FLATAIR

FLCK / FLHK

English/03-2005

INSTALLATION

OPERATION &

MAINTENANCE MANUAL

1

WARNING: Read this manual before installation, reparation o maintenance works.

1.1.- PHYSICAL DATA

1.2.- ELECTRICAL DATA

1.3.- FAN SERVICES

1.4.- OPERATING LIMITS

1.5.- UNIT DIMENSIONS

1.6.- SIZES OF STANDARD AND OPTIONAL OPENINGS

1.7.- AVAILABLE OPTIONS

DATA PAGE FOR UNIT COMMISSIONING

4.- MAINTENANCE

4.1.- PREVENTIVE MAINTENANCE

4.2.- CORRECTIVE MAINTENANCE

4.3.- FAILURE DIAGNOSIS

2.- INSTALLATION

3.- COMMISSIONING AND OPERATION

1.- GENERAL CHARACTERISTICS

PAGE

PAGE

PAGE

PAGE

4

5

6

7

8-11

12-15

16-17

18

18

19-20

21

22

22

23-24

25

26

27

28

29

TABLE OF CONTENTS

PAGE 3

2.1.- PRELIMINARY PREPARATIONS

2.2.- UNIT RECEPTION

2.3.- OPTIONAL TASKS PRIOR TO UNIT INSTALLATION:

CHANGING THE POSITION OF BLOWERS AND AIR INTAKE

2.4.- UNIT LOCATION AND WEIGHT DISTRIBUTION

2.5.- INSTALLATION CLEARANCES

2.6.- DRAINS

2.7.- ELECTRICAL CONNECTIONS

3.1.- PRELIMINARY CHECKS

3.2.- STEPS TO FOLLOW FOR COMMISSIONING THE UNIT

POINTS TO KEEP IN MIND

PAGE 2

Lennox have been providing environmental solutions since 1895, our range of FLATAIR continues to meet the standards that

have made LENNOX a household name. Flexible design solutions to meet YOUR needs and uncompromising attention to

detail. Engineered to last, simple to maintain and Quality that comes as standard. Information on local contacts at

www.lennoxeurope.com.

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be utilised (except in the operation of this product), reproduced,

issued to or made available to third parties without the prior written agreement of Lennox.

2

Make sure to open the power off switch before to install, repair or make maintenance works in the unit, in order to

prevent serious electrical injuries.

To install the unit, keep in mind local and national legislation.

ELECTRICAL CONNECTIONS

ATTENTION - WARNING

Risk of injury with

rotating objects

Low

temperatures

High

temperatures

Risk of injury with

moving objects

Electrical

voltage

Abrasive

surfaces

FILTER CLEANING

Check the air filter and make

sure it is not blocked with dust

or dirt.

If the filter is dirty, wash it in a bowl with neutral

soap and water, drying it in the shade before

inserting it in the unit.

All technical data contained in these operating instructions including the diagrams and technical description remains the property

of Lennox and may not be used (except for the purpose of familiarizing the user with the equipment), reproduced, photocopied,

transferred or transmitted to third parties without prior written authorization from Lennox .

The data published in the operating instructions is based on the latest information available. We reserve the right to make

modifications without notice.

We reserve the right to modify our products without notice without obligation to modify previously supplied goods.

These operating instructions contain useful and important information for the smooth operation and maintenance of your

equipment.

The instructions also include guidelines on how to avoid accidents and serious damage before commissioning the equipment

and during its operation and how to ensure smooth and fault-free operation. Read the operating instructions carefully before

starting the equipment, familiarize yourself with the equipment and handling of the installation and carefully follow the instructions.

It is very important to be properly trained in handling the equipment. These operating instructions must be kept in a safe place

near the equipment.

Like most equipment, the unit requires regular maintenance. This section concerns the maintenance personnel and management.

If you have any queries or would like to receive further information on any aspect relating to your equipment, do not hesitate

to contact us.

The air filter cleaning operations do not

require technical service; however when

an electrical or mechanical operation

is required call an Engineer.

Electric shock hazard can cause injury

or death. Before attempting to perform

any service or maintenance on the

unit, turn OFF the electrical power,

and check that the fan has stopped.

Standard Guidelines to Lennox equipment

POINTS TO KEEP IN MIND

DANGER AND WARNING SIGNS

3

UNIT:

SERIAL Nr.:

INSTALLATION ADDRESS:

INSTALLER:

INSTALLER TEL.:

CHECKS:

SUPPLY VOLTAGE:

DATA INPUT:

Air Intake Temperature, Outdoor Coil:

ºC

DATE OF COMMISSIONING:

INSTALLER ADDRESS:

RATED VOLTAGE OF THE UNIT:

YES NO

GENERAL POWER SUPPLY CONNECTION

CONTROL PANEL CONNECTION

COLD CYCLE

HEATING CYCLE

Air Output Temperature, Outdoor Coil:

ºC

Air Intake Temperature, Indoor Coil:

ºC

Air Output Temperature, Indoor Coil:

ºC

High Pressure:

Low Pressure:

Options Installed:

ºC

ºC

ºC

High Pressure:

Low Pressure:

ºC

Comments:

COMPRESSOR OIL LEVEL INDICATOR

UNIT ON SHOCK ABSORBERS

DRAINAGE WITH TRAP

CLEAN INTERIOR AIR FILTER

CONTROL PANEL IDENTIFICATION CODE

DATA PAGE FOR UNIT COMMISSIONING

ELECTRIC POWER CONSUMPTION

Compressor

Fan outdoor section

Compressor

Fan outdoor section

Fan indoor section Fan indoor section

(Amps)

Air Intake Temperature, Outdoor Coil:

Air Output Temperature, Outdoor Coil:

Air Intake Temperature, Indoor Coil:

Air Output Temperature, Indoor Coil:

4

1.- GENERAL CHARACTERISTICS

FLHA: Heat pump unit R-22

FLCK: Cooling only unit R-407C

FLHK: Heat pump unit R-407C

1.1.- PHYSICAL DATA

Cooling capacity

COMPRESSOR

Nr. / Type

FAN OUTDOOR SECTION

NET WEIGHT

DB.- Dry bulb temperature

WB.- Wet bulb temperature

9,8 11,8

kW

Kg

15,3 19,5

1 / Scroll 1 / Scroll 1 / Scroll 1 / Scroll

22,0 28,1

1 / Scroll 1 / Scroll

26,3

1 / Scroll

10

Heating capacity

10,0 12,0

kW

15,5 20,2 22,5 28,727,0

12 16 22 24 28 30

Cooling capacity

9,4 11,3

kW

14,7 19,2 21,0 27,6

Heating capacity

kW

10,3 12,3 15,6 20,0 22,8 29,8

FLHA 12FLHA 10 FLHA 16 FLHA 22 FLHA 24 FLHA 28

FLHA 30

26,0

27,0

FLCK 12

FLHK 12

FLCK 10

FLHK 10

FLCK 16

FLHK 16

FLCK 22

FLHK 22

FLCK 24

FLHK 24

FLCK 30

FLHK 30

FLCK 28

FLHK 28

(*) Air intake temperature in the indoor exchanger: 27ºC DB/19ºC WB

(*) Air intake temperature in the outdoor exchanger: 35ºC DB

(**) Air intake temperature in the indoor exchanger: 20ºC DB / 12ºC WB

(**) Air intake temperature in the outdoor exchanger: 7ºC DB / 6ºC WB

Refrigerant charge R-22

Refrigerant charge

R-407C

2240 2560 3550 5000

7500 82008000

2620 2920 4000 5500

--- 7000---

Maximum air flow

24002350 3750 4350

Maximum available pressure

100 90 120 150

Pa

4500 5250

160 100

5000

120

m /h.

3

34003500 4950 5900 6600 6400

6400

Minimum air flow

(1)

m /h.

3

Maximum air flow

16501500 2400 3200

Maximum available pressure

120 110 160 180

Pa

4000 4500

240 180

4250

200

m /h.

3

2300

2350

3700

5350

6300 6000

6000

Minimum air flow

(1)

m /h.

3

FAN INDOOR SECTION

(1) With admissible minimum air flow.

210205 285 330 410 435

430

205200 280 325 405 430

425

Kg

UNIT MODELS

UNIT MODELS

gr.

2900 3100 3900 5400 8400 87008600

gr.

Cooling only units FLC

Heat pump units FLH

(*)

(**)

(*)

(**)

FLCK

FLHK

Application

C: Cooling only

H: Heat pump

Type of Refrigerant

A: R-22

K: R-407C

Unit size.

