Lennox G32V Series, G32V5-100, G32V3-75, G32V5-125, G32V-100 L.P. Service Literature

...

Service Literature

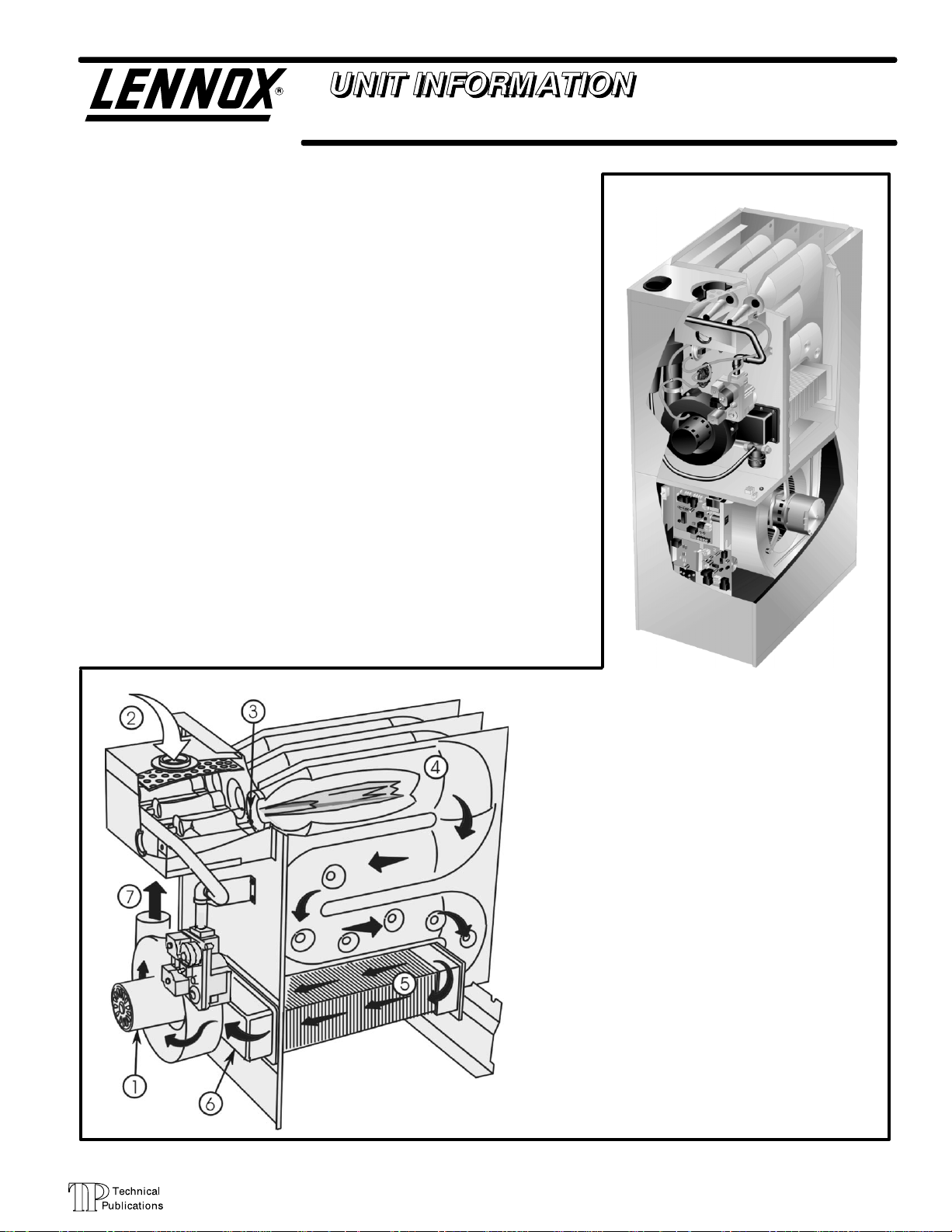

G32V SERIES UNITS

G32V series units are high−efficiency upflow gas furnaces manufactured with

DuralokPlus aluminized steel clamshell-type heat exchangers. G32V units

are available in heating capacities of 75,000 to 125,000 Btuh and cooling applications up to 5 tons. Refer to Engineering Handbook for proper sizing.

Units are factory equipped for use with natural gas. LP kits are available. All

G32V−1 through −4 units feature the Lennox SureLight silicon nitride ignition

system. G32V−5 and later units feature the two stage variable speed SureLight

integrated control board.The G32V units meet the California Nitrogen Oxides

) Standards and California Seasonal Efficiency requirements without mod-

(NO

x

ification. All units use a two−stage gas valve along with a two−stage combustion

air blower. The gas valve is redundant to assure safety shut−off as required by

A.G.A. or C.G.A.

All G32V units are equipped with an electronic variable speed (VSM) fan motor. The VSM consists of an ICM2 motor and control module assembly. The

VSM maintains a specified air volume throughout the entire external static

range.

Information contained in this manual is intended for use by qualified service

technicians only. All specifications are subject to change. Procedures outlined

in this manual are presented as a recommendation only and do not supersede

or replace local or state codes. In the absence of local or state codes, the

guidelines and procedures outlined in this manual (except where noted) are

recommended only.

G32V

Corp. 9816−L10

Revised 02−2004

G32V FURNACE

G32V HEAT EXCHANGE ASSEMBLY

Combustion Process:

1. A call for heat starts the combustion air blower.

2. Outdoor air is drawn through pipe into the burner

compartment where it mixes with gas in a conventional style inshot burner.

3. The SureLight ignition system lights the burners.

4. Combustion products are drawn downward

through the heat exchanger. Heat is extracted

as indoor air passes across the outside surface

of the metal.

5. Latent heat is removed from the combustion

products as air passes through the coil. Condensate (water) is formed as the combustion products cool.

6. As the combustion products exit the coil, condensate is collected and drained away.

7. Combustion products are pulled from the heat

exchanger and forced into the flue.

Page 1

© 1998 Lennox Industries Inc.

Litho U.S.A.

TABLE OF CONTENTS

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Data 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Altitude 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Venting Table 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Unit Components 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SureLight Ignition System 11. . . . . . . . . . . . . . . . . . .

Two−Stage Ignition Control 13. . . . . . . . . . . . . . . . . .

VSP2−1 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VSP3−1 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SureLight Two Stage Variable Speed Control 22.

Blower Compartment 30. . . . . . . . . . . . . . . . . . . . . . .

Heating 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III Start Up 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV Heating System Service Checks 47. . . . . . . . . . . . . .

V Typical Operating Characteristics 49. . . . . . . . . . . . . .

VI Maintenance 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII Wiring Diagrams and Operating Sequence 53. . . .

G32V−1 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G32V−3 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G32V−4 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G32V−5 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VSP2−1 Jumper Summary 70. . . . . . . . . . . . . . . . . .

VSP3−1 Jumper Summary 74. . . . . . . . . . . . . . . . . .

SureLight Jumper Summary 78. . . . . . . . . . . . . . . .

VIII Troubleshooting 81. . . . . . . . . . . . . . . . . . . . . . . . . . .

VSP2−1 Board 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VSP3−1 Board 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICM2 Motor with VSP2−1 83. . . . . . . . . . . . . . . . . . .

ICM2 Motor with VSP3−1 84. . . . . . . . . . . . . . . . . . .

ICM2 Motor with SureLight Control 85. . . . . . . . . . .

SureLight Control 86. . . . . . . . . . . . . . . . . . . . . . . . .

II Placement and Installation 38. . . . . . . . . . . . . . . . . . . .

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect switch(es). Unit may have multiple

power supplies.

Page 2

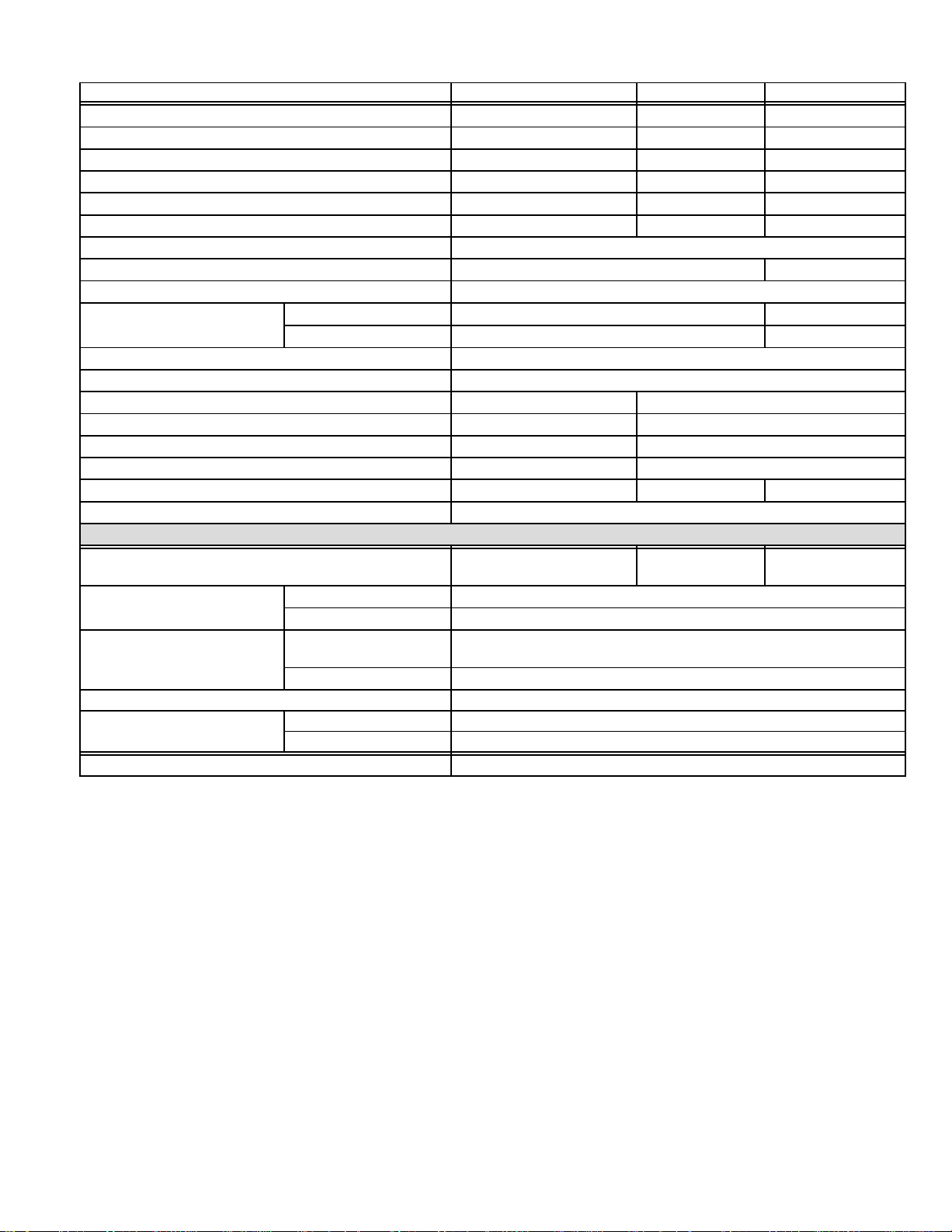

SPECIFICATIONS

Vent/Intake Air Roof

Model No. G32V3−75 G32V5−100 G32V5−125

Input Btuh (kW) − High 75,000 (22.0) 100,000 (29.3) 125,000 (36.6)

Input Btuh (kW) − Low 51,000 (14.9) 68,000 (19.9) 85,000 (24.9)

Output Btuh (kW) − High 67,500 (19.8) 90,000 (26.4) 112,500 (32.9)

Output Btuh (kW) − Low 45,900 (13.4) 61,200 (17.9) 76,500 (22.4)

A.F.U.E. 92.7% 93.2% 94.2%

California Seasonal Efficiency 89.4% 90.1% 91.1%

Exhaust pipe connection (PVC) diameter in. (mm) 2 (51)

Intake pipe connection (PVC) diameter in. (mm) 2 (51) 3 (76)

Condensate drain connection (PVC) in. (mm) 1/2 (12.7)

Temperature rise range F (C)

High static certified by (A.G.A./C.G.A.) in. wg. (Pa) .80 (200)

Gas Piping Size I.P.S. − Natural − in. (mm) 1/2 (12.7)

Blower wheel nominal diameter x width − in. (mm) 10 x 8 (254 x 203) 11−1/2 x 9 (292 x 229)

Blower motor output hp (W) 1/2 1

Nominal cooling that can be added − Tons (kW) 2 to 3 (7 to 10.6) 3−1/2 to 5 (12.3 to 17.6)

No. & size of filters − in. (mm) (1) 14 x 25 x 1 (356 x 635 x 25) (1) 20 x 25 x 1 (508 x 635 x 25)

Shipping weight lbs. (kg) 1 package 161 (73) 201 (91) 221 (100)

Electrical characteristics 120 volts 60 hertz 1 phase (less than 12 amps)

Concentric Vent/Intake Air/Roof Termination Kit 60G77 1/1/2 inch (38 mm)

Vent/Intake Air Roof

Termination Kit vent size

Vent/Intake Air Wall

Termination Kit vent size

Condensate Drain Heat Cable 26K68 6 ft. (1.8 m) − 26K69 24 ft. (7.3 m) − 26K70 50 ft. (15.2 m)

Heat Cable Tape

L.P. Kit 34L29 (−1, −2 models) 11M55 (−3 and later models)

Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for non−weatherized furnaces.

