Lennox CIC 040S, CIC 070D, CIC 045D, CIC 055D, CIC 085D Installation, Operation & Maintenance Manual

...Page 1

lennoxemeia.com

COMPACTAIR

CSC - CSH

CDC - CDH

Installation,

operating

and maintenance

Indoor unit

MIL121E-0613 / 11-2014

Translation of original manual

Page 2

1

3

4

1 -

1.1 5

1.2 5

1.3 7

1.4 12

2 -

2.1 14

2.2 14

2.3 15

2.4 15

2.5 15

2.6 16

2.7 17

3 -

3.1 22

4 -

4.1 23

4.2 23

WARNING: Read this manual before carrying out installation, repair or maintenance work.

All the technical and technological information contained in this manual, including any drawings and technical descriptions provided

by us, remain the property of Lennox and must not be utilised (except in the operation of this product), reproduced, issued to or

made available to third parties without the prior written agreement of Lennox.

INSTALLATION

OPERATION

MAINTENANCE MANUAL

TABLE OF CONTENTS

AIRCOOLAIR/COMPACTAIR

INDOOR UNITS

POINTS TO BEAR IN MIND

Manufacturer’s recommended inspections

DATA PAGE FOR COMMISSIONING OF THE UNIT

GENERAL CHARACTERISTICS

Physical data

Electrical data

Fan performance

Unit dimensions

INSTALLATION

Installation guidelines

Optional task prior to unit installation :

regulating airfl ow in the fans

Service space

Drainage

Refrigerant connections

Electrical connections

Installation of options

COMMISSIONING AND OPERATION

Preliminary checks

MAINTENANCE

Preventive maintenance

Fault diagnosis

Page 3

2

POINTS TO BEAR IN MIND

DANGER AND WARNING SIGNS

Abrasive surfaces

Low temperatures High temperatures Risk of injury from

moving objects

Electrical voltage

Risk of injury from

rotating objects

ELECTRICAL CONNECTIONS

To prevent serious electrical injuries, make sure to switch off the power before doing any installation,

repair or maintenance work on the unit.

To install the unit, bear in mind local and national legislation.

ATTENTION - WARNING

Electric shock can cause injury or death. Before attempting

to perform any service or maintenance on the unit, turn

OFF the electrical power, and check that the fan has

stopped.

The air fi lter cleaning operations does not require technical

service; however, when an electrical or mechanical

operation is required, call an Engineer.

CLEANING THE FILTER

Check the air fi lter and make sure

it is not blocked with dust or dirt.

If the fi lter is dirty, wash it in a bowl with neutral soap and

water, drying it in the shade before re-inserting it in the

unit.

Standard Guidelines for Lennox equipment.

All technical data contained in these operating instructions, including diagrams and technical descriptions, remain the property

of Lennox and may not be used (except for the purpose of familiarizing the user with the equipment), reproduced, photocopied,

transferred or transmitted to third parties without prior written authorization from Lennox.

Data published in the operating instructions are based on the latest information available. We reserve the right to make

modifi cations without notice.

We reserve the right to modify our products without notice and with no obligation to modify goods previously supplied.

These operating instructions contain useful and important information for the smooth operation and maintenance of your equipment.

The instructions also include guidelines on how to avoid accidents and serious damage before commissioning the equipment and

during its operation and how to ensure smooth and fault-free operation. Read the operating instructions carefully before starting

the equipment, familiarize yourself with the equipment and with handling the installation and carefully follow the instructions. It is

very important to be properly trained in handling the equipment. These operating instructions must be kept in a safe place near

the equipment.

Like most equipment, the unit requires regular maintenance. This section concerns maintenance personnel and management.

If you have any queries or would like to receive further information on any aspect relating to your equipment, do not hesitate to

contact us.

The manufacturing of these units is made under the requirements of the ISO 9001 and ISO 14001.

Page 4

3

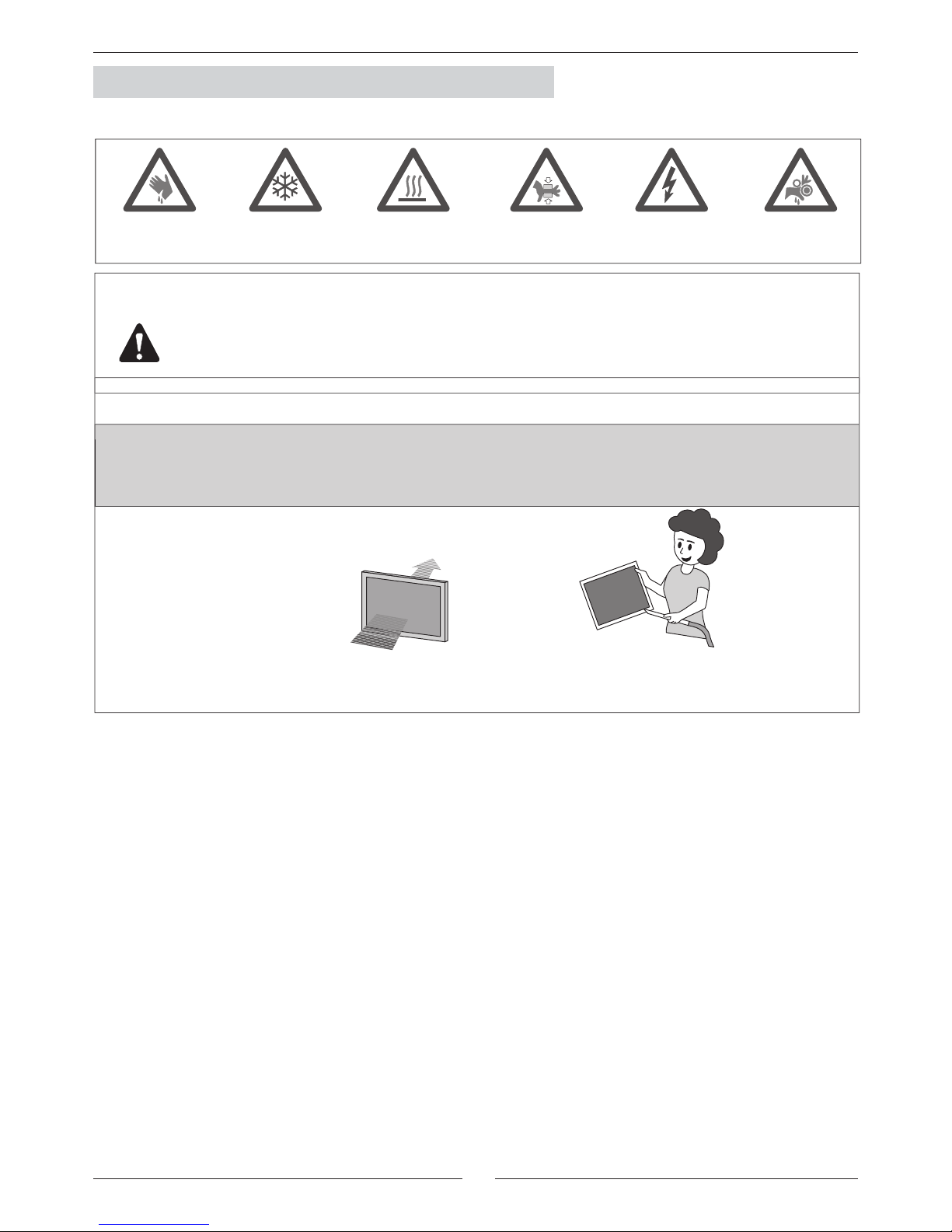

DATA PAGE FOR UNIT COMMISSIONING

COOLING CYCLE

Air fl ow data:

Air intake temperature, Indoor Coil:

ºC

High Pressure:

Low pressure :

HEATING CYCLE

Air fl ow data:

Air intake temperature, Indoor Coil:

ºC

High Pressure:

Low pressure :

YES NO

DRAINAGE WITH TRAP

CLEAN INTERIOR AIR FILTER

GENERAL POWER SUPPLY CONNECTION

DATA INPUT:

ELECTRIC POWER CONSUMPTION (Amps)

Fan indoor section: Fan indoor section:

UNIT: ______________________________________ SERIAL NUMBER : _____________________________

CONTROL PANEL IDENTIFICATION CODE : ______________________________________________________

INSTALLATION ADDRESS: ____________________________________________________________________

INSTALLER : ________________________________ INSTALLER TEL : ______________________________

INSTALLER ADDRESS : _______________________________________________________________________

___________________________________________________________________________________________

COMMISSIONING DATE : _____________________________________________________________________

CHECKS : __________________________________________________________________________________

___________________________________________________________________________________________

SUPPLY VOLTAGE : __________________________ RATED VOLTAGE OF THE UNIT : _________________

Options installed : ____________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