Approximate cooling

capacity in kW

UNIT MODELS

FL C K 22

Type of unit

Horizontal compact

FLATAIR

5

1.- GENERAL CHARACTERISTICS

V/f (50 Hz)

V/f (50 Hz)

1.2.- ELECTRICAL DATA

3,21

kW

3,84 5,65 7,376,25

Total power in Cooling cycle

Total power in heating cycle

Voltage

230V-400V/ 3Ph

230V/ 1Ph

FLHA 12FLHA 10 FLHA 16 FLHA 22 FLHA 24 FLHA 28 FLHA 30

FLCK 12

FLHK 12

FLCK 10

FLHK 10

FLCK 16

FLHK 16

FLCK 22

FLHK 22

FLCK 24

FLHK 24

FLCK 30

FLHK 30

FLCK 28

FLHK 28

kW

kW

kW

kW

Maximum current

Rated absorbed power

2,03 2,54

kW

2,94 3,70 4,85 6,485,48

Total power in cooling cycle

Total power in heating cycle

Voltage

230V-400V/ 3Ph

230V/ 1Ph

kW

kW

0,38

0,38

kW

0,90 1,30 1,35 1,351,35

0,52 0,52

kW

1,10 1,60 1,60 1,601,60

Maximum current

Total current

Start up current

0,38 0.38 0,90 1,30 1,35 1,351,35

0,52 0,52 1,10 1,60 1,60 1,601,60

2,60 3,41

kW

4,11 5,02 5,85 8,837,41

Rated absorbed power

2,26

3,60

2,79 3,68

kW

4,41 5,20 6,05 9,257,43

Total Current

Start up current

3,69

4,58

6,41 8,10

3,16 4,11 5,60 6,74

9,00 12,20

8,60 10,32

10,38

9,20

UNIT MODELS

UNIT MODELS

A

A

3,50

4,31

6,11 7,92

16,7/7,2 19,3/8,7 19,9/11,5 22,4/12,9

2,93 3,44 4,94 6,60

8,80 11,78

7,80 9,43

25,3/14,6 36,5/21,0

10,36

8,43

28,5/16,3

A

7/4 7,4/4,3

A

52,0/30,044,0/25,439,8/23,037,2/21,531,7/18,3

25,0/14,422,4/12,9

A

24,3

2,6

2,6

7,4/4,3 7,4/4,3 7,4/4,3

3,1 3,1

4,8/2,8 7,4/4,3 8,1/4,7 8,1/4,7 8,1/4,7

18,6

A

A

A

A

52,0/30,044,0/25,439,8/23,037,2/21,531,7/18,3

25,0/14,422,4/12,9

A

24,3

7/4 7,4/4,3

2,6

2,6

7,4/4,3 7,4/4,3 7,4/4,3

3,1 3,1

4,8/2,8 7,4/4,3 8,1/4,7 8,1/4,7 8,1/4,7

16,7/7,2 19,3/8,7 19,9/11,5 22,4/12,9 25,3/14,6 36,5/21,028,5/16,3

18,6

Fan outdoor section

Fan indoor section

Compressor (heating cycle)

Fan outdoor section

Fan indoor section

Compressor

Fan outdoor section

Fan indoor section

Compressor (cooling cycle)

Compressor (heating cycle)

Compressor (Cooling cycle)

Compressor

Fan outdoor section

Fan indoor section

240/136226/132182/108

193/110

145/73104/5697/52

101

240/136226/132182/108193/110145/73104/5697/52

101

6

1.3.- FAN SERVICES

1.- GENERAL CHARACTERISTICS

m /h

3

AIR FLOW

m /h

3

AIR FLOW

6300 6000 60002350 2300 3700 53500

NOMINAL

AIR FLOW

10

20

30

40

50

60

70

80

90

100

110

120

130

140

160

180

200

220

240

6225 5925 59252275 2250 3625 5200

6140 5860 58602240 2200 3550 5090

6100 5800 58002190 2150 3475 4960

6010 5725 57252140 2100 3400 4850

5930 56502080 2040 3320 4725

5875 56002025 1975 3240 4610

5790

5600

55101975 1925 3160 4505

5710

5510

54401925 1860 3090 4400

5620

5440

53501840 1800 3000 4300

5540

5350

52751775 1730 2915 4160

5450

5275

51901625 1650 2825 4040

5350

5190

51001500 2750 3925

5320

5100

5000--- 2670 3800

5150

5000

49102580 3700

4940 4700 47002400 3525

4700 4500 45003200

4425 4250

4175

4000

6600 6400 64003500 3400 4950 59000

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

6490 6300 63003410 3325 4850 5800

6340 6200 62003300 3160 4750 5700

6225 6100 61003190 3075 4625 5600

6100 5980 59803080 2980 4525 5495

5960 5870 58702970 2890 4425 5390

5850 5725 57252840 2790 4325 5280

5710 5600 56002700 2690 4225 5180

5600 5490 54902560 2580 4125 5075

5480 5375 53752410 2400 4040 4975

5350 5250 52502350 3940 4875

5200 51003840 4775

5090 50003750 4675

49504575

48004460

46504350

4500

MODELS

10 12 16 22 24 28 30

10 12 16 22 24 28 30

INDOOR UNITS

OUTDOOR UNITS

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

5650

4910

AVAILABLE STATIC PRESSURE Pa.

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

MODELS

NOMINAL

AIR FLOW

AVAILABLE STATIC PRESSURE Pa.

Keep in mind reduction on air flow and static pressure services if you use mufflers or external air filter.

NOTE:

7

1.- GENERAL CHARACTERISTICS

1.4.- OPERATING LIMITS

INDOOR

TEMPERATURE

MAXIMUM TEMPERATURES MINIMUM TEMPERATURES

32ºC DB / 23ºC WB

COOLING CYCLE

OPERATION

21ºC DB / 15ºC WB

OUTDOOR

TEMPERATURE

0ºC (MODELS 22/24/28/30)

19ºC (MODELS 10/12/16) (*)

-10ºC (**)

INDOOR

TEMPERATURE

MAXIMUM TEMPERATURES MINIMUM TEMPERATURES

32ºC DB / 23ºC WB

21ºC DB / 15ºC WB

OUTDOOR

TEMPERATURE

INDOOR

TEMPERATURE

27ºC DB

15ºC DB

OUTDOOR

TEMPERATURE

24ºC DB / 18ºC WB

-10ºC DB / -11ºC WB

0º C (MODELS 22/24/28/30)

19º C (MODELS 10/12/16) (*)

-10ºC (**)

COOLING CYCLE

OPERATION

HEATING CYCLE

OPERATION

OPERATING LIMITS FOR (COOLING ONLY) UNITS

OPERATING LIMITS FOR (HEATING PUMP) UNITS

DB.- Dry Bulb Temperature

WB.- Wet Bulb Temperature

(*) With condensation pressure control (optional), 0 ºC minimum outdoor operating temperature.

(**) With kit got gas bypass valve.

DEPENDING ON MODEL

(TABLE 1)

TABLE 1- COOLING CYCLE MAXIMUM OUTDOOR OPERATING TEMPERATURES

MODELS

Rated outdoor flow

Minimum outdoor flow

10 12 16 22 24 28 30

MODELS WITH REFRIGERANT R-407C

45

43

43

43

44

41

45

41

46

42

42

39

41

38

MODELS

Rated outdoor flow

Minimum outdoor flow

10 12 16 22 24 28 30

MODELS WITH REFRIGERANT R-22

48

46

48

45

47

45

48

46

48

44

46

42

44

40

(*) With condensation pressure control (optional), 0 ºC minimum outdoor operating temperature.

(**) With kit got gas bypass valve.

