Page 1

APPLICATION

GUIDE

ASC/ASH + CIC/CIH

Large ducted split

19 134 kW

AIRCOOLAIR

ASC/ASH

Air cooled condensing unit

20 230 kW

AIRCOOLAIR-AGU-1603-E

lennoxemeia.com

Page 2

Page 3

TABLE OF CONTENTS

AIRCOOLAIR

APPLICATION GUIDE

GENERAL DESCRIPTION

1. 2

OPTIONS

2. 7

GENERAL DATA

3. 13

4.

VENTILATION DATA

Ref : AIRCOOLAIR- AGU-1603-E

16

PERFORMANCES

5.

Cooling and heating capacities

Auxiliary heaters selection

ACOUSTIC DATA

6. 45

ELECTRICAL DATA

7. 49

DIMENSIONAL DATA

8. 54

WEIGHTS DATA

9. 58

10. 59

REFRIGERANT CONNECTIONS

22

44

Product designed and manufactured under a

quality management system certifi ed ISO 9001.

All the technical and technological information contained in this manual, including any drawing and technical descriptions provided

by us, remain the property of Lennox and must not be utilised (except in operation of this product), reproduced, issued to or made

available to third parties without the prior written agreement of Lennox.

Application Guide • AIRCOOLAIR-AGU-1603-E

Our company’s products comply with

European standards.

• 1 •

Page 4

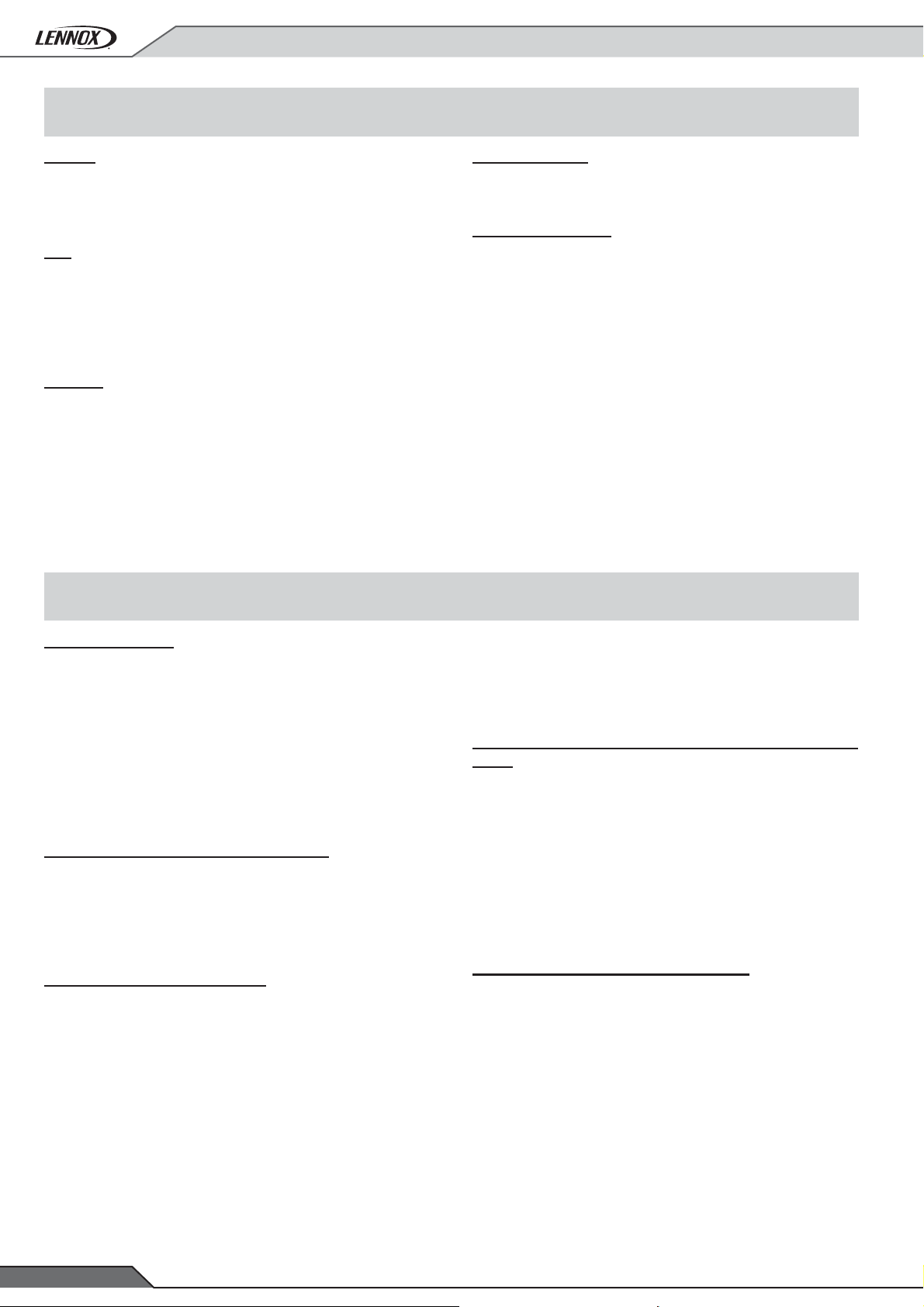

GENERAL DESCRIPTION

AIRCOOLAIR

Split

Condensing unit

20S 140D

ASC/ASH + CIC/CIH A NA

ASC/ASH A

200D & 230D

OUTDOOR UNIT

ASC / ASH 020S 025S 030S 035S 040S 045D 055D 070D 085D 100D 120D 140D 200D 230D

Box

A BOX

AB C DE

B BOX

C BOX

D BOX

INDOOR UNIT

CIC / CIH 020S 025S 030S 035S 040S 045D 055D 070D 085D 100D 120D 140D

Box

ABCD

A BOX

B BOX

C BOX

D BOX

MODEL NUMBER DESCRIPTION

EXAMPLE : ASC 020S NM3M + CIC 020S NM3M

OUTDOOR UNIT INDOOR UNIT

AIRCOOLAIR Common to AIRCOOLAIR and COMPACTAIR ranges

AC

Single split Indoor unit

SI

C = Cooling only

CC

H = Heat pump

COMMON TO AIRCOOLAIR AND COMPACTAIR RANGES

C = Cooling only

H = Heat pump

• 2 •

Cooling capacity in kW

020

S = 1 circuit

S

D = 2 circuits

Not used

N

M R410A

Revision number

3

400 V / 3 / 50 Hz

M

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 5

GENERAL DESCRIPTION

INTRODUCTION

AIRCOOLAIR range is developed from ECOLEAN liquid chiller range and

exists in two versions:

• AIRCOOLAIR SPLIT UNIT

it can be used for medium to large commercial cooling and heating

applications when the premises are not directly accessible from the roof.

AIRCOOLAIR split unit exist in cooling only and heat pump versions.

• AIRCOOLAIR CONDENSING UNIT

It is the outdoor unit without the supply section. This unit is available as

cooling only or as heat pump and can be combined with air handling

units. It provides you with a low noise level, high effi ciency and almost

customized units.

OUTDOOR SECTION

ASC & ASH

Casing

- Casing made of galvanized steel sheet metal painted with a

white RAL 9002 powdered polyester paint and a RAL3003

red stripe.

- Rigid, hot dipped galvanized chassis.

- Unit lifting and handling via the base frame.

- State of the art design with hidden compressors, fans and

pump for perfect architectural integration.

- Side grilles as option to protect the unit during transportation

and against human aggressions.

High effi ciency multiscroll technology

- Exclusive Compliant Scroll® design with both axial and radial

compliance to increase compressor operation tolerance

to liquid refrigerant, substantially improving durability and

reliability.

- Motor cooled by suction gas.

- Motor protection device against high temperature or over

current situations.

- Discharge non-return valve.

- Crankcase heater as standard on heat pump and optional

with winter operation down 0°C for cooling only units.

- Direct on line start.

- Low noise scroll compressors insulated with a compressor

acoustic jacket.

- Compressors mounted on high effi ciency cellular polyurethane

vibration absorbers.

Advanced condenser fan design

Fan-motor assembly using external rotor technology associated

with OWLET high performance aluminum fan blades of the latest

fan technology to improve energy consumption and airfl ow rate

on the outdoor coils while reducing sound power level. Axial fans

speed are 700 or 900 rpm according to models, direct coupling,

with available static pressure up to 75 Pa as standard.

Pressure version for size 100 to 230 : speed axial fans are

1450 RPM, direct coupling, with available static pressure up to

250 Pa. For small sizes, COMPACTAIR is the appropriate unit

for technical room.

.

Heat exchanger

Made of copper tubes and aluminum corrugated swirl fi ns, the

coil heat exchanger are designed to maximize the output.

Refrigerant circuit:

AIRCOOLAIR outdoor units operate with R410A refrigerant.

For cooling only outdoor units, each circuit includes in standard:

- High pressure switch with automatic reset.

- Low and high pressure transducers.

On heat pumps outdoor units, each circuit includes in addition,

as standard :

- Four-way valve

- Liquid receiver

- Thermostatic expansion valve

- Filter drier

Each refrigerant circuit is pressure and leak tested with a

Hydrogen/Nitrogen mixture, and vacuumed before being charged

with nitrogen. All units are then subjected to a complete functional

and operational run test to guarantee perfect sealing before

leaving the factory.

Electrical box:

- Unit wiring in compliance with standard EN 60204-1.

- IP54 water protection.

- Circuit breaker protection for compressors and fans.

- Compressor and fan working contactors.

- Terminal block and wiring for power supply to the unit.

- Power supply 400V/3/50Hz without neutral except for size

20S with neutral.

Application Guide • AIRCOOLAIR-AGU-1603-E

• 3 •

Page 6

GENERAL DESCRIPTION

INDOOR SECTION

CIC & CIH

Casing

Casing made of galvanized steel sheet metal painted with a

white RAL 9002 powdered polyester paint.

Fan

Indoor sections are supplied with one or two double-inlet

centrifugal fans. Double fans are fi tted with a common axle with

one motor. Equipped with adjustable drive, variable pulley and

belt, to set up the right airfl ow on site.

Air fi lter

G4 washable air fi lter; auto extinguishable material with M1

classifi cation.

ENERGY SAVINGS

Heat exchanger

Made of copper tubes and aluminum corrugated swirl fi ns.

Refrigerant circuit:

On cooling only and heat pumps indoor units, each circuit

includes as standard :

- Thermostatic expansion valve

- Filter drier

Each refrigerant circuit is pressure and leak tested with a

Hydrogen/Nitrogen mixture, and vacuumed before being charged

with nitrogen. All units are then subjected to a complete functional

and operational run test to guarantee perfect sealing before

leaving the factory.

R410A refrigerant

Effi cient systems such as AIRCOOLAIR are designed around

R410A refrigerant to achieve the best performances.

- Energy effi cient refrigerant thanks with pressure drop in the

pipes: Higher evaporating pressure and lower condensing

pressure improve compressor EER & COP.

- R410A compressors have a better isentropic effi ciency.

- Environmentally friendly refrigerant: It contains No Chlorine

(ODP = 0).

Free cooling: economizer for Split Unit

Indoor sections are supplied with one or two double-inlet

centrifugal fans. Double fans are fi tted with a common axle with

one motor. Equipped with adjustable drive, variable pulley and

belt, to set up the right airfl ow on site.

Dynamic and alternate defrost

Defrost is necessary to ensure effi cient operation of heat

pumps in winter. The unit starts defrost cycle when the outside

temperature is below a set temperature and repeat the defrost

cycles periodically . It results sometimes in starting an expensive

defrost cycle when it is very cold outside but very dry, or too

warm, in other words when the coil is not frozen.

- Dynamic defrost is Lennox’ answers to unnecessary defrost

cycles. Dynamic defrost detects icing of the coil by monitoring

the difference between refrigerant and outside temperature

and starts the defrost cycle only when required. Under certain

conditions a rooftop unit equipped with this built in dynamic

defrost feature can run several hours in heat pump mode

without starting any defrost cycle. Dynamic defrost can save

up to 15% on annual energy consumption.

- Alternate defrost saves energy by reducing the need for

auxiliary heating during defrost cycles. With Alternate defrost

when one circuit starts a defrost cycle the other circuit is

running in heat pump at full capacity to minimize the need

for auxiliary heating.

Morning anticipation and dynamic set point for Split

Unit :

The unit can be programmed to switch-on in the morning to reach

the occupied zone temperature set point just in time.

Dynamic set point can be used in summer to offset the ambient

temperature set point according to the outdoor temperature.

This is to avoid large temperature difference between indoor and

outdoor. The indoor temperature set point would then increase

with the outdoor temperature improving comfort and saving large

amount of energy

Scheduling / Time zone Management:

In order to ensure the unit perfectly matches the requirements of

the most diffi cult applications in terms of occupation and varying

internal loads, the CLIMATIC 60 offers now up to 7 time zones

per day (Z0 to Z6) adjustable by steps of 10 minutes. Each time

zone can be programmed to follow one of four possible operating

modes: A,B,C & D

• 4 •

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 7

GENERAL DESCRIPTION

CONTROL

The new generation of microprocessor based control, CLIMA TIC

60 equip the AIRCOOLAIR range.

It inherits more than 20 years of technology and fi eld operating

experience from its predecessors Climatic control platforms.

CLIMATIC 60 controller intelligently improves effi ciency and

helps set up and service operations to guarantee long lasting

performance.

CLIMA TIC 60 is designed to provide the best energy effi ciency

throughout unit’s life cycle while ensuring reliable and consistent

operation with user friendly interfaces.

This new controller constantly monitors more machine parameters

than ever to improve unit operation and maximize effi ciency

and reliability

The PI algorithm of the CLIMATIC 60 controls the supply air

temperature and a temperature difference between supply and

return. It is able to optimize the refrigeration circuit operation to

match perfectly the required cooling or heating load maximizing

effi ciency and comfort.

COMFORT AND AIR QUALITY OF SPLIT UNIT

It will also improve reliability with features such as compressor

operating limits monitoring, (High and Low refrigerant pressure

and temperature now measured and displayed on DS60 and

Bus) refrigerant leak detection or compressor operating time

equalization and protection against excessive short cycling.

Faults and alarms

CLIMA TIC 60 manages more than 90 different faults and alarms

codes and can store the last 32 with time and date. The stored

faults and alarms can then be displayed on the DS60 and on

the communication bus with the full text detail.

Intelligent air quality management

With accurate percentage of fresh air the dampers are regularly

calibrated to introduce just the required amount of fresh air in the

building to reduce annual energy consumption. The fresh air ratio

can also be controlled using the indoor CO2 level as an input.

Intelligent heating priority optimization

This feature allows the user to program the priority between the

different heating elements (thermodynamic, electric heaters or

auxiliary heating). This is particularly interesting on units with

electrical pre-heaters. This feature maximizes energy effi ciency

by optimizing heat pump operation depending on the outdoor

temperature.

Filtration

Two fi ltration levels are available. The standard equipment is G4

washable and refi llable fi lters with metallic frame. This type of

confi guration allows to extend the lifecycle of fi lters and reduce

the cost of replacement, changing only the media. G4 pre-fi lter/

F7 fi lter is optional.

Fire Insulation

Air treatment sections are insulated with M1 material: this insures

that the insulation doesn’t burn and doesn’t create toxic smoke.

M0 insulation is in option mechanically fi tted.

Application Guide • AIRCOOLAIR-AGU-1603-E

• 5 •

Page 8

GENERAL DESCRIPTION

PLUG AND PLAY UNIT

Power supply

T o make installation easier, AIRCOOLAIR power supply does not

require «neutral» connection. It is powered by 400 V , 3 phases,

50 Hz except size 20S

Circuit breakers

To improve the safety of the AIRCOOLAIR and extend its life,

circuit breakers protect against over-loading, over intensity and

a disconnected supply phase. Maintenance is also improved as

there is no requirement to change fuses. The electrical panel is

manufactured in accordance with EN60204-1 (1998) electrical

directive.

Adjustable ventilation for Split Unit

Airfl ow and external static pressure characteristics are adjusted

in the factory to deliver the right pulley and belt to be the nearest

to the site needs. However, once on site, the real characteristics

of ventilation requirement might be slightly different than theory

measured on drawings: therefore, AIRCOOLAIR Split unit

is delivered as standard with adjustable pulley opened. This

remains the possibility to adjust the airfl ow accurately at the

commissioning and fi nd the perfect airfl ow for the site comfort

and system effi ciency.

Refrigerant pressure reading :

No need to access to refrigerant pressure gauges.

Refrigerant pressures and superheat on each circuit can be read

directly on the service display DS60 or a BMS as all units are

equipped with high and low pressure transducers and refrigerant

suction temperature probes

Easy access

All access to internal components of the AIRCOOLAIR units are

closed by panels equipped by locks and handle for quick and

easy dismounting. No more screws are used as panel fi xtures.

EXTENDED LIFECYCLE

Assembly quality, compliance to PED 97-23, EN 60204-1, CE,

made in an ISO 9001v2000 factory.

What makes the difference are the small details which have given

LENNOX its reputation. Electrical components are selected to

the highest standards, refrigeration components are generously

sized to ensure maximum performance and reliability. Quality

manufacturing procedures together with a culture of continuous

improvement at all LENNOX factories, ensures the products are

built to the highest standards.

AIRCOOLAIR complies to EN60204 norms, PED 97-23 directive,

is CE compliant and is built in an ISO9001v2000 certifi ed Factory

• 6 •

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 9

OPTIONS

FRESH AIR OPTIONS

Economizer

020S - 045D 055D - 140D

Free cooling is provided through the use of fresh air when it’s

appropriate rather than cooling the return air. Using an economizer

is the easiest and most effi cient way to modulate fresh volumes

and reduce running costs for air conditioning application, as well

as improving air quality. Fully controlled by the CLIMATIC, it is

also able to ensure that minimum fresh air is provided in line

with Indoor Air Quality Regulations. Economizer operates using

a «sensible» control. It is possible to prevent the economizer

from supplying air below a certain temperature (adjustable set

point, 10°C as default).

On sizes 20S to 45D, the economizer is factory fi tted on unit

and tested prior to shipment. It includes 2 dampers operating

from a 24V actuator.

On sizes 55D to 140D, the economizer is delivered as a separate

module that can be installed as monobloc on site. It includes 3

dampers operating from 3x 24V actuators

Exhaust module

The exhaust fans eliminate the air overpressure in the room. It

Return Module

The RETURN FAN module is necessary when the return duct

circuit creates high pressure drops. It offers available static

pressure up to 250-300 Pa.

It includes a separate casing to be connected to the economizer

casing with the ductworks.

The return module drives the opening and closure of the 3

dampers regarding the amount of fresh air introduced.

eDrive: available in Non Standard Request

eDrive, direct transmission on return fan and supply fan :

variable speed fans adjust airfl ow rate to the exact needs

and during unoccupied period. This feature saves up to 30%

annual energy consumption and reduces maintenance costs.

CLIMATIC manages air fl ow rate passing through the unit

following 3 possible strategies.

eDrive control strategies can be changed with each time zone

in occupied or unoccupied mode. Whatever the control strategy, soft starter is still available to infl ate fl exible ducts and

reduce inrush current during fan starts.

- Standard mode : Constant air fl ow rate

- Dead Zone mode : Reduced air fl ow rate in “dead zone”.

- Part Load mode : Variable air fl ow rate during part load and

dead zone.

020S - 045D 055D - 140D

is driven by the Climatic controller.

On sizes 20S to 45D, it is delivered as a separate module that

can be connected to the return duct.

On sizes 55D to 140D, this exhaust fan is in built in the

economizer casing

Application Guide • AIRCOOLAIR-AGU-1603-E

• 7 •

Page 10

OPTIONS

INDOOR AIR QUALITY OPTIONS

High fi ltration level - G4 pre-fi lter / F7 fi ltration

G4 pre-fi lter 50 mm / F7 fi lter 100 mm are both in metallic refi llable

frames. This confi guration allows extending the lifecycle of fi lters

and reducing the cost of replacement, changing only the media.

100 mm fi lters have been selected also to reduce the energy

consumption due to:

- lower pressure drop especially when the fi lters start being

dirty.

- decrease of the replacement frequency.

Analog dirty fi lter and fan control :

This analog pressure sensor analyses the clogging of the fi lters

to inform the user and to allow preventive replacement of the

fi lters that will decrease the energy consumption and increase

the air quality.

Air Quality sensor :

This function allows to adapt the minimum fresh air to the building

occupancy. It measures the CO2 level and adjust the fresh air

volume accordingly.

Indoor air quality is controlled from the CLIMA TIC main controller.

A VOC (V olatile Organic Component) sensor detects the amount

of CO2 in the ambient air between 0 and 2000PPM. The VOC

sensor sends a proportional signal (0-20mA) to the CLIMATIC

controller which will then modulate the fresh air damper.

AUXILIARY HEATERS OPTIONS

Stepped or modulating Electrical heaters

Additional or instead of heat pumps, Lennox offers many auxiliary

heaters on every air-to-air units. This helps to adapt to local

climate requirement, local regulation preferences and applications

variable heating needs.

Standard, Medium and High heating power capacity are available

on each unit size

High electrical heater is also available as modulating instead

of 2-stage heater.

The performances of this option are available in auxiliary heaters

selection: page 44

The electric heater comprises of shielded resistance heaters,

which are smooth anticorrosion tubes 8 W/cm² capacity.

3 security elements are insuring permanent controls of the heaters:

- 2 high temperature limit controls offer overload protection. An

automatic reset safety thermostat is set at 75°C – a manual

reset safety thermostat is set at 105 °C; both located at less

than 150 mm over electric heaters. This is provided as a

standard feature on the electric heater, with the electric power

supply cables made of reticulated silicon rubber, resistant to

temperatures up to 200°C.

- an air pressure differential controls the fan activity and disconnects the electrical heater in case of critical airfl ow

- dual contactor are insuring safe redundancy in case of failure

of one dry contact

Modulating Hot water coil :

This modulating heater is equipped with a 3 way valve offering

accurate comfort and electronic adjustable antifreeze protection.

This avoids the use of glycol in most of European regions.

The hot water coils and control valves are factory fi tted in air

treatment section.

The performances of this option are available in auxiliary heaters

selection page 44.

• 8 •

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 11

OPTIONS

REFRIGERATION OPTIONS INSTALLATION AND SAFETY OPTIONS

Winter cooling operations down to 0 °C

This option allows the AIRCOOLAIR to operate in cooling mode

with an outside temperature down to 0°C (instead of 15°C on

the standard unit).

This is especially needed when free-cooling operation is not

possible. This function is made of condenser fan alternate start/

stop that maintains a constant condensing pressure.

This equipment is standard on heat pump versions

Winter cooling operations down to -15 °C

Unit fi tted with variable speed fans. This option also allows

cooling operation in very low outside temperature (-15°C), with

good performance on condenser fan, belt lifecycle extension

and starting peak current reduction.

Strongly recommended for applications where cooling is required

during winter.

Refrigerant pre-charged

As standard, the units are delivered with Nitrogen. With this

option, the outdoor unit is fi tted with refrigerant and equipped

with service valves option.

Active Acoustic Attenuation System with variable

speed fans

Low Noise option consists in an acoustic jackets .

Besides, with the variable speed fan include in Winter cooling

operations down to -15 °C option, the CLIMA TIC 60 controls the

fan speed limited by the Smart Acoustic System which allows

progressive adaptation of the unit to the building load while

respecting the noise level constraints and the operating limits.

The maximum sound level and the fan strategies can be adjusted

according to the schedule mode in order to benefi t from the

different modes “Auto”, “Auto Quiet” and “Quiet” operation as

well as in heating or cooling mode.

The Active Acoustic Attenuation System can be adjusted

according to the scheduling and can take different values for

each schedule mode.

Main disconnect switch

Main disconnect switch is lockable to make a safe access to

electrical panel. It is installed on the electrical panel door of

the compressor section and controls all parts. Is also used as

emergency cut off: it is mandatory to guarantee a proper access

to this switch. Main disconnect switch is sized accordingly to the

options fi tted in the unit.

Smoke detector

Located downstream of the fi lter, the optical head of the smoke

detector can detect any type of smoke. When this occurs the

unit will stop operating, the return air damper will be fully closed

and the fresh air damper will fully open while sending an alarm

signal to the unit.

In accordance with the European norm, it is also compliant with

the French regulation on public buildings.

Compressor electrical protection

Return lock against 3 phases inversion at installation. This

protection prevents the Scroll compressor from starting and

operatint in the wrong sense: in case of the electrical phases

are wrongly connected, the compressor will not start. The

compressor electrical protection option is particularly required

when the installation of the air conditioning unit is made before

the electrical wirings.

Condenser coil guards:

The condenser coil protection grill prevents light damage to the

coil when shipping and when installed.

Coil Anticorrosion protection:

When the units are installed in potentially aggressive

environments, which can often be the case for example in coastal

environments, it is often a requirement that the coils are specially

treated to protect them against the corrosive effects. LenGuard

anti-corrosion treatment is available on indoor and outdoor units.

M0 Insulation indoor unit:

Because health and safety issue cannot be compromised,

Lennox equips its air treatment units (indoor unit) with a fi re-proof

insulation M0 that is mechanically fi tted to the unit.

Service valves

This option consists in liquid and gas service valves that isolate

the refrigerant section during maintenance. This is particularly

useful when components of the circuit have to be changed. It

reduces the time and cost of maintenance operation.

Long distance refrigerant connection

When the distance between the condensing section and the

treatment section is over 40 meters of cupper piping, this kit has

to be installed. It allows distance up to 65 meters.

Application Guide • AIRCOOLAIR-AGU-1603-E

Anti-vibration mounts rubber type (supplied loose)

These parts reduce the transmission of vibration to the ground

and the general sound level. They are fi xed under the unit at

the points specifi ed by our technical drawing.

Pallet packaging

This unit protection option is wooden pallet packaging with

plastic bag useful during potentially bad shipment condition:

long distance by truck or container.

• 9 •

Page 12

OPTIONS

CONTROL AND COMMUNICATIONS OPTIONS

DC60 remote comfort display (supplied loose)

This is a remote controller for non-technical customer. It has

been designed to aesthetically fi t inside a room and be very easy

to use. It can be installed at maximum 50 meters from the unit.

There are two levels : In the fi rst level, ambient temperature is

provided and the setpoint temperature or offset to this setpoint

temperature can be adjusted (according to settings and rights

offered by the technician). The unit can be turned On and Off in

this level. The full level additionally provides information such

as outdoor temperature, supply temperature, ambient humidity

level, air quality , fresh air damper opening percentage, time zone

and working mode of the given time zone. DC60 Comfort display

shows faults number when the unit is in the failure mode. Customer

can reset fault thanks to a combination of keys. Time and day

of the unit can be seen and modifi ed easily through the DC60.

DS60 Service display (supplied loose)

This plug and play service display and controller allows

maintenance staff to set up, read and modify all unit parameters

(unit settings, operating time and number of compressor starts,

low and high pressure reading, airfl ow rate of supply fan, and

read the history of last 32 faults...).

This controller has been designed to be very user-friendly , with 6

different keys and a graphic display . It includes scrolling menus

and full text (no codes) explanation. It is available in English or

other languages.

BE60 Extension control board

This board has been developed for any customer who wants to

take over the control of the unit using digital or analogue input

signal. With this dry contact board option the customer can set:

• 4 digital inputs (On/Off, clear faults, various component

unloading, heating priority modifi cations, thermostat orders....)

• 4 digital Outputs (alarms reporting, components status,

scheduling time zone and operating mode status, cooling,

heating, defrost and auxiliary heating status...)

• Up to 4 analogue inputs (external temperature humidity

probes, fresh air input signal, force fan speed and temperature setpoint offset).

• 1 analogue output (Humidifi er)

Note that CLIMA TIC controller always stays in charge of all safety

algorithms, defrost operation and free cooling. This option is

required to control the unit with a “universal thermostat”.

The BE60 expansion board is an additional board fi xed on DIN rail.

This board is supplied as standard on AIRCOOLAIR condensing

unit.

Modbus communication interface RS485

Communication card using ModBus protocol with RS485.

Communication interface with a building management system.

DM60 Multi-units display (supplied loose)

The DM60 remote display can manage up to 8 units on a single

Bus. On a multiunit site it makes the installation less expensive

because, not only because of DM60 price, but because only one

bus-wire has to be connected down to the DM60. In addition to

the functions offered by the DC60 display, the DM60 display

provides the percentage of power factor for compressors and

auxiliary heater. Moreover DM60 display allows to set time zones

and to modify working modes for the given time zone. These

information are available for each of the units connected to the

Bus. It can be installed up to 1000 meters from the unit.

BACnet® communication interface RS485

Communication card using Bacnet® protocol with RS485.

Communication interface with a building management system.

LonWorks® communication interface

Communication card using LonTalk® protocol.Communication

interface with a building management system.

Modbus or BACnet® communication interface TCP/

IP

Communication card using Bacnet ® or Modbus with TCP/IP.

Communication interface with building management system.

REMOTE COMFORT DISPLAY

DC60 :

• 10 •

DS60 :

SERVICE DISPLAY

DM60 :

MULTI-UNIT DISPLAY

Application Guide • AIRCOOLAIR-AGU-1603-E

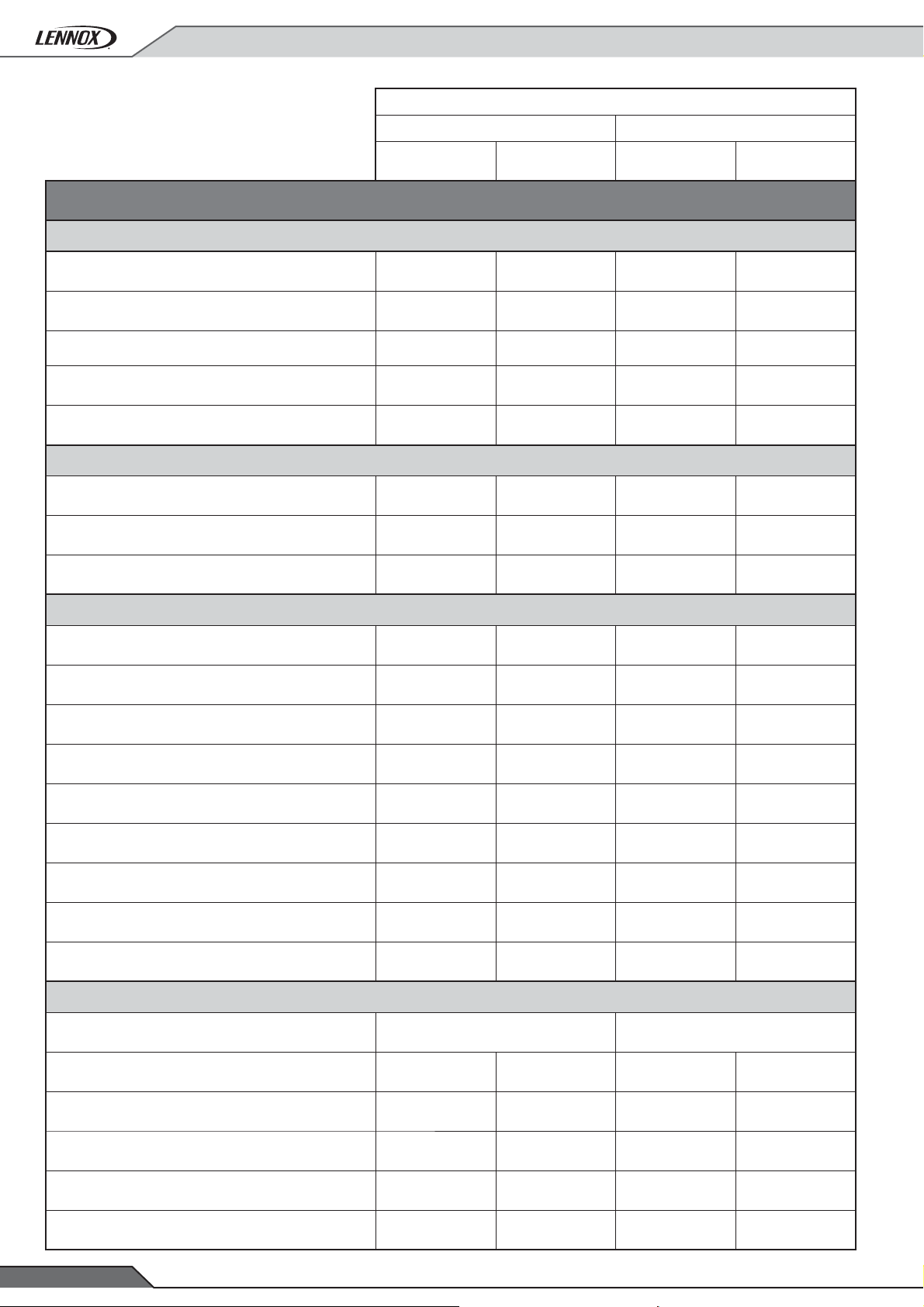

Page 13

OPTIONS

Legend :

STD = As standard

NSR = Non standard request

N/A = Non available

Cooling only Heat pump Cooling only Heat pump

Split unit Condensing unit

INDOOR SECTION : CIC AND CIH

Economizer

Exhaust module

X X N/A N/A

X X N/A N/A

Return module Size 55 - 140

Fresh air over - Return bottom Size 20 - 45

Fresh air left - Exhaust right Size 55 - 140

Filtration

High fi ltration level

G4 prefi ltre / F7 fi ltration

X X N/A N/A

Auxiliary heating

Models

N/A N/A

N/A N/A

N/A N/A

Electrical heater standard

Electrical heater medium

Electrical heater high

Electrical heater high - Modulating

Modulating hot water coil

Control

Smoke detector

Air quality sensor

Remote duct sensor

Analog dirty fi lter and fan control

Airfl ow confi guration

Vertical air supply

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

X X N/A N/A

Other options

M1 insulation indoor unit

Application Guide • AIRCOOLAIR-AGU-1603-E

X X N/A N/A

• 11 •

Page 14

OPTIONS

Legend :

STD = As standard

NSR = Non standard request

N/A = Non available

OUTDOOR SECTION : ASC AND ASH

Refrigeration option

Winter cooling operation down to 0°C outdoor

temperature

Winter cooling operation down to -15°C outdoor

temperature

Service valves

Refrigerant precharged

Long distance refrigerant connection up to 65 m

Electrical and safety

Main disconnect switch

Compressor electrical protection

Models

Split unit Condensing unit

Cooling only Heat pump Cooling only Heat pump

X STD X STD

X NSR X N/A

XXXX

XXXX

X X N/A N/A

XXXX

XXXX

Condenser coil guards

Control & Communication

Advanced control pack (enthalpy and humidity

control)

Modbus communication interface RS485

Lonworks® communication interface

Bacnet® communication interface RS485

Modbus or bacnet® communication interface TCP/

IP

DC60 remote comfort display (supplied loose)

DS60 service display (supplied loose)

DM60 service display (supplied loose)

BE60 expansion control board

Other options

XXXX

X X N/A N/A

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

X X STD STD

High static pressure up to 250 Pa Size 100 - 140 Size 100 - 230

Low noise version

Outdoor coil anticorrosion protection

Outdoor & indoor coil anticorrosion protection

Rubber anti-vibration mounts (supplied loose)

Pallet packaging

• 12 •

XXXX

XXXX

X X N/A N/A

XXXX

XXXX

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 15

GENERAL DATA

LARGE DUCTED SPLIT

Cooling mode - ASC + CIC - ASH + CIH

Gross cooling capacity

Net cooling capacity

Absorbed power

Gross EER

Net EER

(1)

(1)

(1)

(1)

(1)

Heating mode - ASH + CIH

Net heating capacity

Net COP

(1)

Net absorbed power

(1)

(1)

Electrical heater capacity

Hot water coil capacity

(2)

20S 25S 30S 35S 40S

19,9 24,2 27,9 36,5 41,9

kW

19,5 23,5 27,0 35,5 40,5

6,72 8,45 9,82 12,4 14,7

3,13 3,12 3,11 3,19 3,15

2,90 2,78 2,75 2,86 2,75

kW

19,5 25 28,5 36 40

3 3 2,95 3,03 3

6,5 8,33 9,66 11,9 13,3

(3)

S

(3)

M

kW

(3)

H

10 10 10 15 15

15 15 15 20 20

20 20 20 27 27

31 38 40 56 61

Refrigerant circuit

Number of compressors/Number of circuits

Refrigerant charge per circuit (approximate)

Air treatment ventilation

Minimum airfl ow

Maximum airfl ow

Maximum available static pressure

Condensing unit ventilation

Nominal airfl ow

Acoustic data

Outdoor blower outlet sound power

Standard unit (Lw)

Outdoor blower outlet sound power

Low noise unit (Lw)

(1)

(1)

Indoor blower outlet sound power level (Lw)

kg

3

m

Pa

3

m

dB(A)

1/1 1/1 1/1 1/1 1/1

4,9 5,9 6,33 8,84 10,83

3150 4250 4650 6200 6950

/h

4100 5500 6000 8050 9050

685 672 650 729 833

/h

6800 9750 11500 11300 11000

72 76 76 77 78

70 71 70 71 72

75 82 82 82 85

(1) EUROVENT conditions data

Cooling :

Outdoor temperature = 35°C DB

Entering coil temperature 27°C DB / 19°C WB

Heating :

Outdoor temperature = 7°C DB / 6°C WB

Indoor temperature = 20°C DB

Application Guide • AIRCOOLAIR-AGU-1603-E

(2) Air inlet temperature = 20°C

Water temperature = 90-70°C

(3) S = Standard heat

M = Medium heat

H = High heat

• 13 •

Page 16

GENERAL DATA

LARGE DUCTED SPLIT

Cooling mode - ASC + CIC - ASH + CIH

Gross cooling capacity

Net cooling capacity

Absorbed power

Gross EER

Net EER

(1)

(1)

(1)

(1)

(1)

Heating mode - ASH + CIH

Net heating capacity

Net COP

(1)

Net absorbed power

(1)

(1)

Electrical heater capacity

Hot water coil capacity

(1)

45D 55D 70D 85D 100D 120D 140D

48,7 57,3 72,4 86,0 103,9 116,2 140,6

kW

46,5 55,5 69,5 82,0 100,0 111,0 135,0

17 19,8 24,8 29,8 35,7 38,9 48,2

3,28 3,17 3,3 3,33 3,26 3,44 3,3

2,73 2,8 2,8 2,75 2,8 2,85 2,80

kW

49,5 56,5 72,5 80 108 118 137

2,9 3 3 3 3,13 3,05 2,82

17,1 18,8 24,2 26,7 34,5 38,7 48,6

(3)

S

(3)

M

(3)

H

15 20 20 20 27 27 27

kW

20 27 27 27 40 40 40

27 40 40 40 50 50 50

66 91 105 113 171 183 192

Refrigerant circuit

Number of compressors/Number of circuits

Refrigerant charge per circuit (approximate)

Air treatment ventilation

Minimum airfl ow

Maximum airfl ow

Maximum available static pressure

Condensing unit ventilation

Nominal airfl ow

Acoustic data

Outdoor blower outlet sound power

Standard unit (Lw)

Outdoor blower outlet sound power

Low noise unit (Lw)

(1)

(1)

Indoor blower outlet sound power level (Lw)

2/2 2/2 2/2 2/2 3/2 3/2 3/2

kg

6,94 +

6,94

6,42 +

6,42

8,74+

8,74

10,9 +

10,9

13,98 +

11,6

17,32 +

7950 9950 12450 14000 17350 19300 21000

m3/h

9750 12850 15090 16725 22450 24950 24750

Pa

812 747 711 680 812 784 828

m3/h

2 x

9750

2 x

11500

2 x

11300

2 x

11000

22700 +

18100

+18100

79 79 80 81 82 83 87

dB(A)

74 73 74 75 76 76 81

86 80 85 87 85 87 89

11,16

22700

17,23 +

17,1

2 x

22700

(1) EUROVENT conditions data

Cooling :

Outdoor temperature = 35°C DB

Entering coil temperature 27°C DB / 19°C WB

Heating :

Outdoor temperature = 7°C DB / 6°C WB

Indoor temperature = 20°C DB

• 14 •

(2) Air inlet temperature = 20°C

Water temperature = 90-70°C

(3) S = Standard heat

M = Medium heat

H = High heat

Application Guide • AIRCOOLAIR-AGU-1603-E

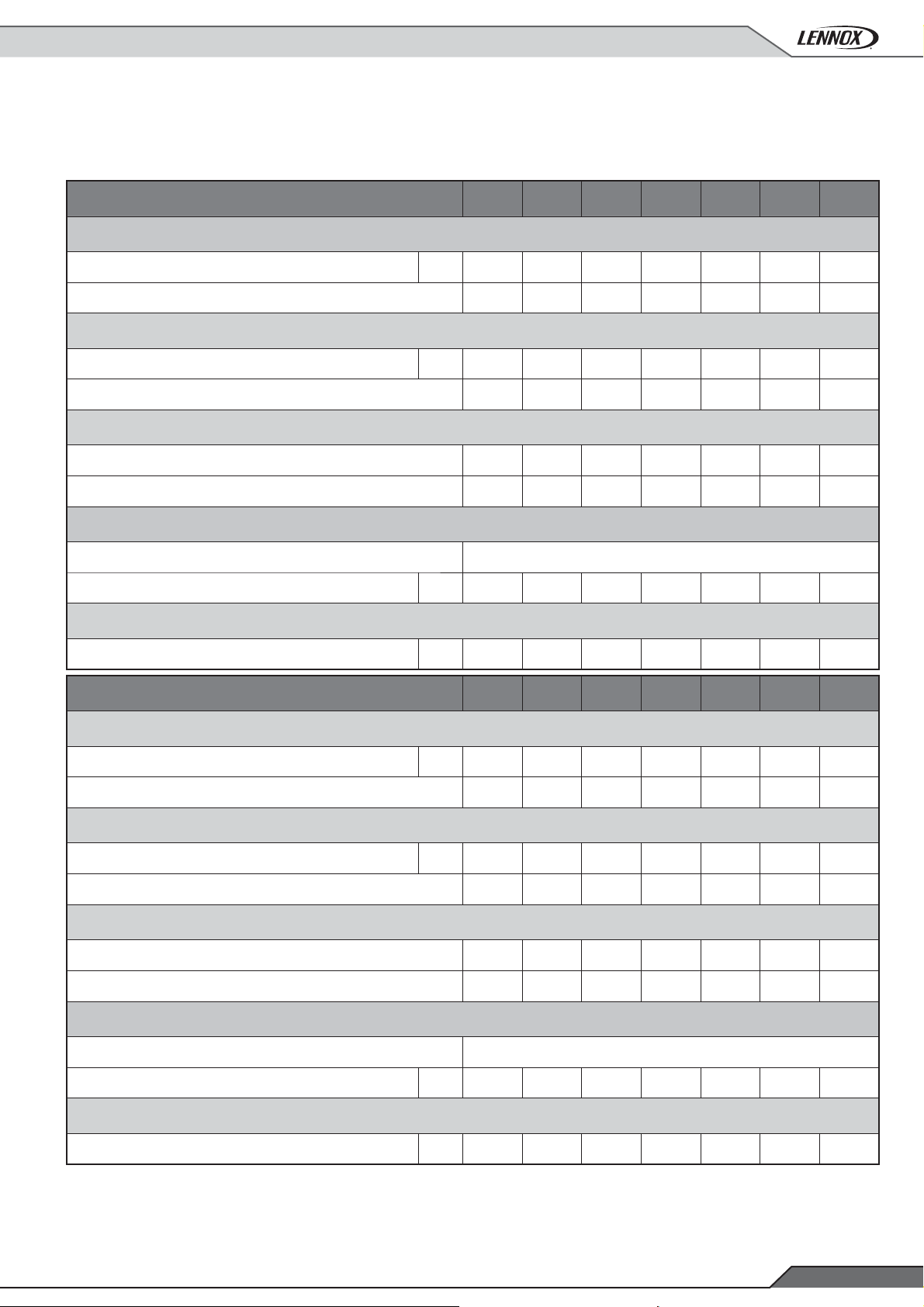

Page 17

GENERAL DATA

CONDENSING UNIT

020S 025S 030S 035S 040S 045D 055D

Cooling mode - ASC

Cooling capacity

(1)

EER

(1)

kW

19,7 24,7 28,4 36,1 42 49,4 56,7

3,06 3,05 2,95 3,03 2,98 3,05 2,94

Heating mode - ASH

Heating capacity

(2)

COP

(2)

kW

19,8 25,0 28,6 36,0 40,2 50,1 57,1

3,20 3,21 3,12 3,24 2,98 3,21 3,1

Refrigerant circuit

Number of compressors/Number of circuits

Capacity steps

1/1 1/1 1/1 1/1 1/1 2/2 2/2

1111122

Electrical data

Voltage 400V/3 Ph/50Hz

Maximum absorbed power

kW

8,55 10,8 12,5 16,4 17,7 21,6 25

Acoustic data

Sound power level

(3)

dB(A)

76 78 81 80 81 81 84

CONDENSING UNIT

070D 085D 100D 120D 140D 200D 230D

Cooling mode - ASC

Cooling capacity

(1)

EER

(1)

kW

72,1 83,9 104 115 141 197 228

3,04 2,96 3,03 3,1 3,05 3,11 3,06

Heating mode - ASH

Heating capacity

(2)

COP

(2)

kW

71,9 80,3 105 114 137 191 218

3,24 3,1 3,24 3,2 3,13 3,19 3,06

Refrigerant circuit

Number of compressors/Number of circuits

Capacity steps

2/2 2/2 3/2 3/2 3/2 4/2 4/2

2222222

Electrical data

Voltage 400V/3 Ph/50Hz

Maximum absorbed power kW

32,8 35,5 45,6 48,7 59,9 83,0 96,2

Acoustic data

Sound power level

(3)

dB(A)

83 84 87 87 90 89 82

(1) Evaporating temperature = 7°C / Ambient temperature = 35°C

(2) Condensing temperature = 50°C / Ambient temperature = 7°C DB/6°C WB

(3) EUROVENT conditions data

Application Guide • AIRCOOLAIR-AGU-1603-E

• 15 •

Page 18

VENTILATION DATA

TREATMENT VENTILATION DATA

LARGE DUCTED SPLIT

ASP

Airfl ow

(m3/h)

3150

3425

3700

4100

ASP

Airfl ow

CIC/CIH 020S

(m3/h)

3150

3425

3700

4100

ASP

Airfl ow

(m3/h)

4250

4625

5000

5500

100 Pa 150 Pa 200 Pa 250 Pa

K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x0,55 682 STD 1x0,55 788 HP1 1x1,1 890 HP1 1x1,1 980

STD 1x0,55 699 STD 1x0,55 800 HP1 1x1,1 896 HP1 1x1,1 984

STD 1x0,55 717 STD 1x0,55 813 HP1 1x1,1 909 HP1 1x1,1 991

STD 1x0,55 735 HP1 1x1,1 921 HP1 1x1,1 1003

No kit

300 Pa 350 Pa 400 Pa 550 Pa

K PI RPM K PI RPM K PI RPM K PI RPM

HP1 1x1,1 1060 HP2 1x1,1 1133 HP3 1x1,5 1204 HP3 1x1,5 1275

HP1 1x1,1 1068 HP2 1x1,1 1135 HP3 1x1,5 1214 HP3 1x1,5 1281

HP1 1x1,1 1074 HP2 1x1,1 1138 HP3 1x1,5 1220 HP3 1x1,5 1289

HP1 1x1,1 1083 HP2 1x1,1 1141 HP3 1x1,5 1233 HP3 1x1,5 1293

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x1,1 753 STD 1x1,1 840 HP1 1x1,5 915 HP1 1x1,5 1009 HP1 1x1,5 1085

STD 1x1,1 770 HP1 1x1,5 860 HP1 1x1,5 942 HP1 1x1,5 1021 HP1 1x1,5 1098

STD 1x1,1 806 HP1 1x1,5 883 HP1 1x1,5 956 HP1 1x1,5 1035 HP2 1x1,5 1091

STD 1x1,1 840 HP1 1x1,5 903 HP1 1x1,5 988 HP1 1x1,5 1059 HP2 1x1,5 1098

ASP

Airfl ow

CIC/CIH 025S

(m3/h)

4250

4625

5000

5500

ASP

Airfl ow

(m3/h)

4650

5050

5450

6000

ASP

Airfl ow

CIC/CIH 030S

(m3/h)

4650

5050

5450

6000

350 Pa 400 Pa 450 Pa 500 Pa 550 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x1,5 1160 HP2 1x1,5 1233 HP2 1x1,5 1279 HP3 1x2,2 1358 HP3 1x2,2 1420

HP2 1x1,5 1169 HP2 1x1,5 1238 HP2 1x1,5 1281 HP3 1x2,2 1364 HP3 1x2,2 1426

HP2 1x1,5 1176 HP2 1x1,5 1246 HP3 1x2,2 1310 HP3 1x2,2 1371 HP3 1x2,2 1431

HP3 1x2,2 1195 HP3 1x2,2 1258 HP3 1x2,2 1321 HP3 1x2,2 1380 HP3 1x2,2 1441

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x1,1 797 STD 1x1,1 876 HP1 1x1,5 956 HP1 1x1,5 1038 HP2 1x2,2 1113

STD 1x1,1 822 STD 1x1,1 903 HP1 1x1,5 980 HP1 1x1,5 1051 HP2 1x2,2 1126

STD 1x1,1 856 HP1 1x1,5 932 HP1 1x1,5 1003 HP1 1x1,5 1074 HP2 1x2,2 1141

STD 1x1,1 895 HP1 1x1,5 970 HP1 1x1,5 1034 HP1 1x1,5 1098 HP2 1x2,2 1161

350 Pa 400 Pa 450 Pa 500 Pa 550 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x2,2 1184 HP2 1x2,2 1251 HP2 1x2,2 1295 HP3 1x3 1380 HP3 1x3 1438

HP2 1x2,2 1197 HP2 1x2,2 1261 HP2 1x2,2 1298 HP3 1x3 1386 HP3 1x3 1445

HP2 1x2,2 1208 HP2 1x2,2 1271 HP2 1x2,2 1303 HP3 1x3 1395 HP3 1x3 1453

HP2 1x2,2 1227 HP2 1x2,2 1278 HP3 1x3 1349 HP3 1x3 1407 HP3 1x3 1465

Standard fan High pressure fan 1 (option)

STD HP1

High pressure fan 2 (option) High pressure fan 3 (option)

HP2 HP3

ASP PI (kW)

• 16 •

Available static pressure (Pa) Power input

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 19

VENTILATION DATA

TREATMENT VENTILATION DATA

LARGE DUCTED SPLIT

ASP

Airfl ow

(m3/h)

6200

6650

7100

8050

ASP

Airfl ow

CIC/CIH 035S

(m3/h)

6200

6650

7100

8050

ASP

Airfl ow

(m3/h)

6950

7550

8150

9050

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x1,5 640 STD 1x1,5 720 HP1 1x2,2 788 HP1 1x2,2 849 HP1 1x2,2 912

STD 1x1,5 663 STD 1x1,5 735 HP1 1x2,2 797 HP1 1x2,2 863 HP1 1x2,2 922

STD 1x1,5 688 HP1 1x2,2 749 HP1 1x2,2 813 HP1 1x2,2 873 HP1 1x2,2 931

STD 1x1,5 735 HP1 1x2,2 788 HP1 1x2,2 848 HP1 1x2,2 903 HP2 1x3 956

350 Pa 400 Pa 450 Pa 500 Pa 550 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x3 972 HP2 1x3 1028 HP2 1x3 1066 HP3 1x3 1134 HP3 1x3 1183

HP2 1x3 979 HP2 1x3 1035 HP2 1x3 1068 HP3 1x3 1139 HP3 1x3 1188

HP2 1x3 986 HP2 1x3 1044 HP2 1x3 1071 HP3 1x3 1144

HP2 1x3 1010 HP2 1x3 1052 HP3 1x3 1111 HP3 1x3 1159

No kit

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa 350 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x2,2 690 STD 1x2,2 757 STD 1x2,2 821 HP1 1x2,2 882 HP2 1x3 940 HP2 1x3 997

STD 1x2,2 726 STD 1x2,2 782 HP1 1x2,2 838 HP1 1x2,2 900 HP2 1x3 956 HP2 1x3 1010

STD 1x2,2 748 STD 1x2,2 808 HP1 1x2,2 863 HP1 1x2,2 919 HP2 1x3 973 HP2 1x3 1024

STD 1x2,2 799 HP1 1x2,2 851 HP1 1x2,2 902 HP2 1x3 951 HP2 1x3 1002 HP2 1x3 1069

ASP

Airfl ow

CIC/CIH 040S

(m3/h)

6950

7550

8150

9050

ASP

Airfl ow

(m3/h)

7950

8675

9400

9750

CIC/CIH 045D

ASP

Airfl ow

(m3/h)

7950

8675

9400

9750

400 Pa 450 Pa 500 Pa 550 Pa 600 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x3 1048 HP2 1x3 1103 HP3 1x4 1154 HP3 1x4 1202 HP3 1x4 1250

HP2 1x3 1053 HP3 1x4 1117 HP3 1x4 1162 HP3 1x4 1209

HP2 1x3 1059 HP3 1x4 1125 HP3 1x4 1172 HP3 1x4 1216

HP2 1x3 1069 HP3 1x4 1144 HP3 1x4 1189 HP3 1x4 1233

No kit

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x2,2 738 STD 1x2,2 800 HP1 1x3 857 HP1 1x3 912 HP1 1x3 967

STD 1x2,2 779 STD 1x2,2 833 HP1 1x3 886 HP1 1x3 938 HP1 1x3 986

STD 1x2,2 817 STD 1x2,2 867 HP1 1x3 917 HP1 1x3 966 HP1 1x3 1014

STD 1x2,2 838 HP1 1x3 884 HP1 1x3 931 HP1 1x3 979 HP1 1x3 1027

350 Pa 400 Pa 450 Pa 500 Pa 550 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP1 1x3 1019 HP2 1x4 1058 HP3 1x4 1154 HP3 1x4 1168 HP3 1x4 1216

HP1 1x3 1041 HP2 1x4 1064 HP3 1x4 1136 HP3 1x4 1183 HP3 1x4 1226

HP2 1x4 1052 HP2 1x4 1073 HP3 1x4 1150 HP3 1x4 1196 HP3 1x4 1240

HP2 1x4 1056 HP3 1x4 1117 HP3 1x4 1161 HP3 1x4 1204 HP3 1x4 1250

Standard fan High pressure fan 1 (option)

STD HP1

High pressure fan 2 (option) High pressure fan 3 (option)

HP2 HP3

ASP PI (kW)

Application Guide • AIRCOOLAIR-AGU-1603-E

Available static pressure (Pa) Power input

• 17 •

Page 20

VENTILATION DATA

TREATMENT VENTILATION DATA

LARGE DUCTED SPLIT

Airfl ow

(m3/h)

9950

10825

11700

12850

Airfl ow

(m3/h)

9950

10825

11700

12850

Airfl ow

(m3/h)

12450

13550

14650

15090

ASP

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa 350 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x2,2 666 STD 1x2,2 748 STD 1x2,2 828 HP1 1x3 903 HP1 1x3 967 HP1 1x3 1033

STD 1x2,2 688 STD 1x2,2 770 HP1 1x3 842 HP1 1x3 913 HP1 1x3 986 HP1 1x3 1041

STD 1x2,2 704 STD 1x2,2 786 HP1 1x3 859 HP1 1x3 931 HP1 1x3 992 HP2 1x4 1010

STD 1x2,2 741 HP1 1x3 820 HP1 1x3 881 HP1 1x3 946 HP2 1x4 971 HP2 1x4 1027

ASP

400 Pa 450 Pa 500 Pa 550 Pa 600 Pa 650 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x4 1047 HP2 1x4 1103 HP2 1x4 1138 HP3 1x5,5 1207 HP3 1x5,5 1256 HP3 1x5,5 1303

HP2 1x4 1057 HP2 1x4 0110 HP2 1x4 1140 HP3 1x5,5 1214 HP3 1x5,5 1262 HP3 1x5,5 1309

HP2 1x4 1065 HP2 1x4 1115 HP2 1x4 1172 HP3 1x5,5 1220 HP3 1x5,5 1268

HP2 1x4 1078 HP3 1x5,5 1132 HP3 1x5,5 1182 HP3 1x5,5 1232

ASP

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa 350 Pa

No kit

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x3 738 STD 1x3 819 STD 1x3 888 HP1 1x4 959 HP1 1x4 1014 HP2 1x5,5 1033

STD 1x3 776 STD 1x3 845 HP1 1x4 909 HP1 1x4 972 HP1 1x4 1033 HP2 1x5,5 1047

STD 1x3 807 HP1 1x4 871 HP1 1x4 931 HP1 1x4 993 HP2 1x5,5 1016 HP2 1x5,5 1069

STD 1x3 819 HP1 1x4 882 HP1 1x4 943 HP1 1x4 1002 HP2 1x5,5 1027 HP2 1x5,5 1078

No kit

ASP

Airfl ow

(m3/h)

12450

13550

14650

15090

ASP

Airfl ow

(m3/h)

14000

15125

16250

16725

ASP

Airfl ow

CIC/CIH 085D CIC/CIH 055DCIC/CIH 070D

(m3/h)

14000

15125

16250

16725

400 Pa 450 Pa 500 Pa 550 Pa 600 Pa 650 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x5,5 1087 HP2 1x5,5 1125 HP3 1x7,5 1189 HP3 1x7,5 1237 HP3 1x7,5 1275 HP3 1x7,5 1329

HP2 1x5,5 1101 HP2 1x5,5 1130 HP3 1x7,5 1197 HP3 1x7,5 1245 HP3 1x7,5 1292 HP3 1x7,5 1339

HP2 1x5,5 1113 HP2 1x5,5 1137 HP3 1x7,5 1212 HP3 1x7,5 1258 HP3 1x7,5 1303

HP2 1x5,5 1117 HP2 1x5,5 1140 HP3 1x7,5 1218 HP3 1x7,5 1264 HP3 1x7,5 1307

No kit

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa 350 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x4 805 STD 1x4 872 STD 1x4 937 HP1 1x5,5 995 HP2 1x7,5 1016 HP2 1x7,5 1070

STD 1x4 838 STD 1x4 898 HP1 1x5,5 959 HP1 1x5,5 1014 HP2 1x7,5 1040 HP2 1x7,5 1088

STD 1x4 863 STD 1x4 925 HP1 1x5,5 986 HP1 1x5,5 1041 HP2 1x7,5 1064 HP2 1x7,5 0110

STD 1x4 882 STD 1x4 937 HP1 1x5,5 994 HP2 1x7,5 1029 HP2 1x7,5 1073 HP2 1x7,5 1114

400 Pa 450 Pa 500 Pa 550 Pa 600 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 1x7,5 1114 HP2 1x7,5 1172 HP3 1x7,5 1214 HP3 1x7,5 1262 HP3 1x7,5 1303

HP2 1x7,5 1122 HP3 1x7,5 1184 HP3 1x7,5 1232 HP3 1x7,5 1275 HP3 1x7,5 1310

HP2 1x7,5 1130 HP3 1x7,5 1201 HP3 1x7,5 1245 HP3 1x7,5 1289 HP3 1x7,5 1331

HP2 1x7,5 1134 HP3 1x7,5 1209 HP3 1x7,5 1253 HP3 1x7,5 1295 HP3 1x7,5 1339

Standard fan High pressure fan 1 (option)

STD HP1

High pressure fan 2 (option) High pressure fan 3 (option)

HP2 HP3

ASP PI (kW)

• 18 •

Available static pressure (Pa) Power input

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 21

VENTILATION DATA

TREATMENT VENTILATION DATA

LARGE DUCTED SPLIT

ASP

Airfl ow

(m3/h)

17350

18875

20400

22450

ASP

Airfl ow

CIC/CIH 100D

(m3/h)

17350

18875

20400

22450

ASP

Airfl ow

(m3/h)

21000

22250

23500

24750

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa 350 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x4 591 STD 1x4 650 STD 1x4 710 HP1 1x5,5 763 HP1 1x5,5 815 HP2 2x4 825

STD 1x4 611 STD 1x4 670 STD 1x4 730 HP1 1x5,5 777 HP1 1x5,5 827 HP2 2x4 834

STD 1x4 637 STD 1x4 690 HP1 1x5,5 744 HP1 1x5,5 792 HP2 2x4 802 HP2 2x4 846

STD 1x4 670 HP1 1x5,5 721 HP1 1x5,5 770 HP2 2x4 788 HP2 2x4 822 HP2 2x4 863

400 Pa 450 Pa 500 Pa 550 Pa 600 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 2x4 870 HP2 2x4 903 HP3 2x4 959 HP3 2x4 997 HP3 2x4 1036

HP2 2x4 879 HP2 2x4 906 HP3 2x4 964 HP3 2x4 1003 HP3 2x4 1041

HP2 2x4 888 HP2 2x4 910 HP3 2x4 971 HP3 2x4 1009

HP2 2x4 896 HP3 2x4 945 HP3 2x4 986

No kit

No kit

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x5,5 630 STD 1x5.5 690 STD 1x5.5 743 HP1 1x7.5 792 HP2 2x4 802

STD 1x5,5 658 STD 1x5.5 710 HP1 1x7.5 763 HP1 1x7.5 810 HP2 2x4 818

STD 1x5,5 690 STD 1x5.5 736 HP1 1x7.5 784 HP1 1x7.5 829 HP2 2x4 838

STD 1x5,5 722 HP1 1x7.5 770 HP1 1x7.5 815 HP2 2x4 817 HP2 2x4 858

ASP

Airfl ow

CIC/CIH 120DCIC/CIH 140D

(m3/h)

21000

22250

23500

24750

ASP

Airfl ow

(m3/h)

21000

22250

23500

24750

ASP

Airfl ow

(m3/h)

21000

22250

23500

24750

350 Pa 400 Pa 450 Pa 500 Pa 550 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 2x4 848 HP2 2x4 888 HP2 1x4 937 HP3 2x5,5 974 HP3 2x5,5 1014

HP2 2x4 863 HP2 2x4 899 HP3 2x5.5 945 HP3 2x5,5 986 HP3 2x5,5 1022

HP2 2x4 876 HP2 2x4 902 HP3 2x5.5 959 HP3 2x5,5 994 HP3 2x5,5 1031

HP2 2x4 892 HP2 2x4 910 HP3 2x5,5 974 HP3 1x5,5 1010

No kit

100 Pa 150 Pa 200 Pa 250 Pa 300 Pa 350 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

STD 1x5,5 611 STD 1x5,5 665 STD 1x5,5 718 HP1 1x7.5 770 HP1 1x7.5 815 HP2 2x4 823

STD 1x5,5 630 STD 1x5,5 681 STD 1x5,5 730 HP1 1x7.5 780 HP1 1x7.5 827 HP2 2x4 832

STD 1x5,5 650 STD 1x5,5 697 STD 1x5,5 750 HP1 1x7.5 792 HP1 1x7.5 837 HP2 2x4 841

STD 1x5,5 665 STD 1x5,5 710 HP1 1x7.5 761 HP1 1x7.5 806 HP2 2x4 813 HP2 2x4 851

400 Pa 450 Pa 500 Pa 550 Pa 600 Pa

K PI RPM K PI RPM K PI RPM K PI RPM K PI RPM

HP2 2x4 867 HP2 2x4 900 HP3 2x5,5 949 HP3 2x5,5 986 HP3 2x5,5 1026

HP2 2x4 875 HP2 2x4 903 HP3 2x5,5 954 HP3 2x5,5 993 HP3 2x5,5 1030

HP2 2x4 882 HP2 2x4 906 HP3 2x5,5 959 HP3 2x5,5 999 HP3 2x5,5 1035

HP2 2x4 890 HP2 2x4 910 HP3 2x5,5 968 HP3 2x5,5 1004 HP3 2x5,5 1041

Standard fan High pressure fan 1 (option)

STD HP1

High pressure fan 2 (option) High pressure fan 3 (option)

HP2 HP3

ASP PI (kW)

Application Guide • AIRCOOLAIR-AGU-1603-E

Available static pressure (Pa) Power input

• 19 •

Page 22

VENTILATION DATA

RETURN VENTILATION DATA

055D

Closed pulley

1 turn

2 turns

3 turns

4 turns

Pulley position

085D

Closed pulley

1 turn

2 turns

3 turns

4 turns

Pulley position

Airfl ow

(

rpm) ↓

755

715

675

635

595

Airfl ow

rpm) ↓

(

755

715

675

635

595

3

Airfl ow (m

/h)

9950 10825 11700 12850

ASP PI ASP PI ASP PI ASP PI

255 2,37 257 2,56 260 2,77 260 3,05

230 2,11 232 2,30 234 2,48 233 2,75

207 1,88 208 2,05 210 2,23 207 2,48

184 1,67 184 1,82 184 1,99 180 2,22

162 1,47 162 1,61 160 1,77 155 1,98

3

Airfl ow (m

/h)

14000 15125 16250 16725

ASP PI ASP PI ASP PI ASP PI

260 3,44 255 3,77 250 4,13

230 3,12 225 3,43 215 3,75 212 3,90

202 2,82 195 3,11 183 3,41 178 3,55

173 2,53 165 2,80 153 3,09 145 3,22

145 2,27 135 2,52 120 2,79 115 2,91

••

070D

Closed pulley

1 turn

2 turns

3 turns

4 turns

Pulley position

100D

Closed pulley

1 turn

2 turns

3 turns

4 turns

Pulley position

Airfl ow

(

rpm) ↓

755

715

675

635

595

Airfl ow

rpm) ↓

(

672

636

601

565

529

3

Airfl ow (m

/h)

12450 13550 14650 15090

ASP PI ASP PI ASP PI ASP PI

260 2,93 260 3,22 258 3,52 255 3,65

235 2,64 233 2,91 228 3,20 225 3,32

208 2,37 205 2,62 198 2,90 195 3,00

182 2,12 176 2,36 168 2,61 165 2,72

157 1,89 150 2,11 140 2,35 135 2,44

Airfl ow (m

3

/h)

17350 18875 20400 22450

ASP PI ASP PI ASP PI ASP PI

293 3,81 293 4,25 291 4,60

263 3,46 261 2,88 258 4,22 251 4,77

234 3,15 232 3,49 227 3,86 218 4,38

205 2,83 202 3,15 196 3,48 185 3,98

178 2,52 173 2,81 166 3,13 153 3,58

••

120D

Closed pulley

1 turn

2 turns

3 turns

4 turns

Pulley position

Airfl ow

rpm) ↓

(

19300 21000 22700 24750

ASP PI ASP PI ASP PI ASP PI

381 380 380 373

766

343 340 337 330

725

305 300 297 287

684

268 263 257 245

644

232 227 220 205

603

EXHAUST VENTILATION DATA

020S - 025S - 030S

Airfl ow (m

Airfl ow m3/h

Available static pressure Pa

Airfl ow m

2000 2500 2750

160 105 75

060S-070S-055D-070D-85D

3

/h

6000 7000 8000

3

/h)

140D

Closed pulley

1 turn

2 turns

3 turns

4 turns

Pulley position

Airfl ow

rpm) ↓

(

766

725

684

644

603

21000 22700 24750

ASP PI ASP PI ASP PI

380 380 373

340 337 330

300 297 287

263 257 245

227 220 205

Airfl ow (m3/h)

035S - 040S - 042S - 045D

Airfl ow m3/h

Available static pressure Pa

3000 3500 4000

210 180 130

100D

Airfl ow m3/h

13200 14300 15400 16500

Available static pressure Pa

260 200 90

Available static pressure Pa

120D - 140D

Airfl ow m3/h

Available static pressure Pa

ASP PI (kW)

• 20 •

Available static pressure (Pa) Power input

13200 14300 15400 16500

230 200 150 50

230 200 150 50

Application Guide • AIRCOOLAIR-AGU-1603-E

Page 23

VENTILATION DATA

OPTION PRESSURE DROP TABLE

Airfl ow

Options

Economizer

Hot water coil

Airfl ow

Options

Economizer

Hot water coil

Unit size

m3/h

PaG4/F7 fi ltration

Unit size

m3/h

PaG4/F7 fi ltration

020S 025S 030S 035S

3150 3425 3700 4100 4250 4625 5000 5500 4650 5050 5450 6000 6200 6650 7100 8050

13 17 20 25 24 31 37 45 28 37 43 54 26 30 34 43

85 93 102 115 120 133 146 165 133 148 163 184 128 140 152 178

15 17 20 23 25 28 32 38 29 33 37 44 25 29 32 39

040S / 042S 045D 055D / 060S

6950 7550 8150 9050 7950 8675 9400 9750 9950 10825 11700 12850

33 38 44 52 42 48 55 58 11 13 16 19

148 164 181 208 175 197 219 230 123 136 150 169

31 35 40 47 38 44 50 54 24 27 31 36

Airfl ow

Options

Economizer

Hot water coil

Airfl ow

Options

Economizer

Hot water coil

Unit size

m3/h

PaG4/F7 fi ltration

Unit size

m3/h

PaG4/F7 fi ltration

070D / 070S 085D 100D

12450 13550 14650 15090 14000 15125 16250 16725 17350 18875 20400 22450

18 21 24 26 22 26 30 32 5 10 15 20

162 181 200 208 188 209 230 239 135 150 166 187

34 39 44 47 41 47 53 55 23 26 30 35

120D 140D

19300 21000 22700 24950 21000 22250 23500 24750

15 20 25 30 20 25 30 35

154 172 190 215 133 143 153 164

27 31 35 41 31 34 37 41

Application Guide • AIRCOOLAIR-AGU-1603-E

• 21 •

Page 24

PERFORMANCES - SPLIT UNITS

COOLING CAPACITIES

ASC/ASH + CIC/CIH 020S

Air inlet temperature at condenser (dry bulb)

20 °C 25 °C 30 °C 35°C 40 °C 45 °C

Airfl ow

3

m

/h

MinimumNominalMaximum

Indoor wet

bulb°CIndoor dry bulb

16

19

3150

22

16

19

3700

22

16

19

4100

22

GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC

°C

21 19,6 12,1 4,4 19,1 11,9 4,7 11,6 18,4 5,1 17,7 11,2 5,6 16,9 10,9 6,3 15,9 10,4 7,2

24 19,7 14,7 4,4 19,2 14,4 4,7 14,1 18,5 5,1 17,8 13,8 5,6 17,0 13,3 6,3 16,0 12,8 7,2

27 19,7 17,3 4,4 19,2 17,0 4,7 16,7 18,6 5,1 17,9 16,3 5,6 17,0 15,8 6,3 16,1 15,2 7,2

24 21,4 11,9 4,6 20,8 11,7 4,9 11,4 20,1 5,3 19,3 11,0 5,8 18,4 10,7 6,4 17,4 10,3 7,4

27 21,5 14,5 4,6 20,9 14,2 4,9 13,9 20,2 5,3 19,4 13,6 5,8 18,5 13,2 6,4 17,5 12,7 7,4

30 21,5 17,0 4,6 20,9 16,7 4,9 16,4 20,3 5,3 19,5 16,1 5,8 18,6 15,6 6,5 17,6 15,1 7,4

27 23,3 11,7 4,7 22,7 11,4 5,0 11,1 21,9 5,4 21,1 10,8 6,0 20,1 10,5 6,6 19,1 10,1 7,6

30 23,4 14,2 4,7 22,8 13,9 5,0 13,6 22,0 5,5 21,2 13,3 6,0 20,2 12,9 6,6 19,2 12,5 7,6

33 23,5 16,6 4,7 22,8 16,4 5,1 16,1 22,1 5,5 21,3 15,8 6,0 20,3 15,4 6,7 19,3 14,9 7,6

21 20,1 12,6 4,5 19,5 12,4 4,9 12,1 18,9 5,3 18,1 11,7 5,8 17,2 11,3 6,4 16,3 10,9 7,4

24 20,2 15,5 4,5 19,6 15,3 4,9 15,0 19,0 5,3 18,2 14,6 5,8 17,4 14,1 6,4 16,4 13,5 7,4

27 20,3 18,4 4,5 19,7 18,2 4,9 17,8 19,1 5,3 18,3 17,4 5,8 17,4 16,8 6,4 16,5 15,9 7,4

24 21,9 12,4 4,7 21,3 12,1 5,0 11,8 20,6 5,4 19,8 11,5 5,9 18,8 11,2 6,6 17,8 10,7 7,6

27 22,0 15,3 4,7 21,4 15,0 5,0 14,7 20,7 5,4 19,9 14,4 5,9 19,0 13,9 6,6 17,9 13,4 7,6

30 22,1 18,2 4,7 21,5 17,9 5,0 17,6 20,8 5,4 20,0 17,2 6,0 19,0 16,7 6,6 18,0 16,1 7,6

27 23,9 12,1 4,8 23,2 11,8 5,2 11,6 22,4 5,6 21,6 11,3 6,1 20,6 10,9 6,8 19,5 10,6 7,8

30 24,0 15,0 4,8 23,3 14,7 5,2 14,4 22,6 5,6 21,7 14,1 6,1 20,7 13,7 6,8 19,6 13,3 7,8

33 24,1 17,8 4,8 23,4 17,6 5,2 17,3 22,6 5,6 21,8 16,9 6,1 20,8 16,5 6,8 19,7 16,0 7,8

21 20,5 13,0 4,5 19,9 12,8 4,8 12,5 19,2 5,2 18,4 12,1 5,7 17,5 11,7 6,4 16,5 11,3 7,3

24 20,6 16,2 4,5 20,0 15,9 4,8 15,6 19,3 5,2 18,5 15,2 5,7 17,7 14,7 6,4 16,7 14,1 7,3

27 20,7 19,3 4,5 20,1 19,0 4,8 18,7 19,4 5,2 18,7 18,2 5,7 17,8 17,7 6,4 16,8 17,0 7,3

24 22,3 12,8 4,7 21,7 12,5 5,0 12,2 20,9 5,4 20,1 11,9 5,9 19,1 11,5 6,5 18,1 11,1 7,5

27 22,4 15,9 4,7 21,8 15,7 5,0 15,3 21,1 5,4 20,2 15,0 5,9 19,3 14,5 6,6 18,2 14,0 7,5

30 22,5 19,1 4,7 21,9 18,8 5,0 18,5 21,2 5,4 20,3 18,0 5,9 19,4 17,5 6,6 18,3 16,9 7,5

27 24,3 12,4 4,8 23,6 12,2 5,2 11,9 22,8 5,6 21,9 11,6 6,1 20,9 11,3 6,8 19,8 10,9 7,7

30 24,4 15,6 4,8 23,7 15,3 5,2 15,0 22,9 5,6 22,0 14,7 6,1 21,0 14,3 6,8 19,9 13,8 7,7

33 24,5 18,7 4,8 23,8 18,5 5,2 18,1 23,0 5,6 22,1 17,8 6,1 21,1 17,3 6,8 20,0 16,8 7,7

HEATING CAPACITIES

ASH+CIH 020S

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

Airfl ow

m3/h

MinimumNominalMaximum

Indoor fan power input (kw)

Minimum airfl ow Nominal airfl ow Maximum airfl ow

Outdoor fan power input (kw)

Nominal airfl ow

Indoor dry bulb

°C

15 12,6 3,88 14,6 4,31 16,6 4,74 18,7 5,17 19,5 5,35 20,6 5,62 22,6 6,09

18 12,6 4,21 14,6 4,65 16,5 5,09 18,5 5,54 19,3 5,73 20,5 6,01 22,4 6,52

20 12,6 4,44 14,6 4,89 16,5 5,34 18,5 5,81 19,2 6,00 20,4 6,30 22,3 6,82

3150

3700

4100

23 12,6 4,82 14,5 5,28 16,5 5,75 18,4 6,24 19,1 6,44 20,3 6,76 22,1 7,32

25 12,6 5,10 14,5 5,56 16,4 6,04 18,3 6,55 19,1 6,76 20,2 7,09 22,0 7,69

27 12,6 5,39 14,5 5,86 16,4 6,35 18,3 6,88 19,0 7,10 20,1 7,45 21,9 8,07

15 12,7 3,77 14,8 4,17 16,9 4,56 18,9 4,95 19,7 5,11 20,9 5,35 23,0 5,78

19 12,7 4,20 14,7 4,60 16,7 5,01 18,7 5,42 19,5 5,59 20,7 5,85 22,7 6,31

20 12,7 4,31 14,7 4,72 16,7 5,13 18,7 5,55 19,5 5,72 20,7 5,98 22,6 6,45

23 12,7 4,68 14,7 5,10 16,6 5,52 18,6 5,95 19,4 6,13 20,5 6,41 22,5 6,91

25 12,7 4,96 14,7 5,37 16,6 5,80 18,5 6,25 19,3 6,43 20,4 6,72 22,4 7,24

27 12,7 5,24 14,7 5,66 16,6 6,10 18,5 6,56 19,2 6,75 20,4 7,05 22,2 7,59

15 12,7 3,64 14,9 4,02 17,0 4,38 19,0 4,75 19,9 4,90 21,1 5,13 23,2 5,52

19 12,7 4,05 14,8 4,44 16,8 4,82 18,8 5,20 19,7 5,36 20,9 5,60 22,9 6,01

20 12,7 4,17 14,7 4,55 16,8 4,93 18,8 5,32 19,6 5,48 20,8 5,72 22,8 6,15

23 12,7 4,53 14,7 4,92 16,7 5,31 18,7 5,71 19,5 5,87 20,6 6,13 22,6 6,58

25 12,7 4,79 14,7 5,18 16,6 5,58 18,6 5,99 19,4 6,15 20,6 6,42 22,5 6,88

27 12,7 5,08 14,7 5,46 16,6 5,86 18,5 6,28 19,3 6,45 20,7 6,73 22,4 7,21

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

0,31 0,38 0,44

0,4

Air inlet temperature at condenser (dry bulb)

GC

(kW) :

• 22 •

Gross cooling capacity Net heating capacity Sensible cooling capacity

NH

(kW) :

SC

(kW) :

Application Guide • AIRCOOLAIR-AGU-1603-E

Compressor absorbed

AC

power

(kW) :

Page 25

PERFORMANCES - SPLIT UNITS

COOLING CAPACITIES

ASC/ASH + CIC/CIH 025S

20 °C 25 °C 30 °C 35°C 40 °C 45 °C

Air inlet temperature at condenser (dry bulb)

Airfl ow

3

m

/h

MinimumNominalMaximum

Indoor wet

bulb°CIndoor dry bulb

16

19

4250

22

16

19

5000

22

16

19

5500

22

GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC

°C

21 24,1 14,8 5,1 23,4 14,5 5,5 22,7 14,1 6,0 21,8 13,7 6,6 20,7 13,3 7,3 19,6 12,7 8,4

24 24,2 18,0 5,2 23,5 17,7 5,5 22,8 17,3 6,0 21,9 16,9 6,6 20,9 16,4 7,3 19,7 15,8 8,4

27 24,2 21,2 5,2 23,6 20,9 5,5 22,8 20,6 6,0 21,9 20,1 6,6 20,9 19,5 7,3 19,8 18,8 8,4

24 26,2 14,5 5,3 25,5 14,2 5,7 24,7 13,8 6,1 23,7 13,4 6,7 22,6 13,0 7,5 21,4 12,5 8,6

27 26,3 17,7 5,3 25,6 17,4 5,7 24,8 17,0 6,2 23,8 16,6 6,7 22,7 16,1 7,5 21,5 15,6 8,6

30 26,4 20,9 5,3 25,7 20,6 5,7 24,9 20,2 6,2 23,9 19,8 6,7 22,8 19,2 7,5 21,6 18,6 8,6

27 28,5 14,2 5,5 27,7 13,9 5,8 26,8 13,5 6,3 25,8 13,1 6,9 24,6 12,7 7,7 23,3 12,3 8,8

30 28,6 17,3 5,5 27,8 17,0 5,9 26,9 16,7 6,3 25,9 16,3 6,9 24,7 15,8 7,7 23,4 15,3 8,8

33 28,7 20,4 5,5 27,9 20,1 5,9 27,0 19,8 6,3 26,0 19,4 6,9 24,8 18,9 7,7 23,5 18,3 8,8

21 24,5 15,2 5,4 23,8 14,9 5,8 23,0 14,5 6,3 22,1 14,1 6,9 21,0 13,7 7,7 19,8 13,1 8,9

24 24,6 18,8 5,4 23,9 18,5 5,8 23,1 18,1 6,3 22,2 17,7 6,9 21,2 17,1 7,7 20,0 16,4 8,9

27 24,7 22,4 5,4 24,0 22,1 5,8 23,2 21,7 6,3 22,3 21,2 6,9 21,2 20,5 7,7 20,2 19,5 8,8

24 26,7 14,9 5,6 25,9 14,6 6,0 25,0 14,2 6,5 24,0 13,8 7,1 22,9 13,4 7,9 21,6 12,9 9,1

27 26,8 18,5 5,6 26,1 18,2 6,0 25,2 17,8 6,5 24,2 17,4 7,1 23,0 16,9 7,9 21,8 16,3 9,1

30 26,9 22,1 5,6 26,2 21,8 6,0 25,3 21,4 6,5 24,3 20,9 7,1 23,2 20,3 7,9 21,9 19,6 9,1

27 29,0 14,5 5,7 28,2 14,2 6,1 27,2 13,9 6,6 26,1 13,5 7,3 24,9 13,1 8,1 23,6 12,6 9,3

30 29,1 18,1 5,7 28,3 17,8 6,2 27,4 17,4 6,7 26,3 17,0 7,3 25,1 16,6 8,1 23,8 16,0 9,3

33 29,3 21,6 5,8 28,4 21,4 6,2 27,5 21,0 6,7 26,4 20,5 7,3 25,2 20,0 8,2 23,9 19,4 9,3

21 24,9 15,6 5,4 24,2 15,3 5,8 23,4 15,0 6,2 22,4 14,5 6,8 21,3 14,0 7,5 20,1 13,5 8,6

24 25,0 19,5 5,4 24,3 19,2 5,8 23,5 18,8 6,2 22,6 18,3 6,8 21,5 17,7 7,5 20,3 17,0 8,6

27 25,1 23,4 5,4 24,4 23,1 5,8 23,6 22,6 6,2 22,9 22,1 6,9 21,9 21,1 7,7 20,7 19,9 8,8

24 27,1 15,3 5,5 26,3 15,0 5,9 25,4 14,6 6,4 24,4 14,2 7,0 23,2 13,8 7,7 22,0 13,3 8,8

27 27,3 19,2 5,6 26,5 18,9 5,9 25,6 18,5 6,4 24,6 18,0 7,0 23,4 17,5 7,7 22,1 16,9 8,8

30 27,4 23,1 5,6 26,6 22,8 5,9 25,7 22,4 6,4 24,7 21,8 7,0 23,5 21,2 7,8 22,2 20,5 8,8

27 29,5 14,9 5,7 28,6 14,5 6,1 27,6 14,2 6,6 26,5 13,9 7,2 25,3 13,4 8,0 23,9 13,0 9,1

30 29,6 18,8 5,7 28,8 18,4 6,1 27,8 18,1 6,6 26,7 17,7 7,2 25,5 17,2 8,0 24,1 16,6 9,1

33 29,7 22,6 5,7 28,9 22,3 6,1 27,9 21,9 6,6 26,8 21,5 7,2 25,6 20,9 8,0 24,2 20,3 9,1

HEATING CAPACITIES

ASH+CIH 025S

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

Airfl ow

m3/h

MinimumNominalMaximum

Indoor fan power input (kw)

Minimum airfl ow Nominal airfl ow Maximum airfl ow

Outdoor fan power input (kw)

Nominal airfl ow

Indoor dry bulb

°C

15 16,1 4,79 18,7 5,27 21,24 5,7 23,75 6,2 24,75 6,4 26,23 6,7 28,67 7,30

18 16,0 5,17 18,6 5,67 21,10 6,2 23,57 6,7 24,54 6,9 26,00 7,2 28,39 7,80

20 16,0 5,45 18,5 5,96 21,01 6,5 23,44 7,0 24,41 7,2 25,84 7,6 28,20 8,17

4250

5000

5500

23 15,9 5,91 18,4 6,42 20,87 6,9 23,26 7,5 24,21 7,7 25,61 8,1 27,93 8,78

25 15,9 6,24 18,4 6,77 20,79 7,3 23,14 7,9 24,08 8,1 25,46 8,5 27,75 9,23

27 15,9 6,60 18,3 7,13 20,70 7,7 23,03 8,3 23,95 8,6 25,32 8,9 27,57 9,71

15 16,5 4,76 19,1 5,20 21,75 5,6 24,32 6,1 25,34 6,2 26,86 6,5 29,36 7,00

19 16,4 5,29 19,0 5,73 21,56 6,2 24,07 6,6 25,07 6,8 26,55 7,1 28,99 7,63

20 16,4 5,43 18,9 5,87 21,52 6,3 24,01 6,8 25,00 6,9 26,47 7,3 28,89 7,81

23 16,4 5,89 18,9 6,33 21,38 6,8 23,83 7,3 24,80 7,5 26,24 7,8 28,62 8,36

25 16,3 6,22 18,8 6,66 21,29 7,1 23,71 7,6 24,67 7,8 26,09 8,2 28,43 8,77

27 16,3 6,58 18,8 7,02 21,21 7,5 23,59 8,0 24,54 8,2 25,94 8,6 28,25 9,21

15 16,5 4,61 19,2 5,02 21,86 5,4 24,48 5,8 25,52 6,0 27,06 6,2 29,60 6,69

19 16,5 5,12 19,1 5,53 21,68 5,9 24,23 6,3 25,24 6,5 26,74 6,8 29,22 7,28

20 16,4 5,26 19,1 5,67 21,63 6,1 24,17 6,5 25,17 6,7 26,67 6,9 29,13 7,44

23 16,4 5,70 18,9 6,11 21,50 6,5 23,98 7,0 24,97 7,1 26,44 7,4 28,85 7,96

25 16,4 6,03 18,9 6,43 21,41 6,8 23,87 7,3 24,84 7,5 26,29 7,8 28,67 8,33

27 16,3 6,37 18,9 6,77 21,32 7,2 23,75 7,7 24,71 7,9 26,14 8,2 28,49 8,73

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

0,54 0,69 0,80

0,67

Air inlet temperature at condenser (dry bulb)

GC

Gross cooling capacity Net heating capacity Sensible cooling capacity

(kW) :

Application Guide • AIRCOOLAIR-AGU-1603-E

NH

(kW) :

SC

(kW) :

Compressor absorbed

AC

power

(kW) :

• 23 •

Page 26

PERFORMANCES - SPLIT UNITS

COOLING CAPACITIES

ASC/ASH + CIC/CIH 030S

Air inlet temperature at condenser (dry bulb)

20 °C 25 °C 30 °C 35°C 40 °C 45 °C

Airfl ow

3

m

/h

MinimumNominalMaximum

Indoor wet

bulb°CIndoor dry bulb

16

19

4650

22

16

19

5450

22

16

19

6000

22

GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC

°C

21 27,9 17,0 5,9 27,1 16,6 6,3 26,2 16,2 6,9 25,1 15,7 7,6 23,8 15,1 8,5 22,3 14,4 9,8

24 28,0 20,6 5,9 27,2 20,3 6,3 26,3 19,8 6,9 25,1 19,2 7,6 23,8 18,6 8,5 22,4 17,8 9,9

27 28,1 24,3 5,9 27,3 23,9 6,3 26,3 23,4 6,9 25,2 22,8 7,6 23,9 22,0 8,5 22,4 21,1 9,9

24 30,4 16,7 6,0 29,5 16,3 6,5 28,5 15,9 7,1 27,3 15,4 7,8 25,9 14,8 8,7 24,3 14,2 10,1

27 30,5 20,3 6,0 29,6 19,9 6,5 28,6 19,5 7,1 27,4 18,9 7,8 26,0 18,3 8,7 24,4 17,6 10,1

30 30,6 23,9 6,0 29,7 23,5 6,5 28,7 23,0 7,1 27,5 22,5 7,8 26,1 21,8 8,7 24,5 20,9 10,1

27 33,1 16,3 6,2 32,1 15,9 6,7 31,0 15,5 7,2 29,7 15,1 8,0 28,2 14,6 8,9 26,6 14,0 10,3

30 33,2 19,8 6,2 32,2 19,5 6,7 31,1 19,0 7,3 29,8 18,6 8,0 28,3 18,0 8,9 26,7 17,3 10,3

33 33,3 23,3 6,2 32,3 23,0 6,7 31,2 22,6 7,3 29,9 22,1 8,0 28,4 21,4 9,0 26,8 20,7 10,3

21 28,5 17,5 6,2 27,7 17,1 6,6 26,6 16,7 7,2 25,5 16,2 8,0 24,1 15,6 9,0 22,6 14,9 10,4

24 28,6 21,6 6,2 27,8 21,2 6,6 26,8 20,7 7,2 25,6 20,1 8,0 24,2 19,4 9,0 22,7 18,5 10,4

27 28,7 25,6 6,2 27,8 25,2 6,6 26,8 24,7 7,2 25,7 24,0 8,0 24,3 23,2 9,0 23,0 22,1 10,2

24 31,0 17,2 6,3 30,1 16,8 6,8 29,0 16,3 7,4 27,7 15,9 8,1 26,3 15,3 9,2 24,7 14,7 10,6

27 31,1 21,2 6,3 30,2 20,8 6,8 29,1 20,4 7,4 27,9 19,8 8,2 26,4 19,2 9,2 24,8 18,4 10,6

30 31,2 25,2 6,3 30,3 24,9 6,8 29,2 24,4 7,4 27,9 23,8 8,2 26,5 23,0 9,2 24,9 22,1 10,6

27 33,7 16,7 6,5 32,7 16,3 7,0 31,5 15,9 7,6 30,2 15,5 8,3 28,7 15,0 9,4 27,0 14,4 10,8

30 33,8 20,7 6,5 32,8 20,4 7,0 31,7 19,9 7,6 30,3 19,4 8,4 28,8 18,8 9,4 27,1 18,2 10,8

33 33,9 24,7 6,5 32,9 24,4 7,0 31,8 23,9 7,6 30,4 23,4 8,4 28,9 22,7 9,4 27,2 21,9 10,9

21 29,0 18,0 6,1 28,1 17,6 6,6 27,1 17,2 7,1 25,9 16,7 7,8 24,5 16,0 8,7 23,0 15,3 10,0

24 29,1 22,4 6,1 28,3 22,0 6,6 27,2 21,5 7,1 26,0 20,9 7,8 24,6 20,1 8,7 23,1 19,2 10,0

27 29,2 26,8 6,1 28,3 26,4 6,6 27,3 25,8 7,1 26,1 25,1 7,8 25,0 24,0 8,9 23,6 22,6 10,1

24 31,6 17,6 6,3 30,6 17,2 6,7 29,5 16,8 7,3 28,2 16,3 8,0 26,7 15,8 8,9 25,1 15,1 10,3

27 31,7 22,0 6,3 30,7 21,6 6,7 29,6 21,1 7,3 28,3 20,6 8,0 26,9 19,9 8,9 25,2 19,1 10,3

30 31,8 26,4 6,3 30,8 26,0 6,7 29,7 25,5 7,3 28,4 24,8 8,0 27,0 24,0 9,0 25,3 23,1 10,3

27 34,3 17,1 6,4 33,3 16,8 6,9 32,1 16,4 7,5 30,7 15,9 8,2 29,1 15,4 9,2 27,4 14,8 10,5

30 34,4 21,5 6,5 33,4 21,1 6,9 32,2 20,7 7,5 30,8 20,2 8,2 29,3 19,6 9,2 27,6 18,9 10,5

33 34,5 25,9 6,5 33,5 25,5 6,9 32,3 25,0 7,5 31,0 24,5 8,2 29,4 23,8 9,2 27,7 22,9 10,5

HEATING CAPACITIES

ASH+CIH 030S

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

Airfl ow

m3/h

MinimumNominalMaximum

Indoor fan power input (kw)

Minimum airfl ow Nominal airfl ow Maximum airfl ow

Outdoor fan power input (kw)

Nominal airfl ow

Indoor dry bulb

°C

15 18,4 5,37 21,4 5,96 24,3 6,54 27,1 7,11 28,3 7,34 29,9 7,69 32,7 8,30

18 18,4 5,83 21,3 6,43 24,1 7,03 26,9 7,62 28,0 7,86 29,6 8,23 32,3 8,88

20 18,4 6,16 21,3 6,77 24,0 7,38 26,8 7,99 27,9 8,24 29,4 8,62 32,1 9,30

4650

5450

6000

23 18,4 6,69 21,2 7,32 23,9 7,94 26,6 8,58 27,7 8,85 29,2 9,26 31,8 9,98

25 18,5 7,08 21,2 7,71 23,9 8,35 26,5 9,01 27,5 9,29 29,1 9,72 31,6 10,48

27 18,5 7,48 21,2 8,12 23,8 8,78 26,4 9,47 27,4 9,75 28,9 10,20 31,4 11,01

15 18,8 5,33 21,8 5,88 24,8 6,41 27,7 6,93 28,9 7,14 30,6 7,46 33,5 8,00

19 18,8 5,96 21,7 6,51 24,6 7,05 27,5 7,60 28,6 7,82 30,2 8,16 33,0 8,74

20 18,8 6,13 21,7 6,68 24,6 7,23 27,4 7,78 28,5 8,00 30,1 8,34 32,9 8,94

23 18,8 6,67 21,6 7,22 24,4 7,78 27,2 8,35 28,3 8,58 29,9 8,94 32,5 9,58

25 18,8 7,05 21,6 7,61 24,4 8,18 27,1 8,76 28,1 9,00 29,7 9,38 32,3 10,04

27 18,8 7,46 21,6 8,02 24,3 8,59 26,9 9,19 28,0 9,44 29,6 9,83 32,1 10,53

15 18,9 5,12 21,9 5,65 24,9 6,15 27,9 6,64 29,1 6,83 30,9 7,13 33,8 7,64

19 18,8 5,73 21,8 6,26 24,7 6,76 27,6 7,27 28,8 7,48 30,5 7,79 33,3 8,33

20 18,8 5,90 21,8 6,42 24,7 6,93 27,6 7,44 28,7 7,65 30,4 7,97 33,2 8,52

23 18,8 6,42 21,7 6,94 24,6 7,45 27,4 7,98 28,5 8,19 30,1 8,53 32,8 9,11

25 18,8 6,79 21,7 7,31 24,5 7,83 27,2 8,36 28,3 8,59 29,9 8,93 32,6 9,53

27 18,8 7,18 21,6 7,70 24,4 8,22 27,1 8,77 28,2 9,00 29,8 9,35 32,4 9,98

NH AC NH AC NH AC NH AC NH AC NH AC NH AC

0,68 0,86 1

0,8

Air inlet temperature at condenser (dry bulb)

GC

(kW) :

• 24 •

Gross cooling capacity Net heating capacity Sensible cooling capacity

NH

(kW) :

SC

(kW) :

Application Guide • AIRCOOLAIR-AGU-1603-E

Compressor absorbed

AC

power

(kW) :

Page 27

PERFORMANCES - SPLIT UNITS

COOLING CAPACITIES

ASC/ASH + CIC/CIH 035S

20 °C 25 °C 30 °C 35°C 40 °C 45 °C

Air inlet temperature at condenser (dry bulb)

Airfl ow

3

m

/h

MinimumNominalMaximum

Indoor wet

bulb°CIndoor dry bulb

16

19

6200

22

16

19

7100

22

16

19

8050

22

GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC GC SC AC

°C

21 36,6 22,8 7,7 35,7 22,3 8,2 34,6 21,8 8,8 33,2 21,3 9,7 31,7 20,6 10,8 29,9 19,8 12,5

24 36,6 27,8 7,7 35,7 27,4 8,2 34,6 26,9 8,9 33,3 26,2 9,7 31,8 25,4 10,8 30,0 24,5 12,5

27 36,6 32,8 7,7 35,7 32,4 8,2 34,6 31,8 8,9 33,3 31,1 9,7 31,8 30,2 10,9 30,0 29,1 12,5

24 39,8 22,3 7,9 38,8 21,9 8,4 37,6 21,4 9,1 36,1 20,9 9,9 34,5 20,2 11,1 32,6 19,5 12,8

27 39,9 27,3 7,9 38,9 26,9 8,4 37,7 26,4 9,1 36,2 25,8 10,0 34,6 25,1 11,1 32,7 24,2 12,8

30 39,9 32,3 7,9 38,9 31,9 8,4 37,7 31,4 9,1 36,2 30,7 10,0 34,6 29,9 11,1 32,8 28,9 12,8

27 43,3 21,8 8,1 42,1 21,4 8,7 40,8 20,9 9,3 39,3 20,4 10,2 37,5 19,8 11,4 35,5 19,2 13,1

30 43,4 26,7 8,1 42,2 26,3 8,7 40,9 25,9 9,4 39,4 25,3 10,2 37,6 24,6 11,4 35,6 23,9 13,1

33 43,4 31,6 8,1 42,3 31,2 8,7 41,0 30,7 9,4 39,4 30,1 10,2 37,7 29,4 11,4 35,7 28,5 13,1

21 36,9 23,2 8,1 36,0 22,8 8,7 34,8 22,3 9,4 33,5 21,7 10,3 31,9 21,0 11,6 30,1 20,2 13,5

24 37,0 28,7 8,1 36,0 28,2 8,7 34,9 27,7 9,4 33,5 27,0 10,4 32,0 26,2 11,7 30,2 25,2 13,6

27 37,0 34,0 8,1 36,1 33,6 8,7 34,9 33,0 9,4 33,6 32,2 10,4 32,3 31,3 11,5 30,7 29,7 13,4

24 40,2 22,8 8,3 39,1 22,3 8,9 37,9 21,8 9,6 36,4 21,3 10,6 34,7 20,6 11,9 32,8 19,9 13,8

27 40,3 28,2 8,3 39,2 27,8 8,9 38,0 27,2 9,6 36,5 26,6 10,6 34,8 25,8 11,9 32,9 24,9 13,8

30 40,3 33,5 8,3 39,3 33,1 8,9 38,0 32,5 9,7 36,5 31,8 10,6 34,9 31,0 11,9 33,0 29,9 13,9

27 43,7 22,2 8,5 42,5 21,8 9,1 41,1 21,3 9,9 39,6 20,8 10,9 37,8 20,2 12,2 35,8 19,6 14,1

30 43,8 27,6 8,5 42,6 27,2 9,1 41,3 26,7 9,9 39,7 26,1 10,9 37,9 25,4 12,2 35,9 24,6 14,1

33 43,8 32,9 8,6 42,7 32,5 9,2 41,3 32,0 9,9 39,7 31,3 10,9 38,0 30,5 12,2 36,0 29,6 14,1

21 37,6 23,8 7,9 36,6 23,4 8,4 35,4 22,9 9,1 34,0 22,3 9,9 32,4 21,6 11,1 30,6 20,8 12,7

24 37,7 29,7 7,9 36,7 29,3 8,5 35,5 28,7 9,1 34,1 28,0 10,0 32,5 27,1 11,1 30,7 26,1 12,8

27 37,7 35,5 7,9 36,7 35,0 8,5 35,8 34,6 9,1 34,5 33,3 10,0 33,1 31,9 11,2 31,5 30,3 12,9

24 40,9 23,3 8,1 39,8 22,9 8,7 38,5 22,4 9,3 37,0 21,8 10,2 35,3 21,2 11,4 33,3 20,4 13,1

27 41,0 29,2 8,1 39,9 28,8 8,7 38,6 28,2 9,4 37,1 27,6 10,2 35,4 26,8 11,4 33,5 25,8 13,1

30 41,0 35,0 8,2 40,0 34,6 8,7 38,7 34,0 9,4 37,2 33,2 10,2 35,5 32,3 11,4 33,5 31,2 13,1

27 44,4 22,7 8,4 43,2 22,2 8,9 41,8 21,8 9,6 40,2 21,3 10,5 38,4 20,7 11,7 36,3 20,0 13,4

30 44,6 28,5 8,4 43,4 28,1 8,9 42,0 27,6 9,6 40,3 27,0 10,5 38,5 26,3 11,7 36,5 25,5 13,4

33 44,6 34,3 8,4 43,4 33,9 8,9 42,0 33,4 9,6 40,4 32,7 10,5 38,6 31,9 11,7 36,6 30,9 13,4

HEATING CAPACITIES

ASH+CIH 035S

-10 °C -5 °C 0 °C 5°C 7 °C 10 °C 15 °C

Airfl ow