Page 1

E

2001 LennoxIndustries Inc.

Dallas, Texas

INSTALLATION

INSTRUCTIONS

DT/DTH/DR/DRH

DR4035 FLUSH-FACED MODEL SHOWN

This appliance may be installed in an aftermarket

permanentlylocated,manufactured(mobile)home,

wherenotprohibited bylocalcodes.Thisappliance

is onlyfor use withthe type ofgas indicated onthe

rating plate. This appliance is not convertible for

use with othergases, unless a certifiedkit is used.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

MERITt

DIRECT VENT

VENTED GAS FIREPLACE/

VENTED GAS FIREPLACE HEATER

850,010M

05/2001

Supersedes 504,023M 11/99

Series

Litho USA

Table of Contents

DT/DTH/DR/DRH Unit Dimensions 2..................

MerittSeries DT/DTH/DR/DRH 2....................

Shipping and Packing List 3..........................

Requirements 3....................................

General 3.........................................

Combustion Air 4...................................

Location Selection 4................................

Installation Clearances 5............................

Framing 6.........................................

Installation 6......................................

Venting 12.........................................

Gas Piping 21......................................

Unit Start-up 21....................................

Adjustments 23.....................................

Service 24.........................................

Wiring Diagram - Millivolt Gas Valves 24...............

Wiring Diagram - Electronic Gas Valves 25.............

Repair Parts List 25.................................

Venting Kits & Available Components 26...............

WH Report No. J20046561

FORYOURSAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Extinguish any open flames.

Do not touch any electrical switch; do not

use any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call

the fire department.

Page 1

Page 2

DT/DTH/DR/DRH Unit Dimensions - inches (mm)

D

D

D

D

D

FRAMING

SPACERS

(Top and Sides

and Rear)

A

G

7 (178)

(Louvered Front Model Shown)

COMBUSTION AIR - 7-1/2 (190)

*CONCENTRIC FLUE

FLUE - 4-1/2 (114)

* DT/DTH - top flue only

DR/DRH - rear flue only

TOP VIEW

NOTE - Eyebrow

hood shown as positioned

in louvered front model.

ELECTRICAL

INLET

2-3/4x2 (70x51)

COVER PLATE with

KNOCKOUT)

C

GAS INLET

(Either Side

and bottom)

3 (76)

2 (51)

B

3 (76)

E

D

FRONT VIEW

Model No. A B C D E **F G

T/DR3025

T/DR3025

DTH/DRH3025

DT/DR3530

T/DR3530

DTH/DRH3530

DT/DR4035

T/DR4035

DTH/DRH4035

T/DR4540

in. 19-7/8 30-1/8 30-1/8 24-1/2 14

mm 505 765 765 616 356

in. 24-7/8 35-1/8 32-1/8 29-1/2 16

mm 632 892 816 749 406

in. 29-7/8 40-1/8 37-1/8 34-1/2 21

mm 759 1019 943 876 533

in. 34-7/8 45-1/8 37-1/8 39-1/2 21

mm 886 1146 943 1003 533

16

(406)

9-3/4

(248)

RIGHT SIDE VIEW

**DR/DRH -rear flue only

1/2 (13)

2 (51)

1-5/8

(42)

18-1/4

464

20-1/4

514

25-1/4

641

25-1/4

641

FIGURE 1

Meritt Series - DT/DTH/DR/DRH

MerittSeries fireplaces are sealed-combustion (direct

vent), heat-circulating gas appliances. The appliances

utilizea100 percentsafetyshut-offgas controlwitheither

a Piezo ignition system or an electronic ignition system.

Models equipped with either electronic ignition or the optionalforcedair fanassemblyrequire 120Velectricalconnection. Decorative trim kits, a brickaded firebox lining,

forced air fan assemblies, a wall thermostat (for usewith

vented gas fireplace heater models only), and hand-held

remote ON/OFF controls are available as options. Refer

to table 1 for model designations.

Thefireplacehas provisionsforside(s) orbottomentryfor

gas piping. This appliance must be vented to the outside

andmustnot be connectedtoa flueservicinganotherappliance.

The appliance must be installed using only approved Lennox

concentric venting components (4-1/2 in. / 7-1/2 in.).

Themillivolt gasvalveused innon-electronicignition units is self-powered and does not require

120V power wiring.

Do not attempt to alter or modify the construction of the

appliance or venting components. Any modification or alteration ofconstructionwillvoid the warranty,certification

and approval of these units.

In vented gas fireplace heater models, burner operation

can be controlled by: a unit- or wall-mounted ON / OFF

switch, or an approved thermostat.

In vented gas fireplace models, burner operation can be

controlled by: a unit- or wall-mounted ON / OFF switch.

On modelswiththeoptional manually-modulated gas valve,

flame appearance and heat output can be controlled at the

gas valve.

TABLE 1

Models Listed

to Vented Gas

Fireplace

Standard

DT/DR3025

DT/DR3530

DT/DR4035

DT/DR4540

*DRH/DTH models available with louver front only.

Models Listed to

Vented Gas

Fireplace Heater

Standard

DTH/DRH3025

DTH/DRH3530

DTH/DRH4035

Suffixes Used with

C - Louver front

F - Flush-Faced Front*

N-NaturalGas

P - Propane Gas (LP)

M - Millivolt System

E - Electronic system

F**

9-15/16

252

12-7/16

316

14-15/16

379

17-7/16

443

Both Models

Page 2

Page 3

Shipping and Packing List

Package 1 of 1 contains:

1 - Assembledventedfireplace /vented fireplaceheater

(includes log set, rock wool)

1 - Envelope containing installation instructions, user’s

manual,warranty,surveycard;and with theDT/DTH

models, also a vent restrictor

1 - Eyebrow

Check for shipping damage. The receiving party should contact last carrier immediately if any shipping damage is found.

All venting components are ordered and shipped separately.

Requirements

Lennox MerittSeries vented gasfireplaces/vented gas

fireplace heaters are Warnock Hersey certified to ANSI

Z21.88b-1999 inUSA(In Canada, CSA-2.33b-M99), and

CAN/CGA-2.17-M91 in both USA and Canada.

Installation of Lennox gas appliances must conform with local buildingcodes.Inthe absence of local codes, unitsmust

be installed according to the current National Fuel Gas

Code(ANSI-Z223.1)inthe United St ates.The National Fuel

Gas Code is available from:

American National Standards Institute, Inc.

11 West 42nd Street

New York, NY 10036

In Canada,installationmust conform with current National Standard of Canada CAN/CGA-B149.1 “Installation

Code for Natural Gas Burning Appliances and Equipment” and CAN/CGA-B149.2 “Installation Code for Propane Gas Burning Appliances and Equipment” and other

applicable local codes.

This appliance is Warnock Hersey certified for installation

clearances to combustible material as listed on appliance

rating plate and in table 2. Accessibility and service clearances must take precedence over fire protection clearances.

TABLE 2 - CLEARANCES TO COMBUSTIBLES

BACK 1/2 in. (13 mm); 0 in. (0 mm) spacers

SIDES 1/2 in. (13 mm); 0 in. (0 mm) spacers

TOP SPACERS 0 in.(0 mm)

FLOOR 0 in. (0 mm)

VENT 1 in. (25.4 mm)*

SERVICE CLEARANCES

FRONT 3 FeeT. (0.9 meters)

* 3 in. (75mm) above any horizontal vent component.

NOTE - For installation on combustible floors, appliance shall

not be installed directly on carpeting, tile, or other combustible material other than wood flooring.

Fireplace must be installed so thatelectrical components

(if applicable) are protected from water.

When120volt power isinstalled,appliance must beelectrically grounded in accordance withlocalcodes.Inaddition, in the United States, installation must conform with

the current National Electric Code, ANSI/NFPA No. 70.

The National Electric Code (ANSI/NFPANo. 70) is available from:

National Fire Protection Association

1BatteryMarchPark

Quincy, MA 02269

In Canada, all electrical wiring and grounding for the unit

must beaccordingtothe current regulations of the Canadian Electrical Code Part I (C.S.A. Standard C22.1) and/

or local codes.

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a maximum

°

temperature rise of 180

These units have been Warnock Hersey certified for

installation in bedrooms and mobile homes.

F(82°C) .

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation,maintenance, or repairwill expose you

to fiberglass wool. Breathing this may cause lung

cancer. (Fiberglass wool is known to the State of

California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposureto this substanceor for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900 USA

1 - This appliance is certified for use with the factory-sup-

plied glass panel only. Do not operate the appliance if

the glass is broken or cracked or if the glass has been

removed. Striking the glass panel may result in glass

breakage. Replacement glass panel must be ordered

from Lennox andshouldonlybeinstalled by a qualified

service technician.

2 - All parts removed for servicing should be replaced be-

fore operating the appliance.

3 - Solid fuel must not be used with this appliance.

4 - Surface temperatures on the appliance are very high.

Make sure that both children and adults are aware of

the danger of burns or clothing ignition.

Page 3

Page 4

5 - W arn the homeowner against leaving young children

unsupervised in the room with the appliance.

6 - Due to high temperatures, locate the appliance out of

traffic and away from furniture and draperies.

7 - Instruct the homeowner not to leave damp or wet

clothingorother flammablematerialto dryonor near

the appliance.

8 - Keep the appliance area clear and free of combustible

materials, gasoline and other flammable vapors and

liquids.

9 - Oninitialstart-up, operate theappliancecontinuous-

ly for10 to 12hoursonthe high flamesetting.During

this period, make sure that the room is well ventilated. This “break-in” procedure is required to burn

off the odors associated with a new fireplace.

Combustion Air

Location Selection

Install the fireplace out of direct sunlight to maximize the

unit’s visible glow effect. Also, consider the following

when selecting a location for the Lennox vented gas fireplace / vented gas fireplace heater :

1 - Allrequirementsindicated inventing section mustbe

met. Thisincludesrestrictions onhorizontalandver-

tical vent lengths and vent termination locations.

2 - Centerappliance betweentwo wallstuds,if possible,

to simplify venting.

3 - If optional blower is used, consider power wiring re-

quirements.

4 - Air circulation patterns should be unobstructed.

These Lennox MerittSeries vented gas fireplaces / vented

gas fireplace heaters havebeen designed to use 100 percent air from outdoors for combustion.

WARNING

Do not installappliancein a corrosive or contaminated

atmosphere. Meet all combustion and ventilation air

requirements, as well as all local codes.

TYPICAL APPLIANCE APPLICATIONS

TOP VENT

APPLICATION

REAR VENT

APPLICATION

TOP VENT

APPLICATION

*RECESSED INSTALLATION

(Side walls must not extend

beyond front edges of

fireplace.)

REAR VENT

APPLICATION

5 - See figure 2 for typical appliance applications.

6 - Do not install appliance directly on carpeting.

7 - If fireplace is to be installed on tile or other combus-

tible material other than wood flooring, it must be

installed on a metal or wood panel extending the full

width and depth of the base.

8 - Providea minimum3ft.(.9m)clearanceinfrontofthe

appliance for service and proper operation.

Note - DT/DTH models have only a top flue outlet .

DR/DRH models have only a rear flue outlet.

*Note - The side walls of mantels may protrude

beyond the front face of the fireplace a maximum

of 5 inches (127mm). See figure 3 for mantel

clearances above the fireplace.

*INSTALLATION WITH ONE SIDE OF UNIT

FLUSH WITH A WALL (Opposite wall must

not extend beyond front of fireplace.)

TOP VENT

APPLICATION

VERTICAL VENT

(Top Vent

Application)

HORIZONTAL VENT

(Top Vent

Application)

TOP VENT

APPLICATION

HORIZONTAL VENT

(Rear Vent Application

With a chase)

FIGURE 2

Page 4

VERTICAL VENT

(Rear Vent

Application)

HORIZONTAL VENT

(Rear Vent Application

without a chase)

Page 5

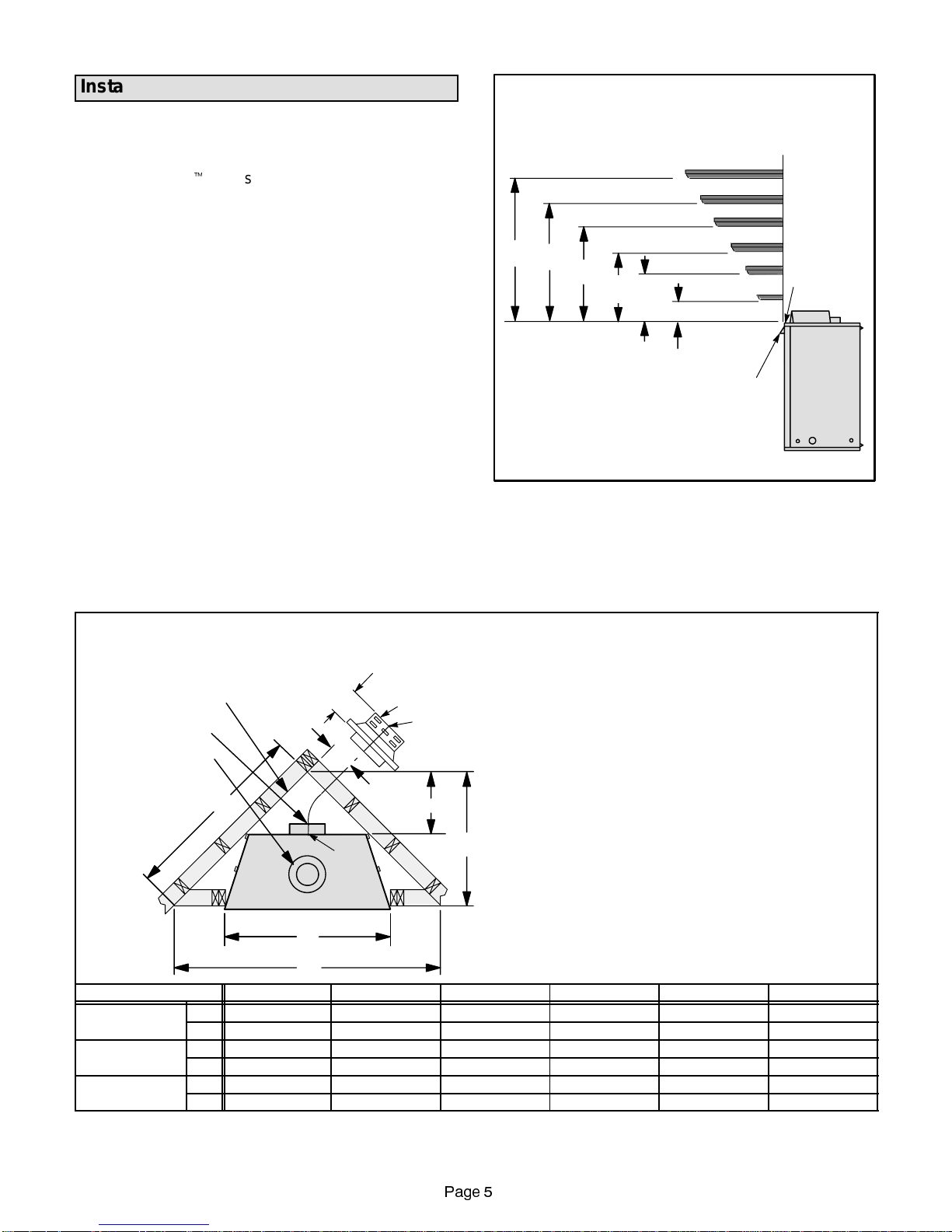

Installation Clearances

MANTEL CLEARANCES

Inches (mm)

Clearances to Combustibles

TheLennoxMerit

t

Seriesventedfireplaces /ventedfireplace heaters are approved with zero clearance to combustible materialsonall sides (as detailedin table 2),with

the following exception: When the unit is installed with

one sideflushwithawall, the wall on theothersideof the

unit must not extend beyondthe front edge of the unit. In

addition, when the unit is recessed, the side walls surrounding the unit must not extend beyond the front edge

of the unit. See figure 2.

