Page 1

CLIMATIC™ 60

9 - 1000 kW

ECOLEAN™

NEOSYS™

User manual

CL60 AC-CHILLER-IOM-1011-E

Air cooled chiller

Page 2

Page 3

• 1 •

CLIMATIC™ 60

2

2

2

2

3

5

7

10

14

16

17

18

19

20

21

22

24

25

27

30

31

32

33

34

35

37

39

44

65

67

CL60-AC CHILLER-IOM-1011-E

CONTROL MANUAL

Ref : CL60-AC CHILLER-IOM-1011-E

TABLE OF CONTENTS

AIR COOLED CHILLER

INTRODUCTION

CLIMATIC™ 60 controller

Compatibility

Warning

OVERVIEW

Compressor

Condenser fan

Fan SMART ACOUSTIC SYSTEM™

Water evaporator

Changeover heating/cooling mode

Coil defrost

Free cooling

Electronic expansion valve

Electrical heater

Power factor corrector

Pump evaporator management

Pump evaporator fl ow control

Pump condenser management

Pump condenser fl ow control

Free input/output

ON/OFF control

Real time lock

Scheduling zone

Scheduling mode

Schedule anticipation start-up

COMMUNICATION

Master / slave

DS60 display

DC60 advanced display or DS60 display

DC60 list

BMS

Alarms

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided by us,

remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to or made available to third

parties without the prior written agreement of Lennox.

Page 4

• 2 • CL60-AC CHILLER-IOM-1011-E

INTRODUCTION

OVERVIEW

CLIMATIC™ 60 CONTROLLER

The new generation of microprocessor based control, CLIMATIC™ 60 may be fi tted to the LENNOX chiller or heat pump range. It inherits

20 years of technology and fi eld operating experience from its predecessors the CLIMATIC™ 1, CLIMATIC™ 2 and CLIMATIC™ 50.

LENNOX has found the latest hardware technology available on the market place and developed software specifi cally designed for

chiller and heat pump applications, maximising the LENNOX unit’s effi ciency and performance.

COMPATIBILITY

This documentation is compatible with the chiller and heat pump range's programs from software version CH060 STD - Vers. 01.0 Rev 00.1:

• ECOLEAN™,

• NEOSYS™.

•

•

•

WARNING

Any parameter modifi cation should be carried out by trained and licensed competent technician. Before start-up or restart of a unit

controlled by the CLIMATIC™ 60, it is mandatory to check adequacy between CLIMATIC™ 60 and the unit with its options. In case

of wrong parameters, the inputs / outputs connections could be incorrect and may create some operation problems for the units and

ultimately breakdowns. LENNOX cannot be held responsible for any claims on the units due to a wrong parameters sequence or a

parameters modifi cation carried out by non competent technicians. In this case, the warranty will be legally null and void.

pLan bus Fieldbus bus

BMS bus

Page 5

• 3 •

1

1

1

1

1

1

1

1

2

2

2

2

3

3

3

3

2

2

2

2

3

3

3

3

12h/24h

6h

9h 3h

12h/24h

18h

21h 15h

1, ., .

., 2, .

1, 2, .

., ., 3

1, ., 3

., 2, 3

1, 2, 3

CL60-AC CHILLER-IOM-1011-E

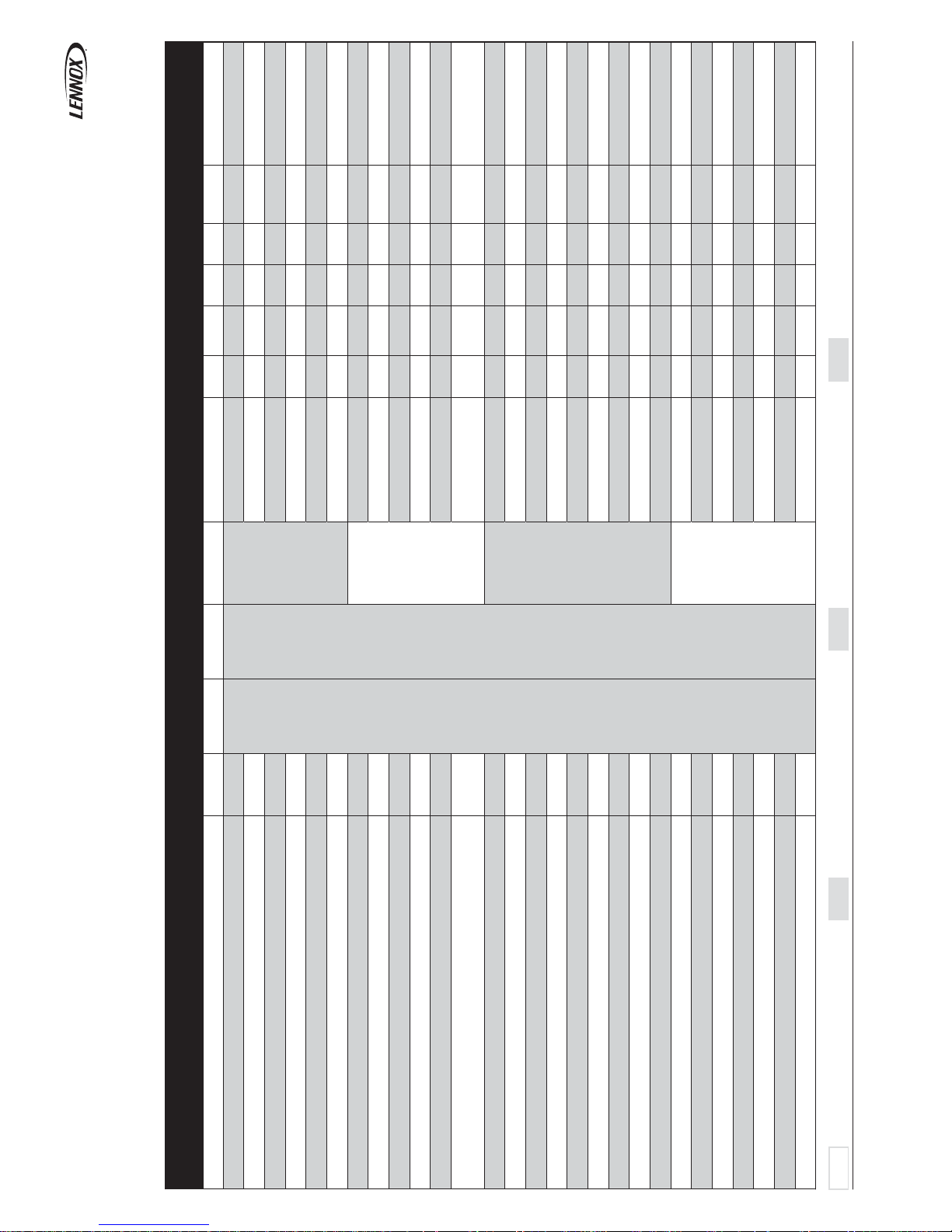

COMPONENTS

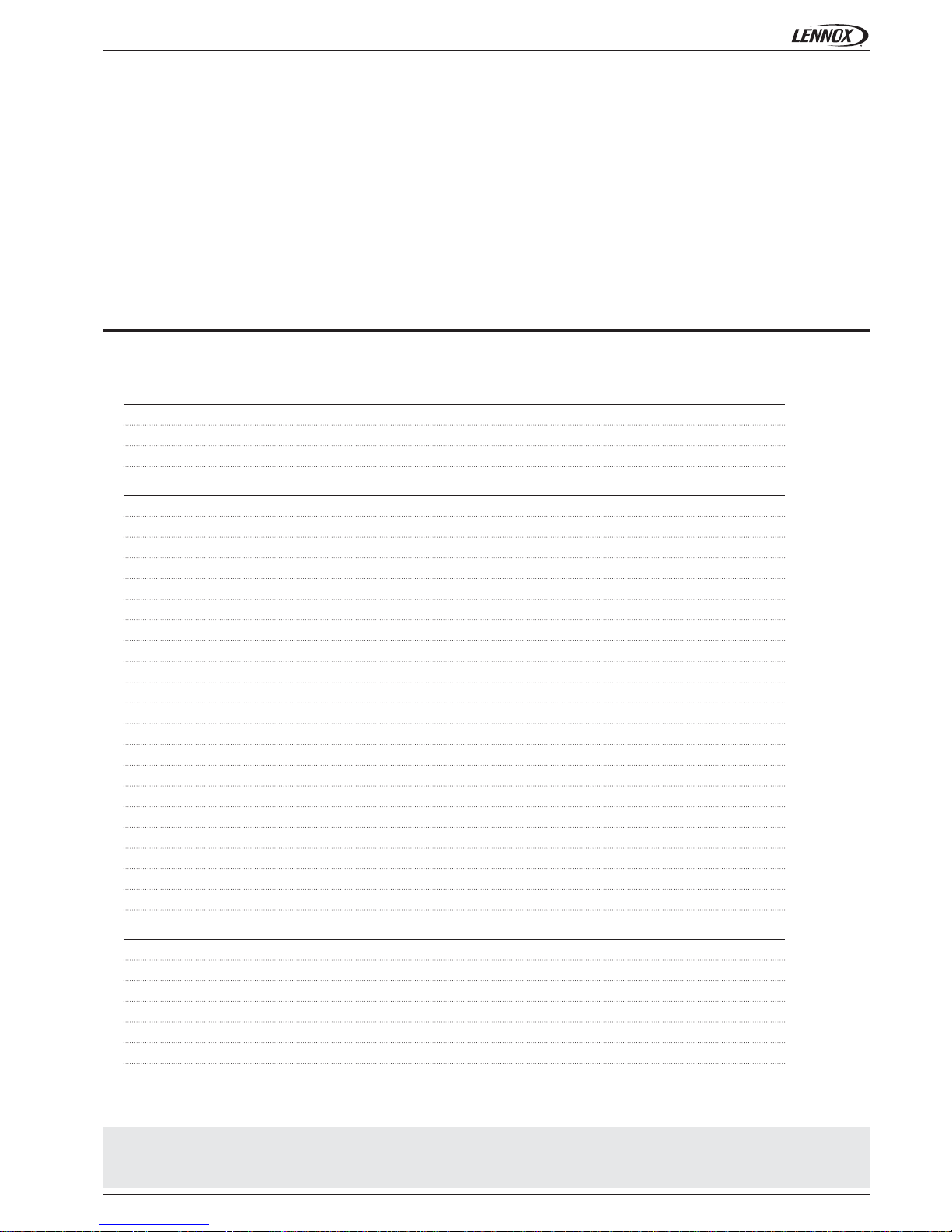

COMPRESSOR

Function

The CLIMATIC™ 60 manages the compressor(s) according to the outlet temperature demand and engages the number of compressor

calculated to reach the water set point.

Description

The CLIMATIC™ 60 offers possibilities to disable some compressor(s) on the circuit. Note this opportunity can also be done by dry

contact (Refer to the “Free input/output” paragraph).

The compressors allowed to run can be pre-specifi ed according to the scheduling and can take different values for each schedule

mode (A, B, C, D, and BMS).

Setting

(3421)

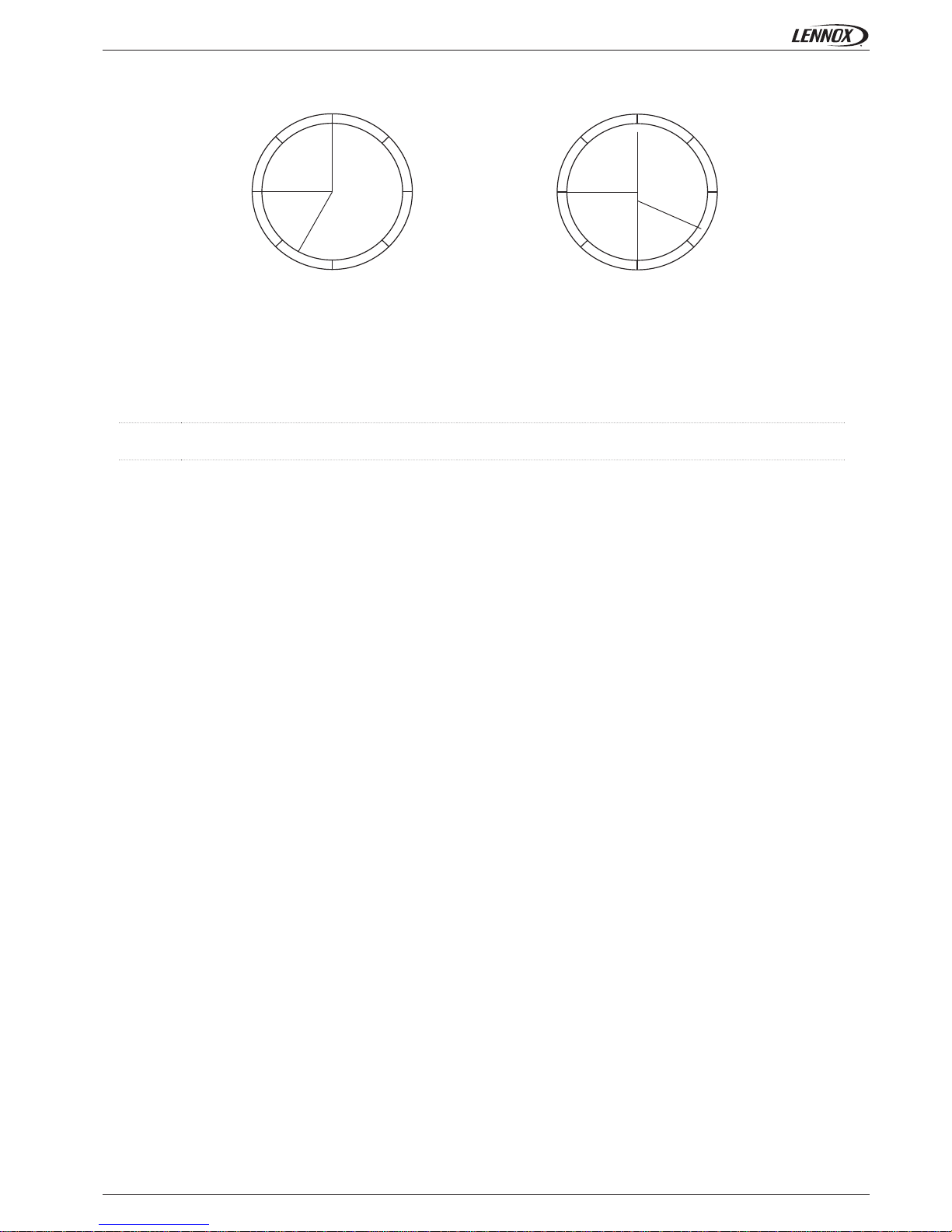

Compressor on circuit

(case od 2 circuits)

NO

Moreover, the circuit priority can be specifi ed (for units with 2 circuits)

“Auto”:

The CLIMATIC™ 60 decides the priority of the circuit which starts fi rst. Note that the priority is swapped when all the compressors are

stopped in order to optimise the operating hours of the two circuits.

C Mode

C1: 1,2,3

C2: 1,2,3

A Mode

C1: 1,.,.

C2: 1,.,.

C Mode

C1: 1,2,3

C2: 1,2,3

B Mode

C1: 1,2,.

C2: 1,2,.

B Mode

C1: 1,2,.

C2: 1,2,.

D Mode

C1: .,.,3

C2: .,.,3

D Mode

C1: .,.,3

C2: .,.,3

Page 6

• 4 •

(3331):

(3332):

