Lennox BAC 042 SNM 3M, BAC 024 SNM 3M, BAC 038 SNM 3M, BAC 052 DNM 3M, BAC 057 DNM 3M Installation, Operating And Maintenance Manual

...Page 1

20 - 85 kW

Installation, operating

and maintenance

BALTIC-IOM-0412-E

BALTIC™ Rooftop units air cooled

Page 2

Page 3

BALTIC™

1

28

74

84

BALTIC-IOM-0412-E

Installation, operating and

maintenance

Ref : BALTIC-IOM-0412-E

TABLE OF CONTENTS

INSTALLATION MANUAL

SERVICE MANUAL

CONTROL MANUAL

CERTIFICATES

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided by us,

remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to or made available to third

parties without the prior written agreement of Lennox.

Page 4

Page 5

• 1 •

BALTIC™

3

5

6

7

7

8

9

10

12

12

12

13

13

13

13

14

14

14

15

16

17

17

17

18

18

19

20

21

23

24

26

BALTIC-IOM-0412-E / Installation manual

INSTALLATION MANUAL

Ref : BALTIC_Installation-IOM-0412-E

TABLE OF CONTENTS

INSTALLATION MANUAL

Safety codes & regulations

TRANSPORT & HANDLING

Mandatory handling devices

LIFTING THE UNITS

Machine dimensions and weights

Minimum clearance around the unit installation

Fork lifting the unit

Removing the forklift protection located under the machine

Lifting the unit with a crane

Lifting the roof curbs

DELIVERY CHECKS

Rating plate

Storage

Maintenance key

Condensate drains

Preliminary checks

Installation requirements

Connections

INSTALLATION ON A ROOF MOUNTING FRAME

Roof opening dimensions

Sealing checks

Leveling adjustable roofcurbs

Positioning the rooftop on adjustable roofcurbs

NON ADJUSTABLE NON ASSEMBLED ROOFCURB INSTALLATION

Frame parts packing

Installation

Assembly

Securing the frame

Sealing checks

CURBING AND FLASHING

HEAT RECOVERY GENERAL DESCRIPTION

PLATE HEAT RECOVERY CONFIGURATIONS

PLATE HEAT RECOVERY INSTALLATION

THERMODYNAMIC HEAT RECOVERY CONFIGURATIONS

THERMODYNAMIC HEAT RECOVERY - SERVICE MANUAL

THERMODYNAMIC HEAT RECOVERY - CONTROL MANUAL

Page 6

• 2 •

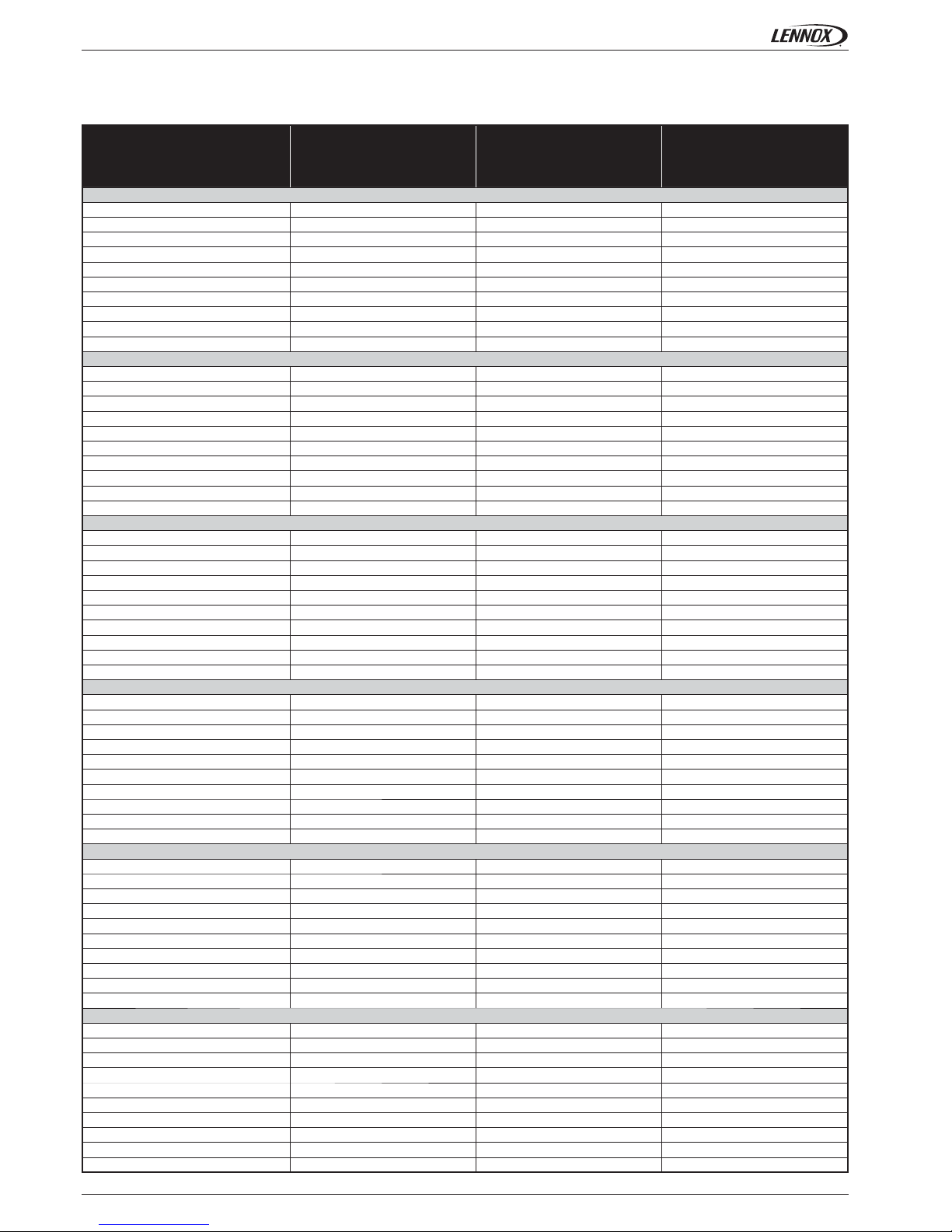

BAC 024 SNM 3M 23,4 - BAC 030 SNM 3M 29,2 - BAC 038 SNM 3M 37,1 - BAC 042 SNM 3M 39,4 - BAC 045 DNM 3M 43,9 - BAC 052 DNM 3M 49,8 - BAC 057 DNM 3M 55,2 - BAC 065 DNM 3M 62,6 - BAC 075 DNM 3M 74,1 - BAC 085 DNM 3M 80,7 - -

BAH 024 SNM 3M 23,4 20,7 BAH 030 SNM 3M 29,2 26,2 BAH 038 SNM 3M 37,1 34,8 BAH 042 SNM 3M 39,4 38,0 BAH 045 DNM 3M 43,9 40,8 BAH 052 DNM 3M 49,8 46,2 BAH 057 DNM 3M 55,2 54,4 BAH 065 DNM 3M 62,6 62,2 BAH 075 DNM 3M 74,1 73,5 BAH 085 DNM 3M 80,7 80,1 -

BAG 024 SSM 3M 23,3 - 20

BAG 030 SSM 3M 28,9 - 20

BAG 038 SSM 3M 36,8 - 20

BAG 042 SSM 3M 39,1 - 20

BAG 045 DSM 3M 43,7 - 33

BAG 052 DSM 3M 49,5 - 33

BAG 057 DSM 3M 54,7 - 33

BAG 065 DSM 3M 61,9 - 33

BAG 075 DSM 3M 73,4 - 60

BAG 085 DSM 3M 79,8 - 60

BAG 024 SHM 3M 23,3 - 46

BAG 030 SHM 3M 28,9 - 46

BAG 038 SHM 3M 36,8 - 46

BAG 042 SHM 3M 39,1 - 46

BAG 045 DHM 3M 43,7 - 60

BAG 052 DHM 3M 49,5 - 60

BAG 057 DHM 3M 54,7 - 60

BAG 065 DHM 3M 61,9 - 60

BAG 075 DHM 3M 73,4 - 120

BAG 085 DHM 3M 79,8 - 120

BAM 024 SSM 3M 23,3 20,8 20

BAM 030 SSM 3M 28,9 26,5 20

BAM 038 SSM 3M 36,8 35,1 20

BAM 042 SSM 3M 39,1 38,4 20

BAM 045 DSM 3M 43,7 41,0 33

BAM 052 DSM 3M 49,5 46,6 33

BAM 057 DSM 3M 54,7 54,9 33

BAM 065 DSM 3M 61,9 62,8 33

BAM 075 DSM 3M 73,4 74,2 60

BAM 085 DSM 3M 79,8 81,0 60

BAM 024 SHM 3M 23,3 20,8 46

BAM 030 SHM 3M 28,9 26,5 46

BAM 038 SHM 3M 36,8 35,1 46

BAM 042 SHM 3M 39,1 38,4 46

BAM 045 DHM 3M 43,7 41,0 60

BAM 052 DHM 3M 49,5 46,6 60

BAM 057 DHM 3M 54,7 54,9 60

BAM 065 DHM 3M 61,9 62,8 60

BAM 075 DHM 3M 73,4 74,2 120

BAM 085 DHM 3M 79,8 81,0 120

BALTIC-IOM-0412-E / Installation manual

INSTALLATION MANUAL

The present manual applies to the following rooftop versions

Item

Net cooling capacity

(kW - Eurovent conditions)

Heating capacity

(kW - Eurovent conditions)

HeatPump

Heating capacity

(KW) GAS

COOLING ONLY

HEAT PUMP

GAS ONLY - STD HEAT

GAS ONLY - HIGH HEAT

DUAL FUEL - STD

DUAL FUEL - HIGH

Page 7

• 3 •BALTIC-IOM-0412-E / Installation manual

INSTALLATION MANUAL

Safety codes & regulations

THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH LOCAL SAFETY CODES AND REGULATIONS AND CAN ONLY BE

USED IN WELL VENTILLATED AREA.

PLEASE READ CAREFULLY THE MANUFACTURER’S INSTRUCTIONS BEFORE STARTING THIS UNIT.

INSPECTIONS AND REQUALIFICATION ACCORDING PRESSURE EQUIPMENT DIRECTIVE MUST FOLLOW THE LOCAL

REGULATIONS WHERE THE UNIT IS INSTALLED.

Important note for unit fi tted with gas burner:

The following note must be followed carefully

THIS MANUAL IS ONLY VALID FOR UNITS DISPLAYING THE FOLLOWING CODES:

GB IR GR DA NO FI IS

In case these symbols are not displayed on the unit, please refer to the technical documentation which will eventually detail any

modifi cations required to the installation of the unit in a particular country.

• If machine is including gas burner, minimum clearance around the unit must be at least 8 m to allow a proper gas fl ue dilution. If

not possible, the fresh air intake must be ducted at least 8 m away from the gas burner exhaust.

• The gas burner air intake and exhaust chimney must not be modifi ed or ducted.

• Before commissioning this type of unit, it’s mandatory to ensure that the gas distribution system is compatible with the adjustments

and settings of the unit.

• Gas module can only be used for outdoor installations.

• Any work on gas module must be carried out by qualifi ed engineer.