Mantel Clearances

Vertical installation clearances to combustible mantels

varyaccordingto thedepthofthemantel. Figure3 details

these required clearances. Mantels constructed of noncombustible materials may be installed at any height

above the appliance opening; however, do not allowanything to hang below the eyebrow.

NOTE -Paint or lacquerusedto finishthemantel mustbe

heat resistant in order to avoid discoloration.

12 (305) MANTEL

10 (254) MANTEL

8 (203) MANTEL

14

(356)

12

(305)

10

(254)

8

(203)

6

(152)

NOTE -Eyebrow shown as positioned

in louvered front model. The eyebrow

position in the flush faced front model

is lower than shown.

6 (152) MANTEL

4 (102) MANTEL

2 (51) MANTEL

4

(102)

TOP OF

APPLIANCE

FIGURE 3

Corner Installations

Units installed across the corner of two joining walls require a minimum diagonal span as detailed in figure 4.

This span accommodates the unit depth.

CORNER INSTALLATIONS

Top (DT/DTH) or Rear (DR/DRH) Vent Application

7in.

Back wall of chase/enclosure

(including any finishing materials)

DR/DRH

DT/DTH

C

Model No. A B C D E F

DT/DTH/DR/DRH 3025

DT/DTH/DR/DRH 3530

DT/DTH/DR/DRH 4035

in.

mm

in.

mm

in.

mm

30-1/8 57-1/2 40-5/8 13-1/2 28-3/4 5

765 1461 1032 343 730 127

35-1/8 57-1/2 40-5/8 13-1/2 28-3/4 5

892 1461 1032 343 730 127

40-1/8 61-3/16 43-11/32 15-7/16 30-11/16 6-3/8

1019 1554 1101 392 779 162

F

A

B

(178 mm)

RECTANGULAR

TERMINATION

b

NOTE -

D

a

Venting requirements for DR/DRH Units (Rear Vent Units)

in corner installations -

- The rectangular termination must be used.

- For the 3025, 3530, and 4035 models, the horizontal vent

E

length “a” to “b,” must not exceed 28 in. (711mm).

FIGURE 4

Page 5

Page 6

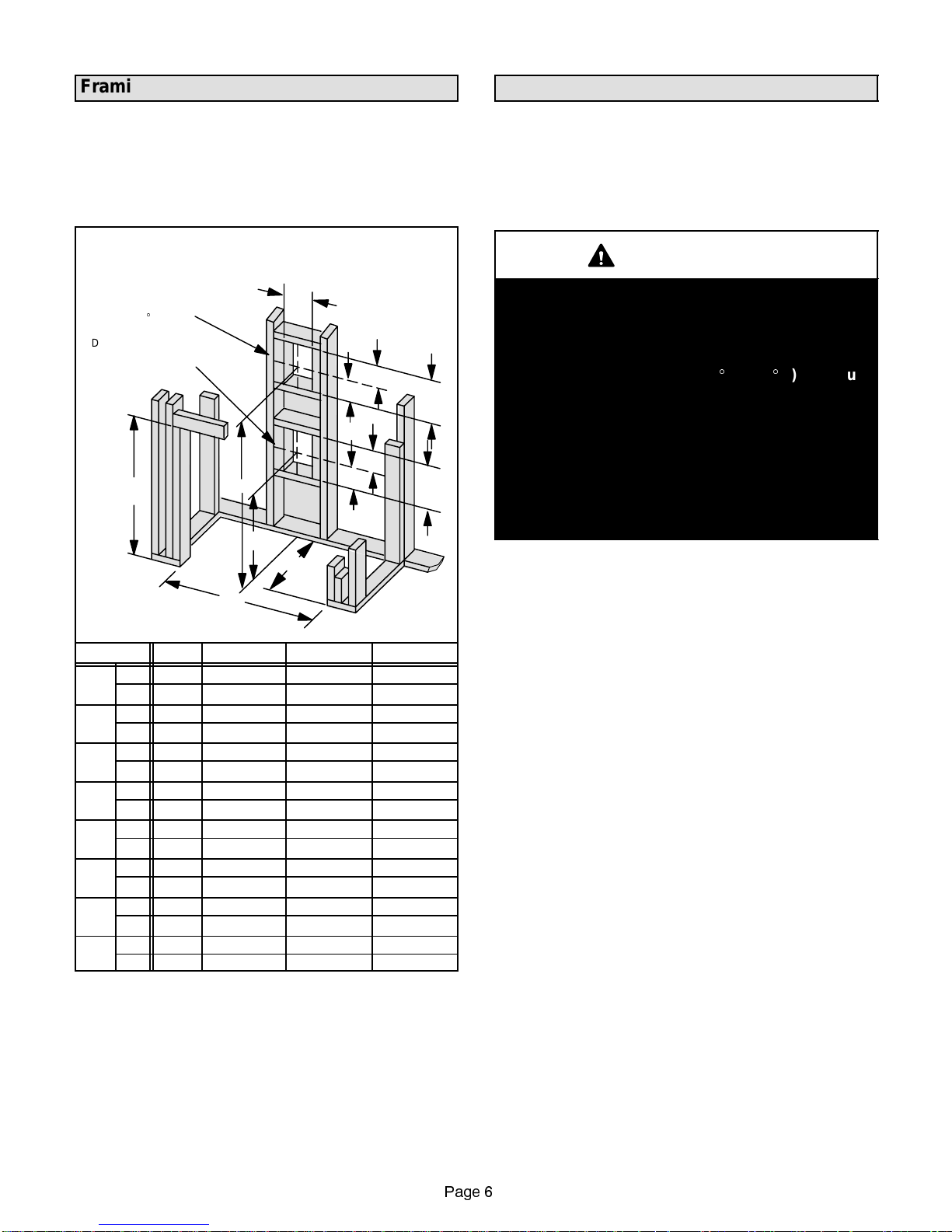

Framing

Installation

Wood or metal framing must accommodate unit outer

shell as shown in figure 5. If unit is to be elevated above

floor level, a solid platform providing continuous support

(e.g. plywood decking) must be constructed.

FRAMING

Framing should be constructed of

2x4 or larger lumber.

DT/DTH VENT FRAMING -

TOP VENT WITH ONE

_

ELBOW

90

DR/DRH VENTFRAMING -

REAR VENTWITH

NO ELBOWS

B

Inches (mm)

Model No. A B C D

DR/

in. 30-1/4 33-1/4 18-1/4 ----

DRH

mm 768 845 464 ----

3025

DR/

in. 35-1/4 35-1/4 20-1/4 ----

DRH

mm 895 895 514 ----

3530

DR/

in. 40-1/4 40-1/4 25-1/4 ----

DRH

mm 1022 1022 641 ----

4035

in. 45-1/4 40-1/4 25-1/4 ----

DR

DR

4540

mm 1149 1022 641 ----

DT/

in. 30-1/4 33-1/4 ---- 38-1/4

DTH

mm 768 845 ---- 972

3025

DT/

in. 35-1/4 35-1/4 ---- 40-1/4

DTH

mm 895 895 ---- 1022

3530

DT/

in. 40-1/4 40-1/4 ---- 45-1/4

DTH

mm 1022 1022 ---- 1149

4035

in. 45-1/4 40-1/4 ---- 45-1/4

DT

DT

4540

mm 1149 1022 ---- 1149

D

C

15-7/8

(403)

A

10-1/2

(267)

5-1/8

(130)

5-1/8

(130)

(178)

7

(178)

7

12-1/8

(308)

12-1/8

(308)

FIGURE 5

Installation should beperformedbyaqualified technician

according to these instructions and local codes.

1 - Carefully remove assembled vented fireplace /

vented fireplace heater from packaging and place in

desired location.

WARNING

Combustible materials may be installed flush with

both sides and top front edges of the fireplace.

Combustible materials must NEVER overlap the

edges onto the front face of the appliance. Joints

between the finished wall and the fireplace edges

_

can only be sealed with a 300

sealant.

Non-combustible materials can be used to cover

the gap between the combustible wall materials

and t he fireplace. On flush-faced models, noncombustiblematerialsmay coverthe upperportion

of thetoppanel down to,butnot beyond the top of,

the eyebrow. You must not modify the air inlet or

outlet grills in any way. Access to panels must not

be obstructed.

2 - Lift and r emove the bus tle; in flus h-faced model

applications, remove the top panel; in louveredface model applications, remove the louvers.

3 - Lower the bottom hinged panel. Remove three se-

curing screwsatthe bottom oftheglass panel.Care-

fully lift and remove the shrink-wrapped glass panel/

log set assembly. Lay the assembly down, and cut

and remove the shrink-wrapping.

4 - Position the logs as shown in figure 6 (3025 units),

figure 7 (3530 units), figure 8 (4035 units), or figure

9 (4540 units). Handle logs carefully, to prevent

breakage. The logs are notched to accommodate

the burner tube, pilot assembly and each other.

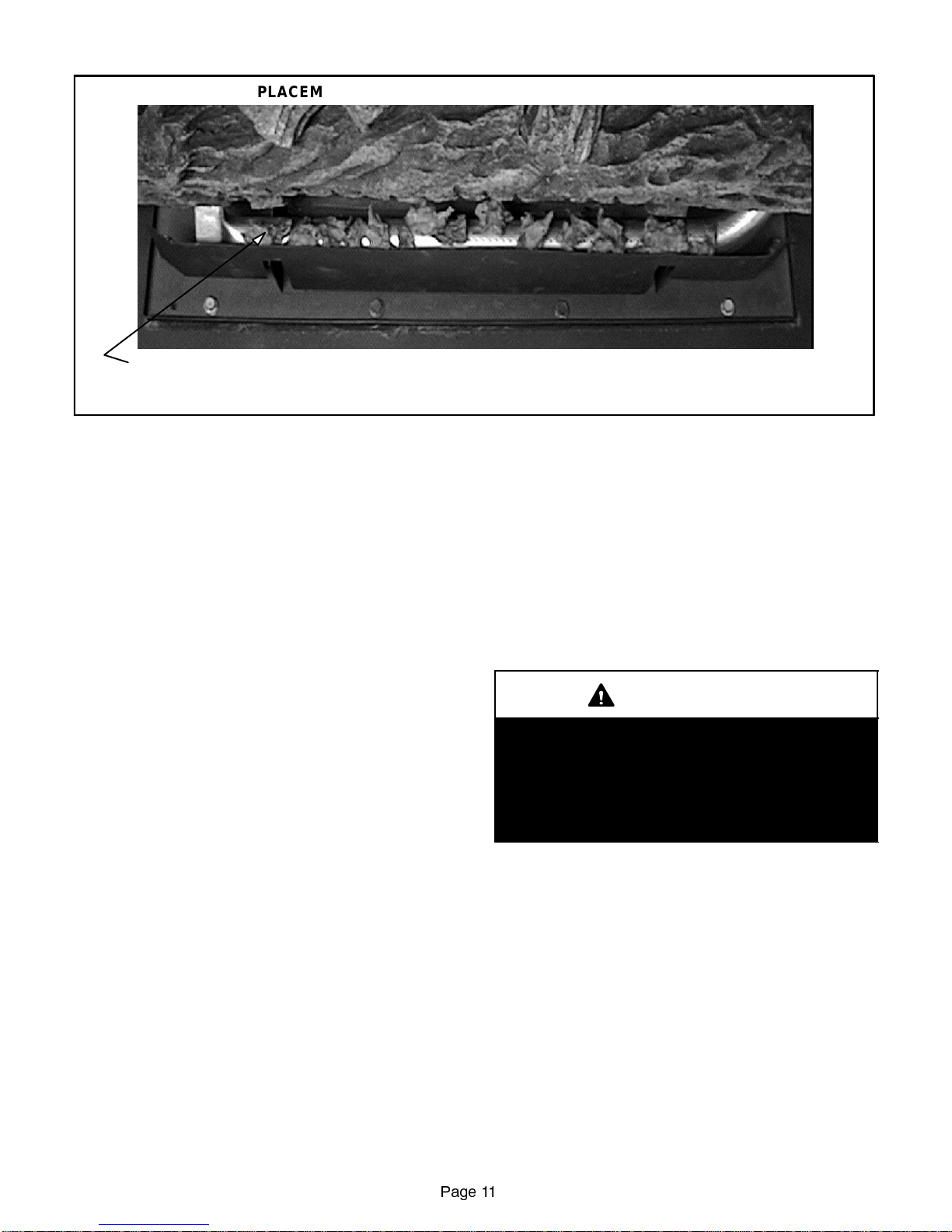

5 - Place rockwool(ember material) as shown in figure 10.

