Lennox Elite ELO183DH Series Installation Instructions Manual

INSTALLATION

E2012 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

IMPORTANT

This unit must be serviced annually by a licensed

professional technician, or equivalent.

WARNING

Improper installation, adjustment, alteration, ser

vice, or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information, consult a licensed profes

sional installer, or equivalent, or service agency.

WARNING

Do not store or use gasoline or other flammable va

pors and liquids in the vicinity of this or any other

appliance.

CAUTION

When venting this appliance, keep vent terminal

free of snow, ice and debris.

INSTRUCTIONS

ELO183DH Series Units

OIL UNITS

506903-01

12/2012

Supersedes 04/2012

Table of Contents

Elite Series Oil Furnace 1........................

Shipping and Packing List 1......................

Unit Dimensions 2...............................

ELO183DH Unit Parts Arrangement 3.............

Oil Burner Parts Arrangement 3...................

Requirements 4.................................

Combustion & Ventilation Air 5....................

Installation 7....................................

Adjustments 8..................................

Venting 9......................................

Flue Connections 10..............................

Supply & Return Air Plenums 11...................

Optional Filter Kit 11..............................

Oil Supply Line Sizing 11.........................

Oil Supply Line & Filter Connections 13.............

Leak Check 13...................................

Electrical Wiring 13...............................

Unit Start-Up & Adjustments 15....................

Service 16......................................

Burner Control 17................................

Troubleshooting 19...............................

Start-Up & Performance Checklist 24...............

Elite® Series Oil Furnace

These instructions are intended as a general guide and do

not supersede local codes in any way. Only licensed pro

fessional technicians, or equivalent, can install and service

the Lennox Elite® Series ELO183DH oil furnaces. In Cana

da, refer to CSA B139 for recommended installation proce

dures. Consult authorities who have jurisdiction before

installation.

WARNING

Never push the ignition reset button more than one

time. Pushing the reset more than once can lead to

a build-up of oil within the heat exchanger resulting

in a fire or explosion.

Shipping & Packing List

Litho U.S.A.

CAUTION

As with any mechanical equipment, personal injury

can result from contact with sharp sheet metal

edges. Be careful when you handle this equipment.

12/12

*2P1212*

1- Assembled oil furnace

1- Draft control

2- Nozzels

Check the components for shipping damage. If you find

any damage, immediately contact the last carrier.

Page 1

506903-01

*P506903-01*

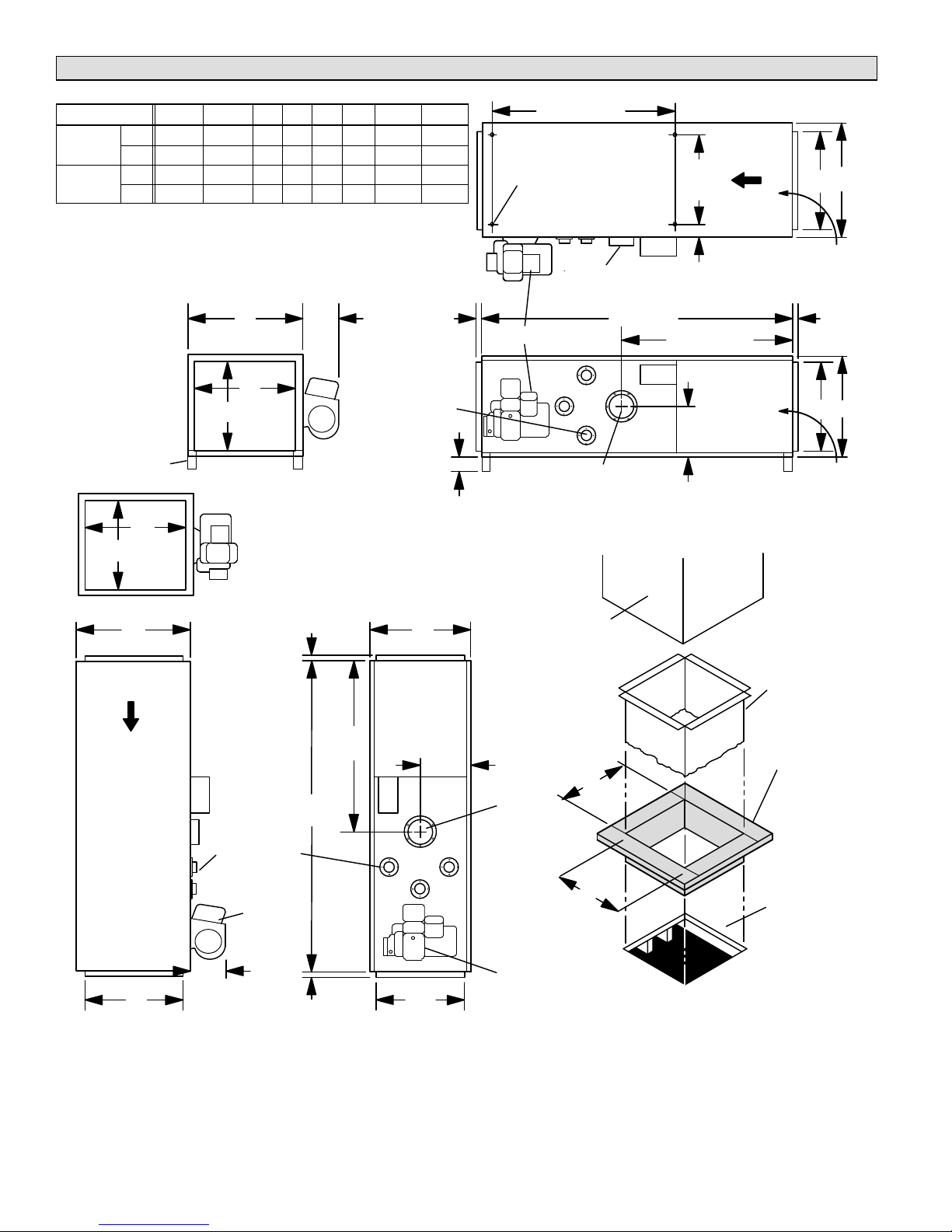

ELO183DH Unit Dimensions - Inches (mm)