(3335):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

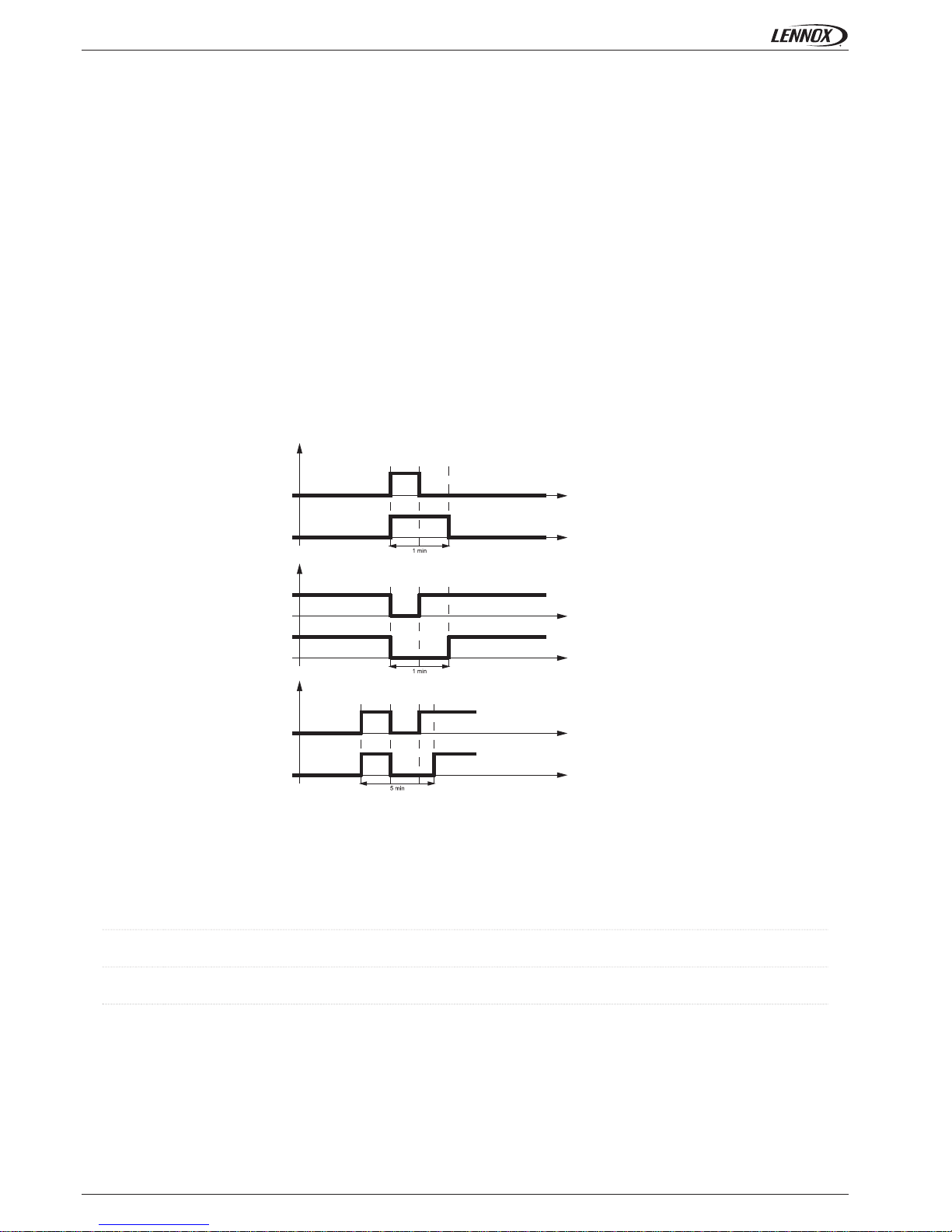

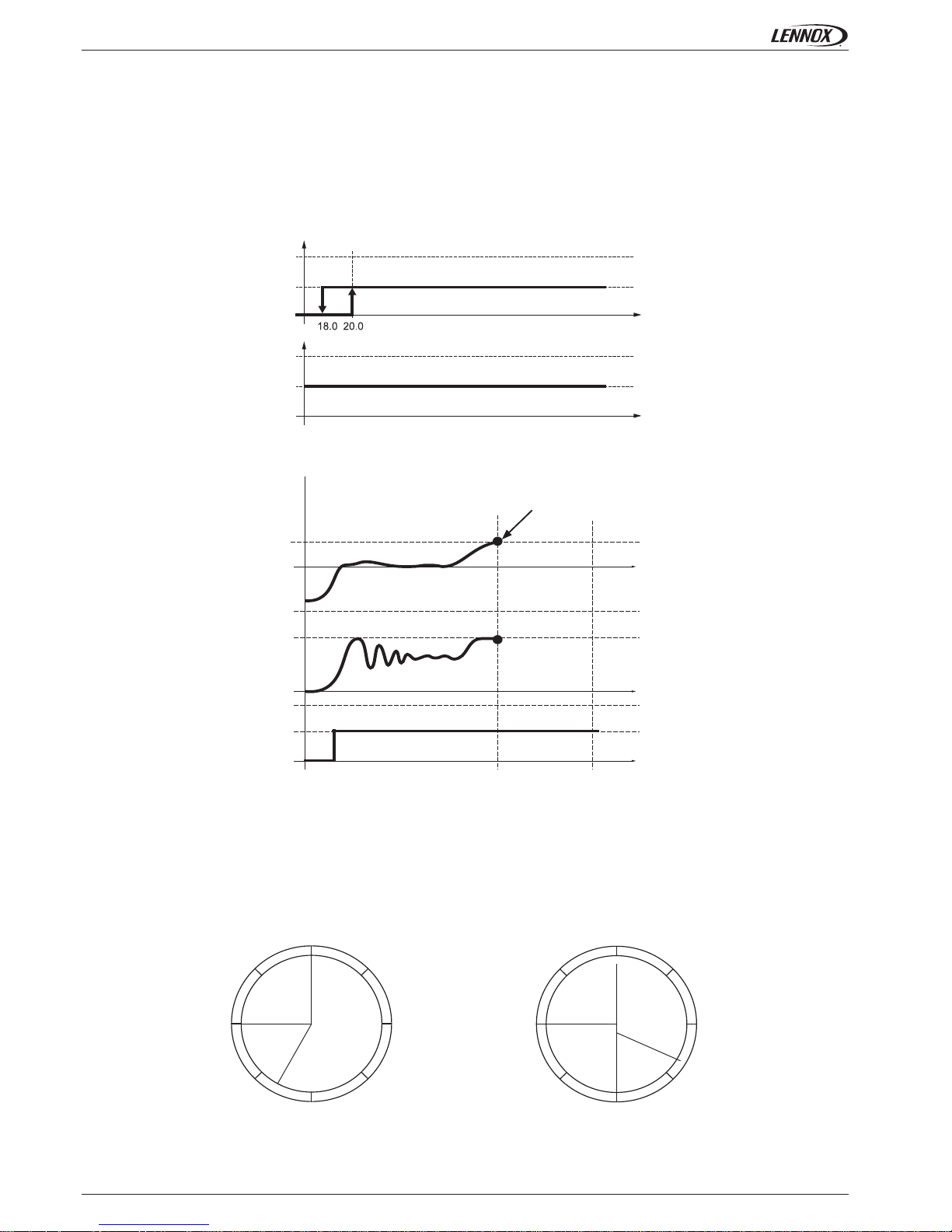

The compressor is subject to various operating time in order to prevent from damage operating.

• The minimum ON time of the compressor is fi xed to 1 minute,

• The minimum OFF time of the compressor is fi xed to 1 minute,

• The minimum between 2 starts of the same compressor is fi xed to 5 minutes.

Compressor demand

Compressor demand

Compressor demand

Compressor output

Compressor output

Compressor output

Settings

The different settings to confi gure the compressors are available in the menu:

“Priority C1”:

The priority is fi xed to circuit 1, which means circuit 1 starts fi rst and stops the last.

“Priority C2”:

The priority is fi xed to circuit 2, which means circuit 2 starts fi rst and stops the last.

Enable of the compressor(s) on circuit 1

Enable of the compressor(s) on circuit 2

Priority of the circuit rotation.

Page 7

• 5 •CL60-AC CHILLER-IOM-1011-E

COMPONENTS

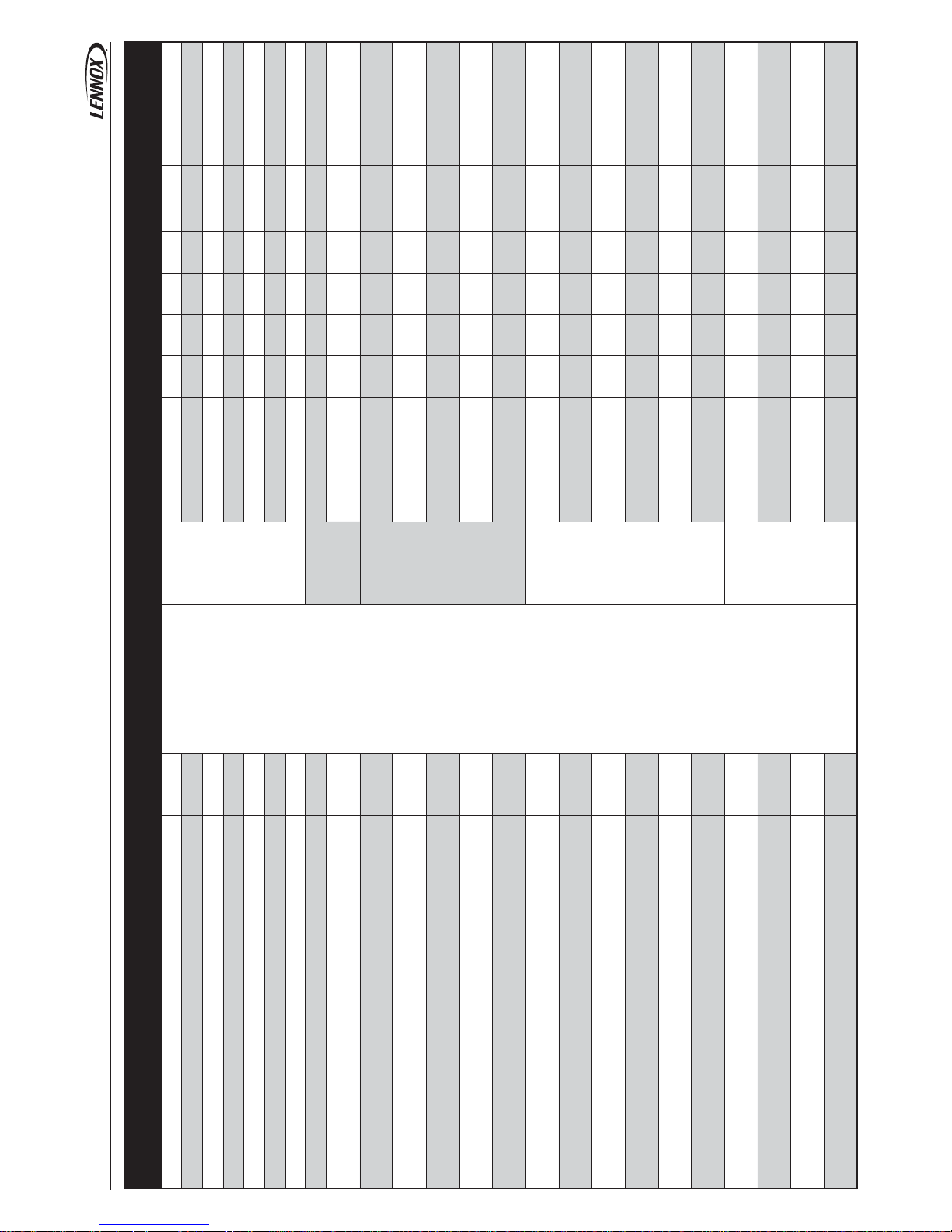

CONDENSER FAN

Function

The CLIMATIC™ 60 is used to maintain the high pressure as stable as possible in order to increase the performance of the unit.

Description

The CLIMATIC™ 60 has 2 different fan managements according to the type of unit:

ECOLEAN™ (without fan speed inverter)

The CLIMATIC™ 60 manages 2 speeds on the fan (low and high speed).

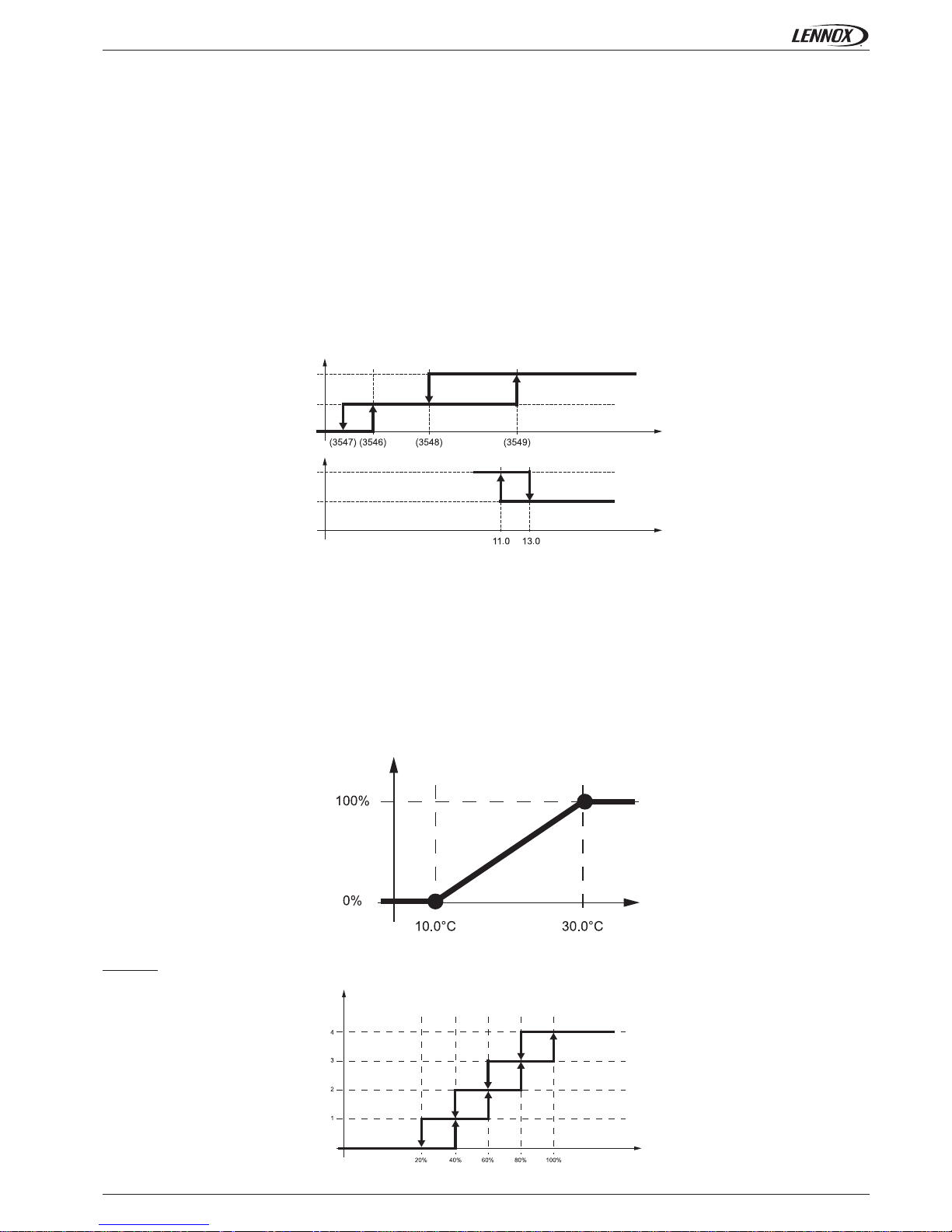

NEOSYS™ standard unit (standard version without fan speed inverter)

The condensing temperature is reached according to the set point selected in the menu (3546). The fans are managed individually

except for the fans which are common for the two circuits.

In order to optimise the reactivity of the system at the startup of the circuit, an anticipation of the fan(s) is forced during the fi rst 30s

according to the outside air temperature.

Example: Case of unit with 4 condenser fans.

Outside air temperature (°C

Stopped

Stopped

HP pressure (Bar)

Low speed

Low speed

High speed

High speed

Cooling mode

Heating mode

Outside air temperature (°C)

Compressor pressure demand (%)

Fan anticipation (%)

Fan stages

Page 8

• 6 •

(3546):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

Time

Temperature HP (°C)

Fan capacity (%)

Condensing set point

Settings

The different settings to adjust the condensing control are available in the menu:

NEOSYS™ (with fan speed inverter)

A fan inverter controlled by a PID algorithm is used to adjust the fans speed variation. Fan's startup anticipation is forced as for the

NEOSYS™ standard unit.

In order to optimise the performance of the unit, the condensing temperature is set according to outside air temperature and tries to

maintain a delta of 12°C (only for unit with electrionic expansion valve).

Note: this functionality can be disabled if the selected setting (3546) is different from the factory value. In this case the condensing

set point is the new selected value.

Outside air temperature (°C)

Set point = ext T° 12.0°C

Condensing set point (°C)

Condensing set point temperature.

Page 9

• 7 •CL60-AC CHILLER-IOM-1011-E

COMPONENTS

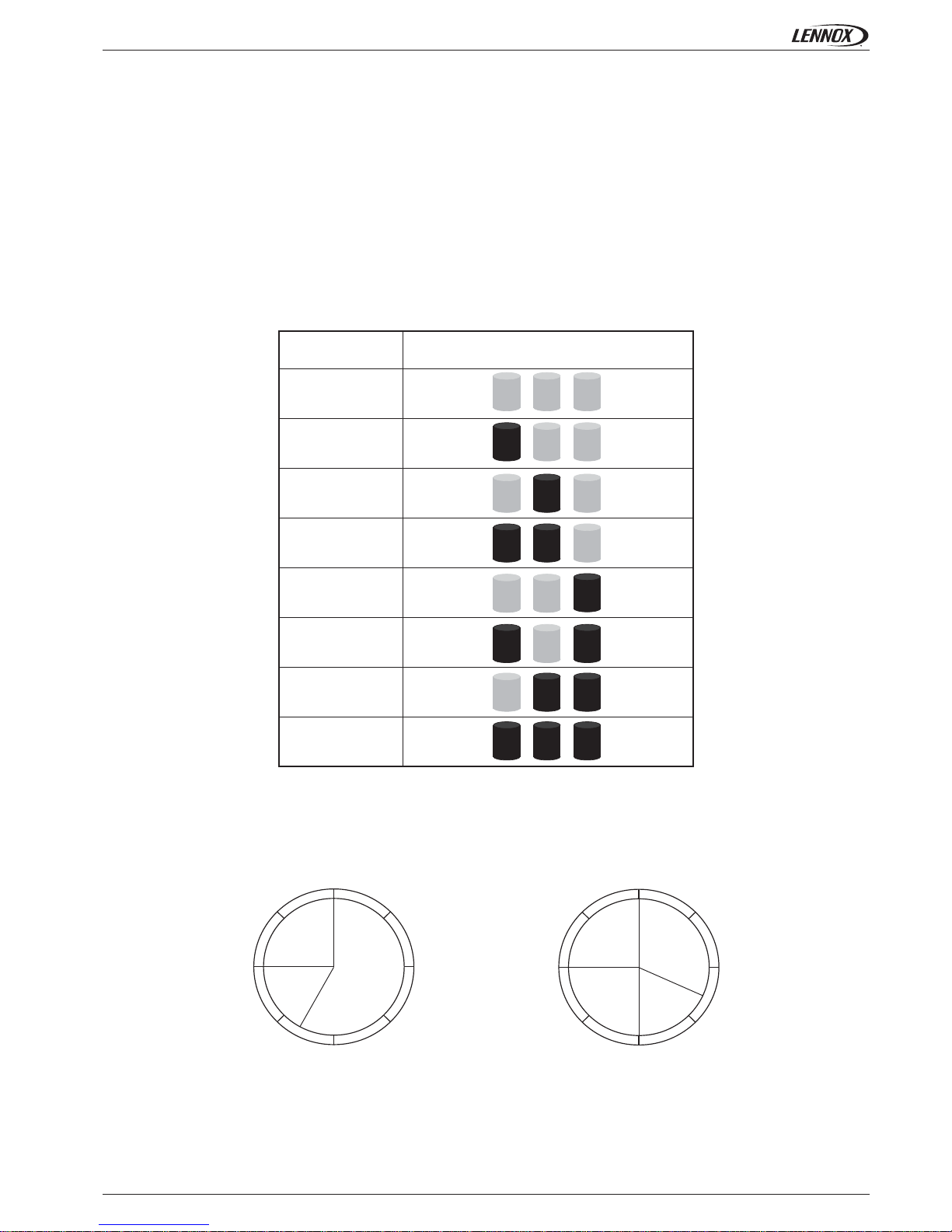

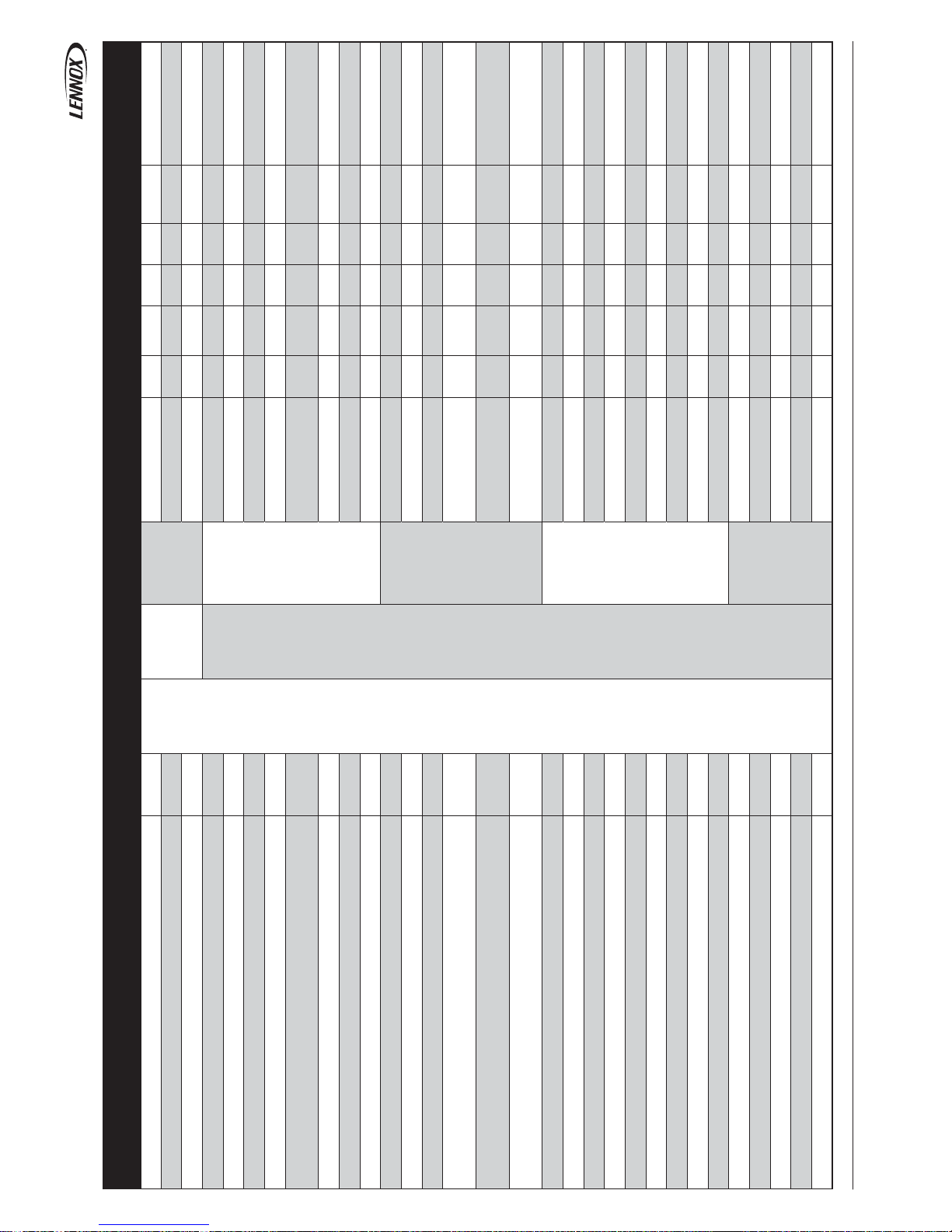

FAN SMART ACOUSTIC SYSTEM™

Function

The CLIMATIC™ 60 controls the fan speed limited by the Smart Acoustic System™ which allows progressive adaptation of the unit

to the building load while respecting the noise level constraints and the operating limits.