All units are compliant with the PED directive 97-23/CE

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided

by us, remain the property of LENNOX and must not be utilised (except in operation of this product),reproduced, issued to or made

available to third parties without the prior written agreement of LENNOX. The technical information and specifi cations contained in

this manual are for reference only. The manufacturer reserves the right to modify these without warning and without obligation to

modify equipment already sold.

All work on the unit must be carried out by a qualifi ed and authorised employee.

Non-compliance with the following instructions may result in injury or serious accidents.

Work on the unit:

• The unit shall be isolated from the electrical supply by disconnection and locking using the main isolating switch.

• Workers shall wear the appropriate personal protective equipment (helmet, gloves, glasses, etc.).

Work on the electrical system:

• Work on electric components shall be performed with the power off (see below) by employees having valid electrical qualifi cation

and authorisation.

Work on the refrigerating circuit(s):

• Monitoring of the pressures, draining and fi lling of the system under pressure shall be carried out using connections provided for

this purpose and suitable equipment.

• To prevent the risk of explosion due to spraying of coolant and oil, the relevant circuit shall be drained and at zero pressure before

any disassembly or unbrazing of the refrigerating parts takes place.

• There is a residual risk of pressure build-up by degassing the oil or by heating the exchangers after the circuit has been drained.

Zero pressure shall be maintained by venting the drain connection to the atmosphere on the low pressure side.

Page 8

• 4 • BALTIC-IOM-0412-E / Installation manual

INSTALLATION MANUAL

• The brazing shall be carried out by a qualifi ed brazier. The brazing shall comply with standard NF EN1044 (minimum 30% silver).

EMC DIRECTIVE COMPLIANCE

WARNING:

This equipment is an “A class“ according CEM Directive. In an industrial environment, this device can create radio electrical noise. In

this case, the owner can be asked to take appropriated actions.

This applies to all machine installed with nominal amps below <75A:

• The short-circuit rate Rsce=33 is defi ned in the EN61000-3-12 standard relative to the harmonics readings on the supply network.

The appliances compliant with the harmonic current limits equivalent to Rsce=33 can be connected in whatever connection point

of the main supply system.

• The maximal allowable impedance of the main supply system Zmax=0.051W is defi ned by EN 61000-3-11 standard relative to

the voltage variation, fl uctuation and fl icker readings. The connection to the supply is a conditional connection submitted to the

preliminary agreement of the power supply local provider.

Replacing components:

• In order to maintain CE marking compliance, replacement of components shall be carried out using spare parts, or using parts

approved by LENNOX.

• Only the coolant shown on the manufacturer’s nameplate shall be used, to the exclusion of all other products (mix of coolants,

hydrocarbons, etc.).

CAUTION:

In the event of fi re, refrigerating circuits can cause an explosion and spray coolant gas and oil.

Transport – Handling- Access:

• Never lift the unit without forklift protections

• An approach ramp must be installed if the unit’s installation requirements tell that it's necessary to reach the main switch, the electrical

cabinet, the compressor and the ventilation compartment. This recommendation is valid for all type of installations.

• It is strictly forbidden to walk or store equipment or material on top of the rooftop unit

Rooftop installation in heavy wind locations

• The roofcurbs (vertical & horizontal) and rooftops installations are designed to withstand winds up to 80 km/h. Above this limit, it’s

recommended to take appropriate actions to secure the installation.

• Ensure the fresh air inlet does not face prevailing wind direction.

Elbow or section changes in ductworks next to the rooftop

• Whatever the supply confi guration is, respect a minimal duct’s length of 2 m before any elbow or any duct’s section change.

• Directional vanes must be fi tted inside any elbow fi tted in return or supply ductwork closer than 5 meter to the machine connection

fl anges.

Filters:

• Do the fi lters fi re classifi cation’s choice according to local regulations.

Fan compartment:

• Stop the power before accessing the fan compartment.

Gas:

• Any work on gas module must be carried out by qualifi ed personnel

• A unit with gas module must be installed in accordance with local safety codes and regulations and can only be used for outdoor

installation.

The technical information and specifi cations contained in this manual are for reference only. The manufacturer reserves the right to

modify these without warning and without obligation to modify equipment already sold.

Page 9

• 5 •BALTIC-IOM-0412-E / Installation manual

TRANSPORT & HANDLING

Mandatory handling devices

MANDATORY HANDLING DEVICES

Handling slings to guide the unit toward

the roof curb

Vacuum lifting beam to position the unit

COMPLIANT NON-COMPLIANT

Page 10

• 6 •

2283+/-15 2250+/-15 1240+/-15 2683+/-20 2310 2309 1240

2783+/-15 2250+/-15 1240+/-15 2683+/-20 2810 2309 1240

3663+/-15 2250+/-15 1240+/-15 2683+/-20 3690 2309 1240

24 30 38 42 45 52 57 65 75 85

696 711 726 726 937 952 967 982 1150 1150

701 716 731 731 947 962 977 992 1165 1165

739 754 769 769 970 985 1000 1015 1225 1225

758 773 788 788 992 1007 1022 1037 1285 1285

744 759 774 774 980 995 1010 1025 1235 1235

763 778 793 793 1002 1017 1032 1047 1295 1295

-12,1 -12,1 -12,1 -12,1 -18,9 -18,9 -18,9 -18,9 -23,2 -23,2

-7 -7 -7 -7 -10,3 -10,3 -10,3 -10,3 -13,6 -13,6

-5,1 -5,1 -5,1 -5,1 -8,6 -8,6 -8,6 -8,6 -9,6 -9,6

0,9 0,9 0,9 0,9 1,8 1,8 1,8 1,8 2,5 2,5

11,2 11,2 11,2 11,2 20,8 20,8 20,8 20,8 30,3 30,3

22,8 22,8 22,8 22,8 30,9 30,9 30,9 30,9 39 39

3 3 3 3 4,5 4,5 4,5 4,5 6 6

14 14 14 14 21,5 21,5 21,5 21,5 31,2 31,2

20,8 20,8 20,8 20,8 26,7 26,7 26,7 26,7 26,7 26,7

25,4 25,4 25,4 25,4 32,5 32,5 32,5 32,5 32,5 32,5

37,4 37,4 37,4 37,4 45 45 45 45 62,3 62,3

49,6 49,6 49,6 49,6 67,5 67,5 67,5 67,5 92,9 92,9

36,2 36,2 36,2 36,2 54,9 54,9 54,9 54,9 86,4 86,4

20,9 20,9 20,9 20,9 28,4 28,4 28,4 28,4 35,9 35,9

65 65 65 65 70 70 70 70 87 87

139 139 139 139 156 156 156 156 195 195

272 272 272 272 295 295 295 295 440 440

218 218 218 218 241 241 241 241 358 358

174 174 174 174 209 209 209 209 239 239

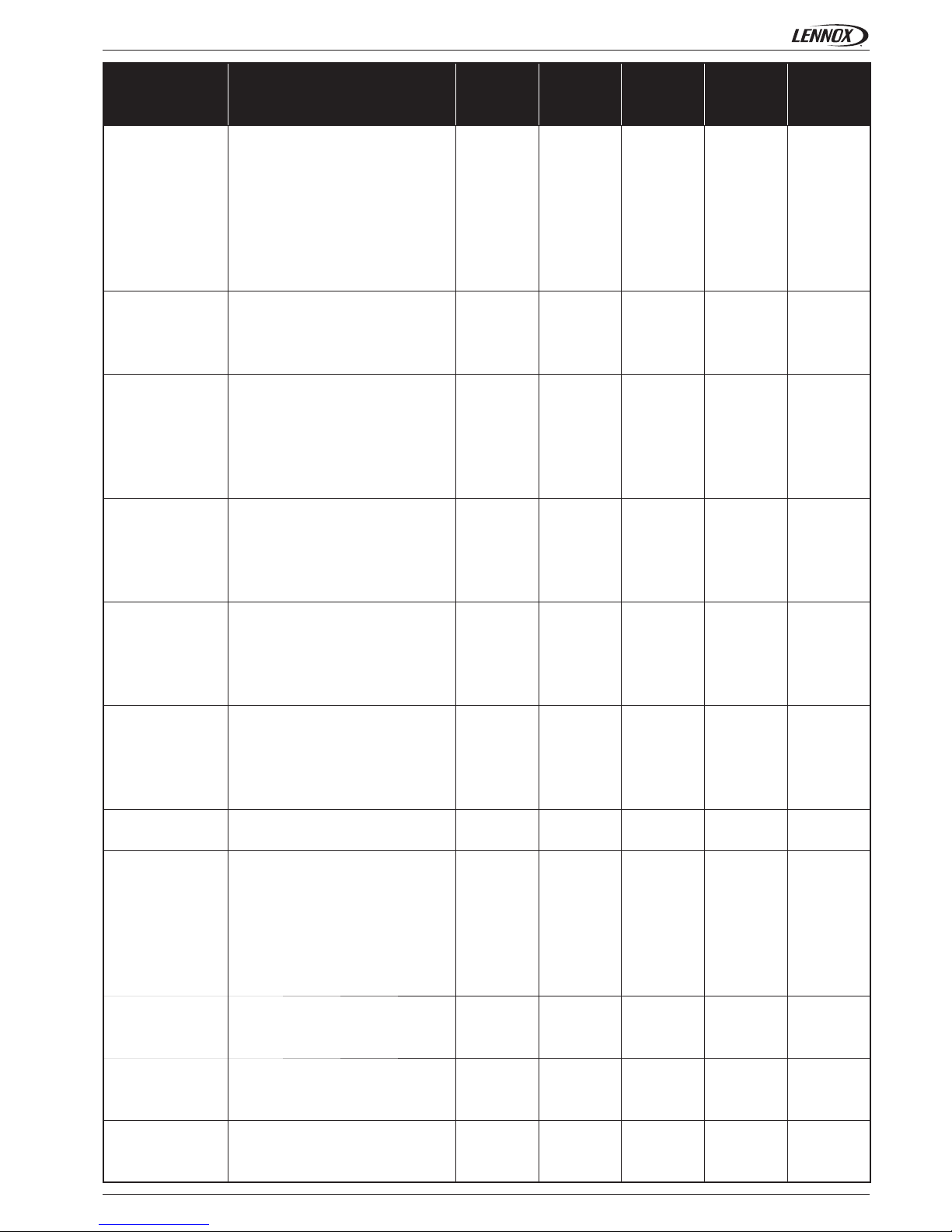

BALTIC-IOM-0412-E / Installation manual

LIFTING THE UNITS

Machine dimensions and weights

Machine Length Width Height

Width with

hood

Transport

lenght

Transport

Width

Transport

Height

Cbox

Dbox

Ebox

Unit

Base weight (kg)

Cooling

HeatPump

Gas S

Gas H

Dual S

Dual H

Option weight (kg)

Horizontal return & supply

Horizontal return & vertical supply

Vertical return & horinzontal supply

Gravity exhaust damper

Power exhaust fan

F7 fi lter

F4 fi lter

Double skin

Electrical heater S

Electrical heater H

Electrical preheater S

Electrical preheater H

Hot water coil

Energy recovery coil

Accessorie weight (kg)

Non ajustable roofcurb

Ajustable roofcurb

Extraction curb vertical

Extraction curb horizontal

Multidirectional curb

Page 11

• 7 •

A

1150

(1)

1650

(1)

2150

(1)

