INSTALLATION

LENNOX

_2001 Lennox Industt]e-_ _nc

Dallas Texas USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

INSTRUCTIONS

G32Q SERIES UNITS

GAS UNITS

504,488M _[_2ech nical

11/2001 blications

Supersedes504,382M LithoU.S.A.

ITahi6of_ __te:nts i ::

UnitDimensions ................................ 2

G32Q Parts Arrangement ....................... 3

Requirements.................................. 4

General ....................................... 5

Installation - Setting Equipment .................. 5

Return Air Opening Guidelines ................... 5

Filters & Optional Filter Assembly ................. 6

Duct System ................................... 7

Pipe & Fittings Specifications .................... 7

Vent Piping L_uidelines.......................... 8

Joint Cementing Procedure ...................... 8

Venting Practices ............................... 9

Gas Piping ................................... 15

Electrical ..................................... 16

Unit Start-Up ................................. 21

Heating Sequence of Operation ................. 22

Blower Operation .............................. 22

Gas Pressure Adjustment ...................... 22

High Altitude Information ....................... 23

Other Unit Adjustments ........................ 23

Service ...................................... 24

Repair Parts .................................. 27

Troubleshooting ............................... 27

Start-Up & Performance Checklist . 32

-AWARNING

WHAT TO DO IF YOU SMELL GAS:

Do not store or use gasoline or other

flammable vapors and liquids in the vi-

cinity of this or any other appliance.

Installation and service must be per-

formed by a qualified installer, service

agency or the gas supplier,

11101 504,488M

• Do not by to light any appliance.

• Extinguish any open flames.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the

fire department.

IIIIIIIIIlHIIIIIIHIIIIIIIIIIIIIIIIII Pagol IIIIHIIIIIIIIllllIIHHItllUlIIHII

1 1116

(41)

_8

(16)'-IP

1 1116 3 5/8

,o-oI

• v 151 ) AIR OUTLET

TOP VIEW

"ql'-- 28 1/2

I I

(724)

T

ELECTRICA

INLETS_

{BothSides)

91- 4(102)

L _____(EitherSide) J

Lt:;:"ZtJ

Return Air

Knockout (Bottom)

SIDE VIEW

21 3/4

(552)

GAS PIPING

INLET

(Both Sides)

4 (I02) E-IP

T

46

(1168)

EXTERNAL

SIDE RETURN

/_R FIL'I1ERK]T

(Either Side

O_onal ,

,lira A_

I I

m

t

AIR FLOW

Return Air

Knockout (Bottom)

FRONT VIEW

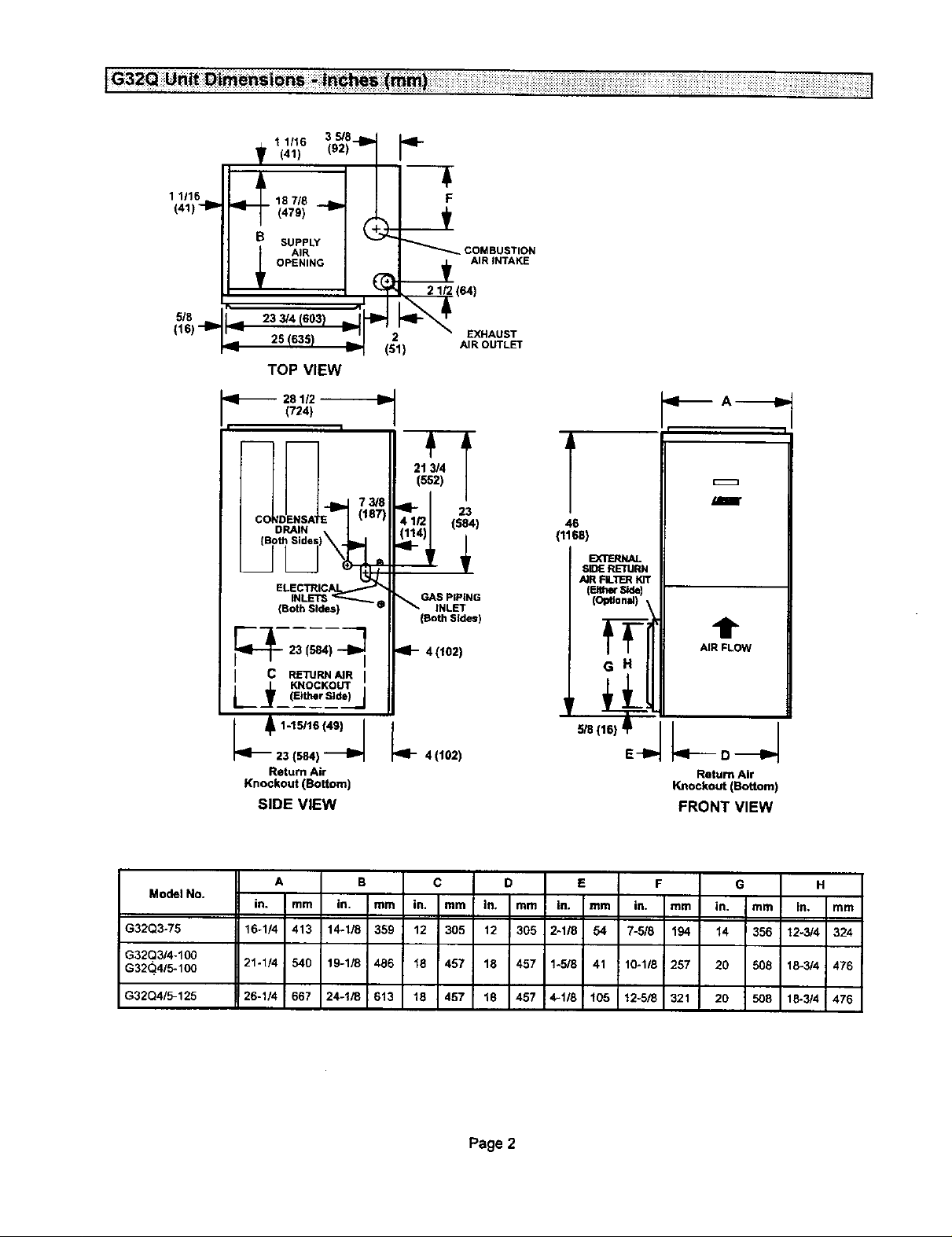

Model No.

G32Q3-75 16-1/4 413 14.1/8 359 12 305 12 305 2-118 54 7-5/8 194 14 356 12-3/4 324

G32Q3/4-100

G32(_4/5-100 21-1/4 540 19-1/8 486 18 457 18 457 1-5/8 41 10-1/8 257 20 508 18-3/4 476

G32Q4/5-125 26-1/4 667 24-1/8 613 18 457 18 457 4-1/8 105 12-5/8 321 20 508 18-3/4 476

A B C D E F G H

in. I mm in. mm in. mm In, mm In. mm in. mm in. mm in, mm

Page 2

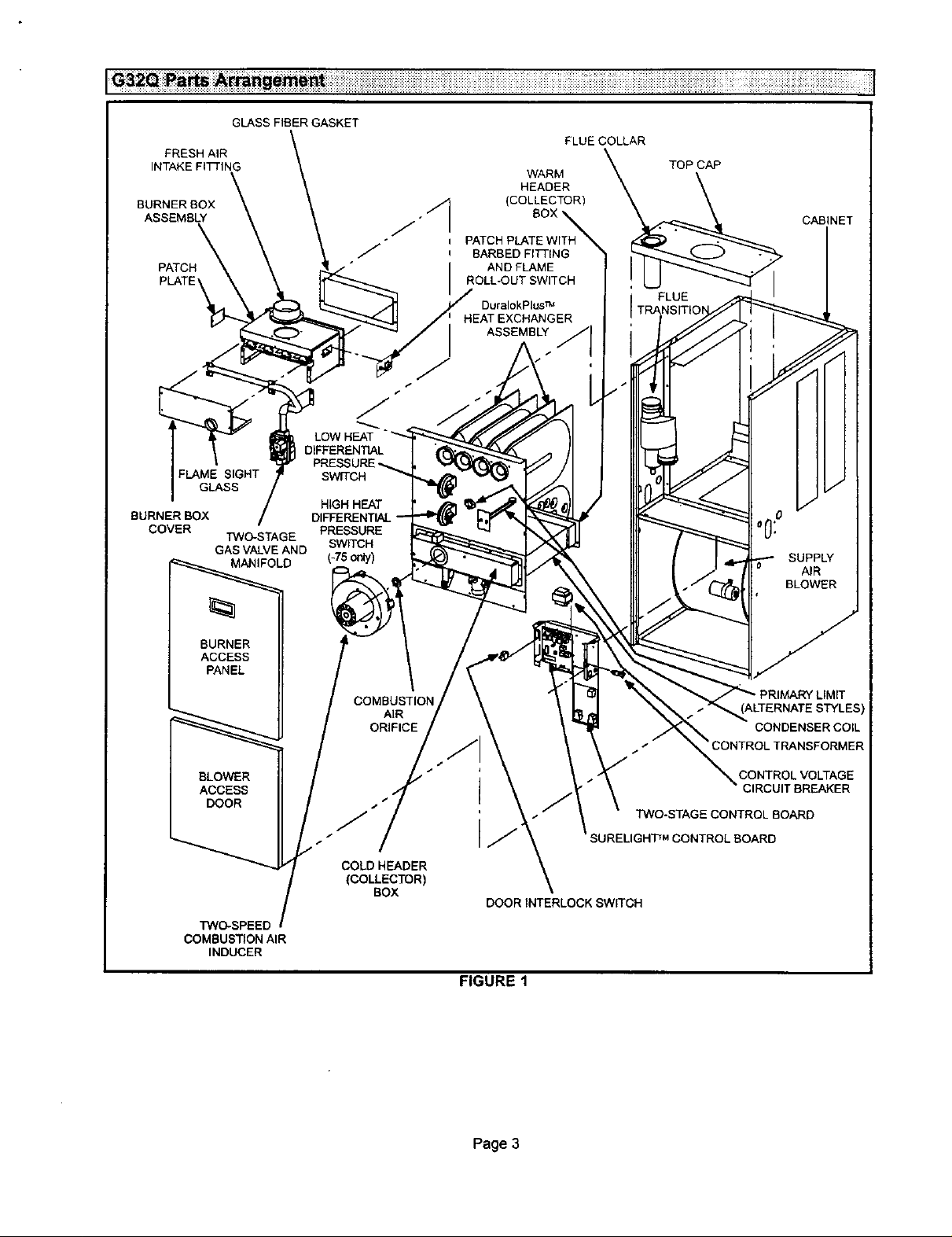

FRESH AIR

INTAKE FITTING

BURNERBOX

ASSEMBLY

PATCH

GLASS FIBER GASKET

HEADER

. BOX

/

_I (COLLECTORTH__

/ PATCH PLATE WITH

l BARBED FITTING

ROLL-OUT SWITCH

HEAT EXCHANGER

WARM

AND FLAME

DuralokPlus TM

ASSEMBLY

FLUE COLLAR

TOP CAP

CABINET

FLUE

FLAME SIGHT p swrrcH

GLASS

BURNER BOX /

COVER ]3NO-STAGE PRESSURE

GAS VALVE AND SWITCH

BURNER

ACCESS

PANEL

BLOWER

ACCESS

DOOR

TWO-SPEED

COMBUSTION AIR

INDUCER

/

MANIFOLD (-75 only)

RESSURE-.

