Lennox CAMH045SM1M, CAMH035SM1M, CAMH085DM1M, CASH025SM1M, CAMH075DM1M Installation, Operating And Maintenance Manual

...Page 1

www.lennoxemea.com

COMPACTAIR

8 - 85 kW

VERTICAL PACKAGED AIR CONDITIONER

INSTALLATION, OPERATING

AND MAINTENANCE

COMPACTAIR ADV IOM-

MIL157E-0218-04/2018

Page 2

• 1 •

2

3

1.

4

4

5-6

7-8

9-10

11

12-13

14-16

17

18-19

20

21

21-24

2.

25

25

25

26

26

27

27

28-30

31-32

33-34

3.

35

35

36-37

38-39

4.

40

40

41

42

43

5.

43

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

Lennox have been providing environmental solutions since 1895, our COMPACTAIR ADVANCED range continues to meet the standards that have made LENNOX a

household name. Flexible design solutions to meet your needs and uncompromising attention to detail. Engineered to last, simple to maintain and Quality that comes as

standard. For information on local contacts at www.lennoxeurope.com.

The manufacturing of these units is made under the requirements of the ISO 9001 and ISO 14001.

All the information contained in this manual, including any drawing and technical descriptions provided by us, remain the property of Lennox and must not be used

(except in the operation of this product), reproduced, issued to or made available to third parties without the prior written agreement of Lennox.

LENNOX, in its commitment to preserve the environment, has an Environmental Management System based on ISO 14001, through which all environmental aspects

generated during its activity are managed and continuously improved, taking into account the life cycle of the products we manufacture and market.

For this reason, you: customer, user and / or maintainer of the equipment, are invited to join our commitment to conserve our environment, and follow the indications that

we expose throughout this manual.

Read this manual before installation, reparation o maintenance works.

POINTS TO BEAR IN MIND

DATA PAGE FOR COMMISSIONING UNIT

GENERAL CHARACTERISTICS

Product range

General description

Physical data

Electrical data

Operating limits

Fan performances

Refrigeration drawings

Sound levels

Dimensions - split units

Dimensions - packaged units

Air supply confi guration

Options

INSTALLATION

Preliminary preparations

Unit acceptance

Unit location

Ducts and sensor installation

Installation clearances

Drains

Cooling connections

Electrical connections

Terminal connection

COMMISSIONING AND OPERATION

Preliminary checks

Preliminary checks at startup

CLIMATIC™ Confi guration

MAINTENANCE

PREVENTIVE MAINTENANCE

MAINTENANCE PLAN

CORRECTIVE MAINTENANCE

FAILURE DIAGNOSIS

END OF LIFE CYCLE OF THE UNIT

Page 3

• 2 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

Switch off the general power switch of the air conditioning unit on the electrical panel of the location.

The cleaning of fi lters does not require specialized personnel, for other types of interventions like electrical or mechanical advise

the specialized technician.

Abrasive

surfaces

Risk of injury by

moving objects

High

temperatures

Low

temperatures

Risk of injury by

rotating objects

Electrical

voltage

ELECTRICAL CONNECTIONS

Make sure to switch off the power before installing, repairing or carrying out maintenance on the unit, in order to prevent

serious electrical injury.

Keep local and national legislation in mind when installing the unit.

Standard Guidelines to Lennox equipment:

All technical data contained in these operating instructions, including the diagrams and technical description remains the property of

Lennox and may not be used (except for the purpose of familiarizing the user with the equipment), reproduced, photocopied, transferred or transmitted to third parties without prior written authorization from Lennox.

The data published in the operating instructions is based on the latest information available. We reserve the right to make modifi

cations without notice.

We reserve the right to modify our products without notice without obligation to modify previously supplied goods.

These operating instructions contain useful and important information for the smooth operation and maintenance of your equipment.

The instructions also include guidelines on how to avoid accidents and serious damage before commissioning the equipment and

during its operation and how to ensure smooth and fault-free operation. Read the operating instructions carefully before starting the

equipment, familiarize yourself with the equipment and handling of the installation and carefully follow the instructions. It is very important to be properly trained in handling the equipment. These operating instructions must be kept in a safe place near the equipment.

Like most equipment, the unit requires regular maintenance. This section concerns maintenance and management personnel.

If you have any queries or would like to receive further information on any aspect relating to your equipment,

do not hesitate to contact us.

POINTS TO BEAR IN MIND

DANGER AND WARNING SIGNS

WARNING - REMEMEBER

Ensure to open the electrical disconnect switch to the network before accessing the unit for its installation, repair or maintenance to avoid possible deaths

or injuries from electric shock.

If the fi lter is too dirty, wash it in a container with water and neutral soap,

drying it in the shade before inserting it back into the unit.

FILTER CLEANING

Page 4

• 3 •

1 ºC

2 ºC

1 ºC

2 ºC

1 ºC

2 ºC

1 ºC

2 ºC

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

D ATA PAGE FOR UNIT COMMISSIONING

UNIT:

INSTALLER TEL:INSTALLER:

CONTROL PANEL IDENTIFICATION CODE:

INSTALLATION ADDRESS:

SERIAL Nr:

CHECKS:

DATE OF COMMISSIONING:

SUPPLY VOLTAGE:

RATED VOLTAGE OF THE UNIT:

UNIT ON SHOCK ABSORBERS

DRAINAGE WITH TRAP

MAIN POWER SUPPLY CONNECTION

CONTROL PANEL CONNECTION

COMPRESSOR OIL LEVEL INDICATOR

YES NO

DATA INPUT:

COOLING CYCLE

Air intake temperature to the outdoor coil:

Air output temperature to the outdoor coil:

High pressure:

Low pressure:

circuit 1

circuit 2

circuit 1

circuit 2

Air intake temperature to the outdoor coil:

Air output temperature to the outdoor coil:

High pressure:

Low pressure:

circuit 1

circuit 2

circuit 1

circuit 2

HEATING CYCLE

ELECTRIC POWER CONSUMPTION (Amps)

Compressor 1

Compressor 3

Outdoor fan section 1

Outdoor fan section 2

Options installed:

Comments:

Compressor 2

INSTALLER ADDRESS:

Compressor 1

Compressor 3

Outdoor fan section 1

Outdoor fan section 2

Compressor 2

Page 5

• 4 •

CA M H 025 S M 1 M

V/Ph/50 Hz

min nom max min nom max

CAMH025SM1M 400 V 3 Ph 8,5 17,9 22,4 5,8 15,2 19,6

CAMH035SM1M 400 V 3 Ph 13,0 26,4 32,4 9,5 22,4 29,5

CAMH045SM1M 400 V 3 Ph 13,8 39,0 45,0 13,9 29,2 42,2

CAMH060DM1M 400 V 3 Ph 41,7 53,9 59,8 35,4 45,8 56,2

CAMH075DM1M 400 V 3 Ph 40,2 64,8 71,0 45,3 56,0 67,7

CAMH085DM1M 400 V 3 Ph 55,3 79,5 85,3 50,9 65,8 80,8

CASH025SM1M CAIH025SM1M 400 V 3 Ph 8,5 17,9 22,4 5,8 15,2 19,6

CASH035SM1M CAIH035SM1M 400 V 3 Ph 13,0 26,4 32,4 9,5 22,4 29,5

CASH045SM1M CAIH035SM1M 400 V 3 Ph 13,8 39,0 45,0 13,9 29,2 42,2

CASH060DM1M CAIH060SD1M 400 V 3 Ph 41,7 53,9 71,0 45,3 56,0 67,7

CASH075DM1M CAIH075DM1M 400 V 3 Ph 40,2 64,8 71,0 45,3 56,0 67,7

CASH085DM1M CAIH085DM1M 400 V 3 Ph 55,3 79,5 85,3 50,9 65,8 80,8

V/Ph/50 Hz

min nom max min nom max

CAMH025SM1M 400 V 3 Ph 3,92 3,06 2,81 4,32 3,42 2,42

CAMH035SM1M 400 V 3 Ph 4,41 2,86 2,46 4,35 3,03 2,28

CAMH045SM1M 400 V 3 Ph 2,49 2,75 2,25 4,24 2,96 2,24

CAMH060DM1M 400 V 3 Ph 6,61 2,78 2,51 3,06 2,99 2,56

CAMH075DM1M 400 V 3 Ph 3,23 2,66 2,51 2,69 2,77 2,48

CAMH085DM1M 400 V 3 Ph 4,97 2,69 2,41 3,00 2,79 2,48

CASH025SM1M CAIH025SM1M 400 V 3 Ph 3,92 3,06 2,81 4,32 3,42 2,42

CASH035SM1M CAIH035SM1M 400 V 3 Ph 4,41 2,86 2,46 4,35 3,03 2,28

CASH045SM1M CAIH035SM1M 400 V 3 Ph 2,49 2,75 2,25 4,24 2,96 2,24

CASH060DM1M CAIH060SD1M 400 V 3 Ph 6,61 2,78 2,51 3,06 2,99 2,56

CASH075DM1M CAIH075DM1M 400 V 3 Ph 3,23 2,66 2,51 2,69 2,77 2,48

CASH085DM1M CAIH085DM1M 400 V 3 Ph 4,97 2,69 2,41 3,00 2,79 2,48

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.1.- PRODUCT RANGE.

