Lennox CIC 040S, CIC 070D, CIC 045D, CIC 055D, CIC 085D Installation, Operation & Maintenance Manual

...

lennoxemeia.com

COMPACTAIR

CSC - CSH

CDC - CDH

Installation,

operating

and maintenance

Indoor unit

MIL121E-0613 / 11-2014

Translation of original manual

1

3

4

1 -

1.1 5

1.2 5

1.3 7

1.4 12

2 -

2.1 14

2.2 14

2.3 15

2.4 15

2.5 15

2.6 16

2.7 17

3 -

3.1 22

4 -

4.1 23

4.2 23

WARNING: Read this manual before carrying out installation, repair or maintenance work.

All the technical and technological information contained in this manual, including any drawings and technical descriptions provided

by us, remain the property of Lennox and must not be utilised (except in the operation of this product), reproduced, issued to or

made available to third parties without the prior written agreement of Lennox.

INSTALLATION

OPERATION

MAINTENANCE MANUAL

TABLE OF CONTENTS

AIRCOOLAIR/COMPACTAIR

INDOOR UNITS

POINTS TO BEAR IN MIND

Manufacturer’s recommended inspections

DATA PAGE FOR COMMISSIONING OF THE UNIT

GENERAL CHARACTERISTICS

Physical data

Electrical data

Fan performance

Unit dimensions

INSTALLATION

Installation guidelines

Optional task prior to unit installation :