Meets California Nitrogen Oxides (NO

Determine from venting tables proper intake and exhaust pipe size and termination kit required.

Polyurethane frame type filter.

NOTE − 2 inch x 3 inch (51 mm x 76 mm) adaptor is furnished with −100 and −125 furnaces for exhaust pipe connection.

Low Fire 30 − 60(16 − 33) 35 − 65 (19 − 36)

High Fire 40 − 70 (22 − 39) 50 − 80 (28 − 44)

OPTIONAL ACCESSORIES (Must Be Ordered Extra)

33K97 2 inch

(51 mm)

33K97− 2 inch (51 mm)

60L46 − 3 inch (76 mm)

2 inch (51 mm) 15F75

3 inch (76 mm) 44J41

2 inch (51 mm)

15F74 (ring kit) 22G44 (close couple) 30G28 (WTK close couple)

30G79 (WTKX close couple with extension riser)

3 inch (76 mm) 44J40 (close couple) 81J20 (WTK close couple)

Fiberglass − 1/2 in. (38 mm) 39G04

Aluminum foil − 2 in. (25 mm) 39G03

) Standard and California Seasonal Efficiency requirements.

x

Page 3

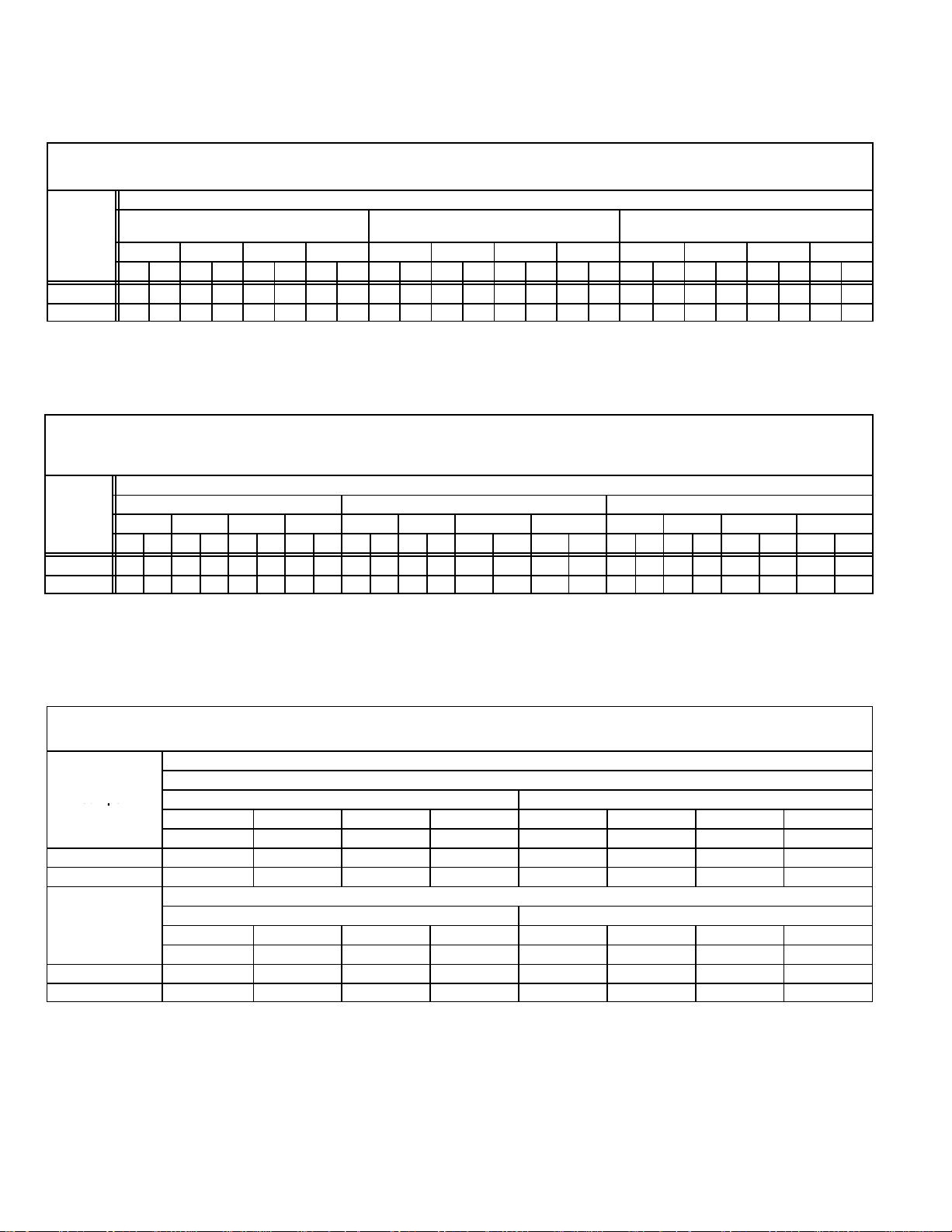

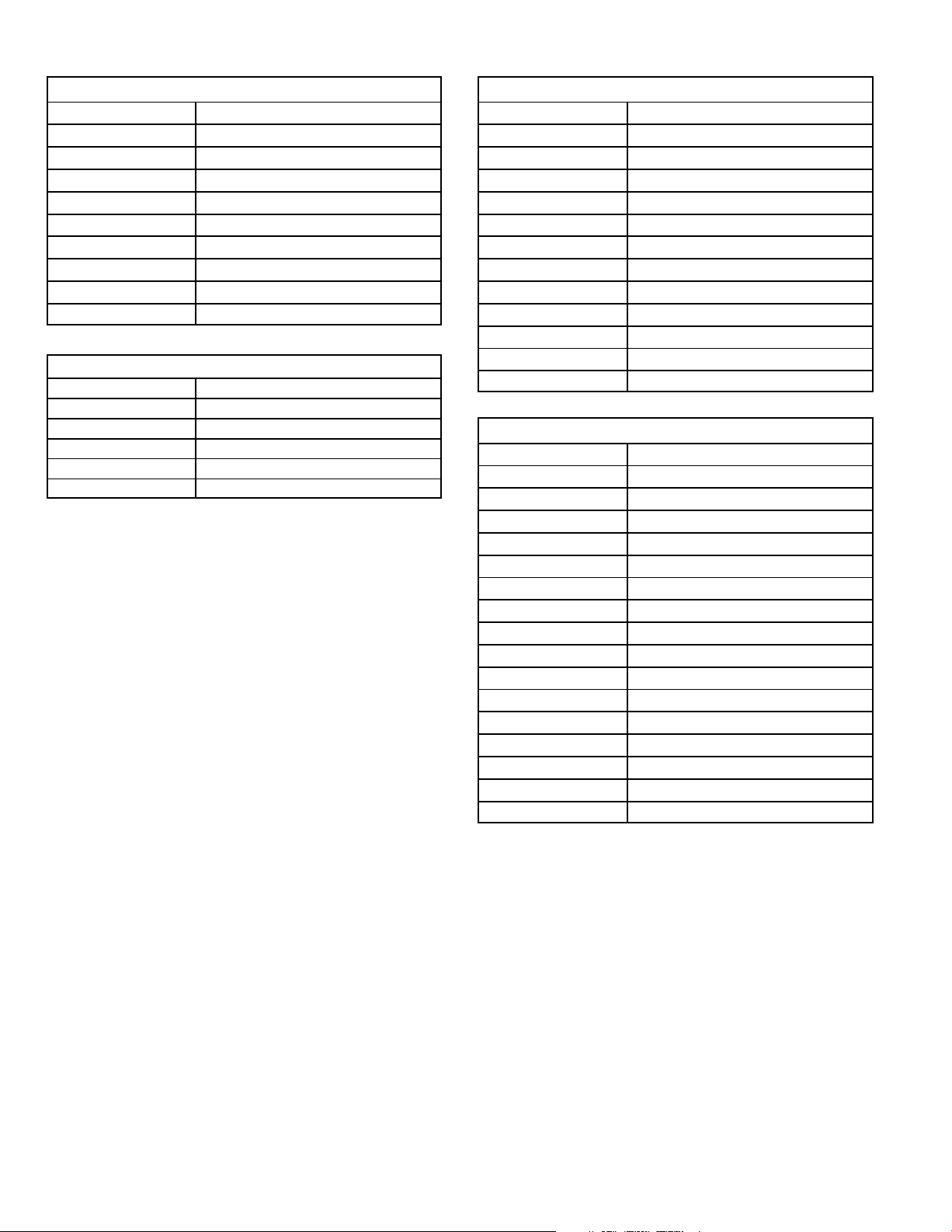

BLOWER PERFORMANCE

Jumper

g

Setting

ADJUST"

Jumper

Positions

Table 1

G32V3−75−1 through −3 Units

0 THROUGH 0.80 IN. W.G. (0 THROUGH 200 PA) EXTERNAL STATIC PRESSURE

VSP2-1 Blower Control Low Speed 3

Factory Settings High Speed 4

ADJUST"

Jumper

Setting

NORM 880 415 930 440 980 465 1040 490 1060 500 1105 520 1260 595 1330 630 1075 510 1150 545 1270 600 1350 635

− 15% 775 365 810 380 850 400 910 430 930 440 970 460 1070 505 1130 535 930 440 990 465 1080 510 1140 540

NOTE The effect of static pressure and filter resistance is included in the air volumes listed.

(Cool, Low Heat Or Continuous Fan)

1 2 3 4 1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

LOW" Speed

0 THROUGH 0.80 IN. W.G. (0 THROUGH 200 PA) EXTERNAL STATIC PRESSURE

VSP2-1 Blower Control G32V5−100 G32V5−125

Factory Settings Low Speed 2 Low Speed 3

ADJUST"

Jumper

Settin

NORM 1140 540 1250 590 1440 680 1550 730 1620 765 1820 860 2000 945 2100 990 1560 735 1720 810 2030 960 2150 1015

NOTE The effect of static pressure and filter resistance is included in the air volumes listed.

G32V5−125 unit only − do not place jumper on tap 1 ("") for high speed or tap 2 ("NORM" or "") for low speed.

LOW" Speed (Cool Or Continuous Fan) HIGH" Speed (Cool) HEAT" Speed

1 2 3 4 1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

− 970 460 1060 500 1280 605 1320 625 1380 650 1550 730 1700 800 1780 840 1330 630 1460 690 1730 815 1830 865

Heat Speed 3

VSP2−1 Jumper Speed Positions

HIGH" Speed (Cool) HEAT" Speed

Table 2

G32V5−100/125−1 through −3 Units

High Speed 4 High Speed 4

Heat Speed 1 Heat Speed 2

VSP2 Jumper Speed Positions

Table 3

G32V3−75−4 Units

0 THROUGH 0.80 IN. W.G. (0 THROUGH 200 PA) EXTERNAL STATIC PRESSURE

VSP3−1 Blower Control Factory Settings ADJUST − NORM

Jumper

Positions

NORM (Normal) 880 415 930 440 980 465 1040 490 1075 510 1150 545 1270 600 1350 635

" (Minus) 15% 775 365 810 380 850 400 910 430 930 440 990 460 1080 510 1140 540

ADJUST"

Jumper

Positions

NORM (Normal) 880 415 930 440 980 465 1040 490 1060 500 1105 520 1260 600 1350 635

" (Minus) 15% 775 365 810 380 850 400 910 430 930 440 970 460 1080 510 1140 540

15% lower motor speed than NORM jumper setting.

NOTE − The effect of static pressure and filter resistance is included in air volumes shown.

NOTE − Continuous Fan only speed is approximately 800 cfm (380 L/s) − non adjustable.

NOTE − Lennox Harmony II zone control applications − MAX CFM is determined by COOL jumper placement with a minimum of approximately 850 cfm (400 L/s) for all positions.

