Page 1

APPLICATION

GUIDE

CHILLED

WATER CASSETTE

CWC - 2P/4P

English/03-2005

Page 2

INDEX

Index AGU CWC-2P/4P

General Description

Specifications

Performances tables

Sound levels

Options

Dimensions

Unit installation

Electrical connections

Drain pipework

Installation of diffuser and inlet grille

Maintenance

Air distribution

Fault analysis

2

3

4-8

8

9-10

11-12

13-14

15-16

16

17

18-20

20

20

Our company is a member of the Eurovent Certification Programme.

Our products comply with European standards.

Lennox have been providing environmental solutions since 1895, our range of Chilled Water Cassette CWC-2P/4P continues

to meet the standards that have made LENNOX a household name. Flexible design solutions to meet YOUR needs and

uncompromising attention to detail. Engineered to last, simple to maintain and Quality that comes as standard.

Information on local contacts at www.lennoxeurope.com.

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be utilised (except in the operation of this product), reproduced,

issued to or made available to third parties without the prior written agreement of Lennox.

1

Page 3

GENERAL DESCRIPTION

CWC

Model

Chilled Water Cassette

The CEILING CASSETTES are designed to operate with chilled and hot water. They provide both cooling and

dehumidification in cooling mode and heating in the latter, cleaning and filtering the air in the process. Electrical

heating elements are available as an option on some units. The units are available with cooling capacities from

1950 to 8450 W and heating capacities from 1400 to 10600 W.

CABINET

The unit chassis is made of galvanised steel and is fully insulated inside.

The units have been designed in order to install them in high ceilings where standard plates 600x600 mm or

600x1200 mm will be used.

DIFFUSER PANEL

Two alternatives can be chosen:

- Plastic diffuser: Made in decorative plastic, with a smooth finish. Internal insulation prevents condensation from

forming. 4 louvres for MODELS 600x600 and 6 louvres for MODELS 600x1200 ensure air distribution.

- Metallic diffuser.

020 (030-040-050-070-090)

Models 600x600: 020-030-040-050

Models 600x1200: 070-090

Close cooling capacity in W x 100

X

1:

Plastic diffuser

2: Metallic diffuser

Y

1: 2 Pipes units

4: 4 Pipes units

HEAT EXCHANGER

Made of copper tubes and aluminium fins. Coils have been designed and manufactured to ensure maximum

efficiency.

FAN

The units are supplied with one (models 600x600) or two (models 600x1200) 3-speed centrifugal fans. The impeller

blades have been designed specifically for this type of units ensuring exceptionally low sound levels and the motor

is protected with internal thermal protection.

AIR DISTRIBUTION

The position of the louvres can be adjusted manually (only for plastic diffuser).

AIR FILTER

A polypropylene washable air filter is incorporated in the unit; it is easily accessible for maintenance.

INTERNAL COMPONENTS

The unit is designed with serviceability in mind, and all components are easily accessible. A drip tray collects

condensate which is removed by means of a condensate pump.

ELECTRIC CIRCUIT

The electrical panel is provided with a terminal block which provides connection to mains power or to a control box

(depending on model).

A fused isolator is not included and where required shall be installed by others.

OPTIONS

Electric heater (depending on model).

Fresh air kit.

- Duct connection.

- Fresh air fan.

- Duct supports.

Air supply to an adjacent room kit.

- Duct connection.

- Duct supports.

Water control valve kit with 2 way or 3 way

proportional control valves.

Auxiliary drip tray.

Thermostat.

Float switch.

Master Slave.

Fitting & testing valves.

Water evacuation security.

2

Page 4

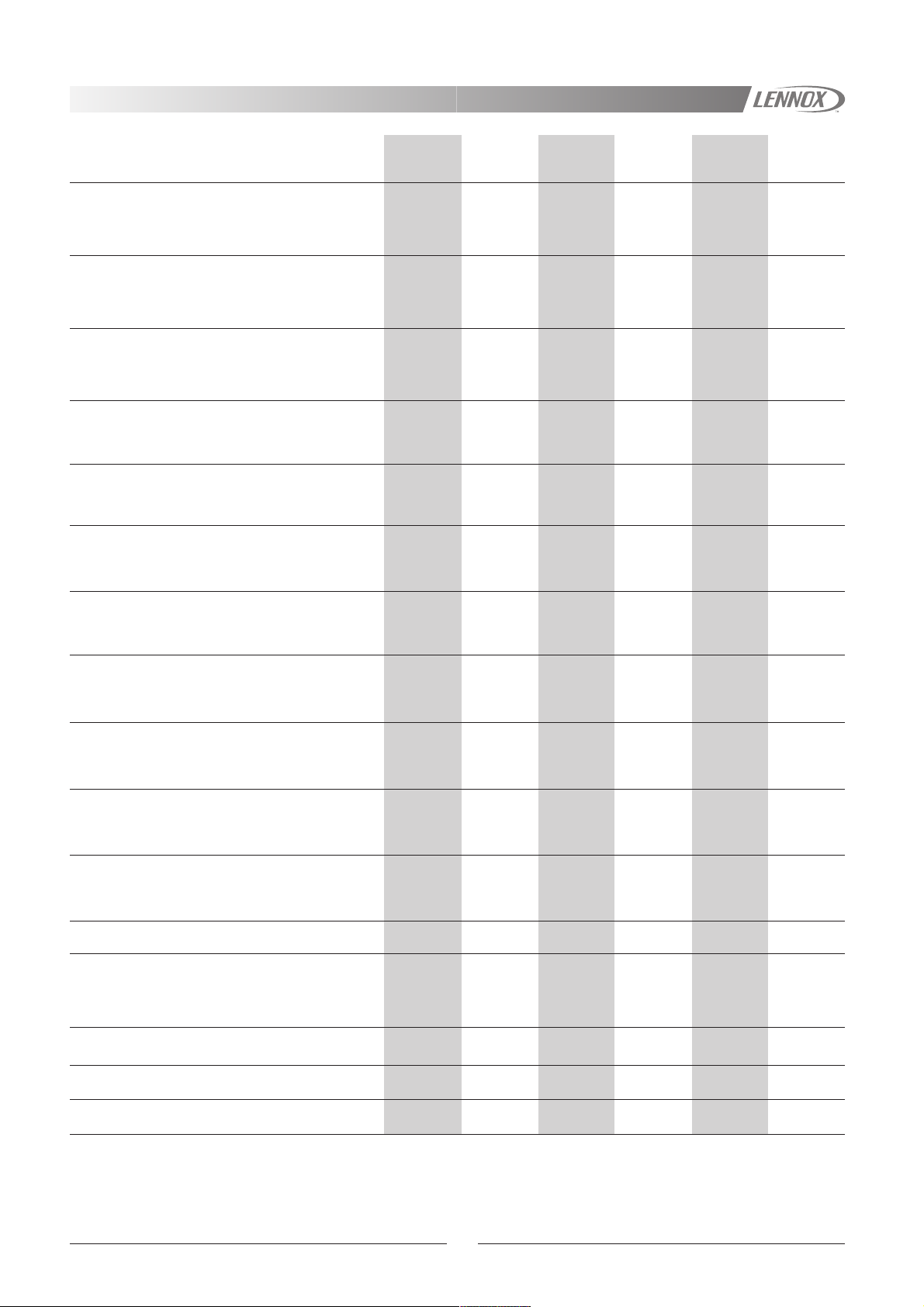

SPECIFICATIONS

CWC - 2P / 4P

Nominal air flow (1)

Total cooling capacity (2)

(2 pipes system)

Total cooling capacity (2)

(4 pipes system)

Sensible cooling capacity (2)

(2 pipes system)

Sensible cooling capacity (2)

(4 pipes system)

Heating capacity (3)

(4 pipes system)

Heating capacity (4)

(2 pipes system)

m3/h

W

W

W

W

W

W

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

L

M

H

CWC 020

445

550

650

1480

1690

1870

1620

1840

2030

1150

1320

1480

1380

1590

1770

1290

1420

1510

2010

2330

2600

CWC 030

400

517

598

2580

3090

3410

2150

2540

2790

2000

2440

2730

1580

1900

2110

1830

2240

2530

2980

3620

4050

CWC 040

553

670

779

3240

3690

4080

2980

3370

3690

2470

2850

3190

2250

2590

2880

2900

3220

3500

3610

4160

4650

CWC 050

650

791

920

4190

4820

5330

3700

4210

4620

3020

3530

3960

2840

3280

3650

3530

4010

4410

5290

6170

6940

CWC 070

987

1164

1342

6290

7040

7740

5320

5920

6470

4370

4950

5510

4000

4520

5010

5670

6240

6750

6650

7430

8260

CWC 090

1126

1323

1569

6940

7770

8710

6350

7070

7880

5040

5710

6490

4910

5540

6260

6170

6910

7670

8700

9860

1123

Pressure drop (water) (2)

cooling circuit

(2 pipes system)

Pressure drop (water) (2)

cooling circuit

(4 pipes system)

Pressure drop (water) (3)

heating circuit

(4 pipes system)

Pressure drop (water) (4)

heating circuit

(2 pipes system)

Power electrical heater (5)

Fan-motor performance

Weight unit

Weight Plastic diffuser

Weight Metallic diffuser

(6)

kPa

kPa

kPa

kPa

kW

W

A

Kg

Kg

Kg

M

H

M

H

M

H

M

H

M

H

L

L

L

L

L

9.3

11.8

14.2

8.9

11.3

14.1

1.9

2.3

2.5

11.2

14.2

17.0

1.5

48

0.17

0.20

0.22

21

3

5

13.3

18.4

22.0

24.8

33.7

39.8

5.3

7.6

9.4

13.2

18.2

21.8

2

48

0.17

0.20

0.22

22

3

5

25.2

31.8

38.0

18.3

22.8

27.0

24.9

30.2

34.9

26.3

33.3

39.7

2

66

0.26

0.28

0.30

23

3

5

24.2

31.0

37.2

24.5

30.8

36.5

25.4

32.0

38.0

28.9

37.0

44.4

N/A

82

0.29

0.30

0.34

24

3

5

18.1

22.1

26.2

12.9

15.7

18.4

19.8

23.4

27.0

20.4

25.0

29.7

2.5-4

2x66

2x0.26

2x0.28

2x0.30

43

5

11

13.6

16.7

20.6

21.0

25.4

31.0

17.3

21.1

25.5

16.4

20.1

24.8

2.5-4

2x82

2x0.29

2x0.30

2x0.34

45

5

11

(1) Values for 0 Pa air available pressure.

