Page 1

Providing indoor climate comfort

CLIMATIC™ 40

MUL37E-0607 12-2009

Original manual translation

User manual

Page 2

1

1

2-4

4

5-7

8-9

10

10

10

11

11

11

12

12

13

13-14

14-15

15

16

17

18-20

21

22-23

24-27

INDEX

CONTENTS PAGE

• INDEX

• DESCRIPTION OF CONTROLS

1.- CLIMATIC 40 CONTROL

2.- DC41 TERMINAL (ECOLEAN)

3.- DC40 REMOTE TERMINAL (AIRCOOLAIR)

• MENU

• REGULATION

1.- ECOLEAN

2.- AIRCOOLAIR

3.- AIRCUBE

• ADVANCED FUNCTIONS

1.- REMOTE ON/OFF

2.- REMOTE WINTER / SUMMER CHANGEOVER

3.- DYNAMIC SET POINT

4.- BMS COMUNICATIONS

5.- TIME BANDS PROGRAM (ECOLEAN)

6.- LOW NOISE

7.- ANALOGUE / DIGITAL INPUT

8.- TIMING AND DELAYS

9.- DEFROST

10.- CONDENSER FAN SPEED CONTROL

11.- FREE COOLING

• PARAMETERS

• SAFETY DEVICES

• INSTRUCTIONS FOR ASSEMBLY AND INSTALLATION

• ALARMS

Page 3

2

PWM

DC 41

BM40

ECOLEAN AIRCOOLAIR AIRCUBE

PWM

DC 40

BM40

PWM

BM40

EAC/EAR-SM ANCM/ANHM KSCM/KSHM

Climatic 40 control, is an electronic device that controls Ecolean EAC/EAR units (chiller units), Aircoolair ANCM/ANHM units (air-air

units) and Aircube KSCM/KSHM units (condensing units).

The thermostat allows the following operations:

• Unit ON/OFF.

• Select system operating mode.

• Set point adjustment.

• Alarm signal relay.

• Display temperature, status of unit and pending alarms.

• Programming of time bands.

• BMS comunications.

• Possibility of remote ON/OFF.

Inlet and outlet water, temperature/pressure condenser and outdoor temperature

probes (optional).

Proportional regulation based on inlet

water temperature (cooling and heating

mode).

Defrost cycle (heat pump units), with pressure tranducer.

Condensing pressure control with temperature probe or pressure transducer.

Flow switch, antifreeze, high and low pressure protections.

Compressors, water pump, fans and electrical heater management.

Return / remote ambient, evaporator, temperature/pressure condenser and outdoor

temperature probes (optional).

Proportional regulation based on remote

ambient /return temperature (cooling,

heating and automatic mode).

Defrost cycle (heat pump units), with pressure tranducer.

Condensing pressure control with temperature probe or pressure transducer.

Antifreeze, high and low pressure protections.

Compressors, indoor and o utdoor fans,

electrical heater and freecooling (optional)

management.

Condenser temperature/pressure probes.

Regulation based on remote free voltage

contacts.

Defrost cycle (heat pump units), with pressure tranducer.

Condensing pressure control with temperature probe or pressure transducer.

High and low pressure protections.

Compressors, indoor (optional) and outdoor fans.

DESCRIPTION OF CONTROLS

Condenser

temperature

/pressure

Inlet water

temperature

Outlet water

temperature

Outside

temperature

(optional)

Fan speed

control

Expansión

board

Condenser

temperature

/pressure

Fan speed

control

Expansión

board

Return air

duct

temperature

Evaporator

temperature

Outside

temperature

(optional)

Fan speed

control

Expansión

board

Free cooling

motor damper

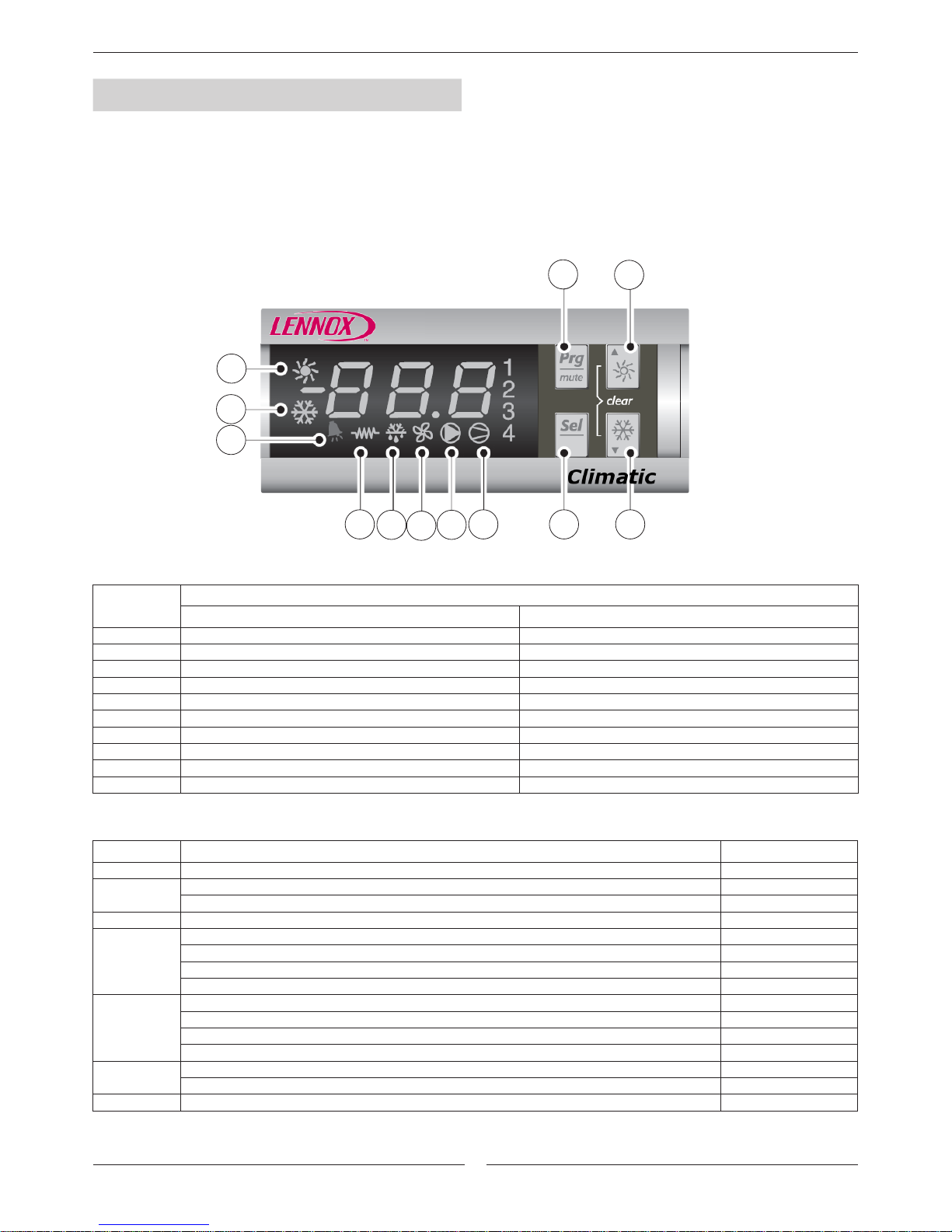

1.- CLIMATIC 40 CONTROL

Return or

remote

ambient

temperature

Page 4

3

H

F

G

E

D

C

B

A L K

I

J

A

B

C

D

E

F

G

H

I

L

I+L

J

K

J+K

L+J

DESCRIPTION OF CONTROLS

CLIMATIC 40 CONTROL

The gure and the table below show the symbols present on the display and on the keypad,together with their meanings:

The main screeen shows: inlet water temperature for ECOLEAN, ambient temperature for AIRCOOLAIR and unit status (On/Off)

for AIRCUBE.

SYMBOL

DESCRIPTION

LED ON LED FLASHING

1 or 2

Compressor 1 and /or 2 (circuit 1) ON. Start up request.

2 or 3

Compressor 3 and /or 4 (circuit 2) ON. Start up request.

At least 1 compressor ON.

Water pump/Indoor fan ON. Start up request.

Condenser fan ON.

Defrost active. Start up request.

Electrical heater ON. Start up request.

Alarm active.

Cooling mode. Cooling mode request.

Heat pump mode. Heat pump mode. Request.

BUTTON DESCRIPTION TIME

Go up a sub-group inside the programming area. Press once

Access the direct parameters. Press for 5 s

Select item inside the programming area / conrm changes to the parameters. Press once

Program parameters afters entering password. Press for 5 s

Select top item inside the programming area. Press once

Increase value. Press once

Switch from standby to heat pump mode and vice-versa. Press for 5 s

Provides immediate access to the condenser and evaporator pressure and temperature probes. Press once

Select bottom item inside the programming area. Press once

Decrease value. Press once

Switch from stand-by to chiller mode and vice-versa. Press for 5 s

Provides immediate access to the condenser and evaporator pressure and temperature probes. Press once

Manual alarm reset. Press for 5 s

Immediately reset the hour counter (inside the programming area). Press for 5 s

Force manual defrost on both circuits. Press for 5 s

Page 5

4

J

L

K

I

I+L

J+K

DESCRIPTION OF CONTROLS

DC41 terminal is an optional keypad that allows the Climatic 40 controller to be managed remotely. The buttons and indications on

the display faithfully reproduce the Climatic 40 user interface.

1.1.1.- TURN ON/OFF THE UNIT

In order to turn on the unit, press the “ ” button for 5 seconds, for the heat pump mode, or the “ ” button, for the cooling

mode.

The display shows unit’s operating mode together with the symbols of the working elements (compressors, water pump etc.).

In order to turn off the unit, press the “ ” button for 5 seconds (if the unit is working in heat pump mode) or the “ ” button (if

the unit is working in the cooling mode).

1.1.2.- SELECTING THE UNIT´S OPERATING MODE

If the unit is on stand-by, the operating mode is selected at start-up (as explained above).

If the unit is working in cooling or heating mode, in order to change the operating mode, you rst have to turn the unit off, and only

then can you turn it on in the operating mode you want.