"

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Heat Speed − 3

Cool Speed − 4

VSP Jumper Speed Positions

HEAT" Jumper

Low Speed High Speed

COOL" Jumper

Low Speed High Speed

Page 4

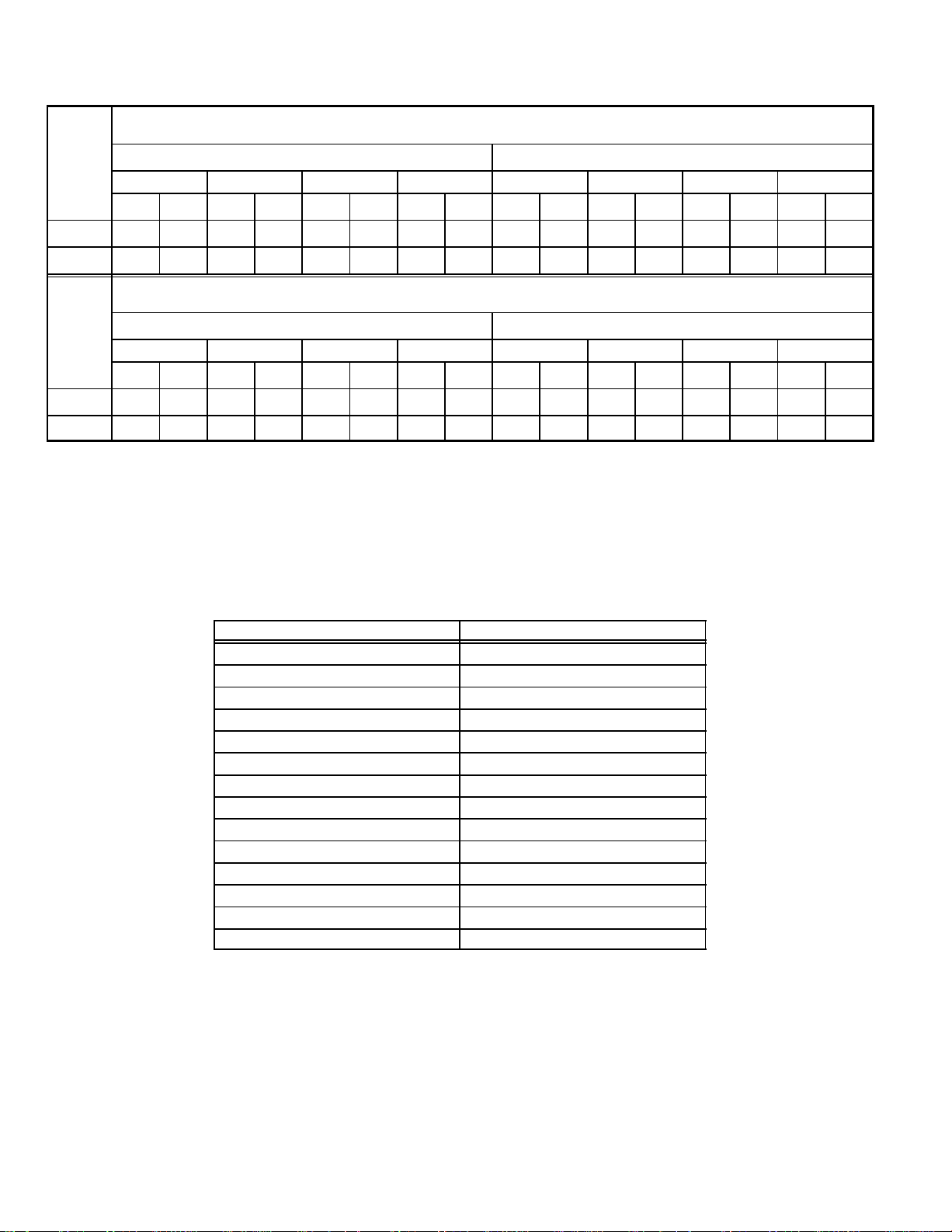

Table 4

ADJUST"

Jumper

Positions

Setti

G32V5−100/125−4 Units

0 THROUGH 0.80 IN. W.G. (0 THROUGH 200 PA) EXTERNAL STATIC PRESSURE

VSP3−1 Blower Control Factory Settings G32V5−100 ADJUST − NORM G32V5−125 ADJUST − (minus)

Jumper

Positions

NORM (Normal) 1140 540 1250 590 1440 680 1550 730 1560 735 1720 810 2030 955 2150 1015

" (Minus) 15% 970 455 1060 500 1280 605 1320 595 1330 625 1460 690 1730 815 1830 865

ADJUST"

Jumper

Positions

NORM (Normal) 1140 540 1250 590 1440 680 1550 730 1620 765 1820 860 2000 945 2100 990

" (Minus) 15% 970 455 1060 500 1280 605 1320 595 1380 650 1550 730 1700 800 1780 840

15% lower motor speed than NORM jumper setting.

G32V5−125 Models Only − Do not place jumper on position #1 (at NORM or " setting) or position #2 (at " setting) for HEAT speed.

NOTE − The effect of static pressure and filter resistance is included in air volumes shown.

NOTE − Continuous Fan only speed is approximately 1150 cfm (545 L/s) − non adjustable.

NOTE − Lennox Harmony II zone control applications − MAX CFM is determined by COOL jumper placement with a minimum of approximately 1140 cfm (540 L/s) for all positions.

"

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Low Speed High Speed

Low Speed High Speed

Heat Speed − 2 Heat Speed − 4

Cool Speed − 4 Cool Speed − 4

VSP Jumper Speed Positions

HEAT" Jumper

COOL" Jumper

TABLE 5

G32V3−75−5 Units BLOWER MOTOR PERFORMANCE

0.0" to 0.8" w.g. (0 through 200 Pa) External Static Pressure Range

Blower Speed Adjustment Settings (Switches 5 and 6)

Cool

Adjust"

ng

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Low Speed High Speed

Norm 880 415 930 440 980 465 1040 490 1060 500 1105 520 1260 595 1330 630

–

775 365 810 380 850 400 910 430 930 440 970 460 1070 505 1130 535

Blower Speed Adjustment Settings (Switches 7 and 8)

Heat

Adjust"

Setting

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Norm 945 446 1025 484 1125 531 1270 599 1080 510 1172 533 1286 607 1452 685

–

803 379 871 411 956 451 1080 510 918 433 996 470 1093 516 1234 582

15% lower motor speed than NORM switch setting.

NOTE − The effect of static pressure and filter resistance is included in air volumes shown.

NOTE − Continuous Fan only speed is approximately 800 cfm (380 L/s) − non adjustable.

NOTE − Lennox Harmony IIt zone control applications − MAX CFM is determined by COOL switch setting with a minimum of approximately 850

cfm (400 L/s) for all positions.

Low Speed High Speed

Page 5

TABLE 6

Setti

G32V5−100/125−5 Units BLOWER MOTOR PERFORMANCE

0.0" to 0.8" w.g. (0 through 200 Pa) External Static Pressure Range

Blower Speed Adjustment Settings (Switches 5 and 6)

Cool

Adjust"

ng

1

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Norm 1140 540 1250 590 1440 680 1550 730 1620 765 1820 860 2000 945 2100 990

–

970 455 1060 500 1280 605 1320 595 1380 650 1550 730 1700 800 1780 840

Low Speed High Speed

2

3 4 1

2

3 4

Blower Speed Adjustment Settings (Switches 7 and 8)

Heat

Adjust"

Setting

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Norm 1140 540 1250 590 1440 680 1550 730 1560 735 1720 810 2030 960 2150 1015

–

15% lower motor speed than NORM switch setting.

G32V5−125 Models Only − Do not set switches for position #1 (at NORM or –" setting) or position #2 (at −" setting) for HEAT speed.

NOTE − The effect of static pressure and filter resistance is included in air volumes shown.

NOTE − Continuous Fan only speed is approximately 1150 cfm (545 L/s) − non adjustable.

NOTE − Lennox Harmony IIt zone control applications − MAX CFM is determined by COOL switch setting with a minimum of approximately 1140

cfm (540 L/s) for all positions.

970 455 1060 500 1280 605 1320 595 1330 660 1460 690 1730 815 1830 865

Low Speed High Speed

FILTER AIR RESISTANCE

cfm (L/s) in. w.g. (Pa)

0 (0) 0.00 (0)

200 (95) 0.01 (0)

400 (190) 0.03 (5)

600 (285) 0.04 (10)

800 (380) 0.06 (15)

1000 (470) 0.09 (20)

1200 (565) 0.12 (30)

1400 (660) 0.15 (35)

1600 (755) 0.19 (45)

1800 (850) 0.23 (55)

2000 (945) 0.27 (65)

2200 (1040) 0.33 (80)

2400 (1130) 0.38 (95)

2600 (1225) 0.44 (110)

Page 6

No gas pressure adjustment is needed when operating from 0 to 4500 ft. (0 to 8 m). See below for correct manifold pressures for altitudes

greater that 4500 ft. (1372 m) for natural and L.P. gas.

Manifold Absolute Pressure (outlet) in. w.g. (kPa)

Model No.

0 to 4500 ft. (0 to 1372 m)

above sea level

G32V−75 natural no adjustment

G32V−100 natural

G32V−125 natural

3.5 (0.88) 3.4 (0.85) 3.3 (0.82) 3.2 (0.80)

G32V−75 L.P. no adjustment

G32V−100 L.P. 7.5 (0.19) 7.3 (0.185) 7.1 (0.180) 7.0 (0.177)

G32V−125 L.P. 7.5 (0.19) 7.3 (0.185) 7.1 (0.180) 7.0 (0.177)

4501 to 5500 ft.

(1373 to 1676 m)

above sea level

5501 to 6500 ft.

(1677 to 1981 m)

above sea level

6501 to 7500 ft.

(1982 to 2286 m)

above sea level

INTAKE AND EXHAUST PIPE VENTING TABLE

HIGH ALTITUDE INFORMATION

Vent Pipe

Maximum

Equivalent Length

75,000 Btuh (22.0 kW) 100,000 Btuh (29.3 kW) 125,000 Btuh (36.6 kW)

Feet Meters in. mm in. mm in. mm

15 4.6 2 51 2 51 2 51

20 6.1 2 51 2 51 3 76

25 7.6 2 51 2 51 3 76

30 9.1 2 51 3 51 3 76

40 12.2 2 51 3 51 3 76

50 15.2 2 51 3 51 3 76

55 16.8 2 51 3 76 3 76

60 18.3 3 76 3 76 3 76

70 21.3 3 76 3 76 3 76

80 24.4 3 76 3 76 3 76

90 27.4 3 76 3 76 3 76

100 30.5 3 76 3 76 3 76

110 33.5 3 76 3 76 3 76

120 36.6 3 76 3 76 3 76

130 39.6 3 76 3 76 − − − − − − − −

MINIMUM PIPE LENGTHS FOR FURNACES G32V−75 5 feet (1.5 m) with two 90 elbows of 2 inch (51 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

VENTING NOTES One 90elbow is equivalent to 5 feet (1.5 m) of straight vent pipe.

Two 45 elbows are equal to one 90 elbow.

One 45 elbow is equivalent to 2.5 feet (.75 m) of straight vent pipe.

One foot (305 mm) length of 2 in. (51 mm) diameter pipe is equivalent to 8 feet (2.4 m) of 3 in. (76 mm) diameter pipe.

Intake and Exhaust pipes must

2 inch x 3 inch (51 mm x 76 mm) adaptor is furnished with −100 and −125 furnaces for exhaust pipe connection.

Exhaust pipe must terminate with 1−1/2 inch (38 mm) diameter pipe for furnaces using1−1/2 (38 mm) or 2 inch (51 mm) diameter pipe runs.

Exhaust pipe must terminate with 2 inch (51 mm) diameter pipe for furnaces using 3 inch (76 mm) diameter pipe runs.

G32V−100 5 feet (1.5 m) with two 90 elbows of 2 inch (51 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

G32V−125 5 feet (1.5 m) with two 90 elbows of 2 inch (51 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

be the same diameter.