NOTE-Yourapplication maynot requirethe useof all

of the provided rock wool. Reserve remaining rock

wool for replacement, if necessary.

6 - Remove cardboard from pressure relief valves lo-

cated on top of the firebox.

7 - Secureappliancetofloorusingfold-downtabsonthe

sides of the fireplace. Additional holes for securing

screwsarealso providedin thebase ofthe unitunder

the firebox.

F (149_C) minimum

Page 6

Page 7

DT/DTH/DR/DRH 3025 LOG PLACEMENT

Log

Number

3

4

1

Log Stamping

Part Number

1

2

196

195

3 197

4 198

Lennox

Part Number

19L61

19L60

19L62

19L63

Lennox Part Number

2

for entire log set: 18L76

1

2

3

4

FIGURE 6

Page 7

Page 8

DT/DTH/DR/DRH 3530 LOG PLACEMENT

Log

4

Number

3

1

Log Stamping

Part Number

1

2

1910

199

3 1911

4 1912

Lennox

Part Number

19L65

19L64

21L10

21L11

Lennox Part Number

for entire log set: 18L77

2

1

2

3

4

FIGURE 7

Page 8

Page 9

DT/DTH/DR/DRH 4035 LOG PLACEMENT

3

4

5

6

Log

Number

Log Stamping

Part Number

1 1919

2 1918

3 1920

1

2

4

5

6

1921 19L70

1922 19L71

1923

Lennox Part Number

Lennox

Part Number

19L67

19L66

19L68

19L69

for entire log set: 18L78

1

3

4

2

5 6

FIGURE 8

Page 9

Page 10

DT/DTH/DR/DRH 4540 LOG PLACEMENT

3

4

7

Lennox

Part Number

19L73

19L72

19L68

19L71

19L74

1

2

Log Stamping

Part Number

1925

1924

Log

6

Number

5

3 1920

1

4

5

2

6

7

1921 19L70

1922

1923 19L69

1926

Lennox Part Number

for entire log set: 18L79

1

2

4

3

5

6

7

FIGURE 9

Page 10

Page 11

PLACEMENT OF EMBER MATERIAL ON FRONT BURNER

SEPARATE ROCK WOOL INTOPIECES ABOUT THE SIZE OF A NICKEL. KEEP THE PIECES FLUFFED UP, NOT MATTED,

AND PLACE APPROXIMATELY AS SHOWNIN THIS FIGURE.

NOTE - TOO MANY EMBERS ON THE FRONT BURNER WILL CAUSE POOR COMBUSTION.

8- Millivolt Wiring (Millivolt Units) -

In applications where the burner switch is to be unitmounted in the field -

Install the switch in the gas valve mounted bracket

and wire according to figure 37.

In applications where the burner switch is to be wallmounted -

Install a field-provided handy box in a convenient

location adjacenttotheappliance. Install the ON/OFF

switch and faceplate and wire according to figure 37.

In thermostat applications -

Install the thermostat in a suitable location and wire

accordingtofigure37.

9- 24 Volt Wiring (Electronic Ignition Units) -

In applications where the burner switch is to be unitmounted in the field -

Install the ON/OFF switch in the gas valve mounted

bracket and wire according to figure 38.

In applications where the burner switch is to be wallmounted -

Install a field-provided handy box in a convenient

location adjacent to the appliance. Install ON/OFF

switch and faceplate and wire according to figure 38.

In thermostat applications -

Install the thermostat in a suitable location and wire

accordingtofigurefigure38.

10 - 120 Volt Wiring -

MillivoltUnits-120voltwiringisrequired onMillivolt

units only when a fan kit is being installed. Wire fan

kitaccordingtofigure37.

ElectronicIgnition UnitsAll electronic ignitionunits

require120volt wiring.Installwiringaccording to figure 38.

When 120 volt electrical power is applied, the appliance must be electrically grounded according to

FIGURE 10

localcodesor,intheabsenceof localcodes,withthe

current National Electric Code, ANSI/NFPA No. 70,

in theUSAor CSA C22.1 CanadianElectricalCode

in Canada.

11 - Prepare the vent collar for use as indicated in the

venting section. AttacheitherLennox flexible or unitized rigid concentric vent to vent collar, at the top

(DT/DTH units) or rear (DR/DRH units), of the appliance as indicated in the venting section. Ventterminations are indicated in venting section.

12 - Make gaspipingconnections asindicatedin gas pip-

ing section.

WARNING

Do not operate appliance unless glass frame is

properly installed. Glass must not be broken or

cracked. If glass is damaged, rep lace with appropriate glass/frame assemblyavailablethrough

Lennoxrepairparts.Substitutionofanyother than

Lennox-specified glass can lead to property damage or personal injury.

13 - Carefully reinstall the glass door. Tighten the three

bolts at the bottom of the door securely.

14- Install the bustle; in flus h-faced model applica-

tions,install thetoppanel;inlouvered -facemodel

applications, install the louvers.

15 -Remove the ey ebrow from its protec tive wrap-

ping.Slidethe eyebrowintothe slotsonthe lower

edges ofthe radiant panel(flush-facedmodelapplications) or the lower edges of the c abinet top

(louvered-face model applications).

NOTE - The eyebrow must be used in all applications.

16 - Continue with theprocedures indicatedinthestart-up

and adjustments section.

Page 11

Page 12

Venting

SECURING RIGID VENT PIPE TO COLLAR

General Requirements

These instructions shouldbe used as a guideline and do

notsupersedelocal codes inany way.Installventaccord-

ingtolocal codes, theseinstructions,thecurrentNational

Fuel Gas Code (ANSI-Z223.1) in the USA or the current

standards of CAN/CGA-B149.1 and -B149.2 in Canada.

This gas fireplace is equipped with a concentric ventcollar for ease of installation. The concentric vent pipe will

bring in outdoor air for combustion and will remove exhaust gases. Vent terminations are ordered separately.

This Lennox gas fireplace is for use only with Lennox

approved concentric vent pipe: rigid vent pipe in vertical

venting applications, and rigid or flexible vent pipe in

horizontal applications. Each vent must be terminated

using a Lennox vent termination. Approved venting kits

and components are listed on page 26 of this manual.

NOTE - The vent terminations are certified for use

with thisunit and mustbe installed withoutmodification.

APPLYONLY LENNOX MILL-PAC BLACKHIGH

TEMPERATURE SEALANT (Catalog No. 10K81)

AND SLIDE RIGID PIPE OVER INNER AND

NOTE - The bottom part of

the outerpipe is omitted in

order toshow the detail of

OUTER COLLARS.

the innerpipe.

USE THREESCREWS TO

SECURE OUTERVENT

PIPE TO OUTERCOLLAR

RIGID VENT

PIPE

FIGURE 11

Sealing and Connecting Flexible Vent Pipe

Flexible vent pipe is packaged and shipped in its contracted state. When installing flexible vent pipe, its length

may beexpandedto twice itscontractedsize.Youshould

expecttoextenda3ft.sectionofflexiblepipeupto6ft.

IMPORTANT

WARNING

All vent system connections/joints must be properly

sealed using only Lennox MILL-P AC BLACK HIGH

TEMPERA TURE SEALANT, Catalog Number 10K81.

Failure to properly seal the vent system could allow

carbon monoxideleakage resulting ininjuryor death.

Sealing and Joining Rigid Vent Pipe

Apply only Lennox MILL-PAC BLACK HIGH TEMPERATURE SEA LANT (Catalog number 10K81)

around outside of inner and outer vent collars befor e

assembling vent tocollar.Outerpipemust also be secured to outer c ollar using three sheet metal screws.

See figure11.Sealant must beappliedto all rigidpipe

joints and the outer pipe must be secured with thr ee

sheet metal screws.

Under no circumstances, may separate sections of

concentric flexible vent pipe be joined together.

When flexible vent pipe is used, both inner and outer

pipes should be secured to the fireplace concentric

collar and to the vent termination using only Lennox

MILL-PACBLACKHIGHTEMPERATURE SEALANT

(Catalog number 10K81) and metal gear clamps as

shown in figure 12.

SECURING VENT PIPE TO COLLAR

NOTE - Part of the outer

pipe is pulled away to show

the detailof the inner pipe.

APPLYONLY LENNOX MILL-PAC

BLACK HIGHTEMPERATURE

SEALANT (Catalog No. 10K81)

AND SLIDEFLEXIBLE PIPE OVER

INNER ANDOUTER COLLARS.

HOLES PROVIDE

SCREWDRIVER ACCESS

FOR TIGHTENING INNER

GEAR CLAMP.

FLEXVENT

GEAR

CLAMPS

OUTER

COLLAR

FIGURE 12

Page 12

Page 13

Vertical Venting Through the Roof

This Lennox gas fireplace is for use only with Lennox

approved concentric vent pipe; only rigid vent pipe may

be used when vertically venting the fireplace through

the roof.

DT/DTH Applications- See figures 16,17, or 18 forvent

length requirements using concentric vent pipe.

DR/DRHApplications- Seefigures 19,20,or21for vent

length requirements using concentric vent pipe.

DT/DTH and DR/DRH Applications -

Figure15provides adetailoftheverticalvent termination.

Figure 22showstheminimum vent termination height requirements above a flat or sloped roof.

General guidelines for vertical vent installations:

1- DT/DTH Models -

Install aventrestrictor(provided) intheflue outlet as

shown in figure 13.

VENT RESTRICTOR INSTALLATION

(DT/DTH UNITS ONLY)

RESTRICTOR

RESTRICTOR

FLUSH

CABINET TOP

INNER

COLLAR

OUTER

COLLAR

2- Horizontal sections of the vent pipe run should

besloped upwarda minimumof 1/4in. perfoot of

horizontal vent in the direction away from t he

fireplace. In addition, horizontal sections of pipe

must be supported using metal straps spaced

every 2 ft.

3 - Maintain proper clearances any time vent pipe must

passthroughinsulated spaces. Useinsulationshield

when vent pipe passes through any insulation.

_

4- Two45

elbows may be used in place of one 90_elbow. This can only occur once in the entire venting

system.

One45

_

elbowmay besubstitutedfor one90_elbow

at any point in the venting system.

The same rise to run ratios as shown in the venting

_

figures must be followed if 45

elbows are used.

FIRESTOP / SPACER

(Vertical Applications Shown)

NOTE - Horizontal applications require 3 inch

(76mm) clearance above

top of vent.

FIGURE 14

TOPFLUEOUTLET

WHEN USING THE TOP FLUE OUTLETIN VERTICAL VENTING

APPLICATIONS, INSTALL RESTRICTOR FLUSH WITH FLUE

COLLAR OUTLET.

SIDE VIEW

FIGURE 13

1 - Provide a firestop / spacer any time vent pipe must

pass throughacombustiblefloor, ceilingorwall. See

figure14.Refer tolistingon page26 forcatalognumbers of Lennox firestop spacers.

VERTICAL TERMINATION DETAIL

LENNOX MILL-PAC

BLACK HIGH

TEMPERATURE

SEALANT

(Catalog Number 10K81)

RIGID VENT

FIGURE 15

Page 13

Page 14

DT/DTH VERTICAL VENTING FIGURES

VERTICAL VENTING WITHOUT ELBOWS

(DT/DTH - Top Vent Units)

Firestop/Spacermust beused anytime

vent pipe passes through combustible

floor or ceiling or wall.

V = 40 feet

Maximum

V

Install flashing and storm

collar at the point the vent pipe

passes through the roof.

VERTICAL VENTING USING TWO 90_ELBOWS

(DT/DTH - Top Vent Units)

H

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

V2

V1

V1 + V2 = 40 ft. Maximum.

H = 17 ft. Maximum.

V1 H

1ft.min. 3ft.max.

2ft.min. 6ft.max.

3ft.min. 9ft.max.

4 ft. min. 12 ft. max.

5 ft. min. 15 ft. max.

17 ft. max.6ft.min.

FIGURE 16

V1 + V2 = 40 ft. Maximum.

H1 + H2 = 17 ft. Maximum.

V1 H1 + H2

1ft.min. 3ft.max.

2ft.min. 6ft.max.

3ft.min. 9ft.max.

4 ft. min. 12 ft. max.

5 ft. min. 15 ft. max.

6 ft. min. 17 ft. max.

VERTICAL VENTING USING THREE 90

(DT/DTH - Top Vent Units)

Firestop/Spacermust beused any

V2

H2

time vent pipe passes through

combustible floor or ceiling or wall.

H1

_

ELBOWS

FIGURE 17

V1

FIGURE 18

Page 14

Page 15

DR/DRH VERTICAL VENTING FIGURES

VERTICAL VENTING USING ONE 90_ELBOW

(DR/DRH - Rear Vent Units)

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

V

H

V+H = 40 ft. MAX.

H = 8 ft. MAX.

VH

1ft.min. 2ft.max.

2ft.min. 4ft.max.

3ft.min. 6ft.max.

4ft.min. 8ft.max.

FIGURE 19

VERTICAL VENTING USING TWO 90_ELBOWS

(DR/DRH - Rear Vent Units)

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

V

H1

H2

VH1+H2

1ft.min. 2ft.max.

2ft.min. 4ft.max.

3ft.min. 6ft.max.

4ft.min. 8ft.max.

40 ft. max. 8 ft. max.

FIGURE 20

V1 + V2 =40 ft. Maximum.

H1 = 8 ft. Maximum

H1 + H2 = 17 ft. Maximum.

V1 H1

1ft.min. 2ft.max. 3ft.max.

2ft.min. 4ft.max.

3ft.min. 6ft.max.

4ft.min. 8ft.max.

5ft.min. 8ft.max.

6ft.min. 8ft.max.

H1 + H2

6ft.max.

9ft.max.

12 ft. max.

15 ft. max.

17 ft. max.

VERTICAL VENTING USING THREE 90_ELBOWS

(DR/DRH - Rear Vent Units)

H2

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

V2

V1

H1

FIGURE 21

Page 15

Page 16

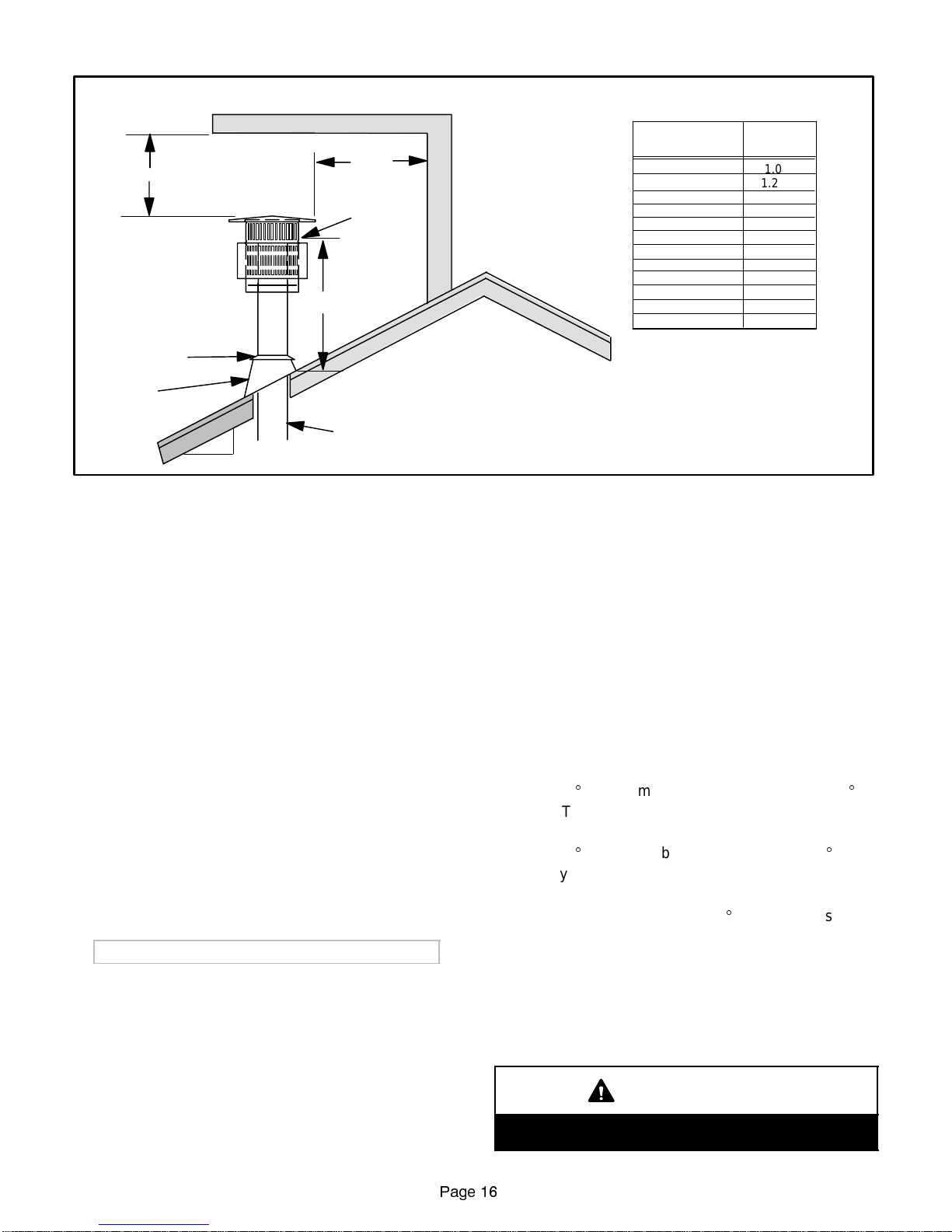

Horizontal Overhang

TERMINATION HEIGHTS FOR VENTS ABOVE

FLAT OR SLOPED ROOFS

2FTMIN.

2FTMIN.

Vent

Termination

Lowest

Discharge

Opening

H*

Storm Collar

*H = MINIMUM HEIGHT FROM ROOF

Flashing

X

12

Roof Pitch is X/12

TO LOWEST DISCHARGE OPENING

Concentric Vent Pipe

FIGURE 22

Detailed steps for installation of the vertical vent at

and above the roof:

1 - Determine the location of the vent’s penetration of

the roof.

2 - Coverthe openingsoftheconcentricventandcutthe

hole in the roof large enough in order to provide a

minimum of one inch (25.4mm) clearance to roof

combustible material.

3 - Frame the vent hole (with material of at least the

same dimensions as the roof rafters) in order to provide adequate nailing support for the roof-to-vent

flashing. (Note - Vent assembly above the roof may

be subjected to high winds).

4 - Install the remaining vent sections and the vent ter-

mination. See figure 22 for minimum allowable termination heights above theroofandminimumallowable clearances to obstacles above the roof.

5 - Use both flashing and a storm collar at the point

where the vent pipe exits the roof. Seal flashing to

roof, and storm collar to vent with non-hardening

caulking compound.

Horizontal Venting Through a Side Wall

This Lennox gas fireplace is for use only with Lennox

approved concentric vent pipe; either rigid or flexible

vent pipe may be used when horizontally venting the

fireplace through a side wall.

DT/DTH Applications- See figures 23,24, or 25 forvent

length requirements using concentric vent pipe.

DR/DRHApplications- Seefigures 26,27,or28for vent

length requirements using concentric vent pipe.

Also, see figure 4 for venting in a corner installation.

Vertical

Wall

OF VENT

ROOF PITCH

FLAT TO 6/12

6/12 TO 7/12

7/12 TO 8/12

8/12 TO 9/12

9/12 TO 10/12

10/12 TO 11/12

11/12 TO 12/12

12/12 TO 14/12

14/12 TO 16/12

16/12 TO 18/12

18/12 TO 20 /12

20/12 TO 21/12

H-FT

1.0

1.25

1.5

2.0

2.5

3.25

4.0

5.0

6.0

7.0

7.5

8.0

General guidelines for horizontal vent installations:

1 - Provide a firestop / spacer any time vent pipe must

pass throughacombustiblefloor, ceilingorwall. See

figure14.Refer tolistingon page26 forcatalognumbers of Lennox firestop spacers.

2- Horizontal sections of the vent pipe run should be

sloped upwarda minimum of 1/4in.per foot of horizontal vent in the direction away from the fireplace.

In addition,horizontalsections of pipe mustbesupported using metal straps spaced every 2 ft.

3 - Maintain proper clearances any time vent pipe must

passthroughinsulated spaces. Useinsulationshield

when vent pipe passes through any insulation.

_

4- Two45

elbows may be used in place of one 90_elbow. This can only occur once in the entire venting

system.

One45

_

elbowmay besubstitutedfor one90_elbow

at any point in the venting system.

The same rise to run ratios as shown in the venting

_

figures must be followed if 45

elbows are used.

5 - The longest length of flexible vent pipe available is 48

inches, measured wheninits compressed form. Flexible vent pipe may not be applicable in every venting

configuration depicted in figures 23, 24, 25, 27, and

28, depending on the total vent length required.

IMPORTANT

Under no circumstances, may separate sections of

concentric flexible vent pipe be joined together.

Page 16

Page 17

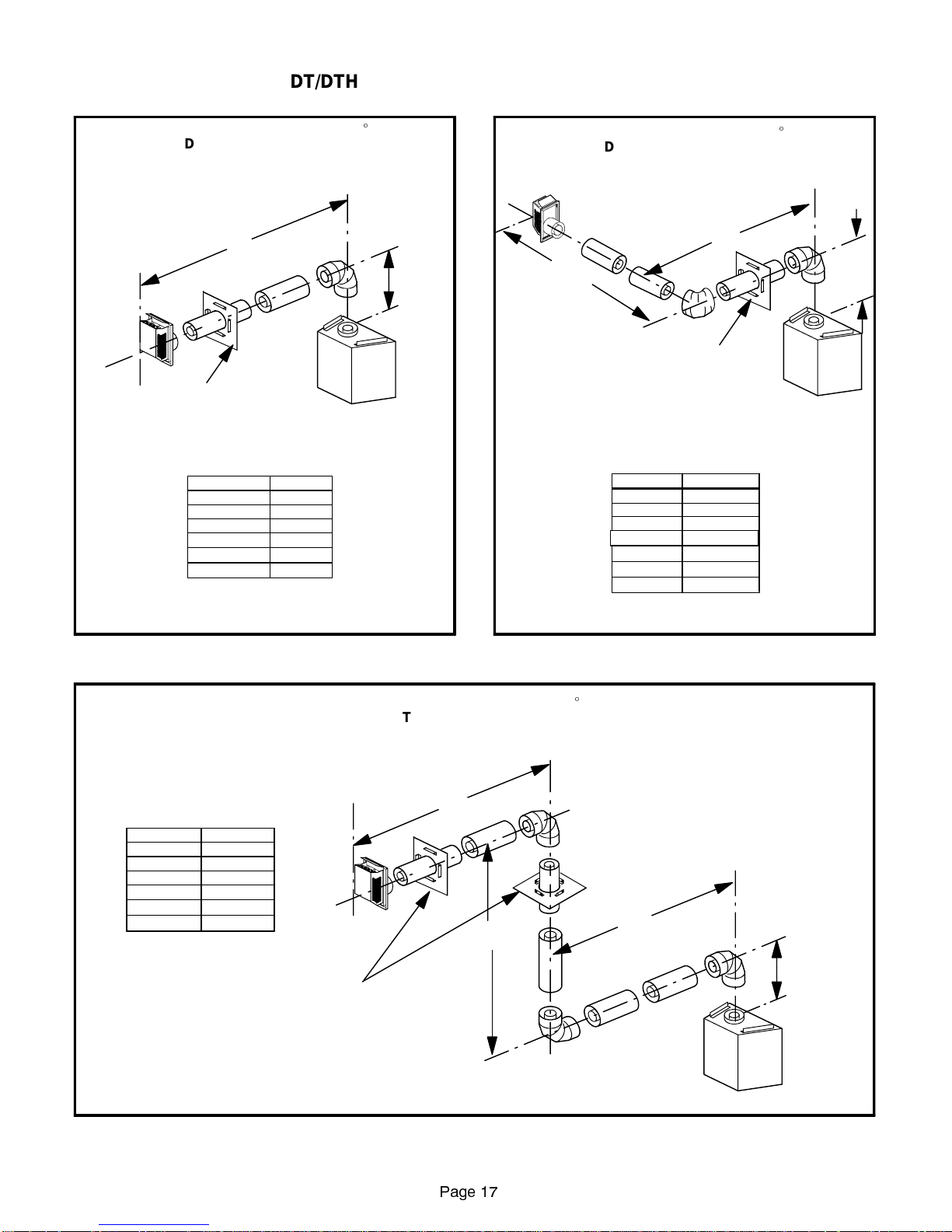

DT/DTH HORIZONTAL VENTING FIGURES

HORIZONTAL VENTING USING ONE 90_ELBOW

(DT/DTH - Top Vent Units)

RIGID VENT PIPE SHOWN; **FLEXIBLE VENT

Rectangular termination shown;

round termination may also be used.

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

**NOTE: THE LONGEST LENGTH OF FLEX AVAILABLE

IS 48INCHES OFCOMPRESSED FLEX.

PIPE MAY ALSO BE USED.

H

* 10-1/2 in. min. forflexible vent pipe.

VH

*1 ft. min.

2ft.min.

3ft.min.

4ft.min.

3ft.max.

4ft.max.

6ft.max.

8ft.max.

5 ft. min. 17 ft. max.

20 ft. max. 17 ft. max.

HORIZONTAL VENTING USING TWO 90_ELBOWS

(DT/DTH - Top Vent Units)

RIGID VENT PIPE SHOWN; **FLEXIBLE VENT

V

Firestop/Spacermust beused any

combustible floor or ceiling or wall.

**NOTE: THE LONGEST LENGTH OF FLEX AVAILABLE

IS 48INCHES OFCOMPRESSED FLEX.

PIPE MAY ALSO BE USED.

H1

H2

time vent pipe passes through

Rectangular termination shown;

round termination may also be used.

* 10-1/2 in. min. forflexible vent pipe.

V1

*1 ft. min.

2ft.min.

3ft.min.

4ft.min.

5ft.min.

6ft.min.

H1 + H2

3ft.max.

6ft.max.

9ft.max.

12 ft. max.

15 ft. max.

17 ft. max.

20 ft. max. 17 ft. max.

V1

FIGURE 23

HORIZONTAL VENTING USING THREE 90_ELBOWS

V1 + V2

2ft.min.

3ft.min.

4ft.min.

5ft.min.

6ft.min.

20 ft. max. 17 ft. max.

*NOTE: THE LONGEST LENGTH OF FLEX AVAILABLE

IS 48INCHES OFCOMPRESSED FLEX.

Rectangular termination shown;

round termination may also be used.

H1 + H2

4ft.max.

6ft.max.

8ft.max.

15 ft. max.

17 ft. max.

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

(DT/DTH - Top Vent Units)

RIGID VENT PIPE SHOWN; *FLEXIBLE VENT

PIPE MAY ALSO BE USED.

