Page 1

CHA/CHP16

Service Literature

Corp. 0109-L2

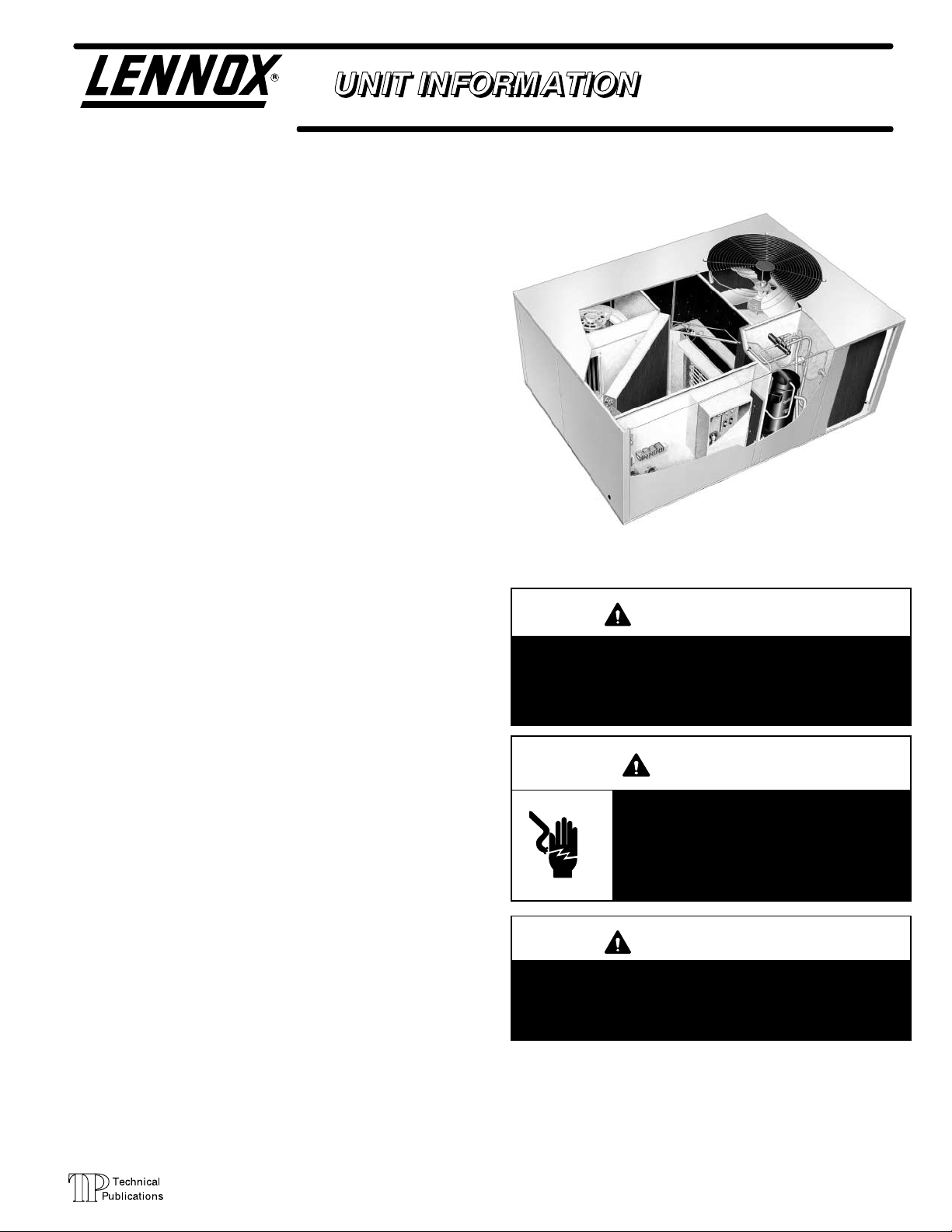

CHA/CHP16, CHP20 SERIES UNITS

CHA/CHP16 and CHP20 series units in the 2 through 5 ton

(7.0 through 17.6 kW) sizes are designed for outdoor roofĆ

top or ground level installations in light commercial applicaĆ

tions. Electric heat is available in several kW sizes. Models

are available in single or three phase power supply and can

be utilized in downflow or horizontal supply and return air.

CHA/CHP16-024/030 model units are equipped with a

reciprocating compressor. CHA/CHP16-036/060 and

CHP20-024/060 model units are equipped with scroll

compressors. The scroll compressor offers high voluĆ

metric efficiency, quiet operation and the ability to start

under system load. Continuous flank contact, mainĆ

tained by centrifugal force, minimizes gas leakage and

maximizes efficiency. The motor is internally protected

from excessive current and temperature.

CHA/CHP16 and CHP20 model units are designed to acĆ

cept any of several different thermostat control systems

with minimum field wiring. Control options such as econĆ

omizer, warm up kit, Honeywell T7300 thermostat or

Honeywell T8600/T8611/T8621 thermostat controls

connect to the unit with jackĆplugs. When plugged in the

controls become an integral part of the unit wiring. Low

voltage thermostat connections facilitate thermostat

field wiring.

Optional electric heat is field installed. Electric heat operĆ

ates in single or multiple stages depending on the kW size.

5kW through 25 kW sizes are available for the CHA/CHP16

and CHP20 units.

Information in this manual is for use by a qualified service

technicial only. All specifications in this manual are subject

to change. Procedures outlined in this manual are repesĆ

ented as a recommendation only and do not supersede or

replace state or local codes.

2 to 5 ton (7.0 to 17.6 kW)

CHP20

IMPORTANT

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personĆ

al injury or loss of life. Installation and service must

be performed by a qualified installer, service agency

or the gas supplier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconĆ

nect switch(es). Unit may have multiple

power supplies.

Page 1

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in personal

injury or death.

2001 Lennox Industries Inc.

Litho U.S.A.

Page 2

TABLE OF CONTENTS

GENERAL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS CHA16 3. . . . . . . . . . . . . . . . . .

SPECIFICATIONS CHP16 4. . . . . . . . . . . . . . . . .

SPECIFICATIONS CHP20 5. . . . . . . . . . . . . . . . . .

OPTIONAL ACCESSORIES CHA/CHP16 6. . . .

OPTIONAL ACCESSORIES CHP20 7. . . . . . . . .

ELECTRICAL DATA CHA16 8. . . . . . . . . . . . . . . .

ELECTRICAL DATA CHP16/20 9. . . . . . . . . . . . .

BLOWER DATA CHA16 10. . . . . . . . . . . . . . . . . . . .

BLOWER DATA CHP16/20 13. . . . . . . . . . . . . . . . .

ACCESSORIES BLOWER DATA 16. . . . . . . . . . . .

I APPLICATION 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

II UNIT COMPONENETS 18. . . . . . . . . . . . . . . . . . . . . .

Control Box 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Components 22. . . . . . . . . . . . . . . . . . . . . . .

Condenser Fan and Indoor Blower 27. . . . . . . . . . .

III OPTIONAL ELECTRIC HEAT 28. . . . . . . . . . . . . . . .

IV PLACEMENT AND INSTALLATION 43. . . . . . . . . . .

V ELECTRICAL CONNECTIONS 43. . . . . . . . . . . . . . .

VI START UP 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII COOLING SYSTEM SERVICE CHECKS 43. . . . . .

VIII HEATING SYSTEM SERVICE CHECKS 44. . . . . .

IX INDOOR BLOWER OPERATION 44. . . . . . . . . . . . .

X MAINTENANCE 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XI ACCESSORIES 46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

XII WIRING AND OPERATION SEQUENCE 52. . . . . .

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit

installation and service to protect the unit's elecĆ

tronic controls. Precautions will help to avoid

control exposure to electrostatic discharge by

putting the unit , the control and the technician at

the same electrostatic potential. Neutralize elecĆ

trostatic charge by touching hand and all tools on

an unpainted unit surface, such as the blower

deck, before performing any service procedure.

Page 2

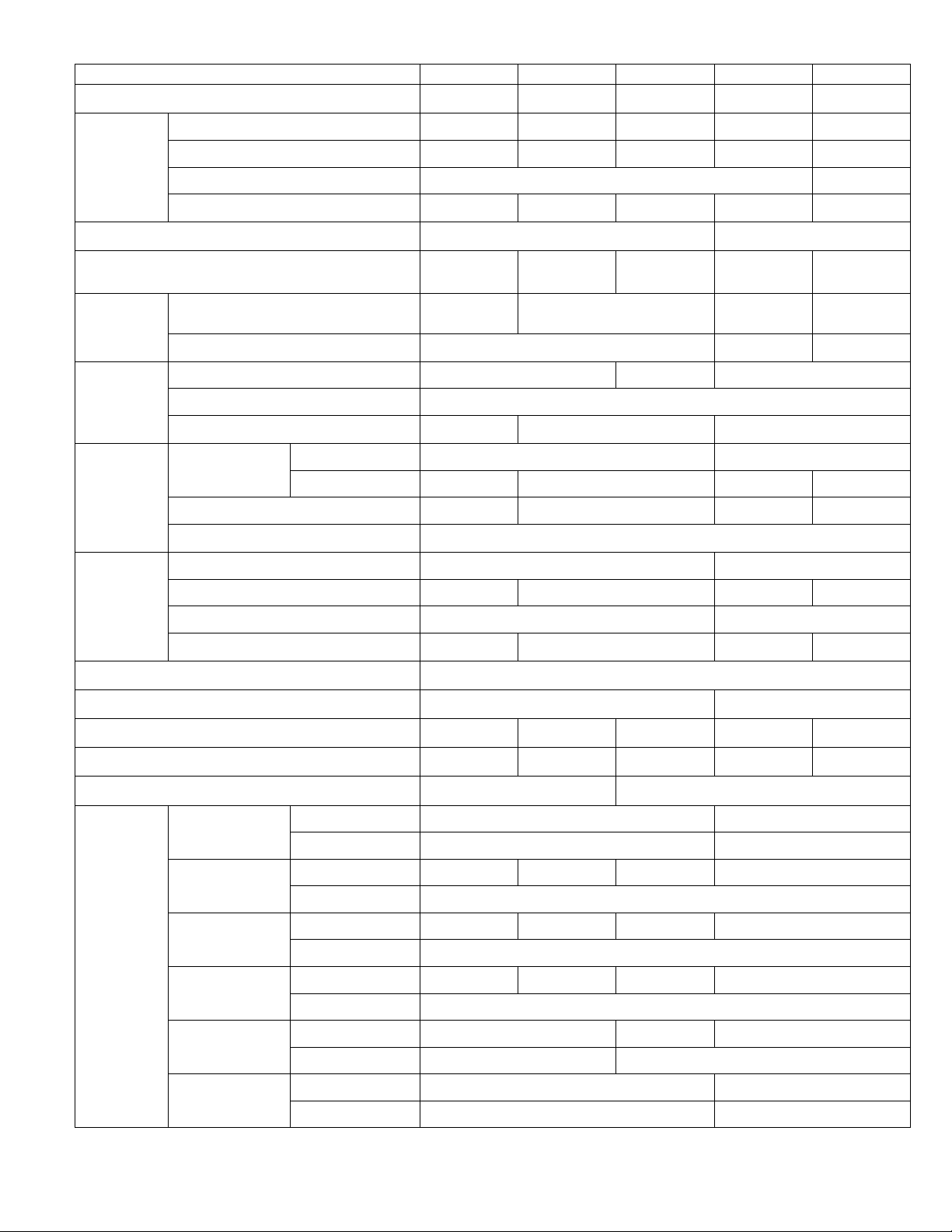

Page 3

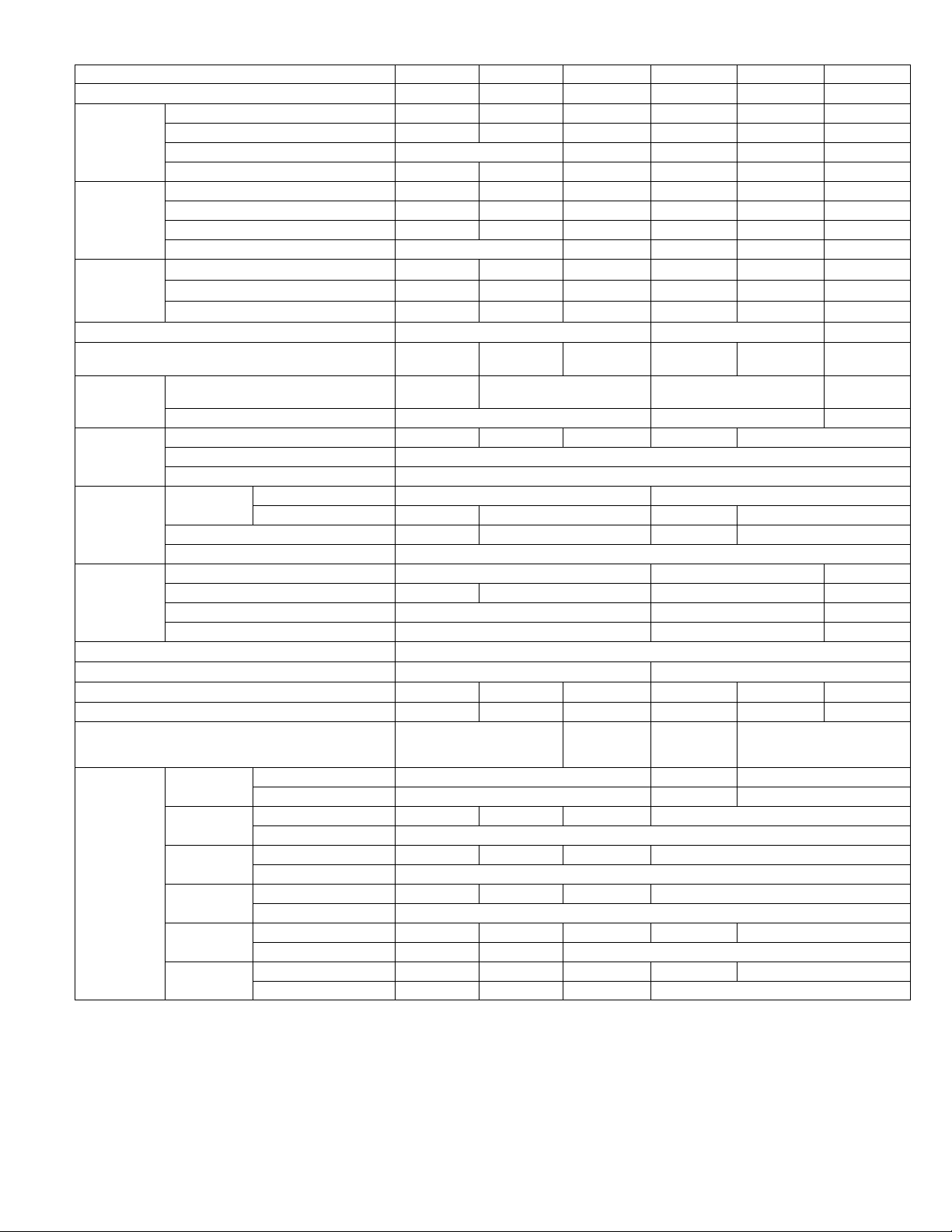

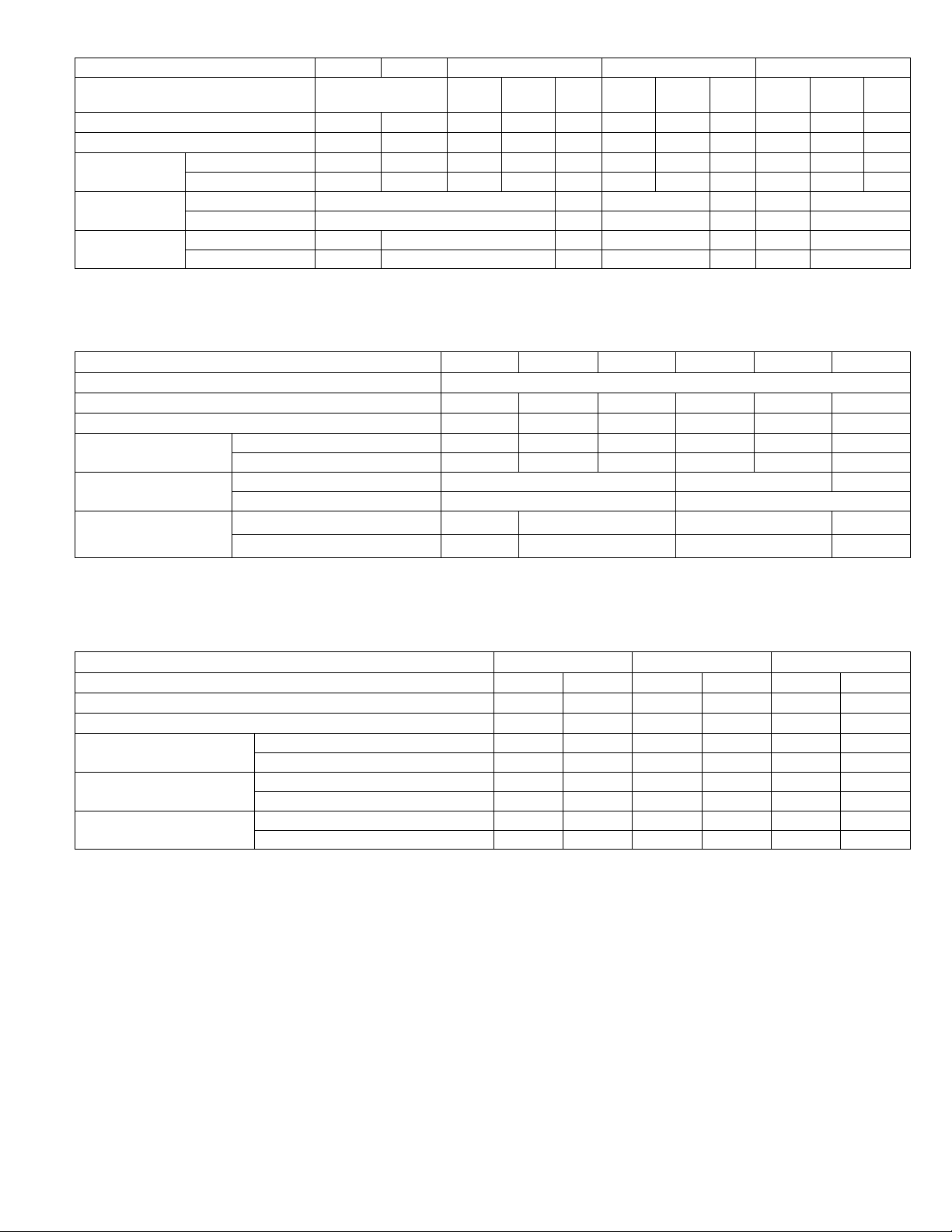

SPECIFICATIONS CHA16

Certified

g

Ratings

Coil

Net face area

Condenser

Condenser

ECH16R-5

ECH16R-7

ECH16R-10

Electric

g

Ratings

Model No. CHA16Ć024 CHA16Ć030 CHA16-036 CHA16-048 CHA16-060

Nominal Tonnage 2 2-1/2 3 4 5

Cooling capacity - Btuh (kW) 22,200 (6.5) 27,600 (8.1) 35,200 (10.3) 45,000 (13.2) 57,000 (16.5)

LARI

Certified

Cooling

Ratin

*Sound Rating Number (db) 80 82

Total unit watts 2550 3210 4045 4890 6065

SEER (Btuh/Watts) 10.0 10.25

s

EER (Btuh/Watts) 8.7 8.6 8.7 9.2 9.4

Refrigerant Charge (HCFC-22)

Blower wheel nominal

Evaporator

Blower

Evaporator

Coil

Condenser

Coil

Condenser

Fan

Condensate drain size mpt - in. (mm) 3/4 (19)

No. & size of cleanable polyurethane filters - in. (mm) (1) 16 x 25 x 1 (406 x 635 x 25) (1) 20 x 25 x 1 (508 x 635 x 25)

diameter x width in. (mm)

Motor horsepower (W) 1/3 (249) 1/2 (373) 3/4 (560)

Net face area - ft.2 (m2) 3.2 (0.30) 4.1 (0.38) 5.8 (0.54)

Tube diameter - in. (mm) & No. of rows 3/8 (9.5) - 2

Fins per inch (m) 15 (591) 17 (669) 15 (591)

Net face area

ft.2 (m2)

Tube diameter - in. (mm) & No. of rows 3/8 (9.5) - 1 3/8 (9.5) - 2 3/8 (9.5) - 1.4 3/8 (9.5) - 2

Fins per inch (m) 20 (787)

Diameter - in. (mm) & No. of blades 20 (508) - 4 24 (610) - 4

Air volume - cfm (L/s) 2400 (1135) 2200 (1040) 4000 (1890) 3600 (1700)

Motor horsepower (W) 1/6 (124) 1/4 (187)

Motor watts 230 220 340 330

Outer coil 8.6 (0.80) 14.3 (1.33)

Inner coil - - - - 8.4 (0.78) 5.9 (0.55) 13.8 (1.28)

3 lbs. 3 oz.

