Page 1

LENNOXOEMPARTS.COM

Service Literature

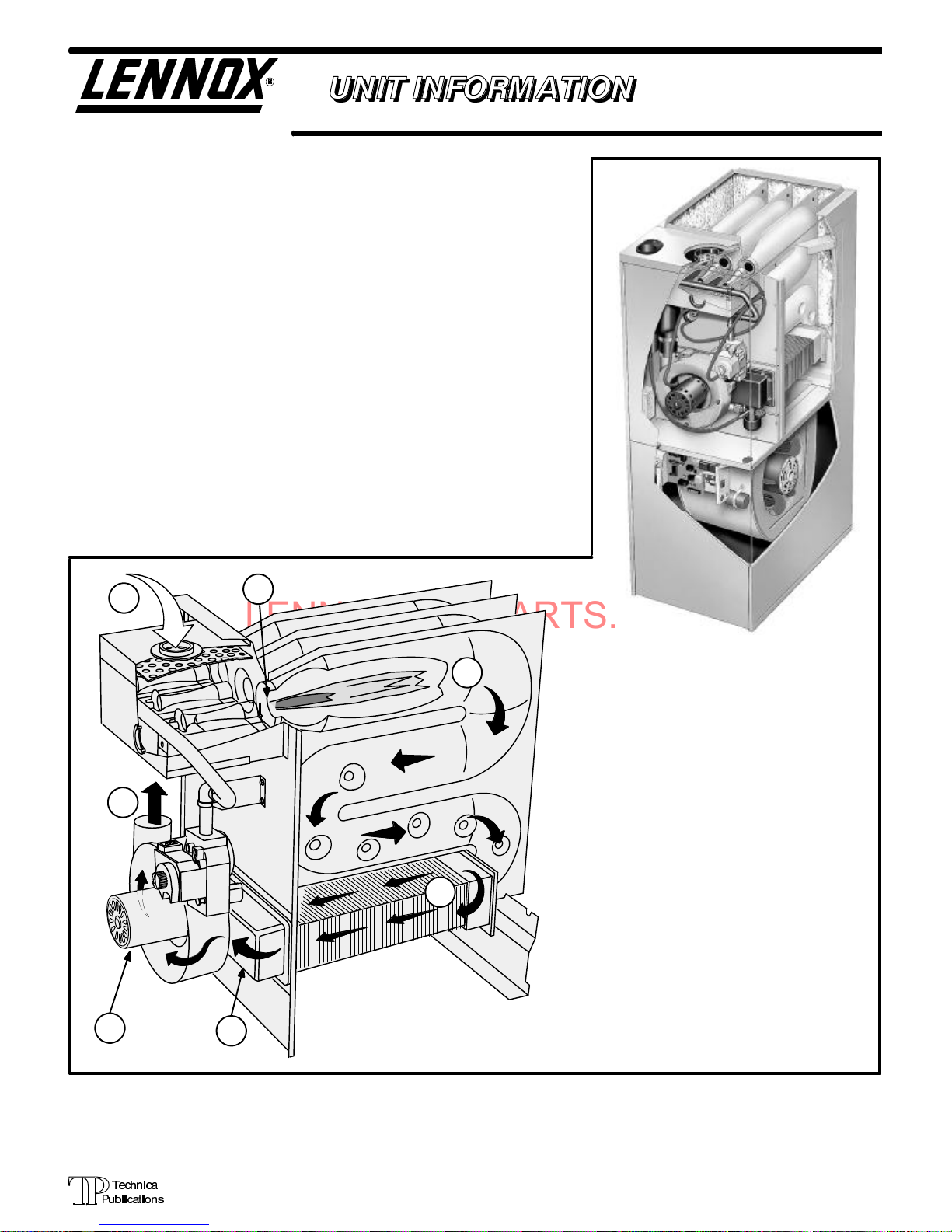

G26 SERIES UNITS

G26series unitsarehigh-efficiencyupflowgas furnacesmanufactured with

DuralokPlust aluminizedsteelclamshell-type heat exchangers. G26units

are available in heating capacities of 50,000 to 125,000 Btuh and cooling

applications upto5 tons. Refer toEngineeringHandbook for proper sizing.

Unitsare factoryequipped foruse with naturalgas. Akit isavailable forconversion to LPGoperation.G26-1 and -2model unitsuse electronic(intermittent pilot) ignition. G26-3, -4, -5 and -6 model units feature the Lennox SureLightT silicon nitrideignitionsystem.Each unitmeets theCalifornia Nitrogen Oxides (NOx) Standards and California Seasonal Efficiency requirements without modification. All units use a redundant gas valve to assure

safety shut-off as required by A.G.A. or C.G.A.

Information containedin this manualis intendedforuse byqualifiedservice

technicians only. All specifications are subject to change. Procedures outlinedin thismanual arepresented asa recommendationonly anddo notsupersede or replace local or state codes. In the absence of local or state

codes,the guidelinesand proceduresoutlined inthis manual(except where

noted) are recommended only.

G26

Corp. 9721-L11

Revised 07-2001

2

7

1

3

G26 FURNACEY

4

FIGURE 1

5

AG26 HEAT EXCHANGE ASSEMBLY

Combustion Process:

1. A call for heat starts the combustion air blower.

2. Outdoorairisdrawnthroughpipeintotheburner

compartment where it mixes with gas in a conventional style inshot burner.

3. TheSureLightignitionsystemlightstheburners.

4. Combustion products are drawn downward

through the heat exchanger. Heat is extracted

as indoor air passes across theoutside surface

of the metal.

5. Latent heat is removed from the combustion

productsasairpassesthroughthecoil.Condensate (water) isformed as the combustion products cool.

6. As the combustion products exit the coil, condensate is collected and drained away.

7. Combustion products are pulled from the heat

exchanger and forced into the flue.

6

Page 1

ã 1997 Lennox Industries Inc.

Litho U.S.A.

Page 2

LENNOXOEMPARTS.COM

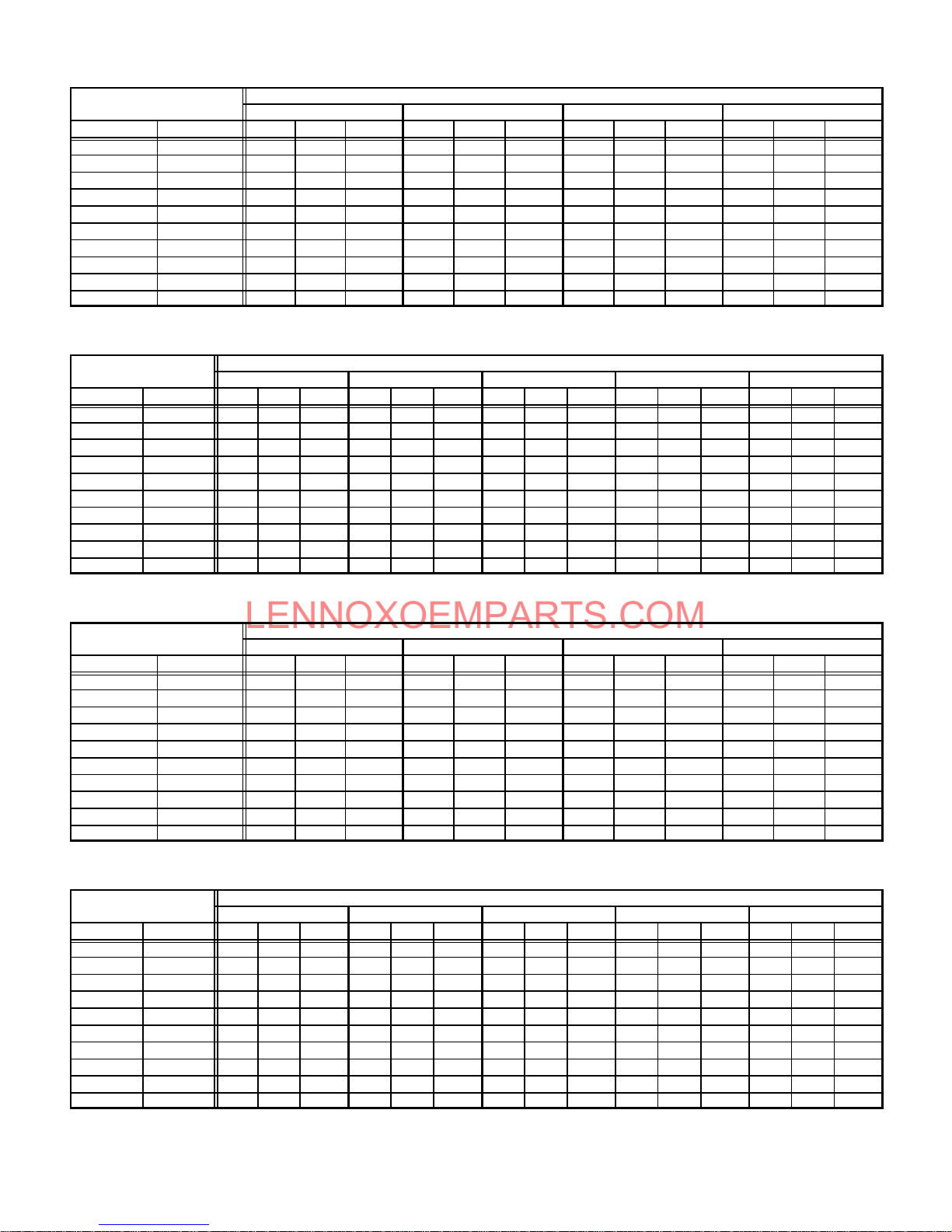

SPECIFICATIONS

GasPipingSizeI.P.S.

GasPipingSizeI.P.S.

Blowerwheelnomina

l

Blowerwheelnomina

l

Nominalcoolin

g

Nominalcoolin

g

¡

Vent/IntakeAirRoo

f

¡

Vent/IntakeAirRoo

f

15F74

(ringkit)

—

22G44

(closecouple)

—30G2

8

(WTKclosecouple

)

TerminationKit(optional)—ventsize

TwinningKit

s

TwinningKit

s

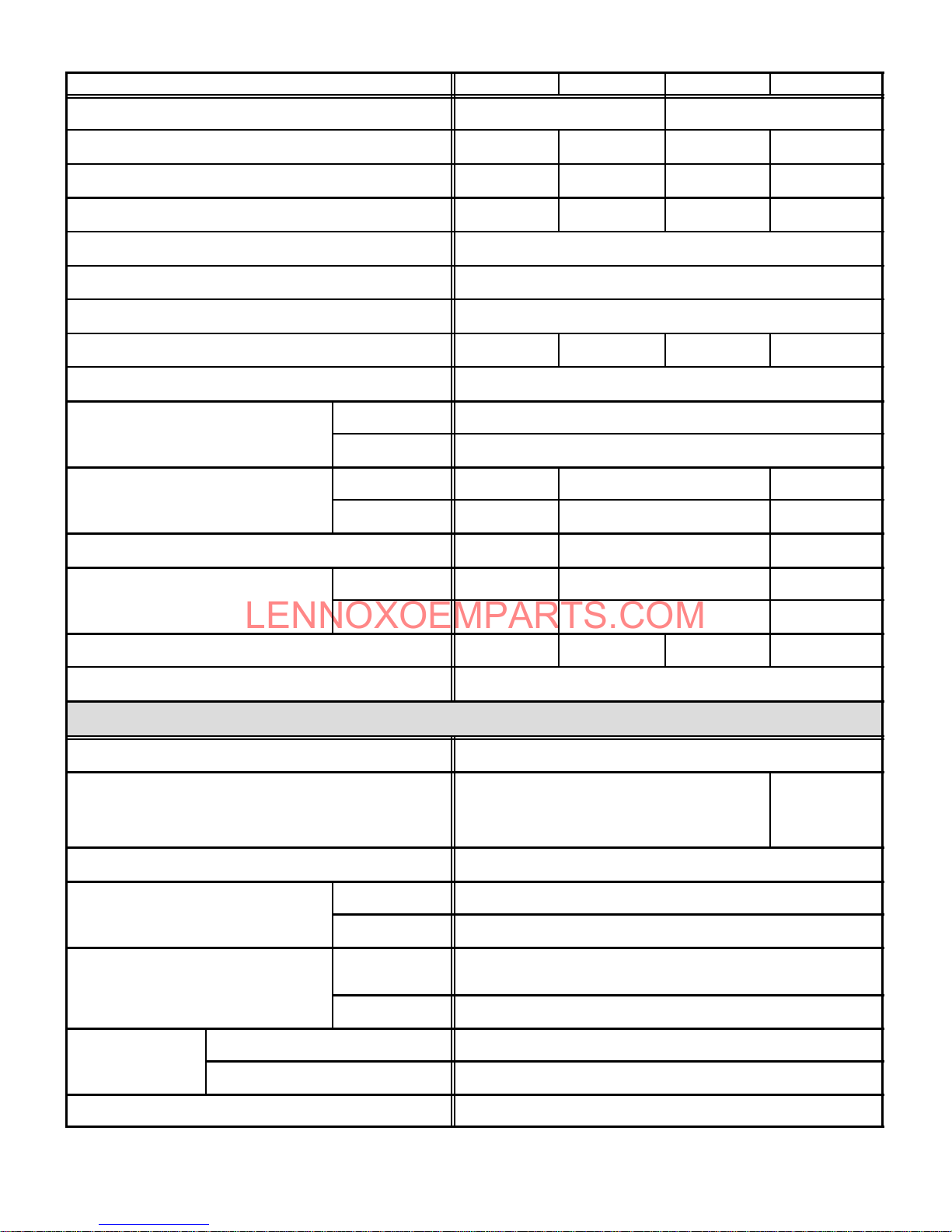

Model No. G26Q2-50 G26Q3-50 G26Q3-75 G26Q4/5-75

Input Btuh(kW) 50,000 (14.7) 75,000 (22.0)

Output Btuh (kW) 46,000 (13.5) 47,000 (13.8) 70,000(20.5) 69,000 (20.2)

lA.F.U.E. 92% 92.4% 92.0% 92.0%

California Seasonal Efficiency 85.9% 86.5% 86.3% 83.8%

¡Exhaust pipe connection (PVC) diameter— in. (mm) 2 (51)

¡Intake pipe connection (PVC) diameter— in. (mm) 2 (51)

Condensate drain connection ( PVC)— in. (mm) 1/2 (12.7)

Temperature rise range — _F (_C) 40-70 (22-39) 30-60 (17-33) 40-70 (22-39) 20-50 (11-28)

High static certified by (A.G.A./C.G.A.) — in. wg. (Pa) .50 (125)

in. 1/2

Natural orLPG/propane

diameter x width

mm 12.7

in. 10 x 7 10 x 8 11-1/2 x 9

mm 254 x 178 254 x 203 292 x 229

Blower motor output — hp (W) 1/5 (149) 1/3 (249) 3/4 (560)

Tons 1 to2 2 to 3 3-1/2 to5

that can be added

Shipping weight — lbs. (kg) 1 package 150 (68) 157 (71) 157 (71) 182 (83)

Electrical characteristics 120 volts — 60 hertz — 1 phase (all models) (less than 12 amps)

kW 3.5 to 7.0 3.5 to 10.6 12.3 to 17.6

b Optional Accessories (Must Be Ordered Extra) b

LPG/Propane kit (optional) 65K27 (all models)

Filter and Filter Rack Kits

}No. & sizeof filters - in. (mm)

Concentric Vent/Intake Air/Roof Termination Kit (optional) 60G77 — 1 1/2 inch (38 mm)

2 inch (51 mm) 15F75

Termination Kit (optional) — vent size

¡Vent/Intake Air Wall

3 inch (76 mm) 44J41

2 inch (51 mm)

Single (44J20) Ten Pack (66K61)

(1) 14 x 25 x 1 (356 x 635 x 25)

30G79 (WTKX close cou ple with extension riser)

Single (44J21)

Ten Pack (66K62)

(1) 20 x 25 x 1

(508 x 635 x 25)

3 inch (76 mm) 44J40 (close cou ple) or 81J20 (WTK close cou ple)

Non-continuous low speed 64H88 (all models)

(optional)

Continuous Low Speed Blower Switch (optional) 44J06 (-1and -2 models) N ot used with Twinning Kits

lAnnual Fuel Utilization Efficiency b ased on U.S. DOE test procedures and FT C labeling regulations. Isolated combu stion system rating for non-weatherized furnaces.