Description

The maximum sound level and the fan strategies can be adjusted according to the schedule mode in order to benefi t from the different

modes “High performance”, “Quiet” and “Quiet++” operation as well as in heating or cooling mode.

The acoustic mode offers 2 possibilities to manage the condenser fan:

Quiet”

In this mode, the fan capacity is limited according to the desired sound level. For fan using low / high speed, the high speed is locked. In

case of condensing temperature too high, the CLIMATIC™ 60 unlocks the limit or the high speed to prevent from unloading compressor.

Outside air temperature (°C

Outside air temperature (°C

Stopped

Stopped

HP pressure (Bar)

Low speed

Low speed

High speed

High speed

Cooling mode

Heating mode

Fan speed (%)

Maximum = (3545)

Maximum = (3545)

Fan capacity (%)

Maximum = 100%

Maximum = 100%

Temperature HP (°C)

(3546) Condensing set point

(3442) Unloading set point

Cooling mode

Heating mode

Page 10

• 8 •

12h/24h

6h

9h 3h

12h/24h

18h

21h 15h

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

“Quiet++”

This mode is similar to the “Quiet” mode except that the fan speed limit or the high speed is never unlocked. In case of condensing

temperature too high, the CLIMATIC™ 60 will unload a compressor to prevent from high pressure security.

The Smart Acoustic System™ can be adjusted according to the scheduling and can take different values for each schedule mode (A,

B, C, D, and BMS).

Outside air temperature (°C

Stopped

Stopped

HP pressure (Bar)

Low speed

Low speed

High speed

High speed

Cooling mode

Heating mode

Fan speed (%)

Maximum = (3545)

Maximum = (3545)

Fan capacity (%)

Maximum = 100%

Maximum = 100%

Temperature HP (°C)

Compressor unloading

(3546) Condensing set point

(3442) Unloading set point

Cooling mode

Heating mode

C Mode

Quiet

A Mode

Quiet+

C Mode

Not Set

B Mode

Not Set

B Mode

Quiet

D Mode

Quiet+

D Mode

Quiet

Page 11

• 9 •

12h/24h

6h

9h 3h

12h/24h

18h

21h 15h

(3544):

(3545):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

C Mode

86dBA

A Mode

84dBA

C Mode

89dBA

B Mode

89dBA

B Mode

86dBA

D Mode

84dBA

D Mode

Quiet

Settings

The different settings to adjust the acoustic mode are available in the menu:

Acoustic mode

Maximum sound level noise (except for fan with low / high speed)

Page 12

• 10 •

12h/24h

6h

9h 3h

12h/24h

18h

21h 15h

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

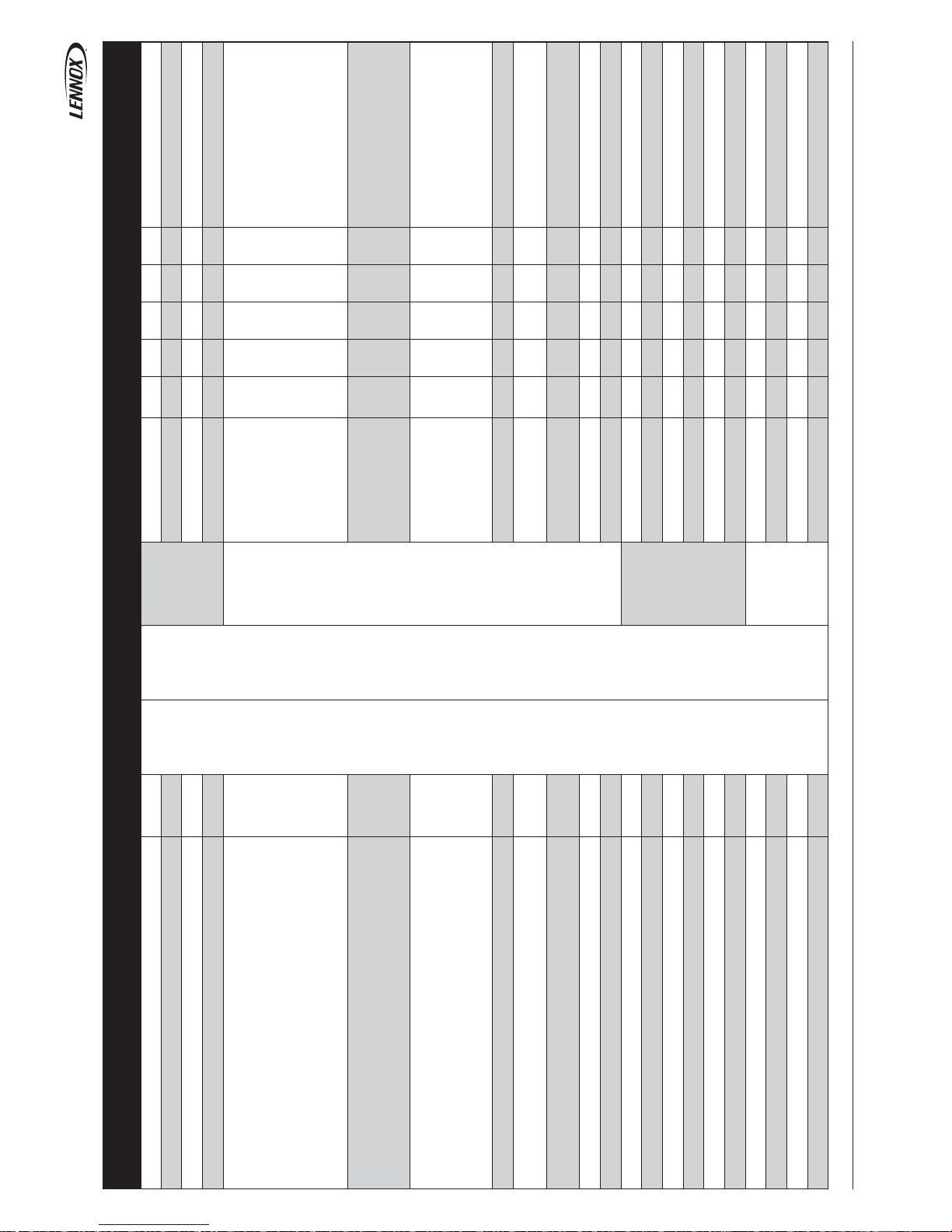

WATER EVAPORATOR

Function

The CLIMATIC™ 60 controls the chilled or heat temperature according to the specifed set point. The desired set point can be set by

different solutions.

Description

The CLIMATIC™ 60 offers various possibilities to specify the water evaporator set point.

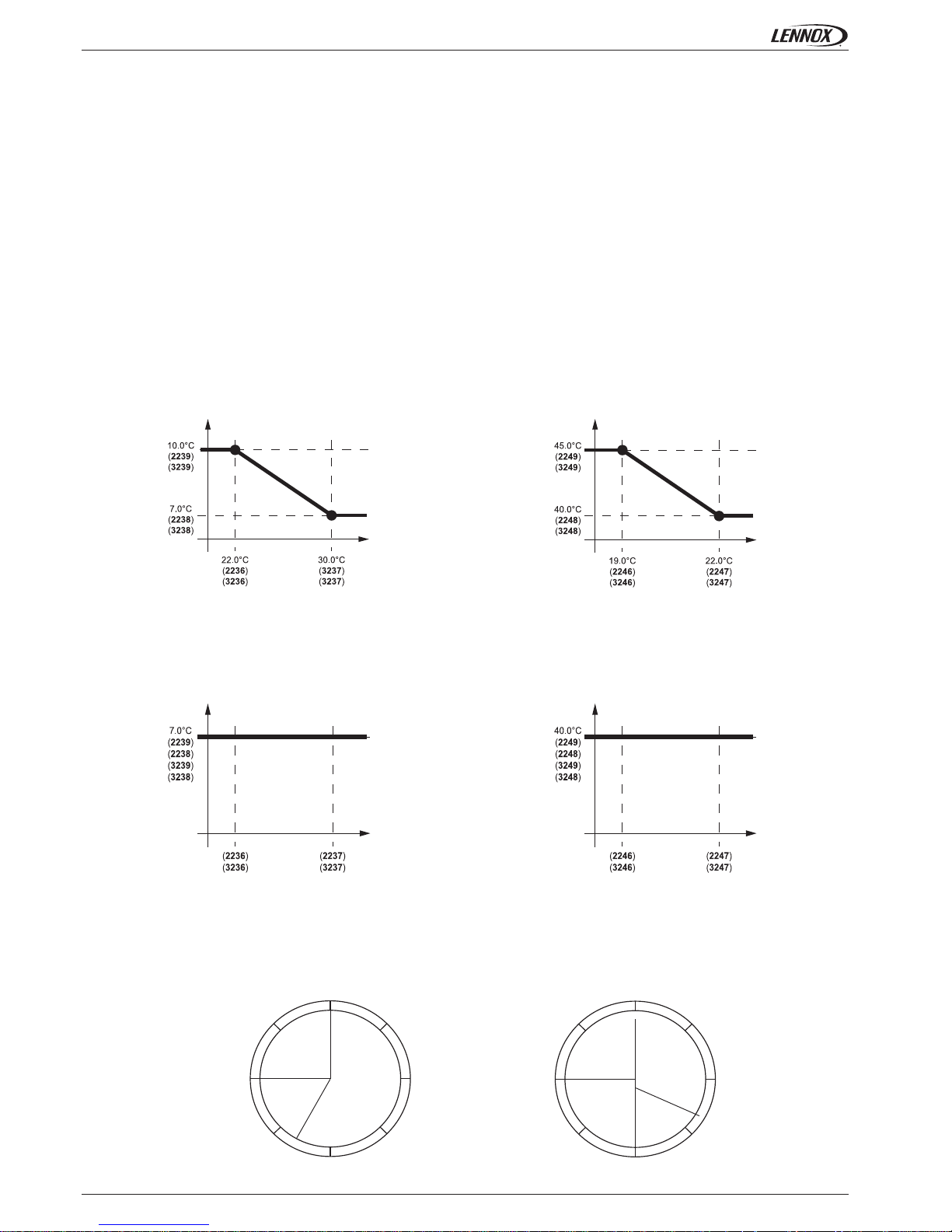

Dynamic value

The CLIMATIC™ 60 determines the appropriate water set point according to the outside temperature in order to optimise the energy

consumption. This method requires to pre-defi ne 2 different water set points corresponding to 2 outside temperatures.

Fix value

In this case the outside temperature has no effect on the water set point and the two set points must be set at the same value.

The cooling and heating set points can be pre-specifi ed according to the scheduling and can take different mode for each schedule

mode (Night, Day, Day A, Day B, and BMS)

Outside air

temperature (°C)

Outside air

temperature (°C)

Outside air

temperature (°C)

Outside air

temperature (°C)

Cooling set point (°C)

Cooling set point (°C)

Heating set point (°C)

Heating set point (°C)

Mode

Day A

07.0°C

Night

Mode

13.0°C

Mode

Day A

07.0°C

Mode

Day B

07.0°C

Mode

Day

07.0°C

Night

Mode

13.0°C

Mode

Day A

09.0°C

Page 13

• 11 •CL60-AC CHILLER-IOM-1011-E

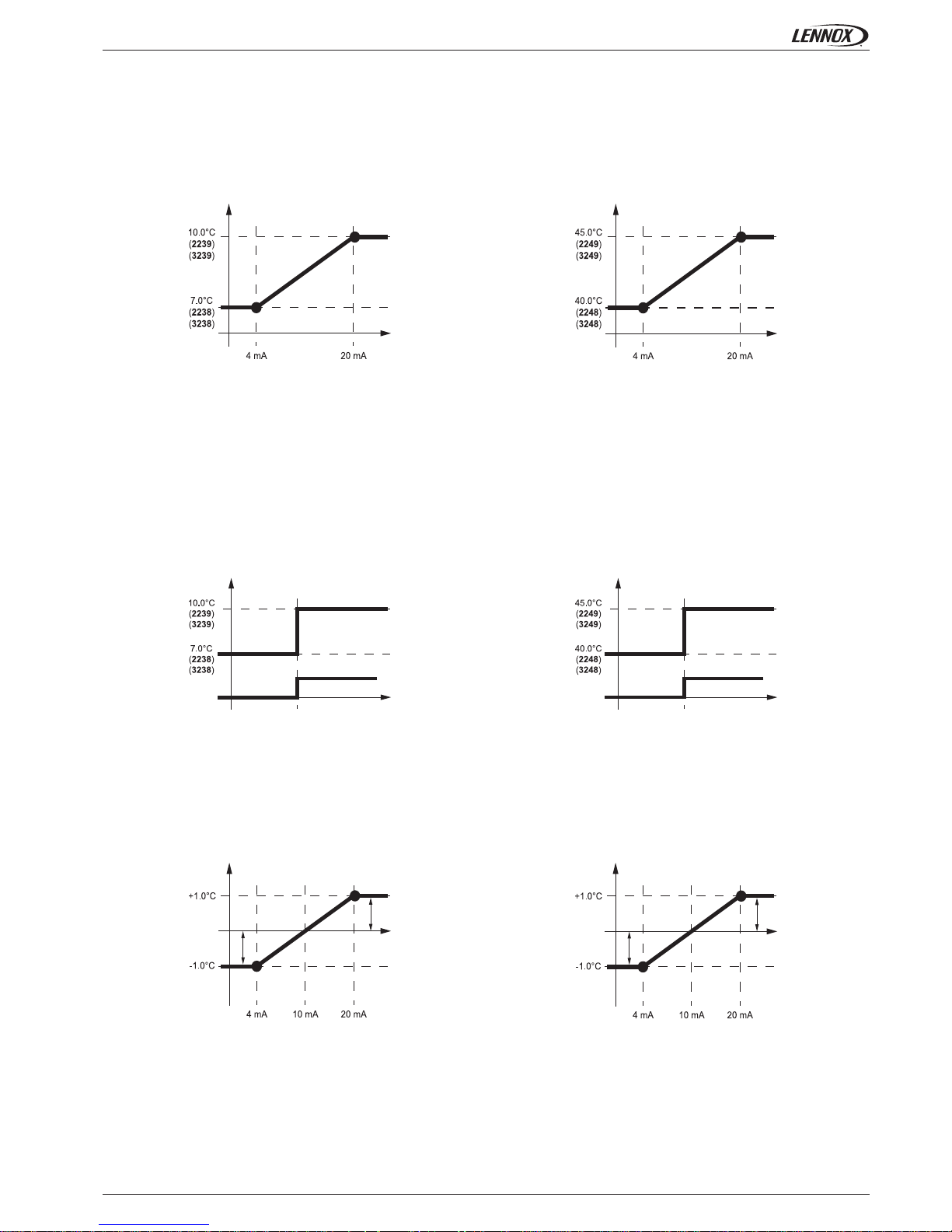

External current 4/20mA signal

In this case the actual set point is calculated according to the analog input current. The set points specify the corresponding set point

for 4mA and for 20mA.

Current input signal

4/20 mA

Current input signal

4/20 mA

Cooling set point (°C) Heating set point (°C)

COMPONENTS

Second external set point

In this case the actual set point is specifed by one of the two set points. The fi nal set point depends on the status of the digital dry

contact allocated to this function.

External current 4/20 mA offset

In this case the set point is set by one of the previous solution and can be adjusted with an offset of +/- 1.0°C.

Digital input contact

Current inpu signal

4/20 mA

Outside air

temperature (°C)

Current inpu signal

4/20 mA

Cooling set point (°C)

Open Open

Closed Closed

Cooling set point (°C)

Actual set point Actual set point

Heating set point (°C)

Heating set point (°C)

Page 14

• 12 • CL60-AC CHILLER-IOM-1011-E

COMPONENTS

DC60 terminal

The water set point is adjustable directly by the DC60. If the read set point is different from the one calculated by the BM60, the

new set point is set by the DC60 during the actual zone. Each time the zone is changing, the DC60 set point is overwriten by the

CLIMATICTM60 set point.

BMS value

The CLIMATIC™ 60 receives the water set point from the BMS. Refers to the “BMS” paragraph for more details.

Settings

The different settings to adjust the water evaporator set points are available in the menu:

Cooling mode

• (2236) or (3236): minimum outside air temperature corresponding to the water evaporator set point (3238) (used only for dynamic

set point),

• (2237) or (3237): maximum outside air temperature corresponding to the water evaporator set point (3239) (used only for dynamic

set point),

• (2238) or (3238):

* Dynamic set point: desired water evaporator temperature set point corresponding to outside air temperature (2236) or (3236),

* Fix set point: desired water evaporator temperature set point.

* External current 4/20 mA signal: water evaporator temperature set point corresponding to a current signal of 4 mA.

* Second external set point: fi rst water evaporator temperature set point corresponding to an opened dry contact.

• (2239) or (3239):

* Dynamic set point: desired water evaporator temperature set point corresponding to outside air temperature (2237) or (3237),

* Fix set point: desired water evaporator temperature set point.

* External current 4/20 mA signal: water evaporator temperature set point corresponding to a current signal of 20 mA.

* Second external set point: second water evaporator temperature set point corresponding to a closed dry contact.

Heating mode

• (2246) or(3246): minimum outside air temperature corresponding to the water evaporator set point (3248) (used only for dynamic

set point),

• (2247) or (3247): maximum outside air temperature corresponding to the water evaporator set point (3249) (used only for dynamic

set point),

• (2248) or (3248):

* Dynamic set point: desired water evaporator temperature set point corresponding to outside air temperature (2246) or (3246),

* Fix set point: desired water evaporator temperature set point.

* External current 4/20mA signal: water evaporator temperature set point corresponding to a current signal of 4 mA.

* First external set point:

fi rst water evaporator temperature set point corresponding to an opened dry contact.

• (2249) or (3249):

* Dynamic set point: desired water evaporator temperature set point corresponding to outside air temperature (2247) or (3247),

* Fix set point: desired water evaporator temperature set point.

* External current 4/20mA signal: water evaporator temperature set point corresponding to a current signal of 20 mA.

* Second external set point: second water evaporator temperature set point corresponding to a closed dry contact.

