Lennox COMFAIR HH, COMFAIR HH 20, COMFAIR HH 10, COMFAIR HH 30, COMFAIR HH 40 Application Manual

...Page 1

lennoxemeia.com

COMFAIR

HH

APPLICATION

GUIDE

High pressure fan coil unit

840 8000 m

3

/h

COMFAIR HH-AGU-1107-E

Page 2

Page 3

• 1 •Application Guide • COMFAIR HH-AGU-1107-E

HIGH PRESSURE FAN COIL UNITS - HH

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General data - Eurovent Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Working limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Aeraulic performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sound power spectrum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Air pressure drops for the main accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Water coil pressure drop diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dimensional data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CONTROLLERS

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

APPLICATION GUIDE

Ref : COMFAIR HH-AGU-1107-E

TABLE OF CONTENTS

COMFAIR HH

High pressure fan coil units

Product designed and manufactured under a quality management system certifi ed ISO 9001.

Our products comply with the European standards.

Our company is a member of the Eurovent Certifi cation Program.

The COMFAIR LENNOX fan coil units are tested and rated in accordance with Eurovent certifi cation program.

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided

by us, remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to or made

available to third parties without the prior written agreement of Lennox.

Page 4

• 2 •

RAM

BAM

PAM

SRE

HH SSP

SFA

Application Guide • COMFAIR HH-AGU-1107-E

GENERAL - HH

Comfair HH fan coil units are designed to operate against higher external static pressures (from 105 to 260 Pa), and are available in

7 sizes.

All standard units can be supplied with a complete range of factory or site fi tted accessories, allowing a multitude of confi gurations

for all typical applications, for example :

• auxiliary condensate drain pan (UTC)

• air Filter section (SFA)

• auxiliary Coil

• fresh air inlet damper (SSP)

• electric heater (SRE)

• inlet, supply and exhaust air plenums (PAM, RAM et BAM)

FAN SECTION

Composed of one or two double inlet centrifugal fans with aluminium blades, mounted in horizontal position and statically and

dynamically balanced. The electric motor is fi tted with overload protection and has three speeds. It is constructed to comply with all

relevant International standards, with a capacitor permanently in circuit. Motors are connected directly to the fan shafts and are located

on anti-vibration mounts to ensure particularly quiet operation.

CHASSIS

The chassis is manufactured from thick (1mm) galvanised sheet steel.

COILS

Water Heat exchangers are copper tubes with aluminium fi ns, bonded to the tubes by a mechanical

expansion process. Coil connections are of female type antitorsion and headers are fi tted with easily

accessible air-vents.

CONTROL PANEL

Comfair HH fan coil units must be controlled from a separate remote controller. A large selection of controllers

with varying levels of function is available to satisfy most requests.

Options delivered separately : Ambient Thermostats (TA), Minimum water temperature thermostat (TC),

Remote (wall mounted) controllers (CD1, CD2/X1, ... ).

AIR FILTER

Simple to remove, it comprises a metal frame containing a washable acrylic fi lter media (fi ltration effi ciency EU 2).

HIGH PRESSURE FAN COIL UNITS - HH

Page 5

• 3 •Application Guide • COMFAIR HH-AGU-1107-E

MANUAL FRESH AIR INLET DAMPER

Produced form Alu-Zinc sheet metal, it allows the introduction of fresh air up to a maximum of 30% of the total air volume.

ELECTRIC HEATER

Electric heater elements meet all of the relevant International safety standards and are fi tted as standard

with a safety cut-out thermostat and automatic reset. Heater elements are factory fi tted with all electrical

wiring and are connected to the control panel via a contactor.

AUXILIARY COIL

In order to offer the best solutions for 4 pipe applications, a supplementary 1 row coil can be ordered

factory fi tted.

INLET, SUPPLY AND EXHAUST AIR PLENUMS

Plenums are constructed from galvanised sheet steel allow for easy connection to ductwork.

