Page 1

INSTALLATION

2002 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

INSTRUCTIONS

G32V SERIES UNITS

GAS UNITS

504,564M

5/2002

Supersedes 504,468M

Table of Contents

G32V Unit Dimensions- inches (mm) 2. . . . . . . . . . . .

G32V Parts Arrangement 3. . . . . . . . . . . . . . . . . . . . . .

Safety Instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation - Setting Equipment 5. . . . . . . . . . . . . . . .

Return Air Opening Guidelines 5. . . . . . . . . . . . . . . . .

Filter & Filter Assembly 6. . . . . . . . . . . . . . . . . . . . . . .

Duct System 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pipe & Fittings Specifications 7. . . . . . . . . . . . . . . . . .

Vent Piping Guidelines 8. . . . . . . . . . . . . . . . . . . . . . . .

Joint Cementing Procedure 9. . . . . . . . . . . . . . . . . . . .

Venting Practices 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Piping 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Control Board Settings 23. . . . . . . . . . . . .

Unit Start-Up 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating Sequence of Operation 27. . . . . . . . . . . . . . .

Gas Pressure Adjustment 31. . . . . . . . . . . . . . . . . . . .

High Altitude Information 32. . . . . . . . . . . . . . . . . . . . .

Other Unit Adjustments 32. . . . . . . . . . . . . . . . . . . . . .

Service 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Parts List 35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integrated Control Board Diagnostic Codes 35. . . . .

Troubleshooting 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up & Performance Check List 42. . . . . . . . . . . .

Litho U.S.A.

Do not store or use gasoline or other flamĆ

mable vapors and liquids in the vicinity of

this or any other appliance.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

05/02

*2P0502*

WARNING

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Extinguish any open flames.

Do not touch any electrical switch; do not use any

phone in your building.

Leave the building immediately.

Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the

fire department.

Page 1

504,564M

*P504564M*

Page 2

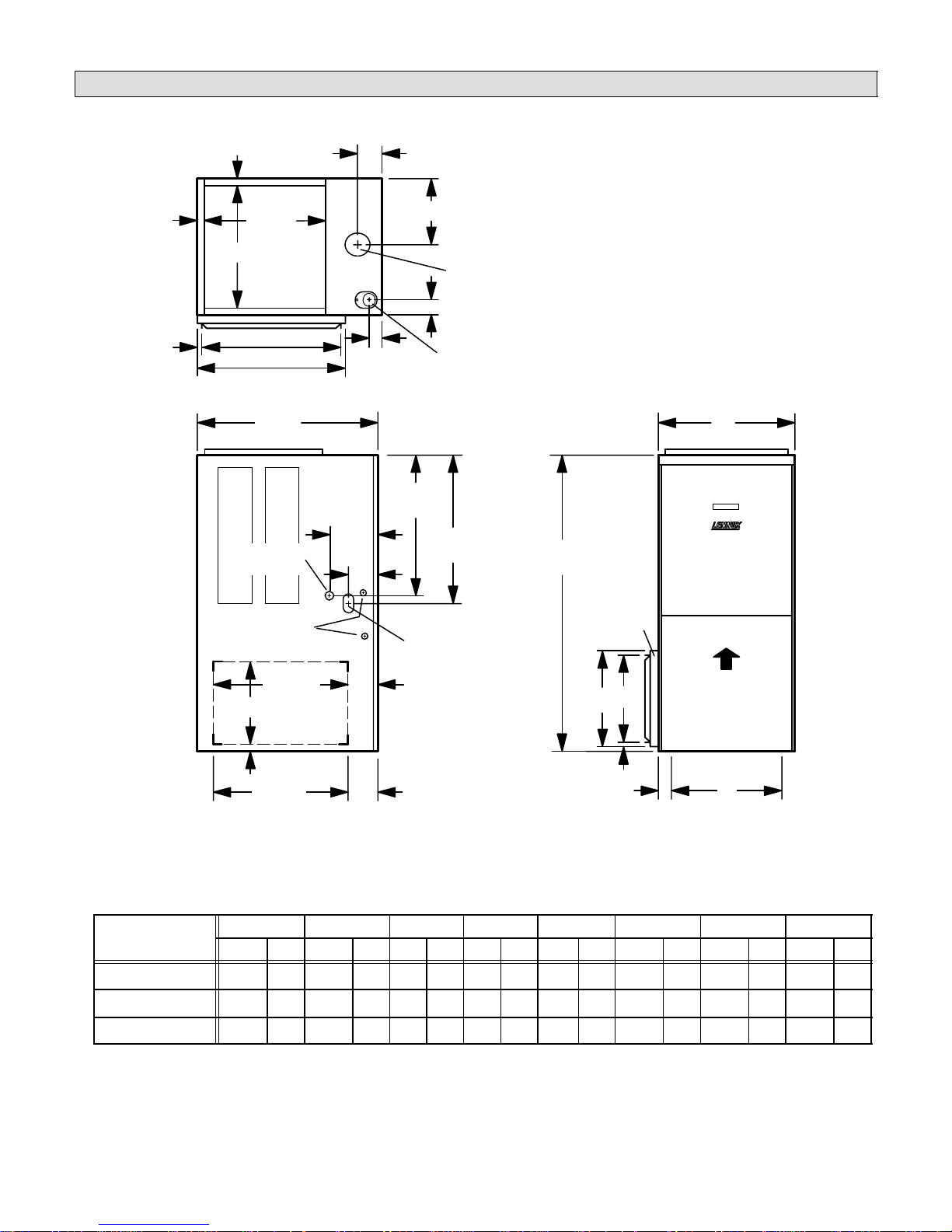

G32V Unit Dimensions - inches (mm)

1 1/16

(41)

5/8

(16)

1 1/16

(41)

18 7/8

(479)

B

SUPPLY

AIR

OPENING

23 3/4 (603)

25 (635)

TOP VIEW

28 1/2

(724)

CONDENSATE

DRAIN

(Both Sides)

ELECTRICAL

INLETS

(Both Sides)

3 5/8

(92)

7 3/8

(187)

2

(51)

2 1/2 (64)

21 3/4

(552)

4 1/2

(114)

GAS PIPING

(Both Sides)

F

COMBUSTION

EXHAUST

AIR OUTLET

23

(584)

INLET

AIR INTAKE

46

(1168)

EXTERNAL

SIDE RETURN

AIR FILTER KIT

(Either Side)

A

(Optional)

23 (584)

C

RETURN AIR

KNOCKOUT

(Either Side)

1-15/16 (49)

23 (584)

Return Air

Knockout (Bottom)

4 (102)

4 (102)

G

5/8 (16)

H

E

AIR FLOW

D

Return Air

Knockout (Bottom)

FRONT VIEWSIDE VIEW

Model No.

G32V3-75 16-1/4 413 14-1/8 359 12 305 12 305 2-1/8 54 7-5/8 194 14 356 12-3/4 324

G32V5–100 21-1/4 540 19-1/8 486 18 457 18 457 1-5/8 41 10-1/8 257 20 508 18-3/4 476

G32V5–125 26-1/4 667 24-1/8 613 18 457 18 457 4-1/8 105 12-5/8 321 20 508 18-3/4 476

A B C D E F G H

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

Page 2

Page 3

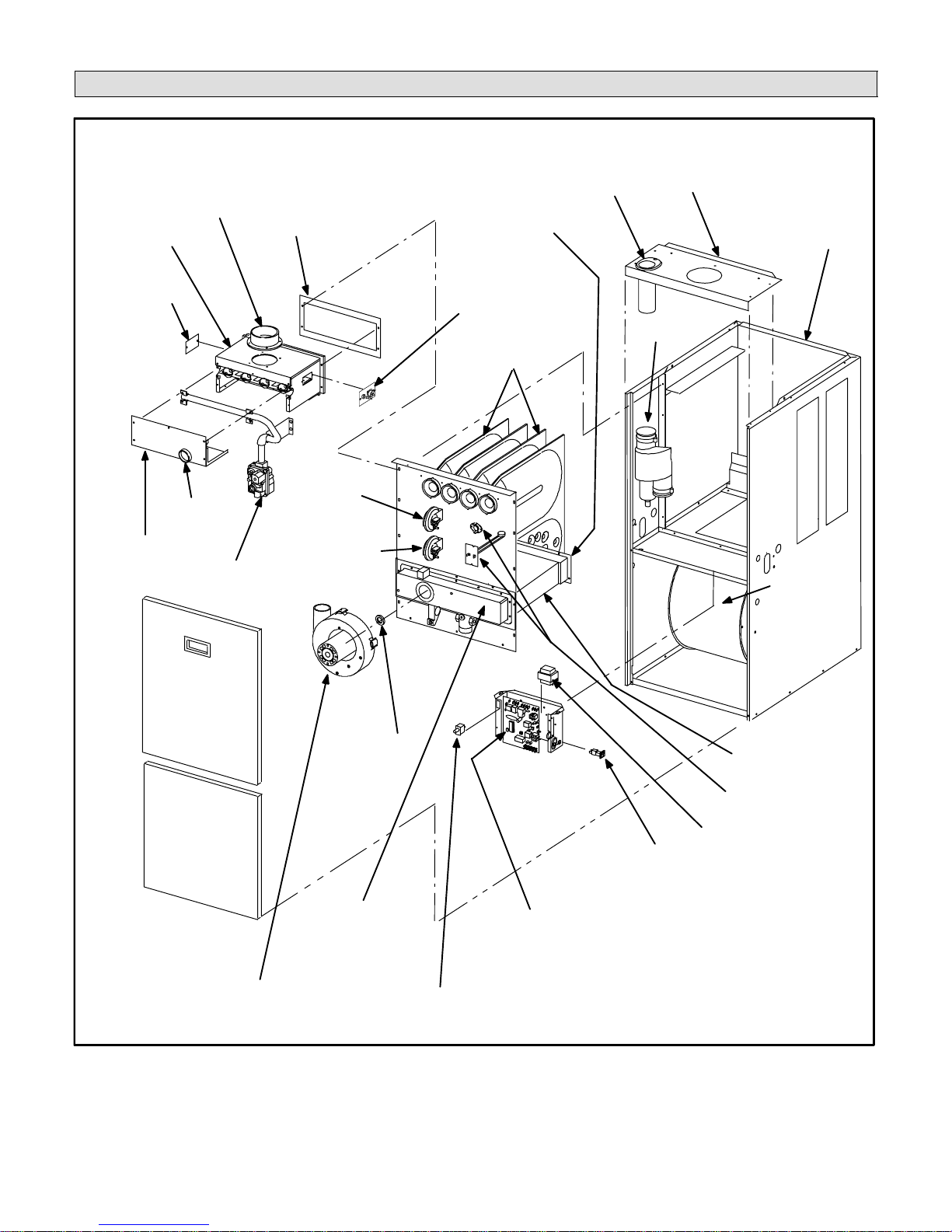

G32V Parts Arrangement

FRESH AIR

INTAKE FITTING

BURNER BOX

ASSEMBLY

PATCH

PLATE

FLAME SIGHT

BURNER BOX

COVER

GLASS

TWOĆSTAGE

GAS VALVE AND

MANIFOLD

GLASS FIBER GASKET

LOW HEAT

DIFFERENTIAL

PRESSURE

SWITCH

HIGH HEAT

DIFFERENTIAL

PRESSURE

SWITCH

(-75 only)

WARM

HEADER

(COLLECTOR)

BOX

PATCH PLATE WITH

BARBED FITTING

AND FLAME

ROLL-OUT SWITCH

DuralokPlus

HEAT EXCHANGER

ASSEMBLY

TM

FLUE COLLAR

TRANSITION

TOP CAP

CABINET

FLUE

SUPPLY

AIR

BLOWER

BURNER

ACCESS

PANEL

BLOWER

ACCESS

DOOR

TWO-SPEED

COMBUSTION AIR

INDUCER

COMBUSTION

AIR

ORIFICE

COLD HEADER

(COLLECTOR)

BOX

SECONDARY COIL

PRIMARY LIMIT

(ALTERNATE STYLES)

TRANSFORMER

CONTROL VOLTAGE

CIRCUIT BREAKER

SURELIGHT TWO-STAGE,

VARIABLE-SPEED

INTEGRATED CONTROL BOARD

DOOR INTERLOCK SWITCH

FIGURE 1

Page 3

Page 4

Safety Instructions

To combustible

Lennox G32V units are Category IV CSA International

certified to ANSI Z21.47 and CSA 2.3 standards.