}Polyurethane frame type filter.

¡Determine fromventingtables proper intake and exhaust pipe size andtermination kitrequired.

Continuous low speed 35J93 (all models)

Page 2

Page 3

LENNOXOEMPARTS.COM

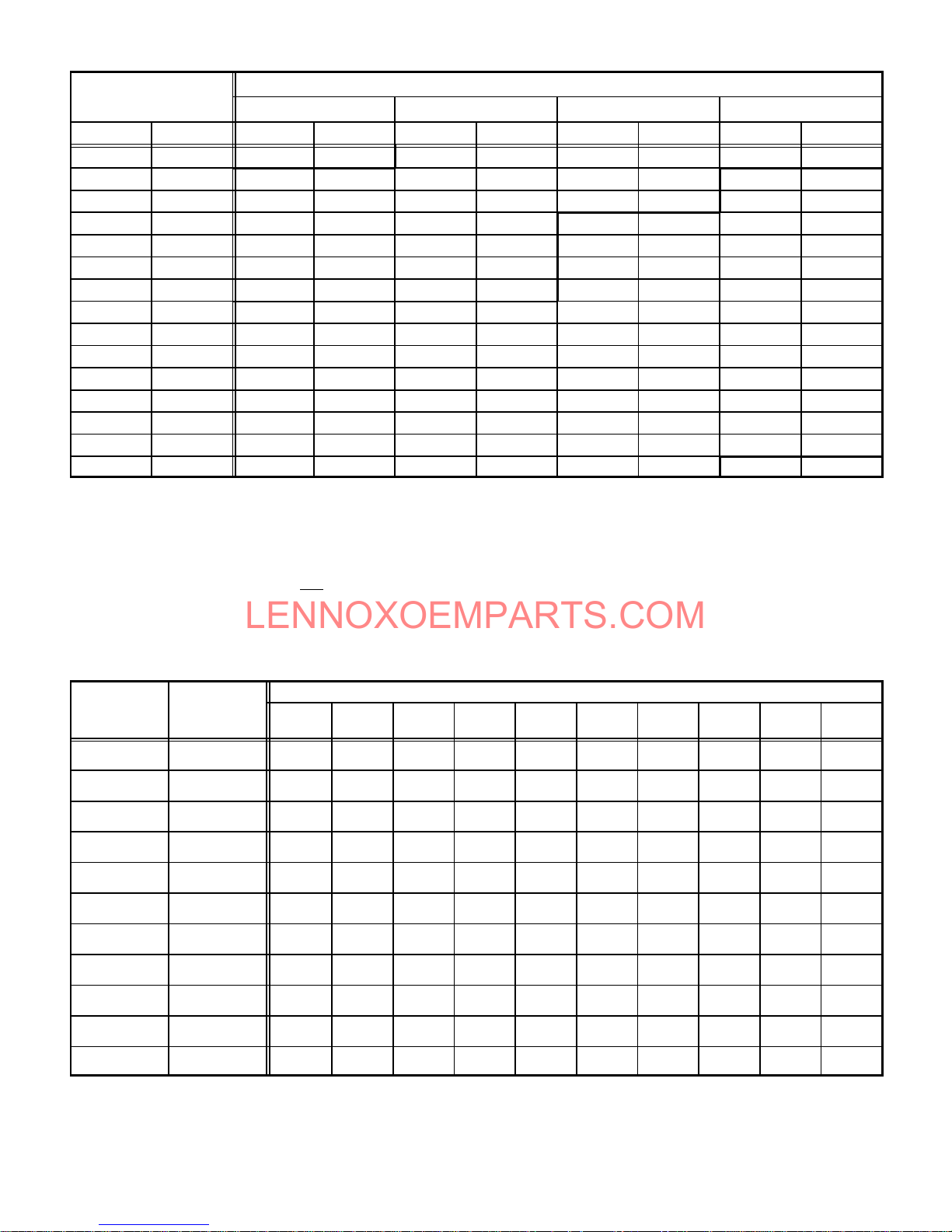

SPECIFICATIONS

GasPipingSizeI.P.S.

GasPipingSizeI.P.S.

Blowerwheelnomina

l

Blowerwheelnomina

l

Nominalcoolin

g

Nominalcoolin

g

¡

Vent/IntakeAirRoo

f

¡

Vent/IntakeAirRoo

f

TerminationKit(optional)—ventsize

TwinningKit

s

TwinningKit

s

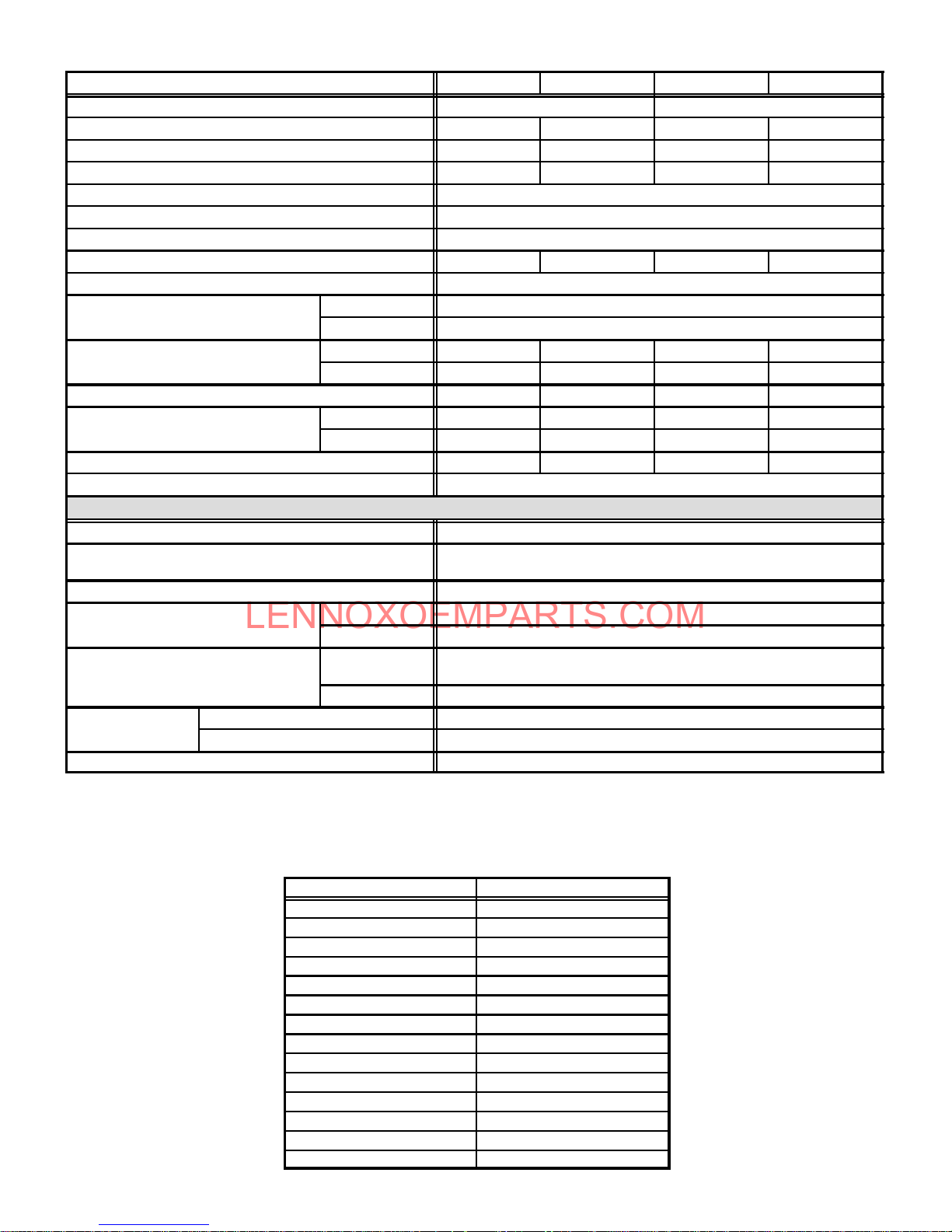

Model No. G26Q3/4-100 G26Q4/5-100 G26Q3/4-125 G26Q4/5-125

Input Btuh (kW) 100,000 (29.3) 125,000 (36.6)

Output Btuh (kW) 91,000 (26.7) 93,000 (27.2) 115,000 ( 33.7) 116,000 (34.0)

lA.F.U.E. 92.0% 92.0% 91.0% 92.0%

California Seasonal Efficiency 86.6% 85.8% 87.5% 87.0%

¡Exhaust pipe connection (PVC) diameter— in. (mm) 2 (51)

¡Intake pipe connection (PVC) diameter— in. (mm) 3 (76)

Condensate drain connection ( PVC)— in. (mm) 1/2 (12.7)

Temperature rise range — _F (_C) 50-80 (28-44) 40-70 (22-39) 55-85 (31-47) 50-80 (28-44)

High static certified by (A.G.A./C.G.A.) — in. wg. (Pa) .50 (125)

in. 1/2

Natural orLPG/propane

diameter x width

Blower motor output — hp (W) 1/2 (373) 3/4 (560) 1/2 (373) 3/4 (560)

that can be added

Shipping weight — lbs. (kg) 1 package 186 (84) 198 (90) 218 (99) 218 (99)

Electrical characteristics 120 volts — 60 hertz — 1 phase (all models) (less than 12 amps)

LPG/Propane kit (optional) 65K27 (all models)

Filter and Filter Rack Kits

}No. & sizeof filters - in. (mm)

Concentric Vent/Intake Air/Roof Termination Kit (optional) 33K97 — 2 inch ( 51 mm)

Termination Kit (optional) — vent size

¡Vent/Intake Air Wall

Non-continuous low speed 64H88 (all models)

(optional)

Continuous Low Speed Blower Switch (optional) 44J06 (-1and -2 models) N ot used with Twinning Kits

lAnnual Fuel Utilization Efficiency b ased on U.S. DOE test procedures and FT C labeling regulations. Isolated combu stion system rating for non-weatherized furnaces.

}Polyurethane frame type filter.

¡Determine fromventingtables proper intake and exhaust pipe size andtermination kitrequired.

NOTE - 2 inch x 3 inch (51 mm x 76 mm) adaptor is furnished with -100 and -125 furnaces for exhaust pipe connection.

Continuous low speed 35J93 (all models)

mm 12.7

in. 10 x 10 11-1/2 x 9 10 x 10 11-1 /2 x 9

mm 254 x 254 292 x 229 254 x 254 292 x 229

Tons 2 to4 3-1/2 to 5 2 to 4 3- 1/2 to 5

kW 7.0 to 14.1 12.3 to17.6 7.0 to14.1 12.3 to 17.6

b Optional Accessories (Must Be Ordered Extra) b

Single (44J21) Ten Pack (66K62)

(1) 20 x 25 x 1 (508 x 635 x 25)

2 inch (51 mm) 15F75

3 inch (76 mm) 44J41

2 inch (51 mm)

3 inch (76 mm) 44J40 (close couple) — 81J20 (WTK close couple)

15F74 (ring kit) — 22G44 (close couple) — 30G28 (WTK close couple)

30G79 (WTKX close cou ple with extension riser)

BLOWER PERFORMANCE DATA

FILTER AIR RESISTANCE

cfm (L/s) in. w.g. (Pa)

0 (0) 0.00 (0)

200 (95) 0.01 (0)

400 (190) 0.03 (5)

600 (285) 0.04 (10)

800 (380) 0.06 (15)

1000 (470) 0.09 (20)

1200 (565) 0.12 (30)

1400 (660) 0.15 (35)

1600 (755) 0.19 (45)

1800 (850) 0.23 (55)

2000 (945) 0.27 (65)

2200 (1040) 0.33 (80)

2400 (1130) 0.38 (95)

2600 (1225) 0.44 (110)

Page 3

Page 4

LENNOXOEMPARTS.COM

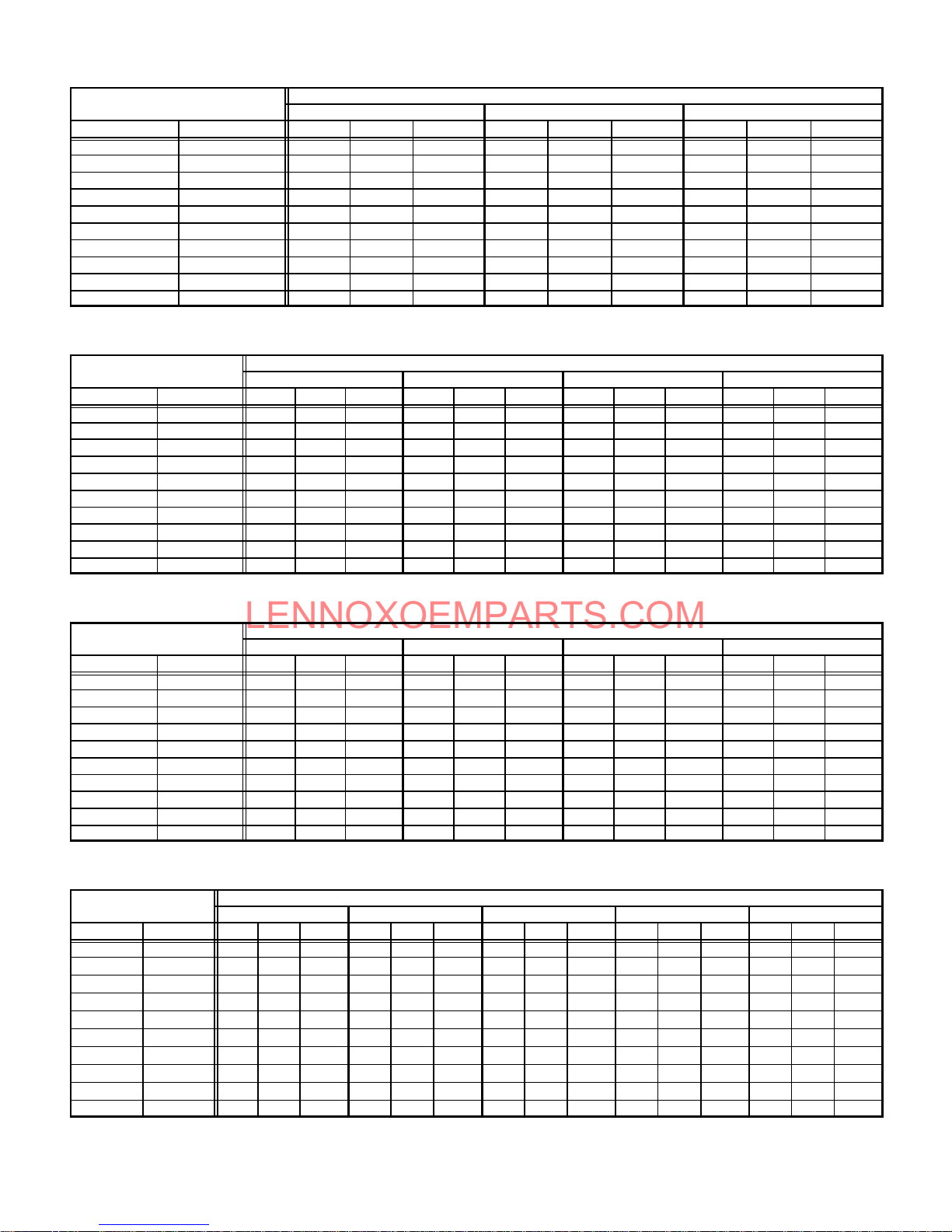

BLOWER PERFORMANCE DATA

External Static

External Static

External Static

External Static

G26Q2Ć50 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1115 525 495 885 415 360 720 340 280

.10 25 1095 515 475 880 415 350 700 330 265

.20 50 1065 505 465 855 405 340 680 320 260

.30 75 1035 490 445 830 390 325 660 310 250

.40 100 995 470 425 755 355 315 645 305 235

.50 125 950 450 405 755 355 300 625 295 225

.60 150 900 425 390 740 350 280 540 255 215

.70 175 815 385 365 660 310 255 530 250 205

.80 200 610 290 340 585 275 240 360 170 180

.90 225 590 280 315 390 185 215 Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium Low