HIGH HEAT

AIR

ORIFICE

z-/"

COLD HEADER

(COLLECTOR)

BOX

DOOR INTERLOCK SWITCH

4. SUPPLY

S/" _ BLOWER

CONDENSERCOIL

CONTROL TRANSFORMER

CONTROL VOLTAGE

CIRCUIT BREAKER

TWO-STAGE CONTROL BOARD

LBOARD

AIR

FIGURE 1

Page 3

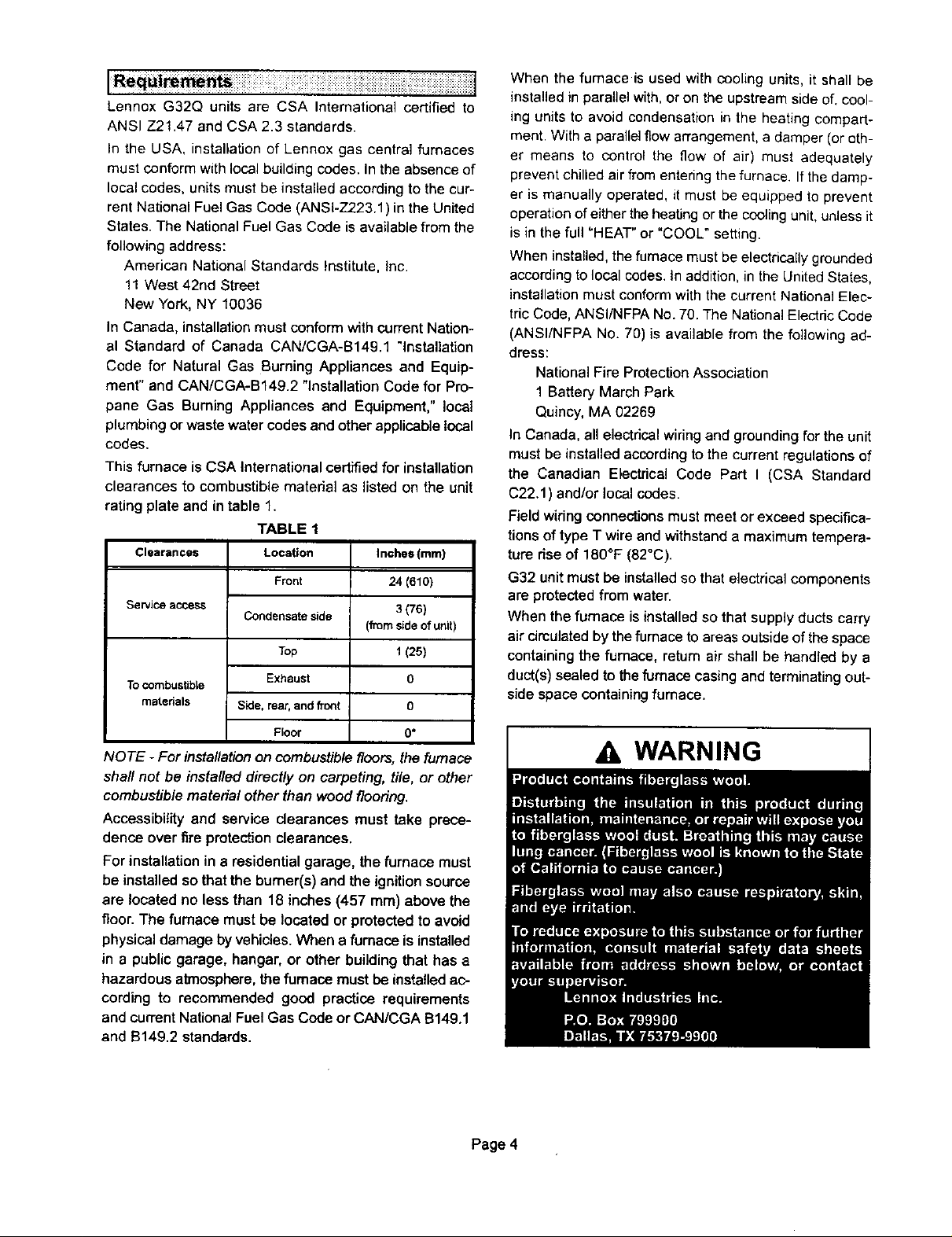

Lennox G32Q units are CSA International certified to

ANSI Z21.47 and CSA 2.3 standards.

In the USA, installation of Lennox gas central furnaces

must conform with local building codes. In the absence of

local codes, units must be installed according to the cur-

rent National Fuel Gas Code (ANSI-Z223.1) in the United

States. The National Fuel Gas Code is available from the

following address:

Amedcan National Standards Institute, Inc.

11 West 42rid Street

New York, NY 10036

In Canada, installation must conform with current Nation-

al Standard of Canada CAN/CGA-B149.1 "Installation

Code for Natural Gas Burning Appliances and Equip-

ment" and CAN/CGA-B149.2 "Installation Code for Pro-

pane Gas Burning Appliances and Equipment," local

plumbing or waste water codes and other applicable local

codes.

This furnace is CSA International certified for installation

clearances to combustible matedal as listed on the unit

rating plate and in table 1.

TABLE 1

Clearances Location

Front

Service access

To combustible

materials Side, rear,and front

Condensate side

Top

Exhaust

Floor

Inches(mrn)

24 (610)

3(76)

(fromsideofunit)

1(2s)

0

0

0*

NOTE -For installation on combustiblefleers, the furnace

shaft not be installed directly on carpeting, tile, or other

combustible material other than wood flooring.

Accessibility and service clearances must take prece-

dence over fire protectionclearances.

For installation in a residential garage, the furnace must

be installed so that the burner(s) and the ignition source

are located no less than 18 inches(457 mm) above the

floor. The furnace must be located or protected to avoid

physical damage by vehicles. When e furnace is installed

in a public garage, hangar, or other building that has a

hazardous atmosphere,the fumace mustbe installed ac-

cording to recommended good practice requirements

and current National Fuel Gas Code or CAN/CGA B149.1

and B149.2 standards.

When the furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of. cool-

ing units to avoid condensation in the heating compart-

ment. With a parallel flow arrangement, a damper (or oth-

er means to control the flow of air) must adequately

prevent chilled air from entering the furnace. If the damp-

er is manually operated, it must be equipped to prevent

operation of either the heating or the cooling unit, unless it

is in the full =HEAT" or "COOL" setting.

When installed, the furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National Elec-

tric Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following ad-

dress:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

In Canada, all electrical wiring and grounding for the unit

must be installed according to the current regulations of

the Canadian Electrical Code Part I (CSA Standard

C22.1 ) and/or local codes.

Field widng connections must meet or exceed specifica-

tions of type T wire and withstand a maximum tempera-

ture dee of 180°F (82°C).

G32 unit must be installed so that electrical components

are protected from water.

When the furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside of the space

containing the furnace, return air shall be handled by a

duct(s) sealed to the furnace casing and terminating out-

side space containing furnace.

A WARNING

Page 4

NOTE - G32 senes units must not be used as a construc-

tion heater dunng any phase of construction. Very low re.

turn air temperatures, harmful vapors and misplacement

of the filters will damage the unit and lower its efficiency.

The G32Q is an upflow gas furnace. A changeover kit

is necessary if the furnace is to be used with L.P. gas,

These instructions are intended as a general guide and

do not supersede Focal codes in any way. Consult authori-

ties having jurisdiction before installation.

Shipping and Packing List

1 - Assembled G32 furnace

1 - 3 inch x 2 inch vent transition piece (-100, -125

units only)

1 - Bag assembly containing:

1 - Electrical make-up box

1 - Widng harness

1 - Snap bushing

2 - Filter clips

1 - Condensate plug

1 - Condensate drain adapter

1 - Brown accessory wire

1 - Green ground wire

4 - Wire nuts

2 - Star washers and screws

8 - Self-tapping screws

1 - Grounding label

1 - Wire tie

3 - Thread-forming screws

Shipping Damage

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

I Insta!iatton' Setttng Equipment

Select a location that allows for required clearances listed

on the unit rating plate. Also consider gas supply connec-

tions, electrical supply, vent connection and installation

and service clearances [24 inches (610 mm) at unit front].

The furnace must be level.

NOTE - 1/3 and 1/2 hp blower motors are equipped with

either four flexible mounting legs or three flexible legs and

one ngid leg. The ngid leg is equipped with a shipping bolt

and a flat white plastic washer (rather than the rubber

mounting grommet used with a flexible mounting leg).

This shipping bolt and flat washer must be removed be-

fore the furnace is put into operation. Once the sh_pping

bolt and washer are removed, the rigid leg will not touch

the blower housing.

_ CAUTION

[ . WARNING I

WARNING

WARNING

Returnaircan be brought ineithersideor atthe bottomof

the unit.Scdbelinesshowthe outlineofeach sideandthe

bottom return air opening.

Page 5

Bottom Return Air Applications

If return air is to terminate through the floor under the fur-

nace, a direct, airtight and sealed connection must be

made to the bottom of the furnace,

1 - Cut opening in floor or platform. Using knockouts

provided, cut bottom of base panel. See figure 2.

KNOCKOUT PATTERN FOR BOTTOM

RETURN AIR APPLICATION

,v vd

iV Vd

_

Bottom Return Air Applications

1 - Remove blower access panel.

2- Install filter clips, provided with unit, by slipping

folded section of clip on edge of bottom opening. See

figure 4.

3 - Place filter in bottom of blower compartment beneath

rear filter clip. Press down on filter sides. Filter clips

flex allowing filter to snap into place.

4 - To remove filter, press clip and pull filter up and out.

BOTTOM RETURN FILTER INSTALLATION

REAR FILT R CLIP

URNACE

BACK

FIGURE 2

2 - Bend a flange on return air plenum and lower into

floor or platform opening, See figure 3.

3 - Position unit over return air opening. Seal unit air

tight with return air plenum•

BOTTOM RETURN AIR APPLICATION

G32 UNIT

RETURN AIR

PLENUM

PROPERLY

SIZED FLOOR

OPENING

FIGURE 3

NOTE - Be cerefu/ not to damage insulation. Check for

tight seal,

Side Return Air Applications

For installationswhere the return air is taken fl'oma retum

airdrop,unitmay be installed with mtum airentl_ through

eitherthe left or rightside of thefurnace.

For sidereturnair applications,cutfurnace cabinetat the

dimensionsgivenon page 2. Embossedcomers are pro-

vided onbothcabinet sidesfor returnairopeninglocation.

i_ii_!'2'i:i:i_:"i:ii:i:i:;'i:!:11:71:i:7i:i:7!:;:i!:ii:ii;ii'i:ii'i:_;:""_'::<"_i:":i_i_ii,ii_::i:!Ti:i;_;:7:%TiJ;:::tT;;:::7:7

This unitis not equippedwith a filteror rack.A field-pro-

videdhigh-velocityfilteris requiredforthe unitto operate

properly.A filter must be in place any time the unit is

operating. The unit does include filter clips for instal-

lation of a field-provided, internally installed filter.

See figure 4.

SIDE _

FURNACE FURNACE

FIGURE 4

Side Return Air Applications

Filter racks are available fromLennoxfor side returnair

applications.See figures5 and 6.

NOTE - Thefilter doormay be shipped in therack behind

thefilter./fnecessa_ remove the filter, retrieve the door

and continuewiththe installationof the rack.

1 - Align filterrack opening withthe inside edge of the

side return opening. Bottom of rack should be

approximately1 inch(25 mm) fromthe bottom and 3

inches(76 mm) from the frontof the unit.

2 - Screw filter rack intoplacewiththe eightselfddll,self

tap screws provided.See figure 5.

3 - Push filter door pinsthrough the two holes in filter

doorfrom the insideof the u-channel. See figure 6.

