Page 1

Providing indoor climate comfort

CLIMATIC™ 50

ROOFTOP & AIRCOOLAIR

CL50-ROOFTOP-IOM-1107-E

User manual

Page 2

Page 3

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

1

Climatic 50

Roof-Top & Aircoolair

INSTALLATION

OPERATING &

MAINTENANCE MANUAL

Ref : CL50-RoofTop-IOM-1107-E

LENNOX have been providing environmental solutions since 1895, our range of Baltic TM rooftop contin ues to meet the

standards that have made LENNOX a household name. Flexible design solutions to meet YOUR needs and uncompromising

attention to detail. Engineered to last, simple to maintain and Quality that becomes a standard. Further Information on

www.lennoxeurope.com.

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be used (except in operation of this product), reproduced,

issued to or made available to third parts without the prior written agreement of Lennox.

The technical informations and specifications contained in this manual are for reference only. The manufacturer reserves the right to modify

these without warning and without obligation to modify equipment already sold.

Page 4

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

2

TABLE OF CONTENTS

Page

INTRODUCTION 3

CONNECTION 4

CONFIGURATION 8

SCHEDULING – CLOCK SETTING 10

VENTILATION 13

THERMOSTAT / HYGROSTAT – SET POINTS 15

THERMOSTAT / HYGROSTAT – CONTROL PRINCIPLE 17

FRESH AIR DAMPER - FREE-COOLING 18

COMPRESSORS 20

DEFROST – HEAT PUMP 22

SUPPLEMENT OF HEATING (OPTION) 23

CUSTOMIZED INPUT/OUTPUT 25

FAULT CODES

Insufficient airflow 28

Filters Clogged or Missing 29

Ambient Temperature and Humidity, Outside Limits 30

Blowing temperature, outside limits 31

Overheating of Electrical Heating Elements 32

Gas Burner Faults 33

External Humidifier fault 34

Hot Water Circulator Fault 34

Fault in Real Time Clock 35

Extension card fault (BE50) 35

Faulty Probes and Sensors 36

Blowing fan 37

Condenser fans 38

Water Condenser Faults 39

Smoke Detector 40

Compressors shut down on LP cut off 41

Compressor shut down onHP cut off or electrical protection 42

COMMUNICATION 43

MASTER/SLAVE 43

BMS 45

CONFIGURING THE BM50 PLAN ADDRESS 46

ALLOCATION OF DISPLAYS TO THE BM50 47

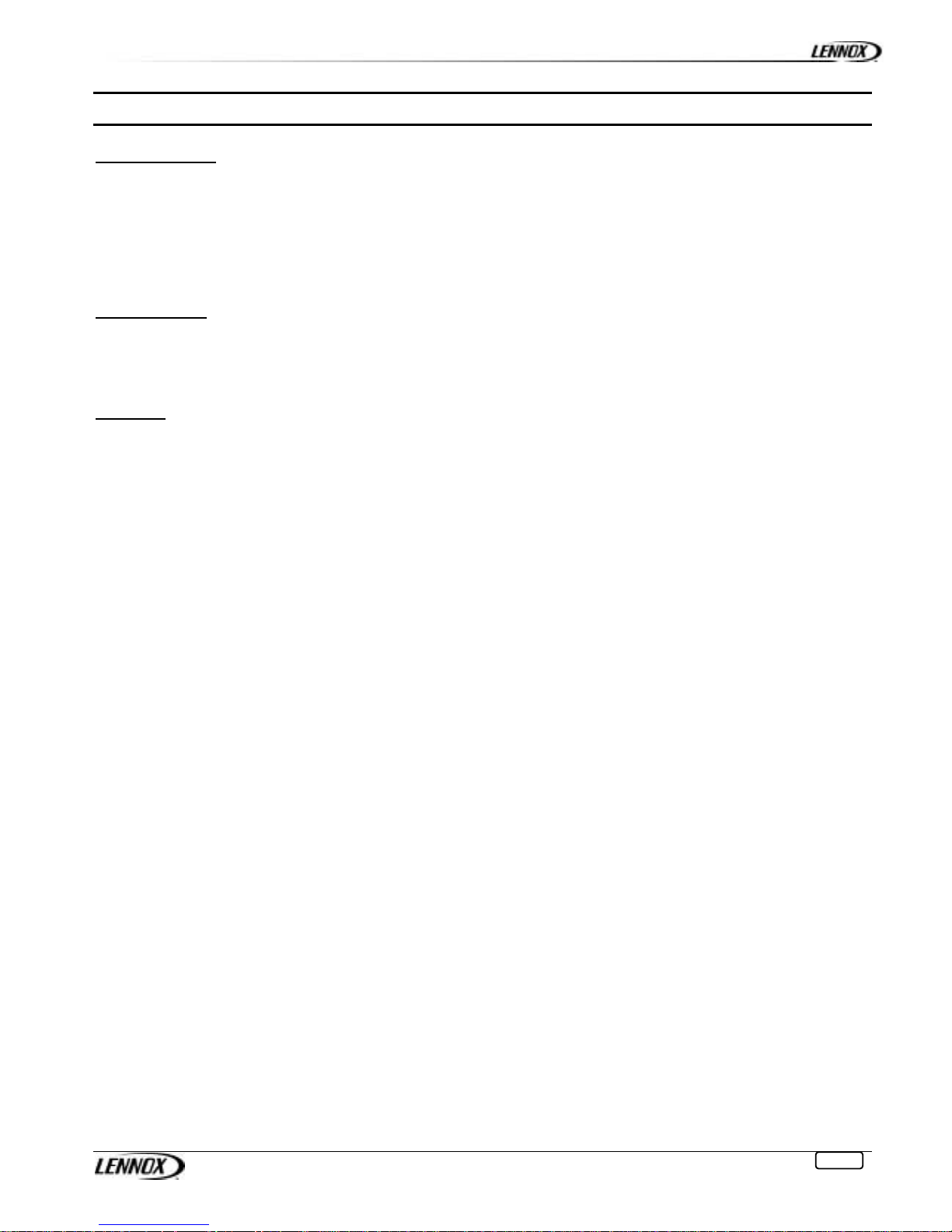

DC50 COMFORT & DM50 MULTI CUSTOMER DISPLAY 48

DS50 SERVICE DISPLAY 53

DS50 MENU TREE 59

CLIMATIC™50 INPUT/OUTPUT MAPPING 67

MODBUS, LONTALK ADRESS TABLES 70

Page 5

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

3

INTRODUCTION

CLIMATIC™50

The new generation of microprocessor based control, CLIMATICTM 50 may be fitted to the Lennox Roof-Top or

AirCooler range. It inherits 20 years of technology and field operating experience from its predecessors the

CLIMATICTM1 and CLIMATICTM 2.

LENNOX has found the latest hardware technology available on the market place and developed a software

specifically designed for Roof-Top and AirCooler applications, maximising the LENNOX units efficiency and

performance.

Compatibility

This documentation is compatible with the programs Roof Top and AirCooler:

• Ranges Baltic, Flexy I, Flexy II, FX and AC, starting from the version 20.0

Warning

Any parameter modification should be carried out by trained and licensed competent technician.

Before start-up or restart of a unit controlled by Climatic 50, it is mandatory to check adequacy between

Climatic 50 and the unit with its options.

• 38xx menus for unit and options

• 39xx menux for communication

In case of wrong parameters, I/O links could be incorrect and may create some operation problems for

the units and ultimately breakdowns.

Lennox cannot be held responsible for any claims on the units due to a wrong parameters sequence or a

parameters modification carried out by non competent technicians. In this case, the warranty will be

legally null and void.

Page 6

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

4

WIRING CONNECTIONS

IMPORTANT WARNING

Any wiring modification on the CLIMATIC 50 must be done by Lennox technician or employees having valid

electrical qualification and authorisation.

For any modification of wiring on the 24V supply or on 4-20mA sensor, check the polarity prior to apply

the power. Wrong polarity may cause serious damage and destroy the Plan network. Lennox will not

accept liability for damage caused by wrong power connection or any wiring modification done by

people without valid training and qualifications.

Any external connection with the unit, using 24Vac voltage should not exceed a length of more than 30m.

It concerns external contacts connected to Climatic™50 logical inputs or humidifier control connection

to the output 0-10v.

Over 30 m, the installer must interface this information with relays or converters.

In any case, the 24Vac control voltage must not be used to drive external function with Climatic™50

logical output

WARNING: Separate as much as possible probes, displays, logical input cables from power cables with strong inductive load, in

order to avoid possible electromagnetic perturbations

.

CONNECTION

SENSORS AND PROBES

External sensors or probes connection must be carried out with the following cable:

- Cable length up to 20m: AWG22 (0.34 mm ²), 1 pair crossed with screen (2 pairs for CO2 sensor).

- Cable length up to 50m: LiYCY-P (0.34 mm ²), 1 pair with general shield. (2 pairs for CO2 sensor).

The cable length should not exceed 50m.

For a better electromagnetic protection, Lennox recommends the use of LiYCY-P cable

ROOM TEMPERATURE PROBE (NTC)

The room temperature probe (- BT10) is connected to the Climatic™ main board BM50 50 entry B7 connector J6 (refer to the unit

electrical wiring diagram).

ROOM HUMIDITY SENSOR (0-20mA/Option)

The room humidity sensor (- BH10) is connected to the Climatic™ extension board BE50 entry B1 connector J9 (refer to the unit

electrical wiring diagram).

ROOM AIR QUALITY SENSOR CO² (4-20mA / Option)

The room air quality sensor (-BG10) is connected to Climatic™ main board BM50 entry B2 connector (refer to the unit electrical

wiring diagram).

DISPLAY DS50

The Display DS50 can be connected to the Climatic™ either on one of the RJ12 connectors located on the board DT50, or

directly on the main board BM50 connector J10.

Connection is carried out by the flat 1.5m cable delivered with this DS50.

In any the case, Display DS50 cannot be remotely connected.

In case of Master/Slave installation, one, and only one, display DS50 must be connected on the pLan bus.

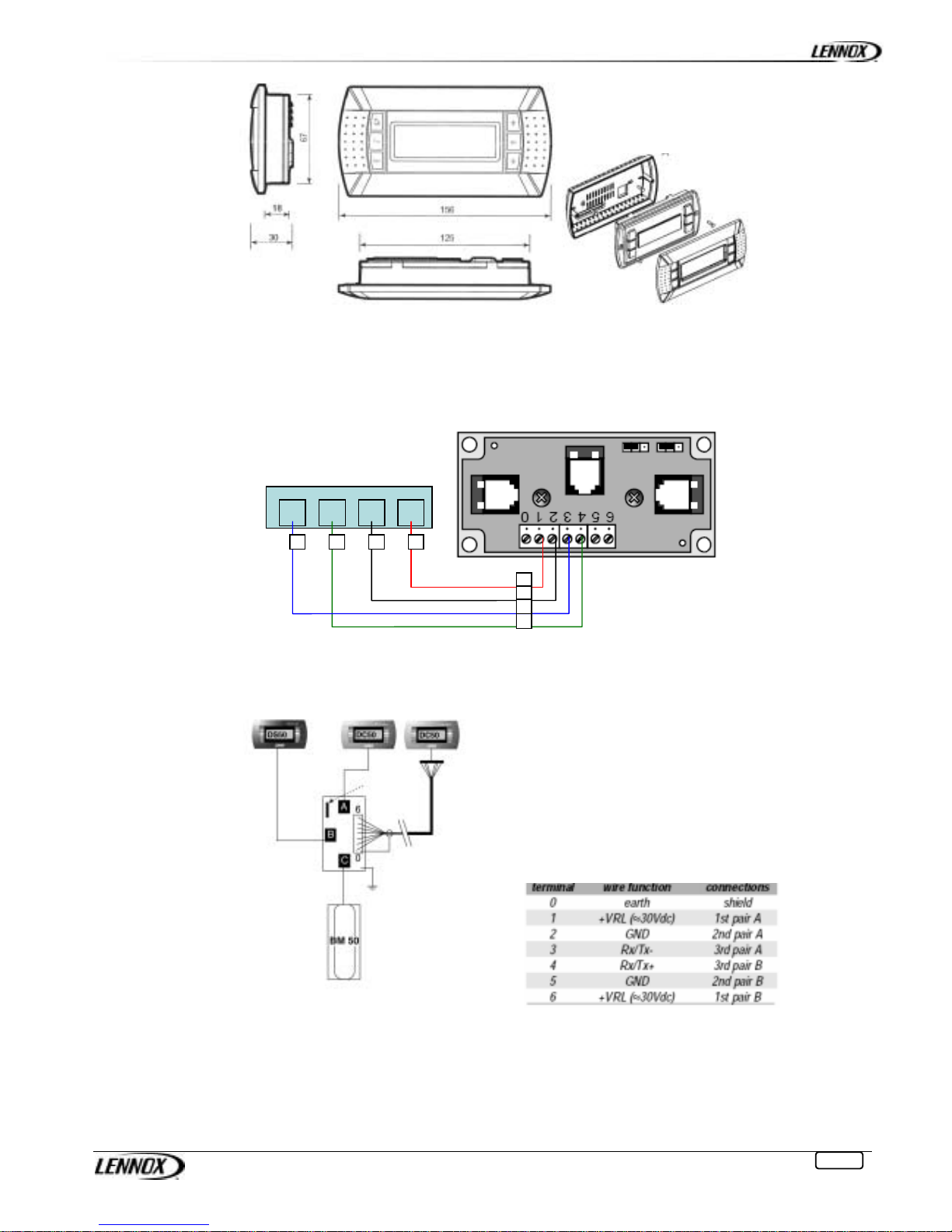

DISPLAY DC50 or DM50 (Remote CONNECTION)

Warning:

A wrong wiring of the display immediately damage it and/or the main board BM50.