G26Q3Ć50 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1485 700 590 1275 600 485 1045 495 390 840 395 310

.10 25 1445 680 565 1250 590 460 1030 485 375 830 390 300

.20 50 1390 655 545 1225 580 445 1010 475 365 815 385 290

.30 75 1345 635 520 1190 560 425 985 465 345 790 375 285

.40 100 1290 610 500 1150 545 405 955 450 335 780 370 275

.50 125 1225 580 480 1095 515 385 920 435 315 735 345 255

.60 150 1160 545 460 1030 485 365 875 415 300 700 330 240

.70 175 1075 505 440 950 450 345 855 405 280 600 285 220

.80 200 975 460 415 865 410 315 645 305 250 510 240 195

.90 225 845 400 385 615 290 265 545 255 225 375 175 180

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh MediumĆLow Low

Air Volume and Motor Watts at Specific Blower Taps

Air Volume and Motor Watts at Specific Blower Taps

G26Q3Ć75 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1490 705 650 1340 630 540 1060 500 440 870 410 360

.10 25 1435 675 625 1305 615 515 1050 495 425 865 410 350

.20 50 1385 655 605 1260 595 490 1025 485 405 850 400 335

.30 75 1330 630 580 1215 575 470 1000 470 385 835 395 325

.40 100 1260 595 560 1160 545 445 965 455 365 810 380 310

.50 125 1200 565 540 1100 520 420 920 435 345 770 365 290

.60 150 1125 530 515 1035 490 400 870 410 325 735 345 280

.70 175 1035 490 495 960 455 375 780 370 305 685 325 265

.80 200 935 440 475 865 410 345 725 340 285 Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć

.90 225 805 380 445 630 295 295 540 255 240 Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh MediumĆLow Low

Air Volume and Motor Watts at Specific Blower Taps

G26Q4/5Ć75 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2415 1140 1240 2120 1000 1015 1875 885 855 1635 770 705 1430 675 585

.10 25 2330 1100 1200 2090 985 1005 1835 865 835 1615 760 700 1420 670 585

.20 50 2265 1070 1165 2045 965 990 1795 845 815 1580 745 690 1390 655 580

.30 75 2210 1045 1145 2000 945 970 1765 835 810 1545 730 675 1365 645 575

.40 100 2145 1010 111 0 1950 920 955 1720 810 795 1510 715 670 1340 630 570

.50 125 2075 980 1085 1885 890 930 1680 795 785 1475 695 665 1310 620 565

.60 150 2000 945 1060 1825 860 910 1630 770 770 1435 675 655 1270 600 555

.70 175 1935 915 1040 1775 840 895 1565 740 755 1395 660 645 1220 575 545

.80 200 1840 870 1005 1705 805 870 1515 715 745 1345 635 630 1165 550 535

.90 225 1760 830 980 1610 760 845 1455 685 725 1275 600 615 111 0 525 530

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh Medium MediumĆLow Low

Air Volume and Motor Watts at Specific Blower Taps

Page 4

Page 5

LENNOXOEMPARTS.COM

BLOWER PERFORMANCE DATA

External Static

External Static

External Static

External Static

G26Q3/4Ć100 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2065 975 920 1760 830 735 1570 740 655 1245 590 520

.10 25 2000 945 875 1730 815 705 1550 730 625 1240 585 490

.20 50 1925 910 845 1685 795 675 1515 715 590 1225 580 470

.30 75 1840 870 800 1625 765 630 1475 695 565 1210 570 455

.40 100 1740 820 760 1550 730 595 1415 670 535 1165 550 430

.50 125 1650 780 730 1460 690 560 1335 630 500 1110 525 405

.60 150 1545 730 700 1370 645 530 1260 595 475 1045 495 385

.70 175 1420 670 660 1250 590 495 1170 550 445 950 450 355

.80 200 1270 600 620 1110 525 445 1025 485 395 825 390 325

.90 225 1045 495 560 965 455 405 885 420 360 700 330 290

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh MediumĆLow Low

G26Q4/5Ć100 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2400 1135 1255 2185 1030 1070 1940 915 905 1740 820 765 1570 740 665

.10 25 2350 111 0 1230 2150 1015 1055 1920 905 885 1710 805 755 1525 720 645

.20 50 2290 1080 1185 2105 995 1025 1875 885 865 1685 795 740 1505 710 640

.30 75 2225 1050 1170 2060 970 1005 1845 870 850 1655 780 730 1485 700 630

.40 100 2165 1020 1130 2010 950 985 1805 850 835 1620 765 720 1450 685 620

.50 125 2105 995 1115 1950 920 960 1755 830 810 1585 750 700 1415 670 605

.60 150 2040 965 1080 1895 895 940 1700 800 790 1540 725 690 1380 650 595

.70 175 1955 925 1045 1820 860 915 1640 775 775 1475 695 670 1340 630 590

.80 200 1850 875 1005 1730 815 885 1580 745 755 1430 675 660 1290 610 580

.90 225 1770 835 985 1650 780 855 1505 710 740 1370 645 645 1225 580 565

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh Medium MediumĆLow Low

Air Volume and Motor Watts at Specific Blower Taps

Air Volume and Motor Watts at Specific Blower Taps

G26Q3/4Ć125 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2070 975 920 1735 820 725 1555 735 640 1235 585 500

.10 25 2010 950 885 1710 805 700 1535 725 625 1225 580 490

.20 50 1950 920 850 1675 790 680 1500 710 600 1210 570 470

.30 75 1975 930 820 1620 765 645 1465 690 575 1185 560 455

.40 100 1785 840 775 1560 735 615 1415 670 545 1140 540 435

.50 125 1700 800 745 1475 695 575 1345 635 520 1090 515 415

.60 150 1585 750 705 1410 665 555 1275 600 490 1035 490 390

.70 175 1475 695 675 1310 620 515 1185 560 460 975 460 370

.80 200 1350 635 640 1200 565 485 1090 515 425 865 410 340

.90 225 1200 565 595 1080 510 445 965 455 385 715 335 300

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh MediumĆLow Low

Air Volume and Motor Watts at Specific Blower Taps

G26Q4/5Ć125 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2400 1135 1210 2175 1025 1040 1965 925 895 1790 845 780 1610 760 670

.10 25 2315 1090 1175 2125 1005 1025 1930 910 875 1760 830 770 1580 745 660

.20 50 2255 1065 1150 2080 980 1000 1880 885 860 1740 820 755 1550 730 645

.30 75 2195 1035 1130 2030 960 975 1840 870 835 1710 805 750 1520 715 635

.40 100 2120 1000 1100 1970 930 960 1790 845 815 1665 785 730 1495 705 630

.50 125 2050 965 1080 1910 900 934 1745 825 800 1620 765 715 1460 690 620

.60 150 1985 935 1050 1840 870 905 1685 795 785 1565 740 705 1415 670 610

.70 175 1885 890 1020 1770 835 890 1635 765 775 1515 715 685 1370 645 595

.80 200 1815 855 1005 1690 800 860 1570 740 750 1450 685 670 1315 620 580

.90 225 1735 820 980 1615 760 835 1485 700 725 1385 655 655 1245 590 565

NOTE Ċ All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High MediumĆHigh Medium MediumĆLow Low

Air Volume and Motor Watts at Specific Blower Taps

Page 5

Page 6

LENNOXOEMPARTS.COM

INTAKE and EXHAUST PIPE VENTING TABLE

Nominal

Internal

Vent Pipe

Maximum

Equivalent Length

50,000 Btuh (14.7 kW) 75,000 Btuh (22.0 kW) 100,000 Btuh (29.3 kW) 125,000 Btuh (36.6 kW)

Minimum Vent Pipe Diameter Required

Feet Meters in. mm in. mm in. mm in. mm

15 4.6 1Ć1/2 38 2 51 2 51 2 51

20 6.1 2 51 2 51 2 51 3 76

25 7.6 2 51 2 51 2 51 3 76

30 9.1 2 51 2 51 3 51 3 76

40 12.2 2 51 2 51 3 51 3 76

50 15.2 2 51 2 51 3 51 3 76

55 16.8 2 51 2 51 3 76 3 76

60 18.3 3 76 3 76 3 76 3 76

70 21.3 3 76 3 76 3 76 3 76

80 24.4 3 76 3 76 3 76 3 76

90 27.4 3 76 3 76 3 76 3 76

100 30.5 3 76 3 76 3 76 3 76

110 33.5 3 76 3 76 3 76 3 76

120 36.6 3 76 3 76 3 76 3 76

130 39.6 3 76 3 76 3 76 Ć Ć Ć Ć Ć Ć Ć Ć

MINIMUM PIPE LENGTHS FOR FURNACES Ċ G26Ć50 Ċ 5 feet (1.5 m) with two 90 elbows of 1Ć1/2 inch (38 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

VENTING NOTES Ċ One 90elbow is equivalent to 5 feet (1.5 m) of straight vent pipe.

Two 45 elbows are equal to one 90 elbow.

One 45 elbow is equivalent to 2.5 feet (.75 m) of straight vent pipe.

One foot (305 mm) length of 2 in. (51 mm) diameter pipe is equivalent to 8 feet (2.4 m) of 3 in. (76 mm) diameter pipe.

Intake and Exhaust pipes must

2 inch x 3 inch (51 mm x 76 mm) adaptor is furnished with Ć100 and Ć125 furnaces for exhaust pipe connection.

Exhaust pipe must terminate with 1Ć1/2 inch (38 mm) diameter pipe for furnaces using1Ć1/2 (38 mm) or 2 inch (51 mm) diameter pipe runs.

Exhaust pipe must terminate with 2 inch (51 mm) diameter pipe for furnaces using 3 inch (76 mm) diameter pipe runs.

See pages 10 thru 12 for Termination Kits available.

G26Ć75 Ċ 5 feet (1.5 m) with two 90 elbows of 2 inch (51 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

G26Ć100 Ċ 5 feet (1.5 m) with two 90 elbows of 2 inch (51 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

G26Ć125 Ċ 5 feet (1.5 m) with two 90 elbows of 2 inch (51 mm) diameter pipe. (15 equivalent feet (4.6 m) total).

be the same diameter.

GAS PIPE CAPACITY - FT3/HR (kL/HR)

Nominal Internal

Iron Pipe Size

-Inches(mm)

1/4

(6.35)

3/8

(9.53)

1/2

(12.7)

3/4

(19.05)

1

(25.4)

1-1/4

(31.75)

1-1/2

(38.1)

2

(50.8)

2-1/2

(63.5)

3

(76.2)

4

(101.6)

Diameter

-Inches(mm)

.364

(9.246)

.493

(12.522)

.622

(17.799)

.824

(20.930)

1.049

(26.645)

1.380

(35.052)

1.610

(40.894)

2.067

(52.502)

2.469

(67.713)

3.068

(77.927)

4.026

(102.260)

10

(3.048)20(6.096)30(9.144)40(12.192)50(15.240)60(18.288)70(21.336)80(24.384)90(27.432)

43

(1.13)

95

(2.69)

175

(4.96)

360

(10.19)

680

(19.25)

1400

(39.64)

2100

(59.46)

3950

(111.85)

6300

(178.39)

11000

(311.48)

23000

(651.27)

29

(.82)

65

(1.84)

120

(3.40)

250

(7.08)

465

(13.17)

950

(26.90)

460

(41.34)

2750

(77.87)

4350

(123.17)

7700

(218.03)

15800

(447.39)

24

(.68)

52

(1.47)

97

(2.75)

200

(5.66)

375

(10.62)

770

(21.80)

1180

(33.41)

2200

(62.30)

3520

(99.67)

6250

(176.98)

12800

(362.44)

NOTE-Capacity given in cubic feet of gas per hour (kilo liters of gas per hour) and based on 0.60 specific gravity gas.

Length of Pipe-Feet(m)

20

(.57)

45

(1.27)

82

(2.32)

170

(4.81)

320

(9.06)

660

(18.69)

990

(28.03)

1900

(53.80)

3000

(84.95)

5300

(150.07)

10900

(308.64)

18

(.51)

40

(1.13)

73

(2.07)

151

(4.28)

285

(8.07)

580

(16.42)

900

(25.48)

1680

(47.57)

2650

(75.04)

4750

(134.50)

9700

(274.67)

16

(.45)

36

(1.02)

66

(1.87)

138

(3.91)

260

(7.36)

530

(15.01)

810

(22.94)

1520

(43.04)

2400

(67.96)

4300

(121.76)

8800

(249.18)

15

(.42)

33

(.73)

61

(1.73)

125

(3.54)

240

(6.80)

490

(13.87)

750

(21.24)

1400

(39.64)

2250

(63.71)

3900

(110.43)

8100

(229.36)

14

(.40)

31

(.88)

57

(1.61)

118

(3.34)

220

(6.23)

460

(13.03)

690

(19.54)

1300

(36.81)

2050

(58.05)

3700

(104.77)

7500

(212.37)

13

(.37)

29

(.82)

53

(1.50)

110

(3.11)

205

(5.80)

430

(12.18)

650

(18.41)

1220

(34.55)

1950

(55.22)

3450

(97.69)

7200

(203.88)

100

(30.480)

12

(.34)

27

(.76)

50

(1.42)

103

(2.92)

195

(5.52)

400

(11.33)

620

(17.56)

1150

(32.56)

1850

(52.38)

3250

(92.03)

6700

(189.72)