(1.45 kg)

9 x 8

(229 x 203)

4 lbs. 6 ozs.

(1.98 kg)

10 x 7 (254 x 178)

4 lbs. 13 ozs.

(2.18 kg)

5 lbs. 8 oz.

(2.49 kg)

10 x 8

(254 x 203)

7 lbs. 7 oz.

(3.37 kg)

11-1/2 x 9

(292 x 229)

Net weight of basic unit - lbs. (kg) 300 (136) 331 (150) 320 (145) 438 (199) 473 (215)

Shipping weight of basic unit - lbs. (kg) 1 package 385 (175) 413 (187) 407 (185) 547 (248) 582 (264)

Electrical characteristics - (60hz) 208/230v - 1 phase 208/230v - 1 ph, 208/230v, 460v or 575v - 3 ph

ECH16R-5

ECH16-5

ECH16R-7

ECH16-7

s

ECH16R-10

ECH16-10

ECH16-15

ECH16-20

ECH16-25

Optional

Electric

Heat

Ratin

*Sound Rating Number in accordance with test conditions included in ARI Standard 270.

LRated in accordance with ARI Standard 210/240 and DOE 95_F (35_F) outdoor air temperature and 80_F (27_C) db/67_F (19_C) wb entering evaporator coil air.

lAnnual Fuel Utilization Efficiency based on DOE test procedures and FTC labeling regulations.

Output - Btuh (kW) 19,000 (5.6) - - - -

lA.F.U.E. 99.0% - - - -

Output - Btuh (kW) 26,000 (7.6) 27,000 (7.9) 26,000 (7.6) 27,000 (7.9)

lA.F.U.E. 99.0%

Output - Btuh (kW) 36,000 (10.5) 37,000 (10.8) 36,000 (10.5) 37,000 (10.8)

lA.F.U.E. 99.0%

Output - Btuh (kW) 53,000 (15.5) 54,000 (15.8) 53,000 (15.5) 54,000 (15.8)

lA.F.U.E. 99.0%

Output - Btuh (kW) - - - - 70,000 (20.5) 71,000 (20.8)

lA.F.U.E. - - - - 99.0%

Output - Btuh (kW) - - - - 88,000 (25.8)

lA.F.U.E. - - - - 99.0%

Page 3

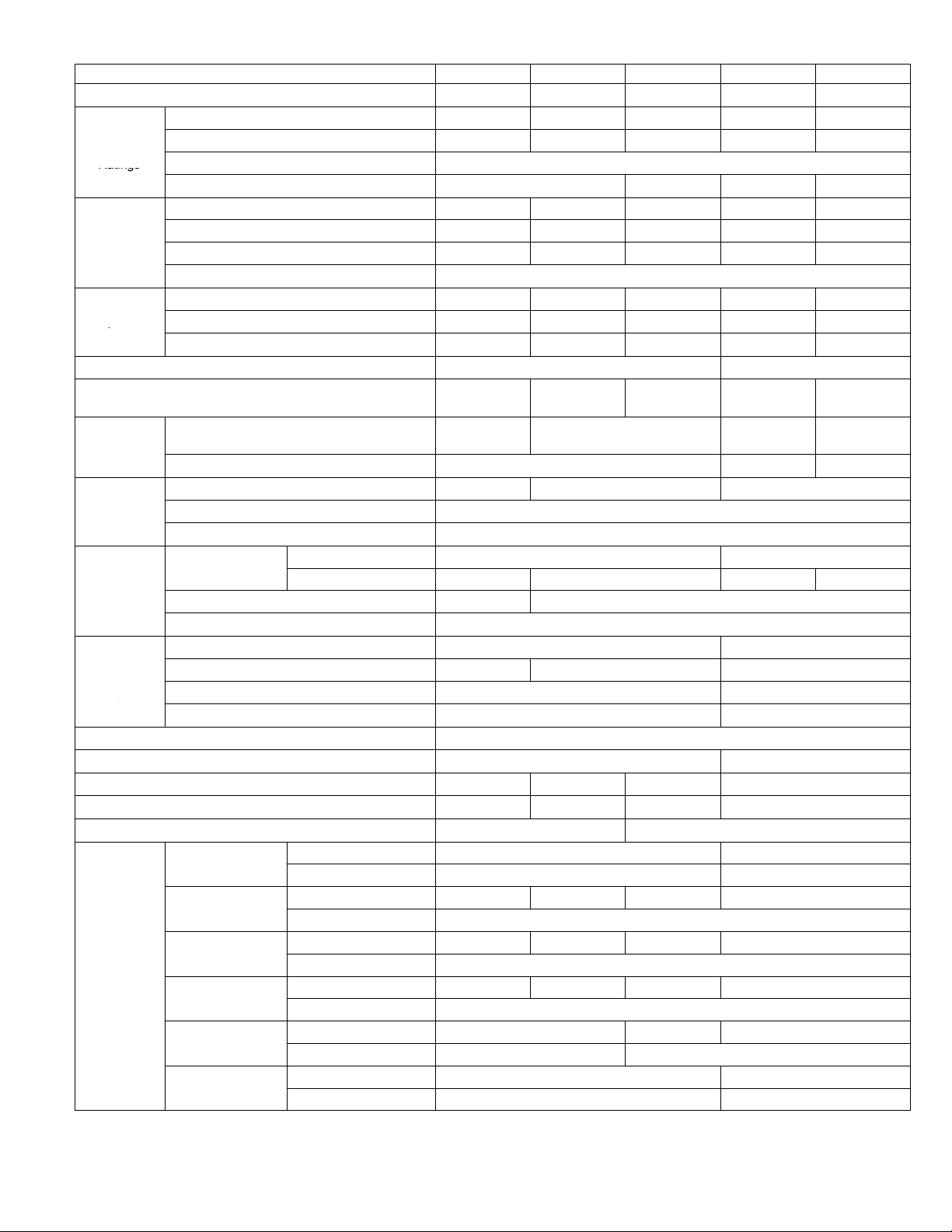

Page 4

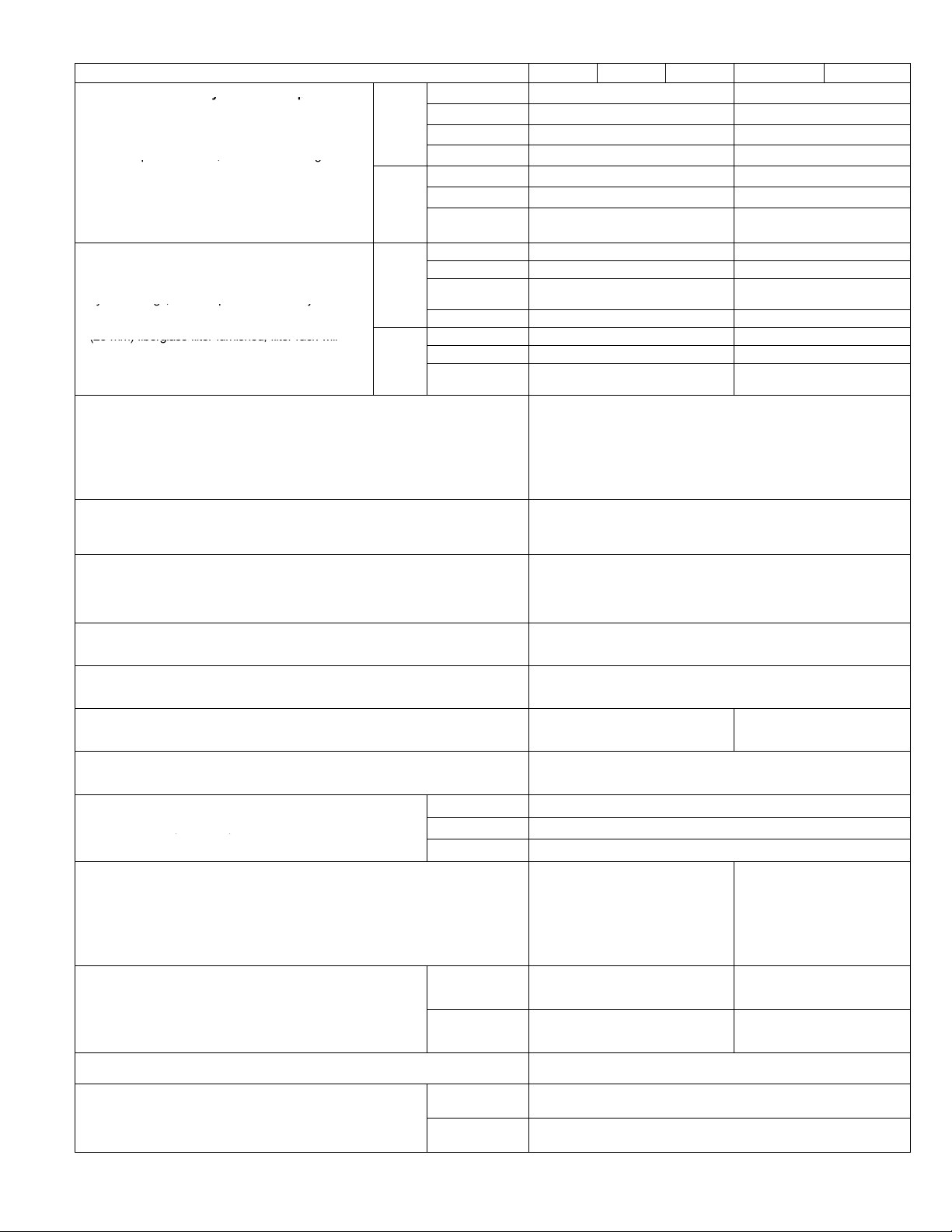

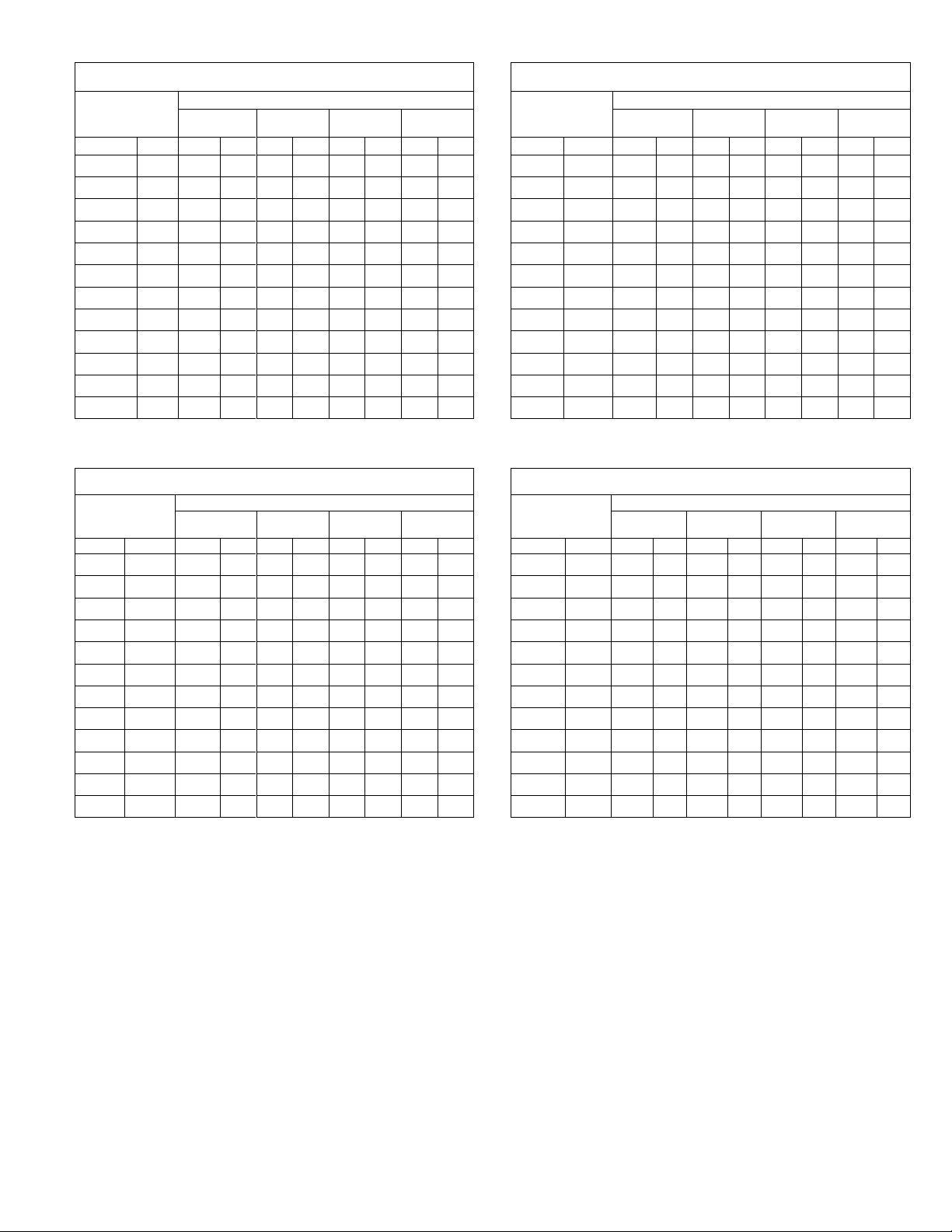

SPECIFICATIONS CHP16

C

Ratings

p

Temperature

Rati

LARI L

p

Coil

Net face area

Outdoor

C

Fan

ECH16R-5

ECH16R-7

ECH16R-10

Electric

Rati

Model No. CHP16Ć024 CHP16Ć030 CHP16-036 CHP16-048 CHP16-060

Nominal Tonnage 2 2-1/2 3 4 5

Cooling capacity - Btuh (kW) 23,800 (7.0) 29,000 (8.5) 34,600 (10.1) 46,500 (13.6) 55,000 (16.1)

LARI

ooling

Ratings

LARI High

Te m

erature

Heating

ngs

Temperature

Heating Ratings

*Sound Rating Number (db) 80 82

Refrigerant Charge (HCFC-22)

Indoor Coil

Blower

Indoor

Coil

Outdoor

Coil

Outdoor

oil

Fan

Condensate drain size mpt - in. (mm) 3/4 (19)

No. & size of cleanable polyurethane filters - in. (mm) (1) 16 x 25 x 1 (406 x 635 x 25) ( 1) 20 x 25 x 1 (508 x 635 x 25)

Net weight of basic unit - lbs. (kg) 332 (151) 340 (154) 354 (161) 535 (243)

Shipping weight of basic unit - lbs. (kg) 1 package 417 (187) 426 (193) 436 (198) 610 (277)

Electrical characteristics - (60hz) 208/230v - 1 phase 208/230v - 1 ph, 208/230v or 460v - 3 ph

Optional

Electric

Heat

ngs

*Sound Rating Number in accordance with test conditions included in ARI Standard 270.

LRated in accordance with ARI Standard 210/240;

Cooling Ratings - 95_F (35_F) outdoor air temperature and 80_F (27_C) db/67_F (19_C) wb entering indoor coil air

High Temperature Heating Ratings - 47 _F (8_C) db/43_F (6_C) wb outdoor air temperature and 70_F (21_C) entering indoor coil air

Low Temperature Heating Ratings - 17_F (-8_C) db/15_F (-9_C) wb outdoor air temperature and 70_F (21_C) entering indoor coil air.

Total unit watts 2615 3185 3870 4915 6225

SEER (Btuh/Watts) 10.0

EER (Btuh/Watts) 9.1 8.6 9.5 8.8

Total capacity - Btuh (kW) 23,800 (7.0) 29,400 (8.6) 35,800 (10.5) 49,500 (14.5) 57,500 (16.8)

Total unit watts 2235 2780 3430 4605 5765

C.O.P. (Coefficient of Performance) 3.12 3.10 3.06 3.14 2.94

HSPF - Region IV (Region V) 6.6 (5.9)

Total capacity - Btuh (kW) 12,800 (3.7) 17,000 (5.0) 22,800 (6.7) 28,000 (8.2) 33,600 (9.8)

ow

Total unit watts 1855 2330 3182 3800 5045

C.O.P. (Coefficient of Performance) 2.02 2.14 2.10 2.16 1.98

Blower wheel nominal diameter x width in. (mm)

5 lbs. 10 oz.

(2.55 kg)

9 x 8

(229 x 203)

6 lbs. 0 oz.

(2.72 kg)

10 x 7 (254 x 178)

7 lbs. 0 oz..

(3.18 kg)

10 lbs. 12 oz.