Unit

COMPACTAIR

ADVANCED

H: Heat pump

Type of refrigerant

M: R-410A

Approximate cooling

capacity in kW

M: Package unit

S: Outdoor unit

I: Indoor unit

S: One Circuit

D: Two Circuits

Number of revision

T: 230V/1/50

M: 400V/3/50

UNIT HEAT PUMP.

UNITS

Cooling capacity (kW) Heating capacity (kW)

PACKAGE

OUTDOOR UNIT INDOOR UNIT

UNITS

EER cold (Kw/Kw) COP heat (Kw/Kw)

PACKAGE

OUTDOOR UNIT INDOOR UNIT

Cooling: Indoor Tª: 27ºC DB / 19ºC WB. Outdoor Tª: 35ºC DB.

Heating: Indoor Tª: 20ºC DB / 12ºC WB. Outdoor Tª: 7ºC DB / 6ºC WB.

Page 6

• 5 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

CASING.

Galvanized and painted sheetmetal casing. The units incorporate metal supports attached to the base, for its correcthoisting. These supports allow to install the unit on the

fl oor, providing great rigidity to the installation of the unit.

The panels are easily interchangeable allowing several

alternatives of impulsion and return air. The outdoor and

indoor sections are insulated thermally and acoustically. In

the indoor units, an insulation with aluminum mesh protection with M1 and F1 classifi cation is used, certifying that

this material is self-extinguishing in case of fi re, avoiding

the formation of fumes that could enter the premises to be

conditioned. In the outdoor units, insulation with M1 classifi cation is used.

Manufactured with copper tubes and corrugated or lourvered aluminum fi ns, designed to get high heat transfer.

Their dimensions and design of the circuits have been

specially studied to obtain the maximum performance of

the exchangers, increasing the capacity of the unit and

reducing the consumption.

EXCHANGERS.

All the models incorporate a Inverter compressor type

Scroll with “brushless” motor (BLDC), which by means of

an electronic system regulates the engine revolutions and

through the frequency variation adapts to the needs of the

installation and modulates the gasfl ow of the refrigerant in

all moment.

Two circuit units incorporate also tandem compressor,

scroll type.

The compressors are mounted on silentblocks.

COMPRESSORS.

The fans of the indoor and outdoor sections are of EC Plug

Fan type. The fans are regulated automatically to obtain a

variable air volume in indoor and outdoor unit.

FANS.

Made with dehydrated copper tubes welded with pressure

sockets with a shutter valve on the suction and unloading

lines, in outdoor and indoor section. The unit incorporates

a high-pressure minipresostat and high-pressure and lowpressure transducers. It incorporates dehydrator fi lter, ex-

pansion system with electronic valves, one in the package

units and two in the split units. The units in heat pump

incorporate suction accumulator to avoid the migration

of liquid to the compressor, reversible valve for inversion

cycle and unidirectional valves. The split units also include

an oil separator.

COOLING CIRCUIT.

Washable air fi lter, self-extinguishing material in case of

fi re with M1 classifi cation, high fi ltering effi ciency, with G4

classifi cation. With the possibility of extracting it from the

lateral side.

Option: High Effi ciency Filter M5+F7.

AIR FILTER.

Designed according to standard EN-60204-1. With thermal protection magnets for compressors and fans. All

compressor and fan motors incorporate internal thermal

protectors. An electronic control governs the operation of

the unit, manages the “driver“ of the compressor, the fans

EC Plug Fan and the electronic expansion valves.

ELECTRICAL CIRCUIT.

1.2.- GENERAL DESCRIPTION.

GENERAL SWITCH.

Located in the access panel to the electrical board and

equipped with a mechanism which only allows the opening

of the panel of the electrical board when the switch is OFF

position.

INDOOR- OUTDOOR UNIT

INTERCONNECT CABLE.

The connection between indoor and outdoor units, must

be carried out using a shielded hose of 3x0.5mm

2

.

The vertical self-contained conditioners, Compactair Advanced range, in the heat pump version are air condensed

units that have been designed for small commercial and residential installations. The units consist of two sections,

an indoor section and an outdoor section, are units that by their design can be supplied in package and split version.

They are designed for operation coupled to a network of air distribution ducts in indoor and outdoor sections. With the

option of incorporating a wide range of accessories and options.

The manufacturing of these units is made under the strict quality requirements of the standard ISO 9001.

Page 7

• 6 •

DC

DM

Service

Display

DS

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

Fresh air:

- Kit Freecooling.

- Return fan module.

Filtration:

- High effi ciency fi lter: M5+F7.

Auxiliary Heat :

- Electrical resistance mounted inside the standard,

medium or high capacity unit.

Security and electricity :

- Air quality sensor (CO

2

).

- Smoke detector.

- Analog dirty fi lter sensor.

- Energy counting.

- Three phases relay for unit electrical protection.

Coils Treatment:

- Anticorrosion protection condensor &

evaporator coils.

Refrigerant circuit:

- Sevice valves.

- Refrigerant precharged.

OPTIONS.

1.- GENERAL CHARACTERISTICS

1.2.- GENERAL DESCRIPTION.

Control and comunication:

- Remote display DC for user.

- Service display DS.

- Multi Unit Display DM.

- Remote probe in environment.

- Modbus RS485 comunication interface.

- LonWorks FTT10 comunication interface.

- BACnet MSTP comunication interface.

- Modbus/BACnet/Ethernet TCP/IP comunication

interface.

- Expansion board

Others:

- A1 Insulation air treatment unit.

- Low noise: compressor acoustic insulation.

Page 8

• 7 •

CAMH025SM1M CAMH035SM1M CAMH045SM1M

22,4 32,4 45

19,6 29,5 42,2

8 13,2 20

8,1 12,9 18,8

2145 2145 2145

1445 1445 1445

895 895 895

445 470 495

CASH025SM1M CASH035SM1M CASH045SM1M

1 / Scroll BLDC 1 / Scroll BLDC 1 / Scroll BLDC

1 / EC Plug Fan 1 / EC Plug Fan 1 / EC Plug Fan

6800 8300 11600

30 30 30

1410 1410 1410

1445 1445 1445

895 895 895

270 290 310

1/2" 5/8" 5/8"

7/8" 1 1/8" 1 13/8"

CAIH025SM1M CAIH035SM1M CAIH045SM1M

1 / EC Plug Fan 1 / EC Plug Fan 1 / EC Plug Fan

1800 / 4500 2800 / 6200 3700 / 7500

50 / 650 62 / 700 75 / 750

836 836 836

1445 1445 1445

895 895 895

175 185 190

1/2" 5/8" 5/8"

7/8" 1 1/8" 1 3/8"

75 75 75

15 15 15

40 40 40

85 85 101

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.3.- PHYSICAL DATA.

SET

Cooling capacity (*) Kw

Heating capacity (**) Kw

Nominal absorbed power (Cold) (*) Kw

Nominal absorbed power (Heating) (**) Kw

DIMENSIONS

Height mm

Width mm

Depth mm

NET WEIGHT Kg

OUTDOOR UNIT

COMPRESSOR Nº / type

FAN

Nominal airfl ow m3/h

Available preassure Pa

DIMENSIONS

Height mm

Width mm

Depth mm

NET WEIGHT Kg

PIPING CONNECTIONS

LIquid inches

Gas inches

INDOOR UNIT

FAN Nº / type

Airfl ow (Min / Max) m3/h

Available preassure (***) Pa

DIMENSIONS

Height mm

Width mm

Depth mm

NET WEIGHT Kg

PIPING CONNECTIONS

Liquid inches

Gas inches

NET WEIGHT OF OPTIONALS

Free-cooling Kg

Electrical Heater Kg

Filter M5+F7 Kg

Return fan Kg

(*) At 120 rps, air intake temperature in indoor exchanger: 27ºC BS / 19ºC BH.

(*) At 120 rps, air intake temperature in outdoor exchanger: 35ºC BS.

(**) At 120 rps, air intake temperature in indoor exchanger: 20ºC BS / 12ºC BH.

(**) At 120 rps, air intake temperature in outdoor exchanger: 7ºC BS / 6ºC BH.

(***) Adjustable by DS terminal.

BS - Dry bulb temperature.

BH - Wet bulb temperature.