In the USA, installation of Lennox gas central furnaces

must conform with local building codes. In the absence of

local codes, units must be installed according to the curĆ

rent National Fuel Gas Code (ANSI-Z223.1/NFPA 54) in

the United States. The National Fuel Gas Code is availĆ

able from the following address:

American National Standards Institute, Inc.

11 West 42nd Street

New York, NY 10036

In Canada, installation must conform with current NationĆ

al Standard of Canada CAN/CGAĆB149.1 Installation

Code for Natural Gas Burning Appliances and EquipĆ

ment" and CAN/CGA-B149.2 Installation Code for ProĆ

pane Gas Burning Appliances and Equipment," local

plumbing or waste water codes and other applicable local

codes.

This furnace is CSA International certified for installation

clearances to combustible material as listed on the unit

rating plate and in table 1.

TABLE 1

Clearances Location Inches (mm)

Front 24 (610)

Service access

To combustible

materials

Condensate side

To p 1 (25)

Exhaust 0

Side, rear, and front 0

3 (76)

(from side of unit)

When the furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of, cooling units to avoid condensation in the heating compartĆ

ment. With a parallel flow arrangement, a damper (or othĆ

er means to control the flow of air) must adequately

prevent chilled air from entering the furnace. If the dampĆ

er is manually operated, it must be equipped to prevent

operation of either the heating or the cooling unit, unless it

is in the full HEAT" or COOL" setting.

When installed, the furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National ElecĆ

tric Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following adĆ

dress:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

In Canada, all electrical wiring and grounding for the unit

must be installed according to the current regulations of

the Canadian Electrical Code Part I (CSA Standard

C22.1) and/or local codes.

Field wiring connections must meet or exceed specificaĆ

tions of type T wire and withstand a maximum temperaĆ

ture rise of 180°F (82°C).

G32V unit must be installed so that electrical components

are protected from water.

When the furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside of the space

containing the furnace, return air shall be handled by a

duct(s) sealed to the furnace casing and terminating outĆ

side space containing furnace.

Floor 0

NOTE - For installation on combustible floors, the furnace

shall not be installed directly on carpeting, tile, or other

combustible material other than wood flooring.

Accessibility and service clearances must take preceĆ

dence over fire protection clearances.

For installation in a residential garage, the furnace must

be installed so that the burner(s) and the ignition source

are located no less than 18 inches (457 mm) above the

floor. The furnace must be located or protected to avoid

physical damage by vehicles. When a furnace is installed

in a public garage, hangar, or other building that has a

hazardous atmosphere, the furnace must be installed acĆ

cording to recommended good practice requirements

and current National Fuel Gas Code or CAN/CGA B149.1

and B149.2 standards.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool dust. Breathing this may cause

lung cancer. (Fiberglass wool is known to the State

of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

Page 4

Page 5

NOTE - G32V series units must not be used as a

construction heater during any phase of construction.

Very low return air temperatures, harmful vapors and misĆ

placement of the filters will damage the unit and lower its

efficiency.

The G32V furnace may be installed in alcoves, closĆ

ets, attics, basements, garages and utility rooms in

the upflow position.

General

The G32V is an upflow gas furnace which is factoryequipped for use with natural gas. A changeover kit is

necessary if the furnace is to be used with L.P. gas. These

instructions are intended as a general guide and do not

supersede local codes in any way. Consult authorities

having jurisdiction before installation.

Shipping and Packing List

1 - Assembled G32V furnace

1 - 3 inch x 2 inch vent transition piece (-100, -125

units only)

1 - Bag assembly containing:

1 - Filter

1 - External filter rack for side return air application

1 - Bag assembly containing:

1 - Electrical make-up box with cover and

grounding screw

4 - Thread-forming make-up box screws

1 - Green ground wire

1 - Wiring harness

1 - Snap bushing

2 - Filter clips

1 - Condensate drain pipe adapter

1 - Condensate plug

4 - Wire nuts

2 - Lockwashers and screws

8 - Self-tapping screws

2 - Filter door pins

1 - Grounding label

1 - Wire tie

Shipping Damage

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

WARNING

Improper installation, adjustment, alteration, serĆ

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and serĆ

vice must be performed by a qualified installer, serĆ

vice agency or the gas supplier.

CAUTION

As with any mechanical equipment, personal injuĆ

ry can result from contact with sharp sheet metal

edges. Be careful when you handle this equipment.

Installation - Setting Equipment

Select a location that allows for required clearances listed

on the unit rating plate. Also consider gas supply connecĆ

tions, electrical supply, vent connection and installation

and service clearances [24 inches (610 mm) at unit front].

The furnace must be level.

CAUTION

G32V unit should not be installed in areas normally

subject to freezing temperatures.

Return Air Opening Guidelines

WARNING

Improper installation of unit can result in personal

injury or death. Combustion and flue products

must never be allowed to enter the return air sysĆ

tem or air in the living space. Use sheet metal

screws and joint tape to seal return air system to

furnace.

In platform installations with furnace return, the

furnace should be sealed airtight to the return air

plenu m . A doo r mu s t never be us e d as a portion of

the return air duct system. The base must provide

a stable support and an airtight seal to the furnace.

Allow absolutely no sagging, cracks, gaps, etc.

For no reason should return and supply air duct

systems ever be connected to or from other heatin g devices such as a fireplace or stove, etc. Fire,

explosion, carbon monoxide poisoning, personal

injury and/or property damage could result.

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can

be drawn into living space resulting in personal inĆ

jury or death.

Return air can be brought in either side or at the bottom of

the unit. Scribe lines show the outline of each side and the

bottom return air opening.

Page 5

Page 6

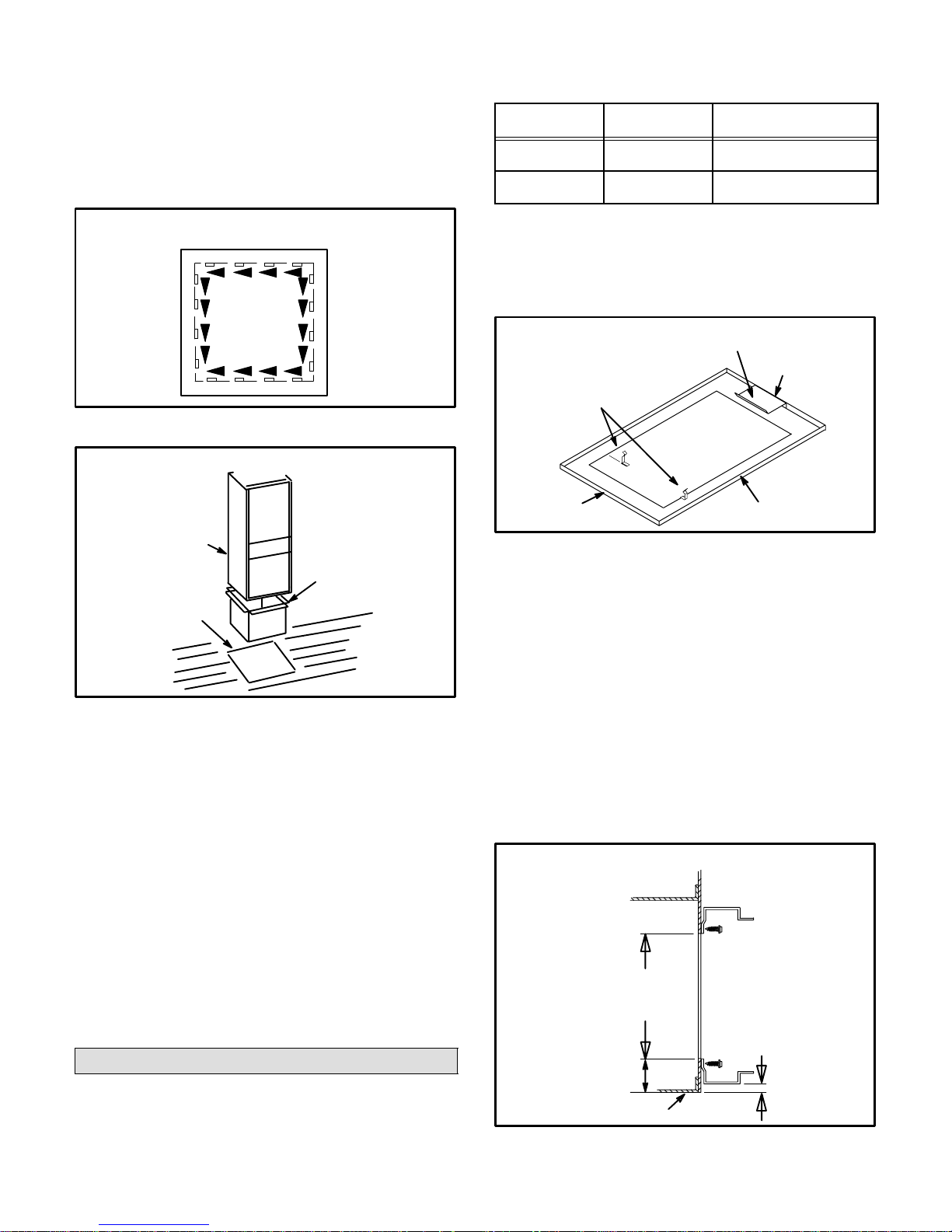

Bottom Return Air Applications

If return air is to terminate through the floor under the furĆ

nace, a direct, airtight and sealed connection must be

made to the bottom of the furnace.

1 - Cut opening in floor or platform. Using knockouts

provided, cut bottom of base panel. See figure 2.

KNOCKOUT PATTERN FOR BOTTOM

RETURN AIR APPLICATION

FIGURE 2

BOTTOM RETURN AIR APPLICATION

FILTER SIZE REQUIREMENTS

TABLE 2

UNIT MODEL

NUMBER

G32V-75 31J81

G32V-100

G32V-125

FILTER PART

NUMBER

P-8-7831

FILTER SIZE

14 inches x 25 inches

(356 x 635 mm)

20 inches x 25 inches

(508 x 635 mm)

Bottom Return Air Applications

1 - Remove blower access panel.

2 - Install filter clips, provided with unit, by slipping

folded section of clip on edge of bottom opening. See

figure 4.

BOTTOM RETURN FILTER INSTALLATION

REAR FILTER CLIP

FURNACE

SIDE FILTER CLIPS (2)

RETURN AIR OPENING

BACK

G32V UNIT

RETURN AIR

PLENUM

PROPERLY

SIZED FLOOR

OPENING

FIGURE 3

2 - Bend a flange on return air plenum and lower into

floor or platform opening. See figure 3.

3 - Position unit over return air opening. Seal unit air

tight with return air plenum.

