Page 1

UNIT INFORMATION

Corp. 1811-L3

Service Literature

May 15, 2018

ELS SERIES UNITS

The ELS units are designed for light commercial applications, with a remotely located blower-coil unit or a furnace

with an add-on evaporator coil. Capacities for the series

are 6, 7-1/2, 10, 12.5, 15 and 20 tons (21, 26, 35, 44,

53, and 70 kW).ELS072, ELS090 and ELS120S4S models have one dual-speed scroll compressor. ELS120S4D,

ELS150S4D, ELS180S4D and ELS240S4D models have

two single-speed scroll compressors. ELS units match

with the ELA blower-coil units. All ELS units are three

phase and use HFC-410A refrigerant.

This manual covers ELS072S4S, ELS090S4S,

ELS120S4S, ELS120S4D, ELS150S4D, ELS180S4D and

ELS240S4D units. It is divided into sections which discuss

the major components, refrigerant system, charging procedure, maintenance and operation sequence.

Information in this manual is intended for qualied service

technicians only. All specications are subject to change.

Procedures in this manual are presented as a recommendation only and do not supersede or replace local or state

codes.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer or

equivalent, service agency, or the gas supplier.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs and HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

WARNING

Electric shock hazard! - Disconnect all power

supplies before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

ELS

6 - 20 TON

Table of Contents

Unit Plumbing Parts Arrangement .................................5

Model Number Identication ........................................ 10

Unit Control Box Components Arrangement ................11

I-UNIT COMPONENTS ................................................12

A-CONTROL BOX COMPONENTS ............................12

B-COOLING COMPONENTS .......................................12

II- REFRIGERANT SYSTEM ....................................... 13

A-Plumbing .................................................................. 13

B-Service Valves ......................................................... 14

III-START-UP ................................................................15

IV-CHARGING ..............................................................16

A-Leak Testing .............................................................. 16

B-Evacuating the System .............................................17

C-Charging ...................................................................18

V-MAINTENANCE ........................................................22

VI-Wiring Diagram and Sequence of Operation ........... 23

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take

care while handling this equipment and wear gloves and

protective clothing.

Page 1

Page 2

SPECIFICATIONS - 6 - 7.5 TON

67

32

53

3(

71

46

23

3(

22

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

General

Data

Connections

(sweat)

Nominal Size - Tons

Liquid line - in. (o.d) (1)3/8 (1)5/8

Suction line - in. (o.d) (1)1-1/8 (1)1-1/8

Refrigerant

(R-410A)

1

Field charge (25 ft. line set) 18 lbs. 0 oz.20 lbs. 0 oz.

Compressor (1) Two-Stage Scroll (1)Two-Stage Scroll

Condenser

Net face area - sq. ft. Outer coil 29.

Coil

Tube diameter - in. & no. of rows 3/8 - 1.

Condenser

Diameter - in. & no. of blades (1) 24 -

Fan(s)

Total air volume - cfm 4700 5600

ELECTRICAL DATA

Line voltage data - 60 hz - 3 phase 208/230V 460V 575V 208/230V 460V 575V

2

Maximum Overcurrent Protection (amps) 40 15 15 60 25 20

Compressor No. of Compressors 111111

Condenser

Fan Motor

(1 phase)

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

Field provided charge with 25 ft. line set. Refer to the Lennox Refrigerant Piping Manual to determine refrigerant charge required with longer length refrigerant lines.

2

HACR type circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

3

Minimum circuit ampacity 24 12 9371

Model No. ELS072S4S ELS090S4S

.5

Factory Charge R-410A holding charge (2 lbs. per stage)

9.3

Inner coil 14.2 28.4

/8 - 2

Fins per inch 20 20

1) 24 - 4

Motor hp (1)1/3 (1)1/2

Rpm 1075 1075

Watts 400 580

Rated load amps 17.6 8.56.3 26.9 12 9

Locked rotor amps 136 66 55 1659

No. of motors 111111

Full load amps 1.7 0.81 31.5 1.2

Locked rotor amps 4.3 2.41.9 63

2.9

3

5

SPECIFICATIONS - 10 TON

General

Data

Connections

(sweat)

Nominal Size - Tons 10 10

Liquid line - in. (o.d) (1)5/8 (2)3/8

Suction line - in. (o.d) (1)1-1/8 (2)1-1/8

Refrigerant

(R-410A)

1

Field charge

(25 ft. line set)

Compressor (1) Two-Stage Scroll (2)Single-Stage Scroll

Condenser

Net face area - sq. ft. Outer coil 29.3 29.3

Coil

Tube diameter - in. & no. of rows 3/8 -

Condenser

Diameter - in. & no. of blades (2) 24 -

Fan(s)

Total air volume - cfm 8300 8300

ELECTRICAL DATA

Line voltage data - 60 hz - 3 phase 208/230V 460V 575V 208/230V 460V 575V

2

Maximum Overcurrent Protection (amps) 80 30 25 40 20 15

Compressor No. of Compressors 1112

Condenser

Fan Motor

(1 phase)

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

Field provided charge with 25 ft. line set. Refer to the Lennox Refrigerant Piping Manual to determine refrigerant charge required with longer length refrigerant lines.

2

HACR type circuit breaker or fuse.

3

3

Minimum circuit ampacity 47 21 16 30 16 13

Rated load amps (total) 34.6 14.8 11 .1 12 (24) 6.3 (12.6) 4.9 (9.8)

Locked rotor amps (total) 240 13094 90 (180) 60 (120) 41 (82)

Full load amps (total) 1.7 (3.4) 0.8 (1.6)1 (2)1.7 (3.4)0.8 (1.6)1 (2)

Locked rotor amps (total) 4.3 (8.6) 2.4 (4.8)1.9 (3.8)4.3 (8.6)2.4 (4.8)1.9 (3.8)

Model No. ELS120S4S ELS120S4D

Factory Charge R-410A holding charge (2 lbs. per stage)

Circuit 1 32 lbs. 0 oz. 12 lbs. 0 oz.

Circuit 2- - - 12 lbs. 0 oz.

Inner coil 28.4 28.4

/8 - 2

Fins per inch 20 20

2) 24 - 3

Motor hp (2)1/3 (2)1/3

Rpm 1075 1075

Watts 830 830

No. of motors 222222

Page 2

Page 3

SPECIFICATIONS - 12.5 - 20 TON

52

23

tS

.k

04

General

Data

Connections

(sweat)

Nominal Size - Tons 12.51

Liquid line - in. (o.d) (2)3/8 (2)5/8 (2)5/8

Suction line - in. (o.d) (2)1-1/8 (2)1-1/8 (2)1-1/8

Refrigerant

(R-410A)

1

Field charge

(25 ft. line set)

Compressor (2) Single-Stage Scroll (2)Single-Stage Scroll (2)Single-Stage Scroll

Condenser

Net face area - sq. ft. Outer coil 34.2 58.7 58.7

Coil

Tube diameter - in. & no. of rows 3/8 - 23/8 -

Condenser

Diameter - in. & no. of blades (2)24 - 4(4) 24 - 3(4) 24 - 3

Fan(s)

Total air volume - cfm 10,300 16,600 16,600

Model No. ELS150S4D ELS180S4D ELS240S4D

Factory Charge R-410A holding charge (2 lbs. per stage)

Circuit 1 15 lbs. 0 oz. 24 lbs. 0 oz.22 lbs. 4 oz.

Circuit 2 15 lbs. 0 oz. 24 lbs. 0 oz.23 lbs. 3 oz.

Inner coil 33.3 57.7 57.7

Fins per inch 20 20 20

Motor hp (2)1/2 (4)1/3 (4)1/3

Rpm 1075 1075 1075

Watts 1130 1660 1660

0

/8 - 2

ELECTRICAL DATA

Line voltage data - 60 hz - 3 phase 208/230V 460V 575V 208/230V 460V 575V 208/230V 460V 575V

2

Maximum Overcurrent Protection (amps) 60 25 25 80 40 30 90 50 40

3

Minimum circuit ampacity 50 21 20 63 31 25 70 36 30

Compressor No. of Compressors 222222222

Rated load amps

(total)

Locked rotor amps

(total)

Condenser

Fan Motor

(1 phase)

No. of motors 222444444

Full load amps

(total)3 (6)

Locked rotor amps

(total)6 (12)

NOTE - Extremes of operating range are plus and minus 10% of line voltage.

1

Field provided charge with 25 ft. line set. Refer to the Lennox Refrigerant Piping Manual to determine refrigerant charge required with longer length refrigerant lines.

2

HACR type circuit breaker or fuse.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements.