Page 9

• 8 •

CAMH060DM1M CAMH075DM1M CAMH085DM1M

59,6 71 85,3

56,2 67,7 80,8

23,8 28,3 35,4

22 27,3 32,6

2145 2145 2145

2813 2813 2813

895 895 895

910 955 975

CASH060DM1M CASH075DM1M CASH085DM1M

1 / Scroll BLDC +

2 / Scroll Tamdem

1 / Scroll BLDC +

2 / Scroll Tamdem

1 / Scroll BLDC +

2 / Scroll Tamdem

2 / EC Plug Fan 2 / EC Plug Fan 2 / EC Plug Fan

16800 20000 23400

30 30 30

1410 1410 1410

2813 2813 2813

895 895 895

575 595 615

5/8" + 5/8" 5/8" + 5/8" 5/8" + 5/8"

1 1/8" + 1 1/8" 1 1/8" + 1 3/8" 1 3/8" + 1 3/8"

CAIH060DM1M CAIH075DM1M CAIH085DM1M

2 / EC Plug Fan 2 / EC Plug Fan 2 / EC Plug Fan

6200 / 12500 6700 / 13500 7500 / 15000

100 / 700 100 / 700 100 / 750

836 836 836

2813 2813 2813

895 895 895

340 360 360

5/8" + 5/8" 5/8" + 5/8" 5/8" + 5/8"

1 1/8" + 1 1/8" 1 1/8" + 1 3/8" 1 3/8" + 1 3/8"

150 150 150

25 25 25

80 80 80

170 202 202

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

SET

Cooling capacity (*) Kw

Heating capacity (**) Kw

Nominal absorbed power (Cold) (*) Kw

Nominal absorbed power (Heating) (**) Kw

DIMENSIONS

Height mm

Width mm

Depth mm

NET WEIGHT Kg

OUTDOOR UNIT

COMPRESSOR Nº / type

FAN

Nominal airfl ow m

3

/h

Available preassure Pa

DIMENSIONS

Height mm

Width mm

Depth mm

NET WEIGHT Kg

PIPING CONNECTIONS

Liquid inches

Gas inches

INDOOR UNIT

FAN Nº / type

Airfl ow (Min / Max) m3/h

Available preassure (***) Pa

DIMENSIONS

Height mm

Width mm

Depth mm

NET WEIGHT Kg

PIPING CONNECTIONS

Liquid inches

Gas inches

NET WEIGHT OF OPTIONALS

Free-cooling Kg

Electrical Heater Kg

Filter M5+F7 Kg

Return fan Kg

1.- GENERAL CHARACTERISTICS

1.3.- PHYSICAL DATA.

(*) At 120 rps, air intake temperature in indoor exchanger: 27ºC BS / 19ºC BH.

(*) At 120 rps, air intake temperature in outdoor exchanger: 35ºC BS.

(**) At 120 rps, air intake temperature in indoor exchanger: 20ºC BS / 12ºC BH.

(**) At 120 rps, air intake temperature in outdoor exchanger: 7ºC BS / 6ºC BH.

(***) Adjustable by DS terminal.

BS - Dry bulb temperature.

BH - Wet bulb temperature.

Page 10

• 9 •

CAMH025SM1M CAMH035SM1M CAMH035SM1M

400V/ 3Ph 400V/ 3Ph 400V/ 3Ph

13,9 18,6 24,5

24,6 33,4 43,6

CASH025SM1M CASH035SM1M CASH035SM1M

400V/ 3Ph 400V/ 3Ph 400V/ 3Ph

8,5 13 18,8

2,7 2,86 2,86

11,2 15,86 21,66

16,2 24,9 35,03

4,2 4,3 4,3

20,4 29,2 39,3

CAIH025SM1M CAIH035SM1M CAIH035SM1M

400V/ 3Ph 400V/ 3Ph 400V/ 3Ph

2,7 2,7 2,9

4,2 4,2 4,3

CAMH025SM1M CAMH035SM1M CAMH035SM1M

10 10 10

15 15 15

20 20 20

14,3 14,3 14,3

21,5 21,5 21,5

28,6 28,6 28,6

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.4.- ELECTRICAL DATA.

ELECTRICAL CONSUMPTIONS.

SET

Voltage V/f (50 Hz)

Total maximum power kW

Total maximum current A

OUTDOOR UNIT

Voltage V/f (50 Hz)

MAXIMUM POWER CONSUMED

Maximum compressor power kW

Outdoor fan power kW

Total maximum power kW

MAXIMUM CURRENT

Maximum compressor current A

Outdoor fan current A

Total maximum current A

INDOOR UNIT

Voltage V/f (50 Hz)

Total maximum power kW

Total maximum current A

OPTIONAL ELECTRICAL COIL

POWER

Standard kW

Medium kW

High kW

CURRENT

Standard A

Medium A

High A

1.- GENERAL CHARACTERISTICS

Page 11

• 10 •

CAMH060DM1M CAMH075DM1M CAMH085DM1M

400V/ 3Ph 400V/ 3Ph 400V/ 3Ph

35,3 40,8 46,8

62,5 72 82,2

CASH060DM1M CASH075DM1M CASH085DM1M

400V/ 3Ph 400V/ 3Ph 400V/ 3Ph

24,2 29,5 35,3

5,7 5,7 5,7

29,92 35,24 41,04

45,5 54,9 65,03

8,6 8,6 8,6

54,1 63,5 73,6

CAIH060DM1M CAIH075DM1M CAIH085DM1M

400V/ 3Ph 400V/ 3Ph 400V/ 3Ph

5,4 5,7 5,72

8,4 8,6 8,6

CAMH060DM1M CAMH075DM1M CAMH085DM1M

15 15 15

20 20 20

40 40 40

21,5 21,5 21,5

28,6 28,6 28,6

57,8 57,8 57,8

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.4.- ELECTRICAL DATA.

ELECTRICAL CONSUMPTIONS.

SET

Voltage V/f (50 Hz)

Total maximum power kW

Total maximum current A

OUTDOOR UNIT

Voltage V/f (50 Hz)

MAXIMUM POWER CONSUMED

Maximum compressor power kW

Outdoor fan power kW

Total maximum power kW

MAXIMUM CURRENT

Maximum compressor current A

Outdoor fan current A

Total maximum current A

INDOOR UNIT

Voltage V/f (50 Hz)

Total maximum power kW

Total maximum current A

OPTIONAL ELECTRICAL COIL

POWER

Standard kW

Medium kW

High kW

CURRENT

Standard A

Medium A

High A

Page 12

• 11 •

32ºC BS / 23ºC BH 21ºC BS / 15ºC BH

48ºC -10ºC

24ºC BS 15ºC BS

25ºC -12ºC

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

BS: Dry Bulb Temperature. BH: Wet bulb temperature.

1.5.- OPERATING LIMITS.

1.- GENERAL CHARACTERISTICS

Operating Limits Maximum temperatures Minimum temperatures

Cooling Cycle

Operation

Indoor temperature

Outdoor temperature

Heating Cycle

Operation

Indoor temperature

Outdoor Temperature

COLD MODE

HEAT MODE

25ºC

15ºC 24ºC

-12ºC

Entrance air temperature to indoor section B.S / B.H

B.H: Wet bulb temperature.

B.S: Dry bulb temperature.

Outdoor

temperature

-10ºC

48ºC

32ºC / 23ºC

Outdoor

temperature

21ºC / 15ºC

Entrance air temperature to indoor section B.S / B.H

B.H: Wet bulb temperature.

B.S: Dry bulb temperature.

Page 13

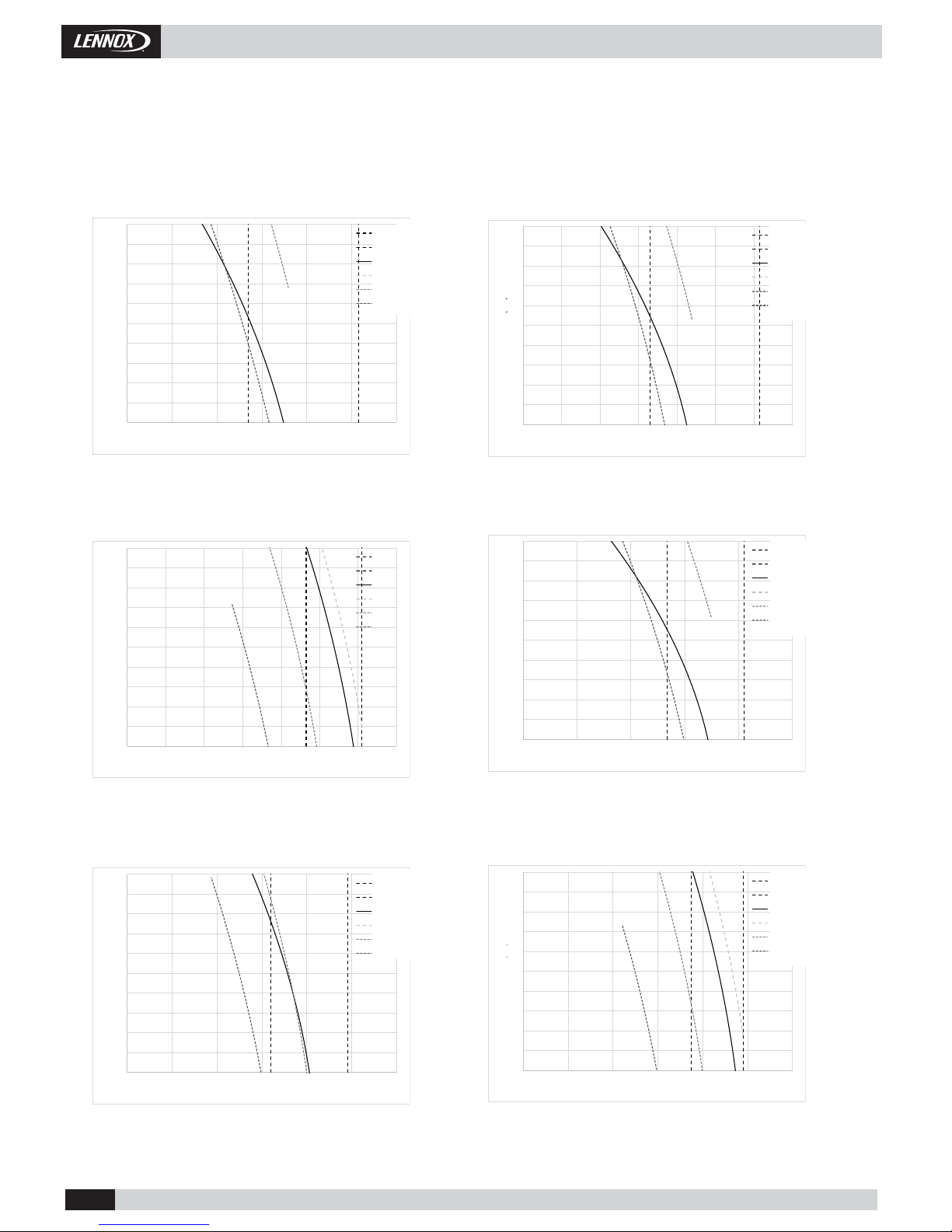

• 12 •

CAMH025SM1M

CAIH025SM1M

CAMH035SM1M

CAIH035SM1M

CAMH045SM1M

CAIH045SM1M

CAMH060DM1M

CAIH060DM1M

CAMH075DM1M

CAIH07520DM1M

CAMH085DM1M

CAIH085DM1M

0

100

200

300

400

500

600

700

800

0 1000 2000 3000 4000 5000 6000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