NOTE - Be careful not to damage insulation. Check for

tight seal.

Side Return Air Applications

For installations where the return air is taken from a return

air drop, unit may be installed using either the left or right

side of furnace.

For side return air applications, cut the furnace cabinet at

the dimensions given in the unit dimensions graphic. EmĆ

bossed corners are pro-vided on both cabinet sides for reĆ

turn air opening location.

FURNACE

FRONT

FURNACE

BASE BOTTOM

FIGURE 4

3 - Place filter in bottom of blower compartment beneath

rear filter clip. Press down on filter sides. Filter clips

flex allowing filter to snap into place.

4 - To remove filter, press clip and pull filter up and out.

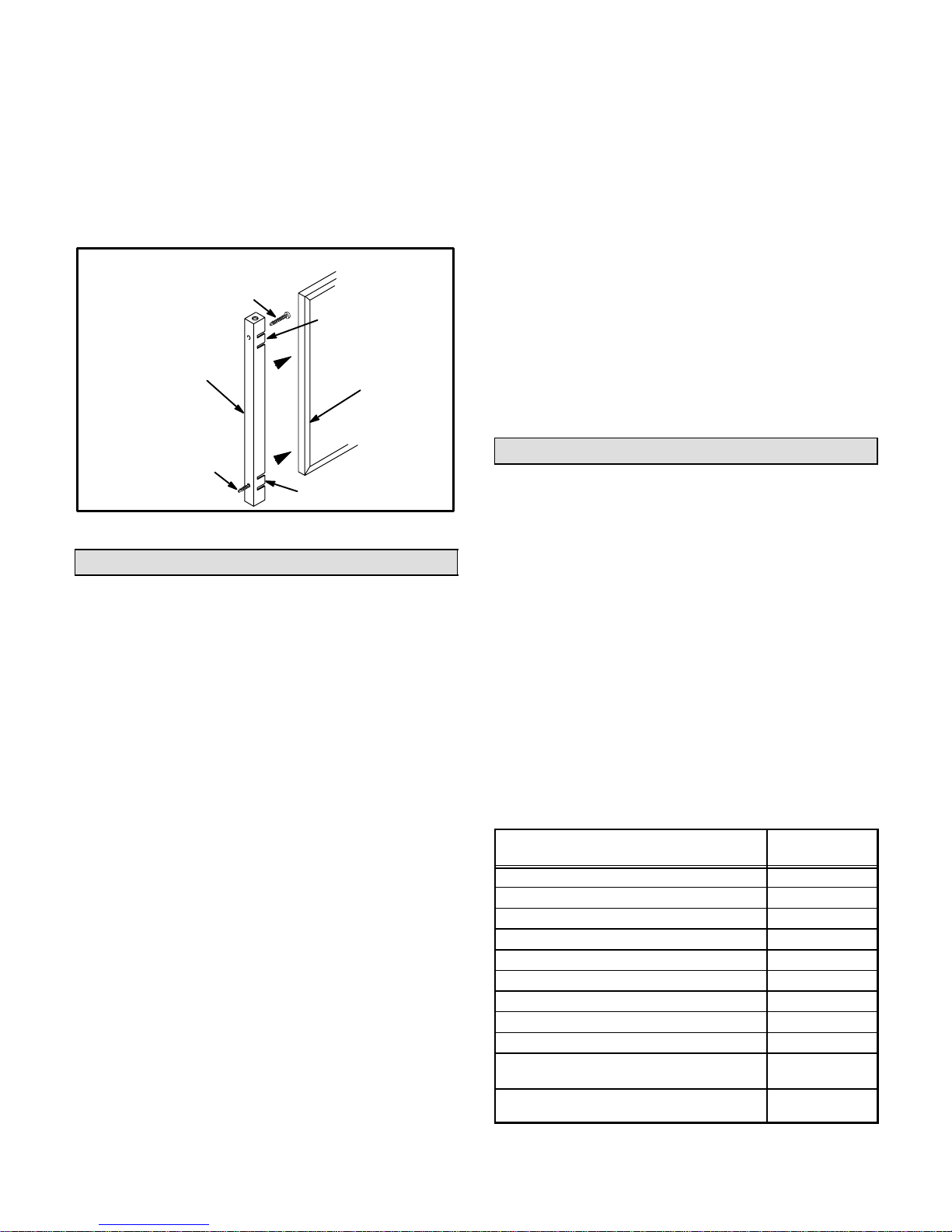

Side Return Air Applications

1 - Align filter rack opening with the inside edge of the

side return opening. Bottom of rack should be

approximately 1 inch (25 mm) from the bottom and 3

inches (76 mm) from the front of the unit.

2 - Screw filter rack into place with the eight self drill, self

tap screws provided. See figure 5.

3 - Push filter door pins through the two holes in filter

door from the inside of the uĆchannel. See figure 6.

SIDE RETURN FILTER INSTALLATION

in. (mm)

BLOWER DECK

RETURN AIR

RETURN

AIR

OPENING

12 in. (305) for

14 in. (356) Filter

18 in. (457) for

20 in. (508) Filter

PLENUM SIZE

12-3/4 in X 23-1/2 in (324 X

597) for 14 in (356) Filter

18-3/4 in. x 23-1/2 in.

(476 x 597)

for 20 in. (508) Filter

Filter & Filter Assembly

A filter and an external filter rack for use in side return air

applications are shipped with the unit. A filter must be in

place anytime the unit is in operation.

Page 6

1-15/16 in.

(49)

CABINET BASE BOTTOM

FIGURE 5

15/16 in

(24)

Page 7

4 - Position filter door on end of filter so that the thumb

tab side of the filter door is away from the furnace.

Squeeze thumb tabs to secure filter to door.

5 - Guide filter and filter door into the filter rack installed

on side of furnace. Push door into filter rack until secure.

6 - To remove filter, pull filter door pins until door is re-

leased from filter rack.

FILTER DOOR ASSEMBLY

FILTER DOOR

PIN

FILTER DOOR

TAB

FILTER

NO TE - For bot to m re tu r n air, ret ur n ai r du ct should be seĆ

cured to the unit using rivets or S-locks. For side return

air, secure return air duct to filter rack using screws. When

using screws, take care to avoid interference with the filĆ

ter which may cause improper filtration.

The ret urn ai r mu s t no t be draw n fro m a room where

another gas appliance (ie., a water heater) is

installed. Even though this furnace draws its combusĆ

tion air from outside of the structure, other gas apĆ

pliances that share a utility room may not. When return

air is drawn from a room, a negative pressure is created

in the room. If a gas appliance is operating in a room

with negative pressure, the flue products can be pulled

back down the vent pipe and into the room. This reverse

flow of the flue gas may result in incomplete combustion

and the formation of carbon monoxide gas. This toxic

gas might then be distributed through the house by the

furnace duct system.

FILTER DOOR

PIN

TAB

FIGURE 6

Duct System

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution. If

the G32V unit is being installed as a replacement for an

existing furnace, the existing supply and return air duct

system should be evaluated to make sure that it is approĆ

priately sized.

The total external static pressure (ESP) should not exĆ

ceed 0.8" w.c. The ESP calculation should include presĆ

sure losses caused by electronic air cleaners, filters,

cooling coils, the duct system, registers and grilles. A

properly sized duct system will help to optimize efficiency

and reliability and to minimize sound levels. Operation of

a G32V unit outside of its specified static pressure range

will result in poor performance and will reduce the useful

life-expectancy of the product and its components.

Supply Air Plenum

Furnaces installed without a cooling coil require the installaĆ

tion of a removable access panel in the supply air duct. The

access panel should be large enough to permit inspection

(either by smoke or reflected light) of the heat exchanger for

leaks after installation. The furnace access panel must alĆ

ways be in place when the furnace is operating and it must

not allow leaks into the supply air duct system.

Return Air Plenum

See dimension illustration for proper return air duct size.

Pipe & Fittings Specifications

All pipe, fittings, primer and solvent cement must conform

with American National Standard Institute and the AmeriĆ

can Society for Testing and Materials (ANSI/ASTM) stanĆ

dards. The solvent shall be free flowing and contain no

lumps, undissolved particles or any foreign matter that

adversely affects the joint strength or chemical resistance

of the cement. The cement shall show no gelation, stratifiĆ

cation, or separation that cannot be removed by stirring.

Refer to table 3 for approved piping and fitting materials.

Primers and solvents must meet ASTM specifications.

PVC primer is specified in ASTM F 656. Use PVC solvent

cement as specified in ASTM D 2564 and ABS solvent

cement as specified in ASTM D 2235. Low temperature

solvent cement is recommended. Metal or plastic strapĆ

ping may be used for vent pipe hangers.

Table 4 lists the available exhaust termination kits. All

Lennox vent terminations are PVC.

TABLE 3

PIPING AND FITTINGS SPECIFICATIONS

PIPE & FITTING MATERIAL

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

Schedule 40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR-21 PVC (Pipe) or SDR-26 PVC (Pipe) D2241

SDR-21 CPVC (Pipe) or SDR-26 CPVC (Pipe) F442

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

PVC-DWV (Drain Waste & Vent Pipe & Fittings)

ASTM

SPECIFICATION

D2661

D2665

Page 7

Page 8

TABLE 4

TERMINATION KITS

Lennox Part

No.

60G77 LB-49107CE

33K97 LB-87942

15F75 LB-49107CC

22G44 LB-49107CD

15F74 LB-49107CB 2" (50.8) Wall Ring Kit

44J41 LB-65678A

44J40 LB-65701A

30G28 WTK

30G79 WTKX

Kit LB# Description-Inches (mm)

1-1/2" (50.8) Concentric

Termination Kit

3" (50.8) Low Pressure Drop ConĆ

centric Term. Kit

2" (50.8) Roof

Termination Kit

2" (50.8) Wall

Assembly Termination Kit

3" (76.2) Roof

Termination Kit

3" (76.2) Wall

Assembly Termination Kit

2" (50.8) Wall

Termination Extended Vent

2" (50.8) Wall

Termination Extension Riser

CAUTION

Solvent cements for plastic pipe are flammable liqĆ

uids and should be kept away from all sources of

ignition. Do not use excessive amounts of solvent

cement when making joints. Good ventilation

should be maintained to reduce fire hazard and to

minimize breathing of solvent vapors. Avoid conĆ

tact of cement with skin and eyes.

When making ABS joints, pieces can be prepared with a

cleaner. When joining ABS to PVC materials, use PVC

solvent cement. Refer to this procedure as specified in

ASTM D3138.

Vent Piping Guidelines

Pipe used for exhaust and intake lines should be sized acĆ

cording to table 5. Note that maximum length of vent pipe

is for one run; either intake or exhaust. Maximum vent

length given is not the total length of intake plus exhaust

vents.

Each 90° elbow is equivalent to 5 feet (1.52 m) of vent

pipe. Two 45° elbows are equivalent to one 90° elbow.

One 45° elbow is equal to 2.5 feet (.76 m) of vent pipe. If

intake and exhaust piping runs are not equal in length and

number of elbows, the larger diameter pipe must be used

for both runs.

TABLE 5

VENT PIPE SIZING TABLE FOR G32V FURNACES

MINIMUM DIAMETER OF INTAKE/EXHAUST PIPE

Vent Pipe

Equivalent Length

Max. Feet (Meters)

15 (4.57) 2" 2" 2"

20 (6.10) 2" 2" 3"

25 (7.62) 2" 2" 3"

30 (9.14) 2" 3" 3"

40 (12.19) 2" 3" 3"

50 (15.24) 2" 3" 3"

55 (16.76) 2" 3" 3"

60 (18.29) 3" 3" 3"

70 (21.34) 3" 3" 3"

80 (24.38) 3" 3" 3"

90 (27.43) 3" 3" 3"

100 (30.48) 3" 3" 3"

110 (33.53) 3" 3" 3"

120 (36.58) 3" 3" 3"

130 (39.62) 3" 3" --

NOTE - Minimum vent pipe for G32V-75, G32V-100, and G32V-125 is 5

feet with 2 elbows of 2-inch diameter pipe.