regulating airfl ow in the fans

Service space

Drainage

Refrigerant connections

Electrical connections

Installation of options

COMMISSIONING AND OPERATION

Preliminary checks

MAINTENANCE

Preventive maintenance

Fault diagnosis

2

POINTS TO BEAR IN MIND

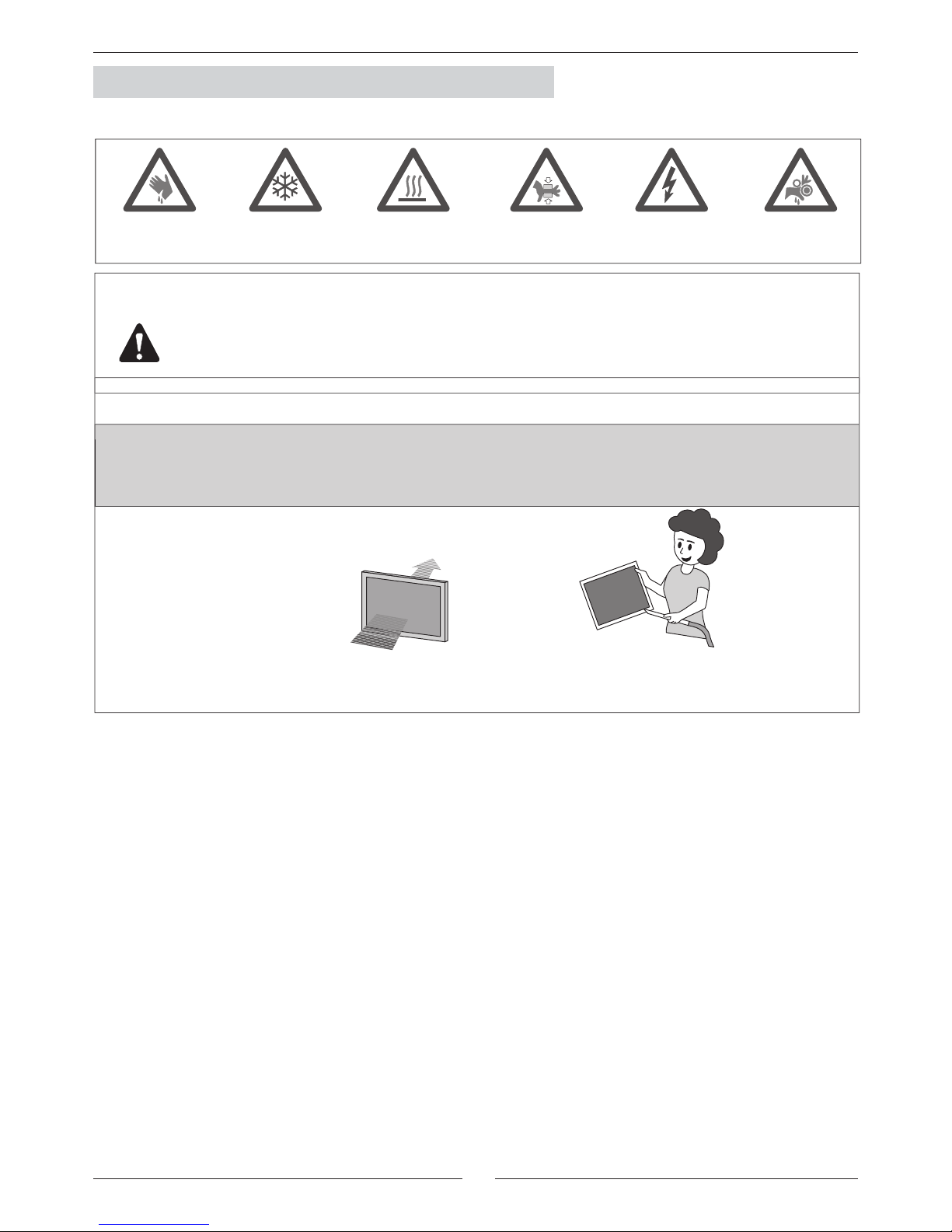

DANGER AND WARNING SIGNS

Abrasive surfaces

Low temperatures High temperatures Risk of injury from

moving objects

Electrical voltage

Risk of injury from

rotating objects

ELECTRICAL CONNECTIONS

To prevent serious electrical injuries, make sure to switch off the power before doing any installation,

repair or maintenance work on the unit.

To install the unit, bear in mind local and national legislation.

ATTENTION - WARNING

Electric shock can cause injury or death. Before attempting

to perform any service or maintenance on the unit, turn

OFF the electrical power, and check that the fan has

stopped.

The air fi lter cleaning operations does not require technical

service; however, when an electrical or mechanical

operation is required, call an Engineer.

CLEANING THE FILTER

Check the air fi lter and make sure

it is not blocked with dust or dirt.

If the fi lter is dirty, wash it in a bowl with neutral soap and

water, drying it in the shade before re-inserting it in the

unit.

Standard Guidelines for Lennox equipment.

All technical data contained in these operating instructions, including diagrams and technical descriptions, remain the property

of Lennox and may not be used (except for the purpose of familiarizing the user with the equipment), reproduced, photocopied,

transferred or transmitted to third parties without prior written authorization from Lennox.