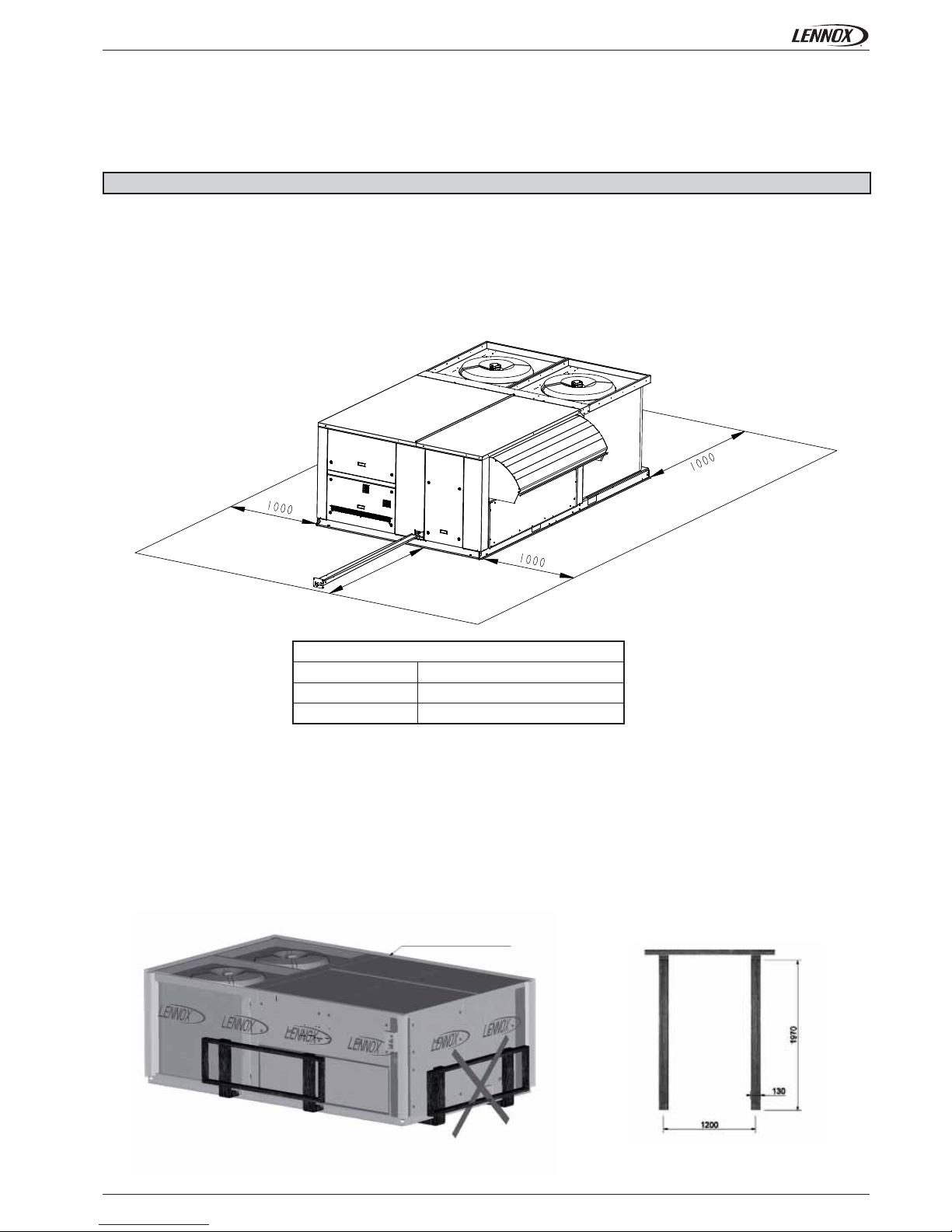

BALTIC-IOM-0412-E / Installation manual

LIFTING THE UNITS

Minimum clearance around the unit installation

Figure below show the required clearances and service access around the unit.

Fork lifting the unit

Do not lift the unit by the side (coil end side or drain pan outlet side). This will damage the unit.

Lift the unit on the long side using a forklift with dimensions according to the fi gure below.

Do not remove the unit plastic cover while lifting.

IMPORTANT note for unit clearances

• Ensure the fresh air inlet does not face prevailing wind direction.

• If machine is including gas burner, minimum clearance around the unit must be at least 8 m to allow a proper gas fl ue dilution. If

not possible, the fresh air intake must be ducted at least 8 m away from the gas burner exhaust.

• In case of extraction option, it is recommended to duct fresh air intake.

Drain pan clearance (A)

C Box

D Box

E Box

Plastic cover must not be removed before

lifting

NO

DO NOT LIFT THIS SIDE

Page 12

• 8 • BALTIC-IOM-0412-E / Installation manual

LIFTING THE UNITS

Removing the forklift protection located under the machine

Before installation, remove the forklift protection which is located under machine desk.

IMPORTANT note about forklift protection removal

Take care not to hurt anybody when removing the forklift rails .

Locate the machine on a safe area while removing the forklift rails from the machine.

Page 13

• 9 •

5 m

BALTIC-IOM-0412-E / Installation manual

LIFTING THE UNITS

Lifting the unit with a crane

Lifting lug dimensions

Use lifting shackles located on each angle of the unit. Maximum diameter of the ring shaft = 20 mm.

Lifting belts length

The unit must be lifted using spacing beams to avoid the belts damages to the casing.

Spacing beams must have a length equal to the machine width – i.e 2250 mm.

Page 14

• 10 • BALTIC-IOM-0412-E / Installation manual

LIFTING THE UNITS

Lifting the roof curbs

Ducting connection details

The supply and return air ducts can be secured to the 30 mm fl anges at the bottom of the roofcurb

Any ducting weight above 100 kg must be fi xed independently to other building frames.

Minimum distance: 30.000 mm

Page 15

• 11 •BALTIC-IOM-0412-E / Installation manual

LIFTING THE UNITS

Exhaust roofcurb

Non adjustable roofcurb Adjustable roofcurb

Multidirectionnal roofcurb

WARNING : all multidirectionnal fl owcurb and horizontal extraction fl ow curb must be secured to the ground

using existing fi xing holes on the frame.

Page 16

• 12 • BALTIC-IOM-0412-E / Installation manual

DELIVERY CHECKS

Rating plate

The rating plate provides a complete reference for the model and ensures that the

unit corresponds to the model ordered. It states the electrical power consumption

of the unit on start-up, its rated power and its supply voltage. The supply voltage

must not deviate beyond +10/-15 %. The start-up power is the maximum value

likely to be achieved for the specifi ed operational voltage. The customer must

have a suitable electrical supply. It is therefore important to check whether the

supply voltage stated on the unit's rating plate is compatible with that of the mains

electrical supply. The rating plate also states the year of manufacture as well as

the type of refrigerant used and the required charge for each compressor circuit.

Storage

When units are delivered on site they are not always required immediately and are sometimes put into storage. In the event of medium

to long-term storage, we recommend the following procedures:

• Ensure that there is no water in the hydraulic systems.

• Keep the heat exchanger covers in position.

• Keep protective plastic fi lm in position.

• Ensure the electrical panels are closed.

• Keep all items and options supplied in a dry and clean place for future assembly before using the equipment.

Maintenance key

On delivery we recommend that you keep the key which is attached to an eyebolt in a safe and accessible

place. This allows you to open the panels for maintenance and installation work.

The locks are ¼ turn + then tighter.

On receipt of new equipment please check the following points.

It is the customer’s responsibility to ensure that the products are in good working order:

• The exterior has not been damaged in any way.

• The lifting and handling equipment are suitable for the equipment and comply with the specifi cations of the handling instructions

enclosed here-in.

• Accessories ordered for on site installation have been delivered and are in good working order.

• The equipment supplied corresponds to the order and matches the delivery note.

If the product is damaged, exact details must be confi rmed in writing by registered post to the shipping company within 48 hours of

delivery (working days). A copy of the letter must be addressed to LENNOX and the supplier or distributor for information purposes.

Failure to comply will invalidate any claim against the shipping company.

Page 17

• 13 •BALTIC-IOM-0412-E / Installation manual

Condensate drains

The condensate drains are not assembled when delivered and are stored in the electrical panel with their clamping

collars. To assemble them, insert them on the condensate tray outlets and use a screwdriver to tighten the collars.

DELIVERY CHECKS

Preliminary checks

Before installing the equipment, the following points MUST be checked:

• Have the forklift protections been removed?

• Is there suffi cient space for the equipment?

• Is the surface on which the equipment is to be installed suffi ciently solid to withstand its weight? A detailed study of the frame must

be made beforehand.

• Do the supply and return ductwork openings excessively weaken the structure?

• Are there any obstructing items which could hinder the operation of the equipment?

• Does the electrical power available correspond to the equipment's electrical specifi cations?

• Is drainage provided for the condensate?

• Is there suffi cient access for maintenance?

• Installation of the equipment could require different lifting methods which may vary with each installation (helicopter or crane). Have

these been evaluated?

• Ensure that the unit is installed in accordance with the installation instructions and local applicable codes.

• Check to ensure that the refrigerant lines do not rub against the cabinet or against other refrigerant lines.

In general, make sure no obstacles (walls, trees or roof ledges) are obstructing the duct connections or hindering assembly and

maintenance access.

Installation requirements

The surface on which the equipment is to be installed must be clean and free of any obstacles which could hinder the fl ow of air to

the condensers:

• Avoid uneven surfaces

• Avoid installing two units side by side or close to each other as this may restrict the airfl ow to the condensers.

Before installing a packaged rooftop unit it is important to understand:

• The direction of prevailing winds

• The direction and position of air fl ows.

• The external dimensions of the unit and the dimensions of the supply and return air connections.

• The arrangement of the doors and the space required to open them to access the various components.

Connections

• Ensure that all the pipe-work crossing walls or roofs are secured, sealed and insulated.

• To avoid condensation problems, make sure that all pipes are insulated according to the temperatures of fl uids and type of rooms.

NOTE: The packaging protection fi tted on the fi nned surfaces must be removed prior to start up.

Page 18

• 14 • BALTIC-IOM-0412-E / Installation manual

INSTALLATION ON A ROOF MOUNTING FRAME

Roof opening dimensions

The roof opening dimensions & maximum slope are defi ned according mechanical drawings.

Sealing checks

Leveling adjustable roofcurbs

Above all, ensure that all the adjustable returns are facing outward. They could be turned inside-out for transport.

Place the roof mounting frame on the trimmer beam by fi rst lining up the inlet and the outlet opening.

After levelling the frame, secure the adjustable returns on the trimmer.

When the frame is correctly positioned, it is essential to secure the assembly with a disconnected stitched welded seam (20 to 30 mm

every 200 mm) or self taping screw diameter M6 along the outside or by using an alternative method.

IMPORTANT note: Prior to put the machine on the curbs make sure polyethylene foam is fi tted on the curb

upper fl ange side (must be delivered with the curb).

IMPORTANT NOTE: Securing the curb

Page 19

• 15 •BALTIC-IOM-0412-E / Installation manual

IMPORTANT note: Prior to put the machine, make sure to put a polyethylene foam on the curb upper fl ange

side (must be delivered in the curb package).