(4.88 kg)

10 x 8

(254 x 203)

Motor horsepower (W) 1/3 (249) 1/2 (373) 3/4 (560)

Net face area - sq. ft. (m2) 3.2 (0.30) 4.1 (0.38) 5.8 (0.54)

Tube diameter - in. (mm) & No. of rows 3/8 (9.5) - 3

Fins per inch (m) 15 (591)

Net face area

sq. ft. (m2)

Outer coil 8.6 (0.80) 14.3 (1.33)

Inner coil 5.3 (0.49) 8.3 (0.77) 9.9 (0.92) 13.8 (1.28)

Tube diameter - in. (mm) & No. of rows 3/8 (9.5) - 1.6 3/8 (9.5) - 2

Fins per inch (m) 20 (787)

Diameter - in. (mm) & No. of blades 20 (508) - 4 24 (610) - 4

Air volume - cfm (L/s) 2350 (1110) 2200 (1040) 3600 (1700)

Motor horsepower (W) 1/6 (124) 1/4 (187)

Motor watts 220 340

ECH16R-5

ECH16-5

ECH16R-7

ECH16-7

ECH16R-10

ECH16-10

Output - Btuh (kW) 19,000 (5.6) - - - -

lA.F.U.E. 99.0% - - - -

Output - Btuh (kW) 26,000 (7.6) 27,000 (7.9) 26,000 (7.6) 27,000 (7.9)

lA.F.U.E. 99.0%

Output - Btuh (kW) 36,000 (10.5) 37,000 (10.8) 36,000 (10.5) 37,000 (10.8)

lA.F.U.E. 99.0%

Output - Btuh (kW) 53,000 (15.5) 54,000 (15.8) 53,000 (15.5) 54,000 (15.8)

ECH16-15

lA.F.U.E. 99.0%

Output - Btuh (kW) - - - - 70,000 (20.5) 71,000 (20.8)

ECH16-20

lA.F.U.E. - - - - 99.0%

Output - Btuh (kW) - - - - 88,000 (25.7)

ECH16-25

lA.F.U.E. - - - - 99.0%

10 lbs. 5 oz.

(4.68 kg)

11-1/2 x 8

(292 x 203)

Page 4

Page 5

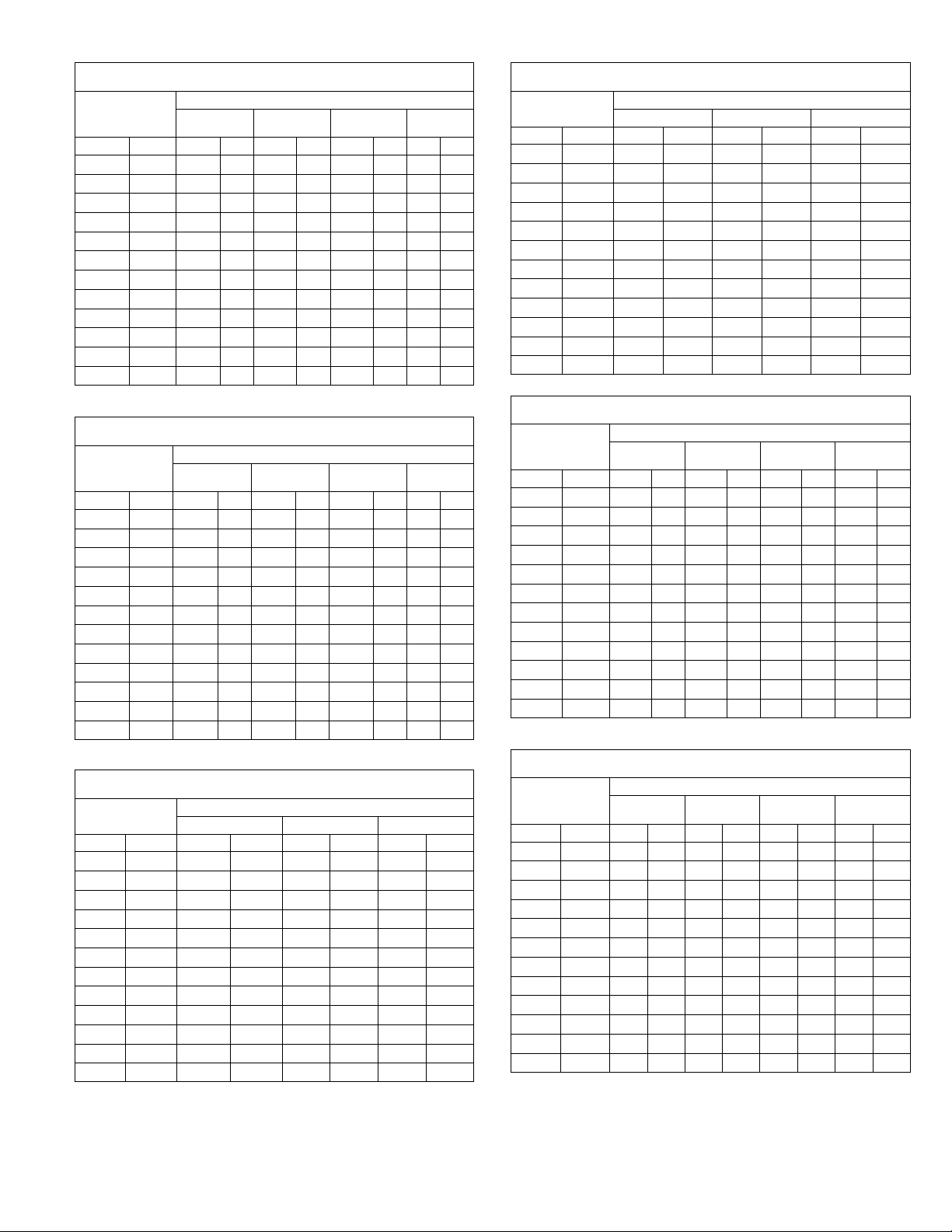

SPECIFICATIONS CHP20

Cooli

g

Ratings

LARI Certified

High

p

Temperature

Bl

Coil

Net face area

Outdoor

Outdoor

ECH16RĆ5

ECH16RĆ7

Electric Heat

ECH16RĆ10

Model No

ECH16Ć15

ECH16Ć20

ECH16Ć25

Model No. CHP20Ć024 CHP20Ć030 CHP20Ć036 CHP20Ć042 CHP20Ć048 CHP20Ć060

Nominal Tonnage 2 2-1/2 3 3-1/2 4 5

Cooling Capacity Ċ Btuh (kW) 24,000 (7.0) 30,200 (8.8) 33,600 (9.8) 43,000 (12.6) 46,500 (13.6) 59,000 (17.3)

LARI

Ratin

High

Temperature

Heating Ratings

LARI Certified

Low

Te m

erature

Heating Ratings

*Sound Rating Number (db) 80 82 84

Refrigerant Charge (HCFCĆ22)

Indoor Coil

ower

Indoor

Outdoor

Coil

Outdoor

Coil Fan

Condensate drain size mpt Ċ in. (mm) 3/4 (19)

No. & size of cleanable polyurethane filters - in. (mm) (1) 16 x 25 x 1 (406 x 635 x 25) (1) 20 x 25 x 1 (508 x 635 x 25)

Net weight of basic unit Ċ lbs. (kg) 305 (138) 355 (161) 355 (161) 455 (206) 535 (243) 535 (243)

Shipping weight of basic unit Ċ lbs. (kg) (1 Pkg.) 390 (177) 419 (190) 419 (190) 525 (238) 610 (277) 610 (277)

Electrical characteristics (60 hz) 208/230v-1ph

Model No.

and

Ratings

*Sound Rating Number in accordance with test conditions included in ARI Standard 270.

lAnnual Fuel Utilization Efficiency based on DOE test procedures and FTC labeling regulations.

LCertified in accordance with the USE certification program, which is based on ARI standard 210/240.

Cooling RatingsĊ 95_F (35_C) outdoor air temperature and 80_F (27_C) db/67_F (19.5_C) wb entering indoor coil air.

High Temperature Heating RatingsĊ 47_F (8_C) db/43_F (6_C) wb outdoor air temperature and 70_F (21_C) entering indoor coil air.

Low Temperature Heating RatingsĊ 17_F (-8_C) db/15_F (-9_C) wb outdoor air temperature and 70_F (21_C) entering indoor coil air.

Total unit watts 2555 3145 3535 4105 4875 6325

ng

SEER (Btuh/Watts) 11. 0 11 .0 5 12.05 11. 00 11.05

s

EER (Btuh/Watts) 9.4 9.6 9.5 10.5 9.5 9.4

Total Capacity Ċ Btuh (kW) 24,200 (7.1) 29,800 (8.7) 34,200 (10.0) 41,500 (12.2) 48,500 (14.2) 62,500 (18.3)

Total unit watts 2245 2800 3000 3880 4695 6180

C.O.P 3.16 3.12 3.34 3.20 3.04 2.98

HSPF Ċ Region IV (Region V) 6.60 (5.90) 7.35 (5.70) 7.15 (6.30) 7.55 (6.70) 6.85 (6.05)

Total Capacity Ċ Btuh (kW) 14,800 (4.3) 18,600 (5.4) 21,400 (6.3) 26,200 (7.7) 31,600 (9.3) 38,600 (11.3)

Total unit watts 2085 2595 2725 3515 4225 5425

C.O.P 2.06 2.10 2.30 2.26 2.20 2.10

Blower wheel nominal diameter x width in. (mm)

5 lbs. 0 oz.

(2.27 kg)

9 x 8

(229 x 203)

6 lbs. 8 oz.

(2.95 kg)

6 lbs. 7 oz.

(2.92 kg)

9 lbs. 12 oz.

(4.42 kg)

10 x 7 (254 x 178) 10 x 8 (254 x 203)

10 lbs. 8 oz.

(4.76 kg)

Motor output Ċ hp (W) 1/3 (249) 1/2 (373) 3/4 (560)

Net face area Ċ sq. ft. (m2) 3.2 (0.30) 4.1 (0.38) 4.1 (0.38) 5.8 (0.54) 5.8 (0.54)

Tube diameter - in. (mm) & No. of rows 3/8 (9.5) Ċ 3

Fins per inch (m) 15 (591)

Net face area

Ċ sq. ft. (m2)

Outer coil 8.6 (0.80) 14.3 (1.33)

Inner coil 5.3 (0.49) 8.3 (0.77) 9.9 (1.28) 13.8 (1.28)

Tube diameter - in. (mm) & no. of rows 3/8 (9.5) - 1.6 3/8 (9.5) Ċ 2 3/8 (9.5) - 1.7 3/8 (9.5) Ċ 2

Fins per inch (m) 20 (787)

Diameter Ċ in. (mm) & No. of blades 20 (508) Ċ 4 24 (610) Ċ 4 24 (610) - 3

Air Volume Ċ cfm (L/s) 2350 (1110) 2200 (1040) 3600 (1700) 4000 (1890)

Motor output Ċ hp (W) 1/6 (124) 1/4 (187) 1/3 (249)

Motor watts 220 340 430

208/230v-1ph

208/230v or

460v - 3ph

208/230v-1ph

208/230v-1ph

208/230v or 460v - 3ph

Output Ċ Btuh (kW) 19,000 (5.6) Ć Ć Ć Ć Ć Ć Ć Ć

lA.F.U.E. 99.0% Ć Ć Ć Ć Ć Ć Ć Ć

Output Ċ Btuh (kW) 26,000 (7.6) 27,000 (7.9) 26,000 (7.6) 27,000 (7.9)

lA.F.U.E. 99.0%

Output Ċ Btuh (kW) 36,000 (10.5) 37,000 (10.8) 36,000 (10.5) 37,000 (10.8)

lA.F.U.E. 99.0%

.

ECH16RĆ7

ECH16Ć7

ECH16RĆ10

ECH16Ć10

Output Ċ Btuh (kW) 53,000 (15.6) 54,000 (15.8) 53,000 (15.6) 54,000 (15.8)

lA.F.U.E. 99.0%

Output Ċ Btuh (kW) Ć Ć Ć Ć Ć Ć Ć Ć 70,000 (20.5) 71,000 (20.8) 71,000 (20.8)

lA.F.U.E. Ć Ć Ć Ć Ć Ć Ć Ć 99.0%

Output Ċ Btuh (kW) Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć 88,000 (25.7) 88,000 (25.8)

lA.F.U.E. Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć Ć 99.0%

10 lbs. 5 oz.

(4.68 kg)

11 x 8

(279 x 203)

Page 5

Page 6

Model No. Ć024 Ć030 -036 -048 -060

yp

p

y

lated air dampers with pressure operated gravity

US

p, g

p

lizes filter furnished with unit, filter rack will accept

hood

ith cl

ly in cabinet, combination outdoor air and recircu

US

yg,p j

sensor, adjustable outdoor air enthalpy control. 1 in

(25 mm) fiberglass filter furnished, filter rack will

hood with alumi

filt

kit

()

p

y

damper assembly replaces blower access panel, manually

Economizer with Gravity Exhaust Dampers

(Down-Flow) Ċ Installs directly in cabinet, recircuĆ

lated air dam

exhaust damper, formed, gasketed damper blades,

nylon bearings, 24v damper motor has adjustable

minimum position switch, electronic discharge air

sensor, adjustable outdoor air enthalpy control. UtiĆ

lizes filter furnished with unit, filter rack will acce

up to 2 in. (51 mm) filter. Removable exhaust air

and outdoor air intake hood w

aluminum mesh filter. Choice of economizer conĆ

trols.

Economizer Dampers (Horizontal) Ċ Installs directĆ

lated air damper, formed, gasketed damper blades,

nylon bearings, 24v damper motor has adjustable

minimum position switch, electronic discharge air

(25 mm) fiberglass filter furnished, filter rack will

accept up to 2 in. (51 mm) filter, outdoor air intake

mizer controls.

Electric Heat Ċ Field installed, helix wound nichrome elements, time delay for eleĆ

ment staging, individual element limit controls, wiring harness, may be twoĆstage

controlled.

ECH16R - Supplemental thermal cutoff safety fuses and thermal

ECH16 - Supplemental secondary limits, heating control relay,

Electric Heat Single Point Power Source Sub-Fuse Box Ċ Use with ECH16R

electric heaters, use in conjunction with ECH16 fuse box for single point power

source applications, installs internal to unit, fuses furnished, constructed of galvaĆ

nized steel with prepunched mounting holes

Unit Single Point Power Source Sub Fuse Box Ċ Installs internal to unit, proĆ

vides sub-fusing to the unit, used in conjunction with ECH16 or ECH16R for single

point power source applications, fuses furnished, constructed of galvanized steel

with prepunched mounting holes and electrical inlet and outlet holes, hinged box

cover

Enthalpy Control, Differential Ċ Used in conjunction with outdoor air enthalpy

control. Determines and selects which air has the lowest enthalpy. Return air enĆ

thalpy sensor field installs in economizer damper section

Gravity Exhaust Dampers Ċ For use with EMDH16. Pressure operated assembly

field installs in the return air duct adjacent to the economizer assembly. Includes

bird screen. - Net Weight

Horizontal Filter Kit (Canada Only) Ċ For horizontal applications, painted steel

cabinet with filter access, disposable, pleated fiber filter furnished, number and

size of filter - Net Weight

Low Ambient Control Kit Ċ Units operate down to 30°F (-1°C) outdoor air temperĆ

ature in cooling mode without any additional controls. A Low Ambient Kit can be

field installed, enabling unit to operate properly down to 0°F (Ć17.7°C).

Roof Curb Power Entry Kit Ċ Allows power entry through

roof mounting frame, knockouts provided in roof frame,

contains 40 in. (1016 mm) armored conduit and installation

hardware, two kits are required, one for low voltage and one

for high voltage. See Dimension Drawing

Roof Mounting Frame Ċ Nailer strip furnished, mates to unit, U.S. National RoofĆ

ing Contractors Approved, shipped knocked down. RMF16-41 may be used on

all sizes, with a slight unit overhang on CHP16-048 and CHP16-060 units - Net

Weight

NOTE (US Only) Ċ Sound Reduction Plate must be ordered separately for field

installation.

Outdoor Air Damper Section Ċ For downĆflow applications,

dam

adjustable, 0 to 25% (fixed) outdoor air, outdoor air hood with

cleanable filter included, number and size of filter - Net Weight

Outdoor Air Damper Section Ċ For horizontal applications, installs in return air

duct adjacent to unit, manually adjustable (fixed) outdoor air - Net Weight

Outdoor Thermostat Kit Ċ Used to lock out some of the

electric heating elements on indoor units where two stage

control is applicable. Outdoor thermostat maintains the

heating load on the low power input as long as possible

before allowing the full power load to come on line

Indoor filter is not furnished with economizer. REMD16 utilizes existing filter furnished with 16 unit.

ers with pressure operated gravit

eanable

num mesh

relay sequencer.

fuse block, thermal relay sequencer (20-25 kW

208/230v) and galvanized steel control box.

er assembly replaces blower access panel, manuall

er. Choice of econoĆ

OPTIONAL ACCESSORIES CHA/CHP16

3 position REMD16-41 - 48 lbs. (22 kg) REMD16-65 - 66 lbs. (30 kg)

US

Only

t

Canada

Only

Ć

Ć

Only

Canada

Ć

Only

Fully Modulating REMD16M-41 - 48 lbs. (22 kg) REMD16M-65 - 66 lbs. (30 kg)

Indoor Filter (1) 16 x 25 x 1 (406 x 635 x 25) (1) 20 x 25 x 1 (508 x 635 x 25)

Outdoor Filter (1) 14 x 25 x 1 (356 x 635 x 25) (1) 18 x 25 x 1 (457 x 635 x 25)

Fully Modulating REMD16M-41S - 85 lbs. (39 kg) REMD16M-65S- 105 lbs. (48 kg)

Indoor Filter (1) 16 x 25 x 1 (406 x 635 x 25) (1) 20 x 25 x 1 (508 x 635 x 25)

Outdoor Filter (1) 19-3/8 x 15-3/4 x 1

3 position EMDH16-41 110 lbs. (50 kg) EMDH16-65 - 130 lbs. (59 kg)

Fully Modulating EMDH16M-41 - 110 lbs. (50 kg) EMDH16M-65 - 130 lbs. (59 kg)

Indoor Filter (1) 20 x 24 x 1 (508 x 610 x 25)

Outdoor Filter (1) 8 x 24 x 1 (203 x 610 x 25) (1) 8 x 28 x 1 (203 x 711 x 25)

Fully Modulating EMDH16M-41S - 70 lbs. (32 kg) EMDH16M-65S - 86 lbs. (39 kg)

Indoor Filter (1) 20 x 20 x 1 (508 x 508 x 25) (1) 20 x 25 x 1 (508 x 635 x 25)

Outdoor Filter

1/2 in. (13 mm) 18H70

1 in. (26 mm) 18H71

1-1/2 in. (39 mm) 18H72

US Only

Canada Only

Thermostat Kit LB-29740BA (56A87)

Mounting Box M-1595 (31461) / BM-10260 (33A09) Canada Only

(1) 16-1/2 x 21-3/4 x 1

HF16-46S - 18 lbs. (8 kg)

RMF16-41 - 75 lbs. (35 kg) 97G59

Plate (order separately) (73H80)

OAD16-41 - 12 lbs. (5 kg)

OAD16-41S - 10 lbs. (5 kg)

Page 6

(419 x 552 x 25)

See Electric Heat Data Tables

See Electric Heat Data Tables

See Electric Heat Data Tables

GEDH16-65 - 4 lbs. (2 kg)

(1) 20 x 20 x 2 in.