GENERAL - HH

Page 6

• 4 •

10 20 30 40 50

3,11 4,02 5,63 6,11 7,23

3,46 5,02 6,93 7,88 9,44

3,63 5,64 7,36 8,63 11

3,82 5,16 7,21 7,79 8,91

4,2 6,35 8,66 9,81 11,3

4,4 7,05 9,2 10,6 13,1

4,3 6,13 8,66 9,23 11,2

4,75 7,62 10,5 11,8 14,5

4,98 8,51 11,2 12,8 16,9

18,1 19,3 20,8 17,2 16,6

21,9 29,2 30 27,3 26,9

24 35,9 33,8 31,9 35,9

16,7 17 17,7 15,1 15,4

20,2 25,7 25,6 23,9 24,9

22,2 31,7 28,9 27,9 33,2

0,11 0,15 0,3 0,31 0,28

0,12 0,19 0,32 0,34 0,41

0,16 0,24 0,32 0,34 0,58

230/1/50

63 53 61 58 62

67 62 68 65 69

68 66 70 69 74

10 20 30 40 50

2,66 4,02 5,4 5,76 6,89

2,93 5 6,66 7,44 9,02

3,1 5,63 7,07 8,04 10,6

3,13 5,12 6,51 7,03 8,31

3,44 6,3 7,82 8,86 10,6

3,6 7 8,3 9,57 12,3

3,61 5,04 7,5 8,23 9,3

3,98 6,27 8,73 9,93 12

4,18 7 9,17 10,6 14

12 14,4 17,7 13,9 14,2

14,5 21,8 25,2 21,8 23

15,9 26,8 28 25 30,8

20 11,9 25,3 13,3 15

24,3 18,4 33,8 19,3 24,9

26,8 22,9 37 21,7 33,8

0,11 0,14 0,3 0,31 0,28

0,12 0,17 0,32 0,34 0,41

0,16 0,22 0,32 0,34 0,58

230/1/50

63 53 61 59 61

67 62 68 66 68

69 66 70 70 73

Application Guide • COMFAIR HH-AGU-1107-E

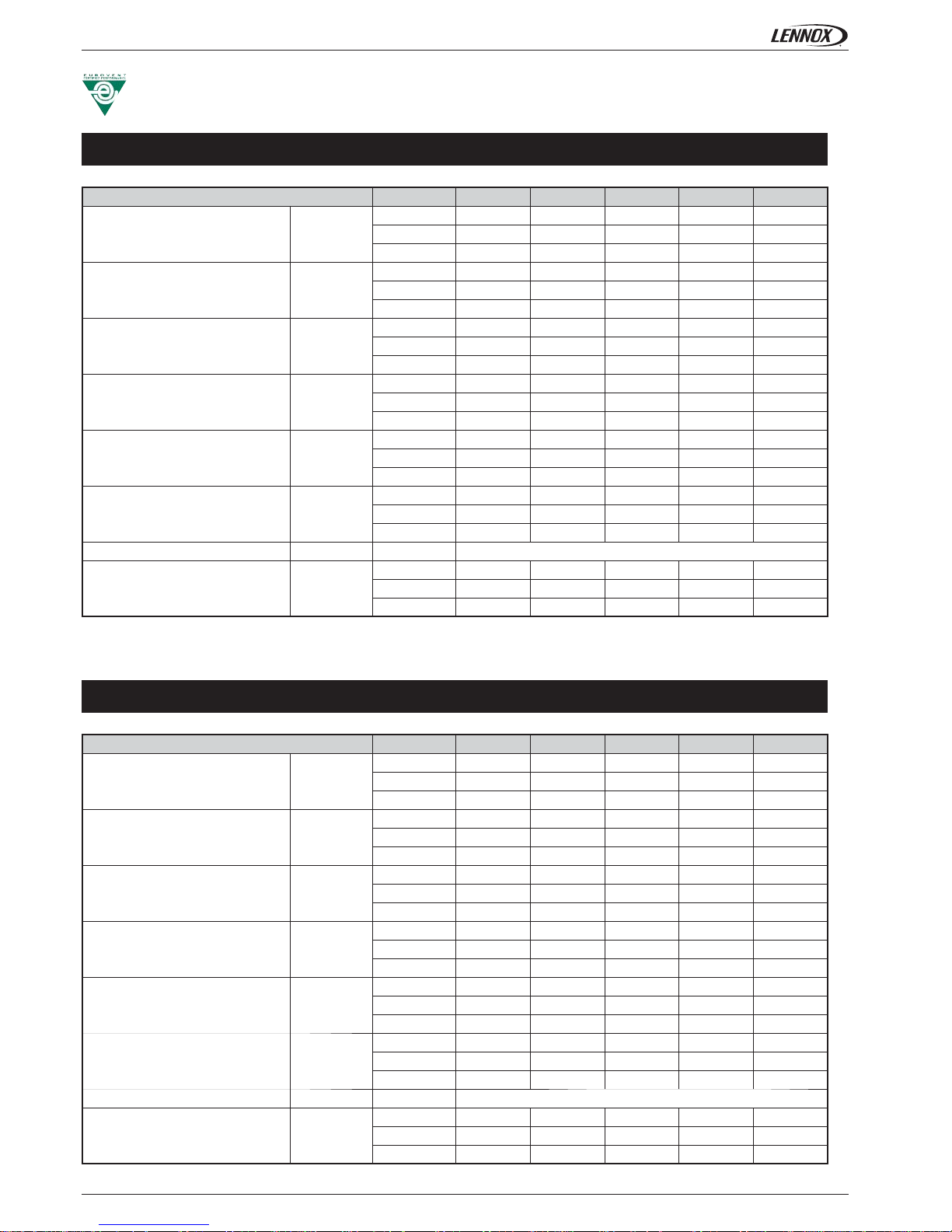

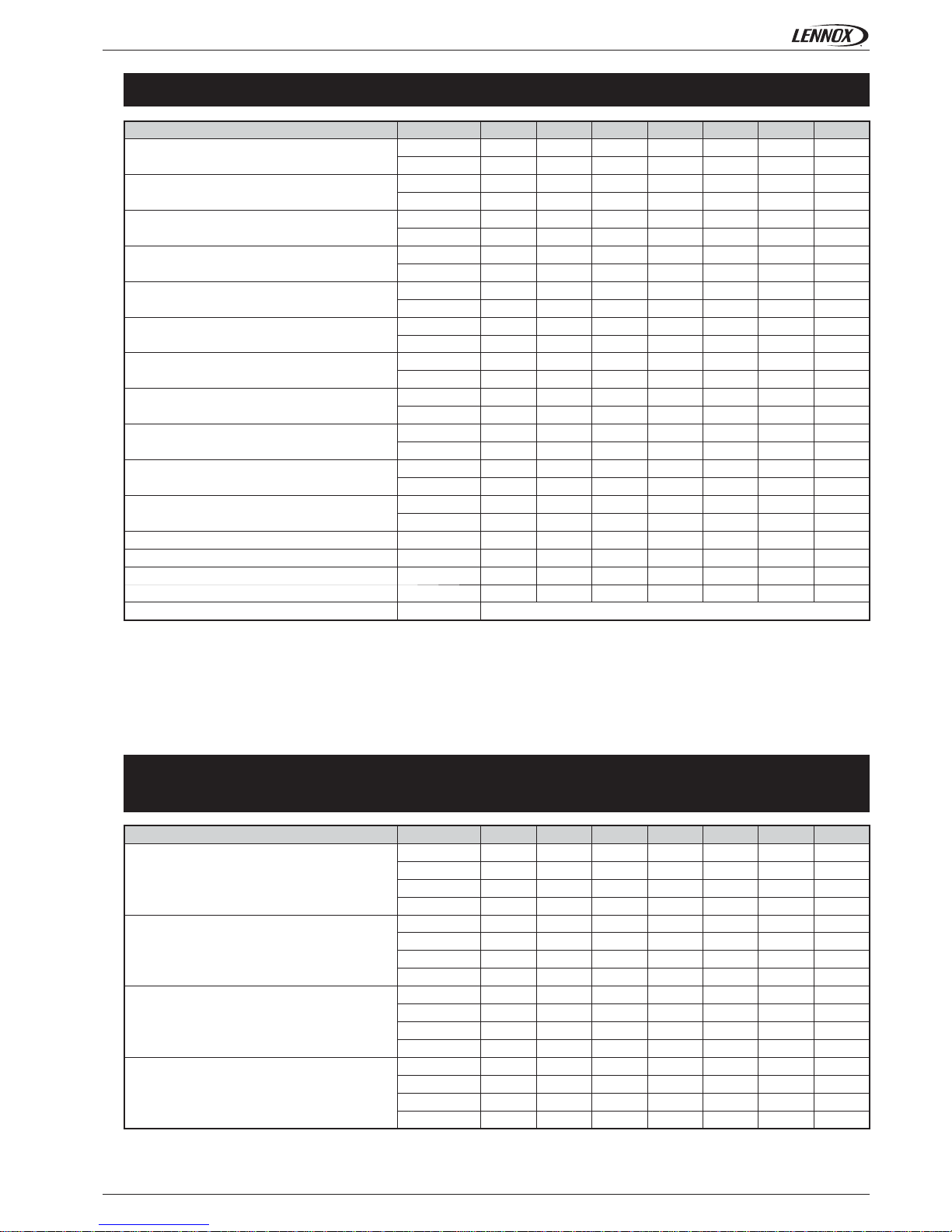

GENERAL DATA - EUROVENT CONDITIONS - HH

All data are at Eurovent conditions.

http://www.eurovent-certifi cation.com/

PROGRAM: FC-2-H

PROGRAM: FC-4-H

COMFAIR HH

Sensible cooling capacity kW

Min

Med

Max

Total cooling capacity kW

Min

Med

Max

Heating capacity kW

Min

Med

Max

Water pressure drops in cooling kPa

Min

Med

Max

Water pressure drops in heating kPa

Min

Med

Max

Fan electrical power kW

Min

Med

Max

Voltage V/Ph/Hz -

Sound power level dB(A)

Min

Med

Max

COMFAIR HH

Sensible cooling capacity kW

Min

Med

Max

Total cooling capacity kW

Min

Med

Max

Heating capacity kW

Min

Med

Max

Water pressure drops in cooling kPa

Min

Med

Max

Water pressure drops in heating kPa

Min

Med

Max

Fan electrical power kW

Min

Med

Max

Voltage V/Ph/Hz -

Sound power level dB(A)