100

200

300

400

500

600

700

800

0 1000 2000 3000 4000 5000 6000 7000 8000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

100

200

300

400

500

600

700

800

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

100

200

300

400

500

600

700

800

0 2000 4000 6000 8000 10000 12000 14000 16000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

100

200

300

400

500

600

700

800

0 2000 4000 6000 8000 10000 12000 14000 16000 18000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

100

200

300

400

500

600

700

800

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.6.- FAN PERFORMANCES.

INDOOR FANS (Nominal speed).

Pressure (Pa)

Air Flow (m 3/h)

Air Flow (m 3/h)

Pressure (Pa)

Air Flow (m 3/h)

Air Flow (m 3/h)

Pressure (Pa)

Pressure (Pa)

Pressure (Pa)

Air Flow (m 3/h)

Air Flow (m 3/h)

Pressure (Pa)

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Page 14

• 13 •

CAMH025SM1M

CASH025SM1M

CAMH035SM1M

CASH035SM1M

CAMH045SM1M

CASH045SM1M

CAMH060DM1M

CASH060DM1M

CAMH075DM1M

CASH075DM1M

CAMH085DM1M

CASH085DM1M

0

50

100

150

200

250

300

350

400

450

500

0 2000 4000 6000 8000 10000 12000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

50

100

150

200

250

300

350

400

450

500

0 2000 4000 6000 8000 10000 12000 14000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

50

100

150

200

250

300

350

400

450

500

0 2000 4000 6000 8000 10000 12000 14000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

50

100

150

200

250

300

350

400

450

500

0 5000 10000 15000 20000 25000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

50

100

150

200

250

300

350

400

450

500

0 5000 10000 15000 20000 25000 30000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

0

50

100

150

200

250

300

350

400

450

500

0 5000 10000 15000 20000 25000 30000

Pressure (Pa)

Air Flow (m3/h)

Min Air Flow

Max Air Flow

Nom Reg

Reg 100%

Reg 80%

Reg 60%

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.6.- FAN PERFORMANCES.

Pressure (Pa)

Air Flow (m 3/h) Air Flow (m 3/h)

Pressure (Pa)

OUTDOOR FANS.

1.- GENERAL CHARACTERISTICS

Pressure (Pa)

Air Flow (m 3/h)

Air Flow (m 3/h)

Pressure (Pa)

Air Flow (m 3/h)

Air Flow (m 3/h)

Pressure (Pa)

Pressure (Pa)

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Min Airfl ow

Max Airfl ow

Nominal

100 %

80%

60%

Page 15

• 14 •

CH

B12B11

Acumulador

Aspiración

Compresor

Scroll BLDC

Válvula expansión

electrónica

Filtro secador

CH

B12

B11

Acumulador

Aspiración

Compresor

Scroll BLDC

Filtro secador

UNIDAD EXTERIORUNIDAD INTERIOR

Separador de aceite

Filtro secador

Válvula 4 vías

Válvula 4 vías

Válvula retención

Válvula retención

Válvula expansión

electrónica

Válvula expansión

electrónica

BS1

BS1

BS14

BS14

B13

B13

BS13

BS13

B13_1

BS13_1

BS4

BS4

BS2

BS2

Ventilador

PLUG FAN

Ventilador

PLUG FAN

Ventilador

PLUG FAN

Ventilador

PLUG FAN

CH

B11

B12

B13

B13_1

BS1

BS14

BS4

BS2

BS13

BS13_1

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.7.- HEAT PUMP PIPING DRAWINGS.

Pressure gauge. (5/16" to be fi tted by the installer).

High pressure switch.

High pressure transducer.

Low pressure transducer.

Crank case heater.

Outdoor temperature sensor.

Unloading sensor.

Suction sensor.

Air return sensor.

Impulsion air sensor.

CAMH025 & CAMH035 & CAMH045

PACKAGE UNITS

PIPING DRAWINGS

CASH/CAIH025 & CASH/CAIH035 & CASH/CAIH045

SPLIT UNITS

PIPING DRAWINGS

Page 16

• 15 •

CH

B11

B21

B12

B22

B13

B23

B13_1

B23_1

BS1

BS14

BS24

BS4

BS2

BS13

BS23

BS13_1

BS23_1

CH

B12B11

Acumulador

Aspiración

Compresor

Scroll BLDC

Válvula expansión

electrónica

Filtro secador

Válvula 4 vías

Válvula retención

BS1

BS14

B13

BS13

BS4

BS2

B22B21

Acumulador

Aspiración

Válvula expansión

electrónica

Filtro secador

Válvula 4 vías

Válvula retención

BS1

BS24

B23

BS23

BS2

BS4

Ventilador

PLUG FAN

Ventilador

PLUG FAN

Batería

Ventilador

PLUG FAN

Ventilador

PLUG FAN

CH

CH

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.7.- HEAT PUMP PIPING DRAWINGS.

Pressure gauge. (5/16" to be fi tted by the installer).

High pressure switch.

High pressure transducer.

Low pressure transducer.

Crank case heater.

Outdoor temperature sensor.

Unloading sensor.

Suction sensor.

Air return sensor.

Impulsion air sensor.

CAMH025 & CAMH035 & CAMH045

PACKAGE UNITS

PIPING DRAWINGS

Page 17

• 16 •

CH

B12

B11

Acumulador

Aspiración

Compresor

Scroll BLDC

Filtro secador

UNIDAD EXTERIORUNIDAD INTERIOR

Separador de aceite

Filtro secador

Válvula 4 vías

Válvula retención

Válvula expansión

electrónica

Válvula expansión

electrónica

BS1

BS14

B13

BS13

B13_1

BS13_1

B22

B21

Acumulador

Aspiración

Filtro secador

UNIDAD EXTERIORUNIDAD INTERIOR

Separador de aceite

Filtro secador

Válvula 4 vías

Válvula retención

Válvula expansión

electrónica

Válvula expansión

electrónica

BS1

BS24

B23

BS23

B23_1

BS12_1

Ventilador

PLUG FAN

Ventilador

PLUG FAN

BS4

BS2

BS2

Ventilador

PLUG FAN

Ventilador

PLUG FAN

Batería

BS4

CH

CH

CH

B11

B21

B12

B22

B13

B23

B13_1

B23_1

BS1

BS14

BS24

BS4

BS2

BS13

BS23

BS13_1

BS23_1

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

CASH/CAIH025 & CASH/CAIH035 & CASH/CAIH045

SPLIT UNITS

PIPING DRAWINGS

1.- GENERAL CHARACTERISTICS

1.7.- HEAT PUMP PIPING DRAWINGS.

Pressure gauge. (5/16" to be fi tted by the installer).

High pressure switch.

High pressure transducer.

Low pressure transducer.

Crank case heater.

Outdoor temperature sensor.

Unloading sensor.

Suction sensor.

Air return sensor.

Impulsion air sensor.

Page 18

• 17 •

025

Hz 63 125 250 500 1000 2000 4000 8000

Lwa

dB(A)

49,9 54,5 63,7 66,3 63,9 61,2 61,9 60,4 70

60,3 66,2 74,1 76,8 76,4 77,0 74,8 74,7 83

50,4 59,1 64,2 67,5 70,2 72,5 68,8 69,6 77

49,9 54,5 63,7 66,3 63,9 61,2 61,9 60,4 70

60,3 65,2 74,1 76,7 75,0 73,4 72,8 71,6 81

50,3 56,3 64,1 66,9 66,9 66,7 64,3 63,8 73

035

Hz 63 125 250 500 1000 2000 4000 8000

Lwa

dB(A)

57,9 62,5 71,7 74,3 71,9 69,2 69,9 68,4 78

64,8 71,6 75,1 75,1 75,7 78,9 75,0 77,5 54

55,5 65,5 65,8 66,1 69,1 72,3 69,4 71,8 77

57,9 62,5 71,7 74,3 71,9 69,2 69,9 68,4 78

64,6 69,9 74,9 74,9 74,5 77,6 72,7 75,3 82

54,8 61,8 65,1 65,2 66,1 68,8 64,5 66,8 74

045

Hz 63 125 250 500 1000 2000 4000 8000

Lwa

dB(A)

