Lennox Compactair LVHA 24E, Compactair LVHA 38E, Compactair LVHA 28E, Compactair LVHA 32E, Compactair LVHK 22E Installation, Operation & Maintenance Manual

...Page 1

COMPACTAIR

LVCK / LVHK

English/03-2005

INSTALLATION

OPERATION &

MAINTENANCE MANUAL

Page 2

1

WARNING: Read this manual before installation, reparation o maintenance works.

1.1.- PHYSICAL DATA

1.2.- ELECTRICAL DATA

1.3.- FAN PERFORMANCES

1.4.- OPERATING LIMITS

1.5.- UNIT DIMENSIONS

1.6.- AVAILABLE OPTIONS

PAGE

PAGE

PAGE

PAGE

4-5

6

7-10

11

12-17

18-33

34

34

35-36

37

38

39

39

40-43

44

45

46

47

48

PAGE 3

2.1.- INSTALLATION GUIDELINES

2.2.- UNIT INSTALLATION

2.3.- OPTIONAL TASK PRIOR TO UNIT INSTALLATION:

CHANGING THE POSITION OF DISCHARGE AND AIR INTAKE

2.4.- OPTIONAL TASK PRIOR TO UNIT INSTALLATION:

FLOW REGULATION IN THE FANS

2.5.- UNIT LOCATION

2.6.- INSTALLATION CLEARANCES

2.7.- DRAINS

2.8.- ELECTRICAL CONNECTIONS

POINTS TO KEEP IN MIND

PAGE 2

3.1.- PRELIMINARY CHECKS

3.2.- STEPS TO FOLLOW FOR COMMISSIONING THE UNIT

4.1.- PREVENTIVE MAINTENANCE

4.2.- CORRECTIVE MAINTENANCE

4.3.- FAILURE DIAGNOSIS

4.- MAINTENANCE

DATA PAGE FOR UNIT COMMISSIONING

2.- INSTALLATION

3.- COMMISSIONING AND OPERATION

1.- GENERAL CHARACTERISTICS

TABLE OF CONTENTS

Lennox have been providing environmental solutions since 1895, our range of COMPACTAIR continues to meet the standards

that have made LENNOX a household name. Flexible design solutions to meet YOUR needs and uncompromising attention

to detail. Engineered to last, simple to maintain and Quality that comes as standard. Information on local contacts at

www.lennoxeurope.com.

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be utilised (except in the operation of this product), reproduced,

issued to or made available to third parties without the prior written agreement of Lennox.

Page 3

2

Risk of injury with

rotating objects

Low

temperatures

High

temperatures

Risk of injury with

moving objects

Electrical

voltage

Abrasive

surfaces

FILTER CLEANING

Check the air filter and make

sure it is not blocked with dust

or dirt.

If the filter is dirty, wash it in a bowl with neutral

soap and water, drying it in the shade before

inserting it in the unit.

All technical data contained in these operating instructions including the diagrams and technical description remains the property

of Lennox and may not be used (except for the purpose of familiarizing the user with the equipment), reproduced, photocopied,

transferred or transmitted to third parties without prior written authorization from Lennox .

The data published in the operating instructions is based on the latest information available. We reserve the right to make

modifications without notice.

We reserve the right to modify our products without notice without obligation to modify previously supplied goods.

These operating instructions contain useful and important information for the smooth operation and maintenance of your

equipment.

The instructions also include guidelines on how to avoid accidents and serious damage before commissioning the equipment

and during its operation and how to ensure smooth and fault-free operation. Read the operating instructions carefully before

starting the equipment, familiarize yourself with the equipment and handling of the installation and carefully follow the instructions.

It is very important to be properly trained in handling the equipment. These operating instructions must be kept in a safe place

near the equipment.

Like most equipment, the unit requires regular maintenance. This section concerns the maintenance personnel and management.

If you have any queries or would like to receive further information on any aspect relating to your equipment, do not hesitate

to contact us.

The air filter cleaning operations do not

require technical service; however when

an electrical or mechanical operation

is required call an Engineer.

Electric shock hazard can cause injury

or death. Before attempting to perform

any service or maintenance on the

unit, turn OFF the electrical power,

and check that the fan has stopped.

Standard Guidelines to Lennox equipment

POINTS TO KEEP IN MIND

DANGER AND WARNING SIGNS

Make sure to open the power off switch before to install, repair or make maintenance works in the unit, in order to

prevent serious electrical injuries.

To install the unit, keep in mind local and national legislation.

ELECTRICAL CONNECTIONS

ATTENTION - WARNING

Page 4

3

DATA INPUT:

COLD CYCLE

HEATING CYCLE

ºC

ºC

ºC

ºC

Fan outdoor section 1

Fan outdoor section 1

circuit 1

circuit 2

circuit 1

circuit 2

ºC

1

ºC

2

ºC

1

ºC

2

ºC

1

ºC

2

ºC

1

ºC

2

circuit 1

circuit 2

circuit 1

circuit 2

Fan outdoor section 2

Fan outdoor section 2

Compressor 1 Compressor 2 Compressor 1 Compressor 2

Air Intake Temperature, Indoor Coil:

Air Output Temperature, Indoor Coil:

High Pressure:

Low Pressure:

Options Installed:

High Pressure:

Low Pressure:

Comments:

ELECTRIC POWER CONSUMPTION

Fan indoor section

(Amps)

Air Intake Temperature, Outdoor Coil:

Air Output Temperature, Outdoor Coil:

Air Intake Temperature, Indoor Coil:

Air Output Temperature, Indoor Coil:

INSTALLATION ADDRESS:

INSTALLER:

INSTALLER TEL.:

CHECKS:

SUPPLY VOLTAGE:

DATE OF COMMISSIONING:

INSTALLER ADDRESS:

RATED VOLTAGE OF THE UNIT:

YES NO

GENERAL POWER SUPPLY CONNECTION

CONTROL PANEL CONNECTION

COMPRESSOR OIL LEVEL INDICATOR

UNIT ON SHOCK ABSORBERS

DRAINAGE WITH TRAP

CLEAN INTERIOR AIR FILTER

CONTROL PANEL IDENTIFICATION CODE

Air Intake Temperature, Outdoor Coil:

Air Output Temperature, Outdoor Coil:

Fan indoor section

DATE PAGE FOR UNIT COMMISSIONING

UNIT:

SERIAL Nr.:

Page 5

4

kW

Kg

kW

kW

kW

Pa

m /h.

3

(1)

m /h.

3

Pa

m /h.

3

m /h.

3

Kg

gr.

gr.

(*)

(**)

(*)

(**)

LVCK

LVHK

(1)

LVCK 22E

LVHK 22E

LVCK 24E

LVHK 24E

LVCK 28E

LVHK 28E

LVCK 32E

LVHK 32E

LVCK 38E

LVHK 38E

LVHA 22E LVHA 24E LVHA 28E LVHA 32E LVHA 38E

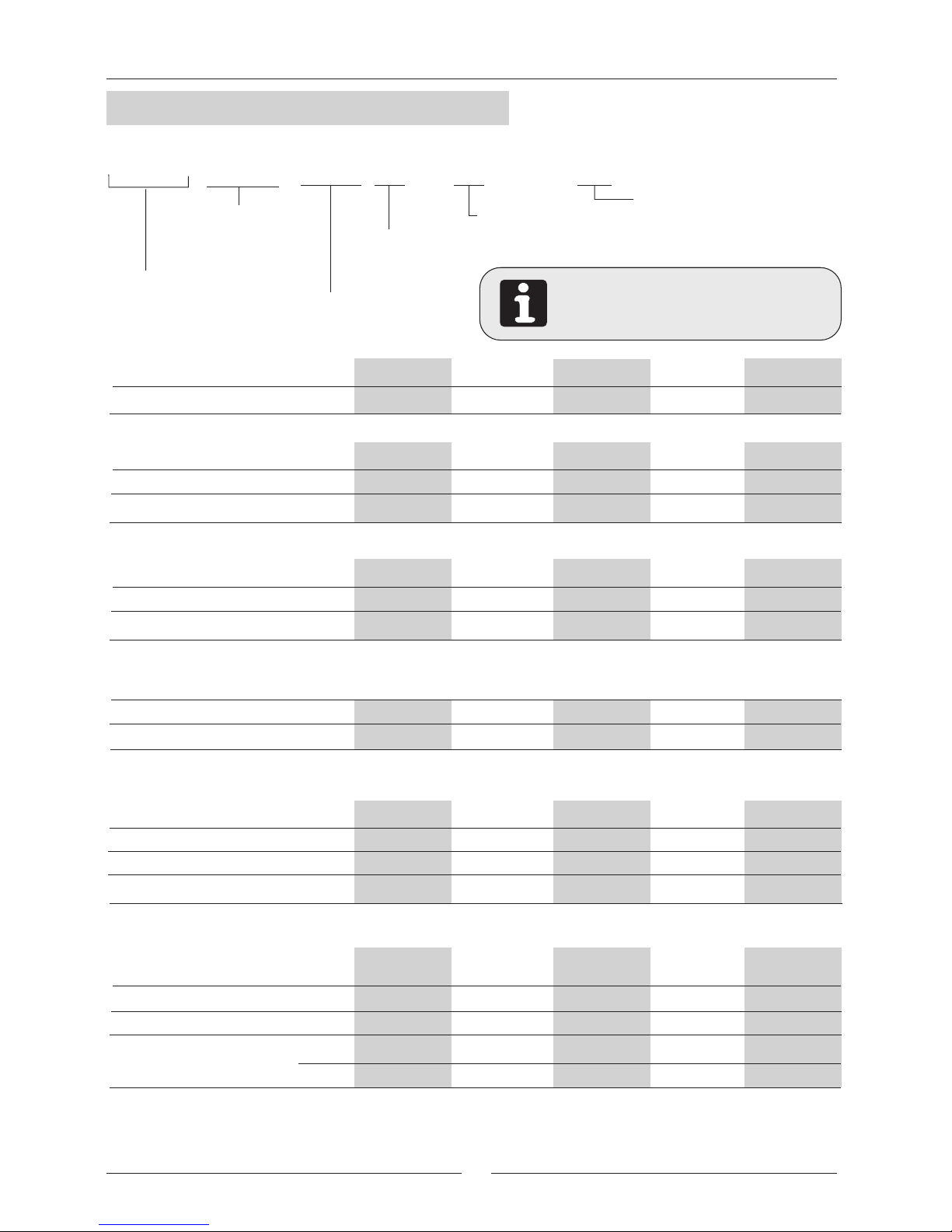

Cooling capacity

COMPRESSOR

FAN OUTDOOR SECTION

NET WEIGHT

Heating capacity

Refrigerant charge R-22

Refrigerant charge

R-407C

Maximum air flow

Maximum available pressure

Minimum air flow

FAN INDOOR SECTION

(1) With admissible minimum air flow.

UNIT MODELS

UNIT MODELS

Cooling only units

Heat pump units

UNIT MODELS

Maximum air flow

Maximum available pressure

Minimum air flow

1 / Scroll

22E

19,50

20,20

19,20

20,40

5100

5700

5600

170

7550

3500

205

4700

310

6000

1 / Scroll

24E

22,00

22,50

21,50

22,70

5600

6250

5600

160

7350

3900

195

5100

370

6550

1 / Scroll

28E

26,50

27,00

26,00

27,30

6700

7400

5600

140

7100

4500

250

5850

385

7500

1 / Scroll

32E

28,70

30,30

28,10

30,90

7600

8450

6500

300

8000

4750

220

6000

390

8900

36,50

1 / Scroll

36,90

38E

35,80

37,60

10500

9500

9000

300

11000

5800

240

7300

505

10900

315 375 390 395 510

LVHA: Heat pump unit R-22

LVCK: Cooling only unit R-407C

LVHK: Heat pump unit R-407C

Type of Refrigerant

A: R-22

K: R-407C

LV C K 24

Type of unit

Vertical compact

COMPACTAIR

VFC

VFC: Voltage free contact

unit version.

------: Standard unit version.

E

E: One circuit

D: Two circuits

DB.- Dry bulb temperature

WB.- Wet bulb temperature

(*) Air intake temperature in the indoor exchanger: 27°C DB/19 °C WB

(*) Air intake temperature in the outdoor exchanger: 35 ºC DB

(**) Air intake temperature in the indoor exchanger: 20°C DB / 12 ºC WB

(**) Air intake temperature in the outdoor exchanger: 7°C DB / 6 ºC WB

Application

C: Cooling only

H: Heat pump

Approximately cooling

capacity in kW

1.1.- PHYSICAL DATA

1.- GENERAL CHARACTERISTICS

Nr. / Type

Cooling capacity

Heating capacity

Page 6

5

kW

Kg

kW

kW

kW

Pa

m /h.

3

(1)

m /h.

3

Pa

m /h.

3

m /h.

3

Kg

gr.

gr.