DEPENDING ON MODEL

(TABLE 1)

8

1.5.- UNIT DIMENSIONS MODELS 10-12

1.- GENERAL CHARACTERISTICS

Detail drawing of

unit anchor support

25

60

40

25

80

50

20 x12

Oval hole

F

1250

40

14

430

422

735

404

Air filter

OUTDOOR

SECTION

INDOOR

SECTION

SIDE A

SIDE B

SIDE C

SIDE D

SIDE C

SIDE D

25

Unit anchor

support

1250

109

430

280

90

159

303

495

Distance between holes 1300

184

452

425

32

1250

495

Drainage

outside thread

3/4'' Male

Electrical box

1250

820

349

27

303

305

25

Thermostat connection

Power supply

connection

123

20

SIDE A

SIDE B

9

249

422

500

32

1300

125

500

324

98

182

355

1300

595

595

1.5.- UNIT DIMENSIONS MODEL 16

1.- GENERAL CHARACTERISTICS

Detail drawing of

unit anchor support

25

60

40

25

80

50

20 x12

Oval hole

F

1330

1330

830

40

25

324

500

27

355

320

25

123

745

474

20

517

Thermostat connection

Power supply connection

Air filter

SIDE A

SIDE B

OUTDOOR

SECTION

INDOOR

SECTION

SIDE A

SIDE B

SIDE C

SIDE D

SIDE C

SIDE D

Drainage

outside thread

3/4'' Male

Unit anchor

support

Distance between holes 1350

25

Electrical box

10

262

462

497

36,5

1450

42

591

324

107

193

355

1450

595

595

1.5.- UNIT DIMENSIONS MODEL 22

Detail drawing of

unit anchor support

25

60

40

25

80

50

20 x12

Oval hole

F

1520

1520

900

40

26

324

620

92

814

593

SIDE A

SIDE B

SIDE A

SIDE B

SIDE C

SIDE D

SIDE C

SIDE D

47

355

25

300

32

515,5

OUTDOOR

SECTION

INDOOR

SECTION

Power supply

connection

Thermostat

connection

Air filter

Drainage

outside thread

3/4'' Male

Unit anchor

support

Distance between holes 1500

25

1.- GENERAL CHARACTERISTICS

Electrical box

11

490

398

1500

82

658

327

95

223,5

355

645

1500

645

410

1.5.- UNIT DIMENSIONS MODELS 24-28-30

Detail drawing of

unit anchor support

25

60

40

25

80

50

20 x12

Oval hole

1800

1800

1025

103

SIDE A

SIDE B

SIDE A

SIDE B

SIDE C

SIDE D

SIDE C

SIDE D

25

677

124

355

40

26

214

775

565,5

537

939

748

OUTDOOR

SECTION

INDOOR

SECTION

Thermostat

connection

Power supply

connection

Air filter

Drainage

outside thread

3/4'' Male

Unit anchor

support

Distance between holes 1550

1.- GENERAL CHARACTERISTICS

25

Electrical box

12

1.- GENERAL CHARACTERISTICS

If the unit is going to be hung using the

anchor supports and the optional air return

opening, the supports must be repositioned

so that the air filter may be removed.

To move the supports, unscrew them from

the inside and fix them again using the

holes located next to the initial position.

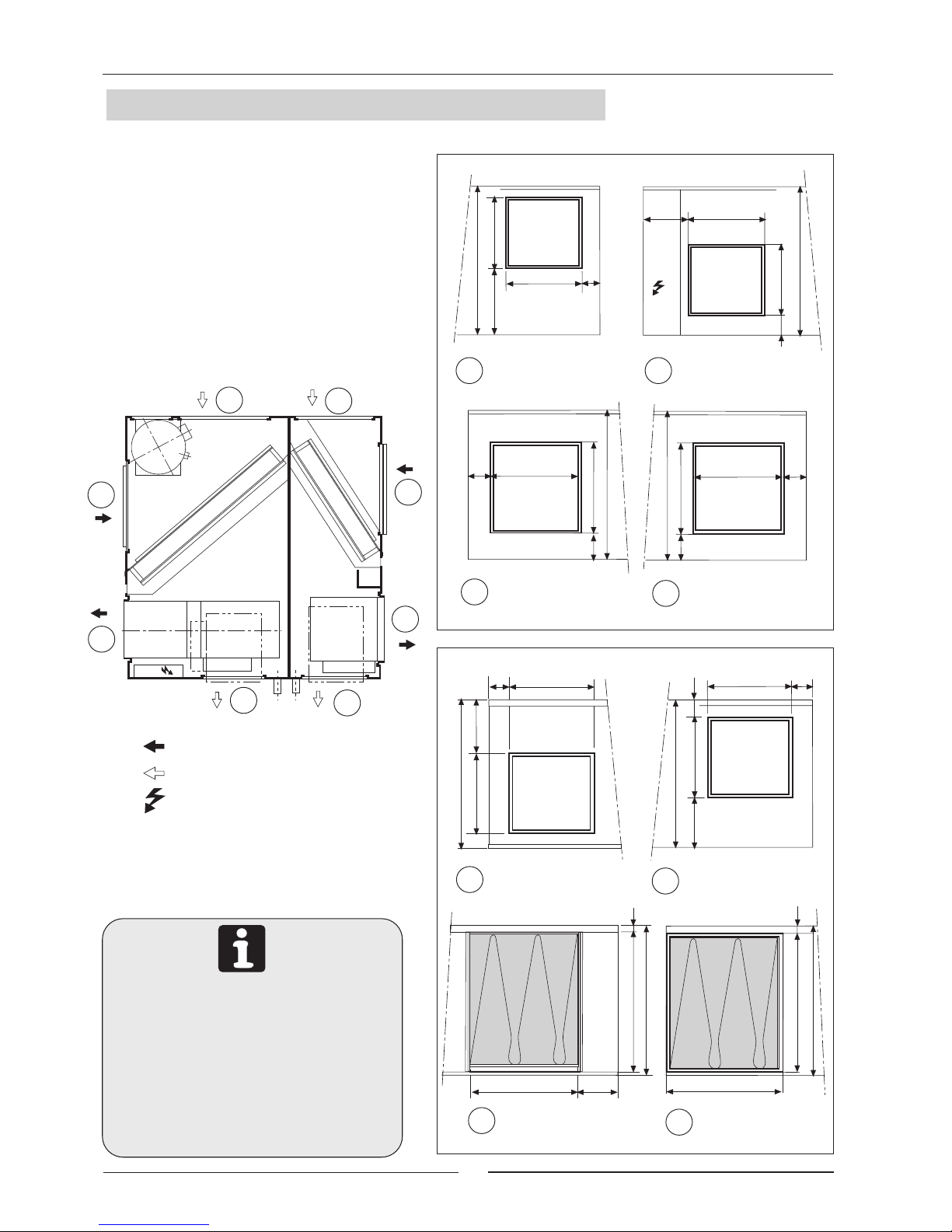

1.6.- UNIT OPENING SIZES MODELS 10-12

ELECTRICAL BOX

STANDARD CONFIGURATION

OPTIONAL CONFIGURATION

OUTDOOR COIL

COMPRESSOR

OUTDOOR

FAN

INDOOR

FAN

INDOOR COIL

E.B.

A0

A1

B0

B1

C1

C0

D0

D1

170

90

280

STANDARD

EXTRACTOR

OPENING

OPTIONAL

BLOWER

OPENING

303

349

495

349

495

303

38

368

303

495

170

OPTIONAL

EXTRACTOR

OPENING

OPTIONAL AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

495

14

STANDARD AIR

RETURN

OPENING

425

495

425

495

123

43

43

495

E.B.

452

269

452184

14

422

430

109

495

159

303

90

280

27

430

422

STANDARD

BLOWER

OPENING

OPTIONAL

BLOWER

OPENING

A1A0

B0

B1

OUTDOOR SECTION

C1

D1

INDOOR SECTION

C0

D0

1.- GENERAL CHARACTERISTICS

13

A1A0

C1

D1

C0

D0

B0

B1

If the unit is going to be hung using the

anchor supports and the optional air return

opening, the supports must be repositioned

so that the air filter may be removed.

To move the supports, unscrew them from

the inside and fix them again using the

holes located next to the initial position.

1.6.- UNIT OPENING SIZES MODEL 16

ELECTRICAL BOX

STANDARD CONFIGURATION

OPTIONAL CONFIGURATION

OUTDOOR COIL

COMPRESSOR

OUTDOOR

FAN

INDOOR

FAN

INDOOR COIL

E.B.

A0

A1

B0

B1

C1

C0

D0

D1

STANDARD

EXTRACTOR

OPENING

OPTIONAL

BLOWER

OPENING

OPTIONAL

EXTRACTOR

OPENING

OPTIONAL AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

STANDARD AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

OPTIONAL

BLOWER

OPENING

OUTDOOR SECTION

INDOOR SECTION

25

517

500

125

595

182

355

98

324

213

500

517

98

324

355

324

595

324

595

355

58

428

355

27

595

123

595

213

500

595

500

595

63

63

595

25

E.B.

422

304

422249

14

A0

A1

B0

B1

C1

C0

D0

D1

A1A0

C1

D1

C0

D0

B0

B1

1.- GENERAL CHARACTERISTICS

If the unit is going to be hung using the

anchor supports and the optional air return

opening, the supports must be repositioned

so that the air filter may be removed.

To move the supports, unscrew them from

the inside and fix them again using the

holes located next to the initial position.

1.6.- UNIT OPENING SIZES MODEL 22

ELECTRICAL BOX

STANDARD CONFIGURATION

OPTIONAL CONFIGURATION

STANDARD

EXTRACTOR

OPENING

OPTIONAL

BLOWER

OPENING

OPTIONAL AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

STANDARD AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

OPTIONAL

BLOWER

OPENING

OPTIONAL

EXTRACTOR

OPENING

OUTDOOR SECTION

INDOOR SECTION

26

515,5

591

42,5

595

193

355

107

324

591

15

193

107

324

355

324

595

324

595

355

391,5

355

595

515,5

595

26

92

595

193

497

595

497

595

61

61

193

E.B.

