Lennox Elite CB30U, Elite CB30U-21, Elite CB30U-26, Elite CB30U-31, Elite CB30U-41 Installation Instructions Manual

...Page 1

zav

,B,2007 Lennox IndustrIes Ins.

Da{las, Texas, USA

INSTALLATION

INSTRUCTIONS

X_ WARNING

_, CAUTION

IMPORTANT

_, IMPORTANT

Elite® Series CB30U Units

AIR HANDLER F[_ Technical

505,340M J_LL Publications

07/07 Litho U.S.A.

Supersedes 504,720M

CB30U Up-flow Unit Dimensions ................ 2

CB30U Up-flow Side Return Air Filter Adapter ..... 2

General Information ............................ 3

Shipping and Packing List ...................... 3

Requirements ................................. 3

Installing the Unit .............................. 3

Brazing Connections ........................... 4

Installing the Condensate Drain .................. 5

Inspecting and Replacing Filters ................. 5

Sealing the Unit ............................... 6

Adjusting the Blower Speed .................... 6

Making Electrical Connections ................... 8

Repairing or Replacing Cabinet Insulation ......... 12

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

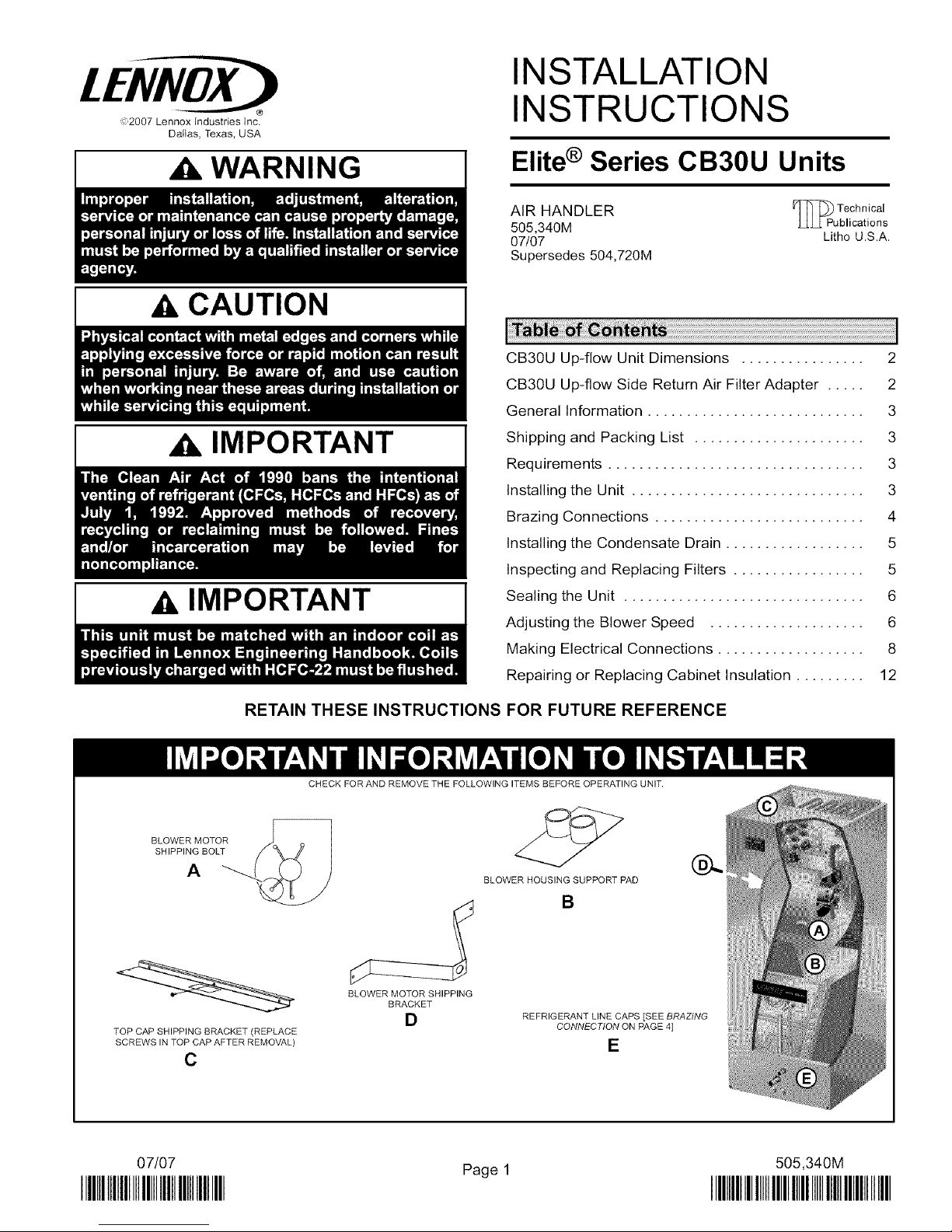

BLOWER MOTOR

SHIPPING BOLT

TOP CAP SHIPPING BRACKET (REPLACE

SCREWS IN TOP CAP AFTER REMOVAL)

C

CHECK FOR AND REMOVE THE FOLLOWING ITEMS BEFORE OPERATING UNIT.

BLOWER HOUSING SUPPORT PAD

B

BLOWER MOTOR SHIPPING

BRACKET

D

REFRIGERANT LINE CAPS [SEE BRAZING

CONNECTION ON PAGE 4]

E

@..