(2) Inlet Air temperature 27ºC DB-19ºC WB. Water temperature 7ºC-12ºC.

(3) Inlet Air temperature 20ºC. Water temperature 70ºC-60ºC.

(4) Inlet Air temperature 20ºC. Water temperature 50ºC/* - Same water flow (2).

(5) Capacity 1-Capacity 2.

(6) Absorbed power (high speed).

3

DB.- Dry bulb

WB.- Wet bulb

N/A: Not available

Page 5

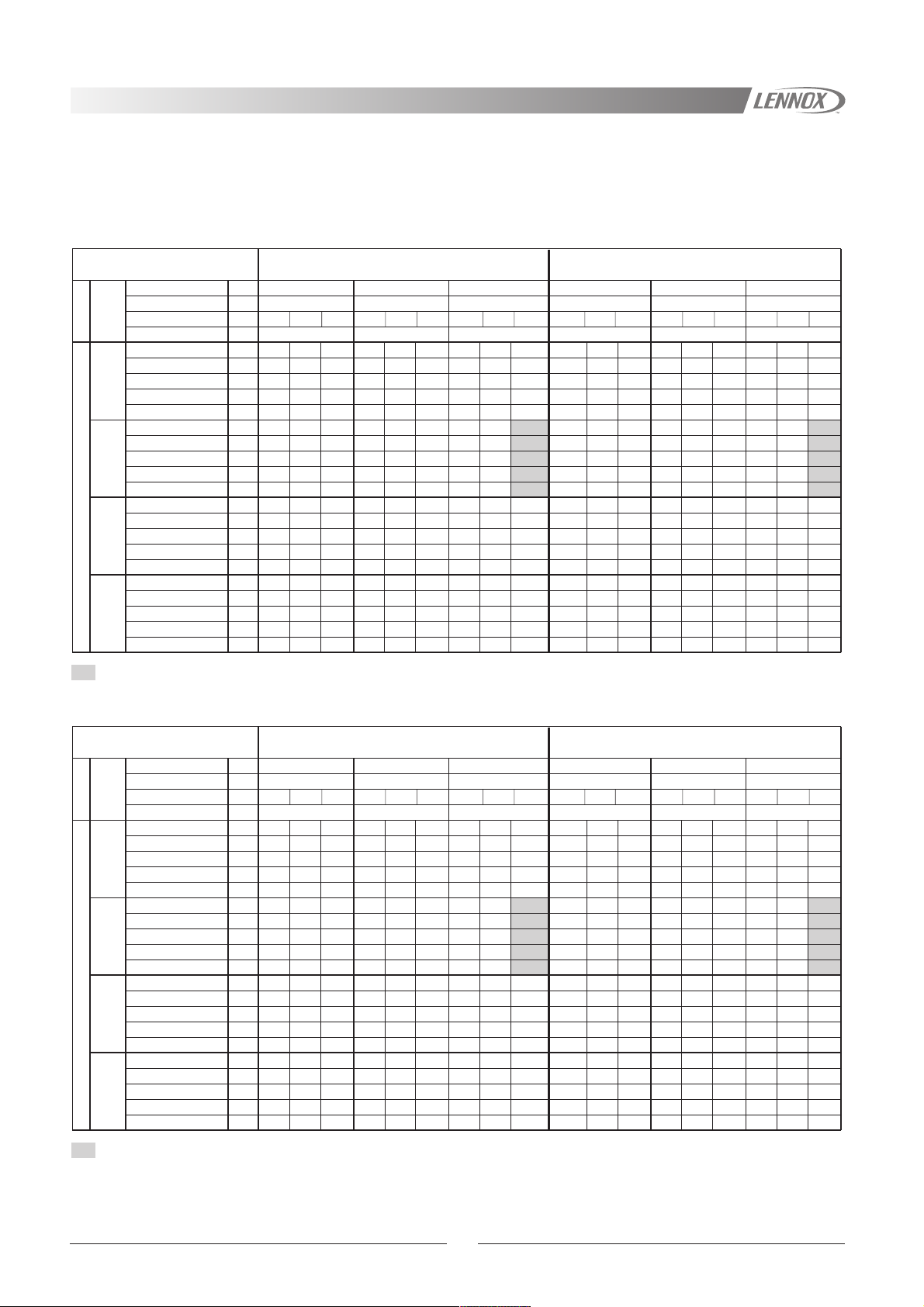

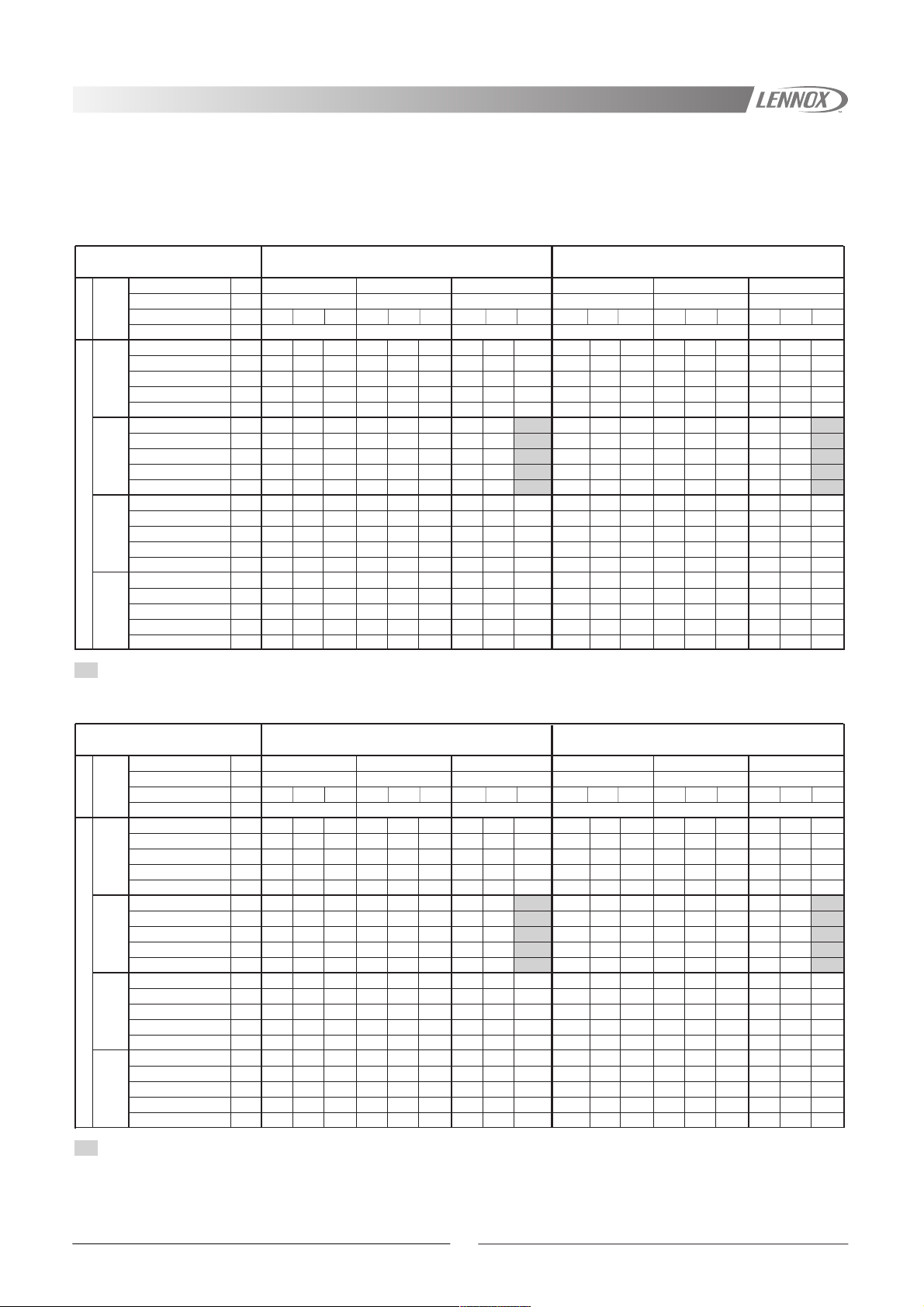

PERFORMANCES TABLES

COOLING CAPACITIES

Speed

Water

Air flow

temp.