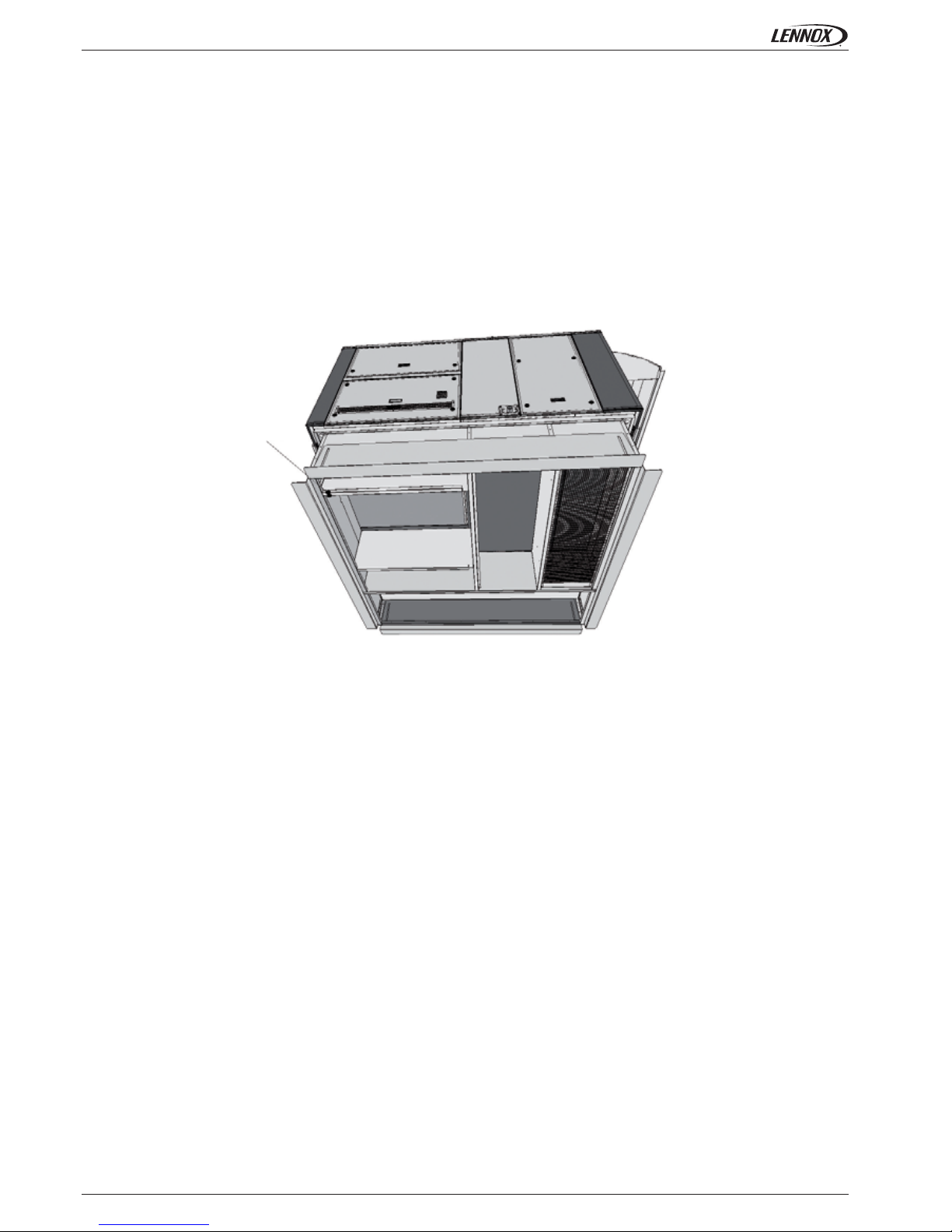

INSTALLATION ON A ROOF MOUNTING FRAME

Positioning the rooftop on adjustable roofcurbs

Page 20

• 16 • BALTIC-IOM-0412-E / Installation manual

NON ADJUSTABLE NON ASSEMBLED ROOFCURB INSTALLATION

Frame parts packing

Different parts are used in the assembly of this roof mounting frame. There are delivered stacked on a pallet.

Water foam - 5680255T

Page 21

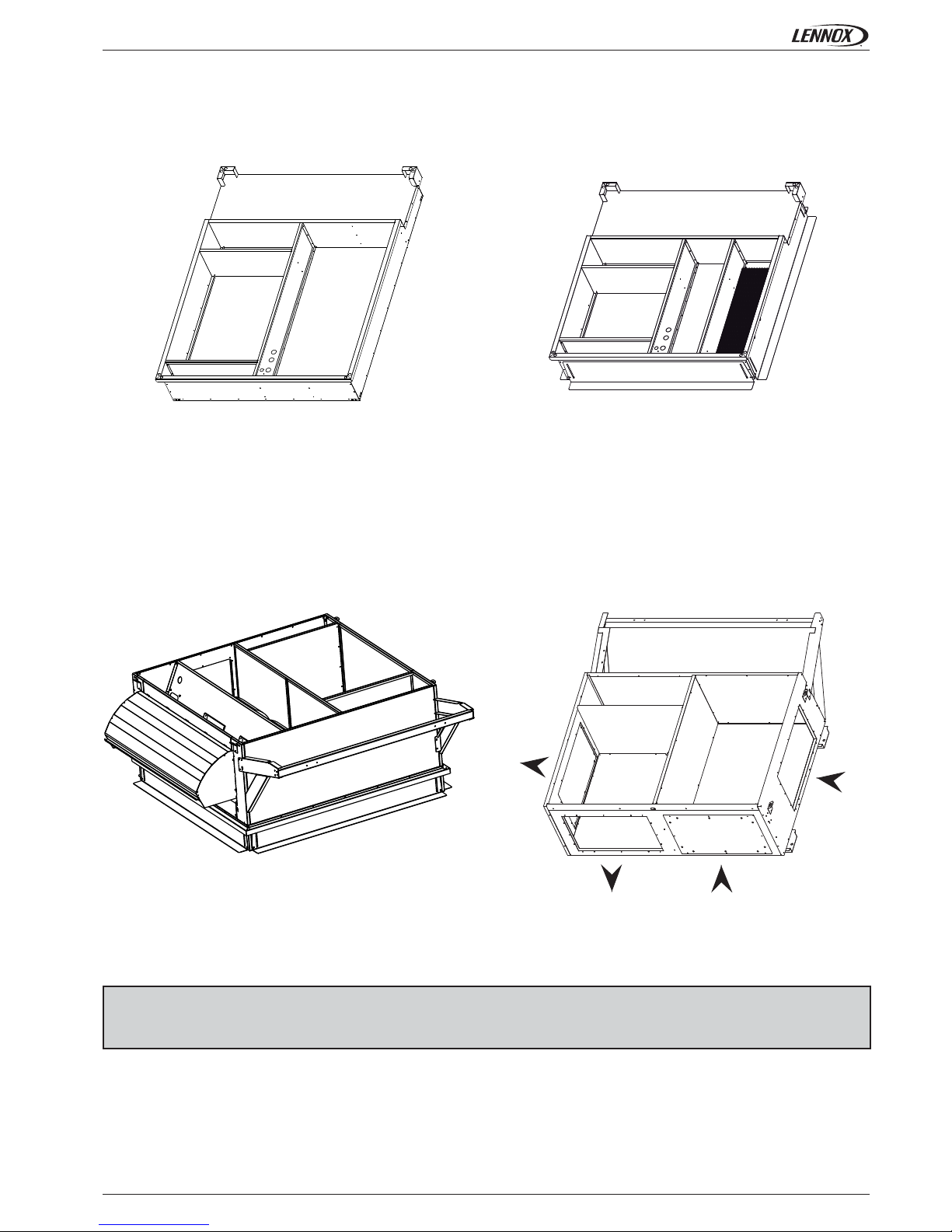

• 17 •BALTIC-IOM-0412-E / Installation manual

NON ADJUSTABLE NON ASSEMBLIED ROOFCURB INSTALLATION

Installation

The roof mounting frame provides support when the units are installed in down-fl ow confi gurations.

The non adjustable, non assembled roof mounting frame can be installed directly on decks having adequate structural strength or on

roof supports under deck. See page 24 for frame dimensions, location of supply and return air opening

NOTE: frame assembly must be installed fl at, levelled within 5mm per linear meter in any direction.

Assembly

The frame is supplied as a single package and shipped folded down for ease of transport and handling. It is easy fi eld assembled as

all parts required are supplied with the frame.

Securing the frame

To ensure proper mating with units, it is mandatory that the roof mounting frame be squared to roof structure as follows:

• With frame positioned levelled in the desired location on roof trusses, tack weld corner of frame.

• Measure frame diagonally from corner to corner as shown above. These Dimensions must be equal in order for the fame to be square.

• It is extremely important to sight frame from all corner to ensure it is not twisted across. Shim frame under any low side. The maximum

slope tolerance is 5mm per linear meter in any direction.

• After the frame has been squared, straightened and shimmed, weld or secure the frame to the roof deck.

NOTE: It must be securely fastened to the roof as per local codes and regulations.

Unit fl oor

Unit support rail

Roof curb

Air duct

Unit fl oor insulation + gasket

Page 22

• 18 •

50

BALTIC-IOM-0412-E / Installation manual

NON ADJUSTABLE NON ASSEMBLIED ROOFCURB INSTALLATION

Sealing checks

CURBING AND FLASHING

Outside of frame must be insulated with rigid type insulation. We

recommend a minimum of 20 mm thick insulation.

Check that the insulation is continuous, counter fl ash and seal around

the frame as shown.

CAUTION: To be effective, the upstream must end below the drop edge.

Where pipes and electrical conduits extend through the roof, fl ashing

must conform to local codes of practice

Before installing the equipment, make sure that seals are not damaged

and check that the unit is secured to the mounting frame. Once in

position, the bottom of the equipment must be horizontal. The installer

must comply with local authority standards and specifi cations.

Rooftop

Roocurb

Sealing

Thermal

400

Mini

IMPORTANT NOTE: After assembling the kit curb and prior to put the machine on it, make sure to put a polyethylene foam on the curb upper fl ange side (must be delivered in the curb package).

Page 23

• 19 •BALTIC-IOM-0412-E / Installation manual

HEAT RECOVERY - GENERAL DESCRIPTION

Heat recovery modules have following interests:

• in winter season and heating mode, the heat in the extract air is exchanged with the fresh air ;

• conversely, in summer season and cooling mode, the heat of the fresh air is transferred to the extract air.

HRMV and HRMH are two plates heat exchanger modules, that differ from each other by their horizontal or vertical confi guration.

TRMO is a thermodynamic heat recovery module, included in the machine. Its main interests are:

• a variable fresh air rate from 25 to 100%,

• a high COP in winter when pre-heating the fresh air due to a favorable evaporating temperature, especially with high air fl ow rate ;

• a high EER in summer when pre-cooling the fresh air due to a favorable condensing temperature, especially with high air fl ow rate.

For those reasons, TRMO will be more suitable than HRMV/HRMH in areas where the difference between indoor temperature and

outdoor temperature is low. For example, in Mediterranean areas, where winter temperatures are not very cold or summer temperatures

are not very high.

Page 24

• 20 •

VRHS

HRVS

VRVS

HRHS

BALTIC-IOM-0412-E / Installation manual

PLATE HEAT RECOVERY CONFIGURATIONS

ERVF + HRMV

EBHO + HRMH

Return

Return

Return

Fresh air

Fresh air

Page 25

• 21 •

2c

2a

x4

x2

5 mm

x6

2b

3b

3a

4

5

6

7

6

7

8

BALTIC-IOM-0412-E / Installation manual

PLATE HEAT RECOVERY INSTALLATION - ERVF + HRMV

Detail B

Detail A

1. Install the fl owcurb according to previous section.

2. Before installing the rooftop:

a. Fix the brackets (5 pieces) on the curb by 24 screws (6x16 mm);

b. ADJUST the position of the attachment bracket so that it is

5 mm above the support surface (without the foam);

c. Install the foam (25x10 mm) on the upper part of the fl owcurb.

