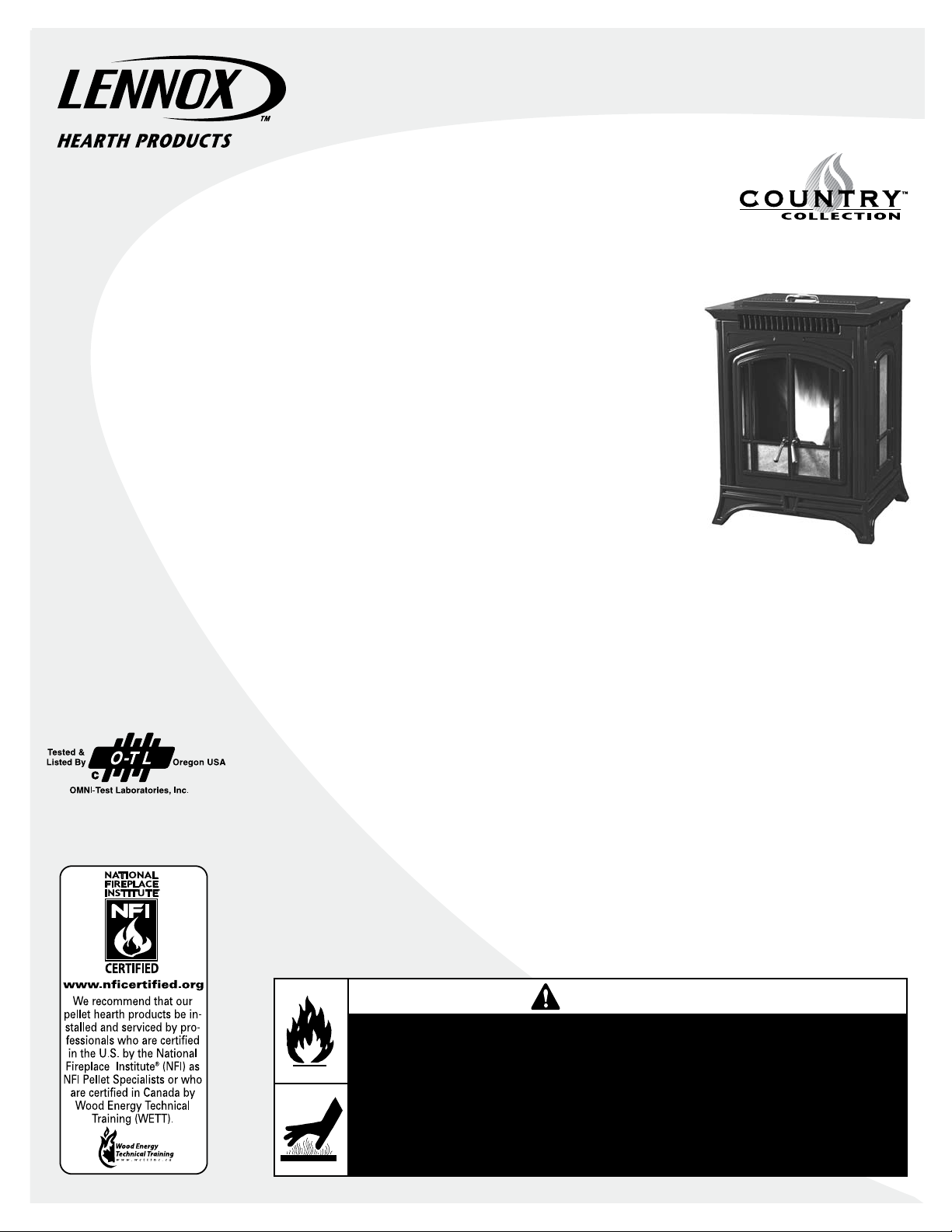

Page 1

INSTALLATION AND OPERATION MANUAL

US

Portland

Free-Standing

Pellet Stove

Save These Instructions

For Future Reference

P/N 775,226M, Rev. A, 02/2009

Report No. 116-S-53-2

Pellet Stove

Model Bella™

A French manual is available upon request. Order P/N 775,226CF.

Ce manuel d’installation est disponible en francais, simplement en faire la demande. Numéro de la pièce

775,226CF.

These appliances must be properly installed and operated in order to prevent the possibility

of a house re. Please read this entire manual before installation and use of this pellet

fuel-burning room heater. Failure to follow these instructions could result in property

damage, bodily injury or even death. Contact your local building or re ofcials

to obtain a permit and information on any installation requirements and

inspection requirements in your area.

WARNINGS

• Hot! Do not touch! The glass and surfaces of this appliance will be

hot during operation and will retain heat for a while after shutting off

the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

• Lennox™ pellet-burning appliances are designed for use as a supplemental heater. They are not intended for continuous use as a primary

heat source.

Page 2

IMPORTANT SAFETY AND WARNING

INFORMATION

READ THIS MANUAL IN ITS ENTIRETY AND UNDERSTAND THESE RULES TO FOLLOW FOR SAFETY

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer

or service agency.

WARNING

Do not attempt to alter or modify the construction of

the appliance or its components. Any modification

or alteration may void the warranty, certification

and listings of this unit.

1. DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

2. Do not connect this appliance to air ducts or any air distribution system.

3. DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING

SYSTEM OF THIS UNIT.

4. Do not use class B venting intended for gas appliances as a

chimney or connector pipe on a pellet-fired appliance.

5. The minimum clearances must be maintained for all combustible surfaces and materials including; furniture, carpet,

drapes, clothing, wood, papers, etc. Do not store combustibles

within this clearance space (see Clearances on Page 5).

6. INSTALLATION DISCLAIMER - It is imperative that the exhaust

venting system be installed correctly and sealed gas-tight

(not allowing exhaust to leak). Follow the vent manufacturer's

instructions for proper installation. Since Lennox Hearth

Products has no control over the installation of your stove,

Lennox Hearth Products grants no warranty, implied or stated

for the installation or maintenance of your stove, and assumes

no responsibility for any consequential damage(s).

7. Burning any kind of fuel consumes oxygen. If outside air is

not ducted to the appliance, ensure that there is an adequate

source of fresh air available to the room where the appliance

is installed.

8. The appliance will not operate using natural draft, nor without

a power source for the blower and fuel feeding systems.

9. Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or “freshen

up” a fire in this heater. Keep all such liquids well away from

the heater while it is in use.

10. The authority having jurisdiction such as municipal building

department, fire department, fire prevention bureau, etc.

should be consulted before installation to determine the

need to obtain a permit.

2

11. APPROVED FUEL: This appliance is designed specifically

for use only with pelletized wood pellets or a mixture of up

to 50% corn mixed with a minimum of 50% pelletized wood

pellets. This mixture of wood pellets and corn should be

evenly pre-mixed before being placed in the units hopper.

.

This appliance is designed and approved for the burning of

wood residue pellets with up to 3% ash content. This appliance is NOT approved to burn cardboard, nut hulls, cherry

pits, etc. regardless if it is in pellet form. Failure to comply

with this restriction will void all warranties and the safety

listing of the stove. Consult with your Lennox Hearth Products

dealer for more information on approved pellet fuels.

12. CONTINUOUS OPERATION: When operated correctly, this

appliance cannot be overfired. Continuous operation at a

maximum burn can, however, shorten the life of the electrical components (blowers, motors, and electronic controls),

and is not recommended. Typical approved operation would

include running at the low to mid range setting with occasional

running on the maximum setting during the coldest periods

of the winter. DO NOT OVER-FIRE THIS STOVE. Follow all

instructions regarding the proper use of this stove.

13.CAUTION: NEVER PUT FINGERS NEAR AUGER. This appliance

is equipped with a hopper lid switch, which is designed to stop

the auger when the hopper lid is opened. NEVER DISCONNECT

OR BYPASSED THIS SWITCH FOR ANY REASON. Pellet fuel is fed

to the Burn-pot by a screw auger. This auger is driven by a

high torque motor. The auger is capable of causing serious

harm to fingers. Keep pellets in the hopper at all times and

keep fingers away from auger. The auger can start and stop

automatically at any time while the stove is running.

14. CAUTION: HOT WHILE IN OPERATION. An appliance hot

enough to warm your home can severely burn anyone touching

it. Keep children, pets, clothing and furniture away. Contact

may cause skin burns. Do not let children touch the appliance.

Train them to stay a safe distance from the appliance.

15. FLY ASH BUILD-UP: For all wood pellet fuel-burning heaters,

the combustion gases will contain small particles of fly-ash.

This will vary due to the ash content of the fuel being burned.

Over time, the fly-ash will collect in the exhaust venting

system and restrict the flow of the flue gases. The exhaust

venting system should be inspected regularly and cleaned

as necessary.

16. SOOT FORMATION: Incomplete combustion, such as occurs

during startup, shutdown, or incorrect operation of the room

heater will lead to some soot formation which will collect in

the exhaust venting system. A precautionary inspection on

a regular basis is advisable to determine the necessity of

cleaning. The exhaust venting system should be inspected

regularly and cleaned as necessary.

17. DISPOSAL OF ASHES: Ashes should be placed in a metal

container with a tight-fitting lid. The closed container of ashes

should be placed on a noncombustible floor or on the ground, well

away from all combustible materials, pending final disposal. If

the ashes are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container until

all cinders have been thoroughly cooled.

18. The instructions must be strictly adhered to. Do not use

makeshift methods or compromise in the installation.

19. Do not abuse the door glass by striking, slamming or similar

trauma. Do not operate the stove with the glass removed,

cracked or broken.

20. SAVE THESE INSTRUCTIONS.

21. See the listing label on the appliance.

Page 3

CONGRATULATIONS!

TESTING / LISTING

When you purchased your new pellet stove, you joined the ranks of

thousands of individuals whose answer to their home heating needs

reflects their concern for aesthetics, efficiency and our environment.

We extend our continued support to help you achieve the maximum

benefit and enjoyment available from your new pellet stove.

Thank you for selecting a Lennox Hearth Products stove as the answer

to your home heating needs.

TABLE OF CONTENTS

Important Safety Information . . . . . . . . . . . . . . . . . . . . Page 2

Packaging List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Testing / Listing, EPA . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Planning Your Installation . . . . . . . . . . . . . . . . . . . . . . . Page 3

Selecting a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Installation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Manufactured Home Installation . . . . . . . . . . . . . . . . . . Page 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Venting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Care and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 24

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 25

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

Component Definitions . . . . . . . . . . . . . . . . . . . . . . . . . Page 32

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 34

Replacement Parts List & Diagrams . . . . . . . . . . . . . . . Page 36

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 41

Safety / Listing Label . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 42

Product Reference Information Page 44

Listing: The listing laboratory is OMNI-Test Laboratories, Inc., Portland, Oregon. The report number is 116-S-53-2 for model Bella pellet

stove.

Testing: In accordance with the specifications and procedures

• Listed and tested to ASTM E1509 & ULC C1482 / ULC S627 for installations as a freestanding room heater

• The safety/listing label is located on the bottom side of the hopper

lid. Please read this safety label carefully. It contains important

information about installation and operation of this appliance.

• This appliance is tested and listed for residential installation according

to current national and local building codes.

• This appliance is on the Colorado Approved pellet stoves list.

EPA (Environmental Protection Agency)

Status: EPA Certified (method 28) -

Lokee Testing Laboratory, Sumner, Washington to rigorous emissions

standards, and has been certified by the Environmental Protection

Agency.

This appliance has been tested by

USING THIS MANUAL

Please read and carefully follow all of the instructions found in this

manual. Please pay special attention to the safety instructions provided

in this manual.

PRODUCT IS SUBJECT TO CHANGE WITHOUT NOTICE

PLANNING YOUR INSTALLATION

Questions To Ask Local Building Official

A correct installation is critical and imperative for reducing fire hazards and

perilous conditions that can arise when wood pellet burning appliances

are improperly installed. The installer must follow all of the manufacturers’ instructions.

WARNING

This installation and operation manual will help you obtain a safe, efficient, dependable installation for your appliance and vent system.

PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE BEGINNING YOUR INSTALLATION

PACKAGING LIST

The assembled pellet stove model Bella™ is packaged with an accessory package which contains the following:

One - Power Cord

One - Installation And Operation Manual

One - Warranty

One - Leg Bolt Down Kit (needed for manufactured homes only)

Check all local building and safety codes before

installation. The installation instructions and appropriate code requirements must be followed exactly

and without compromise. Alterations to the stove are

not allowed. Do not connect the stove to a chimney

system serving another stove, appliance, or any air

distribution duct. Failure to follow these instructions

will void the manufacturers warranty.