Comments : _________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

Page 5

4

C I C 020 S

N

M

3

M

CIC

CIH

020S 025S 030S 035S 040S 045D 055D 070D 085D 100D 120D 140D

108 111 115 150 160 170 242 259 276 470 480 490

2 2 2 2 2 2 2 3 3 3 3 3

10 10 10 10 10 20 20 20 30 45 45 45

50 50 50 75 75 75 165 165 165 190 190 190

10 10 10 12 16 20 20 24 30 40 40 40

6,5 3 3 5 0 3 3 3 13 13 8 8

6,5 3 8 8 3 6 6 16 21 27 14 14

9,5 8 11 8 6 6 19 24 21 27 40 40

25 25 25 28 28 28 37 37 37 65 65 65

n/a n/a n/a n/a n/a n/a 145 145 145 230 230 230

6 6 6 9 9 9 14 14 14 23

23 23

CIC

CIH

020S 025S 030S 035S 040S 045D 055D 070D 085D 100D 120D 140D

0,74 1,45 1,45 1,89 2,69 2,69 2,69 3,63 5,06 5,06 6,38 6,38

1,40 2,59 2,59 3,45 4,80 4,80 4,80 6,48 8,60 8,60 11,1 11,1

6,44 13,0 13,0 17,3 26,4 26,4 26,4 35,6 60,2 60,2 81 81

3N

~400V

50 Hz

3~400V 50Hz

M:400V/3/50

- - - -

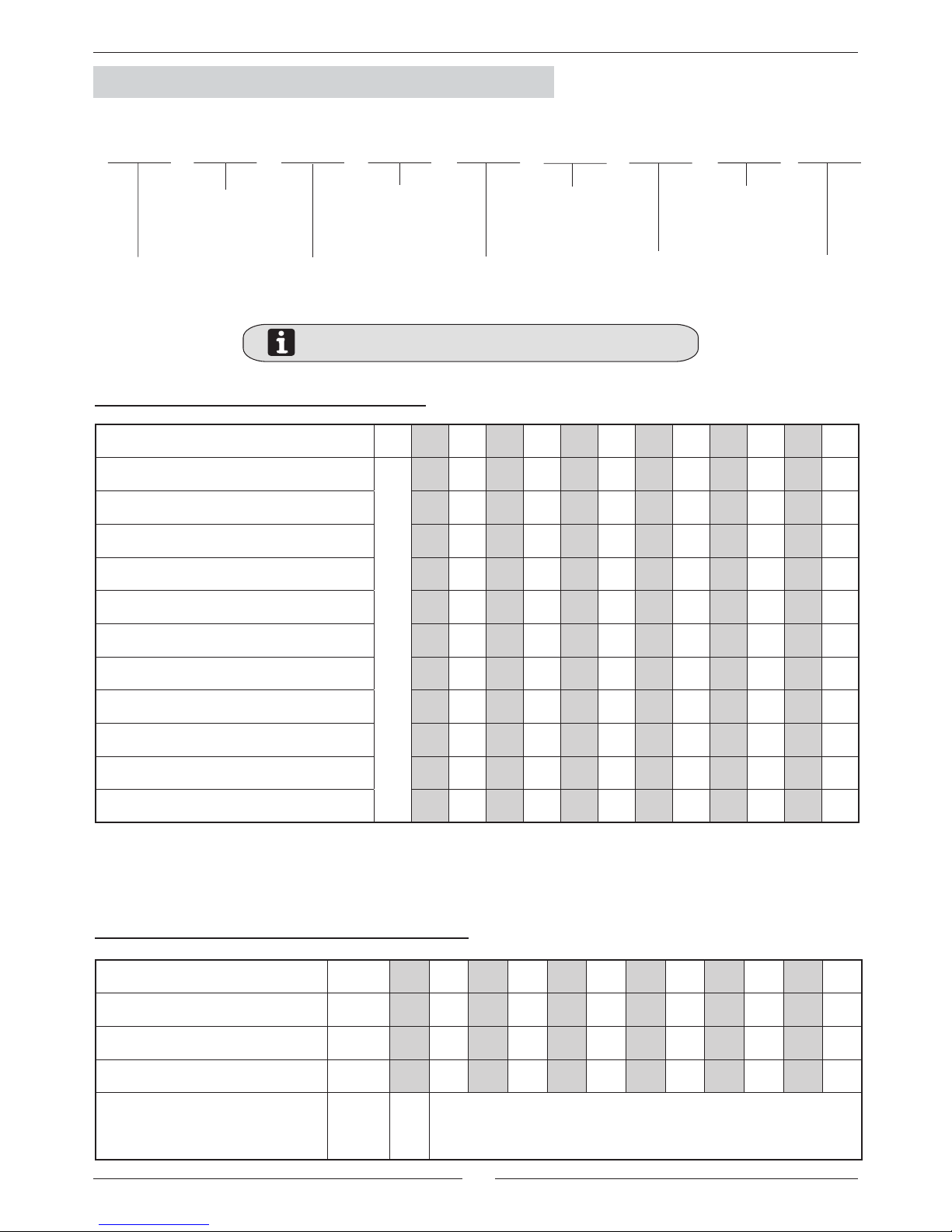

1. GENERAL CHARACTERISTICS

1.1.- PHYSICAL DATA

Type of unit

COMPACTAIR /

AIRCOOLAIR

I: Indoor unit

Type of Refrigerant

M: R-410A

Approximate cooling

capacity in kW.

S: One circuit

D: Two circuits

CIC: Cooling only unit R-410A.

CIH: Heat pump unit R-410A.

1.2.- ELECTRICAL DATA

ELECTRICAL CONSUMPTION FOR STANDARD UNITS

WEIGHT FOR STANDARD UNITS AND OPTIONS

C: Cooling only unit

H: Heat pump unit

Number of revision

MODELS

Indoor unit CIC/CIH

Airsock control

Electrical heater

Free-cooling

Hot water coil kg

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

High effi ciency air fi lter

(G4 prefi ltre/F7 fi ltration)