The optional DC50/DM50 is designed to be mounted on the wall.

Fit the cable from the DT50 board through the back piece

Fasten the back piece to the wall using the rounded head screws supplied in the packaging

Connect the cable from the main board on the connector on the back of the DC50 display

Fasten the front panel on the back piece using the flush head screws supplied

Finally fit the click-on frame

Page 7

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

5

Display DC50 or DM50 is connected to the Climatic™ with the DT50 screw connector.

Connection must be carried out by the following cable:

- Cable length up to 300m: AWG22 (0.34 mm ²), 2 pairs crossed with screen.

- Cable length up to 500m: LiYCY-P (0.34 mm ²), 2 pairs with general shield.

The cable length should not exceed 500m.

For a better electromagnetic protection, Lennox recommends the use of LiYCY-P cable

CONNECTION ON DT50 REPARTITOR

Terminal connection board installation guide DT 50

The board is fitted with three "telephone" RJ12 plugs. Ensure the board is correctly connected.

Standard connection is:

BM50 on connector C

DC50/DM50 on connector A or SC

DS50 on connector B

Jumpers:

"Displays" are supplied directly by the Climatic board with 30Vdc. Take particular care at the path this 30V is taking when several

boards are being used.

J14 and J15 can switch on or off the direct current from the power supply:

- +

GND

VL

DC50 / DM50

DT50

1

1

2

2

4

4

3

3

Page 8

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

6

J14 and J15 set between1-2 :

Connectors A, B, C and screw connector SC are in parallel. Power is supplied to all connectors.

J14 and J15 set between2-3 :

Connectors B and C are powered in parallel but connector A and screw connector SC are not.

Displays connected to these ports will not be powered.

If J14 and J15 are set in different positions the "terminal connection board" DT50 DOES NOT WORK and so the

connected displays do not operate.

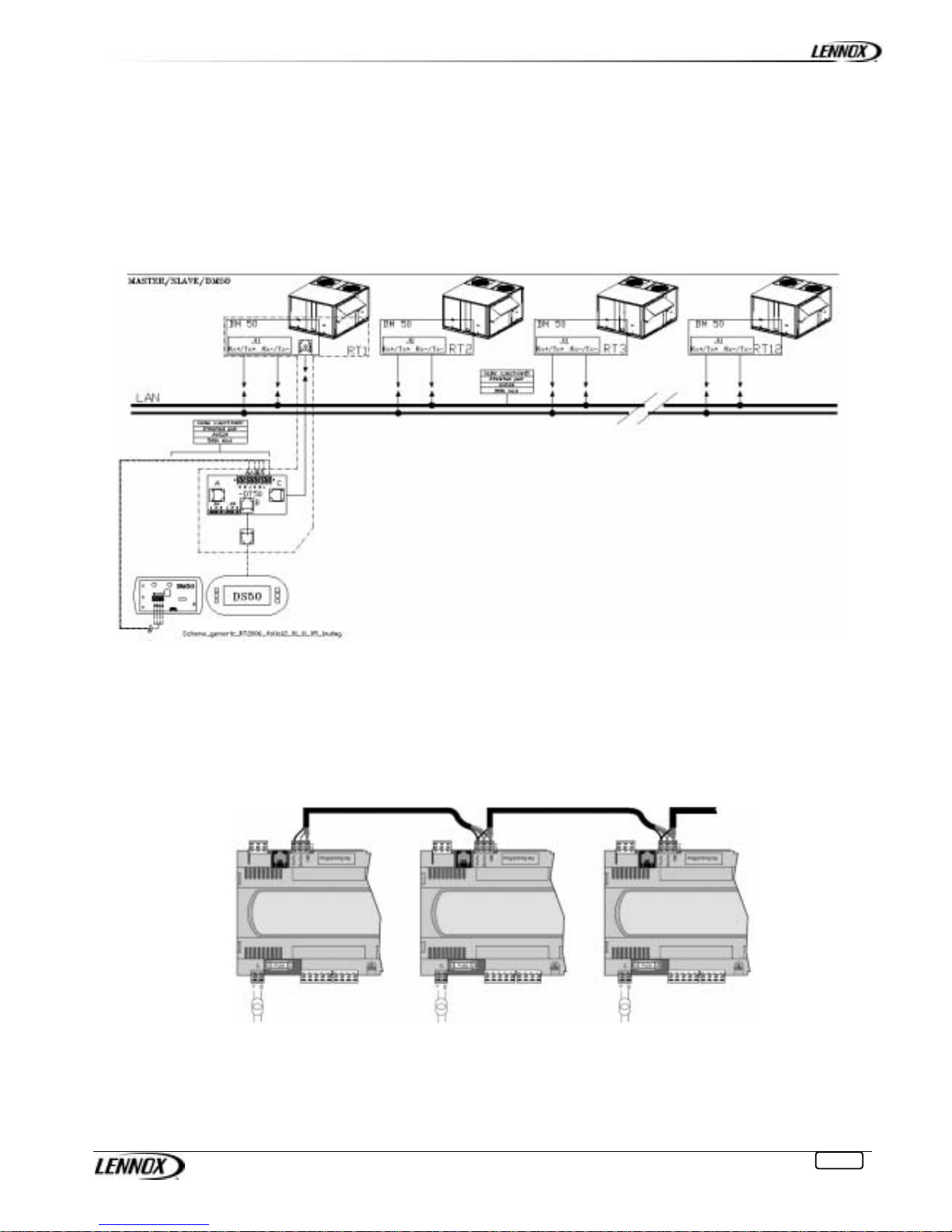

DM50 and COMMUNICATION MASTER/SLAVE

The intercard bus (pLan) is connected to Climatic™ on the J11 connector of board BM50.

A star connection is not recommended, for an optimum operation it is advised to connect a maximum of two cables per unit.

Connection must be carried out by the following cable:

- Cable length up to 300m: AWG22 (0.34 mm ²), 2 pairs crossed with screen.

- Cable length up to 500m: LiYCY-P (0.34 mm ²), 2 pairs with general shield.

The cable length should not exceed 500m.

For a better electromagnetic protection, Lennox recommends the use of LiYCY-P cable

Warning:

The power 24Vac of boards BM50 should not be connected to the earth

Page 9

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

7

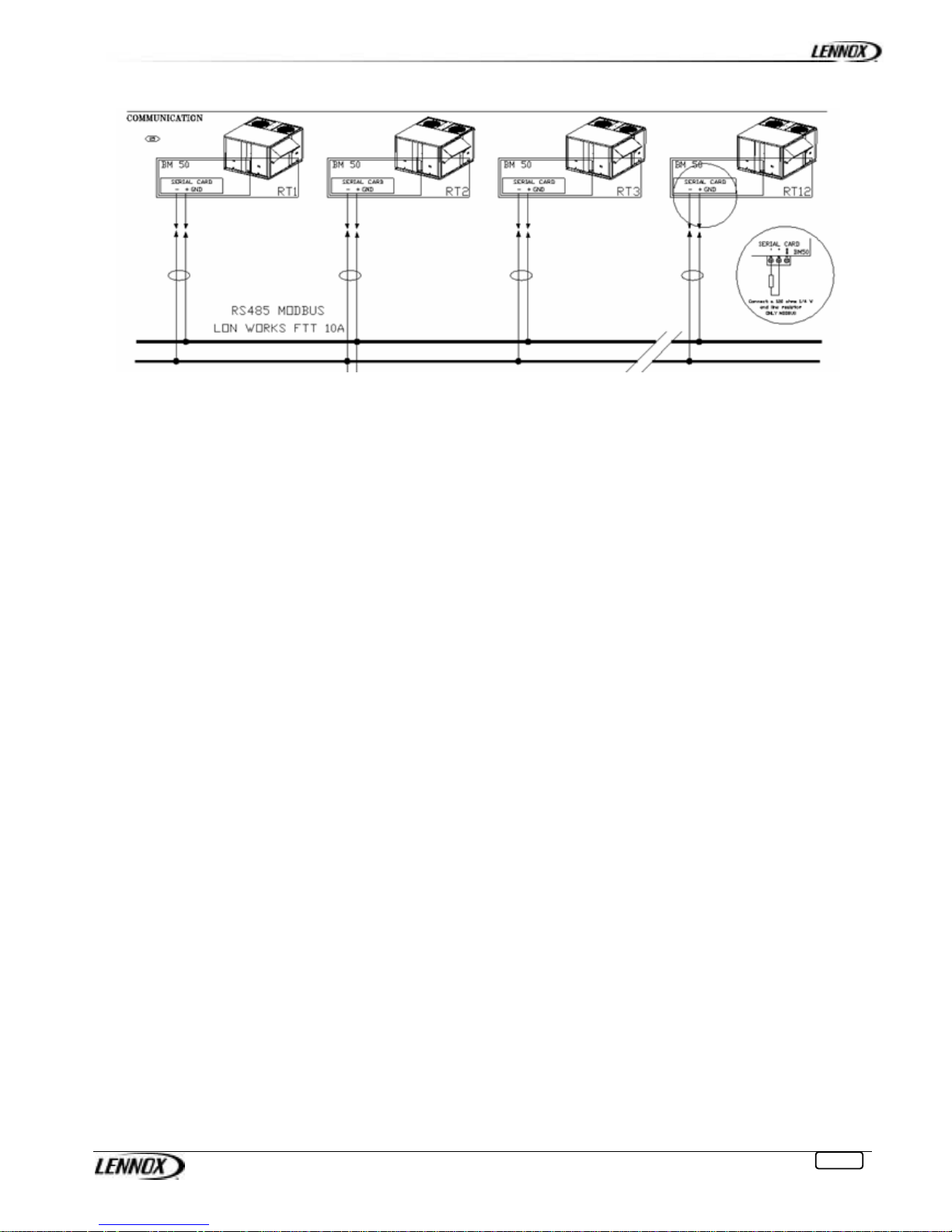

BMS COMMUNICATION

The communication bus is connected to Climatic™ Serial Card daughter board on the BM50.

A star connection is not recommended, for an optimum operation it is advised to connect a maximum of two cables per unit.

In case of RS485bus, a resistance of 120Ω 1/4W can be connected on the last unit between the terminals + and -.

Connection must be carried out by the following cable:

- Cable length up to 300m: AWG22 (0.34 mm ²), 2 pairs crossed with screen.

- Cable length up to 1000m: LiYCY-P (0.34 mm ²), 2 pairs with general shield.

The cable length should not exceed 1000m.

For a better electromagnetic protection, Lennox recommends the use of LiYCY-P cable

Page 10

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

8

CONFIGURATION

Function

LENNOX© proposes a single software for the whole ranges of Roof-Top and Aircooler.

For a first use, before any operation of the unit, Climatic™ must be set with parameters in accordance to the range, the size and

the various options of the unit.

Description

The unit configuration is done with following menus (refer also to Menu Tree chapter):

3811 ! Unit range choice

[BC] Baltic, cooling only

[BH] Baltic, reversible (heat pump)

[BG] Baltic, gas

[BD] Baltic, gas and reversible (heat pump)

[BGN] Baltic, gas, without compressor

[FC] Flexy 1, cooling only

[FC²] Flexy 2, cooling only

[FH] Flexy 1, reversible (heat pump)

[FH²] Flexy 2, reversible (heat pump)

[FG] Flexy 1, gas

[FG²] Flexy 2, gas

[FD] Flexy 1, gas and reversible (heat pump)

[FD²] Flexy 2, gas and reversible (heat pump)