Min

Med

Max

Page 7

• 5 •

10 20 30 40 50 60 70

3640 7050 9200 10600 13100 27800 50600

3130 6063 7912 9116 11266 23908 43516

2870 5640 7360 8630 11000 21100 39500

2,468 4,85 6,33 7,422 9,46 18,146 33,97

4972 8512 11210 12800 16818 32430 60111

4276 7320 9641 11008 14464 27890 51696

626 1213 1582 1823 2253 4782 8703

0,174 0,337 0,441 0,506 0,626 1,328 2,418

24 35,9 33,8 31,9 35,9 34 40

2,4 3,7 3,4 3,3 3,7 3,5 4,1

22,2 31,7 28,9 27,9 33,2 24 30

2,3 3,2 2,9 2,8 3,4 2,4 3,1

8400 14300 18850 21520 28490 54240 100810

7224 12298 16211 18507 24502 46647 86698

722 1230 1621 1850 2450 4664 8670

0,201 0,342 0,45 0,514 0,681 1,296 2,408

18,3 29,6 27,5 26,1 35,6 20,7 27

1,9 3 2,8 2,7 3,6 2,1 2,8

3000 6000 9000 12000 18000

2586 5172 7759 10345 15517

4,56 9,12 13,67 18,23 27,35

4500 9000 12000 18000 24000

3879 7759 10345 15517 20690

6,84 13,67 18,23 27,35 36,46

837 1423 1951 2131 3002 4678 9250

0,233 0,395 0,542 0,592 0,834 1,299 2,569

1360 1360 1200 1207 1382 806 822

68 66 70 69 75 78 81

160 240 320 340 580 1320 2600

0,72 0,97 1,43 1,51 2,58 5,86 11,54

230/1/50

Application Guide • COMFAIR HH-AGU-1107-E

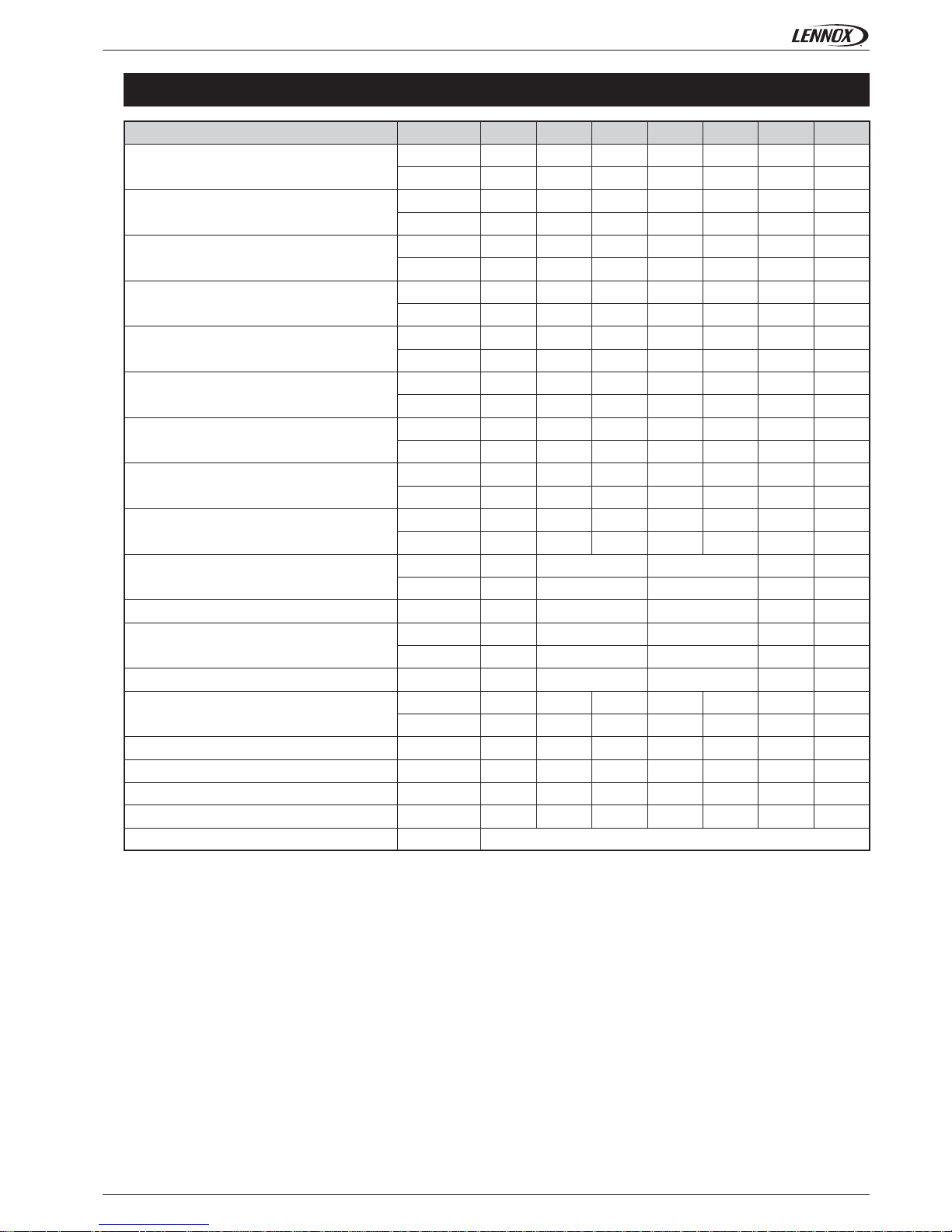

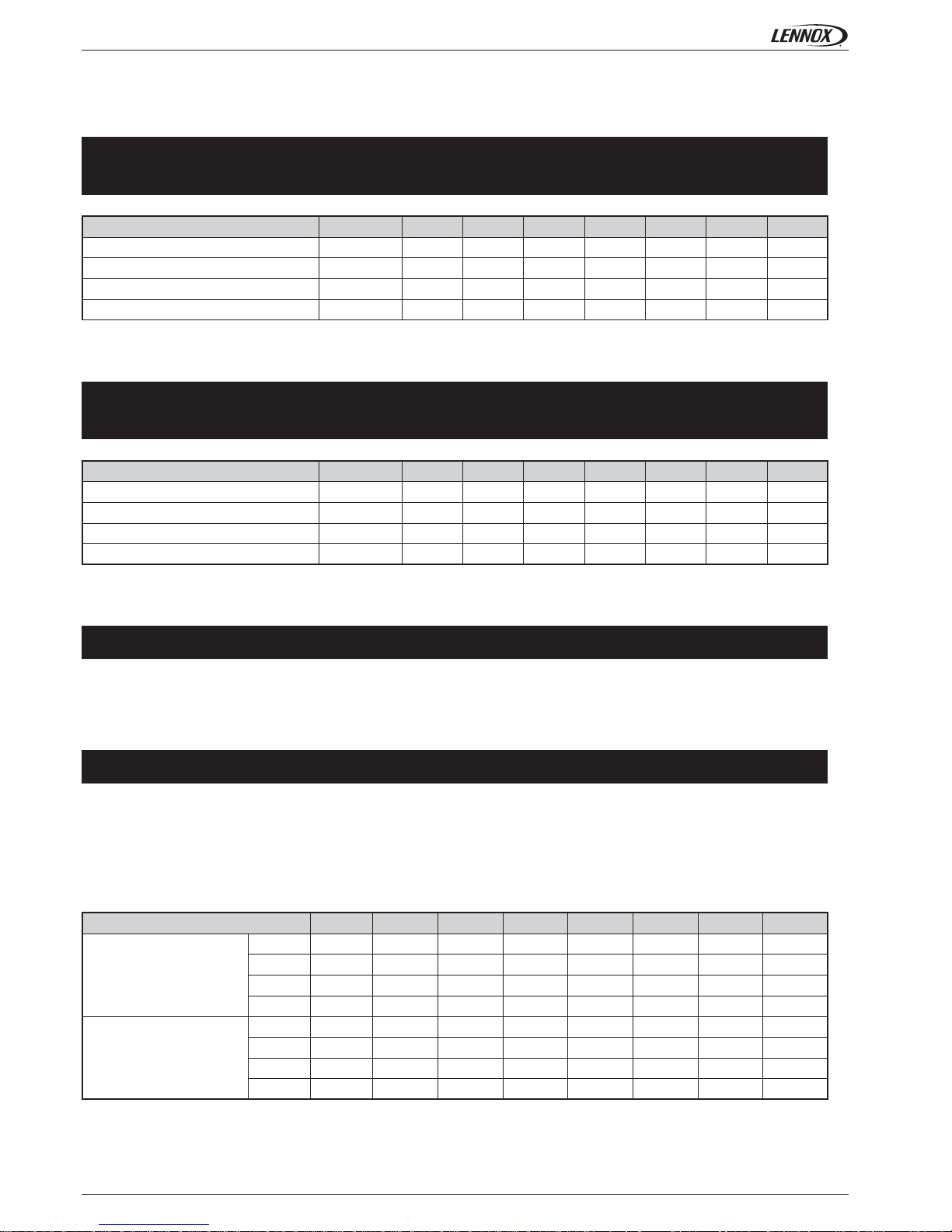

TECHNICAL DATA - HH

2 PIPES SYSTEM

COMFAIR HH

Total cooling capacity

(1)

W

Frig/h

Sensible cooling capacity

(1)

W

Frig/h

Heating capacity

(3)

W

kcal/h

Water fl ow

(1) (3)

l/h

l/s

Water pressure drops in cooling

(1)

kPa

mWG.

Water pressure drops in heating

(3)

kPa

mWG.

Heating capacity

(2)

W

kcal/h

Water fl ow

(2)

l/h

l/s

Water pressure drops in heating

(2)

kPa

mWG.

Electrical heater heating capacity

(4)

W

kcal/h

Electrical heater power input

(4)

A

Electrica heater heating capacity

(5)

W

kcal/h

Electrical heater input current

(5)

A

Air fl ow

(6)

m3/h

m

3

/s

Fan speed

(6)

rpm

Sound power level

(7)

dB(A)

Motor electrical power

(8)

W

Motor electrical input

(8)

A

Electrical supply V/Ph/Hz

Above mentionned technical data are calculated ar the following operating conditions:

- Maximum fan speed

- Standard unit without ducts (fancoil operating without external back pressure)

(1) Cooling: entering water temperature 7°C, leaving water temperature 12°C, entering air temperature 27°C W.B.; 19°C D.B.