63,8 68,4 74,1 74,0 73,1 76,4 71,2 74,0 81

71,6 76,7 81,9 81,8 81,3 85,4 80,8 82,1 90

61,8 68,4 72,2 72,1 72,8 78,1 74,3 73,2 82

63,8 68,4 74,1 74,0 73,1 76,4 71,2 74,0 81

71,5 76,3 81,8 81,8 80,9 84,4 79,3 81,7 89

61,5 66,8 71,9 71,8 71,5 75,3 70,5 71,9 80

060

Hz 63 125 250 500 1000 2000 4000 8000

Lwa

dB(A)

63,5 68,1 77,3 79,9 77,5 74,8 75,5 74,0 83

67,8 73,6 78,1 78,2 78,3 81,5 77,6 79,8 86

58,1 66,5 68,5 69,0 71,2 74,1 71,5 73,4 79

63,5 68,1 77,3 79,9 77,5 74,8 75,5 74,0 83

67,7 72,7 78,0 78,0 77,5 80,7 76,0 78,4 86

57,8 63,8 68,1 68,3 68,9 71,7 68,1 69,9 77

075

Hz 63 125 250 500 1000 2000 4000 8000

Lwa

dB(A)

65,2 69,8 75,5 75,5 74,5 77,9 72,7 75,4 83

71,3 76,5 81,6 81,6 81,1 84,5 80, 82,5 89

61,5 68,2 71,8 71,9 72,5 76,0 72,8 74,9 81

65,2 69,8 75,5 75,5 74,5 77,9 72,7 75,4 83

71,3 76,1 81,6 81,6 80,8 84,1 79,2 81,8 89

61,3 66,6 71,7 71,7 71,3 74,6 70,4 72,6 80

085

Hz 63 125 250 500 1000 2000 4000 8000

Lwa

dB(A)

67,1 71,7 77,4 77,4 76,4 79,8 74,6 77,3 85

74,6 79,5 84,9 84,9 84,2 87,9 83,3 85,1 93

64,7 70,5 75,1 75,0 75,0 79,8 76,0 76,1 84

67,1 71,71 77,4 77,4 76,4 79,8 74,6 77,3 85

74,6 79,3 84,9 84,8 84,0 87,4 82,3 84,9 92

64,6 69,5 74,9 74,9 74,3 77,9 73,3 75,2 83

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.8.- SOUND LEVELES.

Values for the nominal conditions

Standard

unit

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Low noise

option

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Standard

unit

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Low noise

option

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Standard

unit

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Low noise

option

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Standard

unit

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Low noise

option

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Standard

unit

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Low noise

option

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Standard

unit

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Low noise

option

Indoor side in duct

Outdoor side in duct

Outdoor side radiated

Page 19

• 18 •

CAIH 025-035-045

CASH 025-035-045

179966300

1445

3766434

25

19 697

735

40

11267088

25

40

836

88670112

955

202

77 75

1869918

138126543

836

385 462 23

966179

895

TUBO DE DRENAJE M 3/4 G

CABLE INTERCONEXIÓN

UNIDAD EXTERIOR

ALIMENTACIÓN ELÉCTRICA

TUBO DE DRENAJE M 3/4 G

600

1497

15

1410

34052

928

341092

1445

291093

26

172

100

623

1380

870

35

84

11066793

85

1721171102

734

62

581

41

23830

570

895

25

709

109262

340468

ALIMENTACIÓN ELÉCTRICA

CABLE INTERCONEXIÓN

UNIDAD INTERIOR

TUBO DE DRENAJE M 3/4 G

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.9.- SPLIT UNITS DIMENSIONS.

Page 20

• 19 •

CAIH 060-075- 085

CASH 060-075-085

1043

126

1043

301 301

485385

2813

670 88112

955

837

40

25

89

1265

106

1265

89

1869918

836

25

40

19 697

735

11267088

870

202

77

75

298

1047

123

1047

299

35 665 35

2814

TUBO DE DRENAJE M 3/4 G

CABLE INTERCONEXIÓN

UNIDAD EXTERIOR

ALIMENTACIÓN ELÉCTRICA

TUBO DE DRENAJE M 3/4 G

2865

669

222

1092

116

1092

292

340468

1409

13

42

30 238 25

895

570

102 172

172

100

85

62

584 734

1171 1171197

84

709 623

1380

870

92 670 109

2813

1092

58

1092 252319

2491093

56

1092319

34 929

52 340 26

13

42

ALIMENTACIÓN ELÉCTRICA

CABLE INTERCONEXIÓN

UNIDAD INTERIOR

TUBO DE DRENAJE M 3/4 G

TUBO DE DRENAJE M 3/4 G

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.9.- SPLIT UNITS DIMENSIONS.

Page 21

• 20 •

CAMH 025-035-045

138126543

1445

1869918

214537 664 34

179 966 300

7775

533

711

40

19 697

112 670 88

112 670 88

955

40

711

735

85

100

100 1171 170

1527

62

734614

600

1497

928

52

340

1410

65

34 1092

1380

570

30

2145

15

41

84

709 623

667 91108

895

866

172

236 52

966179

385 462 23

1092 31632

TUBO DE DRENAJE M 3/4 G

TUBO DE

DRENAJE

M 3/4 G

TUBO DE

DRENAJE

M 3/4 G

ALIMENTACIÓN ELÉCTRICA

ALIMENTACIÓN ELÉCTRICA

CAMH 060-075-085

All dimensions in millimet

e

669

2865

462 23385

301

1043

126

1043

301

89

1265

106

1265

89

18699

2145

62

734613

100172

85

1171

196

1171

100

170

2895

2814

40

735 1380

2145

88670112

955

42

13

570

30

236

52

711

670

955

112 88

710

40

84

19 697

623709

107 670

866

90

13

42

77

75

533

1095

249

53 319

35

66535

1410

252

1092

58

319

249

1093

63929

52

340

35

1092

1047

123 298

1047

ALIMENTACIÓN ELÉCTRICA

TUBO DE DRENAJE M 3/4 G

TUBO DE DRENAJE M 3/4 G

TUBO DE

DRENAJE

M 3/4 G

TUBO DE

DRENAJE

M 3/4 G

ALIMENTACIÓN ELÉCTRICA

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

1.- GENERAL CHARACTERISTICS

1.10.- PACKAGE UNITS DIMENSIONS.

Page 22

• 21 •

AB CDELMN

1 CIRCUITO

2 CIRCUITOS

1000 148,5 291 38,5 138 789,5 100 307

24

E

D

C

B

A

M

L

N

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

STANDARD EXECUTION

OPTIONAL EXECUTION

(TO BE CARRIED OUT BY THE INSTALLER)

1.11.- AIR SUPPLY CONFIGURATIONS

1.- GENERAL CHARACTERISTICS

1.11.- OPTIONS.

INDOOR UNIT

1 CIRCUIT

025-035-045

INDOOR UNIT

2 CIRCUITS

060-075-085

Free-cooling

1.- OPERATION.

The control compares the values of temperature between outside air and room air by means of the probes; if there

is a negative difference and the safety elements allow (discharge temperature probes) then the control acts on the

servomotor, which opens the outside damper and closes the return damper, allowing cool outside air to enter the

room.

The damper is proportionally regulated. If there is not a great demand for air indoors, it may be enough just to have

free cooling to condition the room. If there is a greater demand for air, the free cooling and the unit may need to be

working in different cooling mode stages.

2.- SUPPLY AND INSTALLATION.

The free cooling option will be supplied loose.

The return probe must be installed in the return air intake duct.

FRESH AIR OPTIONS

Page 23

• 22 •

330

667

1267

330

667

1267

1267

734

700

1250

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

High Effi ciency Filter: M5+F7.

The fi lter is supplied loose and must be placed in the fan exit.

FILTRATION OPTIONS.

INDOOR UNIT

1 CIRCUIT

025-035-045

INDOOR UNIT

2 CIRCUITS

060-075-085

1.11.- OPTIONS.

Return fan

Fan return cabinet is supplied loose

FRESH AIR OPTIONS

HIGH EFFICIENCY

FILTER: M5+F7

INDOOR UNIT

1 CIRCUIT

025-035-045

HIGH EFFICIENCY

FILTER: M5+F7

1.- GENERAL CHARACTERISTICS

Page 24

• 23 •

DC

DM

Service

Display

DS

025 035 045 060 075 085

ELHS2 (Kw) 10 10 10 15 15 15

ELHM2 (Kw) 15 15 15 20 20 20

ELHH2 (kW) 20 20 20 40 40 40

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

DC - User terminal.

Remote controller very easy to use, with the following features:

o Switched on/Switvhed off.

o Operation selection mode: (Cold/Heat/Auto).

o Airfl ow manual adjustment (3 speeds).

o Environment temperature selection.

o Airfl ow settings (Mini/Nominal/Max/Auto).

o Time setting.

o Environment temperature display.

o Alarm codes display.

o Conected units supervision (until 10).

A control DS is requered to activate this function (Expert mode) and it must be

adjust by a Lennox technician.

DS - Service terminal.

Terminal which allows the access to the control menu and adjustment all parameters.

24V customer display situated to a maximum distance of 30 meters to the unit. Remote

reading and modifi cation of the customer parameters.

DM - Terminal to view time and zone settings.

It is possible to confi gure until 7 time zones each day with 4 operating modes per zone.

It can be confi gured with the DM or during installation by a Lennox technician.

1.- GENERAL CHARACTERISTICS

A differential pressure controller measures the charge loss through the evaporator coil and the fi lters. The set point

between dirty and clean can be checked by the installer.

DIRTY FILTER ANALOGICAL INDICATION.

Electric resistance.

