Lennox BAH020SNM, BAG045SSM, BAM020SHM, BAM045SSM, BAC030SNM Installation, Operating And Maintenance

...Page 1

Providing indoor climate comfort

BALTIC R410A

BALTIC R410A-IOM-0708-E

Installation, operating

and maintenance

Page 2

CONTENTS

BALTIC R410A-IOM-0708-E Page 1

INSTALLATION – OPERATING – MAINTENANCE

MANUAL

Ref. BALTIC-IOM-0708-E

The present manual applies to the following ROOFTOP versions:

BAC020SNM BAH020SNM BAG020SHM BAG045SSM BAM020SHM BAM045SSM

BAC030SNM BAH030SNM BAG020SSM BAG055SHM BAM020SSM BAM055SHM

BAC035SNM BAH035SNM BAG030SHM BAG055SSM BAM030SHM BAM055SSM

BAC045SNM BAH045SNM BAG030SSM BAG065DHM BAM030SSM BAM065DHM

BAC055SNM BAH055SNM BAG035SHM BAG065DSM BAM035SHM BAM065DSM

BAC065DNM BAH065DNM BAG035SSM BAG075DHM BAM035SSM BAM075DHM

BAC075DNM BAH075DNM BAG045SHM BAG075DSM BAM045SHM BAM075DSM

NOTES FOR UNIT FITTED WITH GAS BURNER:

THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH LOCAL SAFETY

CODES AND REGULATIONS AND CAN ONLY BE USED IN WELL

VENTILLATED AREA.

PLEASE READ CAREFULLY THE MANUFACTURER’S INSTRUCTIONS

BEFORE STARTING THIS UNIT.

THIS MANUAL IS ONLY VALID FOR UNITS DISPLAYING THE FOLLOWING

CODES: GB IR GR DA NO FI IS

In case these symbols are not displayed on the unit, please refer to the technical

documentation which will eventually detail any modifications required to the

installation of the unit in a particular country.

LENNOX have been providing environmental solutions since 1895, our range of Baltic TM rooftop continues to meet the

standards that have made LENNOX a household name. Flexible design solutions to meet YOUR needs and

uncompromising attention to detail. Engineered to last, simple to maintain and Quality that comes as standard. Information

on local contacts at www.lennoxeurope.com.

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be utilised (except in operation of this product),

reproduced, issued to or made available to third parties without the prior written agreement of Lennox.

The technical information and specifications contained in this manual are for reference only. The manufacturer reserves

the right to modify these without warning and without obligation to modify equipment already sold.

Page 3

CONTENTS

BALTIC R410A-IOM-0708-E Page 2

COMMISSIONING REPORT............................................................................................. 5

INSTALLATION

Transport - Handling ...........................................................................................11

Mandatory handling devices................................................................................12

Dimensions and weights .....................................................................................13

Lifting the units ...................................................................................................14

Lifting the roofcurbs ............................................................................................15

Lifting the energy recovery module ..................................................................... 16

Preliminary checks .............................................................................................17

Minimum clearances around the unit ...................................................................18

Installation on roof mounting frames ....................................................................19

Positioning roofcurb ................................................................ .................19

Non adjustable Non assembled roof curb ................................ .................20

Securing the curb ....................................................................................22

Curbing and flashing ................................ ................................ ................22

Heat recovery installation ................................ ................................ .........23

Economiser and extraction ................................................................................. 24

COMMISSIONING

Electrical connections.......................................................................................... 26

Preliminary checks .............................................................................................26

Starting the unit...................................................................................................27

Powering the unit ................................................................................................ 28

ARRANGEMENT DRAWINGS

BALTIC BAC-BAH-BAG-BAM 020 to 075.............................................................29

Non adjustable roofcurb ..................................................................................... 37

Adjustable roofcurb ............................................................................................38

Multidirectional horizontal roofcurb....................................................................... 42

Exhaust vertical roofcurb.....................................................................................46

Exhaust horizontal roofcurb ................................................................ .................50

Transition roofcurb..............................................................................................53

Energy recovery option........................................................................................54

VENTILATION

Belt tension ........................................................................................................58

Mounting & adjusting pulleys ..............................................................................59

Airflow balancing ................................................................ ................................60

Filters ................................ ................................ ................................ ................71

Fan starter .........................................................................................................72

Page 4

CONTENTS

BALTIC R410A-IOM-0708-E Page 3

HEATING OPTIONS

Hot water coils ................................ ................................ ................................ ...73

Electric heater ................................................................ ................................ ....75

Gas burners .......................................................................................................76

Modulating gas burners................................................................ .......................88

CLIMATIC CONTROLLER

See specific content on page 93 ................................ ................................ .........93

PRINCIPLE SKETCHES

Refrigerant circuits .............................................................................................114

Hot water coil diagram ........................................................................................ 117

MAINTENANCE DIAGNOSTIC

........................................................................................118

MAINTENANCE PLAN ....................................................................................................121

WARRANTY ....................................................................................................................124

CERTIFICATES ...............................................................................................................125

Page 5

PRESSURE EQUIPMENT

BALTIC R410A-IOM-0708-E Page 4

All Baltic Units are compliant with the PED directive 97-23/CE

The following note must be followed carefully

All work on the unit must be carried out by a qualified and authorised employee.

Non-compliance with the following instructions may result in injury or serious accidents.

Work on the unit:

The unit shall be isolated from the electrical supply by disconnection and locking using the main isolating switch.

Workers shall wear the appropriate personal protective equipment (helmet, gloves, glasses, etc.).

Work on the electrical system:

Work on electric components shall be performed with the power off (see below) by employees having valid electrical

qualification and authorisation.

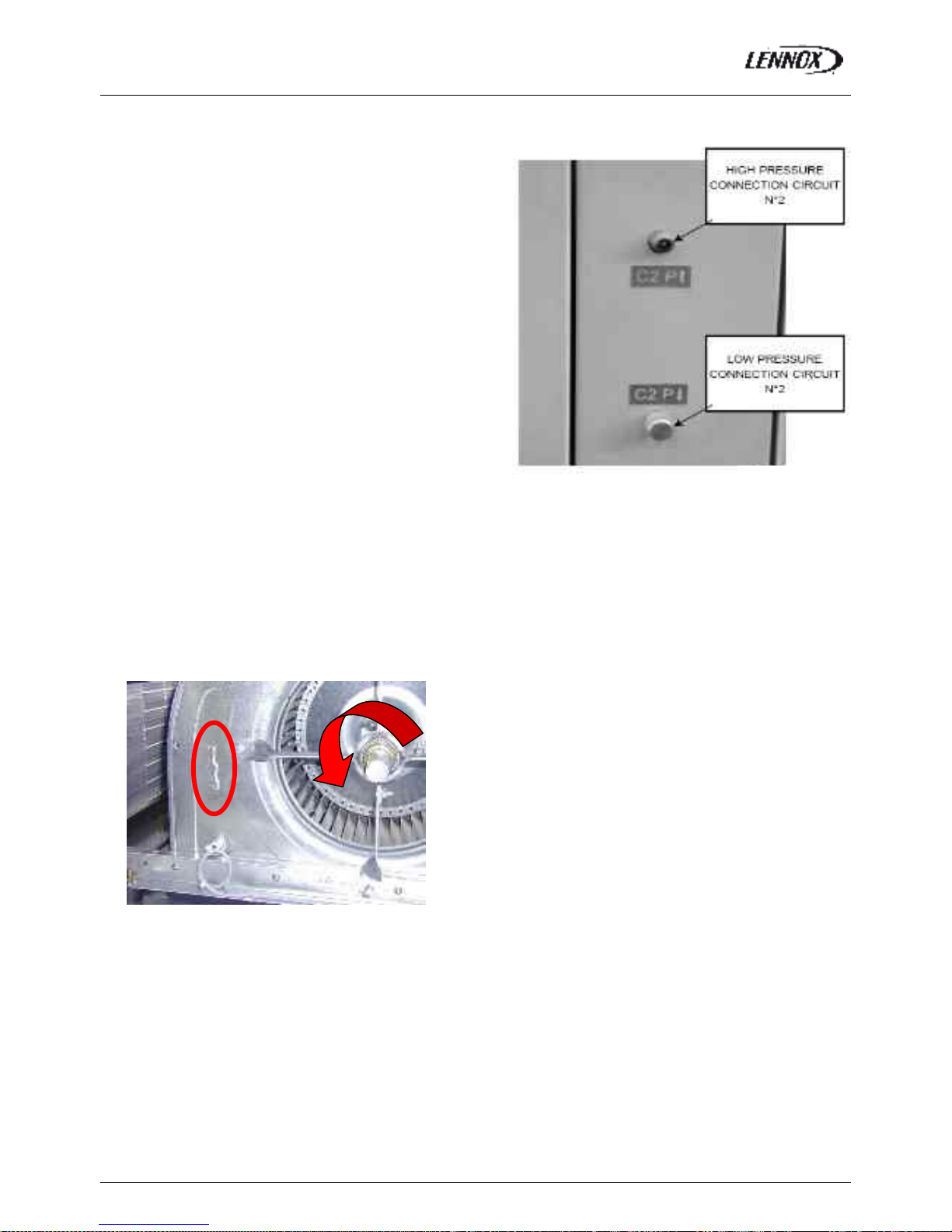

Work on the refrigerating circuit(s):

Monitoring of the pressures, draining and filling of the system under pressure shall be carried out using connections

provided for this purpose and suitable equipment.

To prevent the risk of explosion due to spraying of coolant and oil, the relevant circuit shall be drained and at zero pressure

before any disassembly or unbraz ing of the refrigerating parts takes place.

There is a residual risk of pressure build-up by degassing the oil or by heating the exchangers after the circuit has been

drained. Zero pressure shall be maintained by venting the drain connection to the atmosphere on the low pressure side.

The brazing shall be carried out by a qualified brazier. The brazing shall comply with standard NF EN1044 (minimum 30%

silver).

Replacing components:

In order to maintain CE marking compliance, replacement of components shall be carried out using spare parts, or using

parts approved by Lennox.

Only the coolant shown on the manufacturer’s nameplate shall be used, to the exclusion of all other products (mix of

coolants, hydrocarbons, etc.).

CAUTION:

In the event of fire, refrigerating circuits can cause an explosion and spray coolant gas and oil.

Page 6

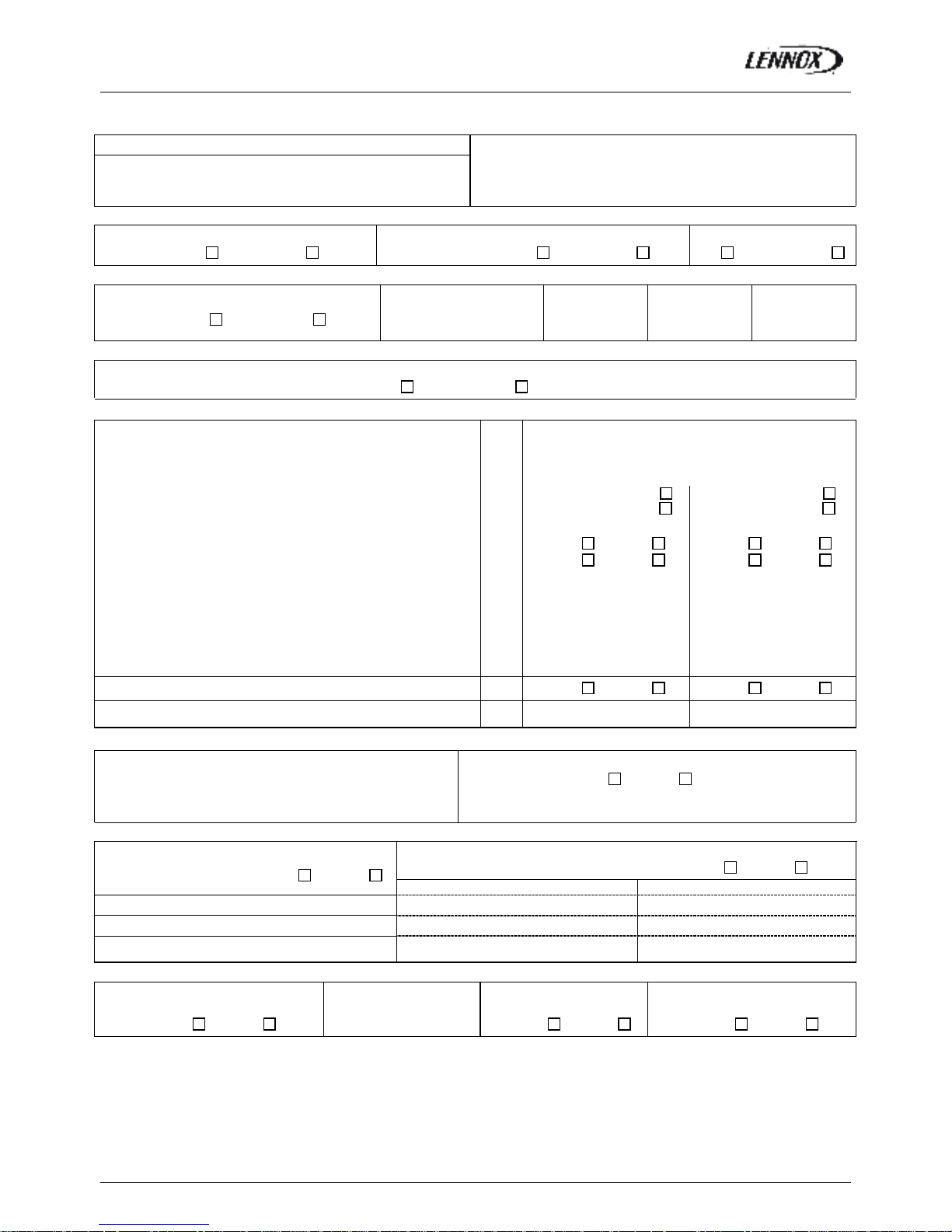

COMMISSIONING REPORT

BALTIC R410A-IOM-0708-E Page 5

Site details / Informations site

Site / Site

Unit Ref/ N° Affaire

Installer/ Installateur

………………………………………

……………………………………....

………………………………………

Controller/ Contrôleur

Model/Model

Serial No/ No Série

Refrigerant / Réfrigérant

………………………………….

……………….…………………

…………………………………

…………………………………

(1) ROOF INSTALLATION / INSTALLATION SUR LE TOIT

Sufficient Access OK / Accès Suffisants

Yes/Oui No/ Non

Condensate drain fitted / Drainage condensats

Installé Yes/Oui No/ Non

Roofcurb / Costière

OK Not OK/PasOK

(2) CONNECTIONS CHECK / VERIFICATIONS DE RACCORDEMENTS

Phase check/ Vérification des Phases

Yes / Oui No / Non

Voltage between Phases

Tension entre Phases

1 / 2

……………….

2 / 3

……………….

1 / 3

……………….