(2) Heating: entering water temperature 50°C, same water fl ow as in cooling, entering air temperature 20°C

(3) Heating: entering water temperature 70°C, leaving water temperature 60°C, entering air temperature 20°C

(4) Electric heaters section SRE - B: electric heaters capacities, lower speed cabling (SRE - B supplied as accessory only)

(5) Electric heaters section SRE - A: electric heaters capacities, high speed cabling (SRE - A supplied as accessory only)

(6) Air fl ow and fan speed: fancoil performances with cleaned fi lter

(7) Sound power level: sound power measured following ISO 23741

(8) Electrical data referred to the maximum available speed

Page 8

• 6 •

10 20 30 40 50 60 70

0,98 0,96

-----

0,98 0,95

-----

0,98 0,96

-----

0,97 0,94

-----

Application Guide • COMFAIR HH-AGU-1107-E

TECHNICAL DATA - HH

CORRECTION COEFFICIENT FOR DIFFERENT AVAILABLE SPEEDS

2 PIPES SYSTEM

COMFAIR HH 10 20 30 40 50 60 70

Total cooling capacity

1 0,84 min 0,74 min 0,79 min 0,74 min 0,68 min 0,77 min 0,78 min

2 0,95 med 0,90 med 0,94 med 0,93 med 0,87 med 0,89 med 0,90 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Sensible cooling capacity

1 0,86 min 0,71 min 0,77 min 0,71 min 0,65 min 0,75 min 0,76 min

2 0,95 med 0,89 med 0,94 med 0,91 med 0,85 med 0,88 med 0,89 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Heating capacity

1 0,86 min 0,72 min 0,77 min 0,72 min 0,67 min 0,75 min 0,77 min

2 0,95 med 0,90 med 0,94 med 0,92 med 0,86 med 0,88 med 0,89 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Air fl ow

1 0,81 min 0,63 min 0,69 min 0,63 min 0,56 min 0,69 min 0,70 min

2 0,93 med 0,85 med 0,91 med 0,89 med 0,80 med 0,84 med 0,85 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

NOTE: The symbol (-) means that for HH30 to HH70, only 3 fan speeds are available. For HH10 and HH20, upon customer request other 3 speeds among the 4 available

speeds can be connected.

Page 9

• 7 •

10 20 30 40 50 60 70

3600 7000 8300 9570 12300 24950 45550

3096 6020 7138 8230 10578 21457 39173

3100 5630 7070 8040 10600 20150 37750

2666 4842 6080 6914 9116 17329 32465

4180 7000 9170 10600 14000 38800 70150

3595 6020 7886 9116 12040 33368 60330

619 1205 1428 1646 2116 4291 7835

0,172 0,335 0,397 0,457 0,588 1,192 2,176

360 602 789 912 1204 3337 6033

0,1 0,167 0,219 0,253 0,334 0,927 1,676

15,9 26,8 28 25 30,8 27 32

1,6 2,7 2,9 2,5 3,1 2,8 3,3

26,8 22,9 37 21,7 33,8 33 36

2,7 2,3 3,8 2,2 3,4 3,4 3,7

2557 4275 5593 6441 8547 23730 42898

2204 3686 4822 5553 7368 20457 36981

446 746 976 1124 1492 4141 7486

0,124 0,207 0,271 0,312 0,414 1,15 2,079

46 39 62 36 58 56 62

4,7 4 6,3 3,7 5,9 5,8 6,3

795 1352 1853 2024 2852 4444 8788

0,221 0,376 0,515 0,562 0,792 1,234 2,441

1365 1365 1205 1214 1387 810 832

69 66 70 70 73 78 81

162 218 322 340 582 1320 2600

0,72 0,97 1,43 1,51 2,58 5,86 11,54

230/1/50

10 20 30 40 50 60 70

0,98 0,96

-----

0,98 0,96

-----

0,98 0,97

-----

0,97 0,94

-----

Application Guide • COMFAIR HH-AGU-1107-E

TECHNICAL DATA - HH

Above mentionned technical data are calculated ar the following operating conditions:

- Maximum fan speed

- Standard unit without ducts (fancoil operating without external back pressure)

(1) Cooling: entering water temperature 7°C, leaving water temperature 12°C, entering air temperature 27°C W.B.; 19°C D.B.

(2) Heating: entering water temperature 70°C, leaving water temperature 60°C, entering air temperature 20°C

(3) Heating: entering water temperature 50°C, same water fl ow as in cooling, entering air temperature 20°C

(4) Air fl ow and fan speed: fancoil performances with cleaned fi lter

(5) Sound power level: sound power measured following ISO 23741

(6) Electrical data referred to the maximum available speed

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

NOTE: The symbol (-) means that for HH30 to HH70, only 3 fan speeds are available. For HH10 and HH20, upon customer request other 3 speeds among the 4 available

speeds can be connected.

4 PIPES SYSTEM

CORRECTION COEFFICIENT FOR DIFFERENT AVAILABLE SPEEDS

COMFAIR HH

Total cooling capacity

(1)

W

Frig/h

Sensible cooling capacity

(1)

W

Frig/h

Heating capacity

(2)

W

kcal/h

Water fl ow in cooling

(1)

l/h

l/s

Water fl ow in heating

(2)

l/h

l/s

Water pressure drops in cooling

(1)

kPa

mWG.

Water pressure drops in heating

(2)

kPa

mWG.

Heating capacity

(3)

W

kcal/h

Water fl ow

(3)

l/h

l/s

Water pressure drops in heating

(3)

kPa

mWG.

Air fl ow

(4)

m3/h

m3/s

Fan speed

(4)

rpm

Sound power level

(5)

dB(A)

Motor electrical power

(6)

W

Motor electrical input

(6)

A

Electrical supply V/Ph/Hz

COMFAIR HH

Total cooling capacity

1 0,87 min 0,73 min 0,78 min 0,73 min 0,68 min 0,76 min 0,78 min

2 0,96 med 0,90 med 0,94 med 0,93 med 0,86 med 0,89 med 0,90 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Sensible cooling capacity

1 0,86 min 0,71 min 0,76 min 0,72 min 0,65 min 0,74 min 0,76 min

2 0,94 med 0,89 med 0,94 med 0,93 med 0,85 med 0,87 med 0,89 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Heating capacity

1 0,89 min 0,77 min 0,82 min 0,78 min 0,73 min 0,78 min 0,80 min

2 0,96 med 0,92 med 0,95 med 0,94 med 0,89 med 0,90 med 0,91 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Air fl ow

1 0,81 min 0,63 min 0,69 min 0,63 min 0,56 min 0,69 min 0,70 min

2 0,93 med 0,85 med 0,91 med 0,89 med 0,80 med 0,84 med 0,85 med

3 1,00 max 1,00 max 1,00 max 1,00 max 1,00 max

4 1,00 max 1,00 max

Page 10

• 8 •

10 20 30 40 50 60 70

175 225 275 325 375 825 1400

1,3 1,1 1 1 1 1 1

1300 1850 2275 2700 3150 6900 11575

70,8 71,9 70 69,9 70,1 70,4 70,3

10 20 30 40 50 60 70

75 125 150 200 225 600 1025

1,2 1 1,3 1 1,2 1,1 1

575 1050 1100 1650 1725 4900 8450

68,5 69,7 70 69,2 69,6 70,7 70,2

10 20 30 40 50 60 70

1

2

3 100 100

4 -----

1

2

39085

4 -----

Application Guide • COMFAIR HH-AGU-1107-E

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

NOTE: The symbol (-) means that for HH30 to HH70, only 3 fan speeds are available. For HH10 and HH20, upon customer request other 3 speeds among the 4 available

speeds can be connected.