(*)

(**)

(*)

(**)

LVCK

LVHK

(1)

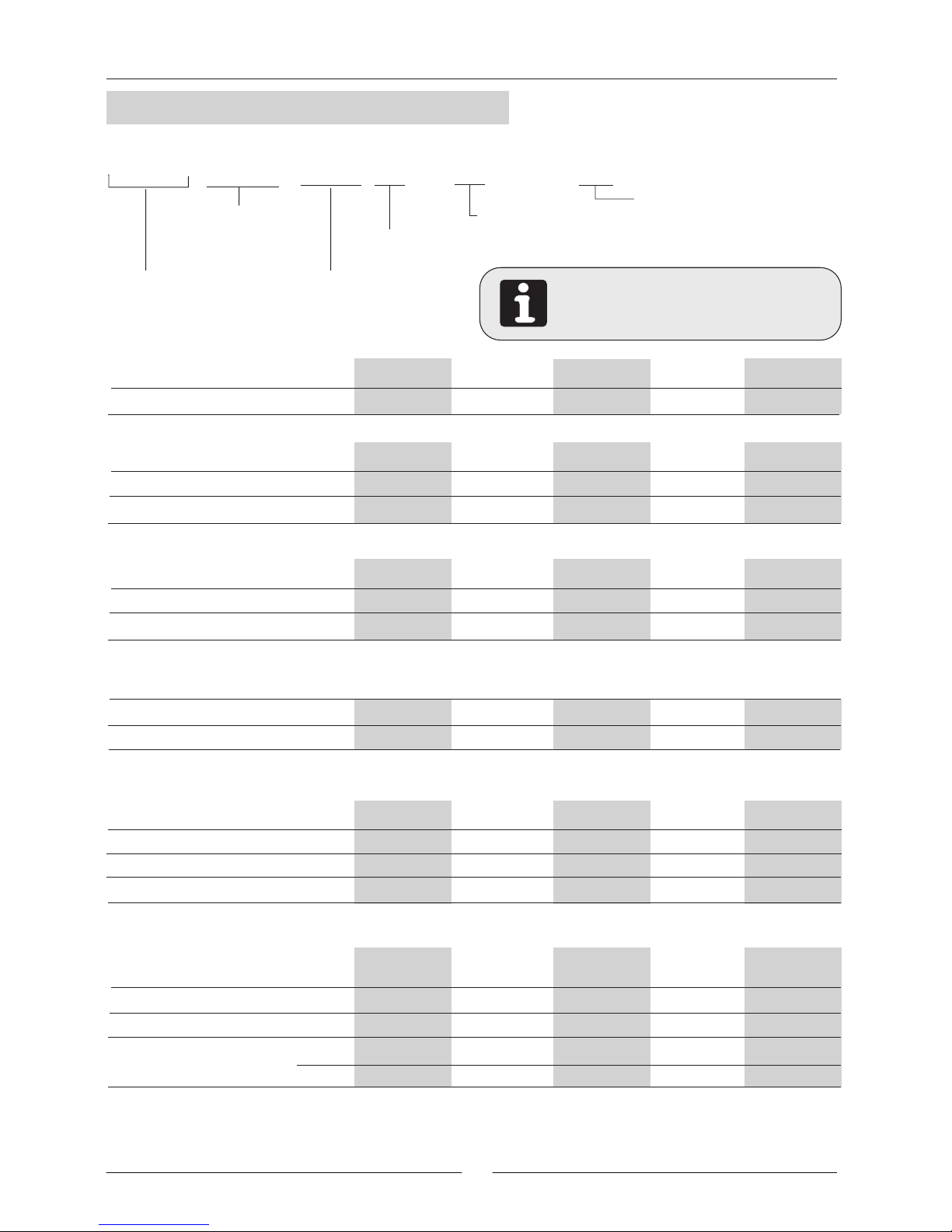

LVHA 44D LVHA 48D LVHA 56D LVHA 64D LVHA 76D

Cooling capacity

FAN OUTDOOR SECTION

NET WEIGHT

Heating capacity

Cooling capacity

Heating capacity

Refrigerant charge R-22

Refrigerant charge

R-407C

Maximum available pressure

Minimum air flow

FAN INDOOR SECTION

(1) With admissible minimum air flow.

UNIT MODELS

UNIT MODELS

Cooling only units

Heat pump units

UNIT MODELS

Maximum available pressure

Minimum air flow

Maximum air flow

Maximum air flow

2 / Scroll

44D

39,00

40,40

38,40

40,80

10200

11400

11200

170

15100

7000

205

9400

620

12000

2 / Scroll

48D

44,00

45,00

43,00

45,40

11200

12500

11200

160

14700

7800

195

10200

740

13100

2 / Scroll

56D

53,00

54,00

52,00

54,60

13400

14800

11200

140

14200

9000

250

11700

780

15000

2 / Scroll

64D

57,40

60,60

56,20

61,80

15200

16900

13000

300

16000

9500

220

12000

785

17800

73,00

2 / Scroll

73,80

76D

71,60

75,20

21000

19000

18000

300

22000

11600

240

14600

935

21800

LVCK 44D

LVHK 44D

LVCK 48D

LVHK 48D

LVCK 56D

LVHK 56D

LVCK 64D

LVHK 64D

LVCK 76D

LVHK 76D

630 750 790 795 945

LV C K

VFC

VFC: Voltage free contact

unit version.

------: Standard unit version.

24

E

Type of Refrigerant

A: R-22

K: R-407C

Type of unit

Vertical compact

COMPACTAIR

LVHA: Heat pump unit R-22

LVCK: Cooling only unit R-407C

LVHK: Heat pump unit R-407C

DB.- Dry bulb temperature

WB.- Wet bulb temperature

(*) Air intake temperature in the indoor exchanger: 27°C DB/19 °C WB

(*) Air intake temperature in the outdoor exchanger: 35 ºC DB

(**) Air intake temperature in the indoor exchanger: 20°C DB / 12 ºC WB

(**) Air intake temperature in the outdoor exchanger: 7°C DB / 6 ºC WB

Application

C: Cooling only

H: Heat pump

Approximately cooling

capacity in kW

E: One circuit

D: Two circuits

1.- GENERAL CHARACTERISTICS

1.1.- PHYSICAL DATA

COMPRESSOR

Nr. / Type

Page 7

6

V/f (50 Hz)

kW

kW

kW

kW

A

A

A

A

A

V/f (50 Hz)

