Page 1

®

AIR CLEANERS/

FILTERS

© 2002 Lennox Industries, Inc.

INSTALLATION INSTRUCTIONS FOR LENNOX MODELS BMAC-12C, BMAC-14CE*, BMAC-20C, BMAC-20CE*INSTALLATION INSTRUCTIONS FOR LENNOX MODELS BMAC-12C, BMAC-14CE*, BMAC-20C, BMAC-20CE*

INSTALLATION INSTRUCTIONS FOR LENNOX MODELS BMAC-12C, BMAC-14CE*, BMAC-20C, BMAC-20CE*

INSTALLATION INSTRUCTIONS FOR LENNOX MODELS BMAC-12C, BMAC-14CE*, BMAC-20C, BMAC-20CE*INSTALLATION INSTRUCTIONS FOR LENNOX MODELS BMAC-12C, BMAC-14CE*, BMAC-20C, BMAC-20CE*

IntroductionIntroduction

Introduction

IntroductionIntroduction

The Lennox Box Media Air Cleaner (BMAC) is shipped with

either a 3” or 5” MERV 8 media air filter depending on the

model. The 5” filter must be replaced every year and the 3”

filter must be replaced every 6 months to ensure maximum

efficiency of both the air filter and air handler. Applications with

higher dust levels may require more frequent replacement.

Upgrade kits are available for BMAC-14CE and BMAC-20CE

models to replace media filters with electronic air cleaner

components.

Please read instructions before installing and using the Healthy

Climate® Box Media Air Cleaner.

Risk of equipment damage and/or high energy usage.Risk of equipment damage and/or high energy usage.

Risk of equipment damage and/or high energy usage.

Risk of equipment damage and/or high energy usage.Risk of equipment damage and/or high energy usage.

Dirty air filters will cause high energy usage and/orDirty air filters will cause high energy usage and/or

Dirty air filters will cause high energy usage and/or

Dirty air filters will cause high energy usage and/orDirty air filters will cause high energy usage and/or

damage to the ventilation system.damage to the ventilation system.

damage to the ventilation system.

damage to the ventilation system.damage to the ventilation system.

Replace filters at recommended intervals.Replace filters at recommended intervals.

Replace filters at recommended intervals.

Replace filters at recommended intervals.Replace filters at recommended intervals.

Risk of property damage, injury or death.Risk of property damage, injury or death.

Risk of property damage, injury or death.

Risk of property damage, injury or death.Risk of property damage, injury or death.

Installation, adjustment, alteration, service and main-Installation, adjustment, alteration, service and main-

Installation, adjustment, alteration, service and main-

Installation, adjustment, alteration, service and main-Installation, adjustment, alteration, service and maintenance must be performed by a qualified servicetenance must be performed by a qualified service

tenance must be performed by a qualified service

tenance must be performed by a qualified servicetenance must be performed by a qualified service

technician.technician.

technician.

technician.technician.

Required ToolsRequired Tools

Required Tools

Required ToolsRequired Tools

• Tin Snip

• Straight Screwdriver

• Rule or Tape Measure

• Drill

Dallas, Texas USA

CACA

CA

CACA

WARNINGWARNING

WARNING

WARNINGWARNING

HEALHEAL

HEAL

504,638M

09/2003

*CE Models are upgradeable to a Healthy Climate® Electronic Air Cleaner

Rules for Safe Installation and OperationRules for Safe Installation and Operation

Rules for Safe Installation and Operation

Rules for Safe Installation and OperationRules for Safe Installation and Operation

1. Read this Owners Manual and the Rules for Safe

2. Follow a regular service and maintenance schedule

3. Maximum static weight for cabinet: 400 lbs.

UTIONUTION

UTION

UTIONUTION

Risk of carbon monoxide poisoning.Risk of carbon monoxide poisoning.

Risk of carbon monoxide poisoning.

Risk of carbon monoxide poisoning.Risk of carbon monoxide poisoning.

Can cause injury or death.Can cause injury or death.

Can cause injury or death.

Can cause injury or death.Can cause injury or death.

Do not operate without access panel in place. Opera-Do not operate without access panel in place. Opera-

Do not operate without access panel in place. Opera-

Do not operate without access panel in place. Opera-Do not operate without access panel in place. Operation of this equipment without the access panel in placetion of this equipment without the access panel in place

tion of this equipment without the access panel in place

tion of this equipment without the access panel in placetion of this equipment without the access panel in place

may cause gas fumes from the heating system to bemay cause gas fumes from the heating system to be

may cause gas fumes from the heating system to be

may cause gas fumes from the heating system to bemay cause gas fumes from the heating system to be

drawn into occupied spaces.drawn into occupied spaces.

drawn into occupied spaces.

drawn into occupied spaces.drawn into occupied spaces.

Sharp edges hazard.Sharp edges hazard.

Sharp edges hazard.

Sharp edges hazard.Sharp edges hazard.

Equipment sharp edges can cause injuries.Equipment sharp edges can cause injuries.

Equipment sharp edges can cause injuries.

Equipment sharp edges can cause injuries.Equipment sharp edges can cause injuries.

Use protective gloves when grasping equipmentUse protective gloves when grasping equipment

Use protective gloves when grasping equipment

Use protective gloves when grasping equipmentUse protective gloves when grasping equipment

edges.edges.

edges.

edges.edges.

BOBO

BO

BOBO

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of filter or

unsatisfactory service.

for efficient operation.

HEALHEAL

X MEDIA X MEDIA

X MEDIA

X MEDIA X MEDIA

WARNINGWARNING

WARNING

WARNINGWARNING

Electrical shock hazard.Electrical shock hazard.

Electrical shock hazard.

Electrical shock hazard.Electrical shock hazard.

Can cause injury or death.Can cause injury or death.

Can cause injury or death.

Can cause injury or death.Can cause injury or death.

Disconnect all remote electrical powerDisconnect all remote electrical power

Disconnect all remote electrical power

Disconnect all remote electrical powerDisconnect all remote electrical power

supplies before servicing.supplies before servicing.

supplies before servicing.

supplies before servicing.supplies before servicing.

WARNINGWARNING

WARNING

WARNINGWARNING

CACA

UTIONUTION

CA

UTION

CACA

UTIONUTION

THY CLIMATHY CLIMA

THY CLIMA

THY CLIMATHY CLIMA

AIR CLEANERAIR CLEANER

AIR CLEANER

AIR CLEANERAIR CLEANER

TETE

TE

TETE

®®

®

®®

Box Media Air Cleaner ModelsBox Media Air Cleaner Models

Box Media Air Cleaner Models

Box Media Air Cleaner ModelsBox Media Air Cleaner Models

BMAC-12C (X0577) BMAC-12C (X0577)

BMAC-12C (X0577) is designed for use with air handlers

BMAC-12C (X0577) BMAC-12C (X0577)

which deliver 1000 to 1600 cfm. BMAC-12C is equipped with

a 3” filter media (X0581) and cannot be upgraded.

BMAC-14CE (X0578)BMAC-14CE (X0578)

BMAC-14CE (X0578) is designed for use with air handlers

BMAC-14CE (X0578)BMAC-14CE (X0578)

which deliver 1000 to 1600 cfm. BMAC14CE is equipped

with a 5” filter media (X0584) and may be upgraded to

Healthy Climate electronic air cleaner using kit X0598.

BMAC-20C (X0589)BMAC-20C (X0589)

BMAC-20C (X0589) is designed for use with air handlers

BMAC-20C (X0589)BMAC-20C (X0589)

which deliver 1600 to 2200 cfm. BMAC-20C is equipped with

a 5” filter media (X0586) and cannot be upgraded.

rails that can be removed to accomodate a 5” filter media

(X1152).

BMAC-20CE (X0580)BMAC-20CE (X0580)

BMAC-20CE (X0580) is designed for use with air handlers

BMAC-20CE (X0580)BMAC-20CE (X0580)

which deliver 1600 to 2200 cfm. BMAC-20CE is equipped

with a 5” filter media (X0587) and may be upgraded to

Healthy Climate electronic air cleaner using kit X0599.

It also has

Shipping and Packing ListShipping and Packing List

Shipping and Packing List

Shipping and Packing ListShipping and Packing List

Package 1 of 1 contains:Package 1 of 1 contains:

Package 1 of 1 contains:

Package 1 of 1 contains:Package 1 of 1 contains:

1 - Box Media Cabinet

1 - Box Media Filter

1 - Cabinet Door

1 - Fastener Screw

1 - Installation Instructions

1 - IAQ Guide and Warranty

Lennox Industries, Inc.Lennox Industries, Inc.

Lennox Industries, Inc.

Lennox Industries, Inc.Lennox Industries, Inc.

Dallas, Texas

1-800-9-LENNOX

www.lennox.com

PART NO. 37-6405BPART NO. 37-6405B

PART NO. 37-6405B

PART NO. 37-6405BPART NO. 37-6405B

Replaces 37-6405A

Page 2

Air Filter OperationAir Filter Operation

Air Filter Operation

Air Filter OperationAir Filter Operation

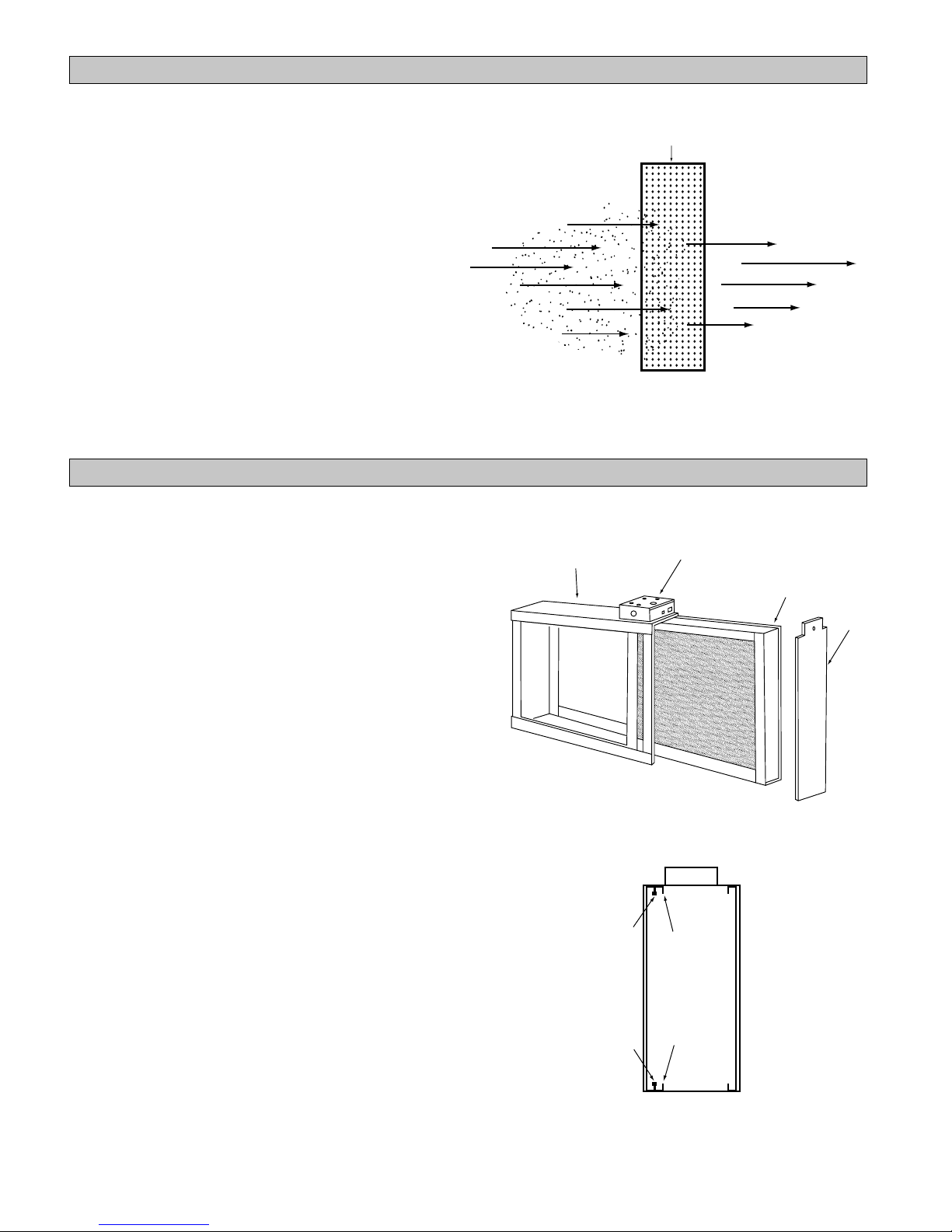

Unfiltered air flows through the return air ducts and into the

BMAC cabinet. As the air flows across the MERV 8 filter, it

captures dust mites, pollen, mold spores, pet dander and

other contaminants that are 0.3 microns or larger.

The filtered and conditioned air is distributed throughout the

living space through the supply air ducts.

Box Media Air Cleaner ConstructionBox Media Air Cleaner Construction

Box Media Air Cleaner Construction

Box Media Air Cleaner ConstructionBox Media Air Cleaner Construction

The BMAC box media air cleaner is easy to install and

maintain. The basic components of the air cleaner are

detailed below and are shown in figure 2.

NONO

TE:TE:

NO

TE: The BMAC-20C unit has two rails that are clipped

NONO

TE:TE:

inside the cabinet (see Fig 2A). These rails can be removed

to allow the cabinet to accomodate a 5” filter media

(X1152). Use a screwdriver to pop out the clips to remove

the rails. The 5” filter media will slide into the cabinet.

The air filter cabinet is installed in the existing return air duct

system and houses either the supplied filter media on “C”

models or the upgrade components (electronic air cleaner

cells) on the “CE” models.

NOTE NOTE

NOTE - An upgrade kit is available for use with CE

NOTE NOTE

models.(CE models do not have removable rails.) Electronic

air cleaner cells are provided in the kit to replace the

existing MERV 8 media filter.

UNFILTERED AIR IN

AIR FILTER COMPARTMENT

3" FILTER or

5" FILTER

Figure 1Figure 1

Figure 1

Figure 1Figure 1

Junction box

(CE models only)

FILTERED AIR OUT

5" FILTER

DOOR

Figure 2Figure 2

Figure 2

Figure 2Figure 2

Clip

Clip

Removable

Rail

Removable

Rail

Figure 2A

2

Page 3

(

)

Box media air filter locationBox media air filter location

Box media air filter location

Box media air filter locationBox media air filter location

LOCATING THE AIR CLEANERLOCATING THE AIR CLEANER

LOCATING THE AIR CLEANER

LOCATING THE AIR CLEANERLOCATING THE AIR CLEANER

Install the air cleaner in the return air duct (air entering

side) of the furnace or air handler as shown in figure 3.

Install the air cleaner in such a way that the face of the filter

is at a right angle to the air stream. Do not install the air

cleaner in the discharge or supply air duct system.

Allow 25” clearance in front of the air cleaner to accommodate removal of media filters or air cleaner cells. Refer

to figure 4 for dimensions.

If air handler return air, or air entering, opening is not large

enough to accommodate air filter, install a field fabricated

sheet metal transition. Transition reduction should be no

more than 4 inches per linear foot, creating an angle of

approximately 20 degrees. Refer to figure 4.

SPECIAL INSTALLATION NOTES:SPECIAL INSTALLATION NOTES:

SPECIAL INSTALLATION NOTES:

SPECIAL INSTALLATION NOTES:SPECIAL INSTALLATION NOTES:

Atomizing spray-type humidifier (if used) must be installed

downstream of the air cleaner.

UV germicidal light (if used) must be installed a minimum

of 6 ft. from the air cleaner when the two are installed in

direct line of sight to one another. If there is a 90 degree

bend or turn in the air duct between the air cleaner and UV

light, a 3 ft. installation clearance is required between the

two.

AIR FLOW

AIR HANDLER

RETURN AIR/

ENTERING AIR

OPENING

AIR HANDLER

NOT TO EXCEED 20

TRANSITION SECTION

Figure 3

AIR CLEANER

IF NEEDED

AIR FLOW

AIR CLEANER

OPENING

DUCT

Dimension/SpecificationsDimension/Specifications

Dimension/Specifications

Dimension/SpecificationsDimension/Specifications

Filter Media Dimensions NominalFilter Media Dimensions Nominal

Filter Media Dimensions Nominal

Filter Media Dimensions NominalFilter Media Dimensions Nominal

in Inches (Millimeters)in Inches (Millimeters)

in Inches (Millimeters)

in Inches (Millimeters)in Inches (Millimeters)

Model No.Model No.

Model No.

Model No.Model No.

BMAC-12C 16 x 25 x 3 X0581

BMAC-14CE 16 x 26 x 5 X0584

BMAC-20C 20 x 25 x 5 X0586

BMAC-20CE 20 x 26 x 5 X0587

Specifications subject toSpecifications subject to

Specifications subject to

Specifications subject toSpecifications subject to

change without notice.change without notice.

change without notice.

change without notice.change without notice.

Filter SizeFilter Size

Filter Size

Filter SizeFilter Size

(406.4 x 635 x 76.2)

(406.4 x 660.4 x 127)

(508 x 635 x 127) X1152

(508 x 660.4 x 127)

Catalog No.Catalog No.

Catalog No.

Catalog No.Catalog No.

F

D

C

B

A

E

Figure 4

Dimensions in Inches (Millimeters)Dimensions in Inches (Millimeters)

Dimensions in Inches (Millimeters)

Dimensions in Inches (Millimeters)Dimensions in Inches (Millimeters)

Model No.Model No.

Model No.

Model No.Model No.

BMAC-12C 24-5/8 21-29/32 13-1/2 16-15/32 17-13/32 4-15/16

BMAC-14CE 26-3/8 23-5/8 13-9/16 16-15/32 19-15/32 6-15/16

BMAC-20C 24-5/16 22-5/16 17-3/16 20-3/16 21-5/32 6-15/16

BMAC-20CE 26-11/32 23-5/8 17-3/4 20-21/32 23-21/32 6-15/16

AA

A

AA

(625.5) (556.4) (342.9) (418.3) (442.1) (125.4)

(669.9) (600.1) (344.5) (418.3) (494.5) (176.2)

(617.5) (566.7) (436.6) (512.8) (537.4) (176.2)

(669.1) (600.1) (450.9) (524.7) (600.9) (176.2)

BB

B

BB

CC

C

CC

DD

D

DD

EE

E

EE

FF

F

FF

3

Page 4

AIR FLOW

Figure 7

Typical ApplicationsTypical Applications

Typical Applications

Typical ApplicationsTypical Applications

AIR FLOW

Figure 5

BASEMENT AIRBASEMENT AIR

BASEMENT AIR

BASEMENT AIRBASEMENT AIR

HANDLER (LOWBOY)HANDLER (LOWBOY)

HANDLER (LOWBOY)

HANDLER (LOWBOY)HANDLER (LOWBOY)

(Figure 5)(Figure 5)

(Figure 5)

(Figure 5)(Figure 5)

Air cleaner is mounted hori-

zontally in return plenum,

just above air handler.

AIR FLOW

Figure 6

DOWNFLOWDOWNFLOW

DOWNFLOW

DOWNFLOWDOWNFLOW

AIR HANDLER (Figure 6)AIR HANDLER (Figure 6)

AIR HANDLER (Figure 6)

AIR HANDLER (Figure 6)AIR HANDLER (Figure 6)

Air cleaner is mounted hori-

zontally in return duct or plenum, just above air handler.

UPFLOW AIR HANDLERUPFLOW AIR HANDLER

UPFLOW AIR HANDLER

UPFLOW AIR HANDLERUPFLOW AIR HANDLER

(Figure 7)(Figure 7)

(Figure 7)

(Figure 7)(Figure 7)

Side installation. Air cleaner

is mounted vertically, where

return air enters side inlet of

air handler.

UPFLOW AIR HANDLERUPFLOW AIR HANDLER

UPFLOW AIR HANDLER

UPFLOW AIR HANDLERUPFLOW AIR HANDLER

(Figure 8)(Figure 8)

(Figure 8)

(Figure 8)(Figure 8)

Installation beneath air handler.

Air cleaner mounts horizontally,

where return air enters from

below. Raise air handler and

install beneath base.

AIR FLOW

AIR FLOW

HORIZONTAL AIR HANDLERHORIZONTAL AIR HANDLER

HORIZONTAL AIR HANDLER

HORIZONTAL AIR HANDLERHORIZONTAL AIR HANDLER

(Figure 10)(Figure 10)

(Figure 10)

(Figure 10)(Figure 10)

Figure 10

Air cleaner is mounted vertically in

the return duct near air handler.

LESS THAN

7 INCHES

FIGURE 9

OFFSET INSTALLATIONOFFSET INSTALLATION

OFFSET INSTALLATION

OFFSET INSTALLATIONOFFSET INSTALLATION

(Figure 9)(Figure 9)

(Figure 9)

(Figure 9)(Figure 9)

OFFSET

AT LEAST

9 INCHES

Typical use of duct offset to match air cleaner opening.

If duct connection to air handler allows less than nine

inches for mounting the air cleaner, shorten the lateral

trunk, or attach an offset fitting to the elbow.

4

Page 5

InstallationInstallation

Installation

InstallationInstallation

WARNINGWARNING

WARNING

WARNINGWARNING

Risk of property damage, injury or death.Risk of property damage, injury or death.

Risk of property damage, injury or death.

Risk of property damage, injury or death.Risk of property damage, injury or death.

Installation, adjustment, alteration, service and main-Installation, adjustment, alteration, service and main-

Installation, adjustment, alteration, service and main-

Installation, adjustment, alteration, service and main-Installation, adjustment, alteration, service and maintenance must be performed by a qualified servicetenance must be performed by a qualified service

tenance must be performed by a qualified service

tenance must be performed by a qualified servicetenance must be performed by a qualified service

technician.technician.

technician.

technician.technician.

REMOVE OLD FILTER AND DISCARDREMOVE OLD FILTER AND DISCARD

REMOVE OLD FILTER AND DISCARD

REMOVE OLD FILTER AND DISCARDREMOVE OLD FILTER AND DISCARD

(Figure 11)(Figure 11)

(Figure 11)

(Figure 11)(Figure 11)

NOTE: This filter may be mounted in the air handler

cabinet.

CLEAN BLOWER COMPARTMENTCLEAN BLOWER COMPARTMENT

CLEAN BLOWER COMPARTMENT

CLEAN BLOWER COMPARTMENTCLEAN BLOWER COMPARTMENT

NOTE: The air filter cannot remove dirt from blower and

ducts.

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

The following is a typical installation of the air cleaner on

an upflow air handler (Figure 7).

1. Place the air cleaner cabinet on the floor. Stand it

upright with the door facing you (Figure 2). If a

horizontal installation is being planned, lay the cabinet

on its side, this will help you to visualize the relative

location of all parts.

2. Unscrew the knob, remove the door (by grasping top

and pulling door away from cabinet) and set it aside.

Remove filter. Set in a safe location until the cabinet

is installed.

3. Set the cabinet next to the air handler (if possible) to

match the opening in the compartment.

If the air handler opening cannot be enlarged, a

transition fitting should be used. (Figure 3).

The cabinet can be attached directly (Figure 12), or a

starting collar can first be fitted to the furnace inlet. A

butt or slip joint can be used.

Securely attach the cabinet to air handler inlet, using

at least two of the mounting holes on each side of the

cabinet.

4. Using butt joint, attach duct (normally an elbow) to the

upstream side of air filter cabinet. (Note the use of the

sheet metal turning vanes inside the elbow to improve

air distribution.) (Figure 13)

NOTE: NOTE:

NOTE: An optional method of attaching duct to the air

NOTE: NOTE:

cleaner cabinet is to modify the cabinet (Figure 14) by

bending the tabs outward at a 90° angle and attaching duct

to tabs.

High Humidity EnvironmentsHigh Humidity Environments

High Humidity Environments: Wrapping cabinet with 2”

High Humidity EnvironmentsHigh Humidity Environments

foil faced insulation (foil on the outside) around the case

(excluding the insulated door) will prevent condensation

on the sides of the unit.

Transition FittingsTransition Fittings

Transition Fittings

Transition FittingsTransition Fittings

If the air duct does not fit the cabinet opening, a transition

fitting should be used. Gradual transitions are preferred

for greatest efficiency. Not more than four inches per

linear foot (approximately 20° angle) should be allowed

(Figure 3).

Figure 11

Air Flow

Optional method

(Bend tabs outward at 90˚ angle)

5. Connect the vertical duct section to the elbow. Wedge

a wood block between floor and elbow for support

(Figure 15).

6. Seal all joints in the return air system downstream

from the air filter with duct tape to prevent dust from

entering the air stream. Tape is usually applied on the

outside of ducts, but may also be applied on the

inside, or both.

7. With the air filter compartment installed, re-install

3” or 5” filter and door. (Figure 2)

NOTENOTE

NOTE: Please remove the plastic bag from the filter

NOTENOTE

media prior to installing the filter media into the air

cleaner cabinet. Proper disposal procedure of

plastic materials should be followed.

5

Turning

Vanes

Figure 13

Figure 14

Page 6

Vertical

Section

Tape All

Joints

Figure 16Figure 16

Figure 16

Figure 16Figure 16

FLOOR

CONDUIT

Wood Block

CACA

UTIONUTION

CA

UTION

CACA

UTIONUTION

Risk of equipment damage and/or high energy usage.Risk of equipment damage and/or high energy usage.

Risk of equipment damage and/or high energy usage.

Risk of equipment damage and/or high energy usage.Risk of equipment damage and/or high energy usage.

Dirty air filters will cause high energy usage and/orDirty air filters will cause high energy usage and/or

Dirty air filters will cause high energy usage and/or

Dirty air filters will cause high energy usage and/orDirty air filters will cause high energy usage and/or

damage to the ventilation system.damage to the ventilation system.

damage to the ventilation system.

damage to the ventilation system.damage to the ventilation system.

Replace filters at recommended intervals.Replace filters at recommended intervals.

Replace filters at recommended intervals.

Replace filters at recommended intervals.Replace filters at recommended intervals.

Figure 15Figure 15

Figure 15

Figure 15Figure 15

For maximum efficiency, your air filter should be

inspected once a month and changed if dirt load is

heavy. The 3” filter should be changed every 6

months and the 5” filter should be changed every

12 months. More frequent changes may be required

in high dust environments.

When changing is required, the following procedure

should be used:

1. Remove door from air filter cabinet by unscrewing

the knob.

Repair Parts and AccessoriesRepair Parts and Accessories

Repair Parts and Accessories

Repair Parts and AccessoriesRepair Parts and Accessories

1

2

4

3

AlAl

ww

aa

ys orys or

Al

w

a

ys or

AlAl

ww

aa

ys orys or

DUCT

AIR CLEANER

2. Remove 3” or 5” filter and throw away.

3. Replace 3” or 5” filter by sliding it into the cabinet.

(Note direction of air flow.)

NOTENOTE

NOTE: Please remove the plastic bag from the filter

NOTENOTE

media prior to installing the filter media into the air

cleaner cabinet. Proper disposal procedure of

plastic materials should be followed.

4. Re-attach door.

WARNINGWARNING

WARNING

WARNINGWARNING

Risk of carbon monoxide poisoning.Risk of carbon monoxide poisoning.

Risk of carbon monoxide poisoning.

Risk of carbon monoxide poisoning.Risk of carbon monoxide poisoning.

Can cause injury or death.Can cause injury or death.

Can cause injury or death.

Can cause injury or death.Can cause injury or death.

