lennoxemeia.com

FMC - H

FIC - H

FSC - H

FLATAIR

APPLICATION

GUIDE

Horizontal packaged air conditioners

10 28 kW

FLATAIR AGU-MSL60-1505-E

• 1 •

2

4

5

7

8

9

10

17

18

25

28

FLATAIR

TM

Application Guide • FLATAIR-AGU-MSL60-1505-E

Ref : FLATAIR AGU-MSL60-1505-E

INDEX

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be utilised (except in operation of this product), reproduced,

issued to or made available to third parties without the prior written agreement of Lennox.

CONTENTS PAGE

1 - General description

2 - Denomination

3 - Range of products /technical features

4 - Operation limits

5 - Fan performances

6 - Sound level

7 - Capacities

9 - Electrical data

10 - Dimensions

11 - Installation

12 - Options

APPLICATION GUIDE

• 2 •

Application Guide • FLATAIR-AGU-MSL60-1505-E

1 - GENERAL DESCRIPTION

FURNITURE

Painted in galvanized metal furniture, high resistant to corrosion.

The units are provided with metal profi les, capable of withstanding

the unit and able as well of installing the unit hung from the ceiling

or mounted on the fl oor .

Panels are easily inter exchangeable, giving several air suction

and return alternatives.

An insulation with a protection of mesh is used in indoor section

with a classifi cation of M1 and F1, certifying that the material is

auto-extinguishable and avoiding the fumes inside the room to

be aconditionned. Auto extinguishable insulation M1 is used in

outdoor units.

COMPRESSORS

All units are provided with scroll compressor, cooling by a suction gas with thermic protection inside the engine, so no other

additional protection is required.

It is mounted on anti-vibration devices both external and internal.

All compresors are R410A

In heat pump units the compressors are provided with a crankcase heater to heat the oil in the compressor so that a suitable

lubrication can take place.

AIR FILTER

Washable air fi lter; auto extinguishable material with M1 clas-

sifi cation, high effi ciency fi ltrate with G2 classifi cation. It can be

removed through the upper part and from both sides.

FAN

Outdoor and indoor fans are centrifugal with an assembled

engine, statically balancing, with a low sound level.

Those fans are assembled to the inserted panel of the units and

split from upper side of the fan with insulated materials to void

vibrations.

EXCHANGER

Made-up with copper pipes and aluminium fi ngs, designed to

get a high heat transfer.

Their dimensions and design of the refrigenrant circuit have

been specially worked to obtain the maximum performance of

the exchanger increasing the power of the unit and reducing

the consumption.

COOLING CIRCUIT

Carried out with welded deshydratable copper pipes with pressure intakes with schraeder valves in the suction and liquid lines

both indoors and outdoor units.

In unit 20-25-30 the pressure intakes in the outdoor section are

approachable from the outer part of the unit.

The unit is equipped with both high-low pressure switches with

an automatic reset. It also has a dehydrating fi lter , expansion

system with restrictors in units 10-12-15; expansion valves in

units 20-25-30. The heat pump units are equipped as well with a

suction accumulator to avoid the liquid return to the compressor,

4 way valve and no-return valve.

ELECTRICAL CIRCUIT

Designed according to EN 60204-1 normative hermetically

sealed to avoid condensation. With circuits breakers to protecto

the unit from overloading.

1.1- GENERAL DESCRIPTION

The horizontal air conditioning units, range Flatair, cooling only or heat pump are air condensed units designed for small shopping

center and housing. They can be supplied either compact or on split system.

Due to their small dimensions they are designed for false ceiling and can be placed in air conducts both indoor and outdoor sections.

A wide range of optionals, completed-factory assembled are also available.

Flatair units are designed for false ceiling mounting, to be installed exclusively indoor. For outdoor mounting, a shelter or roof structure has to be installed, to avoid direct water entry in the sensible parts of the

unit (electrical board, joints between the indoor unit and the outdoor unit).

• 3 •

Application Guide • FLATAIR-AGU-MSL60-1505-E

1 - GENERAL DESCRIPTION

1.2- CONTROL

CLIMATIC 40 VERSION

CLIMATIC 60 VERSION

We have two versions of Control in Flatair units:

- The basic C40 platform, wich includes one terminal in the

unit and another DC40 remote

- The advanced platform C60 which includes one terminal

in the unit, and 3 remote terminals as in option (DC, DS,

DM)

CLIMATIC™ 60 controller intelligently improves effi ciency and

helps set up and service operations to guarantee long lasting

performance.

OPTIMIZED OPERATION AND SETUP

SAVES ENERGY

CLIMATIC™ 60 is designed to provide the best energy

effi ciency throughout unit’s life cycle while ensuring

reliable and consistent operation with user friendly interfaces.

This new controller constantly monitors more machine parameters

than ever to improve rooftop operation and maximize effi ciency

and reliability

1.3- OPTIONS

Flatair units can be equipped with the following options:

- Main switch

- Heating electrical heater, made of blinded elements and assembled inside the unit

- Kit low ambient -15 degrees

- Kit low ambient 0 degrees (only for cooling units)

- 3 Phase controller (only for 3 phase units)

- Customer terminal DC60 (only for CLIMATIC 60 version)

- Service terminal DS60 (only for CLIMATIC 60 version)

- Remote duct sensor in return

- Ambient remote sensor (only en CLIMATIC 40 version)

- Thermostatic freecooling

- Enthalpic freecooling (only in CLIMATIC 60 version)

- Second return damper for kit freecooling

- Different airfl ow confi gurations in return and supply

- BMS communication interface (CLIMATIC 40 as standard and CLIMATIC 60 as an option)

- Echelon communication interface (CLIMATIC 60)

- Bacnet communication interface (CLIMATIC 60)

• 4 •

F

FLATAIR

F M C 015 S N M 1 M

M

S

I

S

C

H

X

M

M

- - -

i

Application Guide • FLATAIR-AGU-MSL60-1505-E

2 - DENOMINATION

EXAMPLE :

Approximate Cooling capacity in kW

Revision number

Compact unit

Outdoor unit

Indoor unit

1 Circuit

Cooling only

Heat pump

Cooling only / heat pump

R410A

400V/3/50

FMC: Cooling only unit R-410A

FMH: Heat pump unit R-410A

• 5 •

A BOX B BOX C BOX D BOX

FCM/FCH

10 12 15 20 25 30

kW 9.7 12 15 19.5 23.5 27

kW 10 12.5 15.5 20.5 25 27.9

mm 495 495 595 595 645 645

mm 1250 1250 1300 1450 1500 1500

mm 1250 1250 1330 1520 1800 1800

Kg 170 174 250 268 322 338

10 12 15 20 25 30

m3/h 3500 3400 4500 5650 6000 5850

m

3

/h 2350 2400 3740 4095 4760 5000

Pa 100 90 120 150 160 100

kg 112 116 165 159 202 208

mm 495 495 595 595 645 465

mm 1250 1250 1300 1450 1500 1500

mm 820 820 830 900 1025 1025

3/8" 3/8" 1/2" 5/8" 5/8" 5/8"

3/4" 3/4" 7/8" 7/8" 1-1/8" 1-1/8"

FIX 10 FIX 12 FIX 15

FIC/H

2O 20

FIC/H 25FIC/H

30

m3/h 2350 2300 3575 4850 5750 5500

m

3

/h 1500 1650 2410 2090 3455 3695

Pa 120 110 160 200 240 180

kg 58 58 85 109 121 131

kg 777788

kg 12 12 12 14 15 15

kg 24 24 24 28 30 30

mm 495 495 595 595 645 645

mm 1250 1250 1300 1450 1500 1500

mm 430 430 500 620 775 775

3/8" 3/8" 1/2" 5/8" 5/8" 5/8"

3/4" 3/4" 7/8" 7/8" 1-1/8" 1-1/8"

Application Guide • FLATAIR-AGU-MSL60-1505-E

3 - MAIN TECHNICAL FEATURES

Cooling capacity *

(cooling only)

Heating capacity*

(heat pump)

DIMENSIONS

Height

Lenght

Depth

NET WEIGHT

OUTDOOR UNIT

FSC/FSH

Number & Type of compressor

FAN

Maximum airfl ow rate

Minimum airfl ow rate

Maximum available presure

(1)

NET WEIGHT

DIMENSIONS

Height

Lenght

Depth

PIPES CONNEXIONS

Liquid m

3

/h

Gas m

3

/h

INDOOR UNIT

FIX

Number & Type of compressor

FAN

Maximum airfl ow rate

Minimum airfl ow rate

Maximum available presure

(1)

NET WEIGHT

OPTIONS WIEGHT

Electrical heater

Free-cooling 1 damper

Free-cooling 2 damper

DIMENSIONS

Height

Lenght

Depth

PIPES CONNEXIONS

Liquid m

3

/h

Gas m

3

/h

(*) Air intake temperature in the indoor exchanger :

27ºC DB/19ºC WB

(*) Air intake temperature in the outdoor exchanger: :

35ºC DB

(1) With admissible minimum air fl ow

DB Dry bulb temperature

WB Wet bulb temperature

1 / Scroll

1 / Scroll

• 6 •

A 10-12 1250 1250 495

B15 1300 1330 595

C20 1450 1520 595

D 25-30 1500 1800 645

A 10-12 1250 430 495

B15 1300 500 595

C20 1450 620 595

D 25-30 1500 775 645

A 10-12 1250 820 495

B15 1300 830 595

C20 1450 900 595

D 25-30 1500 1025 645

FIH 10

2350 2140 1500

FIH 12

2300 2040 1650

FIH 15

3575 3170 2410

FIH 20

4850 4500 3090

FIH 25

5750 5470 3455

FIH 30

5500 5060 3695

FSH 10

3500 2970 2350

FSH 12

3400 2890 2400

FSH 15

4500 4250 3740

FSH 20

5650 5150 4095

FSH 25

6000 5600 4760

FSH 30

5850 5400 5000

FIC/H

FSC/H

Application Guide • FLATAIR-AGU-MSL60-1505-E

3 - MAIN TECHNICAL FEATURES

Box Unit Lenght Deep Height

Packaged

Indoor unit

Outdoor unit

3.2 MINIMUM, MAXIMUM AND NOMINAL AIRFLOW RATES

INDOOR UNIT

AIRFLOW RATE

Maximum Nominal Minimum

OUTDOOR UNIT

3.1 DIMENSIONS

AIRFLOW RATE

Maximum Nominal Minimum

• 7 •

10 12 15 20 25 30

FIX/FIC 58 58 85 109 121 131

FSC 112 116 165 159 202 208

FMC 170 174 250 268 322 338

FIX/FIH 58 58 85 109 121 131

FSH 117 121 170 164 207 213

FMH 175 179 255 273 327 343

777788

12 12 12 14 15 15

24 24 24 28 30 30

Application Guide • FLATAIR-AGU-MSL60-1505-E

OPERATION LIMITS FOR COOLING ONLY UNITS

3 - MAIN TECHNICAL FEATURES

Maximum temperatures Minimum temperatures

Cooling mode

Indoor temperature 32ºC DB / 23ºC WB 21ºC DB / 15ºC WB

Outdoor temperature Table 1

Standard unit : + 15ºC

0ºC(*) / -15ºC(**)

