Lennox ELS SERIES, ELS120S4S, ELS120S4D, ELS090S4S, ELS072S4S Unit Information

...

UNIT INFORMATION

Corp. 1811-L3

Service Literature

May 15, 2018

ELS SERIES UNITS

The ELS units are designed for light commercial applications, with a remotely located blower-coil unit or a furnace

with an add-on evaporator coil. Capacities for the series

are 6, 7-1/2, 10, 12.5, 15 and 20 tons (21, 26, 35, 44,

53, and 70 kW).ELS072, ELS090 and ELS120S4S models have one dual-speed scroll compressor. ELS120S4D,

ELS150S4D, ELS180S4D and ELS240S4D models have

two single-speed scroll compressors. ELS units match

with the ELA blower-coil units. All ELS units are three

phase and use HFC-410A refrigerant.

This manual covers ELS072S4S, ELS090S4S,

ELS120S4S, ELS120S4D, ELS150S4D, ELS180S4D and

ELS240S4D units. It is divided into sections which discuss

the major components, refrigerant system, charging procedure, maintenance and operation sequence.

Information in this manual is intended for qualied service

technicians only. All specications are subject to change.

Procedures in this manual are presented as a recommendation only and do not supersede or replace local or state

codes.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer or

equivalent, service agency, or the gas supplier.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs and HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

WARNING

Electric shock hazard! - Disconnect all power

supplies before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

ELS

6 - 20 TON

Table of Contents

Unit Plumbing Parts Arrangement .................................5

Model Number Identication ........................................ 10

Unit Control Box Components Arrangement ................11

I-UNIT COMPONENTS ................................................12

A-CONTROL BOX COMPONENTS ............................12

B-COOLING COMPONENTS .......................................12

II- REFRIGERANT SYSTEM ....................................... 13

A-Plumbing .................................................................. 13

B-Service Valves ......................................................... 14

III-START-UP ................................................................15

IV-CHARGING ..............................................................16

A-Leak Testing .............................................................. 16

B-Evacuating the System .............................................17

C-Charging ...................................................................18

V-MAINTENANCE ........................................................22

VI-Wiring Diagram and Sequence of Operation ........... 23

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

Page 1

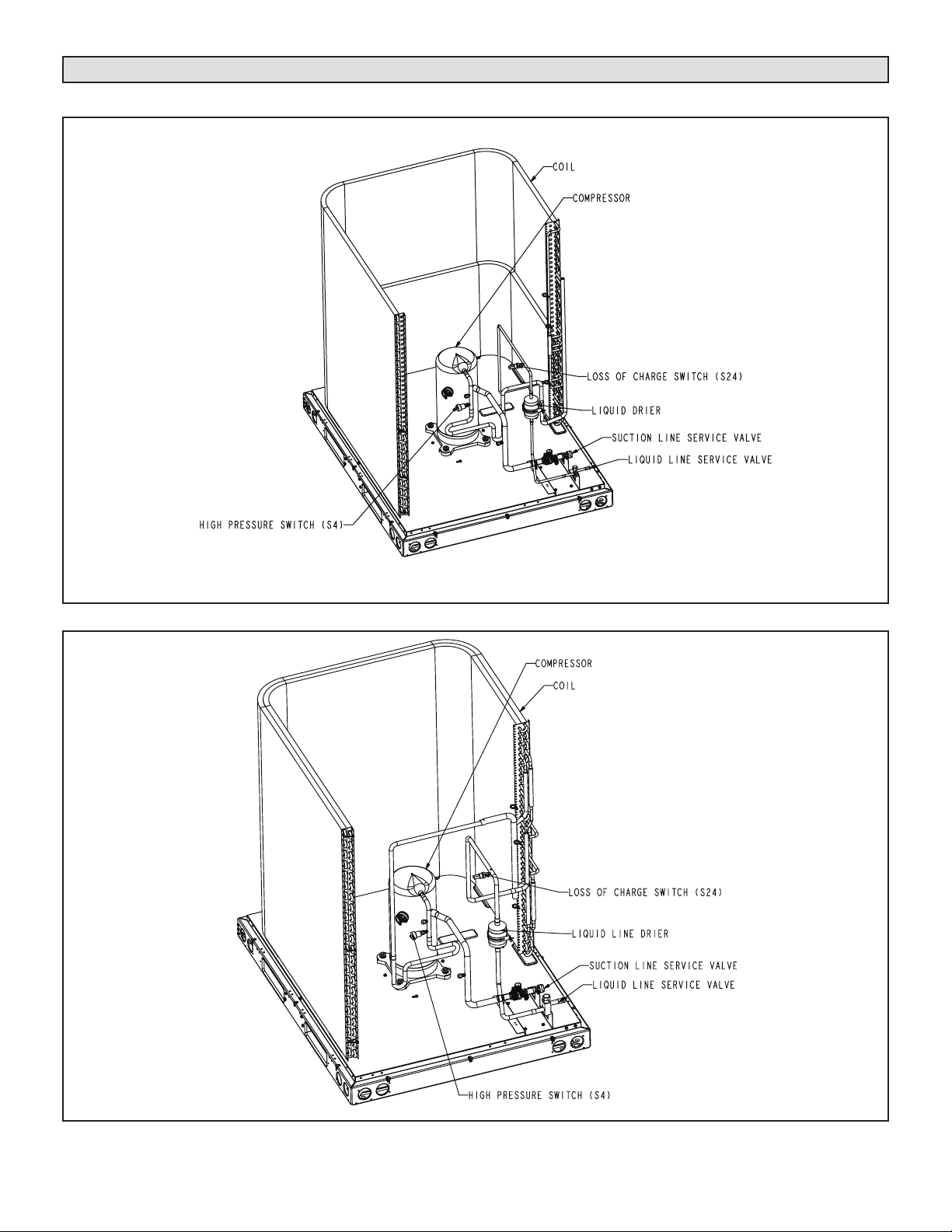

SPECIFICATIONS - 6 - 7.5 TON

67

32

53

3(

71

46

23

3(

22

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

General

Data

Connections

(sweat)

Nominal Size - Tons

Liquid line - in. (o.d) (1)3/8 (1)5/8

Suction line - in. (o.d) (1)1-1/8 (1)1-1/8

Refrigerant

(R-410A)

1

Field charge (25 ft. line set) 18 lbs. 0 oz.20 lbs. 0 oz.

Compressor (1) Two-Stage Scroll (1)Two-Stage Scroll

Condenser

Net face area - sq. ft. Outer coil 29.

Coil

Tube diameter - in. & no. of rows 3/8 - 1.

Condenser

Diameter - in. & no. of blades (1) 24 -

Fan(s)

Total air volume - cfm 4700 5600

ELECTRICAL DATA

Line voltage data - 60 hz - 3 phase 208/230V 460V 575V 208/230V 460V 575V

2

Maximum Overcurrent Protection (amps) 40 15 15 60 25 20

Compressor No. of Compressors 111111

Condenser

Fan Motor

(1 phase)

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

Field provided charge with 25 ft. line set. Refer to the Lennox Refrigerant Piping Manual to determine refrigerant charge required with longer length refrigerant lines.

2

HACR type circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

3

Minimum circuit ampacity 24 12 9371

Model No. ELS072S4S ELS090S4S

.5

Factory Charge R-410A holding charge (2 lbs. per stage)

9.3

Inner coil 14.2 28.4

/8 - 2

Fins per inch 20 20

1) 24 - 4

Motor hp (1)1/3 (1)1/2

Rpm 1075 1075

Watts 400 580

Rated load amps 17.6 8.56.3 26.9 12 9

Locked rotor amps 136 66 55 1659

No. of motors 111111

Full load amps 1.7 0.81 31.5 1.2

Locked rotor amps 4.3 2.41.9 63

2.9

3

5

SPECIFICATIONS - 10 TON

General

Data

Connections

(sweat)

Nominal Size - Tons 10 10

Liquid line - in. (o.d) (1)5/8 (2)3/8

Suction line - in. (o.d) (1)1-1/8 (2)1-1/8

Refrigerant

(R-410A)

1

Field charge

(25 ft. line set)

Compressor (1) Two-Stage Scroll (2)Single-Stage Scroll

Condenser

Net face area - sq. ft. Outer coil 29.3 29.3

Coil

Tube diameter - in. & no. of rows 3/8 -

Condenser

Diameter - in. & no. of blades (2) 24 -

Fan(s)

Total air volume - cfm 8300 8300

ELECTRICAL DATA

Line voltage data - 60 hz - 3 phase 208/230V 460V 575V 208/230V 460V 575V

2

Maximum Overcurrent Protection (amps) 80 30 25 40 20 15

Compressor No. of Compressors 1112

Condenser

Fan Motor

(1 phase)

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

Field provided charge with 25 ft. line set. Refer to the Lennox Refrigerant Piping Manual to determine refrigerant charge required with longer length refrigerant lines.

