Page 1

APPLICATION

GUIDE

FAC - FAG - FAH - FAM

Air cooled rooftop packaged unit

FLEXAIR

85 230 kW

FLEXAIR-AGU-1505-E

lennoxemeia.com

Page 2

Page 3

TABLE OF CONTENTS

FLEXAIR

APPLICATION GUIDE

GENERAL DESCRIPTION

1. 4

OPTIONS DESCRIPTION

2. 14

GENERAL DATA

3. 22

OPTIONS DATA

4. 26

Ref : FLEXAIR-AGU-1505-E

STANDARD UNIT PERFORMANCES

5. 276

FAN PERFORMANCES

6. 42

HEAT RECOVERY SOLUTIONS PERFORMANCES

7. 45

HEATING AUXILIARIES PERFORMANCES

8. 47

ACOUSTIC DATA

9. 52

ELECTRICAL DATA

10. 54

DIMENSIONAL DATA

11.

OPTIONS WEIGHTS AND ACCESSORIES PRESSURE DROPS

12.

56

75

Product designed and manufactured under quality management

systems certifi ed ISO 9001 and ISO 14001.

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided

by us, remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to or made

available to third parties without the prior written agreement of Lennox.

Application Guide /FLEXAIR-AGU-1505-E

www.eurovent-certifi cation.com

www.certifl ash.com

Our company’s products comply

with European standards.

• 1 •

Page 4

• 2 •

Application Guide / FLEXAIR-AGU-1505-E

Page 5

MODEL NUMBER DESCRIPTION

EXAMPLE :

F A C 300 D N M 1 M

FLEXAIR

F

Air cooled

A

Water cooled

W

No condenser

N

M

H

Revision number

R410A

HFO

400V/3/50

M

230V/1/50

T

Cooling

C

Heat pump

H

gas fi red

G

dual fuel

M

heat recovery

X

Cooling capacity in kW

S

D

T

F

High heat

H

Standard heat

S

No heat

N

1 Circuit

2 Circuits

3 Circuits

4 Circuits

No refrigerant

N

Application Guide /FLEXAIR-AGU-1505-E

• 3 •

Page 6

1- GENERAL DESCRIPTION

SUSTAINABLE ENERGY

DEVELOPMENT CHALLENGES

Faced with challenges relating to competitiveness and climate

change, Europe has launched several initiatives for an intelligent

energy strategy.

New regulations refl ect the European Union’s commitments on

climate change and its determination to reach 20% effi ciency

improvement in buildings by 2020.

EPBD

ENERGY PERFORMANCE OF

BUILDING DIRECTIVE

One of the major requirements of the new EPBD is to set Energy

Certifi cates for buildings which grade the energy effi ciency based

on the building annual energy consumption. Soon companies

will have to display their energy certifi cates to the public.

THE EXPERIENCE & COMMITMENT OF

THE EUROPEAN LEADER TO DRIVE

CONTINUOUS ENERGY SAVINGS

LENNOX : THE BEST LIFE CYCLE

COST IN THE MARKET

FLEXAIR provides the best life cycle cost thanks to

high energy effi ciency and reduced set up time and

maintenance costs.

Low Energy consumption

• For a packaged air conditioner, 90% of the CO2

emissions are indirect emissions caused by the

energy consumption.

• 35% energy savings with FLEXAIR when compared to a standard rooftop installed on a retail

building.

• Innovative solutions for long lasting energy savings:

. eDrive Direct transmission variable speed ventilation system

. Advanced refrigeration system with multiscroll R410A com-

pressor assemblies, electronic expansion valves, extended

heat exchange surface area, alternate and dynamic defrost

cycles.

. Fresh air and free cooling management.

. Optimized operation with eClimatic

Lennox contribution to combat rising energy costs and global

warming is to design innovative, effi cient and dependable

products, while providing best comfort and air quality.

As a major player in the European

HVAC market, Lennox is a reference

in sustainable development and has

been assembling its products in ISO14001 certifi ed factories since 2007.

eComfort illustrates Lennox

commitment towards energy

efficiency and environmentally

™

eComfort

efficiency s environment

friendly solutions.

Like any other Lennox Rooftop

unit,

FLEXAIR is Eurovent

certifi ed.

Reduced maintenance Costs

• Fully factory tested plug and play packaged system.

• eDRIVE direct transmission plug-fan with zero maintenance

and airfl ow measurement with eFlow.

• eClimatic, eClimatic

supervision through GPRS with ADALINK Service.

Wizard, unit remote management and

Better recycling management

• Unit assembled in an ISO14001 certifi ed facility.

• Refrigerant R410A to reduce refrigerant charge.

• Reduced material usage with compact packaged design.

• 4 •

Application Guide / FLEXAIR-AGU-1505-E

Page 7

1- GENERAL DESCRIPTION

1.1. GENERAL FEATURES

FLEXAIR range constitutes a packaged solution, easy to deliver

and quick to install on the roof.

Operating range shall be between 46°C and minus 12°C with

4 versions : cooling, heating, cooling with gas burner or dual

heat (heating with gas burner). All units are factory assembled,

internally wired, fully charged with refrigerant, and 100% runtested before leaving the factory.

EC FANS TECHNOLOGY

FLEXAIR units are fi tted with EC fans as standard, the variable

speed option will save energy and reduce maintenance costs.

HIGH INDOOR AIR QUALITY

Filtration

FLEXAIR offers different fi ltration levels, ensuring the minimum

pressure drop.

The unit is fi tted with EU3 fi lters as standard, but it can be

confi gured with :

- G4 fi lters

- G4+F7 fi lter option / effi ciency > 85% / 0,4 μm particles

Free cooling

Some times the thermodynamic cooling can be replaced by

free cooling by introducing cold outside air into the building.

FLEXAIR saves energy with automatic calibration of fresh air :

- Intelligent Fresh Air Management (patent 03 50616)

- Motorised fresh air damper with enthalpy control (option)

- CO2 sensor to adjust the percentage of fresh air to the Indoor

Air Quality (option)

eClimatic ADVANCED CONTROLLER

eClimatic is the new generation controller that improves effi ciency

and helps set up and service operations to guarantees long

lasting performance

1.2. CASING

FLEXAIR indoor section is built with precoated galvanized steel

panels painted in RAL 9003 color, specially designed for corrosion

resistance and to ensure long operation life time.

Double skin can be demanded as an option.

Condensing section mounted in a rigid base frame to ensure

good support for compressors and giving rigidity to the complete

structure.

1.3. ADVANCED REFRIGERANT

CIRCUIT

FLEXAIR presents the most advanced design in the refrigerant

pipes, optimizing pipe length and at the same time giving the

best access for service and maintenance operations.

The exchangers have been specially designed by Lennox for

R410A operation, this copper tube and aluminum fi ns exchangers

have been tested to give the best heat transfer and the best

energy ratios.

The refrigeration circuit is responsible for up to 40% of the annual

energy consumption of a typical packaged air conditioning unit.

FLEXAIR features high effi ciency, environmentally friendly

refrigeration circuits with multiscroll R410A compressors,

electronic expansion valves and optimized heat exchange

surface area.

HEAT RECOVERY SOLUTIONS

FLEXAIR range includes a heat recovery wheel to recovery

energy from the extraction air

This heat recovery wheel is fi tted in a separated module to be

installed on site

Application Guide /FLEXAIR-AGU-1505-E

• 5 •

Page 8

1- GENERAL DESCRIPTION

SAVING ENERGY WITH ADVANCED

REFRIGERATION CIRCUIT DESIGN

R410A refrigerant

Effi cient systems such as FLEXAIR are designed around R410A

refrigerant to achieve the best performances.

• Energy effi cient refrigerant thanks with pressure drop in the

pipes: Higher evaporating pressure and lower condensing

pressure improve compressor EER & COP.

• R410A compressors have a better isentropic effi ciency.

• Environmentally friendly refrigerant:

It contains No Chlorine (ODP =0). Signifi cant refrigerant charge

reduction (-40%) that limits the global warming potential of the

system. R410A optimized heat exchangers use less material

(copper, aluminum …)

1.4. MULTISCROLL COMPRESSOR

TECHNOLOGY

FLEXAIR units are provided with tandem compressors, to profi t

from the multiscroll compressor technology and giving the highest

seasonal performance and the best SEER coeffi cients.

High effi ciency multiscroll technology

Air conditioning equipments are sized to cover the need for the

most critical weather conditions which most likely will occur only

a few days or even a few hours during the year.

Most of the time, in Europe, the external temperature drops below

the reference value and consequently systems usually run 96%

of the time at part load. It is therefore important to design system

around part load performance to achieve the lowest possible

annual energy consumption.

FLEXAIR provides high effi ciency and best possible part load

effi ciencies year round with high effi ciency multiscroll R410A

compressor technology.

Evolution of the net EER with varying capacity load

Net EER

4,5

4,0

3,5

3,0

2,5

MultiScroll + eDrive

A

MultiScroll

Inverter Scroll

B

C

TM

Single Scroll

2,0

1,5

A Multiscroll + eDRIVE C Multiscroll

B Inverter scroll D Single scroll

Source: PERSAPAC Study by Cetiat, Eurovent, Armine & EDF

Lennox Europe Laboratory comparative testing on rooftops

D

10 20 30 40 50 60 70 80 90 100

Capacity load in % of nominal

• 6 •

Application Guide / FLEXAIR-AGU-1505-E

Page 9

1- GENERAL DESCRIPTION

Multiscroll” compressor technology with electronic expansion

valves allows energy consumption reduction when compared

to “inverter” solutions:

• Multiscroll compressors are always running at their best

nominal operating conditions whereas compressors with

inverter control usually run at 90 Hz for nominal point down

to 30 Hz for low capacities.

• Energy consumption due to inverter electronics for speed

variation can reduce effi ciency by up to 5%.

• Multiscroll compressor assemblies optimize heat exchanger

usage during part load operation. For example, with 50%

capacity load, a FLEXAIR would only start one compressor

on each circuit. The running compressors would then benefi t

from the whole heat exchange surface area and the whole

airfl ow rate: The EER is then increased to 4.5 in some cases.

• Multiscroll compressor assemblies improve operating limits

giving the possibility to unload compressors providing cooling

to the building even when the outdoor temperatures are very

high. With unloading, FLEXAIR can operate and supply

cooling operating one compressor with outdoor temperatures

reaching 50°C.

1.5. ELECTRONIC EXPANSION

VALVES

The new electronic expansion valves are directly driven by the

eClimatic and optimize the performances in both cooling and

heating mode and provide reliable and accurate operation in all

conditions all year round.

This model of electronic expansion valves ensures also smooth

and precise control at low capacities for improved part load

performances.

Application Guide /FLEXAIR-AGU-1505-E

• 7 •

Page 10

1- GENERAL DESCRIPTION

1.6- EC FANS IN SUPPLY AND EXTRACTION

EC fan technology offers the maximum effi ciency together with

the minimum power consumption. That’s why FLEXAIR provides

EC fans both in indoor and exhaust section.

FLEXAIR will adapt the fan pressure to the different conditions

of the unit, and will provide high pressure available in the duct

even when all the options have been selected.

The EC plug-fan technology allows:

- Adapting airfl ow at commissioning

- Varying airfl ow during unit operation providing progressive

infl ation of smooth /textile ductworks

- Easy maintenance operations, as there is not pulleys and

belts regulation

eClimatic profi ts about this EC technology by:

- Monitoring the airfl ow in the service terminal

- Compensating the airfl ow if the fi lters are dirty

- Regulating the airfl ow to arrive to the desired set point tem-

perature.

Optimize the air-fl ow to the load demand (reduce consumption

when possible)

2

3

Annual compressor consumption

1

Annual consumption of other electical systems

2

Remaining annual fan motor consumption

3

Energy savings thanks to eDRIVE

4

4

1

40 %

18 %

12 %

30 %

VARIABLE SPEED DRIVE

Airfl ow reduction during part load operation and dead zone can

help save on energy consumption.

Condensing section mounted in a rigid base frame to ensure

good support for compressors and giving rigidity to the complete

structure.

eDRIVE

VENTILATION

eDRIVE is a standard feature

of Lennox FLEXAIR units

for ventilation with direct

transmission, variable speed

drives that saves energy and

reduces maintenance costs.

SAVING ENERGY WITH eDRIVE VARIABLE

SPEED, DIRECT DRIVE FAN.

With a rooftop, the blower fan motor is one of the major contributors

to annual energy consumption. Fans usually run 97% of the year

at full speed to circulate the air inside the building. 42% of the

annual energy consumption of an air conditioner is due to the

fan motor, which can be more than compressors.

There is no need to reduce airfl ow rate too much to achieve

important energy savings: For example reducing airfl ow rate by

only 25% will save 60% on the fan motor energy usage.

Fan absorbed power with variable airfl ow rate

(% of nominal)

Fan absorbed power

Airfl ow rate

(% of nominal)

• FLEXAIR integrates the new eDRIVE which automatically

adjust airfl ow rate to the needs, saving up to 30% annual

rooftop energy consumption.

• Airfl ow Rate can be easily adjusted to the exact needs, thanks

to eFlow the airfl ow measurement and display system.

• eDRIVE will correct power factor to reduce current.

• eDRIVE integrates soft starter feature as standard, that will

reduce inrush current during fan starts and makes the unit

fully compatible with fl exible ducts air diffusion systems.

- 25%

• 8 •

Application Guide / FLEXAIR-AGU-1505-E

Page 11

1- GENERAL DESCRIPTION

1.7- eCLIMATIC NEW CONTROL

Our FLEXAIR range includes our New e-climatic control

generation.The main features of this control are :

- Plastic cover to protect the circuit board from water entry

and humidity and with all the different connection terminals

correctly identifi ed.

- Two independent buses, one for display and sensors connection and another one for internal components.

- Possibility of storing all parameterized conditions before an

alarm is produced.

- Stronger hardware thanks to the plastic cover which protects

the circuit board from water entry and humidity (and at the

same time clearly identify all the different connection terminals)

- More reliable hardware thanks to the different communication buses for internal/main devices (compressors, fans,

etc.) and for the remote/accessory ones (display, probes),

which preserve the regular unit operation even in case of

commissioning miswirings

- Enhanced ClimaticTM regulation thanks to the better embedded processor and to the new Universal I/O chip, which

allows to match better contacts, probes and relays to the

controller board.

- Internal log memory to record unit operating trends (e.g.

temperatures before alarm occurrence).

OPTIMIZED OPERATION AND SETUP

SAVES ENERGY

Three different platforms are available :

● End customer display DC: with basic confi gurations, set

points, main temperature readings and alarms.

● Multiple display DM: graphic customer display with basic

confi guration of the end customer display plus schedule

programming and set of fresh air %.

● Service display DS: Specially focused to maint

4

6

5

2

7

3

1

eClimatic is designed to provide the best effi ciency throughout

unit’s lifecycle while ensuring reliable and consistent operation

with user-friendly interfaces .This controller monitories more

machine parameters than ever to improve energy effi ciency

and reliability

1 Indoor air temperature (humidity and CO2 levels as an option )

2 Outdoor air temperature (outdoor humidity as an option )

3 Return and supply air temperature

4 Filter pressure drop

5 Airfl ow rate with eFlow

Refrigeration circuit effi ciency management

Climatic control regulation

The Climatic controls the blowing air temperature to achieve the

customer comfort in the most effi cient way, matching perfetctly

the cooling/heating load with the optimum unit capacity staging

(multiscroll compressors, heat recovery modules, freecooling,

gas burners, water coils, etc.).

The unit reliability is ensured by a complete set of protections as

compressor envelop control, air-fl ow and pressure drops check,

advanced refrigerant leakage detection, compressor anti short

cycling rules.

All these fetaures are designed to optimize the unit performance,

but at the same time to increase its life-time and make easier

its maintenance.

Dynamic defrost:

It is a standard feature of all Lennox heat pumps. It limits the

number and the duration of the defrost cycles in winter to maximize

COP. With a smart and propietary frost-detection system, the

lennox rooftops autumatically optimize the number and the

durantion of the defrost cycles to get the best units perfonces

in every enviromental conditions.

6 Refrigerant pressures, temperatures & compressor monitoring

7 Power energy metering (option )

Application Guide /FLEXAIR-AGU-1505-E

• 9 •

Page 12

1- GENERAL DESCRIPTION

Free cooling:

It is one of the most important features of this rooftop as it maximise

seasonal effi ciency by reducing the use of thermodynamic cooling

in mid season.

Intelligent fresh air management:

With accurate percentage of fresh air the dampers are regularly

calibrated to introduce just the required amount of fresh air in the

building to reduce annual energy consumption. The fresh air ratio

can also be controlled using the indoor CO2 level as an input.

Intelligent heating priority optimization:

This unique feature on the market, allows the user to program the

priority between the different heating elements (thermodynamic,

electric pre-heaters or auxiliary heating). This is particularly

interesting on dual fuel units or units with electrical pre-heaters.

This feature maximizes energy effi ciency by optimizing heat pump

operation depending on the outdoor temperature.

Full Scheduling

Impressive energy savings can be done with a proper timescheduling that optimizes the unit operation to the different load

scenarios of each installation.

For that reason the Climatic offers a weekly-based calendar with

up to 7 time-bands per day and 4 pre-set modes (Unoccupied,

Day, Day 1, Day 2).

For each of this pre-set modes, plenty of unit settings can be

optimized to the different moments of the day, for example during

the unoccupancy periods the comforrt setpoints could be relaxed,

during the energy-cost peaks hours the hot water coils or gas

burners could be preferred to compressor or electrical heaters,

fresh-air introduction can be reduced to warm-up the building

before customer arrival, etc.

Morning anticipation and dynamic set point

The unit can be programmed to switch-on in the morning to reach

the occupied zone temperature set point just in time.

The rooftop will start heating the building at a different time in

the morning depending on the outdoor temperature: The lower

the outdoor temperature, the earlier the rooftop would start to

ensure that the set point is reached by the time the fi rst occupied

zone (Z1) is starting. This is to avoid early start when outdoor

temperature is mild.

Example for a unit programmed to anticipate morning switch-on

if outdoor temperature is below 10°C at a rate of 10 minutes/°C.

Start time

Z1 = 08h00

Actual switch-on

Z1 = 07h30

Actual temp.

Dynamic set point can be used in summer to offset the ambient

temperature set point according to the outdoor temperature.

This is to avoid large temperature difference between indoor and

outdoor. The indoor temperature set point would then increase

with the outdoor temperature improving comfort and saving large

amount of energy.

Gradient : 10 min / °C

7°C

10°C

10°C

1 2

Unoccupied mode Day mode

3 4

Day1 additionnal mode Day2 additionnal mode

Communication and unit interlink

Master/slave or cascade control is a standard feature of the

FLEXAIR units. It can be used to connect up to 24 rooftops.

The units can then be programmed to optimize effi ciency and

improve reliability following 6 different strategies

Multi rooftops regulation

In case of multi-rooftop installations, The Climatic control of each

unit can improve the unit synergies and optimize the total airconditioning performance, without any additional cost or external

dedicated "Building Manager System", but just linking the units

together (up to 8) in the same network and appling any of the

following smart strategies::

1: Master Slave "total":

The master gives the ventilation order, its set point and its room

temperature/humidity/CO2 to all other rooftops.

2: Master Slave "temperature":

The master gives the ventilation order and its room temperature/

humidity/CO2 to all other rooftops, but they have their own set

point.

• 10 •

Application Guide / FLEXAIR-AGU-1505-E

Page 13

1- GENERAL DESCRIPTION

3: Master Slave "average":

The master gives the ventilation order and the room temperature/

humidity/CO2 used by all rooftop is the average of all rooftop,

each rooftop has its own set point.

4: Master Slave "cooling/heating":

All rooftop are stand-alone but the slaves have to have the same

running mode as the master (Cooling or heating).

5: Master Slave “Back-up”:

One rooftop is the back-up unit and will operate if any of the

other rooftops is stopped due to a major problem.

6: Rolling Back-up mode:

Same as above, except the "back-up" unit will change once a

week on Tuesday.

Note that, the outside temperature/humidity/CO2 given to all

rooftops can either be the average of all unit connected or the

external humidity/temperature of the master, allowing the use

of a single "weather station" for the whole site.

Faults and alarms

eCLIMATIC manages more than 90 different faults and alarms

codes and can store the last 32 with time and date. The stored

faults and alarms can then be displayed on the DS service

display and on the communication bus with the full text detail.

1.8. CONSTRUCTION, INSTALLATION

AND SERVICE

UNIT CONSTRUCTION

FLEXAIR by Lennox is assembled with the highest standards

of quality.

FLEXAIR units comply with the PED 97-23 and EN 60204

standard. It is manufactured in ISO 9001 and ISO 14001 factories.

This construction guarantees high corrosion resistance and lower

the weight impact, also ensuring that the air leakages are reduced

to the minimum. To improve the resistance to anticorrosion, the

panels are prepainted in RAL 9003.

TRANSPORT AND HANDLING

To facilitate handling of the

unit and minimize the risk of

damage, FLEXAIR units are

provided with lifting lugs located

in the base frame of the unit.

For transport and handling,

the units are wrapped in a

retractable plastic protection

PLUG AND PLAY UNIT

All options are factory installed on the unit, which means that

they are ready for use, optimizing the time spent on site for the

installation. Bottom entry (through the base) for electrical power

and hot water (if option fi tted) lines are available as standard.

To make installation easier, FLEXAIR power supply does not

require "neutral" connection. It is powered by 400 V, 3 phases,

50 Hz.

Circuit breakers

To improve safety and extend life time, circuit breakers protect

against over-loading, over current and a disconnected supply

phase. Maintenance is also improved as there is no requirement to

change fuses. The electrical panel is manufactured in accordance

with EN60204 electrical directive.

Numbered wires

All wires and connectors are numbered as shown on the electrical

drawing to facilitate maintenance and diagnostic

Main disconnect switch

The main switch is used as an emergency cut off.

It is mandatory to guarantee a proper accessibility to this switch.

Specifi c footbridges must be installed if the machine environment

is requiring it.

Main disconnect switch is lockable to increase safety around

the rooftop unit.

Switching off the unit with the disconnect switch will reset all.

Disconnect switch will be sized accordingly to the options picked

with the unit.

Application Guide /FLEXAIR-AGU-1505-E

• 11 •

Page 14

1- GENERAL DESCRIPTION

EASY ACCESS TO THE UNIT

COMPONENTS

In FLEXAIR we keep the accessibility of all the components to

the indoor unit, as well as all the internal refrigerant components

1.9. INDOOR AIR QUALITY

FILTERS

As standard the unit comes with EU3 fi lters

We can increase the capacity of fi ltration with an option of G4 and

an option of G4+ F7, to arrive offering an average arrestance of

synthetic dust above 90% (according to EN779:2012).

DOUBLE SKIN PANEL

As an option, indoor unit of FLEXAIR, can be provided by a

double skin panel, to avoid the carrying of insulation particles

inside the building (25mm of thickness).

EC FANS VENTILATION SISTEM

FLEXAIR is fi tted with EC fans as standard, ensuring that no

belt particles can be carried away into building .This ventilation

system is compliant with EN 13977 air quality norm.

ANALOGUE FILTER DETECTION

Thanks to this sensor, the fi lter presence and the proper fan

operation is ensured by a pressure drop above the minimum

threshold, and at the same time the fi lter dirtyness is identifi ed

by a pressure drop above the maximum threshold.

REMOVABLE ALUMINIUM DRAIN PAN

All units are equipped with a sloped removable drain pan in

aluminum which can be removed for maintenance, preventing

the growth of bacteria an algae in the drain pan.

• 12 •

Application Guide / FLEXAIR-AGU-1505-E

Page 15

1- GENERAL DESCRIPTION

1.10- FRESH AIR AND FREE COOLING SYSTEM

Freecooling system is a standard feature for all Lennox rooftops,

with a two sections damper made in aluminum, and connected with

a proportional servomotor commanded by the control e-climatic

.

New buildings that comply with EPBD will have good thermal

insulation with high internal loads and will require cooling even

when outdoor temperatures are low.

Managing fresh air is mandatory in a building to control CO2

level and comfort.

Fresh air management and Free Cooling are standard features

of FLEXAIR that can reduce annual energy consumption.

SAVING ENERGY WITH FRESH AIR

& FREE COOLING

• Thermodynamic cooling can be replaced by Free Cooling

when outdoor temperature is below the building set point

saving up to 15% on annual energy consumption.

• Introducing just the required amount of Fresh Air in a building

can reduce energy consumption.

Because a fresh air damper curve is not linear, it is not accurate

to assume that the percentage of opening of the damper is equal

to the percentage of fresh air entering the building. However, this

linear control of a damper is by far the most used in the industry

With Indoor air quality and running cost of a building being more

important to our customer, FLEXAIR can manage the percentage

of fresh air more accurately.

100

90

80

70

60

50

40

30

20

10

Fresh air rate in % of supply airfl ow

Curve А : ΔP return ducts > Fresh air: Too much fresh air

Curve B : ΔP return ducts < Fresh air: Not enough fresh air

10 20 30 40 50 60 70 80 90 100

% Damper position

A

B

I

f the pressure drop in return air duct is high, the amount of fresh

air actually introduced in the building can be higher than required.

This extra fresh air will have to be cooled in summer and heated

in winter, increasing energy consumption of the system.

FLEXAIR will periodically recalibrates fresh air dampers to ensure

just the required amount of fresh air is introduced in the building.

This recalibration is achieved using the return air, outdoor air

and supply air sensors.

Application Guide /FLEXAIR-AGU-1505-E

• 13 •

Page 16

2- OPTIONS DESCRIPTION

2.1- AUXILIARY HEATING OPTIONS

HOT WATER COILS

A water coil made of copper pipe and

aluminum fi ns can be installed to answer

heating requirements. This water coil

can, for example, be connected to a

boiler or a heat pump. Two sizes of

water coils are proposed to cope with

the cooling and heating requirements.

The water coil is equipped with a 3-way

valve.

To check the different capacities of the water coils, please

refer to the section "Heating auxiliary performances" of this

application guide.

The hot water coil are protected from freezing by the Climatic,

through low enviroment protections based on low supply and

external temperatures, which activates safety procedures lcve

pump starts, valve opening or return air damper opening.

ELECTRIC HEATER

The auxiliary electric heater is made

of shielded resistance heaters, which

are smooth 6 W/cm2 resistances.

The heater is protected against high

temperature with a thermal overload

protection set at 90°C 150mm after the

heating elements.

For any rooftop unit size, two sizes of

electric heater are available as option, S (standard) and H (high).

F Box: 85 to 120 Kw

Standard heat : 30 kW, 2 stages

Medium heat : 54 kW, fully modulating (Triac)

High heat : 72 kW, fully modulating (Triac)

GAS BURNER

FLEXAIR FAM and FAG units are

fi tted with a gas burner. It is a safe and

reliable atmospheric gas burner made

of aluminized steel tube heat exchanger

designed to offer maximum heat transfer

and 92% effi ciency (PCI%).

It runs with natural gas 20 mbar and an

operating range of 13-26 mbar.

The standard gas module offers 2 stages

of control which helps in improving space comfort by avoiding

large supply air temperature deviations. Where more capacity

control is required a modulating version is available with high

heat burner models. With the modulating gas burner the airfl ow

rate in the burner is controlled as the gas fl ow is being reduced

maintaining the burner to its highest effi ciency level.

If required, an expansion device can be provided with the unit

allowing it to operate with gas pressures of up to 300 mbar.

Gas fi red rooftop cannot be installed inside a technical room.

F Box: 85 to 120 Kw

Standard heat (two stages): 60 kW

High heat (modulating): 120 kW

G Box: 150 and 170 kW

Standard heat (two stages): 120 kW

High heat (modulating): 180 kW

H Box: 200 and 230 kW

Standard heat (two stages) : 180 kW

High heat (modulating): 240 kW

G Box: 150 and 170 kW

Standard heat : 45 kW, 2 stages

Medium heat : 72 kW, fully modulating (Triac)

High heat : 108 kW, fully modulating (Triac)

H Box: 200 and 230 kW

Standard heat : 72 kW, 2 stages

Medium heat : 108 kW, fully modulating (Triac)

High heat : 162 kW, fully modulating (Triac)

• 14 •

Application Guide / FLEXAIR-AGU-1505-E

Page 17

2- OPTIONS DESCRIPTION

2.2- HEAT RECOVERY OPTIONS

FLEXAIR RECOVERY ON EXHAUST AIR (HEAT RECOVERY WHEEL)

To match Lennox commitment to a greener planet and to generate FLEXAIR savings FLEXAIR by Lennox can be equipped with one

system to recover FLEXAIR from the extraction air.

Ideal for climates in which the difference between the outdoor temperature and the extraction air temperature is high. This new hybrid

rotary wheel will generate very high sensible but also latent transfer.

Fresh air entry is protected with G4 fi lter.

2.3- FILTRATION OPTIONS

FLEXAIR offer several different levels of fi ltration that will allow

coping with every application and any level of fi ltration demanded

in the installation.

As standard the unit comes with EU3 fi lters

G4 fi lters, offered as standard can give an average arrestance of

synthetic dust above 90% (according to EN779:2012).

As an option, Lennox can offer :

- G4 50 mm metallic frame with replaceable media, for those

environments in which it is expected to change fi lters more

frequently than usual.

- G4 50 mm + F7 100 mm with 90% opacimetric effi ciency and

low pressure drop.

Application Guide /FLEXAIR-AGU-1505-E

• 15 •

Page 18

2- OPTIONS DESCRIPTION

2.4- ELECTRICAL OPTIONS

ENTHALPY CONTROL AND CO2 SENSOR

This option includes combined temperature and humidity

sensors, to ensure that the economizer does not use 100%

fresh air if the outside air has a higher enthalpy than the return

air.

The CO2 sensor A VOC (Volatile Organic Component) detects

the amount of CO2 in the ambient air between 0 and 2000PPM.

(This obviously varies depending upon space occupancy levels).

The VOC sensor sends a proportional signal (0-20mA) to the

controller which will modulate the fresh air.

This option is highly reccomended in commercial installations

like restaurants, shops, etc., where the CO2 level strongly varies

during the day (e.g. depending on the people occupancy). In these

installations in fact the energy savings coming form the correct

air-renewal air-fl ow management (depending on CO2 level) can

defi nitively pay back this sensor cost in a very short time.

ENERGY METER

The FLEXAIR meter option is a device that measures and

displays the following parameters:

3 PHASE CONTROL

This phase control device offers the guarantee of the correct

phase connection, together with an overvoltage and under

voltage protection.

FIRE DETECTOR

It is a thermostat that provides a signal to switch off the unit,

close the fresh air damper and open the return damper when

the temperature in the return air stream is above an adjustable

set point (Factory setting: 70°C).

SMOKE DETECTOR

Located downstream of the fi lter, the optical head of the smoke

detector can detect any type of smoke. When this occurs the

unit will stop operating, the return air damper will be fully closed

and the fresh air damper will fully open while sending an alarm

signal to the unit.

In accordance with the European norm, it is also compliant with

the French regulation on public buildings.

• Average, total and maximum current, voltage and frequency

for each phase.

• Active & reactive power.

• Power factor (Cosφ).

• Total active & reactive FLEXAIR consumption in Wh.

Values for FLEXAIR, current and absorbed power can be reset

with password.

Some of these data will be collected by the controller and made

available in the BMS tables for Modbus, BACnet and Trend

protocols (not available for LonWorks).

• 16 •

Application Guide / FLEXAIR-AGU-1505-E

Page 19

2- OPTIONS DESCRIPTION

2.5- CONTROL OPTIONS

DC™ COMFORT DISPLAY

This is a remote controller for

non-technical customer. It is

designed to fi t aesthetically

inside a room and be very easy

to use. It has a 24V supply to

be connected to the rooftop and

can be installed at maximum

30 meters away from the unit.

The graphical display gives

information such as running

mode of the unit, status of the

fan, set point, % of fresh air,

outside air temperature.

Customer can set the temperature set point for a given time

zone, switch the unit “On” or “Off” and adjust the clock. DC can

display fault codes with a reset possibility, ambient, supply and

outdoor temperature, fresh air damper position (%), time zone

and operating mode pictogram, heating or cooling status.

It is also able to display supply fan airfl ow rate (0-33-66-100%)

and component status for compressors, defrost, condenser fans

and auxiliary heaters.

DC™ comfort display is equipped with a temperature sensor

that can be used as room temperature sensor.

DM™ MULTI-ROOFTOP DISPLAY

COMMUNICATION INTERFACES AND

SUPERVISION:

The CLIMATIC ModBus interface is required to connect the unit

to a BMS using "ModBus protocol". No other hardware than this

board is required to have ModBus communication. One board

required per rooftop. The ModBus interface is available in two

versions to be connected with RS485 or TCP/IP depending on

site requirements.

This board is also mandatory for any connection between one

or several FLEXAIR units and Lennox ADALINK II, Lennox

OneWeb, Lennox Cloud service 3G or LennoxVision supervision

solutions. One BMS interface required per rooftop.

ADALINK II™

Adalink II™ is Lennox’s simplest solution for HVAC installation

supervision to better control the system and improve reliability

and energy effi ciency. One ADALINK II™ can control up to 32

Lennox units on the same site (Chillers, rooftop or any other

unit using controller and above). It displays a site picture with

the status of each unit and allows the user to change set points,

access alarm history and plot charts. It is the ideal tool to save

time and money on maintenance with an expert mode giving

access to all the parameters and set point of the unit.

• Easy local management of important settings

• Possibility to create macro commands to simplify setting and

better control the installation

• Easy scheduling by unit or by zone with a smart user friendly

drag and drop system

• Preventive maintenance to reduce downtime and improve

comfort and energy effi ciency at all time.

• Remote connection via LAN or 3G

• Site maintenance planning

This display gives access to more functionality than the DCTM

and allows managing up to 8 rooftops on a single Bus-wire.

Customer will be able to change the operating time zone and

mode. The rooftops can be connected to operate on a Master/

Slave principle. Installation up to 1000m from the unit.

DS™ SERVICE DISPLAY

This new plug and play service display and controller allows

service personal to set up to read and modify all unit parameters

(Unit settings, operating time and number of compressor starts,

low and high pressure reading, airfl ow rate of supply fan, and

read the history of last 32 faults...).

This controller has been designed to be very user friendly, with

6 different keys and graphic display. It includes scrolling menus

and full text (no codes) explanation. It is available in English or

another alternate language.

ADALINK II™ can also act as a real gateway to the unit, as it can

be used locally or via LAN network with ModBus TCP/IP protocol.

Any BMS can read and write information in the rooftops units using

ADALINK II™ network. Both systems can run at the same time.

Application Guide /FLEXAIR-AGU-1505-E

• 17 •

Page 20

2- OPTIONS DESCRIPTION

2.6- REFRIGERATION OPTIONS

Low Noise Option

As rooftops are often installed in a noise sensitive area, LENNOX

proposes a low noise option on FLEXAIR. To achieve low noise

level, FLEXAIR receives a quieter fan, a compressor jacket and

is fully equipped with acoustic isolation in the refrigerating box.

2.7- FRESH AIR OPTIONS

As managing fresh air is becoming mandatory in most buildings

economiser is now fi tted as standard with the FLEXAIR.

Advanced control pack

Where a higher level of controllability is required to make the

FLEXAIR even more fl exible, LENNOX have compiled a pack

that includes two advanced control features.

• "Enthalpy control on economiser".

The eCLIMATIC and its humidity sensors (return air and fresh

air) ensures that the economiser does not use 100% fresh

air if the outside air has a higher enthalpy than the return air.

This feature is relevant in regions where the relative humidity

is high or when the desired room air condition is very dry.

Anti corrosion protection

When the units are installed in potentially aggressive

environments, which can often be the case for example in coastal

environments, it is often a requirement that the coils are specially

treated to protect them against the corrosive effects.

LenGuard™ anti-corrosion treatment is available for condensers,

evaporators and hot water coil.

Indoor air quality sensor

Indoor air quality is controlled from the eCLIMATIC main

controller. A VOC (Volatile Organic Component) sensor detects

the amount of CO2 in the ambient air between 0 and 2000PPM.

(This obviously varies depending upon space occupancy levels).

The VOC sensor sends a proportional signal (0-20mA) to the

eCLIMATIC controller which will then modulate the fresh air.

• "Humidity control"

The eCLIMATIC and its humidity sensors, analyze dry and

wet bulb temperatures to control dehumidifi cation. Humidity

control is only available if ambient temperature is in cooling

or dead zone. The dehumidifi cation algorithm can dry the air

by passing it through the coil in cooling mode.

A specifi c function in the program can be activated to control

the minimum supply air temperature, by maintaining it equal

to the heating set point, using auxiliary heaters (Electric, Hot

water coil or gas burner).

A proportional 0-10V contact is also available to control an

external humidifi er.

• 18 •

Application Guide / FLEXAIR-AGU-1505-E

Page 21

2- OPTIONS DESCRIPTION

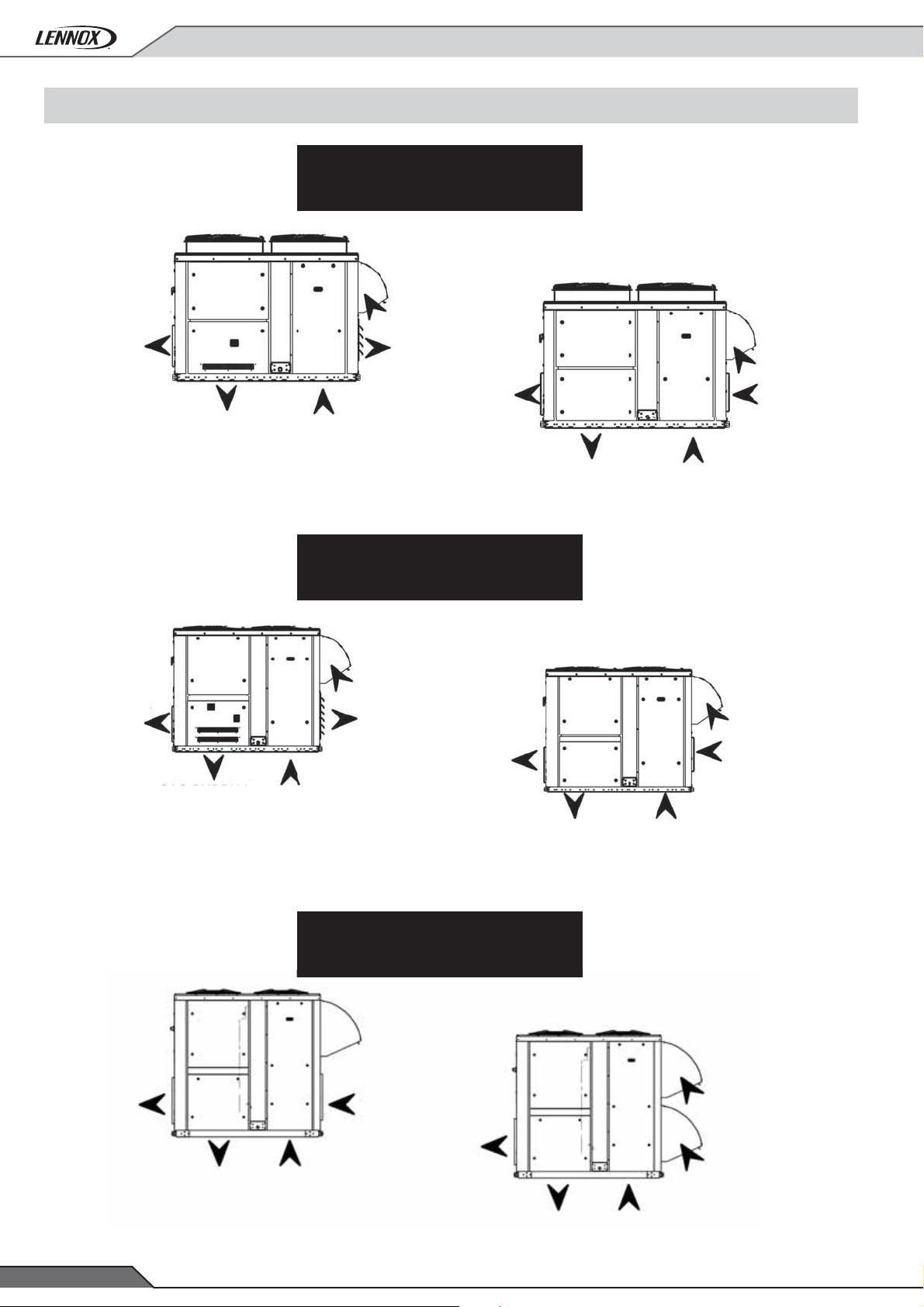

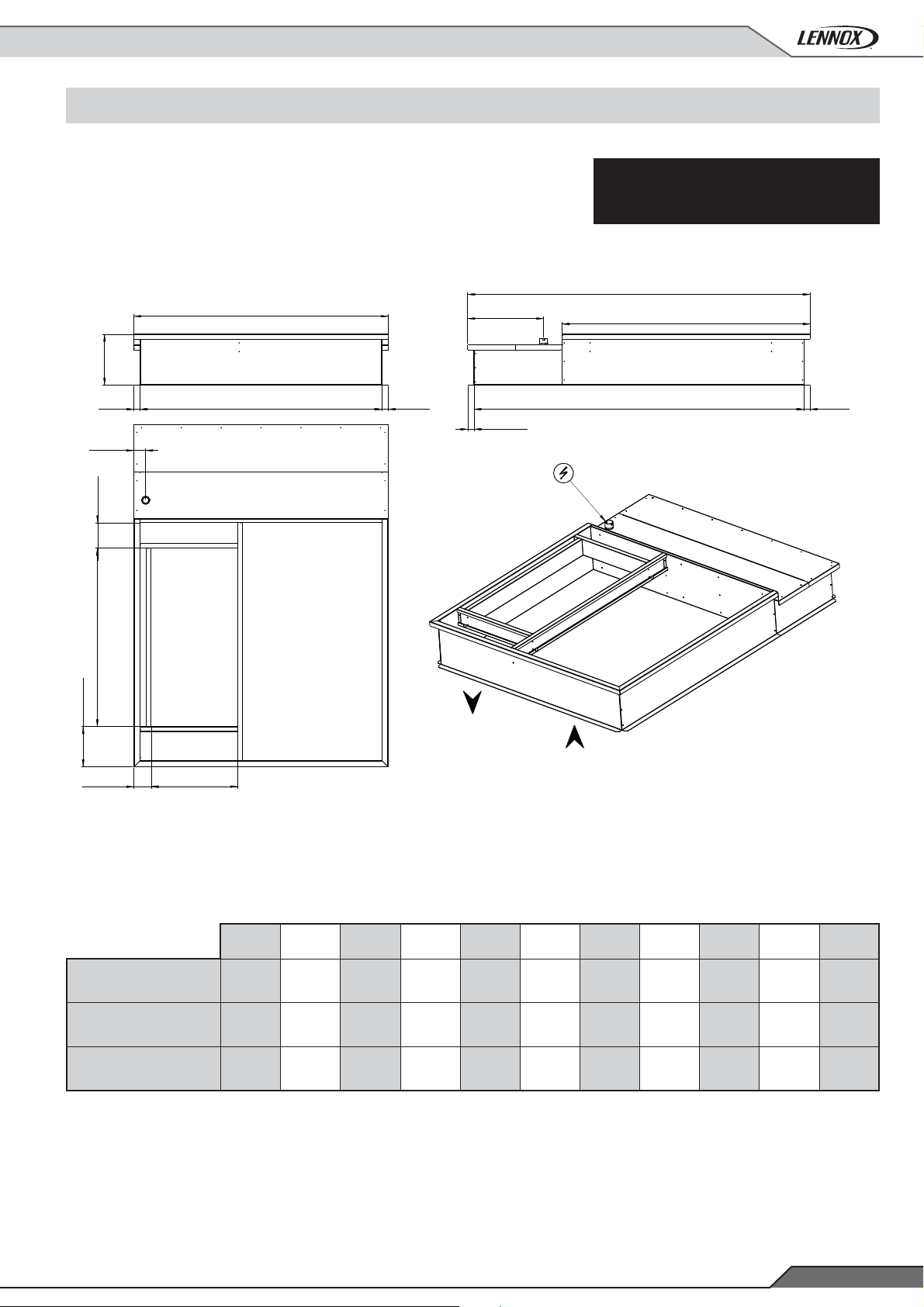

2.8- AIRFLOW CONFIGURATIONS AND ROOFCURBS

BASIC AIRFLOW CONFIGURATIONS

Standard

Unless specifi ed otherwise when ordered, FLEXAIR rooftops

are shipped with downfl ow supply and return confi guration.

Units can be confi gured before shipment with the required

airfl ow confi gurations to suit the building needs.

AIR SOCK CONTROL

A standard feature in FLEXAIR, EC fan regulation allow the air

socks to be progressively fi lled with air on start up. It takes one

minute to go from 0% of air to Nominal airfl ow rate

ROOFCURBS

Non adjustable non assembled roofcurb.

A sturdy mounting frame designed for single package units

providing an automatic weatherproof sealed rooftop installation.

This roofcurb is shipped knocked down and must be assembled

on site.

Adjustable roofcurb.

This adjustable and assembled roofcurb is made of galvanized

steel with 2.5 mm. This adjustable roofcurb is designed to be

installed in roofs with slopes up to 4 to 5% in all directions,

enabling FLEXAIR to be compatible with most roof profi les.

Downfl ow roofcurbs are the easiest and the cheapest way to install

packaged air conditioning systems to a single volume building.

The frame can be secured directly to the roof structure thanks

to its built in adjustable fl anges and sealing liner returns

Multidirectional roofcurb

This option is a required when customer wants to have horizontal

return and horizontal supply on the same side.

It is also required with the power exhaust fan or gravity exhaust

damper options combined with horizontal return fl ow confi guration.

5%

Rooftop

Roofcurb

Thermal insulation

5%

50

Sealing

400 mm minimum

Application Guide /FLEXAIR-AGU-1505-E

• 19 •

Page 22

2- OPTIONS DESCRIPTION

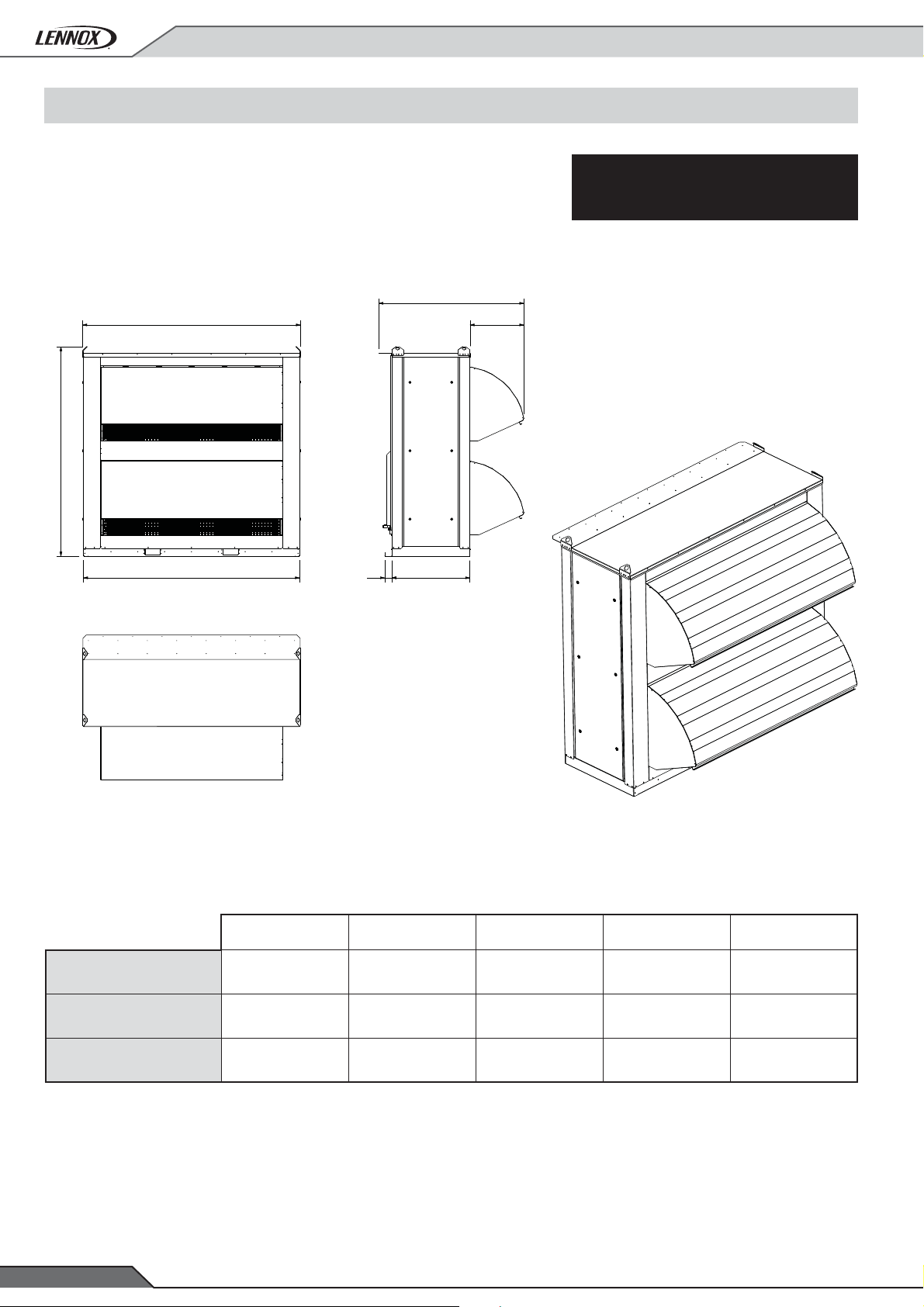

2.9- EXTRACTION OPTIONS

UNIT WITH NO EXHAUST AIR OPTION

1 → 2 : ESP (external static pressure) given in eLencal (LENNOX

units selection tool) corresponds to the static pressure between

inlet and outlet of the unit and includes all options and accessories

delivered with the unit with the exception of the ductwork. This

external static pressure will be used to push the air through the

supply and the return ductwork installed on site.

ESP =

Supply duct pressure drop + return duct pressure drop

Example :

With an eLencal ESP = 350 Pa and a return ductwork pressure

drop of 150 Pa ▬► Remaining available static pressure for the

supply ductwork = 200 Pa

In any case, on a basic unit, the return ductwork pressure drop

should be lower than 150 Pa.

The airfl ow is usually set during start up for a given fresh air

rate. During normal operation the fresh air ratio will change and

eventually the unit will go to full fresh air during free cooling

operation. If the pressure drop in the return ductwork is high,

the fan may trip on over current protection when it operates with

full fresh air where the pressure drop is much lower.

If the return ductwork pressure drop is higher than 150 Pa :

• Select an extraction roofcurb which will include an extraction

fan and the appropriate drive kit for the given airfl ow and

pressure drop.

• FLEXAIR with eDRIVE includes constant airfl ow operation

that can control and limit the airfl ow as the pressure drop

reduces.

Building air tightness Low air tightness

Fresh air & Free cooling

Pressure drop in the

return ductwork

Medium fresh air rate

Free cooling possible

Medium < 150 Pa

2

1

GRAVITY EXHAUST DAMPER

1 → 2: ESP “Supply” in eLencal

Gravity exhaust dampers are used to relief pressure when outside

air is being introduced in a building with good air tightness.

Building air tightness Medium

Fresh air & Free cooling

Pressure drop in the

return ductwork

Building pressure control Low control

Typical applications Warehouses

High fresh air rate

Free cooling

Low < 50 Pa

Building pressure control NO control

Typical applications

• 20 •

Existing hypermarkets and supermarkets

(old buildings with high leakage rates)

2

Application Guide / FLEXAIR-AGU-1505-E

1

Page 23

2- OPTIONS DESCRIPTION

POWER EXHAUST FAN

1 → 2: ESP “Supply” in eLencal.

Power exhaust axial fans with gravity exhaust dampers provide

exhaust air pressure relief when high levels of outside air are

being introduced in the building with good air tightness.

It is interlocked to run when return air dampers are being closed

and supply air blower is in operation. The power exhaust fan runs

when outdoor air dampers are at least 50% open (adjustable

by set point). It is also overload protected. A gravity exhaust

damper is supplied with this option to prevent air from entering

the unit when fan is off.

Building air tightness Medium

Fresh air & Free cooling

Pressure drop in the

return ductwork

Building pressure control Low control

High fresh air rate

Free cooling

Medium 50 Pa to 150 Pa

EXTRACTION ROOFCURB

1 → 3: ESP Return in eLencal

3 → 2: ESP Supply in eLencal

Where system balancing is critical and return ductwork pressure

drop is high, it is recommended to use extraction fan such as

the one located in the extraction roofcurb.

A plug fan installed with a 3rd damper (1 inside the Roofcurb

+ 2 inside the rooftop), is able to extract up to 300 Pa with the

Nominal airfl ow rate of the unit. This roof curb can be used in

either horizontal or downfl ow applications.

Building air tightness High

Fresh air & Free cooling

Pressure drop in the

return ductwork

Building pressure control Pressure balance possible

High fresh air rate

Free cooling

High > 150 Pa

Typical applications Light commercial, petrol stations...

2

1

Typical applications

Theatres, cinemas, data centres, new air

tight buildings with long return ductworks

Application Guide /FLEXAIR-AGU-1505-E

21

• 21 •

Page 24

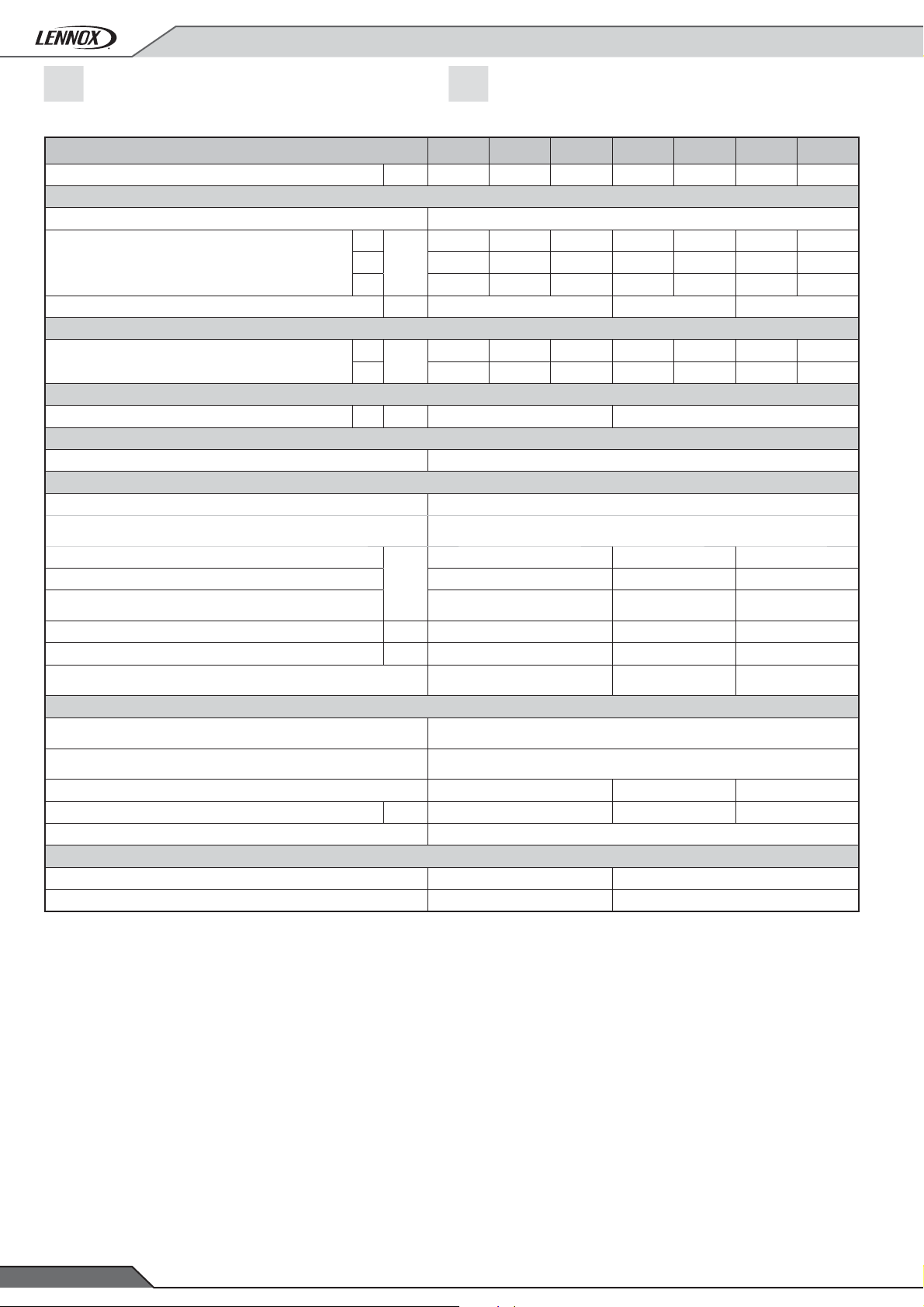

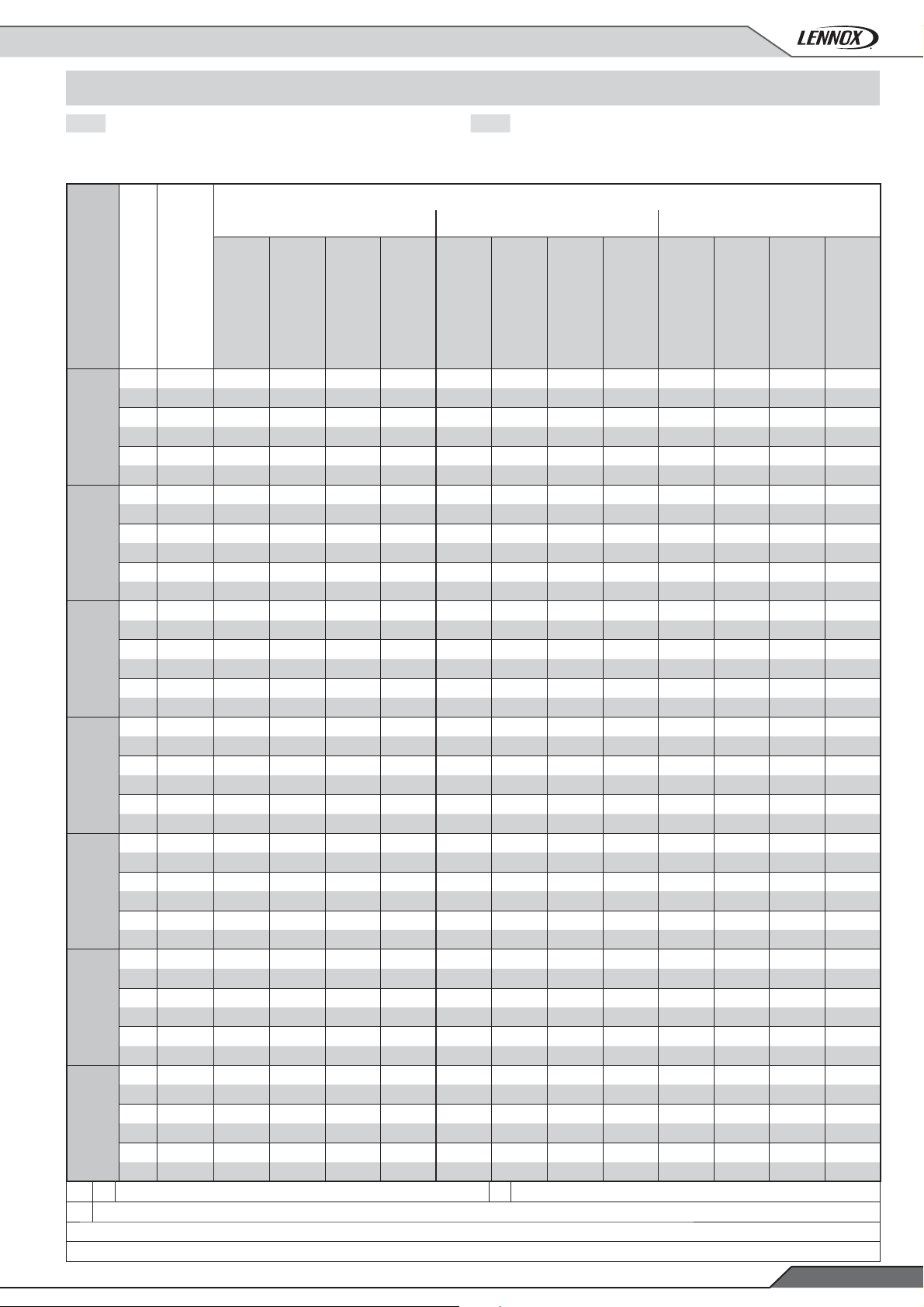

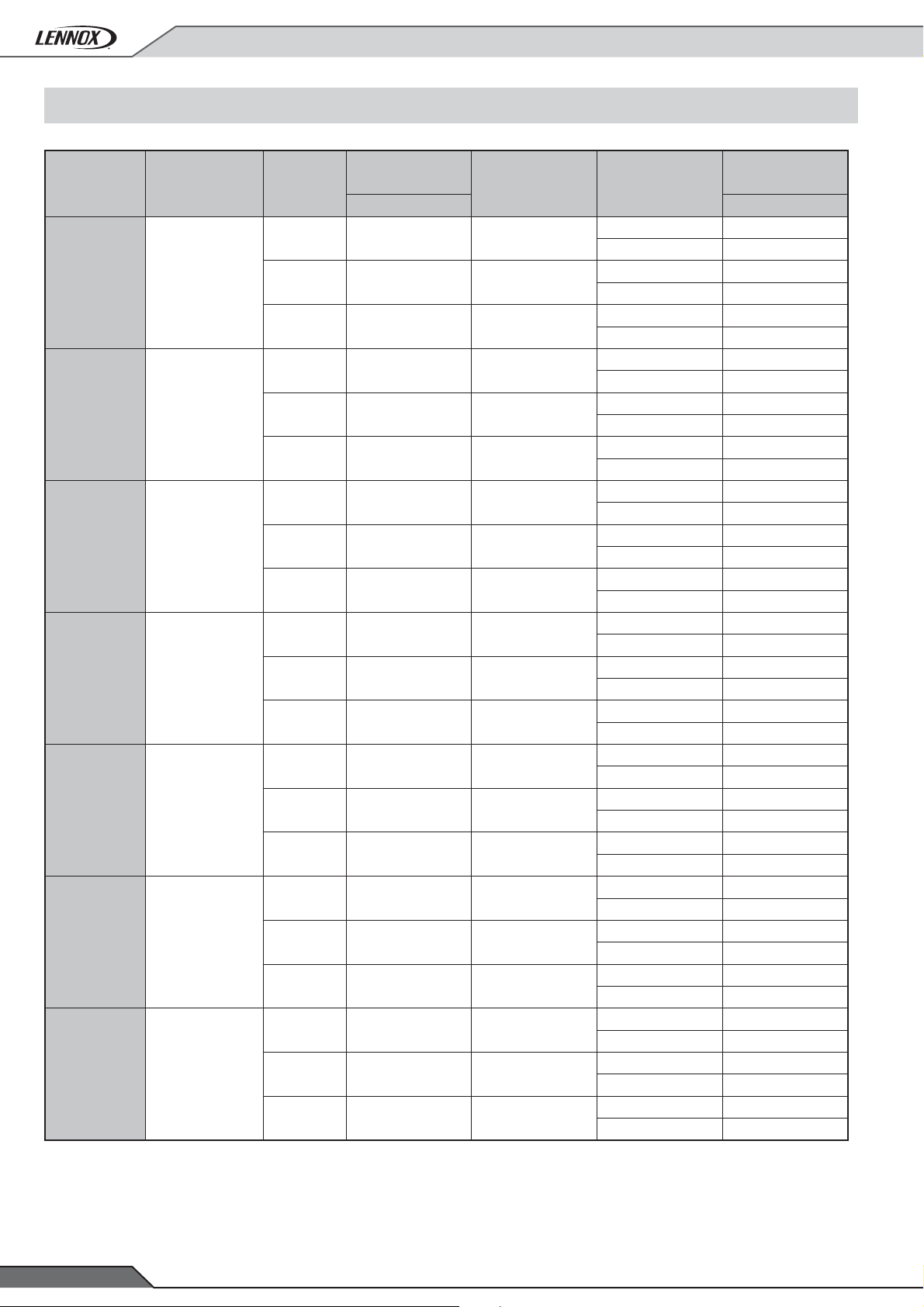

3- GENERAL DATA

FAC FAH

Cooling only Heat pump

FAG FAM

Cooling only with gas fi red heating Heat pump rooftop with gas fi red heating

FLEXAIR 085 100 120

Casing F BOX

3

Nominal airfl ow rate m

Cooling mode (FAC - FAG)

Gross cooling capacity

(1)

Compressor gross power input

Indoor fan absorbed power

Full load amps

(1)

FAC 2,71 4,08 5,28

FAG 3,26 5,14 6,65

Direct start up amps ratio Id/Ia

Gross EER

Global net EER

(2)

(3)

Cooling mode (FAH - FAM)

Gross cooling capacity

(1)

Compressor gross power input

Indoor fan absorbed power

Gross EER

Global net EER

(2)

(3)

FAH 2,71 4,08 5,28

FAM 3,26 5,14 6,65

Heating mode (FAH - FAM)

Net heating capacity

FAH 78,4 94,7 109,0

Compressor gross power input

Indoor fan absorbed power

Gross COP

Global net COP

(2)

(3)

FAH 2,71 4,08 5,28

FAM 3,26 5,14 6,65

Heating - Gas fi red

(4)

Heating capacity kW

Power input kW

S

(4)

H

(4)

S

(4)

H

Thermal effi ciency %

(4)

Gas fl ow (for natural gas at 20 mbar and 15 °C) m

S

(4)

H

Refrigeration circuit

Number of circuits

Compressor type and number

Expansion valve number

Refrigerant charge per circuit 1/2 kg

FAC-FAG

FAH-FAM

Ventilation data

Nominal airfl ow rate

Maximum airfl ow rate

External static pressure / Maximum

(1) All data are at Eurovent conditions (400V/3Ph/50Hz at nominal airfl ow rate),

nominal external static pressure.

Cooling :

• Outdoor temperature = 35°C DB

• Entering coil temperature 27°C DB / 19°C WB

Heating :

• Outdoor temperature = 7°C DB / 6°C WB

• Indoor temperature = 20°C DB

(5)

/h

15000 18500 20500

86,0 101,3 119,3

kW

A

20,1 27,1 31,4

67,5 75,5 103,2

209,3 252,3 293,9

FAC 3,56 3,30 3,29

FAC 3,24 2,92 2,85

FAG 3,15 2,80 2,73

85,0 100,0 117,5

kW

20,6 27,1 31,3

FAH 3,52 3,26 3,24

FAH 3,20 2,88 2,81

FAM 3,11 2,76 2,69

kW

18,3 22,9 28,6

FAH 3,60 3,58 3,26

FAH 3,39 3,32 3,01

FAM 3,34 3,24 2,94

55,2

110,4

60

120

92

3

/h

6,3

12,5

1 scroll + 1 scroll

2

9 / 9 9,1 / 9,1 9,1 / 9,1

9,1 / 9,1 9,2 / 9,2 9,2 / 9,2

15000 18500 20500

3

m

/hMinimum airfl ow rate

12000 14000 15000

23000 23000 23000

Pa

(2) Including compressor + outdoor axial fan + indoor centrifugal fan

(3) Net COP = Net cooling capacity/Total absorbed power

(4) S = Standard heat / H = High heat

(5) At nominal airfl ow rate

150 / 800 150 / 800 150 / 800

• 22 •

Application Guide / FLEXAIR-AGU-1505-E

Page 25

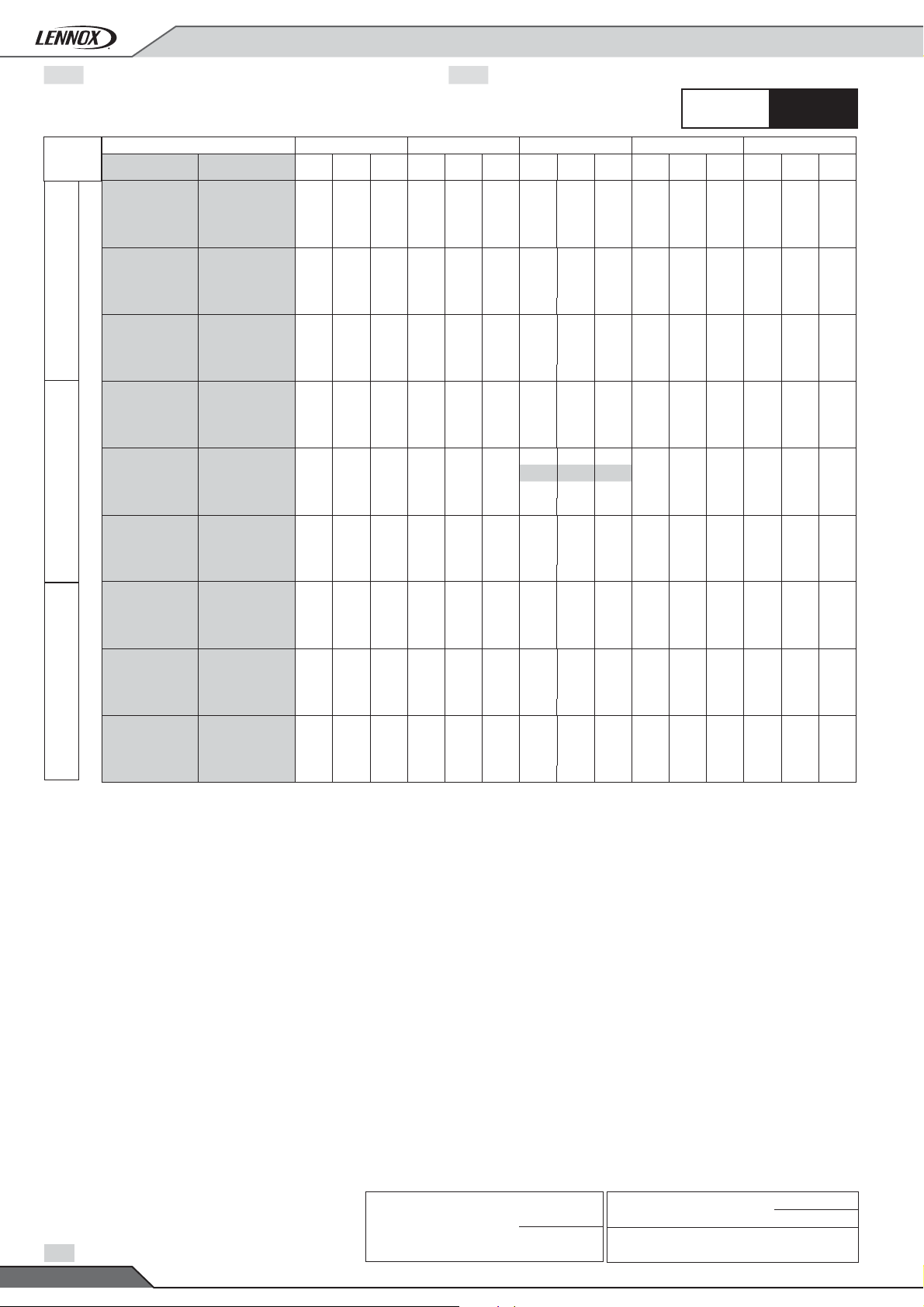

3.- GENERAL DATA

FAC FAH

Cooling only Heat pump

FAG FAM

Cooling only with gas fi red heating Heat pump rooftop with gas fi red heating

FLEXAIR 085 100 120

Indoor fan (FAG - FAM)

Nominal airfl ow rate

3

m

Maximum airfl ow rate

External static pressure / maximum Pa

Fan number

Outdoor fan (axial fan)

Number

Nominal airfl ow rate m

3

Motor power kW

Filter (standard)

Effi ciency / Filter class

Number of fi lters

Filter size

mm

Acoustic data (150 Pa)

Outdoor sound power

Standard unit

Outdoor sound power

Low noise unit

(1)

(1)

dB(A)

Indoor blower outlet sound power

/hMinimum airfl ow rate

/h

15000 18500 20500

12000 14000 15000

23000

150 / 800

2

2

35150 35150 44000

3,12 3,12 4,5

80-85% / G3

8

625 x 500 x 50

80,2 81,7 88,7

78,1 78,1 85,3

86,3 80,7 84,6

Operating limits - Cooling mode

Maxi. outdoor temperature

Indoor 27 °C DB / 19°C WB

(2)

Maxi. outdoor temperature with unloading

Mini. outdoor temperature

Indoor 20°C DB

(3)

Maxi. outdoor temperature

DB/WB with 100% fresh air

°C

48

50

10

38

Operating limits - Heating mode

Mini. outdoor temperature

Indoor 20 °C DB

(2)

Mini. entering indoor coil temperature

Outdoor 7°C DB

°CMini. outdoor temperature with unloading

-15

-15

7

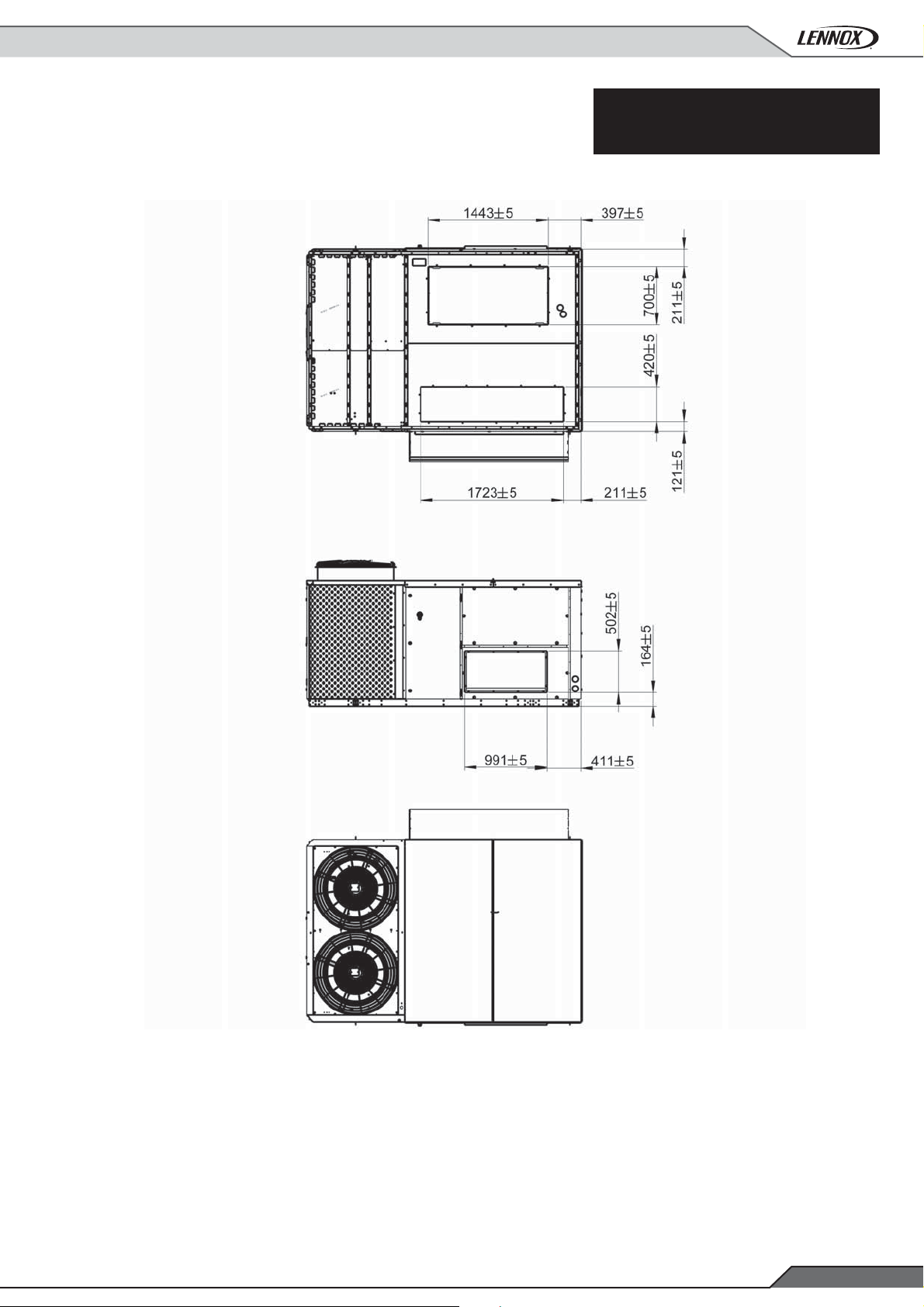

Construction

Casing material Aluminium

Painting Polyester / RAL 9003

Insulation class

A2-s1-d0 / M0

Dimensions

Length

Height

Width with/without fresh air hood

Weight

Standard unit (FAC)

Weight

Gas unit (FAG-H)

(5)

mm

(4)

966 1055 1054

kg

1083 1187 1178

3348

1750

2290 / 2657

(1) All data are at Eurovent conditions (400V/3Ph/50Hz at nominal airfl ow rate),

nominal external static pressure.

Cooling :

• Outdoor temperature = 35°C DB

• Entering coil temperature 27°C DB / 19°C WB

Heating :

• Outdoor temperature = 7°C DB / 6°C WB

• Indoor temperature = 20°C DB

Application Guide /FLEXAIR-AGU-1505-E

(2) Cooling and heating operating limits are given for steady operation with

specifi c temperature conditions.

(3) Below this value, "Low ambient kit" option is required

(4) Down return air and down supply air confi gurations

(5) S = Standard heat / H = High heat

• 23 •

Page 26

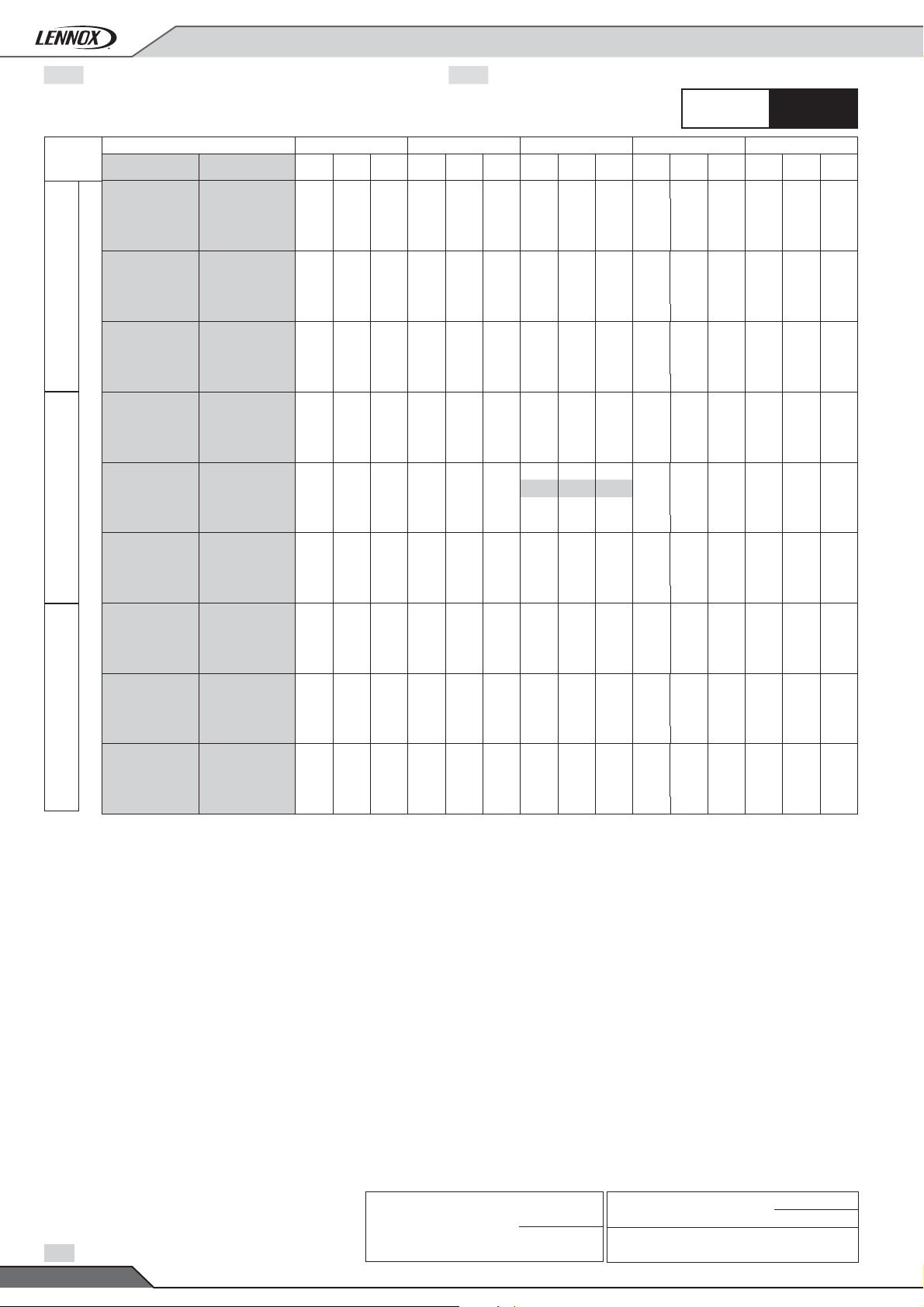

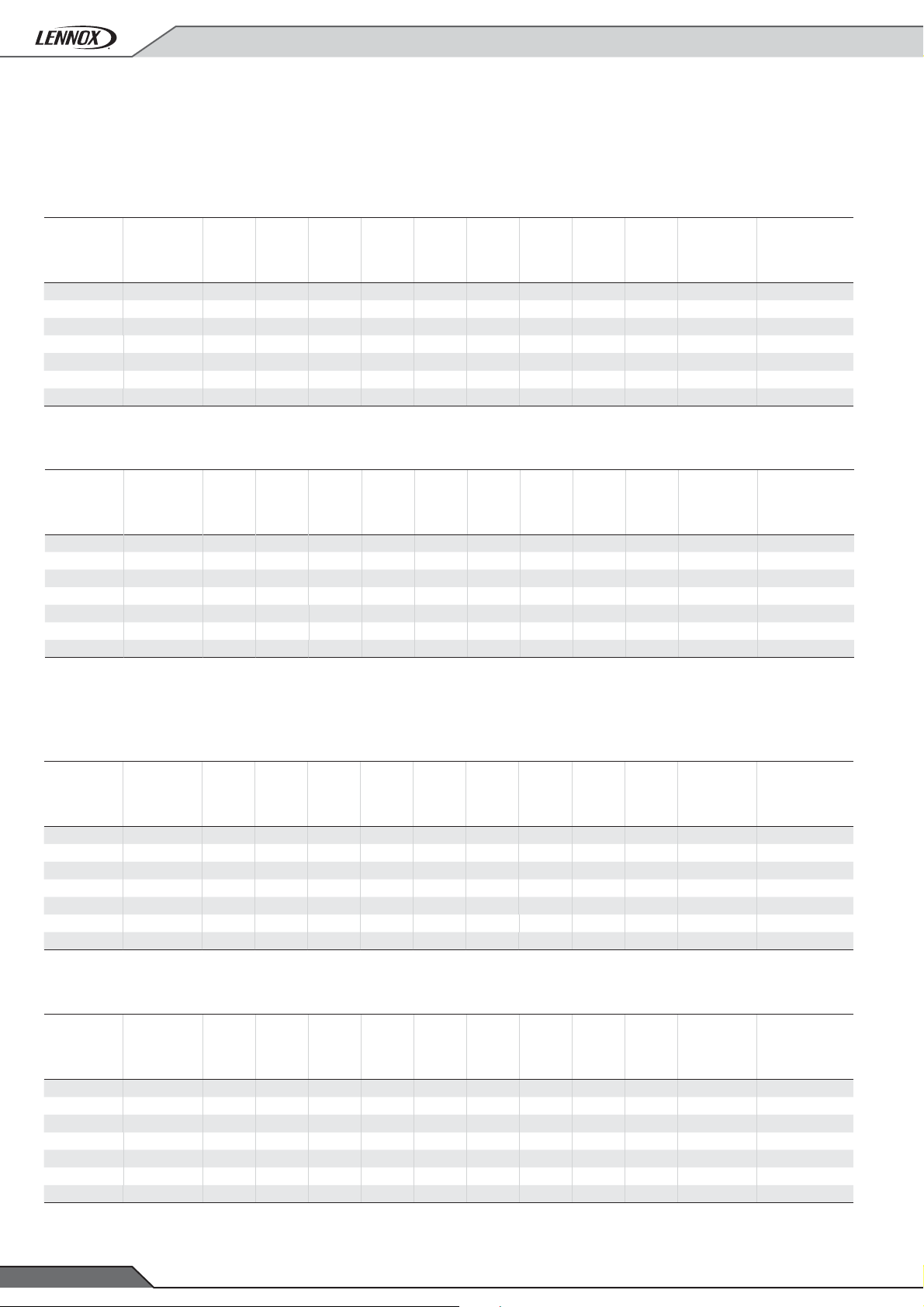

3- GENERAL DATA

FAC FAH

Cooling only Heat pump

FAG FAM

Cooling only with gas fi red heating Heat pump rooftop with gas fi red heating

FLEXAIR™ 150 170 200 230

Casing G BOX H BOX

Nominal airfl ow rate m

Cooling mode (FAC - FAG)

Gross cooling capacity

(1)

Compressor gross power input

Indoor fan absorbed power

Full load amps

(1)

FAC 5,60 8,20 8,74 10,81

FAG 6,76 10,00 10,24 12,95

Direct start up amps ratio Id/Ia

Gross EER

Global net EER

(2)

(3)

Cooling mode (FAH - FAM)

Gross cooling capacity

(1)

Compressor gross power input

Indoor fan absorbed power

Gross EER

Global net EER

(2)

(3)

FAH 5,60 8,20 8,74 10,81

FAM 6,76 10,00 10,24 12,95

Heating mode (FAH - FAM)

Net heating capacity

Compressor gross power input

Indoor fan absorbed power

Gross COP

Global net COP

(2)

(3)

FAH

FAH 5,60 8,20 8,74 10,81

FAM 6,76 10,00 10,24 12,95

Heating - Gas fi red

Heating capacity kW

Power input kW

S

H

S

H

Thermal effi ciency %

Gas fl ow (for natural gas at 20 mbar and 15 °C) m

S

H

Refrigeration circuit

3

/h

28000 30000 35000 39000

147,2 164,6 190,8 230,7

kW

A

44,5 49,5 51,4 61,5

109,8 137,4 155,5 194,5

296,1 283,6 341,4 398,6

FAC 3,08 3,04 3,29 3,26

FAC 2,77 2,65 2,89 2,84

FAG 2,69 2,54 2,80 2,73

141,9 161,8 188,1 227,9

kW

44,3 49,4 51,4 61,5

FAH 2,98 3,00 3,24 3,22

FAH 2,68 2,61 2,85 2,80

FAM 2,60 2,50 2,76 2,70

133,7 155,5 185,2 223,8

kW

33,5 38,6 43,1 57,9

FAH 3,63 3,60 3,73 3,33

FAH 3,38 3,29 3,43 3,09

FAM 3,31 3,21 3,37 3,03

(4)

(4)

(4)

(4)

110,4 110,4 165,6 165,6

165,6 165,6 220,8 220,8

120 120 180 180

180 180 240 240

92 92 92 92

(4)

3

(4)

/h

12,5 12,5 18,8 18,8

18,8 18,8 25 25

Number of circuits

Compressor type and number

Expansion valve number

Refrigerant charge per circuit kg

FAC-FAG

FAH-FAM

Ventilation data

Nominal airfl ow rate

m

Maximum airfl ow rate

External static pressure / Maximum

(1) All data are at Eurovent conditions (400V/3Ph/50Hz at nominal airfl ow rate),

nominal external static pressure.

Cooling :

• Outdoor temperature = 35°C DB

• Entering coil temperature 27°C DB / 19°C WB

Heating :

• Outdoor temperature = 7°C DB / 6°C WB

• Indoor temperature = 20°C DB

(5)

• 24 •

1 scroll +

2 scroll

2 scroll + 2 scroll

2

14,7 / 14,2 14,7 / 14,3 18,5 / 18,5 19,8 / 19,8

15 / 14,5 15,1 / 14,5 18,5 / 18,5 19,8 / 19,8

28000 30000 35000 39000

3

18000 21000 24000 27000

/hMinimum airfl ow rate

35000 35000 43000 43000

Pa

(2) Including compressor + outdoor axial fan + indoor centrifugal fan

(3) Net COP = Net cooling capacity/Total absorbed power

(4) S = Standard heat / H = High heat

(5) At nominal airfl ow rate

150 / 800

Application Guide / FLEXAIR-AGU-1505-E

Page 27

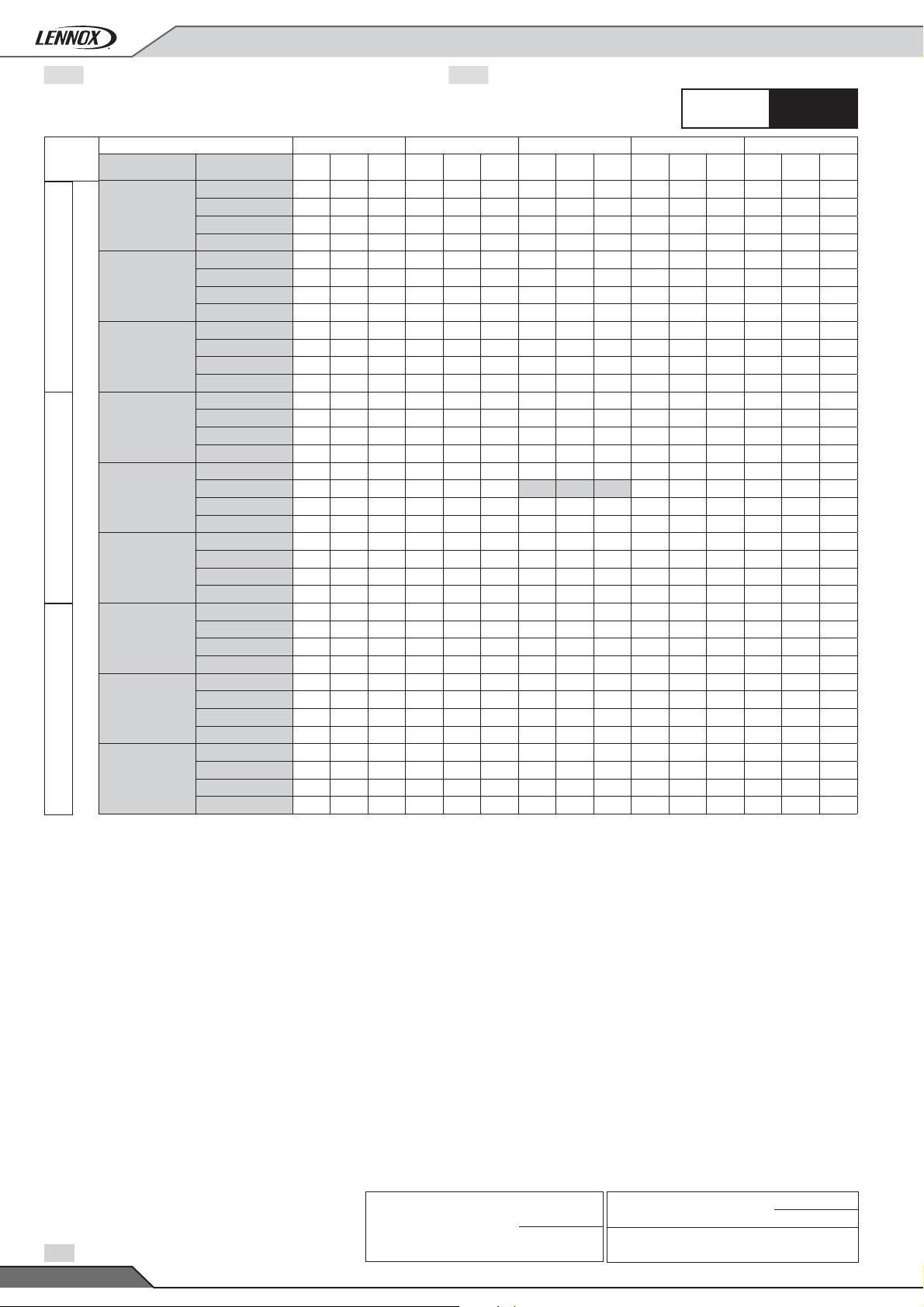

3- GENERAL DATA

FAC FAH

Cooling only Heat pump

FAG FAM

Cooling only with gas fi red heating Heat pump rooftop with gas fi red heating

FLEXAIR™ 150 170 200 230

Indoor fan

Nominal airfl ow rate

Minimum airfl ow rate m

3

Maximum airfl ow rate

External static pressure / maximum

Pa 150 / 800

Fan number

Outdoor fan (axial fan)

Number

Nominal airfl ow rate m

3

Motor power kW

Filter (standard)

Effi ciency / Filter class

Number of fi lters

Filter size

mm

Acoustic data (150 Pa)

Outdoor sound power

Standard unit

Outdoor sound power

Low noise unit

(1)

(1)

dB(A)

Indoor blower outlet sound power

/h

/h

28000 30000 35000 39000

18000 21000 24000 27000

35000 35000 43000 43000

3

2244

38950 49400 69350 88000

2,96 4,16 6,24 8,96

80-85% / G3

12 12 10 + 5 10 + 5

625 x 500 x 50 500 x 500 + 800 x 500

87,3 91,6 85,0 89,1

84,9 88,6 82,2 88,6

92,8 83,8 92,5 96,5

Operating limits - Cooling mode

Maxi. outdoor temperature

Indoor 27 °C DB / 19°C WB

(2)

Maxi. outdoor temperature with unloading

Mini. outdoor temperature

Indoor 20°C DB

(3)

Maxi. outdoor temperature

DB/WB with 100% fresh air

°C

46 46 48 48

45

10

38

Operating limits - Heating mode

Mini. outdoor temperature

Indoor 20 °C DB

(2)

Mini. entering indoor coil temperature

Outdoor 7°C DB

°CMini. outdoor temperature with unloading

-15

-15

7

Construction

Casing material Aluminium

Painting Polyester / RAL 9003

Insulation class

A2-s1-d0 / M0

Dimensions

Length

Height

Width with/without fresh air hood

Weight

Standard unit (FAC)

Weight

Gas unit (FAG-H)

(5)

mm

(4)

kg

4385 4385 5230 5230

1885 1885 2235 2235

2290 / 2753

1454 1550 2027 2143

1599 1704 2297 2411

(1) All data are at Eurovent conditions (400V/3Ph/50Hz at nominal airfl ow rate),

nominal external static pressure.

Cooling :

• Outdoor temperature = 35°C DB

• Entering coil temperature 27°C DB / 19°C WB

Heating :

• Outdoor temperature = 7°C DB / 6°C WB

• Indoor temperature = 20°C DB

Application Guide /FLEXAIR-AGU-1505-E

(2) Cooling and heating operating limits are given for steady operation with

specifi c temperature conditions.

(3) Below this value, "Low ambient kit" option is required

(4) Down return air and down supply air confi gurations

(5) S = Standard heat / H = High heat

• 25 •

Page 28

4- OPTIONS DATA

FAC FAH

Cooling only Heat pump

FAG FAM

Cooling only with gas fi red heating Heat pump rooftop with gas fi red heating

FLEXAIR

Nominal airfl ow rate m3/h

085 100 120 150 170 200 230

15000 18500 20500 28000 30000 35000 39000

Heating - electric

Type of modulation m

S

Available heating capacity kW

M

H

Amps S / M / H

3

/h Staged on S / Triac on M & H

(2)

(2)

(2)

30 30 30 45 45 72 72

54 54 54 72 72 108 108

72 72 72 108 108 162 162

42/75/99 42/75/99 99/149/196

Heating - hot water coil

Available heating capacity

(2)

(1)

S

(2)

H

114 126 133 145 156 177 186

kW

177 201 212 254 275 295 313

Gas modulating

Modulation range

(2)

H

% 40-100 20-100

Axial exhaust fan

Number of fans

3

Heat recovery module

Type of exchanger Wheel exchanger

Protection against frosting on exhaust air Air differential pressure switch 20 to 300 Pa

Lenght

Height

mm

Width with/without fresh air hood

Weight kg

Wheel diameter mm

Number of fi lters

Fresh air / Return air

2146 2330 2516

1796 2170 2418

1422 / 1055 1518 / 1055 1676 / 623

525 635 730

1500 1800 2050

3 / 3 8 / 8 10 / 10

Filter G4 and G4+F7

Effi ciency (gravimetric) / class EN779 / Eurovent G4

90% / G4 / EU4

Effi ciency (opacimetric) / class EN779 / Eurovent F7

Number of fi lters

Filter size mm

8 12 10 + 5

625 x 500 x 50 625 x 500 x 50 500x500 + 800x500

Fire class

Power exhaust fan (axial fan)

Number of fans

Diameter

(1) Conditions : entering water temperature 90°C, leaving water temperature 70°C, entering air temperature 20°C,

S = standart heat, H = high heat

(2) not available with FAG and FAM versions

33

450 560

85% / F7 / EU7

M1

• 26 •

Application Guide / FLEXAIR-AGU-1505-E

Page 29

5- STANDARD UNITS PERFORMANCES

5.1- UNIT PERFORMANCES

FAC FAH

Cooling only Heat pump

COOLING CAPACITY AND ABSORBED POWER

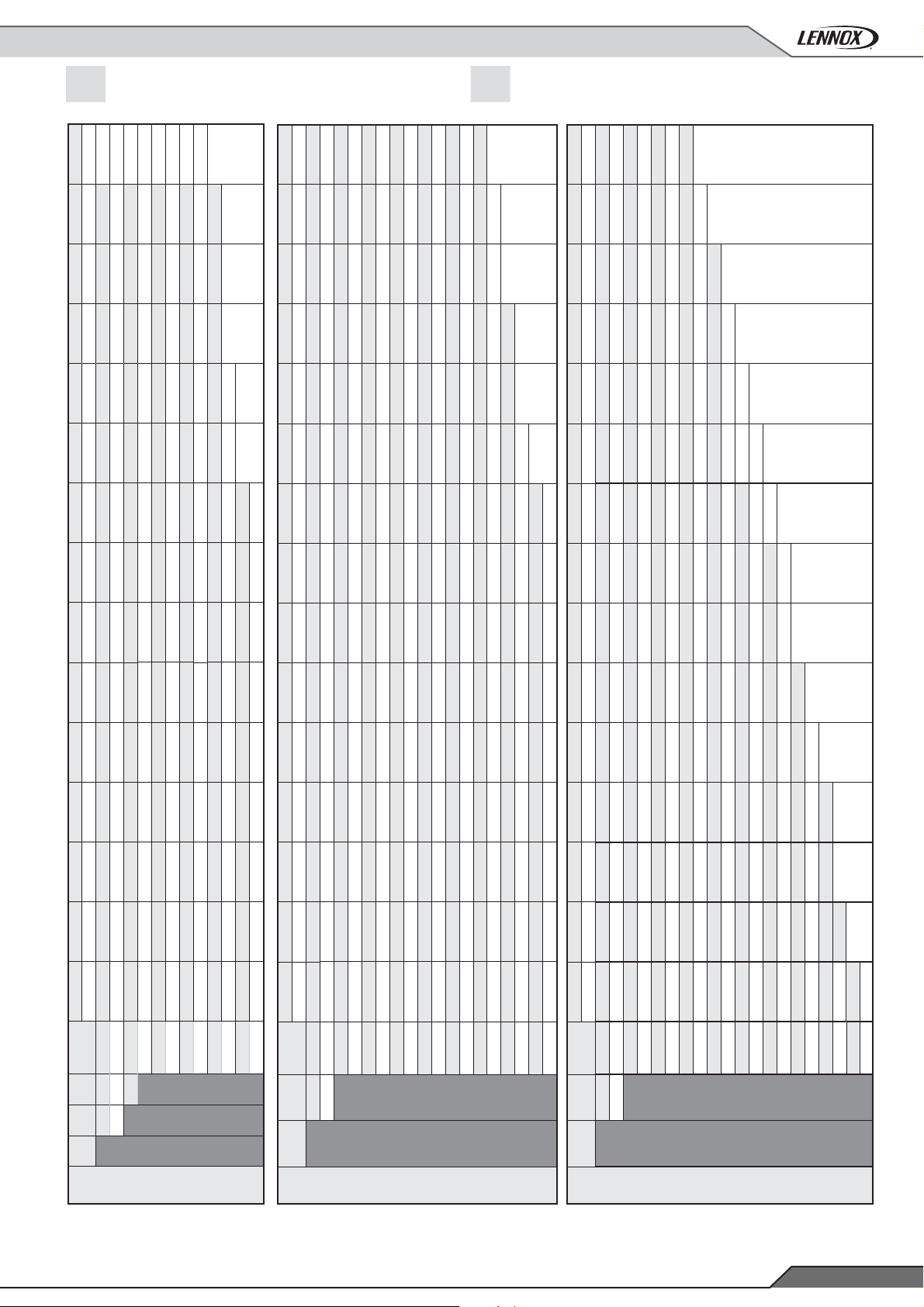

FAH

Wet bulb Dry bulb

/h

3

12 000 m

Minimum airfl ow rate

/h

3

15 000 m

Nominal airfl ow rate

Entering air temperature

/h

3

23 000 m

Maximum airfl ow rate

Outdoor air temperature

16°C

19°C

22°C

16°C

19°C

22°C

16°C

19°C

22°C

21°C

24°C 81,3 65,2 17,0 78,1 63,7 18,7 74,5 62,0 20,7 70,4 60,1 22,9 65,9 58,0 25,3

27°C 82,2 77,0 17,0 79,0 75,6 18,8 75,4 74,0 20,7 71,4 71,3 23,0 67,4 67,4 25,5

30°C 85,1 85,1 17,1 82,4 82,4 18,9 79,2 79,2 21,0 75,5 75,5 23,2 71,4 71,4 25,8

24°C 88,1 52,6 17,4 84,6 50,9 19,1 80,6 49,2 21,1 76,1 47,4 23,2 71,2 45,6 25,7

27°C 88,8 64,9 17,4 85,3 63,3 19,1 81,3 61,6 21,1 76,8 59,7 23,3 71,8 57,7 25,8

30°C 89,7 76,7 17,5 86,2 75,3 19,2 82,2 73,6 21,2 77,7 71,8 23,4 72,7 69,5 25,8

33°C 90,8 88,1 17,5 87,3 86,9 19,3 83,9 83,9 21,3 80,1 80,1 23,5 75,7 75,7 26,1

27°C 96,1 52,2 17,8 92,1 50,3 19,6 87,7 48,5 21,5 82,8 46,8 23,7 77,5 45,1 26,3

30°C 96,7 64,4 17,9 92,8 62,7 19,6 88,4 61,0 21,6 83,5 59,2 23,8 78,2 57,3 26,3

33°C 97,6 76,1 17,9 93,7 74,6 19,7 89,3 73,0 21,6 84,4 71,2 23,9 79,1 69,2 26,4

36°C 98,7 87,3 18,0 94,8 86,1 19,7 90,4 84,7 21,7 85,5 82,9 23,9 80,2 80,2 26,5

21°C

24°C 85,2 73,2 17,2 81,8 71,6 19,0 78,0 69,9 20,9 73,6 67,8 23,1 68,9 65,5 25,5

27°C 86,4 86,4 17,3 83,5 83,5 19,1 80,1 80,1 21,1 76,3 76,3 23,3 72,1 72,1 25,8

30°C 91,4 91,4 17,6 88,3 88,3 19,4 84,8 84,8 21,4 80,9 80,9 23,6 76,4 76,4 26,1

24°C 92,0 58,1 17,6 88,2 56,4 19,3 83,9 54,7 21,3 79,2 52,9 23,4 74,0 51,0 25,9

27°C 92,9 72,9 17,7 89,1 71,2 19,4 84,8 69,5 21,3 80,1 67,5 23,5 74,9 65,3 26,0

30°C 94,0 87,4 17,7 90,2 85,8 19,5 85,9 84,0 21,4 81,1 81,1 23,6 76,6 76,6 26,1

33°C 96,8 96,9 17,9 93,6 93,6 19,7 89,8 89,8 21,7 85,6 85,6 23,9 80,9 81,0 26,5

27°C 100,0 57,5 18,1 95,8 55,7 19,8 91,2 53,9 21,7 86,1 52,2 23,9 80,5 50,4 26,5

30°C 100,9 72,4 18,1 96,7 70,7 19,8 92,1 68,9 21,8 86,9 67,0 24,0 81,3 64,9 26,5

33°C 102,0 86,8 18,2 97,8 85,2 19,9 93,1 83,5 21,9 88,0 81,5 24,1 82,4 79,1 26,6

36°C 103,3 100,8 18,3 99,0 99,0 20,0 95,0 95,0 22,0 90,6 90,6 24,3

21°C

24°C 91,9 91,8 17,6 88,2 88,2 19,3 84,2 84,1 21,3 79,6 79,6 23,5 74,6 74,6 26,0

27°C 97,3 97,3 17,9 93,5 93,5 19,6 89,3 89,3 21,6 84,6 84,6 23,8 79,4 79,4 26,4

30°C 103,1 103,1 18,2 99,2 99,2 20,0 94,8 94,8 22,0 90,0 90,0 24,3

24°C 98,6 70,7 18,0 94,2 69,0 19,7 89,2 67,3 21,6 83,8 65,4 23,8 78,0 63,2 26,3

27°C 100,0 92,4 18,1 95,6 90,5 19,8 90,6 88,4 21,7 85,0 85,0 23,9 79,7 79,8 26,4

30°C 103,4 103,4 18,2 99,4 99,4 20,0 94,9 94,9 22,0 90,0 90,0 24,2

33°C 109,2 109,3 18,6 105,1 105,1 20,4

27°C 106,9 69,8 18,5 102,1 68,2 20,2 96,8 66,5 22,1 91,0 64,7 24,3

30°C 108,3 92,0 18,5 103,5 90,1 20,3 98,2 88,1 22,2

33°C 109,7 109,7 18,6 105,4 105,5 20,4

36°C

25°C 30°C 35°C 40°C 45°C

PT PS PA PT PS PA PT PS PA PT PS PA PT PS PA

80,6 53,0 16,9 77,4 51,4 18,7 73,8 49,7 20,6 69,8 48,0 22,8 65,2 46,2 25,2

84,3 58,6 17,2 80,9 57,0 18,9 77,1 55,3 20,8 72,8 53,5 23,0 68,0 51,5 25,4

90,7 71,4 17,5 86,6 69,7 19,2 82,1 67,9 21,1 77,1 65,9 23,3 71,6 63,5 25,7

FAH

085

HEATING CAPACITY AND ABSORBED POWER

Outdoor air temp

FAH

/h

3

rate

12 000 m

Minimum airfl ow

/h

3

Dry bulb

15 000 m

Nominal airfl ow rate

Entering air temperature

/h

3

rate

23 000 m

Maximum airfl ow

PT :

Gross total cooling/heating capacity in kW

PS :

Sensible heating capacity in kW

PA :

Compressor absorbed power

xxx :

Data according to Eurovent standard conditions

8°C 108,9 18,3 97,2 17,3 97,2 17,3 80,2 15,7 76,2 15,4 67,0 14,5 58,6 13,7 51,0 13,0 48,2 12,7

11°C 107,3 19,4 95,8 18,3 95,8 18,3 79,1 16,7 75,2 16,3 66,2 15,4 58,0 14,6 50,6 13,9 47,9 13,6

14°C 105,6 20,5 94,3 19,4 94,3 19,4 78,0 17,6 74,2 17,2 65,4 16,3 57,4 15,5 50,2 14,8 47,6 14,5

17°C 103,9 21,7 92,8 20,5 92,8 20,5 76,8 18,7 73,1 18,3 64,5 17,3 56,7 16,4 49,8 15,7 47,3 15,5

20°C 102,1 23,0 91,3 21,7 91,3 21,7 75,6 19,8 72,0 19,4 63,6 18,3 56,1 17,4 49,3 16,7 46,9 16,5

23°C 100,3 24,4 89,7 23,0 89,7 23,0 74,3 21,0 70,8 20,5 62,7 19,4 55,3 18,5 48,8 17,7 46,4 17,5

26°C 98,5 26,0 88,1 24,4 88,1 24,4 73,1 22,2 69,7 21,7 61,7 20,5 54,6 19,5 48,3 18,8 46,0 18,5

8°C 111,0 17,1 99,0 16,2 99,0 16,2 81,5 14,8 77,5 14,4 68,0 13,7 59,4 12,9 51,5 12,3 48,6 12,0

11°C 109,3 18,0 97,6 17,1 97,6 17,1 80,5 15,6 76,5 15,3 67,3 14,5 58,8 13,7 51,2 13,1 48,4 12,9

14°C 107,7 19,0 96,1 18,0 96,1 18,0 79,4 16,5 75,5 16,1 66,5 15,3 58,2 14,6 50,8 13,9 48,1 13,7

17°C 106,0 20,1 94,6 19,0 94,6 19,0 78,2 17,4 74,5 17,1 65,6 16,2 57,6 15,5 50,4 14,8 47,8 14,6

20°C 104,2 21,2 93,1 20,1 93,1 20,1 77,1 18,4 73,4 18,1 64,7 17,2 56,9 16,4 50,0 15,8 47,4 15,6

23°C 102,5 22,4 91,6 21,2 91,6 21,2 75,8 19,5 72,2 19,1 63,8 18,2 56,2 17,4 49,5 16,8 47,0 16,6

26°C 100,7 23,7 90,0 22,5 90,0 22,5 74,6 20,6 71,1 20,2 62,9 19,2 55,5 18,4 49,0 17,8 46,6 17,6

8°C 114,7 15,2 102,1 14,5 102,1 14,5 83,6 13,3 79,3 13,1 69,2 12,4 59,9 11,8 51,4 11,3 48,2 11,1

11°C 113,2 16,0 100,7 15,2 100,7 15,2 82,6 14,1 78,4 13,8 68,5 13,2 59,4 12,6 51,1 12,1 48,0 11,9

14°C 111,6 16,8 99,4 16,0 99,4 16,0 81,6 14,9 77,4 14,6 67,7 14,0 58,9 13,4 50,8 13,0 47,8 12,8

17°C 109,9 17,7 97,9 16,9 97,9 16,9 80,5 15,7 76,5 15,5 67,0 14,8 58,3 14,3 50,5 13,9 47,5 13,8

20°C 108,2 18,7 96,5 17,8 96,5 17,8 79,4 16,7 75,4 16,4 66,1 15,8 57,7 15,3 50,1 14,9 47,2 14,9

23°C 106,5 19,7 95,0 18,8 95,0 18,8 78,2 17,6 74,3 17,4 65,3 16,8 57,0 16,3 49,6 16,0 46,9 16,0

26°C 104,8 20,8 93,4 19,9 93,4 19,9 77,0 18,7 73,2 18,4 64,4 17,9 56,4 17,4 49,2 17,2 46,5 17,2

Application Guide /FLEXAIR-AGU-1505-E

20°C 15°C 10°C 7°C 5°C 0°C -5°C -10°C -15°C

.

PT PA PT PA PT PA PT PA PT PA PT PA PT PA PT PA PT PA

Absorbed power by control

device

(kW)

FC/FH 0,3

FC/FD 0,5

Supply fan aborbed power

(kW)

Absorbed power by outdoor fan

(kW)

FC/FH 3,17

FC/FD 4,0

1,8

• 27 •

Page 30

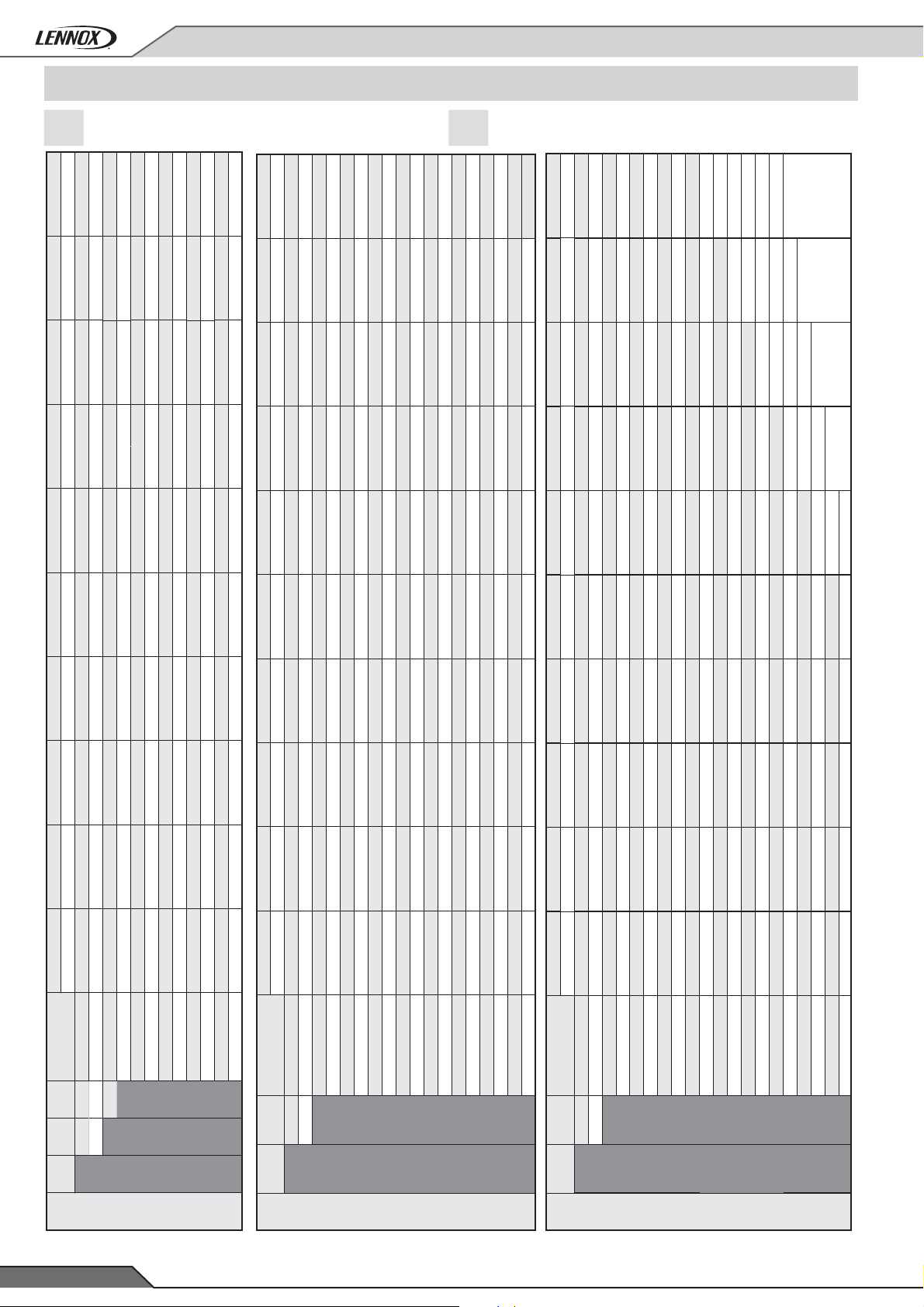

5- STANDARD UNITS PERFORMANCES

FAC FAH

Cooling only Heat pump

COOLING CAPACITY AND ABSORBED POWER

FAC

Wet bulb Dry bulb

16°C

/h

3

19°C

12 000 m

Minimum airfl ow rate

22°C

16°C

/h

3

19°C

15 000 m

Nominal airfl ow rate

Entering air temperature

22°C

16°C

/h

3

19°C

23 000 m

Maximum airfl ow rate

22°C

Temperatura de aire exterior

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

25°C 30°C 35°C 40°C 45°C

PT PS PA PT PS PA PT PS PA PT PS PA PT PS PA

81,2 53,3 16,9 78,2 51,8 18,7 74,7 50,2 20,6 70,8 48,5 22,8 66,4 46,8 25,3

82,0 65,6 17,0 79,0 64,1 18,7 75,5 62,5 20,7 71,6 60,7 22,9 67,2 58,6 25,3

82,9 77,3 17,0 79,9 75,9 18,8 76,4 74,4 20,7 72,3 72,3 22,9 68,5 68,5 25,4

85,6 85,6 17,1 83,0 83,0 18,9 79,9 79,9 21,0 76,4 76,4 23,2 72,4 72,4 25,8

88,7 52,9 17,4 85,3 51,2 19,1 81,5 49,5 21,1 77,2 47,9 23,3 72,4 46,1 25,7

89,5 65,2 17,4 86,1 63,6 19,1 82,2 62,0 21,1 77,9 60,2 23,3 73,1 58,2 25,8

90,5 77,0 17,5 87,0 75,6 19,2 83,2 74,0 21,2 78,8 72,1 23,4 74,0 70,0 25,9

91,6 88,3 17,5 88,1 87,0 19,3 84,6 84,7 21,3 80,9 80,9 23,5 76,7 76,7 26,1

96,6 52,3 17,8 92,8 50,5 19,6 88,5 48,8 21,5 83,8 47,1 23,7 78,7 45,4 26,3

97,4 64,7 17,9 93,6 63,0 19,6 89,3 61,3 21,6 84,6 59,6 23,8 79,4 57,7 26,3

98,4 76,4 17,9 94,5 74,9 19,7 90,3 73,3 21,6 85,5 71,5 23,9 80,3 69,5 26,4

99,5 87,5 18,0 95,6 86,2 19,7 91,3 84,8 21,7 86,6 83,0 23,9 81,4 80,9 26,5

85,0 58,9 17,2 81,8 57,4 18,9 78,1 55,7 20,9 73,9 54,0 23,0 69,3 52,1 25,4

86,0 73,5 17,2 82,7 71,9 19,0 79,0 70,2 20,9 74,8 68,2 23,1 70,1 66,0 25,5

87,0 87,0 17,3 84,3 84,2 19,1 81,0 81,0 21,1 77,4 77,4 23,3 73,2 73,2 25,8

92,0 92,0 17,6 89,1 89,1 19,4 85,7 85,7 21,4 81,8 81,8 23,6 77,5 77,5 26,1

92,7 58,4 17,6 89,0 56,7 19,3 84,9 55,0 21,3 80,4 53,3 23,5 75,4 51,5 25,9

93,6 73,2 17,7 90,0 71,5 19,4 85,8 69,8 21,3 81,3 67,9 23,5 76,2 65,7 26,0

94,7 87,5 17,7 91,0 85,9 19,5 86,9 84,1 21,4 82,3 82,0 23,6 77,7 77,7 26,1

97,5 97,5 17,9 94,3 94,3 19,7 90,6 90,7 21,7 86,6 86,6 23,9 82,0 82,0 26,5

100,7 57,8 18,1 96,6 56,0 19,8 92,1 54,3 21,7 87,2 52,6 24,0 81,8 50,8 26,5

101,6 72,7 18,1 97,6 71,0 19,9 93,1 69,2 21,8 88,1 67,3 24,0 82,7 65,3 26,6

102,8 87,0 18,2 98,7 85,4 19,9 94,1 83,6 21,9 89,2 81,6 24,1 83,7 79,3 26,6

104,0 100,7 18,3 99,9 99,3 20,0 95,8 95,8 22,0 91,5 91,5 24,3

91,5 71,5 17,5 87,5 69,9 19,2 83,1 68,1 21,2 78,3 66,1 23,3 73,0 63,8 25,8

92,8 92,2 17,6 88,9 88,8 19,3 85,0 84,9 21,3 80,6 80,6 23,5 75,8 75,7 26,0

98,0 98,0 17,9 94,3 94,3 19,6 90,2 90,2 21,6 85,7 85,7 23,9 80,7 80,7 26,4

103,8 103,8 18,2 100,0 100,0 20,0 95,8 95,8 22,0 91,1 91,1 24,3 85,9 85,9 26,9

99,5 71,0 18,0 95,2 69,3 19,7 90,4 67,6 21,6 85,1 65,7 23,8 79,5 63,6 26,3

100,8 92,3 18,1 96,5 90,4 19,8 91,7 88,3 21,7 86,4 85,8 23,9 80,8 80,8 26,4

104,0 104,1 18,2 100,2 100,2 20,0 95,8 95,8 22,0 91,0 91,1 24,3 85,8 85,8 26,9

110,0 110,0 18,6 105,9 105,9 20,4

107,8 70,3 18,5 103,1 68,6 20,2 97,9 66,9 22,1 92,3 65,1 24,4 86,2 63,2 26,9

109,2 92,1 18,6 104,4 90,2 20,3 99,2 88,2 22,2 93,6 85,8 24,4

110,3 110,3 18,6 106,2 106,2 20,4

FAC

085

PT :

Gross total cooling/heating capacity in kW

PS :

Sensible heating capacity in kW

PA :

Compressor absorbed power

xxx :

Data according to Eurovent standard conditions

• 28 •

Absorbed power by control

device

(kW)

FC/FH 0,3

FC/FD 0,5

Supply fan aborbed power

(kW)

Absorbed power by outdoor fan

(kW)

Application Guide / FLEXAIR-AGU-1505-E

FC/FH 3,17

FC/FD 4,0

1,8

Page 31

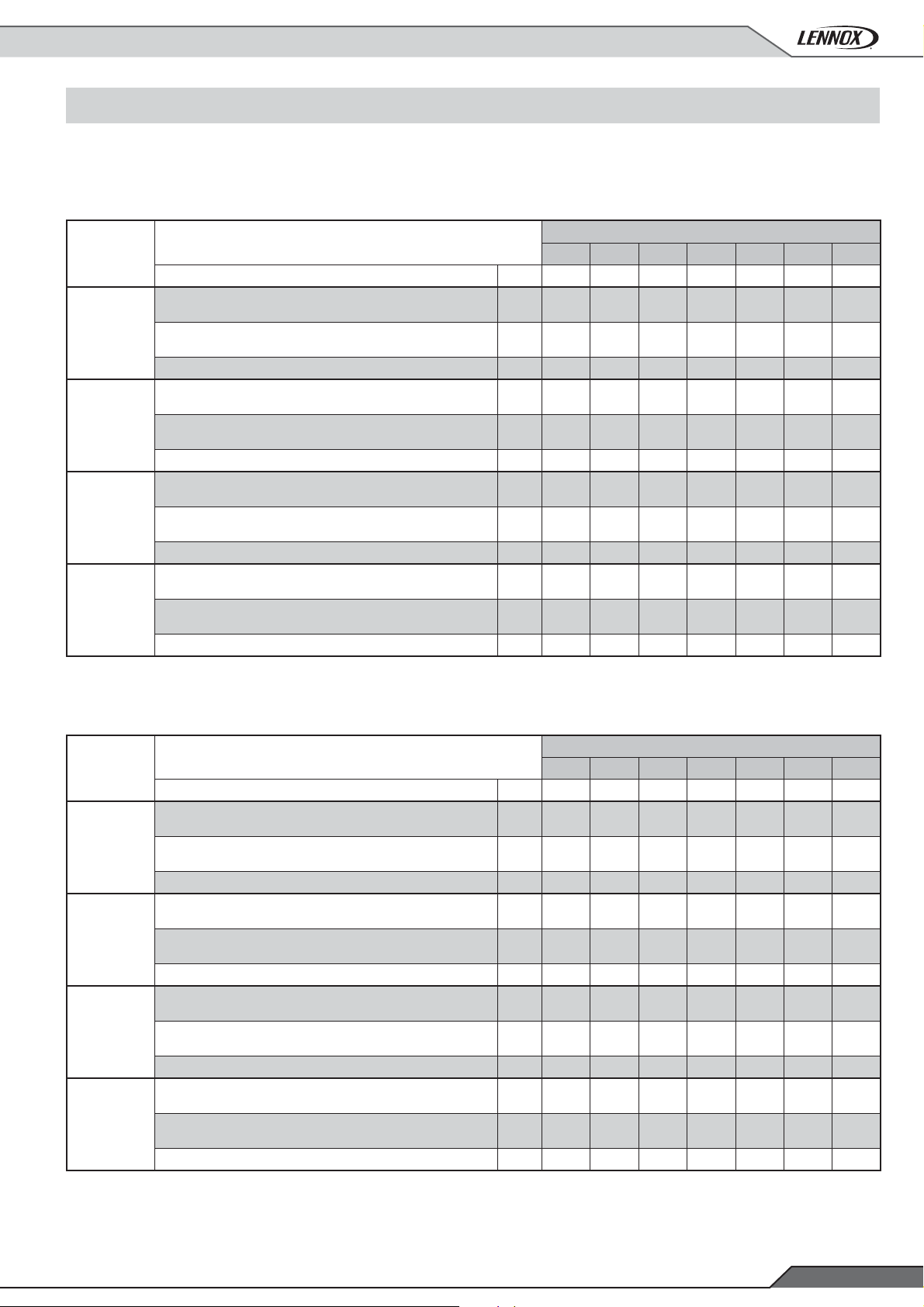

5- STANDARD UNITS PERFORMANCES

FAC FAH

Cooling only Heat pump

COOLING CAPACITY AND ABSORBED POWER

FAH

Wet bulb Dry bulb

16°C

/h

3

19°C

14 000 m

Minimum airfl ow rate

22°C

16°C

/h

3

19°C

18 500 m

Nominal airfl ow rate

Entering air temperature

22°C

16°C

/h

3

19°C

23 000 m

Maximum airfl ow rate

22°C

Outdoor air temperature

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

25°C 30°C 35°C 40°C 45°C

PT PS PA PT PS PA PT PS PA PT PS PA PT PS PA

90,4 60,1 20,3 86,8 58,2 22,2 82,7 56,3 24,3 78,2 54,3 26,6 73,1 52,2 29,1

91,2 74,1 20,4 87,6 72,3 22,3 83,5 70,4 24,4 79,0 68,3 26,7 74,0 65,9 29,2

92,2 87,6 20,5 88,6 86,0 22,3 84,6 84,1 24,4 80,3 80,3 26,8 75,9 75,9 29,5

95,5 95,5 20,7 92,5 92,4 22,6 88,9 88,9 24,8 84,8 84,8 27,2 80,3 80,3 29,9

98,6 59,6 20,9 94,5 57,5 22,8 90,0 55,6 24,9 85,0 53,6 27,2 79,5 51,5 29,8

99,4 73,7 21,0 95,4 71,9 22,9 90,8 69,9 25,0 85,8 67,9 27,3 80,4 65,6 29,9

100,4 87,2 21,1 96,4 85,6 23,0 91,9 83,8 25,0 86,9 81,7 27,4 81,4 79,2 30,0

101,7 100,0 21,2 97,9 97,9 23,0 94,1 94,1 25,2 89,7 89,7 27,7 84,9 84,9 30,4

107,1 58,9 21,5 102,6 56,7 23,4 97,6 54,7 25,5 92,1 52,7 27,9 86,2 50,8 30,5

107,9 73,0 21,6 103,4 71,1 23,5 98,5 69,2 25,6 93,0 67,2 28,0 87,1 65,0 30,6