(508 x 508 x 51 mm)

CHP16 LB-57113BM (27J00)

CHA16 LB-57113BC (24H77)

(1) 5 x 17 x 1 in.

(127 x 432 x 25 mm)

(1) 14 x 6 x 1 in.

(356 x 152 x 25 mm)

OAD3-46/65 - 8 lbs. (4 kg)

(1) 19-7/8 x 22-3/4 x 1

(505 x 578 x 25)

(1) 16 x 25 x 1 (406 x 635 x 25)

(1) 14 x 25 x1 (356 x 635 x 1)

(1) 22-1/2 x 25-1/4 x 1

(571 x 641 x 25)

54G44

HF16-65S - 21 lbs. (10 kg)

(1) 20 x 25 x 2 in.

(508 x 635 x 51 mm)

RMF16-41 - 75 lbs. (35 kg)

OAD16-65 - 12 lbs. (5 kg)

OAD16-65S - 16 lbs. (7 kg)

97G59

Plate (order separately)

(73H80)

RMF16-65 - 86 lbs.

(39 kg) 97G60

Plate (order separately)

(73H82)

(1) 8 x 17 x 1 in.

(203 x 432 x 25 mm)

(1) 18 x 6 x 1 in.

(457 x 152 x 25 mm)

Page 7

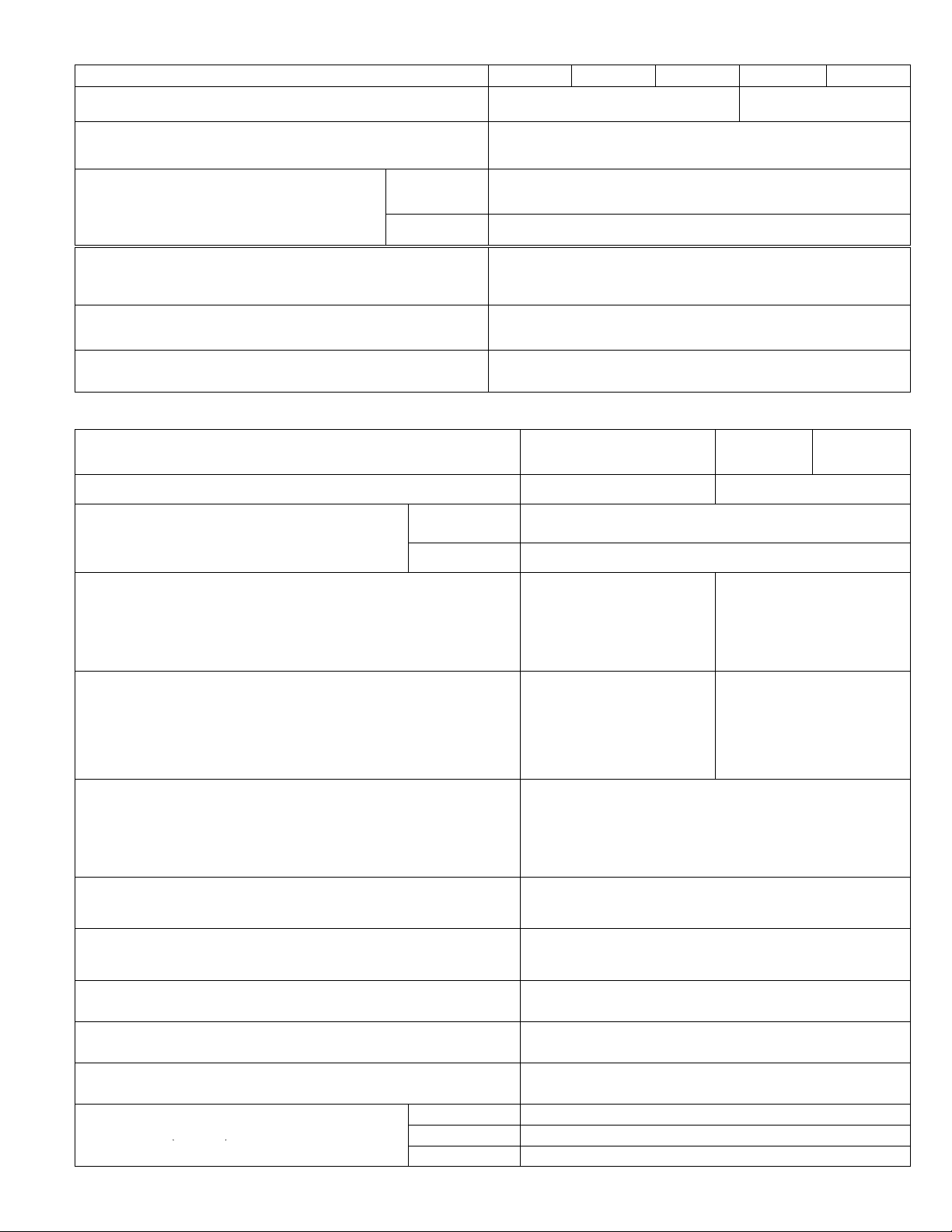

OPTIONAL ACCESSORIES CHA/CHP16 Cont.

nished, interior transition (even air flow), internally

transition (even air flow), internally sealed (prevents recirĆ

kit

()

Model No. Ć024 Ć030 -036 -048 -060

Coil Guards Ċ PVC coated steel wire guards to protect outdoor coil.

Compressor Monitor (Canada Only) Ċ NonĆadjustable switch (low ambiĆ

ent cutĆout) prevents compressor operation when outdoor temperature is

below 35°F (2°C).

Diffusers Ċ Aluminum grilles, large center grille, inĆ

sulated diffuser box with flanges, hanging rings furĆ

nished, interior transition (even air flow), internally

sealed (prevents recirculation), adapts to TĆbar ceilĆ

ing grids or plaster ceilings - Net Weight

Timed Off Control Ċ Prevents compressor shortĆcycling and allows time

for suction and discharge pressure to equalize, permitting the compressor

to start in an unloaded condition. Automatic reset control provides a time

delay between compressor shutoff and startĆup.

Transitions (Supply and Return) Ċ Used with diffusers, installs in roof

mounting frame, galvanized steel construction, flanges furnished for duct

connection, fully insulated - Net Weight

Unit Stand-Off Mounting Kit Ċ Elevates horizontal application units

above mounting surface. Includes six high impact polystyrene standĆoff

mounts. See dimension drawings.

StepĆDown -

double deflecĆ

tion louvers

Flush - fixed

blade louvers

OPTIONAL ACCESSORIES CHP20

Model No.

Coil Guards Ċ PVC coated steel wire guards to protect outdoor coil.

Diffusers Ċ Aluminum grilles, large center grille, insulated

diffuser box with flanges, hanging rings furnished, interior

transition (even air flow), internally sealed (prevents recirĆ

culation), adapts to TĆbar ceiling grids or plaster ceilings Net Weight

Economizer with Gravity Exhaust Dampers (Down-Flow) Ċ Installs directly in

cabinet, recirculated air dampers with pressure operated gravity exhaust dampĆ

er, formed, gasketed damper blades, nylon bearings, 3 position or fully moduĆ

lating 24v damper motor has adjustable minimum position switch, electronic

discharge air sensor, adjustable outdoor air enthalpy control. Utilizes filter furĆ

nished with unit, filter rack will accept up to 2 in. (51 mm) filter. Removable

exhaust air hood and outdoor air intake hood with aluminum mesh filter. Choice

of economizer controls. Model No. - Net Weight - No. & size of filter, in. (mm)

Economizer Dampers (Horizontal) Ċ Installs directly in cabinet, combination outĆ

door air and recirculated air damper, formed, gasketed damper blades, nylon

bearings, 3 position or fully modulating 24v damper motor has adjustable miniĆ

mum position switch, electronic discharge air sensor, adjustable outdoor air enĆ

thalpy control. 1 in (25 mm) fiberglass filter furnished, filter rack will accept up to 2

in. (51 mm) filter, outdoor air intake hood with aluminum mesh filter. Choice of

economizer controls. Model No. - Net Weight - No. & size of filter, in. (mm)

Electric Heat Ċ Field installed, helix wound nichrome elements, time delay for eleĆ

ment staging, individual element limit controls, wiring harness, may be twoĆstage

controlled.

ECH16R - Supplemental thermal cutoff safety fuses and thermal

ECH16 - Supplemental secondary limits, heating control relay,

Electric Heat Single Point Power Source Sub-Fuse Box Ċ Use with ECH16R elecĆ

tric heaters, use in conjunction with ECH16 fuse box for single point power source

applications, installs internal to unit, fuses furnished, constructed of galvanized steel

with prepunched mounting holes

Unit Single Point Power Source Sub Fuse Box Ċ Installs internal to unit, provides

sub-fusing to the unit, used in conjunction with ECH16 or ECH16R for single point

power source applications, fuses furnished, constructed of galvanized steel with

prepunched mounting holes and electrical inlet and outlet holes, hinged box cover

Enthalpy Control, Differential Ċ Used in conjunction with outdoor air enthalpy

control. Determines and selects which air has the lowest enthalpy. Return air enĆ

thalpy sensor field installs in economizer damper section

Gravity Exhaust Dampers Ċ For use with EMDH16. Pressure operated assembly

field installs in the return air duct adjacent to the economizer assembly. Includes

bird screen. - Net Weight

Low Ambient Control Kit - Units operate down to 30°F (-1°C) outdoor air temperaĆ

ture in cooling mode without any additional controls. A Low Ambient Kit can be field

installed, enabling unit to operate properly down to 0°F (Ć17.7°C).

Roof Curb Power Entry Kit Ċ Allows power entry through

roof mounting frame, knockouts provided in roof frame,

contains 40 in. (1016 mm) armored conduit and installaĆ

tion hardware, two kits are required, one for low voltage

and one for high voltage. See Dimension Drawing

relay sequencer.

fuse block, thermal relay sequencer (20-25 kW

208/230v) and galvanized steel control box.

StepĆDown -

double deflecĆ

tion louvers

Flush - fixed

blade louvers

1/2 in. (13 mm) 18H70

1 in. (26 mm) 18H71

1-1/2 in. (39 mm) 18H72

LB-82199CF (47J23)

2 guards per order

T6-1469 (45F08)

RTD9-65 - 67 lbs. (30 kg)

FD9-65 Ć 37 lbs.(17 kg)

LB-50709BK (47J27)

SRT16 - 20 lbs. (9 kg)

38H18

CHP20-024

CHP20-030

CHP20-036

LB-82199CF (47J23)

2 guards per order

RTD9-65 - 67 lbs. (30 kg)

FD9-65 Ć 37 lbs.(17 kg)

REMD16-41 - 48 lbs. (22 kg)

REMD16M-41 - 48 lbs. (22 kg)

EMDH16-41 - 110 lbs. (50 kg)

EMDH16M-41 - 110 lbs. (50 kg)

3 Position:

Modulating:

Indoor: (1) 16 x 25 x 1

(406 x 635 x 25)

Outdoor : (1) 14 x 25 x 1

(356 x 635 x 25)

3 Position:

Modulating:

Indoor : (1) 20 x 24 x 1

(508 x 610 x 25)

Outdoor : (1) 8 x 24 x 1

(203 x 610 x 25)

See Electric Heat Data Tables

See Electric Heat Data Tables

See Electric Heat Data Tables

GEDH16-65 - 4 lbs. (2 kg)

LB-57113BM (27J00)

LB-82199CG (47J24)

3 guards per order

CHP20-042

CHP20-048

LB-82199CG (47J24)

3 guards per order

REMD16-65 - 66 lbs. (30 kg)

REMD16M-65 - 66 lbs. (30 kg)

EMDH16-65 - 130 lbs. (59 kg)

EMDH16M-65 - 130 lbs. (59 kg)

(1) 14 x 25 x1 (356 x 635 x 1)

54G44

3 Position:

Modulating:

Indoor: (1) 20 x 25 x 1

(508 x 635 x 25)

Outdoor : (1) 18 x 25 x 1

(457 x 635 x 25)

3 Position:

Modulating:

Indoor : (1) 16 x 25 x 1

(406 x 635 x 25) &

Outdoor : (1) 8 x 28 x 1

(203 x 711 x 25)

CHP20-060

Page 7

Page 8

OPTIONAL ACCESSORIES CHP20 Cont.

C

Condenser Coil

Evaporator

C

Condenser Coil

Evaporator

Model No. CHP20-024, -030, -036 CHP20-042, -048 CHP20-060

Roof Mounting Frame Ċ Nailer strip furnished, mates to unit, U.S. National

Roofing Contractors Approved, shipped knocked down. RMF16-41 may be

used on all sizes, with a slight unit overhang on CHP20-048 and CHP20-060

units - Net Weight. NOTE (US Only) Ċ Sound Reduction Plate must be ordered

separately for field installation.

Outdoor Air Damper Section Ċ For downĆflow applications, damper assembly reĆ

places blower access panel, manually adjustable, 0 to 25% (fixed) outdoor air, outĆ

door air hood with cleanable filter included, number and size of filter - Net Weight

Outdoor Air Damper Section Ċ For horizontal applications, installs in return

air duct adjacent to unit, manually adjustable (fixed) outdoor air - Net Weight

Outdoor Thermostat Kit Ċ Used to lock out some of the

electric heating elements on indoor units where two

stage control is applicable. Outdoor thermostat maintains

the heating load on the low power input as long as posĆ

sible before allowing the full power load to come on line

Timed Off Control Ċ Prevents compressor shortĆcycling and allows time for

suction and discharge pressure to equalize, permitting the compressor to start

in an unloaded condition. Automatic reset control provides a time delay beĆ

tween compressor shutoff and startĆup.

Transitions (Supply and Return) Ċ Used with diffusers, installs in roof mountĆ

ing frame, galvanized steel construction, flanges furnished for duct connection,

fully insulated - Net Weight

Unit Stand-Off Mounting Kit Ċ Elevates horizontal application units above

mounting surface. Includes six high impact polystyrene standĆoff mounts. See

dimension drawings.

Indoor filter is not furnished with economizer. REMD16 utilizes existing filter furnished with CHP20 unit.

Thermostat Kit LB-29740BA (56A87)

Mounting Box M-1595 (31461)

RMF16-41 - 75 lbs. (35 kg)

Plate (order separately) (73H80)

OAD16-41 - 12 lbs. (5 kg)

(1) 5 x 17 x 1 in.

(127 x 432 x 25 mm)

RMF16-41 - 75 lbs. (35 kg)

Plate (order separately) (73H80)

RMF16-65 - 86 lbs. (39 kg)

Plate (order separately) (73H82)

OAD16-65 - 12 lbs. (5 kg)

(1) 8 x 17 x 1 in.

(203 x 432 x 25 mm)

OAD3-46/65 - 8 lbs. (4 kg)

LB-50709BK (47J27)

SRT16 - 20 lbs. (9 kg)

38H18

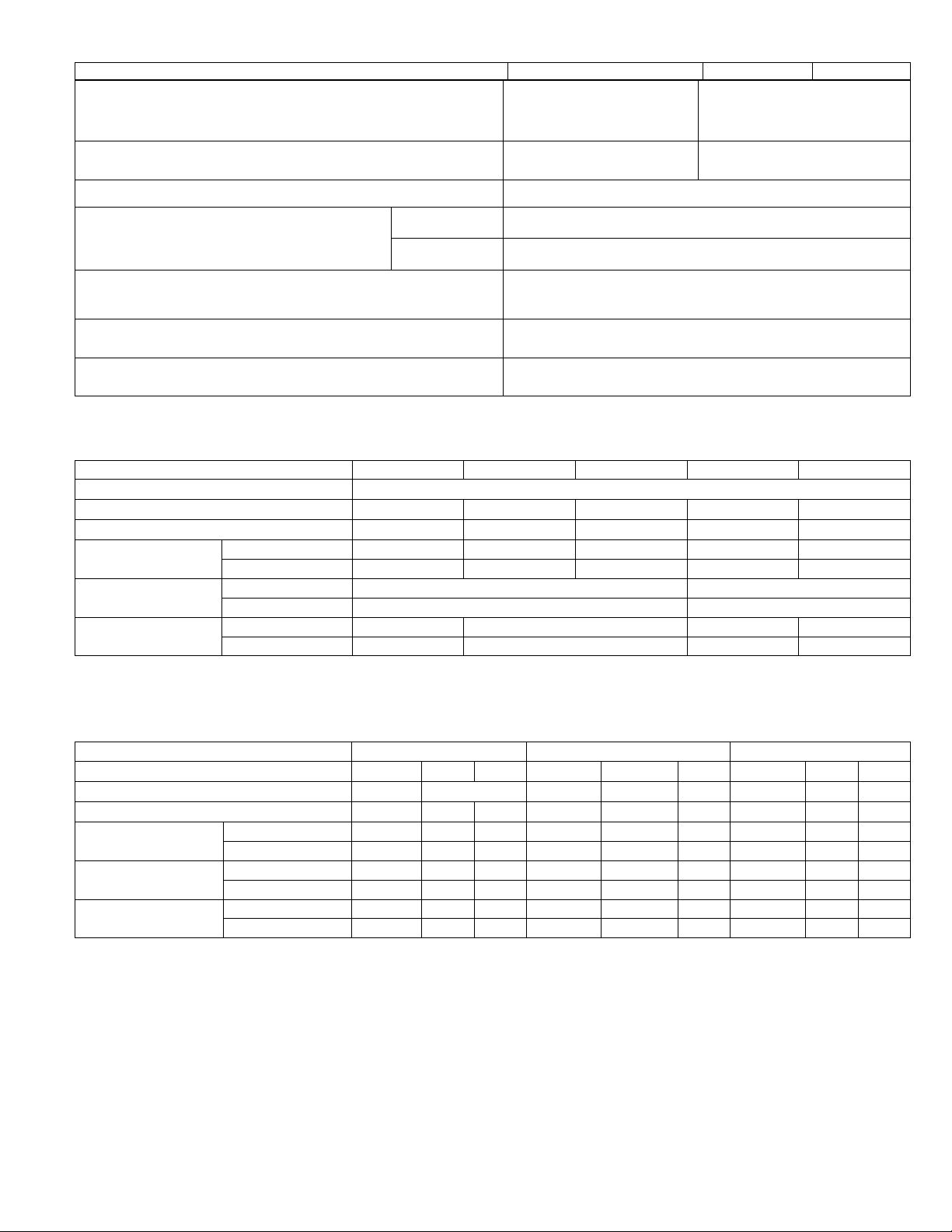

ELECTRICAL DATA CHA16

Single Phase

ModelĂNo. CHA16Ć024 CHA16Ć030 CHA16Ć036 CHA16Ć048 CHA16Ć060

LineĂvoltageĂdataĂ-Ă60Ăhz 208/230v - 1 phase

Recommended maximum fuse size (amps) 25 30 40 50 60

{Minimum Circuit Ampacity 16 21 27 34 41

ompressor

Condenser Coil

FanĂMotor

Evaporator

Blower Motor

{ReferĂtoĂNational or CanadianĂElectricalĂCodeĂmanualĂtoĂdetermineĂwire,ĂfuseĂandĂdisconnectĂsizeĂrequirements.