The installation of this appliance must conform to local codes and applicable state and federal requirements. Familiarity with these requirements

before installation is essential. Important considerations to discuss with

local building officials include:

Applicable codes (i.e. Uniform Mechanical Code, State or Regional

1.

Codes).

Electrical codes:

In USA, NEC, ANSI/NFPA 70 – Latest Edition

In Canada, CSA C22.1 – Latest Edition

3

Page 4

. Power Supply Requirements (continued)

These requirements must be met unless otherwise specified by state

or local authorities.

Power Cord - The power cord must be plugged into a standard, 120

•

Volt, 60 Hz grounded electrical outlet with proper ground and polarity.

The power cord must be routed to avoid contact with any of the hot

or sharp exterior surface areas of the stove.

Power Supply - The units maximum draw during start-up mode will be

•

3.5 Amps and 360 Watts while the igniter is on in the first 8 minutes

of operation. Maximum draw on the unit once in burn mode is 1.8

Amps and 115 Watts. Minimum draw on the unit once in burn mode

is 1.5 Amps and 90 Watts.

Manufactured Home Installations - When installed into a manufactured

•

home, the appliance must be electrically grounded to the steel chassis

(see Page 8, Manufactured Home Requirements).

• Existing Chimneys

• Pellet Fuel Storage

• Aesthetic Considerations

• Roof Design (rafter locations and roof pitch)

• Room Traffic

• Proximity to Combustibles

• Electrical Wiring

CAUTION

These appliances are very heavy. The use of a heavy

duty escalara (stair step hand truck) is recommended

for lifting the appliance.

WARNING

Electrical grounding instructions: This appliance is

equipped with a three-prong (grounding) plug for

your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong

from this plug. Do not route power cord under or in

front of appliance.

2. Local amendments

3. Is a permit required - cost. You may wish to contact your insurance

company to ask if they require this.

4. If outside combustion air is required

5. Rooms where the installation is not allowed

Surge Protectors

A surge protector is recommended to ensure the stove’s electrical components are not damaged due to a surge in the electrical supply. Only

high quality protectors should be used - low quality protectors do not

provide the protection needed.

Smoke Detectors

Since there are always several potential sources of fire in any home, we

recommend installing smoke detectors. If possible, install the smoke

detector in a hallway adjacent to the room (to reduce the possibility of

occasional false activation from the heat produced by these appliances).

If your local code requires a smoke detector be installed within the same

room, you must follow the requirements of your local code. Check with

your local building department for requirements in your area.

Installation / Maintenance Standards

National Fire Protection Association – The primary NFPA standard that

refers to installation and maintenance of pellet stoves and venting is

NFPA 211 – Latest Edition: Chimneys, Fireplaces, Vents, and Solid Fuel

appliances.

SELECTING A LOCATION

The design of your home and where you place your stove will determine

its value as a source of heat. This type of appliance depends primarily on

air circulation (convection) to disperse its heat, and therefore, a central

location is often best. There are other practical considerations, which

must be considered before a final selection of locations is made. Some

of which includes:

NEGATIVE PRESSURE WARNING

This appliance is not designed to be operated in a negative pressure. Very

airtight homes with large kitchen exhaust fans, or homes with furnace

cold air returns located in close proximity to the stove may create negative pressure in the same room as the heating appliance. This can create

dangerous condition, drawing combustion by-products into the home. Be

sure your home has adequate makeup air to eliminate negative pressures

caused by the above-mentioned sources. Outside air connected to the

appliance probably will not resolve such a problem as the stove is not the

source of negative pressure. Lennox Hearth Products accepts no liability

for damages resulting from negative pressures described here.

Ventilation Requirements - Provide adequate air for combustion. The fresh

air requirements of this appliance must be met within the space where it

will be installed. Ventilation is essential when using a solid-fuel-burning

heater. In well insulated and weather tight homes, it may inhibit the rate

the exhaust flows through the venting system (caused by a shortage of

air in the home). The lack of air is caused by many common household

appliances which exhaust air from the home (such as a furnace, heat

pump, air conditioner, clothes dryer, exhaust fans, fireplaces, and other

fuel burning appliances). Also, the combustion process of this heater

uses oxygen from inside the dwelling. If the available fresh air delivery

in the dwelling is insufficient to support the demands of these appliances, problems can result (i.e. excessive negative pressure will result

in performance problems. To correct this problem it may help to open

a window (preferably on the windward side of the house) or install an

outside combustion air duct to the appliance.

FLOOR PROTECTION

This appliance requires noncombustible floor protection (the hearth pad

or alternate floor protection material does not require a thermal rating).

A noncombustible floor protector must fully cover the area beneath the

appliance as illustrated in Figure 1.

If the floor protection is to be stone, tile, brick, etc., it must be mortared

or grouted to form a continuous noncombustible surface. In Canada, if a

chimney connector / venting extends horizontally over the floor, protection

must also cover the floor under the connector / venting and at least 2” (51

mm) to either side (recommended but not required in the US).

4

Page 5

Back

Front

0*” (0 mm)

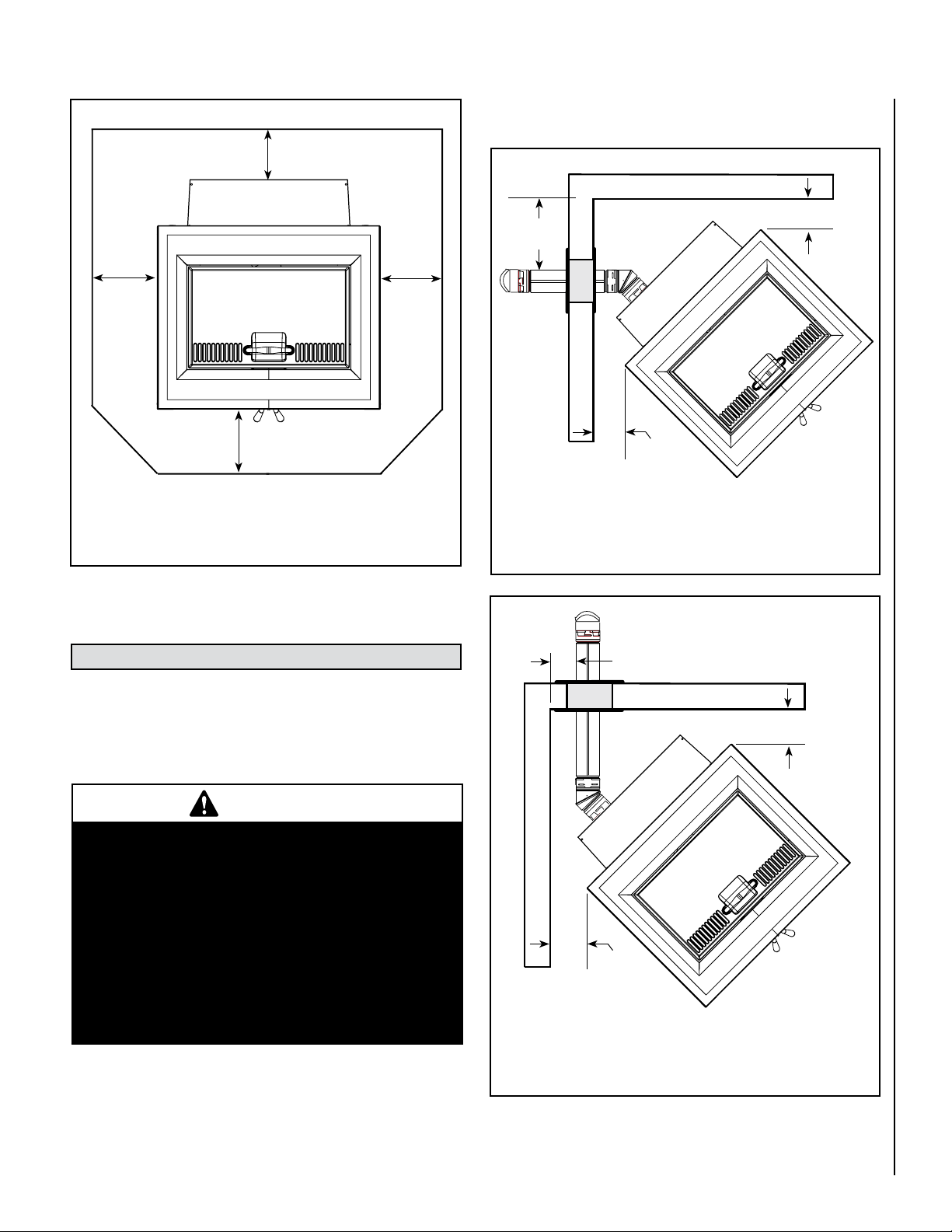

Corner Installations - Clearance to Combustibles

Combustible Wall

3”

(76mm)

Min.

Floor Protector

*Note: Refer to Page 4 for chimney/venting floor protection

requirements and recommendations.

Top View

6” (152mm) Min.

(76mm)

Figure 1 - Floor Protection Requirements

CLEARANCES

3”

Min.

3*”

(76mm)

Top View

Combustible Wall

3-1/2”

(89mm)

*Note:

Refer to pipe Manufacturer's installation instructions

for minimum pipe clearances.

Figure 2 - Left Wall Horizontal Venting

3*”

(76mm)

3-1/2” (89mm)

Standard residential or manufactured home installation. These appliances

require the following minimum clearances to combustibles:

Minimum Clearances To Combustibles

IMPORTANT

•

Minimum clearances specified may not allow

for ease of operation and maintenance (please

take this in to account when planning the instal

lation). If installed to the minimum clearances,

removal of the appliance may be necessary for

servicing.

•

Recommended clearance zone from the front of the

appliance to combustibles is 4 feet minimum.

•

Clearances to combustibles for the appliance

can only be reduced by means approved by the

regulatory authority.

-

Combustible Wall

Combustible Wall

3-1/2”

(89mm)

Refer to pipe Manufacturer's installation instructions

*Note:

for minimum pipe clearances.

Top View

Figure 3 - Right Wall Horizontal Venting

3-1/2” (89mm)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

5

Page 6

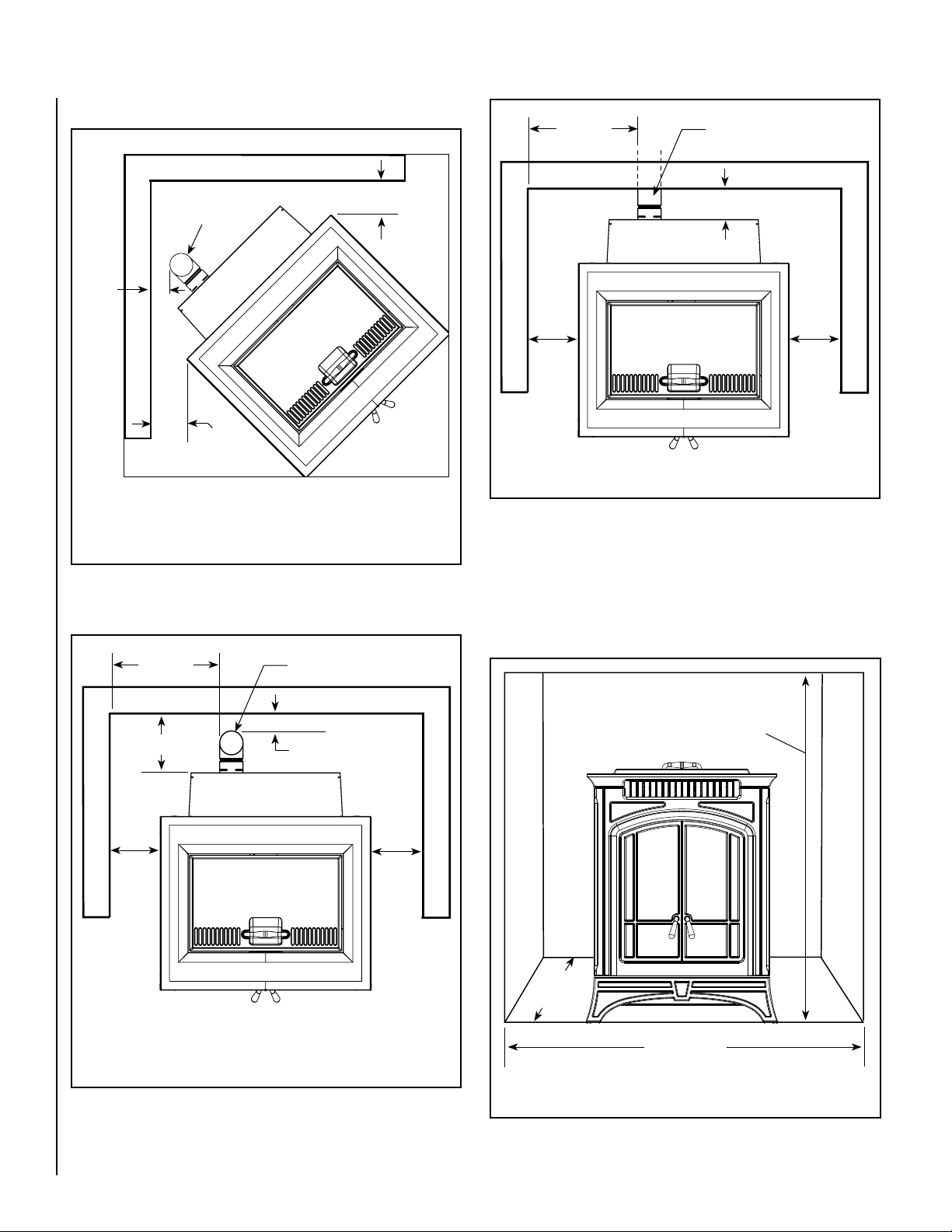

Corner Installations - Clearance to Combustibles

8-11/16”

(221mm)

Horizontal Vent

Combustible Wall

3-1/2” (89mm)

3*”

(76mm)

Vertical Vent

Combustible Wall

Top View

3-1/2”

(89mm)

*Note: Refer to pipe Manufacturer's installation instructions

for minimum pipe clearances.