Minimum Vent Pipe Diameter Required

Page 7

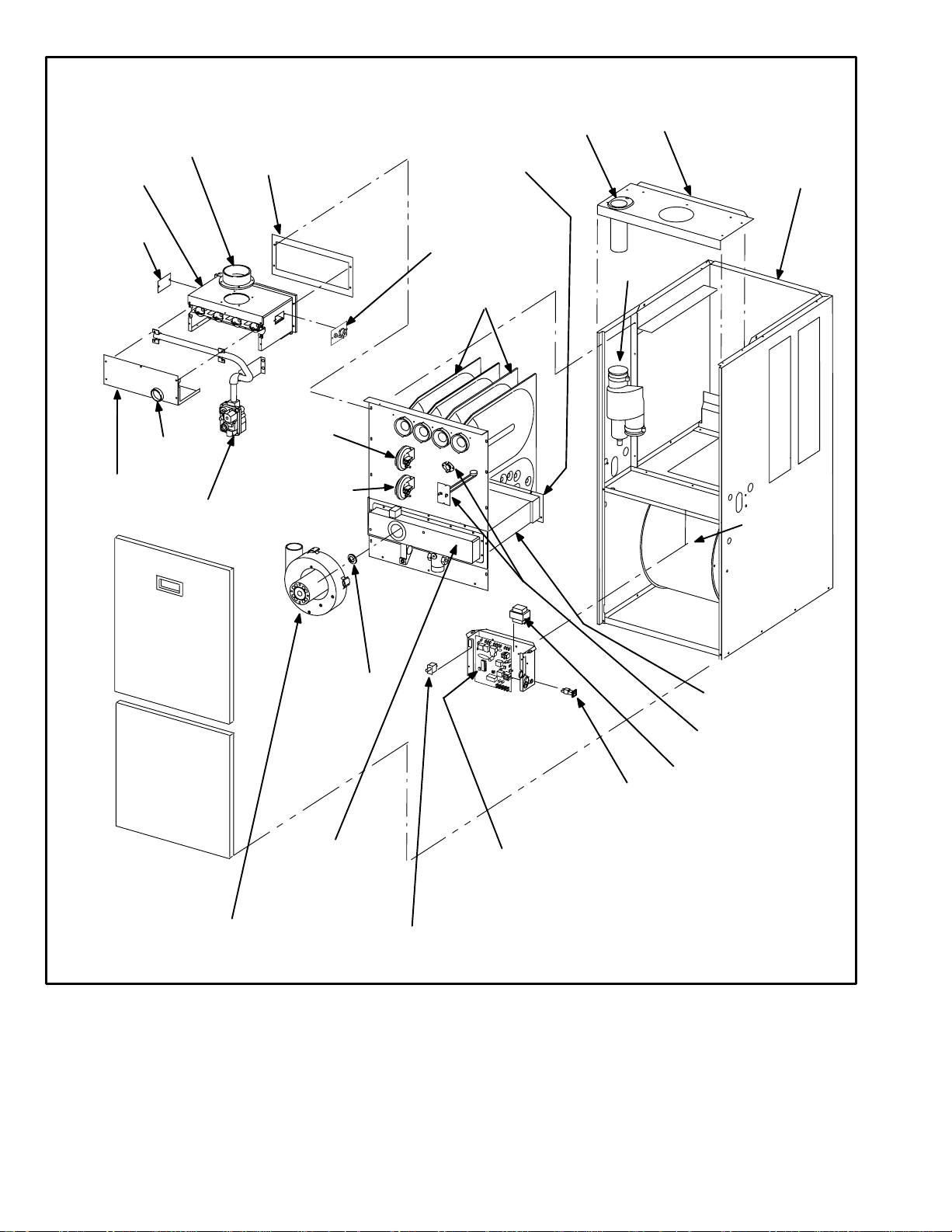

G32V PARTS ARRANGEMENT

FRESH AIR

INTAKE FITTING

BURNER BOX

ASSEMBLY

PATCH

PLATE

FLAME SIGHT

BURNER

BOX

COVER

GLASS

TWO-STAGE

GAS VALVE AND

MANIFOLD

GLASS FIBER GASKET

LOW HEAT

DIFFERENTIAL

PRESSURE

SWITCH

HIGH HEAT

DIFFERENTIAL

PRESSURE

SWITCH

(−75 only)

WARM

HEADER

(COLLECTOR)

BOX

PATCH PLATE WITH

BARBED FITTING

AND FLAME

ROLL−OUT SWITCH

DuralokPlus

HEAT EXCHANGER

ASSEMBLY

TM

FLUE COLLAR

TRANSITION

TOP CAP

CABINET

FLUE

SUPPLY

AIR

BLOWER

BURNER

ACCESS

PANEL

BLOWER

ACCESS

DOOR

TWO−SPEED

COMBUSTION AIR

INDUCER

COMBUSTION

AIR

ORIFICE

COLD HEADER

(COLLECTOR)

BOX

SECONDARY COIL

PRIMARY LIMIT

(ALTERNATE STYLES)

TRANSFORMER

CONTROL VOLTAGE

CIRCUIT BREAKER

SURELIGHT TWO−STAGE,

VARIABLE−SPEED

INTEGRATED CONTROL BOARD

DOOR INTERLOCK SWITCH

FIGURE 1

Page 8

BURNER

ACCESS

COVER

BURNER BOX

MANIFOLD

GAS VALVE

FRESH AIR INTAKE

FITTING

G32V HEAT EXCHANGER

CORBEL ORIFICE

CUPS

SURELIGHT IGNITOR LENNOX DURALOKPLUS

HEAT EXCHANGER ASSEMBLY

COMBUSTION AIR

BLOWER MOTOR

COMBUSTION

AIR BLOWER

BURNER BOX

FLAME SIGHT GLASS

FLUE TRANSITION

LOW HEAT DIFFERENTIAL

PRESSURE SWITCH

HIGH HEAT DIFFERENTIAL

PRESSURE SWITCH

(G32V−75 ONLY)

COMBUSTION AIR BLOWER

DOOR INTERLOCK SWITCH

SURELIGHT CONTROL BOARD*

VSP BLOWER CONTROL BOARD*

BLOWER HOUSING

COLD HEADER

(COLLECTOR )

BOX

G32V GENERAL PARTS ORIENTATION

FIGURE 2

WARM HEADER

CONDENSER COIL

SUPPLY AIR DUCT FLANGE

UPPER VEST PANEL

GAS MANIFOLD

PRIMARY LIMIT

GAS VALVE

COLD HEADER BOX

HEADER BOX

CONDENSATE

LOWER VEST PANEL

CONTROL BOX

CIRCUIT BREAKER

TWO−STAGE CONTROL*

(COLLECTOR)

BOX

TRAP

BLOWER

COMPARTMENT

*NOTE−G32V−1 through −4 units only

BLOWER MOTOR

COIL CHOKE

FIGURE 3

Page 9

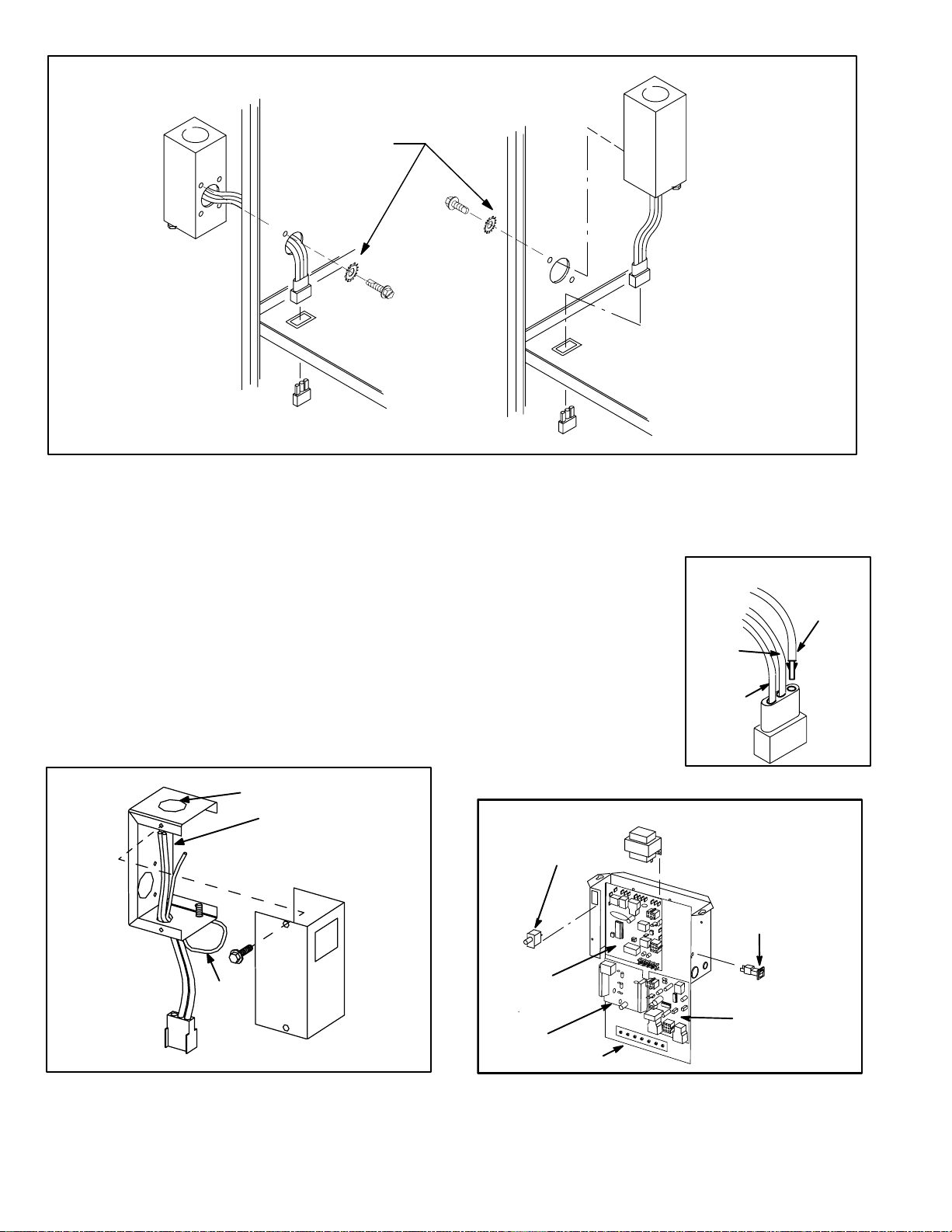

OUTSIDE INSTALLATION

MAKE-UP BOX

MAKE-UP BOX INSTALLATION

Box may be installed inside or outside cabinet and

may be installed on left side or right side of cabinet

STAR WASHERS

MUST BREAK

PAINT ON UNIT

CABINET FOR

PROPER GROUND.

UNIT

CABINET

INSIDE INSTALLATION

MAKE-UP BOX

Line Voltage Enters Through

Knockout In Make-Up Box.

J69 Passes Through Side

Knockout Into Side Of Unit.

JACK J69

BLOWER MULLION

PLUG P69

FIGURE 4

I−UNIT COMPONENTS

G32V unit components are shown in figures 1 and 2. General

parts orientation is shown in figure 3. The gas valve, ignition

control and burners can be accessed by removing the burner

access panel. The blower and blower controls can be accessed by removing the blower access door.

G32V units are designed for bottom and side return air. The

panels are designed to be knocked-out (bottom return) or

cut-out (side return) as required for return air duct connection.

A−Make-Up Box (Figure 5)

The line voltage make-up box is shown in figure 5. The box

may be installed inside or outside the unit and may be installed

on the unit left or right side (figure 4).

MAKE-UP BOX

BOX

POWER ENTRY KNOCKOUT

120V LINE VOLTAGE

PIGTAIL CONNECTIONS

COVER

Line Voltage Enters Make-Up

Box Through Side Of Unit and

J69 Passes Through Bottom

Knockout in Make-Up Box.

BLOWER MULLION

An accessory (brown) output wire is provided with the make-up

box. The wire provides a 120V connection for optional accessories such as electronic air cleaner or humidifier. If used, the

wire is field installed in J69 jack plug by inserting the pin of the

brown wire into the open socket

of the jack. See figure 6. 120V

INSTALLING BROWN

ACCESSORY WIRE TO J69

accessories rated up to 4 amps

total may be connected to this

wire. The neutral leg of the accessory is connected to the

WHITE

NEUTRAL

BROWN

neutral white wire in the makeup box. The accessory terminal

is energized whenever the

blower is in operation.

B−Control Box Components

G32V−1 through −4 CONTROL BOX

DOOR

INTERLOCK

SWITCH

BLACK

J69

FIGURE 6

TRANSFORMER

UNIT

GROUND

JACK J69

to blower deck

Box may be installed inside or outside unit. See Figure 4.

TO BLOWER MULLION

FIGURE 5

SURELIGHT

Page 10

CONTROL

VSP

BOARD

TERMINAL STRIP

FIGURE 7

CIRCUIT

BREAKER

TWO−

STAGE

CONTROL

BOARD

Integrated ignition and blower control components (A92),

unit transformer (T1) and 24V circuit breaker (CB8) are located in the control box. In addition, a door interlock switch

(S51) is located in the control box. Jackplugs allow the control box to be easily removed for blower service.

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage 24volt section of the unit. Transformers on

all models are rated 50VA with a 120V primary and a 24V

secondary.

2. Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box. The

switch provides overcurrent protection to the transformer

(T1). The breaker is rated 3A . If the current exceeds this limit

the breaker will trip and all unit operation will shut-down. The

breaker can be manually reset by pressing the button on the

face.

3.Door Interlock Switch (S51)

A door interlock switch is located on the control box. The

switch is wired in series with line voltage. When the blower

door is removed the unit will shut down.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

NOTE − Do not remove blower access panel to read

SureLight LED lights. A sight glass is provided on the

access panel for viewing.

Tables 9 and 10 show jack plug terminal designations.

Units equipped with the SureLight board can be used with

either electronic or electro−mechanical thermostats without modification. The SureLight ignitor is made of durable

silicon−nitride. Ignitor longevity is also enhanced by voltage ramping by the control board. The board finds the lowest ignitor temperature which will successfully light the

burner, thus increasing the life of the ignitor.

SURELIGHT CONTROL BOARD

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace’s

electronic controls. Precautions will help to

avoid control exposure to electrostatic discharge by putting the furnace, the control and

the technician at the same electrostatic potential. Neutralize electrostatic charge by touching

hand and all tools on an unpainted unit surface,

such as the gas valve or blower deck, before performing any service procedure.

DANGER

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply

replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

4.SureLight Ignition System A92

G32V−1 through −4 units are equipped with the Lennox

SureLight ignition system. The system consists of ignition

control board (figure 8 with control terminal designations

in table 1) and ignitor (figure 9). The board and ignitor work

in combination to ensure furnace ignition and ignitor durability. The SureLight integrated board controls all major furnace operations. The board also features two LED lights

for troubleshooting (and two accessory terminals rated at

(4) four amps. See table 8 for troubleshooting diagnostic

codes.

Page 11

13/32’

FIGURE 8

SURELIGHT IGNITOR

MEASUREMENT IS TO I.D.