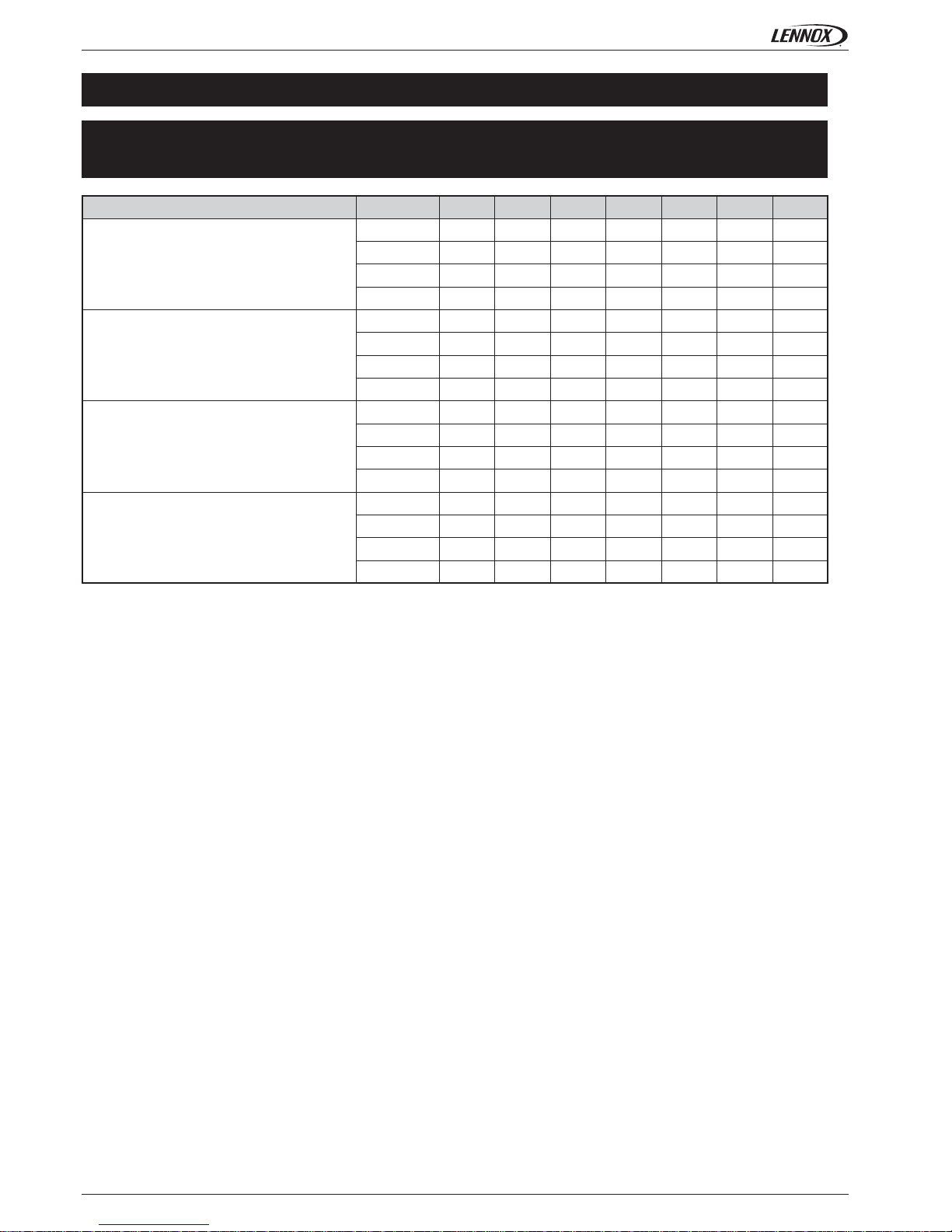

WORKING LIMITS - HH

Maximum entering water temperature: 70°C Maximum entering air temperature: 40°C

Minimum entering water temperature: +4°C Minimum entering air temperature: +4°C

Maximum working pressure: 8 Bar

WATER FLOW AND PRESSURE DROP LIMITS, 3R COIL (HH10 TO HH50)

AND 4R COIL (HH60 AND HH70)

WATER FLOW AND PRESSURE DROP LIMITS, 1 ROW COIL (HH10 TO

HH50) AND 2R COIL (HH60 AND HH70)

Data given for medium water temperature at 9,5°C

3 WAYS VALVE

Using of 2 or 3 ways valves is compulsory when the unit is used for cooling to avoid condensate in the external structure (bearing

structure and cabinet). As alternative install a regulating system to stop coil water entering when the fan is off.

When the units is connected with ducts fan air fl ow is reduced due to the ducting pressure drops.

With very high pressure drops fancoil air fl ow becomes too low and electric motor which is connected to the fan can be damaged. For

this reason we recommand static pressures lower than the maximum limit static pressures indicated in the schedule.

NOTE: When the fancoil is operating with the maximum operating indicated static pressure value, air fl ow is half in comparison with

the unit without ducts at the same working speed. Defi nitively the static presure limit corresponds to the back pressure ables to half

fancoil air fl ow (as a consequence the fancoil unit performances like heating & cooling capacity, will be reduced of about 50%).

MAXIMUM FAN STATIC PRESSURE

Data given for medium water temperature at 65°C

COMFAIR HH

Minimal water fl ow l/h

Minimal water pressure drop kPa

Maximal water fl ow l/h

maximal water pressure drop kPa

COMFAIR HH

Minimal water fl ow l/h

Minimal water pressure drop kPa

Maximal water fl ow l/h

maximal water pressure drop kPa

COMFAIR HH

2 pipes system

Pa 90 min 80 min 115 min 105 min 135 min 220 min 220 min

Pa 95 med 95 med 130 med 130 med 180 med 240 med 240 med

Pa 135 max 135 max 205 max 260 max 260 max

Pa 105 max 105 max

4 pipes system

Pa 75 min 70 min 95 min 90 min 110 min 180 min 180 min

Pa 85 med 80 med 115 med 115 med 155 med 210 med 210 med

Pa 120 max 120 max 180 max 220 max 220 max

Pa 95 max 90 max

Page 11

• 9 •

MIN

MED

MAX

MIN

MED

MAX

MIN

MED

MAX

Application Guide • COMFAIR HH-AGU-1107-E

AERAULIC PERFORMANCES - HH

HH10 - 2 PIPES SYSTEM (3 ROW COIL DATA)

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

Air fl ow (m

3

/h)

Available static pressure (Pa)

Working limit

Air fl ow (m

3

/h)

Available static pressure (Pa)

Working limit

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

MAX

MED

MIN

MAX

MED

MIN

MAX

MED

MIN

HH20 - 2 PIPES SYSTEM (3 ROW COIL DATA)

HH30 - 2 PIPES SYSTEM (3 ROW COIL DATA)

Page 12

• 10 •

MIN

MED

MAX

MIN

MED

MAX

MIN

MED

MAX

MIN

MED

MAX

Application Guide • COMFAIR HH-AGU-1107-E

AERAULIC PERFORMANCES - HH

HH40 - 2 PIPES SYSTEM (3 ROW COIL DATA)

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

Air fl ow (m

3

/h)

Available static pressure (Pa)

Working limit

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

MAX

MED

MIN

MAX

MED

MIN

MAX

MED

MIN

HH70 - 2 PIPES SYSTEM (3 ROW COIL DATA)

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

MAX

MED

MIN

HH50 - 2 PIPES SYSTEM (3 ROW COIL DATA)

HH60 - 2 PIPES SYSTEM (3 ROW COIL DATA)

Page 13

• 11 •

MIN

MED

MAX

MIN

MED

MAX

MIN

MED

MAX

Application Guide • COMFAIR HH-AGU-1107-E

AERAULIC PERFORMANCES - HH

HH10 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

Air fl ow (m

3

/h)

Available static pressure (Pa)

Working limit

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

MAX

MED

MIN

MAX

MED

MIN

MAX

MED

MIN

HH20 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

HH30 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

Page 14

• 12 •

MIN

MED

MAX

MIN

MED

MAX

MIN

MED

MAX

MIN

MED

MAX

Application Guide • COMFAIR HH-AGU-1107-E

HH50 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

HH60 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

AERAULIC PERFORMANCES - HH

HH40 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

Air fl ow (m

3

/h)

Available static pressure (Pa)

Working limit

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be

connected.