Where current does not exceed 100 amps, HACR type circuit breaker may be used in place of fuse (U.S. Only).

NOTEĂ-ĂExtremesĂofĂoperatingĂrangeĂareĂplusĂandĂminusĂ10%ĂofĂlineĂvoltage.

Rated load amps 10.1 13.0 17.7 21.8 26.1

Locked rotor amps 60 69.4 100.0 131.0 170

FullĂloadĂamps 1.1 2.3

LockedĂrotorĂamps 2.2 4.4

FullĂloadĂamps 2.2 3 3.9 5.2

LockedĂrotorĂamps 4.2 6.2 8.3 10

ELECTRICAL DATA CHA16

Three Phase

ModelĂNo. CHA16Ć036 CHA16Ć048 CHA16Ć060

LineĂvoltageĂdataĂ-Ă60Ăhz - 3 phase 208/230v 460v 575v 208/230v 460v 575v 208/230v 460v 575v

Recommended maximum fuse size (amps) 30 15 35 15 15 40 20 15

{Minimum Circuit Ampacity 20 11 9 23 11 10 28 14 12

ompressor

Condenser Coil

FanĂMotor

Evaporator

Blower Motor

{ReferĂtoĂNational or CanadianĂElectricalĂCodeĂmanualĂtoĂdetermineĂwire,ĂfuseĂandĂdisconnectĂsizeĂrequirements.

Where current does not exceed 100 amps, HACR type circuit breaker may be used in place of fuse (U.S. Only).

Motors are rated at 460 volts. Full load amps shown are for step-down transformer output.

NOTEĂ-ĂExtremesĂofĂoperatingĂrangeĂareĂplusĂandĂminusĂ10%ĂofĂlineĂvoltage.

Rated load amps 12.2 6.2 4.6 12.8 6.4 5.1 16.2 8.0 6.5

Locked rotor amps 77 39 31 91 46 37 124 60 47.7

FullĂloadĂamps 1.1 .73 .73 2.3 1.1 1.1 2.3 1.1 1.1

LockedĂrotorĂamps 2.2 1.3 1.3 4.4 2 2 4.4 2 2

FullĂloadĂamps 3.0 1.8 1.8 3.9 1.8 1.8 5.2 2.7 2.7

LockedĂrotorĂamps 6.2 4.4 4.4 8.3 4.4 4.4 10 3.8 3.8

Page 8

Page 9

ELECTRICAL DATA CHP16

C

Outdoor Coil

Indoor Coil

C

Outdoor Coil

Bl

C

Outdoor Coil

Indoor Coil

ModelĂNo. Ć024 Ć030 Ć036 Ć048 Ć060

LineĂvoltageĂdataĂ-Ă60Ăhz 208/230v - 1 phase

Recommended max. fuse size (amps) 25 30 40 30 15 50 35 15 60 40 20

{Minimum Circuit Ampacity 16 21 27 20 11 34 23 11 39 27 13

ompressor

Outdoor Coil

FanĂMotor

Indoor Coil

Blower Motor

{ReferĂtoĂNational or CanadianĂElectricalĂCodeĂmanualĂtoĂdetermineĂwire,ĂfuseĂandĂdisconnectĂsizeĂrequirements.

Where current does not exceed 100 amps, HACR type circuit breaker may be used in place of fuse (U.S. Only).

NOTEĂ-ĂExtremesĂofĂoperatingĂrangeĂareĂplusĂandĂminusĂ10%ĂofĂlineĂvoltage.

Rated load amps 10.1 13.0 17.7 12.2 6.2 21.8 12.8 6.4 25.0 15.5 7.5

Locked rotor amps 60.0 69.4 100.0 77.0 39.0 131.0 91.0 46.0 170.0 124.0 60.0

FullĂloadĂamps 1.1 0.73 2.3 1.1 2.3 1.1

LockedĂrotorĂamps 2.2 1.3 4.4 2.0 4.4 2.0

FullĂloadĂamps 2.1 3.0 1.8 3.9 1.8 4.6 2.4

LockedĂrotorĂamps 4.2 6.2 4.4 8.3 4.4 10.0 3.8

208/230v

1 phase

208/230v

3 phase

460v -

3 phase

208/230v

1 phase

208/230v

3 phase

460v -

3 phase

208/230v

1 phase

208/230v

3 phase

3 phase

ELECTRICAL CHP20

Single Phase

CHP20 ModelĂNo. CHP20Ć024 CHP20Ć030 CHP20Ć036 CHP20Ć042 CHP20Ć048 CHP20Ć060

LineĂvoltageĂdata - 60 hz 208/230v

"RecommendedĂmaximumĂfuseĂsizeĂ(amps) 30 35 40 50 60 70

{MinimumĂCircuitĂAmpacity 19 22 25 32 36 44

ompressors

Outdoor Coil

FanĂMotor

Indoor Coil

ower Motor

(1 phase)

{ReferĂtoĂNationalĂor Canadian ElectricalĂCodeĂmanualĂtoĂdetermineĂwire,ĂfuseĂandĂdisconnectĂsizeĂrequirements.

"WhereĂcurrentĂdoesĂnotĂexceedĂ100Ăamps,ĂHACRĂtypeĂcircuitĂbreakerĂmayĂbeĂusedĂinĂplaceĂofĂfuse.

NOTEĂĊĂExtremesĂofĂoperatingĂrangeĂareĂplusĂandĂminusĂ10%ĂofĂlineĂvoltage.

RatedĂloadĂamps 12.2 13.8 16.1 20.1 23.7 28.8

LockedĂrotorĂamps 61.0 73.0 88.0 104.0 129.0 169.0

FullĂloadĂamps 1.1 2.3 2.4

LockedĂrotorĂamps 2.2 4.4

FullĂloadĂampsĂ 2.1 3.0 3.9 4.6

LockedĂrotorĂampsĂ 4.2 6.2 8.3 10.0

460v -

ELECTRICAL CHP20

Three Phase

CHP20 ModelĂNo. CHP20Ć036 CHP20Ć048 CHP20Ć060

LineĂvoltageĂdata - 60 hz - 3 phase 208/230v 460v 208/230v 460v 208/230v 460v

"RecommendedĂmaximumĂfuseĂsizeĂ(amps) 25 15 35 15 45 20

{MinimumĂCircuitĂAmpacity 17 10 24 13 29 15

ompressors

Outdoor Coil

FanĂMotor

Indoor Coil

Blower Motor (1 phase)

{ReferĂtoĂNationalĂor Canadian ElectricalĂCodeĂmanualĂtoĂdetermineĂwire,ĂfuseĂandĂdisconnectĂsizeĂrequirements.

"WhereĂcurrentĂdoesĂnotĂexceedĂ100Ăamps,ĂHACRĂtypeĂcircuitĂbreakerĂmayĂbeĂusedĂinĂplaceĂofĂfuse.

NOTEĂĊĂExtremesĂofĂoperatingĂrangeĂareĂplusĂandĂminusĂ10%ĂofĂlineĂvoltage.

RatedĂloadĂamps 10.3 5.2 13.5 7.4 17.3 9

LockedĂrotorĂamps 77 39 120 49.5 137 62

FullĂloadĂamps 1.1 0.73 2.3 1.1 2.4 1.3

LockedĂrotorĂamps 2.2 1.3 4.4 2 4.4 2.0

FullĂloadĂampsĂ 3 1.8 3.9 1.8 4.6 2.4

LockedĂrotorĂampsĂ 6.2 4.4 8.3 4.4 10 3.8

Page 9

Page 10

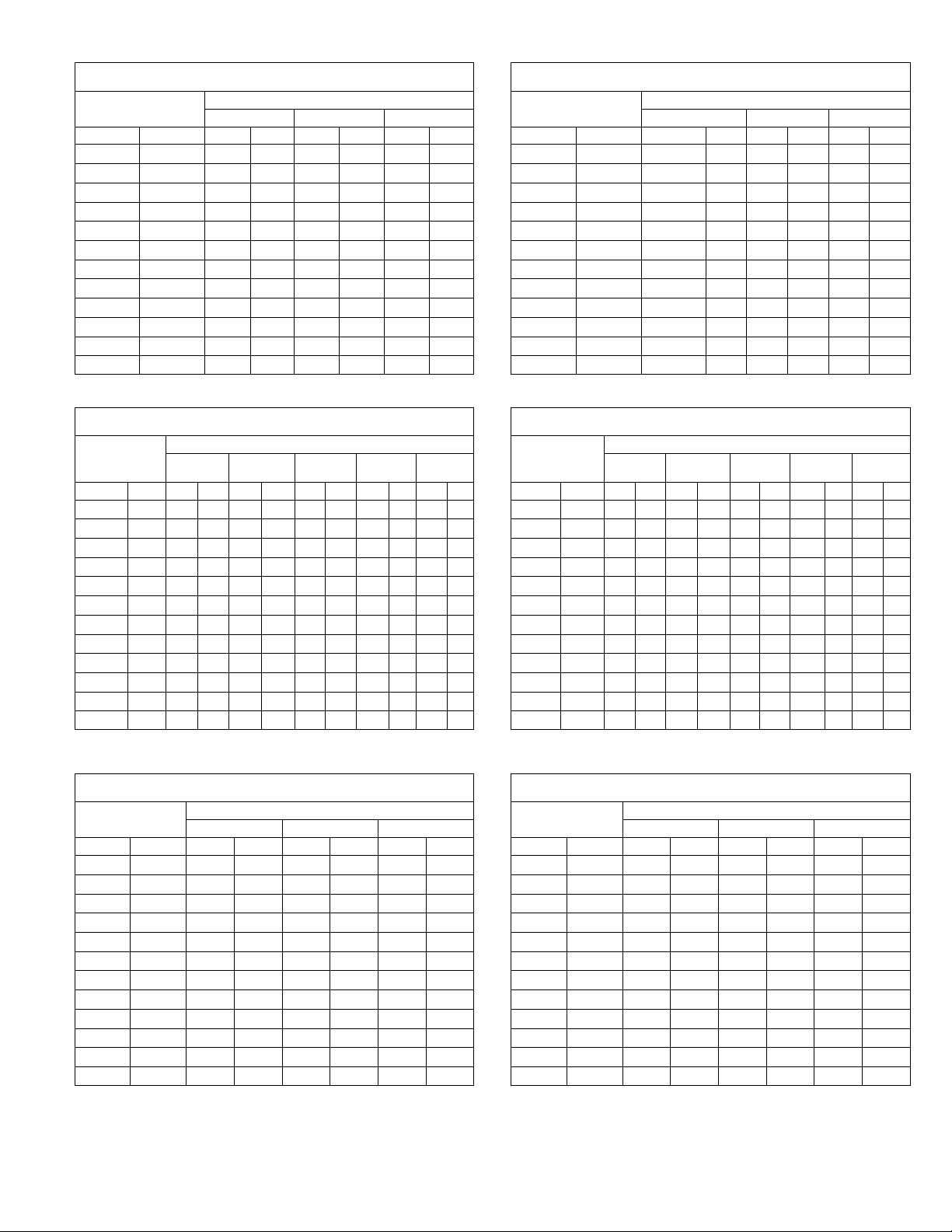

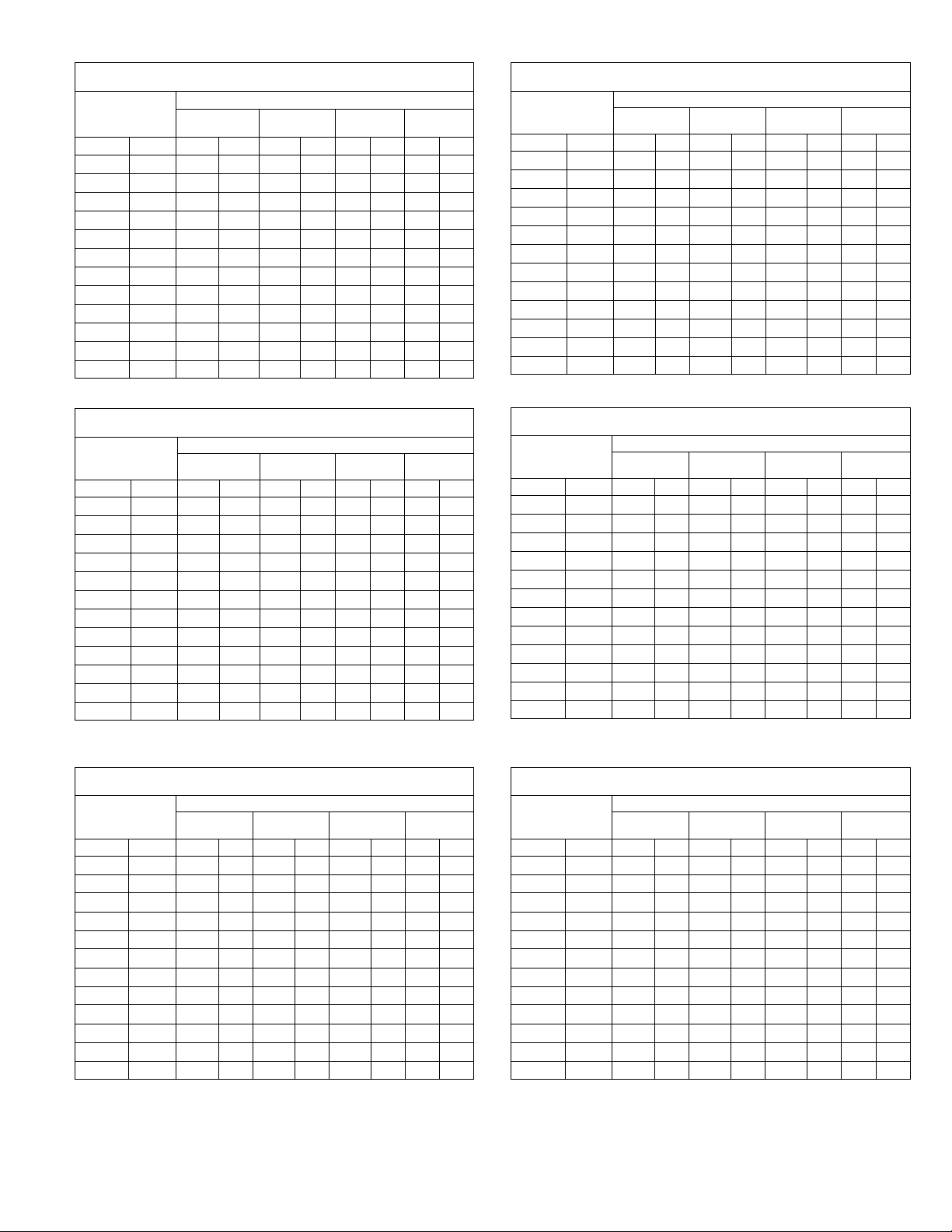

BLOWER DATA CHA16

CHA16-024 BLOWER PERFORMANCE

@ 230 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

0 0 1370 645 950 450 875 415 660 310

.05 12 1365 645 955 450 880 415 670 315

.10 25 1350 635 960 455 885 420 675 320

.15 37 1340 630 960 455 885 420 680 320

.20 50 1320 625 955 450 880 415 680 320

.25 62 1300 615 950 450 875 415 680 320

.30 75 1280 605 940 445 870 410 675 320

.40 100 1220 575 920 435 850 400 660 310

.50 125 1150 545 880 415 820 385 630 295

.60 150 1070 505 835 395 775 365 585 275

.70 175 975 460 780 370 725 340 535 250

.75 185 925 435 745 350 700 330 500 235

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is meaĆ

sured external to the unit with dry coil and without air filter.

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

CHA16-024 BLOWER PERFORMANCE

@ 230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1405 665 905 425 820 385 620 295

.05 12 1400 660 935 440 845 400 640 300

.10 25 1385 655 955 450 865 410 655 310

.15 37 1370 645 975 460 880 415 665 315

.20 50 1355 640 985 465 890 420 670 315

.25 62 1335 630 990 465 895 420 670 315

.30 75 1310 620 985 465 890 420 670 315

.40 100 1260 595 965 455 870 410 650 305

.50 125 1195 565 915 430 830 390 615 290

.60 150 1120 530 840 395 865 410 560 265

.70 175 1035 490 740 350 675 320 490 230

.75 185 990 465 685 325 620 295 445 210

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is measured

external to the unit with dry coil and without air filter.

CHA16-030 BLOWER PERFORMANCE

@ 230 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1355 640 1255 590 1105 520 900 425

.05 12 1345 635 1250 590 1100 520 910 430

.10 25 1330 630 1245 590 1090 515 915 430

.15 37 1310 620 1235 585 1080 510 915 430

.20 50 1290 610 1220 575 1070 505 910 430

.25 62 1270 600 1205 570 1055 500 900 425

.30 75 1245 590 1180 555 1035 490 890 420

.40 100 1190 560 1130 535 990 465 855 405

.50 125 1125 530 1060 500 935 440 805 380

.60 150 1050 495 980 560 870 410 735 345

.70 175 960 455 885 420 790 375 655 310

.75 185 915 430 835 395 745 350 605 285

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is measured

external to the unit with dry coil and without air filter.

CHA16-030 BLOWER PERFORMANCE

@ 230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1445 680 1330 630 1105 520 900 425

.05 12 1435 680 1295 610 1105 520 910 430

.10 25 1420 670 1285 605 1105 520 915 430

.15 37 1400 660 1275 600 1100 520 920 435

.20 50 1380 650 1265 595 1095 515 920 435

.25 62 1360 640 1250 590 1085 510 915 430

.30 75 1335 630 1230 580 1070 505 905 425

.40 100 1280 605 1185 560 1035 490 880 415

.50 125 1220 575 1135 535 995 470 840 395

.60 150 1150 545 1070 505 935 440 790 375

.70 175 1070 505 995 470 870 410 720 340

.75 185 1025 485 955 450 830 390 680 320

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is measured

external to the unit with dry coil and without air filter.