MODELS

Maximum absorbed power

Kw

Maximum current

A

Start up current

A

Voltage

Ph/V/Hz

n/a: not available

Page 6

5

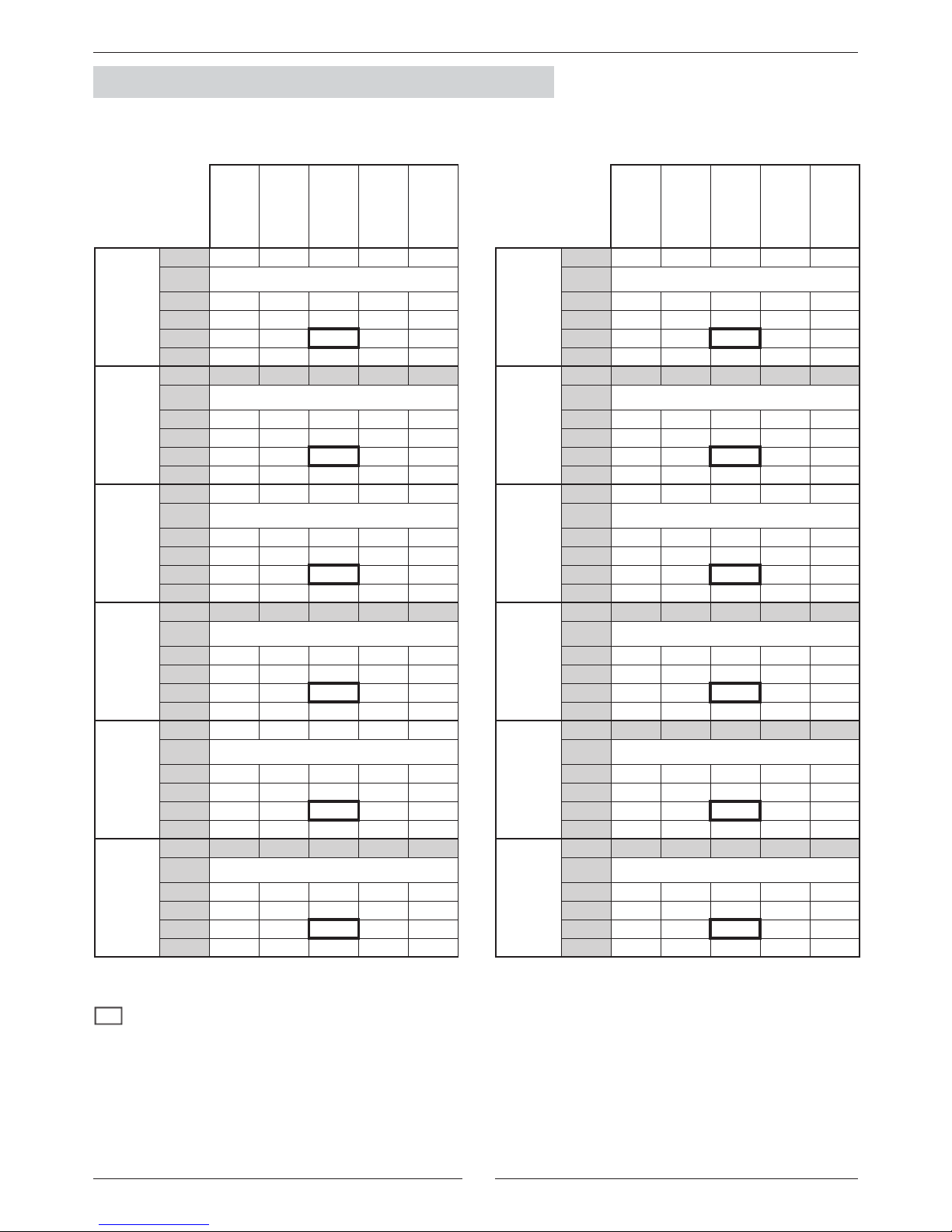

CIC/H 020S CIC/H 025S CIC/H 030S CIC/H 035S

MAP MC MAP MC MAP MC MAP MC

0 0 0 0 0 0 0 0

0,71 1,19 0,44 0,86 0,44 0,86 0,8 1,35

0,71 1,19 1,24 2,21 1,24 2,21 1,74 3,03

1,15 2,05 1,24 2,21 2,18 3,89 1,74 3,03

0,51 2,6 0,51 2,6 0,51 2,6 1,33 6,8

n/a n/a n/a n/a n/a n/a n/a n/a

10 14,3 10 14,3 10 14,3 15 21,5

15 21,5 15 21,5 15 21,5 20 28,6

20 28,6 20 28,6 20 28,6 27 39

CIC/H 040S CIC/H 045D CIC/H 055D CIC/H 070D

MAP MC MAP MC MAP MC MAP MC

0 0 0 0 0 0 0 0

0 0 0,94 1,68 0,94 1,68 1,43 2,12

0,94 1,68 2,37 3,8 2,37 3,8 2,75 4,62

2,37 3,8 2,37 3,8 3,69 3,69 5,16 8,82

1,33 6,8 1,33 6,8 2,65 4,5 2,65 4,5

n/a n/a n/a n/a 2,69 4,8 3,63 6,5

15 21,5 15 21,5 20 28,6 20 28,6

20 28,6 20 28,6 27 39 27 39

27 39 27 39 40 57,8 40 57,8

CIC/H 085D CIC/H 100D CIC/CIH 120D/140D

MAP MC MAP MC MAP MC

0 0 0 0 0 0

1,32 2,5 1,32 2,5 2,41 4,2

3,73 6,7 5,06 8,6 3,74 6,1

3,73 6,7 5,06 8,6 6,38 11,1

2,65 4,5 5,3 9 5,3 9

3,63 6,5 5,06 8,6 6,38 11,1

20 28,6 27 39 27 39

27 39 40 57,8 40 57,8

40 57,8 50 72,3 50 72,3

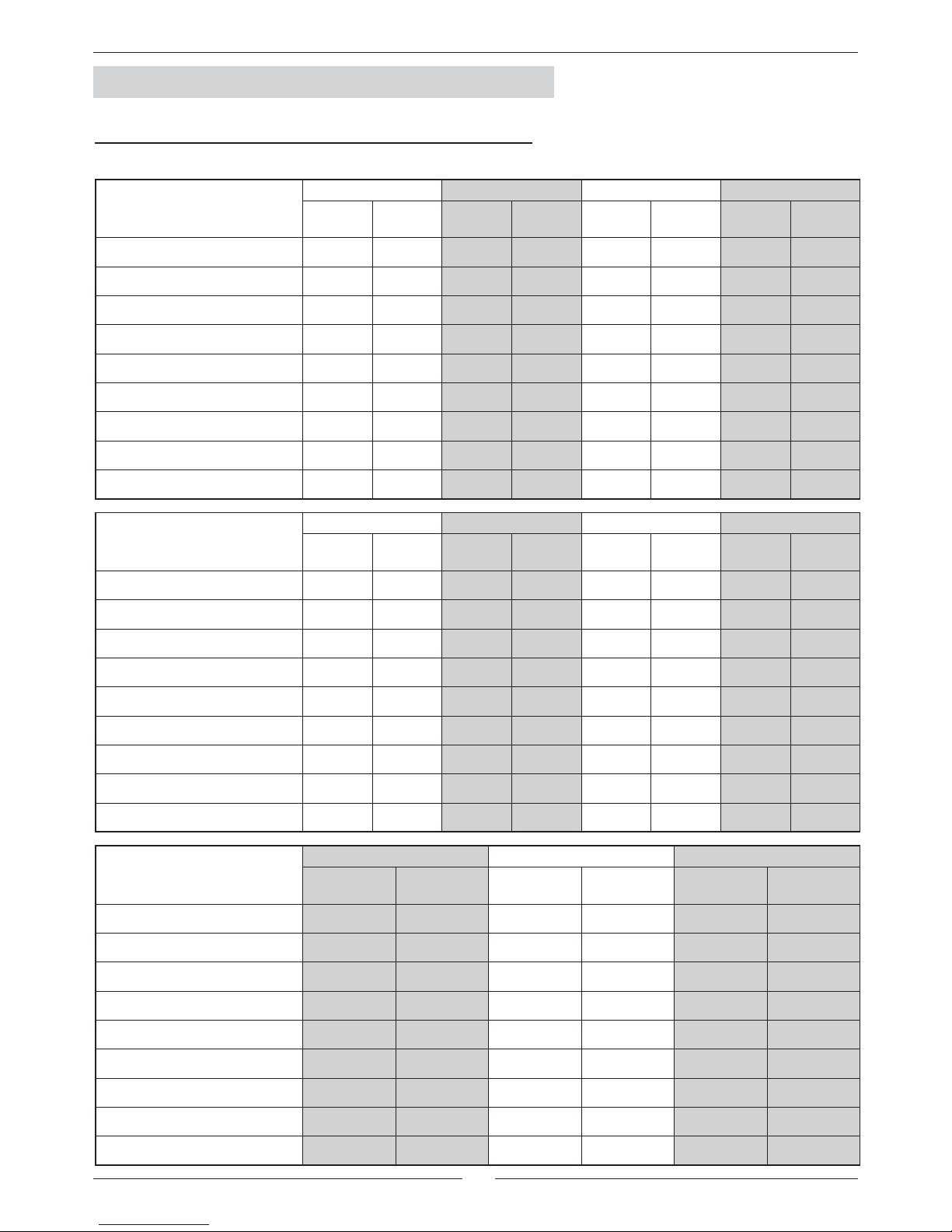

1. GENERAL CHARACTERISTICS

1.2.- ELECTRICAL DATA

ADDITIONAL ELECTRICAL CONSUMPTION FOR THE OPTIONS

kW A kW A kW A kW A

Standard Indoor fan

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

Standard electrical heater

Medium electrical heater

High electrical heater

kW A kW A kW A kW A

Standard Indoor fan

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

Standard electrical heater

Medium electrical heater

High electrical heater

kW A kW A kW A

Standard Indoor fan

Ventilation kit - HP1

Ventilation kit - HP2

Ventilation kit - HP3

Exhaust fan

Return fan

Standard electrical heater

Medium electrical heater

High electrical heater

MAP Maximum absorbed power MC Maximum current

Page 7

6

020S

824 788 753 717 682

3150 167 149 132 116 101

3425 162 143

127

109 93

3700 155 138 120 103 85

4100 • 127

108

90 72

025S

824 788 753 717 682

4250 141 123 103 84 66

4625 129 109

89

69 49

5000 115 92 71 50 28

5500 89 66

42

19 n/a

030S

915 876 836 797 757

4650 173 149 125 103 80

5050 158 133

109

84 60

5450 141 115 89 63 38

6000 • 84

56

28 0

035S

735 704 672 640 609

6200 164 142 119 98 77

6650 153 130

106

83 61

7100 139 114 89 66 42

8050 102 75

48

22 n/a

040S

837 792 748 704 659

6950 213 178 143 109 75

7550 196 158

122

86 50

8150 175 136 97 58 21

9050 136 94

53

10 n/a

045D

937 888 838 788 738

6950 272 227 183 140 97

7550 249 201

155

109 63

8150 • 171 121 72 23

9050 • •

103

51 1

055D

837 792 748 704 659

9950 206 177 148 122 96

10825 195 166

138

110 83

11700 185 154 125 97 68

12850

136

105

75 45

070D

937 888 838 788 738

12450 237 200 163 128 95

13550

•

183

145

109 73

14650

• •

124 85 48

15090

• •

115

75 36

085D

937 888 838 788 738

14000 202 163 125 87 51

15125 182 142

102

62 23

16250 160 117 75 34 n/a

16725 149 105

63

20 n/a

100D

750 710 670 630 591

17350 237 202 167 133 101

18875 223 185

149

115 81

20400

•

168 131 94 59

22450

• •

100

63 25

120D

750 710 670 630 591

19300

207 169 133 98 64

21000

187 48

111

73 38

22700

164 124 84 46 9

24950

•

87

46

5 n/a

140D

750 710 670 630 591

21000

231 192 155 117 82

22250

218 178

140

101 65

23500

204 163 123 84 46

24750

•

146

105

65 25

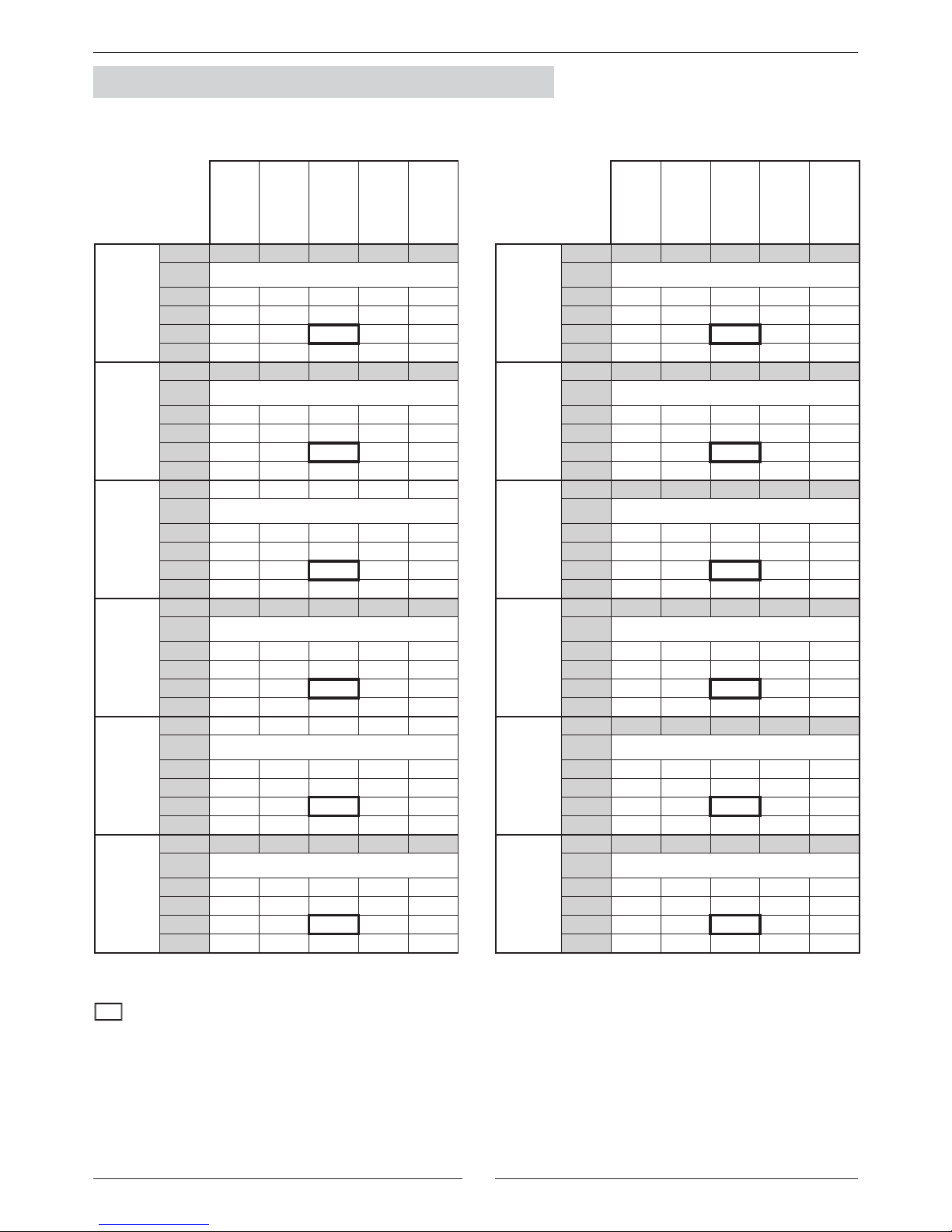

1.3.- FAN PERFORMANCES

1.3.1.- STANDARD FAN PERFORMANCES

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

1. GENERAL CHARACTERISTICS

Page 8

7

020S

1098 1051 1003 956 909

3150 324 294 264 237 211

3425 321 289

261

233 207

3700 317 285 257 229 202

4100 310 279

249

222 193

025S

1098 1051 1003 956 909

4250 308 276 246 218 190

4625 301 269

239

209 180

5000 292 260 228 197 167

5500 278 244

211

178 146

030S

1098 1051 1003 956 909

4650 290 259 228 198 169

5050 280 248

215

184 154

5450 269 235 201 169 138

6000 249 213

178

143 109

035S

937 888 838 788 738

6200 321 281 241 203 167

6650 313 272

232

193 155

7100 306 262 221 181 142

8050 282 236

191

148 105

040S

937 888 838 788 738

6950 298 255 214 174 135

7550 283 240

197

155 113

8150 267 221 176 132 88

9050

•

186

138

90 43

045D

1041 986 931 876 820

6950 371 318 267 217 168

7550 353 298

244

190 139

8150 330 271 215 158 103

9050 316 258

199

141 84

055D

1041 986 931 876 820

9950 357 313 272 232 194

10825 349 304

263

223 185

11700

•

295 253 213 173

12850

• •

239

196 156

070D

1041 986 931 876 820

12450 321 276 232 191 151

13550 307 262

217

174 133

14650 291 244 199 154 110

15090

•

236

190

145 101

085D

1041 986 931 876 820

14000 288 242 197 155 112

15125 272 223

177

132 88

16250 253 203 154 107 60

16725 244 193

144

95 48

100D

837 792 748 704 659

17350 323 279 236 196 157

18875 310 264

221

180 140

20400 296 248 204 162 121

22450

• •

178

133 90

120D

837 792 748 704 659

19300 295 249 206 163 123

21000 278 231

186

142 101

22700 258 209 163 118 74

24950 228 176

127

80

35

140D

837 792 748 704 659

21000 322 275 230 186 145

22250 311 262

216

172 128

23500 299 249 202 157 112

24750 286 234

186

139

94

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

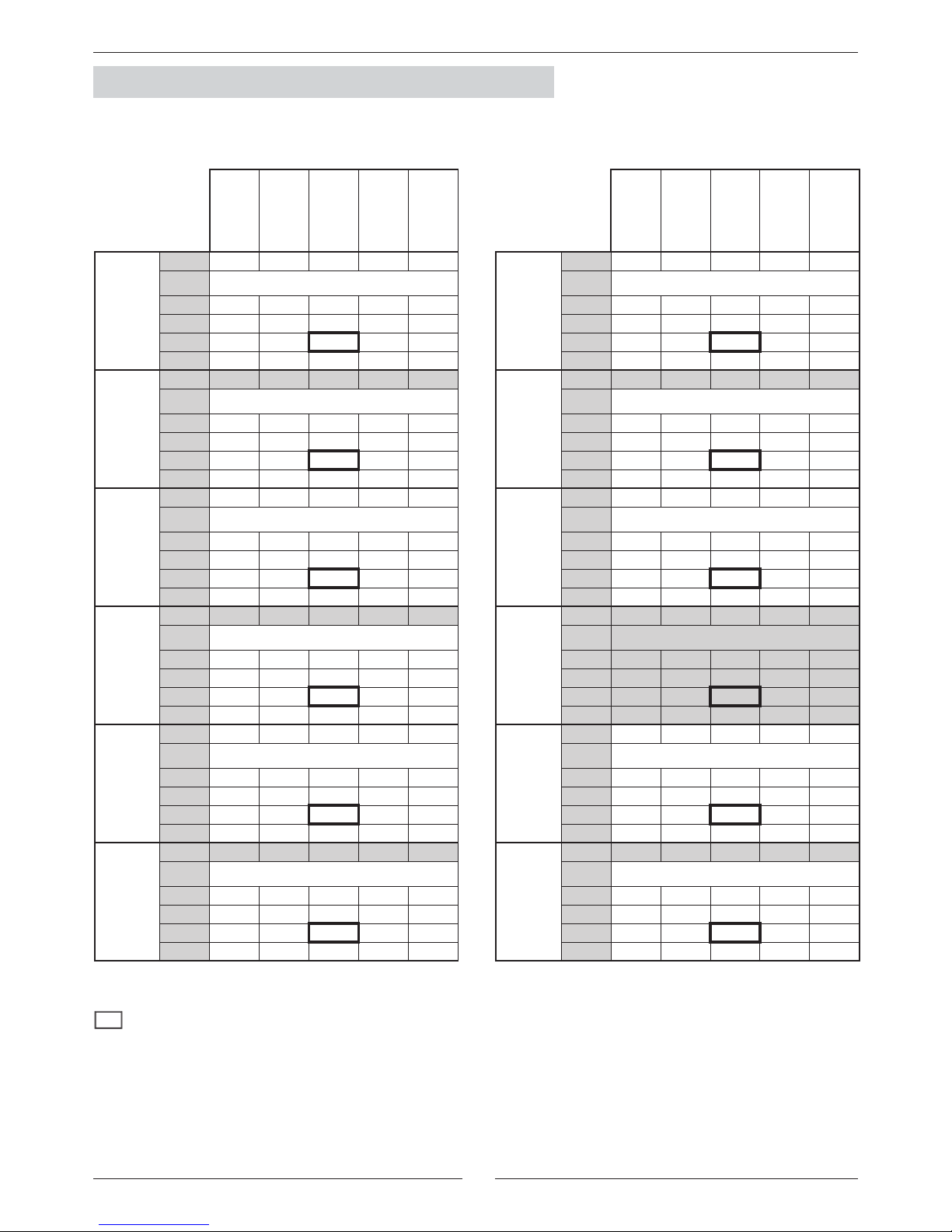

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

1. GENERAL CHARACTERISTICS

1.3.2.- FAN PERFORMANCES WITH KIT HIGH STATIC PRESSURE (OPTIONAL TRANSMISSION)