19.6

(39.2)

136

(272)

8.2

(16.4)

66

(132)

1.5

(3)

(6)

6.6

(13.2)

55

(110)

1.2

(2.4)

3

2.9

(5.8)

25

(50)

164

(328)

1.7

(6.8)

4.3

(17.2)

12.2

(24.4)9 (18)

100

(200)

78

(156)

0.8

(3.2)1 (4)

2.4

(9.6)

1.9

(7.6)

28.2

(56.4)

240

(480)

1.7

(6.8)

4.3

(17.2)

14.7

(29.4)

130

(260)

11.3

(22.6)

93.7

(187.4)

0.8

(3.2)1 (4)

2.4

(9.6)

(7.6)

1.9

WEIGHT DATA

Model No. Ne

lbs.kglbs

072S 318 144 338 153

090S 345 157365 166

120S 452 205 477 216

120D 480 218 505 229

150S 535 243560 254

180S 775 352 800 363

240S 832 377 857 389

hipping

OPTIONS / ACCESSORIES

COMBINED COIL/HAIL GUARDS

T2GARD20L-1 40 18 45 20

T2GARD20M-1 45 20 50 23

T2GARD21M-1 45 20 50 23

T2GARD20N-1- 90 41 10

Page 3

g

5

Page 4

OPTIONS / ACCESSORIES

CABINET

Combined Coil/Hail Guards

XX

Corrosion Protection

OOOOOOO

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXX

Low

XX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

sensor (77N39)

XXXXXXX

CONTROLS

BACnet

BACnet

BACnet

Network Thermostat Control (NTC) C0CTRL07AE1L 17M10 XXXXXXX

NTC Enclosure Kit (required with NTC Controller) A0CTRL32LS1 16H99

L Connection

ELECTRICAL

GFI

Service

Outlets

INDOOR AIR QUALITY

Sensor - Wall-mount, off-white plastic cover with LCD display C0SNSR50AE1L 77N39

Sensor - Wall-mount, off-white plastic cover, no display C0SNSR52AE1L 87N53

Sensor - Black plastic case with LCD display, rated for

plenum mounting

Sensor - Wall-mount, black plastic case, no display, rated for

plenum mounting

CO

Aspiration Box - for duct mounting non-plenum rated CO

®

Module A0CTRL31LS1 17A08

®

Sensor with Display K0SNSR01FF1 97W23

®

Sensor without Display K0SNSR00FF1 97W24

®

Ambient Control (0ºF) A2CWKT01LM1- 16F18 XX

Sensor Duct Mounting Kit C0MISC19AE1- 85L43

2

Item Catalog

No.

ELS

072

S4S

T2GARD51L-1 13T29 XX

T2GARD51M11 13T30 XX

T2GARD51M21 13T32 X

T2GARD51N-1 13T37

Factory

Building Automation System - - - X

A2CWKT04M-1- 16F26 X

A2CWKT02M-1- 16F24 XX

A2CWKT03N-1- 16F25

74M70

(208/230V, 460V only) LTAGFIK10/15/15

67E01

C0SNSR51AE1L 87N52

C0SNSR53AE1L 87N54

2

C0MISC16AE1- 90N43

ELS

090

S4S

ELS

120

S4S

ELS

ELS

120

150

S4D

S4D

ELS

180

S4D

ELS

240

S4D

O - Factory Installed with extended lead time.

