Page 1

USER MANUAL

DC & DM displays

BALTIC

FLEXAIR

ENERGY

AIRCOOLAIR

COMPACTAIR

FLATAIR

AQUALEAN

DC-DM-IOM-1801-E

www.lennoxemea.com

Page 2

Page 3

Summaries

1 Display ‘DC’

1.1 Introduction ................................................................................................................................. 2

1.2 Temperature measurement ........................................................................................................ 2

1.3 Quick Action ................................................................................................................................. 3

1.4 Presentation ................................................................................................................................ 6

1.5 Use ............................................................................................................................................... 7

1.6 DC set in ‘Light’ mode .................................................................................................................. 8

1.7 DC set in ‘Full’ mode .................................................................................................................... 9

1.8 Setting Value ............................................................................................................................ 11

1.9 Activation level 2 ....................................................................................................................... 11

2 Display ‘DM’

2.1 Quick Action ............................................................................................................................... 12

2.2 Functionality of the DM ............................................................................................................. 14

2.3 Organizational screens ............................................................................................................... 21

3 DC, Installation

3.1 Connection ................................................................................................................................. 23

3.2 Ferrites Protection of Displays ................................................................................................... 25

3.3 Temperature Sensor .................................................................................................................. 25

3.4 Configuration ............................................................................................................................. 25

3.5 Initialization ............................................................................................................................... 26

4 ‘DM’, Installation

5.1 Connection ................................................................................................................................. 27

4.2 Connection on the splitter DT50 ................................................................................................ 28

4.3 Ferrites Protection of Displays ................................................................................................... 28

4.4 Configuration ............................................................................................................................. 29

5 DC-DM Communication Master/Slaves

6.1 Connection ................................................................................................................................. 30

7 ALARM LIST ............................................................................................................... 31

DC-DM-ROOFTOP-IOM-1801-E - 1 -

Page 4

Display ‘DC’ 1

1.1 Introduction

The display ‘DC’ is customized for the user.

It allows an overview of the operation of the Unit and allows access to some parameters.

Depending on the setting in the Climatic, two display configurations are possible:

• Mode ‘Light’

• Mode ‘Full’

The 'DC' is designed to be remotely connected of the Unit.

The 'DC' is equipped with a temperature sensor.

The temperature sensor allows the acquisition of room temperature to control.

1.2 Temperature measurement

All Lennox Unit comes with a temperature sensor; it must be placed in the conditioned area.

But if the 'DC' is placed in the area conditioned by the Unit, it is possible, in this case, to use the temperature

measurement of the 'DC'.

DC-DM-ROOFTOP-IOM-1801-E - 2 -

Page 5

1.3 Quick Action

1.3.1 How to See the Operation of the Unit 4 ?

Only if several units are connected to the DC.

Turn the knob to have the text ‘Unit’.

Press the knob to switch in 'Set' mode.

Turn the knob to select number 4.

Press the knob to confirm your choice

1.3.2

Press the button a few seconds.

How to Start all Units connected at this DC ?

The units can not be powered On/Off by the DC if the service display DS is connected.

DC-DM-ROOFTOP-IOM-1801-E - 3 -

Page 6

1.3.3

Only if several units are connected to the DC.

Select the Unit 4 (see: How to See the Operation of the Unit 4 ?)

Turn the knob to have the text ‘I-O’.

Press the knob to switch in 'Set' mode.

Turn the knob to select number 1 (1 for ‘On’, 0 for ‘Off’).

Press the knob to confirm your choice

How to Start Unit 4 ?

The units can not be powered On/Off by the DC if the service display DS is connected.

1.3.4

Turn the knob to have the text ‘Set’.

The value displayed is the temperature setpoint.

How to See the Value of the Current Setpoint Temperature ?

DC-DM-ROOFTOP-IOM-1801-E - 4 -

Page 7

1.3.5

Turn the knob to have the text ‘Set’.

Press the knob to switch in 'Set' mode.

Turn the knob to change the value.

Press the knob to confirm your choice

How to Modify the Value of the Current Setpoint Temperature ?

DC-DM-ROOFTOP-IOM-1801-E - 5 -

Page 8

1.4 Presentation

1.4.1 Showing

1.4.2

Buttons

DC-DM-ROOFTOP-IOM-1801-E - 6 -

Page 9

1.5 Use

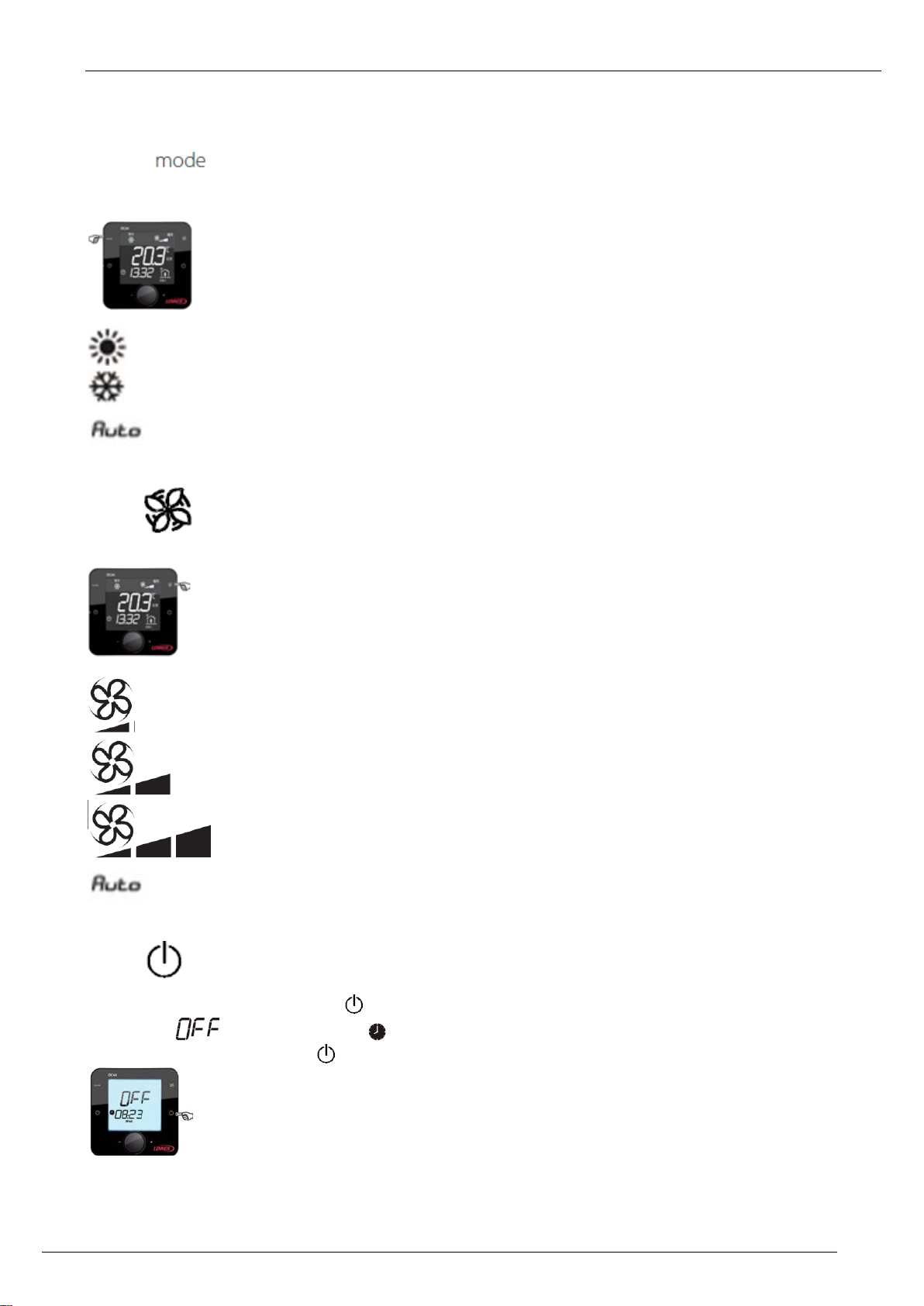

1.5.1 Control operating mode.

Only for Flatair and Aqualean ranges.

Press until the desired operating mode is displayed.