OUTDOOR COIL

COMPRESSOR

OUTDOOR

FAN

INDOOR FAN

INDOOR COIL

462

384

462262

15

A0

A1

B0

C1

C0

D0

D1

A1A0

B0

C1

D1

C0

D0

E.B.

1.- GENERAL CHARACTERISTICS

If the unit is going to be hung using the

anchor supports and the optional air return

opening, the supports must be repositioned

so that the air filter may be removed.

To move the supports, unscrew them from

the inside and fix them again using the

holes located next to the initial position.

1.6.- UNIT OPENING SIZES MODELS 24-28-30

ELECTRICAL BOX

STANDARD CONFIGURATION

OPTIONAL CONFIGURATION

STANDARD

EXTRACTOR

OPENING

OPTIONAL

BLOWER

OPENING

OPTIONAL AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

STANDARD AIR

RETURN

OPENING

STANDARD

BLOWER

OPENING

OPTIONAL

BLOWER

OPENING

OUTDOOR SECTION

INDOOR SECTION

26

565,5

658 82

645

223

355

95

327

658

107

213

258

327

355

410

645

410

645

355

355

645

565,5

645

26

537

40

645

645

214

214

103

103

677

222

OUTDOOR COIL

COMPRESSOR

OUTDOOR

FAN

INDOOR FAN

INDOOR COIL

16

1.- GENERAL CHARACTERISTICS

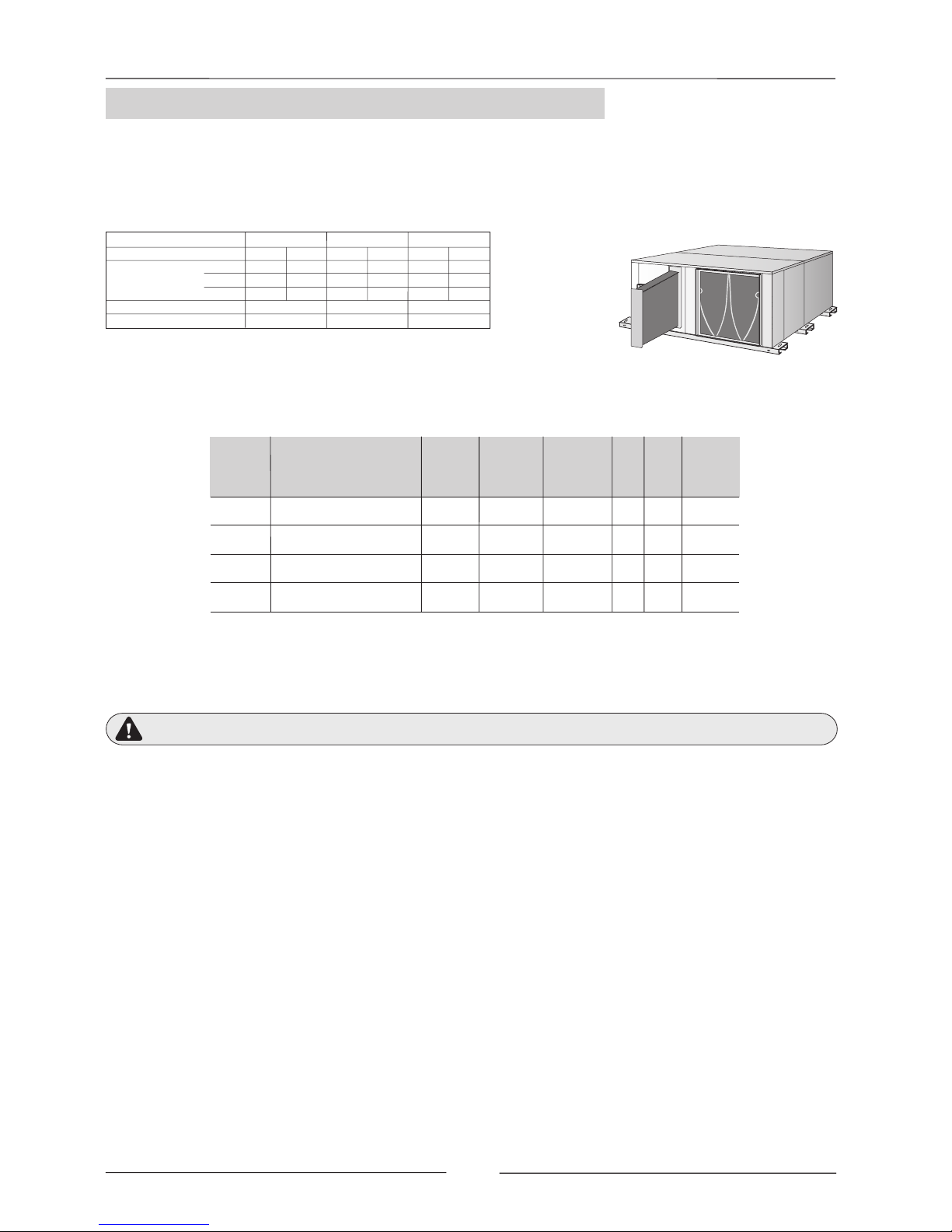

1.7.- AVAILABLE OPTIONS

HOT WATER COIL

It is based on a refrigerating coil made of copper tubing with aluminum swirl fins with

water inlet and outlet connections.

It is supplied mounted inside the unit as picture shows.

MAIN SWITCH

The main switch is located on the access panel to the electrical box in the outdoor section in such a way that the unit is

disconnected when the panel is opened.

(Refer to the size diagram on pages 8 to 11 to see the position of the electrical box access panel).

Check to make sure that the main switch is large enough to handle the current for the unit if electric heaters are installed.

PHASE SEQUENCER (THREE-PHASE UNIT)

The phase sequencer is located in the electrical box in the outdoor section, thus assuring that the unit will not begin operation

while the phase connection of the compressor is not correct. Should this occur, then just switch two phase connections.

ON/OFF CONDENSATION PRESSURE CONTROL (MODELS 10-12-16)

The condensation pressure control consists of a pressure switch, which starts and stops the outdoor fan regulating the

condensation temperature, thus the unit will be able to operate in the cooling cycle when the outdoor temperature is below

19ºC (until 0ºC).

HOT GAS BYPASS VALVE

The purpose of the BYPASS valve is to make it possible for the unit to operate at low outdoor temperatures (until -10°C), to

be used in cooling-only and heat-pump units in the cooling cycle.

It regulates the capacity of the compressor by injecting hot gas from the compressor discharge side to the evaporator.

CONTROL USING A PROGRAMMABLE CONTROLLER:

With the programmable controller option, the desired temperature can be programmed in the area 24 hours a day, 7 days a

week.

ELECTRIC HEATER

Optionally, these units can contain shielded element electric heating batteries that are mounted on the inside of the unit in the

schematic opposite.

The electric heater must get its power from the units electrical box.

A HEATING COIL FROZEN DUE TO LOW AMBIENT CONDITIONS IS NOT COVERED BY THE WARRANTY.

22,7

MODELS LFXO 10

MAXIMUM

CURRENT

(A)

230 / III

400 / III

POWER kW

12-16-22

7

WEIGHTS Kg (*)

STAGES

11

6

15,1

8,7913,1

7

24-28-30

8

1

7,5

18,9

10,9

12

30,2

17,4

6

15,1

8,7

9

22,7

13,1

230 / I

---- ---- ---- ----26,1 ----

(*) Add to the unit's weight.

PROTECTION AGAINST FREEZING:

Use glycol water. GLYCOL IS THE ONLY EFFECTIVE PROTECTION AGAINST FREEZING.

Regulation components should be used and in addition security components if they are needed.

Drain the installation. You must ensure that the manual or automatic air vents have been installed on all high points in the

system. In order to drain the system check that all the drain cocks have been installed on all low points of the system.

DIFFERENCE IN TEMPERATURES

BETWEEN HOT WATER INTAKE

AND THE AIR WHICH ENTERS

THE COIL

50ºC 60ºC 70ºC

WATER

FLOW

L/H

WATER COIL

PRESSURE

DROP

kPa

AIR

PRESSURE

DROP

Pa

10-12

CAPACITY IN W

CAPACITY IN W

CAPACITY IN W

9000 11000 12800

15000 18000 21000

24500 29500 34400

500

1000

1500

0,5

1,5

3

35-30

30-25

25-20

22

24-28-30

16

CAPACITY IN W

14500 17500 20400 1000 1,5

35-30

Nr

ROWS

2

2

2

2

WEIGHT

Kg

4

6

7

5

WATER

OUTLET

DIAMETER

Inches

3/4"

3/4"

3/4"

3/4"

MODELS

FLC/FLH

INDOOR UNIT

nominal-minimum

air flow

17

1.- GENERAL CHARACTERISTICS

1.7.- AVAILABLE OPTIONS

REMOTE ROOM-TEMPERATURE SENSOR, REMOTE DUCT SENSOR

These sensors may be used in conjunction with remote controller, allowing the controller to be mounted in a room away from

the conditioned space.