Model No. A B C D E F G H

ELO183DH

101/114P36

ELO183DH

135/150P60

in. 20‐1/2 20‐1/2 18 18 18 18 3 10‐1/4

mm 521 521 457 457 457 457 76 260

in. 23‐1/2 23‐1/2 21 21 21 21 4‐3/4 11‐3/8

mm 597 597 533 533 533 533 121 289

53 (1346)

4 KNOCKOUTS

(For Suspending)

TOP VIEW

14‐1/2

3‐1/2

(89)

(368)

AIR

F A

FLOW

(4) SPACER LEGS

F

RETURN

E

AIR

OPENING

TOP VIEW

A

A

8

(203)

C

SUPPLY

D

AIR

OPENING

END VIEW FLUE OUTLET

3/4

(19)

HEAT EX

CHANGER

CLEAN OUT

PORTS (3)

1

(25)

BURNER

HORIZONTAL POSITION

OPTIONAL DOWNFLOW COMBUSTIBLE FLOOR BASE

B

3/4

(19)

FRONT OF

FURNACE

FLUE OUTLET

59 (1499)

G

32‐1/2 (826)

H

SIDE

VIEW

RETURN

AIR

3/4

(19)

E B

RETURN

AIR

SUPPLY

AIR DUCT

(Not

Furnished)

AIR

FLOW

32‐1/2

(826)

59

(1499)

HEAT

EXCHANGER

CLEAN OUT

PORTS (3)

BURNER

3/4

8

(203)

SUPPLY AIR OPENING

(19)

DC

SUPPLY AIR OPENING

SIDE VIEW FRONT VIEW

DOWNFLOW POSITION

101/114—

16‐1/4(413)

H

135/150—

20‐1/4(514)

FLUE

OUTLET

101/114—

16‐1/4(413)

135/150—

20‐1/4(514)