Figure 4 - Vertical Venting

Parallel and Alcove Installations - Clearance to

Combustibles

8-11/16”

(221mm)

Vertical Vent

Combustible Wall

2” (51mm)

Combustible Wall

5”

(127mm)

Top View

5”

(127mm)

Figure 6 - Horizontal Vent, Parallel or Alcove

Alcove Installations - Clearance to Combustibles

Minimum clearance from back of stove to back wall = 2 inches

Minimum clearance from sides of stove to wall = 5 inches

Minimum clearance from exhaust pipe to side wall = 8-11/16 inches

Minimum height of ceiling = 60 inches

Minimum alcove width = 33-3/4 inches

MAXIMUM depth of alcove = 48 inches

Combustible Wall

Combustible Wall

4-7/8*” (124mm)

Combustible Wall

5”

(127mm)

Refer to pipe Manufacturer's installation instructions

*Note:

Top View

3*”

(76mm)

5”

(127mm)

Combustible Wall

for minimum pipe clearances.

Figure 5 - Vertical Venting, Parallel or Alcove

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

60”

(1524mm)

Minimum

48”

(1220mm)

Max.

33-3/4”

(857mm)

Minimum

Figure 7 - Alcove Size Requirements

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Page 7

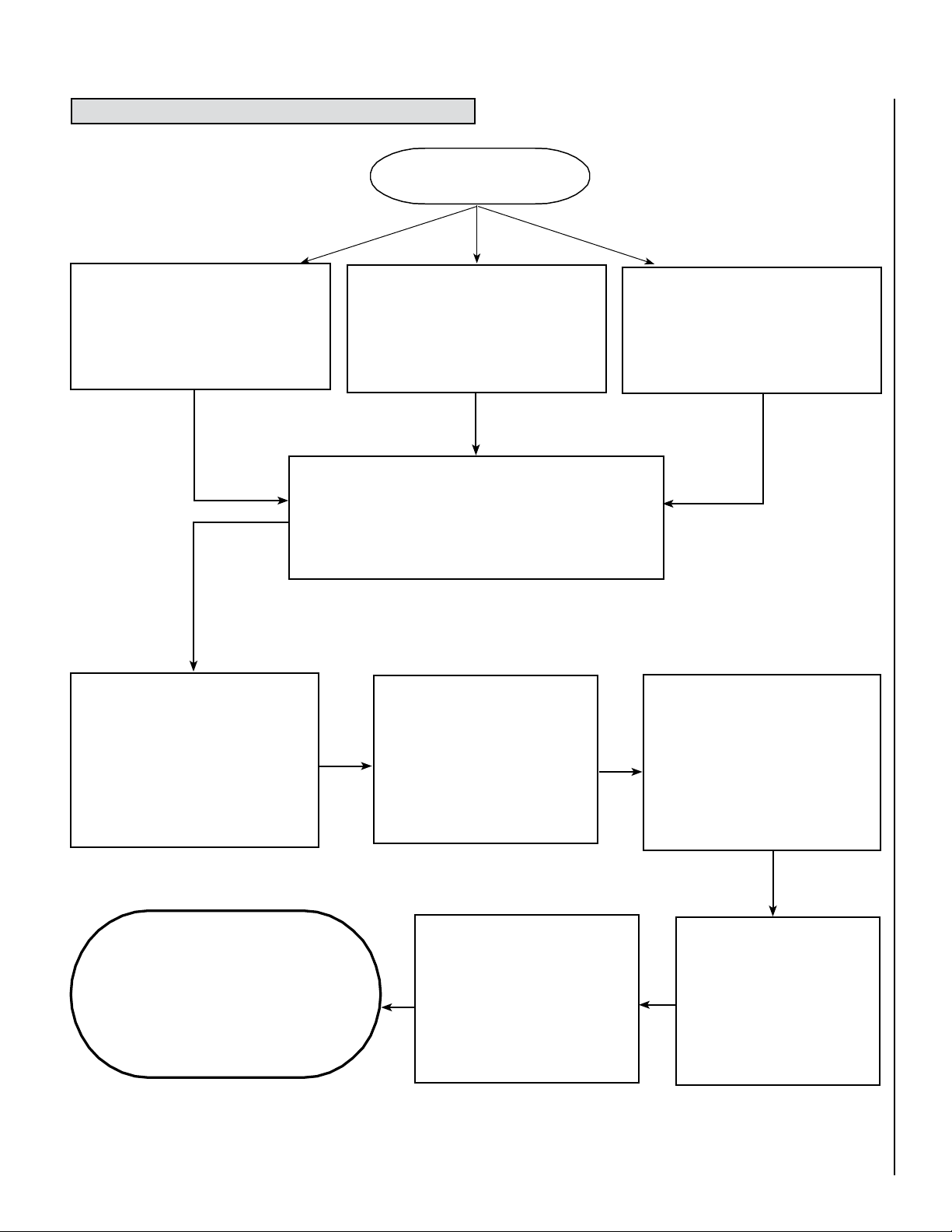

INSTALLATION TIPS

INSTALLATION TIPS

Select Your Installation Type

GOOD INSTALLATION *

Horizontal Installation

(Direct Vent - Outside Wall)

No natural draft. Wind

pressures may affect operation

a: PL-Vent Pipe / Pellet Vent (w/stainless interliner)

b: Stainless Steel flex liner may be used inside existing flue

REQUIRES 3”

DIAMETER STANDARD

PL-VENT / PELLET PIPE

With listed termination kit. If

installation requires in excess of

15’ of pipe, it is recommended a

4” diameter pipe be used.

BETTER INSTALLATION

Vertical & Horizontal Installation

(Up and Out)

Some natural draft aids venting. Wind

pressures may still affect operation

VENTING TYPE

or chimney (woodstove replacement applications)

CAUTION: Do not use Type B-Vent Pipe

MANUFACTURED

HOME

Requires outside air for com-

bustion. Use a galvanized or

stainless steel pipe for duct.

Minimum duct size 3” I.D.

BEST INSTALLATION

Vertical Installation

(Straight Up)

Natural draft improves operation and

negative effects from wind

CLEARANCES TO

COMBUSTIBLES

Ensure all clearances are main-

tained in accordance to instruc-

tions contained on product

safety label and in compliance

with pipe/venting requirements.

POWER SUPPLY

PLEASE REVIEW THIS ENTIRE

INSTALLATION AND OPERA-

TION MANUAL FOR ADDITIONAL

INSTRUCTIONS.

* In horizontal vent installations It is recommended that when an appliance is vented directly through a wall, a minimum of 6 feet (1.83 M) of vertical pipe is

installed to create some natural draft. This will reduce the possibility of smoke or odor entering the dwelling during appliance shutdown or loss of power.

Must have proper polarity and

be grounded.

Note: Use of an extension

cord may adversely effect the

performance of your unit.

SEAL ALL

VENTING JOINTS

Use RTV

(high temp silicone)

7

Page 8

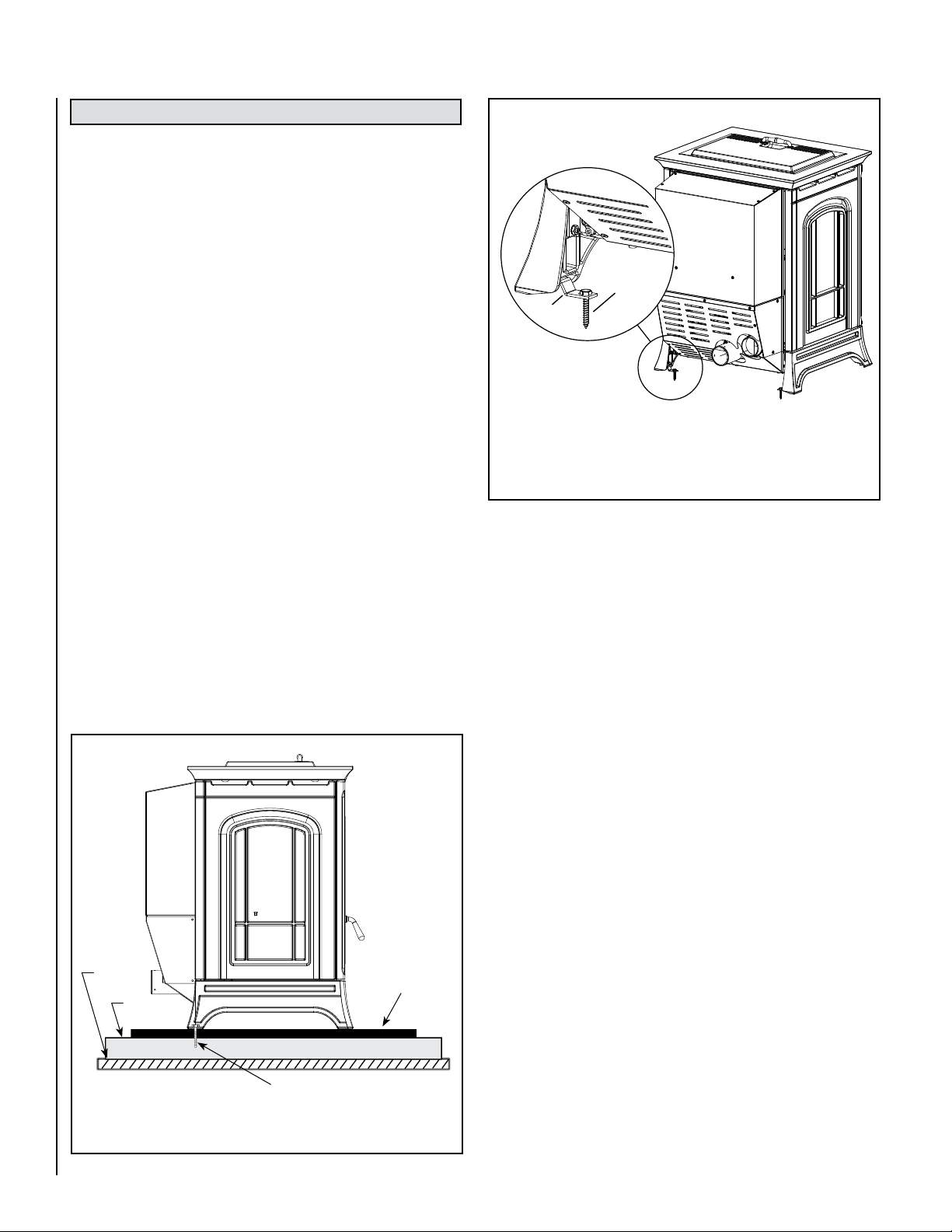

MANUFACTURED HOME INSTALLATION

In addition to the standard installation instructions, the following instructions may be required by local, state or federal building codes:

• Installation should be in accordance with the Manufactured Home and

Safety Standard (HUD), CFR 3280, Part 24.

• The stove must be permanently bolted to the floor

lag screws. The lag screws must be an adequate length to extend

through the hearth pad and into the floor as shown in Figures 8 and 9.

Install the lag screws as shown in these figures. Two lag screws must

be used.

•

Connecting the Bella™ stove to outside combustion air is optional,

except in manufactured home installations and when required by local

building codes. An outside air inlet must be provided for combustion

and be unrestricted while unit is in use. Use a galvanized or stainless

steel pipe for the duct (the outside air inlet on the stove is 3” diameter).

The air intake on the exterior of the home should always be located

substantially below the flue termination. The Inlet shall remain free

of obstruction while unit is in operation and constructed in a manner

so as to prevent material from dropping into the inlet or into the area

beneath the dwelling. The inlet shall also have a screen with openings

not larger than 1/4" to prevent rodents from entering. See Figure

21.

• Stove must be permanently electrically grounded to the steel chassis

of the home using a 8 GA copper wire and a serrated or star washer

(to penetrate paint or protective coating to ensure grounding). The

location selected for ground attachment to the stove must be dedicated

for this purpose. Grounding must comply with NFPA-70-latest edition

standards, CSA C22.1-latest edition in Canada, as well as any local

codes.

• See Pages 12 through 18

for additional information on venting require-

ments.

• WARNING: DO NOT INSTALL THIS STOVE IN A SLEEPING ROOM IN

A MANUFACTURED HOME.

•

CAUTION: THE STRUCTURAL INTEGRITY OF THE MANUFACTURED

HOME FLOOR, WALLS, CEILING/ROOF MUST BE MAINTAINED.

using 1/4" diameter

Lag Screw

Bracket

Attach the provided brackets to the stove using a 5/16" bolt. Install lag

screws through the holes in the bottom of the brackets to secure the legs

to the floor as shown here.

Figure 9 - Manufactured Home Installation

Manufactured Home Exhaust Vent Pipe Installation Guidelines

This stove is approved for venting with Type L and Type PL pellet vent pipe

listed to UL 641 and ULC S609. We recommend the use of venting products manufactured by Security Chimneys International. The pipe should

extend at least 3 feet above the part of the roof through which it passes.

The top of the pipe should be at least 2 feet above the highest required

elevation of any part of the manufactured home within 10 feet of the pipe

(see Page 14, Manufactured Home Chimney Height Requirements).

Chassis

Floor

Lag Screws

Figure 8 - Manufactured Home Installation

If the exhaust vent exits the manufactured home at a location other than

the roof, and exits at a point 7 feet or less above the ground level on which

the manufactured home is position a guard or method of enclosing the

pipe shall be provided at the point of exit for a height of up to 7 feet. The

openings, if any, in this guard shall not allow a 3/4” rod to pass through.

A 1/2” rod could pass through but should not be able to touch the pipe

when inserted through the opening a distance of 4 inches.

Floor

Protector

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Page 9

INSTALLATION

G -

G.

I

I

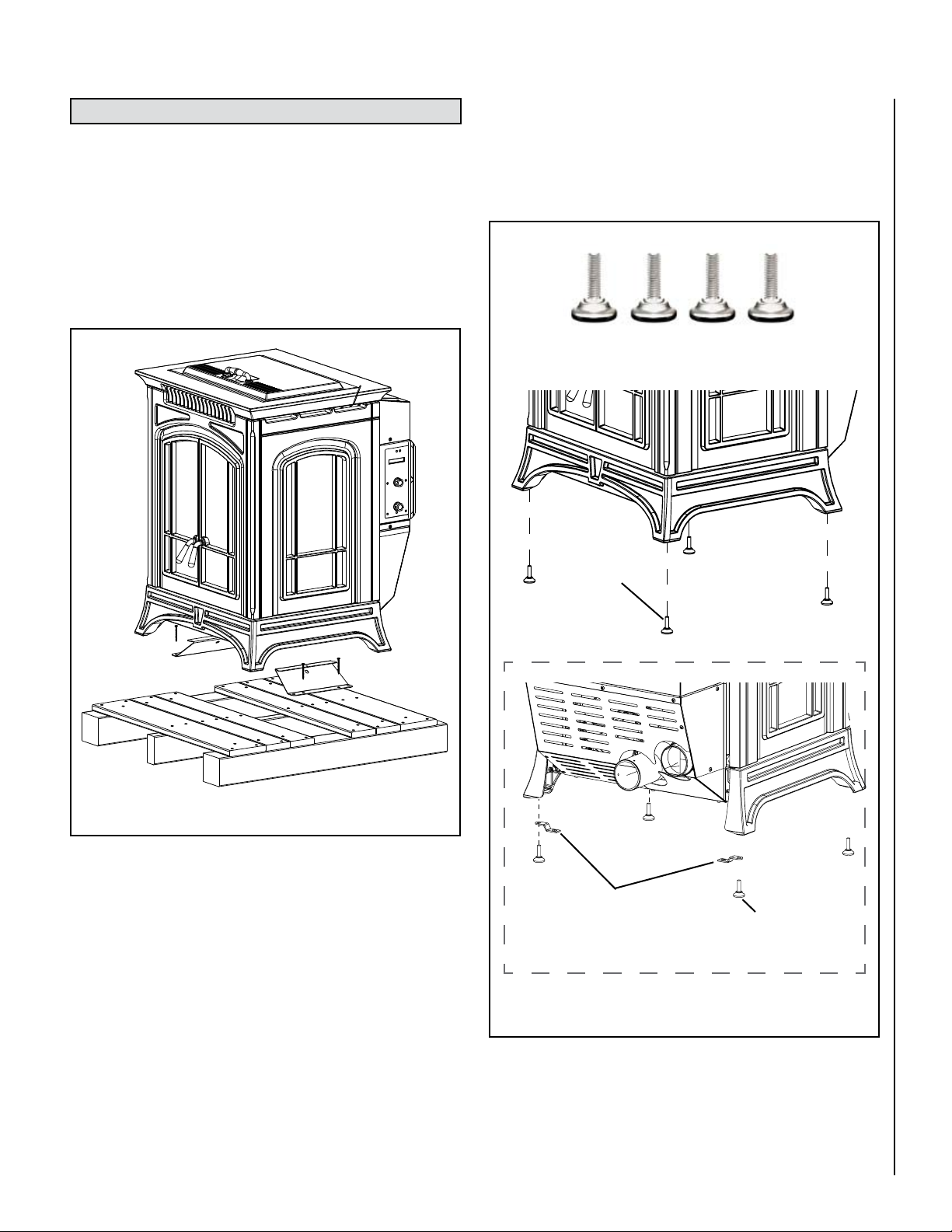

Removing Appliance From Pallet

1. After removing the packaging from the stove, lift the hopper lid, and

remove all prepackaged items that were shipped in the hopper. Next,

open the stove door and remove all prepackaged items.

2. Using a 7/16" socket or wrench, remove the two lag bolts on either

side of the stove and remove brackets by sliding them towards the

center of the unit.

Installation of Leg Leveling Bolts

An optional leg leveling kit is available. In manufactured home installations a leg bolt down kit is also required (provided with stove). Install the

leveling legs and bolt down kits per the instructions provided in kits. See

Figure 11

and Page 41 for leveling leg kit ordering information.

H7638 Leveling Leg Kit (4 per pkg.) (ref. Form # 506033-21)

Figure 10 - Removing Stove From Pallet

Leveling Legs

Manufactured home installations will

also require a bolt down kit which

includes 2 tie down brackets (provided

with stove) (ref. Form # 506033-19)

Figure 11 - Leveling Legs

Leveling Legs

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

9

Page 10

Installation Check List

Draft Adjuster - Adjustment Procedure

It is strongly recommended that you have an Lennox Hearth Products

dealer install your stove. If you install your stove yourself, you should

review your installation plan with an Lennox Hearth Products dealer.

Check list:

Check off each item as you proceed with the installation process.

q Read the ENTIRE stove installation section first

q Determine the appropriate measurements and locations for your

installation.

q Follow the installation directions in this manual.

q Be sure to pre-fit all items before you install, fasten, or set up the

appliance permanently.

qMeasure for exhaust (also outside air tube when applicable) and mark

the location. Place the unit in place to make sure it's correct before

cutting holes in your wall.

Prior to lighting your appliance:

q Review the safety precautions section.

q Review the pellet FUEL section.

q Review and follow the Operating Instructions.

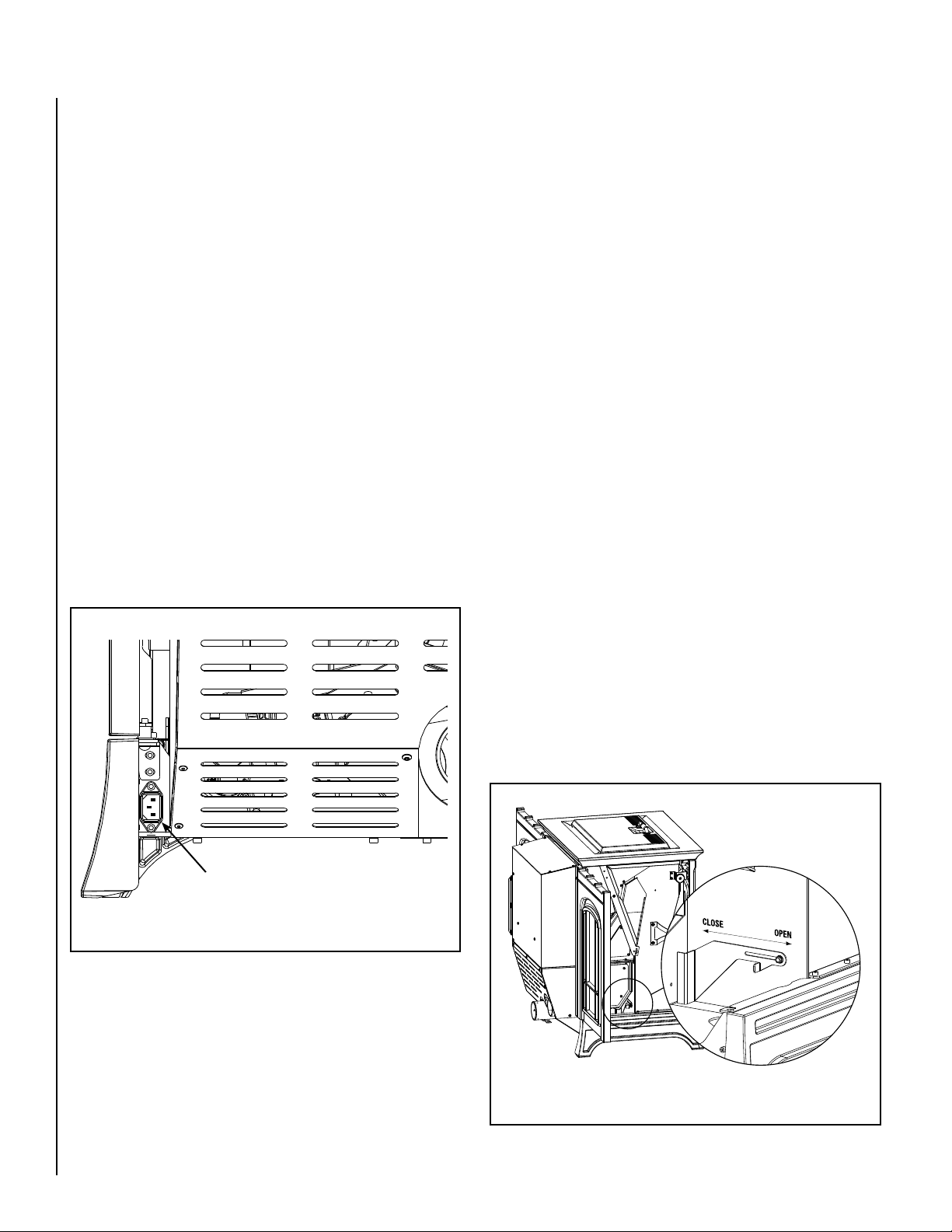

q Plug power cord connector into corresponding connector on the back

of appliance (see Figure 12 showing connector location).

The Bella™ pellet stove has a draft adjuster located at the left side of the

stove directly in front of the combustion blower. Should the stove installation require long runs of vent pipe, a situation may be created where

excessive combustion air is flowing through the firebox and causing

the fuel to burn faster than it can be delivered to the burn pot. Should

this happen, the draft can be slowed down by the adjuster. The stove is

shipped with the adjuster half open. To increase or decrease the draft;

using a 5/16" open end wrench, loosen the bolt (see Figure 13) and move

the adjuster handle toward the center of the stove to decrease and away

from the center of the stove to increase the draft. Retighten the screw

when adjustment is complete.