It is supplied mounted on the unit.

The electrical heater must be supplied from the unit’s electrical box..

AUXILIARY HEATING OPTIONS.

Communications: MODBUS / BACNET / LONWORKS.

The control board is equipped with a RS485 serial communications port which allows remote management through a

communications bus. Depending on the desired communication protocol, the board can be equipped with the ModBUS®,

LonWorks® or BacNET® communications interface.

CONTROL OPTIONS.

Expansion Band.

In the package units, the expansion board is located in its electrical board and in the split units, the expansion board is

situated in the electrical board of the outdoor unit.

Units

1.12.- OPTIONS.

Page 25

• 24 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

Compressor acoustic insulation.

Attenuates the sound level produced by the unit through an insulation that covers the compressor.

Insulation air treatment unit.

This insulation, which covers the indoor unit, provides a fi re propagation rating A1.

OTHER OPTIONS.

1.12- OPTIONS.

1.- GENERAL CHARACTERISTICS

REFRIGERANT CIRCUIT.

Service valves.

Refrigerant precharged.

COILS TREATMENT.

Anticorrosion protection condensor & evaporator coils.

Indoor air quality sensor.

The indoor air quality is controlled with the CLIMATIC ™ main controller through a COV (volatile organic compound)

sensor which detects the amount of CO2 in the air between 0 and 2000 ppm. (This value varies depending on the occupancy levels of the space). The sensor sends a signal (0-20 mA) to the controller to modulate the outside air.

Environment remote sensor.

It can be used when you want to regulate through the temperature where the sensor is situated and not through the

return temperature, which is how the standard unit comes out.

Freecooling.

It is a energy saving system through a regulation of dampers, through which outside air is introduced to the local when

the outside temperature is lower than the local. This option is composed of regulating gate or gates and a servomotor.

Available in two versions with an external air damper, or adding a second damper for the return of the local.

Smoke detector.

Three phases relay for unit electrical protection.

ELECTRIC AND SECURING OPTIONS.

Page 26

• 25 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.- INSTALLATION

2.1.- PRELIMINARY PREPARATIONS.

All INSTALLATION, SERVICE and MAINTENANCE work must be carried

out by QUALIFIED PERSONNEL.

When unpacking the machine, have a correct segregation of non-hazardous waste coming from packaging: Plastic fi lm or other plas-

tic elements, metal strips, wood and pallets, through authorized dealers, or segregate

them in the containers destined for this purpose

Follow the installation instructions established in this manual to avoid disturbing noise caused by movement or shocks due to defi -

cient installation of the unit.

The unit must be transported in a VERTICAL POSITION on its metal mounting frame. Any other position may

cause serious damage to the machine.

When the unit is received, it should be checked to assure that it has received

no shocks or other damage, following the instructions on the packaging. If there is damage, the unit may be rejected by notifying

the LENNOX Distribution Department and stating why the machine is unacceptable on the transport agent’s delivery note. Any later

complaint or claim made to the LENNOX Distribution Department for this type of damage cannot be considered under the Guarantee.

The modifi cations that the customer makes in the units will be under his responsibility and in this case, the declaration of conformity

certifi cate of Lennox manufacturer will not be valid.

Suffi cient space must be allowed to facilitate installation of the unit.

When positioning the unit, be sure that the Rating Plate is always visible since this data will

be necessary to ensure correct maintenance.

The units are designed to be installed with ducts designed by qualifi ed technical staff.

The joints to be used between ducts and openings in the unit should be Elastic Joints.

Avoid the use of BYPASS joints between the extraction air and input air.

The structure where the unit is placed must be able to support the weight of the unit during operation.

2.2.- UNIT ACCEPTANCE.

Defrosting: To avoid ice accumulation in the driptray , it may be necessary to install an electrical

heater and inside the drainage connection , to drain correctly the water. The drainage must be always

accessible through the indoor part , in order to remove easily the dirty than may be accumulated.

Outdoor and packaged units are placed on wood pallet for transportation.

The indoor units have with metal legs which must be removed when positioning the unit

How to hoist the unit

Use forklift for unloading and placement the unit. The unit is not suitable for lifting with crane.

Page 27

• 26 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.- INSTALLATION

2.3.- UNIT LOCATION.

- The bedplate is made up of two metal channels, capable of with standing the weight of the units whether hung from the ceiling or

mounted on the fl oor.

- If the unit is fl oor mounted, then the profi les should be isolated with shock absorbing material such as anti-vibration or pads. Place

the anti-vibration to avoid any buckling.

- The unit is able to work in normal radioelectronic conditions for commercial and residential installations. For any other conditions

please consult.

- If the outside temperature in the area where the heat pump unit is to be installed is low or the cycle functioning are too long, it may

necessary to install an electrical heater, below the likely coils on the drip tray, which avoids the causing of ice in the coil during defrost

cycle.

INDOOR SECTION OUTDOOR SECTION

DUCTS

Supply Install 1 or 2 ducts Mandatory 2 ducts*

Return Install 1 duct Install 1 duct

SENSORS POSITION

Supply Placed in the fan cabinet in the indoor secƟ on.

Return Install in the retun duct

Outdoor Place in the installaƟ on to assure outdoor temperature measurement.

* To avoid by-pass

Place sheet metal duct connections in the indoor air supply and fi ix sensors.

2.4.- DUCTS AND SENSOR INSTALLATION

Page 28

• 27 •

2%

2%

1 m.

1 m.

1 m.

1 m.

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.- INSTALLATION

2.5.- INSTALLATION CLEARANCES.

Clearance around the unit for service and maintenance.

SERVICE SPACE

Space should be left free for access or servicing, to ease the installation of ducts, drainage connections, electric installation and

cleaning fi lters, as well as easy access to the unit.

2.6.- DRAINS.

All the outdoor and indoor sections of these units have a 3/4” steel threaded drain pipe welded to the condensation tray.

The units which have a double circuit (060/075/085) have two drain pipes, one on each side and both have to be connected.

Drainage pipes will be fi tted for each tray through a siphon with a height difference

of 80 mm. to avoid drainage problems from the depression formed by the fans.

The pipes should have an inclination of 2% to ease drainage of condensation.

Also slightly tip the unit toward the drainage side. Check that the

condensation trays are clean and free from dirt and other debris from the works

and that water drains correctly.

The drains must be independents, no connect the condenser drain with the

evaporator drain

Mín. 80 mm.

Inspection and cleaning stopper

LOCATION

Install air entry and exit ducts should be fi tted. The unit should be assembled on bases previously made and stood on absorbent and

antivibrating material to avoid the vibrations being transmitted to the structure of the building.

Place the anti-vibration to avoid any buckling.

To assure proper water evacuation in the base of the unit to avoid overfl ow or ice accumulation

Page 29

• 28 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.- INSTALLATION

2.7.- REFRIGERANT CONNECTIONS

Split units are supplied with gas and liquid lines sealed with copper covers, and located 60mm from casing.

Split units are supplied with nitrogen gas, which must be removed before carrying other operation and then

proceed as follow.

Cupper cover

Brazing

Gas

Liquid

1. Remove the nitrogen gas through the high and low 5/16” service ports located inside and provide a low vacuum for safety.

2. Remove the caps from the connecting lines.

3. Braze the piping connection lines. Select piping diameter from table 2.6.1.

(When brazing refrigerant pipes, nitrogen gas must be supplied into the pipes through the service ports to remove the air).

4. Leak test:

Add nitrogen gas, check that a pressure of 5 kg/cm

2

has been reached and that there are no leaks in the circuit or brazing

by applying soapy water to the pipes which will cause the bubbles to form where there are leaks.

To detect small leaks, proceed as follows:

Add nitrogen gas and check that a pressure of 25 kg/cm2 has been reached, there are no leaks if the pressure remains the same

for at least 24 hours and the fi nal pressure is not less than 10% below the initial pressure.

5. Ensure that the gas line is insulated.

6. Evacuation:

Remove the nitrogen gas, connect the gauge manifold and vacuum pump to both the liquid and gas lines, fully open the gauge

manifold valve and switch on the vacuum pump. Check to make sure the gauge shows a pressure of -750mm Hg. Once a level

of -750mm Hg is reached, keep the vacuum pump running for at least one hour.

7. Refrigerant charge:

- Check TABLE for the amount of refrigerant charge, depending on the length and size of the pipe connections.

- Disconnect the vacuum pump and connect to the refrigerant-charging bottle. Open the charging pump and purge the air from

the hose at the pressure gauge manifold.

- Set up the amount of additional refrigerant on the weighing scale, open the high pressure and charged in the liquid state. If the

total amount of refrigerant charge has not been reached because the pressure is balanced, turn off the high side of the gauge

manifold, turn on the unit, and add the remaining amount of the refrigerant charge required slowly through the low side of the

pressure gauge. (With R-410A refrigerant, the charging bottle must be in a vertical position and charged in the liquid state).

Close the pressure gauge, disconnect it from the from the service port of the unit and fi t caps on the service ports. The unit is

then ready to operate.

During installation operations, keep gas and liquid pipes covered, in order to prevent humidity and dirt,

get into them.

Take special concern about refrigerant pipes are isolated.

Avoid collapse on line installation.

Legislation does not allow refrigerant gas emissions to the atmosphere, so the refrigerants have to be

recycled to avoid being released to the atmosphere. Those recycled refrigerants shall be processed afterwards by an authorized waste manager.