G32V-75

75,000

BTU

G32V-100

100,000

BTU

G32V-125

125,000

BTU

NOTE - When you install a WTKX termination kit as part

of the intake and exhaust piping, the two 2-inch diameter

90° elbows and the 27 inch pipe (in the kit) should be inĆ

cluded in the maximum vent pipe length for each run.

For 75 kBtuh units, connections are provided for 2-inch

diameter vent pipe which should satisfy most venting reĆ

quirements. No transition pieces are provided or needed

for use with 2-inch vent pipe.

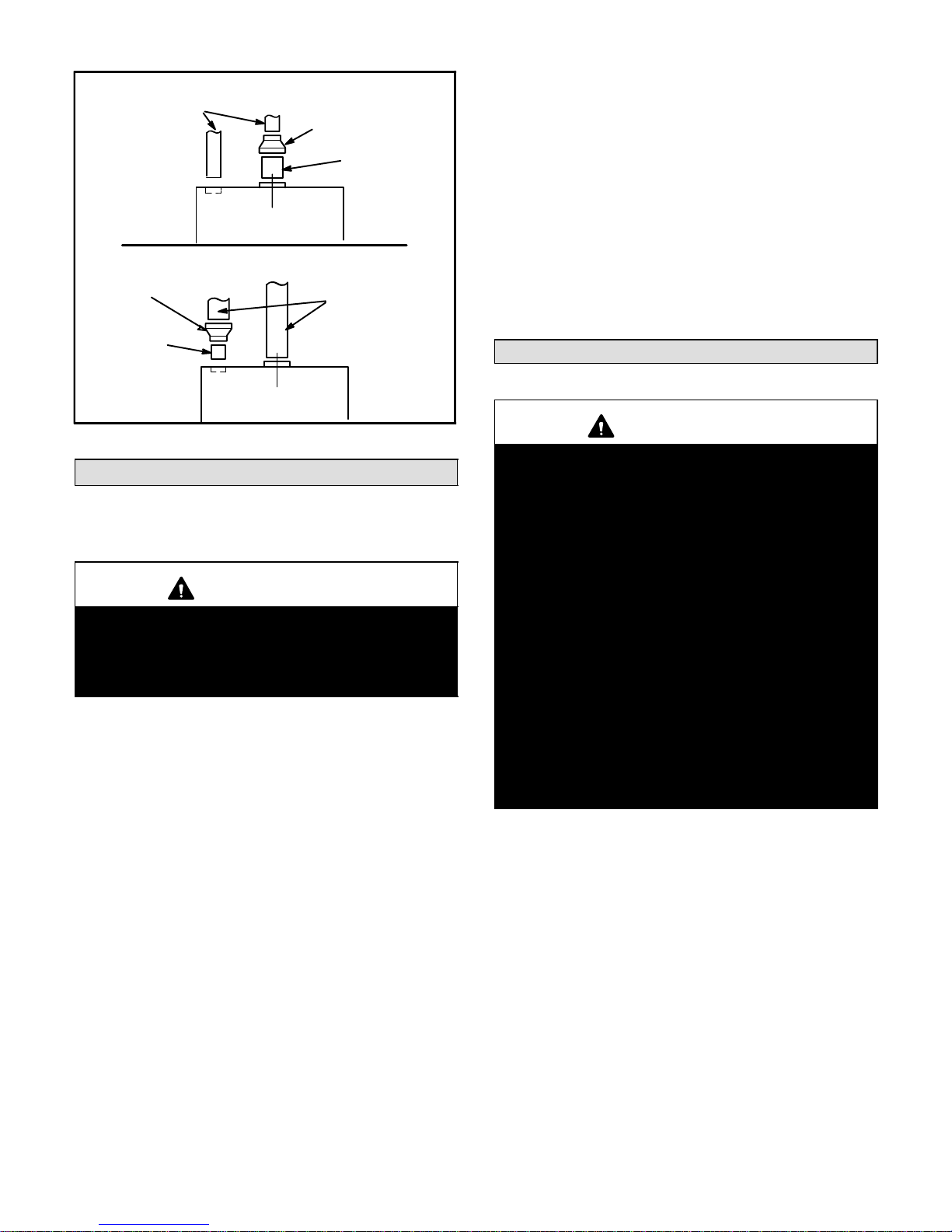

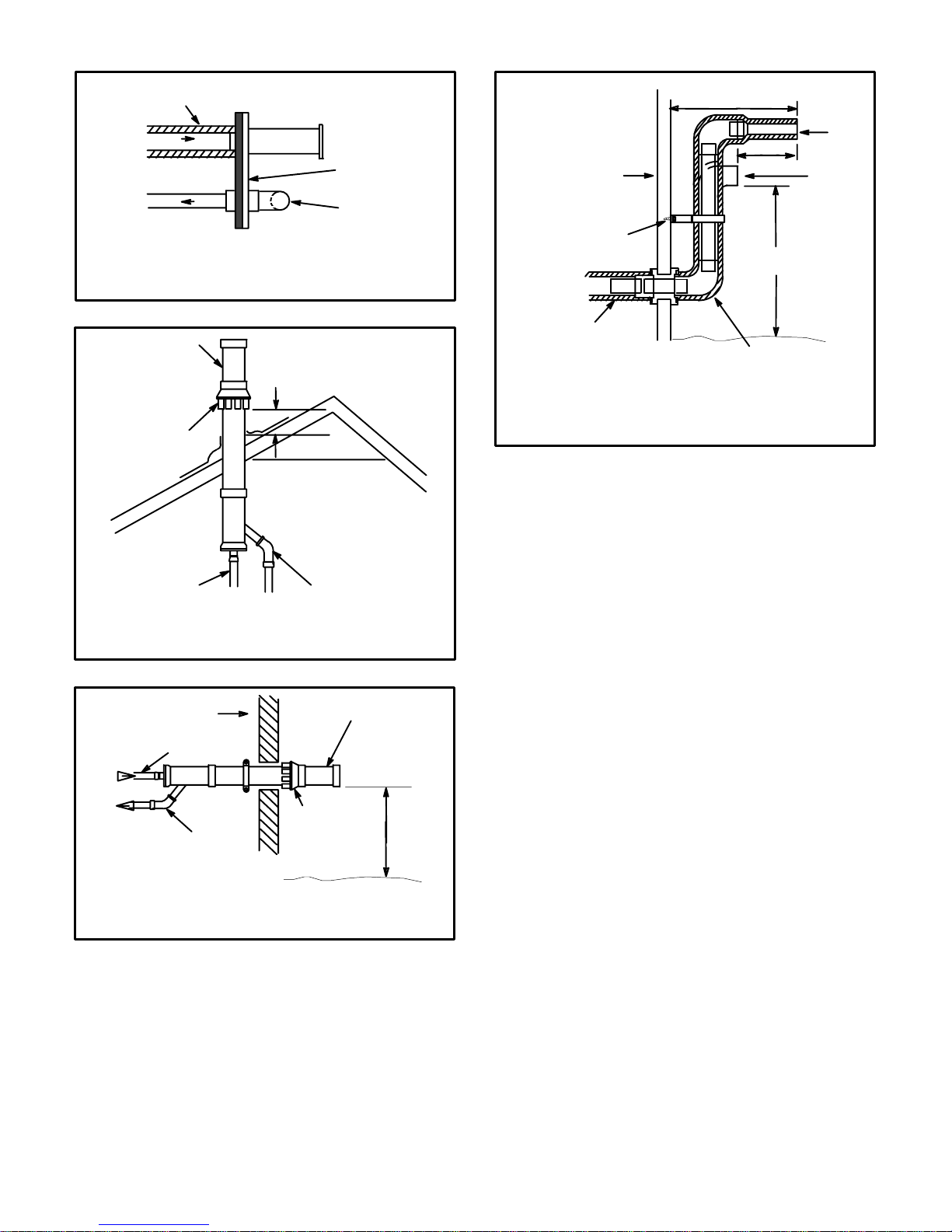

For -100 and -125 kBtuh units, the intake connection is

sized for 3-inch diameter pipe. The exhaust connection

ha s a 2- inc h ni pp le . A pipe transition piece is shipped with

the unit for use with 3-inch pipe. See figure 7 for 2-inch

and 3-inch vent pipe applications.

Most venting applications will require 3-inch vent pipe for

proper unit operation. The intake and exhaust pipe

must never be constructed of different diameter

pipes. Regardless of the diameter of pipe used, the stanĆ

dard roof and wall terminations described in section InĆ

take and Exhaust Piping Terminations should be used.

Exhaust piping must terminate with 1-1/2 inch pipe for

1-1/2 inch or 2 inch vents and 2-inch vent pipe for 3-inch

vents.

Page 8

Page 9

G32V-100 OR -125 WITH 2 IN. VENTING

2 IN. VENT PIPE

2 IN.

OUT

3 IN. X 2 IN.

REDUCER

3 IN.

IN

G32V-100 OR -125 WITH 3 IN. VENTING

3 IN. X 2 IN. REDUCER

2 IN. FIELD

PROVIDED

NIPPLE

2 IN.

OUT

3 IN.

IN

3 IN. FIELD

PROVIDED

NIPPLE

3 IN. VENT PIPE

into socket until it bottoms out. Turn pipe 1/4 turn durĆ

ing assembly (but not after pipe is fully inserted) to

distribute cement evenly.

NOTE - Assembly should be completed within 20 seĆ

conds after last application of cement. Hammer

blows should not be used when inserting pipe.

8 - After assembly, wipe excess cement from pipe at

end of fitting socket. A properly made joint will show a

bead around its entire perimeter. Any gaps may indiĆ

cate a defective assembly due to insufficient solvent.

9 - Handle joints carefully until completely set.

Venting Practices

FIGURE 7

Joint Cementing Procedure

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

WARNING

DANGER OF EXPLOSION! Fumes from PVC glue

may ignite during system check. Disconnect wire

from pressure switch terminal before 115 volt powĆ

er is applied to unit. Reconnect wire after two minĆ

utes of combustion air blower operation.

1 - Measure and cut vent pipe to desired length.

2 - Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in

a leaking joint.

3 - Clean and dry surfaces to be joined.

4 - Test fit joint and mark depth of fitting on outside of

pipe.

5 - Uniformly apply liberal coat of PVC primer for PVC or

ABS cleaner for ABS to inside socket surface of fitĆ

ting and male end of pipe to depth of fitting socket.

6 - Promptly apply solvent cement to end of pipe and inĆ

side socket surface of fitting. Cement should be apĆ

plied lightly but uniformly to inside of socket. Take

care to keep excess cement out of socket. Apply

second coat to end of pipe.

NOTE - Time is critical at this stage. Do not allow

primer to dry before applying cement.

7 - Immediately after applying last coat of cement to

pipe, and while both inside socket surface and end of

pipe are wet with cement, forcefully insert end of pipe

WARNING

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also

cause excess water in the heat exchanger resulting

in rusting and premature heat exchanger failure.