1.1.3.- SELECTING THE WATER TEMPERATURE OF THE SYSTEM

To modify unit’s working set point, you have to change parameter r1 (cool set point) or parameter r3 (heat set point).

To see how to change a parameter, see chapter 3 MENU (SETTINGS AND OPERATING HOURS DISPLAY MENU paragraph).

1.2.1.- TURN ON/OFF THE UNIT

The unit is turned on by closing the On/Off contact and turned off by opening it (see section 1, advanced functions, for more

details).

1.2.2.- SELECTING THE UNIT´S OPERATING MODE

The heating mode is selected by opening the remote changeover contact while the cooling mode is selected byclosing it (see

section 2, advanced functions, for more details).

NOTE

There are no set points to be made for Aircube units because the compressors are directly controlled by remote contacts.

1.2.- AIRCUBE

1.1.- ECOLEAN

1.- CLIMATIC 40 CONTROL

2.- DC41 REMOTE CONTROL (ECOLEAN)

OPTION

Page 6

5

2

41 3

11

7

5

6

10

9

8

POWER

Mode

MODE

FAN

SLEEP

CLOCK

TEMP.

UP/DOWN

1 7

2 8

3 9

4 10

5 11

6

DESCRIPTION OF CONTROLS

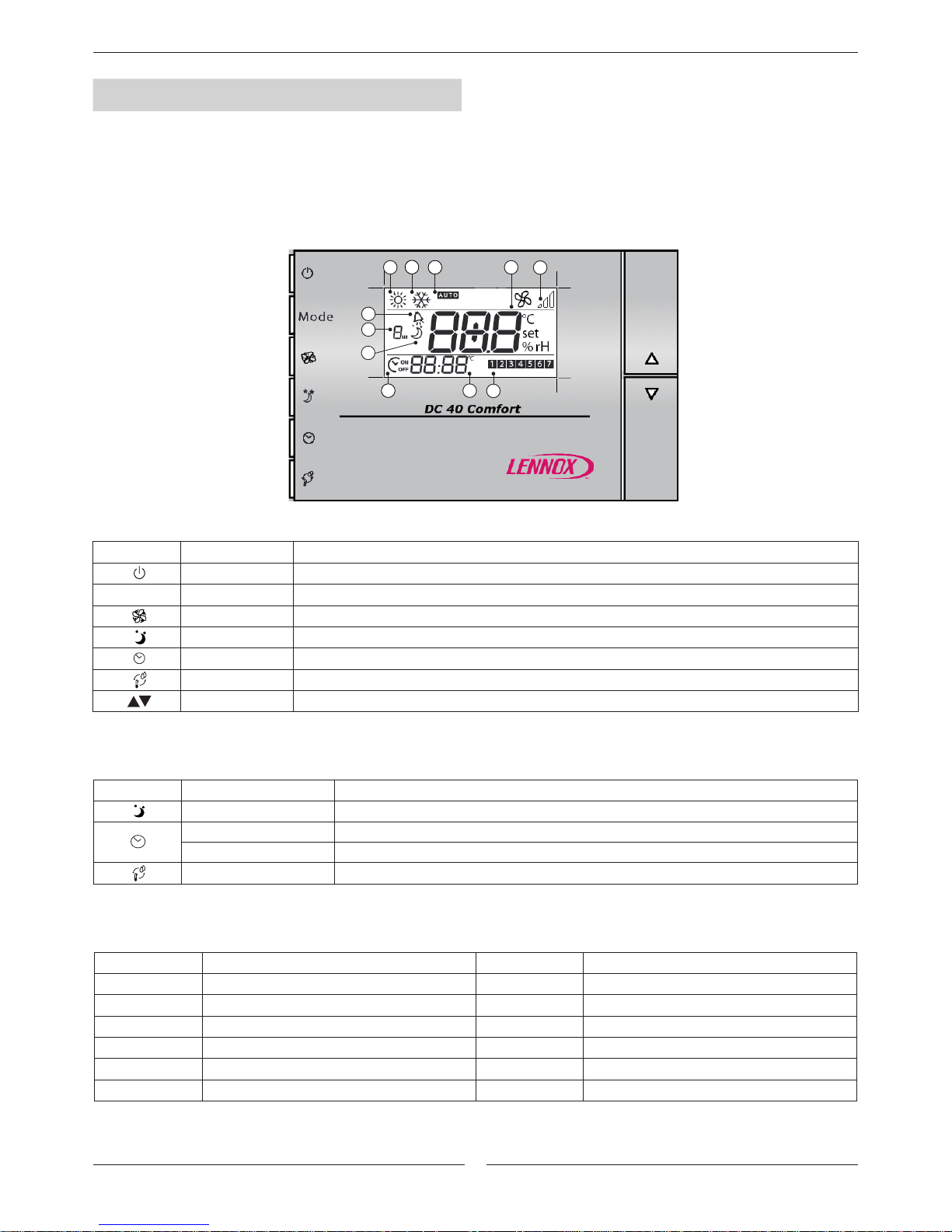

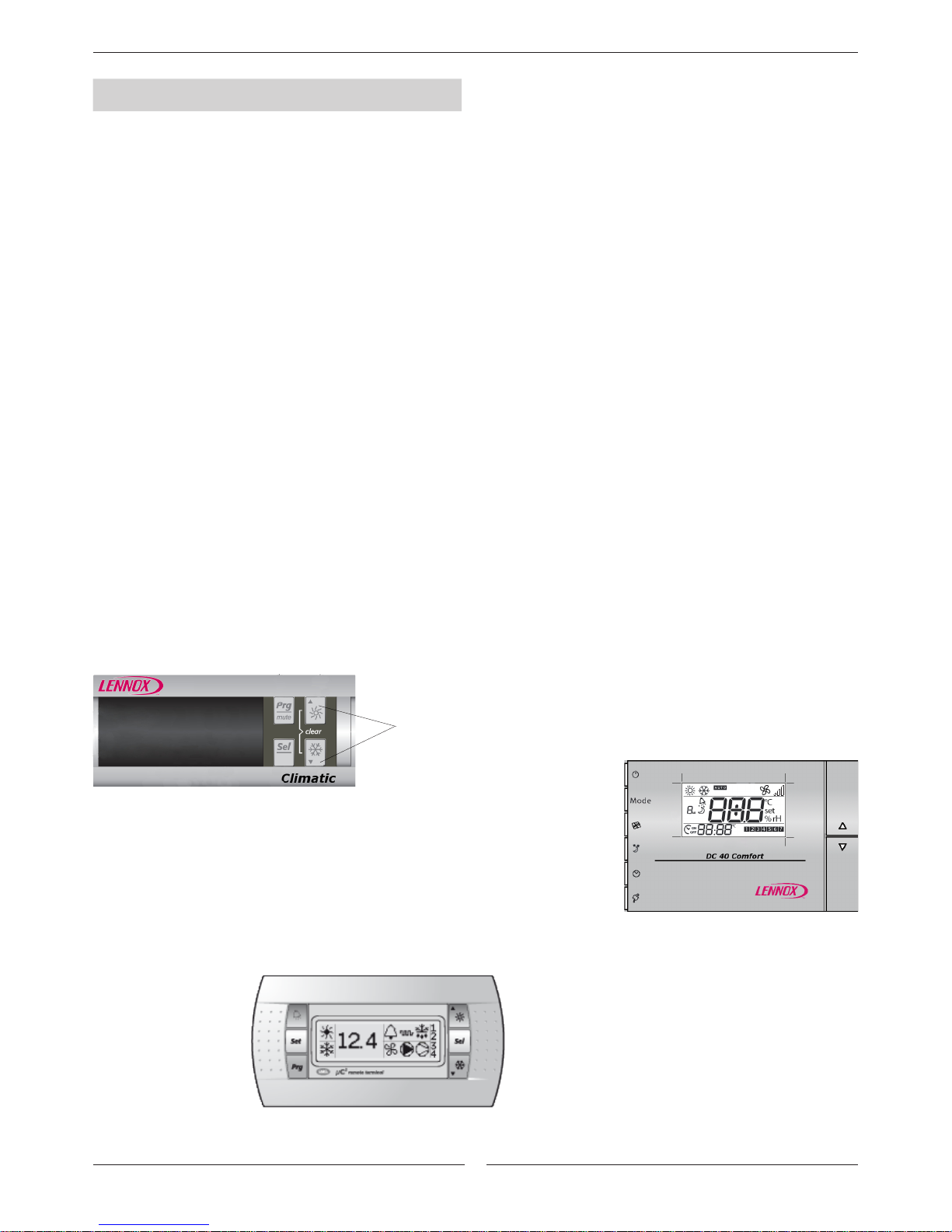

3.- DC40 REMOTE TERMINAL (AIRCOOLAIR)

The illustration and the table below show the symbols that appear on the display and on the keypad and their meanings.

OFF appears in the main eld of the display if the machine is off, or the set point if the machine is working.

Secundary functions:

Display symbols:

BUTTON NAME DESCRIPTION

Switch from stand-by to ON and vice-versa.

Change operating mode (cooling, heating, automatic).

Switch the indoor fan from automatic mode to always ON and vice-versa.

ActivateS/deactivateS the sleep mode.

ActivateS/deactivateS the time bands.

ShowS the set point when the unit is OFF.

Set the temperature.

BUTTON BUTTON PRESS FUNCTION

3 seconds Sets sleep differential value of the current operating mode.

3 seconds Sets the time bands (hour, day, set point).

5 seconds Clock setting.

3 seconds Reset alarms.

SYMBOL MEANING SYMBOL MEANING

Heating mode. On/Off time bands.

Cooling mode. Sleep mode.

Automatic mode. Duration or sleep mode.

Set point. Alarm.

Day of the week (weekday, weekend). Indoor fan mode.

Hour/Temperature.

Page 7

6

This function increases (in cooling mode) or decreases (in heating mode) the operating set point according to the lower level of

comfort required during the night.

Not possible with time bands program.

ACTIVATION

Press “ ” button once. The display shows “ ” symbol with “1HR” ashing.

In this way, sleep function will work for 1 hour.

If you want it to work for longer, press “ ” button repeatedly while “1HR” is still ashing (each press of the button increases by

1 hour, till max 9 hours).