5/8"

OF RETENTION RING

5/16

"

FIGURE 9

TABLE 7

SURELIGHT CONTROL TERMINAL DESIGNATIONS

ACB COOL NOT USED

ACB HEAT NOT USED

PARK NOT USED

ACB LOW NOT USED

ACC ACCESSORY TERMINAL (LINE VOLT)

TX 120VAC TRANSFORMER

HOT 120VAC HOT INPUT

HTG ACC HEAT ONLY ACCESSORY (LINE VOLT)

NEUTRALS 120VAC NEUTRALS

24VAC HOT 24VAC HOT FROM TRANSFORMER

24VAC RTN 24VAC RETURN FROM TRANSFORMER

FLAME SENSE FLAME SENSE TERMINAL

TABLE 8

DIAGNOSTIC CODES

MAKE SURE TO ID LED’S CORRECTLY: REFER TO INSTALLATION INSTRUCTIONS FOR CONTROL BOARD LAYOUT.

LED #1 LED #2 DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS FAST

FLASH

SLOW FLASH ON

OFF SLOW FLASH

ALTERNATING SLOW

FLASH

SLOW FLASH OFF Flame sensed without gas valve energized.

ON SLOW FLASH Rollout switch open. OR: 9 pin connector improperly attached.

ON

ON

OFF

FAST FLASH SLOW FLASH Main power polarity reversed. Switch line and neutral.

SLOW FLASH FAST FLASH Low flame signal. Measures below .61 microAmps. Replace flame sense rod.

ALTERNATING FAST

FLASH

NOTE − Slow flash equals 1 Hz (one flash per second). Fast flash equals 3 Hz (three flashes per second). Drop out flame sense current < 0.20 microAmps

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS FAST

FLASH

ALTERNATING SLOW

FLASH

ON

OFF

ON

ALTERNATING FAST

FLASH

Also signaled during cooling and continues fan.

Power − Normal operation

Normal operation − signaled when heating demand initiated at thermostat.

Primary or Secondary limit open. Units with board 63K89 or 24L85: Limit must close within 5

trials for ignition or board goes into one hour limit Watchguard. Units with board 56L83 or

97L48: Limit must close within 3 minutes or board goes into one hour limit Watchguard.

Pressure switch open or has opened 5 times during a single call for heat; OR: Blocked inlet/

exhaust vent; OR: Condensate line blocked; OR: Pressure switch closed prior to activation of

combustion air blower.

Watchguard − burners fail to ignite.

Circuit board failure or control wired incorrectly.

Improper main ground or line voltage below 75 volts; OR: Broken ignitor; OR: Open ignitor

circuit.

TABLE 9

SureLight BOARD J156 TERMINAL

DESIGNATIONS

PIN # FUNCTION

1 Ignitor

2

3

4

Combustion Air Blower Line Voltage

5

6

Combustion Air Blower Neutral

Not Used

Ignitor Neutral

Not Used

Page 12

TABLE 10

SureLight BOARD J58 TERMINAL

DESIGNATIONS

PIN # FUNCTION

1 Primary Limit In

2

3

4

5

6

Pressure Switch and Primary Limit Out

7

8

9

Gas Valve Common

Roll Out Switch Out

Gas Valve 24V

Pressure Switch In

Not Used

Roll Out Switch In

Ground

Electronic Ignition (See Ignition Sequence Below)

On a call for heat the SureLight control monitors the combustion air blower pressure switch. The control will not begin the heating cycle if the pressure switch is closed (by−

passed). Once the pressure switch is determined to be

open, the combustion air blower is energized. When the differential in the pressure switch is great enough, the pressure switch closes and a 15−second pre−purge begins. If the

pressure switch is not proven within 2−1/2 minutes, the control goes into Watchguard−Pressure Switch mode for a

5−minute re−set period.

After the 15−second pre−purge period, the SureLight ignitor

warms up for 20 seconds after which the gas valve opens

for a 4−second trial for ignition. G32V units with board

24L85, 56L83 or 63K89: the ignitor energizes for the first

second of the 4−second trial. Units equipped with board

97L48: ignitor energizes during the trial until flame is

sensed. If ignition is not proved during the 4−second period,

the control will try four more times with an inter purge and

warm−up time between trials of 35 seconds. After a total of

five trials for ignition (including the initial trial), the control

goes into Watchguard−Flame Failure mode. After a 60−minute reset period, the control will begin the ignition sequence

again.

The SureLight control board has an added feature that prolongs the life of the ignitor. After a successful ignition, the

SureLight control utilizes less power to energize the ignitor

on successive calls for heat. The control continues to ramp

down the voltage to the ignitor until it finds the lowest

amount of power that will provide a successful ignition. This

amount of power is used for 255 cycles. On the 256th call

for heat, the control will again ramp down until the lowest

power is determined and the cycle begins again.

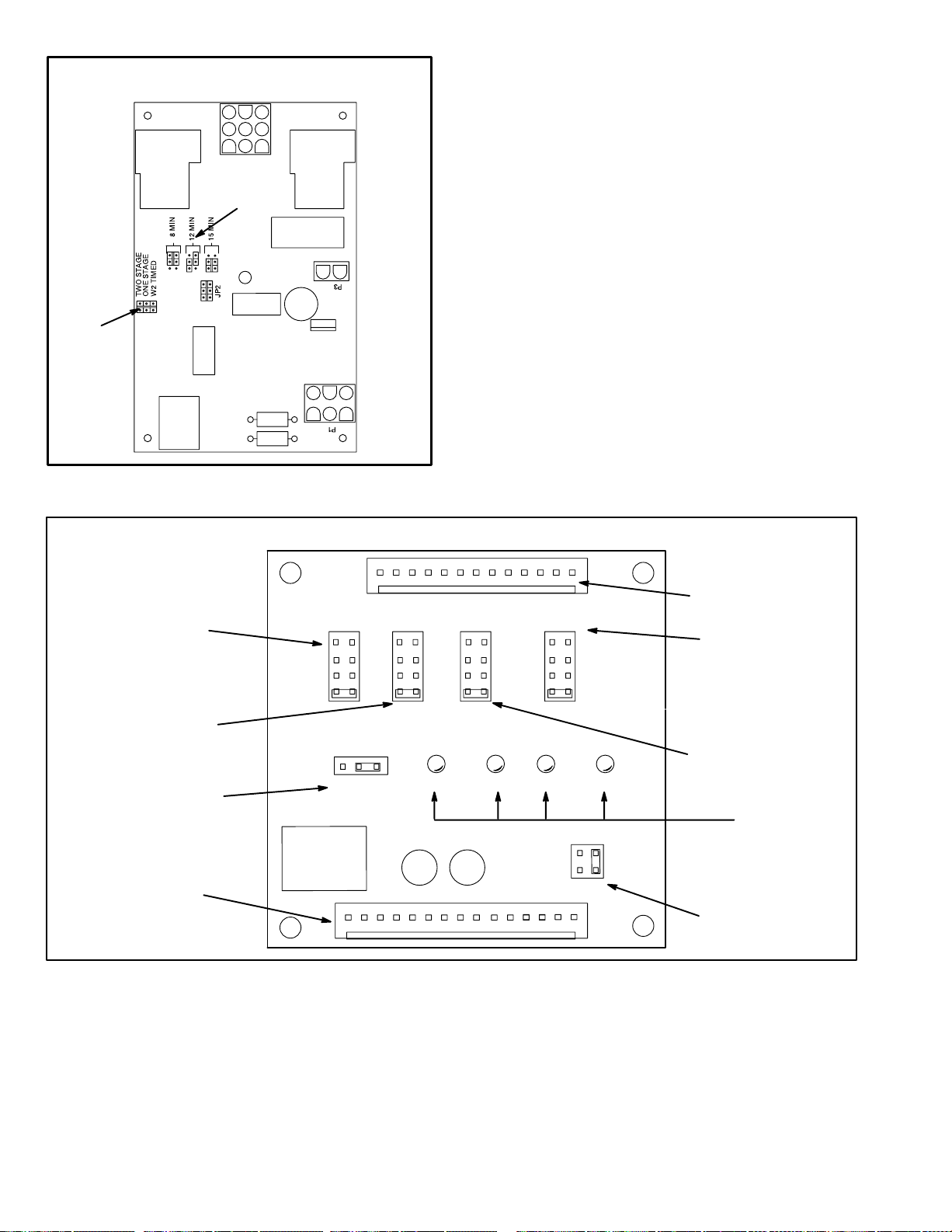

5. Two−Stage Control (A86)

G32V−1 through −4 units

G32V−1 through −4 units are equipped with a two−stage

control (figure 10). The two−stage board acts as a go between from the indoor thermostat to the SureLight ignition

board. The board can be utilized in three modes: with a

SINGLE−STAGE thermostat, a TWO−STAGE thermostat or

with a second−stage (high fire) delay called W2 TIMED. The

two−stage board is equipped with a jumper (see figure 10)

which changes operating modes and a jumper which adjusts second−stage heat delay during W2 TIMED mode.

While in the single−stage thermostat mode (one−stage

jumper setting), the unit will always operate on second−

stage heat. The combustion air blower (B6) will operate on

high speed and indoor blower (B3) will operate on heating

speed. While in the two−stage thermostat mode the unit will

operate on first−stage heat (low fire). The combustion air

blower (B6) and indoor blower will operate on low speed.

The unit will switch to second−stage heat (high fire) on call

from the indoor thermostat W2. While in the W2 TIMED

mode (factory setting 8 minutes) the unit will fire on first−

stage heat (low fire) with the combustion air blower (B6)

and indoor blower (B3) operating on low speed. After a set

time delay the unit switches to second−stage heat (high

fire). The combustion air blower and indoor blower also

switch to second−stage heat mode.

Ignition Sequence Board: 63K89, 24L85 and 56L8301

38

Blower On"

Delay

5 SEC80

Post

Purge

ON

OFF

DEMAND

CAB

IGNITOR

GAS VALVE

INDOOR BLOWER

1

Pre −Purge Ignitor Warmup Trial for

15

34

35

Ignition

Ignition Sequence Board 97L4801

1

ON

OFF

DEMAND

CAB

IGNITOR

GAS VALVE

INDOOR BLOWER

*All controls: blower on time will be 45 seconds after gas valve is energized. Blower off time will depend on OFF TIME" Setting.

Pre −Purge Ignitor Warmup

15

34

Trial for

Ignition

38

Blower On"

Delay

5 SEC80

Post

Purge

Page 13

MODE OF

OPERATION

JUMPER

TWO−STAGE CONTROL BOARD

W2 TIMED ON

DELAY JUMPER

FIGURE 10

6.VSP2−1 Blower Control Board (A24)

G32V −1 / −3 units

G32V units are equipped with a variable speed motor that is

capable of maintaining a specified CFM throughout the external static range. The unit uses the VSP2−1 variable

speed control board, located in the blower compartment,

which controls the blower speed and provides diagnostic

LE Ds. The control has bot h a non−adjustable, factory preset

ON" fan timing delay and an adjustable OFF" fan timing delay

(see figure 13).

The VSP2−1 also senses limit trip condition and turns on the

blower. The G32V limit switch is located in the middle of the

vestibule wall. When excess heat is sensed in t h e h e a t exchanger, the limit switch will open and interrupt the current

to the gas valve, while at the same time the VSP2−1 energizes

the blower on heating speed. The limit automatically resets

when the unit temperature returns to normal and the blower is

de−energized.

Diagnostic LEDs located on the VSP2−1 control board are provided to aid in identifying the unit’s mode of operation. Certain

scenarios will arise depending on the jumper positions. Refer

to figure 11 for identification.

HIGH SPEED

SELECTOR PINS

(COOLING ONLY)

LOW SPEED

SELECTOR PINS

(COOLING, HEATING and

CONTINUOUS FAN)

HEATING STAGE

JUMPER SELECTOR PINS

JP73

15 PIN PLUG

(BOARD TO VARIOUS

POINTS IN FURNACE)

VSP2−1 VARIABLE SPEED CONTROL BOARD SELECTIONS

1

JP2

HIGH LOW ADJUST HEAT

TEST

−

+

NORM

DS3

ON/OFF

HI/LOW

DS1

270

1

2

3

4

DS4

CFM

210

90

150

JP1

1

1

2

3

4

HTG.

BLOWER

12

1

2

3

4

HEAT

DS2

FIGURE 11

JP46

13 PIN PLUG

(BOARD TO MOTOR)

HEATING SPEED

SELECTOR PINS

See table 11 for VSP2

factory settings

OPERATIONAL

SELECTOR PINS

(Affects both heating

and cooling modes)

DIAGNOSTIC

DS LEDS

FAN OFF"

TIMING PINS

Page 14

VSP2−1 BLOWER CONTROL BOARD (A24)

1

J46

HIGH LOW ADJUST HEAT

DS3

TEST

−

+

NORM

HI/LOW

1

2

3

4

DS4

1

2

3

4

HTG.

BLOWER

1

2

3

4

HEAT

IMPORTANT

24 VAC half wave rectified (DC pulse), when

measured with a meter, may appear as a lower

or higher voltage depending on the make of the

meter. Rather than attempting to measure the

output voltage of A24, see G32V BLOWER &

VSP2 BLOWER CONTROL BOARD TROUBLESHOOTING FLOW CHART in the TROUBLESHOOTING section of this manual.