Excessive exposure to contaminated combustion

air will result in safety and performance related

problems. Avoid exposure to the following subĆ

stances in the combustion air supply:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine base swimming pool chemicals

Water softening chemicals

De-icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

The thickness of construction through which vent/air inĆ

take pipes may be installed is a minimum of 3 inches (76

mm) and a maximum of 24 inches (610 mm). If a G32V

furnace replaces a furnace which was commonly vented

with another gas appliance, the size of the existing vent

pipe for that gas appliance must be checked. Without the

heat of the original furnace flue products, the existing vent

pipe is probably oversized for the single water heater or

other appliance. The vent should be checked for proper

draw with the remaining appliance.

Intake Piping

1 - Cement intake piping in slip connector located at top

of unit.

2 - Route piping to outside of structure. Continue with

installation following instructions given in exhaust

and intake piping termination section.

Page 9

Page 10

Exhaust Piping

1 - Cement exhaust piping into flue collar socket located

on the left side of the top cap.

2 - All horizontal runs of exhaust pipe must slope back

toward the unit. A minimum of 1/4 inch (6 mm) drop

for each 12 inches (305 mm) of horizontal run is manĆ

datory for drainage. Horizontal runs of exhaust pipĆ

ing must be supported every 5 feet (1.52 m) using

hangers.

NOTE - Exhaust piping should be checked carefully

to make sure there are no sags or low spots.

NOTE - Exhaust piping must be insulated with 1/2

inch (13 mm) Armaflex or equivalent when run

through unheated space. Do not leave any area of

exhaust pipe open to outside air; exterior exhaust

must be insulated with 1/2 inch (13 mm) Armaflex or

equivalent.

CAUTION

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If verĆ

tical discharge through an existing unused stack is

required, insert PVC pipe inside the stack until the

end is even with the top or outlet end of the metal

stack.

CAUTION

The exhaust vent pipe operates under positive

pressure and must be completely sealed to prevent leakage of combustion products into the livĆ

ing space.

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a

venting system commonly run with separate gas apĆ

pliances, the venting system may be too large to properly

vent the remaining attached appliances. The following

test should be conducted while all appliances (both in opĆ

eration and those not in operation) are connected to the

common venting system. If the venting system has been

installed improperly, corrections must be made as outĆ

lined in the previous section.

1 - Seal any unused openings in the common venting

system.

2 - Visually inspect the venting system for proper size

and horizontal pitch and determine there is no blockĆ

age or restriction, leakage, corrosion or other defiĆ

ciencies which could cause an unsafe condition.

3 - Close all building doors and windows, and all doors

between the space in which the appliances remainĆ

ing connected to the common venting system are loĆ

cated and other spaces of the building. Turn on

clothes dryers and any appliances not connected to

the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they will operate at maximum speed. Do not operĆ

ate a summer exhaust fan. Close fireplace dampers.

4 - Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5 - Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the flame of

match or candle, or smoke from a cigarette or cigar,

or a draft gauge.

6 - After determining that each appliance remaining

connected to the common venting system properly

vents when tested as indicated in step 3, return

doors, windows, exhaust fans, fireplace dampers

and any other gasĆburning appliance to their preĆ

vious condition of use.

7 - If improper venting is observed during any of the

above tests, the common venting system must be

corrected. The common venting system should be

resized to approach the minimum size as deterĆ

mined by using the appropriate tables in appendix G

in the current standards of the National Fuel Gas

Code ANSI Z223-1 in the USA, and the appropriate

Category 1 Natural Gas appliances venting sizing

tables in the current standard of the CAN/

CGA-B149.1 in the Natural Gas Installation Code in

Canada.

Intake and Exhaust Piping Terminations

Intake and exhaust pipes may be routed either horizontalĆ

ly through an outside wall or vertically through the roof. In

attic or closet installations, vertical termination through

the roof is preferred. Figures 8 through 20 show typical

terminations.

1 - Use recommended piping materials for both intake

and exhaust piping.

2 - Secure all joints, including drain leg, gas-tight using

approved cement.

3 - Piping diameters should be determined according

to length of pipe run. See table 5. Locate intake pipĆ

ing upwind (prevailing wind) from exhaust piping.

To avoid recirculation of exhaust gas on roof terĆ

minations, end of exhaust pipe must be higher than

intake pipe.

Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roof and one on the

side. Also, do not exit the intake on one side and the

exhaust on another side of the house or structure.

Page 10

Page 11

4 - Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to ilĆ

lustrations). Maximum separation is 3 inches (76

mm) on roof terminations and 6 inches (152 mm) on

side wall terminations.

5 - Exhaust piping must terminate straight out or up as

shown. In rooftop applications, a 2 inch X 1-1/2 inch

reducer for 2 inch venting, 3 inch x 2 inch reducer for

3 inch venting must be used on the exhaust piping at

the point where it exits the structure to improve the

velocity of exhaust away from the intake piping.

On roof terminations, the intake piping should termiĆ

nate straight down using two 90° elbows. See figure 8.

Inches (mm)

8 (203) MIN

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

3 (76) MAX.

3 x 2 (76 x 51) OR

2 x 1-1/2 (51 x 38)

PVC REDUCER

1/2 (13) FOAM

INSULATION IN

UNCONDITIONED

SPACE

NOTE - During extremely cold temperatures, below

approximately 20°F (6.67°C), units with long runs of

vent pipe through unconditioned space, even when inĆ

sulated, may form ice in the exhaust termination that

prevents the unit from operating properly. Longer run

times of at least 5 minutes will alleviat e mos t icing probĆ

lems. Also, a heatin g cable may be installed on exhaust

piping and termination to prevent freezeĆups. Heating

cable installation kit is available from Lennox. See ConĆ

densate Piping section for part numbers.

NOTE - Avoid recirculation of exhaust back into the inĆ

take pipe.

6 - On field-supplied terminations for side wall exits, exĆ

haust piping should extend a maximum of 12 inches

(305 mm) beyond the outside wall. Intake piping

should be as short as possible. See figure 9.

1/2 (13) ARMAFLEX

INSULATION IN

UNCONDITIONED SPACE

2 (51) PVC 1-1/2 (38) PVC

12 (305) MIN.

2 X 1-1/2

(51 x 38)

PVC REDUCER

3 (76) OR

2 (51) PVC

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES

ROOF TERMINATION KIT

(15F75) LB-49107CC for 2 (51) Venting

(44J41) LB-65678A for 3 (76) Venting

UNCONDITIONED

ATTIC SPACE

FIGURE 8

IMPORTANT

Do not use screens or perforated metal in intake

and exhaust terminations. Doing so will cause

freeze-ups and may block the terminations.

NOTE - If winter design temperature is below 32°F (0°C),

exhaust piping must be insulated with 1/2 inch (13 mm),

Armaflex or equivalent when run through unheated

space. Do not leave any surface area of exhaust pipe

open to outside air; exterior exhaust pipe must be insuĆ

lated with 1/2 inch (13 mm) Armaflex or equivalent. In exĆ

treme cold climate areas, 3/4 inch (19 mm) Armaflex or

equivalent is recommended. Insulation on outside runs of

exhaust pipe must be painted or wrapped to protect inĆ

sulation from deterioration.

1/2 (13) ARMAFLEX

Inches (mm)

INSULATION

OUTSIDE

WALL

TOP VIEW

(15J74) LB-49107CB for 2 (50.8) Venting

WALL RING KIT

6 (152)

MAXIMUM

8 (203)

MINIMUM

2 (51) PVC

COUPLING

FIGURE 9

7 - On field-supplied terminations, a minimum separaĆ

tion distance between the end of the exhaust pipe

and the end of the intake pipe is 8 inches (203 mm).

8 - If intake and exhaust piping must be run up a side

wall to position above snow accumulation or other

obstructions, the piping must be supported every 3

fee t (.91 m) as shown in figure 14. Refer to figures 13

and 15 for proper piping method. WTK wall terminaĆ

tion kit must be extended for use in this application.

See figure 18 or use kit WTKX shown in figure 19.

When exhaust and intake piping must be run up an

outside wall, the exhaust piping is reduced to 1 1/2

inches (38 mm) after the final elbow. The intake pipĆ

ing may be equ i p ped wit h a 90° elbow turndown. UsĆ

in g tu rn- do wn wi ll ad d 5 fe et (1 . 5 m) to th e eq ui va len t

length of the pipe.

Page 11

Page 12

1/2 (12.7) FOAM INSULATION

IN UNCONDITIONED SPACE

Inches (mm)

OUTSIDE WALL

Inches(mm)

UNCONDITIONED

SPACE

OUTSIDE WALL

12 (305) MIN. for 2 (51)

20 (508) MAX. for 3 (76)

8 (203)

MIN.

EXHAUST

INTAKE

PIPE

PIPE

Optional Turndown

TOP VIEW

WALL TERMINATION

(22G44) LB-49107CD for 2 (50.8) Venting

(44J40) LB-65701A for 3 (76.2) Venting

(Intake Only)

FIGURE 10

EXHAUST

TERMINATION

INTAKE

TERMINATION

EXHAUST

CONCENTRIC ROOFTOP TERMINATION

(60G77) LB-49107CE for G32V-75 Units Only

(33K97) LB-87942 for G32V-100 & -125 Units Only

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

INTAKE

Inches (mm)

FIGURE 11

OUTSIDE WALL

EXHAUST

INTAKE

Inches (mm)

CONCENTRIC WALL TERMINATION

(60G77) LB-49107CE for G32V-75 Units Only

(33K97) LB-87942 for G32V-100 & -125 Units Only

EXHAUST

TERMINATION

INTAKE

TERMINATION

12 (305) Min.

above grade.

Shown

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES EVERY

36 (914)

1/2 (13) FOAM

INSULATION IN

UNCONDITIONED

SPACE

WALL RING TERMINATION

(15F74) LB-49107CB for 2 in. (51) Venting

See venting table 5 for maximum venting lengths with

SIDE VIEW

this arrangement.

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

1/2 (13) FOAM

INSULATION

FIGURE 13

9 - Position termination ends so they are free from any

obstructions and above the level of snow accumulaĆ

tion (where applicable). Termination ends must be a

minimum of 12 inches (305 mm) above grade level.

Do not point into window wells, stairwells, alcoves,

courtyard areas or other recessed areas. Do not

position termination ends directly below roof eaves

or above a walkway. Since the G32V is a certified diĆ

rect vent, Category IV gas furnace, the location of

the termination is limited by local building codes. In

the absence of local codes, refer to the current NaĆ

tional Fuel Gas Code ANSI Z223-1 in USA, and curĆ

rent standard CAN/CGA-B149.1 of the Natural Gas

Installation Instructions in Canada for details. The

termination should be at least 12 inches (305 mm)

from any opening through which flue products could

enter the building.

When horizontally vented, minimum clearance for

termination from electric meters, gas meters, regulaĆ

tors and relief equipment is 4 feet (1.2 m) for US

installations. Refer to the current CAN/CGA-B149.1

for installations in Canada or with authorities having

local jurisdiction.

FIGURE 12

Page 12

Page 13

At vent termination, care must be taken to maintain

protective coatings over building materials (proĆ

longed exposure to exhaust condensate can destroy

protective coatings). It is recommended that the exĆ

haust outlet not be located within 6 feet (1.8 m) of a

condensing unit because the condensate can damĆ

age the painted coating.

METAL OR PLASTIC

STRAPPING

OR LARGE

WIRE TIES

FIGURE 14

IMPORTANT

Combustion air intake inlet and exhaust outlet

should not be located within 6 feet (1.8 m) of dryer

vent or combustion air inlet or outlet of another apĆ

pliance. Piping should not exit less than 3 feet (.91 m)

from opening into another building.