ºC

Inlet Air Temperature

in/out

Relative humidity

Total capacity

Sensible capacity

6 / 11

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

7 / 12

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

3 Rows Coil

8 / 13

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

9 / 14

Outlet Air Temperature

Water flow

Water press. drop

Eurovent conditions

CWC 020 2P

Low Speed Medium Speed High Speed Low Speed Medium Speed High Speed

m

ºC

%

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

3

/h

445 550 650 445 550 650

22 25 27 22 25 27 22 25 27 22 25 27 22 25 27 22 25 27

50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10%

0,87

0,87

16,07

156

3,7

0,80

0,80

16,58

143

3,1

0,72

0,72

17,10

130

2,6

0,64

0,64

17,62

117

2,2

1,30

1,08

17,66

229

7,4

1,12

1,01

18,14

199

5,7

0,94

0,93

18,64

168

4,2

0,87

0,87

19,05

156

3,6

1,66

1,22

18,68

291

11,4

1,48

1,15

19,17

261

9,3

1,30

1,08

19,66

230

7,4

1,12

1,01

20,14

198

5,6

1,00

1,00

16,48

180

4,8

0,91

0,91

16,96

164

4,1

0,83

0,83

17,45

149

3,4

0,74

0,74

17,93

134

2,8

1,47

1,24

18,16

261

9,4

1,27

1,16

18,62

226

7,2

1,09

1,09

18,98

195

5,5

1,01

1,01

19,46

180

4,7

1,89

1,40

19,26

332

14,5

1,69

1,32

19,71

298

11,8

1,48

1,24

20,16

262

9,3

1,27

1,16

20,61

225

7,1

1,12

1,12

16,79

200

5,8

1,02

1,02

17,25

184

4,9

0,92

0,92

17,71

167

4,1

0,82

0,82

18,17

150

3,4

1,63

1,38

18,55

288

11,2

1,41

1,29

18,97

250

8,6

1,22

1,22

19,31

218

6,7

1,12

1,12

19,77

201

5,8

2,09

1,57

19,70

368

17,4

1,87

1,48

20,12

329

14,2

1,64

1,39

20,54

290

11,2

1,40

1,29

20,97

249

8,5

0,95

1,05

14,88

169

3,5

0,87

0,95

15,50

155

3,0

0,78

0,86

16,12

141

2,5

0,70

0,77

16,74

126

2,1

1,41

1,29

16,19

249

7,1

1,22

1,21

16,77

216

5,5

1,03

1,12

17,36

182

4,0

0,95

1,05

17,86

170

3,5

CWC 020 4P

1,09

1,81

1,20

1,47

15,38

17,02

317

195

10,9

4,6

1,62

1,00

1,38

1,10

17,60

15,96

284

179

8,9

3,9

1,42

0,90

1,29

0,99

18,19

16,54

250

162

7,1

3,2

1,22

0,80

1,21

0,89

18,77

17,12

215

146

5,4

2,7

1,61

1,49

16,79

284

9,0

1,39

1,39

17,34

246

6,9

1,19

1,31

17,78

212

5,3

1,10

1,21

18,36

196

4,5

2,06

1,68

17,72

361

13,9

1,84

1,59

18,26

324

11,3

1,62

1,49

18,79

285

8,9

1,38

1,39

19,33

245

6,8

1,22

1,34

15,75

218

5,8

1,11

1,22

16,30

199

4,9

1,00

1,11

16,85

181

4,1

0,90

0,99

17,40

162

3,4

1,78

1,66

17,26

314

11,2

1,53

1,55

17,76

272

8,6

1,33

1,46

18,18

237

6,7

1,22

1,35

18,72

219

5,7

2,28

1,88

18,24

400

17,3

2,03

1,77

18,74

358

14,1

1,78

1,66

19,25

315

11,1

1,53

1,55

19,76

271

8,4

Speed

Water

Air flow

temp.

ºC

Inlet Air Temperature

in/out

Relative humidity

Total capacity

Sensible capacity

6 / 11

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

7 / 12

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

3 Rows Coil

8 / 13

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

9 / 14

Outlet Air Temperature

Water flow

Water press. drop

Eurovent conditions

CWC 030 2P

Low Speed Medium Speed High Speed Low Speed Medium Speed High Speed

m

ºC

%

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

3

/h

400 517 598 400 517 598

22 25 27 22 25 27 22 25 27 22 25 27 22 25 27 22 25 27

50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10%

1,46

1,47

10,86

256

5,1

1,43

1,52

10,48

252

4,5

1,25

1,33

11,95

221

3,9

1,14

1,20

12,88

201

3,2

2,23

1,82

11,20

390

10,8

2,04

1,77

11,56

357

8,7

1,70

1,58

13,01

298

6,6

1,42

1,46

13,94

249

4,8

2,77

2,05

11,49

482

15,9

2,58

2,00

11,83

450

13,3

2,25

1,81

13,26

393

10,9

1,98

1,69

14,16

346

8,6

1,73

1,80

11,46

304

6,9

1,73

1,83

11,25

305

6,4

1,51

1,60

12,64

266

5,4

1,36

1,45

13,52

242

4,5

2,67

2,22

11,96

466

15,0

2,43

2,17

12,29

426

11,9

2,02

1,94

13,66

354

9,0

1,79

1,90

13,89

315

7,2

3,32

2,50

12,36

579

22,1

3,09

2,44

12,67

539

18,4

2,69

2,21

14,02

469

15,0

2,35

2,07

14,85

411

11,7

1,99

2,11

11,29

351

9,0

1,93

2,05

11,63

340

7,7

1,68

1,78

12,99

297

6,6

1,52

1,61

13,85

269

5,5

2,94

2,48

12,42

513

17,8

2,68

2,42

12,71

469

14,1

2,21

2,16

14,04

389

10,7

1,99

2,11

14,29

351

8,8

3,67

2,79

12,88

639

26,4

3,41

2,73

13,15

595

22,0

2,96

2,47

14,46

517

17,8

2,58

2,32

15,27

452

13,9

1,22

1,28

12,27

215

8,0

1,18

1,18

13,07

209

8,4

1,08

1,08

13,82

192

7,2

0,98

0,98

14,57

175

6,0

1,87

1,59

12,96

328

17,0

1,69

1,40

14,41

296

16,0

1,46

1,30

15,13

256

12,3

1,22

1,21

15,86

215

8,8

CWC 030 4P

1,43

2,33

1,55

1,79

12,92

13,47

253

407

10,7

25,1

1,40

2,15

1,40

1,58

13,79

15,03

248

375

11,5

24,8

1,28

1,92

1,28

1,49

14,49

15,74

228

337

9,7

20,2

1,16

1,69

1,16

1,39

15,18

16,44

207

296

8,1

15,9

2,21

1,91

13,78

388

23,1

1,99

1,69

15,12

350

21,7

1,72

1,57

15,78

302

16,5

1,52

1,52

16,10

268

13,1

2,76

2,15

14,40

483

34,2

2,54

1,90

15,84

445

33,7

2,27

1,79

16,48

398

27,3

1,99

1,68

17,14

350

21,4

1,78

1,63

13,72

315

13,6

1,55

1,55

14,14

275

13,8

1,42

1,42

14,81

252

11,7

1,29

1,29

15,48

230

9,7

2,65

1,95

15,13

463

27,3

2,18

1,87

15,52

384

25,5

1,88

1,75

16,15

331

19,4

1,68

1,68

16,47

298

15,8

3,31

2,19

15,92

577

40,6

2,79

2,11

16,30

489

39,8

2,49

1,99

16,91

437

32,3

2,18

1,87

17,54

383

25,2

4

Page 6

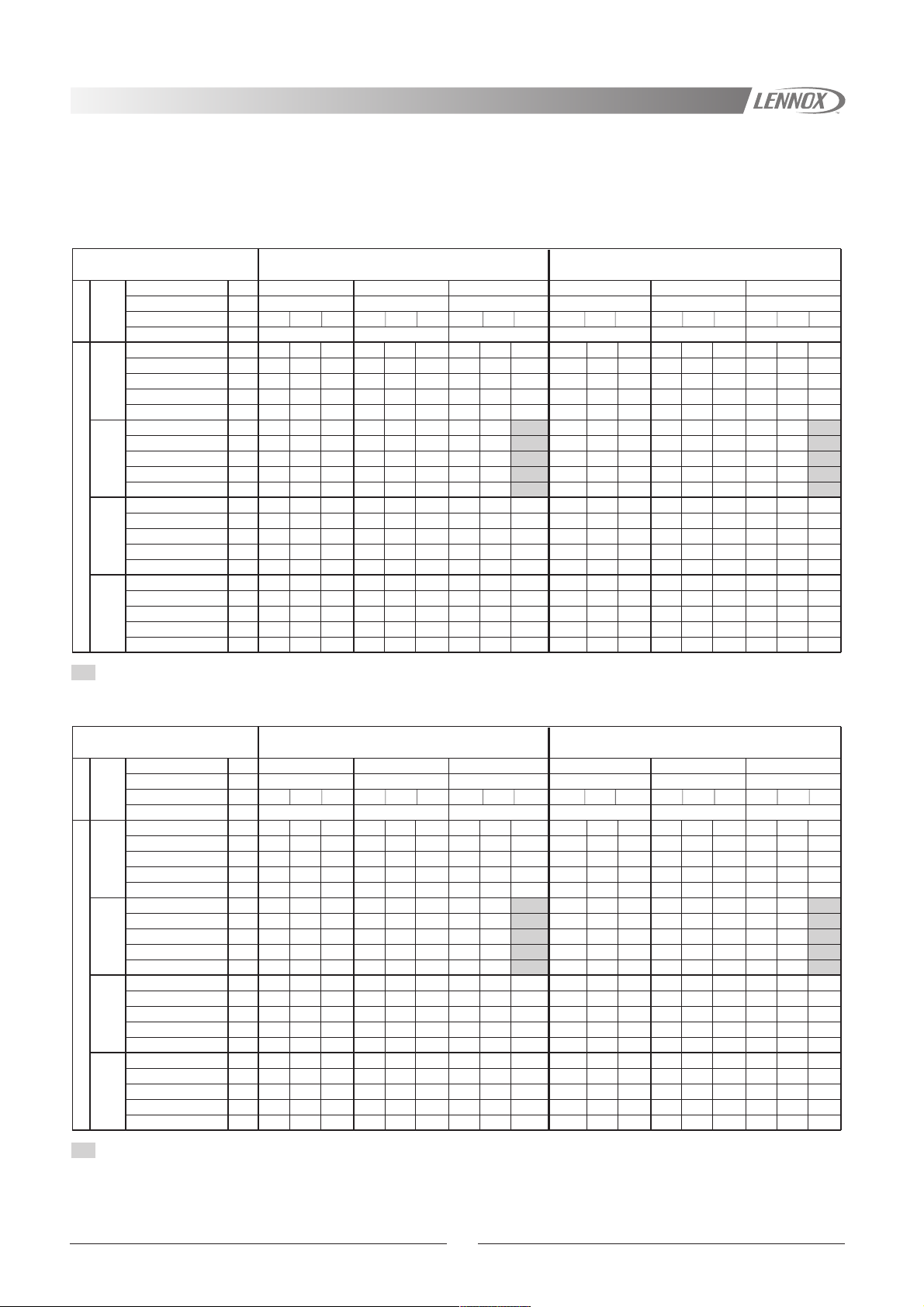

PERFORMANCES TABLES

COOLING CAPACITIES

Speed

Water

Air flow

temp.