VENTILATION HP1

Page 9

8

020S

1177 1126 1075 1024 974

3150

377 342 309 278 247

3425

373 338

306

273 243

3700

369 334 302 269 239

4100

364 329

295

263 232

025S

1318 1261 1204 1147 1091

4250

466 423 381 341 303

4625

461 418

375

335 295

5000

•

412 368 327 287

5500

• •

•

314 273

030S

1339 1268 1197 876 1055

4650

468 413 359 309 261

5050

462 405

352

299 250

5450

454 396 341 289 238

6000

441 383

325

270 216

035S

1103 1044 986 927 869

6200

469 414 362 313 266

6650

463 408

356

305 257

7100

458 402 348 297 247

8050

442 383

327

272 220

040S

1103 1044 986 927 869

6950 449 393 340 289 239

7550 440 382

327

275 223

8150 427 370 312 257 203

9050 405 344

284

225 168

045D

1103 1044 986 927 869

6950 432 373 317 263 211

7550 415 355

296

240 184

8150 395 332 271 211 152

9050 384 320

256

195 134

055D

1172 1109 1047 985 923

9950 514 456 399 346 296

10825 508 448

391

338 286

11700 500 440 383 328 275

12850

• •

369

313 258

070D

1172 1109 1047 985 923

12450 371 421 363 307 252

13550 470 408

348

289 233

14650 457 391 329 268 208

15090 450 383

320

258 196

085D

1172 1109 1047 985 923

14000 452 390 328 268 211

15125 438 371

307

245 183

16250 418 349 282 215 150

16725 408 338

270

202 135

100D

937 888 838 788 738

17350 477 419 364 312 262

18875 469 410

354

299 248

20400 458 398 341 284 232

22450 440 379

319

261 206

120D

937 888 838 788 738

19300 454 396 339 284 232

21000 442 381

323

267 213

22700 426 364 304 246 190

24950 402 337

276

215

157

140D

937 888 838 788 738

21000 486 425 367 311 257

22250 479 416

357

300 245

23500 469 407 346 287 231

24750 460 395

334

274

215

1. GENERAL CHARACTERISTICS

1.3.2.- FAN PERFORMANCES WITH KIT HIGH STATIC PRESSURE (OPTIONAL TRANSMISSION)

VENTILATION HP2

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

Page 10

9

020S

1318 1261 1204 1147 1091

3150 483 438 397 357 319

3425 478 434

393

353 316

3700 474 430 389 349 312

4100 469 425

383

343 305

025S

1500 1420 1340 1261 1181

4250

•

550 485 423 365

4625

•

545

480

418 359

5000

•

541 475 412 352

5500

•

532

466

402 339

030S

1500 1420 1340 1261 1181

4650

•

535 469 408 349

5050

•

529

463

399 340

5450

•

521 455 391 330

6000

•

511

443

376 313

035S

1250 1183 1117 1051 985

6200

•

548 483 421 362

6650

•

545

478

415 355

7100

•

539 472 408 347

8050

•

526

456

390 326

040S

1250 1183 1117 1051 985

6950 602 530 463 399 339

7550 594 522

453

388 326

8150 586 512 442 376 311

9050 570 493

421

351 283

045D

1250 1183 1117 1051 985

6950 589 515 446 381 317

7550 578 501 430 363 295

8150 562 485 411 340 270

9050

553 475 400 326 255

055D

1339 1268 1197 1126 1055

9950 689 612 539 471 406

10825 683 606 533 464 398

11700 677 599 525 457 390

12850

670 590 515 444 376

070D

1339 1268 1197 1126 1055

12450 662 582 508 437 370

13550 652 573

497

424 354

14650 641 561 484 408 336

15090 636 555

477

400 328

085D

1339 1268 1197 1126 1055

14000 636 557 478 406 336

15125 623 542

464

387 315

16250 609 526 445 367 289

16725 602 518

436

357 279

100D

1041 986 931 876 820

17350 606 537 469 407 346

18875 599 529

461

396 334

20400 592 519 451 384 321

22450

•

504

433

364 299

120D

1041 986 931 876 820

19300 587 516 447 382 319

21000 576 503

433

367 303

22700 564 489 418 350 284

24950 543 467

393

322 255

140D

1041 986 931 876 820

21000 620 547 477 411 347

22250 615 541

471

402 337

23500 608 533 462 392 326

24750 601 525

451

380 313

1. GENERAL CHARACTERISTICS

1.3.2.- FAN PERFORMANCES WITH KIT HIGH STATIC PRESSURE (OPTIONAL TRANSMISSION)

VENTILATION HP3

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

Page 11

10

020S-025S-030S 035S-040S-045D 055D-070D-085D

2000 2500 2750 3000 3500 4000 6000 7000 8000

160 105 75 210 180 130 260 200 90

100D 120D-140D

13200 14300 15400 16500 13200 14300 15400 16500

230 200 150 50 230 200 150 50

055D

755 715 675 635 595

9950

255 230 207 184 162

10825

257 232

208

184 162

11700

260 234 210 184 160

12850

260 233

207

180 155

070D

755 715 675 635 595

12450

260 235 208 182 157

13550

260 233

205

176 150

14650

258 228 198 168 140

15090

255 225

195

165 135

085D

755 715 675 635 595

14000

260 230 202 173 145

15125

255 225

195

165 135

16250

250 215 183 153 120

16725

•

212

178

145 115

100D

672 636 601 565 529

17350 293 263 234 205 178

18875 293 261

232

202 173

20400 291 258 227 196 166

22450

•

251

218

185 153

120D

766 725 684 644 603

19300 381 343 305 268 232²

21000 380 340

300

263 227

22700 380 337 297 257 220

24750 373 330

287

245 205

140D

766 725 684 644 603

21000 380 340 300 263 227

22700 380 337

297

257 220

24750 373 330

287

245 205

1.3.3.- FAN PERFORMANCES WITH FREE-COOLING

Return fan performances for each models are:

Air fl ows with exhaust fan for option “free-cooling without return fan”

1. GENERAL CHARACTERISTICS

Models

Airfl ow

m3/h

Available static pressure

(Pa)

Models

Airfl ow

m3/h

Available static pressure

(Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

CLOSED PULLEY

1 TURN

2 TURNS

3 TURNS

4 TURNS

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

rpm

m

3

/h

Available static pressure (Pa)

(●) WRONG STATUS ON ACCOUNT OF MOTOR POWER LIMIT.

NOTE: With long distance kit option, the unit should not operate below its nominal airfl ow.

NOMINAL FACTORY SETTING.

Page 12

11

346 190

407

3

8

7

4

00

7

50

213

346

191

603

1

00

5

3

8

7

400

4

0

7

645

1195

53

8

5

104

.

5

467

455.