Page 6

Page 7

LENNOXOEMPARTS.COM

GLASS FIBER GASKET

FRESH AIR

INTAKE FITTING

BURNER BOX

ASSEMBLY

PATCH

PLATE

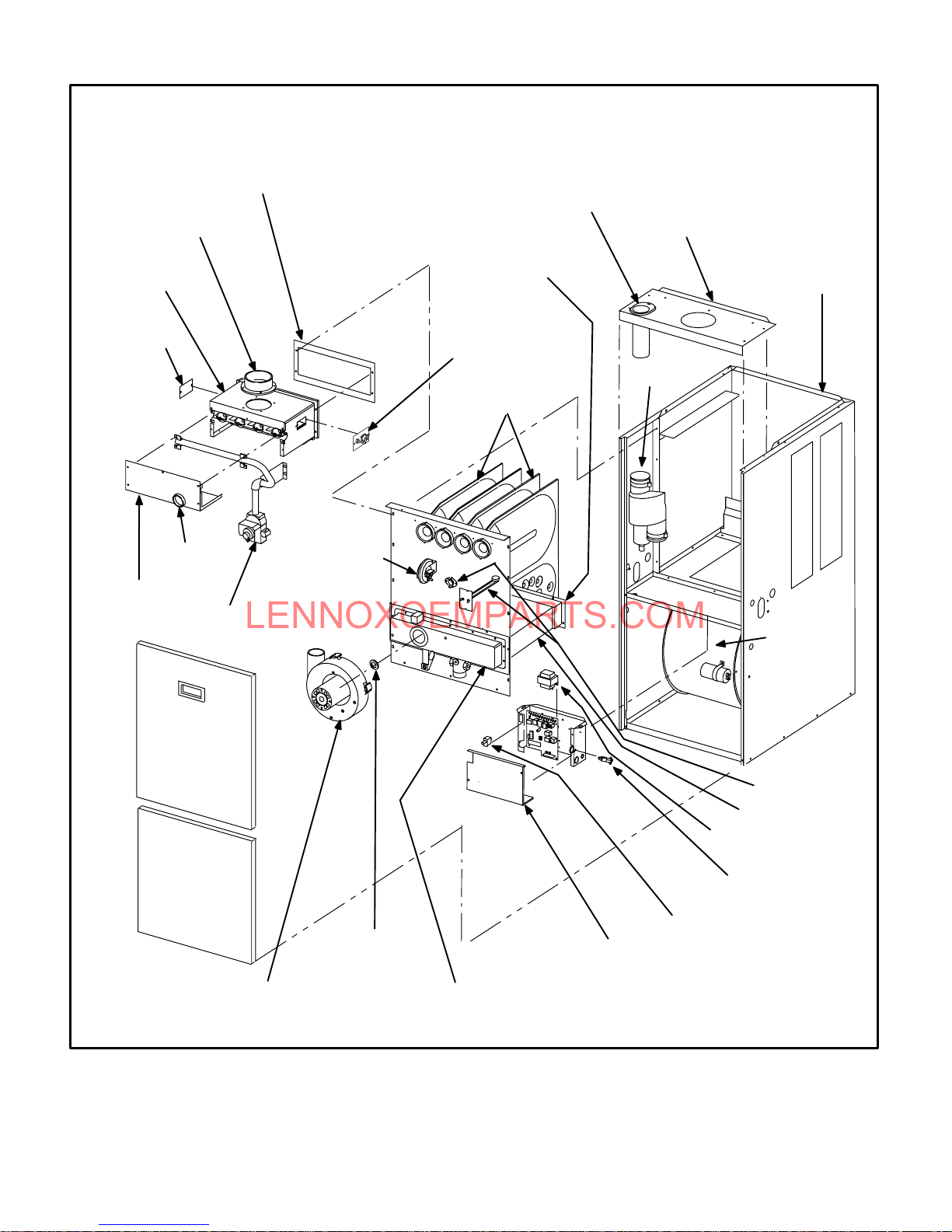

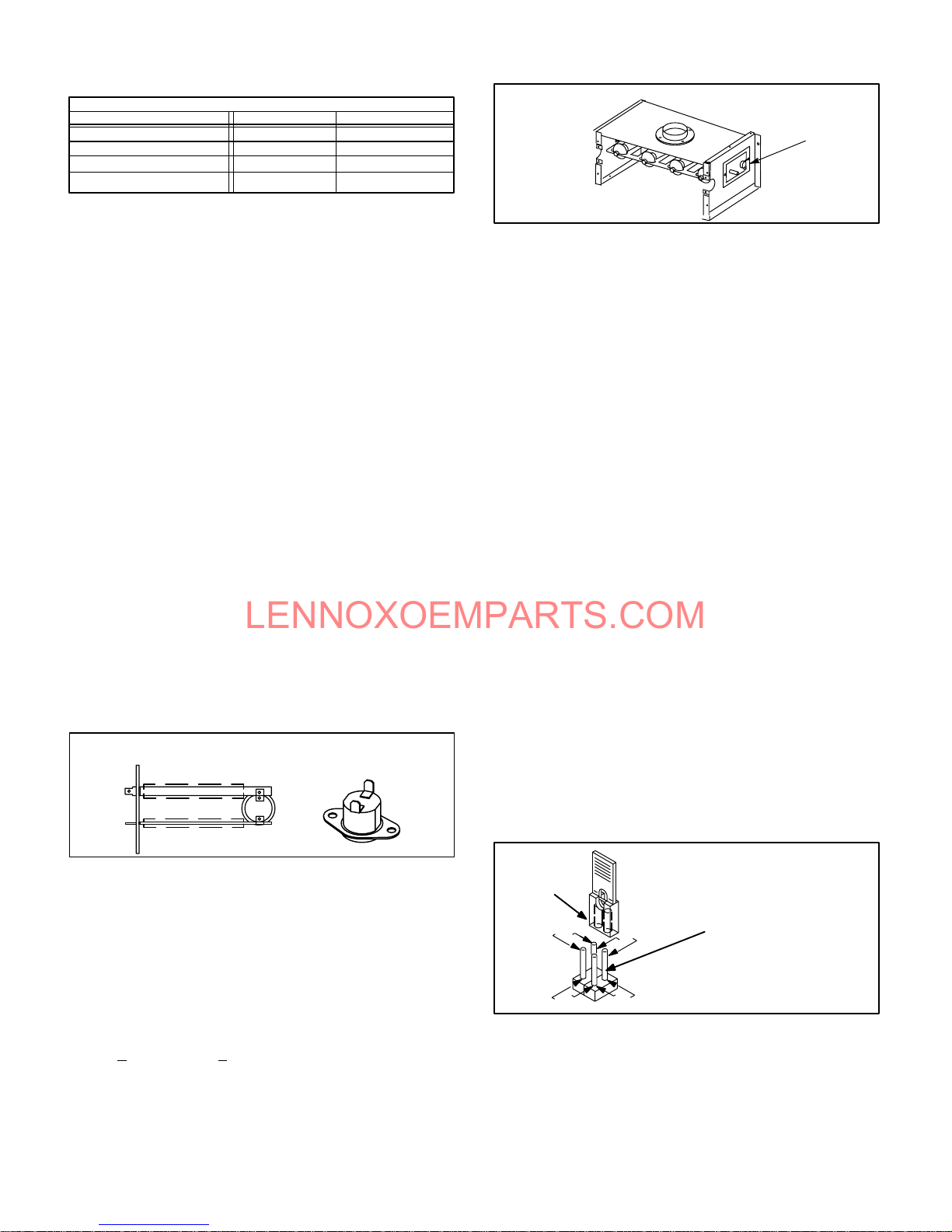

G26-3 THROUGH -6 COMPONENTS

FLUE COLLAR

WARM

HEADER

(COLLECTOR)

BOX

PATCH PLATE WITH

BARBED FITTING

AND FLAME

ROLL-OUT SWITCH

DuralokPlus

HEAT EXCHANGER

ASSEMBLY

TM

TOP CAP

CABINET

FLUE

TRANSITION

FLAME SIGHT

BURNER

BOX

COVER

GLASS

GAS VALVE AND

MANIFOLD

BURNER

ACCESS

PANEL

BLOWER

ACCESS

DOOR

COMBUSTION AIR

BLOWER

COMBUSTION AIR

PROVE (PRESĆ

SURE) SWITCH

COMBUSTION AIR

ORIFICE

COLD HEADER

(COLLECTOR)

BOX

CONTROL TRANSFORMER

DOOR INTERLOCK

CONTROL BOX COVER

SUPPLY

AIR

BLOWER

PRIMARY LIMIT

(ALTERNATE STYLES)

CONDENSER COIL

CONTROL VOLTĆ

AGE

CIRCUIT BREAKER

SWITCH

FIGURE 1

Page 7

Page 8

LENNOXOEMPARTS.COM

BURNER

ACCESS

COVER

BURNER BOX

MANIFOLD

GAS VALVE

FRESH AIR INTAKE

FITTING

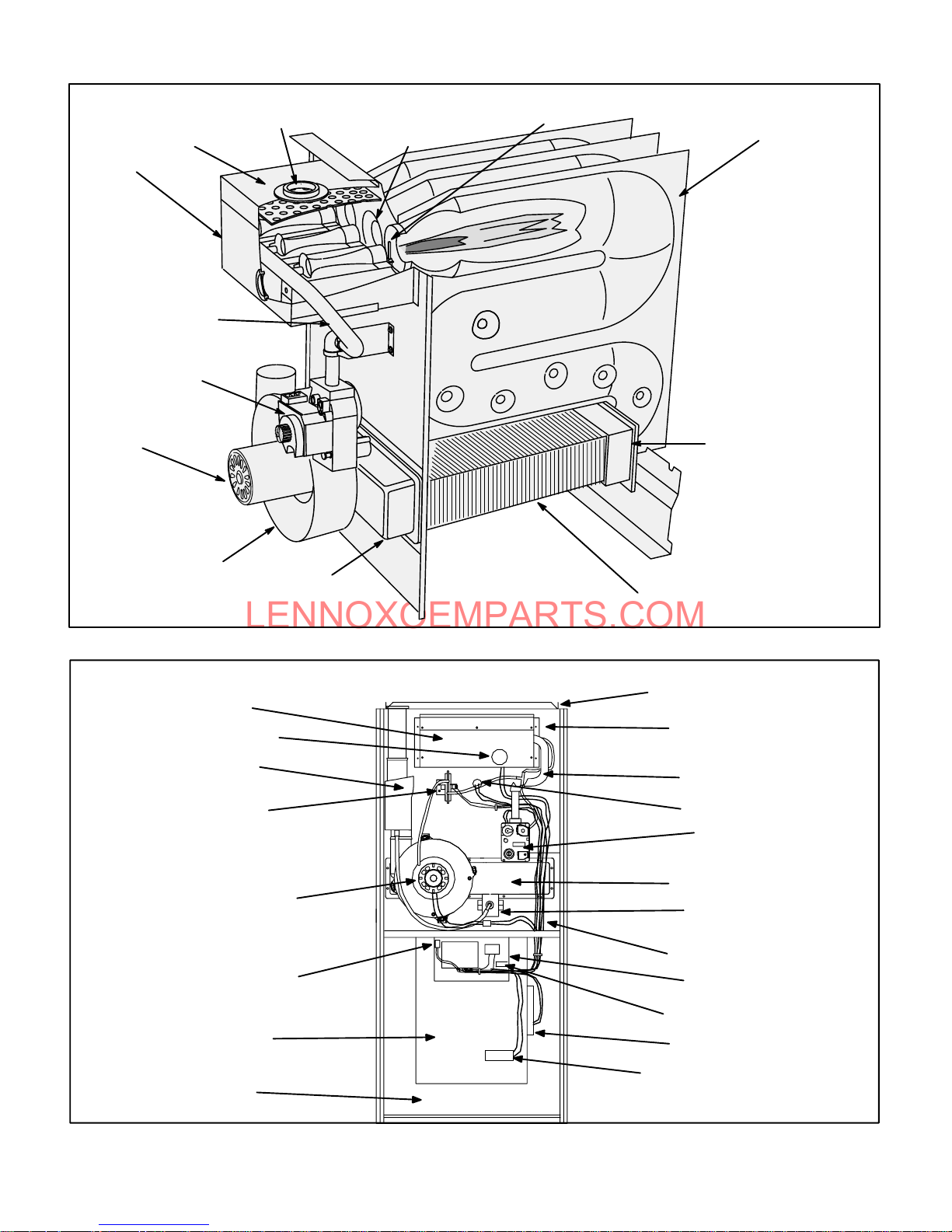

G26 HEAT EXCHANGER

CORBEL ORIFICE

CUPS

SURELIGHT IGNITOR LENNOX DURALOKPLUS

HEAT EXCHANGER ASĆ

SEMBLY

COMBUSTION AIR

BLOWER MOTOR

COMBUSTION

AIR BLOWER

BURNER

FLAME SIGHT GLASS

FLUE TRANSITION

DIFFERENTIAL

(COMBUSTION AIR)

PRESSURE SWITCH

BOX

COLD HEADER

(COLLECTOR )

BOX

FIGURE 2

G26 GENERAL PARTS ORIENTATION

WARM HEAD

(COLLECTOR)

BOX

CONDENSER COIL

SUPPLY AIR DUCT

FLANGE

UPPER VEST PANEL

GAS MANIFOLD

PRIMARY LIMIT

GAS VALVE

COMBUSTION AIR BLOWER

DOOR INTERLOCK

SWITCH

BLOWER HOUSING

BLOWER

COMPARTMENT

FIGURE 3

COLD HEADER BOX

HEADER BOX

CONDENSATE

TRAP

LOWER VEST PANEL

CONTROL BOX

CIRCUIT BREAKER

BLOWER MOTOR

BLOWER MOTOR CAPACITOR

Page 8

Page 9

LENNOXOEMPARTS.COM

OUTSIDE INSTALLATION

MAKEĆUP BOX

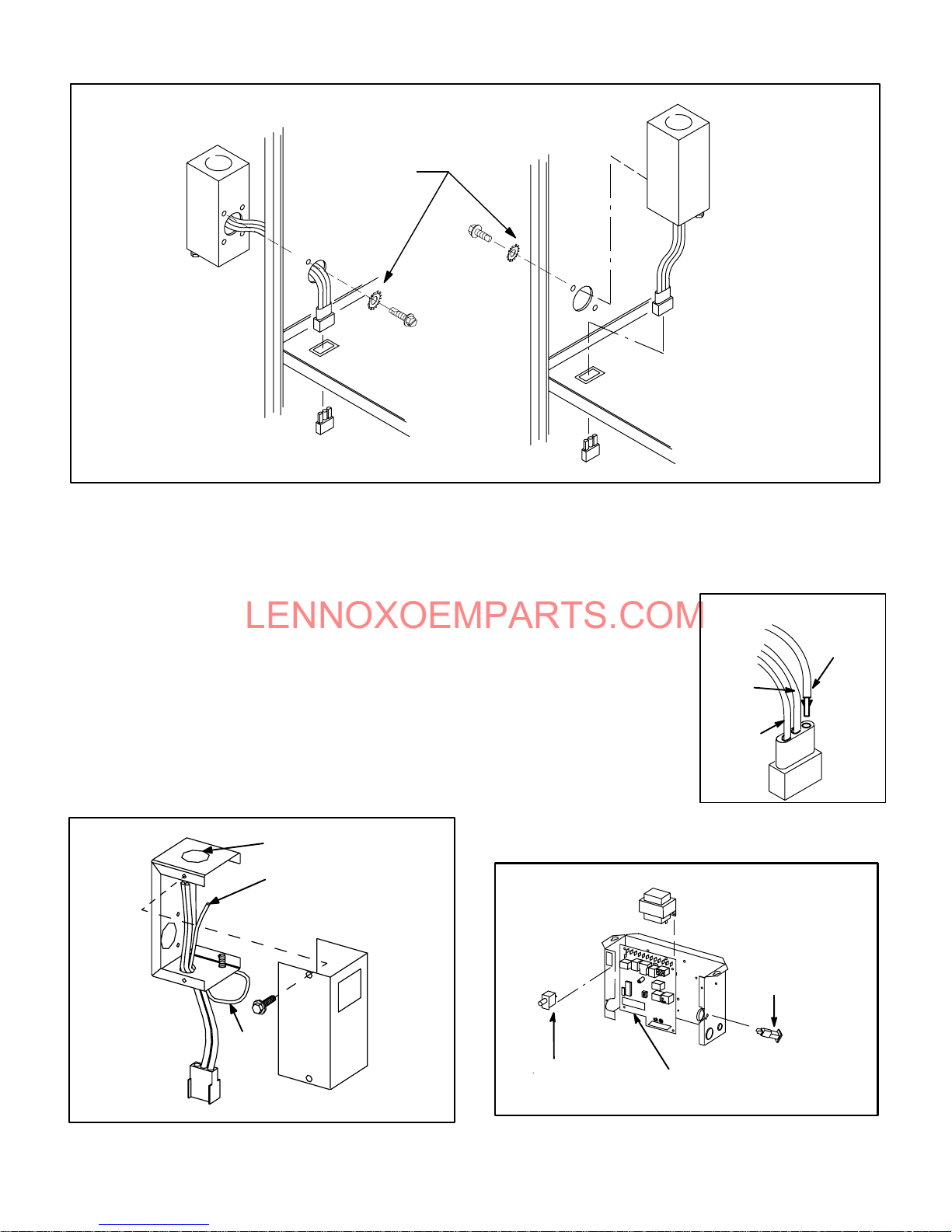

MAKEĆUP BOX INSTALLATION

Box may be installed inside or outside cabinet and may

be installed on left side or right side of cabinet

STAR WASHERS

MUST BREAK

PAINT ON UNIT

CABINET FOR

PROPER

GROUND.

UNIT

CABINET

INSIDE INSTALLATION

MAKEĆUP BOX

Line Voltage Enters Through

Knockout In MakeĆUp Box. J69

Passes Through Side Knockout

Into Side Of Unit.

JACK J69

BLOWER MULLION

PLUG P69

FIGURE 4

I-UNIT COMPONENTS

G26 unit components are shown in figure 1. General parts oriĆ

entation is shown in figure 3. The gas valve, ignition control

and burners can be accessed by removing the burner access

panel. The blower and blower controls can be accessed by

removing the blower access door.

G26 units are designed for bottom and side return air. The

panels are designed to be knockedĆout (bottom return) or

cutĆout (side return) as required for return air duct connecĆ

tion.

A-MakeĆUp Box (Figure 5)

The line voltage makeĆup box is shown in figure 5. The box

may be installed inside or outside the unit and may be

installed on the unit left or right side (figure 4).

MAKEĆUP BOX

BOX

POWER ENTRY KNOCKOUT

120V LINE VOLTAGE

PIGTAIL CONNECTIONS

COVER

Line Voltage Enters MakeĆUp

Box Through Side Of Unit and

J69 Passes Through Bottom

Knockout in MakeĆUp Box.