Those components derived from the recycling of the unit have to be managed by authorized waste manager or be left in local waste facilities according the local normative in each country.

Page 30

• 29 •

2%

2

1

B

L

2%

2%

2

1

C

L

2%

2%

A

L

2

1

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.7- REFRIGERANT CONNECTIONS

To locate the outdoor and the indoor units, refer to the following information:

POSITION C : Install a siphon at the base of the vertical of the gas line; no

more siphons are necessary. Maximum vertical length 16m.

NOTE: The refrigerant connections are brazing

connections. Service valves can be supplied as

option if required.

- THE GAS LINE MUST BE ALWAYS INSULATED.

- THE HORIZONTAL LINES MUST BE TIPPED AT LEAST 2% TOWARD THE OUTDOOR UNIT.

- THE MAXIMUM SPEED INSIDE LINES SHOULD NOT BE MORE THAN 15 m/seg.

OUTDOOR UNIT

INDOOR UNIT

A,B,C : Unit positions

L : Total length

1 = Gas line

2 = Liquid line

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR

UNIT

INDOOR UNIT

POSITION A : A syphon suction must be installed at the base of the vertical of the

gas line, and syphons must be installed every 8 meters upward. The minimum speed

suction must not be below 6m/s. Maximum vertical length 16m.

POSITION B : Tip the lines toward the outdoor unit. Make special attention

to line length longer than 10m and avoid collapse on pipe lines installation.

2.- INSTALLATION

Page 31

• 30 •

1/2

”7/8”108

5/8”

1-1

/8”

17

7

5/8”1-3/8”182

3/4”1-3/8”265

3/4”1-5/8”

27

1

7

/8”1-5/8”

3

74

025S 035S 045S 060D 075D 085D 025S 035S 045S 060D 075D 085D

C1

1/2” 5/8” 5/8” 5/8” 5/8” 5/8” 1/2” 5/8” 5/8” 5/8” 5/8” 5/8”

C2

n/a n/a n/a 5/8” 5/8” 5/8” n/a n/a n/a 5/8” 5/8” 5/8”

C1

7/8” 1 1/8” 1 3/8” 1 1/8” 1 1/8” 1 3/8” 5/8” 7/8” 1 1/8” 7/8” 7/8” 1 1/8”

C2

n/a n/a n/a 1 1/8” 1 3/8” 1 3/8” n/a n/a n/a 7/8” 7/8” 1 1/8”

12 12 12 12 12 12 12 12 12 12 12 12

C1

5/8” 5/8” 3/4” 5/8” 5/8” 3/4” 5/8” 5/8” 3/4” 5/8” 5/8” 3/4”

C2

n/a n/a n/a 5/8” 5/8” 3/4” n/a n/a n/a 5/8” 5/8” 3/4”

C1

1 1/8” 1 3/8” 1 5/8” 1 3/8” 1 3/8” 1 5/8” 5/8” 7/8” 1 1/8” 7/8” 7/8” 1 1/8”

C2

n/a n/a n/a 1 3/8” 1 5/8” 1 5/8” n/a n/a n/a 7/8” 7/8” 1 1/8”

12 12 18 18 18 18 12 12 18 18 18 18

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

TABLE 1: REFRIGERANT LINES SELECTION

n/a: not available

The unit is supplied with brazing connections. As an option , the unit can be supplied with gas precharge from the factory ; in that case only the TABLE 2 has to be taken into account. ( this option includes the service valves).

TABLE 2 : EXTRA REFRIGERANT CHARGE R410A BY METER OF COPPER PIPE

Liq

uid

G

as

gr/m

The unit is precharged from factory with nytrogene . The installer should remove this gas and charge the units

with the charge of refrigerant R410A , shown in the following tables plus the charge by additional meter shown in

the TABLE 2

In the double circuit units , check before connecting C1 and C2 circuits , that they are the same circuit for the indoor

and the outdoor section

REFRIGERANT LINES

UNIT - MODEL

UNIT -MODEL Position A

Vertical line

Total line length

(refrigerant line

length between

indoor and

ourtoor units)

0 to 30 m.

(Standard

conection

unit)

Ø Lquid

Ø Gas

Max. n

er

of bends

30 to 45 m.

Ø Liquid

Ø Gas

Max. n

er

of bends

2.7- REFRIGERANT CONNECTIONS

2.- INSTALLATION

Legislation does not allow refrigerant gas emissions to the atmosphere, so the refrigerants have to be

recycled to avoid being released to the atmosphere. Those recycled refrigerants shall be processed afterwards by an authorized waste manager.

Those components derived from the recycling of the unit have to be managed by authorized waste manager

or be left in local waste facilities according the local normative in each country.

Page 32

• 31 •

CFM

BS1

BS0

BH10

BS2

B51

MS

MC

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.- INSTALLATION

2.8.- ELECTRICAL CONNECTIONS.

- Before making the electrical connections, ensure that all circuit breakers are open.

- To make the elctrical connections, follow the electrical diagram supplied with the unit.

- Take into account the current standard for the installation of the unit, whether local, regional or national standards.

- USE SUPERINMUNIZED DIFFERENTIAL SWITCHES.

2.8.1.- ELECTRICAL CONNECTION FOR PACKAGE UNITS.

Connection 1

Unit Base unit Base unit + ELHS Base unit + ELHM Base unit + ELHHM

025 4G x 6mm² 4G x 10mm²

035 4G x 6mm² 4G x 16mm²

045 4G x 10mm² 4G x 16mm²

060 4G x 16mm²

3 x 50mm²

1 x 25mm²

075

3 x 25mm²

1 x 16mm²

3 x 50mm²

1 x 25mm²

085

3 x 25mm²

1 x 16mm²

3 x 70mm²

1 x 55mm²

Page 33

• 32 •

CFM

BS1

FASHFAIH

BS0

BH10

FM

BS2

MCMS

Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.8.2.- ELECTRICAL CONNECTION FOR SPLIT UNITS.

2.- INSTALLATION

- Before making the electrical connections, ensure that all circuit breakers are open.

- To make the elctrical connections, follow the electrical diagram supplied with the unit.

- Take into account the current standard for the installation of the unit, whether local, regional or national standards.

- USE SUPERINMUNIZED DIFFERENTIAL SWITCHES.

2.8.- ELECTRICAL CONNECTIONS.

Connection 1 Connection 31

Connection 32

Unit Base unit Base unit ELHS ELHM ELHHM Interconnection

025 4G x 4mm² 4G x 2.5mm² 4G x 6mm² 3 x 0.5mm² shielded

035 4G x 6mm² 4G x 2.5mm² 4G x 6mm² 3 x 0.5mm² shielded

045 4G x 6mm² 4G x 2.5mm² 4G x 6mm² 3 x 0.5mm² shielded

060 4G x 10mm² 4G x 2.5mm² 4G x 16mm² 3 x 0.5mm² shielded

075 4G x 16mm² 4G x 2.5mm² 4G x 16mm² 3 x 0.5mm² shielded

085 4G x 16mm² 4G x 2.5mm² 4G x 16mm² 3 x 0.5mm² shielded

Page 34

• 33 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.- INSTALLATION

2.9.1.- TERMINAL CONNECTION WITH PACKAGE UNIT.

IMPORTANT !

THE SHIELDED CONNECTING CABLE BETWEEN THE CONTROL PANEL AND THE UNIT MUST

BE SEPARATED FROM ANY OTHER TYPE OF ELECTRICAL WIRING. CONNECT IT TO THE

ELECTRIC PANEL LOCATED IN THE OUTDOOR UNIT.

NOTES:

- For securing and connecting the Control Panel, consult the control panel Manual supplied with the unit.

- Connection between the DC and the unit must be made using shielded twisted pair cables and shielded

(where the

screens is connected to ground by the side of the electrical panel) and with a hose of two cables.

- The Tx+ and Tx- polarity must strictly comply with the electrical diagram supplied with the unit.

- Wiring the hose separated from the power cables a minimum of 500mm.

- Wiring the hose separated from the halogen lamps a minimum of 500mm.

- Wiring the hose separated from switchboard, antennas, transmitters... a minimum of 500mm.

- NEVER ROLL UP THE EXCESSING HOSE, CUT THE HOSE FROM THE SIDE OF THE TERMINAL.

2.9.- TERMINAL CONNECTION.

Page 35

• 34 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

2.9.2.- TERMINAL CONNECTION WITH SPLIT UNIT.

2.- INSTALLATION

2.9.- TERMINAL CONNECTION.

IMPORTANT !

THE SHIELDED CONNECTING CABLE BETWEEN THE CONTROL PANEL AND THE UNIT MUST BE SEPARATED FROM ANY OTHER TYPE OF ELECTRICAL WIRING. CONNECT IT TO THE ELECTRIC PANEL LOCATED

IN THE OUTDOOR UNIT.

NOTES:

- For securing and connecting the Control Panel, consult the control panel Manual supplied with the unit.

- Connection between the DC and the unit must be made using shielded twisted pair cables and shielded (where the

screens is connected to ground by the side of the electrical panel) and with a hose of two cables.

- The Tx+ and Tx- polarity must strictly comply with the electrical diagram supplied with the unit.

- Wiring the hose separated from the power cables a minimum of 500mm.

- Wiring the hose separated from the halogen lamps a minimum of 500mm.

- Wiring the hose separated from switchboard, antennas, transmitters... a minimum of 500mm.