DS2

12

J73

1

PIN 2 - G - Input signal from thermostat’s fan signal.

PIN 3 - W2 - Input signal for second stage heat from the thermostat.

PIN 4 - DS - Input signal for the blower speed regulation.

PIN 11 - HT - Input signal from the fan limit control.

PIN 13 - 24V - Input 24 VAC power for the VSP2-1.

PIN 14 - 24V - Input 24 VAC power for the VSP2-1.

PIN 1 - Heat - Heat speed input signal to the ICM2 motor.

PIN 4 - High Tap - High Speed programming input.

PIN 6 - On / Off - On / off output signal to the ICM2 motor.

PIN 8 - Hi / Low - Speed regulate input signal to the ICM2 motor.

PIN 9 - Hi / Low - Speed regulate input signal to the ICM2 motor.

PIN 11 - Heat Tap - Heating blower speed programming.

PIN 1 - C - 24 VAC common.

PIN 5 - Limit - Input signal from the external limit.

PIN 6 - R - 24 VAC power to the thermostat.

PIN 7 - C - 24 VAC common.

PIN 9 - CI - Input signal from the fan limit control.

PIN 10 - CO - Output signal to the burner control.

PIN 5 - Low Tap - Low speed programming input.

Pin 8 - C - 24 VAC common.

PIN 12 - ACC - 24 VAC accessory output.

PIN 15 - V - Input signal from the gas line.

PIN 2 - C - 24 VAC common.

PIN 3 - C - 24 VAC common.

PIN 7 - Adjust Tap - ICM2 mode selection.

PIN 10 - Ref. V - ICM2 reference voltage.

PIN 12 - C - 24 VAC common.

PIN 13 - cfm - Motor speed diagnostic signal.

ON/OFF

J73

J46

DS1

270

CFM

210

90

150

VOLTAGES INTO VSP2−1

Voltage across J73 pins 13 to 1 and 6 to 1 is 24VAC as shown here.

34 volts

0

volts

−34 volts

Voltage across J73 pins 4 to 1 is approximately 15-20VDC (straight voltage)

if CCB is used. If Harmony is used a voltage of 0−25VDC should be present.

If CCB or Harmony is not used, pin 4 to 1 voltage is 21VAC.

Refer to unit wiring diagram.

24VAC @ 60Hz.

VOLTAGES FROM VSP2−1 TO ELECTRONICALLY

CONTROLLED BLOWER MOTOR

Voltage across J46 pins 6 to 3 and 1 to 3 is half-rectified AC as shown here.

Approx.

34 volts

0

volts

Voltage across J46 pins 8 and 9 to 3, is approximately 15-20VDC if CCB is used. If

CCB or Harmony is not used, pins 8 and 9 to 3 voltage is approximately 21VAC. If

Harmony is used a voltage of 0−25VDC should be present.

Refer to unit wiring diagram.

24VAC Half-Rectified (DC

Pulse)

@ 60Hz.

FIGURE 12

Diagnostic LED Lights

a − DS3 ON/OFF"

ON/OFF−DS3 indicates there is a demand for the blower motor

to run. When the ON/OFF LED−DS3 is lit, a demand is being

sent to the motor. In heating mode only, there is a 45 sec o nd

fan ON" delay in energizing ON/OFF LED−DS3. The

light will not go off until adjustable fan OFF" delay has

expired.

If ON/OFF LED−DS3 is on and both HIGH/LOW LED−DS1 &

HEAT LED−DS2 are off, the motor will operate in low

speed.

b − DS2 HEAT"

If HEAT LED−DS2 is on, the blower is running in the heat

speed according to the HEAT" jumper setting. The HEAT

LED−DS2 comes on instantaneous and switches off when

the call for heat is satisfied.

NOTE−When the blower is in OFF" delay mode, the motor runs at low speed, therefore the HEAT LED−DS2 is off. It

switches off when the call for heat is satisfied.

c − DS1 HI/LOW"

HIGH/LOW LED−DS1 indicates whether the blower is oper-

ating in high or low speed. When the light is off, the blower is

running in low speed according to the LOW" jumper setting. When HIGH/LOW LED−DS1 is on, the blower is operating in high speed according to the HIGH" jumper setting.

d − DS4 CFM"

CFM LED−DS4 indicates the CFM the unit is operating, ac-

cording to the jumper settings. The light flashes once for

approximately every 100 CFM. For example, if the unit is

operating at 1000 CFM, CFM LED−DS4 will flash 10 times.

If the CFM is 2050, CFM LED−DS4 will flash 20 full times

plus one fast or half flash.

At times the light may appear to flicker or glow. This takes

place when the control is communicating with the motor between cycles. This is normal operation.

The appropriate speed according to application and CFM

need is selected by moving jumper pins.

Page 15

NOTE−On Harmony II zoning applications in the heating mode,

the highest speed obtainable is the same as the highest cooling speed selection. Also, the heating speed (heat jumper position) is only used when the primary limit has been tripped. In

non−zoning applications, refer to the section on the VSP2−1

control.

When W1 is energized, the LOW jumper selections are activated. The HEAT jumper selections are activated when

W2 is energized.

NOTE−In Harmony II zoning applications, HEATING

BLOWER jumper must be in position #2.

c−HEAT"

Jumper Settings

The HEAT jumper is used to set the blower speed to ob-

tain the required CFM as outlined in HEAT SPEED section of the tables on page 3.

IMPORTANT

Before changing jumper setting, make sure the

motor has completely stopped. Any jumper setting change will not take place while the motor

is running.

To change jumper positions, gently pull the jumper off the pins

and place it on the desired set of pins. The following section

outlines the different jumper selections available and conditions associated with each one. Refer to figure 11 for identification.

After the CFM for each application has been determined, the

jumper settings must be adjusted to reflect those given in

the tables on page 3. Using the tables, determine w h i ch r o w

of CFM volumes most closely matches the desired CFM.

Once a specific row has been chosen (NORMAL or −),

CFM volumes from other rows cannot be used. Below are

the descriptions of each of the jumper selections.

Refer to table 11 for factory settings. Refer to the tables on

page 3 for the approximate air volume for each setting.

TABLE 11

VSP2−1 FACTORY SETTINGS

MODEL

NUMBER

G32V3-75

G32V5-100 241

G32V5-120

HIGH LOW HEAT

3

4

3

ADJUST

NORM

NORM

NORM

24

2

a−ADJUST"

The ADJUST pins allow the motor to run at normal speed or

approximately 15% lower than normal speed. The tables on

page 2 give two rows (NORMAL and −) with their respective

CFM volumes. The + adjustment setting is not operab le.

Notice that the normal adjustment setting for heat speed

position #3 is 2000 CFM (944 L/s). After the adjustment setting has been determined, cho s e th e re m a ining speed

jumper settings from those offered in the table.

The HEAT jumper selections are activated with a call for

second-stage heating (W2).

Before changing jumper setting, make sure the

motor has completely stopped. Any jumper setting change will not take place while the motor is

running.

d−HIGH"

The HIGH jumper is used to determine the CFM during

cooling speed. These jumper selections are activated when

G and DS terminals are energized.

e−LOW"

The LOW jumper is used to determine CFM during low

speed cooling. These jumper selections are activated when

G is energized. The LOW jumper may also be used for low

speed heating. See the HEAT" section for details.

f−FAN OFF"

Fan OFF" timings (time that the blower operates after the

heat demand has been satisfied) are determined by the arrangement of a jumper on the VSP2−1 board. See figure 13.

To adjust fan OFF" timings, gently disconnect the jumper

and reposition it across pins corresponding with the new

timing. Fan OFF" time is adjustable from 90 to 330 seconds. The control has a non−adjustable, factory preset on"

fan timing (45 seconds).

WARNING − MAKE SURE TO DISCONNECT POWER

BEFORE CHANGING FAN OFF" TIMINGS.

TIMING

JUMPER

IMPORTANT

FAN-OFF TIME ADJUSTMENT

To adjust fan−off timings:

Remove jumper from VSP2−1 and

select one of the other pin combinations to achieve the desired

time.

The TEST pin is available to bypass the VSP2−1 control and

run the motor at approximately 70% to test that the m o tor i s

operational. This is beneficial primarily in troubleshooting. G must be energized for motor to run.

b−HEATING BLOWER"

For G32V units, place the HEATING BLOWER jumper

across the second and third pins (position #2).

Page 16

270

150 90

FIGURE 13

210

Leave jumper off to achieve

330 second fan−off timing.

TIMING PINS (seconds)

Fan-off timing is factory

set at 90 seconds

NOTEIf fan OFF" time is too low, residual heat in heat

exchanger may cause primary limit S10 to trip resulting

in frequent cycling of blower. If this occurs, adjust blower

to longer time setting.

in relation to specific modes of operation. Some information has been repeated from the previous section to provide

an example. Refer to each diagnostic LED or jumper settings

section for more information.

Table 12 outlines the operation of the variable speed motor

TABLE 12

VSP2−1 G32V−1 / −3 units OPERATION

HEATING MODE

UNITS WITH

SINGLE−STAGE HEATING

NON−ZONED

APPLICATIONS

Using a single−stage thermostat with

one−stage" heating, the HEAT LED−

DS2 is lit when the thermostat calls for

heat. The ON/OFF LED−DS3 is lit after

110 seconds (65 seconds pre−purge

and 45 seconds fan ON" time) from

the time a call for heat is made. This indicates the blower is operating in heating speed.

Using a single−stage thermostat with

W2 TIMED," and W1 calling, the ON/

OFF LED−DS3 is lit to indicate the

blower is operating on low speed.

When the HEAT LED−DS2 is lit, the

blower is operating in heating speed,

and second−stage (W2) heating is calling.

HARMONY ZONED

APPLICATIONS

The blower speed is controlled by the

PWM (pulse width modulation) signal

sent from the control center of the zoning system to the terminal strip’s DS

terminal. HI/LOW LED−DS1 and ON/

OFF LED−DS3 are lit to indicate the

blower is operating.

NOTE−In Harmony II zoning applications, HTG. BLOWER jumper must be

in position #2.

NOTE: For zone applications with Harmony, remove the wire from the pin #3 of the J73 terminal on the VSP control board, insulate the

end, and secure it to prevent from shorting.

Using a two−stage thermostat with first−

stage (W1) calling, the ON/OFF LED−

DS3 is lit to indicate the blower is operating in low speed.

When the ON/OFF LED−DS3 and

HEAT LED−DS2 are lit, the blower is

operating in heating speed and second−stage (W2) heating is calling.

HEAT LED−DS2 is lit with a call for heat

from the thermostat. ON/OFF LED−

DS3 is lit after 110 seconds from the

time a call for heat is made.

The blower speed is controlled by the

PWM (pulse width modulation) signal

sent from the control center of the zoning system to the terminal strip’s DS

terminal. HI/LOW LED−DS1 and ON/

OFF LED−DS3 are lit to indicate the

blower is operating.

NOTE−In Harmony II zoning applications, HTG. BLOWER jumper must be

in position #2.

UNITS WITH

TWO−STAGE HEATING

NON−ZONED

APPLICATIONS

HARMONY ZONED

APPLICATIONS

UNITS WITH SINGLE−SPEED

COMPRESSOR

NON−ZONED

APPLICATIONS

The terminals DS and Y must be jumpered together. With a call for cooling,

terminals G, Y and DS on the unit control board are energized from the thermostat. HI/LOW LED−DS1 and ON/

OFF LED−DS3 are lit to indicate the

blower is operating on high speed.

NOTEY and DS are factory jumpered for single−stage cooling, non−

zoned.

NOTEFor low speed during single−

stage cooling remove jumper from Y

and Ds.

HARMONY ZONED

APPLICATIONS

The blower speed is controlled by the

PWM (pulse width modulation) signal

sent from the control center of the zoning system to the terminal strip’s DS

terminal. HI/LOW LED−DS1 and ON/

OFF LED−DS3 are lit to indicate the

blower is operating.

COOLING MODE

UNITS WITH TWO−SPEED

The ON/OFF LED−DS3 is lit to indicate

the blower is operating in first stage

cooling. This LED is energized on

when a 24VAC thermostat demand is

supplied to the control (terminal G" on

the control board terminal strip).

In second stage, the ON/OFF LED−

DS3 and HI/LOW LED−DS1 are lit to indicate the blower is operating on high

speed (24VAC is supplied to the unit

terminal strip Y2 from Y2 on the thermostat).

NOTE Jumper must be moved from

Y1 to Y2 In two−speed, non−zoned applications.

HARMONY ZONED

The blower speed is controlled by the

PWM (pulse width modulation) signal

sent from the control center of the zoning system to the terminal strip’s DS

terminal. HI/LOW LED−DS1 and ON/

OFF LED−DS3 are lit to indicate the

blower is operating.

COMPRESSOR

NON−ZONED

APPLICATIONS

APPLICATIONS

Page 17

7.VSP3−1 Blower Control Board (A24)

G32V−4 Units

G32V−4 units are equipped with a variable speed motor that

is capable of maintaining a specified CFM throughout the

external static range. The unit uses the VSP3−1 variable

speed control board, located in the blower compartment,

which controls the blower speed and provides diagnostic

LE Ds. The control has bot h a non−adjustable, factory preset

ON" fan timing delay and an adjustable OFF" fan timing delay

(see figure 13).