BLOWER MULLION

An accessory (brown) output wire is provided with the makeĆ

up box. The wire provides a 120V connection for optional acĆ

cessories such as electronic air cleaner or humidifier. If used,

the wire is field installed in J69 jack plug by inserting the pin

of the brown wire into the open

socket of the jack. See figure

6. 120V accessories rated up

to 4 amps total may be conĆ

nected to this wire. The neutral

leg of the accessory is conĆ

INSTALLING BROWN

ACCESSORY WIRE TO J69

BROWN

WHITE

NEUTRAL

nected to the neutral white

wire in the makeĆup box. The

accessory terminal is enerĆ

gized whenever the blower is

in operation.

BLACK

J69

FIGURE 6

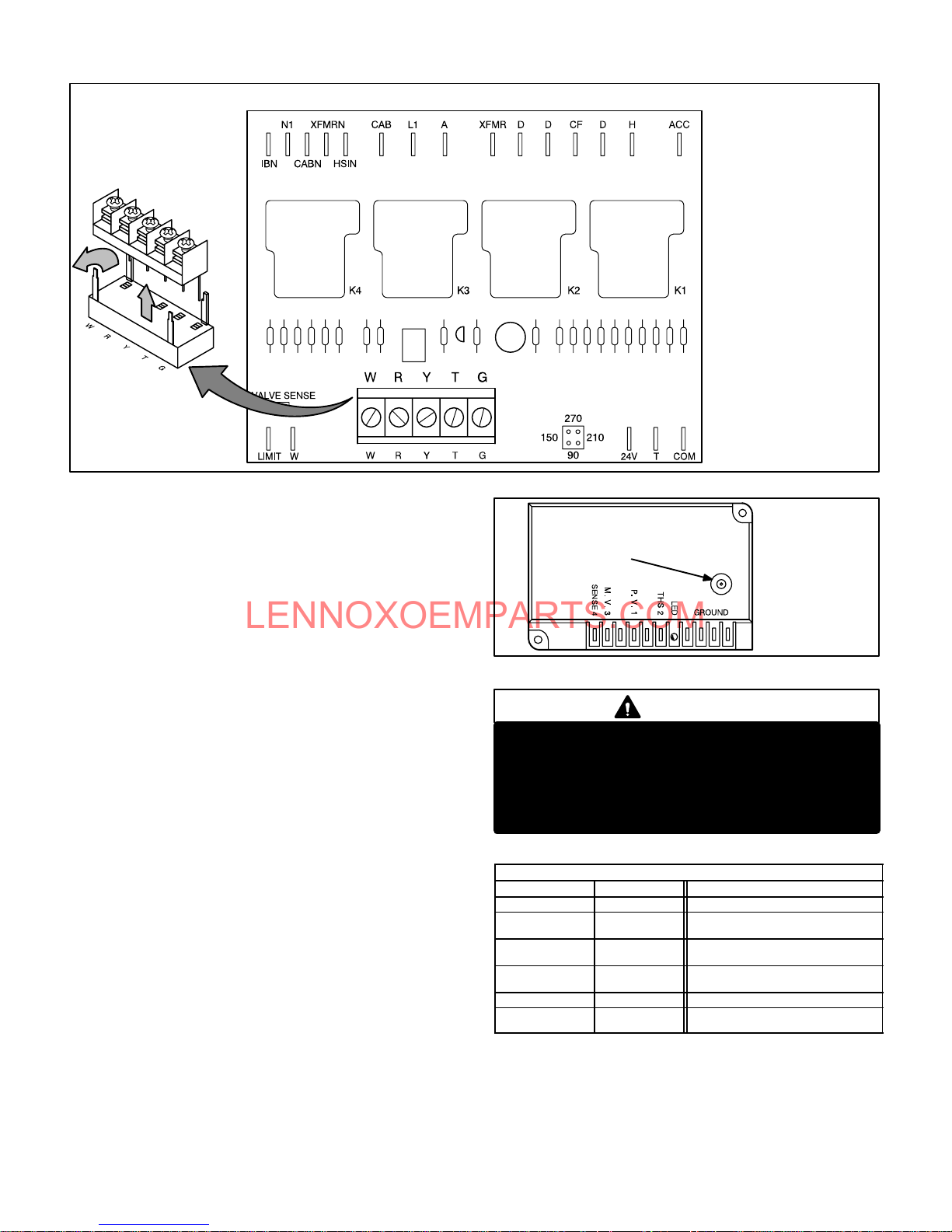

B-Control Box Components

G26 CONTROL BOX

TRANSFORMER

UNIT

GROUND

JACK J69

to blower deck

Box may be installed inside or outside unit. See Figure 4

TO BLOWER MULLION

FIGURE 5

Page 9

DOOR

INTERLOCK

SWITCH

SURELIGHT CONTROL

(-3 through -6 models )

FIGURE 7

CIRCUIT

BREAKER

Page 10

LENNOXOEMPARTS.COM

Electrical blower control components (A15), unit transformĆ

er (T1) and 24V circuit breaker (CB8) are located in the conĆ

trol box. In addition, a door interlock switch (S51) is located

in the control box. Jackplugs and a snapĆoff" terminal strip

allow the control box to be easily removed for blower serĆ

vice.

1- Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage 24volt section of the unit. Transformers on

all models are rated 40VA with a 120V primary and a 24V

secondary.

2- Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box. The

switch provides overcurrent protection to the transformer

(T1). The breaker is rated 3A at 32V. If the current exceeds

this limit the breaker will trip and all unit operation will shutĆ

down. The breaker can be manually reset by pressing the

button on the face.

3-Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VAC is located on

the control box. The switch is wired in series with line voltĆ

age. When the blower door is removed the unit will shut

down.

4-Flame Sensor (-3 through -6 models)

A flame sensor is located on the left side of the burner supĆ

port. See figure 8. The sensor is mounted on a bracket in

the burner support and the tip protrudes into the flame enĆ

velope of the left-most burner. The sensor is fastened to

burner supports and can be removed for service without

removing any part of the burners. During operation, flame

is sensed by current passed through the flame and sensĆ

ing electrode. The SureLight control allows the gas valve

to remain open as long as flame signal is sensed.

NORMAL FLAME SIGNAL u 0.7 MICROAMPS

LOW FLAME SIGNAL v 0.7 MICROAMPS

MINIMUM FLAME SIGNAL v 0.15 MICROAMPS

SENSOR

3/8"

FIGURE 8

NOTE - The G26 furnace contains electronic compoĆ

nents that are polarity sensitive. Make sure that the

furnace is wired correctly and is properly grounded.

IGNITOR

5/16"

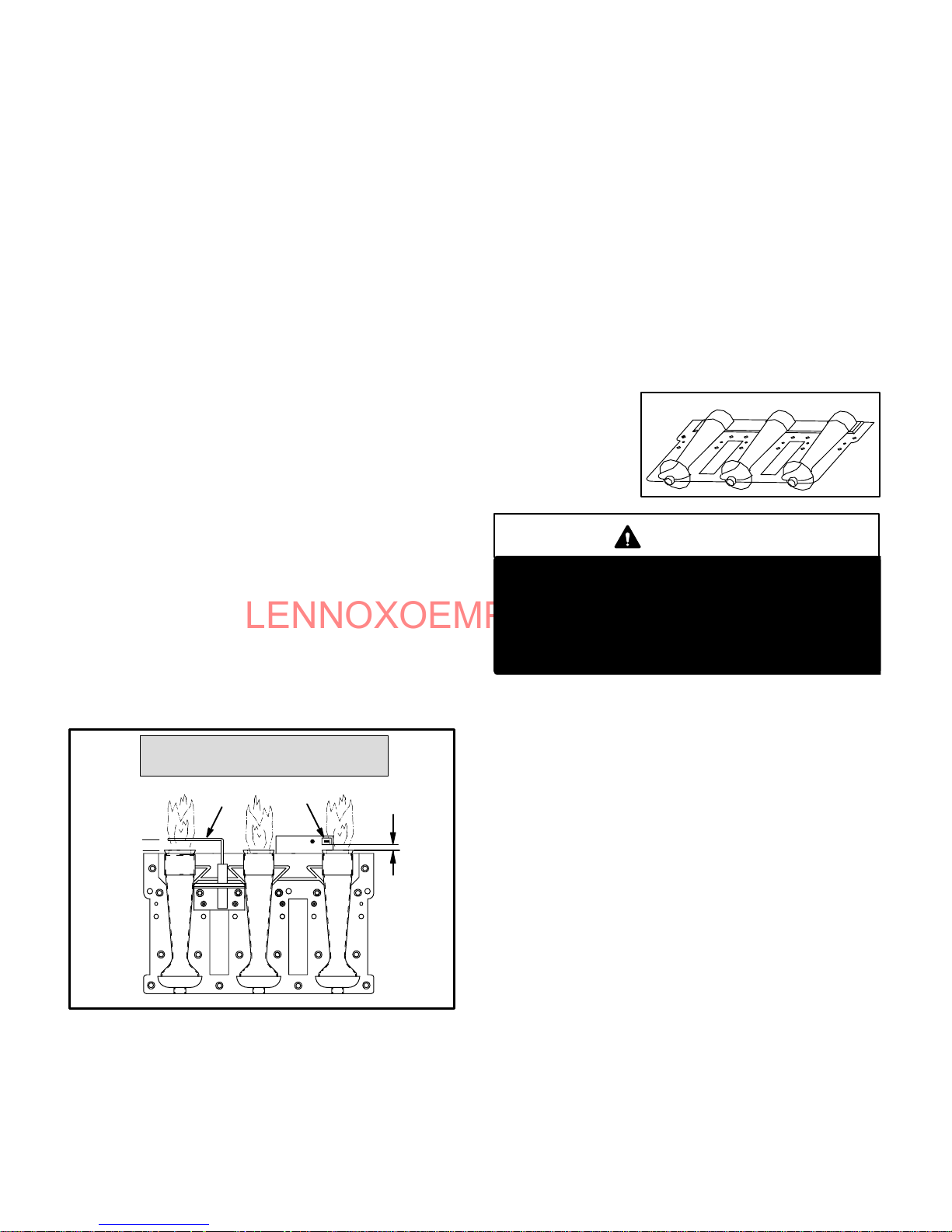

5-Burners

All units use inshot burners (see figure 9). Burners are factory

set and do not require adjustment. A sigh t gl as s is furĆ

nished in the burner box assembly for flame viewing. AlĆ

ways operate the unit with the burner box cover in place.

Burners can be removed as an assembly for service. Burner

maintenance and service is detailed in the MAINTENANCE

section of this manual. Each burner uses an orifice which is

precisely matched to the burner input (see nameplate for

orifice size). The orifice is threaded into the burner manĆ

ifold. The burner is supported by the orifice and will easily

slide off for service. Each orifice and burner are sized speĆ

cifically to the unit. Refer to Lennox Repair Parts Listing for

correct sizing information. A flame retention ring in the end of

each burner maintains correct flame length and shape and

keeps the flame from lifting off the burner head. In addition,

the burner entrance to each clamshell (Figure 2) is fitted with

a corbel cup (orifice)

used to direct the

flow of combustion

products.

TYPICAL BURNER ASSEMBLY

FIGURE 9

DANGER

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply

replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

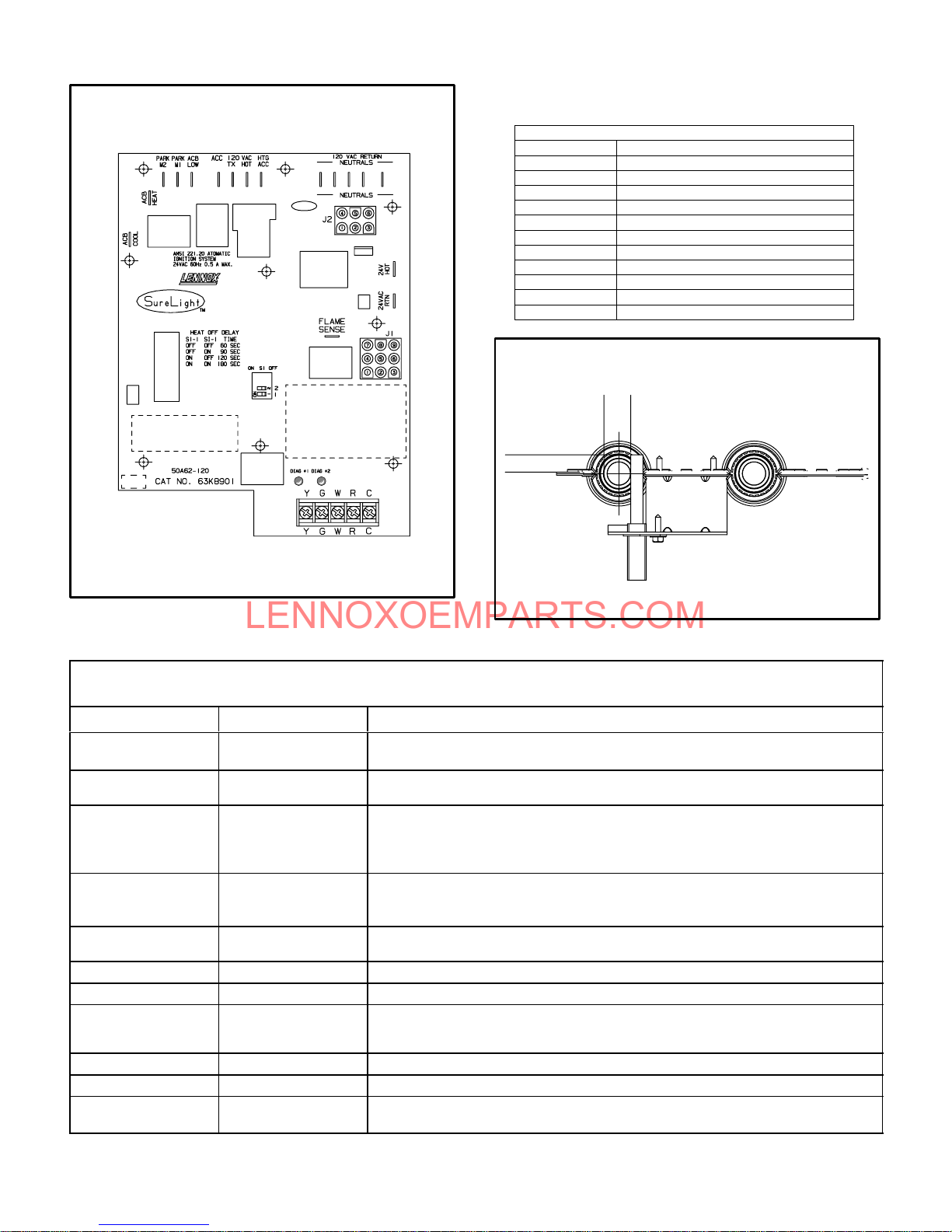

6- SureLight Ignition System A3

(-3 through -6 models)

All G26-3 through -6 model units are equipped with the

Lennox Sure - Light ignition system. The system consists

of ignition control board (figure 10 with control terminal

designations in table 1) and ignitor (figures 8 and 11). The

board and ignitor work in combination to ensure furnace

ignition and ignitor durability. The SureLight integrated

board controls all major furnace operations. The board

also features two LED lights for troubleshooting and two

accessory terminals rated at (4) four amps. See table 2

for troubleshooting diagnostic codes. Table 3 and 4 show

jack plug terminal designations. Units equipped with the

SureLight board can be used with either electronic or

electro-mechanical thermostats without modification.

The SureLight ignitor is made of durable silicon-nitride.

Ignitor longevity is also enhanced by voltage ramping by

the control board. The board finds the lowest ignitor temĆ

perature which will successfully light the burner, thus inĆ

creasing the life of the ignitor.

NOTE - Do not remove blower access panel to read

SureLight LED lights. A sight glass is provided on the

access panel for viewing.

Page 10

Page 11

LENNOXOEMPARTS.COM

SURELIGHT CONTROL BOARD

TABLE 1

SURELIGHT CONTROL TERMINAL DESIGNATIONS

ACB COOL

ACB HEAT

PARK

ACB LOW

ACC

TX

HOT

HTG ACC

NEUTRALS

24VAC HOT

24VAC RTN

FLAME SENSE

Blower - Cooling Speed (Line Volt)

Blower - Heating Speed (Line Volt)

Alternate Blower Speeds (Dead)

Continuous Low Speed Blower

Accessory Terminal (Line Volt)

120VAC Hot to Transformer

120VAC Hot Input

Heat Only Accessory (Line Volt)

120VAC Neutrals

24VAC Hot from Transformer

24VAC Return from Transformer

Flame Sense Terminal

SURELIGHT IGNITOR

MEASUREMENT IS TO I.D.