kW

kW

kW

kW

A

A

A

A

A

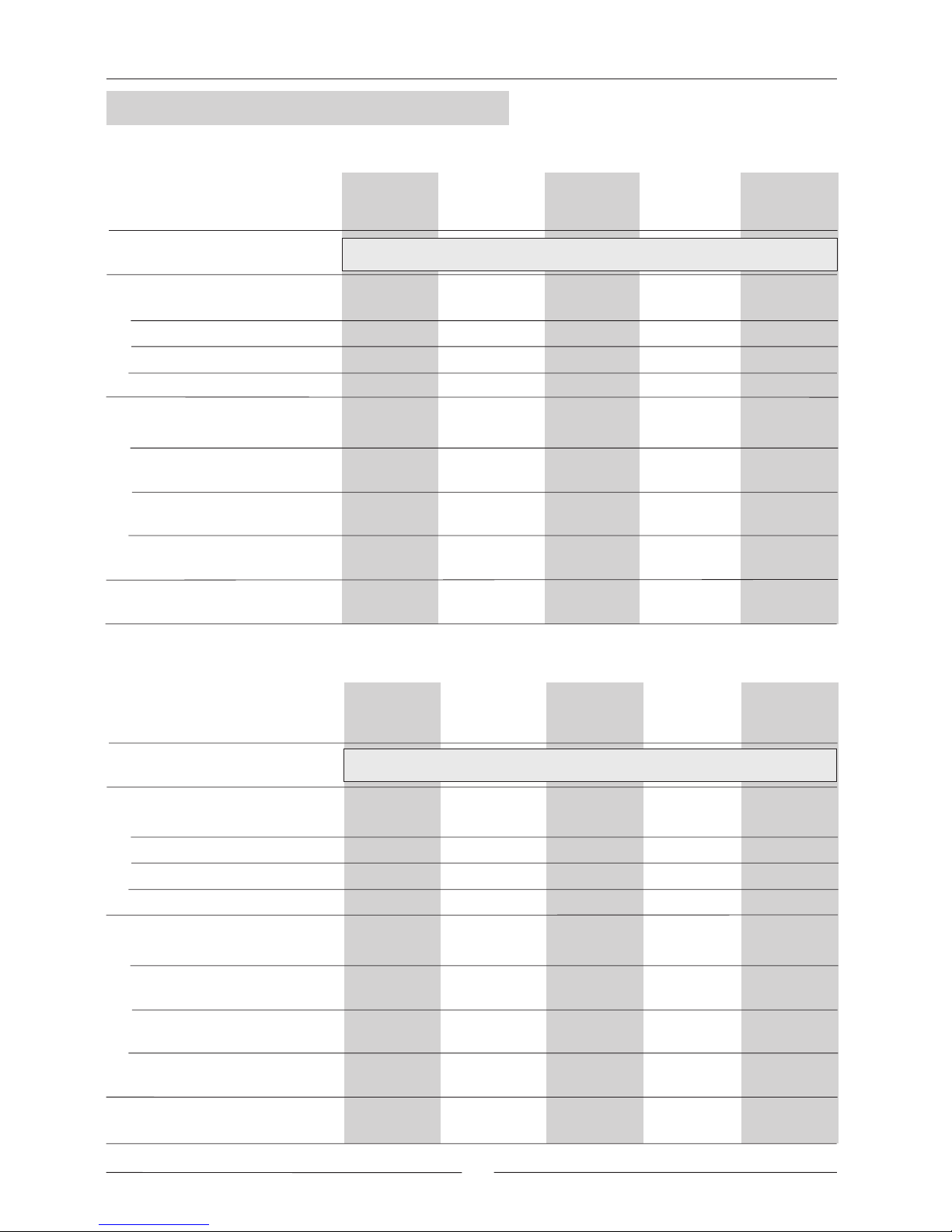

1.2.- ELECTRICAL DATA

Total power

Voltage

Maximum current

Maximum absorbed power

Total power

Voltage

Maximum current

Total current

Start up current

Maximum absorbed power

Total Current

Start up current

UNIT MODELS

Fan outdoor section

Fan outdoor section

Compressor

Fan outdoor section

Compressor

Compressor

Compressor

Fan outdoor section

Fan indoor section

UNIT MODELS

Fan indoor section

Fan indoor section

Fan indoor section

230V-400V/ 3Ph

33,1/19,1

188,7/107,2

4,3/2,5

6,4/3,7

22,4/12,9

1,3

2,2

7,6

11,1

35,0/20,2

176,7/105,2

24,3/14

1,4

2,2

8,62

12,2

4,3/2,5

6,4/3,7

6,2/3,6

6,4/3,7

28,5/16,4

1,5

2,2

11,15

14,9

41,1/23,7

222,6/130,3

6,2/3,6

8,8/5,1

1,8

2,5

12,9

17,2

51,5/29,7

239,0/135,7

36,5/21

2

2,8

15,55

20,4

64,8/36,4

297,7/168,8

6,2/3,6

12,5/7,2

46,1/25,6

LVCK 22E

LVHK 22E

LVHA 22E

LVCK 24E

LVHK 24E

LVHA 24E

LVCK 28E

LVHK 28E

LVHA 28E

LVCK 32E

LVHK 32E

LVHA 32E

LVCK 38E

LVHK 38E

LVHA 38E

230V-400V/ 3Ph

66,4/38,3

222,0/126,4

8,8/5,1

12,8/7,4

44,8/25,8

2,6

4,4

15,2

22,2

70,2/40,5

211,9/125,5

48,6/28

2,8

4,4

17,24

24,4

8,8/5,1

12,8/7,4

12,5/7,2

12,8/7,4

57/32,8

3

4,4

22,3

29,7

82,3/47,4

263,8/154,0

12,5/7,2

17,6/10,2

3,6

5

25,8

34,4

103,1/59,4

290,6/165,4

73/42

4

5,6

31,1

40,7

129,6/72,8

362,5/205,2

12,5/7,2

24,9/14,4

92,2/51,2

LVCK 44D

LVHK 44D

LVHA 44D

LVCK 48D

LVHK 48D

LVHA 48D

LVCK 56D

LVHK 56D

LVHA 56D

LVCK 64D

LVHK 64D

LVHA 64D

LVCK 76D

LVHK 76D

LVHA 76D

R-407C

R-22

1.- GENERAL CHARACTERISTICS

Page 8

7

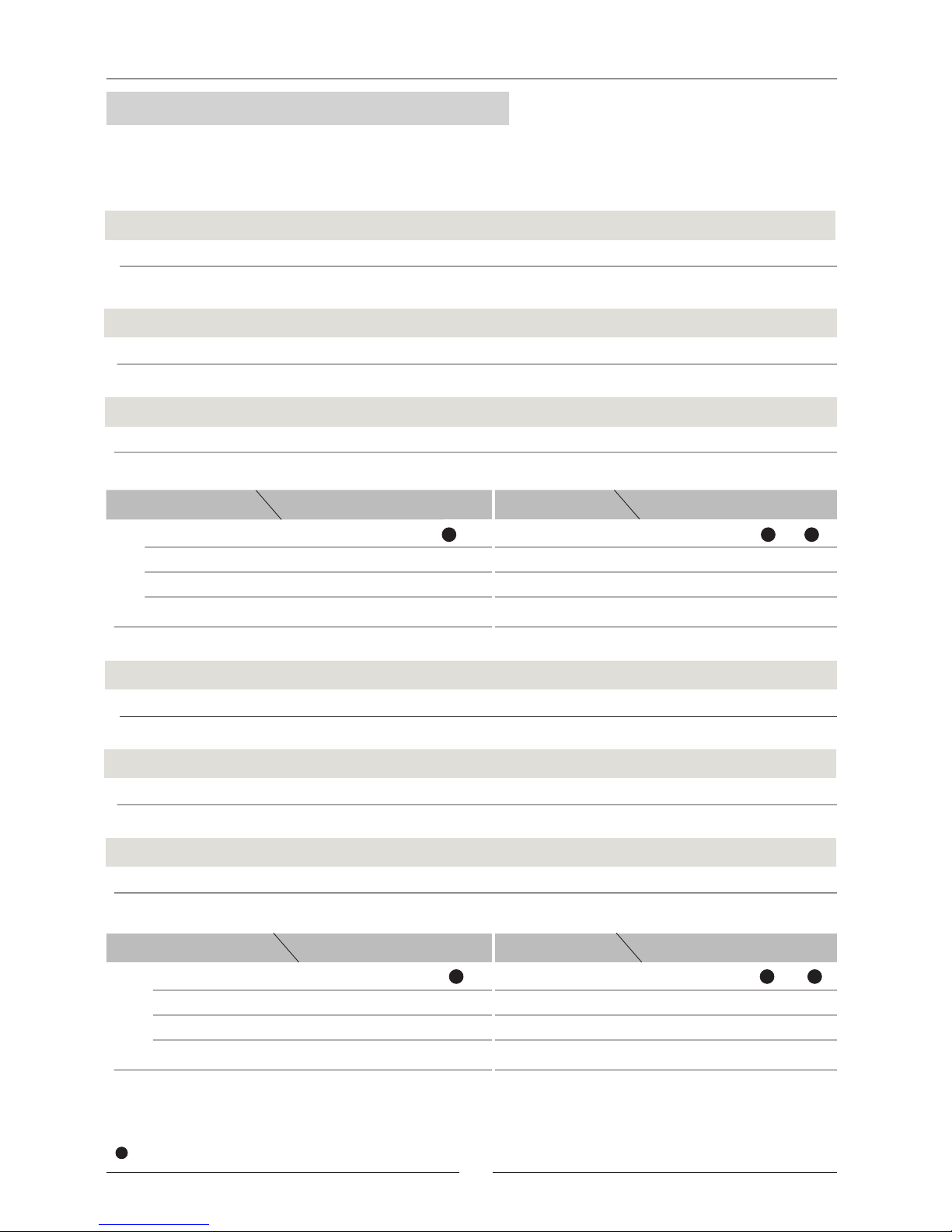

1.3.- STANDARD INDOOR FAN PERFORMANCES

PULLEY

POSITION

22E

3500 3900 4300 4700

24E

3900 4300 4700 5100

28E

4500 4950 5400 5850

32E

5250 5750 60004750

38E

48D

56D

7800 8600 9400 10200

9000 9900

10800

11700

44D

7000 7800 8600 9400

5800 6400 7000 7300

64D

76D

9500 10500 11500 12000

11600 12800 14000 14600

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

205*

165*

195*

150*

165*

125*

130* 115* 90*

105* 80* 60*

55*

20*

90*

195*

150*

165*

125*

130*

90*

115* 90* 55*

80* 60* 20*

15*

___

50*

250*

190*

200*

145*

95*

40*

145* 100* 0*

105* 55*

___

___

___

___

220*

165*

175*

115*

115*

50*

125* 65* 0*

80* 25*

___

___

___

1010

955

900

845

1010

955

900

845

890

840

790

740

890

840

790

740

130*

85*

30*

0*

70*

195*

150*

165*

125*

130*

90*

890

840

790

740

115* 90* 55*

80* 60* 20*

15*

___

50*

250*

190*

200*

145*

95*

40*

145* 100* 0*

105* 55* ___

___

___

85*

1010

955

900

845

30*

___

205*

165*

195*

150*

165*

125*

130* 115* 90*

105* 80* 60*

55*

20*

90*

890

840

790

740

130*

240*

190*

200*

150* 100*

1010

900

845

150* 110* 65*

105* 60* 15*

40*

0*

955

240*

190*

200*

150* 100*

150* 110* 65*

105* 60* 15*

40*

0*

1010

955

900

845

80* 25* ___

___

125* 65* 0* ___

165*

115* 50*

220* 175* 115*

0*

70*

1140

1070

995

920

(*)

( )

AVAILABLE STATIC PRESSURE Pa.

WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: The unit leaves factory with pulley two

turns opened.

1.- GENERAL CHARACTERISTICS

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

Page 9

8

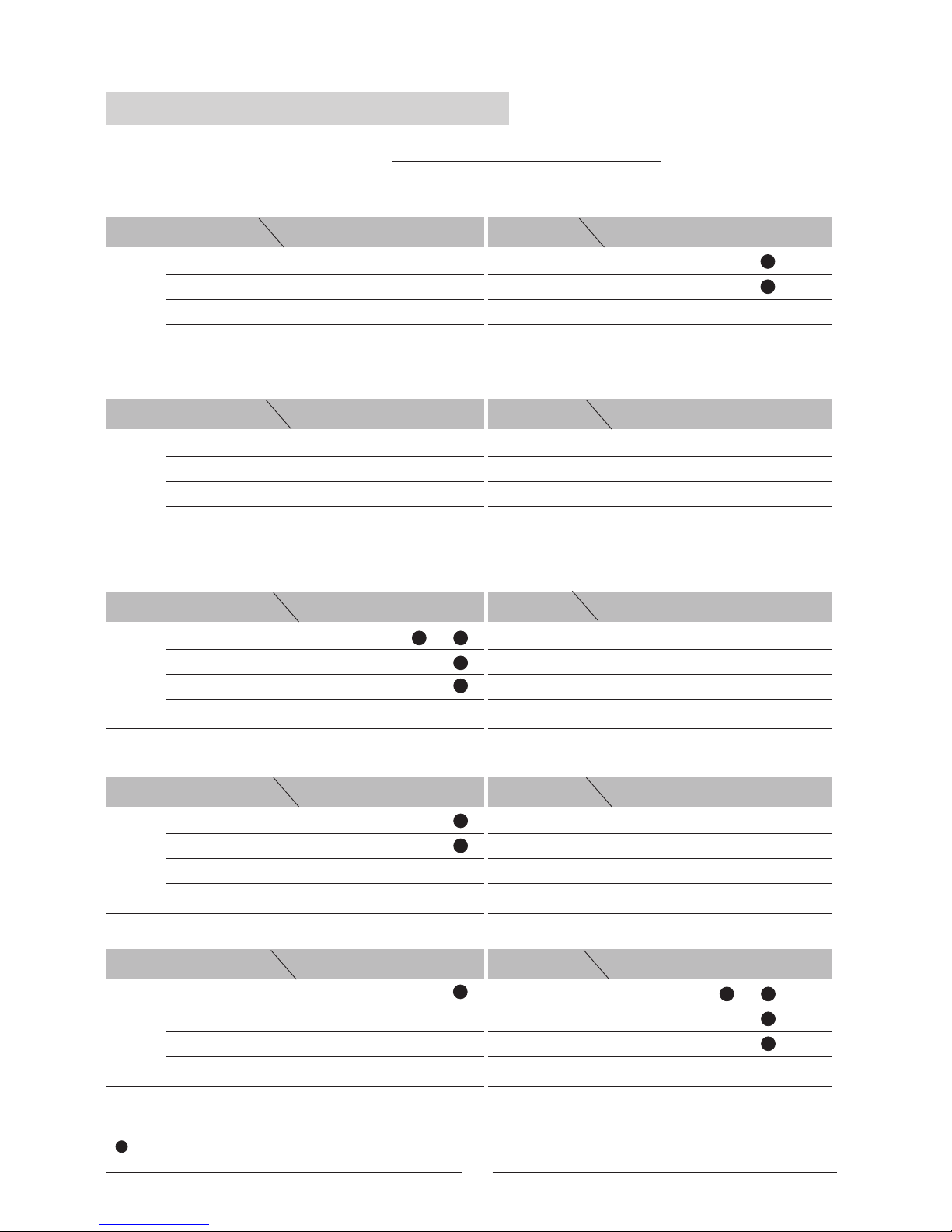

1.3.- STANDARD OUTDOOR FAN PERFORMANCES

22E

24E

28E

32E

38E

5600 6325

7350

5600 6325

7550

AVAILABLE STATIC PRESSURE Pa.

9000 9600 10300 11000

7050

6800

5600 6125

7100

6650

6500 7000 7500 8000

13000

14000

15000

16000

18000

19200

20600

22000

44D

64D

76D

AIR FLOW M3/H

AIR FLOW M3/H

AIR FLOW M3/H

AVAILABLE STATIC PRESSURE Pa.

AVAILABLE STATIC PRESSURE Pa.

AVAILABLE STATIC PRESSURE Pa.

AIR FLOW M3/H

AIR FLOW M3/H

AIR FLOW M3/H

AVAILABLE STATIC PRESSURE Pa.

AVAILABLE STATIC PRESSURE Pa.

11.200 12.650 15.10014.100

48D

11.200 12.650

14.700

13.600

56D

11.200 12.250

14.200

13.300

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

140 90 50 0

160 110 50 0

170 120 50 0

1000

300*

250*

270*

200*

160* 120*

90* 40*

930

870

800

165*

70*

0*

25*

___

110*

1140

300*

230*

275*

200*

175* 140*

115* 75*

1070

995

920

225*

140*

75*

20*

25*

___

1140

1070

995

920

300*

230*

275*

200*

225*

140*

175*

140*

75*

115*

75*

20*

25*

___

1000

930

870

800

300*

250*

270*

200*

165*

160*

120*

70*

90*

40*

0*

110*

25*

___

170 120 50 0

160 110 50 0

140 90 50 0

85*

85*

( )

NOTE: The unit leaves factory with pulley two

turns opened.

(*)

AVAILABLE STATIC PRESSURE Pa.

WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

1.- GENERAL CHARACTERISTICS

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

Page 10

9

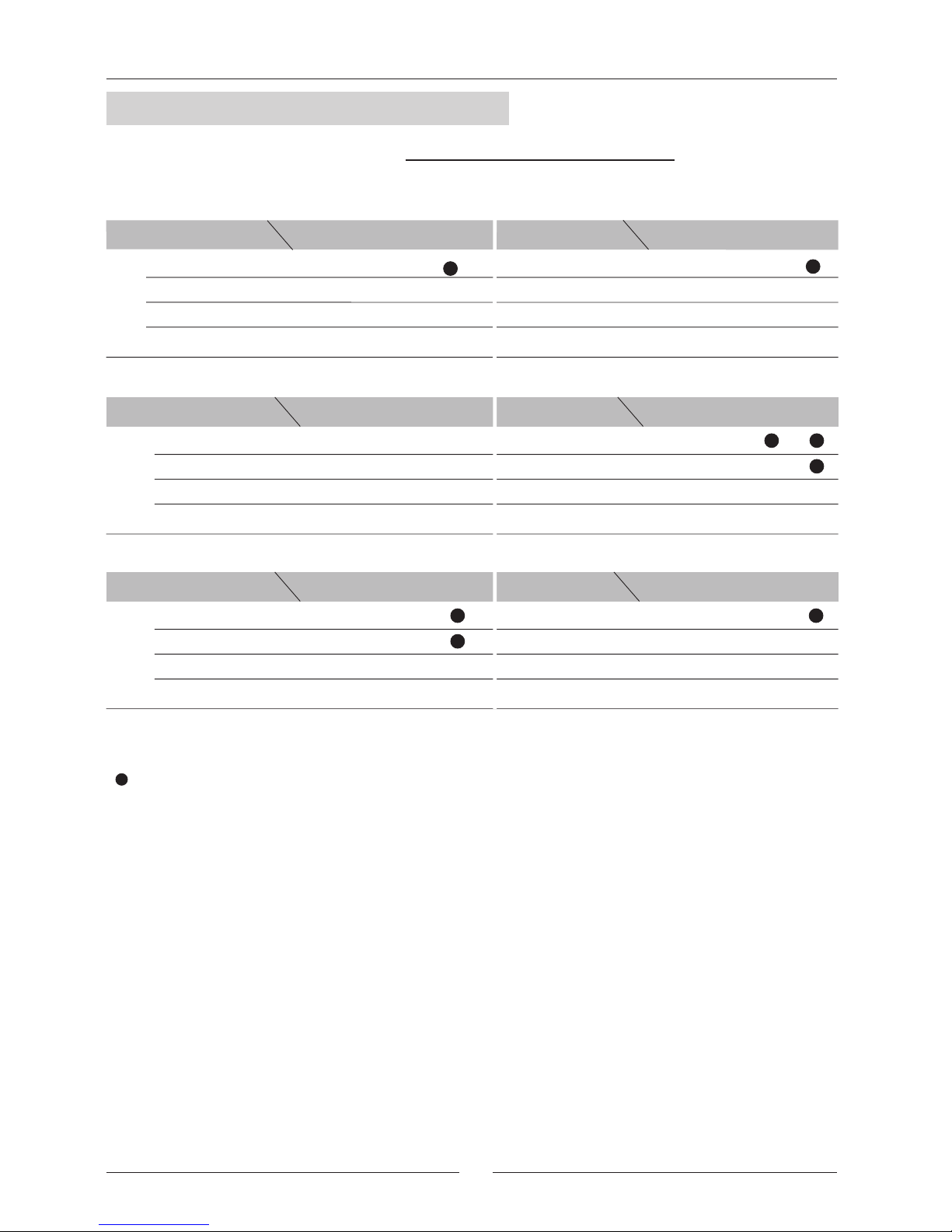

1.3.- INDOOR FAN PERFORMANCES WITH KIT HIGH STATIC PRESSURE TO 400Pa (OPTION)

38E

22E

3500 3900 4300 4700

24E

3900 4300 4700 5100

28E

4500 4950 5400 5850

32E

5250 5750 6000

48D

56D

7800 8600 9400 10200

9000 9900

10800

11700

44D

7000 7800 8600 9400

4750

5800 6400 7000 7300

64D

76D

9500 10500 11500 12000

11600 12800 14000 14600

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

420*

360*

405*

340*

385*

315*

290* 275* 250*

240*

215* 190*

205*

160*

290*

405*

340*

385*

315*

360*

290*

275* 250* 205*

215* 190* 160*

195*

130*

410*

340*

390*

305*

320*

240*

275* 240* 165*

215* 175* 100*

130*

60*

210*

400*

330*

365*

290*

300*

220*

265* 225* 145*

205* 160* 80*

110*

40*

1200

1125

1050

970

1200

1125

1050

970

1140

1070

995

920

1140

1070

995

920

360*

290*

405*

340*

385*

315*

360*

290*

1140

1070

995

920

275* 250* 205*

215* 190* 160*

195*

130*

410*

340*

390*

305*

320*

240*

275* 240* 165*

215* 175* 100*

130*

60*

1200

1125

1050

970

290*

210*

420*

360*

405*

340*

385*

315*

290* 275* 250*

240* 215* 190*

205*

160*

290*

1140

1070

995

920

360*

270*

190*

400*

320*

385*

305* 260*

1200

1050

970

270* 235* 180*

220* 185* 110* 95*

1125

400*

320*

385*

305* 260*

270* 235* 180*

220* 185* 110*

95*

1200

1125

1050

970

1200

1125

1050

970

205* 160* 80*

40*

265* 225* 145* 110*

330* 290* 220*

400* 365* 300*

190*

(*)

( )

NOTE: The unit leaves factory with pulley two

turns opened.