Diagnostic LEDs located on the VSP3−1 control board are provided to aid in identifying the unit’s mode of operation. Certain

scenarios will arise depending on the jumper positions. Refer

to figure 14 for identification.

IMPORTANT

The VSP3−1 also senses limit trip condition and turns on the

blower. The G32V limit switch is located in the middle of the

vestibule wall. When excess heat is sensed in t h e h e a t exchanger, the limit switch will open and interrupt the current

to the gas valve, while at the same time the VSP3−1 energizes

the blower on heating speed. The limit automatically resets

when the unit temperature returns to normal and the blower is

de−energized.

VSP3−1 VARIABLE SPEED CONTROL BOARD SELECTIONS

1

JP2

DELAY PROFILE

SELECTOR PINS

(COOLING ONLY)

COOL SPEED

SELECTOR PINS

(COOLING, HEATING and

CONTINUOUS FAN)

HEATING STAGE

JUMPER SELECTOR PINS

DELAY COOL ADJUST HEAT

1

2

3

4

HTG.

BLOWER

12

HEAT

DS2

24 VAC half wave rectified (DC pulse), when measured with a meter, may appear as a lower or

higher voltage depending on the make of the meter. Rather than attempting to measure the output

voltage of A24, see G32V BLOWER & VSP3

BLOWER CONTROL BOARD TROUBLESHOOTING FLOW CHART in the TROUBLESHOOTING

section of this manual.

JP46

13 PIN PLUG

(BOARD TO MOTOR)

1

2

3

4

TEST

−

+

NORM

DS3

ON/OFF

HI/LOW

DS1

1

2

3

4

DS4

CFM

210

HEATING SPEED

SELECTOR PINS

See table 13 for VSP3−1

factory settings

OPERATIONAL

SELECTOR PINS

(Affects both heating

and cooling modes)

DIAGNOSTIC

DS LEDS

JP73

15 PIN PLUG

(BOARD TO VARIOUS

POINTS IN FURNACE)

JP1

270

1

90

150

FAN OFF"

TIMING PINS

FIGURE 14

Page 18

VSP3−1 BLOWER CONTROL BOARD (A24)

1

J46

DELAY COOL ADJUST HEAT

J73

J46

TEST

−

+

NORM

DS3

ON/OFF

HI/LOW

DS1

270

210

150

1

2

3

4

DS4

CFM

90

1

2

3

4

HTG.

BLOWER

12

J73

1

PIN 2 - G - Input signal from thermostat’s fan signal.

PIN 3 - W2 - Input signal for second stage heat from the thermostat.

PIN 4 - DS - Input signal for the blower speed regulation.

PIN 5 - Limit - Input signal from the external limit.

PIN 6 - R - 24 VAC power to the thermostat.

PIN 9 - CI - Input signal from the fan limit control.

PIN 10 - CO - Output signal to the burner control.

PIN 11 - HT - Input signal from the fan limit control.

PIN 12 - ACC - 24 VAC accessory output.

PIN 13 - 24V - Input 24 VAC power for the VSP2-1.

PIN 14 - 24V - Input 24 VAC power for the VSP2-1.

PIN 15 - V - Input signal from the gas line.

PIN 4 - Delay Tap - Delay profile programming input.

PIN 5 - Cool Tap - Cooling blower programming input.

PIN 6 - On / Off - On / off output signal to the ICM2 motor.

PIN 7 - Adjust Tap - ICM2 mode selection.

PIN 9 - Hi / Low - Speed regulate input signal to the ICM2 motor with CCB1 and

PIN 10 - Ref. V - ICM2 reference voltage.

PIN 11 - Heat Tap - Heating blower speed programming.

PIN 13 - cfm - Motor speed diagnostic signal.

1

2

3

4

HEAT

DS2

PIN 1 - C - 24 VAC common.

PIN 7 - C - 24 VAC common.

Pin 8 - C - 24 VAC common.

PIN 1 - Not Used.

PIN 2 - C - 24 VAC common.

PIN 3 - C - 24 VAC common.

PIN 8 - NOT USED

HARMONY only

PIN 12 - C - 24 VAC common.

Diagnostic LED Lights

DS3 ON/OFF

ON/OFF−DS3 indicates there is a demand for the blower

motor to run. When the ON/OFF LED−DS3 is lit, a demand

is being sent to the motor. In heating mode only, there is a

45−second fan ON" delay in energizing ON/OFF LED−DS3.

Light will not go off until adjustable fan OFF" delay has expired.

If ON/OFF LED−DS3 is on and both HIGH/LOW LED−DS1

& HEAT LED−DS2 are off, the motor will operate in low

speed (heating).

DS2 HEAT

If HEAT LED−DS2 is on, the blower is running in second−

stage heat speed according to the HEAT" jumper setting.

In heating mode only, there is a 45 second delay in energizing HEAT LED−DS2. Light will not go off until adjustable fan

OFF" delay has expired.

DS1 HI/LOW

HIGH/LOW LED−DS1 indicates the blower is operating in

the cooling mode.

DS4 CFM

CFM LED−DS4 indicates the CFM the blower is providing,

according to the jumper settings.

Jumper Settings

IMPORTANT

Before changing jumper setting, make sure the

motor has completely stopped. Any jumper setting change will not take place while the motor

is running.

VOLTAGES INTO VSP3−1

Voltage across J73 pins 13 to 1 and 6 to 1 is 24VAC as shown here.

34 volts

0

volts

−34 volts

Voltage across J73 pins 4 to 1 is approximately 15-20VDC (straight voltage)

if CCB is used. If Harmony is used a voltage of 0−25VDC should be present.

If CCB or Harmony is not used, pin 4 to 1 voltage is 21VAC.

Refer to unit wiring diagram.

24VAC @ 60Hz.

VOLTAGES FROM VSP3−1 TO ELECTRONICALLY

CONTROLLED BLOWER MOTOR

Voltage across J46 pins 6 to 3 and 1 to 3 is half-rectified AC as shown here.

Approx.

34 volts

0

volts

Voltage across J46 pin 9 to 3 is approximately 15-20VDC if CCB is used. If CCB or

Harmony is not used, pin 9 to 3 voltage is approximately 21VAC. If Harmony is used

Refer to unit wiring diagram.

a voltage of 0−25VDC should be present.

24VAC Half-Rectified (DC

Pulse)

@ 60Hz.

FIGURE 15

To change jumper positions, gently pull the jumper off the pins

and place it on the desired set of pins. The following section

outlines the different jumper selections available and conditions associated with each one. Refer to figure 14 for identification.

After the CFM for each application has been determined, the

jumper settings must be adjusted to reflect those given in

the tables on page 3 and 4. Using the tables, determine wh i ch

row of CFM volumes most closely matches the desired

CFM. Once a specific row has been chosen (NORMAL or

−), CFM volumes from other rows cannot be used. Below

are the descriptions of each of the jumper selections. Re-

fer to table 13 for factory settings. Refer to CFM tables for

approximate air volume for each setting.

Page 19

TABLE 13

VSP FACTORY SETTINGS FOR G32V−4 UNITS

MODEL

NUMBER

G32V3−75 4 4 NORM 3

G32V5−100 4 4 NORM 2

G32V5−125 4 4 " 4

NOTE − In Harmony II zoning applications in the heating mode, the

highest cooling speed selected is the highest blower speed obtainable. Also, the fan−only speed is used when the primary limit

has been tripped. In non−zoning applications, refer to the section

on the VSP3−1 control.

DELAY COOL ADJUST HEAT

ADJUST

The ADJUST pins allow the motor to run at normal speed or

approximately 15% lower than normal speed. Blower

tables and the front of this manualgive two rows (NORMAL

and −) with their respective CFM volumes. The + adjustment setting is not operable. Notice that the normal adjustment setting for heat speed position #3 is 2030 CFM (955

L/s) in table 4. After the adjustment setting has been determined, choose the remainder speed jumper settings from

those in the table.

The TEST pin is available to bypass the VSP3−1 control and

run the motor at approximately 70% to test that the motor is

operational. This is beneficial primarily in troubleshooting. G

must be energized for motor to run.

HTG. BLOWER

For G32V−4 units only, place the HTG. BLOWER jumper

across the second and third pins (position #2).

NOTE − In Harmony II zoning applications, HTG. BLOWER

jumper must be in position #2.

HEAT

The HEAT jumper is used to set the blower speed to obtain

the required CFM as outlined in HEAT SPEED section of

tables 3 and 4.

The HEAT jumper selections are activated with a call for

first−stage heating (W1) and second−stage heating (W2).

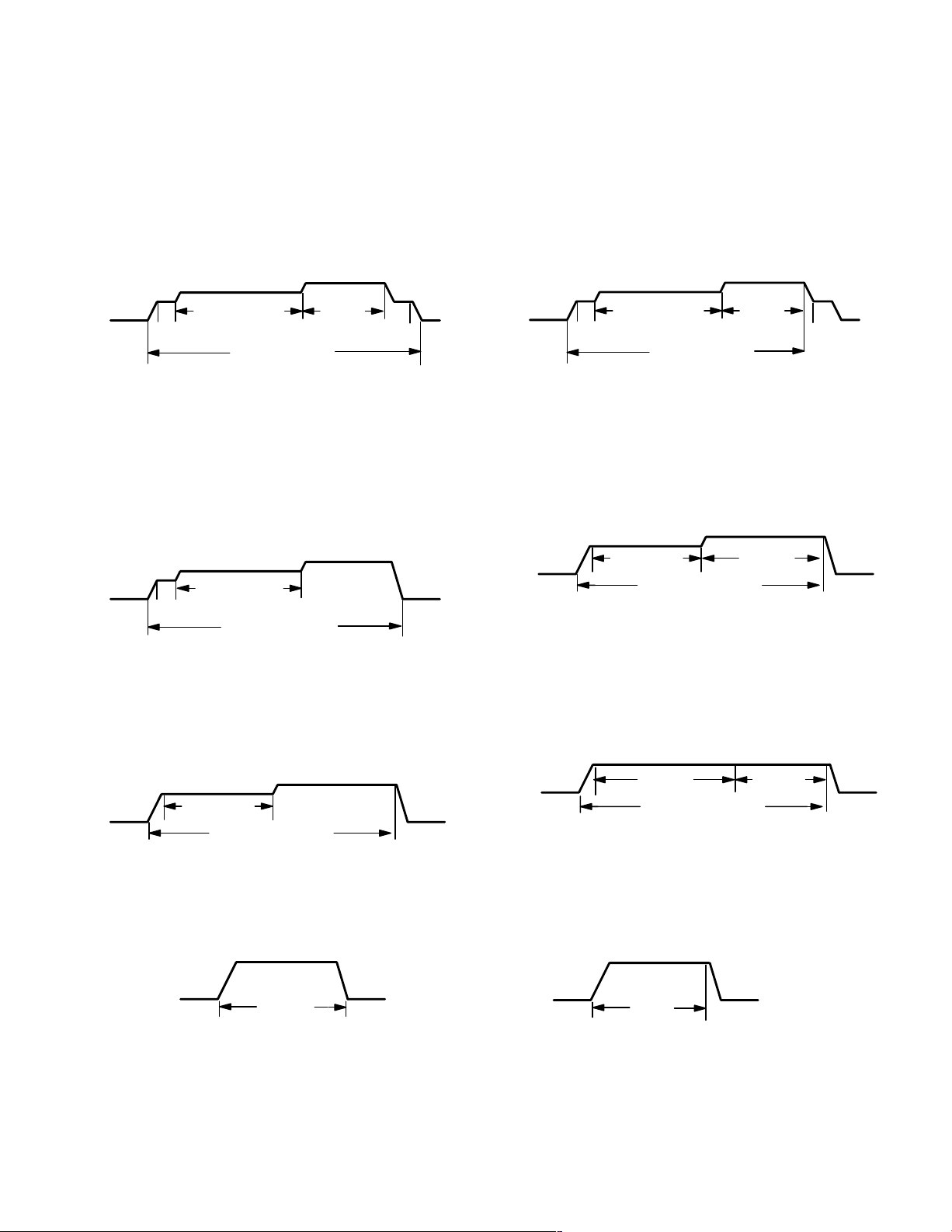

DELAY

The DELAY jumper is used to set the specific motor fan

mode of operation during cooling. Depending on the application, one of four fan options may be chosen by moving

the jumper to the appropriate set of pins.

Options 1, 2, 3, or 4 will have an increased dehumidification

effect on the system. Option 1 will have the least effect and

option 4 will have the greatest effect.

#1 PIN JUMPERED

A − Motor runs at 100% until demand is satisfied.

B − Once demand is met, motor ramps down to off.

A B

100% CFM

COOLING

DEMAND

OFFOFF

#2 PIN JUMPERED

A − Motor runs at 82% for approximately 7−1/2 minutes.

B − If demand has not been satisfied after 7−1/2 minutes,

the motor runs at 100% until demand is satisfied.

C − Once demand is met, motor ramps down to off.