BURNER

Additive Base Raises Furnace

3/4 in. (19 mm) Inch above Floor Level

OPTIONAL

DOWNFLOW

ADDITIVE

BASE

COMBUSTIBLE

FLOOR

Page 2

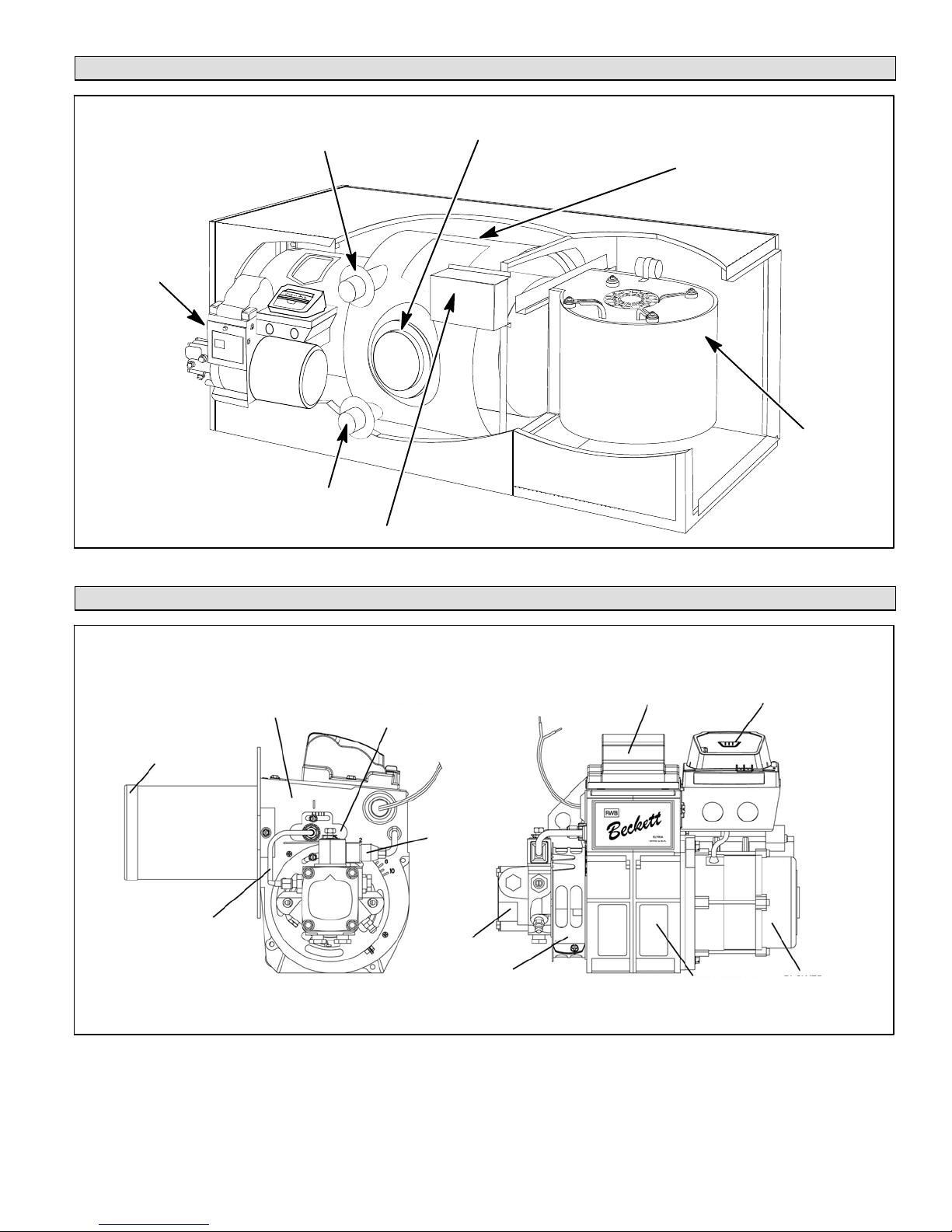

ELO183DH Unit Parts Arrangement

BECKETTR

AFG BURNER

CLEAN-OUT PORT

CLEAN-OUT PORT

FLUE OPENING

HEAT EXCHANGER

INDOOR

BLOWER

CONTROL BOX

Figure 1

ELO183DH Oil Burner Parts Arrangement

MAIN

HEAT

SHIELD

AIR TUBE WITH

ELECTRODE

ASSEMBLY AND

NOZZLE INSIDE

COPPER OIL

TUBE

HOUSING

ESCUTCHEON

PLATE

OIL DELAY

FUEL PUMP

VALVE

AIR BAND AND

AIR SHUTTER

Figure 2

IGNITER

BLOWER WHEEL

WITH AIR GUIDE

(Inside housing)

BURNER CONTROL

(with Reset Button)

BLOWER

MOTOR

Page 3

Requirements

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool dust. Breathing this may cause

lung cancer. (Fiberglass wool is known to the State

of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

air openings are required. Dimensions of combustion air

openings are shown in table 1. One opening shall be below

burner level and the other opening shall be no more than 6

inches from the room's ceiling.

Combustion air openings should provide a minimum free

area one‐half square inch per 1,000 Btu per hour input.

This combustion air should be brought into the area con

taining the furnace below the level of the furnace burner.

IMPORTANT

An opening to the outside for combustion air is

strongly recommended, especially in new homes.

Refer to table 1 or the unit rating plate for specific

combustion air opening dimensions.

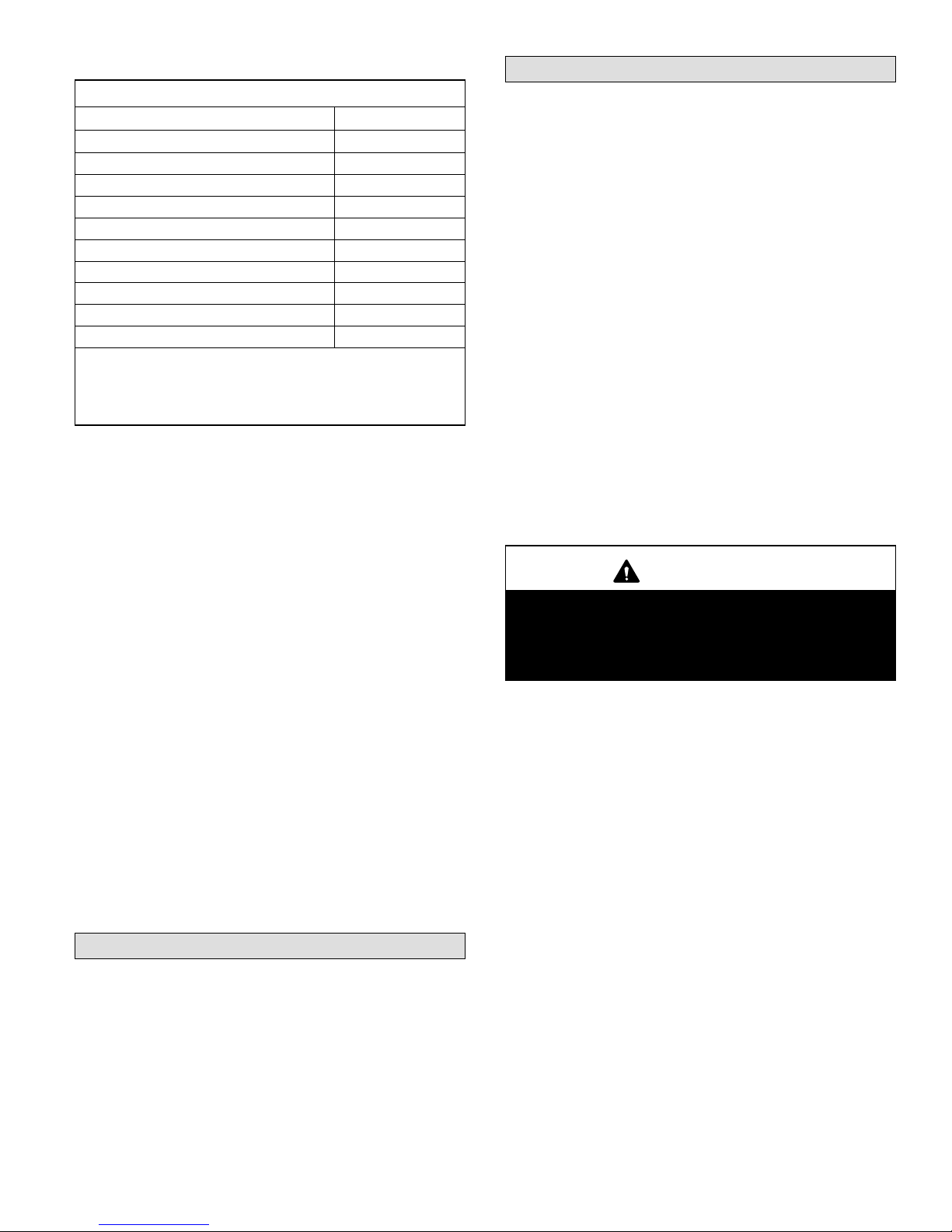

Table 1

Combustion Air Opening Dimensions

Model No. (2 openings required)

WARNING

Improper installation, adjustment, alteration, ser

vice or maintenance can cause property damage,

personal injury or loss of life. Installation and ser

vice must be performed by a qualified installer or

service agency.