07/07

IIIHIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

Page1

505,340M

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

Page 2

3/4

t(19)

3/4 3/4

(19)_ _1_)

DETAIL OF PIPING PLATE

t 5/8

OPTIONAL

ELECTRIC

HEAT

(Field

InstaBed)

FILTER

ACCESS

A

LIQUID

LINE

SUCTION

LINE

K

SIDE VIEW

LINE VOLTAGE LOW VOLTAGE

INLETS INLETS

(Top and Left Side) (Top and

TOP VIEW

Right Side)

I

I

JL__J JL_

5/8 F (215) BottEom

Bottom 5/8

Return Air (16)

(16) Return Air

FRONTVIEW

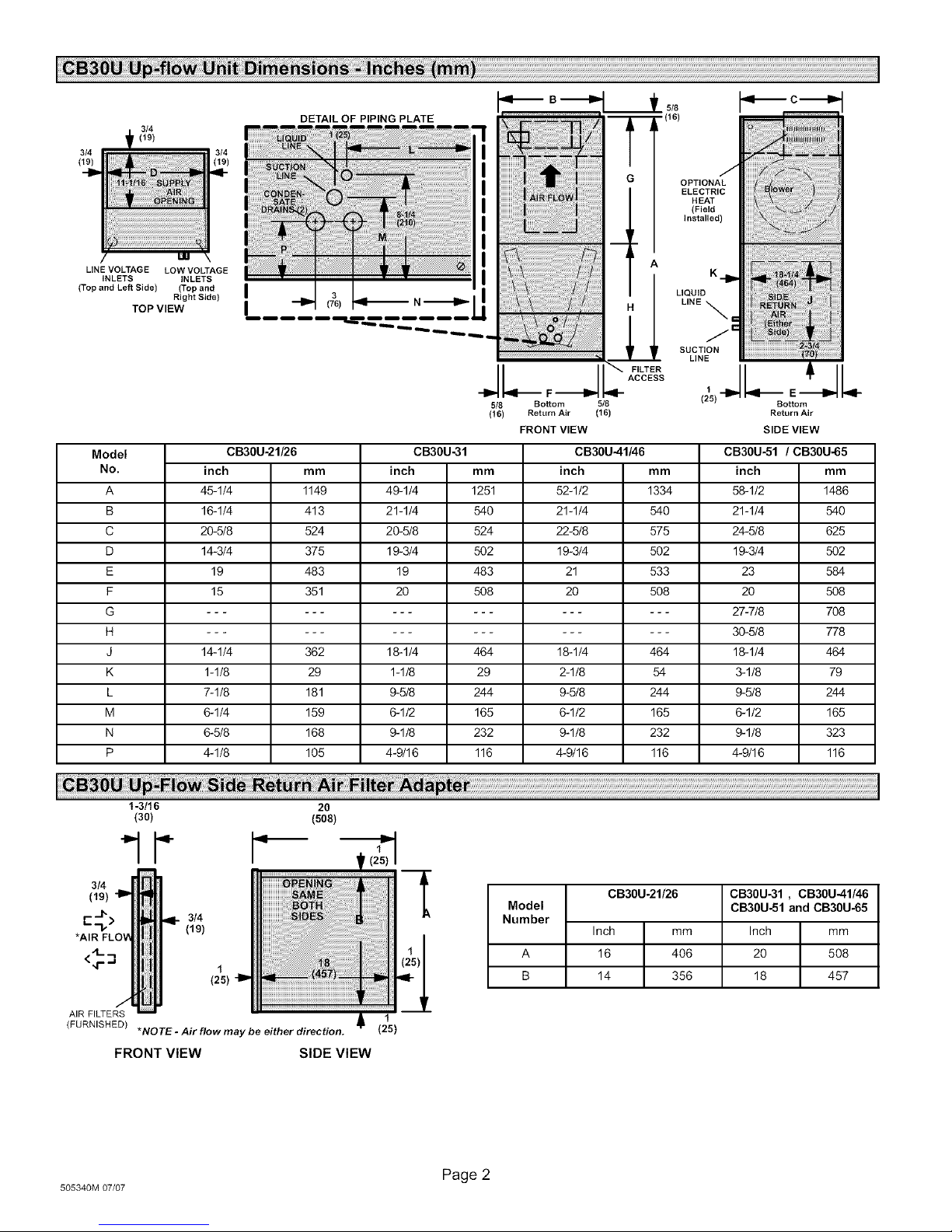

Model CB30U-21/26 CB30U-31 CB30U-51 / CB30U-65

No. inch mm inch mm mm inch mm

A 45-1/4 1149 49-1/4 1251 1334 58-1/2 1486

B 16-1/4 413 21-1/4 540 540 21-1/4 540

C 20-5/8 524 20-5/8 524 575 24-5/8 625

D 14-3/4 375 19-3/4 502 502 19-3/4 502

E 19 483 19 483 533 23 584

F 15 351 20 508 508 20 508

CB30U-41/46

inch

52-1/2

21-1/4

22-5/8

19-3/4

21

2O

G ............... 27-7/8 708

H ............... 30-5/8 778

J 14-1/4 362 18-1/4 464 464 18-1/4 464

K 1-1/8 29 1-1/8 29 54 3-1/8 79

L 7-1/8 181 9-5/8 244 244 9-5/8 244

M 6-1/4 159 6-1/2 165 165 6-1/2 165

N 6-5/8 168 9-1/8 232 232 9-1/8 323

P 4-1/8 105 4-9/16 116 116 4-9/16 116

18-1/4

2-1/8

9-5/8

6-1/2

9-1/8

4-9/16

(19)

3/4

1-3/16

(30)

ii _:_NiN;i!N_;i!iiiili;iiii!ilililililill|!:!:!:;!i!i!_!:!i!ili!iiii_i!!

i

i _iiiiiiiiiiiii'i;!ii_!;i;i

20

(508)

3,, i ii ii ii ii ii ii ii ii iiiiii!;!ii!;'ii]i

(,9, iiiiiiiiiiii i ;! :!: i i i;!i !: ! i i ii i : i ii iiiii i i i iiii iiii iiiiiiiiiiiiiiiiiiiiii!!!!!! iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!ii!ii!iiiiiiii"':ii!i!i!!i!iiiiiiiiiiiiiiiii!i!iiiiiiiiiiii!!ii!i!ii'iiil

(25) '_

1 ii_I:I:I:I:_!_!_!_!_!_!_!:_i_!i_i_i_i!i_i_:iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii:!_:_iii:iI_;!!_!I;_i_i ii_iiiii!iiiiiiiiiii!!i_ii

AIR FILTERS

(FURNISHED)

505340M 07/07

*NOTE - Air flow may be either direction.