(*) With option kit low temperature 0ºC

(**) With option kit low temperature -15ºC

DB.- Dry bulb temperature

WB.- Wet bulb temperature

OPERATION LIMITS FOR HEAT PUMP UNITS

Maximum temperatures Minimum temperatures

Cooling mode

Indoor temperature

32ºC DB / 23ºC WB 21ºC DB / 15ºC WB

Outdoor temperature

Table 1

+ 15ºC STANDARD UNIT

0ºC(*) / -15ºC(**)

Heat pump mode

Indoor temperature

27ºC DB 15ºC DB

Outdoor temperature

Sizes 12-15-20-30 : 25ºC

(1)

Sizes 12-25 : 23ºC

-12ºC

(*) Active CL40 parameter to operate at 0ºC

(**) With option kit low temperature -15ºC

(1) : Indoor temperature : 20°C

DB.- Dry bulb temperature

WB.- Wet bulb temperature

3.3 WEIGHTS

4 - OPERATION LIMITS

FLATAIR (STANDARD)

OPTIONS

MODEL

Cooling only units

Indoor unit

Outdoor unit

Package

(indoor+outdoor)

Heat pump units

Indoor unit

Outdoor unit

Package

(indoor+outdoor)

to add indoor unit

electrical heater

free-cooling 1 damper

free-cooling 2 damper

• 8 •

10 12 15 20 25 30

0

2350 2300 3575 4850 5750 5500

10

2275 2250 3495 4785 5730 5455

20

2240 2200 3410 4715 5705 5405

30

2190 2150 3330 4645 5670 5350

40

2140 2100 3250 4575 5630 5285

50

2080 2040 3170 4500 5580 5220

60

2025 1975 3095 4425 5530 5140

70

1975 1925 3020 4345 5470 5060

80

1925 1860 2945 4260 5405 4965

90

1840 1800 2875 4175 5330 4870

100

1775 1730 2800 4090 5250 4765

110

1625 1650 2735 4000 5165 4655

120

1500 ---- 2665 3910 5075 4640

130

--- --- 2600 3815 4975 4415

140

--- --- 2535 3720 4870 4285

150

--- --- 2470 3620 4755 4150

160

--- --- 2410 3520 4640 4005

170

--- --- --- 3415 4515 3855

180

--- --- --- 3310 4380 3695

190

--- --- --- 3200 4245 ---

200

--- --- --- 3090 4100 ---

210

--- --- --- --- 3945 ---

220

--- --- --- --- 3790 ---

230

--- --- --- --- 3625 ---

240

--- --- --- --- 3455 ---

10 12 15 20 25 30

0

3500 3400 4500 5650 6000 5850

10

3410 3325 4460 5550 5920 5755

20

3300 3160 4410 5450 5840 5665

30

3190 3075 4360 5350 5760 5575

40

3080 2980 4310 5250 5680 5485

50

2970 2890 4250 5150 5600 5400

60

2840 2790 4190 5050 5520 5315

70

2700 2690 4125 4945 5445 5235

80

2560 2580 4055 4840 4365 5155

90

2410 2400 3980 47365 5290 5075

100

2350 --- 3905 4630 5210 5000

110

--- --- 3825 4525 5135 ----

120

--- --- 3740 4420 5060 ----

130

--- --- --- 4315 4985 ----

140

--- --- --- 4205 4910 ----

150

--- --- --- 4095 4835 ----

160

--- --- --- --- 4760 ----

Application Guide • FLATAIR-AGU-MSL60-1505-E

5 - FAN PERFORMANCES

INDOOR UNITS

Nominal airfl ow rate

OUTDOOR UNITS

With option G4 additional pressure drop 50Pa

Keep in mind reduction on air fl ow and static pressure services if you use muffl ers or

external air fi lter.

Available static pressure (Pa)Available static pressure (Pa)

Airfl ow rate (m3/h)

Airfl ow rate (m

3

/h)

• 9 •

dB

Lw dB(A)

Hz 125 250 500 1000 2000 4000 8000

10

73 70 71 72.9 69.3 68.9 62.8 77

12

74 78 69 73.6 66.3 66.1 60.5 77

15

79 74 77 78.0 75.5 72.9 68.0 82

20

81 75 81 81.9 79.2 76.5 72.2 86

25

83 76 76 76.4 75.3 72.4 65.9 81

30

83 75 75 76.0 74.7 71.6 65.0 81

dB

Lw dB(A)

Hz 125 250 500 1000 2000 4000 8000

10

71 67 67 67.4 64.9 64.1 58.3 72

12

71 67 67 67.4 64.9 64.1 58.3 72

15

74 69 72 71.3 69.1 66.0 59.7 76

20

77 71 75 75.8 73.4 70.7 65.7 80

25

79 73 79 80.2 77.4 74.5 74.3 84

30

78 72 77 78.4 75.7 72.9 68.4 83

Application Guide • FLATAIR-AGU-MSL60-1505-E

6 - SOUND LEVEL

With compressor jacket, estimated reduction of 2 Dba

Size

Size

OUTDOOR UNIT

With compressor jacket, estimated reduction of 2 Dba

INDOOR UNIT

• 10 •

NC

(kW) :

NH

(kW) :

SC

(kW) :

AC

(kW) :

FMC/H 10

20 °C 25 °C 30 °C 35°C 40 °C 45 °C

NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC

1500 m

3

/h

16

21

9,56 2,80 5,88 9,29 2,96 5,75 8,96 3,16 5,60 8,57 3,41 5,43 8,12 3,74 5,23 7,62 4,21 5,00

24 9,56 2,80 7,21 9,30 2,96 7,07 8,98 3,16 6,91 8,59 3,41 6,71 8,15 3,74 6,47 7,66 4,20 6,19

27 9,60 2,80 8,41 9,35 2,96 8,27 9,03 3,16 8,09 8,66 3,41 7,87 8,22 3,74 7,61 7,73 4,20 7,29

19

24 10,46 2,84 5,78 10,15 3,00 5,65 9,79 3,21 5,51 9,36 3,46 5,35 8,88 3,80 5,17 8,34 4,29 4,96

27 10,45 2,84 7,14 10,15 3,00 7,00 9,79 3,21 6,84 9,37 3,46 6,65 8,90 3,80 6,43 8,36 4,29 6,18

30 10,48 2,84 8,33 10,18 3,01 8,19 9,83 3,21 8,02 9,42 3,47 7,81 8,95 3,81 7,57 8,42 4,28 7,27

22

27 11,46 2,88 5,61 11,12 3,05 5,48 10,71 3,26 5,35 10,25 3,52 5,21 9,73 3,87 5,06 9,15 4,36 4,88

30 11,44 2,88 6,98 11,10 3,05 6,85 10,70 3,26 6,70 10,25 3,52 6,53 9,73 3,87 6,34 9,16 4,36 6,11

33

11,45 2,88 8,18 11,11 3,05 8,05 10,72 3,26 7,89 10,28 3,52 7,70 9,77 3,87 7,48 9,20 4,36 7,22

2140 m

3

/h

16

21

9,96 3,05 6,61 9,65 3,21 6,48 9,28 3,40 6,32 8,85 3,65 6,14 8,37 3,98 5,93 7,82 4,44 5,68

24 9,98 3,05 8,36 9,67 3,21 8,21 9,31 3,40 8,02 8,89 3,65 7,79 8,41 3,97 7,52 7,87 4,43 7,19

27 10,03 3,05 9,97 9,75 3,22 9,75 9,45 3,42 9,45 9,09 3,68 9,09 8,68 4,02 8,68 8,22 4,49 8,22

19

24 10,90 3,09 6,46 10,55 3,26 6,34 10,15 3,46 6,20

9,68 3,72 6,04

9,16 4,06 5,85 8,57 4,55 5,63

27 10,90 3,09 8,27 10,56 3,26 8,12 10,16 3,46 7,95 9,70 3,72 7,74 9,18 4,06 7,49 8,61 4,54 7,19

30 10,94 3,09 9,91 10,60 3,26 9,74 10,21 3,46 9,54

9,76 3,72 9,30

9,25 4,06 9,00 8,68 4,54 8,64

22

27 11,93 3,13 6,22 11,55 3,31 6,11 11,11 3,52 6,00 10,60 3,78 5,86 10,04 4,14 5,71 9,42 4,64 5,52

30 11,92 3,13 8,08 11,54 3,31 7,95 11,10 3,52 7,79 10,61 3,78 7,61 10,05 4,14 7,39 9,44 4,64 7,13

33

11,94 3,13 9,76 11,57 3,31 9,61 11,14 3,52 9,43 10,65 3,78 9,21 10,10 4,14 8,94 9,49 4,64 8,62

2350 m

3

/h

16

21

10,00 3,15 6,83 9,67 3,31 6,70 9,29 3,51 6,54 8,85 3,77 6,36 8,35 4,11 6,13 7,79 4,59 5,87

24 10,02 3,15 8,71 9,70 3,31 8,55 9,32 3,51 8,35 8,89 3,76 8,11 8,40 4,10 7,82 7,84 4,58 7,47

27 10,18 3,16 10,18 9,91 3,33 9,91 9,59 3,54 9,59 9,21 3,80 9,21 8,79 4,14 8,79 8,31 4,63 8,31

19

24 10,95 3,19 6,68 10,59 3,36 6,56 10,17 3,57 6,42 9,69 3,84 6,25 9,15 4,19 6,06 8,56 4,71 5,82

27 10,95 3,19 8,62 10,60 3,36 8,47 10,18 3,57 8,29 9,71 3,84 8,07 9,18 4,19 7,80 8,59 4,70 7,48

30 10,99 3,19 10,40 10,64 3,36 10,23 10,24 3,57 10,01 9,77 3,84 9,75 9,32 4,21 9,32 8,77 4,73 8,77

22

27 11,99 3,24 6,42 11,59 3,41 6,32 11,14 3,63 6,21 10,62 3,90 6,07 10,05 4,27 5,91 9,42 4,80 5,72

30 11,98 3,24 8,43 11,59 3,41 8,30 11,14 3,63 8,14 10,63 3,90 7,95 10,06 4,27 7,72 9,44 4,80 7,44

33

12,00 3,24 10,26 11,62 3,41 10,11 11,18 3,63 9,91 10,67 3,90 9,68 10,11 4,27 9,39 9,49 4,79 9,04