Data published in the operating instructions are based on the latest information available. We reserve the right to make

modifi cations without notice.

We reserve the right to modify our products without notice and with no obligation to modify goods previously supplied.

These operating instructions contain useful and important information for the smooth operation and maintenance of your equipment.

The instructions also include guidelines on how to avoid accidents and serious damage before commissioning the equipment and

during its operation and how to ensure smooth and fault-free operation. Read the operating instructions carefully before starting

the equipment, familiarize yourself with the equipment and with handling the installation and carefully follow the instructions. It is

very important to be properly trained in handling the equipment. These operating instructions must be kept in a safe place near

the equipment.

Like most equipment, the unit requires regular maintenance. This section concerns maintenance personnel and management.

If you have any queries or would like to receive further information on any aspect relating to your equipment, do not hesitate to

contact us.

The manufacturing of these units is made under the requirements of the ISO 9001 and ISO 14001.

3

DATA PAGE FOR UNIT COMMISSIONING

COOLING CYCLE

Air fl ow data:

Air intake temperature, Indoor Coil:

ºC

High Pressure:

Low pressure :

HEATING CYCLE

Air fl ow data:

Air intake temperature, Indoor Coil:

ºC

High Pressure:

Low pressure :

YES NO

DRAINAGE WITH TRAP

CLEAN INTERIOR AIR FILTER

GENERAL POWER SUPPLY CONNECTION

DATA INPUT:

ELECTRIC POWER CONSUMPTION (Amps)

Fan indoor section: Fan indoor section:

UNIT: ______________________________________ SERIAL NUMBER : _____________________________

CONTROL PANEL IDENTIFICATION CODE : ______________________________________________________

INSTALLATION ADDRESS: ____________________________________________________________________

INSTALLER : ________________________________ INSTALLER TEL : ______________________________

INSTALLER ADDRESS : _______________________________________________________________________

___________________________________________________________________________________________

COMMISSIONING DATE : _____________________________________________________________________

CHECKS : __________________________________________________________________________________

___________________________________________________________________________________________

SUPPLY VOLTAGE : __________________________ RATED VOLTAGE OF THE UNIT : _________________

Options installed : ____________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

Comments : _________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

4

C I C 020 S

N

M

3

M

CIC

CIH

020S 025S 030S 035S 040S 045D 055D 070D 085D 100D 120D 140D

108 111 115 150 160 170 242 259 276 470 480 490

2 2 2 2 2 2 2 3 3 3 3 3

10 10 10 10 10 20 20 20 30 45 45 45

50 50 50 75 75 75 165 165 165 190 190 190

10 10 10 12 16 20 20 24 30 40 40 40

6,5 3 3 5 0 3 3 3 13 13 8 8

6,5 3 8 8 3 6 6 16 21 27 14 14

9,5 8 11 8 6 6 19 24 21 27 40 40

25 25 25 28 28 28 37 37 37 65 65 65

n/a n/a n/a n/a n/a n/a 145 145 145 230 230 230

6 6 6 9 9 9 14 14 14 23

23 23

CIC

CIH

020S 025S 030S 035S 040S 045D 055D 070D 085D 100D 120D 140D

0,74 1,45 1,45 1,89 2,69 2,69 2,69 3,63 5,06 5,06 6,38 6,38

1,40 2,59 2,59 3,45 4,80 4,80 4,80 6,48 8,60 8,60 11,1 11,1

6,44 13,0 13,0 17,3 26,4 26,4 26,4 35,6 60,2 60,2 81 81

3N

~400V

50 Hz

3~400V 50Hz

M:400V/3/50

- - - -

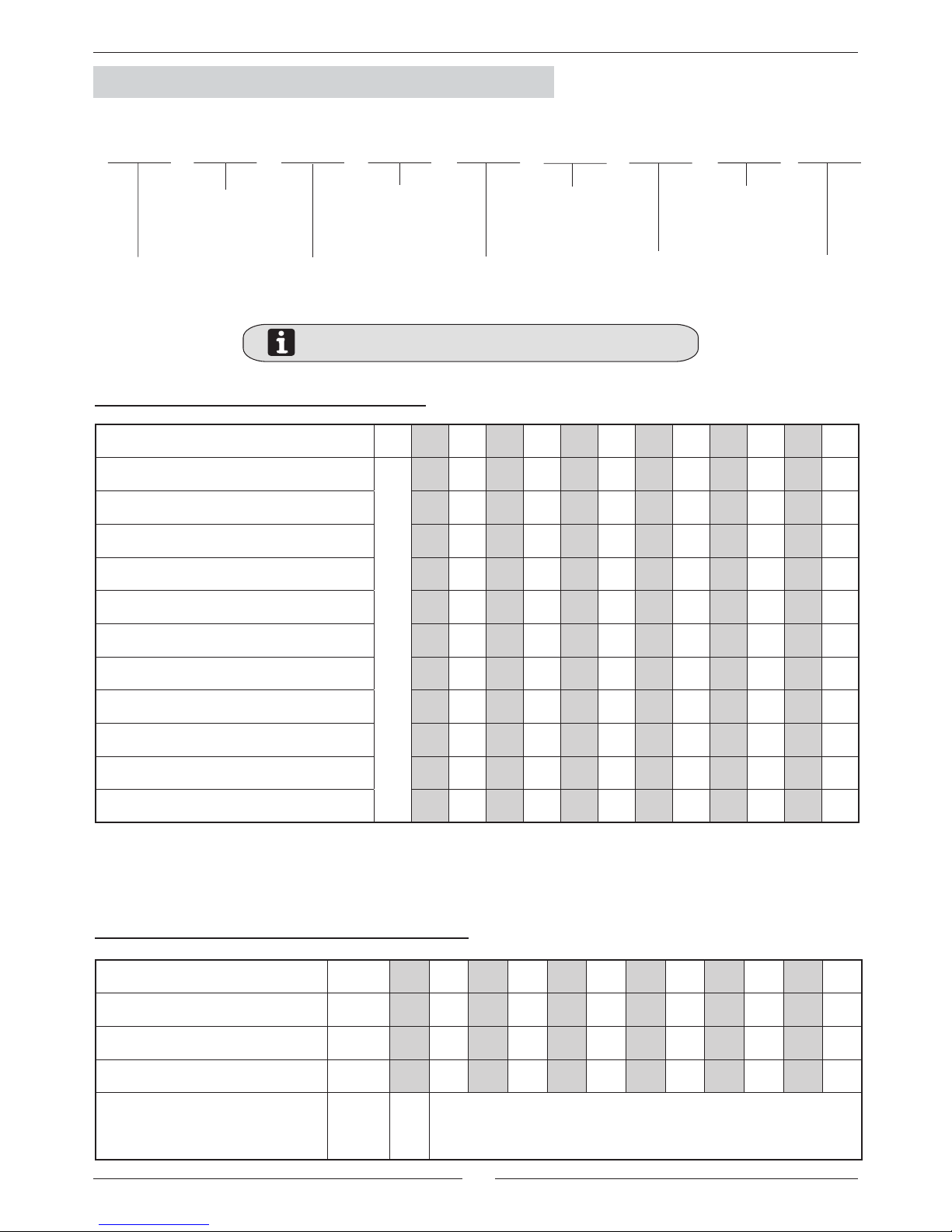

1. GENERAL CHARACTERISTICS

1.1.- PHYSICAL DATA

Type of unit

COMPACTAIR /

AIRCOOLAIR

I: Indoor unit

Type of Refrigerant

M: R-410A

Approximate cooling

capacity in kW.

S: One circuit

D: Two circuits

CIC: Cooling only unit R-410A.

CIH: Heat pump unit R-410A.

1.2.- ELECTRICAL DATA

ELECTRICAL CONSUMPTION FOR STANDARD UNITS

WEIGHT FOR STANDARD UNITS AND OPTIONS

C: Cooling only unit

H: Heat pump unit

Number of revision

MODELS

Indoor unit CIC/CIH

Airsock control

Electrical heater

Free-cooling

Hot water coil kg

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

High effi ciency air fi lter

(G4 prefi ltre/F7 fi ltration)