FRONT VIEW SIDE VIEW

I_ (25)

Page 2

Model CB30U-51 and CB30U-65

CB30U-21/26 CB3OU-31 , CB30U-41/46

Number

Inch mm Inch mm

A 16 406 20 508

B 14 356 18 457

Page 3

WARNING

The CB30U series air handler units are designed for

installation with optional field-installed electric heat and a

matched remote outdoor unit. These units are for indoor

installation only. The CB30U units are designed for up-flow

operations with either bottom or side return air

applications.

These instructions are intended as a general guide and do

not supersede local or national codes in any way. Consult

authorities having jurisdiction before installation. Check

equipment for shipping damage; if found, immediately

report damage to the last carrier.

Package 1 of 1 contains the following:

1--Assembled air handlerunit

In addition to conforming to manufacturer's installation

instructions and local municipal building codes, installation

of Lennox air handler units (with or without optional electric

heat), MUST conform with the following National Fire

Protection Association (NFPA) standards:

• NFPA No. 90A - Standard for Installation of Air

Conditioning and Ventilation Systems

• NFPA No. 90B - Standard for Installation of Residence

Type Warm Air Heating and Air Conditioning Systems

This unit is approved for installation clearances to

combustible materials as listed on the unit rating plate which

is located on the unit. Accessibility and service clearances

must take precedence over combustible material

clearances.

I

CB30U units come from the factory ready for up-flow,

bottom return installation. This unit is not designed for

down-flow or horizontal discharge. Return air for the

CB30U may be either from the bottom or sides of the unit.

Side return air applications require some field

modifications.

WARNING

IMPORTANT

DISASSEMBLE/REASSEMBLE AIR HANDLER UNITS

The air handler units consists of two factory-assembled

sections. It may be necessary to disassemble the sections

when positioning the unit for installation,

To disassemble:

Step 1. Remove access panels,

Step 2, Remove both blower and coil assemblies, This

will lighten the cabinet for lifting,

Step 3, Remove one screw from the left and right posts

To reassemble:

Step 1. Align cabinet sections together.

Step 2, Reinstall screws,

Step 3, Replace blower and coil assemblies,

Step 4, Replace access panel,

UP-FLOW APPLICATION

Use the following procedures to configure the unit for

up-flow operations:

Step 1, Remove access panels and corrugated padding

Step 2. Place unit in desired location. Set unit so that it

Step 3, Mount units that have no return air plenum on a

Table 1. Optional Unit Side Stand (Up-Flow Only)

Model Kit Number

-21, -26, and -31 45K31

41 through-65 45K32

inside the unit, Remove one screw from each

side on the back of the unit, Unit sections will now

separate,

between the blower and coil assembly before

operation,

is level. Connect return and supply air plenums

as required using sheet metal screws.

stand at least 14" from the floor for proper air

return, Lennox offers an optional up-flow unit

stand as listed in table 1.

Page 3

CB30U/CBX27UH SERIES

Page 4

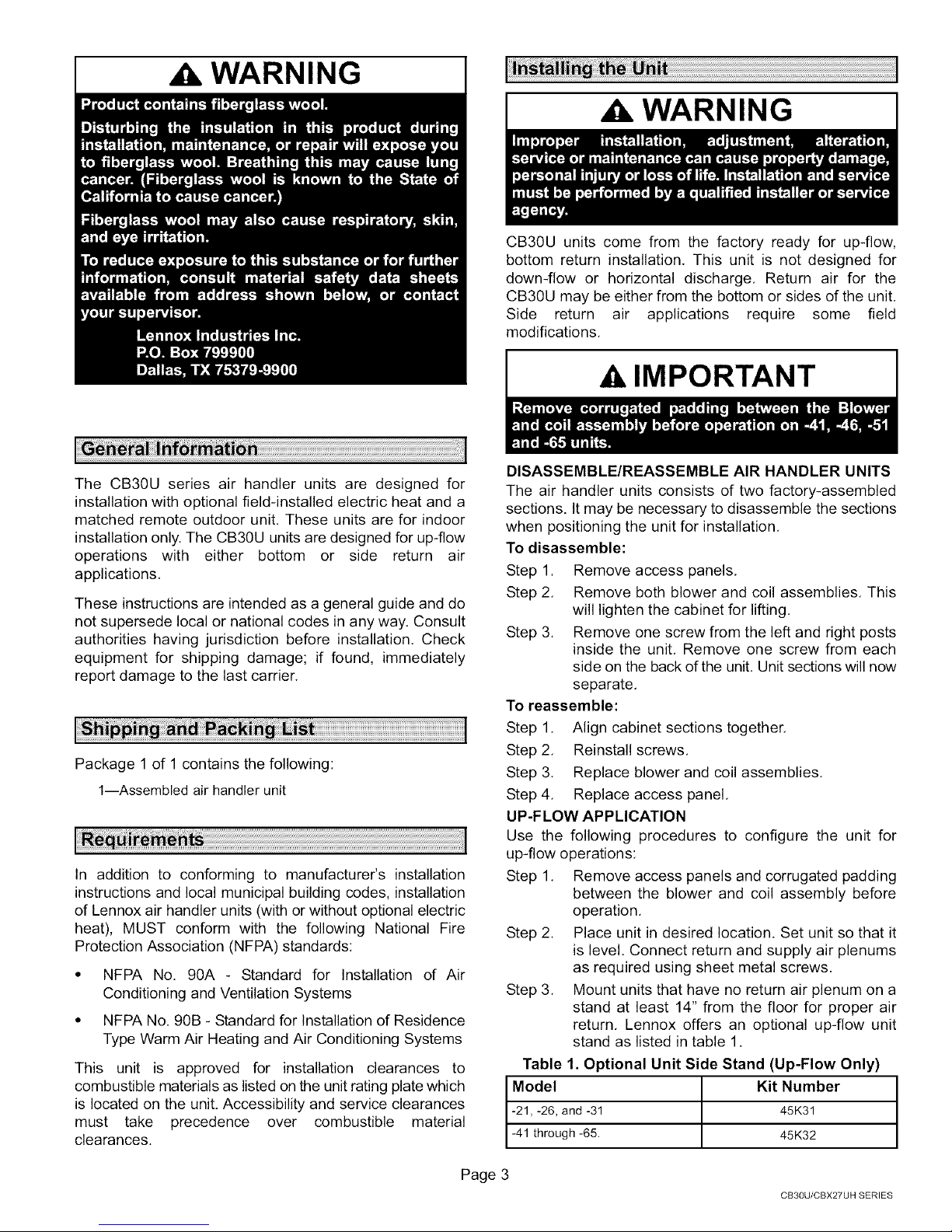

SIDE RETURN AIR APPLICATIONS

The CB30U unit is shipped from the factory ready for

bottom return air application. You can order an optional

side return air filter kit as listed in table 2.