SIDE RETURN FILTER INSTALLATION

in.(turn)

BLOWER DECK _=

RETURN AIR

RETURN 12 in. (305) for

AIR 14 in. 13561Filter

OPENING t8 In. (437) for

20 in, (508) Filter

1-13/t6in.

cAa,NETBASEI; .OM,I

PLENUM SIZE

12-314 In X 23-1/2 In (324 X

597) for 14 In (356) Filter

18-3/4 In. x 23-1/2 In,

(476 x 507)

for 20 In. 1508) Filter

(34)

FIGURE 5

Page 6

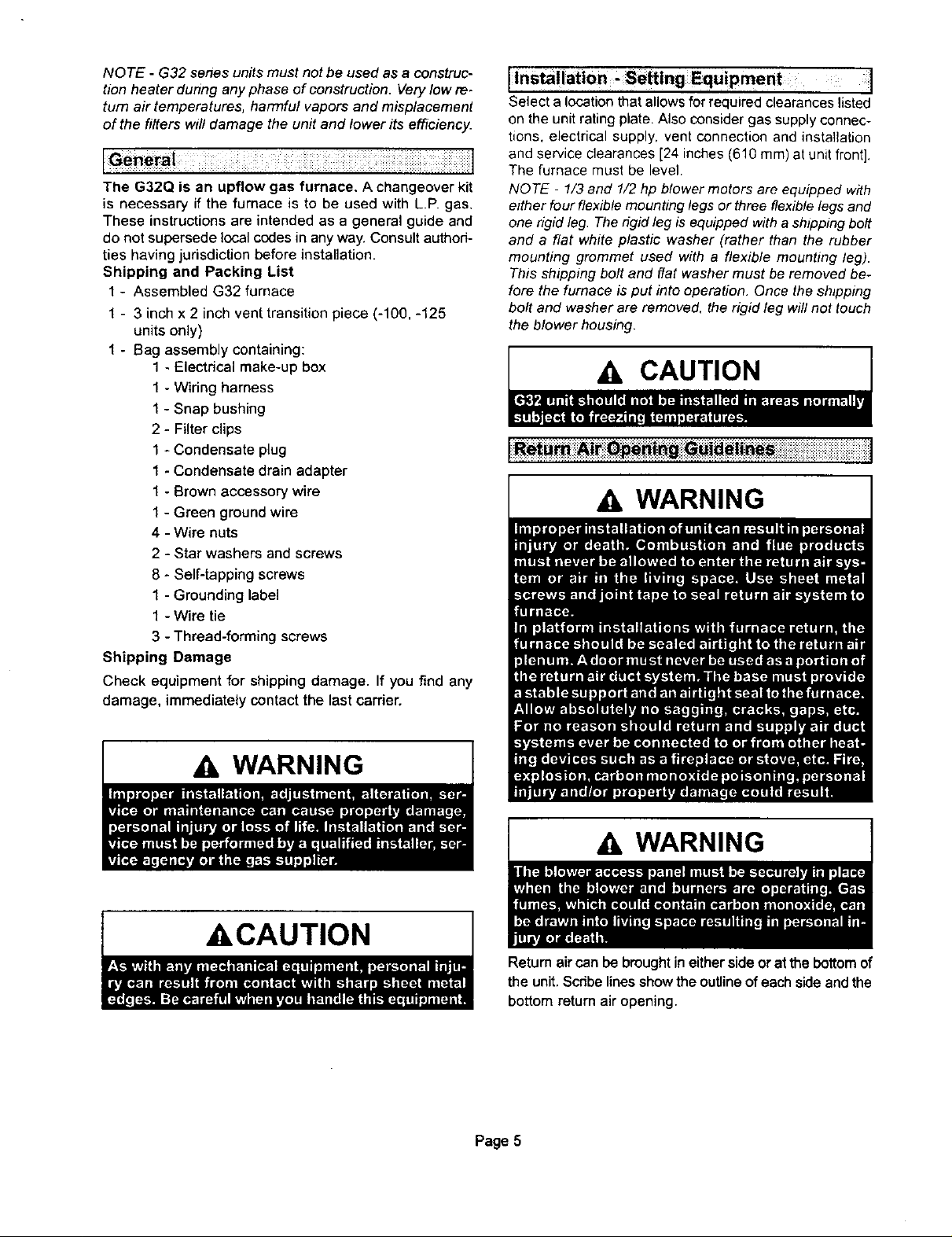

FILTER DOOR ASSEMBLY

FILTER DO0_ _

PIN _T_ TAB

FILTER DOOR I I I _'l]l

FILTER

FIGURE 6

4 - Positionfilter door on end offilter so that the thumb

tab side of the filter door is away from the furnace.

Squeeze thumb tabs to secure filter to door.

5 - Guide filter and filter door into the filter rack installed

on side of furnace. Push door into filter rack until se-

cure.

6 - To remove filter,pull filterdoor pins untildoor is re-

leased from filter rack,

Use industry-approved standards to size and install the

supply and return air duct system. This will resultin a quiet

and low-static system that has uniform air distribution.

Supply Air Plenum

Furnaces installedwithout acoolingcoilrequirethe installa-

tion of aremovable access panel inthe supplyair ducL The

access panel should be large enough to permit inspection

(either by smoke or reflectedlight) ofthe heatexchanger for

leaksafter installation. The furnace access panel must al-

ways be in placewhen the furnace is operatingand it must

not allow leaks into the supply air duct system.

Return Air Plenum

See dimensionillustrationon page 2 for properreturnair

duct size.

NOTE - For bottomreturn air, returnairductshouldbe se-

curedto the unit usingrivets or Sqocks. For side return

air,secure return airduct to filterrackusingscrews. When

using screws, take care to avoid interference with the fil-

ter which may cause improper filtration.

The return air must not be drawn from a room where

another gas appliance (ie,, a water heater) is

installed. Even thoughthisfurnace draws its combustion

air from outside of the structure, other gas appliances that

share a utility room may not. When retum air is drawn

from a room, a negative pressure is created in the room. If

a gas appliance is operating in a room with negative pres-

sure, the flueproducts can be pulled back down the vent

pipe and into the room. This reverse flow of the flue gas

may result in incomplete combustion and the formation of

carbon monoxide gas. This toxic gas might then be dis-

tributed through the house by the furnace duct system.

Pipe & _tttings S _¢ifi_ti_

J :::%:::::::::::::::: ::: : ::

All pipe,fittings,primerand solventcementmust conform

withAmericanNationalStandard Instituteand theAmeri-

can Society for Testingand Materials (ANSI/ASTM) stan-

dards. The solvent shall be free flowing and contain no

lumps, undissolved particles or any foreign matter that

adversely affectsthejoint strength or chemical resistance

of thecement. The cement shall show no gelation, stratifi-

cation, or separation that cannot be removed by stining.

Refer to table 2 for approved piping and fitting materials.

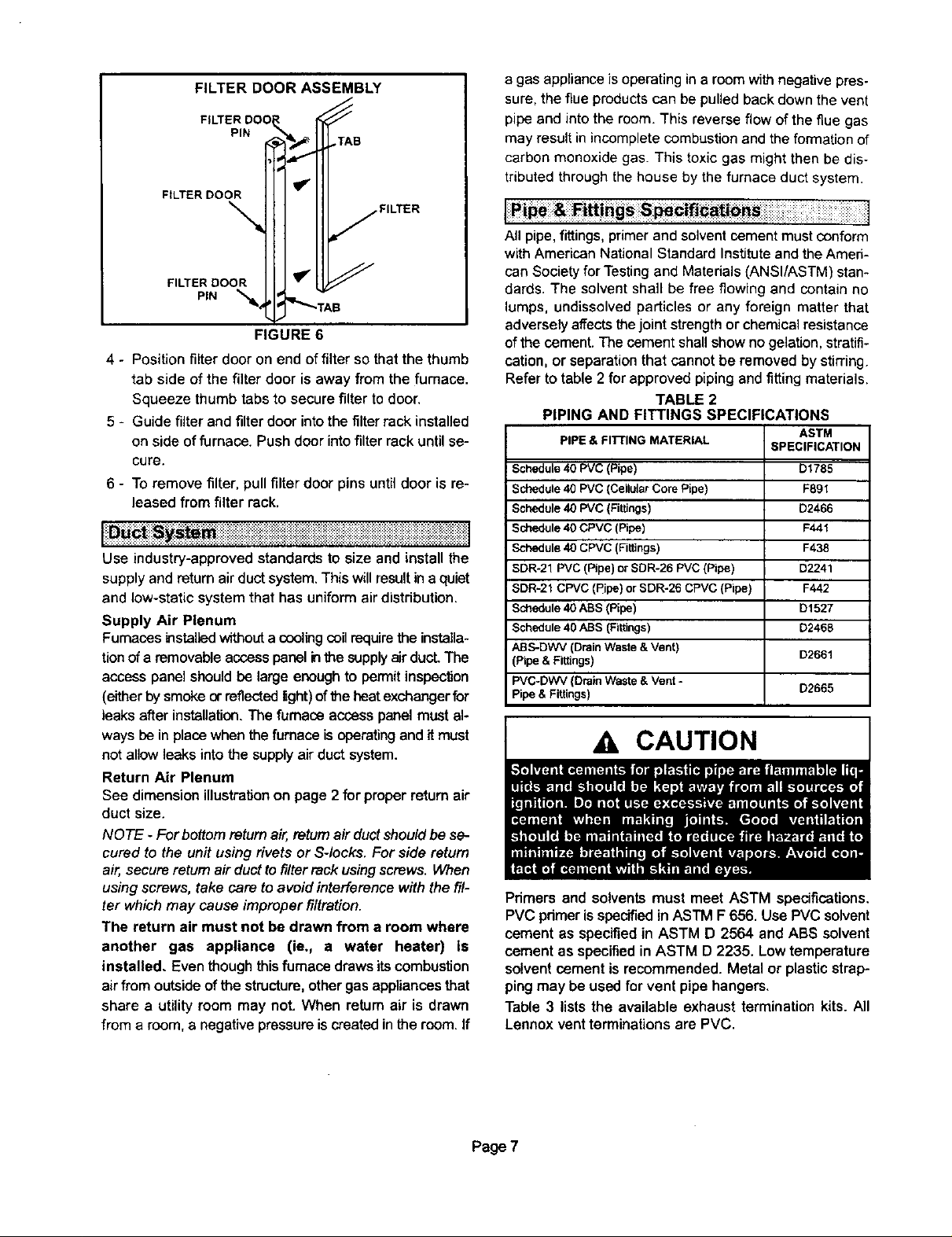

TABLE 2

PIPING AND FITTINGS SPECIFICATIONS

PIPE & FITrlNG MATERIAL SPECIFICATION

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (CellularCore Pipe) F89t

Schedule 40 PVC (Fittings) D2466

Schedule40 CPVC (Pipe) F441

Schedule 40 CPVC (Fittings) F438

SDR-21 PVC (Pipe)or SDR-26 PVC (Pipe) D2241

SDR-21 CPVC (Pipe)or SDR-26 CPVC (Pipe) F442

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings) D2661

PVC-DWV (Drain Waste & Vent - D2665

Pipe & Fittings)

ASTM

A CAUTION

Primers and solventsmust meet ASTM specifications,

PVC pdrnerisspecifiedin ASTM F 656. UsePVC solvent

cement as specified in ASTM D 2564 and ABS solvent

cement as specified in ASTM D 2235. Low temperature

solvent cement is recommended. Metal or plastic strap-

ping may be used for vent pipe hangers.

Table 3 liststhe available exhaust termination kits. All

Lennox vent terminations are PVC.

]

Page 7

TABLE 3

TERMINATION KITS

Lennox Part

No.

60G77

33K97

15F75

22G44

15F74

44J41

44J40

30G28

30G79

Kit LB# Description*Inches (ram)

LB-49107CE

LB-87942

LB-49107CC

LB-49107CD

LB_9107CB

LB-65678A

LB-65701A

WTK

WTKX

1-1/2" (38) Concentric

Termination Kit

3" (50,8) Low Pressure Drop

Concentric Term Kit

2" (50,8) Roof

Termination Kit

2" (50.8) Well

Assembly Termination Kit

2" (50.8) Walt Ring Kit

3" (76,2) Roof

Termination Kit

3" (76.2) Wall

Assembly TerminationKit

2" (50.8) Wall

TerminationExtendedVent

2" (50.6) Wall

TerminationExtensionRiser

When making ABSjoints, pieces can be prepared with a

cleaner. When joining ABS to PVC matedals, use PVC

solvent cement. Refer to this procedure as specified in

ASTM D3138.

Canada Only - In some provinces, PVC primer must be

purple in color, PVC solvent cement must be grey, ABS

solvent cement must be yellow and PVC solvent cement

used when joining ABS to PVC must be white.