Page 10

Page 11

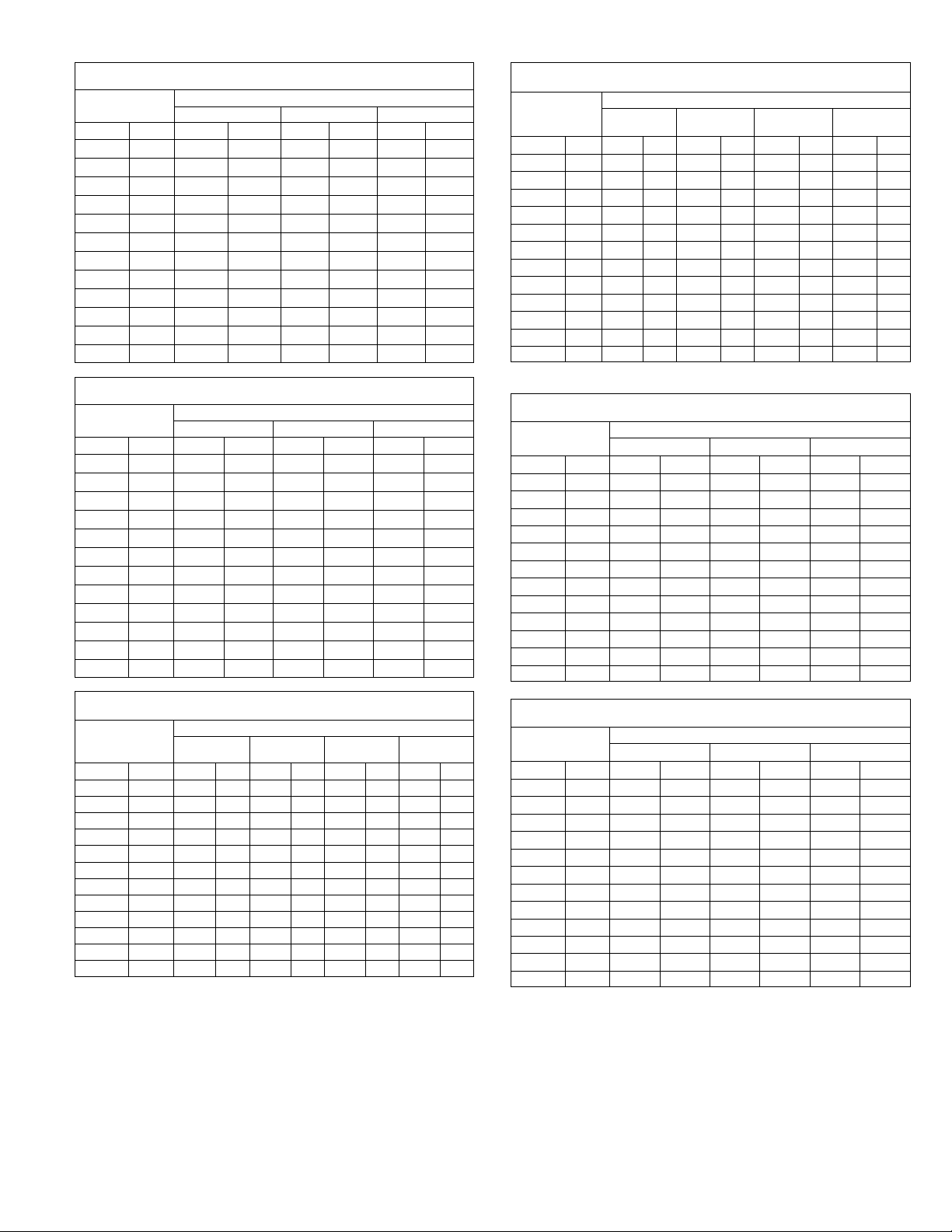

BLOWER DATA CHA16 Cont

External Static

External Static

CHA16-036 BLOWER PERFORMANCE

@ 230 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

0 0 1415 670 1350 635 1135 530 915 430

.05 12 1395 660 1335 630 1125 530 905 425

.10 25 1375 650 1315 620 111 5 525 895 420

.15 37 1360 640 1290 610 111 0 525 890 420

.20 50 1355 640 1275 600 1105 520 885 420

.25 62 1325 625 1255 590 1095 515 875 415

.30 75 1310 620 1235 585 1085 510 865 410

.40 100 1265 595 1195 565 1060 500 845 400

.50 125 1220 575 1155 545 1020 480 825 390

.60 150 1170 550 1105 520 975 460 785 370

.70 175 1115 525 1045 495 925 435 725 340

.75 185 1085 510 1010 475 895 420 685 325

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is meaĆ

sured external to the unit with dry coil and without air filter.

CHA16-036 BLOWER PERFORMANCE

@ 230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

0 0 1490 705 1460 690 1145 540 920 435

.05 12 1470 695 1440 680 1135 535 910 430

.10 25 1450 685 1420 670 1125 530 900 425

.15 37 1435 675 1395 660 1120 530 895 420

.20 50 1430 675 1375 650 1115 525 890 420

.25 62 1400 660 1355 640 1105 520 880 415

.30 75 1380 650 1335 630 1095 515 870 410

.40 100 1335 630 1285 605 1070 505 850 400

.50 125 1285 605 1235 585 1030 485 830 390

.60 150 1235 585 1195 565 985 465 790 375

.70 175 1185 560 1140 540 935 440 730 345

.75 185 1160 545 1110 525 905 425 690 325

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHA16-036 BLOWER PERFORMANCE

@ 460/575 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

0 0 1625 765 1465 690 1100 520

.05 12 1600 755 1445 680 1100 520

.10 25 1570 740 1420 670 1100 520

.15 37 1555 735 1395 660 1095 515

.20 50 1525 720 1385 655 1090 515

.25 62 1485 700 1365 645 1075 505

.30 75 1465 690 1340 630 1070 505

.40 100 1400 660 1285 605 1035 490

.50 125 1335 630 1235 585 1005 475

.60 150 1260 595 1165 550 955 450

.70 175 1170 550 1085 510 875 415

.75 185 1100 520 1045 495 815 385

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

Air Volume at Various Blower Speeds

High

High

High Medium Low

MediumĆ

High

Air Volume at Various Blower Speeds

MediumĆ

High

Air Volume at Various Blower Speeds

MediumĆ

Low

MediumĆ

Low

Low

Low

CHA16-036 BLOWER PERFORMANCE

@ 460/575 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 1710 805 1590 750 1105 520

.05 12 1685 795 1565 740 1105 520

.10 25 1655 780 1535 725 1105 520

.15 37 1630 770 1510 715 1100 520

.20 50 1610 760 1490 705 1095 515

.25 62 1570 740 1470 695 1085 510

.30 75 1540 725 1445 680 1075 505

.40 100 1475 695 1385 655 1040 490

.50 125 1405 665 1330 630 1010 475

.60 150 1335 630 1260 595 960 455

.70 175 1240 585 1185 560 885 420

.75 185 1180 555 1150 545 825 390

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHA16-048 BLOWER PERFORMANCE

@ 230 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 2065 975 1715 810 1515 715 1305 615

.05 12 2055 970 1705 805 1505 710 1300 615

.10 25 2040 965 1690 800 1495 705 1300 615

.15 37 2020 955 1680 795 1485 700 1295 610

.20 50 2000 945 1665 785 1475 695 1290 610

.25 62 1975 930 1650 780 1470 695 1285 605

.30 75 1950 920 1635 770 1450 685 1280 605

.40 100 1885 890 1600 755 1425 670 1260 595

.50 125 1810 855 1565 740 1395 660 1225 580

.60 150 1730 815 1525 720 1360 640 1175 555

.70 175 1645 775 1600 755 1320 625 111 0 525

.75 185 1600 755 1455 685 1295 610 1070 505

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is meaĆ

sured external to the unit with dry coil and without air filter.

CHA16-048 BLOWER PERFORMANCE

@ 230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 2140 1010 1785 840 1535 725 1305 615

.05 12 2115 1000 1770 835 1530 720 1300 615

.10 25 2090 985 1755 830 1520 715 1295 610

.15 37 2070 975 1745 825 1510 715 1290 610

.20 50 2045 965 1730 815 1500 710 1285 605

.25 62 2020 955 1715 810 1490 705 1280 605

.30 75 1995 940 1700 800 1480 700 1275 600

.40 100 1935 915 1665 785 1460 690 1260 595

.50 125 1875 885 1630 770 1430 675 1235 585

.60 150 1800 850 1585 750 1400 660 1205 570

.70 175 1710 805 1530 720 1370 645 1170 550

.75 185 1655 780 1495 705 1355 640 1150 545

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is meaĆ

sured external to the unit with dry coil and without air filter.

Page 11

Page 12

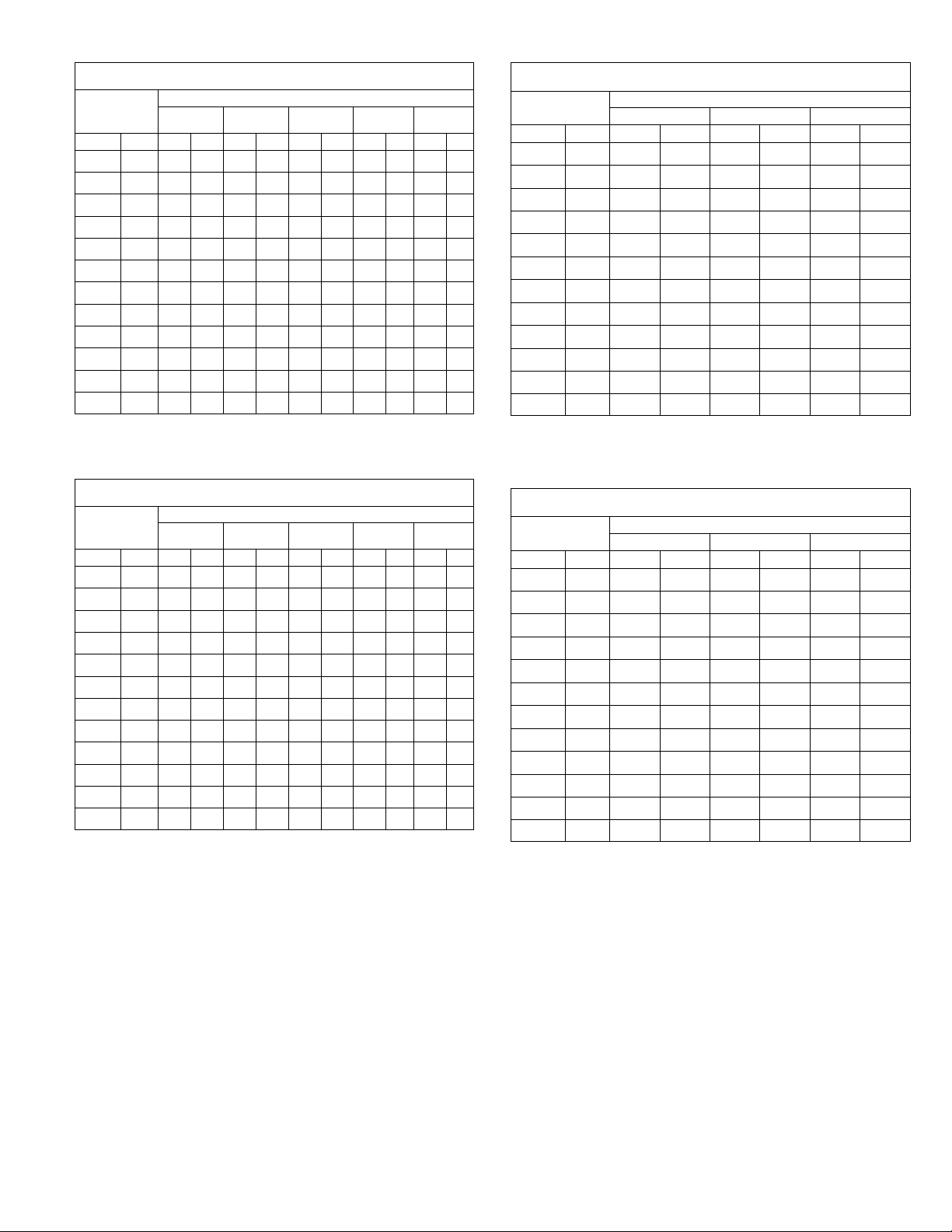

BLOWER DATA CHA16 Cont.

External Static

External Static

External Static

External Static

CHA16-048 BLOWER PERFORMANCE

@ 460/575 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

0 0 2140 1010 1745 825 1175 555

.05 12 2120 1000 1730 815 1175 555

.10 25 2080 980 1720 810 1170 550

.15 37 2045 965 1710 805 1170 550

.20 50 2005 945 1695 800 1165 550

.25 62 1975 930 1680 795 1160 545

.30 75 1940 915 1665 785 1150 545

.40 100 1870 885 1625 765 1135 535

.50 125 1790 845 1580 745 111 0 525

.60 150 1705 805 1515 715 1075 505

.70 175 1605 760 1430 675 1030 485

.75 185 1555 740 1375 650 1000 470

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

Air Volume at Various Blower Speeds

High Medium Low

CHA16-048 BLOWER PERFORMANCE

@ 460/575 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2160 1020 1815 855 1210 570

.05 12 2125 1005 1800 850 1210 570

.10 25 2095 990 1790 845 1200 565

.15 37 2060 970 1780 840 1200 565

.20 50 2025 955 1760 830 1195 565

.25 62 1990 940 1745 825 1190 560

.30 75 1955 925 1730 815 1185 560

.40 100 1885 890 1690 800 1170 550

.50 125 1805 850 1640 775 1140 540

.60 150 1715 810 1575 745 1105 520

.70 175 1615 760 1495 705 1065 505

.75 185 1560 735 1445 680 1040 490

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHA16-060 BLOWER PERFORMANCE

@ 230 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

Medium

MediumĆ

Low

Low

0 0 2725 1285 2490 1175 2235 1055 1940 915 1620 765

.05 12 2695 1270 2435 1150 2210 1045 1930 910 1625 765

.10 25 2665 1260 2430 1145 2185 1030 1925 910 1625 765

.15 37 2635 1245 2415 1140 2160 1020 1910 900 1610 760

.20 50 2600 1225 2395 1130 2140 1010 1895 895 1590 750

.25 62 2555 1205 2365 1115 2130 1005 1880 885 1580 745

.30 75 2510 1185 2335 1100 2115 1000 1865 880 1565 740

.40 100 2445 1155 2275 1075 2060 970 1830 865 1540 725

.50 125 2385 1125 2230 1050 2005 945 1765 835 1505 710

.60 150 2285 1080 2140 1010 1940 915 1725 815 1455 685

.70 175 2210 1045 2075 980 1880 885 1660 785 1405 665

.75 185 2175 1025 2030 960 1845 870 1615 760 1370 645

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is meaĆ

sured external to the unit with dry coil and without air filter.

CHA16-060 BLOWER PERFORMANCE

@ 460/575 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2725 1285 2405 1135 1905 900

.05 12 2680 1265 2365 1115 1890 890

.10 25 2635 1245 2325 1095 1870 880

.15 37 2590 1220 2290 1080 1855 875

.20 50 2550 1205 2255 1065 1840 870

.25 62 2515 1185 2220 1050 1820 860

.30 75 2485 1175 2190 1035 1795 845

.40 100 2395 1130 2120 1000 1745 825

.50 125 2325 1095 2050 965 1680 795

.60 150 2235 1055 1970 930 1570 740

.70 175 2150 1015 1900 895 1560 735

.75 185 2100 990 1860 880 1515 715

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHA16-060 BLOWER PERFORMANCE

@ 230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

Medium

MediumĆ

Low

Low

0 0 2850 1345 2530 1195 2255 1065 1970 930 1640 775

.05 12 2820 1330 2475 1170 2230 1050 1965 925 1645 775

.10 25 2790 1315 2475 1170 2205 1040 1955 925 1645 775

.15 37 2760 1300 2455 1160 2180 1030 1940 915 1630 770

.20 50 2725 1285 2435 1150 2160 1020 1925 910 1610 760

.25 62 2680 1265 2405 1135 2150 1015 1910 900 1600 755

.30 75 2630 1240 2375 1120 2135 1010 1895 895 1585 750

.40 100 2570 1215 2315 1090 2080 980 1860 880 1560 735

.50 125 2510 1185 2270 1070 2025 955 1795 845 1525 720

.60 150 2410 1135 2180 1030 1960 925 1755 830 1475 695

.70 175 2335 1100 2115 1000 1900 895 1690 800 1425 670

.75 185 2300 1085 2070 975 1865 880 1650 780 1390 655

NOTE Ċ For 208v unit operation, derate air volume by 7%. All air data is meaĆ

sured external to the unit with dry coil and without air filter.

CHA16-060 BLOWER PERFORMANCE

@ 460/575 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2850 1345 2430 1145 1940 915

.05 12 2805 1325 2385 1125 1920 905

.10 25 2760 1300 2345 1105 1905 900

.15 37 2715 1280 2310 1090 1885 890

.20 50 2670 1260 2275 1075 1870 880

.25 62 2640 1245 2240 1055 1850 875

.30 75 2605 1230 2210 1045 1825 860

.40 100 2515 1185 2140 1010 1775 840

.50 125 2445 1155 2120 1000 1710 805

.60 150 2355 1110 1990 940 1600 755

.70 175 2270 1070 1920 905 1590 750

.75 185 2225 1050 1880 885 1545 730

NOTE - All air data is measured external to the unit with dry coil and without air filter.