[FGN] Flexy, gas, without compressor

[FW] Flexy, cool water coil, without compressor

[FX] Roof-Top with module 4 dampers

[ANC] Aircooler, cooling only

[ANH] Aircooler, reversible (heat pump

[NSR] Unit of nonstandard request

3812 ! Unit size choice

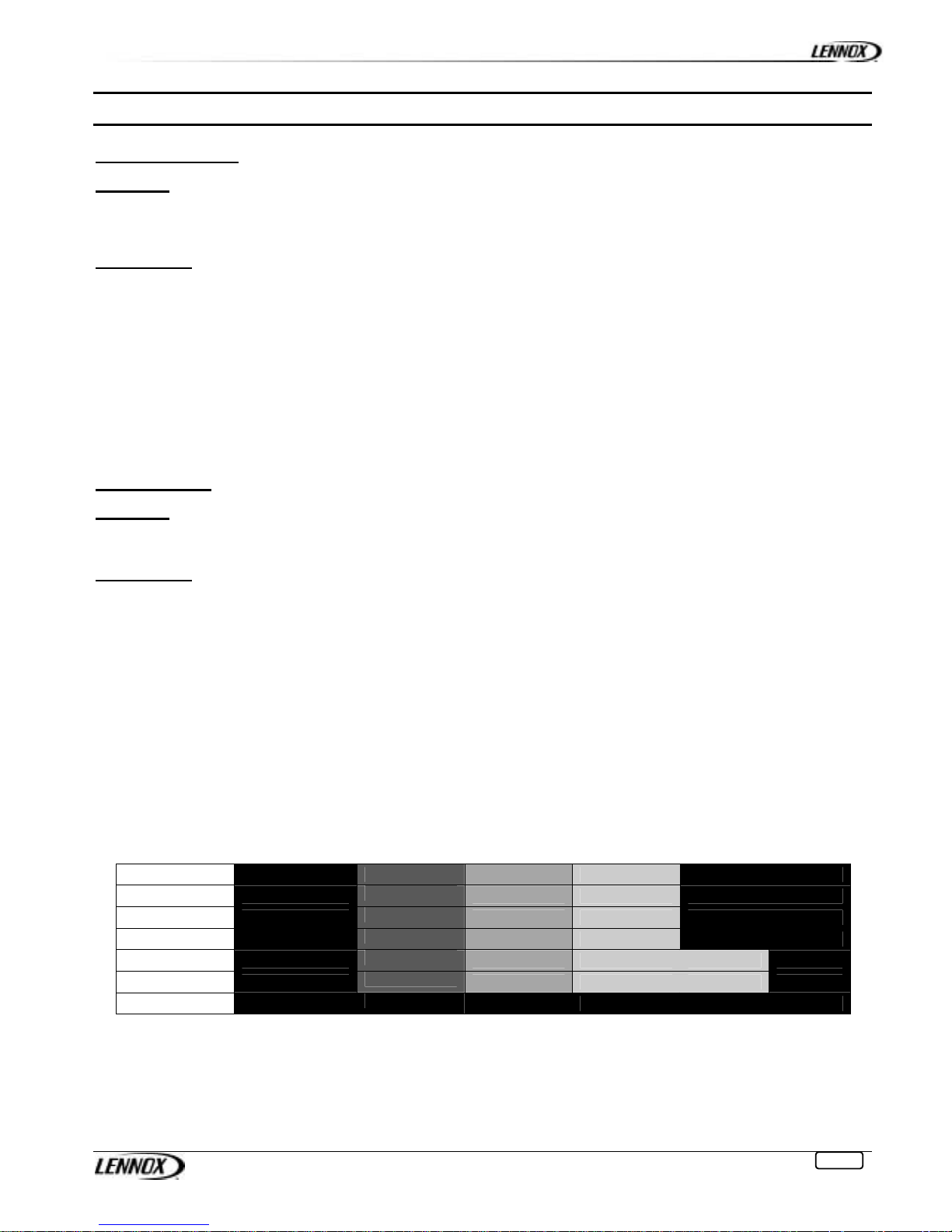

BC BH BG BD BGN FC FC² FH FH² FG FG² FD FD² FGN FWN FX ANC ANH

BCK020NS BHK020NS BGK020SS BDK020SS BGN001S FCK085N FCM085N FHK085N

FHM085N

FGK085S FGM085S FDK085S FDM085S FGN002S FWN002S FXK025N ANCM022E ANHM022E

BCK025NS BHK025NS BGK025SS BDK025SS BGN001H

FCK100N FCM100N FHK100N

FHM100N

FGK100S FGM100S FDK100S FDM100S FGN003S FWN003S FXK030N ANCM026E ANHM026E

BCK030NS BHK030NS BGK030SS BDK030SS

FCK120N FCM120N FHK120N

FHM120N

FGK120S FGM120S FDK120S FDM120S FGN004S FWN004S FXK035N ANCM032E ANHM032E

BCK035NS BHK035NS BGK035SS BDK035SS

FCK140N FCM150N FHK140N

FHM150N

FGK140S FGM150S FDK140S FDM150S FGN005S FWN005S FXK040N ANCM038E ANHM038E

BCK040NS BHK040NS BGK040SS BDK040SS

FCK160N FCM170N FHK160N

FHM170N

FGK160S FGM170S FDK160S FDM170S

FGN002H FWN002H FXK055N ANCM043E ANHM043E

BCK045NS BHK045NS BGK045SS BDK045SS

FCK190N FCM200N FHK190N

FHM200N

FGK190S FGM200S FDK190S FDM200S

FGN003H FWN003H FXK070N ANCM052D ANHM052D

BCK030ND BHK030ND BGK030SD BDK030SD

FCM230N

FHM230N FGK085H

FGM230S FDK085H FDM230S

FGN004H FWN004H FXK085N ANCM064D ANHM064D

BCK035ND BHK035ND BGK035SD BDK035SD

FGK100H FGM085H

FDK100H

FDM085H FGN005H FWN005H FXK100N ANCM076D ANHM076D

BCK040ND BHK040ND BGK040SD BDK040SD

FGK120H FGM100H

FDK120H

FDM100H

FXK110N ANCM086D ANHM086D

BCK045ND BHK045ND BGK045SD BDK045SD

FGK140H FGM120H

FDK140H

FDM120H

FXK140N ANCM112D ANHM112D

BCK050ND BHK050ND BGK050SD BDK050SD

FGK160H FGM150H

FDK160H

FDM150H

FXK170N ANCM128D ANHM128D

BCK060ND BHK060ND BGK060SD BDK060SD

FGK190H FGM170H

FDK190H

FDM170H

ANCM152D ANHM152D

BCK070ND BHK070ND BGK070SD BDK070SD

FGM200H

FDM200H

BHK020HS BGK020HS BDK020HS

FGM230H

FDM230H

BHK025HS BGK025HS BDK025HS

BHK030HS BGK030HS BDK030HS

BHK035HS BGK035HS BDK035HS

BHK040HS BGK040HS BDK040HS

BHK045HS BGK045HS BDK045HS

BHK030HD BGK035HD BDK030HD

BHK035HD BGK040HD BDK035HD

BHK040HD BGK045HD BDK040HD

BHK045HD BGK050HD BDK045HD

BHK050HD BGK060HD BDK050HD

BHK060HD BGK030HD BDK060HD

BHK070HD BGK070HD BDK070HD

3813 ! Activation of the Controls humidity option

3814 ! Activation of the High Efficiency Main fan and/or Variable speed transmission option,

3815 ! Activation of the External Thermostat Temperature Control option,

3821 ! Choice of the type of sensor or probe on the refrigeration circuit

[No] No probe or sensor of installed on the circuits

Page 11

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

9

[NTC] Temperature probe `NTC' on the sticks of the coils

[0-5V] Transmitter of pressure `Ratiométrique' on the circuits

[4-20mA] Transmitter of pressure `4-20mA ' on the circuits

3822 ! Activation of the Low Ambient Kit option,

3823 ! Unit with water condensation

3824 ! Activation of the Alternate Defrost option for the Flexy1 range sizes 85 and 100

3831 ! Choice of the auxiliary heating type.

[No] No auxillary heating

[Hot W/Coil] Hot water coil

[Gas 2] Gas, 1 slope with 2 steps

[Gas 4] Gas, 2 slopes with 2 steps

[Gas 2 Pro.] Gas, 1 modulating slope

[Gas 4 Pro.] Gas, 2 modulating slope

[ElecH. Ste] Electric heaters, without Triac modulation.

[ElecH. Pro] Electric heaters, with Triac, Positioned after the refrigerant coil

[ElecH. Mix] Electric heaters, with Triac, Positioned before the refrigerant coil

3711 ! Choice of the type of gas valves control board.

[BG50] Board BG50

[EF49] Board EF49

[EF48] Board EF48

[EF45] Board EF45

[MMI No] Block gas with output fault in normally open

[MMI Nc] Block gas with output fault in normally closed

3832 ! Choice of the type air mixing box

[No] No fresh air

[100%] All fresh air

[0%-100%] Economiser proportional

[0%-50%] Economiser proportional, limitation to 50% of opening

3517 ! Activation of the air heat recovery option,

3833 ! Choice of the type of air flow sensor

[No] No option

[500pa] Sensor, 0 to 500 pa

[1000pa] Sensor, 0 to 1000 pa

3834 ! Choice of the air quality sensor

[No] No option

[0-2000] Sensor, 0 to 2000 ppm

[350-2000] Sensor, 350 to 2000 ppm (Carel© brand sensor)

Page 12

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

10

SCHEDULING – CLOCK SETTING

CLOCK SETTING

Function

Climatic™ has a real time clock board, allowing dates and hours functionalities (weekly Program, event recording,…).

Description

Menus 3121 to 3125 give the possibility of setting the internal clock.

The day of the week is calculated by Climatic™.

For the countries of the Euro a device allows the automatic swing of the hour summer in hour winter and vice versa. This

functionality can be cancelled by menu 3126.

3121 ! Hour.

3122 ! Minute.

3123 ! Day of the month.

3124 ! Month.

3125 ! Year.

3126 ! Enable automatic switch summer time / winter time.

SCHEDULING

Function

Controlling operation of the unit according to the time and day

Description

CLIMATICTM 50 can handle 4 time zones over the 7 days of the week:

• Zone unoccupied « Night »

• Zone A « Day A »

• Zone B « Day B »

• Zone C « Day C »

•

Starting time (hours and minutes) of each of these zones for each days of the week, can be set using menus 3211 to 3214,

(press ‘Prg’ key to change day).

Each set point integrates the hour and minute’s adjustment, thus a value of 8.3 equal 8.30 a.m.

3211 ! Hour, minute of the night starting time (unoccupied)

3212 ! Hour, minute of the “day A” starting time

3213 ! Hour, minute of the “day B” starting time

3214 ! Hour, minute of “day C” starting time

8h00 12h00 13h50 20h30 22h00

Monday

Unoccupied Z :A Z :B Z :C Unoccupied

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Page 13

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

11

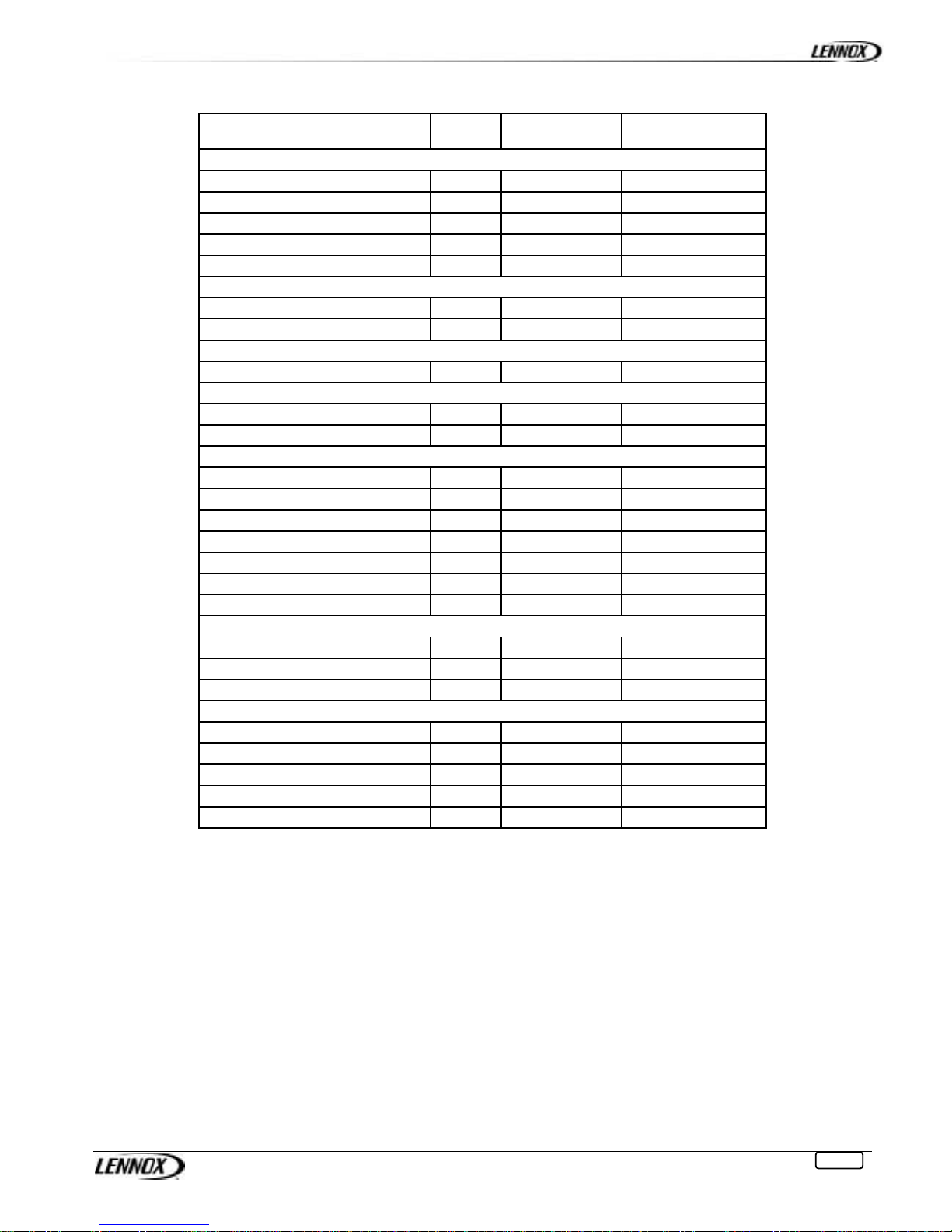

For each time zone, the set following set points following can be modified:

LIST SET POINT BY ZONE Code

DISPLAY

CONFORT

DISPLAY

MAINTENANCE

Ambient temperature

Set point average 3311 Yes Yes

Set point dynamic 3321 Yes Yes

Cooling Set point 3322 Yes

Heating Set point 3323 Yes

Priority of heating 3324 Yes

Reheating of Fresh Air

Enable 3331 Yes

Priority of heating 3332 Yes

Fresh Air

Set point 3312 Yes

Humidity

Dehumidification 3341 Yes

Humidification 3342 Yes

Authorisation

Free Cooling 3353 Yes

Fresh Air by CO² 3354 Yes

Refrigeration by compressor 3355 Yes

Heating by compressor 3356 Yes

Auxiliary heating 3357 Yes

Humidity Control 3358 Yes

Low noise level 3359 Yes

Other

Fan, Activate 3351 Yes

Fan, Activate, in dead zone 3352 Yes

Minimum fresh air (%) 3353 Yes Yes

Programming

Beginning of zone; each day Yes Yes

Start Uno 3211 Yes Yes

Start z.A 3212 Yes Yes

Start z.B 3213 Yes Yes

Start z.C 3214 Yes Yes

With the DS50, for each set point, to press on the key `Prg' to change the periods and to validate the good set point for the good

zone.

Note: “Monday” is considered as the first day of the week for programming the CLIMATIC™50.