- NEVER ROLL UP THE EXCESSING HOSE, CUT THE HOSE FROM THE SIDE OF THE TERMINAL.

Page 36

• 35 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

3.- COMMISSIONING AND OPERATION

3.1.- PRELIMINARY CHECKS BEFORE START UP.

Legislation does not allow refrigerant gas emissions to the atmosphere, so the refrigerants have to be recycled

to avoid being released to the atmosphere. Those recycled refrigerants shall be processed afterwards by an

authorized waste manager.

Those components derived from the recycling of the unit have to be managed by authorized waste manager or be

left in local waste facilities according the local normative in each country.

1. Check that drain pipe connections, their fi xtures and that the level of the unit is tipped toward the drain.

2. Inspect the state of the ducts and grilles (clean and open grilles, no breaks in the duct, etc.).

3. Check that the power supply is the same as stated on the Rating Plate which is in agreement with the electrical diagram for the unit and that cable sizes are correct. Check that tightness of the electrical connections to their terminals

and to ground.

4. Inspect the air fi lter, which should be in its housing and properly positioned (the metal grille should be toward the

inside).

FIGURE FOR THE STANDARD UNIT CONFIGURATION FOR PACKAGE MODELS

060D-075D-085D

Page 37

• 36 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

3.- COMMISSIONING AND OPERATION

3.2.- PRELIMINARY CHECKS DURING START UP.

LENNOX REFAC, S.A. Designs and develops its machines always looking for the greater comfort and well-being of its customers

and users, at the same time as the greater energy effi ciency of the elements that constitute the units. This effort would be fruitless

if it was not united to a responsible use of these equipment. For this reason, we invite you to use these machines in a responsible

way with the environment, combining the adequate comfort, with a responsible consumption of the energy resources. To start the

unit, follow the instructions given in the User Manual for the control supplied with the unit

(requiring operation in any of the modes, cooling, heating, or automatic).

After a time delay, the unit will start.

With the unit operating, check that the fans are turning freely and in the correct direction.

CHECK THAT THE COMPRESSOR IS ROTATING IN THE CORRECT DIRECTION:

- If you have the option phase rotation indicator, use it to check the correct rotation.

- If you do not have three phase return lock, check the correct direction of rotation. The suction pressure decreases and the discharge

pressure increases when the compressor is started.

- If the connection is incorrect, rotation will be reversed, causing a high noise level and a reduction in the amount of current consumed.

If this occurs, the compressor’s internal protection system will operate to shut down the unit. The solution is to disconnect, reverse

two of the phases and connect again.

ASTP Protection is included with the fi x speed compressors . See "Fault diagnosis" for more information.

WITH OPERATING UNIT, CHECK:

- Low pressure and high pressure.

- Use the evaporating and liquid temperature to calculate superheat and subcooling.

- Adjust the refrigerant charge and/or expansion valve according to the preceding values.

Page 38

• 37 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

3.- COMMISSIONING AND OPERATION

The unit must be installed in accordance with local safety

codes and regulations and can only be used in a well ventilated area. Please read carefully the manufacturer’s instructions before starting this unit.

All work on the unit must be carried out by a qualifi ed

and authorised employee.

Non-compliance with the following instructions may result

in injury or serious accidents.

Work on the unit:

The unit shall be isolated from the electrical supply by disconnection and locking using the main isolating switch.

Workers shall wear the appropriate personal protective

equipment (helmet, gloves, glasses,etc.).

Electrical system:

Work on electric components shall be performed with the

power off (see below) by employees having valid electrical qualifi cation and authorisation.

Electrical connections can become loose during transport.

Please check them before starting-up the unit Compressors with specifi c rotation direction. Check the correct

rotation direction of the fan before closing the compressor

circuit breakers. If the direction is incorrect, the phases

must be reversed at the head of the main switch.

Refrigerating circuit(s):

After more than 12 hours of power cut, the cranckcase

heater (compressor) should be powered for 5 hours before any return to service. Non-compliance with this instruction can cause deterioration of the compressors.

Monitoring of the pressures, draining and fi lling of the sys-

tem under pressure shall be carried out using connections

provided for this purpose and suitable equipment. To prevent the risk of explosion due to spraying of coolant and

oil, the relevant circuit shall be drained and at zero pressure before any disassem bly or unbrazing of the refrigerating parts takes place.

To evoid the risks of explosion, cooling gases elements

and oil, shall check, before carrying out any dismant-

ling or dissamble any cooling elements, that the circuit

that cause the explosion and its pressure is zero.

There is a residual risk of pressure build-up by degassing the oil or by heating the exchangers after the circuit

has been drained. Zero pressure shall be maintained

by venting the drain connection to the atmosphere on

the low pressure side.

The brazing shall be carried out by a qualifi ed brazier

and shall comply according to code ASME section IX

following the procedures specifi cation.

Before the start up:

- Raise the system to the test maximum pressure (see

fi rmplate).

- Check the correct behaviour of the high pressure device.

- Check the components general condition and circuit

piping.

Spare parts:

In order to maintain CE marking compliance, replacement of components shall be carried out using spare

parts, or using parts approved by Lennox.

Only the coolant shown on the manufacturer’s nameplate shall be used, to the exclusion of all other products

(mix of coolants, hydrocarbons, etc.).

CAUTION:

In case of fi re, cooling circuits can

cause an explosion and spray

coolant gas and oil.

3.2.- PRELIMINARY CHECKS DURING START UP.

Page 39

• 38 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

3.- COMMISSIONING AND OPERATION

3.3.- CLIMA TIC™ CONFIGURATION

Settings

1. Supply Air-fl ow adjustement (depending on customer requirements)

a. 3333 = nominal air fl ow / pressure

b. 3334 = reduced air fl ow / pressure

2. Scheduling (depending on customer requirements)

a. Zones & Modes (Night/Day/Day I/ DayII)

b. Setpoints per mode

3. Regulation temperature probe selection

a. Select the regulation probe (DC, Return, Customer, etc.) in the Room Temp. Confi g screen

4. Outside temperature probe selection

a. Select the outdoor temp probe (Unit, Customer) in the Outside Temp. Confi g screen

5. Air quality sensor selection (optional)

a. Select the air quality CO2 sensor (Remote, Customer) in the CO2 Confi g screen

6. Remote display confi guration

a. 3151 = DC simple / DC full / DM

7.Minimum fresh air

a. 3121 = minimum opening %

Page 40

• 39 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

Commissioning

Check:

1. Airfl ow Vs Damper

a. Test B.Nom100% :

i. adjust the blower speed % (3333)to get the required air-fl ow

ii. adjust the exhaust speed % (3864) to get the required air-fl ow

b. Test B.Nom0%:

i. adjust the damper compensation (3335) to maintain the required air-fl ow even with damper fully

closed.

ii. adjust the damper compensation (3336) to maintain the required air-fl ow even with damper fully

closed.

2. Filter safety thresholds

a. Test B.Nom100% and Test B.Nom0%: read fi lter ΔP (3442) and adjust the bigger measure multiplied by 2.5

at threshold 3345

3. Frigorifi c circuit tests

a. Cooling mode

i. Test C---Cool: (if variable speed compressor, set speed value)

1. Check circuit pressures and temperatures

2. Check electrical consumptions

b. Heating mode

i. Test C---Heat: (if variable speed compressor, set speed value)

1. Check circuit pressures and temperatures

2. Check electrical consumptions

4. Unit option tests

a. Electrical Auxiliary heaters (Test H1-1 full)

i. Check supply temperature

ii. Check electrical consumption

5. Advanced regulation optimization

a. Auxiliary heaters ΔT (Gas burner or electrical)

i. Heating.

1. Test H1-1: read │Mix-Supply| temp and adjust heaters stage ΔT at menu 3734

b. Staging sequence(compressor/electrical)

i. Aux Heaters Priority 3731= Never/ Always /OutTemp

c. Dynamic setpoint

i. 3225= ΔT between customer set point and outdoor temperature

d. Fine temperature control

i. Smooth 3231= No/ DeadZone/Comfort

Once all the settings have been adjusted, the list of parameters must be downloaded (Wizard tool), stored and signed

by the customer.

3.- COMMISSIONING AND OPERATION

WARNING! During the settings, wait until the

economizer is fully closed or opened, since it

takes 1-2 minutes to switch.

Page 41

• 40 • Installation Manual • COMPACTAIR ADV IOM-MIL157E-0418

4.- MAINTENANCE

SIDE

REMOVAL

PREVENTIVE MAINTENANCE PREVENTS COSTLY REPAIRS,

THIS REQUIRES PERIODIC INSPECTIONS:

- GENERAL STATE OF THE CASING:

Casing, paint, damage due to shocks, rust spots, levelling and supporting, condition of the shock absorbers, if installed,

screwed panels, etc.

- ELECTRICAL CONNECTIONS:

State of hoses, tightness of screws, earthing, current consumption of the compressor and fans and check that the unit is

receiving the correct voltage.

- COOLING CIRCUIT:

Check that the pressures are correct and that there are no leaks. Check that there is no damage to the pipe insulation,

that the condition of the coils is good and that they are not blocked by bits of paper or plastic drawn in by the air fl ow, etc.

- COMPRESSOR:

If a sight glass is fi tted, check the oil level.

Check the condition of the silentblock mountings.

- FANS:

Check that fans turn freely and in the correct direction without excessive noise.

- CONTROL: