Page 1

HEARTH PRODUCTS

™

KITS AND ACCESSORIES

775,251M

Rev. A, 09/2008

INSTALLATION INSTRUCTIONS FOR CONVERTING FROM NATURAL GAS (NG) TO

PROPANE GAS (LP). FOR USE WITH THE FIRESTAR™ GC3 B-VENT GAS FIREPLACE INSERT

KIT CONTENTS (See Figure 1):

1 ea. Robertshaw LP Regulator Kit (A)

1 ea. Robertshaw LP Pilot Orifice (B)

1 ea. #49 LP main burner orifice (39,000 BTU’s) (C)

1 ea. Instruction Sheet

FIRESTAR™ GAS CONVERSION INSTRUCTIONS NG TO LP

CAT. NO. 75173, MODEL FSTR-CK-NG TO LP

AVERTISSEMENT

Cet équipement de conversion sera installé par une

agence qualifiée de service conformément aux instructions du fabricant et toutes exigences et codes applica-

TOOLS NEEDED (See Figure 2):

bles de l'autorisés avoir la juridiction. Si l'information

dans cette instruction n'est pas suivie exactement, un

5/32” Long Allen Wrench Or T-Handle Wrench

#2 Phillips Screwdriver

7/16” Open End Wrench

3/4” Open End Wrench

feu, explosion ou production de protoxyde de carbone

peut résulter le dommages causer de propriété, perte

ou blessure personnelle de vie. L'agence qualifiée de

service est esponsable de l'installation propre de cet

équipment. L'installation n'est pas propre et compléte

jusqu'à l'opération de l'appareil converti est chéque

suivant les critères établis dans les instructions de

A

B

propriétaire provisionnées avec l'équipement.

C

Fig. 2

Figure 2 - Tools Needed

WARNING

Figure 1 - Kit Contents

This conversion kit shall be installed by a qualified

service agency in accordance with the manufacturer's

instructions and all applicable codes and requirements

of the authority having jurisdiction. If the information

in these instructions is not followed exactly, a fire,

explosion or production of carbon monoxide may result

causing property damage, personal injury or loss of

life. The qualified service agency performing this

installation is responsible for the proper installation

of this kit and assumes responsibility for this conversion. The installation is not proper and complete until

the operation of the converted appliance is checked as

specified in the manufacturers instructions supplied

with the kit.

IMPORTANT CANADA

The conversion shall be carried out in accordance with

the requirements of the provincial authorities having

jurisdiction and in accordance with the requirements

of the CAN/CSA B149.1 Installation code.

IMPORTANT LE CANADA SEULEMENT

La conversion devra être effectuée conformément

aux recommandations des autorités provinciales

ayant juridiction et conformément aux exigences

du code d'installation CAN/CSA B149.1 .

IMPORTANT

The burner orifices provided in this kit are only for

use at elevations of 0 to 2,000 feet (610 M) in the

USA and 0 to 4,500 feet (0-1372 M) in Canada. At

higher elevations the BTU input must be de-rated

by 4% for every 1,000 feet (305 M) to maintain

the proper ratio of gas to air. If the installer must

convert the unit to adjust for varying altitudes, a

deration information sticker must be filled out by the

installer and adhered to the appliance at the time

of the conversion. Contact your local gas supplier

for deration requirements for your area.

1

Page 2

READ ALL THE STEPS BEFORE STARTING THE CONVERSION.

LO

HI

INSTALLER NOTICE: THESE INSTRUCTIONS MUST BE LEFT WITH

THE APPLIANCE.

This kit contains components required to convert this appliance

from using Natural Gas to using Propane Gas as the only fuel.

All of these components must be replaced in order for the unit to

operate safely on Propane Gas.

When installing gas components use pipe joint compound or

Teflon tape on all pipe fittings before installing (ensure propane

resistant compounds are used, do not use pipe joint compounds

on flare fittings).

INSTALLATION INSTRUCTIONS

Step 1. TURN OFF THE GAS SUPPLY TO THE APPLIANCE. Unplug the

power cord for the blower.