Table 2. Optional Side Return Air Filter Kit

Model Kit Number

-21 and-26 65K23

All other models 65K24

Use the following procedures to configure the unit for side

return air operations:

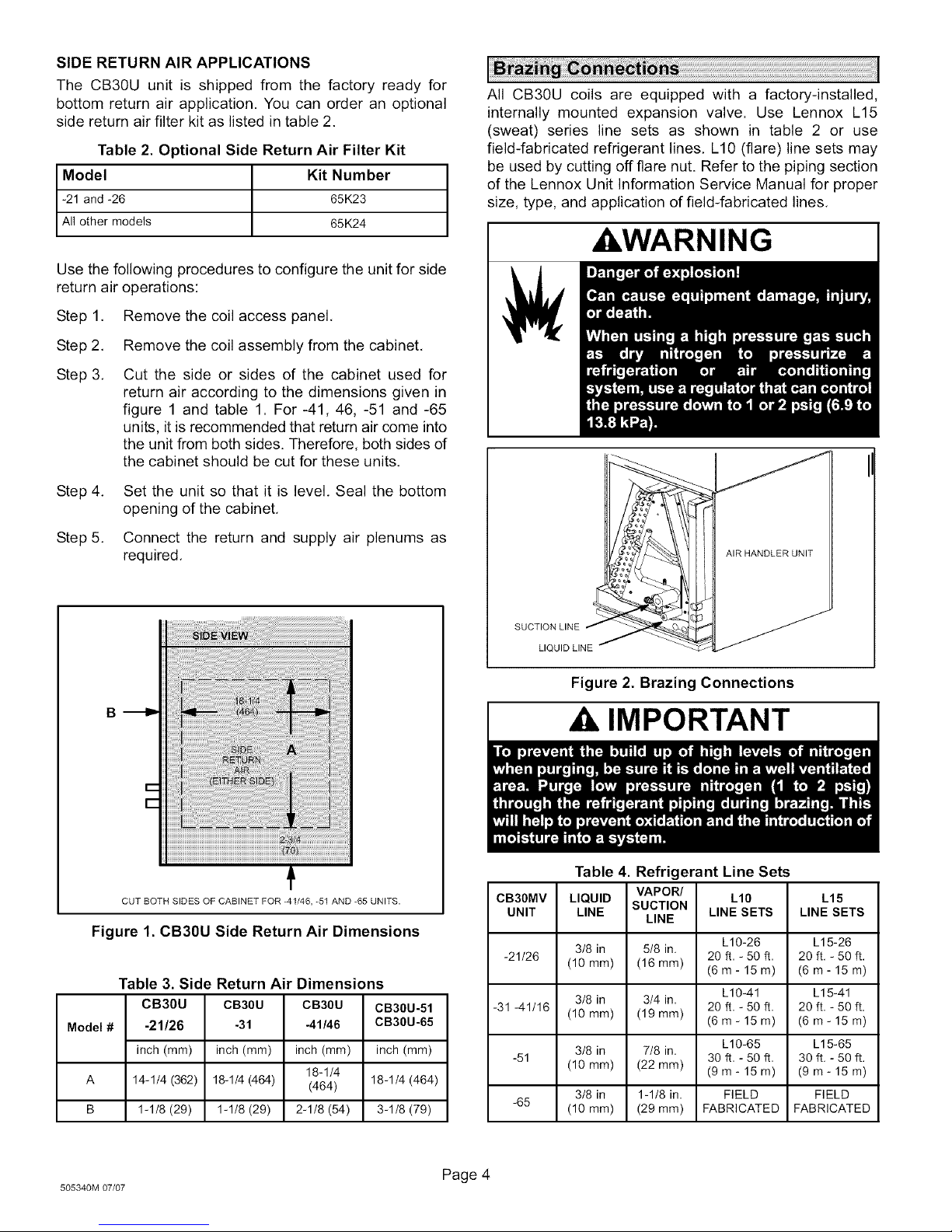

All CB30U coils are equipped with a factory-installed,

internally mounted expansion valve. Use Lennox L15

(sweat) series line sets as shown in table 2 or use

field-fabricated refrigerant lines, L10 (flare) line sets may

be used by cutting off flare nut. Refer to the piping section

of the Lennox Unit Information Service Manual for proper

size, type, and application of field-fabricated lines.

_WARNING

Step 1,

Step 2,

Step 3.

Step 4.

Step 5.

Remove the coil access panel,

Remove the coil assembly from the cabinet,

Cut the side or sides of the cabinet used for

return air according to the dimensions given in

figure 1 and table 1. For -41, 46, -51 and -65

units, it is recommended that return air come into

the unit from both sides. Therefore, both sides of

the cabinet should be cut for these units,

Set the unit so that it is level. Seal the bottom

opening of the cabinet,

Connect the return and supply air plenums as

required.

B

I AIR HANDLER UNIT

SUCTION LINE

LIQUID LINE

Figure 2. Brazing Connections

Ak IMPORTANT

CUT BOTH SIDES OF CABINET FOR -41/46, -51 AND -65 UNITS.

Figure 1. CB3OU Side Return Air Dimensions

Table 3. Side Return Air Dimensions

CB3OU CB30U CB30U CB30U-51

Model # -21/26 -31 -41/46 CB30U-65

inch (mm) inch (mm) inch (mm) inch (mm)

18-1/4

A 14-1/4 (362) 18-1/4 (464) (464) 18-1/4 (464)

B 1-1/8 (29) 1-1/8 (29) 2-1/8 (54) 3-1/8 (79)

505340M 07/07

Page 4

Table 4. Refrigerant Line Sets

CB30MV LIQUID SUCTION L10 L15

UNIT LINE LINE SETS LINE SETS

-21/26 (10 mm) (16 mm) 20 ft, - 50 ft, 20 ft. - 50 ft.