Draft Adjuster

The draft adjuster controls the amount of combustion air that is delivered

to the firebox (see Figure 13).

It will be necessary to monitor the appearance of the flame during the first

4-8 bags of pellets. If the flame is smoky red or orange with evidence of

soot at the top of the flame, the draft adjuster will need to be adjusted

to deliver more combustion air. If the flame is "short" at the higher burn

rates and appears to burn the pellets out of the pot faster than they can

be resupplied, or there are significant variations of flame height within a

single burn setting, the draft adjuster may need to be adjusted to deliver

less combustion air.

After the draft adjuster is adjusted, re-evaluate the appearance of the

flame. It may be necessary to continue adjusting it in increments until

proper combustion is achieved (the flame should become a brighter

yellow and begin to “dance”).

Back of Stove

Plug power cord into connector on back of stove.

Figure 12

After you have begun operation of your appliance:

q Review the routine cleaning / maintenance information.

q Enjoy the warmth from your new Lennox Hearth Products pellet

stove!

Once the draft adjuster has been properly set, and if the routine maintenance is performed as needed, the draft adjuster should not require

readjustment unless you are changing from a premium grade pellet to a

standard or high ash pellet, in which case the draft adjuster may need to

be moved outward from center of the stove to help prevent the accumulation of ash in the burn pot.

Draft Adjustor

A

Figure 13 - Adjustment of Combustion Air

10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Page 11

Draft Adjuster Adjustment Guidelines

Thermostat installation

Lack of Combustion Air:

By opening the draft adjuster, this will increase combustion air delivery.

Symptoms of insufficient combustion air include; unburned fuel, lazy

smoky or red / orange flame, excessive ash or soot, excessive buildup

on glass.

Contributing factors:

• High Altitude – Lack of oxygen

• Restrictive Venting (elbows, horizontal runs, cold external chimneys,

etc.)

• Dirty / Poor Quality Fuel.

• Lack of Maintenance

Note: Excessive amounts of fly-ash built-up in the burn pot, clinkers in

the burn pot or leakage of air (if the burn pot is not properly seated) will

starve the fire for air. See Routine Maintenance, on Pages 25 through

30

for information on cleaning requirements.

Excessive Combustion Air:

Adjusting the draft adjuster to a more closed position will reduce the

combustion air delivery. Symptoms of excessive air include; fuel burns

too quickly (results in smoking or smoldering pellets), white to yellow

flame, etc. If the draft adjuster is open too far, the burning pellets will lift

off the bottom of the burn pot and fly up into the air much like popping

corn does. Another flame characteristic of a draft adjuster that is open

too far is a flame that has significant variation in height on any single

burn setting.

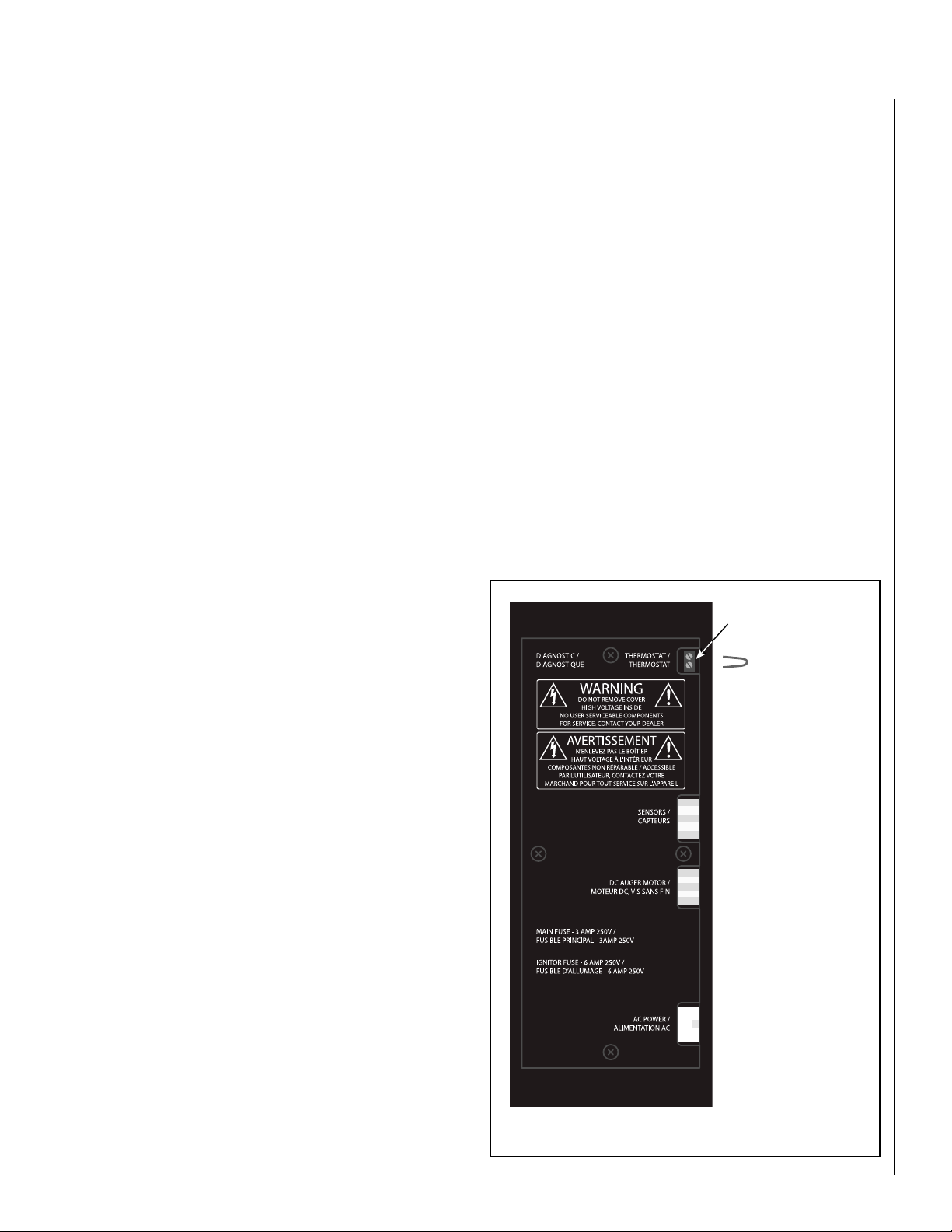

The Bella pellet stove can be operated manually or by thermostat. The

stove comes from the factory wired to operate manually - see control

board operation on Pages 19 through 21. A low voltage thermostat can

be installed on the stove. To install the thermostat:

1. Unplug the stove from the electrical outlet. Open the control board

access door. Locate the black wiring block at the top right on the back

side of the control board (see Figure 14). Loosen the two screws

B at the back of the block, and remove the U shaped jumper wire A

protruding from the block.

2. Insert a wire from the thermostat into one of the slots from which the

jumper wire was removed. Repeat this process for the other thermostat

wire.

Retain the jumper wire for future reinstallation. See Page 21 for thermostat operation instructions.

IMPORTANT NOTE: Install the thermostat per the manufacturers instructions, provided with the thermostat. Failure to follow manufacturers

instructions could result in a malfunction. Pay special attention to the

thermostat location requirements. If the location requirements are not

adhered to the appliance, erratic operation or failure may occur.

Do not mount the thermostat where it may be affected by:

• Radiant heat from the stove, fireplaces, sun or other heat

sources.

• Drafts or dead spots behind doors or in corners.

• Hot or cold air from ducts.

Contributing factor:

• Venting system providing excessive draft.

• Dry, hot burning fuel

Correct Combustion Air / Proper Burn Characteristics:

When the draft adjuster is correctly set, the burning pellets should move

(wiggle) around slightly and the flame should be bright yellow and stay

at relatively even height.

Outside Air Installations

Connecting the Bella™ pellet stove to outside combustion air is optional,

except in manufactured (mobile) home installations and when required

by local building codes. The stove’s air intake will accept 3” ID pipe to

accommodate outside air installations. The air intake on the exterior of the

home should always be located substantially below the flue termination

and must remain free of obstruction. The inlet must also have a screen

with openings not larger than 1/4" to prevent rodents from entering.

B

A

Wiring Block

Remove jumper if

Thermostat IS to

be used

Leave jumper on, if

thermostat is NOT

used

A = Jumper Wire

B = Screws

Figure 14 - Back of Control Board

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

11

Page 12

VENTING REQUIREMENTS

It is recommended that only an Lennox Hearth Products dealer install your

pellet stove. The specified installation requirements must be followed to

ensure conformity with both the safety listing of the appliance and local

building codes. All clearances, installation instructions and precautions

specified by the vent manufacturer must be followed.

Selecting a Location

Review the appliance clearance requirements before installing the venting

system (see Pages 5 and 6). Position the appliance far enough away

from walls to allow adequate room for servicing. Choose the appliance

location with the least amount of interference with the house framing,

plumbing, wiring, etc.

Preferred Vent Configuration

For the best performance, we recommend a vent run design which runs

vertically and terminates above the roof line. This design will allow natural

draft to improve the flow of flue gases and will aid in combustion and

stove performance.

Type of Pipe

This stove is approved for venting with Type L and Type PL pellet vent

pipe (sometimes referred to as “L-Vent pellet vent”, listed to UL 641 or

ULC S609). We recommend the use of venting products manufactured by

Security Chimneys International. Connect the pellet vent pipe or the “tee”

to the flue collar using a minimum of three screws and seal as specified

in “Pipe/Liner Joint Requirements” on this Page. Do not use class B gas

chimney or single wall chimney as a substitute.

Size of Pipe

These pellet stoves are approved for use with the following vent sizes: 3”

(75 mm) standard, or 4” (100 mm), see Page 15 - for determining correct

size vent. When 4” pipe is used: for horizontal vent installations use a 3”

(75 mm) to 4” (100 mm) adapter - available from vent manufacturer. For

vertical installations use a 3” (75 mm) to 4” (100 mm) “tee” - available

from vent manufacturer.

Offsets

In every installation, a single or double clean-out “tee” is recommended

for every ninety-degree offset (this tee will help collect ash residue and

will allow for routine cleaning without the need to disconnect sections

of pipe).

Pipe Clearances/Requirements

See pipe manufacturers instructions for installation of venting components

and clearances. Follow pipe manufacturers installation precautions for

passing pipe through a combustible wall or ceiling (i.e. use an approved

thimble).

Notes

• Offsets and horizontal runs accumulate fly-ash and soot which reduces

the exhaust flow and performance of the stove.

• Total Offsets in venting system should not exceed 270° total in direc

tion change.

• Maximum Vertical Vent - 30 feet (9.14 M)

• Horizontal Runs - The maximum total horizontal run must not exceed

10 feet (3.1 meters).

• Horizontal run of pipe requires 1/4” (7 mm) rise per foot.

• Pellet vent pipe requires 3” (75 mm) clearance from outside of pipe

unless otherwise specified by vent manufacturer - all diameters: 3” (75

mm) and 4” (100 mm). A support bracket must be installed every 4

feet (1.2 m) of pellet vent pipe on the exterior wall of the house unless

otherwise specified by vent manufacturer.

• It is not recommended to terminate exhaust vent on the prevailing wind

side of the house.

• In Canada, where the venting may pass through a wall, or partition of

combustible materials, the installation shall conform to CAN/CSA-B365.

When installing the wall thimble and other venting components, follow

the vent manufacturers instructions. Maintain an effective vapor barrier at the location where the chimney or other component penetrates

12

to the exterior of the structure.

Pipe/Liner Joint Requirements

Silicone sealant and three screws are required to secure the first vent connection to the appliance flue collar. Seal the remaining vent sections per

the vent manufacturers instructions and secure all sections with 3 screws

minimum per section. ALL horizontal joints must be sealed gas-tight (air

tight, sealed connection). Use RTV high temperature silicone or Interam,

if necessary, to provide a complete seal between vent sections.

Connection to Masonry Chimney through a Wall

Be sure to verify the construction of a masonry chimney, as it may have

combustible framing.

Approved liner when relining Masonry or Factory-Built Fireplaces is

2100HT (degree F.) liner listed to UL 1777 or ULC S635.

Connection to an Existing Class A Chimney

A chimney adapter can be used to make the connection from 3” (75

mm) or 4” (100 mm) pellet vent pipe (listed to UL 641 or ULC S609) to

existing UL chimney system. Verify with the pipe manufacturer that your

pipe brands will interconnect.