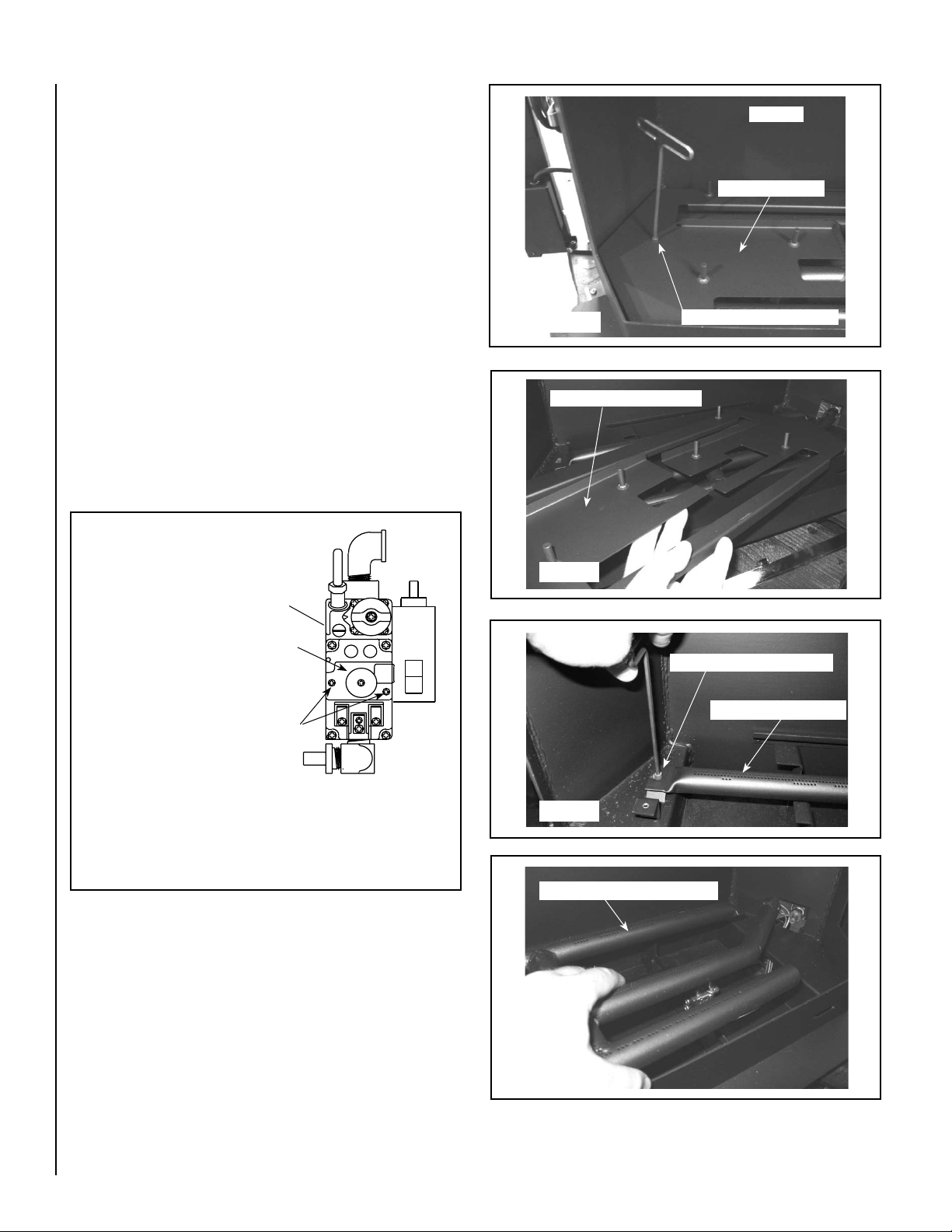

Step 2. Locate the valve behind the right side access door. Using a phil-

lips screwdriver, remove and discard the two pressure regulator

mounting screws (see Figure 3). Remove the pressure regulator

and rubber gasket. Discard all removed components. Install

the new regulator. Ensure the rubber gasket on the back of the

pressure regulator is properly positioned when installing the new

pressure regulator using the new screws supplied with this kit.

Locate the label provided in the regulator kit. Write in the required

information, then affix it to the valve.

Figure 4

Lift Out Air Control Panel

Firebox

Air Control Panel

Remove Allen-Head Screw

Gas Valve

(located in control compartment below firebox)

1. Replace Regulator.

2. Fill out & affix label

from regulator kit to

valve

IMPORTANT NOTE: Do not overtighten the regulator screws.

Overtightened screws may result in little to no difference in

flame height when adjusted from high to low.

Regulator

Remove These

Screws

Figure 3 - Replace Regulator on Valve

Step 3. Remove the glass door by opening both latches on the right and

left side of the door (see Page 18 in the Installation and Operation

Manual). Carefully remove the logs. Exercise care so as not to

break the logs. Set aside in a safe place.