Do not operate without access panel in place. Opera-Do not operate without access panel in place. Opera-

Do not operate without access panel in place. Opera-

Do not operate without access panel in place. Opera-Do not operate without access panel in place. Operation of this equipment without the access panel in placetion of this equipment without the access panel in place

tion of this equipment without the access panel in place

tion of this equipment without the access panel in placetion of this equipment without the access panel in place

may cause gas fumes from the heating system to bemay cause gas fumes from the heating system to be

may cause gas fumes from the heating system to be

may cause gas fumes from the heating system to bemay cause gas fumes from the heating system to be

drawn into occupied spaces.drawn into occupied spaces.

drawn into occupied spaces.

drawn into occupied spaces.drawn into occupied spaces.

PARTS LIST FOR BOX MEDIA AIR CLEANERPARTS LIST FOR BOX MEDIA AIR CLEANER

PARTS LIST FOR BOX MEDIA AIR CLEANER

PARTS LIST FOR BOX MEDIA AIR CLEANERPARTS LIST FOR BOX MEDIA AIR CLEANER

When ordering repair parts, always give the following

information as shown in this list.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER of the Box Media Air Cleaner

der bder b

y “Py “P

ARAR

der b

der bder b

y “P

y “Py “P

T NUMBER”T NUMBER”

AR

T NUMBER”

ARAR

T NUMBER”T NUMBER”

. .

.

. .

. .

. .

.

.

. .

. .

Not b Not b

Not b

Not b Not b

y “ITEM NUMBER”y “ITEM NUMBER”

y “ITEM NUMBER”

y “ITEM NUMBER”y “ITEM NUMBER”

UPGRADE!UPGRADE!

UPGRADE!

UPGRADE!UPGRADE!

ELECTRONIC AIR CLEANER KITELECTRONIC AIR CLEANER KIT

ELECTRONIC AIR CLEANER KIT

ELECTRONIC AIR CLEANER KITELECTRONIC AIR CLEANER KIT

Models BMAC-14CE and BMAC-20CE can be upgraded

to a High Efficiency Electronic Air Cleaner. Call your

local Lennox dealer for details.

DescriptionDescription

Description

DescriptionDescription

Air Cleaner X0577 X0578 X0579 X0580

ItemItem

Item

ItemItem

No.No.

No.

No.No.

1 Cabinet X0588 X0589 X0590 X0591

2 Filter X0581 X0584 X0586 X0587

3 Cabinet Door X0592 X0593 X0594 X0595

4 Screw, Fastener X0596 X0596 X0596 X0596

DescriptionDescription

Description

DescriptionDescription

Electronic Air Cleaner Upgrade Kit X0598 X0599

BMAC-12CBMAC-12C

BMAC-12C

BMAC-12CBMAC-12C

DescriptionDescription

Description

DescriptionDescription

BMAC-14CEBMAC-14CE

BMAC-14CE

BMAC-14CEBMAC-14CE

BMAC-BMAC-

BMAC-

BMAC-BMAC-

12C12C

12C

12C12C

BMAC-14CEBMAC-14CE

BMAC-14CE

BMAC-14CEBMAC-14CE

BMAC-20CBMAC-20C

BMAC-20C

BMAC-20CBMAC-20C

Part NumberPart Number

Part Number

Part NumberPart Number

BMAC-BMAC-

BMAC-

BMAC-BMAC-

14CE14CE

14CE

14CE14CE

BMAC-20CEBMAC-20CE

BMAC-20CE

BMAC-20CEBMAC-20CE

BMAC-BMAC-

BMAC-

BMAC-BMAC-

20C20C

20C

20C20C

X1152

BMAC-20CEBMAC-20CE

BMAC-20CE

BMAC-20CEBMAC-20CE

• Contact your local Lennox dealer to order replacement parts. For the Lennox dealer nearest you, dial

1-800-9-LENNOX, or visit www.lennox.com

PART NO. 37-6405APART NO. 37-6405A

PART NO. 37-6405A

PART NO. 37-6405APART NO. 37-6405A

BMAC-BMAC-

BMAC-

BMAC-BMAC-

20C20C

EE

20C

E

20C20C

EE

Loading...

Loading...