FMH 10

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

1500 m

3

/h

15 6,40 2,44 7,39 2,62 8,37 2,79 9,34 2,96 9,73 3,03 10,31 3,13 11,27 3,31

18 6,40 2,60 7,36 2,77 8,32 2,95 9,27 3,13 9,65 3,20 10,21 3,31 11,15 3,50

20 6,41 2,71 7,36 2,89 8,30 3,07 9,23 3,25 9,60 3,32 10,16 3,44 11,08 3,64

23 6,43 2,88 7,35 3,07 8,27 3,26 9,18 3,45 9,55 3,53 10,09 3,65 10,99 3,87

25 6,45 3,01 7,36 3,20 8,26 3,39 9,16 3,59 9,51 3,68 10,05 3,80 10,93 4,03

27 6,48 3,15 7,37 3,34 8,26 3,54 9,14 3,74 9,49 3,83 10,01 3,97 10,88 4,21

2140 m

3

/h

15 6,62 2,50 7,66 2,63 8,69 2,76 9,72 2,89 10,13 2,94 10,75 3,02 11,76 3,16

19 6,61 2,70 7,62 2,83 8,63 2,96 9,63 3,10 10,02 3,15 10,62 3,23 11,60 3,37

20 6,61 2,76 7,62 2,89 8,61 3,02 9,61 3,15 10,00 3,21 10,59 3,29 11,57 3,43

23 6,63 2,93 7,61 3,06 8,58 3,19 9,55 3,32 9,94 3,38 10,51 3,47 11,47 3,62

25 6,65 3,05 7,61 3,18 8,57 3,31 9,52 3,45 9,90 3,50 10,47 3,59 11,41 3,75

27 6,67 3,18 7,62 3,31 8,56 3,44 9,50 3,58 9,87 3,64 10,43 3,73 11,35 3,89

2350 m

3

/h

15 6,84 2,49 7,90 2,61 8,95 2,73 10,00 2,84 10,42 2,89 11,04 2,96 12,08 3,08

19 6,83 2,69 7,86 2,80 8,88 2,92 9,90 3,03 10,31 3,08 10,91 3,15 11,92 3,28

20 6,83 2,74 7,85 2,85 8,87 2,97 9,88 3,08 10,28 3,13 10,88 3,20 11,88 3,33

23 6,84 2,90 7,84 3,01 8,84 3,12 9,82 3,24 10,22 3,29 10,80 3,37 11,78 3,50

25 6,86 3,02 7,84 3,12 8,82 3,23 9,79 3,35 10,18 3,40 10,76 3,48 11,71 3,62

27 6,88 3,14 7,85 3,24 8,81 3,35 9,77 3,47 10,15 3,52 10,72 3,60 11,66 3,75

Application Guide • FLATAIR-AGU-MSL60-1505-E

Net cooling capacity Net heating capacity Sensible cooling capacity

Compressor absorbed

power

HEATING CAPACITIES

COOLING CAPACITIES

7 - CAPACITIES

Air inlet temperature at condenser (dry bulb)

Mixed air

temperature

°C

Indoor wet

bulb

Indoor dry bulb

Minimum airfl ow rateNominal airfl ow rateMaximum airfl ow rate

Air inlet temperature at condenser (dry bulb)

Indoor Dry Bulb

Minimum

airfl ow

Nominal

airfl ow

Maximum air-

fl ow rate

• 11 •

GC

(kW) :

NH

(kW) :

SC

(kW) :

AC

(kW) :

FMC/H 12

20 °C 25 °C 30 °C 35°C 40 °C 43 °C

NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC

1650 m

3

/h

16

21

12,12 3,88 7,28 11,76 4,13 7,10 11,30 4,45 6,89 10,74 4,88 6,64 10,08 5,50 6,35 9,64 6,03 6,15

24 12,13 3,88 8,79 11,77 4,13 8,60 11,31 4,45 8,37 10,75 4,88 8,09 10,10 5,50 7,75 9,67 6,03 7,51

27 12,14 3,88 10,21 11,79 4,13 10,03 11,33 4,45 9,79 10,78 4,88 9,48 10,13 5,50 9,09 9,70 6,03 8,82

19

24 13,22 3,94 7,16 12,81 4,20 6,97 12,30 4,52 6,77 11,70 4,96 6,53 11,01 5,59 6,26 10,54 6,13 6,08

27 13,22 3,94 8,65 12,82 4,20 8,47 12,32 4,52 8,25 11,72 4,96 7,99 11,03 5,59 7,67 10,56 6,13 7,45

30 13,24 3,94 10,06 12,84 4,20 9,88 12,34 4,52 9,65 11,75 4,96 9,36 11,06 5,60 9,01 10,60 6,14 8,76

22

27 14,41 4,03 6,97 13,95 4,30 6,79 13,41 4,64 6,60 12,76 5,09 6,38 12,02 5,75 6,14 11,53 6,31 5,98

30 14,41 4,03 8,44 13,96 4,30 8,27 13,42 4,64 8,06 12,78 5,09 7,82 12,04 5,75 7,54 11,55 6,31 7,35

33

14,42 4,03 9,82 13,98 4,30 9,65 13,44 4,64 9,44 12,80 5,10 9,19 12,07 5,76 8,87 11,58 6,32 8,65

2040 m

3

/h

16

21

12,48 4,08 7,76 12,08 4,33 7,58 11,58 4,64 7,37 10,99 5,07 7,11 10,30 5,68 6,81 9,84 6,21 6,59

24 12,49 4,08 9,55 12,10 4,33 9,36 11,60 4,64 9,12 11,01 5,07 8,81 10,33 5,68 8,44 9,87 6,21 8,18

27 12,51 4,09 11,26 12,12 4,33 11,06 11,63 4,65 10,79 11,05 5,07 10,45 10,37 5,69 10,01 9,91 6,22 9,71

19

24 13,59 4,15 7,59 13,15 4,40 7,41 12,61 4,73 7,21

11,98 5,17 6,98

11,24 5,81 6,70 10,76 6,36 6,51

27 13,61 4,15 9,39 13,17 4,40 9,20 12,63 4,73 8,97 12,00 5,17 8,69 11,27 5,81 8,35 10,79 6,36 8,12

30 13,63 4,15 11,10 13,19 4,41 10,91 12,66 4,74 10,66

12,03 5,18 10,34

11,31 5,82 9,94 10,83 6,36 9,67

22

27 14,80 4,25 7,34 14,32 4,52 7,18 13,74 4,86 6,99 13,06 5,33 6,79 12,28 6,00 6,54 11,77 6,58 6,38

30 14,82 4,25 9,14 14,33 4,52 8,97 13,76 4,86 8,76 13,08 5,33 8,51 12,31 6,01 8,21 11,80 6,58 8,01

33

14,84 4,26 10,84 14,36 4,52 10,67 13,78 4,87 10,44 13,11 5,34 10,16 12,34 6,01 9,81 11,84 6,59 9,57

2300 m

3

/h

16

21

12,60 4,23 8,05 12,17 4,48 7,88 11,65 4,80 7,66 11,04 5,23 7,39 10,32 5,87 7,07 9,85 6,41 6,85

24 12,61 4,24 10,02 12,20 4,48 9,82 11,68 4,80 9,57 11,07 5,23 9,24 10,36 5,87 8,84 9,88 6,41 8,56

27 12,64 4,24 11,92 12,23 4,49 11,70 11,71 4,81 11,41 11,10 5,24 11,03 10,40 5,87 10,59 9,93 6,41 10,26

19

24 13,73 4,31 7,86 13,26 4,57 7,69 12,70 4,90 7,49 12,04 5,35 7,25 11,28 6,02 6,96 10,78 6,59 6,77

27 13,74 4,31 9,85 13,28 4,57 9,66 12,72 4,90 9,43 12,07 5,36 9,13 11,31 6,02 8,77 10,81 6,59 8,52

30 13,77 4,31 11,76 13,31 4,57 11,56 12,76 4,91 11,29 12,10 5,36 10,94 11,35 6,03 10,52 10,86 6,60 10,21

22

27 14,95 4,42 7,59 14,44 4,69 7,43 13,83 5,05 7,25 13,13 5,53 7,05 12,33 6,24 6,80 11,80 6,85 6,63

30 14,97 4,42 9,59 14,46 4,69 9,42 13,86 5,05 9,21 13,16 5,53 8,95 12,36 6,24 8,63 11,84 6,85 8,41

33

14,99 4,42 11,51 14,49 4,70 11,32 13,89 5,06 11,08 13,20 5,54 10,78 12,40 6,25 10,40 11,88 6,86 10,13

FMH 12

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

1650 m

3

/h

15 8,31 3,31 9,51 3,57 10,69 3,83 11,85 4,10 12,31 4,21 13,00 4,37 14,13 4,65

18 8,40 3,58 9,56 3,85 10,71 4,12 11,84 4,40 12,29 4,51 12,96 4,68 14,05 4,99

20 8,46 3,78 9,60 4,06 10,73 4,33 11,84 4,62 12,28 4,74 12,93 4,92 14,01 5,24

23 8,57 4,12 9,68 4,40 10,77 4,69 11,85 4,99 12,27 5,12 12,91 5,32 13,95 5,67

25 9,73 4,66 10,80 4,96 11,86 5,27 12,28 5,41 12,90 5,61 13,92 5,99

27 11,88 5,58 12,28 5,72 12,89 5,95 13,89 6,35

2040 m

3

/h

15 8,41 3,23 9,65 3,47 10,88 3,69 12,09 3,92 12,56 4,01 13,28 4,15 14,45 4,39

19 8,51 3,57 9,70 3,80 10,89 4,04 12,05 4,27 12,51 4,37 13,20 4,51 14,33 4,77

20 8,53 3,66 9,72 3,90 10,89 4,13 12,04 4,37 12,50 4,46 13,18 4,61 14,30 4,87

23 8,62 3,96 9,78 4,20 10,91 4,44 12,03 4,68 12,48 4,78 13,14 4,94 14,23 5,22

25 8,69 4,19 9,82 4,42 10,94 4,66 12,03 4,92 12,47 5,02 13,12 5,18 14,18 5,47

27 9,87 4,67 10,96 4,91 12,04 5,17 12,47 5,28 13,10 5,45 14,14 5,76

2300 m

3

/h

15 8,50 3,26 9,77 3,48 11,03 3,69 12,26 3,89 12,75 3,97 13,48 4,10 14,69 4,31

19 8,58 3,59 9,81 3,80 11,02 4,01 12,21 4,22 12,68 4,30 13,39 4,43 14,55 4,66

20 8,61 3,68 9,82 3,89 11,02 4,10 12,20 4,31 12,67 4,40 13,37 4,53 14,52 4,75

23 8,68 3,98 9,87 4,18 11,03 4,39 12,18 4,61 12,64 4,69 13,31 4,83 14,43 5,07

25 8,74 4,20 9,90 4,40 11,05 4,61 12,17 4,82 12,62 4,91 13,29 5,05 14,38 5,30

27 8,80 4,44 9,94 4,63 11,07 4,84 12,17 5,06 12,61 5,15 13,26 5,30 14,34 5,56

Application Guide • FLATAIR-AGU-MSL60-1505-E

7 - CAPACITIES

Gross cooling capacity Net heating capacity Sensible cooling capacity

Compressor absorbed

power

HEATING CAPACITIES

COOLING CAPACITIES

Air inlet temperature at condenser (dry bulb)

Mixed air

temperature

°C

Indoor wet

bulb

Indoor dry bulb

Minimum airfl ow rateNominal airfl ow rateMaximum airfl ow rate

Air inlet temperature at condenser (dry bulb)

Indoor Dry Bulb

Minimum

airfl ow

Nominal

airfl ow

Maximum air-

fl ow rate

• 12 •

NC

(kW) :

NH

(kW) :

SC

(kW) :

AC

(kW) :

FMC/H 15

20 °C 25 °C 30 °C 35°C 40 °C 45 °C

NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC

2410 m

3

/h

16

21

14,83 4,75 9,09 14,39 4,98 8,90 13,85 5,25 8,66 13,21 5,60 8,39 12,47 6,06 8,07 11,63 6,72 7,69

24 14,84 4,75 11,40 14,41 4,98 11,16 13,89 5,26 10,88 13,27 5,60 10,53 12,55 6,07 10,12 11,73 6,73 9,63