IMPORTANT

For Canadian Installations Only:

In accordance to CAN/CGA-B149.1 and .2, the miniĆ

mum allowed distance between the combustion air

intake inlet and the exhaust outlet of other apĆ

pliances shall not be less than 12 inches (305 mm).

10 - Suspend piping using hangers at a minimum of every

5 feet (1.52 m) for schedule 40 PVC and every 3 feet

(.91 m) for ABS-DWV, PVC-DWV, SDR-21 PVC,

and SDRĆ26 PVC piping. A suitable hanger can be

fabricated by using metal or plastic strapping or a

large wire tie.

11 - In areas where piping penetrates joists or interior

walls, hole must be large enough to allow clearance

on all sides of pipe as it passes through the center of

the hole.

12 - Isolate piping at the point where it exits the outside

wall or roof.

13 - When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a

vacation home, make provisions for draining conĆ

densate collection trap and lines.

14 - Based on the recommendation of the manufacturer,

a multiple furnace installation may use a group of up

to four termination kits WTK assembled together

horizontally, as shown in figure 17.

Inches(mm)

3 (76) OR

2 (51) 90_ ELBOW

Optional Turndown

(Not Shown)

May Be Used on

Intake Only

(22G44) LB-49107CD for 2(51) Venting

(44J40) LB-65701A for 3(76) Venting

Front View

INTAKE

VENT

1/2 (13) Foam

Insulation in

Unconditioned Space

Inches (mm)

WALL TERMINATION KIT (30G28) WTK

1/2 (13)

FOAM

INSULATION

FRONT VIEW

WALL TERMINATION

FIGURE 15

12

(305)

VENT TERMINATIONS

FIGURE 16

3 x 2 (76 x 51) OR

2 x 1-1/2 (51 x 38)

REDUCER BUSHING LOCAĆ

FOR OFFSET TERMINATION

TION

3 (76) OR

2 (51) 90_ ELBOW

EXHAUST VENT

5

(127)

Side View

EXHAUST VENT

INTAKE VENT

OUTSIDE WALL

Page 13

Page 14

Front View

INTAKE VENT

EXHAUST

VENT

18 MAX.

(457)

5

(127)

5-1/2

(140)

12

(305)

Inches (mm)

Front View

34

(864)

9

(229)

INTAKE

VENT

EXHAUST

VENT

NOTE - Enclosed exhaust pipe is

insulated with 1/2 inch (13 mm)

foam insulation. If intake and exĆ

haust pipes are reversed, slit and

remove foam insulation and

reapply to other vent. Exhaust

vent must be insulated.

Side View

EXHAUST VENT

Inches (mm)

OPTIONAL VENT TERMINATION FOR

MULTIPLE UNIT INSTALLATION

WALL TERMINATION KIT WTK

FIGURE 17

AIR

12

(305)

5Ć1/2

(140)

Minimum

8 (203)

Front View

INTAKE

AIR

5

(127)

EXHAUST

INTAKE

AIR

MODEL WTK WALL TERMINATION KIT (30G28)

EXTENDED VENT FOR GRADE CLEARANCE

VENT TERMINATIONS

FIGURE 18

INTAKE

VENT

COVER EXHAUST

VENT WITH

1/2 (13)

FOAM

INSULATION

EXHAUST

AIR

12 MIN.

(305)

Above Grade

GRADE

Side View

Inches (mm)

12 (305)

Minimum

ABOVE GRADE

GRADE

Side View

4

(102)

12

(305)

GRADE

EXHAUST VENT

8 MIN.

(203)

INTAKE

VENT

OUTSIDE WALL

GRADE

VENT TERMINATIONS

MODEL WTKX (30G79)

EXTENSION RISER FOR GRADE CLEARANCE

FIGURE 19

G32 VENTING IN EXISTING CHIMNEY

3 in. - 8 in.

8 in. - 12 in.

(203 mm - 305 mm)

INTAKE VENT

INSULATION

(OPTIONAL)

TOP PLATE

(18 GA. MIN.)

MIN. 12" (304 mm)

ABOVE ROOF

INSULATE

TO FORM

SEAL

NOTE - Do not discharge exhaust gases directly into any chimney or vent stack.

If vertical discharge through an existing unused chimney or stack is required,

insert piping inside chimney until the pipe open end is above top of chimney and

terminate as illustrated. In any exterior portion of chimney, the exhaust vent

must be insulated.

(76 mm203 mm)

STRAIGHT CUT OR

ANGLE CUT IN DIRECTION

OF ROOF SLOPE

EXHAUST VENT

1/2" (13 mm)

WEATHERPROOF

INSULATION

SHOULDERS OF FITTINGS

PROVIDE SUPPORT FOR

PIPE ON TOP PLATE

ALTERNATE

3 in. - 8 in.

(76 mm203 mm)

INTAKE VENT

EXTERIOR

PORTION

OF CHIMNEY

FIGURE 20

Page 14

Page 15

Condensate Piping

This unit is designed for either right- or left-side exit of

condensate piping. Route the condensate drainline only

within the conditioned space: this prevents possible

freezing of the condensate, which would block the drainline. Use an electric heat cable if you route the condensate line through unconditioned areas.

CAUTION

Do not use copper tubing or existing copper conĆ

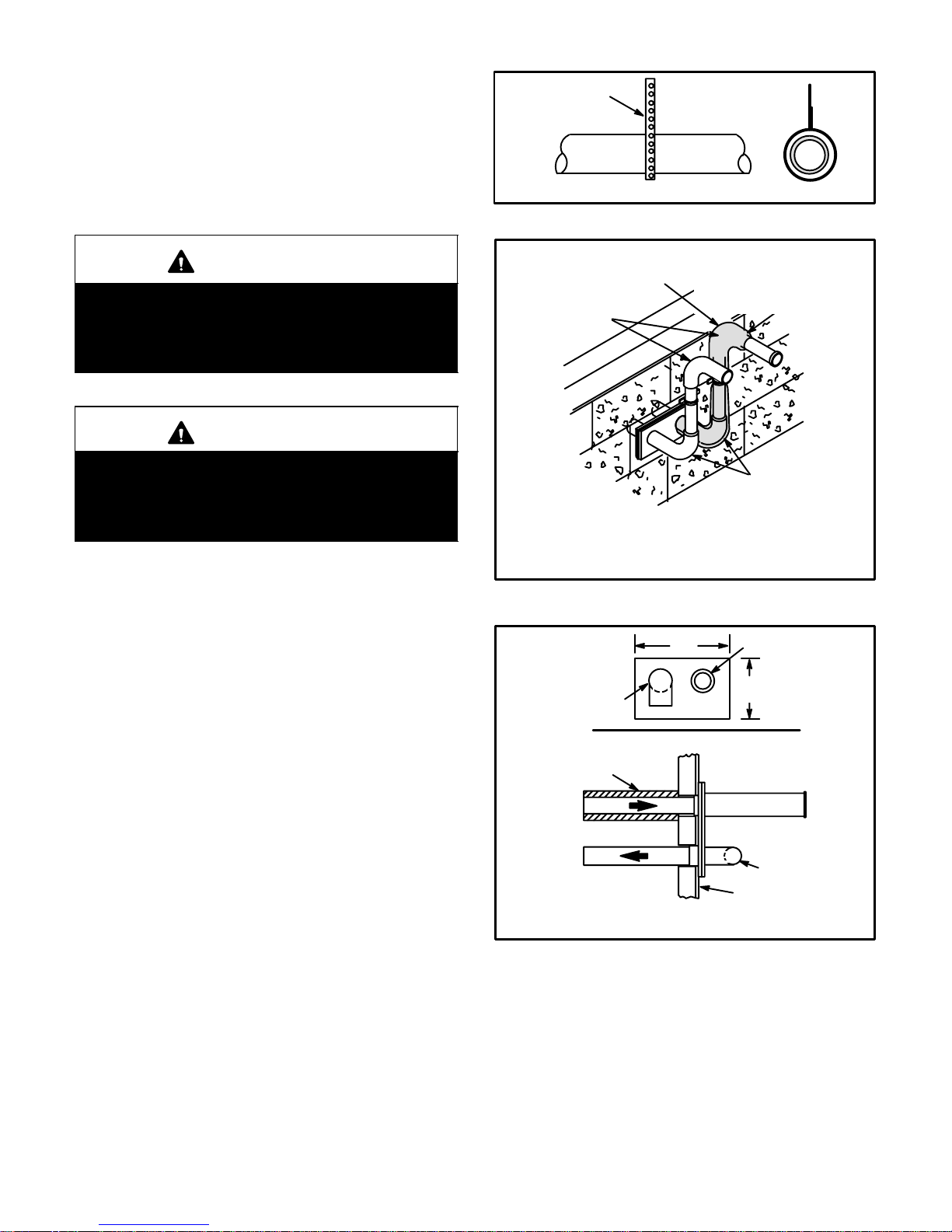

densate lines for drain line.

1 - Determine which side of the unit that the condensate

will exit.

2 - Connect 1/2" (13 mm) plastic pipe plug (provided) in

the unused end of the condensate trap. Install plug

so that it is sealed water tight yet able to be removed.

Do not permanently seal the connection. Teflon tape

is recommended to seal joint. See figure 21.

CONDENSATE ASSEMBLY

(For left or right installation)

COLD

COMBUSTION AIR

BLOWER BRACKET

HEADER

BOX

Right-Hand Side Condensate Exit:

Install the nipple/adapter assembly from the outĆ

side of the cabinet and insert the adapter into the

threaded opening in the condensate trap.

Left-Hand Side Condensate Exit:

Insert nipple/adapter assembly from the left-hand

side of the cabinet and through the combustion air

blower mounting structure into the threaded

opening in the condensate trap.

5 - Connect field-supplied plumbing to nipple and route

to open drain. Plumbing should be vented to a point

higher than the condensing coil. See figure 22.

CONDENSATE PLUMBING

(Plumbing must be vented higher than coil.)

NIPPLE

ADAPTER

ELBOW

CONDENSATE TRAP

NIPPLE

ADAPTER

PLUG

BOOT OR CAP

FIGURE 21

3 - Use the provided adapter (1/2" mpt X 3/4" PVC) and

a field-provided nipple to carry drainage outside the

cabinet. A 1/2" CPVC x 1/2" MPT adapter and 1/2"

CPVC is acceptable for use.

4 - Glue nipple to the adapter using the procedures out-

lined in the Joint Cementing Procedures" section.

The nipple/adapter assembly should be connected

in a non-permanent manner and must be water tight.

Teflon tape is recommended to seal the joint.

FIGURE 22

6 - Connect condensate drain line [1/2" (13 mm) SDR 11

plastic pipe or tubing] to condensate connection on

condensate trap assembly and route to open drain.

Condensate line must be sloped downward away

from condensate trap to the drain. If drain level is

above condensate outlet, use a condensate pump to

pump condensate to the higher level. Condensate

drain line should be routed within the conditioned

space to avoid freezing of condensate and blockage

of drain line. If this is not possible, a heat cable kit

may be used on the condensate trap and condenĆ

sate line. Heating cable kit is available from Lennox

in various lengths; 6 feet (1.8 m) - kit no. 26K68; 24

feet (7.3 m) - kit no. 26K99; and 50 feet (15.2 m) - kit

no. 26K70. Also available from Lennox: 1/2" (12.7

mm) glass fiber tape - 39G04; 2" (50.8 mm) plum foil

tape - 39G03.

Page 15

Page 16

Gas Piping

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outĆ

side the furnace cabinet.

1 - Gas piping may be routed into the unit through either

the left- or right-hand side. Supply piping enters into

the gas valve from the bottom of the valve as shown

in figure 23.