(3)CLIMATIC CONFIGURATION CHECK / VERIFIER LA CONFIGURATION CLIMATIC

CLIMATIC 50 Configured according to the Options and Specifications / CLIMATIC 50 configuré en fonction des options et des

spécifications: Yes/Oui No/ Non

(4) SUPPLY BLOWER SECTION / VENTILATION TRAITEMENT

Type / Type:

Power displayed on plate / Puissance affichée sur la plaque:

Voltage displayed on plate / Tension affichée sur la plaque:

Current displayed on plate / Intensité affichée sur la plaque:

KW

V

A

N°1

……………………

……………………

……………………

N°2

……………………

……………………

……………………

Fan Type / Type de Ventilateur: Forward / Action

Backward / Réaction

Forward / Action

Backward / Réaction

Displayed Belt Length / Longueur Courroie affichée: mm …………………… ……………………

Tension Checked/ Tension Vérifiée: Yes/Oui No/ Non Yes/Oui No/ Non

Alignment Checked / Alignement Vérifié: Yes/Oui No/ Non Yes/Oui No/ Non

Motor Pulley Dia/ Poulie Moteur Dia: DM mm …………………… ……………………

Fan Pulley Dia/ Poulie Ventilateur Dia: DP mm …………………… ……………………

Fan Speed / Vitesse rotation Ventilateur = Motor rpm x DM / DP

Averaged Measured Amps / Intensité Mesurée moyenne:

rpm

A

……………………

……………………

……………………

……………………

Shaft Mechanical Power (Refer to airflow balancing)

Puissance Mécanique à l’Arbre (Voir section réglage débit)

W …………………… ……………………

Operating point checked / Vérif. Point de fonctionnement: Yes/Oui No/ Non Yes/Oui No/ Non

Estimated Airflow / Estimation Débit d’Air m

3

/h …………………… ……………………

(5) AIRFLOW PRESS. SENSOR CHECK / VERIF. DES SECURITES PRESSOSTATS D’AIR

Measured pressure drop / Pertes de charge au pressostat

…………………………… mbar

Set Points Adjusted / Changement des consignes:

Yes/Oui No/ Non

If Yes enter new values/ Si oui noter les nouvelles consignes:

3410: ………… 3411: ………… 3412: …………

(6) EXTERNAL SENSOR CHECKS / VERIFICATION DES CAPTEURS EXTERNES

Check and record temp. in menu 2110 / Vérifier et mesurer les

températures. Dans menu 2110: Yes/Oui No/ Non

Check electrical connections / Vérification des

connections électriques: Yes/Oui No/ Non

100% Fresh Air / 100% Air neuf 100% return Air / 100% Air repris

Supply Temperature / Température Soufflage ………………………..°C ………………………..°C

Return Temperature / Température reprise ………………………..°C ………………………..°C

Outdoor Temperature / Température extérieure ………………………..°C ………………………..°C

(7) MIXING AIR DAMPERS CHECKS / VERIFICATIONS VOLETS DE MELANGE

Dampers open & close freely/

Volets s’ouvrent et se ferment OK

% Minimum FA:

%minimum Air Neuf:

Power exhaust checked/

Ventilateur extraction

Enthalpy sensor(s) checked/

Control enthalpie installé

Yes/Oui No/ Non ……………..% Yes/Oui No/ Non Yes/Oui No/ Non

Page 7

COMMISSIONING REPORT

BALTIC R410A-IOM-0708-E Page 6

(8) REFRIGERATION SECTION / SECTION REFRIGERATION

Outdoor Fan Motor Current / Intensité Moteurs Batterie externe: Check Rotation

Motor 1 / Moteur 1 L1 ……..A L2 ……..A L3 ……A Yes/Oui No/ Non

Motor 2 / Moteur 2 L1 ……..A L2 ……..A L3 ……A Yes/Oui No/ Non

Compressor

Voltage/ Tension

Compresseur.

Motor 3 / Moteur 3 L1 ……..A L2 ……..A L3 ……A Yes/Oui No/ Non Comp1: …….. V

Motor 4 / Moteur 4 L1 ……..A L2 ……..A L3 ……A Yes/Oui No/ Non Comp2: …….. V

Motor 5 / Moteur 5 L1 ……..A L2 ……..A L3 ……A Yes/Oui No/ Non Comp3: …….. V

Motor 6 / Moteur 6 L1 ……..A L2 ……..A L3 ……A Yes/Oui No/ Non Comp4: …….. V

Compressor Amps COOLING / Intensité

Compresseur MODE FROID

Pressures & Temperatures / Pressions & températures

Temperatures / Temperatures Pressures / Pressions

Phase 1 Phase 2 Phase 3

Suction/ Asp

Disch / refoul

LP/ BP

HP / HP

Comp 1 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 2 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 3 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 4 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Check Reversing valves./

Vérifier vannes d’inversion:

Valve1/Vanne1: Yes/Oui No/ Non

Valve2/Vanne2: Yes/Oui No/ Non

Valve3/Vanne3: Yes/Oui No/ Non

Valve4/Vanne4: Yes/Oui No/ Non

Compressor Amps HEATING / Intensité

Compresseur en Pompe à Chaleur

Pressures & Temperatures / Pressions & températures

Temperatures / Temperatures Pressures / Pressions

Phase 1 Phase 2 Phase 3

Suction/ Asp

Disch / refoul

LP/ BP

HP / HP

Comp 1 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 2 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 3 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 4 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

HP cut out / Coupure HP ……Bar LP cut out / Coupure sécurité BP ………..…... Bar

Refrigerant charge / Charge réfrigérant C1 : ………..kg C2 : ………..kg C3 : ………..kg C4 : ………..kg

(8)ELECTRIC HEATER SECTION / SECTION RECHAUFFEUR ELECTRIQUE

Type / Type: …………………………………………………. Serial No/ No Série.:………………………..

AMPS 1st stage (Baltic) / Intensité 1er étage (Bal tic) AMPS 2nd stage (Baltic) / Intensité 2e étage (Baltic)

1 ………………. 2 ………………. 3 ………………. 1 ………………. 2 ………………. 3 ……………….

(9) HOT WATER COIL SECTION / SECTION BATTERIE EAU CHAUDE

Check Three Way Valve Movement / Vérification Mouvement Vanne trois voies: Yes/Oui No/ Non

(10) GAS HEATING SECTION / RAMPE GAZ

Gas Burner N°1 / Brûleur gaz N°1 Gas Burner N°2 / Brûleur gaz N°2

Size / Taille:

……………………….

Valve type / Type vanne:

…………………….

Size / Taille:

……………………….

Valve type / Type vanne:

…………………….

Pipe size/ tuyauterie: Gas type / Type gas : G……. Pipe size/ tuyauterie Gas type / Type gas : G…….

Line press./ press. ligne :

………………………

Drop test / test pression

Yes/Oui No/ Non

line press./ press. ligne :

………………………

Drop test / test pression

Yes/Oui No/ Non

Check manifold pressure/ Pression injection:

High fire/Grande allure…….…Low fire/Petite allure………..

Check manifold pressure/ Pression injection:

High fire/Grande allure…….…... Low fire/Petite allure………..

Pressure cut out airflow press switch / Pression coupure

pressostat débit d’air : ……………………mbar /Pa

Pressure cut out airflow press switch / Pression coupure

pressostat débit d’air : ……………………mbar /Pa

Motor amps

I moteur:

……….A

Flue temp /

temp fumées

……… °C

CO2 %:

………%

CO ppm:

………%

Motor Amps

I Moteur:

……….A

Flue temp /

temp fumées

………. °C

CO2 %:

………%

CO ppm:

………%

(11) REMOTE CONTROL BMS CHECK / VERIFICATIONS BMS CONTROL A DISTANCE

Type / Type:

…………………………..

Sensor type / Type Capteur

………………………………..

Interconnect wiring checked:

Yes/Oui No/ Non

It is recommended that you fill the two tables below before transferring the zone settings to the Climatic controller.

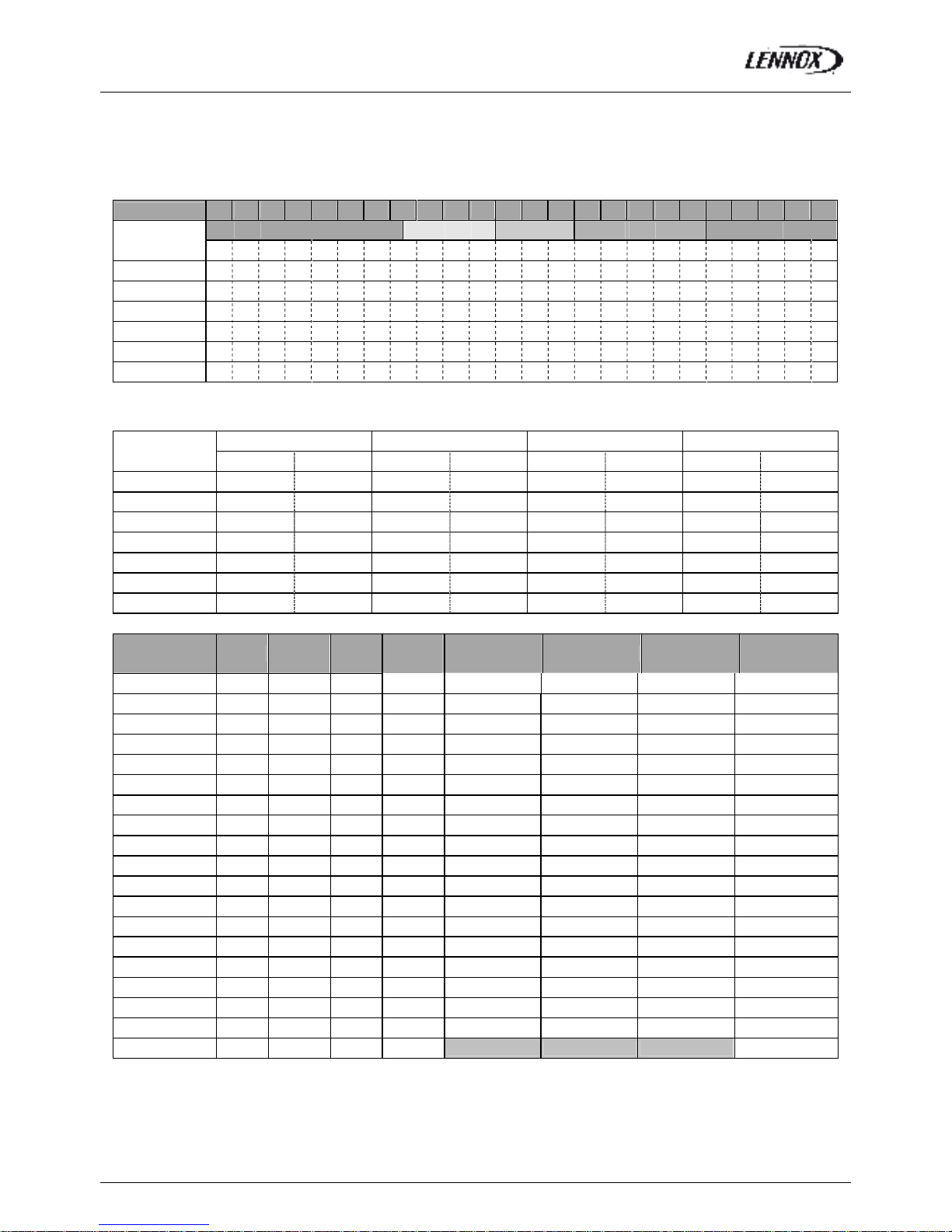

Page 8

COMMISSIONING REPORT

BALTIC R410A-IOM-0708-E Page 7

Il est recommandé de remplir les deux tableaux ci-dessous avant de transférer les consignes de zones vers le contrôleur

Climatic50.

Refer to control section page 55 / Se référer à la section régulation page 55

Time Zones / Zones Horaires

Hour

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Example

UNO

7h15

ZA

11h00

ZB

14h00

ZC

19h00

UNO

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Variables to adjust for each time zone / Consignes à renseigner pour chaque zone horaire

Start z.A Start z.B Start z.C Start UNO

hour (3211) min (3212) hour (3213) min (3214) hour (3215) min (3216) hour (3217) min (3218)

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Description Unit Menu Min

Max

Zone A Zone B Zone C UNOC

Sp Room °C 3311 8 35

Mini.Air % 3312 0 100

Sp Dyna °C 3321 0 99.9

Sp Cool °C 3322 8 35

Sp Heat °C 3323 8 35

Swap Heater On/Off 3324 ~ ~

Activation On/Off 3331 ~ ~

Swap Heater On/Off 3332 ~ ~

Sp.Dehu % 3341 0 100

Sp.Humi % 3342 0 100

Fan On/Off On/Off 3351 ~ ~

Fan Dead On/Off 3352 ~ ~

F.Air On/Off 3353 ~ ~

CO2 On/Off 3354 ~ ~

Comp.Cool. On/Off 3355 ~ ~

Comp.Heat. On/Off 3356 ~ ~

AuxHeat On/Off 3357 ~ ~

Humidif. On/Off 3358 ~ ~

Low Noise On/Off 3359 ~ ~ N/A N/A N/A

COMMENTS:……………………………………………………………………………………………………………………………………

…………………………….……………………………………………………………………………………………………………………….

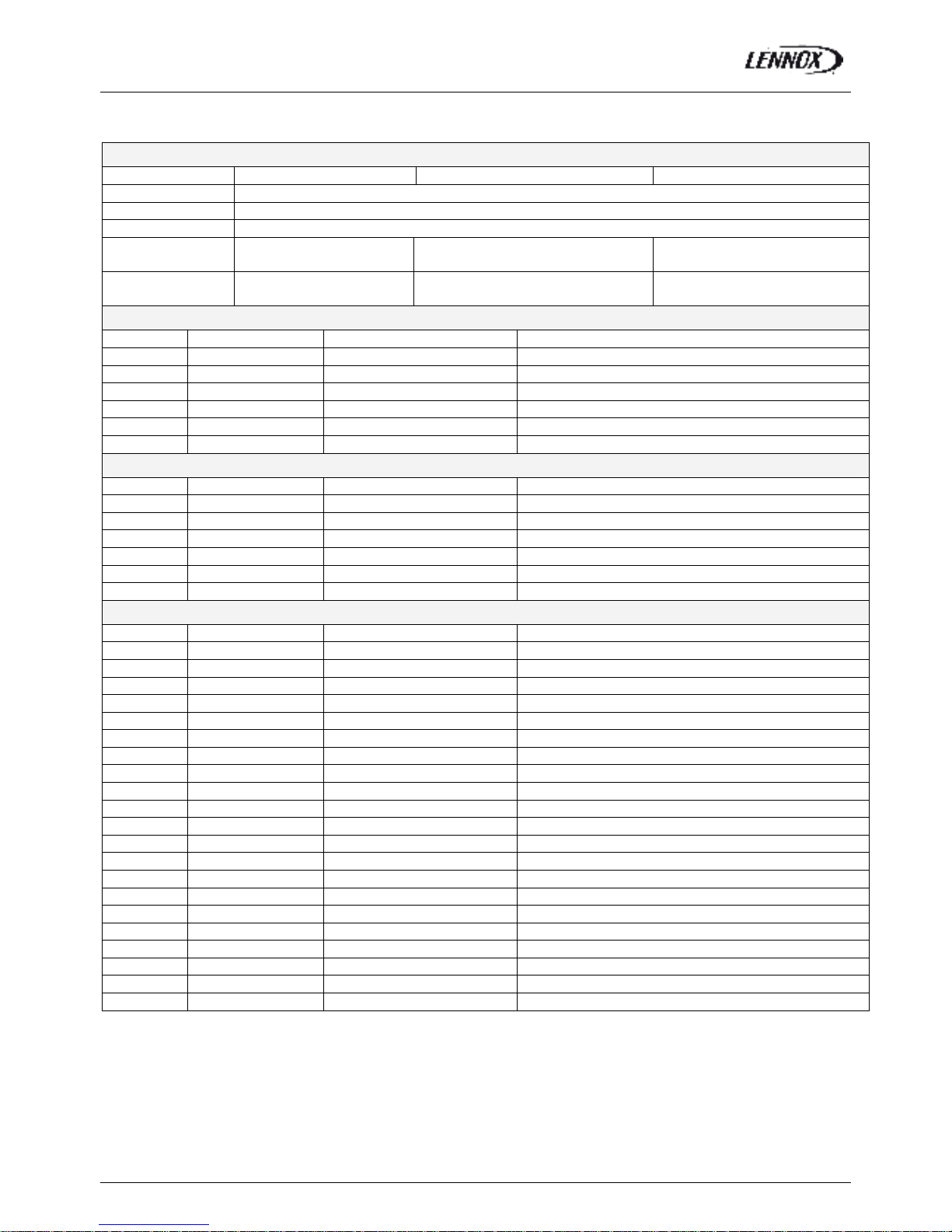

Page 9

COMMISSIONING REPORT

BALTIC R410A-IOM-0708-E Page 8

REFRIGERANT TRANSACTIONS LOGBOOK:

EC Regulation No 842/2006

GENERAL INFORMATION

Site Name

Serial Number

Site Address

Site Operator

Cooling Load

Refrigerant

Type

Refrigerant Quantity (kg)