Page 12

Page 13

BLOWER DATA CHP16/20

CHP16/20Ć024 BLOWER PERFORMANCE

230 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

0 0 1385 655 1025 485 900 425 685 325

.05 12 1380 650 1035 490 915 430 700 330

.10 25 1365 645 1045 495 925 435 710 335

.15 37 1350 635 1045 495 930 440 715 335

.20 50 1330 630 1040 490 930 440 715 335

.25 62 1305 615 1030 485 925 435 715 335

.30 75 1275 600 1010 475 915 430 705 335

.40 100 1205 570 965 455 880 415 680 320

.50 125 1120 530 890 420 820 385 640 300

.60 150 1015 480 800 380 740 350 585 275

.70 175 900 425 685 325 640 300 510 240

.75 185 835 395 615 290 580 275 470 220

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

CHP16/20Ć024 BLOWER PERFORMANCE

230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

0 0 1435 675 1035 490 895 420 625 295

.05 12 1420 670 1050 495 915 430 645 305

.10 25 1400 660 1060 500 925 435 660 310

.15 37 1380 650 1060 500 935 440 670 315

.20 50 1360 640 1060 500 935 440 675 320

.25 62 1335 630 1050 495 930 440 675 320

.30 75 1305 615 1035 490 920 435 670 315

.40 100 1235 585 985 465 875 415 650 305

.50 125 1155 545 910 430 810 380 605 285

.60 150 1065 505 810 380 720 340 545 255

.70 175 960 455 690 325 605 285 465 220

.75 185 905 425 620 295 540 255 415 195

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

Air Volume at Various Blower Speeds

High

High

MediumĆ

High

Air Volume at Various Blower Speeds

MediumĆ

High

MediumĆ

Low

MediumĆ

Low

Low

Low

CHP16/20Ć030 BLOWER PERFORMANCE

230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1485 700 1345 635 111 5 525 920 435

.05 12 1480 700 1340 630 1120 530 930 440

.10 25 1465 690 1335 630 1120 530 940 445

.15 37 1455 685 1325 625 111 5 525 945 445

.20 50 1435 675 1315 620 111 0 525 945 445

.25 62 1420 670 1305 615 1105 520 940 445

.30 75 1400 660 1285 605 1095 515 935 440

.40 100 1350 635 1250 590 1065 505 910 430

.50 125 1295 610 1200 565 1025 485 875 415

.60 150 1230 580 1145 540 975 460 820 385

.70 175 1160 545 1075 505 915 430 755 355

.75 185 1120 530 1040 490 885 420 720 340

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

CHP16/20Ć036 BLOWER PERFORMANCE

230 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1360 640 1270 600 1070 505 890 420

.05 12 1355 640 1250 590 1060 500 885 420

.10 25 1350 635 1230 580 1050 495 880 415

.15 37 1330 630 1220 575 1035 490 870 410

.20 50 1310 620 1210 570 1020 480 860 405

.25 62 1295 610 1190 560 1005 475 845 340

.30 75 1280 605 1170 550 990 470 830 390

.40 100 1230 580 1130 535 960 455 800 380

.50 125 1170 550 1070 505 910 430 760 360

.60 150 1100 520 990 465 850 400 700 330

.70 175 1020 480 890 420 780 370 620 295

.75 185 975 460 830 390 740 350 570 270

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

CHP16/20Ć030 BLOWER PERFORMANCE

230 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1485 700 1250 590 1085 500 905 425

.05 12 1460 690 1250 590 1075 505 900 425

.10 25 1430 675 1240 585 1070 505 895 420

.15 37 1400 660 1235 585 1060 500 890 420

.20 50 1375 650 1225 580 1045 495 885 420

.25 62 1345 635 1215 575 1035 490 875 415

.30 75 1315 620 1200 565 1020 480 865 410

.40 100 1255 590 1165 550 990 465 835 395

.50 125 1190 560 1125 530 950 450 805 380

.60 150 1125 530 1075 510 910 430 770 365

.70 175 1060 500 1015 480 865 410 725 340

.75 185 1025 485 985 465 840 395 700 330

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

Page 13

CHP16/20Ć036 BLOWER PERFORMANCE

230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 1450 685 1370 645 1080 510 900 425

.05 12 1430 675 1350 635 1070 505 890 420

.10 25 1410 665 1330 630 1060 500 880 415

.15 37 1395 660 1310 615 1055 500 875 415

.20 50 1380 650 1290 610 1050 495 870 410

.25 62 1360 640 1270 600 1040 490 860 405

.30 75 1340 630 1250 590 1030 485 850 400

.40 100 1300 615 1210 570 1010 475 830 390

.50 125 1250 590 1170 550 970 460 810 380

.60 150 1200 565 1120 530 930 440 770 365

.70 175 1150 545 1060 500 890 420 710 335

.75 185 1125 530 1025 485 870 410 670 315

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

Page 14

BLOWER DATA CHP16/20 Cont.

External Static

External Static

External Static

External Static

CHP16/20Ć036 BLOWER PERFORMANCE

460 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

0 0 1560 735 1380 650 1070 505

.05 12 1555 735 1355 640 1075 505

.10 25 1540 725 1330 630 1080 510

.15 37 1510 715 1320 625 1070 505

.20 50 1475 695 1315 620 1060 500

.25 62 1450 685 1295 610 1040 490

.30 75 1430 675 1270 600 1025 485

.40 100 1360 640 1215 575 980 460

.50 125 1280 605 1145 540 925 435

.60 150 1185 560 1045 495 850 400

.70 175 1070 505 925 435 750 355

.75 185 990 465 860 405 680 320

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHP16/20Ć036 BLOWER PERFORMANCE

460 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

0 0 1665 785 1490 705 1080 510

.05 12 1640 775 1465 690 1080 510

.10 25 1610 760 1440 680 1080 510

.15 37 1585 750 1420 670 1075 505

.20 50 1555 735 1400 660 1070 505

.25 62 1525 720 1380 650 1060 500

.30 75 1495 705 1355 640 1050 495

.40 100 1435 675 1300 615 1015 480

.50 125 1365 645 1250 590 985 465

.60 150 1295 610 1180 555 935 440

.70 175 1205 570 1100 520 860 405

.75 185 1145 540 1060 500 800 380

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHP20-042 CHP16/20Ć048 BLOWER PERFORMANCE

230 VOLTS (With Down-Flow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

0 0 2015 950 1610 760 1425 670 1240 585

.05 12 2000 945 1595 755 1420 670 1235 585

.10 25 1980 935 1580 745 1415 670 1235 585

.15 37 1960 925 1575 745 1415 670 1230 580

.20 50 1935 915 1560 735 1405 665 1225 580

.25 62 1910 900 1540 725 1395 660 1215 575

.30 75 1885 890 1520 715 1385 655 1205 570

.40 100 1825 860 1485 700 1355 640 1185 560

.50 125 1760 830 1445 680 1315 620 1160 550

.60 150 1690 800 1395 660 1260 595 1130 535

.70 175 1615 760 1335 630 1190 560 1095 515

.75 185 1575 745 1300 615 1145 540 1065 505

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

Air Volume at Various Blower Speeds

High Medium Low

Air Volume at Various Blower Speeds

High Medium Low

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

CHP20-042 CHP16/20Ć048 BLOWER PERFORMANCE

230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High

MediumĆ

High

MediumĆ

Low

Low

0 0 2075 980 1675 790 1445 680 1275 600

.05 12 2060 970 1660 785 1440 680 1270 600

.10 25 2040 965 1645 775 1435 675 1270 600

.15 37 2020 955 1635 770 1435 675 1265 595

.20 50 1995 940 1620 765 1425 670 1260 595

.25 62 1965 930 1600 755 1415 670 1250 590

.30 75 1940 915 1580 745 1405 665 1240 585

.40 100 1880 890 1545 730 1375 650 1220 575

.50 125 1815 855 1500 710 1335 630 1195 565

.60 150 1740 820 1450 685 1280 605 1165 550

.70 175 1655 780 1395 660 1210 570 1130 535

.75 185 1605 755 1365 645 1165 550 1110 525

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

CHP16/20Ć048 BLOWER PERFORMANCE

460 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2075 980 1650 780 1105 520

.05 12 2045 965 1635 770 1105 520

.10 25 2015 950 1625 765 1100 520

.15 37 1980 935 1615 760 1100 520

.20 50 1945 920 1600 755 1095 515

.25 62 1915 905 1585 750 1090 515

.30 75 1880 890 1570 740 1085 510

.40 100 1810 855 1535 725 1070 505

.50 125 1735 820 1490 705 1045 495

.60 150 1650 780 1430 675 1010 475

.70 175 1555 735 1355 640 965 455

.75 185 1500 710 1310 620 935 440

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHP16/20Ć048 BLOWER PERFORMANCE

460 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2090 985 1755 830 111 5 525

.05 12 2065 975 1740 820 111 5 525

.10 25 2035 960 1720 810 111 0 525

.15 37 2005 945 1705 805 111 0 525

.20 50 1975 930 1685 795 1105 520

.25 62 1950 920 1675 790 1100 520

.30 75 1920 905 1650 780 1095 515

.40 100 1860 880 1600 755 1080 510

.50 125 1790 845 1555 735 1055 500

.60 150 1720 810 1495 705 1020 480

.70 175 1640 775 1425 670 975 460

.75 185 1595 755 1385 655 945 445

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

Page 14

Page 15

BLOWER DATA CHP16/20 Cont.

External

External Static

External Static

CHP16/20Ć060 BLOWER PERFORMANCE

230 VOLTS (With Down-Flow Air Openings)

External

Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

0 0 2450 1155 2200 1040 1990 940 1760 830 1460 690

.05 12 2430 1145 2180 1030 1980 935 1750 825 1470 695

.10 25 2410 1135 2170 1025 1970 930 1740 820 1490 705

.15 37 2390 1130 2160 1020 1960 925 1730 815 1500 710

.20 50 2360 111 5 2140 1010 1950 920 1720 810 1490 705

.25 62 2340 1105 2120 1000 1930 910 1710 805 1490 705

.30 75 2320 1095 2100 990 1910 900 1700 800 1480 700

.40 100 2270 1070 2060 970 1880 885 1670 780 1470 695

.50 125 2230 1052 2010 950 1830 865 1640 775 1430 675

.60 150 2170 1025 1930 910 1780 840 1600 755 1390 655

.70 175 2120 1000 1890 890 1730 815 1550 730 1340 630

.75 185 2080 980 1850 875 1700 800 1530 720 1310 620

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

Air Volume at Various Blower Speeds

High

MediumĆ

High

Medium

MediumĆ

Low

Low

CHP16/20Ć060 BLOWER PERFORMANCE

460 VOLTS (With DownĆFlow Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2450 1155 2090 985 1740 820

.05 12 2430 1145 2080 980 1740 820

.10 25 2410 1135 2060 970 1730 815

.15 37 2390 1130 2040 965 1720 810

.20 50 2360 1115 2020 955 1710 805

.25 62 2340 1105 2000 945 1700 800

.30 75 2320 1095 1990 940 1680 795

.40 100 2270 1070 1940 915 1630 770

.50 125 2230 1050 1880 885 1590 750

.60 150 2170 1025 1840 870 1520 715

.70 175 2120 1000 1770 835 1460 690

.75 185 2080 980 1740 820 1440 680

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

CHP16/20Ć060 BLOWER PERFORMANCE

230 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

High

Air Volume at Various Blower Speeds

MediumĆ

High

Medium

MediumĆ

Low

Low

0 0 2570 1215 2220 1050 2000 945 1780 840 1510 715

.05 12 2560 1210 2210 1045 1990 940 1780 840 1520 715

.10 25 2540 1200 2200 1040 1980 935 1770 835 1530 720

.15 37 2520 1190 2190 1035 1970 930 1770 835 1520 715

.20 50 2500 1180 2180 1030 1960 925 1760 830 1510 715

.25 62 2480 1170 2160 1020 1940 915 1750 825 1510 715

.30 75 2440 1150 2140 1010 1920 905 1740 820 1500 710

.40 100 2390 1130 2100 990 1900 895 1710 805 1470 695

.50 125 2320 1095 2060 970 1860 880 1670 790 1440 680

.60 150 2240 1055 2010 950 1810 855 1630 770 1400 660

.70 175 2160 1020 1950 920 1760 830 1580 745 1350 635

.75 185 2120 1000 1920 905 1720 810 1560 735 1330 630

NOTE Ċ For 208v unit operation, derate air volume by 7% All air data is measured

external to the unit with dry coil and without air filter.

CHP16/20Ć060 BLOWER PERFORMANCE

460 VOLTS (With Horizontal Air Openings)

External Static

Pressure

in. w.g. Pa cfm L/s cfm L/s cfm L/s

Air Volume at Various Blower Speeds

High Medium Low

0 0 2570 1215 2100 990 1760 830

.05 12 2560 1210 2090 985 1770 835

.10 25 2540 1200 2070 975 1760 830

.15 37 2520 1190 2050 965 1760 830

.20 50 2500 1180 2030 960 1750 825

.25 62 2480 1170 2010 950 1740 820

.30 75 2440 1150 2000 945 1720 810

.40 100 2390 1130 1960 925 1670 790

.50 125 2320 1095 1910 900 1620 765

.60 150 2240 1105 1870 880 1550 730

.70 175 2160 1020 1800 850 1490 705

.75 185 2120 1000 1760 830 1470 695

NOTE Ċ All air data is measured external to the unit with dry coil and without air filter.

Page 15

Page 16

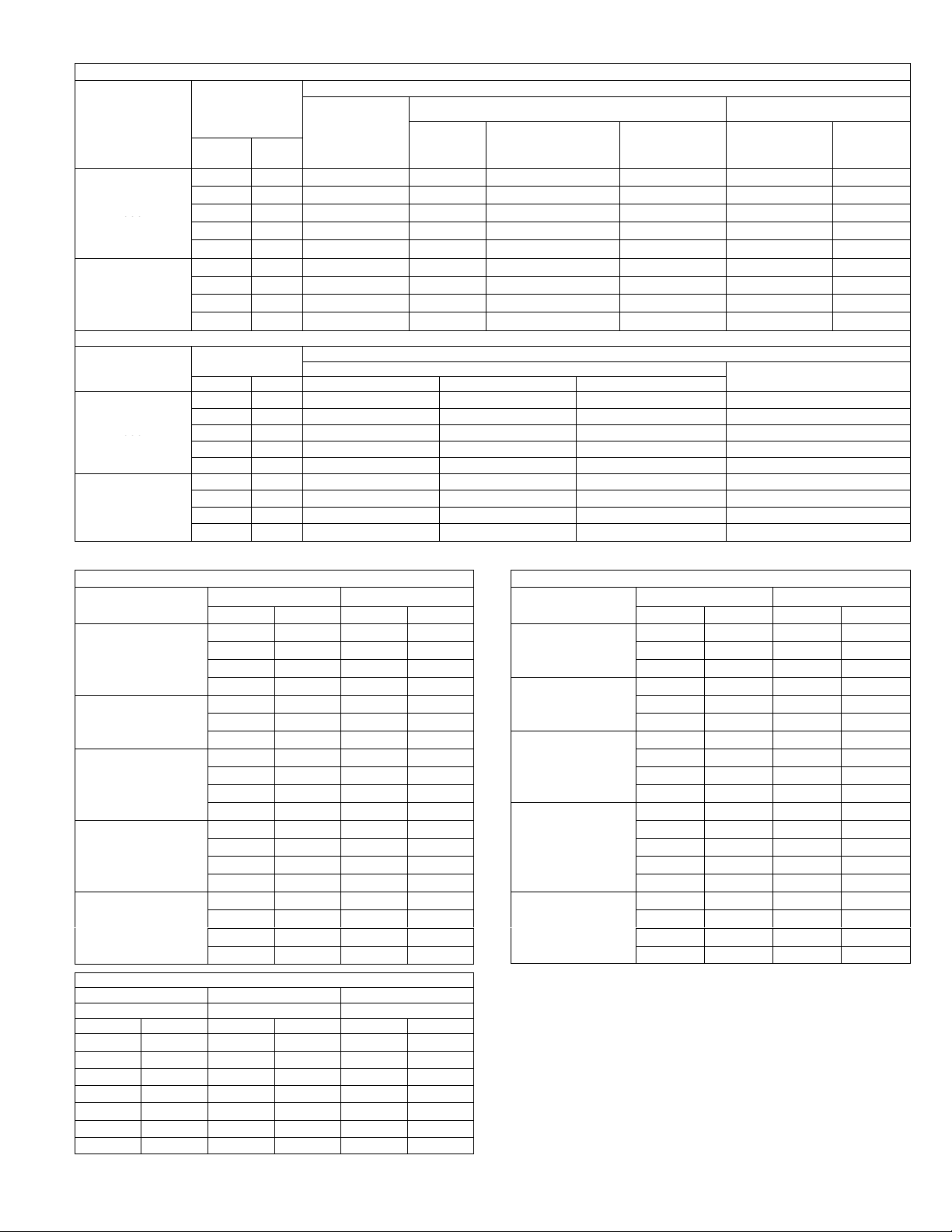

ACCESSORY BLOWER DATA CHA/CHP16/20

Unit

Volume

No

Filter

With Optional

With Optional

With

024

030

048

060

Unit

Air

Model

FD9Ć65

024

030

048

060

Model Numb

CHA16 030

Model Numb

CHP16/20 024

CHP16/20 030

CHP16/20-048

FILTER AND ACCESSORY AIR RESISTANCE CHA/CHP16/20

Unit

Model

No.

.

024

030

036

042

060

DIFFUSER AIR RESISTANCE CHA/CHP16/20

Model

No.

024

030

036

o42

060

Air

Volume

cfm L/s

1 in. (25mm)

Filter

Furnished

600 285 .13 (32) .05 (12) .21 (52) .09 (22) .12 (30) .07 (17)

800 380 .15 (37) .05 (12) .27 (67) .13 (32) .18 (45) .10 (25)

1000 470 .18 (45) .06 (15) .34 (85) .18 (45) .26 (65) .15 (37)

1200 565 .21 (52) .09 (22) .42 (104) .24 (60) .35 (87) .21 (52)

1400 660 .25 (62) .15 (37) .51 (127) .31 (77) .46 (114) .29 (72)

1600 755 .15 (37) .05 (12) .40 (99) .27 (67) .30 (75) .17 (42)

1800 850 .17 (42) .06 (15) .48 (119) .33 (82) .35 (87) .19 (47)

2000 945 .20 (50) .08 (20) .56 (139) .39 (97) .40 (99) .22 (55)

2200 1040 .23 (57) .10 (25) .66 (164) .46 (114) .47 (117) .26 (65)

Air

Volume

cfm L/s 2 Ends Open 1 Side 2 Ends Open All Ends & Sides Open

600 285 .12 (30) .11 (27) .08 (20) .08 (20)

800 380 .15 (37) .13 (32) .11 (27) .11 (27)

1000 470 .19 (47) .16 (40) .14 (35) .14 (35)

1200 565 .25 (62) .20 (50) .17 (42) .17 (42)

1400 660 .33 (82) .26 (65) .20 (50) .20 (50)

1600 755 .43 (107) .32 (80) .20 (50) .24 (60)

1800 850 .56 (139) .40 (90) .30 (75) .30 (75)

2000 945 .73 (182) .50 (124) .36 (90) .36 (90)

2200 1040 .95 (236) .63 (157) .44 (109) .44 (109)

Less

Filter

RTD9Ć65 Diffuser

Total Air Resistance Ċ inches water gauge (Pa)

REMD16 DownĆFlow Economizer

With Optional

Pleated

Polyester

2 in. (51mm) Filter

Total Air Resistance Ċ inches water gauge (Pa)

With Optional

Fiberglass

2 in. (51mm)

Filter

EMDH16 Horizontal

Economizer

With

Furnished

1 in. (25mm)

Filter

FD9Ć65

Diffuser

Less

Filter

WET INDOOR COIL AIR RESISTANCE CHA16

er

CHA16-024

CHA16-030

CHA16-036

CHA16-048

CHA16-060

CEILING DIFFUSER AIR THROW DATA CHA16 CHP16/20

Model No. RTD9-65 FD9-65

Air Volume

cfm L/s ft. m ft. m

1000 470

1200 565

1400 660

1600 755

1800 850

2000 945

2200 1040

Effective throw based on terminal velocities of 75 ft. (22.9 m) per minute.

Air Volume

cfm L/s in. w.g. Pa

600 285

800 380

1000 470

1200 565

800 380

1000 470

1200 565

800 380

1000 470

1200 565

1400 660

1600 755

1800 850

2000 945

2200 1040

1600 755

1800 850

2000 945

2200 1040

Effective Throw Effective Throw Ċ ft.