5

5

3

4

188.5

455.5

1445

1260

53

1

40

0

5

8

0

4

4

5

5

5

9

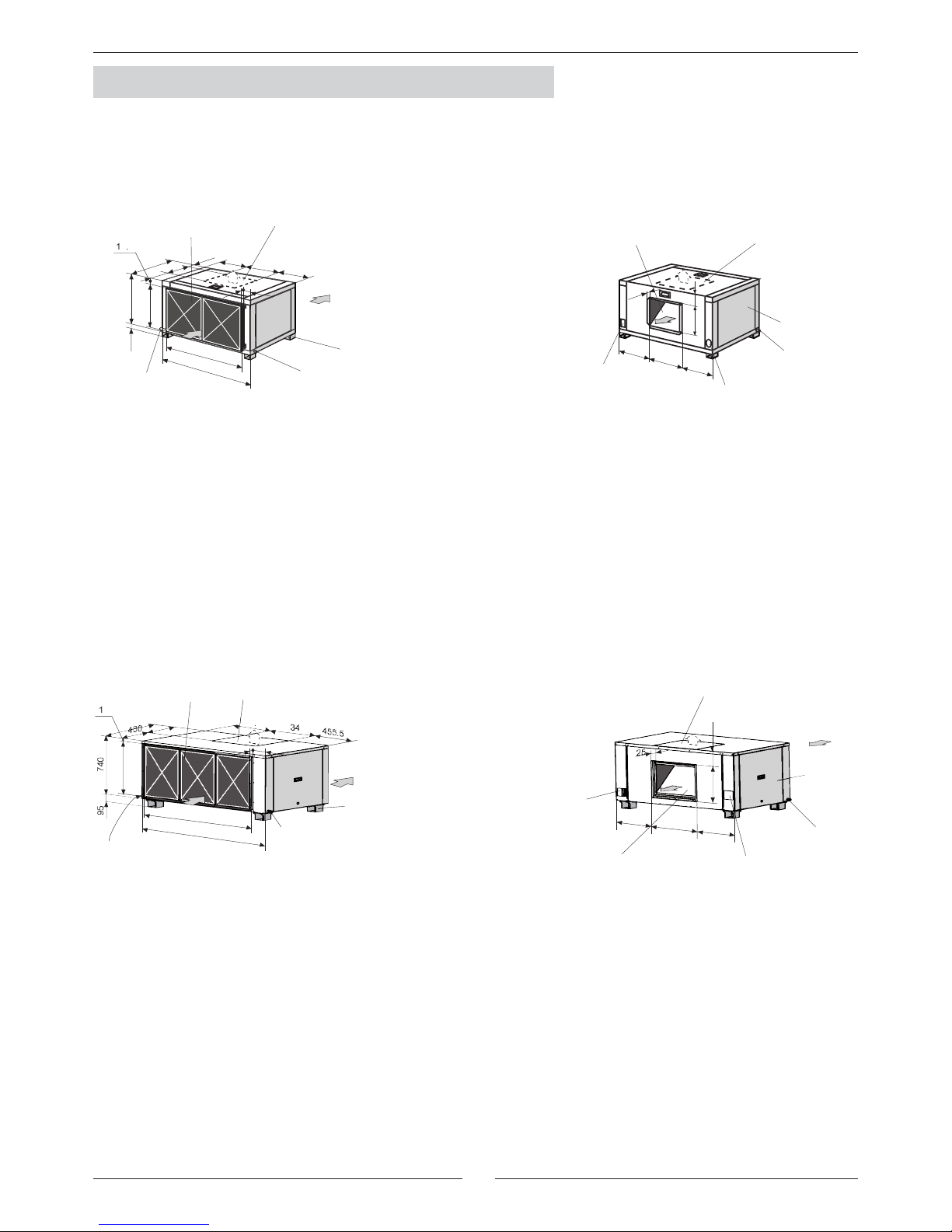

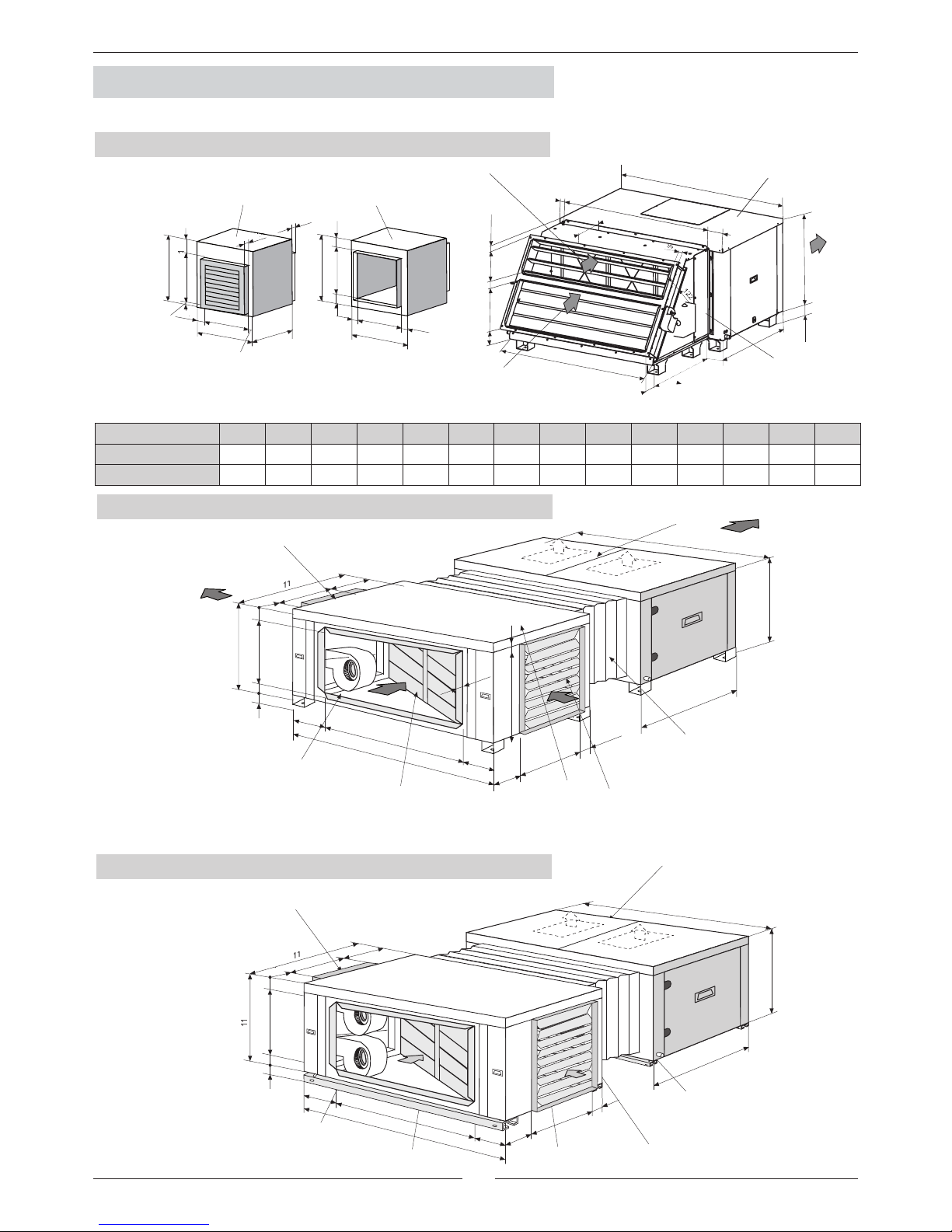

MODELS 020S-025S-030S

MODELS 035S-040S-042S-045D

VERTICAL DISCHARGE

(OPTIONAL)

HORIZONTAL DISCHARGE

STANDARD

Drainage outside

thread 3/4”

Refrigerant connections

Electrical power supply

Access to motor

Drainage outside

thread 3/4”

VERTICAL DISCHARGE (OPTIONAL)

Refrigerant connections

Electrical power supply

HORIZONTAL DISCHARGE

STANDARD

Access to

motor

Air fi lter

VERTICAL DISCHARGE (OPTIONAL)

Drainage outside

thread 3/4”

Drainage outside

thread 3/4”

Transportation

support

VERTICAL DISCHARGE (OPTIONAL)

Drainage outside

thread 3/4”

Air fi lter

Transportation support

Drainage outside

thread 3/4”

1.4.- UNIT DIMENSIONS

1. GENERAL CHARACTERISTICS

Page 13

12

373 524

203

6

4

1

6

0

3

4

1

2

6

0

3

6

4

1

53

1

2

0

1054

1100

266

0

2900

105

0

5

5

5

6

4

1

6

0

3

4

1

2

6

0

3

6

4

1

3

2

1

7

2

6

1

1

9

5

7

0

9

1

695

740

53

75

2

2

9

1

2

2

5

0

5

3

4

9

5

7

0

5

4

4

4

2

9

1

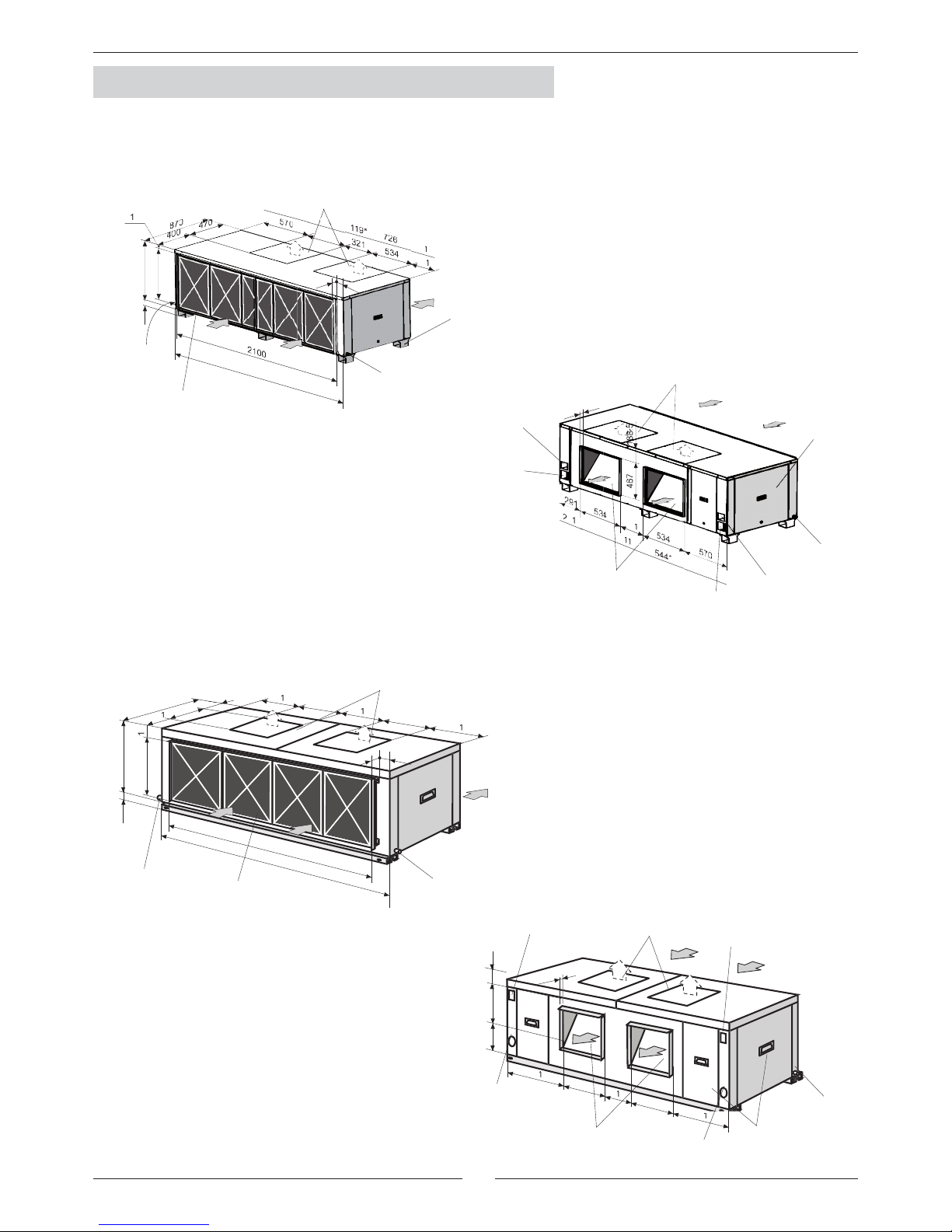

MODELS 060S-070S-055D-070D-085D

MODELS 100D-120D-140D

Air fi lter

Drainage outside

thread 3/4”

VERTICAL DISCHARGE (OPTIONAL)

Drainage outside

thread 3/4”

Air fi lter

Drainage outside

thread 3/4”

VERTICAL DISCHARGE (OPTIONAL)

Drainage

outside

thread 3/4”

Transportation support

HORIZONTAL DISCHARGE STANDARD

VERTICAL DISCHARGE (OPTIONAL)

Electrical power supply

Electrical power supply

Refrigerant connections

Refrigerant connections

Drainage outside

thread 3/4”

Access to motor

VERTICAL DISCHARGE

(OPTIONAL)

Drainage outside

thread 3/4”

HORIZONTAL DISCHARGE (STANDARD)

Refrigerant connections

Electrical power supply

Access to motor

Refrigerant connections

Electrical power supply

* Values with HP2 and HP3 option.