Unit

Manufacturer

Year of Installation

REFRIGERANT ADDITIONS

Date Engineer Quantity (kg) Reason for Addition

REFRIGERANT REMOVAL

Date Engineer Quantity (kg) Reason for Removal

LEAK TESTS

Date Engineer Test Result Follow Up Action Required

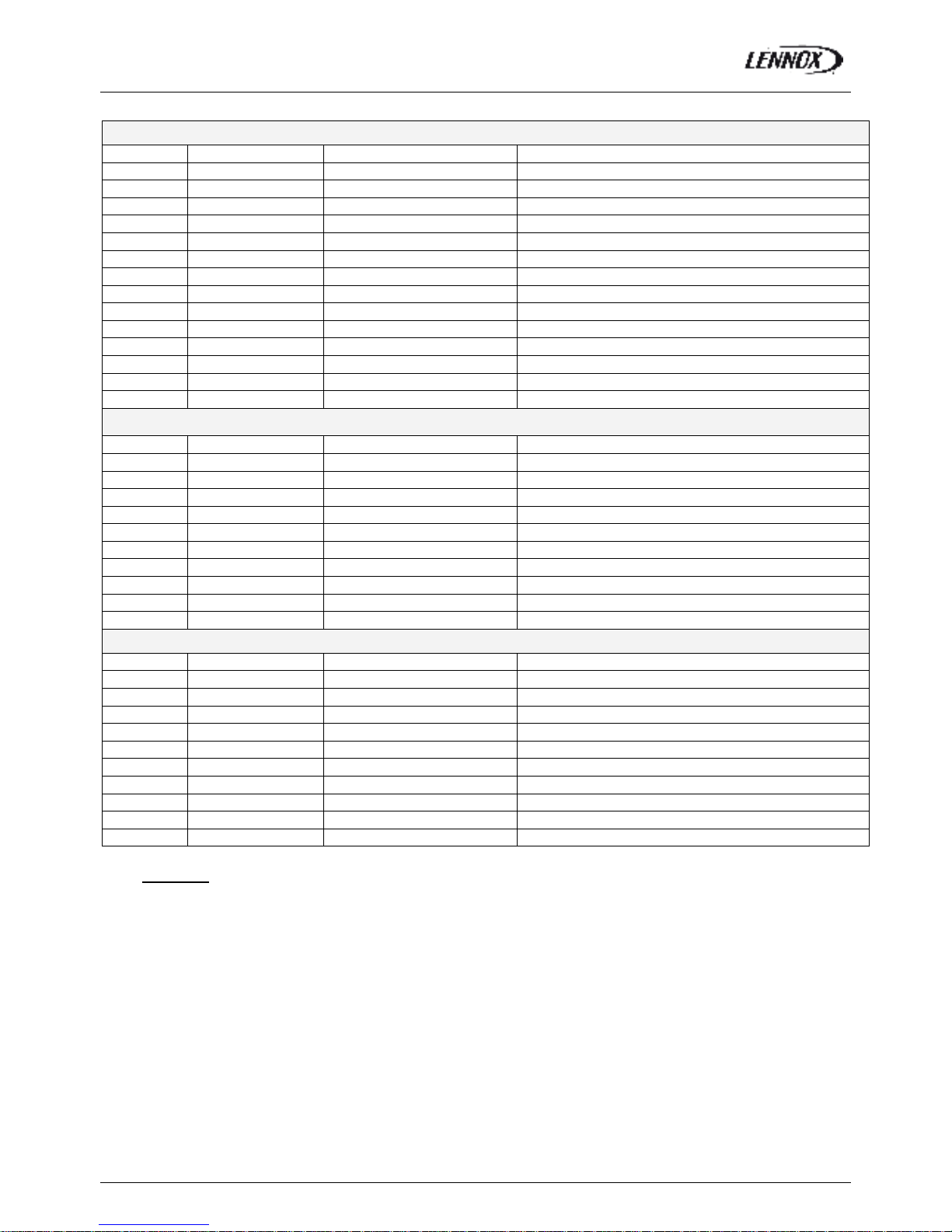

Page 10

COMMISSIONING REPORT

BALTIC R410A-IOM-0708-E Page 9

LEAK TESTS (Part 2)

Date Engineer Test Result Follow Up Action Required

FOLLOW UP ACTIONS

Date Engineer Related to test dated Action Taken

TESTING of AUTOMATIC LEAK DETECTION SYSTEM (If fitted)

Date Engineer Test Result Comments

Remarks: ………………………………………………………………………………………………

………………………………………………………………………………………………………………

………………………………………………………………………………………………………………

………………………………………………………………………………………………………………

………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………………

…………………………………………………………………………………………..…………………………………………………………

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

Page 11

COMMISSIONING REPORT

BALTIC R410A-IOM-0708-E Page 10

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

.………………………………………………………………………………………..………………………………………………………….

………………………………………………………………………………………..……………………………………………………………

Page 12

TRANSPORT - HANDLING

BALTIC R410A-IOM-0708-E Page 11

DELIVERY CHECKS

On receipt of a new equipment please check the following

points. It is the customer’s responsibility to ensure that the

products are in good working order:

- The exterior has not been damaged in any way.

- The lifting and handling equipment are suitable for the

equipment and comply with the specifications of the

handling instructions enclosed here-in.

- Accessories ordered for on site installation have been

delivered and are in good working order.

- The equipment supplied corresponds to the order and

matches the delivery note.

If the product is damaged, exact details must be confirmed

in writing by registered post to the shipping company within

48 hours of delivery (working days). A copy of the letter

must be addressed to Lennox and the supplier or

distributor for information purposes. Failure to comply will

invalidate any claim against the shipping company.

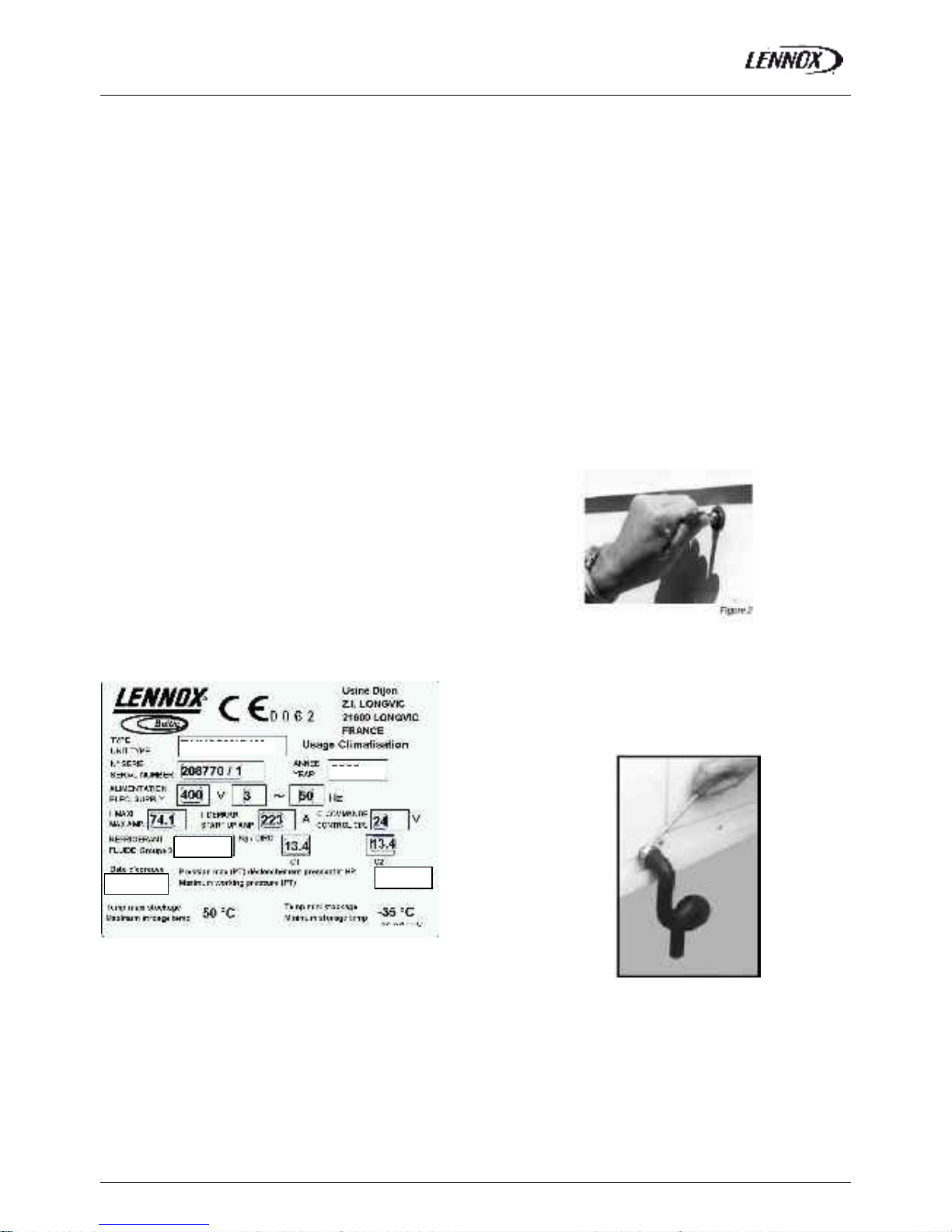

RATING PLATE

The rating plate provides a complete reference for the

model and ensures that the unit corresponds t o the model

ordered. It states the electrical power consumption of the

unit on start-up, its rated power and its supply voltage. The

supply voltage must not deviate beyond +10/-15 %. The

start-up power is the maximum value likely to be achieved

for the specified operational voltage. The customer must

have a suitable electrical supply. It is therefore important to

check whether the supply voltage stated on the unit's rating

plate is compatible with that of the mains electrical supply.

The rating plate also states the year of manufacture as well

as the type of refrigerant used and the required charge for

each compressor circuit.

Fig. 1

STORAGE

When units are delivered on site they are not always

required immediately and are sometimes put into storage.

In the event of medium to long-term storage, we

recommend the following procedures:

- Ensure that there is no water in the hydraulic systems.

- Keep the heat ex changer covers in position (A QUILUX cove r).

- Keep protective pl astic film in position.

- Ensure the electrical panels are closed.

- Keep all items and options supplied in a dry and clean

place for future assembly before using the equipment.

MAINTENANCE KEY

On delivery we recommend that you keep the key which is

attached to an eyebolt in a safe and accessible place. This

allows you to open the panels for maintenance and

installation work.

The locks are ¼ turn + then tighter (figure 2).

CONDENSATE DRAINS

The condensate drains are not assembled when delivered

and are stored

in the electrical panel with their clamping collars.

To assemble them, insert them on the condensate tray outlets

and use a screwdriver to tighten the collars (Figure 3).