Installation of Lennox oil-fired furnaces must conform with

the National Fire Protection Association Standard for the

Installation of Oil Burning Equipment, NFPA No. 31, the

National Electrical Code, ANSI/NFPA No.70 (in the

U.S.A.), CSA Standard CAN/CSA-B139 (in Canada),

Installation Code for Oil Burning Equipment, the Canadian

Electrical Code Part1, CSA 22.1 (Canada), the recom

mendations of the National Environmental Systems Con

tractors Association and any state or provincial laws or lo

cal ordinances. Authorities having jurisdiction should be

consulted before installation. Such applicable regulations

or requirements take precedence over general instruc

tions in this manual.

Chimneys and chimney connectors must be of the type

and construction outlined in section 160 of NFPA No. 31.

Air for combustion and ventilation must conform to stan

dards outlined in section 140 of NFPA No. 31 or, in Cana

da, CSA Standard B139. When installing ELO183DH units

in confined spaces such as utility rooms, two combustion

ELO183DH

-101/114

ELO183DH

-135/150

This unit is approved for clearances to combustible materi

al as listed unit rating plate and in tables 2 or 3. Unit service

and accessibility clearances take precedence over fire

protection clearances.

10” X 20”

11” X 22”

Table 2

Horizontal Installation Clearances

Clearances Inches (mm)

Top of Cabinet 3 (76)

*Bottom and Rear of Cabinet 1 (25)

Front of Cabinet 24 (610)

Service Clearance (Front) 24 (610)

End of Supply Plenum 0 (0)

Supply Air Opening 0 (0)

Return Air Opening 0 (0)

Above Horizontal Warm Air Duct

within 3 ft. (914mm) of Furnace

Flue Pipe Horizontal 7 (178)

Flue Pipe Vertical 7 (178)

*NOTE-When furnace is installed on combustible floor,

1” (25 mm) spacer legs must be installed to elevate unit

off of mounting surface.

0 (0)

Page 4

Table 3

Downflow Installation Clearances

Clearances Inches (mm)

Bottom of Plenum and Ductwork 1 (25)

Plenum Sides 1 (25)

Side of Cabinet 1 (25)

Rear of Cabinet 1 (25)

Front of Cabinet 16 (406)

Service Clearance (Front) 24 (610)

Flue Pipe Horizontal 1 (25)

Flue Pipe Vertical 7 (178)

Return Air Opening 0 (0)

*Floor *Combustible

*NOTE-Clearance for installation on combustible floor if

optional additive base is installed between the furnace

and combustible floor. Not required in add-on coiling ap

plications.

NOTE - Downflow Application Only - For installation on

combustible floors, appliance shall not be installed directly

on carpeting, tile or other combustible material other than

wood flooring. When installed on wood flooring, the addi

tive base must be used. See Unit Dimension illustration.

Combustion & Ventilation Air

Homes built with energy conservation in mind use tight

construction practices. These houses are sealed so well

that it becomes necessary to provide a means of bringing

in air from outside for combustion. Also, exhaust fans, ap

pliance vents, chimneys and fireplaces force additional air

that could be used for combustion out of the house. Unless

outside air is brought into the home for combustion, nega

tive pressure (pressure outside is greater than inside pres

sure) will build to the point that a down draft can occur in the

furnace vent pipe or chimney. Combustion gases enter the

living space creating a potentially dangerous situation. Ne

gative pressure may also interfere with proper combus

tion, causing sooting within the heat exchanger.

The importance of the previous paragraph cannot be over

stated. Users may inadvertently block fresh air intakes af

ter installation.

In the absence of local codes concerning air for combus

tion and ventilation, the following section outlines guide

lines and recommends procedures for operating oil fur

naces in a manner that ensures efficient and safe

operation. Special consideration must be given to com

bustion air needs as well as requirements for exhaust

vents and oil piping.

Combustion Air Requirements

NOTE - Unit must be adjusted to obtain a temperature rise

within the range listed in table 8.

When used in conjunction with a evaporator coil, the fur

nace shall be installed in parallel with, or on the upstream

side of the evaporator coil. In a parallel flow arrangement,

the dampers, or other measures used to control flow of air

flow, shall be adequate to prevent chilled air from entering

the furnace. If the furnace is manually operated, it must be

equipped with means to prevent operation of either unit un

less dampers are in the full‐heat or full‐cool position.

When installed, furnace must be electrically grounded in

accordance with local codes or, in the absence of local

codes, with the current National Electric Code, ANSI/

NFPA No. 70, if an external electrical source is utilized.

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a 63_F (17_C)

temperature rise.

Notice to Home Owner

This furnace is equipped with safety devices that protect

you and your property. If one or more of these devices is

activated, furnace operation will stop. If your home is left

unattended for an extended period of time, equipment op

eration must be checked periodically. If this is not possible,

the water supply to the house should be shut off and the

pipes should be drained. This will prevent problems

associated with a NO HEAT condition (frozen pipes, etc.)

CAUTION

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rust

ing and premature heat exchanger failure. It can also

cause property damage.