-31 -41/16 (10 mm) (19 mm) 20 ft, - 50 ft. 20 ft. - 50 ft.

-51 30 if, - 50 ft, 30 ft. - 50 ft.

-65 (10 ram) (29 ram) FABRICATED FABRICATED

3/8 in 5/8 in.

3/8 in 3/4 in,

3/8 in 7/8 in.

(10 mm) (22 mm) (9 m - 15 m) (9 m- 15 m)

3/8 in 1-1/8 in, FIELD FIELD

VAPOR/

LINE

L10-26 L15-26

(6m- 15m) (6m-15m)

L10-41 L15-41

(6 m - 15 m) (6 m- 15 m)

L10-65 L15-65

Page 5

NOTE - CB3OMV series evaporators use nitrogen or dryair

as aholding charge. If there is no pressure when the rubber

plugs are removed, check the coil or line set for leaks before

installing. After installation, pull a vacuum on theline set and

coil before releasing the unit charge into the system.

NOTE: See outdoor unit instructions on how to flow

nitrogen through line sets.

Step 1. Remove access panel,

Step 2, Remove the refrigerant line caps from the

refrigerant lines,

Step 3, Use a wet rag to protect TXV sensing bulb (or

remove it) when brazing suction line

connections,

Step 4, Place a wet rag against piping plate and around

the suction line connection. The wet rag must be

in place to guard against damage to the paint.

Step 5, With the wet rag in place, position field provided

elbow fitting to air handler's suction line and line

set, Start nitrogen flow before brazing.

Step 6, After the procedure is completed then remove

the wet rag,

Step 7, Place wet rag against piping plate and around

the liquid line connection. Position liquid line

elbow to air handler's suction line and to line set.

Start nitrogen flow and begin brazing both

connections and after procedure is completed

then remove both wet rags,

Step 8, Refer to instructions provided with outdoor unit for

leak testing, evacuating and charging

procedures,

Step 9. Install access panel,

Connect the main condensate drain and route it downward

to an open drain or sump. Do not connect the drain to a

closed waste system. Refer to figure 3 for a typical

condensate trap configuration. If the auxiliary drain is not

connected, it must be plugged,

MINIMUM 1 INCH (25 MM) PIPE DIAMETER

PITCH PER 10 FEET (3048 MM)

TRAP MUST BE DEEP ENOUGH TO OFFSET MAXIMUM STATIC

DIFFERENCE (GENERALLY, 2 INCHES [51 MM] MINIMUM).

OF LINE _. DIFFERENCE

_t .... CO,L

RAIN PAN

Figure 3. Typical Condensate Drain

The following practices are recommended to ensure

condensate removal:

• The drain piping should not be smaller than the drain

connections at drain pan,

• A trap must be installed in the main drain line,

• The trap must be deep enough to offset the difference

in static pressure between drain pan and atmosphere.

Generally, two inches is satisfactory for medium static

applications.

• Horizontal runs must be sloped 1 inch per 10 feet of

drain line to offset friction,

• An open vent inthe drain line will sometimes be required

due to line length, friction, and static pressure,

• Drains should be constructed in a manner to facilitate

future cleaning and should not interfere with filter

access as illustrated in figure 3,

• Auxiliary drain should run to an area where the

homeowner will notice it draining, Refer to local codes,

A IMPORTANT

You can duct mount or install filters in the cabinet, The unit

is not equipped with a filter from the factory. Note that the

filter access door fits over the access panel. Air leaks will

occur if the access panel is placed over the filter door.

Filters should be inspected monthly and must be cleaned

or replaced when they dirty to assure proper furnace

operation,

Reusable filters can be washed with water and mild

detergent, When dry, they should be sprayed with filter

handicoater prior to reinstallation. Filter handicoater is RP

Products coating #418 and is available as Lennox part

number P-8-5069. Replace throw-away type filters when

they are dirty; they cannot be cleaned.

The filter section built into the unit may be used with bottom

return air applications,

To replace filter:

Step 1, Loosen the thumbscrews holding the filter panel

in place.

Step 2. Slide the filter out of the guides on either side of

cabinet,

Step 3, Insert new filter.

Step 4, Replace panel.

See table 5 for replacement filter sizes.

Table 5. Filter Dimensi, >ns

UNIT MODEL

NO.

CB30U-21/26 15 x 20 (381 x508) 16 x 20 (406 x 508)

CB30U-31 20 x 20 (508 x 508) 20 x 20 (508 x 508)

CB30U-41/46 20 x 22 (508 x 559) 20 x 20 (508 x 508)

CB30U-51,-65 20 x 24 (508 x 610) 20 x 20 (508 x 508)

BOTTOM RETURN SIDE RETURN

FILTER SIZE FILTER SIZE

Inches (mm) Inches (mm)

Page 5

CB30U/CBX27UH SERIES

Page 6

Seal the unit so that warm air is not allowed into the

cabinet. Warm air introduces moisture, which results in

water blow-off problems. This is especially important when

the unit is installed in an unconditioned area.

Make sure the liquid line and suction line entry points are

sealed with either the provided flexible elastomeric thermal

insulation, or field provided material (e.g. Armaflex,

Permagum or equivalent). Any of the previously mention

materials may be used to seal around the main and

auxiliary drains, and around open areas of electrical inlets.

AIR VOLUME ADJUSTMENT

Select the Blower speed by changing the taps at the

harness connector at the blower motor as illustrated in

figure 4. For selecting the blower speed and see figure 9 on

page 11 for the unit wiring diagram. Refer to the tables 6

through 10 for blower performance data.

HARNESS

CONNECTOR

MINIMUM BLOWER SPEEDS (WITH ELECTRIC

HEATERS)

Press the tab to release

wire connector, select

connector location for

For the minimum allowable speed for the CB30U series newspeed.Insert wire

units with electric heat, refer to the ECB29/ECB31 untilit clicks.

installation instructions.