Fig. 3

BAM055NM1M

2008

R410A

42.0 bar

18/05/2008

Page 13

TRANSPORT – HANDLING - WARNING

BALTIC R410A-IOM-0708-E Page 12

Handling slings to guide the

unit towards the roofcurb

Vacuum lifting beam to

position the unit

COMPLIANT

NON

-

COMPLIANT

MANDATORY HANDLING DEVICES

Page 14

TRANSPORT – HANDLING

BALTIC R410A-IOM-0708-E Page 13

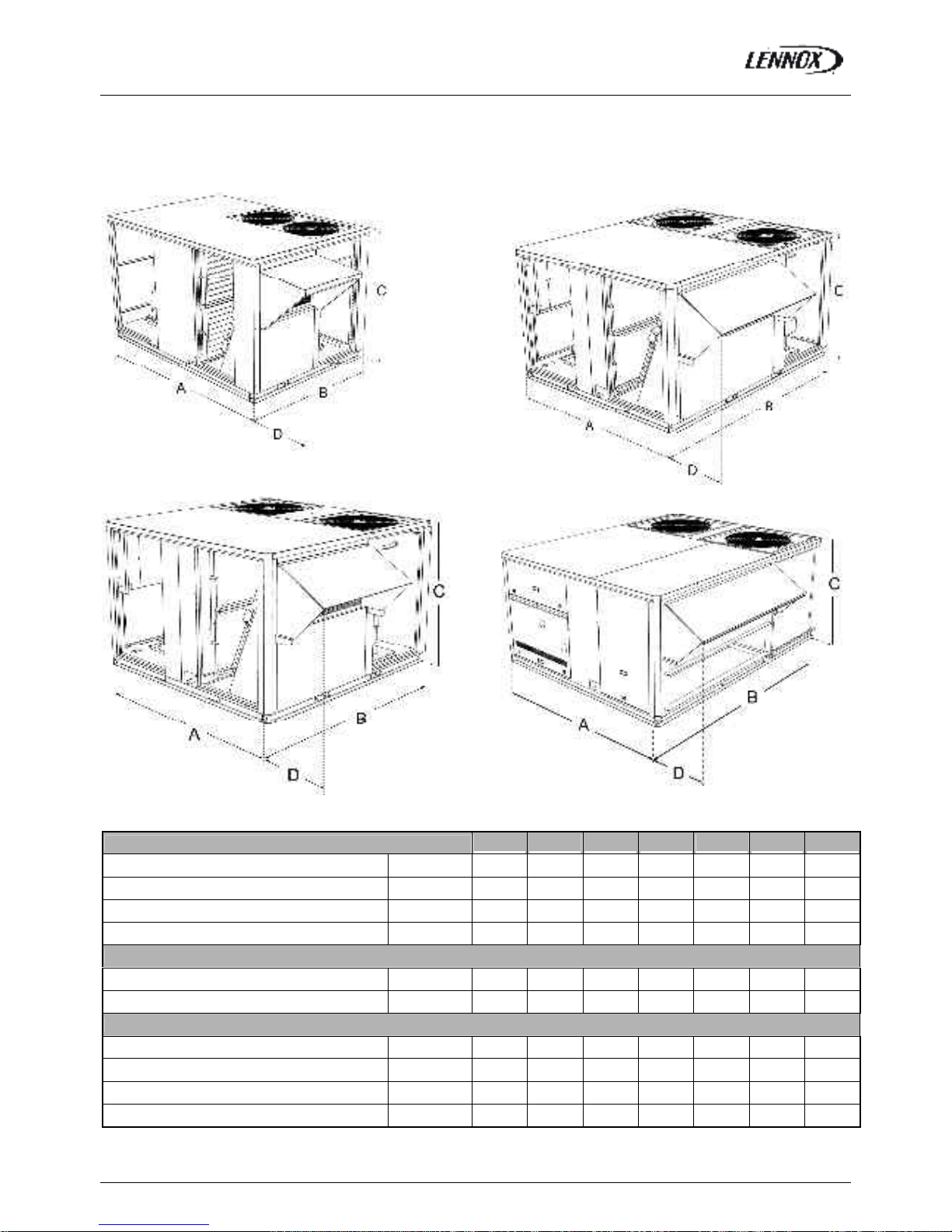

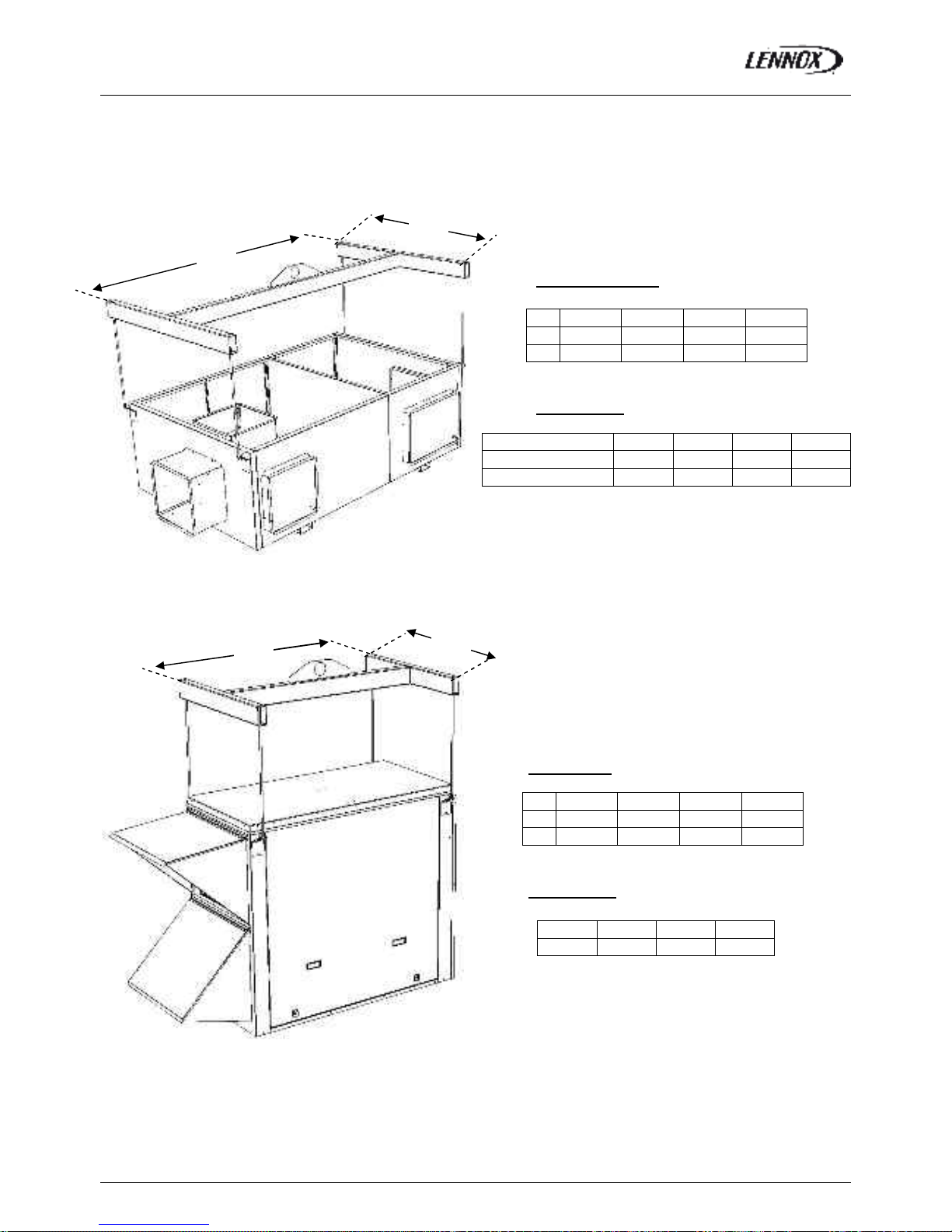

DIMENSIONS AND WEIGHTS

1

2

3

4

BALTIC™ BAC/BAH/BAG/BAM

20S 30S 35S 45S 55S 65D 75D

A mm

2017 2017 1890 1910 1910 2260 2260

B mm

1418 1418 1915 2235 2235 2873 2873

C mm

1220 1220 1221 1221 1221 1225 1225

D mm

484 484 414 418 418 418 418

Weight of standard units

Without hood

kg

394 414 547 604 619 796 852

With hood

kg

417 437 575 677 652 837 893

Poids des unités à gaz

Standard heat without hood

kg

445 465 608 678 693 904 960

Standard heat with hood

kg

468 488 636 711 726 945 1001

High heat without hood

kg

454 474 627 700 715 963 1019

High heat with hood

kg

477 497 655 733 748 1004 1060

Page 15

TRANSPORT – HANDLING

BALTIC R410A-IOM-0708-E Page 14

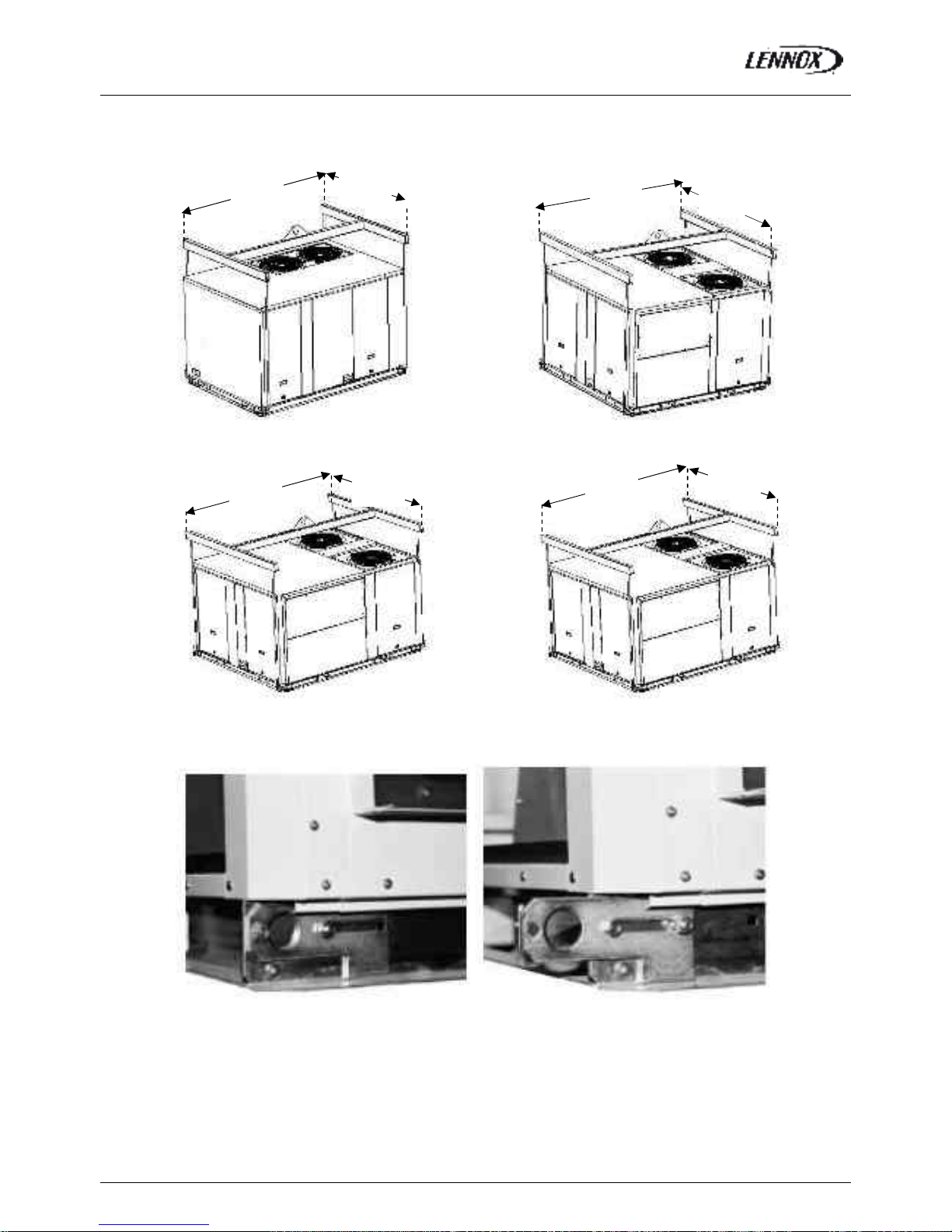

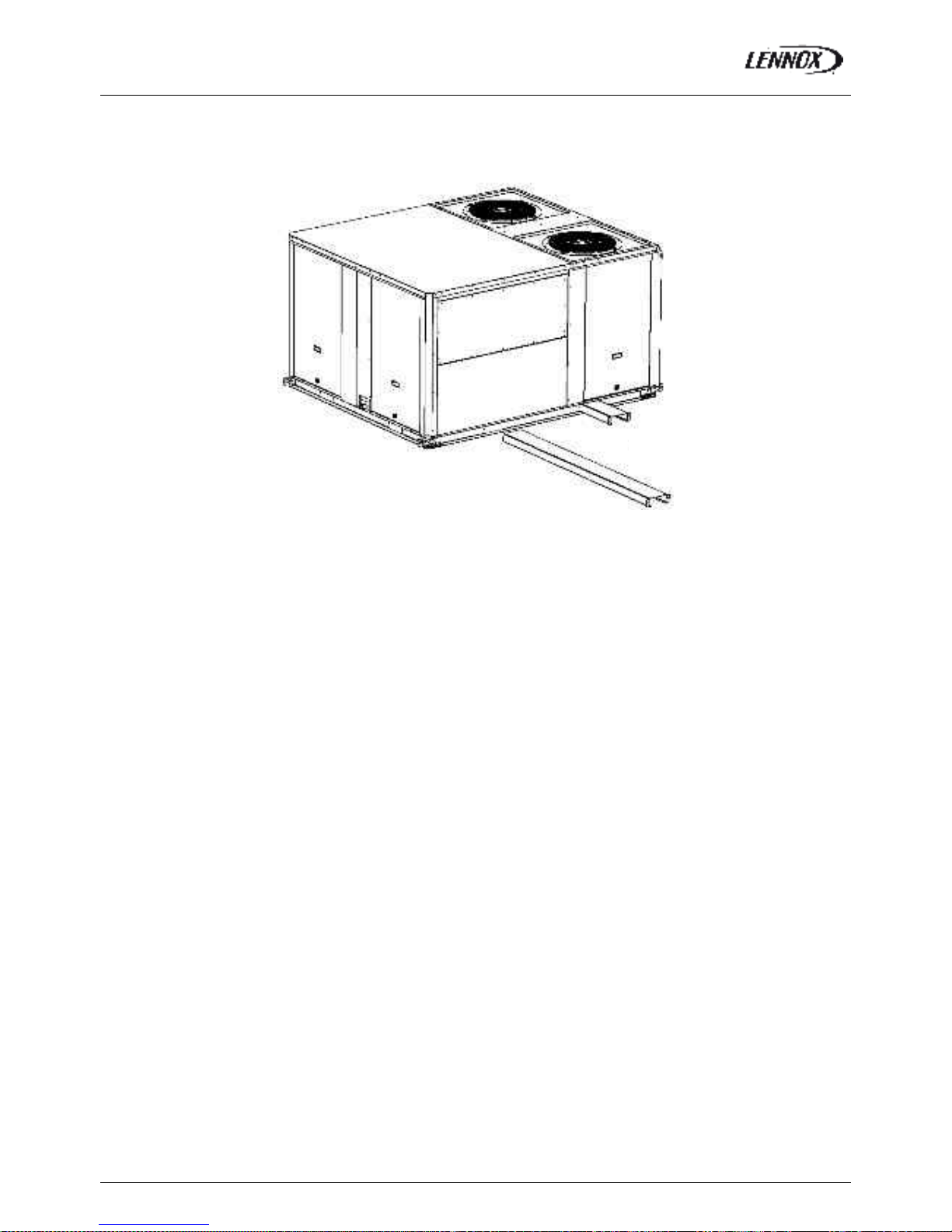

LIFTING THE UNITS

B box C box

D box E box

RETRACTABLE LIFTING LUG

Fig. 9

1850

(mini)

1410

(mini)

1930

(mini)

1700

(mini)

2250

(mini)

1700

(mini)

2890

(mini)

2080

(mini)

Fig. 5 Fig. 6

Fig. 7 Fig. 8

Page 16

TRANSPORT – HANDLING

BALTIC R410A-IOM-0708-E Page 15

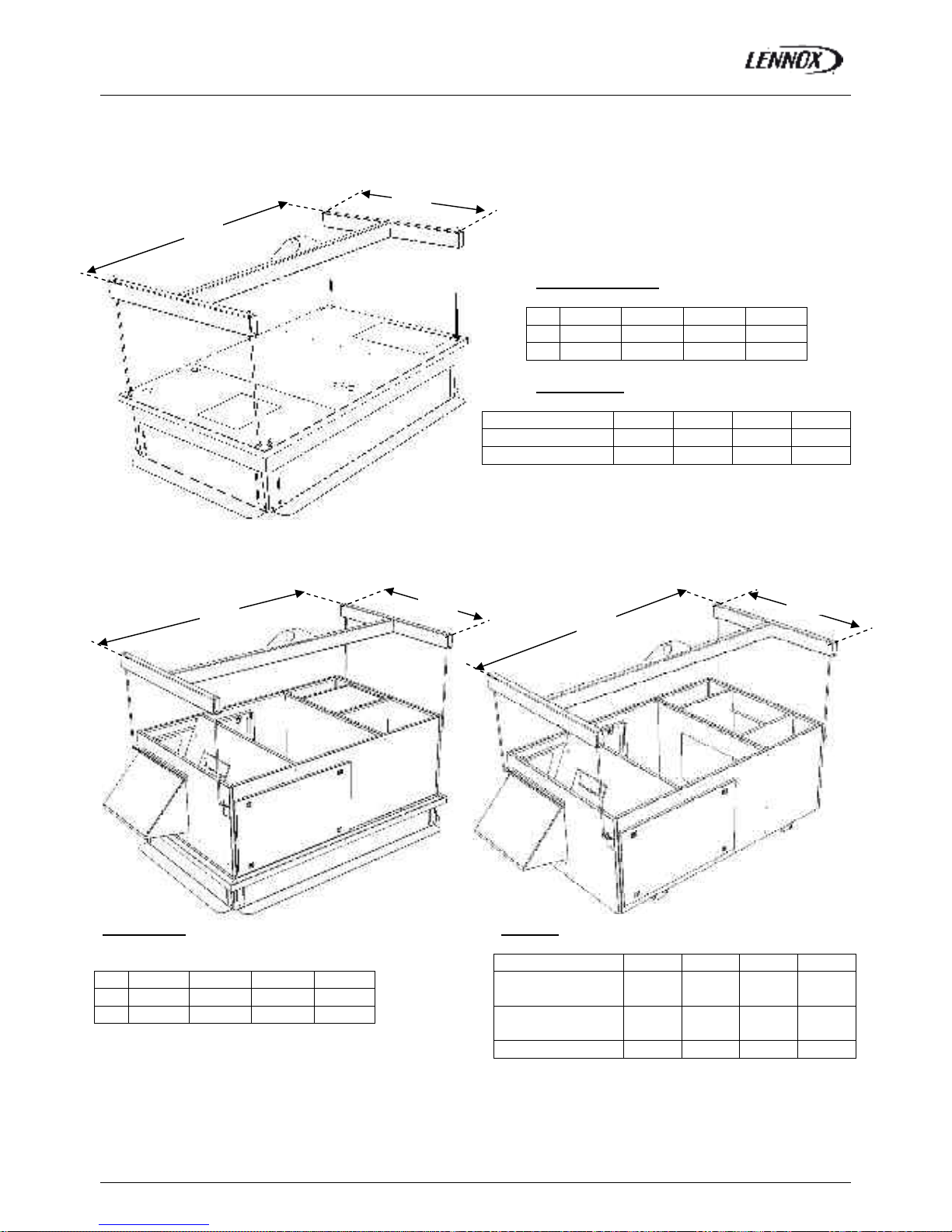

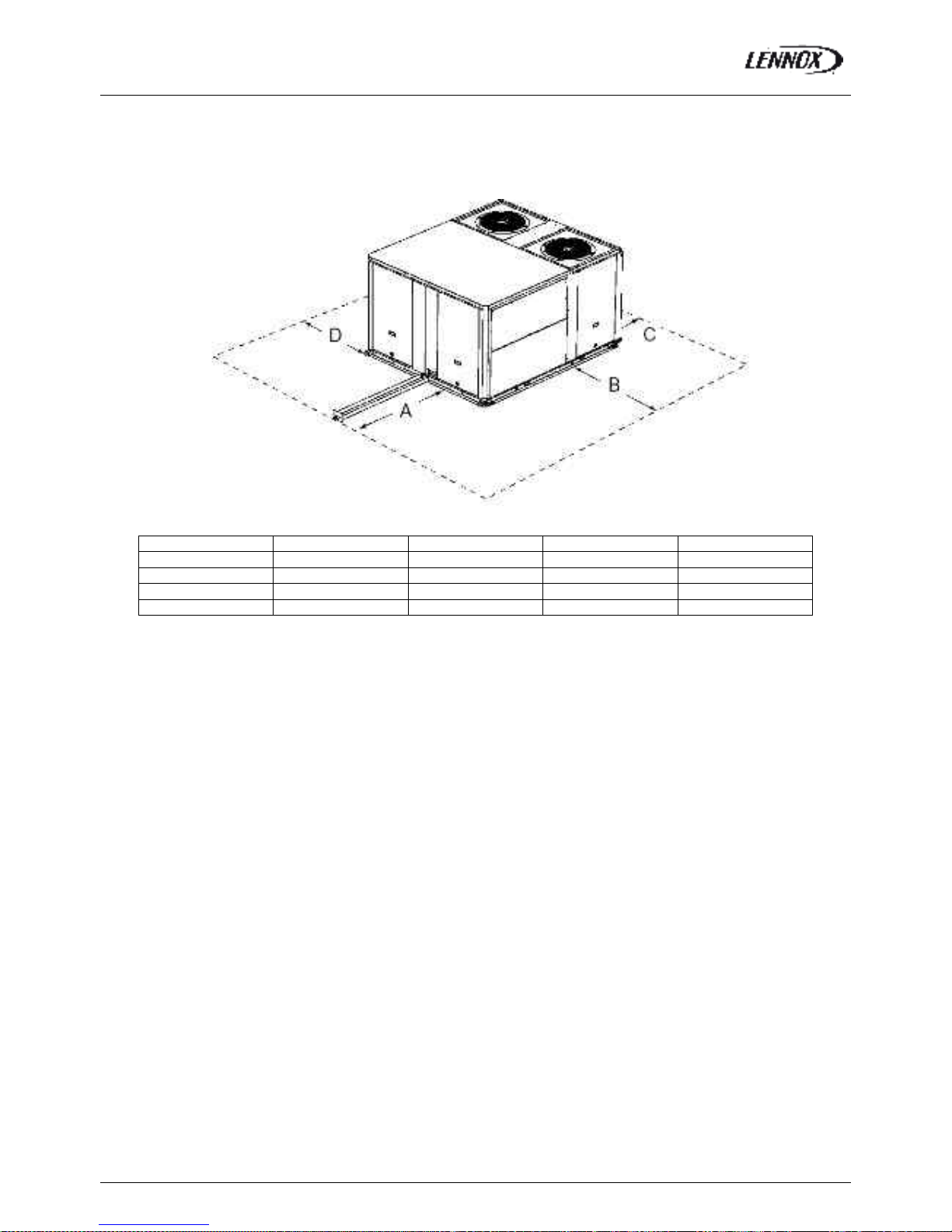

LIFTING THE ROOF CURBS

ADJUSTABLE ROOF CURB

Dimensions (mm)