MODELS

Maximum absorbed power

Kw

Maximum current

A

Start up current

A

Voltage

Ph/V/Hz

n/a: not available

5

CIC/H 020S CIC/H 025S CIC/H 030S CIC/H 035S

MAP MC MAP MC MAP MC MAP MC

0 0 0 0 0 0 0 0

0,71 1,19 0,44 0,86 0,44 0,86 0,8 1,35

0,71 1,19 1,24 2,21 1,24 2,21 1,74 3,03

1,15 2,05 1,24 2,21 2,18 3,89 1,74 3,03

0,51 2,6 0,51 2,6 0,51 2,6 1,33 6,8

n/a n/a n/a n/a n/a n/a n/a n/a

10 14,3 10 14,3 10 14,3 15 21,5

15 21,5 15 21,5 15 21,5 20 28,6

20 28,6 20 28,6 20 28,6 27 39

CIC/H 040S CIC/H 045D CIC/H 055D CIC/H 070D

MAP MC MAP MC MAP MC MAP MC

0 0 0 0 0 0 0 0

0 0 0,94 1,68 0,94 1,68 1,43 2,12

0,94 1,68 2,37 3,8 2,37 3,8 2,75 4,62

2,37 3,8 2,37 3,8 3,69 3,69 5,16 8,82

1,33 6,8 1,33 6,8 2,65 4,5 2,65 4,5

n/a n/a n/a n/a 2,69 4,8 3,63 6,5

15 21,5 15 21,5 20 28,6 20 28,6

20 28,6 20 28,6 27 39 27 39

27 39 27 39 40 57,8 40 57,8

CIC/H 085D CIC/H 100D CIC/CIH 120D/140D

MAP MC MAP MC MAP MC

0 0 0 0 0 0

1,32 2,5 1,32 2,5 2,41 4,2

3,73 6,7 5,06 8,6 3,74 6,1

3,73 6,7 5,06 8,6 6,38 11,1

2,65 4,5 5,3 9 5,3 9

3,63 6,5 5,06 8,6 6,38 11,1

20 28,6 27 39 27 39

27 39 40 57,8 40 57,8

40 57,8 50 72,3 50 72,3

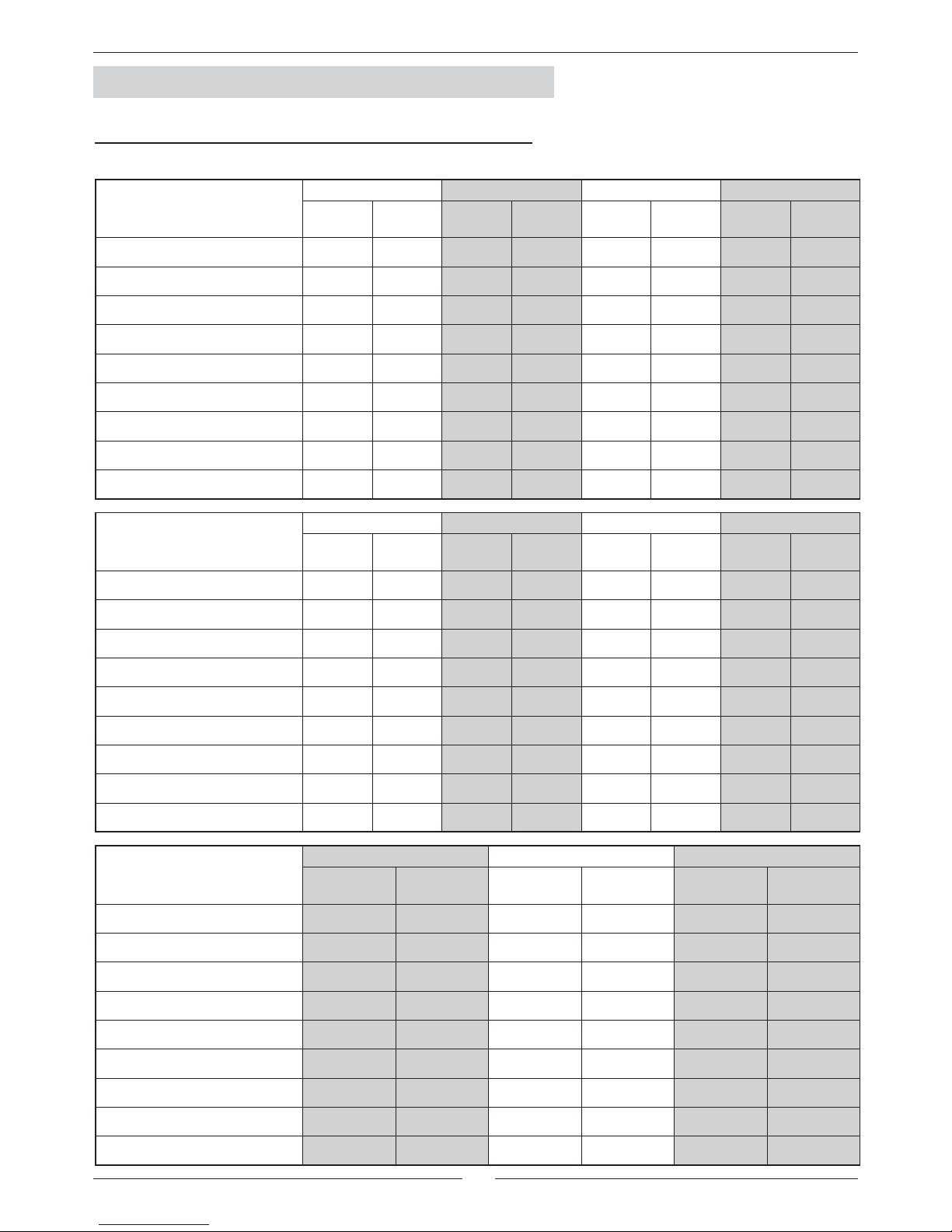

1. GENERAL CHARACTERISTICS

1.2.- ELECTRICAL DATA

ADDITIONAL ELECTRICAL CONSUMPTION FOR THE OPTIONS

kW A kW A kW A kW A

Standard Indoor fan

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

Standard electrical heater

Medium electrical heater

High electrical heater

kW A kW A kW A kW A

Standard Indoor fan

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

Standard electrical heater

Medium electrical heater

High electrical heater

kW A kW A kW A

Standard Indoor fan

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

Standard electrical heater

Medium electrical heater

High electrical heater