Figure 4. Blower Speed Tap Selection

Table 6. CB30U-21/26 Air Handler Performance (208/230v)

External Static Air Volume and Motor Watts at Specific Blower

in. w.g.

.00

.05

.10

.15

,20

.25

.30

.40

.50

.60

.70

.75

Pressure

Pa

o

lO

25

35

50

6o

75

lOO

125

15o

175

185

cfm

1035

1020

1005

985

965

940

920

865

8O5

735

655

615

High

L/s

49O

48O

475

465

455

445

435

410

380

345

310

29O

Watts

390

385

380

375

370

365

360

345

330

320

3o5

295

cfm

85O

840

830

820

8O5

790

770

725

670

610

535

5OO

NOTE - All air data is measured external to the unit with air filter in place

Medium

L/s

4OO

395

395

385

380

37O

365

340

315

285

255

235

bottom return air or side return

with

Watts

3o5

3oo

295

29o

285

28o

275

265

25o

24o

225

215

Taps

Low

cfm L/s Watts

670 315 230

665 315 230

660 310 225

650 305 225

640 300 220

625 295 220

610 290 215

575 270 210

535 250 200

485 230 190

430 200 180

395 190 175

a_ (with bothsides

open). Electric heaters have no appreciable air resistance.

Table 7. CB30U-31 Air Handler Performance (208/230v)

External Static Air Volume and Motor Watts at Specific Blower

in. w.g.

.00

.05

.10

.15

.20

.25

.30

.40

.50

.60

.70

.75

Pressure

Pa

o

lO

25

35

5o

6o

75

lOO

125

15o

175

185

cfm

1255

1245

1230

1205

1170

1125

1065

925

740

520

255

110

High

L/s

59O

59O

58O

57O

55O

53O

5O5

435

350

245

120

5O

Watts

35o

35o

345

340

330

320

315

295

28o

26o

240

23o

cfm L/s

1190 560

1190 560

1175 555

1155 545

1120 530

1080 510

1030 485

895 425

725 340

510 240

260 120

115 55

NOTE - For side return air applications (with both sides open) add:. 10 in. wc. (25 Pa) static capacity to unit performance. Electric heaters

have no appreciable air resistance. Aft air data is measured external to the unit with the air filter in place with bottom return air.

Medium

Watts

315

315

31o

300

290

285

275

255

240

220

2o0

19o

Taps

Low

cfm L/s Watts

1045 495 265

1050 495 265

1040 490 255

1025 485 250

1005 475 245

970 460 235

930 440 225

820 385 205

670 315 185

490 230 165

275 130 145

150 70 135

505340M 07/07

Page 6

Page 7

Table 8. CB3OU-41/46 Air Handler Performance (208/230v)

External Static

Pressure

in. w.g.

.00

.05

.10

.15

.20

.25

.30

.40

.50

.60

.70

.75

Pa

o

lO

25

35

5o

6o

75

lOO

125

15o

175

185

NOTE -For side return a_ applications (with both sides open) add:. 15 in. w._ (35 Pa) static capacity to un# performance. Electric heaters

have no appredable a_ resistance. Aft a_ data _ measured external to the un# with the a_ filter in place with boffom return a_

External Static Air Volume and Motor Watts at Specific Blower Taps

Pressure High Medium Low

in.w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts

.00 0 1805 855 600 1615 765 525 1355 640 445

.05 10 1780 840 585 1605 755 515 1355 640 445

.10 25 1745 825 570 1585 750 505 1355 640 440

.15 35 1710 805 560 1560 735 490 1350 635 425

.20 50 1670 790 545 1535 725 480 1335 630 415

.25 60 1625 765 530 1500 710 465 1320 620 400

.30 75 1575 745 515 1465 690 450 1295 610 390

.40 100 1470 695 485 1375 650 420 1230 580 360

.50 125 1350 635 460 1265 595 395 1145 540 335

.60 150 1215 570 430 1140 535 365 1035 490 310

.70 175 1060 500 400 990 470 335 905 425 285

.75 185 980 460 385 910 430 320 830 390 270

NOTE -For side return a_ applications (with both sides open) add:. 15 in. w._ (35 Pa) static capacity to un# performance. Electric heaters

have no appredable a_ resistance. Aft a_ data _ measured external to the un# with the a_ filter in place with bosom return a_

External Static Air Volume and Motor Watts at Specific Blower Taps

Pressure

in.w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts

.00 0 2040 965 750 1900 895 665 1690 800 585

05 10 2005 945 735 1875 885 650 1680 790 570

10 25 1970 930 725 1845 870 635 1660 785 555

15 35 1935 910 710 1815 855 615 1640 775 545

20 50 1890 890 695 1780 840 600 1615 760 530

25 60 1845 870 680 1740 820 585 1585 745 515

30 75 1800 850 665 1700 800 570 1550 730 500

40 100 1690 800 635 1605 755 540 1470 695 470

50 125 1575 745 605 1495 705 510 1375 650 440

60 150 1445 680 575 1375 650 475 1265 600 410

70 175 1305 615 540 1240 585 445 1140 540 380

80 200 1150 545 510 1095 515 415 1000 470 350

85 210 1070 505 490 1015 480 400 920 435 330

NOTE -For side return a_ applications (with both sides open) add:. 15 in. w._ (35 Pa) static capacity to un# performance. Electric heaters

have no appredablea_resistance. Aft a_data_measured extemaltothe un#withthe a_ filterinplacewithbo#omretum a_

cfm

1610

1590

1560

1530

1490

1450

1405

1305

1185

1050

895

815

Table 9. CB3OU-51 Air Handler Performance (208/230v)

Table 10. CB30U-65 Air Handler Performance (208/230v)

Air Volume and Motor Watts at Specific Blower Taps

High

L/s

76o

750

735

72o

705

685

665

615

560

495

420

385

Watts cfm L/s Watts

510 1510 710 470

500 1490 705 460

490 1465 690 450

480 1440 680 435

470 1405 665 425

455 1370 645 410

445 1330 630 400

415 1235 585 370

390 1125 530 345

360 995 470 315

330 845 400 285

320 765 360 270

Medium

cfm L/s Watts

1360 645 430

1355 640 425

1345 635 415

1330 625 405

1305 615 395

1280 605 380

1245 585 370

1160 545 340

1050 495 310

920 435 280

765 360 245

680 320 230

High Medium Low

Low

Page 7

CB30U/CBX27UH SERIES

Page 8

I

WARNING

Wiring must conform to the current National Electric Code

ANSI/NFPA No. 70, or Canadian Electric Code Part I,

CSA Standard C22,1, and local building codes. Refer to

the following wiring diagrams. See the unit nameplate for

minimum circuit ampacity and maximum overcurrent

)rotection size.