27 15,00 4,76 13,26 14,60 4,99 13,01 14,09 5,27 12,69 13,49 5,62 12,30 12,79 6,08 11,84 12,00 6,72 11,29

19

24 16,26 4,79 8,89 15,77 5,02 8,72 15,17 5,30 8,52 14,48 5,65 8,28 13,68 6,12 8,00 12,79 6,79 7,68

27 16,20 4,79 11,37 15,72 5,02 11,15 15,15 5,30 10,88 14,47 5,66 10,56 13,70 6,13 10,19 12,83 6,80 9,74

30 16,29 4,79 13,32 15,84 5,02 13,07 15,28 5,31 12,77 14,63 5,66 12,40 13,87 6,13 11,96 13,02 6,79 11,45

22

27 17,95 4,83 8,31 17,40 5,06 8,18 16,75 5,34 8,03 16,01 5,70 7,86 15,16 6,16 7,66 14,22 6,81 7,41

30 17,82 4,82 11,01 17,29 5,06 10,82 16,66 5,34 10,60 15,93 5,70 10,34 15,11 6,17 10,02 14,18 6,82 9,65

33

17,84 4,82 13,12 17,33 5,06 12,90 16,72 5,34 12,63 16,01 5,70 12,31 15,21 6,17 11,93 14,30 6,82 11,47

3170 m

3

/h

16

21

15,36 4,98 10,17 14,89 5,20 9,96 14,31 5,47 9,71 13,64 5,82 9,41 12,87 6,28 9,06 12,00 6,93 8,64

24 15,43 4,98 12,89 14,98 5,21 12,63 14,43 5,48 12,30 13,78 5,83 11,92 13,03 6,29 11,46 12,18 6,94 10,91

27 15,67 5,00 15,17 15,23 5,22 14,88 14,70 5,49 14,52 14,10 5,85 14,10 13,45 6,31 13,45 12,71 6,93 12,71

19

24 16,81 5,02 10,00 16,28 5,24 9,82 15,66 5,52 9,60

14,93 5,88 9,34

14,11 6,35 9,04 13,19 7,01 8,67

27 16,82 5,02 12,91 16,31 5,25 12,66 15,70 5,53 12,36 15,00 5,88 12,01 14,20 6,36 11,58 13,30 7,02 11,08

30 16,99 5,03 15,29 16,50 5,26 15,01 15,91 5,54 14,66

15,23 5,89 14,25

14,44 6,36 13,75 13,56 7,01 13,16

22

27 18,52 5,05 9,45 17,94 5,28 9,32 17,27 5,56 9,16 16,49 5,92 8,97 15,61 6,39 8,73 14,64 7,05 8,45

30 18,46 5,05 12,60 17,90 5,28 12,40 17,24 5,56 12,15 16,49 5,92 11,85 15,63 6,40 11,49 14,67 7,06 11,06

33

18,55 5,05 15,16 18,01 5,29 14,91 17,37 5,57 14,61 16,63 5,93 14,23 15,80 6,40 13,79 14,86 7,06 13,26

3575 m

3

/h

16

21

15,46 5,13 10,69 14,97 5,36 10,47 14,38 5,64 10,20 13,69 5,99 9,89 12,90 6,47 9,51 12,02 7,16 9,06

24 15,57 5,14 13,60 15,10 5,37 13,32 14,53 5,65 12,98 13,86 6,00 12,56 13,09 6,48 12,07 12,23 7,16 11,49

27 15,90 5,16 15,90 15,48 5,39 15,48 14,97 5,67 14,97 14,38 6,02 14,38 13,70 6,48 13,70 12,94 7,11 12,94

19

24 16,92 5,16 10,56 16,38 5,40 10,36 15,74 5,68 10,13 14,99 6,05 9,86 14,15 6,54 9,52 13,22 7,25 9,13

27 16,97 5,17 13,66 16,44 5,40 13,40 15,82 5,69 13,09 15,10 6,06 12,70 14,28 6,55 12,25 13,36 7,25 11,71

30 17,17 5,18 16,27 16,67 5,41 15,96 16,06 5,70 15,59 15,36 6,07 15,14 14,57 6,55 14,57 13,73 7,26 13,73

22

27 18,65 5,20 10,04 18,05 5,43 9,90 17,35 5,72 9,73 16,56 6,09 9,52 15,67 6,58 9,27 14,68 7,27 8,96

30 18,62 5,20 13,41 18,05 5,43 13,19 17,37 5,73 12,92 16,60 6,10 12,59 15,72 6,59 12,20 14,75 7,28 11,74

33

18,75 5,20 16,20 18,19 5,44 15,93 17,54 5,73 15,59 16,78 6,10 15,19 15,93 6,59 14,71 14,98 7,28 14,13

FMH 15

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

2410 m

3

/h

15 10,12 4,46 11,66 4,68 13,19 4,89 14,71 5,08 15,31 5,16 16,21 5,28 17,69 5,47

18 10,07 4,69 11,59 4,91 13,08 5,12 14,57 5,33 15,16 5,41 16,04 5,53 17,49 5,73

20 10,04 4,85 11,53 5,07 13,01 5,29 14,47 5,50 15,05 5,58 15,92 5,71 17,35 5,92

23 9,98 5,09 11,44 5,32 12,89 5,54 14,32 5,76 14,89 5,85 15,74 5,99 17,14 6,21

25 9,94 5,25 11,38 5,49 12,81 5,72 14,22 5,95 14,78 6,04 15,62 6,18 17,00 6,42

27 9,90 5,42 11,32 5,66 12,73 5,90 14,12 6,14 14,67 6,24 15,49 6,38 16,85 6,64

3170 m

3

/h

15 10,34 4,47 11,95 4,65 13,55 4,82 15,13 4,98 15,75 5,05 16,69 5,14 18,24 5,30

19 10,28 4,77 11,85 4,95 13,40 5,13 14,94 5,29 15,55 5,36 16,46 5,46 17,97 5,62

20 10,26 4,85 11,82 5,03 13,37 5,20 14,89 5,37 15,50 5,44 16,41 5,54 17,90 5,71

23 10,21 5,09 11,74 5,27 13,25 5,45 14,75 5,62 15,34 5,69 16,23 5,79 17,69 5,97

25 10,17 5,26 11,68 5,44 13,17 5,61 14,65 5,79 15,23 5,86 16,11 5,97 17,55 6,16

27 10,13 5,42 11,62 5,60 13,09 5,78 14,55 5,97 15,12 6,04 15,99 6,16 17,41 6,35

3575

15 10,46 4,56 12,10 4,72 13,74 4,87 15,35 5,01 15,99 5,06 16,95 5,15 18,53 5,29

19 10,40 4,88 12,00 5,03 13,59 5,17 15,17 5,32 15,79 5,37 16,72 5,46 18,27 5,60

20 10,38 4,96 11,98 5,11 13,56 5,25 15,12 5,40 15,74 5,45 16,67 5,54 18,20 5,69

23 10,33 5,21 11,89 5,36 13,44 5,50 14,97 5,65 15,58 5,70 16,49 5,79 17,99 5,95

25 10,29 5,38 11,84 5,53 13,36 5,67 14,88 5,82 15,48 5,88 16,37 5,97 17,85 6,13

27 10,25 5,56 11,78 5,70 13,28 5,84 14,77 5,99 15,37 6,06 16,25 6,15 17,71 6,32

Application Guide • FLATAIR-AGU-MSL60-1505-E

Net cooling capacity Net heating capacity Sensible cooling capacity

Compressor absorbed

power

HEATING CAPACITIES

Air inlet temperature at condenser (dry bulb)

Mixed air

temperature

°C

Indoor wet

bulb

Indoor dry bulb

Minimum airfl ow rateNominal airfl ow rateMaximum airfl ow rate

Air inlet temperature at condenser (dry bulb)

Indoor Dry Bulb

Minimum

airfl ow

Nominal

airfl ow

Maximum air-

fl ow rate

7 - CAPACITIES

COOLING CAPACITIES

• 13 •

GC

(kW) :

NH

(kW) :

SC

(kW) :

AC

(kW) :

FMC/H 20

20 °C 25 °C 30 °C 35°C 40 °C 44 °C

NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC

3090 m

3

/h

16

21

19,16 6,03 11,63 18,60 6,35 11,40 17,92 6,74 11,11 17,11 7,26 10,77 16,19 7,96 10,37 15,37 8,74 9,99

24 19,14 6,02 14,52 18,61 6,34 14,22 17,95 6,74 13,85 17,18 7,26 13,40 16,28 7,96 12,88 15,48 8,75 12,39

27 19,30 6,04 16,83 18,79 6,37 16,48 18,16 6,77 16,06 17,41 7,29 15,55 16,54 8,00 14,95 15,76 8,78 14,39

19

24 20,92 6,17 11,31 20,29 6,50 11,12 19,55 6,90 10,88 18,68 7,42 10,59 17,70 8,12 10,24 16,82 8,91 9,92

27 20,82 6,16 14,41 20,22 6,48 14,13 19,50 6,89 13,79 18,66 7,41 13,39 17,71 8,12 12,91 16,85 8,91 12,47

30 20,89 6,16 16,83 20,32 6,49 16,50 19,63 6,90 16,10 18,82 7,43 15,62 17,89 8,14 15,05 17,05 8,93 14,53

22

27 22,99 6,34 10,52 22,31 6,67 10,39 21,50 7,08 10,22 20,57 7,61 10,01 19,52 8,32 9,76 18,60 9,10 9,52

30 22,81 6,32 13,89 22,15 6,65 13,66 21,37 7,06 13,38 20,47 7,59 13,05 19,45 8,31 12,65 18,54 9,10 12,27

33

22,80 6,32 16,50 22,16 6,65 16,21 21,41 7,07 15,86 20,53 7,60 15,44 19,54 8,32 14,94 18,65 9,11 14,47

4500 m

3

/h

16

21

19,98 6,57 13,41 19,37 6,88 13,15 18,63 7,26 12,82 17,78 7,77 12,42 16,80 8,46 11,95 15,94 9,23 11,52

24 20,10 6,58 16,93 19,51 6,89 16,58 18,81 7,29 16,14 17,98 7,79 15,63 17,03 8,49 15,01 16,18 9,25 14,45

27 20,40 6,62 19,89 19,84 6,94 19,48 19,15 7,33 18,98 18,22 7,97 18,22 17,35 8,72 17,35 16,58 9,55 16,58

19

24 21,78 6,71 13,20 21,10 7,03 12,97 20,30 7,43 12,69

19,38 7,94 12,35

18,34 8,65 11,94 17,43 9,43 11,56

27 21,81 6,71 16,95 21,16 7,04 16,62 20,39 7,44 16,22 19,50 7,96 15,74 18,49 8,67 15,18 17,59 9,45 14,65

30 22,03 6,74 20,04 21,40 7,07 19,64 20,66 7,47 19,16

19,79 8,00 18,59

18,81 8,71 17,91 17,93 9,48 17,29

22

27 23,88 6,88 12,52 23,14 7,21 12,36 22,28 7,62 12,15 21,30 8,14 11,90 20,20 8,86 11,58 19,23 9,65 11,28

30 23,84 6,88 16,57 23,13 7,21 16,29 22,29 7,62 15,95 21,34 8,15 15,55 20,26 8,87 15,06 19,31 9,66 14,61