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

MAX

MED

MIN

HH70 - 4 PIPES SYSTEM (3 ROW + 1 ROW COIL DATA)

Air fl ow (m3/h)

Available static pressure (Pa)

Working limit

Page 15

• 13 •

125 250 500 1000 2000 4000 8000

1 68,1 60,6 59,3 57,9 54,9 52,3 45,9 63

2 71,4 64,5 62,8 62 59 57 51,5 67

3 71,4 65,4 63,3 62,5 59,6 57,6 52,6 67,5

4 71,9 65,7 63,7 62,9 60,1 58,2 53,4 68

1 57,2 51,4 50,9 47,6 44,8 39,5 32 53

2 65,2 60 58,7 56,9 54,1 51,3 45,3 62

3 66,9 61,7 60,1 58,9 56,1 53,8 48,6 64

4 68,4 63,9 61,8 60,6 58,2 56,2 51,4 66

1 61,9 57,6 58,7 55,9 53 49,6 42,7 61

2 67,6 64,2 64,8 64 60,4 52 54 68

3 68,3 65,6 63,8 66,2 62,1 60,9 56,6 70

1 67,5 53,5 54,2 51,9 49,6 46 38,6 58

2 68,3 59,7 61 59,8 57,2 56,2 51,4 65

3 69,2 63,3 64,1 64,3 61 60,5 56,7 69

1 63,7 57,8 58,4 58 54,8 48,2 39,1 62

2 70,4 64,7 63,6 64,2 62,6 59,3 52,2 69

3 75,6 71,2 68,8 69,6 68,7 66,5 61,1 75

1 71,3 66,3 68,8 63,4 58,1 54,1 41,6 69

2 73,8 69 72,7 67,7 62,5 59 48 73

3 74 73,6 77,3 73,1 68,1 64,8 54,7 78

1 67,3 67,8 70,6 65,8 61 56,8 44,7 71

2 75,9 72 75,1 71,2 66,3 62,9 51,9 76

3 73,7 76,9 79,3 76,7 71,9 68,7 58,9 81

125 250 500 1000 2000 4000 8000

1 68,1 60,6 59,3 57,9 54,9 52,3 45,9 63

2 71,4 64,5 62,8 62 59 57 51,5 67

3 71,9 65,9 63,8 63 60,1 58,1 53,1 68

4 72,9 66,7 64,7 63,9 61,1 59,2 53,4 69

1 57,2 51,4 50,9 47,6 44,8 39,5 32 53

2 65,2 60 58,7 56,9 54,1 51,3 45,3 62

3 66,9 61,7 60,1 58,9 56,1 53,8 48,6 64

4 68,4 63,9 61,8 60,9 58,2 56,2 51,4 66

1 61,9 57,6 58,7 55,9 53 49,6 42,7 61

2 67,6 64,2 64,8 64 60,4 52 54 68

3 68,3 65,6 63,8 66,2 62,1 60,9 56,6 70

1 68,5 54,5 55,2 52,9 50,6 47 39,6 59

2 69,3 60,7 62 60,8 58,2 57,2 52,4 66

3 70,2 64,3 65,1 65,3 62 61,5 57,7 70

1 62,7 56,8 57,4 57 53,8 47,2 38,1 61

2 69,4 63,7 62,6 63,2 61,6 58,3 51,2 68

3 73,6 69,2 66,8 67,6 66,7 64,5 59,1 73

1 71,3 66,3 68,8 63,4 58,1 54,1 41,6 69

2 73,8 69 72,7 67,7 62,5 59 48 73

3 74 73,6 77,3 73,1 68,1 64,8 54,7 78

1 67,3 67,8 70,6 65,8 61 56,8 44,7 71

2 75,9 72 75,1 71,2 66,3 62,9 51,9 76

3 73,7 76,9 79,3 76,7 71,9 68,7 58,9 81

Application Guide • COMFAIR HH-AGU-1107-E

SOUND POWER SPECTRUM - HH

2 PIPES SYSTEM

COMFAIR Speeds

Std electric

wiring (*)

Frequence spectrum - Ref. octave band (Hz)

Total sound

power (dB(A))

HH10

Min

Med

Max

HH20

Min

Med

Max

HH30

Min

Med

Max

HH40

Min

Med

Max

HH50

Min

Med

Max

HH60

Min

Med

Max

HH70

Min

Med

Max

COMFAIR Speeds

Std electric

wiring (*)

Frequence spectrum - Ref. octave band (Hz)

Total sound

power (dB(A))

HH10

Min

Med

Max

HH20

Min

Med

Max

HH30

Min

Med

Max

HH40

Min

Med

Max

HH50

Min

Med

Max

HH60

Min

Med

Max

HH70

Min

Med

Max

4 PIPES SYSTEM

Data indicated as min., med., max. concern the 3 standard speeds set at the factory. Upon customer request other 3 speeds among the 6 speeds available can be connected.

Page 16

• 14 •

8,7 7,5 1,2 2,8 5,3 50,6 55,1 110

7,9 6,9 1,1 2,5 4,8 46,2 50,4 101

6,1 5,3 0,8 1,9 3,7 35,4 38,5 77,1

4,5 3,9 0,6 1,4 2,7 26 28,3 56,6

3,1 2,7 0,4 1 1,9 18 19,7 39,3

2 1,7 0,3 0,6 1,2 11,5 12,6 25,2

1,3 1,2 - 0,4 0,8 7,9 8,6 17,1

9,3 8,1 1,2 2,9 8,4 52,1 56,7 113

9 7,8 1,2 2,8 8,1 50,4 54,9 110

6,6 5,7 0,9 2,1 6 37 40,3 80,7

4,6 4 0,6 1,4 4,1 25,7 28 56

2,9 2,5 0,4 0,9 2,7 16,5 17,9 35,9

1,6 1,4 - 0,5 1,5 9,3 10,1 20,2

0,7 0,6 - - 0,7 4,1 4,5 9

14,1 12,2 1,6 4,4 15,8 59,5 64,9 130

12 10,4 1,4 3,8 13,5 50,7 55,2 110

9,5 8,2 1,1 3 10,6 40 43,6 87,3

7,2 6,3 0,8 2,3 8,2 30,6 33,4 66,8

5,3 4,6 0,6 1,7 6 22,5 24,5 49,1

3,7 3,2 0,4 1,2 4,2 15,6 17 34,1

2,4 2,1 0,3 0,7 2,7 10 10,9 21,8

1,6 1,4 - 0,5 1,8 6,6 7,2 14,4

10,9 9,5 1,3 3,4 10,7 45,6 49,7 99,4

9,6 8,3 1,2 3 9,4 40,2 43,8 87,6

7,8 6,8 0,9 2,5 7,6 32,5 35,5 70,9

6,1 5,3 0,7 1,9 6 25,7 28 56

4,7 4,1 0,6 1,5 4,6 19,7 21,5 42,9

3,5 3 0,4 1,1 3,4 14,5 15,8 31,5

2,4 2,1 0,3 0,8 2,4 10 10,9 21,9

1,5 1,3 - 0,5 1,5 6,4 7 14

1 0,9 - 0,3 1 4,2 4,6 9,2

15,4 13,4 1,6 4,4 21,8 57 62,1 124

11,6 10,1 1,2 3,3 16,4 42,7 46,6 93,1

8,3 7,2 0,9 2,4 11,7 30,6 33,3 66,7

5,5 4,8 0,6 1,6 7,8 20,5 22,3 44,6

3,4 2,9 0,3 1 4,7 12,4 13,5 27

1,7 1,5 - 0,5 2,4 6,3 6,9 13,8

1,1 1 - 0,3 1,5 4 4,4 8,8

8,5 7,4 0,9 2,5 13,7 27,6 30,1 60,1

7,9 6,8 0,9 2,3 12,7 25,5 27,8 55,6

6,2 5,4 0,7 1,8 10 20,2 22 43,9

4,8 4,1 0,5 1,4 7,7 15,4 16,8 33,6

3,5 3 0,4 1 5,6 11,3 12,4 24,7

2,4 2,1 0,3 0,7 3,9 7,9 8,6 17,2

1,6 1,4 - 0,5 2,5 5 5,5 11

1 0,9 - 0,3 1,6 3,2 3,5 7

13,7 11,9 1,4 4 12,4 43,8 47,8 95,5

12,9 11,2 1,3 3,8 11,7 41,5 45,2 90,4

10,7 9,3 1,1 3,1 9,7 34,4 37,5 75,1

8,7 7,6 0,9 2,5 7,9 28 30,6 61,1

6,9 6 0,7 2 6,3 22,3 24,3 48,6

5,4 4,7 0,6 1,6 4,9 17,2 18,8 37,5

4 3,5 0,4 1,2 3,6 12,8 14 27,9

2,8 2,4 0,3 0,8 2,6 9 9,8 19,7

1,8 1,6 - 0,5 1,7 5,9 6,5 12,9

1,6 1,4 - 0,5 1,5 5,2 5,7 11,4

Application Guide • COMFAIR HH-AGU-1107-E

AIR PRESSURE DROPS FOR THE MAIN ACCESSORIES - HH

Air fl ow dB(A)