ºC

Inlet Air Temperature

in/out

Relative humidity

Total capacity

Sensible capacity

6 / 11

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

7 / 12

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

3 Rows Coil

8 / 13

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

9 / 14

Outlet Air Temperature

Water flow

Water press. drop

Eurovent conditions

CWC 040 2P

Low Speed Medium Speed High Speed Low Speed Medium Speed High Speed

m

kW

kW

kPa

kW

kW

kPa

kW

kW

kPa

kW

kW

kPa

3

/h

ºC

%

ºC

l/h

ºC

l/h

ºC

l/h

ºC

l/h

553 670 779 553 670 779

22 25 27 22 25 27 22 25 27 22 25 27 22 25 27 22 25 27

50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10%

2,34

4,07

3,27

1,88

1,89

11,66

333

9,7

1,74

1,82

12,03

308

8,4

1,59

1,66

12,88

282

7,1

1,44

1,51

13,74

257

6,0

2,87

2,33

12,23

503

20,5

2,54

2,18

13,04

446

16,4

2,19

2,03

13,88

386

12,6

1,83

1,87

14,73

324

9,1

3,57

2,62

12,65

623

30,1

3,24

2,47

13,46

567

25,2

2,90

2,32

14,27

508

20,6

2,55

2,17

15,09

447

16,3

2,13

2,18

12,13

377

12,2

2,00

2,10

12,51

354

10,8

1,83

1,92

13,33

325

9,2

1,66

1,74

14,15

295

7,7

2,69

12,82

573

25,9

2,89

2,52

13,59

507

20,6

2,49

2,35

14,38

438

15,8

2,17

2,28

14,70

384

12,4

3,03

13,32

711

38,1

3,69

2,85

14,09

645

31,8

3,30

2,68

14,86

578

25,9

2,89

2,51

15,63

507

20,4

2,44

12,52

414

14,4

2,23

2,34

12,91

395

13,2

2,04

2,14

13,69

362

11,2

1,84

1,93

14,49

328

9,3

3,61

3,01

13,30

632

30,9

3,18

2,82

14,04

558

24,5

2,73

2,62

14,79

482

18,7

2,42

2,54

15,12

428

15,0

4,50

3,38

13,87

785

45,6

4,08

3,19

14,61

712

38,0

3,64

3,00

15,34

637

30,9

3,18

2,81

16,07

558

24,2

1,75

1,75

12,39

311

7,5

1,67

1,67

12,86

296

6,4

1,53

1,53

13,63

272

5,5

1,39

1,39

14,41

248

4,6

2,59

2,07

13,65

454

14,9

2,33

1,99

14,07

410

11,7

2,00

1,86

14,81

354

8,9

1,81

1,81

15,09

320

7,4

CWC 040 4P

2,02

3,24

2,02

2,33

14,25

566

22,1

2,98

2,25

14,67

522

18,3

2,66

2,12

15,39

467

14,8

2,32

1,99

16,11

409

11,6

12,88

357

9,6

1,91

1,91

13,35

339

8,2

1,75

1,75

14,09

311

7,0

1,59

1,59

14,83

283

5,8

14,21

14,62

15,30

15,61

2,93

2,39

513

18,5

2,62

2,30

462

14,6

2,25

2,14

397

11,0

2,08

2,08

367

9,5

3,67

2,68

14,89

641

27,6

3,37

2,59

15,30

589

22,8

3,00

2,44

15,96

526

18,4

2,62

2,29

16,64

460

14,3

2,24

2,24

13,29

397

11,6

2,12

2,12

13,73

377

10,0

1,94

1,94

14,44

345

8,4

1,76

1,76

15,16

314

7,0

3,21

2,66

14,66

563

21,8

2,87

2,56

15,04

506

17,2

2,46

2,39

15,70

434

12,9

2,31

2,31

16,02

409

11,4

4,03

2,98

15,41

704

32,6

3,69

2,88

15,79

647

27,0

3,28

2,72

16,42

576

21,7

2,86

2,55

17,06

503

16,8

Speed

Water

Air flow

temp.

ºC

Inlet Air Temperature

in/out

Relative humidity

Total capacity

Sensible capacity

6 / 11

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

7 / 12

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

3 Rows Coil

8 / 13

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

9 / 14

Outlet Air Temperature

Water flow

Water press. drop

Eurovent conditions

CWC 050 2P

Low Speed Medium Speed High Speed Low Speed Medium Speed High Speed

m

kW

kW

kPa

kW

kW

kPa

kW

kW

kPa

kW

kW

kPa

3

/h

ºC

%

ºC

l/h

ºC

l/h

ºC

l/h

ºC

l/h

650 791 920 650 791 920

22 25 27 22 25 27 22 25 27 22 25 27 22 25 27 22 25 27

50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10%

4,61

2,45

2,31

11,23

433

9,4

2,26

2,26

11,47

400

8,1

2,07

2,07

12,36

367

6,9

1,88

1,88

13,25

334

5,8

3,73

2,86

11,69

652

19,7

3,30

2,67

12,55

579

15,8

2,85

2,48

13,43

502

12,2

2,38

2,29

14,31

421

8,8

3,20

12,06

805

28,8

4,19

3,02

12,91

733

24,2

3,76

2,84

13,76

658

19,8

3,31

2,66

14,62

580

15,7

2,80

2,70

11,65

493

11,9

2,63

2,63

11,92

465

10,7

2,41

2,41

12,77

426

9,1

2,18

2,18

13,63

388

7,6

4,27

3,33

12,23

747

25,2

3,78

3,12

13,05

662

20,1

3,26

2,90

13,87

573

15,4

2,71

2,68

14,72

479

11,1

5,31

3,74

12,68

925

37,0

4,82

3,53

13,48

841

31,0

4,31

3,32

14,29

753

25,2

3,78

3,11

15,10

662

19,9

3,08

3,03

12,01

544

14,2

2,94

2,94

12,30

521

13,1

2,69

2,69

13,13

477

11,1

2,44

2,44

13,96

434

9,3

4,73

3,74

12,69

827

30,2

4,17

3,50

13,47

731

24,1

3,59

3,26

14,26

631

18,4

3,19

3,19

14,48

563

14,9

5,88

4,19

13,20

1025

44,5

5,33

3,96

13,97

930

37,2

4,76

3,72

14,74

832

30,2

4,16

3,48

15,52

730

23,7

2,12

2,17

11,90

377

9,3

2,01

2,08

12,30

357

8,4

1,83

1,90

13,14

327

7,1

1,66

1,72

13,99

296

5,9

3,28

2,68

12,51

575

19,8

2,89

2,51

13,32

508

15,8

2,48

2,33

14,12

438

12,0

2,18

2,26

14,46

386

9,6

CWC 050 4P

2,52

4,09

2,61

3,01

12,97

714

29,3

3,70

2,84

13,76

648

24,5

3,30

2,67

14,56

579

19,9

2,89

2,50

15,35

508

15,6

12,01

445

12,5

2,31

2,40

12,81

410

10,8

2,11

2,19

13,61

375

9,1

1,91

1,98

14,42

340

7,6

13,14

13,89

14,65

15,00

3,72

3,10

653

24,9

3,28

2,90

576

19,8

2,81

2,70

495

15,0

2,52

2,61

445

12,3

4,65

3,47

13,69

813

37,0

4,21

3,28

14,44

736

30,8

3,75

3,09

15,18

657

24,9

3,27

2,89

15,92

575

19,5

2,79

2,90

12,46

494

15,1

2,57

2,66

13,23

456

13,0

2,34

2,43

14,00

417

11,0

2,11

2,19

14,78

378

9,2

4,09

3,44

13,65

717

29,5

3,59

3,23

14,37

632

23,4

3,07

3,01

15,09

542

17,7

2,79

2,90

15,46

495

14,9

5,12

3,86

14,28

894

43,9

4,62

3,65

14,98

809

36,5

4,11

3,44

15,68

721

29,5

3,58

3,22

16,39

630

23,0

5

Page 7

PERFORMANCES TABLES

COOLING CAPACITIES

Speed

Water

Air flow

temp.

ºC

Inlet Air Temperature

in/out

Relative humidity

Total capacity

Sensible capacity

6 / 11

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

7 / 12

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

3 Rows Coil

8 / 13

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

9 / 14

Outlet Air Temperature

Water flow

Water press. drop

Eurovent conditions

CWC 070 2P

Low Speed Medium Speed High Speed Low Speed Medium Speed High Speed

m

ºC

%

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

3

/h

987 1164 1342 987 1164 1342

22 25 27 22 25 27 22 25 27 22 25 27 22 25 27 22 25 27

50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10%

4,46

7,76

3,66

3,35

11,73

639

6,9

3,39

3,23

12,08

592

6,0

3,10

2,96

12,92

542

5,1

2,81

2,68

13,76

493

4,3

5,58

4,13

12,32

969

14,7

4,94

3,87

13,13

858

11,7

4,27

3,60

13,95

743

9,0

3,56

3,33

14,79

621

6,5

6,92

4,64

12,77

1200

21,6

6,29

4,37

13,57

1091

18,1

5,63

4,11

14,37

978

14,7

4,95

3,85

15,18

860

11,6

4,08

3,79

12,13

711

8,4

3,83

3,65

12,49

669

7,5

3,50

3,34

13,30

613

6,4

3,18

3,03

14,11

556

5,3

6,24

4,68

12,82

1084

18,0

5,51

4,38

13,60

959

14,3

4,75

4,08

14,38

828

10,9

3,96

3,77

15,17

691

7,8

5,25

13,33

1345

26,5

7,04

4,95

14,10

1221

22,1

6,30

4,66

14,86

1093

18,0

5,52

4,37

15,63

959

14,2

4,22

12,48

779

9,9

4,24

4,05

12,85

741

9,0

3,88

3,70

13,64

679

7,7

3,52

3,36

14,42

616

6,4

6,86

5,19

13,27

1191

21,3

6,05

4,87

14,01

1052

16,9

5,21

4,54

14,75

907

12,9

4,60

4,40

15,07

803

10,3

8,54

5,83

13,84

1480

31,5

7,74

5,51

14,57

1343

26,2

6,91

5,18

15,30

1200

21,3

6,05

4,85

16,05

1052

16,7

3,20

3,20

12,17

560

5,3

2,95

2,95

12,94

517

4,5

2,70

2,70

13,73

473

3,8

2,44

2,44

14,51

429

3,2

4,71

3,78

13,40

819

10,5

4,14

3,54

14,14

722

8,3

3,55

3,29

14,89

620

6,3

3,20

3,20

15,16

560

5,2

CWC 070 4P

3,61

5,88

3,61

4,24

12,60

13,98

631

1021

6,5

15,6

3,32

5,32

3,32

4,00

13,35

14,71

582

925

5,6

12,9

3,03

4,74

3,03

3,76

14,10

15,44

532

825

4,8

10,5

2,74

4,13

2,74

3,53

14,85

16,17

482

720

4,0

8,2

5,24

4,27

13,89

911

12,7

4,60

4,00

14,59

801

10,0

3,93

3,73

15,30

686

7,5

3,61

3,61

15,59

632

6,4

6,56

4,78

14,54

1138

18,9

5,92

4,52

15,23

1029

15,7

5,26

4,25

15,92

916

12,6

4,58

3,99

16,62

799

9,8

3,99

3,99

12,98

698

7,8

3,67

3,67

13,71

643

6,7

3,35

3,35

14,43

588

5,7

3,03

3,03

15,16

532

4,7

5,72

4,73

14,32

995

14,9

5,01

4,43

14,99

874

11,7

4,28

4,14

15,65

747

8,8

4,00

4,00

15,97

699

7,7

7,17

5,30

15,03

1245

22,2

6,47

5,01

15,68

1124

18,4

5,74

4,72

16,34

999

14,8

4,99

4,43

17,00

870

11,5

Speed

Water

Air flow

temp.