AVAILABLE STATIC PRESSURE Pa.

WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

1.- GENERAL CHARACTERISTICS

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

Page 11

10

1.3.- OUTDOOR FAN PERFORMANCES WITH KIT HIGH STATIC PRESSURE TO 350Pa (OPTION)

22E

24E

5600 6325 6800 7350

5600 6325 7050 7550

5600

6125

6650

7100

11200 12650

14100

15100

28E

44D

11200

12650

13600

14700

11200 12250

13300

14200

48D

56D

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

PULLEY

POSITION

PULLEY CLOSED

1 TURN

2 TURNS

3 TURNS

AIR FLOW

1140

365*

290*

325*

250*

240* 190*

185* 140*

1070

995

920

290*

210*

165*

105*

135*

70*

195*

1140

365*

290*

330*

255*

240* 195*

185* 145*

1070

995

920

290*

210*

165*

105*

135*

70*

1140

1070

995

920

365*

290*

325*

250*

290*

210*

240*

190*

165*

185*

140*

105*

135*

70*

1140

1070

995

920

365*

290*

330*

255*

210*

240*

195*

165*

185*

145*

105*

135*

70*

1140

1070

995

920

365*

290*

330*

255*

290*

210*

240*

195*

165*

185*

145*

105*

135*

1140

1070

995

920

365*

290*

330*

255*

290*

210*

240*

195*

165*

185*

145*

105*

195*

135*

70*

70*

195*

270*

195*

(*)

( )

NOTE: The unit leaves factory with pulley two

turns opened.

AVAILABLE STATIC PRESSURE Pa.

WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

1.- GENERAL CHARACTERISTICS

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

Page 12

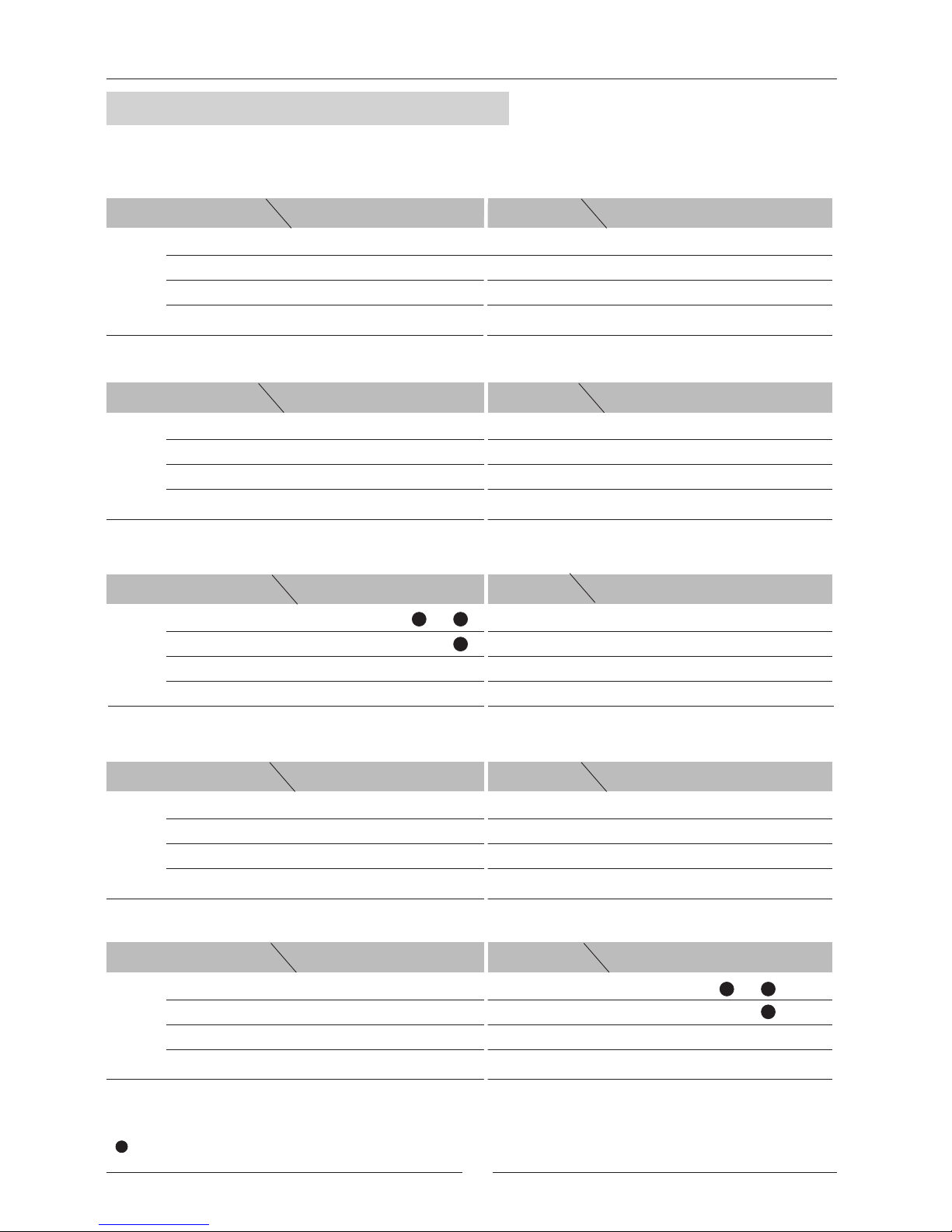

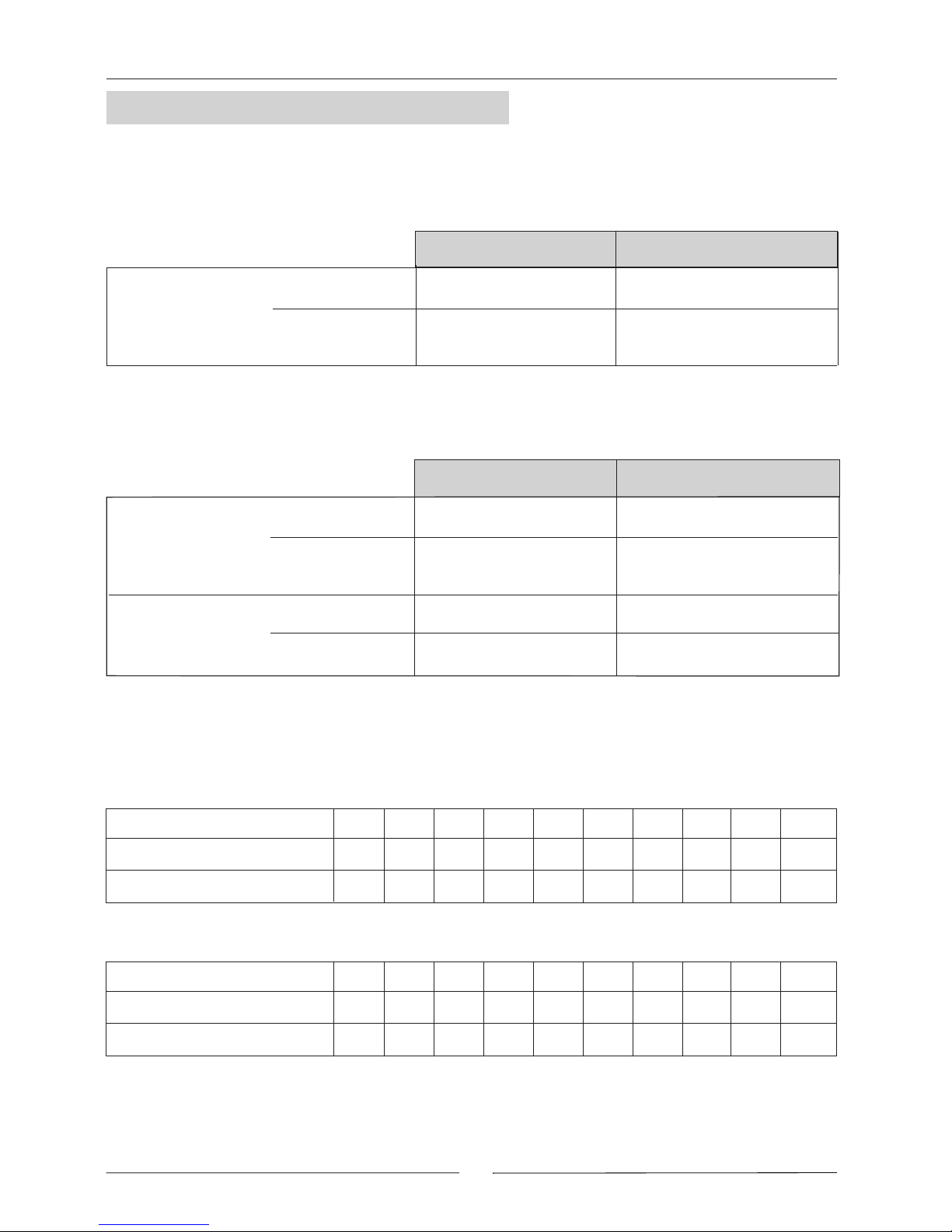

+19º C STANDARD UNIT

0ºC WITH OPTIONAL CPC ON/OFF

-10ºC (*)

INDOOR

TEMPERATURE

OUTDOOR

TEMPERATURE

COOLING CYCLE

OPERATION

MAXIMUM TEMPERATURES MINIMUM TEMPERATURES

MAXIMUM TEMPERATURES MINIMUM TEMPERATURES

INDOOR

TEMPERATURE

OUTDOOR

TEMPERATURE

INDOOR

TEMPERATURE

OUTDOOR

TEMPERATURE

COOLING CYCLE

OPERATION

HEATING CYCLE

OPERATION

32ºC DB / 23ºC WB

DEPENDING ON MODEL

(TABLE 1)

+19ºC STANDARD UNIT

0ºC WITH OPTIONAL CPC ON/OFF

-10ºC (*)

21ºC DB / 15ºC WB

32ºC DB / 23ºC WB

21ºC DB / 15ºC WB

27ºC DB

15ºC DB

24ºC DB / 18ºC WB

-10ºC DB / -11ºC WB

DEPENDING ON MODEL

(TABLE 1)

11

22E

45

43

24E

45

43

28E

43

41

32E

43

40

38E

42

39

44D

45

43

48D

45

43

56D

43

41

64D

43

40

76D

42

39

22E

48

46

24E

48

45

28E

46

44

32E

46

44

38E

45

42

44D

48

46

48D

48

45

56D

46

44

64D

46

44

76D

45

42

(*) With kit hot gas by pass or proportional winter control (options).

(*) With kit hot gas by pass or proportional winter control (options).

1.- GENERAL CHARACTERISTICS

OPERATING LIMITS FOR (HEATING PUMP) UNITS

OPERATING LIMITS FOR (COOLING ONLY) UNITS

1.4.- OPERATING LIMITS

DB.- Dry Bulb Temperature

WB.- Wet Bulb Temperature

TABLE 1-COOLING CYCLE MAXIMUM OUTDOOR OPERATING TEMPERATURES

MODELS

With rated outdoor flow

With minimum outdoor flow

MODELS WITH Refrigerant R-407C

MODELS

With rated outdoor flow

MODELS WITH Refrigerant R-22

With minimum outdoor flow

Page 13

12

1.5.- UNIT DIMENSIONS MODELS 22E-24E-28E-32E

The dimensions referred to the

center of the drill holes for the

supports.

Power supply

connection

Power supply connection

Control panel connection

Control panel

connection

Electrical box

Air filter

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

1990

1350

640

1195

100

100

344

316

191

25

450

53

600

105

25

1005

1255

15

15

550

429

215

750

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

INDOOR

SECTION

OUTDOOR

SECTION

Power supply

Power supply

DISCHARGE

OPTIONAL

Ø 14 (x 4)

20

33

978

99

316

344

191

888

47

25

348

450

429

118

1.- GENERAL CHARACTERISTICS

Page 14

13

The dimensions referred to the

center of the drill holes for the

supports.

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

INDOOR

SECTION

OUTDOOR

SECTION

Power supply

Power supply

DISCHARGE

OPTIONAL

Ø 14 (x 4)

20

33

1103

99

401

344

191

888

47

25

413

470

449

118

Power supply

connection

Power supply connection

Control panel connection

Control panel

connection

Electrical box

Air filter

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

2055

1415

640

1320

100

100

344

401

191

25

470

53

600

105

25

1130

1380

15

15

550

449

215

750

1.5.- UNIT DIMENSIONS MODEL 38E

1.- GENERAL CHARACTERISTICS

Page 15

14

1.5.- UNIT DIMENSIONS MODELS 44D-48D-56D-64D

The dimensions referred

to the center of the drill

holes for the supports.

Ø 16 (x 4)

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

Power supply

INDOOR

SECTION

OUTDOOR

SECTION

Power supply

DISCHARGE

OPTIONAL

34

119

888

56

25

692

348

47

191

978

119

33

978

344

313

240

30

Power supply connection

Control panel connection

Power supply

connection

Control

panel

connection

Electrical box

Air filter

Ø 16 (x 4)

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

1990

1350

640

2250

100

550

100

344

313

240

313

692

191

30

15

15

2010

120

53

600

2310

692

215

750

1.- GENERAL CHARACTERISTICS

Page 16

15

The dimensions referred

to the center of the drill

holes for the supports.