Heating mode

Cooling mode

1.5.2

Only for Flatair and Aqualean ranges.

Press to select the desired speed (min, med, max) or automatic (Auto).

Minimum speed

Automatic mode

Fan Speed Management.

Median speed

Maximum speed

Automatic Speed

1.5.3

By supporting a few seconds, the button you can activate or not (On/Off) the Unit connected.

If the symbol completed by the time is displayed, the Unit is stopped and the 'DC' in sleep mode.

To restart the unit, press the button a few seconds

If the DC is used with the Master/Slaves bus in this case, the 'Off' phase, stops all Rooftop connected on the Bus, 'On'

phase restarts all.

On/Off unit

DC-DM-ROOFTOP-IOM-1801-E - 7 -

Page 10

1.5.4 Setting time

At initialization of the 'DC', the CLIMATIC are synchronized time and day of week with the clock 'DC'.

To view the clock, briefly, press the button

To set the clock press the button a few seconds

The hour value, flashes.

Turn the knob to adjust the desired value.

Press the knob to select your choice.

Then the minute value, flashes.

Turn the knob to adjust the desired value.

Press the knob to select your choice.

| Monday | Tuesday | Wednesday | Thursday | Friday | Saturday | Sunday |

Then the weekday value, flashes.

Turn the knob to adjust the desired value.

Press the knob to select your choice.

After a few seconds 'DC' communicates the new time to the CLIMATIC.

1.5.5

Information available

By rotating the knob you can view or modify the following values:

1.6 DC set in ‘Light’ mode

* : Unit Index selected by the ‘DC’

: Volatile temperature set point current mode (°C)

: : Indoor (Room) temperature (°C)

: Alarms code

* : Available if the option is enabled.

: Adjustable with ‘DC.

1.6.1

If the DC is used with the Master/Slaves bus this item can select or know the Unit Index selected by the 'DC'.

DC-DM-ROOFTOP-IOM-1801-E - 8 -

Unit selected

Page 11

1.6.2

This item allows you to view and/or modify the control temperature required for the Unit selected.

If this point is changed, this value is used until the scheduling changes mode (Day, Day I, Day II, Night, BMS).

At each change of the mode, the CLIMATIC sets the value of this set point on the preset value in the mode concerned.

1.6.3

This item allows you to view the code of different active alarms on the Unit.

If the Unit isn't in alarm, this item is to 0.

1.6.4

This item indicates the measured air temperature in the room conditioning.

The room temperature isn't available if the CLIMATIC is configured to supply control.

Indoor (Room) temperature

Volatile Temperature set point

Alarms code

1.7 DC set in ‘Full’ mode

- : Unit Index selected by the ‘DC’

- *: On/Off of the Unit selected.

- : Predetermined temperature set point current mode (°C)

- : Volatile temperature set point current mode (°C)

- : Alarms code

-

- : Supply temperature (°C)

-

- * : Indoor (Room) humidity (%hr)

- * : Indoor (Room) Air quality (ppm)

- * : Opening of fresh air damper (%)

* : Available if the option is enabled.

: Available if the level 2 is activated.

: Adjustable with ‘DC.

* : Outdoor temperature (°C)

* : Indoor (Room) temperature (°C)

1.7.1

This item can select or know the Unit Index selected by the 'DC'.

1.7.2

If the DC is used with the Master/Slaves bus this item allows you to view and/or change the status of starting or

stopping of the Unit selected.

1.7.3

This item allows you to view and/or modify the control temperature required for the Unit selected.

If this point is changed, this value is used until the scheduling changes mode (A, B, C, D, BMS).

At each change of the mode, the CLIMATIC sets the value of this set point on the preset value in the mode concerned.

DC-DM-ROOFTOP-IOM-1801-E - 9 -

Unit connected

On/Off, Power

Volatile Temperature set point

Page 12

1.7.4 Predetermined Temperature set point

If level 2 is active, this item allows you to view and/or change the preset temperature control for the active mode.

1.7.5

This item allows you to view the code of different active alarms on the Unit.

If the Unit isn't in alarm, this item is to 0.

By this item it's possible to reset the alarm activated. To do this set the value of the item to the value 0.

1.7.6

This item indicates the measure temperature of the air outside.

The outside temperature isn't available for the WSHP range.

1.7.7

This item indicates the measure of outlet air temperature of the Unit.

1.7.8

This item indicates the measured air temperature in the room conditioning.

The room temperature isn't available if the CLIMATIC is configured to supply control.

Alarms code

Outdoor temperature

Supply temperature

Indoor (Room) temperature

1.7.9

This item shows the measured relative humidity of the air in the room conditioning.

The room humidity isn't available if the option of humidity management isn't set.

1.7.10

This item indicates the measured rate of CO² in conditioning room, in ppm.

The measurement of CO² isn't available if the option isn't set.

1.7.11

This item indicates the measured value of the opening rate of the fresh air damper, in%, (mixture of outside air and

return air)

This value is only available if the Unit is equipped with this option.

Indoor (Room) relative humidity

Measurement of CO²

Opening of fresh air damper

DC-DM-ROOFTOP-IOM-1801-E - 10 -

Page 13

1.8 Setting Value

If the value of the selected item is modified .

To activate the modified value

Press the knob .

The symbol appears on the right side of the value.

Turn the knob to adjust the desired value.

Press again on the knob to confirm your choice.

The symbol is no longer displayed on the right side of the value.

The rotation of the knob is for select a new item.

1.9 Activation level 2

(2 buttons on the right simultaneously)

Simultaneously press the keys and .

After some seconds the text appears and the value '000' flashes.

Turn the knob to change the value to select the number 066. Then validate the code by pressing the knob.

If the code is wrong access the setup menu is not possible and the 'DC' returns to the previous display.

If the code is correct the level 2 is actif, and symbol is displayed to the right of the value.

The level 2 is turned off automatically every hour.

DC-DM-ROOFTOP-IOM-1801-E - 11 -

Page 14

Display ‘DM’ 2

The display 'DM' is customized for the user.

It allows an overview of the operation of the Unit and allows access to some parameters.

The 'DM' is designed to be remotely connected of the Unit.

The 'DM' can be connected to several Lennox Units, Between 1 and 8 units

2.1 Quick Action

2.1.1 How to See the Operation of the Unit 4 ?

Press, several times, the button ‘Esc’ to display the page 'Unit'.

Press, several times, the button ‘Down’ to select number 4

Press ‘Enter’ to confirm your choice

Display for a unit to ‘On’ Display for a unit to ‘Off’

DC-DM-ROOFTOP-IOM-1801-E - 12 -

Page 15

2.1.2 How to Start Unit ?

Press ‘Prg’ to activate the setup menu

If necessary, press several times ‘Up’ or ‘Down’ to blacken the icon

Press ‘Enter’ to confirm your choice

Press ‘Up’ or ‘Down’ to change the state ‘Off’ to ‘On’

Press ‘Enter’ to confirm your choice

Press ‘Esc’ to return to the main screen

The units can not be powered On/Off by the DM if the service display DS is connected.

2.1.3

Press ‘Prg’ to activate the setup menu

If necessary, press several times ‘Up’ or ‘Down’ to blacken the icon

The value displayed is the temperature setpoint.

How to See the Value of the Current Setpoint Temperature ?

Press ‘Esc’ to return to the main screen

DC-DM-ROOFTOP-IOM-1801-E - 13 -

Page 16

2.1.4

Press ‘Prg’ to activate the setup menu

If necessary, press several times ‘Up’ or ‘Down’ to blacken the icon

Press ‘Enter’ to confirm your choice

Press ‘Up’ or ‘Down’ to change the value

Press ‘Enter’ to confirm your choice

How to Modify the Value of the Current Setpoint Temperature ?

Press ‘Esc’ to return to the main screen

2.2 Functionality of the DM

2.2.1 Selection of Unit

A DM can be connected to 8 units on the pLan bus. Screens DM connected, alternatively, to one of BM.

The next screen allows selection of the unit to display:

Each of the 8 Unit is represented by a number.

The Unit selected is indicated by its number which is framed.

Each time you press the button 'Down Arrow' connects the display on the next Unit.

Button 'Enter': Go to main screen.

Button 'Down Arrow': Select the next Unit.