Page 15

• 13 •

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

00 0 0

1 8.54 30.8 7.0 + 30.8*5.0/100

2 10.80 61.6 7.0 + 2*30.8*5.0/100

3 11.04 80.8 7.0 + (19.2+2*30.8)*5.0/100

4 12.00 100.0 7.0 + 2*(19.2+30.8)*5.0/100

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

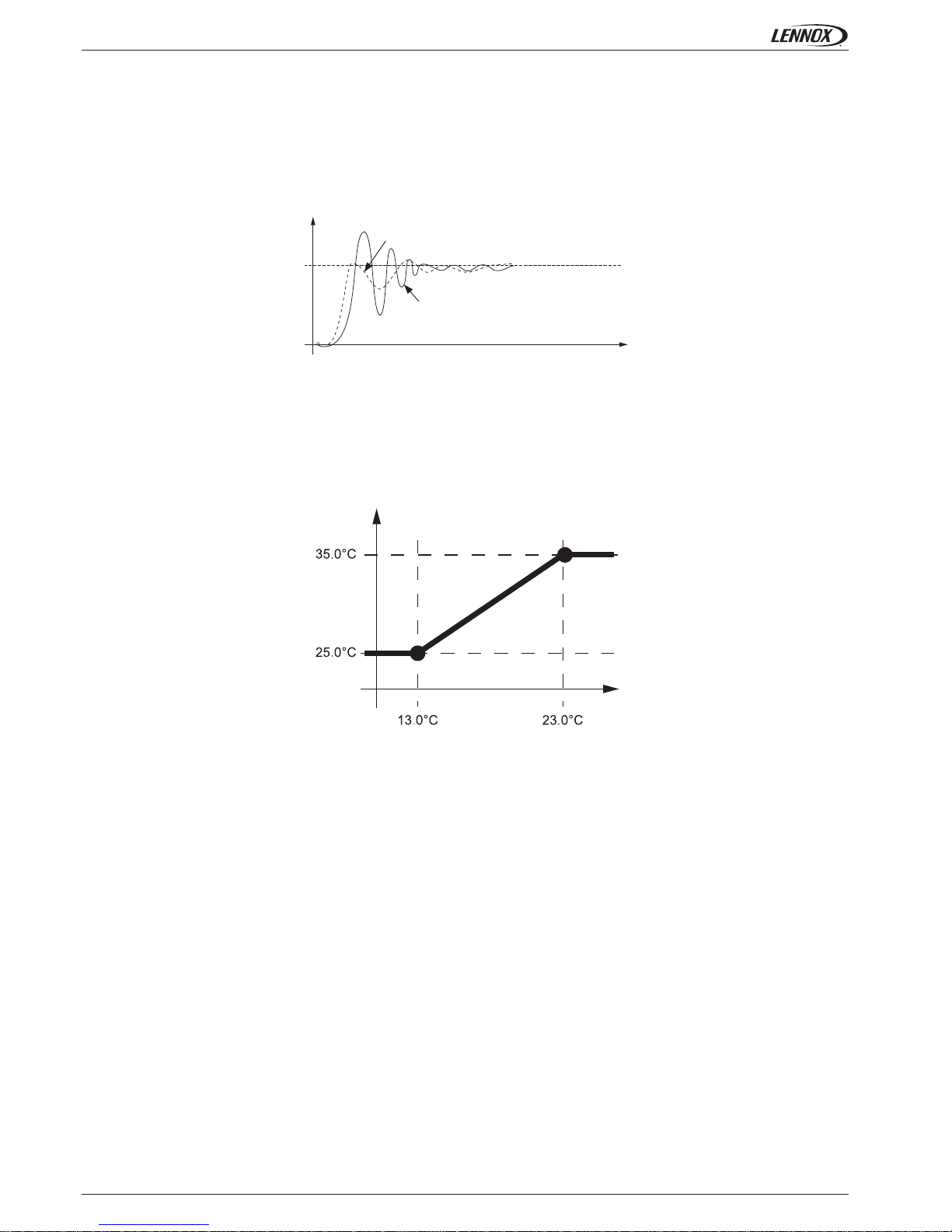

Control

The CLIMATIC™ 60 adjusts and holds the fl uid outlet temperature as close as possible to the set point, by controlling the number of

compressor stages depending on the thermal load of the system. The controller constantly calculates the required capacity to reach the

temperature set point. This variable is called “CAPACITY FACTOR” (CF) and its value can vary from 0 to 100%. It is directly linked to

the number of control stages of the unit. Thus for a unit with 4 stages of regulation, the CF will start and stop a stage with the following

values: ~0-25-50-75-100%. It then evolves following the principles detailed in the diagram.

In order to anticipate, the reference point is recalculated each time the difference between air temperature and set point reaches a

minimum or a maximum.

Moreover the inlet temperature is used to limit the capacity factor to prevent from too slow reactivity of outlet capacity factor of the unit.

Example:

• Unit EAC 2104: cooling capacity: 210KW with:

* C1.Cp1 = 19.2%,

* C1.Cp2 = 30.8%,

* C2.Cp1 = 19.2%,

* C2.Cp2 = 30.8%.

• Maximum delta T° (inlet - outlet) at full load: setting (3261) = 5.0°C.

• Outlet water evaporator temperature set point: setting (3238) = (3239) = 7.0°C.

Difference between the outlet

water temperature and the

set point

Water temperature

can change

CF FROZEN

CF FROZEN

FAST SLOW SLOW FAST

CF INCREASES

(starts more capacity stages)

CF DECREASES

(removes capacity stages)

Stage

Minimum inlet

temp. (°C)

Maximum

capacity factor

(%)

Expression

Compressor

ON circuit 1

Compressor

ON circuit 2

Page 16

• 14 •

12h/24h

6h

9h 3h

12h/24h

18h

21h

15h

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

CHANGEOVER HEATING/COOLING MODE

Function

The CLIMATIC™ 60 controls the changeover mode (for reversible units only) to specify the appropriate demand on heat or chilled

water production.

Description

The changeover can also be pre-specifi ed according to the scheduling and can take different mode for each schedule mode (A, B,

C, D, and BMS).

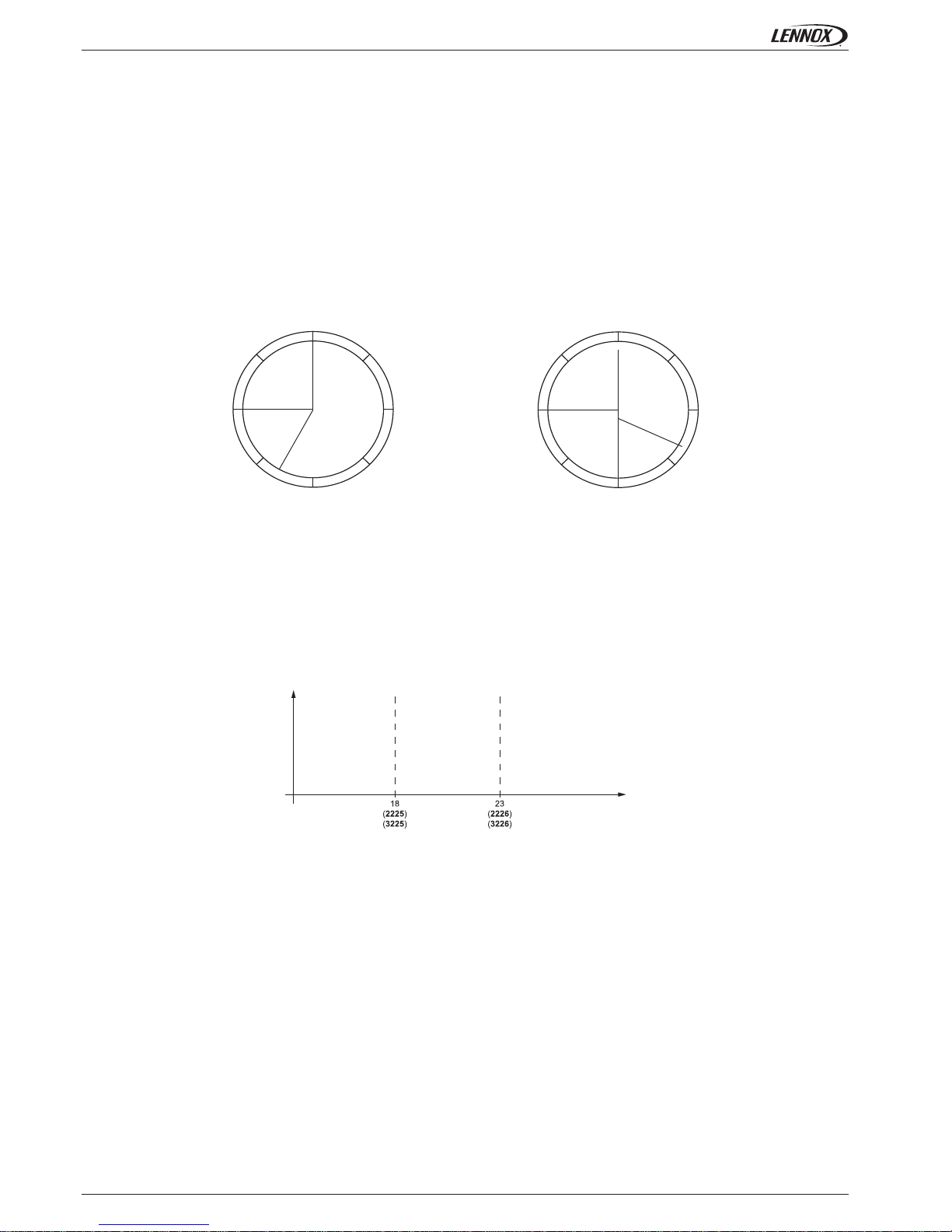

The changeover mode can be set by different solutions:

Automatically:

The CLIMATIC™ 60 determines the appropriate production of water according to the outside temperature and moves automatically

the unit from cooling to heating mode and heating to cooling mode.

If the outside temperature is below the setting value (2225) or (3225), the unit will operate as a heat pump.

If the outside temperature is over the setting value (2226) or (3226), the unit will operate as a chiller.

Manually:

The changeover mode is forced for each schedule mode. The various modes available are “Cool” mode, “Heat” mode or "Dead zone".

In this case the outside temperature has not effect on the changeover mode.

Remotely:

The changeover mode is set according to a remote dry contact connect on a free custom digital input. In this case the unit swaps in

cooling or heating mode according to the status of the digital input. Please refer to the paragraph “Free Input / Output” for more details.

C Mode

Auto

A Mode

Dead zone

C Mode

Cool

B Mode

Cool

B Mode

Heat

D Mode

Heat

D Mode

Auto

Changeover mode

Heating mode

Dead zone

Cooling mode

Outdoor temperature (°C)

Page 17

• 15 •CL60-AC CHILLER-IOM-1011-E

Terminal DC60:

The changeover mode (cool / heat) can be modifi ed by the terminal DC60 by pressing the “mode” button.

When the “Auto” mode is selected, the icon “Cool” or “Heat” is displayed to signal the actual operating mode. Due to communication

delay, after pressing the “mode” button it is advised to wait few seconds, the time to refresh of the icon on the display.

COMPONENTS

Heat Cool Auto Dead zone

Settings

The different settings to adjust the changeover mode are available in the menu:

• (2224) or (3224): changeover mode (Cool, Heat, Auto, Dead zone) for each schedule mode (Night, Day, Day A, Day B, and BMS).

• (2225) or (3225): minimum outside temperature to swap to heating mode. (only if (2224) or (3224)=“Auto”).

• (2226) or (3226): maximum outside temperature to swap to cooling mode. (only if (2224) or (3224)=“Auto”).

Page 18

• 16 • CL60-AC CHILLER-IOM-1011-E

COMPONENTS

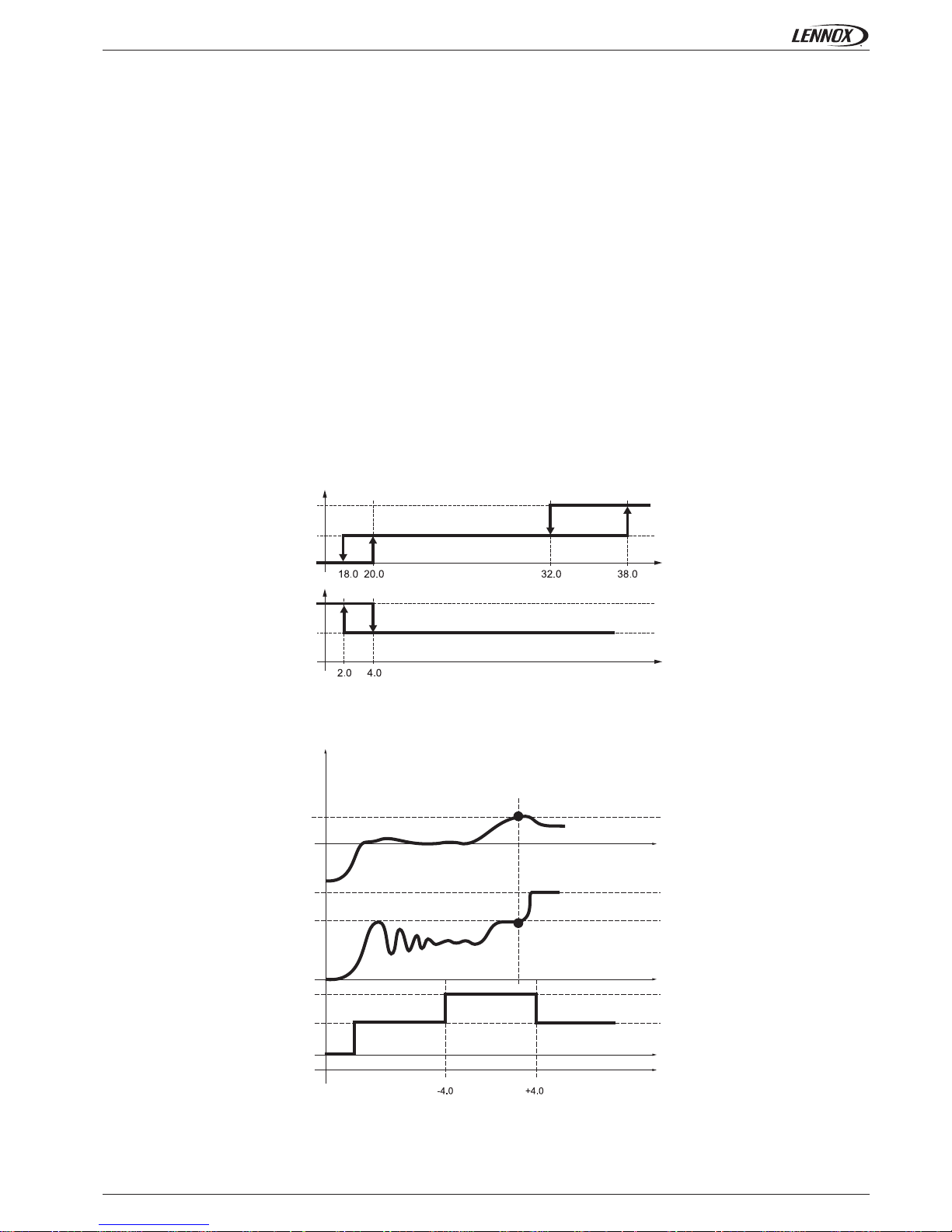

COIL DEFROST

Function

The CLIMATIC™ 60 manages defrost procedure to avoid ice on the evaporator coil in heating pump mode (winter season).

Description

To avoid the icing of the external air exchanger during winter operating, it’s necessary to reverse the refrigerant cycle. There are 2

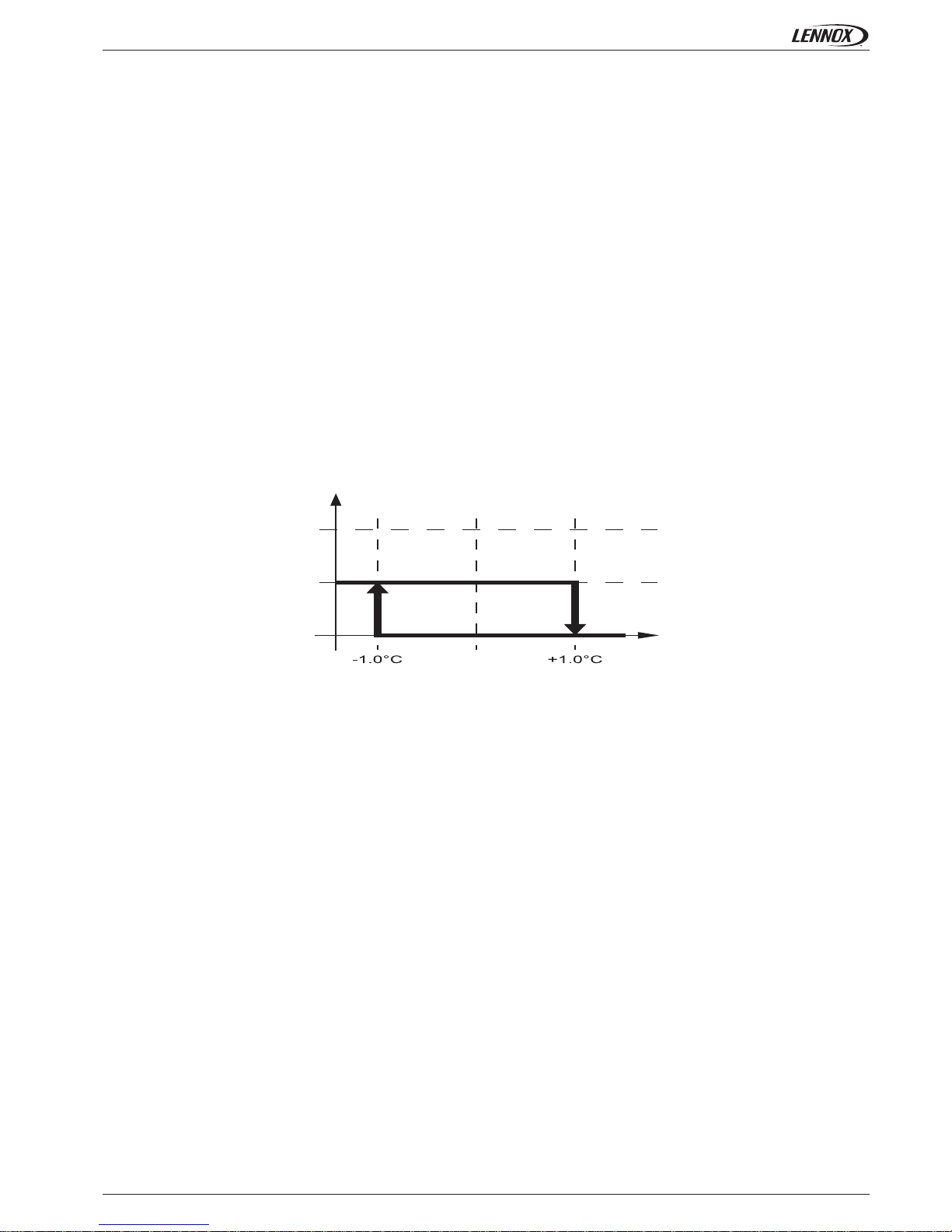

defrost mode:

• cyclic mode,

• dynamic mode (not available in the software CH060 vers.01-rev.0.1).

The defrost procedure is activated if the following conditions are met during 1 minute:

• the outside air temperature is (3562),

• one of the compressor(s) on the circuit has been running for a time (3564) since the last defrost,

• the saturation temperature is (3563).

The defrost procedure is characterized by the following steps:

1. stop the compressors on the concerned circuit,

2. wait for 30 s to equalise the pressure in the circuit,

3. start all compressors on the circuit (if the outlet T° is not too low),

4. reverse the reversing valve when P>2 bars,

5. start all condenser fans when the HP 55.0°C in order to dry the coil,

6. stop all condenser fans when the HP 40.0°C,

7. repeat the steps 4. to 5. 3 times,

8. stop the compressors on the concerning circuit,

9. wait for 1 min to equalise the pressure in the circuit,

10. end of procedure; restart the unit in heating mode.