H2

V2

FIGURE 24

H1

V1

FIGURE 25

Page 17

Page 18

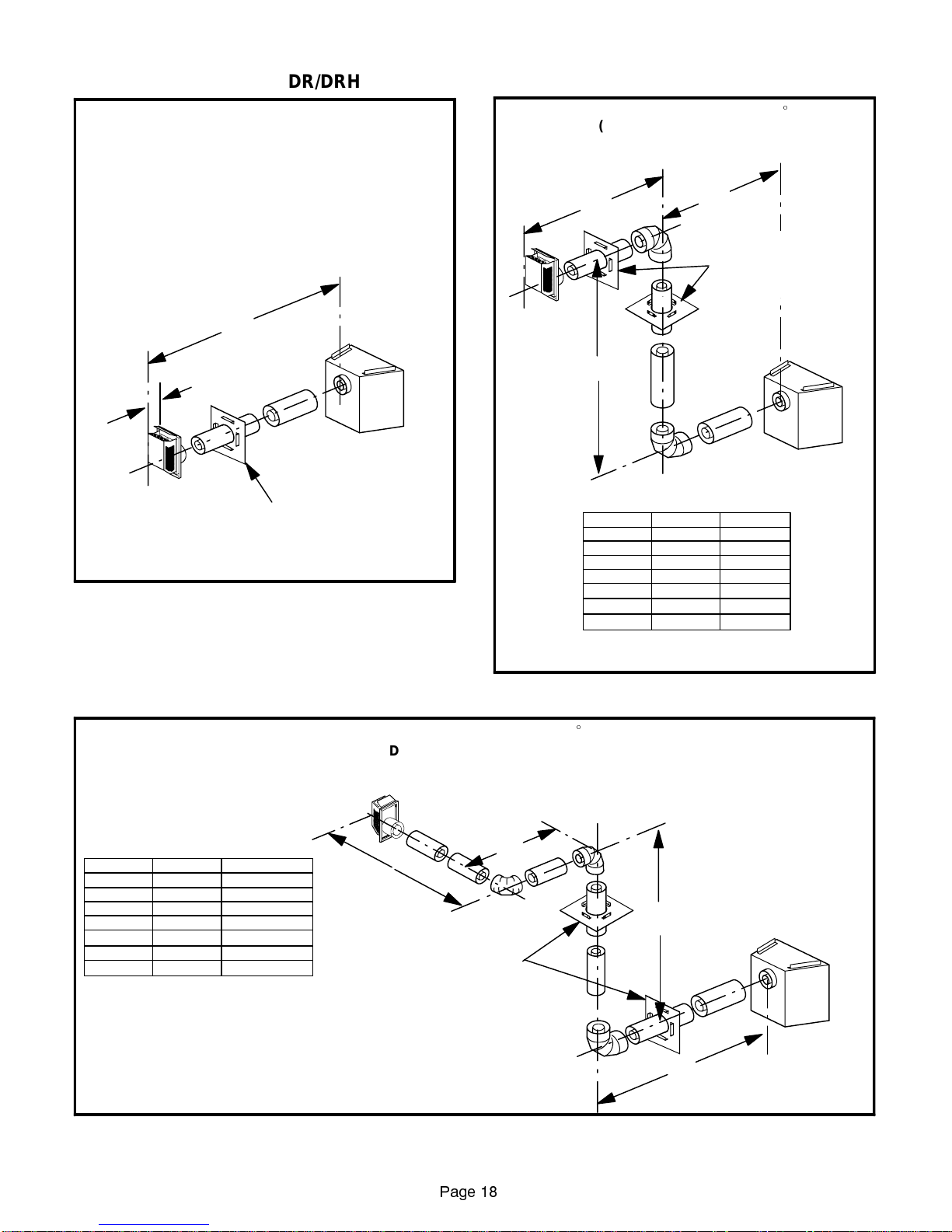

DR/DRH HORIZONTAL VENTING FIGURES

HORIZONTAL VENTING WITHOUT ELBOWS

(DR/DRH - Rear Vent Units)

ONLYTHE RECTANGULAR TERMINATION MAY BE USED.

RIGID VENT PIPE SHOWN; FLEXIBLE VENT PIPE

MAYALSOBEUSED.

**For 3025, 3530, and 4035 models

H = 28 in. (711 mm) Maximum.

**For 4540 models

H = 18 in. (457 mm) Maximum.

**H

7in.

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

FIGURE 26

HORIZONTAL VENTING USING TWO 90_ELBOWS

(DR/DRH - Rear Vent Units)

RIGID VENT PIPE SHOWN; *FLEXIBLE VENT

*NOTE: THE LONGEST LENGTH OF FLEX AVAILABLE

IS 48INCHES OFCOMPRESSED FLEX.

PIPE MAY ALSO BE USED.

H2

H1

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

V

Rectangular termination shown;

round termination may also be used.

VH1

H1 + H2

1ft.min. 2ft.max. 3ft.max.

2ft.min. 4ft.max.

3ft.min. 6ft.max.

4ft.min. 8ft.max.

5ft.min. 8ft.max.

6ft.min. 8ft.max.

20 ft. max. 8 ft. max.

6ft.max.

9ft.max.

12 ft. max.

15 ft. max.

17 ft. max.

17 ft. max.

HORIZONTAL VENTING USING THREE 90_ELBOWS

Rectangular termination shown;

round termination may also be used.

V

H1

H1 + H2 + H3

1ft.min. 2ft.max. 3ft.max.

2ft.min. 4ft.max.

3ft.min. 6ft.max.

4ft.min. 8ft.max.

5ft.min. 8ft.max.

6ft.max.

9ft.max.

12 ft. max.

15 ft. max.

6 ft. min. 8 ft. max. 17 ft. max.

20 ft. max. 8 ft. max.

*NOTE: THE LONGEST LENGTH OF FLEX AVAILABLE

IS 48INCHES OFCOMPRESSED FLEX.

17 ft. max.

RIGID VENT PIPE SHOWN; *FLEXIBLE VENT

FIGURE 27

(DR/DRH - Rear Vent Units)

PIPE MAY ALSO BE USED.

H2

H3

V

Firestop/Spacermust beused any

time vent pipe passes through

combustible floor or ceiling or wall.

H1

FIGURE 28

Page 18

Page 19

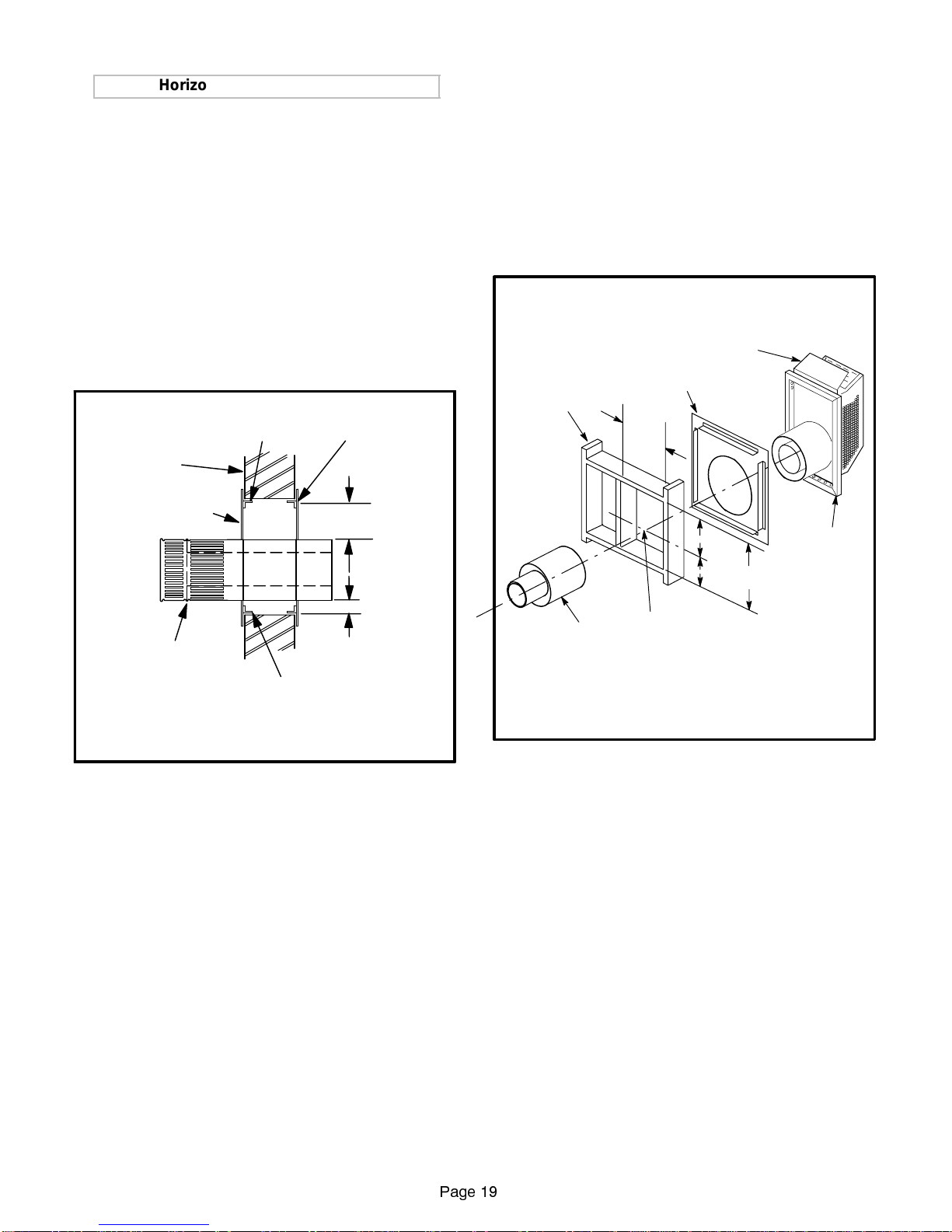

Horizontal Vent Terminations

In the United States, refer to local codes, ANSI Z223.1, and

theventclearanceschartindicated infigure31 forhorizontal

vent termination requirements. In Canada, refer to local

codes, CAN / CGA B149.1 or .2, and the vent clearances

chart indicated in figure 31.

Therectangularvent termination maybeinstalled directly

on the fireplace vent collar. The termination can be adjusted to accommodate wall thicknesses from 5 in.

(127mm) to 9 in.(229mm).Inapplicationswithwall thicknessesrangingfrom9in.(229mm)to13in.(330mm),use

extension JVEXT4 (Catalog Number 12L01) between

Both round (figure 29) and rectangular (figure 30)

vent t erminations are available for use in horizontal

applications. However, the rectangular termination

detailed in figure 30 istheonlyoneapproved for use

inapplications withoutelbowsas detailedinfigure26

or in corner installations as shown in figure 4.

ROUND HORIZONTAL VENT TERMINATION

3 in.(76mm) SPACER INTEGRAL

TO VENT TERMINATION AT TOP

OUTSIDE

WALL SURFACE

FACEPLATE INTEGRAL

TO VENT TERMINATION

VENT TERMINATION

1 in.(25mm) SPACER INTEGRAL TO VENT

Note -

The termination faceplate shall not be recessed into a

wall or siding.

TERMINATIONAT BOTTOM AND SIDES

FIRESTOP / SPACER

ATINSIDE WALLSURFACE

3 in. (76mm)

1in.

(25mm)

fireplace vent collar and termination.

RECTANGULAR VENT TERMINATION

(Shown with rigid vent pipe)

INCHES (mm)

HEATDEFLECTOR

FIRESTOP / SPACER

(See Note 1)

FRAMING

10-1/2

(267)

7

(178)

5-1/8

12-1/8

(130)

(308)

HORIZONTALVENT

Notes 1 - The firestop/spacer may be installed on either side

of the vent framing (interior or exterior side).

2 - The termination base shall not be recessed into a

wall or siding.

CENTER OF VENT

TERMINATION

BASE

(See Note 2)

FIGURE 29

FIGURE 30

Page 19

Page 20

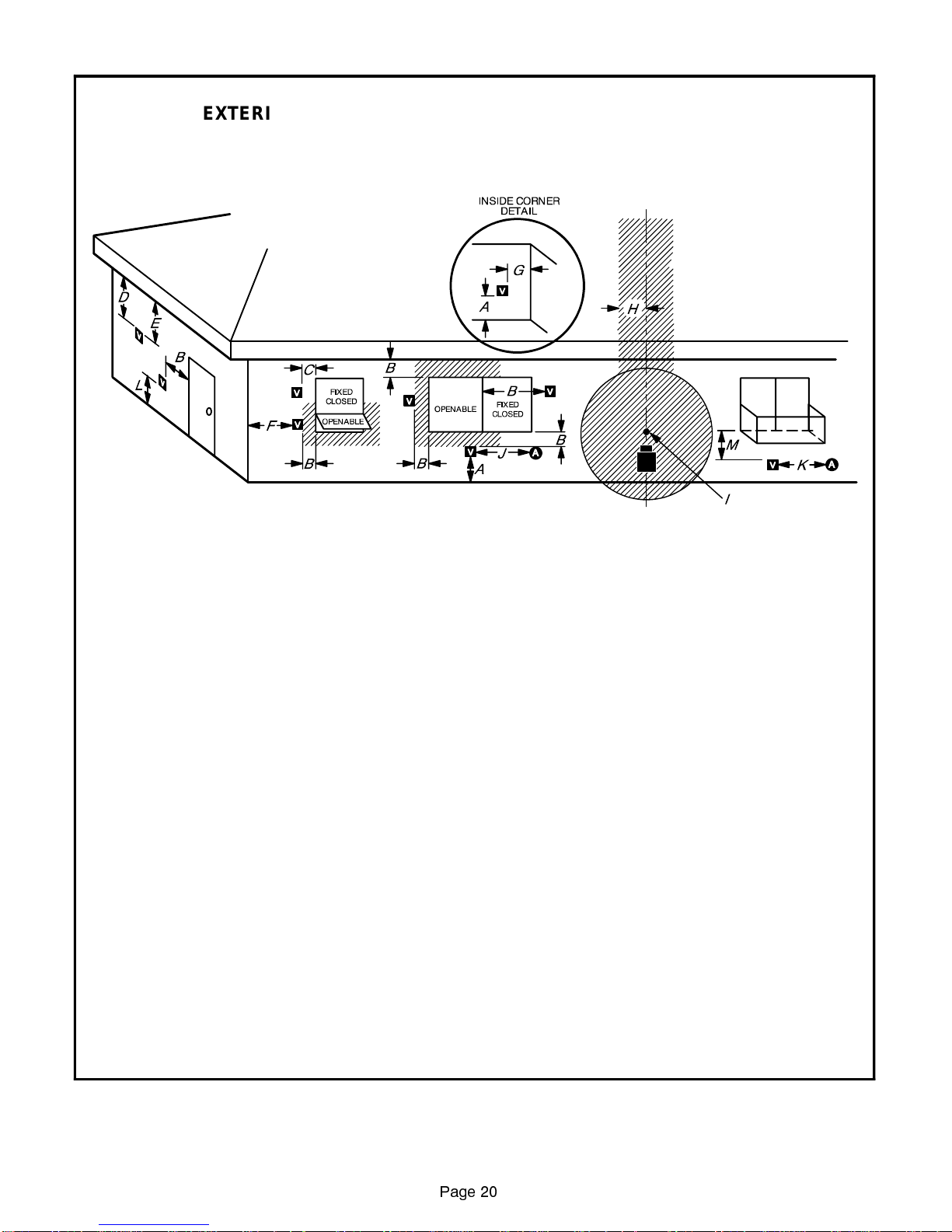

EXTERIOR HORIZONTAL VENT TERMINATION CLEARANCES

A - Clearance above grade, veranda, porch, deck, orbalcony

-- *12 in. (305mm) minimum.