ºC

Inlet Air Temperature

in/out

Relative humidity

Total capacity

Sensible capacity

6 / 11

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

7 / 12

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

3 Rows Coil

8 / 13

Outlet Air Temperature

Water flow

Water press. drop

Total capacity

Sensible capacity

9 / 14

Outlet Air Temperature

Water flow

Water press. drop

Eurovent conditions

CWC 090 2P

Low Speed Medium Speed High Speed Low Speed Medium Speed High Speed

m

ºC

%

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

kW

kW

ºC

l/h

kPa

3

/h

1126 1323 1569 1126 1323 1569

22 25 27 22 25 27 22 25 27 22 25 27 22 25 27 22 25 27

50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10% 50 +/-10%

4,03

3,85

11,65

704

5,2

3,74

3,74

11,94

654

4,5

3,42

3,42

12,79

600

3,9

3,11

3,11

13,64

545

3,2

6,15

4,75

12,21

1069

11,1

5,44

4,45

13,03

947

8,8

4,70

4,14

13,87

819

6,8

3,91

3,82

14,72

684

4,9

7,64

5,34

12,63

1325

16,3

6,94

5,04

13,44

1204

13,6

6,21

4,73

14,26

1079

11,1

5,45

4,43

15,08

949

8,8

4,48

4,36

12,01

783

6,3

4,23

4,23

12,32

739

5,7

3,87

3,87

13,14

677

4,8

3,51

3,51

13,97

615

4,0

6,88

5,39

12,66

1196

13,5

6,08

5,04

13,45

1057

10,8

5,23

4,69

14,25

912

8,2

4,35

4,34

15,07

760

5,9

8,56

6,05

13,14

1485

20,0

7,77

5,71

13,93

1348

16,7

6,94

5,37

14,71

1206

13,6

6,08

5,02

15,49

1058

10,7

5,00

4,97

12,41

874

7,7

4,79

4,79

12,75

838

7,1

4,38

4,38

13,54

768

6,0

3,97

3,97

14,33

697

5,0

7,72

6,13

13,16

1341

16,7

6,80

5,73

13,92

1183

13,2

5,84

5,34

14,68

1019

10,0

5,20

5,20

14,96

909

8,1

9,62

6,88

13,72

1669

24,7

8,71

6,49

14,46

1513

20,6

7,77

6,10

15,21

1351

16,7

6,79

5,72

15,95

1183

13,0

3,66

3,76

11,89

641

7,9

3,45

3,62

12,27

605

7,1

3,15

3,31

13,10

554

6,0

2,86

3,00

13,93

503

5,0

5,62

4,64

12,53

979

17,0

4,96

4,34

13,32

865

13,5

4,27

4,04

14,13

747

10,3

3,74

3,92

14,44

655

8,1

CWC 090 4P

4,06

7,00

4,24

5,20

12,30

12,99

710

1215

9,6

25,1

3,88

6,35

4,07

4,91

12,68

13,78

679

1103

8,8

21,0

3,55

5,67

3,72

4,62

13,48

14,56

622

987

7,4

17,1

3,21

4,97

3,37

4,32

14,29

15,36

564

866

6,2

13,4

6,26

5,23

13,03

1088

20,6

5,51

4,89

13,79

961

16,4

4,74

4,56

14,56

827

12,4

4,21

4,42

14,88

737

10,0

7,80

5,86

13,58

1354

30,5

7,07

5,54

14,32

1227

25,4

6,30

5,21

15,07

1096

20,6

5,51

4,88

15,83

960

16,1

4,75

4,98

12,38

831

12,7

4,37

4,59

13,14

766

10,9

4,00

4,19

13,91

701

9,2

3,61

3,79

14,68

636

7,7

6,97

5,91

13,59

1214

25,1

6,13

5,54

14,31

1069

19,8

5,26

5,16

15,03

919

15,0

4,75

4,99

15,37

832

12,5

8,71

6,62

14,21

1513

37,2

7,88

6,26

14,91

1369

31,0

7,02

5,89

15,62

1221

25,0

6,12

5,53

16,33

1067

19,5

6

Page 8

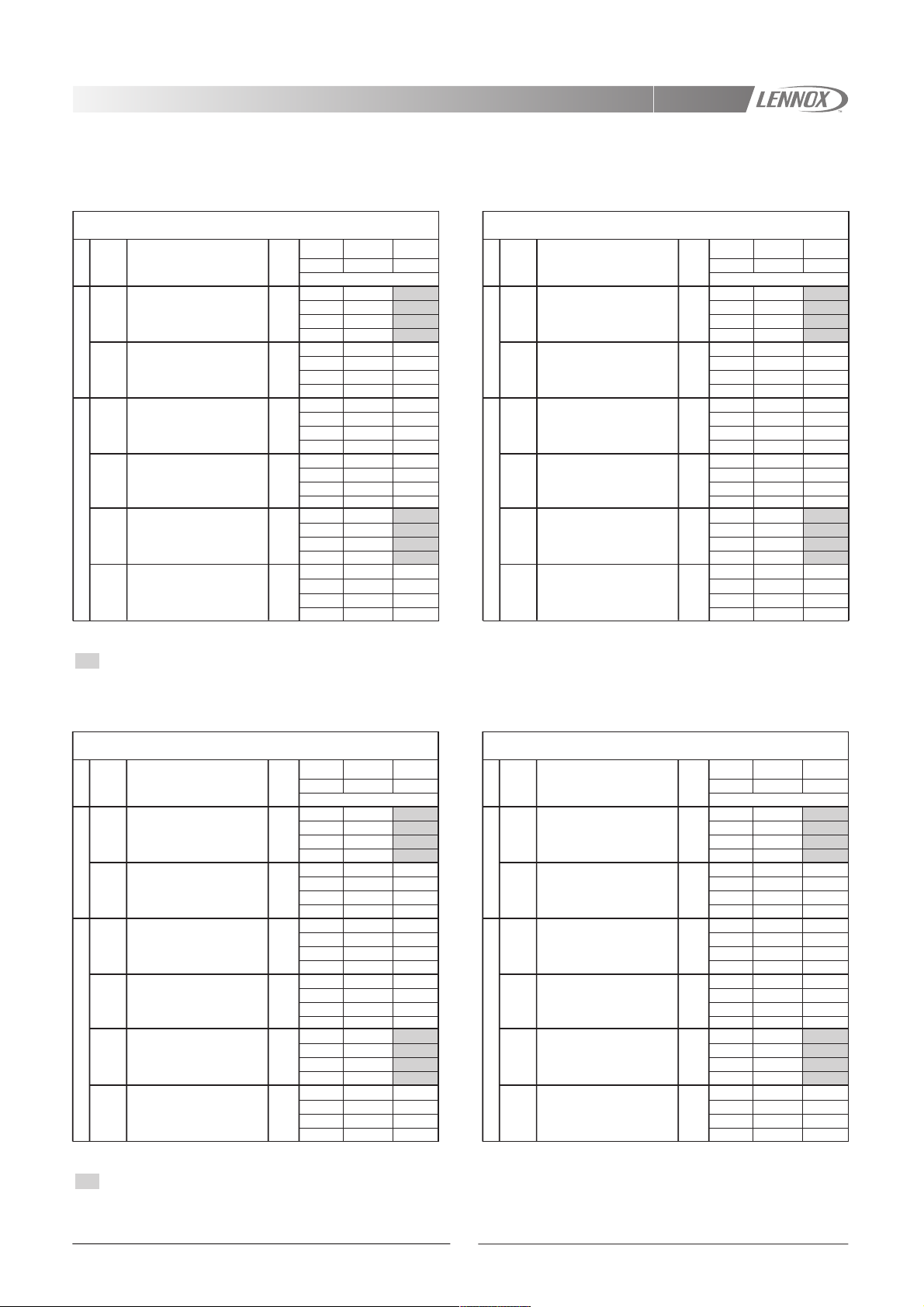

PERFORMANCES TABLES

HEATING CAPACITIES

CWC 020

Water

Speed

temp.

ºC

in/out

50 / (*)

2 Pipes

45 / 40

90 / 70

80 / 60

4 Pipes

70 / 60

60 / 50

Air flow

Inlet Air Temperature

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

m

kPa

kPa

kPa

kPa

Eurovent conditions

(*) Water outlet temperature for same water flow than cooling mode

LM H

3

/h

445 550 650

ºC

2,01

kW

33,7

ºC

261

l/h

11,2

1,71

kW

31,6

ºC

288

l/h

13,7

1,60

kW

30,9

ºC

67

l/h

0,8

1,22

kW

28,3

ºC

51

l/h

0,5

kW

1,29

ºC

28,8

l/h

108

1,9

kPa

0,93

kW

26,3

ºC

77

l/h

1,1

kPa

20

2,33

32,8

298

14,2

1,98

30,9

333

17,8

1,76

29,7

74

0,9

1,34

27,4

56

0,6

1,42

27,8

119

2,3

1,02

25,6

84

1,2

2,60

32,1

329

17,0

2,21

30,3

372

21,8

1,87

28,7

78

1,0

1,43

26,7

59

0,6

1,51

27,1

126

2,5

1,08

25,1

89

1,4

Water

temp.

ºC

in/out

50 / (*)

2 Pipes

45 / 40

90 / 70

80 / 60

4 Pipes

70 / 60

60 / 50

CWC 030

Speed

Air flow

Inlet Air Temperature

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

LM H

3

m

/h

400 517 598

ºC

2,98

kW

42,6

ºC

450

l/h

13,2

kPa

2,49

kW

38,8

ºC

422

l/h

14,0

kPa

2,22

kW

36,8

ºC

94

l/h

2,5

kPa

2,07

kW

35,7

ºC

88

l/h

1,9

kPa

kW

1,83

ºC

33,9

l/h

154

5,3

kPa

1,42

kW

30,8

ºC

120

l/h

3,4

kPa

20

3,62

41,2

539

18,2

3,03

37,8

514

20,0

2,70

35,9

115

3,6

2,52

34,8

107

2,7

2,24

33,1

189

7,6

1,74

30,2

146

4,9

4,05

40,5

595

21,8

3,40

37,2

576

24,5

3,05

35,4

129

4,5

2,83

34,4

120

3,3

2,53

32,8

213

9,4

1,96

29,9

164

6,1

CWC 040

Water

Speed

temp.