DC-DM-ROOFTOP-IOM-1801-E - 14 -

Page 17

2.2.2 Unit ‘Off’

If the Unit is stopped 'Off', this screen is activated.

Button 'Alarm': Go to Alarm list.

Button 'Prg': Go to Setup menus of the unit.

Button 'Esc': Return to the choice of Unit selected.

2.2.3

2.2.3.1 Main

Top left :

Big, numerical value: Measured value of the air temperature in the conditioned space.

Top right:

Bottom right:

Mode state based on the schedule, hour, minute, of Climatic™ :

Unit Operation

Control in heating mode or control in cooling mode

State of the ventilation

Mode Night

Mode Day

Mode Day I

Mode Day II

Bottom left:

If the unit is in alarm, this symbol is displayed.

Button 'Alarm': Go to Alarm list.

Button 'Prg': Go to Setup menus of the unit.

Button 'Esc': Return to the choice of Unit selected.

Button 'Up Arrow': Go to another display of the Unit operation.

Button 'Down Arrow': Go to another display of the Unit operation.

DC-DM-ROOFTOP-IOM-1801-E - 15 -

Page 18

2.2.3.2 Value

To the left of the house:

Visualization of the value of outdoor humidity (if enabled).

Visualization of the value of outdoor temperature.

In the house:

Visualization of the value of indoor humidity (if enabled).

Visualization of the value of the indoor temperature.

Visualization of the value of the rate of indoor air quality (if enabled).

2.2.3.3 Set-points

Visualization of the set point of heating mode.

Visualization of the set point of cooling mode.

2.2.3.4 Operation

Visualization of the opening percentage of fresh air damper.

Visualization of the percentage of compressors engaged.

Visualization of the percentage of heaters engaged.

Button 'Alarm': Go to Alarm list.

Button 'Prg': Go to Setup menus of the unit.

Button 'Esc': Return to main screen.

Button 'Up Arrow': Go to previous display of the Unit operation.

Button 'Down Arrow': Go to next display of the Unit operation.

2.2.4

History used to store the last 99 alarms occurred on the unit.

Each alarm is stored on the date and time the fault occurred.

An active alarm is signified by the symbol 'Bell'.

An alarm not active is signified by the symbol '.'.

Each alarm is signified by a 3 digit code

Alarm list

DC-DM-ROOFTOP-IOM-1801-E - 16 -

Page 19

To have the text of fault code, position the cursor on the desired line, by using the 'Up Arrow' or 'Down Arrow' and

then confirm by pressing 'Enter'

Button 'Esc': Return to main screen.

Button 'Up Arrow': Positions you in the list.

Button 'Enter': Go to text of failure code.

Button 'Down Arrow': Positions you in the list.

2.2.5

2.2.6

Setup menus

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to main screen.

Button 'Up Arrow': Selects the previous function.

Button 'Enter': Go to the screen of the selected function.

Button 'Down Arrow': Selects the next function.

Setting; Customer Temperature

View and/or modify the offset, or set point, of the temperature control desired for the Unit selected.

If the set-point is changed, this value is maintained as long as the scheduling of Unit doesn't change modes (Night,

Day, Day I, Day II, BMS).

At each change of the mode the CLIMATIC sets the value of this set-point on the preset value in the mode concerned.

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus of the unit.

Button 'Up Arrow': Increases the set-point value.

Button 'Enter': Valid the changes then return to Setup menus of the unit.

Button 'Down Arrow': Decreases the set-point value.

DC-DM-ROOFTOP-IOM-1801-E - 17 -

Page 20

2.2.7

View/edit, status of Off/On of the unit.

2.2.8

Setting; On/Off Unit

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus of the unit.

Button 'Up Arrow': Reverses the state.

Button 'Enter': Valid the changes then return to Setup menus of the unit.

Button 'Down Arrow': Reverses the state.

The units can not be powered On/Off by the DM if the service display DS0 is connected.

Setting; Clock of Climatic™

View/edit, hour, minute, day of month, month and year of the clock Climatic™.

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus of the unit.

Button 'Up Arrow': Increases the selected value.

Button 'Enter': Valid the changes and puts you to the next field.

Button 'Down Arrow': Decreases the selected value.

2.2.9

Access to the Setup Menus Plus

DC-DM-ROOFTOP-IOM-1801-E - 18 -

Page 21

2.2.10 Setup menus Plus

Access to the setup menus is protected by a password.

The password must be entered digit by digit.

If the password is correct, the lock opens, and the selection of the choice of function is active.

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus of the unit.

Button 'Up Arrow': Increases the value of the digit password or Selects the previous function.

Button 'Enter': Puts you on the next digit password, or Go to the screen of the selected function.

Button 'Down Arrow': Decreases the value of the digit password or Selects the next function.

2.2.11

Setting; Temperature

View/edit, the set-point heating mode of the schedule mode selected.

View/edit, the set-point cooling mode of the schedule mode selected.

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus Plus of the unit.

Button 'Up Arrow': Change the schedule mode or Increases the set-point value.

Button 'Enter': Valid the changes and puts you to the next field.

Button 'Down Arrow': Change the schedule mode or Decreases the set-point value.

2.2.12

View/edit, the set-point minimum fresh-air of the schedule mode selected.

Setting; Report Minimum Fresh-Air.

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus Plus of the unit.

DC-DM-ROOFTOP-IOM-1801-E - 19 -

Page 22

Button 'Up Arrow': Change the schedule mode or Increases the set-point value.

Button 'Enter': Valid the changes and puts you to the next field.

Button 'Down Arrow': Change the schedule mode or Decreases the set-point value.

2.2.13

View/edit, reset of alarm and safety.

2.2.14

Setting; Reset Alarms

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus Plus of the unit.

Button 'Up Arrow': Reverses the state.

Button 'Enter': Reset alarms, if the word 'Reset' is selected, then return to Setup menus Plus.

Button 'Down Arrow': Reverses the state.

Setting; Schedule of Climatic™

View/edit, hour and minutes of beginning of each zone.

View/edit, the operating mode of the zone.

The schedule is different each weekday.

You must set a schedule for Monday, Tuesday, ..., and Sunday.

Button 'Alarm': Go to Alarm list.

Button 'Esc': Return to Setup menus Plus of the unit.

Button 'Up Arrow': Change the schedule mode or Increases the selected value.

Button 'Enter': Valid the changes and puts you to the next field.

Button 'Down Arrow': Change the schedule mode or Decreases the selected value.

DC-DM-ROOFTOP-IOM-1801-E - 20 -

Page 23

2.3 Organizational screens

2.3.1 Selection of Unit

2.3.2

Unit Operation

2.3.3

Alarm list

DC-DM-ROOFTOP-IOM-1801-E - 21 -

Page 24

2.3.4 Setup menus

DC-DM-ROOFTOP-IOM-1801-E - 22 -

Page 25

DC, Installation 3

The 'DC' has been designed for flush mount assembly, on distribution boxes compliant with the standards in force.

3.1 Connection

WARNING: Separate as much as possible probes, displays, logical input cables

from power cables with strong inductive load, in order to avoid possible

electromagnetic perturbations.

3.1.1 Important warning

An error connecting to the display immediately causes the deterioration of this one

or BM.

Any wiring modification on the CLIMATIC must be done by Lennox technician or employees having valid electrical

qualification and authorization.

DC-DM-ROOFTOP-IOM-1801-E - 23 -

Page 26

3.1.2

The power of the 'DC' can be 24Vac (+10…-15%) 50/60Hz or 24Vdc (22…35Vdc), maximum current of 2VA.

Lennox recommends a 24Vac supply (provided by Unit) for installation of the display less within 30 meters of Unit.

For connection of the display of over 30 meters, a power supply, close to the display, 24Vac must be provided by the

installer.

For an external connection to the Unit (24V) using a transformer class 2 under 0.1A

For any modification of wiring on the 24V supply or on 4-20mA sensor, check the polarity prior to apply the power.

Wrong polarity may cause serious damage and destroy the Plan network. Lennox will not accept liability for

damage caused by wrong power connection or any wiring modification done by people without valid training and

qualifications.

3.1.3

The 'DC' is controlled by a communication bus: RS485 2 wires.

3.1.4

The connection of power and communication must be made by the following cable:

- LiYCY-P (0.34 mm ²), 2 pairs with general shield.

The cable length, with power, should not exceed 30m.