Finally, the display shows the “ ” symbol with the number of hours you choose.

DEACTIVATION

Press the “ ” button once and the sleep function will be deactivated (if it was activated before). The “ ” symbol disappears from the display.

DIFFERENTIAL SETTINGS

Press “ ” button for 3 seconds. The sleep differential (the value by which you increase or decrease the comfort set point)

appears on the display.

Use the “ ” buttons to set the value, then press the “ ” button to accept.

Note that cooling and heating modes have different sleep differential values, so you can modify only the current operating mode’s value.

To set current time:

1. Press the “ ” button for 6 seconds. “rtc” and current time appears on the display (hours are ashing).

2. Set the hour using the “ ” buttons.

3. Press the “ ” button to accept. Minutes start ashing on the display.

4. Set the minutes using the “ ” buttons.

5. Press the “ ” button to accept. “day” and the number of the day of the week appear on the display (Monday=1, Tuesday=2 etc.)

6. Set the day by using the “ ” buttons.

7. Press the “ ” button to accept.

3.1.- TURN ON/OFF THE UNIT WITH REMOTE CONTROL DC40 (AIRCOOLAIR)

3.2.- SELECTING THE UNIT´S OPERATING MODE

Once the unit is turned on, you can select Cooling, Heating or Automatic mode just pressing the “Mode” button. In the automatic

mode you just choose the set point and the system automatically switches from cooling to heating mode, depending on the position

of the ambient temperature with respect to the set point.

3.3.- SELECTING DESIRED ROOM TEMPERATURE

If unit is working, the “ ” buttons allow the desired room temperature to be select (set-point).

The “↑” button allows the current set point to be increased by 0.5ºC.

The “↓” button allows the current set point to be decreased by 0.5ºC.

3.4.- SELECTING THE FAN OPERATING MODE (Aircoolair)

In order to be able to select a fan operating mode, the unit’s operating mode (cooling, heating or auto) must be selected.

Pressing the side button “ ” scrolls through the following modes: FAN CONSTANTLY ON, or AUTO

FAN CONSTANTLY ON: Fan is ON continuously and the “ ” simbol will appear.

AUTO: Fan on and off together with the compressor or with the freecooling, the “ ” symbol will appear.

3.5.- SLEEP FUNCTION

3.6.- CLOCK SETTINGS

To turn on the unit press the “ ” button.

The display shows current operating mode.

DESCRIPTION OF CONTROLS

3.7.- TIME BANDS PROGRAM

This function allows you to programme time bands during the week, each one with a different set point. In this way you can adapt

the cooling/heating provided by the unit according to each moment of the day.

You can set two time bands for the weekdays and another two for the weekend.

Page 8

7

22ºC

25ºC

OFF

OFF

DESCRIPTION OF CONTROLS

CONFIGURATION

NOTE: You must set the DC40 clock before programming time bands.

Time bands programs keep current operating mode (if it was in cool mode, it keeps working in cool mode; if it was in auto

matic mode, it keeps working in automatic mode, etc.).

EXAMPLE IN SUMMER

a) Enter time bands menu. b) Set 1ST time band for weekday start hour. c) Accept.

d) Set 1ST time band of weekday start minutes. e) Accept. f) Set 1ST time band of weekday set point (on/off/tem-

perature).

g) Accept. h) Repeat steps b-c-d-e-f-g to programme 2nd time

band for weekdays.

i) Repeat steps b-c-d-e-f-g-h to programme the two

time bands for weekends.

Weekdays

Time band 1

ashing

Flashing

Flashing

Flashing

Time band 2

Weekend

Flashing

ACTIVATION

DEACTIVATION

3 sec.

Weekdays

Hour

8:00 (Time band 1)

18:00 (Time band 2)

Weekend

Page 9

8

b) Set password “ 22 ” by the

“ ” and “ ” buttons.

MENU

A) PROBES DISPLAY MENU

Press the “ ” button to enter probes display menu.

“ b01”, “b02”, “b04”, “b06” ,“b07” ,“b08” ,“b021”, appears on the display (depending

on the unit’s conguration).

Once the probe is selected, after a few seconds, “b01” turns into its temperature/

pressure measure.

Press “ Sel ” button for 5 seconds.

“ ”, appears on the display.

Move inside the menu as explained below.

1 sec.

5 sec.

B) SETPOINT SETTINGS AND OPERATING HOURS DISPLAY MENU

C) PARAMETERS EDITING MENU

a) Press “ Pgr ” and “ Sel”,

at the same time, for 5

seconds.

c) Press “ Sel ”, to accept.

d) Press “ Sel ”, to enter

parameters Editing menu.

Go up a sub-group inside

the programming area.

UP or increase valve.

Down or decrease valve.

Go down a sub-group or accept

parameter modications inside

the programming area.

5 sec.

Access to the menu:

To go to different values in the menu, proceed as above, the:

Page 10

9

MENU

NOTES:

a) Parameters that have been modied without being conrmed using the “ Sel ” button will return to their previous value.

b) After conrming a modication, escape up to the main menu to save it; otherwise, modications will be cancelled.

c) If no operations are performed on the keypad for 60 seconds, the controller exits the parameter editing menu on timeout

and any changes are cancelled.