[

:: ::,::.:_::: : :: ::.::..: :.:::::::::: .::::::.:::::::::::::::::.:::::::::::::::::;:. :::_:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::: :: :: ::.:]

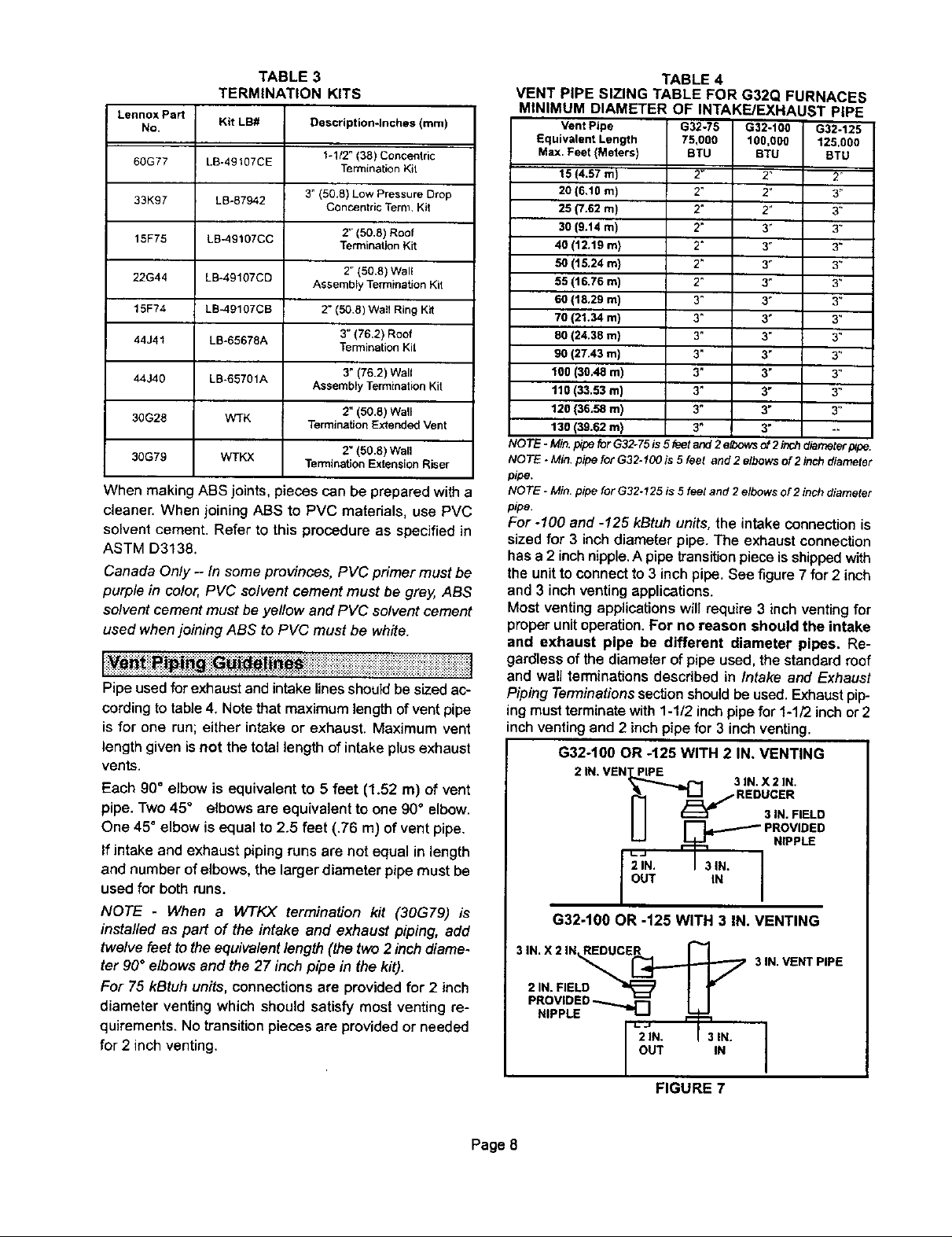

Pipe used for exhaust and intake lines should be sized ac-

cording to table 4. Note that maximum lengthof vent pipe

is for one run; either intake or exhaust. Maximum vent

length given isnot the total length of intake plus exhaust

vents.

Each 90° elbow is equivalent to 5 feet (1.52 m) of vent

pipe. Two 45° elbows are equivalent to one 90° elbow.

One 45° elbow is equal to 2.5 feet (.76 m) of vent pipe.

If intake and exhaust piping runs are not equal in length

and number of elbows, the larger diameter pipe must be

used for both runs.

NOTE - When a WTKX terminaUon kit (30G79) is

installed as part of the intake and exhaust piping, add

twelve feet to the equivalent length (the two 2 inch diame-

ter 90° elbows end the 27 inch pipe in the kit).

For 75 kBtuh units, connections are provided for 2 inch

diameter venting which should satisfy most venting re-

quirements. No transition piecesare provided or needed

for 2 inch venting.

TABLE 4

VENT PIPE SIZING TABLE FOR G32Q FURNACES

MINIMUM DIAMETER OF INTAKE/EXHAUST PIPE

Vent Pipe

Equivalent Length

Max. Feet (Meters)

15 (4.57 m)

20 (6,10 m)

25 (7.62 m)

30 (9.14 m)

40 (12.19 m)

50 (I 5.24 m)

55 (16.76 m)

60 (18,29 m)

70 (21,34 rn)

80 (24.38 m)

90 (27.43 m)

100 (30.48 m)

110 (33,53 m)

120 (36.58 m)

130 (39.62 m)

NOTE - Min. pipeforG32-75 is 5feet and 2elbowsof 2inchdmmeterp_pe.

NOTE - Min. pipe for G32-100 is 5feet end 2 elbowsof 2 inch diameter

pipe,

NOTE - Min. pipe for G32-125 is 5 feet and 2 e/bows of 2 inchdiameter

pipe.

G32-76 G32-100 G32-125

75,000 100,000 125.000

BTU BTU BTU

2" 2" 2'

2" 2" 3"

2" 2" 3"

2" 3" 3_

2" 3" 3"

2" 3" 3"

2" 3" 3"

3" 3" 3"

3" 3" 3"

3" 3" 3"

3" 3" 3"

3" 3" 3"

3" 3" 3"

3" 3" 3"

3" 3" --

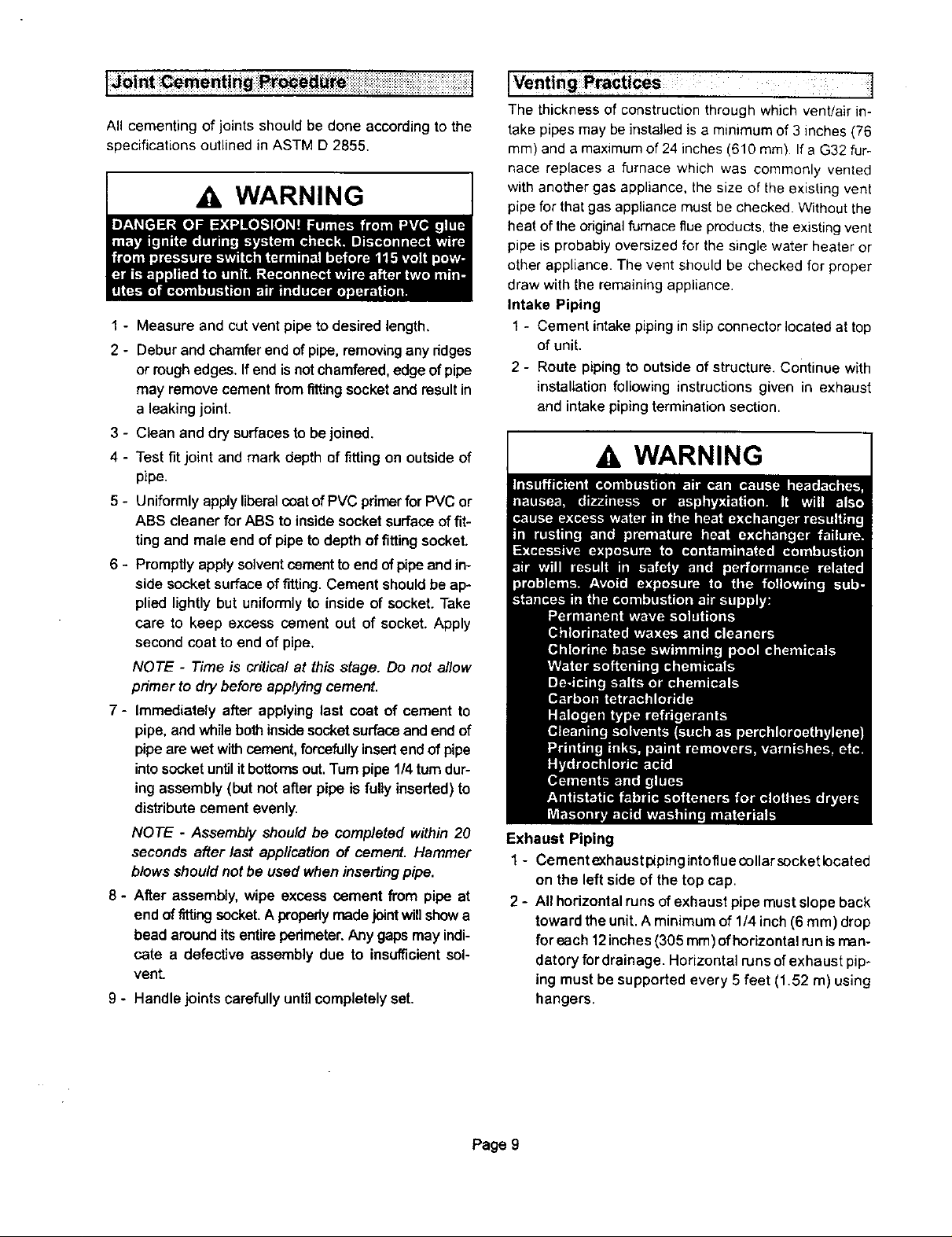

For -100 and -125 kBtuhunits,the intakeconnectionis

sized for 3 inch diameter pipe. The exhaustconnection

has a 2 inchnipple,A pipetransitionpieceis shippedwith

the unitto connectto 3 inchpipe. See figure7 for2 inch

and 3 inchventingapplications.

Most venting applicationswillrequire 3 inchventingfor

properunitoperation.For no reason should the intake

and exhaust pipe be different diameter pipes. Re-

gardlessofthe diameterofpipe used, the standardroof

l

and wail terminationsdescribed in Intake and Exhaust

Piping Terminations sectionshouldbe used.Exhaustpip-

ingmust terminatewith 1-1/2 inchpipefor 1-1/2 inchor 2

inchventingand 2 inch pipe for 3 inchventing.

G32-100 OR -125 WITH 2 IN. VENTING

2 IN. VEN_] 3RIIENI_X C2EIN,

2IN. I 3IN.

OUT N

G32-100 OR -125 WITH 3 IN. VENTING

3 IN. VENT PiPE

L_I

NIPPLE ,..,

OUT IN

FIGURE 7

I

Page 8

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

1 - Measure and cut vent pipe to desired length.

2 - Debur and chamfer end of pipe, removingany ddges

or rough edges. If end is notchamfered, edge of pipe

may remove cement fTomfitting socket and result in

a leaking joint.

3 - Clean and dry surfaces to be joined.

4 - Test fit joint and mark depth offitting on outside of

pipe.

5 - Uniformly applyliberal coatof PVC primer for PVC or

ABS cleaner for ABS to inside socket surface of fit-

ting and male end of pipe to depth of fitting socket.

6 - Promptly apply solvent cement to end of pipeand in-

side socket surface of fitting. Cement should beap-

plied lightly but uniformly to inside of socket. Take

care to keep excess cement out of socket. Apply

second coat to end of pipe.

NOTE - Time is critical at this stage. Do not allow

pnmer to dry before applying cement.

7 - Immediately after applying last coat of cement to

pipe, and while both inside socketsurface and end of

pipe are wet with cement, forcefully insert endof pipe

intosocket until it bottoms out. Turn pipe 1/4turn dur-

ing assembly (but not after pipe is fully inserted) to

distribute cement evenly.

NOTE - Assembly should be completed within 20

seconds after last application of cement. Hammer

blows should not be used when inse_ng pipe.

8 - After assembly, wipe excess cement from pipe at

end of fitting socket.A properlymadejointwillshowa

bead around itsentireperimeter. Anygaps may indi-

cate a defective assembly due to insufficientsol-

vent.

9 - Handle joints carefully untilcompletelyset.

Iventing ractl es

The thickness of construction through which vent!air in-

take pipes may be installed is a minimum of 3inches (76

mm) and a maximum of 24 inches (610 mm). If a G32 fur-

nace replaces a furnace which was commonly vented

with another gas appliance, the size of the existing vent

pipe for that gas appliance must be checked. Without the

heat of the originalfurnace flue products, the existing vent

pipe is probably oversized for the single water heater or

other appliance. The vent should be checked for proper

draw with the remaining appliance,

Intake Piping

1 - Cement intakepipinginslip connectorlocated at top

of unit.

2 - Route pipingto outside of structure.Continue with

installationfollowing instructionsgiven in exhaust

and intakepipingterminationsection.