- REMOTE DUCT SENSOR: The sensor will be located in the return-air duct, detecting the air temperature of the

air being air-conditioned.

- REMOTE ROOM-TEMPERATURE SENSOR: The sensor will be placed in the area to be air-conditioned.

FREECOOLING THERMOSTAT KIT

The Freecooling Thermostat Kit will only operate in cooling-only or heat-pump units in the cooling cycle. This is an energy

saving system that regulates the dampers doors through which outdoor air is taken in when the outdoor temperature is lower

than the area to be air-conditioned.

This kit consists of the damper, a motor, power card and a controller with specific programming, safety thermostat for air

discharge and outdoor sensor, completely factory-assembled.

CRANKCASE HEATER (COOLING-ONLY UNITS)

When the unit is operating at low outdoor temperatures it is advisable to fit a crankcase heater.

The purpose of the heater is to keep the oil in the compressor at the correct temperature while the compressor is stopped so

that it can be properly lubricated when started again.

OUTDOOR AIR FILTER KIT

Field assembly.

The outdoor air filter should be installed on the outdoor air inlet of the outdoor

unit and is recommended when working in heavily contaminated areas that

may soil or clog the outdoor Coil.

Air filter

Adapter parts

Sound muffler

600

41

660

420

660

400

Anti-rain plate

(only models 10-12-16)

Anti-rain hood

Outdoor air intake

Air filter

C

B

A

F

G

D

E

OUTDOOR MOUNTING KIT

Field assembly.

This option has to be ordered for packaged units when they will be installed outside.

The kit includes an air filter and grille for outdoor air intake which should be installed on the suction side of the outdoor unit,

an anti-rain hood which should be installed on the discharge side of the outdoor fan. For units 10-12-16 it includes also an antirain plate which should be installed on the electrical box.

FREECOOLING EXTERNAL MOUNTED KIT

Field assembly.

This option has to be ordered for packaged units with freecooling when they will be installed outside, it includes:

- FREECOOLING 1-DAMPER: It includes an outdoor air inlet grille to cover damper and actuator.

- FREECOOLING 2-DAMPER: It includes an anti-rain cap to cover return air damper.

SOUND MUFFLER

Available for models 16, 22, 24, 28, 30.

Field assembled, designed to be installed at the extractor opening of the

outdoor unit in order to reduce noise, particularly when the outdoor unit is

installed without ducts, free discharge.

This kit contains the sound muffler and adapter parts for fixing it to the unit.

External mounted freecooling 1-damper

External mounted freecooling 2-damper

I

H

G

F

C

B

A

E

D

MODELS

10-12A200

16 200

22 200

24-28-30 200

B

465

460

600

712

C

400

600

600

600

D

635

723

708

784

E

187,4

163

187,5

187,5

F

162

174

159

158,5

G

192

192

192,5

191

H

461

456

592

706

I

153

174

159

158,5

DIMENSIONS

MODELS

10-12A180

16 180

22 180

24-28-30 180

B

432

507

505

544

C

459

429

470

685

D

280

311,8

304,9

304,9

E

313

364

363

363

F

356

330

332

418

G

104

104

96,5

96,5

DIMENSIONS

18

2.- INSTALLATION

Wood

block

Securing

screw

If unloading and placement require the use of a

crane, then secure the suspension cables as

shown in the figure.

The unit must be transported in a HORIZONTAL POSITION on its metal bedplate profiles and TRANSPORTATION

BLOCKS. Any other position may cause serious damage to the machine. When the unit is received, it should be

checked to assure that there are no bumps or other damage, following the instructions on the packaging. If there

is damage, the unit may be rejected by notifying the LENNOX Distribution Department and reporting why the

machine is unacceptable on the transport agents delivery notice. Any later complaint or claim made to the

LENNOX Distribution Department, for this type of anomaly, cannot be considered under the Guarantee.

Sufficient space must be allowed to facilitate placement of the unit. The unit may be mounted outdoors. There

should be NO possibility of flooding if floor mounted.

2.1.- PRELIMINARY PREPARATIONS

All INSTALLATION, SERVICE and MAINTENANCE operations

must be carried out by QUALIFIED PERSONNEL.

When positioning the unit, be sure that the Rating Plate will always be visible since this

data will be necessary to assure proper maintenance.

The units are designed to be installed with ducts, calculated by qualified technical staff. The joints to be used

between ducts and the openings to the unit should be Elastic Joints. Avoid the use of BYPASS joints between the

extraction air and input air in both the outdoor and indoor sections. The structure where the unit is placed must

be able to support the weight of the unit during operation.

2.2.- UNIT RECEPTION

All the units have Metal Bedplate Profiles and Wooden Blocks for transportation.

These wooden blocks must be removed when positioning the unit in its final position.

To remove the transportation blocks,

remove the screw and slide the block along the metal profile.

PLACEMENT OF THE BEDPLATE

AND TRANSPORTATION BLOCKS

Bedplate profile

Wood

block

How to hoist the unit

Use

separators

19

BLOWER:

From the position to the position

RETURN:

From the position to the position

INLET:

From the position to the position

BLOWER:

From the position to the position

1) Remove the ceiling of the unit,

the Blower Panel with Opening and the Service Panel.

2) Remove the motor-fan assembly from the unit

unscrewing the supports from the base,

and throwing away the extension collar, if there is one.

3) Unscrew the supports that have been left

on the fan-motor assembly.

4) Turn the fan-motor assembly to its new position

90º horizontally and 180º on its shaft. The motor

should now be accessible from the Service Panel

in this new position.

5) Screw down the fan-motor assembly in its new

position using the supports.

6) Assemble the Blower Panel with Opening and

the Service Panel in its new position, taking special

care with the weather striping.

1) Remove the Air Filter Panel and the Service

Panel.

2) Switch the position of the Air Filter and Service

Panels.

1) Remove the ceiling of the unit,

the Blower Panel with Opening and the Service Panel.

2) Remove the motor-fan assembly from the unit

unscrewing the supports from the base,

and throwing away the extension collar, if there is one.

3) Unscrew the supports that have been left

on the fan-motor assembly.

4) Turn the fan-motor assembly to its new position

90º horizontally and 180º on its shaft. The motor

should now be accessible from the Service Panel

in this new position.

5) Screw down the fan-motor assembly in its new

position using the supports.

6) Assemble the Blower Panel with Opening and

the Service Panel in its new position, taking special

care with the weather striping.

1) Remove the Intake Opening and the Service

Panel.

2) Switch the position of the Opening and Service

Panels.

SEE LOCATIONS AND SIZES FOR THE OPENINGS IN THEIR STANDARD AND OPTIONAL

POSITIONS ON THE GENERAL MEASUREMENT DRAWINGS.

Blower Panel

with Opening

Extension

Collar

Service

Panel

Fan-motor assembly

Outdoor Section

Service

Panel

Fan-motor assembly

Indoor Section

Blower Panel

with Opening

Air Filter

Panel

Intake

Opening

Service

Panel

Motor

Motor

Extension

Collar

OUTDOOR

SECTION

INDOOR

SECTION

Blower panel

with Opening

Fan motor

Outdoor Section

Service

Panel

Fan-motor assembly

Indoor Section

Blower Panel

with Opening

Service

Panel

Motor

Intake

Opening

Air Filter

Panel

Motor

A0

B0

C0

D0

A1

B1

C1

D1

C0

C1

D0

D1

A0

A1

B0

B1

2.- INSTALLATION

OUTDOOR

SECTION

INDOOR

SECTION

2.3.- OPTIONAL OPERATIONS PRIOR TO UNIT INSTALLATION:

CHANGE IN THE POSITION OF BLOWERS AND AIR INTAKE FOR UNIT MODELS 10-12-16-22

OUTDOOR SECTION INDOOR SECTION

STANDARD AIR INTAKE AND BLOWERS OPTIONAL AIR INTAKE AND BLOWERS

20

BLOWER:

From the position to the position

RETURN:

From the position to the position

INLET:

Not available

BLOWER:

From the position to the position

1) Remove the ceiling of the unit,

the Blower Panel with Opening and the Service Panel.

2) Remove the motor-fan assembly from the unit

unscrewing the supports from the base,

and throwing away the extension collar, if there is one.

3) Unscrew the supports that have been left

on the fan-motor assembly.