Ø 16 (x 4)

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

Power supply

INDOOR

SECTION

OUTDOOR

SECTION

Power supply

DISCHARGE

OPTIONAL

34

119

888

56

25

690

413

47

191

1103

119

33

1103

344

401

318

30

Power supply connection

Control panel connection

Power supply

connection

Control

panel

connection

Electrical box

Air filter

Ø 16 (x 4)

Drainage outside

thread 3/4''

Drainage outside

thread 3/4''

2055

1415

640

2500

100

550

100

344

401

318

401

690

191

30

15

15

2260

120

53

600

2560

690

215

750

1.5.- UNIT DIMENSIONS MODEL 76D

1.- GENERAL CHARACTERISTICS

Page 17

16

1.5 UNIT DIMENSIONS MODELS 44D-48D-56D-64D

WITH KIT 180º TURN FOR INDOOR UNIT (OPTION)

The dimensions referred

to the center of the drill

holes for the supports.

Air filter

Ø 16 (x 4)

Drainage outside

thread 3/4''

Power supply

OUTDOOR

SECTION

Power supply

Drainage outside

thread 3/4''

119

888

56

348

47

978

33

978

640

344

313

240

313

692

191

2010

53

600

120

692

34

750

215

119

30

Power supply connection

Control panel connection

Power supply

connection

Control

panel

connection

Drainage outside

thread 3/4''

INDOOR

SECTION

Ø 16 (x 4)

Drainage outside

thread 3/4''

DISCHARGE

OPTIONAL

Electrical box

1990

1350

2250

100

550

100

30

15

15

2310

25

692

191

344

313

240

1.- GENERAL CHARACTERISTICS

Page 18

17

1.5 UNIT DIMENSIONS MODEL 76D

WITH KIT 180º TURN FOR INDOOR UNIT (OPTION)

The dimensions referred

to the center of the drill

holes for the supports.

Air filter

Ø 16 (x 4)

Drainage outside

thread 3/4''

Power supply

OUTDOOR

SECTION

Power supply

Drainage outside

thread 3/4''

119

888

56

413

47

1103

33

1103

640

344

401

318

401

690

191

2260

53

600

120

690

34

750

215

119

30

Power supply connection

Control panel connection

Power supply

connection

Control

panel

connection

Drainage outside

thread 3/4''

INDOOR

SECTION

Ø 16 (x 4)

Drainage outside

thread 3/4''

DISCHARGE

OPTIONAL

Electrical box

2055

1415

2500

100

550

100

30

15

15

2560

25

690

191

344

401

318

1.- GENERAL CHARACTERISTICS

Page 19

18

1.- GENERAL CHARACTERISTICS

MAIN SWITCH

The main switch is located on the access panel to the electrical box of the outdoor unit.

The main switch is endowed with a clutch gadget, which allows open the panel of the electrical box, when it is on

OFF position.

MODELS LEC (INDOOR UNIT)

22E-24E-28E-32E-38E

MAXIMUM

CURRENT

(A)

230 / III

400/ III

POWER kW

7,5

18,8

10,8

11

27,6

15,9

15

37,7

21,7

44D-48D-56D-64D-76D

15

37,7

21,7

20

50,2

28,9

30

75,3

43,3

WEIGHTS Kg (*)

10 20

22E-24E-28E-32E-38E

(A)

230 / III

400/ III

7,5

18,8

10,8

11

27,6

15,9

15

37,7

21,7

44D-48D-56D-64D-76D

15

37,7

21,7

20

50,2

28,9

11

11

27,6

15,9

11

27,6

15,9

(*) Add to the unit's weight.

(*) Add to the unit's weight.

STAGES

12

10 20

MODELS LEH (INDOOR UNIT)

MAXIMUM

CURRENT

POWER kW

WEIGHTS Kg (*)

STAGES

Check to make sure that the main switch is large enough to handle the current for the unit if electric heaters are

installed.

Security

thermostat

Small case for

contactors and

connections

Situation of the

electrical heater once

installed

Support

ELECTRICAL HEATER

Made of align shielded elements, supplied mounted on the unit as drawing shows.

All the range has three security elements: 2 security thermostat, one automatic other manual reset and an air flow

security pressure switch, which make the electrical heater stops when air flow is not enough.

The electrical heater must be supplied on from the units electrical box.

An small case on the electrical heater protects contactors and electrical connections.

DIRTY FILTER INDICATION

To install on the indoor unit.

It is based on an air flow security pressure switch, which detects the available static pressure through the air filter.

In case the filters are dirties, the detector is activated, showing an alarm, if the fan is ON.

1 1 ó 2

WITH MAIN SWITCH ON. DO NOT REMOVE THE PANEL

ATTENTION!

1.6.- AVAILABLE OPTIONS

Page 20

19

1.- GENERAL CHARACTERISTICS

Situation of the

electrical heater once

installed

Support

Water inlet

Water outlet

PHASE SEQUENCER

The phase sequencer is located in the electrical box in the outdoor section, thus assuring that the unit will not

begin operation while the phase connection of the compressor is not correct. Should this occur, then just switch

two phase connections.

ON/OFF CONDENSATION PRESSURE CONTROL

The condensation pressure control consists of one or two pressure switches, which starts and stops the outdoor

fan, regulating the condensation temperature; thus the unit will be able to operate in the cooling cycle when the

outdoor temperature is below 19ºC, (Until 0ºC).

CRANKCASE HEATER (COOLING-ONLY UNITS)

The purpose of the heater is to keep the oil in the compressor at the correct temperature while the compressor is

stopped so that it can be properly lubricated when starts again.

When the unit is operating at low outdoor temperatures (below 19ºC), it is advisable to fit a crankcase heater.

HOT WATER COIL

It is based on a refrigerating coil made of copper tubing

with aluminum swirl fins with water inlet and outlet

connections.

It is supplied mounted inside the unit as picture shows.

1.6.- AVAILABLE OPTIONS

DIFFERENCE IN TEMPERATURES

BETWEEN HOT WATER INTAKE AND

THE AIR WHICH ENTERS THE

COIL

WATER

FLOW

L/H

WATER COIL

PRESSURE

DROP

kPa

AIR

PRESSURE

DROP

Pa (*)

Nr

ROWS

WEIGHTKg WATER

OUTLET

DIAMETER

Inches

MODELS

LEC / LEH

INDOOR UNIT

(*) Nominal air flow volume

50ºC 60ºC 70ºC

22E-24E

CAPACITY EN W

CAPACITY EN W

CAPACITY EN W

29.000 36.000 44.000

40.000 48.000 56.000

58.000 62.000 88.000

2.200

3.000

4.400

8

15

8

32-40

40

32-40

38E

44D-48D

28E-32E

CAPACITY EN W

33.000 40.000 47.000 2.500 10

32-40

CAPACITY EN W

66.000 80.000 94.000 5.000 10

32-40

56D-64D

CAPACITY EN W

80.000 96.000 112.000 6.000

15

39

76D

2

2

2

2

2

2

10

12

20

10

20

24

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

A HEATING COIL FROZEN DUE TO LOW AMBIENT CONDITIONS IS NOT COVERED BY THE WARRANTY.

PROTECTION AGAINST FREEZING:

Use glycol water. GLYCOL IS THE ONLY EFFECTIVE PROTECTION AGAINST FREEZING.

This kit includes a security thermostat with a probe located inside the hot water coil. When the temperature is

below 4ºC, the unit will stop in order to protect hot water coil and to prevent unit working with very low evaporating

temperatures.

Two wires between indoor and outdoor unit have to be added with this option.

Security thermostat working mode:

- Electrical boxes with Climatic 10 controller: The security stop valve is 4ºC. When the valve is more than 4ºC +

thermostat differential, you can reset the unit pressing "resume" button in the Climatic 10 terminal.

- Electrical boxes with VFC: The security stop valve is 4ºC too. When the valve is more than 4ºC + thermostat

differential, the unit will reset automatically after 5 min of timer.

Drain the installation. You must ensure that the manual or automatic air vents have been installed on all high

points in the system. In order to drain the system check that all the drain cocks have been installed on all low

points of the system.

Page 21

20

1.- GENERAL CHARACTERISTICS

0

(*) Add to the unit data.

MODELS (OUTDOOR UNIT)

DIMENSIONS

A

B

22E-24E-28E-32E

122,5

38E

122,5

44D-48D-56D-64D

44D2-48D2-56D2-64D2

150,5

76D/D2

150,5

WEIGHTS kg (*)

15

20

30

40

102,5

102,5

150,5

150,5

970

1095

1949

2199

C

165

165

165

165

D

342

407

342

407

E

996,5

996,5

996,5

996,5

F

(*) Add to the unit's weight.

MODELS LEC / H (INDOOR)

(A)

230 / III

400/ III

POWER (*) kW

22E

0,2

0,5

0,3

24E

0,4

1,0

0,6

28E

0,8

2,0

1,2

32E

1,0

2,5

1,4

38E

1

2,5

1,4

44D

0,4

1,0

0,6

48D

0,8

2,0

1,2

56D

1,5

3,8

2,2

64D

1,5

3,8

2,2

76D

1,7

4,3

2,5

MODELS KVC / H (OUTDOOR)

(A)

230 / III

400/ III

POWER (*) kW

WEIGHTS Kg (*)

22E

0,4

1,0

0,6

15

24E

0,6

1,5

0,9

15

28E

0,8

2,0

1,2

15

32E

__

__

__

__

38E

__

__

__

__

44D/D2

0,8

2,0

1,2

30

48D/D2

1,2

3,0

1,7

30

56D/D2

1,6

4,0

2,3

30

64D/D2

__

__

__

__

76D/D2

__

__

__

__

02 2055999

WEIGHTS Kg (*)

MAXIMUM

CURRENT (*)

MAXIMUM

CURRENT (*)

It is based on one or two dampers located on the outdoor

unit discharge air, which lets you control condensation

temperature through the air flow.

The damper is moving by a servomotor, which receives a

proportional signal through a pressure detector.

PROPORTIONAL CONDENSING PRESSURE CONTROL BY DAMPERS

KIT MORE STATIC PRESSURE OF AIR DISCHARGE

It is an specific fan to obtain more available static pressure up to 350Pa for outdoor unit and 400Pa for indoor unit.

See air flow data section for optional fan performances.

Electrical data for these optional fans:

Thus the unit will be able to operate in the cooling cycles

when the outdoor temperature is until -10ºC.

COMPRESSOR STARTING CURRENT CONSTRAINED (SOFT STARTER) 400V-III

It is an electronic element, which reduces the

peak compressor starting current up to 40%

(see pages of electrical data without soft starter)

Only available for 400V-III units.

This kit is not available with kit vertical discharge

outdoor unit at the same time.

D

A

C

B

E

F

DAMPER

DAMPER

ACTUATOR

1.6.- AVAILABLE OPTIONS

Dimensions of dampers for this kit:

MODELS (OUTDOOR UNIT)

22E-24E-28E-32E-38E

44D/D2-48D/D2-56D/D2-64D/D2-76D/D2

WEIGHTS (*)

3

6

(*) Add to the unit's weight.

Page 22

21

1.- GENERAL CHARACTERISTICS

HOT GAS BYPASS VALVE

The purpose of the BYPASS valve is to make it possible for the unit to operate at low outdoor temperatures (until

-10°C), to be used in cooling-only and heat-pump units in cooling cycle.

It regulates the capacity of the compressor by injecting hot gas from the compressor discharge side to the coil.

180º TURN OF INDOOR UNIT (Only for double circuit units D)

The unit is supplied such as, the return air to the indoor section and the intake and air discharge air for the outdoor

unit are located on the same side of the unit.

1.6.- AVAILABLE OPTIONS

Standard placement

Optional placement

CONTROL USING A PROGRAMMABLE CONTROLLER:

With the programmable controller option, the desired temperature can be programmed in the area 24 hours a day,

7 days a week.

REMOTE AMBIENT SENSOR AND REMOTE DUCT SENSOR

These sensors may be used in conjunction with remote controller or allowing the controller to be mounted in a

room away from the conditioned space.

- REMOTE DUCT SENSOR: The sensor will be located in the return-air duct, detecting the air temperature of the

air being air-conditioned.

- REMOTE AMBIENT SENSOR: The sensor will be placed in the area to be air-conditioned.

PRECOATED COIL (outdoor unit)

Special protection of the aluminum condenser coil fins, to protect it from aggressive external environmental

conditions.

Page 23

22

1.- GENERAL CHARACTERISTICS

1.- DEFINITION

FREE-COOLING is a saving system in the cooling cycle, this makes the unit take air from the outside to take

advantage of its energy, this system acting as a first cold stage.

It is a saving energy system that's why many countries regulations recommended and others put under an obligation

to install a freecooling system with the unit.

2.- TYPES OF FREECOOLING.

In order to outside air parameters which has to be measured, the types are:

- Thermostatic freecooling :

Measures and compares the outside air temperature with the temperature of the room that has to be aconditioned.

- Enthalpic freecooling :

Measures and compares the outside air enthalpy with the return air enthalpy from the room that has to be

aconditioned.

The enthalpy measures temperature and humidity of air.

3.- COMPONENTS OF FREECOOLING.

The main components are:

- Electronic control and accessories: Their function is to detect the outside and indoor air conditions, through the

probes to solve when freecooling should operate.

- The servomotor and system transmission: They manage the opening and closing the dampers.

- Adjustable dampers.

- Mixing section: Where outside and return air are mixed.

Also an return fan is available, which applies an additional static pressure on the suction and return air duct.

For more details about components and drawings see pages 26,27,28,29.

4.- OPERATION

The control compares the values of temperature/enthalpy between outside air and room air through the probes,

if it is a negative difference and the security elements allow (discharge temperature probes) then the control acts

over the servomotor, which produces the opening of the outside damper and close the return one, entering cool

outside air to the room.

The damper regulation is proportional.

