Page 1

GAS APPLIANCE

KITS AND ACCESSORIES

WARNING: THIS CONVERSION KIT SHALL BE INSTALLED BY A QUALIFIED SERVICE AGENCY IN ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTIONS AND ALL APPLICABLE CODES AND REQUIREMENTS OF THE AUTHORIZED AGENCY HAVING JURISDICTION. IF THE INFORMATION IN THESE INSTRUCTIONS ARE NOT FOLLOWED EXACTLY, A FIRE, EXPLOSION OR PRODUCTION OF CARBON MONOXIDE MAY

RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE. THE INSTALLATION IS NOT

PROPER AND COMPLETE UNTIL THE OPERATION OF

THE CONVERTED APPLIANCE IS CHECKED AS SPECIFIED IN THE OWNER INSTRUCTIONS SUPPLIED WITH

THE KIT.

In Canada

THE CONVERSION SHALL BE CARRIED OUT

IN ACCORDANCE WITH THE REQUIREMENTS

OF THE PROVINCIAL AUTHORITIES HAVING

JURISDICTION AND IN ACCORDANCE WITH

THE REQUIREMENTS OF THE CAN1-B149.1

AND .2 INSTALLATION CODE.

LA CONVERSION DEVRA ÊTRE EFFECTUÉE

CONFORMÉMENT AUX RECOMMANDATIONS

DES AUTORITÉS PROVINCIALES AYANT

JURIDICTION ET CONFORMÉMENT AUX

EXIGENCES DU CODE D'INSTALLATION CAN1B149.1 ET.2.

This Gas Conversion Kit contains all of the

necessary components needed to complete the

conversion of an appliance from the use of one

type of gas to the use of another, including

labeling that must be affixed to ensure safe

operation.

ALWAYS REFER TO THE APPLIANCE INSTALLATION AND HOMEOWNERS CARE AND OPERATION DOCUMENTS BEFORE COMPLETING A CONVERSION. ALL WARNINGS, CAUTIONS AND DETAILED INSTRUCTIONS CONTAINED THEREIN ARE APPLICABLE TO THIS

DOCUMENT.

To complete the conversion proceed as follows:

Note: After converting the valve and gas components, refer to the appliance installation and

homeowners care and operation instructions to

adjust the air shutter opening for the gas type used.

CAUTION: The gas supply shall be shut off

prior to disconnecting the electrical power,

before proceeding with the conversion.

Step 1. Turn off the gas supply to the appli-

ance. Remove the front glass door/frame (if

used) from the appliance. Access the control

compartment.

Step 2. Carefully remove the logs. Exercise

care as not to break the logs.

Step 3. Locate the screws securing the burner

(tray) to the appliance. Remove the burner

and retain the securing screws.

Millivolt Appliances

Step 4. SIT Systems - Refer to

a Torx T20, or a flat screwdriver, remove and

discard the three pressure regulator mounting

screws. Remove the pressure regulator, spring,

poppet, diaphragm and bushing.

750,018M

REV. D 07/2007

GAS CONVERSION KIT (FGCK)

AVERTISSEMENT: CET ÉQUIPEMENT DE CONVERSION SERA

INSTALLÉ PAR UNE AGENCE QUALIFIÉE DE SERVICE

CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT ET

TOUTES EXIGENCES ET CODES APPLICABLES DE L'AUTORISÉS

AVOIR LA JURIDICTION. SI L'INFORMATION DANS CETTE

INSTRUCTION N'EST PAS SUIVIE EXACTEMENT, UN FEU,

EXPLOSION OU PRODUCTION DE PROTOXYDE DE CARBONE

PEUT RÉSULTER LE DOMMAGES CAUSER DE PROPRIÉTÉ,

PERTE OU BLESSURE PERSONNELLE DE VIE. L'AGENCE

QUALIFIÉE DE SERVICE EST ESPONSABLE DE L'INSTALLATION

PROPRE DE CET ÉQUIPMENT. L'INSTALLATION N'EST PAS

PROPRE ET COMPLÉTE JUSQU'À L'OPÉRATION DE L'APPAREIL

CONVERTI EST CHÉQUE SUIVANT LES CRITÈRES ÉTABLIS

DANS LES INSTRUCTIONS DE PROPRIÉTAIRE PROVISIONNÉES

AVEC L'ÉQUIPEMENT.

Discard all removed components. Ensure the

rubber gasket installed on the back of the

replacement pressure regulator is properly

positioned and install the new pressure regulator using the new screws supplied with this kit.

Tighten screws to 25 In. lb. torque.

