Page 1

HEARTH PRODUCTS

KITS AND ACCESSORIES

P/N 506033-35

Rev. NC, 11/2009

FREESTANDING BLOWER SNAP SWITCH RETROFIT KIT

INSTALLATION INSTRUCTIONS FOR INSTALLING A BLOWER SNAP SWITCH

RETROFIT KIT FOR USE WITH COUNTRY COLLECTION™ MODELS S160, SA160,

SS210, ST210, S260 AND ST310 FREESTANDING WOODSTOVES

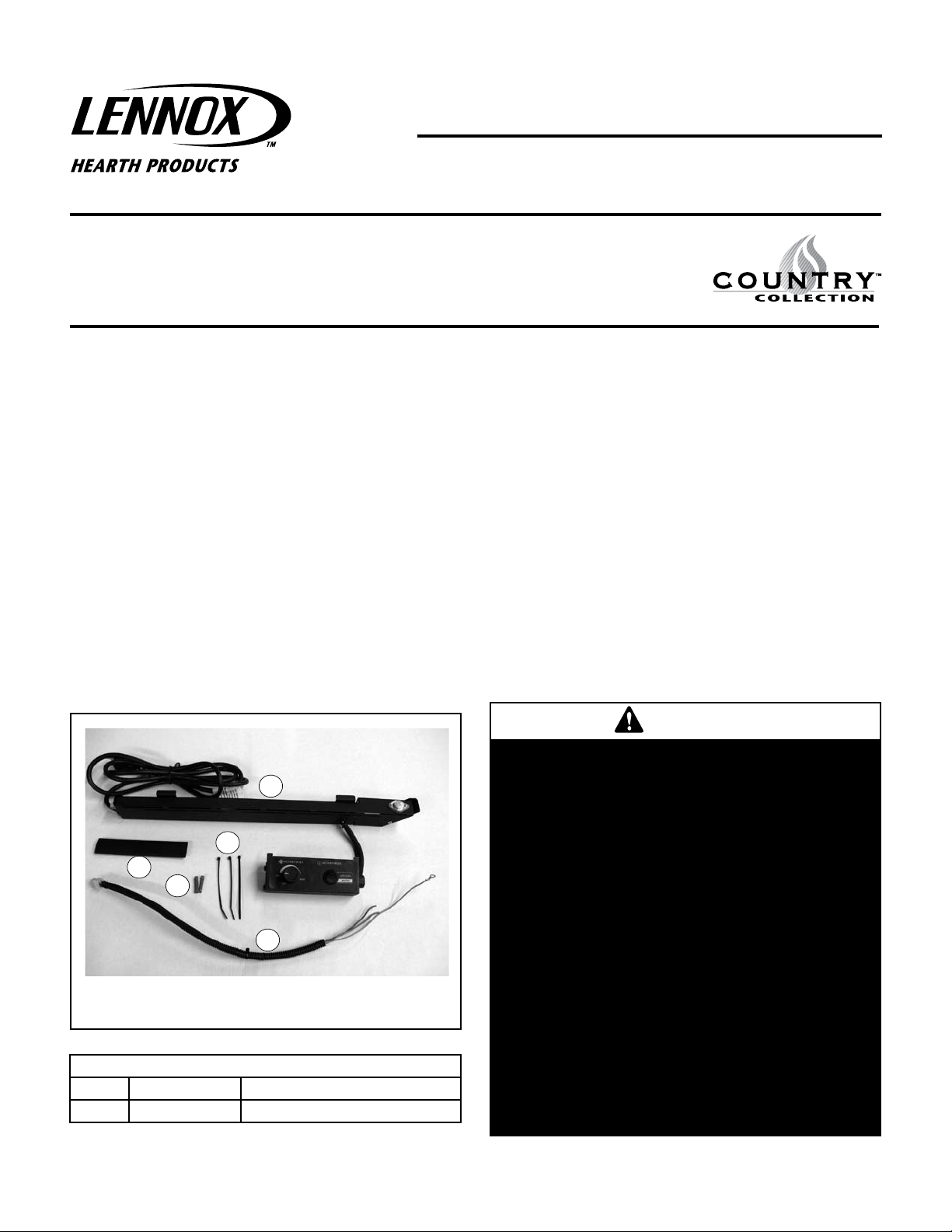

KIT CONTENTS

1 ea. Blower Wire Harness (item #1)