Factory settings:

“Day A” activated from Monday to Saturday 6h!22h

Night mode (unoccupied) for the remaining of time, Sunday included

Page 14

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

12

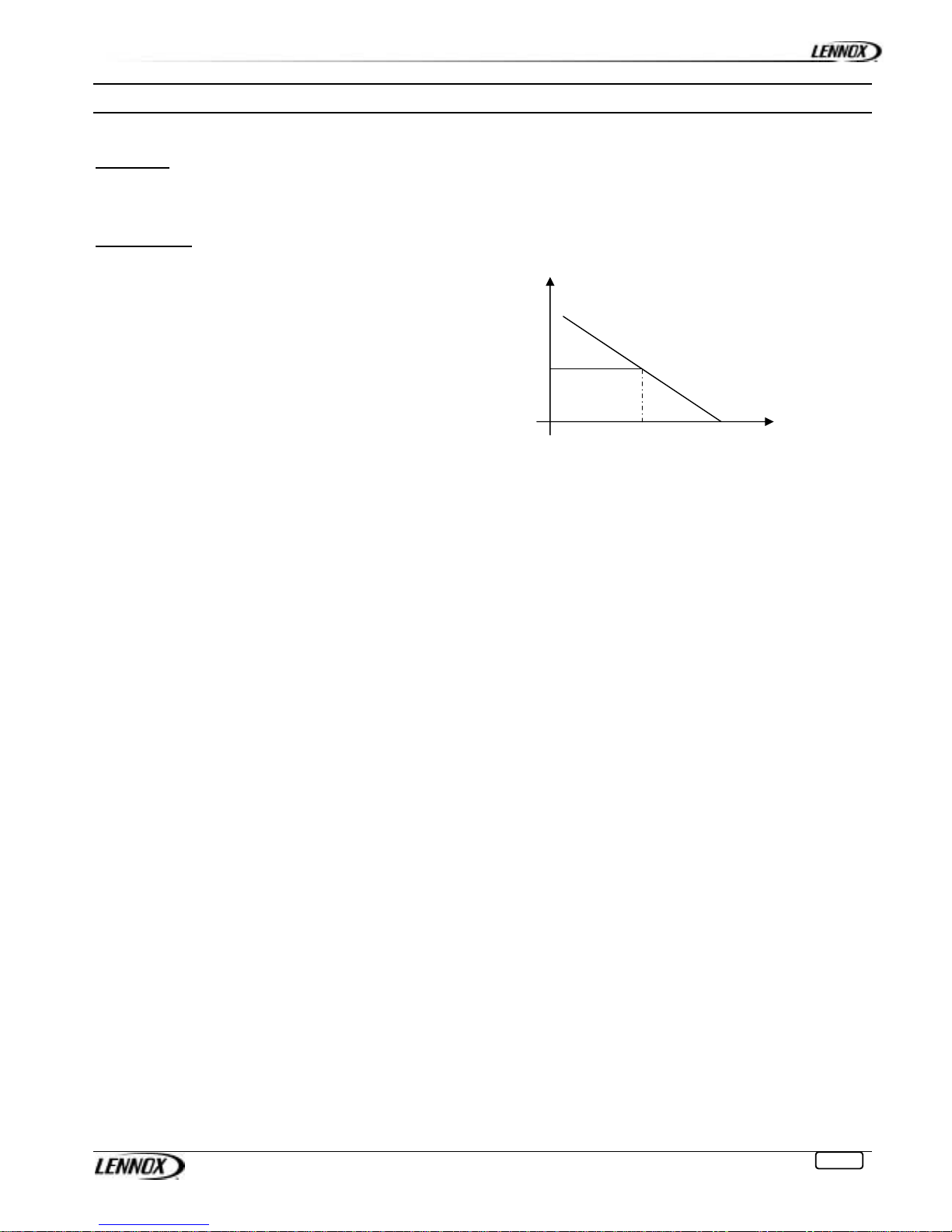

ANTICIPATION

Function

This allows an anticipated start-up in the morning depending on the outdoor temperature.

Description

This function only works for zone A, and allow the machine to

move from unoccupied zone to zone A earlier if the outdoor

temperature is under a certain value. Use this function to

anticipate the heating start-up during cool days.

This can be adjusted with set point 3221 and 3222.

3221 ! bottom of the slope (°C), Anticipation starting point

3222 ! Slope in Minutes of anticipation per degrees

Example:

Unit with Day A starting at 8.00 am; 3221 set to 3°C and 3222 set to 10 mn/°C;

If the outside temperature is 0°C, then Day A will start at 7.30 a.m.

7h30

8h00

Hour of starting zone A

0°C 3°C

Air Temp. Outside

Page 15

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

13

VENTILATION

ON / OFF (Start & Stop)

Function

In general, the unit is considered in operation if its supply fan is in operation.

But, according to the set points, the fan may stop in the temperature control dead zone.

Description

To allow the operation of the unit it is necessary that set point 3111 is set to `On' and that the BM50 logical input ID7 on

the J5 connector is closed.

The 3111 set point adjustment is available on the DC/DM50 with the ON/OFF functionality.

For each scheduled zone defined in Climatic™50, it is possible to set the start/stop state. This functionality allows the

unit to stop during a period of time in the day.

When the Room temperature is within the regulation dead zone, for each scheduled zone defined in the Climatic™50 it is

possible run or stop the fan

3111 ! Main On/Off.

3351 ! On/Off, adjustment by zone.

3352 ! On/Off in the temperature control dead zones, adjustment by zone.

STAGGING START

Function

After a power shut-down, you may get the units to restart gradually in order to avoid overloading issues.

Description

The units do not need to be connected; they must simply have different pLan addresses, (see BM50 pLan address

configuration).

This will enable them to restart (10 x their address number) seconds after the resumption of the power.

Example:

If a unit carries the address n°3, it will start again 30s (3 X 10 seconds) after the resumption of the power.

HIGH EFFICIENCY FANS or/and WITH VARIABLE SPEED TRANSMISSION

Function

The supply fan variable speed option allows two functionalities;

Progressive start or stop (used for the textile duct inflation)

The speed reduction, in temperature control dead zone, in order to bring only the necessary fresh air quantity.

Description

The supply fan speed is originally fixed by the set point 3422.

The speed entered in this set point corresponds to nominal air flow of the installation. This set point can only be adjusted

on site.

Progressive Start / Stop

If set point 3423 is activated;

During fan start up, for 30s, the speed is fixed by the threshold set point 3421. Then during the next 30s the fan

accelerates gradually to reach the speed fixed in the set point 3422.

During the fan stop, the speed gradually reduces to stop completely in 1 minute.

Page 16

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

14

Dead zone reduction speed in

If set point 3424 is activated;

When the room temperature is in the regulation dead zone of regulation (no heating, nor cooling), the speed of the fan is

fixed by the set point 3421 and the fresh air damper is opened at 100%.

If the minimum speed brings a fresh air quantity higher than the defined threshold, the fresh air damper will close

proportionally to reach the desired value.

3421 ! Minimum fan speed threshold (%).

3422 ! Maximum fan speed threshold (%).

3423 ! Activation of progressive Start functionality.

3424 ! Activation of dead zone speed reduction functionality.

EXHAUST FANS

Function

From one to three exhaust fans can be controlled. The start and the stop of these fans depend on the opening of the

fresh air damper.

Description

The fans are activated if the fresh air damper opening percentage is higher than the thresholds fixed by the set points.

3431 ! Fresh air damper threshold, activation of the 1

st

fan (%).

3432 ! Fresh air damper threshold, activation of the 2

nd

fan (%).

3433 ! Fresh air damper threshold, activation of the 3

rd

fan (%).

Page 17

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

15

Heating Threshold (3323)

Customer set point (3311)

Cooling Threshold

(

3322

)

Ambient Temp °C

Dead zone

Heating Mode

∆

∆

Cooling Mode

THERMOSTAT / HYGROSTAT – Set points

SET POINTS, TEMPERATURE

Function

Climatic™ is programmed in order to maintain a temperature as comfortable as possible with the most economic usage

of the unit.

Description

The room temperature is maintained between a minimum

threshold - corresponding to the heating point - and a maximum

threshold - corresponding to the cooling point. The regulation

“dead zone” is defined between these two thresholds.

In order to be user friendly, one temperature set point is used.

This set point is in the middle of the dead zone.

If this set point is modified, it has priority on the 2 thresholds, but

the dead zone range remains defined by the difference between

the 2 thresholds.

If the Thresholds 3322 and 3323 are modified, set point 3311 is

automatically calculated to their average value.

3311 ! Customer temperature set point (°C), adjustment by zone.

3322 ! Cooling temperature threshold (°C), adjustment by zone.

3323 ! Heating temperature threshold (°C), adjustment by zone.

Set point modification by an external signal

The set point can be remotely modified with a signal 4-20mA (see CUSTOMIZED INPUT / OUTPUT)

For a 4 mA signal the temperature set point is decreased by 5°k

For a 20 mA signal the temperature set point is increased by 5°k

A linear rule is applied between the two signals.