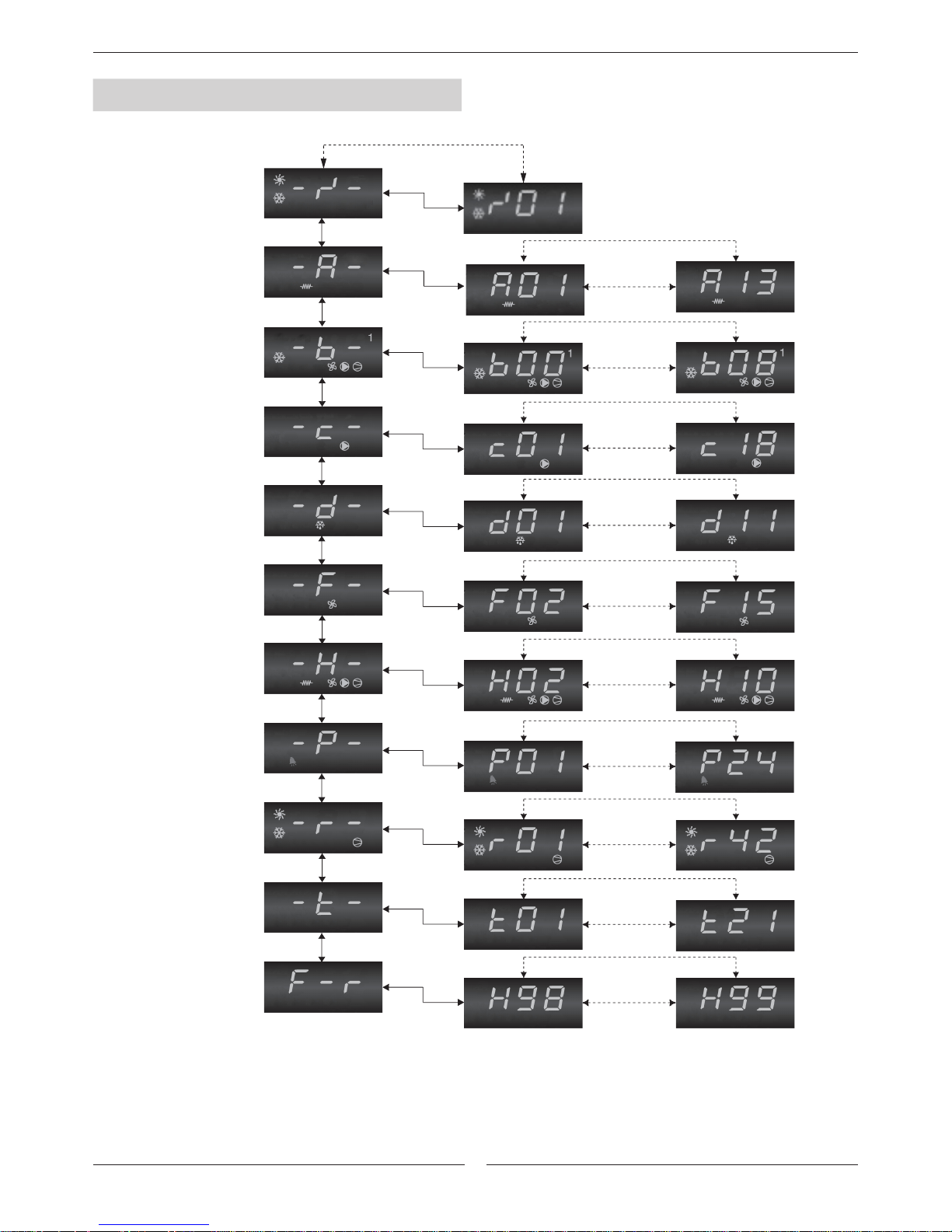

MENU TREE

PROBES SETTINGS

ATIFREEZE AND

ELECTRICAL HEATER

PROBES

COMPRESSORS

DEFROST

FANS

UNIT SETTING

ALARMS

REGULATION

TIMER SETTING

SOFTWARE

Page 11

10

r1

r2

r3

r4

CM2

CM1

r4

r7

CM1

CM2

r7 r2

SP

EH2

EH1

A11

CM1

CM2

r7 r2

SP

A9

A9

A8

r1 10 22 11 9 22 10 8 22 9 8 22 9

r2 0.3 50 2 0.3 50 3 0.3 50 4 0.3 50 4

r3 20 45 41 20 45 42 20 45 43 20 45 43

r4 0.3 50 2 0.3 50 3 0.3 50 4 0.3 50 4

SP 8 32 23 8 32 23 8 32 23

r2 0.3 50 1 0.3 50 2 0.3 50 4

r4 0.3 50 1 0.3 50 2 0.3 50 4

r7 0.3 50 0.5 0.3 50 0.5 0.3 50 0.5

A8 0 20 1.5/2.5 0 20 1.5/3.5 0 20 1.5/4.5

A9 0.3 50 1 0.3 50 1 0.3 50 1

A11 0 20 2.5 0 20 2.5 0 20 2.5

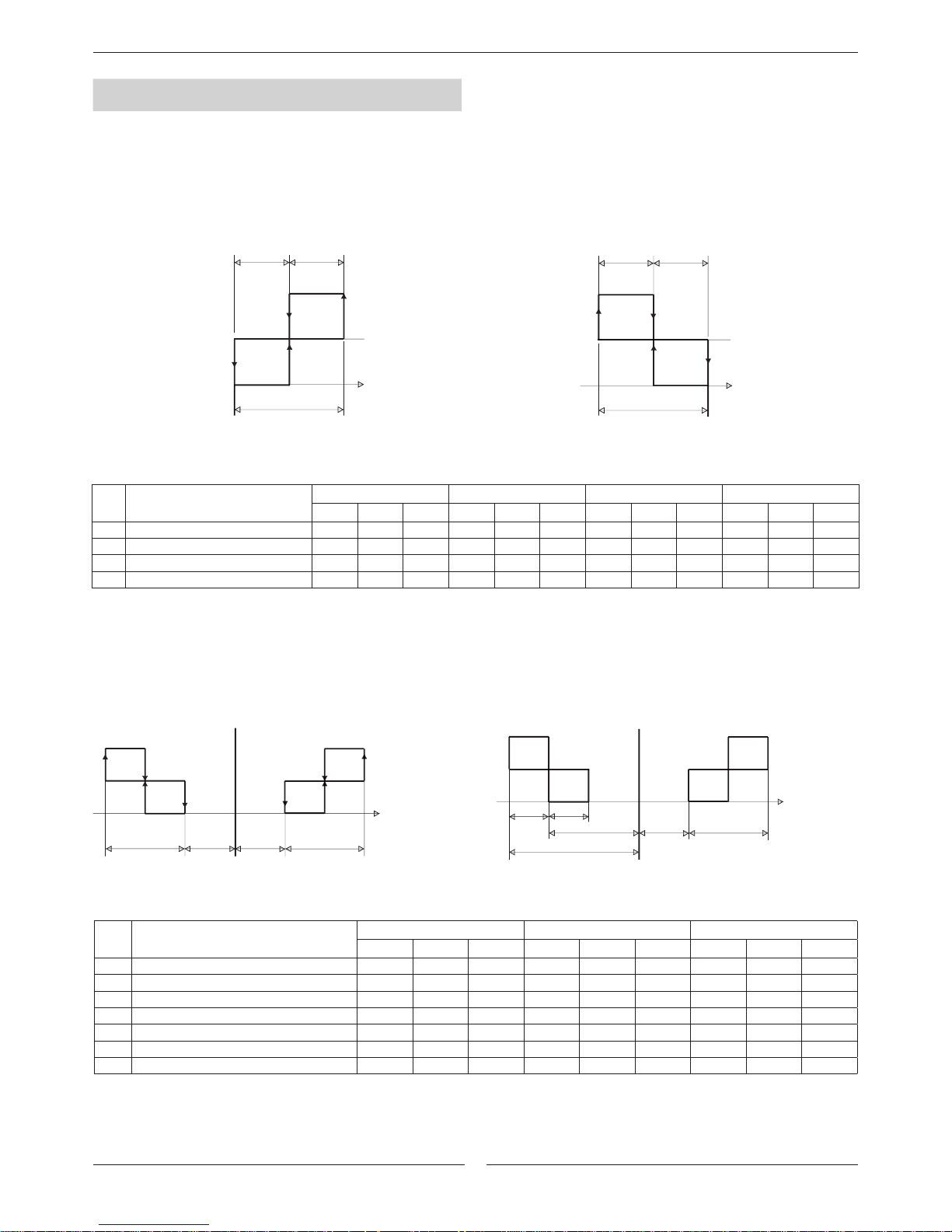

REGULATION

1.- ECOLEAN

Inlet water temperature is thermostatically controlled via set point and tolerance range (differential) as shown in the following

diagrams:

1.1- COOLING OPERATING MODE 1.2- HEATING OPERATING MODE

1.3- AFFECTED PARAMETERS

2.- AIRCOOLAIR

STEP 1

STEP 2

Unit 2 CM

STEP 2 STEP 1

Unit. 2 CM

Ambient (or return air duct) temperature is thermostatically controlled via set point and tolerance range (differential) as shown in the

following diagrams:

2.1- AUTOMATIC MODE

(Heat pump)

2.2- AUTOMATIC MODE

(Cooling only+Electrical heater)

2.3- AFFECTED PARAMETERS

3.- AIRCUBE

Aircube is regulated by digital input. (see section 7, advanced functions, for more details).

HEAT COOL

HEAT COOL

Inlet water

temperature (ºC)

Inlet water

temperature (ºC)

Ambient

temperature (ºC)

Ambient

temperature (ºC)

Par. DESCRIPTION

VALUE UNIT 1CM. VALUE UNIT 2CM. VALUE UNIT 3CM. VALUE UNIT 4CM.

MIN. MAX. DEF. MIN. MAX. DEF. MIN. MAX. DEF. MIN. MAX. DEF.

Cooling set point

Cooling differential.

Heating set point.

Heating differential

Par. DESCRIPTION

UNIT 1 COMPRESSOR UNIT 2 COMPRESSORS UNIT 3 COMPRESSORS

MIN. MAX. DEF. MIN. MAX. DEF. MIN. MAX. DEF.

Set point (DC40).

Cooling differential.

Heating differential.

Dead zone.

SP E.H. 1 cool / SP E.H. 1 heat

Differential E.H.

SP E.H. 2 cool.

Page 12

11

r19

r18

r1

r20

r18

r3

11ºC

SP

14ºC

25ºC 35ºC

r1 = 14ºC

r17 = -0.3

r18 = 3ºC

r19 = 25ºC

r3 = 38ºC

r18 = 3ºC

r20 = 12ºC

r31 = -0.5

SP

38ºC

41ºC

6ºC 12ºC

SP (DC40) = 24ºC

r17 = 0.2

r18 = 2ºC

r19 = 35ºC

SP (DC40) = 21ºC

r18 = 2ºC

r20 = 6ºC

r31 = 0.2

SP

19ºC

21ºC

-4ºC 6ºC

SP

24ºC

26ºC

35ºC 45ºC

r18

SP (DC40)

r20

r18

SP (DC40)

r19

ADVANCED FUNCTIONS

1.- REMOTE ON/OFF

This function allows you to turn the unit on/off by a simply remote contact (contacts 95-96 in ECOLEAN and AIRCOOLAIR

units;contacts 88-89 in AIRCUBE units).

Close contact = ON; Open contact = OFF.

2.- REMOTE CHANGEOVER WINTER/SUMMER

On heat pump units (also in Aircoolair cooling only + electrical heater), cooling or heating mode can be selected by a remote contact (contacts 97-98).

Close contact = Cooling.; Open contact = Heating.

To activate this function set parameter H06=1.

3.- DYNAMIC SET POINT

With this function, which needs to incorporate an additional outdoor temperature probe, it’s possible to adjust the set point

dynamically based on ambient temperature.

The set point value can be increased or decreased when the external conditions are more advantageous, thus achieving extra

energy saving.

Dynamic set point must be activated in the factory.

The user must set the parameters as shown in the graphics below:

ECOLEAN

AIRCOOAIR

WARNING

On Aircoolair units, remote changeover doesn’t work if the automatic mode has been selected by DC40.

Set point ºC

COOL

SP = r1 + (T.ext. - r19) x r17

EXAMPLE

Set point ºC

HEAT

SP = r3 + (T.ext. - r20) x r31

Set point ºC

COOL

Set point ºC

HEAT

SP = SP(DC40) + (T.ext. - r19) x r17

EXAMPLE

SP = SP(DC40) + (T.ext. - r20) x r31

EXAMPLE

EXAMPLE

OPTION

Outdoor temp.. ºC

Outdoor temp.. ºC

Outdoor temp.. ºC

Outdoor temp.. ºC

Outdoor temp.. ºC

Outdoor temp.. ºC

Outdoor temp.. ºC

Outdoor temp.. ºC

Page 13

12

ECOLEAN

AIRCOOLAIR

MODBUS

8:00-18:00 11ºC 11ºC 11ºC 11ºC 11ºC 11ºC 11ºC

18:00-8:00

(t06:t07-t08-t09)

16ºC 16ºC 16ºC 16ºC 16ºC 16ºC 16ºC

ADVANCED FUNCTIONS

4.- BMS COMMUNICATIONS

Given the growing and unstoppable trend towards Building Automation, driven by powerful and ever-evolving connectivity, the

Climatic 40 controller offers the possibility of communicating with Building Management Systems (BMS) via Modbus protocol.

The Modbus standard interface is integrated into the control, so you don’t need any sort of gateway, router, etc.

In order for you to connect to the RS485 serial line, we provide the TTL-RS485 converter as an option for Ecolean and Aircube

units.

Aircoolair units don’t need the converter (it’s integrated) but they do need the ambient or duct remote sensor option.

5.- TIME BANDS PROGRAM (Ecolean)

The Climatic 40 controller allows 2 time bands to be programmed for each day, each with a different set point.

The setting parameters are explained in the following table:**

For further information, please see BMS communication manual.

EXAMPLE (Cooling):

WARNING

Set internal clock before programming time bands (t01=hour, t02=minutes, t03=day, t04=month, t05=year).

To deactivate time bands programme, set start time = end time.

OPTION

COOLING HEATING

TIME SET POINT TIME SET POINT

1st TIME BAND

Rest of the day r1 Rest of the day r3

2nd TIME BAND

Start

(hour:minutes)

t06:t07

r21

Start

(hour:minutes)

t10:t11

r22

End

(hour:minutes)

t08:t09

End

(hour:minutes)

t12:t13

HOUR Monday Tuesday Wednesday Thursday Friday Saturday Sunday

Page 14

13

40%

100%

0%

18 18.5 20 23 23.5 25 26 31

ECOLEAN AIRCOOLAIR AIRCUBE

EAC EAR ANCM ANHM KSCM KSHM

DC40 (b21)

b1

b2

b3*

b4

b6

b7*

b8

_______

- - - - - - -

ADVANCED FUNCTIONS

6.- LOW NOISE

This function is available only in the following units:

ECOLEAN EAC + kit -15ºC y EAR 251-812 SM

AIRCOOLAIR ANCM + kit -15ºC y ANHM 22E-86D

AIRCUBE KSCM + kit -15ºC y KSHM 22E-86D

This function moves the condensing pressure set point in order to lower the fan speed and thus reduce noise (specically at night).