Description of the accessories

Fresh air lower

section (SSP)

With completely

open fresh air

Lower position

Fresh air lower

section (SSP)

With completely

closed fresh air

Lower position

Straight intake/

Supply plenum

(PAM)

90° intake/supply

plenum (RAM)

Intake/Supply

section with

spigot section

(BAM)

Heating section

with electricl

heater (SRE)

Standard air

fi lter in medium

stemming

condition

Standard air fi lter

in limit stemming

condition

CLEANING IS

NECESSARY

COMFAIR HH10

837

800

700

600

500

400

330

COMFAIR HH20

1423

1400

1200

1000

800

600

400

COMFAIR HH30

1951

1800

1600

1400

1200

1000

800

650

COMFAIR HH40

2131

2000

1800

1600

1400

1200

1000

800

650

COMFAIR HH50

3002

2600

2200

1800

1400

1000

800

COMFAIR HH60

4678

4500

4000

3500

3000

2500

2000

1600

COMFAIR HH70

9250

9000

8200

7400

6600

5800

5000

4200

3400

3200

Page 17

• 15 •Application Guide • COMFAIR HH-AGU-1107-E

STANDARD COIL (Ref. water medium temperature 9,5°C)

Water fl ow (l/h)

Water pressure drops (kPa)

Water fl ow (l/h)

Water pressure drops (kPa)

AUXILIARY COIL (Ref. water medium temperature 65°C)

WATER COIL PRESSURE DROP DIAGRAM - HH

Page 18

• 16 •

10 20 30 40 50 60 70

1-1 2-1 2-1 2-1 2-1 1-1 2-2

34

523 873 973 1213 1900

11 12 14 26

2,1

345681626

25x22

66 88

0,144 0,240 0,292 0,364 0,425 0,788 1,235

8,128 13,567 16,495 20,564 23,991 59,407 93,053

1,36 2,18 2,63 3,25 3,79 9,38 14,44

1/2” 3/4” 1” 1”1/4 1”1/2

738 1088 1188 1428 1428 1481 2168

548 898 998 1238 1238 1239 1926

650 1000 1100 1340 1340 1341 2028

300 325 375 675

232 275 575

41 65 75

533 852

96 107 133 235

100 200

35 43

65

28 36 41 46 57 117 192

Application Guide • COMFAIR HH-AGU-1107-E

DIMENSIONAL DATA - HH

GENERAL DIMENSIONS - 2 PIPES SYSTEM

Models HH10 to HH50

Models HH60 and HH70

COMFAIR HH

Fans motor number nr

Coil used for both cooling

and heating

Rows number nr

Finned pack length mm

Number of pipes per row nr

Fin spacing mm

Number of feeding circuits nr

Shape mmxmm

Finned pack depth mm

Frontal surface m²

Total surface of fi ns m²

Water content liter

Hydraulic connections (Ø male gas) Ø

Unit general features

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Gmm

Hmm

Imm

Nmm

Omm

Net weight kg

Page 19

• 17 •

10 20 30 40 50 60 70

1-1 2-1 2-1 2-1 2-1 1-1 2-2

34

523 873 973 1213 1213 1213 1900

11 12 14 26

2

345681626

25x22

66 88

0,144 0,240 0,292 0,364 0,425 0,788 1,235

8,128 13,567 16,495 20,564 23,991 59,407 93,053

1,36 2,18 2,63 3,25 3,79 9,38 14,44

1/2” 3/4” 1” 1”1/4 1”1/2

12

523 873 973 1213 1900

11 12 14 26

2,1

12 31016

25x25

25

0,144 0,240 0,292 0,364 0,425 0,788 1,235

2,709 4,522 5,498 6,855 7,997 29,704 46,527

0,45 0,73 0,88 1,08 1,26 4,69 7,22

1/2” 3/4” 1” 1”1/4

738 1088 1188 1428 1428 1481 2168

548 898 998 1238 1238 1239 1926

650 1000 1100 1340 1341 2028

300 325 375 675

232 275 575

41 65 75

533 852

96 107 133 235

100 200

75 87 113 213

140 240

35 42

95 114

35 32 43

40 65

30 38 44 49 61 130 210

Application Guide • COMFAIR HH-AGU-1107-E

DIMENSIONAL DATA - HH

GENERAL DIMENSIONS - 4 PIPES SYSTEM

Models HH10 to HH50

Models HH60 and HH70

COMFAIR HH

Fans motor number nr

Coil used for cooling

Rows number nr

Finned pack length mm

Number of pipes per row nr

Fin spacing mm

Number of feeding circuits nr

Shape mmxmm

Finned pack depth mm

Frontal surface m²

Total surface of fi ns m²

Water content liter

Hydraulic connections (Ø male gas) Ø

Coil used for heating

Rows number nr

Finned pack length mm

Number of pipes per row nr

Fin spacing mm

Number of feeding circuits nr

Shape mmxmm

Finned pack depth mm

Frontal surface m²

Total surface of fi ns m²

Water content liter

Hydraulic connections (Ø male gas) Ø

Unit general features

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Gmm

Hmm

Imm

Lmm

Mmm

Nmm

Omm

Pmm

Qmm

Net weight kg

Page 20

• 18 •

B

A

F

F

FFC

D

E

26

26

2626

E

B

A

F

F7C

D

E

E

F

10 20 30 40 50 60 70

566 918 1018 1258 1258 1290 1985

546 898 998 1238 1238 1230 1924

195 195 222 222 272 568 568

215 215 242 242 292 625 625

67 67 67 67 67 118 118

10 10 10 10 10 31 31

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

SFA (AIR FILTER SECTION)

SIZES 10 to 50

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

SIZES 60 and 70

Page 21

• 19 •

C

D

B

A

2020

20

20

E

F

115115 M

G

H

I

L2020

C

D

B

A

2020

20

20

E

F

115115 M

G

H

I

L20

20

10 20 30 40 50 60 70

240 240 265 265 310 615 725

200 200 225 225 270 575 575

590 940 1040 1280 1280 1280 1969

550 900 1000 1240 1240 1240 1929

365 600 665 825 825 825 642

185 300 335 415 415 415 1286

70 70 70 70 70 100 100

330 330 330 330 330 625 625

136 136 136 136 136 288 288

200 200 225 225 275 575 575

170 170 170 170 170 498 498

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

SSP (SECTION WITH FRESH AIR LOUVER - MANUAL)

SIZES 10 to 50

SIZES 60 and 70

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Gmm

Hmm

Imm

Lmm

Mmm

Page 22

• 20 •

A

B

C

204

2525

11 11

D

50 50

20425 25

10 20 30 40 50 60 70

648 998 1098 1338 1338 1342 2026

219 219 244 244 294 595 595

197 197 222 222 272 572 572

548 898 998 1238 1238 1242 1926

10 20 30 40 50 60 70

648 998 1098 1338 1338 1342 2026

219 219 244 244 294 416 416

197 197 222 222 272 394 394

548 898 998 1238 1238 1242 1926

A

C

204

2525

11 11

D

50 50

B

20425 25

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

PAM (STRAIGHT PLENUM: INTAKE)

COMFAIR HH

Amm

Bmm

Cmm

Dmm

COMFAIR HH

Amm

Bmm

Cmm

Dmm

PAM (STRAIGHT PLENUM: SUPPLY)