WARNING

Exhaust Piping

1- Cemente_(haustpipthgintofluecollarsocketloceted

on the left side of the top cap.

2 - All horizontalruns ofexhaust pipe mustslopeback

towardthe unit.A minimumof 1/4 inch(6 ram) drop

for each 12inches(305 mm) ofhorizontalrunisman-

datory fordrainage. Horizontal runs ofexhaust pip*

ing mustbe supported every 5 feet (1.52 m) using

hangers.

Page 9

NOTE - Exhaust piping should be checked carefully

to make sure there are no sags or low spots.

NOTE - Exhaust piping must be Insulated wffh 1/2 inch

(13 ram) Armaflex or equivalent when nJn through un-

heated space. Do not leave any area of exhaust pipe

open to outside air. extenor exhaust must be insulated

wrth 1/2 inch (13 ram) Armaflex or equivalent.

{

Zl, CAUTION

CAUTION

Removal of Unit from Common Venting System

In the event thatan existing furnace is removed from a

venting system commonly run with separate gas ap-

pliances, the venting system may be too largeto property

vent the remaining attached appliances. The following

test should be conducted while all appliances (beth inop-

eration and those not in operation) are connected to the

common venting system.If the venting system has been

installed improperly, corrections must be made as out-

lined in the previous section.

1 - Seal any unused openings in the common venting

system.

2 - Visually inspect the venting system for proper size

and horizontal pitchand determinethere is noblock-

age or restdction,leakage, corrosionor other defi-

ciencieswhich couldcause an unsafe condition.

3 - To the extent that it is practical, close all building

doors andwindows,and alldoorsbetweenthe space

in which the appliancesremainingconnectedto the

common venting system are located and other

spaces of the building. Turn on clothes dryers and

any appliancesnot connectedto the common vent-

ing system. Turn on any exhaust fans, suchas range

hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer ex-

haust fan. Close fireplace dampers.

4 - Follow the lightinginstructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5 - Testfor spillage at thedraft hood relief openingafter

5 minutes of main burner operation. Usethe flame of

match or candle, or smoke from a cigarette or cigar,

or a draftgauge.

6- After determining that each appliance remaining

connected to the common venting system properly

vents when tested as indicated in step 3, return

doors, windows, exhaust fans, fireplace dampers

and any other gas-burning appliance to their pre-

I

vious condition of use.

7 - If improper venting is observed dudng any of the

above tests, the common venting system must be

corrected. The common venting system shouldbe

resized to approach the minimum size as deter-

mined by using the appropriate tables in appendixG

in the current standards of the National Fuel Gas

Code ANSI Z223-1 in the USA, and the appropriate

Category 1 Natural Gas appliances venting sizing

tables in the current standard of the CAN/

CGA-B149.1 in the Natural Gas InstalLationCode in

Canada.

Intake and Exhaust Piping Terminations

Intake and exhaustpipesmay be routedeitherhorizontal-

lythrough an outsidewallor verticallythroughthe roof.In

attic or closet instaUations,verticalterminationthrough

the roofis preferred. Figures 8 through20 show typical

terminations.

1 - Use recommendedpiping materials for both intake

and exhaust piping.

2 - Secure all joints,includingdrain leg, gas tightusing

approvedcement.

3 - Pipingdiametersshouldbe determinedaccordingto

length of pipe run.See table 4. Locate intakepiping

upwind (prevailing wind) from exhaust piping. To

avoid recirculation of exhaust gas on roof termina-

tions, end of exhaust pipe must be higher than intake

pipe.

Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roof and oneon the

side. Also, do not exittheintake on one sideand the

exhaust on another side of the house or structure.

4 - intake andexhaust pipes should be placed as close

together as possible at termination end (refer to il-

lustrations). Maximum separation is 3 inches (76

ram) on roof terminations and 6 inches (152 ram)on

sidewall terminations.

5 - Exhaustpipingmust terminate straightout or up as

shown, tn rooftopapplications,a 2 inchX 1-1/2 inch

reducer for 2 inch venting,3 inch x 2 inch reducerfor

3 inch venting must be used on the exhaust piping at

the point where it exits the structure to improve the

velocity of exhaust away from the intakepiping.

Page 10

On roof terminations, the intake piping should termi-

natestraight down using two 90° elbows.See figure 8.

NOTE - If winter design temperature is below 32°F (O°C),

exhaust piping must be insulated with 1/2 inch (13 mm)

Armaflex or equivalent when run through unheated

space. Do not leave any surface area of exhaust pipe

open to outside air," exterior exhaust pipe must be insu-

lated with 1/2 inch (13 ram) Armaflex or equivalent. In ex-

treme cold climate areas, 3/4 inch (19 mm) Armaflex or

equivalent is recommended. Insulation on outside runs of

exhaust pipe must be painted or wrapped to protect in-

sulation from deterioration.

NOTE - During extremely cold temperatures, below

approximately 20°F (6.67°C), units with long runs of vent

pipe through unconditioned space, even when insulated,

may form ice in the exhaust termination that prevents the

unit from operating properly. Longer run times of at least 5

minutes will alleviate most icing problems. Also, a heating

cable may be installed on exhaust piping and termination

to prevent freeze-ups. Heating cable installation kit is

available from Lennox. See Condensate Piping section

for part numbers.

NOTE - Care must be taken to avoid recirculation of ex-

haust back into intake pipe.

6 - On field-supplied terminations for side wall exits, ex-

haust piping should extend a maximum of 12 inches

(305 mm) beyond the outside wall. Intake piping

should be as short as possible. See figure 10.

Inches (ram) 3 x 2 (70 x 51) OR

12 (305) ABOVE SPACE

ACCUMULATION

AVERAGE SNOW

3 (76) OR UNCONDmONED

2 (5t) PVC ATTIC SPACE

PROVIDE SUPPORT

FOR INTAKE AND

F.XHAUST LINES

(15F'75)LB-49107CCfor2 (5t) Venting

(44341)LB-65678Afor 3 (76)Venting

IMAX.

2 x %1/2 (51 x 38)

PVC REDUCER

ROOFTERMINATIONKIT

FIGURE 8

1/2 (13) FOAM

INSULATION IN

UNCONDrrlONED

EXHAUST

INTAKE

TERMINATION

EXHAUST INTAKE

CONCENTRIC ROOFTOP TERMINATION

(60G77) LB-49107CE for G32-75 Units Only

(33K97) LB-87942 for G32-100 & -125 Units Only

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

Inches (mm)

FIGURE 9

1/2 (13) ARMAFLEX

INSULATION IN

UNCONDITIONED SPACE

1/2 (13) ARMAFLEX t'

INSULATION

OUTSIDE j

WALL

Inches (ram)

(15J74) LB-49107CBfor2 (50,8! Venting

TOPVIEW

WALLRINGKIT

12 (305) MIN.

2 X 1-1/2

(51 X 38)

PV REDUCER

_ _ 'VC

I 6 (I 52)

MAXIMUM

_ 2 (_ I PVC

PLING

FIGURE 10

7-

On field-supplied terminations, a minimum separa-

tion distance between the end of the exhaust pipe

and the end of the intake pipe is 8 inches (203 mm).

8-

If intake and exhaust piping must be run up a side

wall to position above snow accumulation or other

obstructions, the piping must be supported every 3

feet (.91 m) as shown in figure 15.Refer to figures 13

and 14 for proper piping method. W'FKwall termina-

tion kit must be extended for use inthis application,

See figure 18 or use kit WTKX shown in figure 19.

When exhaust and intake piping must be run up an

outside wall, the exhaust piping is reduced to 1-1/2

inches (38 mm) after the final elbow. The intake pip-

ing may be equipped with a 90°elbow turndown. Us-

ing 90° turndown will add 5 feet (1.5m) to the equiva-

lent length of the pipe.

Page 11

1/2 (12.7) FOAM INSULATION

IN UNCONDITIONED SPACE

n

qlp

TOPVIEW

WALLTERMINATION

(22G44)LB-49107CDfor2 (50,8)Venting

(44J40)LB-65701Afor3 (76.2)Venting

FIGURE 11

TERMINATION

EXHAUST

INTAKE

Inches (ram)

CONCENTRIC WALL TERMINATION

(60G77) LB-49107CE for G32-75 Units Only

(331(97) LB-87942 for G32-t00 & -125 Units Only

FIGURE 12

Inches (mm)

OUTSIDEWALL

Optional Turndown

Shown

(Intake Onty)

EXHAUST

abovegrade,

courtyard areas or other recessed areas. Do not

position termination ends directly below roof eaves

or above a walkway. Since the G32 is a certified di-

rect vent, Category iV gas furnace, the location of

the termination is limited by local building codes. In

the absence of local codes, refer to the current Na-

tional Fuel Gas Code ANSI Z223-1 in USA, and cur-

rent standard CAN/CGA-B149.1 of the Natural Gas

Installation Instructions in Canada for details. The

termination should be at least 12 inches (305 mm)

from any opening through which flue products could

enter the building.

When horizontally vented, minimum clearance for

termination from electric meters, gas meters, regula-

tors and relief equipment is 4 feet (1.2 m) for US

installations. Refer to the current CAN/CGA-B149.1

for installations in Canada or with authorities having

local jurisdiction.

At vent termination, care must be taken to maintain

protective coatings over building materials (pro-

longed exposure to exhaust condensate can destroy

protective coatings). It is recommended that the ex-

haust outlet not be located within 6 feet (1.8 m) of a

condensing unit because the condensate can dam-

age the painted coating.

Inches(mm)

UNCONDITIONED

SPACE

OUTSIDE WALL

PROVIDE SUPPORT

FOR INTAKE AND /

EXHAUST UNES EVERY

3_(914)

1/2113) FOAM

INSULATION IN

UNCONOmONED

SPACE

(15F74)LE-49107CBfor2 In. (51)Venting

See v.ntlng table 4 for maglng_ venting lengths with this Irmr:l_mant.

SiDEVIEW

WALLRINGTERMINATION

12 (305) MIN for2 (51)

20(5oa)MAXfor3(76):

F

HI II t2(S_0)ASOVE

Ii2 (131FOAM

INSULATION

FIGURE 13

9 - Position terminationends so they are free from any

obstructions and abovethe level ofsnowaccumula-

tion (where applicable). Termination ends must be a

minimum of 12 inches (305 mm) above grade level.

Do not point into window wells, stairwells, alcoves,

10 - Suspend piping using hangers at a minimum ofevery

5 feet (1.52 m) for schedule 40 PVC and every 3 feet

(.91 m) for ABS-DWV, PVC-DWV, SDR-21 PVC,

and SDR-26 PVC piping. A suitable hanger can be

fabricated by using metal or plastic strapping or a

large wire tie.

11 - In areas where piping penetrates joists or interior

walls, hole must be large enough to allow clearance

on all sides of pipe as it passes through the center of

the hole.

12 - Isolate piping at the point where it exits the outside

wall or roof.

Page 12

Inches(turn) 1/2 (13) 3 x 2 {76 x 51) OR

3 (76) OR FOR OFFSET TERMINATION

2 (51) 90_ELBOW

Optional Turndown _ _ 2 (5t) 90" ELBOW

(Not Shown)

May Be Used on

Intake Only FRONT VIEW

FOAM 2 x 1.t/2 (61 x 36)

INSULATION REDUCER BUSHING LOCATION

3 (76) OR

WALL TERMINATION

(22G44) LB-49107CD for 2(51) Venting

(44J40) LB-65701A for 3(76) Venting

FIGURE 14

METALOR PLASTIC

STRAPPING

FIGURE 15

13 - When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a

vacation home, make provisions for draining con-

densate collection trap and lines.

14 - Based on the recommendation of the manufacturer,

a multiplefurnace installation may use a group of up

to four termination kits WTK assembled together

horizontally, as shown in figure 17.