If indoor air demand is not great, could be enough only the freecooling to acondition the room, if the air demand

is greater it is possible need the freecooling working and the unit working on different cooling mode stages.

5.- THERMOSTAT TERMINAL.

Depending on the type of freecooling selected, the thermostat and the electrical box supplied with the unit

will be different.

With thermostatic freecooling the thermostat supplied has the same characteristics than the one supplied

with the standard unit, except because the one for the freecooling is a programmable one.

With enthalpic freecooling the terminal is different than the one supplied with the unit VFC version, its

principal characteristics are: OFF, COOL, HEAT, AUTOMATIC.

THERMOSTAT FOR THERMOSTATIC

FREECOOLING

THERMOSTAT FOR ENTHALPIC

FREECOOLING

Enthalpic freecooling is supplied with duct sensor.

Remote ambient sensor and sensor incorporated

inside the thermostat are available as an option.

Thermostatic freecooling is supplied with sensor

incorporated inside the thermostat.

Remote duct and ambient sensor are available as

an option.

1.6.- AVAILABLE OPTIONS

FREECOOLING

COOL

AUTO

O

N

FAN

SYSTEM

AUTO

HEAT

OFF

Climatic 10

Page 24

23

1.- GENERAL CHARACTERISTICS

SM: Mixing section.

SR: return fan section.

UI: Indoor unit.

UE: Outdoor unit.

- - - - Mechanical installation to be carried out by the installer.

Freecooling supports, to be carried out by the installer.

The electrical box for the freecooling is supplied apart and has to be fixed by the installer.

1

The consumption of the return fan by unit is:

MODELS

MAXIMUM

CURRENT

POWER kW

(A)

230 / III

400/ III

22E

1,3

4,3

2,5

24E

1,4

4,3

2,5

28E

1,5

6,2

3,6

32E

1,8

6,2

3,6

38E

2

6,2

3,6

44D

2,6

8,8

5,1

48D

2,8

8,8

5,1

56D

3

12,5

7,2

64D

3,6

12,5

7,2

76D

4

12,5

7,2

6.- SUPPLY AND INSTALLATION

Configuration of freecooling supply for packaged system:

7.- FREECOOLING WITH RETURN FAN

If an extra static pressure is required on the return air duct, the freecooling should add a return fan section.

This return fan section includes a discharge damper.

The operation dampers for this freecooling with return fan is as follow:

As much as the air intake damper opens, that much the by-pass damper closes and the discharge air damper

opens, for the air return suction (see drawing).

This means that at the same time is reached a free cooled of the room, the discharge or return air and the air of

the room gets removable.

1.6.- AVAILABLE OPTIONS

FREECOOLING

- Packaged system

SM

UI

UE

22E 76D

SM UI

UE

22E 76D

SR

1

1

UNITS

Page 25

24

1.- GENERAL CHARACTERISTICS

48D

7800 8600 9400 10200

1 TURN

PULLEY CLOSED

PULLEY

POSITION

2 TURNS

3 TURNS

AIR FLOW

64D

76D

9500 10500 11500 12000

11600 12800

14000

14600

1 TURN

PULLEY CLOSED

PULLEY

POSITION

2 TURNS

3 TURNS

AIR FLOW

56D

9000 9900 10800 11700

44D

7000 7800 8600 9400

1 TURN

PULLEY CLOSED

PULLEY

POSITION

2 TURNS

3 TURNS

AIR FLOW

1 TURN

PULLEY CLOSED

PULLEY

POSITION

2 TURNS

3 TURNS

AIR FLOW

28E

4500 4950 5400 5850

32E

5250 5750 6000

38E

5800 6400 7000 7300

4750

1 TURN

PULLEY CLOSED

PULLEY

POSITION

2 TURNS

3 TURNS

AIR FLOW

22E

3500 3900 4300 4700

24E

3900 4300 4700 5100

320*

275*

300*

250*

280*

230*

1010

955

900

845

235* 210* 180*

195*

150* 130*

130*

85*

185*

275*

220*

245*

175*

185*

130*

1010

955

900

845

175* 130* 75*

125* 85* 30*

55*

20*

105*

200*

160*

175*

135*

140*

100*

120* 85* 50*

75* 50* 10*

35*

0*

155*

890

840

790

740

120*

90*

280*

250*

240*

205*

220*

160*

195* 160* 110*

150* 115* 70*

70*

30*

110*

1010

955

900

845

180*

330*

290*

320*

275*

300*

250*

250* 235* 210*

200* 195* 150*

180*

130*

230*

1010

955

900

845

280*

175*

130*

130*

80*

85*

30*

80* 30* 0*

35* 0* ___

___

___

0*

160*

110*

80*

40*

35*

0*

60* 0* ___

10* ___ ___

___

____

210*

170*

183*

140*

145*

104*

890

790

740

130* 95* 45*

85* 60* 20*

35*

0*

1140

1070

995

920

1140

1070

995

920

30*

840

0*

___

125*

85*

175*

135*

145*

105*

115*

70*

110* 85* 33*

75*

50* 5*

0*

___

35*

145*

105*

115*

70*

70*

35*

85* 33* 0*

50* 5* ___

___

___

0*

1010

955

900

845

1010

955

900

845

70*

35*

NOTE: The unit leaves factory with pulley

two turns opened.

return fan performances for each models are:

(*)

( )

AVAILABLE STATIC PRESSURE Pa.

WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

1.6.- AVAILABLE OPTIONS

FREECOOLING

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

M3/H

R.P.M.

Page 26

25

1.- GENERAL CHARACTERISTICS

INSTALLER COMPANY NAME: CONTACT PERSON NAME:

TEL.: Fax e-mail

ATTENTION TO : Lennox Refac S.A. CONTACT PERSON NAME:

TEL.: Fax e-mail

ORDER NUMBER:

B.-Select the air flow drive of the indoor unit required: Horizontal or vertical.

Packaged units: As standard vertical air flow drive.

Split and multi-split systems: As standard horizontal air flow drive.

D.- Select if you need return fan with the freecooling

E.-Select the dampers configuration for the freecooling, as following. (In order to be adapted to the ducts of the installation)

8.- SELECTION OF THE UNIT AND FREECOOLING SYSTEM

There are different types of freecooling system, different possibilities of dampers installations, and it could be supplied mounted

or loose.

In order to provide the customer the needed one, fill in the following table and send it to the order department:

E.1- Freecooling dampers position WITHOUT return fan:

The drawings are an upper view of the indoor unit and freecooling

A.-Select the unit needed, packaged, split or multi-split:

(If the unit needed is packaged, the freecooling will be supplied loose. If the unit selected is split or multi-split the freecooling

will be supplied mounted on the indoor unit, except for the freecooling with return fan on models 76D, which is supplied loose

also).

C.-Select the type of freecooling thermostatic or enthalpic and the sensor for freecooling management.

Thermostatic freecooling supplied with sensor incorporated inside the thermostat,

Enthalpic freecooling supplied with duct sensor

(If the humidity conditions where the unit is going to be installed have relevance, is convenient to install an enthalpic freecooling)

Vertical

Horizontal

Thermostatic

Enthalpic

With return fan

Without return fan

Packaged Split Multi-split

Remote ambient sensor

Remote duct sensor

Remote ambient sensor

Sensor incorporated at

the thermostat

1.6.- AVAILABLE OPTIONS

FREECOOLING

E.2- Freecooling dampers position WITH return fan:

The drawings are an upper view of the indoor unit and freecooling

POSITION 1 POSITION 2

POSITION 1

POSITION 2

POSITION 3 POSITION 4

Outdoor air intake

Freecooling

Indoor unit

Return air

Discharge

Outdoor air intake

Freecooling

Indoor unit

Return air

Discharge

Discharge

Discharge air

Return air

Indoor unit

Mixing section

Return air

section

Freecooling

Outdoor air intake

Discharge air

Discharge

Outdoor air intake

Return air

Indoor unit

Mixing section

Return air

section

Freecooling

Discharge

air

Outdoor air intake

Discharge

Return air

Indoor unit

Mixing section

Return air

section

Freecooling

Discharge air

Discharge

Return air

Indoor unit

Mixing section

Return air

section

Freecooling

Outdoor air intake

Page 27

26

1.- GENERAL CHARACTERISTICS

2x1: Nr of cables x section (mm2)

Electrical connections to be

made by the installer

ELECTRICAL BOX

FREECOOLING

POWER SUPPLY

FREECOOLING

TO OUTDOOR UNIT

ELECTRICAL BOX

MIXING

SECTION

INDOOR

UNIT

RETURN

AIR DUCT

DISCHARGE

AIR DUCT

COIL

AIR FILTER

TO OUTDOOR UNIT

ELECTRICAL BOX

MIXING

SECTION

OUTDOOR

AIR INTAKE

STAND OUT DETAIL

T - Transmission

ACTUATOR

P - Potentiometer

EC - Enthalpy measure

LM - Logic module

TF - Transformer

RC - Remote controller

RE - Return Enthalpy sensor

RS - Return Temperature sensor

DS - Discharge Temperature sensor

DA - Damper Actuator

FM - Discharge fan motor

OE - Outside enthalpy sensor

1.6.- AVAILABLE OPTIONS

FREECOOLING

OUTLINE FOR ENTHALPIC FREECOOLING WITHOUT RETURN FAN

FREECOOLING OUTLINE FOR DOUBLE CIRCUIT UNITS

Page 28

27

1.- GENERAL CHARACTERISTICS

2x1: Nr of cables x section (mm2)

Electrical connections to be

made by the installer

MIXING

SECTION

MIXING

SECTION

TO OUTDOOR UNIT

ELECTRICAL BOX

TO OUTDOOR UNIT

ELECTRICAL BOX

TO OUTDOOR UNIT

ELECTRICAL BOX

ELECTRICAL BOX

FREECOOLING

POWER SUPPLY

FREECOOLING

INDOOR

UNIT

RETURN

AIR DUCT

STAND OUT DETAIL

OUTDOOR

AIR INTAKE

AIR FILTER

RETURN

SECTION

DISCHARGE

AIR DUCT

DISCHARGE

AIR

ACTUATOR

T - Transmission

P - Potentiometer

EC - Enthalpy measure

LM - Logic module

TF - Transformer

RC - Remote controller

RE - Return Enthalpy sensor

RS - Return Temperature sensor

RFM - Return fan motor

FM - Discharge fan motor

OE - Outside enthalpy sensor

DA - Damper Actuator

DS - Discharge Temperature sensor

COIL

1.6.- AVAILABLE OPTIONS

FREECOOLING

OUTLINE FOR ENTHALPIC FREECOOLING WITH RETURN FAN

FREECOOLING OUTLINE FOR DOUBLE CIRCUIT UNITS

Page 29

28

1.- GENERAL CHARACTERISTICS

2x1: Nr of cables x section (mm2)

Electrical connections

to be made by the

installer

ELECTRICAL BOX FREECOOLING

ELECTRICAL BOX

MIXING

SECTION

MIXING

SECTION

INDOOR

UNIT

RETURN

AIR DUCT

DISCHARGE

AIR DUCT

STAND OUT DETAIL

OUTDOOR

AIR INTAKE

AIR FILTER

OUTDOOR UNIT

ACTUATOR

T - Transmission

FM - Discharge fan motor

OT - Outside temperature sensor

DA - Damper Actuator

DS - Discharge Temperature sensor

COIL

1.6.- AVAILABLE OPTIONS

FREECOOLING

OUTLINE FOR THERMOSTATIC FREECOOLING WITHOUT RETURN FAN

4x1,5 + PE

3x2,5 + PE

2x1,5 + Shielded

(5x1,5 + Shielded heat pump first stage)

THERMOSTAT

2x1+ Shielded

(3x1 + Shielded heat pump first stage)

FREECOOLING OUTLINE FOR DOUBLE CIRCUIT UNITS

DS DS

3x1

Page 30

29

1.- GENERAL CHARACTERISTICS

2x1: Nr of cables x section (mm2)

Electrical connections

to be made by the

installer

ELECTRICAL BOX FREECOOLING

ELECTRICAL BOX

MIXING

SECTION

MIXING

SECTION

INDOOR

UNIT

RETURN

AIR DUCT

DISCHARGE

AIR DUCT

STAND OUT DETAIL

OUTDOOR

AIR INTAKE

AIR FILTER

RETURN

SECTION

DISCHARGE

AIR

OUTDOOR UNIT

ACTUATOR

T - Transmission

RFM - Return fan motor

FM - Discharge fan motor

OT - Outside temperature sensor

DA - Damper Actuator

DS - Discharge Temperature sensor

COIL

TO OUTDOOR UNIT

ELECTRICAL BOX

1.6.- AVAILABLE OPTIONS

FREECOOLING

OUTLINE FOR THERMOSTATIC FREECOOLING WITH RETURN FAN

4x1,5 + PE

FREECOOLING OUTLINE FOR DOUBLE CIRCUIT UNITS

THERMOSTAT

3x2,5 + PE

DS DS

2x1,5 + Shielded

(5x1,5 + Shielded

heat pump first stage)

2x1+ Shielded

(3x1 + Shielded

heat pump first stage)

3x1

Page 31

30

1.- GENERAL CHARACTERISTICS

RETURN

INDOOR UNIT

OUTDOOR

AIR INTAKE

A

B

D

F

G

H

MIXING SECTION

C

E

I

Electrical box for freecooling is supplied

loose inside the mixing section.

Fix by the installer.

The damper position can be different than the

picture shows. See drawings.

400

160

300

1.6.- AVAILABLE OPTIONS

FREECOOLING

A 640

MODELS

22-24-28-32

640

B

750

750

C98

73,5

D

52

76,5

E

222

222

F

750

876

G

222

222

H

499

500

I

750

750

MODEL

38

22-24=105 / 28-32=110 145

WEIGHTS

Kg

100 100

INDOOR UNIT

MIXING SECTION

ELECTRICAL

BOX FOR

ENTHALPIC

FREECOOLING

DIMENSIONS FREECOOLING WITHOUT RETURN FAN

MODELS 22E-24E-28E-32E-38E

Page 32

31

1.- GENERAL CHARACTERISTICS

The damper position can be different than the

picture shows. See drawings.