4) Turn the fan-motor assembly to its new position

90º horizontally and 180º on its shaft. The motor

should now be accessible from the Service Panel

in this new position.

5) Screw down the fan-motor assembly in its new

position using the supports.

6) Assemble the Blower Panel with Opening and

the Service Panel in its new position, taking special

care with the weather striping.

1) Remove the Air Filter Panel and the Service Panel.

2) Switch the position of the Air Filter and Service

Panels.

1) Remove the ceiling of the unit,

the Blower Panel with Opening and the Service Panel.

2) Remove the motor-fan assembly from the unit

unscrewing the supports from the base,

and throwing away the extension collar, if there is one.

3) Unscrew the supports that have been left

on the fan-motor assembly.

4) Turn the fan-motor assembly to its new position

90º horizontally and 180º on its shaft. The motor

should now be accessible from the Service Panel

in this new position.

5) Screw down the fan-motor assembly in its new

position using the supports.

6) Assemble the Blower Panel with Opening and

the Service Panel in its new position, taking special

care with the weather striping.

SEE LOCATIONS AND SIZES FOR THE OPENINGS IN THEIR STANDARD AND OPTIONAL

POSITIONS ON THE GENERAL MEASUREMENT DRAWINGS.

Blower Panel

with Opening

Extension

Collar

Service

Panel

Fan-motor assembly

Outdoor Section

Service

Panel

Fan-motor assembly

Indoor Section

Blower Panel

with Opening

Air Filter

Panel

Electrical box

panel

Service

Panel

Motor

Motor

Extension

Collar

Blower panel

with Opening

Fan motor

Outdoor Section

Service

Panel

Fan-motor assembly

Indoor Section

Blower Panel

with Opening

Service

Panel

Motor

Intake

Opening

Air Filter

Panel

Motor

2.3.- OPTIONAL OPERATIONS PRIOR TO UNIT INSTALLATION:

CHANGE IN THE POSITION OF BLOWERS AND AIR INTAKE FOR UNIT MODELS 24-28-30

A0

B0

C0

D0

A1

B1

C1

D1

C0

C1

D0

D1

A0

A1

2.- INSTALLATION

OUTDOOR

SECTION

INDOOR

SECTION

D'

Intake

Opening

Electrical box

panel

OUTDOOR SECTION INDOOR SECTION

STANDARD AIR INTAKE AND BLOWERS OPTIONAL AIR INTAKE AND BLOWERS

OUTDOOR

SECTION

INDOOR

SECTION

21

UNIT INSTALLED ON SHOCK ABSORBERS

Ceiling supports

(shock absorbers)

G POINT: Centre of gravity

TABLE 1:

WEIGHT DISTRIBUTION

AND CENTRE OF

GRAVITY COORDINATES

2.- INSTALLATION

Outdoor Sec.

Y

X

Outdoor Sec.

Y

X

MODELS 10-12-16-22

MODELS 24-28-30

Floor supports

(shock absorbers)

WEIGHT DISTRIBUTION (Kg)

CENTRE OF GRAVITY

COORDINATES (G) (mm.)

The bedplate is made up of three galvanized metal channels, capable of withstanding the weight of the units

whether hung from the ceiling or mounted on the floor.

If the unit is floor mounted, then the profiles should be isolated with shock absorbing material such as anti-vibration

or pads. If used, consult the weight distribution table below to make the correct selection. Keep in mind that fans

rotate at approximately 850 rpm.

If the unit is hung, M-10 threaded rods should be used along with shock absorbing ceiling supports.

UNIT HUNG WITH RODS

2.4.- UNIT LOCATION AND WEIGHT DISTRIBUTION

Fan

Comp.

Coil

B

E

A

F

G

Fan

Coil

C

D

Indoor Sec.

XG

YG

Fan

Comp.

B

E

A

F

G

Fan

Coil

C

D

Indoor Sec.

XG

YG

Coil

10

12

16

22

24

28

30

A BCD E F Total

35

65 10 20 40 35 205

35

65 15 20 40 35 210

70

60 15 30 80 30 285

Model

Point

80

70 20 40 75 45 330

90

100 15 65 85 55 410

95

11020658555 430

95

11025708055 435

XG

585

590

565

615

630

600

710

685

760

815

715

825

705

825

YG

22

Trap

Drain pipe

Clearance around the unit for service and maintenance.

2.- INSTALLATION

2.6.- DRAINS

For the unit with optional FREECOOLING, it should be kept in mind that the bedplate anchors

cannot be used to hang the unit.

Consult other options for outdoor mounting or changes in position of the air return duct if the unit

is to be hung.

All indoor sections of these units ( and the outdoor sections for the Heat Pump) have a ¾ steel threaded drain

pipe welded to the condensation tray.

One PVC drain trap is supplied with the Cooling-only units, and two with the heat pump units.

Connect the trap/s to the drain pipe/s on the unit and mount the drain pipe with at least a 2% incline from the trap.

Also slightly tip the unit (2%) toward the drainage side. Check that the condensation trays are clean and free from

dirt and other debris from the works and that water drains correctly.

2.5.- INSTALLATION CLEARANCES

1 m

1 m

1 m

1 m

2%

2%

23

PE L1 L2 L3 N

X1

3N ~ 400V - 50 Hz + PE

2.- INSTALLATION

Electronic

Card

Electric

Box

Control

Panel

- Connect the power supply cables to the terminals in the electric box through the rubber grommet.

- The sections have been calculated for a length no longer than 50m and a voltage drop of 10V. Do not start the

unit if the drop is greater than this.

- The wiring and circuit breakers to be mounted in the installation must comply with the Regulations in force.

- Ground wires must be properly connected and have a greater length than the phase wires.

2.7.- ELECTRICAL CONNECTION

Power supply WITHOUT electric heater.

Power supply WITH electric heater.

Connection to the Control Panel.

1

2

3

- BEFORE MAKING ANY ELECTRICAL CONNECTIONS, BE SURE THAT ALL CIRCUIT BREAKERS ARE

OPEN.

- IN ORDER TO CARRY OUT THE ELECTRICAL CONNECTIONS, FOLLOW THE ELECTRICAL DIAGRAM

SUPPLIED WITH THE UNIT.

3

1 or 2

UNIT

MODEL

Shielded Cable

POWER SUPPLY

230V THREE-PHASE UNITS

POWER SUPPLY

230V SINGLE PHASE UNITS

Indoor

Section

Outdoor

Section

3

10

1

3 x 4 2 x 13 x 16

3

16

12

22

10

24

30

28

4 x 4

4 x 4

4 x 6

4 x 10

4 x 10

4 x 10

4 x 16

2 x 1

2 x 1

2 x 1

2 x 1

2 x 1

2 x 1

2 x 1

4 x 10

4 x 16

4 x 10

4 x 16

4 x 25

4 x 25

4 x 25

3

16

12

22

10

24

30

28

5 x 2,5

5 x 2,5

5 x 4

5 x 4

5 x 4

5 x 4

5 x 6

2 x 1

2 x 1

2 x 1

2 x 1

2 x 1

2 x 1

2 x 1

5 x 4

5 x 6

5 x 4

5 x 10

5 x 10

5 x 10

5 x 10

2

1

2

1

2

Nr. OF CABLES x SECTION (mm )

2

Nr. OF CABLES x SECTION (mm )

2

Nr. OF CABLES x SECTION (mm )

2

Shielded Cable

Power supply

without electric

heater

Power supply

with electric

heater

Power supply

without electric

heater

Power supply

with electric

heater

Shielded Cable

Power supply

without electric

heater

Power supply

with electric

heater

UNIT

MODEL

POWER SUPPLY

400V THREE-PHASE UNITS

UNIT

MODEL

PE L1 L2

X1

L3

3 ~ 230V - 50 Hz + PE

PE N L

X1

1N ~ 230V - 50 Hz + PE

24

2.- INSTALLATION

VOLTAGE OPERATING LIMITS

Since this type of control panel is factory-configured for each application, an identification code located

on the control panel of the terminal itself has been given to each panel.

Any query or request for a replacement of the control panel must be accompanied by this identification

code.

MODELS VOLTAGE

LIMIT

10

10-12-16-22

24-28-30

230V-1Ph-50Hz

230V-3Ph-50Hz

230V-3Ph-50Hz

400V-3Ph-50Hz

400V-3Ph-50Hz

198-264V -1Ph- 50Hz

180-242V -3Ph- 50Hz

342-462V -3Ph- 50Hz

198-264V -3Ph- 50Hz

342-462V -3Ph- 50Hz

Ground connection for the wire

mesh of the shielded cable

2.7- ELECTRICAL CONNECTION

T +

T

-

PE 1 30 31

PE

PE

X1

CONTROL

PANEL

UNIT

ELECTRIC

BOX

Shielded cable,

two connection wires

IDENTIFICATION CODE

FOR THE CONTROL PANEL

A111

Type of control

No. of speeds of the indoor fan

No. of cooling stages

No. of heating stages

Application

C: Cooling only

H: Heat pump

Configuration Version

BASIC TERMINAL DENOMINATION ACCESSORIES

P: Programmable

(Programming schedule)

(INTERNAL FACTORY CODES)

- For securing and connecting the Control Panel, consult the control Panel Manual supplied with the unit.