All oil‐fired appliances require air to be used for the com

bustion process. If sufficient amounts of combustion air

are not available, the furnace or other appliance will oper

ate in an inefficient and unsafe manner. Enough air must

be provided to meet the needs of all fuel‐burning ap

pliances, as well as appliances such as exhaust fans which

force air out of the home. When fireplaces, exhaust fans,

or clothes dryers are used at the same time as the furnace,

much more air is required to ensure proper combustion

and to prevent a down‐draft situation. Insufficient amounts

of air also cause incomplete combustion which can result

in sooting. Requirements for providing air for combustion

and ventilation depend largely on whether the furnace is

installed in an unconfined or confined space.

Unconfined Space

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 50 cubic

feet (1.4 cubic meters) per 1,000 Btu (293 W) per hour of

the combined input rating of all appliances installed in that

space. This space also includes adjacent rooms which are

not separated by a door. Though an area may appear to be

unconfined, it might be necessary to bring in outdoor air for

combustion if the structure does not provide enough air by

Page 5

infiltration. If the furnace is located in a building of tight

construction with weather stripping and caulking around

the windows and doors, follow the procedures outlined for

using air from the outside for combustion and ventilation.

Confined Space

A confined space is an area with volume less than 50 cubic

feet (1.4 cubic meters) per 1,000 Btu (293 W) per hour of

the combined input rating of all appliances installed in that

space. This definition includes furnace closets or small

equipment rooms.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space con

taining the furnace, the return air must be handled by ducts

which are sealed to the furnace casing and which termi

nate outside the space containing the furnace. This is es

pecially important when the furnace is mounted on a plat

form in a confined space such as a closet or small

equipment room. Even a small leak around the base of the

unit at the platform or at the return air duct connection can

cause a potentially dangerous negative pressure condi

tion. Air for combustion and ventilation can be brought into

the confined space either from inside the building or from

outside.

Air from an Adjacent Space

If the confined space housing the furnace adjoins space

categorized as unconfined, air can be brought in by provid

ing two permanent openings between the two spaces.

Each opening must have a minimum free area of 1 square

inch (6.4 square centimeters) per 1,000 Btu (293 W) per

hour of the total input rating of all fuel‐fired equipment in the

confined space. Each opening must be at least 100 square

inches (614.5 square centimeters). One opening shall be

within 12” (305 mm) of the top of the enclosure and one

opening within 12” (305 mm) of the bottom (See figure 1).

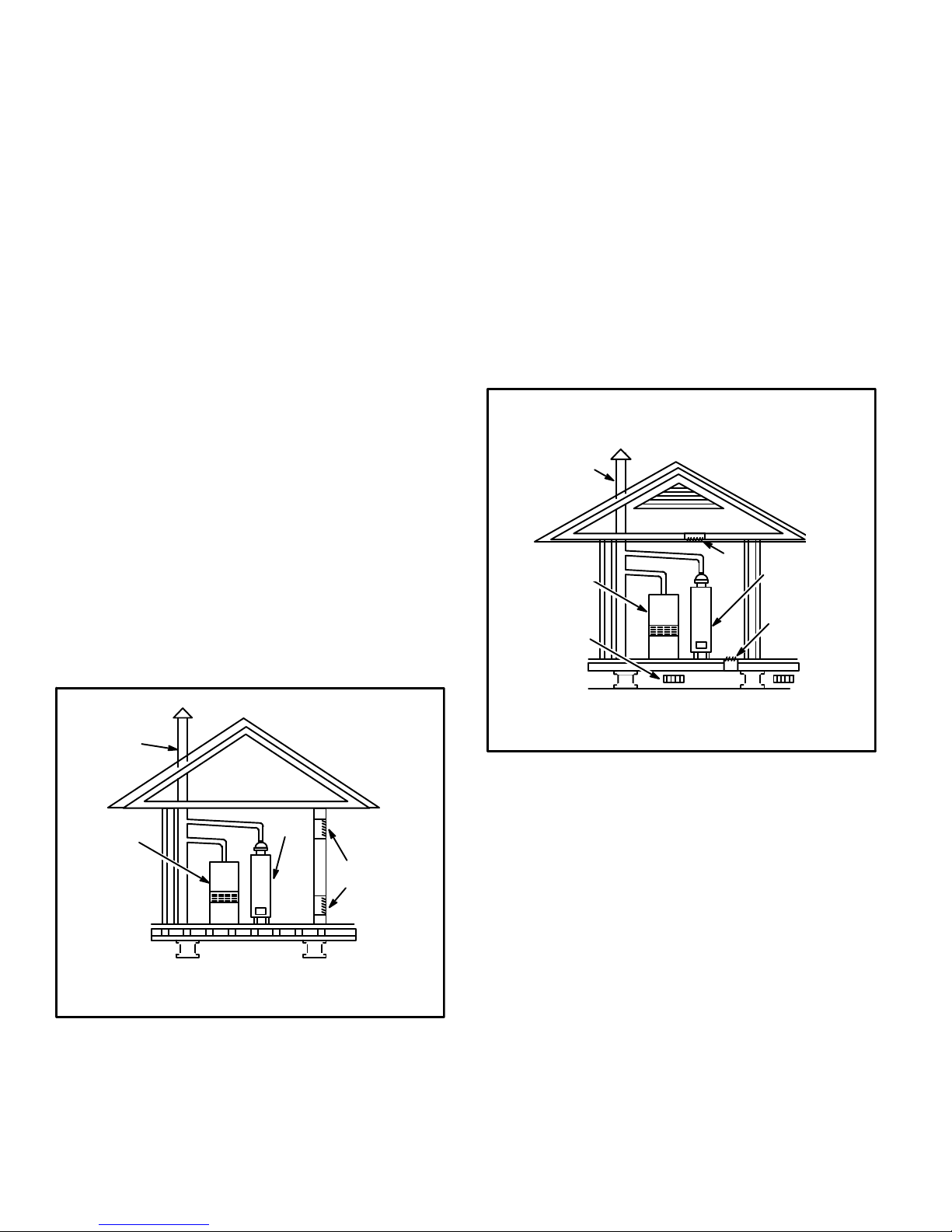

Equipment In Confined Space

All Air From Inside

Chimney or

t

Oil Ven

Air from Outside

If air from outside is brought in for combustion and ventila

tion, the confined space shall be provided with two perma

nent openings. One opening shall be within 12” (305 mm)