The cable length without power (24V external) must not exceed 150m.

For a better electromagnetic protection, Lennox recommends the use of LiYCY-P cable

For extended networks fit a 120 Ohm resistor (R2) between RX/TX+ and RX/TX- on the last device, to avoid possible

communication problems.

Power supply

Communication

Cable Features

DC-DM-ROOFTOP-IOM-1801-E - 24 -

Page 27

3.2 Ferrites Protection of Displays

To prevent radio interference that may cause miscommunication or destruction of elements on the screen, you need

to equip each end of the cable a ferrite (supplied by Lennox).

3.3 Temperature Sensor

All Lennox Unit comes with a temperature sensor; it must be placed in the conditioned area.

But if the 'DC' is placed in the area conditioned by the Unit, it is possible, in this case, to use the temperature

measurement of the 'DC'.

To indicate the CLIMATIC your choice, set the point 3213:

- ‘128' to use the measure of the 'DC'

- ‘1 BM-B12' or '2 BM-B1' to use the remote probe

Note:

- - For Unit with a 'medium' CLIMATIC :

Connect the remote sensor between points B12 and GND, terminal block J18.

- - For Unit with a 'small' CLIMATIC:

By default the CLIMATIC control the temperature measurement of return. If you want to control on a

measure of room temperature, disconnect the return probe between points B1 and GND, terminal block J13.

Connect the remote sensor in place.

3.4 Configuration

For communicate with the CLIMATIC this basic parameters of internal ‘DC’ must to be settled.

3.4.1

To do this, when the 'DC is powered; simultaneously press the keys and .

After some seconds the text appears and the value '000' flashes

Turn the knob to change the value to select the number 022. Then validate the code by pressing the knob.

If the code is wrong access the setup menu is not possible and the 'DC' returns to the previous display.

If the code is correct the display shows

Setup Menu

(2 buttons on the right simultaneously)

DC-DM-ROOFTOP-IOM-1801-E - 25 -

Page 28

3.4.2 Choice of Parameters

By rotating of the knob you can view and modify the following parameters:

- : Address 'DC' on the communication bus (Always set to value 31)

- : Communication speed (always set to value 2)

- : Backlight mode

- : Intensity of the backlight

- : Probe calibration

- : Screen contrast

- : Disabling 'Bip' keys

- : Password (Always set to value 22)

- : Real Time Clock 'DC'; Year

- : Real Time Clock 'DC'; Month

- : Real Time Clock 'DC'; Day

- : Real Time Clock 'DC'; weekday (1 = Monday)

- : Real Time Clock 'DC'; Hour

- : Real Time Clock 'DC'; Minute

- : Exits the Settings mode

3.4.3

To activate the modified mode value:

After to have select the desired parameter by rotating the knob .

Press the knob .

The symbol appears on the right side of the value.

Turn the knob to adjust the desired value.

Press again on the knob to confirm your choice.

The symbol is no longer displayed on the right side of the value.

The rotation of the knob is for select a new setting.

3.4.4

Changing the Value of Parameters

Mandatory values

- : 31

- : 2

- : 22

3.5 Initialization

If the connection between the CLIMATIC and the 'DC is not correct (Offline) screen displays only the symbol .

In this case check:

- - The connection between CLIMATIC and 'DC'

- - The setting of the 'DC'

- - The power of CLIMATIC

If the connection between the CLIMATIC and the 'DC is correct (Online) to power up the screen displays only the

symbol .

This phase allows the CLIMATIC to set up the 'DC' with options of Unit.

After some seconds, DC is operational.

DC-DM-ROOFTOP-IOM-1801-E - 26 -

Page 29

‘DM’, Installation 4

The "DM" was designed for wall mounting.

The optional DM delivered is designed to be wall mounted.

Positioning the cable through the rear

Fasten the rear wall using button head screws provided in the package.

Connect the cable from the main board on the jack on the back of the screen DM

Attaching the front panel on the back using countersunk screws provided.

Snap frame.

4.1 Connection

WARNING: Separate as much as possible probes, displays, logical input cables

from power cables with strong inductive load, in order to avoid possible

electromagnetic perturbations.

4.1.1 Important warning

An error connecting to the display immediately causes the deterioration of this one

or BM.

Any wiring modification on the CLIMATIC must be done by Lennox technician or employees having valid electrical

qualification and authorization.

4.1.2

The 'DM' is powered by the BM.

4.1.3

The 'DM' is controlled by a communication bus: RS485 2 wires.

4.1.4

The connection of power and communication must be made by the following cable:

- For a length of 0 to 300m: AWG22 (0.34 mm ²), two crossed pairs with screen.

- For a length of 0 to 500m: LiYCY-P (0.34 mm ²), two pairs shielded general.

The cable length should not exceed 500m.

For better protection of electromagnetic disturbances Lennox recommends the installation of cable LiYCY-P

DC-DM-ROOFTOP-IOM-1801-E - 27 -

Power supply

Communication

Cable Features

Page 30

4.2 Connection on the splitter DT50

The display DM connects to Climatic™ on the screw terminals of the card DT50.

4.2.1

The board is equipped with three RJ12 phone jacks and a screw connector (SC).

Jumpers:

The "displays" are directly supplied by the Climatic™ board with a 30 VDC power supply. Pay attention to the value of

this voltage when multiple cards are used.

J14 and J15 closed or cut the power supply:

J14 and J15 set between 1-2:

Connectors A, B, C and SC are in parallel. Power is available on all connectors.

J14 and J15 set between 2-3:

B and C connectors are supplied in parallel but the connectors A and SC are not.

Displays connected to these ports are not powered.

If J14 and J15 are set differently, the dispatcher DT50 DOESN'T WORK and therefore displays connected don't work

Installation Guide dispatcher DT50

4.3 Ferrites Protection of Displays

To prevent radio interference that may cause miscommunication or destruction of elements on the screen, you need

to equip each end of the cable a ferrite (supplied by Lennox).

DC-DM-ROOFTOP-IOM-1801-E - 28 -

Page 31

4.4 Configuration

4.4.1 Brightness / Contrast

The display is equipped with a contrast, but it can be adjusted manually. For manual adjustment of contrast,

simultaneously press the keys 'Alarm' and 'Prg' and press buttons 'Arrow' or 'Down Arrow' to increase or decrease the

contrast.

4.4.2

The address of the terminal (DM) must be checked after putting the card to 'On'.

Access the setup mode by pressing the keys 'Arrow', 'Enter' and 'Down Arrow' for at least 5 seconds.

Press the 'Enter' to place the cursor on the 'Setting'

With the 'Arrow' or 'Down Arrow' set the address of the display 31 of DM, then confirm by pressing 'Enter'

The screen 'Display address changed' is displayed.

If after 5 seconds the display is not correct;

Access, a second time, the setup mode by pressing the keys 'Arrow', 'Enter' and 'Down Arrow' for at least 5 seconds,

until the next screen.

Press the 'Enter' to place the cursor on the 'Setting'

Press a second time on the 'Enter' key to place the cursor on the line I / O board address'

With the 'Arrow' or 'Down Arrow' replace '-' by the address of the BM connected and confirm by pressing 'Enter'

Configuring the address of the terminal

DC-DM-ROOFTOP-IOM-1801-E - 29 -

Page 32

DC-DM 5

Communication Master/Slaves

If the communication bus Master/Slaves is connected between several Unit (Maximum 8)

The 'DM', connected on this bus, allows viewing, alternatively, information of all connected units.

5.1 Connection

The inter-bus boards (pLan) Climatic™ connects to connector J8 on the BM.

'Star’ connection is not recommended for optimum performance. It is advisable to connect a maximum of two cables

per unit.

Warning:

The BM 24Vac cards should not be connected to the 'Earth'

5.1.1

The connection must be wired as follows:

- For a length of 0 to 300m: AWG22 (0.34 mm ²), a twisted pair shielded.

- For a length of 0 to 500m: LiYCY-P (0.34 mm ²), a pair overall shield.

The cable length should not exceed 500m.

For better protection of electromagnetic disturbances Lennox recommends the installation of cable LiYCY-P

Cable Features

5.1.2

Each Climatic™ must be set with a communication address different.

The address setting must be done with a DS in (3171).

The value of the addresses must be between 1 and 8

Each Climatic™ must be set with the same number of identification Master (ID).