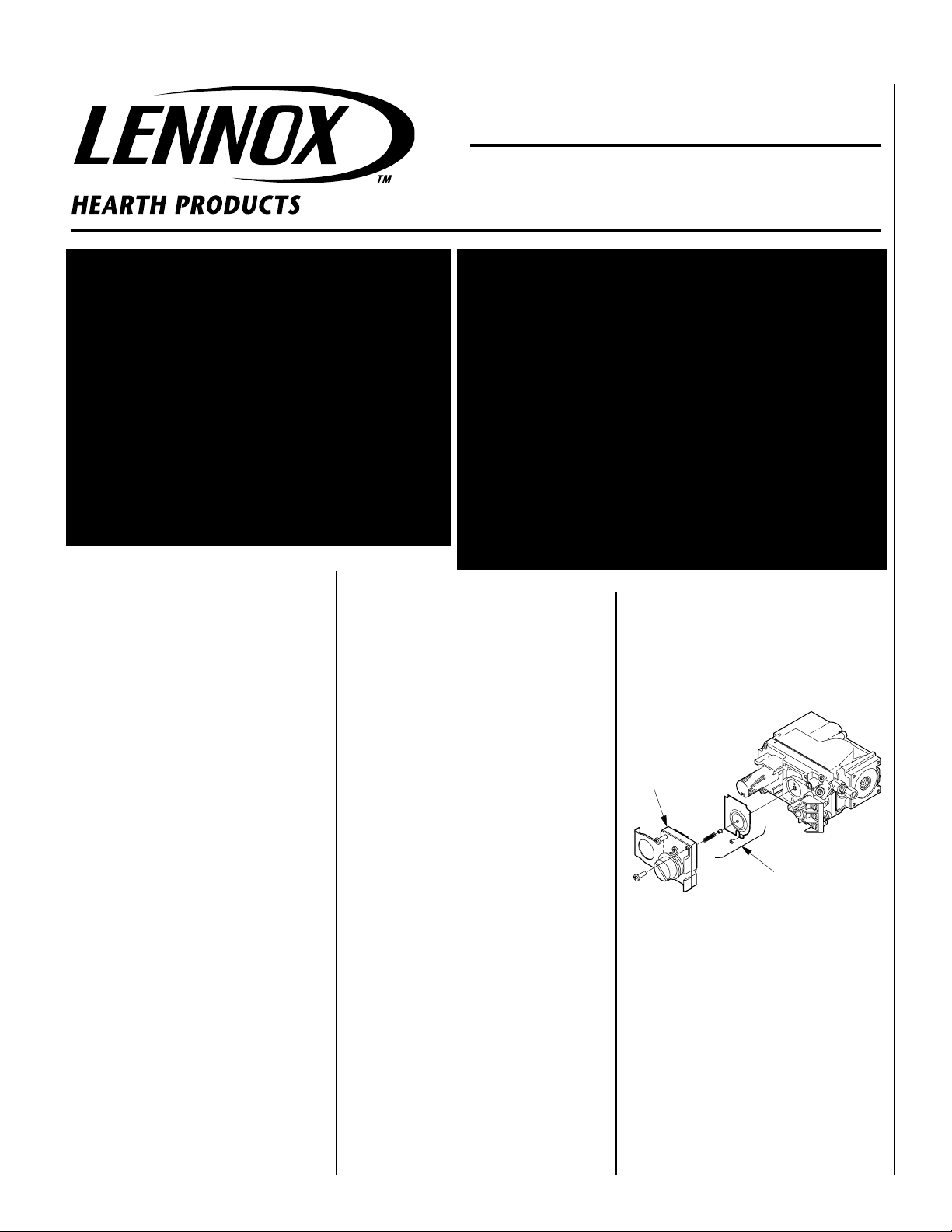

SIT VALVE

Pressure

Regulator

Remove

These

Components

Figure 1

Figure 1

. Using

Step 5. Honeywell Systems - See

Remove the black thread-protecting cap. Remove the conversion flip cap by turning it

counterclockwise. Invert the flip cap so that the

letters associated with the desired gas type are

positioned closest to the valve body.

NG is for natural gas and LP is for propane.

Tighten the flip cap by turning it clockwise.

Replace the black thread-protecting cap.

Figure 2

.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

1

Page 2

HONEYWELL

VALVE

Flip Cap

Thread

Protector

Hood

Ignitor Rod

³⁄₈" Min

(9 mm)

Test

Port

Slotted

Cap

CONTROL

OFFION

I

G

N

I

T

E

I

S

P

Figure 2

Step 6. Refer to

Figure 3

and remove the pilot

hood assembly to access the hexed pilot orifice. Using a (4mm) Allen wrench, remove and

replace the orifice with the one provided with

this kit.

sembled, with proper flame.

Figure 4

shows the pilot reas-

Figure 5

shows

a typical pilot to burner relationship.

Pilot

Orifice

Pilot

Nozzels

Figure 4

Figure 5

Pilot

(Millivolt LMBV 36 Shown)

Burner

Adjusting

Spring

Screw

Figure 7

Step 8. Refer to

Figure 6

and replace the pilot

orifice as follows: Remove the ignitor assembly retainer clip, and carefully remove the

ignitor assembly. Exercise extreme care to

prevent damage to or breakage of the ignitor

assembly. Remove the screw securing the

pilot assembly to its mounting bracket. Back

off the flare nut at the end of the pilot gas line

to free the pilot assembly from the gas line.

Remove the pilot orifice and replace it with the

one provided with this conversion kit. Reinstall the pilot assembly by reversing the steps

detailed here.

When reinstalling the ignitor assembly, use

extreme care to prevent damage and breakage. Do not apply any leverage to the ignitor

assembly while restoring the retainer clip to

its original position.

Figure 3

Electronic Appliances

Step 7. Honeywell Electronic Valves - See

Figure 7

. Remove the slotted cap screw, oring, pressure-regulating adjusting screw and

spring. Retain all parts for possible later use.

Install new components from this kit. Black

cap and red spring for propane gas units.

Silver cap and stainless steel spring fro natural

gas units.

2

Pilot

Assembly

Pilot

Orifice

Ignitor

Assembly

Retaining

Clip

Flare Nut

Note: If the ignitor assembly is damaged, a replacement kit is available, order Catalog Number 87L54.

Figure 6

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 3

ALL FIXED SETTING SIT VALVES

Millivolt Appliances

Step 9. SIT Systems - Refer to

Figure 1

. Using

a Torx T20, or a flat screwdriver, remove and

discard the three pressure regulator mounting

screws. Remove the pressure regulator, spring,

poppet, diaphragm and bushing.

Discard all removed components. Ensure the

rubber gasket installed on the back of the

replacement pressure regulator is properly

positioned and install the new pressure regulator using the new screws supplied with this kit.

Tighten screws to 25 In. lb. torque.

Step 10. Refer to

Figure 3

and remove the

pilot hood assembly to access the hexed pilot

orifice. Using a (4mm) Allen wrench, remove

and replace the orifice with the one provided

with this kit.

sembled, with proper flame.

Figure 4

shows the pilot reas-

Figure 5

shows

a typical pilot to burner relationship.

Electronic Appliances

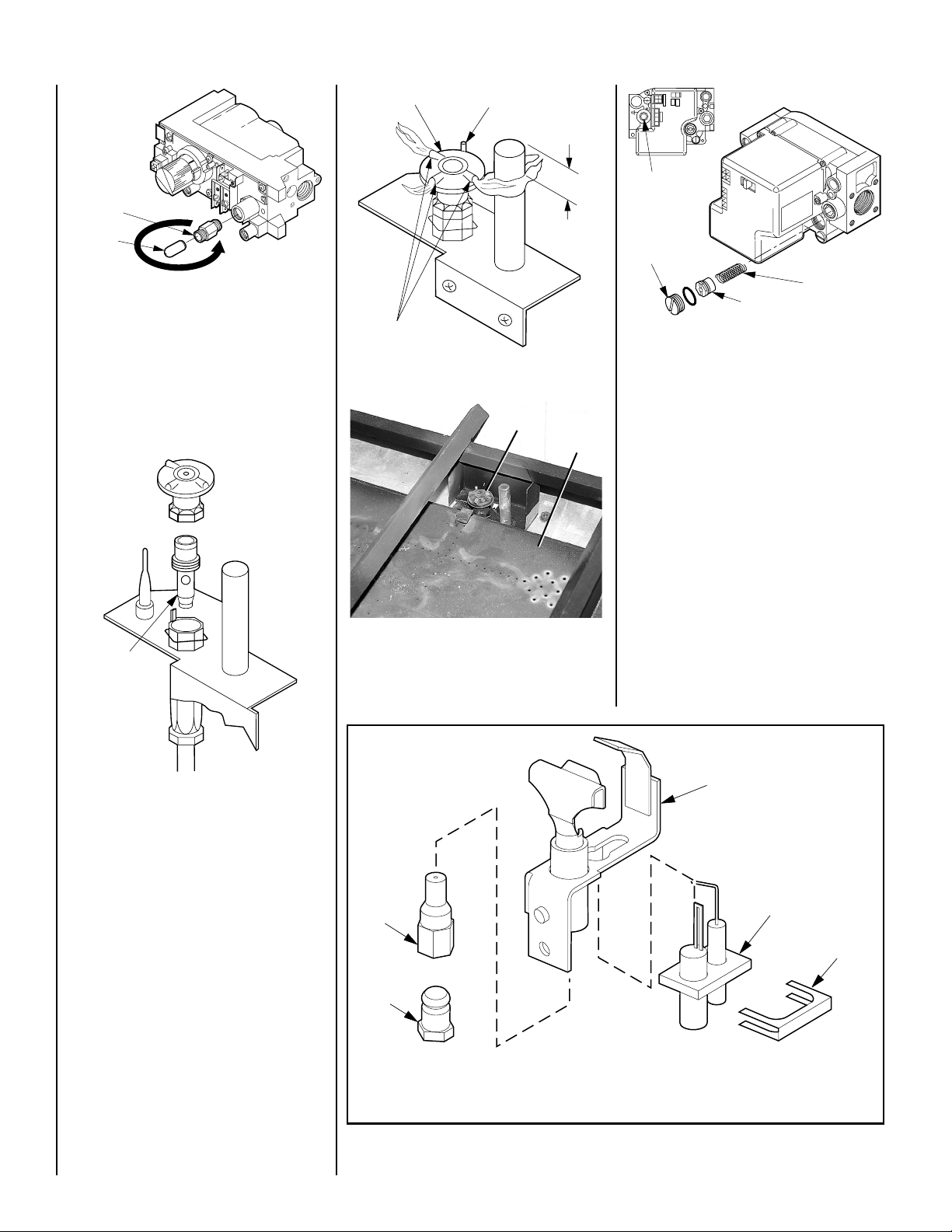

Step 11. SIT Systems - See

Figure 8

. Using a

Torx T20, or a flat screwdriver, remove and

discard the three pressure regulator mounting

screws. Remove the pressure regulator, spring,

poppet, diaphragm and bushing. Discard all

removed components.

Using a standard tin snip cutting tool, proceed

to trim shoulder off of the regulator provided

with the kit. Ensure the rubber gasket installed

on the back of the replacement pressure regulator is properly positioned and install the new

modified pressure regulator using the new

screws supplied with this kit. Tighten screws to

25 In. lb. torque.

SIT VALVE

Step 12. Refer to

Figure 6

and replace the pilot

orifice as follows: Remove the ignitor assembly retainer clip, and carefully remove the ignitor assembly. Exercise extreme care to pre-

vent damage to or breakage of the ignitor

assembly. Remove the screw securing the

pilot assembly to its mounting bracket. Back

off the flare nut at the end of the pilot gas line to

free the pilot assembly from the gas line.

Remove the pilot orifice and replace it with the

one provided with this conversion kit. Reinstall the pilot assembly by reversing the steps

detailed here.

When reinstalling the ignitor assembly, use

extreme care to prevent damage and breakage. Do not apply any leverage to the ignitor

assembly while restoring the retainer clip to

its original position.

All Models

Step 13. Unscrew the orifice from the manifold

and replace it with the one provided with this kit

(

Figure 9

).

Figure 9

Step 14. Reassemble all removed compo-

nents by reversing the procedures outlined in

the preceding steps. Use pipe joint compound

or Teflon tape on all pipe fittings before installing (ensure propane resistant compounds are

used in propane applications, do not use pipe

joint compounds on flare fittings). Adjust the

air shutter opening on the burner tube, refer to

Note

on page 1.

Step 15. Attach appropriate conversion kit

label (

Figure 10

) next to the rating plate on the

appliance. Attach the installer conversion

label next to the gas valve, after filling out the

information on the label. Refer to the Installation Instructions for required input rating.

THIS APPLIANCE HAS BEEN CONVERTED TO:

NATURAL GAS

INPUT BTU/HR – 50,000

MANIFOLD PRESSURE – 3.5"

ORIFICE SIZE – (0.130)

THIS APPLIANCE HAS BEEN CONVERTED TO:

PROPANE/LPG

INPUT BTU/HR – 50,000

MANIFOLD PRESSURE – 10"

ORIFICE SIZE – (0.080)

Figure 10

Step 16. Turn on gas supply and test for gas

leaks, using a gas leak test solution (also

referred to as bubble leak solution).

Step 17. Attach manometer to the manifold

side pressure test fitting (¹⁄₄" Allen wrench for

Electric units) and adjust screw until pressure

reads 3.5 inches water column (6.54 MmHg)

for natural gas, and 10.0 inches water column

(18.69 MmHg) for propane gas. Refer to the

Installation Instructions and the Table below.

Inlet Gas Supply Pressure

Fuel #

Propane

Natural

Minimum

11.0" WC

(2.74 kPa)

4.5" WC

(1.24 kPa)

Maximum

13.0" WC

(3.23 kPa)

10.5" WC

(2.61 kPa)

Modified Kit

Pressure Regulator

- After Trim

Figure 8

Remove

These

Components

Kit Pressure

Regulator - Before

Trim

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Step 18. For detailed Lighting Instructions,

refer to the Homeowners/Care And Operations

instructions.

3

Page 4

Lennox Hearth Products reserves the right to make changes at any time, without notice, in design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2000 by Lennox Hearth Products

P/N 750,018M REV. D 07/2007

4

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...