B - Clearance to openable window or door --*12 in. (305mm)

minimum.

C - Clearance to permanently closed window -- minimum 9 in.

(228mm)intheUnitedStatesand12in.(305mm)inCanada

recommended to prevent condensation on window.

D - Vertical clearanceto ventilated soffitlocated abovethe ter-

minalwithinahorizontaldistance of18 in. (457mm)fromthe

center line of the terminal -- 18 in. (457mm) minimum.

E - Clearance to unventilated soffit -- 12in. (305mm) minimum.

F - Clearance to outside corner -- 5 in. (127mm) minimum.

G - Clearance to inside corner -- 6 in. (152mm) minimu m).

†A vent shall notterminate directlyabove asidewalk orpaved drivewaywhich islocated betweentwo

single family dwellings and serves both dwellings.*

‡Only permitted if veranda,porch, deck, or balcony is fully open on aminimumof two sides beneath

the floor.*

*As specified in CAN/CGA B149 Installation Codes.

NOTE - Local codes or regulations may require different clearances.

H - *Nottobeinstalledaboveameter/regulatorassemblywith-

in3ft.(.9m)horizontally fromthecenterlineofthe regulator.

I - Clearance to service regulator vent outlet -- 3 ft. (915mm)

in the UnitedStates and *6ft. (1.8m) in Canada minimum.

J - Clearance to non-mechanicalair supply inlet tobuilding or

the combustion air inlet to any other appliance -- 9 in.

(228mm)in theUnitedStatesand*12 in.(305mm) in Canada minimum.

K - Clearance tomechanicalair supply inlet-- 3ft. (915mm)in

the United States and *6 ft. (1.8m) in Canada minimum.

L - †Clearance above pavedsidewalk ora paveddriveway lo-

cated on public property -- *7 ft. (2.1m) minimum.

M - ‡Clearance under veranda,porch,deck,or balcony--12in.

(305mm) minimum.

N - Vent termination must not be located in a recessed area.

FIGURE 31

Page 20

Page 21

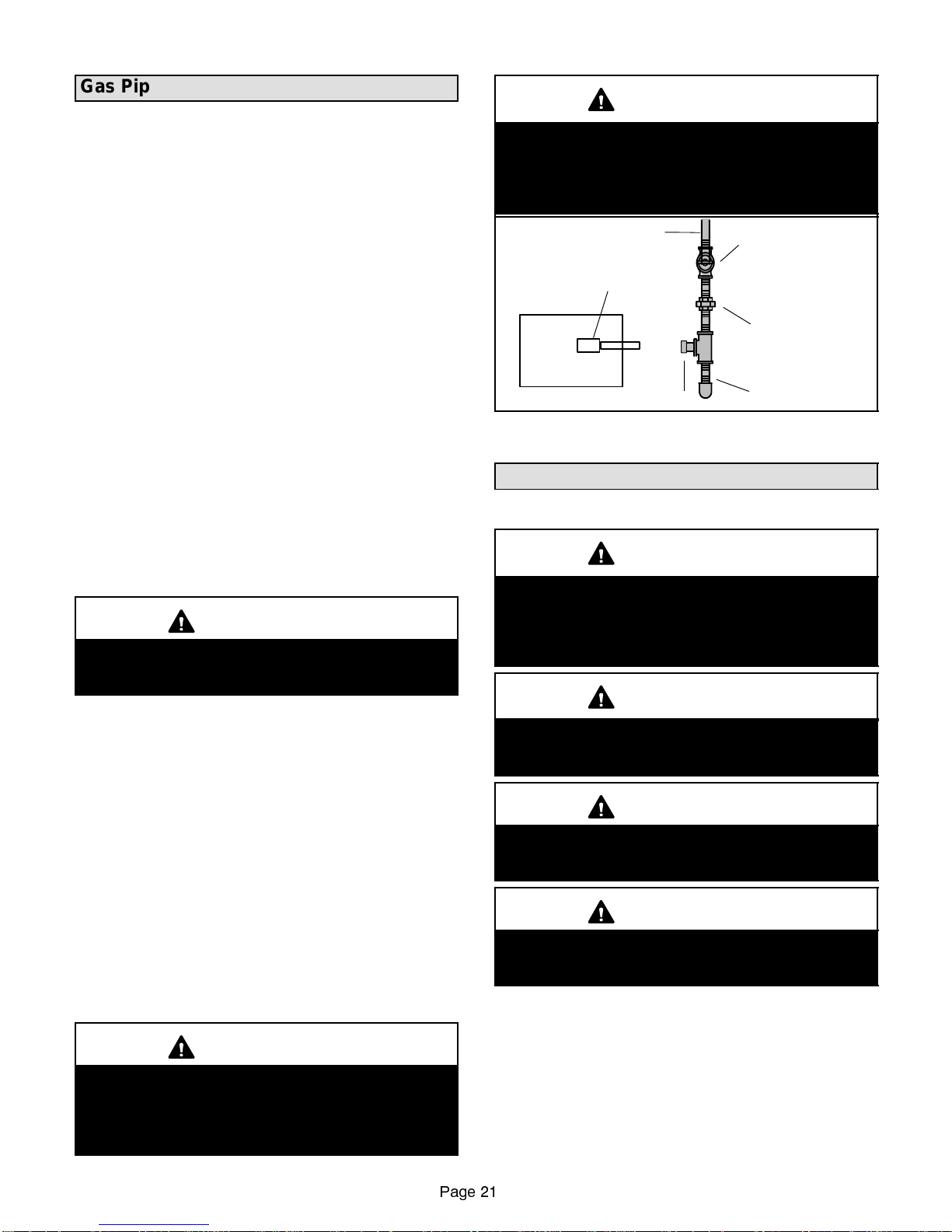

Gas Piping

In the U.S. and Canada, both flexible and rigid gas pipe

areapprovedforuse with theseappliances.Consult local

codes for gas piping practices.

1 - Lennox gas fireplaces are shipped standard for left

or rightsideorbottom installation of gas piping. Simply connect gas supply to gas valve. Gas valve connection is 3/8 in.

2 - When connecting gas supply,factorssuch aslength

of run, number of fittings and furnace rating (if applicable) must be considered to avoid excessive pressure drop.

3 - Gas piping must not run in or through air ducts,

clotheschutes,chimneys orgas vents,dumbwaiters

or elevator shafts.

4 - Piping should be sloped 1/4 inch per 15 feet upward to-

ward the meter from the appliance. The piping must be

supported at proper intervals (every 8 to 10 feet) using

suitable hangers or straps.

5 - In some localities, codes may require installation of

an equipment shut-off valve and union (both furnished by installer) external to the unit. Union must

be of the ground joint type. See figure 32.

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified petroleum

gases.

NOTE - In case emergency shutoff is required, close equipment shut-off valve and disconnect main power to unit.

These devices should be properly labeled by the installer.

The appliance must be isolated from the gas supply system by closing its equipment shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.48 kPa).

The appliance and its appliance main gas valve must be

disconnected from the gas supply piping system during

anypressuretestingofthegassupplysystem attestpressures in excess of 1/2 psig (3.48 kPa). See figure 32.

LEAK CHECK

After gas piping is completed, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means.

CAUTION

Some soaps used for leak detection are corrosive

to certainmetals. Carefully rinse pipingt horoughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of ignition to check for gas leaks.

IMPORTANT

Appliancegasvalves canbe damagedifsubjected

to more than 1/2 psig (3.48 kPa) pressure. Th erefore, when pressure testing the gas supply piping

system in this p ressure range, the applian ce g as

valve must be disconnected and isolated.

GAS SUPPLY PIPING SYSTEM

ISOLATE APPLIANCE

MAIN GASVALVE DURING

TESTING

APPLIANCE

CAP

FIGURE 32

EQUIPMENT

SHUT-OFF VALVE

Equipment shut-off

valve will not holdtest

pressures greaterthan

1/2 psig(3.48kPa).

GROUND

JOINT

UNION

DRIP LEG

Unit Start-up

FORYOURSAFETYREADBEFORELIGHTING

WARNING

Do not use this appliance if any part has been

underwater. Immediately call a qualified service

technician to inspect the fireplace and to replace

any partofthe control system and any gascon t rol

which has been under w ater.

WARNING

If overheating occurs or if gas supply fails to shut

off, close the manual shut-off valve to the appliance

before shutting off electrical supply.

CAUTION

Before attempting to perform any service or

maintenance, turn th e electrical po wer to appliance OFF at disconnect swit ch.

WARNING

Do not operate appliance unless glass frame is

properly installed. Glass must not be broken or

cracked.

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Use only your hand to turn the gas control knob. Never use

tools. If the knob will not turn by hand, do not try to repair it,

call a qualified service technician. Force or attempted repair

may result in a fire or explosion.

Page 21

Page 22

WARNING

If youdo not followtheseinstructionsexactly,a fire

or explosion may result causing property damage,

personal injury or loss of life.

PLACING FIREPLACE INTO OPERATION

(Millivolt Valves with Piezo Ignitor)

Fireplaces which include a millivolt valve are equipped

with a pilotwhichmustbelitbya Piezo ignitor (red ignitor

button). When lighting the pilot, follow these instructions

exactly.

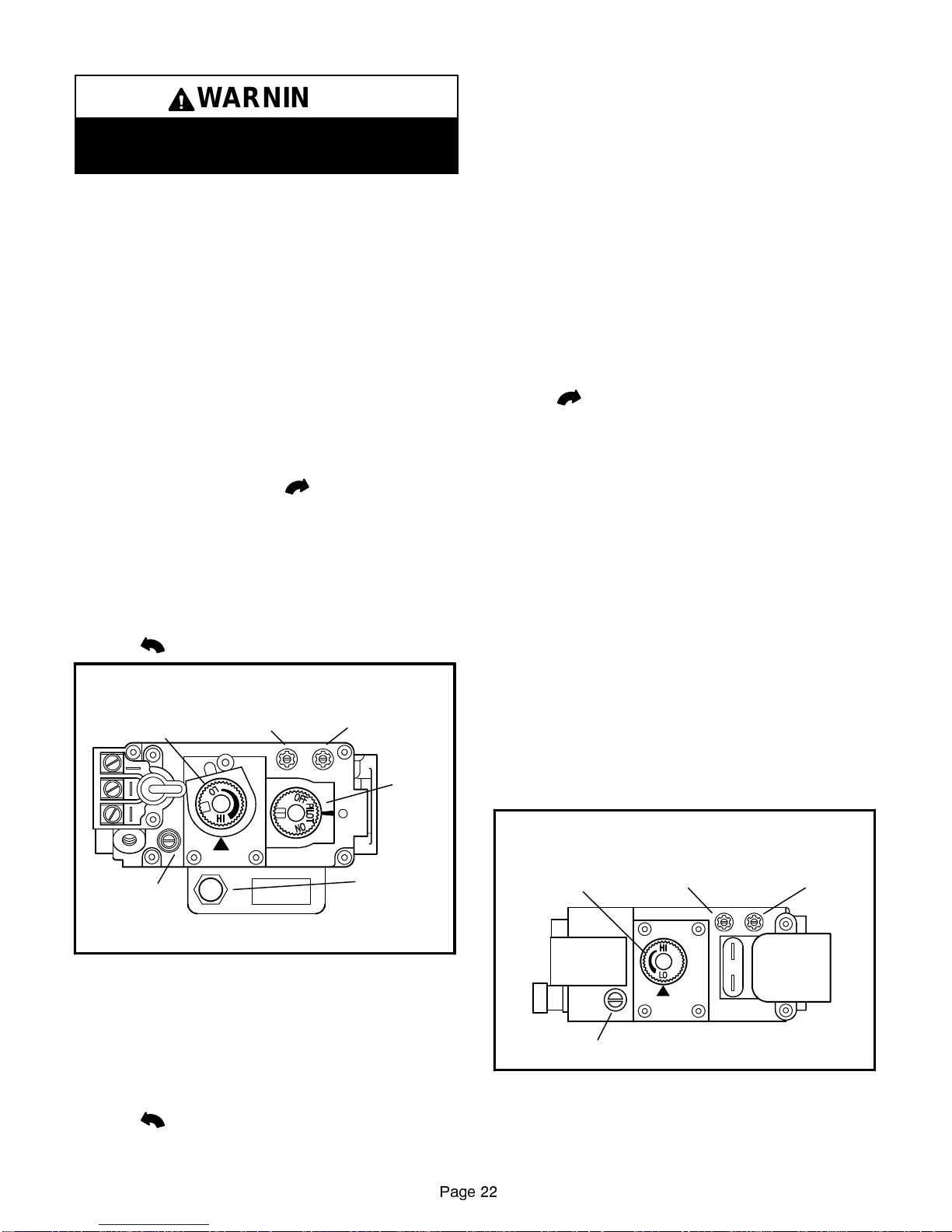

GAS VAL VE OPERATION - Millivolt Valve (Figure 33)

1- STOP! Read the safety information at the beginning

of this section.

