order to maintain proper air velocity.

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 2665 1260 1440 2325 1095 1100 1865 880 890 1410 665 690

0.10 25 2615 1235 1405 2310 1090 1065 1915 905 865 1465 690 685

0.20 50 2530

0.30

75 2470 1165 1330 2235 1055 1015 1920 905 825 1590 750 670

1195 1370 2280 1075 1055 1925 910 850 1570 740 675

0.40 100 2380 1125 1290 2175 1025 985 1910 900 805 1590 750 655

0.50 125 2310

0.60

150 2200 1035 1230 2055 970 935 1835 865 765 1580 745 630

1090 1265 2120 1000 965 1890 890 790 1595 755 645

0.70 175 2120 1000 1190 1970 930 900 1790 845 740 1545 730 605

0.80 200 2025

0.90

NOTES − All air data is measured external to unit without filter (not furnished − field provided).

225 1930 910 1110 1800 850 835 1655 780 685 1440 680 570

955 1160 1890 890 875 1720 810 710 1515 715 590

G43UF−60D−135 PERFORMANCE (Less Filter) − Bottom Return Air, Side Return Air with Optional RAB Return Air Base,

Return Air from Both Sides or Return Air from Bottom and One Side.

External Static

Pressure

High

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0.00

0 2730 1290 1465 2425 1145 1125 2055 970 915 1560 735 680

0.10 25 2670 1260 1440 2400 1135 1100 2065 975 890 1590 750 675

0.20 50 2600

0.30

75 2525 1190 1360 2315 1095 1045 2035 960 845 1615 760 655

1225 1400 2365 1115 1070 2045 965 865 1620 765 665

0.40 100 2445 1155 1325 2260 1065 1015 2020 955 820 1615 760 645

0.50 125 2360

0.60

150 2290 1080 1255 2130 1005 965 1900 895 755 1600 755 615

1115 1280 2195 1035 985 1960 925 790 1610 760 635

0.70 175 2205 1040 1220 2035 960 910 1825 860 730 1570 740 600

0.80 200 2110

0.90

NOTES − All air data is measured external to unit without filter (not furnished − field provided).

225 1970 930 1120 1835 865 830 1680 795 690 1540 725 545

995 1195 1945 915 880 1765 830 710 1540 725 580

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

Air Volume / Watts at Different Blower Speeds

Medium−High Medium−Low Low

G43UF / Page 15

Page 16

Visit us at www.lennox.com

For the latest technical information, www.lennoxdavenet.com

Contact us at 1−800−4−LENNOX

NOTE − Due to Lennox’ ongoing committment to quality, Specifications, Ratings and Dimensions subject to change without notice and without incurring liability.

Improper installation, adjustment, alteration, service or maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualified installer and servicing agency.

©2005 Lennox Industries Inc.

Loading...

Loading...