L2 LI

BLOWER RELAY

K3 INDOOR I __

CIRCUIT

_LI (Black)

_LZ (Orange)

#m---L3

FIELD-SUPPLIED

WIRE NUTS

Select the proper supply circuit conductors according to

tables 310-16 and 310-17 in the National Electric Code,

ANSI/NFPA No, 70 or tables 1 through 4 inthe Canadian

Electric Code, Part I, CSA Standard C22,1.

This unit is provided with knockouts for conduit. Refer to

figure 9 on page 11 for unit schematic wiring diagram

and figures 5, 6, 7 and 8 for typical field wiring.

Separate openings have been provided for 24V low

voltage and line voltage. Refer to the dimension illustration

of specific location.

NOTE-USE COPPER

CONDUCTORSONLY,

REFER TO UNIT RATINO PLATE

FOR MINIMUM CIRCUIT AMPACITY

TRANSFORMER

AND MAXIMUM OVERCURRENT

PROTECTION SIZE

,II--

Ir

If

z_

GROUND

THERMOSTAT

_1 I L

BREAKER OR

CB1 CIRCUIT _

FUSE

J J TERMINAL

I BLOCK I

--J

TBI I

--J

Figure 5. Cooling Only

-- LINE VOLTAGE FIELD INSTALLED

.... CLASS 2 VOLTAGE FIELD INSTALLED

NEC/CEC

NOTE-ALL REMAINING WIRES

FACTORY INSTALLED

Z_ TO EXTERNAL LOAD 24VAC

AT .50 AMP MAXIMUM

/_FACTORY INSTALLED JUMPERS

505340M 07/07

Page 8

Page 9

L2 LI

LL

CIRCUN

r.i I L

BREAKERS f %_€'*_

_'_ERMINAL

1 i_ O_}

GROUND

I-., /-_ _ TERMINALI O

L-

Ir

Figure 6. Cooling Only and with Electric Heating Applications

L2 LI

HEAT ELEMENT _1

K32

HEAT RELAY _I

'L_,

__i__ __ .j I

J

K 3 INDOOR

BLOWER RELAY

BR ........

OR TRANSFORMER

FUSE

I I

NOTE-USE COPPER

CONDUCTORSONLY,

REFER TO UNIT RATING PLATE

FOR MINIMUM CIRCUIT AMPACITY

AND MAXIMUM OVERCURRENT

PROTECTION SIZE

NOTE-ALL REMAINING WIRES

FACTORY INSTALLED

.... CLASS 2 VOLTAGE FIELD INSTALLED

Z_ TO EXTERNAL LOAD 24VAC

Z_THERMOSTAT HEAT ANTICIPATION

Z_ WHEN TWO STAGE THERMOSTAT IS USED,

_FACTORY INSTALLED JUMPERS

LINE VOLTAGE FIELD INSTALLED

NEC/GEC

AT .50 AMP MAXIMUM

SETTING .€ AMP (ELECTRIC HEAT)

CONNECT SECOND STAGE HEAT BULB TO

TERMINAL "W2," AND REMOVE JUMPER

BETWEEN TERMINALS "R" AND "W2."

L3 CONNECTION USED ON (Y VOLTAGE) THREE PHASE ELECTRIC

HEATERS ONLY.

CIRCUIT BREAKERS

IL

CIRCUI"

,,I----

CLASS 2 VOLIADE FIELD INSIALLEO "h

NEC/CEC

NOTE-ALL REMAINING WIRES FACTORY INSTALLE

OR TERMINAL BLOCK

---D

[]

GROUND

BREAKER OR

CB1 CIRCUIT

TBI

TERMINAL

IJ

TO EXTERNAL LOAD 24VAC AT

.50 AMP MAXIMUM

FACTORY INSTALLED JUMPERS

/_ Y2 USED ONLY WHEN TWO SPEED COM-

PRESSOR IS USED (HP21).

USING SERVICE LIGHT OPTION ($54) WITH

SOME ELECTRONIC THERMOSTATS MAY RE-

QUIRE MOVING S54 COMMON WIRE TO Y1 IN

HEAT PUMP UNIT

/_ COMMON USED ONLY ON SOME THERMOSTATS.

Z_ AMBIENT COMPENSATING THERMISTOR CONNECTION USED ONLY

ON SOME THERMOSTATS.

[__.11

I II

I II

I II

I II

L_

F

K 3 INDOOR

BLOWER RELAY

TRANSFORMER

FUSE

I I

J I

_ uJI LI

J s, Z_

THERMOSTAT

fILl II

Figure 7. Heat Pump Only

Page 9

HEAT PUMP CLASS 2

VOLTAGE TERMINALS

CB30U/CBX27UH SERIES

Page 10

L2 LI

[L

CIRCUIT

CIRCUIT BREAKERS OR

TERMINAL BLOCK

GROUND

,,I

HEAT ELEMENT #I

K32

HEAT RELAY 'I

_TBI

TERMINAL /_

BLOCK _=_

K3 INDOOR

BLOWER RELAY

fuse

c_ TRANSFORMER

FUSE

I I

I I

J

HEAT PUMP APPLICATION

WITH ELECTRIC HEAT

CLASS 2 VOLTAGE FIELD INSTALLED

NEC/CEC

NOTE-ALL REMAINING WIRES FACTORY INSTALLED

//_ THERMOSTAT HEAT ANTICIPATION SETTING 0.4

AMP ELECTRIC HEAT

//_ FACTORY INSTALLED JUMPERS

THERMOSTAT Z_

EM _I2E2ATRELAY_ ,Z_(_

$23

OUTDOOR

THERMOSTAT

(IF USED)