33

23,96 6,89 19,88 23,27 7,22 19,52 22,47 7,64 19,09 21,54 8,18 18,58 20,49 8,90 17,97 19,56 9,69 17,41

4850 m

3

/h

16

21

19,93 6,82 13,83 19,30 7,15 13,54 18,56 7,56 13,20 17,69 8,11 12,78 16,70 8,86 12,28 15,82 9,71 11,82

24 20,08 6,84 17,47 19,48 7,17 17,09 18,76 7,59 16,64 17,92 8,14 16,09 16,96 8,89 15,44 16,10 9,73 14,85

27 20,46 6,88 20,46 19,92 7,22 19,92 19,26 7,63 19,26 18,50 8,17 18,50 17,62 8,90 17,62 16,83 9,69 16,83

19

24 21,73 6,96 13,67 21,04 7,30 13,43 20,23 7,72 13,13 19,30 8,28 12,76 18,25 9,04 12,32 17,32 9,90 11,91

27 21,80 6,97 17,55 21,14 7,31 17,20 20,35 7,74 16,77 19,45 8,30 16,27 18,42 9,07 15,66 17,52 9,92 15,11

30 22,05 7,00 20,78 21,41 7,35 20,36 20,65 7,78 19,85 19,78 8,34 19,24 18,78 9,11 18,53 17,89 9,96 17,87

22

27 23,85 7,13 13,06 23,09 7,48 12,88 22,22 7,91 12,65 21,22 8,48 12,38 20,11 9,25 12,03 19,13 10,11 11,71

30 23,84 7,13 17,23 23,11 7,48 16,94 22,26 7,92 16,58 21,29 8,49 16,14 20,21 9,26 15,62 19,25 10,13 15,13

33

23,99 7,15 20,69 23,29 7,50 20,31 22,47 7,94 19,85 21,53 8,52 19,30 20,47 9,30 18,66 19,53 10,16 18,06

FMH 20

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

3090 m

3

/h

15 13,12 5,19 15,13 5,57 17,14 5,93 19,15 6,30 19,96 6,45 21,18 6,67 23,20 7,06

18 13,12 5,51 15,08 5,89 17,05 6,26 19,03 6,65 19,82 6,80 21,01 7,04 22,99 7,45

20 13,13 5,73 15,06 6,12 17,00 6,50 18,95 6,89 19,73 7,06 20,90 7,30 22,86 7,74

23 13,15 6,10 15,04 6,49 16,94 6,88 18,84 7,30 19,61 7,47 20,75 7,73 22,67 8,19

25 13,16 6,35 15,03 6,75 16,90 7,16 18,78 7,59 19,53 7,76 20,66 8,04 22,55 8,53

27 13,19 6,62 15,02 7,03 16,87 7,45 18,72 7,89 19,46 8,08 20,57 8,37 22,43 8,88

4500 m

3

/h

15 13,56 5,29 15,68 5,60 17,80 5,89 19,92 6,19 20,77 6,31 22,05 6,49 24,19 6,80

19 13,53 5,69 15,59 5,99 17,65 6,29 19,72 6,60 20,55 6,72 21,80 6,91 23,88 7,24

20 13,53 5,80 15,57 6,10 17,62 6,40 19,68 6,71 20,50 6,83 21,74 7,03 23,80 7,36

23 13,52 6,13 15,52 6,43 17,53 6,74 19,54 7,05 20,35 7,18 21,56 7,38 23,59 7,73

25 13,52 6,37 15,50 6,67 17,48 6,97 19,46 7,30 20,26 7,43 21,45 7,64 23,45 8,00

27 13,53 6,62 15,47 6,91 17,43 7,22 19,38 7,55 20,17 7,69 21,35 7,90 23,32 8,28

4850 m

3

/h

15 13,79 5,50 15,93 5,77 18,07 6,05 20,23 6,32 21,09 6,43 22,38 6,60 24,55 6,89

19 13,75 5,92 15,83 6,19 17,92 6,46 20,02 6,74 20,86 6,85 22,12 7,03 24,23 7,34

20 13,74 6,03 15,81 6,30 17,89 6,57 19,97 6,85 20,80 6,97 22,06 7,14 24,15 7,45

23 13,73 6,38 15,75 6,64 17,79 6,91 19,83 7,20 20,65 7,32 21,88 7,50 23,93 7,83

25 13,72 6,62 15,72 6,88 17,73 7,16 19,74 7,45 20,55 7,57 21,76 7,76 23,79 8,10

27 13,72 6,88 15,70 7,14 17,68 7,41 19,66 7,71 20,46 7,83 21,65 8,03 23,65 8,38

Application Guide • FLATAIR-AGU-MSL60-1505-E

Gross cooling capacity Net heating capacity Sensible cooling capacity

Compressor absorbed

power

HEATING CAPACITIES

Air inlet temperature at condenser (dry bulb)

Mixed air

temperature

°C

Indoor wet

bulb

Indoor dry bulb

Minimum airfl ow rateNominal airfl ow rateMaximum airfl ow rate

Air inlet temperature at condenser (dry bulb)

Indoor Dry Bulb

Minimum

airfl ow

Nominal

airfl ow

Maximum air-

fl ow rate

7 - CAPACITIES

COOLING CAPACITIES

• 14 •

NC

(kW) :

NH

(kW) :

SC

(kW) :

AC

(kW) :

FMC/H 25

20 °C 25 °C 30 °C 35°C 40 °C 44 °C

NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC

3455 m

3

/h

16

21

23,00 7,15 13,63 22,35 7,54 13,33 21,55 8,03 12,98 20,58 8,67 12,56 19,46 9,57 12,06 18,44 10,61 11,59

24 22,91 7,13 16,87 22,28 7,53 16,52 21,50 8,03 16,08 20,55 8,69 15,55 19,45 9,60 14,92 18,45 10,65 14,34

27 23,05 7,15 19,43 22,45 7,55 19,05 21,68 8,06 18,56 20,76 8,72 17,97 19,67 9,65 17,26 18,69 10,71 16,60

19

24 25,15 7,29 13,21 24,42 7,68 12,94 23,52 8,18 12,63 22,47 8,83 12,25 21,25 9,73 11,82 20,17 10,75 11,41

27 24,97 7,27 16,71 24,25 7,67 16,38 23,38 8,17 15,97 22,34 8,83 15,48 21,15 9,75 14,89 20,08 10,80 14,35

30 25,01 7,27 19,42 24,32 7,68 19,04 23,46 8,19 18,58 22,45 8,86 18,01 21,28 9,79 17,34 20,22 10,85 16,71

22

27 27,60 7,49 12,18 26,77 7,89 11,97 25,79 8,40 11,73 24,64 9,06 11,45 23,34 9,98 11,11 22,18 11,01 10,80

30 27,31 7,46 16,02 26,51 7,87 15,72 25,54 8,39 15,37 24,42 9,06 14,96 23,14 9,99 14,46 21,99 11,06 14,00

33

27,25 7,46 18,96 26,46 7,87 18,62 25,52 8,39 18,21 24,42 9,08 17,70 23,15 10,03 17,10 22,03 11,11 16,53

5470 m

3

/h

16

21

24,31 7,92 15,92 23,55 8,28 15,59 22,63 8,75 15,19 21,55 9,36 14,70 20,32 10,22 14,12 19,21 11,21 13,58

24 24,44 7,93 20,01 23,70 8,30 19,60 22,80 8,78 19,08 21,75 9,40 18,46 20,53 10,28 17,71 19,44 11,27 17,01

27 24,80 7,97 23,44 24,08 8,35 22,98 23,20 8,83 22,40 22,17 9,47 21,68 20,97 10,35 20,82 28,25 7,35 26,61

19

24 26,43 8,09 15,65 25,58 8,47 15,35 24,57 8,96 15,00

23,41 9,60 14,56

22,08 10,49 14,04 20,90 11,51 13,56

27 26,46 8,10 20,02 25,63 8,48 19,63 24,65 8,98 19,14 23,50 9,63 18,55 22,19 10,54 17,85 21,03 11,58 17,20

30 26,73 8,13 23,62 25,92 8,52 23,16 24,95 9,02 22,60

23,82 9,68 21,91

22,54 10,60 21,08 21,39 11,65 20,31

22

27 28,84 8,32 14,79 27,90 8,72 14,57 26,80 9,23 14,29 25,55 9,91 13,95 24,13 10,85 13,53 22,88 11,92 13,14

30 28,77 8,32 19,51 27,86 8,73 19,17 26,78 9,25 18,75 25,54 9,94 18,24 24,14 10,90 17,62 22,91 11,99 17,04

33

28,93 8,34 23,37 28,03 8,76 22,95 26,97 9,28 22,44 25,75 9,98 21,81 24,38 10,95 21,05 23,16 12,06 20,34

5750m

3

/h

16

21

24,01 8,37 16,20 23,23 8,79 15,86 22,30 9,32 15,43 21,21 10,05 14,92 19,95 11,09 14,30 18,83 12,32 13,73

24 24,17 8,39 20,34 23,41 8,81 19,91 22,50 9,36 19,37 21,43 10,09 18,71 20,19 11,15 17,92 19,09 12,39 17,19

27 24,56 8,43 23,84 23,82 8,86 23,36 22,93 9,41 22,75 21,90 10,06 21,90 20,79 11,01 20,79 19,80 12,09 19,80

19

24 26,12 8,54 16,01 25,26 8,97 15,69 24,24 9,53 15,31 23,05 10,28 14,85 21,71 11,36 14,30 20,52 12,62 13,78

27 26,19 8,55 20,43 25,34 8,99 20,01 24,34 9,55 19,50 23,18 10,32 18,88 21,85 11,41 18,13 20,68 12,70 17,44

30 26,48 8,58 24,09 25,66 9,03 23,62 24,67 9,60 23,02 23,53 10,37 22,29 22,23 11,48 21,41 21,07 12,77 20,60

22

27 28,53 8,77 15,24 27,57 9,22 15,00 26,46 9,81 14,70 25,19 10,60 14,33 23,75 11,73 13,88 22,49 13,05 13,44

30 28,49 8,77 20,01 27,56 9,23 19,64 26,47 9,83 19,19 25,21 10,63 18,65 23,80 11,78 17,99 22,56 13,13 17,37

33

28,67 8,80 23,94 27,76 9,26 23,50 26,69 9,87 22,95 25,46 10,68 22,28 24,06 11,84 21,47 22,84 13,20 20,72

FMH 25

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

3455 m

3

/h

15 16,02 6,72 18,42 7,21 20,79 7,71 23,15 8,22 24,09 8,42 25,49 8,74 27,80 9,30

18 16,00 7,13 18,35 7,64 20,67 8,16 22,98 8,69 23,90 8,91 25,27 9,25 27,53 9,85

20 15,99 7,43 18,31 7,95 20,60 8,48 22,87 9,03 23,78 9,26 25,13 9,62 27,36 10,26

23 15,99 7,92 18,26 8,46 20,50 9,02 22,72 9,60 23,60 9,85 24,92 10,24 27,11 10,93

25 16,00 8,28 18,23 8,83 20,44 9,41 22,63 10,02 23,50 10,29 24,80 10,69 26,94 11,43