Horizontal Vent Installations

On all horizontal vent installations (short, horizontal runs with no vertical

pipe); care should be taken when choosing a location for terminating the

vent. It is not recommended to directly vent the exhaust on the prevailing wind side of the house. It is recommended that when an appliance is

vented directly through a wall, a minimum of 6 feet (1.83 M) of vertical

pipe should be installed to create some natural draft. This will reduce

the possibility of smoke or odor entering the dwelling during appliance

shutdown or loss of power.

Vent Termination

Do not terminate vent in an enclosed or semi-enclosed area such as:

carports, garage, attic, crawl space, under a deck, porch, narrow walkway,

closely fenced area, or any location that can build up a concentration of

fumes such as a stairwell, covered breezeway etc.

Vent surfaces can get hot enough to cause burns if touched. Adults

should supervise children when they are in the area of a hot stove.

Non-combustible shielding or guards may be required.

Termination Cap

The termination of the outside chimney of the pellet stove shall be located

in accordance with the following:

A. Higher than 3 feet (.92 m) above any forced air inlet (air conditioner,

etc.) located within 10 feet (3 m).

B. Not less than 4 feet (1.2 m) below, 4 feet (1.2 m) horizontally from or

1 foot (3.1 m) above any gravity air inlet (door, window, etc.) which

flue gases could reenter the dwelling.

C. Not less than 2 feet (.6 m) from combustible materials such as an

adjacent buildings, fences, protruding parts of the structure, roof

overhang, plants and shrubs, etc. and not less than 7 feet (2.1 m)

-

above grade when located adjacent to the public sidewalks (access).

The final termination of the exhaust system must be configured so that

flue gases do not jeopardize the safety of people passing by, overheat

combustible portions of nearby structures or enter the dwelling.

D. Not less than 3 feet (.92 m) below an eave (maximum overhang of 3

feet (.92 m) or any construction that projects more than 2” (51 mm)

from the plane of the wall.

E. The distance from the bottom of termination to grade is 12” (305 mm)

minimum. This is conditional upon plants and nature of grade surface: Be

careful to choose a location for the vent termination which does not expose

people or shrubs to high heat from the exhaust gases. The exhaust gases

are not hot enough to ignite grass, plants and shrubs located in the vicinity

of the termination although they should be a minimum of 3 feet (.92 m)

away. The grade surface under the termination must not be a lawn.

F. Since sparks may escape from the exhaust pipe of any stove, use

caution when positioning the vent pipe. Refer to pipe manufacturer’s

instructions when installing and terminating the exhaust. The vent pipe

should be horizontal and never run the pipe in a downward direction

(recommend a 1/4” [7 mm] rise per foot horizontal).

Page 13

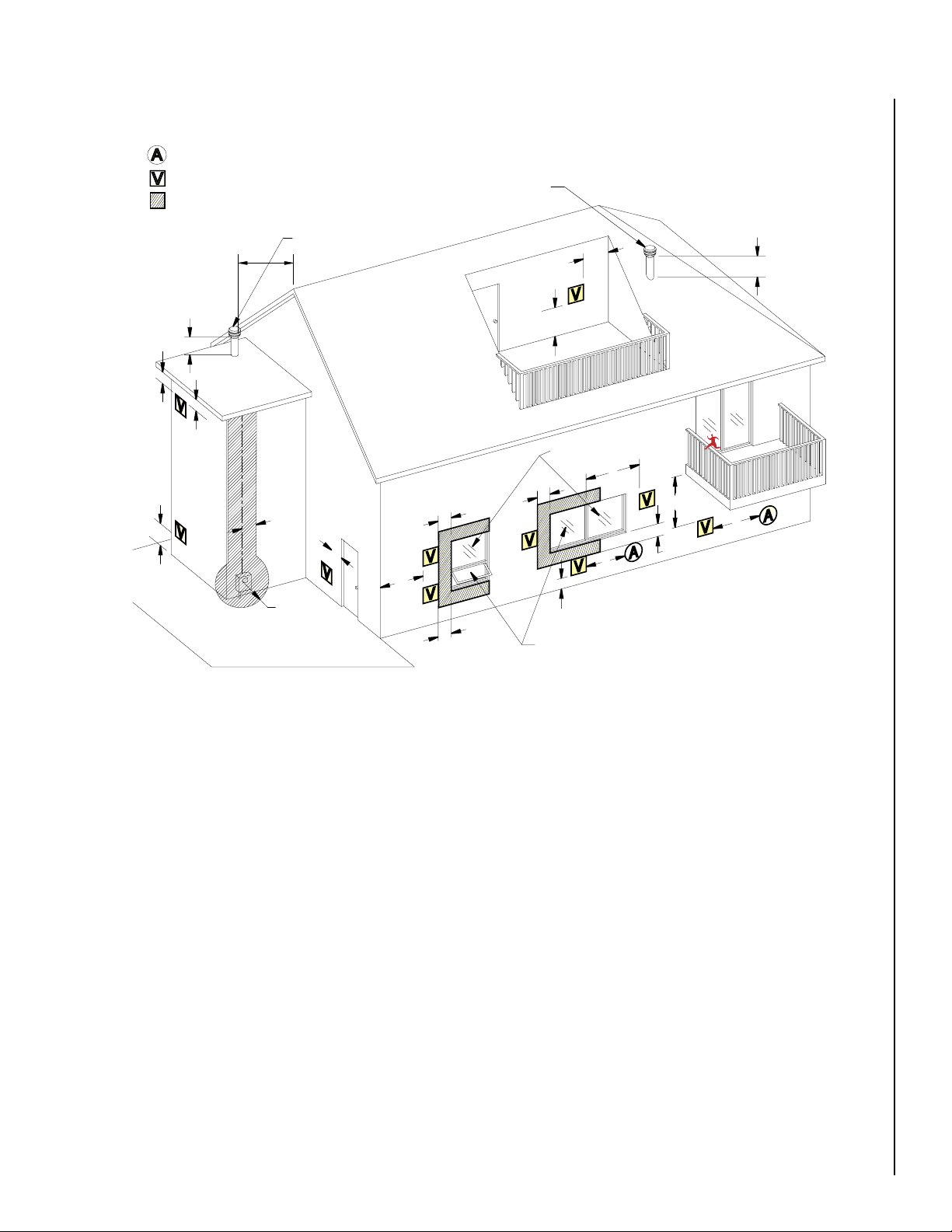

Vent Termination Locations

Vent Terminal

Area Where Terminal Is Not Permitted

(From Eave)

Vertical Terminal

Vertical Terminal

Fixed Closed

Able To Open

A

A

B

B

B

B

C

D

E

F

G

H

J

K

L

M

N

24”

(610mm)

B

Air Supply Inlet

24”

(610mm)

A = Clearance above grade, veranda, porch, deck, or bal-

cony (min. 12”/30cm).

B = Clearance to window or door that may be opened (min.

12”/30cm above - 48”/1.2m below and to the side).

C = Clearance to permanently closed window *(min.

D = Vertical clearance to ventilated soffit located above

12”/30cm).

the terminal within a horizontal distance of *(min.

24”/60cm) from the centerline of the terminal (min.

22”/55cm) check with local code.

E = Clearance to unventilated soffit *(min. 12”/30cm).

F = Clearance to outside corner *(min. 12”/30cm).

G = Clearance to inside corner *(min. 12”/30cm).

H = Not to be installed above a meter/regulator assembly

within *(min. 36”/90cm) horizontally from the center-

line of the regulator.

J = Clearance to service regulator vent outlet *(min.

72”/1.8m).

K = Clearance to non-mechanical air supply inlet to build

ing or the combustion air inlet to any other appliance

Figure 15

*(min. 48”/1.2m).

L = Clearance to a mechanical air supply inlet *(min.

120”/3.1m).

M = **Clearance above paved sidewalk or a paved driveway

located on public property *(min. 84”/2.1m).

N = ***Clearance under veranda, porch, deck, or balcony

(min. 12”/30cm).

Notes:

* Local codes or regulations may require different clear

ances.

** A vent shall not terminate directly above a sidewalk or

paved driveway which is located between two single

family dwellings and serves both dwellings.

*** Only permitted if veranda, porch, deck, or balcony is

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

-

fully open on a minimum of two sides beneath the

floor.

-

13

Page 14

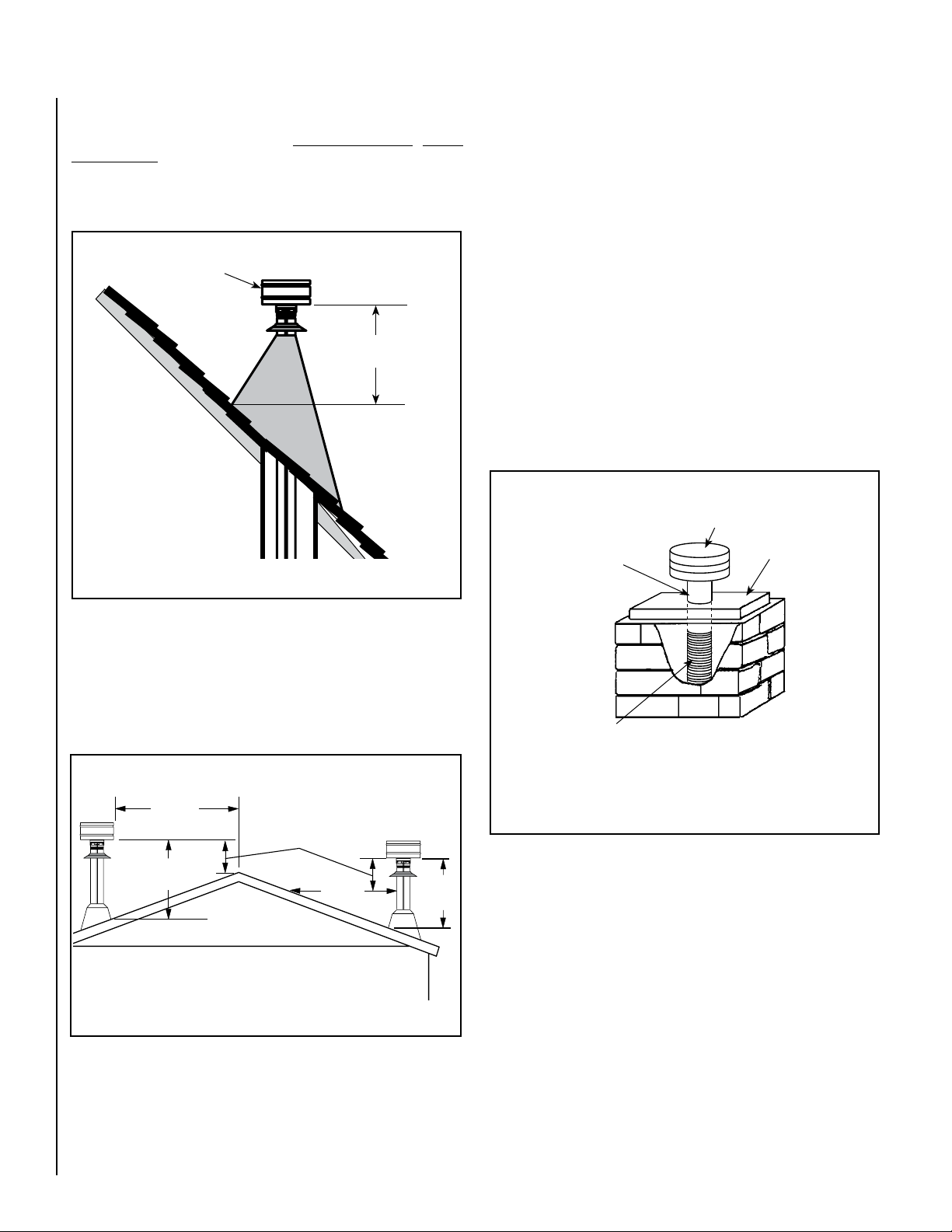

Chimney Height Requirements - Site Built Residential Home

Less than

10 Feet (3 m)

10 Feet

(3 m)

3 Feet (914 mm)

Minimum

2 Feet (610 mm) Min.

3 Feet

(914 mm)

Min.

m = meter

mm = millimeter

The vent termination height required is - USA, 1-foot minimum; Canada

3-feet minimum above the roof penetration point as illustrated below (Ref.

USA - National Standard, NFPA 211-latest edition and Canada National

Standard CSA B365-01-latest edition. Check with your local building

official for additional requirements for your area.

Termination Cap

Must Be Listed To

UL 641 or ULC S609

To pass inspection in nearly any jurisdiction, the chimney must meet both

safety and exhaust flow requirements. The (3’ by) 2’ by 10’ rule applies

to both masonry and factory-built chimneys.