1. GENERAL CHARACTERISTICS

1.4.- UNIT DIMENSIONS

Page 14

13

1

4

2

6

3

5

7

3

2

1

3

B A

7

3

B A

1

2

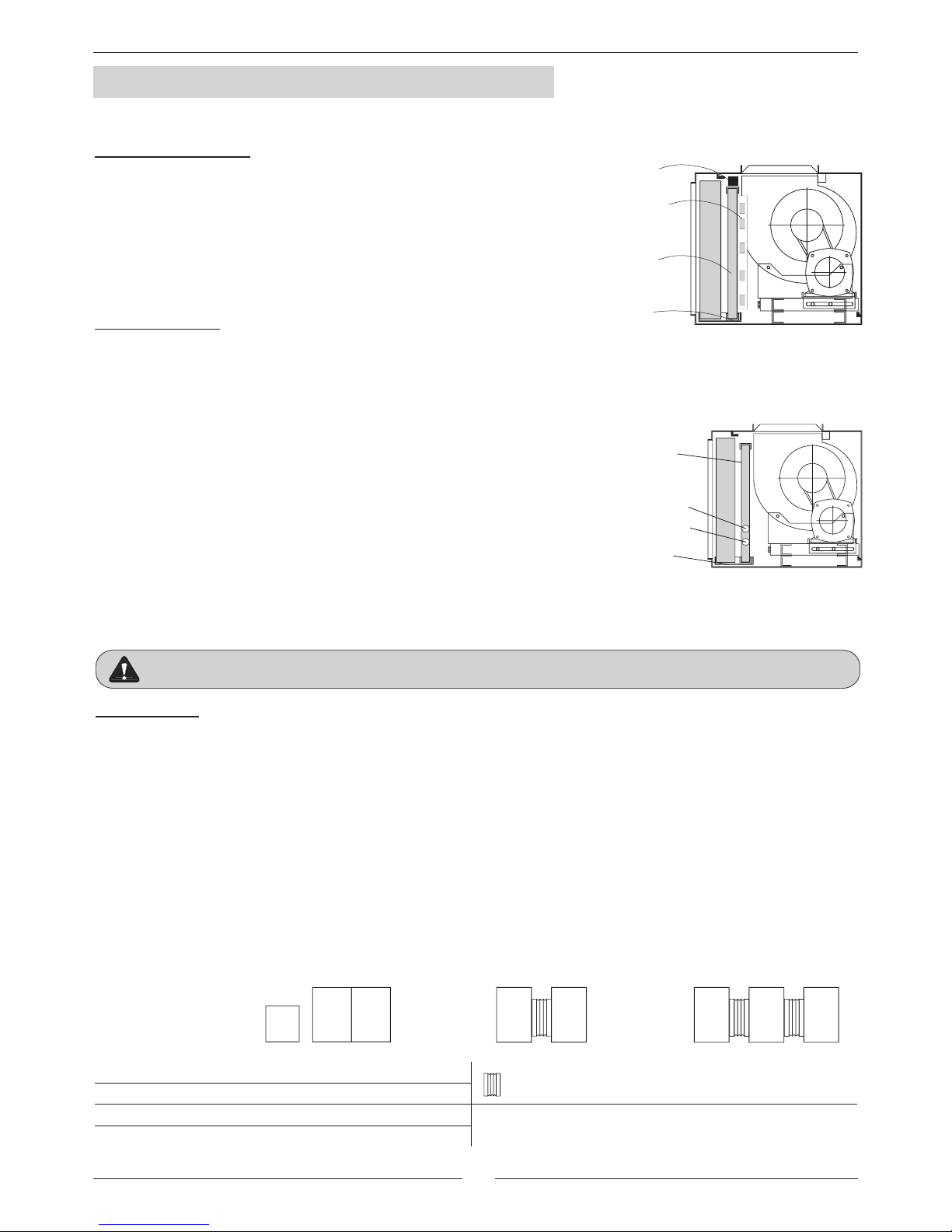

2.1.- INSTALLATION GUIDELINES

2.2.- OPTIONAL OPERATIONS PRIOR TO UNIT INSTALLATION:

VENTILATION FOR CIC-CIH UNITS IS PROVIDED BY:

1.- Centrifugal fan (single or double).

2.- Drive motor.

3.- Pulley fi xed to the fan.

4.- Adjustable pulley on the fan motor.

5.- Pulley belt.

6.- Base of the motor with displacement system for tensioning belts.

7.- Tensioning screw.

The unit must be transported in a HORIZONTAL POSITION on its metal legs. Any other position may cause serious damage to

the machine. When the unit is received, it should be checked to ensure that there are no knocks or other damage, following the

instructions on the packaging. If there is damage, the unit may be rejected by notifying the LENNOX Distribution Department and

explaining on the transport agent’s delivery notice why the machine is unacceptable. Any complaint or claim made subsequently to

the LENNOX Distribution Department for this type of anomaly cannot be considered under the Guarantee.

Suffi cient space must be allowed to facilitate placement of the unit.

ALL INSTALLATION, SERVICE and MAINTENANCE operations must be carried out by QUALIFIED PERSONNEL.

When positioning the unit, be sure that the Rating Plate will always be visible since this data will be necesary to

assure proper maintenance.

The units are designed to be installed with ducts, calculated by qualifi ed technical staff. The joints to be used between ducts and

the openings to the unit should be Elastic Joints. Avoid the use of BYPASS joints between the extraction air and input air in both the

outdoor and indoor sections. The structure where the unit is placed must be able to support the weight of the unit during operation.

If there are problems of height, the transport supports can be removed by unscrewing them from

the base

(Units 020S to 085D).

REGULATING AIRFLOW AT THE FANS

The unit fan has an adjustable pulley on the drive motor so that, when the fan is switched off, the pulley diameter can be adjusted

to modify the unit’s air fl ow, as required.

1. Fixed part.

2. Moving part.

3. Fixing screw.

CLOSE PULLEY:

To increase the air fl ow from the fan,

turn the moving part in direction “B”. (Clockwise).

OPEN PULLEY:

To reduce airfl ow, turn in direction “A”. (Anticlockwise).

TENSION OF BELTS

The belts can be easily tensioned by means of the tensioning screw incorporated into the

base of the motor in the transmission unit, which also makes it easy to carry out servicing

properly.

When the tensioning screw is turned, the fan motor is moved sideways in order to tension

the pulley.

ADJUSTABLE PULLEYS

SIMPLE PULLEY

DOBLE PULLEY

DISPLACEMENT

2. INSTALLATION

Page 15

14

1m

1m

1m

1m

2%

C1

C2

2.3.- SERVICE SPACE

Free space should be left to enable access for servicing, in order to check the installation of

the cables, drainage connections, electrical installation and cleaning fi lters, as well as to give

easy access to the unit.

2.4.- DRAINAGE

All units have a 3/4” steel threaded drainage pipe welded to the condensation tray.

Drainage pipes will be fi tted for each tray through a siphon with a height difference of 80

mm. to avoid drainage problems from the depression formed by the fans. The pipes should

have a 2% slope to enable condensation to be drained easily.

Also tip the unit slightly (2%) toward the drainage side. Check that the condensation trays are clean

and free of dirt and other debris from the installation work and that water drains correctly.

UNIT

Min. 80 mm

Inspection and cleaning cap.

2.5.- REFRIGERANT CONNECTIONS

The unit is supplied with gas and liquid lines, sealed with copper caps.

THE UNITS ARE SUPPLIED WITH NITROGEN GAS. THIS MUST BE REMOVED BEFORE PROCEEDING AS FOLLOWS:

1 Remove the nitrogen gas through the top and bottom 5/16” service ports, leaving a vacuum as a safety measure.

2 Remove the caps from the connecting pipes.

3 Braze the connecting pipes.

(When brazing refrigerant pipes, nitrogen gas must be supplied through the service ports into the pipes to remove

any air).

DURING INSTALLATION OPERATIONS, KEEP GAS AND LIQUID PIPES COVERED, IN ORDER TO PREVENT HUMIDITY AND

DIRT FROM GETTING INTO THEM.

TAKE SPECIAL CARE TO ENSURE THAT REFRIGERANT PIPES ARE INSULATED.

AVOID COLLAPSE ON PIPE LINES INSTALLATION.

- 100D and 120D units model use different sizes of pipe connections: big size

for circuit 1 and small size for circuit 2.

Please be sure to connect indoor unit circuits C1 and C2 to the corresponding C1 and C2 circuits of the outdoor unit.

2. INSTALLATION

Legislation does not allow refrigerant gas emissions to the atmosphere, so the refrigerants have to be recycled to avoid being

released to the atmosphere. Those recycled refrigerants shall be processed afterwards by an authorized waste manager.

Those components derived from the recycling of the unit have to be managed by authorized waste manager or be left in local

waste facilities according the local normative in each country.

Page 16

15

DS

AS

RS

RS HR/T

CO2

DPT

AS HRT

DIFS

LDRP

DADS

BAC

DS

AS

AS

HR/T

DPT

DIFS

RS

3

BAC

2

DADS

LDRP

CO2

RS

HR/T

6

5

4

020

4G x 1,5 mm²

(STD/HP1)

4G x 1,5 mm²

(HP2/HP3)

4G x 2,5 mm²

6G x 1,5 mm²

4G x 6 mm²

6G x 1,5 mm²

4G x 10 mm²

6G x 1,5 mm²

4G x 10 mm²

7G x 1,5 mm²

6G x 1,5mm² 4G x 1,5mm²

N/A

025

030

035

4G x 6 mm²

6G x 1,5 mm²

4G x 10 mm²

6G x 1,5 mm²

040-042

045

055-060

4G x 1,5 mm²

(STD/HP1)

4G x 2,5 mm²

(HP2/HP3)

4G x 10 mm²

6G x 1,5 mm²

4G x 25 mm²

6G x 1,5 mm²

4G x 25 mm²

7G x 1,5 mm²

4G x 1,5mm²

070

085

100

4G x 2,5 mm²

(STD/HP1)

2 x (4G x 2,5 mm²)

(HP2/HP3)

4G x 2,5mm²

120

140

2.6.- ELECTRICAL CONNECTIONS

- BEFORE MAKING ANY ELECTRICAL CONNECTIONS, BE SURE THAT ALL CIRCUIT BREAKERS ARE OPEN.

- IN ORDER TO CARRY OUT THE ELECTRICAL CONNECTIONS, FOLLOW THE ELECTRICAL DIAGRAM SUPPIED WITH THE

UNIT.

CONNECTION OF CONTROL ELEMENTS:

VOLTAGE OPERATING LIMITS: 342-462V

To be connected by installer

POWER SUPPY

COMPONENT

Nr WIRES X SECTION

Discharge sensor STANDARD 2 x 1 mm² (shielded)

Remote ambient sensor STANDARD 2 x 1 mm² (shielded)

Remote duct sensor OPTION 2 x 1 mm² (shielded)

Duct remote sensor for enthalpic free-cooling OPTION 6x 1 mm² (shielded)

CO2 Air quality probe. (Available only with enthalpic free-cooling). OPTION 4 x 1 mm² (shielded)

Air differential pressure transducer OPTION 3 x 1 mm² (shielded)

Remote ambient sensor for enthalpic free-cooling OPTION 6 x 1 mm² (shielded)

Dirty fi lter sensor OPTION 3 x 1.5 mm² (shielded)

Long distance connection OPTION

3 x 1,5 mm² (1 circuit units)

2 x (3 x 1,5 mm² ) (2 circuits units)

Smoke detector OPTION 7 x 1,5 mm²

Hot water coil OPTION 5 x 1,5 mm²

POWER SUPPLY

FAN

2

ELECTRICAL HEATER 3

FREE-COOLING 4 EXHAUST FAN 5 RETURN FAN 6

STANDARD MEDIUM HIGH MODULATING

2. INSTALLATION

Page 17

16

*

055D-140D

* *

055D-140D020S-045D

MS

EF

IU

MS

IU

RS MS IU

EF

MS

RS

*

IU

HOT WATER COIL

PROTECTION AGAINST FREEZING:

• Use glycol water. GLYCOL IS THE ONLY EFFECTIVE

PROTECTION AGAINST FREEZING.

This kit includes a safety thermostat with a probe located inside the hot

water coil. When the temperature drops below 4ºC, the unit will stop in

order to protect the hot water coil and to prevent the unit from working

with very low evaporating temperatures.

Five wires must be added between indoor and outdoor unit with this

option.

Hot water coil includes regulating valve:

- ON/OFF for standard and multi split.

- Proportional (0-10V).

You must ensure that manual or automatic air vents have been

installed on all high points in the system. In order to drain the system,

check that drain valves have been installed at all low points of the

system.

Location of the hot

water coil once

installed

Water inlet

Water outlet

Support

2.7.- OPTIONS INSTALLATION

ELECTRICAL HEATER

The electrical heater must be supplied from the unit’s

electrical box.

Safety thermostat

Small panel for contactors

and connections

Location of the electrical

heater once installed

Support

A HEATING COIL FROZEN DUE TO LOW AMBIENT CONDITIONS IS NOT COVERED BY THE WARRANTY.