5. Place the two upper mounting bars through the two top slots.

6. Install the heat recovery module on the bracket by taking care

to position properly the lower mounting bar.

Don't forget to remove the lifting covers from the module.

7. Slide the 'T' plate into the lifting lug and place the bolt through it. On the opposite side, place also the

bolt (detail A).

8. Finally tighten the heat recovery module with the 4 bolts 8x60mm to compress

the foam (2 bolts on the upper mounting bars (detail B) and the 2 bolts placed

in step 7).

3. a.

Fix the lower mounting bar of the heat recovery module

using 4 screws (6x16 mm) and remove the side doors;

b. Make sure that the foam is not damaged (20x15 mm).

4. Install the Rooftop and remove the lifting covers.

Page 26

• 22 •

2b

2a

5

5

6

7

6

BALTIC-IOM-0412-E / Installation manual

PLATE HEAT RECOVERY INSTALLATION - EBHO + HRMH

PLATE HEAT ELECTRICAL CONNECTIONS

1. Make sure that the support surface enables to install the

rooftop and the heat recovery module perfectly horizontal.

2. a.

Fix the lower mounting bar of the heat recovery module using

4 screws (6x16 mm) and remove the side doors

;

b. Make sure that the foam is not damaged (20x15 mm).

3. Install the rooftop and remove the lifting covers.

4. Place the two upper mounting bars through the two top slots.

5. Install the heat recovery module by taking care to position

properly the lower mounting bar.

Don't forget to remove the lifting covers from the module.

6. Slide the 'T' plate into the lifting lug and place the bolt through it. On the opposite side, place also the

bolt ( detail A).

7. Finally tighten the heat recovery module with the 4 bolts 8x60mm to compress

the foam (2 bolts on the upper mounting bars ( detail B ) and the 2 bolts placed

in step 6).

Detail B

Detail A

Two components have to be connected in the space between the plate heat exchanger and the economizer:

• For the air pressostat, connect and tighten the 2 spade-tips on

terminal 1 and 3 (no polarity) :

• For the actuator, assembly the two parts of the connector:

Page 27

• 23 •

VRHS

HRVS

VRVS

HRHS

BALTIC-IOM-0412-E / Installation manual

THERMODYNAMIC HEAT RECOVERY CONFIGURATIONS

ERVF + TRMO

EBHO + TRMO

Return

Return

Return

Fresh air

Fresh air

Page 28

• 24 •

TRMO

ABA054 ARA073 ARA081

TGEL10-6.5 TGEL10-9 TGEL10-9

2.5 kg 3.5 kg 4.5 kg

BALTIC-IOM-0412-E / Installation manual

THERMODYNAMIC HEAT RECOVERY - SERVICE MANUAL

1. REFRIGERATION CIRCUIT

Frigorifi c components access:

Compressor is located in the fi x condenser part. Its access for electrical checking and

pressure taps (HP and LP) is made through the screwed access door behind the hinged

coil.

4-way valve, thermostatic expansion valve, dryer, and sensors are located on the

e-Drive™ supply compartment.

C-box D-box E-box

Compressors

Thermostatic expansion valves

Refrigerant load

WARNING! During the settings, wait until the economizer is fully closed or opened, since it takes 1-2 minutes

to switch.

Electrical components:

• For D and E-box, specifi c TRMO components are located in the electrical box.

• For C-box, specifi c TRMO components are located on the back of the electrical box, and can be accessible from the supply e-Drive™

compartment.

Circuit specifi cations:

2. COMMISSIONING

Electrical connections:

• All wire connections are factory made.

Starting up:

• CLIMATIC™ confi guration:

- Power the unit

- Check the confi guration of the CLIMATIC™ 60 with the DS60 in expert mode. See § Control Manual / Confi guration

• Flow rate settings:

Make sure that both supply and exhaust air fl ow are balanced. See section EBHO or ERVF. Balancing is correctly set if:

- with Test = 'B.Nom 100%': at 100% fresh air, set the exhaust Flow 3864 = supply fl ow 3333;

- then switch Test = 'B.Nom 0%':

1. reduce coeffi cient 3866 until the louvers are closed;

2. then if the fl ow (supply and exhaust) is far from the previous fl ow settings, set coeffi cient 3335;

3. fi nally, repeat step 1 and 2 to obtain a constant fl ow whatever the fresh air mode.

- same settings have to be realized for reduced fl ow - 3334 and 3865.

• Start the TRMO circuit (circuit 3): switch Test='C3--Cool'

- check the sense of rotation of the circuit 3 compressor;

- check frigorifi c values (HP, LP, overheating and subcooling).

• Repeat the last operations with Test='C3--Heat'

Page 29

• 25 •

ARA054WAA 4220463P

ARA073WAA 4220464R

ARA081WAA 4220465T

4310508K

4310509L

4310510M

4310511N

4310512P

4310513R

TGEL10-6.5 TRMO 4720940L

TGEL10-9 TRMO 4720913W

STF0413G 4740100M

24V 50 4740103R

HP 42bar OFF 4730184H

HP 4/20mA -1/45bar 4770207M

LP 4/20mA -1/20bar 4770208N

BE60 4770668P

4770709Z

BALTIC-IOM-0412-E / Installation manual

THERMODYNAMIC HEAT RECOVERY - SERVICE MANUAL

3. SERVICE DIAGNOSTIC

Refrigeration

Fault Possible causes and symptoms Solution

Low LP and LP cut out

Alarm 317: main frigorifi c issue Lack of charge, obstructed components

Alarm 327: too low LP

Freezing: wait that coil is defrosted by

exhaust air;

Air fl ow too low on evaporating side (too low

speed rate / fouled fi lter or coil).

HP problem and HP cut out

Incorrect airfl ow rates

Check fan (exhaust or supply) function of

the mode (Amps) and also fi lter.

Refrigerant charge too high

Check the refrigerant charge load according

to the refrigerant load table.

See also frigorifi c diagnostic of BALTIC™ III section 'Refrigeration'.

Indoor or exhaust fan blower:

For both indoor supply fan and exhaust fan, same faults, causes and solutions than for BALTIC™ III are expected. See diagnostic of

BALTIC™ III 'Indoor fan blower'.

4. SPARE PARTS LIST

Refrigeration components R410a Designation Family Code

Compressor

Comp.

Comp.

Comp.

Indoor coil

ID C-box TRMO Coil

ID D-box TRMO Coil

ID E-box TRMO Coil

Exhaust coil

Exhaust coil TRMO Coil

Exhaust coil TRMO Coil

Exhaust coil TRMO Coil

Expansion valve

Refrig.

Refrig.

4 way valve Refrig.

4 way valve coil Refrig.

HP pressostat Refrig.

HP sensor Refrig.

LP sensor Refrig.

Electrical & control components Designation Family Code

CLIMATIC™ extension

Control

Connector for BE60 Control

Page 30

• 26 • BALTIC-IOM-0412-E / Installation manual

THERMODYNAMIC HEAT RECOVERY - CONTROL MANUAL

1. CONFIGURATION

Confi guration of CLIMATIC™ 60 with the DS60 in expert mode for TRMO (with a modulating exhaust fan):

3813 RECOV. = Comp. for TRMO

3815 EXHAUST = Modulate for both ERVF & EBHO

3816 KIT

3817 Motor to be checked function of your need

3818 Fan

2. USE

Protection:

• Operating envelop Protection: compressor stopped during 6 minutes.

- 328: min HP = 20.5°C condensation;

- 329: max HP = 62°C condensation;

- 319: min LP = between -24.5°C and 1.6°C (function of the condensation temperature) during 5 min => freezing or air fl ow on

evaporator issue;

- 327: max LP = 26°C.

- 317: limit LP -27°C during 120 sec => frigorifi c failure (lack of refrigerant /closed components)

• Anti freezing Protection consist in defrosting the exhaust coil in heating mode with the extract air.

Control

• No specifi c parameters have to be set for TRMO control.

• Operation:

- TRMO runs if there is heating or cooling needs;

- above 50% fresh air, TRMO compressor has priority to start;

- under 15°C return or under 20% fresh air, TRMO compressor is not authorized to start.

Page 31

• 27 •

BALTIC™

28

30

32

35

36

36

36

36

37

41

42

43

44

45

46

47

47

48

51

55

56

59

59

59

59

60

61

64

67

68

BALTIC-IOM-0412-E / Service manual

SERVICE MANUAL

Ref : BALTIC_Service-IOM-0412-E

TABLE OF CONTENTS

INSTALLATION MANUAL

Safety codes & regulations

COMMISSIONING RECORD SHEET

REFRIGERANT TRANSACTIONS LOGBOOK: EUROPEAN REGULATION N° 842/2006

PRESSURE EQUIPEMENT DIRECTIVE INFORMATIONS

COMMISSIONING

Before turning on the power

Wire connection tightness checks

CLIMATIC™ confi guration

Powering the unit

EDRIVE™ VENTILATION

FRESH AIR HOOD

FILTERS

REFRIGERATION CIRCUIT

HEATING OPTIONS

Hot water coils

Electric heater

Electrical preheater

GAS BURNERS

Preliminary checks before start-up

Starting up the gas burner

Standard start-up chronology

Burner safety checks

Gas module

MODULATING GAS BURNERS

Modulating gas (under patent inpi mai 2004)

Burner safety checks

Gas burner troubleshouting

Disassembling of gas burner for maintenance purposes

Modulating gas

RECOVERY WATER COIL

SERVICE DIAGNOSTIC

SPARE PART LIST

WARRANTY

MAINTENANCE PLAN

Page 32

• 28 • BALTIC-IOM-0412-E / Service manual

INSTALLATION MANUAL

Safety codes & regulations

THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH LOCAL SAFETY CODES AND REGULATIONS AND CAN ONLY BE

USED IN WELL VENTILLATED AREA.

PLEASE READ CAREFULLY THE MANUFACTURER’S INSTRUCTIONS BEFORE STARTING THIS UNIT.

INSPECTIONS AND REQUALIFICATION ACCORDING PRESSURE EQUIPMENT DIRECTIVE MUST FOLLOW THE LOCAL

REGULATIONS WHERE THE UNIT IS INSTALLED.

Important note for unit fi tted with gas burner:

The following note must be followed carefully

THIS MANUAL IS ONLY VALID FOR UNITS DISPLAYING THE FOLLOWING CODES:

GB IR GR DA NO FI IS

In case these symbols are not displayed on the unit, please refer to the technical documentation which will eventually detail any

modifi cations required to the installation of the unit in a particular country.

• If machine is including gas burner, minimum clearance around the unit must be at least 8 m to allow a proper gas fl ue dilution. If

not possible, the fresh air intake must be ducted at least 8 m away from the gas burner exhaust.

• The gas burner air intake and exhaust chimney must not be modifi ed or ducted.

• Before commissioning this type of unit, it’s mandatory to ensure that the gas distribution system is compatible with the adjustments

and settings of the unit.

• Gas module can only be used for outdoor installations.

• Any work on gas module must be carried out by qualifi ed engineer.