- Keep in mind that the Control Panel cable is a SHIELDED CABLE and the wire mesh is only grounded

on the electric box side.

- The T+ and T- polarity must strictly agree with the electrical diagram supplied with the unit.

IMPORTANT

THE SHIELDED CONNECTION CABLE BETWEEN THE CONTROL PANEL AND THE UNIT MUST

BE SEPARATE FROM ANY OTHER TYPE OF ELECTRICAL WIRING.

CONNECT IT TO THE ELECTRIC BOX LOCATED IN THE OUTDOOR UNIT.

25

3.- COMMISSIONING AND OPERATION

Check that drain pipe connections and their fixtures are secure and that the level of the unit is tipped toward

the drain.

Inspect the state of the ducts and grilles (clean and open grilles, no breaks in the duct, etc.).

Check that the power supply is the same as stated on the Rating Plate which is in agreement with the electrical

diagram for the unit and that cable sizes are correct.

Check that tightness of the electrical connections to their terminals and to ground.

Check the control panel connections.

(If the connection is wrong, the unit will not operate and the control panel display will not light).

Inspect the Air Filter, which should be in its housing and correctly positioned (the metal grille should be toward

the inside).

Check with your hand that the fans turn freely.

3.1.- PRELIMINARY CHECKS

Close the unit and check that there are no loose panels.

Units have the correct refrigerant charge. Do not change it.

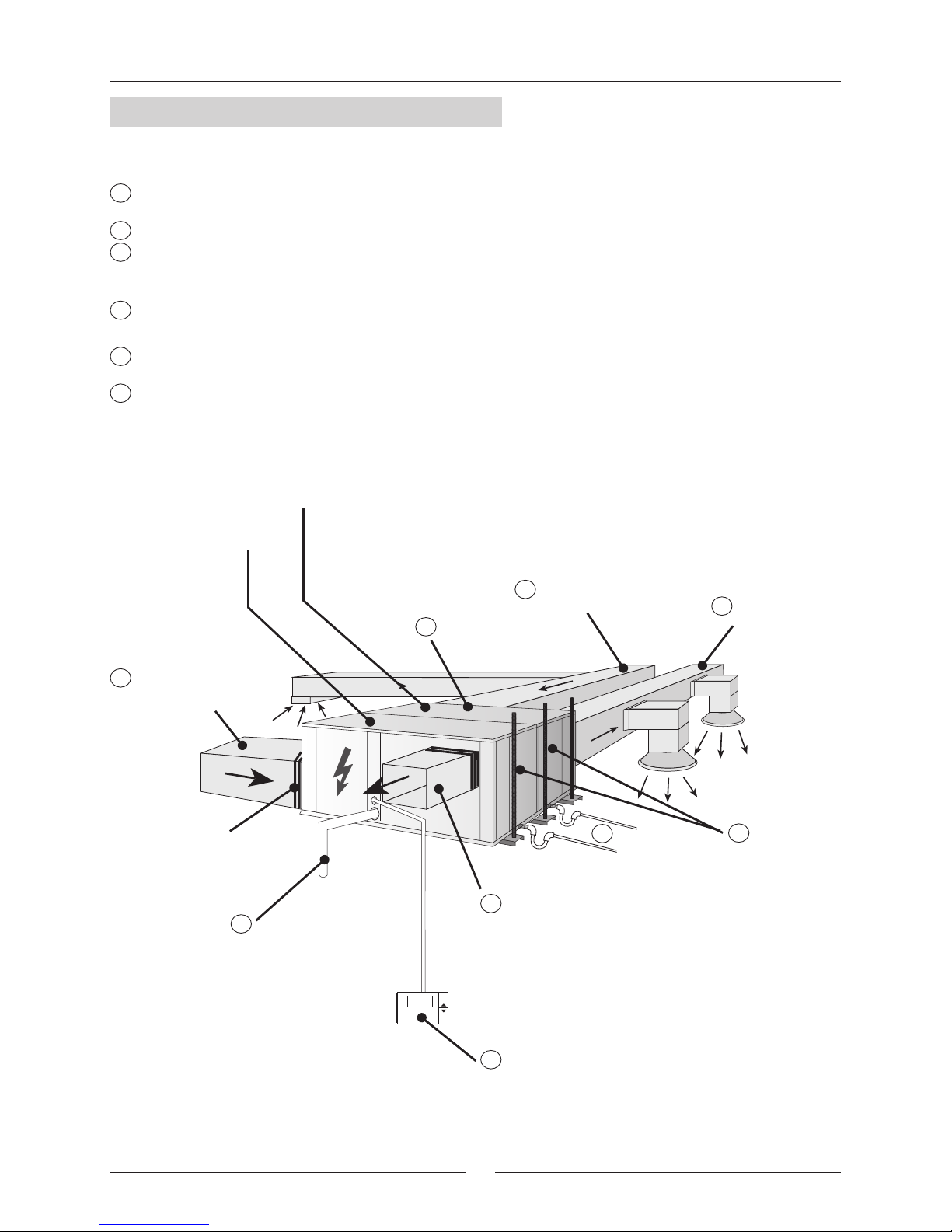

Return air

duct

Supply air duct

Outdoor air

intake duct

Outdoor discharge

duct

Power Supply

Control Panel

Air Filter

Fan access

OUTDOOR SECTION

INDOOR SECTION

Flexible joint

at Openings

FIGURE FOR THE STANDARD UNIT CONFIGURATION FOR MODELS 24-28-30

Trap

Drain

pipe

1

1

2

2

2

2

2

3

3

4

4

5

5

6

6

26

2

2

2

3.- COMMISSIONING AND OPERATION

- On the heat pump units, the compressor has a single phase electric heating element to assure a separation

between the Refrigerant and the oil in the housing. This heater is activated when the compressor is off and stops

working when the compressor is on.

About eight hours before start up or after a long shutdown period, voltage should be supplied to the unit so that

this heater will be activated.

- To start the unit, follow the instructions given in the Control Panel Manual supplied with the unit (requesting

operation in any of the modes, cooling, heating, or automatic).

After a time lapse, the unit will start.

- With unit operating, check that the fans are turning freely and in the proper direction.

3.2.- STEPS TO FOLLOW FOR COMMISSIONING THE UNITS

- Check compressor oil level, if sight glass included (on the sides of the compressor, the level should be between

1/4 and 3/4 in the sight glass, while during operation the level should be between 3/4 and full).

- Connect high and low pressure gauges and check that operating pressure values are normal.

- Measure electrical consumption for the unit and check that it is near what is indicated on the Rating Plate.

- Check the electrical consumption of the compressor and the fans with what is specified in the physical data sheets.

- In the case of a Heat Pump unit, make a cycle change on the Control Panel checking that the 4-way valve makes

the change correctly. Check the pressure values in the new cycle.

- Remember the low pressure switch is reset automatically and the high pressure switch is reset electronically.

- Check that pressure switches stop the unit:

FOR THE COOLING CYCLE UNIT:

Stop the outdoor fan by disconnecting it. The high pressure should rise and the pressure switch should stop the

compressor at 27.5 kg/cm . Reconnect the fan and electrically reset the pressure switch by pressing the RESUME

button on the Control Panel for 5 seconds and wait for the anti-cycle time (5 minutes), afterwards, the unit will

start-up again.

Stop the indoor fan by disconnecting it. The low pressure should drop and the unit should stop when the pressure

gauge reaches 1 kg/cm . The unit will start up again when the pressure rises and the pressure gauge indicates

2 kg/cm . Once this has been carried out, stop the unit and reconnect the fan.

- Start the unit again and when everything is operating normally, take a reading of all the data and fill out the

Commissioning Sheet.

Scroll type compressors only compress in one direction of the rotation. Single phase models are always

started up in the proper direction; however, the three phase models, turn in either direction depending on

the order of the power supply phases. Therefore, it is essential that the phase connection for scroll-type

three-phase compressors be carried out correctly (the correct direction of rotation can be checked when

the pressure on the suction side decreases and the pressure on the discharge side increases when the

compressor is activated. If the connection is wrong, the rotation will be reversed causing a high noise level

and a reduction in the amount of current consumed. If this occurs, the compressors internal protection

system will kick in shutting down the unit. The solution is to disconnect, switch the wires between two of

the phases and connect again).