If low noise is active during cooling, the condenser control set points are increased by 5º bar. If low noise is active in heating, the

set points are reduced by 1º bar.

Set F15=3 to active this function.

Also set the following parameters:

Low noise cooling mode shift is illustrated in the following picture.

7.- ANALOGIC / DIGITAL INPUT

PROBES TABLE

* Except: EAC 1003-1103-1303-1403-1604-1804-SM

ANCM 112D-128D-152D.

KSCM 112D-128D-152D-214D

NOTE:

Optional kits could change probes settings.

PROBE

Ambient temperature

Inlet water temperature Return or remote ambient temperature **

Outlet water temperature 1st Circuit evaporator temperature

1st Circuit condenser

temperature

Outdoor

temperature **

1st Circuit condenser

temperature

Outdoor

temperature **

1st Circuit condenser

temperature

Outdoor

temperature **

1st Circuit condenser

pressure

Outdoor

temperature **

1st Circuit condenser

pressure

1st Circuit condenser

pressure

2st Circuit evaporator temperature

2st Circuit condenser

temperature

2st Circuit condenser

temperature

2st Circuit condenser

pressure

2st Circuit condenser

pressure

2st Circuit condenser

pressure

** Optional elements.

SPEED FAN

CONDENSER

PRESSURE (bar)

COOLING HEATING

TIME FAN TIME FAN

Rest of day Standard Rest of day Standard

Start

(hour:minutes)

t14:t15

LOW

NOISE

Start

(hour:minutes)

t18:t19

LOW

NOISE

End

(hour:minutes)

t16:t17

End

(hour:minutes)

t20:t21

Standard

“Low noise”

Page 15

14

ON

ON

ECOLEAN AIRCOOLAIR AIRCUBE

EAC EAR ANCM ANHM KSCM KSHM

ID1

ID2

ID3

ID4

ID5

ID6

ID7

ID8

ID9

ID10

120 2

3005

ON

ON

ON

ON

CM2

CM1

ADVANCED FUNCTIONS

DIGITAL INPUT TABLE

COMPRESSOR

8.- TIMING AND DELAYS

In order to protect compressors from destructively cycling on and off, following protection delays have been set:

Time

(sec.)

unit

COMPRESSOR- WATER PUMP (ECOLEAN)

In both heating and cooling modes, the compressors start 150 seconds after the water pump has started, in order to stabilize the

water system.

In addition to that, the water pump stops 4 minutes after the last compressor has stopped, in order to take advantage of the

remaining thermal energy in the exchanger.

Compressor

Water pump

240 s.

150 s.

DIGITAL INPUT

Flow switch Termal overload fan ON/OFF

Cool/Heat Cool/Heat Cool/Heat Cool/Heat

High pressure circuit 1

Low pressure circuit 1

ON/OFF ON/OFF Step 1

Step 3

Step 2

High pressure circuit 2

Low pressure circuit 2

Step 4

Page 16

15

150” 5” 90” 150”90”150”

30/35

5.7

60”

60”

30” 30”

60”

The defrosting process is activated during heating mode in the heat pump units, when the outside temperature is low and the

outdoor coil is likely to be frozen. To melt the ice, the defrosting function will switch the unit to cooling operation for a short period.

During defrosting mode, the low pressure is at minimum level, so the pressure switch is disabled in this mode.

The defrost cycle is illustrated in the following picture.

9.- DEFROST

ADVANCED FUNCTIONS

WATER PUMP- WATER FLOW SWITCH (ECOLEAN)

The water ow switch ensures that the water pump does not work when there is no water ow. At rst, there is a by-pass during

the rst 150 seconds of water pump operation which operates according to the water ow switch signal. When the alarm has been

activated, the water pump is stopped. The water pump starts again every 90 seconds for 150 seconds, in order to try to reset the

alarm. This procedure is repeated 5 times and after that the pump remains stopped until the alarm is reset manually.

ALARM

PUMP

close

open

ow

If the pressure does not reach 30/35 bars within 8 minutes from the start of the defrost cycle, the cycle nishes because of maximum time and the display shows “dF1” or “dF2” (according to the circuit).

The time between two defrost cycles for the same circuit is 40 minutes. The time between two defrost cycles of the two circuits is

10 minutes.

Condenser pressure

(bar)

Compressors

Reverse valve

HEAT

DEFROST

HEAT

Page 17

16

40%

100%

0%

18 18.5 20 26

40%

100%

0%

18 19 28 40

0ºC

22 bar

15ºC

28 bar

30ºC

30 bar

35ºC

37 bar

+7ºC

ADVANCED FUNCTIONS

The function of the fan speed control is to prevent very low condensing temperatures during cooling mode operation at outside

temperatures of between 0ºC and 46ºC.

Depending on the unit, this function could be:

1.1.- PROPORTIONAL CONTROL BASED ON PRESSURE

Models: ECOLEAN: EAC + kit -15ºC and EAR 251-812 SM

AIRCOOLAIR: ANCM + kit -15ºC and ANHM 22E-86D

AIRCUBE: KSCM + kit -15ºC and KSHM 22E-86D

In this case, it is a proportional fan speed control, which varies the fan voltage supplied to the fan.

10.- CONDENSER FAN SPEED CONTROL

FAN

SPEED

CONDENSER

PRESSURE (bar)

NOTE

At start-up the fan works at maximum speed for 20 seconds,

so as to overcome the mechanical inertia of the motor.

1.2.- PROPORTIONAL CONTROL BASED ON PRESSURE TEMPERATURE

Models: ECOLEAN: EAC 251-812 SM

AIRCOOLAIR: ANCM 22E-86D

AIRCUBE: KSCM 22E-86D

In this case too, it is a proportional fan speed control, which varies the voltage supplied to the fan.

FAN

SPEED

CONDENSER

TEMPERATURE (ºC)

NOTA

At start-up, the fan works at maximum speed for 20 seconds,

so as to overcome the mechanical inertia of the motor.

The same time is observed with regard to compressor start-up

(irrespective of the condensing temperature) in order to

improve temperatures probes reading.

1.3.- ON/OFF CONTROL BASED ON PRESSURE

Models: ECOLEAN: EAR* 1003-1804 SM

AIRCOOLAIR: ANHM* 112D-152D

AIRCUBE: KSHM* 112D-214D

ON/OFF, through the control and change between high and low fan speed through pressure switches.

The fans for these models incorporate 2 speeds. The fans work on high or low speed according to:

COOLING MODE:

The on/off and low/high fan speed is managed according to the

condensing pressure. See the illustration below:

HEATING MODE (heat pump units only). The low/high fan speed

is managed according to the outdoor temperature thermostat.

See the illustration below:

High speed

Low speed

High speed

Low speed

Outdoor temperature ºC

COOLING MODE

HEATING MODE

Approx. outside temperature ºC

Condensing pressure

NOTE*: In these same models, but in cooling only version, the fan speed management is the same, apart from that, the ON/OFF

signal is provide by a pressure switch instead of the control.

Page 18

17

CM2

CM3

CM1

23 23.5 24 26

SP

24.5

R02/4

23

23.5 25

r40 0 9 1

r41 0 100 20

ADVANCED FUNCTIONS

11.- FREE COOLING

This option takes advantage of external conditions for cooling mode.

Freecooling is enabled when outdoor temperature is 1ºC lower than indoor temperature; when the former is:

- < 10ºC, the compressors are deactivated and the air intake gate fully opened in order to refresh with outdoor air only (sufcient under

these conditions).

- >10ºC, the air intake gate opens and delays the compressors, which turn on only if there would be insufcient outdoor fresh air

to achieve the comfort setpoint.

The illustration below shows freecooling regulation.

With free cooling

Open air damper.

Close air damper.

Without freecooling

Stop air damper.

Ambient temperature (ºC)

Ambient temperature (ºC)

OPTION

To get a constant air renewal, when freecoling conditions are satised, the damper is mantained opened partially (20%), according to

the following values.

Par. DESCRIPTION Min. Max. Def.

This indicates when to carry out the minimum opening of the damper.

0= Never.

1= with freecooling.

2= with freeheating.

3= with freecooling and freeheating

4= always, except with freecooling y freeheating.

5= always, except with freeheating.

6= always, except with freecooling.

7= always

8= only for cooling mode.

9= only for heating mode.

% minimum percentage opening damper.

Page 19

18

A01 A7 A4 0.1 ºC 3,0 2 ------

A02 0,3 122 0.1 ºC 5,0 5 ------

A03 0 150 1 0 30 ------

A04 A1 R16 0.1 ºC 4,5 ------ ------

A05 0,3 50 0.1 ºC 1,0 ------ ------

A08

A1 R16 0.1 ºC 35 ------ ------

0 20 0.1 ºC ------

1.5 (ANCM)

------

2.5 (ANHM 22E-43E)

3.5 (ANHM 52D-86D)

4.5 (ANHM 112D-152D)