ºC

in/out

50 / (*)

2 Pipes

45 / 40

90 / 70

80 / 60

4 Pipes

70 / 60

60 / 50

Air flow

Inlet Air Temperature

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

m

kPa

kPa

kPa

kPa

Eurovent conditions

(*) Water outlet temperature for same water flow than cooling mode

LM H

3

/h

553 670 779

ºC

3,61

kW

39,8

ºC

567

l/h

26,3

3,01

kW

36,5

ºC

508

l/h

26,9

3,82

kW

40,9

ºC

162

l/h

11,0

3,03

kW

36,6

ºC

128

l/h

7,7

kW

2,90

ºC

35,9

l/h

244

24,9

kPa

2,18

kW

31,9

ºC

183

l/h

15,3

kPa

20

4,16

38,8

645

33,3

3,48

35,7

588

35,0

4,25

39,2

180

13,3

3,37

35,2

142

9,3

3,22

34,6

272

30,2

2,42

31,0

203

18,5

4,65

38,1

712

39,7

3,89

35,1

658

42,9

4,61

37,9

195

15,4

3,65

34,2

154

10,7

3,50

33,6

295

34,9

2,63

30,2

220

21,4

Water

temp.

ºC

in/out

50 / (*)

2 Pipes

45 / 40

90 / 70

80 / 60

4 Pipes

70 / 60

60 / 50

CWC 050

Speed

Air flow

Inlet Air Temperature

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

LM H

3

/h

650 791 920

m

ºC

5,29

kW

44,7

ºC

733

l/h

28,9

kPa

4,42

kW

40,6

ºC

749

l/h

30,9

kPa

4,69

kW

41,9

ºC

199

l/h

11,8

kPa

3,87

kW

38,0

ºC

163

l/h

8,5

kPa

kW

3,53

ºC

36,5

l/h

298

25,4

kPa

2,73

kW

32,7

ºC

229

l/h

16,2

kPa

20

6,17

43,6

841

37,0

5,17

39,8

877

41,0

5,32

40,4

226

14,8

4,38

36,8

185

10,6

4,01

35,4

339

32,0

3,09

31,8

260

20,3

6,94

42,9

930

44,4

5,82

39,2

987

50,7

5,84

39,2

248

17,6

4,80

35,8

203

12,6

4,41

34,5

373

38,0

3,40

31,2

285

24,1

7

Page 9

PERFORMANCES TABLES

HEATING CAPACITIES

CWC 070

Water

Speed

temp.

ºC

in/out

50 / (*)

2 Pipes

45 / 40

90 / 70

80 / 60

4 Pipes

70 / 60

60 / 50

Air flow

Inlet Air Temperature

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

m

kPa

kPa

kPa

kPa

Eurovent conditions

(*) Water outlet temperature for same water flow than cooling mode

LM H

3

/h

987 1164 1342

ºC

6,65

kW

40,4

ºC

1091

l/h

20,4

5,50

kW

36,9

ºC

938

l/h

18,6

7,45

kW

42,9

ºC

318

l/h

9,0

6,05

kW

38,6

ºC

258

l/h

6,3

kW

5,67

ºC

37,4

l/h

483

19,8

kPa

4,31

kW

33,2

ºC

366

l/h

12,3

kPa

20

7,43

39,3

1221

25,0

6,14

36,0

1046

23,4

8,18

41,3

349

10,6

6,63

37,3

283

7,4

6,24

36,2

531

23,4

4,73

32,3

402

14,5

8,26

38,7

1343

29,7

6,83

35,4

1164

28,3

8,84

40,0

377

12,2

7,16

36,2

305

8,5

6,75

35,2

575

27,0

5,11

31,5

434

16,7

Water

temp.

ºC

in/out

50 / (*)

2 Pipes

45 / 40

90 / 70

80 / 60

4 Pipes

70 / 60

60 / 50

CWC 090

Speed

Air flow

Inlet Air Temperature

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

Total capacity

Outlet Air Temperature

Water flow

Water pressure drop

LM H

3

m

/h

400 517 598

ºC

8,70

kW

43,4

ºC

1204

l/h

16,4

kPa

7,26

kW

39,6

ºC

1238

l/h

17,7

kPa

8,20

kW

42,1

ºC

350

l/h

8,0

kPa

6,72

kW

38,1

ºC

286

l/h

5,7

kPa

kW

6,17

ºC

36,6

l/h

525

17,3

kPa

4,73

kW

32,7

ºC

402

l/h

10,9

kPa

20

9,86

42,6

1348

20,1

8,25

38,9

1406

22,3

9,16

41,0

391

9,8

7,50

37,2

319

7,0

6,91

35,8

588

21,1

5,29

32,1

449

13,3

11,23

41,7

1513

24,8

9,41

38,2

1604

28,3

10,15

39,6

433

11,8

8,30

36,0

353

8,4

7,67

34,8

653

25,5

5,87

31,3

497

16,1

WATER PRESSURE DROP WITH GLYCOL

As the percentage of glycol increases, the standard pump flow decreases due to the increased pressure characteristics. This

means that the cooling and heating duties will decrease. As a result, the pressure drop must be multiplied by the coefficient

shown in the following table:

Ethylene glycol %

Pressure drop

10%

x 1.07

20%

x 1.12

30%

x 1.20

SOUND LEVELS

CWC SOUND POWER LEVEL SPECTRA dB ref. 1pW

FAN

FREQUENCY (Hz)

SPEEDMODEL 125 250 500 1K 2K 4K 8K

CWC 020

2

3

1

1

CWC 030

2

3

1

CWC 040

2

3

1

CWC 050

2

3

1

CWC 070

2

3

1

CWC 090

2

3

Lw dB(A): Sound power level dB(A) ref 10 (-12) W EUROVENT conditions.

Lp dB(A): Sound pressure level dB(A) ref 2x10 (-5) N/m

36,1

38,4

39,5

32,7

40,7

41,6

39,3

44,3

47,2

49,9

49,4

50,1

42,5

45,9

48,7

46,0

49,0

53,1

39,9

45,3

47,8

39,4

44,2

47,5

45,9

49,2

52,1

51,0

54,4

60,6

49,6

53,2

56,7

53,4

56,5

61,0

41,1

45,7

49,9

39,7

44,9

48,5

46,0

49,8

52,2

50,2

53,4

59,0

49,4

54,0

57,6

54,1

57,4

61,0

34,4

25,9

41,3

36,6

46,1

40,9

33,4

27,0

40,4

36,1

44,6

41,7

41,4

36,7

47,1

44,6

50,3

49,0

47,0

45,9

51,4

49,8

56,3

55,1

46,5

42,3

52,0

49,8

55,8

54,2

51,1

50,4

55,3

54,7

59,3

58,6

2

calculated in a room of 100m3 and 0,5 seconds reverberation time.

Room NR guide: The NR figures above are calculated in a room of 100m

8

21,7

32,8

31,8

22,2

23,1

28,1

24,4

32,9

40,1

37,2

44,3

50,8

28,4

38,1

45,2

39,5

45,8

51,9

3

and 0,5 seconds reverberation time.

23,9

27,5

26,2

23,5

23,6

23,9

23,8

24,4

27,7

26,1

31,8

39,9

23,8

26,0

32,3

27,7

34,4

42,8

Lw

dB(A)

41

47

51

40

46

50

47

52

55

53

56

62

51

56

60

56

60

64

Lp

dB(A)

32

38

42

31

37

41

38

43

46

44

47

53

42

47

51

47

51

55

NR

GUIDE

28

33

37

27

32

36

33

39

43

40

44

49

38

44

48

44

48

52

Page 10

OPTIONS

ELECTRIC HEATER (only for CWC 020-030-040-070-090 2P). TECHNICAL DATA

POWER

VOLTAGE

1.5 kWCWC 020 2P

230 V 1Ph -50Hz

2 kWCWC 030-040 2P

2.5 kW / 4 kWCWC 070-090 2P

230 V 1Ph -50Hz

230 V / 400 V 3Ph-50Hz

Side knockouts panel are provided. One to connect a fresh air inlet duct, and another to connect an air distribution

duct to deliver air to an adjacent room.

FRESH AIR MAKE UP (FIG. 5)

INSTALLATION

Remove the 68 mm insulation material and cut out the prepunched side knockouts.

Secure the duct connection flange to the unit. Conducts can be of flexible polyester type or corrugate aluminium,

externally covered with anticorrosion material.

Install a supplementary fresh air fan for the introduction of fresh air into the unit. The fan motor must be controlled

by an ON-OFF switch.

Fresh air flow must be less than 10% of the total air flow, to avoid operating problems. A speed controller should

be installed in the supplementary fan motor, for adjusting the air flow.

AIR SUPPLY TO AN ADJACENT ROOM (FIG. 6)

INSTALLATION

Remove the 150 mm insulation material and cut out the prepunched side knockouts. For models 600x600, the

two prepunched side knockouts must not be used at the same time to provide conditioned air to an adjacent

room. For models 600x1200, do not use the same fan to provide air conditioned to both ducts.

Cut away the polystyrene around the inside edge of the opened panel, remove the polystyrene.

Use a duct connection flange and a suitable duct.

Air supply to an adjacent room requires that outlet corresponding with the duct is closed.

An air inlet grille must be fitted (if possible near the floor) between the air conditioned room (where the unit is

situated) and the adjacent room.

Conducts can be of flexible polyester type or corrugate aluminium, externally covered with anticorrosion material.