Step 4. Using a 5/32” allen wrench, remove the allen-head screw on the

left side of the air control panel as shown in Figure 4, then lift

out air control panel as shown in Figure 5.

Figure 5

Remove Allen-Head Screw

Burner Tube Assembly

Figure 6

Lift Out Burner Tube Assembly

Step 5. Using a 5/32” allen wrench, remove the screw which secures

burner tube assembly as shown in Figure 6. Then lift out burner

tube assembly as shown in Figure 7.

2

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE.

Figure 7

Page 3

Step 6. Using a 7/16” open-end wrench, remove the pilot orifice by loosening

LO

HI

the nut (see Figure 5) on the end of the pilot supply tube. Once the

nut is removed, slide the nut down the tube, then pull the supply

tube down no more than 1/2” out of the fitting and orifice will fall

out. Once the orifice is out, discard it and put the new one in, then

reinstall the nut.

Pilot Assembly

Pilot Tube Nut

Figure 8

Step 8. Adjust the air shutter as follows (see Page 12 in the Installation

and Operation Manual); The main burner has an adjustable air

shutter located at the end of the burner (see Figures 10 and 11).

Using a phillips screwdriver, loosen the air shutter setscrew just

enough so the air shutter can be rotated by hand (See Figures 10

and 11).

The setscrew for the air shutter is secured tightly from the factory

so that it does not rotate from the factory setting during shipping.

Once you loosen the setscrew just enough so that it can be rotated

by hand, then reinstall the burner tube, you will be able to access

and adjust the air shutter from behind the right side panel to a

100% open gap for propane gas (below valve).

After step 12, with the appliance lit and fully warmed up, evaluate

the burner flame appearance and re-adjust air shutter for proper

flame appearance, if necessary.

Step 7. Using a 3/4” open-end wrench, remove burner orifice. Replace

with #49 LP orifice that is supplied in this kit. Make sure to use

pipe sealing compound on threads of new orifice (see Figure 9).

Gas Valve

Burner Orifice

Figure 9 - Replace Burner Orifice

Setscrew

Air Shutter

Figure 10

Figure 11

NOTE: DIAGRAMS AND ILLUSTRATIONS ARE NOT TO SCALE.

Air Shutter

3

Page 4

Step 9. Turn on gas supply and test for gas leaks using a gas leak test

solution (see Test Procedure on Page 11 in the Installation and

Operation Manual).

Step 10. Using a manometer, test the inlet and manifold gas pressure per

instructions in the Installation and Operation Manual (Page 11)

and as shown in the following 2 tables.

Millivolt Pilot

Gas Pilot Hood

3/8” to

1/2”

Inlet Gas Supply Pressure

Fuel # Minimum Maximum Desired

LP

10.5" WC/po. C.E

(2.62 kPa)

13.0" WC/po. C.E

(3.23 kPa)

11" WC/po. C.E

(2.74 kPa)

Manifold Gas Supply Pressure

Fuel # Low High

LP

(Lo) 5.4" WC/po. C.E

(1.35 kPa)

(Hi) 10.0" WC/po. C.E

(2.49 kPa)

Step 11. Reinstall the the log set and glass door assembly. See Pages

9 and 10 (Log Set Installation) and Page 18 (Door Assembly

Installation) in the Installation and Operation Manual.

Step 12. Light the appliance per the lighting instructions label on appliance

(when viewing the insert from the front, it is located behind the

right side door, on the right) or lighting instructions on Page 13

in the Installation and Operation Manual. Inspect for proper pilot

and burner flame appearances. See Flame Color and Behavior

on Page 14 and Inspect The Pilot System For Proper Flame on

Page 16 in the Installation and Operation Manual. Also see

Figures 12 and 13.

Igniter

Figure 12 - Proper Pilot Flame Appearance

Soot at

Flame Tip

Dark Orange

Flame

No Blue Flame

Center

IMPROPERLY

BURNING FLAME

Soot above

Flame Tip

Ports on Pan

Burner Assembly

PROPERLY

BURNING FLAME

Figure 13 - Burner Flame Appearance

Thermopile

No Soot at

Flame Tip

Semi-Transparent

Yellow Flame

Blue Flame

Center

Lennox Hearth Products reserves the right to make changes at any time, without notice, in

design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2008 Lennox Hearth Products

P/N 775,251M REV. A 09/2008

4

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...