The ID must be equal to the communication address of the card where the DC is connected.

The ID setting must be done with a DS in (3173).

Each Climatic™ must be set with the same sub-bus identification.

The sub-bus setting must be done with a DS in (3172).

For each Climatic, with a DS, you must set in (3151) the type of remote display, DC or DM.

DC-DM-ROOFTOP-IOM-1801-E - 30 -

Setting

Page 33

MENU

• Problem with the pump

switch.

Water Condenser, Flow

low water flow rate.

ALARM LIST

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

• Air system obstructed or

001

Blower, Flow Switch, Cut-off.

The differential pressure

between the treatment unit and

the filters is too small.

Delayed: 1min,

Waiting stop: 1min,

Enabled: 3min after Blower

start.

Full stop. 3/day

closed,

• Belts broken,

• Problem with the fan wiring,

• Problem with the pressure

transmitter wiring,

• Incorrect settings of the safety

threshold.

• Check the system,

• Replace the belts,

• Check the connections,

• Check the settings (2333 or

3343).

DS

[2332]

[3342]

Water Condenser, Flow

Switch Cut Off.

002

003

004

004

005

The flow switch has detected a

low water flow rate in the

condenser heat exchanger.

Delta-T.

The ΔT(|inlet-outlet|) of the

condenser heat exchanger has

too low or too high, detect a

Blower, Filters, Clogged.

The differential pressure

between the treatment unit and

the filters is too high.

Blower, Filters, Clogged.

Clogged or Missing Filters

Alarm keeps active during 168

hours (7 days non stop).

Blower, Filters, Missing.

The differential pressure

between the treatment unit and

the filters is too low.

Delayed: 5s,

Waiting stop: 1min,

Enabled: 5s after one

compressor start.

Threshold: < 1K, > 40K,

Delayed: 10min,

Waiting stop: 2min,

Enabled: 10min after one

compressor start.

Threshold: > [2335][3345],

Delayed: 10min,

Enabled: 10min after Blower

start.

Delayed: 168h. Full stop. Manually

Threshold: > [2334][3344],

Delayed: 10min,

Enabled: 10min after Blower

start.

Stop all

compressors.

Stop all

compressors.

Signalling. Automatic

Signalling. Automatic

3/day

3/day

control wiring,

• Problem with the flow switch

wiring,

• Dirty or clogged water filter,

• Wrong setting of the flow

• Problem with the pump

control wiring,

• Dirty or clogged water filter.

• Filters clogged,

• Problem with the pressure

transmitter wiring,

• Incorrect settings of the safety

threshold.

• Filters clogged,

• Problem with the pressure

transmitter wiring,

• Incorrect settings of the safety

threshold.

• Filters missing,

• Problem with the pressure

transmitter wiring,

• Incorrect settings of the safety

threshold.

• Check the pump connections ,

• Check the flow switch

connections,

• Clean the water filter,

• Check the flow switch

settings.

• Check the pump connections,

• Clean the water filter.

• Fit new filters,

• Clean or replace the filters,

• Check the connections,

• Check the settings (2335 or

3345).

• Fit new filters,

• Clean or replace the filters,

• Check the connections,

• Check the settings (2335 or

3345).

• Fit new filters,

• Clean or replace the filters,

• Check the connections,

• Check the settings (2334 or

3344).

[2533]

[2531]

and

[2532]

[2332]

[3342]

[2332]

[3342]

[2332]

[3342]

DC-DM-ROOFTOP-IOM-1801-E - 31 -

Page 34

DS

MENU

Water Condenser, Water

level detector.

Main, Power Supply,

'400V')

Hot Water, Risk of Frosting.

frosting on the system.

• Problem with wiring

pressure.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

008

009

011

012

013

014

Level.

Water leak detected by the

Electrical Fault.

Main 400V power supply is not

present (Customer contact

Electrical Heaters,

Overheating.

The status of the safety

thermostat of the main

electrical heater signals an

oveheating on the system.

Fresh Air, Electrical Heater,

Overheating.

The status of the safety

thermostat of the Fresh Air

electrical heater signals an

oveheating on the system.

The safety thermostat of the

hot water signals a risk of

Gas Burner 1.

The gas burner control box has

generated a fault and is no

longer controlling the fume

extractor fan.

Waiting stop: 1s (W aiting for

the closure of the contact),

Delayed: 30s.

Enabled: At power on. Full stop. Automatic

Delayed: 5s,

Enabled: 5s after one electrical

heater start.

Delayed: 5s,

Enabled: 5s after one electrical

heater start.

Delayed: 1s. Full stop. Manually

Delayed: 5s,

Waiting stop: 4min,

Enabled: 6min after gas burner

requested (10s for eNeRGy).

Stop all

compressors.

Stop the

electrical heater

If [3114] = True:

Full stop.

Stop the

electrical heater

If [3114] = True:

Full stop.

Stop the gas

burner

If [3114] = True:

Full stop.

10/day • Leakage on the piping. • Check the piping. [2536]

Manually

Manually

3/day

• Main power issue,

• Wrong setting.

• Problem with wiring of the

electrical heaters,

• Air system obstructed or

closed,

• Filter clogged,

• Belts broken.

• Problem with wiring of the

electrical heaters,

• Air system obstructed or

closed,

• Fresh air damper closed,

• Belts broken.

• Check the connections,

• The fresh air damper is

blocked opening.

connection,

• Problem with electronic gaz

controler,

• Problem with gas supply or

• Check the main power

tension,

• Check the settings (3131 to

3147).

• Check the connections of the

electrical heaters,

• Check the air system,

• Clean the filters,

• Replace the belts.

• Check the connections of the

electrical heaters,

• Check the air system,

• Check air damper,

• Replace the belts.

• Check the connections.

• Check air damper.

• Check the connections.

• Check gas burner.

[2181]

to

[2197]

[2723]

[2882]

[2733]

[2713]

Gas Burner 2.

The gas burner control box has

015

generated a fault and is no

longer controlling the fume

extractor fan.

DC-DM-ROOFTOP-IOM-1801-E - 32 -

Delayed: 5s,

Waiting stop: 4min,

Enabled: 6min after gas burner

requested (10s for eNeRGy).

Stop the gas

burner

If [3114] = True:

Full stop.

3/day

• Air system obstructed or

closed,

• Filter clogged,

• Belts broken.

• Check the air system,

• Clean the filters,

• Replace the belts.

[2716]

Page 35

DS

MENU

• Problem with wiring

pressure.

• Problem with wiring

pressure.

• Problem with wiring

pressure.

• Problem with wiring

pressure.

• Problem with wiring

pressure.

• Check the air system / Check

• Check the setting (3252).

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

016

017

018

019

020

Gas Burner, Overheating.

The status of the safety

thermostat signals an

oveheating on the system.

Gas Burner 3.

The gas burner control box has

generated a fault and is no

longer controlling the fume

extractor fan.

Gas Burner 4.

The gas burner control box has

generated a fault and is no

longer controlling the fume

extractor fan.

Gas Burner 5.

The gas burner control box has

generated a fault and is no

longer controlling the fume

extractor fan.

Gas Burner 6.

The gas burner control box has

generated a fault and is no

longer controlling the fume

extractor fan.

Delayed: 5s,

Enabled: 5s after one gas

burner requested.

Delayed: 5s,

Waiting stop: 4min,

Enabled: 6min after gas burner

requested.

Delayed: 5s,

Waiting stop: 4min,

Enabled: 6min after gas burner

requested.

Delayed: 5s,

Waiting stop: 4min,

Enabled: 6min after gas burner

requested.

Delayed: 5s,

Waiting stop: 4min,

Enabled: 6min after gas burner

requested.

Stop the gas

burner

If [3114] = True:

Full stop.

Stop the gas

burner

If [3114] = True:

Full stop.

Stop the gas

burner

If [3114] = True:

Full stop.

Stop the gas

burner

If [3114] = True:

Full stop.

Stop the gas

burner

If [3114] = True:

Full stop.

Manually

3/day

3/day

3/day

3/day

connection,

• Problem with electronic gaz

controler,

• Problem with gas supply or

connection,

• Problem with electronic gaz

controler,

• Problem with gas supply or

connection,

• Problem with electronic gaz

controler,

• Problem with gas supply or

connection,

• Problem with electronic gaz

controler,

• Problem with gas supply or

connection,

• Problem with electronic gaz

controler,

• Problem with gas supply or

• Check the connections.