1 ea. Snap Switch and Control Panel Housings (item #2)

1 ea. 6” of 3/4” Heat Shrink Tube (item #3)

2 ea. Butt Connectors (item #4)

3 ea. Wire Ties (item #5)

1 ea. Instruction Sheet

TOOLS NEEDED

5/32 Allen Wrench Or T Handle Wrench

Cutting Pliers

Wire Crimpers

9/16” Socket Wrench

9/16” Open End Wrench

Crescent Wrench

3/8” End Wrench

Large Flat Head Screwdriver

GENERAL INFORMATION

This retrofit kit works in conjunction with the optional

circulation blower kit. The kit provides a variable speed control (rheostat)

and snap switch, which will allow for the option of automatic thermal

activation of the blower, when desired and blower speed control (see

Blower Operation on Page 8).

If you encounter any problems, need clarification of these instructions or

are not qualified to properly install this kit, contact your local distributor

or dealer.

Read this instruction sheet in its entirety before beginning the installation.

ALL WARNINGS AND PRECAUTIONS IN THE INSTALLATION AND

OPERATION MANUAL PROVIDED WITH THE APPLIANCE APPLY TO

THESE INSTRUCTIONS.

SHUT DOWN THE STOVE AND ALLOW IT TO COMPLETELY COOL BEFORE

PROCEEDING.

COUNTRY COLLECTION™ WOODSTOVES

700-CFM room air

2

5

3

4

1

Figure 1 - Kit Contents

FREESTANDING BLOWER SNAP SWITCH RETROFIT KIT

Cat. No. Model Description

H7918

SSK-BLWR-FSB700 Blower Retrofit Kit, FS Woodstoves

The blower must be plugged directly into a properly

grounded three-prong receptacle, 120 VAC, 60 Hz, single

phase. Do not cut or remove the grounding prong from

this plug. Do not route power cord under or in front of

appliance.

Installation must be in accordance with National Electrical Code, ANSI/NFPA 70 - latest edition. In Canada,

the current CSA C22-1 Canadian Electrical Code - latest

edition.

DANGER: Disconnect power before servicing blower.

In the event that you remove the blower for any reason,

make sure a cover plate (available from Lennox Hearth

Products) is installed before using the heater. Excessive

rear wall temperatures will result if the stove is burned

without the cover plate. The cover plate is not necessary

if a blower has never been installed because a knock-out

will be in place to act as the cover.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

WARNINGS

1

Page 2

INSTALLATION INSTRUCTIONS

Removing Existing Blower From Stove

Step 1.

UNPLUG POWER CORD AND ENSURE APPLIANCE IS COLD

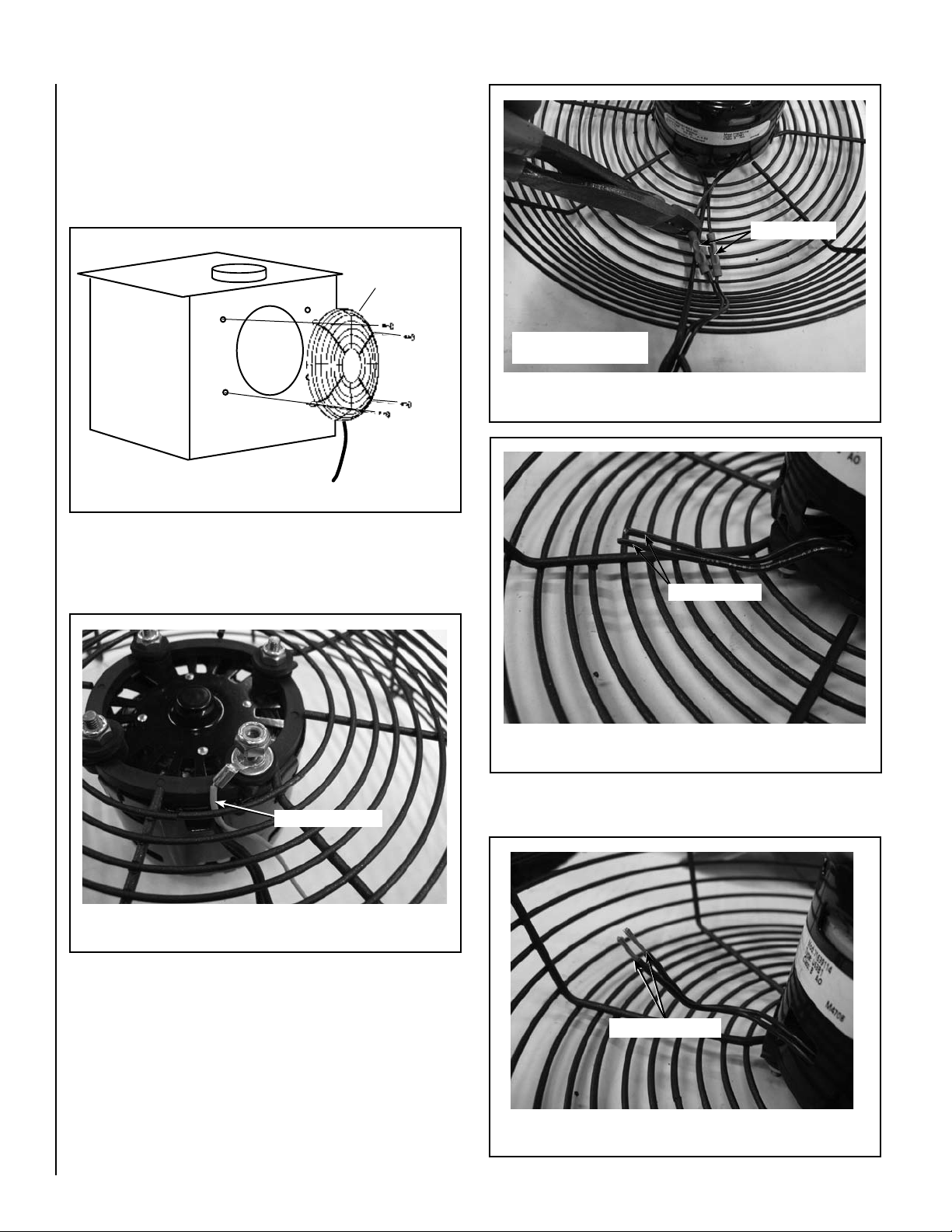

Step 2. Using a 5/32 allen wrench/T-handle, remove the blower mounting

allen screws from blower, and remove blower from stove. See

Figure 2.

Blower

Stove Back

Figure 2

Butt Connectors

Cut black wires on motor

side of butt connectors

Figure 4

Step 3. Using a crescent wrench, remove the fan blade. NOTE: Fan nut is

reverse thread.

Step 4.

Using a 3/8” end wrench, remove the ground (green) wire from the

blower stud. See Figure 3.

Green Ground Wire

Figure 3

Step 5. Carefully remove the black heat shrink sleeve material from

blower wires.

Step 6.

Cut both butt connectors on the motor side. Note: Cut at the

connector being careful to not remove any more wire than is

necessary. See Figures 4 and 5.