INDOOR UNIT

FREE COOLING

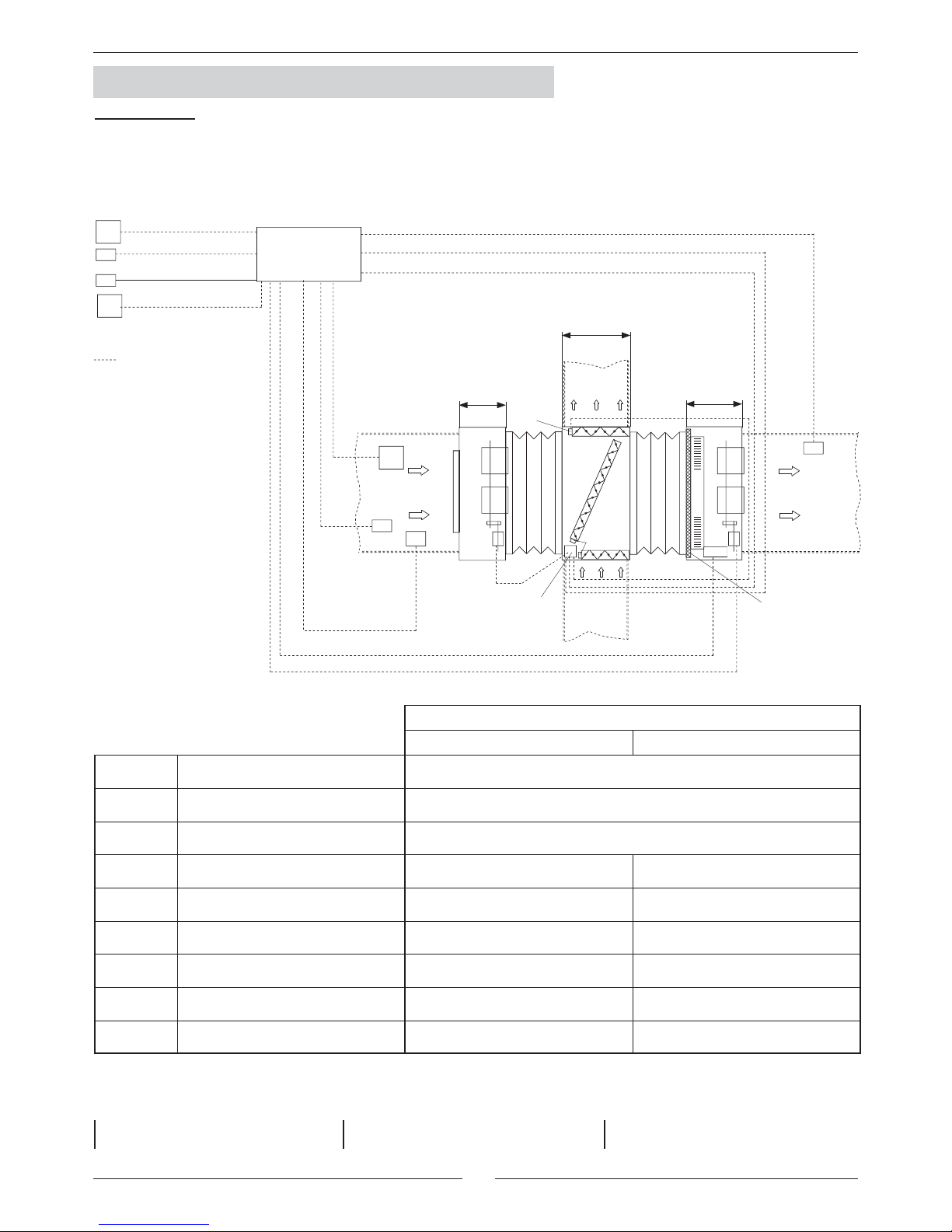

1.- OPERATION

The control compares the values of temperature/enthalpy between outside air and room air by means of the probes; if there is a

negative difference and the safety elements allow (discharge temperature probes) then the control acts on the servomotor, which

opens the outside damper and closes the return damper, allowing cool outside air to enter the room.

The damper is proportionally regulated.

If there is not a great demand for air indoors, it may be enough just to have free cooling to condition the room. If there is a greater

demand for air, the free cooling and the unit may need to be working in different cooling mode stages.

2.- SUPPLY AND INSTALLATION

The free cooling option can be delivered as a packaged system or as a split system.

The mixing section will be delivered with the unit for models 020S to 045D and as a split system for the remaining models.

Return fan section will be delivered with the unit.

Confi guration of free cooling supply:

2. INSTALLATION

Exhaust fan

Flexible duct to be installed by the customer.

Mixing section

Return fan section

*

Mixing and return fan sections can be together or not.

Indoor unit

Page 18

17

DM

FM

OS

HR/T

OS

AS

AS

HR/T

DPT

CO

2

RS

RS

HR/T

DS

EFM

EFM

3x1.5

4 x 1.5

FM

DM

CO

2

RS

RS

HR/T

DPT

DS

OS

HR/T

OS

AS

AS

HR/T

≥1m

DM EFM FM

THERMOSTATIC AND ENTHALPIC FREE-COOLING WITHOUT RETURN FAN

CIC/CIH 020S TO 045D

THERMOSTATIC AND ENTHALPIC FREE-COOLING WITHOUT RETURN FAN

CIC/CIH 055D TO 140D.

C60 VERSION

FRESH AIR INTAKE

OUTDOOR UNIT

DISCHARGE AIR

DUCT

RETURN AIR DUCT

AIR FILTER

HEATER

MIXING SEC-

TION

INDOOR UNIT

ELECTRICAL

BOX

2x1 Shielded

2x1 Shielded

DISCHARGE AIR

DUCT

HEATER

MIXING SECTION

INDOOR UNIT

OUTDOOR UNIT

RETURN AIR

DUCT

FRESH AIR

INTAKE

ELECTRICAL

BOX

AIR FILTER

5x1 Shielded

2x1 Shielded

2x1 Shielded

5x1 Shielded

3x1 Shielded

3x1 Shielded

2x1 Shielded

5x1 Shielded

ELECTRICAL BOX

ELECTRICAL BOX

3x1 Shielded

3x1 Shielded

5x1 Shielded

2x1 Shielded

6x1.5+3x1.5 (With EFM)

4x1 Shielded

2x1 Shielded

2x1 Shielded

6Gx1 Shielded

To be wired by the

installer

To be wired by the

installer

The drawings show the side

view

The drawings show the top

view

5x1.5 (Standard version)

2x1 Shielded

2x1 Shielded

4X1.5 (4x2.5, 100D and 140D models)

6x1.5+4x1.5 (With EFM)

5x1.5 (Standard version)

2. INSTALLATION

FREE-COOLING

Damper actuator Exhaust fan motor Indoor fan motor

Page 19

18

FMRFM

CO

2

RS

RS

HR/T

OS

HR/T

OS

AS

AS

HR/T

4X2.5

DPT

4X2.5

DM

DS

DM

3x1

DM RFM FM

DS

OS

AS

RS

RS HR/T

CO2

DPT

OS HR/T

AS HR/T

To be wired by the

installer

The drawings show the top

view

2. INSTALLATION

FREE-COOLING

THERMOSTATIC AND ENTHALPIC FREE-COOLING WITH RETURN FAN

CIC/CIH 055D TO 140D

FRESH AIR

INTAKE

DISCHARGE AIR

DUCT

HEATER

INDOOR UNIT

RETURN AIR

DUCT

DISCHARGE

AIR

RETURN SECTION

AIR FILTER

5x1 Shielded

2x1 Shielded

2x1 Shielded

5x1 Shielded

3x1 Shielded

3x1 Shielded

2x1 Shielded

ELECTRICAL

BOX

MIXING SECTION

ELECTRICAL BOX

2x1 Shieled

6x1.5+4x2.5 (With EFM)

5x1.5 (Standard version)

OUTDOOR UNIT

Damper actuator Return fan motor Indoor fan motor

Free-Cooling

Thermostatic Enthalpic

Discharge sensor Standard

Outdoor sensor Standard

Remote ambient sensor Standard

Duct sensor

Option

it replaces AS

N/A

Duct remote sensor N/A

Option

It replaces AS HR/T

CO2 Air quality probe N/A Option

Air differential pressure transducer Option Option

Outdoor sensor N/A Standard

Remote ambient sensor N/A Standard

Page 20

19

740

87

0

23

2

.5

8

0

4

1

13.5

1

8

1.5

490

47

8.5

28 679 28

312

1

62

6

312

679

38

5

0

2

2

5

0

2

2

5

0

A B C D E F G H I J K L M N

020S-030S

1000 148,5 291 38,5 138 74,5 1027 92,5 1194 640 749 789,5 100 307

035S-045D

1250 129,3 311,3 41 229,4 34 1282 129 1445 735 870 791 110 314

525

3

9

0

5

0

0

17

22.5

5

0

0

4

9

4

0

2

4

9

5

0

0

8

7

.

5

A

C

K

L

B

F

G

H

I

N

D

E

M

24

1100

1050

2

33

803

114

147

507

496

45 1010

45

312.5

22

75

31

2.5

1008

38

5

0

2

9

0

0

2

9

0

0

MODELS 055D-070D-085D

INDOOR UNIT

SECTION OF FLEXIBLE

DUCT TO BE INSTALLED

BY THE CUSTOMER

2100 x 698mm

2

OUTDOOR AIR

DAMPER

MIXING SECTION

DISCHARGE FRAME

490x508x40

EXHAUST FAN (OPTION)

RETURN AIR

An exhaust fan may be included with free cooling without return

fan.

FREE-COOLING WITHOUT RETURN FAN

The position of the damper may be different from the one shown in the picture. See drawings.

RETURN AIR

MIXING SECTION

EXHAUST FAN

(View front)

INDOOR UNIT

OUTDOOR AIR

EXHAUST FAN

(View back)

MODELS 020S to 045D

MODELS

MODELS 100D-120D-140D

INDOOR UNIT

OUTDOOR AIR DAMPER

MIXING SECTION

DISCHARGE FRAME

803x1008x40

EXHAUST FAN (OPTION)

RETURN AIR

SECTION OF FLEXIBLE

DUCT TO BE INSTALLED

BY THE CUSTOMER

2660 x 1054mm

2

2. INSTALLATION

Page 21

20

740

8

70

232.5

804

113.