All units are compliant with the PED directive 97-23/CE

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided

by us, remain the property of LENNOX and must not be utilised (except in operation of this product),reproduced, issued to or made

available to third parties without the prior written agreement of LENNOX. The technical information and specifi cations contained in

this manual are for reference only. The manufacturer reserves the right to modify these without warning and without obligation to

modify equipment already sold.

All work on the unit must be carried out by a qualifi ed and authorised employee.

Non-compliance with the following instructions may result in injury or serious accidents.

Work on the unit:

• The unit shall be isolated from the electrical supply by disconnection and locking using the main isolating switch.

• Workers shall wear the appropriate personal protective equipment (helmet, gloves, glasses, etc.).

Work on the electrical system:

• Work on electric components shall be performed with the power off (see below) by employees having valid electrical qualifi cation

and authorisation.

Work on the refrigerating circuit(s):

• Monitoring of the pressures, draining and fi lling of the system under pressure shall be carried out using connections provided for

this purpose and suitable equipment.

• To prevent the risk of explosion due to spraying of coolant and oil, the relevant circuit shall be drained and at zero pressure before

any disassembly or unbrazing of the refrigerating parts takes place.

• There is a residual risk of pressure build-up by degassing the oil or by heating the exchangers after the circuit has been drained.

INSTALLATION MANUAL

Page 33

• 29 •BALTIC-IOM-0412-E / Service manual

INSTALLATION MANUAL

Zero pressure shall be maintained by venting the drain connection to the atmosphere on the low pressure side.

• The brazing shall be carried out by a qualifi ed brazier. The brazing shall comply with standard NF EN1044 (minimum 30% silver).

EMC DIRECTIVE COMPLIANCE

WARNING:

This equipment is an “A class“ according CEM Directive. In an industrial environment, this device can create radio electrical noise. In

this case, the owner can be asked to take appropriated actions.

This applies to all machine installed with nominal amps below <75A:

• The short-circuit rate Rsce=33 is defi ned in the EN61000-3-12 standard relative to the harmonics readings on the supply network.

The appliances compliant with the harmonic current limits equivalent to Rsce=33 can be connected in whatever connection point

of the main supply system.

• The maximal allowable impedance of the main supply system Zmax=0.051W is defi ned by EN 61000-3-11 standard relative to

the voltage variation, fl uctuation and fl icker readings. The connection to the supply is a conditional connection submitted to the

preliminary agreement of the power supply local provider.

Replacing components:

• In order to maintain CE marking compliance, replacement of components shall be carried out using spare parts, or using parts

approved by LENNOX.

• Only the coolant shown on the manufacturer’s nameplate shall be used, to the exclusion of all other products (mix of coolants,

hydrocarbons, etc.).

CAUTION:

In the event of fi re, refrigerating circuits can cause an explosion and spray coolant gas and oil.

Transport – Handling- Access:

• Never lift the unit without forklift protections

• An approach ramp must be installed if the unit’s installation requirements tell that it's necessary to reach the main switch, the electrical

cabinet, the compressor and the ventilation compartment. This recommendation is valid for all type of installations.

• It is strictly forbidden to walk or store equipment or material on top of the rooftop unit

Rooftop installation in heavy wind locations

• The roofcurbs (vertical & horizontal) and rooftops installations are designed to withstand winds up to 80 km/h. Above this limit, it’s

recommended to take appropriate actions to secure the installation.

• Ensure the fresh air inlet does not face prevailing wind direction.

Elbow or section changes in ductworks next to the rooftop

• Whatever the supply confi guration is, respect a minimal duct’s length of 2 m before any elbow or any duct’s section change.

• Directional vanes must be fi tted inside any elbow fi tted in return or supply ductwork closer than 5 meter to the machine connection

fl anges.

Filters:

• Do the fi lters fi re classifi cation’s choice according to local regulations.

Fan compartment:

• Stop the power before accessing the fan compartment.

Gas:

• Any work on gas module must be carried out by qualifi ed personnel

• A unit with gas module must be installed in accordance with local safety codes and regulations and can only be used for outdoor

installation.

The technical information and specifi cations contained in this manual are for reference only. The manufacturer reserves the right to

modify these without warning and without obligation to modify equipment already sold.

Page 34

• 30 •

1/2 2/3 1/3

N°1 N°2

3410: 3411: 3412:

BALTIC-IOM-0412-E / Service manual

COMMISSIONING RECORD SHEET

Site details Controller

Site Model

Unit Ref Serial No

Installer Refrigerant

(1) ROOF INSTALLATION

Suffi cient Access OK Condensate drain fi tted Roofcurb

Yes No Yes No OK Not OK

(2) CONNECTIONS CHECK

Phase check

Voltage between Phases

Yes No

(4) SUPPLY BLOWER SECTION

Type

Power displayed on plate kW

Voltage displayed on plate V

Current displayed on plate A

Fan type Forward Backward Forward Backward

Displayed coupling ref mm

Alignment checked Yes No Yes No

Fan speed rpm

Averaged measured amps A

Shaft mechanical mower

(Refer to airfl ow balancing)

W

Operating point checked Yes No Yes No

Read airfl ow m

3

/h

(6) EXTERNAL SENSOR CHECKS

Check electrical connections Yes No

Check and record temp. in

menu 2110

Yes No

100% Fresh Air 100% return Air

Supply temperature °C °C

Return temperature °C °C

Outdoor temperature °C °C

(7) MIXING AIR DAMPERS CHECKS

Dampers open & close freely % Minimum FA

Power

exhaust checked

Enthalpy sensor(s) checked

Yes No % Yes No Yes No

(5) AIRFLOW PRESSURE SENSOR CHECK

Measured pressure drop

Set points adjusted

Yes No

mBar

If yes enter new values

(3) CLIMATIC™ CONFIGURATION CHECK

CLIMATIC™ 60 Confi gured according to the options and specifi cations

Yes No

Page 35

• 31 •

123123

BALTIC-IOM-0412-E / Service manual

COMMISSIONING RECORD SHEET

(8) REFRIGERATION SECTION

Outdoor fan motor current Check rotation

Compressor voltageMotor 1 L1: A L2: A L3: A Yes No

Motor 2 L1: A L2: A L3: A Yes No

Motor 3 L1: A L2: A L3: A Yes No Comp1: V

Motor 4 L1: A L2: A L3: A Yes No Comp1: V

Motor 5 L1: A L2: A L3: A Yes No Comp3: V

Motor 6 L1: A L2: A L3: A Yes No Comp4: V

Compressor amps - COOLING Pressures & temperatures

Phase 1 Phase 2 Phase 3

Temperatures Pressures

Suction Disch LP HP

Comp1 A A A °C °C Bar Bar

Comp2 A A A °C °C Bar Bar

Comp3 A A A °C °C Bar Bar

Comp4 A A A °C °C Bar Bar

Check Reversing valves

Valve 1: Yes No Valve 3: Yes No

Valve 2: Yes No Valve 4: Yes No

Compressor amps - HEATING Pressures & temperatures

Phase 1 Phase 2 Phase 3

Temperatures Pressures

Suction Disch LP HP

Comp1 A A A °C °C Bar Bar

Comp2 A A A °C °C Bar Bar

Comp3 A A A °C °C Bar Bar

Comp4 A A A °C °C Bar Bar

HP cut out: Bar LP cut out: Bar

Refrigerant charge C1: kg C2: kg C3: kg C4: kg

(10) HOT WATER COIL SECTION

Check Three Way Valve Movement

Yes No

(11) GAS HEATING SECTION

Gas Burner N°1: Gas Burner N°2:

Size: Valve type: Size: Valve type:

Pipe size: Gas type:

G

Pipe size: Gas type:

G

Line press:

Drop test

Line press:

Drop test

Yes No Yes No

Check manifold pressure: Check manifold pressure:

High fi re Low fi re High fi re Low fi re

Pressure cut out airfl ow press switch mBar/Pa Pressure cut out airfl ow press switch mBar/Pa

Motor amps: Flue temp: CO

2

%: CO ppm: Motor amps: Flue temp: CO2 %: CO ppm:

A°C%% A°C%%

(12 REMOTE CONTROL BMS CHECK

Type: Sensor type:

Interconnect wiring checked:

Yes No

(9) ELECTRIC HEATER SECTION

Type Serial No

AMPS 1

st

stage (BALTIC™) AMPS 2nd stage (BALTIC™)

Page 36

• 32 • BALTIC-IOM-0412-E / Service manual

REFRIGERANT TRANSACTIONS LOGBOOK: EUROPEAN REGULATION N° 842/2006

Site name: Serial Number:

Site address:

Site operator:

Cooling load :

Refrigerant type: Refrigerant quantity (kg)

Unit manufacturer Year of installation

General information

Date Engineer Quantity (kg) Reason for addition

Refrigerant additions

Date Engineer Quantity (kg) Reason for removal

Refrigerant removal

Date Engineer Test Result Follow up action required

Leak tests (part 1)

Page 37

• 33 •BALTIC-IOM-0412-E / Service manual

REFRIGERANT TRANSACTIONS LOGBOOK: EUROPEAN REGULATION N° 842/2006

Date Engineer Test Result Follow up Action Required

Leak tests (part 2)

Date Engineer Related to test dated Action taken

Follow up actions

Date Engineer Test result Comments

Testing of automatic leak detection system (if fi tted)

Page 38

• 34 •

R410A

C

24 1 6,1 6,1

30 1 6,1 6,1

38 1 8,1 8,1

42 1 8,1 8,1

D

45

1 6,5 6,5

2 6,5 6,5

52

1 6,5 6,5

2 6,5 6,5

57

1 8,0 8,0

2 8,0 8,0

65

1 8,0 8,0

2 8,0 8,0

E

75

1 10,5 10,5

2 10,5 10,5

85

1 10,5 10,5

2 10,5 10,5

BALTIC-IOM-0412-E / Service manual

REFRIGERANT TRANSACTIONS LOGBOOK: EUROPEAN REGULATION N° 842/2006

Refrigerant load according to model size

Comments:

Refrigerant Box Model

Number of

circuit

Cooling only units

Load (kg)

(BAC BAG)

Heat pump units

Load kg

(BAH BAM)

Page 39

• 35 •

29,5

42 bar R410A

42 bar R410A

BALTIC-IOM-0412-E / Service manual

PRESSURE EQUIPEMENT DIRECTIVE INFORMATIONS

CE marking compliance

These units are CE marked according to Pressure Equipement Directive.

Periodical visit according european pressure equipment directive

According to Pressure Equipments Directive, periodical controls on site are expected on equipments equal or above category II.

Name plate example

Section Phase PS (bars gauge)

Suction Vapor

Discharge Vapor

Liquid Liquid / Vapor

Page 40

• 36 • BALTIC-IOM-0412-E / Service manual

COMMISSIONING

WARNING: commissioning must only be carried out by trained refrigeration engineers whom qualifi cation

certifi cates are compliant with the local regulation

WARNING: ensure that the power supply includes 3 phases with no neutral

WARNING: check the wire connection tightness

WARNING: a compressor rotating in the wrong direction will fail shortly.

Before turning on the power

Wire connection tightness checks

CLIMATIC™ confi guration

See CLIMATIC™ section

Powering the unit

Power up the unit by closing the isolator switch (if fi tted).

At this point the blower should start unless the CLIMATIC™ does not energise the contactor. Once the fan is running, check the rotation

direction. Refer to the rotation arrow located on the fan.

The fans and compressors direction of rotation is checked during the end of line test. They should therefore all turn in either the right

or wrong direction.

Ensure that the power supply between the building and the unit meets local authority standards and that the cable specifi cation satisfi es

the start-up and operating conditions displayed on the name plate.

Check the following wire connections for tightness:

• Main switch connections,

• Mains wires linked to the contactors and circuit breakers

• Cables in the 24V control supply circuit.

If the fan turns in the wrong direction (the right direction is shown below), disconnect the

main power supply to the machine at the building's mains switch, reverse two phases

and repeat the above procedure.

Close all circuit breakers and power up the unit.

If now only one of the components rotates in the wrong direction, disconnect the power

supply at the machine's isolator switch (if fi tted) and reverse two of the component’s

phases on the terminal within the electrical panel.

Check the current drawn against the rated values, in particular on the supply fan.

If the readings on the fan are outside the specifi ed limits, this usually indicates excessive

air fl ow which will affect the life expectancy. In this case reduce rpm using eDrive™.

Page 41

• 37 •BALTIC-IOM-0412-E / Service manual

eDrive™ VENTILATION

eDrive™ assembly instructions & specifi cation

The fl exible elastomeric tire is removable without removing the plates

The material is natural rubber

Temperature range from -42°C to + 82°C

Easy to assemble

Page 42

• 38 •

1,5 24 25 PV40 28-20 al24 28-20 al25

2,2 28 25 PV40 28-20 al28 28-20 al25

3 28 25 PV40 28-20 al28 28-20 al25

4 28 25 PV40 28-20 al28 28-20 al25

5,5 38 25 PV60 40-25 a38 40-25 al25

2,2 28 30 PV50 30-25 al28 30-25 al30

3 28 30 PV50 30-25 al28 30-25 al30

4 28 30 PV50 30-25 al28 30-25 al30

38 30 PVP50 30-25 al30

38 40 PV 60 40-25 al 38 40-25 al 40

BALTIC-IOM-0412-E / Service manual

eDrive™ VENTILATION

eDrive™ mounting

eDrive™ assembly is designed to have no adjustment to be made inside the machine

In case of vertical misalignment one could use metallic washer located under the motor to adjust height

eDrive™ airfl ow reading

eDrive is controling the airfl ow within the operating range of each kit.

Airfl ow rate calculation inputs are rpm and power absorbed output read on the inverter variable bus.

The airfl ow rate calculation formula is calibrated according lab tests.

eDrive™ coupling dimensions

Coupling

Machine

size

Motor size

kW

Motor shaft

diameter

mm

Fan shaft

diameter

mm

Coupling

reference

Coupling type

PP

Motor moteur

bushing

ref

Fan taper

Ref

C box 2 x Taper lock bushing

C box 2 x Taper lock bushing

C box 2 x Taper lock bushing

C box 2 x Taper lock bushing

C box 2 x Taper lock bushing

D box 1 Taper lock bushing + D30

D box 1 Taper lock bushing + D30

D box 1 Taper lock bushing + D30

D&E box 5,5 to 7,5 1 Taper lock bushing + D38

E box 9 to 11 2 x Taper lock bushing

Max radial misalignment 3mm Vibration absorbtionMax angular misalignment 4° Max axial range 8 mm

Page 43

• 39 •

AT 15-11 S 1,5 0,80 K1 553 962 3600 4800 3,6

AT 15-11 S 2 0,83 K2 610 1170 3750 6000 4,9

AT 15-11 S 3 0,85 K3 697 1330 4500 7050 6,6

AT 15-11 S 4 0,85 K4 78 1371 5550 8250 8,4

AT 15-11 S 5,5 0,87 K5 882 1417 7200 8400 12,2

ADH 355 L 2,2 0,83 K1 581 939 5500 6900 4,9

ADH 355 L 3 0,85 K2 660 1208 5500 8300 6,6

ADH 355 L 4 0,85 K3 738 1396 6100 9700 8,4

ADH 355 L 5,5 0,87 K4 823 1439 7100 11500 12,2

ADH 355 L 7,5 0,88 K5 938 1501 9500 13100 16,3

AT 15-11 G2L 5,5 0,87 K1 648 1302 10000 13500 12,2

AT 15-11 G2L 7,5 0,88 K2 774 1385 10000 16000 16,3

AT 15-11 G2L 9 0,88 K3 880 1378 10000 17750 17,6

AT 15-11 G2L 9 0,88 K4 880 1417 10000 19000 17,6

AT 15-11 G2L 11 0,89 K5 911 1417 10000 19000 23

AT 15-11 S 1,5 0,80 K1 592 949 3600 4650 3,6

AT 15-11 S 2 0,83 K2 690 1155 3750 5700 4,9

AT 15-11 S 3 0,85 K3 788 1386 4500 6900 6,6

AT 15-11 S 4 0,85 K4 907 1449 5400 7950 8,4

AT 15-11 S 5,5 0,87 K5 1015 1533 6750 8400 12,2

ADH 355 L 2,2 0,83 K1 651 929 5500 6500 4,9

ADH 355 L 3 0,85 K2 727 1206 5500 7900 6,6

ADH 355 L 4 0,85 K3 826 1409 6100 9300 8,4

ADH 355 L 5,5 0,87 K4 930 1499 7100 11100 12,2

ADH 355 L 7,5 0,88 K5 1070 1578 8700 13100 16,3

AT 15-11 G2L 5,5 0,87 K1 760 1310 10000 13000 12,2

AT 15-11 G2L 7,5 0,88 K2 898 1431 10000 15250 16,3

AT 15-11 G2L 9 0,88 K3 994 1476 10000 17250 17,6

AT 15-11 G2L 9 0,88 K4 994 1476 10000 17250 17,6

AT 15-11 G2L 11 0,89 K5 1072 1525 10000 19000 23

BALTIC-IOM-0412-E / Service manual

eDrive™ VENTILATION

eDrive™ is protecting the fan & motor against over-speed & over-amps

eDrive™ is designed to keep motor and fan in its available operating range thanks to the kit confi guration selected in CLIMATIC™ 60

control. The CLIMATIC™ control is limiting rpm & absorbed power. The table below shows the operating ranges per box and kit size.

Box Fan type

Motor

kW

Effi ciency Kit Comment

rpm

min

rpm

max

Qv min Qv max Imax

C Box

BAH

BAC

D Box

BAH

BAC

E Box

BAH

BAC

Fan shaft D30

Fan shaft D30

Fan shaft D40

Fan shaft D30

Fan shaft D40

Box Fan type

Motor

kW

Effi ciency Kit Comment

rpm

min

rpm

max

Qv min Qv max Imax

C Box

BAH

BAC

D Box

BAH

BAC

ADHE 355

ADHE 355

ADHE 355

ADHE 355

ADHE 355

E Box

BAH

BAC

Axe D30

Axe D30

Axe D30

Axe D30

Axe D30

eDrive™ unit operating ranges

Gas unit eDrive™ operating ranges

Page 44

• 40 • BALTIC-IOM-0412-E / Service manual

eDrive™ VENTILATION

eDrive™ fan inverter confi guration

eDrive™ Inverter confi guration is prepared in the factory to communicate with CAREL & to be confi gured specifi cally for the customer

machine.

eDrive™ Fan inverter parameters are confi gured via the CLIMATIC™ 60 unit confi guration (See CLIMATIC™ Section).

This confi guration is selecting the proper parameters to run eDrive™ in its operating range depending on fan type & motor size.

If ever, the Inverter loose fan control (No Fan or Wrong fan speed & Compressor or Heating stay on), one may check the Inverter

confi guration as below:

“0.0” will be displayed in this case on the Inverter instead of the regular “0” or “xxx” rpm

Switch to unlock mode:

F700 = 0

F732 = 0

On Inverter, set the TYP parameter to 3 value. (reinitialize the Inverter to the default values) then confi gure the following setpoints:

CMOD=2

FMOD=4

F800=1

F801=0

F802=11

F803=0

Then switch OFF the whole machine & then switch ON.

Then the CLIMATIC™ is going to send all the proper machine confi guration to Inverter (motor size, fan type, Imax, safety parameters) .

Page 45

• 41 •BALTIC-IOM-0412-E / Service manual

FRESH AIR HOOD

Installing

The fresh air hood has to be opened and secured during commissioning.

The 3 parts of the fresh air hood have to be assembled thanks to self taping screws delivered in the spare part box

Check the proper position of the black seal on the top of the hood cover.

Wind direction

The prevailing wind has to be taken into account while choosing the machine position on the building roof.

It’s highly recommended to avoid putting the fresh air hood in the prevailing wind direction to avoid water ingress risks.

If this is not possible please contact us to require specifi c water droplet strainer in the hood section.

WARNING: the fresh air hood cover can hurt your head if you don’t pay attention while turning around the unit.

Page 46

• 42 • BALTIC-IOM-0412-E / Service manual

FILTERS

Filter replacement

After opening the fi lter access panel, lift the fi lter retaining log. The fi lters can then be removed and replaced easily by sliding the dirty

fi lters out and clean ones in.

The CLIMATIC™ 60 controller can monitor the pressure drop across the fi lter

The following set points can be adjusted depeding on the installation.

• “Airfl ow” in page 3343 = 25Pa by default

• “No fi lter “ in page 3344 = 50Pa by default

• “Dirty Filter” in page 3345 = 250Pa by default

The actual pressure drop measured accross the coil can be read on the CLIMATIC™ Display in menu 3342.

The following faults may be identifi ed

• Fault code 001 AIRFLOW FAILURE, if measured ΔP across the fi lter and coil is below the value set in page 3343

• Fault code 004 DIRTY FILTERS, if measured ΔP across the fi lter and coil is above the value set in page 3344

• Fault code 005 MISSING FILTERS, if measured ΔP across the fi lter and coil is below the value set in page 3345.

Page 47

• 43 •

24 30 38 42 45 52 57 65 75 85

E2V30 E2V30 E2V30 E3V45 E2V30 E2V30 E2V30 E2V30 E2V30 E3V45

BALTIC-IOM-0412-E / Service manual

REFRIGERATION CIRCUIT

Electronic expansion valve

2 electronic valves types are fi tted on BALTIC™: E2V & E3V

EEV adjustments

EEV allows the control of superheat in bifl ow operation (see CLIMATIC™ 60 sections).

E2V welding instructions

Electronic expansion valves are sensitive to dust – strainers must be used in case of replacing.

E3V welding instructions

Cbox Dbox Ebox

Model designation

Reference

Page 48

• 44 •

8 Bars

110 °C

BALTIC-IOM-0412-E / Service manual

HEATING OPTIONS

Hot water coils

The hot water coil is fi tted with a three way proportional valve . Two spanners must be used to

tighten the connections. One spanner must maintain the valve body when connecting the pipework to the main. Failure to do so may damage the pipes joints and invalidates the warranty.

Filling up and starting the system

• Adjust the control for Heating by reducing the simulated ambient temperature down to 10°C

• Check that the red indicators located under the valve actuator are moving correctly with the

signal.(Arrow on the picture)

• Fill the hydraulic system and bleed the coil using the air vents. Check incoming hot water

fl ow rate.

• Check the various connections for possible leaks

Freeze protection

Check the hydraulic system contains glycol for protection against freezing. Glycol is the only effective protection against freezing. The

antifreeze must protect the unit against freezing under winter conditions.