of the top of the enclosure and one within 12” (305 mm) of

the bottom. These openings must communicate directly or

by ducts with the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free

area of 1 square inch (6.4 square centimeters) per 4,000

Btu (1172 W) per hour of total input rating of all equipment

in the enclosure. (See figure 2.) When communicating with

the outdoors through horizontal ducts, each opening shall

have a minimum free area of 1 square inch (6.4 square

centimeters) per 2,000 Btu (586 W) per total input rating of

all equipment in the enclosure (See figure 3).

Equipment In Confined Space

(Inlet Air from Crawl Space and Outlet Air to

Chimney or

Oil Vent

Oil

Furnace

Ventilation

Louvers

(For unheated

crawl space)

NOTE-The inlet and outlet air openings shall each have a free area of

at least one square inch (6.4 square centimeters) per 4,000 Btu (1172

W) per hour of the total input rating of all equipment in the enclosure.

All Air From Outside

Ventilated Attic)

Ventilation Louvers

(Each End Of Attic)

Outlet

r

Ai

Water

Heater

Inlet

Air

Figure 2

Oil

Furnace

NOTE-Each opening shall have a free area of at least 1 square inch

(6.4 square centimeters) per 1,000 Btu (293 W) per hour of the total

input rating of all equipment in the enclosure, but not less than 100

square inches (614.5 square centimeters).

Water

Heater

Figure 1

Openings

(To Adjacent Room)

When ducts are used, they shall be of the same cross-sec

tional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3” (76 mm). In calculating free area,

the blocking effect of louvers, grilles, or screens must be

considered. If the design and free area of protective cover

ing is not known for calculating the size opening required, it

may be assumed that wood louvers will have 20 to 25 per

cent free area and metal louvers and grilles will have 60 to

75 percent free area. Louvers and grilles must be fixed in

the open position or interlocked with the equipment so that

they are opened automatically during equipment opera

tion.