A 640

MODELS

44-48-56-64

640

B

749

749

C 100,5

100,5

D

50,5

50,5

E

250

312,5

F

1750

1875

G

250

312,5

H

499

499

I

750

750

MODEL

76

44-48=220 / 56-64=240

265

WEIGHTS

Kg

130

135

INDOOR UNIT

MIXING SECTION

Electrical box for freecooling is supplied

loose inside the mixing section.

Fix by the installer.

400

160

300

1.6.- AVAILABLE OPTIONS

FREECOOLING

DIMENSIONS FREECOOLING WITHOUT RETURN FAN

ELECTRICAL

BOX FOR

ENTHALPIC

FREECOOLING

MODELS 44D-48D-56D-64D-76D

INDOOR UNIT

RETURN

OUTDOOR

AIR INTAKE

A

B

G

H

MIXING SECTION

I

C

D

E

F

Page 33

32

1.- GENERAL CHARACTERISTICS

RETURN

INDOOR UNIT

OUTDOOR

AIR INTAKE

A

B

D

I

J

K

C

E

F

G

H

M

L

RETURN DAMPER

Electrical box for freecooling is supplied

loose inside the mixing section.

Fix by the installer.

The damper position can be different than the

picture shows. See drawings.

400

160

300

1.6.- AVAILABLE OPTIONS

FREECOOLING

A 640

MODELS

22-24-28-32

640

B

750

750

C98

73,5

D

52

76,5

E

48

48

F

750

750

G

102

102

H

186

186

I

822

948

J

186

186

K

96,5 96,5

L

750

750

MODEL

38

WEIGHTS

Kg

500 500

M

22-24=105 / 28-32=110 145

100 100

INDOOR UNIT

MIXING SECTION

22-24=120 / 28-32=125 125

RETURN SECTION

DIMENSIONS FREECOOLING WITH RETURN FAN

ELECTRICAL

BOX FOR

ENTHALPIC

FREECOOLING

MODELS 22E-24E-28E-32E-38E

Page 34

33

1.- GENERAL CHARACTERISTICS

INDOOR UNIT

OUTDOOR

AIR INTAKE

A

B

D

I

J

K

C

E

F

G

H

M

L

RETURN

RETURN DAMPER

Electrical box for freecooling is supplied

loose inside the mixing section.

Fix by the installer.

The damper position can be different than the

picture shows. See drawings.

400

160

300

1.6.- AVAILABLE OPTIONS

FREECOOLING

A 640

MODELS

44-48-56-64

640

B

749

749

C 100,5

100,5

D

50,5

50,5

E

48

48

F

750

750

G

102

102

H

186

311

I

1878

1878

J

186

311

K

500 500

M

750

750

MODEL

76

WEIGHTS

Kg

96,5 96,5

L

44-48=220 / 56-64=240

265

130

135

INDOOR UNIT

MIXING SECTION

195

200

RETURN SECTION

DIMENSIONS FREECOOLING WITH RETURN FAN

ELECTRICAL

BOX FOR

ENTHALPIC

FREECOOLING

MODELS 44D-48D-56D-64D-76D

Page 35

34

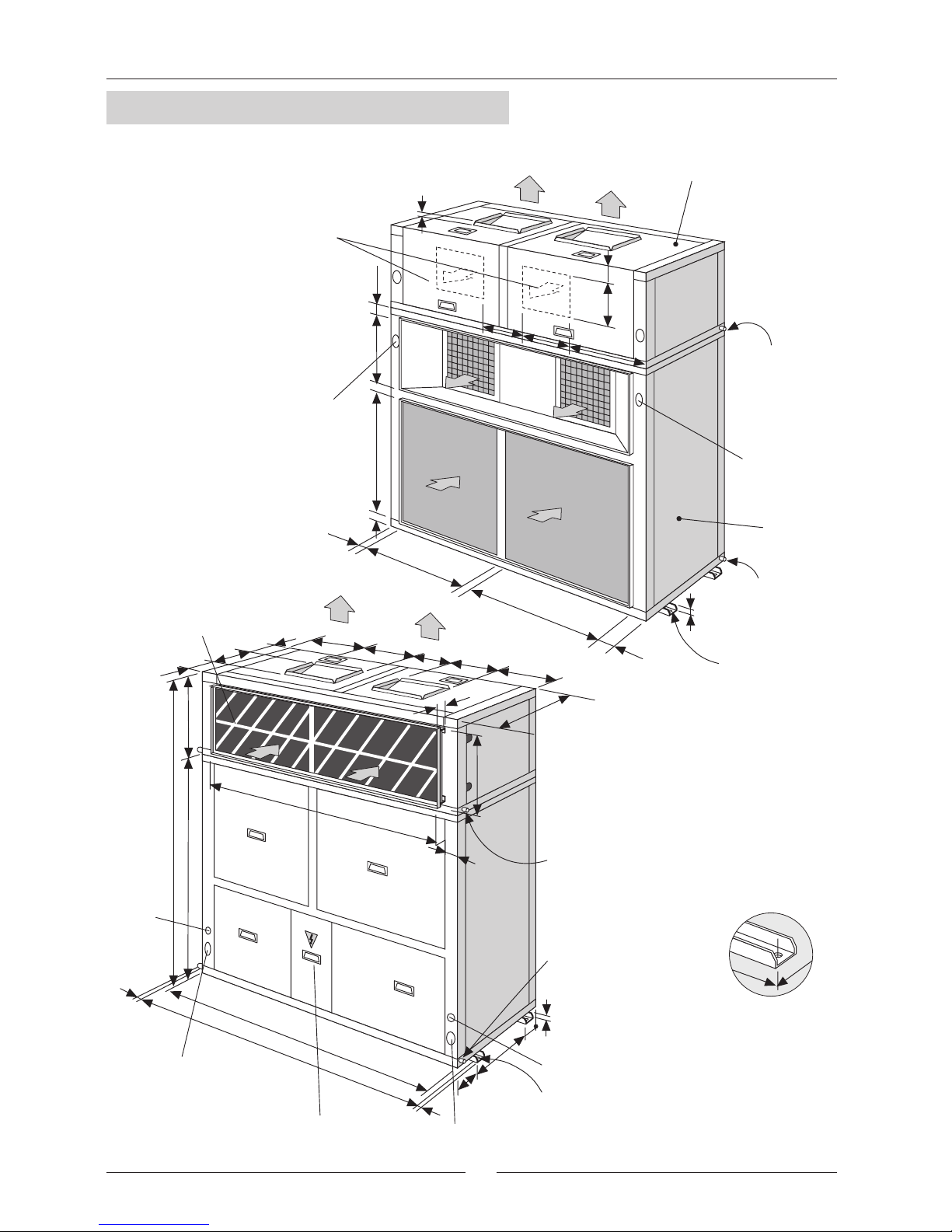

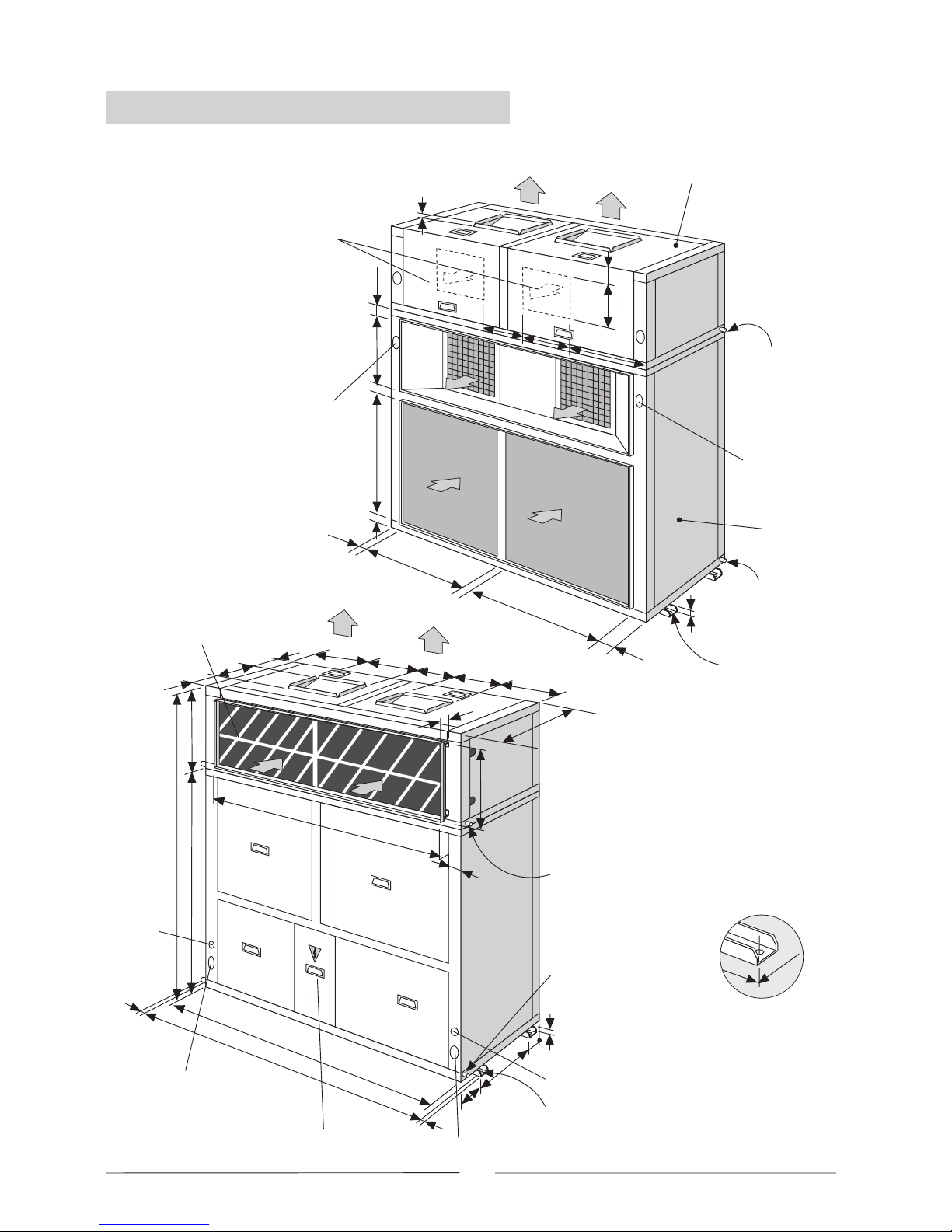

How to hoist the unit

The units are designed to be installed with ducts, calculated by qualified technical staff. The joints to be used

between ducts and the openings to the unit should be Elastic Joints. Avoid the use of BYPASS joints between the

extraction air and input air in both the outdoor and indoor sections. The structure where the unit is placed must

be able to support the weight of the unit during operation.

If unloading and placement require the use of a crane, then secure the suspension cables as shown in the figure.

All the units have Metal Bedplate Profiles.

When positioning the unit, be sure that the Rating Plate will always be visible since this

data will be necessary to assure proper maintenance.

The unit must be transported in a VERTICAL POSITION on its metal bedplate profiles and TRANSPORTATION

BLOCKS. Any other position may cause serious damage to the machine. When the unit is received, it should be

checked to assure that there are no bumps or other damage, following the instructions on the packaging. If there

is damage, the unit may be rejected by notifying the LENNOX Distribution Department and reporting why the

machine is unacceptable on the transport agents delivery notice. Any later complaint or claim made to the

LENNOX Distribution Department, for this type of anomaly, cannot be considered under the Guarantee.

Sufficient space must be allowed to facilitate placement of the unit. The unit may be mounted outdoors. There

should be NO possibility of flooding if floor mounted.

All INSTALLATION, SERVICE and MAINTENANCE operations

must be carried out by QUALIFIED PERSONNEL.