2- TurnOFF theburnerswitch(ifapplicable),orsetthe

thermostat to the lowest setting (if applicable).

3 - Turn off all electrical power to appliance.

4 - Open the bottom panel. Push in gas control knob

slightly and turn clockwise

NOTE - Knob cannot be turned from PILOT to OFF

unless knob is pushed in slightly. Do not force.

5 - Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier

from a neighbor’s phone. Follow the gas supplier’s instructions. If you do not smell gas go to next step.

6 - Presspartiallyandturngasvalveknob counterclock-

wise

to PILOT.

MILLIVOLT GAS VALVE

(Optional manually-modulated gas valve shown)

HI/LO FLAME

ADJUSTMENT KNOB

PILOT

ADJUSTMENT

SCREW

MANIFOLD

GAUGE PORT

to OFF.

PUSH-BUTTON

SUPPLY

GAUGE PORT

CONTROL

KNOB

PIEZO

IGNITOR

10- Turn ON the burner switch (if applicable), or set the

thermostat to the desired setting (if applicable).

11- Close the bottom panel.

NOTE - If gas valve is turned to OFF from ON or PILOT

whileapplianceis in operation,gasvalvewill latch inOFF

position for 25 seconds.

12- If the appliance will not operate, follow the instructions

“Turning OffGastoUnit”andcall your servicetechnician

or gas supplier.

TURNING OFF GAS TO UNIT

1- TurnOFF theburnerswitch(ifapplicable),orsetthe

thermostat to the lowest setting (if applicable).

2 - Turn off all electrical power to appliance.

3 - Open the bottom panel.

4 - Push in gas control knob slightly and turn clock-

wise

to OFF. Do not force.

5 - Close the bottom panel.

PLACING FIREPLACE INTO OPERATION

(Electronic Gas Valves)

Fireplaces equipped withanignition device which will automaticallylighttheburner.Do nottry tolight theburner

by hand. Follow these instructions exactly.

GAS VALVE OPERATION- Electronic Valve (Figure 34)

1- STOP! Read the safety information at the beginning

of this section.

2- TurnOFF theburnerswitch(ifapplicable),orsetthe

thermostat to the lowest setting (if applicable).

3 - Turn off all electrical power to the appliance.

4 - This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

5 - Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier

from a neighbor’s phone. Follow the gas supplier’s in-

structions. If you do not smell gas go to next step.

ELECTRONIC GAS VALVE

(Optional manually-modulated gas valve shown)

HI/LO FLAME

ADJUSTMENT

KNOB

MANIFOLD

GAUGE PORT

SUPPLY

GAUGE PORT

GAS VALVE SHOWN IN PILOT POSITION

FIGURE 33

7 - Push control knob in until it stops and hold knob in this

position. Immediately light the pilot by pushing the red

Piezo ignitor button. Continue to press control knob for

25 seconds after the pilot is lit. Release knob. It should

pop back up. Pilot should remain lit. If pilot goes out, repeat steps 5 through 10.

8 - Presspartiallyandturngasvalveknob counterclock-

wise

to ON.

9 - Restore electrical power to appliance (if applicable).

Page 22

PILOT

ADJUSTMENT SCREW

FIGURE 34

6 - Restore electrical power to the appliance.

7- TurnON the burner switch (if applicable), or set the

thermostat to the desired setting (if applicable).

Page 23

8 - If the appliance will not operate, follow the instruc-

tions turning off gas to unit and call a servicetechnician or gas supplier.

TURNING OFF GAS TO UNIT

1- TurnOFF theburnerswitch(ifapplicable),orsetthe

thermostat to the lowest setting (if applicable).

2 - Turn off all electrical power to appliance.

3- TurnOFF gas supply at main manual shut-off valve lo-

cated near the fireplace.

Adjustments

NOTE - The air shutter for theburnerprimary airopening

is factory-set. Do not adjust the factory-set position.

GAS FLOW

This burner / log set has been adjusted for the proper gas

flow at the factory. No adjustment is necessary other than

the pilot flame. See pilot flame adjustment section.

GAS PRESSURE

Check gas inlet pressure with the appliance firing at the

maximum rate. A minimum of 4.5 in. w.c. (1.12 kPa) and

maximum of 7.0in.w.c. (1.74 kPa) fornatural gasshould

be maintained. When LP/Propane gas is used, a minimumof11.0in. w.c.(2.74kPa) andamaximum of 13.0in.

w.c. (3.23 kPa) must be maintained.

Maximum manifold pressure is 3.5 in. w.c. (0.87 kPa)for

naturalgasand 10in. w.c.(2.49kPa)for LP/Propanegas.

HIGH ALTITUDE INSTALLATION

Installations in the USA -

Units are tested and approved for elevations of 0-2000

feet (0-610 meters).

When installing this unit at an elevation above 2000 feet

(610meters),decreasethe inputrateby changing theexisting burner orificetoasmaller size. Input rate should be

reduced 4 percent for each 1000 feet (305 meters) of

elevation above sea level. For assistance in determining

the proper orifice size, check with the local gas utility or

consult the latest edition of the National Fuel Gas Code

(ANSI Z223.1, appendix F).

Installations in Canada -

Units are tested and approved for elevations of 0-4500

feet (0-1372 meters).

When installing this unit at an elevation above 4500

feet(1372meters),consultthelocalauthoritieshaving

jurisdiction.

ELECTRICAL

NOTE-Thesechecksarenecessaryonlyifoptionalblower kit has been applied.

1 - Check all wiring for loose connections.

2 - Check for correct voltage at unit (unit operating).

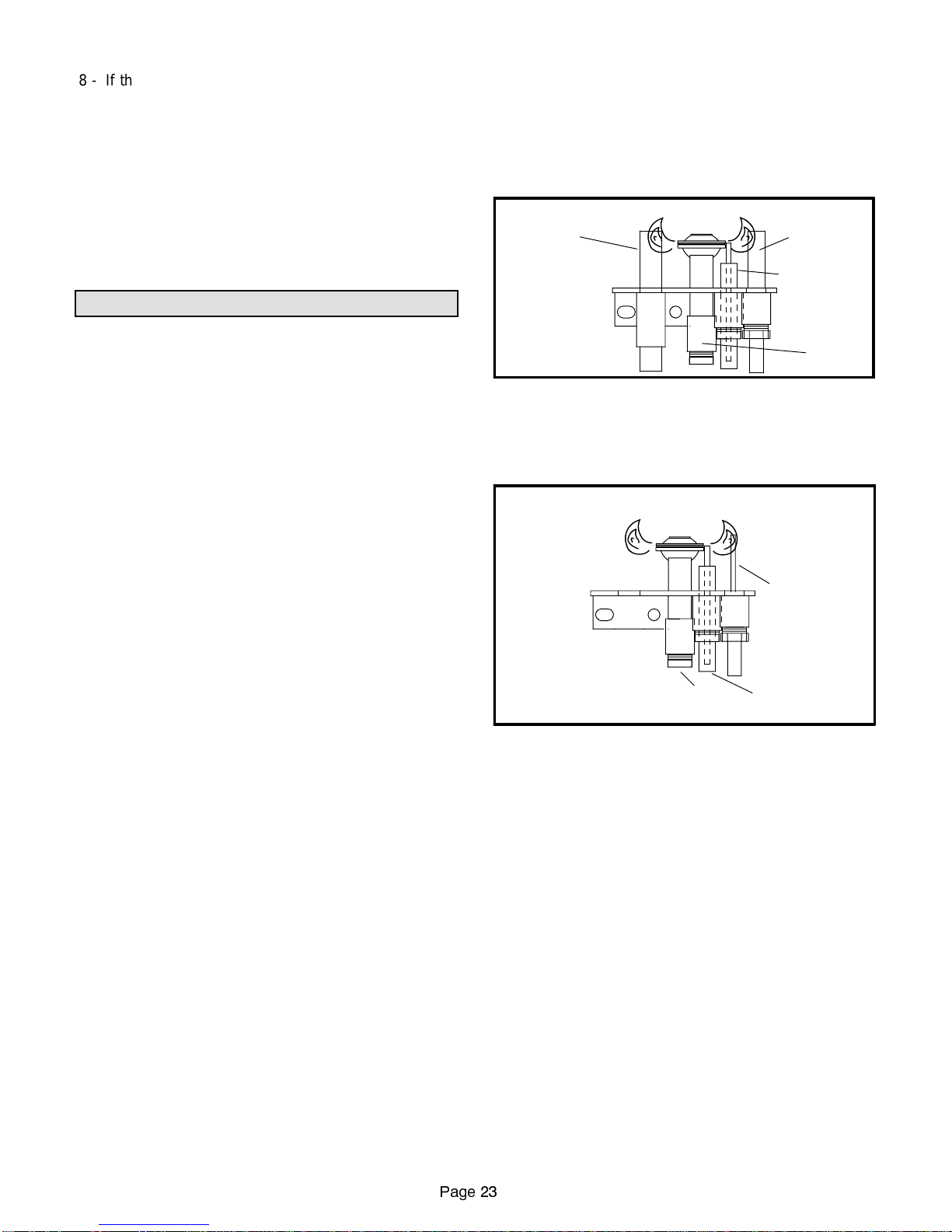

PILOT FLAME ADJUSTMENT

A - Millivolt System

To ensure proper gas valve operation, the pilot flame

should impinge upon both the thermopile and the low

mass thermocouple. See figure 35. The pilot flame adjustment screw is shown in figure 33.

PILOT FLAME - (Millivolt systems)

THERMOPILE

NOTE -Flame must

impinge upon both

thermopile and low

mass thermocouple

to insureproper appliance operation.

LOW MASS

THERMOCOUPLE

PIEZO IGNITOR

PILOT

FIGURE 35

B - Electronic Ignition System

To ensure proper gas valve operation, the pilot flame

shouldimpingeupontheflamesensor.Seefigure 36.The

pilot flame adjustment screw is shown in figure 34.

PILOT FLAME - (Electronic Ignition systems)

FlAME SENSOR

NOTE -Flame mustimpinge

upon flamesensor to insure

proper appliance operation.

IGNITORPILOT

FIGURE 36

BURNER FLAME ADJUSTMENT

The burner flame may be adjusted by turning the HI/LO

knob on the gas valve to obtain the required heating outputandflame appearance.Seefigure 33or34. The burner flame should be inspected at the beginning of each

heatingseasonandburnersshouldbecleanedbyaqualified service technician. The flame colorwillstabilizeafter

15 minutes of operation.

FAILURE TO OPERATE

If unit fails to operate check the following:

1 - Is thermostat calling for heat, if applicable?

2 - Is ON/OFF wall switch in ON position, if applicable?

3 - Is pilot lit, if applicable?

4 - Is gas turned ON at meter?

5 - Is gas valve in ON position (millivolt units)?

6 - Is gas turned ON at the appliance shut-off valve?

7 - Is electr ical power turned ON to the appliance (if

applicable)?

Page 23

Page 24

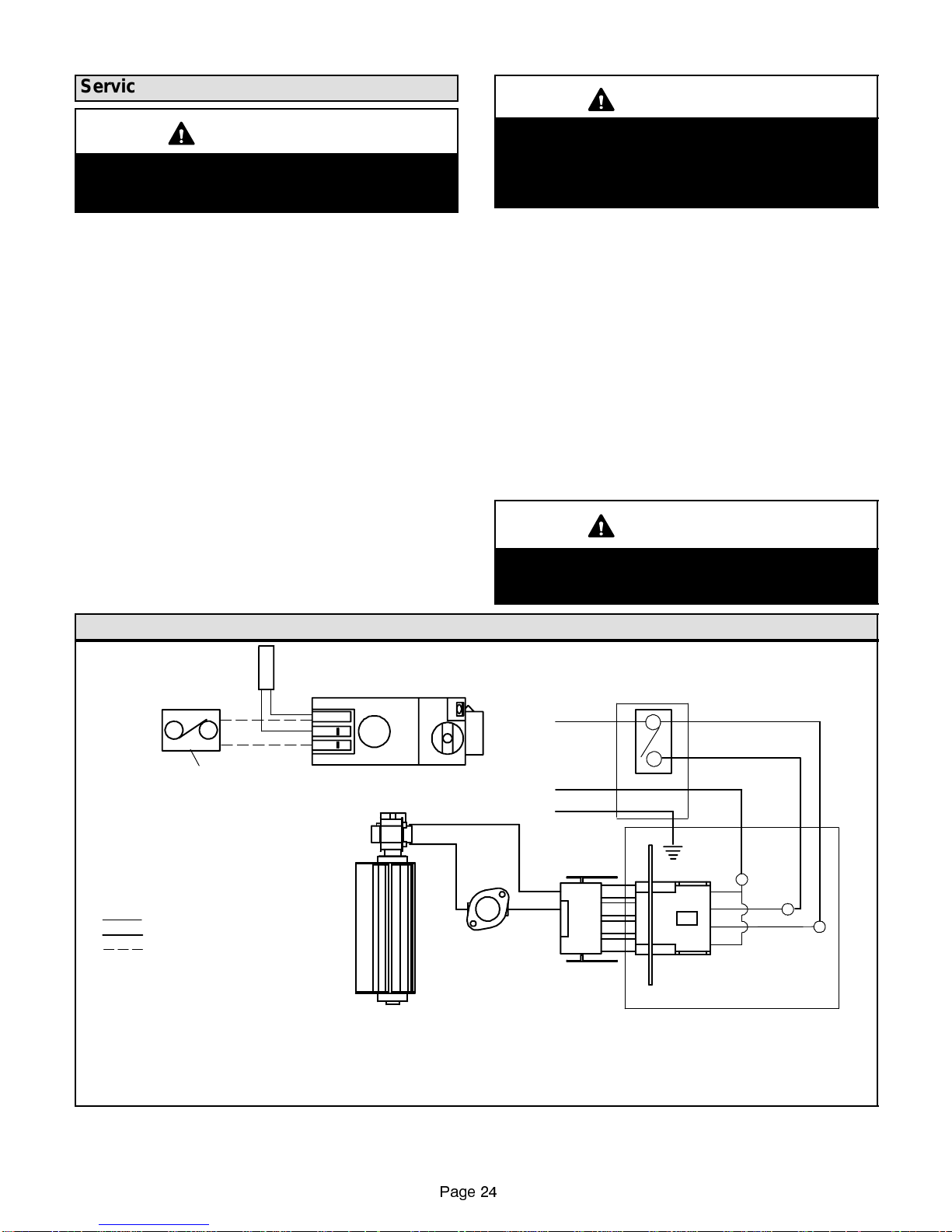

Service

WARNING

Disconnect power before servicing unit.