* Ref. USA - National Standard, NFPA 211-latest edition and Canada

National Standard CSA B365-01-latest edition. Vents installed with a

listed cap shall terminate in accordance with the terms of the cap’s

listings.

Termination When Connected to Masonry Chimney or Existing

Class A Chimney

USA 1 Foot Minimum

CANADA 3 Feet Minimum

Termination height is

measured above the

highest point where

it passes through the

roof surface.

Figure 16 - Site Built Residential Home Chimney Height Requirements

Chimney Height Requirements - Manufactured Homes

The chimney must extend 3 feet (.92m) above the level of roof penetration and a minimum of 2’ (.61m) higher than any roof surface within 10

feet (3m) (see Figure 17). Check with your local building officials for

additional requirements for your area.

Requires A Listed Termination Cap *

Top Of Flue Must Be 2’

Higher Than Any Part Of

Roof Within 10’ Horizontal

Top Of Flue Must Be

3’ Higher Than Highest Point Of Roof

Penetration

A flexible corrugated chimney liner has much greater resistance to the

flow of flue gases than does a rigid liner. For this reason we recommend

that a larger, 4” liner be used on vertical runs exceeding 15 feet or that

rigid venting be used. See Figure 18.

If a flexible corrugated chimney liner is used, it must be fully extended

to eliminate any sagging and to improve the exhaust flow.

Listed Pellet Vent

1’ Section of PL Vent

(listed to UL 641 or

ULC S609)

3” or 4” liner

(listed to UL 1777

or ULC S635)

Termination Cap

Chase Cover

Termination When

Connected to Masonry

Chimney or Existing

Class A Chimney

Figure 18 - Existing Chimney Termination

Figure 17 - Manufactured Home Chimney Height Requirements

14

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Page 15

Determining Size Of Pipe To Install

A

E

F

H

G

B

C

D

To determine what diameter pipe to use in an installation (3” or 4”), first

find the “equivalent pipe length” using the following guidelines, then plot

this number and the altitude on the chart (Figure 19).

30

4 “ Diameter Only

20

Fill out the installation chart, and calculate your total equivalent pipe

length. After you have the total equivalent pipe length, use the Pipe

Selection Chart (Figure 19) to determine if your installation requires 3”

or 4” exhaust pipe.

Installation Chart

Type of Pipe # of Elbows or

Feet of pipe

90° Elbows/

Tee (A & G)

45° Elbows

(C)

Horizontal

(B & F)

Vertical (E) x .5 Feet (.15 m)

Equivalent Feet Total Equivalent

Feet

x 5 Feet (1.5 m)

x 3 Feet (1 m)

x 1 Feet (.3 m)

Table 1

Sample Installation Chart

Type of Pipe # of Elbows or

90° Elbows/

Tee (A & G)

45° Elbows

(C)

Horizontal

(B & F)

Vertical (E) 8 x .5 Feet (.15 m) 4 (1.2 m)

Feet of pipe

2 x 5 Feet (1.5 m) 10 (3 m)

1 x 3 Feet (1 m) 3 (1 m)

3 x 1 Feet (.3 m) 3 (1 m)

Total Equivalent Feet = 20

Equivalent Feet Total Equivalent

Feet

Table 2 - Sample Chart for Figure 20

3 or 4”

0

Diameter

1

3

2

Altitude x 1000 Feet

5

4

10

Equivalent Pipe Length (Feet)

0

Figure 19 - Pipe Selection Chart

All equivalent pipe styles

NOTE:

shown for model Bella™ pellet stove.

A - 90 Degree Elbow

B - 1’ Horizontal Pipe

C - 45 Degree Elbow

D - Standoff Braces

E - 8’ Vertical Pipe

F - 2’ Horizontal Pipe

G - 90 Degree Tee

H - Wall Thimble

6

7

9

8

10

Figure 20 - See Sample Installation Chart

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

15

Page 16

Standard Horizontal Vent Installation

Installing the Bella™ Pellet Stove

This stove is approved for venting with Type L and Type PL pellet vent

pipe listed to UL 641 or ULC S609. We recommend the use of venting

products manufactured by Security Chimneys International.

1. Locate the proper position for the listed type “PL” wall thimble. Avoid

cutting wall studs when installing your pipe. Use a saber saw or keyhole

saw to cut the proper diameter hole through the wall to accommodate

the wall thimble. Use extreme caution to avoid cutting into power lines

within the wall of the home. The hole size will depend on the brand

of pellet vent that you are using. Install the wall thimble in the hole.

ALL INTERLOCKING PIPE CONNECTIONS MUST BE SEALED GAS-

2.

TIGHT AND SECURED TOGETHER PER VENT MANUFACTURER

INSTRUCTIONS.

Position the stove approximately 12” (305 mm) from the wall on the

floor pad. Push the “PL” pipe through the wall thimble. Squeeze a

bead of high temperature silicone (RTV) sealer around the end of the

machined portion of the 3” (76 mm) pipe connector on the back of

the stove. Firmly push on a section of “PL” pipe until inner pipe liner

pushes into the bead of RTV sealer.

3. Push the stove with pipe attached towards the wall (the pipe will go

through the wall thimble). Do not position the back of the stove closer

than 2” (51mm) from the wall (see Clearances, Pages 5 and 6).

4. Install listed type “PL” 45 degree elbow with rodent screen or cap on

outside end of pipe. The Inlet shall remain free of obstruction while

unit is in operation and constructed in a manner so as to prevent

material from dropping into the inlet or into the area beneath the

dwelling. The inlet shall also have a screen with openings not larger

than 1/4" to prevent rodents from entering.

5. If the installation includes a source of outside combustion air; cut a

separate hole through the wall for the fresh air tube. This tube should

be 3” (762 mm) minimum diameter I.D., steel only. Connect outside

air pipe to air inlet on stove. This tube must be terminated with a 45

degree elbow or hood.

Notes:

• Combustion air may also be drawn from a vented crawl space under

the home.

• All joints for connector pipe are required to be fastened together per the

vent manufacturers instructions. If vented horizontally, joints must be

made gas-tight (air tight, sealed connection) in a manner as specified

on this page (see instruction #2). INSTALL VENT AT CLEARANCES

SPECIFIED BY THE VENT MANUFACTURER.

• Greater back clearance will improve the ease of serviceability of the

stove.

• The end of the exhaust pipe must extend a minimum of 12” (305 mm)

from the outside of the building.

16

Combustion

Air Inlet

Collar

Figure 21 - Horizontal Vent Installation

Silicone sealant and three screws required on the first vent connection.

Secure and seal the remaining vent sections PER VENT MANUFACTURER INSTRUCTIONS.

Exhaust

Port

Metal Fresh Air Pipe

OPTIONAL (EXCEPT

FOR MOBILE HOME

INSTALLATIONS)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Straight “PL-Vent”

Pipe

Holes through

the Wall for the

Thimble and

Fresh Air Pipe

Wall

Thimble

45° Elbow

Joint for Fresh

Air Pipe

45° Elbow

12” (305 mm)

Min. From

Outer Wall

12”(305 mm)

From

Ground or Other

Surface

Page 17

Vent Configurations

Listed Rain Cap

(all installations)

A vertical run of 6 feet

45°

Clean-Out

Tee

90°

is recommended

Figure 22 - Horizontal and Up 6 Feet

Horizontal installations that terminate without

any vertical sections of pipe are approved;

however, wind may direct flue gases toward

the house causing discoloring problems. For

this reason, horizontal and up 6 feet or horizontal and through the eave installations are

recommended. See Figures 24 and 25.

Exterior

Vertical Vent

Clean-Out

Tee

Figure 24 - Horizontal and Up Through the Eave

Listed Rain Cap

(all installations)

Interior

Vertical Vent

into an Existing Class A

Chimney

Vented into

existing 6” or 8”

diameter wood

stove pipe.

1 Foot

Minimum

Figure 23 - Horizontal

Figure 25 - Wood Stove Pipe Retrofit

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

17

Page 18

Masonry Chimney

Fireplace

When venting into a masonry chimney, the pellet pipe can terminate just

inside the chimney. However, it is recommended to run the pellet pipe to

the top of the chimney.

Complete Liner

and Listed

Termination Cap

Optional

Clean-Out

Access Door

When venting into a fireplace chimney, the pellet pipe can terminate just

above the damper. However, it is recommended to run the pellet pipe to

the top of the chimney.

Complete Liner and

Listed Termination

Cap

Figure 26 - Vertical Vent Into a Masonry Flue

Figure 28 - Vertical Vent Into a Factory-Built Fireplace

Figure 27 - Positive Flue Connection Into a Masonry Chimney

18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Figure 29 - Positive Flue Connection Into a Factory-Built Fireplace

Page 19

CARE AND OPERATION

OFF

MIN

MAX

LOW

HIGH

FAN HEAT

FAN SPEED

IGNITION / HEAT CONTROL

Simple Operating Instructions

1. Start

FIRST TIME USE

2. Preparation

a] Check hopper and remove

any materials from hopper

and auger

b] Check cast burn pot for

proper fit (ensure cast burn

pot is set securely in the base

- see Figure 34)

c] Check door gasket and door

latch to ensure tight seal

(see Figure 31)

d] Connect power cord to

grounded power supply

outlet

3. Priming the Auger

(Optional)

a] Fill hopper with pellets

Note: Use quality grade pellet

fuel

b] Turn the "IGNITION/HEAT

CONTROL" dial to begin the

ignition sequence

e] When pellets begin to drop

from feed tube into burn pot,

turn dial to "OFF"

4. Stove is now ready for

start-up

5. To Start Your Stove

a] Check hopper, and fill with

pellets, if necessary.

b] Turn the "IGNITION/HEAT

CO N TROL " di a l to the

desired heat setting.

The convection blower will

not turn on until the stove

has reached operating temperature.

6. Pellets will drop into burn

pot and stove will light

in approximately 3 to 7

minutes

Does the Stove Light?

Yes

7. Once the ignition sequence

is complete, the stove will

enter "heating" mode and

run at the chosen setting

8. After approx. 5 minutes

adjust draft adjuster if

necessary to obtain a

bright vibrant flame.

Notes:

• If the draft adjuster is too

far inward the flame will

be lazy/sooty and the fuel

will pile up in the burn pot

(see Page 10).

• If the draft adjuster is

too far outward the flame

might burn erratically.

See Page 21 for further

instructions on adjusting the

draft adjuster using thermostat vs manual modes.

Convection

(room air)

Control Dial

LCD Status

Screen

7a. Follow the troubleshooting

No

section in this manual

Does the Stove Light?

Ignition / Heat

Control Dial

Contact your Lennox Hearth

Products dealer for further

assistance

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

No

9. To Turn Off Pellet Stove

a] Turn the "IGNITION/HEAT

CONTROL" dial to the "OFF"

position.

Yes

b] Stove goes into cool-down

mode. Pellets stop feeding

and the fire goes out within

2 minutes after the auger

is shut off, the room air

blower and exhaust blower

will automatically shut off in

approximately 15 minutes.

10. Thank you for purchasing a Lennox

Hearth Products Pellet Stove

END

19

Page 20

Control Board

OFF

MIN

MAX

LOW

HIGH

FAN HEAT

FAN SPEED

IGNITION / HEAT CONTROL

The control board has a six position integrated switch which controls

the fuel feed rate, combustion blower speed and room air blower speed

simultaneously. There is a separate blower speed control that overrides

the integrated switch which will allows you to reduce the speed of the

room air blower, thus reducing the noise level of the stove.

The control board regulates all functions of the stove. The following is a

list of the board’s components:

•

LCD Display Screen - See LCD Screen Displays on Pages 21, 22 and

23.

The LCD display provides information on the status of the stove,

burn mode, failure mode, burn setting, time left in start-up cycle etc.

which should result in reduced diagnosis time.

•

Room Air Blower Speed - Adjusts blower speed from low to high settings. When adjusting to lower speed settings, the feed rate may adjust

accordingly to the blower speed, so the stove will not overheat.

•

Ignition / Heat Control- Initiates ignition and controls the level of

heat output from the stove.

•

Igniter Fuse - Six amp fuse to protect the igniter heating element.

•

Control Board Fuse - Three amp fuse to protect the control board.

NOTE: Upon the stove’s initial light up, or if the stove has previously run

out of pellets, the auger feed tube may not contain a sufficient number of

pellets to allow the stove to continue burning after the ignition sequence.