A9 0 20 0.1 ºC 1 1 ------

A11

A1 R16 0.1 ºC 33 ------ ------

0 20 0.1 ºC ------ 2.5 (ANCM 52D-86D) ------

A13 A7 R16 0.1 ºC ------ 7 ------

b0 0 11 1 N 0 11 10

b1 ------ ------ ------ ºC

b2 ------ ------ ------ ºC

b3 ------ ------ ------ ºC

b4 ------ ------ ------ ºC/bar

b5 ------ ------ ------ ºC

b6 ------ ------ ------ ºC

b7 ------ ------ ------ ºC

b8 ------ ------ ------ ºC/bar

b21 ------ ------ ------ ºC

C01 0 999 1 0 0 0

C02 0 999 1 120 120 120

C03 0 999 1 300 300 300

C04 0 999 1 2 2 2

C05 0 999 1 0 0 0

C06 0 999 1 5 5 5

C07 0 999 1 150 0 0

C08 0 150 1 4 0 0

C10 0 8000 100

C11 0 8000 100

C12 0 8000 100

C13 0 8000 100

C14 0 100 100 0 0 0

C15 0 8000 100

C17 0 150 1

0 0 0

C18 0 150 1

0 1 0

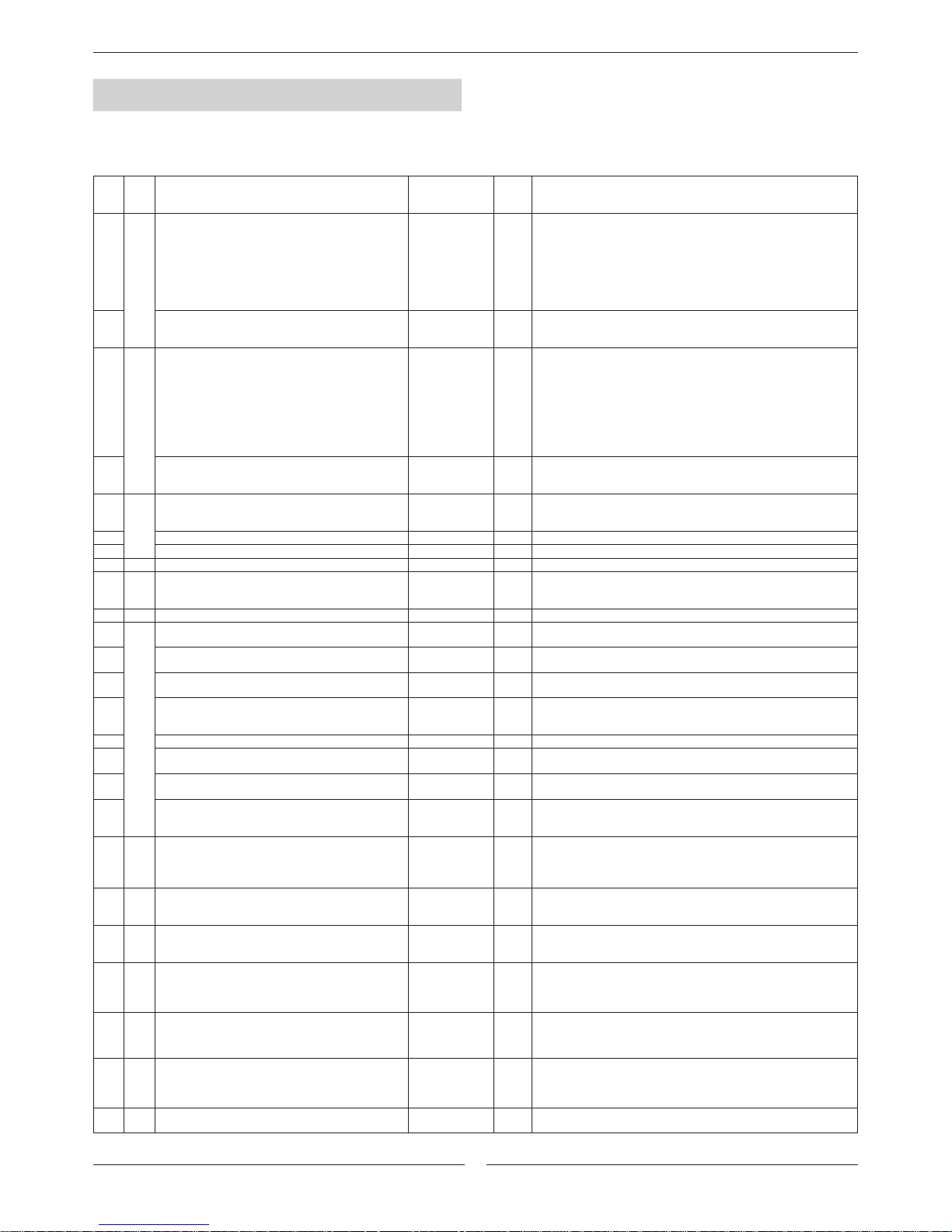

PARAMETERS

PAR.

DESCRIPTION MIN. MAX. VAR. UD.

BY DEFAULT

ECOLEAN AIRCOOLAIR AIRCUBE

Antifreeze and electrical heater

Antifreeze alarm set point.

Antifreeze differential.

By-pass time for antifreeze alarm. sec.

Antifreeze heater set point.

Antifreeze heater differential.

Auxiliary heater absolute set point (1st step).

Auxiliary heater relative set point (1st step).

Auxiliary heater differential.

Auxiliary heater absolute set point (2st step).

Auxiliary heater relative set point (1st step).

Lower discharge air temperature in freecooling.

Probes

Cong. of probe to be shown on the display:

0= probe B1. 1= probe B2

2= probe B3. 3= probe B4

4= probe B5. 5= probe B6

6= probe B7. 7= probe B8

8= Set point without compensation.

9= Dynamic set point with possible compensation.

10= Remote ON/OFF digital input status.

11= Terminal DC40 probe.

Probe B1.

Probe B2.

Probe B3.

Probe B4

Probe B5.

Probe B6.

Probe B7.

Probe B8.

Probe DC40.

Timming and delays

Min. compressor ON time. sec.

Min. compressor OFF time. sec.

Delay between 2 starts of the same compressor. sec.

Delay between starts of the 2 compressor. sec.

Delay between 2 shut-downs of the 2 compressors. sec.

Delay at start up. sec.

Delay in switching on the compressor after switching on the pump.

sec.

Delay in switching off the compressor after switching off the pump. min.

Compressor 1 timer. hours

Compressor 2 timer. hours

Compressor 3 timer. hours

Compressor 4 timer. hours

Compressor operation timer threshold (0=not used). hours

Evaporator pump timer. hours

Minimum time between 2 pump starts.

min.

Minimum pump/indoor fan ON time.

min.

Page 20

19

d01 0 1 1 ag 1 1 1

d03 1 D04 0.1 bar 5.7 5.7 5.7

d04 D03 /12 0.1 bar 35 30 30

d05 10 150 1 60 60 60

d06 0 150 1 0 0 0

d07 1 150 1 8 8 8

d08 10 150 1 40 40 40

d09 0 150 1 10 10 10

F02 0 3 1 int.

1 (EAC 1003-1804) 1 (ANCM 112D-152D) 1 (KSCM 112D-214D)

2 (EAR 1003-1804) 2 (ANHM 112D-152D) 2 (KSHM 112D-214D)

3 (EAC/EAR 251-812) 3 (ANCM/HM 22E-86D) 3 (KSCM/HM 22E-86D)

F05

-40 176 0.1 ºC 28 28 28

/11 /12 0.1 bar

F06

0 50 0.1 ºC 12 12 12

0 30 0.1 bar 6 6 6

F07

0 50 0.1 ºC 10 10 10

0 F5 0.1 bar 2 2 2

F08

-40 176 0.1 ºC 30 30 30

/11 /12 0.1 bar

F09

0 50 0.1 ºC 1 1 1

0 30 0.1 bar 5 5 5

F10

0 50 0.1 ºC 0 0 0

0 F8 0.1 bar 13 13 13

F11 0 120 1 20 20 20

F15 0 3 1 ag 0 0 0

F16 0 50 0.1 bar 5 5 5

F17 0 50 0.1 bar 1 1 1

H06 0 1 1 ag 0 0 0 (KSCM) 1 (KSHM)

H07 0 1 1 ag 1 1 1

H10 1 200 1 ud. 1 1 1

H23 0 1 1 ag 0 0 0

H97 0 999 1 ag

H99 0 999 1 ag

P04 0 3 1 ag 1 1 1

PARAMETERS

PAR.

DESCRIPTION MIN. MAX. VAR. UD.

BY DEFAULT

ECOLEAN AIRCOOLAIR AIRCUBE

Defrost

Defrosting cycle activation.

Start defrosting pressure.

End defrosting pressure.

Min. time to start a defrosting cycle. sec.

Min. duration of a defrosting cycle. sec.

Max. duration of a defrosting cycle. min.

Delay between 2 defrosting cycle requests with in the same circuit.

min.

Defrosting delay between the 2 circuits. min.

Fan

Fan operating mode:

0= Always ON.

1= Depending on compressor (in parallel operating mode).

2= Depending on compressors in ON/OFF control.

3= Depending on compressors in speed control mode.

Temp. value for min. speed cooling.

Pressure value for min. speed cooling. 20 (if F2=3) / 22 (if F2=2) 20 (if F2=3) / 22 (if F2=2) 20 (if F2=3) / 22 (if F2=2)

Differential value for max. speed in cooling mode (temp).

Differential value for max. speed in cooling mode (pres).

Fan shut-down differential in cooling mode (temp).

Fan shut-down differential in cooling mode (pres).

Temperature value for min. speed in heating mode.

Pressure value for min speed cooling. 12 (if F3=3) / 22 (if F3=2) 12 (if F3=3) / 22 (if F3=2) 12 (if F3=3) / 22 (if F3=2)

Differential value for max. speed in heating mode (temp).

Differential value for max. speed in heating mode (pres).

Fan shut-down differential in heating mode (temp).

Fan shut-down differential in heating mode (pres).

Fan starting time.

Activation Low Noise:

0= Deactivate.

1= Activate only in cooling mode.

2= Activate only in heating mode.

3= Activate both in cooling and heating mode.

Differential Low Noise in cooling mode.

Differential Low Noise in heating mode.

Setting

Activate remote change over:

0= Deactivate.

1= Activate.

ON/OFF remoto:

0= Deactivate.

1= Activate.

Serial address.

Activate Modbus.

Expansion board software version.

Software version.

Alarms

Enable part load in high pressure:

0= Capacity control deactivated.

1= Capacity control activated for high pressure.

2= Capacity control activated for low pressure.

3= Capacity control activated for high and low pres.