Service should be performed by a qualified technician.

Control compartment, burners and circulating air passageways must be kept clean. The appliance should be

inspected annually; however, more frequent cleaning

may be necessary due to excessive amounts of lint or

dust.

At the beginningofeachheatingseason,service items A

to C as described below:

A - BLOWERS (If applicable)

Check and clean blower wheels for any debris. Blower

motorsareprelubricatedfor extendedbearinglife.Nofurther lubrication is needed.

B - VENT TERMINATION

WARNING

Some soaps used for leak detection are corrosive

to certainmetals. Carefully rinse pipingt horoughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of ignition to check for gas leaks.

FIRE BOX

Periodically inspect fire box for corrosion. If necessary,

wipe clean using a damp rag or vacuum using brush attachment.

GLASS / FRAME ASSEMBL Y

Clean inside and outside glass surfaces usinga mild detergent/water solution and a soft cloth. DO NOT use abrasive

cleansers which might scratch the high-temperature glass

surface. DO NOT clean glass when surface is hot to the

touch. Glass cleaner is available as Lennox part number

19N74.

Glass/frame assembly must be properly reinstalled after

service. All three screwsmust be installed and tightened

securely.

Make sure there is no blockage at the vent termination.

C - PILOT AND BURNERS

Inspectpilotand burnerflames.If necessary,lightly brush

burner ports to dislodge any obstructions.

Wiring Diagram - Millivolt Gas Valves

THERMOPILE

TP-TH

TP

TH

BURNER ON/OFF SWITCH

(UNIT-MOUNTED)

OR BURNER ON/OFF SWITCH

(WALL-MOUNTED)

OR THERMOSTAT

(See Note 2)

LEGEND

W-WHITE

BK - BLACK

FACTORY INSTALLED

120V FIELD INSTALLED

MILLIVOLT (See Note 2)

GAS VALVE

TEMP. SENSOR

Do not operate appliance unless glass frame is

properly installed. Glass must not be broken or

cracked.

120 VAC

NEUTRAL

GROUND

WHITE

BLACK

(See Note 1)

BLACK

WHITE

GREEN

BK

CONNECTOR

WARNING

FAN SWITCH

(See Note 1)

W

BK

BK

W

Note 1:

Note 2:

OPTIONAL FAN KITS

Fan Kit FK1 contains Fan only. (Fan Switch is field-provided)

Fan Kit FK2 contains Fan, Temp. Sensor and Fan Switch.

BURNER SWITCHES AND THERMOSTAT

Unit-mounted ON / OFF switch is available as a factory-installed option or can be ordered separately and field-inst alled.

Wall-mounted ON / OFF switch is field-provided;

Thermostat is available as a factory-provided option in vented fireplace heater model installations.

FAN(SeeNote1)

JUNCTION BOX

FIGURE 37

Page 24

Page 25

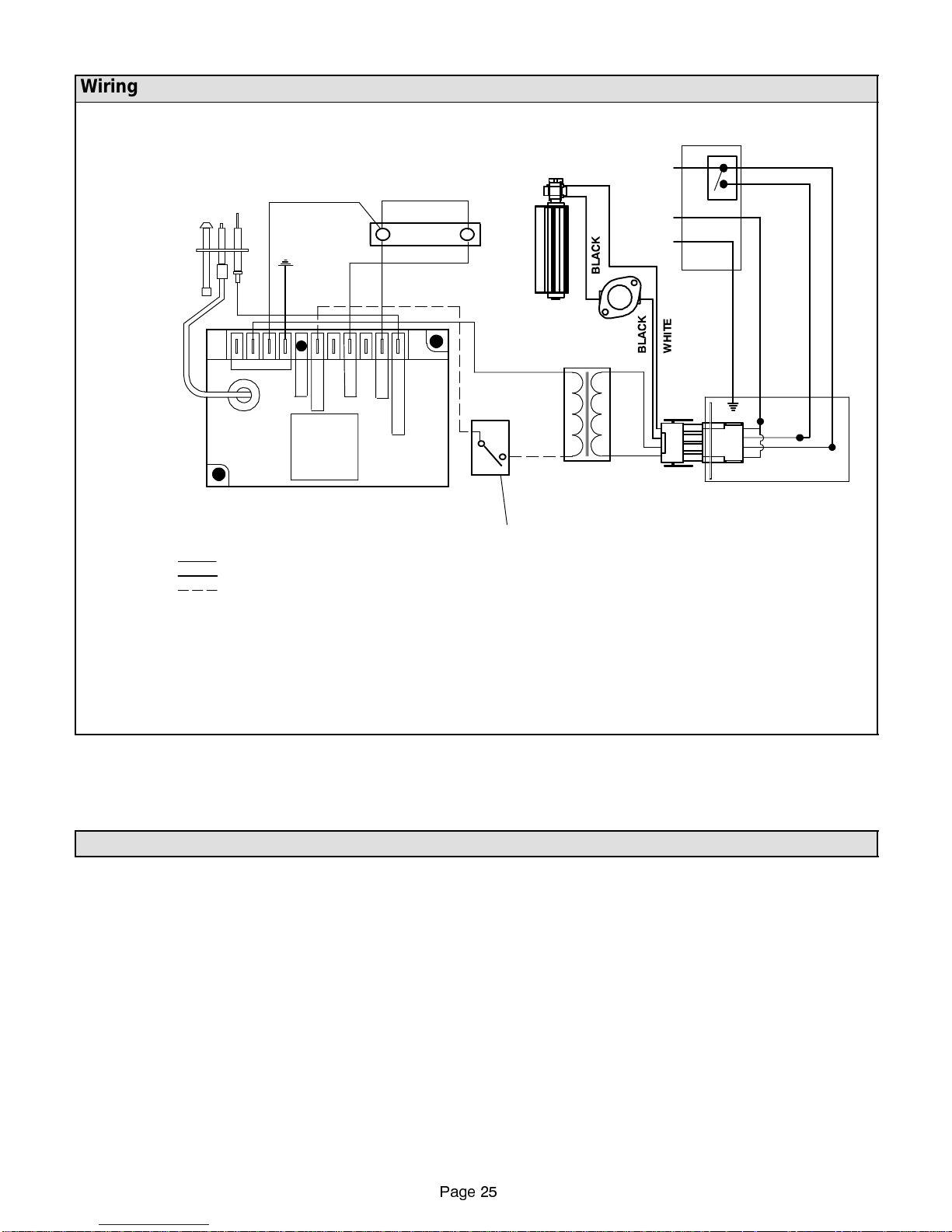

Wiring Diagram - Electronic Gas Valves

A

H

NSWITC

F

(See Note 1)

PILOT BURNER

IGNITOR-SENSOR

ASSEMBLY

PILOT

GAS

SUPPLY

ELECTRONIC

IGNITION

CONTROL

BOARD

Note 1:

OPTIONAL FAN KITS

Fan Kit FK1 contains Fan only. (Fan Switch is field-provided)

Fan Kit FK2 contains Fan, Temp. Sensor and Fan Switch.

Note 2:

BURNER SWITCHES AND THERMOSTAT

Unit-mounted ON / OFF switch is available as a factory-installed option or can be ordered separately and field-inst alled.

Wall-mounted ON / OFF switch is field-provided;

Thermostat is available as a factory-provided option in vented fireplace heater model installations.

BROWN

GROUND

D

LEGEND

W-WHITE

BK - BLACK

FACTORY INSTALLED

120V FIELD INSTALLED

24V (See Note 2)

L

E

ORANGE

2

T

H

S

BK

WHITE

GREEN

YELLOW

EV2

GAS

WHITE

EV1

VALVE

RED

FAN(SeeNote1)

120 VAC.

NEUTRAL

GROUND

TEMP. SENSOR

(See Note 1)

3

1

P

V

4

M

S

E

V

N

S

E

BLUE

24V.

RED

BK

120V.

WHITE

J-BOX

BK

BK

W

W

TRANSFORMER

CONNECTOR

BURNER ON/OFF SWITCH (UNIT-MOUNTED)

OR BURNER ON/OFF SWITCH (WALL-MOUNTED)

OR THERMOSTAT

(See Note 2)

Repair Parts

The following repair parts are available through independent Lennox dealers.Whenorderingparts, it is important to

include the complete appliance model number listed on the Warnock Hersey rating plate.

Cabinet Parts

Heating Parts

Burner tube

Gas manifold

Gas Logs

FIGURE 38

Control Parts

Gas valve

Thermopile (Millivolt models)

Piezo push button ignitor (Millivolt models)

Low mass thermocouple (Millivolt models)

Ignitor

Pilot burner

On/Off switch

Thermostat

Transformer (Electronic ignition models)

Electronic ignition module (Electronic ignition models)

Page 25

Page 26

Venting Kits and Available Components

The following is a list of venting kits and components approved for use with the gas fireplace:

Catalog

Number

96K70 12” Compressed Flex Termination (Round)

96K71 18” Compressed Flex Termination (Round)

96K72 24” Compressed Flex Termination (Round)

96K73 36” Compressed Flex Termination (Round)

96K74 48” Compressed Flex Termination (Round)

98K08 12” Compressed Flex Termination (Square)

98K09 18” Compressed Flex Termination (Square)

98K10 24” Compressed Flex Termination (Square)

98K11 36” Compressed Flex Termination (Square)

98K12 48” Compressed Flex Termination (Square)

96K80 Firestop Spacer - Horizontal Vent

96K82 1’ Coaxial Unitized Rigid Pipe

96K83 2’ Coaxial Unitized Rigid Pipe

96K84 3’ Coaxial Unitized Rigid Pipe

96K85 5’ Coaxial Unitized Rigid Pipe

96K86 1’ Coaxial Adjustable Pipe

96K87 Firestop Spacer - Vertical Vent

96K88 90_Elbow

96K89 45_Elbow

96K90 Flat Roof Flashing

96K91 1/12 - 7/12 Pitched Roof Flashing

97K01 8/12 - 12/12 Pitched Roof Flashing

96K92 Support Plate

96K93 Support Strap

96K94 Attic Insulation Shield

96K95 Horizontal Term. for Rigid Pipe (Round)

96K96 Vertical Term. for Rigid Pipe (Round)

98K13 Horizontal Term. for Rigid Pipe (Square)

12L01 JVEXT4 - 4” Vent Extension

96K13 Circulating Air Fan

96K14 Circ. Air Fan with Temp. Control & Rheostat

96K98 Termination Heat Deflector

96K99 Riser Kit (Flex connections only)

97K00 Wall Termination Heat Guard

10K81 Mill-Pac Black High Temperature Sealant

97K72 30” Grate Kit

97K73 35” Grate Kit

97K74 40” Grate Kit

97K75 45” Grate Kit

96K16 30” 4-Piece Polished Brass Trim Assembly

96K17 35” 4-Piece Polished Brass Trim Assembly

Description

Catalog

Number

96K18 40” 4-Piece Polished Brass Trim Assembly

96K19 45” 4-Piece Polished Brass Trim Assembly

96K20 30” 3-Piece Polished Brass Trim Assembly

96K21 35” 3-Piece Polished Brass Trim Assembly

96K22 40” 3-Piece Polished Brass Trim Assembly

96K23 45” 3-Piece Polished Brass Trim Assembly

96K15 Free-Standing Heat Guard (40/45”Models)

96K30 30” Heat Guard

96K31 35” Heat Guard

96K32 40” Heat Guard

96K33 45” Heat Guard

11K97 Free-Standing Heat Guard (30/35”Models)

96K15 Free-Standing Heat Guard (40/45”Models)

96K34 3/8”Stainless Steel Flex Connector (12”)

96K35 3/8”Stainless Steel Flex Connector (24”)

26N04 Remote Control

98K99 Deluxe Remote Control

60P60 White-Rodgers 1E30W-60 Thermostat (F_)

10N64 White-Rodgers 1E30W-60 Thermostat (C_)

96K09 Brickaded Interior for 30” Rear Vent Units

96K10 Brickaded Interior for 35” Rear Vent Units

96K11 Brickaded Interior for 40” Rear Vent Units

96K12 Brickaded Interior for 45” Rear Vent Units

96K05 Brickaded Interior for 30” Top Vent Units

96K06 Brickaded Interior for 35” Top Vent Units

96K07 Brickaded Interior for 40” Top Vent Units

96K08 Brickaded Interior for 45” Top Vent Units

96K40 On/Off Switch (Unit-mounted)

96K41 Split Logs - 30”

96K42 Split Logs - 35”

96K43 Split Logs - 40”

96K44 Split Logs - 45”

96K45 30” Polished Brass 2-pc. Bustle w/Side Strips

96K46 35” Polished Brass 2-pc. Bustle w/Side Strips

96K47 40” Polished Brass 2-pc. Bustle w/Side Strips

97K48 45” Polished Brass 2-pc. Bustle w/Side Strips

96K49 30” Polished Brass 6-pc. Louvers

96K50 35” Polished Brass 6-pc. Louvers

96K51 40” Polished Brass 6-pc. Louvers

96K52 45” Polished Brass 6-pc. Louvers

Description

Page 26

Loading...

Loading...