The duct length can be calculated by taking into account the pressure drop through the unit, using the following

table:

Air flow supplied to an adjacent room in m

UNIT/MODELS

Air flow

Available

pressure

600x600 600x1200

Duct connection Ø75 mm (*)

Duct Ø125mm

Air inlet grille and filter

CWC 020-030 2P

CWC 020-030 4P

m3/h

Pa

Fan (*)

Reduction

125-75mm (*)

175 100 25

0815

Air intake

Duct Ø125mm

Duct Ø150mm

FIG. 5

3

/h, fresh air fan at high speed:

CWC 040 2P

CWC 040 4P

200 100 25

01020

Duct connection Ø75 mm (*)

Reduction

125-75mm (*)

Conic tapping

150x125 (*)

Fan (*)

Air inlet grille

and filter

Air intake

CWC 050 2P

CWC 050 4P

250 125 25

02030

600x600 600x1200

Duct connection

Ø150mm flange

and clip (*)

FIG. 6

(*) Elements included in optional kit

CWC 070 2P

CWC 070 4P

400 200 50

01020

Insulated flexible

duct Ø150

Grille

CWC 090 2P

CWC 090 4P

500 250 50

02030

Duct connection Ø150mm

flange and clip (*)

Grille

Insulated flexible

duct Ø150

9

Page 11

OPTIONS

WATER CONTROL VALVE KIT (2 AND 3 WAYS, ON/OFF AND PROPORTIONAL)

MODEL 600x600

2 PIPES SYSTEM 4 PIPES SYSTEM

Water control valve

(3 ways)

NOTE THE CORRECT

POSITION OF THE

WATER CONTROL

VALV E

MODEL 600x1200

Water control valve

(3 ways) proportional

Coupling

Water connection

Main wire

Auxiliary drip tray

Condensate

pump flexible

hose

Air vent

Water control valve

Condensate

pump flexible

hose

Auxiliary drip tray

2 PIPE SYSTEM

Water control valve

Air vent

Main wire

Hot water control valve

Cool water control valve

Connect each valve ON/OFF

to its corresponding connector

(cooling connector and

heating connector).

4 PIPE SYSTEM

CAUTION

Auxiliary drip tray

Connecting

flexible hose

Drain tube from

auxiliary drip tray

Drain tube from

drip tray

AUXILIARY DRIP TRAY

Main wire

Auxiliary

drip tray

NOTE THE CORRECT

POSITION OF THE

WATER CONTROL

VALV E

Main wire

Hot water

control valve

Auxiliary drip tray

Install the auxiliary drip tray as shown in the illustration.

Connect the drain tube from drip tray to the auxiliary drip tray.

The condensate drains from auxiliary drip tray will be pumped away.

NOTE: Proportional valves, must be connected to a proportional

Drain tube from

auxiliary drip tray

flow regulation control (not included in optional kit)

FITTING & TESTING VALVES

It includes fitting and testing valves and in addition auxiliary drip tray is included too.

WATER EVACUATION SECURITY

With this option, water pump works if there is an over flow in the drip tray.

Auxiliary

drip tray

Connecting flexible hose

Cool water

control valve

Drain tube from

drip tray

10

Page 12

DIMENSIONS

MODELS 600 x 600

23.5

91

121

247

PLASTIC DIFFUSER

Air vent

Ø150

72

32

40

4 x hanging brackets (M 8)

Outlet water

connection 1/2 G

Inlet water

connection 1/2 G

Electrical cable

entry point

247

121

Outlet hot water

72

32

23.5

61

91

40

connection 1/2 G

Inlet hot water

connection 1/2 G

Inlet cool water

connection 1/2 G

Outlet cool water

connection 1/2 G

4 PIPES SYSTEM2 PIPES SYSTEM

METALLIC DIFFUSER

575

Air vent

4 x hanging

brackets (M 8)

Electrical cable

Ø 150

entry point

Drain tube 16mm OD

Condensate pump flexible

hose 10mm ID 15mm OD

30.6

54.66

284

46.5

720

489.74

489.74

575

54.66

17.5

540

17.5

30.6

CASSETTE UNIT

720

Drain tube 16mm OD

Condensate pump flexible

hose 10mm ID 15mm OD

30

284

46.5

619

619

575

CASSETTE UNIT

123

143

Fresh air knockout panel

for branch duct

Ø68

Ø150

PLASTIC DIFFUSER PANEL

Branch duct knockout hole, to supply air

into adjacent area

196

273

298

Fresh air knockout panel

for branch duct

11

143

123

Ø68

Ø150

METALLIC DIFFUSER PANEL

Branch duct knockout hole, to supply air

into adjacent area

196

273

298

Page 13

DIMENSIONS

30

90

MODELS 600 x 1200

Outlet hot water

connection 1/2''G

Outlet cool water

connection 3/4''G

Inlet cool water

connection 3/4''G

197

152

2 PIPES SYSTEM 4 PIPES SYSTEM

Outlet cool water

connection 3/4''G

Inlet cool water

connection 3/4''G

Inlet hot water

connection 1/2''G

PLASTIC DIFFUSER

Condensate pump flexible hose

10 mm ID 15 mm OD

75

251

Ø150

4x Hanging brackets

Branch duct knockout hole, to supply

air into adjacent area

17.5

Auxiliary electrical board

24

63

Electrical cable entry point

Drain tube 16 mm OD

1140

Main electrical board

284.8

17.5

123

720

75

251

Ø 150

24

4x Hanging brackets

Branch duct knockout hole, to supply

air into adjacent area

METALLIC DIFFUSER

Condensate pump flexible hose

10 mm ID 15 mm OD

1140

284.8

63

Drain tube 16 mm OD

1140

Electrical cable entry point

123

619

29.5 51.9493.6

Fresh air knockout panel

for branch duct

143

527

46.5

Ø68

196

527

273

121

1320

575

CASSETTE UNIT

PLASTIC DIFFUSER PANEL

298

12

1219

37

575

46.5

Ø68

143

Fresh air knockout panel

for branch duct

CASSETTE UNIT

METALLIC DIFFUSER PANEL

196

273

298

Page 14

UNIT INSTALLATION

1. The unit should be positioned centrally within the room. The ceiling must be horizontal to ensure that the unit

is on level and that condensate water can drain away thoroughly. The unit must be installed in a position where

there is sufficient strength in the structure to support the weight of the unit. The false ceiling must have at less a

height of 308 mm.

MODEL 600x600

MODEL 600x1200

Cassette

unit

308

Diffuser panel

2.

Ensure there is sufficient space around the unit to service it. Where there is a false ceiling, ensure that there is

308

Diffuser panel

Cassette

unit

enough space to provide access. Where there is a false panelled ceiling ensure that there is sufficient adjacent

space to remove the panels.

MODEL

600x600

(**)

INSTALLATION CLEARANCES

Min.500

(**)

720

720

298

Min.500

(**)

MODEL

600x1200

Min. 500

(**)

Min. 500

(**)

3. Models 600x600: cut the false ceiling to a maximum dimension of 625x625mm. For a panelled ceiling remove

one panel of 600x600mm.

Models 600x1200: cut the false ceiling to a maximum dimension of 625x1225mm. For a panelled ceiling remove

two panels of 600x600 or one of 600x1200mm.

4. Install the suspension rods to the ceiling, the rods should

have three nuts and two washers, as in next figure. The

setting up template can be used to indicate the position for

the suspension rods.

NOTE: Before marking the fixing points to the ceiling,

ensure that the unit is positioned in the correct orientation

taking into account of where the electrical cabinet is required.

Ensure that water pipes can be run easily. When the unit

is fixed it is not easy to change position.

1

2

Nut

Washers

Suspension rods M-8

1

2

2

1

1

SETTING UP TEMPLATE MODEL 600x1200SETTING UP TEMPLATE MODEL 600x600

575

Fixing

points

575

54.66

30.6

489.74

489.74

30.6

54.66

17.5

540

17.5

42.5 42.5

600

5. The water connections should be positioned before unit is installed.

13

1140

Fixing points

1225

55.2

493.6

51.2

Page 15

UNIT INSTALLATION

6. For Models 600x600, to facilitate the connections of water pipes and the drain tube, is advisable to disassemble

the supporting bracket situated on this corner. Once the installation is completed, the bracket must be reassembled.

7. When lifting the cassette into position care should be taken not to lift the unit by the drip tray, water connection

or drain tube; these elements could be damaged. The cassette should be lifted by the hanging brackets. The hanging

brackets should be insulated with the supplied insulation.

8. The cassette brackets hook over the washer.

MODEL 600x600 MODEL 600x1200

Tighten the cassette with the lower nuts.

9. Check to ensure the unit is level. The drain

will then automatically be lower than the rest of

the drip tray.

10. Tighten the nuts on the suspended rods to ensure a distance of 25 mm between the bottom face of the body

of the unit and false ceiling.

MODEL 600x600 MODEL 600x1200

PLASTIC DIFFUSER

False

ceiling

25

False

ceiling

25

Plastic diffuser panel

25

Metallic diffuser panel

25

METALLIC DIFFUSER

False

ceiling

25

False

ceiling

25

Plastic diffuser panel

25

25

Metallic diffuser panel

14

Page 16

ELECTRICAL CONNECTIONS

MODELS

600x600

MODELS

600x1200

2

1

UNIT

CWC020 2P / CWC030 2P

CWC040 2P/ CWC050 2P

CWC 020 4P / CWC 030 4P

CWC 040 4P / CWC 050 4P

CWC070 2P / CWC090 2P

CWC070 4P / CWC090 4P

1

2

Power supply

Thermostat

connections

VOLTAGE

50Hz

230 V / 1Ph

230 V / 1Ph

230 V / 1Ph

230 V / 1Ph

MODELS 600 x 600

POWER SUPPLY WIRING

This equipment must be installed in accordance

with national regulations. A suitable means of

disconnecting all supply poles must be provided

in the power supply wiring. The power supply must

incorporate suitably rated fused or circuit breaker

protection.

NUMBER OF WIRES X SECTION

COOL WATER COOL AND HOT WATER

1 1

3 X 1.5mm

3 X 1.5mm

3 X 1.5mm

2

2

2

2

7 X 1.5mm

7 X 1.5mm

7 X 1.5mm

---- ----

2

3 X 1.5mm

2

3 X 1.5mm

2

3 X 1.5mm

2

2

2

3 X 1.5mm27 X 1.5mm

2

8 X 1.5mm

7 X 1.5mm

8 X 1.5mm

2

2

2

2

CWC 2P

CWC 2P

CHILLED WATER CHILLED WATER AND HOT WATER

01 2 342 512

230V/50HZ 1Ph + N

CWC 4P

CHILLED WATER

578123

46

678

578123

46

THERMOSTAT

CASSETTE UNIT

ELECTRIC WIRING DIAGRAM

For electrical connection refer to

wiring diagram

in the unit.