27 16,01 8,67 18,21 9,24 20,38 9,84 22,54 10,48 23,39 10,76 24,67 11,19

5470 m

3

/h

15 16,69 6,77 19,27 7,14 21,82 7,51 24,35 7,88 25,36 8,03 26,87 8,26 29,36 8,66

19 16,63 7,26 19,14 7,63 21,62 8,00 24,09 8,38 25,07 8,54 26,53 8,79 28,96 9,21

20 16,62 7,39 19,11 7,76 21,58 8,13 24,03 8,52 25,00 8,68 26,45 8,93 28,86 9,36

23 16,59 7,81 19,03 8,18 21,45 8,55 23,84 8,95 24,80 9,12 26,22 9,38 28,58 9,84

25 16,57 8,11 18,98 8,48 21,36 8,86 23,73 9,27 24,67 9,44 26,08 9,71 28,40 10,19

27 16,56 8,43 18,94 8,80 21,29 9,18 23,62 9,60 24,55 9,78 25,93 10,06 28,22 10,56

5750

15 17,12 7,21 19,72 7,54 22,30 7,87 24,85 8,21 25,87 8,35 27,39 8,57 29,91 8,94

19 17,05 7,74 19,58 8,06 22,09 8,39 24,58 8,74 25,57 8,89 27,05 9,12 29,50 9,52

20 17,04 7,88 19,55 8,20 22,05 8,53 24,52 8,89 25,50 9,03 26,97 9,26 29,41 9,67

23 17,00 8,34 19,47 8,65 21,91 8,98 24,33 9,35 25,30 9,50 26,74 9,74 29,12 10,17

25 16,99 8,67 19,42 8,98 21,83 9,31 24,22 9,68 25,17 9,84 26,59 10,08 28,94 10,53

27 16,97 9,03 19,37 9,32 21,75 9,66 24,10 10,03 25,04 10,20 26,44 10,45 28,76 10,92

Application Guide • FLATAIR-AGU-MSL60-1505-E

Net cooling capacity Net heating capacity Sensible cooling capacity

Compressor absorbed

power

HEATING CAPACITIES

COOLING CAPACITIES

Air inlet temperature at condenser (dry bulb)

Mixed air

temperature

°C

Indoor wet

bulb

Indoor dry bulb

Minimum airfl ow rateNominal airfl ow rateMaximum airfl ow rate

Air inlet temperature at condenser (dry bulb)

Indoor Dry Bulb

Minimum

airfl ow

Nominal

airfl ow

Maximum air-

fl ow rate

7 - CAPACITIES

• 15 •

GC

(kW) :

NH

(kW) :

SC

(kW) :

AC

(kW) :

FMC/H 30

20 °C 25 °C 30 °C 35°C 40 °C 41 °C

NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC NC AC SC

3695 m

3

/h

16

21

27,18 8,87 16,14 26,31 9,37 15,73 25,21 10,02 15,24 23,88 10,89 14,66 22,32 12,17 13,97 21,98 12,50 13,82

24 27,15 8,87 19,69 26,30 9,37 19,25 25,22 10,02 18,70 23,90 10,90 18,03 22,35 12,18 17,20 22,01 12,52 17,01

27 27,18 8,88 22,96 26,35 9,38 22,52 25,28 10,03 21,92 23,98 10,92 21,17 22,44 12,21 20,22 22,11 12,54 20,01

19

24 29,61 9,10 15,82 28,63 9,63 15,40 27,41 10,31 14,93 25,96 11,25 14,38 24,27 12,63 13,74 23,91 12,99 13,60

27 29,57 9,09 19,36 28,60 9,63 18,92 27,40 10,32 18,38 25,96 11,26 17,74 24,29 12,64 16,97 23,93 13,00 16,80

30 29,59 9,10 22,58 28,64 9,63 22,13 27,45 10,33 21,56 26,03 11,27 20,85 24,37 12,66 19,96 24,01 13,02 19,77

22

27 32,26 9,31 15,37 31,16 9,86 14,97 29,82 10,59 14,52 28,25 11,58 14,02 26,45 13,04 13,45 26,06 13,42 13,32

30 32,21 9,30 18,87 31,12 9,86 18,45 29,80 10,59 17,95 28,24 11,58 17,36 26,45 13,05 16,66 26,07 13,43 16,51

33

32,21 9,30 22,04 31,14 9,87 21,61 29,83 10,60 21,08 28,29 11,60 20,43 26,51 13,06 19,63 26,13 13,45 19,45

5060 m

3

/h

16

21

28,49 9,38 18,20 27,49 9,86 17,80 26,27 10,48 17,30 24,81 11,33 16,68 23,11 12,58 15,93 22,74 12,90 15,76

24 28,48 9,38 22,81 27,50 9,86 22,34 26,29 10,49 21,72 24,85 11,34 20,95 23,17 12,59 19,99 22,80 12,91 19,77

27 28,54 9,39 27,13 27,57 9,87 26,61 26,38 10,50 25,90 25,04 11,66 25,04 23,62 13,09 23,62 23,31 13,46 23,31

19

24 31,01 9,62 17,73 29,90 10,13 17,34 28,55 10,81 16,88

26,97 11,73 16,32

25,16 13,10 15,64 24,77 13,45 15,49

27 31,00 9,61 22,39 29,90 10,13 21,94 28,57 10,81 21,36 27,00 11,74 20,65 25,20 13,11 19,77 24,81 13,46 19,57

30 31,04 9,62 26,73 29,95 10,14 26,23 28,64 10,82 25,57

27,09 11,75 24,72

25,30 13,12 23,67 24,92 13,48 23,43

22

27 33,76 9,84 17,10 32,52 10,39 16,74 31,06 11,11 16,33 29,36 12,10 15,84 27,42 13,56 15,26 27,01 13,94 15,13

30 33,73 9,83 21,80 32,51 10,38 21,38 31,06 11,11 20,86 29,37 12,10 20,22 27,45 13,56 19,44 27,04 13,94 19,26

33

33,75 9,84 26,15 32,55 10,39 25,69 31,11 11,12 25,08 29,44 12,11 24,32 27,53 13,58 23,37 27,13 13,96 23,16

5500 m

3

/h

16

21

28,47 9,80 18,76 27,43 10,32 18,34 26,16 11,00 17,82 24,66 11,95 17,18 22,93 13,37 16,39 22,55 13,74 16,21

24 28,47 9,80 23,64 27,45 10,32 23,14 26,20 11,01 22,50 24,71 11,96 21,67 22,99 13,38 20,65 22,62 13,76 20,42

27 28,53 9,81 28,25 27,57 10,37 27,57 26,51 11,08 26,51 25,25 12,06 25,25 23,79 13,51 23,79 23,47 13,89 23,47

19

24 31,02 10,04 18,27 29,87 10,59 17,89 28,48 11,33 17,41 26,86 12,36 16,83 25,00 13,91 16,12 24,60 14,32 15,96

27 31,02 10,03 23,25 29,88 10,60 22,77 28,50 11,34 22,17 26,89 12,37 21,41 25,05 13,92 20,48 24,66 14,33 20,27

30 31,06 10,04 27,90 29,94 10,60 27,36 28,58 11,35 26,65 26,99 12,39 25,74 25,16 13,94 24,61 24,77 14,35 24,35

22

27 33,80 10,25 17,62 32,52 10,85 17,27 31,01 11,63 16,86 29,27 12,73 16,36 27,30 14,39 15,75 26,87 14,82 15,61

30 33,78 10,25 22,66 32,52 10,85 22,23 31,02 11,63 21,69 29,29 12,74 21,02 27,33 14,39 20,19 26,91 14,83 20,00

33

33,81 10,25 27,36 32,56 10,85 26,87 31,08 11,64 26,22 29,37 12,75 25,40 27,42 14,41 24,38 27,01 14,84 24,15

FMH 30

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

2695 m

3

/h

15 18,30 7,75 21,01 8,31 23,70 8,87 26,37 9,43 27,43 9,66 29,02 10,01 31,65 10,61

18 18,32 8,25 20,97 8,82 23,59 9,40 26,19 9,99 27,23 10,23 28,78 10,60 31,35 11,24

20 18,35 8,60 20,95 9,19 23,53 9,78 26,09 10,39 27,11 10,64 28,63 11,03 31,16 11,71

23 18,40 9,18 20,94 9,78 23,46 10,40 25,95 11,04 26,95 11,31 28,43 11,72 30,89 12,46

25 18,45 9,59 20,95 10,21 23,42 10,84 25,87 11,51 26,85 11,79 28,31 12,23 30,73 13,01

27 18,51 10,03 20,96 10,65 23,39 11,31 25,80 12,01 26,76 12,31 28,20 12,77 30,57 13,60

50600 m

3

/h

15 18,63 7,57 21,49 8,04 24,33 8,50 27,16 8,96 28,28 9,14 29,96 9,42 32,75 9,90

19 18,61 8,18 21,39 8,66 24,14 9,13 26,88 9,60 27,97 9,79 29,60 10,08 32,30 10,59

20 18,61 8,34 21,37 8,82 24,10 9,29 26,82 9,77 27,90 9,96 29,52 10,26 32,19 10,78

23 18,63 8,86 21,32 9,34 23,99 9,82 26,64 10,31 27,70 10,51 29,28 10,83 31,89 11,38

25 18,66 9,23 21,30 9,71 23,93 10,19 26,54 10,70 27,58 10,91 29,13 11,23 31,70 11,80

27 18,69 9,62 21,29 10,09 23,88 10,58 26,45 11,10 27,47 11,32 28,99 11,66 31,52 12,26

5500 m

3

/h

15 18,97 7,86 21,88 8,29 24,77 8,71 27,65 9,13 28,79 9,30 30,50 9,56 33,34 10,00

19 18,94 8,50 21,76 8,93 24,57 9,35 27,35 9,78 28,46 9,96 30,12 10,23 32,87 10,69

20 18,93 8,67 21,74 9,10 24,52 9,52 27,29 9,95 28,39 10,13 30,04 10,40 32,76 10,88

23 18,94 9,22 21,68 9,64 24,40 10,06 27,10 10,50 28,18 10,69 29,79 10,97 32,45 11,47

25 18,96 9,61 21,65 10,02 24,33 10,44 26,99 10,90 28,05 11,08 29,63 11,38 32,25 11,90

27 18,98 10,01 21,64 10,42 24,27 10,85 26,89 11,31 27,93 11,50 29,49 11,81 32,06 12,35

Application Guide • FLATAIR-AGU-MSL60-1505-E

Gross cooling capacity Net heating capacity Sensible cooling capacity

Compressor absorbed

power

HEATING CAPACITIES

COOLING CAPACITIES

Air inlet temperature at condenser (dry bulb)

Mixed air

temperature

°C

Indoor wet

bulb

Indoor dry bulb

Minimum airfl ow rateNominal airfl ow rateMaximum airfl ow rate

Air inlet temperature at condenser (dry bulb)