Cut Wires Shown

Figure 5

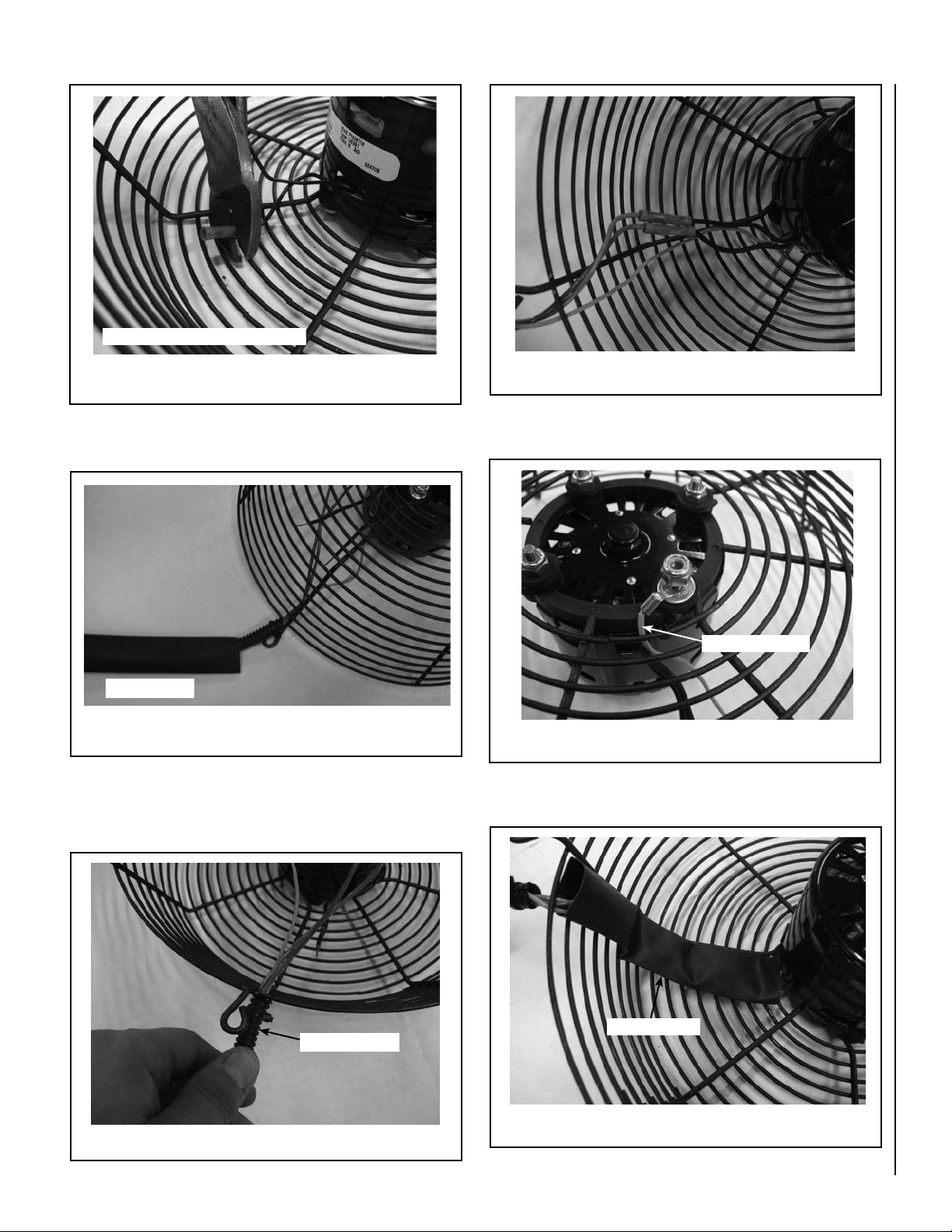

Step 7. Strip blower wires and connect butt connectors to both. See

Figures 6 and 7.

Strip wires as shown

Figure 6

2

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 3

Crimp on butt connectors to both wires

Figure 7

Step 8. Slide the supplied 6” of 3/4” heat shrink tube over the (3) blower

harness wires. See Figure 8.

Heat shrink tube

Figure 8

Step 9. Placing edge of wire loom at edge of blower cage, connect the

black blower lead wires to the wires on the blower harness, using

butt connectors already installed. NOTE: Trimming harness wires

to correct length may be necessary. See Figures 9 and 10.

Figure 10

Step 10. Reconnect the new ground wire to the motor stud. See Figure

11.

Green Ground Wire

Figure 11

Step 11. Slide the heat shrink tube to the motor, covering wires and con-

nectors. See Figure 12.

Figure 9

Wire Loom Tubing

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Heat Shrink Tube

Figure 12

3

Page 4

Step 12. Shrink the tube with heat (heat gun, hair dryer, etc.)

Step 13.

Secure wires in the heat shrink tube to the fan cage using (3)

wire ties making sure wires/heat shrink tube follow contour of

inner side of blower cage. Cut off the excess wire tie. NOTE*

BE SURE WIRES ARE CLEAR OF FAN BLADE!!! See Figures

13 and 14.