REMEMBER THAT THE COMPRESSOR IS A SCROLL TYPE COMPRESSOR:

27

4.- MAINTENANCE

-GENERAL STATE OF THE CASING :

Furniture, paint, deterioration due to bumps, rust spots, leveling and supporting, state of the shock absorbers,

if installed, screwed panels, etc.

- ELECTRICAL CONNECTIONS :

State of hoses, tightness of screws, grounding, current draw of the compressor and fans and checking that the

unit is receiving the correct voltage.

- COOLING CIRCUIT :

Check that pressure values are correct and that there are no leaks. Check that there is no damage to the pipe

insulation, that the state of the coils is correct and that there are no chips or clogs retained by the air flow, etc.

- COMPRESSOR :

Inspect the oil level, if sight glass is present.

Inspect the state of the silent block fixtures.

- DRAINS :

Check that water drains correctly and that the drain trays are clean.

- FANS :

Check that fans turn freely and in the correct direction without excesive noises.

- CONTROL :

Check Set Points and normal operation.

- AIR FILTER :

The air filter can be removed through the side by sliding it over the rail or down. (See figure).

For down removal, remove the one or two profiles supporting it (depending on the model) which are under the

filter guide rail and screwed into the unit.

The filter should be cleaned with a vacuum cleaner or washed in soapy water.

The frequency for cleaning or changing the air filters will depend on the quality air in the area (fumes, vapors,

suspended dust particles, etc.).

Remember that the metal grille should be always toward the inside of the unit.

4.1.- PREVENTIVE MAINTENANCE

DOWN

REMOVAL

SIDE

REMOVAL

PREVENTIVE MAINTENANCE PREVENTS COSTLY REPAIRS.

BECAUSE OF THIS PERIODIC INSPECTIONS ARE REQUIRED.

Remember that the Control Panel may program a notification parameter, for cleaning or

replacement of air filters depending on the number of hours of fan operation in the indoor section.

28

4.- MAINTENANCE

If some component in the cooling circuit must be replaced, follow these recommendations:

- Always use original replacement parts.

- Remove the entire refrigerant charge from the unit through the schrader valves located in the outdoor section.

Create a slight vacuum as a safety measure.

- Regulation prohibits the release on the refrigerant into the atmosphere.

- If cuts must be made in the pipe work, use pipe cutters. Do not use saws or any other tools that produce filings.

- All brazing must be carried out in a nitrogen atmosphere to prevent corrosion from forming.

- Use silver alloy brazing rod.

- Take special care that the flame from the torch is aimed in the opposite direction from the component to be

welded and is covered with a wet rag in order to avoid overheating.

- Take very special care if 4-way or check valves are to be replaced since these have internal components that

are very heat-sensitive such as plastic, teflon, etc.

- If a compressor must be replaced, disconnect it electrically and un-braze the suction and discharge lines. Remove

the securing screws and replace the old compressor with the new one. Check that the new compressor has the

correct oil charge, screw it to the base and connect the lines and electrical connections.

- Carry out the vacuum above and below through the schrader valves of the outdoor unit until -750 mm Hg is

reached.

Once this level of vacuum has been reached, keep the pump in operation for at least one hour. DO NOT USE

THE COMPRESSOR AS A VACUUM PUMP.

- Charge the unit with refrigerant according to the data on the Rating Plate for the unit and check that there are

no leaks.

4.2.- CORRECTIVE MAINTENANCE

IMPORTANT

MAKE SURE THAT THE UNIT IS COMPLETELY DISCONNECTED FROM THE POWER SUPPLY

WHEN CARRYING OUT ANY TYPE OF WORK ON THE MACHINE

If R-407C Refrigerant is used in the unit, the following precautions characteristic of this gas should

be taken:

- The Vacuum Pump must have a Check Valve or Solenoid Valve.

- Pressure Gauges and Hoses for the exclusive use with R-407C Refrigerant should be used.

- The charge should be carried out in the Liquid Phase.

- Always use scales to weight-in charge- Use the Leak Detector exclusive for R-407C Refrigerant.

- Do not use mineral oil, only Synthetic oil to ream, expand or make connections.

- Keep pipes closed before using them and be very thorough about any possible dirt (dust, filings,

burrs, etc.).

- When there is a leak, gather what is left of the charge, create a vacuum in the unit and completely

recharge with new R-407C Refrigerant.

- Brazing should always be carried out in a nitrogen atmosphere.

- Reamers should always be well sharpened.

PRECAUTIONS TO BE TAKEN IN THE USE OF R-407C Refrigerant

Direction of the flame

Silver alloy welding rod

Wet rag

Component to be welded

Nitrogen

29

FAILURE

POSSIBLE CAUSES POSSIBLE SOLUTIONS

UNIT DOES NOT START

Failure in the power supply, or

insufficient voltage.

UNIT STOPS DUE TO HIGH

PRESSURE DURING THE

COOLING CYCLE

The same causes and solutions as the Cooling Cycle but with reference to

the coils and Indoor Fan.

UNIT STARTS AND STOPS IN

SHORT CYCLES

Compressor overcharged.

Inspect suction and discharge pressure

values and correct.

UNIT STOPS DUE TO HIGH

PRESSURE DURING THE

HEATING CYCLE

UNIT STOPS DUE TO LOW

PRESSURE

LOAD AND ABNORMAL

NOISE IN THE

COMPRESSOR (SCROLL)

WATER LEAKS

Circuit breakers have opened.

Power cable or Control Panel cable

is defective.

Connect the power supply or check

the voltage.

Reset.

Inspect and Correct.

High Pressure switch is defective.

Outdoor fan is not working.

Outdoor Fan turns in the wrong

direction.

Outdoor Coil is dirty or clogged for

passing air

Check Cut-off Pressure or

change Pressure Switch if necessary.

Check for voltage, inspect the motor and

turbine or replace if necessary.

Switch the power phases.

Inspect and Clean.

Low pressure switch defective.

Check the Cut-off Pressure with a

pressure gauge and change the

Pressure switch if necessary.

Indoor Fan is not working.

Check for voltage and inspect the

motor, turbine and replace if necessary.

Indoor Fan turns in the wrong

direction.

Switch the power phases.

Lack of refrigerant. Leak. Correct leak, create vacuum and charge.

Dirty Air Filter Inspect and Clean.

Clogged Cooling Circuit.

Dirty filter drier.

Compressor cuts off due to Klixon.

Inspect input voltage and voltage drop.

Lack of Refrigerant. Correct leak and replace.

Power supply phases inverted

(three-phase compressor).

Inspect and switch power phases.

Clogged drainage.

Inspect and Clean.

Loose drainage pipe connections.

Correct connection.

Dirty and overflowing trays.

Inspect and Clean.

Inspect and Correct or Change the

Filter drier.

4.- MAINTENANCE

Excess charge of the Refrigerant.

4.3.- FAILURE DIAGNOSIS

In case of failure or malfunction of the unit, the Display on the Control Panel will show an Error or Alarm warning

explained in the Control Panel Manual. Nevertheless, whenever there is an unit failure, the unit should be shut

down and our Service Technicians consulted.

Remove the charge and charge

according to the data on the Rating Plate.

30

COD: MIL60E-0501 03-2005

Due to Lennox's ongoing commitment to quality, Specifications, Ratings and Dimensions subject to change without notice and without incurring liability.

Improper installation, adjustment, alteration, service or maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualified installer and servicing agency.

www.lennoxeurope.com

BELGIUM,

LUXEMBOURG :

CZECH REPUBLIC :

FRANCE :

GERMANY :

IRELAND :

NETHERLANDS :

POLAND :

PORTUGAL :

RUSSIA :

SLOVAKIA :

SPAIN :

UKRAINE :

UNITED KINGDOM :

OTHER COUNTRIES :

LENNOX BENELUX N.V./S.A.

www.lennoxbelgium.com

LENNOX JANKA a.s.

www.janka.cz

LENNOX FRANCE

www.lennoxfrance.com

LENNOX DEUTSCHLAND GmbH

www.lennoxdeutschland.com

LENNOX IRELAND

www.lennoxireland.com

LENNOX BENELUX B.V.

www.lennoxbenelux.com

LENNOX POLSKA Sp. z o. o.

www.lennoxpolska.com

LENNOX PORTUGAL Lda.

www.lennoxportugal.com

LENNOX DISTRIBUTION MOSCOW

www.lennoxrussia.com

LENNOX SLOVENSKO s.r.o.

www.lennoxdistribution.com

LENNOX REFAC S.A.

www.lennox-refac.com

LENNOX DISTRIBUTION KIEV

www.lennoxrussia.com

LENNOX UK

www.lennoxuk.com

LENNOX DISTRIBUTION

www.lennoxdistribution.com

Loading...

Loading...