Page 6

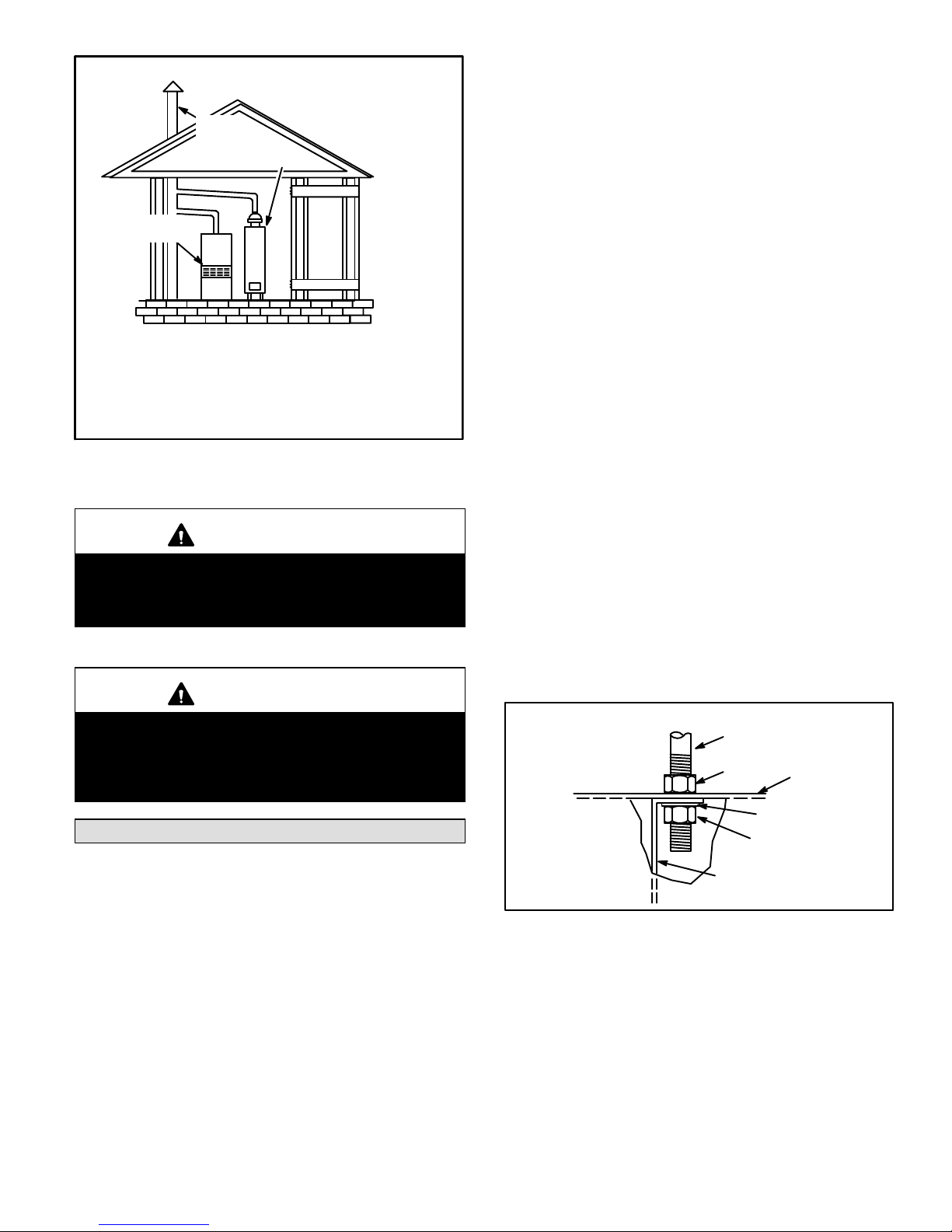

Equipment In Confined Space

All Air From Outside

Chimney

Or Oil

Vent

Oil

Furnace

NOTE-Each air duct opening shall have a free area of at least one

square inch (6.4 square centimeters) per 2,000 Btu (586 W) per hour

of the total input rating of all equipment in the enclosure. If the equip

ment room is located against an outside wall and the air openings

communicate directly with the outdoors, each opening shall have a

free area of at least one square inch (6.4 square centimeters) per

4,000 Btu (1172 W) per hour of the total input rating of all other equip

ment in the enclosure.

Water

Heate

r

Outlet Air

Inlet Air

Figure 3

CAUTION

Combustion air openings in the front of the furnace

must be kept free of obstructions. Any obstruction

will cause improper burner operation and may re

sult in a fire hazard or injury.

CAUTION

The barometric draft control shall be in the same at

mospheric pressure zone as the combustion air in

let to the furnace. Deviation from this practice will

cause improper burner operation and may result in

a fire hazard or injury.

Horizontal Application

The ELO183DH furnace is shipped from the factory in the

horizontal left hand air discharge application. Air flow may

be reversed to right side discharge or unit may be used as

downflow.

1. Reversing Airflow for Right Hand Discharge

D Rotate the furnace 180_ so that, when facing the

front, the warm discharge is to the right.

D Remove the nuts in the bracket that hold the burn

er to the furnace front. Rotate the burner and burn

er mounting plate 180_ and reinstall the nuts.

D Remove the screws that hold the limit control in

place. Use the provided knockout hole to relocate

the limit control to the top side of the front panel.

2. Installation on Non-Combustible Material

D Set the furnace on non‐combustible material

(such as concrete blocks, bricks or angle iron).

Install spacer legs, provided with unit, by using the

cabinet screws from each corner of the unit.

D Use a level to check the level of furnace in at least

two directions. Use shims or non‐combustible ma

terial. A minimum clearance of 1” must be main

tained between bottom of furnace and combus

tible material.

3. Suspended Installation

D To suspend the furnace, remove knockouts in top

of panel at warm air discharge and at blower panel

(Refer to unit dimensions). Use 3/8” rods cut to de

sired length.

D Use one flat washer and two nuts for each rod (a

nut and washer on the inside of unit and the other

“locking” nut on the outside of unit; see figure 4).

Level the unit by adjusting the nuts on the inside of

unit.

Hanger Rod Installation

ROD

LOCKING

NUT

TOP OF

FURNACE

Installation

When installed, ELO183DH furnaces must be level. If the

furnace is not level, place fireproof wedges or shims be

tween the low side of the furnace and floor. Make sure the

weight of the furnace is evenly distributed on all four cor

ners. Strain on sides of the cabinet causing cracking and

popping noises may occur if weight of furnace is not evenly

distributed.

Set the unit in desired location keeping in mind the clear

ances list in tables 2 and 3. Also keep in mind oil supply

connections, electrical supply, flue connections and suffi

cient clearance for installing and servicing unit.

ELO183DH series units may be installed in a crawl space

under a house, utility room or in a wide variety of sus

pended applications.

WASHER

NUT

BLOWER COMPARTMENT

DIVISION PANEL

Figure 4

Downflow Application

When installing the ELO183DH in a downflow position and

on combustible flooring, a combustible floor base must be

used. See Unit Dimension illustration.

1. Rotate the furnace so that return is on top and supply

is on bottom. Refer to table 3 for clearances to com

bustible flooring.

2. Remove the nuts in the bracket that hold the burner to

the furnace front. Rotate the burner and burner mount

ing plate 90_ and reinstall the nuts.

Page 7

3. It is also recommended that the upper rear screw hold

ing the blower housing to the blower deck be removed

before installation in a closet. Removing this screw al

lows for easy service and removal of the blower as

sembly in a closet installation.

Adjustments

Neither the nozzle setting nor the air adjustments are fac

tory set. The furnace is fire-tested and the limit control is

checked to make sure it functions properly; no factory set

tings are made. During installation, the furnace must be

adjusted to ensure proper operation. The installing dealer/

contractor must have and use proper test equipment in or

der to correctly adjust the oil furnace. The use of test equip

ment is more critical than ever due to tighter tolerances

needed to keep the furnace operating efficiently.

Among the test equipment for an oil furnace, the proper

combustion test kit should contain the following:

D Draft gauge

D CO

or O2 analyzer

2

D Smoke tester

D Pressure gauge

D High temperature thermometer

D Oil vacuum gauge

D Beckett T-501 or Z-2000 nozzle gauge

D Knowledge of proper test equipment operation

CAUTION

Improper nozzle and/or air adjustment of this unit

may result in sooting problems. Refer to the follow

ing section for correct adjustment procedures.