MAP Maximum absorbed power MC Maximum current

6

020S

824 788 753 717 682

3150 167 149 132 116 101

3425 162 143

127

109 93

3700 155 138 120 103 85

4100 • 127

108

90 72

025S

824 788 753 717 682

4250 141 123 103 84 66

4625 129 109

89

69 49

5000 115 92 71 50 28

5500 89 66

42

19 n/a

030S

915 876 836 797 757

4650 173 149 125 103 80

5050 158 133

109

84 60

5450 141 115 89 63 38

6000 • 84

56

28 0

035S

735 704 672 640 609

6200 164 142 119 98 77

6650 153 130

106

83 61

7100 139 114 89 66 42

8050 102 75

48

22 n/a

040S

837 792 748 704 659

6950 213 178 143 109 75

7550 196 158

122

86 50

8150 175 136 97 58 21

9050 136 94

53

10 n/a

045D

937 888 838 788 738

6950 272 227 183 140 97

7550 249 201

155

109 63

8150 • 171 121 72 23

9050 • •

103

51 1

055D

837 792 748 704 659

9950 206 177 148 122 96

10825 195 166

138

110 83

11700 185 154 125 97 68

12850

136

105

75 45

070D

937 888 838 788 738

12450 237 200 163 128 95

13550

•

183

145

109 73

14650

• •

124 85 48

15090

• •

115

75 36

085D

937 888 838 788 738

14000 202 163 125 87 51

15125 182 142

102

62 23

16250 160 117 75 34 n/a

16725 149 105

63

20 n/a

100D

750 710 670 630 591

17350 237 202 167 133 101

18875 223 185

149

115 81

20400

•

168 131 94 59

22450

• •

100

63 25

120D

750 710 670 630 591

19300

207 169 133 98 64

21000

187 48

111

73 38

22700

164 124 84 46 9

24950

•

87

46

5 n/a

140D

750 710 670 630 591

21000

231 192 155 117 82

22250

218 178

140

101 65

23500

204 163 123 84 46

24750

•

146

105

65 25

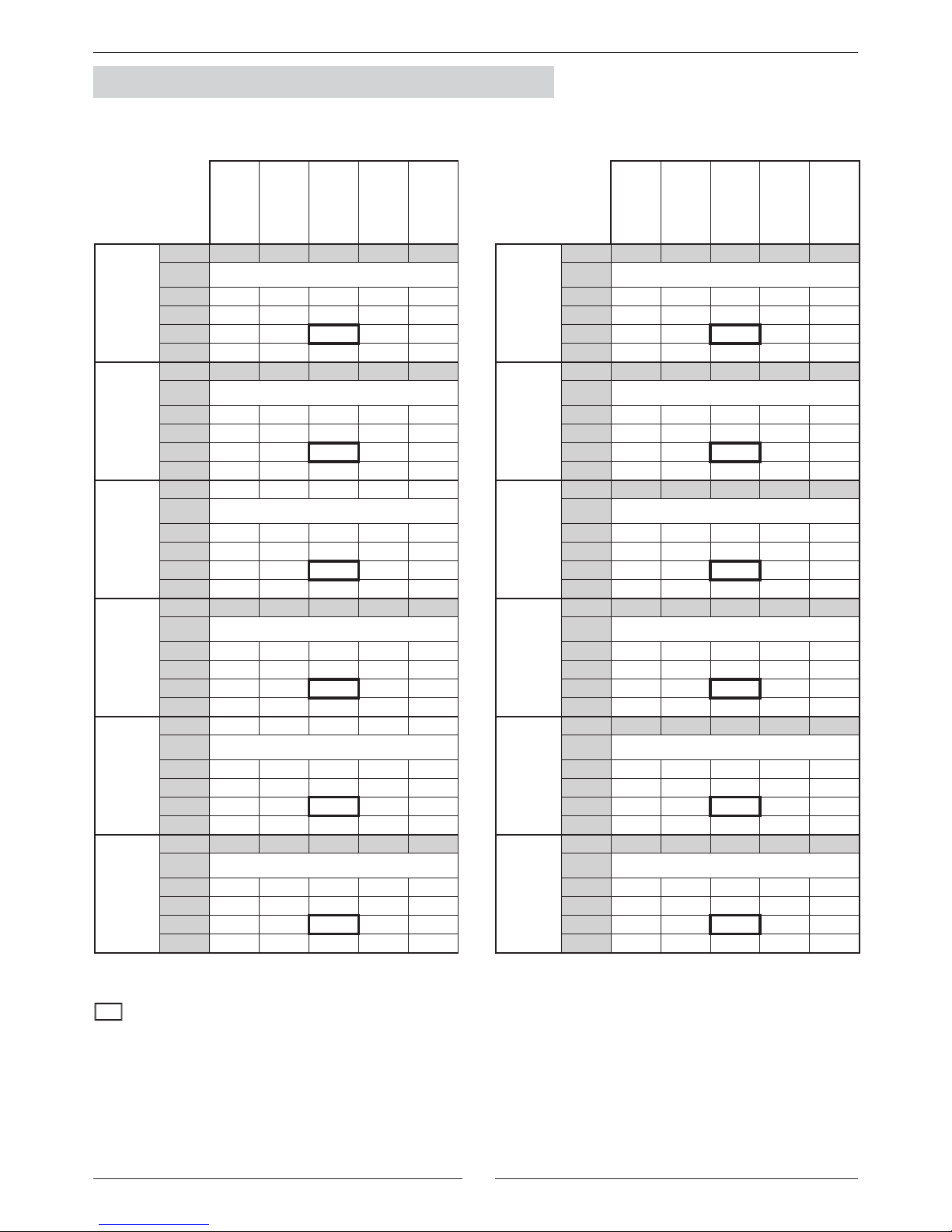

1.3.- FAN PERFORMANCES

1.3.1.- STANDARD FAN PERFORMANCES

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

1. GENERAL CHARACTERISTICS

7

020S

1098 1051 1003 956 909