Front View _,_, "_'l/EXHAUST VENT

Front View EXHAUST

18M

i EXHAUST VENT

Side View_

Inches (ram) • INTAKE

VENT

OPTIONAL VENT TERMINATION FOR

MULTIPLE UNIT INSTALLATION

WALL TERMINATION KIT WTK

FIGURE 17

Front View

INTAKE

AIR

1127)..L

IZ

(3os)

5

COVER EXHAUST

EXHAUST

GRADE

//// EXHAARUS_ SideView

_--T_-- ----n

// (('-_-_-_" II

INTAKE

AIR

/ / @1 812031

/ / I_=_,,,I,,,=_l Inches (ram)

//,ii II r'--r

lJil,

12

VENT WITH

1/2(13)

FOAM

INSULATION

AIR

t 2 MIN

(30_)

Above Grade

1/2 (13) Foam

Insulation in

Unconditioned _ace F

Inches (mm) L_

VENT TERMINATIONS

WALL TERMINATION KIT 130G28) WTK

FIGURE t6

Side View

EXHAUST VEN_

INTAKE VENT

OUTSIDE WALL

Page 13

/ / Mn}mum

/ / ABO'_GPJmE

, GRADE

VENT TERMINATIONS

MODEL WTK WALL TERMINATION KIT (30G28)

EXTENDED VENT FOR GRADE CLEARANCE

FIGURE 18

Inches (mm)

Front View

9

I '10" VENT

= _ NOTE - Enclosed ex_us_ pipe _s

[

INTAKE foam insu_abon If in_al(ear_ ex-

VENT hsusl I_pes am reversed, sl=land

34

_,EXHAUST

insuleted w;th _F2 i,_Ch(13 ram)

r_move foam instJlat_ot_ and

vent mr=st be insulated

freezing of the condensate, which would block the drain-

line. Use an electric heat cable if you route the conden-

sate line through unconditioned areas.

A CAUTION

Ii teat)ply to OUmr vent Exhaust

Side View

EXTENSION RISER FOR GRADE CLEARANCE

4

USTVENT

o

iNTAKE

VENT

E

VENT TERMINATIONS

MODEL WTKX (30GT9)

FIGURE 19

G32Q VENTING IN EXISTING CHIMNEY

NOTE - Do not dischal_e exhaust gases dit ently into or vent stack.

II ventCal discharge through at, ex_6ng unused chimney or stack ts require<J,

i_sertpipingintgde chlm,'.eyurdilthepipeopenendIs abovetopof _y and

termimlte as iltusttstad. I. any extedor po(tlon of ¢ilrmney, the exhaust vent must

be insulated.An alternatemethodistoflitthechimneywithvetrmc.ulitoorequal

to take advantage of its acoustic and thermal properties,

FIGURE 20

Condensate Piping

This unit is designed for either right- or left-side exit of

condensate piping. Route the condensate drainiine only

within the conditioned space: this prevents possible

1 - Determine which side condensate will exit the unit.

2- Connect 1/2 inch (13 mm) plastic pipe plug (pro-

vided) in the unused end of the condensate trap.

Install plug so that it is sealed water tight yet able to

be removed. Do not permanently seal the connec-

tion. Teflon tape is recommended to seal joint. See

figure 21.

CONDENSATE ASSEMBLY

(Forleftor rightinstallation)

COLD

COMBUSTION AIR HEADER

INDUCER BRACKET BOX

ADAPTER

ELBOW

CONDENSATE TRAP

NIPPLE BOOTORCAP

ADAPTER

FIGURE 2t

3 - Use the providedcondensate drain adapter (3/4" x

1/2") and a field-providednipple to carry drainage

outside the cabinet. If a fieldsubstitute is needed, 1/2

inch CPVC x 1/2 inch MPT adapter and 1/2 inch

CPVC is acceptable for use.

4 - Glue nipple to the adapter using the procedures out-

lined in the "Joint Cementing Procedures" section.

The nipple/adapter assembly should be connected

in a non-permanentmanner and must be water tight.

Teflon tape is recommended to seal the joint.

For Right-Hand Side Condensate Exit:

Install the nipple/adapter assembly from the out-

side of the cabinet and insert the adapter intothe

threaded opening in the condensate trap.

For Left-Hand Side Condensate Exit:

Insertnipple/adapterassemblyfrom the left hand

side of the cabinet and through the combustion air

inducer mounting structure into the threaded

opening in the condensate trap.

5 - Connect field-supplied plumbing to nipple and route

to open drain. Plumbing should be vented to a point

higher than the condensing coil. See figure 22.

Page14

CONDENSATE PLUMBING

(Plumbing must be vented higher than coll.)

FIGURE 22

6- Connect condensate drain line (1/2 inch [13 mm]

SDR 11 plastic pipe or tubing)to condensate con-

nection on condensate trap assembly and route to

open drain. Condensate line must be sloped down-

ward away from drip legto drain. If the drain level is

above condensate outlet, use a condensate pump to

pump the condensate to the higher level. Conden-

sate drain line should be routed within the condi-

tioned space to avoid freezing of condensate and

blockage of drain line. If this is not possible,a heat

cable kit may be used on the condensate line. Heat-

ing cable kit is available from Lennox in various

lengths; 6 feet (1.8 m) - kit no. 18K48; 24 feet (7.3 m)

- kit no. 18K49; and 50 feet (15.2 m) - kit no. 18K50.

3 - The gas piping must not run in or through air ducts,

clothes chutes, gas vents or chimneys, dumb wait-

ers orelevator shafts. Centergas line through piping

hole. Gas line should not touch side of unit. When

left-hand gas plumbing is required, gas line should

be installed in the lower half of knockout so that pip-

ing will clear combustion air inducer. See figure 24.

4 - The piping should be sloped 1/4inch (6.4mm) per 15

feet (4.57 m) upward toward the meter from the fur-

nace. The piping must be supported at properinter-

vals [every 8to 10feet (2.44 to 3.01 m) using suitable

hangers or straps. A drip leg should be installed in

vertical pipe runs to the unit.

5 - Some local codesmay require installationof a manu-

al main shut-off valve and union (furnished by the in-

staller) external to the unit. Union must be of the

groundjointtype,

II

CAP-_D-I_I U

FIGURE 23

NOTE - Installa 1/8inch NPTplugged tapin the field pip

ing upstream ofthe gas supplyconnection to the unit.The

tap must be accessible for test gauge connection. See

figure 24.

LEFT SIDE PIPING

MANUAL MAIN

SHUT-OFF

VALVE

1 - Gas piping may be muted into the unitthrough either

the left- or right-hand side. Supply piping enters into

the gas valve from the bottom of the valve asshown

in figure 24.

2- When connecting the gas supply, factors such as

length of run, number of fittings and furnace rating

must be considered to avoid excessive pressure

drop. Table 5 lists recommended pipe sizes for typi-

cal applications.

NOTE - Use two wrenches when connecting gas pip-

ing to avoid transferring torque to the manifold.

1/8in. NPT

PLUGGED

TAP

GAS VALVE

.... --I, RIGHT SIDE PIPING

_(.=.___=.-,_t_ (STANDARD)

118In. NPT

PLUGGED

..........................j,AP

GAS VALVE

FIGURE 24

Page 15

GAS PIPE CAPACITY - ft.3/hr Im31hrl

Nominal

Iron Pipe Size

-InchesImm)

t/4

(635)

3/8

(6,53)

(127)

314

(19.05)

1

(254)

1-1/4

(31.75)

Io1/2

(381)

2

(5O.8)

2-112

(83.5)

3

(76.2)

4

(101.6)

NOTE - Capacity j

Internal Length of Pipe-Feet (m)

Diameter 10 20 30 40 50 60 70 80 90 100

.InchesImm) (3.048) (6.096) (9.144) (12.192) 115.2401 (18.288) (21.336) (24.384) (27.432 (30.480)

364 43 29 24 29 18 18 15 14 19 12

(9 246) (1 13) (.82) (68) (.57) (81) (45) ( 401 (40} (3?) (.34)

493 95 65 52 45 40 36 33 31 29 27

(12.5221 (269) (1.84) (1 47) (127) (113) (1.02) (73) (88) (.82) (75)

622 175 120 97 82 73 66 61 57 53 50

(17.799) (496) (340) (2.75) (232) (2.07) (1.87) (173) (101) (1.50) (142)

.824 360 250 200 176 161 138 125 118 110 103

(20.930) (10.19) {706) (566) (4.81) (4.28) (3.91) (3 54) (3.34) (3 11) (292)

1049 680 468 379 320 288 260 240 220 208 !95

(26.645) (19,25) (13.17) (10,62) (9,06) (807) (7.36) (6 90) (6.23) (580) (6.62)

1.380 1400 960 770 660 580 630 490 460 430 400

(35.052) (39.64) (26.90) (21.80) (18,69) (1642) (15.01) (13.67) (13.031 (1218) (11.33)

1.610 21 O0 466 1180 990 900 810 750 690 650 620

(40.894) (59.46) (41.34) (3341) (2803) (2548) (22.94) (2124) (19.54) (1841) (17,56)

2.0_7 3950 2750 2200 1906 1680 1520 1400 1300 1220 1150

(52.502) (111.85) (77,87) (62.30) (5380) (47.57) (43.041 (3964) (36.81) (34.58) (32.56)

2469 6300 4350 9520 3000 2650 2400 2250 2050 1950 1880

(67 713) (17839) (12317) (9967) (84.95) (75.04) (67.96) (63.71) (58,05) (55.22) (52.38)

3068 11000 7700 6250 5300 4750 4300 3900 3700 3450 3250

(77.927) (31148) (218.03) (17698) (150.07) (134.50) (121,76) (110.43) (104.77) (97,69) (92.03)

4 026 23000 15800 12800 10900 9700 8800 St00 7500 7200 6700

(102.260) (651.27) (447.39) (362 44) (308.64) (274.67) (249.t8) (229.99) (212.37) (203.88) (189.72)

'iven in cubsc feet (m 3) o f gas per hour and based on O.60 specific gravity gas.

Leak Check

After gas piping is completed, carefully check all piping

connections (factory- and field-installed) for gas leaks.

Use a leak detecting solution or other preferred means.

CAUTION

TABLE 5

Figure 28 shows thermostat designations for identifica-

tion purposes. Refer to figure 29 for control box arra nge-

ment, figure 30 for adetail of the Surelight _integrated

control, figure 32 for point-to-point field wiring and figure

33 for schematic wiring diagram and troubleshooting,

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

A, IMPORTANT 1

iii::i:: i.................j

A field make-up box is provided for line voltage wiring.

Line voltage wiring to unit is done through the J69 jack

from the field make-up box to plug P69 from the control

box. See figures26 and 27 for make-up box installation.

1 - Install field make-up box on either side, inside orout

of the cabinet. Knockouts are provided in box and

cabinet to run wiring. See figures 26 and 27.

2 - Remove cap from knockout in blower deck on the

same side as the installed make-up box.

A IMPORTANT

Page 16

3- Electrically ground unit in accordance with local

codes or, in the absence of local codes, in accor-

dance with the current National Electric Code (ANSI/

NFPA No. 70) and in Canada with the current Cana-

dian Electric Code part 1 (CSA standard C22.1). The

ground wire is provided in the field make-up box.

To ensure proper grounding of the furnace, two star

washers are included in the electrical make-up box

bag assembly. Place the star washer on secudng

screw before installing the make-up box. Make sure

the star washer breaks the paint on the cabinet so

that the washer is touching metal. Unit is not properly

grounded if paint has not been removed by star

washer.

4- An optional 120 volt accessory wira is provided with

G32 units. Install the brown accessory wire into J69

jack plug by inserting the pin of the brown wire into

the open socket of the

jack. See figure 25. Any

INSYALUNG BROWN

ACCESSORY WIRE TO J69

accessory rated up to 4

amps can be connected to

BROWN

this wire. Connect the

neutral leg of the accesso-

NEUTRAL

ryto the neutral whitewire

in the make-up box. The

accessory terminal is en-

BLAC

WNIT_

ergized whenever the

blower is in operation.

5 - Insert the three-pin (P69)

FIGURE 25

plug from the control box

into the knockout provided in the blower deck.

6 - Connect jack (J69) from make-up box tojack plug in

blower deck.

7 - Select wire size according to the blower motor amps.

8 - Snaphole bushing is provided for the widng entry

hole in the cabinet. A snapholeplug is providedto

seal the unused wire entry hole

INTERIOR MAKE-UP BOX INSTALLATION

__._ / J69

FIGURE 26

EXTERIOR MAKE-UP BOX INSTALLATION

BUSHING

J69

(Shown with

accesso_

wire connec_d)

P69 from

ControlBox

FIGURE 27

G32Q and CONDENSING UNIT

THERMOSTAT DESIGNATIONS

(Refer to specific thermostat and outdoor unit,)

Two-Stage Condensing _nit

Thermostat*/ COkq'ROLBOARD_/ _ _H,sUN,T

® .... ....... ....