2.- INSTALLATION

2.2.- UNIT RECEPTION

2.1.- PRELIMINARY PREPARATIONS

Use

separators

Page 36

35

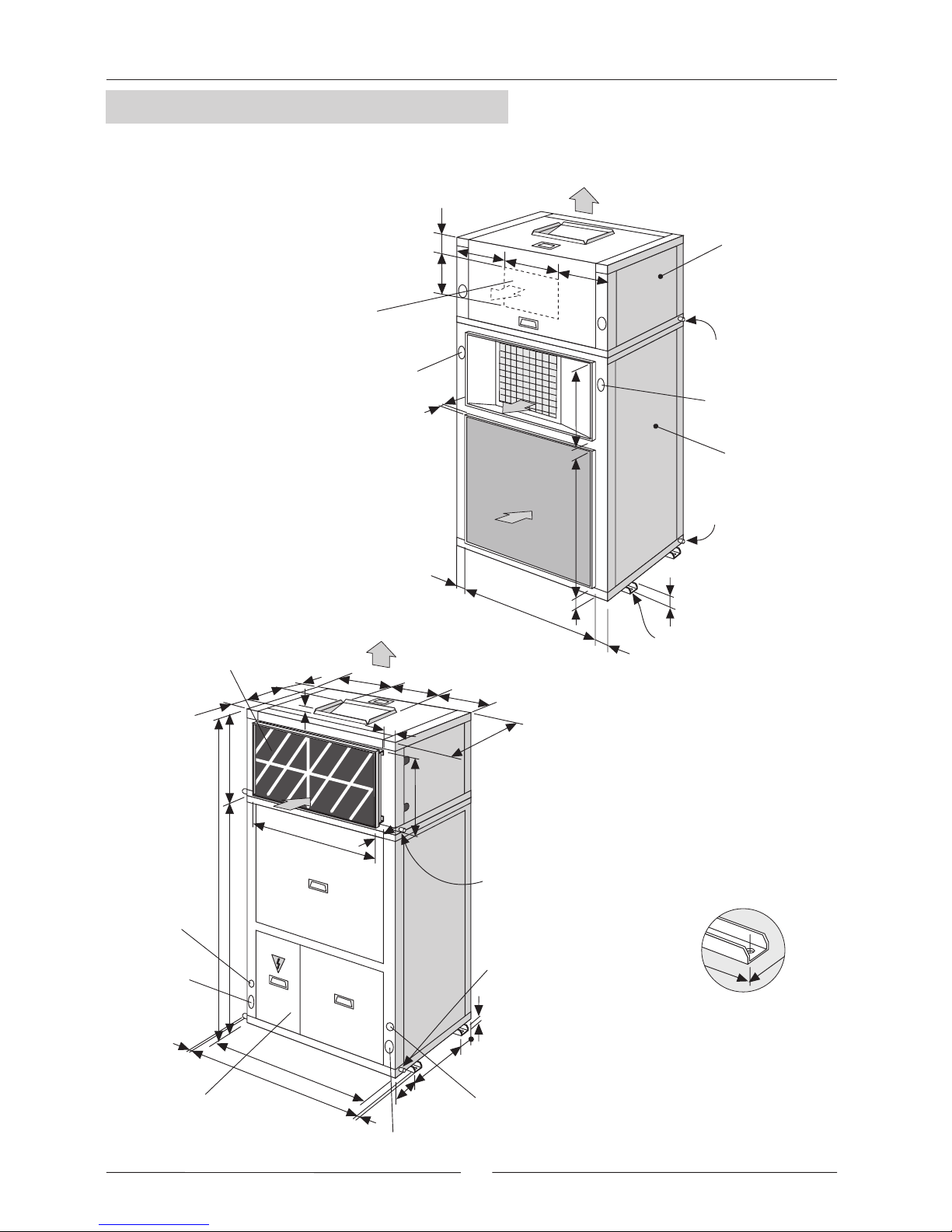

DISCHARGE AIR STANDARD

DISCHARGE AIR OPTIONAL

1 Check that unit is electrically disconnected.

2 Unscrew and remove side covers (1) and (3).

3 Loosen the transmission belts and disassemble them.

4 Remove the pulley from the fan axle.

5 Remove the fan and their supports (2).

6 Turn the fan until horizontal discharge position is reached.

7 Replace the fan on the supports (2) which should not be moved.

8 Place the pulley on the fan axle on the side which coincides with the motor: assemble the belts and align

them.

9 Tense the belts correctly.

10 Replace the upper and lateral covers and screw them down

(1) and (3).

VERTICAL

DISCHARGE

STANDARD

HORIZONTAL

DISCHARGE

(OPTIONAL)

2.3.- OPTIONAL OPERATIONS PRIOR TO UNIT INSTALLATION:

CHANGE IN THE POSITION OF THE INDOOR FAN FOR

UNIT MODELS 22E-24E-28E-32E-38E

2.- INSTALLATION

3

2

3

2

1

1

3

1

1

3

Page 37

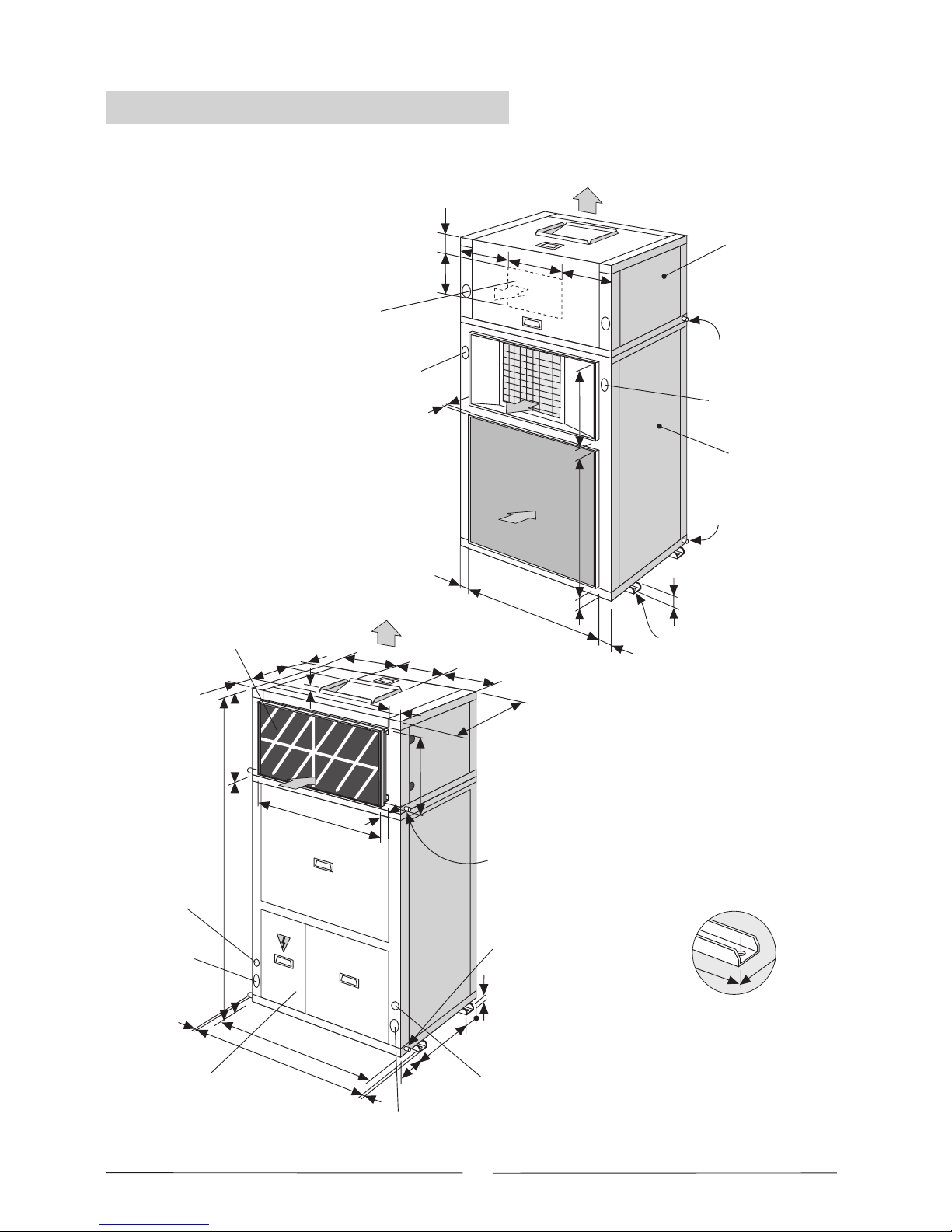

36

1 Check that unit is electrically disconnected.

2 Unscrew and remove side covers (1) and (3).

3 Loosen the transmission belts and disassemble them.

4 Remove the pulley from the fan axle.

5 Remove the fan and their supports (2).

6 Turn the fan until horizontal discharge position is reached.

7 Replace the fan on the supports (2) which should not be moved.

8 Place the pulley on the fan axle on the side which coincides with the motor: assemble the belts and align

them.

9 Tense the belts correctly.

10 Replace the upper and lateral covers and screw them down

(1) and (3).

DISCHARGE AIR STANDARD

DISCHARGE AIR OPTIONAL

VERTICAL

DISCHARGE

STANDARD

HORIZONTAL

DISCHARGE

(OPTIONAL)

2.3.-

2.- INSTALLATION

OPTIONAL OPERATIONS PRIOR TO UNIT INSTALLATION:

CHANGE IN THE POSITION OF THE INDOOR FAN FOR

UNIT MODELS 44D-48D-56D-64D-76D

3

2

3

2

1

1

3

3

3

1

1

3

Page 38

37

CLOSED PULLEY:

To increase the fan flow, turn the mobile part in

direction "B" (Clock wise).

OPEN PULLEY:

To reduce the flow, turn in direction "A"

(Unclock wise).

1. Fixer part

2. Mobil part

3. Fixing screw

TENSION OF BELTS

The belts can be easily tensioned through the tensing

screw incorporated into the bases of the motor of the

transmitting units which also enables a good servicing to

be carried out.

When the tensing screw is moved, the motor fan is moved

to the sides in order to tension the pulley.

FLOW REGULATION IN THE FANS

The fan for all indoor units and for outdoor units models KVCK/ KVHK/ KVHA 32E- 38E- 64D- 76D, have a

variable pulley incorporated into the activating motor, by which it is possible to vary, when the fan is off its

diameter to modify the air flow of the unit, as required.

1.- Centrifugal fan ( single or double).

2.- Activating motor.

3.- Fixed pulley at the fan.

4.- Variable pulley at the motor fan.

5.- transmission pulley or pulleys.

6.- Base of the motor with displacement system for

tensioning of belts.

7.- Tensing screw.

3

1

2

4

5

6

7

A

B

3

1

2

A

B

3

2

1

2

SIMPLE PULLEY

DOUBLE PULLEY

7

VARIABLE PULLEYS

DISPLACEMENT

2.- INSTALLATION

2.4.-OPTIONAL OPERATIONS PRIOR TO UNIT INSTALLATION:

THE VENTILATION FOR LVCK- LVHA- LVHK UNITS IS FORMED BY:

Page 39

38

UNIT INSTALLED ON SHOCK ABSORBERS

2.5.- UNIT LOCATION

- The unit is able to work in normal radioelectronic conditions for commercial and residential installations. For any

other conditions please consult.

- If the outside temperature in the area where the heat pump unit is to be installed is low or the cycle functioning

are too long, it may necessary to install an electrical heater, below the likely coils on the drip tray, which avoids

the causing of ice in the coil during defrost cycle.

- If the outdoor unit is going to be installed outside. It may be recommended to install isolation around the panel

of electrical box, to make sure it became hermetic.

- The bedplate is made up of two metal channels, capable

of with standing the weight of the units.

- If the unit is floor mounted, then the profiles should be

isolated with shock absorbing material such as anti-vibration

or pads. Keep in mind that fans rotate at approximately

850 rpm.

For the ones with variable pulley belts, see performances

tables.

2.- INSTALLATION

Floor supports

(shock absorbers)

Page 40

39

SERVICE SPACE

Space should be left free for access or servicing, to ease the installation of cables, drainage connections, electric

installation and cleaning filters, as well as easy access to the unit.

Drainage pipes will be fitted for each tray through a siphon with a

height difference of 80 mm. to avoid drainage problems from the

depression formed by the fans. The pipes should have an inclination

of 2% to ease drainage of condensation.

Also slightly tip the unit (2%) toward the drainage side. Check that the condensation trays are clean and free from

dirt and other debris from the works and that water drains correctly.

All the indoor and outdoor sections of these units have a 3/4 steel threaded drain pipe welded to the condensation

tray.

Clearance around the unit for service and maintenance.

2.6.- INSTALLATION CLEARANCES

Inspection and cleaning stopper.

2%

Min. 80 mm.

2 %

UNIT

2.- INSTALLATION

2.7.- DRAINS

1 m.

1 m.

1 m.

1 m.

Page 41

40

Printer circuit

board

Electrical

Box

Thermostat

connection

PE L1 L2 L3 N

X1

3N ~ 400V - 50 Hz + PE

PE L1 L2

X1

L3

3 ~ 230V - 50 Hz + PE

POWER SUPPLY

400V THREE-PHASE UNITS

UNIT

MODEL

UNIT

MODEL

POWER SUPPLY

230V THREE-PHASE UNITS

Power supply without electric heater

MODELS VOLTAGE

LIMIT

28E/56D

24E/48D

32E/64D

22E/44D

38E/76D

Power supply with electric heater

Power supply without electric heater

Power supply with electric heater

Nr. OF CABLES x SECTION (mm )

2

Nr. OF CABLES x SECTION (mm )

2

1 1

28E

24E

32E

22E

38E

48D

44D

56D

76D

64D

1 1

28E

24E

32E

22E

38E

48D

44D

56D

76D

64D

230 V-1Ph-50Hz

230 V-3Ph-50Hz

230 V-3Ph-50Hz

400 V-3Ph-50Hz

400 V-3Ph-50Hz

198-264 V -1Ph- 50Hz

180-242 V -3Ph- 50Hz

342-462 V -3Ph- 50Hz

198-264 V -3Ph- 50Hz

342-462 V -3Ph- 50Hz

5 x 4

5 x 4

5 x 6

5 x 6

5 x 10

5 x 10

5 x 10

5 x 10

5 x 10

5 x 16

5 x 16

5 x 25

5 x 25

5 x 16

5 x 25

5 x 25

5 x 35

5 x 35

5 x 50

5 x 10

4 x 10

4 x 10

4 x 10

4 x 16

4 x 16

4 x 25

4 x 25

4 x 25

4 x 25

4 x 25

4 x 35

4 x 35

4 x 70

4 x 70

4 x 35

4 x 50

4 x 50

4 x 70

4 x 95

4 x 95

1

VOLTAGE OPERATING LIMITS

Power supply to the unit.

- BEFORE MAKING ANY ELECTRICAL CONNECTIONS, BE SURE THAT ALL CIRCUIT BREAKERS ARE

OPEN.

- IN ORDER TO CARRY OUT THE ELECTRICAL CONNECTIONS, FOLLOW THE ELECTRICAL DIAGRAM

SUPPLIED WITH THE UNIT.

- Connect the power supply cables to the terminals in the electric box through the grommet.

- The sections have been calculated for a length no longer than 50m and a voltage drop of 10V.

Do not start the unit if the drop is greater than this.

- The wiring and circuit breakers to be mounted in the installation must comply with the Regulations in force.

- Ground wires must be properly connected and have a greater length than the phase wires.

INDOOR

SECTION

OUTDOOR

SECTION

2.- INSTALLATION

2.8.- ELECTRICAL CONNECTION

1

Page 42