3150 324 294 264 237 211

3425 321 289

261

233 207

3700 317 285 257 229 202

4100 310 279

249

222 193

025S

1098 1051 1003 956 909

4250 308 276 246 218 190

4625 301 269

239

209 180

5000 292 260 228 197 167

5500 278 244

211

178 146

030S

1098 1051 1003 956 909

4650 290 259 228 198 169

5050 280 248

215

184 154

5450 269 235 201 169 138

6000 249 213

178

143 109

035S

937 888 838 788 738

6200 321 281 241 203 167

6650 313 272

232

193 155

7100 306 262 221 181 142

8050 282 236

191

148 105

040S

937 888 838 788 738

6950 298 255 214 174 135

7550 283 240

197

155 113

8150 267 221 176 132 88

9050

•

186

138

90 43

045D

1041 986 931 876 820

6950 371 318 267 217 168

7550 353 298

244

190 139

8150 330 271 215 158 103

9050 316 258

199

141 84

055D

1041 986 931 876 820

9950 357 313 272 232 194

10825 349 304

263

223 185

11700

•

295 253 213 173

12850

• •

239

196 156

070D

1041 986 931 876 820

12450 321 276 232 191 151

13550 307 262

217

174 133

14650 291 244 199 154 110

15090

•

236

190

145 101

085D

1041 986 931 876 820

14000 288 242 197 155 112

15125 272 223

177

132 88

16250 253 203 154 107 60

16725 244 193

144

95 48

100D

837 792 748 704 659

17350 323 279 236 196 157

18875 310 264

221

180 140

20400 296 248 204 162 121

22450

• •

178

133 90

120D

837 792 748 704 659

19300 295 249 206 163 123

21000 278 231

186

142 101

22700 258 209 163 118 74

24950 228 176

127

80

35

140D

837 792 748 704 659

21000 322 275 230 186 145

22250 311 262

216

172 128

23500 299 249 202 157 112

24750 286 234

186

139

94

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

1. GENERAL CHARACTERISTICS

1.3.2.- FAN PERFORMANCES WITH KIT HIGH STATIC PRESSURE (OPTIONAL TRANSMISSION)

VENTILATION HP1

Loading...

Loading...