G32 $UREUGHT

J_J=l _G COMPRESSQR OMPRESSC_

(_ J_ -°_"_L°_-_ .(-_ G32"rwo_AGECONTROL

®_ @ co.Mo.A ,so,,T

"$1ngll-_tlge B_s most it don not contain W2 tmrmlnal

and Wl terminal is designated as W.

FIGURE 28

9- Install room thermostat according to instructions

provided with thermostat. See figure 28 for thermo-

stat designations. If furnace isbeing used with heat

pump refer to FM21 installation instruction.

NOTE - W2 thermostat connection (pigtail) must be

made at two-speed control board. SureLightTM board

is not equipped with a W2 terminal

10 - Install a separate disconnect switch near the unit so

power can be turned off for servicing.

11 - Complete wiring connections to equipment using

wiring diagrams provided with unit and in figures 32

and 33. Use 18-gauge wire or larger for thermostat

connections.

12 - The two-stagerelay board controls first- and second-

stage furnace operation providing maximum comfort

and efficiency. The furnace may be controlled by ei-

ther a single- or two-stage room thermostat.

13 - The blower will run on continuous fan speed with the

low speed tap connected to the (ACB LOW) 120 volt

terminal and the thermostat set to "FAN ON" when

there is no call for heating or cooling.

Page 17

G32Q CONTROL BOX

DOOR

INTERLOCK

SWITCH

._,_ C=RCU_

TRANSFORMER

'_1_ _BREA_ER

SURELIGHT /

CONTROL

TWO_TAGE

_ _'--'-CONTROL

BOARD

FIGURE 29

SURELIGHT INTEGRATED CONTROL BOARD

IIZ II LO_ TX HOT :_(_ ,_

"_-III 0110 UIIO I

÷ _.._, .. _

÷ L_____J _

FANDELAY SFJ_-_E JI

--

ACBCOOL

ACB HEAT

PARK

ACB LOW

ACC

TX

HOT

HTG ACC

NEUTRALS

24VAC HOT

24VAC RTN

FLAME SENSE

TERMINAL DESIGNATION_

Blower - Coollr_ Bleed {LineVolt)

Blower- Heatina SPeed (LineVolt)

AJtemateBlower SPeeds (Dead}

ContinuousLowSpeed Blower

AccessoryTerminal (Line VoW4ampmax.)

120VAC Hot to Transformer

120VAC Hot Input

Heat Only Accessory (Line VoltI

120VAC Neutrals

24VAC Hot from Transformer

24VAC Return from Transformer(Common)

Flame Sense Terminal

o.P --

I

I I I

........... J J

i I

_.__ _--.-J ® ®

I

Y G W R C

Y Q W R C

LOW VOLTAGE TERMINAL

/ CONN ECTJON TO THERMOSTAT

* FACTORY SET AT SOSECONDS

FIGURE 30

Page 18

G32Q TWO-STAGE CONTROL BOARD

MODE OF

OPERATION

JUMPER

(Factory set

at TWO STAGE)

W2 TIMED

ON DELAY

JUMPER

(Factoryset

at 8 minutes.)

0

FIGURE 31

TYPICAL G32Q FIELD WIRING DIAGRAM

FIGURE 32

Page 19

F20M/_C

4.5 E]_(4

I|F IJ_D] O

TYPICAL G32Q SCHEMATIC WIRING DIAGRAM

HION NEAT

,,o

SlO

srj Ti_ IVI

Ll'_b_m

II I I I I

it i I i i

IIilll

I --_'

Ul_ LIMIT SI]_

r---n 2

c_urr l_

AiR Lml_

W_

(ill

FIGURE 33

Page 20

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING

CAUTION

BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next tothe floor because

some gas isheavier than air and will settle on thefloor.

This unit isequipped with a gas control knob. Use only

yourhand to turnthegas controlknob.Never use tools.If

knob willnot turn by hand, do not try to repair it. Call a

qualified service technician. Force or attempted repair

may result ina fire or explosion.

G3Q2 unitsare equippedwitha SureLighFMignitionsys-

tem. Do not attemptto manuallylightburnerson thisfur-

nace. Each timethethermostatcallsfor heal the burners

willautomaticallylight.The ignitordoes not get hotwhen

there is no callfor heat on unitswithSureLighF= ignition

system.

Gas Valve Operation

WARNING

1 - STOPf Read the safetyinformationat the beginning

of this section.

2 - Set thermostat to lowest setting,

3 - Turn off all electricalpower to furnace,

4- This furnace is equipped with an ignition device

whichautomatically lightsthe burner, Do not tryto

lightthe burnerby hand.

5 - Remove unit access panel.

6 - Turn gas valve knob to OFF position. See figure 34.

7 - Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier

from a neighbor's phone. Follow the gas supplier's

instructions. If you do not smell gas go to next step.

HONEYWELL VR8205 SERIES GAS VALVE

HIGH FIRE

ADJUSTING SCREW

(under cap)

MANIFOLD

PRESSURE

TAP

LOW FIRE

ADJUSTING SCREW

(under cap)

INLET PRESSURE

TAP

GAS VALVE SHOWN IN OFF POSITION

FIGURE 34

8 - Turn gas valve knobtoON position,

9 - Replace access panel.

10 - Turn on all electrical power to unit,

11 - Set thermostat to desired setting,

12 - If the appliance willnot operate, follow the instruc-

tions given in "Turning Off Gas To Unit" section and

call your service technician or gas supplier.

Turning Off Gas To Unit

1 - Set thermostatto lowest setting,

2 - Turn off all electrice]powerto unit if serviceis to be

performed.

3 - Remove access panel.

4 - Turn gas valve knob to OFF position, Do not force.

5 - Replace access panel.

NOTE - The thermostatselec_onjumper on the two-stage

controlboard is factory-setin the "TWO-STAGE"_,

Applications Using A Single,Stage Thermostat

A * Heating Sequence - Mode of Operation Jumper in

"ONE-STAGE" Position

NOTE - To operate in thismode, the mode of operation

jumper on the two-stage control board must be in the

"ONE STAGE" position. See figure 31,

1 - On a call for heat,thermostat contacts close sending

a signal to the integrated control module. Module

runs self-diagnostic program and checks high limit

switches for normally dosed contacts and pressure

switches for normally open contacts.

2 - Control module energizes combustion air inducer at

high speed for 15-second prepurge.

3 - Control modulechecks pressure switches and high

limit switch for closed contacts.

Page 21

4- After the prepurge is complete and the pressure

switch is closed, a 20-second initial ignitor warm-up

period begins.

5 - After warm-up period, gas valve is energized on sec-

ond stage (high heat).

6 - Gas valve opens and gas is ignited. When flame is

established, flame sensor sends signal to control

module to de-energize the ignitor.

NOTE - If the flame is not detected after the first igni-

tion attempt, the control module de-energizes the

gas valve and the prepurge / ignition sequence is re-

peated. After five ignition trials without proof of

flame, the unit will go into a Watchguard / Flame Fail-

ure mode. In Watchguard mode, control will repeat

the prepurge and ignition trial sequence after 60 min-

utes of unsatisfied thermostat demand.

7 - After flame is sensed, 45-second FAN ON delay be-

gins. Indoor blower is energized on high heating

speed after delay. ACC and HTGACC terminals are

energized.

8 - When heat demand issatisfied, gas valve is de-ener-

gized, combustion air inducer goes to 5-second

postpurge and adjustable FAN OFF delay begins.

B - Heating Sequence - Mode of Operation Jumper in

"W2 TIMED" Position

NOTE - To operate in this mode, the mode of operation

jumper on the two-stage control board must be in the "W2

TIMED" position. See figure 31.

1 - On call for heat from a single-stage thermostat,

operation sequence followssteps 1through4 as out-

lined above insingle-stageheating sequence.

2 - Gas valveisenergizedonlow heat(firststage).Ignition

occursand signalissentfrom control moduleto two-

stage controlboard to begin"W2 ON" delay (factory

set at 8 minutes).See figure 31 for delaysettings.

3 - "FAN ON" delay begins. When delay ends, indoor

blower motor isenergized on low speed.

4 - If the selected"W2 ON"delayends and the demand

for heat is still not satisfied, the two-stage control

switchesthefurnace tosecondstage operation(high

heat). In second stage operation, the following oc-

cur: combustionair inducer motor is energized at

highspeed;indoorblowermotorisenergizedon high

heating speed; and gas valve is energized on high

heat after an 8-second delay.

5 - When the demand for heat is satisfied, the high- and

low-heat gas valves are de-energized, the combus-

tion air inducer goes into the 5-second post purge op

oration on low speed and the indoor blower motor

goes into the FAN OFF delay on low speed.

Applications Using A Two-Stage Thermostat

C - Heating Sequence - Mode of Operation Jumper in

"13NO-STAGE" Position (Factory Setting)

The sequence of operation isthe same as outlined above

(in section B), except that low-heat and high-heat opera-

tion is controlled from the room thermostat.

1 - When the thermostat is set to "FAN ON,"the indoor

blower will runon continuousfan speedwhen there is

no cooling or heating demand.

2 - When the G32 is running in the low heat (first stage)

mode, the indoor blower wilt run on continuous fan

speed.

3 - When the G32Q is running in the high heat (second

stage) mode, the indoor blower willrun on the heat-

ing speed.

4 - When there is a cooling demand, the indoor blower

will runon the cooling speed.

Gas Flow

Tocheckfor propergas flowto thecombustionchamber.

determinetheBtu(kW) inputfromtheunitratingplate.Di-

vide thisinputratingby the Btu (kW) per cubicfoot (cubic

meter)of availablegas. The resultisthe requirednumber

ofcubicfeet (cubicmeter) perhour.Determinethe flowof

gas throughthe gasmeterfor two minutesandmultiplyby

30 to getthe houdy flowof gas.

Gas Pressure

1 - Check gas line pressurewith unitfiringat maximum

rate. A minimumof4.5 in.w.c.(1.12 kPa)for natural

gasshould be maintained.

2 - Afterline pressure has been checkedand adjusted,

checkhighheatregulatorpressure.See figure34 for

gas pressureadjustment screwlocation.High heat

manifoldpressureis given intable 6.

Page 22

Manifold Pressure (outlet) in.w.g (kPa)

Model No.

G32-75 natura_

G32-100 natural

G32-125 natural

G32-75 L.P

G32-100 L,P.

G32-125 L,P.

0 to 4500 ft. (0 to 1372 m)

above sea level

3.8

3.5 (0.87)

7.5

7.5 (1.90)

7.5 11.90)

4501 to 5500 ft.

(1373 to 1676 m)

above sea level

34(0.85)

7.3 (1.81)

7.3 (1.81 }

Manifold Pressure Measurement & Adjustment

NOTE - Pressure test adaptor kit (10L34) is available

from Lennox to facilitate manifold pressure measure-

ment.

1 - Connect test gauge to outlet tap on gas valve.

2 - Disconnect pressure sensing hose from gas valve

and plug hose by covering opening with tape or

equivalent. Leave barbed fitting on valve open to at-

mosphere. See figure 35 for differential pressure

switch circuitry on 75 kBtuh models. Only 75 kBtuh

models are equipped with a secondpressure switch.

Other models have single pressure switch.

TABLE 6

3,5

7.5

5501 to 6500 ft.

(1677 to 1981 m)

above sea level

35

3.3 (0.82)

7.5

7.1 (1.80)

7.1 (1.8o)

6501 to 7500ft,

(1982to2286 m)

above sea level

3.5

3.2 (0.80)

7.5

7.0 (1.74)

7.0 (1.74)

NOTE - Shut unit off and remove manometer as soon as

an accurate reading has been obtained. Takecare to re-

place pressure tap plug.

NOTE - During this test procedure, the unit will be overt/r-

ing:

• Operate unitonly long enough to obtain accurate read-

ing to prevent overheating heat exchanger.

• Attempts toclock gas valve during this procedure will

be inaccurate. Measure gas flow rate only during nor-

mal unit operation.

6 - When test iscomplete removeobstruction from hose

and return hose to gas valve barbed fitting.