11. reverse the reversing valve when P>2bar.

Note

• In case of alarm on the circuit during the defrost procedure, the defrosting is cancelled.

• If the HP pressure doesn’t reach 55°C after 6 min, during the step 6, the defrost procedure is cancelled.

• During the step 4 the compressor(s) could not start in order to not decrease too much the water temperature of the system.

Settings

The different settings to adjust the defrosting procedure are available in the menu:

• (3561): defrost mode (cyclic, dynamic),

• (3562): minimum of outside air temperature to enable defrost procedure,

• (3563): critical saturation temperature to enable defrost procedure

• (3564): minimum of interval time to enable defrost procedure.

Outlet water temperature (°C)

Compressor in defrost

Page 19

• 17 •

(3164):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

FREE COOLING

Function

The freecooling option ensures to reduce the electrical consumption using the outside air temperature to produce cool water.

Description

The freecooling uses water coil with helicoids fans controled by the CLIMATIC™ 60. The freecooling has a higher priority face to the

compressors. Once the freecooling capacity is over 95% for 2 min, the compressors can be engaged if necessary in order to reach

the cooling set point. If the freecooling capacity decreases below 90%, the capacity factor of the compressor(s) capacity is locked to

give the priority to the freecooling.

The freecooling is enabled if the following conditions are met:

• the unit is ready (On/Off, water fl ow, none alarm, etc..),

• the freecooling fan driver is operating (none alarm)

• outside temperature < (Inlet temperature – 3°C).

Settings

The setting to confi gure the freecooling option is available in the menu:

Confi guration of the freecooling option.

Page 20

• 18 •

(2224):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

ELECTRONIC EXPANSION VALVE

Function

The electronic expansion valve (EEV) option offers higher effi cient control of the superheating temperature.

Description

The electronic expansion valve is driven by an external board (Electronic Valve Driver - EVD) which includes a PID algorithm to control

the superheating. The EVD is linked to the CLIMATIC™ 60 to send data like capacity, step, pressure, temperature.

Settings

The setting to adjust superheat temperature option is available in the menu:

Note: the modifi cation of the superheating set point is taken in account at the next startup of the circuit.

Superheat set point.

Page 21

• 19 •

(3164):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

ELECTRICAL HEATER

Function

The electrical heater option is an additional heating capacity to help the heat pump to reach the set point during hard winter period.

Description

The electrical heater option has 2 uses:

Antifreeze heater

In this case, the heater is used to prevent the evaporator water from antifreeze. The heater is activated when the low alarm temperature

appears in cooling mode or when the safety low temperature is reached in heating mode.

Auxiliary heater

The heater is activated when the water temperature is far from the set point and the compressor(s) are fully running. In this case, the

heater is used to help the compressors to reach the heating set point.

Settings

The setting to confi gure the electrical heater is available in the menu:

Heating set point

Outlet water temperature (°C)

Confi guration of the electrical heater.

Page 22

• 20 •

(3163):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

POWER FACTOR CORRECTOR

Function

The power factor correction is an additional capacitor bank to compensate the apparent power energy.

Description

The CLIMATIC™ 60 controls the status of the circuit breaker to inform (generate an alarm) in case of short circuit in the capacitor bank.

Settings

The setting to confi gure the power factor correction is available in the menu:

Confi guration of the power factor correction..

Page 23

• 21 •

(3341):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

PUMP EVAPORATOR MANAGEMENT

Function

The CLIMATIC™ 60 offers in option a solution to manage a single or double evaporator pump(s).

Description

In case of double pumps, the CLIMATIC™ 60 can manage various possibilities of pumps operating.

Priority to pump 1

The CLIMATIC™ 60 specifi es the priority to pump 1 to start fi rst. Pump 2 is used only as a backup pump and will start only if pump 1

is in alarm. Pump 1 is kept ON as soon as the machine is enabled.

Auto priority to pump 1

Same confi guration as case 1, except that the pump will be stopped in case of dead zone changeover (winter / summer).

Priority to pump 2

The CLIMATIC™ 60 specifi es the priority to pump 2 to start fi rst. Pump 1 is used only as backup pump and will start only if pump 2 is

in alarm. Pump 2 is kept ON as soon as the machine is enabled.

Auto priority to pump 2

Same confi guration as case 3, except that the pump will be stopped in case of dead zone changeover (winter / summer).

No priority

The CLIMATIC™ 60 specifi es automatically the priority of the pump according to the operating hour counter. The fi rst pump to start

will be the one which has the less number of hours of operation. In order to equalize the number of hours the unit is stopped every

tuesday at 02 am to re-specify the priority.

Note: the total operating hour are displayed on the DC60 Advanced on 2 numbers in the menus (2314) and (2315) (pump n°1).

Example:

(2314) = 0123,

(2315) = 4567,

Total Hour = (2314)*10000 + (2315) = 01234567 hours.

No auto priority

Same confi guration as case 5, except that the pump will be stopped in case of dead zone changeover (winter / summer).

Settings

The different settings to adjust the pump mode are available in the menu:

Pump(s) rotation type

Page 24

• 22 • CL60-AC CHILLER-IOM-1011-E

COMPONENTS

PUMP EVAPORATOR FLOW CONTROL

Function

The CLIMATIC™ 60 offers the possibility to have a fl ow control in option.

Description

There are up to 4 modes to manage the evaporator water fl ow.

Fix speed

The CLIMATIC™ 60 maintains a fi x fl ow according to the maximum desired speed. The fl ow is set to the minimum desired fl ow only

when no compressor is running.

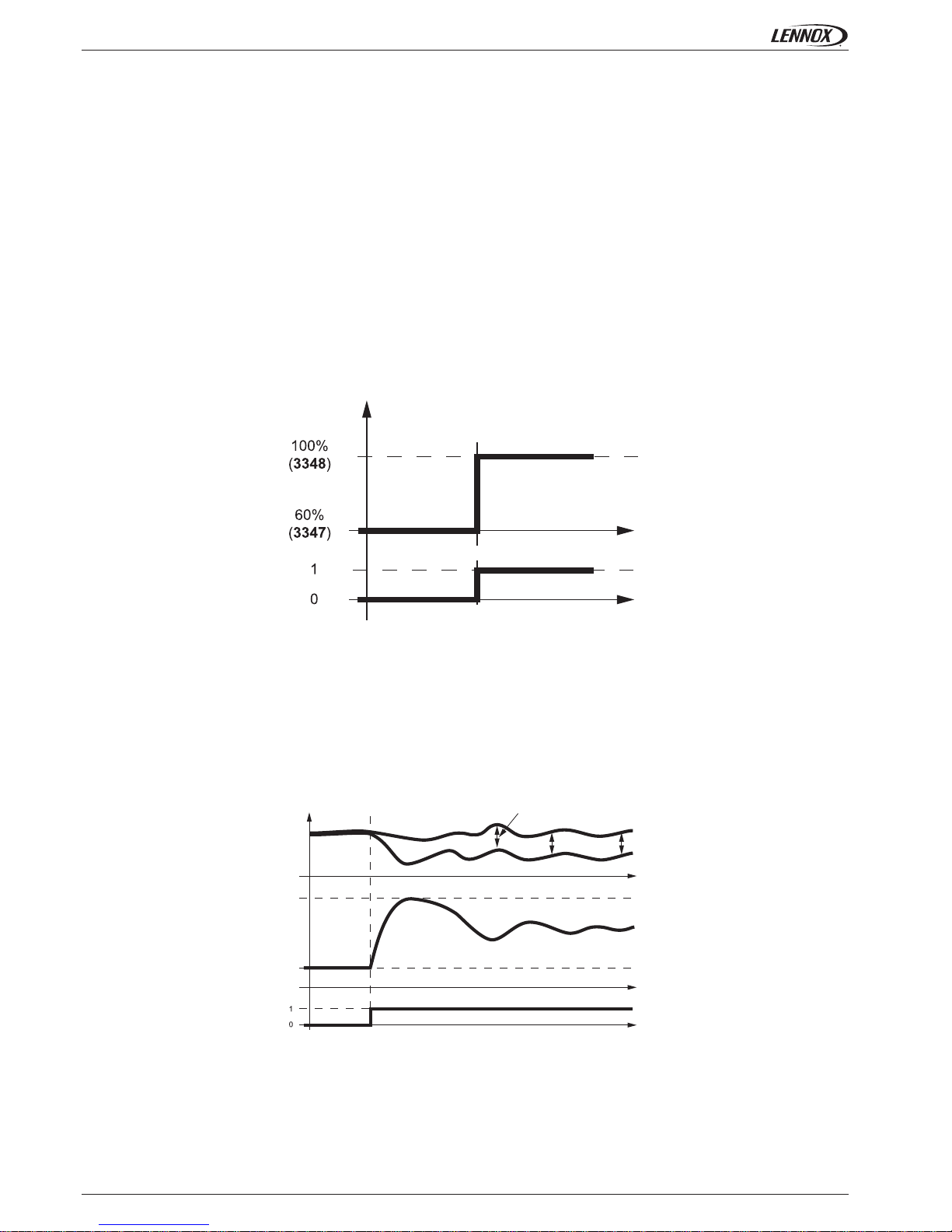

Fix delta of temperature

The CLIMATIC™ 60 maintains a fi x delta of temperature according to inlet and outlet temperature probe on the evaporator. The desired

delta of temperature is customized in the menu (3344).

Compressor(s)

Outlet water temperature

Compressor(s)

Flow output

Inlet water temperature

Output fl ow (%)

(3344) Fix delta temperature

(3347) Minimum 60%

(3348) Maximum 100%

Page 25

• 23 •

(3342):

(3344):

(3345):

(3346):

(3347):

(3348):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

Settings

The different settings to adjust the fl ow control are available in the menu:

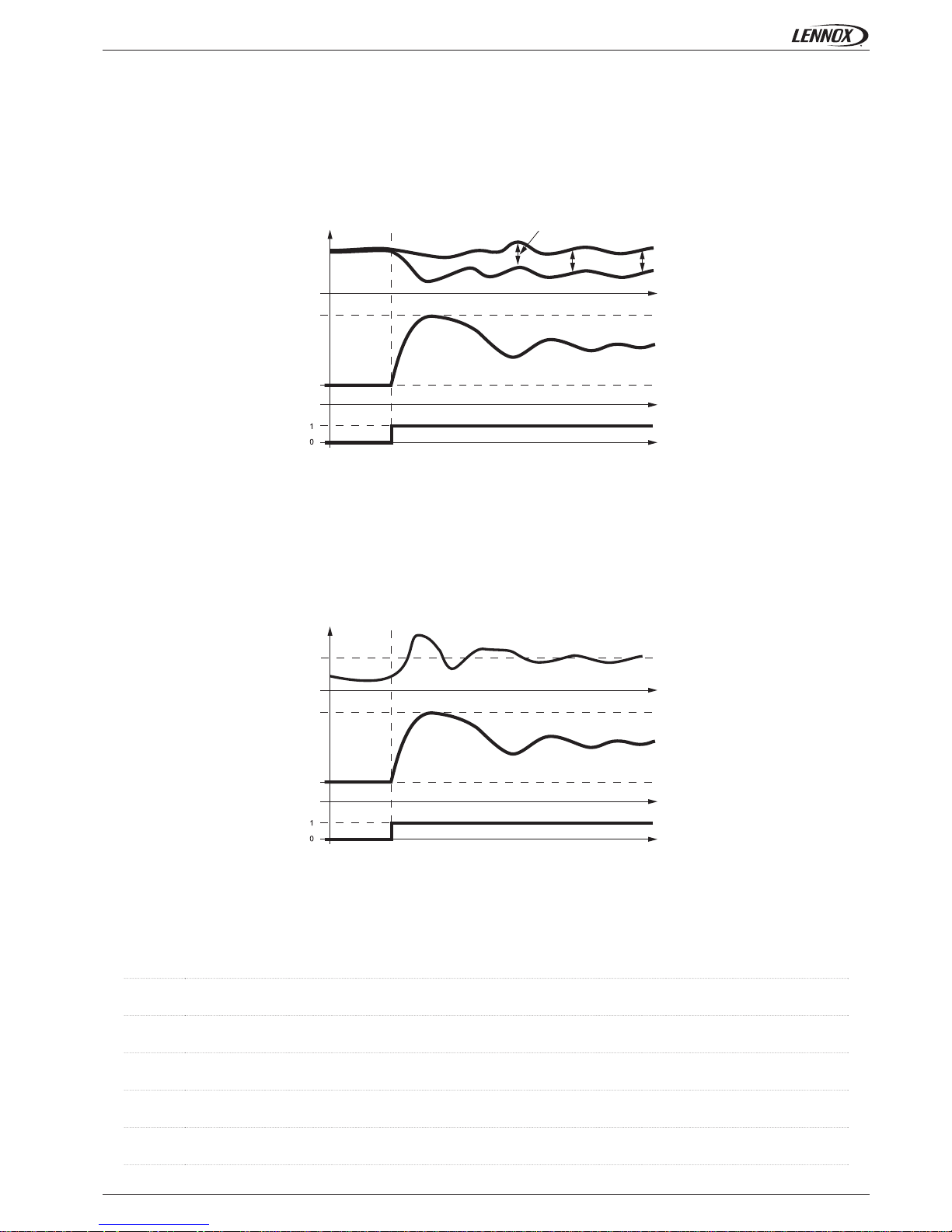

Fix delta of pressure

The CLIMATIC™ 60 maintains a fi x delta of pressure according to the transducers (in and out) on the pump. The desired delta of

pressure is customized in the menu (3345).

Fix output pressure

The CLIMATIC™ 60 maintains a fi x output pressure according to the output transducer on the pump. The desired output pressure is

customized in the menu (3346).

Compressor(s)

Compressor(s)

Pressure out

Pressure out

Output fl ow (%)

Output fl ow (%)

Pressure in

(3345) Fix delta pressure

(3347) Minimum 60%

(3347) Minimum 60%

(3348) Maximum 100%

(3348) Maximum 100%

(3346) Set point

Type of fl ow control

Desired delta of temperature on the water evaporator (outlet - inlet)

Desired delta of pressure on the water pump (outlet - inlet)

Desired output pressure on the water pump (Out),

Minimum fl ow on the water evaporator

Maximum fl ow on the water evaporator

Page 26

• 24 •

(3381):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

PUMP CONDENSER MANAGEMENT

Function

The CLIMATIC™ 60 offers in option a solution to manage a single or double condenser pump(s).

Description

In case of double pumps the CLIMATIC™ 60 can manage various possibilities of operating of the pumps.

Priority to pump 1

The CLIMATIC™ 60 specifi es the priority to pump 1 to start fi rst. Pump 2 is used only as backup pump and will start only if pump 1 is

in alarm. Pump 1 is kept ON as soon as the unit is enabled.

Auto priority to pump 1

Same confi guration as case 1, except that the pump will be stopped in case of dead zone changeover (winter / summer).

Priority to pump 2

The CLIMATIC™ 60 specifi es the priority to pump 2 to start fi rst. Pump 1 is used only as backup pump and will start only if pump 2 is

in alarm. Pump 2 is kept as soon as the unit is enabled.

Auto priority to pump 2

Same confi guration as case 3, except that the pump will be stopped in case of dead zone changeover (winter / summer).

No priority

The CLIMATIC™ 60 specifi es automatically the priority of the pump according the operating hour counter. The fi rst pump to start will

be the one which has the less number of hours of operation. In order to equalize the number of hours the unit is stopped every tuesday

at 02 am to re-specify the priority.

Note: The total operating hour are displayed on the DC60 Advanced on 2 numbers in the menus (2344) and (2345) (Pump N°1).

Example:

(2344) = 0123,

(2345) = 4567,

Total hour = (2344)*10000 + (2345) = 01234567 hours.

No auto priority

Same confi guration as case 5, except that the pump will be stopped in case of dead zone changeover (winter / summer).

Settings

The different settings to adjust the pump mode are available in the menu:

Pump(s) type of rotation

Page 27

• 25 •CL60-AC CHILLER-IOM-1011-E

COMPONENTS

PUMP CONDENSER FLOW CONTROL

Function

The CLIMATIC™ 60 offers the possibility to have fl ow control in option.

Description

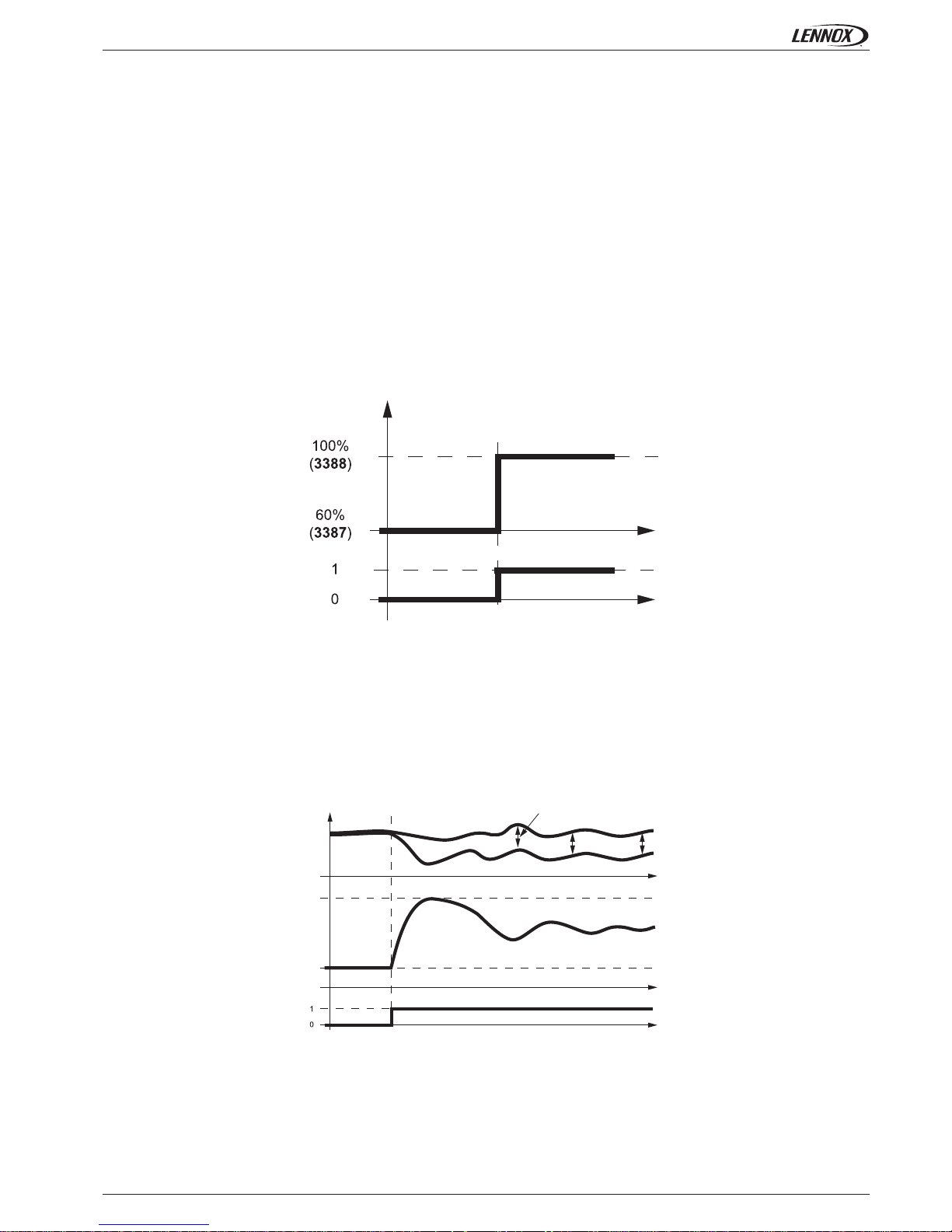

Fix fl ow

The CLIMATIC™ 60 maintains a fi x fl ow according to the maximum desired speed. The fl ow is set to the minimum desired fl ow only

when no compressor is running.