Indoor Dry Bulb

Minimum

airfl ow

Nominal

airfl ow

Maximum air-

fl ow rate

7 - CAPACITIES

• 16 •

x 0.97 x 1.00 x 1.01 x 0.98 x 1.00 x 1.01

x 0.90 x 1.00 x 1.03 x 0.95 x 1.00 x 1.02

x 0.98 x 1.00 x 1.01 x 0.91 x 1.00 x 1.03

x 0.98 x 1.00 x 1.01 x 0.98 x 1.00 x 1.01

Application Guide • FLATAIR-AGU-MSL60-1505-E

7 - CAPACITIES

CORRECTION COEFICIENTS

CALCULATION OF COOLING CAPACITY DEPENDING ON AIR FLOW

INDOOR & OUTDOOR AIRFLOW RATES

INDOOR & OUTDOOR AIRFLOW RATES

CALCULATION OF HEATING POWER DEPENDING ON AIR FLOW

Sizes 10-12-15-20 Sizes 25-30

Minimum Nominal Maximum Minimum Nominal Maximum

Cooling capacity

Sensible capacity

Sizes 10-12-15-20 Sizes 25-30

Minimum Nominal Maximum Minimum Nominal Maximum

Cooling capacity

Sensible capacity

• 17 •

10-230 l 10 12 15 20 25 30

5,5 5,3 6,6 7,8 10,4 12,6 14,2

31,7 13,7 16,0 18,6 23,6 30,0 31,0

90,2 34,1 39,7 49,0 75,3 82,3 86,9

133,7 48,7 57,2 70,8 109,6 120,0 127,0

10-230 l 10 12 15 20 25 30

3 3 4.5 7.5

66 6 9

99 12

13.0 7.5 11.3 18.8

26.1 15 15 22.5

- 22.5 22.5 30

10-230 l 10 12 15 20 25 30

0,4 0,4 0,4 0,8 1,0 1,3 1,3

2,6 2,6 2,6 2,8 4,3 4,3 4,3

1,7 1,7 1,7 1,8 2,8 2,8 2,8

2,6 2,6 2,6 2,8 4,3 4,3 4,3

10-230 l 10 12 15 20 25 30

5,1 4,9 6,1 7,0 9,4 11,3 13,0

29,1 11,1 13,4 15,8 19,3 25,7 26,7

87,6 31,5 37,1 46,2 71,0 78,0 82,6

131,1 46,1 54,6 68,0 105,3 115,7 122,7

Application Guide • FLATAIR-AGU-MSL60-1505-E

8 - ELECTRICAL DATA

UNITS WITHOUT ELECTRICAL HEATER (STANDARD UNITS)

PACKAGED UNIT (INDOOR+ OUTDOOR)

INDOOR UNIT

OUTDOOR UNIT

ELECTRICAL HEATER (add the following consumption for heat pump units)

TYPE

Maximum power (KW)

Maximum current (A)

Starting current (A)

LRC (A)

TYPE

Power input (kW)

Maximum current (A)

TYPE

Maximum power (KW)

Maximum current (A)

Starting current (A)

LRC (A)

TYPE

Maximum power (KW)

Maximum current (A)

Starting current (A)

LRC (A)

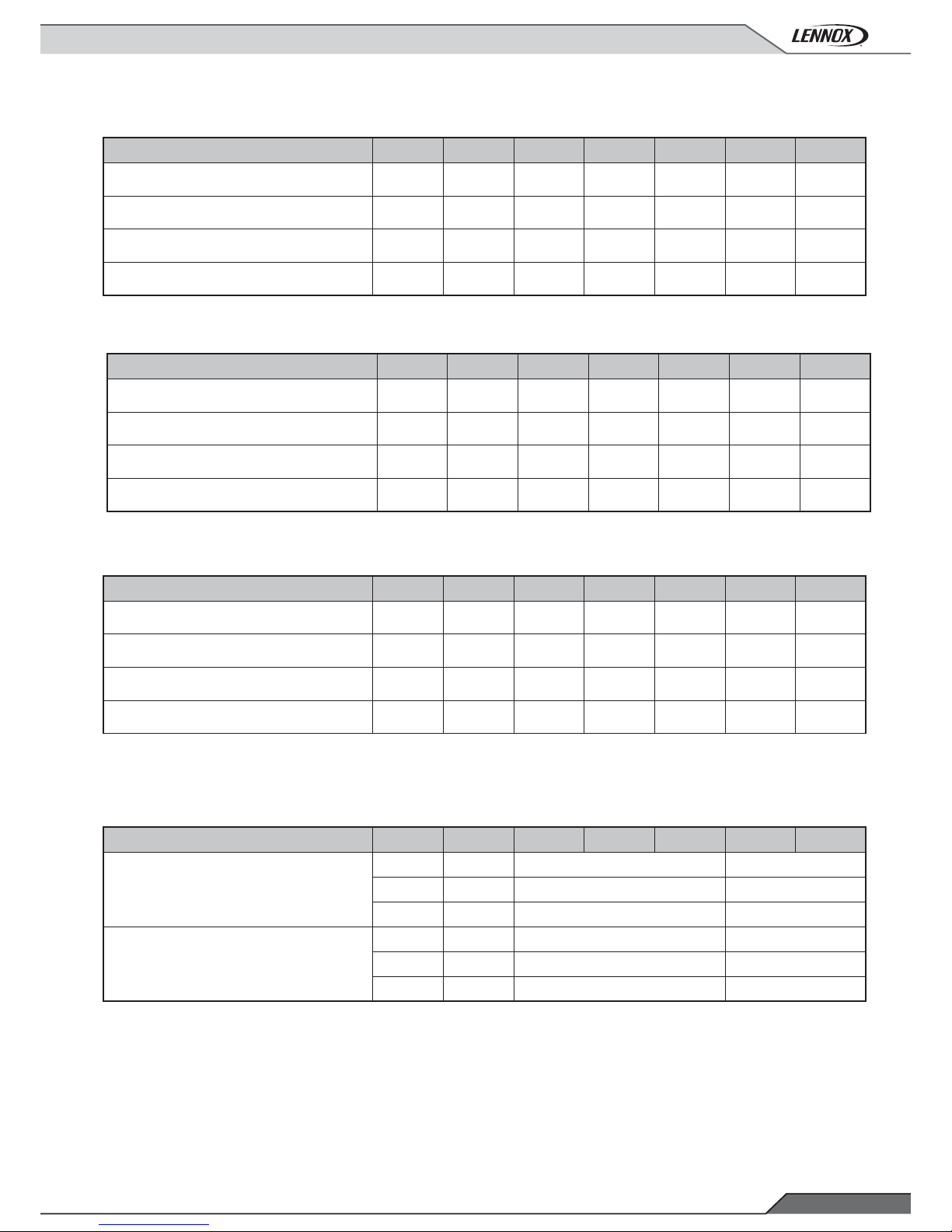

• 18 •

FIX 10-12

FSC / FSH 10-12

Application Guide • FLATAIR-AGU-MSL60-1505-E

9 - DIMENSIONS

9.1 - UNIT DIMENSION

• 19 •

FIX 15

FSC / FSH 15

Application Guide • FLATAIR-AGU-MSL60-1505-E

9 - DIMENSIONS

9.1 - UNIT DIMENSION

• 20 •

FIC / FIH 20

FSC / FSH 20

Application Guide • FLATAIR-AGU-MSL60-1505-E

9 - DIMENSIONS

9.1 - UNIT DIMENSION

• 21 •

FIC / FIH 25-30

FSC / FSH 25-30

Application Guide • FLATAIR-AGU-MSL60-1505-E

9 - DIMENSIONS

9.1 - UNIT DIMENSION

• 22 •

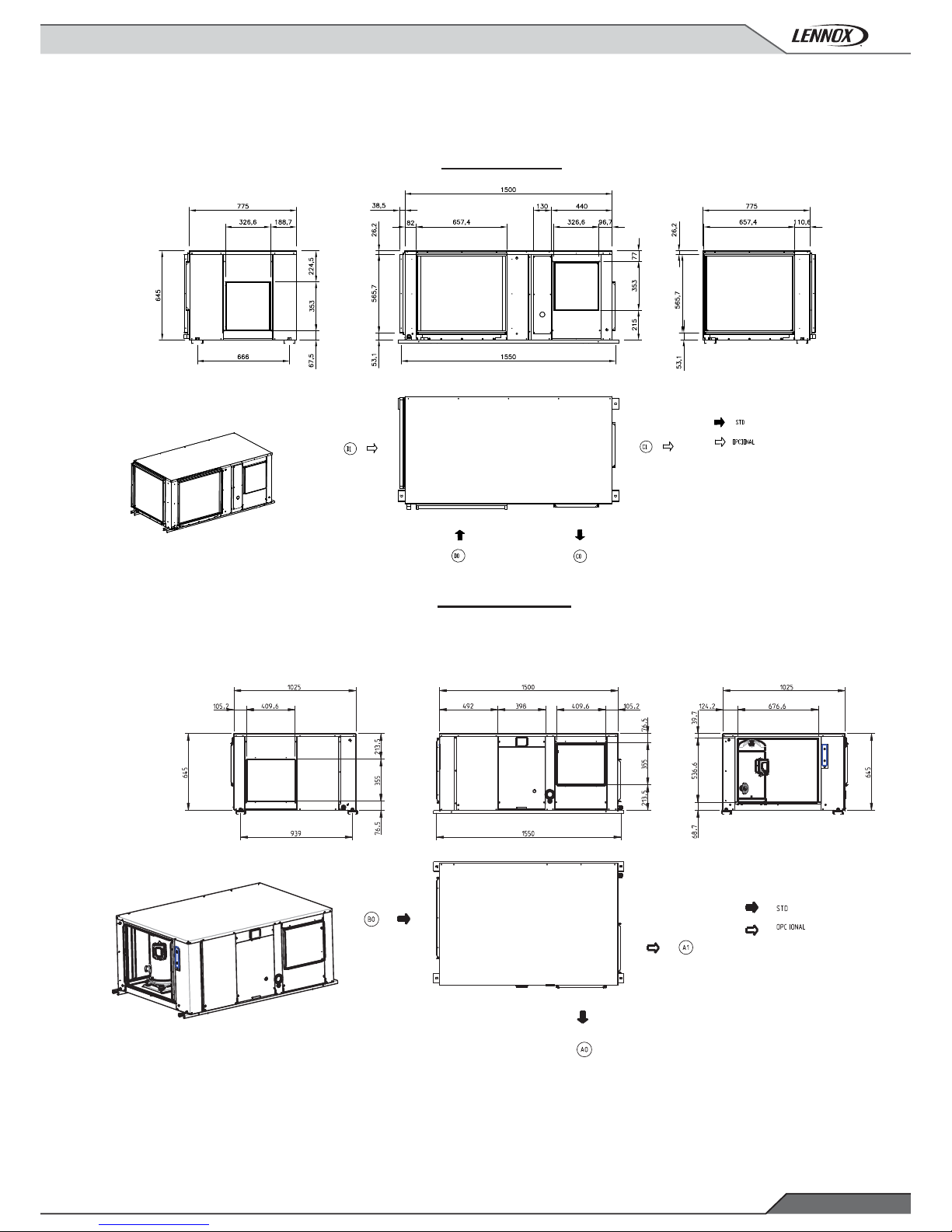

FMC/FMH 10-12

FMC/FMH 15

Application Guide • FLATAIR-AGU-MSL60-1505-E

9 - DIMENSIONS

9.1 - UNIT DIMENSION

• 23 •

FMC/FMH 20

FMC/FMH 25-30

Application Guide • FLATAIR-AGU-MSL60-1505-E

9 - DIMENSIONS

9.1 - UNIT DIMENSION

• 24 •

Application Guide • FLATAIR-AGU-MSL60-1505-E

9.2.- DUCT POSITION

MODELS 10-12-15

MODEL 20

MODELS 25-30

Packaged unit

SPLIT UNIT

Packaged unit

SPLIT UNIT

Packaged unit

SPLIT UNIT

Outdoor fan

Indoor fan

Outdoor fan

Indoor fan

Outdoor fan

Indoor fan

Indoor fan

Indoor fan

Indoor fan

Outdoor fan

Outdoor fan

Outdoor fan

Outdoor coil

Outdoor coil

Outdoor coil

Outdoor coil

Outdoor coil

Outdoor coil

Indoor coil

Indoor coil

Indoor coil

Indoor coil

Indoor coil

Indoor coil

Compressor

Compressor

Compressor

Compressor

Compressor

Compressor

Electrical heater

Electrical heater

Electrical heater

Electrical heater

Electrical heater

Electrical heater

STANDARD

OPTION

ELECTRICAL BOX

9 - DIMENSIONS

• 25 •

Application Guide • FLATAIR-AGU-MSL60-1505-E

10 - INSTALLATION

10.1 - REFRIGERANT CONNECTIONS

Split units are supplied with gas and liquid lines sealed with copper covers, and located 60mm from casing.