• Check gas burner.

• Check the connections.

• Check gas burner.

• Check the connections.

• Check gas burner.

• Check the connections.

• Check gas burner.

• Check the connections.

• Check gas burner.

#

[2781]

[2783]

[2785]

[2787]

Supply Temperature, Too

High.

021

022

DC-DM-ROOFTOP-IOM-1801-E - 33 -

The temperature measur ed by

the probe is outside of the

permitted range.

Supply Temperature, Too

Low.

The temperature measured by

the probe is outside of the

permitted range.

Threshold: > [3254],

Delayed: 5s,

Enabled: 2min after Blower

start.

Threshold: < [3252],

Delayed: 10min or 5min if Hot

Water Coil,

Waiting stop: 10min,

Enabled: 2min after Blower

start.

Stop all

compressors

and heaters.

Full stop. 3/day

Automatic

• Insufficient airflow,

• Temperature probe failed,

• Problem with wiring of probe,

• Wrong setting.

• Insufficient airflow / Air

damper jammed open,

• Temperature probe failed,

• Problem with wiring of probe,

• Wrong setting.

• Check the air system,

• Replace probe,

• Check the connections of the

probe,

• Check the setting (3254).

the air damper, mechanically

and electrically,

• Replace probe,

• Check the connections of the

probe,

[2231]

[2231]

Page 36

DS

MENU

Water Condenser

permitted range.

Water Condenser

permitted range.

Water Condenser, Pump.

a failure on the system.

• Problem with wiring

• Pump failure.

Humidifier.

signals a failure on the system.

Room, Air Hr% or g/kgAS,

permitted range.

Room, Air Hr% or g/kgAS,

permitted range.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

023

024

025

026

027

029

Room Temperature, Too

High.

The temperature measured by

the probe is outside of the

permitted range.

Room Temperature, Too

Low.

The temperature measured by

the probe is outside of the

permitted range.

Temperature, Too Low

The temperature measured by

the probe is outside of the

Temperature, Too High

The temperature measured by

the probe is outside of the

The status of the pump signals

Air Quality, Too High.

The value measured by the

sensor is outside of the

permitted range.

Threshold: > [3256],

Delayed: 15s,

Enabled: 2min after Blower

start.

Threshold: < [3255],

Delayed: 15s,

Enabled: 2min after Blower

start.

Threshold: < [3531],

Delayed: 15s.

Threshold: > [3532],

Delayed: 15s.

Delayed: 5s.

Threshold: > [3855],

Delayed: 15s.

Signalling. Automatic

Signalling. Automatic

Stop all

compressors.

Stop all

compressors.

Stop all

compressors.

Signalling. Automatic

Automatic

Automatic

Manually

• Insufficient airflow,

• Temperature probe failed,

• Problem with wiring of probe,

• Wrong setting.

• Insufficient airflow,

• Temperature probe failed,

• Problem with wiring of probe,

• Wrong setting.

• Water loop temperature too

low,

• Wrong setting.

• Water loop temperature too

high,

• Wrong setting.

connection,

• Problem with wiring

connection (sensor in short

circuit or disconnected),

• Sensor damaged,

• Wrong setting.

• Check the air system,

• Replace probe,

• Check the connections of the

probe,

• Check the setting (3256).

• Check the air system,

• Replace probe,

• Check the connections of the

probe,

• Check the setting (3255).

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Check the setting (3531).

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Check the setting (3532).

• Check the wiring connections,

• Check the pump.

• Check the wiring connections,

• Replace the sensor,

• Check the setting (3855).

[2221]

[2221]

[2531]

or

[2532]

[2531]

or

[2532]

[2535]

[2853]

031

032

033

DC-DM-ROOFTOP-IOM-1801-E - 34 -

The status of the humidifier

Too Low.

The value measured by the

sensor is outside of the

Too High.

The value measured by the

sensor is outside of the

Delayed: 1min.

Threshold: < [3258],

Delayed: 15s,

Enabled: 2min after Blower

start.

Threshold: > [3259],

Delayed: 15s,

Enabled: 2min after Blower

start.

Stop the

humidifier.

Signalling. Automatic

Signalling. Automatic

Automatic

• Problem with wiring

connection.

• Humidity sensor failed,

• Problem with wiring of sensor,

• Wrong setting.

• Humidity sensor failed,

• Problem with wiring of sensor,

• Wrong setting.

• Check the wiring connections. [2923]

• Check the wiring connections,

• Replace the sensor,

• Check the setting (3258)

• Check the wiring connections,

• Replace the sensor,

• Check the setting (3259)

[2265]

or

[2266]

[2265]

or

[2266]

Page 37

DS

MENU

Hot Water, Pump.

circulator has operated.

Stop the pump,

valve.

• Problem with wiring

• Pump failure.

Recovery, Motor.

on the system.

Recovery, Air Flow, Sensor.

measured is incorrect.

Recovery, Outlet

measured is incorrect.

CLIMATIC board, Real Time

clock battery is faulty

Expansion Board, BE N°1,

network.

Expansion Board, BE N°2,

network.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

041

051

052

054

056

059

070

The electrical protection of the

The status of the wheel

recovery motor signals a failure

Recovery, Wheel.

The ΔT(|outdoor-outlet

recovery|) temperature is lower

than the safety limit.

Recovery, Filters, Clogged.

The differential pressure

between the treatment unit and

the filters is too high.

The value of the sensor

Temperature, Probe.

The value of the probe

Clock, Battery.

The CLIMATIC™ real time

Delayed: 15s,

Enabled: 5s after pump start

Delayed: 10s,

Enabled: 30s after motor start.

Threshold: < [3874],

Delayed: 30s,

Waiting stop: 5min,

Enabled: 15min after motor

start.

Threshold: > [3875],

Delayed: 1min.

Delayed: 15s. Stop the motor. Automatic

Delayed: 15s. Stop the motor. Automatic

Delayed: 1s Signalling. Automatic • Battery low voltage • Replace the clock battery #

Close hot water

Stop the motor. Manually

Stop the motor. 3/day

Signalling. Automatic

Manually

connection,

• Problem with wiring

connection,

• Wheel motor failure.

• Wheel belts broken,

• Problem with wiring

connection (sensor in short

circuit or disconnected),

• Sensor damaged,

• Wrong setting.

• Filters clogged,

• Problem with the pressure

transmitter wiring,

• Incorrect settings of the safety

threshold.

• Sensor failure,

• Problem with wiring of sensor.

• Probe failure,

• Problem with wiring of probe.

• Check the wiring connections,

• Check the pump.

• Check the wiring connections,

• Check the motor.

• Replace the belts

• Check the wiring connections,

• Replace the probes,

• Check the setting (3874).

• Fit new filters,

• Clean or replace the filters,

• Check the connections,

• Check the settings (3875).

• Check the sensor

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

[2744]

[2878]

[2873]

or

[2875]

[2876]

[2876]

[2875]

Link Failure.

071

072

DC-DM-ROOFTOP-IOM-1801-E - 35 -

The expansion board 1 is

disconnected from the Fieldbus

Link Failure.

The expansion board 2 is

disconnected from the Fieldbus

Delayed: 1s,

Enabled: 30s after power on.

Delayed: 1s,

Enabled: 30s after power on

Signalling. Automatic

Signalling. Automatic

• Expansion board failed,

• Problem with wiring of

fieldbus,

• Wrong setting.

• Expansion board failed,

• Problem with wiring of

fieldbus.

• Replace expansion board,

• Check the bus connections,

• Check the setting (3121 to

3147).

• Replace expansion board,

• Check the bus connections

#

#

Page 38

DS

MENU

Blower, Inverter, Link Failure.

network.

Exhaust, Inverter, Link

network.

Circuit 1, Condenser Fan,

network.

Stop C1

compressors.

Circuit 2, Condenser Fan,

network.

Stop C2

compressors.

Circuit 1, Coompressor,

from the Fieldbus network.

Expansion Board, BE N°3,

network.

Expansion Board, eSlave,

Fieldbus network.

Blower, Air Flow and Filters,

measured is incorrect.