Fix delta of temperature

The CLIMATIC™ 60 maintains a fi x delta of temperature according to the inlet and outlet temperature probe on the condenser. The

desired delta of temperature is customized in the menu (3384).

Compressor(s)

Outlet water temperature

Compressor(s)

Flow output

Inlet water temperature

Output fl ow (%)

(3384) Fix delta temperature

(3387) Minimum 60%

(3388) Maximum 100%

Page 28

• 26 •

(3382):

(3384):

(3385):

(3386):

(3387):

(3388):

CL60-AC CHILLER-IOM-1011-E

Fix delta of pressure

The CLIMATIC™ 60 maintains a fi x delta of pressure according to the transducers (in and out) on the pump. The desired delta of

pressure is customized in the menu (3385).

COMPONENTS

Settings

The different settings to adjust the fl ow control are available in the menu:

Fix output pressure

The CLIMATIC™ 60 maintains a fi x output pressure according to the output transducer on the pump. The desired output pressure is

customized in the menu (3386).

Fix condensing temperature

The CLIMATIC™ 60 maintains a fi x condensing temperature according to the outlet probe on the condenser. The condensing set

point is customized in the menu (3546).

Compressor(s)

Compressor(s)

Pressure out

Pressure out

Output fl ow (%)

Output fl ow (%)

Pressure in

(3385) Fix delta pressure

(3387) Minimum 30% 60%

(3387) Minimum 60%

(3388) Maximum 100%

(3388) Maximum 100%

(3386) Set point

Time

Temperature HP (°C)

Fan capacity (%)

Condensing set point

Type of fl ow control

Desired delta of temperature on the water evaporator (outlet - inlet)

Desired delta of pressure on the water pump (outlet - inlet)

Desired output pressure on the water pump (outlet),

Minimum fl ow on the water condenser

Maximum fl ow on the water condenser

Page 29

• 27 •CL60-AC CHILLER-IOM-1011-E

COMPONENTS

FREE INPUT/OUTPUT

Function

The CLIMATIC™ 60 has free input / output on the main board BM60 and the expansion board BE60 to offer different possibilities to

customize input / output for remote control of the unit.

Description

The free customized input / output number is:

• 2 free input contacts (normally opened) on BM60,

• 1 free output contact (normally opened) on BM60,

• 4 free input contacts (normally opened) on BE60,

• 4 free contacts (normally opened) output on BE60,

• 4 free analog inputs on BE60.

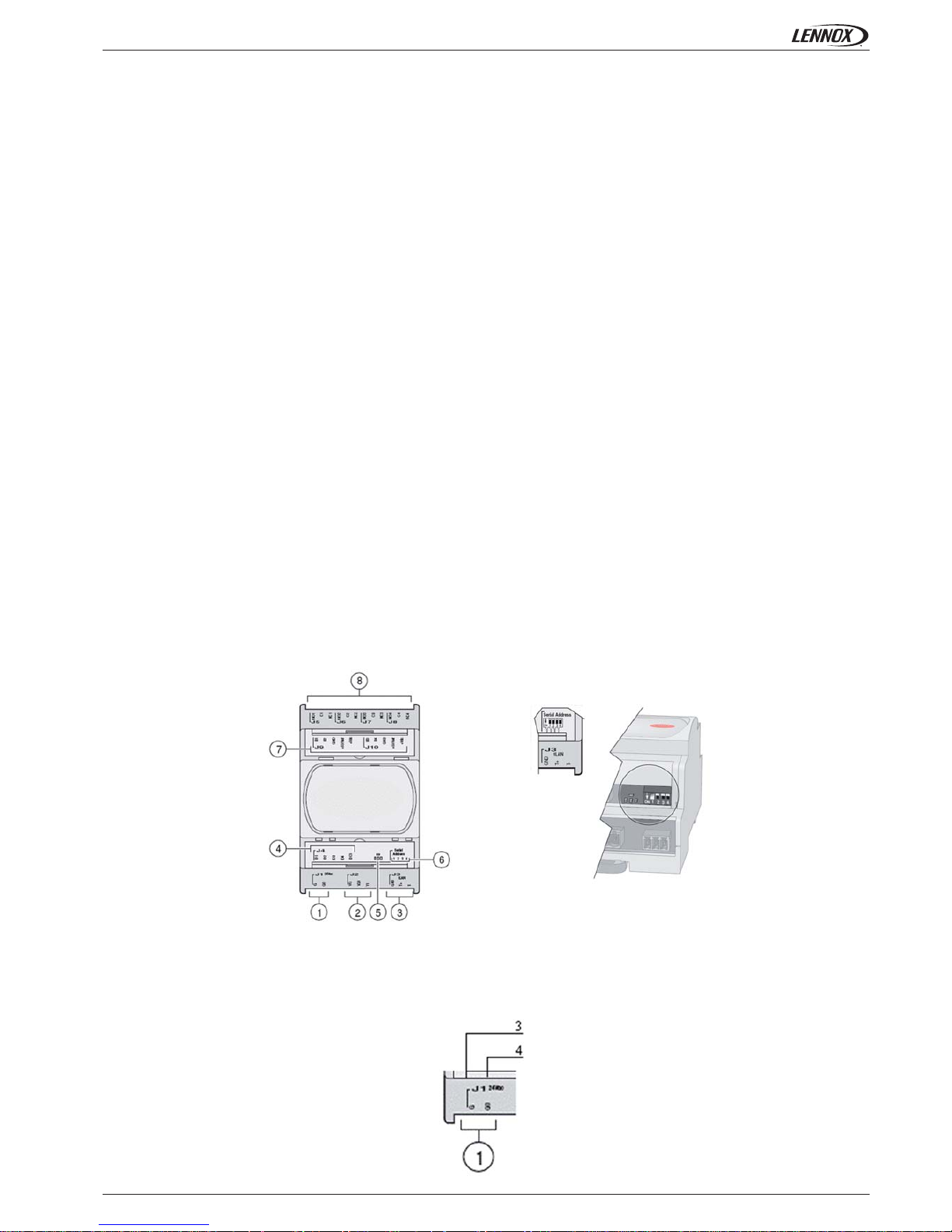

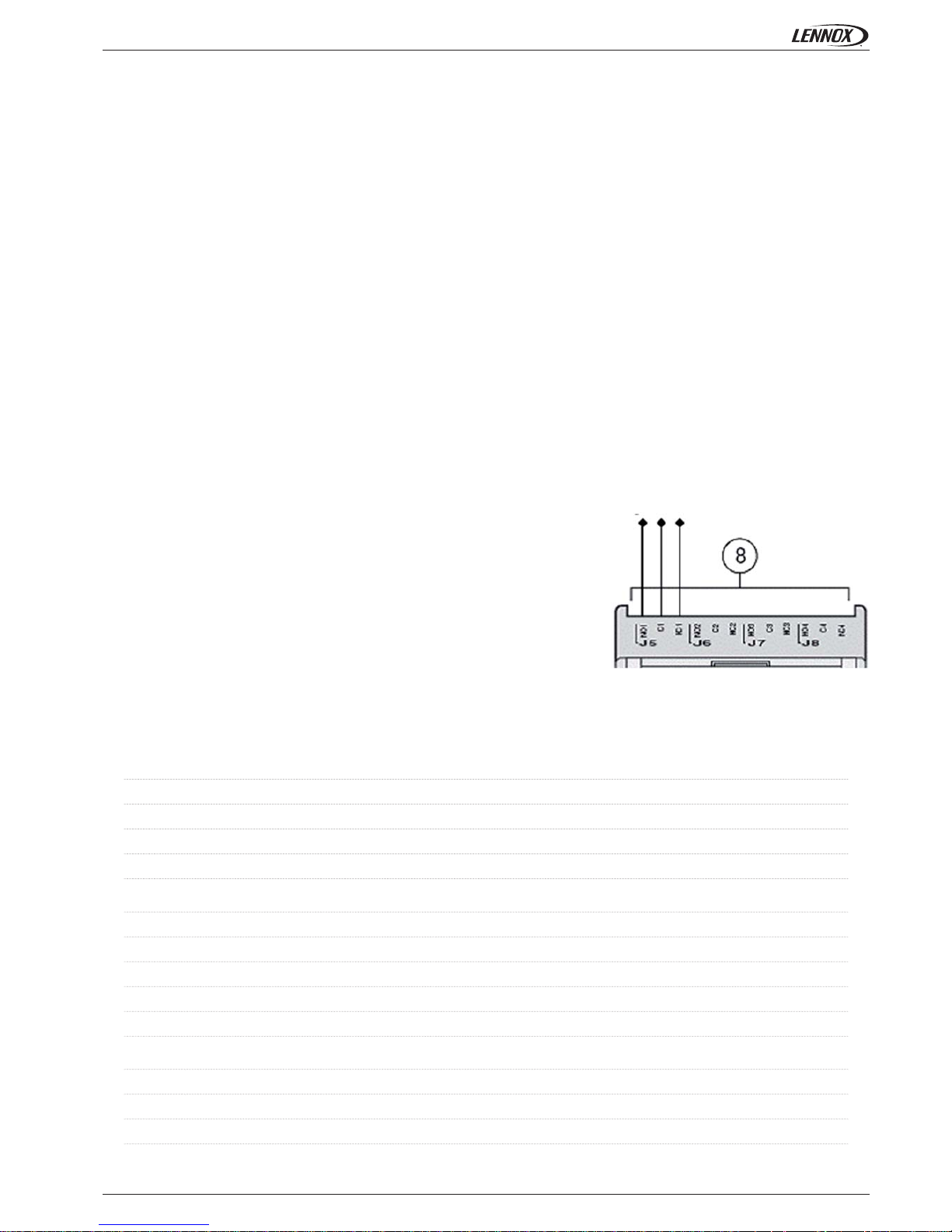

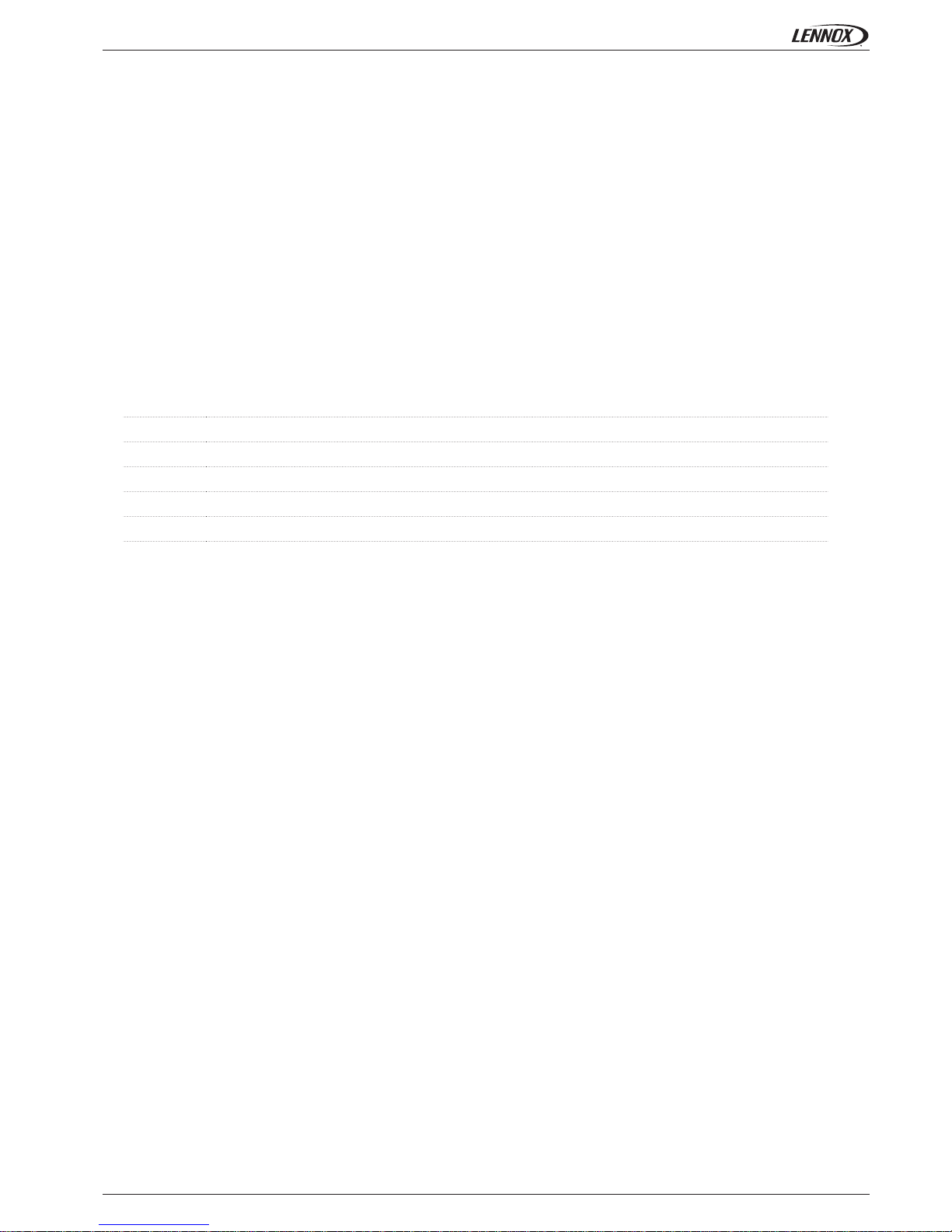

The expansion board BE60 is an additional board fi xed on DIN rail. The description of the various connectors is:

1. Power supply of the board,

2. Analog output 0/10V: not used,

3. Network bus to the CLIMATIC™ 60 BM60,

4. 4 digital inputs: dry contacts only,

5. LED status of the network bus,

6. Serial address dip-switch of the network bus,

7. 4 analog inputs confi gurable by pair B1-B2 and B3-B4,

8. 4 digital outputs: dry contacts only.

Power supply

The expansion board BE60 is powered in 24Vac, +/-15%, 50-60Hz, Pmax=6W.

Page 30

• 28 • CL60-AC CHILLER-IOM-1011-E

COMPONENTS

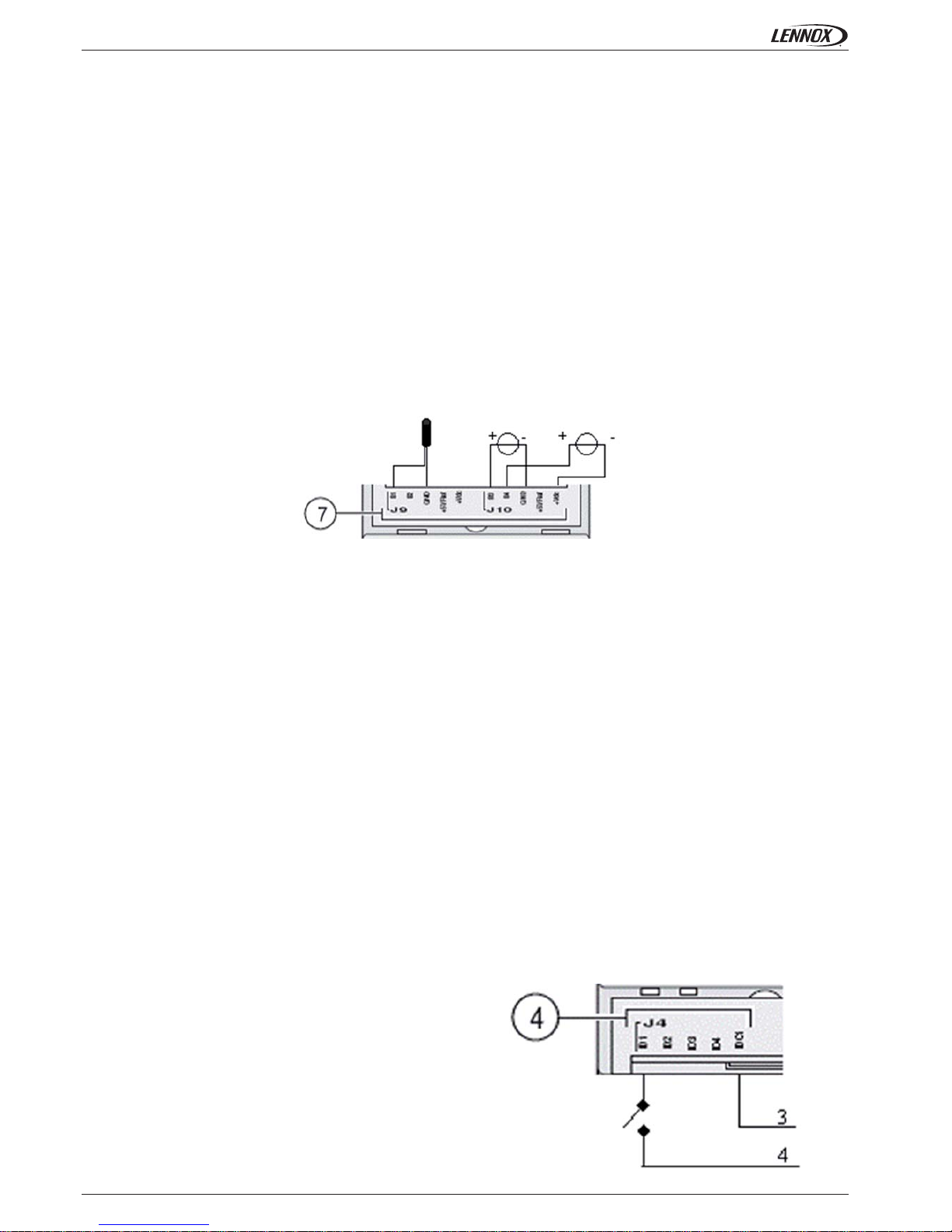

Analog input

The 4 analog inputs can be used as NTC probe (-50T90 °C; R/T 10 K at 25 °C) or 4/20mA (Impedance = 100) current signal.

They are confi gurable by pair B1-B2 and B3-B4. The confi guration of the type of the input is automatically set by the CLIMATIC™ 60.

The analog input can be confi gurated to be used as one of these items:

0. not set,

1. desired water set point,

2. desired offset set point,

3. free NTC probe.

Digital input

The 4 digital inputs must be used with dry contacts according to the following example. The digital input can be confi gurated to be

used as one of these items:

0. not set,

1. remote On/Off,

2. remote reset alarm,

3. swap to second water set point,

4. force the cooling mode,

5. force the heating mode,

6. force the dead zone mode,

7. force the defrost delay (10 min),

8. disable circuit 1 (all compressors),

9. disable circuit 2 (all compressors),

10. disable circuit 1(compressor 1),

11. disable circuit 1 (compressor 2),

12. disable circuit 1 (compressor 3),

13. disable circuit 2 (compressor 1),

14. ddisable circuit 2 (compressor 2),

15. ddisable circuit 2 (compressor 3),

16. force A mode,

17. force B mode,

18. force C mode,

19. force D mode,

20. force BMS mode,

21. electrical heaters status,

22. free digital input.