B box C box D box E box

A 1890 1735 1735 2085

B 1100 1295 1545 1995

Weights (kg)

B box C box D box E box

No aux.heating 87 94 104 152

With aux.heating 86 90 100 138.2

EXHAUST ROOF CURB

Dimensions

B box C box D box E box

A 2050 1900 1900 2250

B 1160 1360 1610 2060

Weights

B box C box D box E box

Vertical No

aux.heating

192 220 240 370

Vertical With

aux.heating

194 194 240 365

Horizontal 142 168 185 301

Fig. 10

Fig. 11 Fig. 12

Page 17

TRANSPORT – HANDLING

BALTIC R410A-IOM-0708-E Page 16

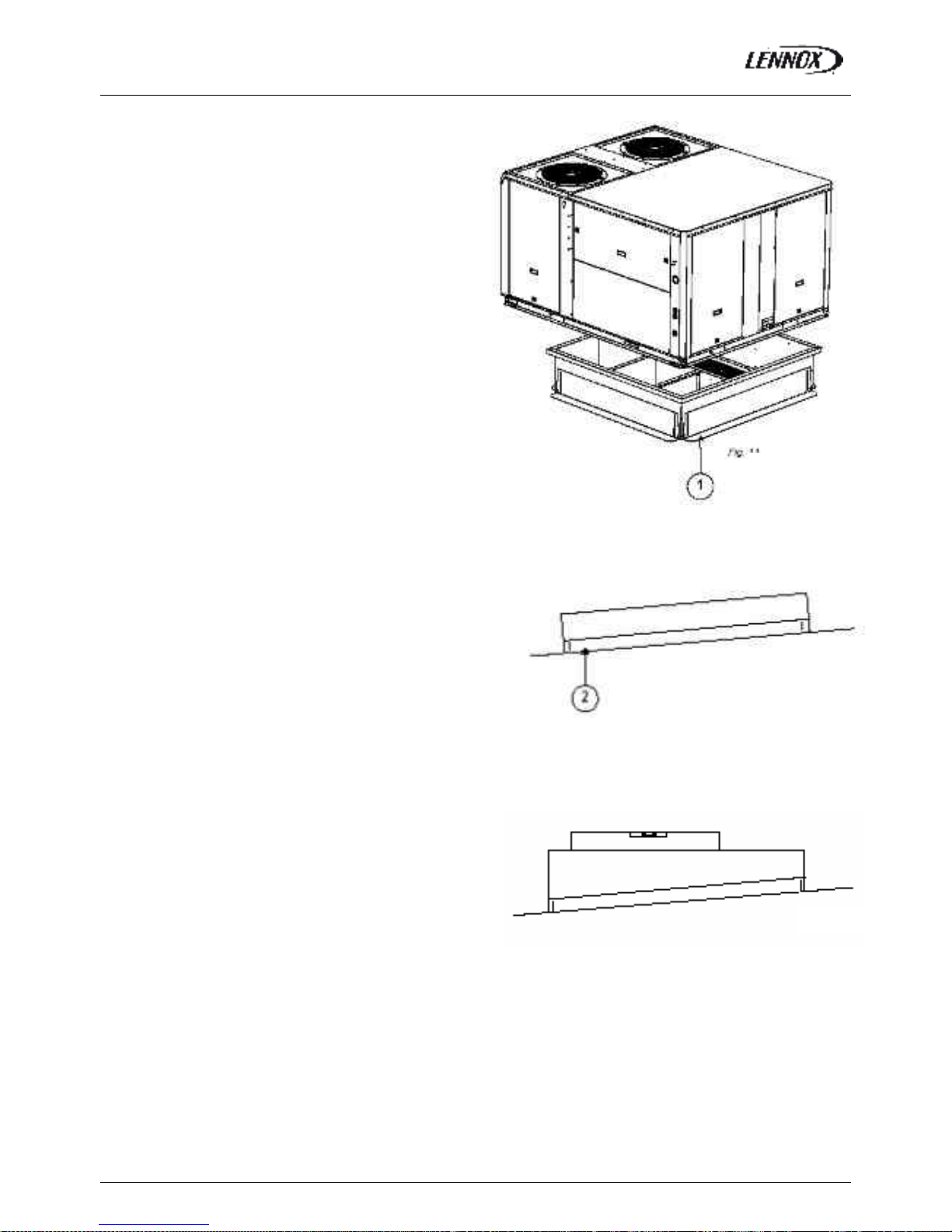

MULTIDIRECTIONNAL ROOF CURB

Dimensions (mm)

B box C box D box E box

A 2050 1900 1900 2250

B 1160 1360 1610 2060

Weights (kg)

B box C box D box E box

No aux.heating 81 88 100 147

With aux.heating 90 93 103 146.7

LIFTING THE ENERGY RECOVERY MODULE

Dimensions

B box C box D box E box

A 1290 1290 1290 1290

B 820 1170 1547 1895

Weights (kg)

B box C box D box E box

143 172 229 317

Fig.13

Fig.14

Page 18

INSTALLATION

BALTIC R410A-IOM-0708-E Page 17

FORKLIFT PROTECTIONS

REMOVE THE FORKLIFT PROTECTIONS BEFORE INSTALLATION

PRELIMINARY CHECKS

Before installing the equipment, the following points MUST

be checked:

- Have the forklift protections been removed?

- Is there sufficient space for the equipment?

- Is the surface on which the equipment is to be

installed sufficiently solid to withstand its weight? A

detailed study of the frame must be made beforehand.

- Do the supply and return ductwork openings

excessively weaken the structure?

- Are there any obstructing items which could hinder the

operation of the equipment?

- Does the electrical power available correspond to the

equipment's electrical specifications?

- Is drainage provided for the condensate?

- Is there sufficient access for maintenance?

- Installation of the equipment could require different

lifting methods which may vary with each installation

(helicopter or crane). Have these been evaluated?

- Ensure that the unit is installed in accordance with the

installation instructions and local applicable codes.

- Check to ensure that the refrigerant lines do not rub

against the cabinet or against other refrigerant lines.

In general, make sure no obstacles (walls, trees or roof

ledges) are obstructing the duct connections or hindering

assembly and maintenance access.

INSTALLAT ION REQUIREMENTS

The surface on which the equipment is to be installed must

be clean and free of any obstacles which could hinder the

flow of air to the condensers:

-Avoid uneven surfaces

-Avoid installing two units side by side or close to each

other as this may restrict the airflow to the condensers.

Before installing a packaged Rooftop unit it is important to

understand:

- The direction of prevailing winds

-The direction and position of air flows.

-The external dimensions of the unit and the

dimensions

of the supply and return air connections.

-The arrangement of the doors and the space required

to open them to access the various components.

CONNECTIONS

-Ensure that all the pipe-work crossing walls or roofs

are secured, sealed and insulate d.

-To avoid condensation problems, make sure that all

pipes are insulated according to the temperatures of

fluids and type of rooms.

NOTE: The AQUILUX protection sheets fitted to the finned

surfaces must be removed prior to start up.

Fig. 15

Page 19

INSTALLATION

BALTIC R410A-IOM-0708-E Page 18

MINIMUM CLEARANCE AROUND THE UNIT

Figure 4 shows the required clearances and service access around the unit.

NOTE: Ensure the fresh air inlet does not face prevailing wind direction.

A B C D

B Box 1000

(1)

1500

(2)

1500 1000

C Box 1200

(1)

1500

(2)

1500 1000

D Box 1400

(1)

1500

(2)

1500 1000

E Box 1800

(1)

1500

(2)

1500 1100

(1) Add 1 meter if the units are equipped with gas burner

(2) Double this distance if the units are equipped with extraction

Fig. 16

Page 20

INSTALLATION ON A ROOF MOUNTING FRAMES

BALTIC R410A-IOM-0708-E Page 19

POSITIONING ROOFCURBS

As levels are adjustable, observe the following

recommendations when installing the equipment.

Above all, ensure that all the adjustable returns are facing

outward (“1” figure 17). They are usually turned inside-out

for transport.

Place the roof mounting frame on the trimmer beam by first

lining up the inlet and the outlet opening. (“2”- figure 18)

After levelling the frame, secure the adjustable returns on

the trimmer.

It is important to centre the unit on the roof frame.

Fig. 17

Fig. 18

Fig. 19

Page 21

INSTALLATION ON A ROOF MOUNTING FRAMES

BALTIC R410A-IOM-0708-E Page 20

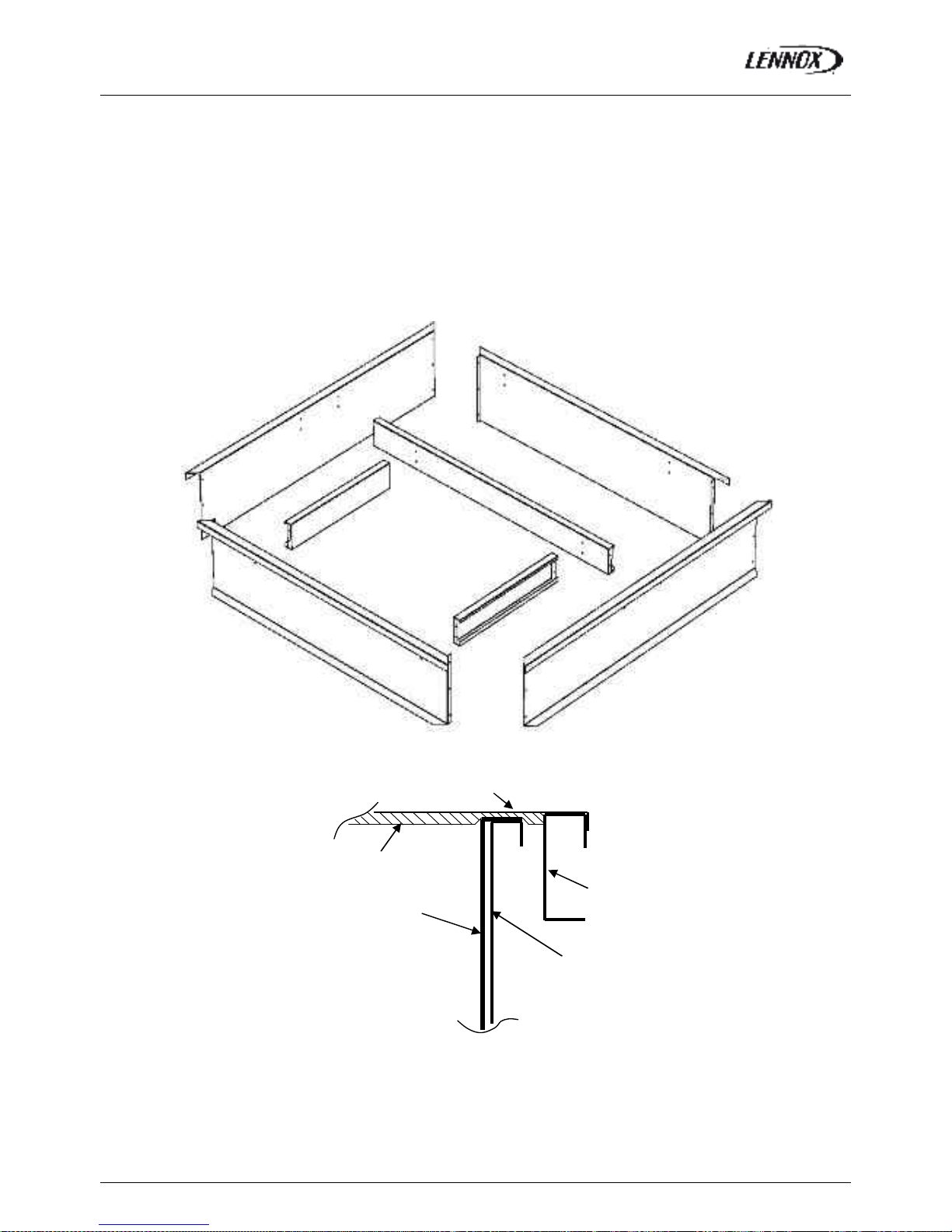

NON ADJUSTABLE NON ASSEMBLIED ROOFCURB

FRAME PARTS IDENTIFICATION

Figure 20 shows the different parts used in the assembly of this roof mounting frame.

INSTALLATION

The roof mounting frame provides support when the units are installed in down-flow configurations.

The non adjustable, non assembled roof mounting frame can be installed directly on decks having adequate structural strength

or on roof supports under deck. See page 24 for frame dimensions, location of supply and return air opening

NOTE: frame assembly must be installed flat, levelled within 5mm per linear meter in any direction.

UNIT FLOOR

UNIT FLOOR

AIR DUCT

UNIT Support rail

ROOFCURB

Fig. 20

Fig. 21

Page 22

INSTALLATION ON A ROOF MOUNTING FRAMES

BALTIC R410A-IOM-0708-E Page 21

NON ADJUSTABLE NON ASSEMBLED ROOFCURB

ASSEMBLY

The frame is supplied as a single package and shipped folded down for ease of transport and handling. It is easy field

assembled as all parts required are supplied with the frame.