Split units are supplied with nitrogen gas, this must be removed and then proceed as folow:

Cupper

cover

Brazing

Gas

Terminal

block

Liquid

Service ports

During installation operations, keep gas and liquid pipes covered, in order to prevent humidity and dirt,

get into them.

Take special concern about refrigerant pipes are isolated.

Avoid collapse on line installation.

1. Remove the nitrogen gas through the high and low 5/16” service ports located inside and provide a low vacuum for safety.

2. Remove the caps from the connecting lines.

3. Braze the piping connection lines. Select piping diameter from table 2.7.1.

(When brazing refrigerant pipes, nitrogen gas must be supplied into the pipes through the service ports to remove the air).

4. Leak test:

Add nitrogen gas, check that a pressure of 5 kg/cm

2

has been reached and that there are no leaks in the circuit or brazing

by applying soapy water to the pipes which will cause the bubbles to form where there are leaks.

To detect small leaks, proceed as follows:

Add nitrogen gas and check that a pressure of 25 kg/cm

2

has been reached, there are no leaks if the pressure remains the same

for at least 24 hours and the fi nal pressure is not less than 10% below the initial pressure.

5. Ensure that the gas line is insulated.

6. Evacuation:

Remove the nitrogen gas, connect the gauge manifold and vacuum pump to both the liquid and gas lines, fully open the gauge

manifold valve and switch on the vacuum pump. Check to make sure the gauge shows a pressure of -750mm Hg. Once a level

of -750mm Hg is reached, keep the vacuum pump running for at least one hour.

7. Refrigerant charge:

- Check TABLE 3.1. and 3.2. for the amount of refrigerant charge, depending on the length and size of the pipe connections.

- Disconnect the vacuum pump and connect to the refrigerant-charging bottle. Open the charging pump and purge the air from

the hose at the pressure gauge manifold.

- Set up the amount of additional refrigerant on the weighing scale, open the high pressure and charged in the liquid state. If the

total amount of refrigerant charge has not been reached because the pressure is balanced, turn off the high side of the gauge

manifold, turn on the unit, and add the remaining amount of the refrigerant charge required slowly through the low side of the

pressure gauge. (With R-410A refrigerant, the charging bottle must be in a vertical position and charged in the liquid state).

Close the pressure gauge, disconnect it from the from the service port of the unit and fi t caps on the service ports. The unit is

then ready to operate.

• 26 •

10 12 15 20 25 30

3/8” 3/8” 1/2” 1/2” 5/8” 5/8”

3/4” 3/4” 7/8” 7/8” 1 1/8” 1 1/8”

15 15 15 15 15 15

12 12 12 12 12 12

Application Guide • FLATAIR-AGU-MSL60-1505-E

10 - INSTALLATION

10.2 - REFRIGERANT CONNECTIONS

To locate the outdoor and the indoor units, refer to the following information:

A,B,C: Units positions

L: Total length

1: Gas line

2: Liquid line

POSITION A:

A syphon suction must be installed on the vertical line of the gas line 1, and syphons must be installed every 8 meters upward. The

minimum speed suction must not be below 6 m/s.

POSITION B:

Tip the lines toward the outdoor unit. Make special attention to the line length longer than 10m and avoid collapse on pipe lines

installation.

w

DISPOSICIÓN C:

Install a syphon at the base of the vertical line, no more syphons are necessary.

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

INDOOR UNIT

REFRIGERANT LINES

SIZE

Total length

0 to 30m

Liquid

Gas

Maximum vertical line length (m)

Maximum number of bends

For other positions and lines lengths between 30 and 50m or longer, consult the commercial-technical department, pipe dimensions, syphon suction, isolations, refrigerant load, line lengths.

Split units are supplied with nitrogen gas.

The installer should remove this gas and charge the units with the charge of refrigerant

R410A , shown in the table 2.7.2 plus the charge by additional meter shown in the table 2.7.3.

TABLE 2.7.1.: REFRIGERANT LINES

• 27 •

3/8” 3/4” 57

1/2” 7/8” 108

5/8” 1 1/8” 177

10 12 15 20 25 30

2,14 2,57 3,55 4,46 5,38 6,15

2,5 2,93 4 4,9 6,3 7

10

230V-1Ph-50 Hz 198-264 V

400V-3Ph-50 Hz

342-462 V

12-15-20-25-30 400V-3Ph-50 Hz

10 5 x 2,5 5 x 4

12 5 x 2,5 5 x 4

15 5 x 4 5 x 6

20 5 x 4 5 x 10

25 5 x 6 5 x 10

30 5 x 6 5 x 10

10 3 x 4 3 x 16

Application Guide • FLATAIR-AGU-MSL60-1505-E

MODELS

Refrigerant charge

R-410A

Cooling only

Heat pump

TABLE 2.7.2 : REFRIGERANT CHARGE

TABLE 2.7.3 : EXTRA REFRIGERANT CHARGE R410A BY METER

Liquid Gas g/m

10 - INSTALLATION

10.3 - ELECTRICAL CONNECTIONS

- Before making any electrical connections, ensure that all circuit breakers are open.

- In order to make the electrical connections, follow the electrical diagram supplied with the unit.

POWER SUPPLY

POWER SUPPLY 230V

SINGLE PHASE UNITS

SIZE

Nº of cables x section (mm²)

Supply without electrical

coil Supply with electrical coil

VOLTAGE OPERATING LIMITS: 342-462V

SIZE VOLTAGE LIMIT

POWER SUPPLY 400V THREE-PHASE UNITS

SIZE

Nº of cables x section (mm²)

Supply without electrical

coil Supply with electrical coil

• 28 •

DC 40

90 91 92 93 94

GND TX+ TX- GO

G

GND

TX+

TX-

GO

G

Application Guide • FLATAIR-AGU-MSL60-1505-E

DC 40 THERMOSTAT, ELECTRICAL CONNECTION

IMPORTAN

T

THE SHIELDED CONNECTING CABLE BETWEEN THE CONTROL PANEL AND THE UNIT MUST BE SEPARATED FROM

ANY OTHER TYPE OF ELECTRICAL WIRING. CONNECT IT TO THE ELECTRIC PANEL LOCATED IN THE OUTDOOR UNIT.

2 x Shielded twisted pairs AWG 20. 100 m maximum.

1x Shielded twisted pair AWG20 + 2 x 1,5 mm. 200m maximum.

CONTROL PANEL

NOTES:

- For securing and connecting the Control Panel, consult the control panel Manual supplied with the unit.

- Connection between the DC40 and the unit must be made using shielded twisted pair cables (where the screens

are connected to the control panel and the unit Electrical box).

- The Tx+ and Tx- polarity must strictly comply with the electrical diagram supplied with the unit.

10 - INSTALLATION

• 29 •

10

1F

10

3F

12 15 20 25 30

3 4.5 7.5

69

-9 12

Application Guide • FLATAIR-AGU-MSL60-1505-E

11 - OPTIONS

ELECTRIC HEATER

Optionally, these units can contain shielded element electric heating batteries that are mounted on the inside of the

unit in the schematic opposite.

The electric heater must get its power from the unit’s electrical box.

UNIT

STANDARD (kW)

MEDIUM (kW)

HIGH

MAIN SWITCH

The main switch is located on the access panel to the electrical box in the outdoor section in such a way that the unit is disconnected when the panel is opened.

(Refer to the size diagram a pages 20 to 31 to see the position of the electrical box access panel).

Check to make sure that the main switch is large enough to handle the current for the unit if electric heaters are installed.

PHASE SEQUENCER (THREE-PHASE UNIT)

The phase sequencer is located in the electrical box in the outdoor section, thus assuring that the unit will not begin operation while

the phase connection of the compressor is not correct. Should this occur, then just switch two phase connections.

REMOTE ROOM TEMPERATURE SENSOR, REMOTE DUCT SENSOR

These sensors may be used in conjunction with remote controller, allowing the controller to be mounted in a room away from the

conditioned space.

- REMOTE DUCT SENSOR : The sensor will be located in the return air duct, detecting the air temperature of the air being air

conditioned.

- REMOTE ROOM TEMPERATURE SENSOR : The sensor will be placed in the area to be air conditioned.

KIT 0 DEGREES TEMPERATURE :

This kit includes an crankase heater in the cooling only version , to allow working with outdoor temperatures up to 0 degrees .In

heat pump orders , this crankase heater comes as standard .

KIT -15 DEGREES TEMPERATURE :

This kit includes a proportional regulation of the outdoor fan , to allow working with outdoor temperatures up to minus 15 degrees.

FREECOOLING ONE DAMPER

Fresh air damper regulated by the control , to introduce fresh air from the ambient if the temperature conditions are favourable .

SECOND DAMPER FREECOOLING

Second damper for the freecooling , to regulate the return air regarding the % of fresh air introduced in the room . This option is

only valid with the option FREECOOLING ONE DAMPER.

LOW NOISE LEVEL

Compressor jacket to reduce the sound level around 2 dBA.

AIRFLOW CONFIGURATIONS

These units have different confi gurations to manage the airfl ow , both in the indoor and outdoor section .

lennoxemeia.com

+7 495 626 56 53

+34 915 401 810

+380 44 585 59 10

+44 1604 669 100

+ 32 3 633 3045

+33 1 64 76 23 23

+49 (0) 211 950 79 600

+ 39 02 495 26 200

+ 31 332 471 800

+48 22 58 48 610

+351 229 066 050

LENNOX DISTRIBUTION

+33 4 72 23 20 20

RUSSIA

SPAIN

UKRAINE

UNITED KINGDOM AND IRELAND

BELGIUM AND LUXEMBOURG

FRANCE

GERMANY

ITALY

NETHERLANDS

POLAND

PORTUGAL

SALES OFFICES :

OTHER COUNTRIES :

Due to Lennox’s ongoing commitment to quality , the specifi cations,

ratings and dimensions are subject to change without notice and

without incurring liability.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualifi ed installer

and servicing agency

FLATAIR AGU-MSL60-1505-E

Loading...

Loading...