X - Field Installed

Page 4

Page 5

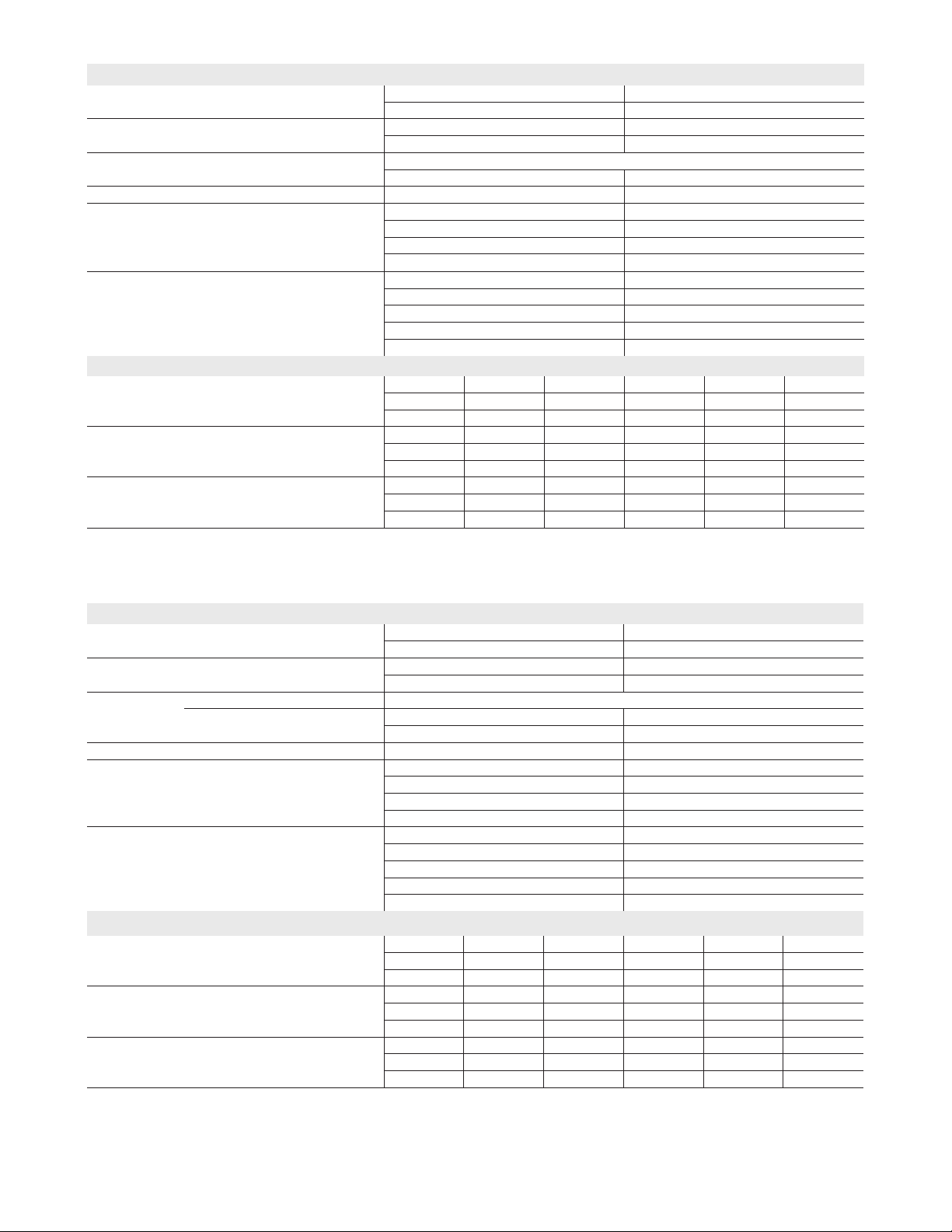

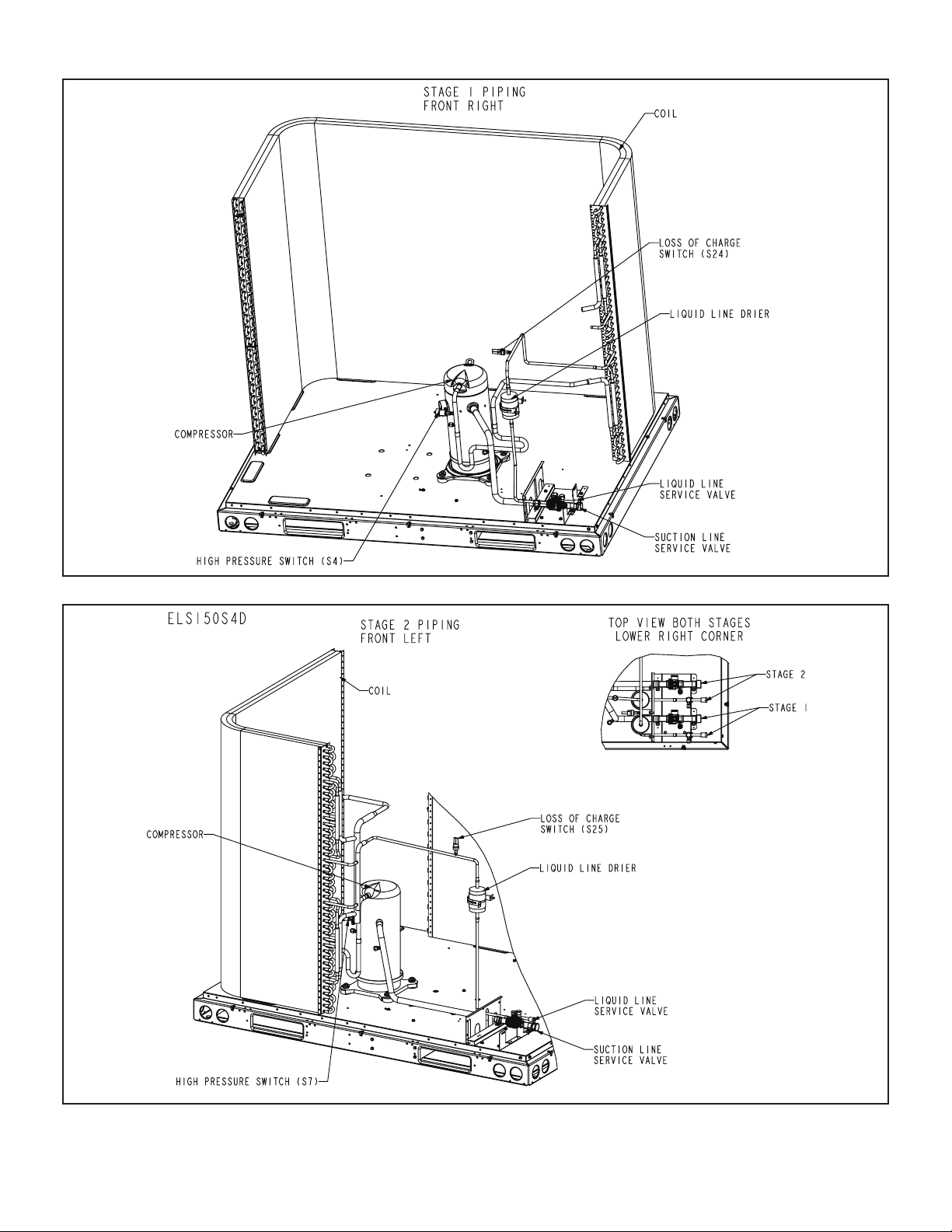

Unit Plumbing Parts Arrangement

ELS072S4S

ELS090S4S

Page 5

Page 6

ELS120S4S

ELS120S4D – STAGE 2

Page 6

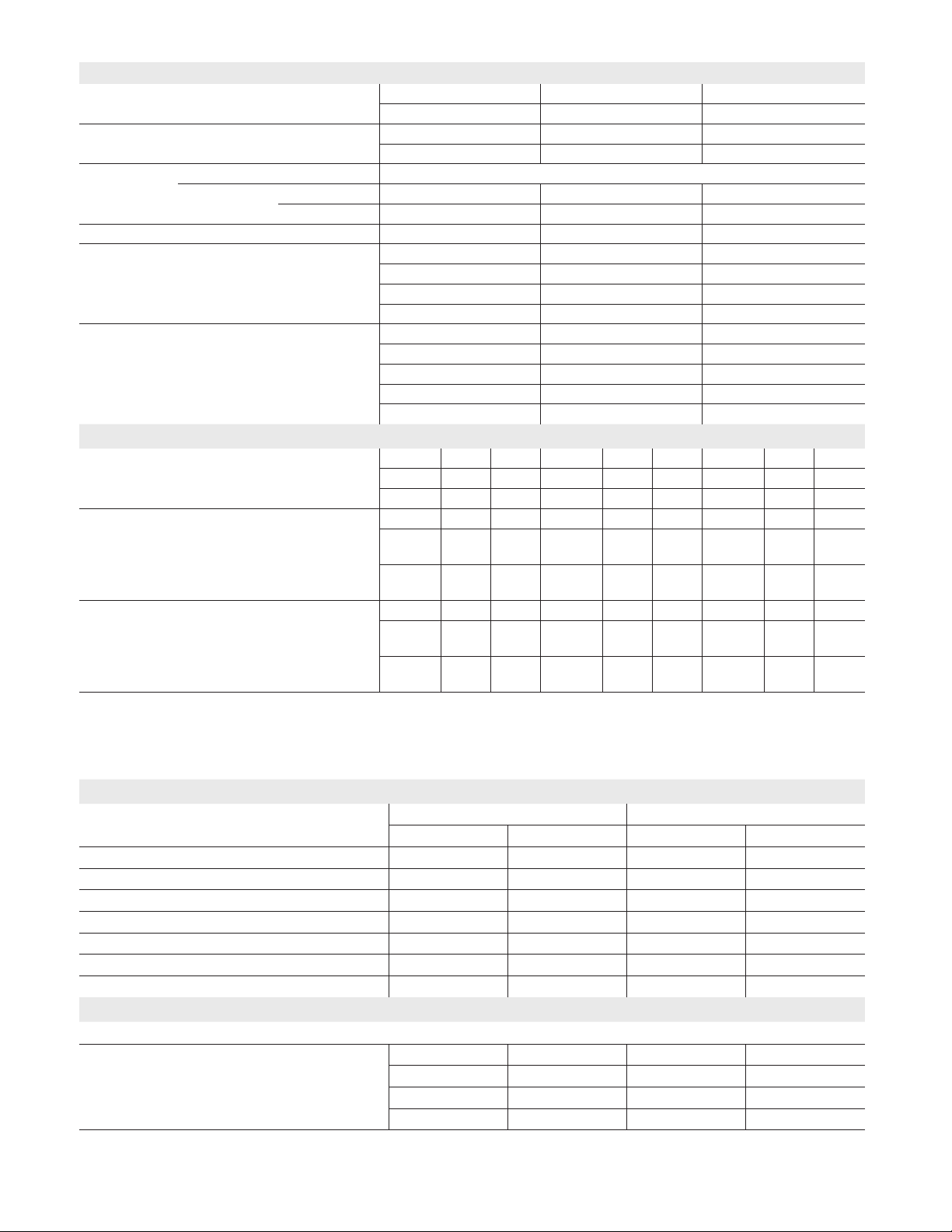

Page 7

ELS120S4D – STAGE 1

ELS150S4D – STAGE 2

Page 7

Page 8

ELS150S4D – STAGE 1

ELS180S4D – STAGE 2

Page 8

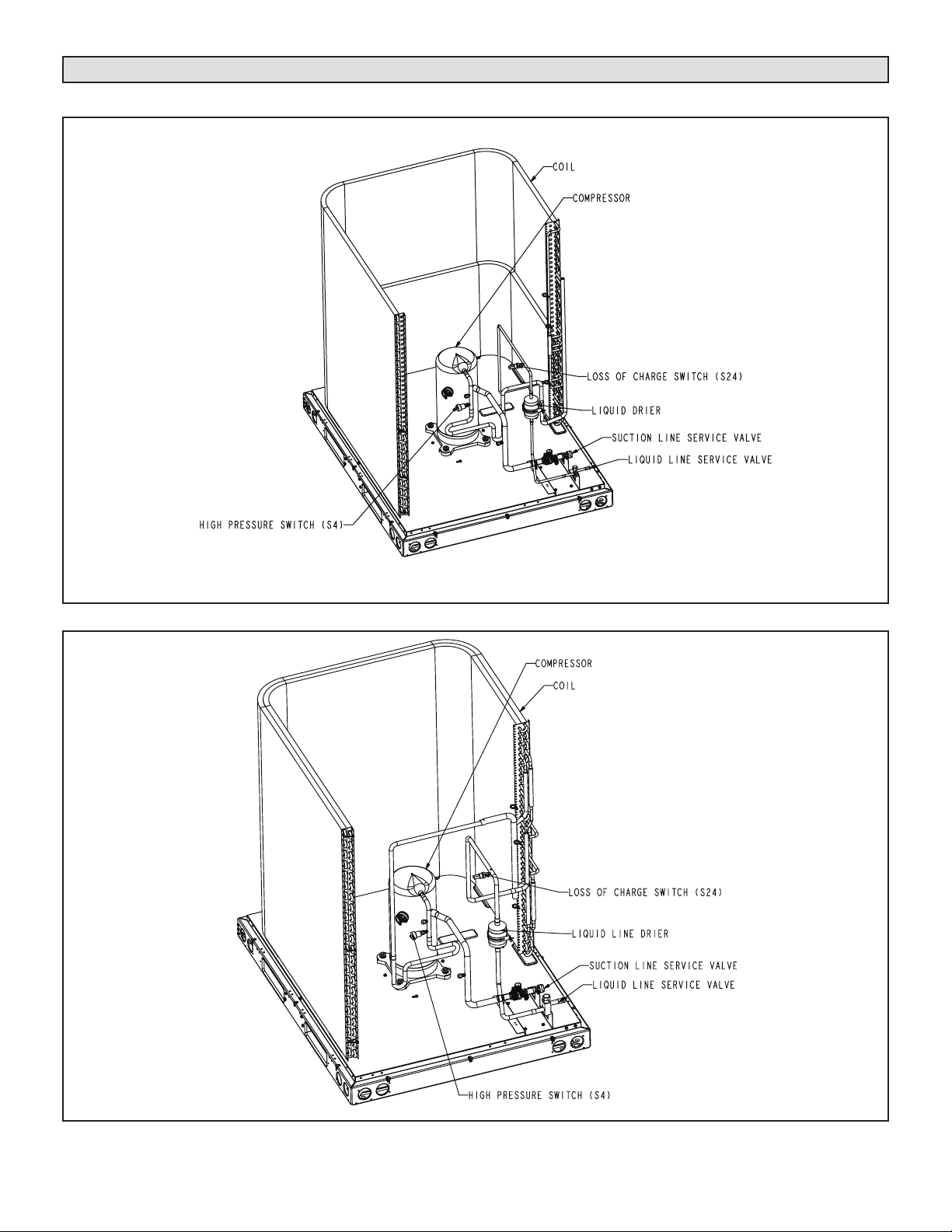

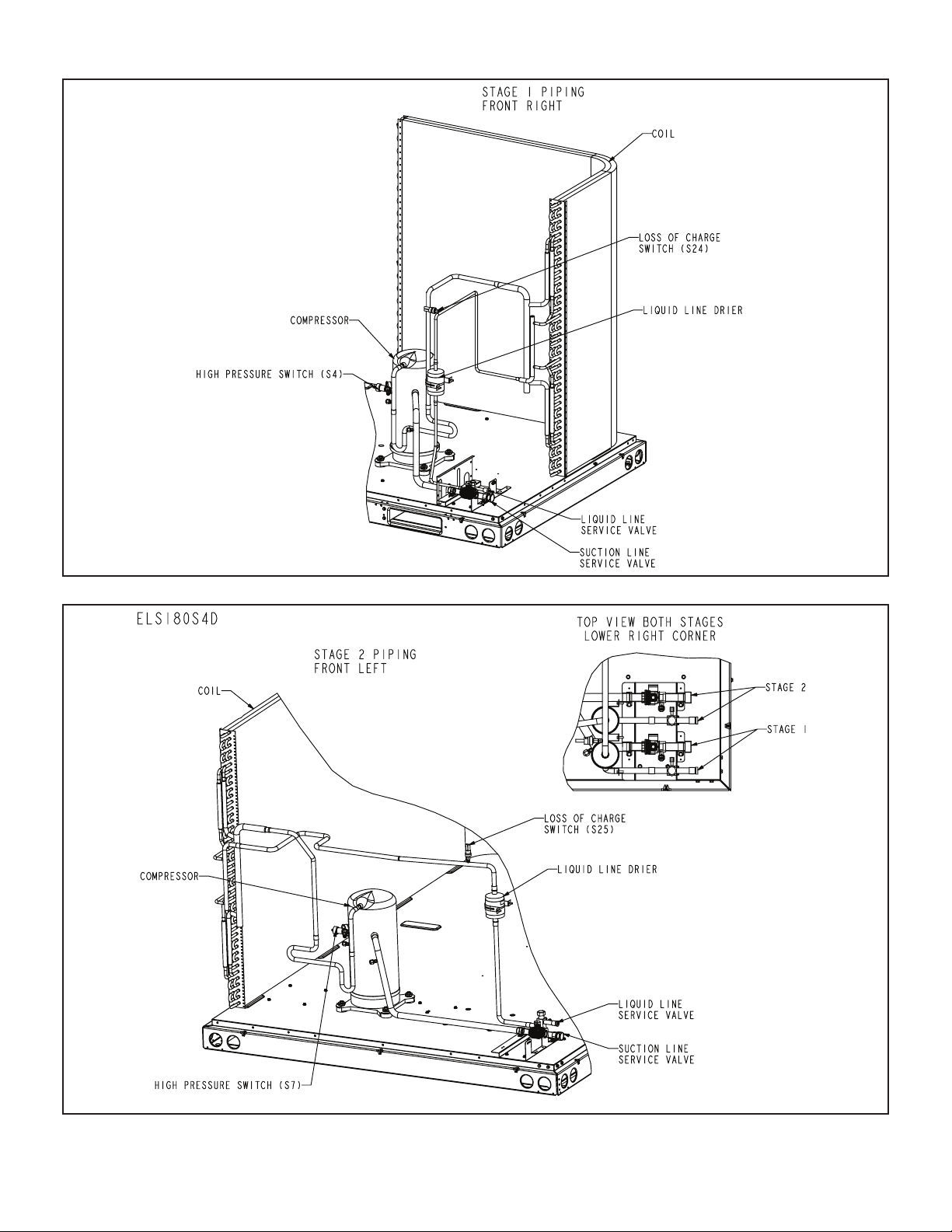

Page 9

ELS180S4D – STAGE 1

ELS240S4D – STAGE 2

Page 9

Page 10

ELS240S4D – STAGE 1

ELSY1120 S S4 D

Model Number Identication

Brand/Family

Elite™ Product Line

S = Split System Air Conditioner

Nominal Cooling Capacity -

090 = 7.5 Tons

120 = 10 To ns

150 = 12.5 Tons

180 = 15 To ns

240 = 20 To ns

Tons

072 = 6 Tons

Minor Design Sequence

1 = 1st Revision

2 = 2nd Revision

3 = 3rd Revision

Part Load Capability

S = Single Stage Compressor

T = Two Stage Compressor

Refrigerant Circuits

S = Single Circuit

D = Dual Circuits

Refrigerant Type

4 = R-410A

Cooling Efficiency

S = Standard Efficiency

Voltage

Y = 208/230V‐3 phase‐60hz

G = 460V‐3 phase‐60hz

J = 575V‐3 phase‐60hz

M = 380/420V‐3 phase‐50hz

Page 10

Page 11

Unit Control Box Components Arrangement

ICM CONTROLLER

(FIELD INSTALLED)

ICM CONTROLLER

(FIELD INSTALLED)

TRANSFORMER

TRANSFORMER

ELS072/090S

ICM CONTROLLER

(FIELD INSTALLED)

TRANSFORMER

TRANSFORMER

ELS120S

ICM CONTROLLER

(FIELD INSTALLED)

CONTACTOR

ELS120D/ELS150D

CONTACTOR

ELS180D / ELS240D

Page 11

Page 12

I-UNIT COMPONENTS

ORANGE

BLACK

208/230V TRANSFORMER

The ELS parts arrangements are shown on pages 5 - 10

and control boxes on page 11.

WARNING

Electrostatic discharge can affect

electronic components. Take care

during unit installation and service to

ELECTROSTATIC

DISCHARGE

(ESD)

Precautions and

Procedures

A-CONTROL BOX COMPONENTS

1 - Transformer T1 & T18

All ELS models use a single line voltage to 24VAC transformer mounted in the control box. Transformer T1 supplies power to control circuits in the ELS unit. The transformer is rated at 70VA and is protected by a 3.5 amp

circuit breaker (CB8). CB8 is internal to the transformer.

The 208/230 (Y) voltage transformers use two primary

voltage taps as shown in gure 1, while 460 (G) and 575

(J) voltage transformers use a single primary voltage tap.

T18 is identical to T1 used in ELS120, 150, 180 and 240

and is protected by internal circuit breaker CB18.

NOTE – 208 volt units are eld wired with the red wire

connected to control transformer. 230 volt units are factory

wired with the orange wire connected to control transfomer primary.

2 - Terminal Strip TB14 & TB2

Terminal strip TB14 used in all units distributes 24V power

and common from the transformer T18 to the control box

components. Terminal block TB2 used in the 120, 150,

180 and 240 units, distributes line voltage to line voltage

components.

3 - Condenser Fan Capacitors C1, C2, C18, C19

All ELS units use single-phase condenser fan motors. Motors are equipped with a fan run capacitor to maximize

motor efciency. Condenser fan capacitors C1, C2, C18

and C19 assist in the start up of condenser fan motors B4,

B5, B21 and B22. Capacitor ratings will be on condenser

fan motor nameplate.

protect the unit’s electronic controls.

Precautions will help to avoid control

exposure to electrostatic discharge

by putting the unit, the control and the

technician at the same electrostatic

potential. Touch hand and all tools

on an unpainted unit surface before

performing any service procedure to

neutralize electrostatic charge.

BLUE YELLOW

SECONDARY

208 VOLTS

RED

230 VOLTS

PRIMARY

FIGURE 1

4 - Compressor Contactor K1 (all units) K2 (120S4D,

150, 180, 240)

All compressor contactors are three-pole double-break

contactors with auxiliary switch with a 24V coil. In

ELS072, 090 and 120S4S, K1 energizes compressor B1.

In ELS120S4D, 150, 180 and 240 units, K1 and K2 energize compressors B1 and B2.

5 - Condenser Fan Relay K10 (all units) K149 (180, 240)

Condenser fan relays K10 and K149 are DPDT with a 24V

coil. In all units K10 energizes condenser fan B4 (fan 1) in

response to thermostat demand. In the ELS120S4D, 150,

180 and 240, K10 also energizes condenser fan B5 (fan 2)

In the ELS180 and 240 K149 energizes condenser fans B21

(fan 3) and B22 (fan 4) in response to thermostat demand.

6 - Cooling Relays K66 (120S4D, 150, 180, 240) & K67

(all units)

Cooling relays K66 and K67 are N.O. DPDT relays. K66

is energized from ”Y1” (1st stage cool), which in turn energizes contactor K2. K67 is energized by ”Y2” (2nd stage

cool), which in turn energizes contactor K1. This sequence

is the start up of compressors B1 and B2.

B-COOLING COMPONENTS

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

1 - Compressor

ALL ELS model units use scroll compressors. ELS072,

ELS090 and ELS120S4S models have one two-stage scroll

compressor. ELS120S4D, ELS150S4D, ELS180S4D and

ELS240S4D models have two single-stage scroll compressors.

Compressor consists of two involute spiral scrolls matched

together to generate a series of crescent shaped gas

pockets between them.

During compression, one scroll remains stationary while

the other scroll orbits around it.

Gas is drawn into the outer pocket, the pocket is sealed as

the scroll rotates.

As the spiral movement continues, gas pockets are

pushed to the center of the scrolls. Volume between the

pockets is simultaneously reduced.

When pocket reaches the center, gas is now high pressure and is forced out of a port located in the center of the

xed scrolls.

During compression, several pockets are compressed simultaneously resulting in a smooth continuous compression cycle.

Continuous ank contact, maintained by centrifugal force,

minimizes gas leakage and maximizes efciency.

Scroll compressor is tolerant to the effects of slugging and

contaminants. If this occurs, scrolls separate, allowing liquid or contaminants to be worked toward the center and

discharged.

Page 12

Page 13

Low gas pulses during compression reduces operational

sound levels.

Compressor motor is internally protected from excessive

current and temperature.

Compressor is installed in the unit on resilient rubber

mounts for vibration free operation.

Compressor B1 operates during all cooling demand and

is energized by contactor K1 upon receiving rst stage demand. Compressor B2 operates only during second stage

cooling demand, and is energized by contactor K2. See

ELECTRICAL section or compressor nameplate for com-

pressor specications.

ELS072, ELS090 and ELS120S4S Two Stage Models

A 24-volt DC solenoid valve inside the compressor controls

staging. When the 3-way solenoid is energized it moves

the lift ring assembly to block the ports and the compressor

operates at full-load or 100% capacity. When the solenoid

is de-energized the lift ring assembly moves to unblock the

compressor ports and the compressor operates at partload or approximately 67% of its full-load capacity.

The “loading” and “unloading” of the two stage scroll is

done “on the y” without shutting off the single-speed

compressor motor between stages.

FIGURE 2. Two-Stage Scroll Compressor

2 - Crankcase Heaters HR1 (all units) and HR2

(120S4D, 150, 180, 240)

All ELS series units use a belly-band type crankcase heater. Heater HR1 is wrapped around compressor B1 and

heater HR2 is wrapped around compressor B2. HR1 and

HR2 assure proper compressor lubrication at all times.

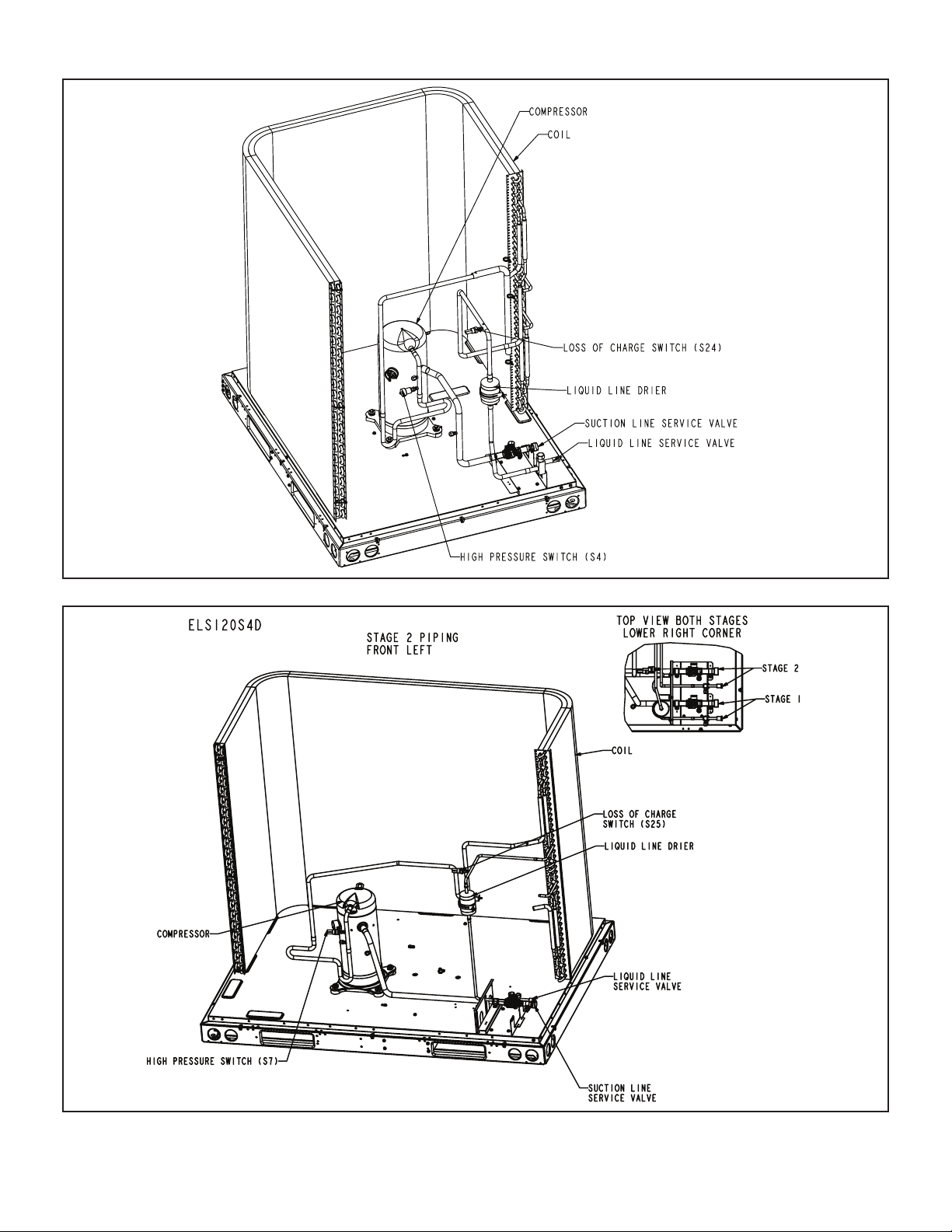

3 - High Pressure Switch S4 (all units) & S7 (120S4D,

150, 180, 240)

The high pressure switch is a manual-reset SPST N.C.

switch which opens on a pressure rise. The switch is located in the compressor discharge line and is wired in series with the compressor contactor coil. When discharge

pressure rises to 640 + 10 psig (4413 + 69 kP ) the switch

opens and the compressor is de-energized.

4 - Filter Drier (all units)

All ELS model units have a lter drier that is located in the

liquid line of each refrigerant circuit at the exit of each condenser coil. The drier removes contaminants and moisture

from the system.

5 - Condenser Fan B4 (all units) B5 (120S4S,120S4D,

150, 180, 240) B21 & B22 (180, 240)

See pages 2 and 3 for the specications on the condenser fans used in the ELS units. All condenser fans have

single- phase motors. The ELS072 and 090 units are

equipped with a single condenser fan. The ELS120 and

150 are equipped with two fans and the 180 and 240 have

four fans. The fan assembly may be removed for servicing

by removing the fan grill, unplugging the motor then loosening the motor bracket. The assembly will lift out.

6 - Loss of Charge Switch S24 & S25

The loss of charge switch is an auto-reset SPST N.C.

switch which opens on a pressure drop (almost a complete

loss of charge). All ELS units have S24 and the 120S4D

through 240 have S25. The switch is located in the liquid

line and wired in series with compressor contactor and

high pressure switch. S24 is wired in series with rst stage

cool and S25 is wired in series with second stage cool.

When pressure drops below 40+ 5 psig (indicating loss of

charge in the system) the switch opens and compressor

is de-energized. The switch automatically resets when refrigerant is added and pressure in the discharge line rises

above 90+ 5 psig.

7 - Head Pressure Control A190 & A191 and Pressure

Transducer A188 & A189

The low ambient kit is designed to maintain the head pressure across the liquid line by varying the condenser speed

fan.

Head pressure Control A190 (all units) and A191 (ELS180,

240) is used to set the desired liquid line pressure (315

psig in ELS units). The pressure transducer A190 (All

units) A191 (120S4D through 240) measures the liquid

line pressure sending an analog signal to the head pressure controller. If pressure falls below set point, the head

pressure controller reduces the fan speed to increase the

liquid line pressure to the set point.

II- REFRIGERANT SYSTEM

A-Plumbing

Field refrigerant piping consists of liquid and suction lines

connecting the condensing unit and the indoor unit. Liquid

and suction service valves are located in a compartment

at the corner of the unit below the control box. Piping can

be routed directly from the service valves or eld supplied

elbows can be added to divert the piping as required Refer

to table 1 for eld-fabricated refrigerant line sizes for runs

up to 50 linear feet (15 m).

TABLE 1

ELS Unit Liquid Line Suction Line

072 3/8" (10mm) 1-1/8" (29mm)

090 5/8" (16mm) 1-1/8" (29mm)

120S4S 5/8" (16mm) 1-1/8" (29mm)

120S4D 3/8" (10mm) 1-1/8" (29mm)

150 3/8" (10mm) 1-1/8" (29mm)

180 5/8" (16mm) 1-1/8" (29mm)

240 5/8" (16mm) 1-1/8" (29mm)

Page 13

Page 14

Refrigerant Line Limitations

6

6

Cap Tightening

Distances

You may install the unit in applications that have line set

lengths of up to 50 linear feet (15 m) with refrigerant line

sizes as outlined in table 1 (excluding equivalent length of

ttings). Size refrigerant lines greater than 50 linear feet

(15m or greater) according to the Lennox Refrigerant Piping Design and Fabrication Guidelines (Corp. 9351-L9) or

latest version.

B-Service Valves

OPERATING SERVICE VALVES

The liquid and suction line service valves are typically

used for removing refrigerant, ushing, leak testing, evacuating, checking charge and charging.

IMPORTANT

Only use Allen wrenches of sufcient hardness (50Rc

- Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory-torqued (from 9 ft-lbs

for small valves, to 25 ft-lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using an

Allen wrench rated at less than 50Rc risks rounding

or breaking off the wrench, or stripping the valve stem

recess.

Each valve is equipped with a service port which has a

factory-installed valve stem.

1/12 TURN

12

1

2

3

4

7

5

9

10

8

11

1/6 TURN

12

1

2

3

4

7

5

FIGURE 3

11

10

9

8

IMPORTANT

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and tted

snugly over the cap before tightening.

TABLE 2

Torque Requirements

Part Recommended Torque

Service valve cap 8 ft.-lb. 11 NM

Sheet metal screws 16 in.-lb. 2 NM

Machine screws #10 28 in.-lb. 3 NM

Compressor bolts 90 in.-lb. 10 NM

Gauge port seal cap 8 ft.-lb. 11 NM

To Access Angle-Type Service Port:

A service port cap protects the service port core from contamination and serves as the primary leak seal.

1 - Remove service port cap with an appropriately

sized wrench.

2 - Connect gauge to the service port.

3 - When testing is completed, replace service port cap

and tighten as follows:

• With Torque Wrench: Finger tighten and then tight-

en per table 2.

• Without Torque Wrench: Finger tighten and use an

appropriately sized wrench to turn an additional 1/6

turn clockwise as illustrated in gure 2.

To Open Liquid Line Service Valve:

1 - Remove stem cap with an adjustable wrench.

2 - Using service wrench and 5/16" hex head extension

if needed (part #49A71) back the stem out

counterclockwise until the valve stem just touches

the retaining ring.

3 - Replace stem cap. Tighten nger tight, then tighten

an additional 1/6 turn. Do not over torque.

To Close Liquid Line Service Valve:

1 - Remove stem cap with an adjustable wrench.

2 - Using service wrench and 5/16" hex head extension

if needed (part #49A71), turn stem clockwise to seat

the valve. Tighten rmly.

3 - Replace stem cap. Tighten nger tight, then tighten

an additional 1/6 turn. Do not over torque.

Service (Ball) Valve

Some ELS units are equipped with a full service ball valve,

as shown in gure 4. One service port that contains a

valve core is present in this valve. A cap is also provided

to seal off the service port. The valve is not rebuildable so

it must always be replaced if failure has occurred.

Opening the Suction Line Service Valve

1 - Remove the stem cap with an adjustable wrench.

2 - Using a service wrench, turn the stem

counterclockwise for 1/4 of a turn.

3 - Replace the stem cap and tighten it rmly.

Closing the Suction Line Service Valve

1 - Remove the stem cap with an adjustable wrench.

2 - Using a service wrench, turn the stem clockwise for

1/4 of a turn.

3 - Replace the stem cap and tighten rmly.

Page 14

Page 15

Liquid And Suction Line Service Valve

(Valve Open)

SUCTION LINE (BALL TYPE) SERVICE VALVE

VALVE CORE

insert hex

wrench here

service

port

to outdoor coil

service port

cap

Schrader

valve

to indoor coil

Liquid And Suction Line Service Valve

(Valve Closed)

service

port

to outdoor coil

insert hex

wrench here

stem cap

stem cap

III-START-UP

The following is a general procedure and does not apply

to all thermostat control systems. Refer to sequence of

operation in this manual for more information.

IMPORTANT

Crankcase heaters must be energized for 24 hours before

attempting to start compressors. Set thermostat so there

is no compressor demand before closing disconnect

switch. Attempting to start compressors during the 24hour warm-up period could result in damage or failed

compressors.

1 - Set fan switch to AUTO or ON and move the system

selection switch to COOL. Adjust the thermostat to a

setting far enough below room temperature to bring

on compressors. Compressors will start and cycle

on demand from the thermostat (allowing for unit

and thermostat time delays).

2 - Each circuit is eld charged with HCFC-410A

refrigerant.

3 - Refer to Charging section for proper method of

checking and charging the system.

service

port cap

Schrader valve open

to line set when valve

is closed (front seated)

(valve front seated)

FIGURE 4

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90

ROTATE STEM COUNTERCLOCKWISE 90

TO CLOSE

TO COMPRESSOR

SERVICE PORT

CAP

STEM CAP

STEM

(SHOWN OPEN)

FROM INDOOR COIL

SERVICE PORT

to indoor coil

TO OPEN

BALL

IMPORTANT

Three-phase scroll compressors must be phased

sequentially to ensure correct compressor rotation

and operation. At compressor start-up, a rise in

discharge and drop in suction pressures indicate proper

compressor phasing and operation. If discharge and

suctions pressures do not perform normally, follow the

steps below to correctly phase in the unit.

1 - Disconnect power to the unit.

2 - Reverse any two eld power leads (L1 and L3

preferred) to the unit.

3 - Reapply power to the unit.

Discharge and suction pressures should operate at their

normal start-up ranges.

NOTE - Compressor noise level will be signicantly higher when phasing is incorrect and the unit will not provide

cooling when compressor is operating backwards. Continued backward operation will cause the compressor to

cycle on internal protector.

FIGURE 5

Page 15

Page 16

IV-CHARGING

A-Leak Testing

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

Fire, Explosion and Personal Safety hazard.

Failure to follow this warning could result in

damage, personal injury or death.

Never use oxygen to pressurize or purge

refrigeration lines. Oxygen, when exposed

to a spark or open ame, can cause re and/

or an explosion, that could result in property

damage, personal injury or death.

1 - Connect an HFC-410A manifold gauge set as

illustrated in gure 6.

2 - Open the valve on the HFC-410A cylinder (suction

only).

3 - Open the high pressure side of the manifold to allow

HFC-410A into the line set and indoor unit. Weigh in

a trace amount of HFC-410A. [A trace amount is a

maximum of two ounces (57 g) refrigerant or three

pounds (31 kPa) pressure].

4 - Close the valve on the HFC-410A cylinder and the

valve on the high pressure side of the manifold

gauge set.

5 - Disconnect the HFC-410A cylinder.

6 - Connect a cylinder of dry nitrogen with a pressure

regulating valve to the center port of the manifold

gauge set.

7 - Adjust dry nitrogen pressure to 150 psig (1034 kPa).

Open the valve on the high side of the manifold

gauge set in order to pressurize the line set and the

indoor unit.

8 - After a few minutes, open one of the service valve

ports and verify that the refrigerant added to the

system earlier is measurable with a leak detector.

NOTE - Amounts of refrigerant will vary with line lengths.

9 - Check all joints for leaks.

10 - Purge dry nitrogen and HFC-410A mixture.

11 - Correct any leaks and recheck.

12 - After leak testing, disconnect gauges from service

ports.

Page 16

Page 17

MANIFOLD

A

Connect an HFC-410A manifold gauge set high pressure hose to the

HFC-410A and nitrogen containers.

NOTE - Remove cores from service valves if not already done.

suction valve service port.

B With both manifold valves closed, connect the cylinder of HFC-410A

refrigerant to the center port of the manifold gauge set.

C After the line set has been connected to both the indoor and outdoor

units, check the line set connections and indoor unit for leaks. Use the

following procedure to test for leaks:

NOTE - LATER IN THE PROCEDURE, THE HFC-410A CONTAINER WILL BE REPLACE BY THE

NITROGEN CONTAINER.

NITROGEN

GAUGE SET

OUTDOOR UNIT

B-Evacuating the System

OUTDOOR UNIT

A

A34000 1/4 SAE

TEE WITH

SWIVEL

COUPLER

C

B

HFC-410A

FIGURE 6

MICRON GAUGE

50

TO SUCTION

SERVICE VALV E

TO SUCTION

SERVICE VALV E

A

MANIFOLD

GAUGE SET

TO LIQUID

LINE SERVICE

VALV E

B

D

NITROGEN

VACUUM PUMP

HFC-410A

RECOMMEND MINIMUM

3/8” HOSE

A Connect low side of manifold gauge set with 1/4 SAE in-line tee to suction line

service valve

B Connect high side of manifold gauge set to liquid line service valve

C Connect micron gauge available connector on the 1/4 SAE in-line tee.

D Connect the vacuum pump (with vacuum gauge) to the center port of the

manifold gauge set. The center port line will be used later for both the

FIGURE 7

Page 17

Page 18

WARNING

Possible equipment damage.

Avoid deep vacuum operation. Do not use compressors

to evacuate a system. Extremely low vacuum can cause

internal arcing and compressor failure. Damage caused

by deep vacuum operation will void warranty.

IMPORTANT

Use a thermocouple or thermistor electronic vacuum

gauge that is calibrated in microns. Use an instrument

capable of accurately measuring down to 50 microns.

Evacuating the system of non-condensables is critical for

proper operation of the unit. Non-condensables are dened as any gas that will not condense under temperatures and pressures present during operation of an air

conditioning system. Non-condensables and water suction combine with refrigerant to produce substances that

corrode copper piping and compressor parts.

NOTE - Remove cores from service valves if not already

done.

1 - Connect an HFC-410A manifold gauge set as

illustrated in gure 5.

2 - Open both manifold valves and start the vacuum

pump.

3 - Evacuate the line set and indoor unit to an absolute

pressure of 23,000 microns (29 inches of mercury).

NOTE - During the early stages of evacuation, it is desirable to close the manifold gauge valve at least once to

determine if there is a rapid rise in pressure this indicates

a relatively large leak. If this occurs, repeat the leak testing procedure.

NOTE - The term absolute pressure means the total actual pressure within a given volume or system, above the

absolute zero of pressure. Absolute pressure in a vacuum

is equal to atmospheric pressure minus vacuum pressure.

4 - When the absolute pressure reaches 23,000

microns (29 inches of mercury), close the manifold

gauge valves, turn off the vacuum pump and

disconnect the manifold gauge center port hose

from vacuum pump. Attach the manifold center

port hose to a dry nitrogen cylinder with pressure

regulator set to 150 psig (1034 kPa) and purge the

hose. Open the manifold gauge valves to break the

vacuum in the line set and indoor unit. Close the

manifold gauge valves.

5 - Shut off the dry nitrogen cylinder and remove the

manifold gauge hose from the cylinder. Open the

manifold gauge valves to release dry nitrogen from

the line set and indoor unit.

6 - Reconnect the manifold gauge to vacuum pump,

turn pump on, and continue to evacuate line set and

indoor unit until the absolute pressure does not rise

above 500 microns within a 20-minute period after

shutting off vacuum pump and closing the manifold

gauge valves.

7 - When the absolute pressure requirement above has

been met, disconnect the manifold hose from the

vacuum pump and connect it to an upright cylinder

of HFC-410A refrigerant. Open the manifold gauge

valve pressure line set to break vacuum with 2 to

5 psi.

8 - Perform the following:

A - Close manifold gauge valves

B - Shut off HFC-410A cylinder

C - Reinstall service valve cores by removing manifold

hose from service valve. Quickly install cores

with core tool while maintaining a positive system

pressure.

D - Replace the stem caps and secure nger tight, then

tighten an additional one-sixth (1/6) of a turn as

illustrated in gure 2.

C-Charging

ELS units have a factory holding charge of 2 pounds of

HFC-410A in each circuit. Additional refrigerant will need

to be added during installation (table 3).

TABLE 3

Adding Refrigerant

lbs

Stage 2

lbs

for 25ft

line set

Liq.

Line

Dia.

Suction

Line

Dia.

Ounces

Adjustment

per foot of

line set

1

Stage 1

Models

ELS072S4S 18.5N/A 3/8 1-1/8 0.7

ELS090S4S 21.75N/A 5/8 1-1/8 1.7

ELS120S4S23N/A 5/8 1-1/8 1.7

ELS120S4D12123/8 1-1/8 0.7

ELS150S4D15 15.53/8 1-1/8 0.7

ELS180S4D 23.75 23.55/8 1-1/8 1.7

ELS240S4D 22.5 23.55/8 1-1/8 1.7

1

If line set length is greater than 25 feet, add this amount

for 25ft

line set

to each circuit. If line set is less than 25 feet, subtract this

amount from each circuit. Refer to Lennox Refrigerant

Piping Design and Fabrication Guidelines for more information.

NOTE - Refrigerant line sets longer than 200 feet (60 meters) are not recommended. For assistance contact Lennox Application Department.

To check the charge, use the following procedure:

1 - Attach gauge manifolds and operate unit in cooling

mode until system stabilizes (approximately ve

minutes). Make sure outdoor air dampers are

closed.

2 - Use a thermometer to accurately measure the

outdoor ambient temperature.

3 - Apply the outdoor temperature to tables 5 and 6 to

determine normal operating pressures.

Page 18

Page 19

4 - Compare the normal operating pressures to

the pressures obtained from the gauges. Minor

variations in these pressures may be expected due

to differences in installations. Signicant differences

could mean that the system is not properly charged

or that a problem exists with some component in

the system. Correct any system problems before

proceeding.

5 - If discharge pressure is high, remove refrigerant

from the system. If discharge pressure is low, add

refrigerant to the system.

• Add or remove charge in increments.

• Allow the system to stabilize each time refrigerant is

added or removed.

CHARGE VERIFICATION - APPROACH METHOD

Use the following approach method along with the normal

operating pressures to conrm readings.

1 - Using the same thermometer, compare liquid

temperature at service valve to outdoor ambient

temperature.

Approach Temperature = Liquid temperature minus

ambient temperature

TABLE 5

HFC-410A Normal Operating Pressures (Liquid ±10 and Suction ±5 psig) (Single-Stage Units)**

2 - Approach temperature should as indicated in table

4 for each stage. An approach temperature greater

than this value indicates an undercharge. An

approach temperature less than this value indicates

an overcharge.

3 - Do not use the approach method if system pressures

do not match pressures in table 5 except when the

outdoor ambient temperature is below 65ºF (18ºC).

The approach method is not valid for grossly overor undercharged systems.

TABLE 4

HFC-410A Approach Temperatures

Approach

Models Stage

ELS072S4S 1 4.0 2.2

ELS090S4S 1 7.0 3.9

ELS120S4S 1 4.0 2.2

ELS120S4D

ELS150S4D

ELS180S4D

ELS240S4D

1 5.0 2.8

2 5.0 2.8

1 7.0 3.9

2 5.0 2.8

1 4.0 2.2

2 4.0 2.2

1 7.0 3.9

2 8.0 4.4

Temperature

(ºF)

Approach

Temperature

(ºC)

Temp*

65 F (18 C)

75 F (24 C)

85 F (29 C)

95 F (35 C)

105 F (41 C)

115 F (46 C)

125 F (52 C)

STD. CFM

*Temperature of air entering outdoor coil.

**With indoor conditions at 80ºF dry bulb and 67ºF wet bulb temperatures.

Liquid Suction Liquid Suction Liquid Suction

245 137 240 128 243 135

327 143 338 131 332 138

377 145 385 133 378 139

426 148 435 135 434 141

484 150 489 136 491 142

540 155 545 140 548 146

-072S4S -090S4S -120S4S

283 141 294 130 285 136

2600 2725 3850

Page 19

Page 20

TABLE 6

HFC-410A Normal Operating Pressures (Liquid ±10 and Suction ±5 psig) (Dual-Stage Units)**

-120S4D

Temp*

65 F (18 C) 244 133 240 133

75 F (24 C) 282 136 278 135

85 F (29 C) 326 139 322 137

95 F (35 C) 373 141 372 138

105 F (41 C) 423 142 420 141

115 F (46 C) 477 144 476 143

125 F (52 C) 534 147 539 145

STD. CFM 4000

Temp*

F (C)*

65 F (18 C) 233 110 236 110

75 F (24 C) 274 120 276 119

85 F (29 C) 317 128 319 125

95 F (35 C) 364 134 366 131

105 F (41 C) 418 138 416 132

115 F (46 C) 475 141 468 134

125 F (52 C) 536 143 529 136

STD. CFM 5150

STAGE 1

Liquid Suction Liquid Suction

-180S4D

STAGE 1

Liquid Suction Liquid Suction

-120S4D

STAGE 2

-180S4D

STAGE 2

-150S4D

STAGE 1

Liquid Suction Liquid Suction

254 132 254 130

291 135 289 133

337 138 336 134

381 140 382 136

432 142 433 139

487 144 489 141

543 147 550 145

4400

-240S4D

STAGE 1

Liquid Suction Liquid Suction

236 129 236 128

275 132 275 129

321 134 322 131

370 137 368 133

420 139 425 136

477 142 478 139

539 146 534 144

6975

-150S4D

STAGE

-240S4D

STAGE

2

2

*Temperature of air entering outdoor coil.