5/8"

OF RETENTION RING

13/32'

FIGURE 10

FIGURE 11

TABLE 2

DIAGNOSTIC CODES

MAKE SURE TO ID LED'S CORRECTLY: REFER TO INSTALLATION INSTRUCTIONS FOR CONTROL BOARD LAYOUT.

LED #1 LED #2 DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS FAST

FLASH

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS FAST

FLASH

Also signaled during cooling and continues fan.

Normal operation - signaled when heating demand initiated at thermostat.

Primary or Secondary limit open. Units with board 63K8901 or 24L85: Limit must

SLOW FLASH ON

close within 5 trials for ignition or board goes into one hour limit Watchguard.

Units with board 56L83 or 97L48: Limit must close within 3 minutes or board

Pressure switch open or has opened 5 times during a single call for heat; OR:

OFF SLOW FLASH

Blocked inlet/exhaust vent; OR: Condensate line blocked; OR: Pressure switch

closed prior to activation of combustion air blower.

ALTERNATING SLOW

FLASH

SLOW FLASH OFF

ON SLOW FLASH

ON

ON

OFF

FAST FLASH SLOW FLASH

SLOW FLASH FAST FLASH

ALTERNATING FAST

FLASH

NOTE - Slow flash equals 1 Hz (one flash per second). Fast flash equals 3 Hz (three flashes per second). Drop out flame sense current < 0.15 microAmps

ALTERNATING SLOW

FLASH

ON

OFF

ON

ALTERNATING FAST

FLASH

Flame sensed without gas valve energized.

Rollout switch open. OR: 9 pin connector improperly attached.

Circuit board failure or control wired incorrectly.

Main power polarity reversed. Switch line and neutral.

Low flame signal. Measures below .7 microAmps. Replace flame sense rod.

Improper main ground or line voltage below 75 volts; OR: Broken ignitor; OR:

Power - Normal operation

goes into one hour limit Watchguard.

Watchguard - burners fail to ignite.

Open ignitor circuit.

Page 11

Page 12

LENNOXOEMPARTS.COM

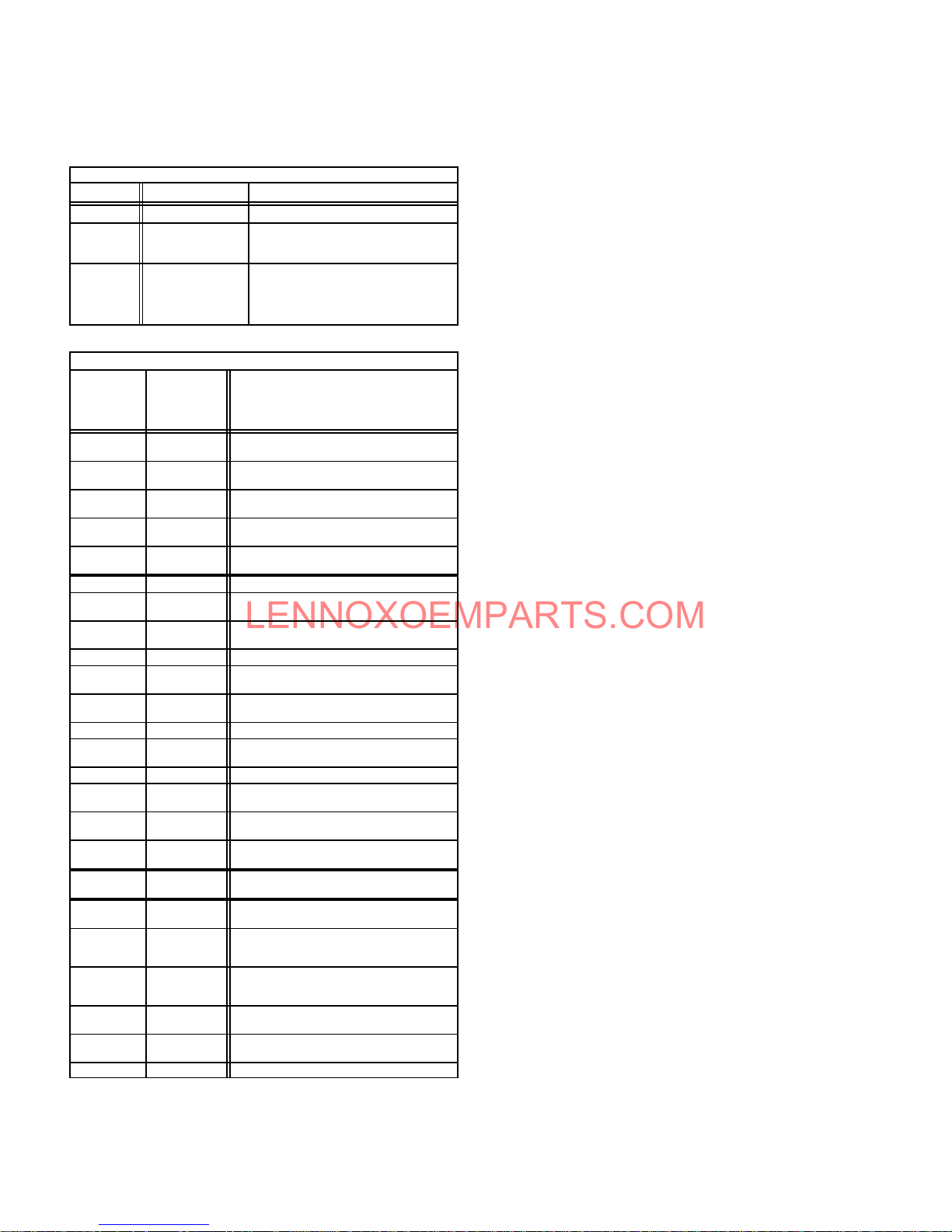

TABLE 3

SureLight BOARD J156 (J2) TERMINAL

PIN # FUNCTION

1 Ignitor

2

3

4

5

6

DESIGNATIONS

Not Used

Ignitor Neutral

Combustion Air Blower Line Voltage

Not Used

Combustion Air Blower Neutral

TABLE 4

SureLight BOARD J58 (J1) TERMINAL

PIN # FUNCTION

1 Primary Limit In

2

3

4

5

6

7

8

9

DESIGNATIONS

Gas Valve Common

Roll Out Switch Out

Gas Valve 24V

Pressure Switch In

Pressure Switch and Primary Limit Out

Not Used

Roll Out Switch In

Ground

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace's

electronic controls. Precautions will help to

avoid control exposure to electrostatic disĆ

charge by putting the furnace, the control and

the technician at the same electrostatic potenĆ

tial. Neutralize electrostatic charge by touching

hand and all tools on an unpainted unit surface,

such as the gas valve or blower deck, before perĆ

forming any service procedure.

a-Electronic Ignition

On a call for heat the SureLight control monitors the comĆ

bustion air blower pressure switch. The control will not beĆ

gin the heating cycle if the pressure switch is closed (bypassed). Once the pressure switch is determined to be

open, the combustion air blower is energized. When the

differential in the pressure switch is great enough, the

pressure switch closes and a 15-second pre-purge beĆ

gins. If the pressure switch is not proven within 2-1/2 minĆ

utes, the control goes into Watchguard-Pressure Switch

mode for a 5-minute re-set period.

After the 15-second pre-purge period, the SureLight igniĆ

tor warms up for 20 seconds after which the gas valve

opens for a 4-second trial for ignition. G26 units with board

63K89, 24L85 or 56L83: the ignitor stays energized for the

first second of the 4-second trial. Units with board 97L48:

ignitor stays energized for the full 4-second ignition trial. If

ignition is not proved during the 4-second period, the conĆ

trol will try four more times with an inter purge and warm-up

time between trials of 35 seconds. After a total of five trials

for ignition (including the initial trial), the control goes into

Watchguard-Flame Failure mode. After a 60-minute reset

period, the control will begin the ignition sequence again.

The SureLight control board has an added feature that

prolongs the life of the ignitor. After a successful ignition,

the SureLight control utilizes less power to energize the igĆ

nitor on successive calls for heat. The control continues to

ramp down the voltage to the ignitor until it finds the lowest

amount of power that will provide a successful ignition.

This amount of power is used for 255 cycles. On the 256th

call for heat, the control will again ramp down until the lowĆ

est power is determined and the cycle begins again.

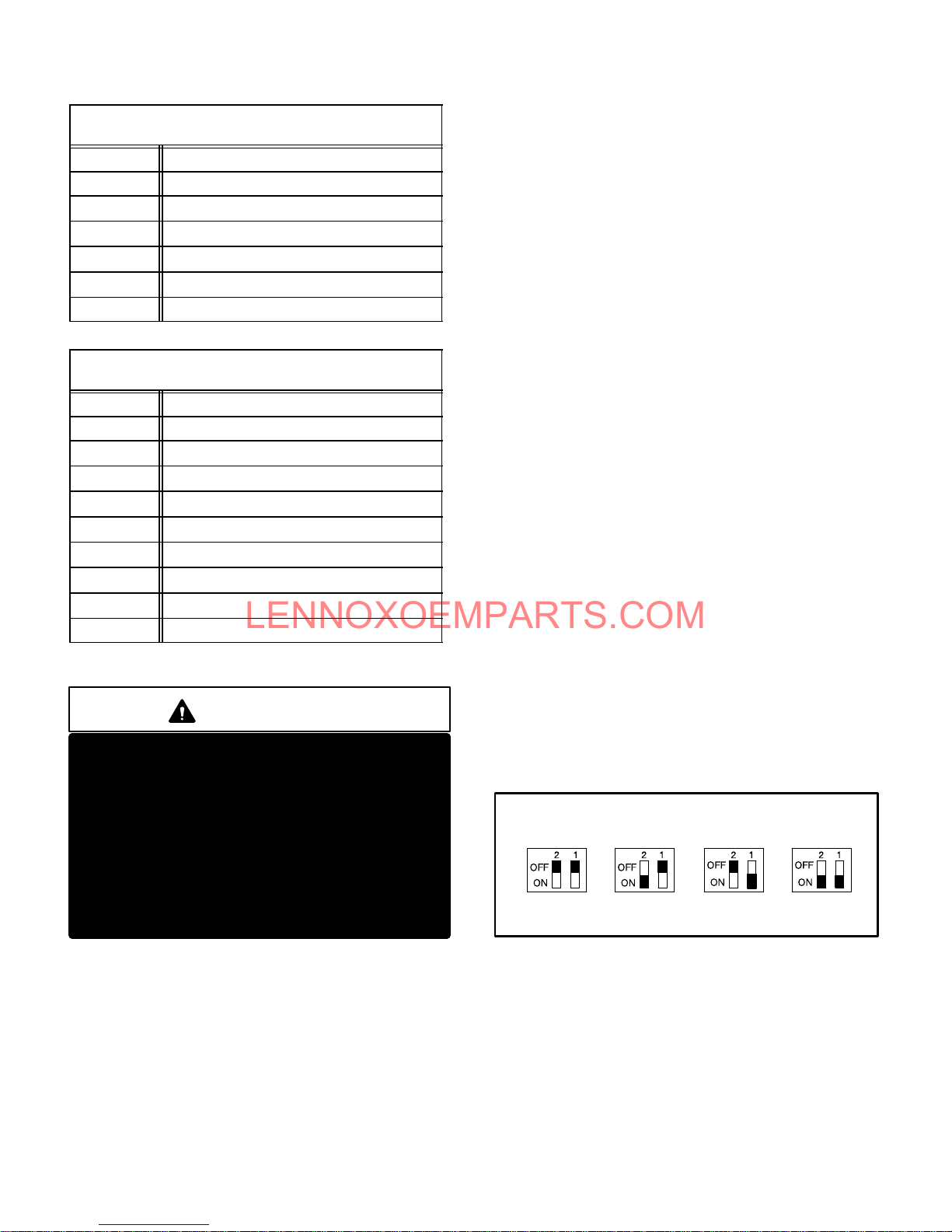

b-Fan Time Control

The fan on time of 45 seconds is not adjustable. Fan off

time (time that the blower operates after the heat demand

has been satisfied) can be adjusted by flipping the dip

switches located on the SureLight integrated control. The

unit is shipped with a factory fan off setting of 90 seconds.

Fan off time will affect comfort and is adjustable to satisfy

individual applications. See figure 12.

FANĆOFF TIME ADJUSTMENT

60sec. 90sec. 120sec. 180sec.

To adjust fan-off timing, flip dip switch to desired setting.

FIGURE 12

7-Blower Motors and Capacitors

All G26 units use direct drive blower motors. All motors

used are 120V permanent split capacitor motors to ensure

maximum efficiency. See table 5 for ratings.

Page 12

Page 13

LENNOXOEMPARTS.COM

TABLE 5

BLOWER MOTOR HP

G26Q2

G26Q3

G26Q3/4

G26Q4/5

G26 BLOWER RATINGS 120V 1PH

1/5

1/3

1/2

3/4 40MFD 370V

CAP

5MFD 370V

5MFD 370V

7.5MFD 370V

8-Combustion Air Blower (B6)

All G26 units use a combustion air blower to move air

through the burners and heat exchanger during heating opĆ

eration. The blower uses a PSC or shaded Pole 120VAC

motor. PSC motors use run capacitors. The motor operates

during all heating operation and is controlled by blower conĆ

trol A15. The blower operates continuously while there is a

call for heat. The ignition control is prevented from proceedĆ

ing through the ignition sequence until combustion air blower

operation is sensed by the prove switch.

The pressure switch connected to the combustion air blower

housing is used to prove combustion air blower operation.

The switch monitors air pressure in the blower housing. DurĆ

ing normal operation, the pressure in the housing is negaĆ

tive. If the pressure drops (becomes more positive), the

pressure switch opens. When the pressure switch opens,

the ignition control (A3) immediately closes the gas valve to

prevent burner operation.

9-Primary Limit Control (S10)

The primary limit (S10) on G26 units is located in the

middle of the heating vestibule panel. When excess heat

is sensed in the heat exchanger, the limit will open. If the

limit is tripped, the furnace control energizes the supply air

blower and de-energizes the gas valve. The limit automatiĆ

cally resets when unit temperature returns to normal. The

switch is factory set and cannot be adjusted. The switch

may have a different setpoint for each unit model numĆ

ber. However, the setpoint will be printed on the side of

the limit.

SPADE CONNECTORS

G26 SERIES UNITS AND ALTERNATE STYLE

LIMIT CONTROL (S10) FOR

Units may be equipped with either style limit.

LIMIT

INSULATING COVER (s)

FIGURE 13

10-Rollout Switch (S47) -3 Through -6

Flame rollout switch S47 is a SPST N.C. high temperature

limit located on the right side of the burner box assembly (see

figure 14). S47 is wired to the burner ignition control A3.

When S47 senses flame rollout (indicating a blockage

in the combustion passages), the flame rollout switch

trips, and the ignition control immediately closes the

gas valve.

Switch S47 in all G26 units is factory preset to open at

200F + 12F (93C + 6.7C) on a temperature rise. All

flame rollout switches are manually reset. A kit (#65K60) is

available for G26 -1 and -2 models.

FLAME ROLLOUT SWITCH (S47)

FLAME ROLLOUT

SWITCH (S47)

FIGURE 14

11- BCC2-3 Blower Control A15

(-1 and -2 models)

All G26-2 and -1 model units utilize the BCC2Ć3 blower conĆ

trol manufactured by Heatcraft. The BCC2Ć3 is a printed cirĆ

cuit board which controls the supply air blower and monitors

primary limit and gas valve operation. The control has a

nonĆadjustable, factory preset fanĆon" timing. Fan off" timĆ

ing is adjustable. The board is divided into two sections,

120 and 24VAC. Line voltage comes into the board on the

120VAC side. See figure 16.

Fan Timings

Fan off" timing (time that the blower operates after the heat

demand has been satisfied) is determined by the arrangeĆ

ment of a jumper across pins on the BCC2Ć3 blower control

board. See figure 15. To adjust fan off " timing, gently disĆ

connect jumper and reposition across pins corresponding

with new timing. Fan on" time is factory set at 45 seconds

and is not adjustable.