Passive

4/20 mA

signal

Active

4/20 mA

signal

NTC probe

Dry contact

Page 31

• 29 •

(3131):

(3132):

(3133):

(3134):

(3135):

(3141):

(3142):

(3143):

(3144):

(3145):

(3146):

(3151):

(3152):

(3153):

(3154):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

Digital output

The 4 digital outputs are dry contacts and the maximum commutable power is 2000VA, 250Vac.

The digital output can be confi gurated to be used as one of these items:

0. not set,

1. general alarm (alarm minor),

2. general fault (alarm major),

3. general alarm on circuit 1,

4. general alarm on circuit 2,

5. general alarm on condenser,

6. general alarm on evaporator pump(s),

7. fl ow evaporator alarm,

8. unit enable,

9. unit available (ready to start),

10. unit running (one compressor ON),

11. unit running 100% (all compressor(s) ON),

12. unit operating in cooling mode,

13. unit operating in heating mode,

14. unit operating in dead zone mode,

15. unit operating in zone 0

16. unit operating in zone 1,

17. unit operating in zone 2,

18. unit operating in zone 3,

19. unit operating in zone 4,

20. unit operating in zone 5,

21. unit operating in zone 6,

22. unit operating in mode A,

23. unit operating in mode B,

24. unit operating in mode B,

25. unit operating in mode D,

26. unit operating in mode BMS,

27. output for additional electrical heater 1,

28. output for additional electrical heater 2,

29. output for additional electrical heater 3,

30. output for additional electrical heater 4,

31. free digital output.

Settings

The different settings to confi gure the custom I/O are available in the menu:

setting for the digital output on the connector BM60-J14-NO7,

setting for the digital output on the connector BE60-J5-NO1,

setting for the digital output on the connector BE60-J6-NO2,

setting for the digital output on the connector BE60-J7-NO3,

setting for the digital output on the connector BE60-J8-NO4.

setting for the digital input on the connector BM60-J4-ID4,

setting for the digital input on the connector BM60-J4-ID7,

setting for the digital input on the connector BE60-J4-ID1,

setting for the digital input on the connector BE60-J4-ID2,

setting for the digital input on the connector BE60-J4-ID3,

setting for the digital input on the connector BE60-J4-ID4.

setting for the analog input on the connector BE60-J9-B1,

setting for the analog input on the connector BE60-J9-B2,

setting for the analog input on the connector BE60-J10-B3,

setting for the analog input on the connector BE60-J10-B4.

Dry contact

Note: in case of communication loss beetween BE60 and BM60, the expansion board inputs / outputs keeps the previous status before

this communication loss.

Page 32

• 30 •

(2111), (3111):

(2112), (3112):

(2113), (3113):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

ON / OFF CONTROL

Function

There are various ways to start up the unit: manually or automatically.

Description

There are up to 4 ways to start / stop the unit with the CLIMATIC™ 60:

• The unit can be turned ON or OFF manually by the terminals DC60 Advanced or DS60 in the menu (2111) or (3111) or DC60.

• A remote contact can also be connected directly to the electrical box to switch the unit ON or OFF. The switch status is displayed

in the menu (2112) or (3112).

• The startup of the unit can be confi gured according to a scheduling in the menu (2113) or (3113).

• The BMS can write directly in the general ON/OFF to start / stop the unit.

Note: the unit is considered as “ON” if only all settings (2111), (2113), (2113) are set to ON.

Settings

The different settings to start up are available in the menu:

General ON /OFF,

Remote ON /OFF,

Schedule ON /OFF.

Page 33

• 31 •

(2121):

(2122):

(2123):

(2124):

(2125):

(2126):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

REAL TIME LOCK

Function

The CLIMATIC™ 60 board includes a real time clock which permits a schedule programmation and alarm events recording.

Description

The clock is updated by terminal DC60 Advanced or DC60 or DS60 or BMS. Moreover, the time change is automatically updated for

winter (last Sunday of October at 3h00) and summer (last Sunday of March at 2h00). This functionality can be disabled in menu (2126).

To update the clock by BMS, a fl ag must be set to 1 before sending the new date.

Note: if the DS60 is connected, the clock can’t be updated by the DC60.

Settings

The different settings to start up are available in the menu:

Clock hour,

Clock minute,

Clock day (of the month),

Clock month,

Clock year,

Automatic clock update.

Page 34

• 32 •

12h/24h

6h

9h

15h

3h

12h/24h

18h

21h

(2131):

(2141):

(2142):

(2143):

(2144):

(2145):

(2146):

(2147):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

SCHEDULING ZONE

Function

The CLIMATIC™ 60 is provided by a real time clock which offers solutions to specify a weekly schedule.

Description

The CLIMATIC™ 60 schedule manages up to 7 different clock zones per day fand from monday to sunday. The zone can start at

different time each day of the week in order to optimise the operating of the unit.

Settings

The different settings to adjust the scheduling zone are available in the menu:

Note: start time can take different values from monday tosunday. Start time of zone 0 must be set to 00h00.

the visibility of the settings (2141) to (2147) depend on the settings (2131). The zones not used are hidden.

Zone 6

Zone 4

Zone 0

Zone 1

Zone 5

Zone 3

Zone 2

Monday

Sunday

Number of zone desired,

Starts time of zone 0 from monday to sunday

Starts time of zone 1 from monday to sunday

Starts time of zone 2 from monday to sunday

Starts time of zone 3 from monday to sunday

Starts time of zone 4 from monday to sunday

Starts time of zone 5 from monday to sunday

Starts time of zone 6 from monday to sunday

Page 35

• 33 •

12h/24h

6h

9h

15h

3h

12h/24h

18h

21h

(2132):

(2151):

(2152):

(2153):

(2154):

(2155):

(2156):

(2157):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

SCHEDULING MODE

Function

The CLIMATIC™ 60 is able to control different modes for each zone declared in order to optimise the operating of the unit.

Description

The CLIMATIC™ 60 can manage up to 4 different modes.

Settings

The different settings to adjust the scheduling mode are available in the menu:

Note: the mode used can take different values from monday to sunday.

the visibility of the settings (2151) to (2157) depend on the settings (2132). The modes not used are hidden.

C Mode

A Mode

C Mode

B Mode

B Mode

D Mode

D Mode

Monday

Sunday

Number of mode desired

Mode used during the period of zone 0 from monday to sunday

Mode used during the period of zone 1 from monday to sunday

Mode used during the period of zone 2 from monday to sunday

Mode used during the period of zone 3 from monday to sunday

Mode used during the period of zone 4 from monday to sunday

Mode used during the period of zone 5 from monday to sunday

Mode used during the period of zone 6 from monday to sunday

Page 36

• 34 •

(2161):

(2162):

CL60-AC CHILLER-IOM-1011-E

COMPONENTS

SCHEDULE ANTICIP ATION START-UP

Function

The CLIMATIC™ 60 allows the start up of the unit before the pre-specifi ed hour of the fi rst zone (zone 1) of the day.

Description

This function is able to start the unit during zone 0 earlier if the outdoor temperature is under a specify threshold. The typical application

is to start the unit in heating mode if the weather is too cold compare to the actual season.

Example:

• (2142): zone 1 start time: 8h00,

• (2161): foot anticipation: 10.0°C,

• (2162): gradient anticipation: 10 mm/°C.

In this example the foot is set to the value 10.0°C, which means zone 1 will always start at 8h00 if the outside air temperature is higher

than 10.0°C. If the outside air temperature is less than 10.0°C zone 1 will start according to the selected gradient and the difference

between the foot value and the actual outside air temperature (10.0 - 7.0 = 3.0 x 10 = 30 min). Then, the new start time for zone 1 is 7h30.

Settings

The different settings to adjust the anticipation are available in the menu:

zone 1 start time (h)

Outdoor temperature (°C)

(2142) Z1 start time

8h00

Calculates Z1 start time

7h30

Gradient = 10 mm/°C

Foot anticipation

radient anticipation

Page 37

• 35 •

BM60..B. Rx-/Tx- BM60..B. Rx-/Tx-

BM60..B. Rx+/Tx+ BM60..B. Rx+/Tx+

17% 17%17% 17%

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

MASTER / SLAVE

Function

The CLIMATIC™ 60 offers possibilities to connect up to 8 units to allow relationship between each unit in order to perform the system.

The pLAN bus is connected to CLIMATIC™ 60 on the J8 connector of board BM60. A star connection is not recommended. For an

optimum operation it is advised to connect a maximum of two cables per unit.

The cable length should not exceed 500 m and you must use a 2 pairs with general shield like LiYCY-P (0.34 mm²).

Description

There are 2 different modes to manage the units (“Cascade” & “Backup”)

The cascade mode:

The cascade mode is used to engage additional cooling / heating capacity in order to reach the water set point. This master/slave

operating includes 2 modes:

• Twin mode: the units work simultaneously in order to equalize the number of compressors stages to perform the capacity of the unit.

The control manages only the capacity increase. The stage(s) decrease is controlled individually by each unit. The power factor

capacity power is also controlled individually on each unit according to its demand.

Unit n°1

Unit n°7Unit n°2

Max: 500 m

Unit n°8

Unit n°1

Unit n°7Unit n°2

Unit n°8

Page 38

• 36 •

….U1 U2 U3 U4 ….

….U4 U1 U2 U3 ….

….U3 U4 U1 U2 ….

….U2 U4 U3 U1 ….

100%

0%

15%

0%

20%

0%

17%

17%

17%

0%

20%

20%

CL60-AC CHILLER-IOM-1011-E

The backup mode

Used to help the system in case of alarm(s) on the unit running. The unit in standby will start only if one of the other unit(s) running is

in alarm. In this case the unit in alarm will be stopped and replace by the one which was in standby.

The CLIMATIC™ 60 manages also the rotation between the declared units . In “Cascade” mode, that means that the fi rst unit to start

will change every week. In “Rol.Backup” mode, the unit in “Backup” is swapped every week.

Example:

In case of 4 units, the rotation is as follow:

• Chain mode: the units starts one after the other in serial sequence. In case of evaporator pump(s) in the unit, the pump(s) is engaged

according to the demand of the system.

The selectd unit in standby is the one which has the higher critical(s) alarm(s). In case of disconnection of the slave(s) unit(s) (@pLAN

= 2 8) from the master unit (@pLAN = 1) on the pLAN bus, the disconnected unit will operate alone.

Week Example Unit rotation

Week (n modulo 5) Week 1

Week (n+1 modulo 5) Week 2

Week (n+2 modulo 5) Week 3

Week (n+3 modulo 5) Week 4

Unit n°1

Unit n°1

Unit n°1

Unit n°7

Unit n°7

Unit n°7

Unit n°2

Unit n°2

Unit n°2

Unit n°8

Unit n°8

Unit n°8

ALARM

Page 39

• 37 •CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

DC60 DISPLAY

Function

The DC60 display is customized for the user to show a global operating overview of the unit and allow access to some settings. In

case of remote display, the cable length should not exceed 30 m.

Description

The DC60 terminal displays various status of the unit and offers the possibility to override the initial operating of the unit. Use the wheel

button to display the data desired in the big area. The small area specifi es the type of the data displayed.

Set point “SET”:

Specify the evaporator water set point calculated by CLIMATIC™ 60. The set point can be modifi ed directly by the DC60. Note that

the selected value will automatically be overwritten by CLIMATIC™ 60 when the actual zone will change (Z0 Z6) if a scheduling

has been defi ned.

Unit number “UNIT”:

Specify the evaporator water outlet temperature.

Outlet temperature “OUT”:

Specify the evaporator water outlet temperature.

Inlet temperature “IN”

Specify the water evaporator inlet temperature.

Outside temperature “Air”

Specify the outside air temperature.

Alarm code “AL-”

Specify the active alarm(s) code(s).

Low pressure “LP-1”

Specify the low pressure of circuit 1.

High pressure “HP-1”

Specify the high pressure of circuit 1.

Low pressure “LP-2”

Specify the low pressure of circuit 2.

High pressure “HP-2”

Specify the high pressure of circuit 2.

Schedule zone

specify the schedule operating zone.

Changeover mode

Big area

Unit mode

Small area

Status area

Page 40

• 38 • CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Settings

The CLIMATIC™ 60 offers possibilities of override operations.

On/Off

When the “power” button is pressed during few seconds, the unit is ordered to start or stop. When the unit is “OFF”, the clock is displayed.

Changeover mode

The changeover mode (cool / heat) can be modifi ed through the DC60 terminal by pressing the “mode” button.

When the “Auto” mode is selected, the icon “Cool” or “Heat” is displayed to signal the actual operating mode of the unit. Due to

communication delay, after pressing the “mode” button, it is well advised to wait few seconds, the time to refresh of th icon on the display.

Clock: there is two way to modify the clock hour:

• Press the “clock” button during few seconds. When the hour is blinking, turn the wheel button to select the desired hour and validate

by pressing the wheel button. Once the hour is validated, repeat the procedure for the minute and the weekday.

• Press the “On/off” and “Fan” buttons simultaneously during few seconds. When the terminal displays “CODE”, select the password

“22” and validate by pressing the wheel button. Then select the item to modify (“year” Year, “mont Month, “nday” day of

the month, “uday” weekday, “hour” Hour, “mins” Minute).

Night mode, Day mode, Day A mode, Day B mode, GTC mode

The DC60 terminal also displays the status of the main component of the unit in the status area. The icons can take different appearance

according to the status of the component.

Defrost

Compressors

General alarm

Pump OFF (icons hidden)

Pump ON (icons visible)

Pump alarm (icons blinking)

Evaporator pump(s)

Heat Cool Auto

Page 41

• 39 •

Display address

setting ........: xx

I O Board address: xx

-LENNOX--LENNOX-

Language

-English

CH 060 STD

Vers: 01.0

Rev: 00.0

Boot: 4.05

Language

-English

CH 060 STD

Vers: 01.0

Rev: 00.0

Boot: 4.05

111

212

313

414

515

616

717

818

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

DC60 ADVANCED DISPLAY OR DS60 DISPLAY

Function

The DC60 Advanced or DS60 terminals are plug and play displays, to confi gure the unit.

• the DC60 Advanced is the display installed on the front panel of NEOSYS™ units.

• the DS60 is designed for maintenance and expert service people who want to access to advanced functionalities.

Description

The terminal address is automatically set by the CLIMATIC™ 60 when connected. The address can yet be assigned manually to

establish the communication with the CLIMATIC™ 60. The procedure to confi gure the DC60 Advanced / DS60 is:

1. Press the buttons “”, “”, “” keys at the same time during 5 seconds,

2. Use the “” key to move the cursor on the address number,

3. Use the “”, “” keys to select the value “11 18” for the DC60 Advanced, "32" for the DS60 (or DS50) and confi rm with the “”

key (the cursor go directly to the next data).

Display address

CLIMATIC™ BM60 address

4. If the address has been modifi ed, the next screen is displayed. In that case restart step 1.

UNIT NUMBER DC60 ADVANCED ADDRESS

Page 42

• 40 •

Display address

changed

Terminal con g

Press ENTER

to continue

P01: Adr Priv / shared

Trm1 31 Pr

Trm2 None -Trm3 None -- OK?

No

-LENNOX-

Language

-English

CH 060 STD

Vers: 01.0

Rev: 00.0

Boot: 4.05

Bios: 5.09

|

|

|

|

|

|

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

5. Use the “”, “” keys to select the desired address of CLIMATIC™ 60. CLIMATIC™ 60 address must be at the address “1” except

if there is several units linked. The next screen is displayed.

6. Press the “” key to go to the next step.

7. The following screen describes the used connection type. Set the display as a Private “Pr” terminal. The other terminals (Trm2 and

Trm3) are not used. So their addresses must be adjusted to “None”. Finally confi rm the modifi cations, swapp the text “No” to “Yes”

and validate with the“” key.

After a star up, the fi rst screen contains the main information about the CLIMATIC™ 60‘s software.

Private displayDisplay address

Page 43

• 41 •

(0000)

1 Alarm

2 User

3 Expert

Unit: 01

Zone: 0

Mode: A

Wednesday

01/09/10

14:32:50

|

|

|

|

|

|

|

|

|

|

Alarm 01

01>04/10.14h23 * 114

02>22/09.11h23 = 114

03>00/00.00h00 = 000

04>00/00.00h00 = 000

05>00/00.00h00 = 000

06>00/00.00h00 = 000

07>00/00.00h00 = 000

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

The DC60 Advanced / DS60 is organised in 3 menus:

• (1000): alarms history,

• (2000): user menus for maintenance people,

• (3000): (Only for DS60) Expert menus for service people (restricted area). To access to the “EXPERT” level, push the “PRG” button

during few seconds when the fi rst screen (Language) is shown.

To access to alarms history, press the “ALARM” key when you are in the main menu (0000). The CLIMATIC™ 60 saves up to the last

32 alarms. An active alarm is signaled by the symbol “*” whereas an alarm inactive is symbolized by the “=”.

To reset the current active alarm(s) press the “ALARM” key.

Actual zone, mode

Actual clock

The menu is organised in arborescence tree with submenus. The actual menu is identifi ed by the number in parentheses in the top

left corner of the screen.

Number of active alarm(s)

Alarm code

Alarm code

Active alarm (*)

Active alarm (*)

Alarm trip hour

Page 44

• 42 •

(3230)01 Mode A

3 Outlet 13.3

4 Setpoint 07.0

4 Capacity 000.0%

4 Air 1 22.0

4 Air 2 30.0

4 Water 1 07.0

4 Water 2 07.0

|

|

|

|

|

|

|

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

The “” and “” keys are used to move the cursor on the desired item. Then use the “” key to enter in the selected submenu. To

escape a menu use "ESC" the key.

Menu (3000)

Menu (3100)

Menu (3110) Menu (3160)

Menu (3820)Menu (3810)

Menu (3800) Menu (3161) Menu (3169)

Menu (3821) Menu (3829)

The submenus contains 2 types of data: the read only data (like a temperature probe for example) and the read/write setpoints (like the

cooling water setpoint for example). The data are identifi ed by a cursor symbol “>” whereas the setpoint are identify by a symbol “>>”.

Customizable setting for different mode

Actual set point

Page 45

• 43 •

(3230)01 Mode A

3 Outlet 13.3

4 Setpoint 07.0

4 Capacity 000.0%

4 Air 1 22.0

4 Air 2 30.0

4 Water 1 07.0

4 Water 2 07.0

(3230)01 Mode A

Water 2

07.0

20.0

07.0

05.0

06.0

>

|

|

|

|

|

|

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

To modify a setting, move the cursor on the desired item and press the “” key. A new screen displays information concerning this

set point. To modify it, use the “” and “” keys and validate by pressing the “” key. If the setting is customizable according to the

schedule mode, press the “PRG” key to select different value for the A, B, C& D mode.

: to quickly increment or decrement the setting, hold the “” or “” keys during few time.