2 - When connecting the gas supply, factors such as

length of run, number of fittings and furnace rating

must be considered to avoid excessive pressure

drop. Table 6 lists recommended pipe sizes for typiĆ

cal applications.

NOTE - Use two wrenches when connecting gas pipĆ

ing to avoid transferring torque to the manifold.

3 - The gas piping must not run in or through air ducts,

clothes chutes, gas vents or chimneys, dumb waitĆ

ers, or elevator shafts. Center gas line through piping

hole. Gas line should not touch side of unit. When

left-hand gas plumbing is required, gas line should

be installed in the lower half of knockout so that piping will clear combustion air blower. See figure 23.

LEFT SIDE PIPING

4 – The piping should be sloped 1/4 inch (6.4 mm) per 15

feet (4.57 m) upward toward the meter from the furĆ

nace. The piping must be supported at proper interĆ

vals [every 8 to 10 feet (2.44 to 3.01 m)] using suitĆ

able hangers or straps. A drip leg should be installed

in vertical pipe runs to the unit.

5 - In some localities, codes may require installation of a

manual main shutĆoff valve and union (furnished by

the installer) external to the unit. Union must be of the

ground joint type.

NOTE - Install a 1/8 inch NPT plugged tap in the field pipĆ

ing upstream of the gas supply connection to the unit. The

tap must be accessible for test gauge connection. See

figure 24.

MANUAL MAIN SHUT-OFF

VALVE WILL NOT HOLD

NORMAL TEST PRESSURE

1/8 in. (3.2 mm) NPT

PLUGGED TAP

CAP

FURNACE

ISOLATE

GAS VALVE

FIGURE 24

Leak Check

After gas piping is completed, carefully check all piping

connections (factory- and field-installed) for gas leaks.

Use a leak detecting solution or other preferred means.

MANUAL MAIN

SHUT-OFF

VALV E

1/8 in. NPT

PLUGGED

TAP

GAS VALVE

GAS VALVE

RIGHT SIDE PIPING

(STANDARD)

FIGURE 23

MANUAL MAIN

SHUT-OFF

VALV E

1/8 in. NPT

PLUGGED

TAP

IMPORTANT

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame, or other sources of igniĆ

tion to check for gas leaks.

IMPORTANT

The furnace must be isolated from the gas supply

piping system by closing its individual manual

shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 psig (3.45 kPa). See figure 24.

The furnace and its individual shut-off valve must

be disconnected from the gas supply piping sysĆ

tem during any pressure testing of the system at

test pressures greater than 1/2 psig (3.45 kPa).

Page 16

Page 17

Nominal Internal

Nominal

Internal

Iron Pipe Size

-Inches(mm)

1/4

(6.35)

3/8

(9.53)

1/2

(12.7)

3/4

(19.05)

1

(25.4)

1-1/4

(31.75)

1-1/2

(38.1)

2

(50.8)

2-1/2

(63.5)

3

(76.2)

4

(101.6)

Diameter

-Inches(mm)

.364

(9.246)

.493

(12.522)

.622

(17.799)

.824

(20.930)

1.049

(26.645)

1.380

(35.052)

1.610

(40.894)

2.067

(52.502)

2.469

(67.713)

3.068

(77.927)

4.026

(102.260)

NOTE - Capacity given in cubic feet (m

GAS PIPE CAPACITY - ft.3/hr (m3/hr)

TABLE 6

Length of Pipe-Feet (m)

10

(3.048)20(6.096)30(9.144)40(12.192)50(15.240)60(18.288)70(21.336)80(24.384)90(27.432)

43

(1.13)

95

(2.69)

175

(4.96)

360

(10.19)

680

(19.25)

1400

(39.64)

2100

(59.46)

3950

(111.85)

6300

(178.39)

11000

(311.48)

23000

(651.27)

3

) of gas per hour and based on 0.60 specific gravity gas.

29

(.82)

65

(1.84)

120

(3.40)

250

(7.08)

465

(13.17)

950

(26.90)

460

(41.34)

2750

(77.87)

4350

(123.17)

7700

(218.03)

15800

(447.39)

24

(.68)

52

(1.47)

97

(2.75)

200

(5.66)

375

(10.62)

770

(21.80)

1180

(33.41)

2200

(62.30)

3520

(99.67)

6250

(176.98)

12800

(362.44)

20

(.57)

45

(1.27)

82

(2.32)

170

(4.81)

320

(9.06)

660

(18.69)

990

(28.03)

1900

(53.80)

3000

(84.95)

5300

(150.07)

10900

(308.64)

18

(.51)

40

(1.13)36(1.02)

73

(2.07)66(1.87)

151

(4.28)

285

(8.07)

580

(16.42)

900

(25.48)

1680

(47.57)

2650

(75.04)

4750

(134.50)

9700

(274.67)

(3.91)

(7.36)

(15.01)

(22.94)

(43.04)

(67.96)

(121.76)

(249.18)

16

(.45)

138

260

530

810

1520

2400

4300

8800

15

(.42)

33

(.73)

61

(1.73)

125

(3.54)

240

(6.80)

490

(13.87)

750

(21.24)

1400

(39.64)

2250

(63.71)

3900

(110.43)

8100

(229.36)

14

(.40)

31

(.88)

57

(1.61)

118

(3.34)

220

(6.23)

460

(13.03)

690

(19.54)

1300

(36.81)

2050

(58.05)

3700

(104.77)

7500

(212.37)

13

(.37)

29

(.82)

53

(1.50)

110

(3.11)

205

(5.80)

430

(12.18)

650

(18.41)

1220

(34.55)

1950

(55.22)

3450

(97.69)

7200

(203.88)

100

(30.480)

12

(.34)

27

(.76)

50

(1.42)

103

(2.92)

195

(5.52)

400

(11.33)

620

(17.56)

1150

(32.56)

1850

(52.38)

3250

(92.03)

6700

(189.72)

Electrical

A field make-up box is provided for line voltage wiring.

Line voltage wiring to unit is done through the J69 jack

from the field make-up box to plug P69 from the control

box. See figures 25 and 26 for make-up box installation.

Refer to figure 27 for schematic wiring diagram and trouĆ

bleshooting, figure 28 for point-to-point field wiring and

figure 29 for a detailed illustration of the Surelight inteĆ

grated control.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic comĆ

ponents. Take precautions during furnace installaĆ

tion and service to protect the furnace's electronic

controls. Precautions will help to avoid control exĆ

posure to electrostatic discharge by putting the

furnace, the control and the technician at the same

electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an unĆ

painted unit surface, such as the gas valve or blowĆ

er deck, before performing any service procedure.

1 - Select circuit protection and wire size according to

the unit nameplate. The power supply wiring must

meet Class 1 restrictions.

2 - A snaphole bushing is provided to seal around the

wiring as it enters the cabinet. A snaphole plug is proĆ

vided to seal the unused wire entry hole.

3 - Install a separate disconnect switch (protected by eiĆ

ther a fuse or circuit breaker) near the unit so that

power can be turned off for servicing.

4 - Install field makeĆup box on either side, inside or out

of the cabinet. Knockouts are provided in box and

cabinet to facilitate wiring. See figures 25 and 26.

To ensure proper grounding of the furnace, two lockĆ

washers are included in the electrical make-up box

bag assembly. Place each lockwasher on a securing

screw before installing the make-up box. Make sure

the lockwasher breaks the paint on the cabinet so

that the washer is touching metal. Unit is not properly

grounded if paint has not been removed by the lockĆ

washer.

5 - Remove cap from knockout in blower deck on the

same side as the installed make-up box.

6 - Insert the three-pin (P69) plug from the control box

into the knockout provided in the blower deck.

7 - Connect jack (J69) from make-up box to jack plug in

blower deck.

8 - Before connecting the thermostat or the power wirĆ

ing, check to make sure the wires will be long enough

for servicing at a later date. Remove the blower acĆ

cess panel to check the length of the wire.

9 - Electrically ground unit in accordance with local

codes or, in the absence of local codes, according to

the current National Electric Code (ANSI/NFPA No.

70) and in Canada with the current Canadian Electric

Code part 1 (CSA standard C22.1). The ground wire

is provided in the field make-up box.

Page 17

Page 18

IMPORTANT

Ignition control will not operate unless unit is propĆ

erly grounded. 120V supply must be installed with

correct polarity.

CAUTION

Bundle all wires connected to control board in

such a way that drip loops are formed. Drip loops

direct damaging moisture away from control

board.

INTERIOR MAKE-UP BOX INSTALLATION

MAKE-UP

BOX

J69

BUSHING

FIGURE 25

EXTERIOR MAKEĆUP BOX INSTALLATION

MAKE-UP

BOX

J69

P69 from

Control Box

BUSHING

10 -One line voltage EAC" terminal is provided on the

furnace control board. Any electronic air cleaner

rated up to one amp can be connected to this termiĆ

nal with the neutral leg of the circuit being connected

to the neutral EAC" terminal. See figure 29 for conĆ

trol board configuration. This terminal is energized

when the indoor blower is operating.

11 -One line voltage HUM" terminal is provided on the

furnace control board. Any humidifier rated up to one

amp can be connected to this terminal with the neuĆ

tral leg of the circuit being connected to the neutral

HUM" terminal. See figure 29 for control board conĆ

figuration. This terminal is energized in the heating

mode whenever the combustion air inducer is operĆ

ating.

12 - Install room thermostat according to instructions

provided with thermostat. The furnace may be conĆ

trolled by either a single- or two-stage thermostat. If

furnace is being used with heat pump refer to FM21

installation instruction.

13 - Complete wiring connections to equipment using

wiring diagrams provided with unit and figures 27

and 28. Use 18-gauge wire or larger that is suitable

for Class II rating for thermostat connections. See

table 7 for diagrams for specific applications.

Indoor Blower Speeds

1 - When the thermostat is set to FAN ON," the indoor

blower will run continuously at approximately 38% of

the second-stage cooling speed when there is no

cooling or heating demand.

2 - When the G32V unit is running in the heating mode,

the indoor blower will run on the heating speed desigĆ

nated by the positions of dip switches 11 and 12.

3 - When there is a cooling demand, the indoor blower

will run on the cooling speed designated by the posiĆ

tions of dip switches 5 and 6.

P69 from

Control Box

FIGURE 26

Page 18

Page 19

TYPICAL G32V SCHEMATIC WIRING DIAGRAM

FIGURE 27

Page 19

Page 20

TYPICAL G32V FIELD WIRING DIAGRAM

FIGURE 28

Thermostat

1 Heat / 1 Cool

NOTE - Use dip

switch 3 to set

second-stage

heat ON delay.

ON-10 minutes.

OFF-15 minĆ

utes.

1 Heat / 1 Cool

with CCB1

NOTE - Use dip

switch 3 to set

second-stage

heat ON delay.

ON-10 minutes.

OFF-15 minĆ

utes.

TABLE 7

Field Wiring Applications

Jumper Settings (See figure 29)

E20

Term. Strip

Y1 to Y2

W914 W951

SINGLE Yes Intact Intact

SINGLE Yes Cut Intact

Wiring Connections

S1

T'STAT

S1

T'STAT

CONTROL

TERM. STRIP

CCB1

CONTROL

TERM. STRIP

OUTDOOR

UNIT

OUTDOOR

UNIT

Page 20

Page 21

Thermostat

1 Heat / 2 Cool

NOTE - Use dip

switch 3 to set

second-stage

heat ON delay.

ON-10 minutes.

OFF-15 minĆ

utes.