Room, Air T°, Probe.

measured is incorrect.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

073

074

075

076

077

078

The EC fans or inverters are

disconnected from the Fieldbus

Failure.

The EC fans or inverters are

disconnected from the Fieldbus

Inverter, Link Failure.

The EC fans or inverters are

disconnected from the Fieldbus

Inverter, Link Failure.

The EC fans or inverters are

disconnected from the Fieldbus

Inverter, Link Failure.

The inverter is disconnected

Link Failure.

The expansion board 3 is

disconnected from the Fieldbus

Delayed: 30s,

Enabled: 30s after power on

Delayed: 30s,

Enabled: 30s after power on

Delayed: 15s,

Enabled: 30s after power on

Delayed: 15s,

Enabled: 30s after power on

Delayed: 15s,

Enabled: 30s after power on

Delayed: 1s,

Enabled: 30s after power on.

Full stop. Automatic

Full stop. Automatic

condenser

fans,

Stop C1

condenser

fans,

Stop C2

Stop C1

compressor.

Signalling. Automatic

Automatic

Automatic

Automatic

• Fans failed,

• Problem with wiring of

fieldbus.

• Fans failed,

• Problem with wiring of

fieldbus.

• Fans failed,

• Problem with wiring of

fieldbus.

• Fans failed,

• Problem with wiring of

fieldbus.

• Driver failed,

• Problem with wiring of

fieldbus.

• Expansion board failed,

• Problem with wiring of

fieldbus.

• Replace fan,

• Check the bus connections

• Replace fan,

• Check the bus connections

• Replace fan,

• Check the bus connections

• Replace fan,

• Check the bus connections

• Replace driver,

• Check the bus connections

• Replace expansion board,

• Check the bus connections

#

#

#

#

#

#

Link Failure.

079

080

081

DC-DM-ROOFTOP-IOM-1801-E - 36 -

The eClimatic on internal split

unit is disconnected from the

Sensor.

The value of the sensor

The value of the probe

Delayed: 1s,

Enabled: 30s after power on.

Delayed: 15s. Full stop. Automatic

Delayed: 15s.

Stop all

compressors

and heaters.

Only

ventilation.

Automatic

Automatic

• Slave eClimatic failed,

• Problem with wiring of

fieldbus.

• Sensor failure,

• Problem with wiring of senso r.

• Probe failure,

• Problem with wiring of probe.

• Replace slave eClimatic,

• Check the bus connections

• Check the sensor

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

#

[2332]

[3342]

[2213]

Page 39

DS

MENU

Room, Air Hr%, Probe.

measured is incorrect.

Outside, Air T°, Probe.

measured is incorrect.

Outside, Air Hr%, Sensor.

measured is incorrect.

Supply, Air T°, Probe.

measured is incorrect.

Water Condenser, Inlet,

measured is incorrect.

Water Condenser, Outlet,

measured is incorrect.

Return Temperature, Probe.

measured is incorrect.

Air Quality, Sensor.

measured is incorrect.

Blower Pressure, Sensor.

measured is incorrect.

Delayed: 15s,

start.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

082

083

084

085

086

087

088

089

090

The value of the sensor

The value of the probe

The value of the sensor

The value of the probe

Probe.

The value of the probe

Probe.

The value of the probe

The value of the probe

The value of the sensor

The value of the sensor

Delayed: 15s.

Delayed: 15s.

Delayed: 15s.

Delayed: 5s.

Delayed: 15s.

Delayed: 15s.

Delayed: 15s.

Delayed: 15s,

Enabled: 1min after power on.

Delayed: 15s. Full stop. Automatic

Only

ventilation.

Only

ventilation.

Only

ventilation.

Only

ventilation.

Stop all

compressors.

Stop all

compressors.

Only

ventilation.

Signalling. Automatic

Automatic

Automatic

Automatic

Automatic

Automatic

Automatic

Automatic

• Sensor failure,

• Problem with wiring of sensor.

• Probe failure,

• Problem with wiring of prob e.

• Sensor failure,

• Problem with wiring of sensor.

• Probe failure,

• Problem with wiring of probe.

• Probe failure,

• Problem with wiring of probe.

• Probe failure,

• Problem with wiring of probe.

• Probe failure,

• Problem with wiring of probe.

• Sensor failure,

• Problem with wiring of sensor.

• Sensor failure,

• Problem with wiring of sensor.

• Check the sensor

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the sensor

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the sensor

• Check the wiring connections.

• Check the sensor

• Check the wiring connections.

[2265]

[2211]

[2261]

[2221]

[2531]

[2532]

[2216]

[2853]

[2332]

[3342]

Blower, Fan.

091

092

DC-DM-ROOFTOP-IOM-1801-E - 37 -

The fan motor control is no

longer active.

Blower, Inverter.

Alarm reading by bus on fans

inverter.

Delayed: 5s,

Enabled: 3min after power on,

Enabled: 10s if [3316] = False.

Waiting stop: 30s,

Enabled: 15s after one fan

Full stop. Manually

Full stop. 3/day

• Electric circuit breaker cut,

• Fan motor damaged,

• Fire safety thermostat active

• Thermal motor protection

devices activated,

• Problem with wiring

connection.

• Fan motor damaged,

• Thermal motor protection

devices activated.

• Check, Replace the fan

motor,

• Reset the thermostat,

• Check the air system,

• Check the connection.

• Check fans motor. #

[2313]

Page 40

DS

MENU

Delayed: 15s,

start.

Fire / Smoke, Detected.

CLIMATIC board, Power Off

start.

EVD N°1, Link Failure.

network.

inverter.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

• Electric circuit breaker cut,

093

Exhaust, Fan.

The fan motor control is no

longer active.

Delayed: 5s,

Enabled: 20s after fans start.

Full stop. Manually

• Fan motor damaged,

• Fire safety thermostat active

• Thermal motor protection

devices activated,

• Problem with wiring

connection.

• Check, Replace the fan

motor,

• Reset the thermostat,

• Check the air system,

• Check the connection.

[2313]

094

099

100

101

102

103

Exhaust, Inverter.

Alarm reading by bus on fans

inverter.

The stand-alone detector

switch (DAD) has detected the

presence of smoke in the unit.

A long period without power

supply has been detected.

Time for compressor crankcase

to sufficiently warm up enough

to avoid refrigerant flooded

The driver 1 of EEV is

disconnected from the Fieldbus

Circuit 1, Fan Condenser.

The thermal motor protection of

the condenser fan has detected

an over temperature.

Circuit 1, Fan Condenser

Inverter.

Alarm reading by bus on fans

Waiting stop: 30s,

Enabled: 15s after one fan

Delayed: 1s.

Threshold: Outside

temperature < 10°C,

Enabled: If cut-off lasts more

than 6 hours at power on.

Delayed: 30s,

Enabled: 1min after power on.

Delayed: 5s,

Waiting stop: 30min,

Enabled: 5s after fan start.

Delayed: 15s.

Full stop. 3/day

Full stop,

Open the fresh

air damper.

Stop all

compressors.

Stop C1 and/or

C2

compressors.

Stop C1

compressors.

Stop C1

compressors.

Manually • Problem with the DAD • Check the connection. [2341]

Automatic

8 hours

Automatic

3/day

Automatic

• Fan motor damaged,

• Thermal motor protection

devices activated.

• Long period without power

supply

• Driver failed,

• Problem with wiring of

fieldbus.

• Electric circuit breaker cut,

• Fan motor damaged,

• Thermal motor protection

devices activated,

• Problem with wiring

connection.

• Fan motor damaged,

• Thermal motor protection

devices activated.

• Check fans motor. #

• Check the unit power-supply #

• Replace driver,

• Check the bus connections

• Check, Replace the fan

motor,

• Check the connection.

• Check fans motor. #

[2215]

#

DC-DM-ROOFTOP-IOM-1801-E - 38 -

Page 41

DS

MENU

Circuit 1, Leak Refrigerant,

refrigerant circuit.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

Detected.

110

The CLIMATIC has detected a

risk of leakage of the

… Signalling. Manually • Refrigerant leakage • Check the circuit operating #

114

115

116

117

Circuit 1, Compressor,

Electrical Failure.

An electrical failure happened

in the compressors of the

circuit.

Circuit 1, Safety High

Pressure, Cut-off.