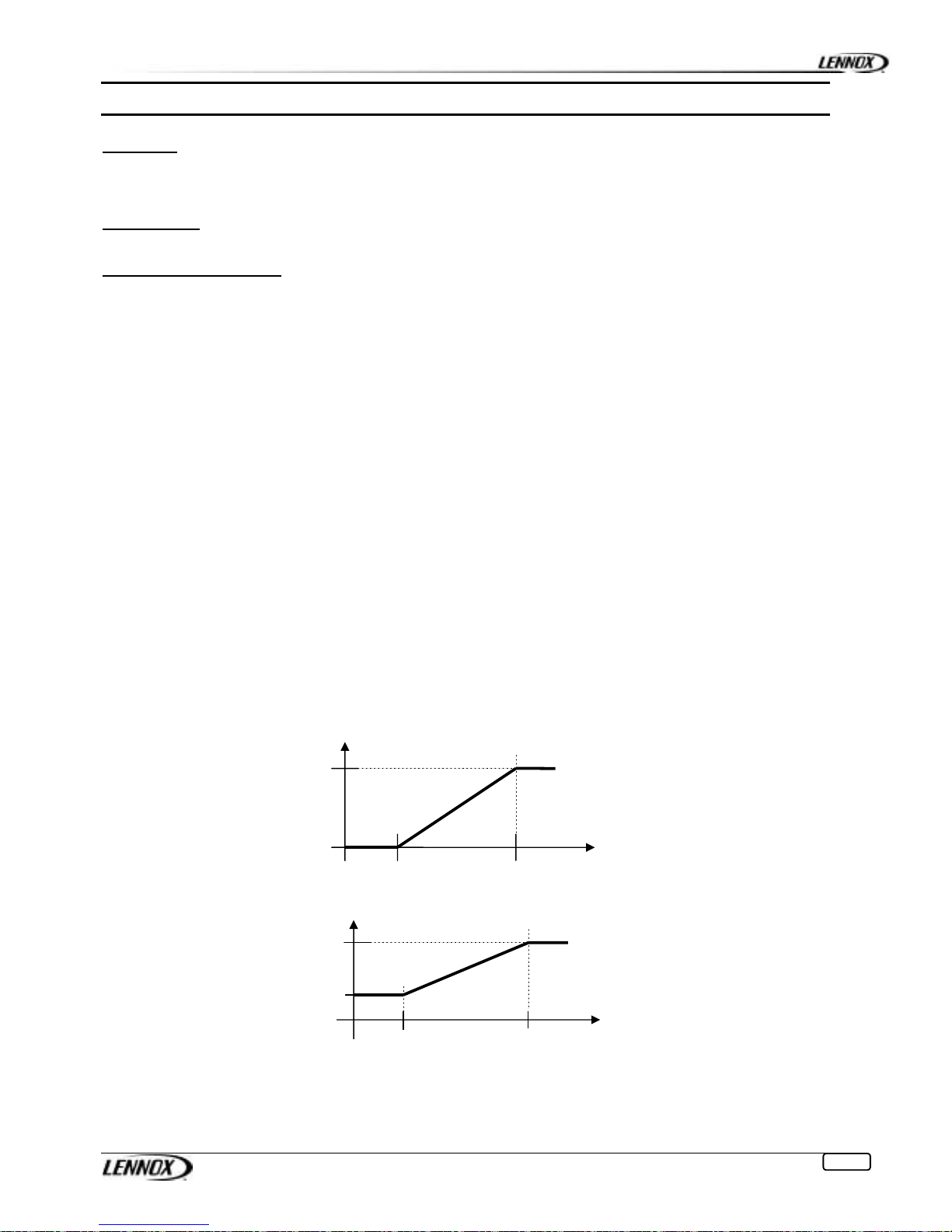

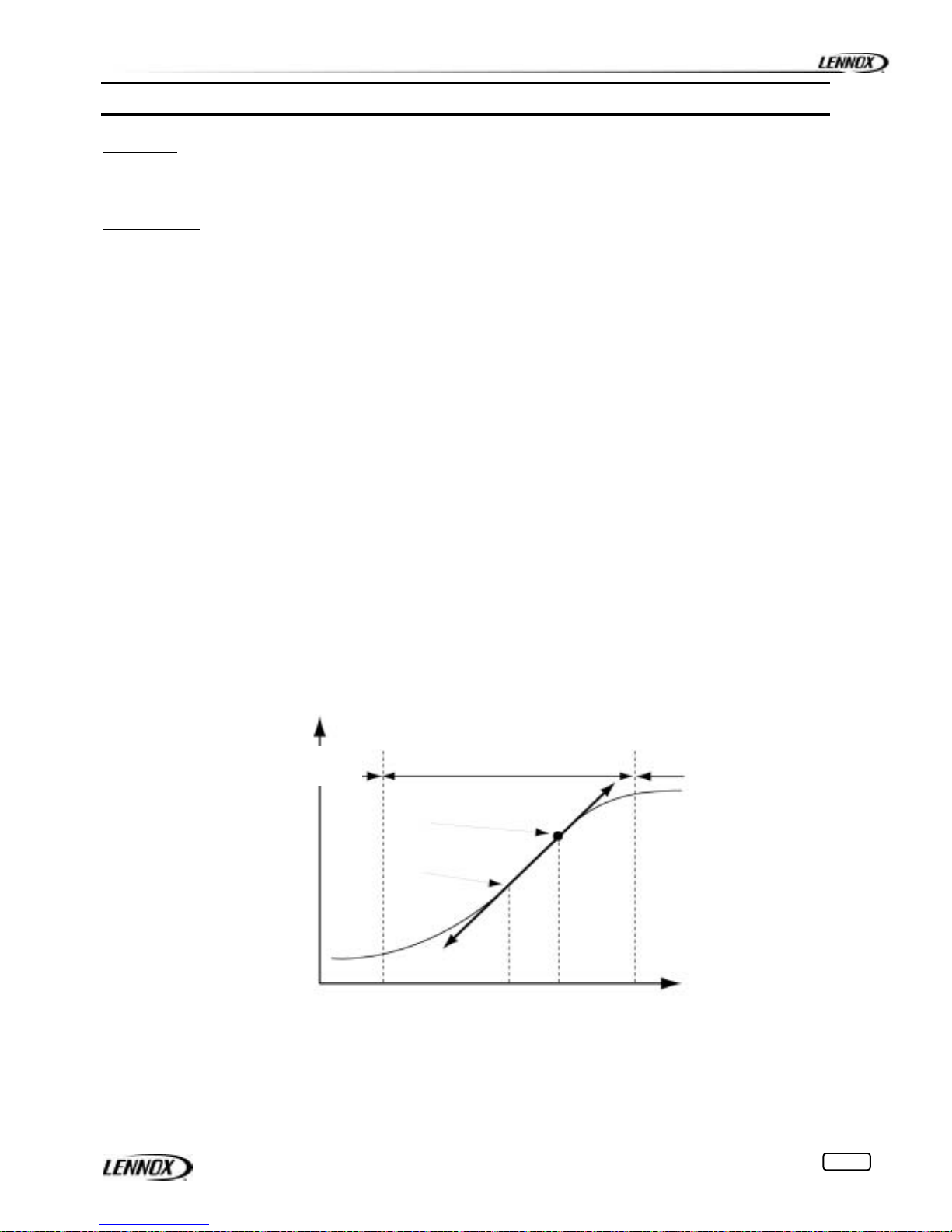

DYNAMIC SET POINT

Function

This function allows to obtain a proportional shift of the cooling threshold according to the outside temperature.

Description

The cooling threshold starts to increase once the outside air temperature is over the cooling threshold plus the value of

the dynamic set point.

If you don’t wish to use this function, allot to the option dynamic set point the value 99.9°c

Example:

If the cooling threshold is equal to 25°C and that the dynamic set point is equal to 6K

The cooling threshold drift will start for an outside temperature of 31°C (25°C + 6K) and then the threshold will follow the

outside temperature evolution keeping a 6K difference.

3321 ! Dynamic set point (K), adjustment by zone.

Page 18

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

16

FRESH AIR REHEATING SET POINT

Function

Climatic™ may be set to maintain a comfortable blowing temperature, by compensating the cold contribution of fresh air

in winter.

Description

If this function is activated:

• If the room temperature is in regulation dead zone, or heating mode, the blowing air regulation rule will maintain a

blowing temperature at least equivalent to the heating threshold.

• If the room temperature is in cooling mode, the minimum blowing temperature will be equal to the safety low limit

threshold plus 2K.

3331 ! Activation of the control of reheating of the fresh air, adjustment per zone.

HUMIDITY SET POINT (option)

Function

The relative humidity of room is maintained between two thresholds, a minimum threshold corresponding to the point of

humidification and a maximum threshold corresponding to the point of dehumidification.

Description

Dehumidification

It is ensured by the compressors in cooling mode.

It is active in the dead zone and cold mode of room temperature control.

Climatic™ gives priority to the temperature.

To ensure a complement of heating, the fresh air reheating set point must be activated.

Humidification

A signal 0-10v is generated proportionally to the regulation request.

3341 ! Dehumidification threshold - Relative humidity (%hr), adjustment by zone.

3342 ! Humidification threshold - Relative humidity (%Hr), adjustment by zone.

3358 ! Activation or inhibition, humidity control.

Page 19

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

17

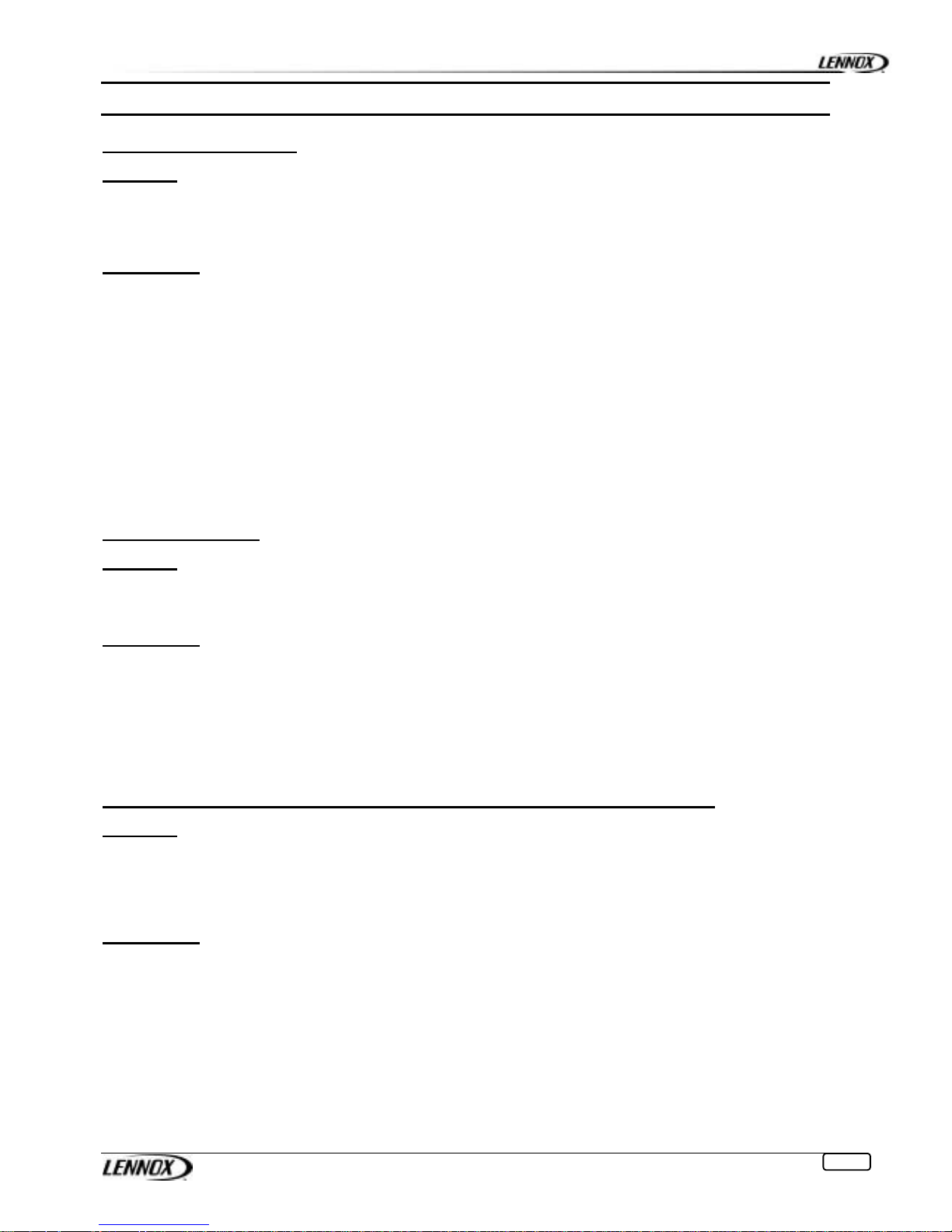

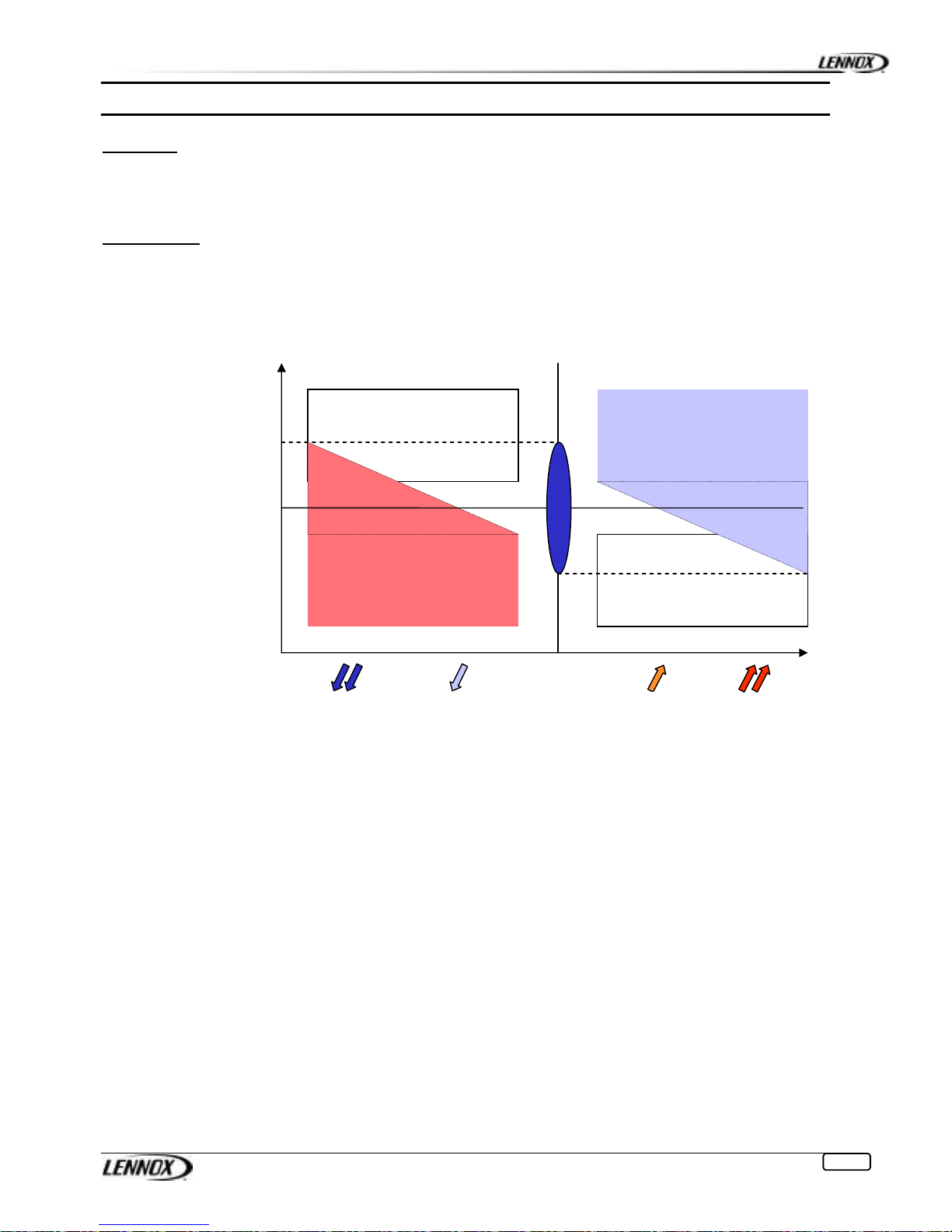

THERMOSTAT / HYGROSTAT – Control principle

Function

Adjust and hold the room air temperature or humidity as close as possible to the set point, by controlling the number of

compressor stages depending on the thermal load of the system.

Description

CLIMATICTM50 control constantly calculates the required capacity to reach the temperature set point.

This variable is called “CAPACITY FACTOR” (CF) and its value can vary from 0 to 100%.

It is directly linked to the number of control stages of the unit.

Thus for a unit with 4 stages of regulation, the CF will start and stop a stage with the following values:

0-25-50-75-100.

It then evolves following the principles detailed in the diagram below (case of a cooler):

In order to anticipate, the reference point is recalculated each time the difference between air temperature and set point

reach a minimum or a maximum.

The rate of change of the Capacity Factor (CF) is determined by another parameter called “REACTIVTY” and which

value is in: % of CF / °C (Diff vs Set point) / min

3361 ! REACTIVITY for the cooling mode.

3362 ! REACTIVITY for the heating mode.

3363 ! REACTIVITY for the fresh air reheating mode

For the option of control humidity

3364 ! REACTIVITY for the dehumidification mode.

3365 ! REACTIVITY for the humidification mode.

Permutation, Cold or Heat Mode (Change-Over ; optional)

The choice of the operating mode in cooling or heating is automatically carried out according to the room temperature

and the temperature set points adjustment.

Meanwhile as an option, using free contacts on parametric inputs, it is possible to disable one mode or another. (see

Customized Input / Output (BE.50))

• With a free contact on [Sw Dis.Cool] The contact closing will disable the cooling mode.

• With a free contact on [Sw Dis.Heat] The contact closing will disable the heating mode.

Difference between

the Room

Temperature and the

set point

Room Temperature

Change rate

0°K

+ 2°K

- 1°

K

- 2°

K

FAST

SLOW

CF FROZEN

CF INCREASES

(Start more Capacity Stages)

CF FROZEN

CF DECREASES

(Removes Capacity Stages)

+ 1°K

SLOW FAST

Page 20

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

18

FRESH AIR DAMPER - Free-Cooling

Function

Ensure a minimum fresh air introduction into the room and/or a free-cooling, thus reducing electric consumption.