Cursor symbol for set point

User save value

Minimum value

Factory value

Maximum value

Cursor symbol for data

Page 46

• 44 •

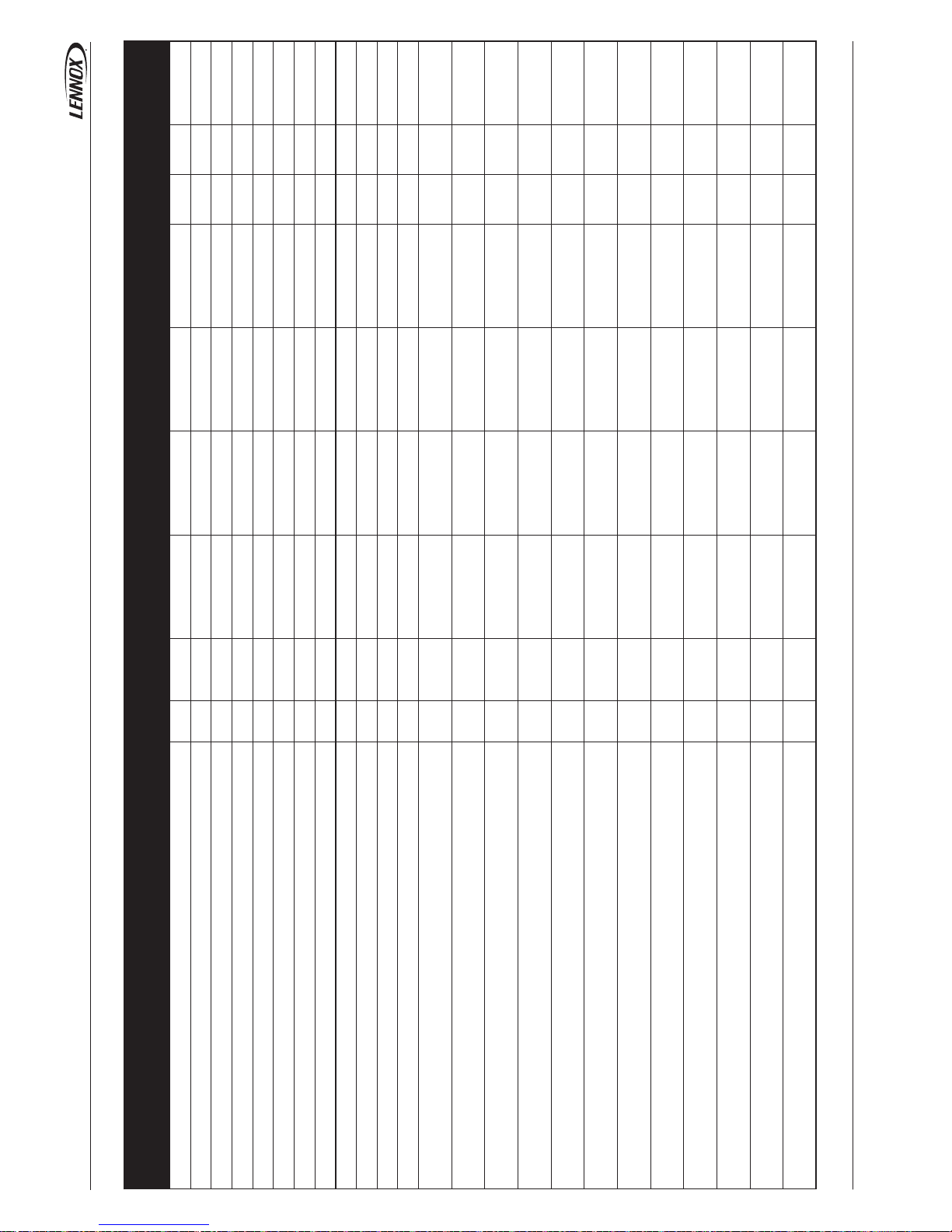

R/W/Z Min Std Max

1111 Alarm *** *** Historic

2111

User

Unit

General

On/Off R/W * 0 * 1

2112 On/Off Input R * 0 * 1

2113 On/Off Mode R/W/Z * 0 1 1

2114 Reset Alarm R/W * 0 0 1

2115 Box Tß R °C -50 * 105

2116 Status R * List * *

2121

Clock

Hour R/W HH 0 * 23

2122 Minute R/W mm 0 * 59

2123 Day R/W DD 1 * 31

2124 Month R/W MM 1 * 12

2125 Year R/W yy 1 * 99

2126 Win/Sum R/W * 0 1 1

2131

General schedule

Nbr Zone R/W NN 1 3 6

2132 Nbr Mode R/W NN 1 1 4

2133 Weekday R D 1 * 7

2134 Day R DD 1 * 31

2135 Year R YY 1 * 99

2136 Hour R HH 0 * 23

2137 Minute R mm 1 * 59

2138 Zone R * 0 * 6

2139 Mode R * 1 * 5

2141

Time schedule

Time Z0 R/W HH 0 24 24

2142 Time Z1 R/W HH 0 24 24

2143 Time Z2 R/W HH 0 24 24

2144 Time Z3 R/W HH 0 24 24

2145 Time Z4 R/W HH 0 24 24

2146 Time Z5 R/W HH 0 24 24

2147 Time Z6 R/W HH 0 24 24

Unit Min Std Max

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

DS60 LIST

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Unit Comments

Alarm historic

General On/Off

Remote On/Off

Schedule On/Off

Reset the active alarm(s)

Electrical box temperature

General status of the unit

Hour clock setting

Minute clock setting

Day clock setting

Month clock setting

Year clock setting

Automatic update for winter/summer time

Number of zone

Number of mode

Actual day of the week

Actual day of the month

Actual year

Actual hour

Actual minute

Actual schedule zone

Actual schedule mode

Start time of zone 0

Start time of zone 1

Start time of zone 2

Start time of zone 3

Start time of zone 4

Start time of zone 5

Start time of zone 6

Unit Minimum Standard Maximum

Page 47

• 45 •

R/W/Z Unit Min Std Max

2151

User

Unit

Schedule Mode

Mode Z0 R/W * 1 1 5

2152 Mode Z1 R/W * 1 1 5

2153 Mode Z2 R/W * 1 1 5

2154 Mode Z3 R/W * 1 1 5

2155 Mode Z4 R/W * 1 1 5

2156 Mode Z5 R/W * 1 1 5

2157 Mode Z6 R/W * 1 1 5

2161

Anticipation

Foot R/W °C -10 10 20

2162 Gradient R/W m/°C 0 0 100

2171

Custom relay

BM.NO7 R *

2172 BE.NO1 R *

2173 BE.NO2 R *

2174 BE.NO3 R *

2175 BE.NO4 R *

2181

Custom switch

BM.Id4 R *

2182 BM.Id7 R *

2183 BE.Id1 R *

2184 BE.Id2 R *

2185 BE.Id3 R *

2186 BE.Id4 R *

2191

Custom signal

BE.B1 R *

2192 BE.B2 R *

2193 BE.B3 R *

2194 BE.B4 R *

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Comments

Mode during zone 0

Mode during zone 1

Mode during zone 2

Mode during zone 3

Mode during zone 4

Mode during zone 5

Mode during zone 6

Bottom of the slope

Slope value in minute per degrees

Confi guration of the free output BM.NO7

Confi guration of the free output BE.NO1

Confi guration of the free output BE.NO2

Confi guration of the free output BE.NO3

Confi guration of the free output BE.NO4

Confi guration of the free input BM.Id4

Confi guration of the free input BM.Id7

Confi guration of the free input BE.Id1

Confi guration of the free input BE.Id2

Confi guration of the free input BE.Id3

Confi guration of the free input BE.Id4

Confi guration of the free input BE.B1

Confi guration of the free input BE.B2

Confi guration of the free input BE.B3

Confi guration of the free input BE.B4

Page 48

• 46 •

R/W/Z Unit Min Std Max

2211

User

Water

General

Inlet R °C -50 * 105

2212 Inlet Ref. R °C -50 * 105

2213 Outlet R °C -50 * 105

2214 Outlet Ref. R °C -50 * 105

2215 Delta Tß R °C 0 * 105

2216 Setpoint R °C -10 * 50

2217 Capacity R % 0 * 100

2218 Flow R * 0 * 1

2221

Changeover

Status R * * * *

2222 Outside R °C -50 * 105

2223 Outside Ref. R °C -50 * 105

2224 Mode R/W * 0 0 4

2225 AirTßWinter R/W °C -10 18 30

2226 AirTßSummer R/W °C 19 23 30

2231

Cooling

Status R * * * *

2232 Inlet R °C -50 * 105

2233 Outlet R °C -50 * 105

2234 Setpoint R °C -10 * 50

2235 Capacity R °C 0 * 100

2236 Air Slope 1 R/W/Z °C -11 22 50

2237 Air Slope 2 R/W/Z °C -11 30 50

2238 Water 1 R/W/Z °C 19 7 20

2239 Water 2 R/W/Z °C 19 7 20

2241

Heating

Status R * * * *

2242 Inlet R °C -50 * 105

2243 Outlet R °C -50 * 105

2244 Setpoint R °C -10 * 50

2245 Capacity R °C 0 * 100

2246 Air Slope 1 R/W/Z °C -11 22 50

2247 Air Slope 2 R/W/Z °C -11 30 50

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Comments

Evaporator inlet probe T°

Evaporator inlet reference T°

Evaporator outlet probe T°

Evaporator outlet reference T°

Evaporator delta T° (Inlet-Outlet)

Evaporator set point

Evaporator capacity

Evaporator fl ow switch

Changeover status

Outside air probe T°

Outside air reference T°

Changeover mode

0=Not Used,

1=Cool,

2=Heat,

3=Auto,

4=Dead zone.

Winter Air T° to swap in heating mode

Summer Air T° to swap in cooling mode

Evaporator status

Evaporator inlet reference T°

Evaporator outlet reference T°

Evaporator set point

Evaporator cooling capacity

Outside air set point X1 in cool

Outside air set point X2 in cool

Evaporator set point Y1 in cool

Evaporator set point Y2 in cool

Evaporator status

Evaporator inlet reference T°

Evaporator outlet reference T°

Evaporator set point

Evaporator cooling capacity

Outside air set point X1 in heat

Outside air set point X2 in heat

Page 49

• 47 •

R/W/Z Unit Min Std Max

2248

User

Water

Heating

Water 1 R/W/Z °C 40 45 50

2249 Water 2 R/W/Z °C 40 45 50

2251

Custom

Sp 4/20mA R °C 4 * 20

2252 Sp +/-1ßC R °C -1 * 1

2253 Sp Nß2 R * 0 * 1

2311

Pump

Evaporator P1

Status R * List * *

2312 Sw State R * 0 * 1

2313 Output R * 0 * 1

2314 Hour H R HH 0 * 9999

2315 Hour L R HH 0 * 9999

2316 Flow R * 0 * 1

2321

Evaporator P2

Status R * List * *

2322 Sw State R * 0 * 1

2323 Output R * 0 * 1

2324 Hour H R HH 0 * 9999

2325 Hour L R HH 0 * 9999

2326 Flow R * 0 * 1

2331

Evaporator Flow

T.In R °C -50 * 105

2332 T.Out R °C -50 * 105

2333 P.In R Bar 0 * 6

2334 P.Out R Bar 0 * 6

2335 Delta dT R °C 0 * 20

2336 Delta dP R Bar 0 * 6

2337 Capacity R % 0 * 100

2338 Flow R m3 0 * 100

2339 Flow R * 0 * 1

2341

Condenser P1

Status R * List * *

2342 Sw State R * 0 * 1

2343 Output R * 0 * 1

2344 Hour H R HH 0 * 9999

2345 Hour L R HH 0 * 9999

2346 Flow R * 0 * 100

2351

Condenser P2

Status R * List * *

2352 Sw State R * 0 * 1

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Comments

Evaporator set point Y1 in heat

Evaporator set point Y2 in heat

External evaporator set point

External offset evaporator set point

Second set point switch status

Evaporator pump 1 status

Evaporator pump 1 input

Evaporator pump 1 output

Evaporator pump 1 output

Evaporator pump 1 output

Evaporator fl ow switch

Evaporator pump 2 status

Evaporator pump 2 input

Evaporator pump 2 output

Evaporator pump 1 output

Evaporator pump 1 output

Evaporator fl ow switch

Evaporator T° inlet

Evaporator T° outlet

Evaporator pressure in

Evaporator pressure out

Evaporator delta T°

Evaporator delta pressure

Evaporator fl ow capacity

Evaporator fl ow meter

Evaporator fl ow switch

Condenser pump 1 status

Condenser pump 1 input

Condenser pump 1 output

Condenser pump 1 output

Condenser pump 1 output

Condenser fl ow switch

Condenser pump 2 status

Condenser pump 2 input

Page 50

• 48 •

R/W/Z Unit Min Std Max

2353

User

Pump

Condenser P2

Output R * 0 * 1

2354 Hour H R HH 0 * 9999

2355 Hour L R HH 0 * 9999

2356 Flow R * 0 * 100

2361

Condenser Flow

T.In R °C -50 * 105

2362 T.Out R °C -50 * 105

2363 P.In R Bar 0 * 6

2364 P.Out R Bar 0 * 6

2365 Delta dT R °C 0 * 105

2366 Delta dP R Bar 0 * 6

2367 Capacity R % 0 * 100

2368 Flow R m3 0 * 100

2369 Flow R * 0 * 1

2411

Compressor

Circuit 1

P.HP R Bar -50 * 105

2412 T.HP R °C -50 * 105

2413 T.Liquid R Bar -50 * 105

2414 P.LP R °C -50 * 105

2415 T.LP R °C -50 * 105

2416 T.Suction R °C -50 * 105

2417 Discharge 1 R °C -50 * 150

2418 Discharge 2 R °C -50 * 150

2421

Cir.1 Comp.1

Confi gR****

2422 Status R * List * *

2423 Sw State R * 0 * 1

2424 Output R * 0 * 1

2425 Time H R HH 0 * 9999

2426 Time L R HH 0 * 9999

2427 Start H R * 0 * 9999

2428 Start L R * 0 * 9999

2431

Cir.1 Comp.2

Confi gR****

2432 Status R * List * *

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Comments

Condenser pump 2 output

Condenser pump 1 output

Condenser pump 1 output

Condenser fl ow switch

Condenser T° inlet

Condenser T° outlet

Condenser pressure in

Condenser pressure out

Condenser delta T°

Condenser delta pressure

Condenser fl ow capacity

Condenser fl ow meter

Condenser fl ow switch

Condensing pressure circuit 1

Condensing T° circuit 1

Saturated pressure circuit 1

Saturated T° circuit 1

Liquid T° circuit 1

Suction T° circuit 1

Discharge T° 1 circuit 1

Discharge T° 2 circuit 1

Confi guration compressor 1 circuit 1

Status compressor 1 circuit 1

Input compressor 1 circuit 1

Output compressor 1 circuit 1

Hour counter compressor 1 circuit 1 LSB

Hour counter compressor 1 circuit 1 MSB

Start counter high compressor 1 circuit 1 LSB (example : 123)

Start counter low compressor 1 circuit 1 MSB (example 456)

Confi guration compressor 2 circuit 1

Status compressor 2 circuit 1

Page 51

• 49 •

R/W/Z Unit Min Std Max

2433

User

Compressor

Cir.1 Comp.2

Sw State R * 0 * 1

2434 Output R * 0 * 1

2435 Time H R HH 0 * 9999

2436 Time L R HH 0 * 9999

2437 Start H R * 0 * 9999

2438 Start L R * 0 * 9999

2441

Cir.1 Comp.3

Confi gR****

2442 Status R * List * *

2443 Sw State R * 0 * 1

2444 Output R * 0 * 1

2445 Time H R HH 0 * 9999

2446 Time L R HH 0 * 9999

2447 Start H R * 0 * 9999

2448 Start L R * 0 * 9999

2451

Circuit 2

P.HP R Bar -50 * 105

2452 T.HP R °C -50 * 105

2453 T.Liquid R Bar -50 * 105

2454 P.LP R °C -50 * 105

2455 T.LP R °C -50 * 105

2456 T.Suction R °C -50 * 105

2457 Discharge 1 R °C -50 * 150

2458 Discharge 2 R °C -50 * 150

2461

Cir.2 Comp.1

Confi gR****

2462 Status R * List * *

2463 Sw State R * 0 * 1

2464 Output R * 0 * 1

2465 Time H R HH 0 * 9999

Unit Min Std Max

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Comments

Input compressor 2 circuit 1

Output compressor 2 circuit 1

Hour counter compressor 2 circuit 1 LSB

Hour counter compressor 2 circuit 1 MSB

Start counter high compressor 2 circuit 1 LSB (example : 123)

Start counter low compressor 2 circuit 1 MSB (example 456)

Confi guration compressor 3 circuit 1

Status compressor 3 circuit 1

Input compressor 3 circuit 1

Output compressor 3 circuit 1

Hour counter compressor 3 circuit 1 LSB

Hour counter compressor 3 circuit 1 MSB

Start counter high compressor 3 circuit 1 LSB (example : 123)

Start counter low compressor 3 circuit 1 MSB (example 456)

Condensing pressure circuit 2

Condensing T° circuit 2

Saturated pressure circuit 2

Saturated T° circuit 2

Liquid T° circuit 2

Suction T° circuit 2

Discharge T° 1 circuit 2

Discharge T° 2 circuit 2

Confi guration compressor 1 circuit 2

Status compressor 1 circuit 2

Input compressor 1 circuit 2

Output compressor 1 circuit 2

Hour counter compressor 1 circuit 2 LSB

Unit Minimum Standard Maximum

Page 52

• 50 •

R/W/Z Unit Min Std Max

2466

User

Compressor

Cir.2 Comp.1

Time L R HH 0 * 9999

2467 Start H R * 0 * 9999

2468 Start L R * 0 * 9999

2471

Cir.2 Comp.2

Confi gR****

2472 Status R * List * *

2473 Sw State R * 0 * 1

2474 Output R * 0 * 1

2475 Time H R HH 0 * 9999

2476 Time L R HH 0 * 9999

2477 Start H R * 0 * 9999

2478 Start L R * 0 * 9999

2481

Cir.2 Comp.3

Confi gR****

2482 Status R * List * *

2483 Sw State R * 0 * 1

2484 Output R * 0 * 1

2485 Time H R HH 0 * 9999

2486 Time L R HH 0 * 9999

2487 Start H R * 0 * 9999

2488 Start L R * 0 * 9999

2491

Other

Sw HP C1 R * 0 * 1

2492 Sw HP C2 R * 0 * 1

2493 V4V C1 R * 0 * 1

2494 V4V C2 R * 0 * 1

2511 Condenser Circuit 1 Confi gR****

CL60-AC CHILLER-IOM-1011-E

COMMUNICATION

Description Menu 4

th

digit 3

rd

digit 2

nd

digit 1

st

digit Comments

Hour counter compressor 1 circuit 2 MSB

Start counter high compressor 1 circuit 2 LSB (example : 123)

Start counter low compressor 1 circuit 2 MSB (example 456)

Confi guration compressor 2 circuit 2

Status compressor 2 circuit 2

Input compressor 2 circuit 2

Output compressor 2 circuit 2

Hour counter compressor 2 circuit 2 LSB

Hour counter compressor 2 circuit 2 MSB

Start counter high compressor 2 circuit 2 LSB (example : 123)

Start counter low compressor 2 circuit 2 MSB (example 456)

Confi guration compressor 3 circuit 2

Status compressor 3 circuit 2

Input compressor 3 circuit 2

Output compressor 3 circuit 2

Hour counter compressor 3 circuit 2 LSB

Hour counter compressor 3 circuit 2 MSB

Start counter high compressor 3 circuit 2 LSB (example : 123)

Start counter low compressor 3 circuit 2 MSB (example 456)

Safety high pressure switch circuit 1

Safety high pressure switch circuit 2

Reversing valve circuit 1

Reversing valve circuit 2

Confi guration condenser circuit 1

Page 53

• 51 •

R/W/Z Unit Min Std Max

2512

User

Condenser

Circuit 1

Status R * List * *

2513 Sw State R * 0 * 1

2514 Condensing R °C -50 * 67

2515 Setpoint R °C 25 * 45

2516 Capacity R % 0 * 100

2517 Speed Low R * 0 * 1

2518 Speed High R * 0 * 1

2521

Circuit 2

Confi gR****

2522 Status R * List * *

2523 Sw State R * 0 * 1