The condensing pressure read

by the pressure transducer

exceeds the maximum limit.

Circuit 1 Compressor, Delta

Pressure (HP-LP), Too Low.

The Δp(|High-Low|) pressure is

lower than the safety limit.

Circuit 1, Safety Low

Pressure, Cut-off.

The suction temperature

calculated by the LP pressure

sensor is lower than the

permitted threshold.

Waiting stop: 30min,

Enabled: 5s after one

compressor start.

Threshold: > 42bar/64°C,

Waiting stop: 30min,

Enabled: 5s after one

compressor start.

Threshold: < 1bar,

Delayed: 5s,

Waiting stop: 1min,

Enabled: 1min after one

compressor start.

Threshold: < -27°C,

Delayed: 2min,

Waiting stop: 30min,

Enabled: 6min after one

compressor start.

Or

Threshold: < -33°C,

Delayed: Immediately,

Enabled: immediately.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

3/day

3/day

3/day

3/day

or

Manually

• Problem with wiring

connection, pressure switch or

compressor internal safety

switch

• Coil condenser dirty,

• Fan condenser not operating.

• Too much Refrigerant charge,

• Problem with wiring

connection, pressure

transducer

• Coil condenser dirty,

• Fan condenser not operating.

• Electric circuit brea ker cut,

• Problem with wiring

connection,

• Reversing valve locked

• Refrigerant charge • Check the circuit operating [2416]

• Check the wiring connection,

• Clean the coil condenser,

• Check the fan operating.

• Check the circuit operating,

• Check the wiring connection,

• Clean the coil condenser,

• Check the fan operating.

• Check the compressor,

• Check the wiring connection,

• Check the reversing valve

swap

[2423]

[2433]

[2414]

[2412]

and

[2414]

DC-DM-ROOFTOP-IOM-1801-E - 39 -

Page 42

DS

MENU

Threshold: [3513] 0% Glycol <

mode.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

118

119

121

122

Circuit 1, Water Evaporator,

Risk of Frosting.

The suction temperature

calculated by the LP pressure

sensor is lis too low and may

pose a risk for the water

evaporator.

Circuit 1 Compressor,

Condensing T°, Too Low.

The temperature measured by

the probe is outside of the

permitted range.

Circuit 1, Superheat T°, Too

Low.

The value calculed is outside of

the permitted range.

Circuit 1, Superheat T°, Too

High.

The value calculed is outside of

the permitted range.

0°C,

Threshold: [3513] 50% Glycol <

-20°C,

Delayed: 5s,

Waiting stop: 6min,

Enabled: 2s after one

compressor start in heating

Threshold: < 21.5°C,

Delayed: 6min,

Waiting stop: 30min,

Enabled: 3min after one

compressor or condenser fan

start/stop.

Threshold: < [3621] - 3K,

Delayed: 6min,

Waiting stop: 6min,

Enabled: 6min after one

compressor start, then 3min

after one compressor or

condenser fan start/stop.

Threshold: (LP < 5°C) < 15K,

Threshold: (LP > 5°C) < 25K,

Delayed: 6min,

Waiting stop: 6min,

Enabled: 6min after one

compressor start, then 3min

after one compressor or

condenser fan start/stop.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

6/day

Automatic

3/day

3/day

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

[2412]

[2414]

[2616]

[2616]

Circuit 1, Subcooling, Too

123

DC-DM-ROOFTOP-IOM-1801-E - 40 -

Low.

The value calculed is outside of

the permitted range.

Threshold: < 0.6K,

Delayed: 6min,

Enabled: 3min after one

compressor or condenser fan

start/stop.

Signalling. Automatic

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

[2623]

Page 43

DS

MENU

Circuit 1 Compressor, MOP

permitted range.

Threshold: (HP < 20°C) < 5°C,

start/stop.

Threshold: (HP < 35°C) < -

start/stop.

Circuit 1, Elec. Expansion

failure on the system.

Circuit 1, High Pressure,

measured is incorrect.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

124

127

128

129

Circuit 1, Subcooling, Too

high.

The value calculed is outside of

the permitted range.

operating, (Max Operating

Press.).

The suction temperature

calculated by the LP pressure

sensor is outside of the

Circuit 1 Compressor, LOP

operating, (Low Operating

Press.).

The suction temperature

calculated by the LP pressure

sensor is outside of the

permitted range.

Circuit 1 Compressor,

Condensing T°, Too High.

The temperature measured by

the probe is outside of the

permitted range.

Threshold: > 16K,

Delayed: 6min,

Enabled: 3min after one

compressor or condenser fan

start/stop.

Threshold: (HP > 45/30°C) <

26/15°C,

Delayed: 6min,

Enabled: 3min after one

compressor or condenser fan

25°C,

Threshold: (HP < 55°C) < -5°C,

Threshold: (HP > 65°C) <

12.5°C,

Delayed: 1min,

Enabled: 3min after one

compressor or condenser fan

Threshold: > 61°C,

Delayed: 20s,

Waiting stop: 6min,

Enabled: 3min after one

compressor or condenser fan

start/stop.

Signalling. Automatic

Signalling. Automatic

Signalling. Automatic

Stop C1

compressors.

Automatic

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

[2623]

[2412]

and

[2414]

[2412]

and

[2414]

[2414]

Circuit 1 Compressor,

Discharge T°, Too High.

130

132

141

DC-DM-ROOFTOP-IOM-1801-E - 41 -

Over-temperature detected on

the 1st circuit discharge

temperature.

Valve, Motor.

The driver of EEV signals a

Sensor.

The value of the sensor

Threshold: > 140°C,

Delayed: 20s,

Waiting stop: 6min,

Enabled: 5s after one

compressor start.

Delayed: 1s.

Delayed: 15s.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

3/day • Compressor failure • Check the compressor

Automatic • EEV failure • Check the EEV #

Automatic

• Sensor failure,

• Problem with wiring of sensor.

• Check the sensor

• Check the wiring connections.

[2426]

[2436]

[2414]

Page 44

DS

MENU

Circuit 1, Low Pressure,

measured is incorrect.

Circuit 1, Liquid

measured is incorrect.

Circuit 1, Suction T°, Probe.

measured is incorrect.

Circuit 1, Discharge T°,

measured is incorrect.

Circuit 1, BLDC, Low

guaranteed.

Circuit 1, BLDC, Compressor

alarm.

Circuit 1, BLDC, Out of

permitted range.

CODE DESCRIPTION CONDITION EFFECT RESET POSSIBLE CAUSES POSSIBLE REMEDIES

142

143

144

145

148

149

Sensor.

The value of the sensor

Temperature, Probe.

The value of the probe

The value of the probe

Probe.

The value of the probe

Circuit 1, BLDC, High

Discharge Temperature.

Over-temperature detected on

the inverter circuit discharge

temperature.

Pressure Difference.

The Δp(|High-Low|) pressure

persists for a period of time

under the limit value.

Thus optimal lubrication is not

Delayed: 15s.

Delayed: 15s.

Delayed: 15s.

Delayed: 15s.

Threshold: > 60°C,

Waiting stop: 6min,

Enabled: Compressor start.

Waiting stop: 6min,

Enabled: Compressor start.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

Stop C1

compressors.

Automatic

Automatic

Automatic

Automatic

3/day

3/day

• Sensor failure,

• Problem with wiring of sensor.

• Probe failure,

• Problem with wiring of probe.

• Probe failure,

• Problem with wiring of probe.

• Probe failure,

• Problem with wiring of probe.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Check the sensor

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Check the probe

• Check the wiring connections.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,

• Replace the expansion valve.

[2412]

[2415]

[2614]

[2426]

[2426]

[2412]

Fails to Star.

A specific algorithm checks

150

151

DC-DM-ROOFTOP-IOM-1801-E - 42 -

whether the compressor

actually started and, if this is

not the case, signals failed

compressor start through an

Envelop.

The suction temperature

calculated by the LP pressure

sensor is outside of the

Waiting stop: 6min,

Enabled: Compressor start.

Waiting stop: 6min,

Enabled: Compressor start.

Stop C1

compressors.

Stop C1

compressors.

3/day

3/day

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Limit indoor/outdoor

temperature conditions,

• Refrigerant charge,

• Problem with the expansion

valve.

• Wait normal tempetaure

conditions,

• Check the circuit operating,