Description

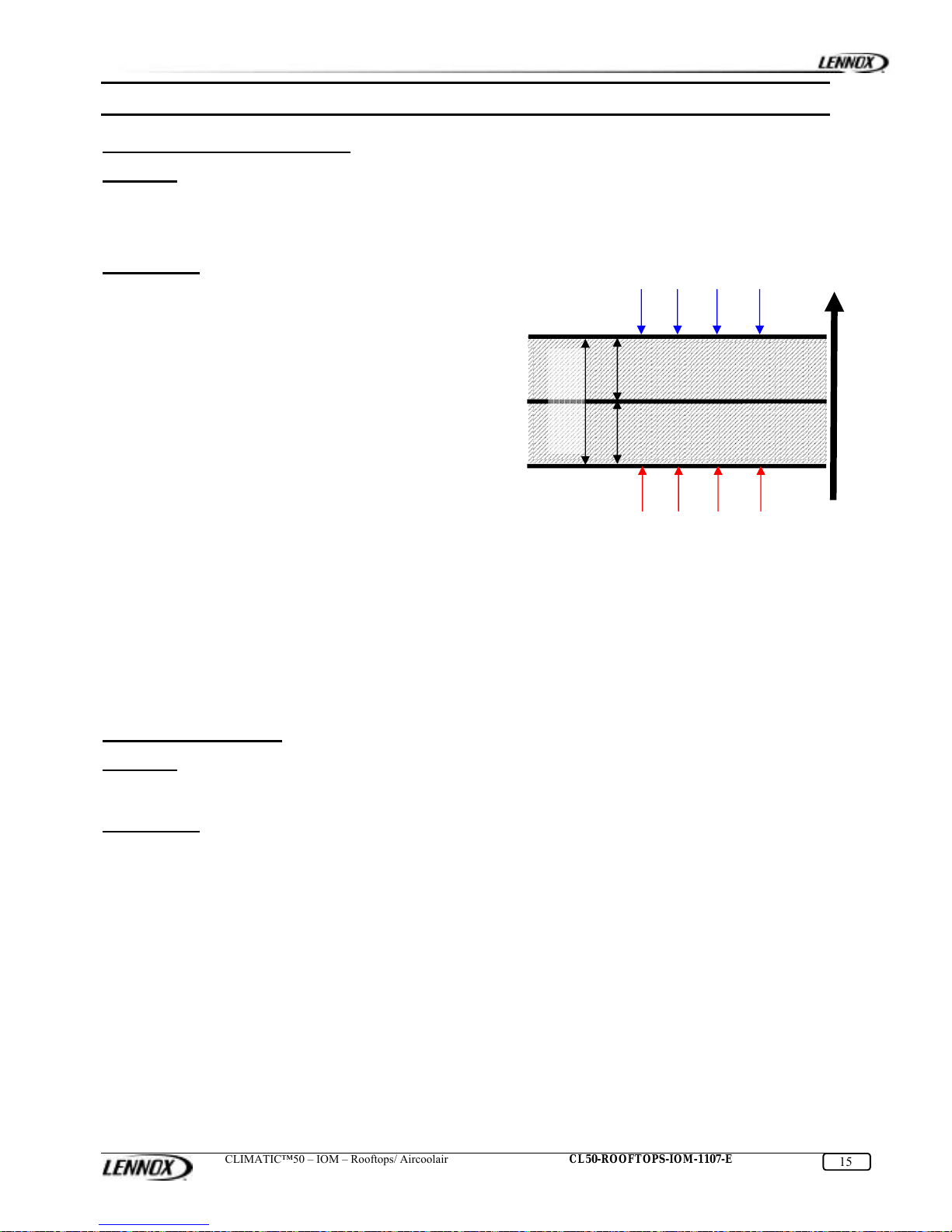

MINIMUM FRESH AIR

Adjustment by set point

The fresh air rate is adjustable by set point.

3312 ! Minimum opening of the fresh air damper, %, adjustment by zone.

Adjustment by free contacts (optional)

With the customized free contacts, the fresh air rate can be adjusted. (see Customized Input / Output (BE.50))

• With a free contact on [0% F.A.]) The contact closing will close completely the damper.

• With a free contact on [100% F.A.] The contact closing will open completely the damper.

• With a free contact on [10% F.A.], [20% F.A.], [30% F.A.], [40% F.A.] or [50% F.A.] The contact closing will open the

damper to the mentioned rate.

If several contacts are customized with this functionality, the air damper will open according to the sum value of all closed

contacts.

In any case, the minimum fresh air rate will be fixed according to the highest value between the set point and the request

by contacts.

Adjustment by external signal (optional)

The minimum fresh air can be remotely modified by a signal 4-20mA. (See Customized Input / Output (BE.50))

For a signal of 4 mA applied on [F.A Offset] the threshold is set to 0%

For a signal of 20 mA applied on [F.A Offset] the threshold is set to 100%

A linear rule is applied between the two limits.

Air quality sensor, CO² (optional)

If a CO² sensor is connected to the unit, the minimum value of fresh air is calculated according to the CO² rate.

This functionality can be activated, or not, within the 4 day zones.

Two opening mode may be selected:

• Fresh air damper opening between 0% and the minimum fresh air set point [0-Min]

• Fresh air damper opening between the minimum fresh air set point and the maximum fresh air set point. [Min-max]

0

2000 ppm

Set point

3513

Set point

3514

Minimum

Fresf Ai

r

Set point

3512

0 2000

ppm

Set point

3513

Set point

3514

Minimum

Fresh Ai

r

Page 21

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

19

2132 ! CO² rate measured value of the (ppm).

3354 ! CO² function authorization, adjustment by zone.

3515 ! CO² function mode [0-Min], [Min-Max].

3513 ! CO² rate (ppm), threshold until which the 0% or the minimum fresh air is maintained.

3514 ! CO² rate (ppm), threshold from which the minimum fresh air or the 100% is used.

3512 ! Maximum fresh air damper opening.

Fresh air damper Calibration

The real fresh air volume introduced into the system is not always proportional to the damper opening percentage. That

is particularly true when the return air duct system is sized to give excessive pressure losses.

It results with excessive fresh air input, and thus with an increase of the system exploitation costs. From now on, it is

possible to calibrate the fresh air using three temperature probes: one in the blowing section, another in the return air

and the last one in the outdoor temperature.

Using these three probes, Climatic™50 calculates and memorizes the exact percentage of fresh air for each position of

the damper.

Blowing T° = Return T° x %Return Air + Fresh air T° x %Fresh Air

This adjustment sequence takes place periodically when all heating and cooling elements are off.

3516 ! Fresh air damper calibration authorization.

FREE COOLING

From a room temperature need (Capacity Factor) the damper opens according to a proportional rule on the blowing

temperature.

0% need = Minimum fresh air.

100% need = low limit threshold (3373) + 2K

The user may choose to limit the fresh air damper operation with contacts or set points modification (see minimum fresh

air § above). The outdoor temperature or humidity value may also limit the opening.

Outdoor temperature

The Free-Cooling is stopped if the outside temperature is higher than the return or room temperature.

The Free-Cooling is stopped if the outside temperature is lower or higher than the threshold defined in set point (3511).

Free cooling is forbidden on high limit for a set point adjustment over +20.0°c.

Free cooling is forbidden on low limit for a set point adjustment lower than +20.0°c.

Outdoor humidity (optional)

If humidity control option is selected, the Free-cooling is stopped if the external absolute humidity (water weight) is

higher than the indoor absolute humidity.

Set point

The Free-Cooling is stopped if the set point (3353) is No

Free contact (optional)

Stop of Free-Cooling by closing customized free contacts. (See minimum fresh air § above)

[0% A.N.] = the register of air is completely closed.

[100% A.N.] = the register of air is completely open.

3353 ! Economiser functionauthorization, adjustment by zone.

3373 ! Low limit blowing temperature threshold.

3511 ! Outdoor temperature threshold for authorization of the economiser function.

3512 ! Maximum fresh air damper opening

Page 22

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

20

COMPRESSORS

Function

From a room temperature need (Capacity Factor) the compressors are started and stopped with a determined sequence

in order to minimize the anti short cycle protection effect and to equalize the operating time.

Description

Compressors Start/Stop sequences.

This sequence is set by the memorized compressor operating time and it also includes the other compressors back-up

function, if they are not available. For circuits with tandem compressors, it is possible to favour the unit performance,

COP, rather than the compressor operating time balance (3642).

The compressor starts if all the following conditions are satisfied:

• The unit, the compressor and the circuit do not have major faults.

• The control requires the starting of the compressor.

• The compressor has the lowest operating time among the stand by compressors.

• The compressor has not been brought into service for at least 6 minutes.

Every compressor state can be checked on the following menus: 2512, 2522, 2532…, 2562

To check the operating time of each compressor use menus: 2519, 2529….2569

To reset an operating time counter, put the DS50 cursor on the line and press the key `Enter' during 20 seconds.

Compressor operation authorization.

The user may choose to limit the operation of the compressors by using contacts or set points modification.

Outdoor temperature

Cooling mode

Stop of all compressors if the outdoor temperature is lower than the threshold (3612)

Stop of 50% of the compressors if the outdoor temperature is lower than the threshold (3611)

Note: if the option `Low Ambient Kit' is activated (3822) these two functionalities are disabled.

Heating mode (Heat pump)

Stop of all compressors if the outdoor temperature is higher than the threshold (3613)

Set points

Stop of one or several compressors if the compressor number is not displayed in the address (3641)

Cooling mode

Stop of all compressors if the instruction (3355) is set to [No]

Limitation to 50% of the compressors if the instruction (3359) is set to [Yes]

Immediate stop of 50% of the compressors if the instruction (3643) is set to [Yes]

Heating mode (Heat pump)

Stop of all the compressors if the instruction (3356) is set to [No]

Note: Address 3355 and 3356 can be set differently for zones A, B, C, Uno or BMS

Note: The address 3359 can be set differently for zones Uno or BMS

Free contacts (Optional - See Customized Input / Output (BE.50))

Stop of one or several compressors if the compressor number is not displayed in the address (3641)

Stop of 50% of the compressors if the contact [Dis. 50%Cp] is close.

Stop of all the compressors if the contact [Dis. Cp/Ah] or [Dis. Comp] is close.

High pressure offloading (FLEXY 2 tandem only)

With tandem compressors, it is possible to reduce the circuit capacity by stopping one of the two compressors before the

high pressure reaches its limits in order to keep a partial capacity with high outdoor temperature.

If the condensing pressure is higher than 40b and continuously increases with all the fans in operation at full speed, 1

compressor of the considered circuit is stopped.

Page 23

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

21

3355 ! Compressors authorization in cooling mode, adjustment by zone.

3356 ! Compressors authorization in heating mode, adjustment by zone.

3359 ! Limitation to 50% of the compressors, in Unoccupation and BMS mode.

3611 ! Low outdoor temperature threshold for limitation to 50% of the compressors, in cooling mode

3612 ! Low outdoor temperature threshold for stopping all compressors in cooling mode.

3613 ! High outdoor temperature threshold for stopping all compressors in heating mode..

3641 ! Compressors authorization.

3642 ! Rotation mode choice.

3643 ! Off loading of 50% of the compressors.

Page 24

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

22

DEFROST – Heat Pump

Function

Avoid the evaporator icing (external coil) in heat pump operation in winter time.

Description

To avoid the icing of the external air exchanger in winter operation, it is necessary to reverse the refrigerant cycle on a

regular basis to de-ice by heating the exchanger.

The defrost is activated when the air temperature is under a set point (3422)

When defrost is demanded, the sequence is as following:

1. Pre-heating of supplementary heating elements during 1 minute (Option)

2. Stop compressors and fans

3. Reverse 4 way valve

4. Start compressors.

5. When the fans are started several times (3625) or if compressors are in operation for more than 6 minutes, stop

the compressors.

6. Reverse 4 way valve

7. End of defrost

Two different type of Defrost demand are possible.

• Dynamic defrost (set point 3621 = Dynamic)

• Cycling defrost (set point 3621 = Cyclic)

Cycling defrost

The unit will start a cyclic defrost under a regular period of time (instruction 3624)

Dynamic defrost

This allows the unit to start the defrost cycle only when required. This is achieved through the measurement of the

temperature difference between the coil and the outdoor. The defrost will be initiated shortly after the Climatic50 has

located the largest gradient in the curve.

3621 ! Defrost mode.

3622 ! Outside air temperature under which the defrost cycle is activated.

3623 ! LP temperature under which the defrost cycle is activated for the cyclic mode and defrost cycle activation

sensibility for the dynamic mode (standard ratio between dry coil ∆T and iced coil ∆T) .

3624 ! Minimum compressors operating time between 2 defrosts

3625 ! Number of fans Restart operations according to the pressure.

Temperature difference

between coil and outdoor

Coil

clean

Coil freezing

Coil

frozen

Defrost cycle start

Highest gradient

Time

Page 25

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

23

SUPPLEMENT OF HEATING (Option)

Fonction

Units may be equipped with 3 types of supplementary heating:

Gas (BG, FG et BD, FD)

Hot water coils (BC, FC et BH, FH)

Electric heaters (BC, FC et BH, FH)

From a room temperature need (Capacity Factor) the supplement of heating stages are started and stopped with a predetermined order.

Description

Operation priority, Compressors / Additional heating

From factory setting, in heat pump mode, Climatic™ starts compressors first and then if necessary, starts additional

heating.

This sequence may be reversed with set points for the ambient temperature regulation and for fresh air pre-heating.

3324 ! Priority inversion from compressors to supplementary heating, air temperature regulation, adjustment by zone.

3332 ! Priority inversion from compressors to supplementary heating, fresh air regulation, adjustment by zone.

Operation authorization

The user may choose to limit the operation of the compressors by using contacts or set points modification.

Set points

Stop of additional heating if the set point (3357) is set tp ‘No’.

Note: The address (3357) can be set differently for zones A, B, C, Ino ou GTC

Contact

Stop of the gaz module if the free contacts [Dis. Cp/Ah] or [Dis. AuxH.] are closed. (See Customized Input / Output

(BE.50)).

3357 ! Supplementary heating authorization adjustment by zone.

ELECTRICAL HEATERS

Electrical heaters are stopped if the outside temperature is above a threshold in set point (3721).

The capacity of electrical heaters piloted by a Triac may be limited. The set point (3723) fixes the maximum threshold.

For electrical heaters piloted by a Triac and positioned before the coil, if the mixing air temperature is below the threshold

in set point (3722), the electrical heaters are activated to 100%.

For electrical heaters piloted by a Triac and positioned after the coil, if the blowing air temperature is below the threshold

in set point (3722), the electrical heaters are activated to 100%.

Pour les résistances électrique pilotées par Triac et positionnées après la batterie de détente directe ; si la température

de soufflage est inférieure au seuil de la consigne 3722 les résistances sont activées à 100%

3721 ! Outside air temperature threshold for electrical heaters authorization.

3722 ! Minimum temperature threshold, Triac.

3723 ! Maximum capacity threshold, Triac.

HOT WATER

Protection against freezing with minimum water flow.

If the outside air temperature is below the set point (3331), the valve will open to a minimum fixed in the threshold (3332).

Freezing fault

In general, in case of detection of hot water coil icing, the valve will open to 100%. Due to certain hydraulic network,

pumps or tracing, the coil protection is done by closing the valve. This can be activated with the set point 3733.

3731 ! Outside air temperature threshold for authorization, minimum water flow.

3732 ! Valve opening threshold , minimum water flow.

3733 ! Valve action in case of freezing fault.

Page 26

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

24

HOT WATER CIRCULATOR

The Climatic may drive a circulator for the hot water hydraulic circuit.

The activation mode of the circulator must be determined according to the circuit.

3741 ! Circulator operating mode.

[No] No circulator

[Frost.Al.] Circulator activation in case of freezing fault

[Start Heat.] Circulator activation in heating mode for air temperature regulation.

[Started] Circulator activation as soon as the blowing fan is activated.

Page 27

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

25

CUSTOMIZED INPUT/OUTPUT

Function

On the BM.50 card and with the optional expansion board BE.50, it is possible to customize some input / output for

remote control of the unit. So it is possible to customize

• 5 digital outputs NC or NO set up with parameters 3841, 3842, 3843 and 3845

• 6 digitals inputs set up by parameters 3851, 3852, 3853 and 3854

• 4 analogical inputs (4-20mA or Lennox NTC temperature probe), set up with parameters 3861, 3862, 3863 et 3864

Description

Il est possible de paramétrer les fonctions suivantes :

SORTIE DIGITALE NC ou NO - CONTACTS SECS

Following information could be recovered from each contact :

[Not Used.] No contact

[Filter Al

.] Filter fault

[Blower Al

.] Blowing fan fault

[Comp. Al.] Compressor fault

[Gas Al] Gaz fault

[ElecH. Al] Electrical heater fault

[Frost. Al] Alarm, freezing risk

[Smoke. Al.] Smoke detector alarm

[Heat. Mode] Heating mode

[Humidif.] Humidifier pilote

[Z:A] Unit operating Mode A

[Z:B] Unit operating Mode B

[Z:C] Unit operating Mode C

[Uno] Unit operating Mode Inoccupied

[Bms] Unit operating Mode BMS

[LibrFree] Free for BMS acting

[Exhaust 1] Drive exhaust fan n°1

[Exhaust 2] Drive exhaust fan n°2

[Exhaust 3] Drive exhaust fan n°3

3841 ! Setting of connector BM50-J17-N12.

3842 ! Setting of connector BE50-J5-N1.

3843 ! Setting of connector BE50-J6-N2.

3844 ! Setting of connector BE50-J7-N3.

3845 ! Setting of connector BE50-J8-N4.

ENTREE DIGITALE 24V AC ou DC

following orders can be sent on each contact:

[Not Used] No contact

[Sw Unoc.] Force Unoccupied Mode

[Dis. Cp/AH] Stop of all compressors and auxillary heating

[Dis. Comp. ] Stop of all compressors

[Dis. 50%Cp] Immediate stop of 50% of the compressors

[Dis. AuxH.] Stop of supplementary heating

[Sw Dis.Cool] Cancellation of cooling mode

[Sw Dis.Heat] Cancellation of heating mode

[State Humi] Humidifier fault input

[0% F.A. ] Force 0% fresh air

[10% F.A.] Add 10% fresh air

[20% F.A. ] Add 20% fresh air

[30% F.A.] Add 30% fresh air

[40% F.A.] Add 40% fresh air

[50% F.A.] Add 50% fresh air

[100% F.A.] Force 100% fresh air

[Low Speed] Force low speed ventilation

[Free] Free for BMS system information.

Page 28

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

26

3851 ! Setting of connector BM50-J8-ID13.

3852 ! Setting of connector BM50-J8-ID14.

3853 ! Setting of connector BE50-J4-ID1.

3854 ! Setting of connector BE50-J4-ID2.

3855 ! Setting of connector BE50-J4-ID3.

3856 ! Setting of connector BE50-J4-ID4.

ENTREE ANALOGIQUE

It is possible to make the following actions:

[Not Used] Not used

[S.P Offset] Ambient temperature set point offset – 4-20mA signal.

[F.A Offset] Minimum fresh air set point – 4-20mA signal.

[Weather T.] Entry for a Meteo temperature sensor

[Weather H.] Entry for a meteo humidity sensor

[Free NTC] Free temperature probe connection

[Free Hr.] Free relative humidity sensor connection

Ambient temperature set point offset – 4-20mA signal:

The 4-20mA signal sent to the unit is linearly converted using a -5K to +5K range of temperature set point.

For example: for a unit set point of 20°C

A 4mA signal will give a 15°C unit temperature set point

A 20mA signal will give a 20°C unit temperature set point

A 20mA signal will give a 25°C unit temperature set point

Minimum fresh air set point – 4-20mA signal:

The 4-20mA signal sent to the unit is linearly converted to a 0% - 100% fresh air damper opening request.

Entry for a Meteo temperature sensor:

The 4-20mA signal sent to the unit is linearly converted using a -40°C to +80°C range, this measure will replace the one

given by the unit sensor.

Entrée d’une sonde météo, en humidité :

The 4-20mA signal sent to the unit is linearly converted using a 0% to 100% range, , this measure will replace the one

given by the unit sensor.

Free temperature probe connection:

Lennox NTC sensor. The measured value will be displayed on following addresses 2161, 2162, 2163 or 2164.

Free relative humidity sensor connection:

The 4-20 mA signal sent to the unit is linearly converted using a 0% to 100% range. The measured value will be

displayed on following addresses 2165, 2166, 2167 or 2168.

3861 ! Setting of connector BE50-J9-B1.

3862 ! Setting of connector BE50-J9-B2.

3863 ! Setting of connector BE50-J10-B3.

3864 ! Setting of connector BE50-J10-B4.

Page 29

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

27

ERROR CODES

001

"Airflow"

004

Filters, Clogged up

005

Filters, Missing

011

Electric heating elements

012

High Temperature, Blowing

013

Low Temperature, Ambient

014

Gas burner, 1

015

Gas burner, 2

022

Low Temperature, Blowing

023

High Temperature, Ambient

031

Humidifier

032

Low Humidity, Ambient

033

High Humidity, Ambient

041

Pump

070

Clock card

071

BE50

081

Temperature sensor, Ambient

082

Humidity sensor, Ambient

083

Temperature probe, Outside

084

Humidity sensor, Outside

085

Temperature probe, Blower

086

Circuit 1, Temperature sensor, Water condenser Outlet

087

Circuit 2, Temperature sensor, Water condenser Outlet

088

Temperature sensor, return or Mixing air

091

Treatment Fan

092

Circuit 1, Condenser fan

093

Circuit 2, Condenser fan

094

Circuit 3, Condenser fan

095

Circuit 4, Condenser fan

096

Low temperature, Water Condenser

097

High temperature, Water Condenser

098

Flow rate, water condenser

099

Smoke detector

111

Circuit 1, Probe or Sensor

115

Circuit 1, High pressure or electrical protection

117

Circuit 1, Low pressure

121

Circuit 2, Probe or Sensor

125

Circuit 2, High pressure or electrical protection

127

Circuit 2, Low pressure

131

Circuit 3, Probe or Sensor

135

Circuit 3, High pressure or electrical protection

137

Circuit 3, Low pressure

141

Circuit 4, Probe or Sensor

145

Circuit 4, High pressure or electrical protection

147

Circuit 4, Low pressure

Page 30

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

28

Insufficient airflow

Error code: 001

Description

The pressure differential between the treatment unit and the filters is small although the fan has been running for more

than 3 minutes.

∆p < safety threshold for more than 20 seconds

2131 ! ∆p.

3411 ! Safety threshold

Action

" Immediate shutdown of the complete unit.

" Fault signalling.

If a DS50 is connected to the unit; Memorisation and display of all faults

Otherwise; Memorisation and display of the 3rd daily fault only.

Reset

The unit restarts automatically 2 minutes after making safe.

The fault will no longer be reset automatically after 3 cut outs in the same day and must be reset manually.

Note: The fault counter is cleared and reset every day at 11 am, provided the maximum number of faults has not been

reached.

Possible causes Solving the problem

Air system obstructed or closed Check the system

Broken belts Replace the belts

Problem with the fan wiring Check the connections

Problem with the pressure transmitter wiring Check the connections

Incorrect setting of the safety threshold Check the settings

Page 31

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

29

Filters Clogged or Missing

Error code: 004, 005

Description

The pressure differential between the treatment unit and the filters is small although the fan has been running for more

than 3 minutes.

Filters missing: ∆p < safety threshold for more than 1 minute

Clogged filters: ∆p > safety threshold for more than 1 minute

2131 ! ∆p.

3412 ! Safety threshold, filters missing.

3413 ! Safety threshold, blocked filters.

Action

" No safety.

" Fault signalling. Memorisation is displayed

" Display of fault.

004, Filters clogged

005, filters missing

Reset

Automatic reset of the fault as soon as the pressure returns to the authorized operating range.

Possible causes Solving the problem

Filters removed and not replaced Fit new filters

Filters clogged Clean or replace the filters

Problem with the pressure transmitter wiring Check the connections

Incorrect setting of the safety thresholds Check the settings

Page 32

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

30

Ambient Temperature and Humidity, Outside Limits

Error code: 013, 023, 032, 033

Description

The ambient temperature or humidity of the air measured by the sensor is outside the permitted range.

Lower limit of ambient temperature: Ambient temperature < safety threshold

Upper limit of ambient temperature: Ambient temperature > safety threshold

Lower limit of ambient humidity: Ambient humidity < safety threshold

Upper limit of ambient humidity: Ambient humidity > safety threshold

2112 ! Ambient temperature

3371 ! Safety threshold, lower limit of ambient temperature

3372 ! Safety threshold, upper limit of ambient temperature

2122 ! Ambient humidity

3378 ! Safety threshold, lower limit of ambient humidity

3379 ! Safety threshold, upper limit of ambient humidity

Action

" No safety.

" Fault signalling. Memorisation is displayed

" Display of fault.

013, Lower limit of ambient temperature.

023, Upper limit of ambient temperature.

032, Lower limit of ambient humidity.

033, Upper limit of ambient humidity.

Reset

Automatic resetting of fault as soon as the temperature or humidity returns within the permitted operating range.

Possible causes Solving the problem

Temperature probe or humidity sensor failed Replace probe or sensor.

Problem with wiring of probe or sensor Check the connections of the probe or sensor

Page 33

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

31

Blowing temperature, outside limits

Error code: 012, 022

Description

The temperature of the blown air measured by the sensor is outside the permitted range or the hot water system frost

thermostat is activated.

Lower blower temperature limit: Blower temperature < safety thresholds

Upper blower temperature limit: Blower temperature > safety thresholds

2113 ! Ambient temperature

3373 ! 1st safety threshold, lower blower temperature limit

3374 ! 2nd safety threshold, lower blower temperature limit

3375 ! 3rd safety threshold, lower blower temperature limit

3376 ! 1st safety threshold, upper blower temperature limit

3377 ! 2nd safety threshold, upper blower temperature limit

Action

" 1st lower limit safety threshold:

One compressor stops immediately, then the others progressively.

Fresh air regulator set to minimum opening.

" 2nd lower limit safety threshold:

All compressors stop.

Fresh air regulator closes.

" 3rd lower limit safety threshold or activation of frost thermostat:

If there is a hot water unit; the complete unit stops immediately.

Otherwise; the unit stops after 15 minutes.

" 1st upper limit safety threshold:

One compressor or back-up heating stage stops immediately, then the others progressively.

" 2nd lower limit safety threshold:

All the compressors and all the back-up heating stages stop.

" Fault signalling. Memorisation is displayed.

" Display of fault.

012, 2nd upper blower temperature limit threshold.

022, 3rd lower blower temperature limit threshold or activation of frost thermostat.

Reset

Automatic resetting of fault as soon as the temperature returns to within the permitted operating range, except 3rd safety

threshold lower limit which requires a manual reset.

Possible causes Solving the problem

Insufficient airflow Check the air system

Air damper jammed open Check the air damper, mechanically and electrically

Frost safety thermostat activated Manually reset the pressure switch

Probe failure. Replace the probe.