THERMOSTAT

01 2 342 512

230V/50HZ 1Ph + N

CWC 4P

CHILLED WATER AND HOT WATER

578123

46

678

578123

46

RC 311-X2

01 2 342 512

230V/50HZ 1Ph + N

678

CASSETTE UNIT

01 2 342 512

230V/50HZ 1Ph + N

678

MODELS 600 x 1200

CWC 2P-4P

CHILLED WATER CWC 070-090 2P

CHILLED WATER AND HOT WATER CWC 070-090 4P

CWC 2P

CHILLED WATER AND HOT WATER

CWC 070-090 2P

01 2 342 512

230V/50HZ 1Ph + N

578123

46

678

THERMOSTAT

RC-311-X2

CASSETTE UNIT

15

01 2 342 512

230V/50HZ 1Ph + N

578123

46

678

Page 17

ELECTRICAL CONNECTIONS

Electric shock hazard can cause

WARNING

MODEL 600x1200MODEL 600x600

injury or death. Before attempting

to perform any service or

maintenance on the unit, turn OFF

the electrical power, and check that

the fan has stopped.

Cover plate for

electrical box

Terminal

plate

cover

Cover plate

for auxiliary

electrical box

Cover plate for

electrical box

Terminal

plate

cover

ACCESS TO THE ELECTRICAL COMPONENTS OF THE UNIT

Removing the corresponding plate cover screws gives access to the electrical board and terminal plate, as indicated on the

drawing.

ELECTRICAL WIRING DIAGRAM

For electrical connection refer to wiring diagram in the unit.

1

2

3

Electrical inlets, power supply and remote controller.

1

2

Terminal plate.

3

Electrical connections

(it depends on versions).

DRAIN PIPEWORK

MODELS 600 x 1200MODELS 600 x 600

Condensate

Condensate

pump flexible

hose

Drain tube

CONDENSATE PUMP FLEXIBLE HOSE

The unit is fitted with a condensate pump to ensure condensate removal.

To ensure that there is condensate flow, the drain tube must be installed with a fall of 2% without obstructions, or without

rising sections.

To avoid any unpleasant odours from the drainage system a trap must be fitted with a trap depth of no less than 50 mm.

The condensate pump has a maximum lift of 200 mm. The rising tube must be always vertical.

On completion the drain line must be insulated.

pump flexible

hose

Drain tube

Max.200mm

2%

2%

50

DRAIN TUBE

The drain tube is connected to drip tray.

This drain tube is supplied with a cap; the cap can be removed when it is necessary to remove any water that accumulates

in the drip tray.

16

Page 18

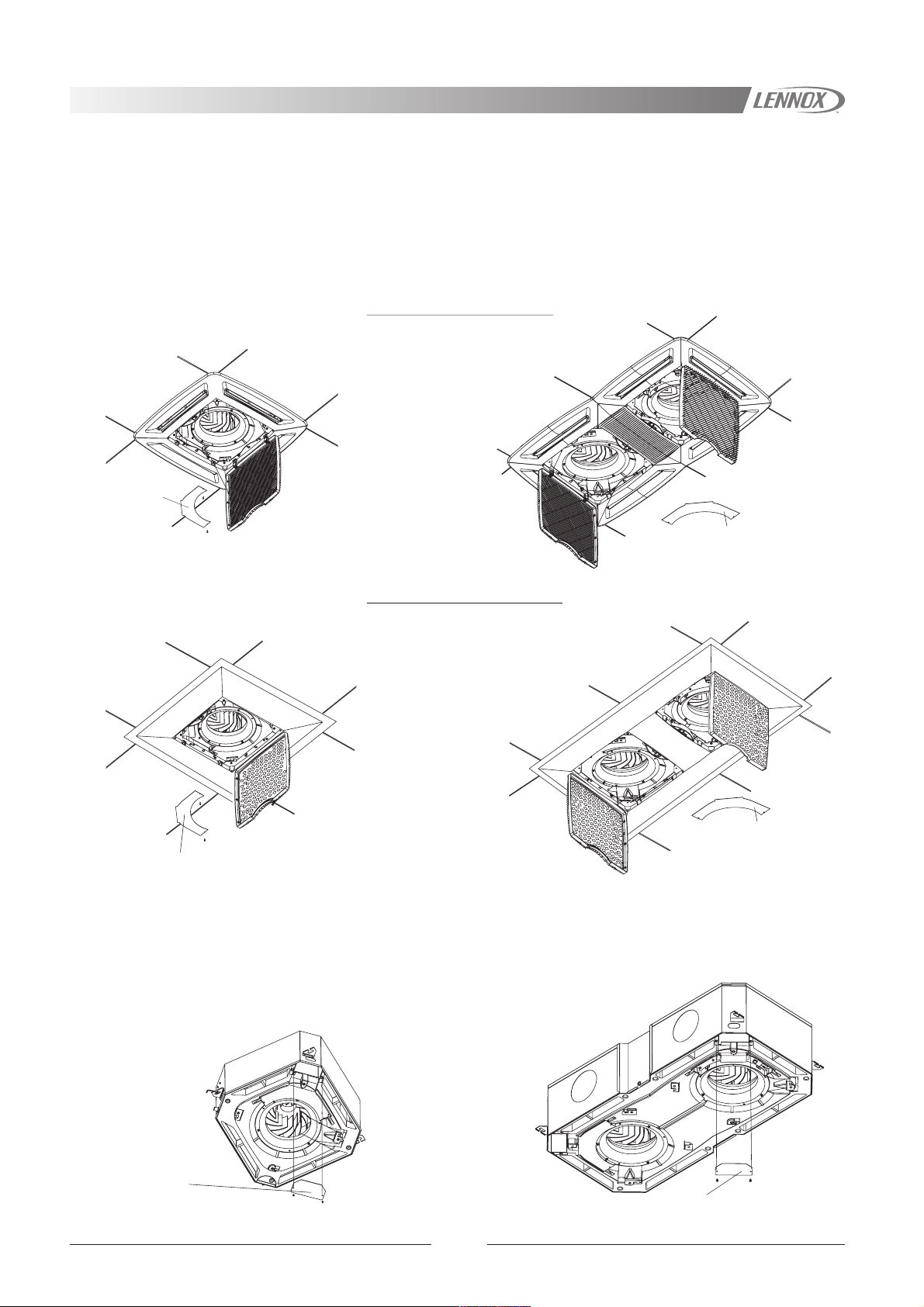

INSTALLATION OF DIFFUSER AND INLET GRILLE

WARNING: Electric shock hazard can cause injury or death. Before attempting to perform any service or maintenance

MOUNTING THE DIFFUSER PANEL TO THE UNIT

Check that the position in which the diffuser is mounted is the right one.

1. - Release the air intake grille.

2. - The diffuser panel can then be provisionally positioned on the cassette using the fixing clips.

3. - The diffuser is fastened with the bolts supplied.

4. - Make sure that the frame has not been deformed in the installation, by an excessive tighten of the bolts. There must be

no recirculation of air between intake and outlet air paths.

The diffuser panel is sealed with insulation to avoid air gaps between the unit and the air panel. The insulation can be compressed

from 8 mm to 3 mm, allowing the panel to be tightened to the cassette by up to 5 mm.

MOUNTING THE AIR INTAKE GRILLE AND FILTER ASSEMBLY

1.- The grill fixing hooks should be fitted into the holes provided.

2.- The stays need to be placed between the diffuser and the inlet grille.

3.- The grille is mounted on the diffuser via two hand triggers. Initially pull

off the hand triggers, then insert the grille into the diffuser and release

the hand triggers. When this operation is completed the grille is

attached to the diffuser.

MODEL 600x600

Diffuser

on the unit, turn OFF the electrical power, and check that the fan has stopped.

PLASTIC DIFFUSER PANEL

MODEL 600x1200

Unit

Hooks

DETAIL A

panel

Swing motor

Air filter

Hooks

Stays

Air intake

grille

A

Hand triggers

Swing motor

Stays

Hand

triggers

Unit

Diffuser panel

Swing

motor

Air intake grille

A

Air filter

METALLIC DIFFUSER PANEL

MOUNTING THE DIFFUSER PANEL TO THE UNIT

1.- Release the air intake grille on the unit.

Open the grille by way of one hand trigger, which is close to the Lennox brand. The grille will swing down supported by two

screws located on the opposite side of the hand trigger.

2.- Fix the bolts supplied (Do mot used other kind of bolts), to the unit (Do not fasten at moment).

3.- The diffuser is positioned on the cassette, by introducing the bolts supplied on the hole through the bigger part (see detail

A) and displace the diffuser to the small part of the hole. Then fasten the four bolts supplied to the unit.

4.- Make sure that the frame has not been deformed in the installation, by an excessive tighten of the bolts. There must be no

recirculation of air between intake and outlet air paths.

The diffuser panel is sealed with insulation to avoid air gaps between the unit and the air panel. The insulation can be compressed

from 8 mm to 3 mm, allowing the panel to be tightened to the cassette by up to 5 mm.

MODEL

Cassette unit

MODEL 600x1200

Cassette unit

600x600

Air filter

Diffuser

panel

Detail A

Air grille

B

Trigger

DETAIL A

DETAIL B

Detail A

Diffuser

panel

Triggers

A

Air grille

B

Air filter

17

Page 19

MAINTENANCE

WARNING: Electric shock hazard can cause injury or death. Before attempting to perform any service or maintenance

on the unit, turn OFF the electrical power, and check that the fan has stopped.

ALWAYS INSTALL THE FILTER

If the unit operates without the filter, there is a risk of damaging the unit through dust contamination.

CLEANING THE AIR FILTER

PLASTIC DIFFUSER PANELPLASTIC DIFFUSER PANEL

1.- Stop the unit.

2.- Open the air intake grille on the unit.

Open the grille by way of two hand triggers. The grille will swing down supported by the stays and the hooks.

3.- Release the air intake grille from de unit.

To release the grille pull it down until the stays can be unlock from the diffuser, then pull it back to an angle greater of 90º and

lift it lightly, finally the grille hooks will come away from the diffuser.

4.- Remove the air filter once the air intake grille has been released

Clean the air filter depending on the operation conditions and working time, (approximately once every 6 months).

Use a vacuum cleaner to clean dust off. If the filter is too dirty, wash it with water and neutral detergent. Dry the filter before

re-fitting.

5.- Replace the filter in the right position.

6.- Close the air intake grille.

Place the hand triggers on position again.

HOOKS

MODEL

600x600