Page 21

20

r1 R13 R14 0.1 ºC

11 (EAC/EAR 251-431)

24 ------10 (EAC/EAR 472-812)

9 (EAC/EAR 1003-1804)

r2 0.3 50 0.1 ºC

2 (EAC/EAR 251-431) 1 (ANCM/HM 22E-43E)

------3 (EAC/EAR 472-812) 2 (ANCM/HM 52D-86D)

4 (EAC/EAR 1003-1804) 4 (ANCM/HM 112D-152D)

r3 R15 R16 0.1 ºC

41 (EAC/EAR 251-431)

22 ------42 (EAC/EAR 472-812)

43 (EAC/EAR 1003-1804)

r4 0.3 50 0.1 ºC

2 (EAC/EAR 251-431) 1 (ACHM 22E-43E)

------3 (EAC/EAR 472-812) 2 (ANHM 52D-86D)

4 (EAC/EAR 1003-1804) 4 (ANHM 112D-152D)

r7 1 50 0.1 ºC ------ 0.5 ------

r17 -5 5 0.1 ------ 0 0 ------

r18 0.3 20 0.1 ºC 3 2 ------

r19 -40 176 0.1 ºC 25 35 ------

r20 -40 176 0.1 ºC 12 6 ------

r21 R13 R14 0.1 ºC 16 28 ------

r22 R15 R16 0.1 ºC 35 18 ------

r23 0 8 1 ag 0 0 ------

r24 R15 R16 0.1 ºC ------ 23 ------

r25 -40 80 0.1 ºC -15 -15 -15

r31 -5 5 0.1 ------ 0 0 0

t01 0 23 1 ------

t02 0 59 1 ------

t03 1 31 1 ------

t04 1 12 1 ------

t05 0 99 1 ------

t06 0 23 1 ------ 0 0 0

t07 0 59 1 ------ 0 0 0

t08 0 23 1 ------ 0 0 0

t09 0 59 1 ------ 0 0 0

t10 0 23 1 ------ 0 0 0

t11 0 59 1 ------ 0 0 0

t12 0 23 1 ------ 0 0 0

t13 0 59 1 ------ 0 0 0

t14 0 23 1 ------ 0 0 0

t15 0 59 1 ------ 0 0 0

t16 0 23 1 ------ 0 0 0

t17 0 59 1 ------ 0 0 0

t18 0 23 1 ------ 0 0 0

t19 0 59 1 ------ 0 0 0

t20 0 23 1 ------ 0 0 0

t21 0 59 1 ------ 0 0 0

PARAMETERS

WARNING

Default values could vary depending on optional kits or improvements.

PAR.

DESCRIPTION MIN. MAX. VAR. UD.

BY DEFAULT

ECOLEAN AIRCOOLAIR AIRCUBE

Regulation

Cooling set point.

Differential in cooling mode.

Heating set point.

Differential in heating mode.

Dead zone.

Cooling compensation constant.

Maximum distance from the set point.

Start compensation temerature in cooling mode.

Start compensation temerature in heating mode.

Second cooling set point.

Second heating set point.

Select automatic change over probe.

Automatic change over set point.

Outside temp. set point to stop compressors.

Heating compensation constant.

Clock

Real Time Clock (RTC) hours.

Real Time Clock (RTC) minutes.

Real Time Clock (RTC) days.

Real Time Clock (RTC) month.

Real Time Clock (RTC) years.

Start hours for 2nd set point in cooling.

Start mimutes for 2nd set point in cooling.

End hours for 2nd set point in cooling.

End minutes for 2nd set point in cooling.

Start hours for 2nd set point in heating.

Start mimutes for 2nd set point in heating.

End hours for 2nd set point in heating.

End minutes for 2nd set point in heating.

Start hours for 2nd low noise cooling.

Start mimutes for 2nd low noise in cooling.

End hours for 2nd low noise in cooling.

End minutes for 2nd low noise in cooling.

Start hours for 2nd low noise in heating.

Start mimutes for 2nd low noise in heating.

End hours for 2nd low noise in heating.

End minutes for 2nd low noise in heating.

Page 22

21

SAFETY DEVICES

This protection is activated by the control of the unit when the outlet water temperature probe (b2), located inside the water

exchanger, measures +4.5ºC and deactivates when the outlet water temperature probe reaches +5.5ºC again.

When the protection is activated, the following occurs:

- If the unit is operating in STAND-BY mode: the water pump goes on, as does the electrical heater for the water exchanger

and the electrical heater of the water tank (if included).

ANTIFREEZE PROTECTION (ECOLEAN).

DO NOT TURN OFF THE POWER TO THE UNIT. WHEN THE POWER IS OFF THE ANTI FREEZE PROTECTION

WILL NOT OPERATE.

- If the unit is operating on cooling mode: it powers the electrical heater of the water tank, the electrical heater of the water

exchanger, and it activates the hot gas injection valve (if the unit incorporates these options).

This alarm is activated when the outlet water temperature probe (b2) measures a value of + 3 ºC (in standard unit).

The unit is stopped. The alarm can be reset manually when the outlet water temperature reaches + 8ºC (in standard unit).

LOW WATER TEMPERATURE ALARM (ECOLEAN).

The unit is protected by means of a temperature probe located in the indoor piping, when the indoor temperature goes drops 2ºC:

WITHOUT FREECOOLING

- The compressors shut down and the antifreeze alarm goes on.

- The alarm is reset automatically when the temperature reaches 7ºC.

WITH FREECOOLING

- Air intake gate closes,

- Once the gate is completely closed, the compressors shut down and the antifreeze alarm goes on.

When the air intake gate is closing, if the temperature in the indoor piping goes up 2ºC, the gate stops and stays in the position

reached; then, if the temperature reaches goes over 7ºC, the air damper starts to open or, if the temperature goes down 2ºC, the

damper start to close again.

ANTIFREEZE PROTECTION (AIRCOOLAIR).

In addition to that, in order to prevent frozen air discharging when freecooling without the compressors working (outdoor temp.

<10ºC), if the temperature in the indoor piping goes down 7ºC, the air intake gate starts to mix outdoor air with return air, thus

increasing the temperature of the discharge air.

NOTE: Low water temperature options can change the values of antifreeze protection and low water temperature alarm.

Page 23

22

GND

TX+

TX-

GO

G

ASSEMBLY AND INSTALLATION INSTRUCTIONS

DC40.

Installation instructions

1. Separate the cover of the instrument from the bodypart using a screwdriver as shown in Fig. 8.1.

2. Open the instrument with a “hinge” movement, pivoting the cover of the instrument upwards.

Lower view

Fig. 8.1

Fig. 8.2

3. Fix the rear part to the wall, taking care that the connection cables pass through the hole in the centre of the rear casing.

The distances between the fastening holes are designed so as to be able to t the DC40 to a ush-mounting connection box

compliant with the CEI C.431 - IEC 670 standards. If this is not available, use the fastening holes on the casing as a guide

for drilling the holes in the wall, and then use the kit of screws and plugs supplied.

4. Connect the cables to the terminals located in the casing as indicated in the casing itself or in the electrical diagram.

5. Once the installation is complete, t the terminal onto the casing by pivoting the cover with a “hinge” movement and close it.

When closing, make sure that the pins on the board t into the corresponding terminals.

Installation warnings

- Disconnect the power supply before working on the DC40 during operations of assembly, maintenance and replacement.

- The terminal must be fastened to the wall in such a way as to allow the circulation of air through the slits on the rear casing.

- Avoid installing the boards in environments with the following characteristics:

- Avoid locations where there is a great variation in room temperature.

- Near doors leading to the outside.

- On outside walls.

- Where it will be exposed to direct sunlight or to conditioned air ow.

- Where there are strong magnetic and/or radio frequency interference (for example, near transmitting antennae).

Keep the DC40’s inductive load cables separate from

those of any power devices (contactors, etc.) in order to

prevent electromagnetic interference.

Do not lay power and communications cables together

- Run a connection from the electrical box in the outdoor unit to

the DC40 device:

. 91 and 92 terminal blocks respectively to Tx+ and Tx-

(Twisted pair for communications).

. 93 and 94 terminal blocks respectively to GO and G.

(Twisted pair for 24VAC power).

. 90 to GND. (shield).

2 x TWISTED PAIR

SCREEN WIRE AWG20

L.max=100m

1 x TWISTED PAIR

SCREEN WIRE AWG20

+ 2 x 1,5 mm

2

L.max=200m

Page 24

23

156.2

A

RJ12 – Power supply

RS485 24 Va

c

G

G0

– +

GND

DC41

Max. L=10m.

92

91

90

93 94

DT41

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Installation instructions:

1. Pass the telephone cable through the hole in the rear of the casing.

2. Fasten the rear of the casing to the box using the round-head screws.

3. Connect the telephone cable to the RJ12 terminal of the DC41.

4. Rest the front panel on the rear of the casing and fasten the assembly using the countersunk screws, as shown in Fig. 8.3.

5. Finally, click the frame in place.

DC41.

Electrical connections:

1. Disconnect the power supply before working on the DC41 during operations of assembly, maintenance and replacement.

2. Make the connection between the “DT41” power supply and the DC41 terminal using the telephone cable (80 cm)

supplied. If the cable is not long enough, use a pin-to-pin telephone cable with a maximum length of 10 m.

Fig. 8.3

Fig. 8.4

Thelefone cable

Max. L.=200m. AWG20.

Keep the DC41’s inductive load cables separate from

those of any power devices (contactors, etc.) in order to

prevent electromagnetic interference.

Do not lay power and communications cables together

- Connect from the electrical box in the outdoor unit to DT41 device:

. 91 and 92 terminal blocks respectively to Tx+ and Tx -. (Twisted pair for communications).

. 93 and 94 terminal blocks respectively to GO and G. (Twisted pair for power 24VAC).

. 90 to GND. (shield).

Max. L.=200m

Ø=1,5mm

2

2 x TWISTED PAIR

SCREEN WIRE AWG20

Max. L.=100m

1 x TWISTED PAIR

SCREEN WIRE AWG20

+ 2 x 1,5 mm

2

Max. L.=200m

Insert 120Ω terminal resistor between + y - of DT40 device (see electrical drawing) for lines longer then 20m.

Page 25

24

CLIMATIC 40

DC 40

DC 41

ALARMS

The unit self-protects by means of safety devices; when any of these safety devices detects an anomaly, this is shown on

the Climatic 40 display and, in Aircoolair units only, also on the DC41 display (even if it has a different alarm code), in order

to warn the operator.

Depending on the type of anomaly, Climatic 40 shows:

• Alarm. Serious anomaly. This is one that has a direct effect on the operation of the unit.