Drain the installation

You must ensure that the manual or automatic air vents have been installed on all high points in the system. In order to drain the

system, check that all the drain valves have been installed on all low points of the system.

Heating hot water coils frozen due to low ambient conditions are not covered by the warranty.

Electrolytic corrosion

Attention is drawn to the corrosion problems resulting from electrolytic reaction created by unbalanced earth connections. Any coil

damaged by electrolytic corrosion is not covered by the warranty.

Warning: glycol based fl uids may produce corrosive agents when mixed with air.

Maximum working pressure:

Maximum working temperature:

Page 49

• 45 •

12 16,3 10,8 17,0 11,8 17,8 12,8

24 32,6 21,5 34,0 23,5 35,6 25,6

27 36.7 24.3 38.3 26.6 40.1 28.8

36 48,9 32,3 51,1 35,3 53,3 38,4

45 61.1 40.5 63.8 44.3 66.8 48.0

48 65,2 43,0 68,1 47,0 71,1 51,3

54 73,4 48,4 76,6 52,9 80,0 57,7

BALTIC-IOM-0412-E / Service manual

HEATING OPTIONS

Electric heater

The BALTIC™ electric heaters are stand alone options which are fi tted in the heating section of the unit. As for the hot water coil or

the gas burner this option slides into the heating compartment located under the supply fan.

In order to reduce the pressure drops the airfl ow is ducted around the shielded resistances. The resistances are made smooth stainless

steel tubes with a capacity of 6W/cm2.

It is protected as standard, against overheat via a high temperature overload protection set at 98°C and located less than 150mm

after the heater itself.

There are three sizes available for each size of unit:

S: Standard heat

H: High heat

The standard heat electric heaters are staged control with 50% or 100%. The high heat version is controlled through a fully modulating

triac.

380V 400V 415V

Module size

(kW)

Current (A) Cap (kW) Current (A) Cap (kW) Current (A) Cap (kW)

WARNING: electric heater is connected heater to mains power – risk of electrical shock – switch off the unit

prior to open this section

Page 50

• 46 •

26 26 26 26

35 35 35 35

52 52

52 52 52 52

69 69 69 69

104 104

BALTIC-IOM-0412-E / Service manual

HEATING OPTIONS

Electrical preheater

Pre-heater is running only with high fresh air rate under low outdoor ambient temperature (see setpoint in CLIMATIC™ section).

A metallic fi lter is installed between air fi lter & electrical resistance to protect against heat radiations.

WARNING: electric pre-heater is connected heater to mainS power – risk of electrical Shock – switch off the

unit prior to open this section

WARNING: electric pre-heater metallic fi lter must not be plugged by dust

Amps per model

size

C BOX D BOX E BOX

24 30 38 42 45 52 57 65 75 85

Size S / H

S 18 kW

S 24 kW

S 36 kW

H 36 kW

H 48 kW

H 72 kW

Page 51

• 47 •

24 30 38 42 45 52 57 65 75 85

1111111111

1111111122

24 30 38 42 45 52 57 65 75 85

1,9 3,2 5,7

4,5 5,7 11,5

BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Preliminary checks before start-up

Note:

Any work on the gas system must be carried out by qualifi ed personnel.

This unit must be installed in accordance with local safety codes and regulations and can only be used in planed installation conditions

for outdoor.

Please read carefully the manufacturer’s instructions before starting a unit.

Before commissioning a unit with gas burner, it is mandatory to ensure that the gas distribution system (type of gas, available

pressure…) is compatible with the adjustment and settings of the unit.

Check access and clearance around the unit

• make sure one can move freely around the unit.

• a minimum one-meter clearance must be left in front of the burnt gas exhaust fl ue.

• combustion air inlet and burnt gas exhaust(s) must not be obstructed in any way.

Supply network pipe sizing

Male threaded connection for gas burner: 3/4”

Check that the gas supply line can provide the burners with the pressure and the gas fl ow rate necessary to provide the heating

nominal output.

Starting up the gas burner

Purge the pipe-work near the connection on the ignition control valve for a few seconds.

• check that the unit's treatment “fan” blower is running.

• set the control to “on” this will priorities the gas burner.

• increase the set temperature (room set point temperature) to a temperature higher

than the actual room temperature.

For modulating gas we have just H power for c, d & e-box

• the gas supply of a rooftop gas unit must be realized according to sound engineering practice and the local safety codes and rules.

• in any case the diameter of pipe-work connected to each rooftop must not be smaller than the diameter of the connection on the

rooftop unit.

• make sure that a shut-off isolation valve has been installed before each rooftop.

• check the supply voltage to the exit of the power supply's transformer t3 of the burner: it must be between 220 and 240v.

Unit size

S power

H power

Unit size

S power

H power

Gas fl ow - m3/h (for G20 at 20 mbar and 15°C)

Number of male threaded connections (3/4”)

Page 52

• 48 •

123456789

10112930313233343536373839404142434445

46

398

399

400

401

BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Standard start-up chronology

Time in seconds

Operations

Control operation sequence

Extraction fan

Smoke extraction fan "ON"

30 to 45 seconds pre-ventilation

Fire-up spark electrode 4s

Opening of the gas valve

"high heat"

Flame propagation towards the

ionisation probe

If ionisation within 5sec:normal

running

Otherwise fault on gas ignition

control block

After 5 minutes, fault reported on

the CLIMATIC™ controller

If incorrect sequence, refer to the fault analysis table to identify the problem.

Page 53

• 49 •BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Pressure adjustments on Honeywell pressure regulating

valve type vk 4105 g

Pressure regulator adjustment with 300mbar gas supply:

High heat injection pressure checks

• place the tube of the “accurate” manometer to the out port on

the gas injector support bar after having loosened the screw

by one turn.

Check and adjust if necessary the valve outlet pressure to 8,4

mbar (G20) / 12,3 mbar for groningue (G25) & 31,4 mbar for

propane (G31)

• the burner must run in high heat mode for this check.

• place the tube of the “accurate” manometer on the inlet pressure

port of the gas regulating valve after having loosened the screw

by one turn

• Check and adjust if necessary the valve inlet pressure to

20 mbar (g20) or 25 mbar for groningue (g25) or 37 mbar for

propane (g31). After gas burner ignition.

Low heat adjustment

Page 54

• 50 •

20,0 +/- 1 3,5 +/- 0,1 8,4 +/- 0,2

25,0 +/- 1,3 5,0 +/- 0,1 12,3 +/- 0,2

37,0 +/- 1,9 14,0 +/- 0,3 31,4 +/- 0,6

2,90 kΩ 1,69 kΩ

BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Low heat injection pressure checks

• switch the control to low heat

• check and adjust if necessary the outlet pressure to 3,5 mbar

(G20) or 5 mbar for groningue(G25) & 14 mbar for propane

(G31)

Valve electrical control

Pressure adjustments table for each type of gas (mbar)

Category

Supply

pressure

Low heat

injection min,

High heat

injection

G20

G25 (groningue)

G31 (GPL)

• after the adjustment of the low heat, re-verify the high heat

• re-position the stoppers and close the pressure ports

• check these values with an ohmmeter.

Page 55

• 51 •BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Burner safety checks

Smoke extractor pressure switch test

• with the gas burner running, disconnect the fl exible tube fi tted

to the pressure taping on the pressure switch.

• the fl ame must disappear and the extraction fan must carry

on running.

• however, no fault will be displayed (gas ignition control block

or CLIMATIC™).

Ionisation probe test

• with the gas burner running, disconnect the terminal plug

coming from the ionisation probe to the gas ignition control box.

Gas pressure switch test

• with the gas burner running, close the shut off valve located

before the rooftop.

• the fl ame disappears

• the fan is still running and attempting to restart the burner

(restart cycle 30 to 45 seconds).

• if the ignition probe is not reconnected at the end of the ignition

sequence the burner will stop completely.

• the fault light on the gas ignition control block is on.

• manually reset the gas ignition control block to eliminate the

fault

In case of problems refer to the start up sequence fl owchart

next page

• the burner stops completely.

• however, no fault light will be displayed on the gas ignition

control block. After 6 minutes, the CLIMATIC™ will display a

fault.

• reset the CLIMATIC™.

• after reconnecting of the tube, the burner will restart after a

period of 30 to 45 seconds pre-ventilation.

Page 56

• 52 • BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Gas burner fi re-up sequence

Operation from control

Thermostat GAS =Closed

Gas ignition control block signal

Pre-ventilation 30 seconds

Gas valve remains open

Extraction fan ON

Fire-up eectrode 4s

Normal operation

Gas valve open

Gas control valve closes

BURNER STOPS

Gas control valve closes

BURNER STOPS

Fault on gas control

block

6 minutes delay

Fault on CLIMATIC™

Supply thermostat limit?

(Auto Reset)

Air press switch ON

or backfi re thermostat?

Gas low pressure switch?

Signal from ionisation probe still ON?

AIR pressure switch ON

backfi re thermostat ON?

Ionisation 1 second after the end of sparking?

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 57

• 53 •BALTIC-IOM-0412-E / Service manual

GAS BURNERS

Gas burner troubleshouting

If faults reported on CLIMATIC™

• reset the CLIMATIC™.

• check voltage: 230v after circuit breaker.

• check gas isolation shut-off valves are open.

• check gas pressure at the inlet of the gas valves. It must be >20 mbar when the burners shut down.

• adjust the set points to priorities the burner. Increase the value of the room temperature set point to a temperature higher than

actual room temperature.

Diagnostic table baltic gas burner

Stage Normal operation Possible fault Action Possible solution

Heating requested

Green, yellow & red

l.e.d. ON

All l.e.d. OFF

→ fault on the blower

thermostat

Check connections on the

blower thermostat.

Replace thermostat

Yellow & red l.e.d. OFF

→ lack of gas supply

Check valve’s opening &

supply pressure

Restore gas supply

Red l.e.d. OFF

→ fault on the superheat

thermostat on the gas burner

support bar

Check thermostat’s operation

after manual reset

Replace thermostat

L.e.d on

Extraction fans are

running

After 10 seconds safety

shutdown by the ignition

control block

Check connections of the

control block on the gas valve

Check impedance of electro

valve’s coils: (1) = 2.90kΩ; (2)

= 1.69kΩ

repositioning of the control

block on the valve

Replace valve

Nothing happens

Check the free movement of

the fan wheel

Check electrical connection

on the gas ignition control

block and on ef connection

board

Check the fan supply voltage

Replace fan

Replace ef connection board

if necessary

Extraction fan is on

After 30 to 45 seconds:

pre-ventilation the

fi re-up electrode should

spark.

Continuous ventilation without

sparks from fi re-up electrode

Check the fi re-up electrode

Check the pressure drop at

the pressure switch: it must

be higher than 165 pa

+check the good operation of

the pressure switch using an

ohmmeter and by artifi cially

creating a depression in the

tube.

Re-position the pressure

switch tube.

Change the pressure switch.

Continuous ventilation

and sparks from fi re up

electrode.

After a few seconds the

gas burner fi res-up

After 4 seconds the gas

burner still not operating

and safety shutdown by the

ignition control block.

Check injection pressure

during start-up (value for high

heat)

Remove the control box from

the gas block.

Remove the air from the gas

pipe-work

Adjust the injection pressure

to high heat value.

Change the control box if the

gas valve is ok.

Within 4 seconds the gas

burner fi res-up but safety

shutdown from the ignition

control block.

Check the position and

connection of the ionisation