It may be necessary to initiate the startup a second time by turning the

Ignition/Heat Control dial to the "off" position and then back to your desired

heat setting. It is important to always empty (when cool) the burn pot of

pellets before starting the stove a second time.

WARNINGS

Never empty pellets from the burn pot into the

hopper. Pellets that may appear to be cool may

retain enough heat to ignite other pellets resulting

in smoke or fire damage.

DO NOT OVERFIRE THIS STOVE. This may cause

serious damage to your stove and void your warranty. It also may create a fire hazard in your home.

IF ANY EXTERNAL PART OF THE UNIT BEGINS TO

GLOW, YOU ARE OVERFIRING. Immediately turn

the heat control dial to the "OFF" position.

Filling the Hopper

Figure 30 - Control Board

FRONT

BACK

To fill the hopper when stove is off:

1. Lift the hopper lid to it's full opened position.

2. Fill the hopper with pellets.

3. Check to make sure there are no remaining pellets on top of the

hopper that may prevent the hopper lid from fully closing.

4. Close Hopper lid.

To fill the hopper when stove is in operation:

1. Repeat steps 1 thru 4 above.

2. When finished, check the LCD screen on the controller to verify that

the stove is still in normal heating mode.

3. If the message on the screen does not say "Heating" rather it alter

nates between "Hopper Left Open" and "Cooling Down" simply reset

the stove by turning the Heat Control Dial to "Off" and then back to

your desired heat setting and the stove will run the igniter for 4-5

minutes to make sure there is a sustainable fire after refueling.

NOTE:

This is an exclusive feature of the Bella™ to assure the highest

reliability, safety and convenience.

Lighting

Follow instructions on Page 19.

-

20

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Page 21

Manual Operation

After the stove is burning (see lighting instructions on Page 19), the heat

control dial controls the pellet burn rate and the stove’s heat output. Turning the dial to the low setting allows the stove to burn about 1.8 pounds

of pellets per hour. Turning the dial to high allows the stove to burn 4.9

pounds of pellets per hour. Once set, the stove will continue to burn at

this rate until shut off.

Thermostat Operation

This stove will operate with a low voltage thermostat. See Page 11 for

instructions on installing the optional wall thermostat. Once installed, the

thermostat will control the operation of the stove.

IMPORTANT: When connected to a thermostat, it is necessary to turn

the heat control dial to your desired heat setting for the initial burn. After

the initial ignition sequence, when the thermostat calls for heat (the room

temperature is less than the temperature set on the thermostat) and the

heat control dial is not in the off position, the stove will burn at the heat

control dial setting. The higher the setting, the quicker the room will heat

up. Once the thermostat no longer calls for heat (the room is up to the

desired temperature), the stove will continue to burn for one additional

hour at the lowest setting. If the thermostat does not call for heat again

during that hour, the stove will shut off. During that hour, if the thermostat

calls for heat again, the stove will again burn at the heat control dial setting

until the thermostat no longer calls for heat. If the stove shuts off after

that hour it will relight when the thermostat calls for heat.

3.

The hopper lid switch circuit is open which indicates the hopper lid is not

properly closed during the ignition sequence. If the hopper lid remains open,

the shutdown cycle will start within the time indicated on the display screen.

See Page 32 for more information about the hopper switch.

4 HOPPER OPEN - HEATING

1A

C L O S E H O P P E R L I D

1B

4.

F U E L F E E D O F F

2

S H U T D O W N I N $ $

If the hopper lid remains open for more than 45 seconds the stove will enter

it's COOL DOWN mode followed by the FINAL SHUTDOWN mode. To reset,

turn the heat control dial to off and then back on to your desired setting. See

Page 32

for more information about the hopper switch.

5 HEAT LIMIT

1A

1B

2

% % % % @ @ @ @ @ @ @ @

5.

Your stove is equipped with a heat limit switch which senses a rise in the

H E A T L I M I T

R E D U C E D F L A M E

operating temperature and will reduce the feed rate accordingly. This usually

occurs when the stove is in the high burn setting with the convection blower

set to minimum (which isn't the most efficient combination). When the stove

cools down it will automatically re-enter NORMAL HEATING mode at the setting

indicated on the heat control dial.

LCD Display Screen - Normal Mode Screens

1 IGNITING

1A

1B

W A I T # # M I N U T E S

2

% % % % S T A R T

The stove has been switched on to your desired heat sequence #1 through #5.

1.

Your stove is in IGNITE/START-UP mode which is a preset sequence which

will run 11 to 20 minutes and will switch to NORMAL HEATING mode when

sufficient temperature has been reached.

2 HEATING

1A

1B

2

% % % % @ @ @ @ @ @ @ @

Your stove has entered NORMAL HEATING mode and is burning on the heat

2.

setting indicated in the lower right corner of the LCD Screen as well as the

heat control dial.

3 HOPPER OPEN - IGNITING

1A

C L O S E H O P P E R L I D

1B

I G N I T I O N P A U S E D

2

S H U T D O W N I N $ $

I G N I T I N G

H E A T I N G

H E A T I N G

6 THERMOSTAT OFF - LOW HEAT

1A

1B

6.

T H E R M O S T A T O F F

L O W H E A T

2

S H U T D O W N I N # # #

The room has reached the temperature specified by the thermostat. When the

thermostat quits calling for heat, the stove automatically enters the THERMOSTAT IDLE mode and drops to the low burn setting. If the thermostat does not

call for heat again within the next hour, the stove will enter the COOL DOWN

mode, followed by the SHUTDOWN mode. If the thermostat calls for heat at

any point in the thermostat idle mode, the stove will resume operation in the

NORMAL BURN mode specified by the heat control dial.

LCD Display Screen - Cool-down Screens

7 HEAT SWITCH OFF COOL-DOWN

1A

1B

2

% % % % O F F

7.

You have turned your stove off and the auger has stopped feeding pellets to

the burn pot. Once the unit runs through the HEAT SWITCH OFF COOL-DOWN

mode, it will go into HEAT SWITCH OFF SHUTDOWN mode.

C O O L I N G D O W N

C O O L I N G D O W N

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

21

Page 22

8 THERMOSTAT OFF COOL-DOWN

1A

1B

2

% % % % O F F

8.

The thermostat has not called for heat for over an hour, the stove has completed

C O O L I N G D O W N

T H E R M O S T A T O F F

it's thermostat low burn idle and has entered into the COOL DOWN mode which

will be followed by the FINAL SHUTDOWN mode. If the thermostat calls for heat

again during this sequence, the stove will automatically enter the START-UP

mode.

9 AIR SEAL COOL-DOWN

1A

1B

2

This error occurs when the stove has lost vacuum. This could be from an open

9.

C O O L I N G D O W N

A I R S E A L L O S T

E R R O R

glass door, damaged or dislodged gaskets or door seal, a sustained strong gust

of wind into the venting/chimney, an electrical "brown out," failed combustion

blower or failed vacuum switch.

10 HOPPER OPEN COOL-DOWN

1A

1B

H O P P E R L E F T O P E N

2

C O O L I N G D O W N

E R R O R

LCD Display Screen - Cold Shutdown Screens

13 HEAT SWITCH OFF SHUTDOWN

1A

1B

13. The heat control dial has been turned to the "Off" position, the stove has

1A

1B

14. Your stove has completed the THERMOSTAT IDLE, and THERMOSTAT COOL

1A

1B

S H U T T I N G D O W N

S H U T T I N G D O W N

2

O F F I N # # M I N

completed it's cool down sequence, all snap switches register cold. The

SHUTDOWN mode is a timed sequence, when complete all blowers, auger

etc. will be turned off.

14 THERMOSTAT OFF SHUTDOWN

S H U T T I N G D O W N

T H E R M O S T A T O F F

2

O F F I N # # M I N

DOWN modes, the thermostat still hasn't called for heat again and the stove

has entered into it's final shutdown sequence.

15 OVERHEAT SHUTDOWN

S H U T T I N G D O W N

S T O V E O V E R H E A T E D

2

E R R O R

10. The hopper lid has been left open too long or isn't fully closed. To clear the

error, make sure hopper lid is closed then reset the stove by turning the heat

control dial to "Off" then back to your heat setting of choice and the stove will

re-enter START-UP mode.

11 AUGER TORQUE COOL-DOWN

1A

1B

2

C O O L I N G D O W N

A U G E R J A M M E D

E R R O R

11. The DC brushless auger motor has sensed an over-torque or potential auger

jam situation, the automatic reverse sequence has failed to clear the obstruction and the stove has entered into the COOL DOWN mode and will continue

into the SHUTDOWN mode.

12 NO FIRE COOL-DOWN

1A

1B

2

12.

Your stove's proof of fire switch has failed to detect fire and has entered into

C O O L I N G D O W N

N O F I R E D E T E C T E D

E R R O R

COOL DOWN mode.

15. The high limit snap switch has been activated due to excessive heat or a failed

component and the stove is in it's final shut down sequence. Contact your

dealer.

16 AIR SEAL SHUTDOWN

1A

1B

S H U T T I N G D O W N

A I R S E A L L O S T

2

O F F I N # # M I N

16. Your stove has lost vacuum, completed it's air seal cool down sequence and

has entered the FINAL SHUTDOWN mode. Refer to screen #9 for list of possible

causes. Turn heat control dial to "off" and then back on to restart.

17 HOPPER OPEN SHUTDOWN

1A

1B

S H U T T I N G D O W N

H O P P E R L E F T O P E N

2

O F F I N # # M I N

17. The hopper lid has been left open too long or isn't fully closed. To clear the

error, make sure hopper lid is closed then reset the stove by turning the heat

control dial to "Off" then back to your heat setting of choice and the stove will

re-enter START-UP mode.

19 AUGER TORQUE SHUTDOWN

1A

1B

S H U T T I N G D O W N

A U G E R J A M M E D

2

O F F I N # # M I N

22

18. The stove was unable to clear an obstruction in the auger or drop tube and is

in the process of shutting down.

Page 23

19 NO FIRE SHUTDOWN

1A

1B

S H U T T I N G D O W N

N O F I R E D E T E C T E D

2

O F F I N # # M I N

25 AUGER JAM ERROR

1A

A U G E R J A M E R R O R

1B

A U G E R J A M E R R O R

2

O F F T O C L E A R

19. Your stove's proof of fire switch has failed to detect fire, the stove has completed

it's COOL DOWN mode and is in the process of shutting down.

LCD Display Screen - Off Mode Screens

20 HEAT SWITCH OFF

1A

1B

2

O F F O F F

20.

Your stove's heat control dial is in the off position and all loads are currently

off.

21 THERMOSTAT OFF

1A

1B

2

O F F O F F

21.

The thermostat is not calling for heat, the stove is off.

Note: The heat control dial may still be set to the low through high positions, in

which case when the thermostat calls for heat again the stove will automatically

ignite.

22 OVERHEAT ERROR

1A

1B

2

22.The high limit snap switch has been activated due to excessive heat or a failed

component, The stove has completed it's cool down and shutdown sequences

and the stove is currently off. Contact your dealer.

S T O V E O F F

S T O V E O F F

T H E R M O S T A T O F F

T H E R M O S T A T O F F

O V E R H E A T E R R O R

O V E R H E A T E R R O R

O F F T O C L E A R

25. The stove was unable to clear an obstruction in the auger or drop tube, the

COOL DOWN and SHUT DOWN modes have been completed and the stove

is currently off. To clear the error the heat control dial must be turned to the

"Off" position although the obstruction will have to be cleared before normal

operation can resume. Contact dealer for assistance.

26 NO FIRE ERROR

1A

N O F I R E E R R O R

1B

N O F I R E E R R O R

2

26.

Your stove's proof of fire switch has failed to detect fire, the stove has com-

O F F T O C L E A R

pleted it's cool down and shut down sequences and is currently off. To clear

error turn heat control dial to the "off" position.

LCD Display Screen - Other Screens

27 OVERHEAT CONTACT DEALER

1A

1B

27.

28.

O V E R H E A T E R R O R

O V E R H E A T E R R O R

2

C O N T A C T D E A L E R

The high limit snap switch has been activated due to excessive heat or a failed

component and the stove is currently off. Contact your dealer or service representative. This error can only be cleared by an authorized representative.

28 SOFTWARE VERSION

1A

1B

2

C O N T R O L L E R

C O N T R O L L E R

0 6 0 V E R 1 . 0 0

This is the version of software your control board is currently running.

23 AIR SEAL ERROR

1A

1B

23.

A I R S E A L E R R O R

A I R S E A L E R R O R

2

O F F T O C L E A R

Your stove has lost vacuum, completed it's air seal cool down and shut down