2

HACR type circuit breaker or fuse.

3

3

Minimum circuit ampacity 47 21 16 30 16 13

Rated load amps (total) 34.6 14.8 11 .1 12 (24) 6.3 (12.6) 4.9 (9.8)

Locked rotor amps (total) 240 13094 90 (180) 60 (120) 41 (82)

Full load amps (total) 1.7 (3.4) 0.8 (1.6)1 (2)1.7 (3.4)0.8 (1.6)1 (2)

Locked rotor amps (total) 4.3 (8.6) 2.4 (4.8)1.9 (3.8)4.3 (8.6)2.4 (4.8)1.9 (3.8)

Model No. ELS120S4S ELS120S4D

Factory Charge R-410A holding charge (2 lbs. per stage)

Circuit 1 32 lbs. 0 oz. 12 lbs. 0 oz.

Circuit 2- - - 12 lbs. 0 oz.

Inner coil 28.4 28.4

/8 - 2

Fins per inch 20 20

2) 24 - 3

Motor hp (2)1/3 (2)1/3

Rpm 1075 1075

Watts 830 830

No. of motors 222222

Page 2

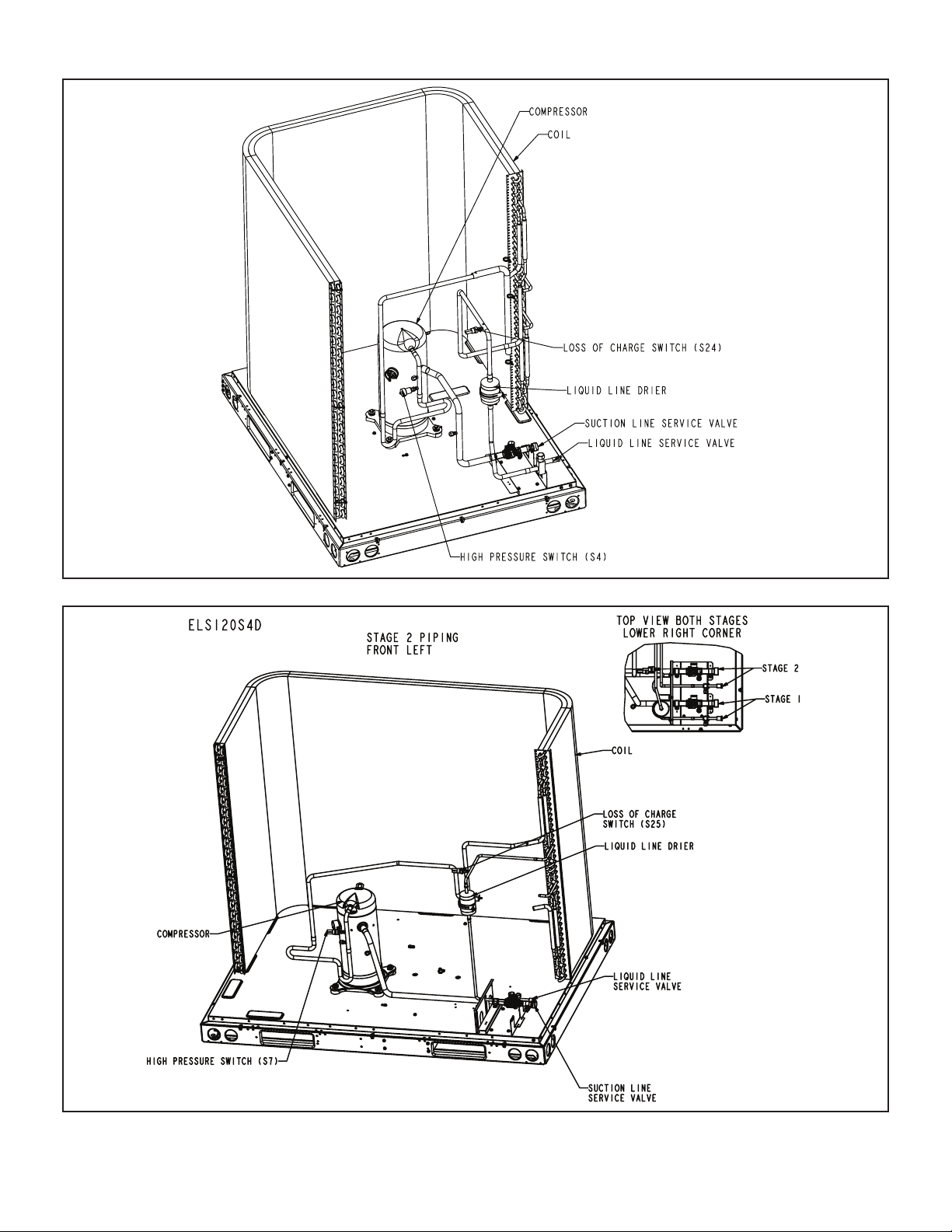

SPECIFICATIONS - 12.5 - 20 TON

52

23

tS

.k

04

General

Data

Connections

(sweat)

Nominal Size - Tons 12.51

Liquid line - in. (o.d) (2)3/8 (2)5/8 (2)5/8

Suction line - in. (o.d) (2)1-1/8 (2)1-1/8 (2)1-1/8

Refrigerant

(R-410A)

1

Field charge

(25 ft. line set)

Compressor (2) Single-Stage Scroll (2)Single-Stage Scroll (2)Single-Stage Scroll

Condenser

Net face area - sq. ft. Outer coil 34.2 58.7 58.7

Coil

Tube diameter - in. & no. of rows 3/8 - 23/8 -

Condenser

Diameter - in. & no. of blades (2)24 - 4(4) 24 - 3(4) 24 - 3

Fan(s)

Total air volume - cfm 10,300 16,600 16,600

Model No. ELS150S4D ELS180S4D ELS240S4D

Factory Charge R-410A holding charge (2 lbs. per stage)

Circuit 1 15 lbs. 0 oz. 24 lbs. 0 oz.22 lbs. 4 oz.

Circuit 2 15 lbs. 0 oz. 24 lbs. 0 oz.23 lbs. 3 oz.

Inner coil 33.3 57.7 57.7

Fins per inch 20 20 20

Motor hp (2)1/2 (4)1/3 (4)1/3

Rpm 1075 1075 1075

Watts 1130 1660 1660

0

/8 - 2

ELECTRICAL DATA

Line voltage data - 60 hz - 3 phase 208/230V 460V 575V 208/230V 460V 575V 208/230V 460V 575V

2

Maximum Overcurrent Protection (amps) 60 25 25 80 40 30 90 50 40

3

Minimum circuit ampacity 50 21 20 63 31 25 70 36 30

Compressor No. of Compressors 222222222

Rated load amps

(total)

Locked rotor amps

(total)

Condenser

Fan Motor

(1 phase)

No. of motors 222444444

Full load amps

(total)3 (6)

Locked rotor amps

(total)6 (12)

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

Field provided charge with 25 ft. line set. Refer to the Lennox Refrigerant Piping Manual to determine refrigerant charge required with longer length refrigerant lines.

2

HACR type circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

19.6

(39.2)

136

(272)

8.2

(16.4)

66

(132)

1.5

(3)

(6)

6.6

(13.2)

55

(110)

1.2

(2.4)

3

2.9

(5.8)

25

(50)

164

(328)

1.7

(6.8)

4.3

(17.2)

12.2

(24.4)9 (18)

100

(200)

78

(156)

0.8

(3.2)1 (4)

2.4

(9.6)

1.9

(7.6)

28.2

(56.4)

240

(480)

1.7

(6.8)

4.3

(17.2)

14.7

(29.4)

130

(260)

11.3

(22.6)

93.7

(187.4)

0.8

(3.2)1 (4)

2.4

(9.6)

(7.6)

1.9

WEIGHT DATA

Model No. Ne

lbs.kglbs

072S 318 144 338 153

090S 345 157365 166

120S 452 205 477 216

120D 480 218 505 229

150S 535 243560 254

180S 775 352 800 363

240S 832 377 857 389

hipping

OPTIONS / ACCESSORIES

COMBINED COIL/HAIL GUARDS

T2GARD20L-1 40 18 45 20

T2GARD20M-1 45 20 50 23

T2GARD21M-1 45 20 50 23

T2GARD20N-1- 90 41 10

Page 3

g

5

OPTIONS / ACCESSORIES

CABINET

Combined Coil/Hail Guards

XX

Corrosion Protection

OOOOOOO

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXX

Low

XX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

sensor (77N39)

XXXXXXX

CONTROLS

BACnet

BACnet

BACnet

Network Thermostat Control (NTC) C0CTRL07AE1L 17M10 XXXXXXX

NTC Enclosure Kit (required with NTC Controller) A0CTRL32LS1 16H99

L Connection

ELECTRICAL

GFI

Service

Outlets

INDOOR AIR QUALITY

Sensor - Wall-mount, off-white plastic cover with LCD display C0SNSR50AE1L 77N39

Sensor - Wall-mount, off-white plastic cover, no display C0SNSR52AE1L 87N53

Sensor - Black plastic case with LCD display, rated for

plenum mounting

Sensor - Wall-mount, black plastic case, no display, rated for

plenum mounting

CO

Aspiration Box - for duct mounting non-plenum rated CO

®

Module A0CTRL31LS1 17A08

®

Sensor with Display K0SNSR01FF1 97W23

®

Sensor without Display K0SNSR00FF1 97W24

®

Ambient Control (0ºF) A2CWKT01LM1- 16F18 XX

Sensor Duct Mounting Kit C0MISC19AE1- 85L43

2

Item Catalog

No.

ELS

072

S4S

T2GARD51L-1 13T29 XX

T2GARD51M11 13T30 XX

T2GARD51M21 13T32 X

T2GARD51N-1 13T37

Factory

Building Automation System - - - X

A2CWKT04M-1- 16F26 X

A2CWKT02M-1- 16F24 XX

A2CWKT03N-1- 16F25

74M70

(208/230V, 460V only) LTAGFIK10/15/15

67E01

C0SNSR51AE1L 87N52

C0SNSR53AE1L 87N54

2

C0MISC16AE1- 90N43

ELS

090

S4S

ELS

120

S4S

ELS

ELS

120

150

S4D

S4D

ELS

180

S4D

ELS

240

S4D

O - Factory Installed with extended lead time.

X - Field Installed

Page 4

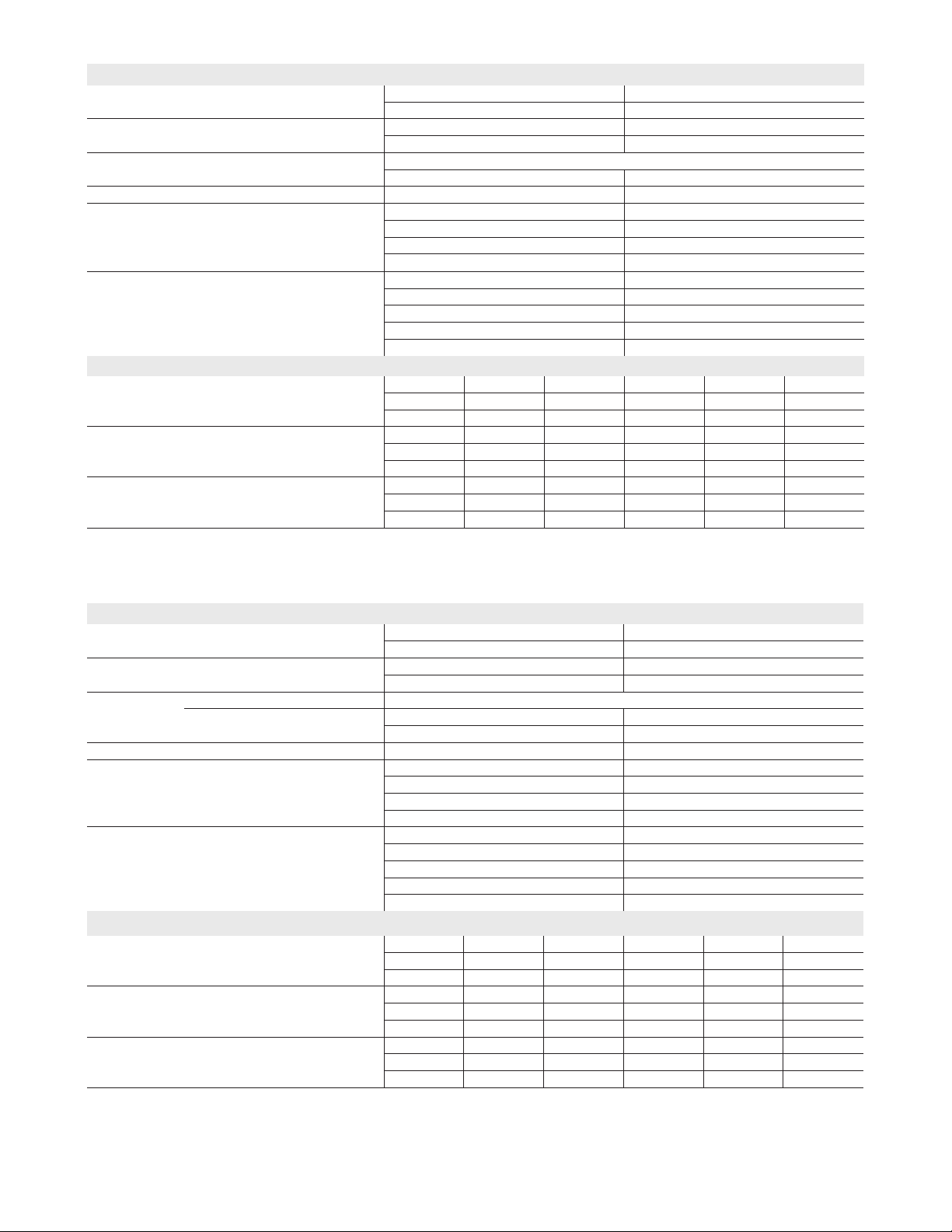

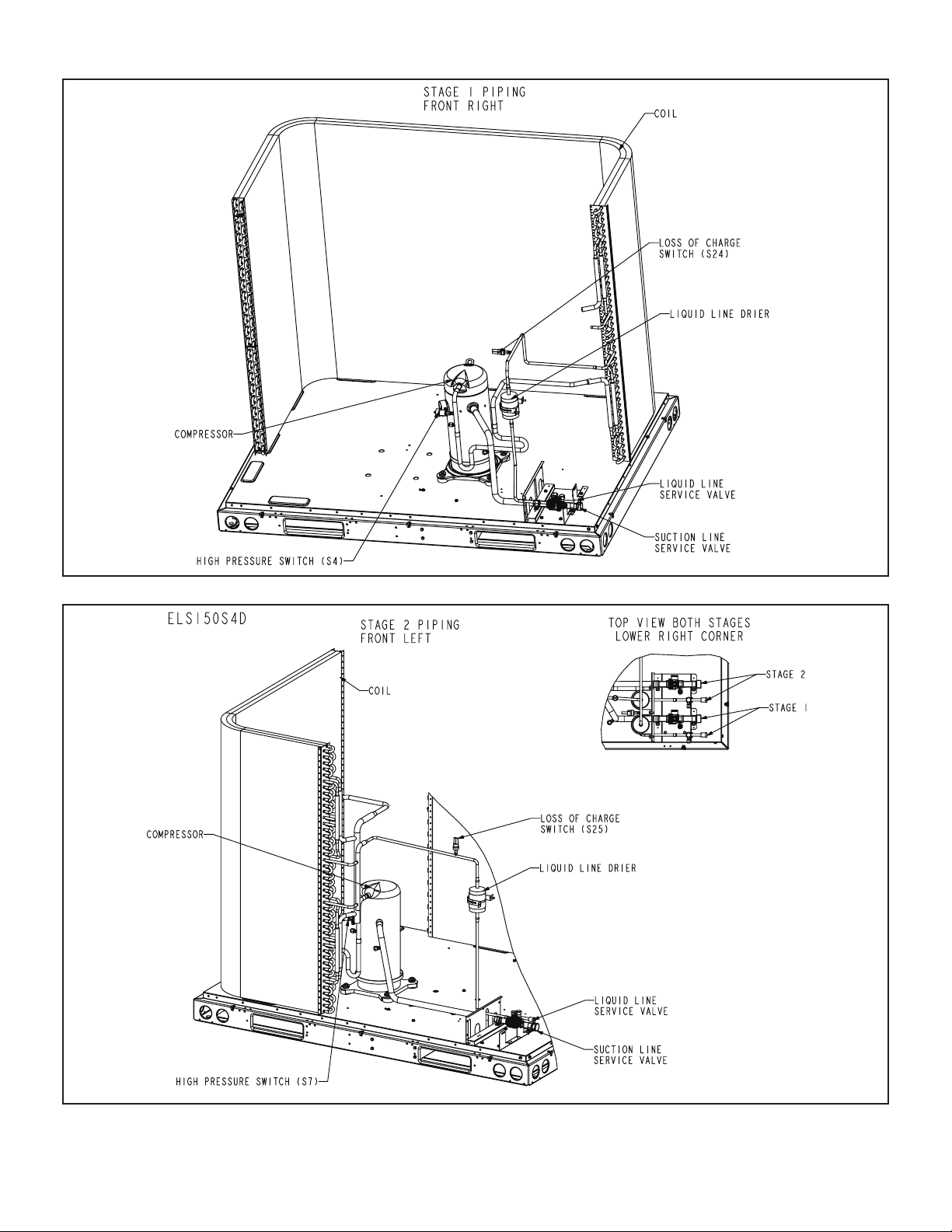

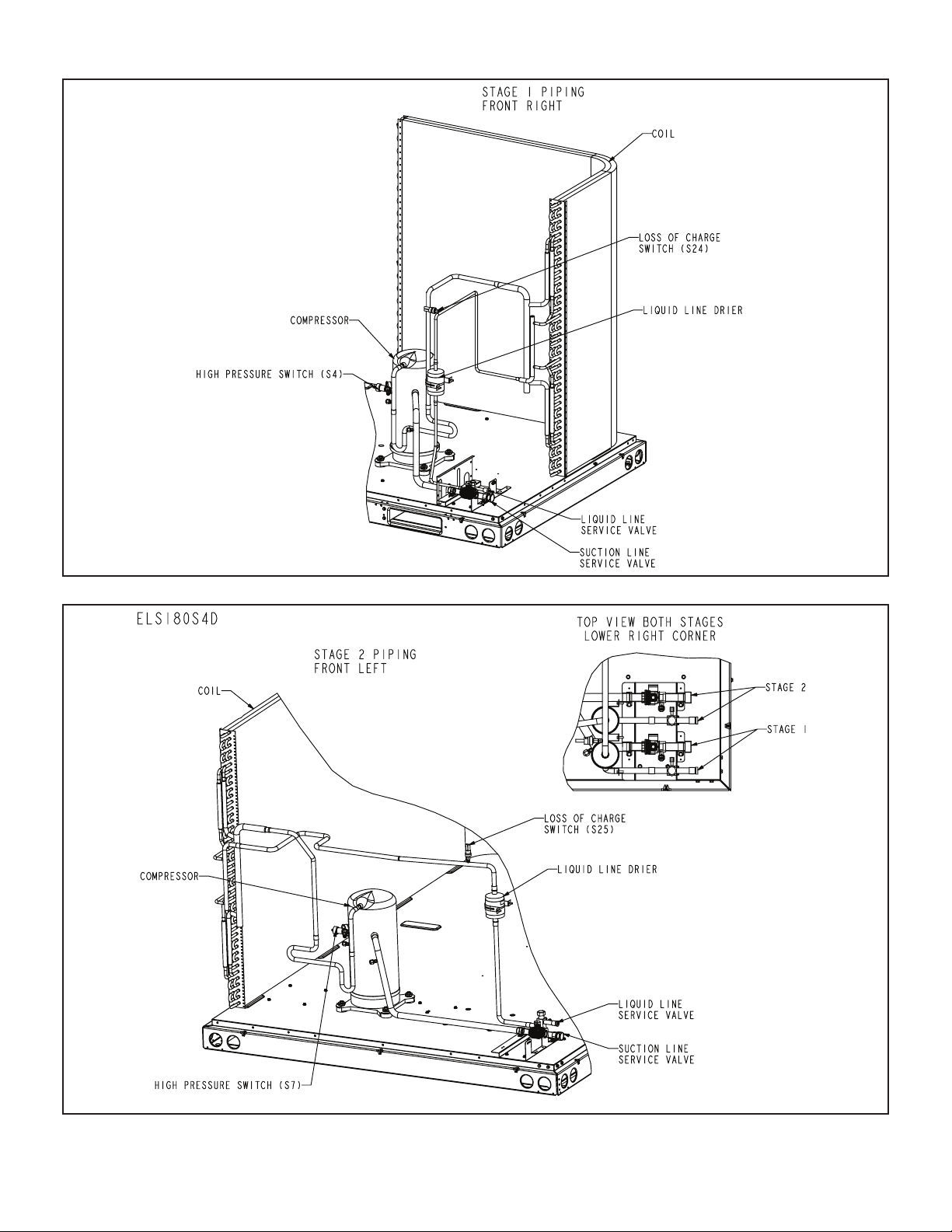