NOTEĊIf fan off" time is set too low, residual heat in

heat exchanger may cause primary limit S10 to trip reĆ

sulting in frequent cycling of blower. If this occurs, adĆ

just blower to longer time setting.

Figure 15 shows the various fan off" timings and how jumper

should be positioned. Unit is shipped with a factory fan off"

setting of 90 seconds. Fan off" time will affect comfort and

efficiency and is adjustable to satisfy individual applications.

The fan off" timing is initiated after a heating demand but not

after a blower or cooling demand (that is, when indoor therĆ

mostat switch is changed from ON to AUTO and heating/

cooling demand is not present, the blower stops immediateĆ

ly).

FANĆOFF TIME ADJUSTMENT

To adjust fanĆoff timing:

TIMING

JUMPER

270

150

Remove jumper from BCC2Ć3 and seĆ

lect one of the other pin combinations

to achieve the desired time.

210

90

TIMING

PINS

(seconds)

Leave jumper off for

330 second fanĆoff timing.

FIGURE 15

Page 13

Page 14

LENNOXOEMPARTS.COM

G26 BLOWER CONTROL Ć BCC2Ć3 (A15)

DETACHABLE

STRIP ON EARLY

BOARDS ONLY

Table 8 shows

terminal designations.

FIGURE 16

12-Ignition Control (-1 and -2 models)

G26 -1 and -2 model units use an intermittent pilot ignition

manufactured by Johnson Controls. The ignition control is

located on the upper vest panel.

Unit Operation

When there is a call for heat, the control is prevented from

beginning an ignition sequence until the pressure switch

proves combustion air blower operation. When the pressure

switch closes, the control generates a spark and opens the

pilot valve to ignite the pilot. When flame is sensed, the conĆ

trol opens the main gas valve and the pilot ignites the main

burners. The indoor blower starts after a 45 second delay.

Gas valve remains open and combustion air blower continĆ

ues to run until demand stops, flame sensor senses loss of

flame, a limit opens or the prove switch opens. If any of these

events occur during a thermostat demand, the gas valve

closes.

The control will attempt ignition for 85 seconds. If ignition is

not successful, the control will lockout (indicated by flashĆ

ing LED). Within one hour the control will momentarily reĆ

move then reapply the thermostat signal and the ignition

sequence will begin again (Watchguard circuit). If pilot

ignition is successful, but flame is lost when the main valve

opens, the ignition sequence will retry up to 15 more times.

If ignition is not successful after the 16th try, the control will

shutĆdown and must be reset manually. Manual reset is

accomplished by removing thermostat demand for at least

2 seconds then reapplying demand.

Table 8 shows

terminal designations.

IGNITION CONTROL A3

SPARK

OUTPUT

SEE TABLE 6

FOR TERMINAL

DESIGNATIONS

FIGURE 17

DANGER

Shock hazard. Spark related components contain

high voltage. Disconnect power before servicing.

Control is not field repairable. If control is inoperĆ

able, simply replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

TABLE 6

IGNITION CONTROL A3 TERMINAL DESIGNATIONS

Terminal Type Function

GROUND 1/4" Spade Cabinet Ground

THS 2 1/4" Spade

P. V. 1 1/4" Spade

M.V.3 1/4" Spade

SENSE 4 1/4" Spade Microamp Flame Sensing Input

Unmarked

Pin Type

Bare Wire

Safety Limit 24VAC Input

From Differential Switch

24VAC Output to Pilot Operator

24VAC Output to Main Operator

of Gas Valve

of Gas Valve

High Voltage Spark Output

Page 14

Page 15

LENNOXOEMPARTS.COM

Diagnostic LED

The furnace control is equipped with a diagnostic LED

used for troubleshooting the unit and the control. LED

functions are shown in table 7.

TABLE 7

Furnace Control A3 Diagnostic LED

LED State Meaning Remedy

Steady On Normal Operation Ć Ć Ć Ć

Slow Flash

(1 sec. on/

5 sec. off)

Off

BLOWER CONTROL A15 TERMINAL DESIGNATIONS

Ter mi na l

(Designation

on Wiring

Diagram)

Y

G

R

W

T

IBN (N) 1/4" Spade 120VAC Indoor Blower Common

N1 (N) 1/4" Spade

CABN (N) 1/4" Spade

XFMRN(N) 1/4" Spade 120VAC Transformer Common

HSIN (N) 1/4" Spade

CAB 1/4" Spade

L1 1/4" Spade 120VAC Line Voltage In

A 1/4" Spade

XFMR 1/4" Spade 24VAC In From Transformer

D 1/4" Spade

CF 1/4" Spade

H 1/4" Spade

ACC 1/4" Spade

24V

(24)

LIMIT

(L)

W 1/4" Spade

VALV E

SENSE (V)

T 1/4" Spade

COM (C) 1/4" Spade 24VAC Common To Transformer

Control Retry

Period

Control Failure or

Power Failure or

Hard Lockout

Type Function

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

Detachable

Screw Strip

1/4" Spade 24VAC Input From Transformer

1/4" Spade

3/16" Spade 24VAC Input From Gas Valve

Failed to Sense Flame. Ignition ConĆ

If Power and Gas Supply are OK, Try

Removing T'stat Demand For At Least

30 Seconds. If LED Remains Off

When Demand Is Returned, Replace

trol Will Retry

Before Locking Out.

Control.

TABLE 8

Cooling Demand

Blower Demand

24VAC to Thermostat

Heating Demand

24VAC Common

To Indoor Thermostat

120VAC Neutral

(L2 Line Voltage Neutral)

120VAC Combustion Air Blower ComĆ

120VAC Hot Surface Ignition

Combustion Air Blower

to Blower Cooling Tap

Dummy Connection for

Unused Blower Leads

Continuous Blower Tap

Switched 120VAC to Accessory (ElecĆ

tronic Air Cleaner, Humidifier, Etc.)

24VAC In From Primary Limit. Limit

Open: Closes Gas Valve and Turns On

Blower Limit Closed: Allows Ignition

24VAC Thermostat Demand Output

Through Differential Switch to THS"

Terminal of Ignition Control

24VAC Common From

Ignition Control and Gas Valve

mon

Common (Not Used)

Switched 120VAC to

Switched 120VAC

Switched 120VAC to

Switched 120VAC to

Blower Heating Tap

Johnson G776 Ignition Control Operation

Th e infor ma tion in t his sec ti on is pro tected by a co py right iss ued by

Johnson Controls, Inc., and is reproduced with permission.

On a call for heat from indoor thermostat, the ignition control

energizes and ignition control LED lights (steady on). The

combustion air blower is energized. After 15 second preĆ

purge period, the control simultaneously opens pilot valve

and sends spark to pilot electrode.

If pilot ignites within 85 seconds, flame sensor detects pilot

flame and signals ignition control to energize the main

valve. The main valve cannot be energized until sensor

detects pilot flame. Spark continues until pilot flame is

sensed or 85 seconds has elapsed.

When pilot flame is sensed, main valve is energized and

spark turns off. The ignition control remains in run" mode

until indoor thermostat is satisfied or flame lost.

If pilot flame is not sensed before the end of the 85 second trial

for ignition, the control enters the 100% shutoff mode. The

spark circuit and pilot valve deĆenergize and the ignition conĆ

trol automatically begins the 60 minute retry delay period.

During the 60 minute delay the diagnostic LED continually

flashes on for one second and off for five seconds. After the

delay period, another trial for ignition sequence starts, beginĆ

ning with preĆpurge.

If pilot flame goes out while the indoor thermostat is calling

for heat, both main and pilot valves deĆenergize within 0.8

seconds and remain deĆenergized for five seconds. After

this delay, the spark and pilot valve energize until flame is

sensed or the 85 second trial for ignition period ends. If this

flameout" cycle repeats 16 times (pilot flame is estabĆ

lished and then lost), the control locks out and the LED

goes off. A new trial for ignition sequence begins after the

thermostat contacts are opened for 2 seconds and then

closed.

If flame is detected when the thermostat calls for heat, it

must extinguish within 30 seconds for normal operation. If

flame is still present after 30 seconds, the control goes into

lockout and the LED goes off.

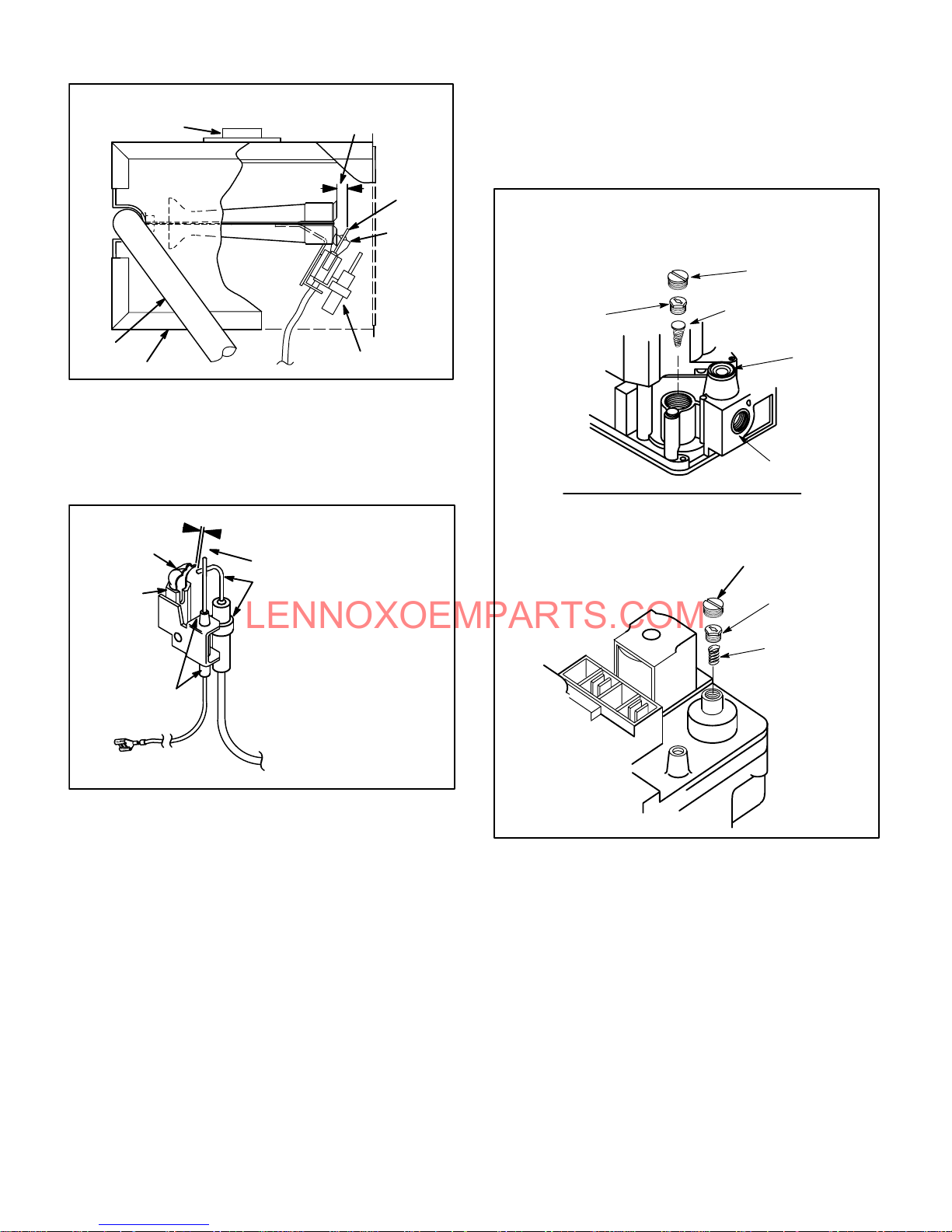

13-Pilot, Spark Electrode, Flame Sensor

(-1 and -2 models)

Figure 18 shows the arrangement of pilot, flame sensor,

spark electrode and burners. The ignition control uses diĆ

rect spark to ignite the pilot. The pilot ignites the burners

and the burners crossĆlight. The flame sensor uses flame

rectification to sense pilot ignition. The ignition control reĆ

quires that pilot flame must be sensed before the main gas

valve is allowed to open. Typically, a 2 to 4 second delay

occurs between the pilot ignition and the main valve openĆ

ing. Figure 19 shows the gap between the tip of the elecĆ

trodes and the burner surface. It is important that the gap

be maintained for consistent ignition of pilot flame.

Page 15

Page 16

LENNOXOEMPARTS.COM

TYPICAL BURNER PILOT/ELECTRODE ORIENTATION

FRESH AIR INTAKE

MANIFOLD

BURNER BOX

view looking at side of burners

GAP

BURNERS

FLAME SENSOR

SPA RK

ELECĆ

TRODE

PILOT

HOOD

FIGURE

18

Both pilot and main burner flame should be predominantly

blue and strong in appearance. Pilot flame must surround

the end of flame sensor for proper operation of pilot safety

circuit.

PILOT HOOD

PILOT

1/8 (.125) Inch "1/32 (.031)

GAP

SPARK ELECTRODE

place when reading manifold pressure.

An LPG changeover kit is available. The kit includes main and

pilot burner orifices (pilot orifice for -1 and -2 units only) and a

regulator conversion kit. All L.P. orifices can be identified by a

band around the orifice. Natural gas orifices do not have the

band.

HONEYWELL VR8204 GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

PRESSURE

REGULATOR

ADJUSTING

SCREW

(White)

REGULATOR

COVER SCREW

(Black)

SPRING Tapered End

Down (Red)

INLET

PRESSURE

TAP

GAS INLET

WHITE RODGERS 36E GAS VALVE

REGULATOR ADJUSTMENT SCREW

LOCATION

REGULATOR

COVER SCREW

ADJUSTING SCREW

(White)

PILOT, SPARK ELECĆ

TRODE

FLAME SENSOR

SENSOR WIRE

AND FLAME SENSOR

SPARK WIRE

FIGURE 19

14-Gas Valve

The G26 uses a gas valve manufactured by Honeywell or

White Rodgers. See figure 20. The valve is internally reĆ

dundant to assure safety shutĆoff. If the gas valve must be

replaced, the same type valve must be used.

24VAC terminals and gas control knob are located on top of

the valve. All terminals on the gas valve are connected to

wires from the ignition control. 24V applied to the MV" termiĆ

nals on the Honeywell or M/C or 1/2 terminals on the White

Rodgers opens the main valve. Inlet and outlet pressure taps

are located on the valve. A regulator adjustment screw (figure

20 ) is located on the valve. Regulator cover screw must be in

SPRING

FIGURE 20

100% Sealed Combustion

The burner box is completely sealed and operates under a

negative pressure. A pressure hose is connected from the

burner box to the gas valve regulator and differential presĆ

sure switch. The gas valve senses the pressure in the

burner box and changes gas valve output based on

changes in burner box pressure. The intent is to compenĆ

sate for different vent configurations which can greatly afĆ

fect the rate of the unit.

Page 16

Page 17

LENNOXOEMPARTS.COM

NORMAL OPERATION (Natural Gas Units)

3.5

3.4

OPERATION AT THIS EXTREME

MAY INDICATE A BLOCKED

OUTLET OR OTHER PROBLEM

3.3

3.2

3.1

3.0

2.9

2.8

GAS VALVE OUTPUT

2.7

2.6

MANIFOLD PRESSURE (positive inches water column)

2.5

Gray area indicates normal operating range + 10% of manifold pressure

The purpose of this chart is to explain unit operation . Each unit may vary depending

on installation, altitude, intake/exhaust configuration and other factors.

OPERATION AT THIS EXTREME

MAY INDICATE A BLOCKED

INLET OR OTHER PROBLEM

BURNER BOX PRESSURE

(Negative inches water gauge

measured on right side of burner box)

FIGURE 21

15-Differential Pressure Switch (S64)

(Combustion Air Prove Switch)

G26 series units are equipped with a differential pressure

switch located on the vestibule panel. The switch is conĆ

nected to the combustion air blower housing by means of a

flexible silicon hose. A separate hose connects the presĆ

sure switch to the burner box and the gas valve regulator.

The switch monitors air pressure in the combustion air

blower housing and burner box.