**With indoor conditions at 80ºF dry bulb and 67ºF wet bulb temperatures.

TABLE 7. Approach Temperatures – Residential Matchups

Models Approach Temperature

Outdoor Indoor Stage (ºF) (+/- 1) (ºC) (+/- 0.5)

ELS120S4D

ELS120S4D (2) CH33-62D

ELS120S4D (2) CH23-068

ELS120S4D (2) CX35-60C

ELS120S4D (2) CX35-60D

(2) CBA27UHE-060 or

(2) CBA38MV-060

1 4 2.2

2 4 2.2

1 4 2.2

2 4 2.2

1 4 2.2

2 4 2.2

1 4 2.2

2 4 2.2

1 4 2.2

2 4 2.2

Page 20

Page 21

TABLE 8. Normal Operating Temperatures – Residential Matchups

ELS120S4D + (2) CBA27UHE-060 or

(2) CBA38MV-060

Normal Operating Pressures Normal Operating Pressures Normal Operating Pressures

Liquid at

ODSV

Suction

STAGE 1

STAGE 2

(ºF)

65 251 133 65 240 125 65 241 128

75 292 135 75 280 129 75 281 131

85 340 137 85 324 132 85 325 134

95 391 140 95 372 135 95 373 137

105 446 143 105 425 139 105 427 141

115 505 145 115 483 143 115 484 144

125 569 148 125 545 146 125 547 147

65 250 131

75 287 134 75 282 128 75 283 131

85 333 136 85 326 131 85 326 133

95 384 139 95 374 134 95 375 136

105 441 142 105 427 137 105 428 139

115 501 144 115 484 141 115 486 142

125 566 147 125 548 145 125 550 146

ELS120S4D + (2) CH33-62D ELS120S4D + (2) CH23-068

(ºF)

STAGE 1

65 241 125

STAGE 2

Liquid at

ODSV

Suction

(ºF)

STAGE 1

65 242 128

STAGE 2

Liquid at

Normal Operating Temperatures – Residential Matchups

ELS120S4D + (2) CX35-60C ELS120S4D + (2) CX35-60D

Normal Operating Pressures Normal Operating Pressures

STAGE 1

STAGE 2

(ºF)

65 241 130 65 240 127

75 282 133 75 281 130

85 326 136 85 325 134

95 374 139 95 373 137

105 427 142 105 427 141

115 485 145 115 484 145

125 548 148 125 548 148

65 243 129

75 282 132 75 282 130

85 327 135 85 327 133

95 375 138 95 374 136

105 428 141 105 428 139

115 486 144 115 486 143

125 550 147 125 550 146

Liquid at

ODSV

Suction

(ºF)

STAGE 1

65 241 127

STAGE 2

Liquid at

ODSV

ODSV

Suction

Suction

Page 21

Page 22

V-MAINTENANCE

Installation and service must be performed by a licensed

professional installer (or equivalent) or a service agency. At the beginning of each cooling season, the system

should be checked as follows:

WARNING

Electric Shock Hazard. Can cause injury or

death. Unit must be properly grounded in

accordance with national and local codes.

Line voltage is present at all components

when unit is not in operation on units with

single-pole contactors. Disconnect all remote

electric power supplies before opening

access panel. Unit may have multiple power

supplies.

OUTDOOR UNIT

1 - Clean and inspect outdoor coil (may be ushed with

a water hose). Ensure power is off before cleaning.

2 - Outdoor unit fan motor is pre-lubricated and sealed.

No further lubrication is needed.

3 - Visually inspect all connecting lines, joints and coils

for evidence of oil leaks.

4 - Check all wiring for loose connections.

5 - Check for correct voltage at unit (unit operating).

6 - Check amp draw on outdoor fan motor.

UNIT NAMEPLATE: _________ ACTUAL: __________

NOTE – If insufcient heating or cooling occurs, the

unit should be gauged and refrigerant charge should be

checked.

INDOOR COIL

1 - Clean coil if necessary.

2 - Check connecting lines, joints and coil for evidence

of oil leaks.

3 - Check condensate line and clean if necessary.

INDOOR UNIT

1 - Clean or change lters.

2 - Blower motors are prelubricated and permanently

sealed. No more lubrication is needed.

3 - Adjust blower speed for cooling. Measure the

pressure drop over the coil to determine the correct

blower CFM. Refer to the unit information service

manual for pressure drop tables and procedure.

4 - Belt Drive Blowers - Check belt for wear and proper

tension.

5 - Check all wiring for loose connections.

6 - Check for correct voltage at unit. (blower operating)

7 - Check amp draw on blower motor.

UNIT NAMEPLATE: _________ ACTUAL: __________

Page 22

Page 23

VI-Wiring Diagram and Sequence of Operation

A-ELS072-120S

6

R

TB14

CB8

T1

208V

400V

240/460/575V

24V

C2

CB8

K10,-1

K67-1

S24

T1

TB14

C1

CIRCUIT BREAKER-TRANS T1

C

SWITCH-LOSS OF CHARGE,COMP 1

TRANSFORMER-CONTROL

TERMINAL STRIP-CLASS II VOLTAGE

S24

4

1

4

1

3

2

1

3

2

COOL 2

COOL 1

1 - Cooling demand energizes at thermostat terminal

Y1. Voltage passes through N.C. loss of charge

switch S24 and N.C. high pressure switch S4.

2 - Compressor contactor K1 and outdoor fan relay

K10 are energized.

3 - K1-1 closes, energizing compressor B1 on low

Page 23

LINE VOLTAGE FIELD INSTALLED

DENOTES OPTIONAL COMPONENTS

II

WIRING DIAGRAM

09/17

DUAL SPEED COMPRESSOR

ELS-072,090,120-G,J,M,Y

2011

SECTION A2

537903-01

REV. 0

speed and K10-1 closes, energizing outdoor fan

B4 and B5 in ELS120S. K1-2 opens to de-energize

crankcase heater HR1.

4 - On two-speed systems, voltage passes through

K67-1, energizes compressor solenoid L34,

switching compressor to high speed.

Page 24

B-ELS120S4D, 150

R

TB14

6

4

CIRCUIT BREAKER-TRANS T1

CB8

208V

400V

240 / 460 / 575V

K1-2

S25

K2-2

1

4

3

B4

3

SWITCH-LOSS OF CHARGE,COMP 1

S24

SWITCH-LOSS OF CHARGE,COMP 2

S25

TRANSFORMER-CONTROL

T1

S24

1

2

CB8

208V

T1

400V

240 / 460 / 575V

1

3

2

B5

C2

C1

TB14

C

LINE VOLTAGE FIELD INSTALLED

DENOTES OPTIONAL COMPONENTS

II

COOL 2

COOL 1

TERMINAL STRIP-CLASS II VOLTAGE

K10,-1

K66,-1,2

K67,-1,2

TB14

First Stage Cool

1 - Cooling demand energizes K66 relay coil at

thermostat terminal Y1.

2 - K66-1 contacts close, voltage passes through S24

loss of charge switch and high pressure switch S4,

energizing compressor contactor K1.

3 - At the same time, K66-2 contacts close, energizing

outdoor fan relay K10.

4 - K1-1 closes, energizing compressor B1. K10-1

closes energizing outdoor fans B4 and B5. K1-2

Page 24

WIRING DIAGRAM

08/17

ELS-120,150-G,J,M,Y

SECTION A 3

REV. 0

537904-01

opens to de-energize crankcase heater HR1.

Second Stage Cool

5 - Cooling demand energizes K67 relay coil at

thermostat terminal Y2.

6 - K67-1 contacts close, voltage passes through S25

loss of charge switch and S7 high pressure switch

energizing compressor contactor K2.

7 - K2-1 closes energizing compressor B2. K2-2 opens

to de-energize crankcase heater HR2.

Page 25

C-ELS180, 240

208V

CB8

T1

AND

R

TB14

6

9

4

9

6

6

CB8

5

2

S25

S24

208V

T1

COOL 2

C2

COOL 1

C1

400V

240 / 460 / 575V

CIRCUIT BREAKER-TRANS T1

CB8

3

K10,-1

K66,-1,2

K67,-1,2

K149,-1

4

3

1

1

2

400V

240 / 460 / 575V

3

1

2

TB14

C

SWITCH-LOSS OF CHARGE,COMP 1

S24

S25

SWITCH-LOSS OF CHARGE,COMP 2

T1

TRANSFORMER-CONTROL

4

3

1

2

TB14

TERMINAL STRIP-CLASS II VOLTAGE

3

1

2

DENOTES OPTIONAL COMPONENTS

LINE VOLTAGE FIELD INSTALLED

II

First Stage Cool

1 - Cooling demand energizes K66 relay coil at

thermostat terminal Y1.

2 - K66-1 contacts close, voltage passes through S24

loss of charge switch and high pressure switch S4

energizing contactor K1.

3 - At the same time, K66-2 closes energizing relay K10.

4 - K1-1 contacts close, energizing compressor B1.

K10-1 contacts close energizing outdoor fans B4

and B5. K1-2 opens to de-energize crankcase

heater HR1.

Page 25

WIRING DIAGRAM

08/17

SINGLE SPEED COMPRESSOR

ELS-180,240-G,J,M,Y

SECTION A 4

REV. 0

537905-01

Second Stage Cool

5 - Cooling demand energizes K67 relay coil at

thermostat terminal Y2.

6 - K67-1 contacts close, voltage passes through S25

loss of charge switch and S7 high pressure switch

energizing K2.

7 - At the same time, K67-2 closes, energizing relay K149.

8 - K2-1 contacts close energizing compressor B2 and

K149-1 contacts close, energizing outdoor fans B21

and B22. K2-2 opens to de-energize crankcase

heater HR2.

Loading...

Loading...