Wires / Heat Shrink Tube

WOODSTOVES WITH PEDESTAL BASE

Leg based units, see instructions on Page 6.

Step 1. From rear of stove, using a 9/16” wrench or socket, loosen both

left and right pedestal mounting bolts but do not fully remove

the bolts from threaded holes as shown in Figure 15.

Bolts

Back View of Pedestal

Figure 13

Figure 14

Step 14.

Step 15.

Wire Ties

Reinstall the blower fan blade.

Reinstall the blower assembly as shown in Figure 2 and the

following instructions; Ensure the wiring harness on the blower

cage is at the bottom right when mounted to the back heat shield

of the stove. Be aware that the blower wiring harness should

be clear of the back of the firebox and blower fan blades. The

blower can now be fastened to the back of the heat shield with

the four screws and washers that were removed earlier in this

step using the 5/32” allen wrench/T-handle. Visually inspect

that the blower is centered in large opening on the back of the

heatshield. If not centered in the opening the fan blades could

make contact with the heatshield making excessive noise. Once

everything is correctly in place you can then tighten down all

four screws. Tighten the screws moderately tight but do not

over tighten as you may strip the holes out.

Figure 15

Step 2. Insert a large flat head screwdriver or pry bar into the small open-

ing between the pedestal mounting flange and the bottom firebox

of the stove. Use the large screwdriver or pry bar to increase

the opening size between the firebox bottom and pedestal. See

Figure 16 - This increased opening between the pedestal and

bottom firebox will be needed to insert the snap switch bracket

mounting tabs.

Firebox

Pedestal Mounting Flange

Figure 16

Step 3. Insert snap switch bracket mounting tabs between the pedestal

and the firebox bottom. See Figure 17.

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 5

Snap Switch

Bracket Tabs

Step 6. Locate the 3/8” diameter x 1/2” long bolt on the bottom of the

firebox near the draft handle. Using a 9/16” wrench or socket

loosen this bolt but do not remove from threaded hole. See

Figure 20. Note: This bolt was holding the stoves shipping legs

on the stove and should have been reinstalled with the other

three bolts that were holding the shipping legs on the stove per

the pedestal instructions.

Draft Handle

Figure 17

Step 4. While holding the snap switch bracket against the pedestal, slide

the bracket towards the rear of the stove until it comes to a stop.

Once the snap switch bracket is in place you can then remove the

flat head screwdriver or pry bar that was used to create the opening

between the firebox bottom and pedestal. See Figure 18.

Snap Switch

Housing

Figure 18

Bolt

Figure 20

Step 7. Locate front slot on the control box as shown in Figure 21.

Slot

Figure 21

Step 5. With the snap switch bracket in place, using a 9/16” wrench or

socket wrench you can now tighten down both left and right side

pedestal bolts. See Figure 19.

Tighten Left

and Right

Pedestal Bolts

Figure 19

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Step 8. Install the control box by sliding the front control box slot over the

3/8” bolt head from Step 6. Slide control box towards the center

of the stove until it stops on the tabs. See Figure 22.

Tabs

Figure 22

5

Page 6

Step 9. Using a 9/16” open end wrench tighten down the 3/8” bolt hold-

ing the control box. See Figure 23.

Figure 23

WOODSTOVES WITH LEG BASE

Step 1. Using a 9/16” wrench or socket loosen the left heat shield bolt.

This bolt is located on the bottom side of the leg heatshield as

shown. See Figure 26.

Left Heat Shield Bolt

Step 10. Connect the wire harness from blower to female connector on

rear of snap switch bracket. See Figure 24.

Figure 24

Step 11. Visually inspect wires are clear of contact with bottom of firebox.

See Figures 23 through 25.

Figure 26

Step 2. Insert snap switch bracket between the heatshield and the bottom

of firebox making sure entire assembly is on the left side of the

heatshield bolt. Slide back until the notch on the bottom front of

the bracket falls into the lip on the front of the heatshield, and assembly is parallel with side of firebox. See Figures 27 and 28.