TABLE 7

Field Wiring Applications (Continued)

Jumper Settings (See figure 29)

E20

Term. Strip

Y1 to Y2

W914 W951

SINGLE No Intact Intact

Wiring Connections

S1

T'STAT

CONTROL

TERM. STRIP

OUTDOOR

UNIT

1 Heat / 2 Cool

SINGLE No Cut Intact

with CCB1

NOTE - Use dip

switch 3 to set

second-stage

heat ON delay.

ON-10 minutes.

OFF-15 minĆ

utes.

2 Heat / 2 Cool TWO No Intact Intact

S1

T'STAT

S1

T'STAT

CCB1

CONTROL

TERM. STRIP

CONTROL

TERM. STRIP

OUTDOOR

UNIT

OUTDOOR

UNIT

2 Heat / 2 Cool

TWO No Cut Intact

with CCB1

Page 21

S1

T'STAT

CCB1

CONTROL

TERM. STRIP

OUTDOOR

UNIT

Page 22

TABLE 7

Field Wiring Applications (Continued)

Jumper Settings (See figure 29)

Thermostat

E20

Term. Strip

Y1 to Y2

W914 W951

2 Heat / 1 Cool TWO Yes Intact Intact

Wiring Connections

S1

T'STAT

CONTROL

TERM. STRIP

OUTDOOR

UNIT

FM21 Heat

Pump / 1 Cool

Harmony

Application*

2 Heat / 1 Cool

SINGLE Yes Intact Cut

TWO Yes Cut Intact

*Disconnect existing

furnace transformer

and replace with 75VA,

24V transformer if deĆ

frost option to be used.

75VA, 24V

TRANSFORMER*

NOTE - Wiring connecĆ

tions to outdoor unit and

thermostat made at

FM21 control board per

FM21 instructions.

TEMP.

MOD.

SWITCH

FAN LO

FAN LINE

HARMONY

CONTROL

TERM. STRIP

CONTROL

TERM.

STRIP

FM21

NOTE Remove

Y1/Y2 jumper

for two-stage

cooling.

OUTĆ

DOOR

UNIT

Harmony

TWO No Cut Intact

Application*

2 Heat / 2 Cool

*Cut wires at pin positions 2 and 13 of J/P46. Insulate ends to prevent a short. Blower operates on PWM signal generated by Harmony. Harmony

overrides blower speed taps. Blower speed varies according to zone demand. Low and high-fire controlled by temperature modulating switch.

Page 22

TEMP.

MOD.

SWITCH

FAN LO

FAN LINE

HARMONY

CONTROL

TERM.

STRIP

OUTĆ

DOOR

UNIT

Page 23

Integrated Control Board Settings

TWO-STAGE, VARIABLE SPEED INTEGRATED CONTROL BOARD

DIAGNOSTIC

LEDs

DIP

SWITCHES

1 - 3

E20

THERMOSTAT

SELECTION

JUMPER

1/4" QUICK CONNECT TERMINALS

THERMOSTAT CONNECTIONS (TB1)

LEDs

ON-BOARD

JUMPER W914

(cut when CCB1 or

Harmony II are used)

FACTORY-

INSTALLED

JUMPER

ON-BOARD

JUMPER W951

(cut when heat pump is

used with FM21)

DIP

SWITCHES

5 - 12

LED

FIGURE 29

G32V units are equipped with a two-stage, variable

speed SureLight integrated control. This control manĆ

ages ignition timing, heating mode fan off delays and inĆ

door blower speeds based on selections made using the

control dip switches and jumpers. The control includes an

internal watchguard feature which automatically resets

the ignition control when it has been locked out because

the burner has failed to light. After one hour of continuous

thermostat demand for heat, the watchguard will break

and remake thermostat demand to the furnace and autoĆ

matically reset the control to relight the furnace.

Thermostat Selection Jumper (E20)

This unit may be used with either a single-stage or twostage thermostat. The thermostat selection jumper, loĆ

cated just below dip switches 1 through 3, must be propĆ

erly positioned for the particular application. The jumper

is factory positioned for use with a two-stage thermostat.

If a single-stage thermostat is to be used, the jumper must

be repositioned.

DIP SWITCH FUNCTIONS

DIP SWITCH(ES) FUNCTION

1 and 2 Blower Off Delay

3 Second Stage ON Delay (Single-stage t'stat)

4 Not used

5 and 6 Cooling Mode Blower Speed

7 and 8 Blower Speed Adjustment

9 and 10 Cooling Mode Blower Ramping Profile

11 and 12 Heating Mode Blower Speed

a - Select TWO" for two-stage heating operation conĆ

trolled by a two-stage heating thermostat (factory

setting);

b - Select SINGLE" for two-stage heating operation

controlled by a single-stage heating thermostat.

This setting provides a timed delay before secondstage heat is initiated.

Dip Switch Settings

Switches 1 and 2 -- Blower Off Delay -- The blower-on

delay of 45 seconds is not adjustable. The blower-off deĆ

lay (time that the blower operates after the heating deĆ

mand has been satisfied) can be adjusted by moving

switches 1 and 2 on the integrated control board. The unit

is shipped from the factory with a blower-off delay of 90

seconds. The blower off delay affects comfort and is adĆ

justable to satisfy individual applications. Adjust the blowĆ

er off delay to achieve a supply air temperature between

90° and 110°F at the exact moment that the blower is de-

Page 23

Page 24

energized. Longer off delay settings provide lower supply

air temperatures; shorter settings provide higher supply

air temperatures.The table below provides the blower off

timings that will result from different switch settings.

TABLE 8

Blower Off Delay Switch Settings

Blower Off Delay

(Seconds)

Switch 1 Switch 2

60 Off Off

90 Off On

120 On Off

180 On On

Switch 3 -- Second Stage Delay (Used with SingleStage Thermostat Only) -- This switch is used to deterĆ

mine the second stage on delay when a single-stage therĆ

mostat is being used. The switch is factory-set in the ON

position, which provides a 10-minute delay before secĆ

ond-stage heat is initiated. If the switch is toggled to the

OFF position, it will provide a 15-minute delay before secĆ

ond-stage heat is initiated. This switch is only activated

when the thermostat selector jumper is positioned for

SINGLE-stage thermostat use.

Switch 4 -- Not used in G32V application.

Switches 5 and 6 -- Cooling Mode Blower Speed --

Switches 5 and 6 are used to select cooling blower motor

speed. The unit is shipped from the factory with the dip

switches positioned for high speed (4) indoor blower moĆ

tor operation during the cooling mode. The table below

provides the cooling mode blower speeds that will result

from different switch settings. Refer to tables 13 through

13 for corresponding cfm values.

TABLE 9

Cooling Mode Blower Speeds

Speed Switch 5 Switch 6

1 - Low On On

2 - Medium Low Off On

3 - Medium High On Off

4 - High (Factory) Off Off

Switches 7 and 8 -- Blower Speed Adjustment --

Switches 7 and 8 are used to select blower speed adjustĆ

ment settings. The unit is shipped from the factory with

the dip switches positioned for NORMAL (no) adjustĆ

ment. The dip switches may be positioned to adjust the

blower speed by -15% to better suit the application. The

table below provides blower speed adjustments that will

result from different switch settings. Refer to tables 13

and14 for corresponding cfm values.

TABLE 10

Blower Speed Adjustment

Adjustment Switch 7 Switch 8

NORMAL (Factory) Off Off

-15% (approx.) Off On

Switches 9 and 10 -- Cooling Mode Blower Speed

Ramping -- Switches 9 and 10 are used to select cooling

mode blower speed ramping options. Blower speed

ramping may be used to enhance dehumidification perĆ

formance. The switches are factory set at option A which

has the greatest effect on blower motor performance. The

table below provides the cooling mode blower speed

ramping options that will result from different switch setĆ

tings. The cooling mode blower speed ramping options

are detailed below.

TABLE 11

Cooling Mode Blower Speed Ramping

Ramping Option Switch 9 Switch 10

A (Factory) Off Off

B On Off

C Off On

D On On

Ramping Option A (Factory Selection)

Motor runs at 50% for 1/2 minute.

Motor then runs at 82% for approximately 7-1/2 miĆ

nutes.

If demand has not been satisfied after 7-1/2 minutes,

motor runs at 100% until demand is satisfied.

Once demand is met, motor runs at 50% for 1/2 minĆ

ute.

Motor ramps down to off.

OFF

1/2 MIN

50% CFM

7-1/2 MIN

82% CFM

COOLING DEMAND

100%

CFM

1/2 MIN

50% CFM

OFF

Ramping Option B

Motor runs at 50% for 1/2 minute.

Motor then runs at 82% for approximately 7-1/2 miĆ

nutes.

If demand has not been satisfied after 7-1/2 minutes,

motor runs at 100% until demand is satisfied.

Once demand is met, motor ramps down to off.

OFF

1/2 MIN

50% CFM

7-1/2 MIN

82% CFM

COOLING DEMAND

100% CFM

OFF

Ramping Option C

Motor runs at 82% for approximately 7-1/2 minutes.

If demand has not been satisfied after 7-1/2 minutes,

the motor runs at 100% until demand is satisfied.

Once demand is met, motor ramps down to off.

OFF

7-1/2 MIN

82%CFM

COOLING DEMAND

100% CFM

OFF

Ramping Option D

Motor runs at 100% until demand is satisfied.

Once demand is met, motor ramps down to off.

Page 24

Page 25

100% CFM

COOLING

DEMAND

OFFOFF

Switches 11 and 12 -- Heating Mode Blower Speed --

Switches 11 and 12 are used to select heating mode blowĆ

er motor speed. The unit is shipped from the factory with

the dip switches positioned for medium low (2) speed inĆ

door blower motor operation during the heating mode.

The table below provides the heating mode blower

speeds that will result from different switch settings. Refer

to tables 13 and 14 for corresponding cfm values.

TABLE 12

Heating Mode Blower Speeds

Speed Switch 11 Switch 12

1 - Low On On

2 - Medium Low

(Factory)

Off On

3 - Medium High On Off

4 - High Off Off

On-Board Jumper W914

On-board jumper W914, which connects terminals DS

and R on the integrated control board, must be cut when

the furnace is installed with either the Harmony II zone

control board or the CCB1 EfficiencyPlus humidity conĆ

trol. Refer to table 15 for operation sequence in applicaĆ

tions including a G32V, CCB1 and single-speed outdoor

unit. Table 16 gives the operation sequence in applicaĆ

tions with a two-speed outdoor unit.

On-Board Jumper W951

On-board jumper W951, which connects terminals R and

O on the integrated control board, must be cut when the

furnace is installed in applications which include a heat

pump unit and the FM21 FuelMaster control board.

Factory-Installed Jumper Y1 to Y2

A factory-installed jumper from Y1 to Y2 terminals on the

integrated control board terminal strip must be removed if

two-stage cooling will be used.

Diagnostic LEDs (DS1 and DS2)

Two diagnostic LEDs are located on the two-stage, variĆ

able speed integrated control just to the left of the first

bank of dip switches. The LED flashes correspond with

diagnostic codes detailed on page 35.

Status LEDs (HEAT, HI/LO, ON/OFF and CFM)

The integrated control includes four LEDs which indicate

operating status. The green ON/OFF LED is lit any time

the blower is operating. The green CFM LED indicates

the blower motor speed. Count the number of blinks beĆ

tween the two-second pauses to determine the CFM.

Each blink represents approximately 100 CFM. The yelĆ

low HI/LO LED is lit when the W914 (DS to R) jumper has

not been clipped for CCB1 or Harmony operation. The

yellow HEAT LED is lit when the indoor blower is operatĆ