5

3

1

2

3

1

2

28 679

4

90

47

8.5

18

1.5

5

0

2

2

5

0

6

5

0

2

2

5

0

1626

95

28

1100

1050

233

8

0

3

114

1008

148

2

275

148

45

1010

80

3

2

14.5

0

13

2.50

5

0

2

9

0

0

3

8

INDOOR UNIT

OUTDOOR AIR

DAMPER

RETURN DAMPER

RETURN AIR

SECTION OF FLEXIBLE DUCT TO

BE INSTALLED BY THE CUSTO-

MER

1626 x 679mm

2

SECTION OF FLEXIBLE

DUCT TO BE INSTALLED

BY THE CUSTOMER

2100 x 698 mm

2

DISCHARGE FRAME

DISCHARGE AIR

DIMENSIONS FREE-COOLING WITH RETURN FAN

MODELS 055D-070D-085D

2. INSTALLATION

MODELS 100D-120D-140D

INDOOR UNIT

SECTION OF FLEXIBLE

DUCT TO BE INSTALLED

BY THE CUSTOMER

2275 x 1010 mm

2

SECTION OF FLEXIBLE

DUCT TO BE INSTALLED

BY THE CUSTOMER

2660 x 1054 mm

2

DISCHARGE FRAME

803x1008x40

DISCHARGE AIR

OUTDOOR AIR

DAMPER

RETURN DAMPER

RETURN AIR

Page 22

21

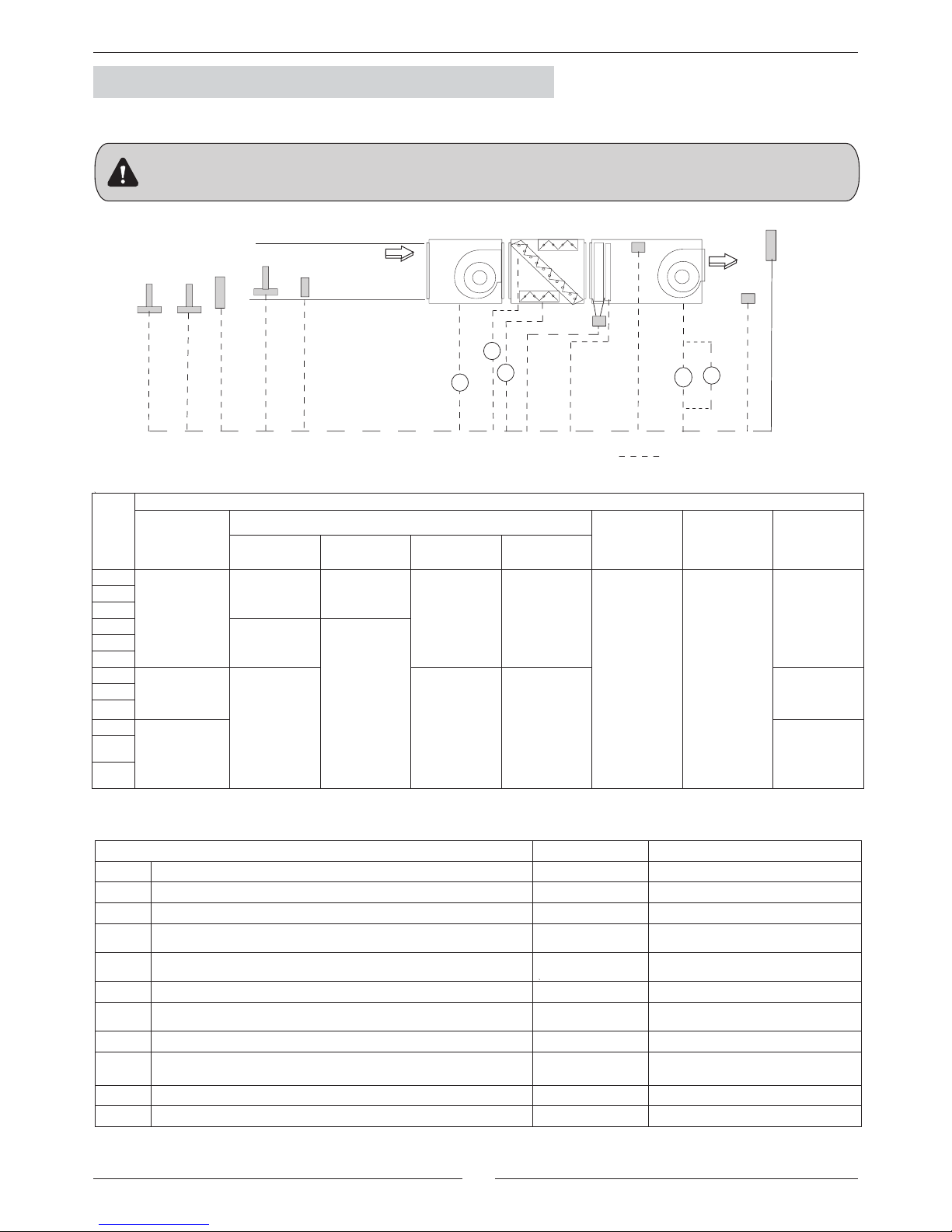

3. COMMISSIONING AND OPERATION

3.1.- PRELIMINARY CHECKS BEFORE FIRST OPERATION

1. Check that drainage connections and their fi xtures are secure and that the level of the unit is tipped toward the drain.

2. Inspect the condition of the ducts and grilles (grilles are clean and clear of obstructions, no breaks in the duct, etc.).

3. Check that the power supply is the same as stated on the Rating Plate and is in accordance with the electrical diagram for the

unit and that cable sizes are correct.

4. Check that the electrical connections are tightened onto their terminals and to earth.

Inspect the Air Filter, which should be in its housing and correctly positioned (the metal grille should be facing inwards).

5. Check with your hand that the fan turns freely.

SKETCH FOR THE STANDARD UNIT CONFIGURATION IN DOUBLE CIRCUIT UNITS

LOCATION

The unit can be installed outside (if an outdoor kit installation has been ordered). If this is installed, air entry and exit ducts should

be fi tted. The indoor unit should be assembled on bases that have been prepared beforehand. It should stand on absorbent and

anti-vibration material to avoid vibrations being transmitted to the structure of the building.

DISCHARGE IN THE UNIT

MODELS 045D TO 140D

Always to be done through a common duct or plenum.

INDOOR SECTION

DISCHARGE AIR

INDOOR SECTION

FLEXIBLE JOINT IN OUTLETS

RETURN AIR DUCT

INTERNAL FAN ACCESS

DRAIN PIPE

TRAP

Page 23

22

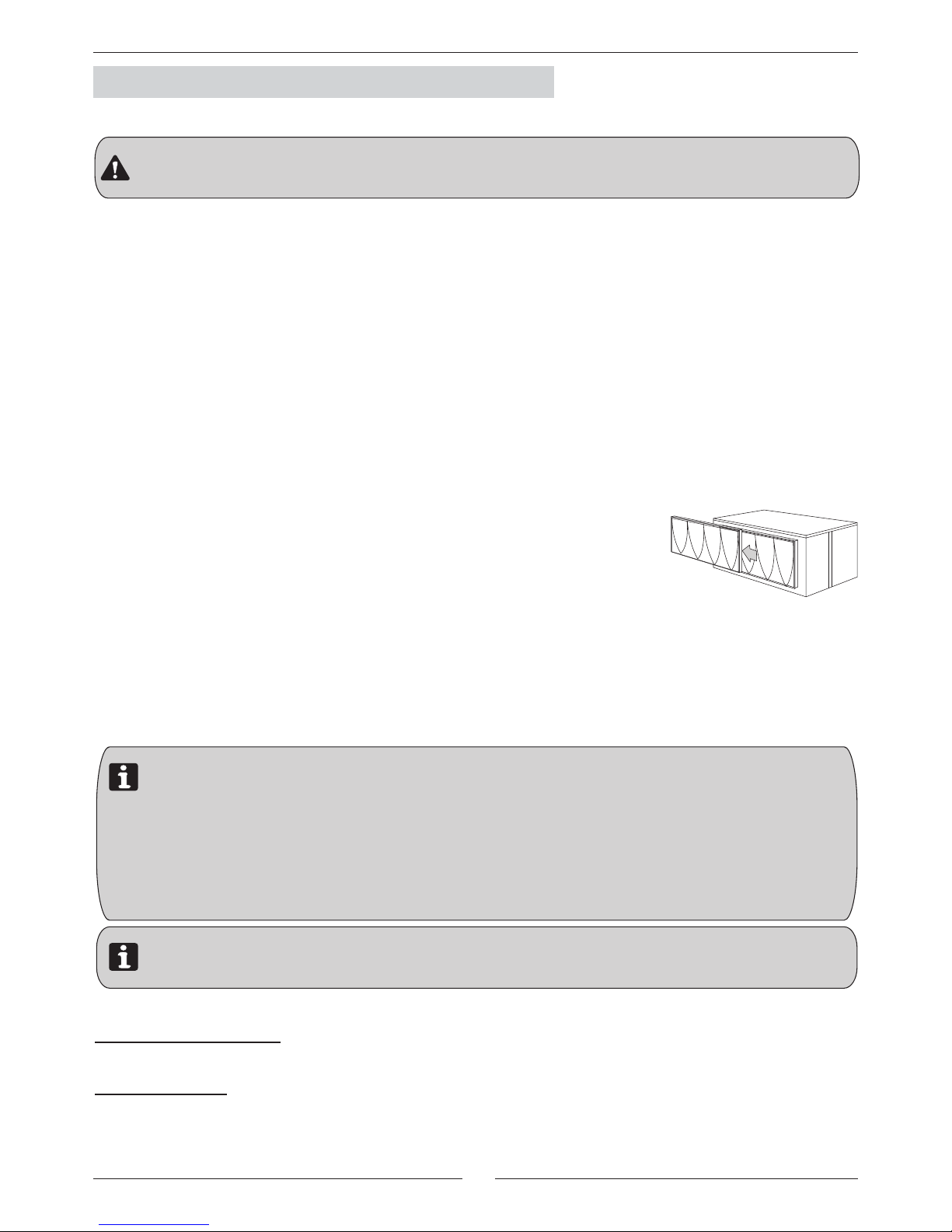

4.1.- PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE HELPS TO AVOID COSTLY REPAIRS, SO PERIODIC INSPECTIONS ARE REQUIRED:

GENERAL CONDITION OF THE HOUSING:

Fittings, paintwork, damage from knocks, rust spots, levelling and supporting, condition of the shock absorbers, if installed,

bolted on panels, etc.

ELECTRICAL CONNECTIONS:

Condition of hoses, tightness of screws, earthing, current draw of the compressor and fans and checking that the unit is receiving

the correct voltage.

COOLING CIRCUIT:

Check that pressure values are correct and that there are no leaks. Check that there is no damage to the pipe insulation,

that the state of the batteries is correct and that there are no material clogging the duct and obstructing the air fl ow, etc.

DRAINS:

Check that water drains correctly and that the drain trays are clean.

FAN:

Check that fans turn freely and in the correct direction without excessive noises.

AIR FILTER :

The air fi lter can be removed through the side by sliding it over the rail or downwards.

(See fi gure).

For downwards removal, remove the two profi les that support it (depending on the model)

which are under the fi lter guide rail and screwed onto the unit.

The fi lter should be cleaned with a vacuum cleaner or washed in soapy water.

The frequency for cleaning or changing the air fi lters will depend on the quality air in the area (fumes, vapors, suspended dust

particles, etc.).

Remember that the metal grille should always be toward the inside of the unit.

SIDE REMOVAL

Remember that the Control Panel may program a notifi cation parameter, for cleaning or replacement of air fi lters depending on the number of hours of fan operation in the indoor section.

4. MAINTENANCE

4.2.- FAULT DIAGNOSIS

DIRTY FILTER INDICATION

If the fi lters are dirty, the detector activates an alarm, but only if the fan is ON.

SMOKE DETECTOR

In this case it would initiate shutdown sequence the unit, fully close the return air damper and open the fresh air damper up to 100% and send an alarm signal to the unit.

All the components derived from the recycling of the unit should be managed according local legislation, and have to be

classifi ed and separated while dealt by authorized waste manager or be left in local waste facilities.

Refrigerant fl uids, electronic boards, heat exchangers and the oil extracted from the refrigerant circuit, as well as the

oil recipients used must be recycled as hazardous waste according the local normative through an authorized waste

manager or be left in local waste facilities. The rest of the components considered as non-hazardous wastes must be

recycled according to the corresponding norms.

At the end of its life, the equipment should be recycled in local waste facilities or by an authorized waste manager.

Page 24

lennoxemeia.com

( +7 495 626 56 53

( +34 902 533 920

( +38 044 585 59 10

( +44 1604 669 100

( + 32 3 633 3045

( +33 1 64 76 23 23

( +49 (0) 40 589 6235 13

( + 39 02 495 26 200

( + 31 332 471 800

( +48 22 58 48 610

( +351 229 066 050

LENNOX DISTRIBUTION

( +33 4 72 23 20 00

RUSSIA

SPAIN

UKRAINE

UNITED KINGDOM AND IRELAND

BELGIUM AND LUXEMBOURG

FRANCE

GERMANY

ITALY

NETHERLANDS

POLAND

PORTUGAL

Due to Lennox’s ongoing commitment to quality, the specifi cations,

ratings and dimensions are subject to change without notice and

without incurring liability.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualifi ed installer

and servicing agency

SALES OFFICES :

OTHER COUNTRIES :

Translation of original manual

MIL121E-0613 / 11-2014

Loading...

Loading...