Heat Shield

Snap Switch Bracket

Figure 27

Snap Switch Harness

Figure 25

Step 12. Plug the power cord into a grounded 120 VAC receptacle. Do

not route the power cord under the stove or allow it to come in

6

contact with any surface of the stove.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Snap Switch Bracket

Figure 28

Page 7

Step 3. Locate the tabs on the back of the control box. Slide the tabs

onto the upper edge of the left side heatshield. See Figures 29

and 30.

Upper Edge Of The

Left Side Heatshield

Step 5. Plug the blower harness into plug on rear of snap switch bracket.

See Figure 32.

Snap Switch Bracket

Blower Wire Harness

Figure 29

Tabs

Control Box

Figure 30

Step 4. Using a 9/16” wrench, slowly start to tighten the bottom heatshield

bolt. While tightening bolt, and before snug, make sure the snap

switch housing does not shift. DO NOT OVERTIGHTEN. Make sure

snap switch is making firm, flat contact with ashlip, and does not

shift. See Figure 31.

Figure 32

Step 6. Visually inspect wires are clear of contact with firebox. See

Figures 32 and 33.

Bottom of Firebox

Snap Switch Harness

Figure 33

Step 7. Plug the power cord into grounded 120 VAC receptacle. Do

not route the power cord under the stove or allow it to come in

contact with any surface of the stove.

Figure 31

Snap Switch

Snap Switch

Housing

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

7

Page 8

ROOM AIR

BLOWER

SPEED

CONTROL/OFF

TWO POSITION

SWITCH

MANUAL/TEMPERATURE

AUTO-RESET

TEMPERATURE

SWITCH N/O

POWER CORD

3-RED

3-RED

YLW

BLK

WHT

4-GRN

1-BRN

1-BRN

4-GRN

3-RED

NOTE: SWITCH CONDITIONS

GIVEN AT ROOM TEMPERATURE

N/C = NORMALLY CLOSED

N/O = NORMALLY OPEN

= FEMALE DISCONNECT

= MALE DISCONNECT

= STUD CONNECTION

Blower Operation

The blower can be operated manually or automatically (blower will

turn on when the stove is hot and turn off when the stove is cool).

The rocker switch on the control panel allows you to select between

manual operation or automatic operation as follows (see Figure 23):

MANUAL OPERATION: Turn rocker switch to the “MANU-

AL” position and adjust rheostat knob to the desired speed. The blower

will have to be manually turned “OFF” by rotating the rheostat knob

counterclockwise until it clicks.

turned on. Likewise, when the stove cools off, the blower is turned off

to prevent circulating cool air. Depending on the size and intensity of the

fire it may be necessary to adjust the fan speed accordingly to ensure uninterrupted fan operation. For example a small fire may require a slower

fan speed to keep the heat output by the fan consistent. If the blower is

operated in manual mode, it may be necessary to adjust the blower speed

as the fire begins to burn down and the stove is no longer hot enough to

effectively heat the air moved by the blower. If the air coming from the

blower feels cool, one should either decrease the blower speed or stoke

the fire to build up more heat.

AUTO OPERATION: Turn rocker switch to the “AUTO” posi-

tion and the rheostat to the ON position (rotate rheostat knob clockwise

until it clicks). When the stove warms up, the blower will automatically

turn on (adjust rheostat knob to the desired speed setting). When the

stove cools down, the blower will automatically turn off.

Rheostat Operation - The highest blower speed is obtained by turning

the rheostat knob clockwise until it clicks “ON”, then rotate towards

“HIGH” to increase blower speed. Rotate the knob clockwise for a

lower speed. To turn off, continue to rotate the knob counterclockwise

until it clicks “OFF.”

Blower Operation Guidelines

While in auto operation mode, the blower will turn off and on based on the

temperature of the stove. Auto operation ensures there is sufficient heat

build-up to warm the air being moved by the blower before the blower is

Blower Speed Control

Knob (rheostat)

Figure 35 - Blower Controls

Manual / Auto

Rocker Switch

8

Figure 34 - Wiring Schematic

Lennox Hearth Products reserves the right to make changes at any time, without notice, in

design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2009 Lennox Hearth Products

P/N 506033-35 Rev. NC 11/2009

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...