75 kBtuhDIFFERENTIALPRESSURESWITCHCIRCUITRY

BURNER

LOW HEAT

DIFFERENTIAL

PRESSURE BARS

SWITCH

TEE

HIGH HEAT

DIFFERENTIAL

PRESSURE

SWITCH

COMBUSllON

AIR PRESSURE

SENSING HOSE

COMBUSTION

AIR INOUCER PRESSURE

HONEYWELL PPS SWITCH

PRESSURE SENSING

SWITCH HOSE

SHOWN

LEFT SIO_ OF PRESSURE SWITCH = MORE NEGATIVE

RIGH'r SIDE OF PRESSURE SWITCH = LESS NEGATIVE (Closer to Zero)

BOX

SOX

SENSING

HOSE

GAS

VALVE

SENSING

HOSE

GAS

VALVE

FIGURE 35

3 - Start uniton high heat and allow5 minutes for unitto

reach steady state.

4- While waiting for the unit to stabilize, notice the

flame. Flame should be stable and should not lift

from burner. Natural gas shouldbum blue.

5 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

table 6.

Refer to table 6 for manifold pressuresettings for installa-

tions at altitudes from 0 to 7500 feet (0 to 2286 m).

NOTE - In Canada, certification for installations at eleva-

tions over 4500 feet (1372m) is thejurisdiction of local au-

thorities.

The two pressure switches (highand low heat) are factory

set and are not to be adjusted.

NOTE - Disconnect power to unit before making any

adjustments.

Heat Anticipation Settings

Thermostat anticipatorsetting (if adjustable) shouldbe

set accordingto amps listedon widngdiagram on unit.

Flame Rollout Switch

Factoryset: No adjustment necessary.

Limit Control

Factoryset: No adjustmentnecessary.

Pressure Switches

Factoryset: No adjustmentis necessary.

Fan Control

The fan-on delayof45 secondsisnotadjustable.The fan-

offdelay (timethat the blower operates after the heating

demandhas been satisfied)can be adjustedby moving

the jumper on the integrated control board. The unitis

shipped witha factory fan-off delay of180 seconds.The

fan-off delay will affectcomfort and isadjustabletosatisfy

individual applications. See figure 36.

Page 23

FAN*OFFDELAYADJUSTMENT

60sec, 90sec. 120sec, 180sec.

To adjust fan-off delay, flip dip switch to desired setting.

FIGURE 36

Temperature Rise

Check temperature rise and, if necessary, adjust blower

speed to maintain temperature rise withinrange shown

on unit rating plate.

Two-Stage Control

The two-stagecontrolallows the field selection of one of

three modes of operation:

a - "TWO STAGE" operationcontrolledby a two-stage

roomthermostat;

b- "ONE STAGE" operation controlled by a single-

stage room thermostat(high heat only); and

c - "W2 TIMED" operationwithsecondstage timedON

controlledby a single-stageroomthermostat.Three

second-stage timed ON settings are available for

fieldselection. They are 8, 12 and 15 minutes.(The

factory setting is 8 minutes.) Refer to figure 31 for

controlboard layout and jumper locations.

Electrical

1 - Check all wiringfor loose connections.

2 - Check circuitbreaker located on unitcontrolbox.

3 - Check for the correct voltage at thefurnace (furnace

operating).

4 - Check amp-draw on the blower motor.

Motor Nameplate Actual

NOTE - Do not secure electrical conduit directly to duct-

ing or structure.

Blower Speeds

Refer to blower speed selection charton unit wiring dia-

gram.

NOTE - CFM readings are takenextema/ to unitwitha dry

evaporatorcoil fi/terinsta//ed and without any other ac-

cessories,

Electronic Ignition

The SureLight TM integratedcontrol hasan added feature

of an internalwatchguard control The feature serves as

an automaticreset devicefor ignitioncontrotslockedout

because the burner has failed to light.After one hourof

continuousthermostatdemand for heat, the watchguard

willbreak and remake thermostatdemand to the furnace

and automaticallyreset the controlto relightthefurnace.

Bumer Flame

Start burnerand allow tooperate for a few minutestoes-

tablishnormalburningconditions.Check burner flameby

observation. Flame should be predominantly blue and

strongin appearance.

Check burnerflame periodicallytoensure properoperation.

CAUTION

Annual Service

At the beginning of each heating season, systemshould

be checked as follows by a qualified service technician:

Electrical

1 - Check allwiringfor looseconnections.

2 - Check circuitbreaker located on unitcontrolbox,

3 - Check forthecorrectvoltageat thefurnace(furnace

operating).

4 - Check amp-draw on the blower motor.

Motor Nameplate Actual

5 - Check to see that heat (if applicable) is operating.

Blower

Check the blowerwheels for debris and clean ifneces-

sary. The blower motors are prelubricated for extended

bearing life. No further lubdcetion is needed.

Filters

1 - Filtersmustbe cleanedor replaced whendirtyto as-

sure proper furnaceoperation.

2- Reusable foam filters used with the unit can be

washed with water and mild detergent. When dry,

theyshouldbe sprayedwithfilterhandicoaterpdorto

reinstallation.FilterhandicoaterisRP Productscoat-

ing no. 418 and is available as Lennox part no.

P-8-5069.

3 - If replacement is necessary, order Lennox part no.

31J81 for 14 inchesx 25 inches(356 x 635 ram) filter

for G32-75 units and P-8-7831 for 20 inches x 25

inches (508 x 635 ram) filterfor G32-100 and -125

units.

Intake and Exhaust Lines

Check intake and exhaust lines and all connections for

tightnessand make surethere is noblockage,hJsocheck

condensate linefor free flowdudngoperation.

Insulation

Outdoorpipinginsulationshoutdbe inspectedyeadyfor

deterioration. If necessary,replace withsame materials.

Winterizing and Condensate Trap Care

1 - Turn offpower to unit.

Page 24

2 - Have a shallow pan ready to empty condensate wa-

ter. Avoid spilling water into the control box.

3 - Remove clamp from flue assembly and remove boot

or cap. Empty water from cap. Visually inspect bot-

tom of flue assembly. Replace boot and clamp.

4 - Remove boot from condensate trap and empty wa-

ter. Inspect trap then replace boot.

Cleaning DuralokPlus TM Heat Exchanger

If cleaning the heat exchanger is necessary, follow the

procedures below, and refer to figure 1 while you disas-

semble the furnace. Place papers or protective covering

in front of the furnace while you remove the heat exchang-

er assembly.

1 - Turn off electrical and gas power supplies to fumaea.

2 - Remove upper and lower furnace access panels.

3 - Remove four screws around air intake fitting and lift

intake pipe up and away.

4 - Loosen hose clamp securing top of flue transition to

bottom of flue collar. Remove screw secudng flue

collar to top cap and lift exhaust pipe and flue collar

up and away.

5 - If electrical field make-up box is located inside the

unit, it must be removed.

6 - Remove gas supply line connected to gas valve.

7 - Mark all gas valve wires and disconnect them from

valve. Mark and remove wires from flame roll-out

switch.

8 - Remove top cap of unit.

9 - Remove sensor wire from SureLight_ control. Dis-

connect 2-pin plugfrom the ignitor.

10 - Mark and disconnect pressure switch tubing from

both sides of the pressure switch(es).

11 - Loosen two screws holding gas manifold support at

vestibule panel.

12 - Remove four burner box screws at the vestibule pan-

ei and remove burner box and gas valve/manifold as-

sembly with bracket.

13 - Drain condensate trap. Disconnect condensate line

from the outside of unit. Remove condensate line

from condensate trap by turning the adapter fitting

counterclockwise. The fitting has standard right

hand threads.

14 - Disconnect the drain hose from the flue transition to

the elbow on the cold header (collector) box trap.

15 - Disconnect the 3-pin plugfrom the combustion air in-

ducer at the blower deck. Remove four screwsfrom

combustion air inducer and remove flue transition

and inducerassemblyfrom cabinet.Take care notto

lose the combustionair orifice.

16 - Mark and disconnectall remaining wires from heat-

ingcompartment components.

17 - Disengage strain relief bushing from blower deck

and pull bushing and wires into the blower section.

18 - Remove the limit switch and the pressure switch(es)

from the vestibule panel.

19 - Remove two screws from the front cabinet flange at

the blower deck. Remove front screws from cabinet

at blower deck on left and right sides. Cabinet sides

must be slightly spread to clear heat exchanger pas-

sage.

20 - Remove screws along vestibule sides and bottom

which secure vestibule panel and heat exchanger

assembly to cabinet. Removeheat exchanger.

21 - Back wash heat exchanger with soapy water solu-

tion or steam. If steam is used it must be below

275°F (135°C).

22-Thoroughly rinse and drain the heat exchanger.

Soap solution can be corrosive so take care that en-

tire assembly is completely dnsed.

23 - Reinstall heat exchanger into cabinet making sure

that the clamshells of the heat exchanger assembly

are resting in the notches of the support located at

the rear of the cabinet. This can be viewed by remov-

ing the indoor blower and examining through the

blower opening.

24 - Resecure the supporting screws along the vestibule

sides and bottom to the cabinet.

25 - Reinstall cabinet screws onsides and front flange at

blower deck.

26 - Reinstall the limit switch and pressure switches on

the vestibule panel.

27 - Route heating component wiring back through the

hole in the blower deck and reinsert strain relief

bushing.Reconnectwires.

28 - Reinstallthe combustion air inducer. Check to en-

sure thatthe plasticorifice on the blower inlet has not

fallen out. See figure 1. Reconnect the 3-pin plug to

the wire harness. Reinstall the flue transition in the

cabinet and reattech the drain tube. Routethe drain

tube below the combustion air inducer housing and

to the elbow on the cold header (collector) box trap.

See figure 35.

29 - Reinstallcondensate line with adapter to condensate

trap. Use freshTeflon tape to ensure a leak-freejoint.

Re-connectto condensate line outside of the unit.

30 - Reinstall the burner box. Tighten the screws holding

the support bracket. It is important that the glass fiber

gasket not be damaged so it will provide acontinu-

ous seal between the burner box and the vestibule

panel.

31 - Reconnect pressureswitch tubing by connecting the

tubing from the bomer box to the barbed fitting on the

bottomand the tubing from the combustion air induc-

er to the barbed fittingon the top. See figure 35.

32 - Reconnect the sensor and ignitor wires.

33 - Reinstall top cap to unit.

Page25

34 - Reconnect widng to gas valve. Brown wire to "HI,"

yellow wire to "C" and orange wire to "M." Reconnect

wires to name roll-out switch.

NOTE - Unit is polarity-sensitive. 120V supply wiring

must be installed correctly

35 - Reconnect main gas line to gas valve. Use second

wrench on gas valve to avoid transferring torque to

the gas manifold.

36 - Reinstall field make-up box if removed.

37 - Reinstall exhaust pipe/flue collar and secure flue col-

lar to the unit top cap using existing screw. Insert the

bottom of the flue collar into the top of the flue transi-

tion and tighten hose clamp.

38-Reinstall intake pipe fitting on burner box with

screws.

39 - Replace both upper and lower access panels.

40 - Refer to instruction on verifying gas and electrical

connections when re-establishing supply.

41-Following lighting instructions from installation

manual, light and run unit for 5 minutes to ensure

heat exchanger is clean, dry and operating safely.

Cleaning the Bumer Assembly

1 - Turn off electrical and gas power supplies to furnace.

Remove upper and lower furnace access panels.

2 - Disconnect the gas supply line to gas valve. Depend-

ing on gas plumbing installation, the gas manifold

may move aside enough that breaking the union may

not be necessary.

3 - Remove five screws from edges of burner box cover.

4 - Loosen two screws on bottom of burner box front.

The cover is key holed at these screw point so

screws do not need to be removed. Pulloff cover and

set aside.

6 - Mark all gas valve wiresand disconnect them from

valve.

7 - Mark and disconnect sensor wires from the burner

box at the ignition control. Disconnect 2-pin plug

from the ignitor at the burner box.

8- Loosen two screws at the gas manifold support

bracket.

9 - Pull on the left side of the gas manifold and follow

with tension to the right side. The manifold support

bracket will be free of the mounting screwson the

vestibule panel. Set the gas manifold/gas valve as-

sembly aside. Take care not to damage foam gas-

kets on each end of the gas manifold.

10-Using a 1/4 inch nut driver, remove the burner

mountingscrewsfrom underneaththe burners.

11-While supporting ignitor and sensor lines at the

grommet, grasp burners and simultaneously pull

burners and grommet out of the burner box.

12 - Remove ignitor and sensor bracket assemblies from

burners using a 1/4 inch nut driver to remove two