Unit Plumbing Parts Arrangement

ELS072S4S

ELS090S4S

Page 5

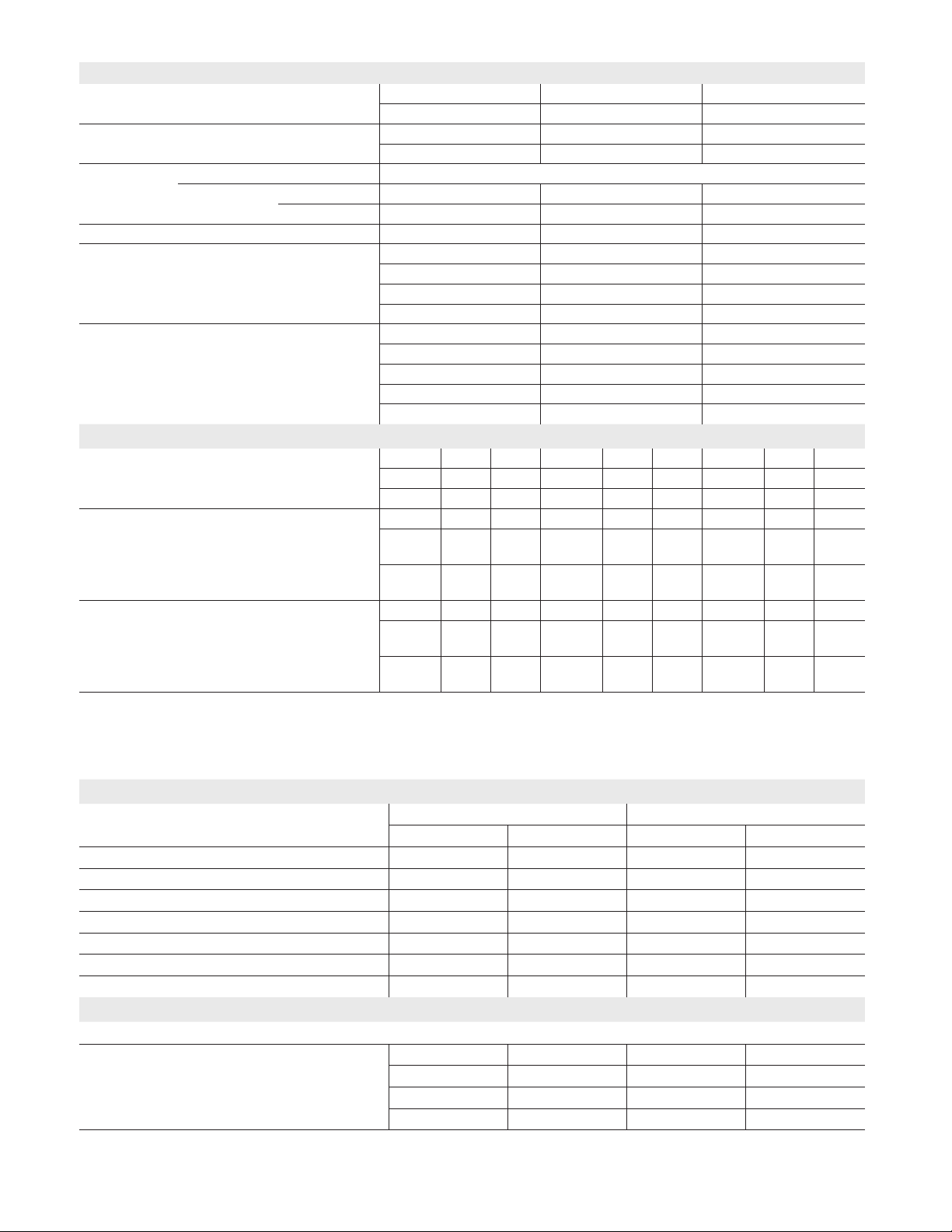

ELS120S4S

ELS120S4D – STAGE 2

Page 6

ELS120S4D – STAGE 1

ELS150S4D – STAGE 2

Page 7

ELS150S4D – STAGE 1

ELS180S4D – STAGE 2

Page 8

Loading...

Loading...