• Warning. Non-serious anomaly. This is one that has no direct effect on the operation of the unit.

The activation of an alarm results in:

- Alarm code being shown on Climatic 40 display alternately with the main menu.

- Only in Aircoolair units, an alarm code (different from the one for the Climatic 40) being shown on the DC40 display alternately with

the main menu.

- A red bell appears on the Climatic 40 display and the alarm relay is activated. (contacts 99-100).

- In some cases, depending on the type of alarm, some of the outputs may be blocked, thus stopping the unit.

The activation of a warning results in:

- A warning code being shown only on the Climatic 40 display, alternately with the main menu.

ALARMS/WARNINGS DISPLAY

Some alarms are reset automatically. When the cause is no longer present, they disappear from the display.

Others alarms are reset manually and, once the alarm conditions have disappeared, they need to be reset by the user as shown

below:

ALARM/WARNING RESET

5 Sec.

5 Sec.

3 Sec.

Page 26

25

HP1

HP

HP2

LP1

LP

LP2

TP

T

TC1 ------ -----TC2 ------ ------

LA ------ ------ ------

FL ------

FLb ------ ------ ------

E1

E00

E2

E3

E4

E5 ------ ------

E6

E7

E8

Hcl-4 Hc ------

EPr ------

------

Epb ------

ESP ESP

EL1-2 ------

dF1-2 ------ ------

d1-2 ------ ------ ------

ALARMS

ALARMS/WARNINGS CODES

DISP

CL40/

DC41

DISP

DC40

DESCRIPTION EFFECT RE ACTION

High pressure switch alarm, circuit 1.

This alarm may indicate the following problems:

- High pressure switch protection.

- Compressor stopped.

- Excessive refrigerant charge.

- Insufcient water ow in heating cycle (Ecolean).

Circuit 1

compressors

stop

AUTO/

MAN.

After 3

times in

1 hour

Reset and check:

- Coil is clean and not blocked.

- Water ow on the heating cycle (Ecolean).

- Outdoor fan during cooling cycle.

- Indoor fan during heating cycle (Aircoolair).

- Compressor protection.

- Condenser air temperature is very high.

- Refrigerant charge.

High pressure switch alarm, circuit 2.

The same as previous alarm but this time referring to

circuit 2.

Circuit 2

compressors

stop

AUTO/

MAN.

After 3t/h

The same as previous alarm but this time referring to circuit 2.

Low pressure switch alarm, circuit 1.

This alarm may indicate the following problems:

- Low refrigerant.

- Low water ow in cooling cycle (Ecolean).

- Outdoor fan stopped.

- Low pressure switch protection.

Circuit 1

compressors

stop

AUTO/

MAN.

After 3

times in

1 hour

Reset and check:

- Coil is clean and not blocked.

- Water ow on the cooling cycle (Ecolean).

- Outdoor fan during heating cycle.

- Indoor fan during cooling cycle.

- Fuses of the fan.

- Evaporation air temperature is very low.

- Check refrigerant charge.

- Expansion valve.

Low pressure switch alarm, circuit 2.

The same as previous alarm but this time referring to

circuit 2.

Circuit 2

compressors

stop

AUTO/

MAN.

After 3t/h

The same as previous alarm but this time referring to circuit 2.

Indoor fan thermal protection alarm. (Aircoolair only):

- Fan thermal protection open.

- Faulty power supply.

Unit stops MAN.

Reset and check:

- Fan.

- Power supply.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Water ow switch alarm.

This indicates low water ow in the unit. (Ecolean) only.

After 5 minutes it automatically requires to be reset manually.

Unit stops

AUTO/

MAN.

- Check water circuit is not blocked.

- Check water lter.

- Check water pump operation.

Not used. Call Technical Service.

B1 probe error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B1 probe (see electrical diagram), check continui-

ty and change the faulty component.

B2 probe error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B2 probe (see electrical diagram), check continui-

ty and change the faulty component.

B3 probe error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B3 probe (see electrical diagram), check continui-

ty and change the faulty component.

B4 probe/pressure transducer error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B4 probe/pressure transducer (see electrical

diagram), check continuity and change the faulty component.

Not used. Call Technical Service.

B6 probe error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B6 probe(see electrical diagram), check continuity

and change the faulty component.

B7 probe error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B7 probe (see electrical diagram), check continui-

ty and change the faulty component.

B8 probe/pressure transducer error.

Faulty probe or connection.

Unit stops AUTO

Check connection of B8 probe/pressure transducer (see electrical

diagram), check continuity and change the faulty component.

Warning.

Compressor operating time limit exceeded. AUTO

Check:

- Compressor operating time (parameter C10).

- Compressor operating time limit (par. C15). Disabled by default.

Warning.

Climatic 40 hardware error.

AUTO Call Technical Service.

Warning.

Climatic 40 hardware error.

Unit stops AUTO Call Technical Service.

Expansion board error. Unit stops AUTO

Check:

- Green LED is on inside the board.

- J4-J9 connections (see electrical diagram).

Call Technical Service.

Warning.

Condensing fan speed control hardware error.

Outdoor fan at

maximum

speed.

AUTO

- Check CFM board connections (see electrical diagram).

Call Technical Service.

Warning.

Circuit 1-2 defrost ends due to maximum time (8 minutes).

AUTO

Warning.

Circuit 1-2 defrosting.

Page 27

26

A1

A12

A2

Ht ------ ------

Lt ------ ------ ------

AHt ------ ------ -----HLt ------ ------ ------

ELS ------ ------

EHS ------

Ed1 ------ ------ ------

Ed2 ------ ------ -----SH1 ------ ------ -----SH2 ------ ------ -----nO1 ------ ------ -----nO2 ------ ------ -----LO1 ------ ------ -----LO2 ------ ------ -----HA1 ------ ------ -----HA2 ------ ------ -----EP1 ------ ------ -----EP2 ------ ------ -----ES1 ------ ------ -----ES2 ------ ------ -----EU1 ------ ------ -----EU3 ------ ------ ------

Eb1 ------ ------ ------

Eb2 ------ ------ ------

L ------ ------ -----Ed1 ------ ------ -----Ed2 ------ ------ ------

PH1 ------ ------ -----PH2 ------ ------ -----SUL ------ ------ ------

tEr OcH

AcH ------ ------

Ahu ------ ------

AtE ------ ------

CEr ------ -----UEr ------ ------

ALARMS

ALARMS/WARNINGS CODES

DISP

CL40/

DC41

DISP

DC40

DESCRIPTION EFFECT RE ACTION

Antifreeze alarm.

- ECOLEAN Outlet temperature < 3ºC. Reset MAN.

- AIRCOOLAIR circuit 1 indoor piping temperature <

2ºC. Reset AUTO.

-ECOLEAN

compressors

stop.

- AIRCOOLAIR

Close freecooling

air dumper and

stops circuit 1

compressors 1

MAN/

AUTO

ECOLEAN: Reset and check:

- Check the water lter.

- Check water ow.

- Check that the water pump is connected to the unit’s power supply.

AIRCOOLAIR: Check:

- Indoor unit air lter.

- Air damper working correctly.

Antifreeze alarm, circuit 2. (Aircoolair only).

Circuit 2 indoor piping temperature < 2ºC. Reset

AUTO.

Close

freecooling air

dumper and

stops circuit 1

compressors 2

AUTO

Check:

- Indoor unit air lter.

- Air damper working correctly.

High ambient temperature warning.

Ambient temperature > 40ºC.

AUTO

Check location of ambient probe; avoid places where measurement of

the ambient temperature by the internal sensor may be altered.

Warning the low ambient temperature.

Disabled by default.

Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Low power supply warning.

Power supply < 20.4V. AUTO Check power supply of controller = 24V (see electrical diagram).

High power supply warning.

Power supply > 26.4V. Unit stops AUTO Check power supply of controller = 24V (see electrical diagram).

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Not used. Call Technical Service.

Alarm, faulty communication between DC40 and

Climatic 40. (Aircoolair only).

Unit stops AUTO

- DC40 connections (see electrical diagrams).

Call Technical Service.

Generic alarm.

Some active alarms on Climatic 40.

Check Climatic 40 alarm code and act by accordingly.

Not used. Call Technical Service.

DC40 internal probe alarm.

Faulty internal probe.

Call Technical Service.

DC40 setting error. Call Technical Service.

DC40 hardware error. Call Technical Service.

Page 28

27

ALARMS

ALARM LOG

The Climatic 40 has a log where signicant events that stop (alarms) or limit (warnings) the operation of the unit are saved.

In order to enter the Alarm Log menu, proceed as explained in chapter 3 MENU in the paragraph PARAMETERS EDITING MENU,

entering the password 44 instead of 22.

Up to 25 events can be saved, highlighting in order: event code, start hours, start minutes, start day, start month, end hours, end

minutes, end day, end month.

WARNING

The alarm log is active and operative only if the clock board is tted.

If there are no alarms saved, “noH” is displayed.

EVENT CODE

START MONTHS

END MONTHS

START HOURS START MINUTES START DAYS

END HOURS END MINUTES END DAYS

Page 29

28

NOTES

Page 30

29

NOTES

Page 31

30

NOTES

Page 32

www.lennoxeurope.com

www.lennoxbelgium.com

www.lennox.cz

www.lennoxfrance.com

www.lennoxdeutschland.com

www.lennoxuk.com

www.lennoxnederland.com

www.lennoxpolska.com

www.lennoxportugal.com

www.lennoxrussia.com

www.lennoxdistribution.com

www.lennoxspain.com

www.lennoxrussia.com

www.lennoxdistribution.com

Due to Lennox’s ongoing commitment to quality,

the Specifications, Ratings and Dimensions are

subject to change without notice and without

incurring liability.

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage or personal injury.

Installation and service must be performed by a

qualified installer and servicing agency.

MUL37E-0607 12-2009

Original manual translation

BELGIUM, LUXEMBOURG

CZECH REPUBLIC

FRANCE

GERMANY

GREAT BRITAIN

NETHERLANDS

POLAND

PORTUGAL

RUSSIA

SLOVAKIA

SPAIN

UKRAINE

OTHER COUNTRIES

Loading...

Loading...