Wiring problem with the probe Check the probe connections

Page 34

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

32

Overheating of Electrical Heating Elements

Error code: 011

Description

A safety thermostat in the electric heater unit has operated or the control contactor has not been activated.

Action

" Heating elements switched off immediately.

" Fault signalling. Memorisation is displayed.

Reset

Manual reset.

Possible causes Solving the problem

Air system obstructed or closed Check the system

Filters clogged Clean the filters

Broken belts Replace the belts

Problem with the wiring of the heating elements Check the connections

Page 35

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

33

Gas Burner Faults

Error code: 014, 015

Description

The gas burner control box has generated a fault and is no longer controlling the fume extractor fan.

Action

" The gas burner shuts down immediately.

" Fault signalling.

If a DS50 is connected to the unit; Memorisation and diplay of all faults.

Otherwise; Memorisation and display only of the 3rd daily fault.

" Display of fault.

014, 1st gas burner.

015, 2nd gas burner

Reset

The burner restarts automatically 2 minutes after safety setting by electrically resetting the burner control box.

The fault will no longer be reset automatically after 3 cutouts in the same day and must be reset manually.

Note: The fault counter is cleared and reset every day at 11 am, provided the maximum number of faults has not

been reached.

Possible causes Solving the problem

See IOM Flexy Read the documentation

Problem with the wiring of the gas burners Check the connections

Page 36

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

34

External Humidifier fault

Error code: 031

Description

A switch outside the unit reports a fault associated with a humidifier.

Action

" The humidifier controller stops immediately.

" Fault signalling. Memorisation is displayed.

Reset

The humidifier controller restarts automatically when the switch closes.

Possible causes Solving the problem

Problem with the external humidifier Check the humidifier

Hot Water Circulator Fault

Error code: 040

Description

The electrical protection of the circulator has operated.

Action

" The circulator stops immediately.

" Fault signalling. Memorisation is displayed.

Reset

Manual reset.

Possible causes Solving the problem

Problem with the circulator Check the wiring

Page 37

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

35

Fault in Real Time Clock

Error code: 070

Description

The real time clock card, incorporated in the Climatic™ card, is defective.

Action

" Fault signalling. Memorisation is displayed.

Reset

Automatic reset.

Possible causes Solving the problem

The battery is exhausted Replace the daughter card

The daughter card is not inserted correctly Check the connection

Extension card fault (BE50)

Error code: 071

Description

Communication between the BM50 and the BE50 is down.

Action

" Compressors 3 and 4 stop, for the Flexy range.

" Fault signalling. Memorisation is displayed.

Reset

The fault disappears automatically as soon as communication is reestablished.

Possible causes Solving the problem

Incorrect addressing of the BE50 Configure the Serial Address dip-switches (on, off, off, off)

BM50 or BE50 damaged Replace the defective component

Problem with the BIOS Replace the BIOS with version 3A.57 or 3.64 or above

Incorrect wiring or loose connection between

BM50 and BE50

Check connections and wiring

Page 38

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

36

Faulty Probes and Sensors

Error code: 081, 082, 083, 085, 086, 087, 088, 111, 121, 131, 141

Description

One or more temperature probes or pressure sensors in the cooling systems or elsewhere are short circuited,

cut or disconnected.

Action

" Blowing or outside ambient temperature:

The compressors and additional heaters shut down, ventilation remains.

" Temperature or pressure for circuit:

All compressors in the circuit shut down.

" Fault signalling. Memorisation is displayed.

" Display of fault.

081, Temperature sensor; Ambient.

082, Humidity sensor; Ambient.

083, Temperature sensor; Outside.

085, Temperature sensor; Blowing

086, Temperature sensor; Outlet 1 of condensation heat exchanger.

087, Temperature sensor; Outlet 2 of condensation heat exchanger.

088, Temperature sensor; Return air.

111, Temperature sensor or pressure probe; Circuit 1.

121, Temperature sensor or pressure probe; Circuit 2.

131, Temperature sensor or pressure probe; Circuit 3.

141, Temperature sensor or pressure probe; Circuit 4.

Reset

The unit returns to normal operation after the signal from the faulty probes or sensors is re-established.

Possible causes Solving the problem

Damaged probes or sensors Replace probe or sensor

Incorrect wiring or loose connection on a probe or sensor Check probe and sensor connections and wiring

Page 39

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

37

Blowing fan

Error code: 091

Description

The air conditioning fan motor control is no longer active.

Action

" The unit stops immediately.

" Fault signalling. Memorisation is displayed.

Reset

Manual reset.

Possible causes Solving the problem

Fire safety thermostat active Reset the thermostat

Motor thermal protection devices activated Check the air system

Motor thermal protection devices activated Check the motors

Problem with the fan wiring Check the connections

Page 40

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

38

Condenser fans

Error code: 092, 093, 094, 095

Description

The condenser fan motor control is no longer active.

Action

" The compressors and fans in the circuit shut down immediately.

" Fault signalling.

If a DS50 is connected to the unit; Memorisation and diplay of all faults.

Otherwise; Memorisation and display only of the 3rd daily fault.

" Display of fault.

092, Fan; Circuit 1.

093, Fan; Circuit 2.

094, Fan; Circuit 3.

095, Fan; Circuit 4.

Reset

The safety device is automatically cancelled 30 minutes after activation.

The fault will no longer be reset automatically after 3 cutouts in the same day and must be reset manually.

Note: The fault counter is cleared and reset every day at 11 am, provided the maximum number of faults has not

been reached.

Possible causes Solving the problem

Motor thermal protection devices activated Check the air system

Motor thermal protection devices activated Check the motors

Problem with the fan wiring Check the connections

Page 41

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

39

Water Condenser Faults

Error code: 096, 097, 098

Description

The water outlet temperature from the heat exchanger measured by the sensor is outside the permitted range or the

water flow detection device is not active.

Lower temperature limit: Water outlet temperature < safety threshold

Upper temperature limit: Water outlet temperature > safety threshold

2572 ! Temperature of circuit 1

2573 ! Temperature of circuit 2

3631 ! Safety threshold, lower limit of water output temperature

3632 ! Safety threshold, upper limit of water outlet temperature

Action

" Immediate shut down of compressors.

" Fault signalling.

If a DS50 is connected to the unit; Memorisation and diplay of all faults.

Otherwise; Memorisation and display only of the 3rd daily fault.

" Display of fault.

096, Lower limit.

097, Upper limit.

098, Insufficient water flow in condenser.

Reset

Automatic reset of the fault as soon as the temperature returns to the permitted operating range.

The fault will no longer be reset automatically after 3 cutouts in the same day and must be reset manually.

Note: The fault counter is cleared and reset every day at 11 am, provided the maximum number of faults has not

been reached.

Possible causes Solving the problem

Damaged probes or sensors Replace probe or sensor

Incorrect wiring or loose connection on a probe or sensor Check probe and sensor connections and wiring

Page 42

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

40

Smoke Detector

Error code: 099

Description

The stand-alone detector switch (DAD) checking for the presence of smoke in the unit is activated.

Action

" Immediate shutdown of the unit and opening of the fresh air controller.

" Fault signalling. Memorisation is displayed.

Reset

Manual reset.

Possible causes Solving the problem

Problem with the DAD wiring Check the connections

Page 43

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

41

Compressors shut down on LP Cutoff

Error code: 117, 127, 137, 147

Description

The low pressure switch of the circuit has been open for 2 minutes, while one compressor in the Circuit has operated

for 2 minutes.

The low pressure switch of the Circuit has been open for 1 hour.

Action

" Immediate shut down of the compressors in the circuit.

" Fault signalling.

If a DS50 is connected to the unit; Memorisation and diplay of all faults.

Otherwise; Memorisation and display only of the 3rd daily fault.

" Display of fault.

117, Circuit 1.

127, Circuit 2.

137, Circuit 3.

147, Circuit 4.

Reset

Automatic reset of the fault as soon as the low pressure becomes greater than the safety pressure switch cutoff limit

The fault will no longer be reset automatically after 3 cutouts in the same day and must be reset manually.

Note: The fault counter is cleared and reset every day at 10 am provided the maximum number of faults has

not been reached.

Possible causes Solving the problem

Not enough refrigerant in the circuit Adjust the refrigerant charge

Faulty expansion valve Check that the expansion valve is operating correctly

Filter drier blocked Replace the filter drier

Faulty low pressure switch Replace the low pressure switch

Page 44

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

42

The compressors shut down on HP Cutoff or Electrical Protection

Error code: 115, 125, 135, 147

Description

During start up or operation of a compressor:

The HP pressure switch of the Circuit is open.

The internal protection of a compressor in the Circuit has tripped.

The flow thermostat of a compressor in the Circuit has tripped.

Action

" Immediate shut down of the compressors in the circuit.

" Fault signalling.

If a DS50 is connected to the unit; Memorisation and diplay of all faults.

Otherwise; Memorisation and display only of the 3rd daily fault.

" Display of fault.

115, Circuit 1.

125, Circuit 2.

135, Circuit 3.

145, Circuit 4.

Reset

The safety device is automatically cancelled 30 minutes after activation.

The fault will no longer be reset automatically after 3 cutouts in the same day and must be reset manually.

Note: The fault counter is cleared and reset every day at 10 am provided the maximum number of faults has not

been reached.

Possible causes Solving the problem

Dirty condenser Clean the condenser

Fan out of order Replace the fan

Incorrect wiring of the high pressure switch Check the wiring of the high pressure switch

Dirty filter drier Replace the filter drier

Page 45

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

43

COMMUNICATION

MASTER/SLAVE

Function

Link several units in order to allow a “Master/Slave” relationship between each units.

Description

Configuration of the pLan network

To configure the addresses of the cards for the pLan network, see chapter: (Configuring the pLan address of the BM50)

For the pLan network, each unit must have a different address:

Unit 1 ! Master unit

Units 2 to 12 ! Slave units

Master/Slave Modes

Several master/slave modes are available and may be configured by using set points 3922 and 3923:

Cold/hot Master/Slave mode:

All the units are stand-alone, but:

• If the master is calling for cooling, the heating adjustment of the slaves is inhibited.

• If the master is calling for heating, the cooling adjustment of the slaves is inhibited.

“Token” Mode:

This mode limits the number of compressors in operation.

Use set point 3922 to set the maximum number of compressors that can operate simultaneously for all the units

connected.

Back-up mode;

The unit with the highest pLan address is used as a back-up in the event of a fault in another unit.

In the event of different faults on several units, the following fault priority is applied:

1. The unit stops

2. Fault in one sensor or probe

3. Fault in one or more compressors

4. Fault in a back-up heater

5. Temperature Limit fault

6. Filter fault

If the ambient temperature is exceeded, fault 013 or 023, the back-up unit will restart to compensate for the loss of power

of the other units.

Rotating back-up mode:

Same as above, except the "back-up" unit changes every Tuesday at 09.00 if none of the other units is faulty.

Master DC50

Function configurable using set point 3924:

Activation of this function enables one, and only one, DC50 to be connected for a maximum of 12 units.

• The DC50 must be connected to the Master unit (pLan address 1).

• The functions between the Master BM50 and its DC50 are standard.

• The Master BM50 communicates its Start or Stop status to its slaves, the current range and the values

of its temperature and minimum fresh air set points.

• The slaves BM50s communicate a summary of their Alarms to the master. A 902 alarm on the master unit

represents activation of a fault on slave unit 2 (903 for 3, etc).

This function is incompatible with the Back-up mode.

Page 46

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

44

Reference Temperature, Humidity and CO2.

Function may be configured using set points 3922, 3925, 3926 and 3927

The ambient temperature and humidity (set point 3925), the temperature and humidity of the external air (set point 3926)

and/or the valeur of CO² (set point 3927) used for regulation can be determined from the following calculations:

[Not Used ! Each machine regulates with its own sensors

[M/S Temp] ! Slave units regulate with the values of the Master unit probes or sensors

[M/S Aver.] ! All the units regulate with the average of the values of the probes or sensors on the bus

To calculate the averages, the number of units connected must be entered in set point 3922

In all modes, each unit is independent for fault management.

3921 ! pLan address, see chapter: Configuring the pLan address of the BM50

3922 ! Number of cards connected or number of compressors desired

3923 ! Choice of function

[Not Used] None

[M/S C/H] Cooling/Heating Master/Slave Mode

[Token] Limiting the number of active compressors

[Backup] Back-up mode

[Rol.Backupt] Back-up mode + weekly rotation

3924 ! Activation, Master DC50

3925 ! Choice of management of ambient temperatures and humidity

3926 ! Choice of management of outside temperatures and humidity

3927 ! Choice of management of air quality sensors

Page 47

CLIMATIC™50 – IOM – Rooftops/ Aircoolair CL50-ROOFTOPS-IOM-1107-E

45

BMS

Function

This is used to link a Climatic™ to a BMS network for remote control of the unit.

Description

The Climatic™ 50 can communicate using various protocols:

MODBUS protocol for connection with KP06 (see specific KP06 manual) or other Lennox communication products

(3932 = Modbus)

MODBUS protocol (3932 = Modbus)

LONWORKS system (3932 = LonWorks)

BACNET system (3932 = Bacnet)

TREND system (3932 = Trend)

ADALINK system (3932 = Adalink)

CLIMALINK system (3932 = Climatic)

Tables of MODBUS, LONWORKS, BACNET & TREND addresses are given in an appendix at the end of this manual.

The identification number of each unit can be set (3931) and the communication speed is adjustable between 1200 Bd

and 19200 Bd (3933).

3931 ! Address of the unit on the bus

3932 ! Choice of type of protocol

3933 ! Choice of communication speed

MODBUS protocol

For this option the BM50 must be fitted with the PCO1004850 card

This card is used to interface a BM50 with an RS485 type bus.

The card provides optically coupled isolation between the regulator and the RS485serial network.