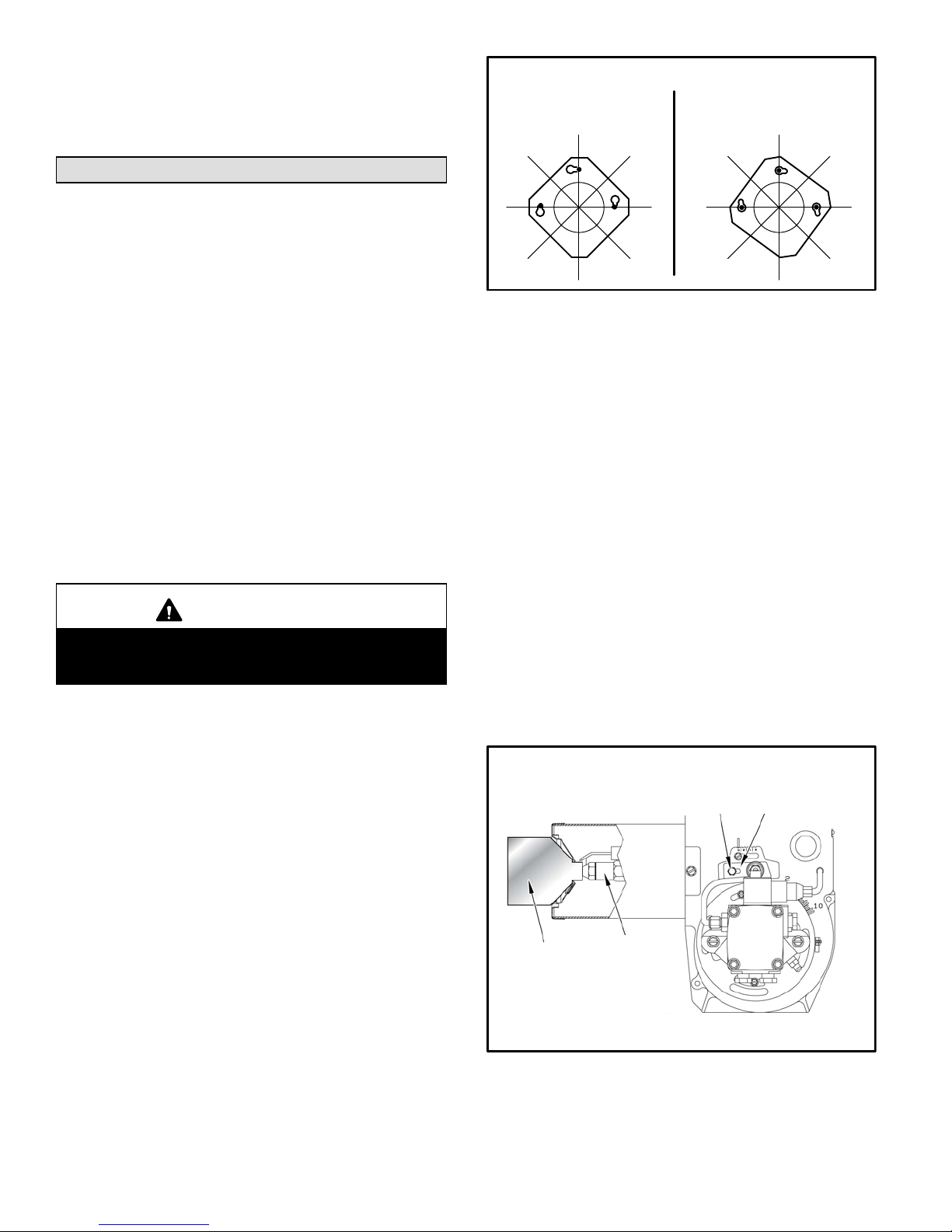

Nozzle Adjustment

Proper adjustment of the nozzle assembly is critical. Be

fore the flue pipe and oil lines are installed, the nozzle as

sembly must be checked for proper depth and alignment.

You must remove the entire burner assembly (not just the

nozzle) from the furnace to check the nozzle depth and

alignment. The smaller sized firing nozzle has been facto

ry-installed. This should be verified by the installer. A larger

nozzle has been provided in the bag assembly for use with

ELO183DH114 and 150 units. Inspect the spark trans

former leads also to ensure they are still attached to the

electrodes.

The burner assembly is attached to the vestibule panel by

three nuts. Slots are provided in the mounting flange for re

moving the burner assembly from the vestibule. Loosen

the nuts and turn the whole burner assembly clockwise

(figure 5) to remove the entire burner assembly from the

furnace. There is adequate wire to remove the burner with

out disconnecting wires. Once removed, turn the burner

around in the vest panel area.

ELO183DH Series Burner Removal

First, loosen three nuts which

attach burner to vest panel.

Next, rotate burner clockwise

on slots then pull toward you.

Figure 5

To correctly check and adjust the nozzle depth and align

ment, use the Beckett T-501 or Z-2000 gauge.

To check the oil nozzle depth, insert the small end of the

gauge into the end of the cone and measure from the flat of

the end cone to the face of the nozzle. When nozzle depth

is correct, the tip of the nozzle should just touch the end of

the gauge. Refer to the illustration sheet provided with the

gauge. Note that the scale side of the gauge is not used for

this purpose. If necessary, loosen the escutcheon plate

securing screw and slide the entire nozzle assembly for

ward or backward within the air tube (figure 6). Re-secure

escutcheon plate screw when adjustment is completed.

To check nozzle alignment, again insert the small end of

gauge into the end cone and measure the nozzle and elec

trode alignment against the center lines marked on the

gauge (again refer to enclosed illustration sheet). If the

nozzle is not centered, but found to be too far left or right, a

new nozzle assembly will need to be ordered. Do not at

tempt to adjust by bending the 90 degree elbow in the oil

line.

Take care to properly re-install burner assembly when

nozzle adjustment has been completed.

Beckett Oil Burner Nozzle Adjustment

Burner must be removed from

furnace for this procedure.

T-501 Gauge

To Adjust Nozzle

1-Loosen escutcheon plate screw.

2-Slide entire nozzle/electrode assembly back and forth inside air

tube until nozzle just touches gauge.

2

1

Escutcheon Plate

Figure 6

Page 8

Loading...

Loading...