Page 23

• 21 •

A

C

B

88

B

D11 11

E

25

25

174 25

G

5088 50

25

FF

204 25

25

A

C

B

88

B

44

44

21

21

1111

D

E

2525

FF174

202 202

404

2525

G50

88

50

10 20 30 40 50 60 70

648 998 1098 1338 1338 1342 2029

84 159 109 128 128 131 *

380 580 780 980 980 980 1929

197 197 222 222 272 394 394

204 204 204 204 204 404 404

15 15 15 15 15 115 115

548 898 998 1238 1238 1242 1929

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

SRE (HEATING SECTION WITH ELECTRIC HEATER - 380V)

SIZES 10 to 50

SIZES 60 and 70

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Gmm

Page 24

• 22 •

F

D

E

19

19

74

C

C

B

A

1818

18

A

18

G1919

C

B

A

19

19

F

D

E

19

19

74

C

19

A

19

G

1919

10 20 30 40 50 60 70

552 902 1002 1242 1242 1242 1932

315 315 340 340 390 650 650

200 200 225 225 275 395 395

360 360 360 360 360 490 670

340 340 340 340 340 470 650

115 115 115 115 115 255 255

265 265 265 265 265 395 575

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

RAM (90° PLENUM: SUPPLY)

SIZES 10 to 50

SIZES 60 and 70

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Gmm

Page 25

• 23 •

F

D

E

19

19

74

C

C

B

A

18

18

18

A

18

G1919

C

B

A

19

19

19

A

19

G

19

19

F

D

E

19

19

74

C

10 20 30 40 50 60 70

552 902 1002 1242 1242 1245 1932

315 315 340 340 390 650 650

200 200 225 225 275 575 575

360 360 360 360 360 670 670

340 340 340 340 340 650 650

115 115 115 115 115 75 75

265 265 265 265 265 575 575

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

RAM (90° PLENUM: INTAKE)

SIZES 10 to 50

SIZES 60 and 70

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Gmm

Page 26

• 24 •

E

B

CCDD

A

E

A

F

6930

10 20 30 40 50 60 70

550 900 1000 1240 1245 1245 1935

200 200 226 226 276 416 416

135 181 227 170 135 322,5 244,5

280 270 272 300 325 600 482

100 100 113 113 138 208 208

2xØ200 3xØ200 3xØ200 4xØ200 4xØ200 2xØ400 4xØ400

E

B

CCDD

A

E

A

F

6930

10 20 30 40 50 60 70

550 900 1000 1240 1245 1245 1935

200 200 226 226 276 576 576

135 181 227 170 135 320 242

280 270 272 300 325 600 482

100 100 113 113 138 288 288

2xØ200 3xØ200 3xØ200 4xØ200 4xØ200 2xØ400 4xØ400

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

BAM (STRAIGHT: SUPPLY)

BAM (STRAIGHT: INTAKE)

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Page 27

• 25 •

B

A

F

E

32

32

C

D

10 20 30 40 50 60 70

600 952 1052 1292 1292 1290 1985

249 249 276 276 326 625 625

570 922 1022 1262 1262 1260 1260

219 219 246 246 296 595 595

539 891 991 1231 1231 1230 1926

188 188 215 215 265 565 565

10 20 30 40 50 60 70

600 952 1052 1292 1292 1290 1985

249 249 276 276 326 445 445

570 922 1022 1262 1262 1260 1260

219 219 246 246 296 415 415

539 891 991 1231 1231 1230 1926

188 188 215 215 265 385 385

B

A

F

E

115*

115*

45

C

D

INTAKE SUPPLY

10 20 30 40 50 60 70

600 952 1052 1292 1292 1290 1985

249 249 276 276 326 625 625

570 922 1022 1262 1262 1260 1260

219 219 246 246 296 595 595

539 891 991 1231 1231 1230 1926

188 188 215 215 265 565 565

10 20 30 40 50 60 70

600 952 1052 1292 1292 1290 1985

249 249 276 276 326 445 445

570 922 1022 1262 1262 1260 1260

219 219 246 246 296 415 415

539 891 991 1231 1231 1230 1926

188 188 215 215 265 385 385

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

FAM (CONNECTION FLANGE)

GAM (ANTI-VIBRATING JOING)

INTAKE SUPPLY

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

COMFAIR HH

Amm

Bmm

Cmm

Dmm

Emm

Fmm

Page 28

• 26 •

FCC

SFA

SSP

RAM

PAM

PAM

PAM

M

PAM

RAM

PAM

RAM

R

A

BAM

PAM

SRE

PAM

B

PAM

SRE

PAM

BAM

SRE

SRE

SRE

FAM+GAM+FAM

130

251 12

251

12

200

373

12

373

12

Application Guide • COMFAIR HH-AGU-1107-E

ACCESSORIES - HH

EXAMPLE OF ACCESSORIES

AUXILIARY DRAIN PAN

Page 29

• 27 •

HH 10 - 50

230/50 - 18

20

2

6

90

<34

66 x 44 x 60

55 x 38 x 32

±0350

HH 60 - 70

230/50 - 10,8

150

5,4

110

<34

195 x 130 x 122

Application Guide • COMFAIR HH-AGU-1107-E

CONDENSATE DRAIN PUMP

This pump is used to eliminate the condensation that collects in the tray in installations where

there is no self-emptying outlet. The pump comes with fi lter to withhold impurities, fl oat with

activation contact, suction pipe, pump body complete with control electronics and overheating

protection, wiring.

PUMP

Alarm contact normally closed that automatically cuts off the air conditioning system compressor or valve, thermal protection 90° on

the pump coil, electrical connection by plug (delivered with 1 m cable), rubber mounting bracket included, ...

AVANTAGES

Small size, low noise level.

ACCESSORIES - HH

This pump is used to eliminate the condensation that collects in the tray in installations where

there is no self-emptying outlet.

Main supply V/Hz - W

Max. fl ow rate l/h

Max. suction head m

Max. discharge head m

Alarm contact NC 8 A resistive

Thermal protection (overheat) °C

Sound level at 1 m dB(A)

Pump dimensions (Lxlxh) mm

Detection unit dimensions (Lxlxh) mm

Weight (including box) kg

Main supply V/Hz - A

Max. fl ow rate l/h

Max. suction head m

Alarm contact NC 4 A resistive

Thermal protection (overheat) °C

Sound level dB(A)

Pump dimensions mm

Page 30

• 28 •

Application Guide • COMFAIR HH-AGU-1107-E

CONTROLLERS

GENERAL DESCRIPTION

CD2X6

Wall mounted - 3 digits display

On/Off - Heating/Cooling - 3 speeds

Ambiant temperature knob adjustment

RCE 10E

Wall mounted

On/Off - Heating/Cooling - 3 speeds

Ambiant temperature knob adjustment

Wall mounted

CD2X6 RCE10E

Characteritics

On/Off

Manual speed control

Automatic fan control

Manual Heating/Cooling control

Automatic Heating/Cooling control

Temperature setting knob

External centralised contact

Windows contact

Digital display

On/Off valve control

Modulating valve control

Available for

2 pipes

2 pipes + electrical heater

4 pipes

Page 31

Page 32

lennoxemeia.com

+7 495 626 56 53

+34 902 533 920

+38 044 585 59 10

+44 1604 669 100

+ 32 3 633 3045

+33 1 64 76 23 23

+49 (0) 40 589 6235 0

+ 39 02 495 26 200

+ 31 332 471 800

+48 22 58 48 610

+351 229 066 050

LENNOX DISTRIBUTION

+33 4 72 23 20 00

RUSSIA

SPAIN

UKRAINE

UNITED KINGDOM AND IRELAND

BELGIUM AND LUXEMBOURG

FRANCE

GERMANY

ITALY

NETHERLANDS

POLAND

PORTUGAL

Due to Lennox’s ongoing commitment to quality, the specifi cations,

ratings and dimensions are subject to change without notice and

without incurring liability.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualifi ed installer

and servicing agency

SALES OFFICES :

OTHER COUNTRIES :

COMFAIR HH-AGU-1107-E

Loading...

Loading...