C

OFF

OFF

A

7 1/2 MIN

82%CFM

B

100% CFM

COOLING DEMAND

#3 PIN JUMPERED

A − Motor runs at 50% for 1/2 minute.

B − Motor then runs at 82% for approximately 7−1/2 min-

utes.

C − If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D − Once demand is met, motor ramps down to off.

C D

100% CFM

OFF

OFF

A

1/2 MIN

50% CFM

B

7 1/2 MIN

82% CFM

COOLING DEMAND

#4 PIN JUMPERED

A − Motor runs at 50% for 1/2 minute.

B − Motor then runs at 82% for approximately 7−1/2 min-

utes.

C − If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D − Once demand is met, motor runs at 50% for 1/2 min-

ute.

E − Motor ramps down to off.

C D

100%

CFM

1/2 MIN

50% CFM

E

OFF

OFF

A

1/2 MIN

50% CFM

B

7 1/2 MIN

82% CFM

COOLING DEMAND

COOL

The cool jumper is used to set the blower speed to obtain

the required CFM as outlined in tables 3 and 4.

VSP Operation

Table 14 and 15 outline the operation of the variable speed

motor in relation to specific modes of operation. Some information has been repeated from the previous section to provide an example. Refer to each diagnostic LED or jumper

settings section for more information.

Page 20

TABLE 14

p

Normal operation

blower speed follow thermostat

removal during 1st

ifi

ill i

,

When humidity demand is satisfied

satisfied during

th

gp p

Call f

idit

g

Call for 1st stage

Call for 2nd stage

Reduced blower speed (dehumidifi-

)

mostat demand), slide switch is

G32V−4 UNITS WITH CCB1, & TWO−SPEED OUTDOOR UNIT OPERATING SEQUENCE

Operating Sequence System Demand System Response

System

Condition

Step

Thermostat

Demand

*Relative Humidity

(EfficiencyPlus Lights)

***Compressor

Speed

Blower CFM

(COOL)

Comments

Normal operation

Call for humidity

removal during 1st

stage thermostat

demand

Significant increase

in humidity during

thermostat demand.

Humidity demand

satisfied during

thermostat demand.

or hum

removal during 2nd

stage thermostat

demand

*Call for 1st stage

cooling after call for

humidity removal.

Call for 2nd stage

cooling after call for

humidity removal

Call for cooling after

significant increase

in humidity

Humidity demand

satisfied between

thermostat demands

(unit off cycle).

y

1 Y1 Acceptable (None) Low

2 Y2 Acceptable (None) High HIGH COOL

1 Y1 Acceptable (None) Low

2 Y1

Demand

3

satisfied

4 Y1 Slightly over setpoint (1) High

1 Y1 Acceptable (None) Low

2 Y1

1 Y1 Over Setpoint High

2 Y1

3 None Acceptable (None) Off Off

4 Y1 Acceptable (None) Low

1 Y2 Acceptable (None) High HIGH COOL

2 Y2

3 Y2 Acceptable (None) High HIGH COOL

1 None Slightly over setpoint (1) Off Off Dehumidification mode (high speed

2 Y1 Slightly over setpoint (1) Low

1 None Slightly over setpoint (1) Off Off

2 Y2 Slightly over setpoint (1) High

1 None

2 Y1 or Y2

1 None Over setpoint (1 or more) Off Off

2 Y1 or Y2

Change to slightly

over setpoint (1)

Slightly over setpoint (1) Off Off

Change to significantly

over setpoint (2 or more)

Change to Acceptable

(None)

Change to slightly

over setpoint (1)

Significantly over setpoint

(2 or more)

Significantly over

setpoint (2 or more

Change to

acceptable (None)

Low

High

High HIGH COOL

High

Off Off

High

High HIGH COOL

55% of

HIGH COOL

55% of

HIGH COOL

55% of

HIGH COOL

**77%/74% of

HIGH COOL

55% of

HIGH COOL

**77%/74% of

HIGH COOL

**77%/74% of

HIGH COOL

55% of

HIGH COOL

**77%/74% of

HIGH COOL

55% of

HIGH COOL

**77%/74% of

HIGH COOL

**77%/74% of

HIGH COOL

Compressor demand and indoor

blower s

Dehumidification mode begins with

next thermostat demand, after initial

thermostat demand is satisfied.

If humidity increases significantly

over setpoint, or if slide switch is

moved sign

ately go into dehumidification mode

(in presence of thermostat demand).

When humidity demand is satisfied

blower immediately shifts to the

HIGH COOL CFM in order to hasten

e end of the cycle. Unit can only

shift out of high speed compressor

operation at beginning of next cycle.

Blower immediately changes speed

in response to thermostat demand.

compressor) begins with next ther-

mostat demand after initial demand is

Reduced blower speed (dehumidifi-

cation speed) begins immediately

If humidity increases significantly

over setpoint, or if slide switch is

moved, unit immediately goes into

dehumidification mode (in presence

While unit is not operating (no ther-

mostat demand

moved down and back up. Blower

and compressor operate at high

speed until next thermostat demand.

eed follow thermostat

demand

cantly, unit w

satisfied.

with thermostat demand

of thermostat demand).

, slide switch is

mmedi-

,

Note − When changing unit mode of operation from cooling to heating, indicating lights that are on will stay on until the first thermostat heating demand.

*IMPORTANT - If power to unit is turned on with CCB1 calling for humidity removal, outdoor unit may be locked into high speed

indefinitely. To reset, move humidity slide switch all the way down then back up to desired setpoint (with unit running)

** Reduced blower speed is 77% of COOL for the V3 units; 74% of COOL for V5.

***If the two−speed control on a two−speed outdoor unit is set for LATCH 2 (15 minutes) or LATCH 3 (30 minutes), the compressor

will latch into high speed after a Y1 demand has occurred for that period of time.

Page 21

Heating Mode Cooling Mode

Units With

Single−Stage Heating

Non−Zoned Applications

Using a single−stage thermostat

with "one−stage" heating, the HEAT

LED−DS2 is lit when the thermostat

calls for heat. The ON/OFF LED−

DS3 is lit after 110 seconds (65 seconds prepurge and 45 seconds fan

"ON" time) from the time a call for

heat is made. This indicates the

blower is operating in high speed

heat.

Using a single−stage thermostat

with "W2 TIMED" and W1 calling,

the ON/OFF LED−DS3 is lit to indicate the blower is operating on low

speed heat.

When HEAT LED−DS2 is lit, the

blower is operating in high speed

heat and second−stage (W2) is calling.

G32V−4 Units with VSP3−1

TABLE 15

Units With

Two−Stage Heating

Non−Zoned Applications

Using a two−stage thermostat with

first−stage (W1) calling, the ON/

OFF LED−DS3 is lit to indicate the

blower is operating in low speed

heat.

When the ON/OFF LED−DS3 and

HEAT LED−DS2 are lit, the blower is

operating in high speed heat and

second−stage (W2) is calling.

HEAT LED−DS2 is lit with a call for

heat from the thermostat. ON/OFF

LED−DS3 is after 110 seconds from

the time a call for heat is made.

Units With

Single−speed Compressor

Non−Zoned Applications

Y1−DS and Y1−Y2 must be jumpered together. With a call for cooling, G, Y1, Y2 and DS on the unit

control board are energized from

the thermostat. HI/LOW LED−DS1

and ON/OFF LED−DS3 are lit to indicate a call for cooling.

Note − Y1 to DS and Y1 to Y2 are

factory jumpered for single−stage

cooling, non−zoned applications.

Units With

Two−speed Compressor

Non−Zoned Applications

Y1−DS must be jumpered together.

With a call for single−stage cooling,

G, Y1, and DS on the unit control

board are energized from the Thermostat. With a call for second−stage

cooling, G, Y1, Y2, and DS on the

unit control board are energized

from the thermostat. In both cases,

HI/LOW LED−DS1 and ON/OFF

LED−DS3 are lit to indicate a call for

cooling.

Note − Jumper Y1−Y2 must be removed for units with two−speed

compressor.

Harmony Zoned Applications

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s DS terminal. HI/LOW LED−

DS1 and ON/OFF LED−DS3 are lit

to indicate the blower is operating.

Note − In Harmony II zoning applications, HTG BLOWER jumper must

be in position #2.

Harmony Zoned Application

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s DS terminal. HI/LOW LED−

DS1 and ON/OFF LED−DS3 are lit

to indicate the blower is operating.

Note − In Harmony II zoning applications, HTG BLOWER jumper must

be in position #2.

Harmony Zoned Application

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s DS terminal. HI/LOW LED−

DS1 and ON/OFF LED−DS3 are lit

to indicate the blower is operating.

Harmony Zoned Application

The blower speed is controlled by

the PWM (pulse width modulation)

signal sent from the control center

of the zoning system to the terminal

strip’s DS terminal. HI/LOW LED−

DS1 and ON/OFF LED−DS3 are lit

to indicate the blower is operating.

NOTE − For zone applications with Harmony, remove the wire from pin #2 and pin #13 of the J49 terminal at the motor and the wire

from pin #3 of the J73 terminal on the VSP control board, insulate the ends and secure to prevent shorting.

8.Two Stage Variable Speed Control (A24)

G32V−5 and later Units

(DS3, DS6, DS7 and DS8) to show furnace status. The

board also has two accessory terminals rated at (1) one

amp each. See table 20 for status code and table 21 for

troubleshooting diagnostic codes.

WARNING

Shock hazard.

Disconnect power before servicing. Integrated

Control Board is not field repairable. If control is

inoperable, simply replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

G32V−5 and later units are equipped with the Lennox two−

stage, variable speed integrated SureLight control board.

The system consists of a ignition / blower control board

(figure 16 with control terminal designations in tables 16

through 19) and ignitor (figure 9). The board and ignitor

work in combination to ensure furnace ignition and ignitor

durability. The SureLight integrated board controls all major furnace operations. The board features two LED lights,

DS1 and DS2 for troubleshooting and four LED lights

Electronic Ignition

At the beginning of the heat cycle the SureLight control

monitors the combustion air inducer prove switch. The control will not begin the heating cycle if the prove switch is

closed (by−passed). Once the prove switch is determined to

be open, the combustion air inducer is energized on low

(first stage) heat speed.

G32V−75 Only

At the beginning of the heat cycle the SureLight control

monitors the first and second stage combustion air inducer

prove switches. The control will not begin the heating cycle

if the first stage prove switch is closed (by−passed). Like

wise the control will not begin second stage heat if the second stage prove switch is closed and will allow first stage

heat only. However, if the second stage prove switch closes

DURING first stage pre−purge, the control will still respond

to second stage heat.

Page 22

Once the prove switch (first stage prove switch for

G32V−75) is determined to be open, the combustion air inducer is energized on low (first stage) heat speed. When

the differential in the prove switch is great enough, the

prove switch closes and a 15−second pre−purge begins. If

the switch is not proven within 2−1/2 minutes, the control

goes into Watchguard−Pressure Switch mode for a 5−minute re−set period. After the 15−second pre−purge period, the

SureLight ignitor warms up for 20 seconds after which the

gas valve opens for a 4−second trial for ignition. The ignitor

energizes during the trial until flame is sensed. If ignition is

not proved during the 4−second period, the control will try

four more times with an inter purge and warm−up time between trials of 35 seconds. After a total of five trials for ignition (including the initial trial), the control goes into Watchguard−Flame Failure mode. After a 60−minute reset period,

the control will begin the ignition sequence again.

The SureLight control board has an added feature that prolongs the life of the ignitor. After a successful ignition, the

SureLight control utilizes less power to energize the ignitor

on successive calls for heat. The control continues to ramp

down the voltage to the ignitor until it finds the lowest

amount of power that will provide a successful ignition. This

amount of power is used for 255 cycles. On the 256th call

for heat, the control will again ramp down until the lowest

power is determined and the cycle begins again.

TW0−STAGE, VARIABLE SPEED INTEGRATED

CONTROL BOARD

DIAGNOSTIC

LEDs

DIP

SWITCHES

1 − 3

LEDs

DIP

SWITCHES

5 − 12

LED

Two Stage Operation / Thermostat Selection Jumper

The control can be utilized in two modes: SINGLE−STAGE

thermostat or TWO−STAGE thermostat. The thermostat

selection jumper E20, located just below dip switches 1

through 3 (figure 16), must be positioned for the particular

application. The jumper is factory set on TWO" for use with

a two−stage thermostat with two stage heat. Re−position

jumper to SINGLE" for use with a single stage thermostat

with two stage heat.

While in the single−stage thermostat mode (single jumper

setting), the burners will always fire on first−stage heat. The

combustion air inducer will operate on low speed and indoor blower will operate on low heat speed. After a 10 minute recognition period, the unit will switch to second stage

heat. While in the two−stage thermostat mode (two jumper

setting) the burners will fire on first−stage heat. The combustion air inducer will operate on low speed and indoor

blower will operate on low heat speed. The unit will switch

to second−stage heat on call from the indoor thermostat. If

there is a simultaneous call for first and second stage heat,

the unit will fire an first stage heat and switch to second

stage heat after 30 seconds of operation. See Sequence of

Operation flow charts in the back of this manual for more

detail.

ON−BOARD

ON−BOARD

JUMPER W914

(cut when CCB1 or

Harmony II are used)