10-17 3-5 15-20 5-6

11-18 3-5 16-22 5-7

12-19 4-6 17-24 5-7

12-20 4-6 18-25 5-8

13-21 4-6 20-28 6-9

14-23 4-7 21-29 6-9

16-25 5-8 22-30 7-9

Air Resistance

0.05 12

0.06 15

0.07 17

0.08 20

0.09 22

0.10 25

0.11 27

0.09 22

0.10 25

0.11 27

0.12 30

0.11 27

0.12 30

0.13 32

0.14 35

0.08 20

0.09 22

0.10 25

0.11 27

(m)

WET INDOOR COIL AIR RESISTANCE CHP16/20

er

CHP16/20-024

CHP16/20-030

CHP16/20-036

CHP20--042

-

CHP16/20-060

Air Volume

cfm L/s in. w.g. Pa

600 285

800 380

1000 470

800 380

1000 470

1200 565

800 380

1000 470

1200 565

1400 660

1400 660

1600 755

1800 850

2000 945

2200 1040

1600 755

1800 850

2000 945

2200 1040

Air Resistance

0.05 12

0.06 15

0.07 17

0.09 22

0.10 25

0.11 27

0.07 17

0.08 20

0.09 22

0.10 25

0.12 30

0.13 32

0.14 35

0.15 37

0.16 40

0.11 27

0.12 30

0.13 32

0.14 35

Page 16

Page 17

BLOWER ASSEMBLY

ELECTRICHEAT

ELEMENT

CHA/CHP16, CHP20 PARTS ARRANGEMENT

(shown with scroll compressor)

CONDENSER FAN

COMPRESSOR

CONTROL BOX

CMCI DEFROST

CONTROL

TRANSFORMER

T1

TERMINAL STRIP

TB32

TRANSFORMER T4

(024, 030, 036)

FAN RELAY

INBLOOR BLOWER

CONTACTOR K3

COMPRESSOR

CONTACTOR K1

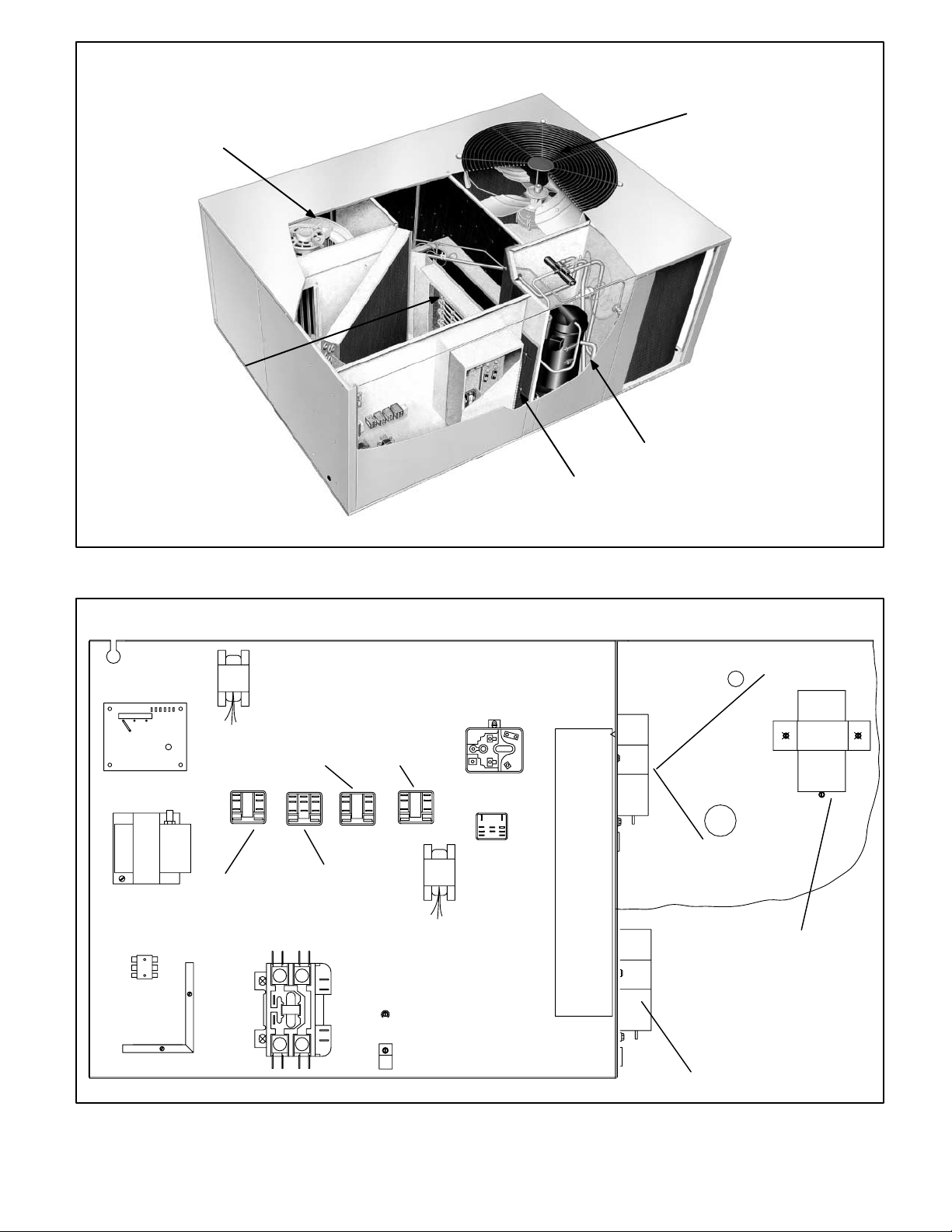

FIGURE 1

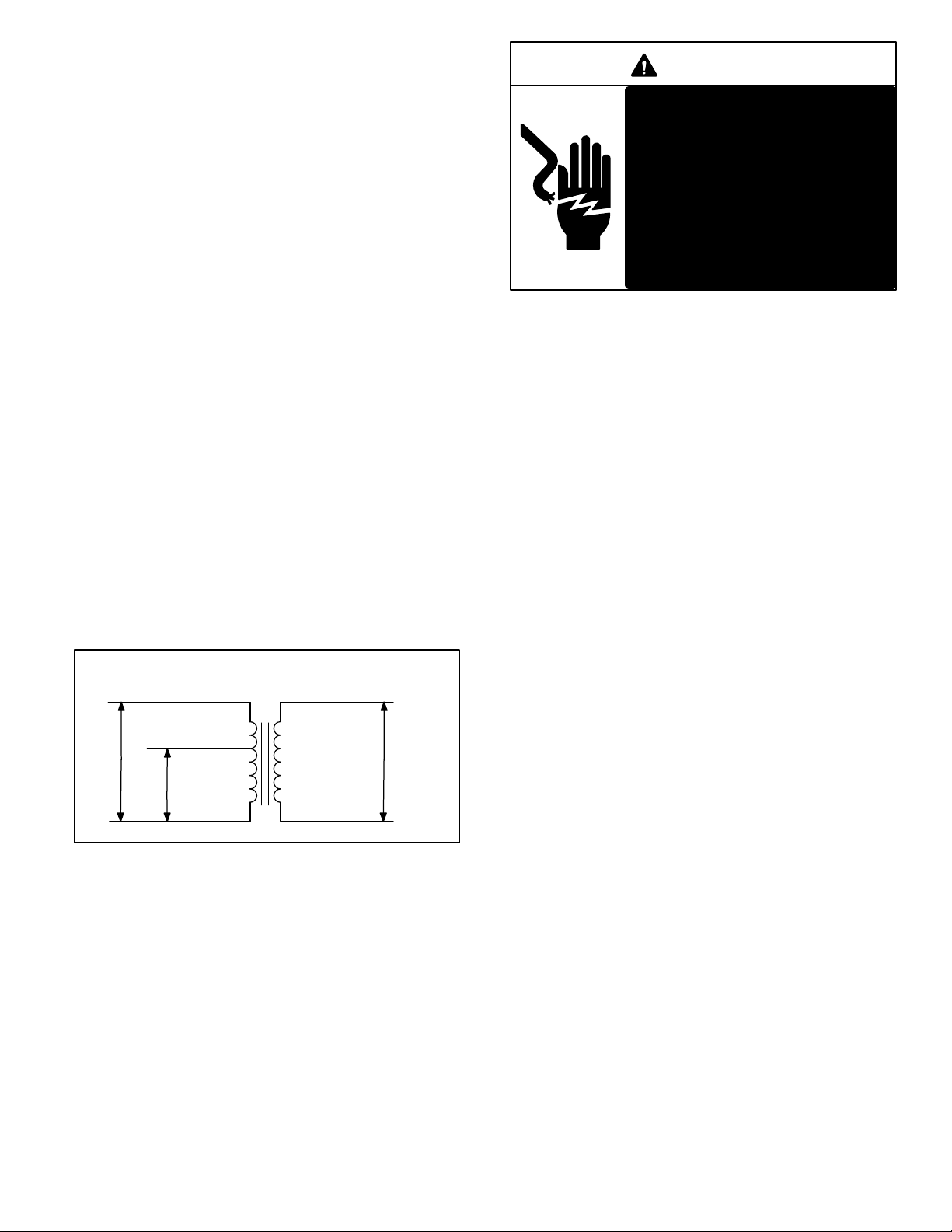

CHA/CHP16, CHP20 CONTROL BOX

HARD START RELAY K31

CHA/CHP16-024/030

OUTDOOR

K10

DEFROST

RELAY

TRANSFER

REALY

K8

LATCH RELAY

K6

K4

TRANSFORMER T4

(042, 048, 060)

CAPACITOR C12

ALL P VOLT UNITS

CAPACITOR C1

CHP20-036, -060 G,J,M VOLTS

CHA/CHP16-036 G, J, M VOLTS

ALL Y VOLTAGE UNITS

CAPACITOR C1

CHP16/20-048-G. J, M, VOLTS

CHP16-060-G, J, M, VOLTS

FIGURE 2

Page 17

CAPACITOR C7

CHA/CHP16-024/030

Page 18

I-APPLICATION

CHA/CHP16/20 2, 2 1/2 and 3 ton units are in the one cabiĆ

net size. CHA/CHP16/20 3.5, 4 and 5 ton units are also one

in one cabinet size. All CHA/CHP16/20 model units are apĆ

plicable for commercial, single or three phase installations.

CHA/CHP16/20 models are factory equipped with the hardĆ

ware required for installing Lennox' optional thermostat conĆ

trol systems like the T7300 or T8600 (refer to the EngineerĆ

ing Handbook for more specific application data).

II-UNIT COMPONENTS

CHA/CHP16/20 unit components are shown in figure 1.

A-Control Box Components

CHA/CHP16/20 control box is shown in figure 2. The control

box is located adjacent to the compressor compartment, beĆ

hind the control box access panel in front of the unit.

The condenser fan can be accessed by removing the fan

grill located on top of the unit.

The indoor blower access panel (all units) is located on the

opposite side of the unit from the heating compartment acĆ

cess.

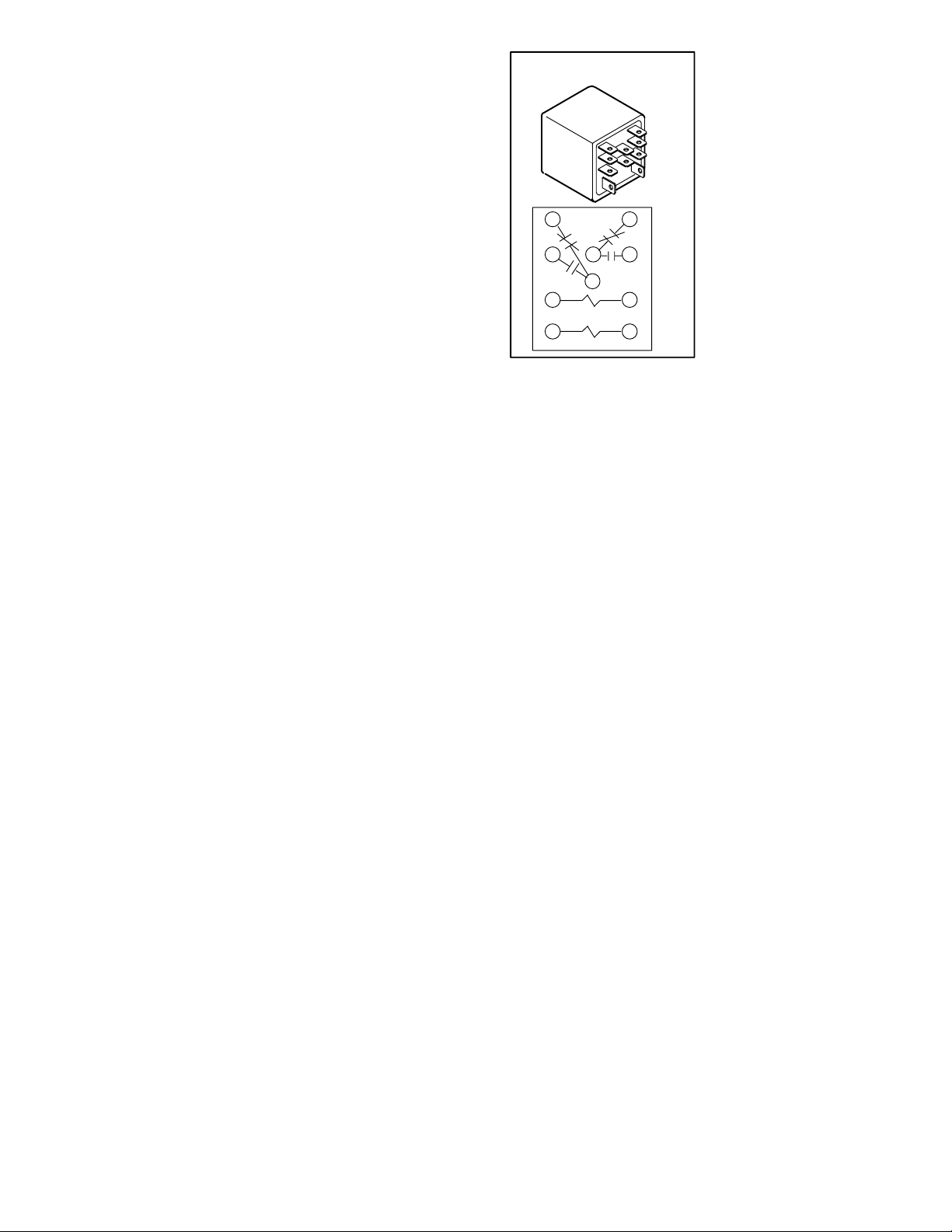

1-Transformer T1

All CHA/CHP16/20 series units use a single line voltage to

24VAC transformer mounted in the control box. The transĆ

former supplies power to control circuits in the unit. TransĆ

formers are rated at 70VA and use two primary voltage taps

as shown in figure 3. T1 is protected by a 3.5 amp circuit

breaker (CB8).

208 / 240 VOLT TRANSFORMER

PRIMARY SECONDARY

ORANGE

240 VOLTS

RED

208 VOLTS

BLUE

24 VOLTS

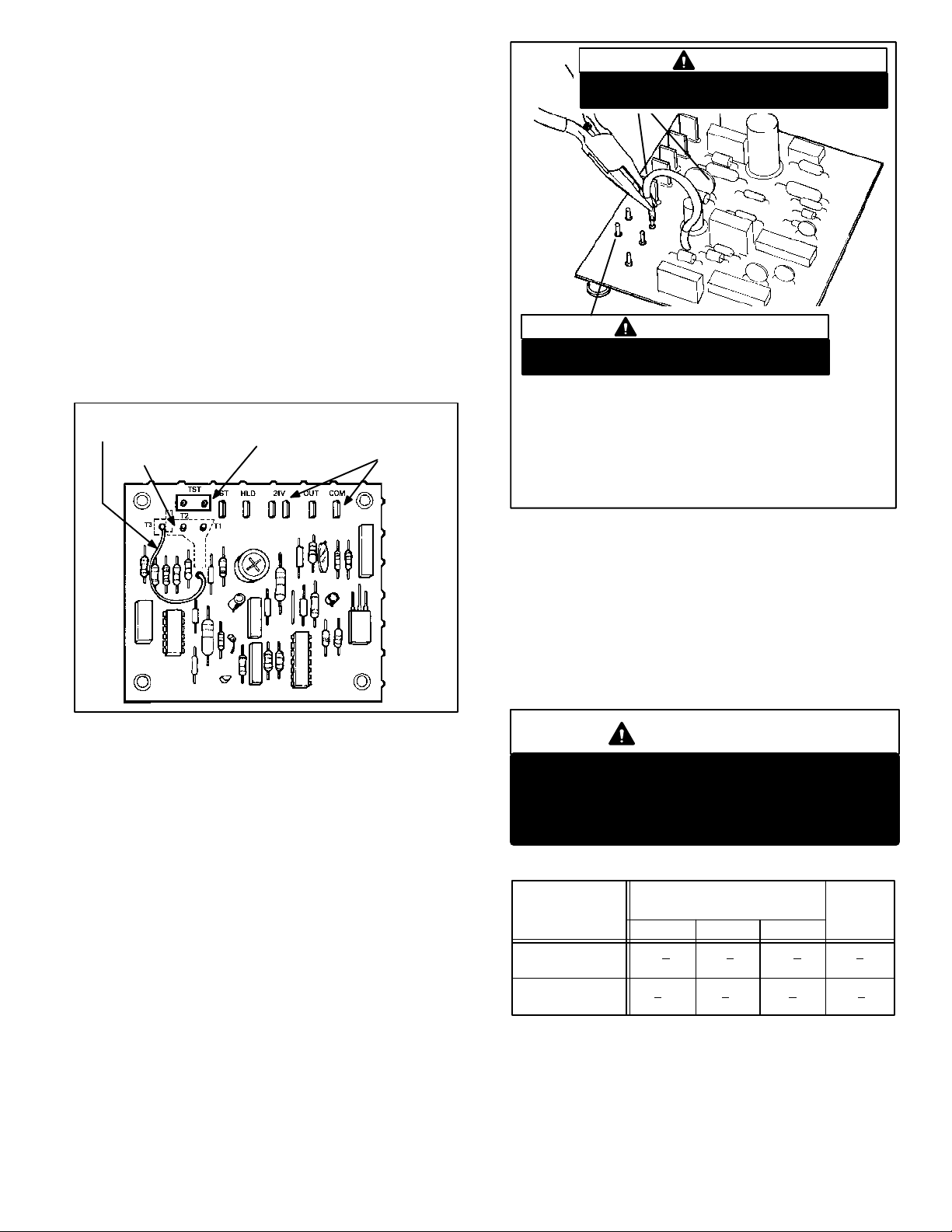

DANGER

Single -phase units use single