[ I

J I

I

/_ WHEN OUTDOOR THERMOSTAT IS USED, CONNECT LEADS TO TERMINALS "R" AND "W2" (M If

AND REMOVE JUMPER BETWEEN TERMINALS "R' AND "W2." U3

//_ EMERGENCY HEAT RELAY (USED ONLY IF OUTDOOR T'STAT IS USED) FIELD PROVIDED AND _I:_-

INSTALLED NEW INDOOR UNIT. 24VAC 5VA MAX NEC/CEC CLASS 2 (J¢r

/_ USING SERVICE LIGHT OPTION ($54)WITH SOME ELECTRONIC THERMOSTATS MAY RE- I_ _--

QUIRE MOVING $54 COMMON WIRE TO Y1 IN HEAT PUMP UNIT. "5::1h

A

COMMON USED ONLY ON SOME THERMOSTATS. I--_-

//_ Y2 USED ONLY WHEN TWO SPEED COMPRESSOR IS USED (HP21). --

//_ AMBIENT COMPENSATING THERMISTOR CONNECTION USED ONLY ON SOME THERMOSTATS.

_2

HIC

SI

I

I

I

]

DD

5

z

o

o

rqE]D

o

i,,I,

oo

Figure 8. Heat Pump Applications with Electric Heat

505340M 07/07

Page 10

Page 11

FIELD WIRING FOR ECB

SERIES UNITS WITHOUT

CIRCUIT BREAKERS

A CIRCUITi_ Z2_

LI _ :

L2 _ r

ALS = : _ ALS--_--

A EOGIPMENT EQUIPMENT

z_EQUIPMENT GROUND LOCATED IN INDOOR UNIT

GROUND GROUND

CONNECT POWER WIRES PROM

A HEATER LABELED LI,LZ ON

Z_ "P" VOLTAGE UNITS AND

LI,L2,LB ON "Y" VOLTAGE

UNITS TO TB2 TERMINAL

STRIP IN INDOOR UNIT,

J2 BLUE

%-I

/

FIELD WIRING FOR ECB SERIES

UNITS WITH CIRCUIT BREAKERS

CIRCUIT 3 CIRCUIT Z CIRCUIT I

A cBs Z_ z_ CB2Z_ Z_ CB_A

--Z_ LS_ -- ALB_

LI "ll"'xT % L p'mII'XT_

L2 ...le.....-2- L2"II'" 2

EQOIPMENT EQUIPMENTGROUND GROUND

A LB IS NOT PRESENT ON

L_

(P) ELECTRIC HEATERS

Z_ THE NUMBER OF CIRCUITS VARY

ACCORDING TO HEATER MODEL.

REFER TO FAN COIL NAMEPLATE

FOR ACTUAL NUMBER EMPLOYED

24V POWER R

f

A

-6 _)CB8

EQUIP (

GROUND --

BLUE

3 5PD MOTOR 5 SPD MOTOR MOTOR SPEED

A

REFER TO FACTORY BLOWER SPEED TAP SELECTION

CHART ON UNIT FOR BLOWER SPEED INFORMATION

_L NEC/CEC CLASS 2 3VA

USE COPPER CONDUCTORS ONLY,

REFER TO UNIT RATING PLATE FOR MINIMUM

CIRCUIT AMPACITY AND MAXIMUM OVER-

CURRENT PROTECTION SIZE

A

LS CONNECTION USED ON (Y) ELECTRIC HEATERS ONLY

BLOWER G

CB SERIES

KEY COMPONENT

B5 MOTOR-BLOWER

C4 CAPACITOR-BLOWER MOTOR

CB8 CIRCUIT BREAKER-TRANS TI

FI FUSE-TRANSFORMER

J2 JACK-ELECTRIC HEAT

KB,-f,_ RELAY-CONTACTORrBLOWER

K4_,-! RELAY-ECONOMIZER HEAT

T! TRANSFORMER-CONTROL

TBI TERM. STRIP-CLASS II

ICB3 ICIRCUIT BREAKER_ELECT. HTI

ITB_ ITERMINAL STRIP _UNIT

MOTOR SPEED TAP CHART

I I COMMON

2 2 HIGH

5 4 MEDIUM

4 6 LOW

DESCRIPTION

ECB SERIES

CIRCUIT BREAKER-ELECT, HT

DESCRIPTION HT

CIRCUIT BREAKER-ELECT,

3 MEDIUM HIGH

5 MEDIUM LOW

[_H:I 24V COMMON C

ECON

Wl

W2

THIS WIRE USED ON "T"

VOLTAGE UNITS ONLY

A EBB USED ON 51 AND 61 UNITS ONLY

-- -- CLASS II VOLTAGE FIELD WIRING

LINE VOLTAGE FIELD WIRING

Figure 9. CB30U Air Handler Typical Wiring Diagram

SPEED

MOTOR SHOWN

Page 11

CB3OU/CBX27UH SERIES

Page 12

,&IMPORTANT I

Matt or foil-faced insulation is installed in indoor equipment

to provide a barrier between outside air conditions

(surrounding ambient temperature and humidity) and the

varying conditions inside the unit. If the insulation barrier is

damaged (wet, ripped, torn or separated from the cabinet

walls), the surrounding ambient air will affect the inside

surface temperature of the cabinet. The

temperature/humidity difference between the inside and

outside of the cabinet can cause condensation on the

inside or outside of the cabinet which leads to sheet metal

corrosion and subsequently, component failure,

REPAIRING DAMAGED INSULATION

Areas of condensation on the cabinet surface are an

indication that the insulation is in need of repair.

If the insulation in need of repair is otherwise in good

condition, the insulation should be cut in an X pattern,

peeled open, glued with an appropriate all-purpose glue

and placed back against the cabinet surface, being careful

to not overly compress the insulation so the insulation can

retain its original thickness. If such repair is not possible,

replace the insulation. If using foil-faced insulation, any

cut, tear, or separations in the insulation surface must be

taped with a similar foil-faced tape.

Figure 1. Repairing Insulation

,&WARNING

505340M 07/07

Page 12

Loading...

Loading...