The switch is a singleĆpole singleĆthrow normally open

pressure switch electrically connected in series with the

ignition control. The purpose of the switch is to prevent

burner operation if the combustion air blower is not operatĆ

ing or if sufficient combustion air is not available,

On startĆup, the switch senses that the combustion air blowĆ

er is operating. It closes a circuit to the ignition control when

the difference in pressure across the pressure switch inĆ

creases above 0.2 in. w.c. The pressure sensed by the

-1.0-0.20 -0.4 -0.6 -0.8

switch is relative to the pressure in the burner box. In order

for the furnace to operate, the larger negative must alĆ

ways be on the combustion air blower side of the

switch. If the flue or air inlet become obstructed during opĆ

eration, the switch senses a loss of pressure differential

(drops below 0.20 in. negative w.c.) and opens the circuit to

the ignition control.

NORMAL OPERATION (L.P. Gas Units)

7.0

6.9

OPERATION AT THIS EXTREME

MAY INDICATE A BLOCKED

OUTLET OR OTHER PROBLEM

6.8

6.7

6.6

6.5

6.4

6.3

GAS VALVE OUTPUT

6.2

6.1

MANIFOLD PRESSURE (positive inches water column)

6.0

OPERATION AT THIS EXTREME

MAY INDICATE A BLOCKED

INLET OR OTHER PROBLEM

-1.0-0.20 -0.4 -0.6 -0.8

BURNER BOX PRESSURE

(Negative inches water column

measured on right side of burner box)

Gray area indicates normal operating range + 10% of manifold pressure

The purpose of this chart is to explain unit operation . Each unit may vary depending

on installation, altitude, intake/exhaust configuration and other factors.

FIGURE 22

Figures 21 and 22 show how gas valve output changes as

burner box pressure changes. Generally, a lower burner

box pressure produces a leaner gas/air mixture and a

higher burner box pressure produces a richer mixture. A

procedure showing how to check manifold pressure is

shown on page 29.

DIFFERENTIAL PRESSURE SWITCH CIRCUITRY

BURNĆ

TEE

DIFFERENTIAL

PRESSURE

SWITCH

COMBUSTION

AIR PRESĆ

SURE SENSĆ

ING HOSE

COMBUSTION

AIR BLOWER

LEFT SIDE OF PRESSURE SWITCH = MORE NEGATIVE

RIGHT SIDE OF PRESSURE SWITCH = LESS NEGATIVE (Closer to Zero)

ER

BOX

HOSE

BARB

BURNER

BOX

SENSING

HOSE

GAS

VALV E

SENSING

HOSE

GAS

VALV E

PRESSURE

SWITCH

SENSING

HOSE

FIGURE 23

The switch is factory set and is not adjustable. It is a safety

shutĆdown control and MUST not be bypassed.

Figure 24 shows the pressure differential required to obĆ

tain unit operation. If the switch does not successfully

sense the required differential, the switch cannot close

and the furnace cannot operate.

When measuring the pressure differential, readings

should be taken at the pressure switch.

Page 17

Page 18

LENNOXOEMPARTS.COM

-1.2

CHART REPESENTS NORMAL OPERATING

CHARACTERISTICS OF THE PRESSURE SWITCH ONLY

AND SHOULD NOT BE USED FOR TROUBLSHOOTING

-1.0

-0.8

-0.6

-0.4

-0.2

COMBUSTION AIR BLOWER STATIC PRESSURE

DIFFERENTIAL SWITCH CLOSED

0

-0.4 -0.6 -0.8 -1.2

BURNER BOX STATIC PRESSURE

FIGURE 24

Temporarily jumpering the pressure switch when troubleĆ

shooting will determine if the pressure switch and furnace

are operating properly. However, this may not indicate if

the sealed combustion system is operating properly. If the

unit cannot attain 0.2 inches differential, the unit will not

operate. Be sure to remove jumper when finished. See

Warning this page.

WARNING

Safety Hazard. Turn off gas supply before jumpĆ

ering switch or testing switch differential. If

switch is operating properly and sealed comĆ

bustion system is operating improperly, a poĆ

tentially lethal situation will be created when

switch is bypassed. DO NOT ALLOW UNIT TO

OPERATE WITH SAFETY SYSTEMS BYPASSED.

Checks of pressure differential can be made as an aid in trouĆ

bleshooting. It is important to remember that the switch must

see" 0.2 inches differential in order for the furnace to operate.

Lack of differential usually indicates problems in the intake or

exhaust piping but may indicate problems in the heat exĆ

changer, condenser coil, header boxes, combustion blower or

other components. Generally, if both readings are closer to

zero (figure 24) the unit may have a restricted flue outlet or

other problem. If both readings are farther from zero (figure

24) the unit may have a restricted flue inlet or other problem.

DIFFERENTIAL SWITCH OPEN

(Furnace will not operate)

-1.0-0.20

Measuring pressure differential

The differential pressure is the difference in pressure meaĆ

sured on either side of the pressure switch:

1 - Remove thermostat demand and allow to cycle off.

2 - Disconnect hose from left side of pressure switch and

install Tee as shown in figure 25.

TEE AND 1/4"i.d. RUBBER HOSE FIELD

PROVIDED

USED FOR MEASURING PRESĆ

SURE ACROSS BURNER BOX

AND COMBUSTION AIR BLOWER

TO PRESSURE

SWITCH

TO PRESSURE

SENSING HOSE

TO DRAFT GAUGE

FIGURE 25

3 - Install draft gauge to open end of Tee.

4 - Operate unit and observe draft gauge reading. ReadĆ

ings will change as heat exchanger warms.

a. Take one reading immediately after startup.

b. Take a second reading after unit has reached

steady state (approximately 5 minutes).

5 - Remove thermostat demand and allow to cycle off.

6 - Remove draft gauge and Tee. Reinstall combustion air

sensing hose to left side of pressure switch.

7 - Disconnect hose from right side of pressure switch

and install Tee as shown in figure 25.

8 - Install draft gauge to open end of Tee.

Page 18

Page 19

LENNOXOEMPARTS.COM

9 - Operate unit and observe draft gauge reading. ReadĆ

ings will change as heat exchanger warms.

a. Take one reading immediately after startup.

b. Take a second reading after unit has reached steady

state (approximately 5 minutes). Both readings should

fall above the line shown in figure 24.

10- Compare readings to figure 24. Be sure to compare

only like readings (compare startup reading to startup

reading, then compare steady state reading to steady

state reading). Subtract the absolute steady state

readings from one another. This will be the pressure

differential. In order for the furnace to operate, the

larger negative must always be on the combustion

air blower side of the switch

Example - one side of the pressure switch reads .60"

and the other side of the pressure switch reads .10".

Pressure differential is .60" - .10"= .50"

The pressure differential should be greater

than 0.20" W.C.

(49.72Pa).

11- When test is complete, remove thermostat demand

and allow unit to cycle off.

12- Remove draft gauge and Tee. Reinstall pressure

switch sensing hose to left side of pressure switch.

If pressure switch does not close at start up or differential is

less than .20" the following should be checked.

1 - Restriction in exhaust and or intake vent.

2 - Pressure switch lines are routed correctly and for

damage.

3 - Condensate in pressure switch lines.

4 - Wiring of pressure switch to furnace.

5 - Blocked heat exchanger or leak in heat exchanger.

II-PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

A-PVC Joint Cementing Procedure

6 - Promptly apply solvent cement to end of pipe and inĆ

side socket surface of fitting. Cement should be apĆ

plied lightly but uniformly to inside of socket. Take

care to keep excess cement out of socket. Apply secĆ

ond coat to end of pipe.

NOTE-Time is critical at this stage. Do not allow primer

to dry before applying cement.

7 - Immediately after applying last coat of cement to pipe,

and while both inside socket surface and end of pipe

are wet with cement, forcefully insert end of pipe into

socket until it bottoms out. Turn pipe 1/4 turn during

assembly (but not after pipe is fully inserted) to distribĆ

ute cement evenly. Once joint is made, PVC may

swell. Hold joint together until bonded (approximately

20 seconds).

NOTE-Assembly should be completed within 20 secĆ

onds after last application of cement. Hammer blows

should not be used when inserting pipe.

8 - After assembly, wipe excess cement from pipe at end

of fitting socket. A properly made joint will show a

bead around its entire perimeter. Any gaps may indiĆ

cate a defective assembly due to insufficient solvent.

9 - Handle joints carefully and support properly until comĆ

pletely set.

B-Venting Considerations

The thickness of construction through which vent/air intake

pipes may be installed is 24" (610mm) maximum and 3"

(76mm) minimum. If a G26 furnace replaces a furnace which

was commonly vented with another gas appliance, the size

of the existing vent pipe for that gas appliance must be

checked. Without the heat of the original furnace flue prodĆ

ucts, the existing vent pipe may be oversized for the single

water heater or other appliance. The vent should be checked

for proper draw with the remaining appliance.

CAUTION

WARNING

DANGER OF EXPLOSION! Fumes from PVC glue

may ignite during system check. Remove spark

plug wire from ignition control before 120V power

is applied. Reconnect wire after two minutes.

1 - Measure and cut vent pipe to desired length.

2 - Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

3 - Clean and dry surfaces to be joined.

4 - Test fit joint and mark depth of fitting on outside of

pipe.

5 - Uniformly apply liberal coat of PVC primer for PVC or

ABS cleaner for ABS for at least 5 to 15 seconds to inĆ

side socket surface of fitting and male end of pipe to

depth of fitting socket. Remove puddles of primer before

applying cement.

Page 19

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. Excessive exĆ

posure to contaminated combustion air will result

in safety and performance related problems.

Avoid exposure to the following substances in the

combustion air supply:

Permanent wave solutions;

Chlorinated waxes and cleaners;

Chlorine base swimming pool chemicals;

Water softening chemicals;

De-icing salts or chemicals;

Carbon tetrachloride;

Halogen type refrigerants;

Cleaning solvents (such as perchloroethylene);

Printing inks, paint removers, varnishes, etc.;

Hydrochloric acid;

Cements and glues;

Antistatic fabric softeners for clothes dryers; and

Masonry acid washing materials.

Page 20

LENNOXOEMPARTS.COM

Intake Piping

1 - Cement intake piping in slip connector located at top

of unit.

2 - Route piping to outside of structure. Continue with

installation following instructions given in exhaust and

intake piping termination section.

Exhaust Piping

1 - Cement exhaust piping into flue collar socket located

on the left side of the top cap.

2 - All horizontal runs of exhaust pipe must slope back toĆ

ward unit. A minimum of 1/4" (6mm) drop for each 12"

(305mm) of horizontal run is mandatory for drainage.

Horizontal runs of exhaust piping must be supported

every 5 ft. (1.52m) using hangers for schedule 40 pipe.

All other pipe must be supported every 3 ft. (.91m).

NOTE - Exhaust piping should be checked carefully to

make sure there are no sags or low spots.

NOTE - Exhaust piping must be insulated with 1/2"

(13mm) Armaflex or equivalent when run through unĆ

heated space. Do not leave any area of exhaust pipe

open to outside air; exterior exhaust must be insulated

with 1/2" (13mm) Armaflex or equivalent.

CAUTION

Do not discharge exhaust into an existing stack

or stack that also serves another gas appliance.

If vertical discharge through an existing unused

stack is required, insert PVC pipe inside the stack

until the end is beyond the top or outlet end of the

metal stack.

CAUTION

The exhaust vent pipe operates under positive

pressure and must be completely sealed to preĆ

vent leakage of combustion products into the livĆ

ing space.

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a

venting system commonly run with separate gas apĆ

pliances, the venting system may be too large to properly

vent the remaining attached appliances. The following test

should be conducted while all appliances (both in operaĆ

tion and those not in operation) are connected to the comĆ

mon venting system. If the venting system has been

installed improperly, corrections must be made as outlined

in the previous section.

1 - Seal any unused openings in the common venting sysĆ

tem.

2 - Visually inspect the venting system from proper size

and horizontal pitch and determine there is no blockĆ

age or restriction, leakage, corrosion and other defiĆ

ciencies which could cause an unsafe condition.

3 - Insofar as is practical, close all building doors and winĆ

dows and all doors between the space in which the apĆ

pliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliances not conĆ

nected to the common venting system. Turn on any exĆ

haust fans, such as range hoods and bathroom exĆ

hausts, so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampĆ

ers.

4 - Follow the lighting instruction. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5 - Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of

match or candle, or smoke from a cigarette, cigar.

6 - After it has been determined that each appliance reĆ

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gasĆburning appliance to their previous

condition of use.

7 - If improper venting is observed during any of the

above tests, the common venting system must be

corrected. The common venting system should be resized to approach the minimum size as determined by

using the appropriate tables in appendix G in the curĆ

rent standards of the National Fuel Gas Code ANSI

Z223-1 in the U.S.A., and the appropriate Category 1

Natural Gas and Propane appliances venting sizing

tables in the current standards of the CAN/

CGA-B149.1 and .2 in the Natural Gas and Propane

Installation Code in Canada.

Intake and Exhaust Piping Terminations

Intake and exhaust pipes may be routed either horizontally

through an outside wall or vertically through the roof. In atĆ

tic or closet installations, vertical termination through the

roof is preferred. Figures 26 through 38 show typical terĆ

minations.

1 - Use recommended piping materials for both intake

and exhaust piping.

2 - Secure all joints, including drain leg, gas tight using

approved primer and cement.

Page 20

Page 21

LENNOXOEMPARTS.COM

3 - Piping diameters should be determined according to

length of pipe run. See vent pipe specifications on

page 6. Locate intake piping upwind (prevailing wind)

from exhaust piping. To avoid re-circulation of exĆ

haust gas on roof terminations, end of exhaust pipe

must be higher than intake pipe.

Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roof and one on the

side. Also, do not exit the intake on one side and the

exhaust on another side of the house or structure.

4 - Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to ilĆ

lustrations). Maximum separation is 3" (76mm) on

roof terminations and 6" (152mm) on side wall terĆ

minations.

5 - Exhaust piping must terminate straight out or up as

shown. In rooftop applications, a 2" X 1-1/2" reducer for

2" venting, 3" x 2" reducer for 3" venting must be used

on the exhaust piping after it exits the structure to imĆ

prove the velocity of exhaust away from the intake pipĆ

ing.

On roof terminations, the intake piping should termiĆ

nate straight down using two 90 elbows (See figure

26).

Inches(mm)

3(76) MAX.

3 x 2 (76 x 51) OR

2 x 1-1/2 (51 x 38)

PVC REDUCER

NOTE - If winter design temperature is below 32 F (0C), exĆ

haust piping must be insulated with 1/2" (13mm), Armaflex or

equivalent when run through unheated space. Do not leave

any surface area of exhaust pipe open to outside air; exterior

exhaust pipe must be insulated with 1/2" (13mm) Armaflex or

equivalent. In extreme cold climate areas, 3/4" (19mm) ArĆ

maflex or equivalent is recommended. Insulation on outside

runs of exhaust pipe must be painted or wrapped to protect

insulation from deterioration.

NOTE - During extremely cold temperatures, below

approximately 20F (6.67C), units with long runs of vent

pipe through unconditioned space, even when insulated,

may form ice in the exhaust termination that prevents the

unit from operating properly. Longer run times of at least 5

minutes will alleviate most icing problems. Also, a heating

cable may be installed on exhaust piping and termination

to prevent freeze-ups. Heating cable installation kit is

available from Lennox. See Condensate Piping section for

part numbers.

NOTE - Care must be taken to avoid re-circulation of exĆ

haust back into intake pipe.

6 - On field supplied terminations for side wall exits, exĆ

haust piping should extend a minimum of 12"

(305mm) beyond the outside wall. Intake piping

should be as short as possible. See figure 27.

1/2 (13) ARMAFLEX

INSULATION IN

UNCONDITIONED SPACE

12 (305) MIN.

2 X 1-1/2

(51 x 38)

PVC REDUCER

8 (203) MIN

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

3 (76) OR

2 (51) PVC

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES

(15F75) LB-49107CC for 2 (51) Venting

(44J41) LB-65678A for 3 (76) Venting

ROOF TERMINATION KIT

1/2 (13) FOAM

INSULATION IN

UNCONDITIONED

SPACE

UNCONDITIONED

ATTIC SPACE

FIGURE 26

IMPORTANT

Do not use screens or perforated metal in intake

and exhaust terminations. Doing so will cause

freeze-ups and may block the terminations.

2 (51) PVC 1-1/2 (38) PVC

1/2 (13) ARMAFLEX

Inches (mm)