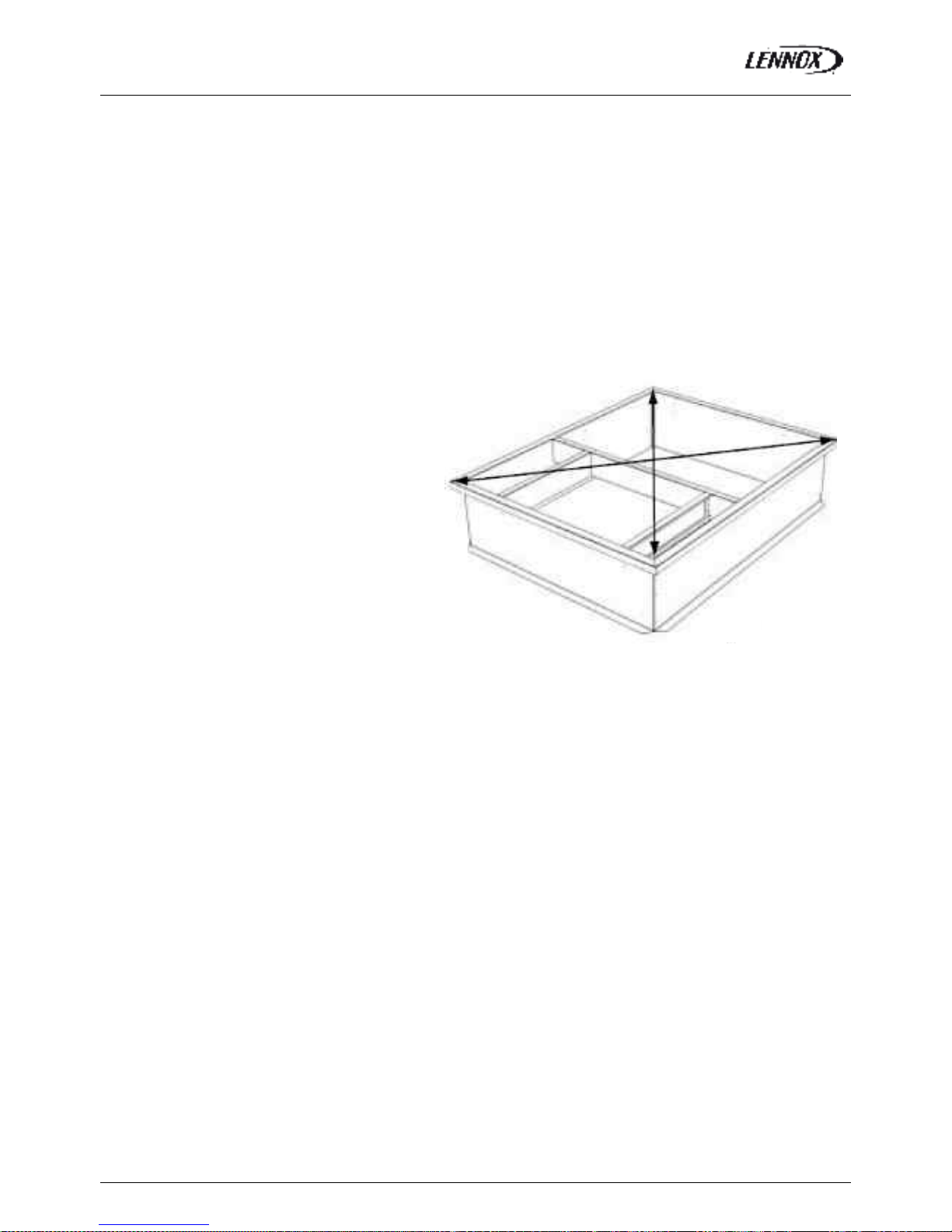

SECURING THE FRAME

To ensure proper mating with units (figure 22), it is mandatory that the roof mounting frame be squared to roof structure as

follows:

-With frame positioned levelled in the desired location

on roof trusses, tack weld corne r of frame.

-Measure frame diagonally from corner to corner as

shown in figure 16. These Dimensions must be equal in

order for the fame to be square.

-It is extremely important to sight frame from all corner

to ensure it is not twisted across. Shim frame under any

low side. The maximum slope tolerance is 5mm per

linear meter in any direction.

-After the frame has been squared, straightened and

shimmed, weld or secure the frame to the roof deck.

NOTE: It must be securely fastened to the roof as per local codes and regulations.

Fig. 22

Page 23

INSTALLATION ON A ROOF MOUNTING FRAMES

BALTIC R410A-IOM-0708-E Page 22

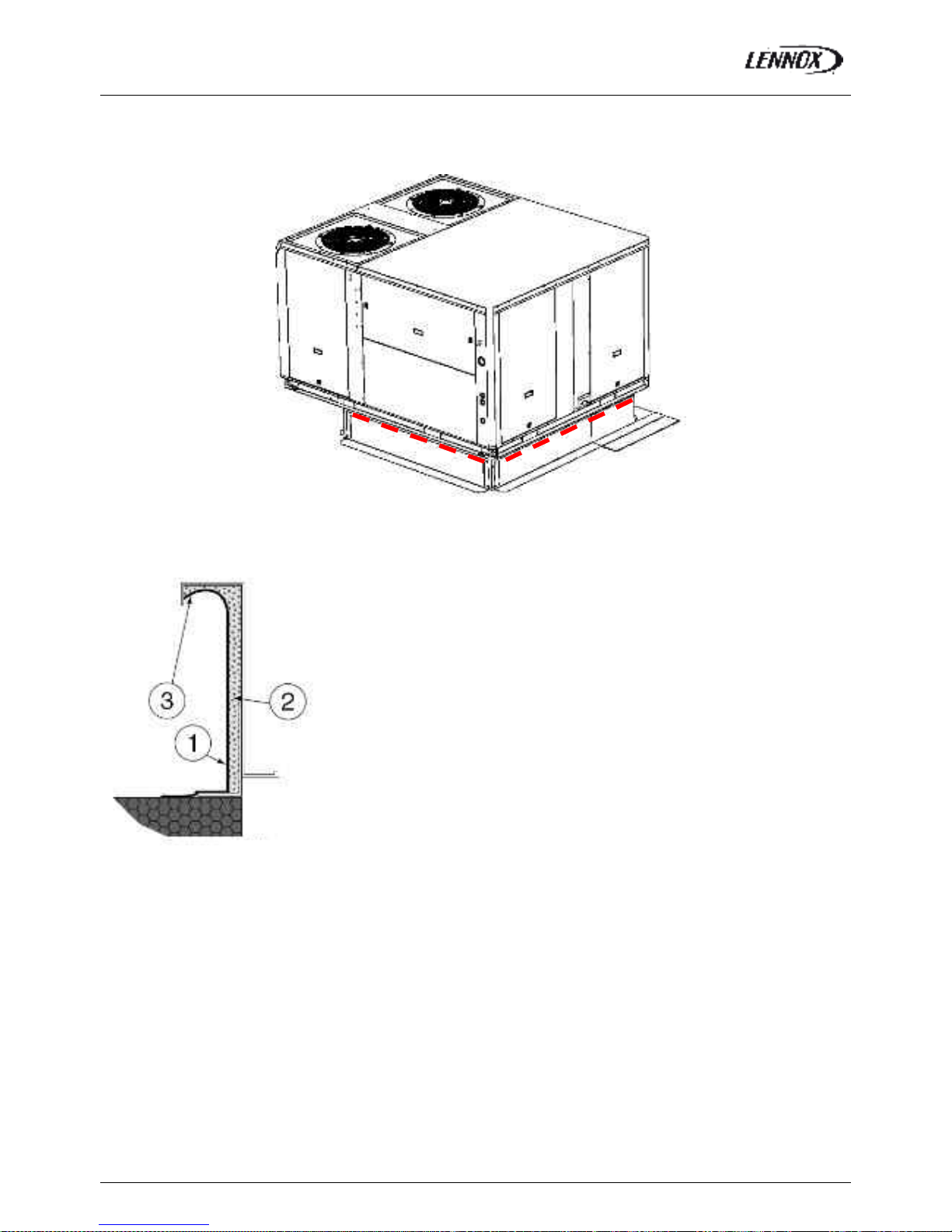

SECURING THE CURB

When the frame is correctly positioned, it is essential to secure the assembly with a disconnected stitched welded seam (20 to

30 mm every 200 mm

- - - -) along the outside or by using an alternative method.

CURBING AND FLASHING

Outside of frame must be insulated with rigid type insulation;

We recommend a minimum of 20 mm thick insulation (2 figure 24).

Check that the insulation is continuous, counter flash and seal around the frame

as shown in (1-figure 24).

CAUTION: To be effective, the upstream must end below the drop edge (3 - figure

24).

Where pipes and electrical conduits extend through the roof, flashing must

conform to local codes of practice

Before installing the equipment, make sure that seals are not damaged and check that the unit is secured to the mounting

frame. Once in position, the bottom of the equipment must be horizontal.

The installer must comply with local authority standards and specifications.

Fig. 23

Fig. 24

Page 24

INSTALLATION ON A ROOF MOUNTING FRAMES

BALTIC R410A-IOM-0708-E Page 23

Heat Recovery Installation

1) The unit being already erected on the roof curb, position the elbow by plugging the returns (A) in the slits (B) of the

framework of the unit: see detail

2) Fix the elbow with caged nuts at envisaged places (C)

3) Apply mastic on the two side studs and on the superior stud of the energy recovery box.

4) Pose the energy recovery box on the elbow

5) Fix the energy recovery box thanks to the two edges at 45° right and left with self-drilling screws (D)

1

4

Fig. 25

Page 25

ECONOMISER AND EXTRACTION

BALTIC R410A-IOM-0708-E Page 24

Economiser

Free cooling can be provided through the use of fresh air where appropriate rather than

cooling excessive amounts of return air.

The economiser is factory fitted and tested prior to shipment.

It includes two dampers operating from a 24V actuator

Rain hood

It also includes a factory fitted rai n hood. Hoods is folded during transportation to limit

risks of damage and must be unfolded on site as shown on fig. 26

Extraction

Installed with economiser assembly, the gravity exhaust dampers relieve the pressure

when outside air is introduced into the system.

When large amount of fresh air is introduced into the system power exhaust fans can be

used to equalise the pressures.

The extraction fan runs when return air dampers are being closed and supply air blower is

in operation. The extraction fan runs when outdoor air dampers are at least 50% open

(adjustable value). It is overload protected.

NOTE: When horizontal flow configuration is required, the multidirectional roof curb will be

installed.

0-25% fresh air manual (Fig. 27)

It is enough to loosen the mobile grid's screws and to make it slip.

0%: screw into limit stop on the right

25%: screw into limit stop on the left

Fig. 27

Fig. 26

Page 26

ECONOMISER AND EXTRACTION

BALTIC R410A-IOM-0708-E Page 25

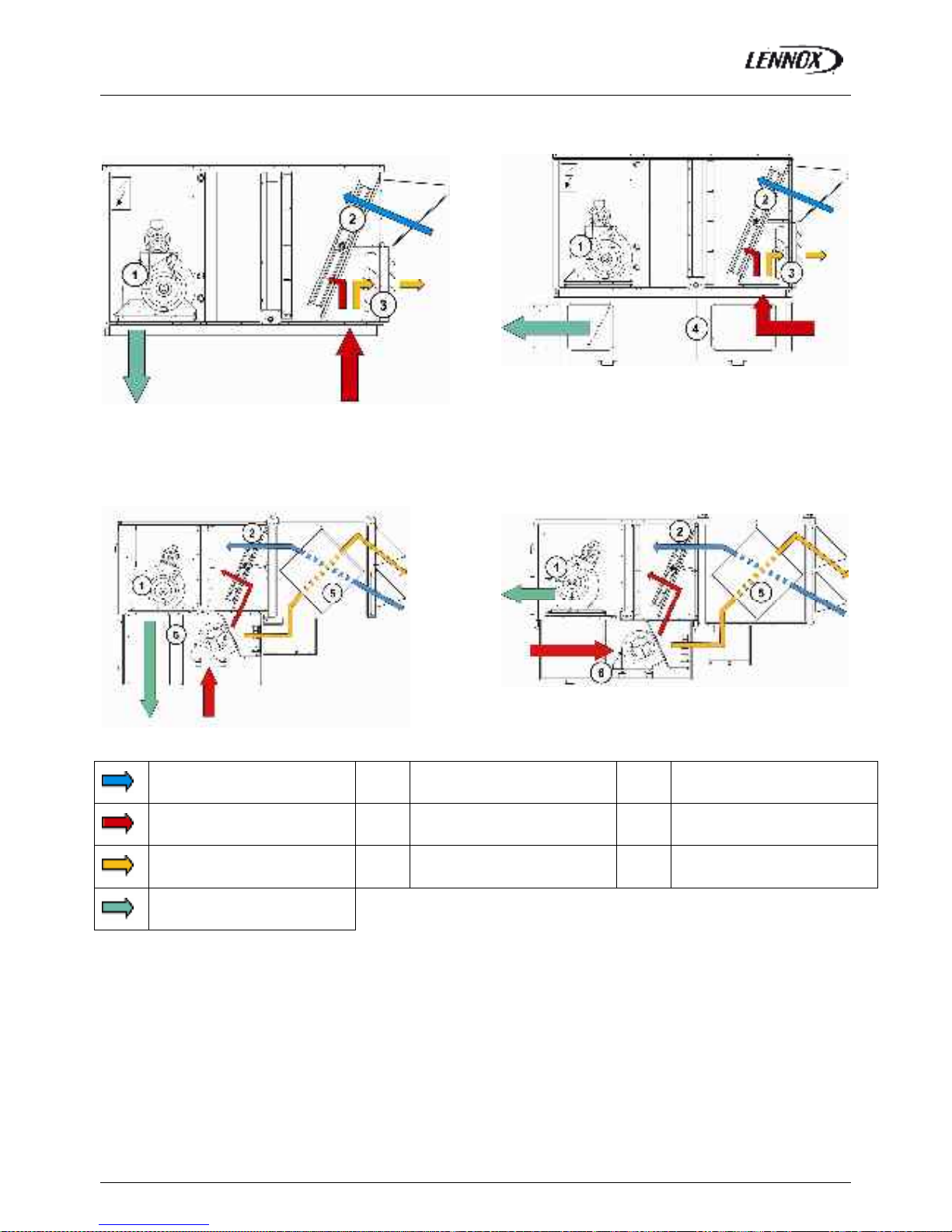

VERTICAL FLOW

ENERGY RECOVERY MODULE + EXHAUST

ROOFCURB

(Vertical flow)

MULTIDIRECTIONAL ROOFCURB

ENERGY RECOVERY MODULE + EXHAUST

ROOFCURB

(Horizontal flow)

Fresh air 1 Supply fan 4 Multidirectional roofcurb

Return air 2 Economiser damper 5 Heat recovery module

Exhaust air 3 Exhaust damper 6 Exhaust Roofcurb

Supply air

Page 27

COMMISSIONING

BALTIC R410A-IOM-0708-E Page 26

THIS WORK MUST ONLY BE CARRIED OUT

BY TRAINED REFRIGERATION ENGINEERS

FILL THE COMMISSI ONNING SHEET AS YOU GO

ALONG

ELECTRICAL CONNECTIONS

Ensure that the power supply between the building and the

unit meets local authority standards and that the cable

specification satisfies the start-up and operating conditions.

ENSURE THAT THE POWER SUPPLY

INCLUDES 3 PHASES

(+ NEUTRAL if the unit is equipped with the

power exhaust fan)

Check the following wire connections for tightness:

Main switch connections, mains wires linked to the

contactors and circuit breakers and the cables in the

24V control supply circuit.

How to connect roof curbs and energy recovery module

Cables and their connectors corresponding to the roof curb’

motor and actuator and extraction box’ ones are already

rolled up in these elements; it is enough to bring them

through the openings envisaged and to connect them on

the sites indicated on the figure 28.

It’s the same procedure when you have an energy recovery

module.

PRELIMINARY CHECKS

Ensure that all drive motors are secure.

Ensure that the adjustable pulley blocks are secure and

that the belt is tensioned with the transmission correctly

aligned. Refer to the next section foe details.

Using the electrical wiring diagram, check the

conformity of the electrical safety devices (circuit

breaker settings, presence and rating of fuses).

Check the temperature probe connections.

Fig.29

Connector for the roof

curb motor or the

extraction box’ one

Connector for the roof

curb actuator or the

extraction box’ one

Connector for the

energy recovery

module + Fresh air

sensor

Fig. 28

Page 28

COMMISSIONING

BALTIC R410A-IOM-0708-E Page 27

STARTING THE UNIT

At this point the unit circuit breakers should be open

You will need a DS50 maintenance controller or Climalook

with appropriate Interface.

Fig. 30

The jumpers are factory set and the configuration switches

are adjusted depending on the op tion the type of unit.

Connecting the CLIMATIC displays

Fig. 31

Close the 24V Control Circuit breakers.

Fig. 32

The CLIMATIC 50 starts after 30s

Reset the DAD photo (If fitted)

Fig. 33

Check and adjust the control settings.

Refer to the control section in this manual to adjust the

different parameters

Language o r

ENGLISH

RT 050.001

BIOS. 0000 Boot 0000

Page 29

COMMISSIONING

BALTIC R410A-IOM-0708-E Page 28

POWERING THE UNIT

- Power up the unit by closing the isolator switch (if fitted).

- At this point the blower should start unless the climatic

does not energise the contactor. In this particular case

the blower can be forced by bridging the port NO7 and

C7 on connector J14 on the Climatic. Once the fan is

running, check the rotation direction. Refer to the rotation

arrow located on the fan.

- The fans and compressors direction of rotation is

checked during the end of line test. They should therefore

all turn in either the right or wrong direction.

NOTE: A compressor rotating in the wrong direction will

fail.

- If the fan turns in the wrong direction (the right direction

is shown on figure n° 27), disconnect the main power

supply to the machine at the building's mains switch,

reverse two phases and repeat the above procedure.

- Close all circuit breakers and power up the unit, remove

the bridge on connector J14 if fitted.

- If now only one of the components rotates in the wrong

direction, disconnect the power supply at the machine's

isolator switch (if fitted) and reverse two of the

component’s phases on the terminal within the electrical

panel.

- Check the current drawn against the rated values, in

particular on the supply fan (ref. page 34).

- If the readings on the fan are outside the specified

limits, this usually indicates excessive air flow which will

affect the life expectancy and the thermodynamic

performances of the unit. This will also increase the risks

of water ingress into the unit. Refer to the "Air Flow

Balancing" section to correct the problem.

At this point attach the manometers to the refrigerant circuit

Fig. 34

RUN TEST

Start unit in cooling mode

Thermodynamic readings using manometers and prevailing

environmental conditions

No rated values are given here. These depend on the

climatic conditions both outside and inside the building

during operation. However, an experienced refrigeration

engineer will be able to detect any abnormal machine

operation.

Safety test

- Check Air pressure switch (if fitted) "Dirty filter" detection

test: vary the set-point value (menu page 3413 on DS50)

in respect to the air pressure value. Observe the response

of the CLIMATIC™.

- Same procedure for detecting "Missing Filter" (page

menu 3412) or "Air Flow Detection" (page menu 3411).

- Check the smoke detection function (if fitted).

- Check the Firestart by press ing the test button (if fitted).

- Disconnect the circuit breakers of the capacitor fans and

check the high pressure cut-out points on different

refrigerant circuits.

Reverse cycle test

This test is designed to check the good operation of the 4way reversing valves on heat pump reversible systems.

Start the reverse cycle by adjusting the cold or hot

temperature threshold data according to the i ndoor and

outdoor conditions at the time of te st (menu 3320)

Fig. 35

Page 30

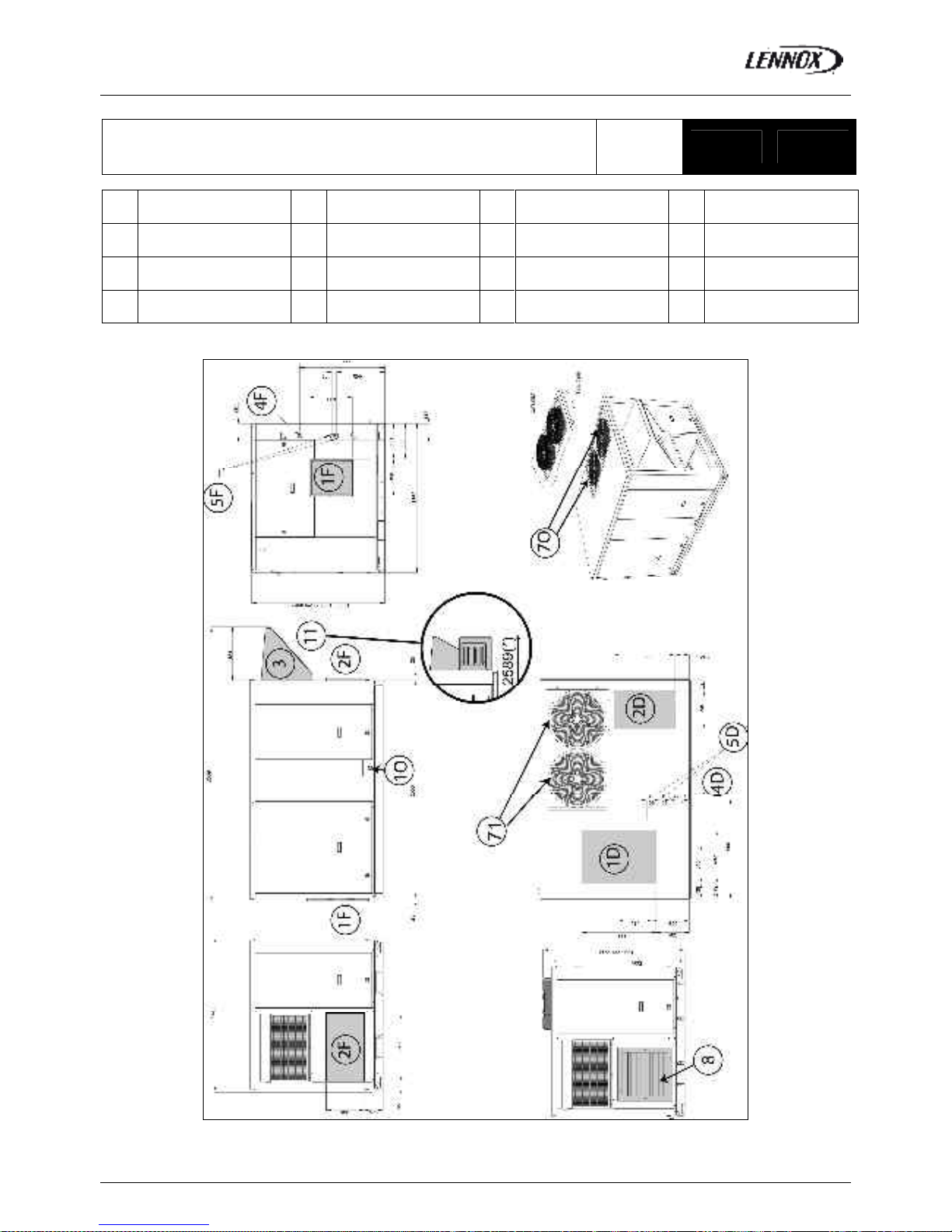

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 29

WITH OPTIONS

(Return and supply opening shown on this drawing do not apply to

BAC/BAH with electric heater or hot water coil )

BAC

BAH

020 030

1D Down supply air 3 Fresh air 5D Down hot water entry 8 Extraction

1F Front supply air 4F Front main power entry 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 5F Front hot water entry 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 31

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 30

WITH OPTIONS

(Return and supply opening shown on this drawing do apply to BAC/BAH

with electric heater or hot water coil )

BAG

BAM

020 030

1D Down supply air 3 Fresh air 8 Extraction

1F Front supply air 4F Front main power entry 6 Gas supply inlet 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 32

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 31

WITH OPTIONS

(Return and supply opening shown on this drawing do not apply to BAC/BAH with electric

heater or hot water coil )

BAC

BAH

035

1D Down supply air 3 Fresh air 5D Down hot water entry 8 Extraction

1F Front supply air 4F Front main power entry 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 5F Front hot water entry 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 33

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 32

WITH OPTIONS

(Return and supply opening shown on this drawing do apply to BAC/BAH with electric

heater or hot water coil )

BAG

BAM

035

1D Down supply air 3 Fresh air 8 Extraction

1F Front supply air 4F Front main power entry 6 Gas supply inlet 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 34

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 33

WITH OPTIONS

(Return and supply opening shown on this drawing do not apply to

BAC/BAH with electric heater or hot water coil )

BAC

BAH

045 055

1D Down supply air 3 Fresh air 5D Down hot water entry 8 Extraction

1F Front supply air 4F Front main power entry 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 5F Front hot water entry 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 35

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 34

WITH OPTIONS

(Return and supply opening shown on this drawing do apply to BAC/BAH

with electric heater or hot water coil )

BAG

BAM

045 055

1D Down supply air 3 Fresh air 8 Extraction

1F Front supply air 4F Front main power entry 6 Gas supply inlet 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 36

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 35

WITH OPTIONS

(Return and supply opening shown on this drawing do not apply to

BAC/BAH with electric heater or hot water coil )

BAC

BAH

065 075

1D Down supply air 3 Fresh air 5D Down hot water entry 8 Extraction

1F Front supply air 4F Front main power entry 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 5F Front hot water entry 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 37

ARRANGEMENT DRAWINGS

BALTIC R410A-IOM-0708-E Page 36

WITH OPTIONS

(Return and supply opening shown on this drawing do apply to BAC/BAH

with electric heater or hot water coil )

BAG

BAM

065 075

1D Down supply air 3 Fresh air 8 Extraction

1F Front supply air 4F Front main power entry 6 Gas supply inlet 9 Smoke outlet

2D Down return air 4D

Down main power

entry

71 Outdoor coil inlet 10 Condensate drainage

2F Front return air 70 Outdoor coil outlet

(*) Total Length (unit + option)

Page 38

NON ADJUSTABLE ROOFCURB

BALTIC R410A-IOM-0708-E Page 37

BAC = Cooling only unit

BAH = Heat pump unit

BAG = Cooling only unit with gas fired heating

BAM = Heat pump unit with gas fired heating

ALL UNITS

1D Down supply air 8 Main Power Entry 030-035-040-045-050

2D Return air 8’ Main Power Entry 020-025

Type Size A B C D E F G H I J

020

030

1183 1893 691 400 246 246 515 50 1783 1083

035 1380 1740 790 400 351 240 675 50 1640 1280

045

055

1630 1740 1050 400 352 229 675 50 1640 1530

065

All

075

2080 2090 1400 400 425 255 720 156 1990 1980

Roof opening I x J

Page 39

ADJUSTABLE ROOFCURB

BALTIC R410A-IOM-0708-E Page 38

020 030

A B

BAC / BAH _BAG / BAM or BAC / BAH with auxiliary heating 247 691

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry

Roof opening 1795 x 1085

Page 40

ADJUSTABLE ROOFCURB

BALTIC R410A-IOM-0708-E Page 39

035

A B C D

BAC / BAH _BAG / BAM or BAC / BAH with auxiliary heating 636 351 790 241

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry

Roof opening 1642 x 1282

Page 41

ADJUSTABLE ROOFCURB

BALTIC R410A-IOM-0708-E Page 40

045 055

A B C D

BAC / BAH _ BAG / BAM or BAC / BAH with auxiliary heating 352 1050 230 637

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry

Roof opening 1642 x 1532

Page 42

ADJUSTABLE ROOFCURB

BALTIC R410A-IOM-0708-E Page 41

BAC

BAH

BAG

BAM

065 075

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry

Page 43

MULTIDIRECTIONAL HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 42

BAC

BAH

BAG

BAM

020 030

1F 2F

1F’

Front supply air

2F’

Front return air

(*) This roofcurb is also necessary for all cooling only or heatpump rooftop with auxiliary electric heater or hot water coil.

WARNING : ONLY ONE OF THE 4 FOLLOW INGS POSSIBILITIES :

2F - 1F / 2F - 1F'

2F' - 1F / 2F' - 1F'

Page 44

MULTIDIRECTIONAL HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 43

BAC

BAH

BAG

BAM

035

1F 2F

1F’

Front supply air

2F’

Front return air

(*) This roofcurb is also necessary for all cooling only or heatpump rooftop with auxiliary electric heater or hot water coil.

WARNING : ONLY ONE OF THE 4 FOLLOW INGS POSSIBILITIES :

2F - 1F / 2F - 1F'

2F' - 1F / 2F' - 1F'

Page 45

MULTIDIRECTIONAL HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 44

BAC

BAH

BAG

BAM

045 055

1F 2F

1F’

Front supply air

2F’

Front return air

(*) This roofcurb is also necessary for all cooling only or heatpump rooftop with auxiliary electric heater or hot water coil.

WARNING : ONLY ONE OF THE 4 FOLLOW INGS POSSIBILITIES :

2F - 1F / 2F - 1F'

2F' - 1F / 2F' - 1F'

Page 46

MULTIDIRECTIONAL HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 45

BAC

BAH

BAG

BAM

065 075

1F 2F

1F’

Front supply air

2F’

Front return air

WARNING : ONLY ONE OF THE 4 FOLLOW INGS POSSIBILITIES :

2F - 1F / 2F - 1F'

2F' - 1F / 2F' - 1F'

Page 47

EXHAUST VERTICAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 46

020 030

A B

BAC / BAH without auxiliary heating 395 542

BAG / BAM or BAC / BAH with auxiliary heating 691 246

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 48

EXHAUST VERTICAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 47

035

A B C

BAC / BAH without auxiliary heating 632 400 348

BAG / BAM or BAC / BAH with auxiliary heating 350 790 240

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 49

EXHAUST VERTICAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 48

045 055

A B B C

BAC / BAH without auxiliary heating 749 500 382 496

BAG / BAM or BAC / BAH with auxiliary heating 351 1050 229 636

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 50

EXHAUST VERTICAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 49

BAC

BAH

BAG

BAM

065 075

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 51

EXHAUST HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 50

BAC

BAH

BAG

BAM

020 030 035

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 52

EXHAUST HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 51

BAC

BAH

BAG

BAM

045 055

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 53

EXHAUST HORIZONTAL ROOFCURB

BALTIC R410A-IOM-0708-E Page 52

BAC

BAH

BAG

BAM

065 075

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 54

TRANSITION ROOFCURB

BALTIC R410A-IOM-0708-E Page 53

BAC

BAH

BAG

BAM

065 075

1D Down supply air 4D Down main power entry

2D Down return air 5D Down hot water entry

8 Main power entry 9 Exhaust

Page 55

ENERGY RECOVERY OPTION

BALTIC R410A-IOM-0708-E Page 54

020 030

Part 1 and 2 are supplied loose + Fresh air and extracted air hood closed

Exhaust air

Fresh air

Exhaust air

Fresh air

Page 56

ENERGY RECOVERY OPTION

BALTIC R410A-IOM-0708-E Page 55

035

Part 1 and 2 are supplied loose + Fresh air and extracted air hood closed

Exhaust air

Fresh air

Exhaust air

Fresh air

Page 57

ENERGY RECOVERY OPTION

BALTIC R410A-IOM-0708-E Page 56

045 055

Part 1 and 2 are supplied loose + Fresh air and extracted air hood closed

Exhaust air

Fresh air

Exhaust air

Fresh air

Page 58

ENERGY RECOVERY OPTION

BALTIC R410A-IOM-0708-E Page 57

065 075

Part 1 and 2 are supplied loose + Fresh air and extracted air hood closed

Exhaust air

Fresh air

Exhaust air

Fresh air

Page 59

VENTILATION BELT TENSION

BALTIC R410A-IOM-0708-E Page 58

BELT TENSION

On delivery, the drive belts are new and correctly

tensioned. After the first 50 operating hours check and

adjust the tension. 80% of the total elongation of belts is

generally produced during the first 15 hours of operation.

Before adjusting the tension, make sure that the pulleys are

correctly aligned.

To tension the belt, set the height of motor support plate by

moving the plate adjustment screws.

The recommended deflection is 20 mm per metre from

centre to centre.

Check that according to the diagram below (figure 37), the

following ratio rem ains the same.

A (mm)

= 20

P (mm)

The belts should always be replaced when:

- The disk is set to maximum,

- The belt rubber is worn or the wire is visible.

Replacement belts must have the same rated size as the

ones they are replacing. If a transmission system has

several belts, they must all be from the same

manufacturing batch (compare serial numbers).

Fig.36

NOTE:

An under-tensioned belt will slip, heat and wear

prematurely. On the other hand, if a belt is over-tensioned,

the pressure on the bearings will cause them to over-heat

and wear prematurely. Incorrect alignment will also cause

the belts to wear prematurely.

Fig. 37

Page 60

VENTILATION : PULLEYS

BALTIC R410A-IOM-0708-E Page 59

MOUNTING AND ADJUSTING PULLEYS

Fan pulley removal

Remove the 2 screws and put one of them in the extraction

threaded screw.

Screw in fully. The hub and the pulley will separate from

each other.

Remove the hub and the pulley by hand without damaging

the machine.

Fig. 38

Fan pulley installation

Clean and de-grease the shaft, hub and conical bore of the

pulley. Lubricate the screws and install the hub and pulley.

Position the screws without turning them.

Place the assembly on the shaft and screw in the screws

alternatively and evenly. Using a mallet or a hammer with a

wooden wedge, tap on the face of the hub to keep the

assembly in place. Torque the screws to 30 Nm.

Take the pulley in both hands and shake it vigorously to

make sure everything is in place.

Fill the holes with grease for protection.

NOTE : During installation, the key should never protrude

out of its groove.

After 50 operating hours, check that the screws are still in

place.

Fig.39

MOTOR PULLEY INSTALLATION AND REMOVAL

The pulley is held in position by the key and a screw

located in the groove. After unlocking, removing this screw

by pulling against the shaft spindle (if necessary, use a

mallet and tap uniformly on the hub to remove it).

To assemble, proceed in the reverse order after having

cleaned and de-greased the motor shaft and the pulley

bore.

PULLEYS ALIGNMENT

After adjusting one or both of the pulleys, check the

transmission alignment using a ruler placed on the inner

face of the two pulleys.

NOTE: The warranty may be affected if any major

modification is made to the

transmission without obtaining our agreement beforehand.

Fig. 40

Page 61

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 60

The actual resistance of ductwork systems is not always identical to the calculated theoretical values. To rectify this, it may be

necessary to modify the pulley and be lt setting. To this effect, the motors are fitted with variable pulleys.

SITE TEST AND MAINTENANCE

Measure the motor absorbed power.

If the absorbed power is greater and the pressure lower than the rated values, the ventilation system has a lower pressure drop

than anticipated. Reduce the flow by reducing the rpm. If the system resistance is significantly lower than design, there is a risk

that the motor will overheat resulting in an emergency cut out.

If the absorbed power is lower and the pressure greater than the rated values, your system has a higher pressure drop than

anticipated. Increase the flow by increasing the rpm. At the same time you will increase the absorbed power which may result in

having to increase the motor size.

To carry out the adjustment and to avoid a time-consuming re-start, stop the machine and if necessary lock the main switch.

First unscrew the 4 Allen screw(s) on the pulley (see figure11).

Actual diameter (DM) or distance between faces for a given number of turns

from fully closed with SPA belt in (mm)

Pulley

type

Pulley

External

Diameter

Min

Dia /

Min

Dist

Max

Dia /

Max

Dist

Nb of turns

from fully

closed to

fully open

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

95 116 5 114 112 110 108 106 103

101.3

99.2 97.1 95 -

8450 /

D8450

120

20.2 28 5 21 21.8 22.5 23.3 24.1 24.9

25.7

26.4 27.2 28 -

110 131 5 129 127 125 123 121 118 116 114 112 110 -

8550 /

D8550

136

20.6 31.2 5 21.6 22.7 23.8 24.8 25.9 26.9 28 29.1 30.1 31 -

Table_2

The easiest way to determine the fan rotation speed is to

use a Tachometer. If not available the fan rpm can be

estimated using the following two methods.

1

st

Method with the pulley secured in place:

Measure the distance between the two outside faces of the

pulley.

Using table (2) the motor pulley actual diameter can be

estimated

L

Fig. 41

Page 62

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 61

2

nd

method when adjusting the pulley :

-Close the pulley fully and count the number of turns

from fully closed position. Using table_2 determine the

motor pulley actual diameter.

-Record the fix fan pulley diameter.(DF)

-Determine the fan speed using the following formulae:

Where: rpm

MOTOR

:from the motor plate or table_3

DM : from table2

DF: from machine

Once the pulleys are adjusted and the belt checked and

tensioned, start the fan motor and record the Amps and

Voltage between the phases :

Using the measured data and table_3

-Theoretical mechanical power at the fan shaft:

P

meca fan

= P

meca Motor

x

Transmission

P

meca fan

= P

elec

x

meca motor

x

Transmission

P

meca fan

= V x I x 3 x cos x

meca motor

x

Transmission

This formula can be approximated in this way

P

meca fan

= V x I x 1.73 x 0.85 x 0.76 x 0.9

With the fan “rpm” and the mechanical power at the fan

shaft an operating point and the supplied airflow can be

estimated using the fan curves.

CHECKING AIRFLOW AND ESP

Using the fan curves on page 25, 26, 27, the airflow, the

total pressure available (P

TOT

) and the corresponding

dynamic pressure (Pd) can now be estimated, for a specific

operating point;

The next step consists in estimating the pressure losses

across the unit.

This can be achieved using the “dirty filter pressure sensor”

and the accessories pressure drop table: table_4

Also the pressure drop due to the duct inlet into the roof-top

unit can be taken as 20 to 30 Pa.

P

INT

= P

filter + coil

+ P

Inlet

+ P

Options

using the results from above, the external static pressure

(ESP) can then be estimated:

ESP = P

TOT

- Pd - P

INT

Table_ 3 Motor information

Motor Size Nom. Speed

Cos

meca motor

0.75 kW 1400 rpm 0.77 0.70

1.1kW 1429 rpm 0.84 0.77

1.5kW 1428 rpm 0.82 0.79

2.2kW 1436 rpm 0.81 0.81

3.0kW 1437 rpm 0.81 0.83

4kW 1438 rpm 0.83 0.84

5.5kW 1447 rpm 0.83 0.86

7.5kW 1451 rpm 0.82

0.87

Page 63

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 62

PERFORMANCES

ACCESSORIES PRESSURE DROPS

BAC = Cooling only rooftop

BAH = Heat pump rooftop

BAG = Cooling only rooftop with gas fired heating

BAM = Heat pump rooftop with gas fired heating

Economiser

EU4

Filters

F7

Filters

Water

Coil

Hot Electric heater

(Pa)

Roofcurb

Multi

directional

Heat

Recovery

module

Size Airflow

(Pa) (Pa) (Pa) (Pa) S M H (Pa) (Pa)

Fresh

(1)

2900 18 0 39 31 57 58 60 16 23 108 69

3600 28 6 66 46 105 107 109 24 35 161 105

020

4300 39 12 98 61 146 149 151 35 50 226 151

3600 28 6 66 46 75 77 79 24 35 161 105

4500 43 14 108 66 133 135 138 38 55 247 165

030

5400 62 25 160 89 187 190 193 55 79 352 238

5000 22 5 62 51 75 78 81 25 24 149 105

6300 36 14 104 76 134 138 141 39 38 230 167

035

7600 52 24 155 105 189 193 197 58 56 331 243

6500 23 3 52 56 81 85 89 20 29 113 80

8100 36 10 86 82 141 145 150 32 45 170 124

045

9700 51 18 127 113 196 201 207 46 64 239 177

7200 28 6 66 67 94 98 102 25 35 136 98

9000 44 14 108 99 160 165 170 39 55 207 153

055

10800 63 25 160 136 224 230 236 56 80 293 220

8600 16 3 50 58 62 67 72 19 12 129 91

11500 29 12 96 90 112 119 125 33 37 223 162

065

13000 37 18 125 119 152 159 167 43 26 282 207

9 950 22 7 70 75 74 79 85 25 16 171 123

13500 35 16 117 113 128 135 142 40 25 204 223

075

14000 56 31 194 172 186 195 204 65 40 326 240

Page 64

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 63

EXAMPLE

The unit used for this example is a BAH035NSM1M with Economiser and Electric Heater type H

It is fitted with a fan which curve is shown on page 26 and a 2.2kW motor.

- Motor rpm: 1430 rpm

- cos

= 0.81

- Voltage = 400V

- Current = 3.77A

P

mech fan

= V x I x 3 x cos x

mech motor

x

Transmission

= 400 x 3.77 x 3 x 0.81 x 0.76 x 0.9 = 1.45kW

The unit is also fitted with a transmission kit 7

- Fixed Fan pulley: 160mm

- Motor adjustable pulley type “8450” opened 4 turns from fully closed or measured distance between pulley end plates is

25.7mm: from table 2 it can be determined that the motor pulley has a diameter of 99.2mm

rpm

FAN

= rpm

MOTOR

x DM / DF = 1430 x 99.2 / 160 = 886.6 rpm

Using the fan curve below the operating point can be located.

It can be determined that the fan is providing approximately 6300 m3/h with a total pressure P

TOT

= 530 Pa

The pressure losses in the unit are the sum of all

pressure drops across the different parts of a unit:

- Coil and filter (measured) = 104 Pa

- Inlet into the unit = 30 Pa

- Options = 23 Pa for economiser and 91 Pa for

electric heater H

P = 104 + 30 + 23 + 91 = 248 Pa

The dynamic pressure at 7200m3/h is given at the

bottom of the fan curve (page 26).

Pd = 81Pa

The external static pressure available is therefore

ESP = P

TOT

- Pd - P

INT

=580 - 110 - 248 = 201 Pa

Fig. 42

Page 65

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 64

PERFORMANCE CURVES

AT12

-

9S

ROOF TOP

Page 66

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 65

ROOF TOP

AT15

-

11S

Page 67

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 66

ROOF TOP

AT15

-

15S

Page 68

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 67

AT15

-

11G2L

ROOF TOP & EXHAUST ROOF CURB

Page 69

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 68

AT10

-

10S

EXHAUST ROOF CURB

Page 70

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 69

EXHAUST ROOF CURB

AT10

-

8G2L

Page 71

VENTILATION: AIRFLOW BALANCING

BALTIC R410A-IOM-0708-E Page 70

EXHAUST ROOF CURB

AT10

-

10G2L

Page 72

VENTILATION: FILTERS

BALTIC R410A-IOM-0708-E Page 71

FILTER REPLACEMENT

After opening the filter access panel, lift the filter retaining log.

The filters can then be removed and replaced easily by sliding the dirty filters out and cle an ones in.

The CLIMATIC controller can monitor the pressure drop across the filter (If option fitted)

The following set points can be adjusted depeding on the installation.

“Airflow” in page 3411 = 25Pa by default

“No filter “ in page 3412 = 50Pa by default

“Dirty Filter” in page 3413 = 250Pa by default

The actual pressure drop measured accross the coil can be re ad on the Climatic Display DS50 in menu 2131

.

The following faults may be identified

-Fault code 0001 AIRFLOW FAILURE, if measured ΔP across the filter and coil is below the value set in page 3411

-Fault code 0004 DIRTY FILTERS, if measured ΔP across the filter and coil is above the value set in page 3413

-Fault code 0005 MISSING FILTERS, if measured ΔP across the filter and coil is below the value set in page 3412

Fig. 43

Page 73

VENTILATION: FANSTART

BALTIC R410A-IOM-0708-E Page 72

AIR SOCK CONTROL

Menu

- Press the Button “Mode” to enter and exit menus

- The Vertical arrows allow to seek each options

- The “Enter” button allow to select a menu or a parameter to modify it, it also allows to validate it once

modified

Quick Setting

- Press the mode button and enter the quick menu “AUF”

- Modify and check the “AUF” sub-menus

o AU1 “automatic acceleration/deceleration” must be set to ZERO

o Acc “acceleration” : set to 50 s

o Dec “deceleration” : set to 30 s

o LL “low speed” : set to 0Hz

o UL “high spee” : set to 50Hz

o tHr “motor thermal current” : adjust this setpoint equal to nominal motor amps

o uL “ motor nominal frequency” : set to 50Hz

o uLu “nominal motor voltage” : set to 400V

If those parameters are unseen, check that the “loc rem” button located in front is lighting because this allows a

remote parameter control. Push this button to get the control back into the display

Page 74

HEATING: HOT WATER COIL

BALTIC R410A-IOM-0708-E Page 73

HYDRAULIC CONNECTIONS

The hot water coil is fitted with a three way proportional valve

and two isolating shut off valves. Two spanners must be

used to tighten the connections. One spanner must maintain

the valve body when connecting the pipe-work to the main.

Failure to do so may damage the pipes joints and invalidates

the warranty.

Filling up and starting the system

- Adjust the control for Heating by reducing the simulated

ambient temperature down to 10°C

- Check that the red indicators located under the valve

actuator are moving correctly with the signal.

- Fill the hydraulic system and bleed the coil using the

air vents. Check incoming hot water.

- Check the various connections for possible leaks

FREEZE PROTECTION

1) Glycol for freeze protection.

Check the hydraulic system contains Glycol for protection

against freezing.

GLYCOL IS THE ONLY EFFECTIVE PROTECTION

AGAINST FREEZING

The antifreeze must protect the unit and avoid icing under

winter conditions.

WARNING: Mono-ethylene glycol based fluids may produce

corrosive agents when mixed with air.

2) Drain the installation.

You must ensure that the manual or automatic air bleeders

have been installed on all high points in the system. In order

to drain the system, check that all the drain cocks have been

installed on all low points of the system.

HEATING HOT WATER COILS FROZEN DUE TO LOW

AMBIENT CONDITIONS ARE NOT COVERED BY THE

WARRANTY.

ELECTROLYTIC CORROSION

Attention is drawn to the corrosion problems resulting from

electrolytic reaction created by unbalanced earth

connections.

ANY COIL DAMMAGED BY ELECTROLYTIC CORROSION

IS NOT COVERED BY THE WARRANTY

Fig. 45

Page 75

HEATING: HOT WATER COIL

BALTIC R410A-IOM-0708-E Page 74

Connection HWC B box Connection HWC C box

Connection HWC D box Connection HWC E box

Pipe Internal Diameters (DN)

MAXIMUM WORKING PRESSURE: 8 BARS

MAXIMUM WORKING TEMPERATURE: 110°C

B020 B030 B035 B045 B055 B065 B075

H 20 20 20 25 25 25 25

Fig. 46

Page 76

HEATING: ELECTRIC HEATER

BALTIC R410A-IOM-0708-E Page 75

GENERAL INFORMATION

The Baltic electric heaters are stand alone options which are fitted in the heating section of the unit. As for the hot water coil or

the gas burner this option slides into the heating compartment located under the supply fan.

In order to reduce the pressure drops the airflow is ducted around the shielded resistances. The resistances are made smooth

stainless steel tubes with a capacity of 6W/cm2.

It is protected as standard, against overheat via a high temperature overload protection set at 90°C and located less than

150mm after the heater itself.

There are three sizes available for each size of unit:

S: Standard heat

M: Medium heat

H: High heat

The standard and Medium heat electric heaters are staged control with 50% or 100%. The high heat versions is controlled

through a fully modulating triac.

380V 400V 415V

Module size Current Capacity Current Capacity Current Capacity

(kW) (A) (kW) (A) (kW) (A) (kW)

12 16,3 10,8 17,0 11,8 17,8 12,8

24 32,6 21,5 34,0 23,5 35,6 25,6

27

36.7 24.3 38.3 26.6 40.1 28.8

36 48,9 32,3 51,1 35,3 53,3 38,4

45 61.1 40.5 63.8 44.3 66.8 48.0

48 65,2 43,0 68,1 47,0 71,1 51,3

54 73,4 48,4 76,6 52,9 80,0 57,7

Fig. 47

Page 77

HEATING: GAS BURNER

BALTIC R410A-IOM-0708-E Page 76

PRELIMINARY CHECKS BEFORE START-UP

NOTE :

ANY WORK ON THE GAZ SYSTEM MUST BE CARRIED

OUT BY QUALIFIED PERSONNEL.

THIS UNIT MUST BE INSTALLED IN ACCORDANCE WITH

LOCAL SAFETY CODES AND REGULATIONS AND CAN

ONLY BE USED IN PLANED INSTALLATION CONDITIONS

FOR OUTDOOR.

PLEASE READ CAREFULLY THE MANUFACTURER’S

INSTRUCTIONS BEFORE STARTING A UNIT.

BEFORE COMMISSIONING A UNIT WITH GAZ BURNER,

IT IS MANDATORY TO ENSURE THAT THE GAZ

DISTRIBUTION SYSTEM (type of gas, available pressure…)

IS COMPATIBLE WITH THE ADJUSTMENT AND

SETTINGS OF THE UNIT.

Check access and clearance around the unit

Make sure one can move freely around the unit.

A minimum one-meter clearance must be left in front of the

burnt gas exhaust flue.

Combustion air inlet and burnt gas exhaust(s) must NOT

be obstructed in any way.